Patents

Literature

76 results about "Phenylphosphonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Proton exchange membrane for medium-temperature fuel cell and preparation thereof

InactiveCN101407626AHigh operating temperatureImprove mechanical propertiesCell component detailsSolid electrolyte fuel cellsFuel cellsAlcohol fuel

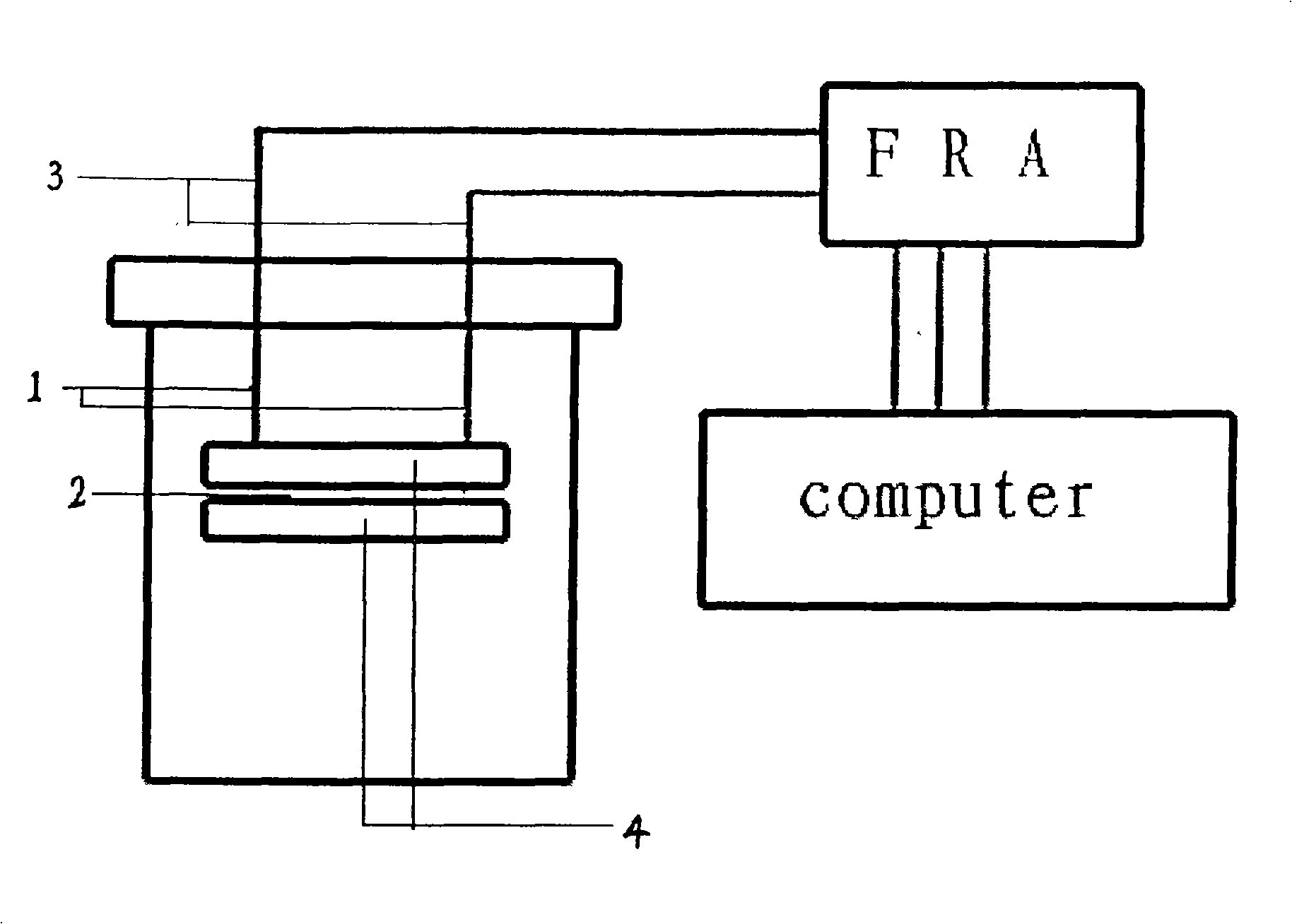

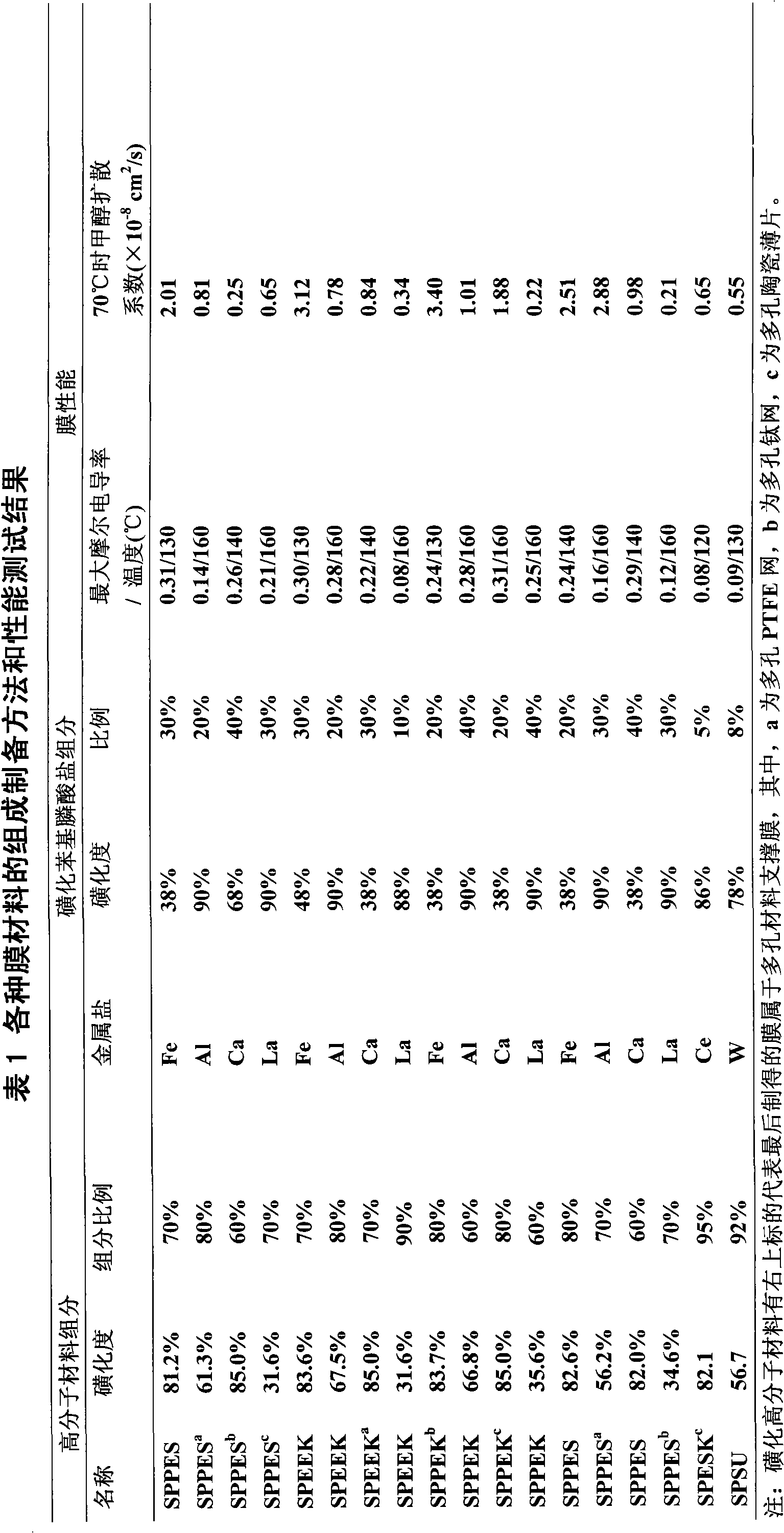

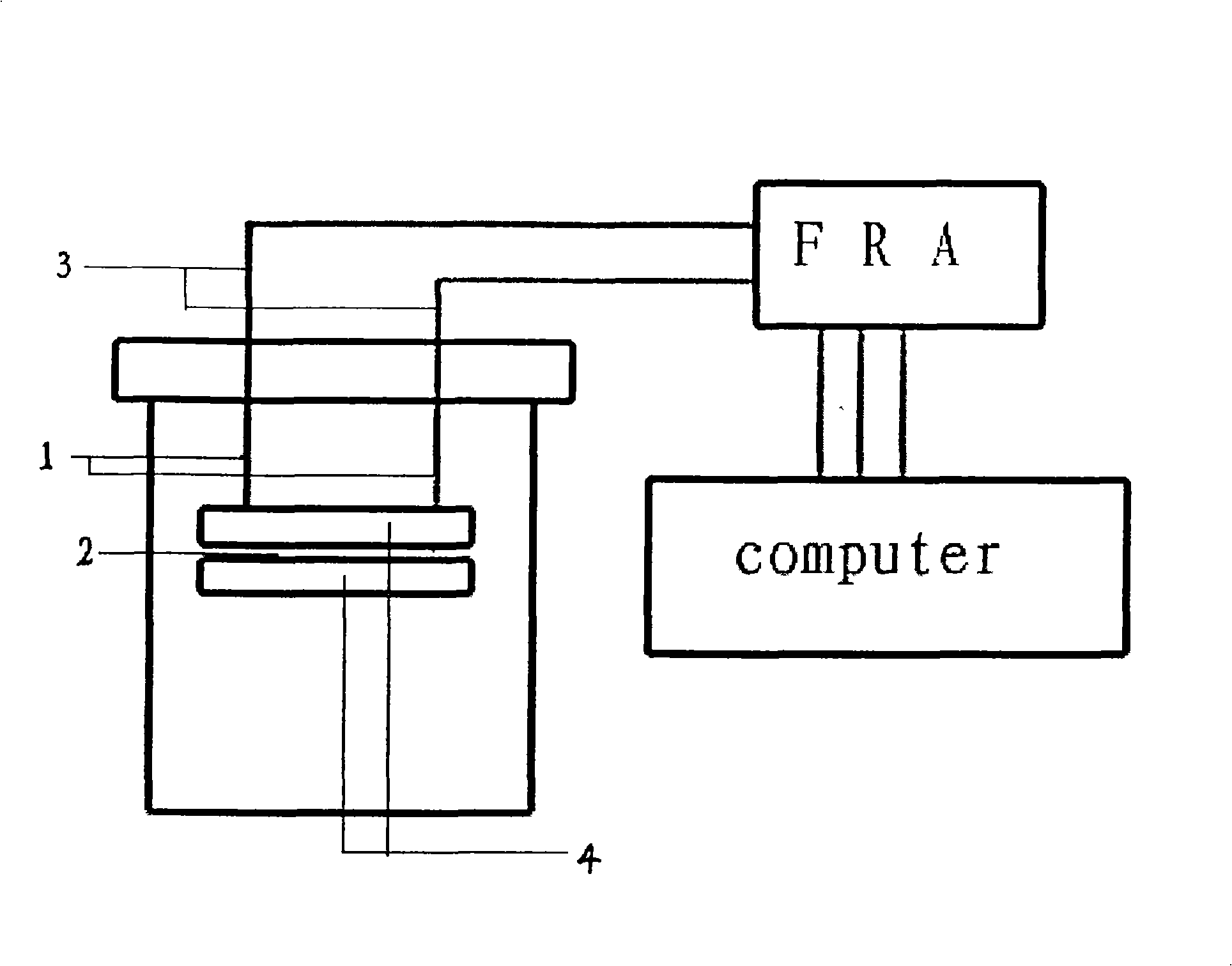

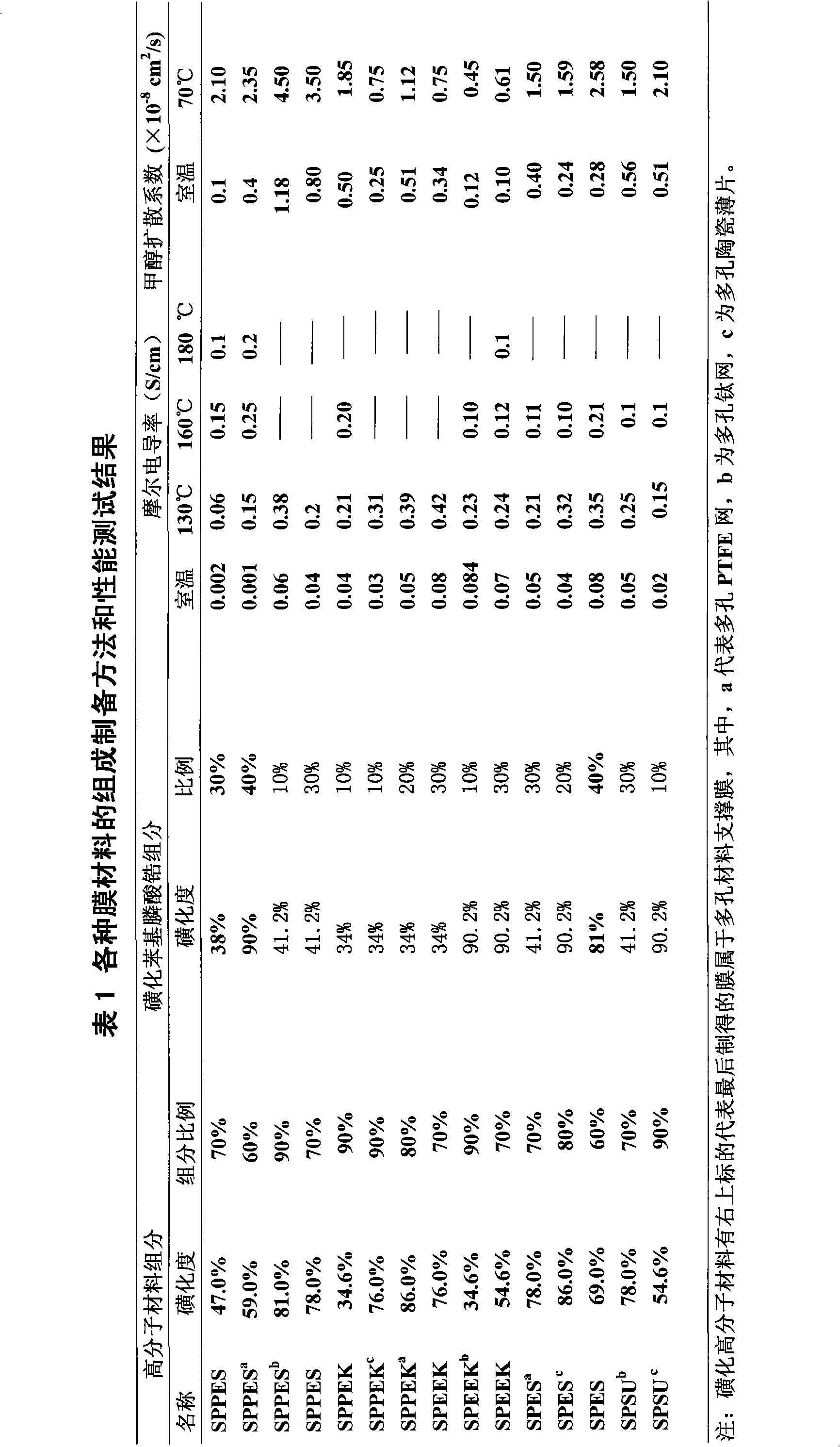

The invention relates to a proton exchange membrane of fuel cells which can be used at medium temperature, which is a proton exchange membrane doped with sulfonated phenyl zirconium phosphonic acid. The proton exchange membrane is characterized in that the membrane preparing materials consist of sulfonated high molecular material and sulfonated phenyl zirconium phosphonic acid salts, wherein, the degree of sulfonation of sulfonated high molecular material selects 20 percent to 85 percent and accounts for 60 percent to 95 percent of the weight percentage of the membrane preparing material; and the degree of sulfonation of sulfonated phenyl zirconium phosphonic acid salts selects 30 percent to 90 percent accounts for 5 percent to 40 percent of the weight percentage of the membrane preparing material. Porous supporting materials can also be added into the membrane so as to improve strength of the membrane and reduce the deformability. The membrane preparing materials fill pores with the porous supporting materials and form a layer of membrane at the outer surface of the porous supporting materials. The invention is applicable to medium-temperature alcohol fuel cells so as to improve operating temperature of the fuel cells and improve the performance of the fuel cells.

Owner:SHANDONG UNIV OF TECH

Sulfonation phenylphosphonic acid zirconium doping proton exchanging film and method of producing the same

InactiveCN101402790AImprove thermal stabilityImprove mechanical propertiesCell component detailsFuel cell detailsFuel cellsMethanol fuel

The invention relates to a proton exchange membrane adulterated with sulfonation zirconium phenylphosphonate which is characterized in that: the film-making material thereof consists of a sulfonation high molecular material and sulfonation zirconium phenylphosphonate; wherein, the sulfonation degree choice of the sulfonation high molecular material is 20 percent to 85 percent which accounts for 60 percent to 95 percent of the mass percent of the film-making material; and the sulfonation degree choice of the sulfonation zirconium phenylphosphonate is 30 percent to 90 percent which accounts for 5 percent to 40 percent of the mass percent of the film-making material. Besides, a porous supporting material can be added to the film so as to improve the strength of the film and reduce the deformability thereof. The film-making material fills the holes of the porous supporting material and forms a layer of thin film on the outer surface of the porous supporting material. The proton exchange membrane is applicable to intermediate temperature direct methanol fuel cells so as to improve the application temperature of the proton exchange membrane and the property of the fuel cells.

