Patents

Literature

31results about How to "Meet the requirements of fracturing construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracturing fluid system of CO2 cleaning foam

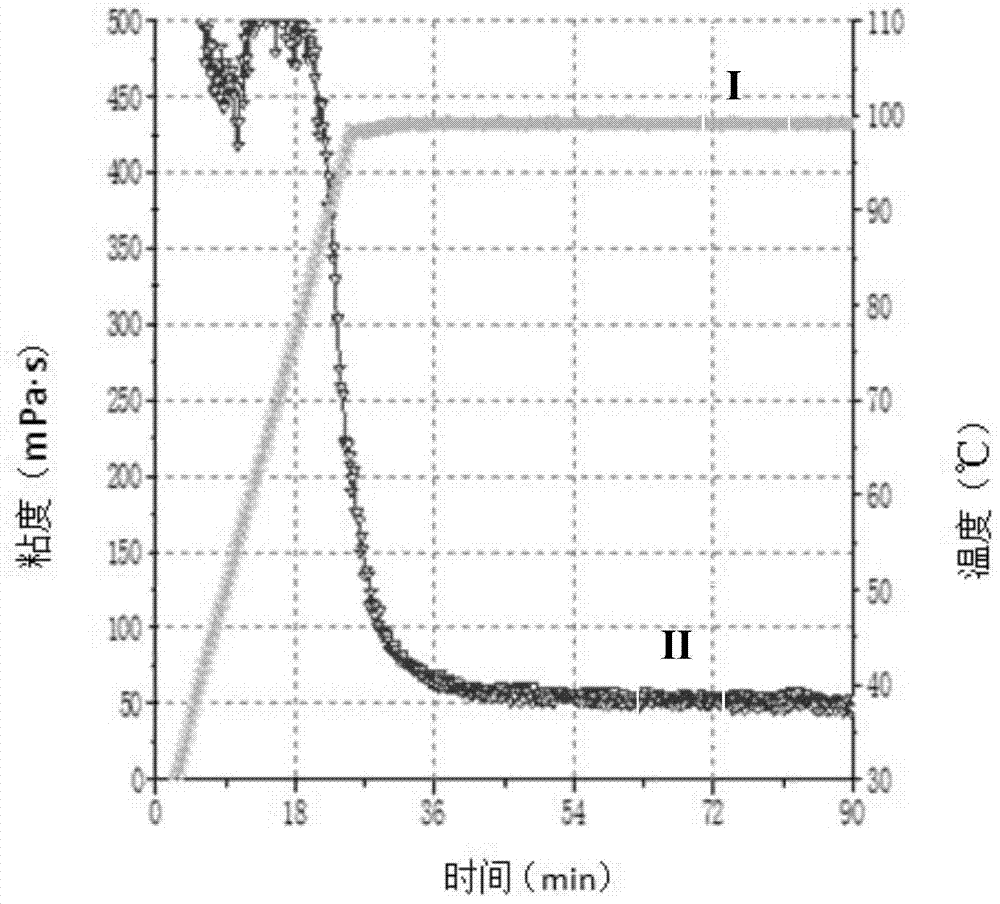

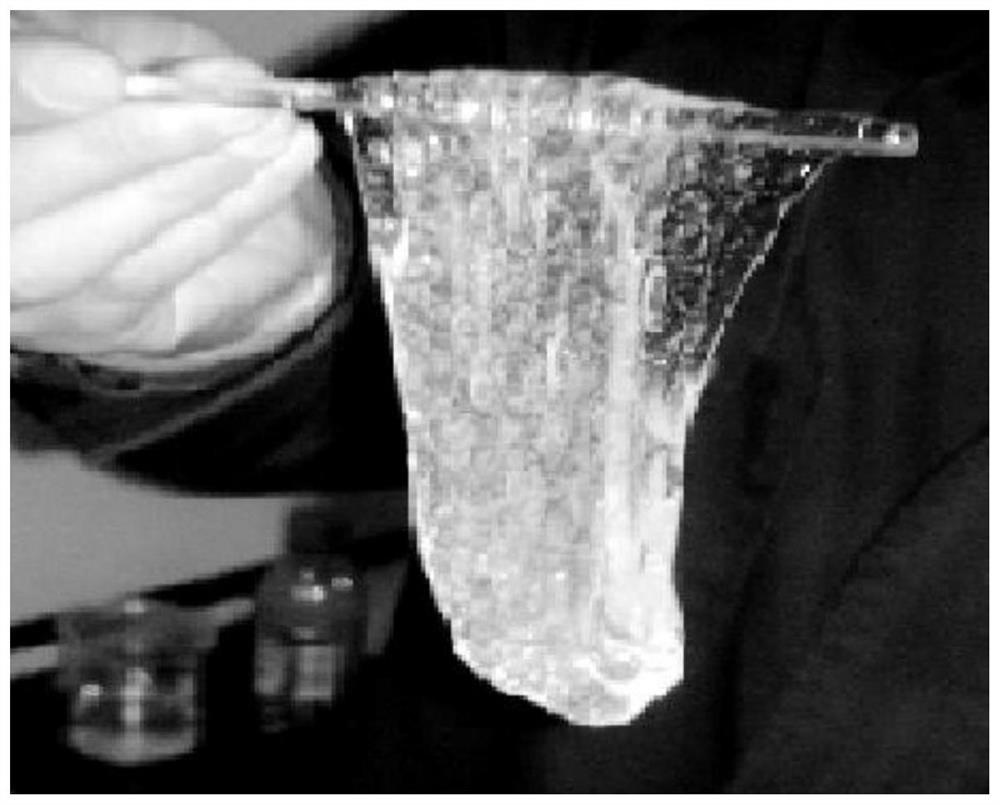

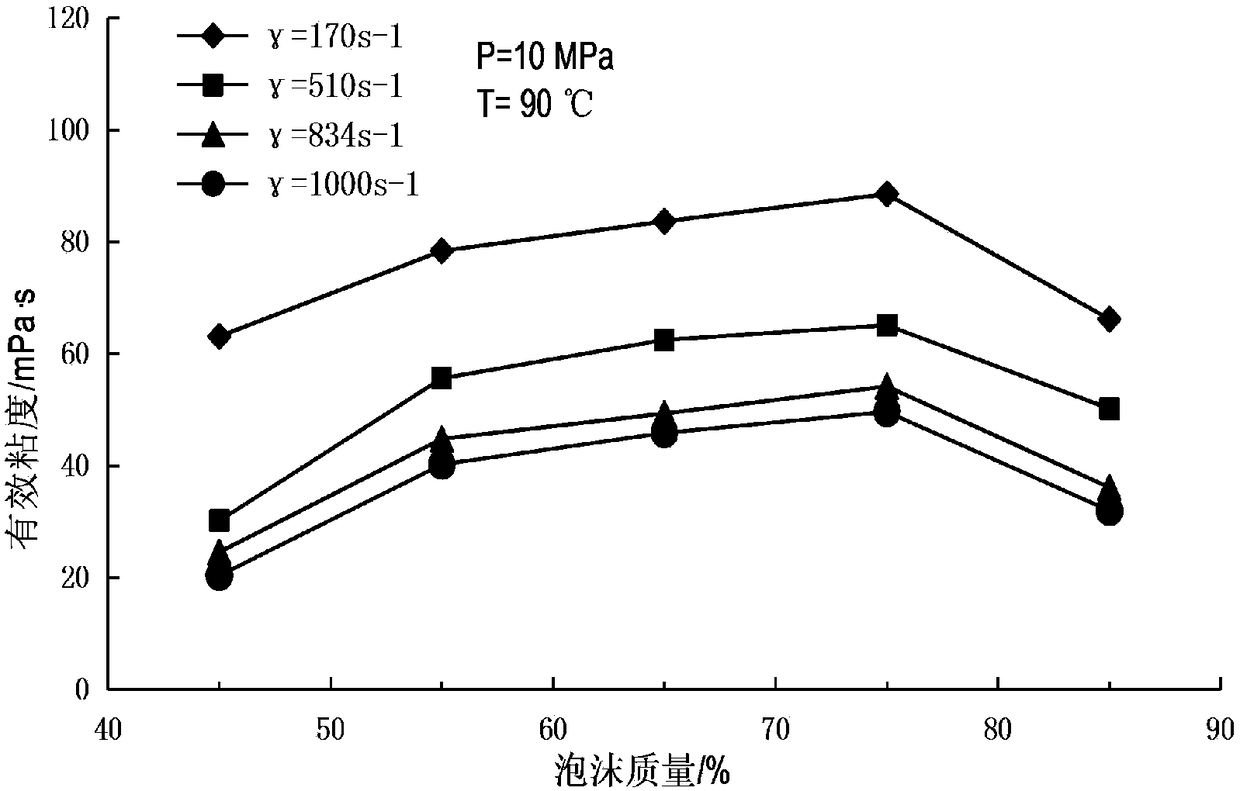

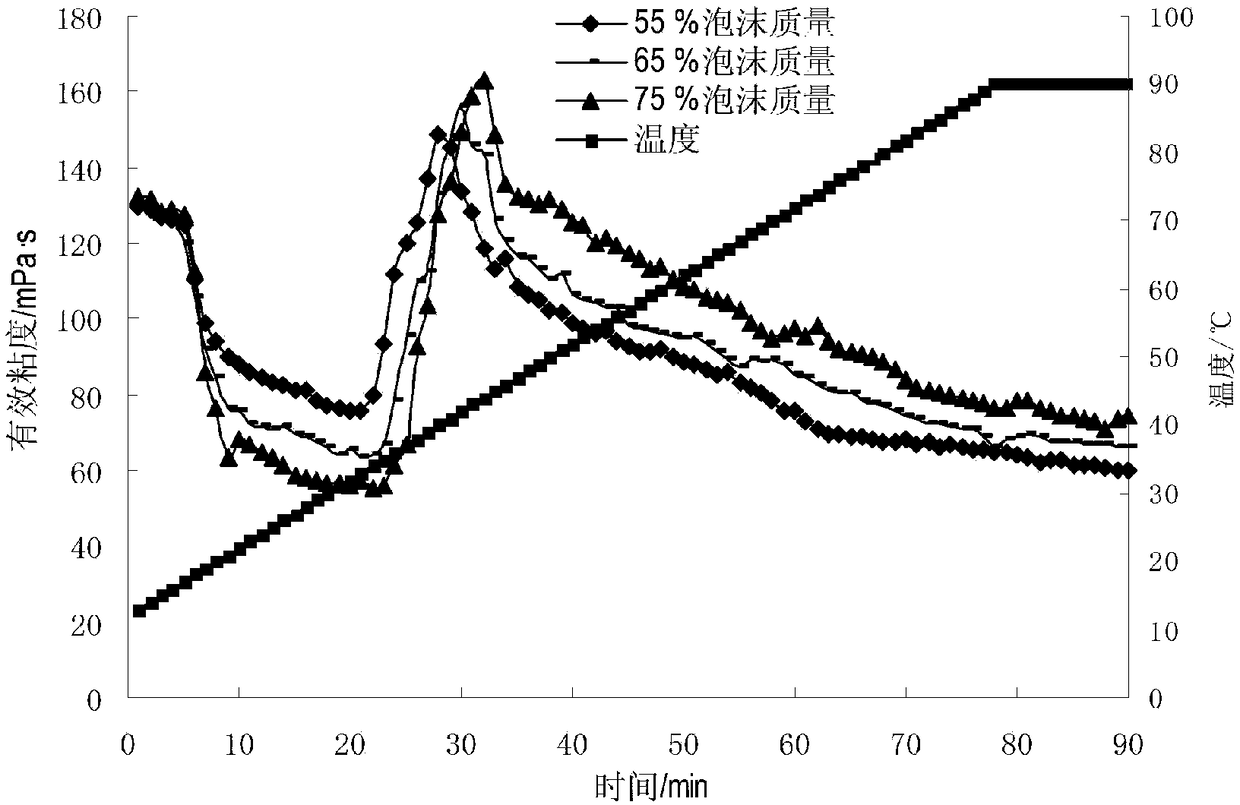

The invention relates to a fracturing fluid system used in an oil and gas field, in particular to a fracturing fluid system of CO2 cleaning foam. The fracturing fluid system comprises the following components in percentage by weight: 0.3-0.8 percent of water-soluble hydrophobic association polymer, 0.25-0.55 percent of rheological auxiliary agent, 0.5-3.0 percent of clay stabilizer, 0.1-0.5 percent of foaming agent, 0.01-0.2 percent of gel breaker, 30.0-80.0 percent of liquid CO2 and the balance of water. Compared with the prior art, in the fracturing fluid system of the CO2 cleaning foam, a cross-linking agent is not needed, the foamability is good, the foam stability is high, the sand-carrying capability is strong, gel breaking is easy to control, no residue is generated after gel breaking, the superficial / interfacial tension of gel-breaking liquid is low, and the damage to the formation is less, and therefore, the fracturing fluid system can be used for fracturing modification of hypoisotonic, low-pressure and water-sensitive storage layers at the temperature of 60-140 DEG C.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

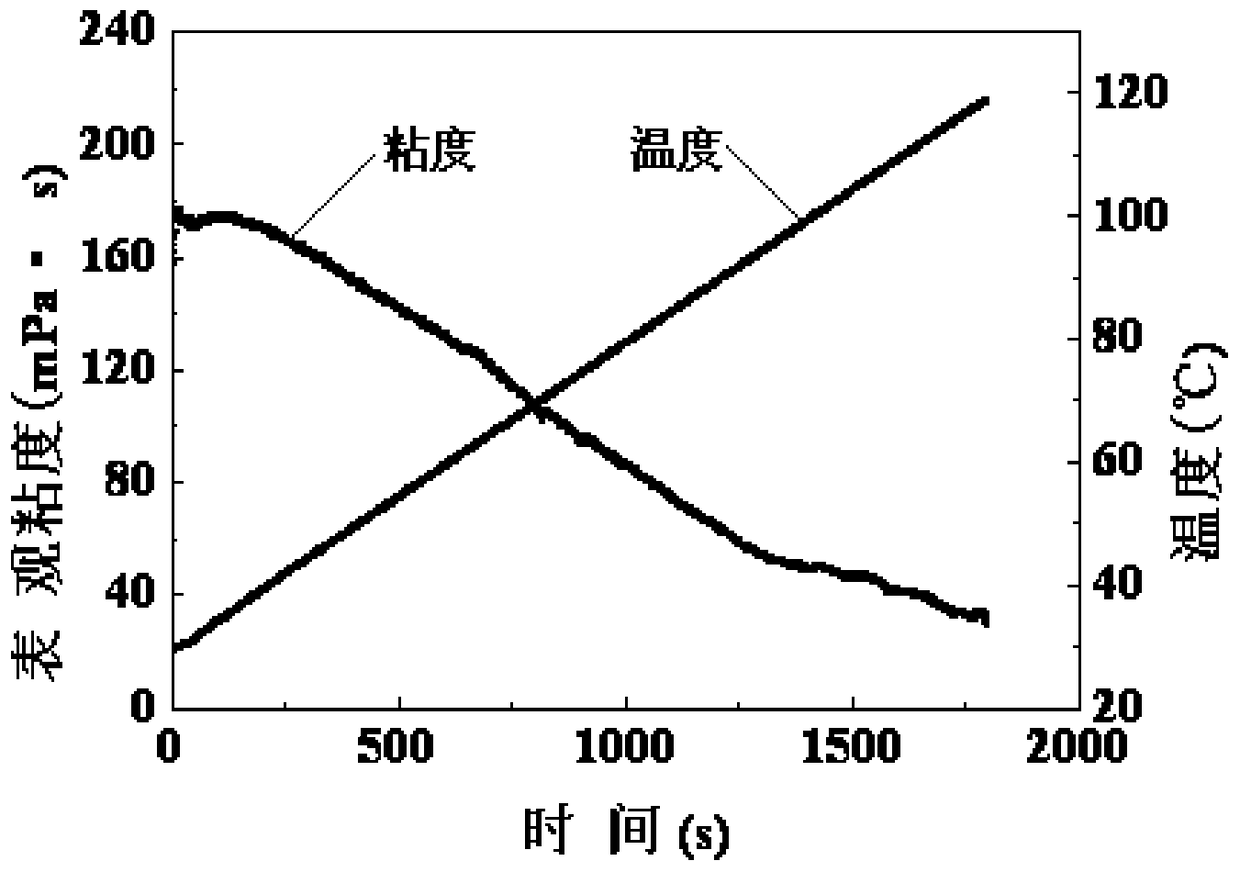

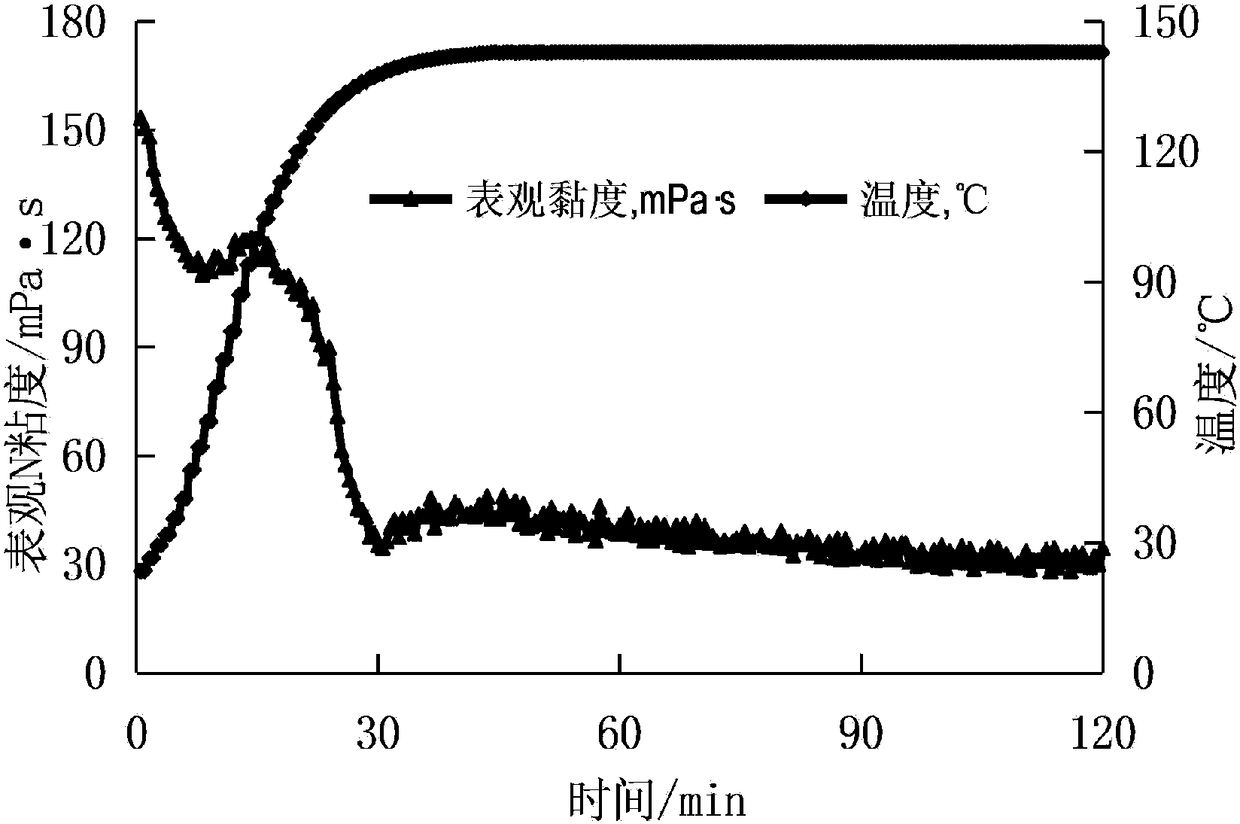

High temperature resistant cleansing emulsion or microemulsion fracturing fluid and preparation method thereof

ActiveCN102838980AIncrease contentReduce apparent viscosityProductsReagentsApparent viscosityPolymer science

The invention relates to a high temperature resistant cleansing emulsion or microemulsion fracturing fluid and a preparation method thereof. The emulsion fracturing fluid is composed of a continuous oil phase, a polymer (I)-containing dispersed water phase and an emulsifier. The preparation method of the emulsion fracturing fluid includes: preparing a mixed solution of the oil phase and the emulsifier, preparing a four-monomer containing water phase, conducting a polymerization reaction in the presence of an initiating agent, and other steps. The product provided in the invention has low apparent viscosity, and can dissolve rapidly. When the emulsion dissolves into gel, the emulsifier can have a synergistic effect with an association polymer, thus further improving and maintaining the viscosity, and helping to prevent leak-off and help flowback. An oxidation gel breaking way is employed for gel breaking, the gel can be completely broken, and the gel breaking solution has low viscosity and contains no residue. The emulsion fracturing fluid is easy to undergo flowback, and has low damage to the stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

