Patents

Literature

386results about How to "Improve fracturing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

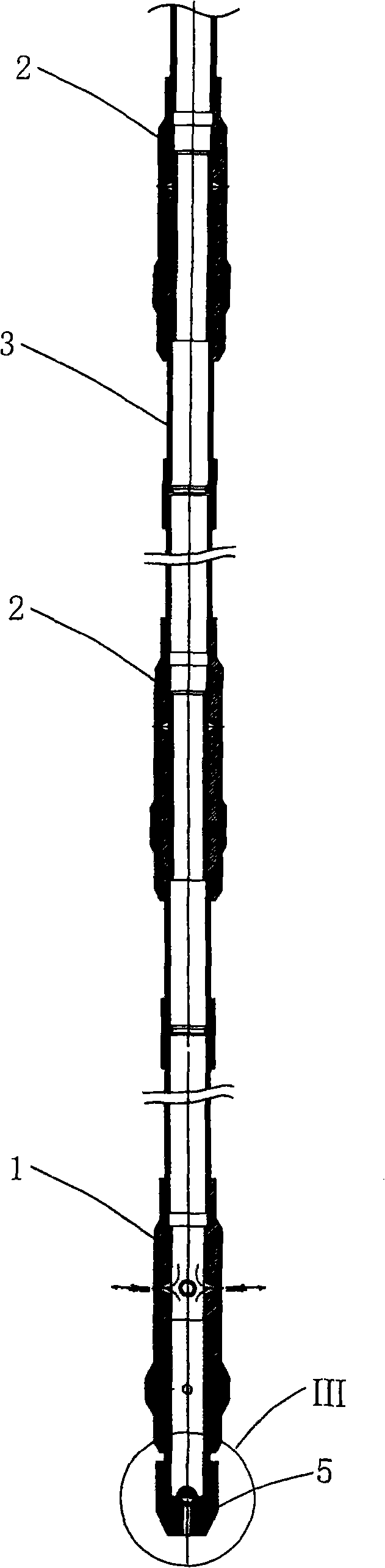

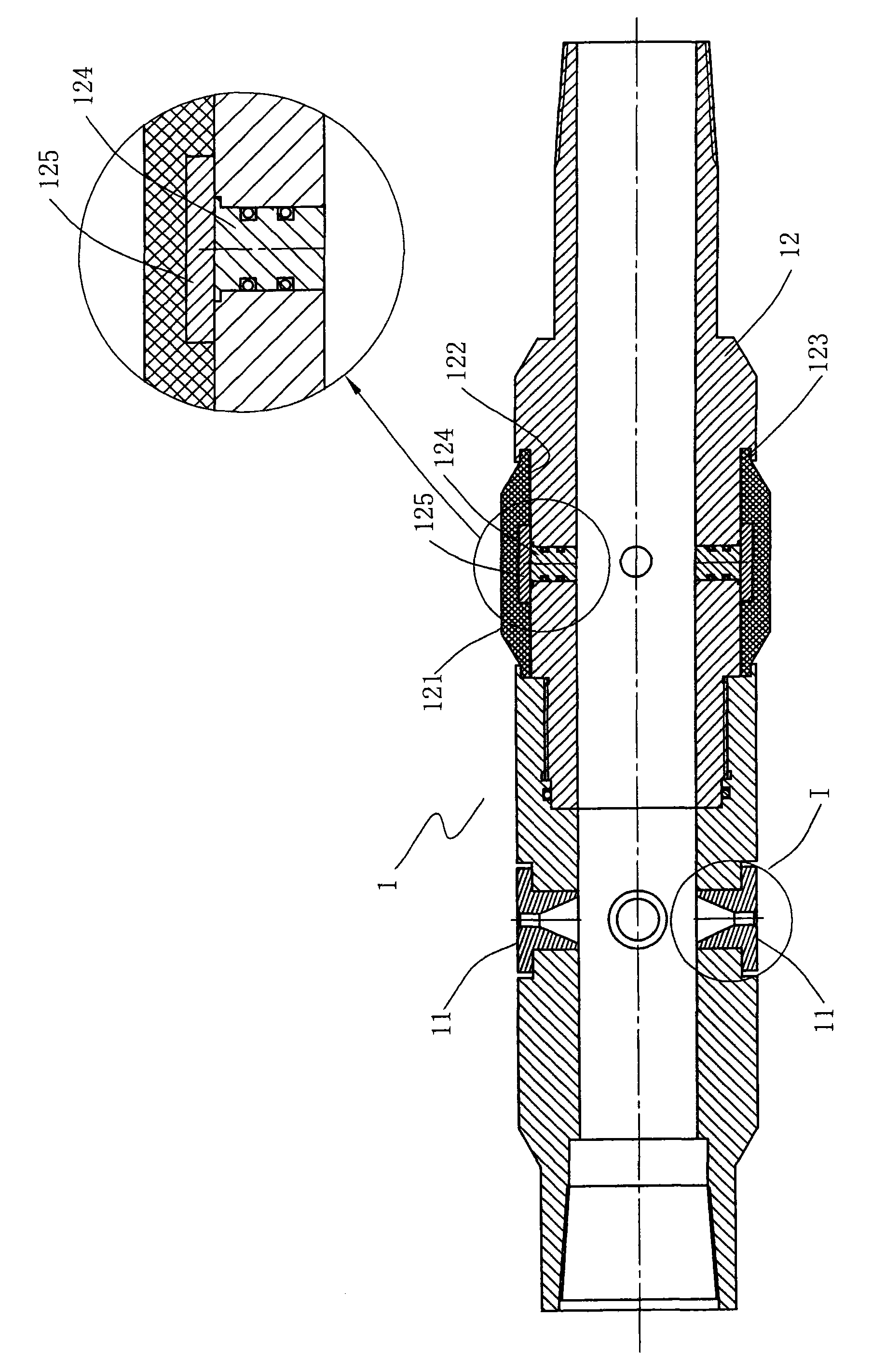

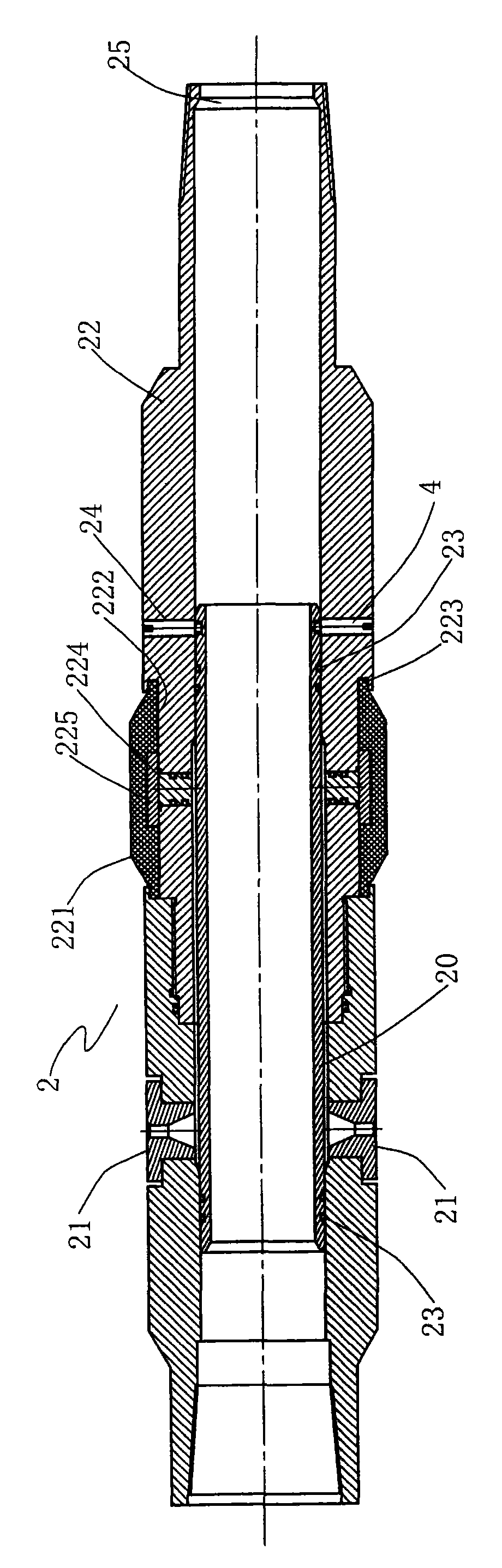

Abrasive jetting device and method for abrasive jetting flow and jetting perforation and multiple fracturing

InactiveCN101539007AAvoid defects that require moving the downhole stringGood sealingFluid removalLiquid spraying apparatusHorizontal wellsOil field

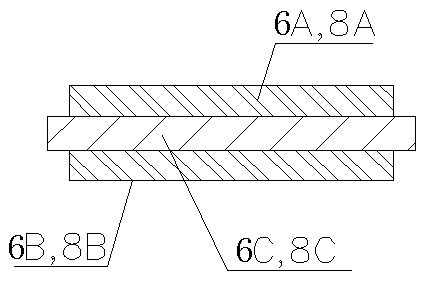

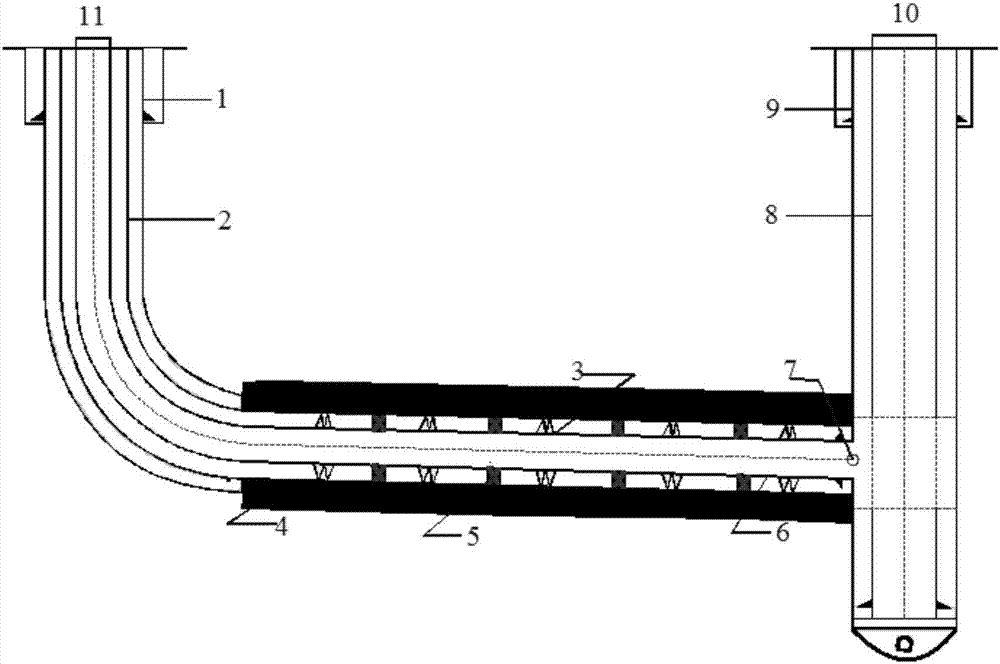

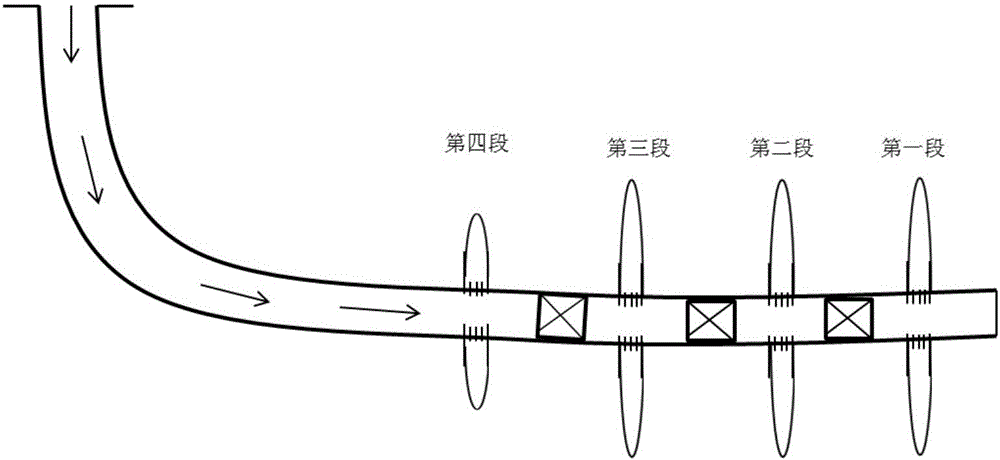

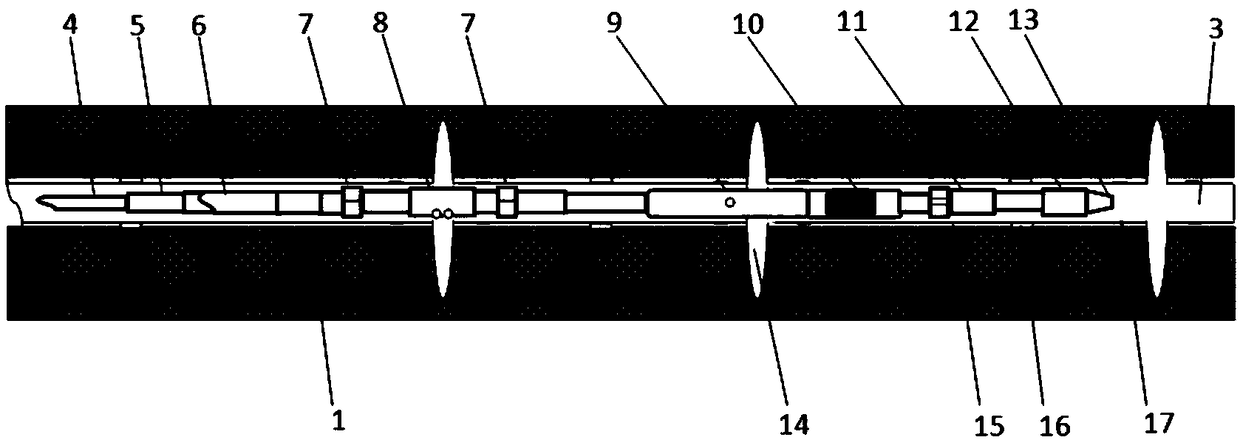

The invention relates to an abrasive jetting device and a method for abrasive water jet perforation and multiple fracturing; wherein the abrasive jetting device has multistage jet guns which are connected in series; the jet guns are all hollow columns; the side walls thereof are respectively provided with at least two nozzles; the lower part of each stage of jet gun is provided with a packer; the side wall of the packer is provided with a sealing sleeve which can expand outward under the action of high-pressure liquid; the jet guns comprise a first stage bottom jet gun arranged at the lower part of the abrasive jetting device and multistage upper jet guns arranged above the bottom jet gun; wherein all the upper jet guns are respectively provided with a sliding sleeve which can seal the nozzle of the stage of jet gun and sealing sleeve; and the sliding sleeve can slide to the lower part of the sealing sleeve under the action of external force so as to open the nozzle and the sealing sleeve. The invention can be used for casing straight wells or horizontal wells, solves the problem of layered or staged fracturing in the straight wells or the horizontal wells in oil fields, and achieves the purposes of saving fracturing cost, improving fracturing effect and reducing the construction risk.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

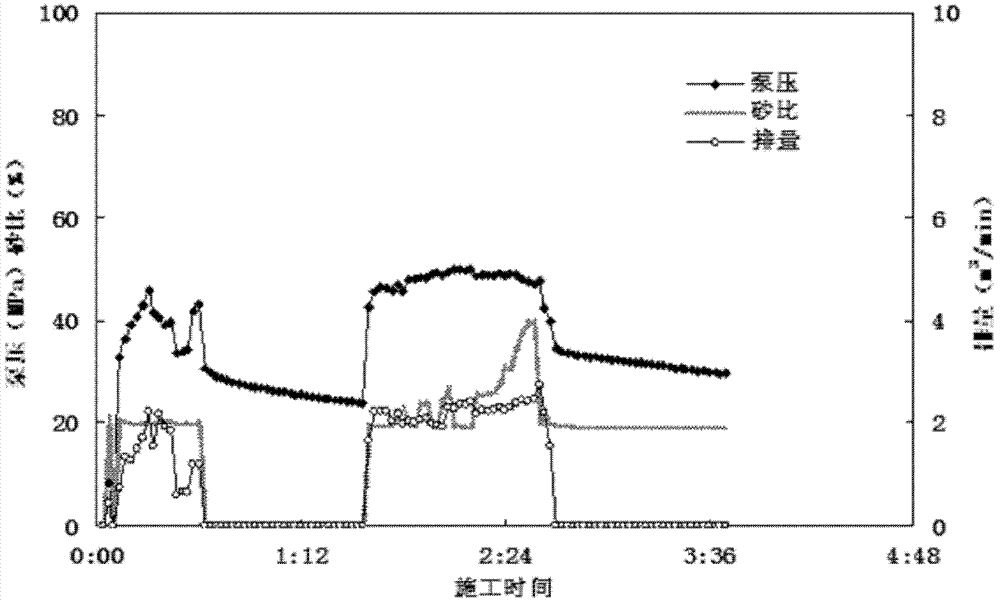

Fracturing method for comprehensively controlling fracture height

InactiveCN103089224AGuaranteed construction successAvoid invalid extensionFluid removalFracturing fluidWell control

