Patents

Literature

44 results about "Weld quality assurance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weld quality assurance is the use of technological methods and actions to test or assure the quality of welds, and secondarily to confirm the presence, location and coverage of welds. In manufacturing, welds are used to join two or more metal surfaces. Because these connections may encounter loads and fatigue during product lifetime, there is a chance they may fail if not created to proper specification.

Argon arc welding technological method for nickel base alloy tubes

ActiveCN104759743AImprove high temperature durabilityGood room temperatureArc welding apparatusWelding/cutting media/materialsWeld quality assuranceAlloy

The invention discloses an argon arc welding technological method for nickel base alloy tubes. The argon arc welding technological method includes the following steps of selecting welding materials; conducting blanking and machining grooves, wherein cold cutting is adopted for blanking, and the grooves are machined; clearing the grooves and surfaces around the grooves, wherein areas in the range from 50 mm to100 mm around the grooves are cleared; conducting PR detection on the grooves; conducting connector pairing, wherein a pairing gap is controlled within the range from 1 mm to 2 mm, and no staggered edges exist; conducting backing welding, wherein backing welding is conducted sectionally and symmetrically; conducting filling and cosmetic welding, wherein a multilayer and multichannel welding mode is adopted, welding interlayer temperature is controlled not to exceed 100 DEG C, and specific welding technological parameters are set; conducting postwelding inspection. The argon arc welding technological method can effectively solve the problems that during welding of centrifugal casting ZG45Ni35Cr25NbM nickel base alloy tubes, hot cracks exist, weld metal is overheated, incomplete fusion occurs and roots of welds are not fused. Satisfying welding quality of nickel base alloy tubes is achieved, and use performance of nickel base alloy tubes is guaranteed.

Owner:中国石油天然气第一建设有限公司

Automatic welding process of stainless steel pipes

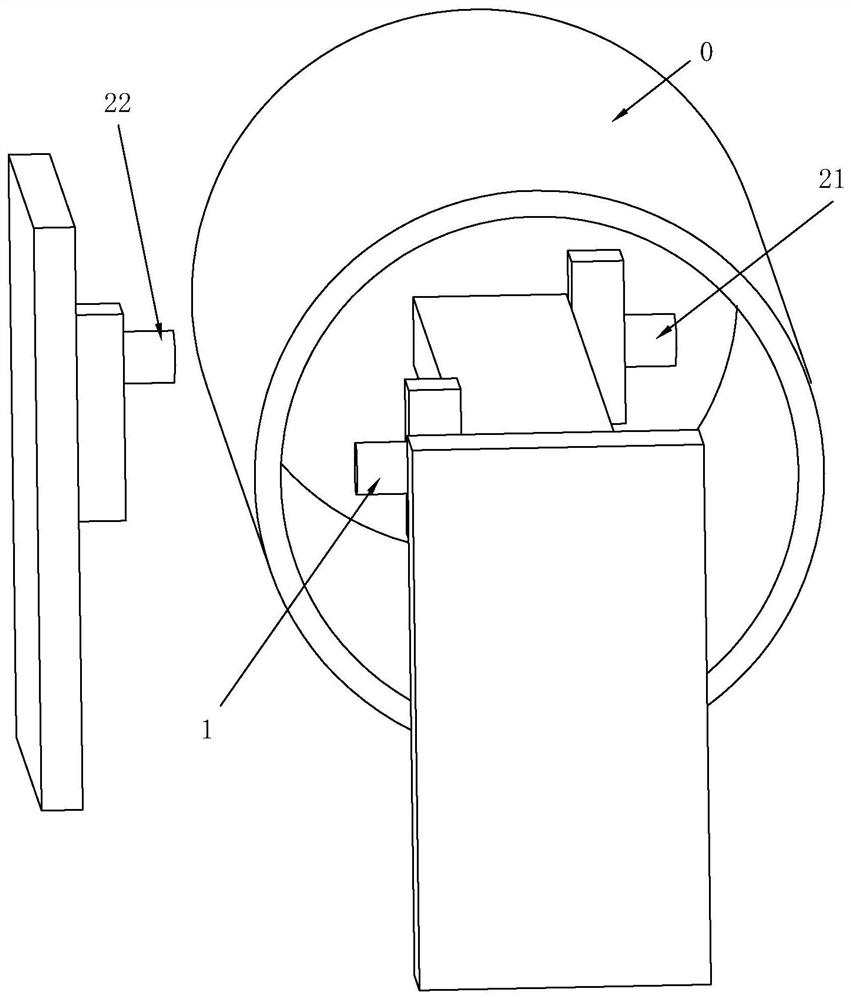

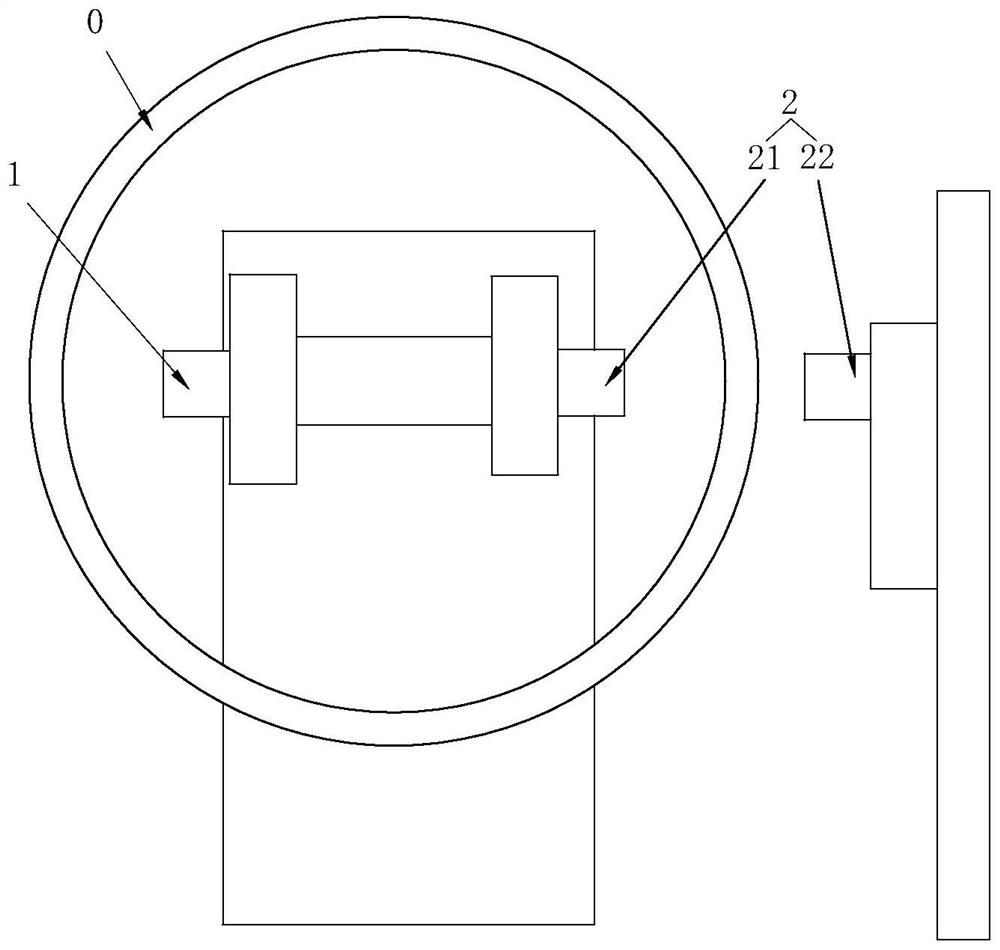

ActiveCN111745319AGuaranteed accuracyGuaranteed tightnessWelding/cutting auxillary devicesAuxillary welding devicesWeld quality assuranceStructural engineering

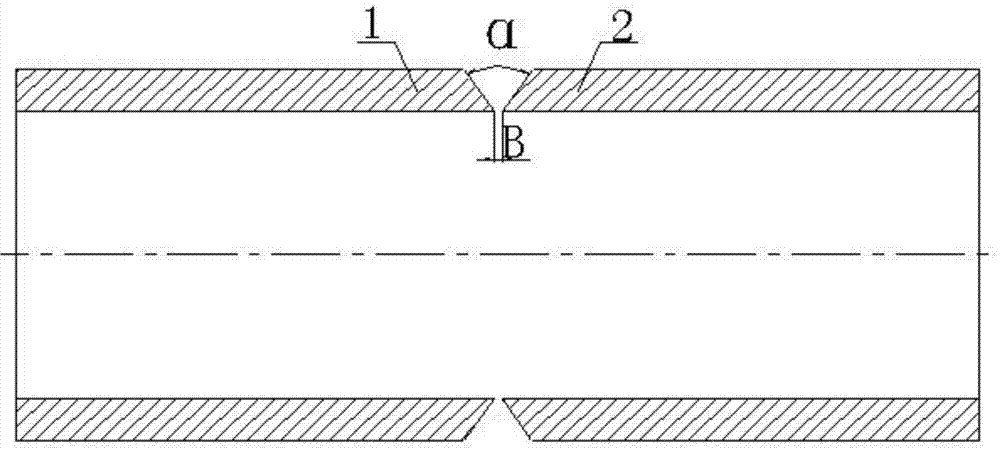

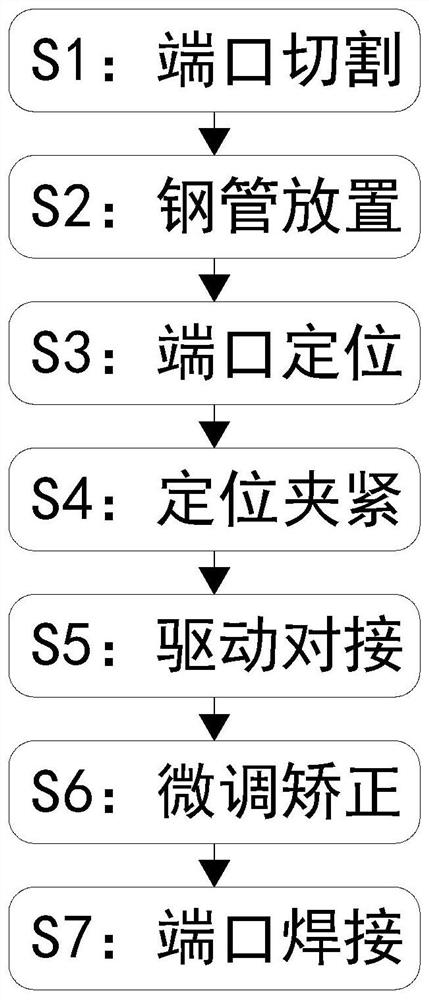

The invention relates to an automatic welding process of stainless steel pipes, in particular to an automatic welding fixture for the stainless steel pipes. The automatic welding fixture comprises a fixture table, a butt-joint synchronous driving mechanism arranged on the lower part of the fixture table, two positioning clamping mechanisms for correspondingly positioning and clamping two stainlesssteel pipes one to one, a positioning baffle plate mechanism for positioning welding end ports of the two stainless steel pipes and a fine-adjusting correcting mechanism for fine-adjusting and correcting. According to the fixture related in the process, the welding auxiliary butt-jointing can be conducted for the stainless steel pipes welded vertically at two end ports, the accurate butt-jointingof the welding end ports of the two stainless steel pipes can be automatically and quickly achieved, the accuracy and tightness of the welding end port butt-jointing are ensured, thus the welding quality of a welding product is ensured, and the welding strength and welding beautiful degree are ensured.

Owner:徐州同乐管业有限公司

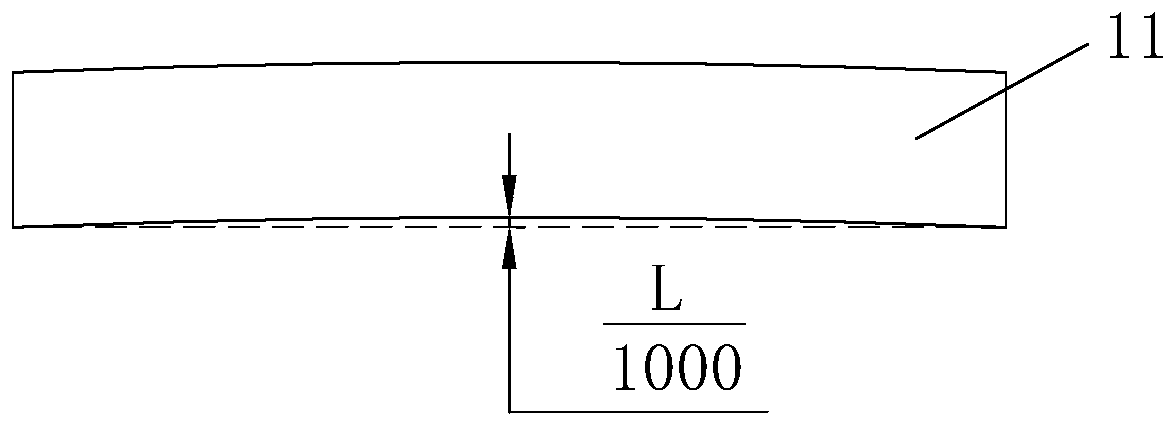

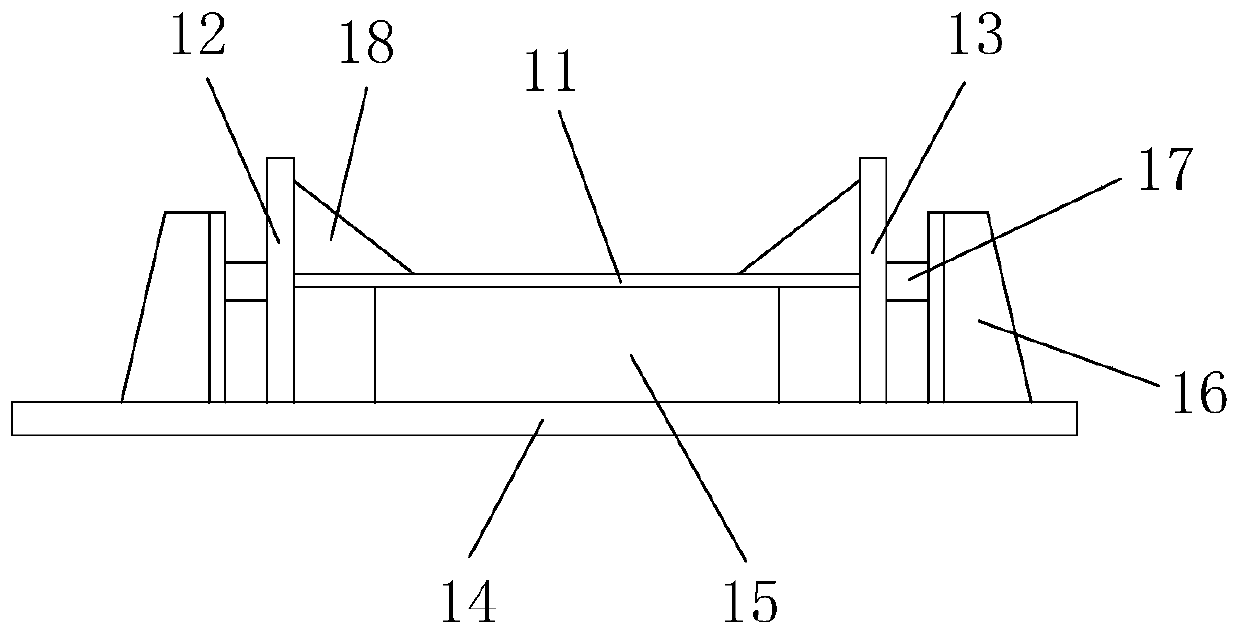

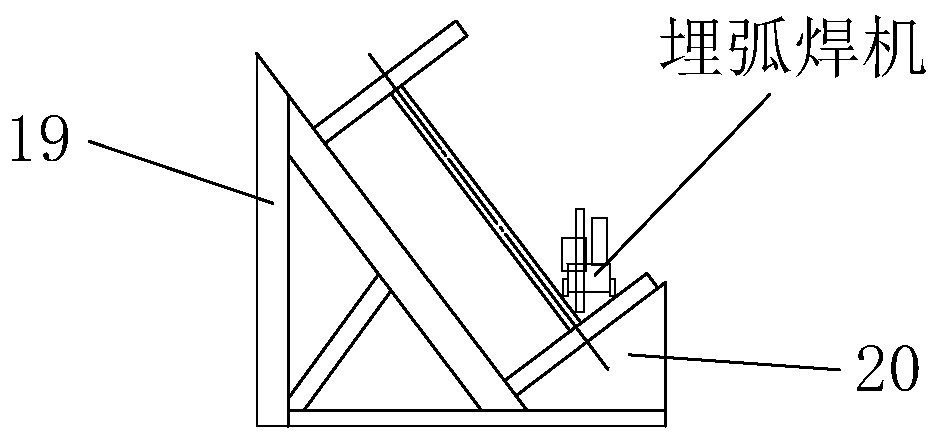

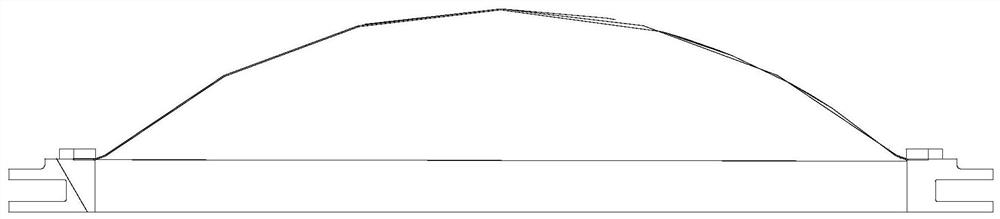

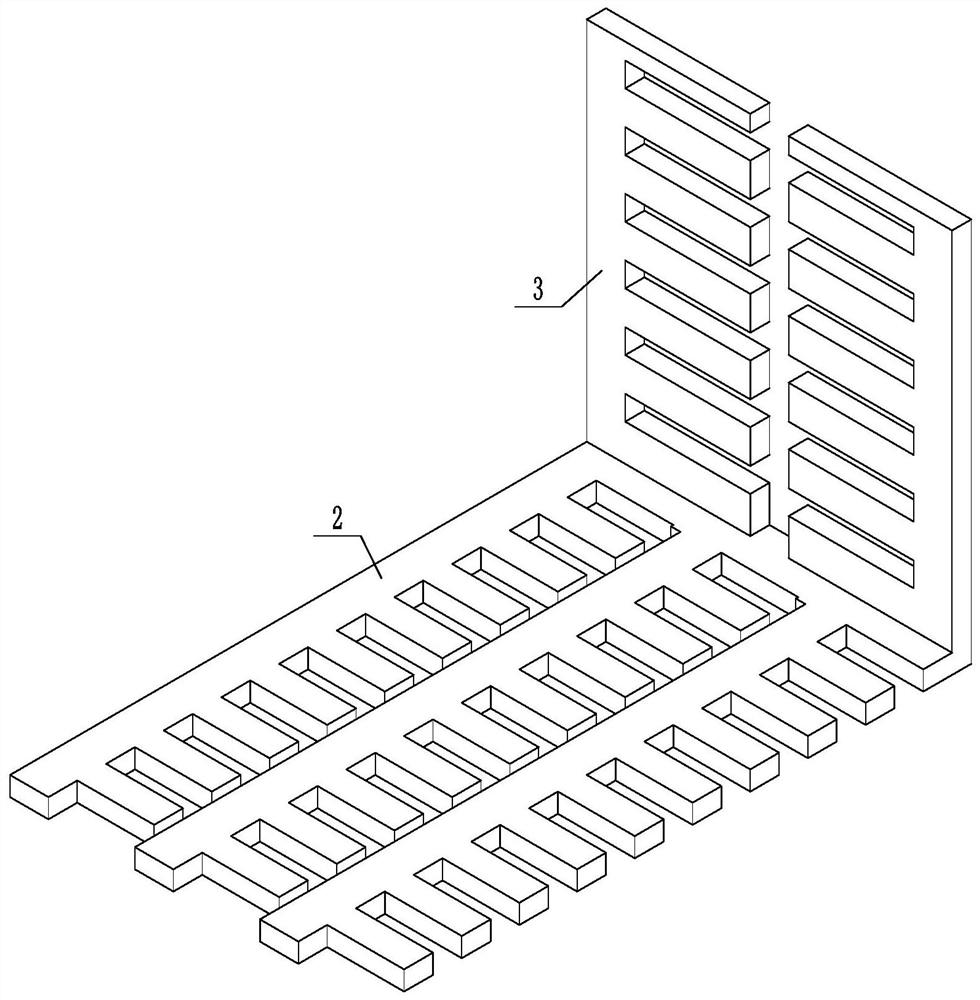

Method for manufacturing large tonnage heavy solid-web crane beam pre-arch camber

ActiveCN110877191ALess downswingShorten the construction periodLoad-engaging girdersNumerical controlWeld quality assurance

The invention relates to a method for manufacturing a large tonnage heavy solid-web crane beam pre-arch camber. The method comprises the steps that 1, check of drawings and sizing calculation are conducted; 2, steel plate snapline setting out is conducted; 3, numerical control cutting and discharging are conducted; 4, groove feculence cleaning and smooth grinding are conducted; 5, an H-shaped steel group is assembled; 6, welding resistance stiffening plate is conducted; and 7, anticorrosive coating is conducted. According to the method manufacturing the large tonnage heavy solid-web crane beampre-arch camber, a manufacturing method which combines the pre-arching camber, a special assembly platform, and welding tires with a reasonable welding sequence is adopted, at the same time, attention is paid to controlling welding deformation and welding quality, overall quality is ensured, the occurrence of the situation of down-wrapping is reduced, the construction period can be shortened, andmore working time is provided for subsequent works.

