Welding method for NM400 wear-resistant steel

A welding method and technology of wear-resistant steel, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as large carbon equivalent, high cost, and complicated welding process, and achieve improved surface wear resistance , wear resistance integration, simple welding process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

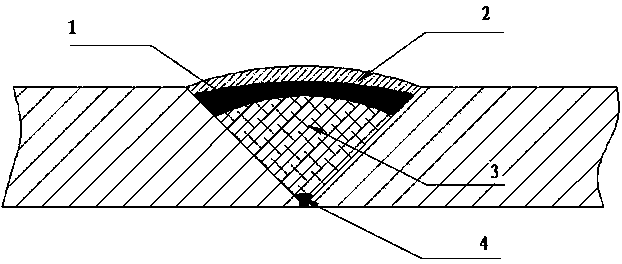

[0024] Embodiment 1: comprise the steps:

[0025] (1) Pretreatment before welding;

[0026] Make a single-sided V-shaped groove at the butt joint, with a groove angle of 45°, a blunt edge of 2mm, and a root gap of 1.5mm; use a wire brush to clean the groove and the 40mm surface on both sides of the groove to remove oil and rust until exposed Metallic luster; use A407 electrode for spot welding according to the required structure and fix it for welding;

[0027] (2) Weld the bottom seam;

[0028] The bottom layer 4 welds are arc welded with manual electrodes, the electrode grade is A407, and its material is C=0.08~0.20, Mn=1.0~2.5, Si≤0.75, Cr=25.0~28.0, Ni=20.0~22.5, using φ5. 0 electrode, welding current is 200A , The arc voltage is 22V, the welding speed is 10cm / min, the strip transport method adopts the straight line transport method, the weld seam width is 5mm, and the weld seam thickness is 4mm;

[0029] (3) The middle layer 3 is welded;

[0030] Flame heating the we...

Embodiment 2

[0035] Embodiment 2: comprise the steps:

[0036] (1) Pretreatment before welding;

[0037] Make a single-sided V-shaped groove at the butt joint, with a groove angle of 50°, a blunt edge of 1.5mm, and a root gap of 2mm; use a wire brush to clean the groove and the 40mm surface on both sides of the groove to remove oil and rust until it is exposed Metallic luster; use A407 electrode for spot welding according to the required structure and fix it for welding;

[0038] (2) Weld the bottom seam;

[0039] The bottom layer 4 welds are arc welded with manual electrodes, the electrode grade is A407, and its material is C=0.08~0.20, Mn=1.0~2.5, Si≤0.75, Cr=25.0~28.0, Ni=20.0~22.5, using φ5. 0 electrode, welding current is 200A , The arc voltage is 22V, the welding speed is 10cm / min, the strip transport method adopts the straight line transport method, the weld seam width is 5mm, and the weld seam thickness is 4mm;

[0040] (3) The middle layer 3 is welded;

[0041] Flame heating th...

Embodiment 3

[0046] Embodiment 3: comprise the steps:

[0047] (1) Pretreatment before welding;

[0048] Make a V-shaped groove on one side and one side at the T-shaped joint, with a groove angle of 60°, a blunt edge of 2mm, and a root gap of 2mm; use a wire brush to clean the groove and the 40mm surface on both sides of the groove to remove oil and rust. Until the metallic luster is exposed; use A407 electrode for spot welding according to the required structure and fix it for welding;

[0049] (2) Weld the bottom seam;

[0050] The welding seam of the bottom layer is arc welding with manual electrode. The welding rod, the welding current is 200A, the arc voltage is 22V, and the welding speed is 10cm / min.

[0051] (3) Intermediate layer welding;

[0052] Flame heating the welding seam and its surrounding area of 200mm, using an infrared thermometer to measure the temperature up to 350°C, and keeping the temperature constant for 5 minutes; the middle layer welding seam uses ER50-6 we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com