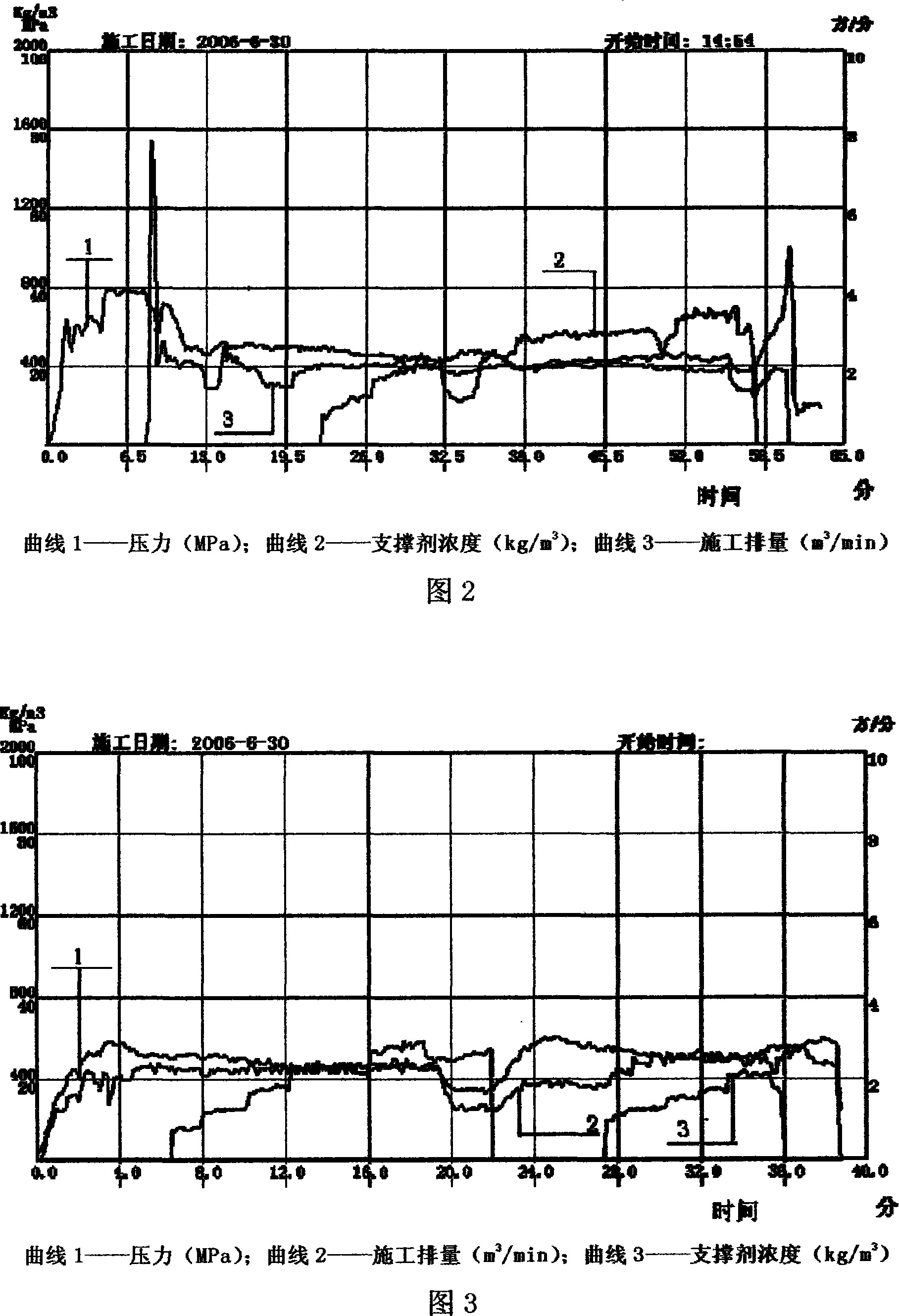

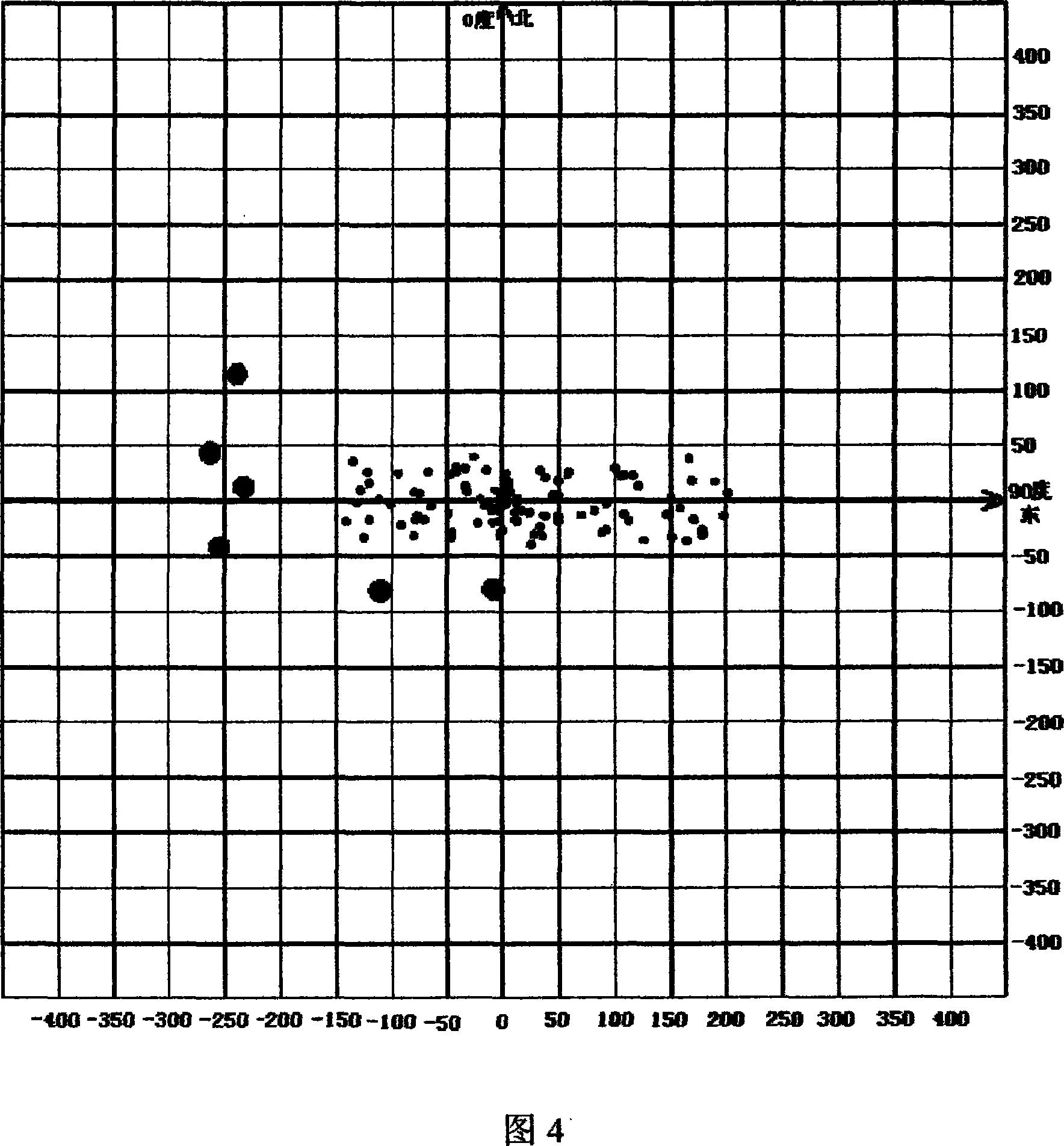

The invention discloses a fracturing method for comprehensively controlling fracture height. The method includes: injecting reversing agent to form an artificial isolating layer, using clean fracturing fluid, controlling construction scale, designing construction pumping programs of variable displacement and low displacement, using a combination of supporting agent with different grain sizes, and adjusting the pumping programs according to construction pressure monitoring results. The fracturing method for comprehensively controlling fracture height is simple in process, convenient to operate, evident in construction effect, capable of being widely used in renovation construction of oil-gas reservoirs with a thin target reservoir stratum and small stress difference between the reservoir stratum and the isolating layer, and capable of well controlling vertical extension of fractures so as to avoid ineffective extension of a communication water layer, a gas layer or in the vertical direction, lower using amount of the fracturing fluid and the supporting agent, reduce cost of fracturing construction and improve effect of fracturing modification yield increase.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving complexity index of deep shale gas fracture

ActiveCN106567702AIncreased Fracture Complexity IndexImprove fracturing effectFluid removalEconomic benefitsFracturing fluid

The invention relates to a method for improving the complexity index of a deep shale gas fracture. The method is characterized in that when a fracturing design of the a deep shale gas well is performed, selection and an injection manner of a fracturing fluid, selection of a supporting agent, and the number of perforations are optimized and controlled, and an artificial main fracture can be opened and communicate with a natural fracture as much as possible in an extending process; extension of a single fracture is longer, expansion of the single fracture is wider, and finally the complexity of the deep shale gas fracture can be improved to the greatest extent. The method can be used for deep shale gas reservoirs having the depth of more than 3500 meters and in which the natural fractures containing carbonate minerals are distributed in a reconstruction range of the artificial main fracture, and a certain included angle is formed between the fracturing main fracture and the natural fractures. The method is reasonable in design, is simple in process, is easy to operate, is high in fracturing construction successful rate, can effectively increase the volume of deep shale gas segment fracturing fractures, can remarkably improve the fracturing construction effect, and can acquire more economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

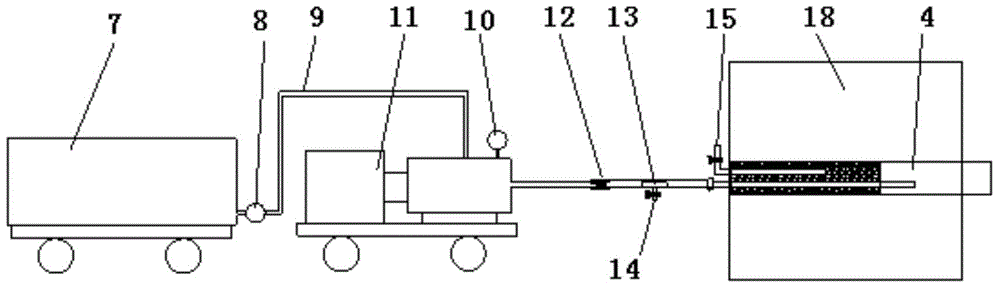

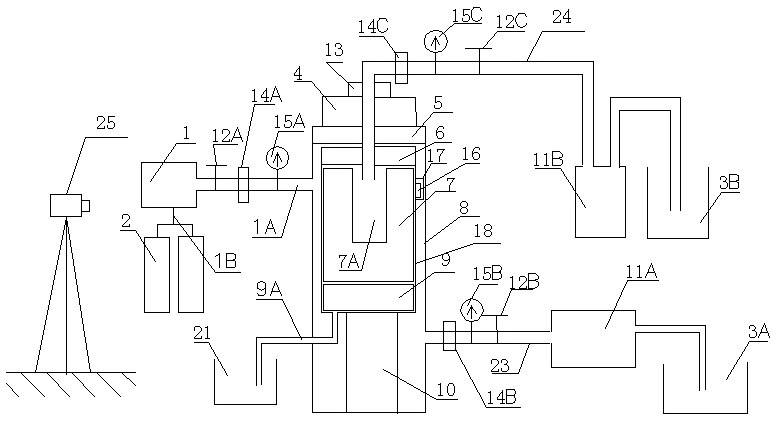

Coal seam liquid carbon dioxide fracturing device and method

The invention discloses a coal seam liquid carbon dioxide fracturing device and method. The device comprises a supplying unit for supplying liquid carbon dioxide, a fracturing pump, a hole packer, a first pipeline and a second pipeline; the hole packer is used for being placed in a drill hole in a coal seam to be fractured and comprises an grouting pipe, a first hole sealing capsule, a second hole sealing capsule and a fracturing pipe, one end of the grouting pipe and one end of the fracturing pipe penetrate through the first hole sealing capsule and are fixed on the first hole sealing capsule, the other end of the fracturing pipe penetrates through the second hole sealing capsule and is fixed on the second hole sealing capsule, and the other end of the grouting pipe is located between the first hole sealing capsule and the second hole sealing capsule. The coal seam liquid carbon dioxide fracturing device and method are capable of increasing the output of a mine and improving permeability of the coal seam and lump coal output rate.

Owner:XIAN UNIV OF SCI & TECH

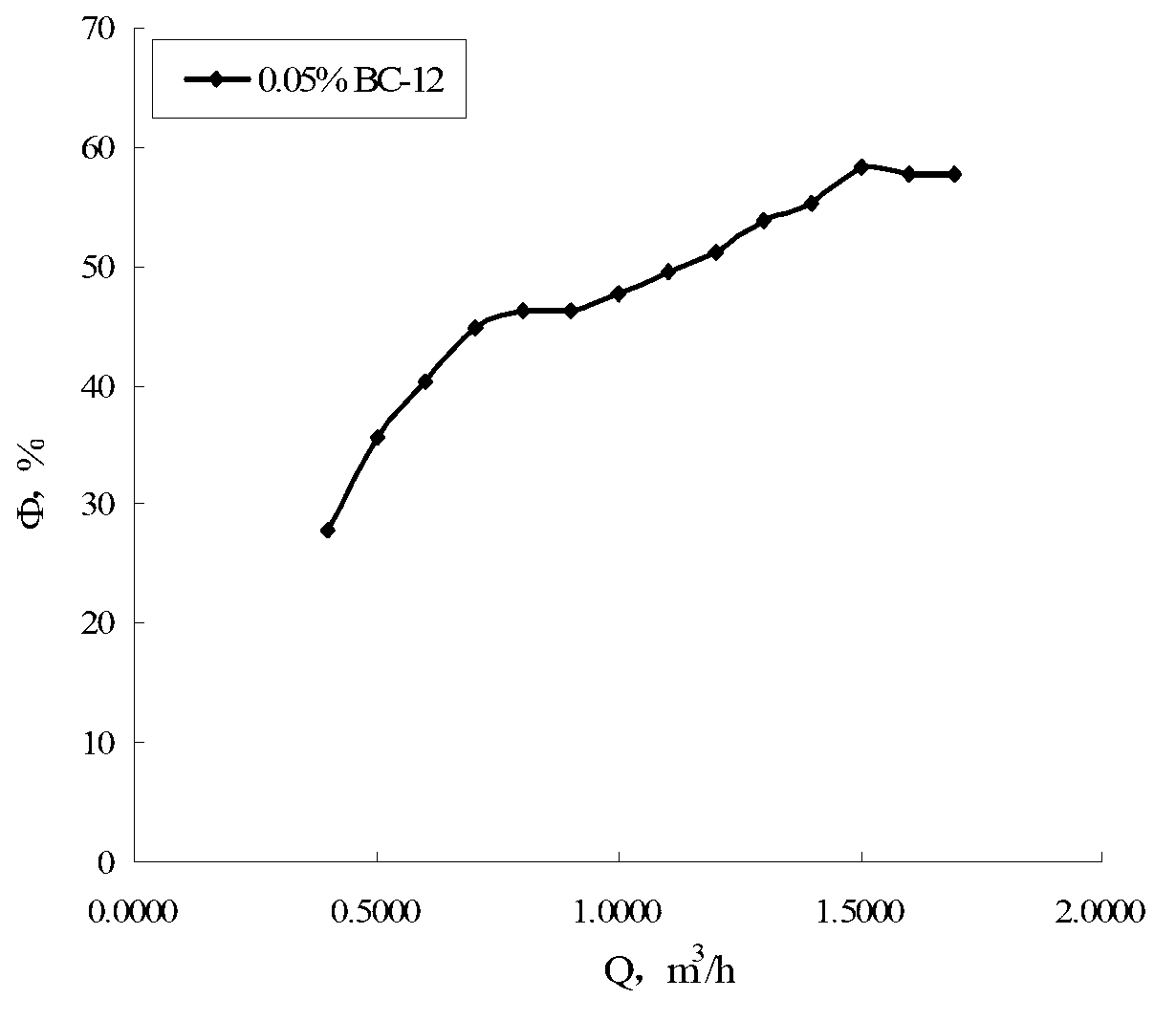

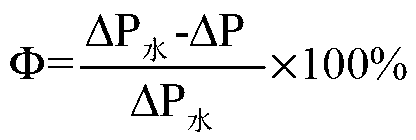

Slickwater fracturing fluid drag reducer and preparation method thereof

ActiveCN103013488AImprove stabilityReduce system complexity indexDrilling compositionFunctional monomerFracturing fluid

The invention discloses drag reducer which can be applied to slickwater fracturing fluid and a method for preparing drag reducer. The method includes: adding organic salt into acrylamide and functional monomer aqueous solution to prepare an aqueous phase, adding the aqueous phase into an oil phase system consisting of surfactant and base oil under the condition of high-speed stirring to form a stable W / O (water in oil) type microemulsion system, feeding nitrogen for dispersing oxygen, and adding initiator for polymerization to form a branchless long chain structure. The polymer microemulsion is a transparent or semitransparent thermodynamic stable system, can be quickly swelled into water and is directly usable. Adding a small quantity of the drag reducer during fluid transport can improve flow quantity and reduce energy consumption to some extent, and the drag reduction effect can reach 30%-65% when the drag reducer is compared with clear water. The drag reducer has the advantages of high stability, dissolving speed and dissolving performance, convenience in use, remarkable drag reduction effects and the like and is applicable to the slickwater fracturing technology, and excellent yield increasing effects are obtained after the drag reducer is applied to field fracturing operations.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

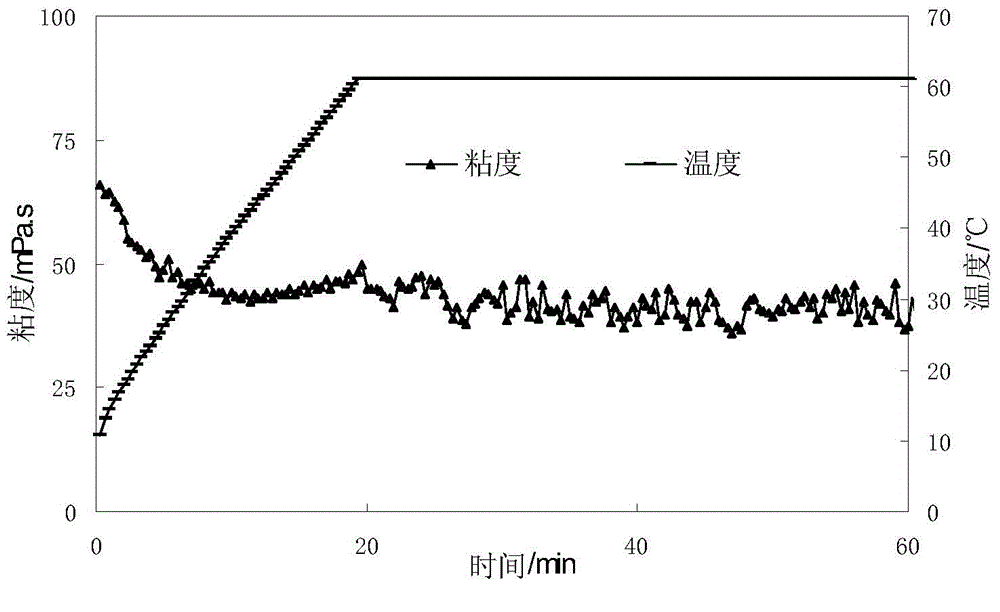

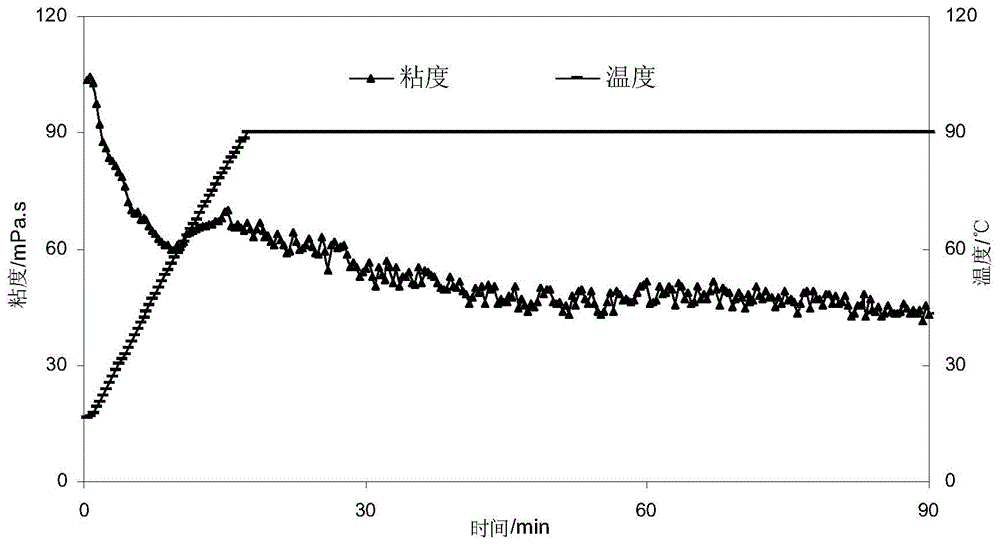

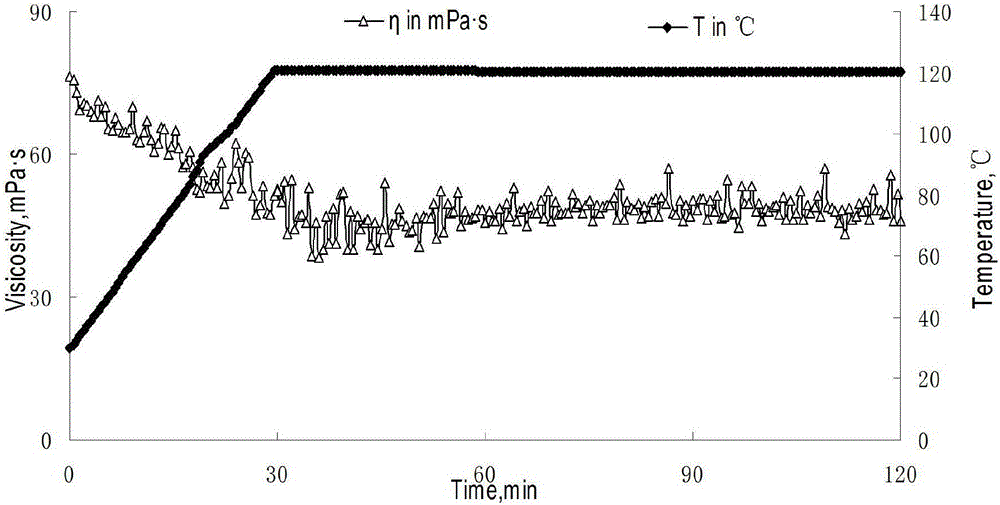

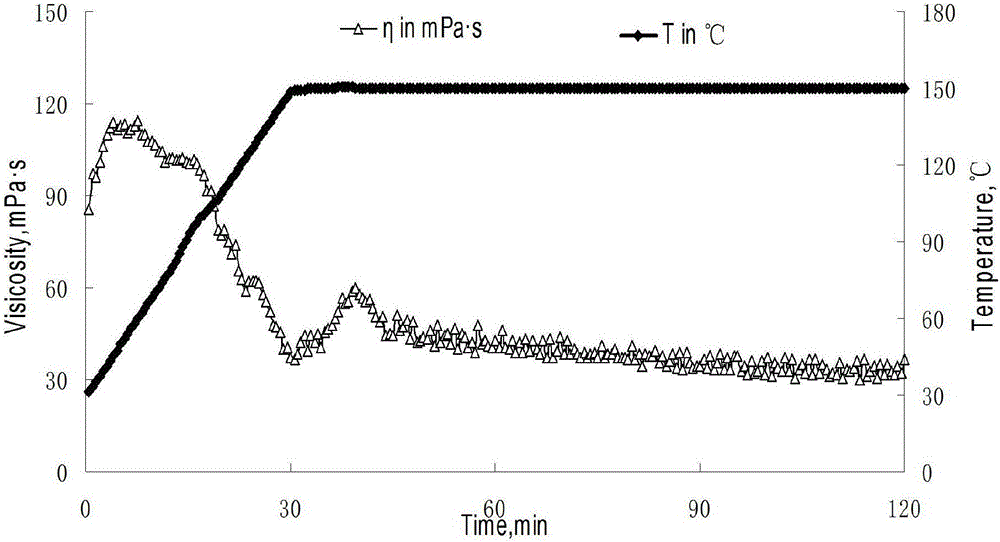

Acid clean fracturing fluid and preparation method thereof

InactiveCN101812290AImprove fracturing efficiencyImprove fracturing effectDrilling compositionInorganic saltsAcid fracturing

The invention relates to acid clean fracturing fluid and a preparation method thereof. The acid clean fracturing fluid consists of the following components in percentage by mass: 2 to 6 percent of surfactant, 1 to 4 percent of inorganic salt, 0.05 to 0.15 percent of counter-ion salt, 0.1 to 0.3 percent of cosolvent, 2 to 10 percent of acid and the balance of water. The method comprises the following steps of: dissolving the surfactant in the acid to prepare uniform liquid; adding the liquid into aqueous solution containing the inorganic salt, the counter-ion salt and the cosolvent; and stirring the mixture for 1 to 2 minutes to obtain the fluid having good viscoelasticity. The acid clean fracturing fluid is used for the fracturing of oil-gas fields at the temperature of between 60 and 120 DEG C, has the advantages of low viscosity, high elasticity, low friction resistance, high sand carrying, high effective control joints, increment on joint length and the like, can realize sand acid fracturing and finish all processes of acid fracturing and acidification, and has no residues after gel breaking and no damage to stratums.

