9Ni steel sintered flux and preparation method thereof

A technology of sintering flux and flux, which is applied in the direction of manufacturing tools, welding media, welding equipment, etc., can solve the problems of poor welding effect and no 9Ni steel, etc., and achieve the effect of beautiful shape, beautiful weld seam and easy control of chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

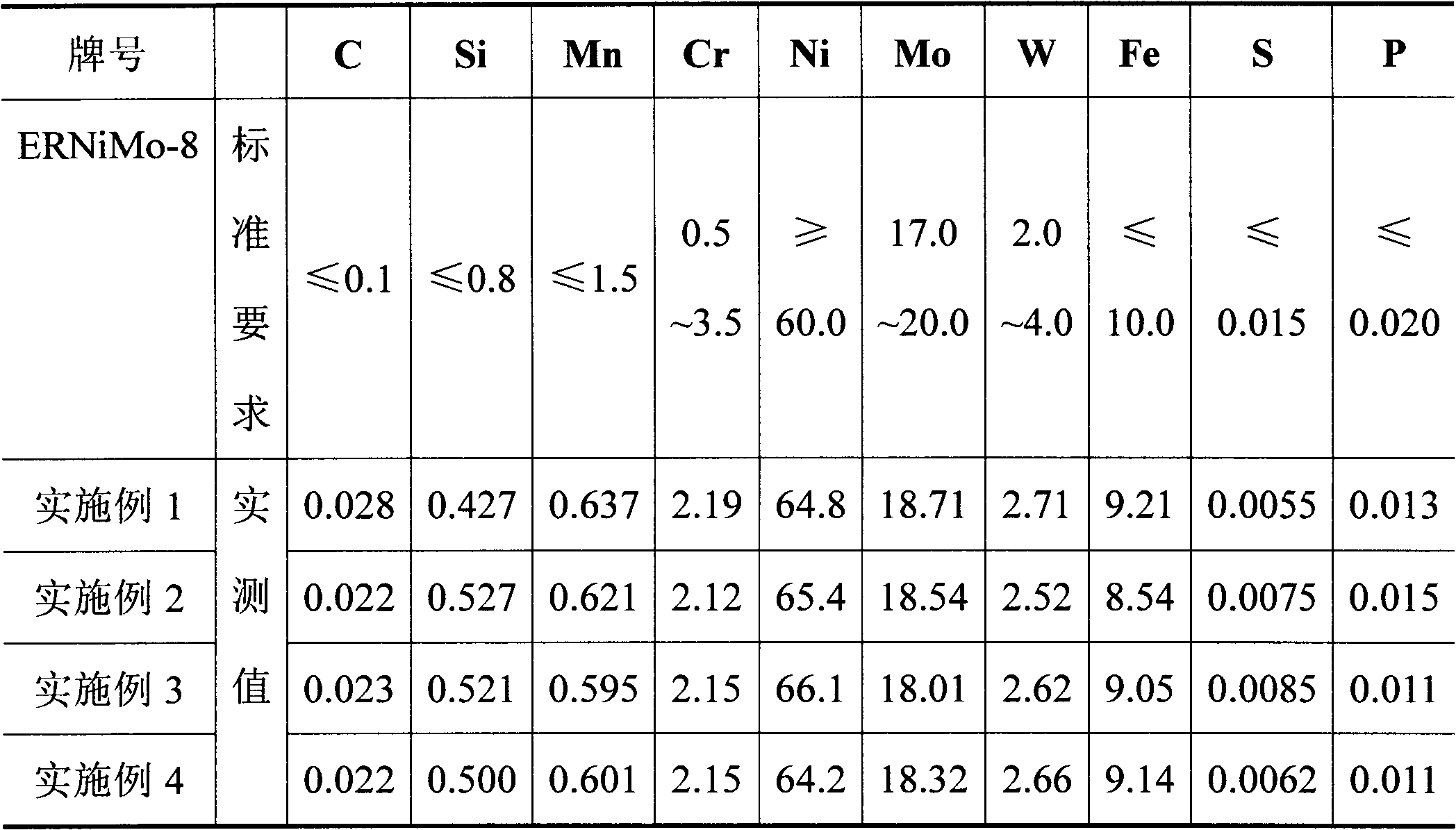

[0025] The specific composition of the flux components is given in Table 1 below. The manufacturing method is as follows: after dry mixing the mineral raw materials and the iron alloy in the formula for 5 minutes, adding water glass to wet mixing, M=2.6 of the water glass, Be=42-45 at room temperature, and the ratio