Owner:SHANDONG UNIV OF TECH

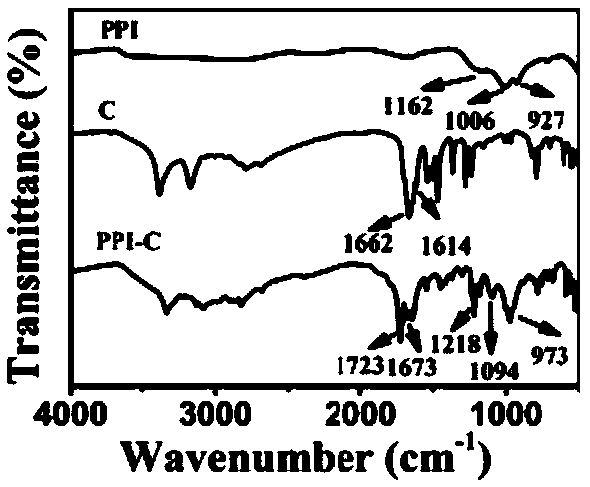

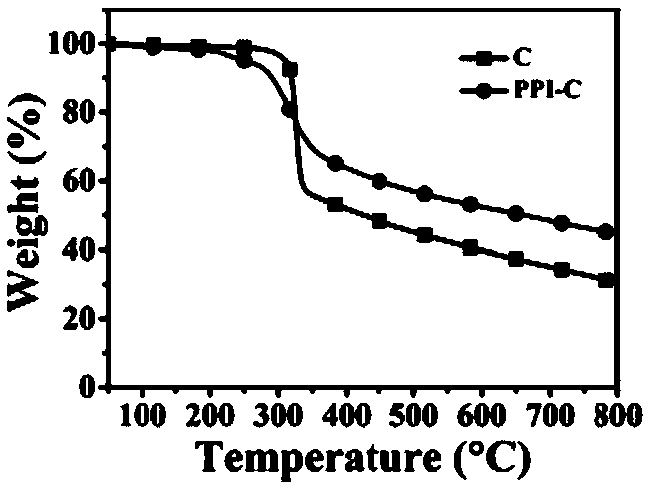

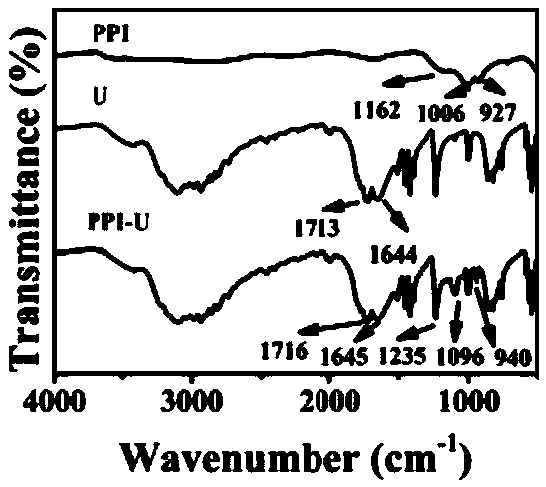

Alkaloid phosphate flame retardant and preparation method thereof

The invention discloses an alkaloid phosphate flame retardant and a preparation method thereof. Alkaloid phosphate is formed from alkaloid monomer X and phosphoric acid monomers Y through reaction, and is subjected to surface coating modification treatment by epoxy resin or polyurethane, and the alkaloid phosphate flame retardant is obtained. Water resistance and compatibility of the flame retardant with polymers are improved. The alkaloid monomer X is one or more of cytosine (C), uracil (U), adenine (A), guanine (G) and thymine (T). The phosphoric acid monomers Y are pyrophosphoric acid, perphosphoric acid, polyphosphoric acid, phenylphosphonic acid and phytic acid. A series of phosphorus-containing base salts are prepared from bases of bio-based compounds as a raw material, and the phosphorus-containing base salts can be used as a flame retardant additive and have higher flame retardant efficiency. Therefore, a feasible embodiment is provided for improving the flame retardant efficiency of the bio-based flame retardant additive.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Biodegradable resin composition

ActiveUS20100063177A1Group 5/15 element organic compoundsConductive materialPhosphateCarboxylic acid

The invention relates to a biodegradable resin composition containing a biodegradable resin, a plasticizer and a crystal nucleus agent, the plasticizer being a compound containing two or more ester groups in the molecule thereof, wherein at least one alcohol component constituting the ester contains an alkylene oxide having 2 to 3 carbon atoms, added in the average amount of 0.5 to 5 moles per one hydroxyl group, and the crystal nucleus agent is a mixture of the following crystal nucleus agent (1) and crystal nucleus agent (2); the crystal nucleus agent (1) being the following crystal nucleus agent (1-1) or crystal nucleus agent (1-2): crystal nucleus agent (1-1): at least one selected from compounds having a hydroxyl group and an amide group in the molecule thereof; and crystal nucleus agent (1-2): at least one selected from hydroxy fatty acid esters; crystal nucleus agent (2): at least one selected from a metal salt of phenylphosphonic acid, a metal salt of a phosphate, a metal salt of an aromatic dialkyl sulfonate, a metal salt of rosinic acids, an aromatic carboxylic acid amide, rosinic acid amide, carbohydrazides, N-substituted ureas, salts of melamine compounds and uracils.

Owner:KAO CORP

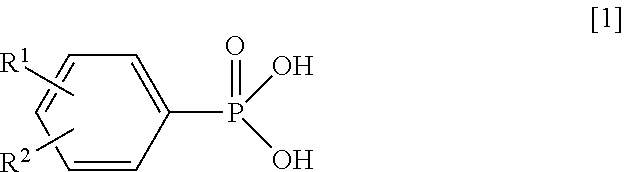

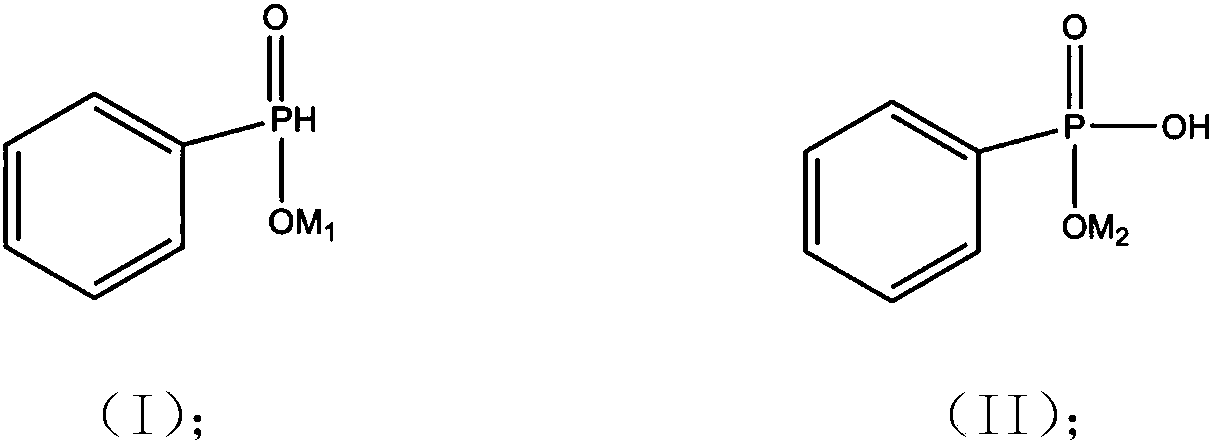

Poly(3-hydroxyalkanoate) resin composition

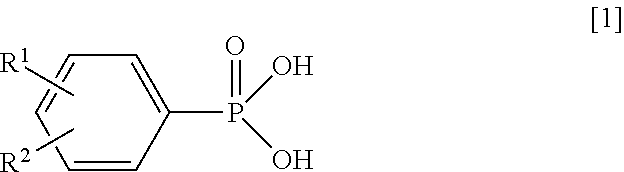

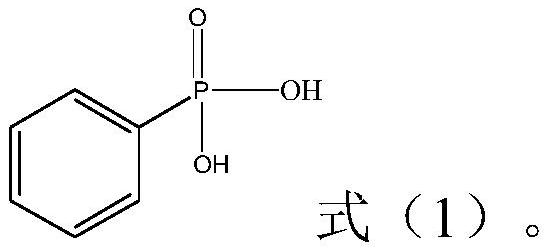

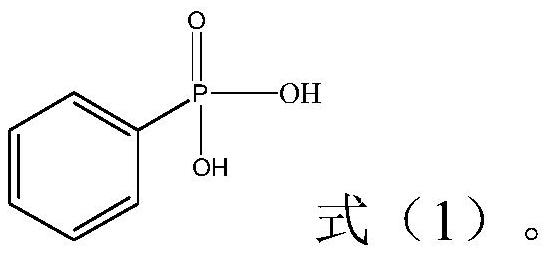

There is provided a P3HA resin composition to which a crystal nucleating agent suitable for the promotion of the crystallization of a P3HA resin is added. A poly(3-hydroxyalkanoate) resin composition comprising: a poly(3-hydroxyalkanoate) resin; and a metal salt of a phenylphosphonic acid compound of Formula [1]:(where R1 and R2 are each independently a hydrogen atom, a C1-10 alkyl group, or a C2-11 alkoxycarbonyl group), wherein the metal salt is at least one selected from the group consisting of a lithium salt, a sodium salt, a potassium salt, a magnesium salt, a calcium salt, a barium salt, a manganese salt, an iron salt, a cobalt salt, a nickel salt, a copper salt, a silver salt, an aluminum salt, and a tin salt.

Owner:NISSAN CHEM IND LTD

Biodegradable resin composition

ActiveUS20100210756A1Group 5/15 element organic compoundsConductive materialPolymer sciencePhosphate

The invention relates to a biodegradable resin composition containing a biodegradable resin, a plasticizer and a crystal nucleus agent, the plasticizer being a compound containing two or more ester groups in the molecule thereof, wherein at least one alcohol component constituting the ester contains an alkylene oxide having 2 to 3 carbon atoms, added in the average amount of 0.5 to 5 moles per one hydroxyl group, and the crystal nucleus agent is a mixture of the following crystal nucleus agent (1) and crystal nucleus agent (2); the crystal nucleus agent (1) being the following crystal nucleus agent (1-1) or crystal nucleus agent (1-2): crystal nucleus agent (1-1): at least one selected from compounds having a hydroxyl group and an amide group in the molecule thereof; and crystal nucleus agent (1-2): at least one selected from hydroxy fatty acid esters; crystal nucleus agent (2): at least one selected from a metal salt of phenylphosphonic acid, a metal salt of a phosphate, a metal salt of an aromatic dialkyl sulfonate, a metal salt of rosinic acids, an aromatic carboxylic acid amide, rosinic acid amide, carbohydrazides, N-substituted ureas, salts of melamine compounds and uracils.

Owner:KAO CORP

Phenyl phosphonate with photocatalytic activity as well as preparation method and application thereof

InactiveCN108690072ARaw materials are cheap and easy to getEasy to prepareHydrocarbon from carbon oxidesOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventSolvent

The invention provides phenyl phosphonate with photocatalytic activity as well as a preparation method and application thereof, and belongs to the technical field of photocatalytic materials. The preparation method for phenyl phosphonate comprises the following steps that metal salt and phenylphosphonic acid are dissolved in an organic solvent, and a solvothermal method is adopted to prepare phenyl phosphonate. According to phenyl phosphonate as well as the preparation method and application thereof, a phenyl phosphonate photocatalytic material is synthesized by adopting the solvothermal method for the first time and is applied to photocatalytic hydrogen production and carbon dioxide reduction; and meanwhile, the raw materials are low in price, easy to obtain, environmentally-friendly, safe and pollution-free, the preparation method is simple and easy to operate, and the values of industrial production and practical application are achieved.

Owner:SHANDONG UNIV

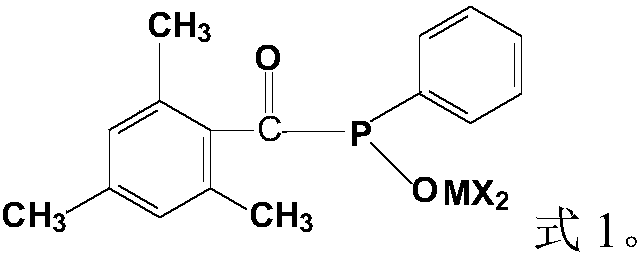

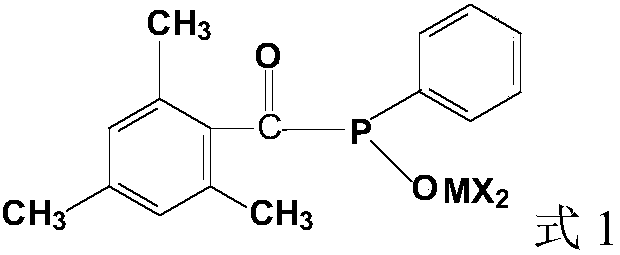

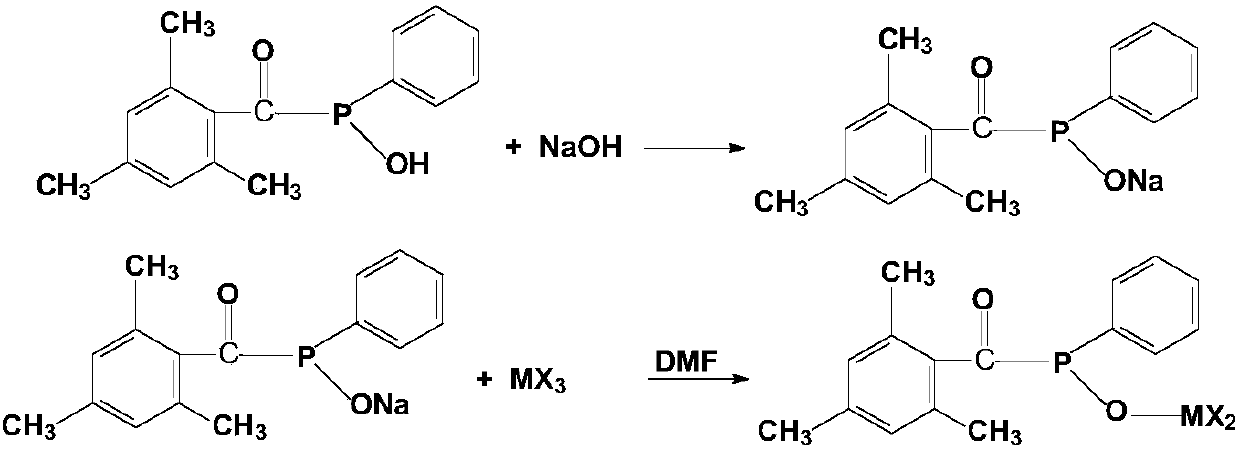

LED-UV printing ink initiator, preparation method thereof and LED-UV printing ink containing same

InactiveCN107916026AAchieve solidificationAchieve the production goal of energy saving and environmental protectionGroup 5/15 element organic compoundsInksUV curingRare earth

The invention discloses a novel LED-UV printing ink initiator. The novel LED-UV printing ink initiator is a rare earth derivative of 2,4,6-trimethylbenzoyl phenylphosphonic acid and can be abbreviatedas TPO-MX2, wherein TPO<-> is a 2,4,6-trimethylbenzoyl phenylphosphonate radical, M is a trivalent rare earth metal ion, and X is a monovalent anion. Meanwhile, the invention also provides LED-UV printing ink containing the LED-UV printing ink initiator, complete curing can be realized when the LED-UV printing ink is applied to curing under strict production conditions such as high speed and lowthermal radiation, and the traditional UV curing printing ink can be completely replaced, so that the aims of saving energy and protecting the environment are achieved.

Owner:长飞光纤潜江有限公司

Solid acid catalyst for preparing biodiesel and preparation method thereof

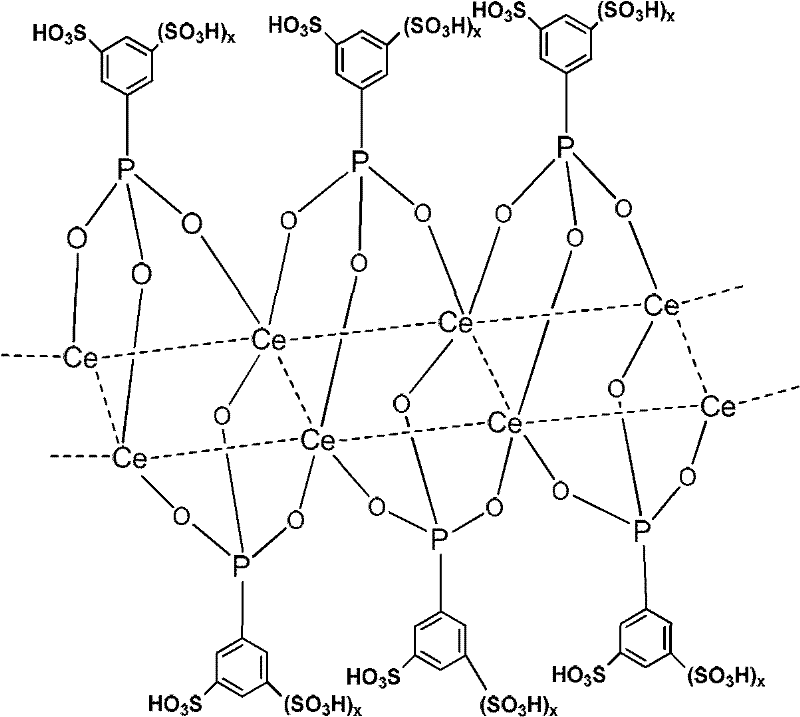

InactiveCN102441432AEliminate vacuum dehydration processHigh degree of sulfonationFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodieselCerium

The invention belongs to the field of catalyst preparation, and relates to a solid acid catalyst for preparing biodiesel and a preparation method thereof. The solid acid catalyst is sulfonated cerium phenyl phosphinate, and the sulfonation degree is 100-200%. The preparation method comprises the following two steps: introducing SO3 into a mixed solution of phenylphosphonic acid and 1,2-dichloroethane, thus preparing sulfonated phenylphosphonic acid; and adding ammonium ceric nitrate completely dissolved in a nitric acid solution into the sulfonated phenylphosphonic acid solution, stirring while heating, centrifuging, repeatedly washing the precipitate, and drying. The catalyst is widely applicable to the reactant raw grease, can be easily recycled, and has the advantages of low requirements for water and other impurities in the raw material, moderate reaction, high catalytic activity and no pollution.