Owner:SHAANXI UNIV OF SCI & TECH

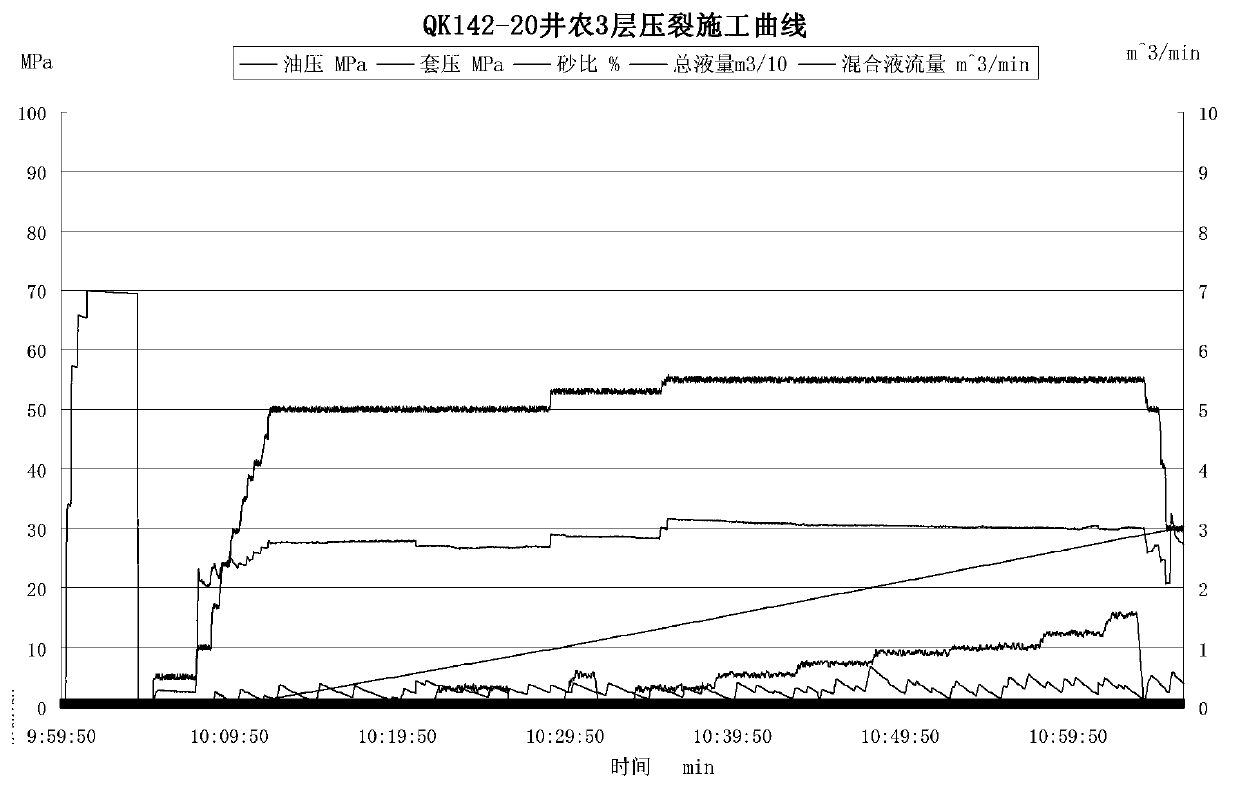

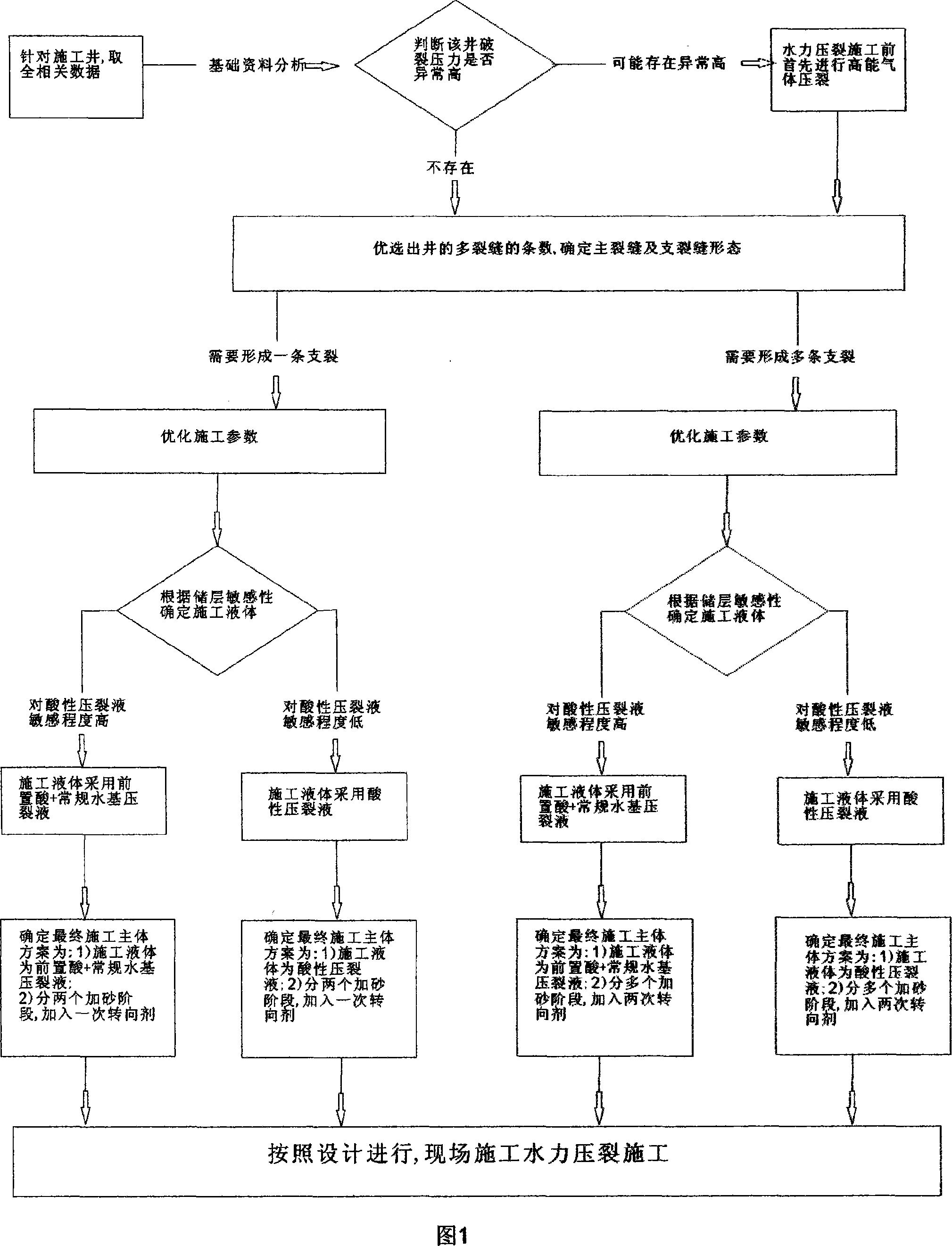

Fracturing process for enhancing low permeability reservoir deliverability

ActiveCN101113669AGuaranteed permeabilityIncreased productivity after pressingFluid removalAcid fracturingClay minerals

The invention relates to an oil field production technique, in particular to a fracturing method applied under the oil well to improve new well production capacity of low permeability reservoir before being brought into production. The fracturing reformation course at least comprises common fracturing technique and is characterized in that the method uses a compound application of more than two techniques of the use of acid fracturing liquid, or diversion agent or acid liquid and diversion agent by adopting high-energy gas fracturing technique; the upper sealed fracturing pipe is adopted during the working of hydraulic fracturing; the acid liquid is adopted during a pad fluid stage as the working liquid; the diversion agent is added for one or more times to seal fractured cracks; an increasing working flow rate is adopted before and after the adding of the diversion agent. The method of the invention can increase oil discharging area after fracturing, reduce expansion rate of clay minerals in fractured reservoir and improve completion of oil well reformation, fracturing effect and production capacity of low permeability reservoir after fracturing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Coal and rock bore hydraulic fracture experimental apparatus

InactiveCN102031954AImprove fracturing effectEasy to take pictures and recordEarth material testingFluid removalPressure systemAcoustic emission

The invention discloses a coal and rock bore hydraulic fracture experimental apparatus, which comprises a sample device system, a confining pressure system, a fracture system, a sealing system and a monitoring system, wherein the sample device system comprises a sample cylinder, the bottom in the sample cylinder is provided with a screen drum of which the bottom is provided with a water outlet pipe, a sample is accommodated in the sample cylinder above the screen drum, and a simulated bore is formed in the sample; the confining pressure system comprises an air filling subsystem and a water filling subsystem; the fracture system comprises a fracture high-pressure water pump of which a water outlet is communicated with the simulated bore through a fracture pipeline; the sealing system comprises a sample cylinder sealing device and an experimental cylinder sealing device; and the monitoring system comprises an acoustic emission sensor arranged on an external wall of the sample cylinder. By the coal and rock bore hydraulic fracture experimental apparatus, a simulated experiment can be performed in a laboratory to investigate the change rules of crack initiation, expansion and extension in the hydraulic fracture process of a coal mine underground coal seam bore, and know a crack extending direction so as to guide field fracture; therefore, the fracture effect is greatly improved.

Owner:HENAN POLYTECHNIC UNIV

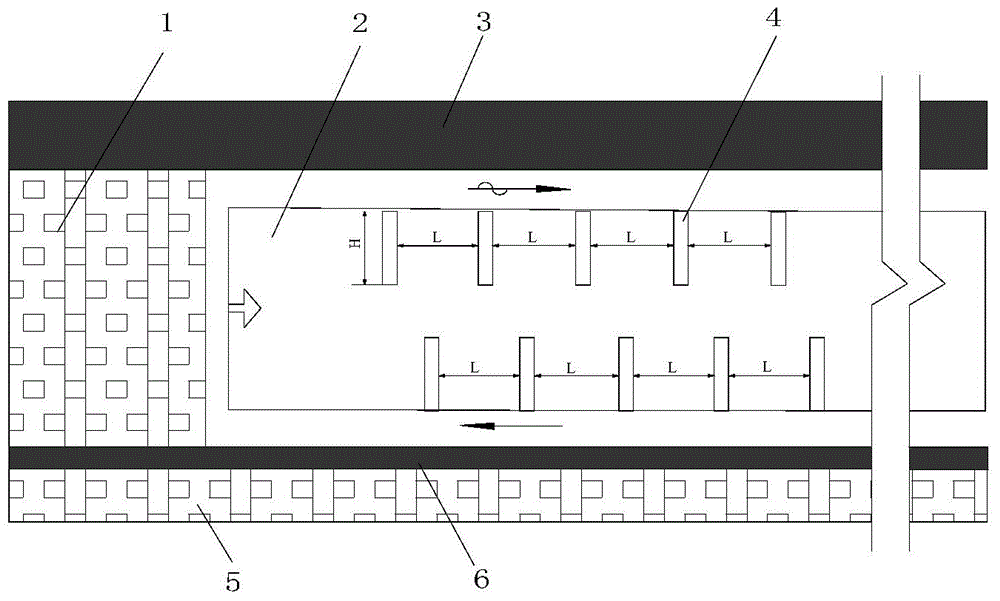

Open-hole horizontal well multi-cluster sliding sleeve staged fracturing string and fracturing method thereof

The invention discloses an open-hole horizontal well multi-cluster sliding sleeve staged fracturing string and a fracturing method thereof. According to the invention, a ball-throwing open type multi-cluster sliding sleeve is introduced on the basis of an existing mature open-hole horizontal well staged fracturing technology, wherein the main method comprises the following steps of: installing a plurality of groups of multi-cluster sliding sleeves in each packed-off interval, after finishing the installation, opening the plurality of groups of multi-cluster sliding sleeves step by step in a packed-off interval by throwing a ball, and matching with a standard ball-throwing open type sliding sleeve so as to isolate each fractured interval. According to the novel process, a plurality of major fractures can be formed in each packed-off interval, the reservoir transformation intensity is high, the drainage volume is expanded simultaneously, the defect that a sliding sleeve is mounted in each packed-off interval to form only one major fracture during the existing open-hole horizontal well staged fracturing is solved, the fracturing effect is greatly improved, and the yield of an oil-gas well can be furthest increased simultaneously.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

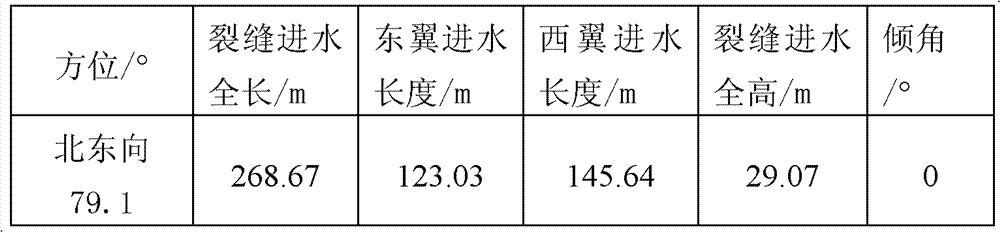

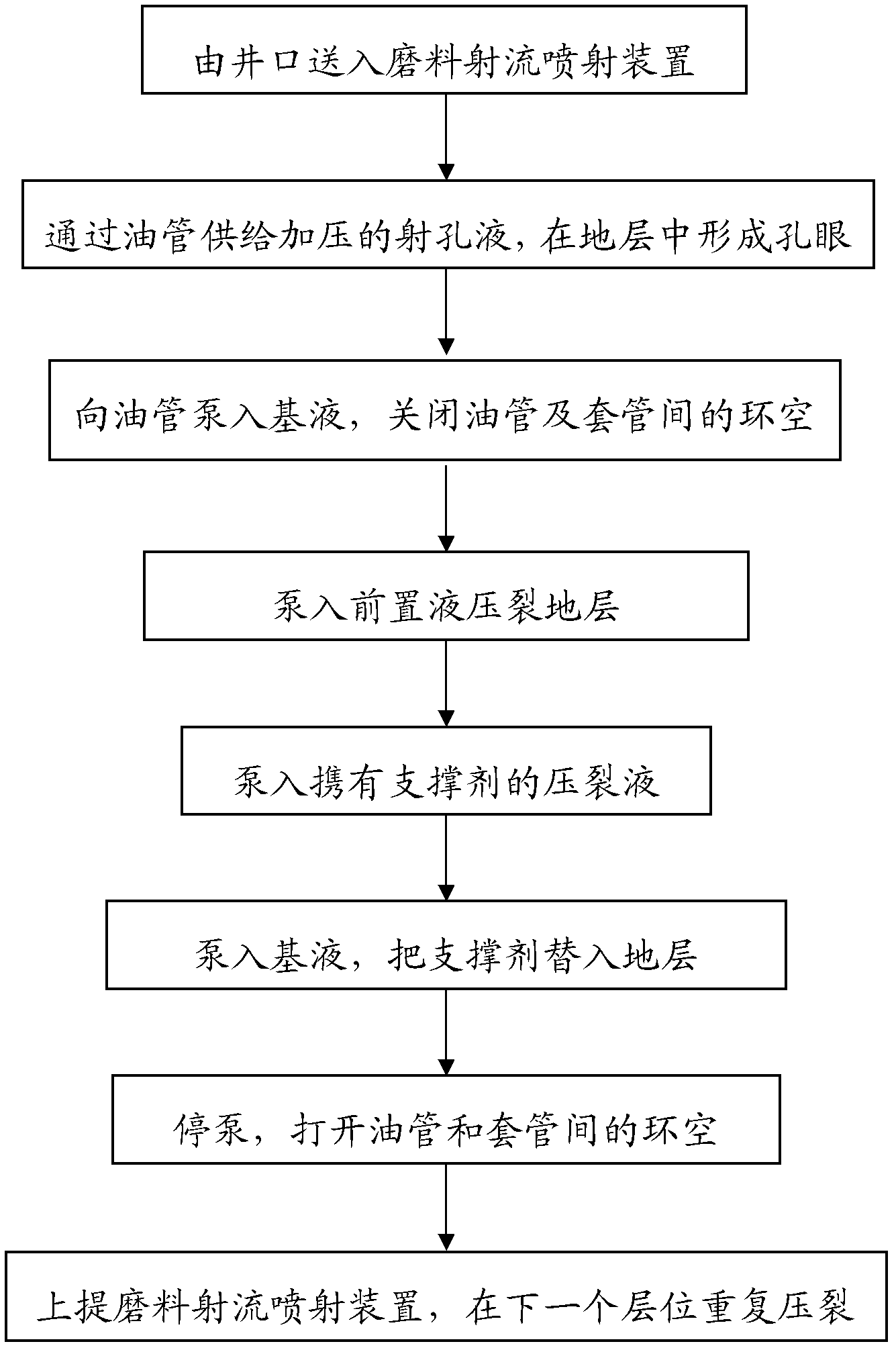

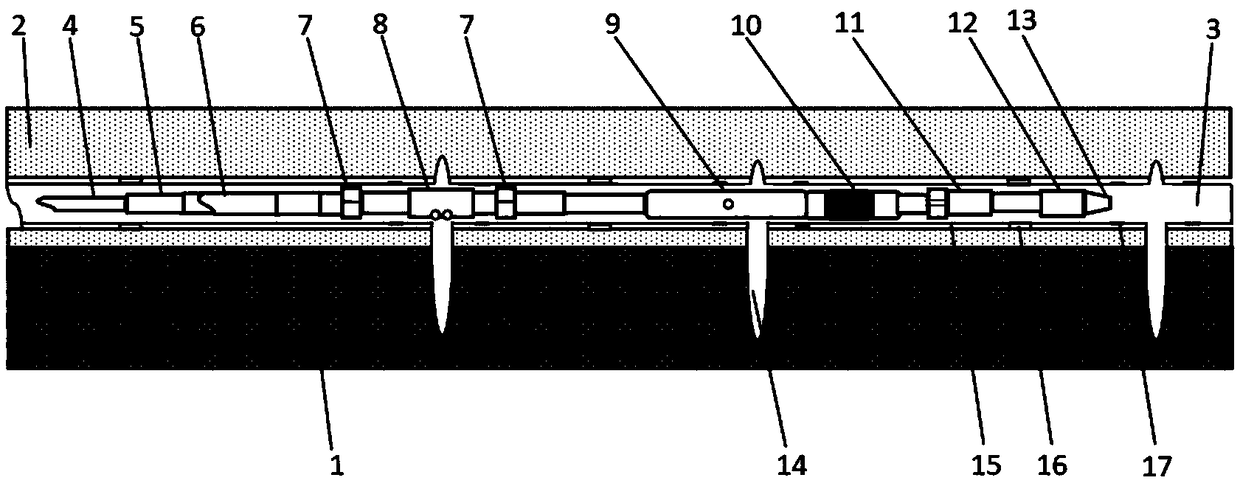

Drainage method of non-cell-cementation cased-hole-completion coal bed gas horizontal well

ActiveCN107387034AAvoid pollutionImprove fracturing effectFluid removalSand blastingProduction effect

The invention discloses a drainage method of a non-cell-cementation cased-hole-completion coal bed gas horizontal well. The method includes: a U-shaped butted well is used, the horizontal section of the horizontal well is deployed along the declination direction of a coal bed and a direction parallel to the minimum main stress of the coal bed, and well completion is performed by using casing running and an external self-expansion casing packer in a non-cell-cementation manner; the setting section, perforation and fracturing section of the external casing packer of the horizontal well are optimized; perforation is performed in a large-displacement and fixed-direction hydraulic abrasive perforation manner, and slug insertion type sand-carrying fracturing is performed on the horizontal well section by section in a large-displacement, large-scale, high-prepad-fluid-ratio and medium-sand-ratio manner; draining is performed at the wellhead of a drainage vertical well, and gas production is performed at the wellhead of the horizontal well. The drainage method has the advantages that pollution of a coal reservoir and production and operation costs can be lowered, the fracturing transformation effect and draining and gas production effect of the non-cell-cementation cased-hole-completion horizontal well are improved, the drainage efficiency and effect of the horizontal well are increased, the coal bed gas content of soft, broken and low-permeability coal beds can be lowered in a large-range and fast manner, and intensified coal bed gas drainage is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

