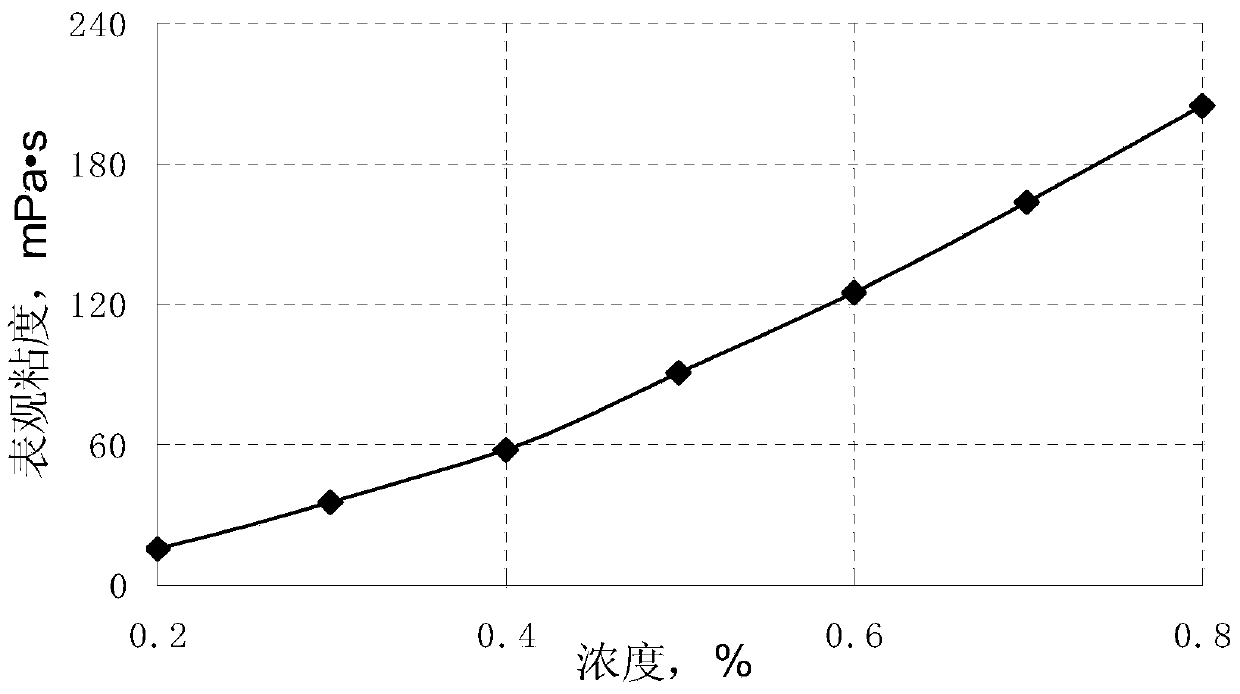

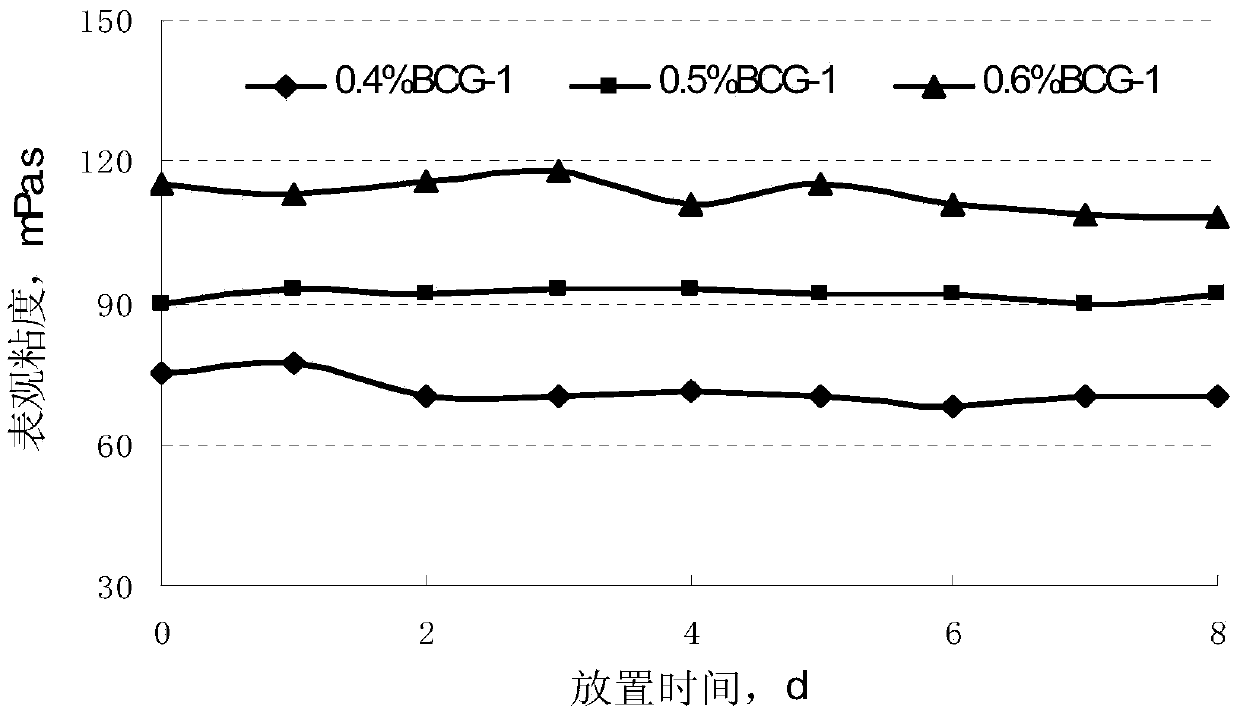

Cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid and preparation method thereof

A multi-component copolymerization and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of small temperature range and insufficient temperature resistance, and achieve a wide applicable temperature range, smooth construction, and increased production. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Synthesis of cross-linkable high temperature resistant and residue-free multi-component copolymerization fracturing fluid thickener

[0050] Add acrylic acid, acrylamide, hexadecyldimethyldiallylammonium chloride, 2-acrylamido-2-methylpropanesulfonic acid and water into the reaction kettle and mix evenly, add caustic soda to adjust the pH value, The pH measured by the precise pH value is 8.8, adding the emulsifier sodium dodecylbenzene sulfonate, adding the redox initiator ammonium persulfate-sodium bisulfite, reacting at a temperature of 42°C for 5.5h, and at 90°C After hydrolysis for 5 hours, a colloidal product is obtained, and the colloid is granulated, dried, and pulverized to obtain a fracturing fluid thickener;

[0051] Taking the reaction total system quality as 100%, wherein, acrylic acid accounts for 3% of the total mass, acrylamide accounts for 33% of the total mass, cetyl dimethyl diallyl ammonium chloride accounts for 8% of the total mass, 2 -Acr...

Embodiment 2

[0053] Example 2 Synthesis of cross-linking agent for fracturing fluid

