Patents

Literature

276 results about "Barium fluoride" patented technology

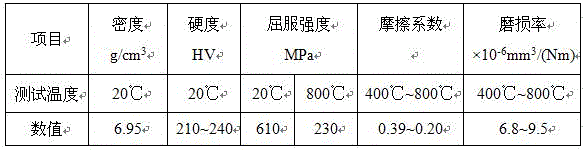

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium fluoride (BaF₂) is a chemical compound of barium and fluorine and is a salt. It is a solid which can be a transparent crystal. It occurs in nature as the mineral frankdicksonite.

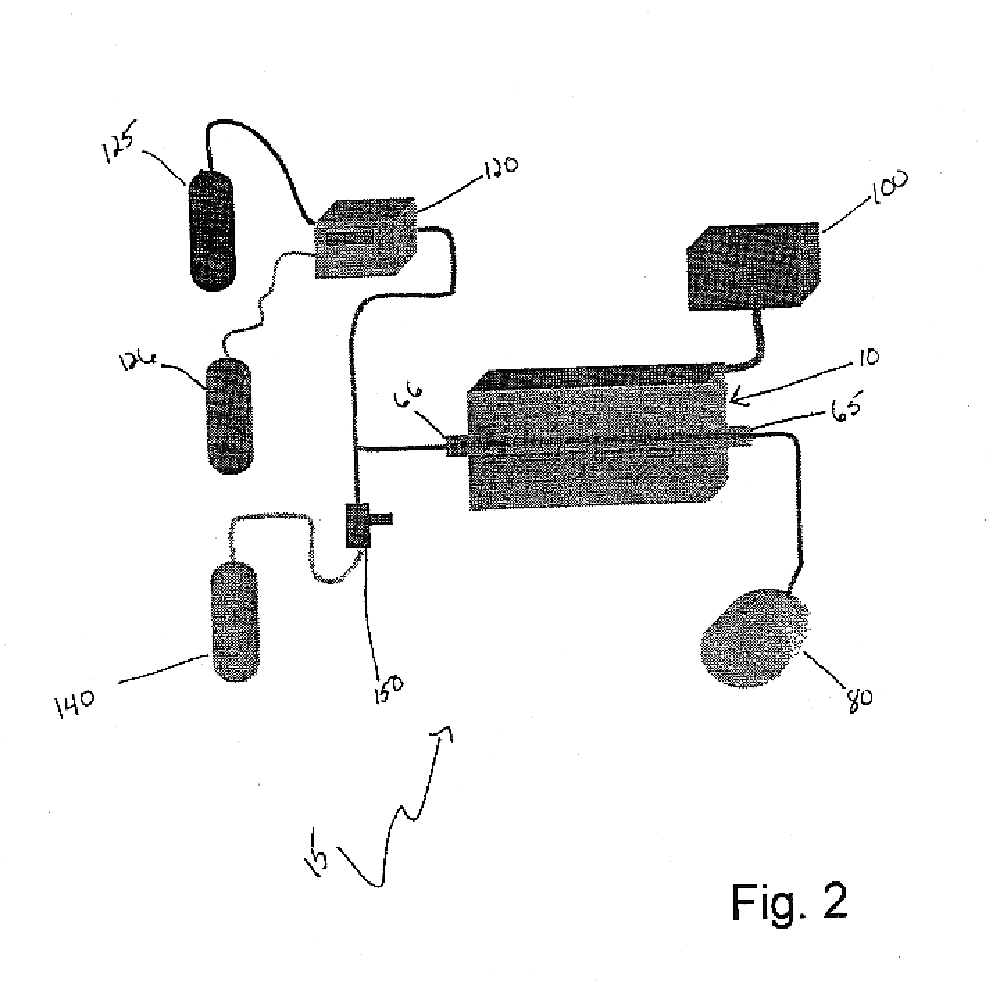

Nanocomposite scintillator, detector, and method

InactiveUS20080093557A1Material analysis by optical meansLuminescent compositionsSodium iodideTungstate

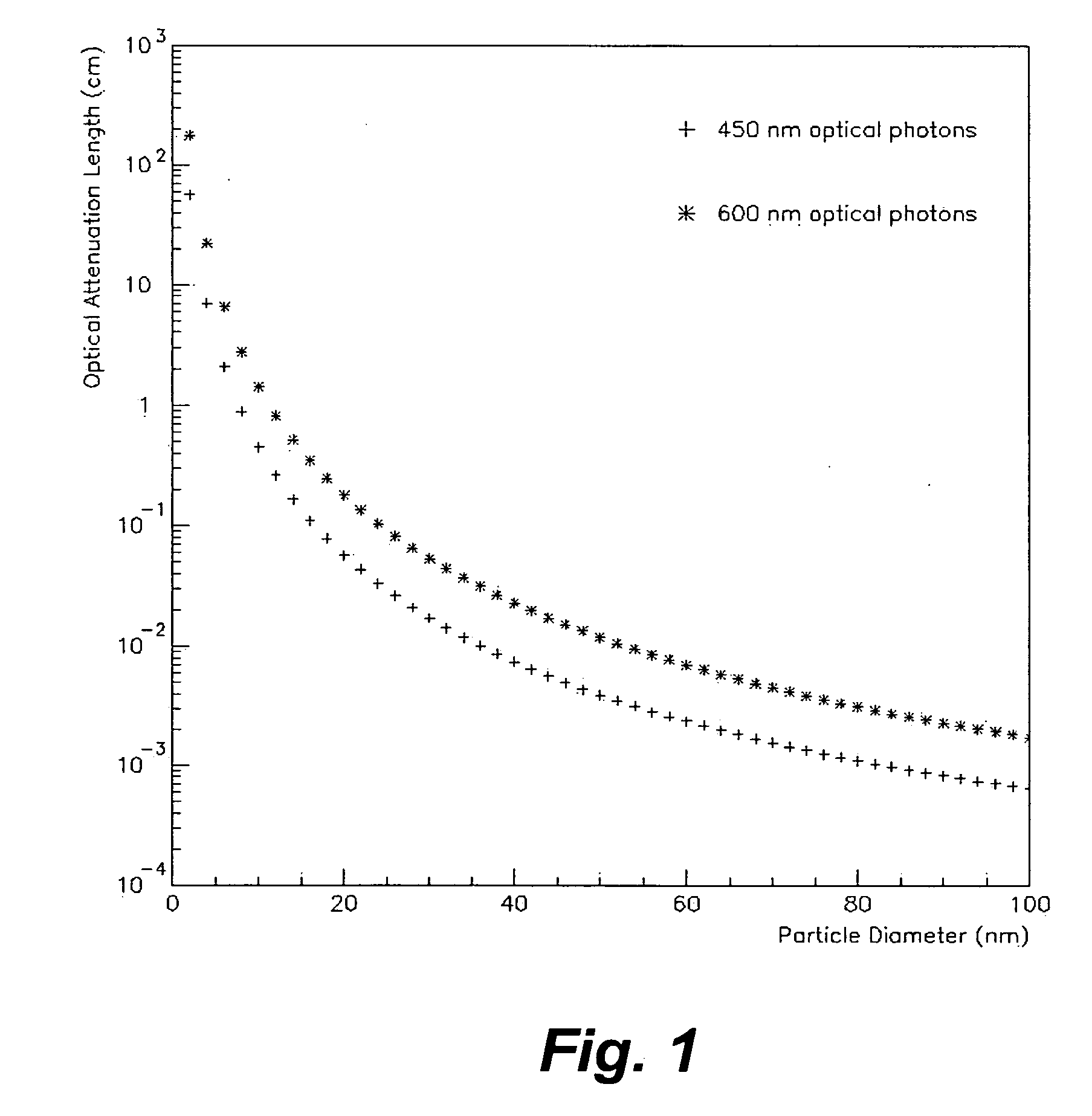

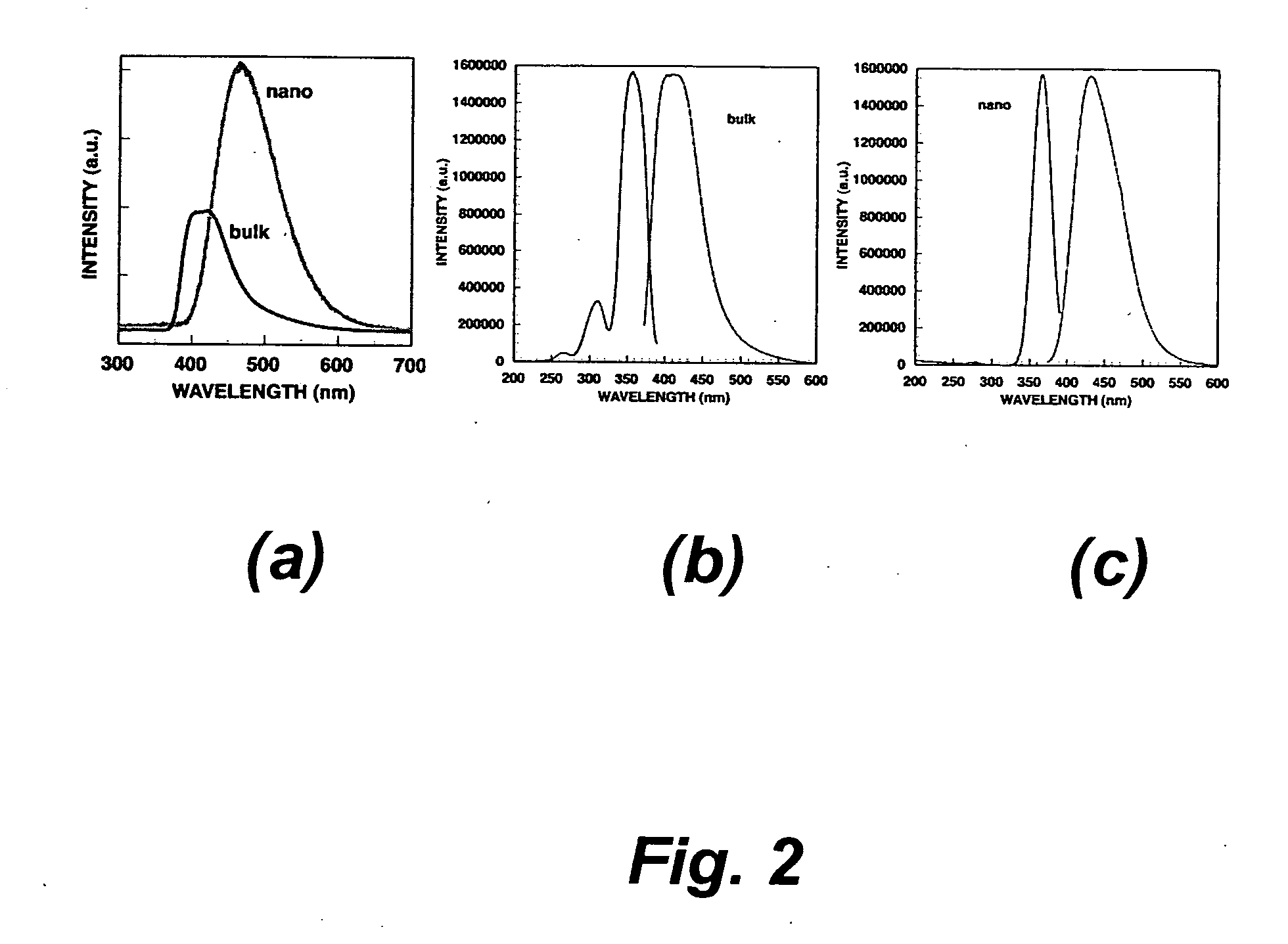

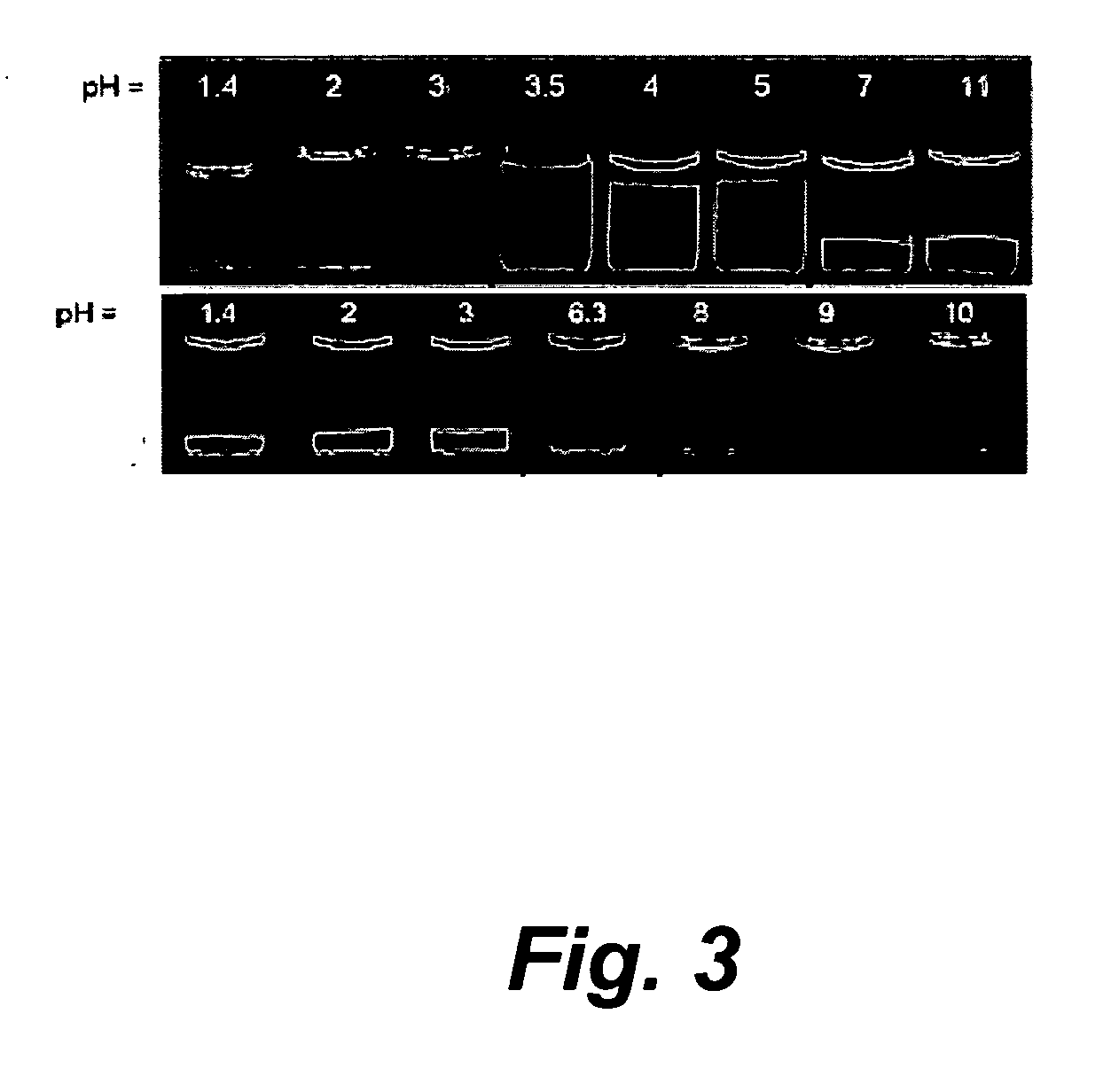

A compact includes a mixture of a solid binder and at least one nanopowder phosphor chosen from yttrium oxide, yttrium tantalate, barium fluoride, cesium fluoride, bismuth germanate, zinc gallate, calcium magnesium pyrosilicate, calcium molybdate, calcium chlorovanadate, barium titanium pyrophosphate, a metal tungstate, a cerium doped nanophosphor, a bismuth doped nanophosphor, a lead doped nanophosphor, a thallium doped sodium iodide, a doped cesium iodide, a rare earth doped pyrosilicate, or a lanthanide halide. The compact can be used in a radiation detector for detecting ionizing radiation.