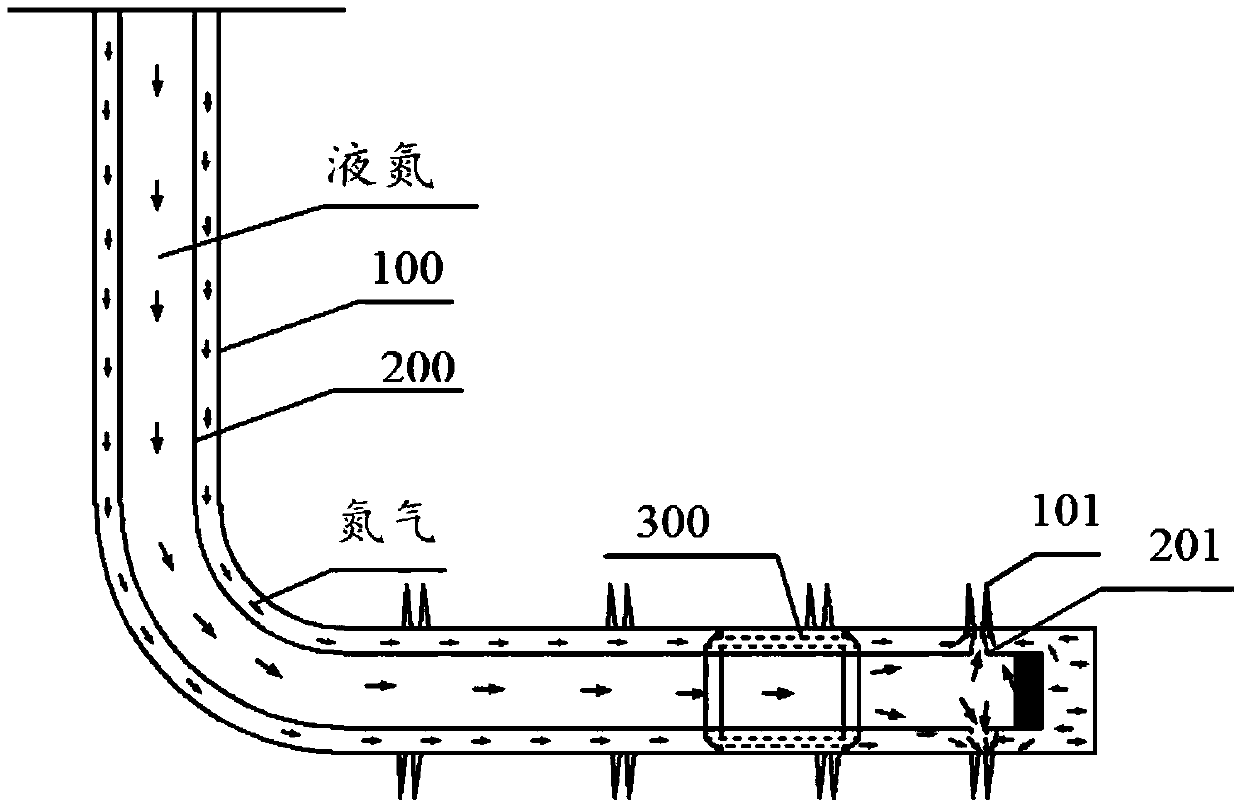

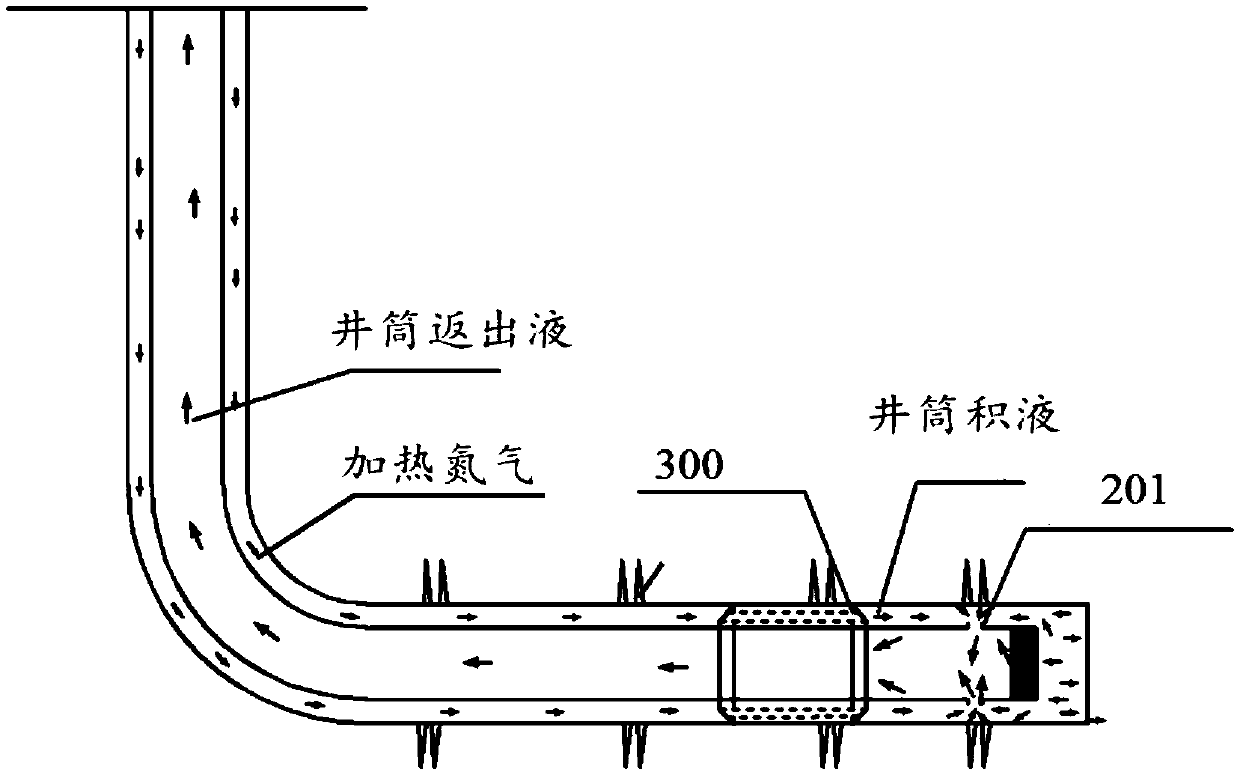

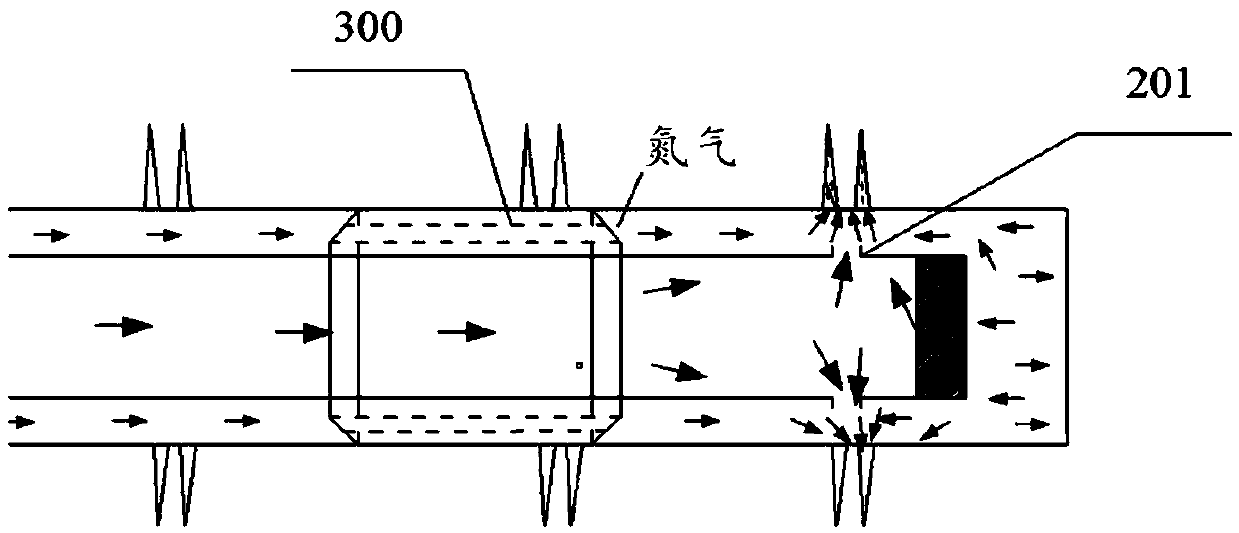

Horizontal well liquid nitrogen ice crystal temperature plugging staged fracturing method for coalbed methane

The invention provides a horizontal well liquid nitrogen ice crystal temperature plugging staged fracturing method for coalbed methane and belongs to the technical field of well fracturing. The method includes: perforating a stratum interval to discharge wellbore liquid, then using liquid nitrogen to open a stratum crack through pressing, allowing the liquid nitrogen to enter the crack, and injecting water to the inlet of the crack to form ice crystal temperature plugging due to the fact that the water freezes at the inlet of the crack under the effect of the liquid nitrogen so as to complete the fracturing of the stratum interval. The fracturing method has the advantages that the coal rock permeability around the crack can be increased effectively, coalbed methane discharge area can be increased, and yield can be increased evidently; in addition, an extremely-low reservoir environment is produced in a reservoir by using liquid nitrogen fracturing, the injected water freezes at the inlet of the crack and around the inlet of the crack to form the ice crystal temporary plugging, only one single-channel packer is needed to achieve the staged fracturing effect, and the method is simple in procedures, easy to operate, capable of saving time and space and capable of increasing operation efficiency.

Owner:SOUTHWEST PETROLEUM UNIV

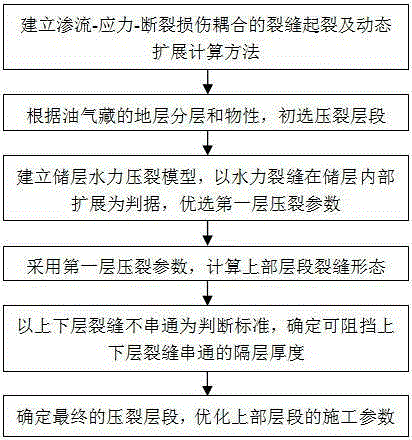

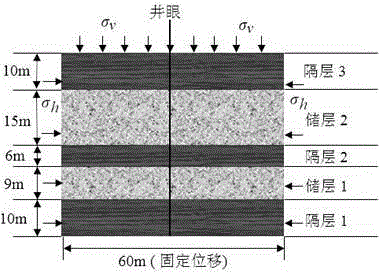

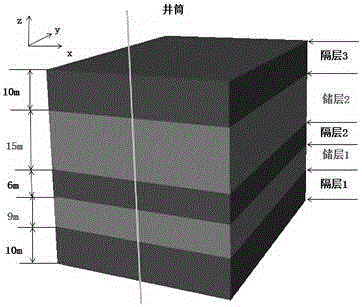

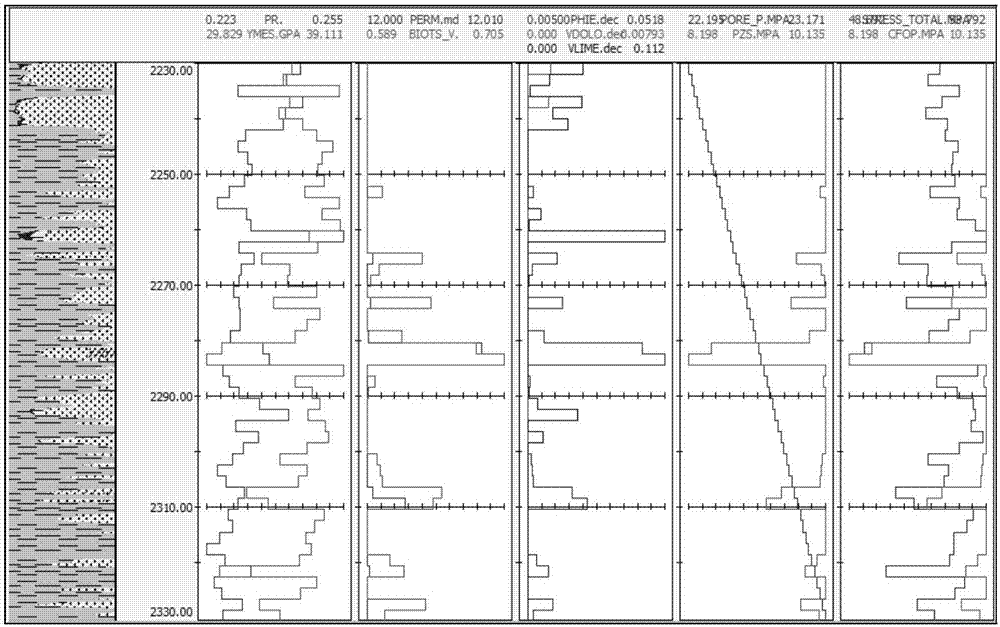

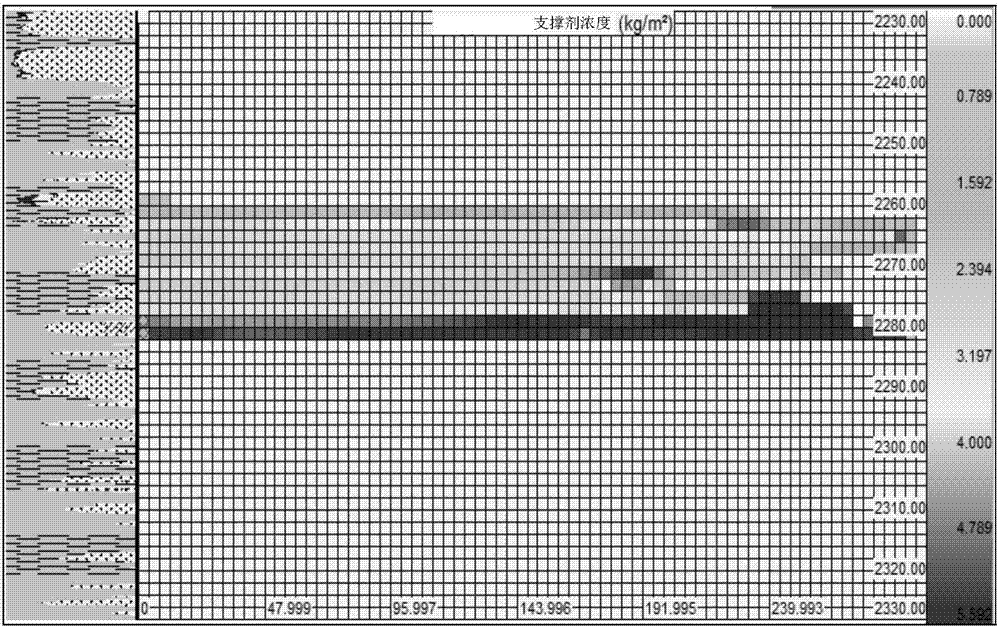

Vertical well separate layer fracturing interval optimization and construction parameter optimization designing method

InactiveCN105201484AEffective supportOptimize construction parametersFluid removalStress boneEnvironmental geology

The invention provides a vertical well separate layer fracturing interval optimization and construction parameter optimization designing method, and the method comprises the following steps of (1) establishing a porous flow-stress-fracture and damage coupling fracture initiation and dynamic expansion computing method; (2) primarily selecting the fractured interval according to the strata division and the reservoir physical property of the oil and gas reservoir; (3) establishing a reservoir hydrfracturing model, and taking the extension of hydraulic fracture in reservoir stratum as a criterion, and optimizing a first layer of fracture parameter; (4) adopting the first layer of fracture parameter, and calculating fracture shape of the upper part interval; (5) taking non-communication of the upper interval fracture and the lower interval fracture as a criteria, and calculating fracture shape of the upper part interval under different interlayer thickness to determine the interlayer thickness capable of blocking the communication of upper interval fracture and the lower interval fracture; (6) determining the final fracture interval, and optimizing the construction parameters of the upper interval. According to the method provided by the invention, the stress interference of the primary fracture initiation to secondary fracture initiation is taken into account, the communication of the hydraulic fractures of the upper interval and the lower interval is avoided, and the production capacity of each interval is greatly exerted.

Owner:SOUTHWEST PETROLEUM UNIV

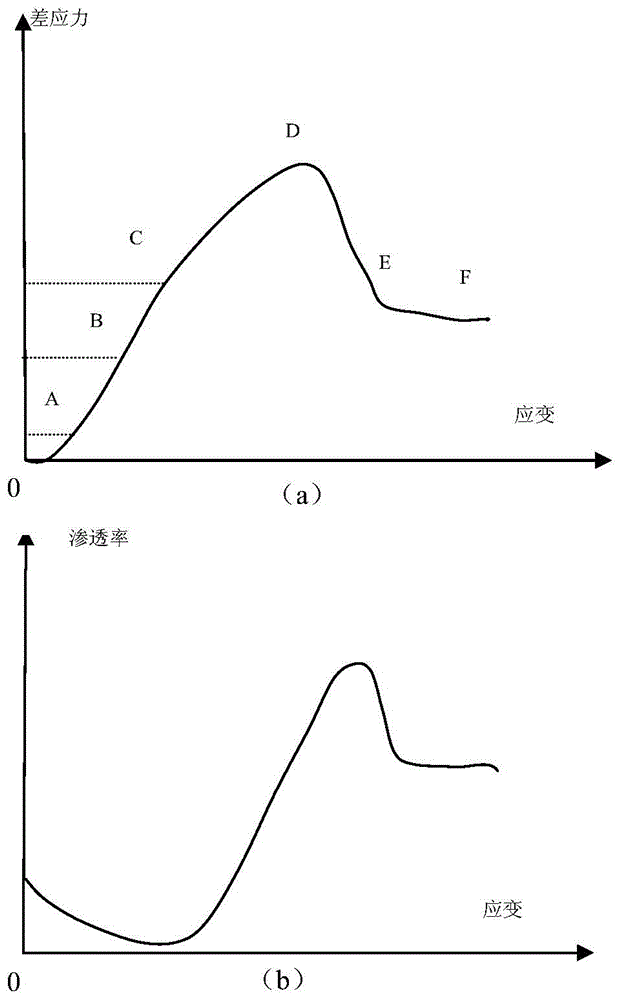

Active water fracturing technology of coal-bed gas well

ActiveCN102094612AImprove diversion capacityLarge flow areaFluid removalFracturing fluidHydraulic fracturing

The invention relates to the coal-bed gas exploitation technology, and in particular relates to an active water fracturing technology of a coal-bed gas well, which is used for solving the problem that the yield of coal-bed gas can not be effectively improved by the existing hydraulic fracturing technology owing to a poor fracturing effect. The fracturing technology comprises the following steps: (1) circulation; (2) pressure test; (3) extrusion test; (4) fracturing; (5) support; and (6) pressure release, wherein, in steps (1), (3), (4) and (5), a fracturing fluid is prepared from clear water, a surfactant and a bactericide based on the volume ratio of 2000:1:1; in steps (4) and (5), the pumping delivery of a fracturing pump is 5-9m<3> / min; and the fracturing fluid is infused into the well via a sleeve by utilizing the fracturing pump. By utilizing the fracturing technology, the problem that the yield of coal-bed gas can not be effectively improved by the existing hydraulic fracturing technology owing to a poor fracturing effect is effectively solved, thus the technology is applicable to coal-bed gas exploitation.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

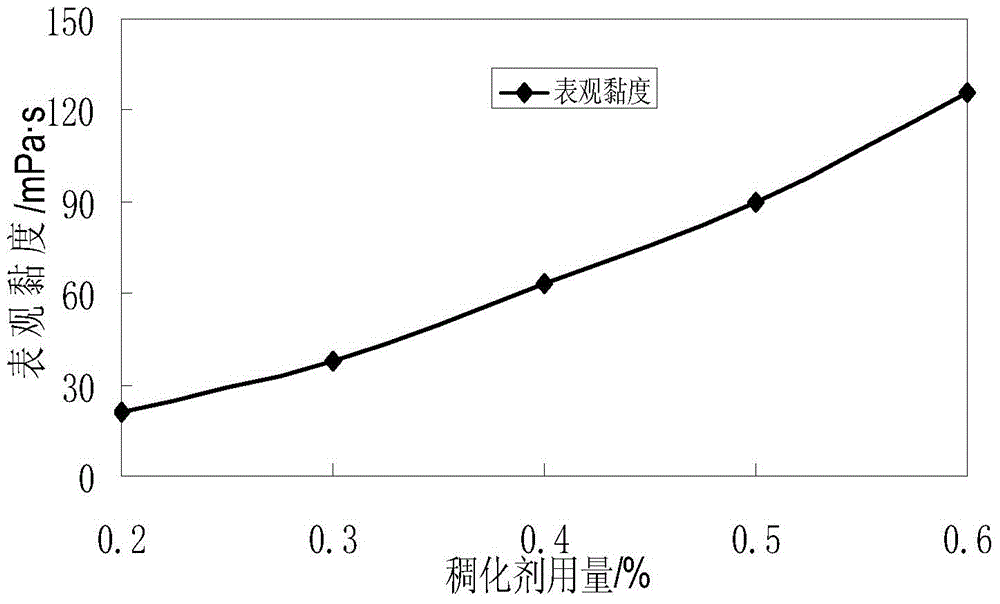

Clean carbon dioxide foam fracturing fluid and preparation method thereof

ActiveCN104531129AFine foamImprove foam stabilityDrilling compositionPotassium persulfatePolymer science

The invention discloses clean carbon dioxide foam fracturing fluid and a preparation method thereof, and relates to the technical field of oilfield chemistry and fracturing production increase. The carbon dioxide foam fracturing fluid is mainly composed of a base solution, a foaming agent, a gel breaker and liquid carbon dioxide with the mass ratio being 100 to 0.15-0.45 to 0.02-0.08 to 100-900. The base solution is formed by 0.2%-0.55% of a thickening agent and water. The thickening agent is mainly formed by bisacrylamide, vinyl pyrrolidone, kation unsaturated monomer, anion unsaturated monomer, an initiator, sodium carbonate, an emulsifying agent and a hydrotropy agent. The foaming agent is mainly formed by hexadecyl dimethyl tertiary amine, dimethyl sulfate, caustic soda flakes, potassium persulfate and solvent. The clean carbon dioxide foam fracturing fluid has the advantages of being high in foam stability, high in temperature resistance and shear resistance, high in sand-carrying performance, wide in applicable temperature range, extremely low in residue content, high in backflow performance, and small in secondary damage to a reservoir after fracturing, thereby improving the fracturing effect and increasing the reservoir productivity.

