Patents

Literature

32results about How to "Improve weld toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding method for NM400 wear-resistant steel

ActiveCN104227180AAvoid it happening againImprove toughnessArc welding apparatusWelding/soldering/cutting articlesWear resistantStainless steel electrode

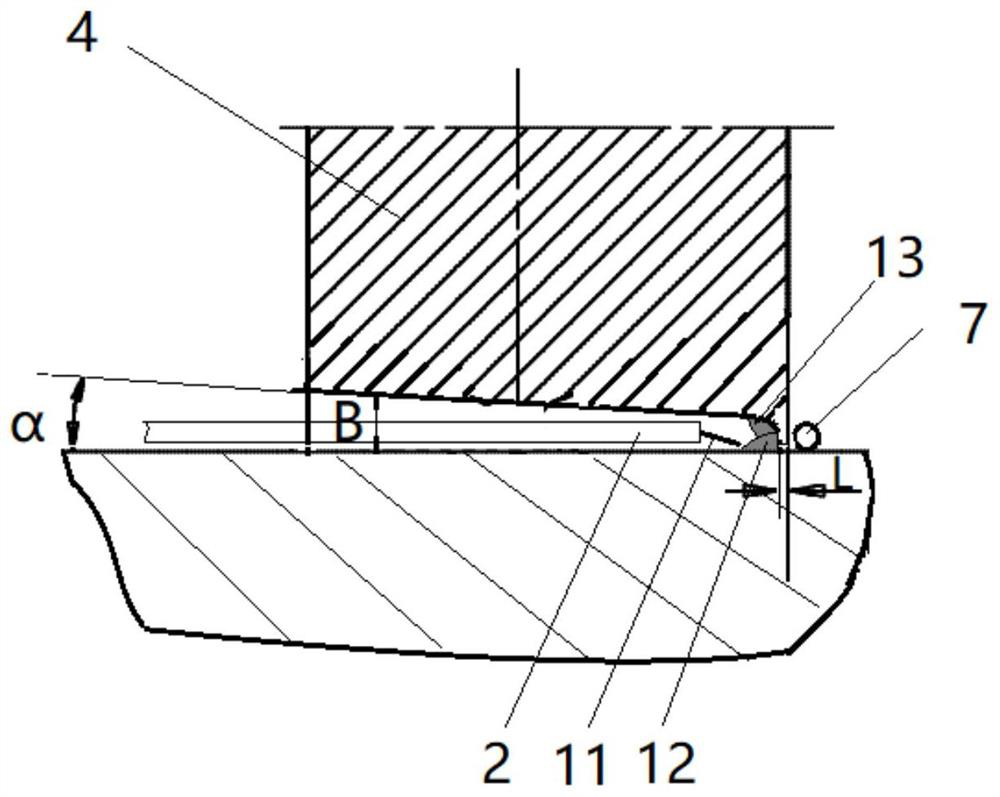

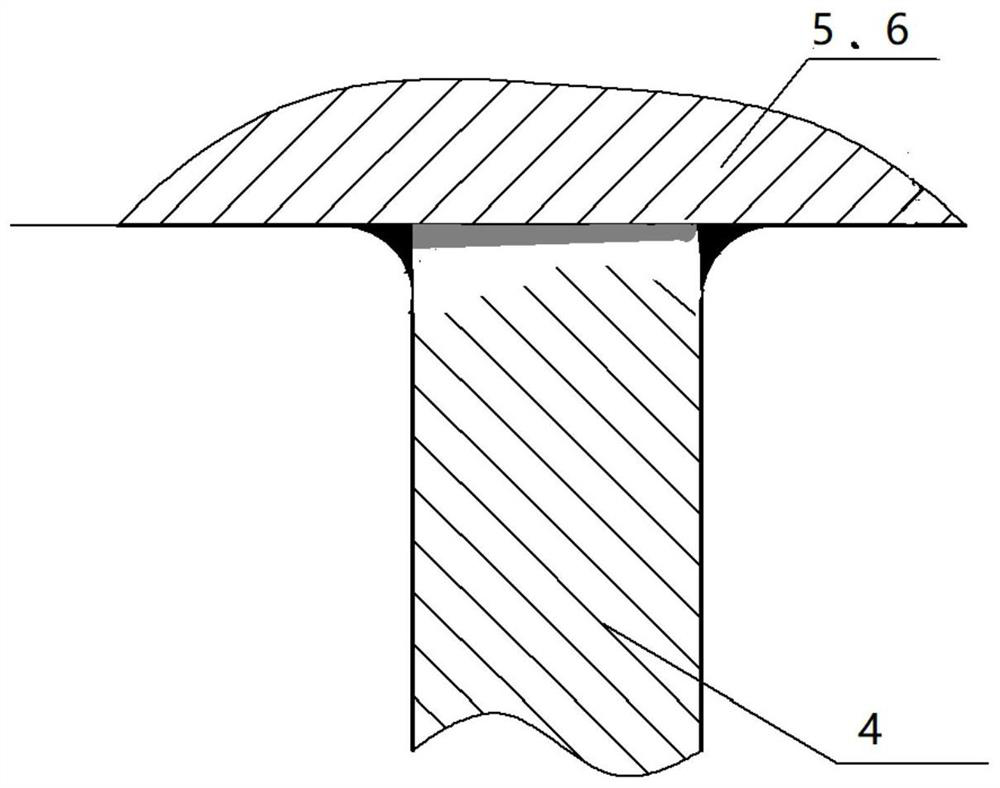

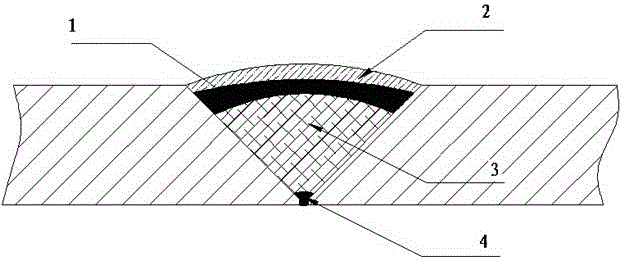

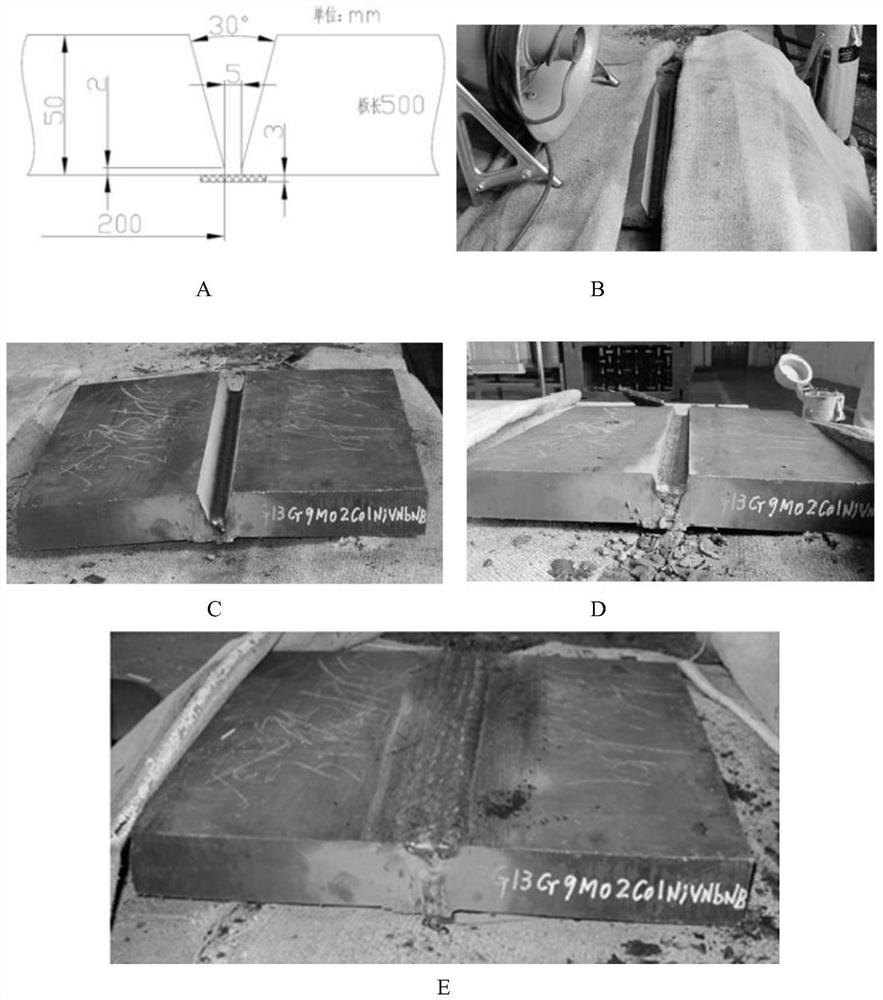

The invention provides a welding method for NM400 wear-resistant steel. The welding method comprises the following steps: after adopting an A407 stainless steel electrode as a bottoming welding joint, locally preheating the welding joint and the area in peripheral 200mm scope, wherein the preheating temperature is 350-400 DEG C and the temperature is kept constant for 5 minutes; performing multilayer multichannel welding by using an ER50-6 welding stick matched with CO2 gas protection welding, wherein the height of each layer of welding joint is not more than 4mm and the interlayer temperature is controlled to be above 150 DEG C; using the A407 stainless steel electrode for welding a transition layer at the height of 2-3 layers of welding joints from the surface of a base metal, wherein the thickness of the transition layer is more than 3mm; lastly, using a D212 electrode for covering and polishing the surplus height of the welding joint and welding toe, wherein the surplus height of the welding joint is not more than 3mm. Preheating before welding is not required, heat insulation after welding is not required, the welding technique is simple and the cost is low. The toughness of an NM400 wear-resisting steel welding joint is improved and the integration of the strength, toughness and wear-resistance of the joint is realized.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

Hot rolling wire rod for 60 kg-stage high-strength welding wire and production method thereof

ActiveCN109706391AReduce manufacturing costGood performance and stabilityImpurityCooling temperature