Owner:五矿二十三冶建设集团第二工程有限公司

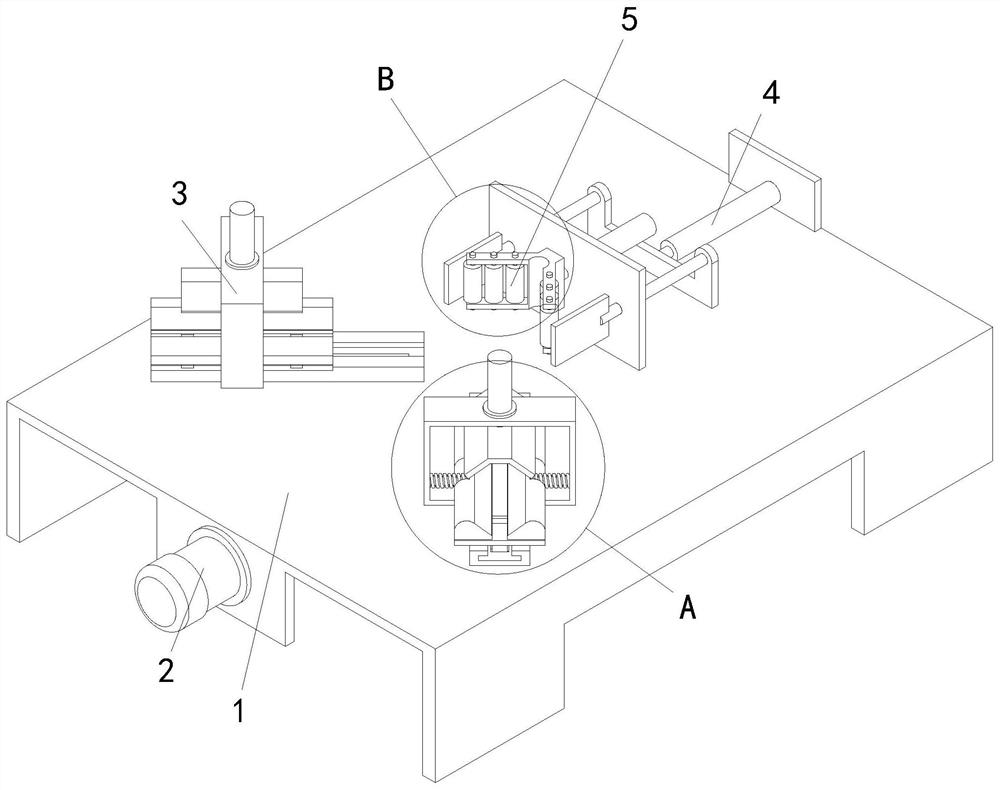

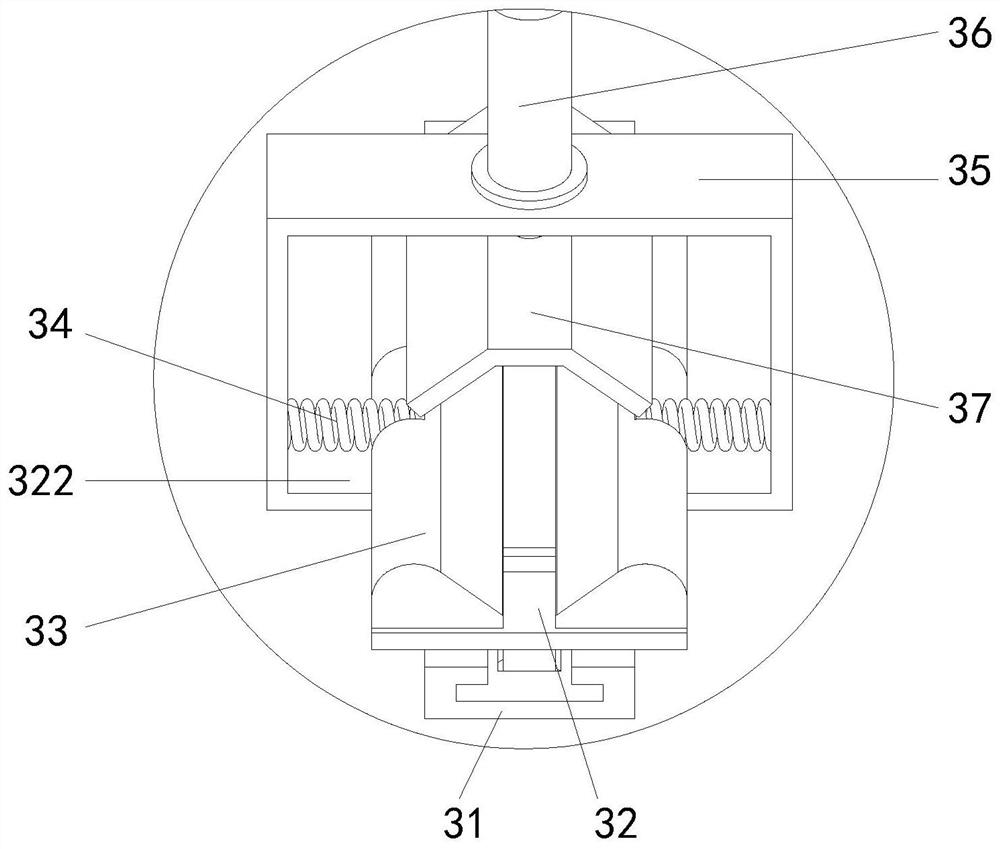

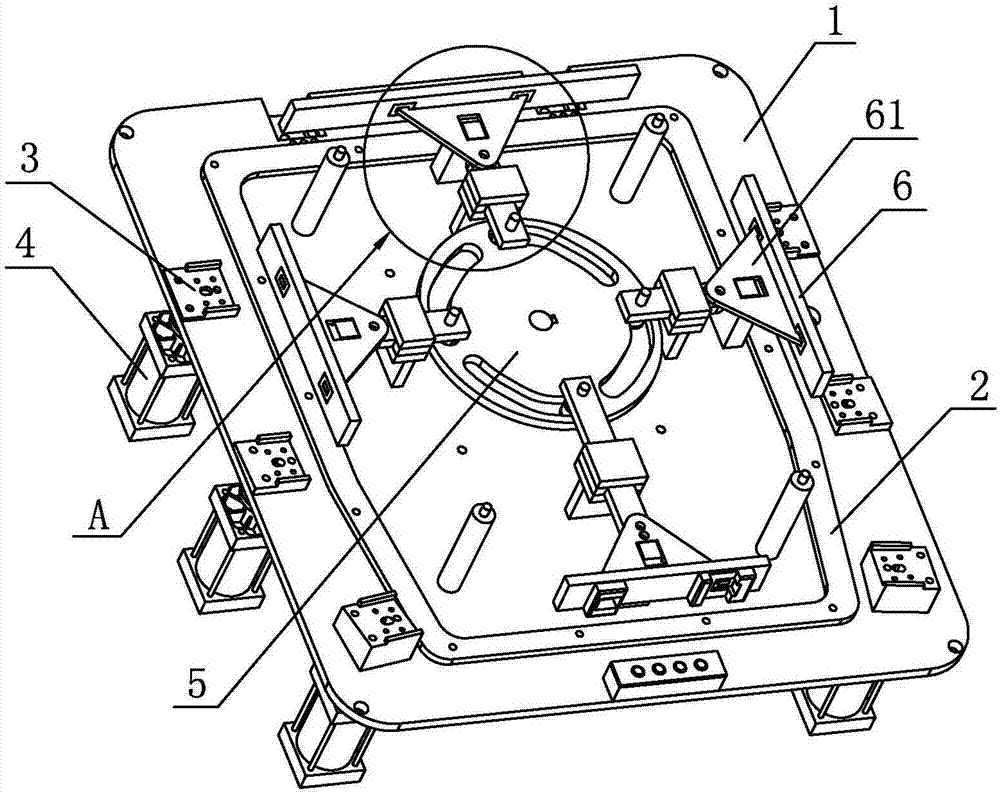

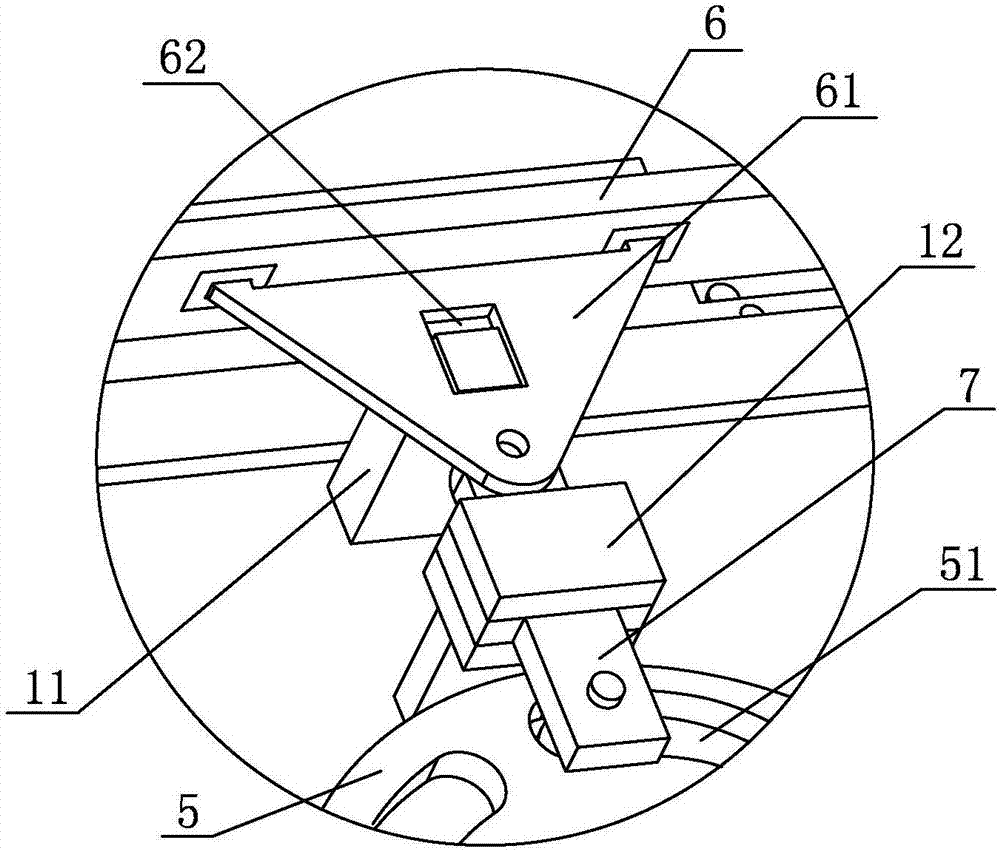

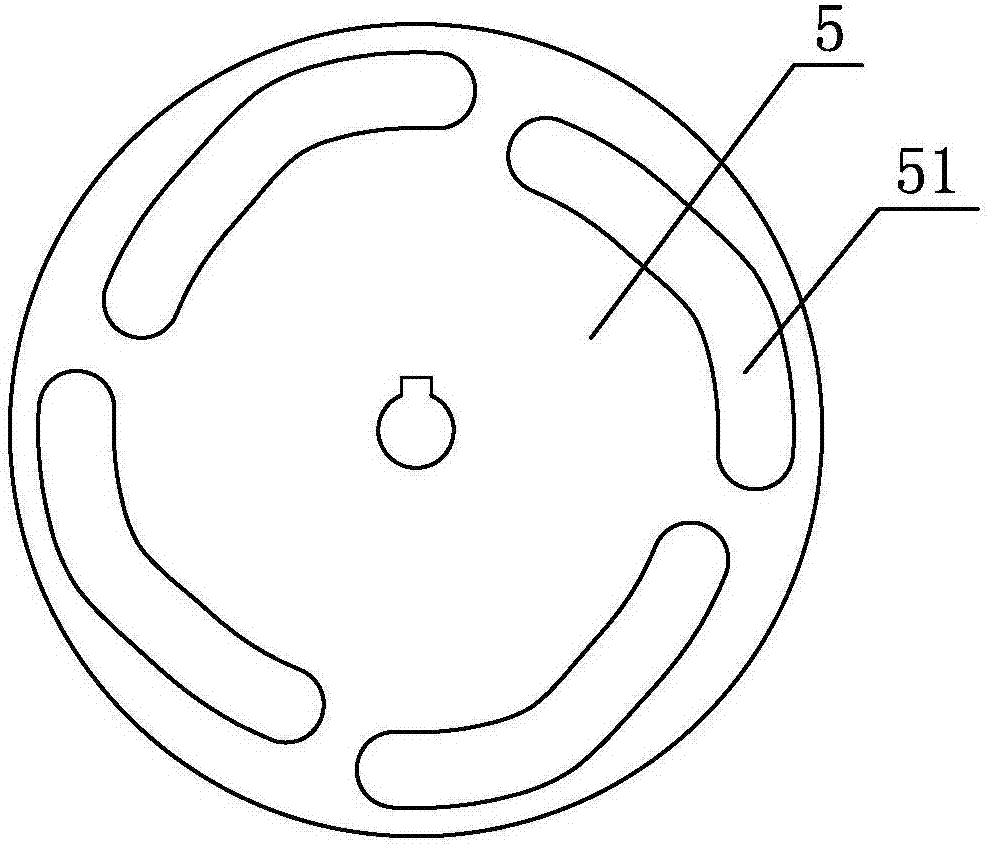

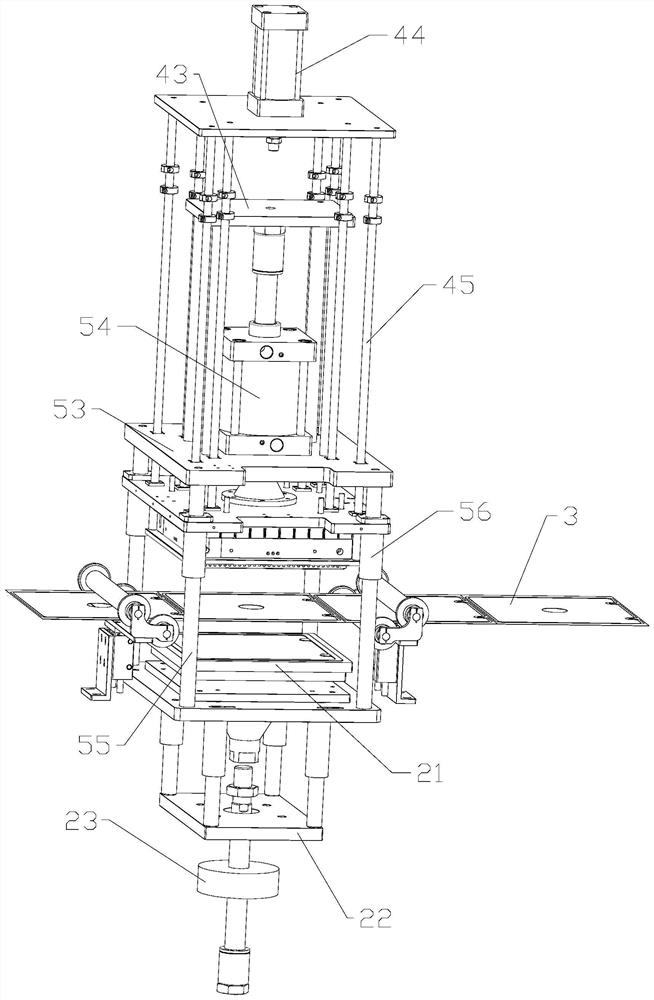

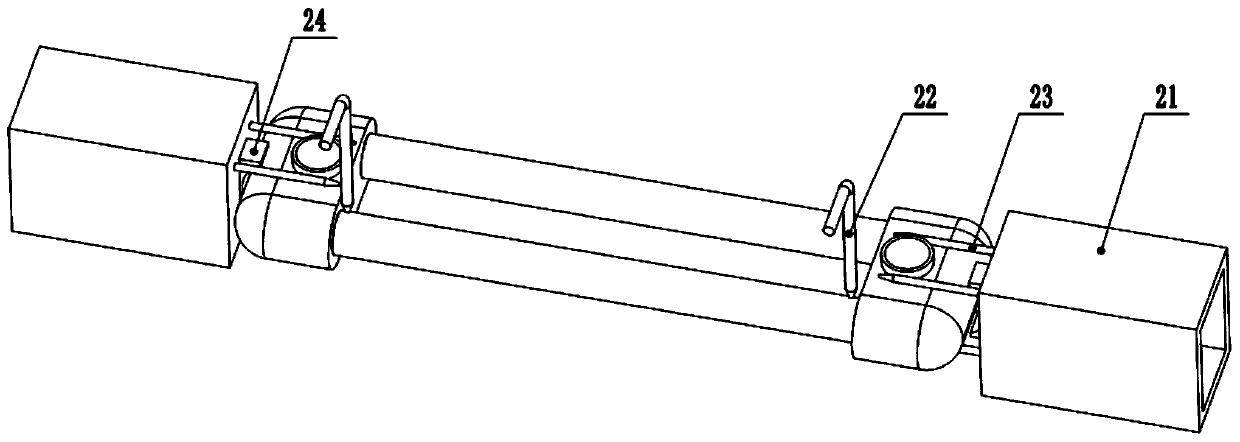

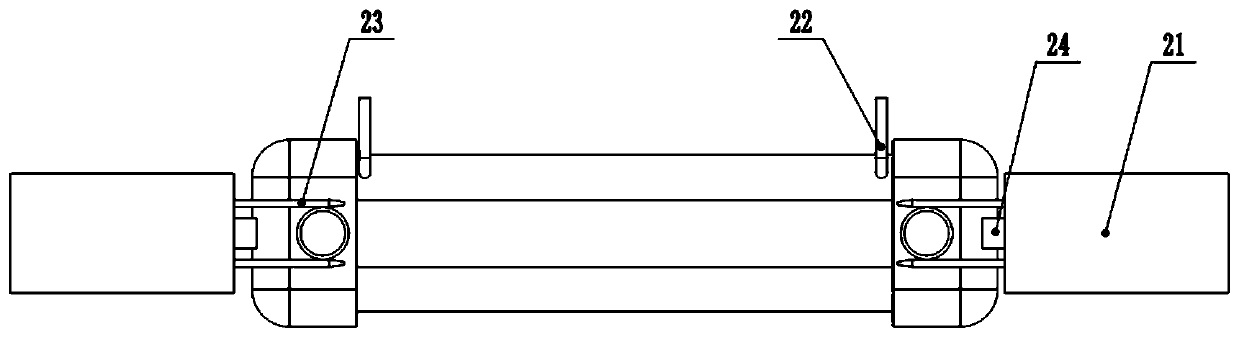

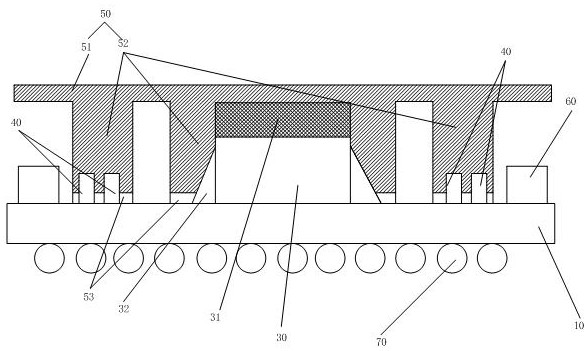

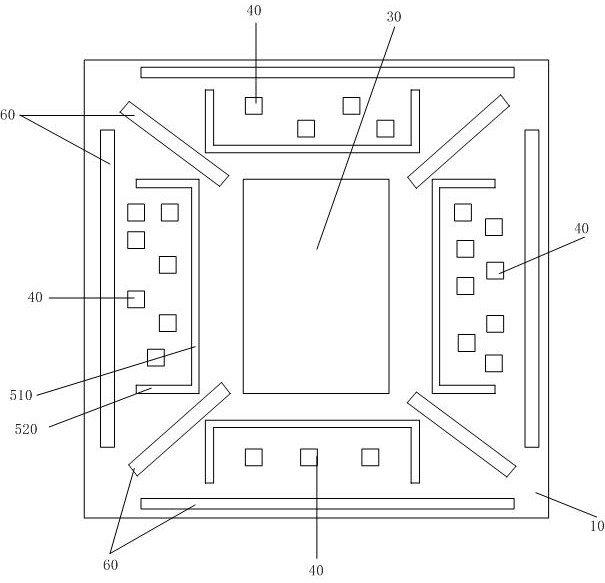

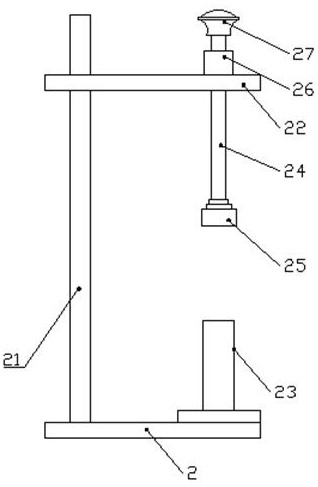

Welding positioning tool of battery box body of electric automobile

PendingCN107350684AReduce welding distortionGuaranteed connection strengthWelding/cutting auxillary devicesAuxillary welding devicesAutomotive batteryElectrical battery

The invention discloses a welding positioning tool of a battery box body of an electric automobile. The tool comprises a bottom plate and a box body inner cavity limiting plate fixedly arranged on the bottom plate, wherein a plurality of connecting seat bases corresponding to connecting seats on the battery box body in position in a one-to-one mode are arranged on the bottom plate, and a lifting driving mechanism is arranged on each connecting seat base. The tool is characterized in that a box body side wall outward supporting mechanism is arranged on the bottom plate, and has the advantages that due to the fact that the box body side wall outward supporting mechanism is arranged on the bottom plate, before the connecting seats are welded, the side walls of the battery box body are supported outwards through the box body side wall outward supporting mechanism, the welding deformation of the side walls is reduced, the welding quality between the connecting seats and the side walls of the box body is improved, and the connecting strength of the battery box body is guaranteed.