Owner:SHANDONG UNIV OF TECH

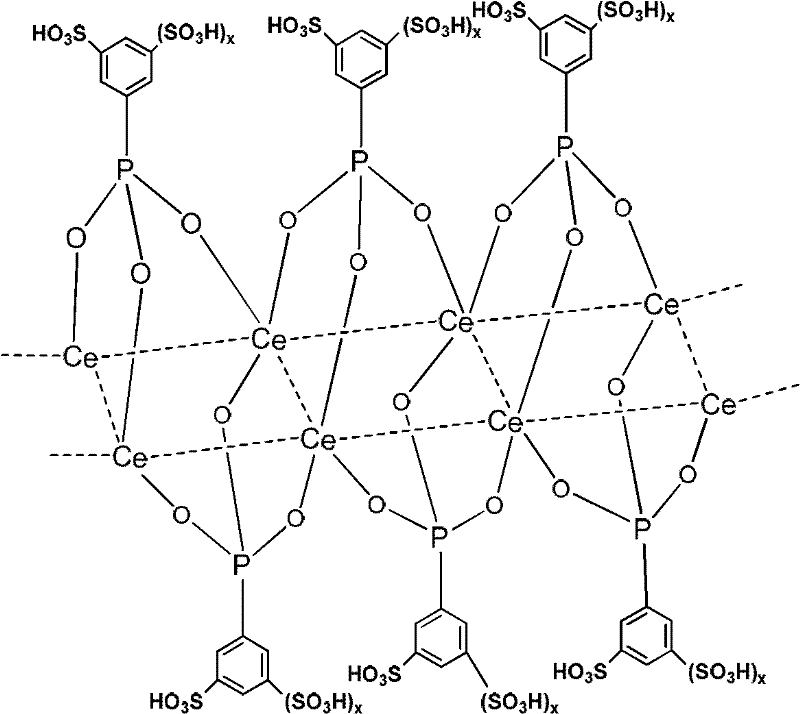

High-tenacity flame-retardant bismaleimide resin and preparation method thereof

InactiveCN104530430ALow viscosityImproved molding process typeGroup 5/15 element organic compoundsDiphenylmethaneClaisen rearrangement

The invention relates to a high-tenacity flame-retardant bismaleimide resin and a preparation method of the high-tenacity flame-retardant bismaleimide resin. The resin is composed of 100 parts of diphenylmethane bismaleimide, 1-100 parts of diallyl bisphenol A, 1-100 parts of bisphenol A diallyl ether, 1-50 parts of O,O-bis(4-(allyloxy) phenyl) phenyl phosphonic acid). Both the bisphenol A diallyl ether and the O,O-bis(4-(allyloxy) phenyl) phenyl phosphonic acid) undergo claisen rearrangement at a high temperature to be transformed into derivatives of diallyl and then participate in the curing reaction of the resin, and therefore the bisphenol A diallyl ether can effectively decrease the viscosity of a prepolymer at a low temperature and improve the forming process of the resin; phosphorus in the O,O-bis(4-(allyloxy) phenyl) phenyl phosphonic acid) can restrain combustion of the resin and make the resin generate a small amount of smoke without poisonous or corrosive gas in combustion, meets environmental requirements and has good compatibility with the resin.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

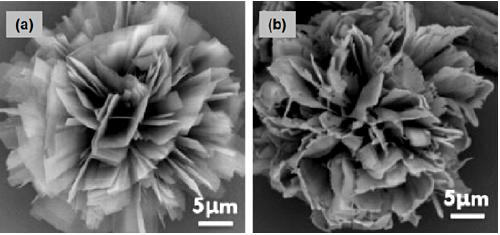

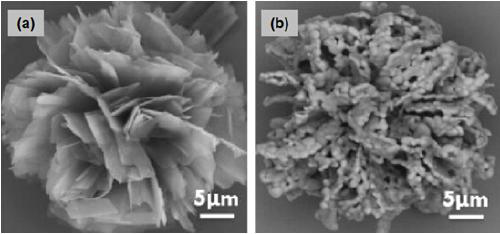

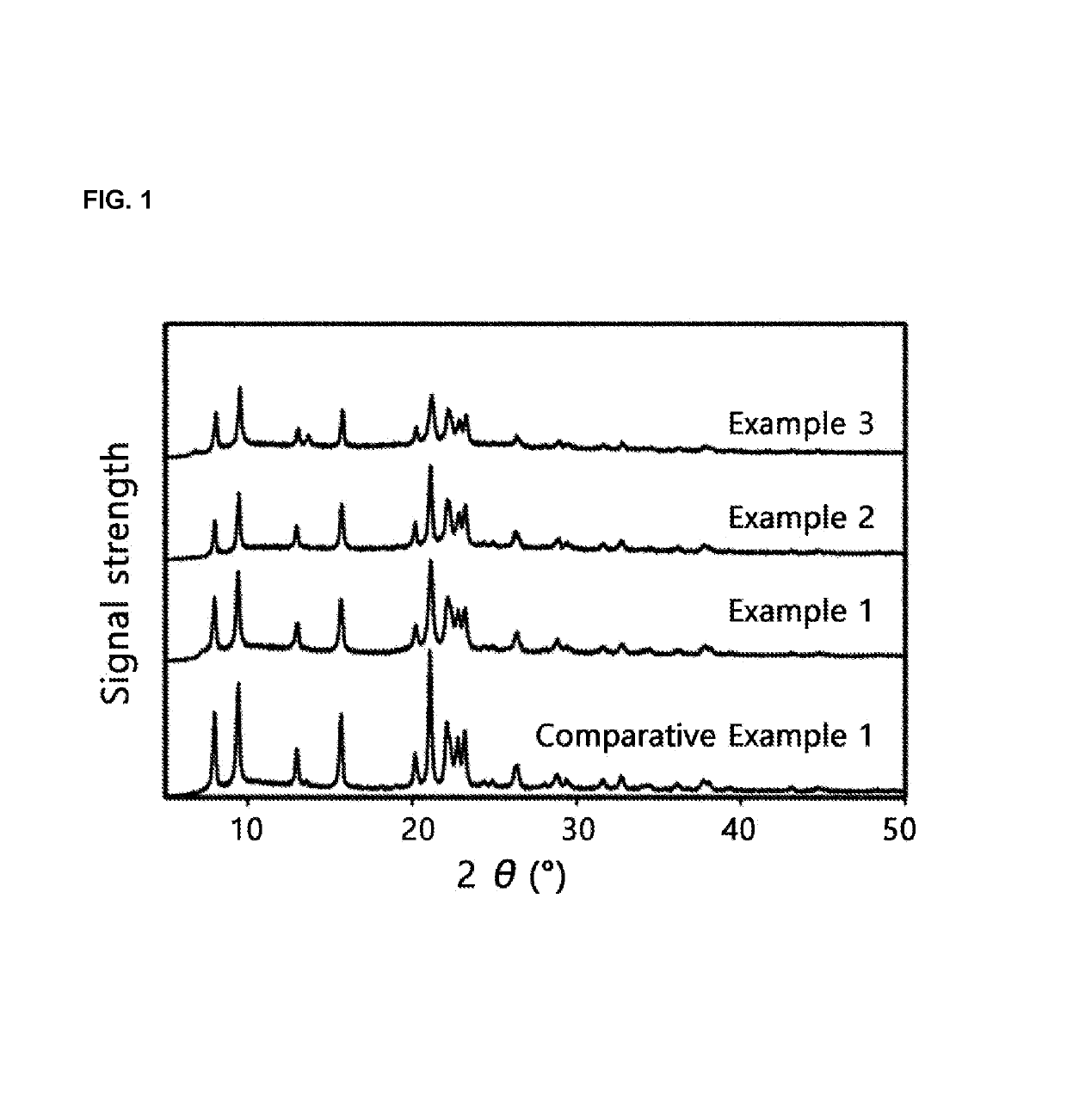

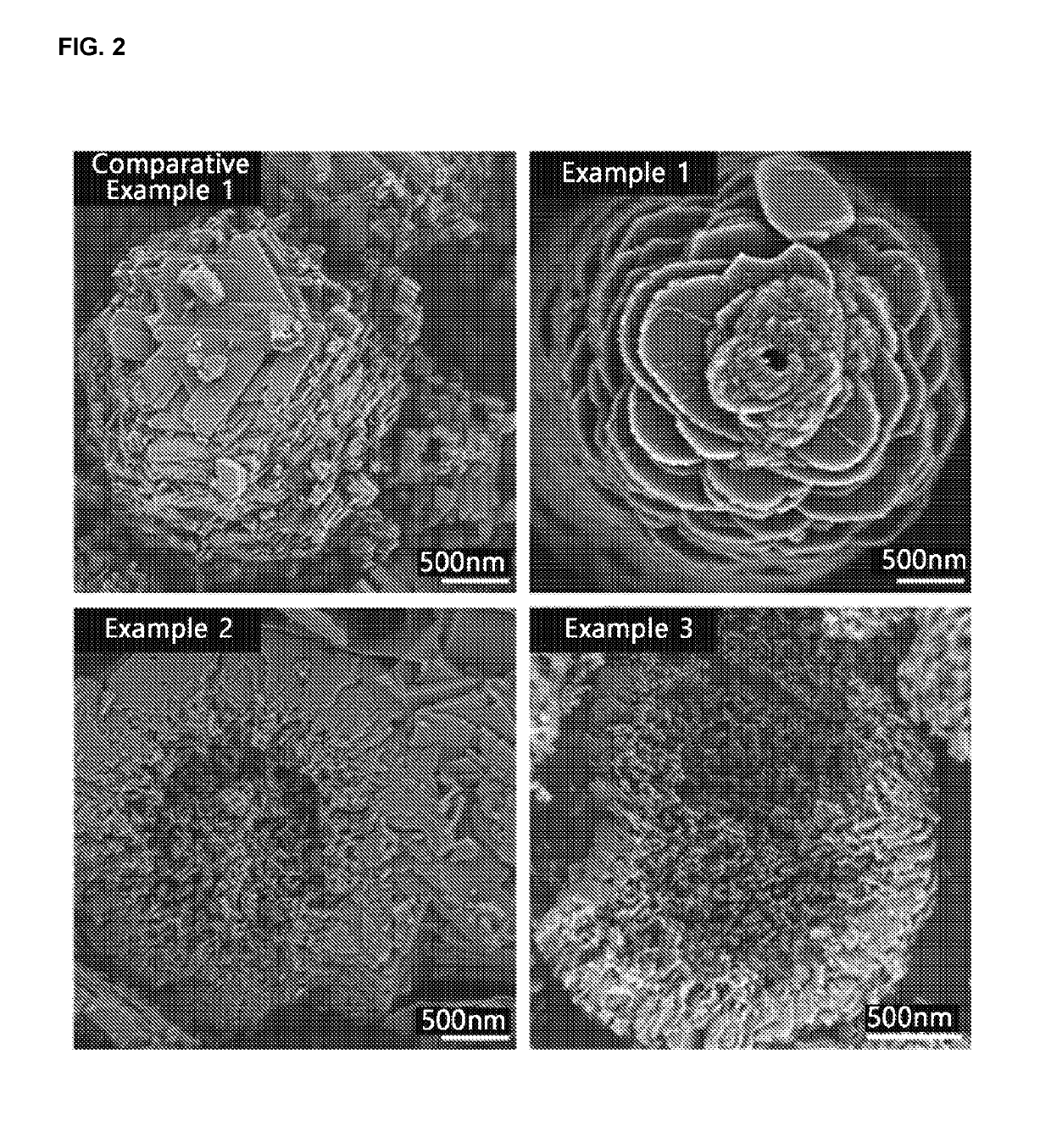

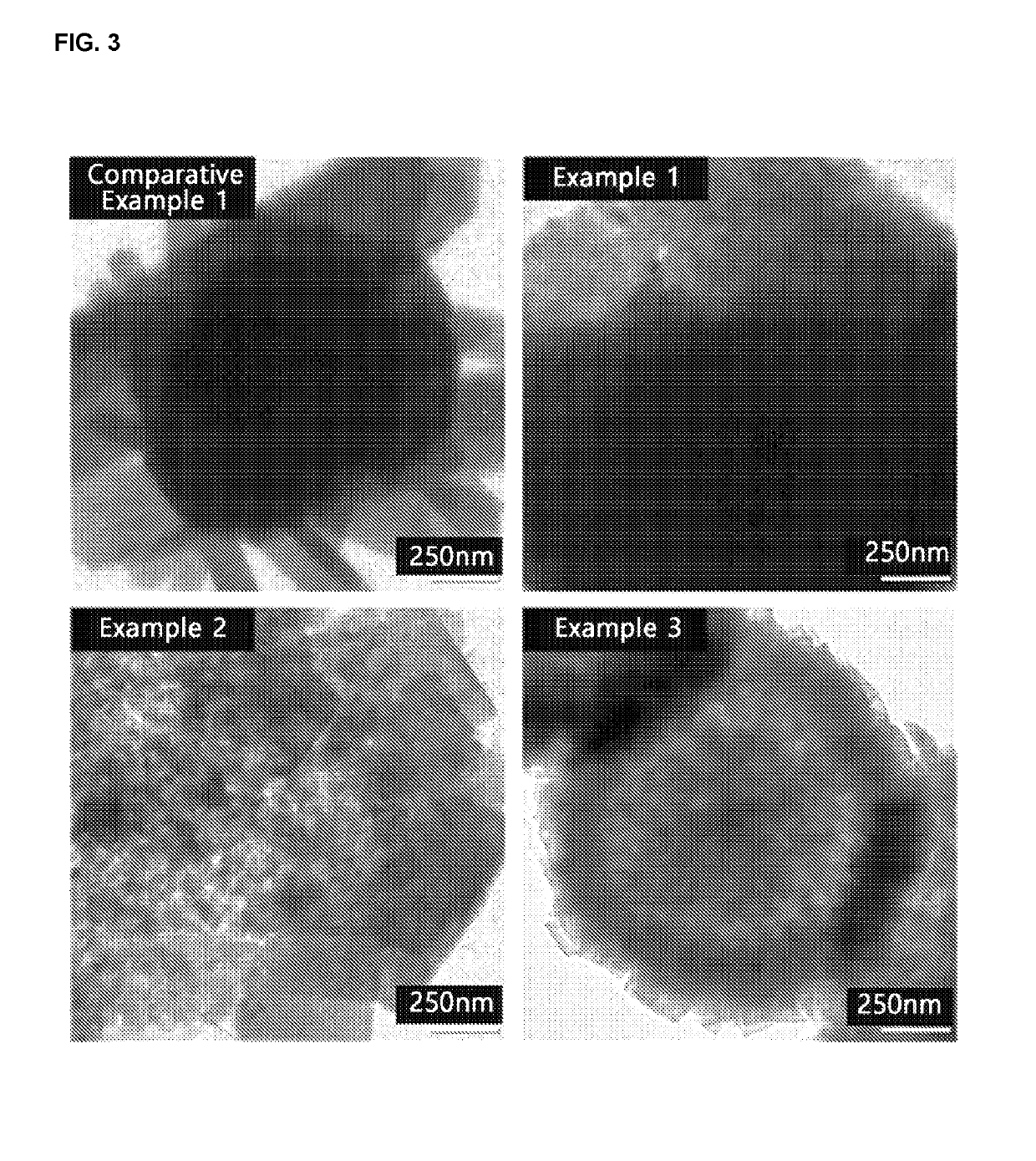

Method for manufacturing of multi-level pore zeolite and utilization as catalyst for hydroisomerization of normal paraffins of multi-level pore zeolite prepared thereby

ActiveUS20170158970A1High hydroisomerizationImprove cloud point and pour pointEsterified saccharide compoundsSugar derivativesAlkaneIsomerization

The present disclosure relates to a method for preparing a multi-level pore zeolite, including: (A) a step of mixing a silicon precursor, an aluminum precursor, a phosphorus precursor, a structure directing agent and water; a step of (B) adding phenylphosphonic acid, carbon black or a mixture thereof to the mixture prepared in the step (A) and mixing the same; a step of (C) crystallizing the mixture prepared in the step (B) by heat-treating the same; and a step of (D) calcining the crystallization product, and utilization of the prepared multi-level pore zeolite as a catalyst for hydroisomerization of normal paraffins. The catalyst exhibits improved isoparaffin yield when it is used as a catalyst for hydroisomerization of normal paraffins such as diesel or lube base oil by supporting an active metal component because residence time of reactants and products in the zeolite crystals are decreased due to mesopores and the proportion of external acid sites to total acid sites is low. Also, cloud point and pour point are effectively improved and high hydroisomerization reactivity is achieved without product loss.