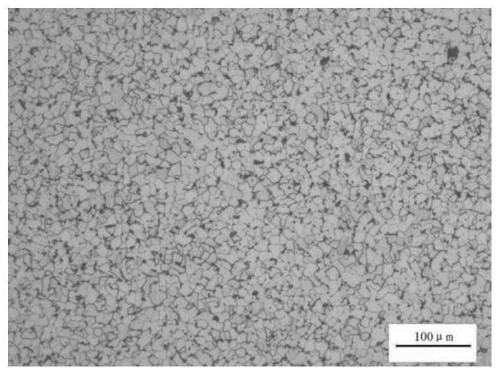

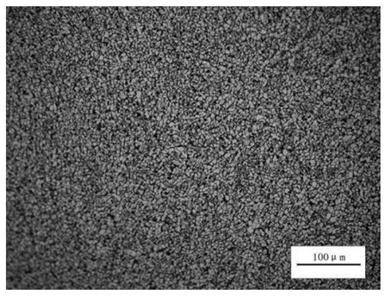

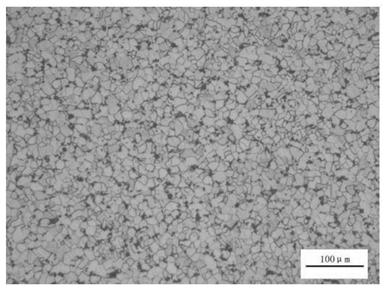

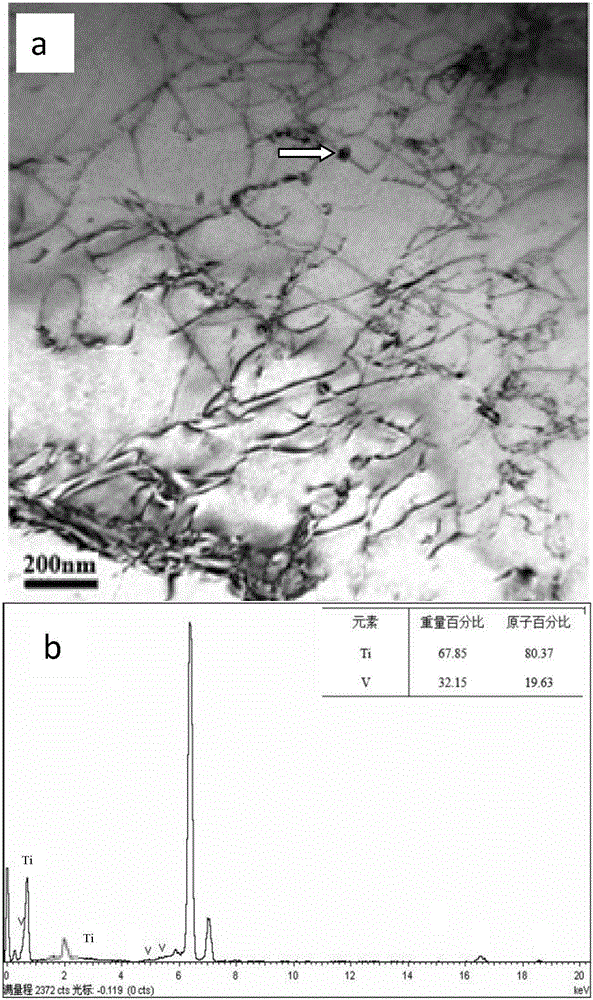

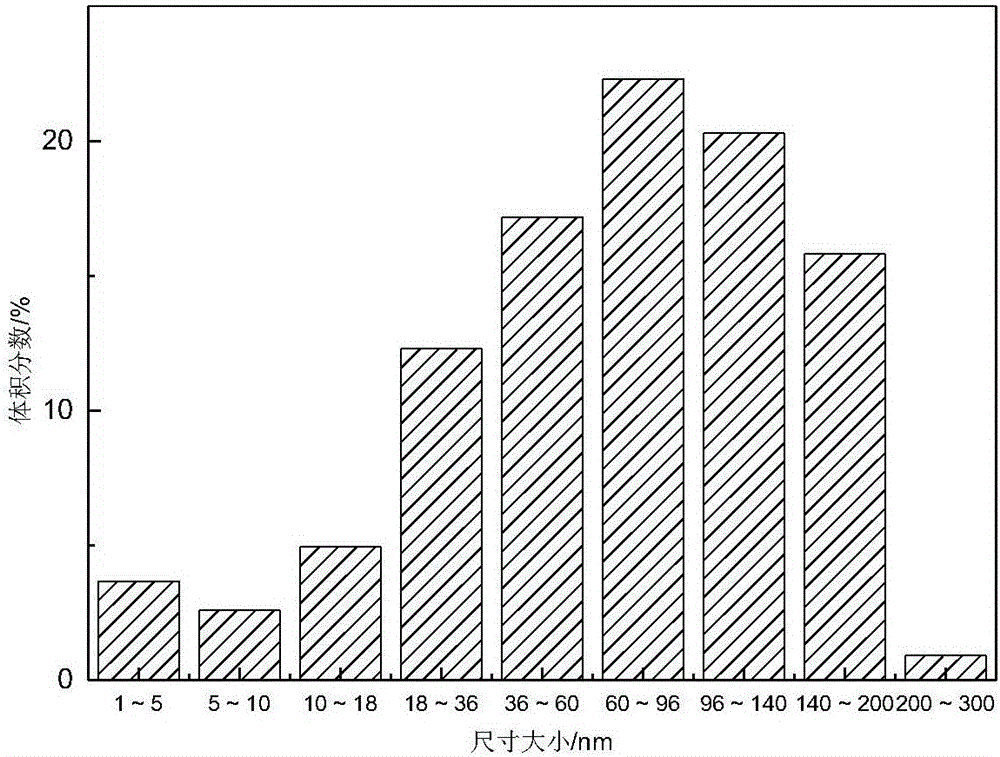

The invention discloses a hot rolling wire rod for a 60 kg-stage high-strength welding wire and a production method thereof. The hot rolling wire rod comprises the following chemical components including, by mass, 0.06% to 0.12% of C, 0.40% to 0.80% of Si, 1.50% to 2.00% of Mn, 0.020% or less of P, 0.020% or less of S, 0.040% to 0.060% of V, 0.050% to 0.090% of Ti, 0.20% to 0.45% of Cr and the balance Fe and unavoidable impurities. The production method comprises steel making, continuous casting, heating, rolling, spinning and cooling procedures. According to the hot rolling wire rod for the 60 kg-stage high-strength welding wire and the production method thereof, the hot rolling wire rod for high-strength welding is produced through vanadium and titanium alloying, microstructures of equiaxial ferrite and pearlite are obtainedin cooperation with control over the finish rolling temperature, spinning temperature, cooling temperature and winding temperature, the hot rolling wire rod is processed into a gas shielded welding rod, the deposited metal tensile strength is 600 MPa to 700 MPa, and the wire rod is low in cost and good in performance stability.

Owner:HEBEI IRON AND STEEL

Welding method for Q460 high-strength steel tube of extra-high-voltage power transmission steel tube tower

ActiveCN102886593AReduced tendency to cold crackingGuarantee welding qualityArc welding apparatusTubular articlesSheet steelAlloy

The invention relates to a welding method for the Q460 high-strength steel tube of an extra-high-voltage power transmission steel tube tower, and the welding method comprises the following steps of: using a low-alloy high-strength steel plate having a yield strength of 460 MPa level, grinding the both sides of the low-alloy high-strength steel plate into single-surface grooves, bending the low-alloy high-strength steel plate into a primarily-formed steel tube with longitudinal slits, performing backing welding on welding joints, welding by means of CO2 gas shielded welding, and using JM68 welding wires; and continuously welding by means of submerged arc automatic welding during filling and covering, using CHW-S9 submerged arc welding wires, and using an SJ101 flux. According to the invention, aiming problems in welding for the Q460 high-strength steel tube, the CO2 gas shielded welding is combined with selection for the JM68 welding wires and reasonable welding parameters, and the CO2 gas shielded welding is combined with welding using the CHW-S9 welding wires and the SJ101 flux, thus improving the toughness and the quality of the welding joints, and increasing production efficiency and promoting the large-scale production simultaneously.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

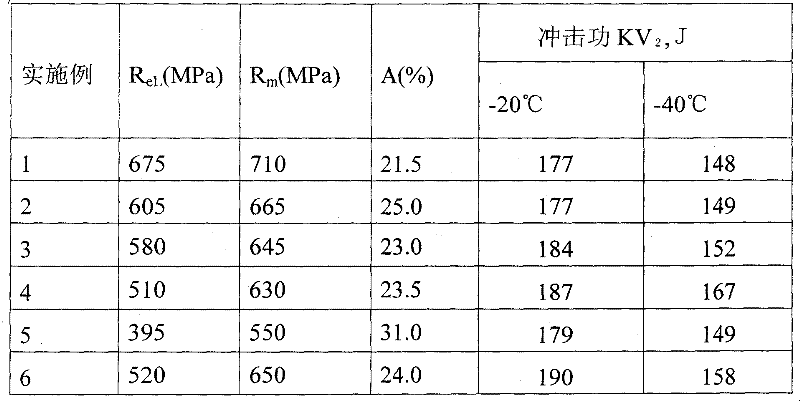

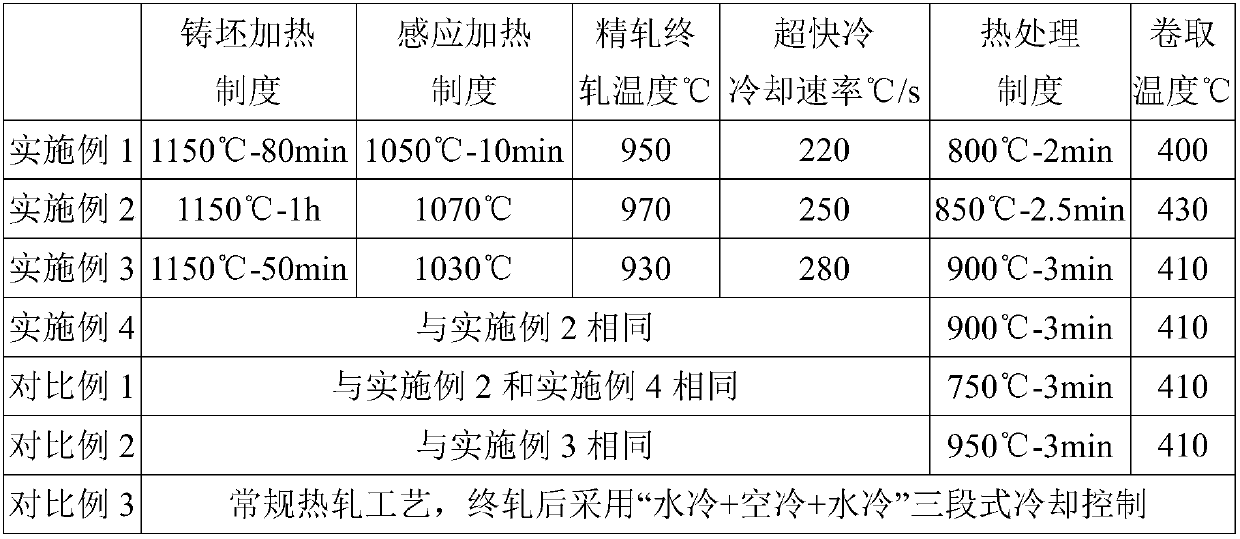

Low-temperature-resistant hot-rolled H-shaped steel and preparation method thereof

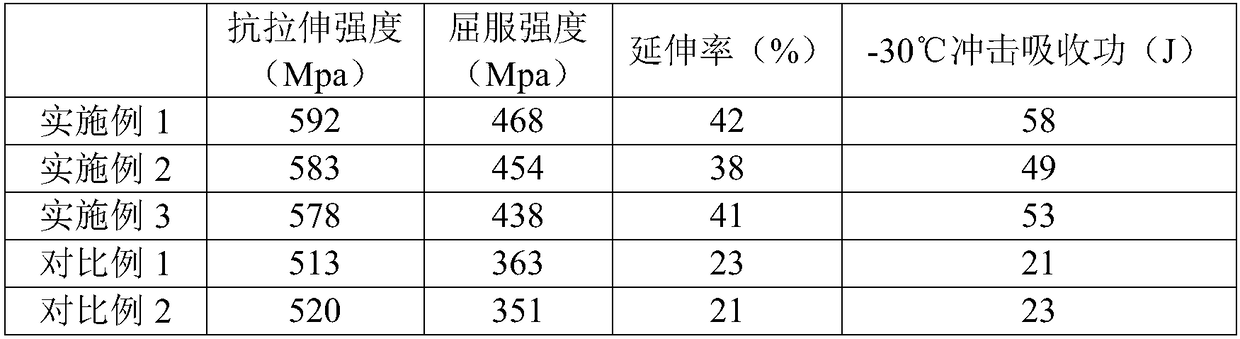

The invention discloses a low-temperature-resistant hot-rolled H-shaped steel and a preparation method thereof. The hot-rolled H-shaped steel comprises the following chemical components in percentage by weight: 0.07-0.10% of C, 0.2-0.4% of Si, 1.30-1.60% of Mn, at most 0.020% of P, at most 0.015% of S, 0.015-0.070% of V, 0.010-0.030% of Ti, and the balance of Fe and inevitable impurities. The production method comprises the following steps: converter smelting, LF (ladle furnace) refining, continuous casting, rolling and the like. The structure of the H-shaped steel is a polygonal ferrite and pearlite structure, the yield strength is 350-450 MPa, the tensile strength is 480-600 MPa, the percentage elongation after fracture is greater than or equal to 22%, and the -40-DEG C V-notch Charpy impact energy is greater than or equal to 200J.