of potassium sodium water glass is K:Na= 3:1; then granulated, dried in the atmosphere for 3 hours, put into an oven for 2 hours at a low temperature of 150 °C, baked at a high temperature of 800 °C for 1 hour, cooled with the furnace, and then crushed and sieved to obtain a finished flux of 12-60 mesh. After 150℃±10℃ low temperature baking for 2h, 800℃±30℃ high temperature baking for 1h, then cooling with the furnace, passing through a 12-60 mesh sieve, the finished sintered flux is obtained.

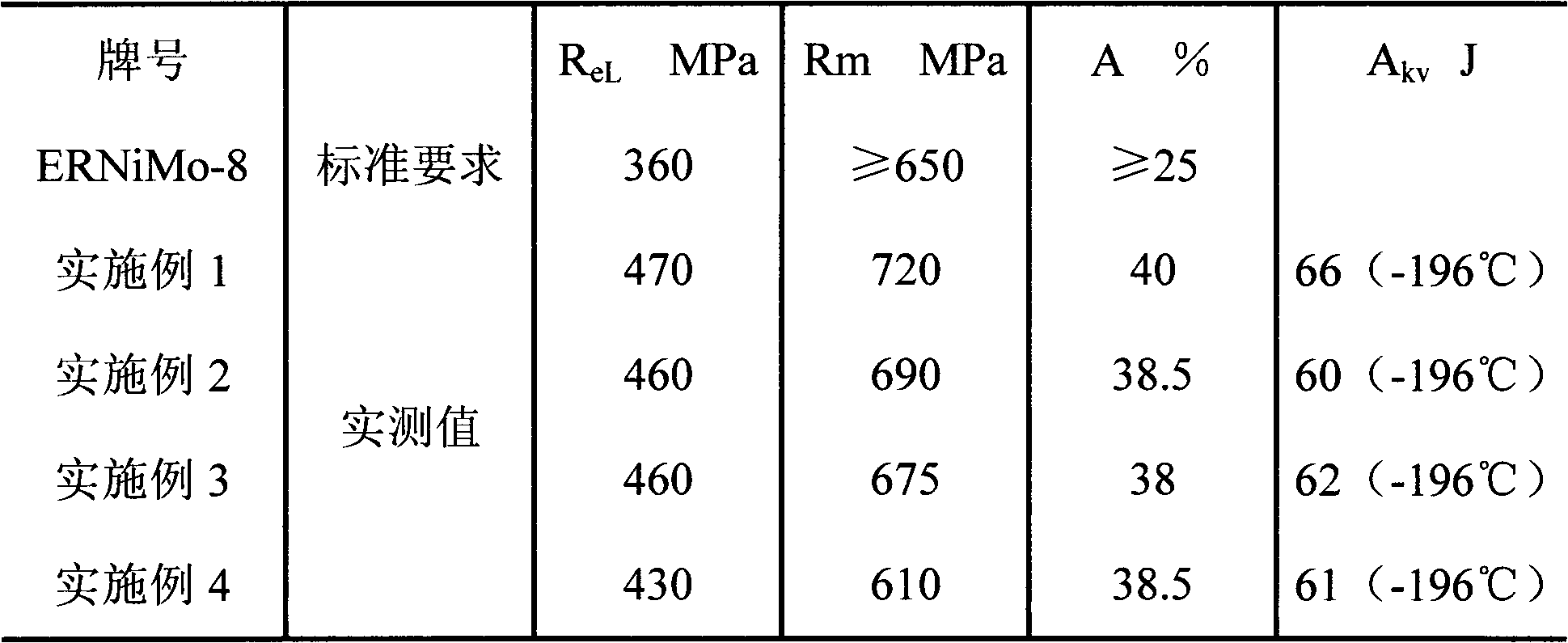

[0026] The ERNiMo-8 welding wire is used with the sintered flux of the present invention to be deposited, and the chemical composition and properties of the deposited metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com