Owner:RGT UNIV OF CALIFORNIA

Thermal spray compositions for abradable seals

Owner:SULZER METCO CANADA INC

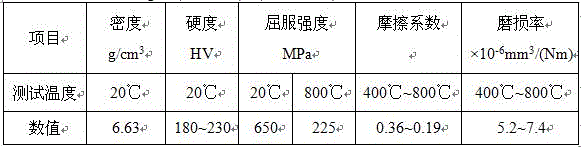

High-entropy alloy self-lubricating composite material and preparation method thereof

ActiveCN105908049AGood self-lubricating performanceGood mechanical propertiesHigh entropy alloysRoom temperature

The invention discloses a high-entropy alloy self-lubricating composite material. According to the high-entropy alloy self-lubricating composite material, four-element high-entropy alloy CoCrFeNi serves as a matrix, and silver, graphite, molybdenum disulfide, calcium fluoride, barium fluoride and cerium oxide serve as a lubrication phase; the silver element content is 2%-15%, the sum of the content of the graphite and the content of the molybdenum disulfide is 5%-10%, and the content of the graphite is equal to that of the molybdenum disulfide; the sum of the content of the calcium fluoride and the content of the barium fluoride is 5%-10%, and the ratio of the content of the calcium fluoride to the content of the barium fluoride is 4:6; the content of the cerium oxide is 3%-8%; the balance is the four-element high-entropy alloy CoCrFeNi; and all the contents are expressed by mass percent. The invention further discloses a preparation method of the composite material. The composite material provided by the invention has good self-lubricating performance and meanwhile has excellent strength and toughness within the wide temperature region (the room temperature to 800 DEG C).

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

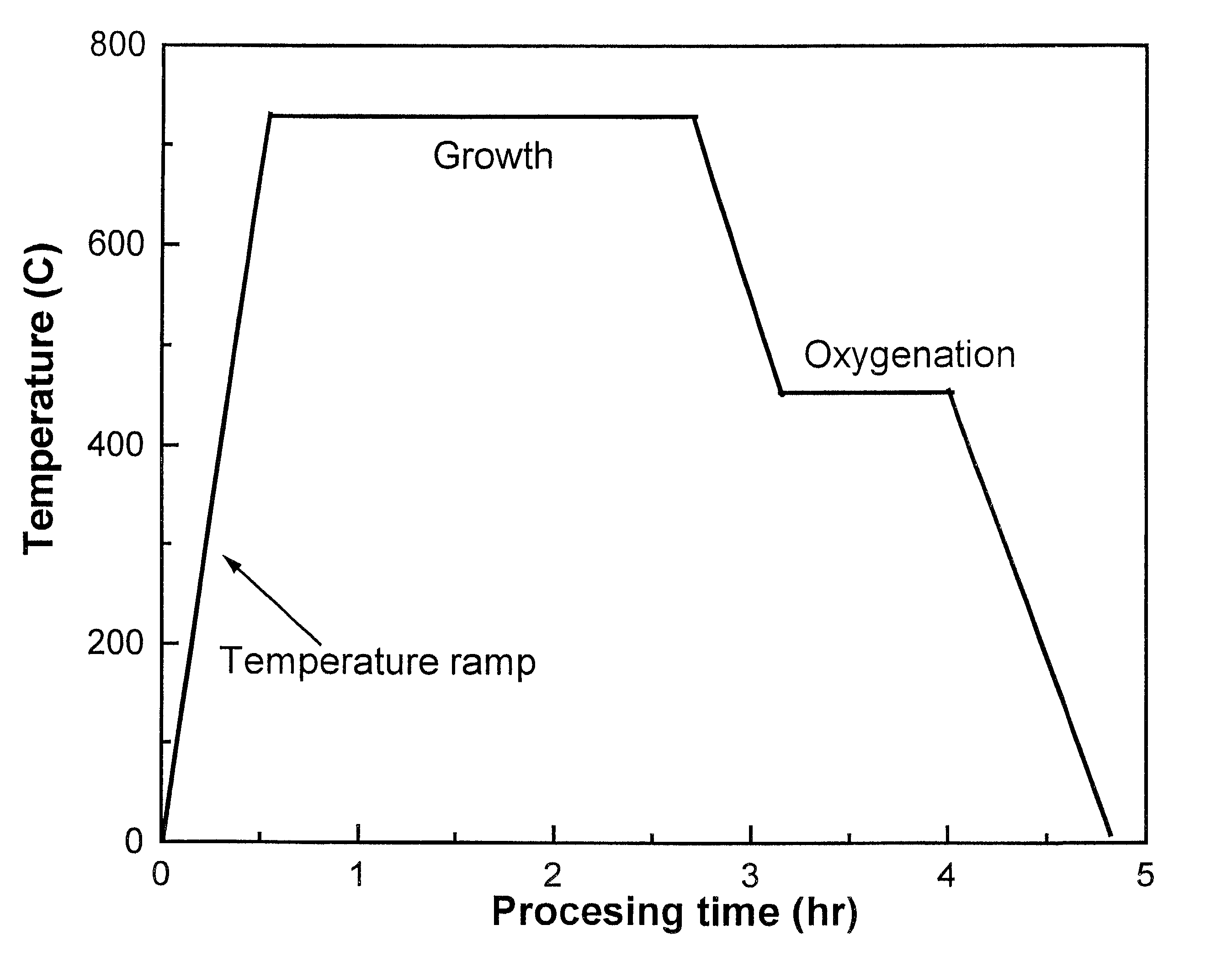

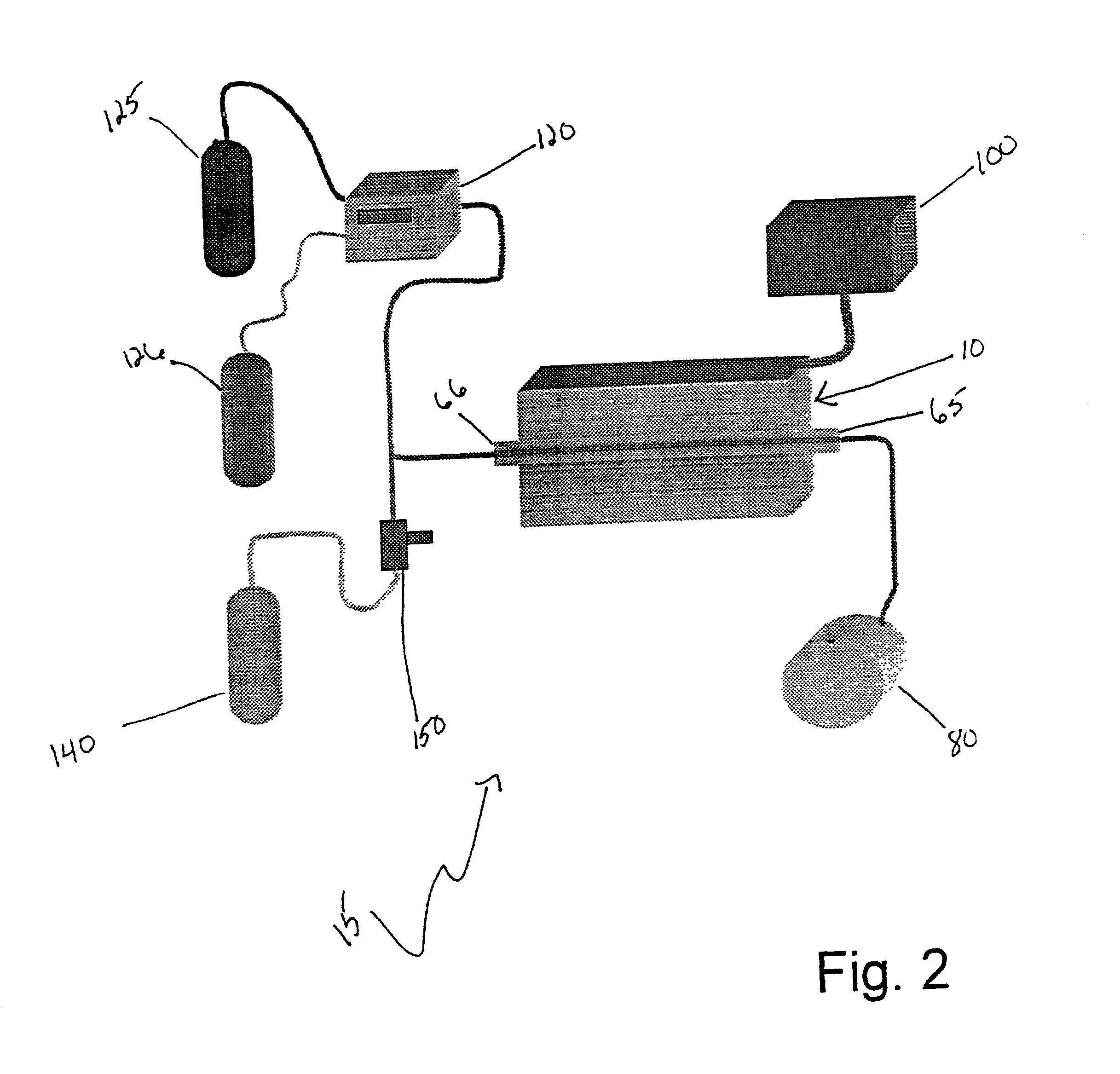

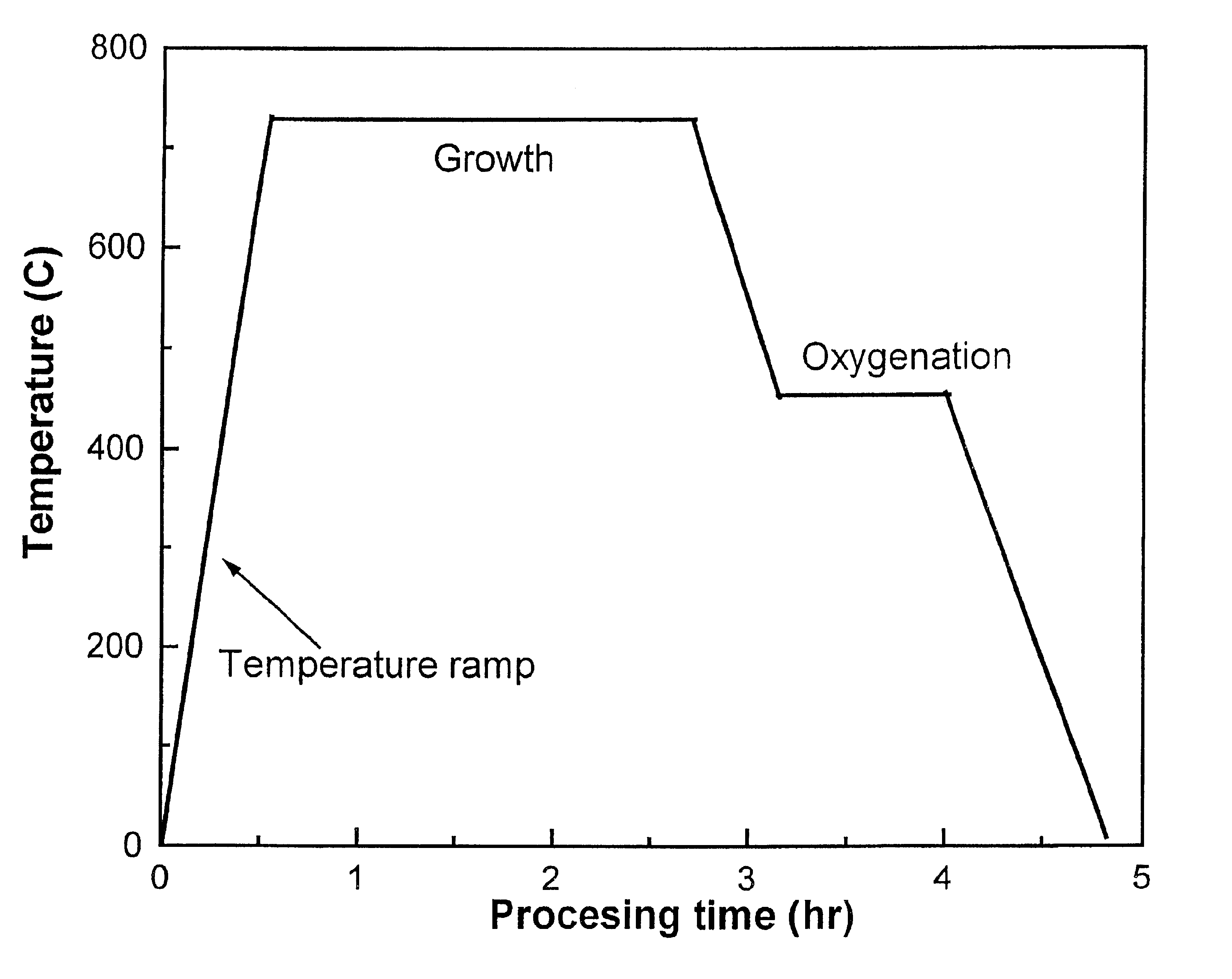

Synthesis of YBa2Cu3O7 using sub-atmospheric processing

InactiveUS20030050195A1Conductive materialVacuum evaporation coatingWater vaporVolumetric Mass Density

The present invention is a method of forming thick films of crystalline YBa2Cu3O7 that includes forming a precursor film comprising barium fluoride (BaF2), yttrium (Y) and copper (Cu). The precursor film is heat-treated at a temperature above 500° C. in the presence of oxygen, nitrogen and water vapor at sub-atmospheric pressure to form a crystalline structure. The crystalline structure is then annealed at about 500° C. in the presence of oxygen to form the crystalline YBa2Cu3O7 film. The YBa2Cu3O7 film formed by this method has a resistivity of from about 100 to about 600 muOhm-cm at room temperature and a critical current density measured at 77 K in a magnetic field of 1 Tesla of about 1.0x105 Ampere per square centimeter (0.1 MA / cm2) or greater.

Owner:BROOKHAVEN SCI ASSOCS

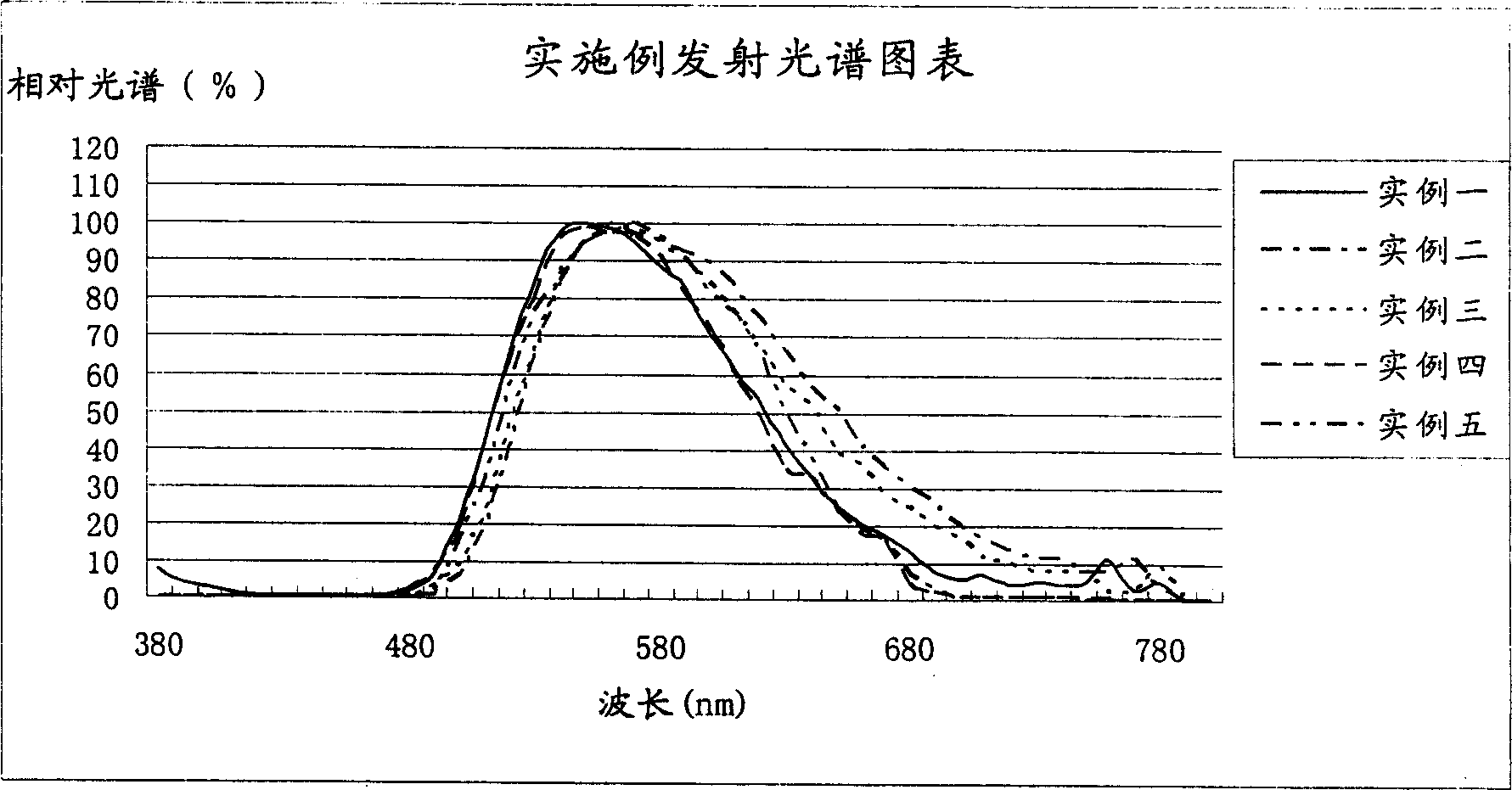

Synthesis of YAG luminescent material for white LED

InactiveCN1818016AImprove luminous brightnessLow attenuation characteristicsGas discharge lamp usageLuminescent compositionsLithium chlorideRare earth

Synthesis of yttrium aluminum garnet luminescent material for white light LED is carried out by proportioning by chemical component formula (Y1-x-yMyCex) 3Al5O12, weighing raw material, mixing with flux additive, putting into corundum crucible, firing in oxidation atmosphere furnace, crushing, mesh screening, acid washing by dilute nitric acid solution to indifference, extraction filtering, drying powders, firing the powder at reduction atmosphere, and screen grading to obtain the final product. It uses two kinds or above of boric acid, barium fluoride, strontium fluoride, lithium chloride or lithium fluoride as composite flux and mixes with other rare earth or metal oxide. It has excellent single crystal particular growth, powder fluidity, better brightness and low decrement.