Owner:SHANDONG IRON & STEEL CO LTD

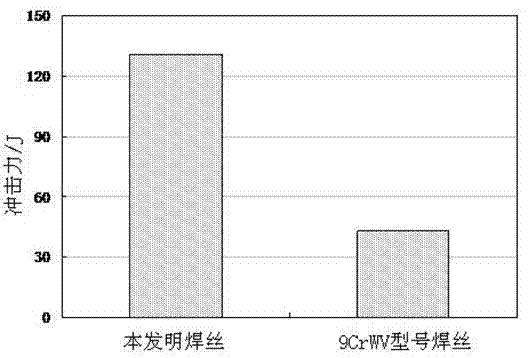

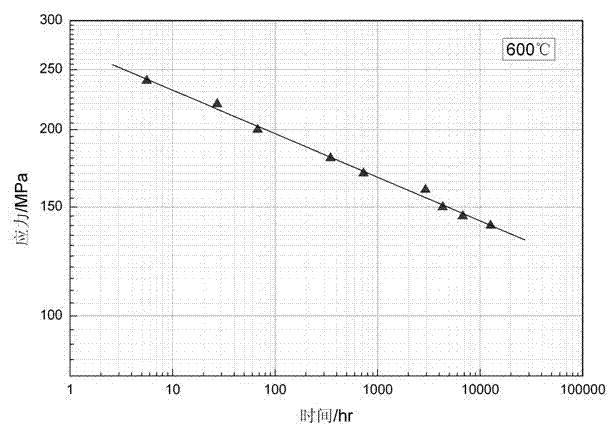

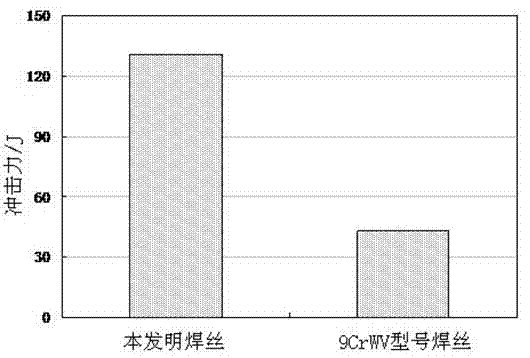

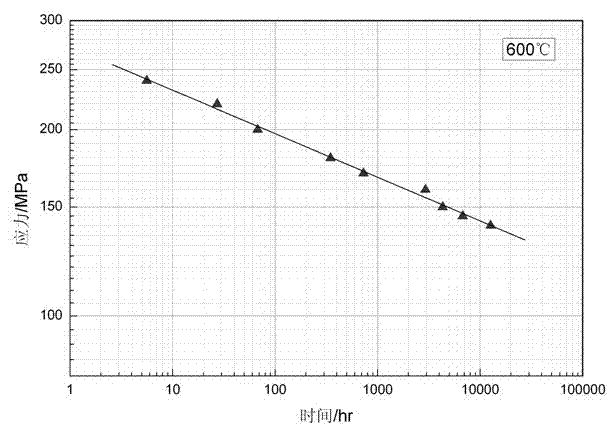

P92 steel submerged arc welding wire

ActiveCN102189352AImprove weld toughnessGuaranteed high temperature performanceWelding/cutting media/materialsSoldering mediaWeld seamSubmerged arc welding

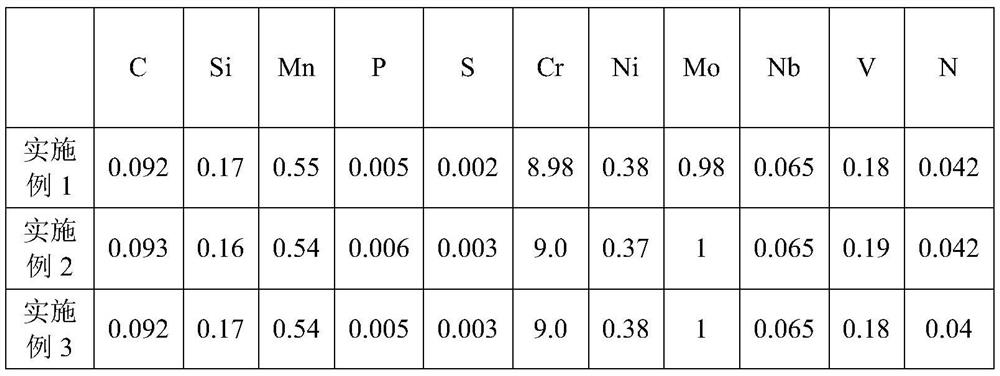

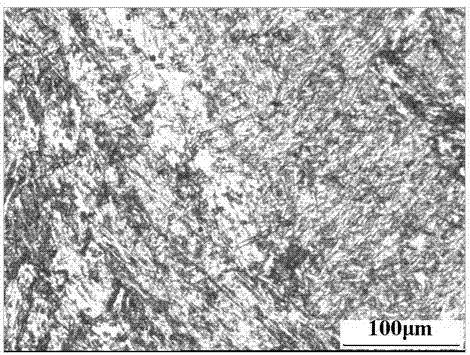

The invention discloses a P92 steel submerged arc welding wire, which contains the following chemical components in percentage by mass: 0.06 to 0.08% of C, not less than 0.40% of Si, 0.4-1.0% of Mn, not less than 0.015% of P, not less than 0.015% of S, 9.0 to 10% of Cr, 0.3 to 0.6% of Mo, 0.15 to 0.25% of V, 1.5 to 2.0% of W, not less than 0.6% of Ni, 0.03 to 0.07% of Nb, 0.8 to 1.0% of Co, 0.001to 0.05% of B, 0.03 to 0.07% of N, and the balance of Fe. The welding wire is used in the submerged arc welding, on the premise of guaranteeing high temperature performance of a welding joint, the toughness of a weld seam is increased, and the application of a highly efficient welding method of the submerged arc in the boiler production is ensured.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