Owner:CHENGDU BAICHUN PETROLEUM TECH

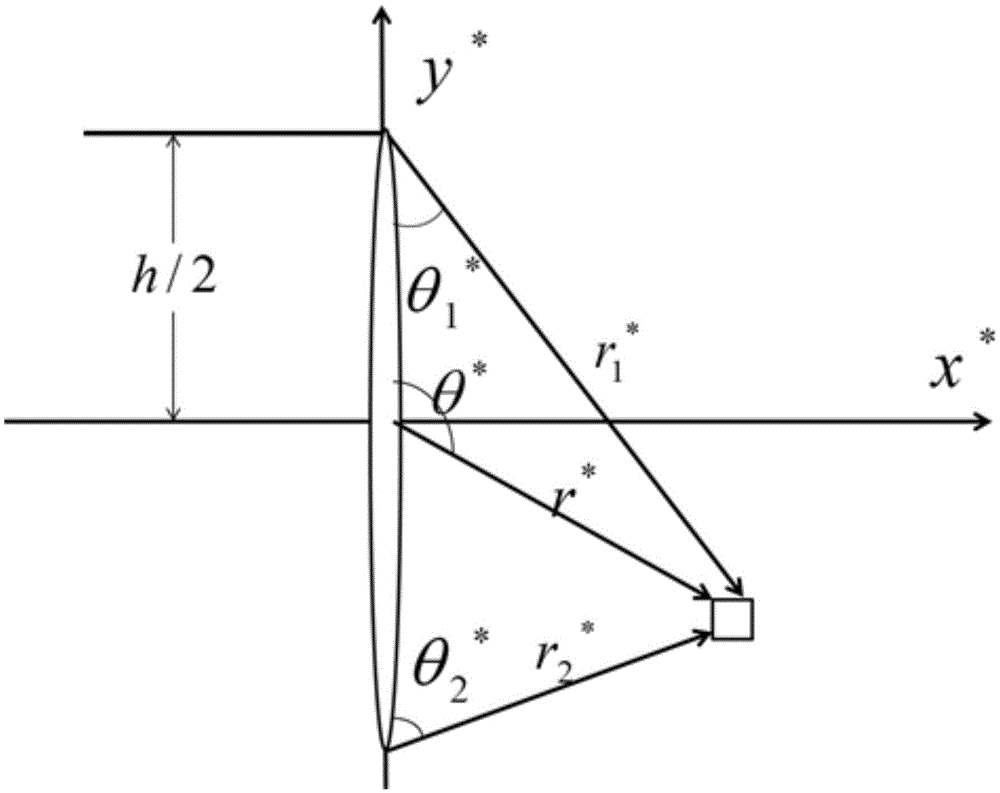

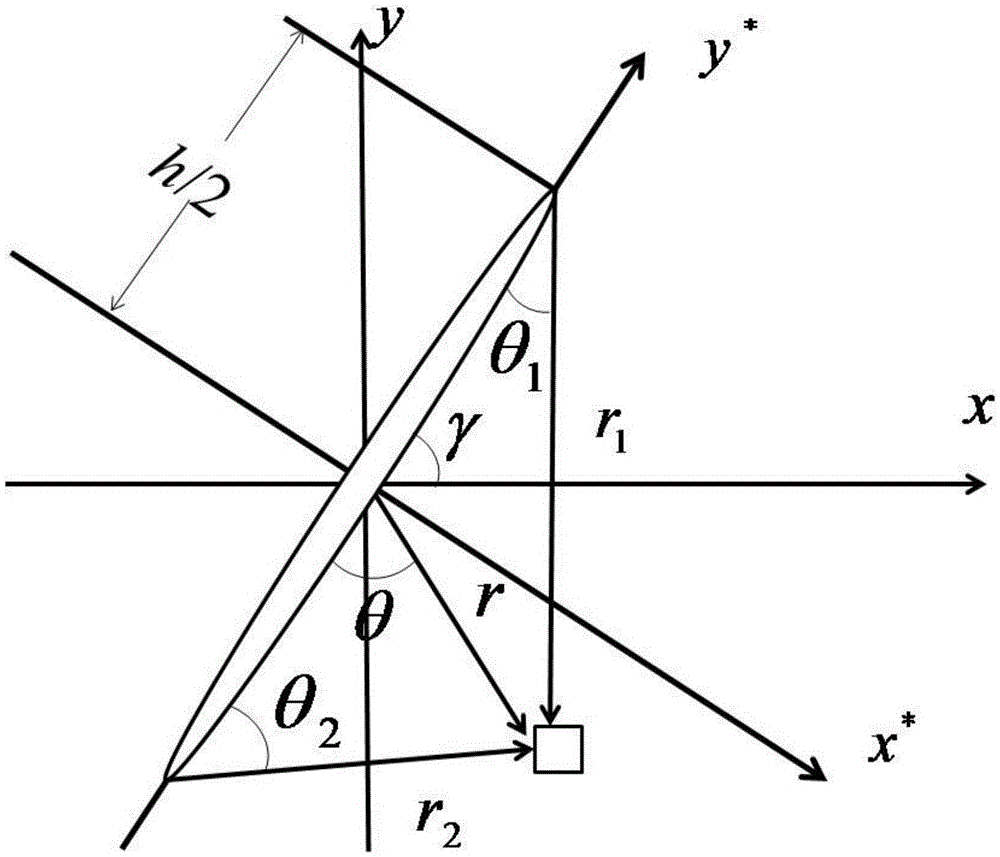

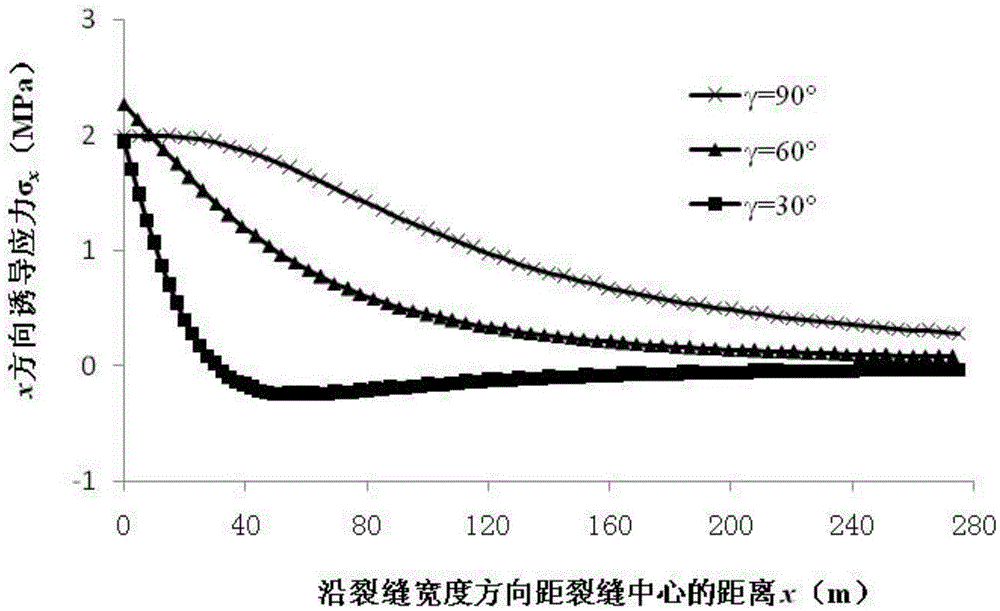

Method for calculating hydraulic fracturing inclined crack induced stress of shale reservoir

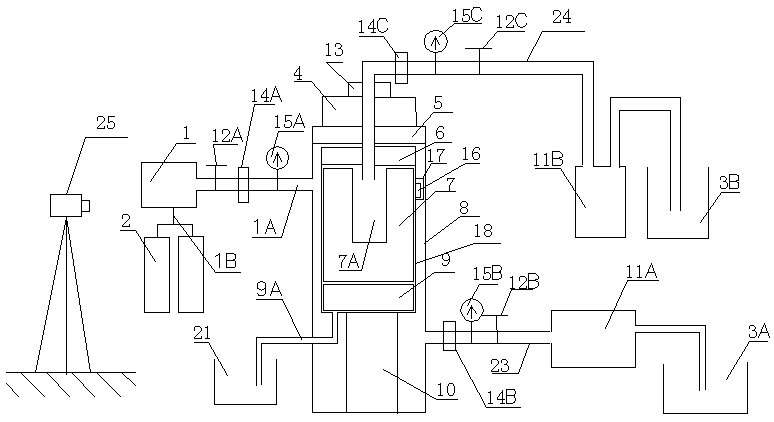

ActiveCN105550410AImprove fracturing effectSpecial data processing applicationsHydraulic fracturingInduced stress

The application discloses a method for calculating a hydraulic fracturing inclined crack induced stress of a shale reservoir. The method comprises the following steps of: 1, collecting basic parameters of the shale reservoir and a hydraulic crack; 2, establishing a calculation model of the hydraulic fracturing inclined crack induced stress of the shale reservoir; and 3, calculating the hydraulic fracturing inclined crack induced stress of the shale reservoir, and by analyzing change rules of the inclined crack induced stress in an x crack width direction and a z crack length direction, determining a stress inverted region. According to the method disclosed by the application, aiming at the inclined crack induced stress formed in the horizontal well fracturing process of the shale reservoir, simulation is carried out, and an induced stress field distribution condition under the inclined crack is analyzed, so that guidance is provided for optimization of a hydraulic crack position where the complex crack is formed by a fracturing horizontal well of the shale reservoir, and a fracturing effect of the shale gas reservoir is improved.

Owner:SOUTHWEST PETROLEUM UNIV

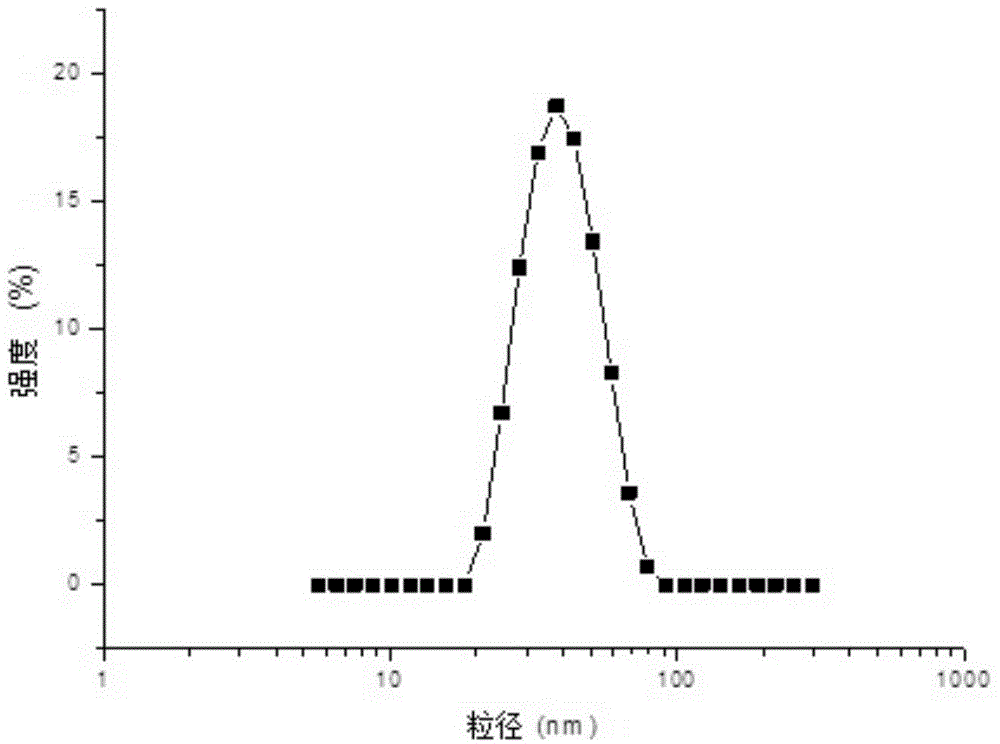

Nanometer microemulsion cleanup additive

InactiveCN104789205AGood liquid flowback effectGood performance in cleaning water lock damageFluid removalDrilling compositionSolventOrganic acid

The invention provides a nanometer microemulsion cleanup additive. The invention provides a concentrate of the nanometer microemulsion cleanup additive. The concentrate comprises 20-45wt% of oil, 15-45wt% of a surfactant, 0.1-35wt% of a cosolvent, 0.1-5wt% of an organic acid, and the balance of water. The invention also provides the nanometer microemulsion cleanup additive prepared by using the concentrate. Amino silicone oil is used as the necessary component of the oil, so the nanometer microemulsion cleanup additive has high fluid flow-back efficiency; the nanometer microemulsion cleanup additive and a fracturing fluid are injected into an oil well to carry out fracturing reconstruction of an oil-gas reservoir, so the fracturing fluid has a good water lock damage clearing performance and promotes the flow-back of the fracturing fluid, thereby the fracturing reconstruction effect of the oil-gas reservoir is improved, and the output of natural gas is increased; and the nanometer microemulsion cleanup additive is simple to prepare, and is convenient to use.

Owner:PETROCHINA CO LTD

Phase change fracturing method

ActiveCN108561111ALow viscosityShorten the timeFluid removalDrilling compositionTime delaysFracturing fluid

The invention provides a phase change fracturing method. The method includes the following steps that a fracturing fluid is injected into a stratum to generate cracks in the stratum, and injection ofthe fracturing fluid is stopped after the to-be-generated cracks reach preset requirements; a phase change reaction liquid and a time delay heat generating agent which can be subjected to a phase change reaction at preset temperature are injected into the stratum; after injection of the phase change material liquid is substantially completed, the time delay heat generating agent exerts a heat generating action to make phase change of the phase change material liquid to complete phase change fracturing. According to the provided technical scheme, since there is no solid phase injection, not only can the friction resistance of tubular columns be effectively reduced, but also the happening time and progress of the phase change reaction can be effectively controlled due to the use of the delayheat generating agent, so that a better fracturing effect is achieved. Especially for low-temperature reservoirs, a heat generation effect of the delay heat generating agent greatly increases the rate of the phase change reaction so that the phase change material liquid can rapidly form a solid phase at a preset position, the phase change time is shortened, and the probability of successful construction is increased.

Owner:PETROCHINA CO LTD

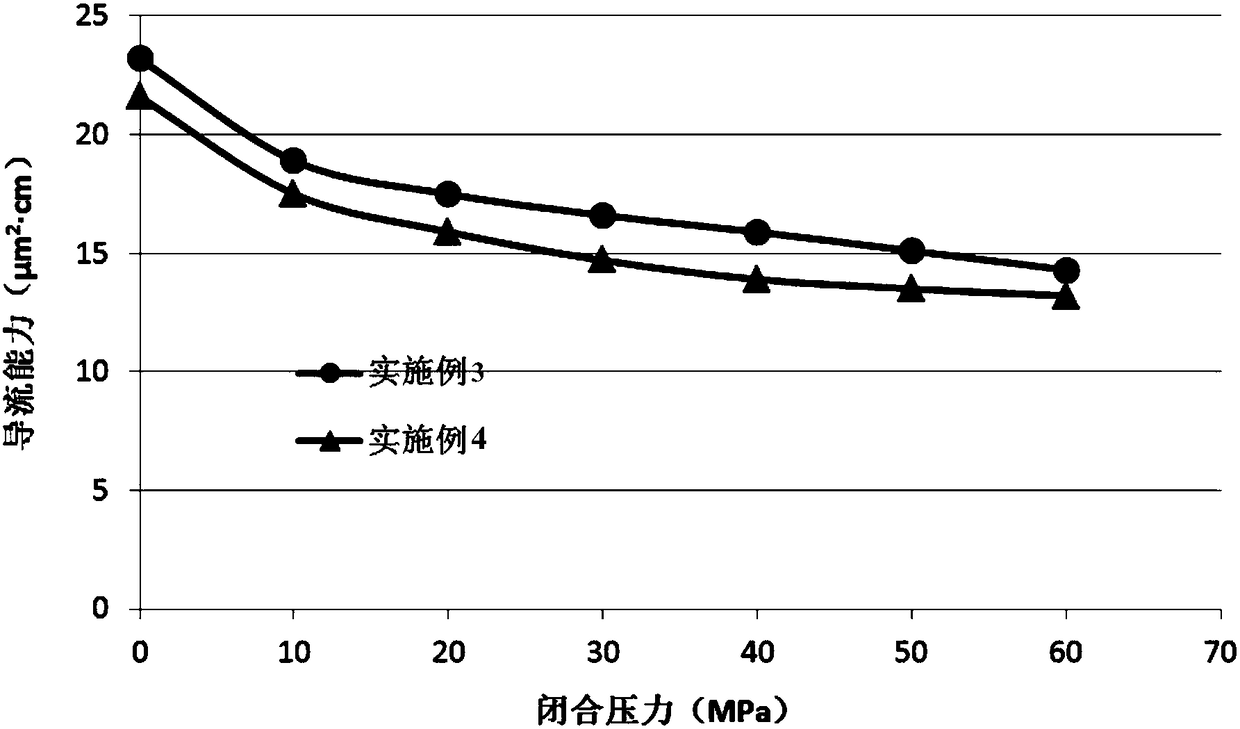

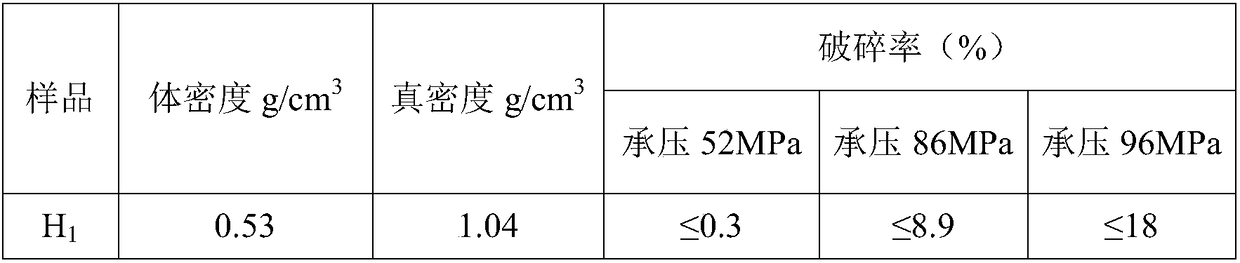

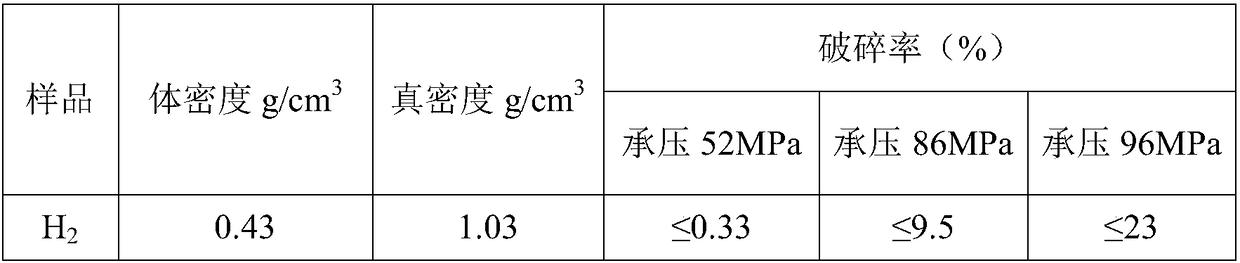

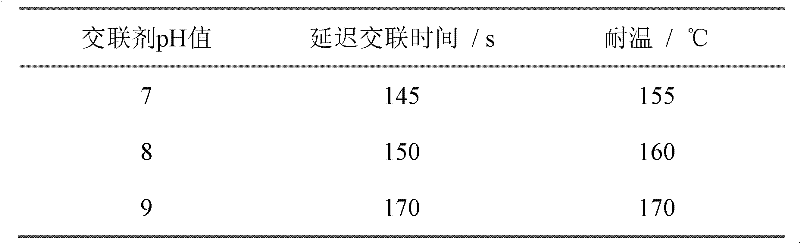

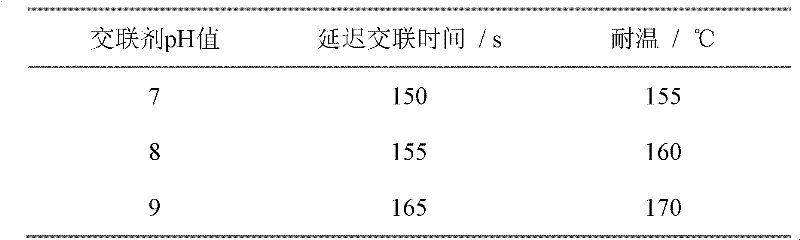

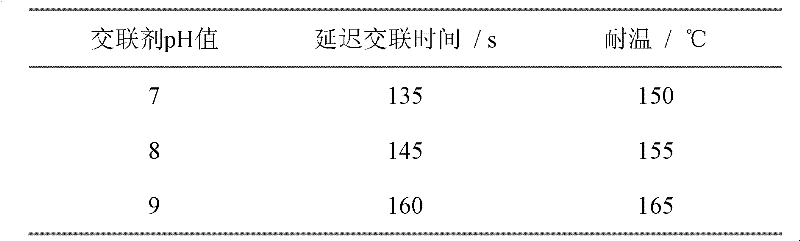

Method for preparing high temperature retarding-type organic boron zirconium cross linking agent

InactiveCN102337113AImprove diversion capacityIncrease production capacityDrilling compositionCross-linkGlycerol

The invention relates to a method for preparing a high temperature retarding-type organic boron zirconium cross linking agent, which comprises the following steps of: adding organic zirconium salt into a three-neck flask filled with a mixed solvent of water and glycerol; stirring to ensure the organic zirconium salt to be totally dissolved; then adding a boron compound; performing a reaction for 30 to 60 minutes at a temperature of 60 DEG C; adding polyatomic alcohol, triethanolamine and EDTA-2Na (Ethylene Diamine Tetraacetic Acid-2Na); heating to a temperature of 80 DEG C and performing a reaction for 4 to 5 hours; and regulating the pH to the range of 7 to 9 by aqueous solution of NaOH with the concentration of 20 percent to obtain the boron zirconium cross linking agent. The cross linking agent prepared by the method disclosed by the invention has the characteristics of small using amount, controllable retarding cross-linking time, high temperature resistance, easiness for gel breaking, low damage and low fraction resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid and preparation method thereof

ActiveCN104178102AHigh apparent viscosityImprove structural strengthDrilling compositionCross-linkPolymer science

The invention discloses a cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid and a preparation method thereof. The preparation method comprises the following steps of (1) preparing a thickener for the fracturing fluid; (2) preparing a cross-linking agent for the fracturing fluid; (3) preparing a gel breaker for the fracturing fluid and (4) preparing the cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid. The fracturing fluid prepared by adopting the preparation method has the characteristics of excellent viscoelasticity, temperature resistance and shear resistance, sand-carrying performance and wide applicable temperature range; the fracturing fluid can well meet the requirement on the fracturing construction, and the content of the residue is very low; after the fracturing, the secondary harm to a reservoir is small and thus the fracturing effect is improved and the production capacity of the reservoir is increased.