Owner:YUYAO HUIMEI ELECTRIC APPLIANCE

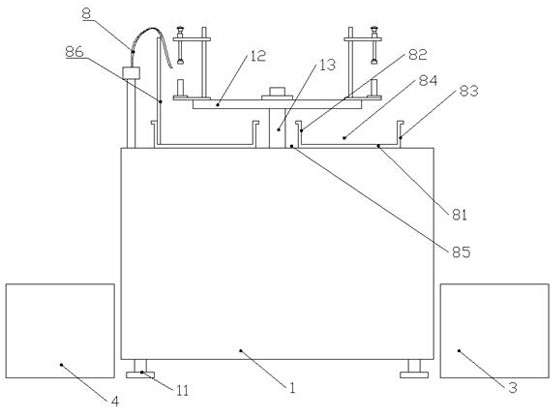

Automobile air conditioner accessory welding machine

PendingCN112894238APrevent looseningAvoid misalignmentWelding/cutting auxillary devicesAuxillary welding devicesGear wheelWeld quality assurance

The invention discloses an automobile air conditioner accessory welding machine. According to the automobile air conditioner accessory welding machine designed by the invention, when the accessory welding work is performed, accessories can be well clamped and fixed through a welding workbench, a transmission gear, a first transmission rack, a second transmission rack, a clamping and fixing plate and an elastic strip, the accessories can be subjected to clamping and fixing well, the accessories are prevented from being loosened and dislocated during welding work, and contact between the accessories is tighter and firmer, then the welding quality is improved, and normal proceeding of the welding work is guaranteed; and through an arranged adjusting, regulating and positioning structure, the flexibility of the welding work can be improved, the actual requirements of the accessory welding work are met, convenience is brought to workers, accordingly, the working efficiency is improved, and the economic benefits of welding work are improved.

Owner:向群

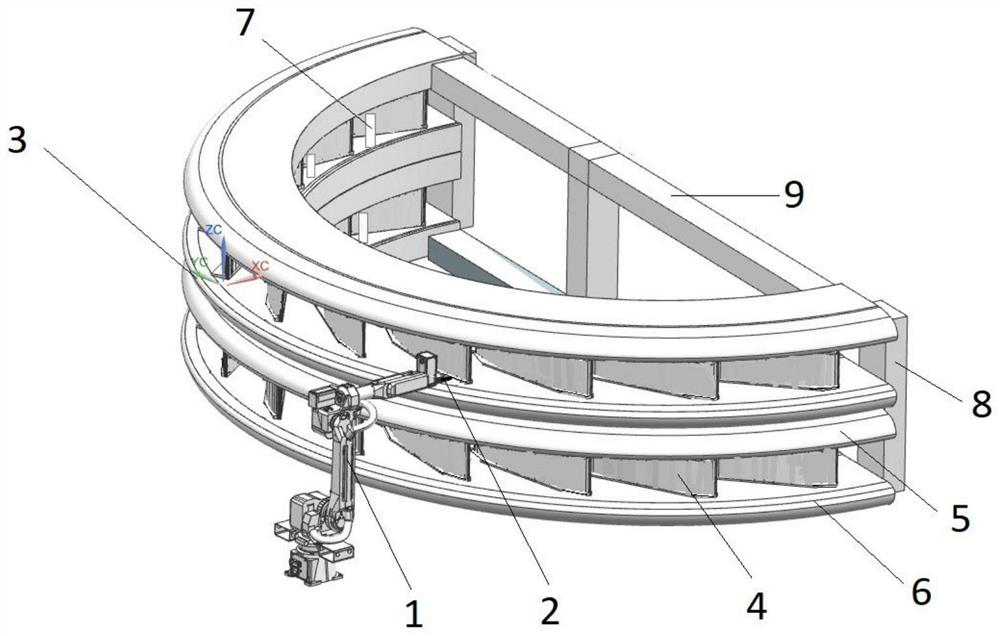

Efficient horizontal position welding process method for pumping storage seat ring fixed guide vane

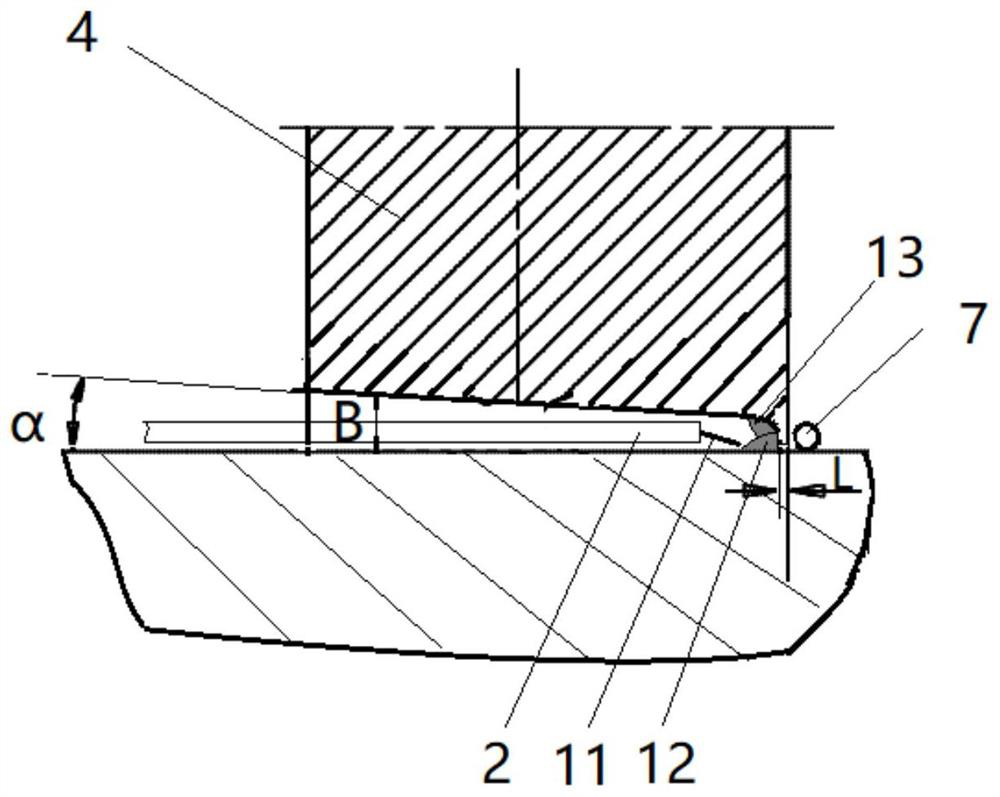

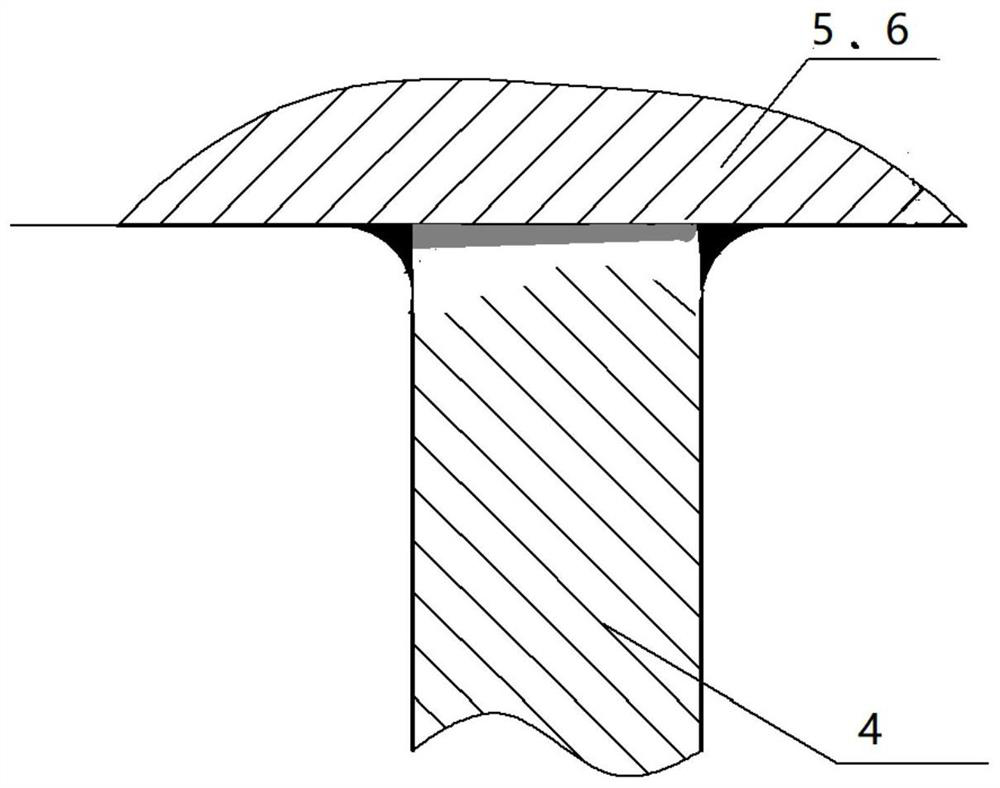

InactiveCN113134661AInnovation of Welding Process MethodReduce the amount of weld fillerArc welding apparatusWorkpiece edge portionsWeld quality assuranceEngineering

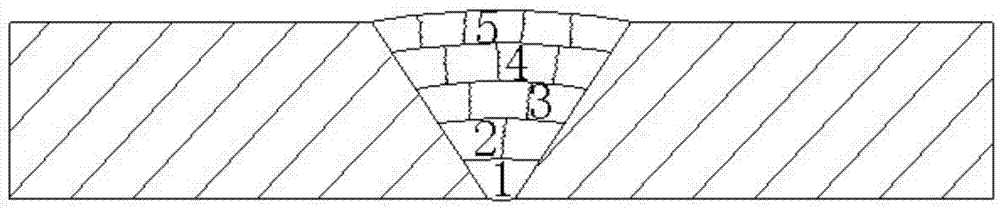

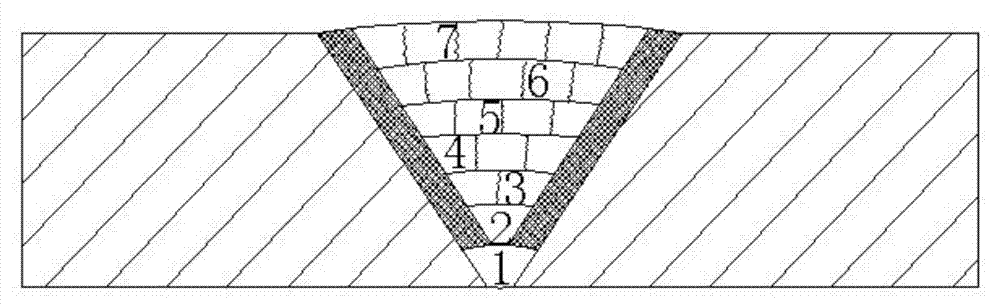

The invention discloses an efficient horizontal position welding process method for a pumping storage seat ring fixed guide vane. Firstly, the seat ring fixed guide vane with the thickness of 150-260 mm is processed into a narrow gap groove with the width of 10-25 mm, robot narrow gap gas shield welding accessibility is simulated offline, welding path programming is carried out, two sections of a seat ring are stacked, the seat ring is placed at a horizontal position, the narrow gap groove is welded to 1 / 4-1 / 3 depth after alternate backing welding, back gouging and fillet welding are conducted on the back face, and then the narrow gap groove is welded alternately. In the welding process, two paths are welded on each layer, the lower path is welded firstly, then the upper path is welded, a robot programming position register is used for achieving welding path automatic deviation, a weld pool edge linear image obtained through a CMOS welding camera is used for judging and adjusting welding deviation, and the problem about the fusion quality of the side wall of efficient robot narrow gap horizontal welding of the seat ring is solved. Compared with conventional manual welding, the welding amount is reduced by 60%-80%, the procedure of turning over the seat ring in a reciprocating manner is omitted, and the production efficiency is improved by 1-2 times under the guarantee of the stable and reliable welding quality.