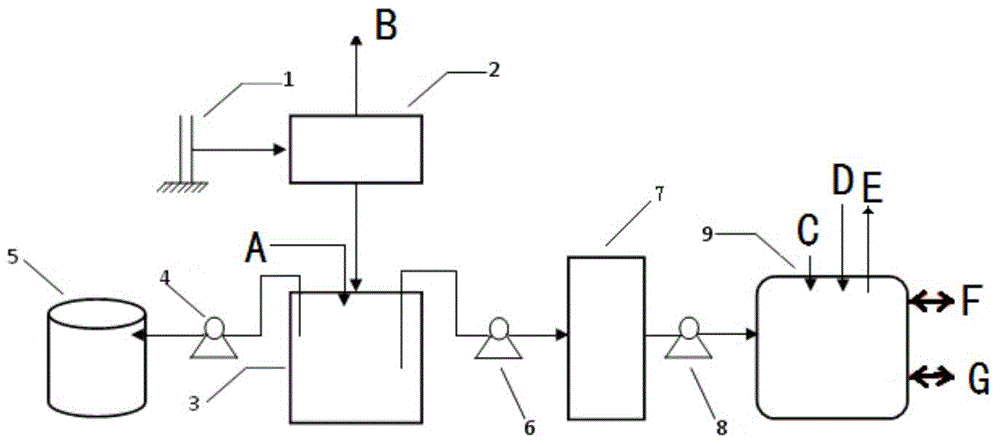

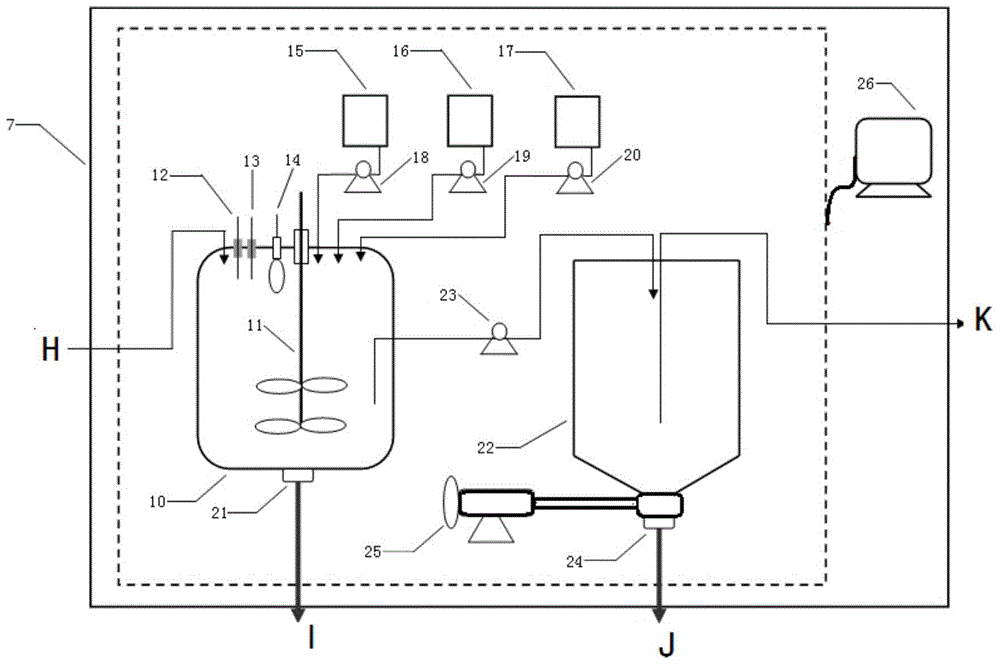

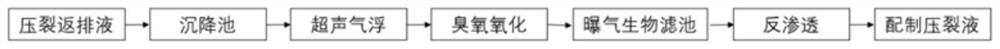

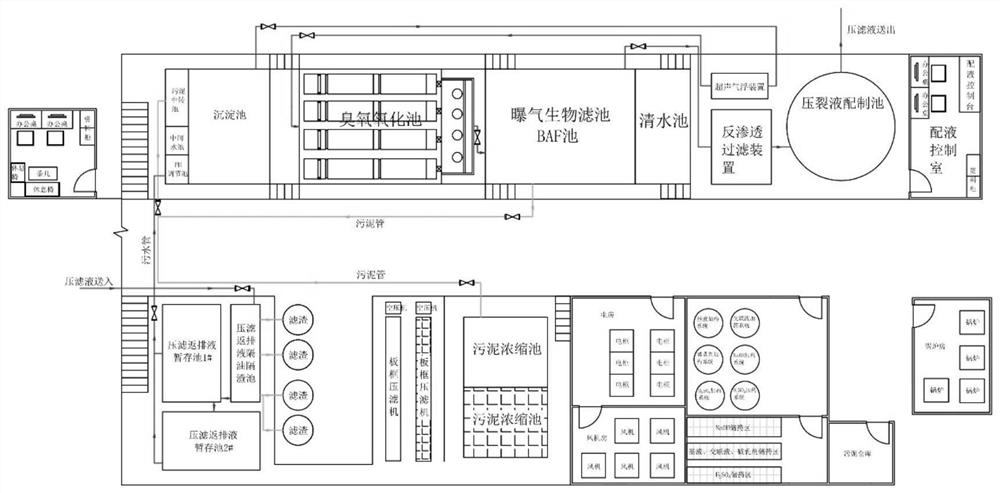

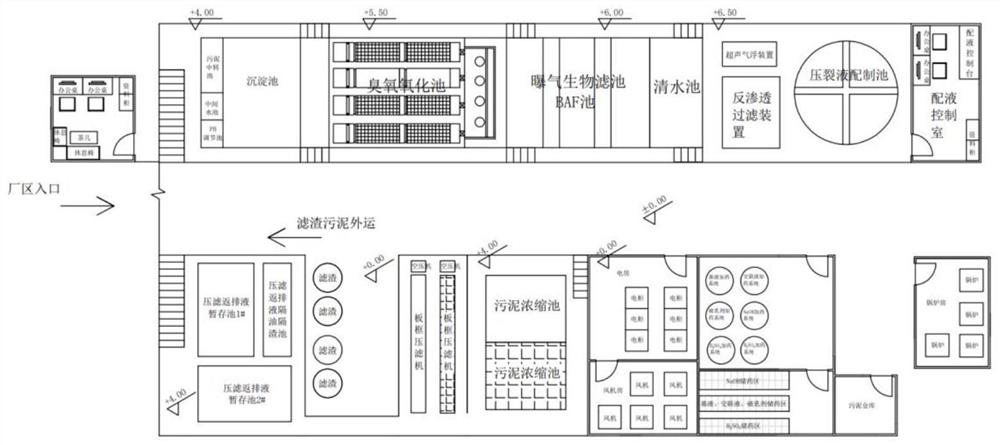

Reutilization method and treatment device for flow-back fracturing fluid

ActiveCN104692564ATime-consuming and labor-intensive solutionReduce harmWater/sewage treatment by centrifugal separationFluid removalFracturing fluidUltraviolet

The invention provides a reutilization method and a treatment device for flow-back fracturing fluid, belonging to the technical field of cyclic utilization of fracturing fluid and energy saving and emission reduction in the process of oil and gas exploitation. The method comprises the following steps: allowing the flow-back fracturing fluid to flow back from a wellhead and to pass through a gas-liquid separation device for gas-liquid separation; allowing the obtained liquid to enter a sedimentation tank and carrying out desanding and deoiling; allowing the treated liquid to enter the flow-back fracturing fluid treatment device via a lift pump, carrying out on-line water treatment, and enabling the water quality of the treated liquid to meet the requirement of reutilization through process treatments like ultraviolet sterilization, chemical precipitation for removal of high-valence metal ions, and flocculation and centrifugation for removal of suspended matters; allowing the treated liquid to enter a fracturing fluid mixing tank; testing the water quality of the liquid and analyzing the concentration of residual additives; supplementing lost additives; testing the properties of the fracturing fluid; and carrying out fracturing operation. According to the invention, treatment effect is good; when the treated flow-back fracturing fluid is reutilized, the requirement of fracturing operation is met; thus, the cyclic utilization of the fracturing fluid and energy saving and emission reduction are realized.

Owner:PETROCHINA CO LTD

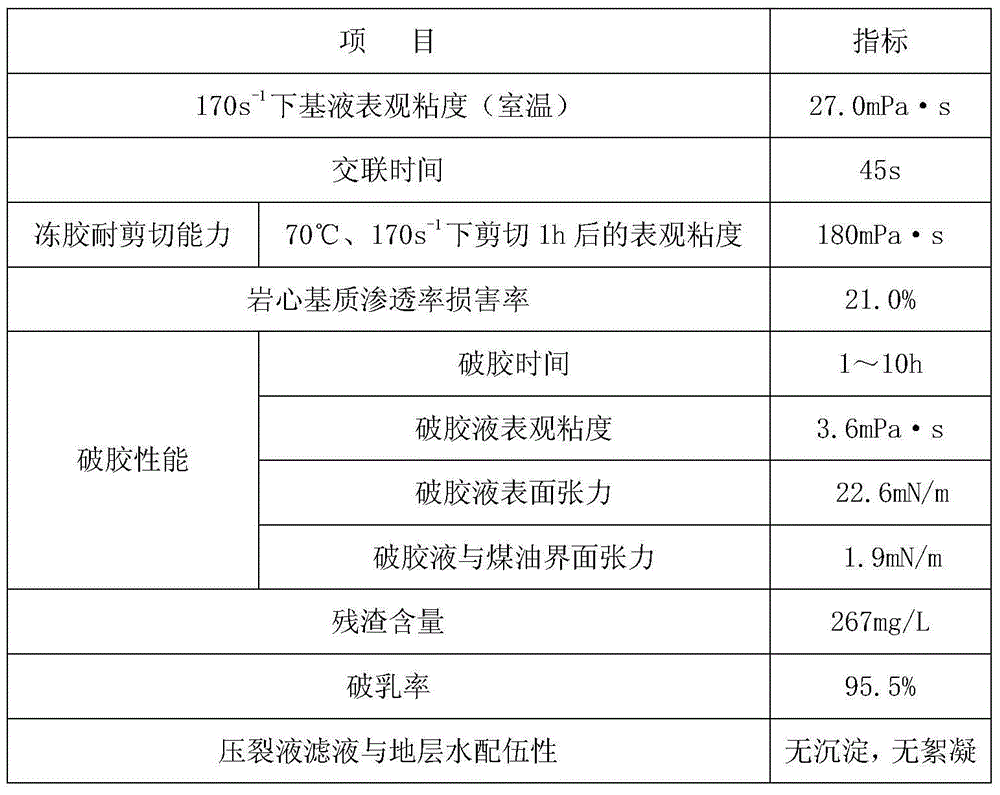

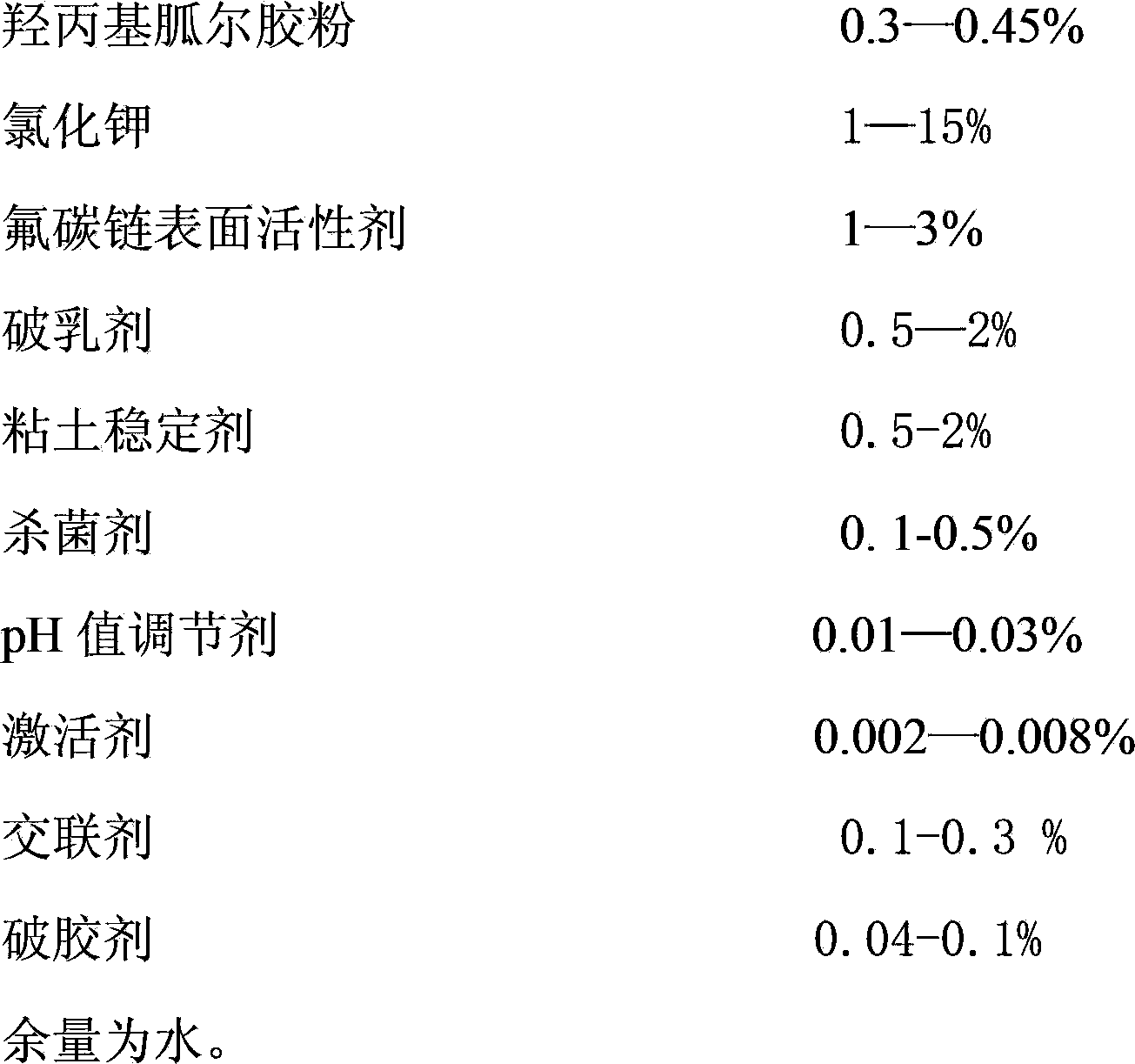

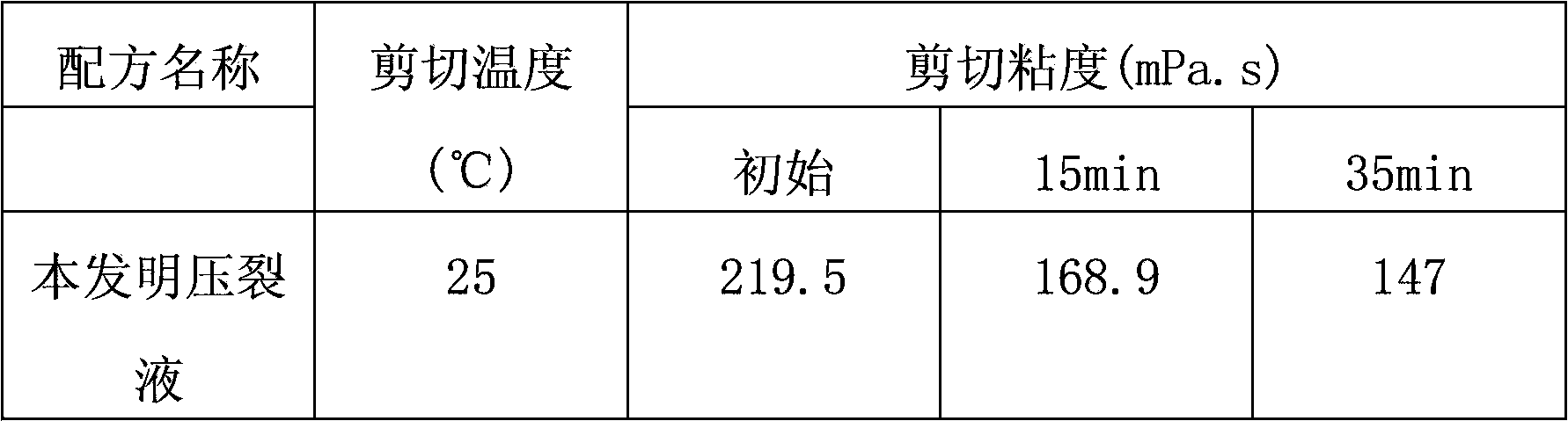

Ultralow-temperature guanidine gum fracturing fluid

InactiveCN103484092AEasy to useReduce pollutionDrilling compositionFracturing fluidHydroxypropyl guar

The invention relates to an ultralow-temperature guanidine gum fracturing fluid comprising 0.3%-0.45% of hydroxypropyl guar gum, 1-15% of KCl, 1-3% of a discharge aiding agent, 0.5-2% of a demulsifying agent, 0.5-2%% of a clay stabilizer, 0.1-0.5% of a fungicide, 0.01-0.03% of a pH value regulator, 0.002-0.008% of an activator, 0.1-0.3% of a crosslinking agent, 0.04-0.1% of a gel breaker, and the balance being water. The using effect of the fracturing fluid can be improved to a great extent, and the fracturing fluid can completely break gel and flow back at a low temperature of 15 DEG C-35 DEG C.

Owner:PETROCHINA CO LTD

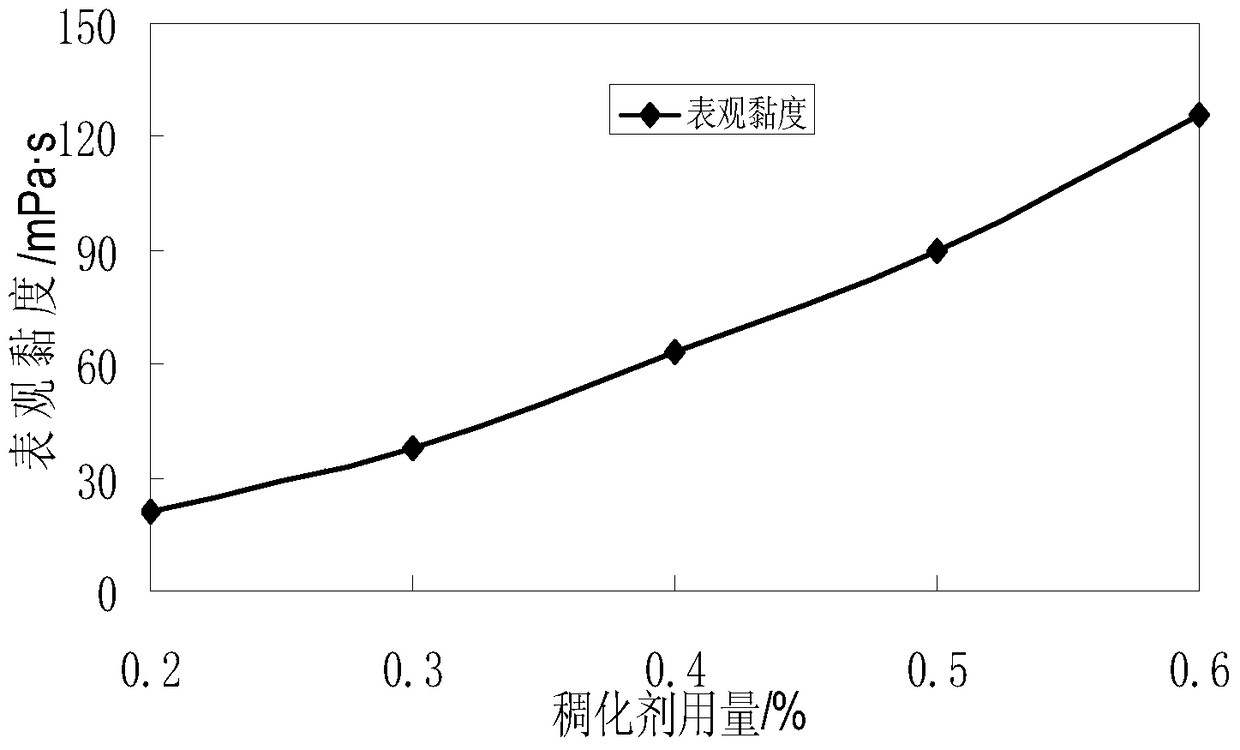

Fracturing fluid thickening agent and preparation and application thereof

ActiveCN103265939AImprove temperature and shear resistanceImprove yieldDrilling compositionPotassium persulfateThermal insulation

The invention relates to a fracturing fluid thickening agent and preparation and application thereof. The thickening agent is mainly prepared from the following components in percentage by weight: 15-20% of acrylamide monomer, 6-10% of acrylic monomer, 3-6% of sodium carbonate, 3-8% of 2-acrylamide-2-methylpropanesulsonic acid, 1-4% of dimethyldiallylammonium chloride (60% aqueous solution), 0.03-0.08% of potassium persulfate and the balance of water. The preparation comprises the following steps of: adding the acrylic monomer and water into a reaction kettle; starting stirring and slowly adding sodium carbonate, wherein the adding speed is proper when the bubbles generated by the reaction do not overflow out of the reaction kettle; stirring till sufficient dissolution; adding 2-acrylamide-2-methylpropanesulsonic acid, and stirring till sufficient and uniform mixing; adding the acrylamide monomer and dimethyldiallylammonium chloride, and stirring till sufficient dissolution; heating the reaction liquid to 40 DEG C, introducing nitrogen, and performing thermal insulation stirring for 20 minutes; adding potassium persulfate; continuously introducing nitrogen, and stirring for 30 minutes; stopping the stirring, and reacting for 4 hours to obtain gel; and grinding the reaction product, drying and granulating to obtain the thickening agent.

Owner:PETROCHINA CO LTD

Thickener and preparation method and application thereof

ActiveCN106279523AGood drag reduction effectGood thickening effectDrilling compositionFracturing fluidPropenyl

The invention provides a thickener and a preparation method and application thereof. The preparation method of the thickener includes the following steps that 1, 25-35 parts by weight of hydrophilic propenyl monomers are dissolved in 65-75 parts by weight of water, then the pH value is regulated, and a solution with the pH of 6.5-7.5 is obtained; 2, 1-5 parts by weight of hydrophobic monomers and 0.5-2 parts by weight of emulsifier are added into the solution, stirring is carried out, and 0.05-0.3 part by total weight of initiator is added in batches under a protective atmosphere for a polymerization reaction, wherein the hydrophilic propenyl monomers include acrylamide, acrylic acid and 2-acrylamido-2-methylpropane sulfonic acid in the weight ratio of (15-20):(4-5):(5-15). By adding the thickener in the process of preparing fracturing fluid from highly mineralized water, the fracturing fluid with a high thickening capacity can be formed, and fracturing construction requirements can be effectively met.