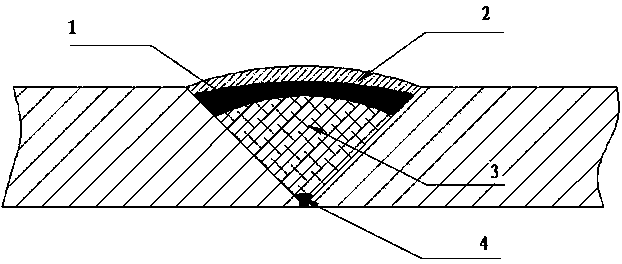

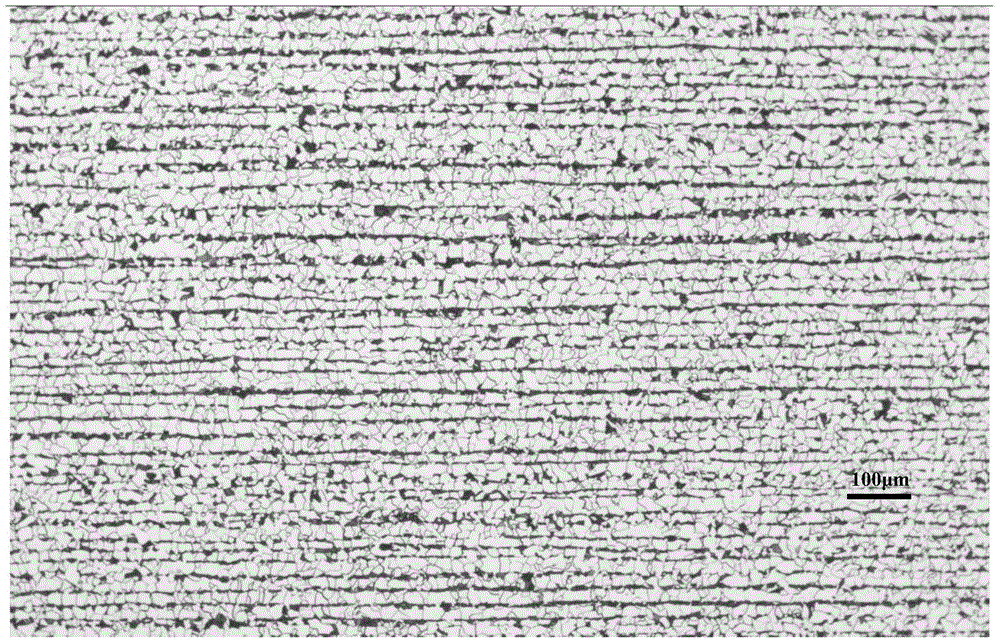

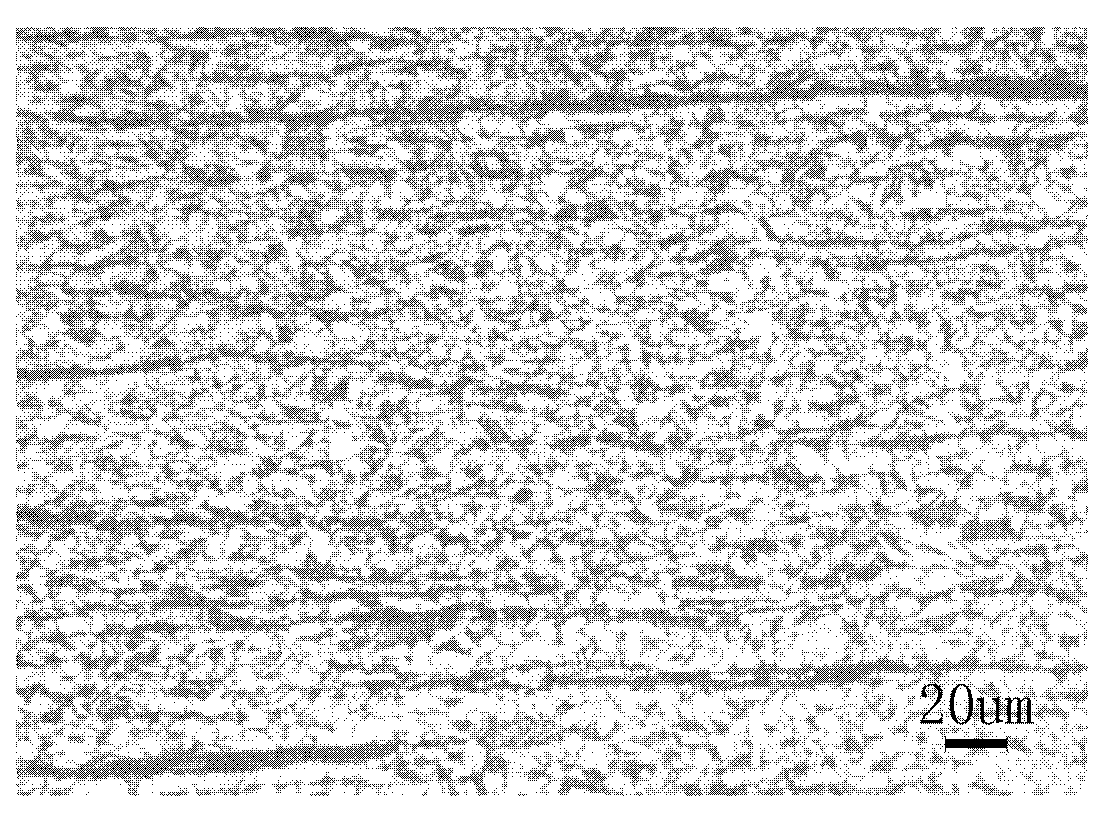

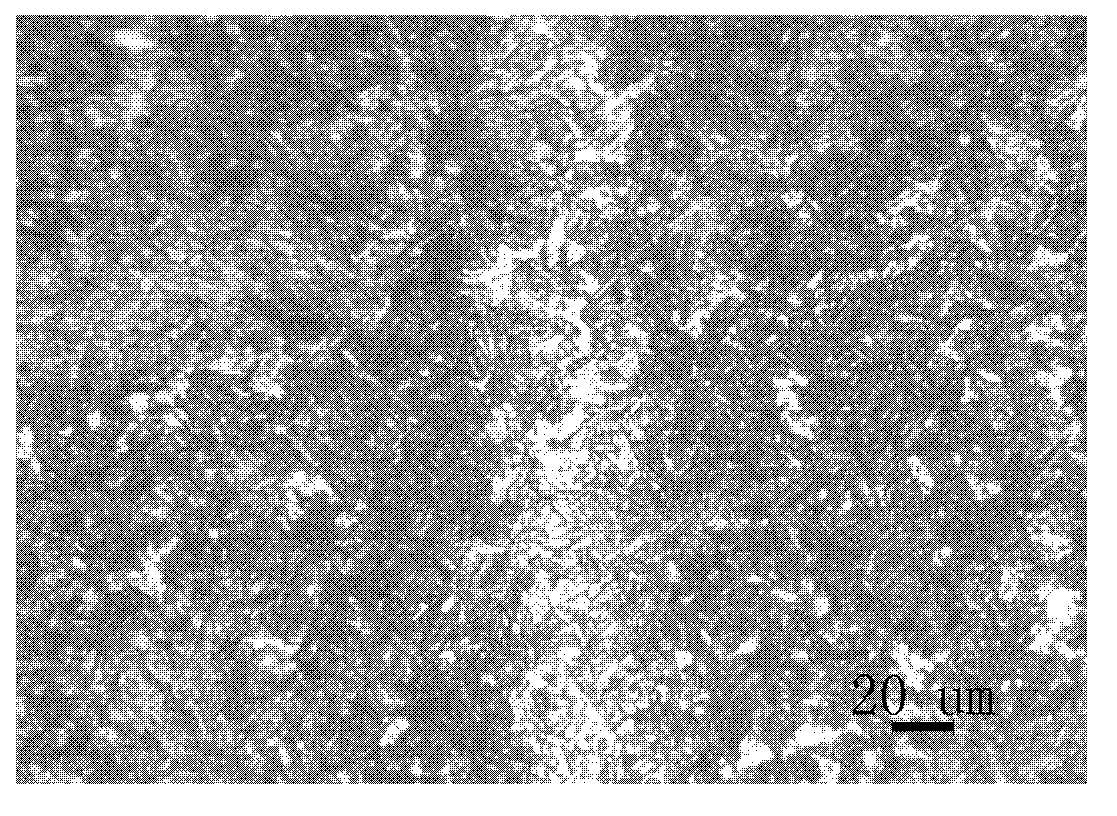

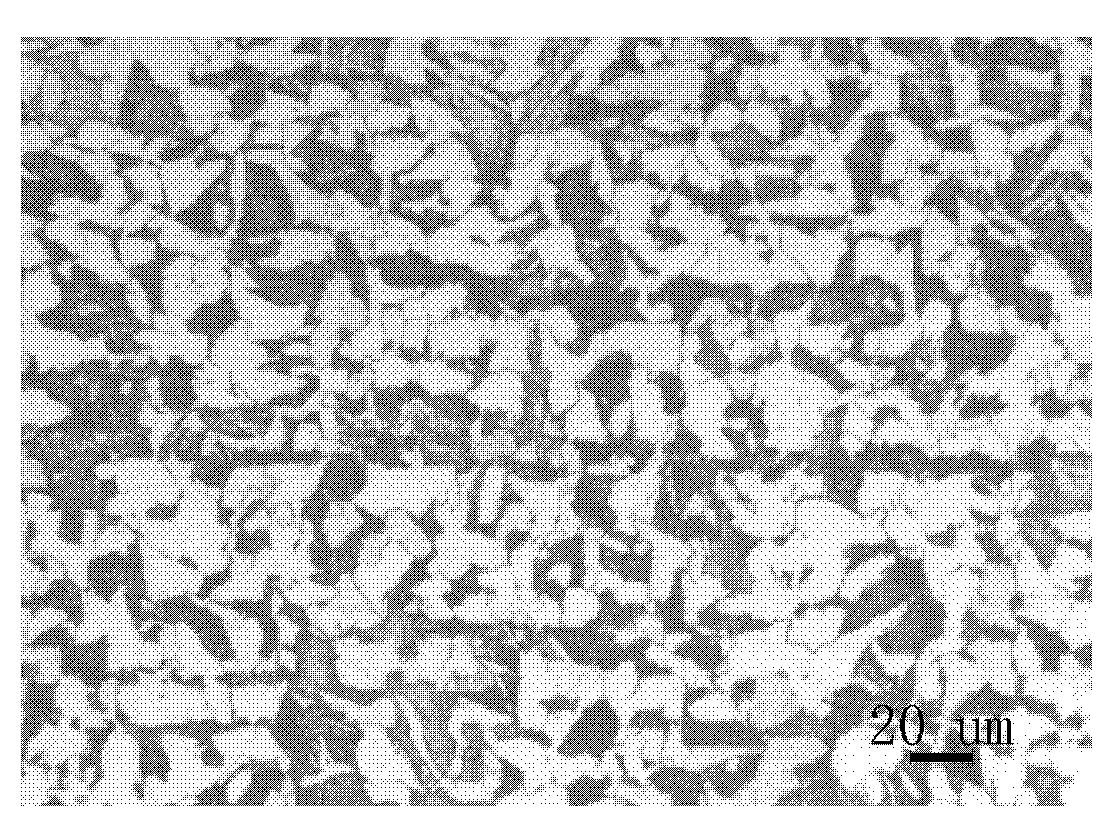

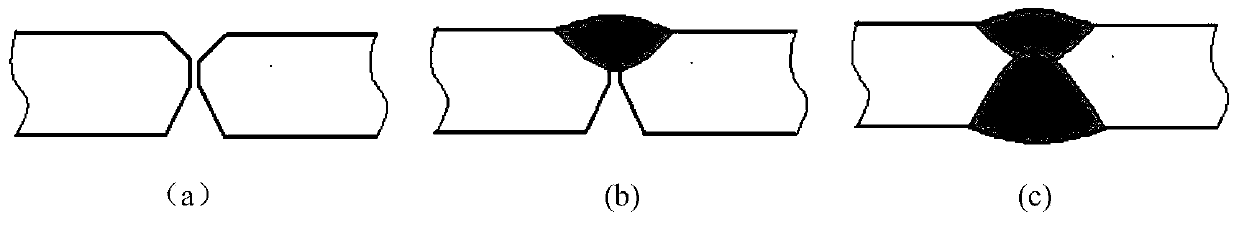

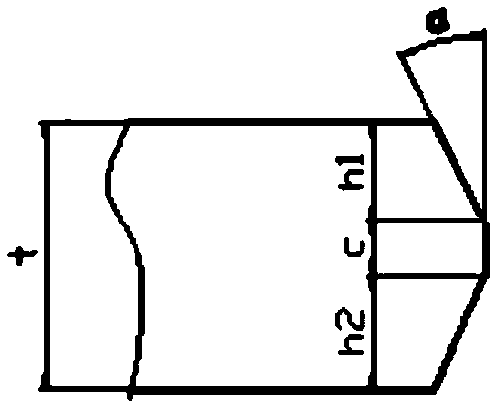

Method for optimizing weld seam structure and properties of HFW(High Frequency Welded) pipes

The invention relates to a method for optimizing the weld seam structure and properties of HFW(High Frequency Welded) pipes, comprising the following steps of: firstly, continuously and quickly heating an HFW pipe by a medium-frequency induction furnace to above an austenite phase transition temperature and quickly thoroughly heating; and then performing hot mechanical rolling treatment on the HFW pipe at the austenitizing temperature for eliminating the residual stress of a weld seam and thinning grains in the weld seam and heat-affected zones under the effects of mechanical extrusion force and rolling temperature, so that the structure and mechanical property of the weld seam reach basically the same degrees as the parent metal. The method for optimizing the weld seam structure and properties of HFW pipes improves the structure and properties of the weld seam, obviously increases the grain size of the weld seam from 2-4 levels to 8-11 levels, obviously reduces the groove corrosion sensitivity coefficient of the weld seam, and improves the corrosion resistance, plasticity and toughness of the weld seam.

Owner:BAOJI PETROLEUM STEEL PIPE

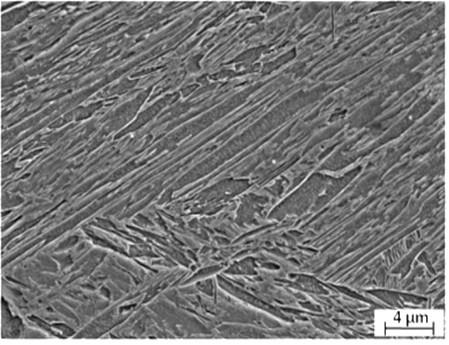

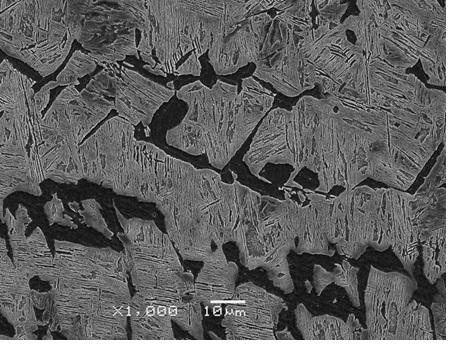

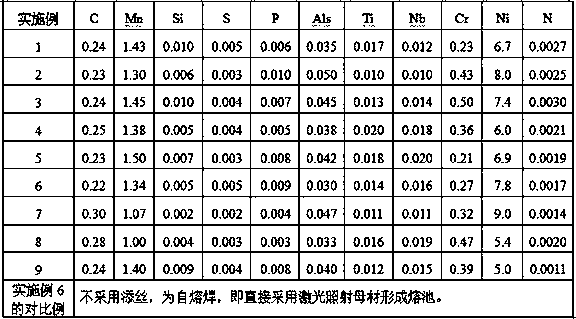

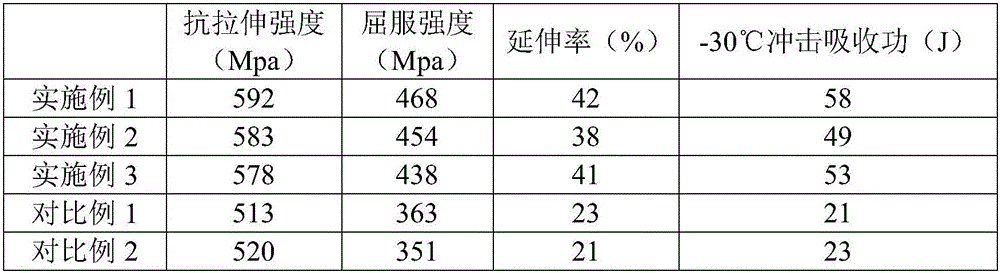

Welding wire for laser butt welding of Al-Si coated plates formed by hot-stamping and butt welding method

ActiveCN111390425AImprove weld toughnessGood mechanical propertiesWelding/cutting media/materialsSoldering mediaStampingWeld bead

The invention provides a welding wire for laser butt welding of Al-Si coated plates formed by hot-stamping and a butt welding method. The welding wire comprises no more than 0.30% of C, 1.0%-1.5% of Mn, no more than 0.005% of S, no more than 0.010% of P, 0.030-0.050% of Als, no more than 0.001% of Si, 5.0%-9.0% of Ni, 0.21%-0.50% of Cr, 0.010%-0.020% of Nb, 0.010%-0.020% of Ti, no more than 0.0030% of N, and the balance Fe and inevitable impurities. The butt welding method comprises the steps that two Al-Si coated plates are fixed through a welding clamp, wherein a gap is reserved between thetwo Al-Si coated plates; the diameter of the welding wire is determined according to the size of the gap; laser butt welding is conducted; and then, hot-stamping formation is conducted. By the adoption of the welding wire, pretreatment of a coating is not needed; and the laser butt welding method is simple, and the performance of welds is better than that of parent metal.

