Nickel base welding rod of Ni-Cr-Mo alloy system

A technology of nickel-chromium-molybdenum alloy and nickel-based welding rod, which is applied in welding medium, welding equipment, metal processing equipment, etc., can solve the problem of unretrieved nickel-based welding rod, etc., achieve good welding processability, simple production process, and slag removal convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

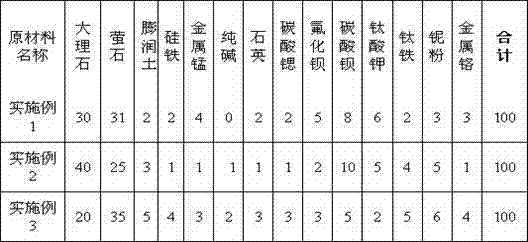

[0034] The formula of embodiment is as shown in table 1.

[0035] Table 1 (%)

[0036]

[0037] The composition of the ERNiCrMo-3 welding core used in the examples is (%): C0.033, Si0.094, Cr: 21.50, Mn0.050, Fe0.141, Cu0.062, Nb+Ta: 3.59, S0.005 , P0.011, Mo9.35, Ni65.23.

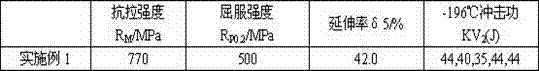

[0038] The implementation effect is shown in Table 2 and Table 3.

[0039] Table 2 Chemical composition of deposited metal (%)

[0040] element C mn Si S P Cr Ni Mo Nb Fe Cu Example 1 0.037 0.854 0.607 <0.0050 0.0053 20.60 58.75 8.90 3.06 6.27 0.017

[0041] Table 3 Mechanical properties of deposited metal

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com