[0054] Add xylene into the reaction kettle as a solvent, add dodecyldimethyl tertiary amine, n-octadecyl alcohol and dimethyl sulfate as reactants, add sodium carbonate to adjust the pH value, and measure the pH value with precision pH test paper to be 7.9 , adding the catalyst azobisisobutyronitrile, and carrying out the hydrocarbylating reaction at 51° C. for 4 hours. After the reaction, cool and filter to obtain a solid product of the crosslinking agent for fracturing fluid.

[0055] In the above-mentioned reaction system, taking the total reaction system mass as 100%, wherein, hexadecyl dimethyl tertiary amine accounts for 18% of the total mass, n-stearyl alcohol accounts for 25% of the total mass, and dimethyl sulfate accounts for the total mass. 16% of the total mass, sodium carbonate accounts for 2% of the total mass, azobisisobutyronitrile accounts for 1% of the total mass, and the rest is the sol...

Embodiment 3

[0057] Embodiment 3 Preparation of gel breaker for fracturing fluid

[0058] Add polyimide and ethyl acetate (oil phase), a compound coating material, into the reaction kettle and stir to dissolve, then add potassium persulfate, blow nitrogen and stir, and control the solution temperature to 80°C. After reacting for 30 minutes, add emulsifier (Span 85 and Tween 60), thickener polyethylene glycol 600, and add water, keep the reaction temperature at 80°C, continue the reaction for 60 minutes, stop the reaction, spray the reactant through a spray drying device and granulate, and dried at 70°C until constant weight to obtain a gel breaker for fracturing fluid.

[0059] In the above reaction system, taking the total reaction system mass as 100%, polyimide accounts for 35% of the total mass, potassium persulfate accounts for 25% of the total mass, ethyl acetate accounts for 14% of the total mass, and the emulsifier Accounting for 8% of the total mass (the mass ratio of Span 85 to T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com