Owner:TANGSHAN IRON & STEEL GROUP +1

Welding method for 12Cr5Mo martensite stainless steel

ActiveCN106312242AEliminate heat treatmentEasy to install on siteArc welding apparatusWelding/cutting media/materialsSlagManganese

The invention relates to a welding method for 12Cr5Mo martensite stainless steel. The welding method comprises the following steps: step I, preparing a 12Cr5Mo martensite stainless steel groove, carrying out butt-joint assembly on the groove, and pre-heating a welded part of the groove at a pre-heating temperature being 100-150 DEG C; and step II, separately carrying out a primary welding process, a secondary welding process and a tertiary welding process on the welded part of the groove by use of a welding rod, wherein the welding rod is composed of a welding core and a coating; and the welding core consists of the following raw materials: C, Ni, Cr, Mn, Si, Ti, Nb, V, Ta, Zr, La, Ce, Pr, W, N and Fe. The coating consist of the following components: rutile, titanium dioxide, potassium feldspar, mica, calcium carbonate, nitrogen containing ferrochromium, electrolytic manganese, metal nickel, ferrocolumbium, magnesium oxide, yttrium oxide, sodium fluosilicate, hydroxypropyl methyl cellulose, phenolic resin and melamine. According to the welding method, a welding process is simple, welding seam molding is beautiful, slag is easily separated and deposition efficiency is high; and the obtained welding seam metal has excellent mechanical performance and mechanical property.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

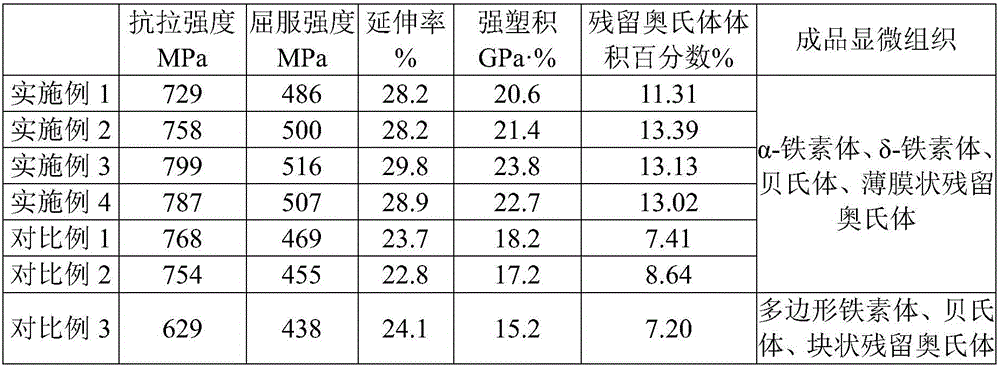

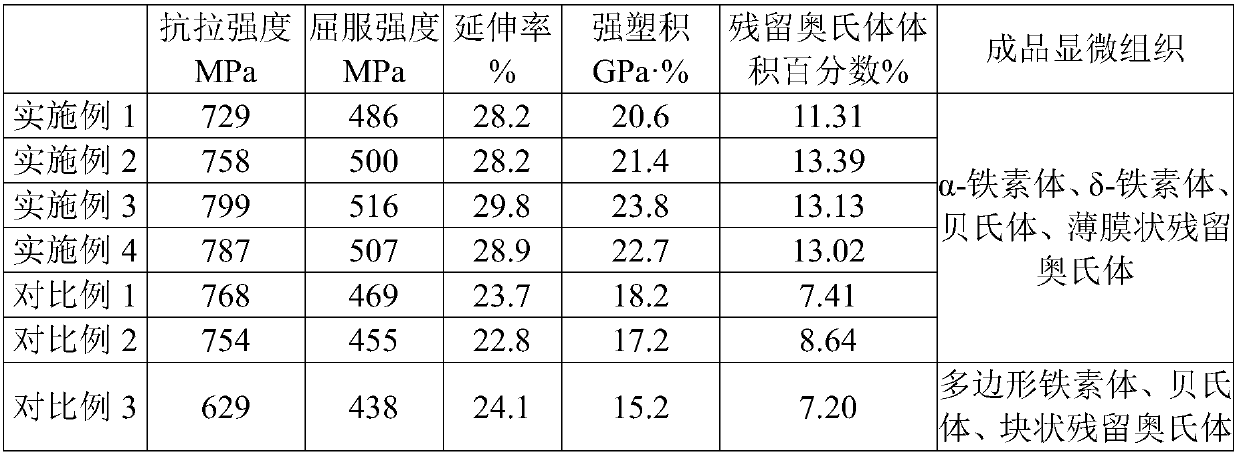

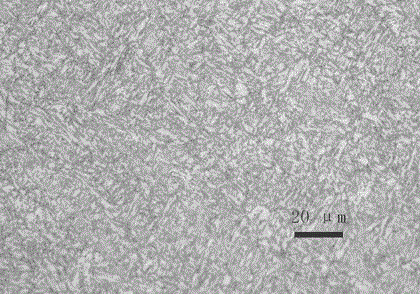

Preparation method of delta-ferrite-containing TRIP (transformation induced plasticity) steel

The invention discloses a preparation method of delta-ferrite-containing TRIP (transformation induced plasticity) steel, and belongs to the technical field of high-strength steel for automobiles. The delta-ferrite-containing TRIP steel comprises the following chemical components in percentage by mass: 0.24-0.28% of C, 0.5-1.0% of Si, 1.8-2.5% of Mn, 2.9-3.7% of Alt, no more than 0.01% of P, no more than 0.008% of S+N and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: hot rolling, induction heating, ultra-fast cooling and heat treatment. The steel structure disclosed by the invention contains delta-ferrite, thereby improving the weldability. During composition design, the Al content is increased, thereby obtaining high elongation percentage, lowering the density of the steel, and effectively realizing lightweight development. The structure of the steel finished product comprises alpha-ferrite, delta-ferrite, bainite, thin-film retained austenite (or martensite / austenite island), wherein the volume percent of the retained austenite is 11.31-13.39%. The yield strength of the steel is 486-516 MPa, the tensile strength is 729-799 MPa, the elongation percentage is 28.2-29.8%, and the product of strength and elongation is 20.6-23.8 GPa.%.

Owner:UNIV OF SCI & TECH BEIJING

Solder wire material for stainless steel

InactiveCN101318271AReduce hardenabilityImprove the size of inclusionsWelding/cutting media/materialsSoldering mediaChemical compositionWeld seam

The invention discloses a welding wire material for stainless steels and the weight percentage of the concrete chemical compositions of the welding wire material is as follows: C, 0.07 to 0.09; Si, 0.65 to 0.95; Mn, 6.7 to 7.2; P, less than or equal to 0.02; S, less than or equal to 0.015; Cr, 18.5 to 19.5; Ni, 8.0 to 9.5; Mo, less than or equal to 0.4; the remaining is Fe and inevitable impurities. The welding wire material is used for 304 austenitic stainless steels, and welding seams are smooth after the welding is performed and metals at the welding seams have the similar performance as mother metal, no black skin exists and the cost is low.

Owner:JIANGSU XINGHAI SPECIAL STEEL

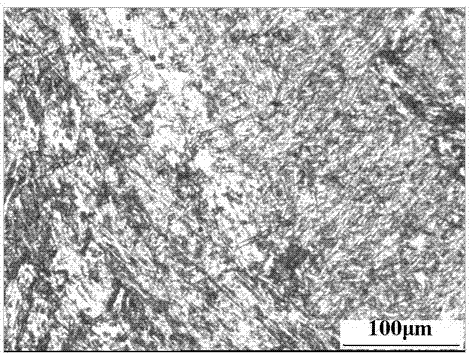

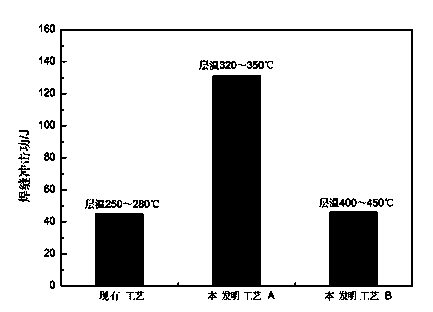

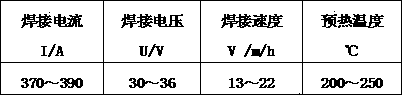

Welding technology of P92 steel submerged automatic arc welding for power station boiler

InactiveCN103978294AReduced crack susceptibilityInhibition formationArc welding apparatusWelding/cutting media/materialsPower stationEngineering

The invention relates to a welding technology of P92 steel submerged automatic arc welding for a power station boiler. According to a specific method, welding wires are selected, wherein the content of C is 0.06-0.08wt%, the content of Co is 0.9-2.0wt%, the contents of other elements are the same as that of a base material, and the diameters of the welding wires are 2.4mm; the specific welding method comprises the following steps: firstly preheating; beginning to weld until the temperature is 200-250 DEG C by preheating, wherein the welding speed is constantly kept to be 13-22 m / h, and the interlayer temperature is controlled to be 300-350 DEG C; stopping welding when the temperature is over 350 DEG C, and going on welding when the temperature is reduced to be lower than 350 DEG C and not lower than 200 DEG C. Therefore, the welding technology has the advantages that the crack sensitivity of weld joints is reduced and the formation of delta-ferrites is inhibited by selecting a low-carbon Co-alloying welding material, so that the tenacity of the weld joints is improved. According to the technology, the upper limit of the interlayer temperature can be promoted to be 350 DEG C, and thus the welding efficiency is greatly improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

