Patents

Literature

1117 results about "Strontium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium carbonate (SrCO₃) is the carbonate salt of strontium that has the appearance of a white or grey powder. It occurs in nature as the mineral strontianite.

Transparent lead-free fritted glaze with low expansion coefficient and preparation method thereof

The invention relates to a transparent lead-free fritted glaze with low expansion coefficient and a preparation method thereof. The fritted glaze comprises the following chemical ingredients of: 59 to 66 percent of SiO2, 10 to 15 percent of Al2O3, 5 to 10 percent of B2O3, 3 to 6 percent of CaO, 4 to 8 percent of MgO, 0 to 3 percent of K2O, 0 to 2 percent of Na2O, 0 to 1 percent of Li2O, 1 to 5 percent of ZnO and 0 to 2 percent of SrO; and the fritted glaze comprises the raw materials of: 10 to 25 percent of kaolin, 15 to 30 percent of quartz, 10 to 25 percent of potassium feldspar, 0 to 8 percent of dolomite, 2 to 6 percent of grammite, 10 to 20 percent of roasted talc, 1 to 6 percent of zinc oxide, 2 to 8 percent of boric acid, 5 to 15 percent of calcium borate, 1 to 5 percent of alumina, 0 to 2 percent of lithium carbonate and 0 to 3 percent of strontium carbonate. The expansion coefficient of the fritted glaze is 3.7-4.5*10-6 / DEG C (RT to 500 DEG C), the melted temperature is 1400 DEG C to 1500 DEG C, the glaze firing temperature is 1130 DEG C to 1230 DEG C; and the transparent lead-free fritted glaze has fine and bright glaze surface, high transparency, low expansion coefficient as well as no lead precipitation and is particularly suitable for double-fired hard porcelain body with lower expansion coefficient.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Beneficiation of rare earth elements bearing ancylite

ActiveUS20170028410A1Small sizeHigh gradient magnetic separatorsFlotationStrontium carbonateRare-earth element

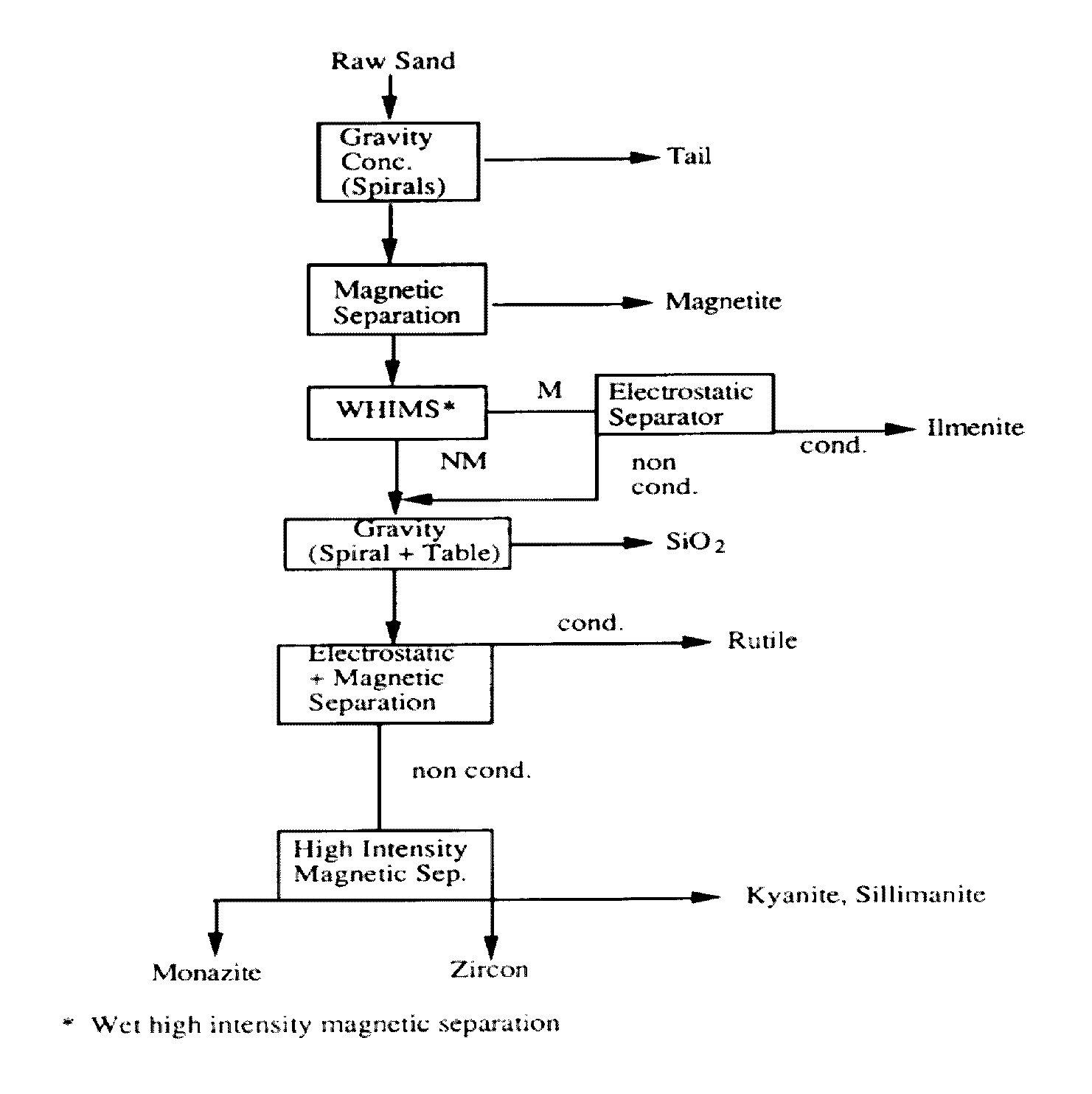

Disclosed herein are methods and systems for recovery of ancylite, a rare earth mineral comprising strontium carbonate, from rare earth ore. In many embodiments, the disclosed methods and systems provide for recovery of greater than 50% of the ancylite from an ancylite containing ore. In many embodiments, the ore is subjected to flotation in the presence of an acid, for example a hydroxamic acid, such as octanohydroxamic acid. The ore may also be subjected to magnetic separation, for example wet high intensity magnetic separation.

Owner:COLORADO SCHOOL OF MINES

Method for preparing sodium sulfhydrate from hydrogen sulfide tail gas

InactiveCN101186280AImprove protectionReduce pollutionSulfur compoundsSodium hydrosulfideAbsorption rate

A purpose of the invention is to provide a sodium hydrosulfide preparation method utilizing hydrogen sulfide exhaust. The invention not only can resolve the treatment problems of the three wastes of barium carbonate and strontium carbonate enterprises, but also can reuse calcium sulfate, the byproduct from the preparation of sodium hydrosulfide, as raw materials for other chemical production, which realizes the recycling of raw materials and products. The production ability of the traditional alkali solution absorbing method, the absorbing adaptability of mixed hydrogen sulfide exhaust and the sodium hydrosulfide preparation rate are enhanced; while the production cost is reduced and the exhaust can be discharged according to standards after being absorbed by alkali solution. The invention resolves the problems of low absorption rate of hydrogen sulfide gas, low production efficiency of preparation of sodium hydrosulfide, large investment of technical devices and difficulty of solid phase recycling existing in a method of 'one step for preparation of sodium hydrosulfide' using hydrogen sulfide gas, calcium hydroxide and sodium sulfide as raw materials.

Owner:QINGDAO AOHAIKE TRADE

Efficient composite modifying-refining agent for hypoeutectic cast aluminium-silicon alloy and treatment process

InactiveCN1936044ASimplify the melt handling processImprove performanceStrontium carbonateSilicon alloy

The invention relates to a high efficiency compounded refiner for hypoeutectic aluminum-silicon alloy and the method of application. It contains 10-30wt% NaCl, 10-15wt% KCl, 10-20wt% sodium fluoride, 1-30wt% potassium fluoborate, and 1-20wt% potassium fluotitanate, 1-20wt% strontium carbonate, 1-15wt% cerium fluoride, 5-20wt% granular lanthanum abundant mixed rare earths and 1-5% heachloroethane. After taking the process of heating, dehydrating, mixing according to the ratio to equal, pressing to molding, it could be sealed to use. The technology includes the following steps: after the magnesium alloy melting in crucible, heating to 720-740 degree centigrade and removing the slag, standing for 3-5 minutes, pressing the refiner into alloy liquid to take refining process for 5-10 minutes, standing for 5-10 minutes after process to gain hypoeutectic aluminum-silicon alloy melt. The invention simplifies melt process technology, lowers cost and improves the capability of alloy.

Owner:重庆工学院

Thermosetting Powder Coating Composition

InactiveUS20080085965A1Improve corrosion resistanceImprove moisture resistancePolyester coatingsStrontium carbonatePreservative

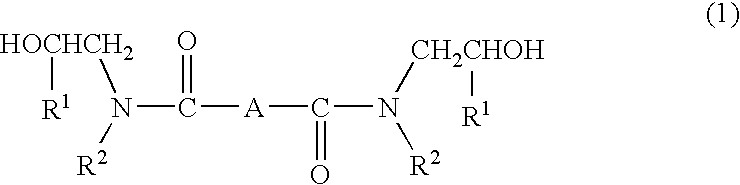

The present invention provides a thermosetting powder coating composition that is capable of forming a coating film having excellent moisture resistance, excellent corrosion resistance, etc. More specifically, the present invention provides a thermosetting powder coating composition comprising a carboxy-containing resin (A), a β-hydroxyalkylamide curing agent (B), and an anticorrosive (C) that comprises a strontium carbonate-modified aluminum phosphate.

Owner:KANSAI PAINT CO LTD

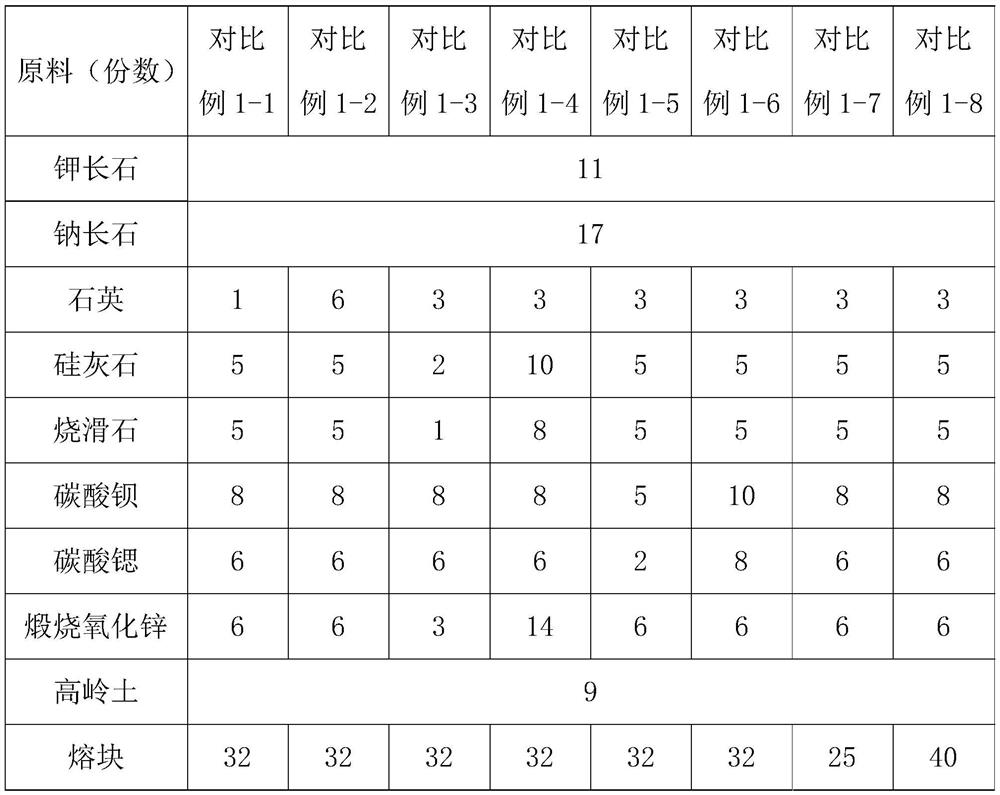

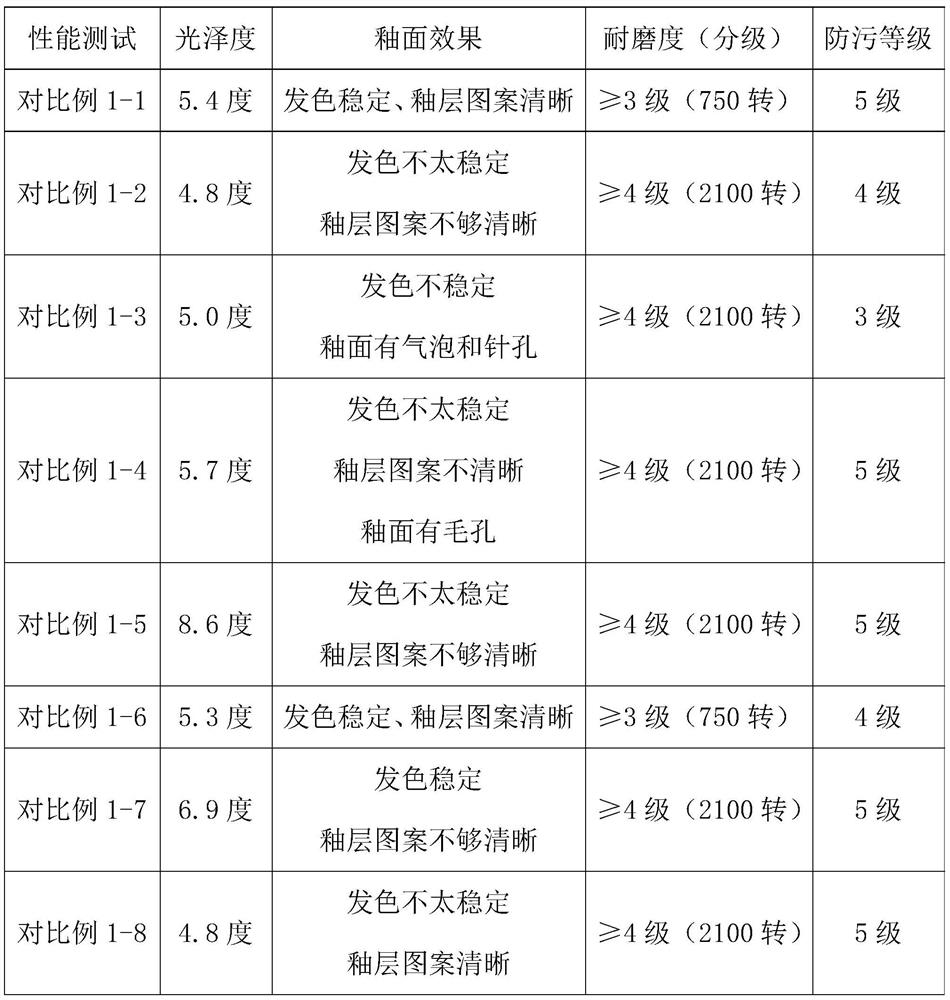

Low-gloss transparent glaze, ceramic tile using low-gloss transparent glaze and preparation method of ceramic tile

The invention discloses low-gloss translucent glaze, a ceramic tile using the low-gloss translucent glaze and a preparation method of the ceramic tile. The low-gloss transparent glaze is prepared from the following raw materials in parts by mass: 26-30 parts of feldspar, 2-4 parts of quartz, 4-6 parts of wollastonite, 4-6 parts of calcined talc, 7-9 parts of barium carbonate, 5-7 parts of strontium carbonate, 5-7 parts of calcined zinc oxide, 8-10 parts of kaolin and 30-33 parts of frit. According to the low-gloss transparent glaze provided by the technical scheme, the surface gloss of a fired glaze layer is low, the 3D layering sense is clear, the color development range of the glaze is wide, the production cost is low, and the defects in the prior art are overcome. The invention further provides a preparation method of the ceramic tile using the low-gloss transparent glaze, which has the advantages of simple steps and high operability, and is beneficial to ensuring the stable color development of the ceramic tile and enhancing the 3D stereoscopic effect of the ceramic tile. The technical scheme further provides the ceramic tile prepared by the preparation method of the ceramic tile, and the ceramic tile is stable in color development and strong in transparency.

