Patents

Literature

311 results about "Stainless steel electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DCEP (Direct Current Electrode Positive) is used for most stainless-steel welding. A 1or 2% argon-oxygen mixture is recommended for most stainless steel spray arc welding. On square butt welds, a backup strip should be used to prevent weld-metal drop through.

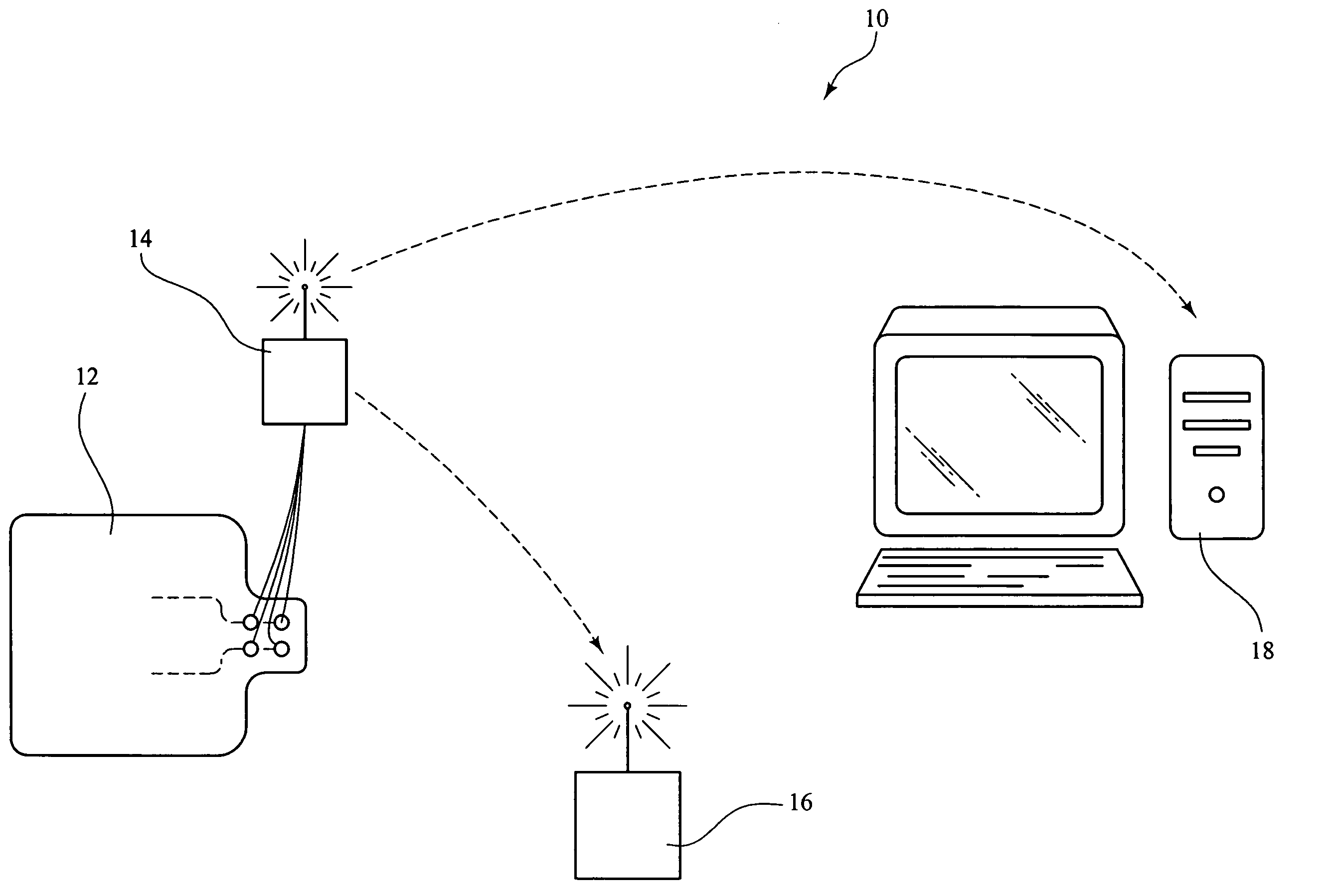

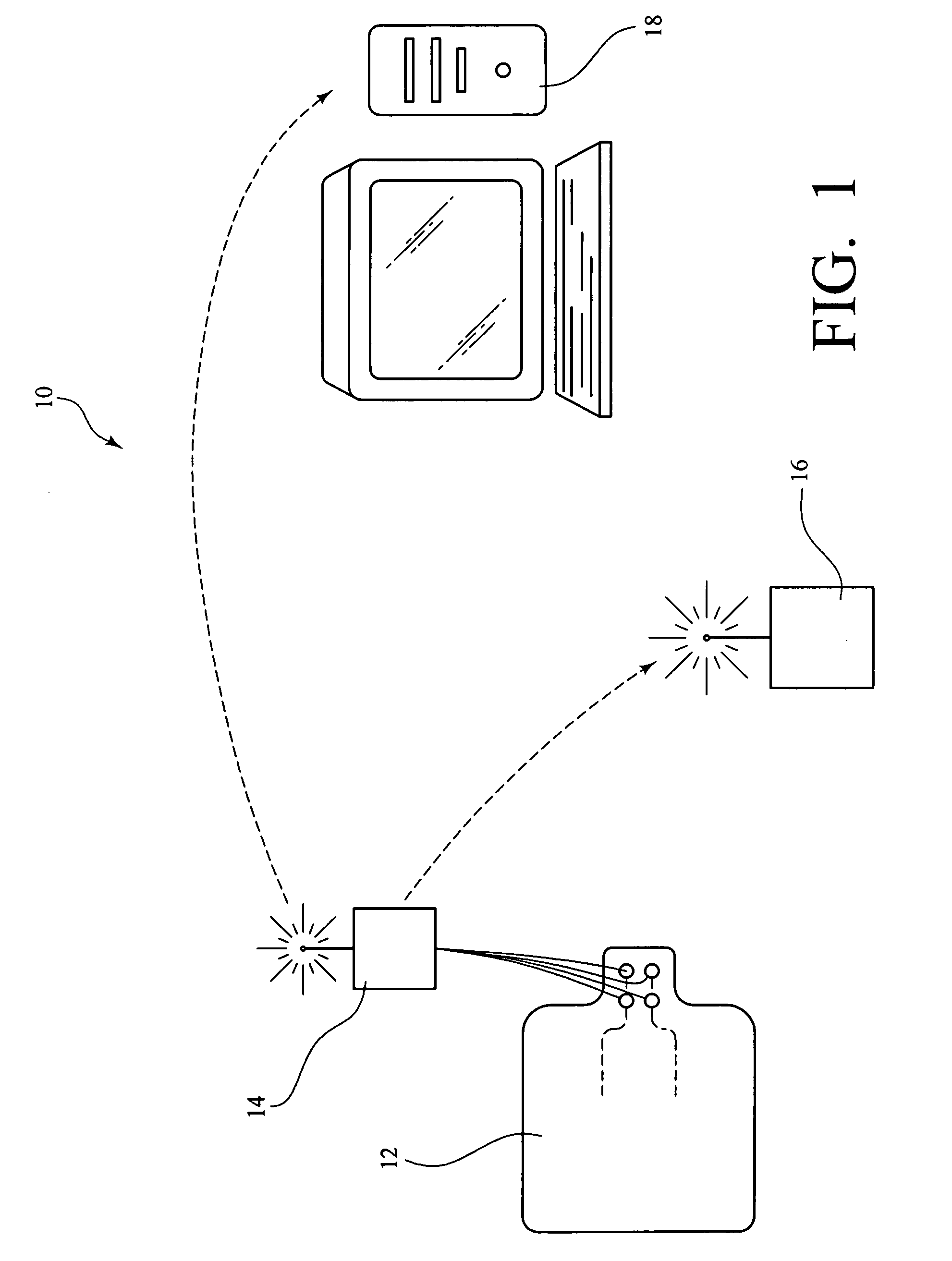

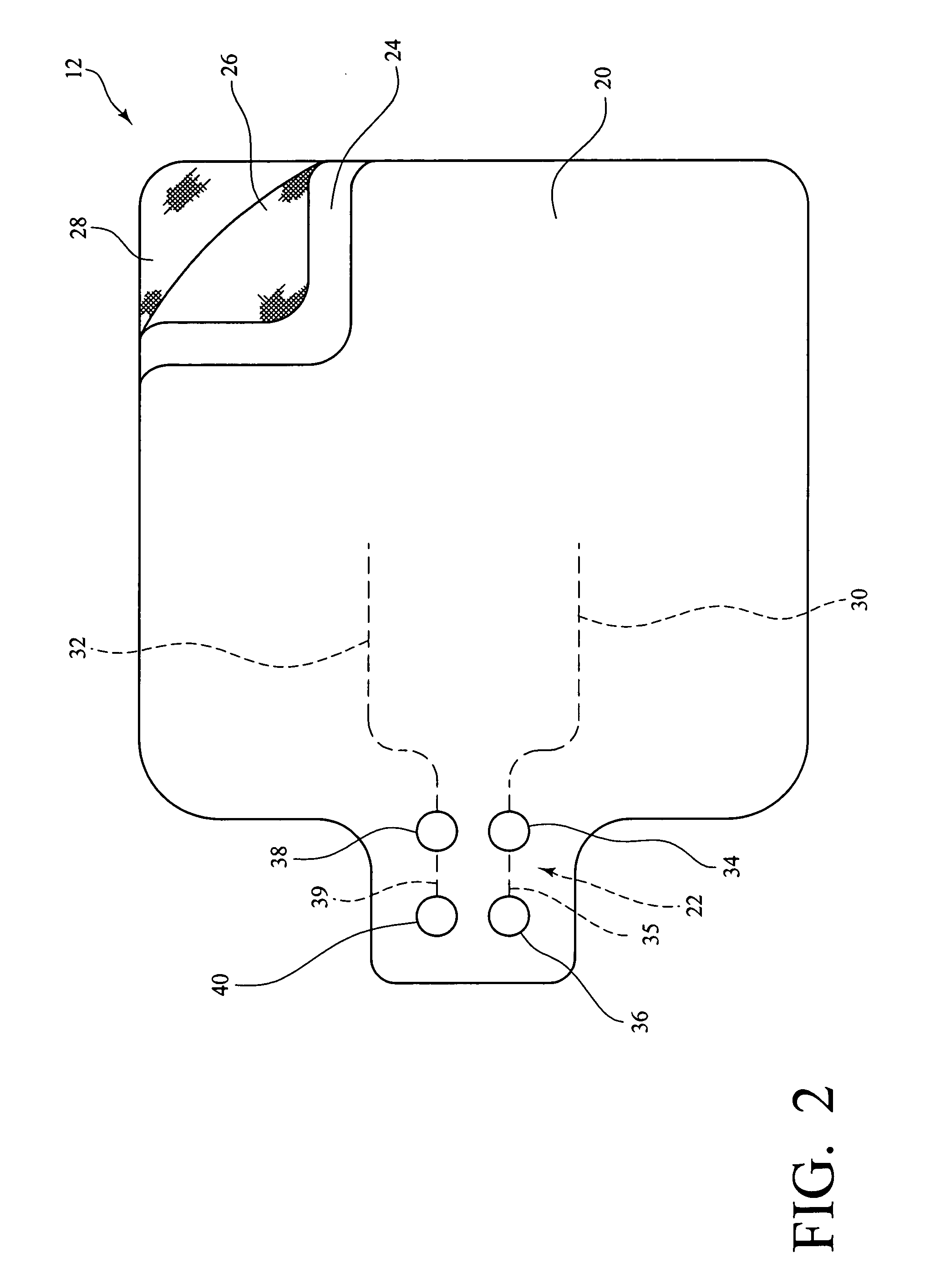

Apparatus for incontinence detection and notification

An apparatus for incontinence detection and notification comprises a notification component, for providing notice that an incontinent event has occurred, and a sensor. The sensor includes a sensing pad for collecting and retaining fluid resulting from the incontinent event, and a circuit housed within the sensing pad. The circuit has a pair of stainless steel electrodes, which are in electronic communication with the notification component. A closed circuit is created between the electrodes by the fluid resulting from the incontinent event, causing an electronic signal to be communicated to the notification component. The circuit may also include a plurality of connectors placed in electronic communication with the notification component to diagnose a disconnected or poorly connected circuit.