Owner:HARBIN ELECTRIC MASCH CO LTD

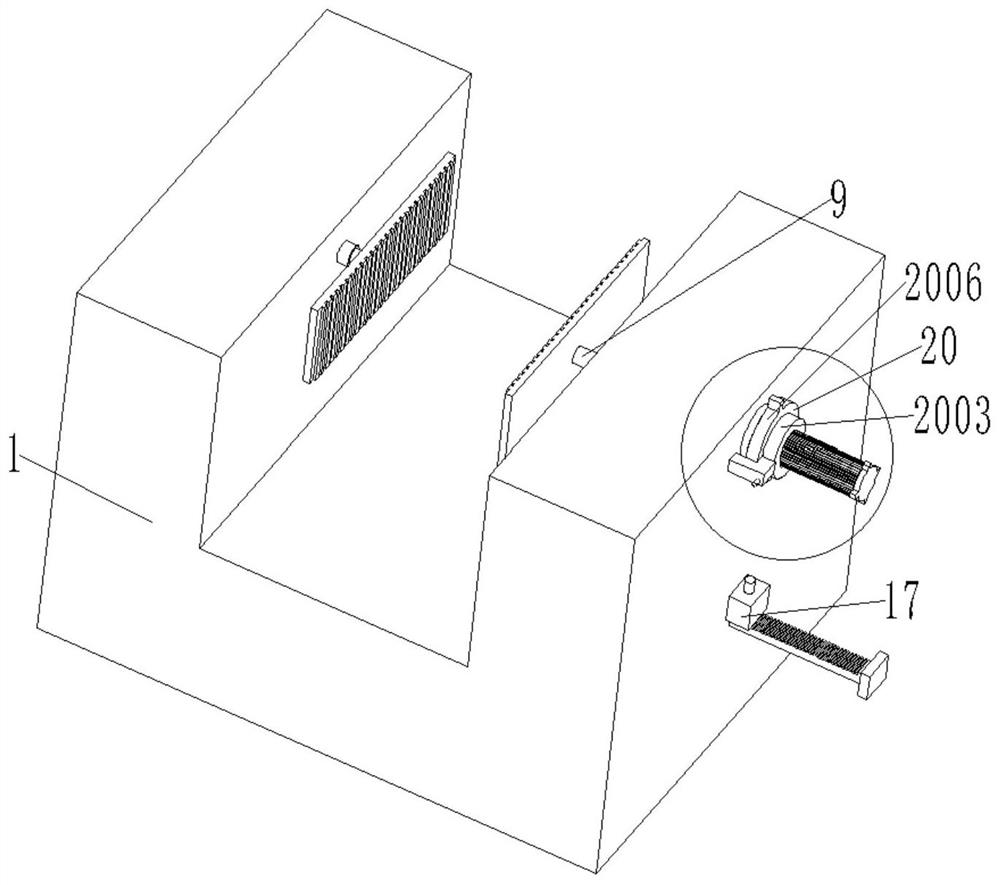

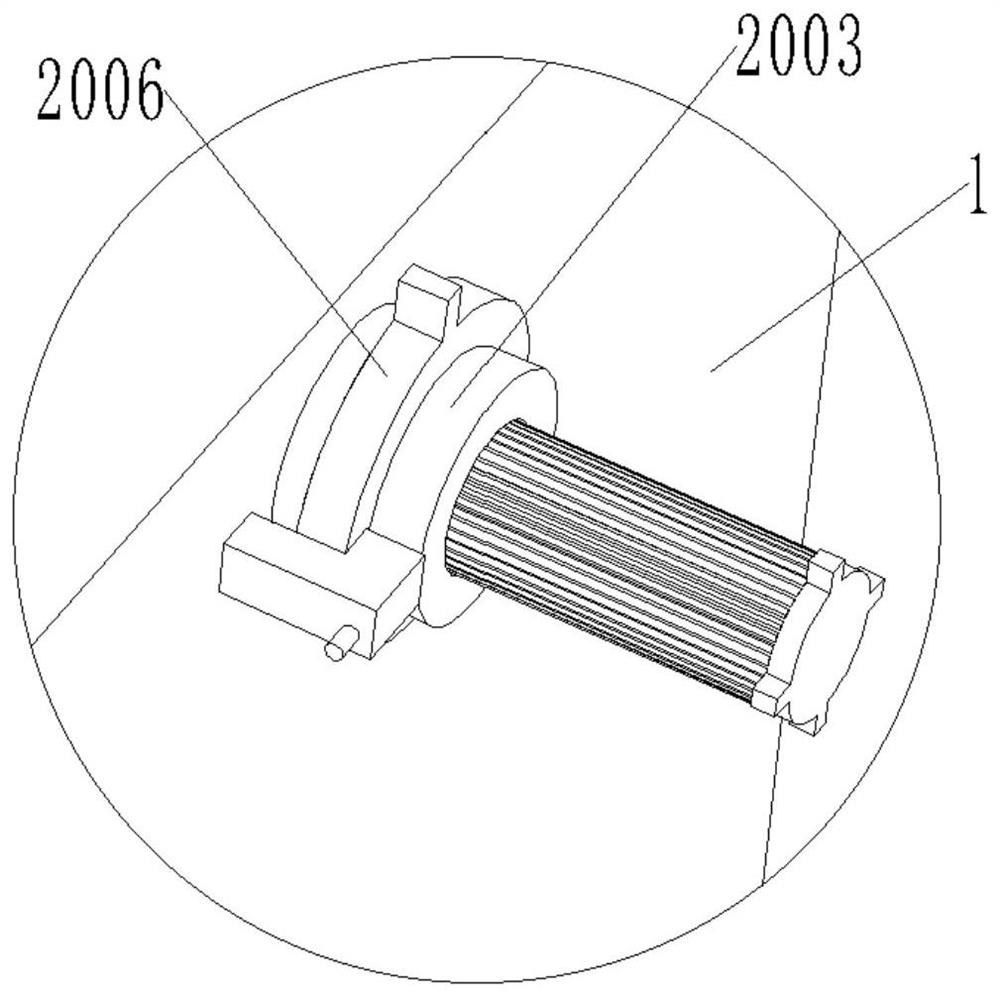

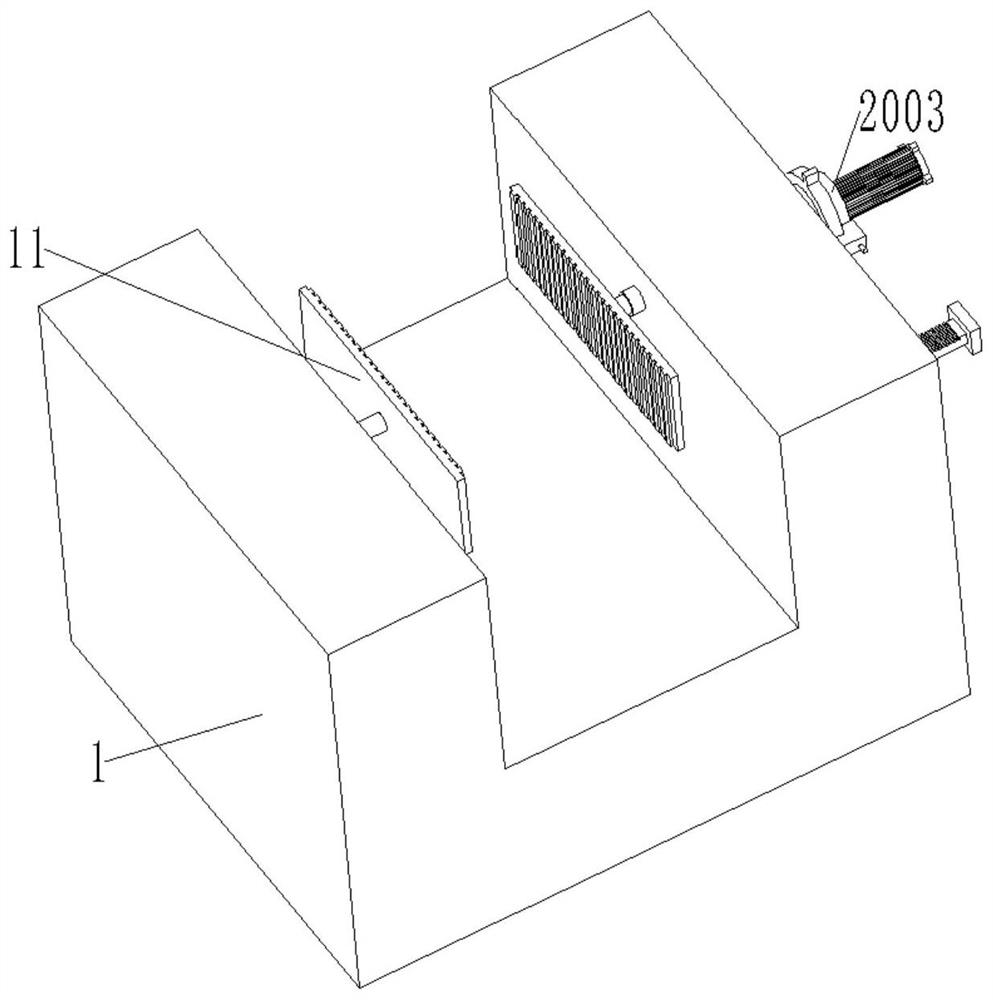

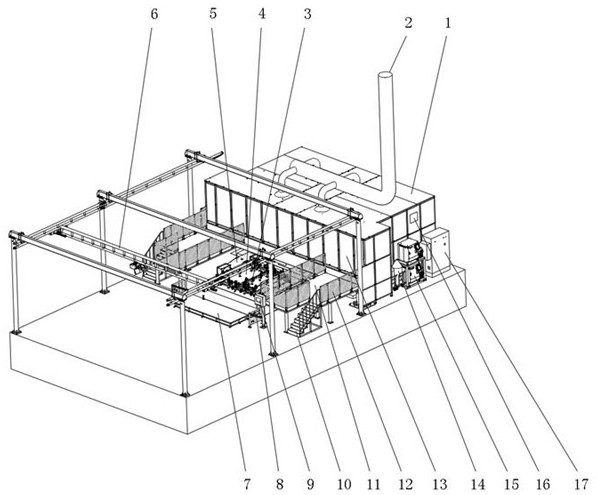

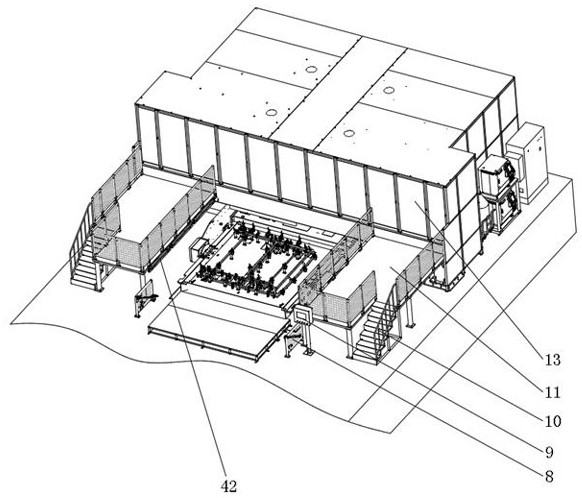

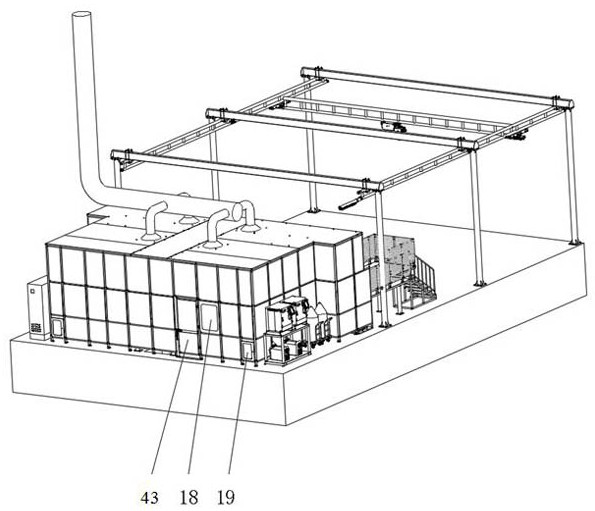

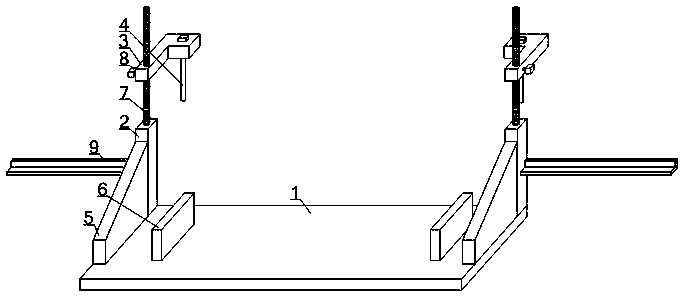

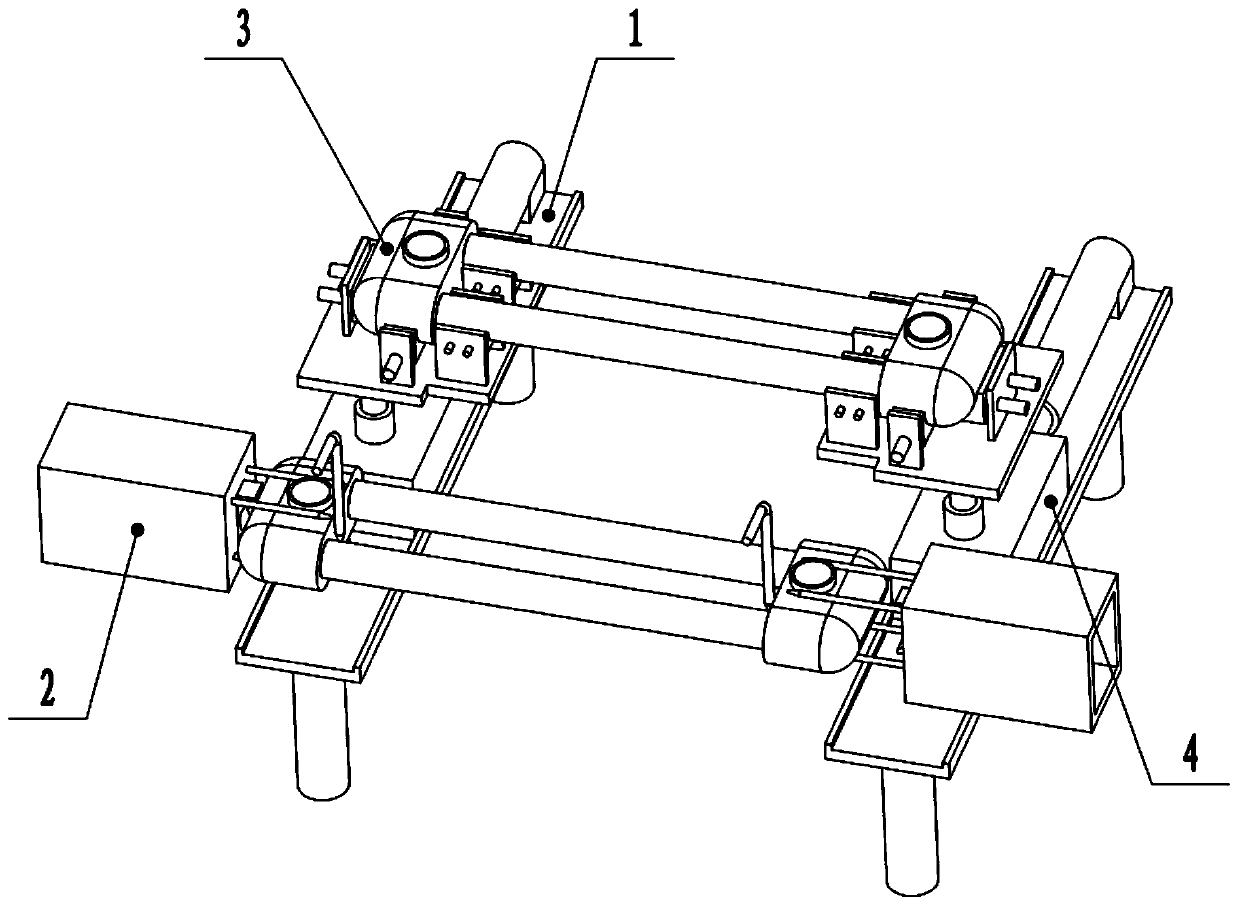

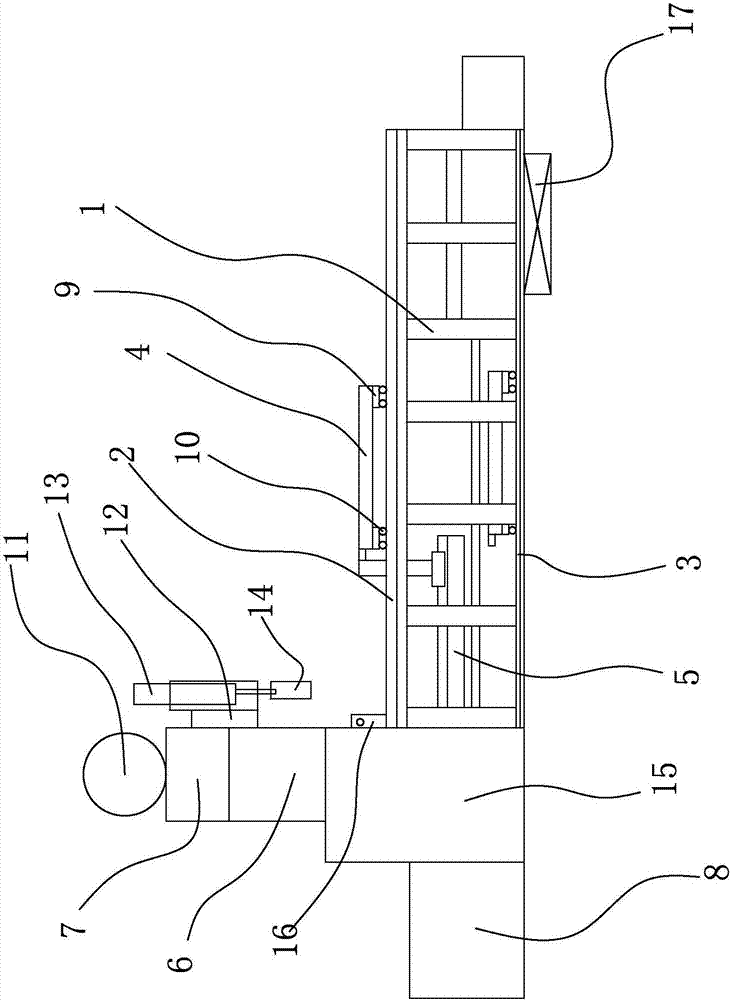

Rotary intelligent automatic welding workstation for five large pieces of passenger car body framework

PendingCN112045287AEnsure consistent welding qualityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesNew energyWorking environment

The invention discloses a rotary intelligent automatic welding workstation for five large pieces of a passenger car body framework. The rotary intelligent automatic welding workstation comprises a welding workshop and a rotary type positioner, the rotary type positioner can rotate around a main shaft, a grating protection device is arranged in front of the rotary type positioner, and at least onewelding robot is arranged on each of the left side and the right side of the rotary type positioner in the welding workshop. A laser locating tracking device and an anti-collision device are arrangedon each welding robot, a wire feeder, a welding wire cylinder and a gun cleaning, wire shearing and silicone oil spraying device are arranged at one side of each welding robot, and a KBK auxiliary hoisting device is arranged in front of the welding workshop. According to the rotary intelligent automatic welding workstation, automation of the welding process of the large-size new energy passenger car body framework is achieved, manual welding is replaced, the welding quality is improved, the consistency of the welding quality of the passenger car body framework is guaranteed, the welding efficiency of the passenger car body framework is improved, and the working environment of workers is improved.

Owner:SHANGHAI RO INTELLIGENT SYST

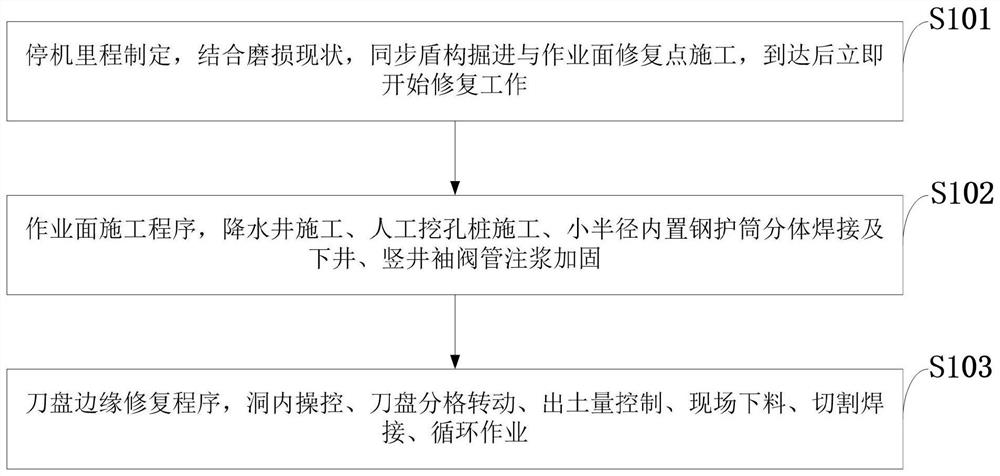

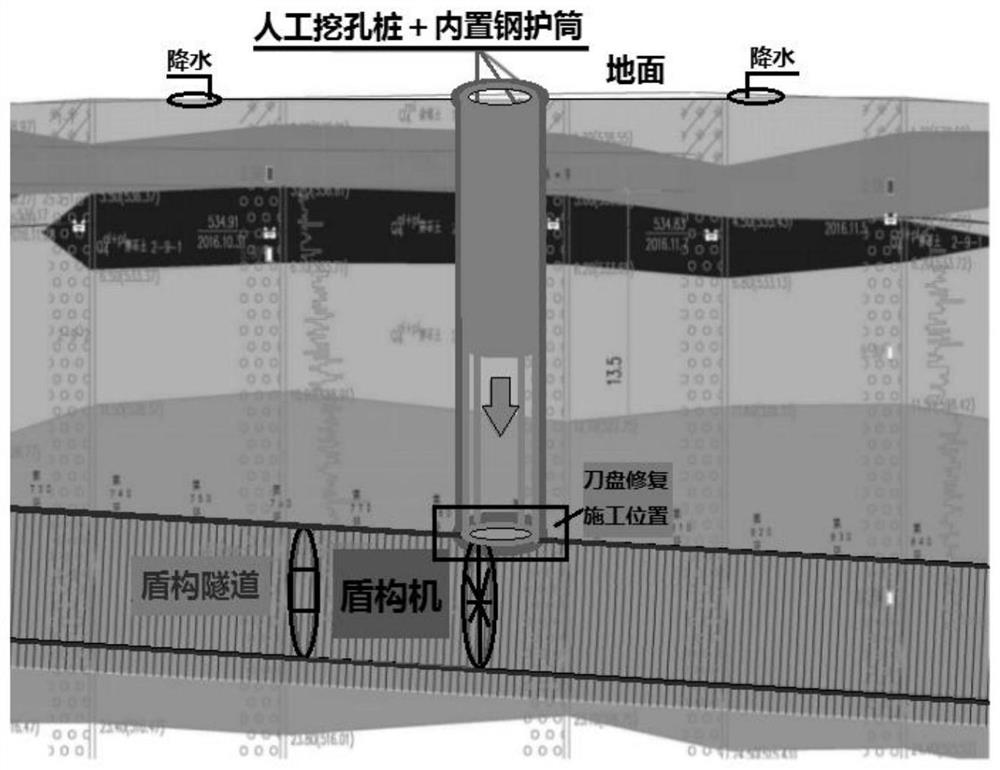

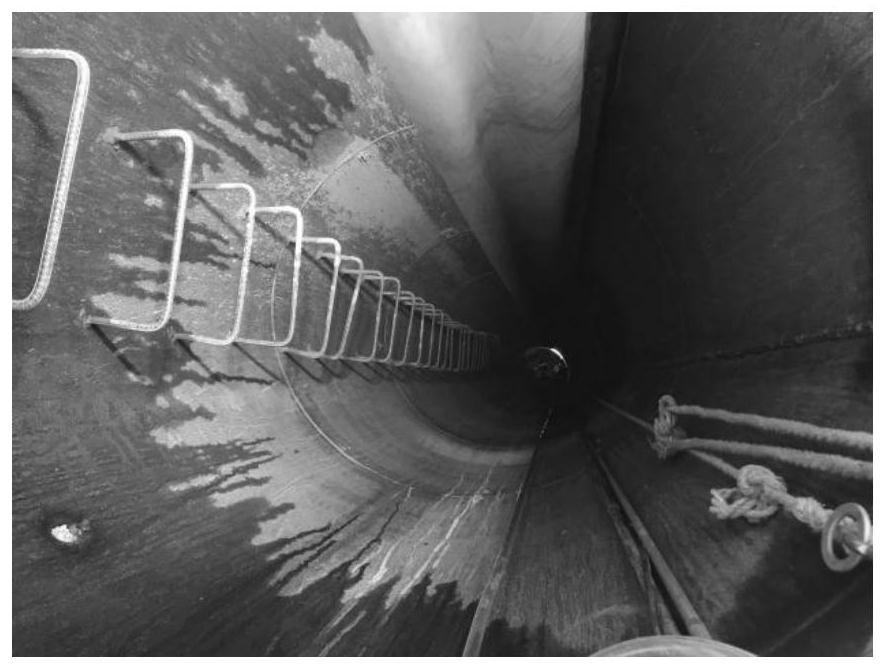

Shield cutterhead edge rapid repair construction method based on high-abrasion stratum

InactiveCN111946350AMeet security requirementsMeet space requirementsShaft sinkingTunnelsArchitectural engineeringWeld quality assurance

The invention belongs to the technical field of shield cutterhead edge repairing, and discloses a shield cutterhead edge rapid repairing construction method based on a high-abrasion stratum. The method comprises the steps of shutdown mileage setting; a working surface construction procedure; and a cutterhead edge repair procedure. According to the shield cutterhead edge rapid repairing construction method based on the high-abrasion stratum, a vertical shaft working face construction scheme of manual hole digging pile construction, small-radius steel casing split welding and well descending andsleeve valve pipe grouting reinforcement is adopted, and the construction safety and space requirements of the high-abrasion stratum are met; a multi-dimensional repairing type selection scheme is formulated according to the cutterhead abrasion conditions at different positions, on-site feeding is carried out, a multi-layer and multi-pass welding method is combined, a gas shielded welding processthe same as or similar to a gas shielded welding process in an original factory manufacturing process is selected, the welding quality is strictly controlled, and the repairing effect is guaranteed;and a working well is excavated in advance to be synchronous with shield tunneling, the next step of work can be linked after the shutdown mileage is reached, and the problem that the repairing construction period of the high-abrasion stratum is delayed due to measures of shutdown reinforcement, in-tunnel repairing auxiliary cavern expanding excavation, operation platform building and the like issolved.