Owner:S-OIL +1

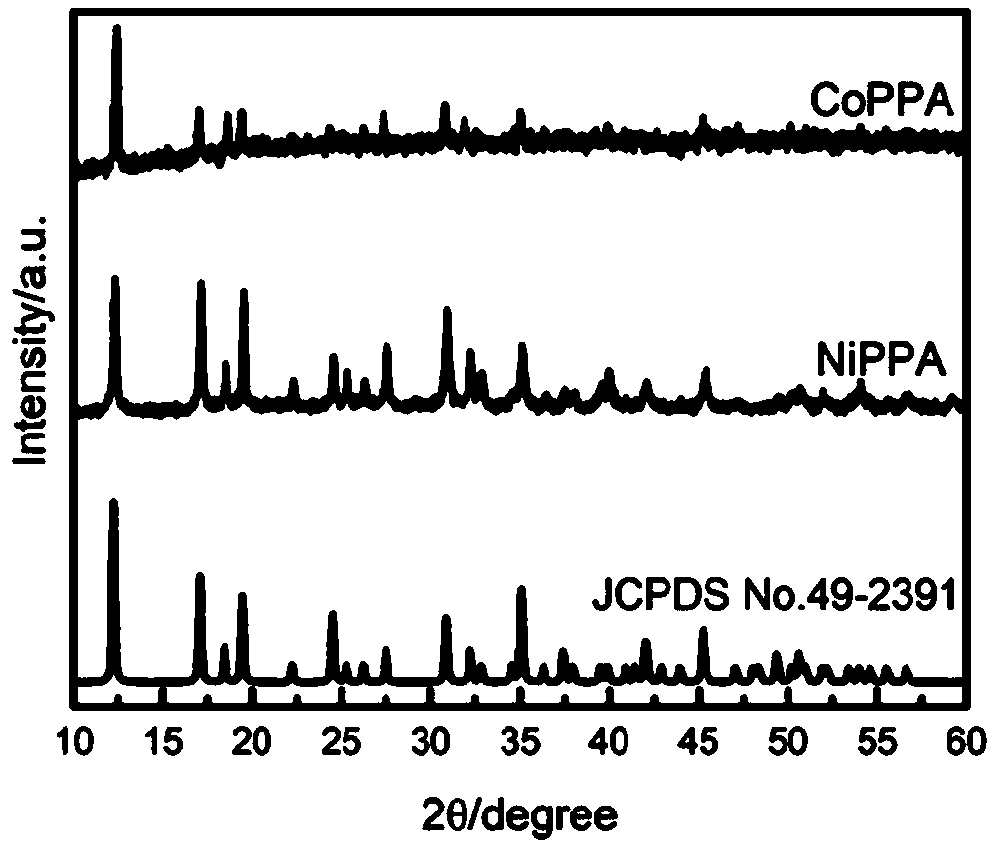

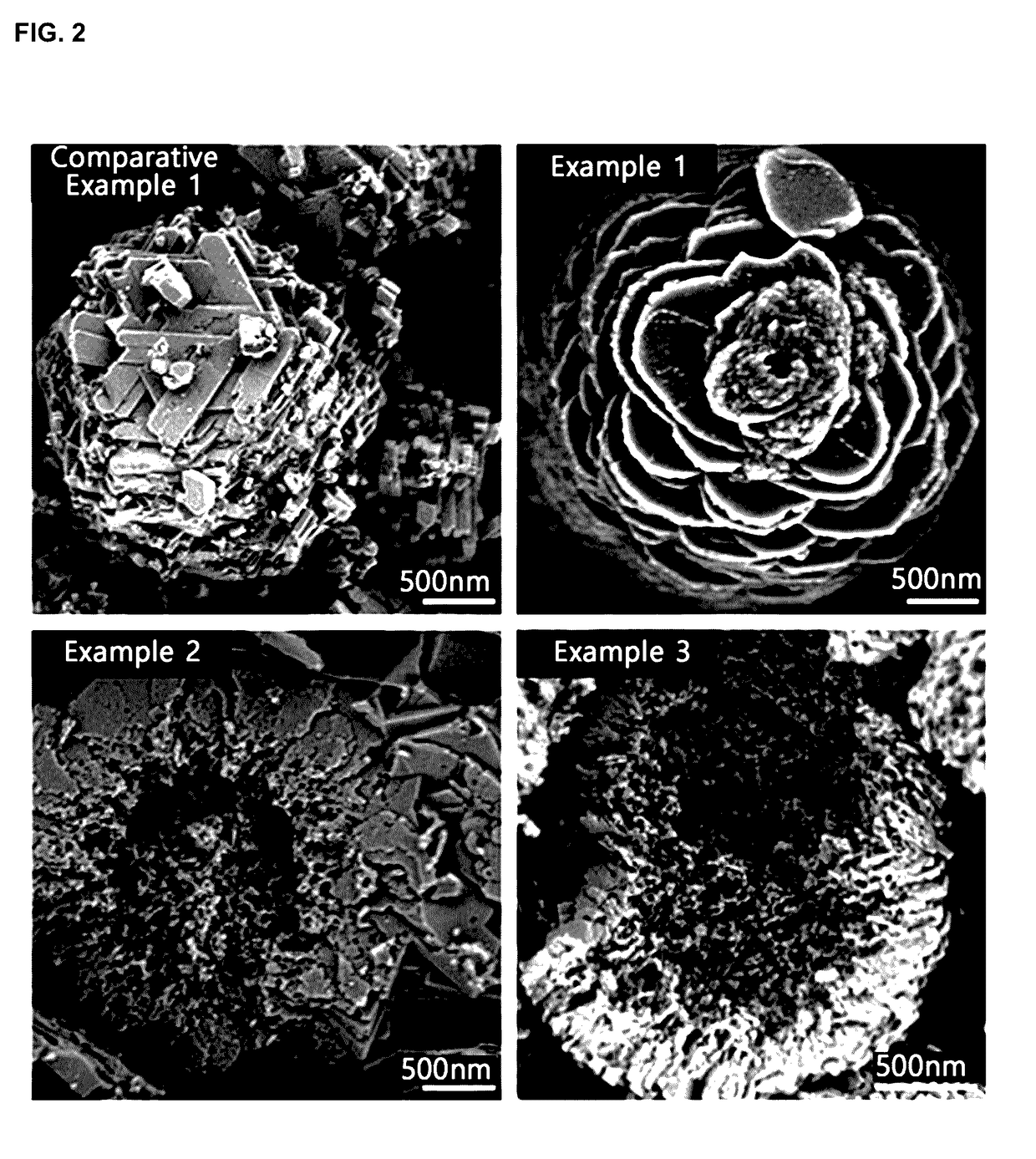

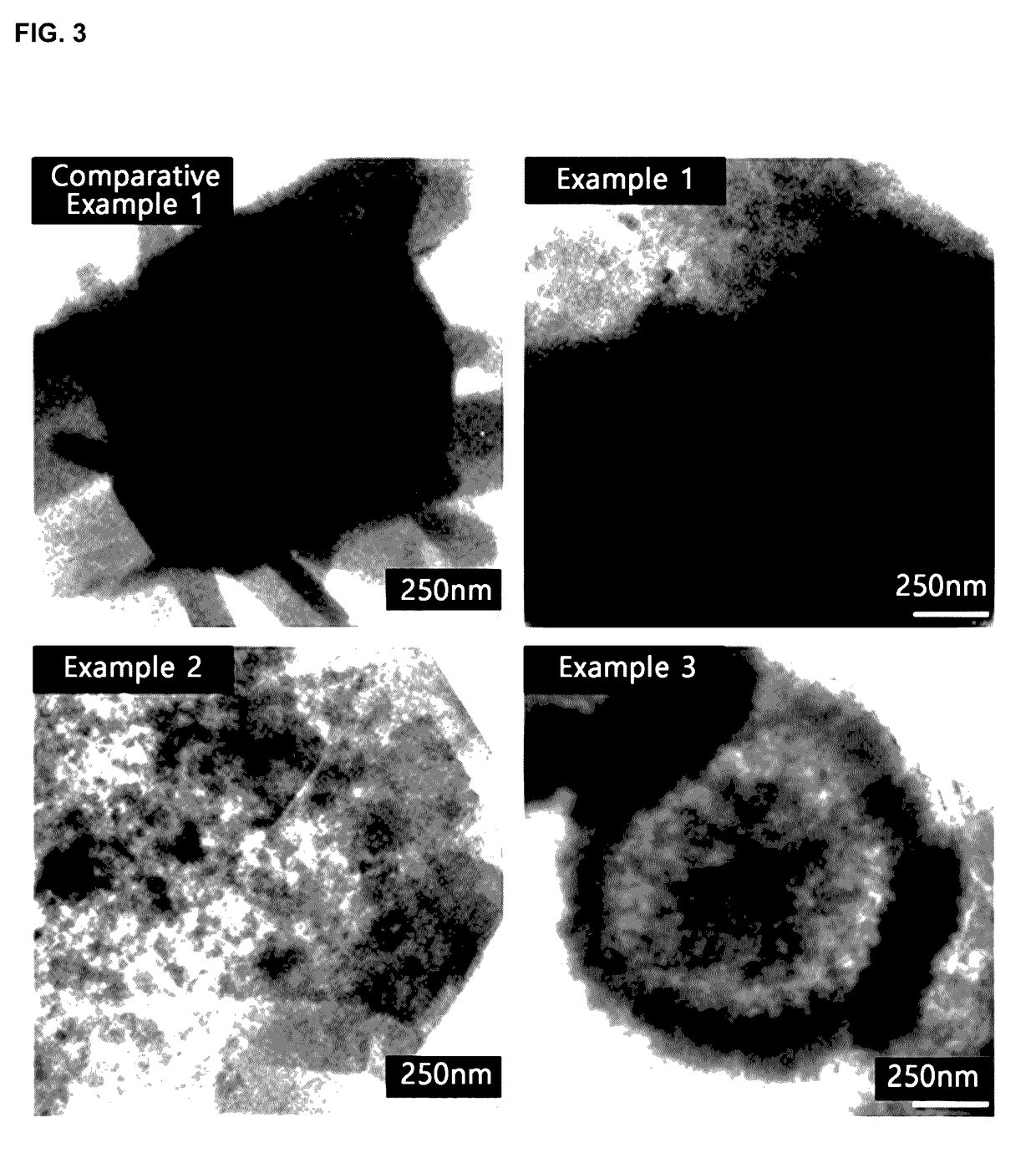

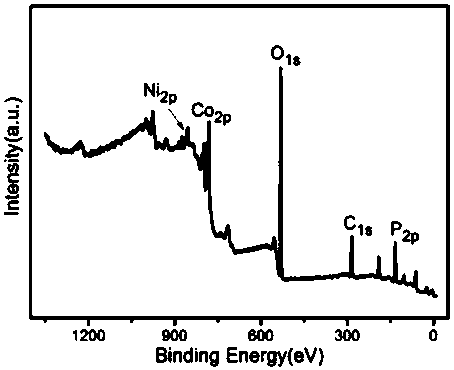

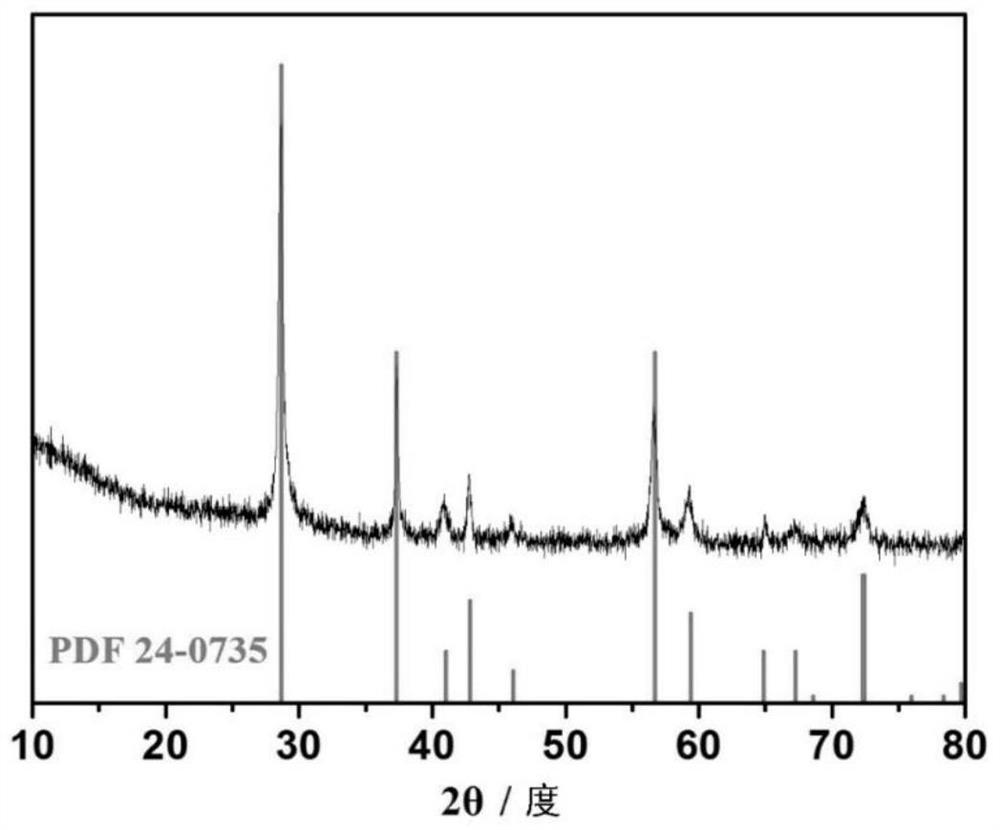

Cobalt-nickel bimetal phosphate flower-like microsphere electrocatalyst and preparation method thereof

InactiveCN109894128AHigh specific surface areaSpecial three-dimensional flower-like microsphere structurePhysical/chemical process catalystsElectrodesMicrospherePhosphate

The invention discloses a cobalt-nickel bimetal phosphate flower-like microsphere electrocatalyst and a preparation method thereof. The preparation method comprises the steps of adjusting PH with urea, and slowly synthesizing cobalt-nickel bimetal organic phosphoric compound flower-like microsphere precursor CoNiPP; carrying out high temperature treatment at different temperatures to obtain the cobalt-nickel bimetal phosphate flower-like microsphere electrocatalyst which still well retains the flower-like microsphere structure of the precursor and which has a structural general formula of CoNiPP-T, with T=700-900 DEG C. The flower-like microsphere structure helps effectively increase specific surface area and porosity of a material, thereby adding more transfer channels of internal electrons during electrocatalytic reaction; organic benzene rings in phenylphosphonic acid are removed and decomposed by calcining to obtain a porous carbon coating layer, so that the quantity of active sites for electrocatalytic reaction can be increased. In addition, double metals are present, each metal corresponds to a different active site, and therefore, the quantity of active sites for electrocatalytic reaction can also be increased.