Owner:HAIRE GLEN M +1

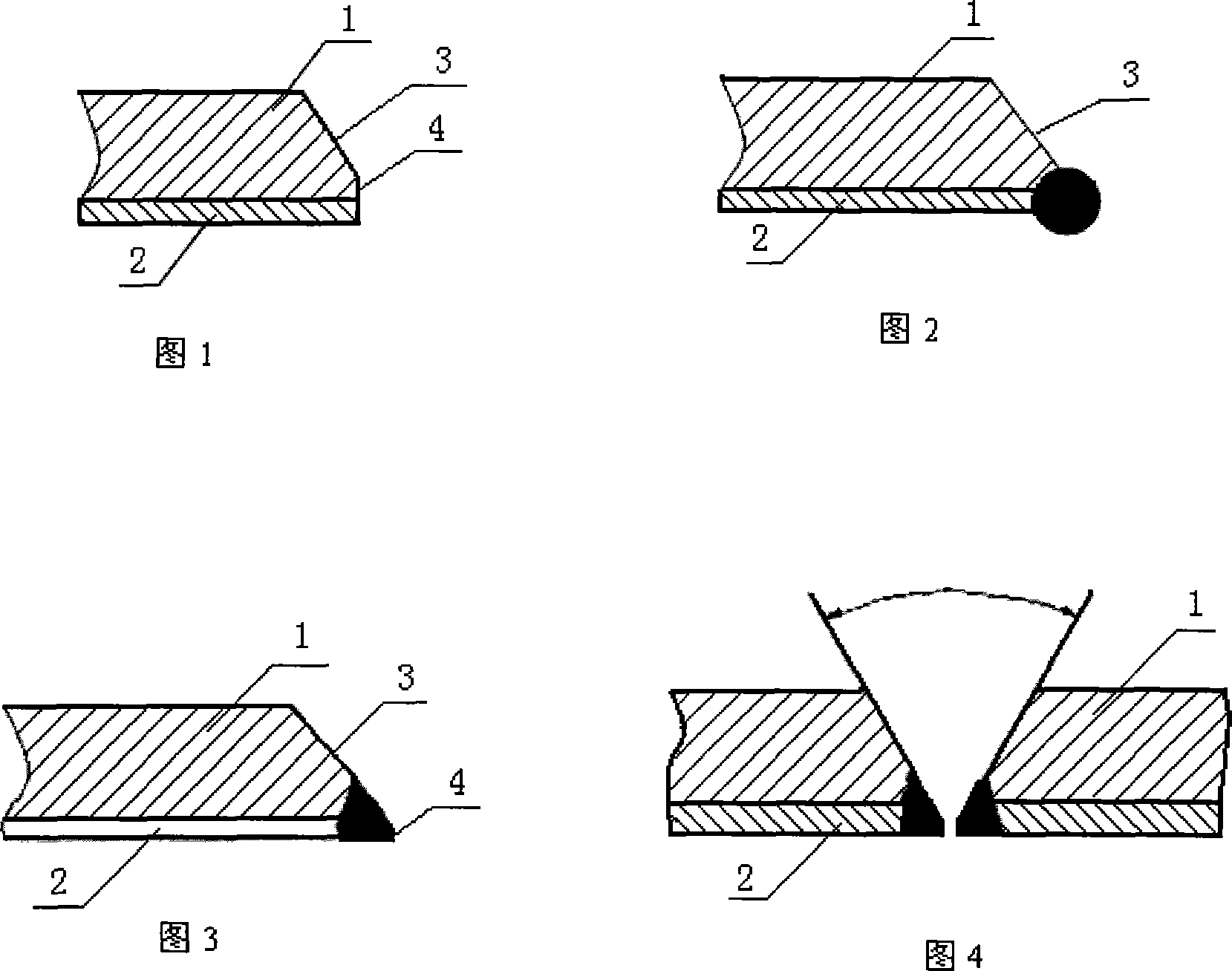

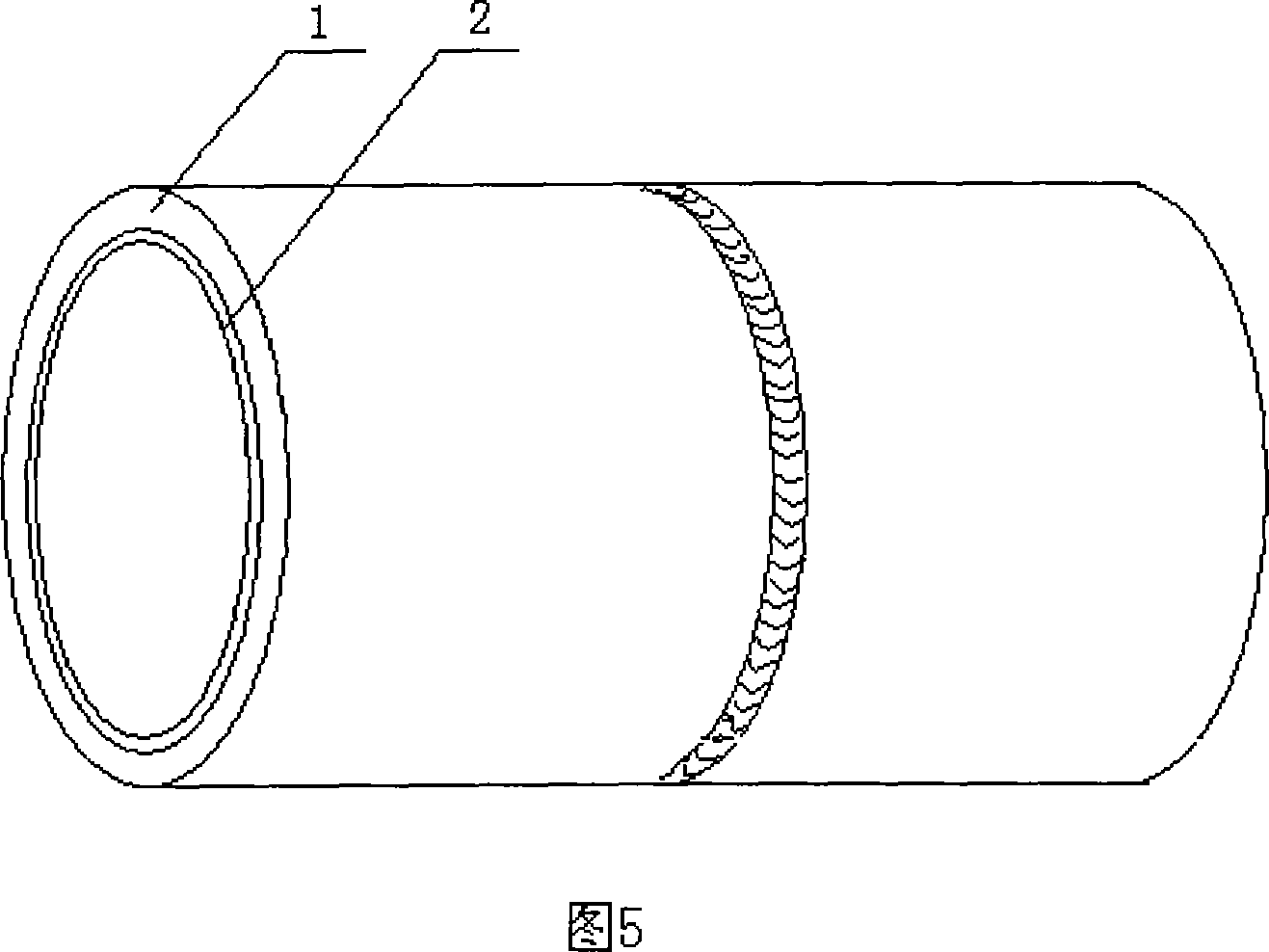

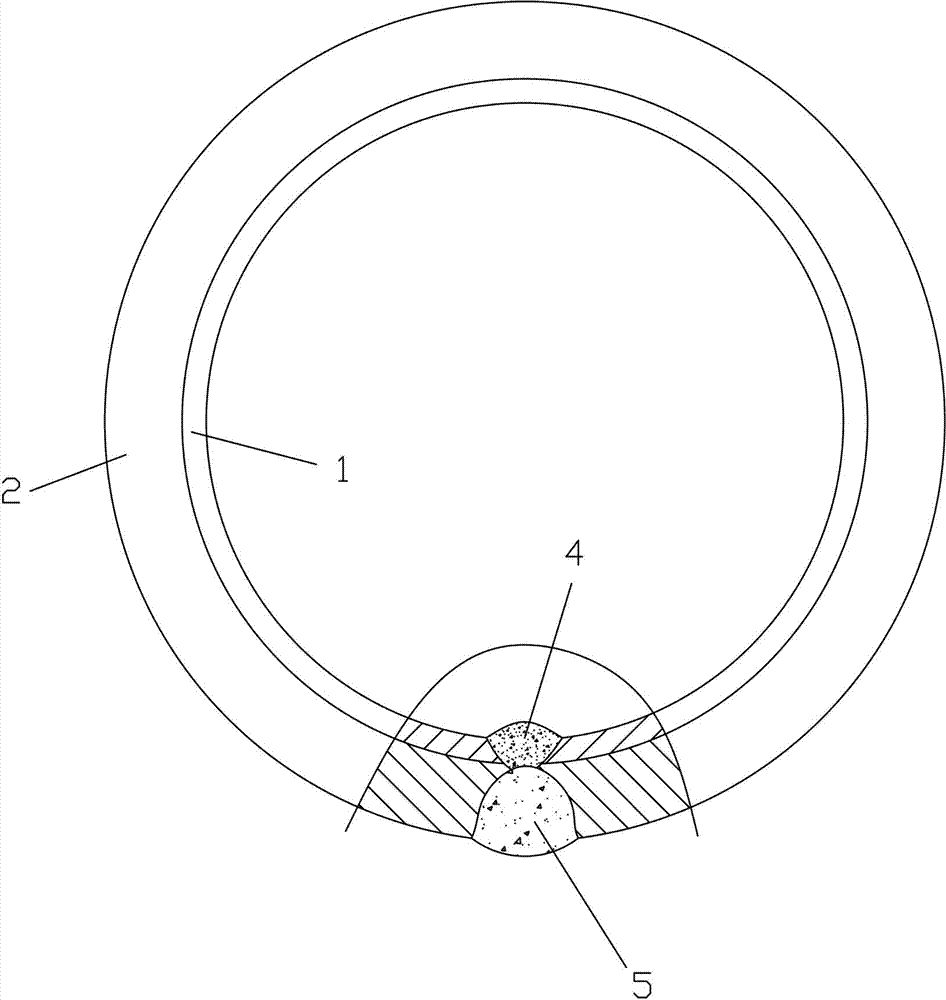

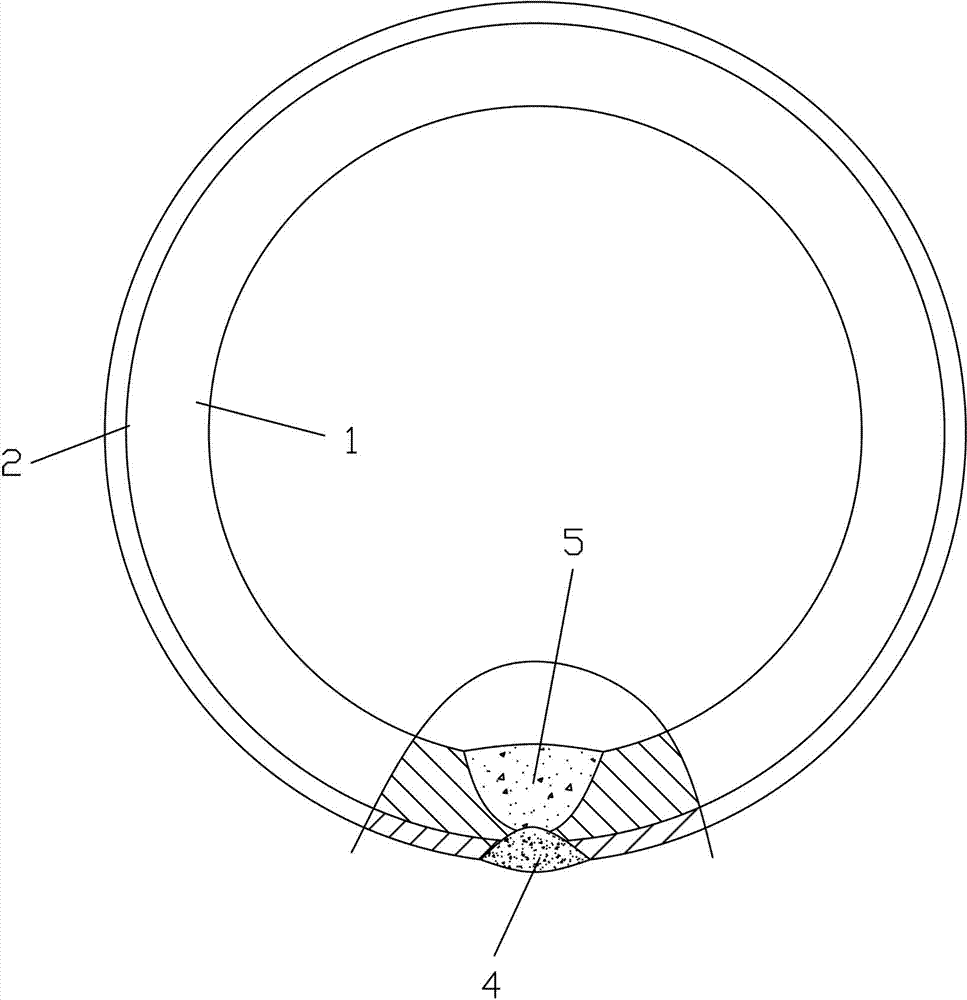

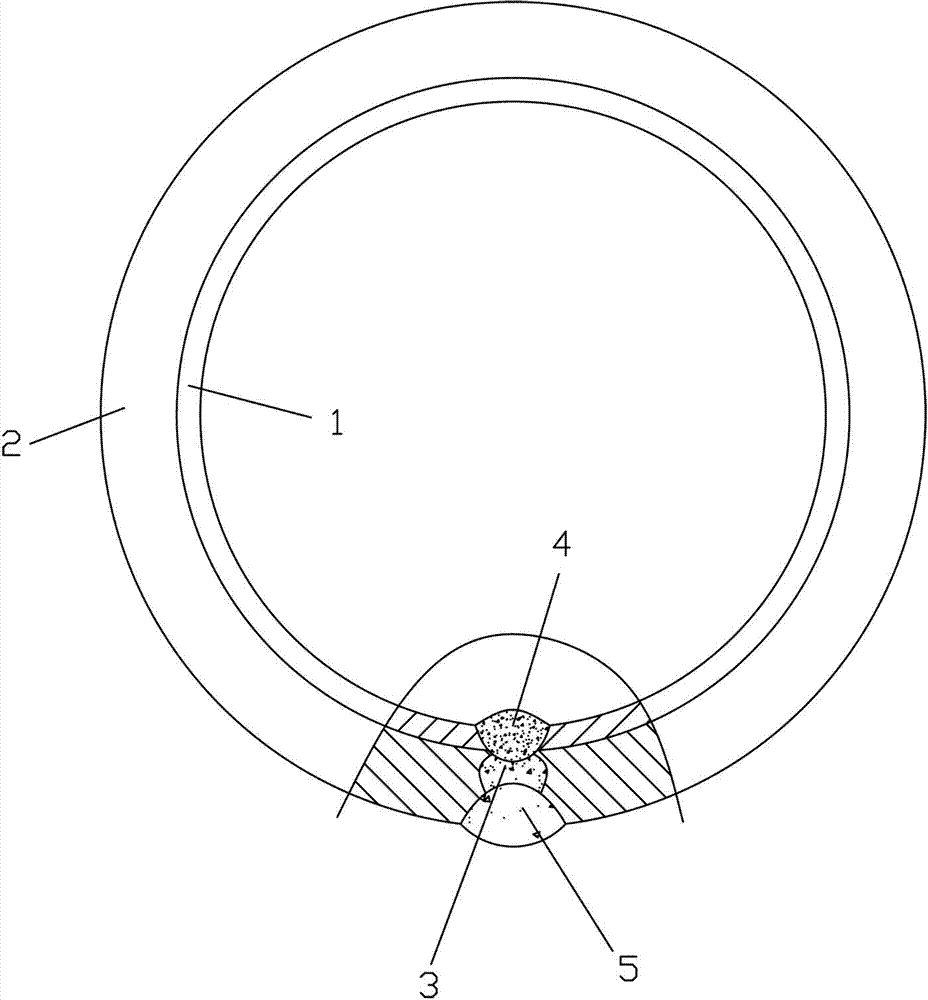

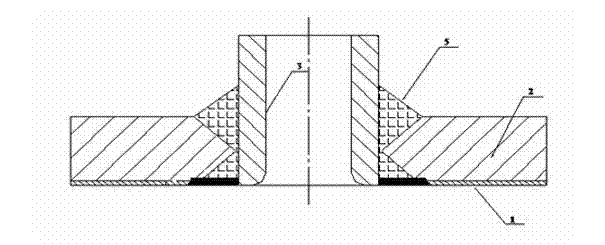

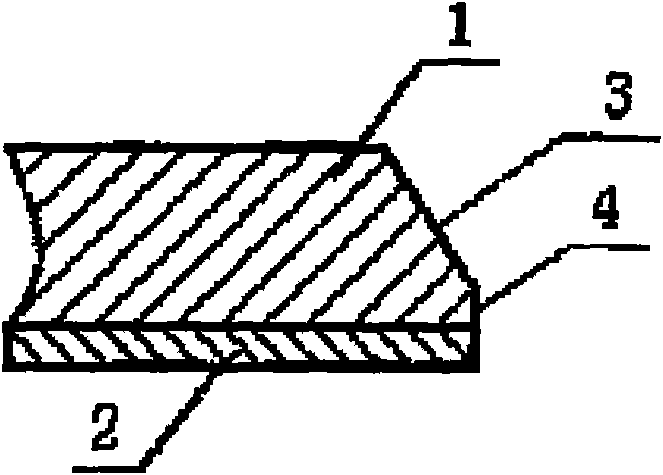

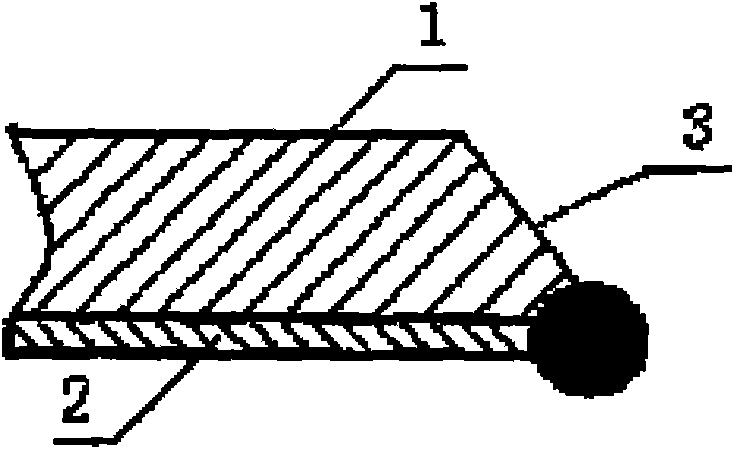

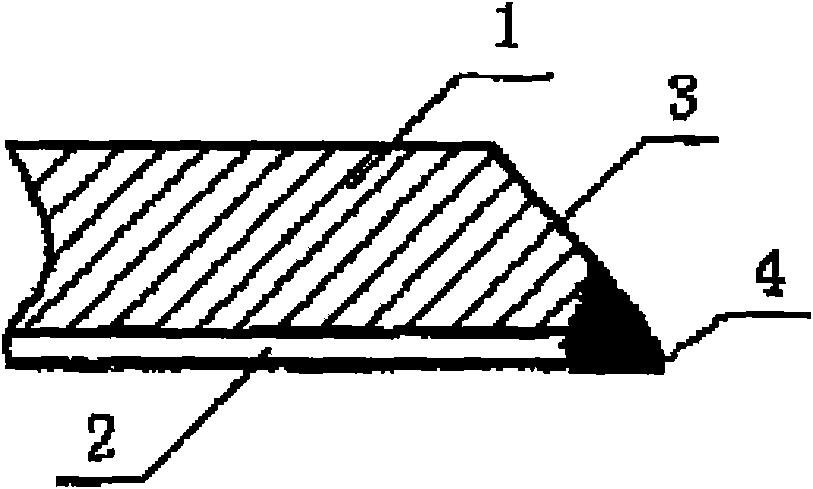

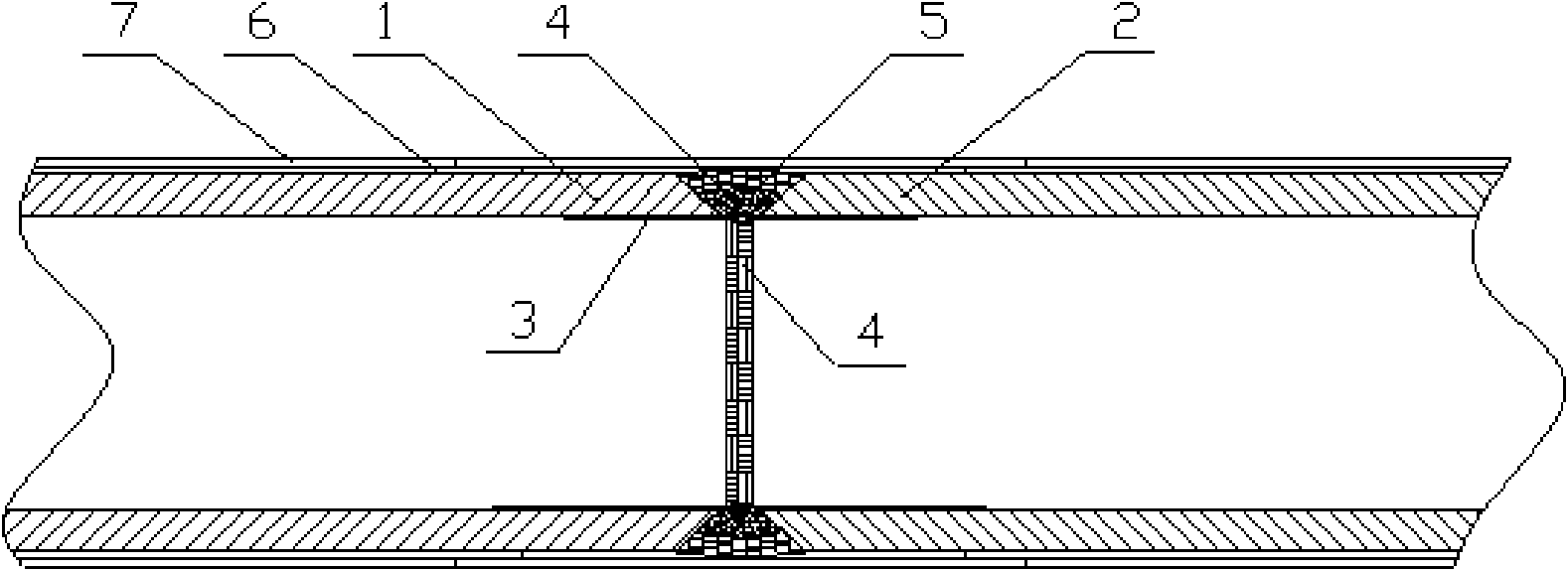

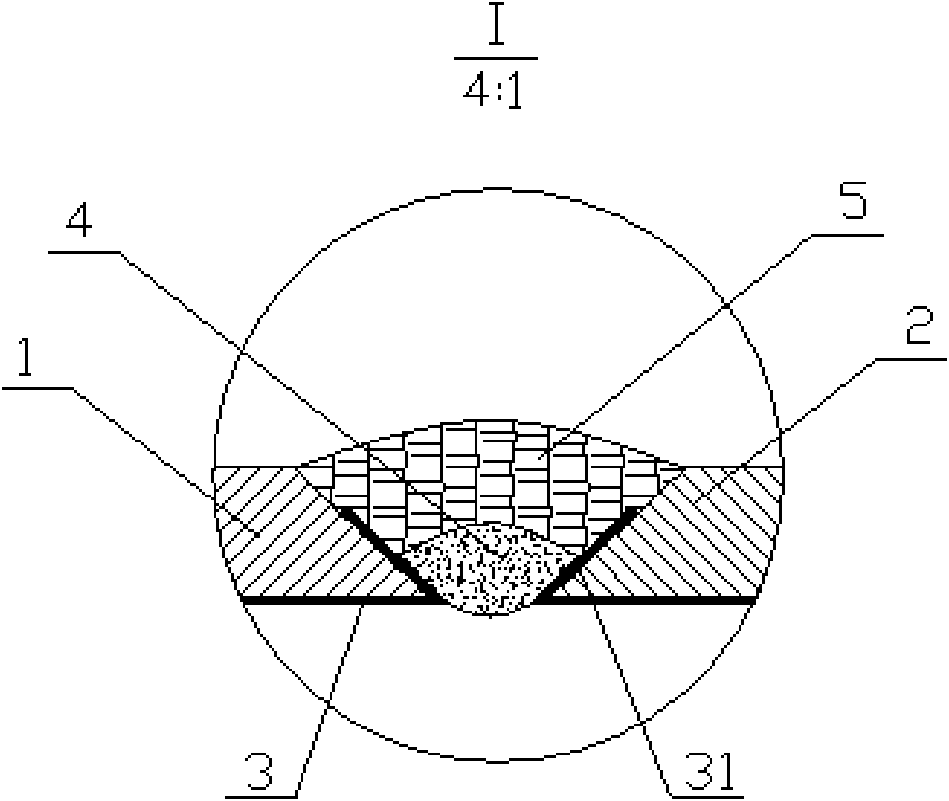

Thin-wall stainless steel double-layer and carbon steel base layer composite tube girth weld welding method

ActiveCN101100013AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsWeld seamMaterials science

The process of ring welding composite pipe comprising one thin stainless steel layer and one carbon steel base layer includes the following steps: 1. chamfering and eliminating oil stain; 2. bead welding and trimming chamfer; 3. pairing bimetal composite pipe chamfers; 4. argon shielded tungsten arc welding in the bottom; 5. welding the second layer to weld the base layers of two composite pipes; and 6. filling welding and finishing welding. During the welding process, stainless steel electrode and 309 or 309Mo welding material are adopted for reaching high strength and high toughness of the weld seam, and the chamfers have increased effective thickness of stainless steel layer for high welding quality and high corrosion resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

