High-refractive-index ultraviolet-transparent glass and manufacturing method thereof

A high refractive index, outer glass technology, applied in the field of glass materials, can solve the problems of not being suitable for the process requirements of optical fiber panel image intensifiers, poor chemical stability of glass, etc., and achieve good acid resistance chemical stability, high refractive index, and transmission high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

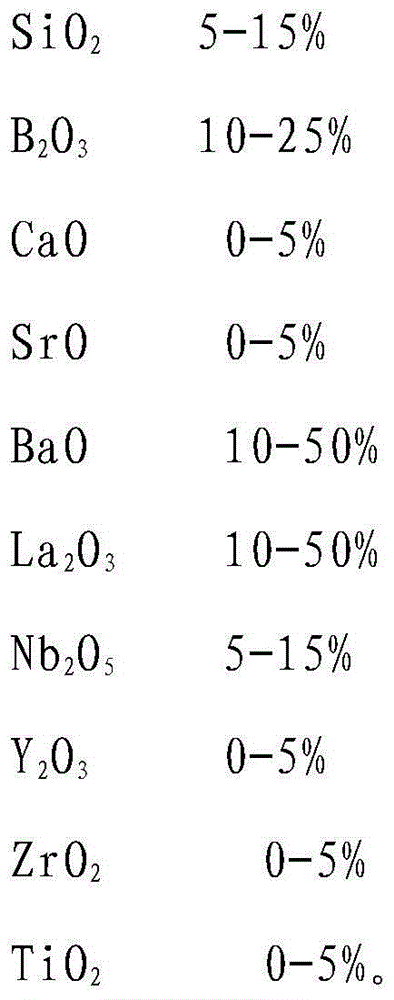

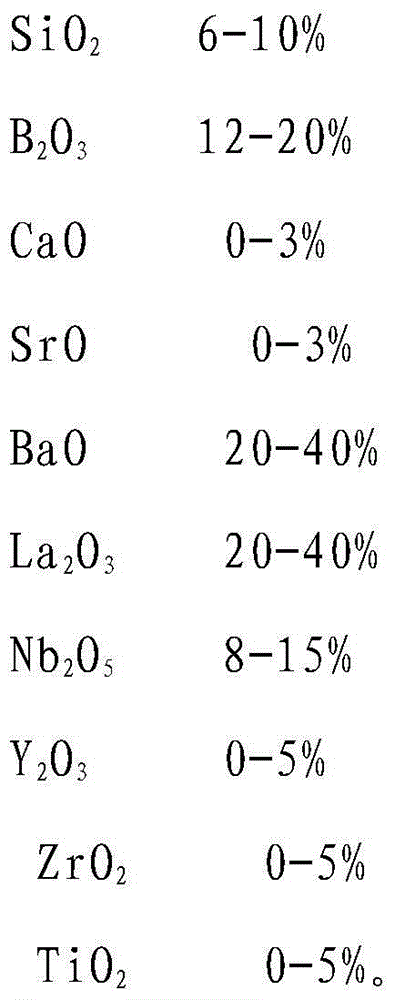

Method used

Image

Examples

Embodiment 1

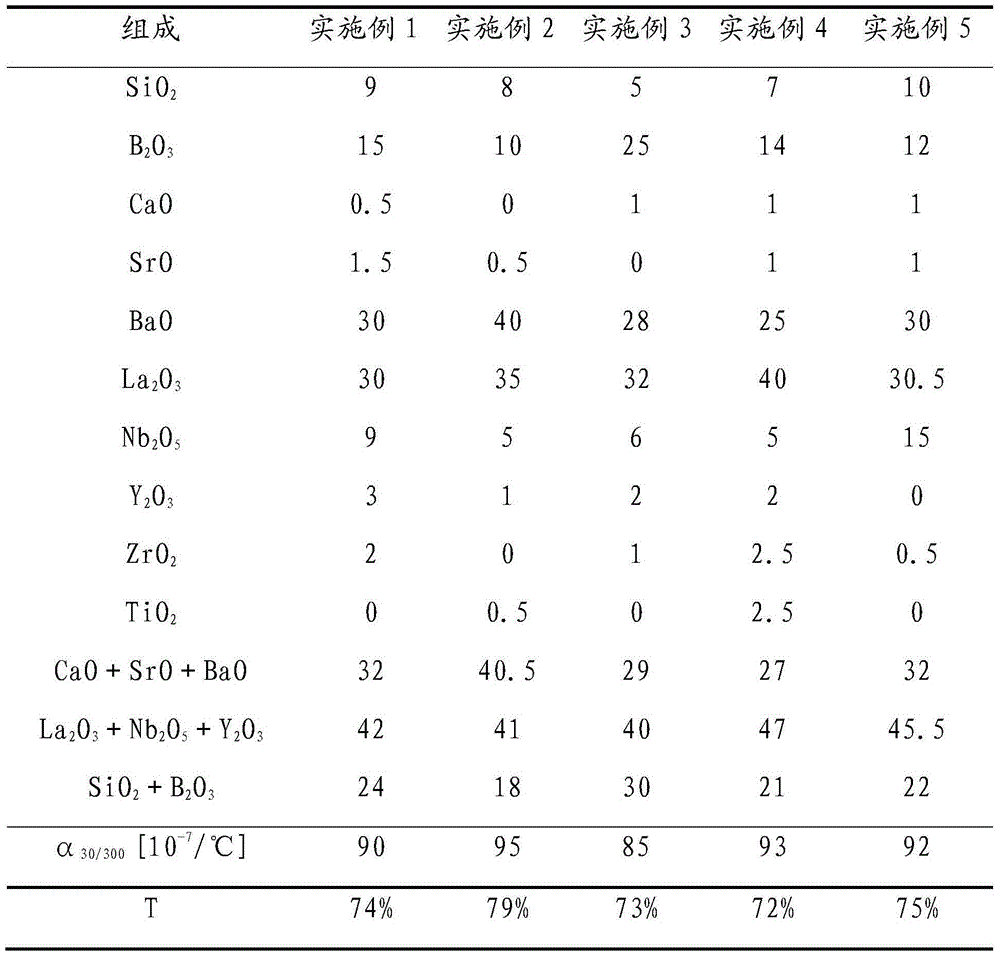

[0045] First, select the raw material according to the glass composition in Example 1 of Table 1, the raw material requirements, quartz sand (high purity, 150 μm oversize is less than 1%, 45 μm undersize is less than 30%, Fe 2 o 3 Content less than 1PPm), boric acid or boric anhydride (400μm sieve is less than 10%, 63μm sieve is less than 10%), calcium carbonate (analytical pure, average particle size 250μm), strontium carbonate (analytical pure, purity ≥ 99.0 %), barium carbonate (analytical pure, purity ≥ 99.0%), dilanthanum trioxide (5N), niobium pentoxide (5N), yttrium trioxide (5N), zirconia (analytical pure), titanium dioxide (analytical pure ), and oxides of variable valence elements such as Fe in glass raw materials 2 o 3 etc. are strictly controlled, and