Owner:PETROCHINA CO LTD

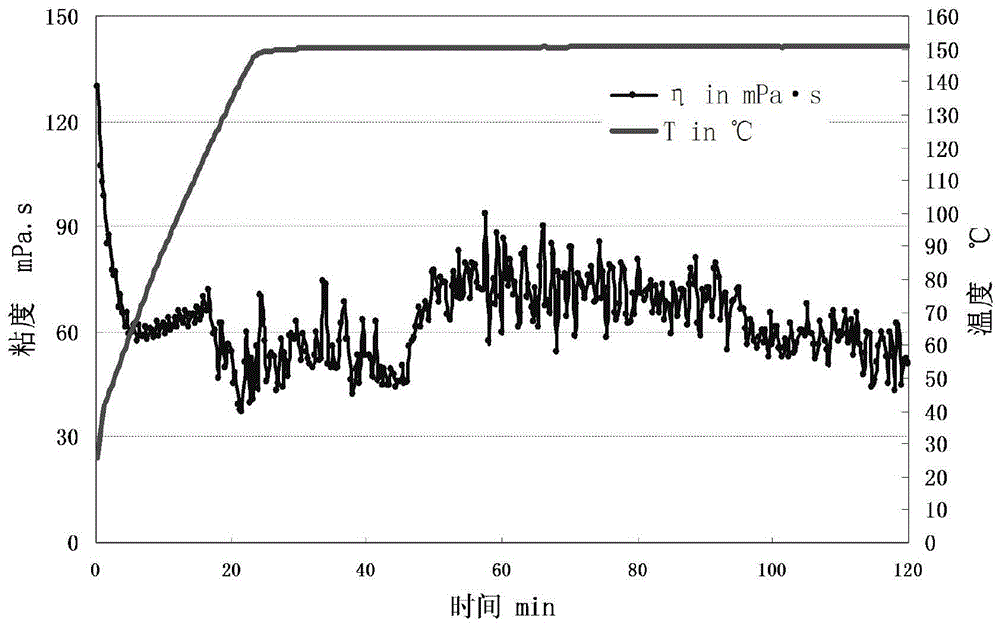

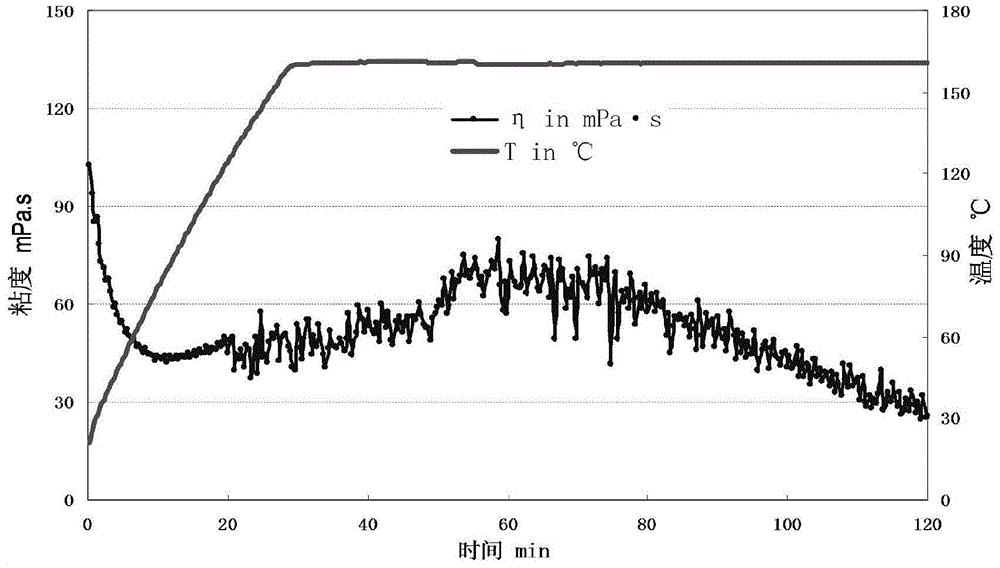

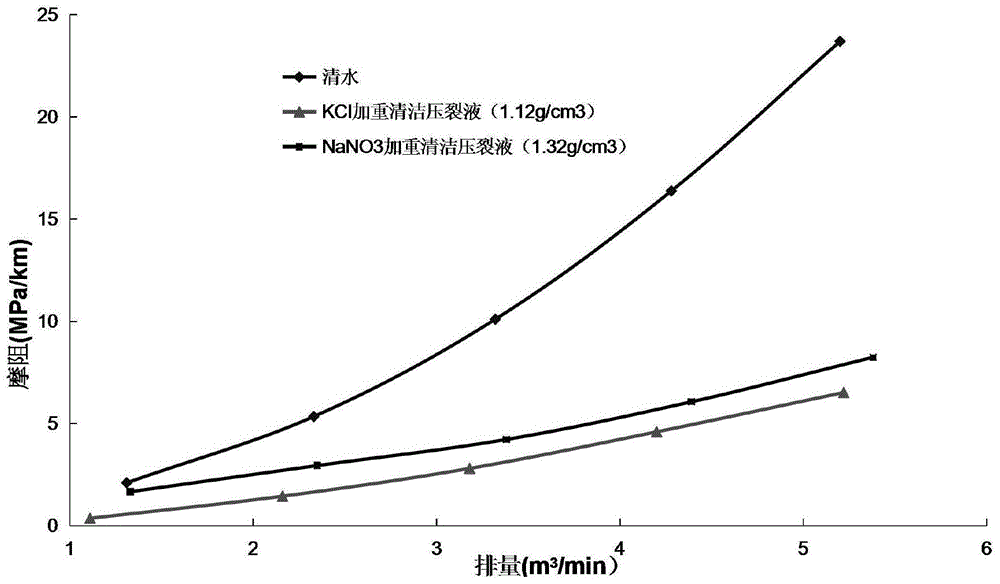

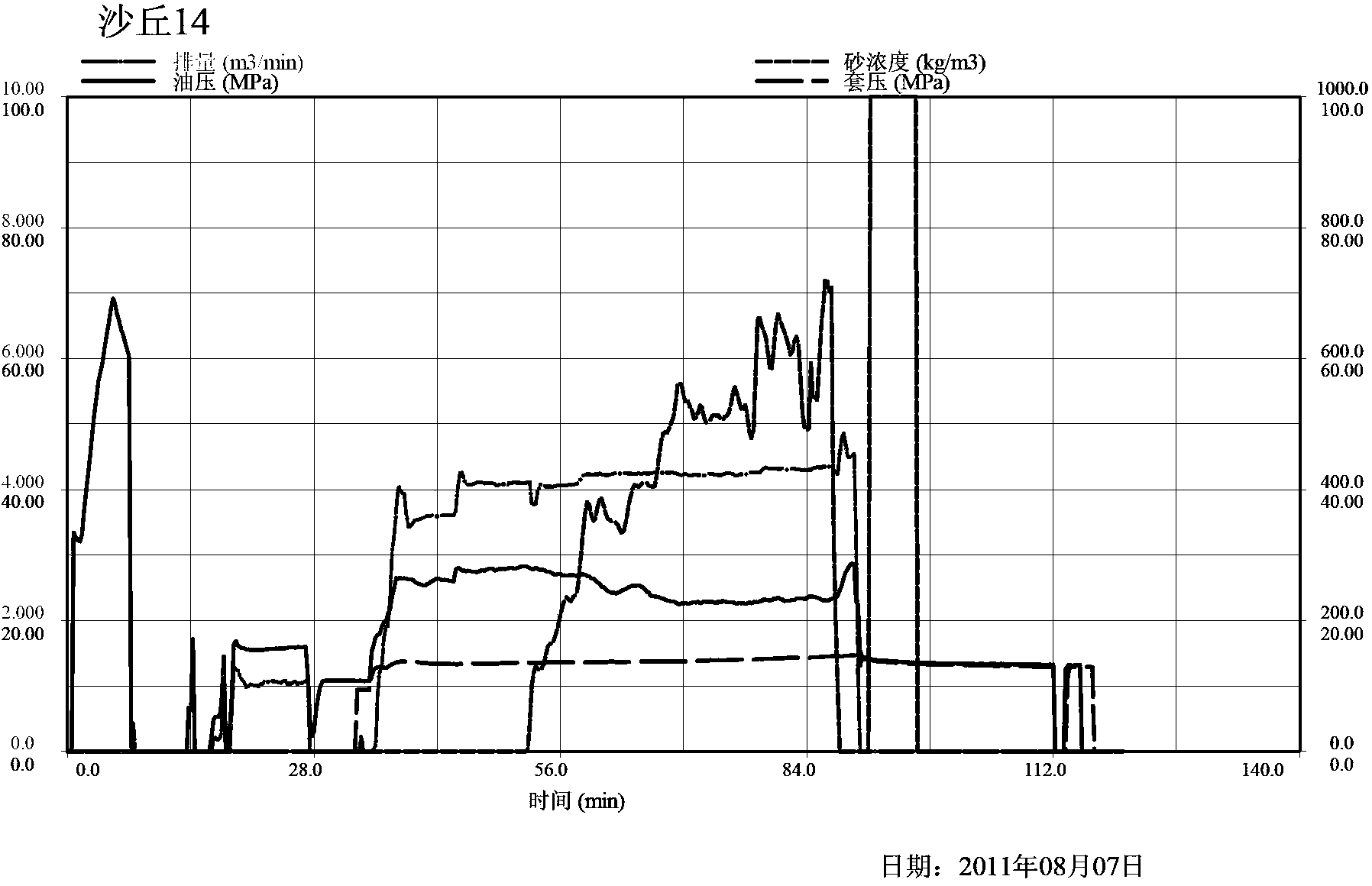

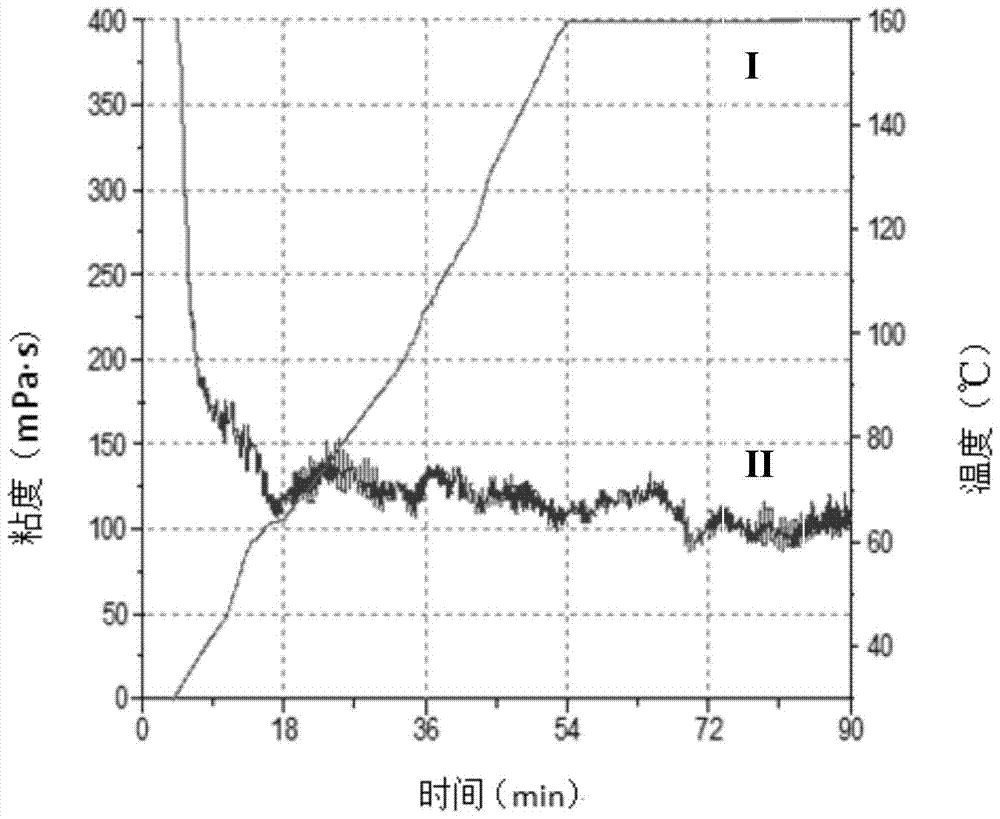

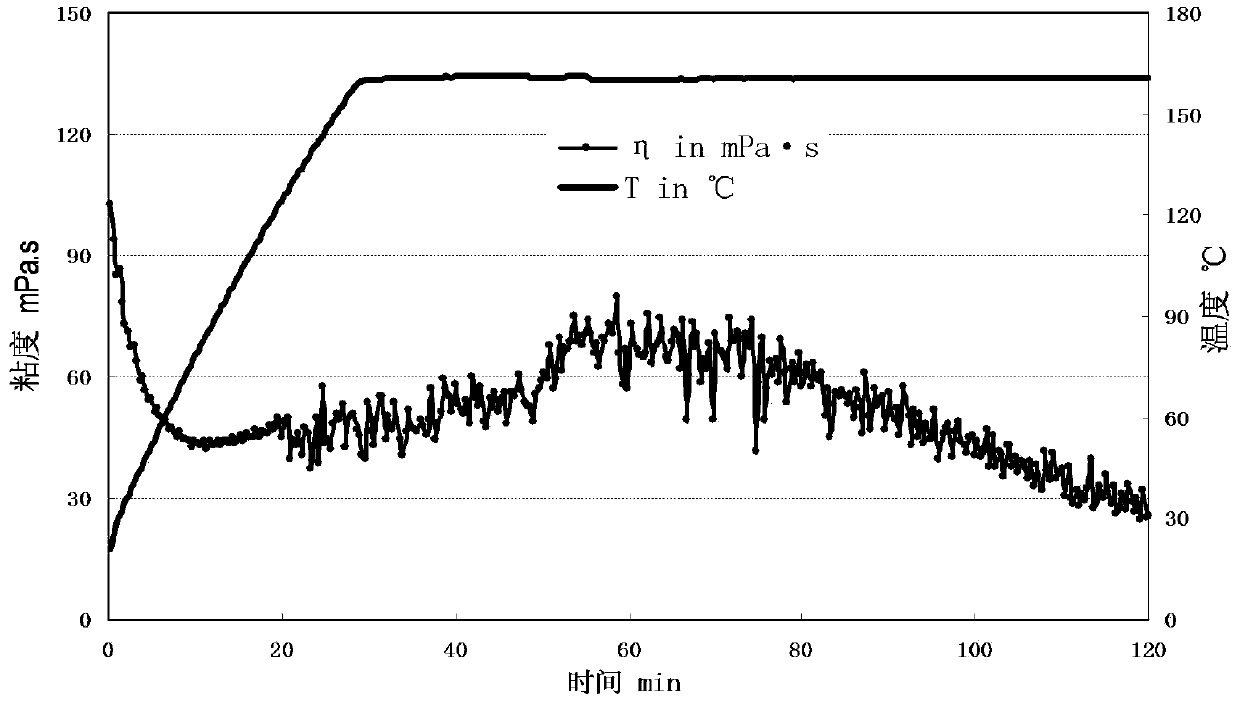

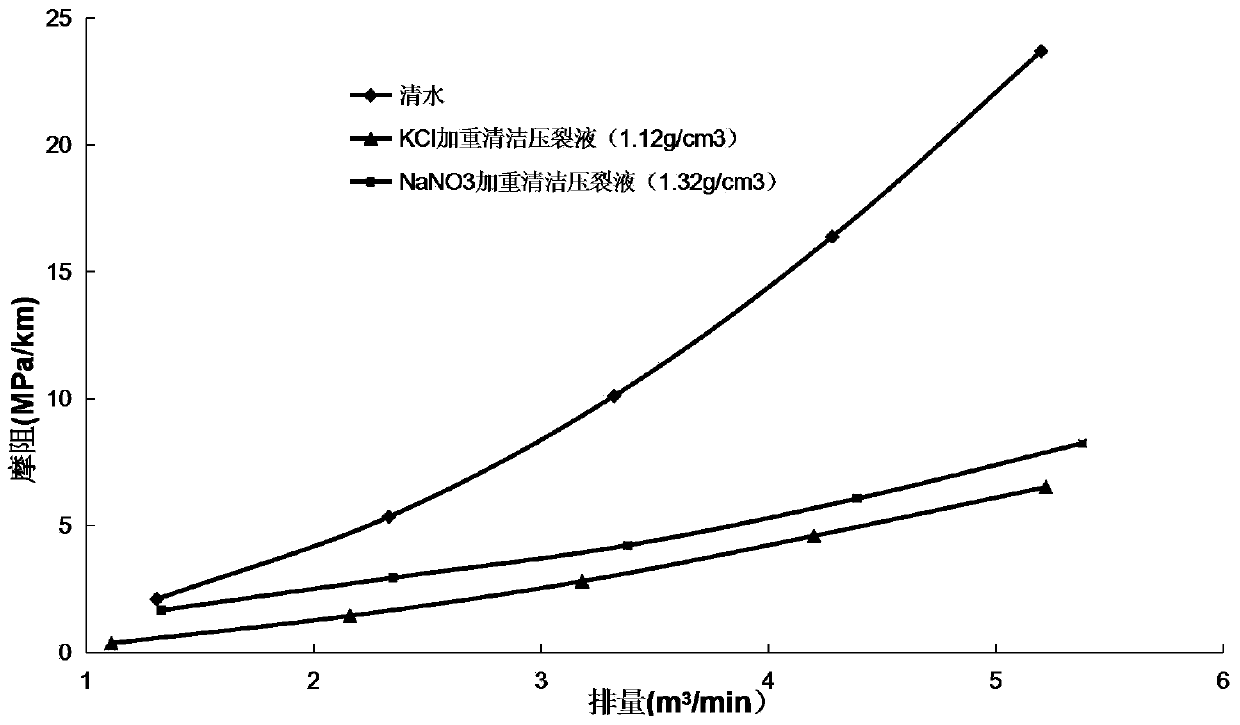

High-temperature-resistance low-friction weighted clean fracturing fluid and preparation method thereof

ActiveCN105733547APromote swellingEnhanced associationDrilling compositionReduction rateHigh pressure

The invention discloses a high-temperature-resistance low-friction weighted clean fracturing fluid which is suitable for high-temperature and high-pressure reservoir reconstruction at 170 DEG C and a preparation method thereof.The fracturing fluid is prepared from, by weight, 0.2%-0.8% of high-temperature-resistance thickening agent, 0.1%-0.8% of system synergist, 0.1%-0.3% of high temperature stabilizer, 0%-42% of weighting agent and the balance fresh water.The high-temperature-resistance low-friction weighted clean fracturing fluid has the following functions and advantages that the weighting agent can be adopted for weighting, and the density is adjustable between 0 and 1.32 g / cm<3>; good temperature-resistance and anti-shearing properties are achieved, and the requirement of high-temperature deep well fracturing construction at 170 DEG C can be met by adjusting a formula; a good resistance reduction property is achieved, pipeline friction resistance can be effectively reduced, and the resistance reduction rate can reach 70%; the fracturing fluid is a fluid with a reversible structure, and the structure damage after high shearing is small; the residue content of the fracturing fluid is decreased to below 10 mg / L, damage to a reservoir and supporting cracks is reduced, the fracturing effect is improved, and the reservoir productivity is increased.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

Gel breaking and emulsion breaking oil-in-water emulsification fracturing fluid

InactiveCN103484093ASimple preparation processEasy to operateDrilling compositionPolymer scienceFracturing fluid

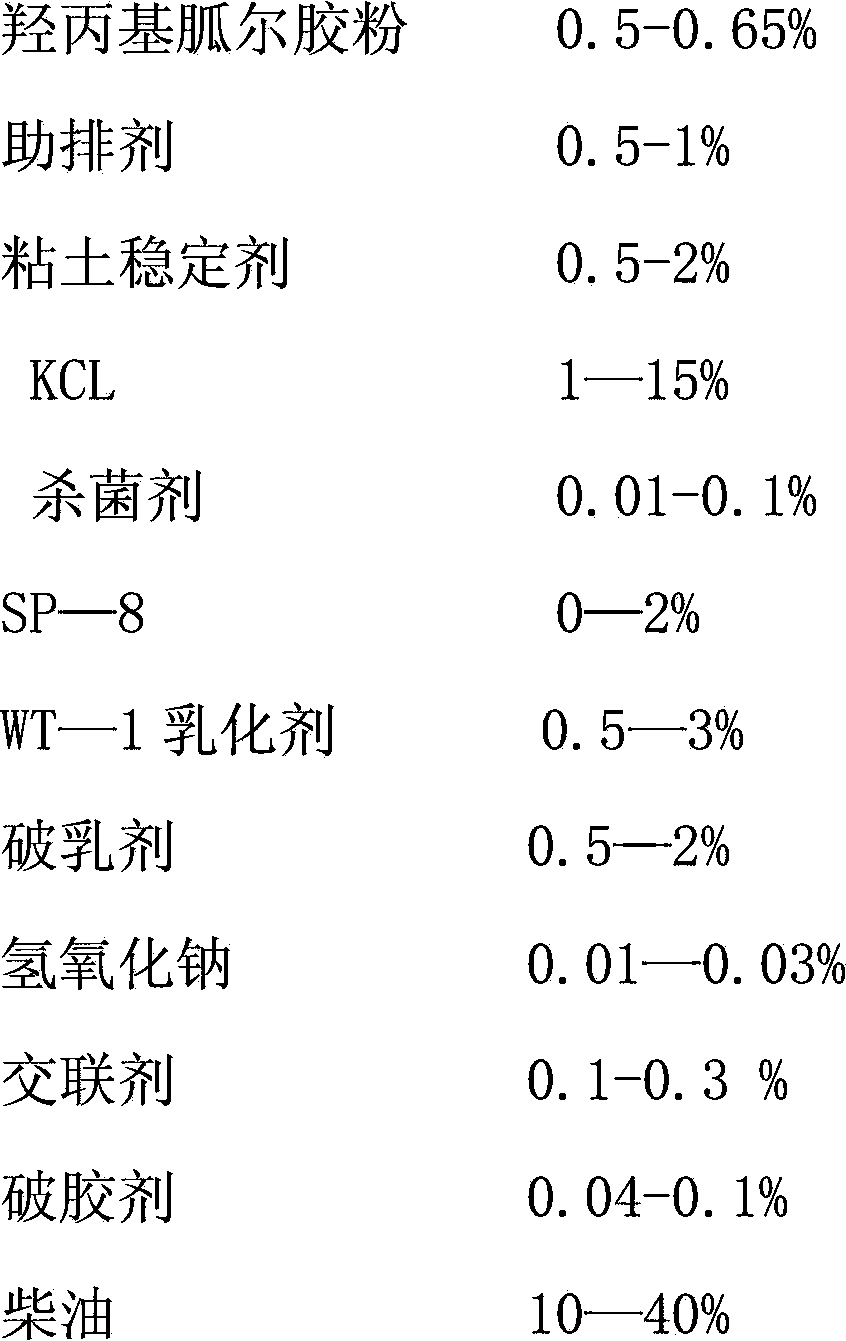

The present invention relates to a gel breaking and emulsion breaking oil-in-water emulsification fracturing fluid, which comprises, by mass, 0.5-0.65% of hydroxypropyl guar gum, 1-15% of KCl, 0.1-2% of OP-10, 0.5-3% of WT-1, 1% of a cleanup additive, 0.5-2% of an emulsion breaker, 0.5-2% of a clay stabilizer, 0.01-0.1% of a bactericidal agent, 0.01-0.03% of sodium hydroxide, 5-40% of diesel fuel, and the balance of water. With the gel breaking and emulsion breaking oil-in-water emulsification fracturing fluid, a use effect of the fracturing fluid can be substantially increased, such that the fracturing fluid can be subjected to complete gel breaking, and emulsion breaking can be performed under the stratum condition.