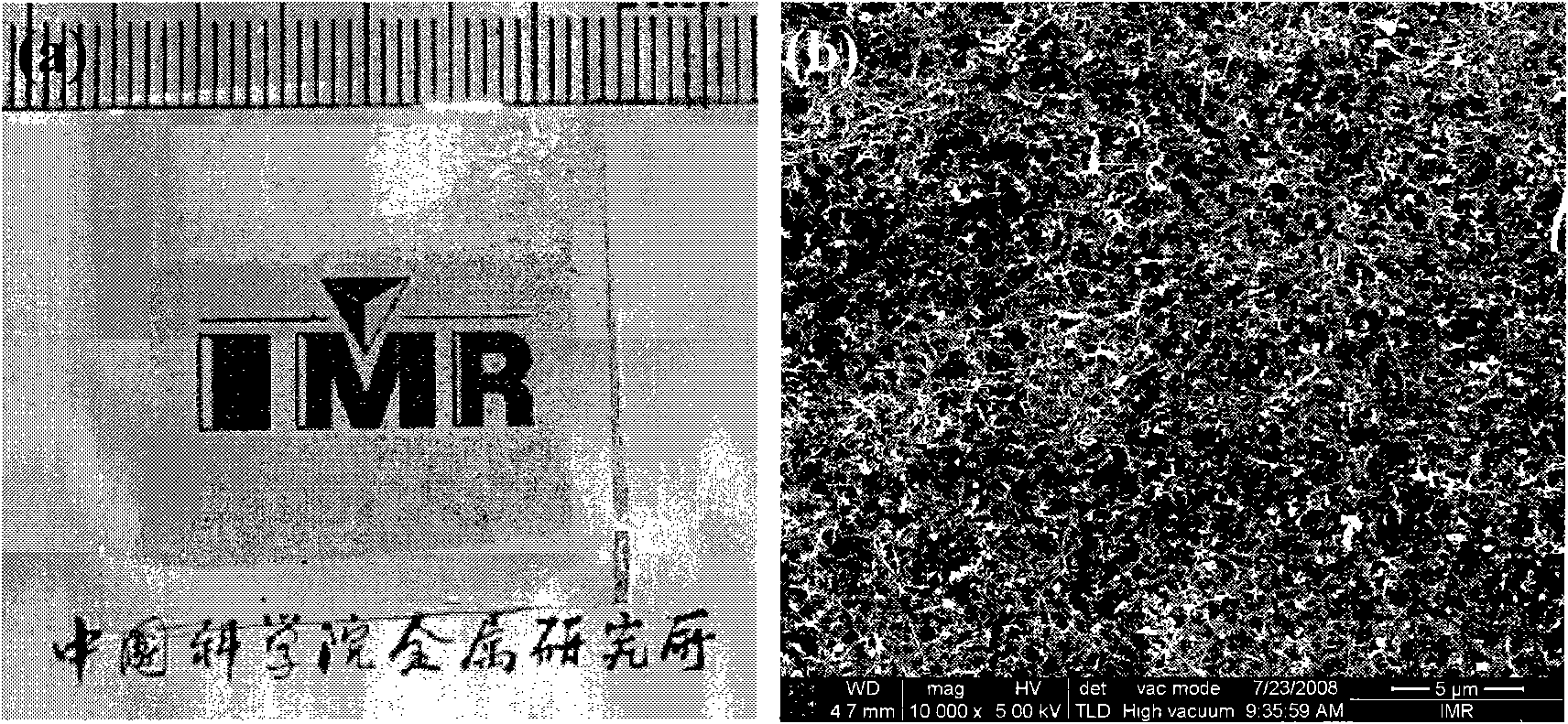

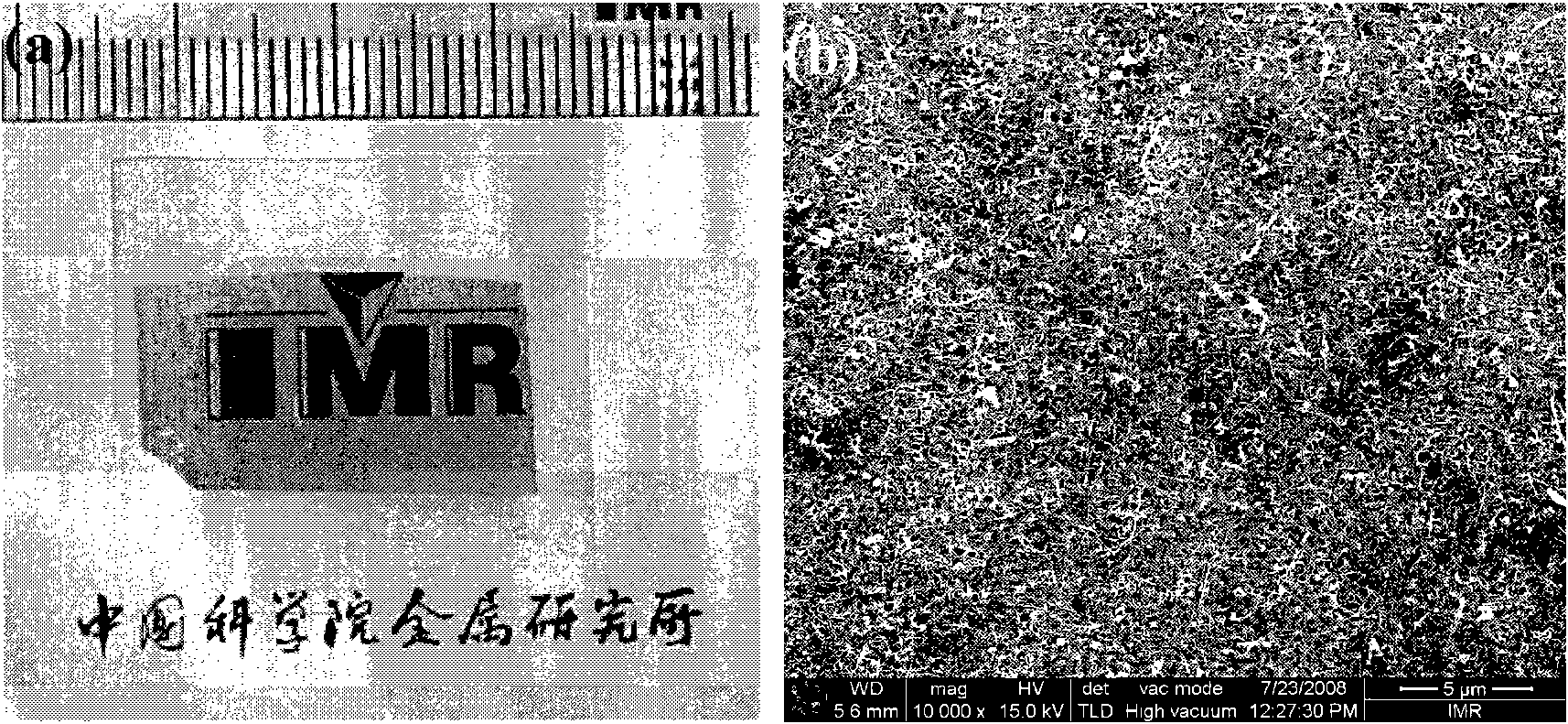

Method for preparing flexible carbon nano tube transparent conductive thin-film material and electrodeposition device

ActiveCN101654784ALow costElectrodeposition process is fastElectrophoretic coatingsMetallic material coating processesUltrasound - actionCarbon nanotube

The invention relates to a method for preparing a flexible carbon nano tube transparent conductive thin-film material and an electrodeposition device, which are suitable for preparing uniform, high-transparency and high-conductivity flexible transparent conductive thin films. The method comprises: dispersing carbon nano tubes in aqueous solution by using an anionic surfactant under the action of ultrasonic waves, centrifuging the solution, using supernate as a plating solution and adding ammonia to make the plating solution alkaline; uniformly depositing the carbon nano tubes dispersed in theplating solution on a polished surface of a stainless steel electrode by using an electro-deposition method to obtain uniform carbon nano tube thin films with a thickness of 20 to 200 nanometers; andtransferring the carbon tube thin films to the surface of a flexible and transparent polymer substrate to form flexible, transparent and conductive thin films. The electrodeposition device mainly comprises an adjustable stabilized direct current power supply and a rectangular electrophoresis tank with a stainless steel inert electrode plate, wherein carbon nano tubes deposits on a polished positive plate to form films. The method and the electrodeposition device are simple and easily controllable in process parameters and can be used in large-area and continuous preparation of flexible, transparent and conductive films.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

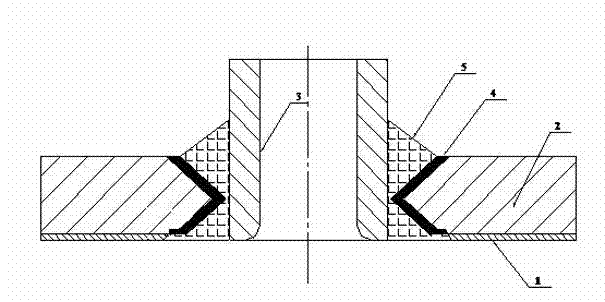

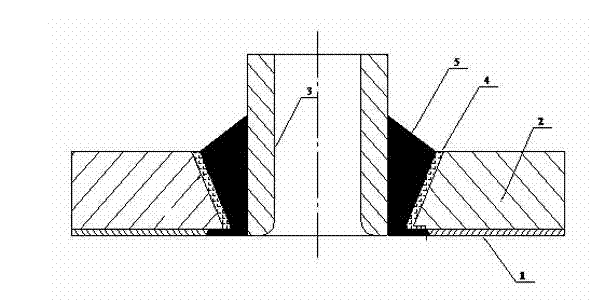

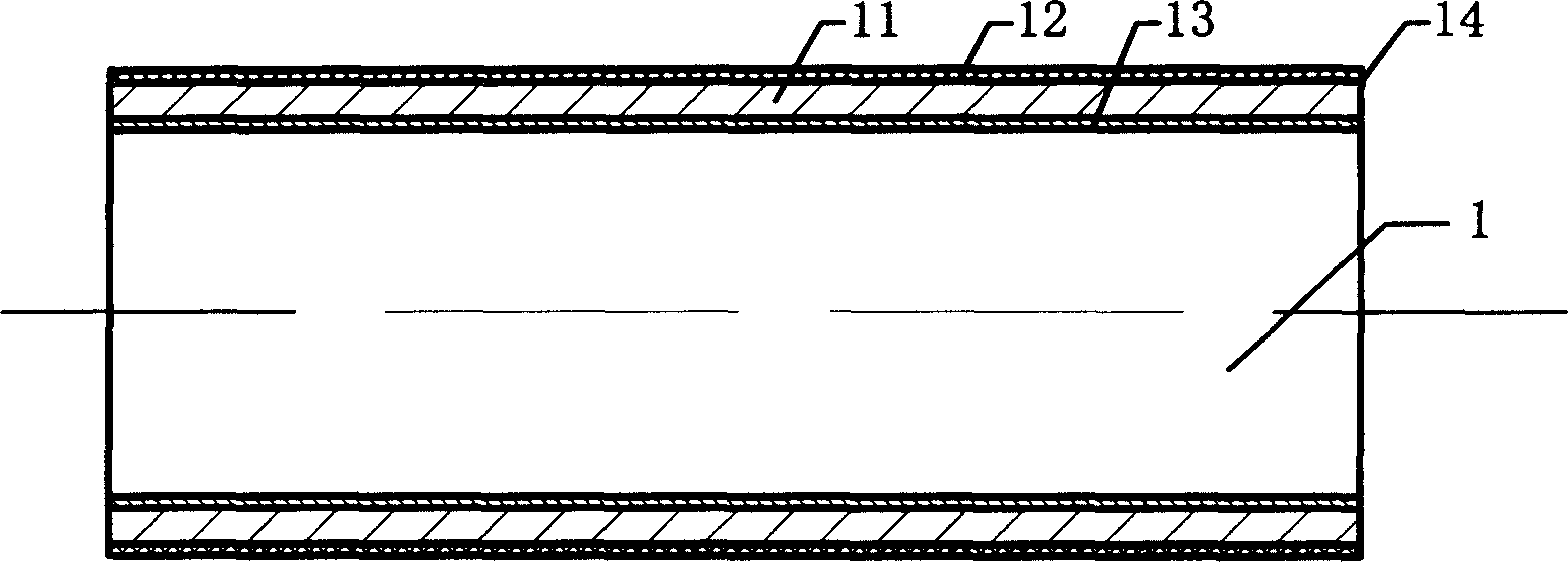

Stainless steel compound welding steel pipe and manufacturing method thereof

ActiveCN102889434AImprove corrosion resistanceImprove structural strengthRigid pipesStainless steel electrodeUltimate tensile strength

The invention discloses a stainless steel compound welding steel pipe and a manufacturing method thereof. The stainless steel compound welding steel pipe is formed by welding stainless steel compound hotly-rolled rolling plates through a welding line, wherein the welding line is formed by a stainless steel compound welding line and a carbon steel welding line. The manufacturing method comprises the following steps of: milling an edge and arranging a groove; when putting a stainless steel compound layer on the inner layer, firstly utilizing gas shield welding to weld a middle layer; then, utilizing a stainless steel welding strip to weld a stainless steel compound layer welding line in an argon arc welding manner; then, utilizing a carbon steel welding strip to weld the carbon steel welding line by a submerged-arc welding manner; when the stainless steel layer is less than 0.9 mm, directly welding a stainless steel welding line by submerged-arc welding; and when the stainless steel compound layer is located at the outer layer, firstly welding the carbon steel welding line by adopting the carbon steel welding strip and the submerged-arc welding, and adopting the stainless steel welding strip and the argon arc welding manner to weld the stainless steel compound layer welding line. According to the stainless steel compound welding steel pipe and the manufacturing method thereof, the manufactured stainless steel compound welding steel pipe has high structural strength and strong corrosion resistance; and the bonding strength of an inner pipe and an outer pipe is not less than 200 MPa.

Owner:ZHEJIANG KINGLAND & PIPELINE TECH

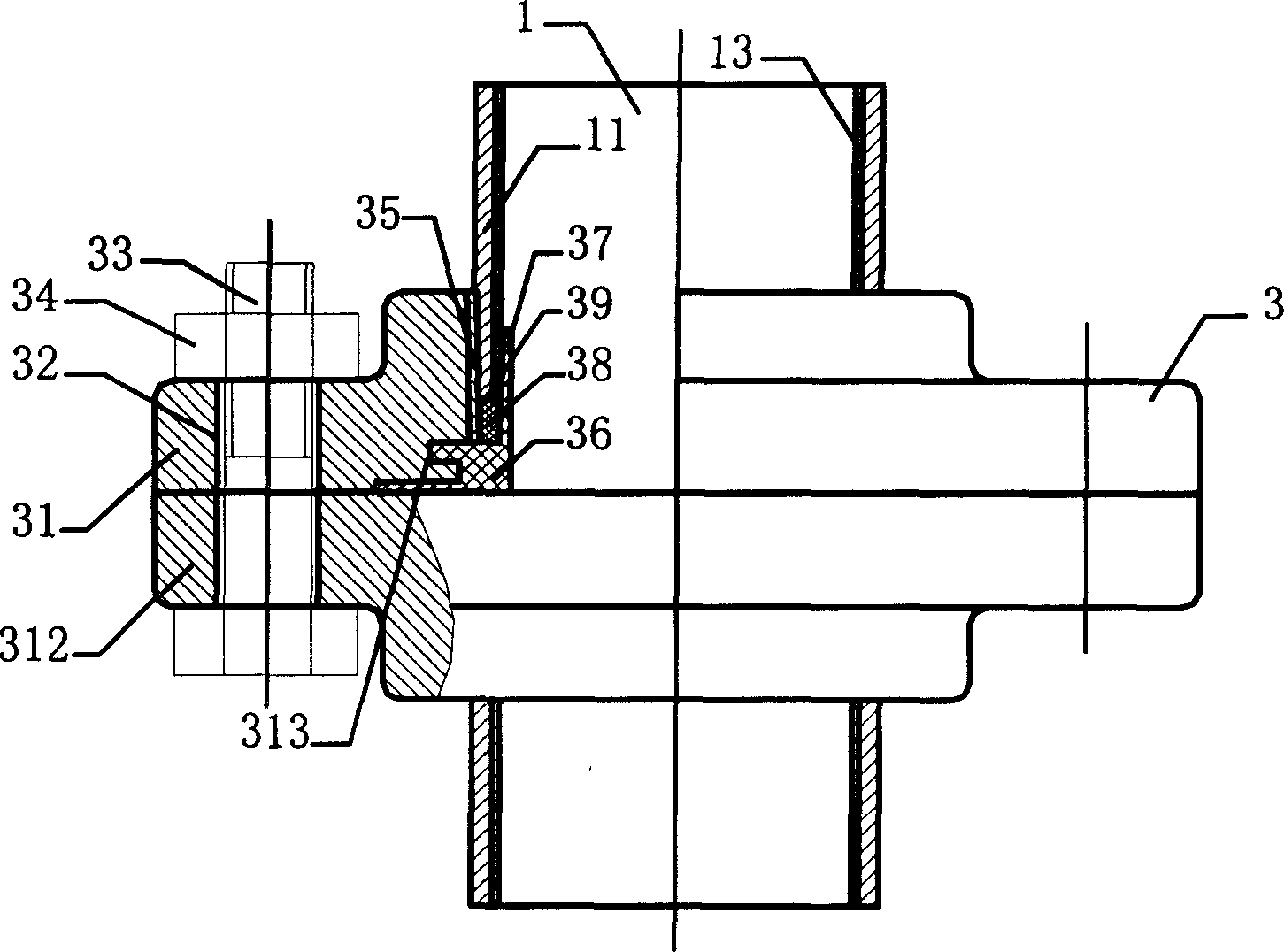

Welding method for stainless steel composite board pressure vessel shell and insert-type stainless steel connecting pipe

InactiveCN102513713AAvoid crackingEasy to useFurnace typesWorkpiece edge portionsChromium nickelStainless steel electrode

The invention discloses a welding method for a stainless steel composite board pressure vessel shell and an insert-type stainless steel connecting pipe. The method comprises the steps of a) arranging a pipe hole of the stainless steel connecting pipe in a stainless steel composite board pressure vessel shell, and manufacturing a pipe hole wall to be a primary bevel with a K shape or a single V shape; b) performing bead-welding on a primary bevel surface by using high chromium nickel stainless steel welding rods to form a transition isolating layer with certain thickness, so as to form a secondary bevel; c) carrying out stress-relief heat treatment on the stainless steel composite board pressure vessel shell after the bead welding; and d) welding corner connecting joints between the stainless steel connecting pipe and the stainless steel composite board bead-welding layer by using stainless steel welding rods with different materials according to a stainless steel composite layer on a composite board. As the transition isolating layer with the certain thickness is firstly bead-welded on the primary bevel of the basic layer side of the stainless steel composite board by using the high chromium nickel stainless steel welding rods, and then the corner connecting joints are welded by the stainless steel welding rods, so that carbon steel and low alloy steel components are transited into stainless steel components, the welding line plasticity can be transited from low to high, cracks are avoided, and the using performance is reliable.

Owner:CSSC SHENGHUI EQUIP

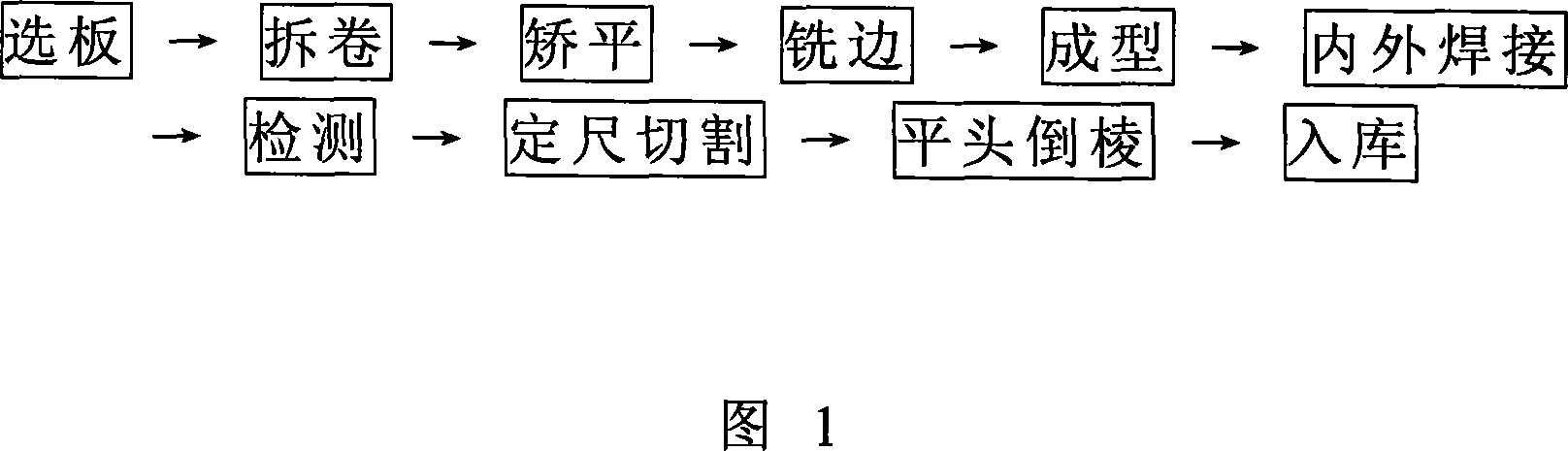

Method for Manufacturing helix composite steel tube

InactiveCN101085455ASimple processReduce manufacturing costWelding/cutting auxillary devicesArc welding apparatusStainless steel electrodeMetallurgy

The spiral complex steel tube is made by processing on common spiral tubes through the procedures of selecting roll plates based on the tube caliber, dismantling the roll, rectifying and smoothening, milling, forming, in and out welding, inspection, fixed dimensional cutting, flatted edging, putting to the warehouse, with the roll plates being of stainless carbon steel complex ones, welding using stainless steel weld bar.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +2