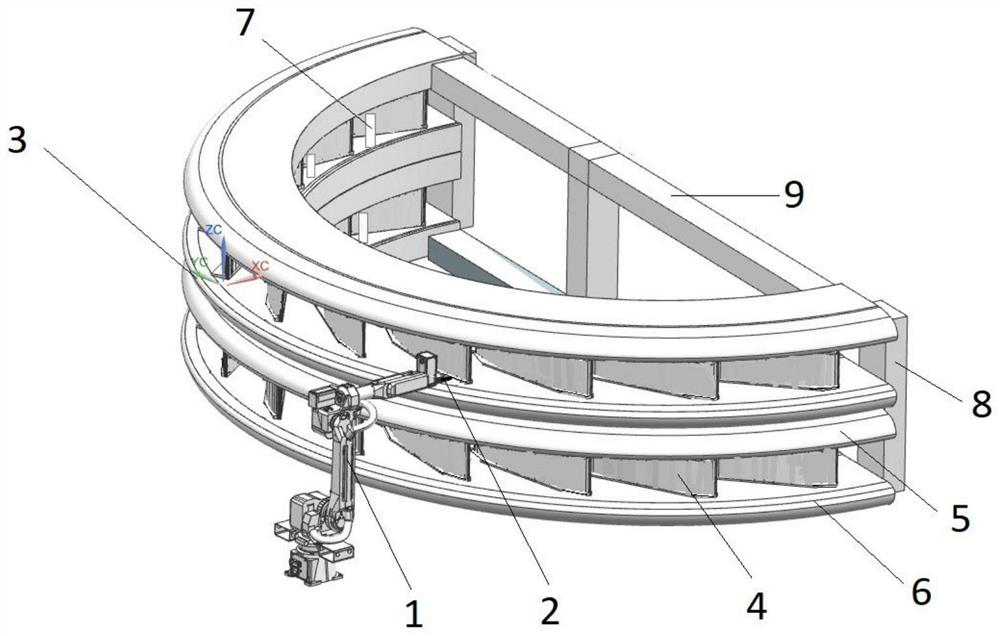

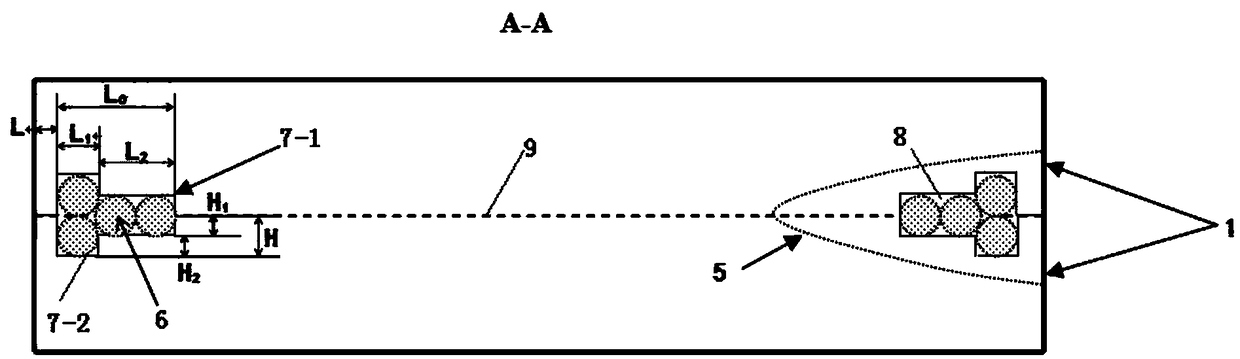

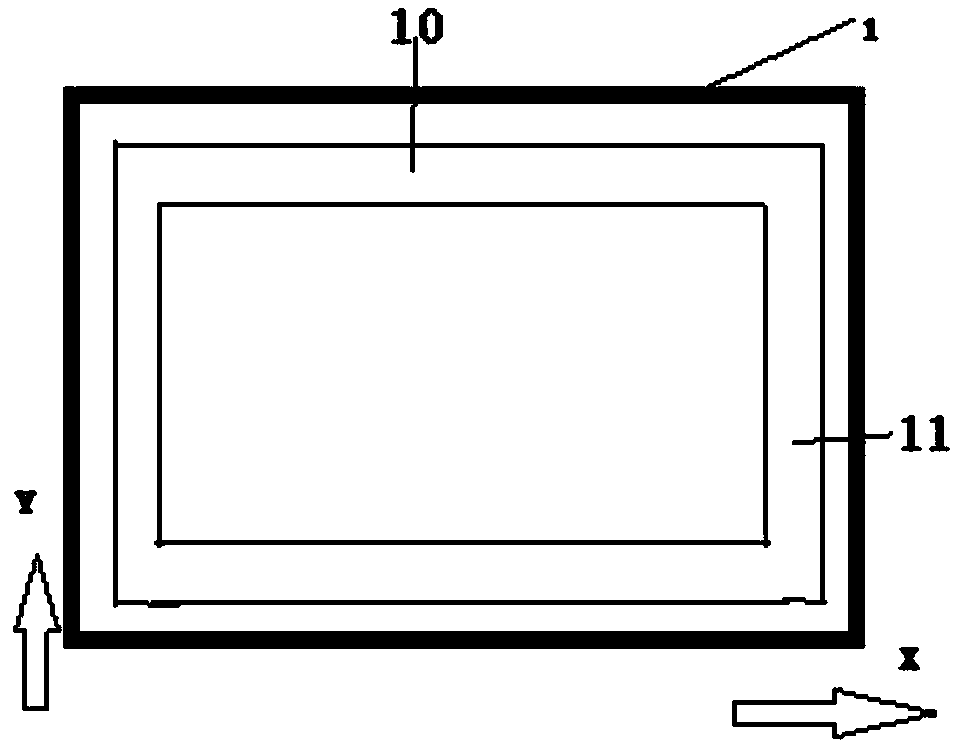

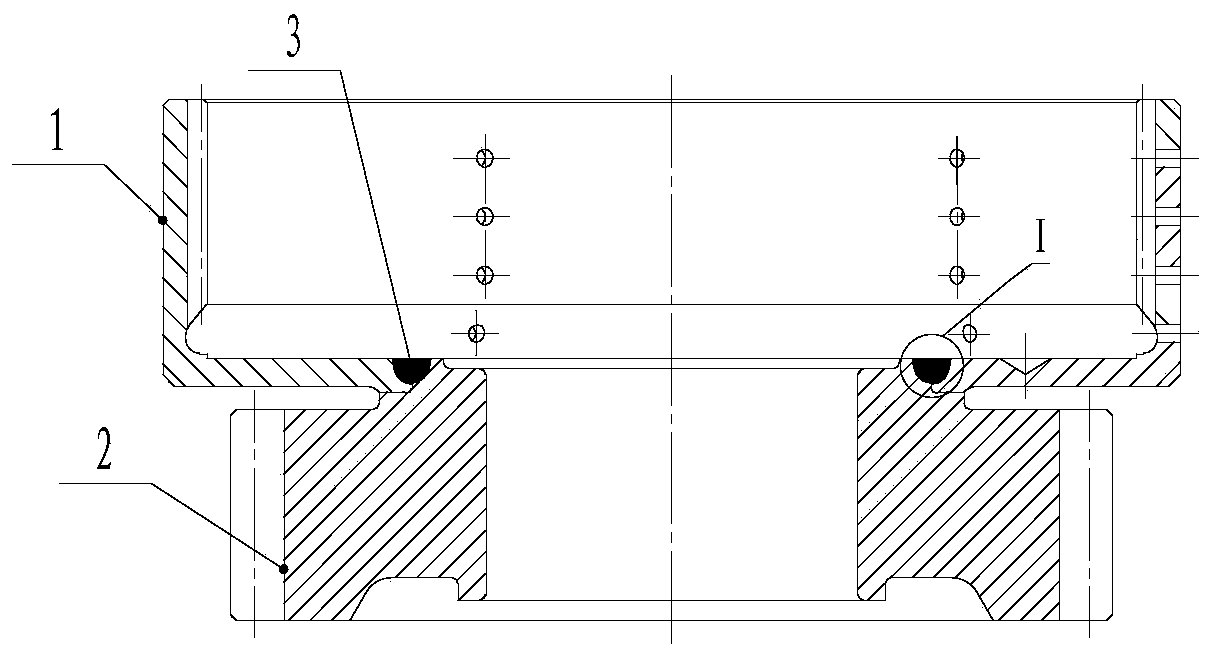

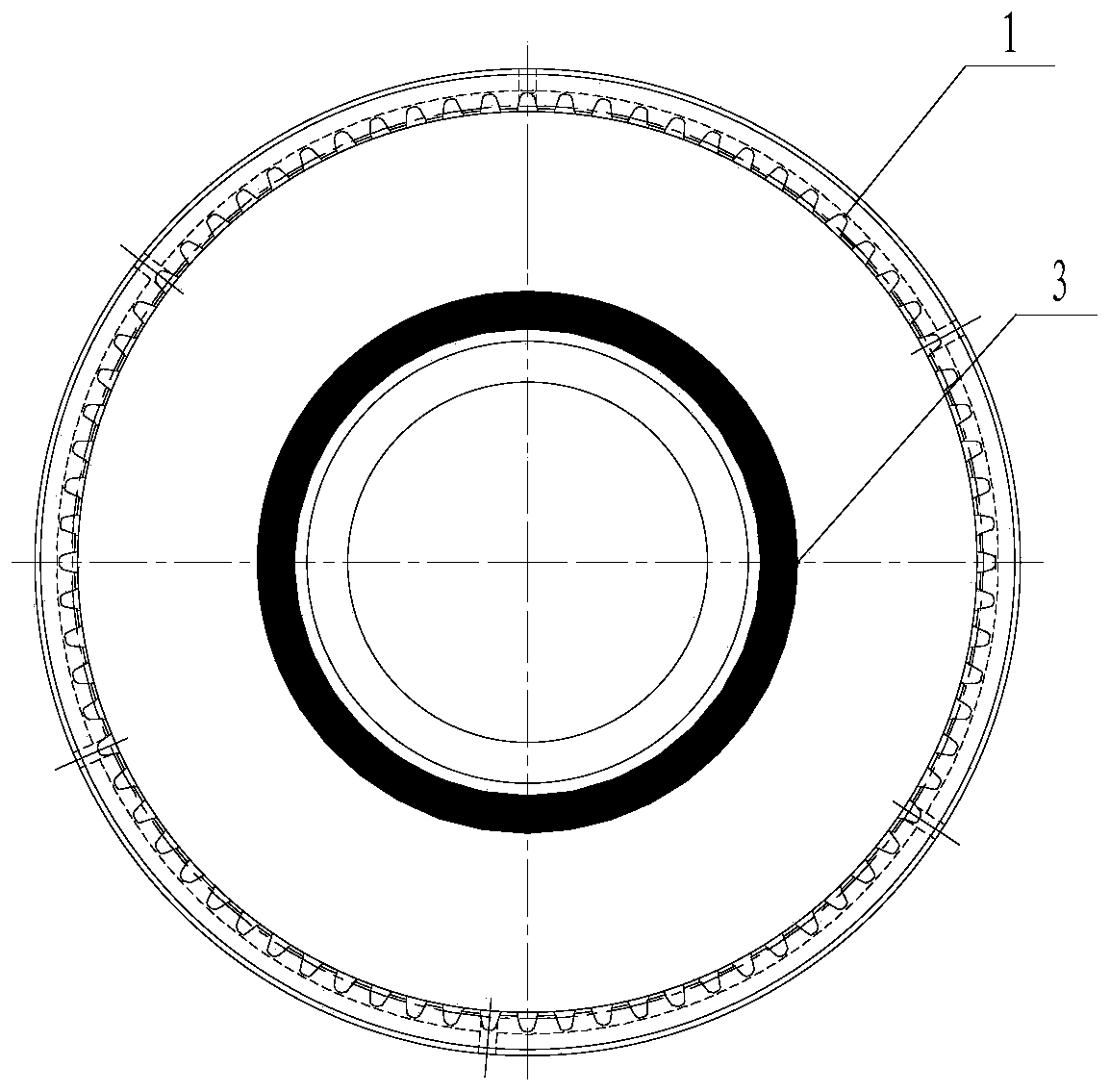

Efficient horizontal position welding process method for pumping storage seat ring fixed guide vane

InactiveCN113134661AInnovation of Welding Process MethodReduce the amount of weld fillerArc welding apparatusWorkpiece edge portionsWeld quality assuranceEngineering

The invention discloses an efficient horizontal position welding process method for a pumping storage seat ring fixed guide vane. Firstly, the seat ring fixed guide vane with the thickness of 150-260 mm is processed into a narrow gap groove with the width of 10-25 mm, robot narrow gap gas shield welding accessibility is simulated offline, welding path programming is carried out, two sections of a seat ring are stacked, the seat ring is placed at a horizontal position, the narrow gap groove is welded to 1 / 4-1 / 3 depth after alternate backing welding, back gouging and fillet welding are conducted on the back face, and then the narrow gap groove is welded alternately. In the welding process, two paths are welded on each layer, the lower path is welded firstly, then the upper path is welded, a robot programming position register is used for achieving welding path automatic deviation, a weld pool edge linear image obtained through a CMOS welding camera is used for judging and adjusting welding deviation, and the problem about the fusion quality of the side wall of efficient robot narrow gap horizontal welding of the seat ring is solved. Compared with conventional manual welding, the welding amount is reduced by 60%-80%, the procedure of turning over the seat ring in a reciprocating manner is omitted, and the production efficiency is improved by 1-2 times under the guarantee of the stable and reliable welding quality.

Owner:HARBIN ELECTRIC MASCH CO LTD

A welding method for nm400 wear-resistant steel

ActiveCN104227180BAvoid it happening againImprove toughnessArc welding apparatusWelding/soldering/cutting articlesWear resistantStainless steel electrode

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

Manufacturing process of large-diameter land wind power tower

InactiveCN113319527AAvoid Welding DefectsGuaranteed welding formArc welding apparatusNumerical controlProduct inspection

The invention discloses a manufacturing process of a large-diameter land wind power tower. The tower is formed by connecting a plurality of tower barrel sections. The manufacturing process comprises the following specific steps: inspecting a plate, then carrying out numerical control cutting, blanking and beveling to obtain a fan-shaped plate; rolling the fan-shaped plate to obtain tower barrel joints, and rounding the tower barrel joints; carrying out spot welding positioning and misalignment inspection on the longitudinal joints of the tower barrel joints; then welding longitudinal joints of the tower barrel joints, polishing welded joints, carrying out secondary roundness correction, and carrying out nondestructive testing; carrying out sanding and paint spraying treatment on the tower barrel joints subjected to longitudinal seam welding; assembling the tower barrel joints sequentially, carrying out staggered joint inspection and assembly welding, and carrying out nondestructive testing after the welded joints are polished; welding flanges to the two ends of the tower barrel sections respectively, carrying out surface anti-corrosion treatment and internal part assembling, and finally carrying out finished product inspection; and manufacturing the wind power tower after the multiple matched tower barrel sections are assembled in pairs through flanges. The welding seam quality can be effectively improved, and the safety of the tower is improved.