Owner:常熟市江南荧光材料有限公司

Use of coated proppant to minimize abrasive erosion in high rate fracturing operations

InactiveUS7730948B2Avoid excessive wearReduce erosionSynthetic resin layered productsCellulosic plastic layered productsHigh rateIndium

Owner:BAKER HUGHES INC

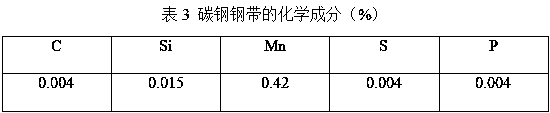

Gas-shielded overlaying flux cored soldering wire for repairing hot-forging mould

ActiveCN102029482ASimple welding processGood welding wire crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceFerrosilicon

The invention discloses a gas-shielded overlaying flux cored soldering wire for repairing a hot-forging mould, which is manufactured by taking SPCC-SD cold-rolling low-carbon steel belts as raw materials of a soldering wire and utilizing a conventional flux cored transient alloy way, a universal flux cored standard and a flux cored soldering wire manufacturing technique. The soldering wire flux core contains fluoride, calcium carbonate, feldspar, magnesia and alloy powder according to a proportion, wherein the fluoride comprises calcium fluoride, sodium fluoride and barium fluoride, and the alloy powder contains iron powder, high-carbon ferrochrome, electrolytic manganese, ferrosilicon, ferromolybdenum, ferrovanadium, nickel powder, tungsten powder and cobalt powder. The invention has the following beneficial effects: because the gas-shielded overlaying flux cored soldering wire takes CO2 or a gas mixture with volume percentage ratio of 80% Ar and 20% CO2 as the protective gas, the gas-shielded overlaying flux cored soldering wire has the advantages of great soldering technique, stable electric arc, less splash, easy deslagging, good crack resistance, great high-temperature hardness and thermal fatigue resistance, continuous soldering and improvement on production efficiency.

Owner:TIANJIN YONGCHANG WELDING WIRES

Making a dispersion managing crystal

InactiveUS6630117B2Magnesium fluoridesCalcium/strontium/barium fluoridesLithography processCrystalline materials

The present invention provides fluoride lens crystals for VUV optical lithography systems and processes. The invention provides a barium fluoride optical lithography crystal for utilization in 157 nm optical microlithography elements which manipulate below 193 nm optical lithography photons. The invention includes a barium fluoride crystalline material for use in dispersion management of below 160 nm optical lithography processes.

Owner:CORNING INC

Nickel-based welding rod for AC welding

InactiveCN101745758AGood production technologyImprove yieldWelding/cutting media/materialsSoldering mediaSodium BentoniteSlag

The invention relates to the technical field of welding materials, in particular to a nickel-based welding rod for AC welding, the welding rod adopts a high-nickel alloy welding wire which is in line with the requirements of GB / T13814-2008 on ENi1008 ingredients as a welding core, and a drug paper comprises the following components: 40-50% of marble, 2-5% of potassium titanate, 20-28% of fluorite, 2-7% of barium fluoride, 1.5-3% of bentonite, 1-3% of zircon sand, 1-2% of soda ash, 1-3% of metal manganese, 3-7% of ferrosilicon containing 43.0-47.0% of Si, 1-3% of magnesium alloy containing 47-53% of Al and 7-10% of barium carbonate. When in welding, the welding rod can realize stable arc, almost no spatter, good slag detachability and excellent operating performance of the welding rod; and the shape of a weld seam is beautiful, and a wetting angle of the weld seam is moderate.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

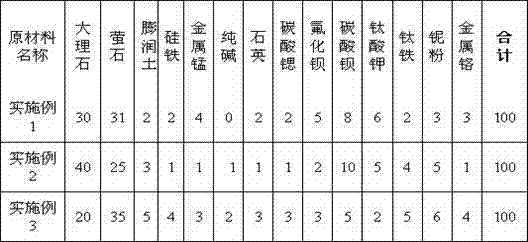

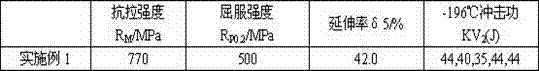

Nickel base welding rod of Ni-Cr-Mo alloy system

InactiveCN102962603AHigh strengthImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaNiobiumFerrosilicon

The invention introduces a nickel base welding rod of a Ni-Cr-Mo alloy system. The nickel base welding rod comprises a core wire and a coating and is characterized in that the core wire is an ERNiCrMo-3 core wire; and the coating comprises 20-40% of marble, 25-35% of fluorite, 2-5% of bentonite, 1-4% of ferrosilicon, 1-4% of manganese metal, 0-2% of sodium carbonate, 1-3% of quartz, 1-3% of strontium carbonate, 2-5% of barium fluoride, 5-10% of barium carbonate, 2-6% of potassium titanate, 2-5% of ferrotitanium, 3-6% of niobium powder and 1-4% of chromium metal. The nickel base welding rod produced by the invention is relatively high in strength, has deposited metal tensile strength which is up to more than 760MPa, is better in low-temperature impact toughness, has an impact powder average value of more than 40J at minus 196 DEG C, and is favorable in welding technological efficiency, stable in arcing during welding, easy in operation, good in formation of welding seams, convenient in deslagging, simple in production process and lower in cost.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

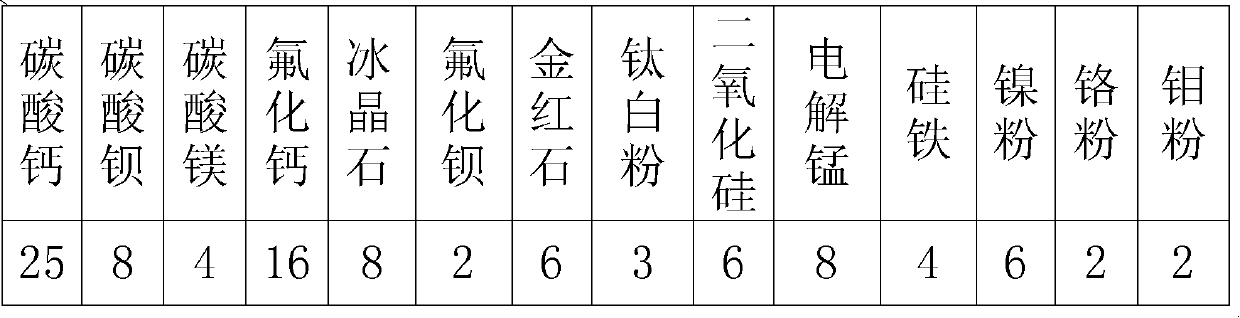

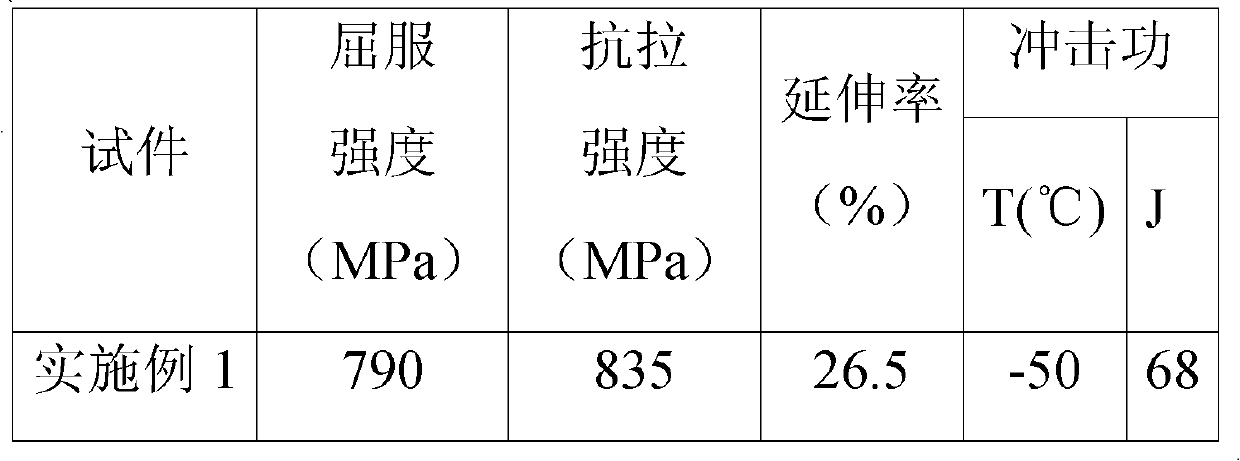

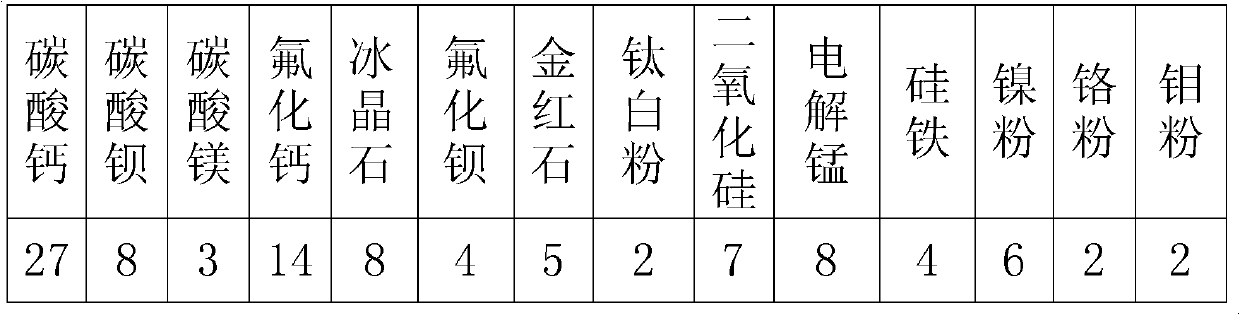

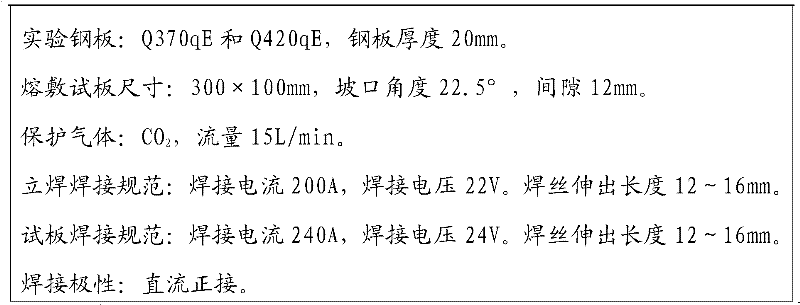

High-strength and high-toughness low alloy steel electric welding rod

ActiveCN102554500AExcellent welding performance in all positionsArc stabilizationWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention publishes a high-strength and high-toughness low alloy steel electric welding rod, which consists of a core and a covering, wherein the covering is coated on the outer wall of the core, and the weight factor of the covering in the total weight of the welding rod is 0.4-0.5; the core comprises the following components in percentage by weight: 0.01-0.08 percent of C, 0.10-0.25 percent of Si, 0.30-0.55 percent of Mn, 0.005-0.20 percent of Cr, 0.005-0.30 percent of Ni, 0.007-0.012 percent of P, 0.007-0.012 percent of S and the balance of Fe; and the covering is of a basic slag system and comprises the following components in percentage by weight: 20-30 percent of calcium carbonate, 1-5 percent of magnesium carbonate, 5-10 percent of barium carbonate, 10-20 percent of calcium fluoride, 1-8 percent of cryolite, 1-5 percent of barium fluoride, 3-8 percent of rutile, 1-5 percent of titanium white, 2-10 percent of silicon dioxide, 5-10 percent of electrolytic manganese, 2-5 percent of ferrosilicon, 4-8 percent of nickel powder, 1-3 percent of chromium powder and 1-3 percent of molybdenum powder. The welding rod is adopted for welding; the strength of a welded joint is 800 MPa; the impact energy at -50 DEG C is greater than 60 J; the diffusible hydrogen content is 2-3 ml / 100 g; and the electric welding rod is mainly applied to welding of 80 kg of low alloy steel structure.

Owner:KUSN GINTUNE WELDING

Synthesis of YBa2CU3O7 using sub-atmospheric processing

The present invention is a method of forming thick films of crystalline YBa2Cu3O7 that includes forming a precursor film comprising barium fluoride (BaF2), yttrium (Y) and copper (Cu). The precursor film is heat-treated at a temperature above 500° C. in the presence of oxygen, nitrogen and water vapor at sub-atmospheric pressure to form a crystalline structure. The crystalline structure is then annealed at about 500° C. in the presence of oxygen to form the crystalline YBa2Cu3O7 film. The YBa2Cu3O7 film formed by this method has a resistivity of from about 100 to about 600 muOhm-cm at room temperature and a critical current density measured at 77 K in a magnetic field of 1 Tesla of about 1.0x10<5 >Ampere per square centimeter (0.1 MA / cm<2>) or greater.