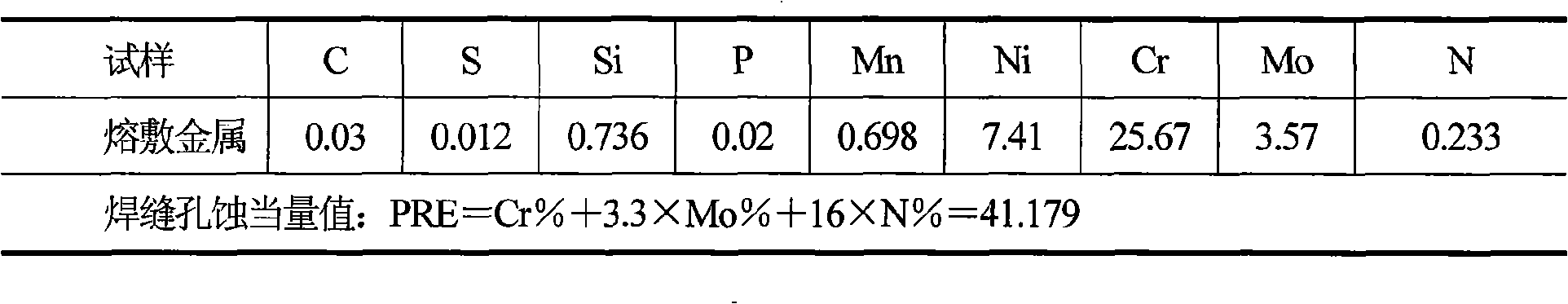

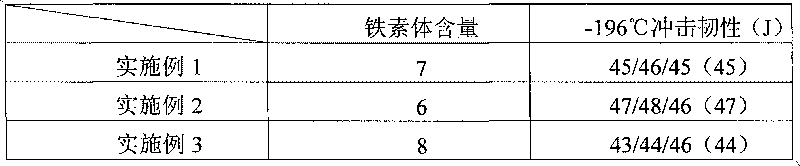

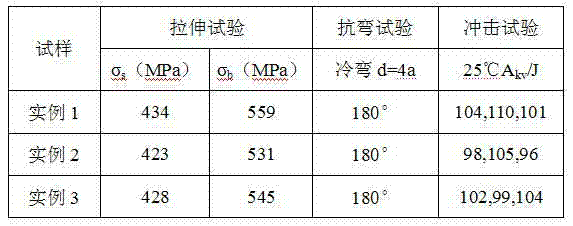

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

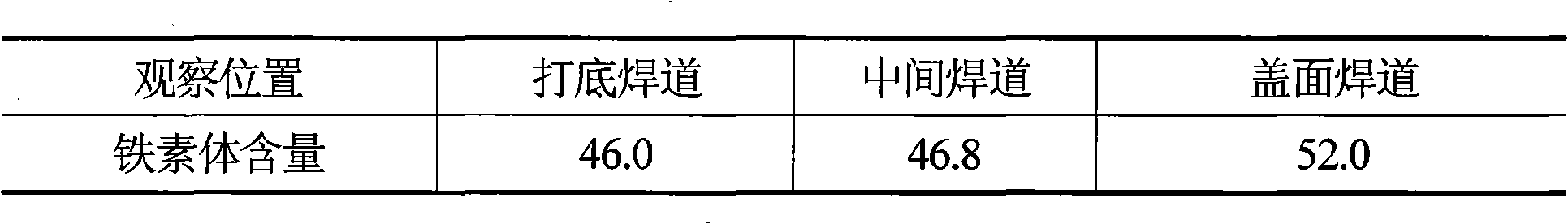

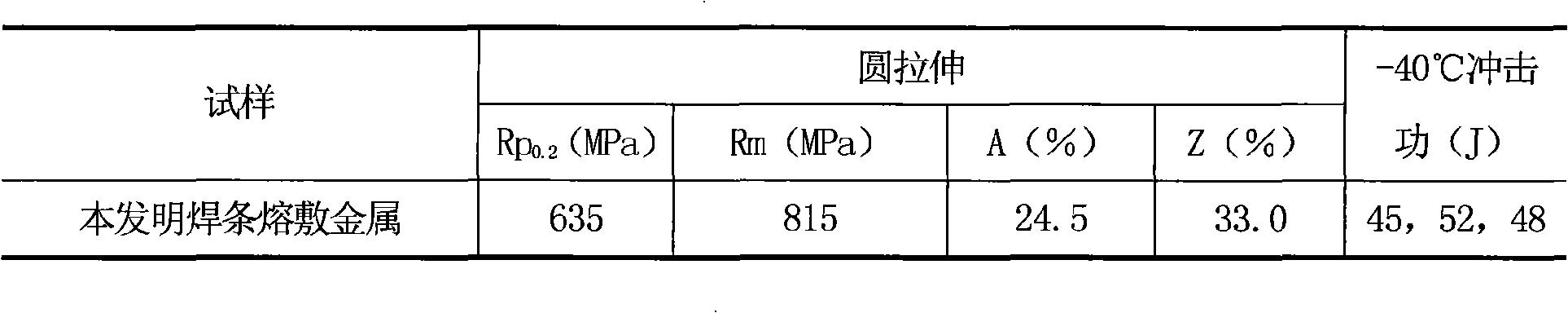

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

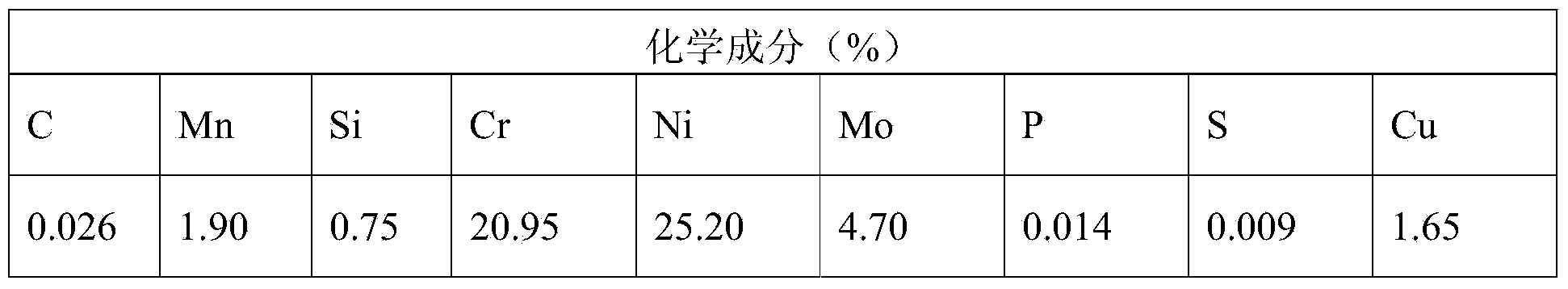

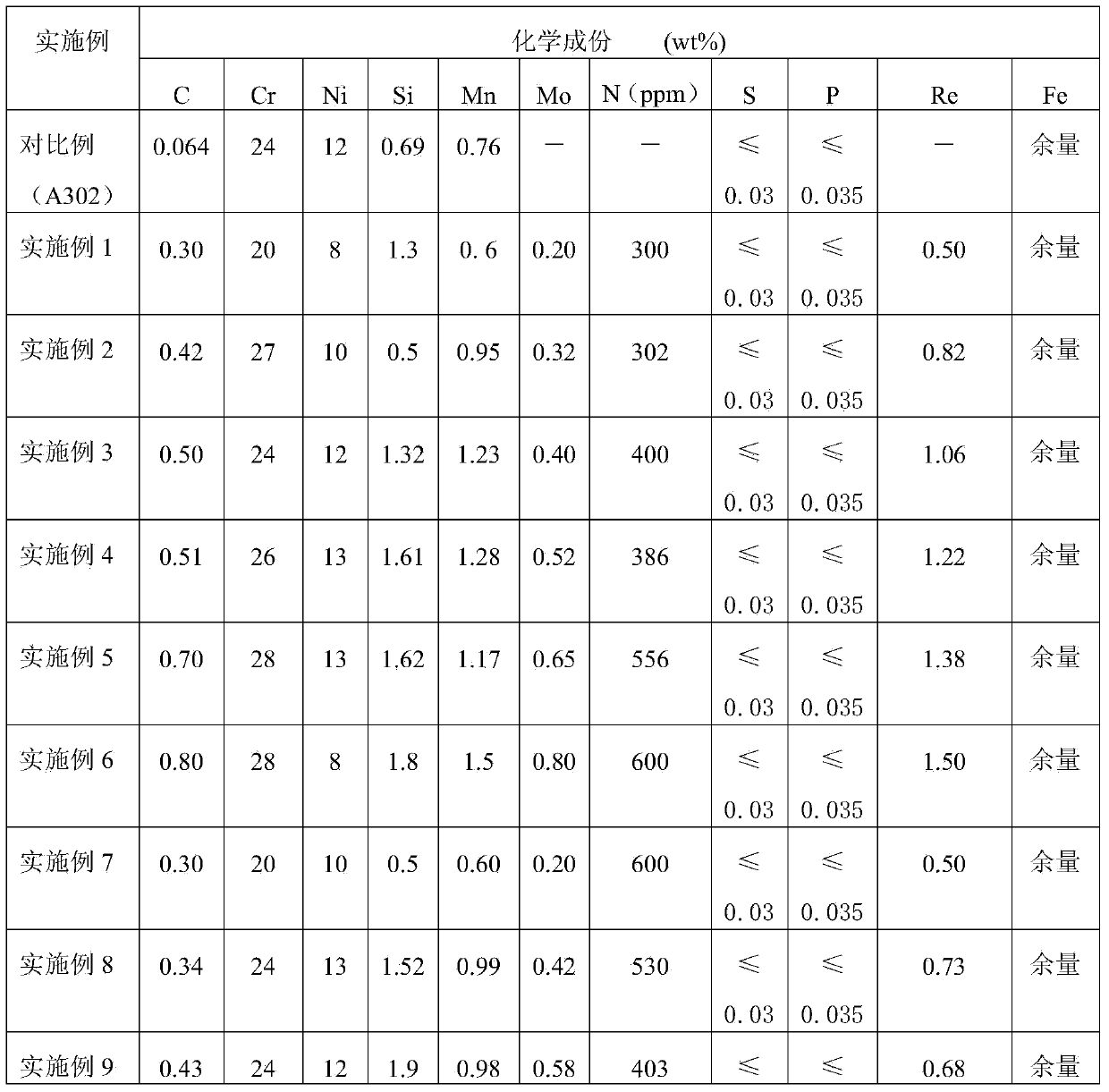

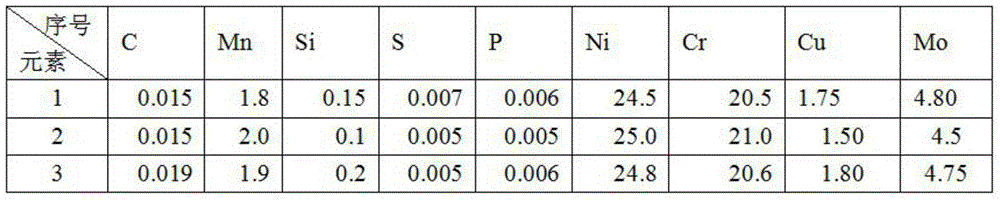

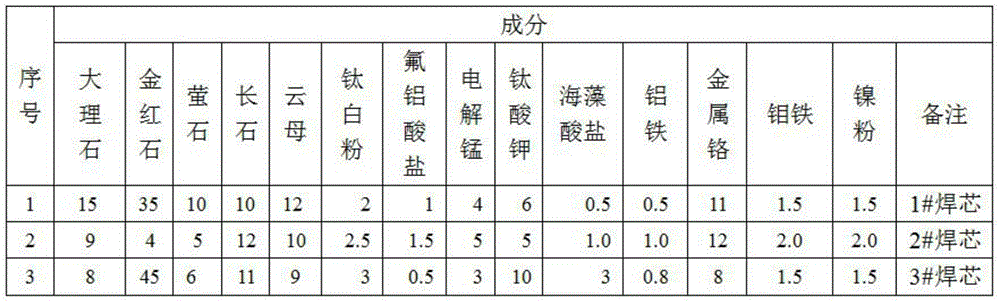

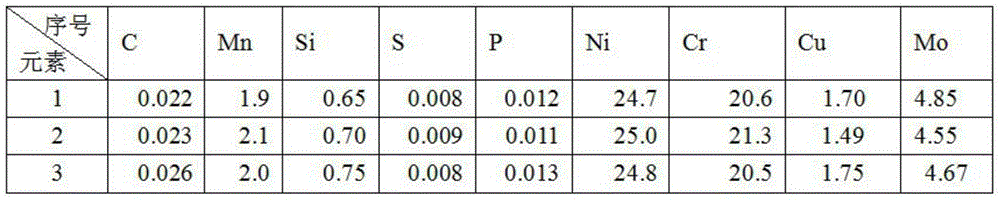

Superaustenitic stainless steel electrode

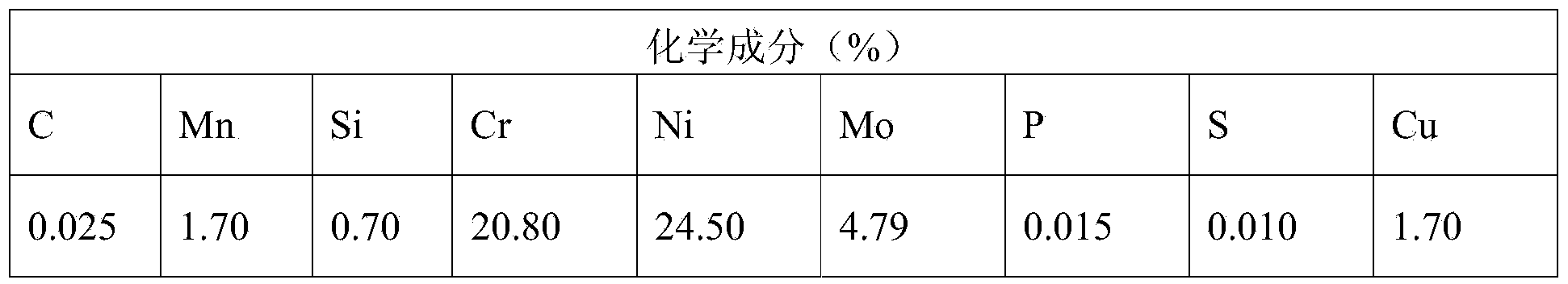

ActiveCN103921018AThe amount of addition is adaptableReduce lossWelding/cutting media/materialsSoldering mediaElectrolysisPhosphoric acid

The invention provides a superaustenitic stainless steel electrode. A coating of the superaustenitic stainless steel electrode at least comprises the following components, by mass, 35 to 45 percent of rutile, 2 to 5 percent of titanium dioxide, 6 to 12 percent of marble, 6 to 12 percent of dolomite, 1 to 3 percent of quartz, 3.5 to 6.5 percent of cryolite, 4 to 8 percent of dehydrated feldspar, 3 to 5 percent of dehydrated phlogopite, 6 to 8 percent of chromium metal, 6 to 8 percent of electrolytic manganese, 3 to 6 percent of ferrotitanium, 1 to 2 percent of chromium oxide green, 2 to 4 percent of nickel powder, 0.5 to 1.5 percent of ferromolybdenum and 0.5 to 1.5 percent of sodium alginate. The coating of the superaustenitic stainless steel electrode is formed by mixing all the components according to the proportions, potassium and sodium are added to be mixed with sodium silicate, and the coating coats a core wire H02Cr20Ni25Mo4Cu to form the electrode. Carbon content is extremely low, comprehensive corrosion of sulfuric acid and phosphoric acid can be resisted, the corrosion of acetic acid at any temperature and in any concentration under ordinary pressure can be resisted, and an ideal welding material is provided for steel for manufacturing various strong acid storing and transporting containers.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

Welding method for NM400 wear-resistant steel

ActiveCN104227180AAvoid it happening againImprove toughnessArc welding apparatusWelding/soldering/cutting articlesWear resistantStainless steel electrode

The invention provides a welding method for NM400 wear-resistant steel. The welding method comprises the following steps: after adopting an A407 stainless steel electrode as a bottoming welding joint, locally preheating the welding joint and the area in peripheral 200mm scope, wherein the preheating temperature is 350-400 DEG C and the temperature is kept constant for 5 minutes; performing multilayer multichannel welding by using an ER50-6 welding stick matched with CO2 gas protection welding, wherein the height of each layer of welding joint is not more than 4mm and the interlayer temperature is controlled to be above 150 DEG C; using the A407 stainless steel electrode for welding a transition layer at the height of 2-3 layers of welding joints from the surface of a base metal, wherein the thickness of the transition layer is more than 3mm; lastly, using a D212 electrode for covering and polishing the surplus height of the welding joint and welding toe, wherein the surplus height of the welding joint is not more than 3mm. Preheating before welding is not required, heat insulation after welding is not required, the welding technique is simple and the cost is low. The toughness of an NM400 wear-resisting steel welding joint is improved and the integration of the strength, toughness and wear-resistance of the joint is realized.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

Double-phase stainless steel electric welding bar

InactiveCN101817123AHigh strengthGood formabilityWelding/cutting media/materialsSoldering mediaArc stabilityElectrolysis

The invention discloses a double-phase stainless steel electric welding bar, and relates to the stainless steel electric welding field of electric arc welding. The invention provides a novel titanium-calcium type double-phase stainless steel electric welding bar, which has good welding performance such as little splash, low cost, good slag removal performance and the like. The electric welding bar is characterized in that: according to the coating formula, the electric welding bar comprises the following components in part by weight: 35 to 38 parts of rutile, 8 to 10 parts of natural mica, 1 to 2 parts of potassium titanate, 5 to 7 parts of marble, 10 to 12 parts of iron powder, 1 to 2 parts of bentonite, 2 to 3 parts of electrolytic manganese, 3 to 5 parts of fluorite, 1 to 2 parts of potassium feldspar, 1 to 2 parts of sodium alginate, 2 to 3 parts of chromium nitride, 20 to 24 parts of chromium metal, 8 to 10 parts of ferromolybdenum, 2 to 4 parts of magnesite, 2 to 4 parts of nickel powder and 1 part of Teflon. The welding process performance of the stainless steel welding bar is improved, and particularly the application range of the stainless steel welding bar is enlarged during welding, so the double-phase stainless steel electric welding bar has good welding performance such as good electric arc stability, little splash, low cost, good slag removal performance and the like.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

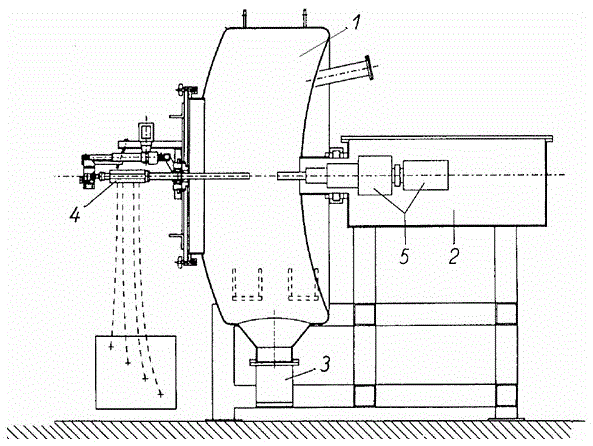

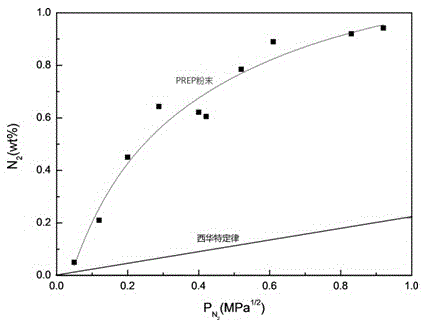

Preparation method of high-nitrogen stainless steel spherical powder

InactiveCN105618776AEnhance nitrogen increase rateIncrease powder nitrogen contentStainless steel electrodeMetal impurities

The invention provides a preparation method of high-nitrogen stainless steel spherical powder. The preparation method comprises the following steps: preparing materials according to stainless steel components and carrying out a melting process of a mother alloy ingot; preparing the mother alloy ingot into a common stainless steel electrode bar through forging and machining; carrying out pre-vacuumizing treatment on atomization equipment and introducing high-purity nitrogen gas; conveying the electrode bar into an atomization chamber through a feeding system and heating the end face of the electrode bar by using a plasma torch; ionizing the nitrogen gas in an electric arc region into nitrogen ions, high-energy nitrogen molecules and un-ionized nitrogen neutral atoms so as to improve the nitrogen content of stainless steel; preparing metal liquid drops by using a centrifugal effect of a rotary electrode and instantly condensing the metal liquid drops into spherical metal powder; after cooling the high-nitrogen stainless steel spherical powder, removing non-metal impurities through an electrostatic impurity removing device; and finally, carrying out powder package by adopting multilayered vacuum heat sealing. The preparation method of the high-nitrogen stainless steel spherical powder has the characteristics of high production efficiency, strong batch stability, high fine powder yield and the like; and the stainless steel spherical powder with high nitrogen content, good purity, strong mobility and smooth and clean surface can be easily prepared.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