Owner:肇庆乐华陶瓷洁具有限公司

Micropore hydrogenated aluminum porcelain tube and preparation thereof

ActiveCN101412619AUniform distribution of microporesLower firing temperatureGas phaseTemperature resistance

The invention relates to the field of an alumina ceramic pipe, in particular to a micropore alumina ceramic pipe and a method for preparing the same, and solves the problems that the prior art can not satisfy four good performances of high temperature resistance, corrosion resistance, high insulativity, and nontoxicity at the same time. The invention provides the micropore alumina ceramic pipe which is prepared from the following raw materials: 88 to 95 percent of alpha aluminum oxide, 2 to 4 percent of suzhou clay, 2 to 4 percent of talcum powder, 0.2 to 2 percent of calcium carbonate, 0.1 to 1.5 percent of strontium carbonate, and 0.2 to 1.5 percent of silicon dioxide. The method uses fluoride containing calcination alpha aluminum oxide powder together with five additives of the suzhou clay, the talcum powder, the calcium carbonate, the strontium carbonate, and the silicon dioxide which are mixed and ground evenly to prepare the micropore alumina ceramic pipe, so that the firing temperature of the ceramic piece is greatly reduced; and through exact formulation design, solid phase, liquid phase and gas phase are collocated reasonably, thus the prepared micropore ceramic piece not only has evenly distributed micropores and good mechanical strength, but also does not change the four good performances of the aluminum oxide.

