Thickener and preparation method and application thereof

A technology of thickener and initiator, which is applied in the field of thickener and its preparation, can solve the problem that the thickener cannot be used for fracturing fluid, etc., and meet the requirements of fracturing construction, good drag reduction performance and thickening ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

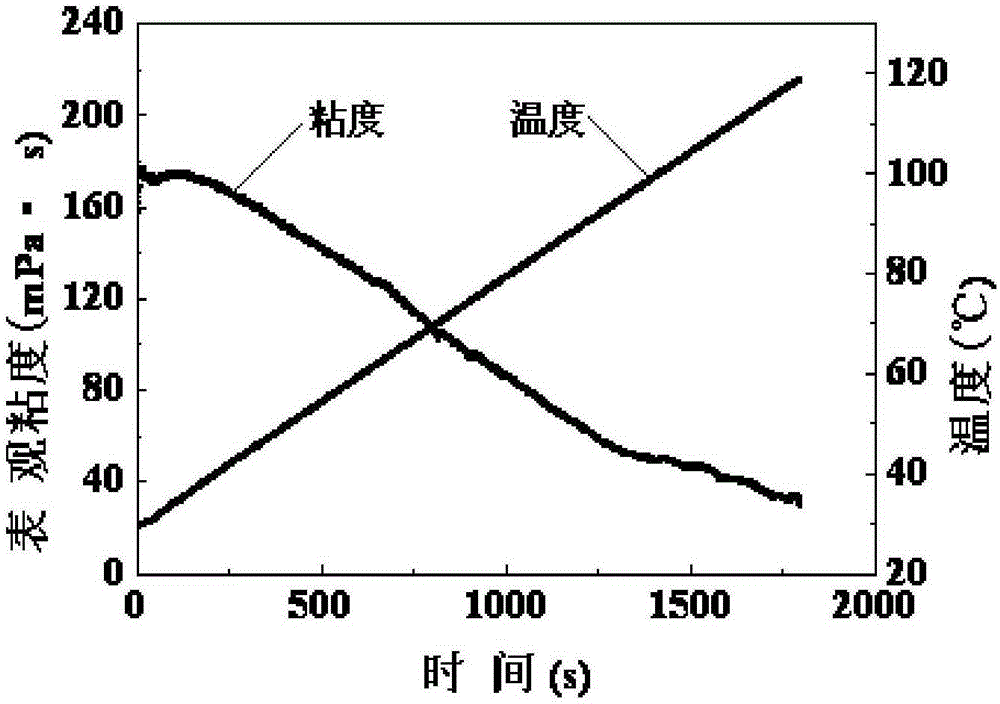

Image

Examples

Embodiment 1

[0030] Add the hydrophilic acrylic monomer composed of 20g acrylamide, 5g acrylic acid and 5g 2-acrylamido-2-methylpropanesulfonic acid into 70g distilled water, after the hydrophilic acrylic monomer is fully dissolved, use a mass The content is 30% sodium hydroxide solution to adjust the pH value to about 7 to prepare the solution.

[0031] Add 2g of dimethyl allyl octadecyl ammonium chloride and 1g of N-vinylpyrrolidone to the above solution, then add 0.5g of polyethylene glycol 12000, after stirring evenly, the solution is heated to 30°C, and Nitrogen was passed through the solution for 60 minutes, and then 0.08 g of an initiator composed of potassium persulfate and sodium bisulfite was added to initiate the polymerization reaction. After about 12 hours of reaction, 0.02 g of an initiator composed of potassium persulfate and sodium bisulfite was added. After reacting for about 1 hour, the viscosity of the reaction system increases. After continuing to react for 5 hours, coo...

Embodiment 2

[0036] Add the hydrophilic acrylic monomer composed of 20g acrylamide, 5g acrylic acid and 7g 2-acrylamido-2-methylpropanesulfonic acid into 68g distilled water, after the hydrophilic acrylic monomer is fully dissolved, use a mass The solution is prepared by adjusting the pH value to about 7 with 20% sodium hydroxide solution.

[0037] Add 1g of dimethyl allyltetradecyl ammonium chloride and 1g of N-vinylpyrrolidone to the above solution, then add 1.2g of Tween 80, stir well, heat the solution to 30°C, and add to the solution Introduce nitrogen for 80 minutes, then add 0.06 g of an initiator composed of ammonium persulfate and sodium bisulfite to initiate the polymerization reaction, and after about 12 hours of reaction, continue to add 0.02 g of an initiator composed of ammonium persulfate and sodium bisulfite to initiate Polymerization reaction, after reacting for about 2 hours, the viscosity of the reaction system increases, continue to react for 8 hours and then cool to ro...

Embodiment 3

[0040] Add the hydrophilic acrylic monomer composed of 18g acrylamide, 4g acrylic acid and 8g 2-acrylamido-2-methylpropanesulfonic acid into 70g distilled water, after the hydrophilic acrylic monomer is fully dissolved, use a mass Content is 35% sodium hydroxide solution to adjust the pH value to about 7 to prepare the solution.

[0041] Add 1.5g dimethyl allyl stearyl ammonium chloride and 1.5g N-vinylpyrrolidone to the above solution, then add 1.5g Tween 60, after stirring evenly, the solution is heated to 40°C, and Nitrogen was passed through the solution for 60 minutes, and then 0.1 g of an initiator composed of potassium persulfate and sodium thiosulfate was added to initiate the polymerization reaction. After about 16 hours of reaction, 0.02 g of an initiator composed of potassium persulfate and sodium thiosulfate was added. After reacting for about 0.5h, the viscosity of the reaction system increases. After continuing to react for 10h, cool to room temperature to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com