Owner:淮安新能源材料技术研究院

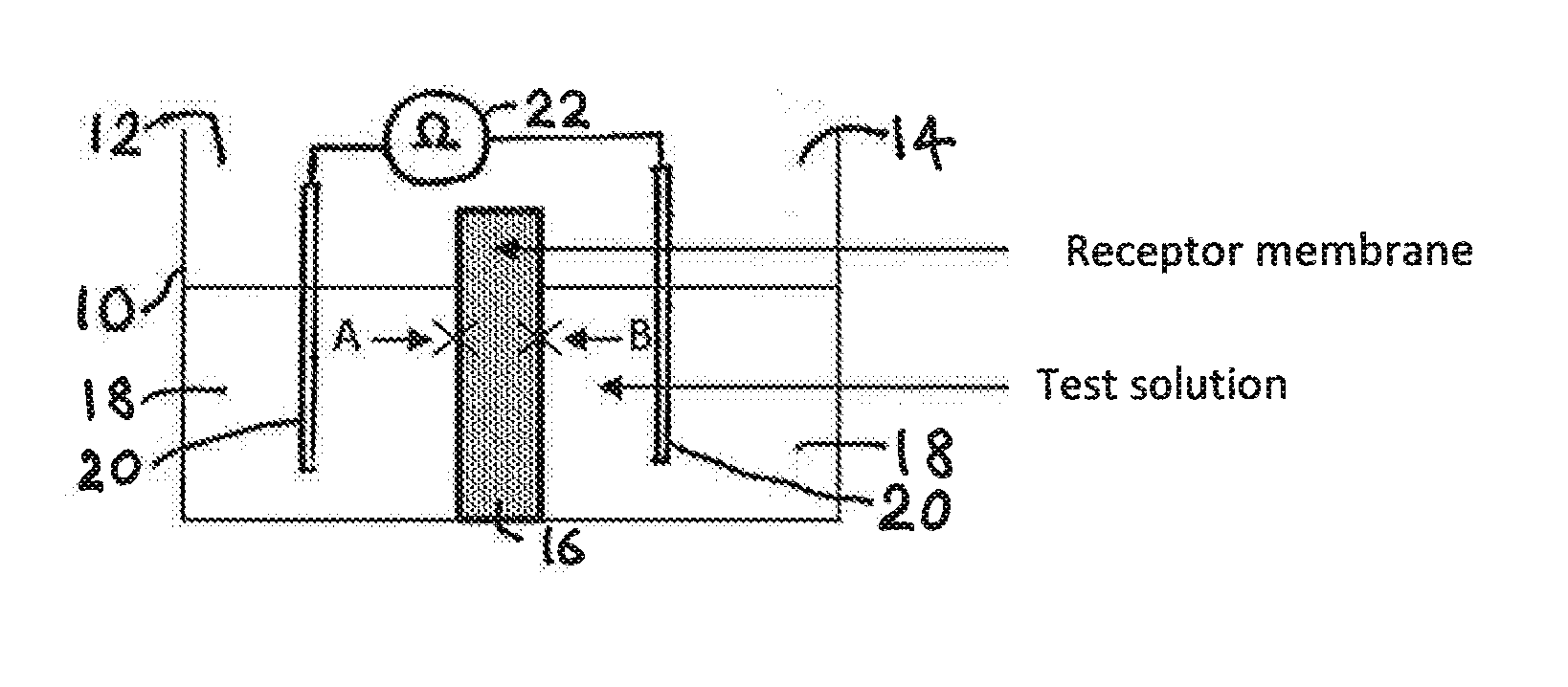

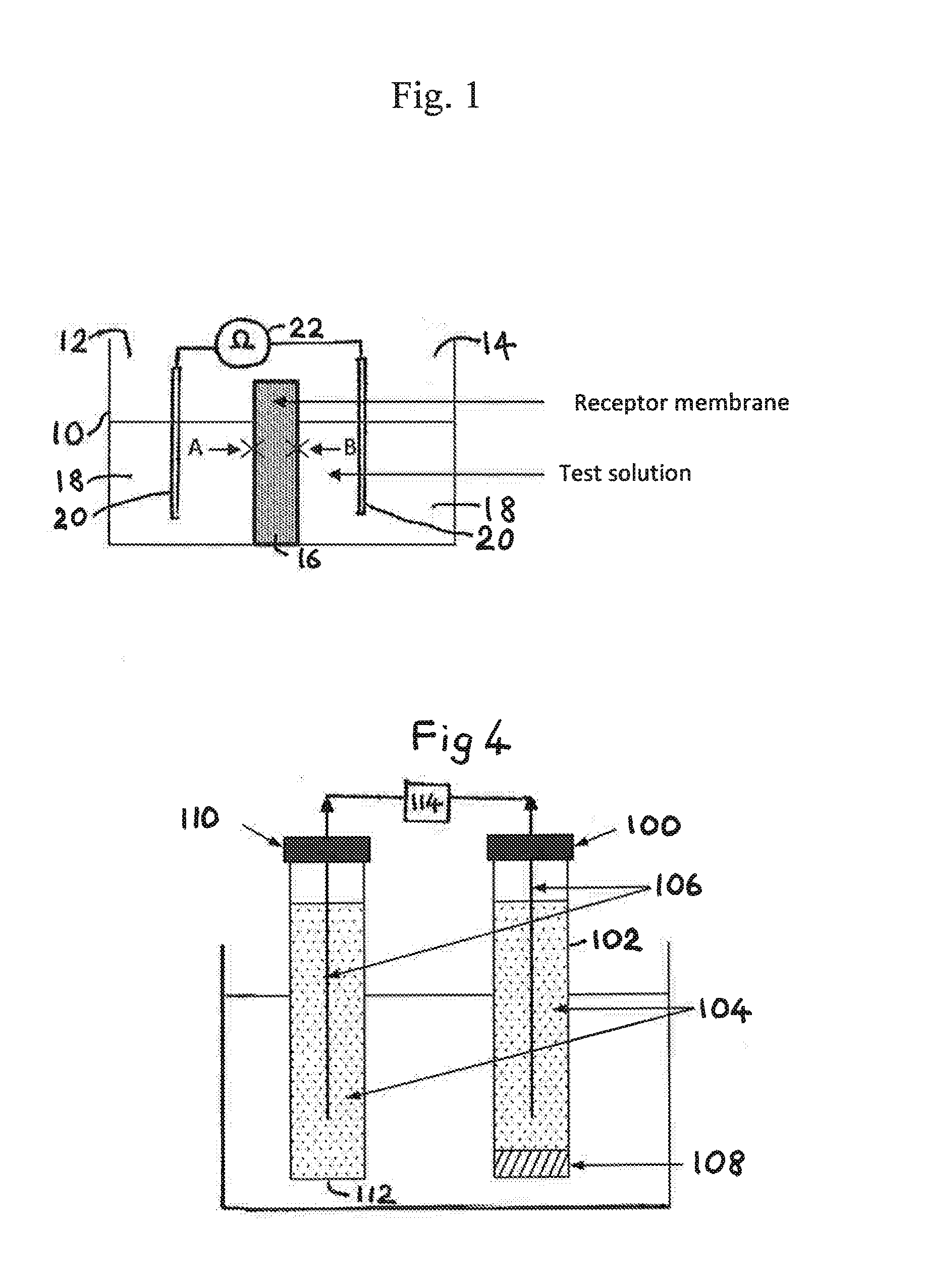

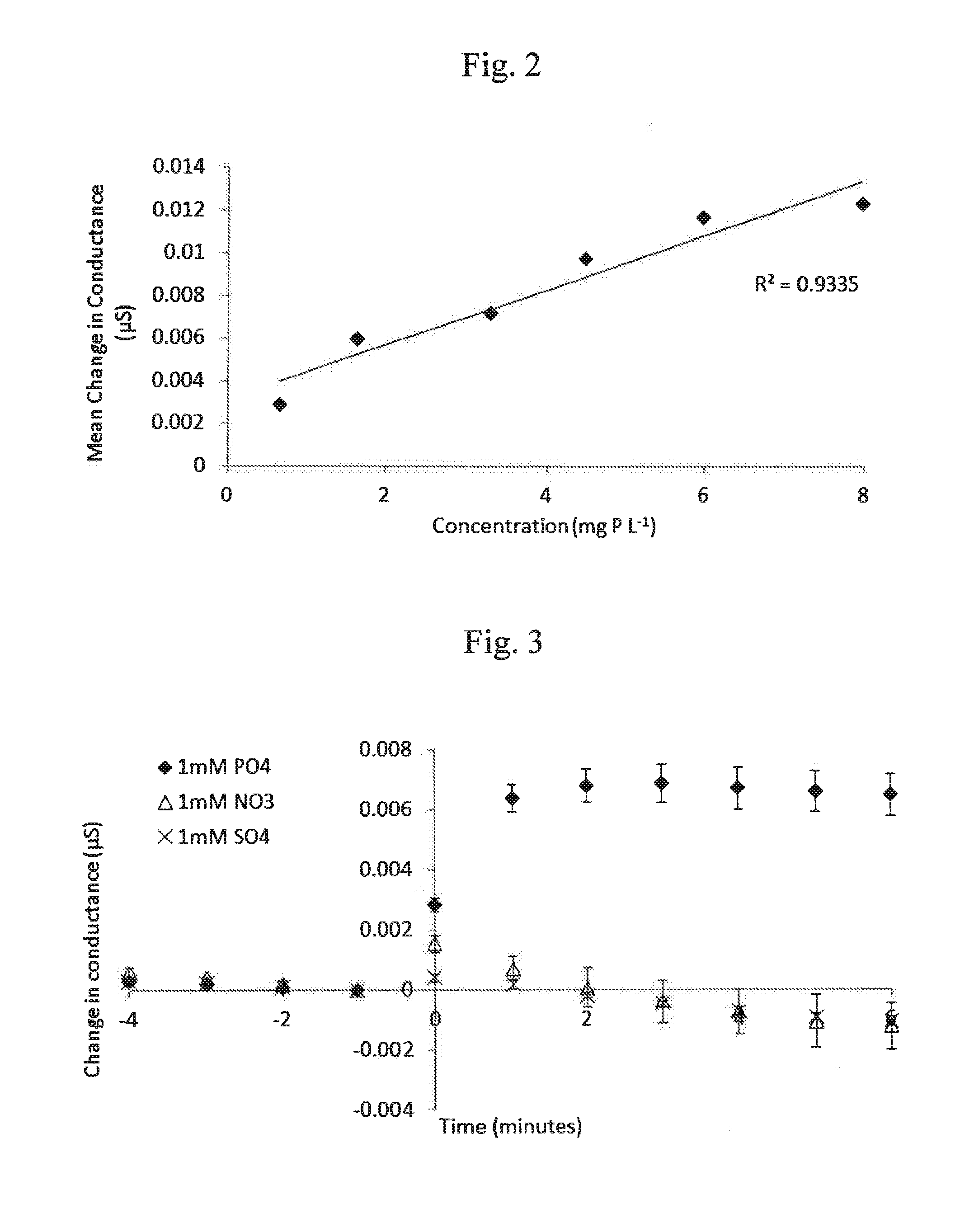

Phosphate sensor, its use and its method of preparation

InactiveUS20160077042A1Robust and convenient and reliable approachIncrease costSemi-permeable membranesMembranesFunctional monomerPhosphate

Owner:CRANFIELD UNIVERSITY +1

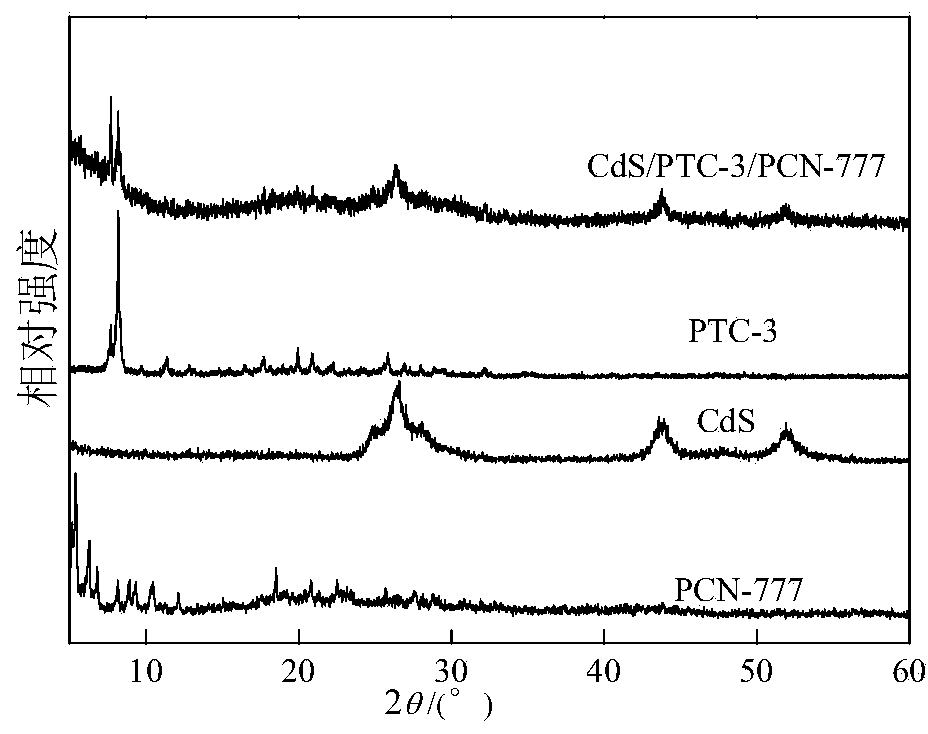

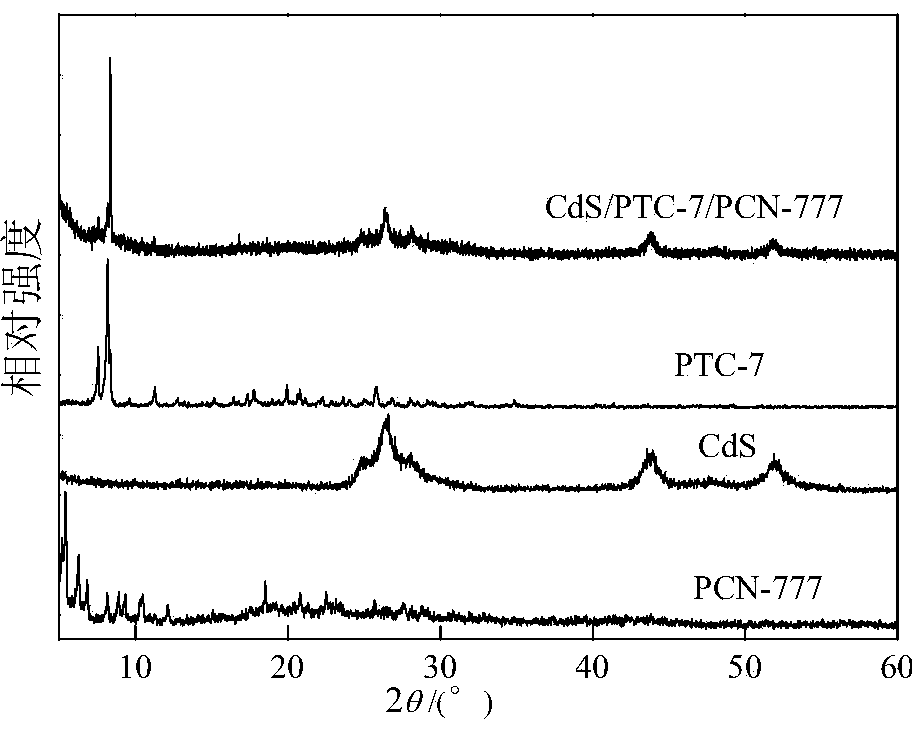

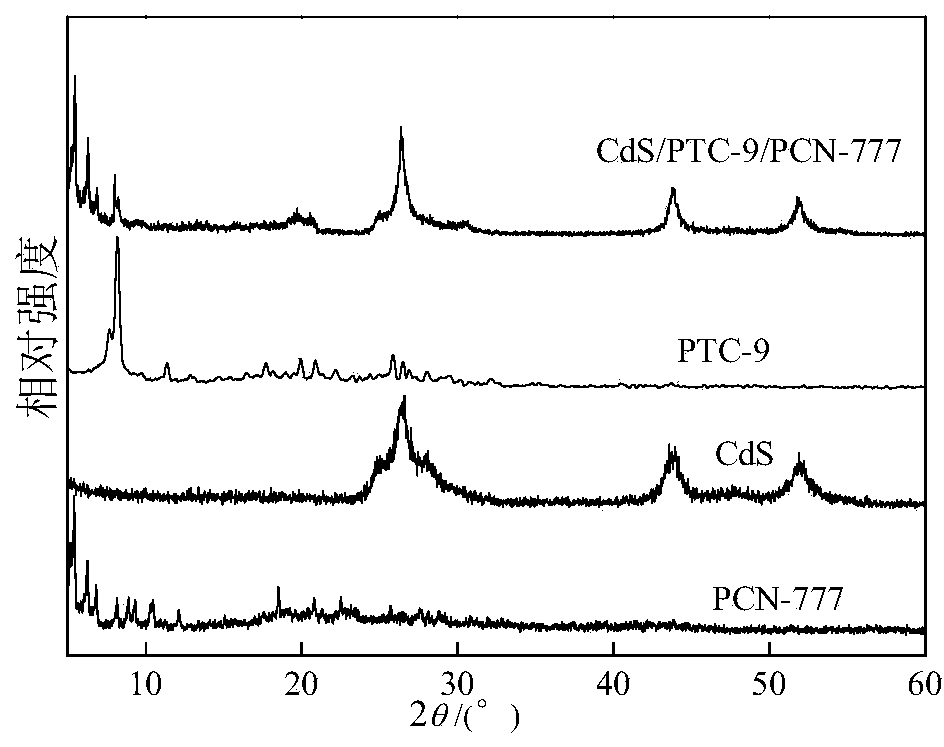

Multi-component composite titanium oxygen cluster (PTCs) CdSPCN-777 photocatalyst for decomposing water to produce hydrogen

PendingCN111185247AEasy to separateEnhanced photocatalytic responsivenessOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionPerfluoroacetic AcidPhenylphosphonic acid

The invention discloses a multi-component composite titanium oxide cluster (PTCs) CdSPCN-777 photocatalyst for decomposing water to produce hydrogen, belonging to the technical field of photocatalyticmaterials. The multi-component composite titanium oxide cluster (PTCs) CdSPCN-777 photocatalyst for decomposing water to produce hydrogen has excellent catalytic efficiency. The preparation method for the multi-component composite titanium oxide cluster (PTCs) CdSPCN-777 photocatalyst comprises the following steps: allowing zirconium oxychloride, 2,4,6-tri(4-carboxyphenyl)-1,3,5-triazine, DEF andtrifluoroacetic acid to react so as to synthesize PCN-777; dispersing Cd<2+> into the PCN-777 so as to obtain PCN-777 containing Cd<2+>; then allowing the PCN-777 containing Cd<2+> to react with a sulfur source so as to obtain CdS / PCN-777; and mixing the CdS / PCN-777, phenylphosphonic acid, organic acid and isopropanol, and allowing an obtained mixture to react with Ti(OiPr)4 so as to obtain (PTCs)CdSPCN-777. According to the invention, the hydrogen production capacity of the (PTCs)CdSPCN-777 reaches 2.37 mmol / (g.h) or above.

