DTRO membrane welding heating mechanism and DTRO membrane welding machine

A heating mechanism and welding machine technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of membrane material peeling, affecting the use effect of membrane materials, and difficult membranes to be fixed. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

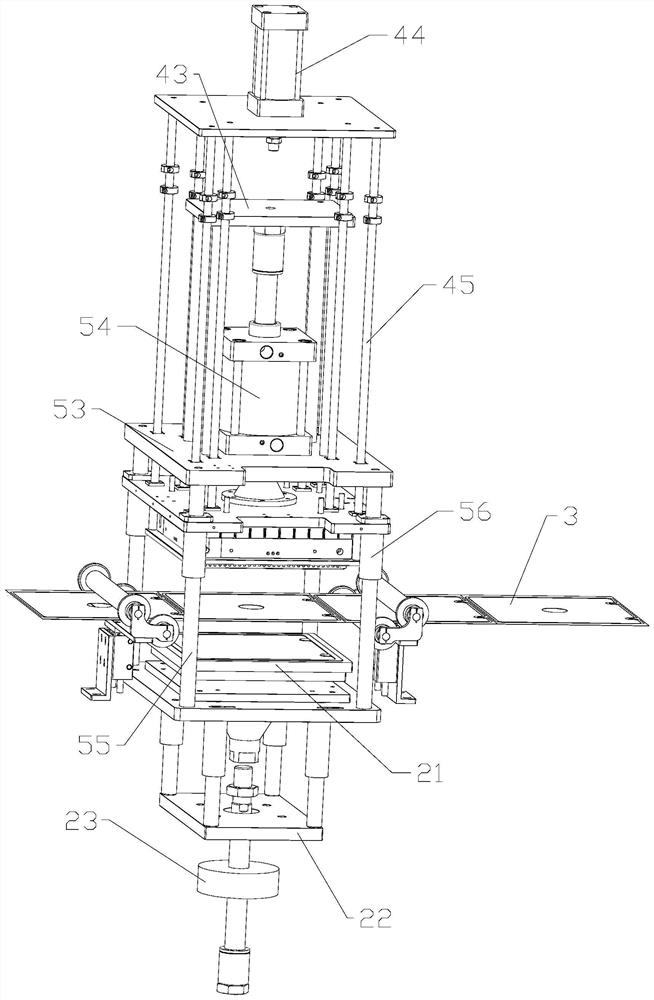

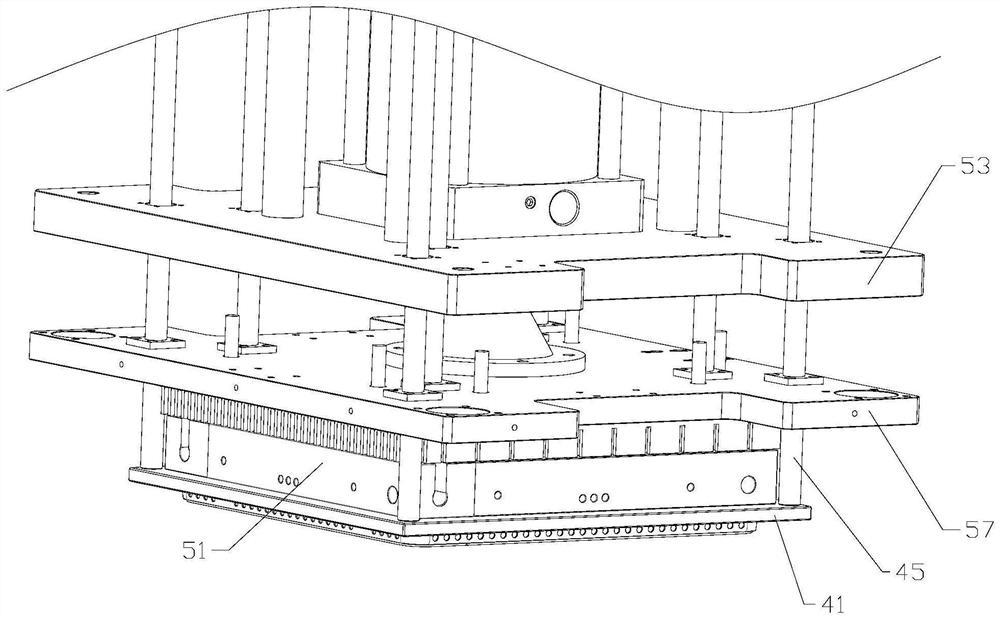

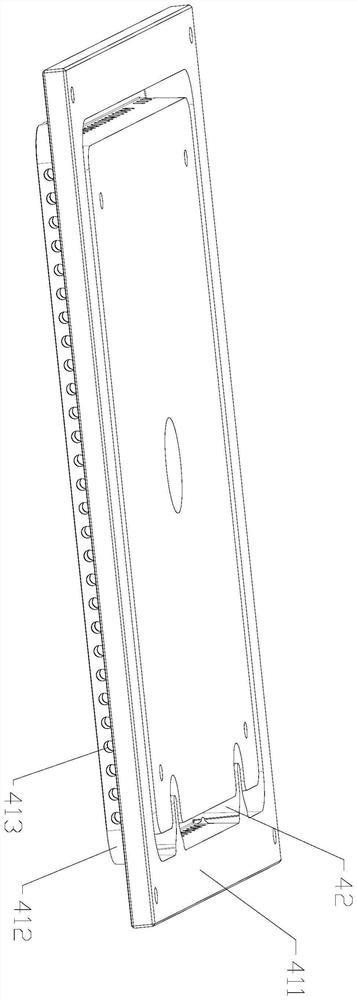

[0033] See attached Figure 1-5As shown, a DTRO diaphragm welding heating mechanism of the present invention is installed on the machine platform 1, including a lower mold assembly, including a supporting lower plate 21 that can move up and down under the action of the lower mold driving member, and the supporting lower plate 21 is used for Support the diaphragm 3 to be welded; the upper mold assembly includes a thermally conductive upper plate 41 that can move up and down under the action of the upper mold driver to press against the diaphragm 3, and the thermally conductive upper plate 41 is provided with a through The heat conduction groove 42 on its upper and lower end surfaces; the heating assembly includes a heating plate 51 that can move up and down under the effect of the lifting drive assembly, and the lower end of the heating plate 51 is provided with a heat conduction groove that can move in the heat conduction groove 42. The sizing heating plate 52 heated by the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com