Owner:中铁二十局集团第三工程有限公司

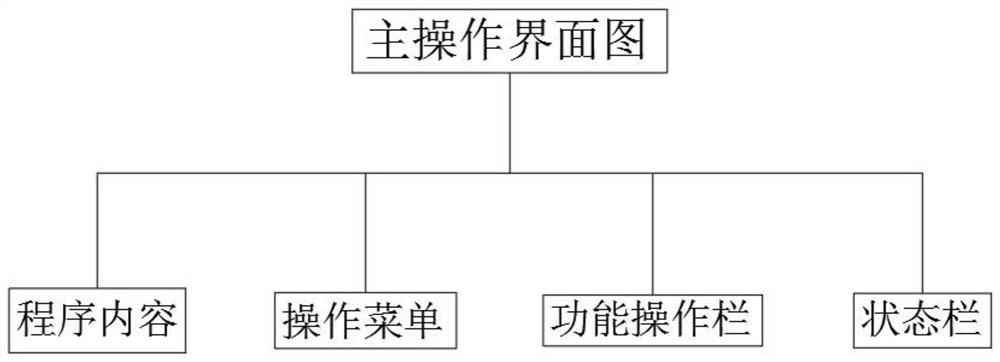

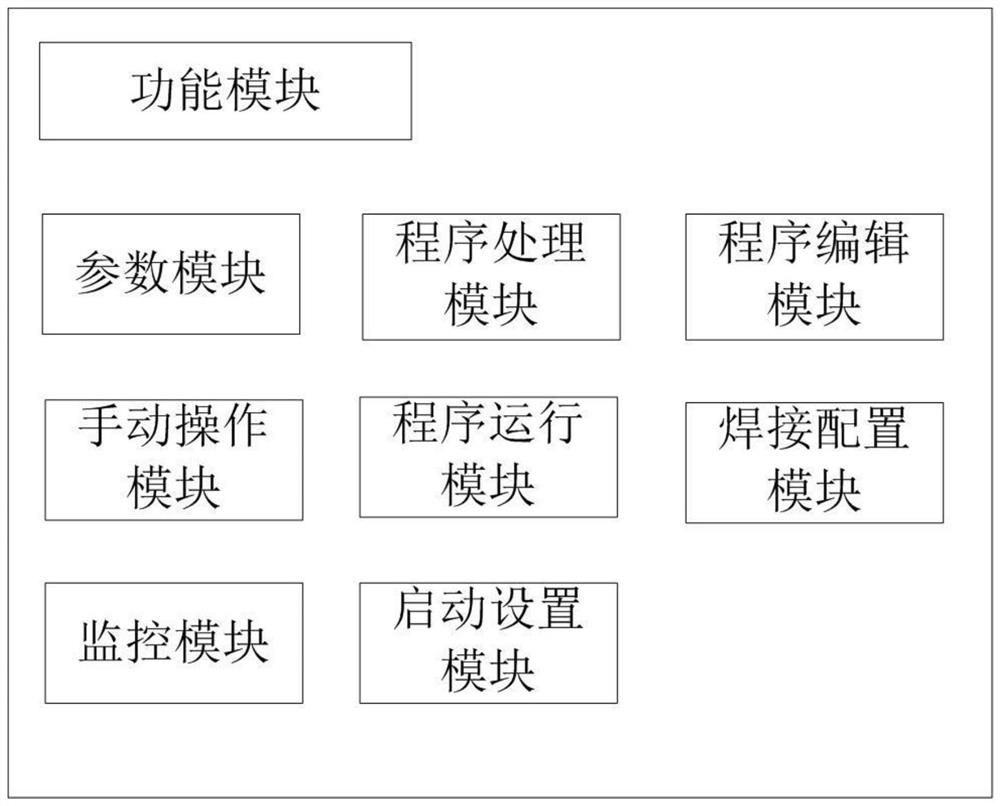

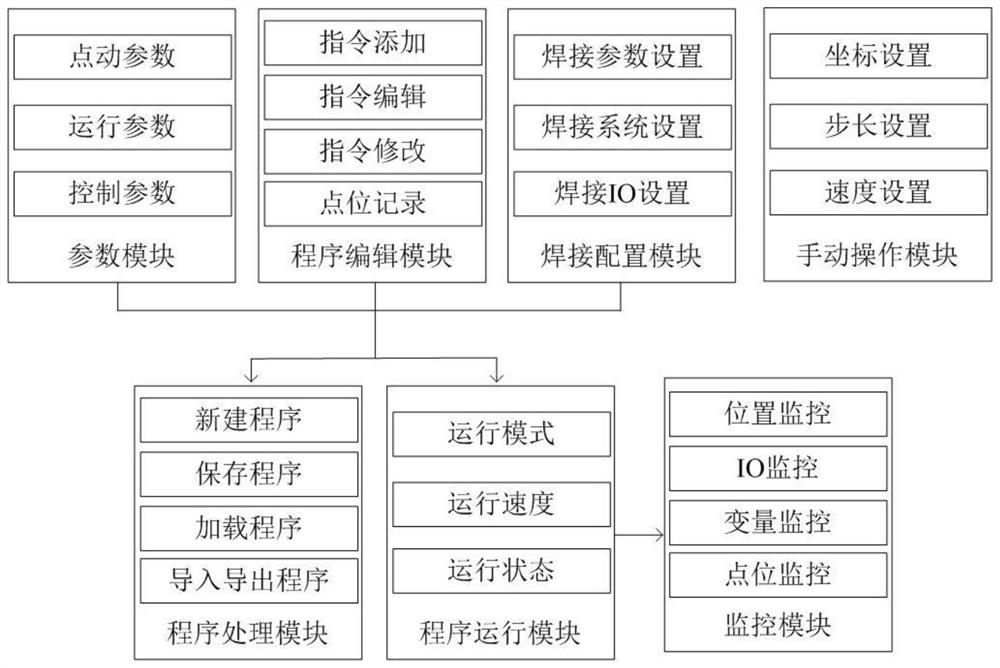

Demonstrator system and demonstration method of arc welding robot

PendingCN113146001AGuaranteed uniformityConvenient teachingProgramme-controlled manipulatorElectrode supporting devicesRotational axisWeld quality assurance

The invention belongs to the technical field of robots, and particularly relates to a demonstrator system and a demonstrating method of an arc welding robot. The demonstrator system comprises a robot, a welding machine, a demonstrator and a controller; a welding gun is arranged at the tail end of the robot, and the robot is used for contact welding with a workpiece; the welding machine is used for controlling parameters related to arc starting, arc extinguishing and welding; the demonstrator is used for demonstrating a welding seam, and regulating the welding seam; the controller is used for storing a welding seam track, recording set parameters and controlling the robot to operate; the robot is a serial six-axis robot, comprises six rotating shafts and can operate in a single-axis mode or in a linkage mode; the welding gun is installed on the outer wall of the robot; and tool calibration for the welding gun needs to be carried out on the tail end of the installed welding gun. According to the invention, the welding seam is easy to modify, an operator can select an instruction of a line where a point position which needs to be modified is located in a manual mode to move the robot to the corresponding position and click the 'position record'; the welding quality is stabilized and improved; and the uniformity of a welded product is guaranteed.

Owner:WUXI XINJIE ELECTRICAL

Explosive welding method of 2507 super duplex stainless steel clad plate

InactiveCN101559524AReduce usageEffective compoundWelding/soldering/cutting articlesMetal working apparatusExplosive claddingSheet steel

The invention relates to an explosive cladding process of metals. The process is characterized by comprising the following steps: substrate treatment, composite treatment, applying and pairing, explosive cladding, repair welding, heat treatment and post-treatment. The process can help clad 2507 super duplex stainless steel with general steel plates effectively so that the clad steel plates can have the required strength on the premise of owning all the advantages of the 2507 super duplex stainless steel, thus saving consumption of expensive metals. The clad steel plates have high welding quality, and can certainly remain stable in long-term use without sealing off.

Owner:SICHUAN JINGLEI SCI & TECH CO LED

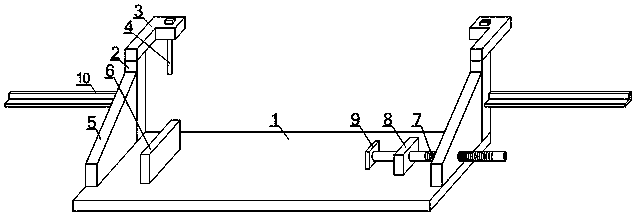

Auxiliary mechanism for installing support lug during automobile assembling

InactiveCN107755943ASimple structureEasy to implementWelding/cutting auxillary devicesAuxillary welding devicesWeld quality assuranceEngineering

The invention discloses an auxiliary mechanism for installing lugs during automobile assembly, including a supporting base, two positioning columns, two horizontal indicating plates and two positioning mechanisms, wherein the two positioning columns are respectively fixed on the left and right sides of the upper end surface of the supporting base. end, and the rear end face of the positioning column is flush with the rear end face of the support base. The positioning mechanism includes a limit rod and a positioning mounting plate arranged horizontally. One end of the positioning mounting plate is provided with a positioning perforation that runs through its upper and lower end surfaces. The limit rod passes through the positioning perforation. Adjustment hole. The upper ends of the two positioning columns are all fixed with a vertical positioning screw rod, and the two positioning screw rods pass through the threaded adjustment holes of the two positioning mechanisms in one-to-one correspondence. The horizontal indicating board is arranged horizontally, and the two horizontal indicating boards are respectively connected with two positioning columns. When the invention is applied, it is convenient to carry out and position the lugs to be welded, thereby facilitating subsequent welding and ensuring welding quality.

Owner:陈蕾

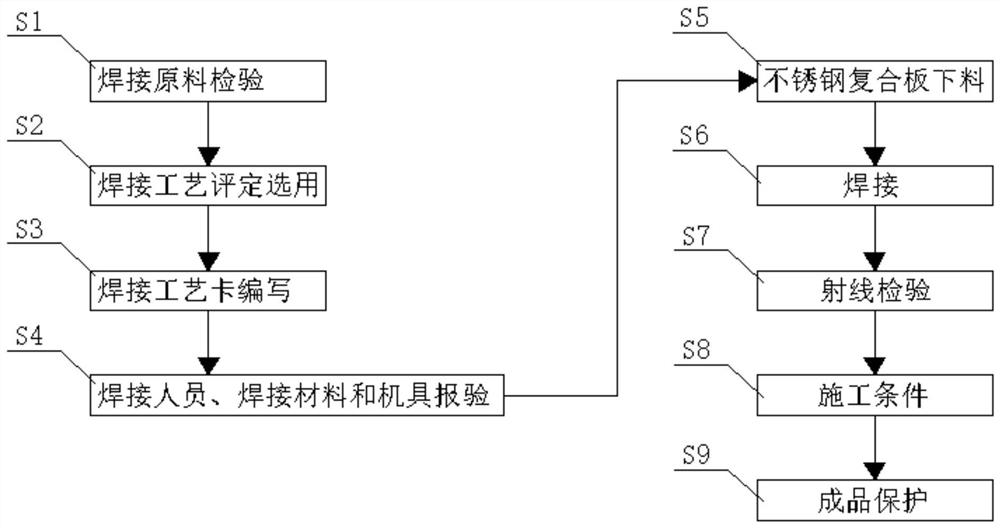

Research and development of construction process for controlling composite board welding cracks

InactiveCN112008195ASolve the problem of cracksControl Welding DefectsWelding accessoriesWeld quality assuranceSS - Stainless steel

The invention discloses research and development of a construction process for controlling composite board welding cracks, and relates to the technical field of composite board welding crack construction processes. The research and development of the construction process comprises the steps of welding raw material inspection, welding process evaluation selection, welding process card writing, welding personnel, welding material and machine tool inspection, stainless steel composite board blanking, welding, ray inspection, construction condition and finished product protection. According to thewelding process evaluation selection, the material and specification of stainless steel composite boards on site are counted, and proper welding process evaluation is selected; and according to welding process card writing, a welding process card suitable for on-site construction is wrote according to the welding process evaluation. The research and development of the construction process for controlling the composite board welding cracks has the advantages that the cracks can be effectively prevented, the welding quality is improved, safe and reliable operation of equipment is guaranteed, the service life of the equipment is prolonged, and reference is provided for companies to better control welding defects in similar engineering construction in the future, and the problem that the cracks are generated in composite board welding is solved.

Owner:杨虹

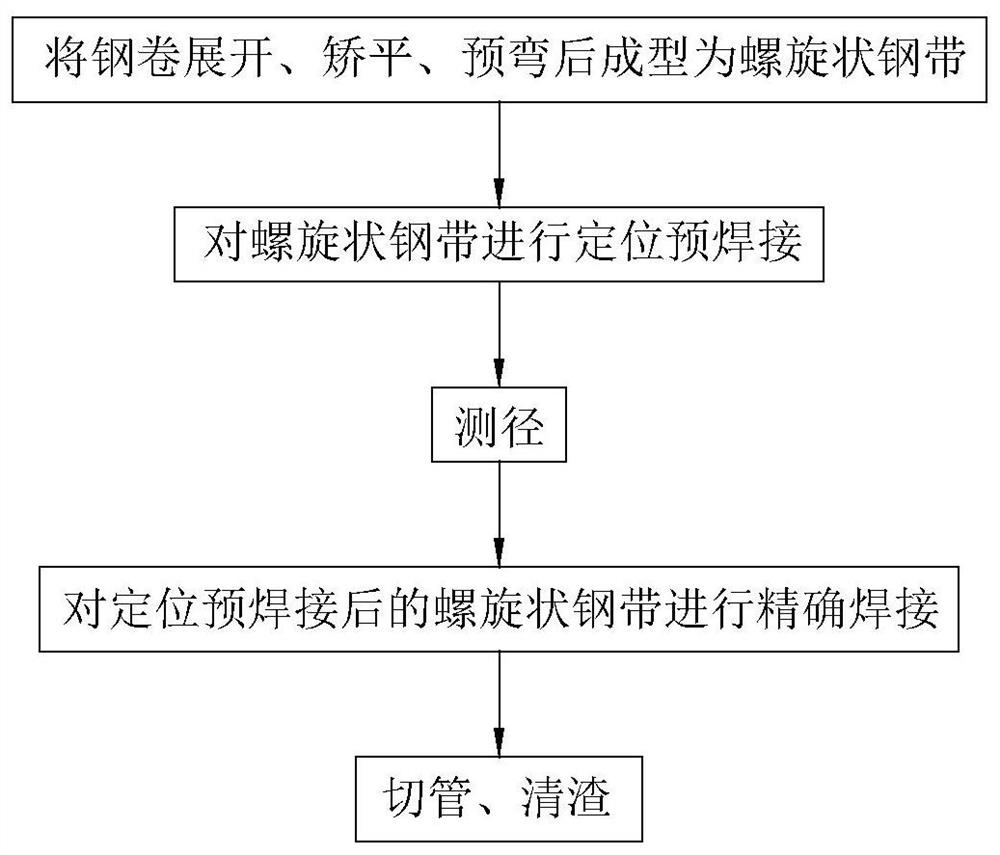

Production method for large-diameter thick-wall steel pipe

InactiveCN113084452AReduce temperature rise rateReduce temperature riseWeld quality assuranceWeld seam

The invention belongs to the technical field of steel pipe production equipment, and particularly relates to a production method for a large-diameter thick-wall steel pipe. The production method aims at solving the problem that an existing large-diameter thick-wall spiral welded pipe is formed through one-time welding and is difficult to repair. According to the technical scheme, the production method for the large-diameter thick-wall steel pipe comprises the following steps of: performing positioning pre-welding on a spiral steel belt; measuring the diameter; and performing accurate welding on the spiral steel belt obtained after positioning pre-welding; wherein the welding seam strength after positioning pre-welding is smaller than the welding seam strength after accurate welding. The production method for the large-diameter thick-wall steel pipe has the beneficial effects that second-time welding mode of positioning pre-welding and accurate welding is adopted, diameter measurement is performed after positioning pre-welding, and repairing is facilitated when the steel pipe is unqualified; and positioning pre-welding has a preheating effect, steel pipe temperature rise speed and temperature rise amount are reduced, the welding quality is improved, and the steel pipe performance is guaranteed.

Owner:浙江科鑫重工有限公司

Brake device of steel bar friction welding machine

InactiveCN111745288ARealize stuck positioningGuarantee welding qualityNon-electric welding apparatusFriction weldingBrake

The invention discloses a brake device of a steel bar friction welding machine. A belt wheel and a transmission belt which are arranged on the brake device to drive a rotating main shaft to rotate andoperate, and a second movable clamping block arranged in a fixed ring and a positioning clamping groove formed in a rotating ring are clamped and fixed to clamp and position the rotating ring, and therefore, the rotating main shaft can rapidly operate and suddenly stop, a brake of the rotating main shaft of the friction welding machine does not produce suddenly stop sliding when stopping working,the rotating main shaft is guaranteed to not slightly swing back and forth in the brake stopping process, the workpiece welding quality is guaranteed, and the work economic benefits are guaranteed. The brake device has a clamping effect on the position of a T-shaped movable extrusion block, so that the T-shaped movable extrusion block does not rebound reversely in the moving process, the clampingconnection of the second movable clamping block and the positioning clamping groove is prevented from being loosen, and the sudden stop effect is ensured.

Owner:徐舒婕

Repair Welding Process for Defects in Cladding of Stainless Steel Composite Plates

InactiveCN101774063BWon't hurtGuarantee welding qualityWelding/cutting auxillary devicesArc welding apparatusHeat-affected zoneCrazing