Owner:温州市润基精密陶瓷件有限公司

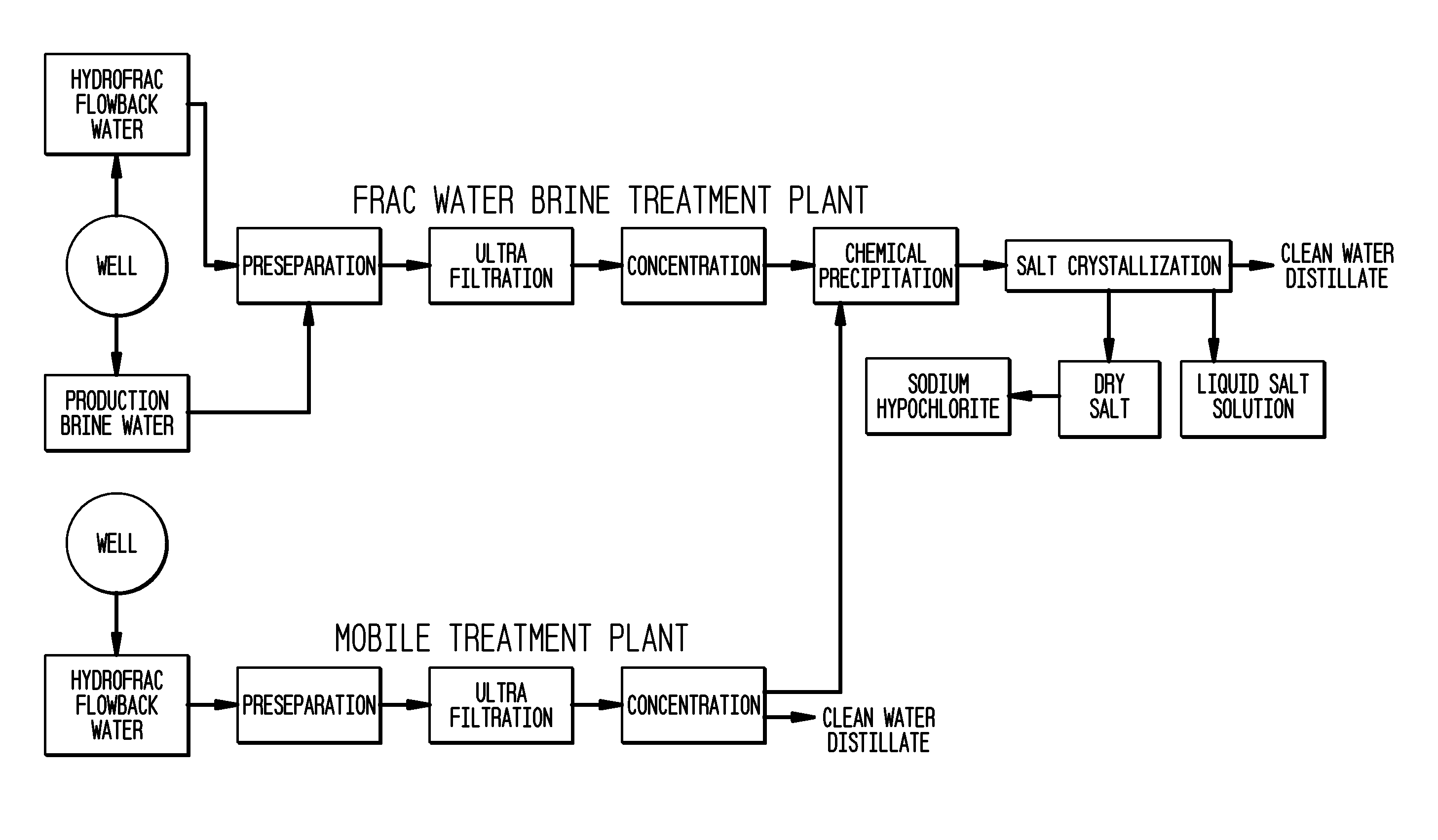

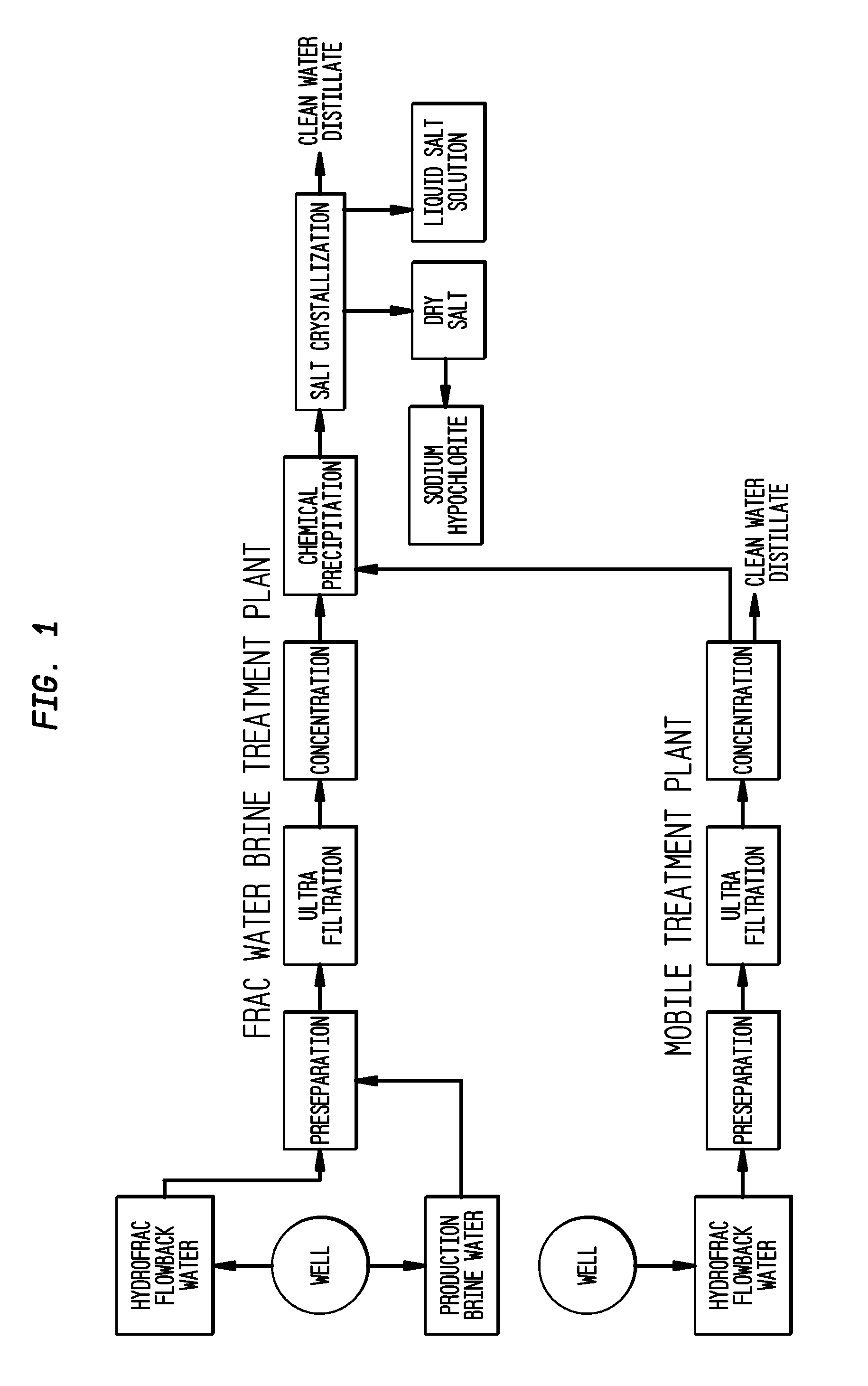

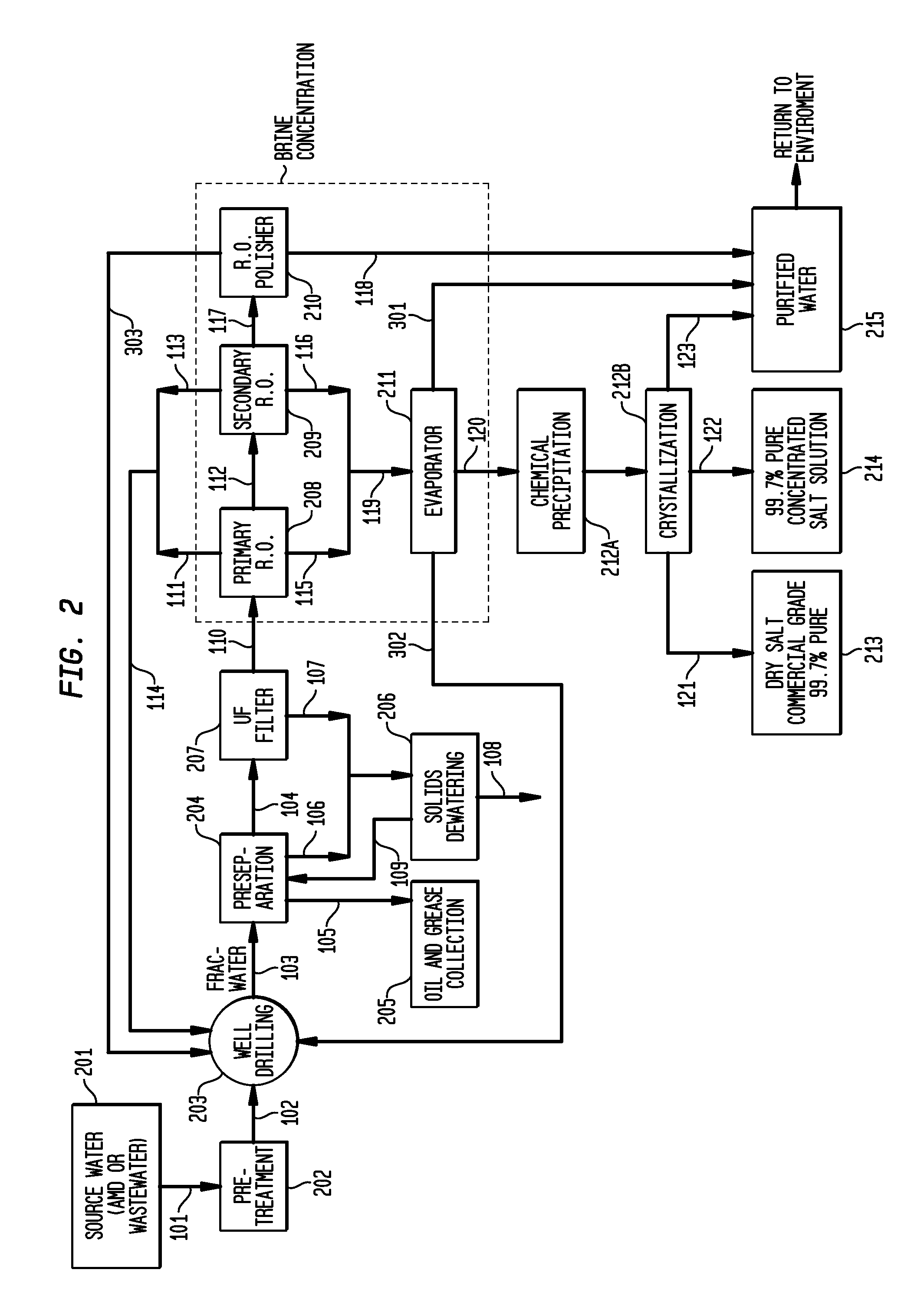

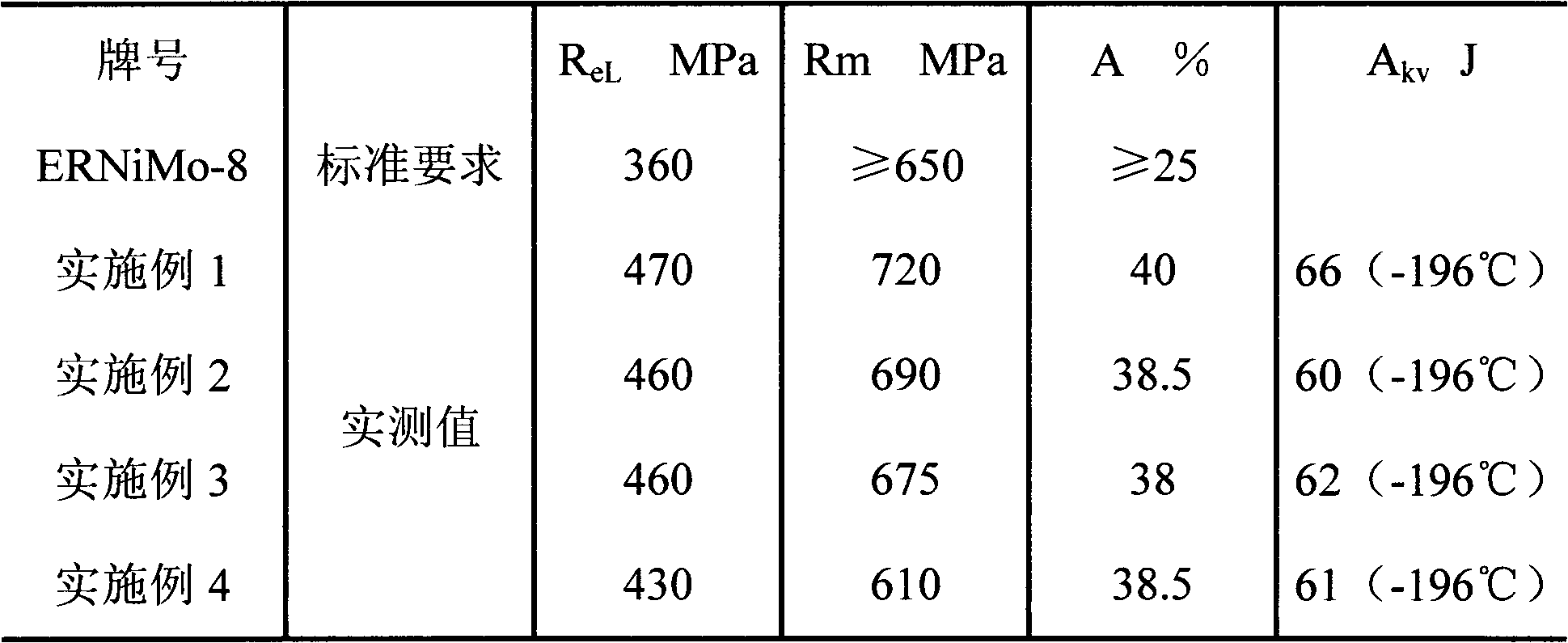

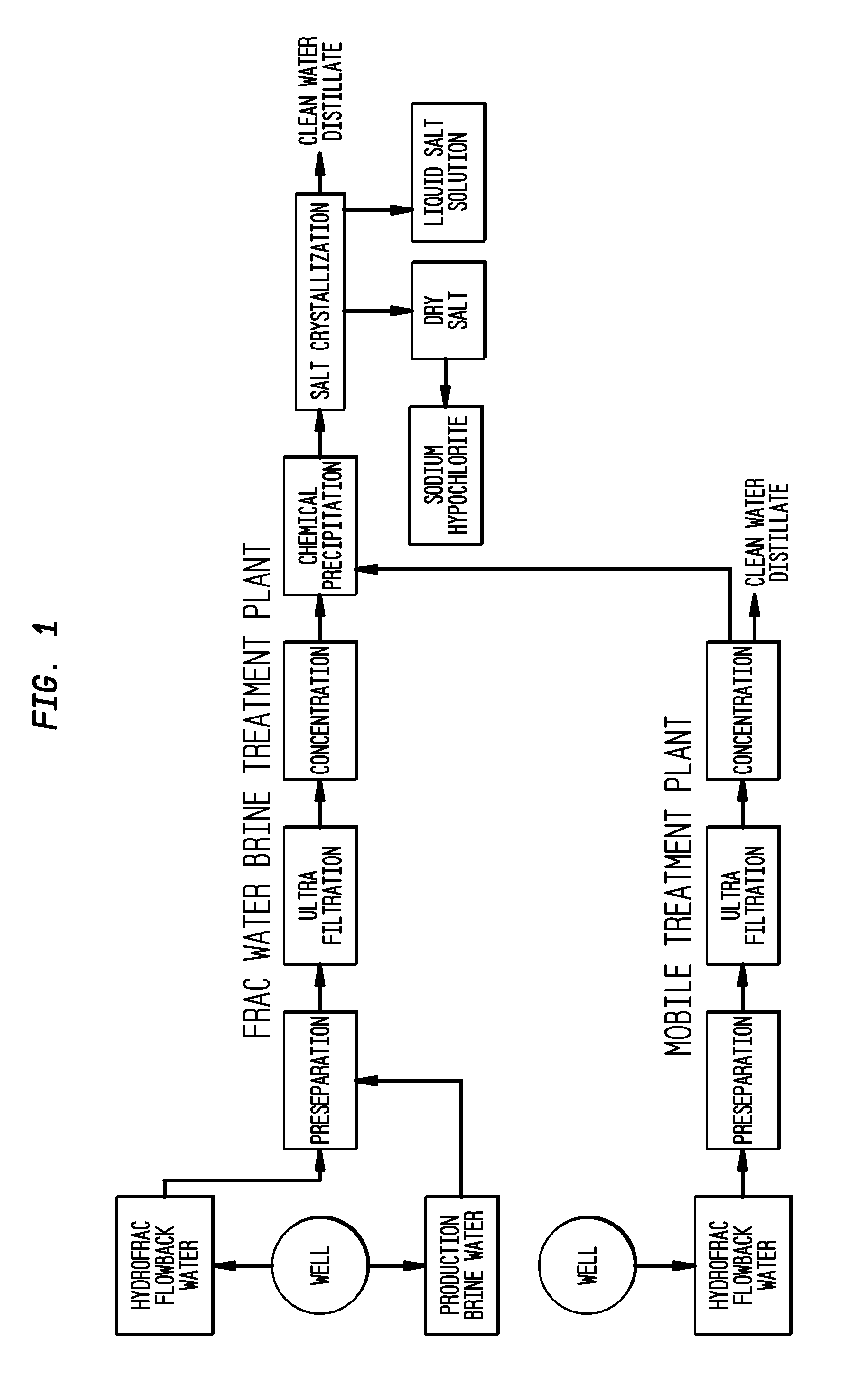

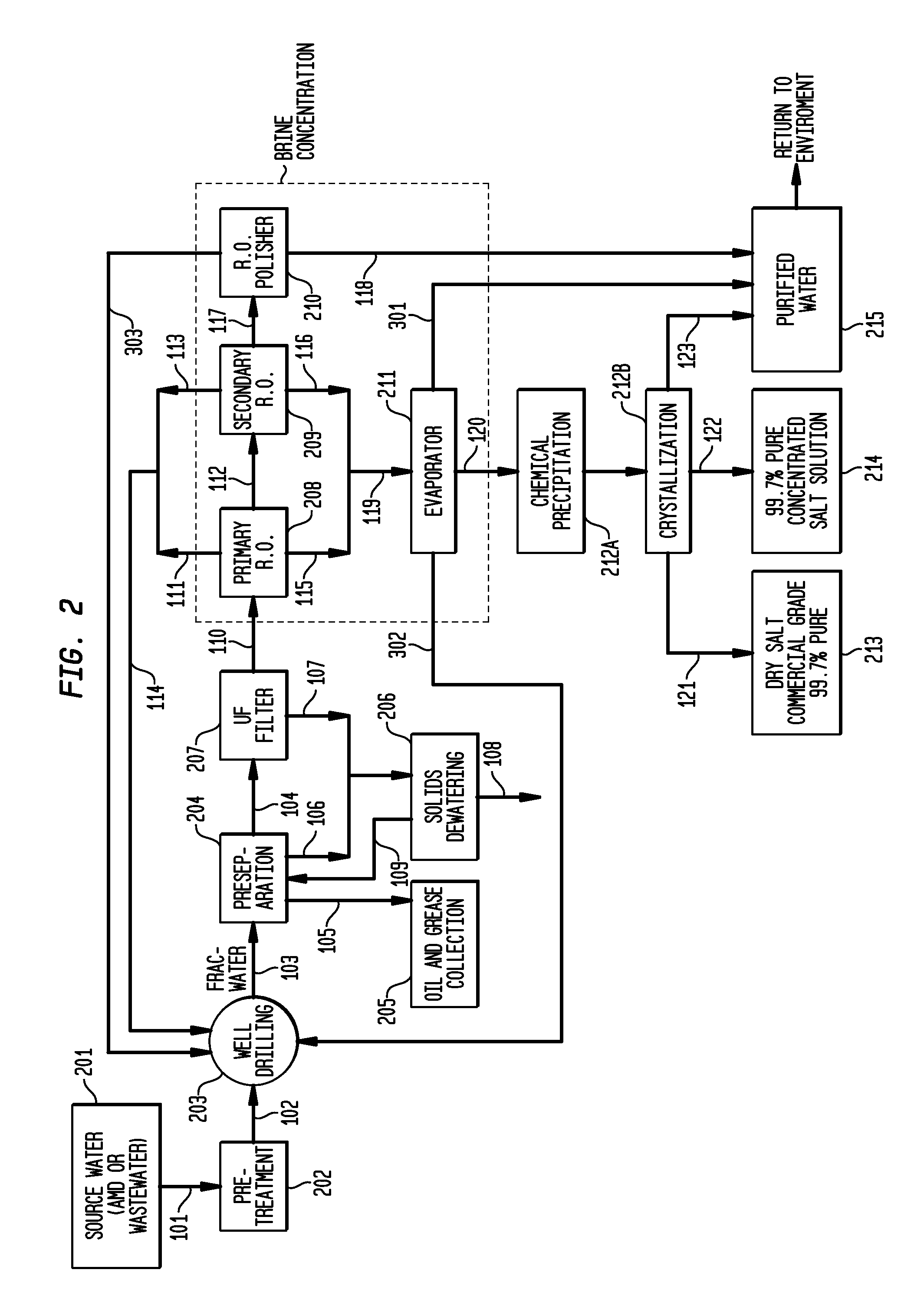

Method of making pure salt from FRAC-water/wastewater

ActiveUS8158097B2Yield maximizationQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesWater useParticulates

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

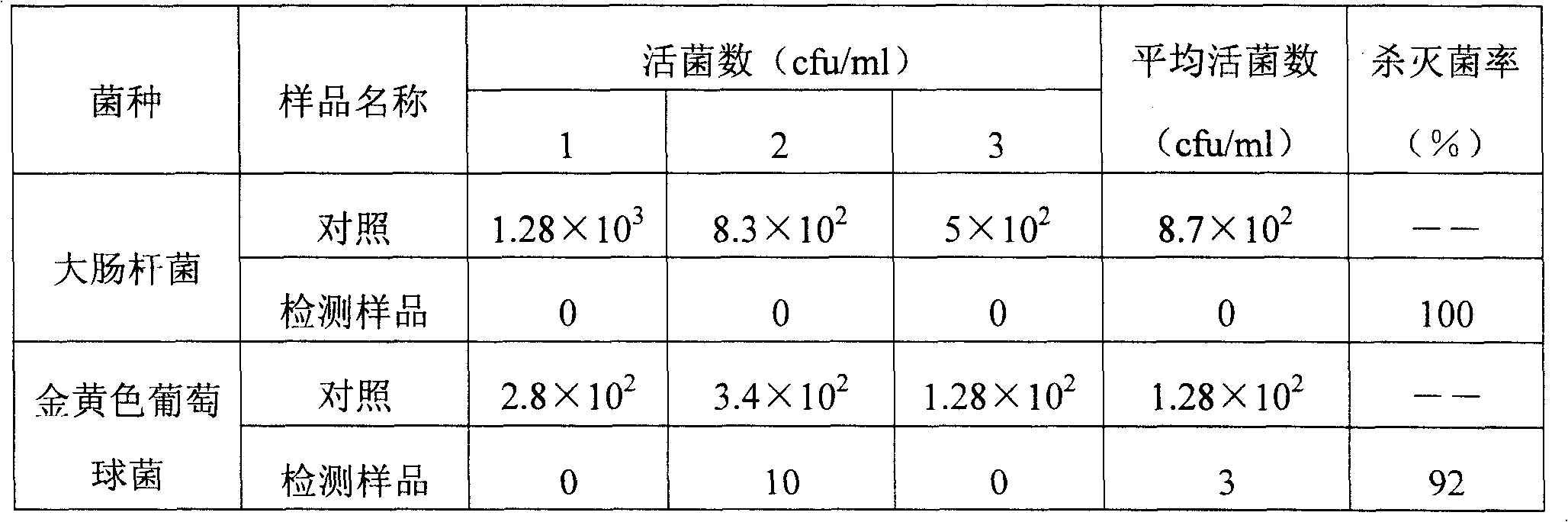

Applique antibacterial ceramic cutter

The invention relates to an applique antibacterial ceramic cutter, and belongs to the technical field of daily ceramics. The cutter comprises a cutter blank, and is characterized in that the outer surface of the cutter blank is covered with a layer of antibacterial self-cleaning ceramic glaze; the antibacterial self-cleaning ceramic glaze is prepared from the following raw materials in percentageby weight: 15 to 30 percent of quartz, 20 to 40 percent of feldspar, 10 to 20 percent of borax, 6 to 18 percent of boric acid, 3 to 7 percent of barium carbonate, 2 to 5 percent of sodium carbonate, 4to 9 percent of bentonite, 0 to 6 percent of phosphorus pentoxide, 10 to 20 percent of zinc oxide, 0 to 6 percent of titanium oxide, 1 to 5 percent of strontium carbonate, 0 to 4 percent of lithium carbonate, 1 to 4 percent of cooked steatite, 1 to 6 percent of alumina, and 1 to 4 percent of rare-earth; and the rare-earth is one or a mixture of arbitrary two of the cerium oxide, the cerium lanthanum chloride and the lanthanum nitrate. The cutter has the effect of antibacterial self-cleaning, has beautiful appearance, and is suitable for the occasion of high-grade application.