Owner:CHENGDU BAICHUN PETROLEUM TECH

Layered refracturing method

ActiveCN107965305AAvoid unfavorable situations such as filtration damageImprove completenessFluid removalSection planeFracturing fluid

The invention provides a layered refracturing method. The method includes the following steps that the reservoir characteristic parameter and the initial crack characteristic parameter are obtained; and a layered refracturing mode, the fracturing fluid and layered refracturing construction parameter are selected; if necessary, initial cracks are repaired; refracturing is conducted to obtain new cracks; balancing and replacement are conducted. According to the method, a suitable layered refracturing mode is selected, the initial cracks and a propping agent are made full use of, the process parameters of refracturing are optimized so as to achieve optimum matching with a reservoir and form the new cracks, on this basis, the fracturing extent of each layer is improved, the height and extending of the new cracks are controlled, the crack propping profile is rationally optimized and controlled, the complexity degree of the new cracks is improved, and the volume is effectively transformed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for slight fracture supporting, capable of increasing fracture stabilization period

ActiveCN107503729AImprove support efficiencyImprove fracturing effectFluid removalViscous fingeringStructure of the Earth

The invention discloses a method for slight fracture supporting, capable of increasing a fracture stabilization period. The method comprises the steps of (1) evaluation of a microstructure of reservoir rocks, (2) a first-stage injection phase, and (3) second-stage and third-stage injection phases. During the second step, (1) an ultralow-viscosity fracture solution carrying a micro-particle-diameter supporting agent is injected to communicate and extend natural fracture systems with micro scales, a low-viscosity fracture solution carrying a small-particle-diameter supporting agent is injected to communicate and extend natural fracture systems with large scales; a middle-viscosity fracture solution carrying a middle-particle-diameter supporting agent is injected to extend fracture systems with large scales; and (4) a high-viscosity fracture solution carrying a large-particle-diameter supporting agent is injected to extend fracture systems with the maximum scale. According to the invention, through fine evaluation of the microstructure of the reservoir rocks, alternate multi-stage injection, utilization of viscous fingering effects of various liquids with different viscosities, multi-scale sand adding and other methods, the fracture systems with the different scales within a full seam length scope of a main fracture can be fully expanded, extended and supported; and a "valid reshaping volume" of fractures and "supporting efficiency" of cracks are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

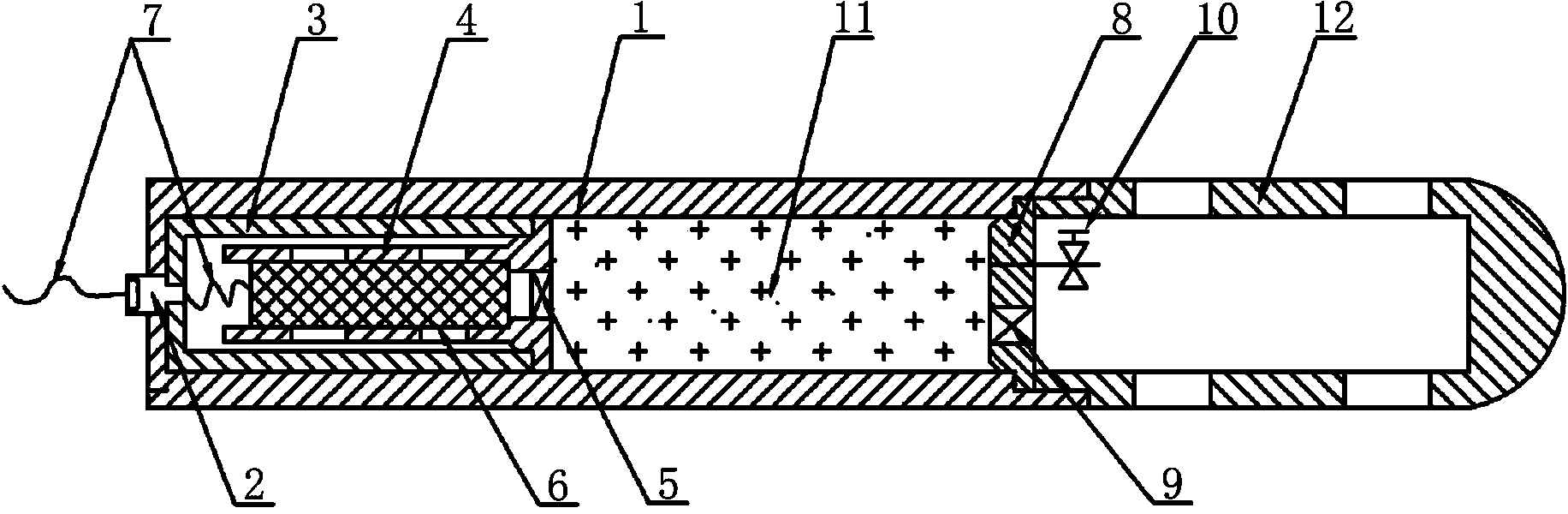

Chemical and physical combined explosion fracturing device and manufacturing method thereof

ActiveCN103352684ASolve the limited effect of fracturingSolution rangeFluid removalInterference fitHigh pressure

The invention relates to the fracturing technology, in particular to a chemical and physical combined explosion fracturing device and a manufacturing method of the chemical and physical combined explosion fracturing device. The chemical and physical combined explosion fracturing device and the manufacturing method of the chemical and physical combined explosion fracturing device resolve the problems at the existing fracturing technology is limited in fracturing effect, narrow in application range and poor in use safety. The chemical and physical combined explosion fracturing device comprises a fracturing device outer shell, wherein the front portion of an inner cavity of the fracturing device outer shell is in interference fit with a powder chamber outer barrel, an inner cavity of the powder chamber outer barrel is provided with a powder screening pipe in a sleeved mode, a first explosion film is arranged on an opening in the rear end of the powder screening pipe in a sealing mode, an inner cavity of the powder screening pipe is filled with a powder pillar which is connected with an ignition line, a pressing nut is arranged on an opening in the rear end of the fracturing device outer shell in a sealing mode, a through hole penetrating through the front portion and the rear portion is formed between the front end surface and the rear end surface of the pressing nut, a second fracturing film is arranged on the through hole in a sealing mode, and the rear portion of the inner cavity of the fracturing device outer shell is filled with high-pressure CO2 in a sealing mode. The chemical and physical combined explosion fracturing device and the manufacturing method of the chemical and physical combined explosion fracturing device are suitable for the development of petroleum, natural gas, coal bed gas, shale gas and the like, and suitable for a pre-fracturing and permeability-increasing process of extraction of coal bed gas under a coal mine shaft.

Owner:ZHONGBEI UNIV

Low-harm micro-molecular guar gum fracturing fluid

ActiveCN102352233AReduce harmImprove fracturing effectDrilling compositionCross-linkFracturing fluid

The invention relates to a low-harm micro-molecular guar gum fracturing fluid. The fracturing fluid comprises base fluid, 0.05-0.8 wt% of gum breaking agent and 0.4-0.8 wt% of cross-linking agent. The base fluid comprises the following components in percentage by weight: 0.2-0.5% of micro-molecular guar gum, 0.1-1% of discharge aiding agent, 0.5-3% of clay stabilizing agent, 0.02-0.2% of pH adjusting agent, 0.01-0.1% of sterilizing agent, 0.01-0.05% of dispersing agent and the balance of water. The micro-molecular guar gum is modified guar gum with 400000-800000 molecular weight, the gum breaking agent is ammonium persulfate or sodium persulfate, and the cross-linking agent is borax or organic cross-linking agent. In the invention, although the addition amount of guar gum is small, the viscosity of a cross-linked liquid is equivalent to the common fracturing fluid, the harm of the fracturing fluid to strata is effectively reduced, and the effects of fracturing and reformation are improved.

Owner:SOUTHWEST PETROLEUM UNIV

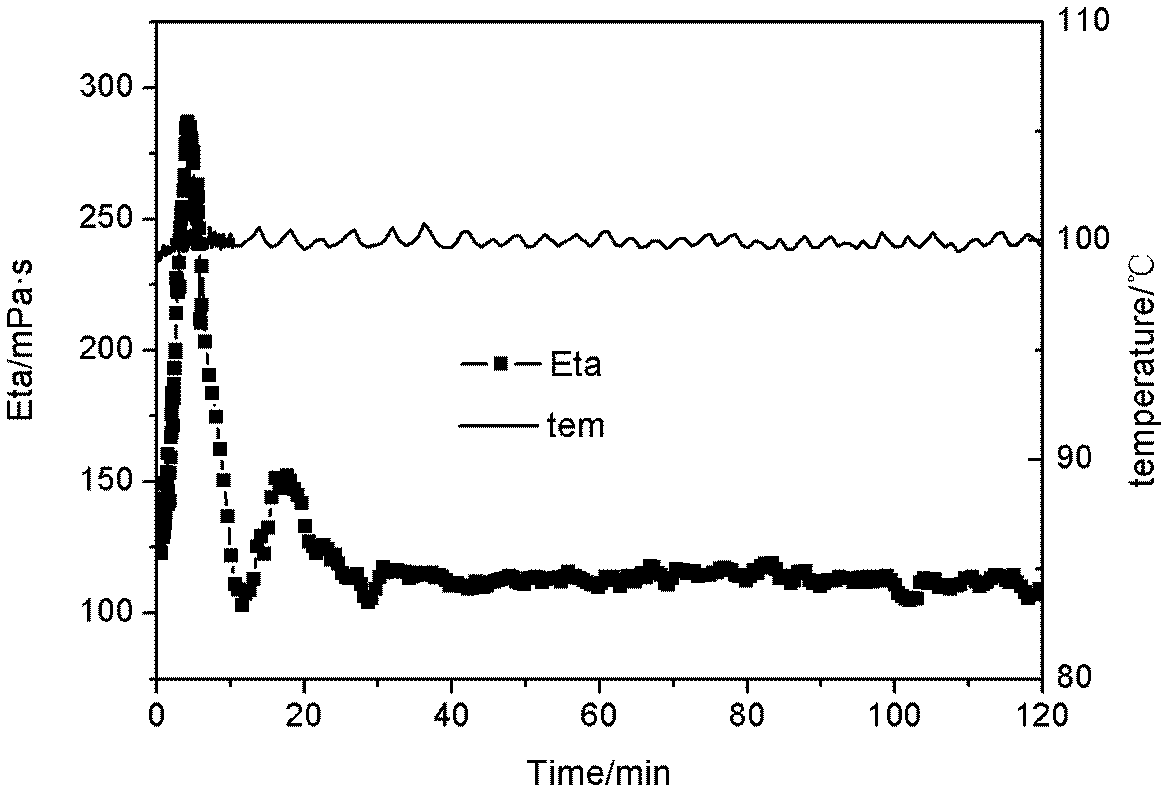

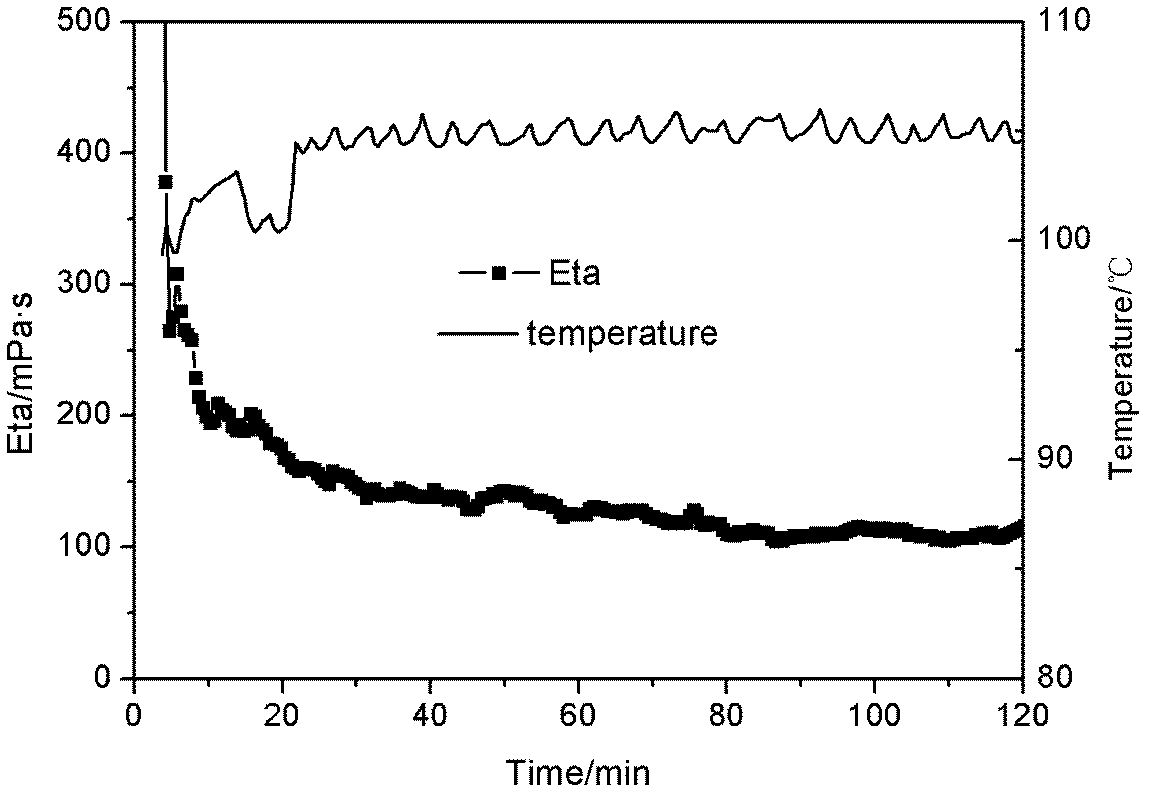

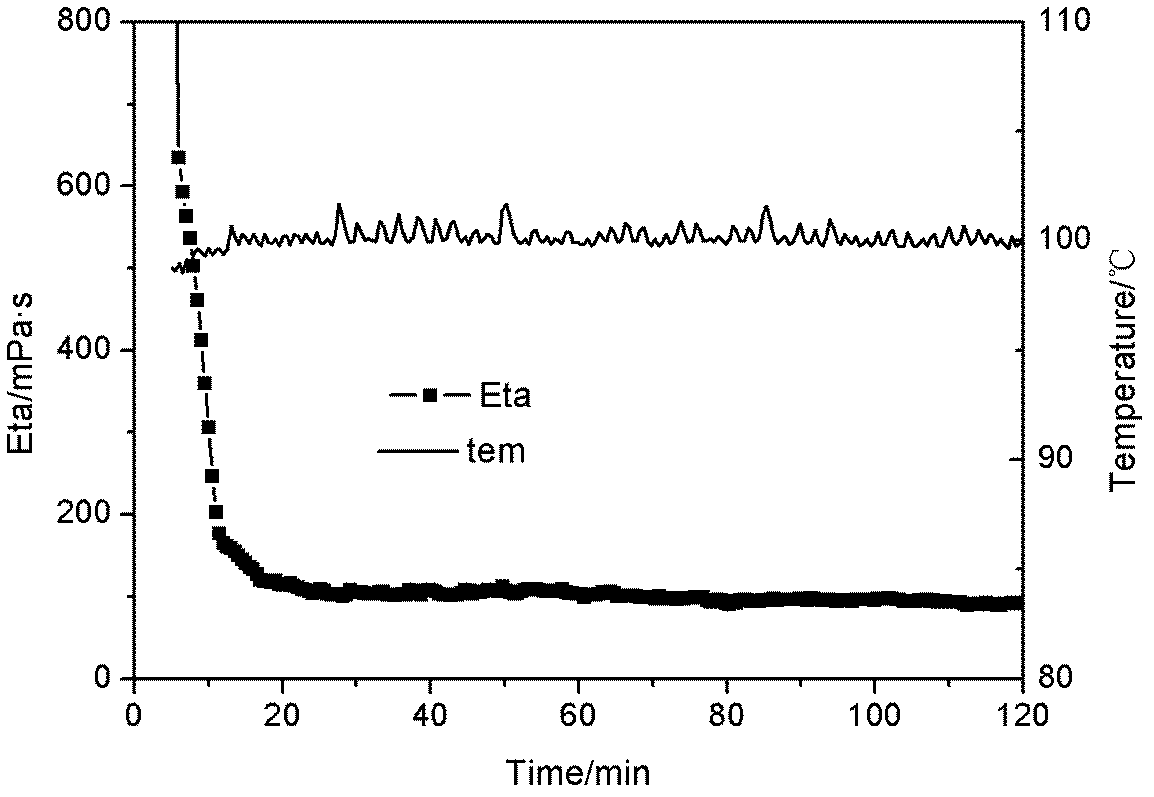

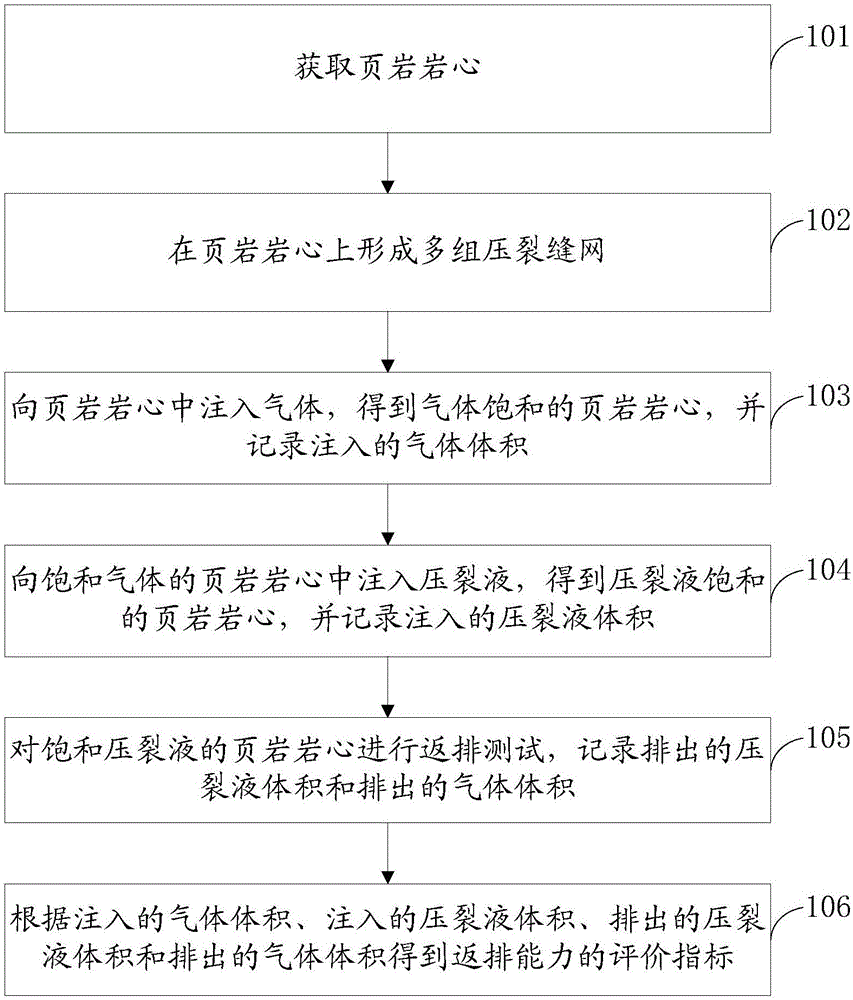

Method and device for evaluating fracturing fluid flowback capacity of shale staged fracturing horizontal well

PendingCN106596380AImprove the transformation effectIncreased production from shale gas wellsPermeability/surface area analysisShale gasEnvironmental geology

The invention discloses a method and device for evaluating the fracturing fluid flowback capacity of a shale staged fracturing horizontal well and belongs to the field of shale gas development. The method includes the steps of obtaining a shale core, forming multiple groups of fracturing seam nets on the shale core, injecting gas in the shale core to obtain the gas-saturated shale core, recording the volume of the injected gas, injecting fracturing fluid in the gas-saturated shale core to obtain the fracturing fluid saturated shale core, recording the volume of the fracturing fluid, conducting flowback test on the fracturing fluid saturated shale core, recording the volume of the discharged fracturing fluid and the volume of the discharged gas, and calculating a flowback capacity evaluation index. The method can be used for the study of the fracturing fluid flowback capacity of the shale staged fracturing horizontal well through an indoor similar physical simulation method and can provide a scientific basis for improving shale reservoir fracturing and rebuilding effects and improving shale gas-well production, and formulation of a reasonable shale staged fracturing horizontal well discharge and mining system is easily achieved.