Owner:BROOKHAVEN SCI ASSOCS

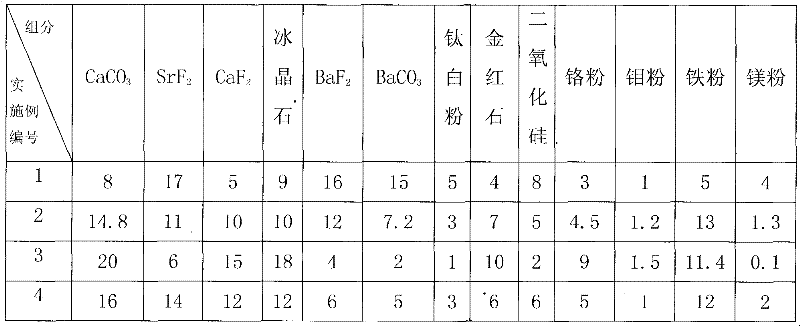

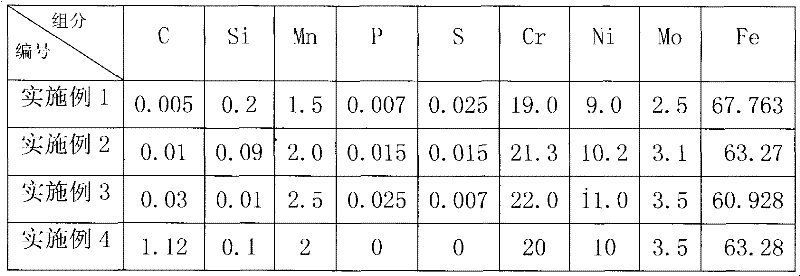

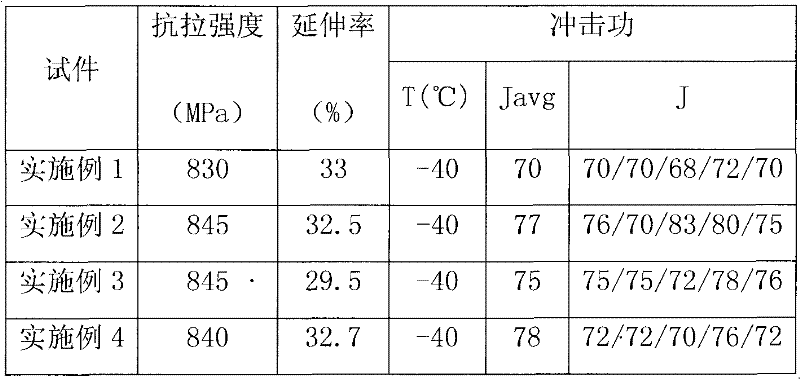

Two-phase stainless steel electrode

ActiveCN102233489AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaSlagWeld seam

The invention discloses a two-phase stainless steel electrode, which comprises a core wire and a coating, wherein the coating is coated on the outer wall of the core wire and accounts for 0.4 to 0.5 percent of the total weight of the electrode. The core wire comprises the following components in percentage by weight: 0.005 to 0.030 percent of C, 0.01 to 0.20 percent of Si, 1.50 to 2.50 percent ofMn, 0 to 0.025 percent of P, 19.0 to 22.0 percent of Cr, 9.0 to 11.0 percent of Ni, 2.5 to 3.5 percent of Mo and the balance of Fe. The coating comprises the following components in percentage by weight: 8 to 20 percent of calcium carbonate, 2 to 15 percent of barium carbonate, 5 to 15 percent of calcium fluoride, 6 to 17 percent of strontium fluoride, 4 to 16 percent of barium fluoride, 9 to 18 percent of cryolite, 4 to 10 percent of rutile, 1 to 5 percent of titanium white, 2 to 8 percent of silicon dioxide, 3 to 9 percent of chromium powder, 1 to 1.5 percent of molybdenum powder, 0.1 to 4 percent of magnesium powder and 5 to 13 percent of iron powder. After the coating components are uniformly mixed, an adhesion agent is added into the mixture. The two-phase stainless steel electrode has high strength, high tenacity and intercrystalline corrosion resistance; and during welding, an electric arc is stable, splashing phenomena is reduced, a welding seam is well molded, slag is easy toremove, and the electrode has high operability.

Owner:KUSN GINTUNE WELDING

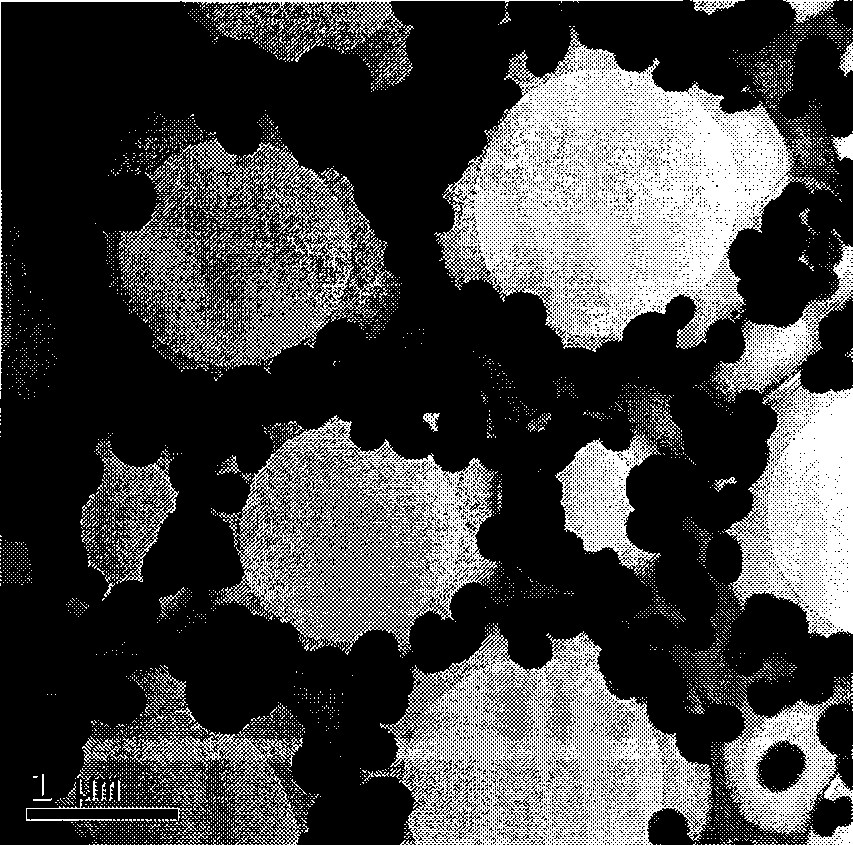

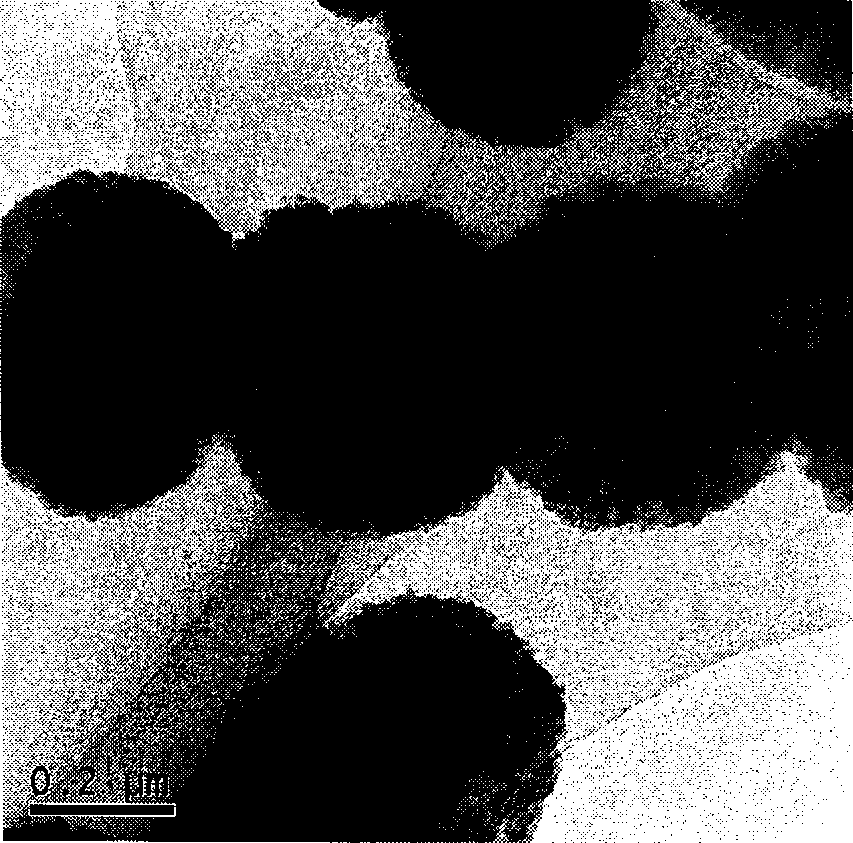

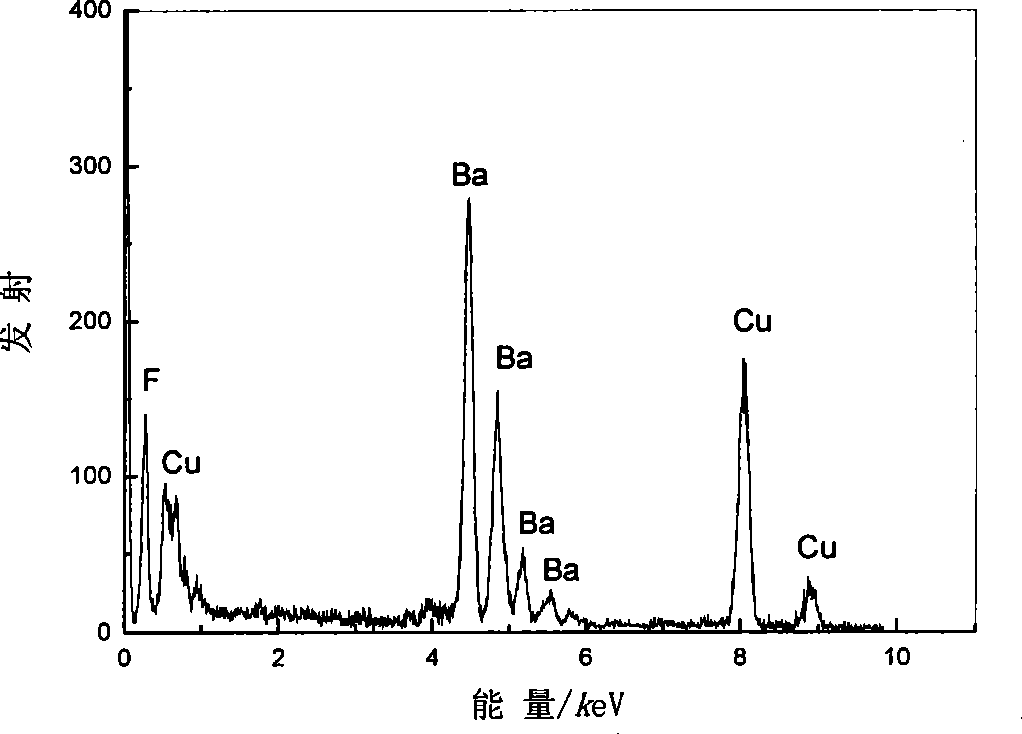

Method for preparing chain shaped barium fluoride nanospheres with DNA as mould plate

InactiveCN101367545AMorphological rulesGood optical performanceTitanium halidesNano structuringMixed systems

The invention discloses a method for preparing chain-shaped barium fluoride nano-ball adopting DNA as the template, and belongs to the technical field of the nano materials, which comprises the following steps: Ba(NO3)2 ultra-saturated solution is added into the DNA system, and is mixed with the DNA system in whirl way for 3 to 8 minutes; under the conditions of 20 to 30 DEG C and 50 to 150 r / min, the mixture is shaken for 2 to 4 hours; NH4F ultra-saturated solution is added in the mixed system, and is mixed in whirl way for 5 to 20 seconds, and is shaken for 3 to 5 hours under the conditions of 20 to 30 DEG C and 50 to 150 r / min. The entire system is kept quietly at the temperature of 4 to 8 DEG C to get the chain-shaped barium fluoride nano-ball adopting DNA as the template. The invention can directly adopt the biological nano structure existing in the nature as the template to synthesize the chain-shaped nano-ball structure that is different from the original methods for preparing BaF2, thereby not only preventing the complicate preparation craftwork of the conventional template, but also being completed under the moderate conditions of the normal temperature and the normal atmosphere; moreover, the method has simple craftwork, low cost, easy controlled reaction and high productivity.

Owner:YANSHAN UNIV

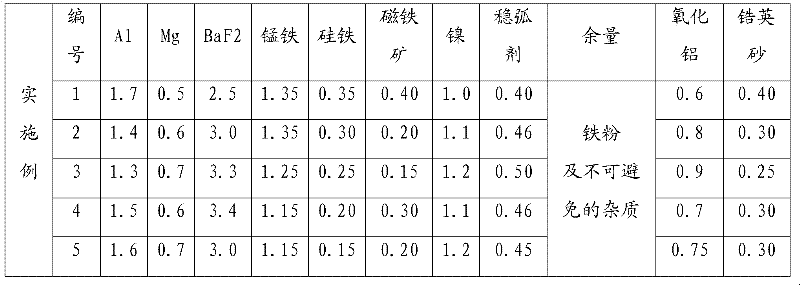

Basic flux-cored wire for bridge steel

InactiveCN102343488AMeet the requirements of all-position weldingImprove welding efficiencyWelding/cutting media/materialsSoldering mediaMagnetiteFerrosilicon

The invention discloses a basic flux-cored wire for bridge steel and belongs to the field of welding materials. The basic flux-cored wire comprises a carbon steel coating and a coated flux core and is characterized by comprising the following components calculated according to the proportion accounting for total weight of the flux-cored wire: 1.3-1.7 percent of aluminum, 0.5-0.6 percent of magnesium, 2.5-3.4 percent of barium fluoride, 1.15-1.35 percent of ferromanganese, 0.15-0.35 percent of silicoferrite, 0.15-0.40 percent of magnetite, 1.0-1.2 percent of nickel, 0.4-0.5 percent of arc stabilizer, 0.6-0.9 percent of aluminum oxide, 0.25-0.4 percent of zircon sand and the balance of ferrous powder and inevitable impurities, wherein the arc stabilizer is formed by mixing potassium titanate, magnesite, cryolite and potassium silicate powder according to weight ratio of 2:2:4:2. The flux-cored wire can meet all-position welding and has the characteristics of high welding efficiency, lowsplash, low soot amount and favorable cracking resistance; and the weld metal has the tensile strength of 500-690MPa and low-temperature impact ductility (-50DEG C) more than or equal to 54J.

Owner:WUHAN HIRUN ENG EQUIP

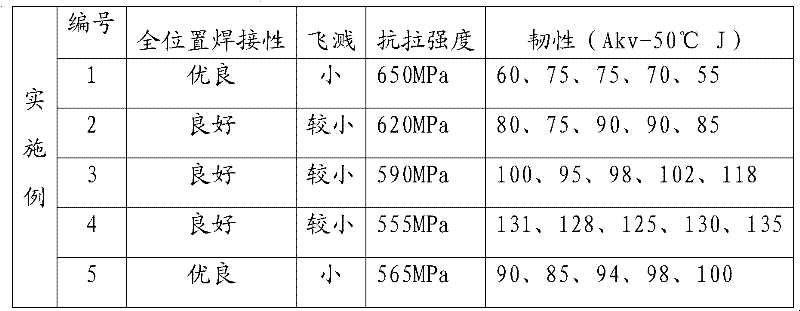

Cr13 series overlay welding self-protection flux-cored wire

InactiveCN101011785AArc stabilizationImprove stiffnessWelding/cutting media/materialsSoldering mediaHigh carbonSlag

The invention relates to the Cr13 series build-up self-shielded welding wire aiming to solve the wastes of material, low production efficiency, complex equipment and high cost of existing build-up welding material. It features in the mass percentage of calcium fluoride 10-20%, barium fluoride 10-20%, soda 1-2%, chrome metal 30-40%, metal powder 3-10%, manganese metal 3-5%, high carbon ferro-chrome 0-6%, Al-Mg alloy 8-14%, potassium titanate 3-7%, magnesia 2-5%. It has stable electric arc, good welding seam, easy for slag peeling clinker coating, with good self-shield effect in the welding process.