Owner:PANZHIHUA UNIV

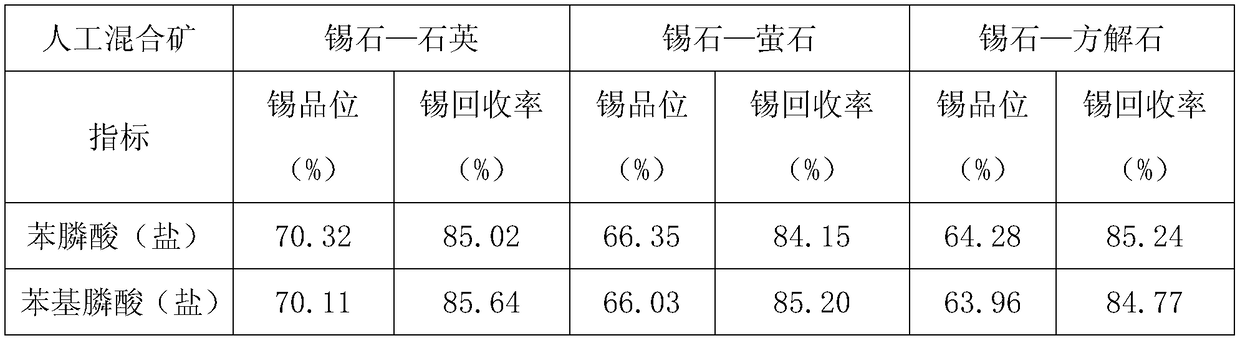

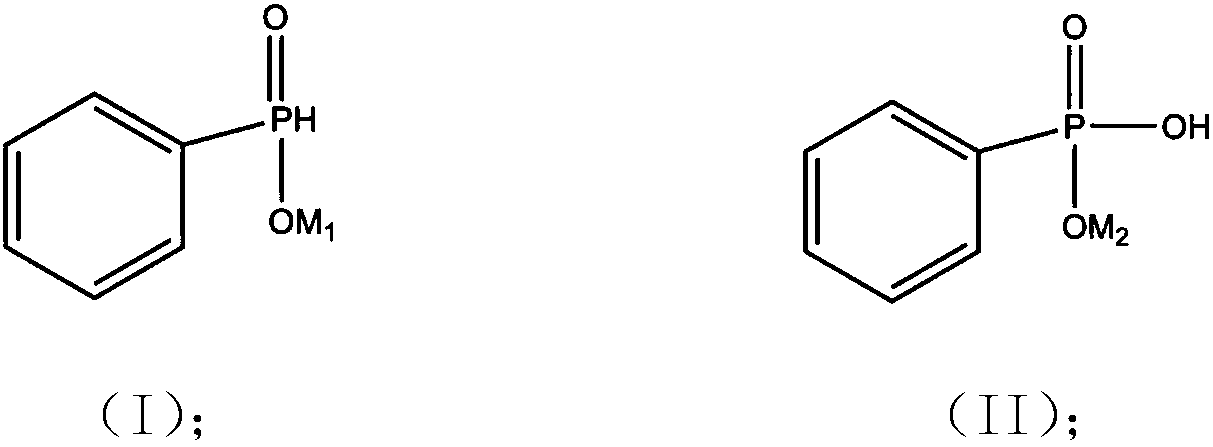

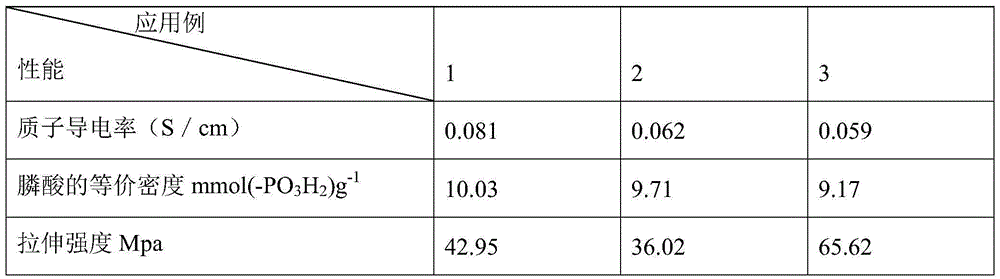

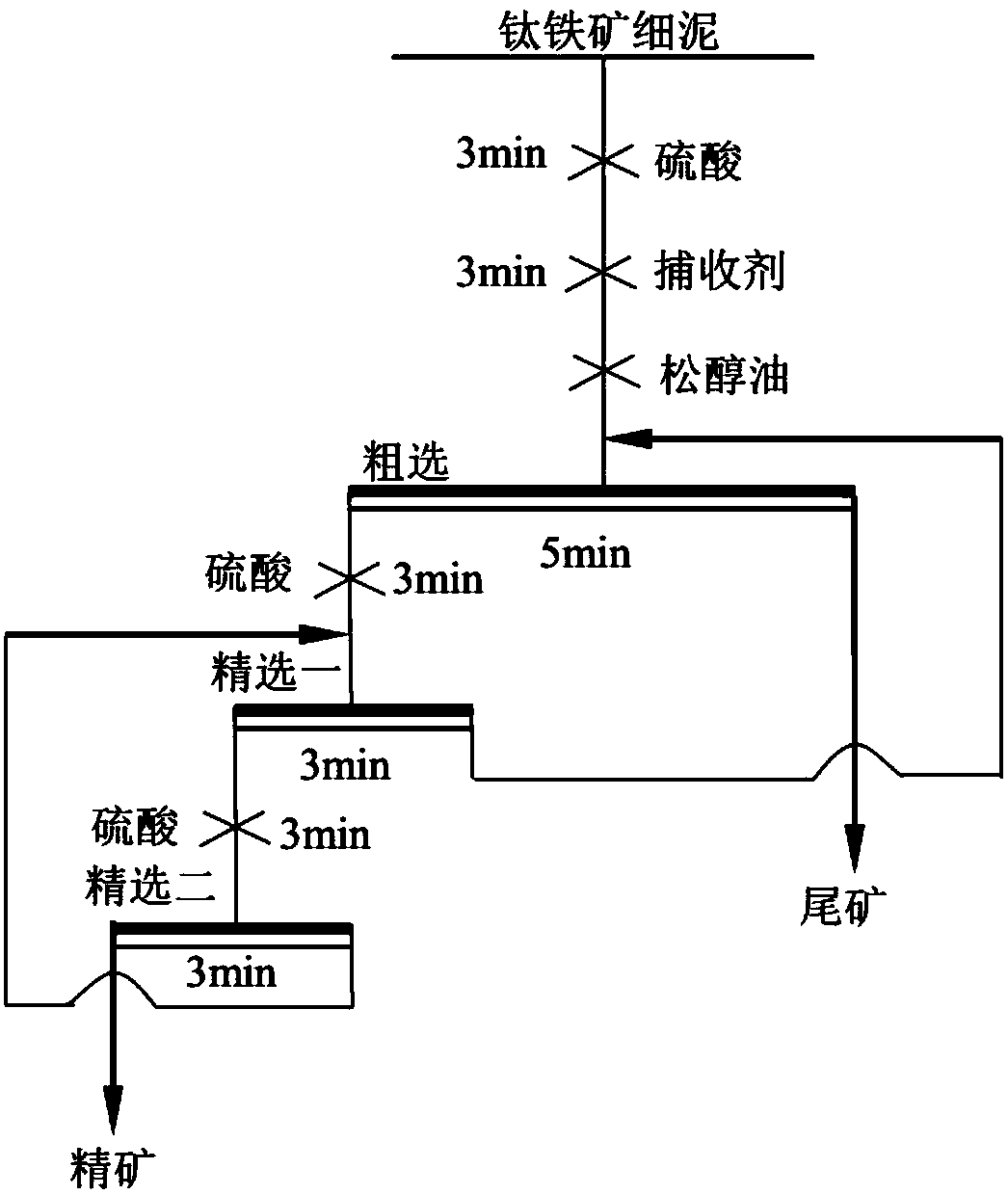

Collector comprising aromatic phosphonic acid and salt of aromatic phosphonic acid and application of collector

The invention discloses a collector comprising aromatic phosphonic acid and salt of aromatic phosphonic acid and application of the collector, and belongs to the technical field of flotation. The collector comprising aromatic phosphonic acid and salt of aromatic phosphonic acid comprises phenylphosphinic acid and salt of phenylphosphinic acid and / or phenyl phosphonic acid and salt of phenyl phosphonic acid and is applied to flotation separation of cassiterite and gangue minerals. The aromatic phosphonic acid and salt of aromatic phosphonic acid are used as the cassiterite collector, the collector water solubility is improved, the collector has good selectivity, cassiterite and the gangue minerals such as quartz, fluorite and calcite can be effectively separated, and the collector can achieve flotation of cassiterite under the condition with a wide pulp pH range.

Owner:NORTHEASTERN UNIV

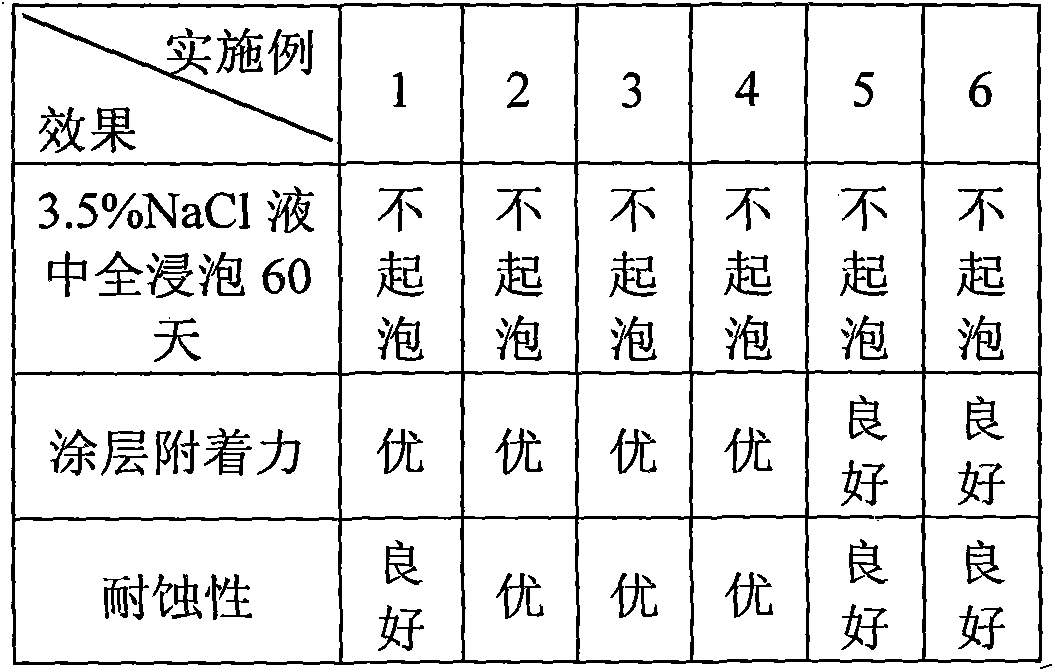

Aluminium-alloy chromium-free in-situ phosphating liquid and preparation method thereof

InactiveCN104278264AImprove corrosion resistanceImprove bindingMetallic material coating processesChromium freeNitrite

The invention discloses an aluminium-alloy chromium-free in-situ phosphating liquid and a preparation method thereof. The luminium-alloy chromium-free in-situ phosphating liquid comprises the compositions in percent by mass: 1-5% of phenylphosphonic acid, 0.1-0.3% by tartaric acid, 0.1-0.3% of citric acid, and the balance an organic wetting dispersant and organic paint. Phenylphosphonic acid is taken as the main composition of an in-situ phosphating agent, tartaric acid and citric acid are taken as organic additives, and the phosphating liquid does not contain nitrites, does not contain nickel ion and chromium ion, and is free of pollution to environment. Phenylphosphonic acid and the organic paint form a stable uniformly-mixed film-forming substance, and an organic coating is formed on the surface of an aluminium alloy base body, so that metal phosphating processing and coating of the organic coating are combined, multiple coating operations are simultaneously finished in one process, and the economic cost of the multi-step coating technology and the operation complexity are effectively reduced. Operations of phosphating processing and chromate sealing are reduced, time, energy, resource and labor force are saved, discharge of toxic substances is reduced, and the preparation method is a green clean technology. Additionally, the preparation method is simple, convenient to operate and use, and free of technological difficulty.

Owner:XINXIANG UNIV

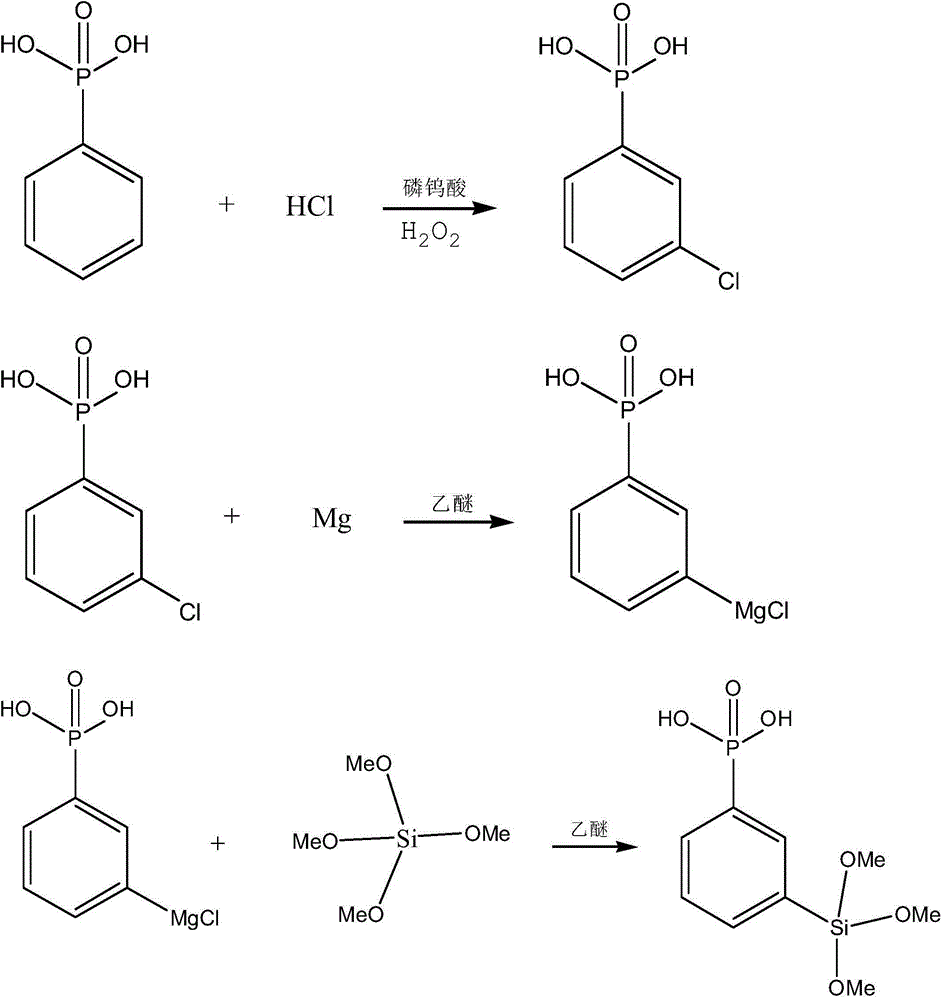

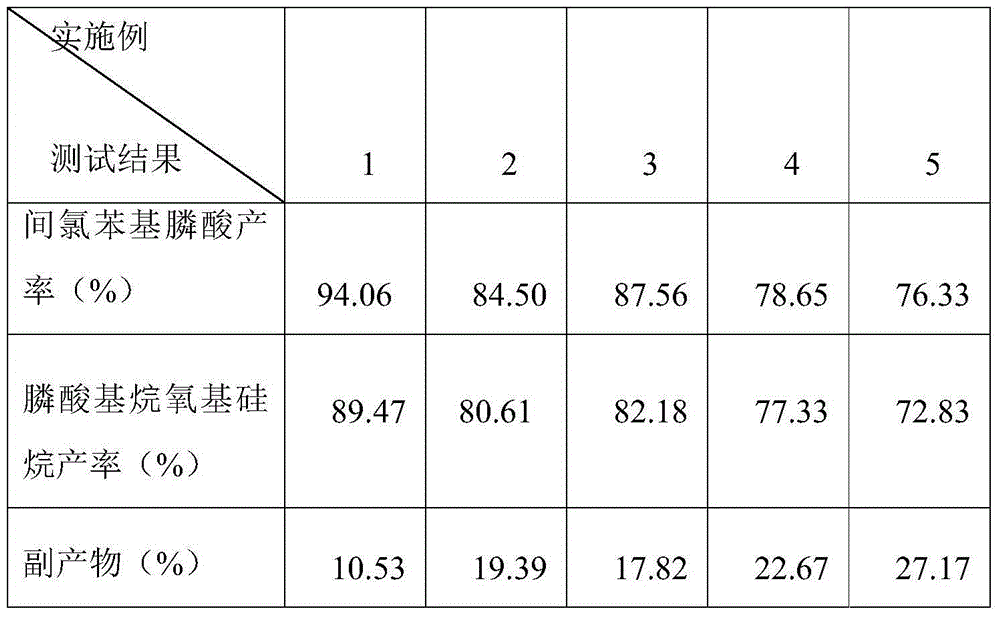

Grignard reaction-based method for preparing phenylphosphonic acid trimethoxy silane

InactiveCN104086591AQuick responseReduce the temperatureGroup 5/15 element organic compoundsSolid electrolyte fuel cellsIce waterGrignard reagent

The invention discloses a grignard reaction-based method for preparing phenylphosphonic acid trimethoxy silane. The method comprises the following steps: 1) adding dry magnesium powder and iodine to an absolute ether under water-free and oxygen-free conditions, and adding an m-Chlorophenyl phosphonic acid to participate into reaction, so as to obtain a grignard reagent of the m-Chlorophenyl phosphonic acid; 2) dropwise adding an anhydrous diethyl ether solution of tetramethoxysilane to the grignard reagent of the m-Chlorophenyl phosphonic acid under the water-free and oxygen-free conditions at 0-5 DEG C, carrying out micro-boiling, so that a reaction mixture flows back, then cooling on an ice-water bath, separating out an ether layer, washing and drying, and then obtaining a crude product ether solution; collecting a fraction at 137-141 DEG C, so as to obtain the phenylphosphonic acid trimethoxy silane. The phenylphosphonic acid trimethoxy silane prepared by the method has the advantages of fast reaction speed, low temperature, high yield, fewer side effects and stable phosphonic acid content, can be applied to a proton exchange membrane, and is especially applicable to a high-temperature proton exchange membrane.