Owner:PETROCHINA CO LTD

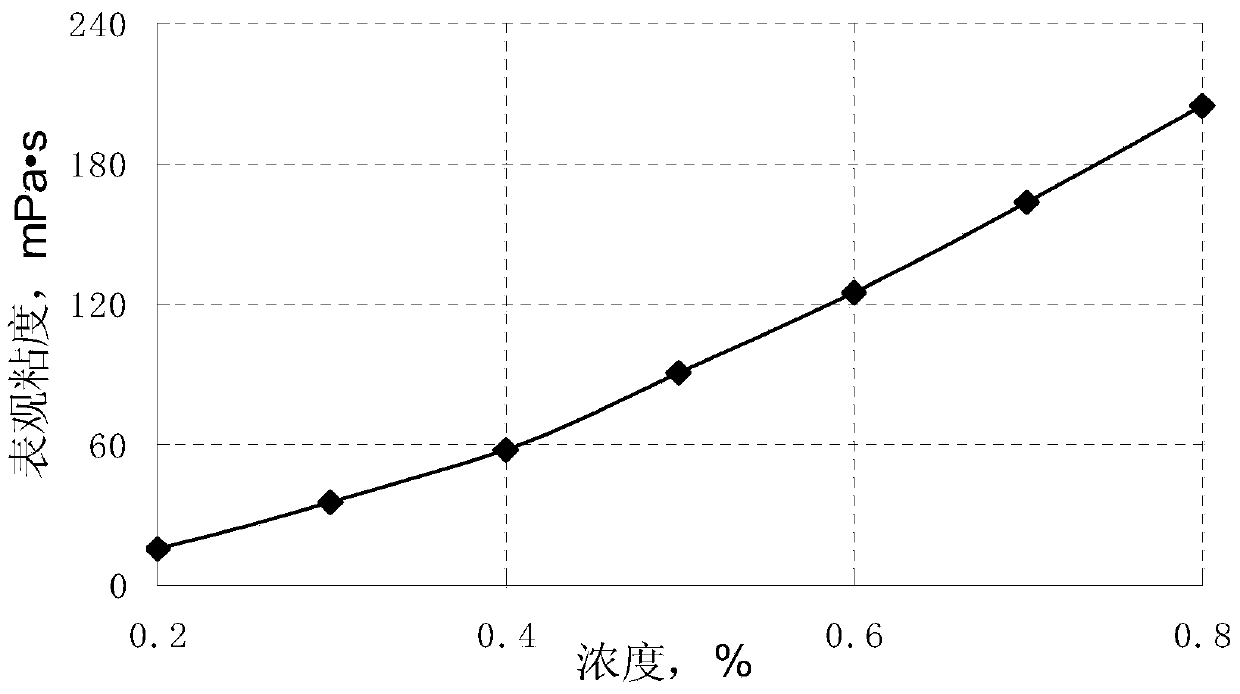

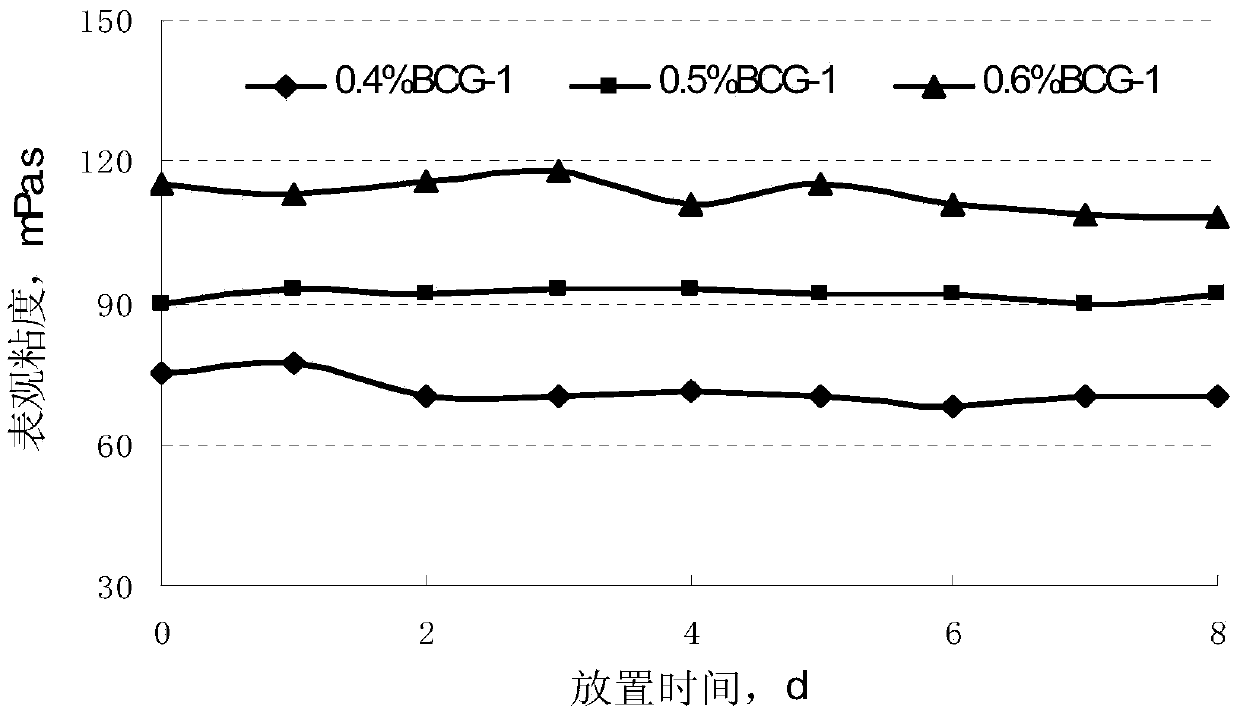

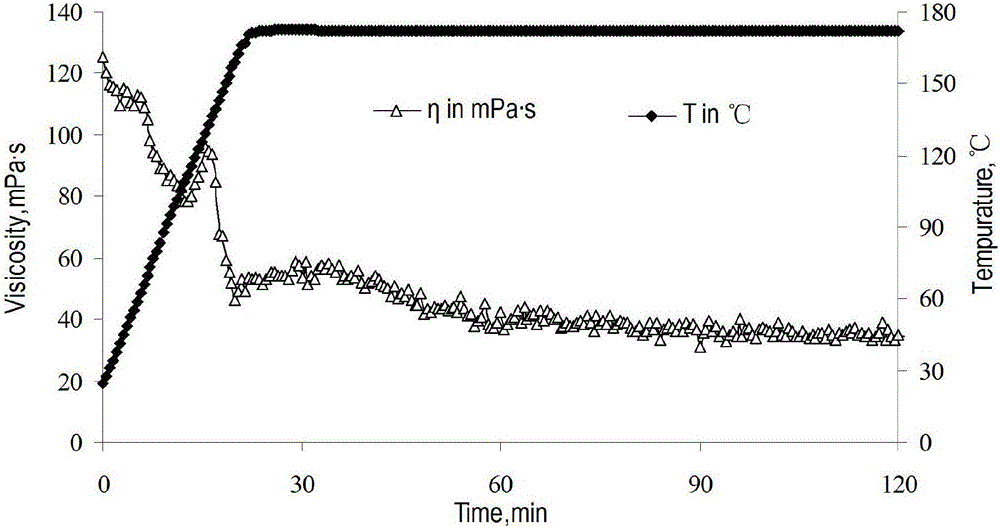

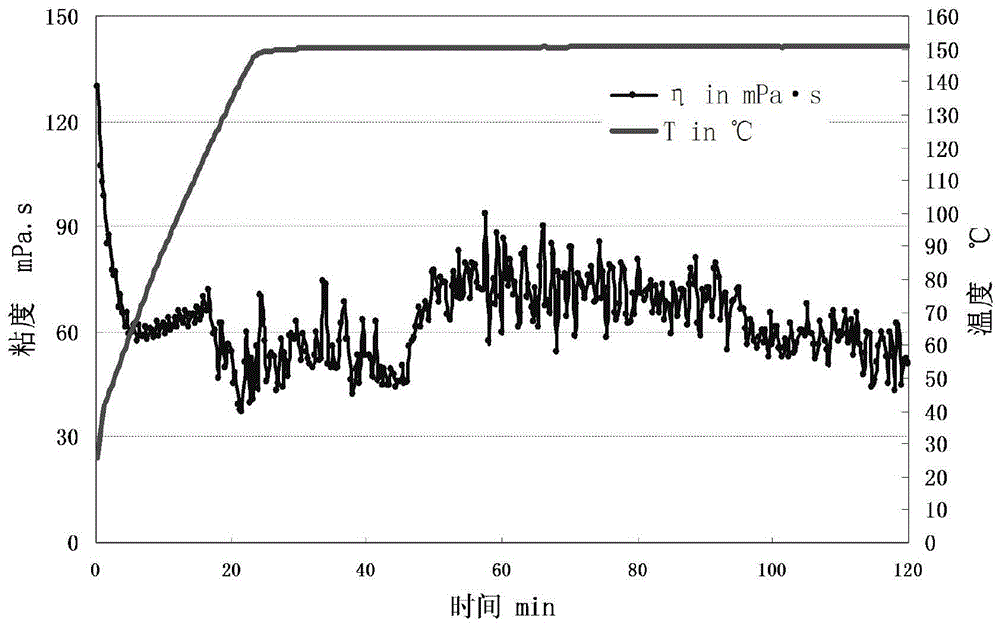

Supramolecular polymer clean fracturing fluid resistant to high temperature of 170 DEG C

The invention discloses supramolecular polymer clean fracturing fluid resistant to high temperature of 170 DEG C. The fracturing fluid is prepared from the following components in percentage by weight: 0.2 to 0.5 percent of thickening agent for the clean fracturing fluid, 0.1 to 0.5 percent of viscosity synergist, 0.2 to 0.4 percent of structural intensifier, 0.05 to 0.2 percent of deoxidant, 0.1 to 0.3 percent of metal ion chelating agent, 1 to 2 percent of clay stabilizer and the balance of fresh water. According to the clean fracturing fluid, a reversible supramolecular network structure is formed through the intermolecular interaction, and the thickening agent is low in use concentration and can be used for effectively controlling the viscosity of a base solution of the fracturing fluid and improving the pumping performance of the fluid; viscoelastic sand-carrying of the fracturing fluid is realized by low viscosity and high viscoelasticity; the temperature resistance can reach 170 DEG C under a long-term shear condition; the shear resistance is excellent, and the fluid viscosity and the structure after high shear can be effectively recovered; the construction friction is low, and the equipment load and the fracturing construction risk are reduced; the residue content is low, so that the damages to a reservoir stratum and prop fractures are greatly reduced, and the fracturing stimulation effect is greatly improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

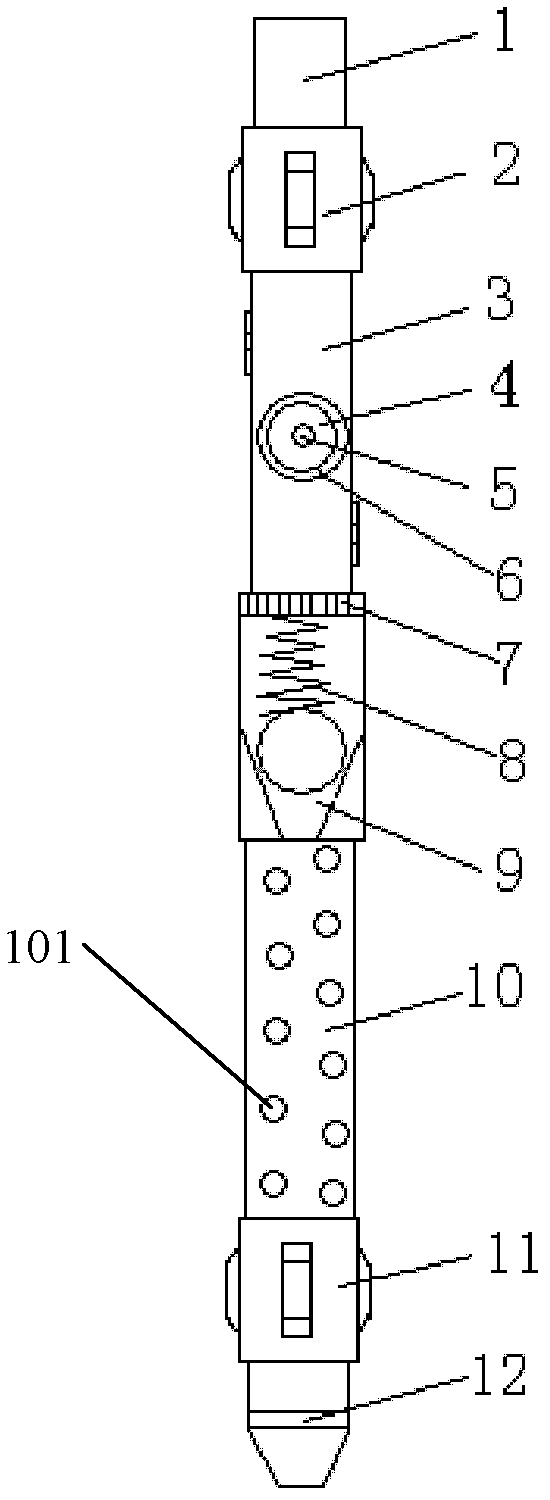

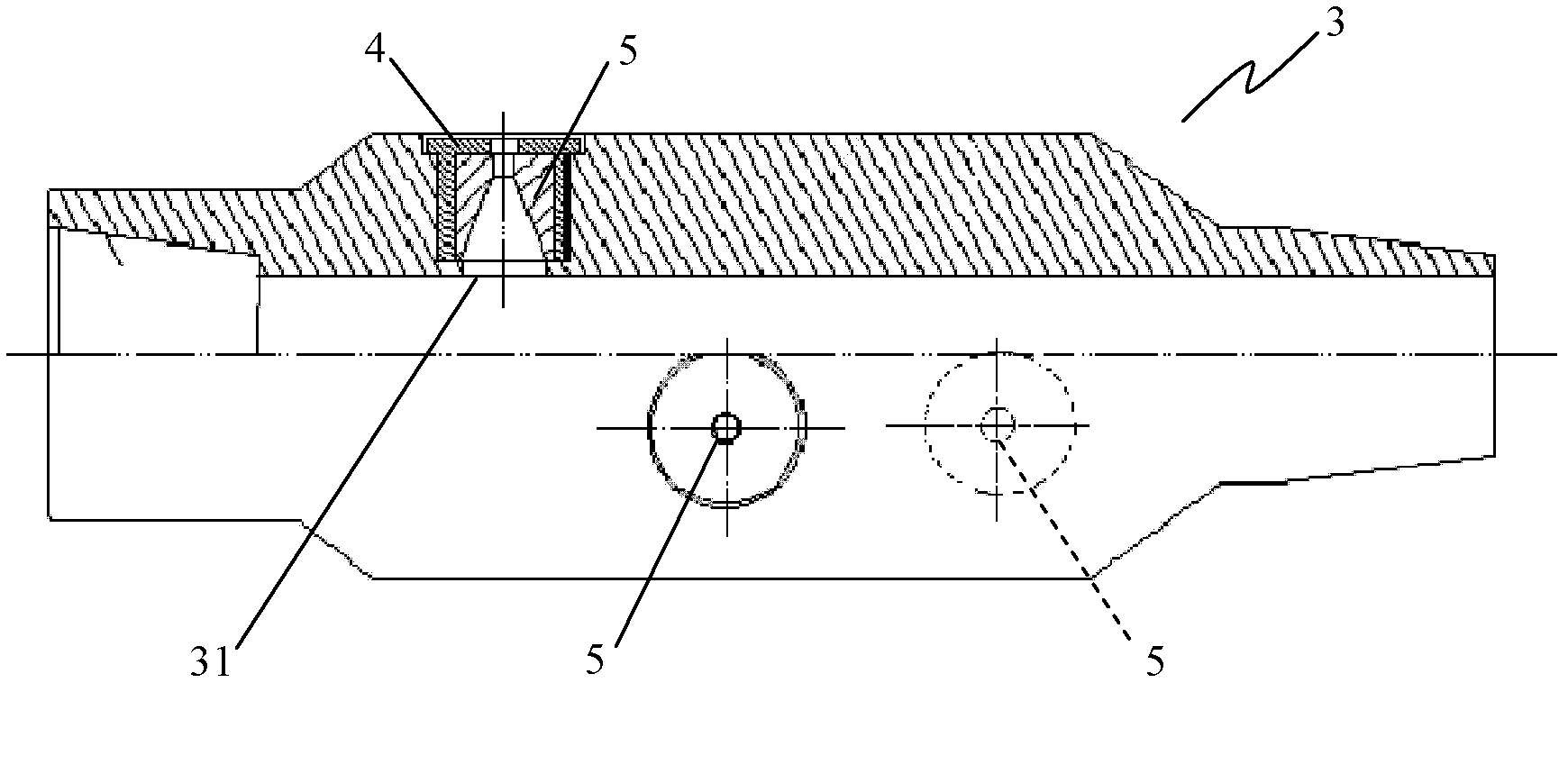

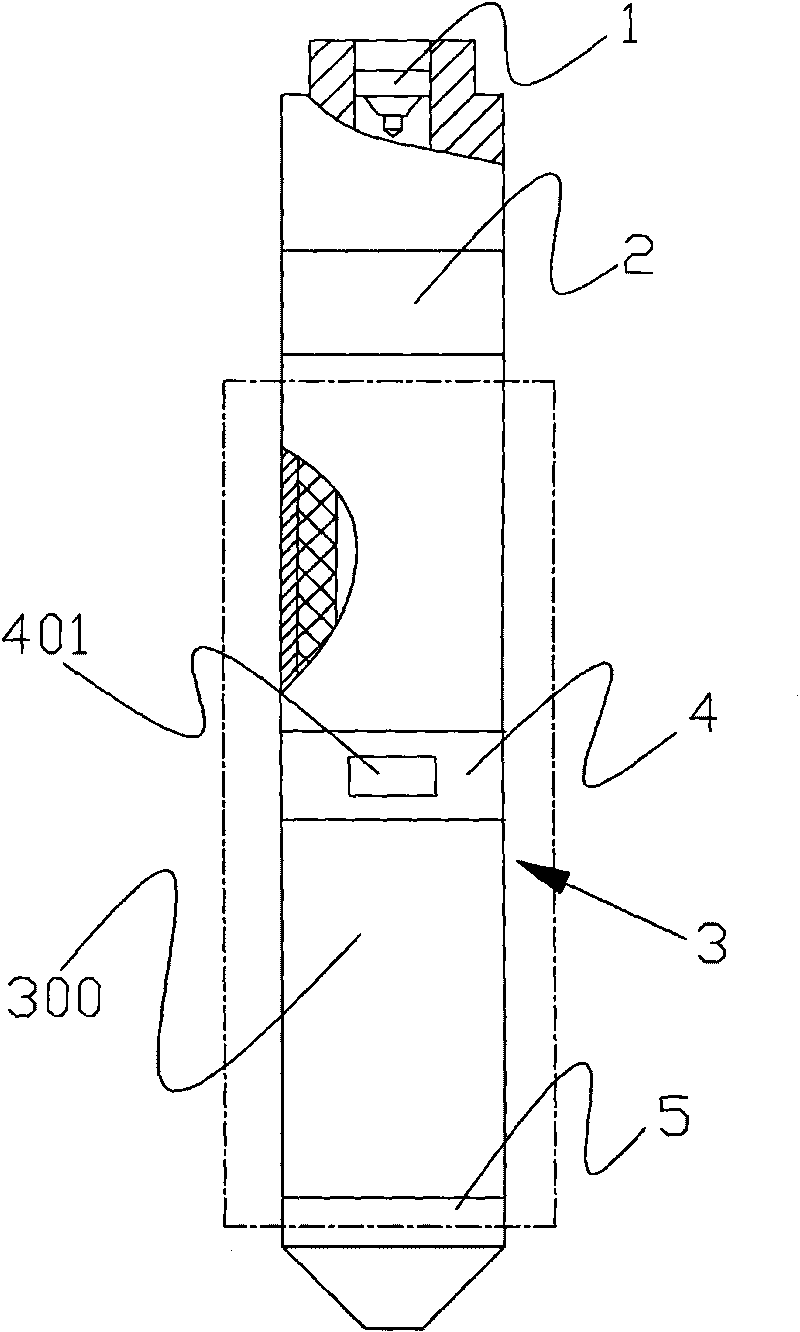

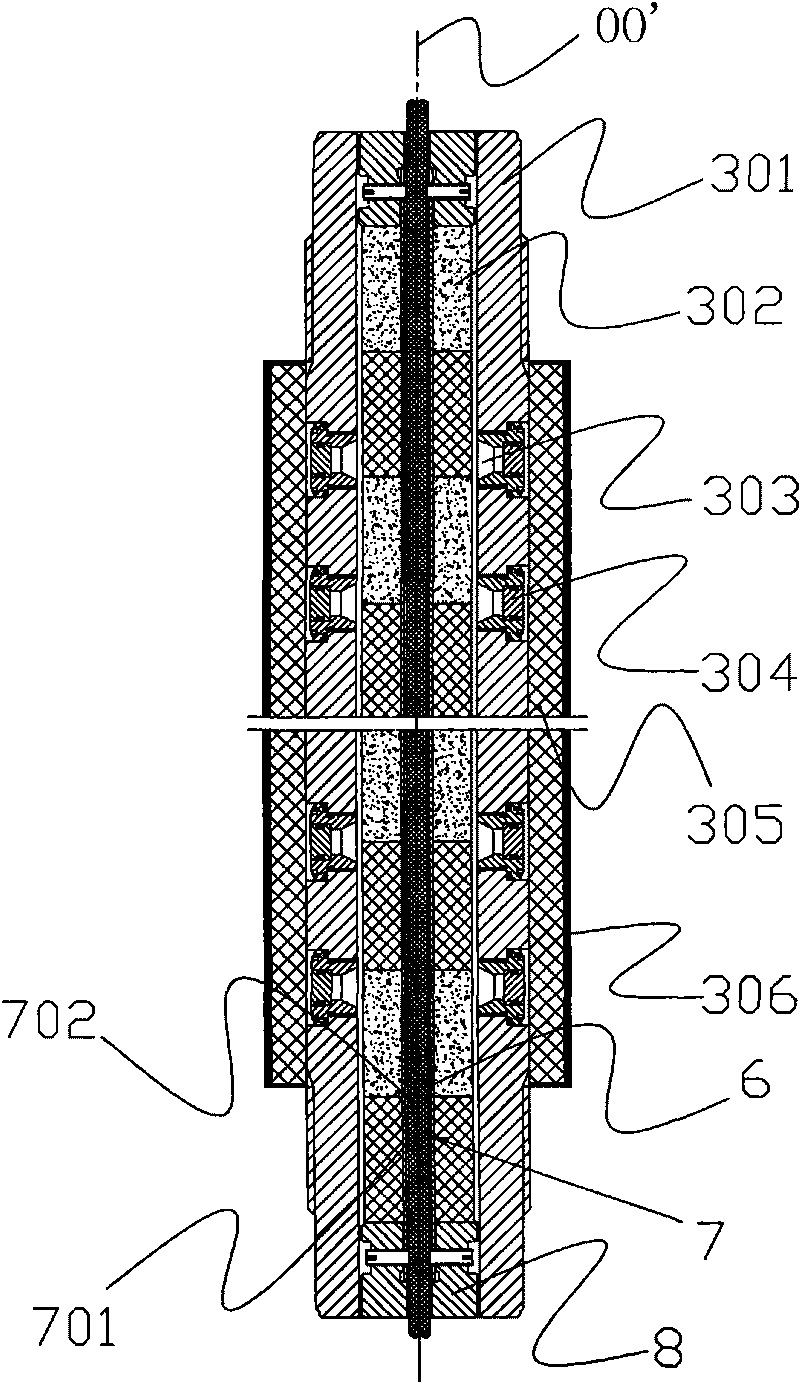

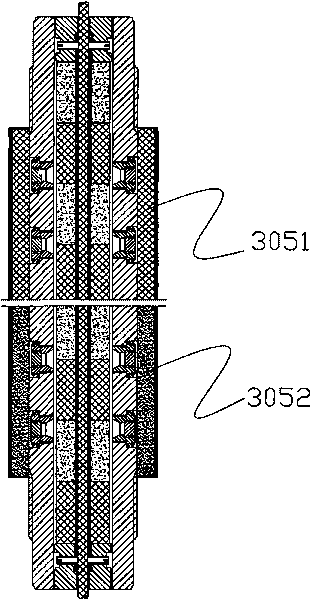

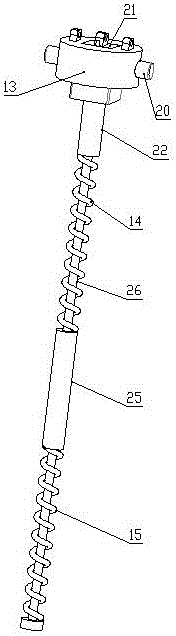

Abrasive material jet injection device

InactiveCN102493791APrecisely targeted layered fracturingAvoid blindnessFluid removalJet injectionSpray nozzle

The invention relates to an abrasive material jet injection device which is provided with a spray gun for injecting abrasive material jet, wherein the spray gun is provided with at least two nozzles, and the spray gun is connected with an oil tube. The abrasive material jet injection device has simple structure and is easy to assemble and maintain. The key part (nozzle) in the device has longer service life so as to satisfy the requirements of two operations of perforating and fracturing. Because a check valve and a sieve tube are arranged, the phenomenon that the nozzle of the injection device is subjected to sand jamming can be greatly lowered; meanwhile, when the device is subjected to sand jamming faults, base fluid is pumped into the annulus of an annular tube, the base fluid enters the injection device via the check valve by the sieve tube, which is convenient to flush the device, and therefore the well can be subjected to backflushing to ensure that the operation is successfully carried out. Because a packer is omitted, construction equipment is simplified. According to the abrasive material jet injection device, the defect of the known technology is overcome, abrasive material jet pore forming and fracturing are combined, and therefore layering can be precisely carried out in a vertical well or sectional fracturing can be precisely carried out in a horizontal well section.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Controllable pulse gas energy pressure cracking device

ActiveCN101737026AGas pressure controllableGood fracturing effectFluid removalPressure risePeak pressure

The invention relates to a controllable pulse gas energy pressure cracking device used in mining of an oil and gas well, which comprises a gas energy pressure cracking device and igniters or exploders and tail plugs, wherein the igniters or exploders and the tail plugs are respectively arranged at two ends of the gas energy pressure cracking device, and the gas energy pressure cracking device comprises a gas energy pressure cracking assembly. The igniters or exploders and inner grains in the gas energy pressure cracking assembly are connected together through ignition channels. The gas energypressure cracking assembly comprises a center pipe, the inner grains filled into the center pipe and an outer cartridge arranged at the outer part of the center pipe. The pipe wall of the center pipeis provided with a pressure release fire transmission channel and a channel sealing cover. The invention solves the problem of low capacity caused by uncontrollability of the pressure cracking process and ineffective communication between stratum and a mineshaft in the prior art. The invention can form effectively outstretched communication between the net-shaped multi-crack construction and the mineshaft at the immediate vicinity of wellbore in the target bed through controlling the rate of pressure rise, peak pressure, pressure platform and total energy of the gas energy pressure cracking, thereby greatly improving the capacity of the oil and gas well.