Owner:BEIJING UNIV OF TECH

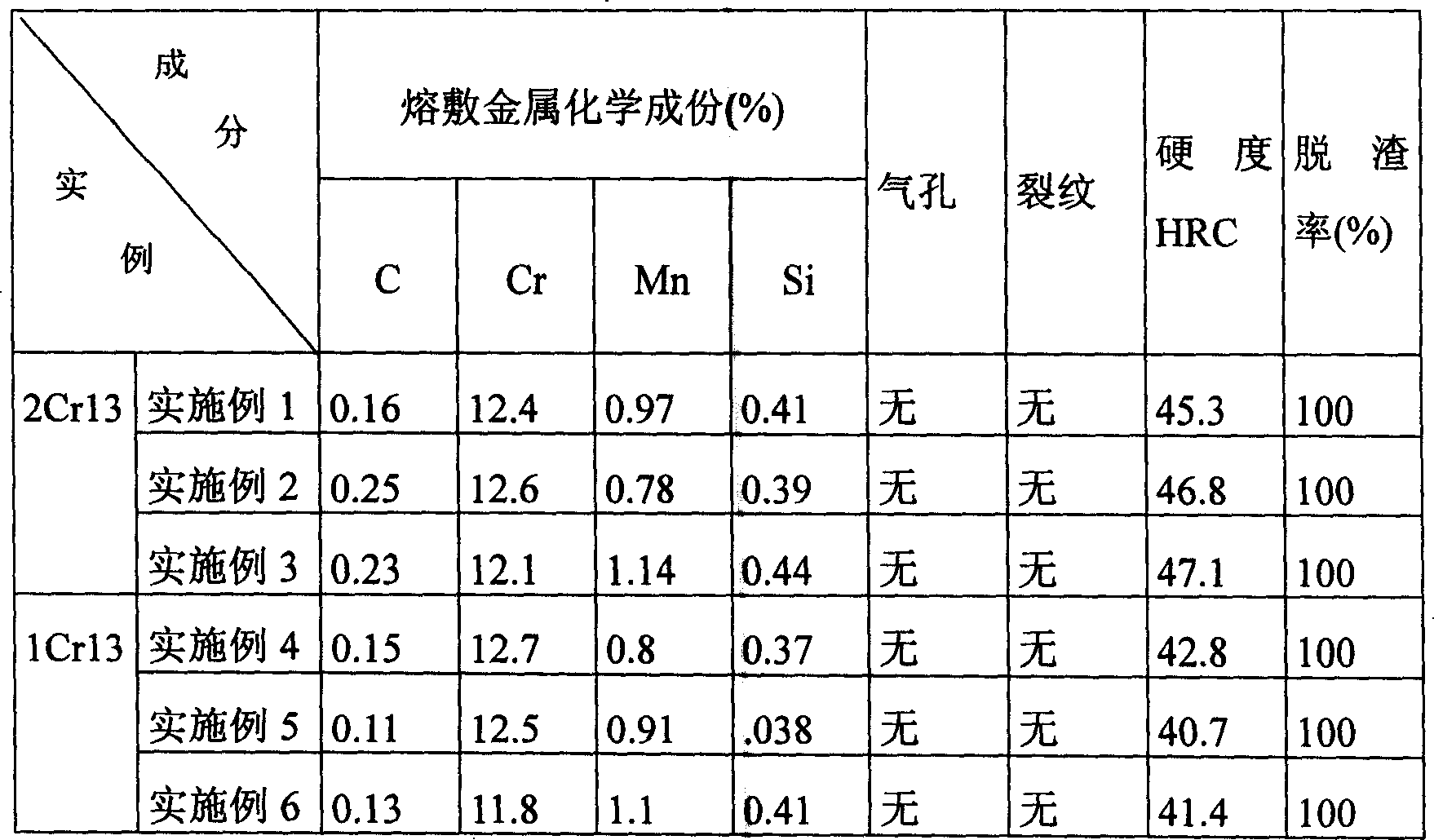

Self-shielded flux-cored wire for X80 pipeline steel

ActiveCN106944765AEasy to useImprove self-protection performanceWelding/cutting media/materialsSoldering mediaAbsorbed energyWeld seam

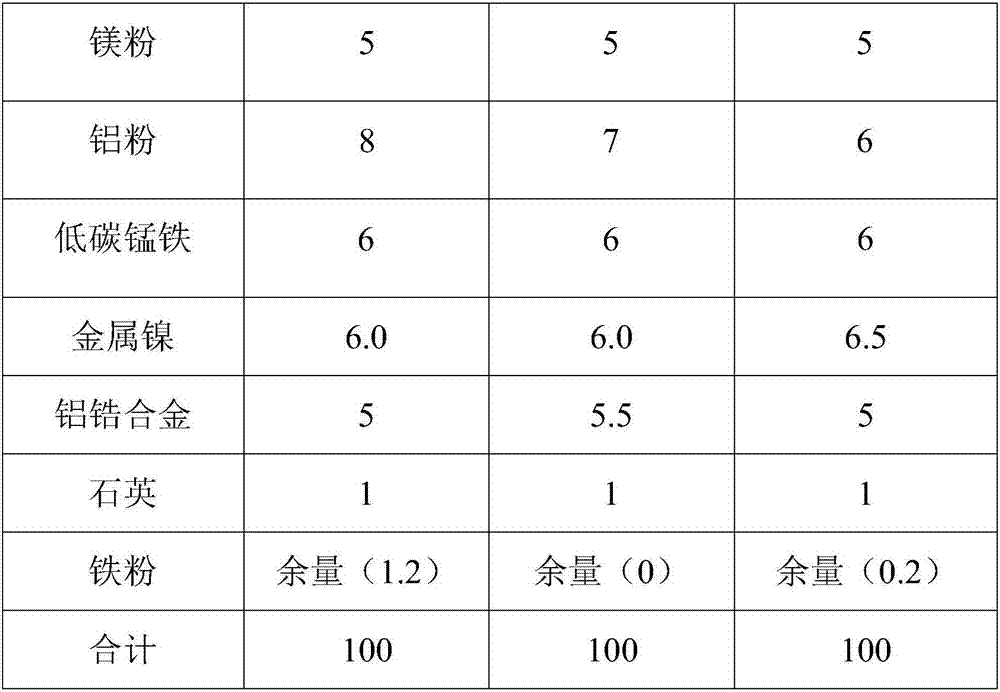

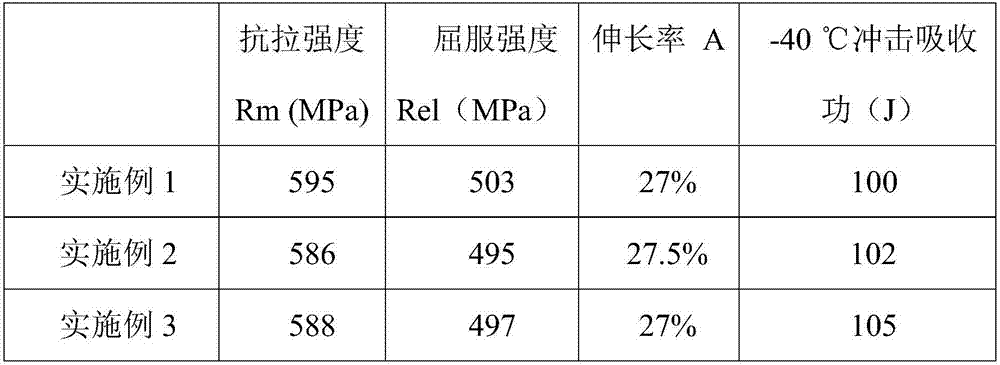

The invention provides a self-shielded flux-cored wire for X80 pipeline steel. The self-shielded flux-cored wire comprises wire skin made of mild-carbon steel strips and a flux core, and is characterized in that a formula of powder of the flux core comprises components in percentage by mass as follows: 40%-50% of barium fluoride, 10%-20% of calcium fluoride, 5%-10% of lithium fluoride, 2%-5% of barium carbonate, 1%-5% of cerium fluoride, 1%-2% of ferric oxide, 0%-2% of zirconium oxide, 0%-4% of titanium dioxide, 5%-8% of magnesium powder, 5%-10% of powdered aluminium, 6%-8% of low-carbon ferromanganese, 6%-8% of metallic nickel, 5%-10% of aluminium-zirconium alloy, 1%-5% of quartz and 0%-5% of iron powder. The self-shielded flux-cored wire is suitable for all-position welding of pipelines and good in welding processing property, wire deposited metal has good mechanical properties, impact absorbing energy of a V-shaped notch at the temperature of subzero 40 DEG C of the wire deposited metal reaches 100 J or higher, and the requirement of welding seam toughness is met.

Owner:WUHAN UNIV OF SCI & TECH

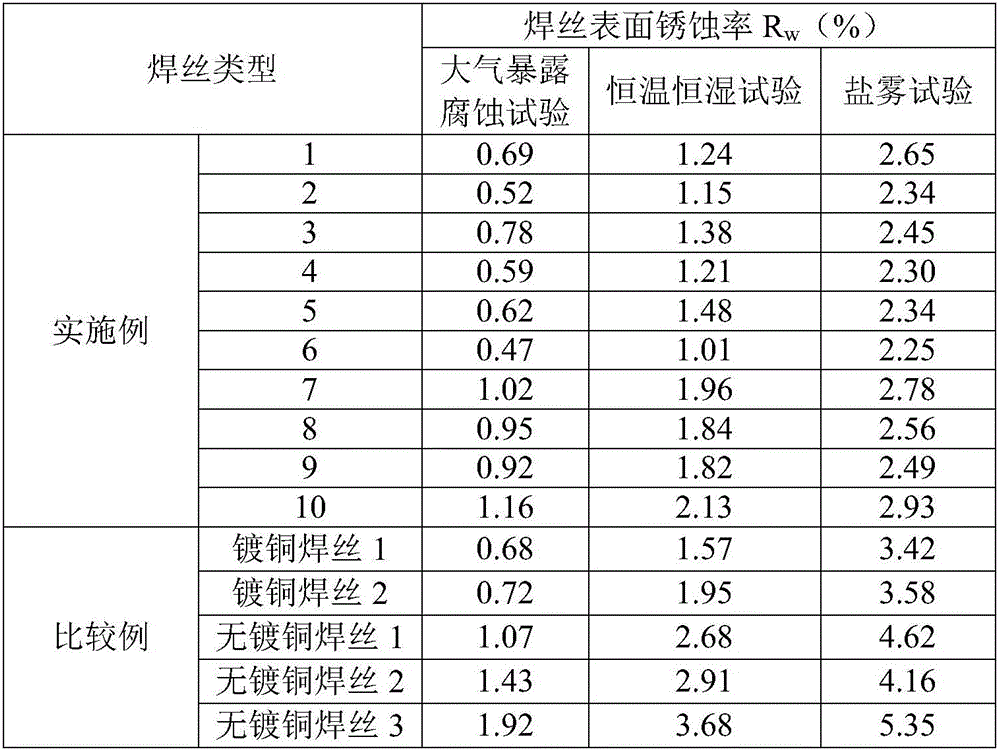

Environment-friendly copper-plating-free solid welding wire surface nano composite coating

ActiveCN106808114ASolve serious wear and tearSolve the problem of poor rust resistanceWelding/cutting media/materialsSoldering mediaCopper platingPetroleum

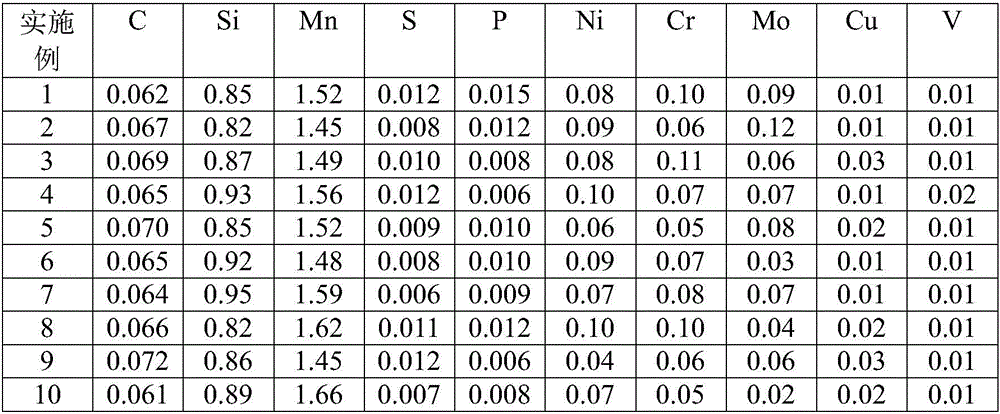

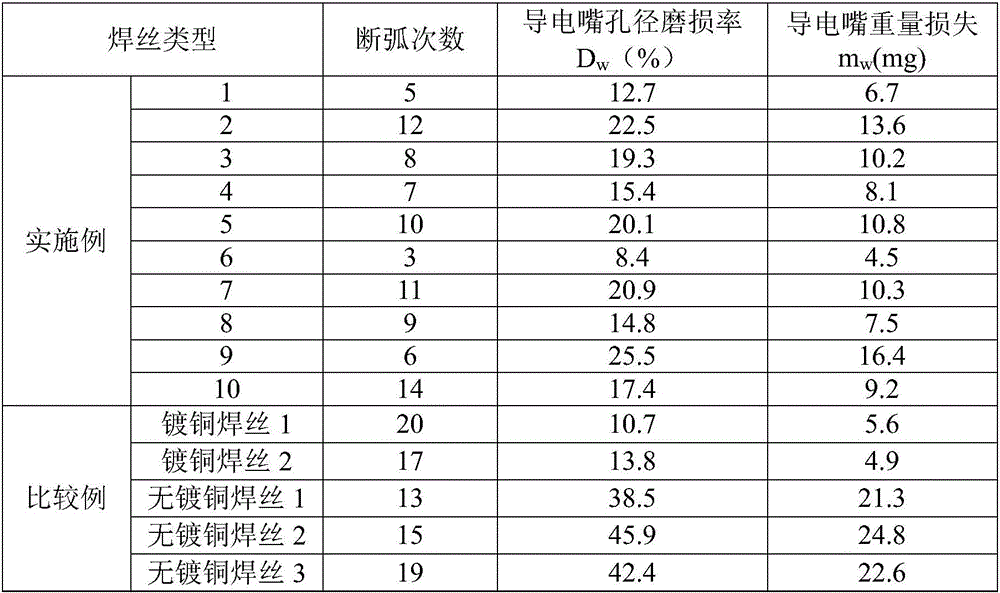

The invention provides an environment-friendly copper-plating-free solid welding wire surface nano composite coating and belongs to the field of welding wires. The coating is prepared from nano solid powder, anti-rust oil and arc stabilizing agent at a mass ratio of (0.5-1.5): (0.2-1.0): (1.2-2.0); the nano solid powder consists of nano graphite fluoride powder, nano molybdenum powder, nano molybdenum disulfide, nano tungsten disulfide or nano ferroferric oxide, micron calcium fluoride or micron barium fluoride, and micron PTFE powder; the anti-rust oil is prepared from perfluoropolyether synthetic oil, rapeseed oil, sorbitan monooleate, petroleum sodium sulfonate, lanolin, nano serpentine, calcium naphthenate, polyisobutylene-bis-succinimide, zinc dialkyl dithiophosphate and molybdenum dialkyldithiocarbamate; the arc stabilizing agent is composed of one or more of alkali metal compounds. The prepared coating is good in wear resistance and rust resistance, stable in electric arc during welding and less in conductive nozzle wear and meanwhile has less pollution to the environment.

