Bionic cow-nosed ray oscillating pectoral fin driven by wires of large-deformation flexible mechanism

A flexible mechanism and wire-driven technology, applied in the field of bionic swinging pectoral fins, can solve the problems of insufficient simulation of complex flexible features and flexible deformation, low propulsion performance of bionic swinging pectoral fins, natural prototypes, limited driving and processing levels, etc., to achieve reduction Small impact, smooth wave transmission, and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

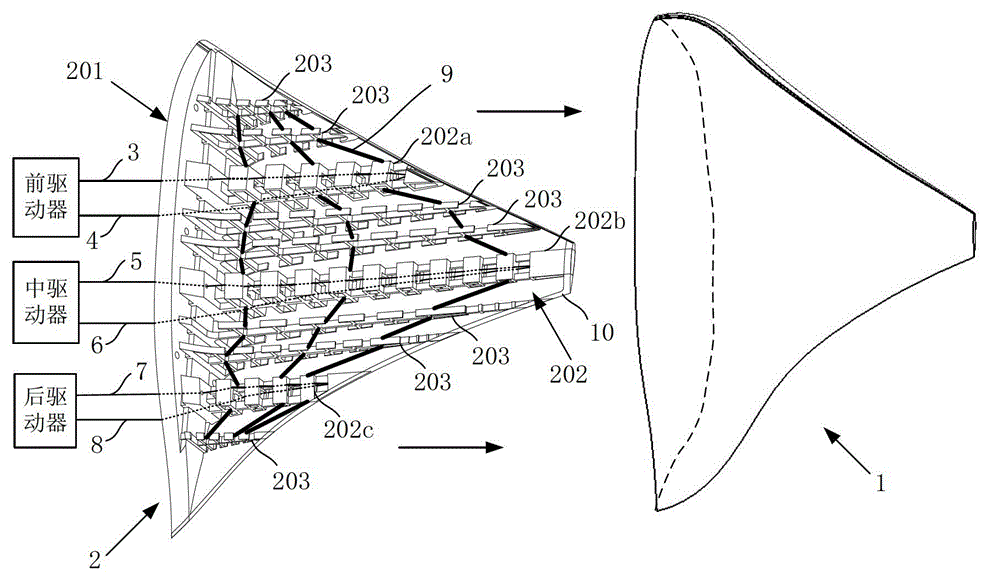

[0021] The bionic bullnose ray of the present invention swings the pectoral fins, including the pectoral fin skin 1 and the pectoral fin skeleton 2 set inside the pectoral fin skin 1, such as figure 1 As shown, the pectoral fin skeleton 2 is composed of a base plate 201 and fin rays 202 . The base plate 201 is arranged along the chord direction of the swinging pectoral fin of the bionic bullnose ray, and is used to support the root of the pectoral fin skin 1 and to install the fin rays 202 at the same time.

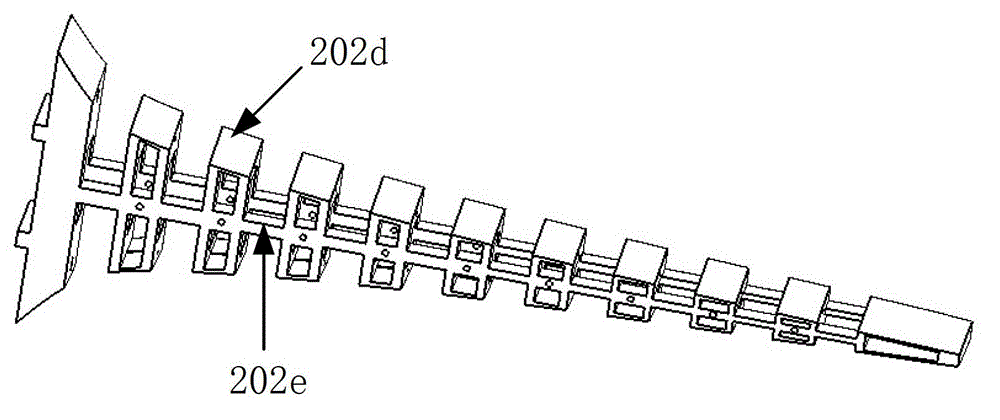

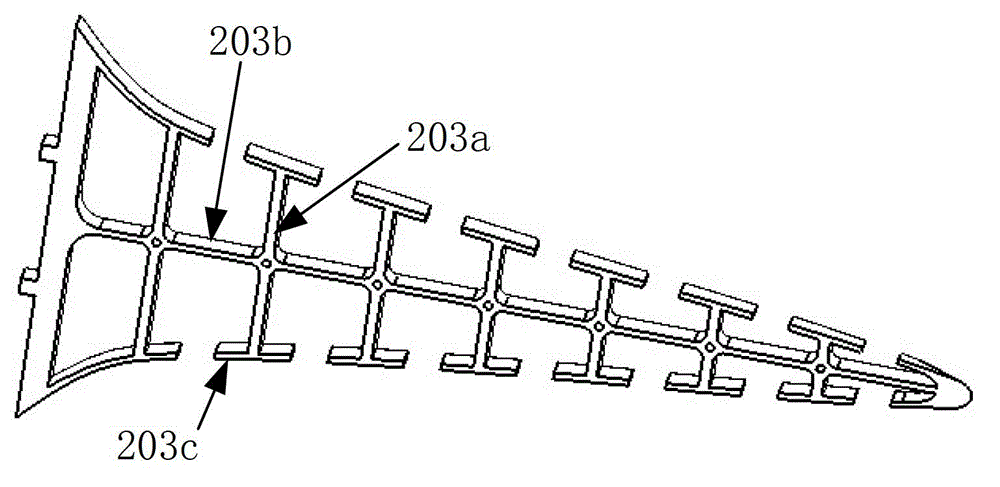

[0022] The fin rays 202 include a front fin ray 202a, a middle fin ray 202b and a rear fin ray 202c; The structure similar to the span-wise cross-sectional shape of the prototype of the pectoral fin rays of the Oxnose ray is used as the main swinging part for the bionic Oxnose ray to swing the pectoral fin, and supports the bionic shape of the pectoral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com