Owner:PETROCHINA CO LTD

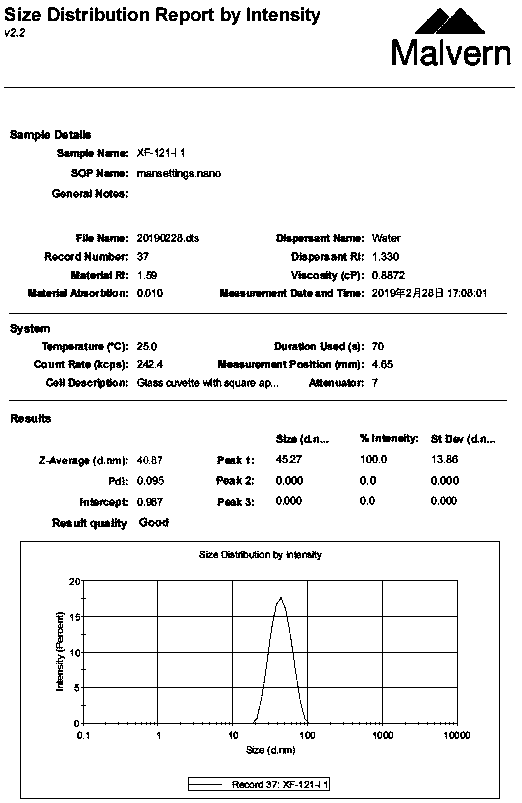

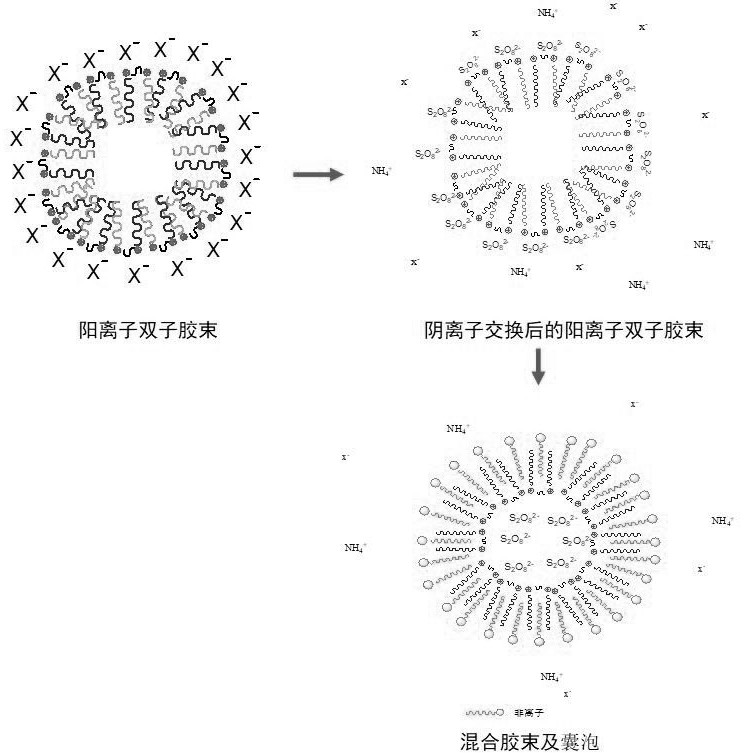

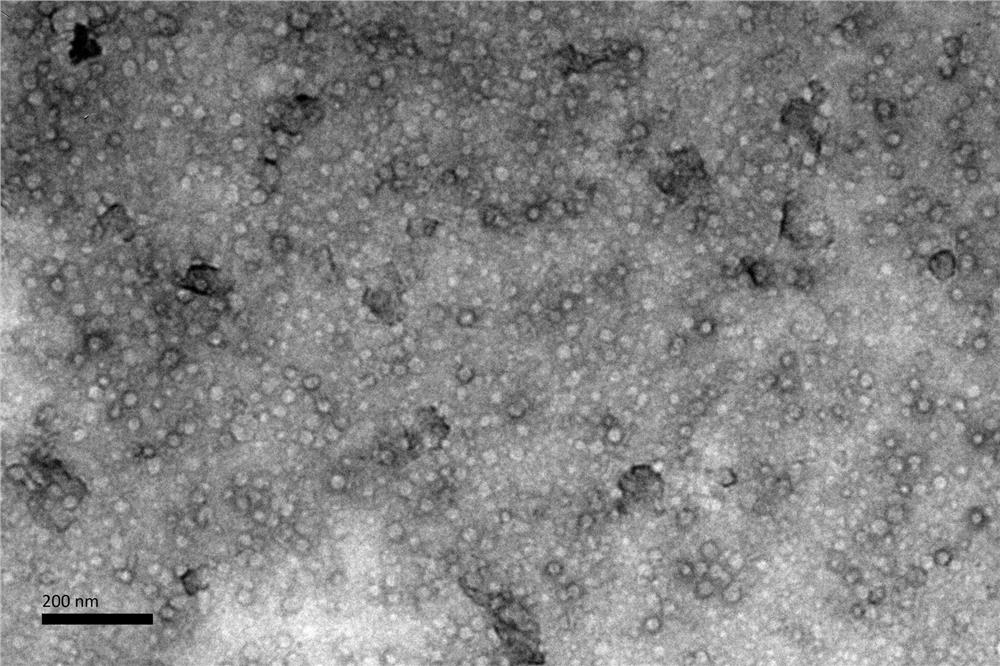

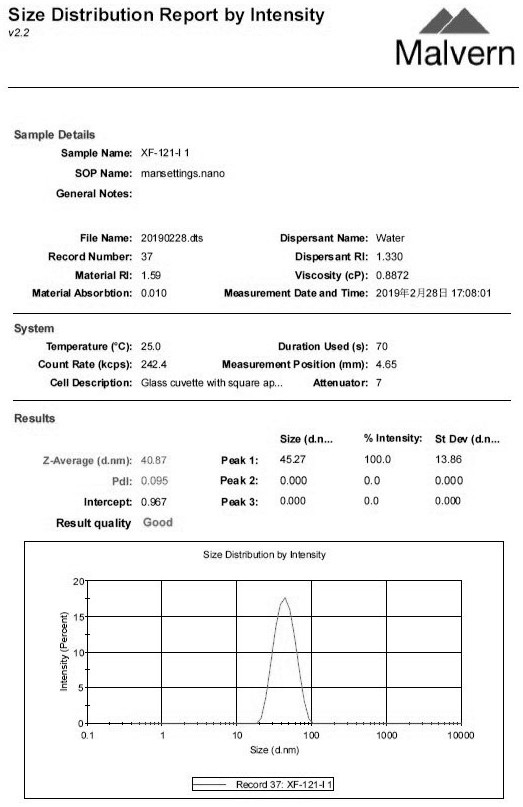

Nano liquid destroying agent for fracturing fluid and preparation method thereof

The invention discloses a nano liquid destroying agent for fracturing fluid and a preparation method thereof. The nano liquid destroying agent for the fracturing fluid is prepared from, by weight, 5.2-16.4% of peroxide, 2.3-10% of a gemini surfactant, 8.4-16.0% of a nonionic emulsifier, 1.9-4.4% of an auxiliary additive and 62.5-78.5% of a solvent; the structure of the nano liquid destroying agentfor the fracturing fluid is that the nonionic emulsifier and the gemini surfactant form a mixed micelle or vesicle having a closed double layer structure, and the peroxide and the inner layer structure constitute an ion pair and are wrapped inside the micelle or vesicle; the mixed micelle or vesicle size of the nano liquid destroying agent is nanometer-scale and specifically is between 15 and 100nanometre. The agent can meet the gel breaking requirements of the polymer fracturing fluid and the silicone fracturing fluid, and has the advantages of good storage stability at room temperature, weak corrosiveness, long storage period and good delayed gel breaking effect.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

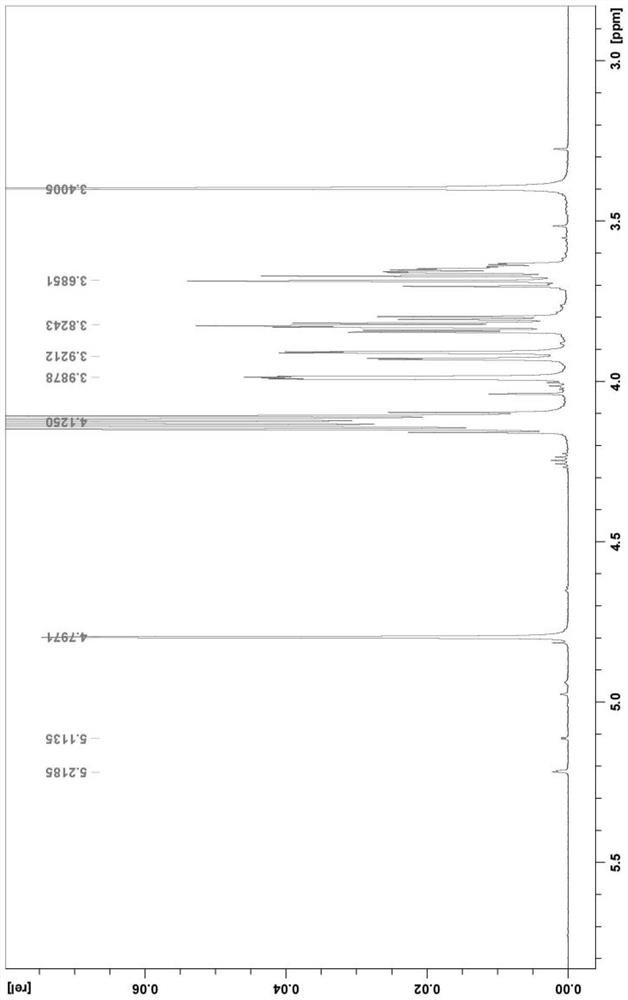

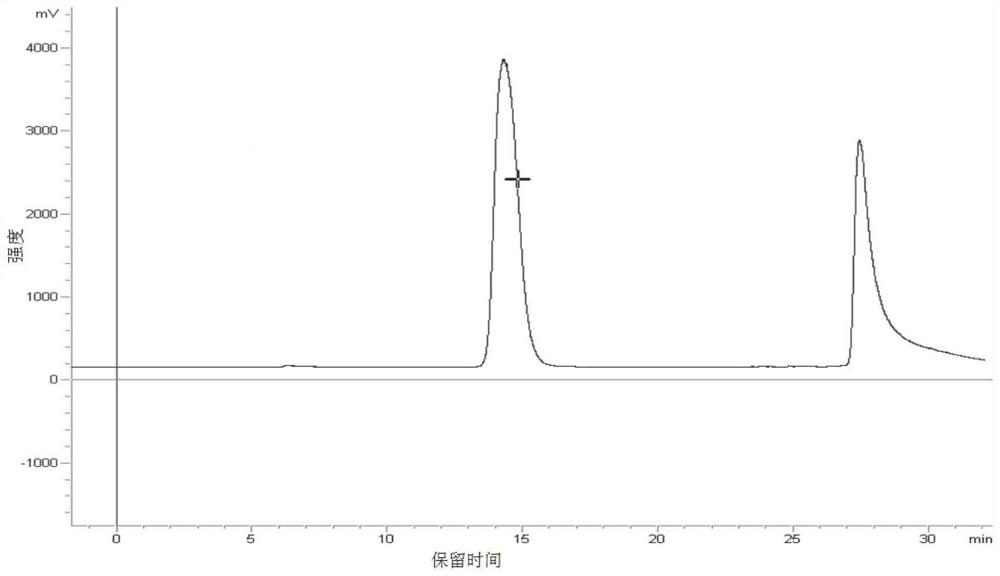

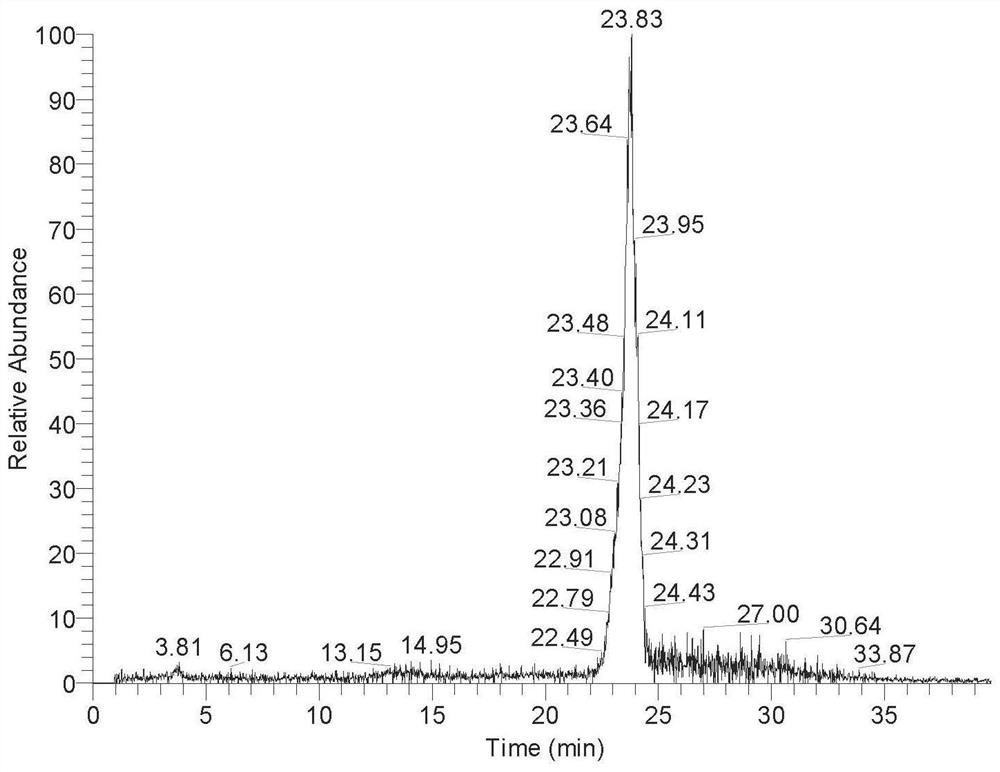

High temperature resistant organic zirconium crosslinking agent and preparation method thereof, a fracturing fluid jelly and preparation method thereof

ActiveCN104927828BImprove temperature resistanceImprove shear resistanceDrilling compositionPolyolAlcohol

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Fracturing fluid and preparation method thereof

InactiveCN111635750APromote swellingMeet construction requirementsDrilling compositionPlant GumsCross linker

The invention provides a fracturing fluid and a preparation method thereof. The fracturing fluid comprises vegetable gum, a synergist, a cross-linking agent, an optional clay stabilizer, a cleanup additive, water and an optional bactericide. The fracturing fluid comprises the following components in percentage by mass: 0.2%-0.75% of vegetable gum, 0.1%-10% of a synergist, 0.25%-0.65% of a cross-linking agent, 0-2% of a clay stabilizer, 0.05%-1% of a cleanup additive, 0-0.1% of a bactericide and the balance of water.

Owner:北京斯迪莱铂油气技术有限公司

Polymer acidic cross-linking agent and preparation method thereof

The invention provides a polymer acidic cross-linking agent, which is prepared from the following raw materials in percentage by weight: 20-30% of a complexing agent, 0.1-5% of nanoparticles with core-shell structure, 5-10% of a zirconium compound, 1-3% of a stabilizer, 3-5% of a corrosion inhibitor and the balance of deionized water, wherein the nanoparticles with the core-shell structure take sulfide-loaded amorphous alumina as a core and oligomeric chitosan as a shell material, and the particle size of the nanoparticles is 50-500 nm. According to the cross-linking agent, the problem of more residues after gel breaking of a zirconium cross-linking agent is remarkably improved, the flowback rate is remarkably increased, and the damage to a reservoir is remarkably reduced.

Owner:陕西天成旭化工科技有限公司

Method for preparing fracturing fluid by utilizing polymer type fracturing flow-back fluid

PendingCN113462376AIncrease innovationImprove the effect of air flotation and oil removalWater treatment parameter controlTreatment using aerobic processesThermodynamicsPlant Gums

The invention discloses a method for preparing fracturing fluid by utilizing polymer type fracturing flow-back fluid, and relates to the technical field of fracturing flow-back fluid reutilization. The invention aims to solve the problem of pollution of fracturing flow-back fluid to the environment and reduce the fracturing construction cost. The method comprises the following steps of: mixing 0.2-0.4 parts of base fluid, 0.002-0.004 parts of a cross-linking agent, 0.00002-0.00005 parts of a gel breaker and 99.6-99.8 parts of fracturing flow-back fluid subjected to reverse osmosis treatment, and fully stirring to obtain fracturing fluid. The base fluid is prepared from 25 parts of guanidine gum, 5 parts of a cleanup additive, 4 parts of a demulsifying agent, 5 parts of sodium carbonate, 1 part of sodium bicarbonate, 50 parts of a liquid clay stabilizer, 3 parts of a defoaming agent, 5 parts of a vegetable gum stabilizer and 3 parts of a sterilizing agent. The method for preparing fracturing fluid by utilizing polymer type fracturing flow-back fluid is obtained.