Owner:WUHAN UNIV OF TECH

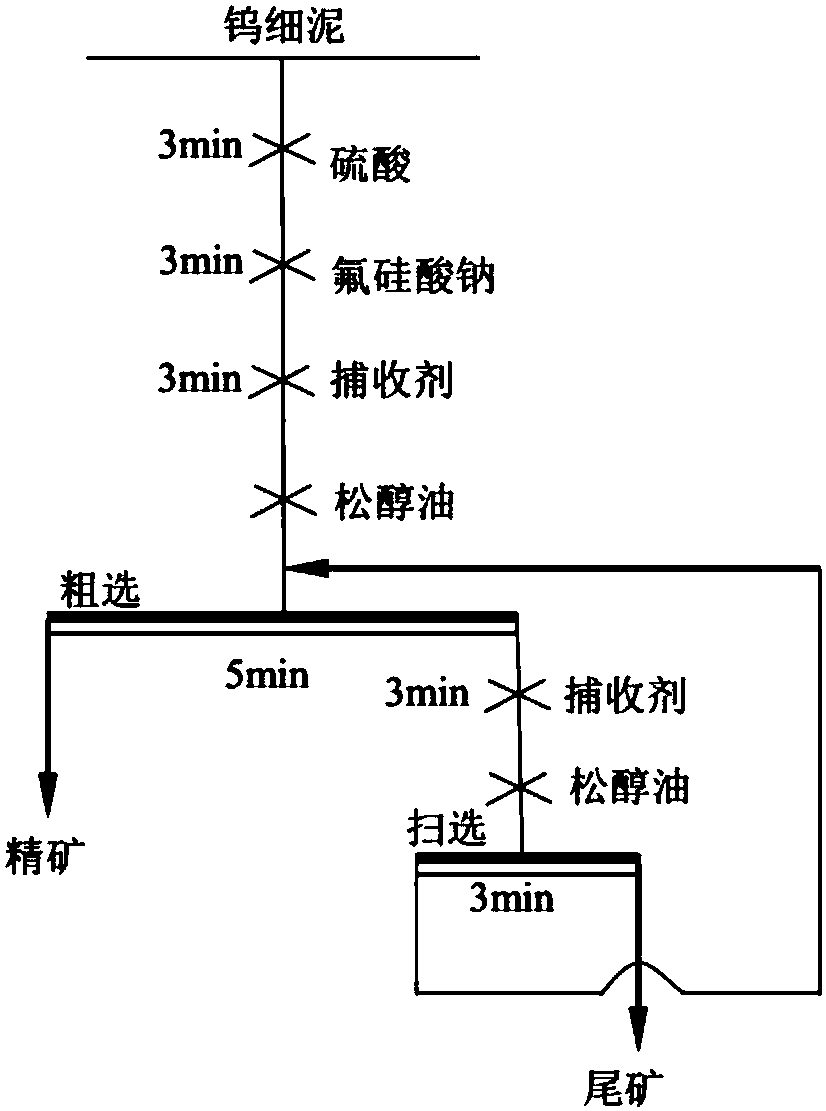

Non-sulfide mineral flotation collector and application thereof

The invention discloses a non-sulfide mineral flotation collector and application of the non-sulfide mineral flotation collector, and belongs to the technical field of mineral flotation collectors. The non-sulfide mineral flotation collector is prepared from carboxyl phenylphosphonic acid and salt thereof and has the advantages of being good in water solubility in normal temperature, easy to disperse, high in collection capability, good in selectivity and the like, and is mainly used for flotation and separation of valuable mineral in ilmenite, scheelite, wolframite, rutile, cassiterite, fluorite, rare earth ore, bauxite, manganese carbonate ore or phosphate minerals. The collector is low in cost, safe, environmentally friendly, high in flotation recycling rate and suitable for large-scaleindustrial application.

Owner:NORTHEASTERN UNIV

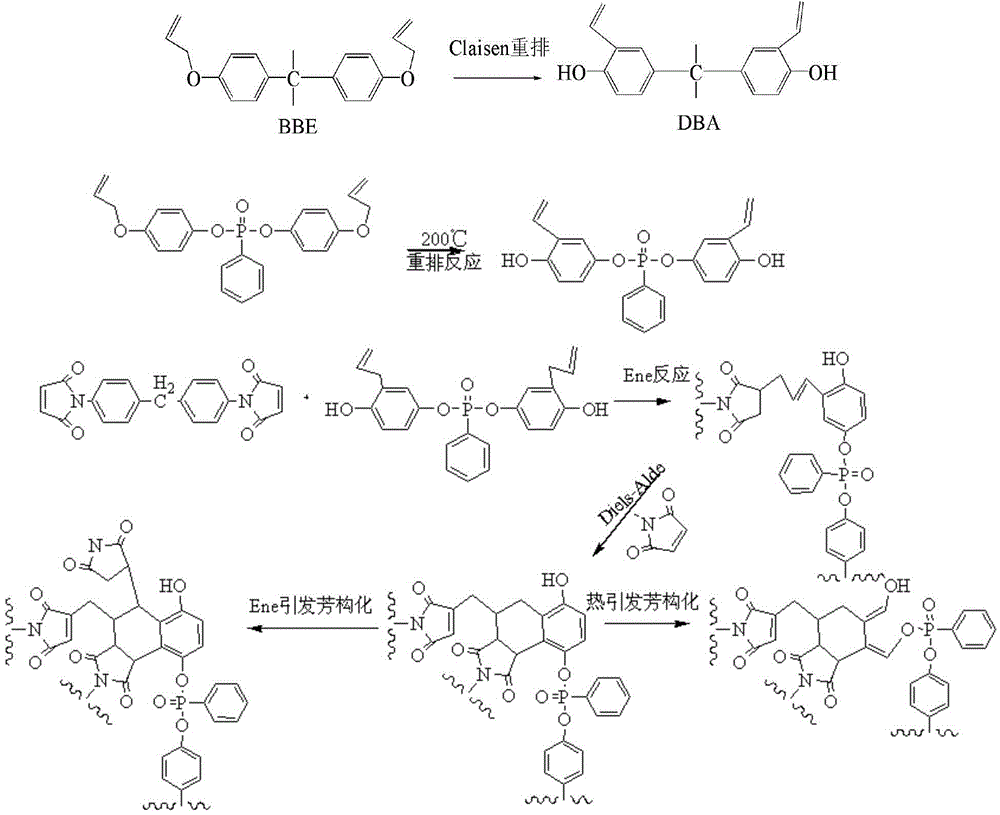

Method for manufacturing of multi-level pore zeolite and utilization as catalyst for hydroisomerization of normal paraffins of multi-level pore zeolite prepared thereby

ActiveUS10428280B2High hydroisomerizationImprove cloud point and pour pointEsterified saccharide compoundsSugar derivativesAlkanePhenylphosphonic acid

The present disclosure relates to a method for preparing a multi-level pore zeolite, including: (A) a step of mixing a silicon precursor, an aluminum precursor, a phosphorus precursor, a structure directing agent and water; a step of (B) adding phenylphosphonic acid, carbon black or a mixture thereof to the mixture prepared in the step (A) and mixing the same; a step of (C) crystallizing the mixture prepared in the step (B) by heat-treating the same; and a step of (D) calcining the crystallization product, and utilization of the prepared multi-level pore zeolite as a catalyst for hydroisomerization of normal paraffins. The catalyst exhibits improved isoparaffin yield when it is used as a catalyst for hydroisomerization of normal paraffins such as diesel or lube base oil by supporting an active metal component because residence time of reactants and products in the zeolite crystals are decreased due to mesopores and the proportion of external acid sites to total acid sites is low. Also, cloud point and pour point are effectively improved and high hydroisomerization reactivity is achieved without product loss.

Owner:S-OIL +1

Dry lithium battery separator and preparation method thereof

ActiveCN109742295AImprove heat resistanceImprove production efficiencyCell component detailsPorosityPolytetramethylene terephthalate

The invention belongs to the technical field of lithium battery separators, and particularly relates to a dry lithium battery separator and a reparation method thereof. The lithium battery separator comprises a core layer and surface layers disposed on both sides of the core layer, wherein the core layer comprises 93.8-97% of polyethylene, 2.5-5% of polybutylene terephthalate, and 0.5-1.2% of phenylphosphonic acid metal salt, and the percentage composition is the percentage by weight; the surface layers comprise 91.5-96.2% of polypropylene, 3-7% of polybutylene terephthalate, and 0.8-1.5% of phenylphosphonic acid metal salt, and the percentage composition is the percentage by weight. The dry lithium battery separator provided by the invention, by introducing incompatible polybutylene terephthalate into a three-layer composite structure of polypropylene / polyethylene / polypropylene, promoting the formation of micronized crystals, and forming a microporous structure with high porosity andupper and lower penetrating micropores through a biaxial stretching process, is completely different from the traditional micropore preparation technology, which avoids the high precision requirementof the process in the traditional micropore preparation technology and reduces the difficulty of preparation of micropores.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

Method for nitrifying paradichlorobenzene by using solid acid catalyst

ActiveCN105152936AEmission reductionRealize the purpose of resource recyclingOrganic-compounds/hydrides/coordination-complexes catalystsNitro compound preparationLiquid wastePtru catalyst

The invention relates to a method for nitrifying paradichlorobenzene by using a solid acid catalyst, which comprises the following steps: (1) preparing a 0.3 mol / L zirconium oxychloride solution with a teflon beaker in a fuming cupboard, adding a proper amount of HF, sufficiently stirring until the HF is completely dissolved, and transferring into a constant-pressure dropping funnel for later use; (2) preparing a 1.0 mol / L phenylphosphonic acid solution in the fuming cupboard; (3) slowly and dropwisely adding the zirconium oxychloride solution into the phenylphosphonic acid solution, and keeping the temperature; (4) after keeping the temperature, carrying out vacuum filtration, continuing carrying out water washing and vacuum filtration on the obtained solid until the Cl<-> concentration of the last filtrate is constant, and drying the finally obtained filter residue in a drying oven; (5) taking 1 mol of paradichlorobenzene, heating at 70 DEG C until the paradichlorobenzene is completely molten, and adding 1-3g of solid acid catalyst; and (6) slowly and dropwisely adding 1.1 mol of fuming nitric acid, and reacting. The method has the advantages of less liquid waste discharge and recyclable solid acid, and implements resource regeneration; and the conversion rate of chlorinated aromatics is up to 99% or above.

Owner:JIANGSU LONGCHANG CHEM

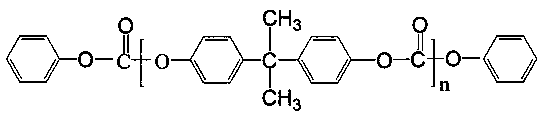

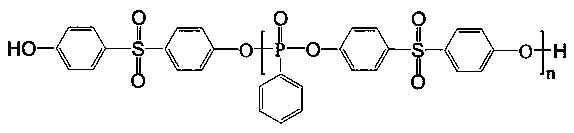

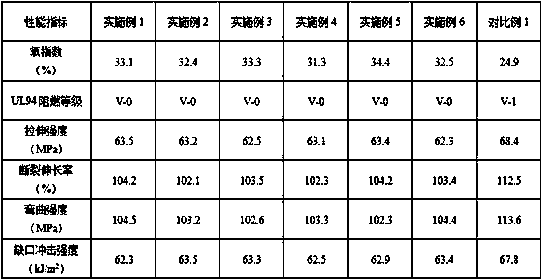

Polycarbonate/poly(bisphenol sulfone phenyl phosphonate) flame-retarding material and preparation method

The invention relates to the technical field of flame-retarding polymer materials and provides a polycarbonate / poly(bisphenol sulfone phenyl phosphonate) flame-retarding material and a preparation method. The method includes: synthesizing a polycarbonate oligomer with bisphenol A and diphenyl carbonate; synthesizing a poly(bisphenol sulfone phenyl phosphonate) oligomer with phenylphosphonic dichloride and bisphenol S; then performing block copolymerization on the polycarbonate oligomer and the poly(bisphenol sulfone phenyl phosphonate) oligomer to make the polycarbonate / poly(bisphenol sulfonephenyl phosphonate) flame-retarding material. In the preparation method, with the poly(bisphenol sulfone phenyl phosphonate) being a reactive flame retardant, the problems that an additive flame retardant is poor in flame-retarding effect due to non-uniform dispersion and reduced in mechanical performance due to poor interfacial compatibility.

Owner:成都其其小数科技有限公司

PTT based flame retardant and antistatic masterbatch

The invention discloses a PTT based flame retardant and antistatic masterbatch, which comprises the following components by mass: 15%-40% of PTT resin, 20%-30% of PSPPP, 15%-30% of polydimethylsiloxane, 5%-15% of antimony trioxide, 0.5%-2% of polytetrafluoroethylene, 8%-15% of POE, 5%-10% of an antistatic agent, 0.5%-2% of an antioxidant, and 0.5%-5% of a dispersant. The antistatic agent is one or more of polyethylene oxide, polyether ester amide, polyether ester imide, glycerol monostearate and polyether ester amide compound. When applied to a PTT production process, the PTT based flame retardant and antistatic masterbatch has excellent flame retardant, toughening and antistatic modification effects when the mass fraction is 5%-15%, and has the advantages of good machinability, convenient use, low cost, strong adaptability, simple preparation process, and easy industrial production, popularization and application.

Owner:王妮娜

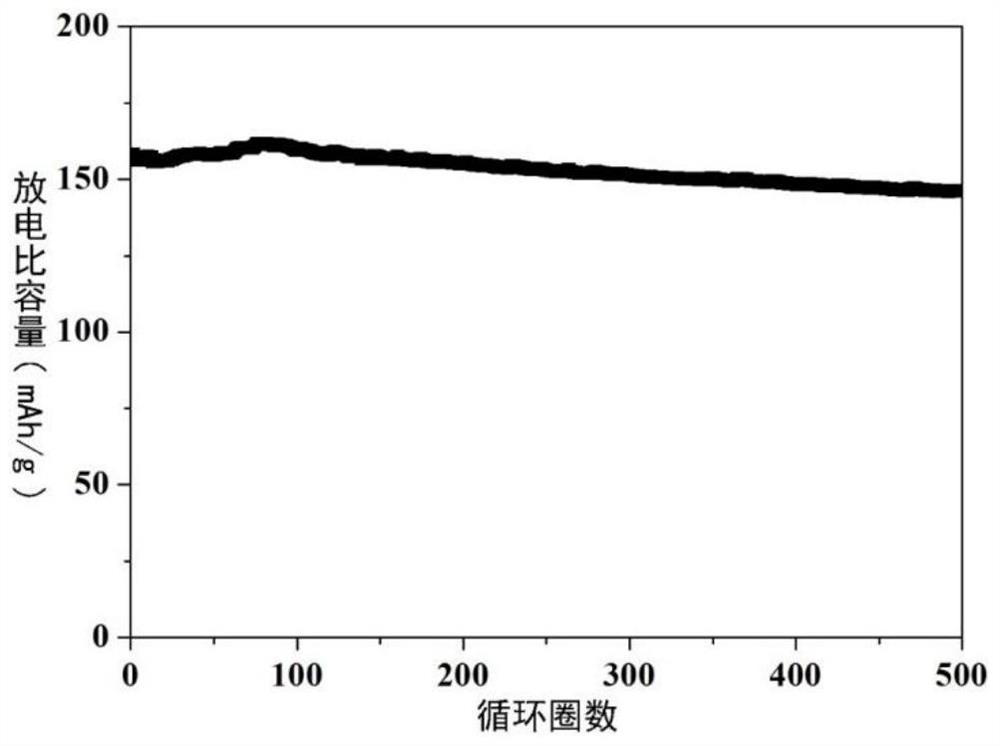

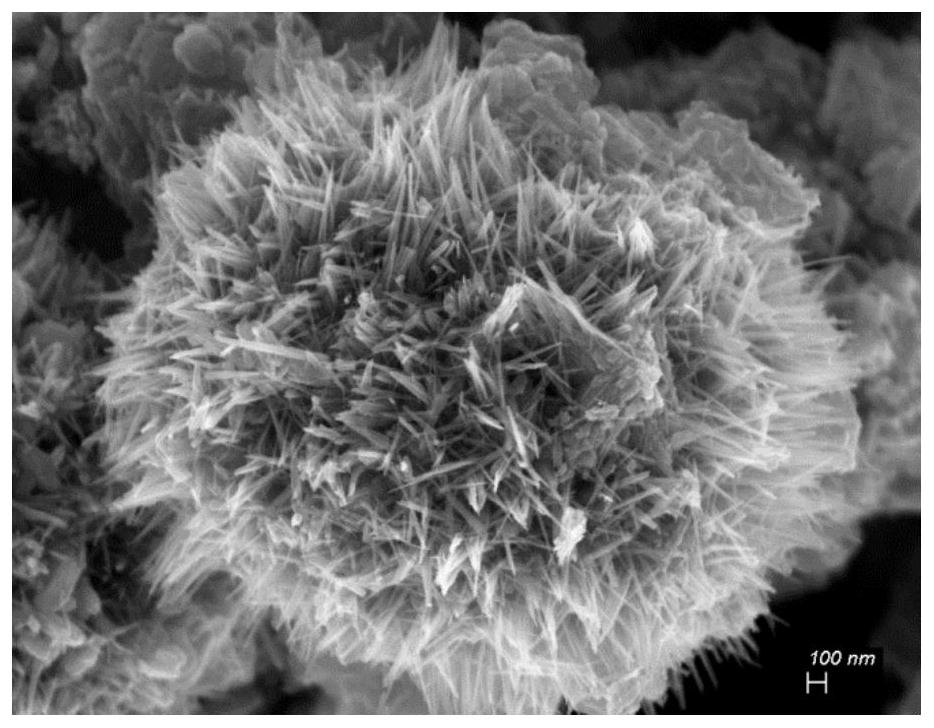

Preparation method of cluster MnO2, secondary zinc-manganese battery positive electrode material and secondary zinc-manganese battery