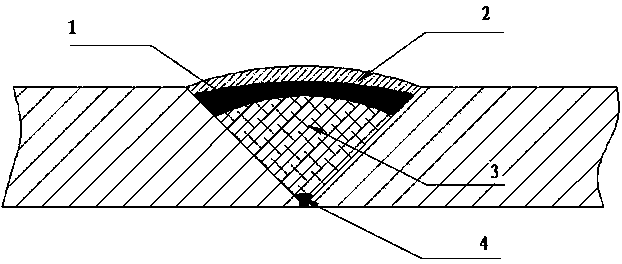

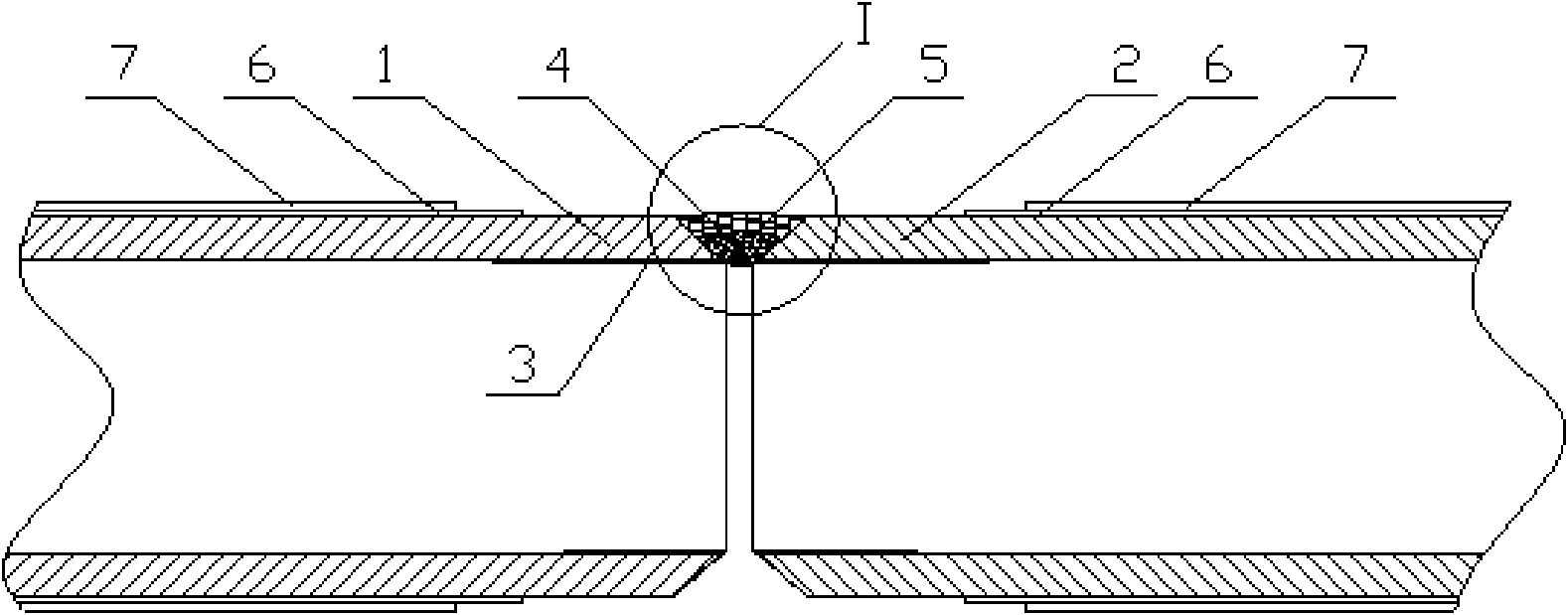

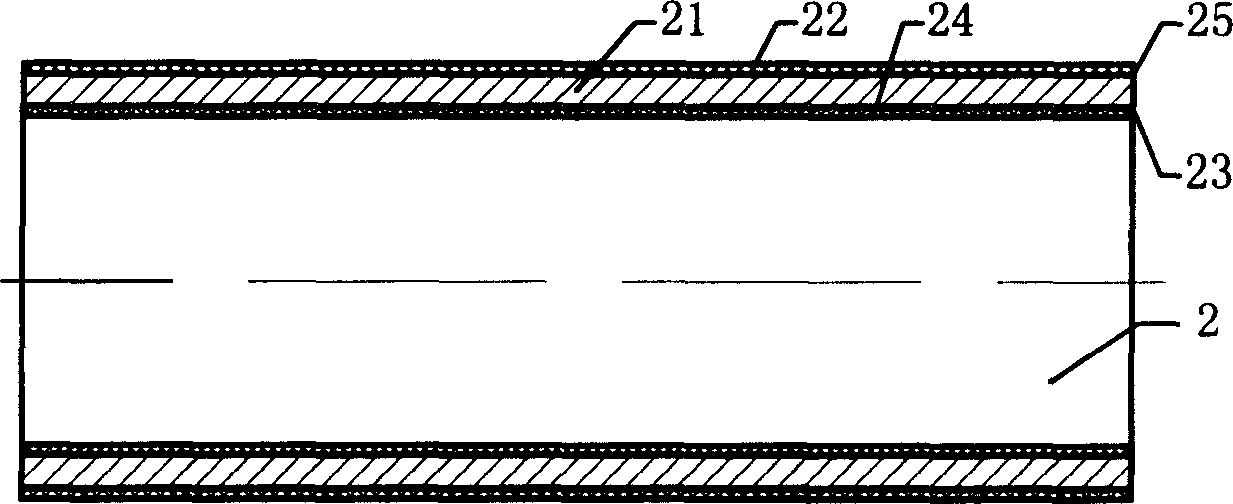

Method for welding circumferential weld between metal thin-wall clad layer and base layer of clad pipe

InactiveCN101927390AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsStainless steel electrodeUltimate tensile strength

The invention provides a method for welding circumferential weld between a metal thin-wall clad layer and a base layer of a clad pipe, which is used for welding circumferential weld of dual-metal clad steel pipes. The method is characterized by (A) groove processing: cleaning oil stains on the groove; (B) carrying out surfacing on the truncated edge, close to the clad layer, of the groove and coping the groove; (C) fitting up the groove of the dual-metal clad pipe; (D) root backing weld: adopting the gas tungsten arc welding method and carrying out welding along the groove of the dual-metal clad pipe under the state of argon-filled protection inside the pipe; (E) carrying out second layer welding on the root backing weld and welding the welding base layer of the dual-metal clad pipe; and (F) filled welding and cosmetic welding: wherein the welding materials are stainless steel electrodes. The method has the following effects: adopting 309 or 309Mo welding materials, thus ensuring the strength and good toughness of the weld; eliminating the gaps which probably exist between the clad layer and the base layer at the end of the groove; and increasing the effective thickness of the stainless steel layer at the groove root so that the quality of the welding joints are insensitive to misalignment, thus ensuring the corrosion resistance.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

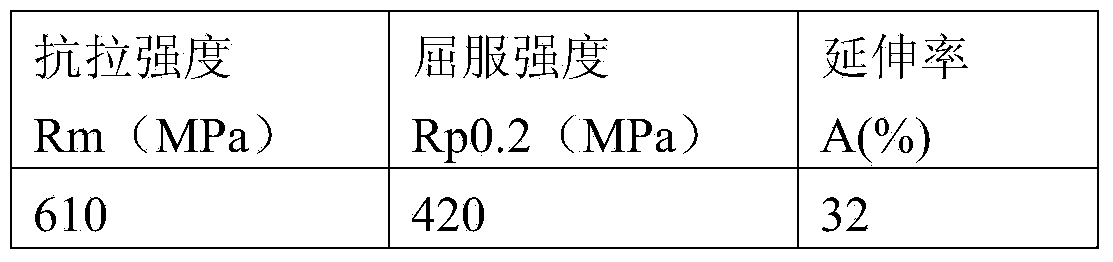

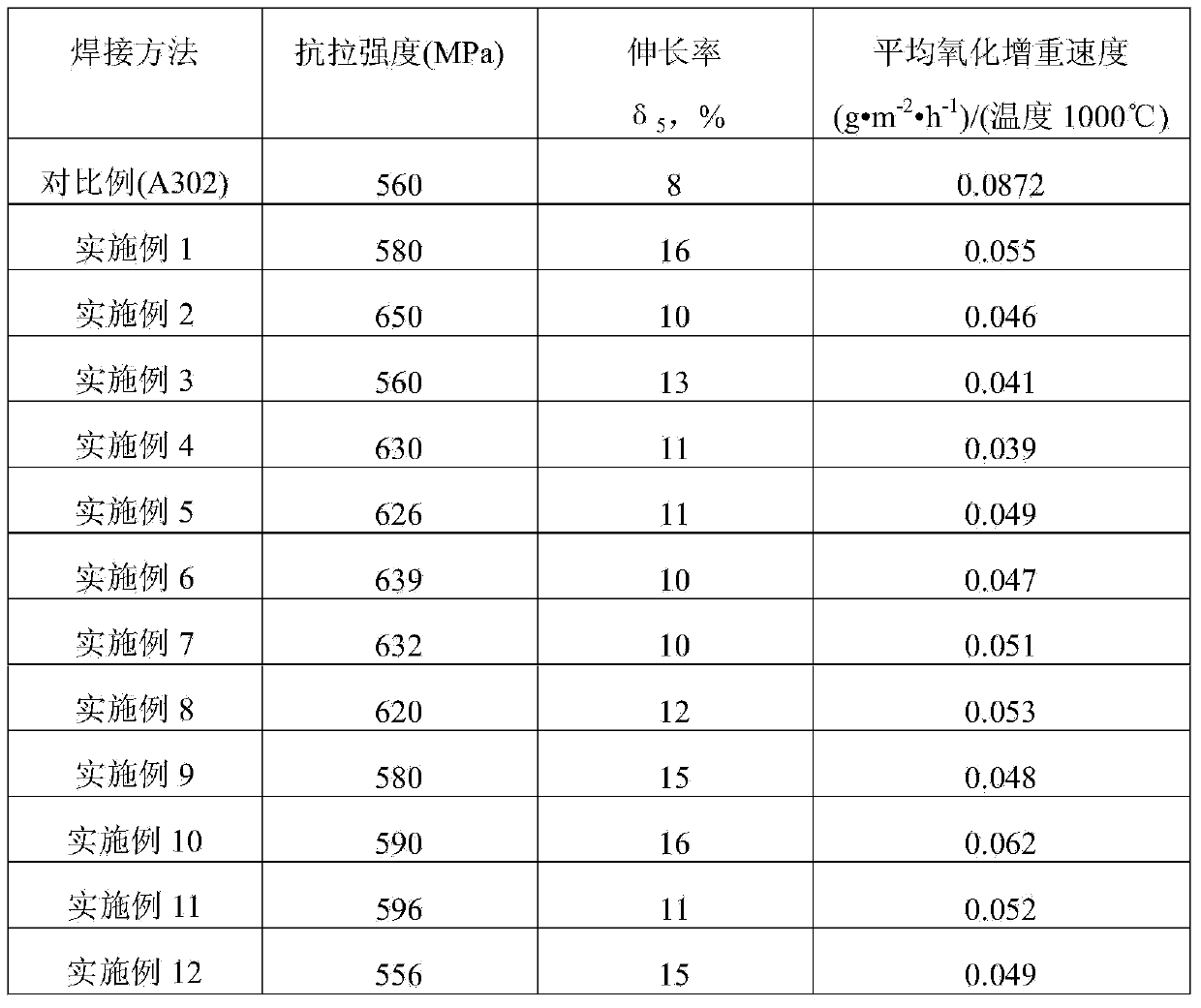

Special stainless steel electrode for deep refrigerating project

The invention relates to a special stainless steel electrode for a deep refrigerating project, belonging to the field of welding material; the special stainless steel electrode is formed by mixing the following powered raw materials b weight parts: 38-46 parts of rutile, 12-15 parts of marble, 1-3 parts of titanium pigment, 1-3 parts of quartz, 4-6 parts of mica, 4-6 parts of silicon iron, 2-4 parts of ferrotitanium, 6-8 parts of electrolytic manganese, 3-5 parts of chromium metal, 1-3 parts of calcium solvent, 1-3 pars of sodium carbonate, 4-7 parts of cryolite, 6-8n parts of feldspar, and potassium sodium water glass with 2 percent of total weight of powered materials; the mixture is stirred uniformly and is press-coated on a stainless steel core wire to form a stainless steel electrode. The ferrite content in weld metal is suitable, ferrite number FN of the weld metal is 6-8; the weld metal has good minus 196 DEG C low temperature impact property, the average value of the V-shaped impact work of the weld metal at below 196 DEG C is 45j, thereby completely meeting engineering needs.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Stainless steel welding rod of new dregs series

InactiveCN1958213AReduce slag viscosityImprove conductivityWelding/cutting media/materialsSoldering mediaArc stabilitySlag

A welding stainless steel electrode with improved slag detachability and welding quality is composed of a core and a coated flux layer prepared proportionally from rutile, feldspar, marble, fluorite, wollastonite, megnesite, titaniunm oxide powder, hematite, aluminum fluoride, mice, barium carbonate, Cr, Ni, sodium carbonate, electrolytic manganese and ferrotitanium.

Owner:HARBIN UNIV OF SCI & TECH

Device and method for detecting porosity of saturated soil

InactiveCN103091226AEasy to operateSimple methodPermeability/surface area analysisPorositySoil properties

The invention discloses a measurement device for detecting the porosity of saturated soil and an application method of the device. The measurement device comprises a cutting ring, a stainless steel electrode, a cutting ring, an organic glass box and an impedance tester. When the impedance of a soil sample is measured, the cutting ring is selected according to the property of the soil sample; the stainless steel electrode is connected with the impedance tester through a connecting wire; when the impedance of pore water is measured, the organic glass box is selected and the stainless steel electrode is connected with the impedance tester through the connecting wire; and a frequency selector and an electric level adjuster are connected with a computer through the impedance tester. The device disclosed by the invention can be used for collecting the soil sample, preparing the saturated soil sample, setting electric signal frequency and impedance testing voltage and determining the resistivity of the saturated soil and pore water; and soil properties and cementation factors are selected according to the property of the soil sample and the porosity is obtained by the computer. The measurement device disclosed by the invention has the characteristics of simplicity and feasibility, low cost, short measurement period, accurate result and the like; expensive equipment is not needed and an operation method is simple; and the measurement device can be operated in a laboratory or a filed and the practical applicability is very high.

Owner:TAIYUAN UNIV OF TECH

Industrial production method of chromium-free white cast iron with high wear resistance

The invention discloses an industrial production method of a chromium-free white cast iron with high wear resistance. The method comprises the following steps: the content of each component in the cast iron are (mass percent %): 2.8 to 3.1 of C, 0.8 to 1.4 of Si, 0.5 to 0.8 of Mn, 0.9 to 1.1 of Cu, 0.6 to 0.8 of Mo, 0.3 to 0.5 of V, 0.18 to 0.22 of B and the balance of Fe; the amounts of a modifier added in every 100 unit mass of the cast iron are: 0.6 to 1.0 of Re, 0.1 to 0.3 of Al, 0.1 to 0.3 of Nb and 0.1 of N; the raw materials for cast iron are added into a medium frequency induction furnace for melting, (bauxite is employed for producing crucible), the chromium-free cast iron is prepared, the modifier is added at the bottom of a ladle according to a proportion when the cast iron is casted; the obtained chromium-free cast iron is performed by a heat treatment, the chromium-free white cast iron with high wear resistance can be obtained; according to the method, the chromium element which is the cheapest can be removed, the performance of the obtained cast iron material of the invention can be reached to a performance of a high chromium cast iron through a heat treatment. A common stainless steel welding rod is employed for repair welding, so that the material cost is greatly reduced, and chromium-free white cast iron with high wear resistance is convenient for industrialized production.

Owner:CHANGCHUN UNIV OF TECH

Stainless steel electrode special for magnesium reduction pot

ActiveCN101362260ANot prone to redness and crackingLow costWelding/cutting media/materialsSoldering mediaCrack resistanceFerrosilicon

The invention relates to a stainless steel welding rod specially used for the reduction pot in the magnesium industry, which belongs to the field of welding material. The welding rod is formed by mixing the following powder raw materials, adding 2.8M and 48 degree Be potassium sodium water glass which is 25 percent of the total weight of the powder raw materials, and uniformly stirring and coating the materials on the stainless steel core welding-wire through extrusion: according to the part by weight, the powder raw materials comprise 43-52 parts of marble, 16-23 parts of fluorspar, 1-3 parts of white titanium pigment, 1-3 parts of quartz, 1-3 parts of mica, 4-6 parts of ferrosilicon, 3-5 parts of ferrotitanium, 4-6 parts of ferromanganese, 8-12 parts of ferrochrome, 1-3 parts of calcium solvent, 1-3 parts of soda ash, and 8-12 parts of nitrided ferro-chromium; according to the mass percent, the core welding-wire comprises the following chemical compositions: smaller than or equal to 0.15 of C, smaller than or equal to 0.35 of Si, 1.0-2.5 of Mn, smaller than or equal to 0.03 of P, smaller than or equal to 0.015 of S, 8.0-10.0 of Ni, 25.0-28.0 of Cr, smaller than or equal to 0.75 of Mo, smaller than or equal to 0.75 of Cu, and residue of Fe. The welding rod has strong oxidation resistance, sulfidation resistance and corrosion resistance, good crack resistance, high welding efficiency, large electric arc blowing force, and good welding performance; during the welding, the electrode coating is uneasy to turn red and crack, the rest part of the welding rod is short, the slag release is easy in a deep and narrow groove, special equipment is not required, and the cost is low.

Owner:BEIJING JINWEI WELDING MATERIAL

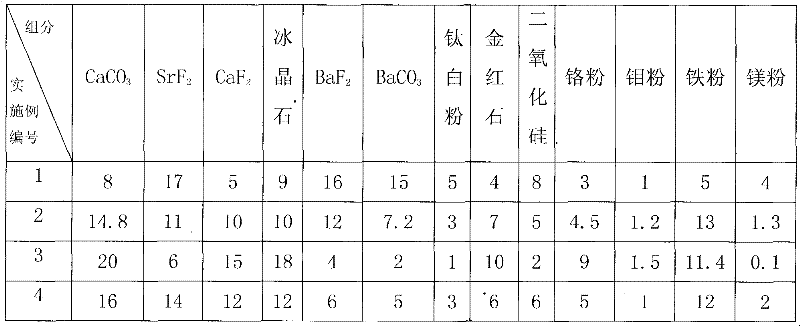

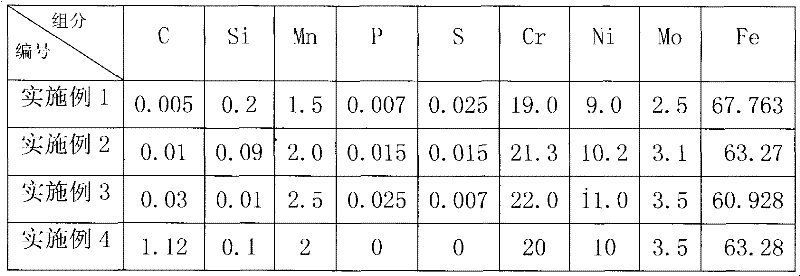

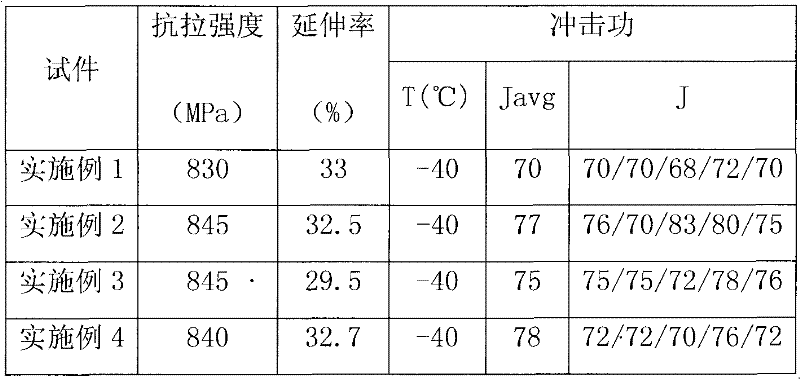

Two-phase stainless steel electrode

ActiveCN102233489AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaSlagWeld seam

The invention discloses a two-phase stainless steel electrode, which comprises a core wire and a coating, wherein the coating is coated on the outer wall of the core wire and accounts for 0.4 to 0.5 percent of the total weight of the electrode. The core wire comprises the following components in percentage by weight: 0.005 to 0.030 percent of C, 0.01 to 0.20 percent of Si, 1.50 to 2.50 percent ofMn, 0 to 0.025 percent of P, 19.0 to 22.0 percent of Cr, 9.0 to 11.0 percent of Ni, 2.5 to 3.5 percent of Mo and the balance of Fe. The coating comprises the following components in percentage by weight: 8 to 20 percent of calcium carbonate, 2 to 15 percent of barium carbonate, 5 to 15 percent of calcium fluoride, 6 to 17 percent of strontium fluoride, 4 to 16 percent of barium fluoride, 9 to 18 percent of cryolite, 4 to 10 percent of rutile, 1 to 5 percent of titanium white, 2 to 8 percent of silicon dioxide, 3 to 9 percent of chromium powder, 1 to 1.5 percent of molybdenum powder, 0.1 to 4 percent of magnesium powder and 5 to 13 percent of iron powder. After the coating components are uniformly mixed, an adhesion agent is added into the mixture. The two-phase stainless steel electrode has high strength, high tenacity and intercrystalline corrosion resistance; and during welding, an electric arc is stable, splashing phenomena is reduced, a welding seam is well molded, slag is easy toremove, and the electrode has high operability.