Owner:三桶油环保科技(宜兴)有限公司

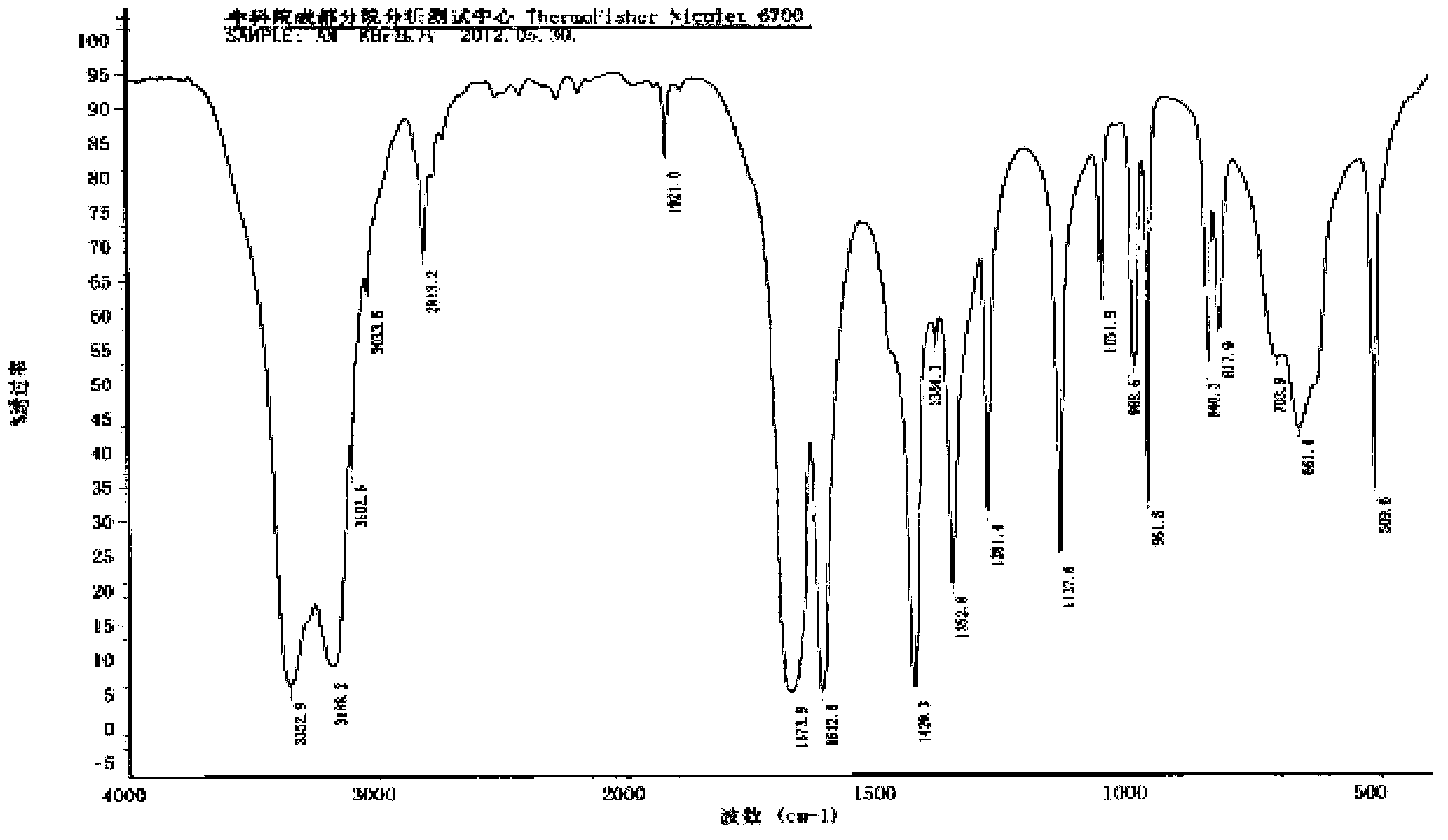

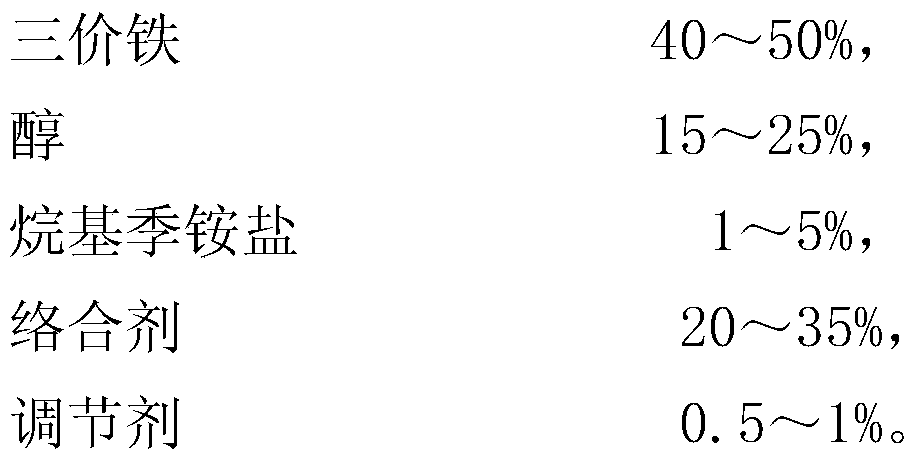

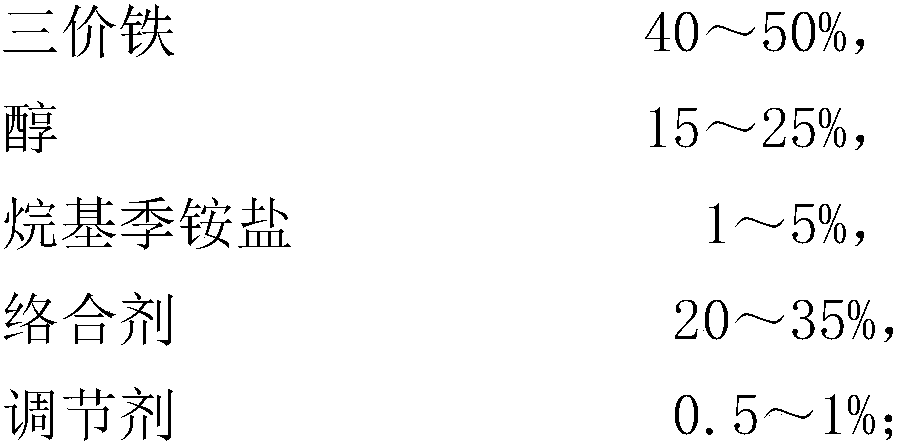

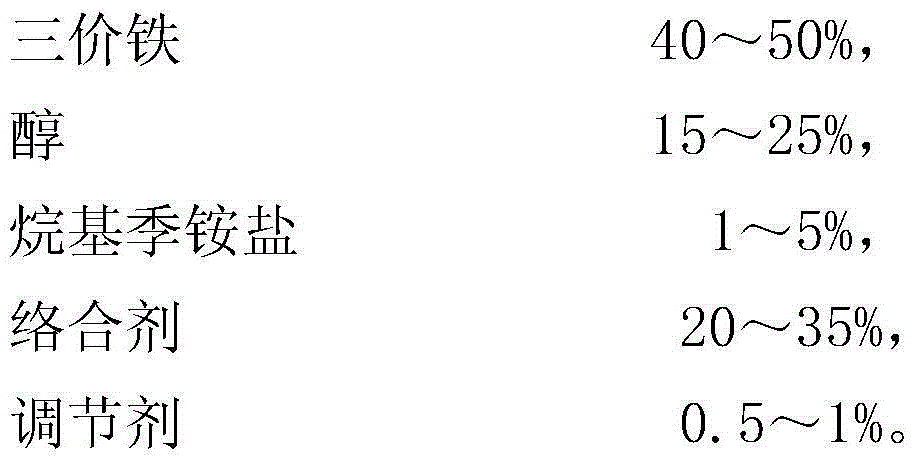

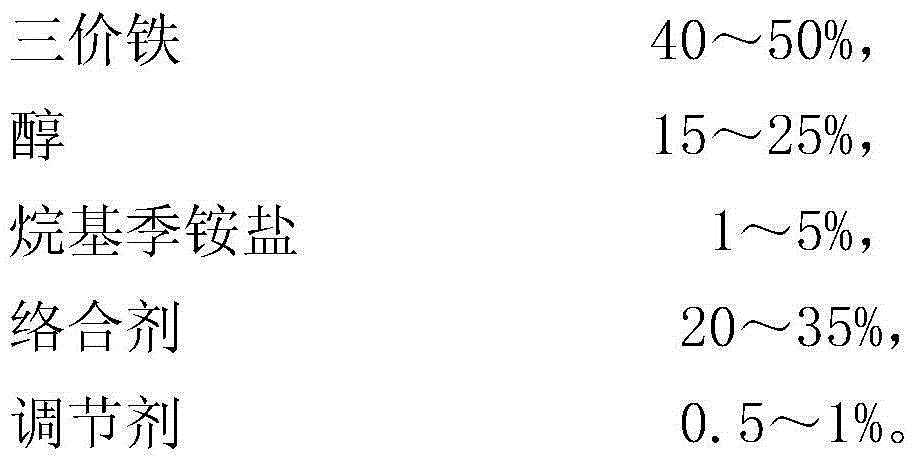

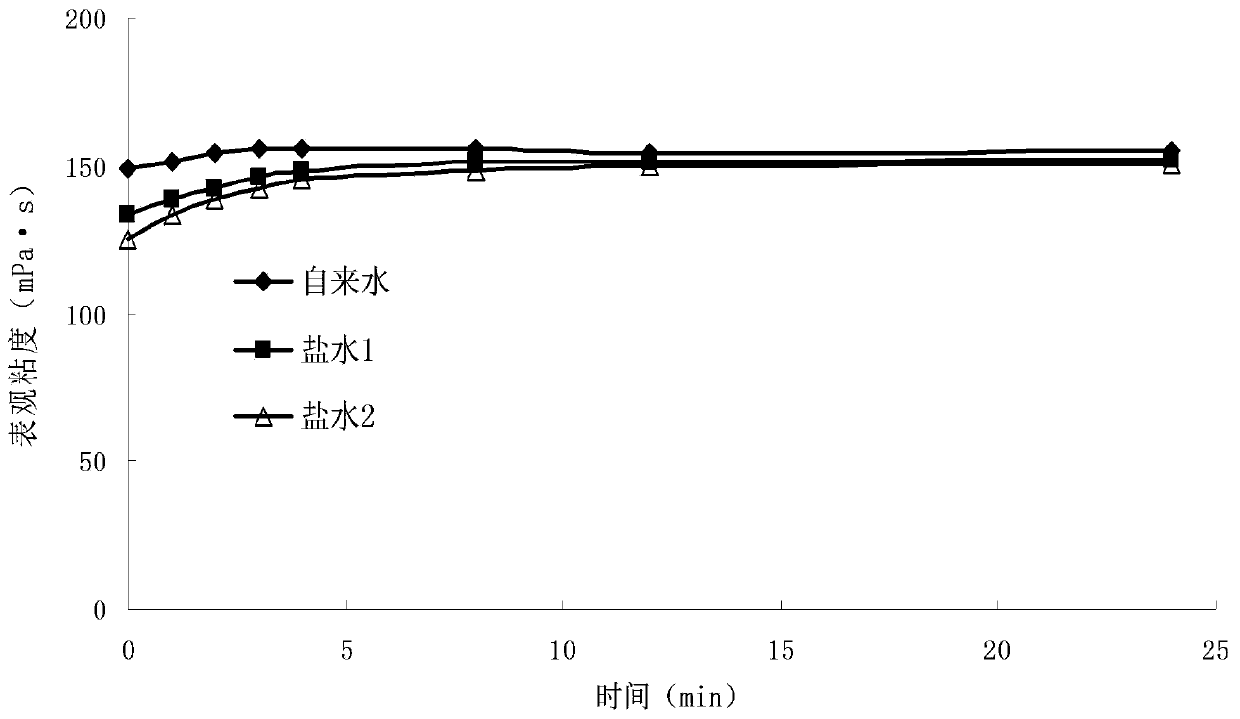

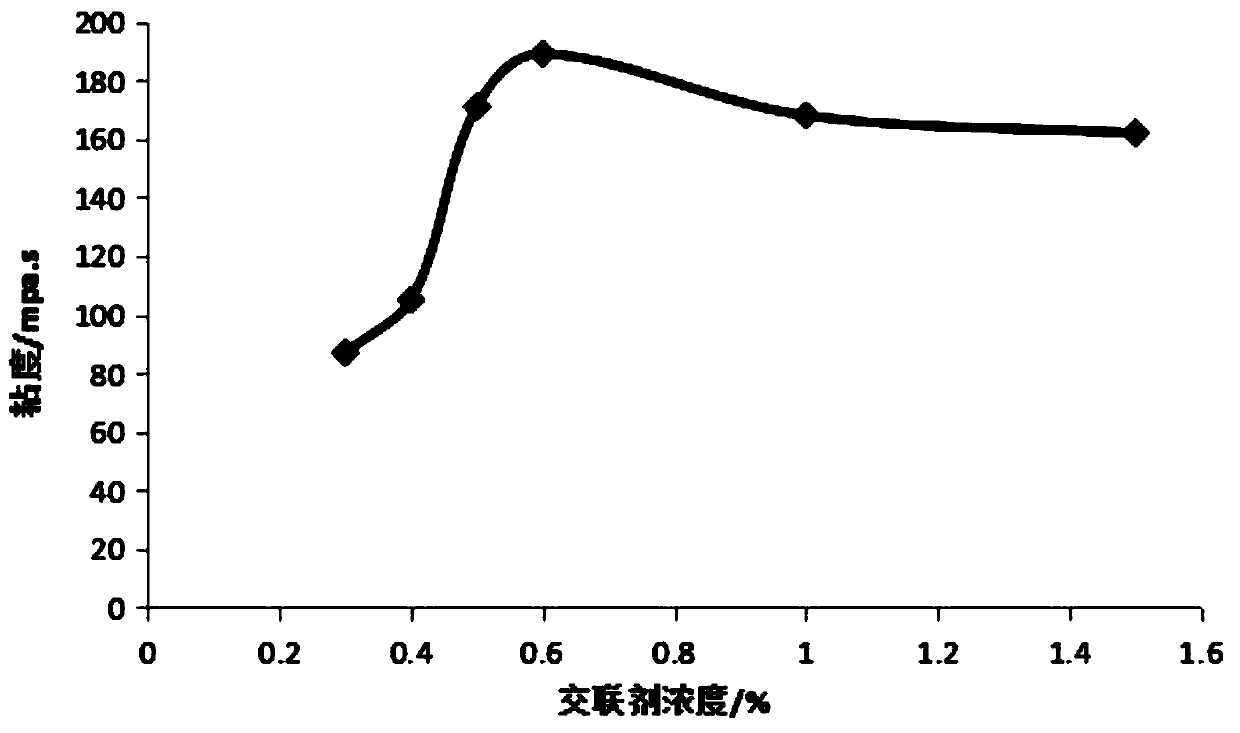

A kind of low-carbon hydrocarbon fracturing fluid crosslinking agent and preparation method thereof

InactiveCN105219371BMeet the requirements of fracturing constructionImprove temperature resistanceDrilling compositionAlcoholEngineering

The invention discloses a low-hydrocarbon fracturing fluid cross-linking agent and a preparation method thereof. The cross-linking agent is prepared from, by weight, 40%-50% of ferric iron, 15%-25% of alcohol, 1%-5% of alkyl quaternary ammonium salt, 20%-35% of complexing agent and 0.5%-1% of modifier. The preparation method of the cross-linking agent includes the following steps that the bath temperature is adjusted to be 50-60 DEG C, and the stirring speed is controlled to be 100-500 r / min; under the condition that refined nitrogen is introduced, the ferric iron and the complexing agent are added first, the alcohol and the alkyl quaternary ammonium salt are added after reacting is conducted for 2 hours, then the modifier is added after reacting is conducted for 3.5 hours, and accordingly the low-hydrocarbon fracturing fluid cross-linking agent is obtained. The cross-linking agent is good in cross-linking effect, the temperature resistance is improved, and cross-linking time can be adjusted according to field needs. The preparation method is reliable in principle and easy and convenient to operate, and market application prospects are broad.

Owner:SOUTHWEST PETROLEUM UNIV

Epoxysuccinic acid modified mannoside, preparation method and application thereof, fracturing fluid cross-linking agent and fracturing fluid

PendingCN114262353AIncrease delay timeReduce frictionSugar derivativesDrilling compositionEpoxyCarboxyl radical

The invention provides epoxy succinic acid modified mannoside, a preparation method and application thereof, a fracturing fluid cross-linking agent and a fracturing fluid, and relates to the technical field of cross-linking agents. When the epoxy succinic acid modified mannoside with the structure as shown in the formula I provided by the invention can be used as a ligand to be applied to a fracturing fluid cross-linking agent, adjacent carboxyl and hydroxyl of the epoxy succinic acid modified mannoside can form a five-membered ring with a stable structure with central particles (zirconium ions, titanium ions, aluminum ions or boron atoms); compared with gluconate and modified gluconic acid, the alpha-methyl-D-mannoside has a better chelation effect and longer delayed cross-linking time, and has a very good application prospect in the aspects of preparation of chelates, cross-linking agents, detoxification drugs, foods or functional materials by using the alpha-methyl-D-mannoside as a ligand or a cross-linking agent.

Owner:昆山京昆油田化学科技有限公司

A boron cross-linking agent and its use in preparing boron cross-linked fracturing fluid suitable for high-temperature deep wells

ActiveCN104893705BReduce the chance of bondingControlling the speed of crosslinkingGroup 3/13 element organic compoundsDrilling compositionCross-linkPolymer science

The invention discloses a boron cross-linking agent and a boron crosslinking fracturing fluid used for high temperature deep well. The boron cross-linking agent is a boron-based multi-element chelate, which takes a boron-containing compound and a chelating agent as main materials and water as a solvent for reacting under certain pH value and temperature. The boron crosslinking fracturing fluid comprises the following components by mass percentage: 0.02-0.04% of boron cross-linking agent, 0.3-0.6% of thickening agent hydroxypropyl guanidine gum, 0.02-0.03% of bactericide dodecyl dimethyl benzyl chloride, 1-2% of clay stabilizing agent potassium chloride, 0.02-0.03% of high temperature stabilizing agent stabilizing agent sodium hyposulfite, 0.04-0.05% of fluorocarbon surfactant, 0.02-0.03% of PH conditioning agent sodium hydroxide and balance of water. The boron cross-linking agent can effectively control the crosslinking speed, the boron crosslinking fracturing fluid has good high temperature resistance and high shear performance, and has the advantages of low frictional resistance, easy flowback and wide market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of thickener and its preparation method and application

ActiveCN106279523BGood drag reduction effectGood thickening effectDrilling compositionFracturing fluidPropenyl

The invention provides a thickener and a preparation method and application thereof. The preparation method of the thickener includes the following steps that 1, 25-35 parts by weight of hydrophilic propenyl monomers are dissolved in 65-75 parts by weight of water, then the pH value is regulated, and a solution with the pH of 6.5-7.5 is obtained; 2, 1-5 parts by weight of hydrophobic monomers and 0.5-2 parts by weight of emulsifier are added into the solution, stirring is carried out, and 0.05-0.3 part by total weight of initiator is added in batches under a protective atmosphere for a polymerization reaction, wherein the hydrophilic propenyl monomers include acrylamide, acrylic acid and 2-acrylamido-2-methylpropane sulfonic acid in the weight ratio of (15-20):(4-5):(5-15). By adding the thickener in the process of preparing fracturing fluid from highly mineralized water, the fracturing fluid with a high thickening capacity can be formed, and fracturing construction requirements can be effectively met.