Owner:BEIJING UNIV OF TECH

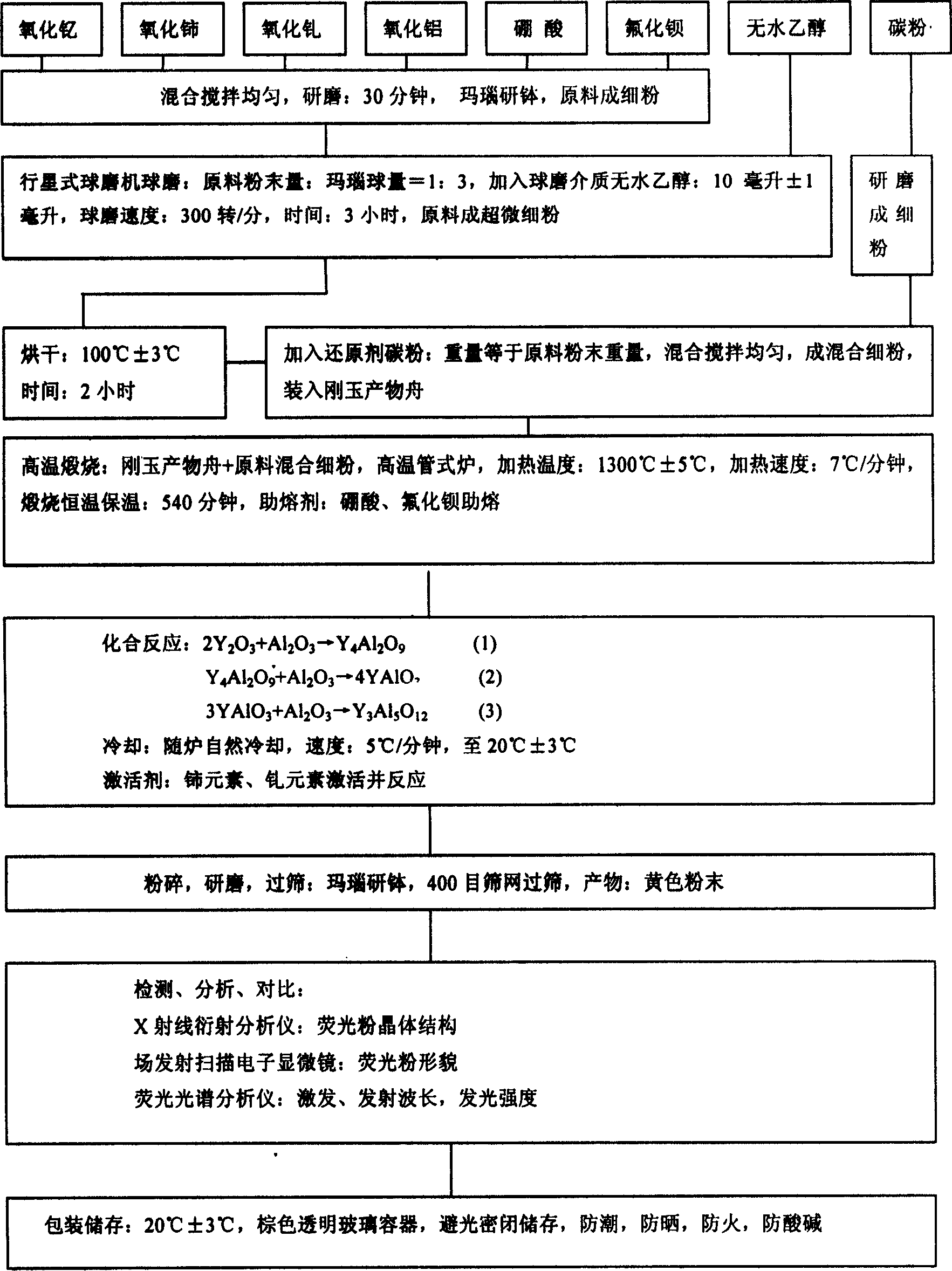

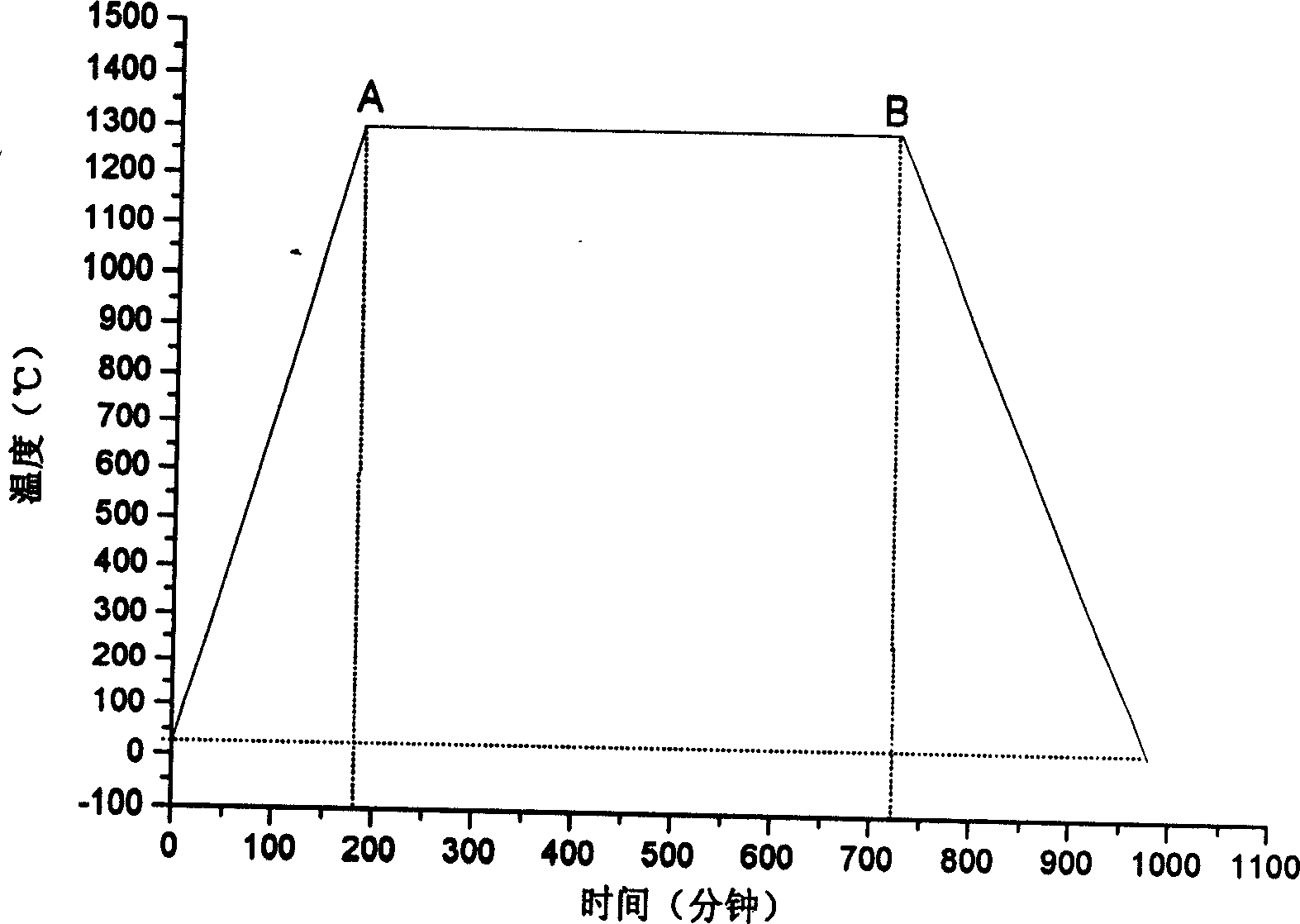

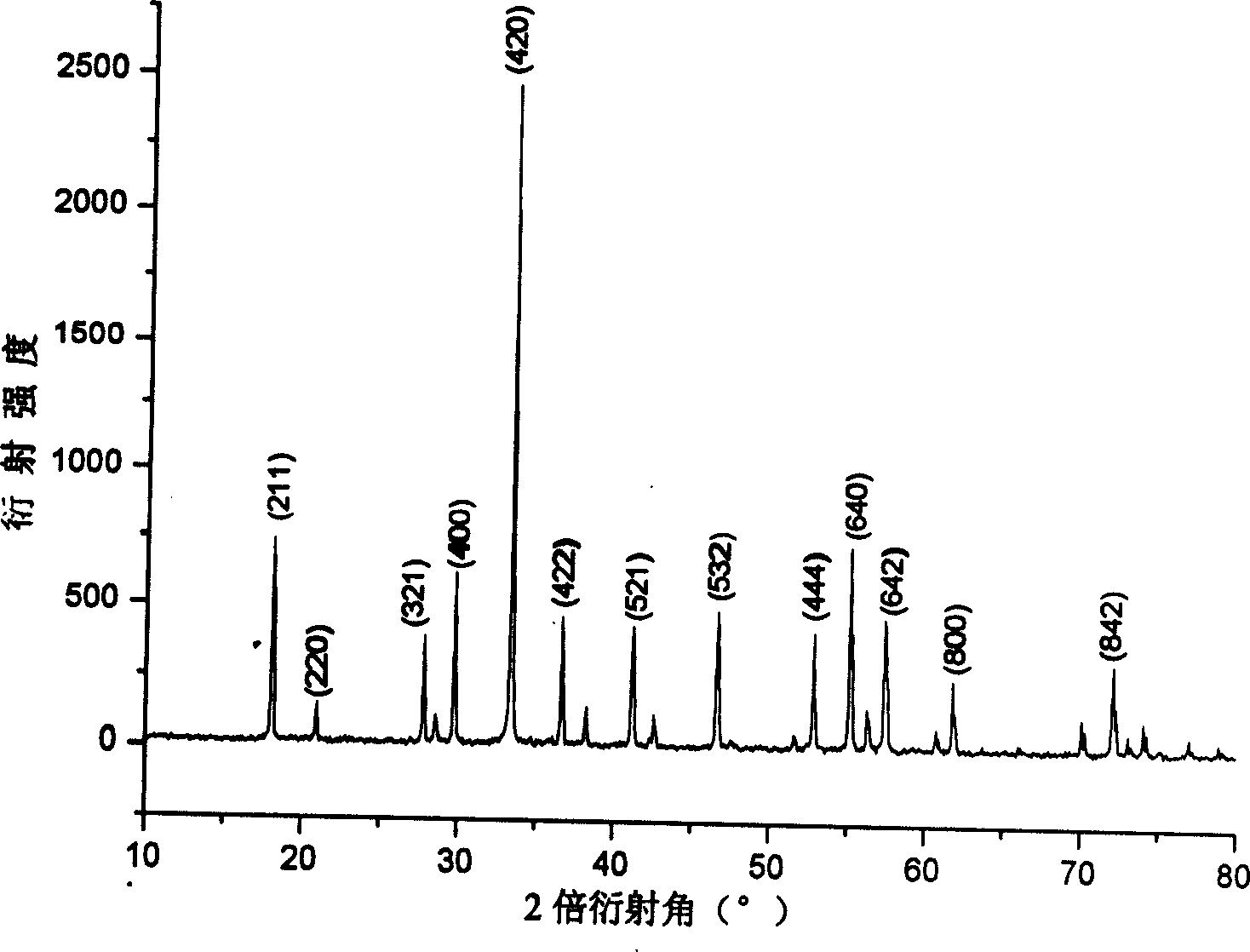

Cerium, gadolinium activated yttrium aluminium garnet fluorescent powder and preparation method

InactiveCN1730607AUniform particle distributionHigh yieldLuminescent compositionsGadolinium oxideCerium

The invention relates to a cerium, gadolinium activated yttrium aluminium garnet fluorescent powder and preparation method, wherein the fluorescent powder is prepared from yttrium oxide, aluminium oxide, cerium oxide, gadolinium oxide, boric acid, barium fluoride, carbon powder, anhydrous alcohol as raw material, cerium oxide, gadolinium oxide and water as activating agent, boric acid and barium fluoride as fluxing agent, anhydrous alcohol as ball grinding medium, carbon powder as reducing agent through raw material mixing, grinding, ball grinding, calcining in high temperature pipe heater, cooling down, grinding, sieving, detecting, packaging and storing.

Owner:TAIYUAN UNIV OF TECH +1

Middle-infrared band ultrathin slab lens based on meta-material

The invention provides a middle-infrared band ultrathin slab lens based on meta-material. The middle-infrared band ultrathin slab lens comprises a circular barium fluoride slab substrate. V-shaped metal bar structures are etched on the circular barium fluoride slab substrate. A gold film is coated on the V-shaped metal bar structures. On the V-shaped metal bar structures, different phases phi of V-shaped metal bar structures are arranged at positions of different radiuses r. Different V-shaped metal bar structures are arranged along a radial direction so that concentric rings are formed. The V-shaped metal bar structures arranged on each concentric ring are identical. A method of utilizing 16 groups of V-shaped metal bar structures to continuously adjust and control the phase is firstly put forward, and the middle-infrared band slab lens is processed by utilizingcombination of photo-etching and film coating methods. Compared with a conventional convex lens, a conventional curved surface Fourier transform function is substituted by phase adjustment and control through the V-shaped metal bar structures. The lens has ultrathin and slab characteristics so that weight and size are greatly reduced.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