Owner:KUSN GINTUNE WELDING

Stainless welding rod used for underwater wet welding

ActiveCN103084759AGood deoxygenationPromote alloyingWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention discloses a high-intensity stainless welding rod used for underwater wet welding. The stainless welding rod used for underwater wet welding comprises two parts including a covering and a core wire and is characterized in that the core wire is 304L stainless steel and the covering is composed by rutile, feldspar, dolomite, carboxymethyl cellulose, manganese powder, silicon iron and nickel powder. The covering comprises, by weight, 40%-52% of rutile, 20%-30% of feldspar, 5%-10% of dolomite, 5%-10% of carboxymethyl cellulose, 5%-9% of manganese powder, 1%-4% of silicon iron and 0%-5% of nickel powder. The high-performance rod used for underwater wet welding is simple in preparation procedure, simple in arc starting in welding, stable in electric arc combustion, good in arc restarting capacity, and beautiful in shape of a gained welding joint. The strength of extension of a butt joint can reach 530 Mpa. When the cold bend angle of the butt joint is 180 degrees, the butt joint is still in good condition and no fissures occur. The stainless welding rod used for underwater wet welding has the advantages of being simple and simple in process, convenient to test and operate, high in production efficiency and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

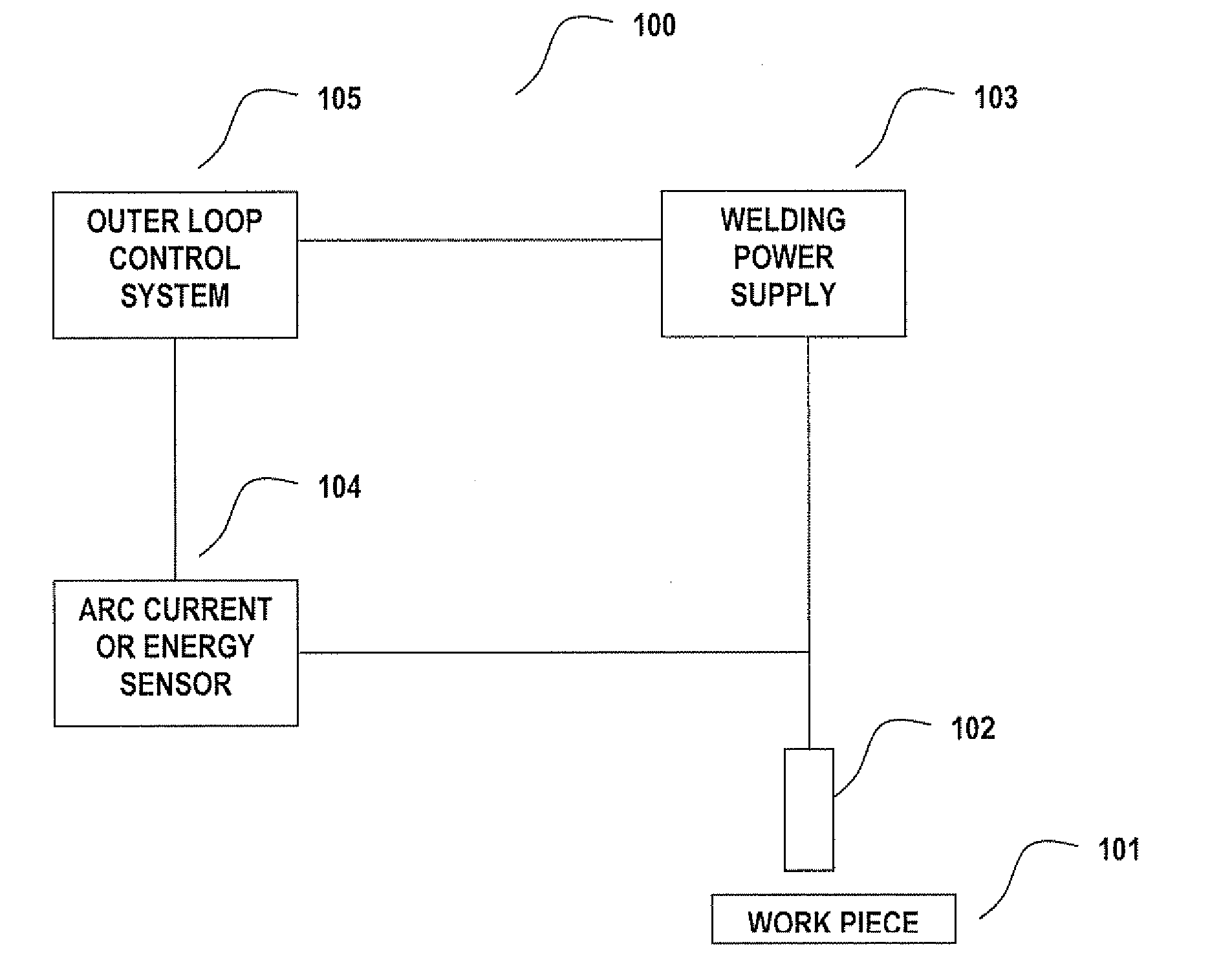

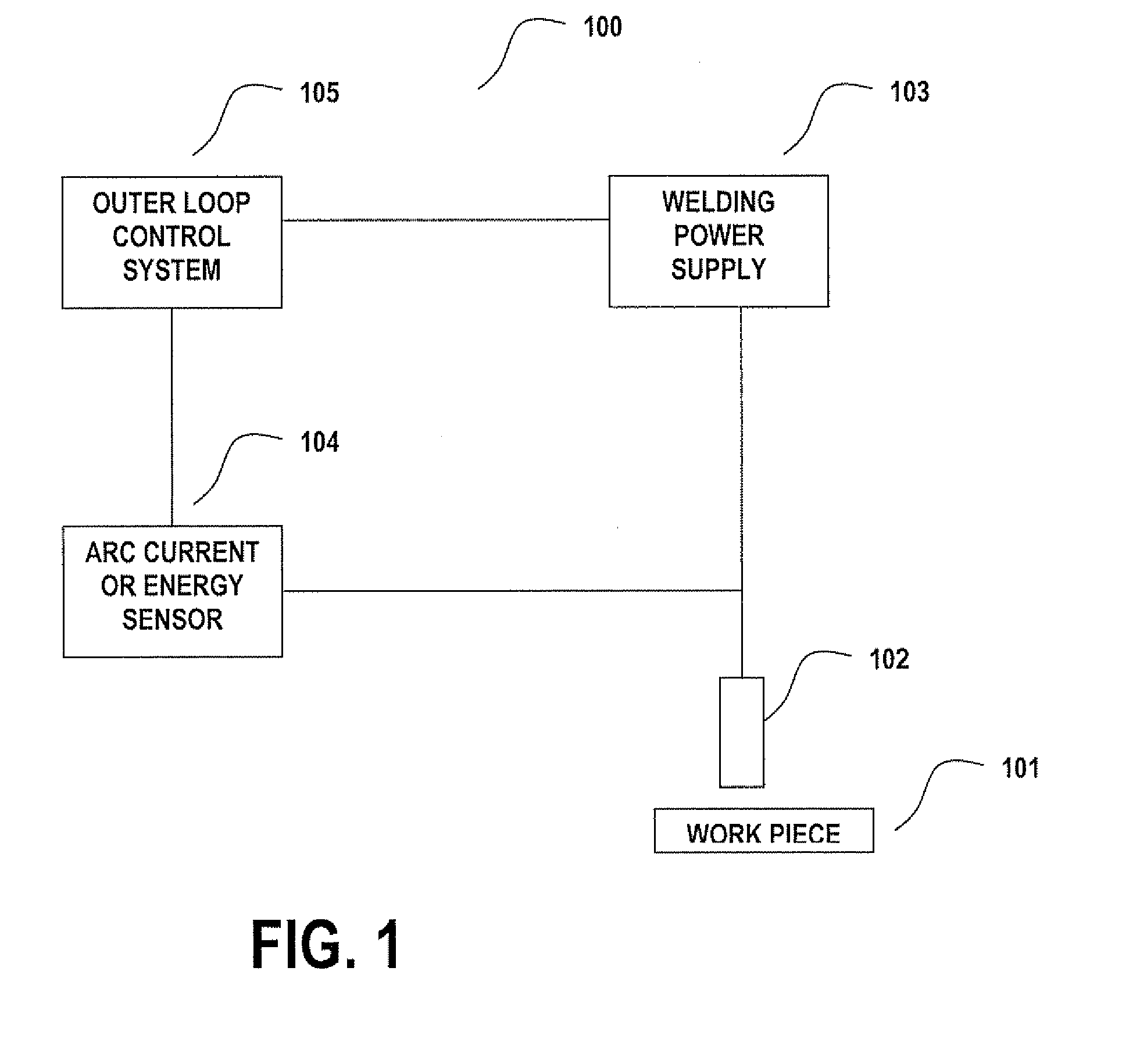

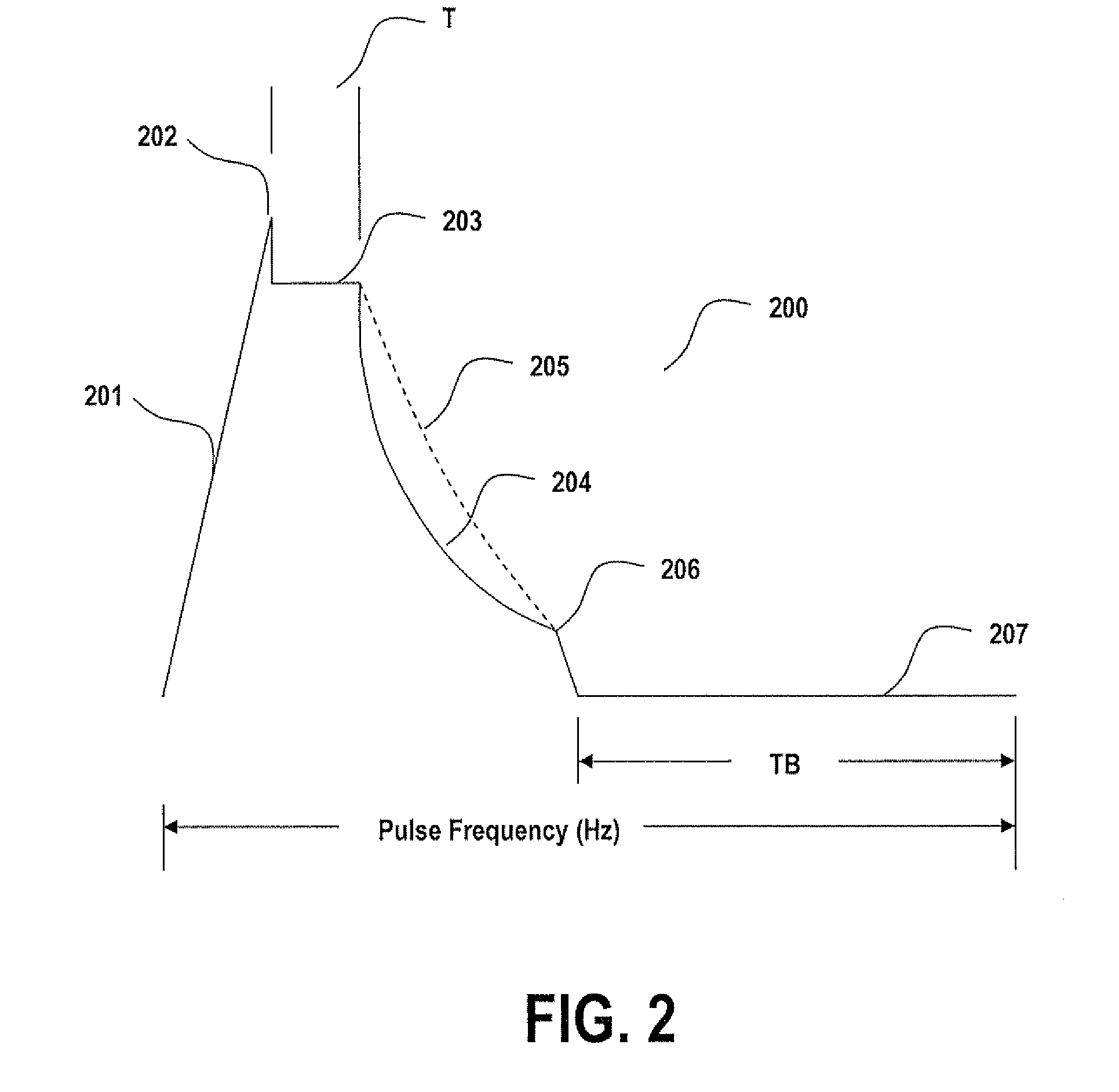

Outer-loop control for use with nickel and duplex stainless steel filler alloys and carbon dioxide containing shielding gas

A method of welding with high nickel content and duplex stainless steel electrodes using adaptive outer loop control to change at least one of a peak current or pulse frequency of a pulse waveform used for welding. The pulse waveform is changed based on a detected change in contact tip to work distance between the electrode and the work piece. The arc generated between the work piece and the electrode is shielded by a shielding gas which contains carbon dioxide and an inert gas.

Owner:LINCOLN GLOBAL INC

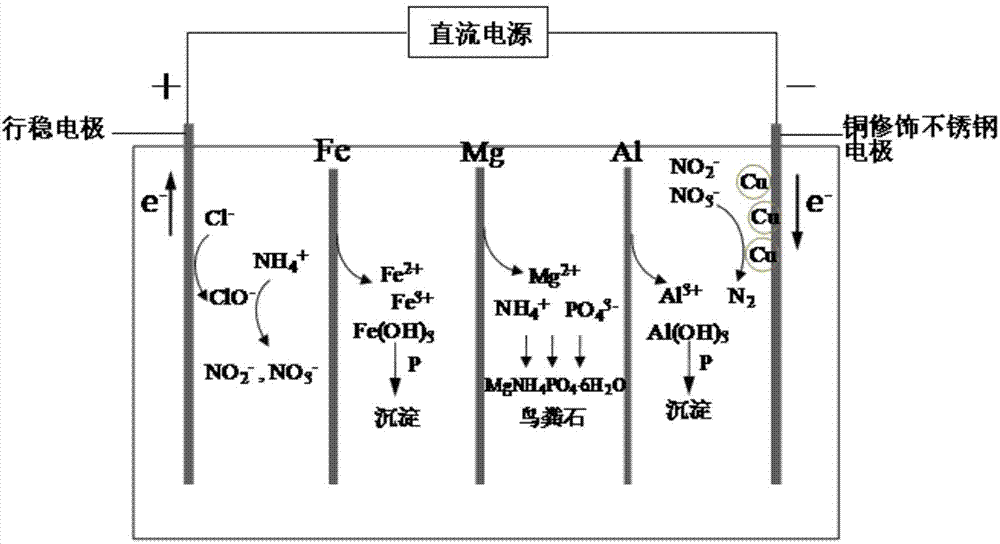

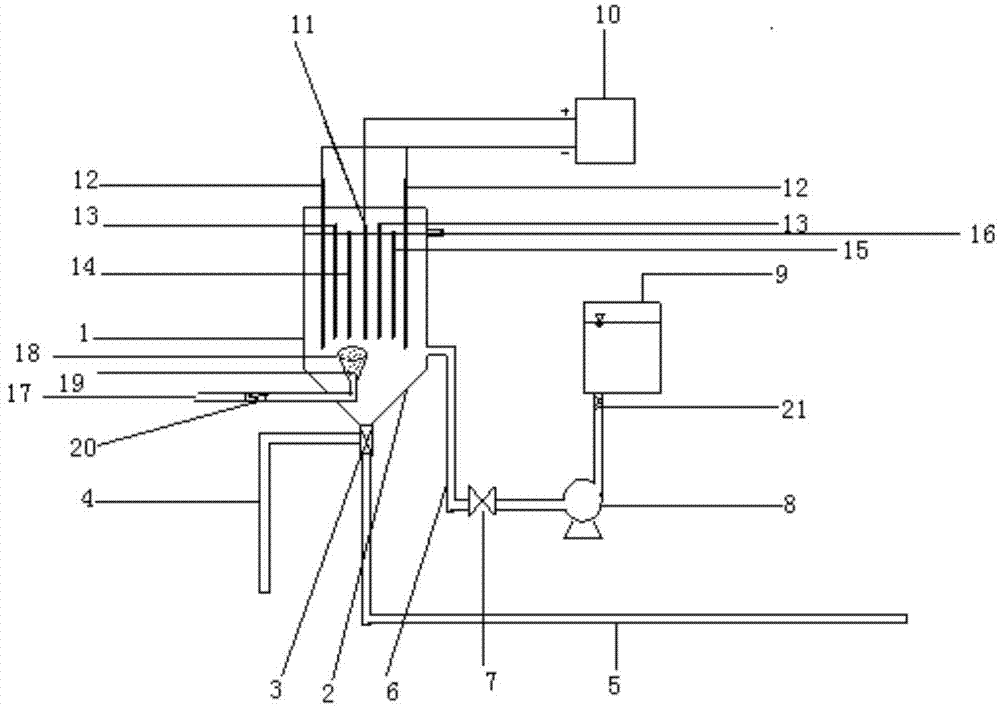

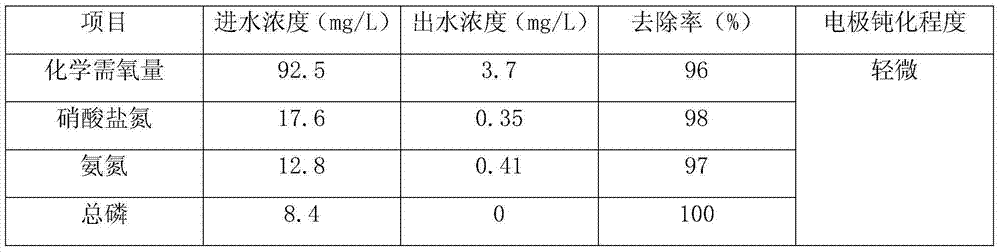

Electrochemical synchronous nitrogen and phosphorus removal apparatus and municipal sewage treatment method

InactiveCN103936106ASimple structureEasy to operateWater/sewage treatment using germicide/oligodynamic-processChemical oxygen demandMaterial resources

The invention discloses an electrochemical synchronous nitrogen and phosphorus removal apparatus and a municipal sewage treatment method, and belongs to the technical field of sewage treatment. A dimensionally stable electrode, an iron electrode, an aluminum electrode, a magnesium electrode and a copper modified stainless steel electrode which are commonly used in an electrochemical water treatment technology are combined to realize the nitrogen and phosphorus removal treatment of the municipal sewage in a same electrolytic cell. The apparatus has the advantages of simple structure, operation convenience, high efficiency, stable indexes of discharged water, and realization of the large-scale automatic sewage treatment. The municipal sewage method has the advantages of simple technology, operation convenience, manpower and material resource saving, low energy consumption, high removal rate of sewage pollution indexes, and realization of the removal rate of each of the municipal sewage indexes comprising the chemical oxygen demand, nitrate nitrogen, ammonia nitrogen and total phosphorus to reach above 92%.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