Owner:PETROCHINA CO LTD

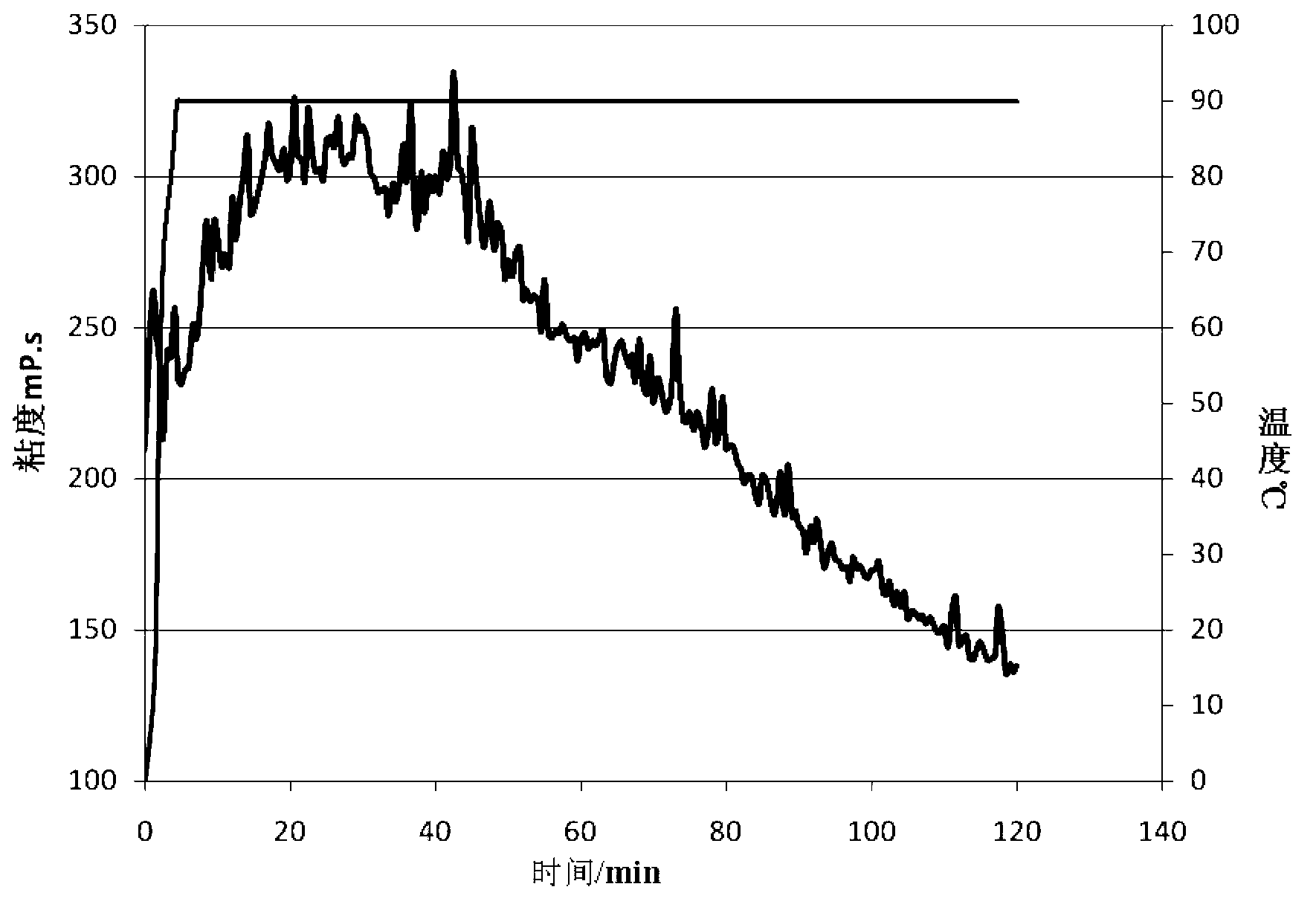

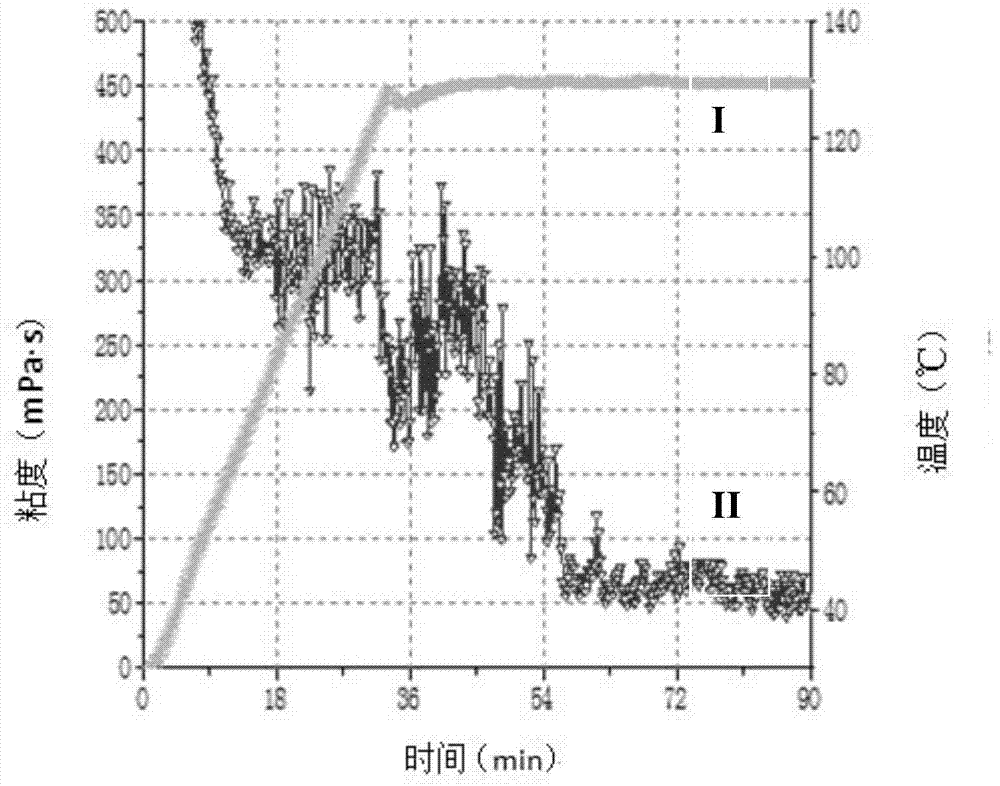

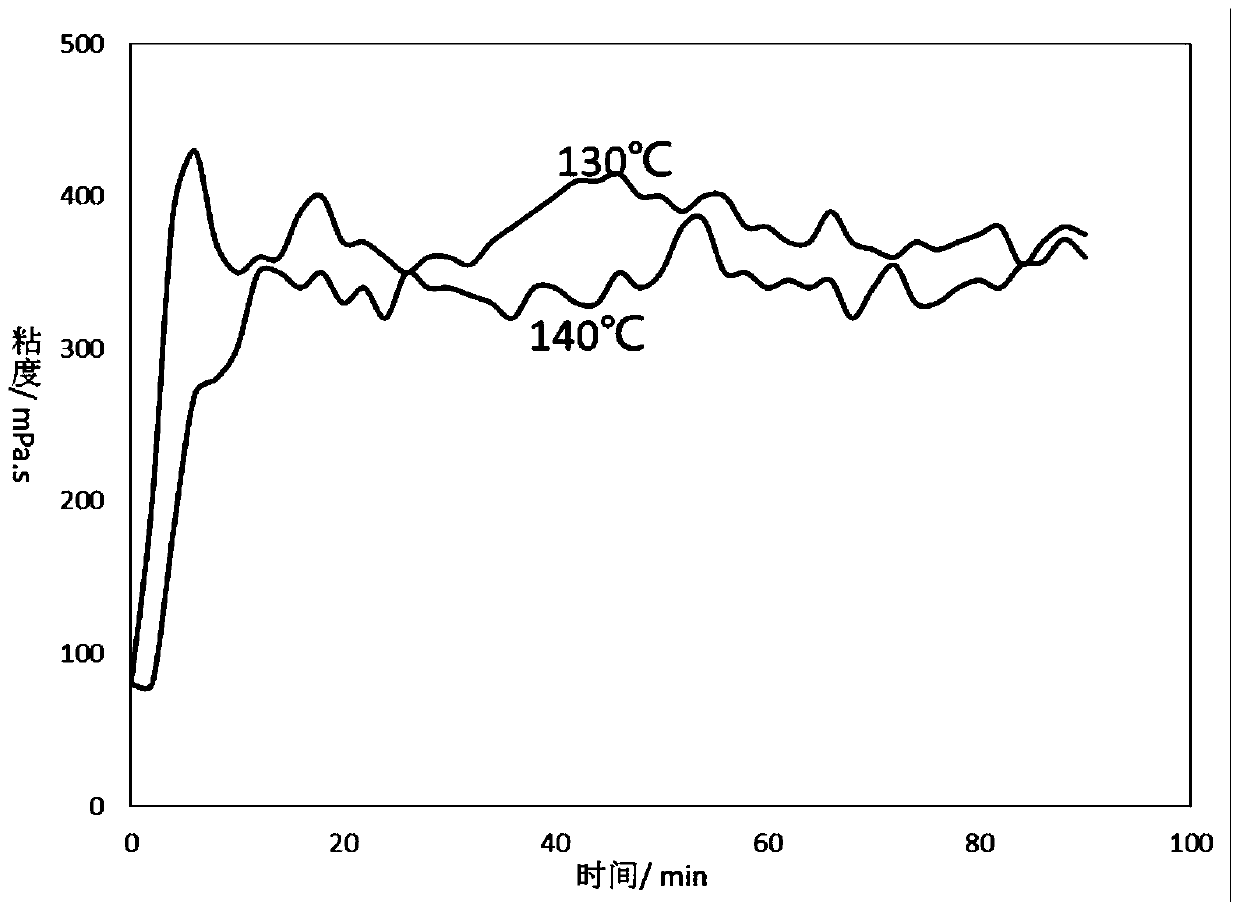

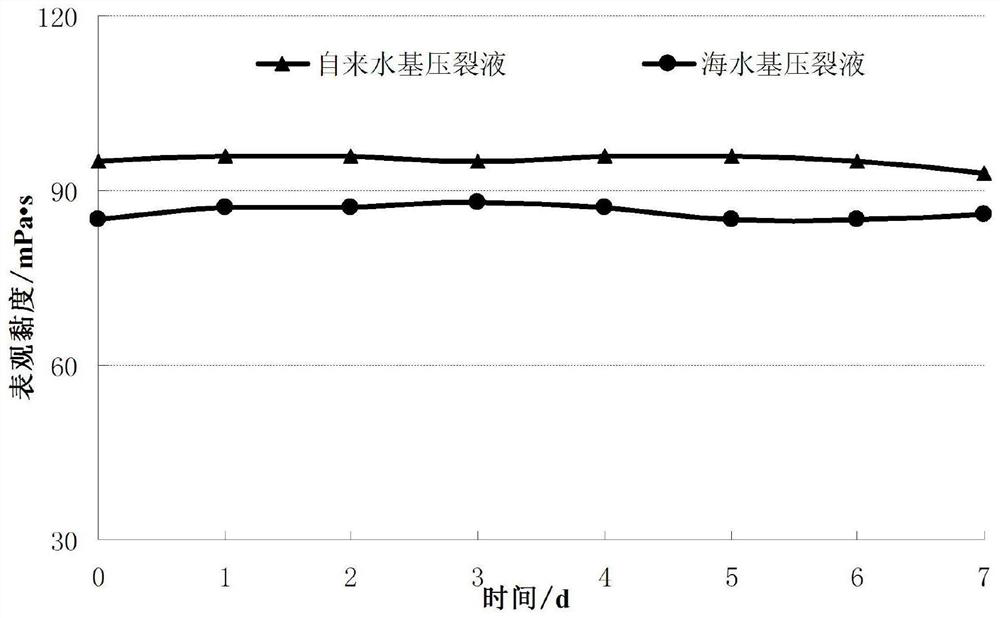

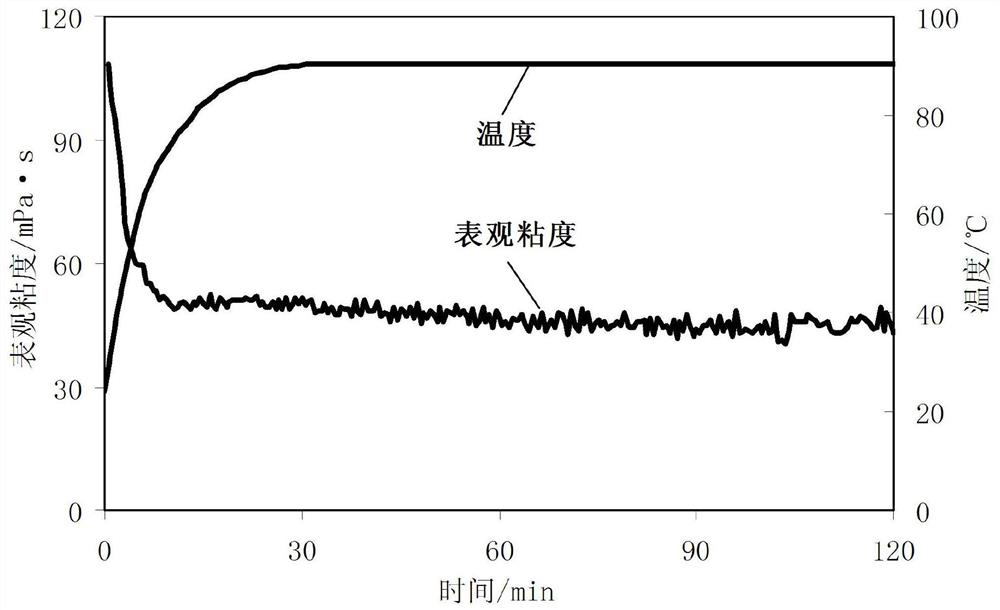

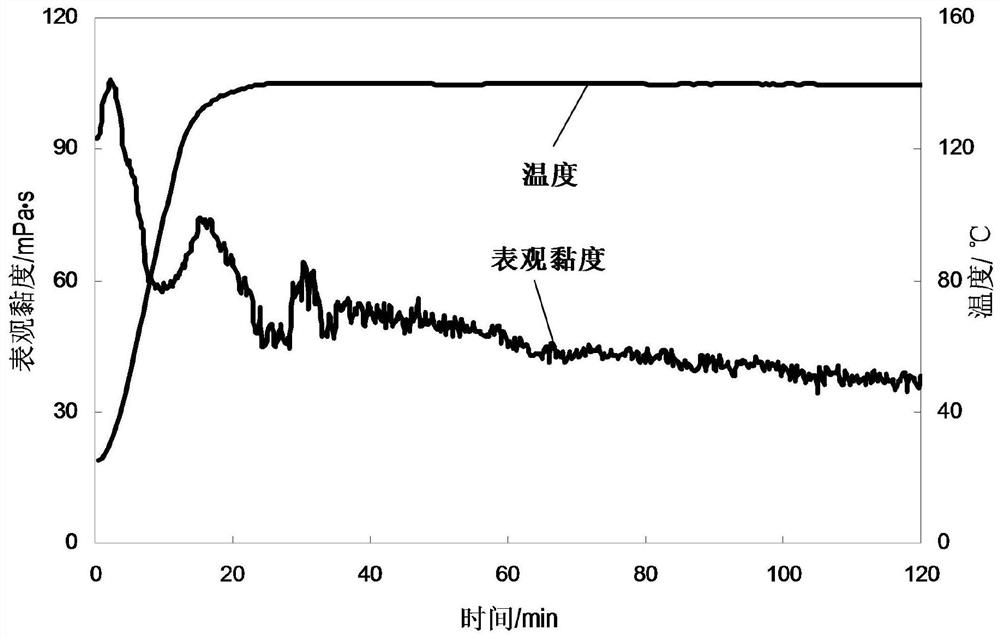

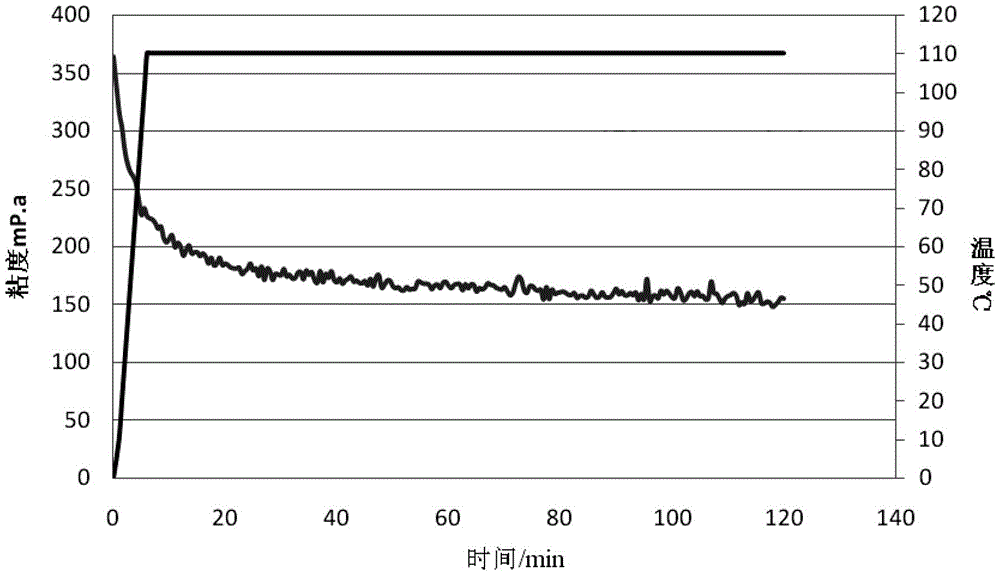

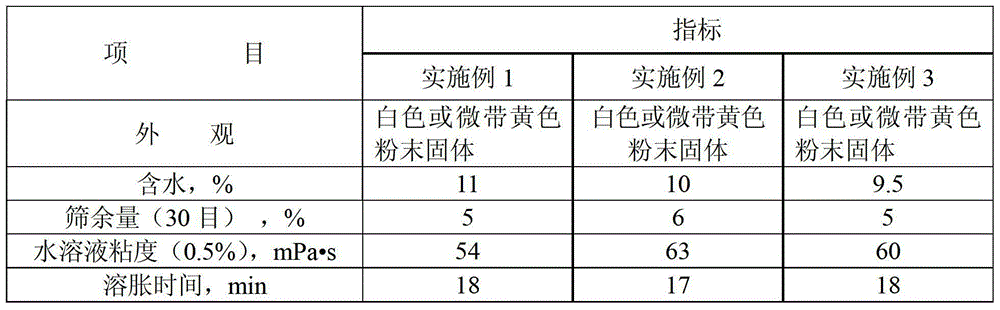

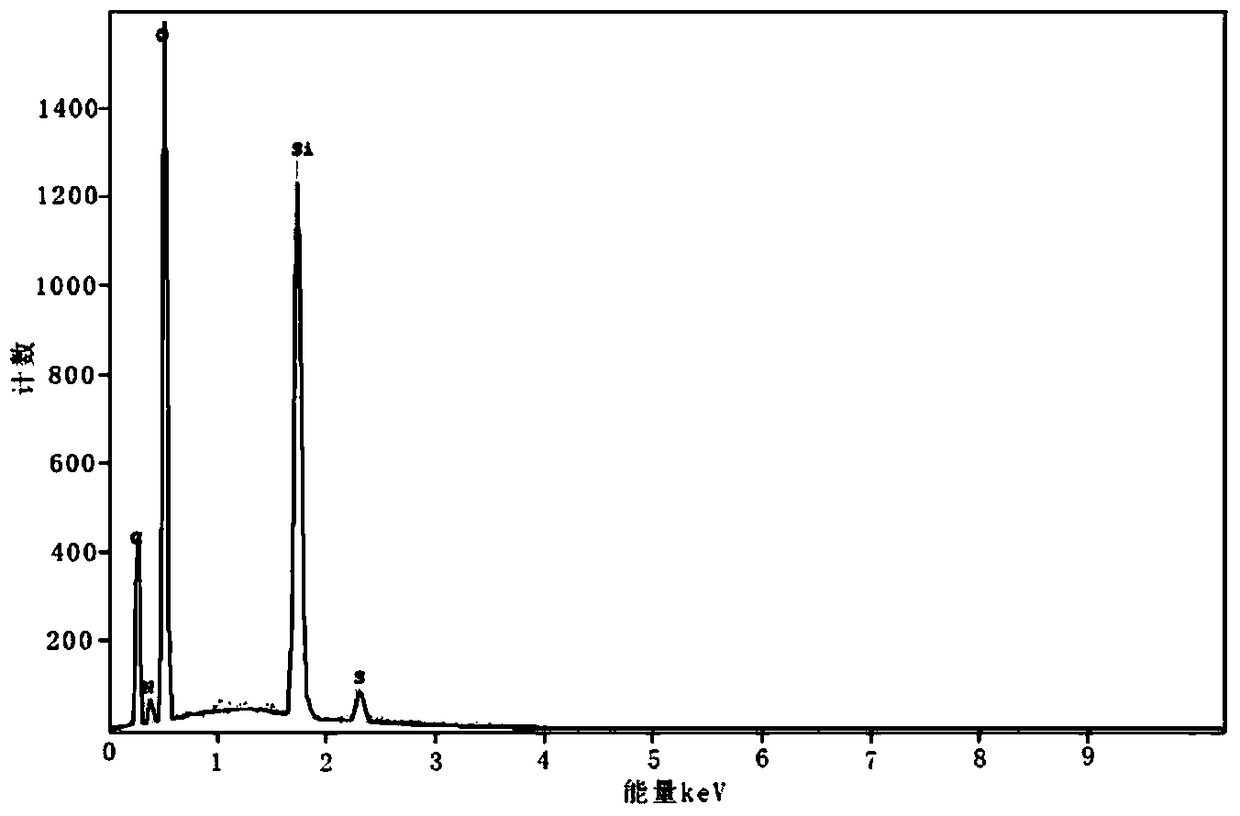

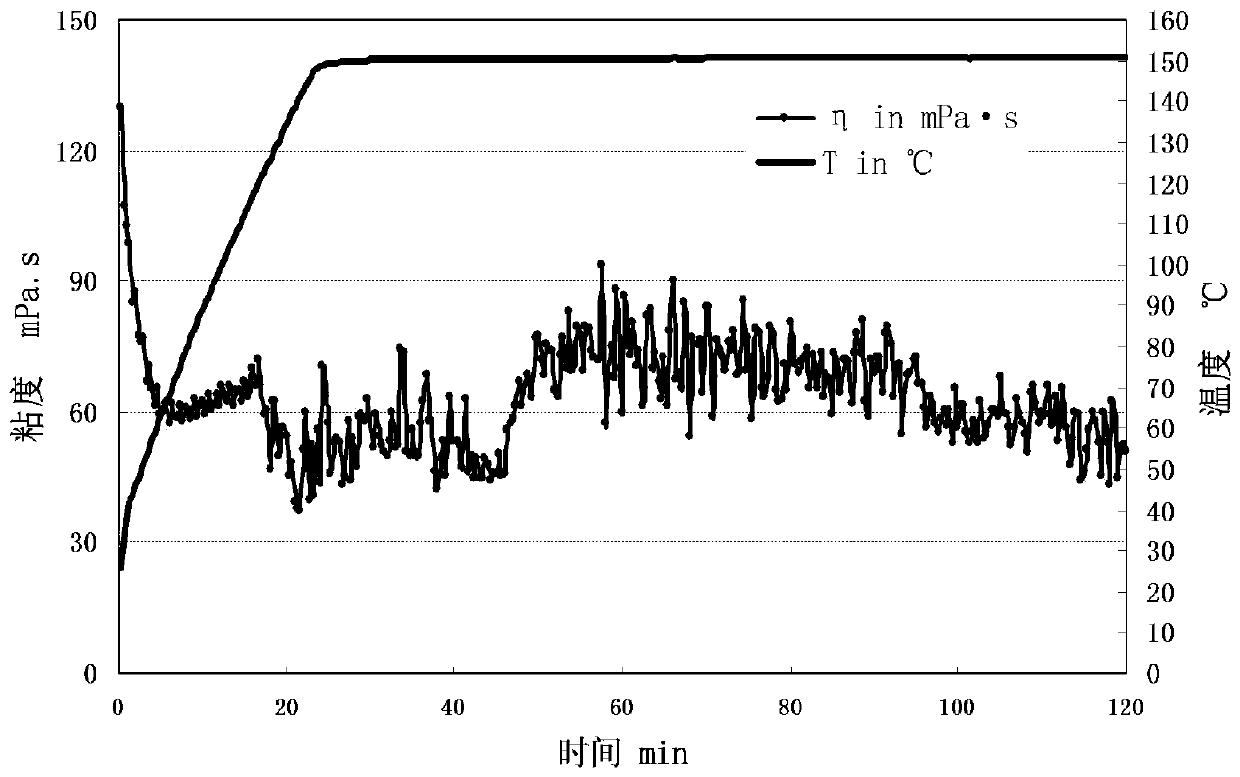

High temperature resistant seawater-based polymer fracturing fluid capable of continuous mixing and preparation method thereof

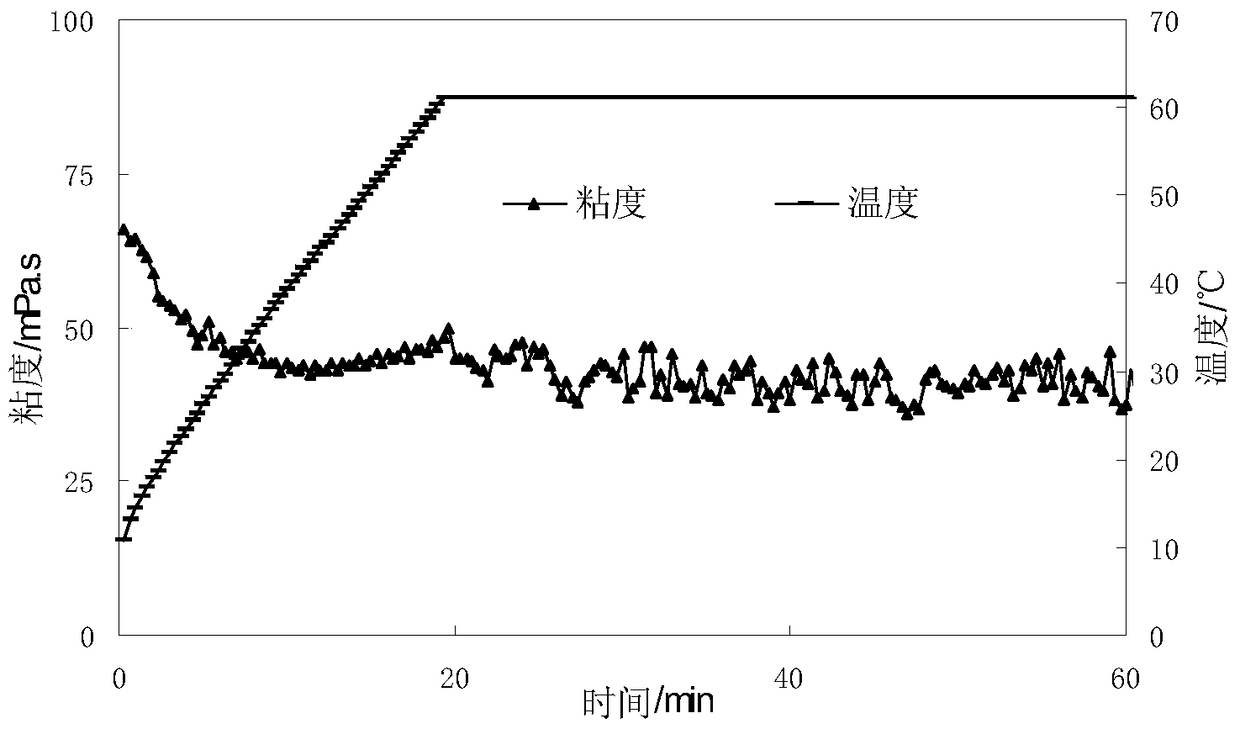

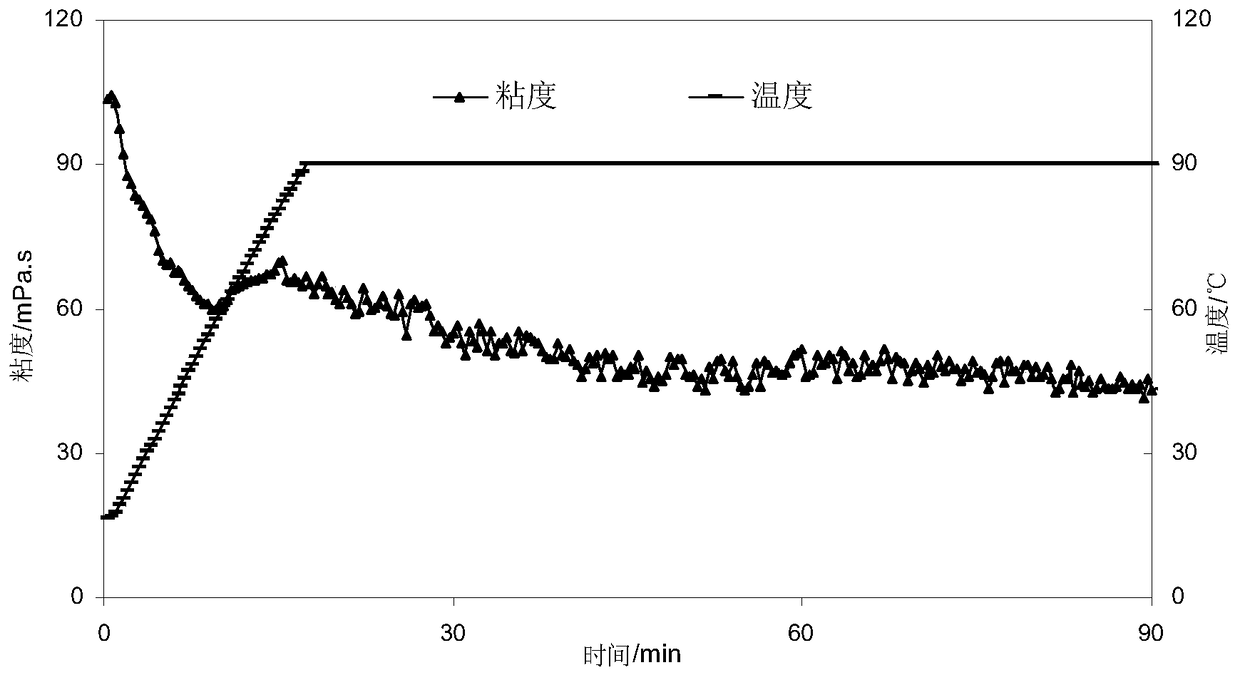

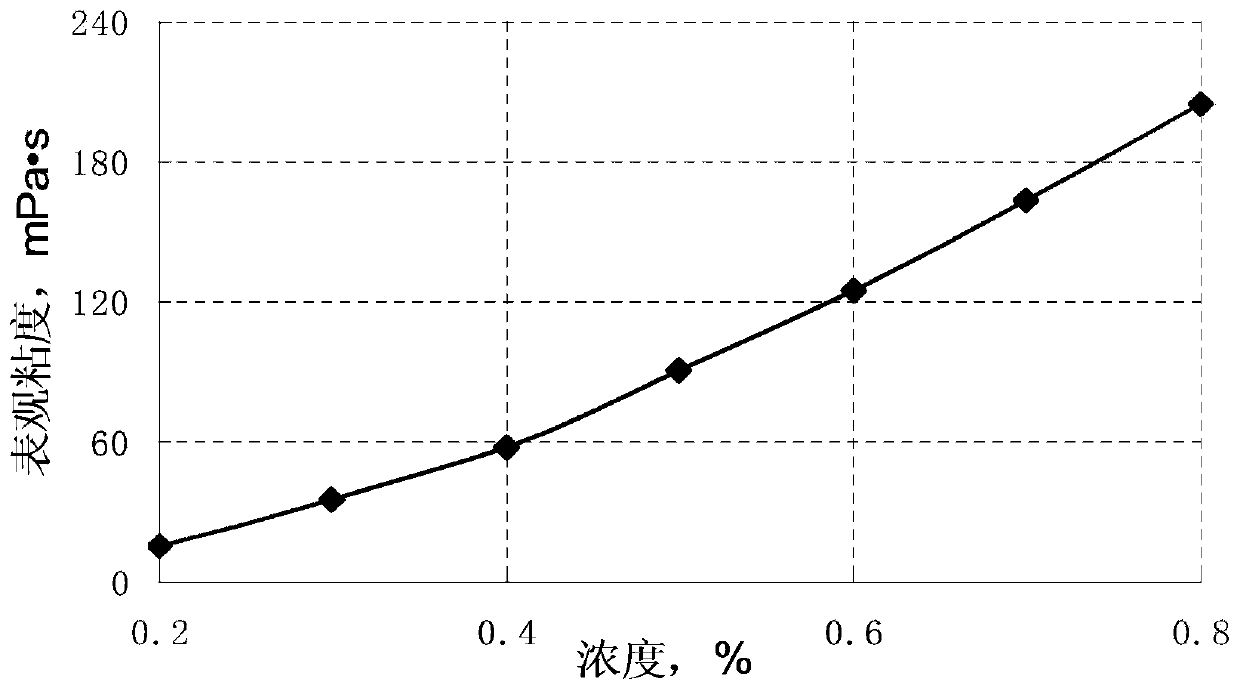

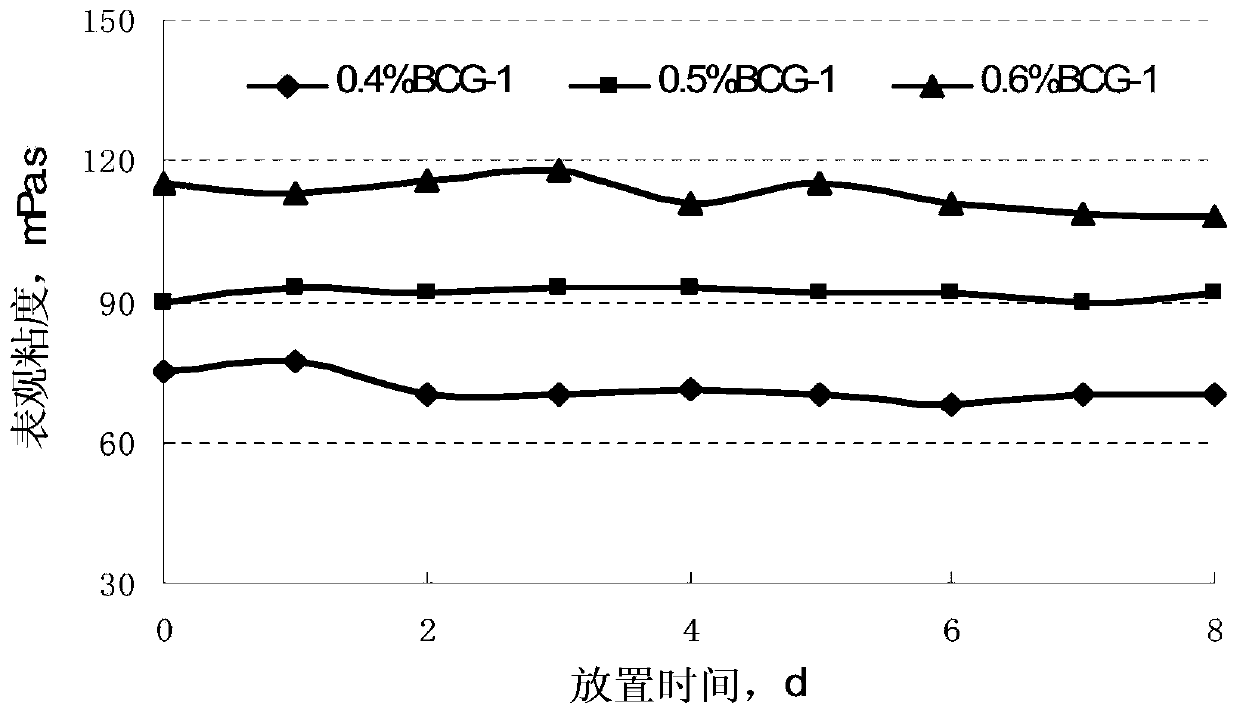

ActiveCN107474816BAlleviate needsReduce construction costsDrilling compositionApparent viscosityFracturing fluid

A high-temperature resistant seawater-based polymer fracturing fluid capable of continuous blending and a preparing method thereof are disclosed. The fracturing fluid includes 0.4-0.8 wt% of a thickening agent, 0.3-0.6 wt% of an auxiliary synergist, 0.2-0.4 wt% of an activating agent, 0.2-0.4 wt% of a metal ion stabilizer, and 0.3-0.4 wt% of a temperature stabilizer, with the balance being seawater. Beneficial effects of the fracturing fluid are that: a water-soluble multi-component copolymer is adopted as the thickening agent of the fracturing fluid system so that the fracturing fluid can rapidly swell in seawater having a high degree of mineralization; a low-viscosity high-elasticity fluid having a high space structure is formed through synergistic effects (non-crosslinking functions) with the auxiliary synergist; a sand-carrying property is good when the apparent viscosity is greater than 20 mPa.s; the prepared fracturing fluid is not eroded by bacteria, has characteristics of salt resistance, good temperature resistance and shearing resistance, low harm, no residue after cleaning, and the like, and can be prepared in batch or mixed continuously by adopting sea water; and the fracturing fluid can significantly reduce offshore fracturing construction costs and can increase fracturing construction efficiencies and reservoir yield-increasing effects.

