Nano liquid destroying agent for fracturing fluid and preparation method thereof

A fracturing fluid and breaking agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of polymer molecular chain not being completely broken, fracturing fluid breaking glue, etc., to achieve safe storage and use Improve performance, reduce corrosion, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

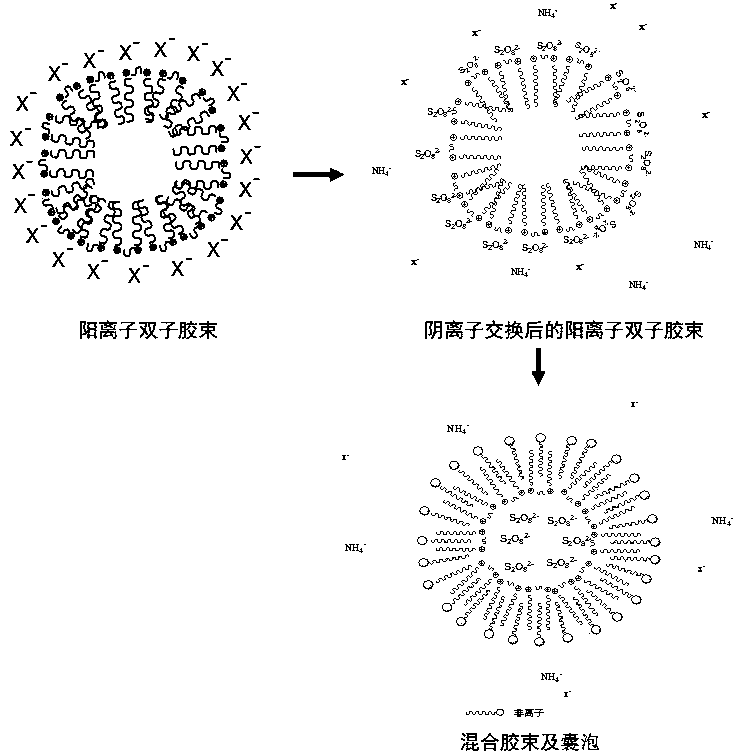

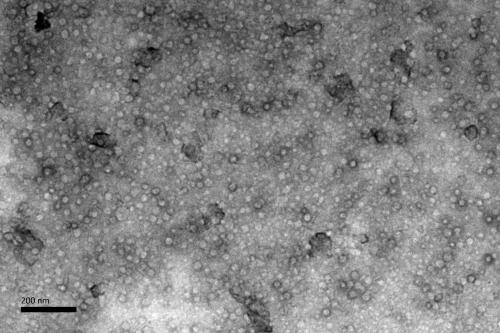

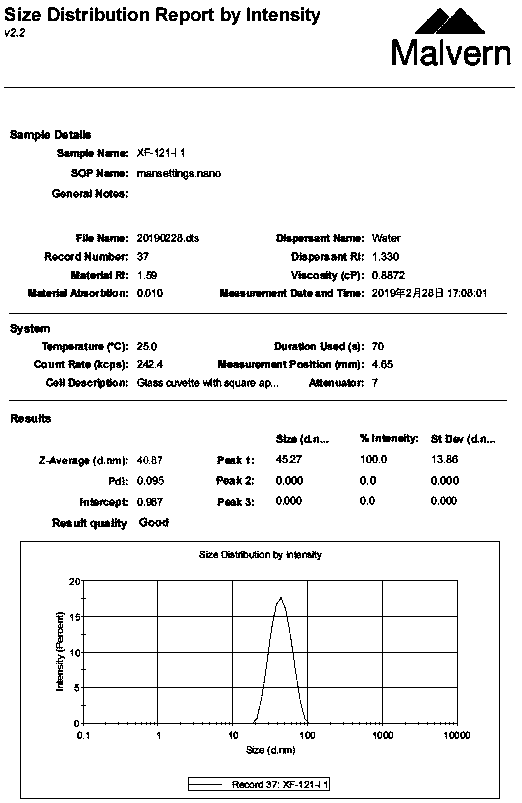

Method used

Image

Examples

Embodiment 1

[0036] S1. Add 1.6g of cationic Gemini 8-3-8 [C 8 h 17 (CH 3 ) 2 N(CH 2 ) 3 N(CH 3 ) 2 C 8 h 17 Br 2 )] put it into the reaction kettle, heat up to 80-90°C and fully heat and melt, control the heating rate to 3°C / min during the heating process, start stirring and slowly put in 10g of water, the stirring speed is 120r / min, and the temperature is controlled at 60 -80°C, stop heating after adding water, put 4g of non-ionic emulsifier TX-30 into the reaction kettle, establish internal circulation through the emulsification pump, and turn on the refrigeration at the same time to control the liquid temperature in the reaction kettle at 30±2°C;

[0037] S2. Add auxiliary additives 1g OP-30 and 0.4g OS-15 to 15g aqueous solution containing 5g ammonium persulfate, stir evenly, and slowly drop into the solution obtained in S1 under mechanical stirring, and the dropping time is controlled at 50-70min , after the completion, continue to shear and stir for 10 minutes, keep the em...

Embodiment 2

[0039] 2.5g cationic Gemini 12-4-12 type [C 12 h 25 (CH 3 ) 2 N(CH 2 ) 4 N(CH 3 )2 C 12 h 25 Br 2 )] put it into the reaction kettle, heat up to 80-90°C and fully heat and melt, control the heating rate to 2°C / min during the heating process, start stirring and slowly put in 30g of water, the stirring speed is 160r / min, and the temperature is controlled at 60 -80°C, stop heating after adding water, put 4g of non-ionic emulsifier EL-60 into the reaction kettle, establish internal circulation through the emulsification pump, and turn on the refrigeration at the same time to control the liquid temperature in the reaction kettle at 30±2°C;

[0040] S2. Add auxiliary additive 1.3g OS-15 to 10g of aqueous solution containing 2.5g of ammonium persulfate and stir evenly, and slowly drop into the solution obtained in S1 under mechanical stirring. The dropping time is controlled at 50-70min, and continue to cut Cut and stir the reaction for 10 minutes, and keep the emulsificatio...

Embodiment 3

[0042] S1. Put 5g of cationic Gemini 16-5-16 type [C 16 h 33 (CH 3 ) 2 N(CH 2 ) 5 N(CH 3 ) 2 C 16 h 33 Br 2 )] put it into the reaction kettle, heat up to 80-90°C and fully heat and melt, control the heating rate to 3°C / min during the heating process, start stirring and slowly put in 25.3g of water, the stirring speed is 140r / min, and the temperature is controlled at 60-80°C, stop heating after adding water, put 8g of non-ionic emulsifier APG1214 into the reactor, establish internal circulation through the emulsification pump, and turn on the refrigeration at the same time to control the liquid temperature in the reactor at 30±2°C;

[0043] S2. Add auxiliary additives 1.5g T20 and 0.2g Pingpingjia O-10 to 10g aqueous solution containing 4g ammonium persulfate, stir evenly, and slowly drop into the solution obtained in S1 under mechanical stirring, and the dropping time is controlled at 50-70min , after the completion, continue to shear and stir for 10 minutes, and ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com