Owner:XIAN NEW CHANNELING GASOLINEEUM TECH

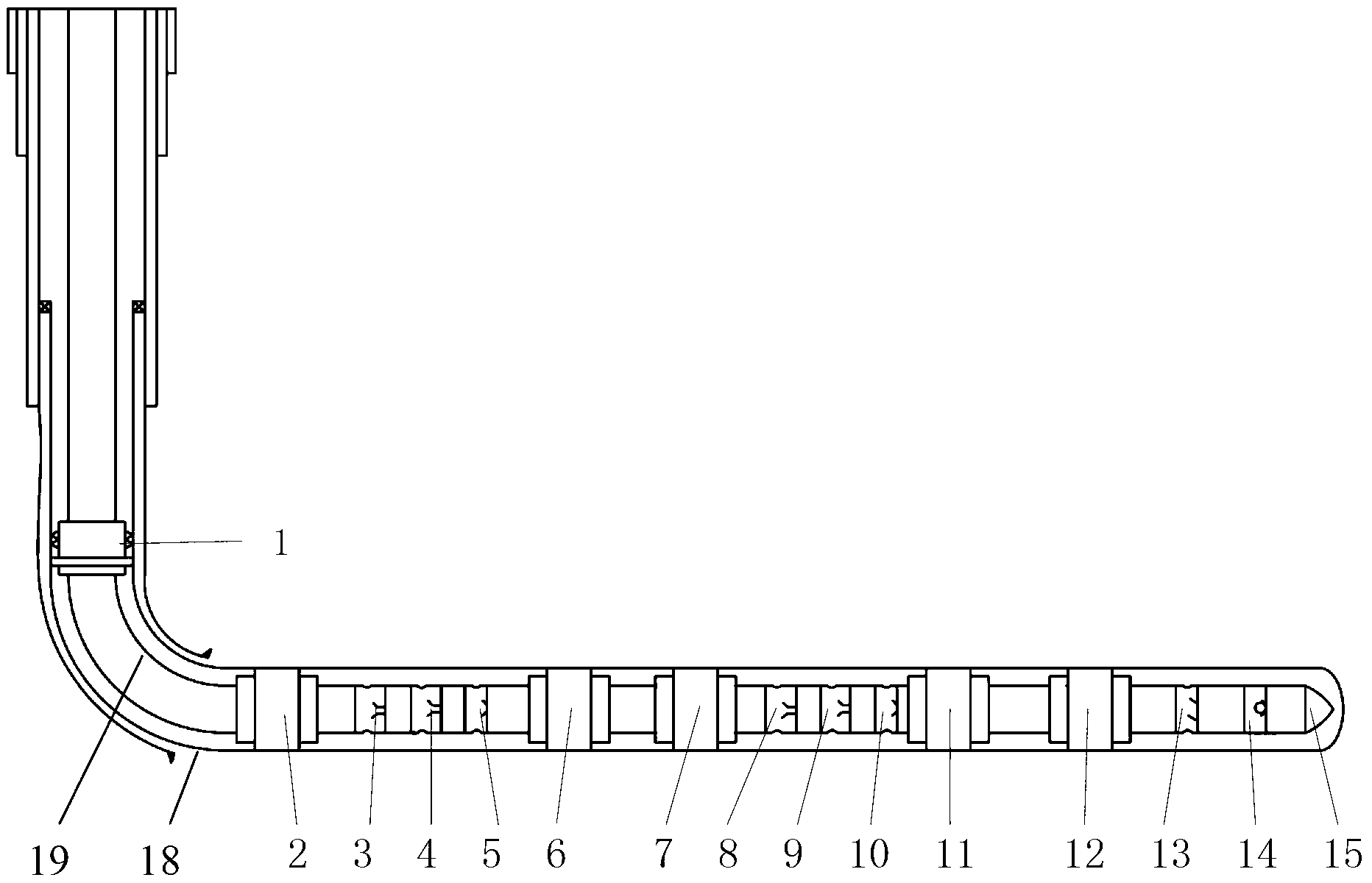

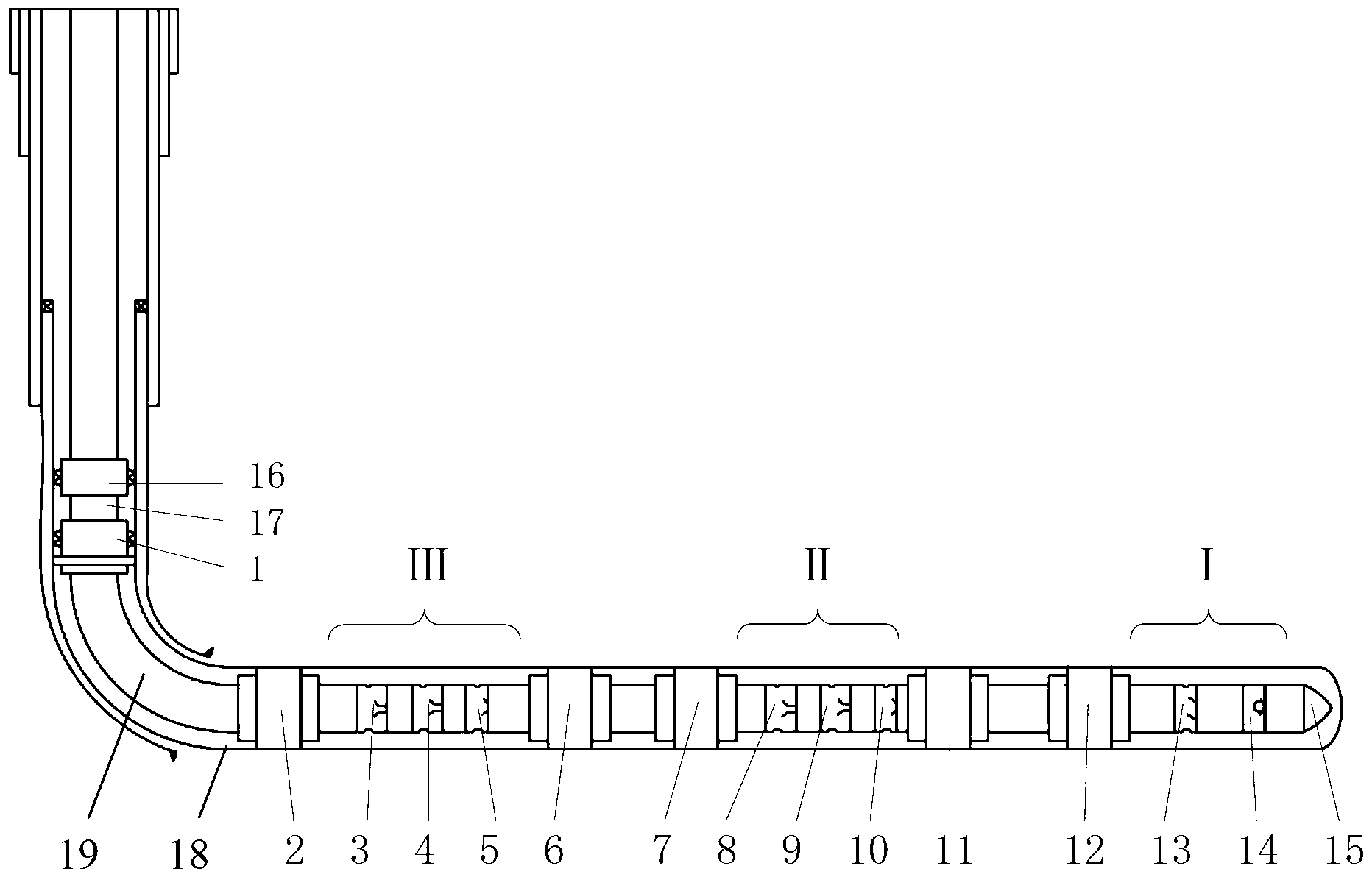

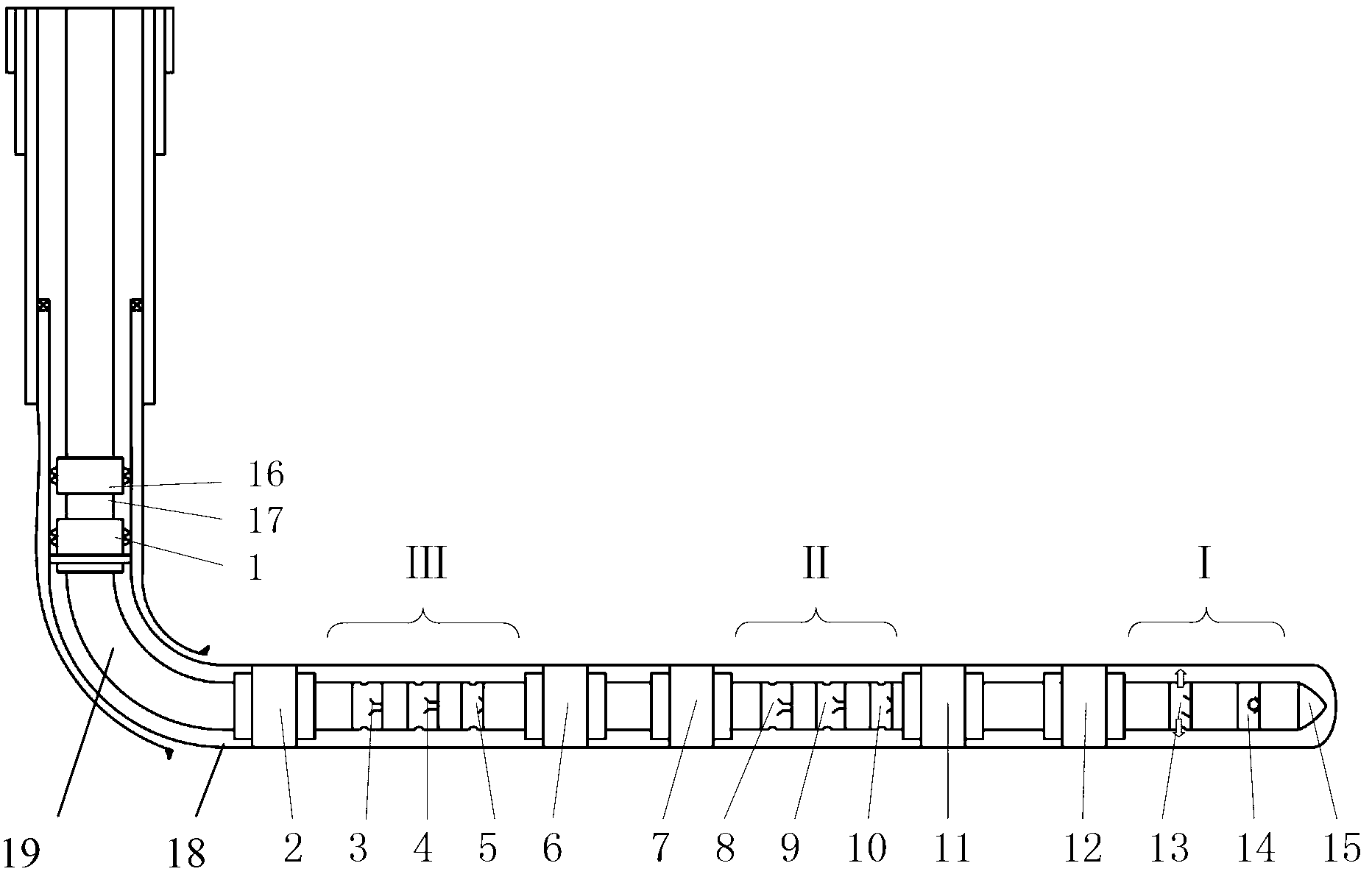

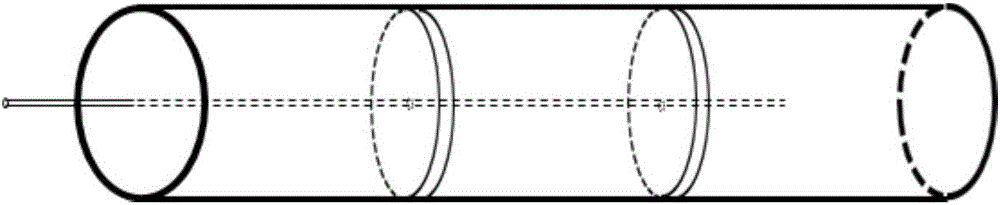

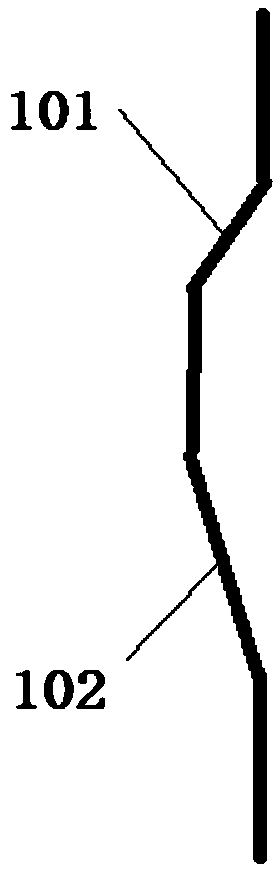

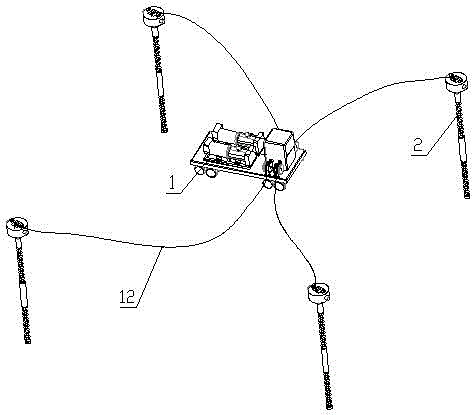

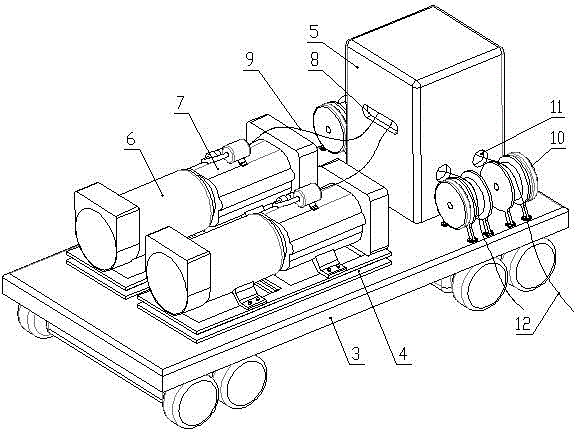

Coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method

ActiveCN109339855AAvoid prone to collapse holesAvoid problems such as drill stickingFluid removalGas removalSand blastingCoiled tubing

The invention relates to a coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method. The method includes the steps that first, a gas extraction long drilled hole is constructed in a mudstone or sandstone roof with a certain distance to the top boundary of a broken soft coal seam or a hard layer of the broken soft coal seam or a hard coal seam with a good coal body structure; second, a guiding shoe and a rigid casing are lowered; third, cement paste blocking is carried out on annular space between the gas extraction long drilled hole and the rigid casing so as to solidify the hole; fourth, packing staging is carried out through a mode of dragging a packer by coiled tubing, an ejector carries out sand blasting perforation, and fracturing is carried out on the annulus between the coiled tubing and the casing; fifth, a fracturing tool is lifted out, and uniform blowout of fracturing fluid is carried out. The method can solve the problems that in existing gas extraction hole-drilling, hole forming is difficult, the crack initiation position of fracturing cracks is not determined, the fracturing cracks extend short, the fracturing modification effect is poor, the extraction affecting range is small and nonuniform, and extraction duration is short, and realizes gas extraction long drilled hole forming and multi-level precise staged fracturing.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Resistance wire type coal seam heating device

ActiveCN106223916AGuaranteed power generation efficiencyGuaranteed power supplyFluid removalGas removalFracturing fluidEngineering

The invention provides a resistance wire type coal seam heating device. The device comprises a mobile ground power generation system and a plurality of downhole heaters, wherein the mobile ground power generation system provides electric energy for the downhole heaters; each downhole heater comprises a coal seam upper permanent joint, a reinforcement pipe, an upper resistance wire and a lower resistance wire; the coal seam upper permanent joint is formed by an upper cylinder and a lower square cylinder; a square groove is formed in the top of the cylinder; an installing hole is formed in the square cylinder; two fracturing fluid inlet pipe joints are connected at the side parts of the coal seam upper permanent joint; a square joint is assembled in the square groove; the lower end face of the square joint is connected with an installing pipe penetrating through the installing hole; the upper resistance wire is arranged at the upper part of the reinforcement pipe in a sleeving manner and the lower resistance wire is arranged at the lower part of the reinforcement pipe in a sleeving manner. The device has the beneficial effects that the device adopts the method of injecting thermal fracturing fluid; the resistance wires are adopted by heating equipment for heating; a mobile ground power supply vehicle is adopted as main power supply equipment; the device has the advantages of convenience in operation, diverse functions, safety and reliability and capability of fully increasing the gas output.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

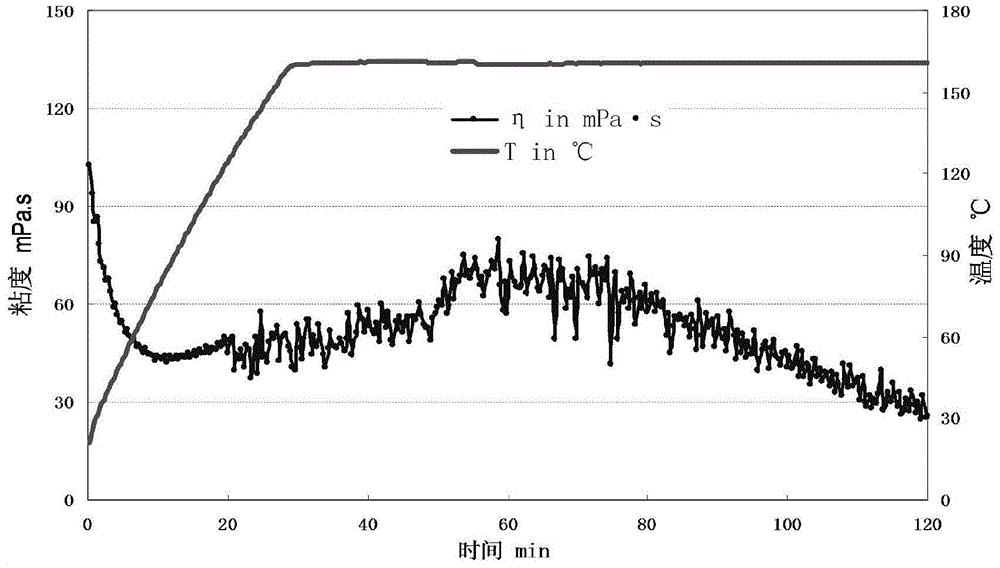

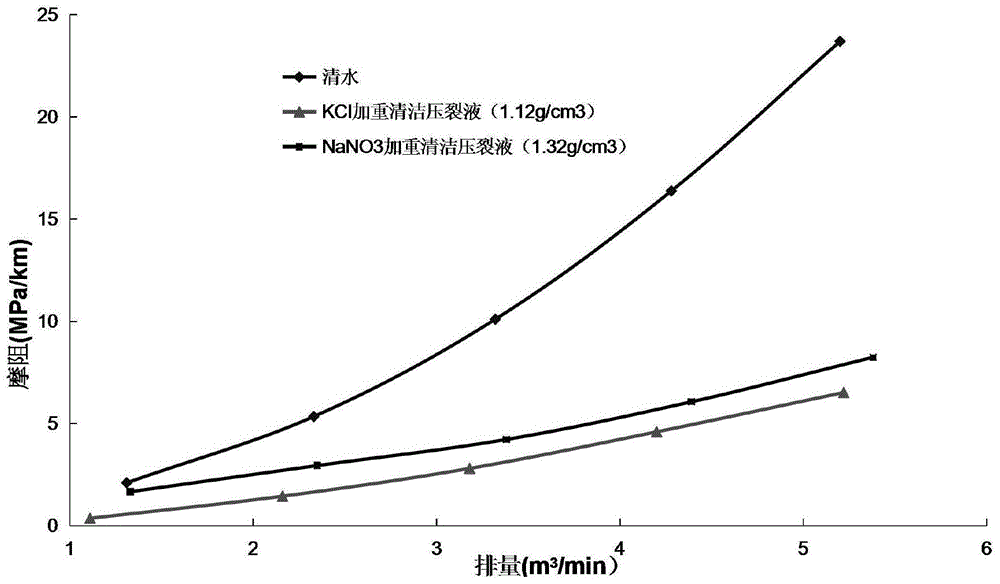

High-temperature-resistance low-friction weighted clean fracturing fluid and preparation method thereof

ActiveCN105733547APromote swellingEnhanced associationDrilling compositionReduction rateHigh pressure

The invention discloses a high-temperature-resistance low-friction weighted clean fracturing fluid which is suitable for high-temperature and high-pressure reservoir reconstruction at 170 DEG C and a preparation method thereof.The fracturing fluid is prepared from, by weight, 0.2%-0.8% of high-temperature-resistance thickening agent, 0.1%-0.8% of system synergist, 0.1%-0.3% of high temperature stabilizer, 0%-42% of weighting agent and the balance fresh water.The high-temperature-resistance low-friction weighted clean fracturing fluid has the following functions and advantages that the weighting agent can be adopted for weighting, and the density is adjustable between 0 and 1.32 g / cm<3>; good temperature-resistance and anti-shearing properties are achieved, and the requirement of high-temperature deep well fracturing construction at 170 DEG C can be met by adjusting a formula; a good resistance reduction property is achieved, pipeline friction resistance can be effectively reduced, and the resistance reduction rate can reach 70%; the fracturing fluid is a fluid with a reversible structure, and the structure damage after high shearing is small; the residue content of the fracturing fluid is decreased to below 10 mg / L, damage to a reservoir and supporting cracks is reduced, the fracturing effect is improved, and the reservoir productivity is increased.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com