Owner:SOUTHWEST PETROLEUM UNIV +1

A kind of fracturing fluid thickener and its preparation and application

ActiveCN103265939BImprove temperature and shear resistanceImprove yieldDrilling compositionPotassium persulfateThermal insulation

The invention relates to a fracturing fluid thickening agent and preparation and application thereof. The thickening agent is mainly prepared from the following components in percentage by weight: 15-20% of acrylamide monomer, 6-10% of acrylic monomer, 3-6% of sodium carbonate, 3-8% of 2-acrylamide-2-methylpropanesulsonic acid, 1-4% of dimethyldiallylammonium chloride (60% aqueous solution), 0.03-0.08% of potassium persulfate and the balance of water. The preparation comprises the following steps of: adding the acrylic monomer and water into a reaction kettle; starting stirring and slowly adding sodium carbonate, wherein the adding speed is proper when the bubbles generated by the reaction do not overflow out of the reaction kettle; stirring till sufficient dissolution; adding 2-acrylamide-2-methylpropanesulsonic acid, and stirring till sufficient and uniform mixing; adding the acrylamide monomer and dimethyldiallylammonium chloride, and stirring till sufficient dissolution; heating the reaction liquid to 40 DEG C, introducing nitrogen, and performing thermal insulation stirring for 20 minutes; adding potassium persulfate; continuously introducing nitrogen, and stirring for 30 minutes; stopping the stirring, and reacting for 4 hours to obtain gel; and grinding the reaction product, drying and granulating to obtain the thickening agent.

Owner:PETROCHINA CO LTD

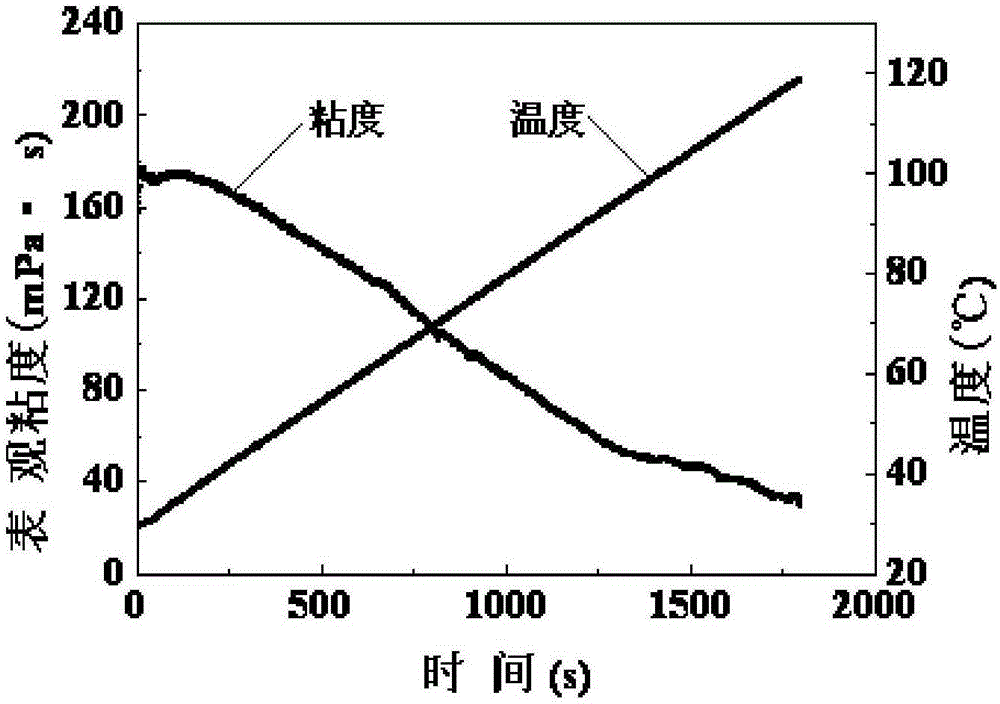

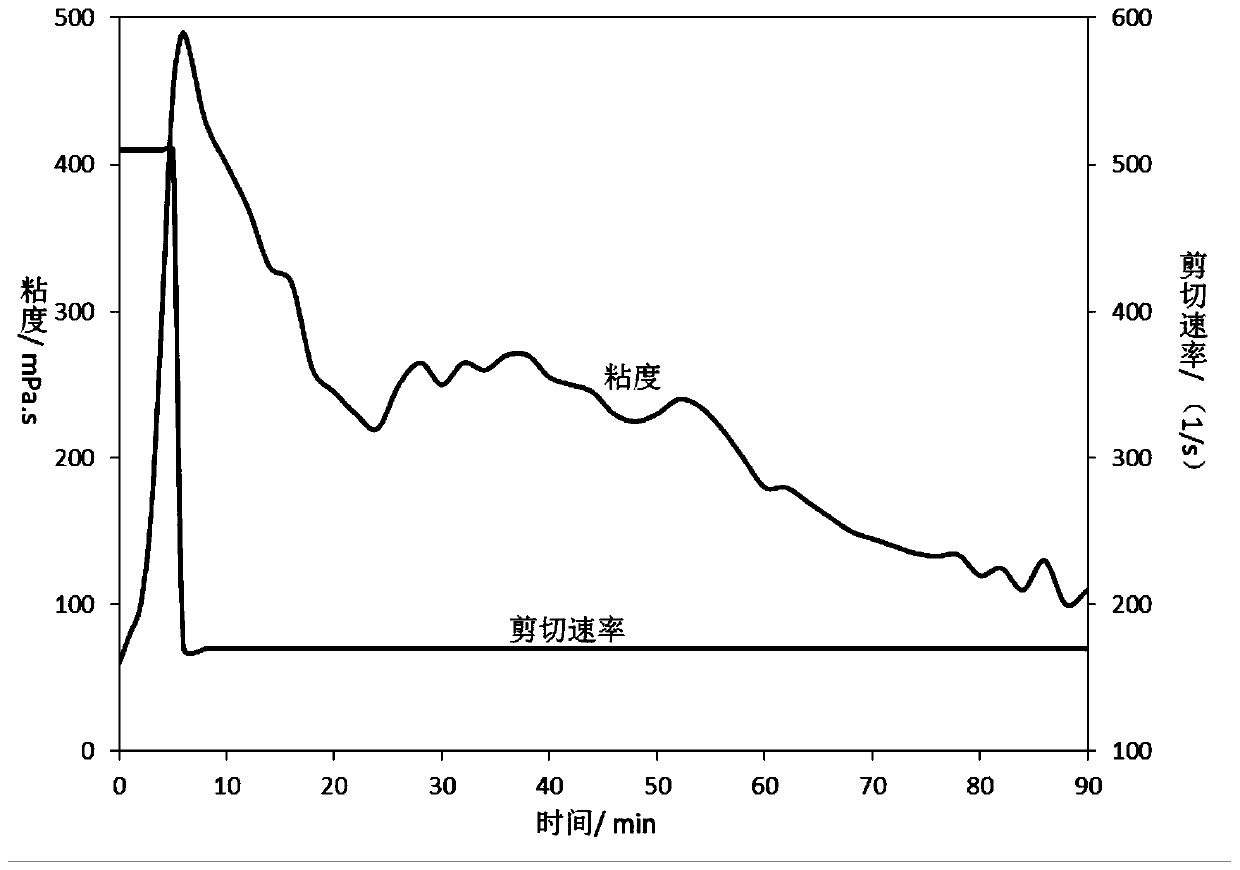

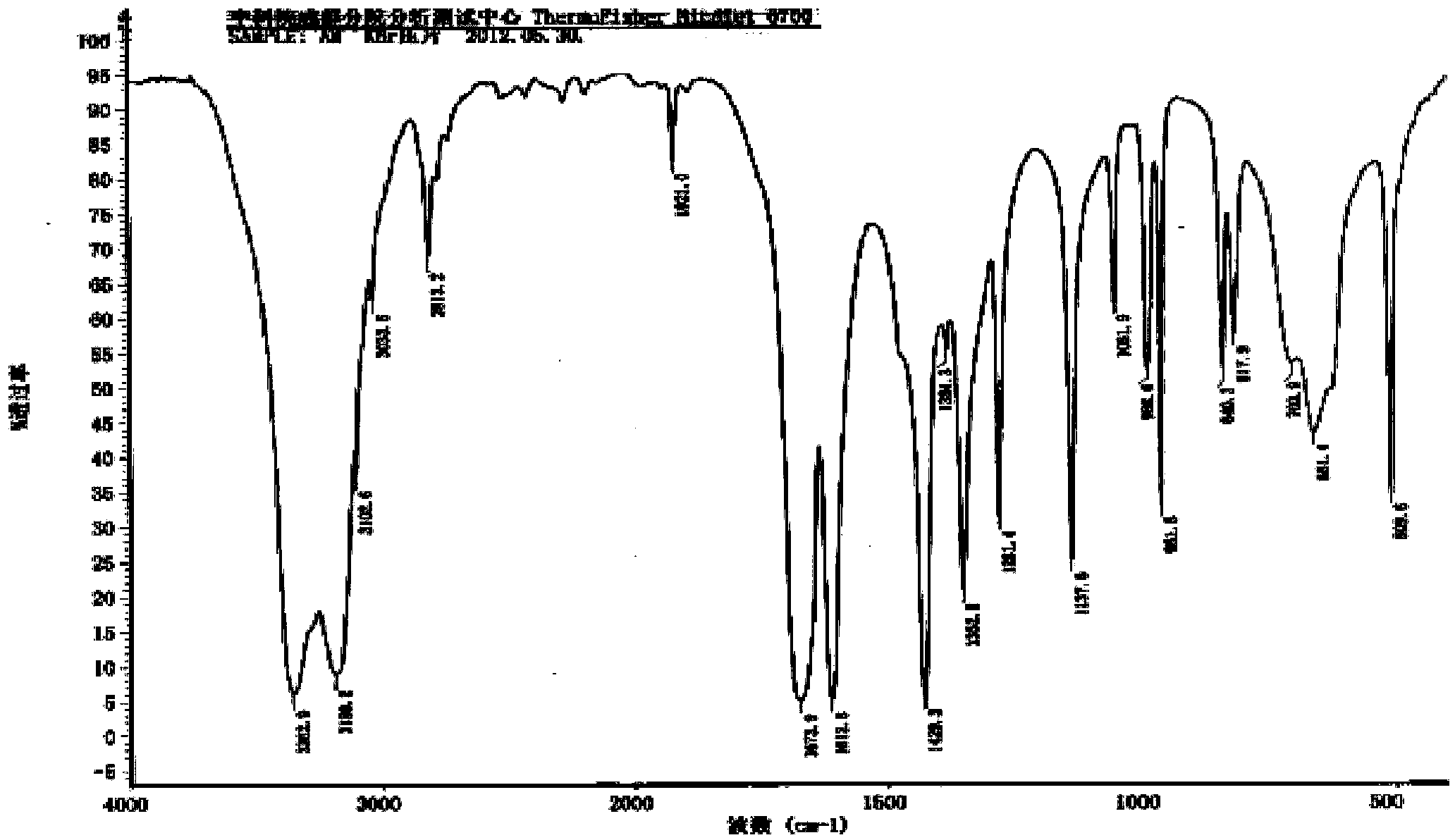

A linear gel fracturing fluid for automatic gel breaking in reservoirs and its preparation method

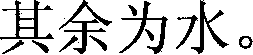

The invention discloses a linear gel fracturing fluid for automatically breaking a reservoir in shale gas fracturing and a preparation method thereof. The linear gel fracturing fluid is formed through self-assembly of an anionic hydrophobic associated polymer and a thermally-unstable cationic surfactant. According to the technical scheme, the method comprises the following steps: (1) copolymerizing dodecylmaleimide serving as a hydrophobic monomer and acrylamide to obtain the anionic hydrophobic associated polymer; (2) reacting long-carbon-chain tertiary amine with CO2 to prepare a thermally-unstable ammonium bicarbonate cationic surfactant; (3) adding a thermally-unstable surfactant of 100 to 600mg.L<-1> with a hydrophobic associated polymer solution slightly lower than a critical association concentration to form the linear gel fracturing fluid for automatically breaking the reservoir. The linear gel fracturing fluid for automatically breaking the reservoir has high proppant carrying capacity in the ground and a shaft; the thermally-unstable surfactant is decomposed in the reservoir, and the linear gel fracturing fluid plays a role in automatic breaking, so that damage to the reservoir is reduced; the linear gel fracturing fluid has a wide application prospect in shale gas fracturing.

Owner:SOUTHWEST PETROLEUM UNIV

Linear gel fracturing fluid for automatically breaking reservoir and preparation method thereof

InactiveCN106978157AEasy to makeIncrease elasticityDrilling compositionPolymer scienceFracturing fluid

The invention discloses a linear gel fracturing fluid for automatically breaking a reservoir in shale gas fracturing and a preparation method thereof. The linear gel fracturing fluid is formed through self-assembly of an anionic hydrophobic associated polymer and a thermally-unstable cationic surfactant. According to the technical scheme, the method comprises the following steps: (1) copolymerizing dodecylmaleimide serving as a hydrophobic monomer and acrylamide to obtain the anionic hydrophobic associated polymer; (2) reacting long-carbon-chain tertiary amine with CO2 to prepare a thermally-unstable ammonium bicarbonate cationic surfactant; (3) adding a thermally-unstable surfactant of 100 to 600mg.L<-1> with a hydrophobic associated polymer solution slightly lower than a critical association concentration to form the linear gel fracturing fluid for automatically breaking the reservoir. The linear gel fracturing fluid for automatically breaking the reservoir has high proppant carrying capacity in the ground and a shaft; the thermally-unstable surfactant is decomposed in the reservoir, and the linear gel fracturing fluid plays a role in automatic breaking, so that damage to the reservoir is reduced; the linear gel fracturing fluid has a wide application prospect in shale gas fracturing.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of anti-high temperature delayed gel breaker and preparation method thereof

Owner:PETROCHINA CO LTD

High temperature resistant clean CO2 foam fracturing fluid suitable for unconventional oil and gas reservoir development

ActiveCN105567213BImprove stabilityReduce apparent viscosityDrilling compositionFunctional monomerSlag

Owner:CHENGDU BAICHUN PETROLEUM TECH

A kind of clean carbon dioxide foam fracturing fluid and preparation method thereof

ActiveCN104531129BStrong viscosity increasing abilityFine foamDrilling compositionPotassium persulfatePolymer science

