High-tenacity flame-retardant bismaleimide resin and preparation method thereof

A technology of bismaleimide resin and bismaleimide, which is applied in the field of high-toughness flame-retardant bismaleimide resin and its preparation, can solve the problems affecting the molding process and the lack of resin flame retardancy , high viscosity of the prepolymer, etc., to improve the molding process, facilitate dispersion, and have good flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

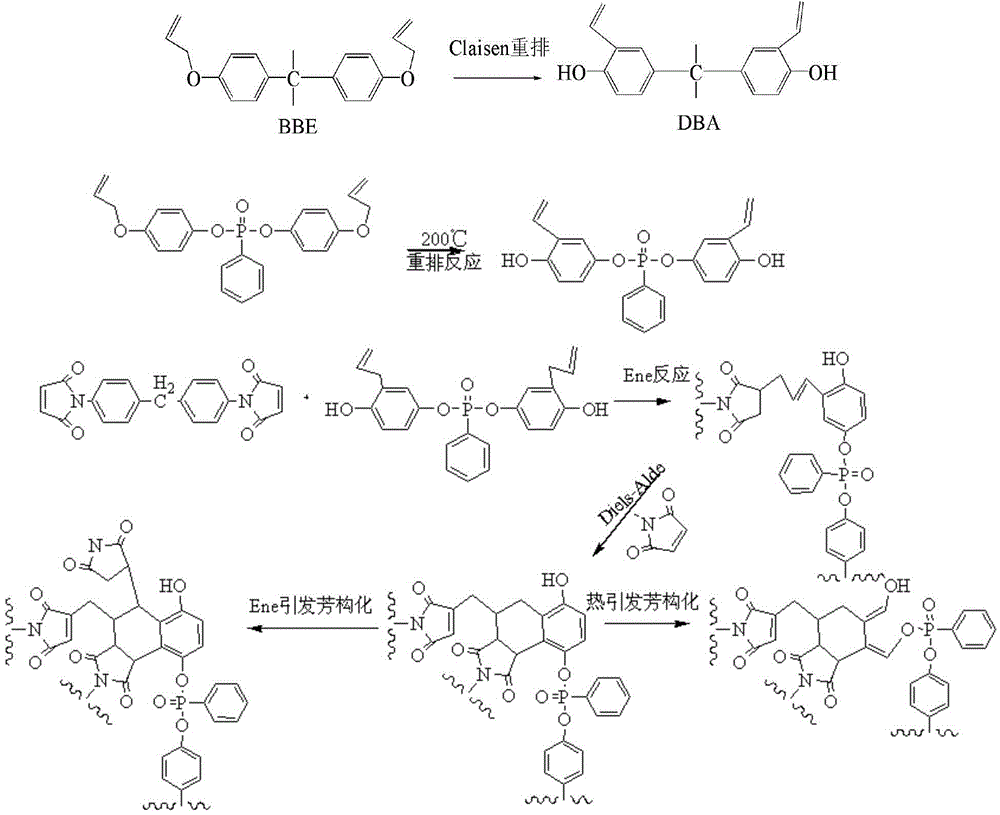

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Add 0.01mol of O,O-bis(4-(hydroxy)phenyl)phenylphosphonate and 200ml of N,N-dimethylformamide into the three-necked flask, after dissolving, add 0.02mol of Sodium hydroxide or potassium carbonate, stirred at 30°C for 1.5h, added 0.025mol of allyl chloride, after 5h, washed with water, extracted with ethyl acetate, washed twice with distilled water, dried with anhydrous magnesium sulfate, Filtration, distillation, and removal of the organic solvent gave a pale yellow liquid O,O-bis(4-(allyloxy)phenyl)phenylphosphonate.

[0024] Step 2: Add 100 parts of diphenylmethane type bismaleimide, 20 parts of diallyl bisphenol A and 30 parts of bisphenol A diallyl ether into a beaker, and heat and melt at 80-160° C. , stir evenly, add 5 parts of O,O-bis(4-(allyloxy)phenyl)phenylphosphonate, after stirring evenly, pour it into a mold that has been preheated for more than 30 minutes, and put it into a 140- In a vacuum box at 160 °C, after defoaming, put it into a blast dryin...

Embodiment 2

[0026] Step 1: Add 0.01mol of O,O-bis(4-(hydroxy)phenyl)phenylphosphonate and 500ml of N,N-dimethylformamide into the three-necked flask, after dissolving, add 0.03mol of Sodium hydroxide or potassium carbonate, after stirring at 40°C for 2h, add 0.03mol of allyl chloride, after 6h, wash with water, extract with ethyl acetate, then wash twice with distilled water, dry with anhydrous magnesium sulfate, filter , Distillation, and remove the organic solvent to obtain light yellow liquid O,O-bis(4-(allyloxy)phenyl)phenylphosphonate.

[0027] Step 2: Add 100 parts of diphenylmethane type bismaleimide, 30 parts of diallyl bisphenol A and 40 parts of bisphenol A diallyl ether into a beaker, and heat and melt at 80-160° C. , stir evenly, add 7 parts of O,O-bis(4-(allyloxy)phenyl)phenylphosphonate, after stirring evenly, pour it into a mold that has been preheated for more than 30 minutes, and put it into a 140- In a vacuum box at 160 °C, after defoaming, put it into a blast drying bo...

Embodiment 3

[0029] Step 1: Add 0.01mol of O,O-bis(4-(hydroxy)phenyl)phenylphosphonate and 700ml of N,N-dimethylformamide into the three-necked flask, after dissolving, add 0.04mol of Sodium hydroxide or potassium carbonate, after stirring at 40°C for 3h, add 0.03mol of allyl chloride, after 7h, wash with water, extract with ethyl acetate, wash twice with distilled water, dry with anhydrous magnesium sulfate, filter , Distillation, and remove the organic solvent to obtain light yellow liquid O,O-bis(4-(allyloxy)phenyl)phenylphosphonate.

[0030]Step 2: Add 100 parts of diphenylmethane type bismaleimide, 30 parts of diallyl bisphenol A and 40 parts of bisphenol A diallyl ether into a beaker, and heat and melt at 80-160° C. , stir evenly, add 7 parts of O,O-bis(4-(allyloxy)phenyl)phenylphosphonate, after stirring evenly, pour it into a mold that has been preheated for more than 30 minutes, and put it into a 140- In a vacuum box at 160 °C, after defoaming, put it into a blast drying box for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com