Owner:淄博博纳科技发展有限公司

Warm eye-protection matte glaze for building ceramic tiles, and preparation technology thereof

The invention discloses a warm eye-protection matte glaze for building ceramic tiles, and a preparation technology thereof. The preparation technology comprises the following steps: (1) weighing clay,feldspar, quartz, talcum, dolomite, limestone, borax, zirconium silicate, zinc oxide, alumina, barium carbonate and strontium carbonate according to the chemical composition range, crushing the weighed materials to form 180-350 mesh particles, mixing the particles, sintering the obtained mixture at 1480-1580 DEG C to form a glassy melt, and quenching the glassy melt with water to obtain a matte frit for the ceramic tile glaze; and (2) adding clay raw materials and a glaze slip performance regulator to the frit, and performing full wet ball-milling to obtain a matte glaze slip. The compositionof the formula is slightly changed, so the glaze obtained after sintering has the advantages of high strength, high wear resistance, high aging resistance and long service life; the glaze is flat, fine and smooth, is free of pinholes, and has silky or velvet gloss, and the glossiness of the glaze is 3-5 DEG less than that of existing products, so the glaze makes people have soft, quiet and comfortable eye-protection feeling; and the tile matte glaze has tender and soft hand feeling, and is warm.

Owner:FOSHAN UNIVERSITY +1

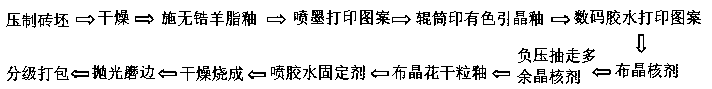

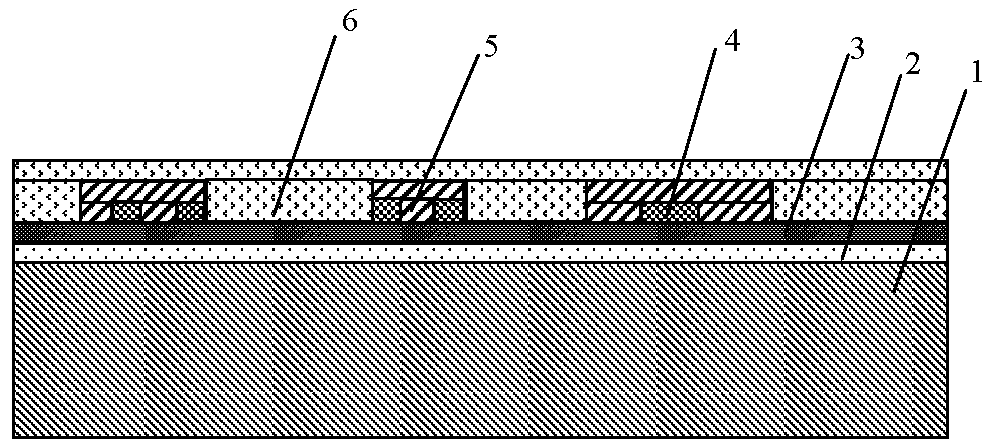

Colored seeding glaze, and positioning crystal pattern ceramic tile prepared using same

The invention discloses a colored seeding glaze, and a positioning crystal pattern ceramic tile prepared using. The colored seeding glaze comprises a base glaze and a coating pigment, and raw materials of the base glaze comprises, by mass, 24-30% of potassium feldspar, 6-10% of albite, 10-14% of calcined kaolin, 3-5% of calcite, 1-3% of dolomite, 7-9% of barium carbonate, 3-5% of strontium carbonate, 5-7% of wollastonite, 1-3% of calcined talc, 2-4% of zinc oxide, 14-20% of seeding agent frit, 1-3% of tungsten oxide, 2-4% of calcium phosphate and 1-3% of tin oxide.

Owner:MONALISA GRP CO LTD

Wear-resistant antifouling glazed brick glaze and preparation method thereof

The invention discloses a wear-resistant antifouling glazed brick glaze and a preparation method thereof. The wear-resistant antifouling glazed brick glaze comprises raw glaze powder, No.1 frit powderand No.2 frit powder, wherein the raw glaze powder comprises the following raw materials in percentage by weight: 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 1-5% of wollastonite, 8-15% of nepheline, 5-10% of zinc oxide, 0-5% of calcite and 6-12% of strontium carbonate, wherein the No.1 frit powder is prepared from kaolin, calcined talc and fluorite, and the No.2 frit powder is prepared from zinc oxide, strontium carbonate and borax. The wear-resistant antifouling glazed brick glaze contains a large number of cordierite microcrystals, and the cordierite microcrystals have the characteristics of transparency, high hardness and the like, so that the wear resistance and the antiskid effect of a glaze layer can be enhanced, and thecontradiction between the transparency and the wear resistance of the glaze layer can be solved.

Owner:佛山市东鹏陶瓷发展有限公司

Coal-saving devulcanized coke cleaning clean synergistic agent and preparation technique thereof

InactiveCN101348743ALower ignition pointImprove oxidation effectSolid fuelsStrontium carbonateFerrosilicon

The invention relates to a process for preparing a clean synergist for saving coal, desulfurization and cleaning coke. Active calcium oxide and magnesium hydrate are mixed and added with sodium carbonate, ferrosilicon powders, manganese dioxide, strontium carbonate and barium hydroxide in turn and finally added with active carbon and evenly mixed to prepare the clean synergist which comprises the following compositions in percentage by weight: 20 to 30 percent of the active calcium oxide, 9 to 12 percent of the magnesium hydrate, 12 to 20 percent of the sodium carbonate, 8 to 10 percent of active carbon, 12 to 15 percent of the ferrosilicon powders, 8 to 12 percent of the manganese dioxide, 3 to 5 percent of the strontium carbonate and 5 to 7 percent of the barium hydroxide. on the premise of unchanging the prior coal burning process and equipment of various boilers and the prior smoke exhaust process and equipment, the clean synergist of the process is only needed to add according to the physicochemical index of coal used by customers, thereby achieving the functions of saving the coal, the desulfurization and cleaning the coke.

Owner:陈宏谋 +1

Mixing fireworks and producing method thereof

A mixed 'firecracker-fireworks' having the effects of firecracker and fireworks and generating 5 colors is prepared from potassium perchlorate, Mg-Al alloy powder, strontium carbonate, phenolic resin, polyvinyl chloride, strontium nitrate, sulfur, glutinous rice flour, etc. Its advantages are simple preparing process, dual effect, multiple color and long perdurability.

Owner:黄远清 +1

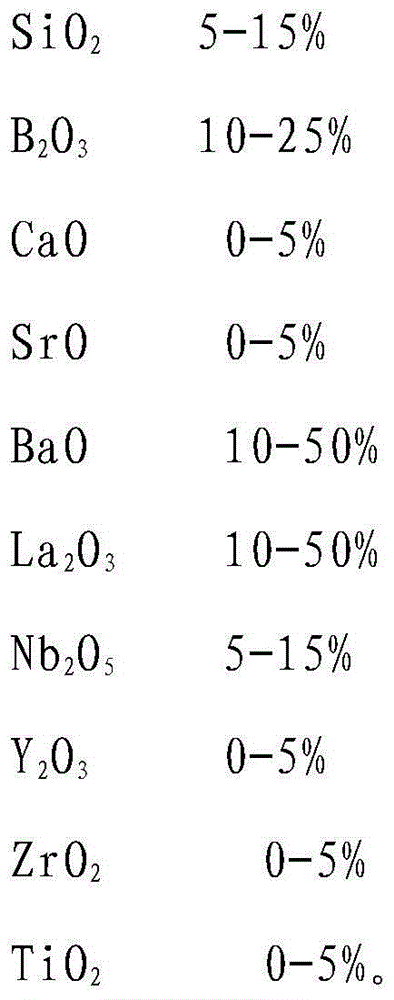

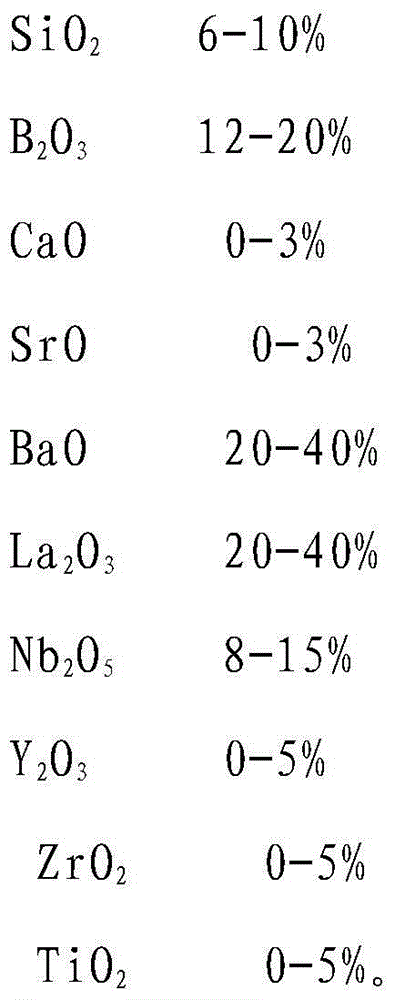

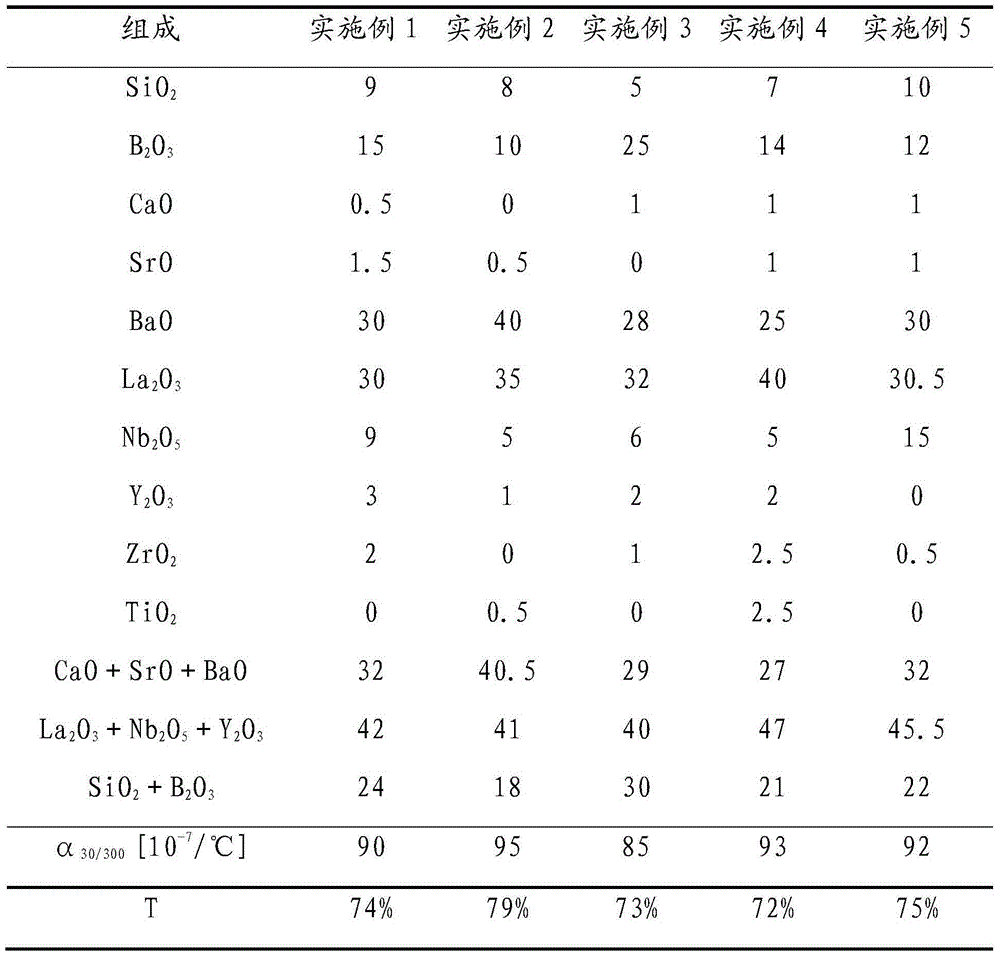

High-refractive-index ultraviolet-transparent glass and manufacturing method thereof

ActiveCN104402218AHigh refractive indexExcellent acid resistance and chemical stabilityFiberRefractive index

The invention discloses high-refractive-index ultraviolet-transparent glass and a manufacturing method thereof. The high-refractive-index ultraviolet-transparent glass comprises following components, by weight, 5-15% of SiO2, 10-25% of B2O3, 0-5% of CaO, 0-5% of SrO, 10-50% of BaO, 10-50% of La2O3, 5-15% of Nb2O5, 0-5% of Y2O3, 0-5% of ZrO2 and 0-5% of TiO2. The invention also provides the manufacturing method of the high-refractive-index ultraviolet-transparent glass. The method includes following steps: placing quartz sand, boronic acid or boron anhydrous, calcium carbonate, strontium carbonate, barium carbonate, lanthanum oxide, niobium pentoxide, yttria, zirconium oxide and titanium dioxide according to requirement in a formula into a pure-platinum crucible with addition of a reduction agent, melting the materials at 1400-1600 DEG C for 6-10 hours with stirring for 2-3 times during the melting process, and casting the molten glass into a specified specification. The invention also discloses an application of the high-refractive-index ultraviolet-transparent glass in an ultraviolet-transparent optical fiber plate. The high-refractive-index ultraviolet-transparent glass is high in refractive index and transmittance and is good in chemical stability.