Owner:CHENGDU BAICHUN PETROLEUM TECH

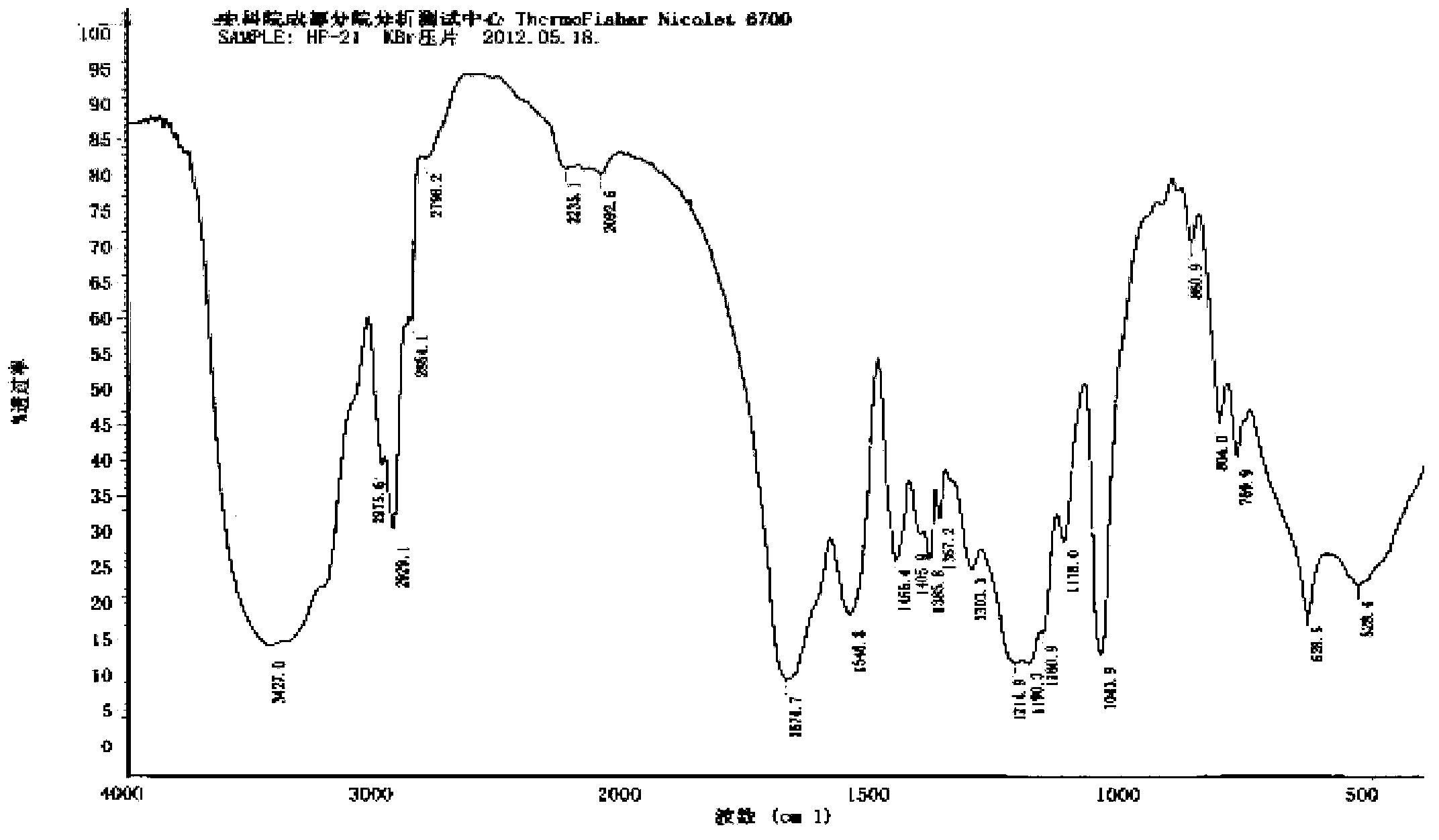

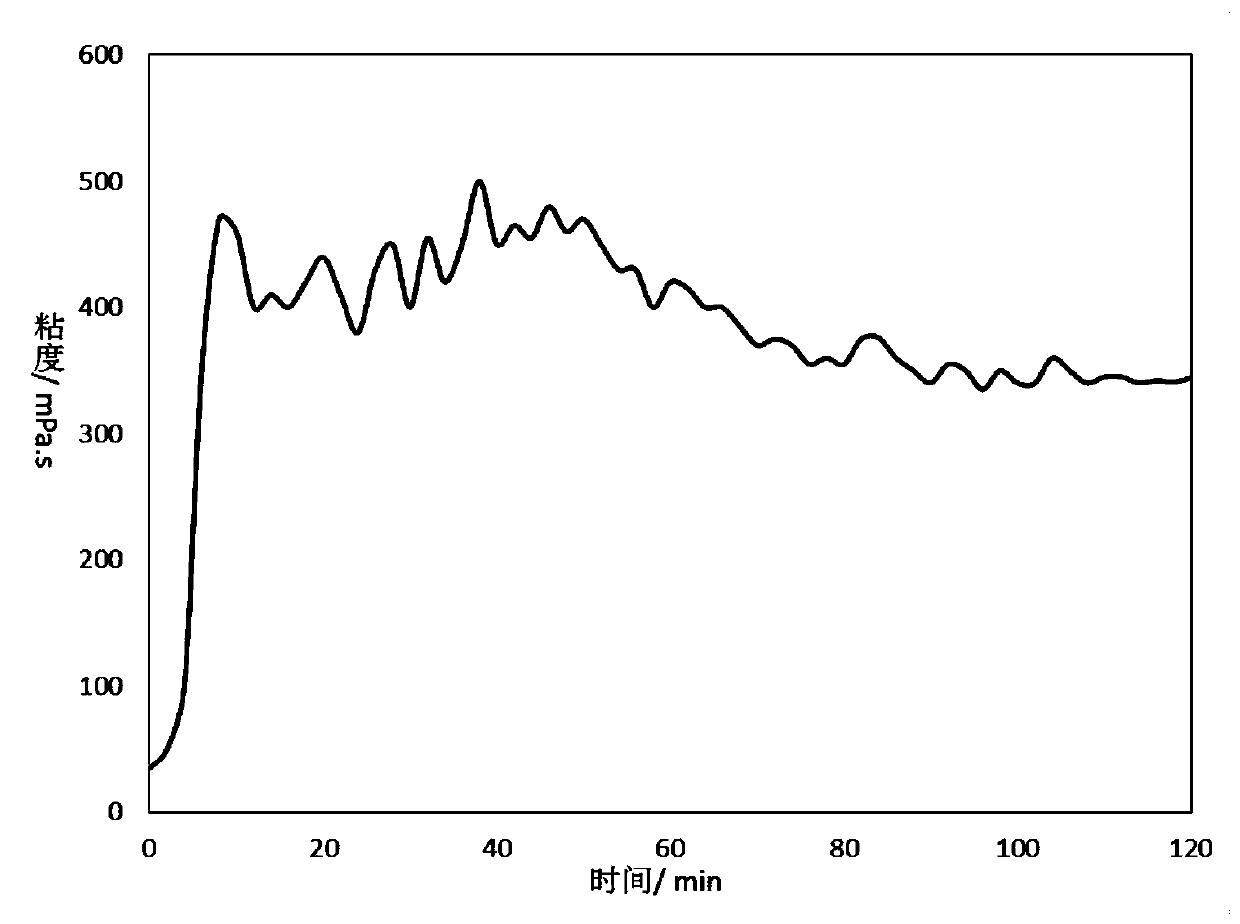

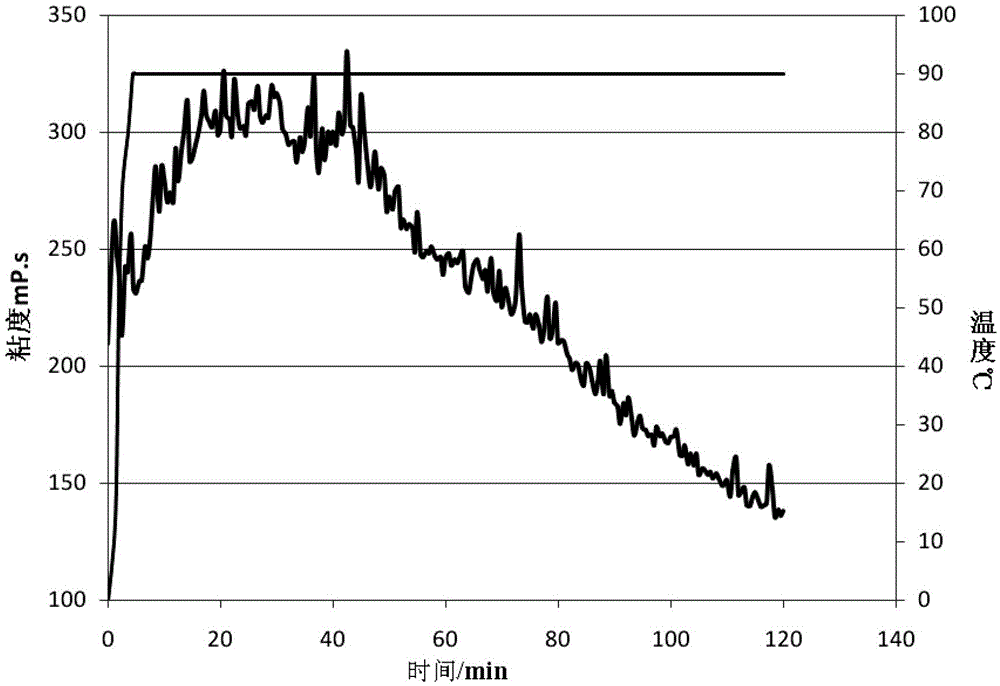

A cross-linkable high-temperature-resistant and residue-free multi-component copolymerization fracturing fluid and its preparation method

ActiveCN104178102BStrong viscosity increasing abilityReduce contentDrilling compositionFracturing fluidCross linker

The invention discloses a cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid and a preparation method thereof. The preparation method comprises the following steps of (1) preparing a thickener for the fracturing fluid; (2) preparing a cross-linking agent for the fracturing fluid; (3) preparing a gel breaker for the fracturing fluid and (4) preparing the cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid. The fracturing fluid prepared by adopting the preparation method has the characteristics of excellent viscoelasticity, temperature resistance and shear resistance, sand-carrying performance and wide applicable temperature range; the fracturing fluid can well meet the requirement on the fracturing construction, and the content of the residue is very low; after the fracturing, the secondary harm to a reservoir is small and thus the fracturing effect is improved and the production capacity of the reservoir is increased.

Owner:CHENGDU BAICHUN PETROLEUM TECH

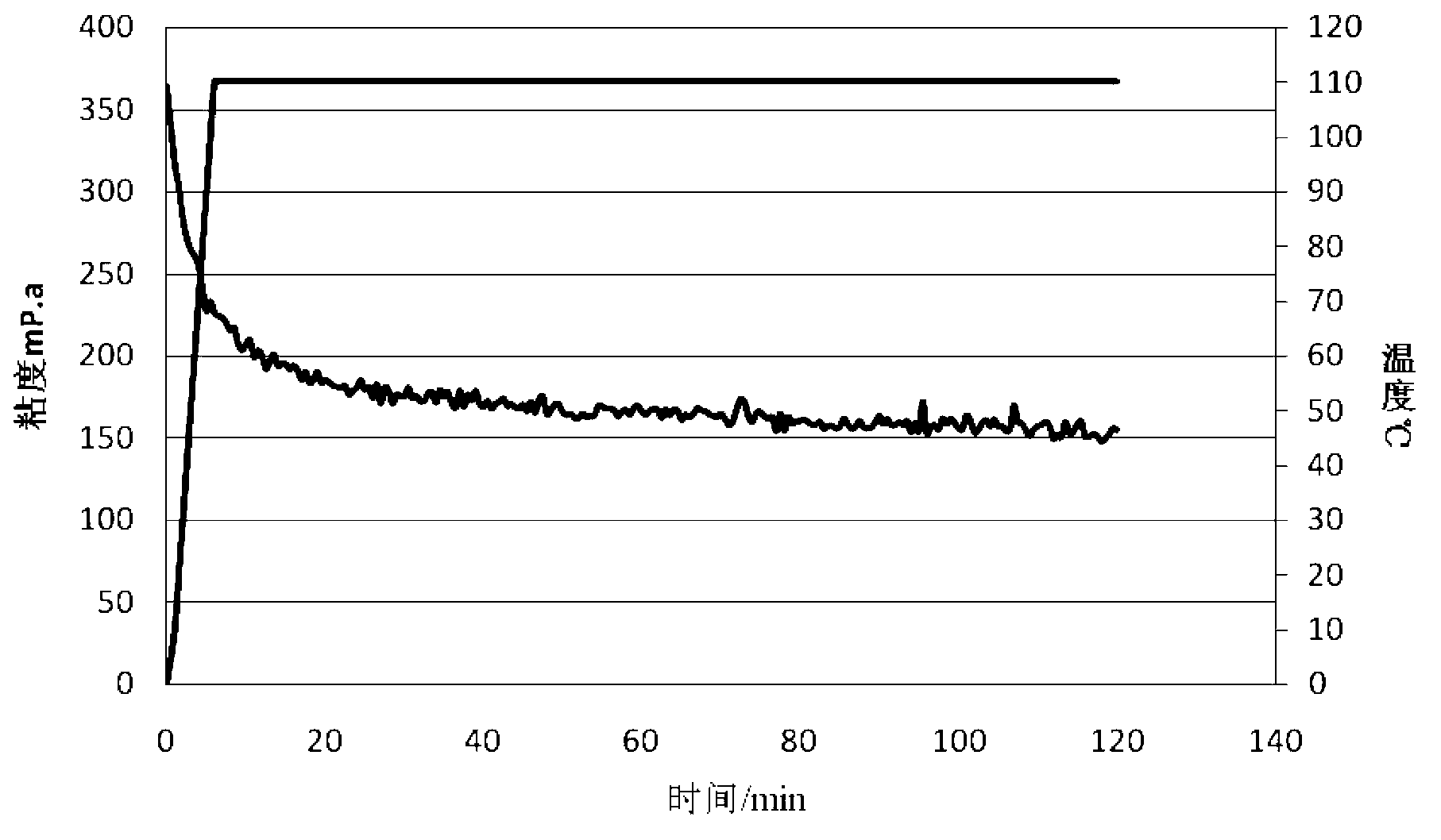

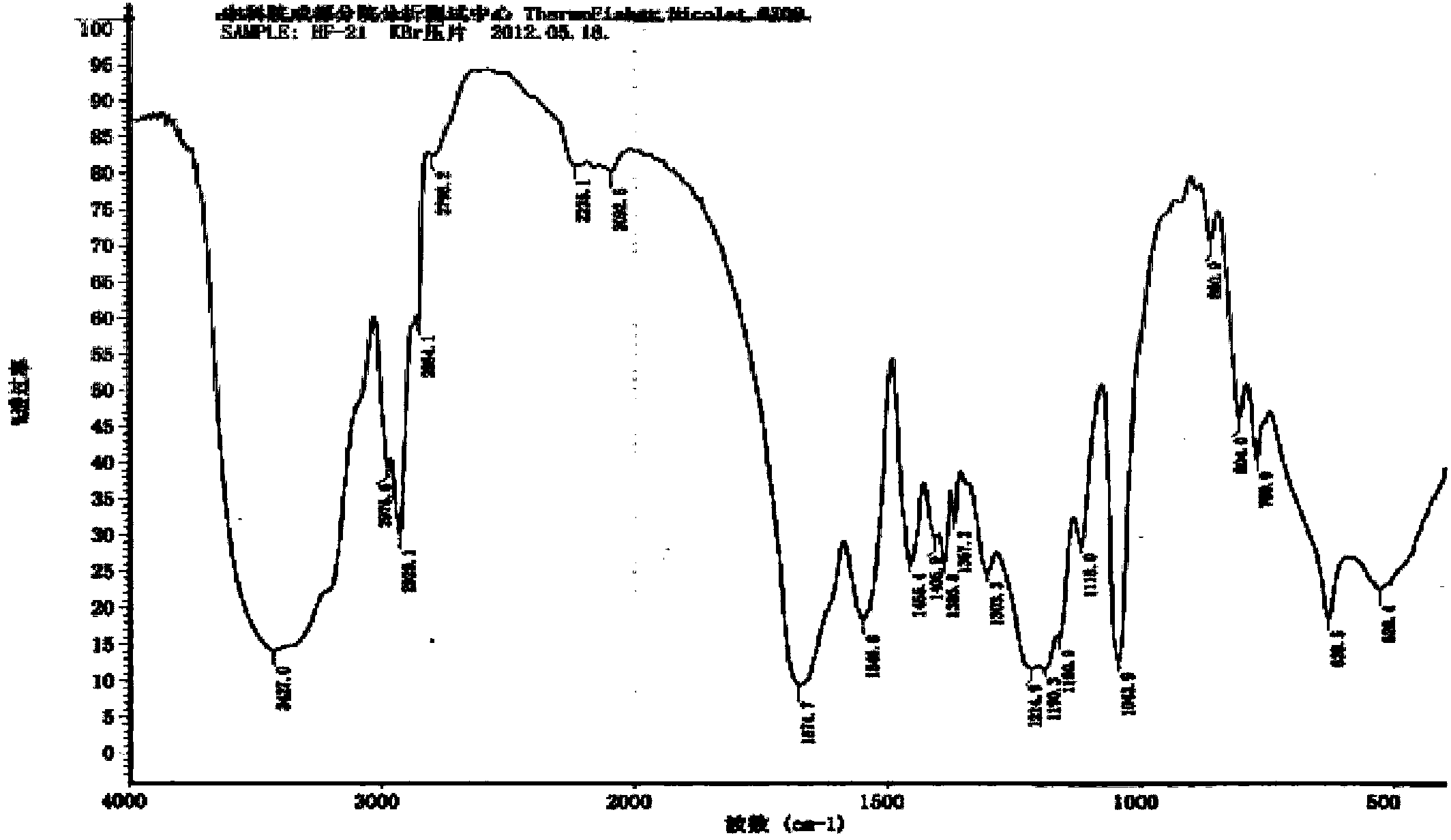

High temperature resistant cleansing emulsion or microemulsion fracturing fluid and preparation method thereof

ActiveCN102838980BIncrease contentReduce apparent viscosityProductsReagentsApparent viscosityPolymer science

The invention relates to a high temperature resistant cleansing emulsion or microemulsion fracturing fluid and a preparation method thereof. The emulsion fracturing fluid is composed of a continuous oil phase, a polymer (I)-containing dispersed water phase and an emulsifier. The preparation method of the emulsion fracturing fluid includes: preparing a mixed solution of the oil phase and the emulsifier, preparing a four-monomer containing water phase, conducting a polymerization reaction in the presence of an initiating agent, and other steps. The product provided in the invention has low apparent viscosity, and can dissolve rapidly. When the emulsion dissolves into gel, the emulsifier can have a synergistic effect with an association polymer, thus further improving and maintaining the viscosity, and helping to prevent leak-off and help flowback. An oxidation gel breaking way is employed for gel breaking, the gel can be completely broken, and the gel breaking solution has low viscosity and contains no residue. The emulsion fracturing fluid is easy to undergo flowback, and has low damage to the stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

A high-temperature-resistant, low-friction, aggravated clean fracturing fluid and its preparation method

ActiveCN105733547BImprove salt resistancePromote swellingDrilling compositionThermodynamicsFracturing fluid

The invention discloses a high-temperature-resistance low-friction weighted clean fracturing fluid which is suitable for high-temperature and high-pressure reservoir reconstruction at 170 DEG C and a preparation method thereof.The fracturing fluid is prepared from, by weight, 0.2%-0.8% of high-temperature-resistance thickening agent, 0.1%-0.8% of system synergist, 0.1%-0.3% of high temperature stabilizer, 0%-42% of weighting agent and the balance fresh water.The high-temperature-resistance low-friction weighted clean fracturing fluid has the following functions and advantages that the weighting agent can be adopted for weighting, and the density is adjustable between 0 and 1.32 g / cm<3>; good temperature-resistance and anti-shearing properties are achieved, and the requirement of high-temperature deep well fracturing construction at 170 DEG C can be met by adjusting a formula; a good resistance reduction property is achieved, pipeline friction resistance can be effectively reduced, and the resistance reduction rate can reach 70%; the fracturing fluid is a fluid with a reversible structure, and the structure damage after high shearing is small; the residue content of the fracturing fluid is decreased to below 10 mg / L, damage to a reservoir and supporting cracks is reduced, the fracturing effect is improved, and the reservoir productivity is increased.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

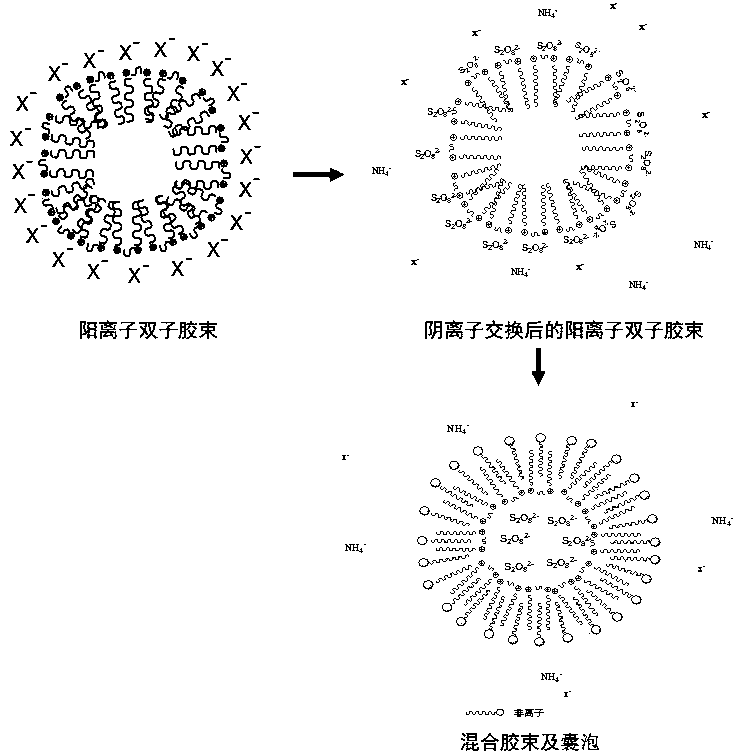

A kind of nano liquid breaker for fracturing fluid and preparation method thereof

ActiveCN110003879BMeet the requirements of fracturing constructionWeak corrosiveDrilling compositionMixed micelleActive agent

The invention discloses a nano-liquid breaker for fracturing fluid and a preparation method thereof. The nano-liquid breaker for fracturing fluid is made of the following components in weight ratio, peroxide 5.2%-16.4%; Gemini surface Active agent: 2.3%-10%; non-ionic emulsifier 8.4%-16.0%; auxiliary additive: 1.9-4.4%; solvent: 62.5-78.5%; the structure of the nano-liquid breaker for fracturing fluid is non-ionic The emulsifier and the gemini surfactant form mixed micelles or vesicles with a closed double-layer structure, and the peroxide forms an ion pair with the inner layer structure and is wrapped inside the micelles or vesicles; the fracturing fluid uses nano-liquids The size of the mixed micelles or vesicles of the destroying agent is nanoscale, specifically between 15-100nm. The invention can meet the gel-breaking requirements of polymer fracturing fluid and guar gum fracturing fluid, and has the characteristics of good storage stability at room temperature, weak corrosion, long storage period, good delayed gel-breaking effect, and the like.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

Low-hydrocarbon fracturing fluid cross-linking agent and preparation method thereof

InactiveCN105219371AMeet the requirements of fracturing constructionImprove temperature resistanceDrilling compositionCross-linkAlcohol

The invention discloses a low-hydrocarbon fracturing fluid cross-linking agent and a preparation method thereof. The cross-linking agent is prepared from, by weight, 40%-50% of ferric iron, 15%-25% of alcohol, 1%-5% of alkyl quaternary ammonium salt, 20%-35% of complexing agent and 0.5%-1% of modifier. The preparation method of the cross-linking agent includes the following steps that the bath temperature is adjusted to be 50-60 DEG C, and the stirring speed is controlled to be 100-500 r / min; under the condition that refined nitrogen is introduced, the ferric iron and the complexing agent are added first, the alcohol and the alkyl quaternary ammonium salt are added after reacting is conducted for 2 hours, then the modifier is added after reacting is conducted for 3.5 hours, and accordingly the low-hydrocarbon fracturing fluid cross-linking agent is obtained. The cross-linking agent is good in cross-linking effect, the temperature resistance is improved, and cross-linking time can be adjusted according to field needs. The preparation method is reliable in principle and easy and convenient to operate, and market application prospects are broad.

Owner:SOUTHWEST PETROLEUM UNIV

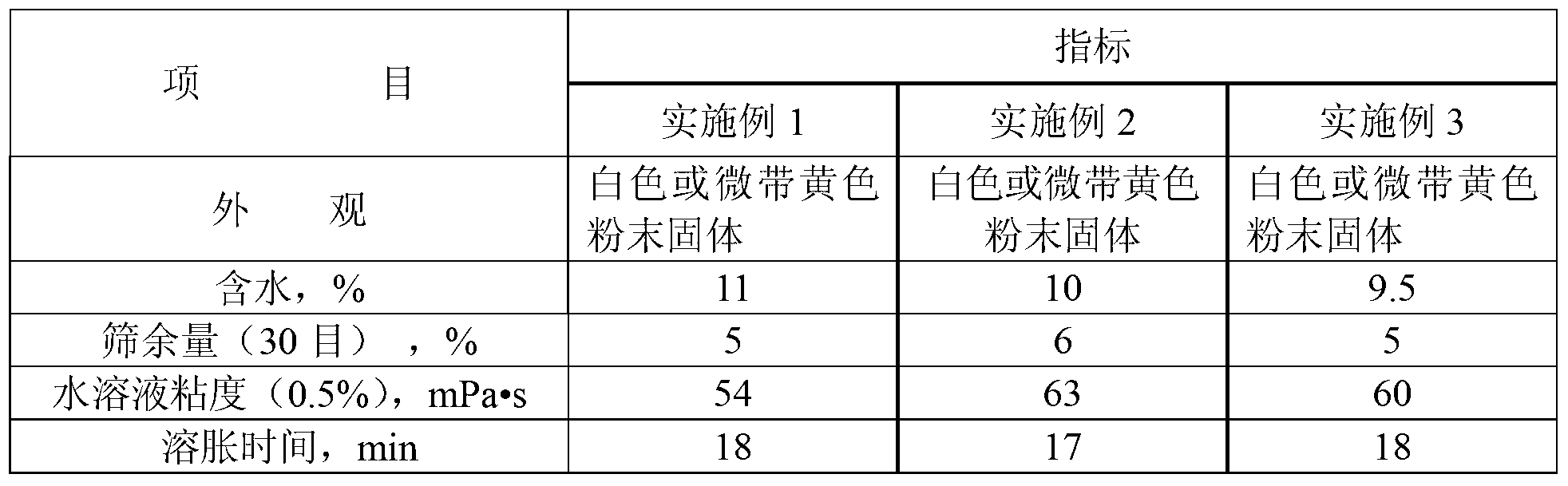

A kind of inverse microemulsion thickener for online fracturing construction and preparation method thereof

ActiveCN108676120BStability is not affectedReduce dosageDrilling compositionHydrophilic monomerFunctional monomer

The invention discloses a reversed-phase microemulsion thickening agent applied to online fracturing construction. The reversed-phase microemulsion is prepared from the following ingredients in percentage by mass: 10.0 to 15.0% of acrylamide, 5.0 to 8.5% of acrylic acid, 0.02 to 0.15% of strong hydrophilic monomer, 0.1 to 0.5% of functional monomer A, 0.5 to 1.5% of functional monomer B, 3.0 to 8.0% of pH regulator, 2.0 to 3.0% of solubilizer, 7.0 to 9.0% of compound emulsifier, 20.0 to 35.0% of oil solvent, 0.05 to 0.07% of initiator and the balance of deionized water. A preparation method ofthe thickening agent comprises the following steps: firstly, dissolving the pH regulator, the acrylic acid, the solubilizer, the acrylamide, the strong hydrophilic monomer, the functional monomer A and the functional monomer B into the deionized water and stirring to prepare a reaction phase; evenly mixing the oil solvent and the compound emulsifier to obtain a continuous phase; adding the reaction phase into the continuous phase, stirring at high speed to prepare reversed-phase microemulsion and performing polymerization reaction under the action of the initiator to obtain the reversed-phasemicroemulsion thickening agent. The thickening agent disclosed by the invention not only achieves continuous mixture and online construction, but also has excellent temperature resistance, shear resistance and salt resistance.

Owner:四川奥赛德材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com