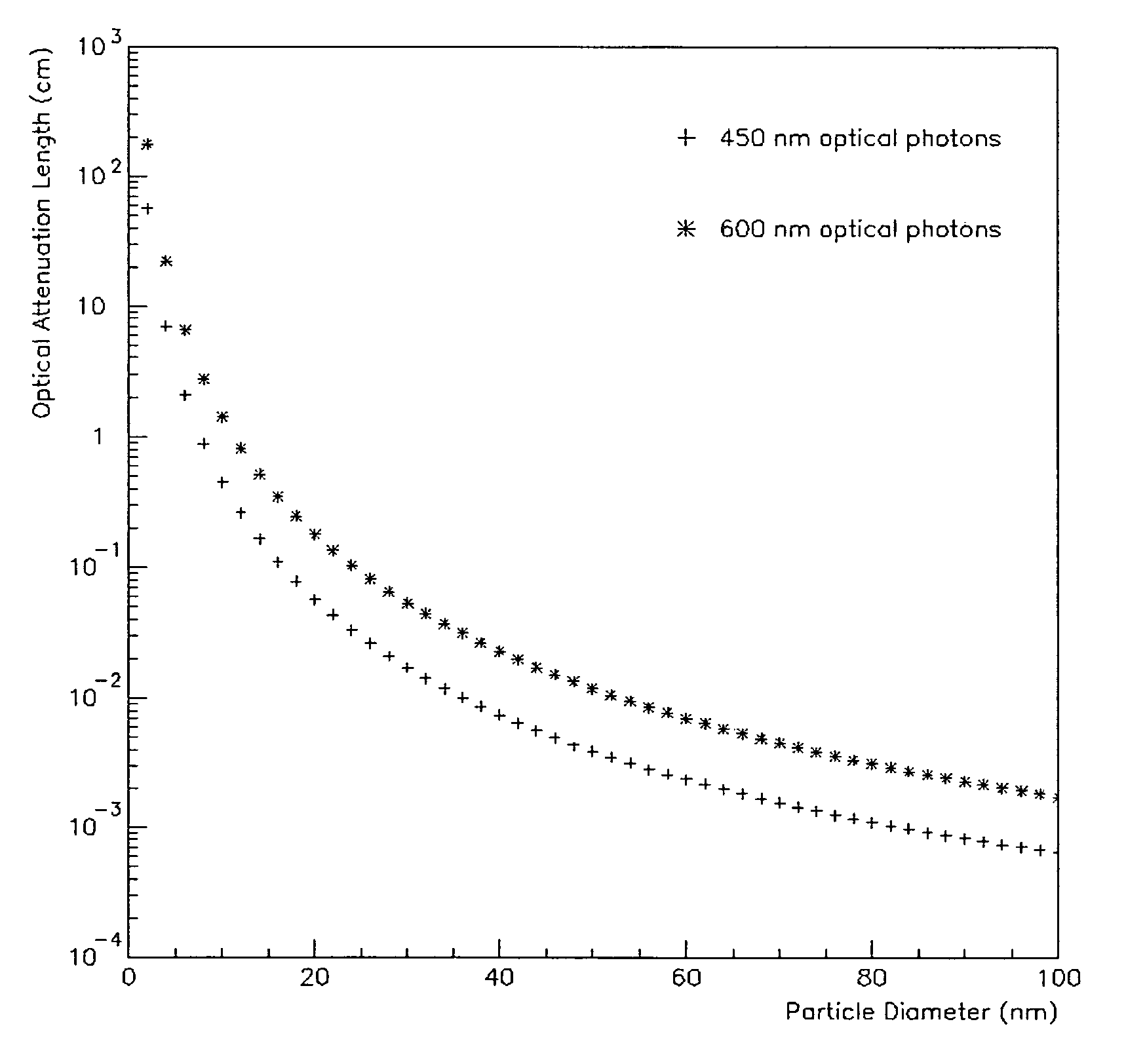

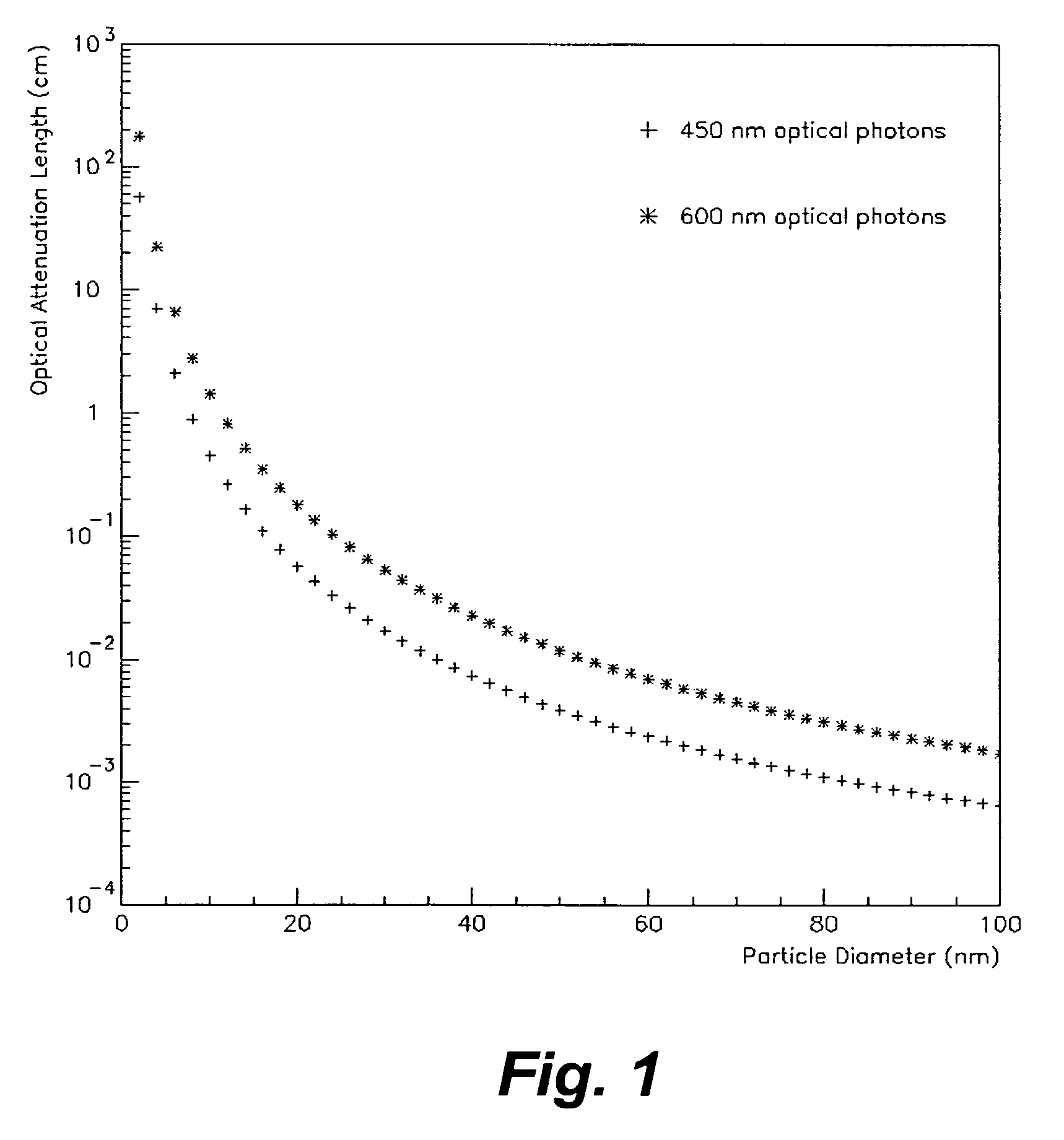

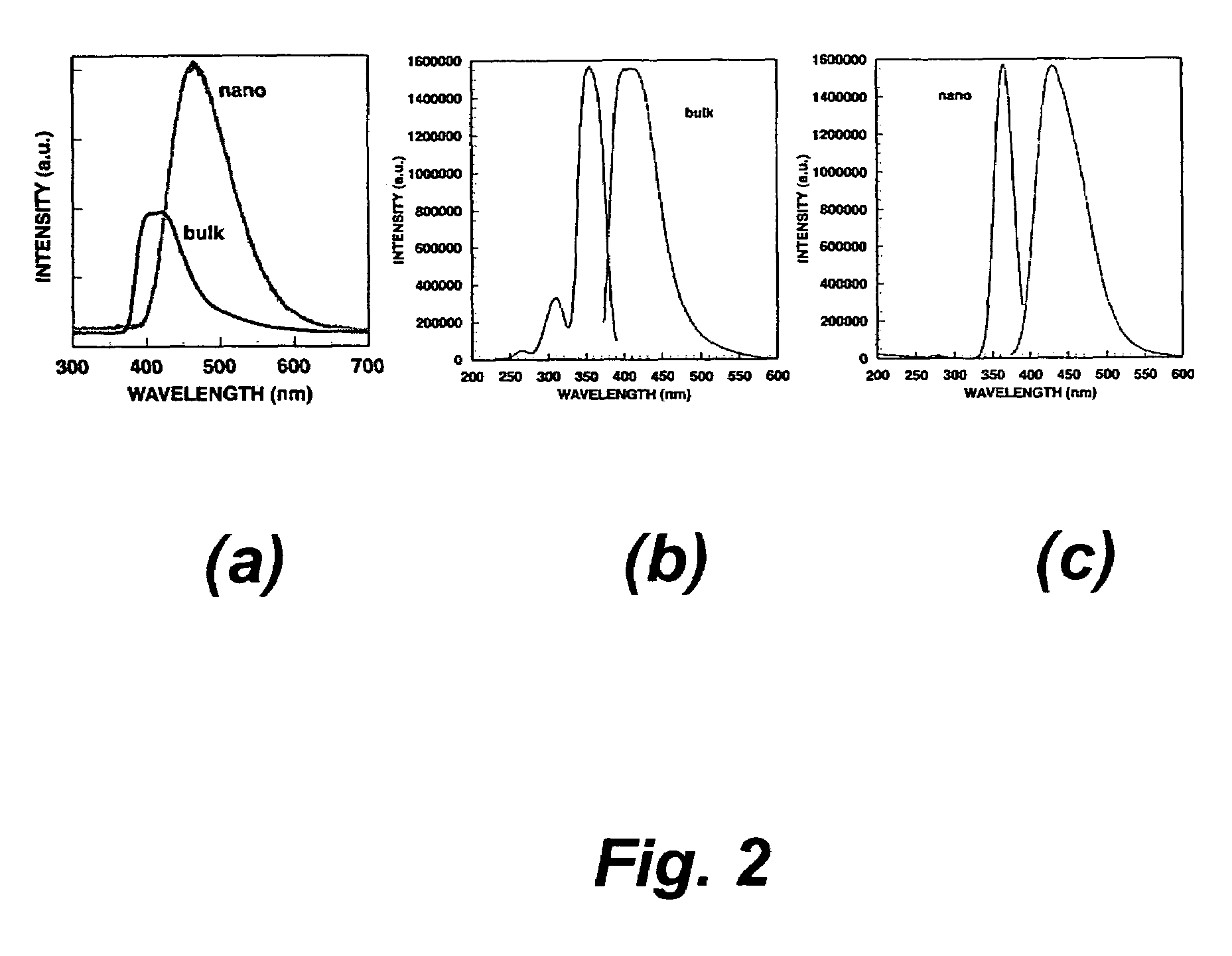

Nanocomposite scintillator, detector, and method

A compact includes a mixture of a solid binder and at least one nanopowder phosphor chosen from yttrium oxide, yttrium tantalate, barium fluoride, cesium fluoride, bismuth germanate, zinc gallate, calcium magnesium pyrosilicate, calcium molybdate, calcium chlorovanadate, barium titanium pyrophosphate, a metal tungstate, a cerium doped nanophosphor, a bismuth doped nanophosphor, a lead doped nanophosphor, a thallium doped sodium iodide, a doped cesium iodide, a rare earth doped pyrosilicate, or a lanthanide halide. The compact can be used in a radiation detector for detecting ionizing radiation.

Owner:RGT UNIV OF CALIFORNIA

High-carbon high-chrome high-vanadium wearable surfacing self-shielded flux-cored wire

InactiveCN105798484AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention discloses a high-carbon high-chrome high-vanadium wearable surfacing self-shielded flux-cored wire. According to the flux-cored wire, the core is prepared from the following components in mass percentage: 5-25% of high carbon ferro-chrome, 30-60% of chromium carbide, 15-35% of ferrovanadium, 0.5-5% of ferromolybdenum, 1-4% of electrolytic manganese, 1-4% of ferrosilicon, 1-4% of ferroboron, 1-5% of graphite, 1-5% of aluminium magnesium, 0-3% of zircon sand, 0-4% of marble, 0-3% of barium fluoride, 0-5% of barium carbonate, 0-3% of sodium fluosilicate, and 0-5% of fluorite; the skin of the flux-cored wire is a mild-carbon steel strip, the diameter is 1.6-4.0mm, and the counterweight ratio is 44-53%. According to the flux-cored wire disclosed by the invention, the rigidity and wearability of surfacing alloy can be greatly improved and the toughness of the surfacing alloy cannot be reduced; and the prepared surfacing alloy can be widely applied to surfacing repair of parts with severe low and intermediate stress abrasion at low temperature, intermediate temperature and high temperature and manufacture of new parts.

Owner:GRIPM ADVANCED MATERIALS CO LTD

Thermal spray compositions for abradable seals

A thermal spray composition and method of deposition for abradable seals for use in gas turbine engines, turbochargers and steam turbines. The thermal spray composition includes a solid lubricant and a ceramic preferably comprising 5 to 60 wt % total of the composition in a ratio of 1:7 to 20:1 of solid lubricant to ceramic, the balance a matrix-forming metal alloy selected from Ni, Co, Cu, Fe and Al and combinations and alloys thereof. The solid lubricant is at least one of hexagonal boron nitride, graphite, calcium fluoride, lithium fluoride, magnesium fluoride, barium fluoride, tungsten disulfide and molybdenum disulfide particles. The ceramic includes at least one of albite, illite, quartz and alumina-silica.

Owner:SULZER METCO CANADA INC

Refractory steel alkaline flux-cored wire with excellent removability of slag

InactiveCN101041214AIncrease coverageUniform coverageArc welding apparatusWelding/cutting media/materialsSlagManganese

The invention relates to a basic flux-cored wire of heat-resistant steel with good slag detachability, belonging to the welding field of material processing technology. The invention solves the problem that the prior basic flux-cored wire of heat-resistant steel sticks slag seriously. The invention is characterized in that components of added flux-core are 25-37% of barium fluoride, 12-14% of metal chromium, 5-20% of Fe powder, 5-10% of silicon iron, 2-6% of Al-Mg alloy powder, 5-8% of marble, 2-4% of zirconium oxide, 7-12% of Ti, 10-11% of ferromolybdenum, 1-4% of Na2CO3 and 3-4% of manganese. The invention is provided with easy slag detachability, stable electrical arc, very small and thin splashing particle, beautiful welding line formation and good welding process performance.

Owner:BEIJING UNIV OF TECH

Self-protecting flux-cored wire for composite manufacturing (remanufacturing) of continuous casting rolls and process

ActiveCN108994425AMeet the technical requirements of nitrogen-containing wireMeet technical requirementsArc welding apparatusWelding/cutting media/materialsFerrosiliconManganese

The invention discloses a self-protecting flux-cored wire for composite manufacturing (remanufacturing) of continuous casting rolls and a process. The flux-cored wire comprises, by weight, 20%-60% ofmicro-carbon ferrochrome, 8%-14% of nickel, 1%-6% of molybdenum, 2%-5% of 75 ferrosilicon, 4%-6% of manganese, 0.5%-2% of rare earth oxide, 1%-3% of ferrotitanium, 1%-5% of aluminium magnesium alloy,5%-16% of rutile, 0.5%-2% of potash feldspar, 0.5%-2% of alumina and magnesia, 1%-5% of fluorite, 0.2%-3% of sodium fluoride, 0-10% of high nitrogen ferrochrome, 0-8% of high carbon ferrochrome, 0-1.2% of graphite, 0-25% of chromium powder, 0-3% of ferrovanadium and ferroniobium, 0-2% of barium fluoride, 0-3% of sodium fluosilicate, 0-3% of lithium fluoride, 0-1% lithium carbonate and the balanceiron powder. A large welding height single-layer surfacing forming process is adopted, and good process performance, high efficiency and high cost performance are achieved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Thin-layer slag protecting medicinal powder for welding high strength steel

InactiveCN102581520AReduce the cost of updatesEasy to getWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses a thin-layer slag protecting medicinal powder for welding high strength steel. The medicinal powder is prepared by uniformly mixing an alloy and a slag forming and arc stabilizing agent. The content of the alloy accounts is 88-92wt% (weight percent), and the content of the slag forming and arc stabilizing agent accounts is 12-8wt%. The alloy comprises the following elements by weight percent: 0.06-0.10% of C, 1.0-5.0% of Si, 1.2-3.4% of Mn, 0.72-1.4% of Mo, 0.5-1.4% of Cr, 1.4-5.2%Ni, 0.30-0.70% of Ti and the balance of Fe; the slag forming and arc stabilizing agent is prepared by mixing the following materials in parts by weight: 15-30 parts of rutile, 8-25 parts of potash potassium feldspar, 1-5 parts of magnesia, 2-10 parts potassium titanate, 2-8 parts of sodium fluoride, 0-8 parts of sodium fluosilicate, 5-12 parts of barium fluoride and 0-4 parts of cerium oxide rare earth. The medicinal powder can be used together with a welding torch with the powder and gas supplying double function, thereby overcoming the defects that the high-strength steel welding wire is hard to obtain from a wire rod, the welding wire is produced by multiple thermal treatment, and the cost is high.

Owner:SHANDONG UNIV

Self-shielded flux-cored wire for non-magnetic steel 20Mn23Al and preparing method of wire

InactiveCN107322181AHigh tensile strengthImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconShielding gas

The invention discloses a s elf-shielded flux-cored wire for non-magnetic steel 20Mn23Al. The wire comprises a flux core and a skin; the flux core is composed of 18 to 28% of chromium powder, 2 to 8% of nickel powder, 1.5 to 3.5% of molybdenum powder, 2.5 to 10% of manganese powder, 0.5 to 1.5% of ferrosilicon powder, 2 to 8% of aluminum and magnesium, 0.5 to 1.5% of ferrocolumbium, 0.5 to 1% of ferrotitanium, 10 to 17% of barium fluoride, 5 to 15% of magnesium oxide, 1 to 5% of aluminum oxide, 0.5 to 1.5% of cerium oxide, 1 to 3.5% of quartz sand, 18 to 26% of rutile, 2 to 8% of zircon sand, 1 to 3% of lithium carbonate, 0.5 to 3% of calcium carbonate and 0.5 to 5% of iron oxide powder. The wire is used for 20Mn23Al welding, protection gas does not need to be added, a welding joint with higher tensile strength and corrosion resistance can be obtained, the welding wire is simple in preparing method, and large-scale batched production is facilitated.