Owner:CHINA BUILDING MATERIALS ACAD

Leadless enamel blocks

A non-lead fritted glaze for ceramics is prepared from quartz, feldspar, borax, boric acid, barium carbonate, stalactite, zinc oxide, strontium carbonate, lithium carbonate, prepared talc, and aluminium hydroxide through proportionally mixing, fusing at 1300-1350 deg.C, quenching in water, and grinding. Its advantages are wide range of calcine temp, low calcine temp. high surface finish quality, no lead, and high antiwear performance.

Owner:SHANDONG JINLING MINING CO LTD

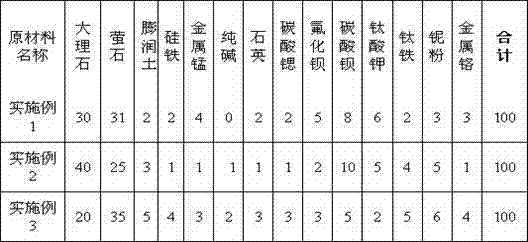

Nickel base welding rod of Ni-Cr-Mo alloy system

InactiveCN102962603AHigh strengthImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaNiobiumFerrosilicon

The invention introduces a nickel base welding rod of a Ni-Cr-Mo alloy system. The nickel base welding rod comprises a core wire and a coating and is characterized in that the core wire is an ERNiCrMo-3 core wire; and the coating comprises 20-40% of marble, 25-35% of fluorite, 2-5% of bentonite, 1-4% of ferrosilicon, 1-4% of manganese metal, 0-2% of sodium carbonate, 1-3% of quartz, 1-3% of strontium carbonate, 2-5% of barium fluoride, 5-10% of barium carbonate, 2-6% of potassium titanate, 2-5% of ferrotitanium, 3-6% of niobium powder and 1-4% of chromium metal. The nickel base welding rod produced by the invention is relatively high in strength, has deposited metal tensile strength which is up to more than 760MPa, is better in low-temperature impact toughness, has an impact powder average value of more than 40J at minus 196 DEG C, and is favorable in welding technological efficiency, stable in arcing during welding, easy in operation, good in formation of welding seams, convenient in deslagging, simple in production process and lower in cost.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

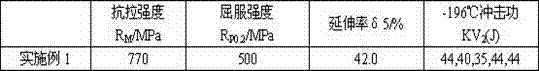

Preparation method of microwave dielectric ceramics materials

ActiveCN103130499ALower sintering temperatureReduce manufacturing costCeramicsStrontium carbonateHigh energy

The invention discloses a preparation method of microwave dielectric ceramics materials. The preparation method of the microwave dielectric ceramics materials comprises that the mixed powder of strontium carbonate, alumina, lanthanum oxide and titanium oxide are mechanically and evenly mixed in a spherical tank to form powder particles; and first time high energy ball milling is carried out on the powder particles to mill the powder particles evenly. The powder after the first time high energy ball milling is high-temperature calcined in a closed container to form precursor powder; and a second time high energy ball milling is carried out on the precursor powder to further mill the precursor powder evenly so as to form ceramic powder. The preparation method of the microwave dielectric ceramics materials sinters microwave dielectric ceramics materials with high densified mediation electric constant and a high quality factor by adopting low temperature, sintering temperature can be greatly lowered, sintering time can be greatly shortened, high densification is achieved, and therefore production cost and technical difficulty are reduced.

Owner:ANHUI TATFOOK TECH CO LTD

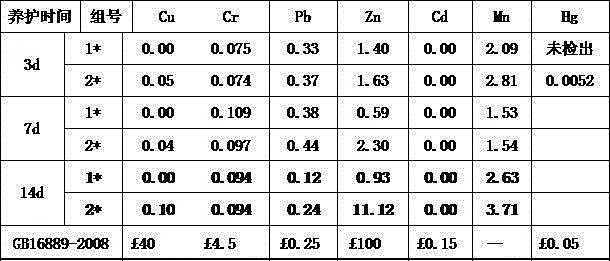

Municipal solid waste incineration fly ash curing method

InactiveCN104607434AReduce dosageRealize comprehensive utilizationSolid waste disposalStrontium carbonateEnvironmental engineering

The invention discloses a municipal solid waste incineration fly ash curing method. The method comprises the steps of mixing waste incineration fly ash, cesium carbonate waste residue, potassium carbonate and cement according to the ratio of (40-50): (25-38): (3-6): (15-25); then, feeding right amount of purified water into the mixture, evenly mixing, enabling a molding model to be filled with the mixture, extruding and compacting; after that, standing the model in the air for 24 hours, and then demoulding to obtain a cured green body; maintaining the cured green body to obtain a cured body which can be directly buried, wherein the maintaining time is not shorter than 14 days. According to the method, the cesium carbonate waste residue is taken as an important raw material for curing the fly ash, so that the consumption of the cement is greatly reduced, waste recycling is realized, and the waste incineration fly ash curing cost is lowered. After the method is used, the compressive strength of the cured body and the heavy metal leaching completely meet the landfill requirements.

Owner:CHONGQING UNIV

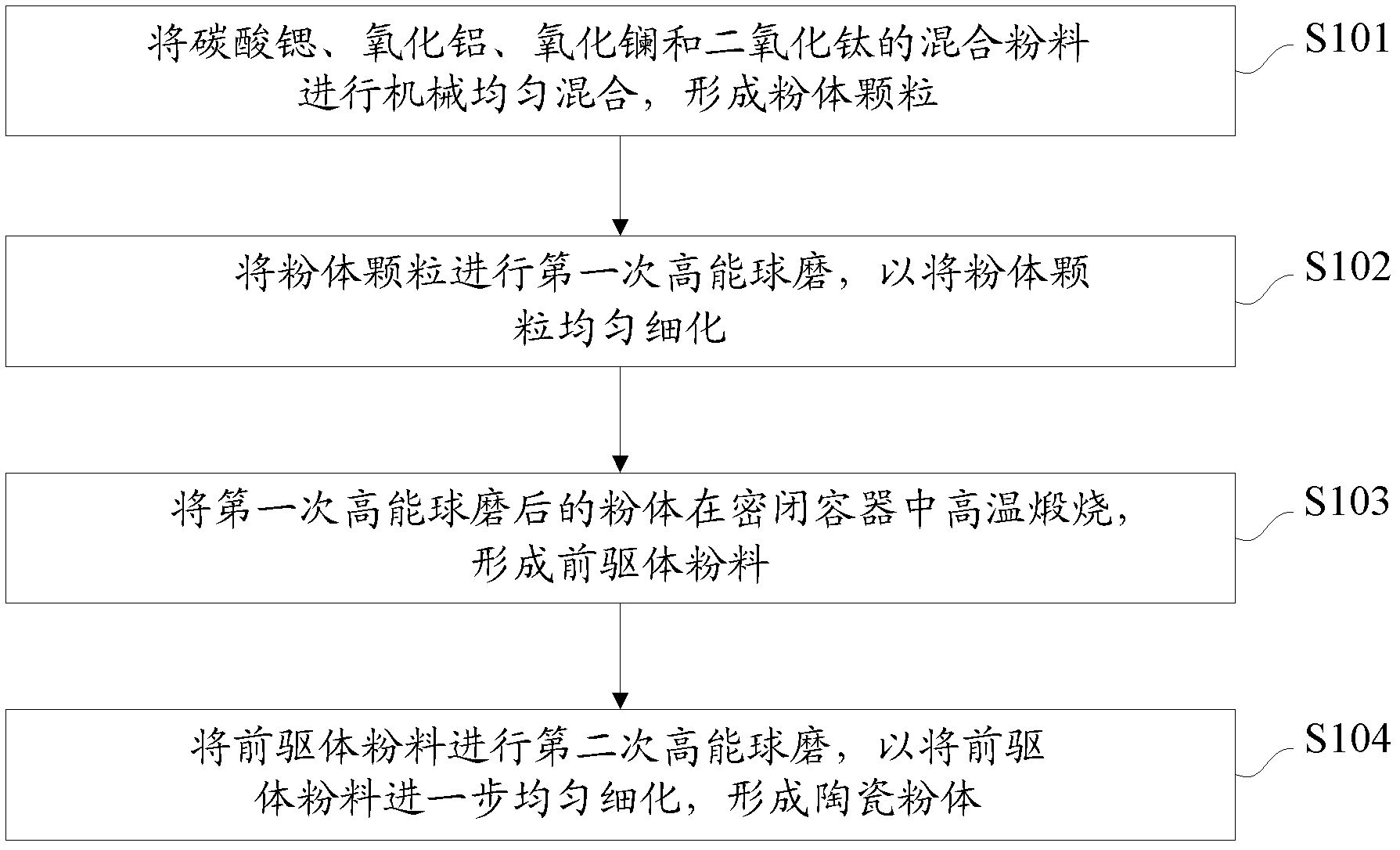

High-energy ball milling preparation method of barium titanate-based semiconductor ceramics

InactiveCN101805178AUniform grain distributionFine grain distributionGrain treatmentsBarium titanateAdhesive

The invention discloses a method for preparing a barium titanate-based PTC (Positive Temperature Coefficient) semiconductor ceramic fine crystalline structure, which comprises the following steps: using barium carbonate, titanium dioxide, yttrium oxide, manganese nitrate, strontium carbonate or / and calcium carbonate as raw materials, filtering slurry by using ZrO2 spherules with the diameter of 1 to 2mm and a gap with the thickness of 1mum, wherein the rotating speed is 1400 to 2400rpm and the ball milling time is 1 to 3 hours, and finally obtaining barium titanate-based PTC powder with the grain diameter of 20 to 50nm; then adding a dispersant, an adhesive and a plasticizer for mixing and ball milling for 3 to 5 hours, then standing for 5 to 12 hours, removing bubbles, carrying out physical aggregation, and finally carrying out sieving treatment to obtain casting slurry; and finally carrying out casting operation for the casting slurry to prepare a barium titanate ceramic green body. The obtained chip fine crystal PTC is characterized in that the magnetic crystal grain size is below 2 microns, the room temperature resistivity is not more than 120 Omega.cm, the lift-drag ratio is not less than 4*103, and the Curie temperature is 80 to 120 DEG C.