Owner:SHANGHAI TAISHENG WIND POWER EQUIP

Heat-resistant steel hand welding rod for ultra-supercritical CB2 steel and preparation method thereof

ActiveCN113857717AReduce manufacturing costImprove performanceWelding/cutting media/materialsSoldering mediaSlag (welding)Metal

The invention belongs to the technical field of welding rod preparation, and discloses a heat-resistant steel hand welding rod for ultra-supercritical CB2 steel and a preparation method thereof. The heat-resistant steel hand welding rod is composed of a special H08Cr9MoV alloy core wire (produced by Jiangsu Yonggang Group Co., Ltd.) with low content of impurities such as phosphorus and sulfur and a coating wrapping the surface of the special H08Cr9MoV alloy core wire. The main components of cladding metal are 9% of Cr, 1.5% of Mo, 1% of Co, 1% of Ni and 0.2% of V, and meanwhile, trace alloy elements such as Nb, N and B are added, so that the weld joint deposited metal has good mechanical properties, especially impact energy performance after heat treatment, and the impact energy is larger than or equal to 47J in a normal temperature state. The tensile strength of the deposited metal and a welding joint is 630-750MPa under the heat treatment condition of 730-740 DEG C and time of 12h. According to the hand welding rod manufactured by the method, electric arcs are stable in the welding process, splashing is small, welding slag is uniform in covering, slag removal is good, weld joint forming is attractive, all-position welding can be carried out, and the welding process performance is good.

Owner:SUZHOU SITRI WELDING TECH RES INST CO LTD

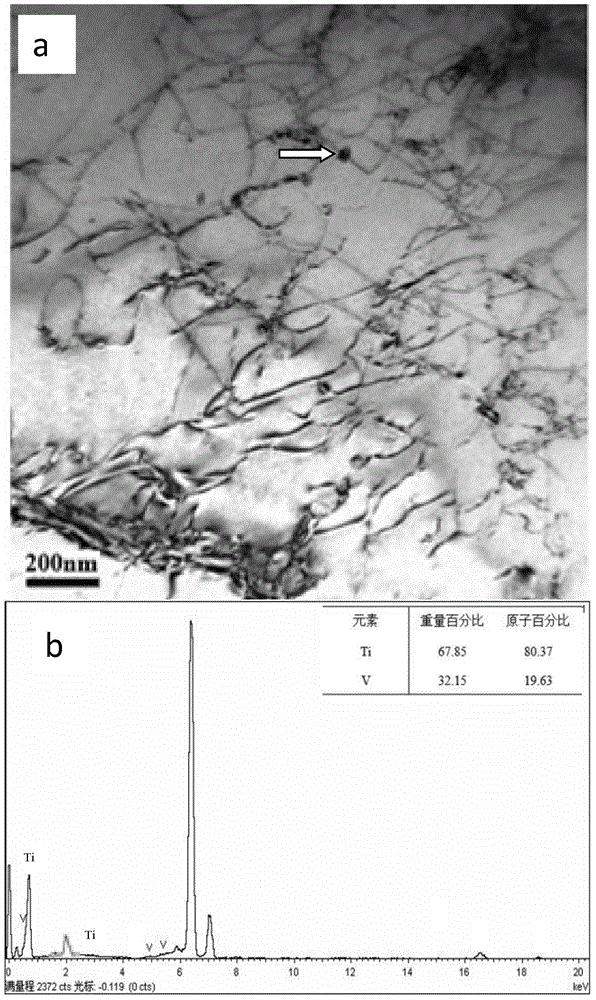

Alloy powder used for improving flexibility of dual-phase steel laser welding joints and application method of alloy powder

InactiveCN103521762AEasy to makeReduce energy consumptionLaser beam welding apparatusAlcoholEvaporating dish

The invention discloses alloy powder used for improving flexibility of dual-phase steel laser welding joints and an application method of the alloy powder. The application method includes pouring absolute ethyl alcohol into an evaporating dish, weighing 13.5-14.5% of ferrous alloy powder, 82.5-83.5% of ferrous powder, 1-1.5% of aluminum powder, 0.8-1.2% of vanadium powder and 0.8-1.2% of cerium oxide into the evaporating dish, and stirring uniformly to prepare sticky alloy powder liquid; cleaning abutted surfaces of a workpiece to be welded, uniformly coating the sticky alloy powder liquid on the abutted surfaces and the peripheral area, and then performing laser welding. The alloy powder is simple to prepare, low in energy consumption and easy to popularize, and elongation rate of welding joint breakage is increased to 4.28% from 2.40%.

Owner:TIANJIN UNIV

Welding repair method of 4145h forging and its repaired 4145h forging

The invention provides a 4145H forged piece, which relates to technical field of welding of rolled steels. The method of repair welding of 4145H forged piece mainly includes steps of preparing before welding, welding and annealing. The method of repair welding of 4145H forged piece uses welding wires of the forged piece itself to make surfacing, resolving problems of generating blowholes, cold cracks, slag inclusions and the problem of higher hardness in prior arts of using conventional repair welding method. Additionally, the method of repair welding realizes the technical effect of no cracking, and the effect of that the materials of weld bead structure conforms to the forged piece itself.

Owner:HENAN ZHONGYUAN HEAVY FORGING

Preparation method of surfacing alloy flux-cored wire

InactiveCN110814578AHigh hardnessImprove wear performanceWelding/cutting media/materialsSoldering mediaChromium carbideManganese

The invention belongs to the technical field of surfacing materials, and particularly relates to a preparation method of a surfacing alloy flux-cored wire. An alloy is prepared from the following components in percentage by mass: 0.2-0.6% of carbon, 0.4-0.8% of silicon iron, 26-30% of chromium carbide, 1-3% of magnetite, 0.2-1.0% of sodium fluoride, 0.2-1.5% of potassium titanate, 0.1-0.22% of nickel, 0.8-1.8% of manganese, and the balance of iron, and after burdening and smelting, the surfacing alloy flux-cored wire is prepared through technologies such as electroslag remelting, cogging, annealing, pickling, coping and cold drawing. The surfacing alloy flux-cored wire has good wear performance and red hardness, and peeling of a surfacing layer can be prevented.

Owner:湖北秦鸿新材料有限公司

Surfacing alloy flux-cored wire

InactiveCN110814572AHigh hardnessImprove wear performanceWelding/cutting media/materialsSoldering mediaChromium carbideFerrosilicon

The invention belongs to the technical field of surfacing materials, and particularly relates to a surfacing alloy flux-cored wire. The surfacing alloy flux-cored wire comprises the following chemicalcomposition of, in percentage by weight, 0.2% to 0.6% of carbon, 0.4% to 0.8% of ferrosilicon, 26% to 30% of chromium carbide, 1% to 3% of magnetite, 0.2% to 1.0% of sodium fluoride, 0.2% to 1.5% ofpotassium titanate, 0.1% to 0.22% of nickel, 0.8% to 1.8% of manganese and the balance iron, and has good wear performance and red hardness, and can prevent peeling of a surfacing layer.

Owner:湖北秦鸿新材料有限公司

P92 steel submerged arc welding wire

ActiveCN102189352BGuaranteed high temperature performanceImprove weld toughnessWelding/cutting media/materialsSoldering mediaWeld seamToughness

The invention discloses a P92 steel submerged arc welding wire, which contains the following chemical components in percentage by mass: 0.06 to 0.08% of C, not less than 0.40% of Si, 0.4-1.0% of Mn, not less than 0.015% of P, not less than 0.015% of S, 9.0 to 10% of Cr, 0.3 to 0.6% of Mo, 0.15 to 0.25% of V, 1.5 to 2.0% of W, not less than 0.6% of Ni, 0.03 to 0.07% of Nb, 0.8 to 1.0% of Co, 0.001to 0.05% of B, 0.03 to 0.07% of N, and the balance of Fe. The welding wire is used in the submerged arc welding, on the premise of guaranteeing high temperature performance of a welding joint, the toughness of a weld seam is increased, and the application of a highly efficient welding method of the submerged arc in the boiler production is ensured.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

High-toughness gas shielded welding wire and preparation method and use method thereof

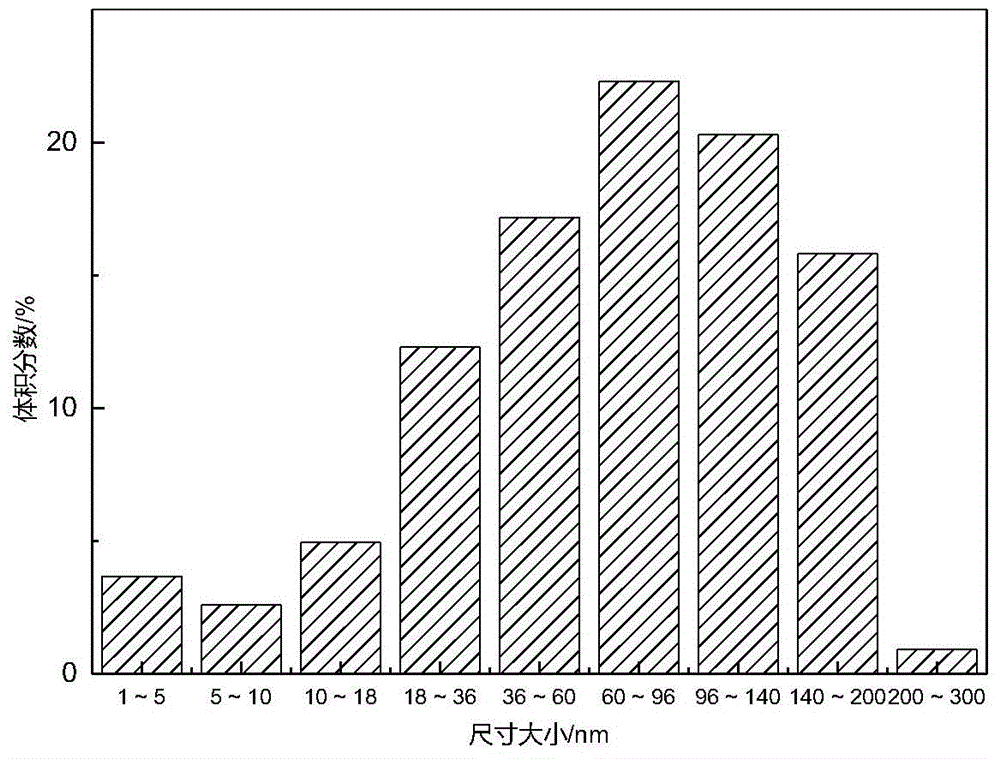

InactiveCN101704170BSimple welding processImprove weld toughnessManufacturing convertersWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

The invention discloses high-toughness gas shielded welding wire and a preparation method and a use method thereof. The high-toughness gas shielded welding wire comprises the following chemical components in percent by weight: 0.05-0.09 C, 0.9-2.0 Mn, 0.40-0.65 Si, 0.01-1.0 Ni, 0.01-0.3 Cu, 0.01-0.35Cr, 0.01-0.3 Mo, 0.01-0.15 Ti, 0.020 or less P, 0.015 or less S, 0.001-0.005 O, 0.005-0.025Als, 0.005-0.025 Ca, and the balance of Fe and inevitable impurities. The welding wire simultaneously can satisfy the equation that the carbon equivalent CE=0.38-0.50%. The preparation method of the high-toughness gas shielded welding wire comprises the following steps of: performing the desulfurization treatment on molten steel, smelting by a converter or an electric furnace, refining by ladle furnace or ladle argon blowing, continuous casting, rolling, forming wires by pulling and the like. The mixed gases including 70-90 volume percent of Ar and 10-30 volume percent of rich Ar are adopted as the shielded gas in welding. Practices show that welding seams welded by the high-toughness gas shielded welding wire has higher toughness.