Owner:XIAN UNIV OF TECH

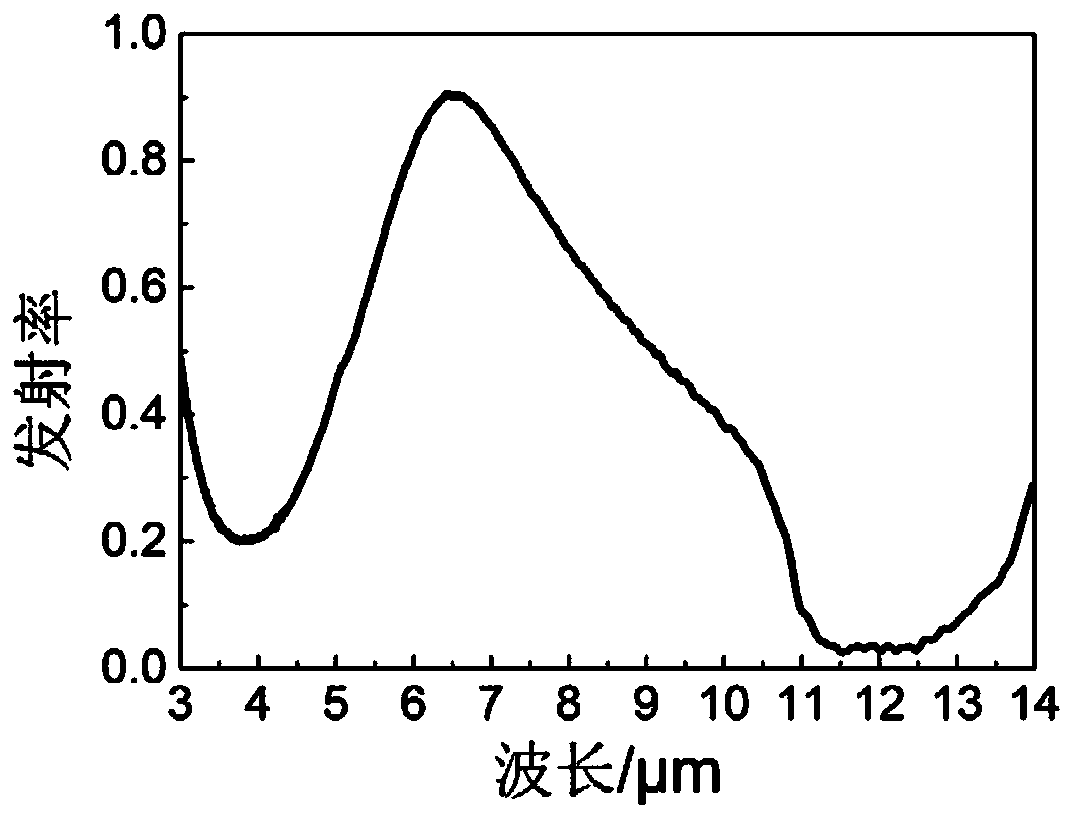

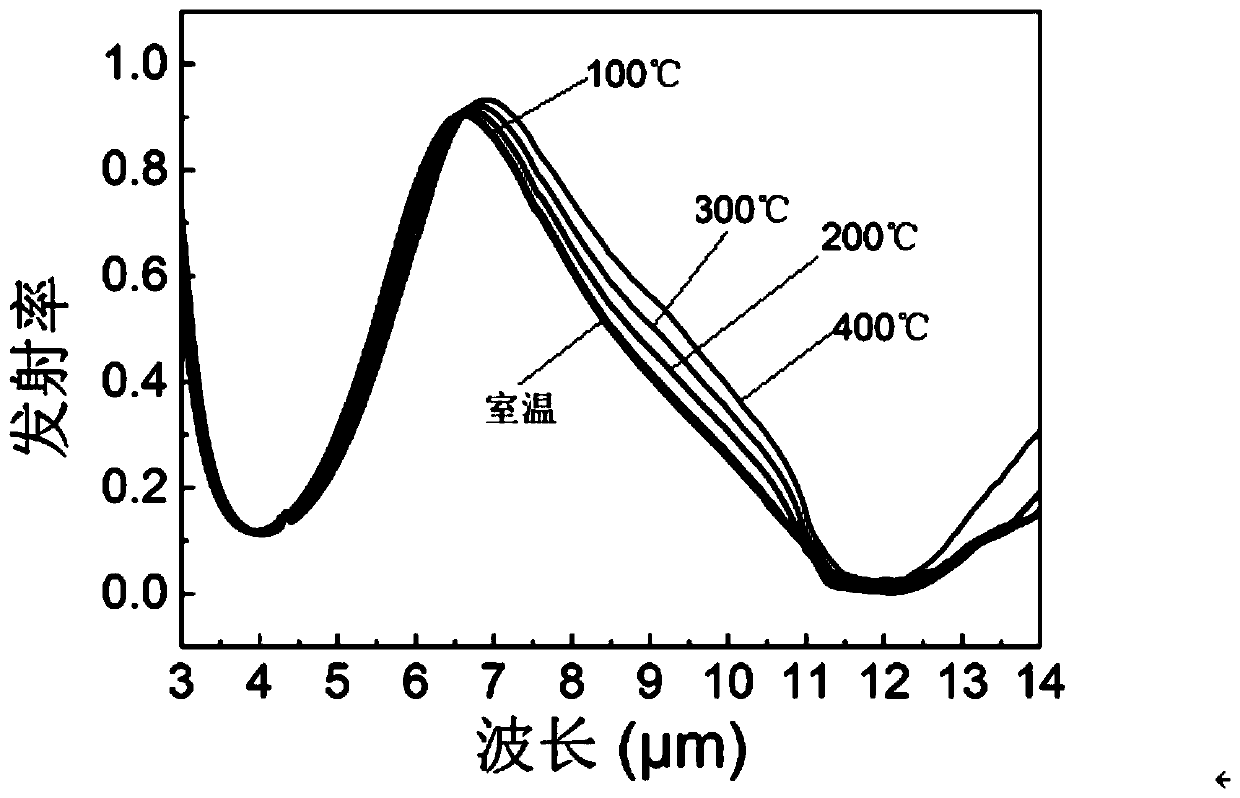

Spectral selective radiation infrared stealth material and preparation method thereof

ActiveCN111158069ASimple structureOptimized areaMetal layered productsOptical elementsZinc selenideLow emissivity

The invention discloses a spectral selective radiation infrared stealth material which sequentially comprises a substrate, an aluminum nitride layer and a dielectric layer, the dielectric layer is composed of a plurality of dielectric layers A and dielectric layers B which are arranged alternately; the dielectric layer A is made of any one of germanium, tellurium and silicon, and the dielectric layer B is made of any one of zinc sulfide, zinc selenide, magnesium fluoride, barium fluoride and calcium fluoride. The preparation method of the material comprises the following steps: (1) cleaning and drying the substrate; (2) preparing an aluminum nitride layer on the surface of the substrate by adopting a magnetron sputtering or tape casting method; and (3) adopting magnetron sputtering or electron beam evaporation, depositing a dielectric layer A on the aluminum nitride layer firstly, then depositing a dielectric layer B on the aluminum nitride layer, depositing the dielectric layer A andthe dielectric layer B repeatedly and alternately until the designed number of layers is reached, and completing preparation of the infrared stealth material. The spectral selective radiation infraredstealth material disclosed by the invention considers the requirements of low emissivity and radiation heat dissipation, and has important significance for better realizing infrared stealth.

Owner:NAT UNIV OF DEFENSE TECH

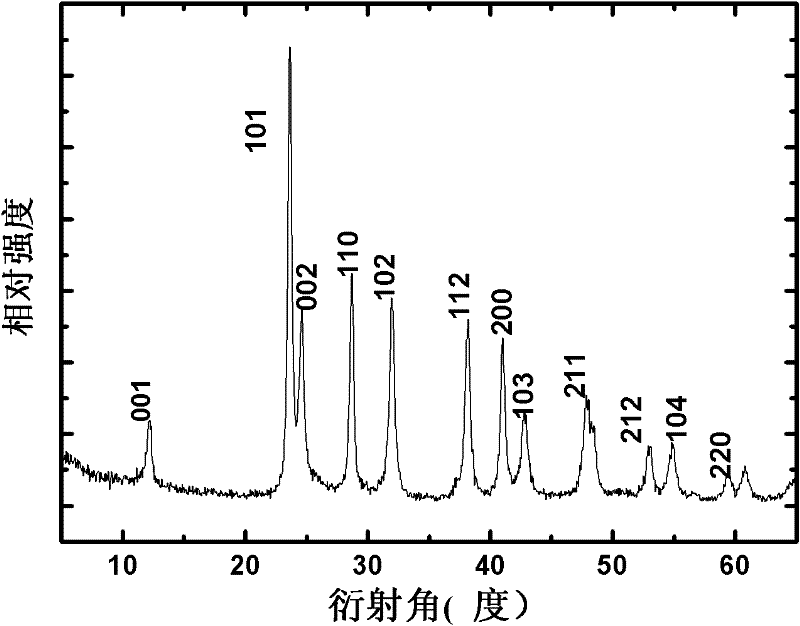

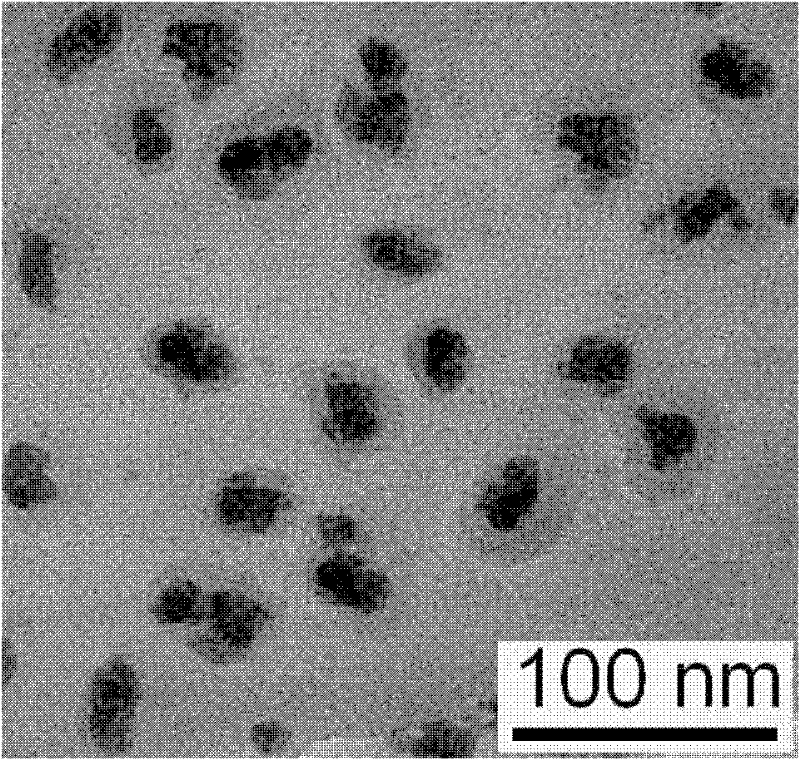

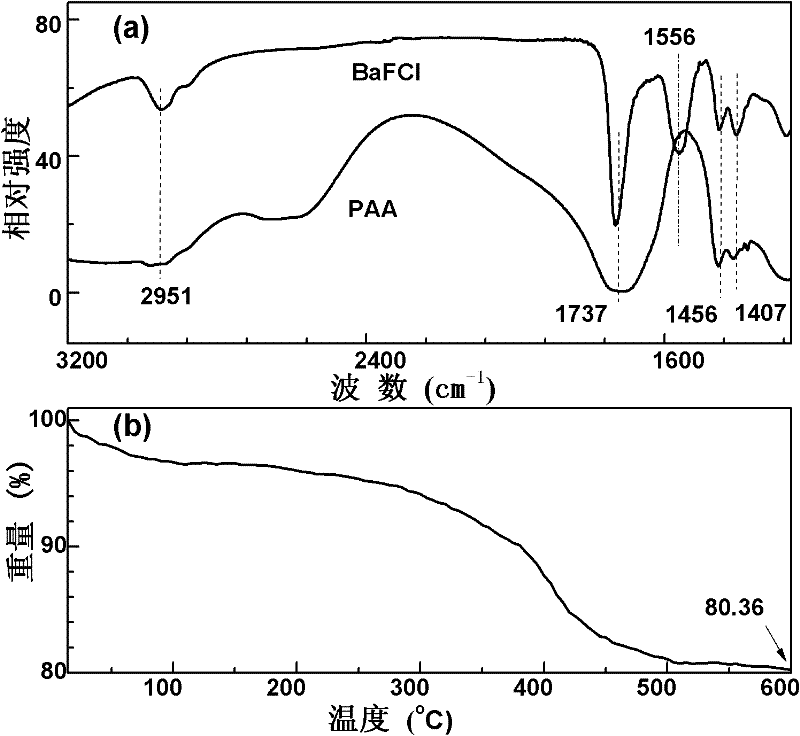

Surface carboxylic acid functionalized water-soluble rare earth doped barium fluoride chloride nano-luminescent material and preparation method thereof

InactiveCN102260497ASimple preparation processGood surface functionalization with carboxylic acidsLuminescent compositionsFluorescenceActive agent

The invention provides a surface carboxylic acid functionalized water-soluble rare earth doped barium fluoride chloride nano-luminescent material and a preparation method thereof, and relates to the preparation of a surface-functionalized water-soluble nano-luminescent material. The composition of the barium fluoride chloride nano-luminescent material prepared by the present invention is: XLn3+-(1-x)BaFCl (Ln=Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb ; x=0-60mol%). Using PAA as a surfactant, a water-soluble rare earth-doped barium fluoride chloride nanoluminescent material with surface carboxylic acid functionalization was prepared by one-step reaction. Through transmission electron microscope, infrared absorption spectrum, thermogravimetric curve and other test methods, it is proved that PAA is effectively coated on the surface of nanoparticles. The obtained nanopowder has good water solubility, and the carboxylic acid groups on its surface lay the foundation for the next step of binding biomolecules. By doping with different rare earth ions, the material can realize strong fluorescence emission of rare earth ions from the visible to the infrared range.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

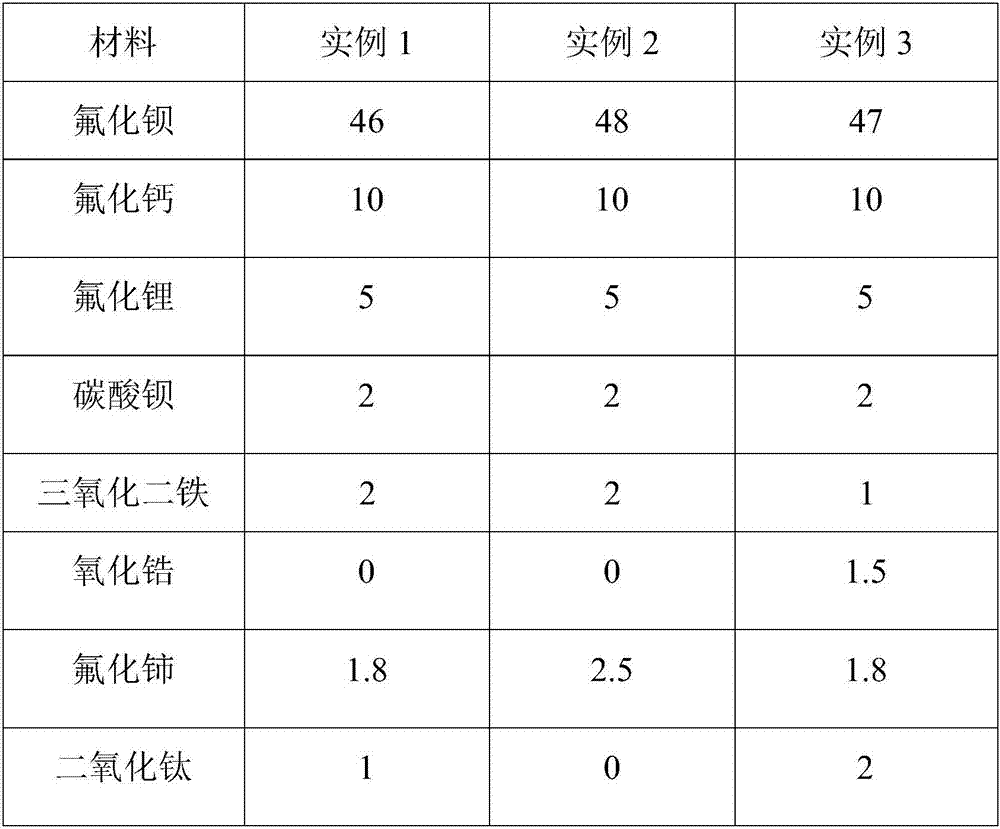

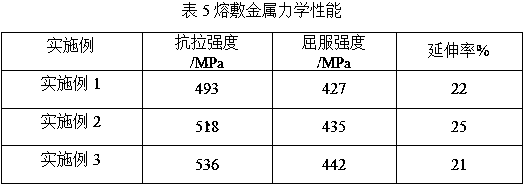

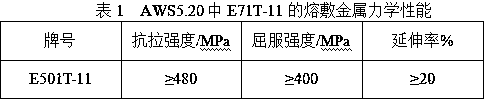

Small-sized self-shielded flux-cored wire suitable for all-position welding and application thereof

ActiveCN109530960AReduce O, N contentReduce N contentWelding/cutting media/materialsSoldering mediaManganeseRare earth

The invention belongs to the technical field of welding materials, and particularly relates to a small-sized self-shielded flux-cored wire suitable for all-position welding. The small-sized self-shielded flux-cored wire suitable for all-position welding comprises a carbon steel skin and a flux core filled in the carbon steel skin, wherein the flux core comprises the following the components according to the total mass percent of the flux core: 25-30% of barium fluoride, 4-7% of lithium fluoride, 2-3% of rare earth fluoride, 14-16% of magnesium powder, 8-12% of aluminum powder, 1-2% of graphite, 4-7% of manganese metal and the balance being iron powder. The invention also provides application of the small-sized self-shielded flux-cored wire suitable for all-position welding. The small-sizedself-shielded flux-cored wire is used for the welding of a light steel structure. When the flux-cored wire provided by the invention is used for welding, gas protection is not needed, and the weldingprocess is protected only by slagging, gas-making and strong reducing substances in the flux core components during welding; the small-sized self-shielded flux-cored wire has strong anti-wind capability and high deposition efficiency and meets E71T-11 related requirements in American Standard AWS 5.20.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com