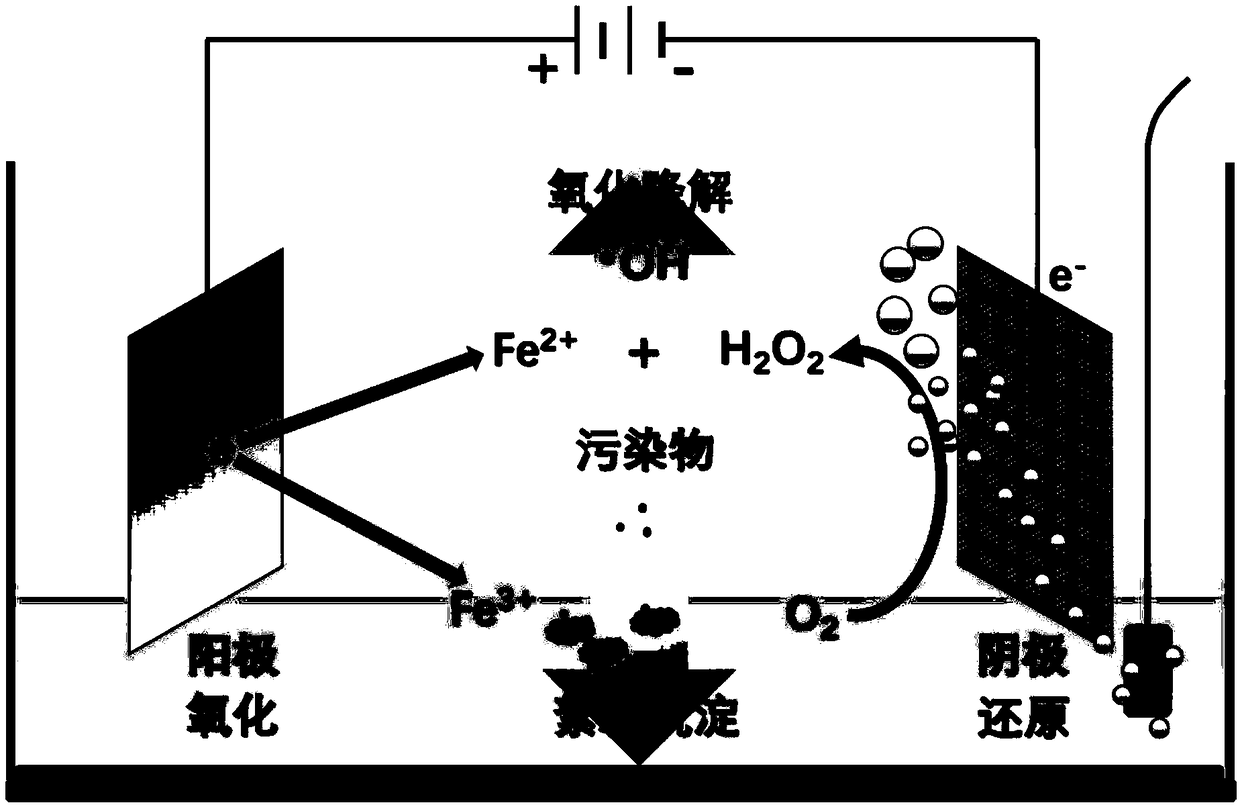

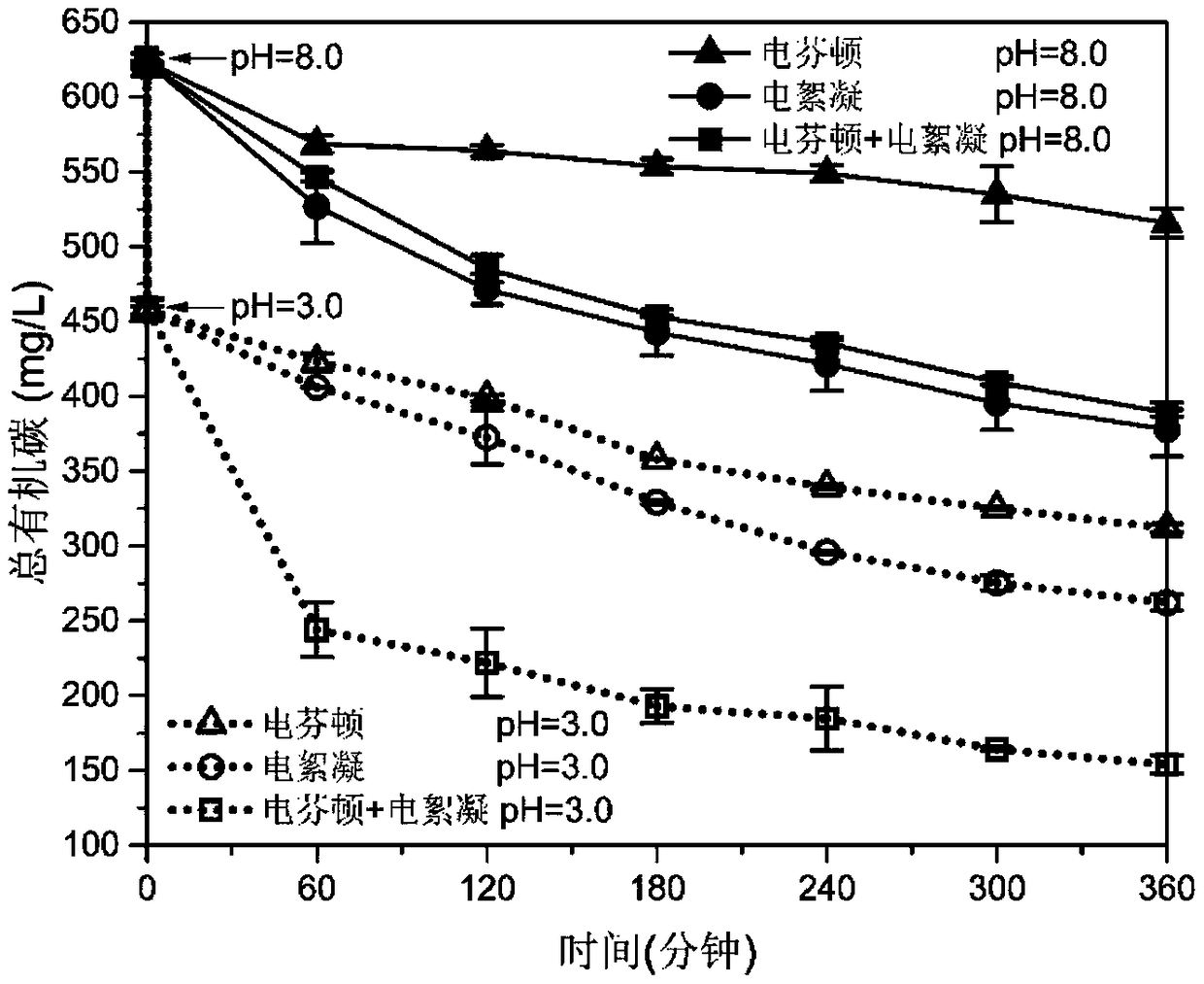

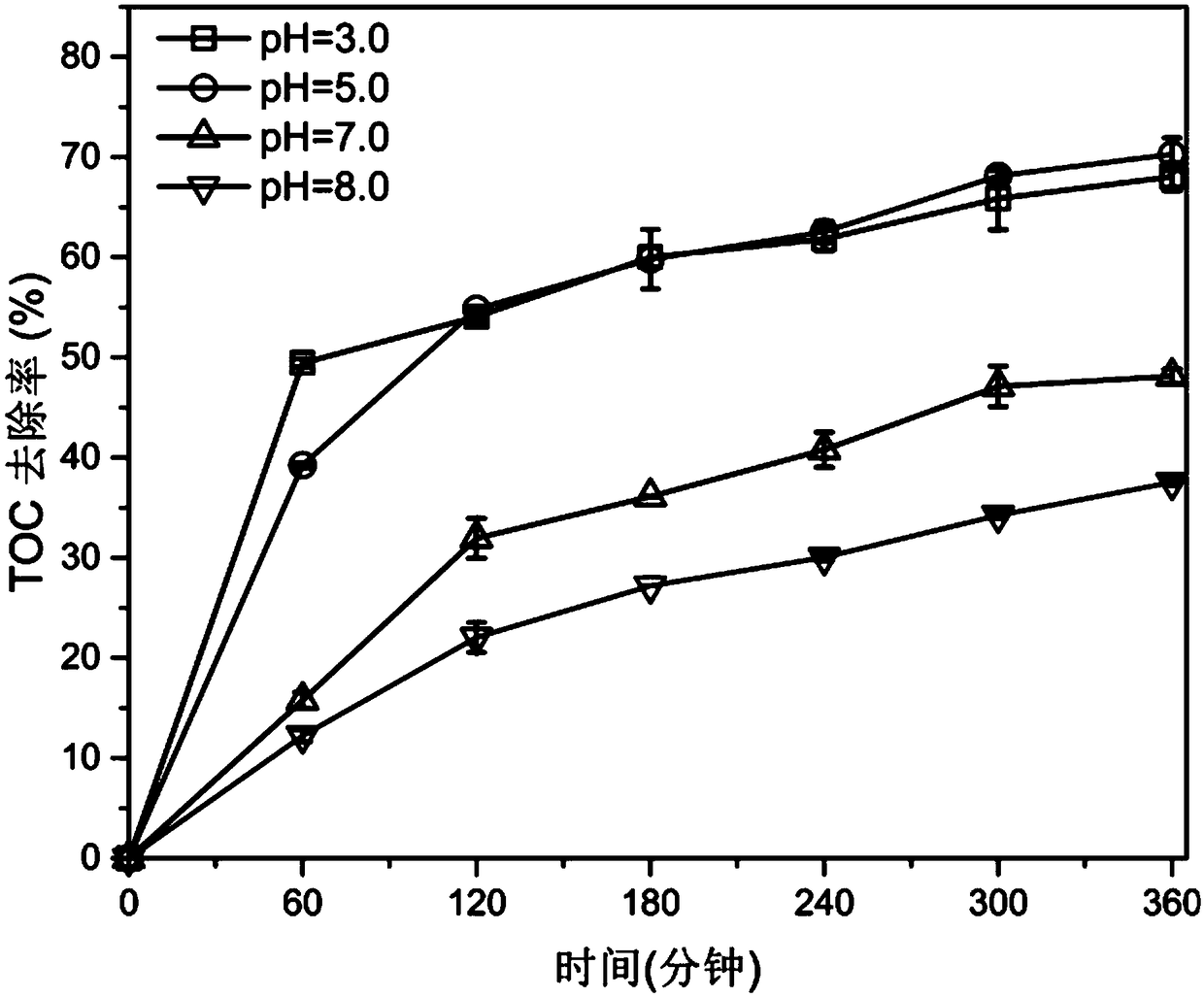

Method for treating landfill leachate on basis of electro-Fenton and electroflocculation coupling

InactiveCN108928892AAvoid transportAvoid dangerWater treatment compoundsWater/sewage treatment by oxidationCarbon fibersElectron

The invention relates to a method for treating landfill leachate on the basis of electro-Fenton and electroflocculation coupling. According to the method, ferrum or a stainless-steel electrode servesas an anode, carbon fibers or modified carbon fibers serve as a cathode, dissolved oxygen is subjected to a two-electron oxygen reduction reaction on the surface of the cathode so as to produce hydrogen peroxide, and the produced hydrogen peroxide and Fe(II) produced by the anode are subjected to a catalyzed reaction so as to produce a strong oxidant hydroxyl free radical; and anode-produced and ferrous-oxidated-produced Fe(III) is subjected to a series of hydrolysis and polymerization processes so as to form a variety of hydroxyl complexes and hydroxides, and thus, colloidal impurities, suspending impurities and heavy-metal ions in the landfill leachate are subjected to flocculating settling and are separated. According to the method, hydrogen peroxide is produced in situ, the risk generated during the transportation, storage and use of the hydrogen peroxide is avoided, the treatment process is clean, and hydrogen peroxide and a flocculant are not required to be externally and continuously added. According to the method, electroflocculation and electro-Fenton technologies are combined, electrode materials are cheap and readily available, the preparation method is simple, the treatment cycle is short, and refractory organic matters and heavy-metal ions can be effectively removed from the landfill leachate.

Owner:TSINGHUA UNIV

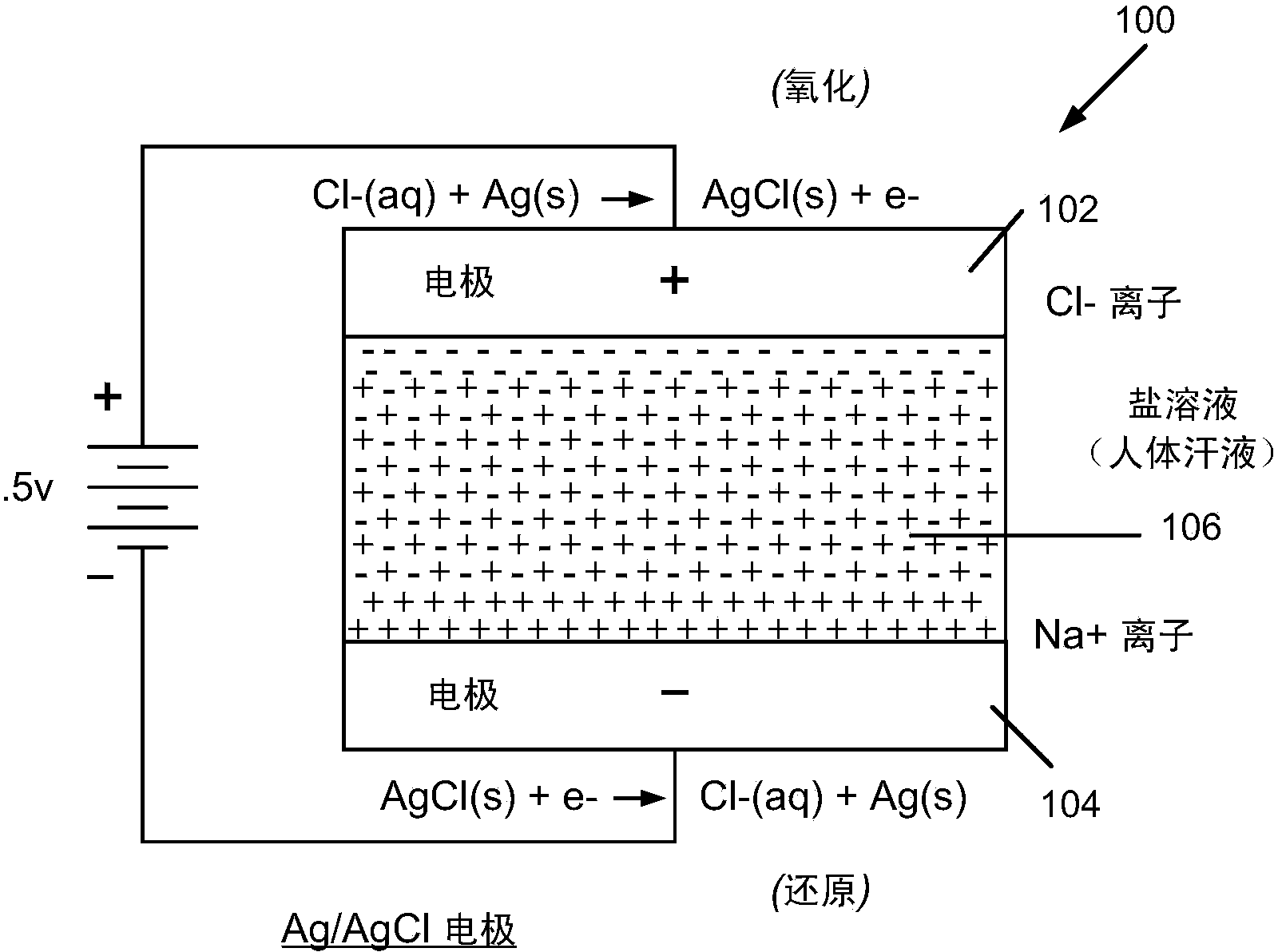

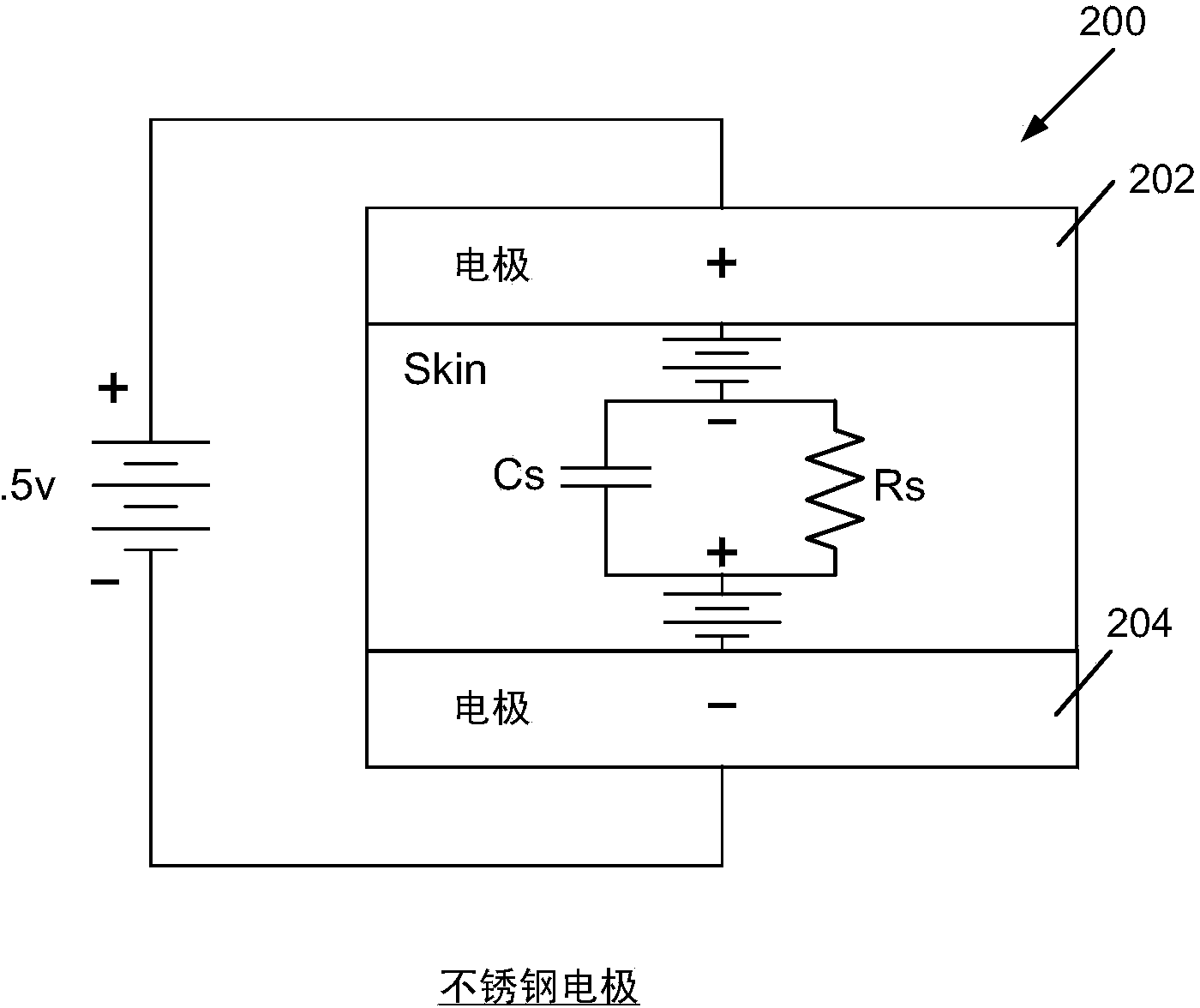

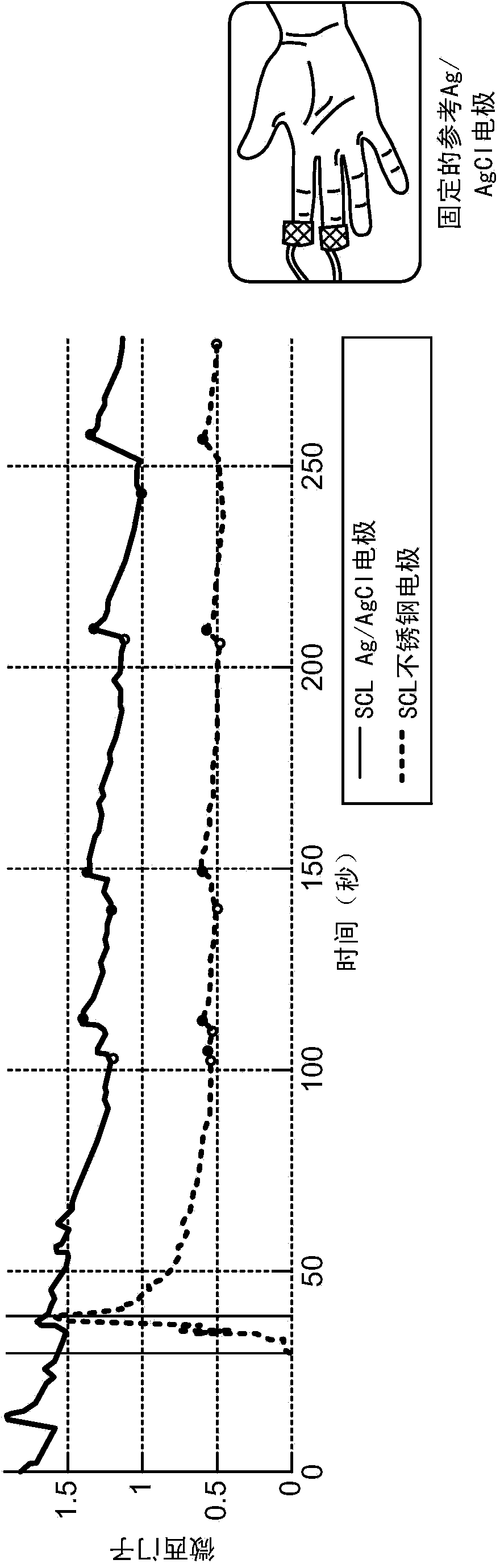

Methods and devices for acquiring electrodermal activity

Handheld devices using an array of stainless steel electrodes located on an edge and / or back of the handheld devices for acquiring electrodermal activity are provided. The stainless steel electrode array may allow for the skin conductance level (SCL) or skin conductance response (SCR) on an individual to be measured and collected. The skin conductance signal may be related to sympathetic nervous system activity which is a major component of human emotion, known as arousal, or emotional intensity such as anxiety, stress, fear, or excited, etc.

