Poly(3-hydroxyalkanoate) resin composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

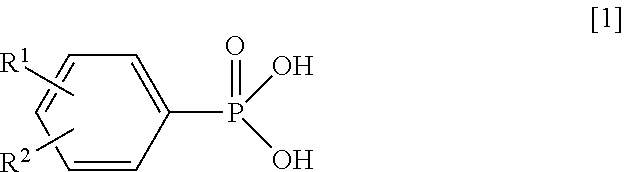

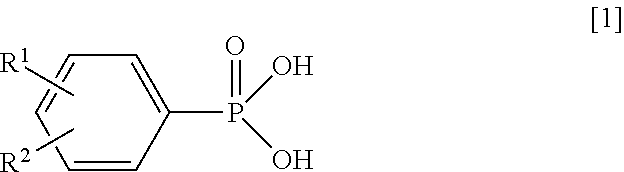

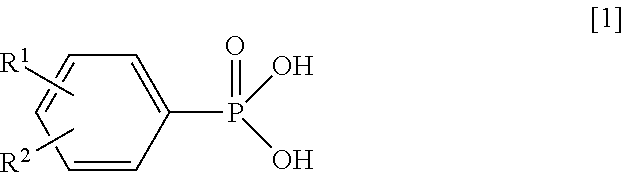

Synthesis of Magnesium Phenylphosphonate (PPA-Mg)

[0064]Into a reaction vessel equipped with a stirrer were charged 10.2 g (50 mmol) of magnesium chloride hexahydrate (manufactured by Wako Pure Chemical Industries, Ltd.) and 100 g of water, and the mixture was stirred to obtain a uniform solution. Next, to this solution being stirred at room temperature (about 25° C.), a solution in which 7.8 g (50 mmol) of PPA and 4.2 g (105 mmol) of sodium hydroxide had been dissolved in 68 g of water was added, and the resultant solution was stirred for additional 1 hour. The produced solid was filtered by vacuum filtration and was washed with water. The resultant wet product was dried at 200° C. for 6 hours to obtain target magnesium phenylphosphonate as white powder.

synthesis example 2

Synthesis of Calcium Phenylphosphonate (PPA-Ca) (1)

[0065]Operating in the same manner as in Synthesis Example 1 except that 7.4 g (50 mmol) of calcium chloride dihydrate (manufactured by Wako Pure Chemical Industries, Ltd.) was used in place of magnesium chloride hexahydrate, target calcium phenylphosphonate (1) was obtained as white powder.

[0066]A scanning electron microscope (SEM) [JSM-7400F manufactured by JEOL Ltd.] image of the resultant powder was observed. Particles of the powder were strip-shaped, and the average of the approximately maximum minor axis (where the size of the strip-shaped particle is represented by , and these figures satisfy ) of 50 particles extracted at random was about 1 μm.

synthesis example 3

Synthesis of Manganese Phenylphosphonate (PPA-Mn)

[0067]Operating in the same manner as in Synthesis Example 1 except that 9.9 g (50 mmol) of manganese chloride tetrahydrate (manufactured by Wako Pure Chemical Industries, Ltd.) was used in place of magnesium chloride hexahydrate, target manganese phenylphosphonate was obtained as pale pink powder.

[0068]The resultant manganese phenylphosphonate, which was an anhydride immediately after being dried, changed to a monohydrate in an air atmosphere at room temperature (about 25° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Crystallization enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com