ActiveCN114573033AHigh shock densityHigh specific surface area characteristicsCell electrodesSecondary cellsElectrolytic agentNanowire

The invention discloses a preparation method of cluster MnO2, a secondary zinc-manganese battery positive electrode material and a secondary zinc-manganese battery, the preparation method comprises the following steps: dissolving manganese salt and peroxydisulfate in water, and adding phenyl phosphonic acid or phenyl phosphonate to obtain a mixed solution; carrying out hydrothermal reaction on the mixed solution to obtain turbid liquid containing manganese dioxide precipitate; and carrying out suction filtration, washing and drying on the turbid liquid to obtain the micro-nano cluster spherical manganese dioxide. The cluster MnO2 prepared by the method disclosed by the invention is of a micro-nano cluster structure, specifically, nano wires are organically polymerized into micron-sized cluster particles, and the cluster MnO2 has the characteristic of high specific surface area of a nano material and can be in full contact with electrolyte, so that the reaction sites of active substances are increased, and the conductivity and electrochemical activity of an electrode are improved; the electrode reversibility of the secondary aqueous zinc-manganese battery positive electrode material is effectively enhanced, and the cycling stability is improved; and the capacity retention ratio reaches up to 94.2% after 500 cycles at the current density of 500mA / g.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Fire retardation ABS/PMMA/polyester alloy material preparation method

The present invention provides an ABS / polyester alloy material, particularly to a halogen-free fire retardation ABS / PMMA / polyester alloy material, and belongs to the technical field of polymer materials. The fire retardation ABS / PMMA / polyester alloy material comprises the following components, by weight, 100-150 parts of ABS, 20-30 parts of PMMA, 10-20 parts of poly(butylene terephthalate), 10-15 parts of chlorinated polyvinyl chloride, 5-10 parts of polycaprolactone, 5-10 parts of calcium stearate, 4-8 parts of phenylphosphonic acid, 4-8 parts of antimony trioxide, 3-6 parts of an antioxidant, 3-6 parts of a toughening agent, 4-7 parts of a coupling agent, 1-2 parts of an ultraviolet absorber, 3-5 parts of a smoke suppression agent, 5-10 parts of talc powder, and 4-8 parts of potassium titanate crystal whisker. According to the present invention performances of ABS, PMMA, PBT and other resin materials are comprehensively utilized, fire retardation can achieves 0 grade, and the material does not contain halogen, and has good mechanical strength.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

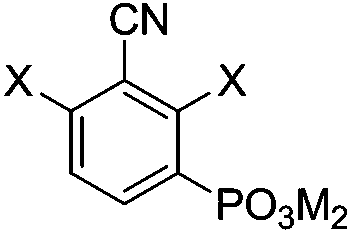

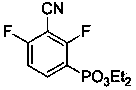

Preparation methods of 3-nitrile-2,4-dihalogeno phenylphosphonic acid and salts thereof

ActiveCN104004016ASemi-permeable membranesGroup 5/15 element organic compoundsDistillationPhenylphosphonic acid

The invention discloses a series of polymerizable novel organic monomers 3-nitrile-2,4-dihalogeno phenylphosphonic acids and salts and preparation method thereof. The 3-nitrile-2,4-dihalogeno phenylphosphonic acid is a product prepared through mixing 3-nitrile-2,4-dihalogeno phenylphosphonate with acids, heating the obtained mixture for reaction, adding alkaline into the obtained product so as to adjust the pH value to 7-8, drying water by distillation, dissolving obtained solids by using methanol, removing insolubles by filtering, drying the methanol by spinning, and recrystallizing obtained solids by using water and ethyl alcohol. The novel organic monomers have a polymerization reaction with other monomers in a high-boiling-point aprotic organic solvent and in the presence of a mid-strong base, and then the obtained products are acidified, so that novel polymer materials containing phosphonate and a phosphonic acid are respectively obtained. The materials show good nanofiltration / reverse osmosis desalination and proton conduction properties.

Owner:TIANJIN NORMAL UNIVERSITY

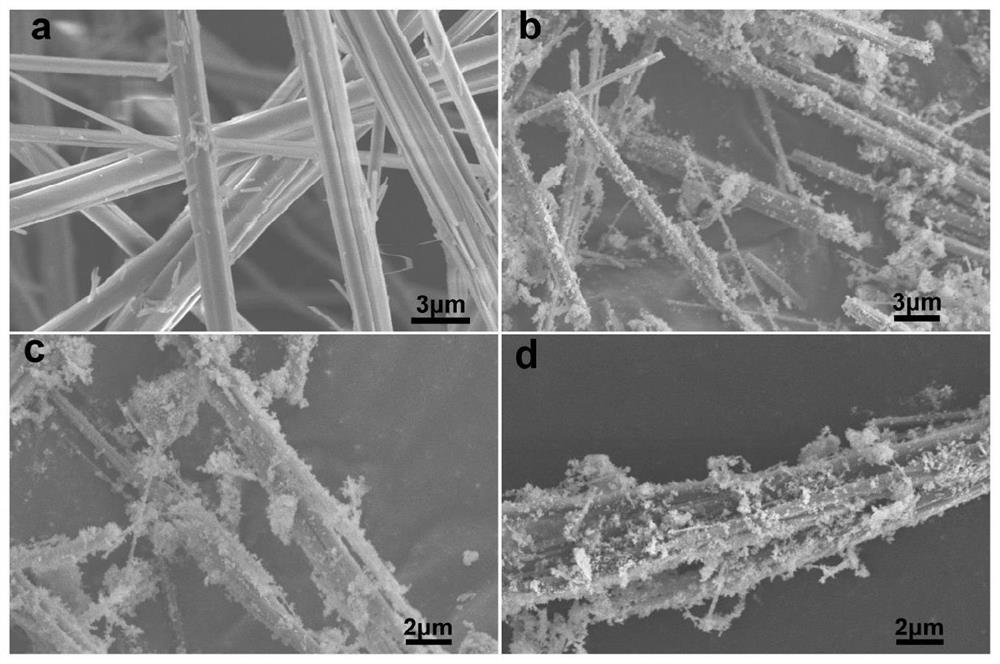

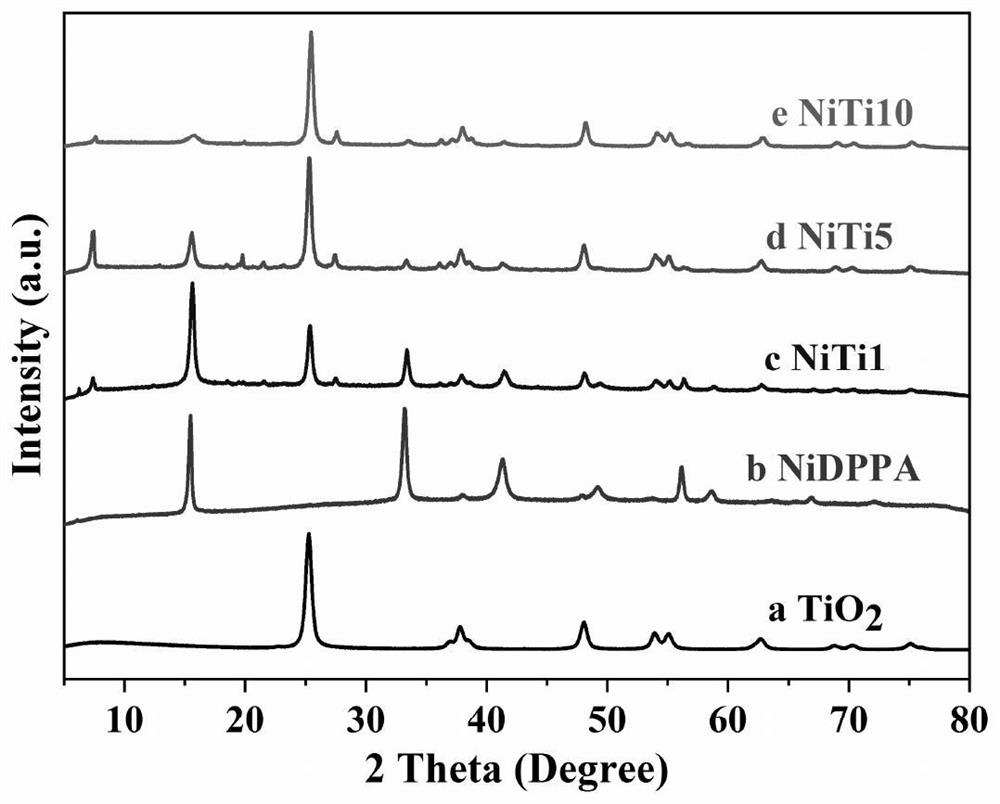

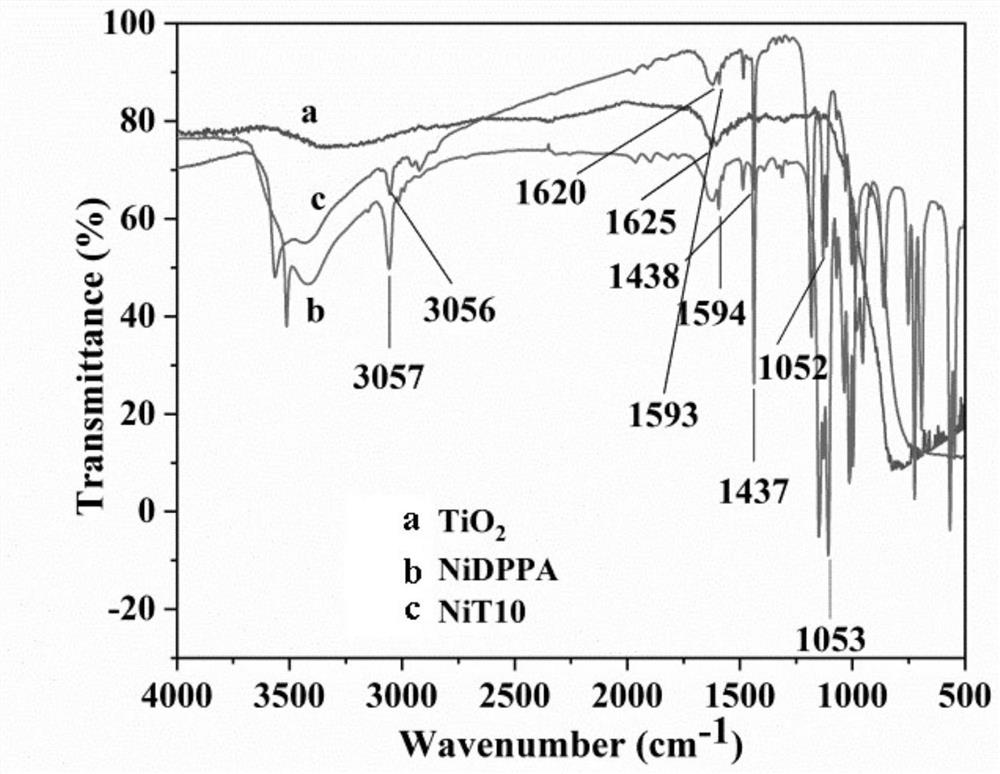

Nickel complex/TiO2 composite material as well as preparation method and application thereof

InactiveCN114471735AHigh activityImprove stabilityHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsNickel saltPhysical chemistry

The invention relates to the technical field of photocatalysis, in particular to a nickel complex / TiO2 composite material and a preparation method and application thereof. The chemical formula of the nickel complex / TiO2 composite material is NiC < 24 > H < 20 > P < 2 > O < 4 > / X < 2 > O < 2 >, wherein X represents 1, 5 or 10. The preparation method of the nickel complex / TiO2 composite material comprises the following steps: taking nickel salt, diphenylphosphonic acid and TiO2 as raw materials, and carrying out solvothermal reaction. The nickel complex / TiO2 composite material provided by the invention has excellent activity and stability in hydrogen production by photocatalytic oxidation of ethanol; moreover, the composite material is simple in synthesis method, mild in reaction condition and easily available in raw materials.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

High-temperature resistant fresh-keeping film and production process thereof

InactiveCN105131441AImprove tear resistanceGood fresh-keeping effectPolyvinyl alcoholTemperature resistance

The invention discloses a high-temperature resistant fresh-keeping film and a production process thereof. To solve the technical problems in the prior art, the fresh-keeping film is characterized by comprising the following components in parts by weight: 100 parts of poly methacrylic, 2-6 parts of dioctyl phthalate, 1-2 parts of polyvinyl alcohol, 2-4 parts of dioctyl adipate, 2-4 parts of a flexibilizer, 2-5 parts of polyimide, 2-4 parts of dodecyl acid dioctyltin, 2-5 parts of polysulfonyldiphenylene phenyl phosphonate, 1-2 parts of polyoxyethylene lauryl ether of which the number of EOs is 10, 1-3 parts of silicon dioxide and 100 parts of water. The fresh-keeping film is easy to pull out and cut, and can be easily bonded with glass ceramic and stainless steel cooked wheaten food containers; the fresh-keeping film is an environment-friendly fresh-keeping film produced by adding a plurality of additives into polyethylene plastic for mixing, so that the efficacies of high-temperature resistance, good tearing resistance, good fresh-keeping effect, long quality guarantee period and bacterium resistance can be achieved.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Organized calcium based montmorillonite loaded polylactic acid crystal nucleating agent and preparation method thereof

InactiveCN106565991AIncreased effective nucleation sitesHigh nucleation efficiencyMontmorilloniteRoom temperature

The invention provides an organized calcium based montmorillonite loaded polylactic acid crystal nucleating agent and a preparation method thereof. The organized calcium based montmorillonite loaded polylactic acid crystal nucleating agent comprises the following raw materials: organized calcium based montmorillonite and phenylphosphonic acid, wherein the weight ratio of the organized calcium based montmorillonite to the phenylphosphonic acid is (5-100): 1. The preparation method comprises the following steps: uniformly mixing the organized calcium based montmorillonite with the phenylphosphonic acid at room temperature, then carrying out heating to 165 to 185 DEG C until the phenylphosphonic acid is completely molten, carrying out stirring at 165 to 185 DEG C for 1 to 10 minutes, and carrying out cooling to room temperature so as to obtain the organized calcium based montmorillonite loaded polylactic acid crystal nucleating agent, wherein a preferred treatment temperature is 170 to 180 DEG C. The organized calcium based montmorillonite loaded polylactic acid crystal nucleating agent provided by the invention has the following advantages: the organized calcium based montmorillonite is used as a carrier, and calcium phenylphosphate generated by a reaction of the phenylphosphonic acid with the organized calcium based montmorillonite is highly dispersed on the surface of the organized calcium based montmorillonite, so formed effective nucleation points are increased, and nucleation efficiency is improved.

Owner:HUBEI GUANGHE BIO TECH

Epoxy resin composition and preparation method thereof

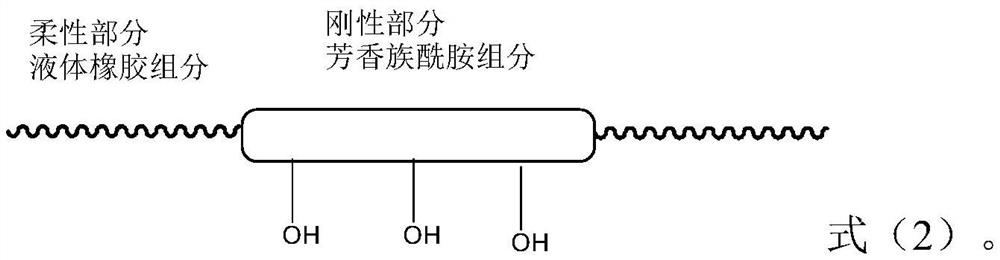

The invention provides an epoxy resin composition and a preparation method thereof. The composition contains epoxy resin, filler, a surface treating agent, a stress absorbent and a curing agent, wherein the surface treating agent contains phenylphosphonic acid represented in the formula (1), phenylphosphonic acid accounts for 30% or more of total content of the surface treating agent, the adding quantity of the surface treating agent is 0.01-0.07 mg / m<2> through calculation based on specific surface area of the filler, and the stress absorbent is rubber modified active polyamide resin represented as the formula (2). With adoption of phenylphosphonic acid as the surface treating agent, the originally hydrophilic filler surface is changed into a partly hydrophilic and partly hydrophobic filler surface, so that overall water absorption of an epoxy molding compound can be reduced, strength between the filler and the resin is also enhanced, and long-storage stability of the epoxy resin composition is improved; and with adoption of the stress absorbent, internal stress of the epoxy resin composition is reduced, heat resistance of the epoxy resin composition is improved, and failure phenomena of layering and the like of the epoxy resin composition are avoided.

Owner:JIANGSU HHCK NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com