the finished glass Fe 2 o 3 The content of the reducing agent is less than 1PPm, and the ingredients meet the glass chemical composition in Table 1. Carbon powder or tartaric acid is introduced into the glass batc...

Embodiment 2

[0047] The actual composition of the glass refers to Example 2 in Table 1, using the same raw materials and raw material requirements as in Example 1, and adopting a melting process system of melting at 1400 ° C for 10 hours and the same test conditions as in Example 1, and the carbon powder is 0.5% , 0.5% tartaric acid, in Table 1 shows the basic properties of the samples. (1) The refractive index is 1.85; (2) The ultraviolet light transmittance reaches 79% when the wavelength is 350nm; (3) The average linear expansion coefficient of 30-300°C is 95×10 -7 / °C.

Embodiment 3

[0049] The actual composition of the glass refers to Example 3 in Table 1, uses the same raw materials and raw material requirements as in Example 1, and adopts a melting process system of melting at 1600 ° C for 6 hours and the same test conditions as in Example 1, and the carbon powder is 0.04% , 0.06% tartaric acid, in Table 1 shows the basic properties of the sample. (1) The refractive index is 1.77; (2) The ultraviolet light transmittance reaches 73% when the wavelength is 350nm; (3) The average linear expansion coefficient of 30-300°C is 85×10 -7 / °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com