Owner:HUAZHONG UNIV OF SCI & TECH

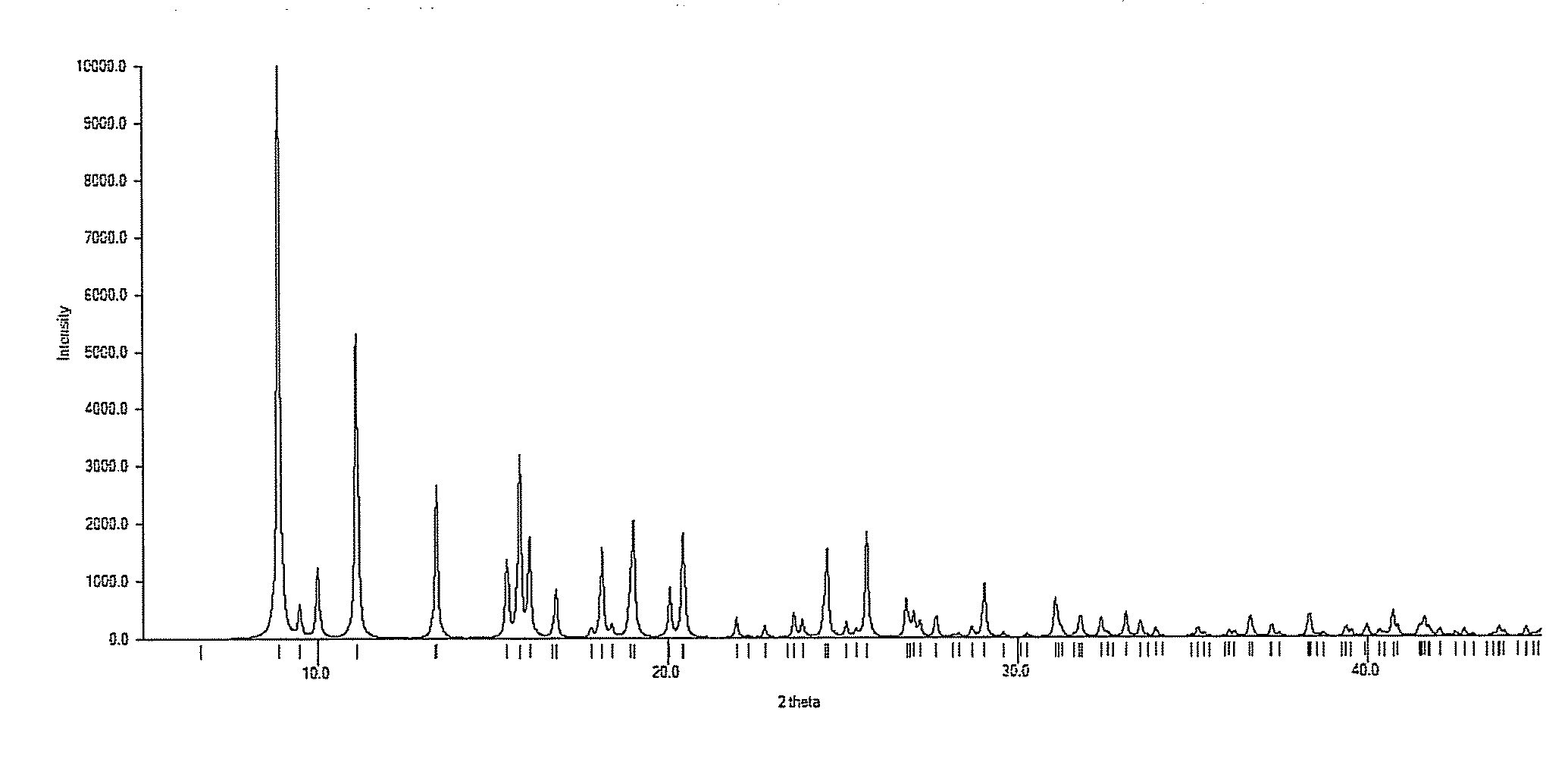

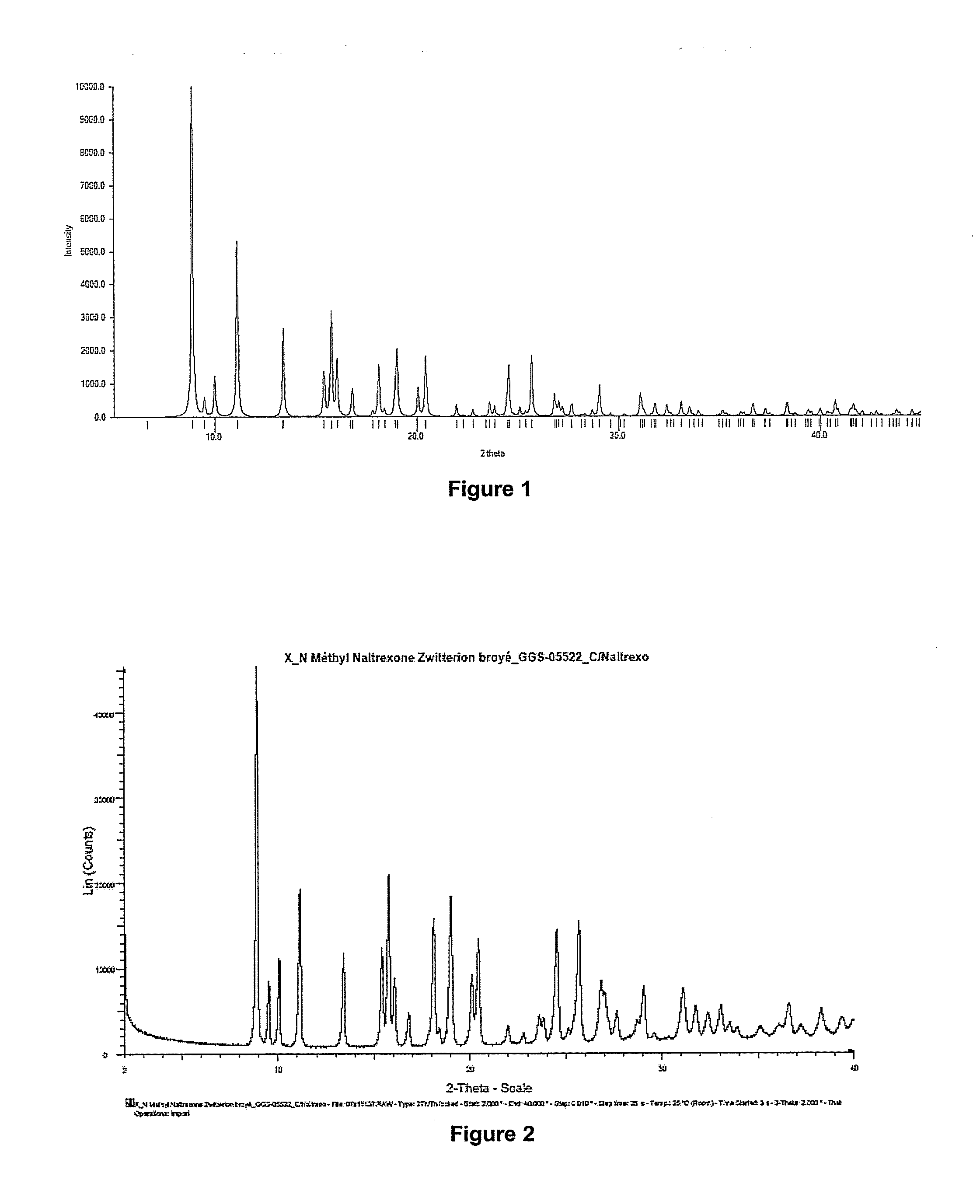

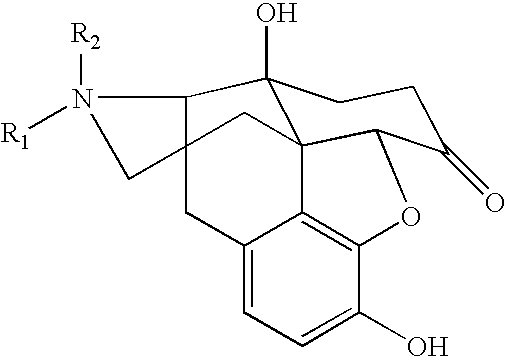

Process for preparing n-alkylnaltrexone halides

The invention relates to a novel process for preparing N-methylnaltrexone bromide, comprising at least the steps consisting in:(i) reacting N-methylnaltrexone methyl sulfate in aqueous solution with an alkaline agent chosen from the group constituted by sodium carbonate, potassium carbonate, calcium carbonate, magnesium carbonate, cesium carbonate, strontium carbonate and mixtures thereof, for a pH of the aqueous reaction medium of between 7 and 10, and then in(ii) reacting the product thus obtained with hydrobromic acid, which is added for a pH of the aqueous reaction medium of between 0.5 and 5, in order thus to obtain the N-methylnaltrexone bromide.

Owner:SANOFI SA

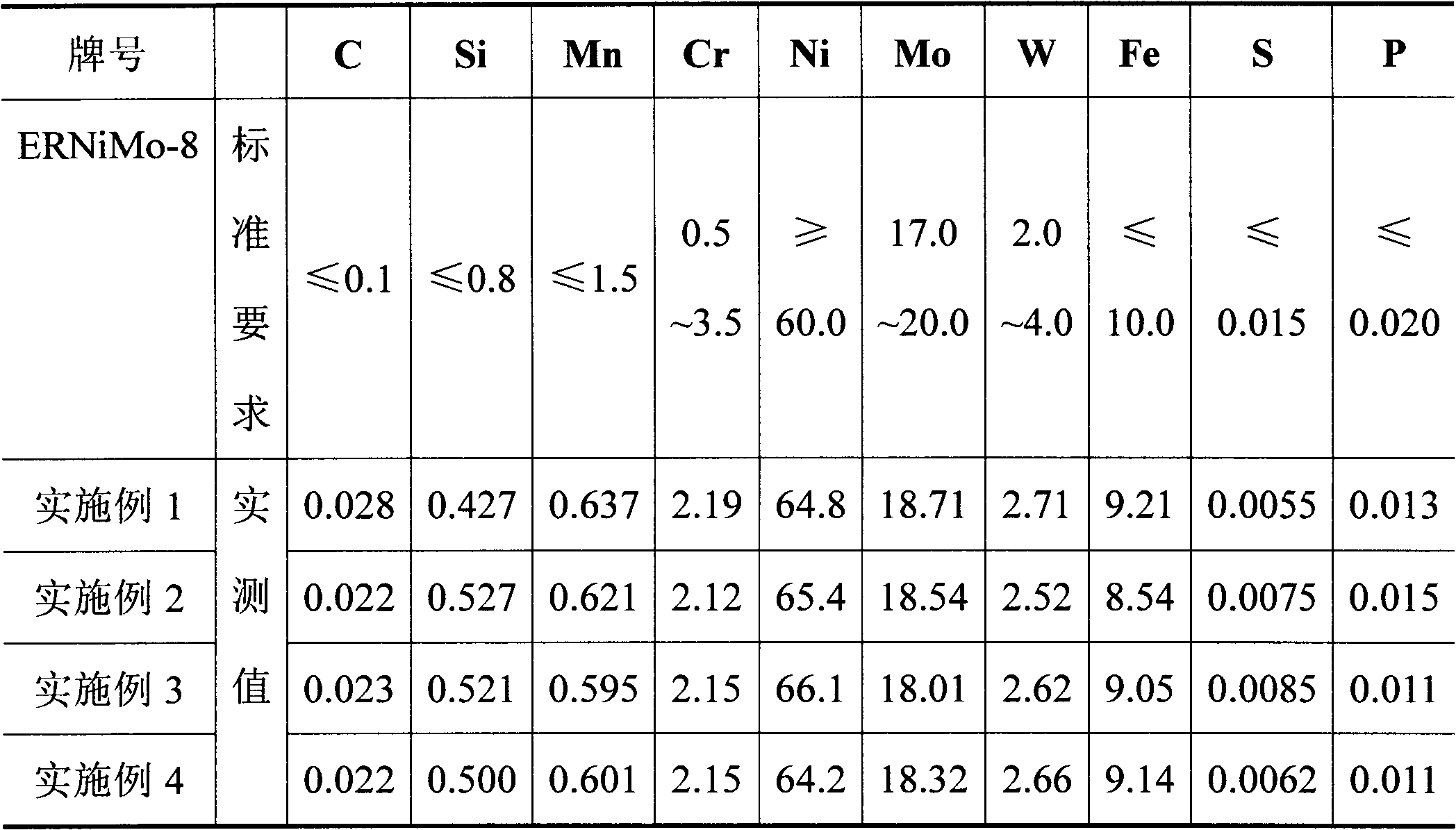

9Ni steel sintered flux and preparation method thereof

InactiveCN101954553AArc stabilizationBeautiful weld shapeWelding/cutting media/materialsSoldering mediaCooking & bakingWeld seam

The invention belongs to the field of welding material production, and discloses a 9Ni steel sintered flux and a preparation method thereof. The sintered flux comprises the following components in percentage by weight: 20 to 30 percent of dead-burned magnesite clinker, 8 to 18 percent of fluorite, 20 to 30 percent of corundum, 1 to 3 percent of elpasolite, 10 to 20 percent of grammite, 2 to 8 percent of strontium carbonate, 1 to 5 percent of rutile, 1 to 3 percent of silicon iron, 1 to 3 percent of ferrotitanium, 1 to 5 percent of manganese metal, 1 to 5 percent of magnesium fluoride and 1 to 3 percent of chromium oxide green. The preparation method comprises the following steps of: performing dry-mixing on mineral materials and iron alloy in a formula for 5 minutes; adding water glass to perform wet-mixing; then pelleting the mixture; drying pellets for 3 hours under the atmospheric environment; baking the pellets in a baking oven at a low temperature of 150 DEG C for 2 hours; then baking the pellets at a high temperature of 800 DEG C for 1 hour; performing furnace cooking, and crushing and screening the pellets to obtain a 12-60-mesh finished product of the flux. When the flux disclosed by the invention is matched with an ERNiMo-8 welding wire to perform welding, the flux has the following characteristics that: 1) a welding seam process has high performance, electric arcs during welding are stable, the surface of a welding seam is white and bright without an oxide color, molten slag is turned up automatically and can be taken off with a slight contact, the welded seam is formed to have a beautiful appearance, the welding bead height is moderate, and the welded same infiltration angle is moderate; 2) the flux can be matched with the ERNiMo-8 welding wire in use, and the comprehensive mechanical property is high; and 3) the flux can be matched with the ERNiMo-8 in use, and the chemical components of a deposited metal are easy to control.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Method of making pure salt from frac-water/wastewater

ActiveUS20110104038A1Easy to produceQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesParticulatesWater use

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

Bone-china exquisite glaze and method for fabricating bone-china exquisite products by using bone-china exquisite glaze

The invention relates to a bone-china exquisite glaze. The glaze comprises the following components in parts by weight: 16-24 parts of silica, 0-8 parts of clay, 28-38 parts of feldspar, 12-18 parts of borax, 0-7 parts of boric acid, 10-17 parts of barium carbonate, 0-5 parts of strontium carbonate, 0-8 parts of lithium carbonate, 2-12 parts of zinc oxide, 0-6 parts of aluminum hydroxide, 0-3 parts of talc, 0-12 parts of calcite and 0-1 part zirconium silicate. The glaze has the advantages of good transmittance and no opaque phenomenon and is exquisitely carved and glittering and translucent like jewels; the invention also provides a method for fabricating bone-china exquisite products from bone-china exquisite glaze, according to the method, residual bubbles can be eliminated, at the same time, the expansion coefficients of the glaze and the bone china are matched, quick heating and cooling resistance of products are improved and the cracking problem is avoided.

Owner:潮州市雅森陶瓷实业有限公司

Rubber ferromagnetic oxide powder and preparation method thereof

InactiveCN101445363AImprove magnetismAppropriate granularityMagnetsStrontium carbonateGrowth control

The invention provides a rubber ferromagnetic oxide powder and a production process thereof. Iron red and strontium carbonate or barium carbonate are adopted as raw materials, an additive which is favorable to the low-temperature pre-sintering effect improvement and the growth control of crystal grains is preferably added, and a magnetic powder with higher magnetic property and processing property is obtained through the pre-sintering and pulverizing processes, and is suitable to be as a raw material of products such as seals of refrigerator doors, magnetic seals of doors and windows and advertising magnets. The invention has the advantages that the annealing process is not required in the process of preparing the ferromagnetic oxide powder, thereby reducing manufacture cost, lowering energy consumption, and reducing emission.

Owner:BGRIMM TECH CO LTD

Nickel-based welding rod for welding of ultralow-temperature container steel

InactiveCN106514049ASimple welding processImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaAlternating currentRutile

The invention discloses a nickel-based welding rod for welding of ultralow-temperature container steel and belongs to the technical field of nickel-based welding rods. The nickel-based welding rod comprises a welding core and a coating covering the surface of the welding core. The welding core comprises the chemical components of, by weight percentage, 0-0.1% of C, 0-0.6% of Si, 1.5%-4.5% of Mn, 0-0.012% of S, 0-0.015% of P, 0-17.0% of Cr, 4.5%-9.5% of Mo, 0.5%-2.0% of Nb, 0.5%-2.0% of W, and the balance Ni. The coating comprises the powdery materials of, by weight percentage, 20%-38% of marble, 5%-8% of strontium carbonate, 1%-4% of potassium feldspar, 3%-13% of fluorite, 2%-10% of magnesium fluoride, 3%-15% of cryolite, 10%-20% of rutile, 2%-7% of ferrotitanium, 2%-6% of ferro-aluminium, 0.5%-2% of aluminum magnesium powder, 4%-7% of ferro-molybdenum, 2%-5% of ferroniobium and 1%-3% of ferrotungsten, and the sum of all the components is 100%. The nickel-based welding rod has excellent welding manufacturability in horizontal, transverse, vertical, overhead and other welding positions when an alternating current power source is adopted for welding, and the nickel-based welding rod also has excellent low temperature toughness.