Owner:孙伟松 +1

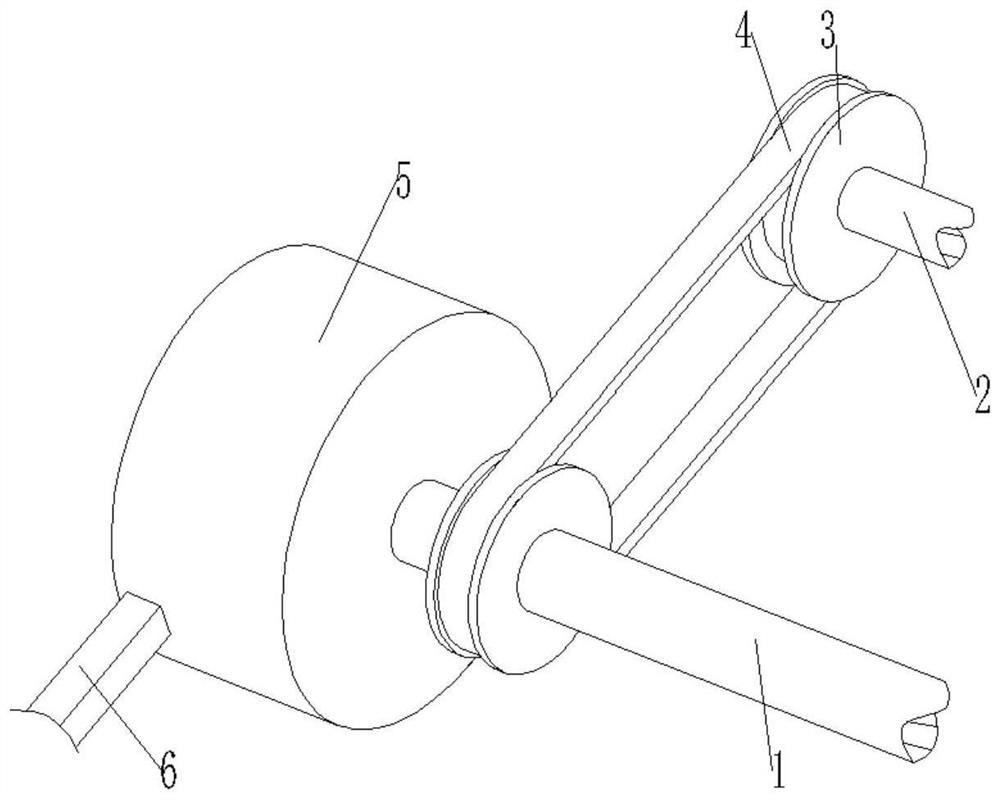

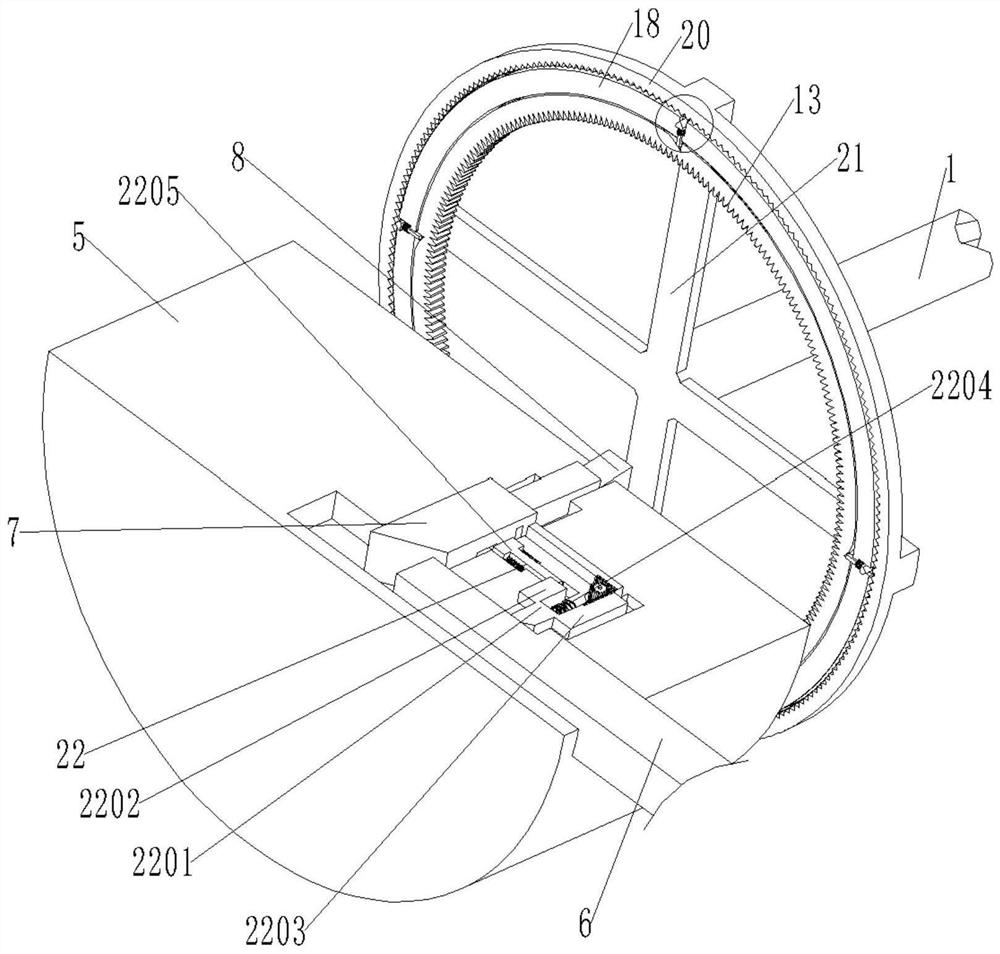

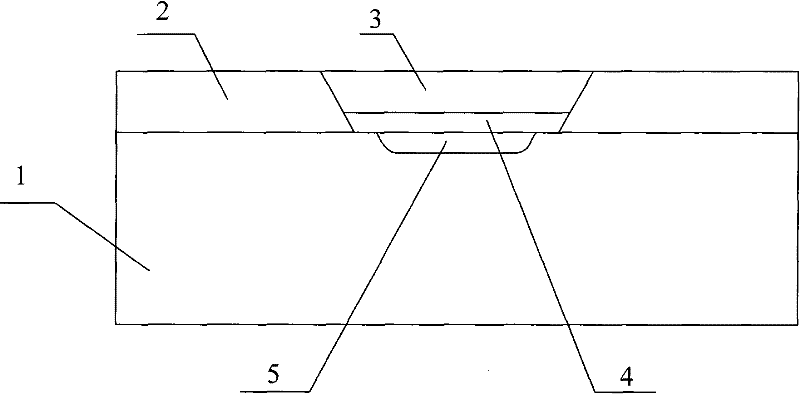

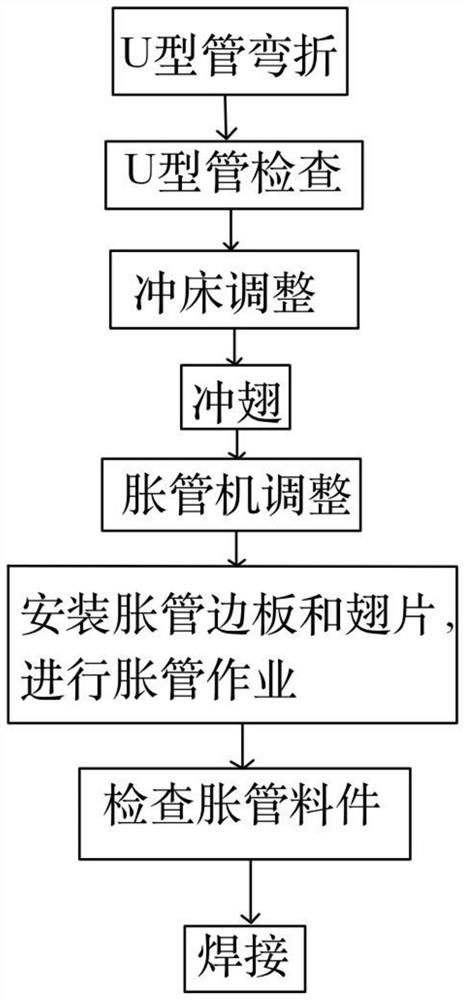

Expanded tube welding production method of simple evaporator

PendingCN112845661AQuality assuranceSimple and rigorous operationHeat exchange apparatusPunchingWeld quality assurance

The invention discloses an expanded tube welding production method of a simple evaporator, which comprises the steps of bending a U-shaped tube, punching, shearing and mounting fins, mounting each component of the evaporator, expanding the tube, welding and the like. The method is simple and rigorous to operate, through a simple and clear self-inspection program, the quality of materials in each step is guaranteed, the yield is increased, and the production cost is reduced; In the welding process, the welding quality is ensured by controlling the temperature and selecting welding rods, and the sealing performance of products is ensured.

Owner:广东澳森热交换系统有限公司

Heavy truck cab welding device

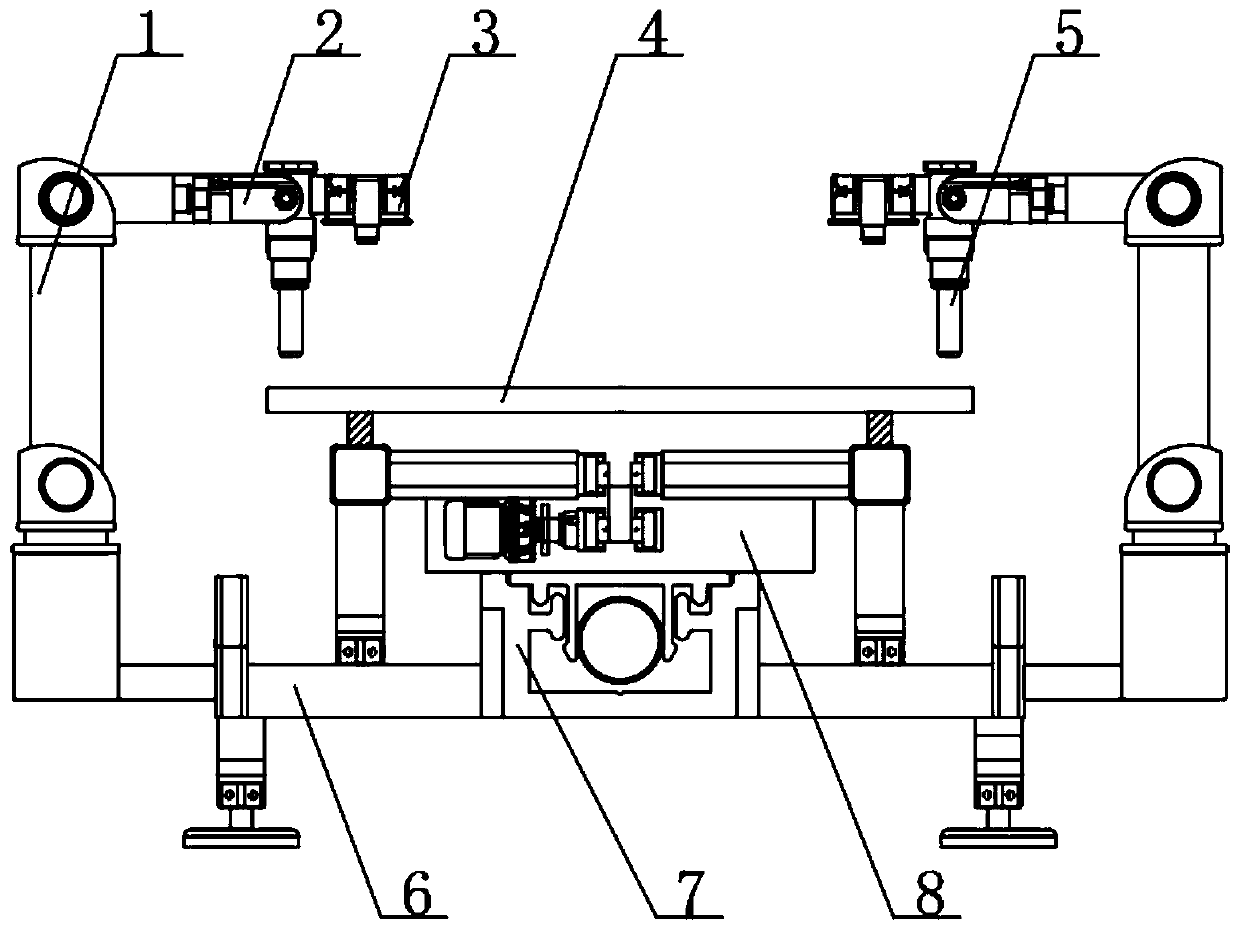

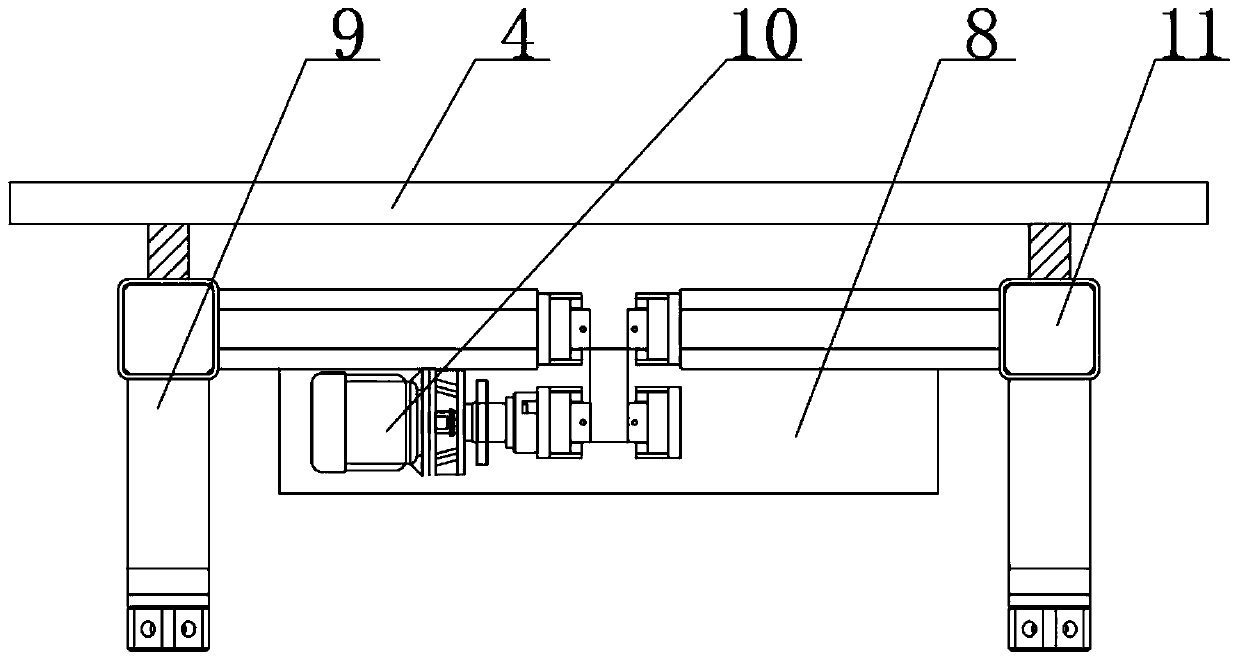

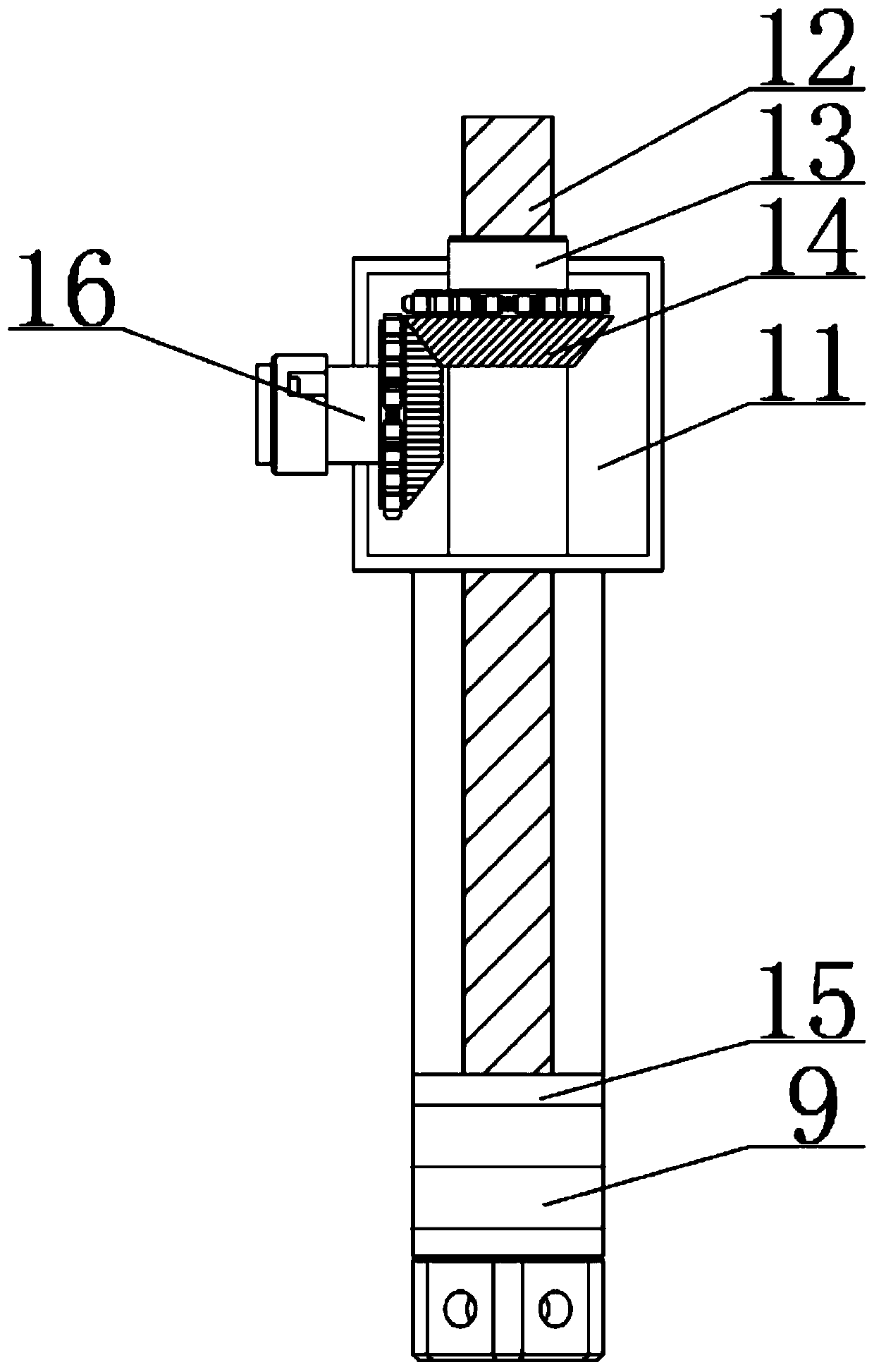

PendingCN110666417AEasy to adjustEasy to handleWelding/cutting auxillary devicesAuxillary welding devicesWeld quality assuranceStructural engineering

The invention relates to the technical field of heavy truck machining, in particular to a heavy truck cab welding device. Mechanical arms, welding arms, fixing frames and a base are included. A material conveying line rail is arranged at the middle position above the base and provided with a transmission base. Stand columns are symmetrically arranged on the left side and the right side of the transmission base. Transmission boxes are arranged at the positions above the two stand columns. The mechanical arms are provided with the welding arms, and welding heads are arranged at the ends, close to a supporting plate, of the welding arms. The welding heads are rotationally connected with the welding arms through rotation shafts and provided with the fixing frames, trapezoid blocks are symmetrically arranged at the two side positions in the fixing frames and are in sliding connection with the fixing frames, and guide wheels are arranged on the inner sides of the trapezoid blocks. In the heavy truck cab welding device, through the arrangement of the welding arms, the fixing frames and cameras, the welding quality of the device is improved, device welding stability is guaranteed, and thedevice machining range is enlarged.

Owner:阜阳常阳汽车部件有限公司

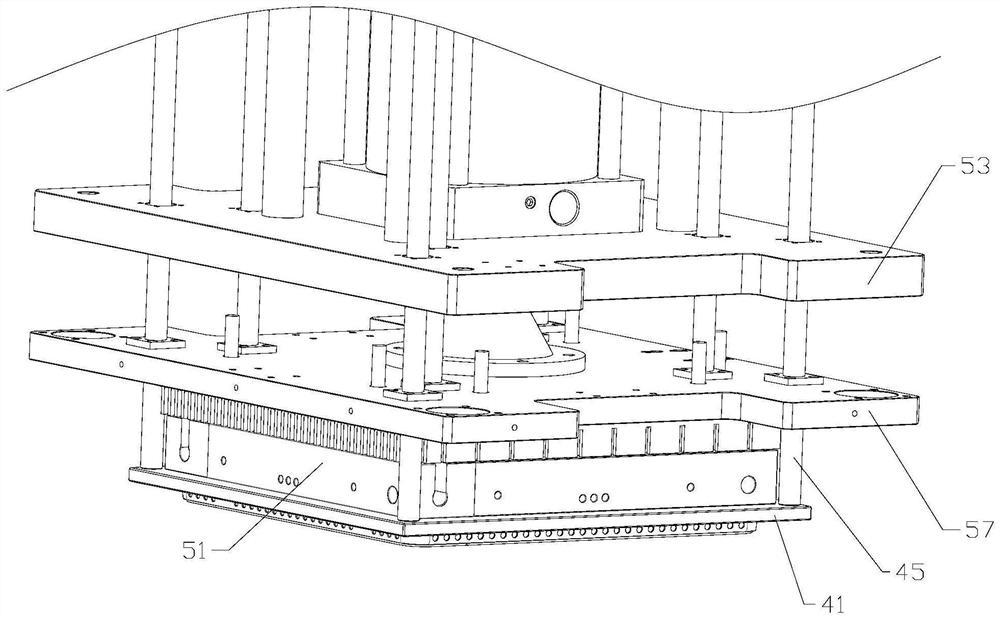

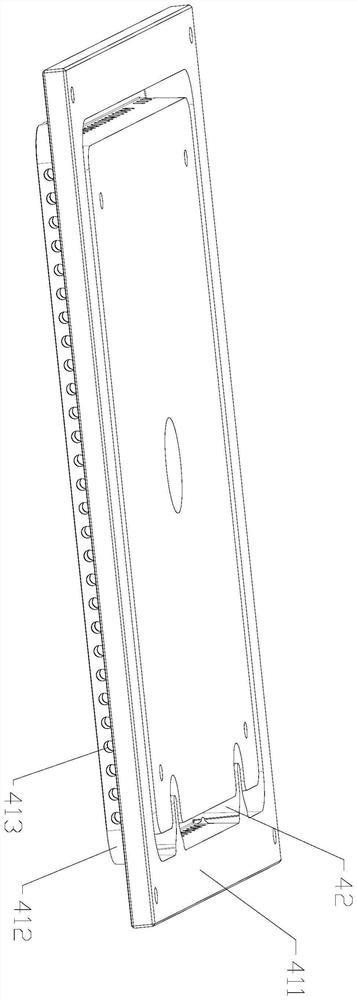

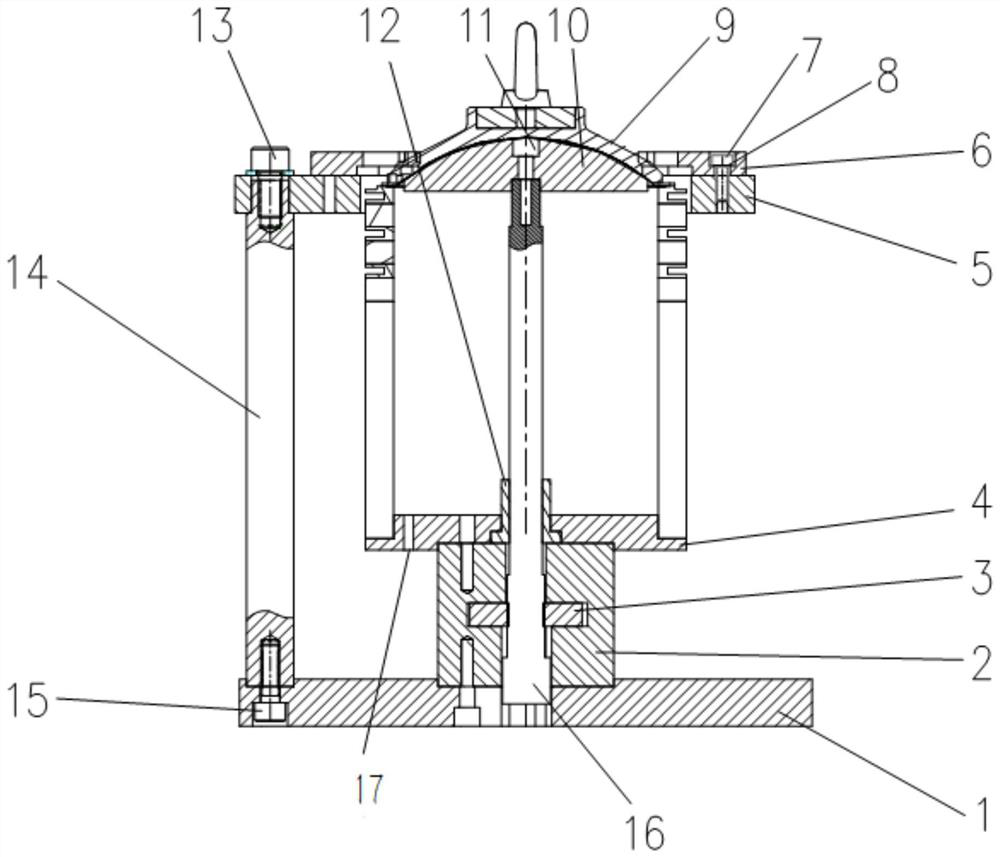

DTRO membrane welding heating mechanism and DTRO membrane welding machine

ActiveCN114407375AAchieve supportAchieve positioningSemi-permeable membranesWeld quality assuranceReverse osmosis

The invention discloses a DTRO (Disk Tubular Reverse Osmosis) diaphragm welding heating mechanism and a DTRO diaphragm welding machine, the welding heating mechanism is mounted on a machine table and comprises a lower die assembly and a lower support plate, the lower support plate can move up and down under the action of a lower die driving part, and the lower support plate is used for bearing a diaphragm to be welded; the upper die assembly comprises a heat conduction upper plate which can move up and down under the action of an upper die driving part so as to be pressed against the diaphragm, and a heat conduction through groove penetrating through the upper end face and the lower end face of the heat conduction upper plate is formed in the heat conduction upper plate; the heating assembly comprises a heating plate capable of moving up and down under the action of a lifting driving assembly, and a shaping heating plate capable of moving in the heat conduction groove and heating the heat conduction groove is arranged at the lower end of the heating plate; the lower end of the shaping heating plate can extend out of the lower end of the heat conduction upper plate along the heat conduction through groove. According to the diaphragm welding device, the diaphragm is reinforced and shaped through mechanical cooperation, the welding quality of the diaphragm is improved, and the finished product quality of the diaphragm is guaranteed.