Owner:QUALCOMM INC

Stainless steel electrode

InactiveCN102554510AStable physical and chemical propertiesImprove pass rateWelding/cutting media/materialsSoldering mediaElectrolysisManganese

A stainless steel electrode belongs to the field of welding materials, and is characterized in that chemical components of the electrode (in weight percent) include 40% of rutile, 8% of potassium feldspar, 3% of iron ores, 1.8% of potassium titanate, 1.8% of titanium white powder, 1.8% of metal chromium, 2.4% of fluorite (dried), 2.4% of cryolite, 8% of electrolytic manganese, 0.18% of bismuth oxide, 12% of micro-carbon ferrochromium, 7% of mica (dried), 1.5% of alginate calcium, 0.4% of ferroaluminium and 9.72% of marble. Compared with the prior art, the stainless steel electrode can generate arc, can also be melted to form filler metal for a welding line, and is high in corrosion resistance, and physical and chemical performances of deposited metal are stable.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

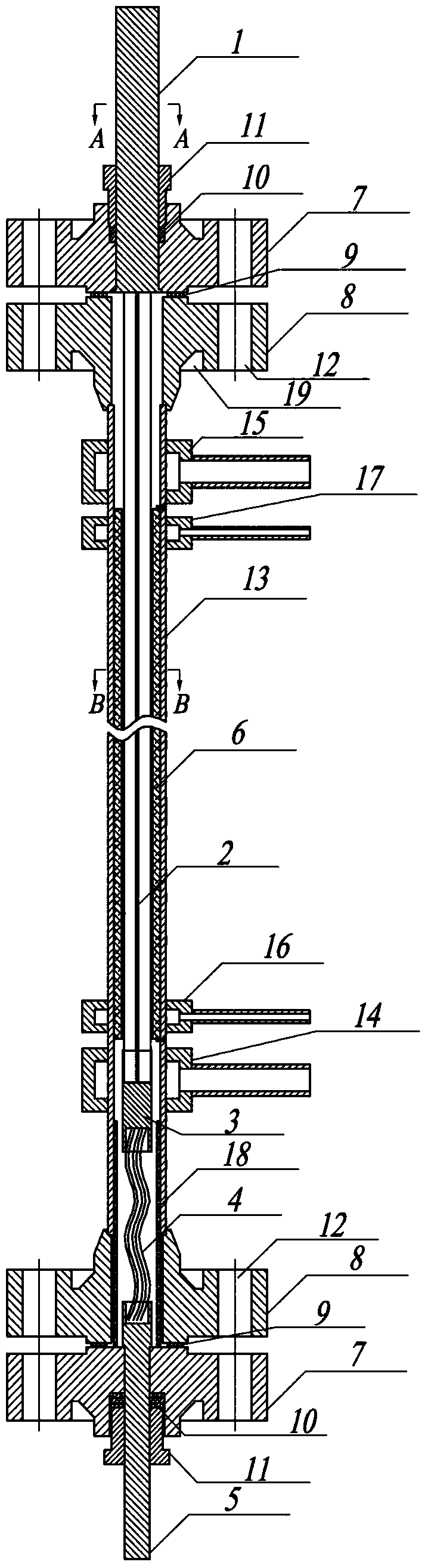

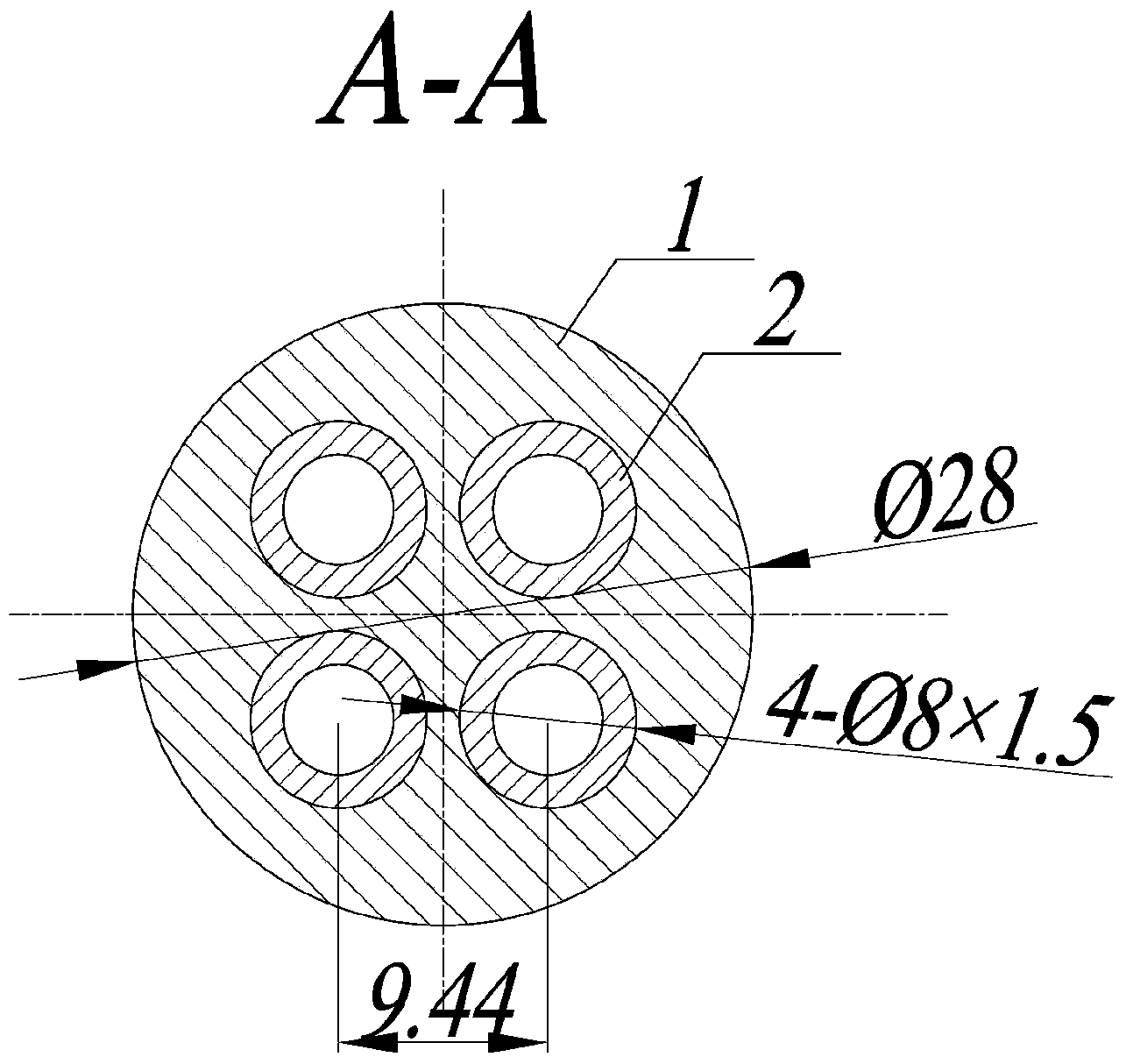

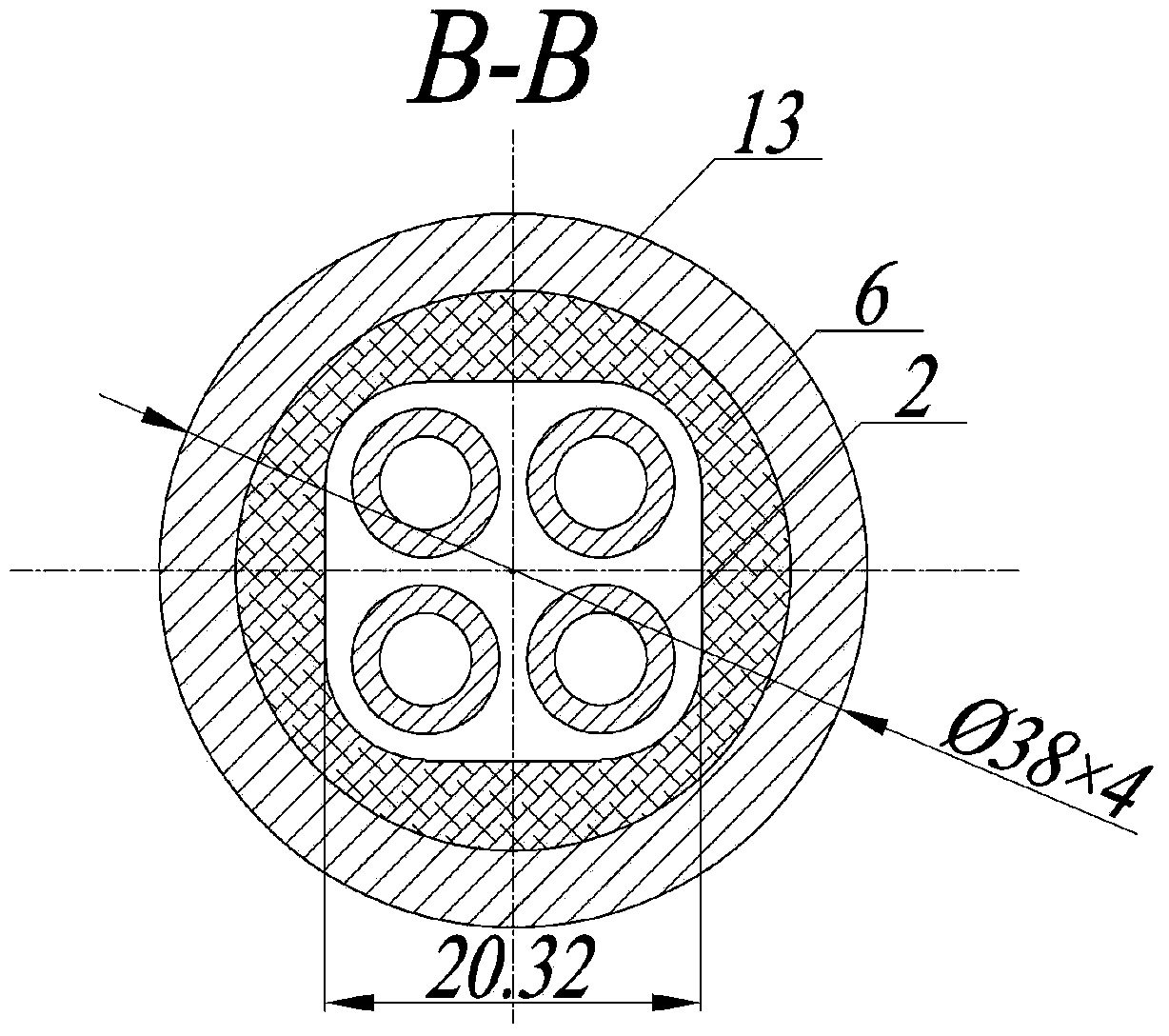

Rod bundle test piece for simulating supercritical water-cooled reactor fuel element

ActiveCN104078087AReasonable structureEasy to processNuclear energy generationNuclear monitoringTransformerCopper electrode

The invention discloses a rod bundle test piece for simulating a supercritical water-cooled reactor fuel element. The rod bundle test piece comprises a sealings insulation piece, a ceramic lining pipe and a heating pipe, wherein the heating pipe is electrified to be heated to simulate fission heat of the fuel element, so that the relevant thermotechnical-hydraulic characteristic research is carried out; the sealing insulation piece consists of a top high-pressure sealing flange, a sealing insulation pad, a middle stainless steel outer pipe and a bottom high-pressure sealing flange; the stainless steel pipe is welded with the flanges; the ceramic lining pipe is circular in outer part and square in inner part; four fillets are formed in an internal square structure; the middle part of the heating pipe consists of four stainless steel pipes; a stainless steel electrode and a copper electrode are respectively arranged on the top and at the bottom of the heating pipe and are communicated with an alternating current transformer to heat the heating pipe through alternating current; the heating pipe is inserted into the ceramic lining pipe; a clearance between the heating pipe and the ceramic lining pipe is a flowing channel; fluid flows in the channel to bring away heat of the heating pipe; the sealing insulation piece is arranged on the outer layer of the ceramic layer and serves as a pressure boundary, so that sealing and electric insulation effects under conditions of high temperature and high pressure are achieved.

Owner:XI AN JIAOTONG UNIV

Stainless steel welding rod used for 904 L steel welding

ActiveCN105537801AHigh purityImprove performanceWelding/cutting media/materialsWelding/soldering/cutting articlesElectrolysisCrack resistance

The invention discloses a stainless steel welding rod used for 904 L steel welding. The stainless steel welding rod comprises a welding core and a titanium-calcium type coating covering the outside of the welding core. The welding core comprises, by weight, 0%-0.02% of C, 1.50%-2.50% of Mn, 0%-0.30% of Si, 24.0%-26.0% of Ni and the like. The coating comprises, by weight, 30%-45% of rutile powder, 8%-15% of marble powder, 3%-10% of fluorite powder, 8%-12% of feldspar, 9%-12% of mica, 1.5%-3% of titanium dioxide, 0.5%-1.5% of fluoroaluminate, 3%-5% of electrolytic manganese and the like. According to the stainless steel welding rod used for 904 L steel welding, the electric arc stability and the liquidity of a molten pool are good, and slag shells of molten slag are uniformly covered; deslagging is easy; a formed welding seam is flat, and the welding seam crack resistance is good; the purity of the chemical composition of postwelding deposited metal is high, and the performance is superior.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Repair-proof welded connection technology of inner walls of plastic-coated steel tubes

The invention relates to the technical fields of metal surface anti-corrosion and pipe connection and discloses a repair-proof welded connection technology of the inner walls of plastic-coated steel tubes. The welded connection technology comprises the following steps: a. removing rust of the steel tubes; b. spraying metal coating at the ends of the steel tubes through thermal spraying; c. preparing thin-walled stainless steel jackets; d. installing the thin-walled stainless steel jackets in the steel tubes, performing tube expansion to ensure that the thin-walled stainless steel jackets are lined to the inner walls of the steel tubes; e. flanging the ends of the thin-walled stainless steel jackets according to the root shape of the steel tubes to form turnups; f. coating hierarchical coating on the outer walls of the steel tubes; g. transferring the steel tubes with the thin-walled stainless steel jackets to a site; h. welding the thin-walled stainless steel jackets by using stainless steel welding rods; i. welding the steel tubes by using carbon steel welding rods; j. repairing the hierarchical coating on the outer surface of the steel tubes and k. detecting. The invention avoids the repair of the inner wall of the steel tubes, eliminates corrosion blind spots, can not reduce the internal diameter of the steel tubes and flow rate and can greatly improve the installation efficiency of pipes.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

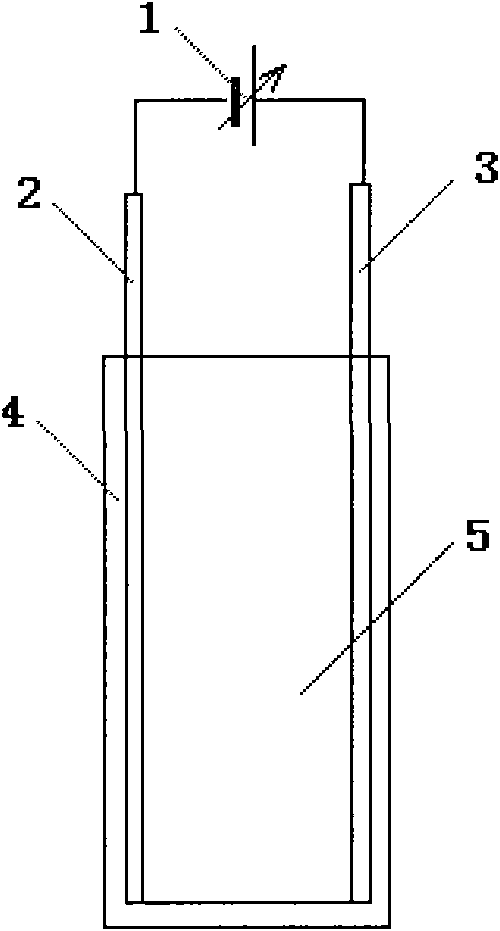

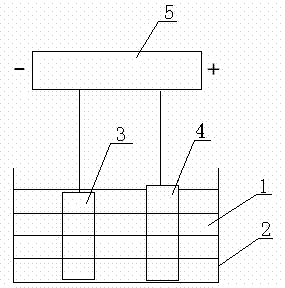

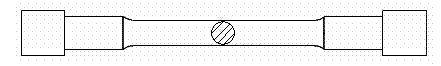

Device and method for detecting hydrogen embrittlement sensibility in high-strength steel surface treatment process

InactiveCN104502196ADetection of susceptibility to hydrogen embrittlementSolving problems with hydrogen embrittlement susceptibility testing methodsPreparing sample for investigationMaterial strength using tensile/compressive forcesStainless steel electrodeTest sample

The invention discloses a device and a method for detecting hydrogen embrittlement sensibility in a high-strength steel surface treatment process. The device comprises a high-strength steel hydrogen-charged test sample (3), an electrolyte tank (2) taking hydrochloric acid with concentration of 15-18% as an electrolyte (1), a stainless steel electrode (4), and a direct-current power supply (5) with adjustable voltage and time. The method comprises the following steps: charging hydrogen into the high-strength steel hydrogen-charged test sample by virtue of a hydrogen-charging device and by simulating a high-strength steel common surface treatment process, after the hydrogen-charging is completed, cleaning the high-strength steel hydrogen-charged test sample (3) and carrying out slow extension on the high-strength steel hydrogen-charged test sample (3) to test tensile strength and the maximum force, then carrying out fracture scanning morphology analysis on the high-strength steel hydrogen-charged test sample (3), and finally evaluating the hydrogen embrittlement sensibility of high-strength steel for the surface treatment process according to the analysis result. In which surface treatment process the high-strength steel is liable to generate hydrogen embrittlement can be judged, and in which surface treatment process the high-strength steel cannot be used or used with caution is determined, thus providing guidance for the high-strength steel surface treatment processes.

Owner:DONGFENG COMML VEHICLE CO LTD

Composite steel pipe with flange and manufacturing method thereof

The invention discloses a flannel composite steel pipe and manufacturing method, which is characterized by the following: (1) the outer galvanizing steel pipe or inner liner film stainless steel pipe forms inner liner stainless steel composite steel pipe through diameter reducing or enlarging; (2) when the composite steel pipe and flannel adapt screw connection, the flannel lining part contains silicon gel sealing ring; when the pipe body tightens the flannel through screw, the pipe body end clings the silicon gel sealing ring; (3) the inner layer of inner lining stainless steel pipe is film wall stainless pipe, which is welded with flannel through stainless steel bar; when the composite steel pipe with flannel is assembled, the fluid in the pipe and stainless steel pipe and welding gap touch; (4) two ends of polythene plastics is closed through chuck in the heat air stove through grafting heat melting gel, which is blown into lining composite pipe; (5) the end part of lining composite pipe with flannel is blown into bellmouthing shape, whose end is blown to cling the flannel end face to form flannel end face plastic-covering layer; the inner pipe wall and flannel end form the integral plastic-covering layer.

Owner:钱乐中 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com