Owner:CENT IRON & STEEL RES INST

Bone matte glaze and method for manufacturing bone china product by using same

The invention relates to bone matte glaze. The bone matte glaze comprises, by weight, 100 parts of frits, 3-8 parts of clay, 2-12 parts of aedelforsite, 3-6 parts of aluminum oxide, 6-15 parts of zinc oxide and 6 parts of stannic oxide. The frits comprise, by weight, 16-24 parts of quartz, 28-38 parts of potash feldspar, 12-18 parts of borax, 0-7 parts of boric acid, 0-5 parts of strontium carbonate, 0-8 parts of lithium carbonate, 0-10 parts of zinc oxide, 0-3 parts of talcum, 0-12 parts of calcite and 0-0.5 part of zirconium silicate. The glaze surface of a product using the glaze is fine, smooth, resistant to pollution, resistant to acid and alkali, easy to wash and suitable for the decoration means such as decal. The invention further provides a method for manufacturing the bone china product by using the bone matte glaze. The method is simple in firing process, stable in production and good in benefit.

Owner:GUANGDONG SONGFA CERAMICS

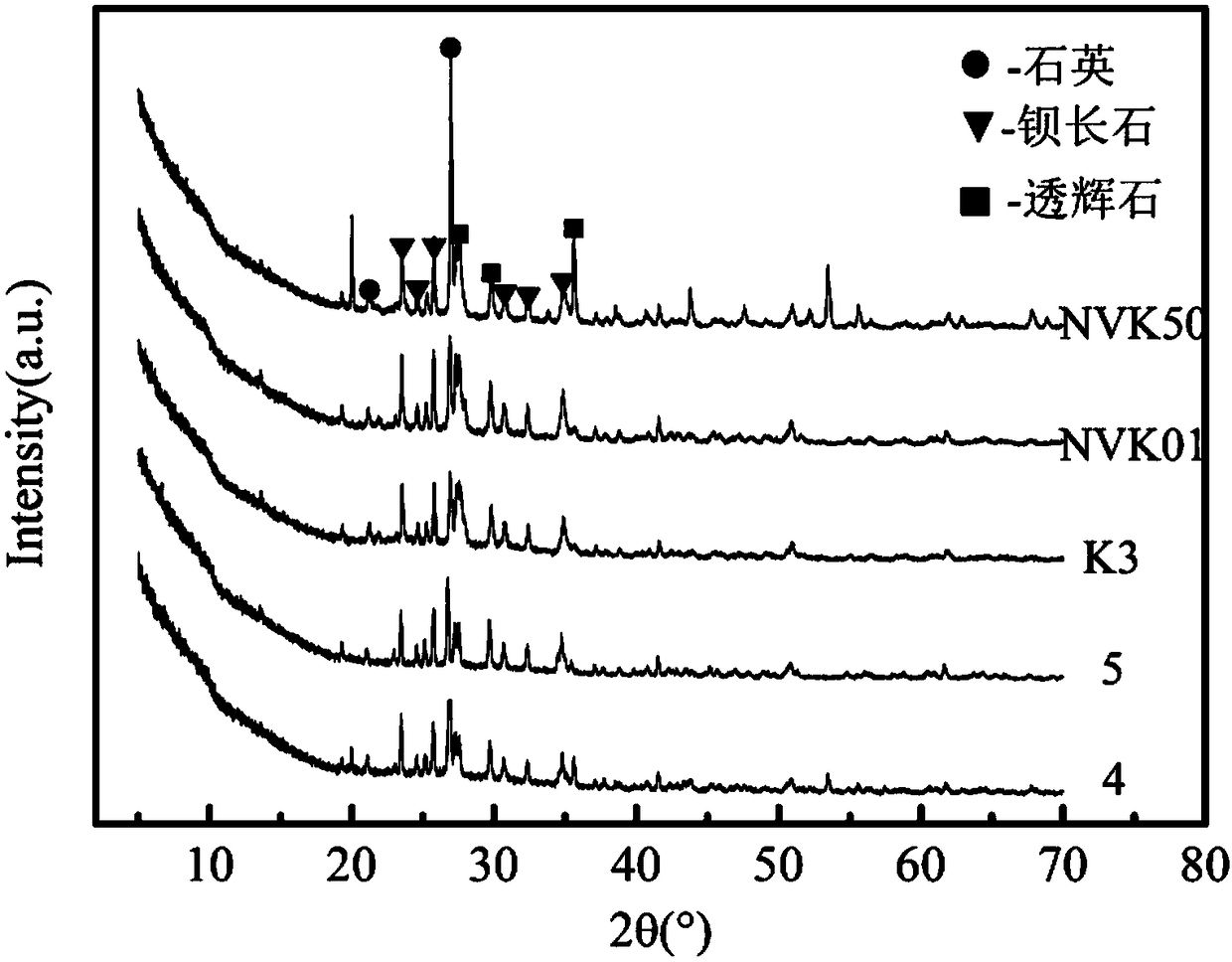

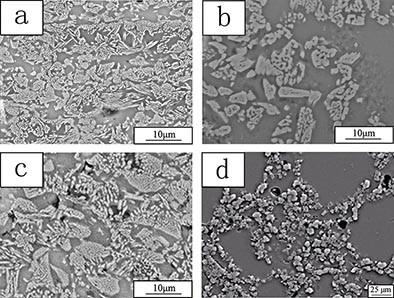

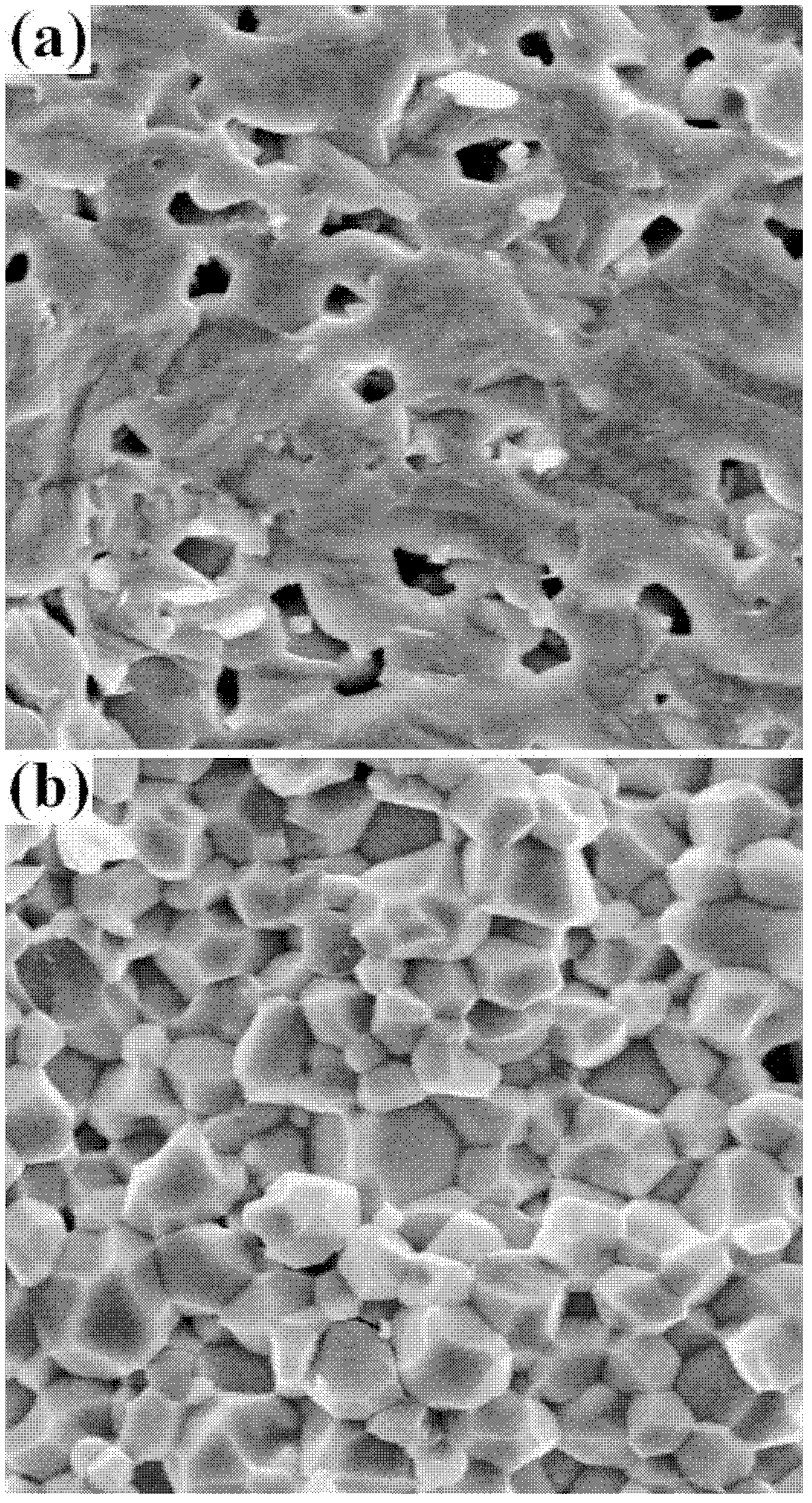

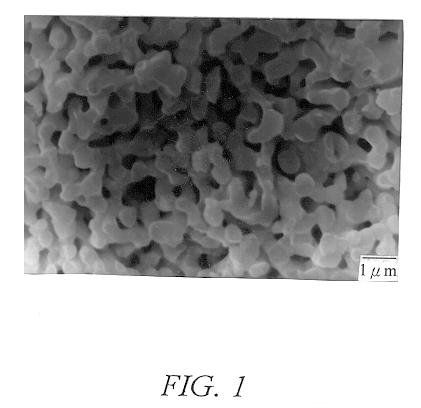

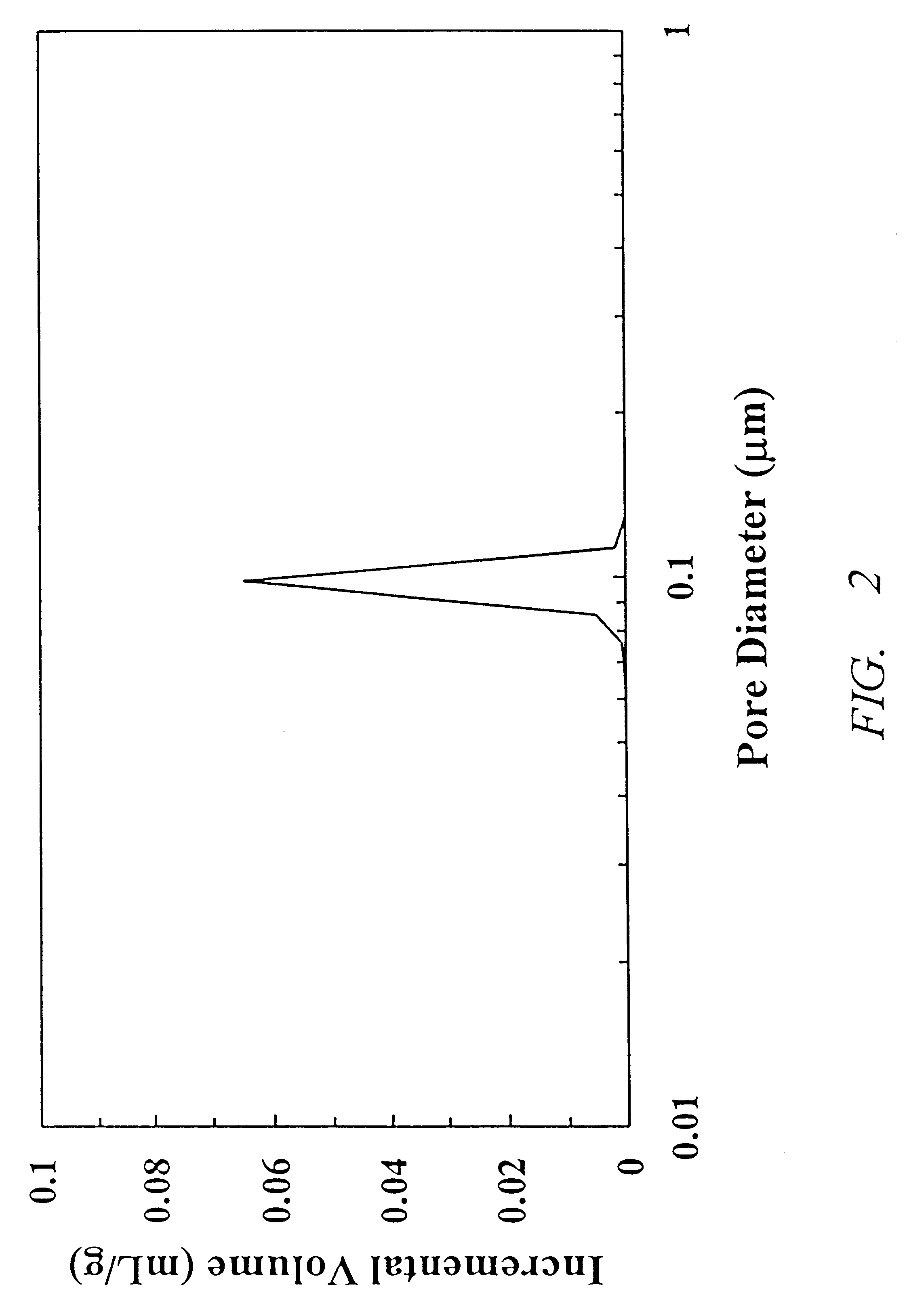

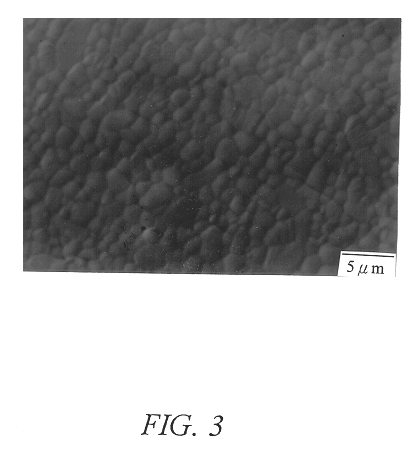

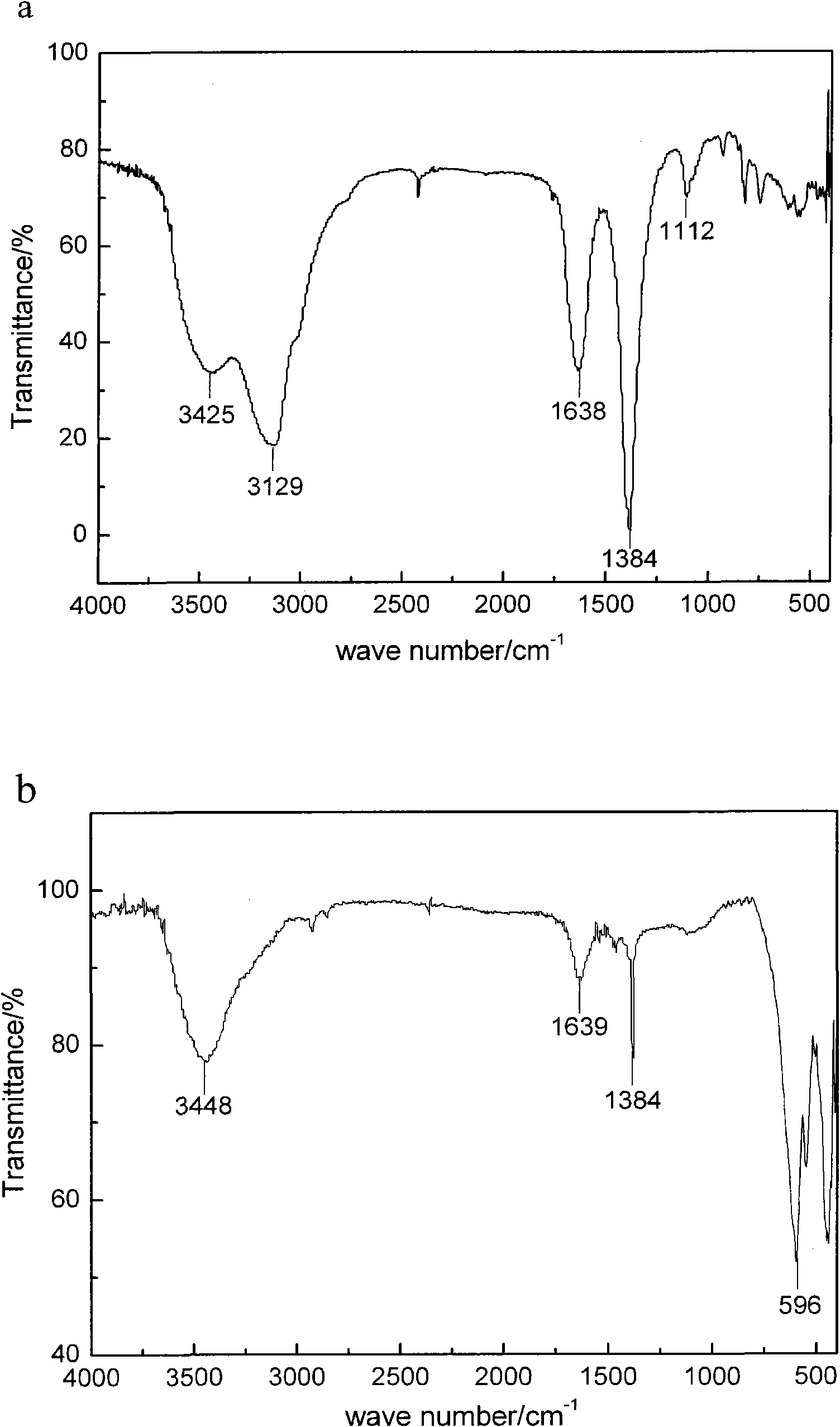

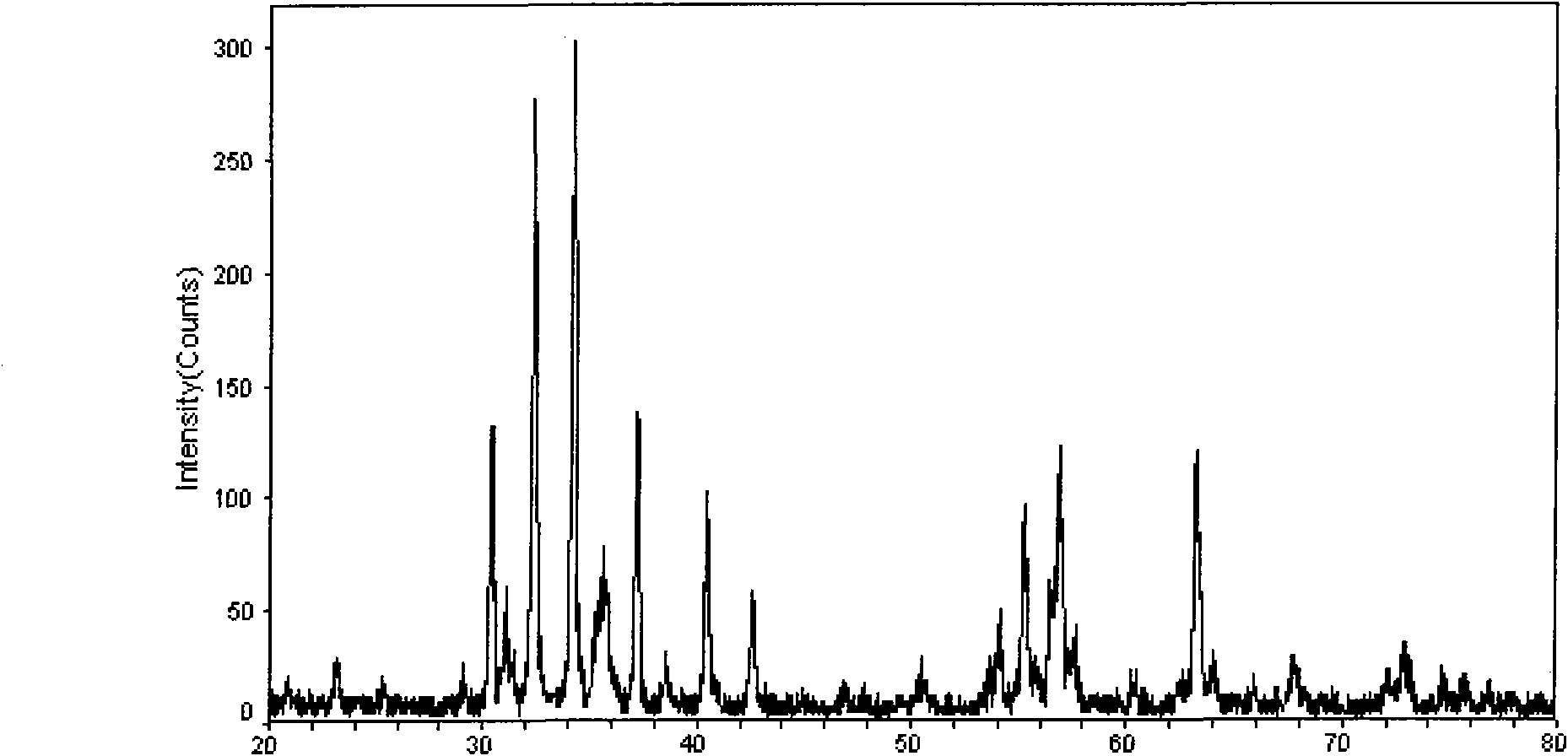

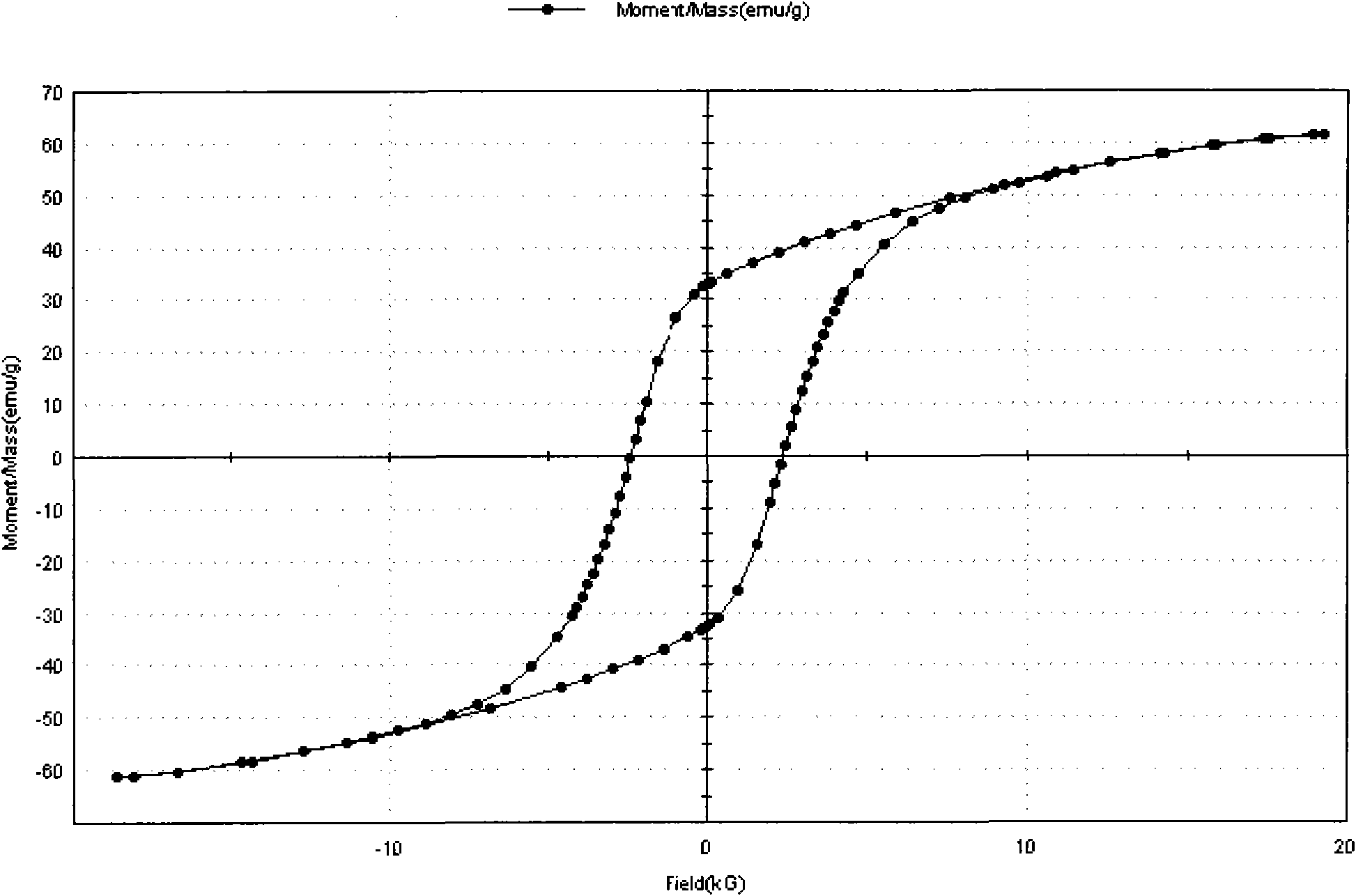

Preparation of translucent strontium barium niobate ceramics using reaction sintering

InactiveUS6403053B1Low costHigh densityOxide/hydroxide preparationVanadium oxidesStrontium carbonateStrontium barium niobate

In this patent, reaction sintering was used to prepare translucent strontium barium niobate ceramics (SrxBa1-xNb2O6, x=0.2-0.7). High purity powders of strontium carbonate (SrCO3) and barium carbonate (BaCO3) were mixed with niobium oxide (Nb2O5), respectively, at the same mole using ball milling. The mixed powders were dried and ground by a mortar. Thereafter, they were calcined at 800-1050° C. for 1-4 h in air to form strontium niobate (SrNb2O6) and Barium niobate (BaNb2O6), respectively. Precursor powders of strontium niobate (SrNb2O6) and barium niobate (BaNb2O6) were mixed in appropriate ratios and pressed. Compacts were reaction-sintered in a temperature range of 1300 to 1320° C. in O2 and then heat-treated in a temperature range of 1260 to 1275° C. in O2. We also propose the related basic principles and microstructures.

Owner:NAT SCI COUNCIL