Owner:苏州捷之诚自动化科技有限公司

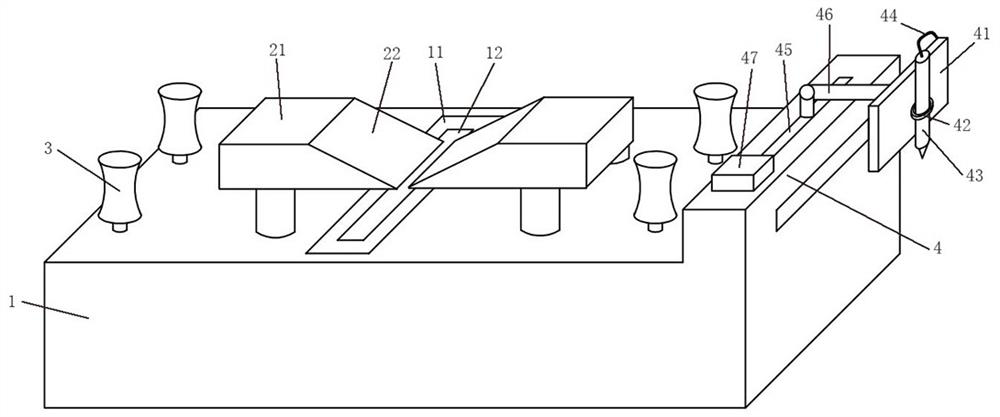

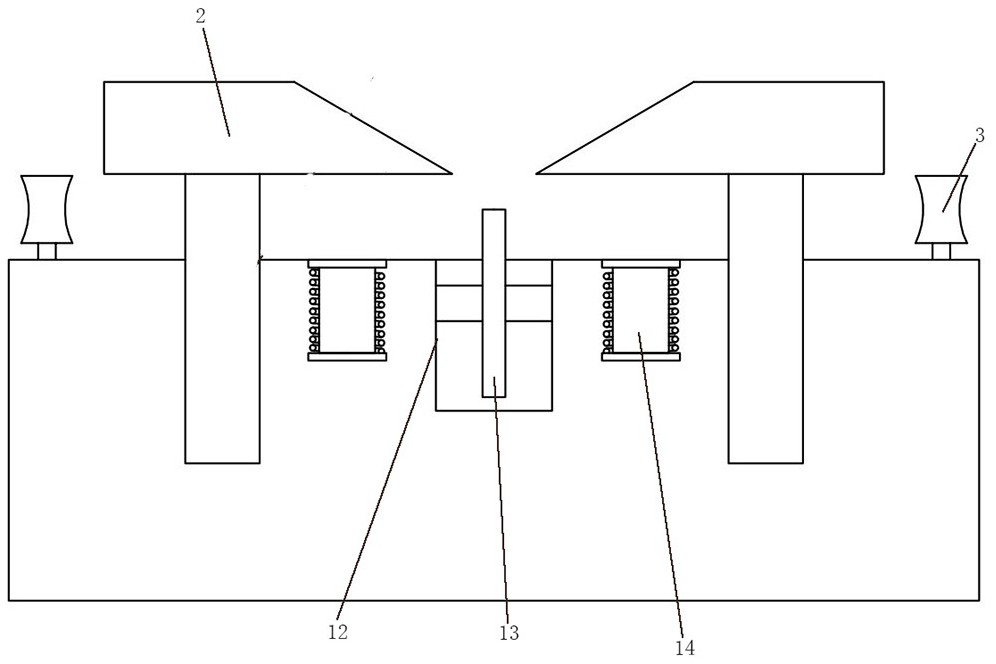

A stamping plate butt welding device

ActiveCN109434344BGood welding performanceEliminate Welding DefectsWelding/cutting auxillary devicesAuxillary welding devicesButt weldingWeld quality assurance

The invention relates to a butt welding device for stamping plate parts. The butt welding device for the stamping plate parts comprises a welding platform, a pair of press disks, a pair of limiting columns and a welding device, wherein the press disks and the limiting columns are arranged at the transverse ends of the welding platform, and the welding device is arranged on one side of the weldingplatform. The limiting columns comprise at least a pair of guide wheels horizontally opposite arranged; and the press disks comprise rectangle matrixes and press blocks extending outward from the sides of the matrixes, and the press blocks of the pair of press disks are opposite to each other. According to the butt welding device of the stamping plate parts, the two parts stamped out of the largerparts separately are facilitated to be welded, the welding quality of the welding place is ensured, and the actually seamless joint after welding is ensured; meanwhile, the shape of the periphery ofthe welding place is ensured to be aligned, and deforming does not appear due to the residual stress of welding; and meanwhile, the functions of automatic alignment and welding are achieved, and the production efficiency is improved. Through the beneficial effects, the integral forming of the large stamping parts after separating and stamping can be realized, and the cost of mold tools can be reduced and the quality of products produced can be improved at the same time.

Owner:ANHUI KEYUAN MACHINERY

Heat pipe automatic welding method

ActiveCN108526807BRealize automatic weldingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWeld quality assuranceEngineering

The invention relates to the field of radiator welding, in particular to a radiator pipe automatic welding method. The method comprises the steps of clamping and locating, spot welding, welding and conveying. Through the welding method, automatic welding on sheet heads and a steel pipe is achieved, and all welding operation can be completed through one-time locating; the welding efficiency of radiator pipes is improved, and the labor intensity of workers is reduced; meanwhile, the welding quality of the sheet heads and the steel pipe is improved, and the qualified rate of finished products ofradiator pipes is guaranteed.

Owner:青岛恒泰散热器有限公司

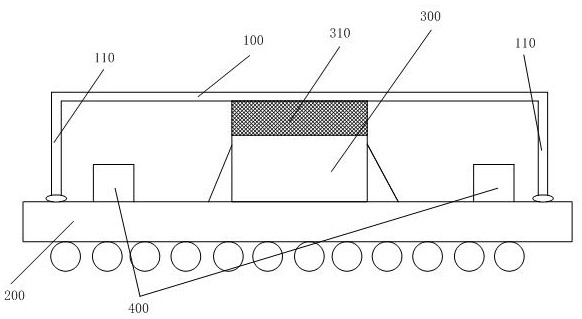

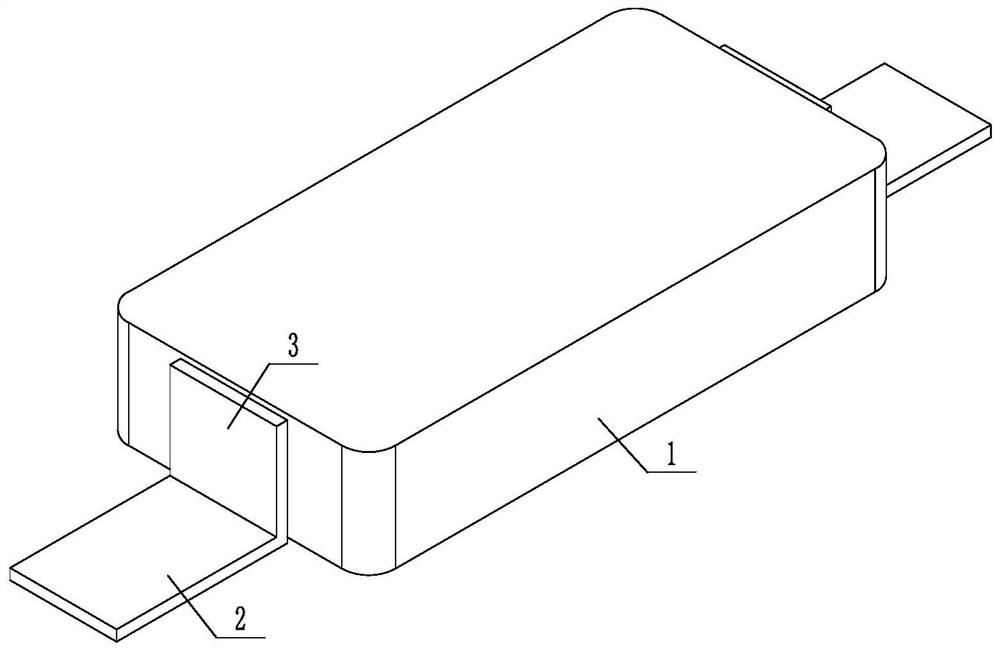

Packaging structure and forming method of packaging structure

ActiveCN111739855AGuarantee welding qualityGuaranteed StrengthSemiconductor/solid-state device detailsSolid-state devicesWeld quality assuranceMaterials science

The invention discloses a packaging structure and a forming method of the packaging structure. According to the invention, the packaging structure comprises a heat dissipation structure, wherein the first heat dissipation part of the heat dissipation structure can separate a solder layer from a passive element, so that the risk of short circuit caused by the fact that metal solder splashes to thepassive element during solder layer welding is avoided; the first heat dissipation part is located in the area close to the center of the substrate, so that the influence of warping of the substrate on the welding layer can be reduced so as to avoid the breakage of the solder layer structure; the multiple first heat dissipation parts are arranged at intervals, and when reflux soldering is conducted on the solder layer, volatilized soldering flux can be discharged from gaps between the first heat dissipation parts, so that the soldering quality of the solder layer is guaranteed, and the strength of the solder layer is guaranteed; and according to the packaging structure and the forming method of the packaging structure, the reliability of the product can be improved, and the yield of the product is improved.

Owner:SUZHOU TF AMD SEMICON CO LTD

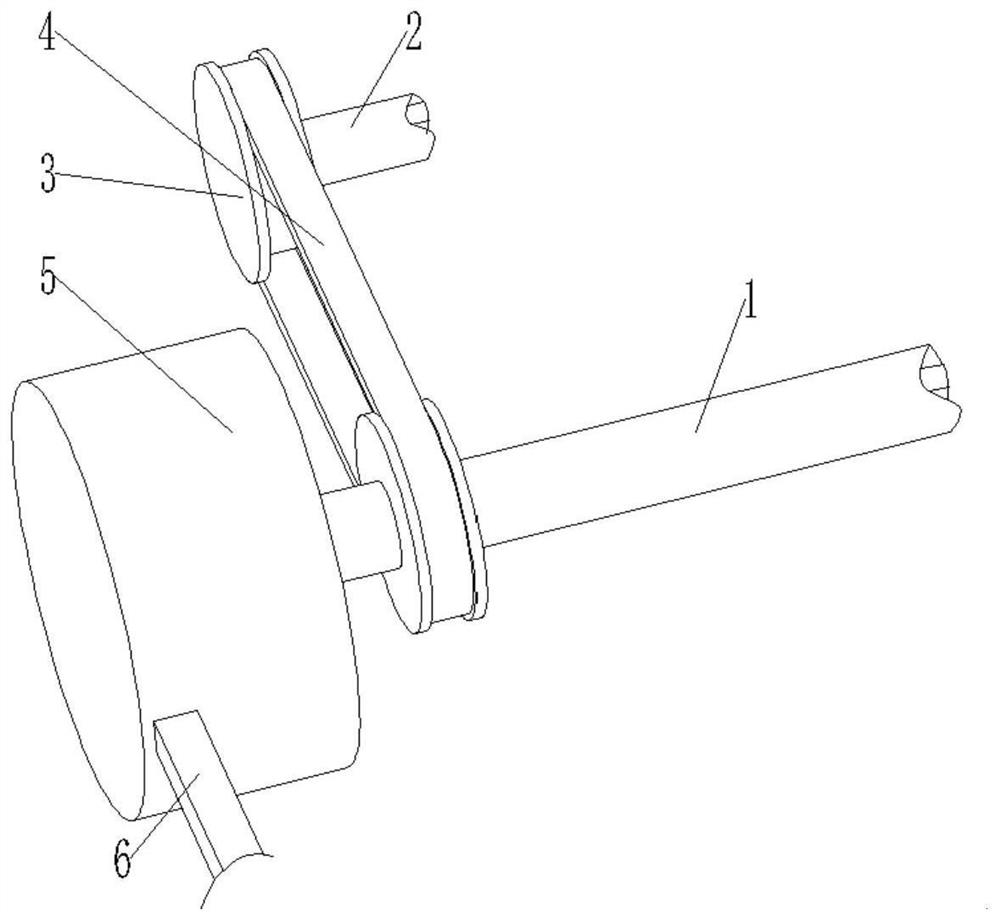

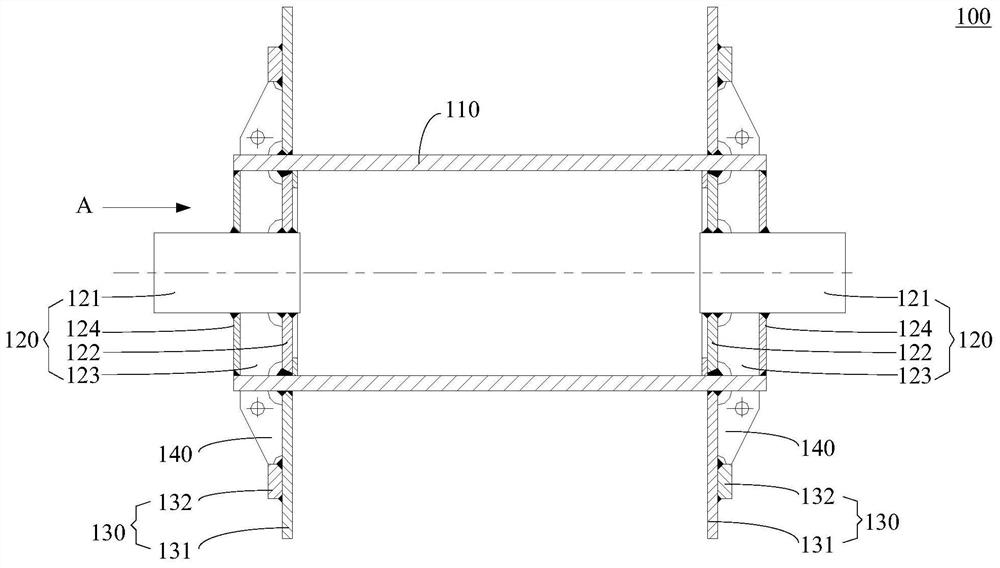

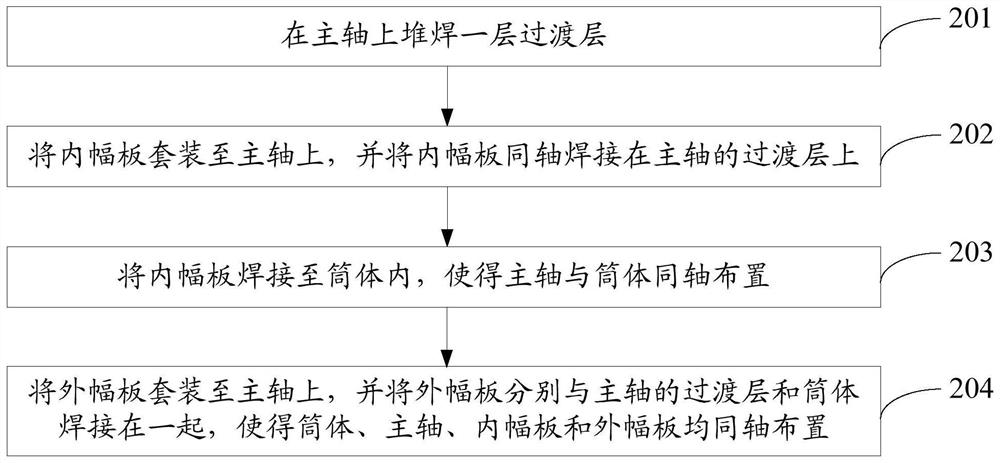

Manufacturing method of roller structure

ActiveCN110539096BGuaranteed service lifeImprove crack resistanceWelding apparatusCrack resistanceWeld quality assurance

The invention discloses a method for manufacturing a drum structure, which belongs to the technical field of mechanical processing. The main shaft of the drum structure is made of 35CrMo material, and the manufacturing method includes: surfacing a layer of transition layer on the main shaft, the transition layer is E501T-1L material; fitting the inner panel to the main shaft, and coaxial with the inner panel Welded on the transition layer of the main shaft; Weld the inner panel into the cylinder so that the main shaft and the cylinder are arranged coaxially; Set the outer panel on the main shaft, and weld the outer panel to the transition layer of the main shaft and the cylinder respectively Together, the barrel, the main shaft, the inner panel and the outer panel are arranged coaxially. In the present invention, a transition layer of E501T-1L material is surfacing on the main shaft. The E501T-1L material has good crack resistance and no cracks will be generated during welding, thereby improving the quality of the main shaft and the inner and outer panels. The welding quality between them ensures the service life of the spindle.