Owner:武钢集团有限公司

A kind of preparation method of trip steel containing δ-ferrite

Owner:UNIV OF SCI & TECH BEIJING

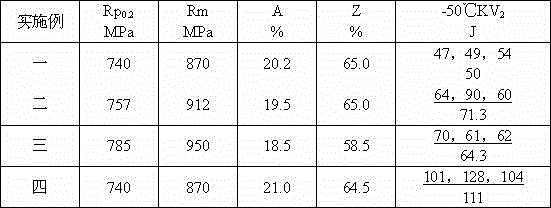

High-strength high-tenacity sintered flux for afterheat-free welding

InactiveCN103273222BRight melting pointModerate viscosityWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses a high-strength high-tenacity sintered flux for afterheat-free welding. The sintered flux is mixed sinter composed of dry powder and pure sodium water glass with the modulus of 2.8-3.2, and the addition amount of the water glass is 18-20% of the weight of the dry powder. The dry powder is composed of, by weight percent, 18-23% of fluorite, 33-37% of magnesia, 14-17% of bauxite, 3-5% of quartz, 7-12% of marble, 9-13% of wollastonite, 0-1.5% of ferromolybdenum, 1-3% of rare earth fluoride, 1-2% of silicon iron, 1-3% of manganese ore, and 0-3% of borax. Compared with the prior art, the sintered flux can form welding slag with an appropriate melting point and good viscosity and surface tension. In the welding process, arc combustion is stable, welding line transition is smooth, spreading is good, and appearance of welding lines is attractive. The oxygen content in the welding lines is lowered. The sintered flux can be matched with the WS80S welding wire for welding 10CrNi5MoV steel, yield strength of metal of the welding lines can reach more than 735MPa, the metal of the welding lines is -50 DEG C, impact energy can reach more than 50J, and the metal of the welding lines of afterheat-free welding can be crack-free.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A Vacuum Electron Beam Welding Method of Pre-embedded Welding Wire

InactiveCN106513974BLow susceptibility to weld cracksImprove mechanical propertiesElectron beam welding apparatusWelding/soldering/cutting articlesButt weldingHigh energy

The invention provides a welding stick embedding vacuum electron beam welding method. A low-carbon welding stick is embedded in an initial weldment, and two continuous casting sheet billets are stacked and welded together through an electron beam in the vacuum environment and then are used for subsequent steel rolling production. The low-carbon welding stick is embedded, chemical components of a molten bath can be finely adjusted, a peritectic reaction area is avoided, and welding crack sensitivity of base metal is reduced. Compared with self-fluxing vacuum electron beam welding, the beneficial effects of high-energy density, high penetration performance, the small welding deformation area, easy control, the high production efficiency and the like of self-fluxing vacuum electron beam welding can be kept, meanwhile, the assembling precision during butt welding can be obviously improved, welding line formation is improved, and the mechanical performance of connectors is improved. By means of the method, the problem that a self-fluxing vacuum electron beam welding method is adopted in crack sensitivity steel grade welding, welding cracks happen is solved, the application range of vacuum electron beam welding is greatly enlarged, the method is suitable for mass industrial production, and obvious economical and social benefits are achieved.

Owner:TIANJIN UNIV

Welding method of low carbon alloy structural steel gear assembly

ActiveCN107243687BImprove welding efficiencyReduce energy consumptionArc welding apparatusWelding/cutting media/materialsFusion weldingMixed gas

Owner:SHANDONG LINGONG CONSTR MACHINERY

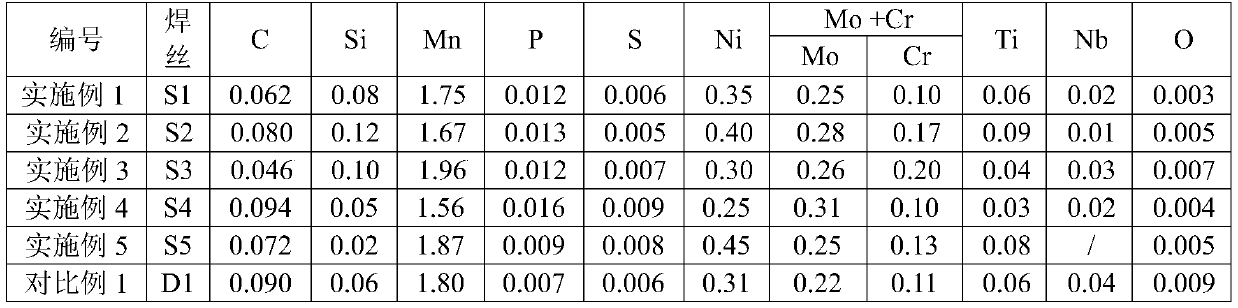

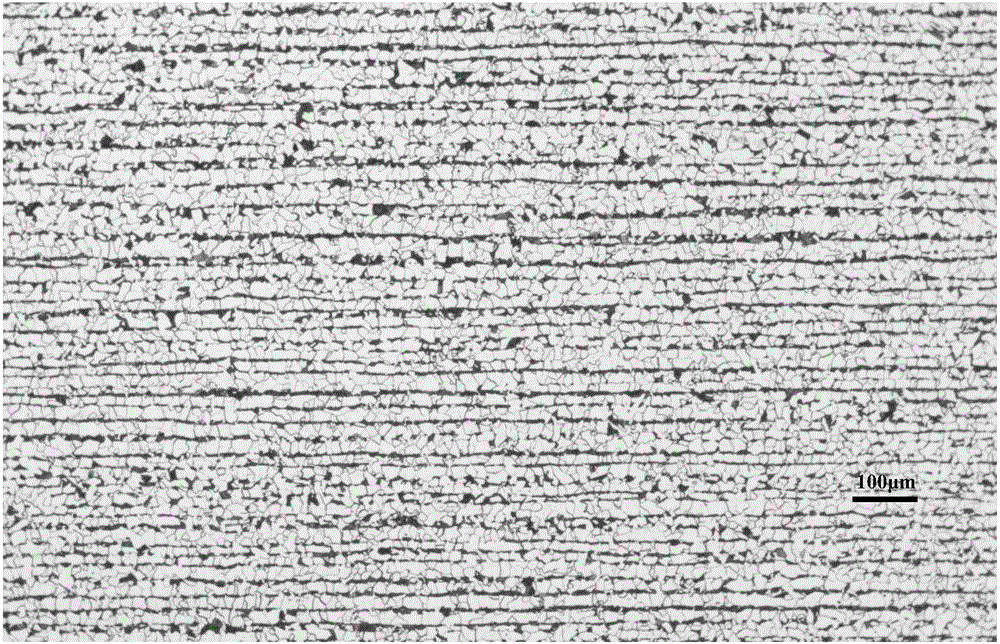

A kind of welding wire for double pass submerged arc welding of 630mpa grade high nb steel

ActiveCN107900555BImprove problems such as insufficient strength and toughnessReduce manufacturing costWelding/cutting media/materialsSoldering mediaAlloyToughness

The invention discloses a welding wire for 630 MPa grade high Nb steel double submerged arc welding. The welding wire comprises, by mass, 0.04-0.10% of C, no more than 0.15% of Si, 1.50-2.00% of Mn, no more than 0.018% of P, no more than 0.01% of S, 0.20-0.50% of Ni, 0.30-0.50% of Mo+Cr, 0.02-0.10% of Ti, no more than 0.03% of Nb, no more than 80 ppm of O, no more than 0.02% of Als, and the balance Fe. According to the welding wire for 630 MPa grade high Nb steel double submerged arc welding, a Mn-Ni-Mo-Cr alloy system is adopted and combined with means such as Ti and Nb micro-alloying, weaklyalkaline sintered flux is matched, mechanical properties of deposited metal and strength and toughness of a high Nb steel double submerged arc welding joint can be taken into account simultaneously,and the problems such as poor strength and toughness of an existing high Nb steel double submerged arc welding joint are effectively relieved.

Owner:武汉钢铁有限公司

A kind of low-temperature-resistant hot-rolled H-shaped steel and its preparation method

The invention discloses a low-temperature-resistant hot-rolled H-shaped steel and a preparation method thereof. The hot-rolled H-shaped steel comprises the following chemical components in percentage by weight: 0.07-0.10% of C, 0.2-0.4% of Si, 1.30-1.60% of Mn, at most 0.020% of P, at most 0.015% of S, 0.015-0.070% of V, 0.010-0.030% of Ti, and the balance of Fe and inevitable impurities. The production method comprises the following steps: converter smelting, LF (ladle furnace) refining, continuous casting, rolling and the like. The structure of the H-shaped steel is a polygonal ferrite and pearlite structure, the yield strength is 350-450 MPa, the tensile strength is 480-600 MPa, the percentage elongation after fracture is greater than or equal to 22%, and the -40-DEG C V-notch Charpy impact energy is greater than or equal to 200J.

Owner:SHANDONG IRON & STEEL CO LTD

Welding method of 12cr5mo martensitic stainless steel

ActiveCN106312242BSmall coefficient of thermal expansionImprove performanceArc welding apparatusWelding/cutting media/materialsSlagMartensitic stainless steel

The invention relates to a welding method for 12Cr5Mo martensite stainless steel. The welding method comprises the following steps: step I, preparing a 12Cr5Mo martensite stainless steel groove, carrying out butt-joint assembly on the groove, and pre-heating a welded part of the groove at a pre-heating temperature being 100-150 DEG C; and step II, separately carrying out a primary welding process, a secondary welding process and a tertiary welding process on the welded part of the groove by use of a welding rod, wherein the welding rod is composed of a welding core and a coating; and the welding core consists of the following raw materials: C, Ni, Cr, Mn, Si, Ti, Nb, V, Ta, Zr, La, Ce, Pr, W, N and Fe. The coating consist of the following components: rutile, titanium dioxide, potassium feldspar, mica, calcium carbonate, nitrogen containing ferrochromium, electrolytic manganese, metal nickel, ferrocolumbium, magnesium oxide, yttrium oxide, sodium fluosilicate, hydroxypropyl methyl cellulose, phenolic resin and melamine. According to the welding method, a welding process is simple, welding seam molding is beautiful, slag is easily separated and deposition efficiency is high; and the obtained welding seam metal has excellent mechanical performance and mechanical property.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

A welding method of q460 high-strength steel pipe for UHV transmission steel pipe tower

ActiveCN102886593BReduced tendency to cold crackingGuarantee welding qualityArc welding apparatusTubular articlesAlloyTower

The invention relates to a welding method for the Q460 high-strength steel tube of an extra-high-voltage power transmission steel tube tower, and the welding method comprises the following steps of: using a low-alloy high-strength steel plate having a yield strength of 460 MPa level, grinding the both sides of the low-alloy high-strength steel plate into single-surface grooves, bending the low-alloy high-strength steel plate into a primarily-formed steel tube with longitudinal slits, performing backing welding on welding joints, welding by means of CO2 gas shielded welding, and using JM68 welding wires; and continuously welding by means of submerged arc automatic welding during filling and covering, using CHW-S9 submerged arc welding wires, and using an SJ101 flux. According to the invention, aiming problems in welding for the Q460 high-strength steel tube, the CO2 gas shielded welding is combined with selection for the JM68 welding wires and reasonable welding parameters, and the CO2 gas shielded welding is combined with welding using the CHW-S9 welding wires and the SJ101 flux, thus improving the toughness and the quality of the welding joints, and increasing production efficiency and promoting the large-scale production simultaneously.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Alloy powder for improving the toughness of dual-phase steel laser welding seam and its application method

InactiveCN103521762BEasy to makeReduce energy consumptionLaser beam welding apparatusEvaporating dishWeld seam

The invention discloses alloy powder used for improving flexibility of dual-phase steel laser welding joints and an application method of the alloy powder. The application method includes pouring absolute ethyl alcohol into an evaporating dish, weighing 13.5-14.5% of ferrous alloy powder, 82.5-83.5% of ferrous powder, 1-1.5% of aluminum powder, 0.8-1.2% of vanadium powder and 0.8-1.2% of cerium oxide into the evaporating dish, and stirring uniformly to prepare sticky alloy powder liquid; cleaning abutted surfaces of a workpiece to be welded, uniformly coating the sticky alloy powder liquid on the abutted surfaces and the peripheral area, and then performing laser welding. The alloy powder is simple to prepare, low in energy consumption and easy to popularize, and elongation rate of welding joint breakage is increased to 4.28% from 2.40%.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com