Preparation method of nanometer strontium ferrite magnetic powder

The invention relates to the production of magnetic materials, in particular to a preparation method of nanometer strontium ferrite magnetic powder (SrFe12O19), comprising the following specific steps of: weighting strontium carbonate and ferric nitrate crystal according to the mole ratio of 1:12 of Sr and Fe, solving the strontium carbonate and the ferric nitrate crystal by nitric acid and deionized water, adding tartaric acid and polyethylene glycol after evenly mixing, and regulating the pH value to be 7 by using ammonia water; and heating the obtained mixed liquid to be sol-gel, drying the sol-gel, and carrying out the sectional roasting on the dried sol-gel at 860-1,100 DEG C to prepare powdery magnetic nanometer strontium ferrite. Due to the synergistic effect of the polyethylene glycol, the tartaric acid is used for the first time as a main complexing agent to prepare strontium ferrite so that a precursor directionally grows up, the anisotropy is increased and the saturation magnetization strength Ms is improved. The test shows that the crystallite dimension is 20-45nm, the saturation magnetization strength Ms is 78.4emu / g, and the intrinsic coercivity is 3163.3G. The excellent performance of the magnetic powder is suitable for automobile motor magnets and magnetic recording media materials.

Owner:CHONGQING UNIV

Double-layered crystal glaze and preparation method thereof

The invention discloses double-layered crystal glaze and a preparation method thereof. The double-layered crystal glaze comprises bottom glaze and surface glaze, wherein the bottom glaze is prepared from the following components in parts by weight: 30-35 parts of feldspar, 21-23 parts of quartz, 7-12 parts of calcite, 4-5 parts of Guizhou soil, 3-5 parts of zinc oxide, 7.5-10 parts of zirconium silicate and 7-11 parts of strontium carbonate; the surface glaze is prepared from the following components in parts by weight: 22-25 parts of feldspar, 24-25 parts of borax, 5-10 parts of quartz, 12-15 parts of calcite, 4-5 parts of Guizhou soil, 23-25 parts of zinc oxide, 9-10 parts of zirconium silicate, 5-8 parts of dolomite and 0.5 part of chromophore. According to the invention, the sintering time of the crystal glaze can be shortened, so that the cost is lowered. The double-layered crystal glaze can be produced on a large scale, and the production quantity of the double-layered crystal glaze is improved.

Owner:LILING TAORUN INDAL DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com