Owner:WUHAN MARINE MACHINERY PLANT

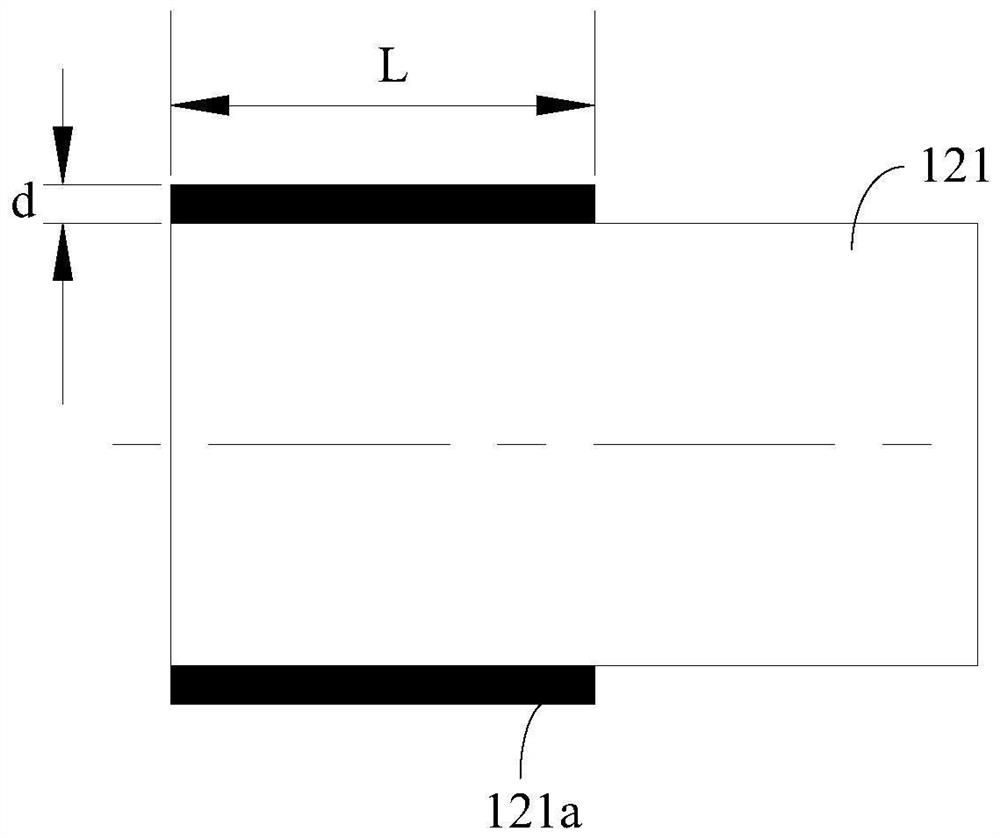

Laser machining method and welding tool for capacitive transducer

ActiveCN112846508AImprove flatnessImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesThin metalLaser processing

The invention relates to a laser machining method and a welding tool for a capacitive transducer. The laser machining method comprises the following steps of machining and forming a cylinder body, an ultrathin metal plate and a lap joint circular ring, and machining and forming an annular mounting groove in one end of the cylinder body; sequentially assembling the ultrathin metal plate and the lap joint circular ring through a welding tool and pressing the ultrathin metal plate and the lap joint circular ring in the mounting groove in one end of the cylinder body, wherein the diameter of the ultrathin metal plate is equal to that of the mounting groove, and welding interfaces are arranged between the peripheral wall of the lap joint circular ring and the cylinder body; introducing protective gas into the cylinder body; and using a laser welding device for sequentially completing welding of the welding interfaces. According to the method, laser sealing welding of the ultrathin metal plate can be realized, the welding quality can be improved, the air tightness of the capacitive transducer is ensured, and meanwhile, the product percent of pass is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Welding method for ITO target material and Mo backboard

PendingCN114833417AAvoid deformationGuaranteed welding effectFinal product manufactureMetal working apparatusWeld quality assuranceWelding process

The invention relates to a welding method for an ITO target material and a Mo back plate. The welding method comprises the following steps that (1) the ITO target material and the Mo back plate are heated to target temperatures respectively; (2) keeping the temperature of the ITO target material and the Mo back plate unchanged, and infiltrating the welding surface of the ITO target material and the welding surface of the Mo back plate; (3) forming a welding flux groove in the welding surface of the Mo back plate, adding molten welding flux into the welding flux groove, and attaching the ITO target material to the welding flux groove; and (4) a buffer layer is arranged on the surface of the ITO target material, natural cooling is conducted in the pressure applying process, and welding of the ITO target material and the Mo back plate is completed. According to the welding method, the ITO target material and the Mo back plate are not prone to deformation in the welding process, the welding binding rate is high, the welding quality of the ITO target material and the back plate is improved, and the magnetron sputtering quality is guaranteed.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Bilateral feeding gantry type welding machine

InactiveCN106984922AReduce shockGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWeld quality assuranceEngineering

The invention relates to the field of welding equipment, and discloses a double-side feeding gantry welding machine. Firstly, the iron support is placed on one side of the plate frame fixture, and the second horizontal sliding part is controlled to slide laterally along the main horizontal guide rail through the control box. The second horizontal slider pushes the plate and frame clamp to slide and feed material laterally, the plate and frame clamp drives the first or third horizontal slide to slide laterally along the first horizontal guide rail, and the second guide rail moves up and down along the gantry column, The welding head slides and translates along the second guide rail. The welding head welds the iron support on the plate and frame fixture. The first cylinder supports the plate and frame fixture, which can buffer the impact of the welding head on the plate and frame fixture to ensure the welding quality. At the same time, when the welding head finishes welding the iron support on the plate and frame fixture, the plate and frame fixture returns to its original position, and the plate and frame fixture with the iron support on the other side can be pushed by the second transverse sliding member. Lower horizontal slide feeding, continuous welding, high welding efficiency.

Owner:JIANGMEN CITY PENGJIANG DISTRICT ZHISHAN HARDWARE CRAFTWORK

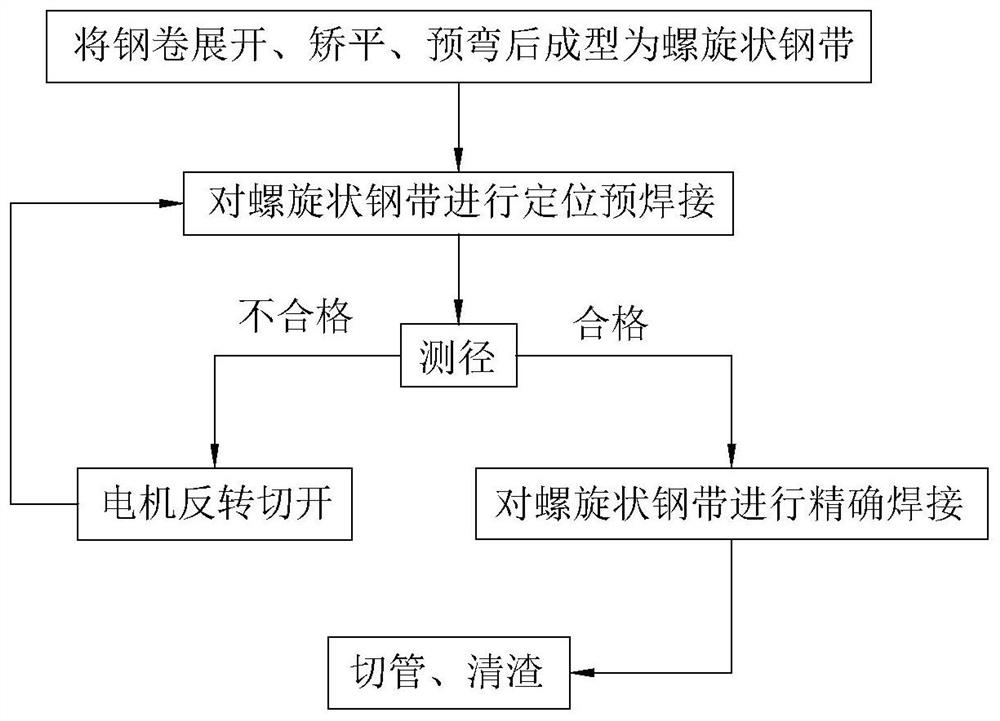

Large-diameter thick-wall steel pipe welding equipment

InactiveCN112958994AReduce temperature rise rateReduce temperature riseWelding/cutting auxillary devicesAuxillary welding devicesWeld quality assuranceThick wall

The invention belongs to the technical field of steel pipe welding equipment, and particularly relates to large-diameter thick-wall steel pipe welding equipment. In order to overcome the defect that an existing large-diameter thick-wall spiral welded pipe is formed through one-time welding and is difficult to repair, the following technical scheme is adopted, the large-diameter thick-wall steel pipe welding equipment comprises a positioning pre-welding device, a diameter measuring device and a precise welding device, wherein the positioning pre-welding device is used for pre-welding the steel pipe; the diameter measuring device is used for measuring the diameter and the ovality of the steel pipe; the precise welding device is used for carrying out performance welding on the steel pipe; and the precise welding device is located behind the positioning pre-welding device in the advancing direction of the steel pipe. According to the large-diameter thick-wall steel pipe welding equipment, a secondary welding mode is adopted, diameter measurement is carried out after positioning and pre-welding, and repairing is conveniently carried out when the steel pipe is unqualified; and positioning pre-welding has a preheating effect, the steel pipe temperature rise speed and temperature rise amount are reduced, the welding quality is improved, and the steel pipe performance is guaranteed.

Owner:浙江科鑫重工有限公司

Device for assisting in assembling supporting lug in automobile assembling process

InactiveCN107755945AAvoid displacementSimple structureWelding/cutting auxillary devicesAuxillary welding devicesDashboardLocking mechanism

The invention discloses a device for auxiliary installation of support lugs when assembling automobiles, comprising a support base, two positioning columns, two reinforcing rib plates, two horizontal indicating plates, two positioning mechanisms and a locking mechanism, Two positioning columns are respectively fixed on both ends of the upper end surface of the support base, and a positioning mechanism is fixed on the upper end of each positioning column. The positioning mechanism includes a positioning mounting plate connected to the upper end of the positioning column and a limit rod passing through the positioning mounting plate. . The two horizontal indicating plates are respectively connected with the two positioning columns, the two reinforcing rib plates are respectively connected with the front end surfaces of the two positioning columns, and the two reinforcing rib plates are both connected to the upper end surface of the support base. A threaded adjustment hole is arranged on a reinforcing rib plate, the locking mechanism includes a positioning screw rod and a limit block connected to the end of the positioning screw rod, and the positioning screw rod passes through the screw thread adjustment hole. When the present invention is applied, it is convenient to lock and position the lugs to be welded, thereby facilitating subsequent welding and ensuring the welding quality.

Owner:陈蕾

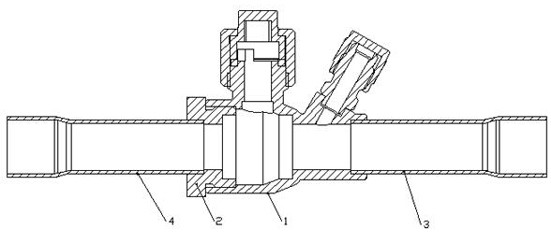

A processing method for ball valve of refrigeration system

ActiveCN113001064BRapid coolingImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWeld quality assuranceEngineering

The invention relates to a processing method for a ball valve in a refrigeration system, comprising the following steps: firstly, sending the processed copper connecting pipe, valve body and valve cover into a special welding system for standby; The valve body and valve cover are preheated. After the preheating is over, the welding torch and the flame nozzle are used for welding. After the welding is completed, three cooling water pipes are used to spray cooling water to gradually cool the welding place. The cooled workpiece is taken out manually, and the welding of the valve body, valve cover and copper connection pipe is completed. The advantage of the present invention is that: the processing method of the present invention is based on a special welding system, and then cooperates with the temperature and time of preheating, and the temperature and time of welding, so as to improve the welding quality and ensure the stability of welding. The temperature and other parameters are controlled, so that the welding place can be cooled rapidly, and the welding place will not be affected by the rapid cooling, so as to ensure the quality of welding.

Owner:NANTONG OEM REFRIGERATION EQUIP

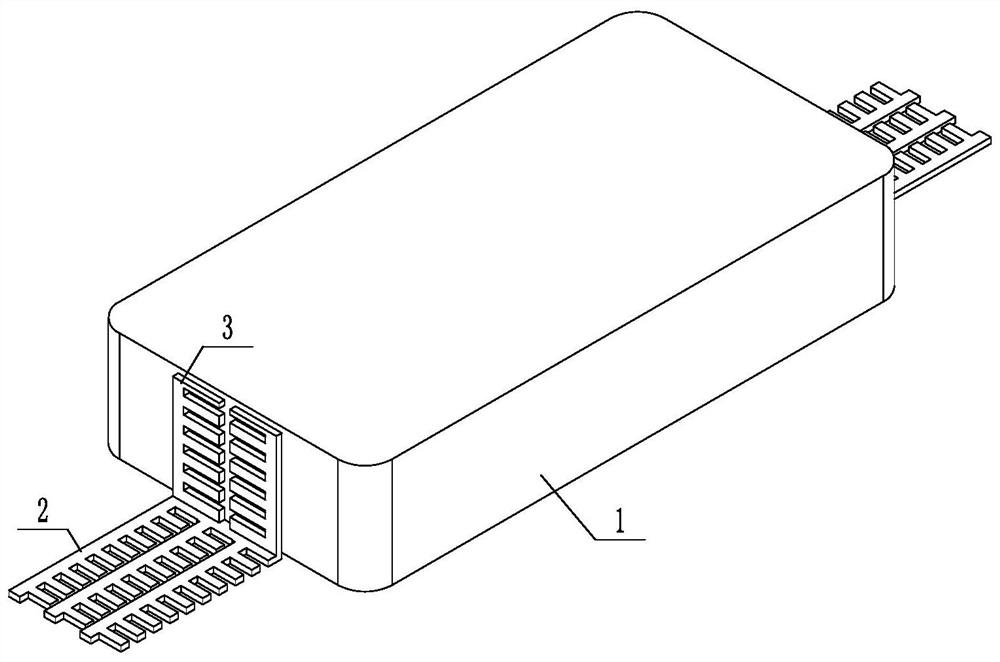

A Design Method to Solve the Production Deviation of qfn Package Parts

ActiveCN111009474BSolve the problem of production deviationIncrease the welding areaSemiconductor/solid-state device manufacturingWeld quality assuranceDesign methods

A design method for solving the production deviation of QFN packaged parts, which relates to the server field, the steps are as follows: the pins on the bottom surface of the packaged parts are extended to both sides to form an extended horizontal pin and a vertical pin is provided in the vertical direction; The inside of the extension horizontal pin is provided with a large-area hollow. A gap is provided in the middle of the vertical pin. There are multiple horizontal notches extending left and right on both sides of the gap. The invention can solve the problem of production deviation of QFN-type packaged parts: for example, the center of gravity is easily unstable. After the welding is completed, the problem of deviation occurs, resulting in the parts not being in good contact with the PCB. After improvement, this Such parts will not be misaligned during production, and at the same time, the welding area can be increased, the welding quality can be improved, and the welding reliability can be ensured, thus ensuring the stability and safety of the product.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

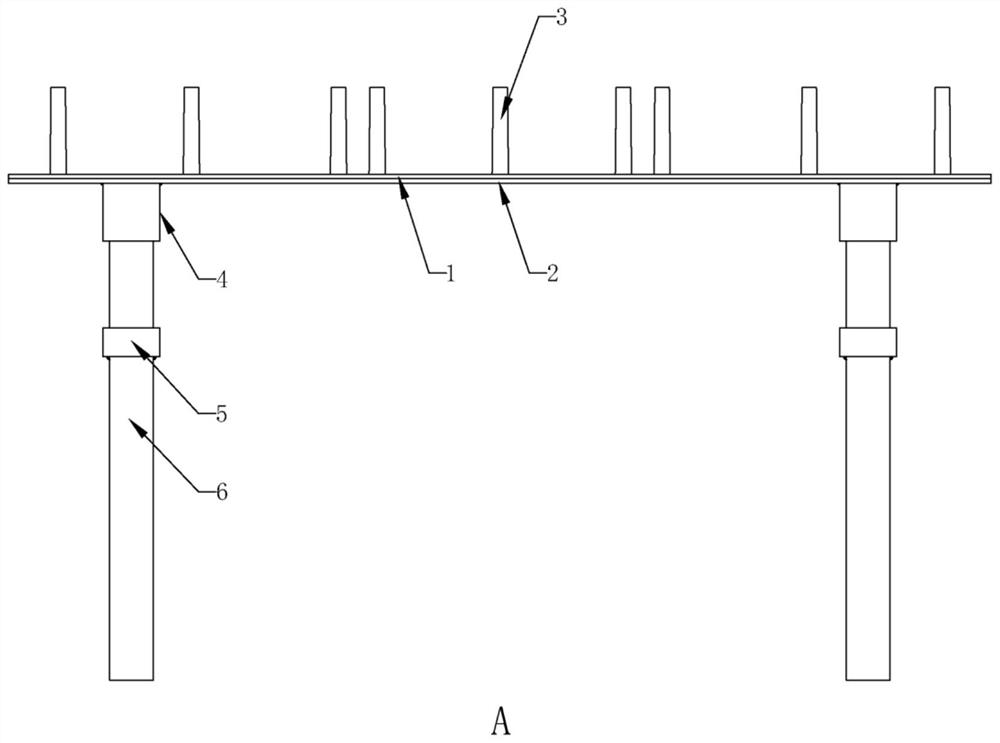

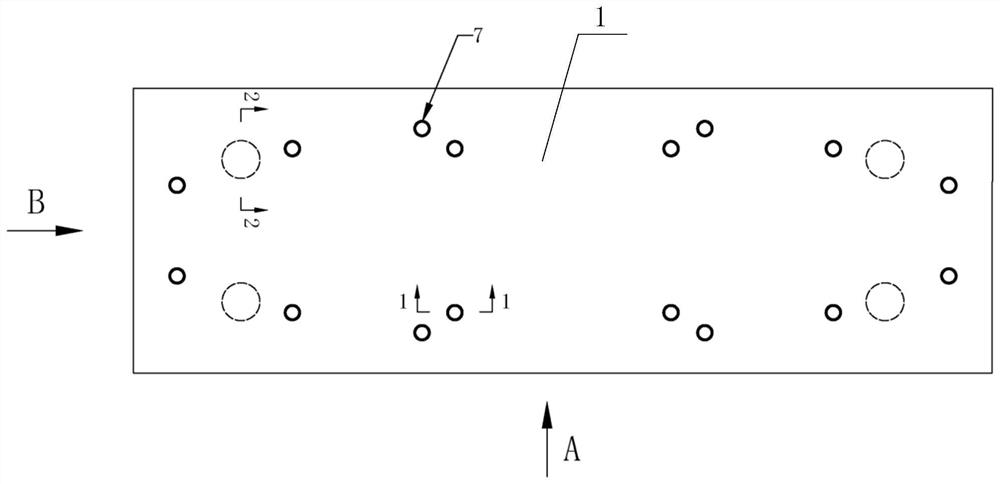

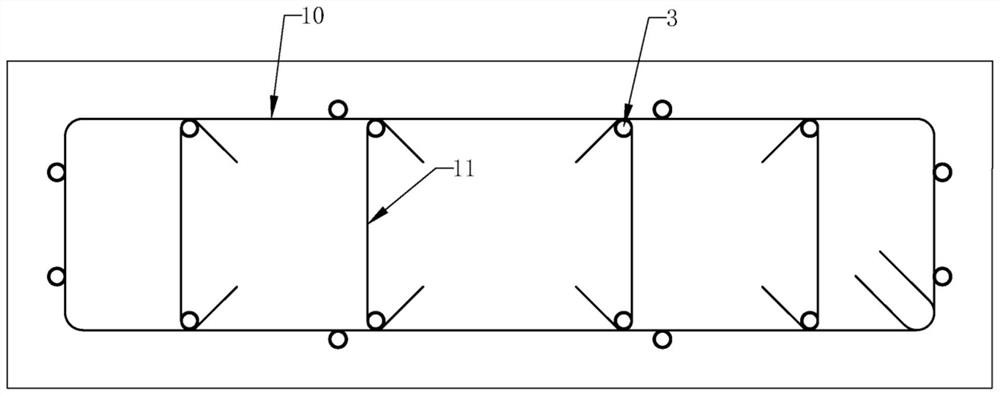

Shield segment reinforcing mesh manufacturing tool

PendingCN114733985AEasy to take outQuick take outWire networkHydro energy generationMesh reinforcementWeld quality assurance

The invention discloses a shield segment reinforcing mesh manufacturing tool, belongs to the technical field of engineering machinery, and particularly relates to a shield segment reinforcing mesh machining device. The key technology is that the operation platform comprises an upper-layer platform, a lower-layer platform, stand columns and the limiting columns, the top ends of the stand columns penetrate through the lower-layer platform and are fixed to the lower surface of the upper-layer platform, and the bottom ends of the limiting columns penetrate through the upper-layer platform and are fixed to the upper surface of the lower-layer platform; limiting sleeves are fixed to the joints of the lower-layer platform and the stand columns, limiting rings are fixed to the upper portions of the stand columns, and the lower-layer platform is connected with an air cylinder. The device has the beneficial effects that the limiting columns on the operation platform are telescopic, when a reinforcing mesh is manufactured, the air cylinder is started, the lower-layer platform drives the limiting columns to move downwards, the reinforcing mesh can be conveniently and rapidly taken out at the moment, operation is easy and convenient, and therefore the manufacturing efficiency of the reinforcing mesh is improved, the welding quality of the reinforcing mesh is guaranteed, and the manufacturing precision of the mesh is guaranteed.

Owner:SINOHYDRO BUREAU 7 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com