Patents

Literature

129 results about "2-Acrylamido-2-methylpropane sulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

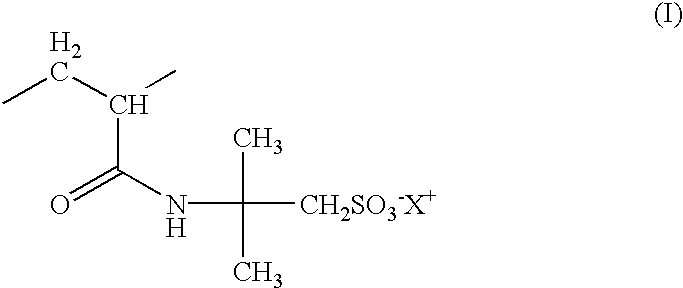

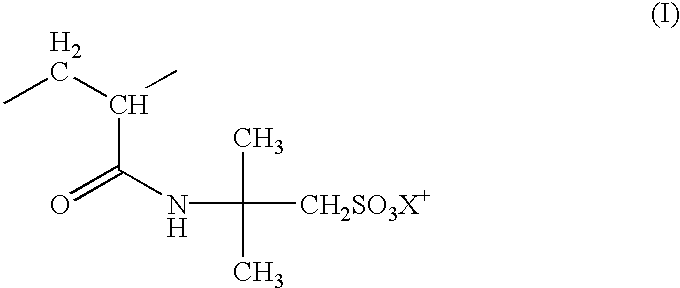

2-Acrylamido-2-methylpropane sulfonic acid (AMPS) was a Trademark name by The Lubrizol Corporation. It is a reactive, hydrophilic, sulfonic acid acrylic monomer used to alter the chemical properties of wide variety of anionic polymers. In the 1970s, the earliest patents using this monomer were filed for acrylic fiber manufacturing. Today, there are over several thousands patents and publications involving use of AMPS in many areas including water treatment, oil field, construction chemicals, hydrogels for medical applications, personal care products, emulsion coatings, adhesives, and rheology modifiers.

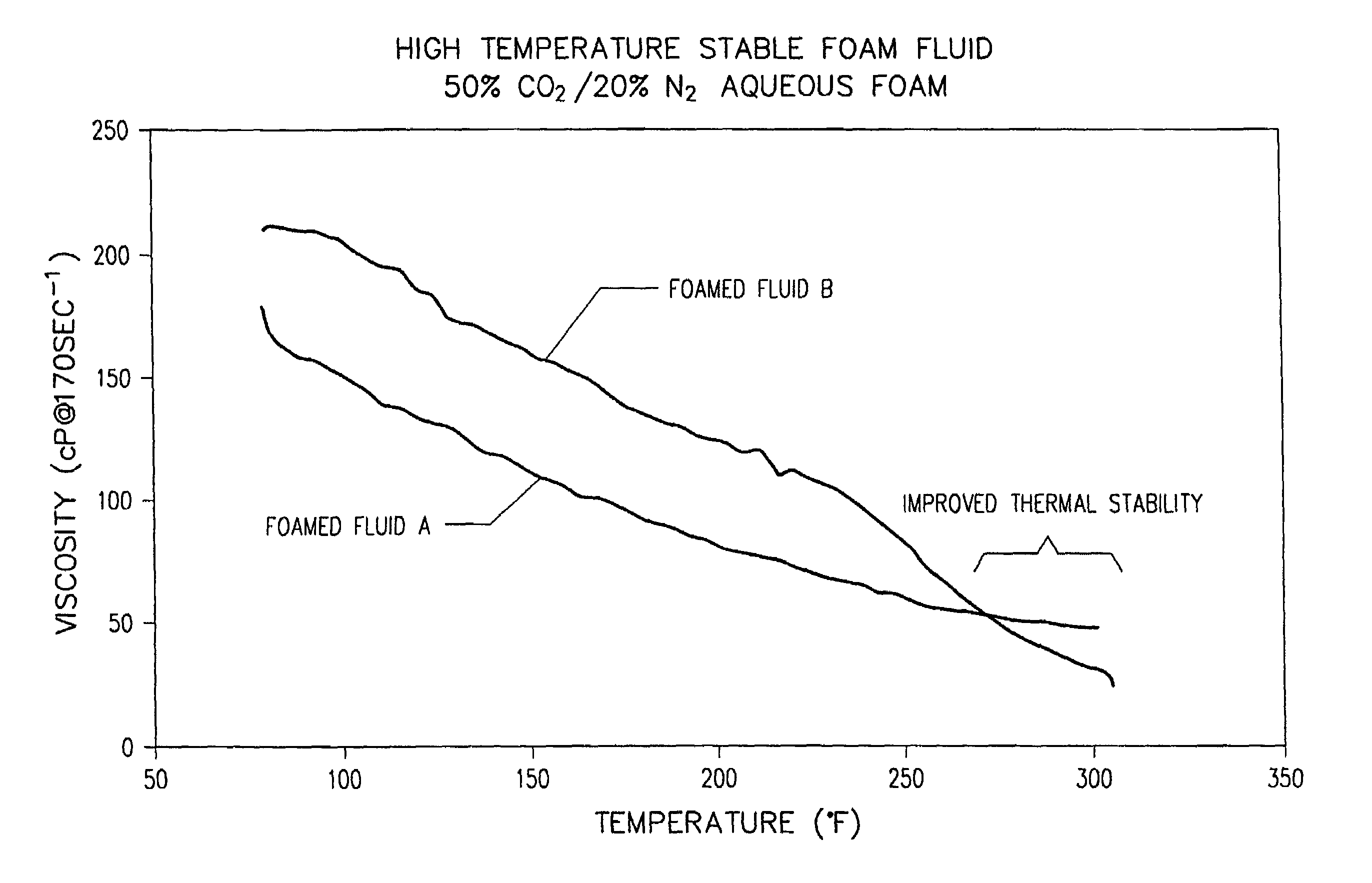

Methods of fracturing high temperature subterranean zones and foamed fracturing fluids therefor

The present invention provides methods of fracturing high temperature subterranean zones and viscous aqueous foamed fracturing fluids therefor. A fracturing fluid of this invention comprises water, a terpolymer of 2-acrylamido-2-methylpropane-sulfonic acid, acrylamide and acrylic acid or salts thereof, a gas, a foaming agent and a viscosity breaker for effecting a controlled reduction in the viscosity of the fracturing fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

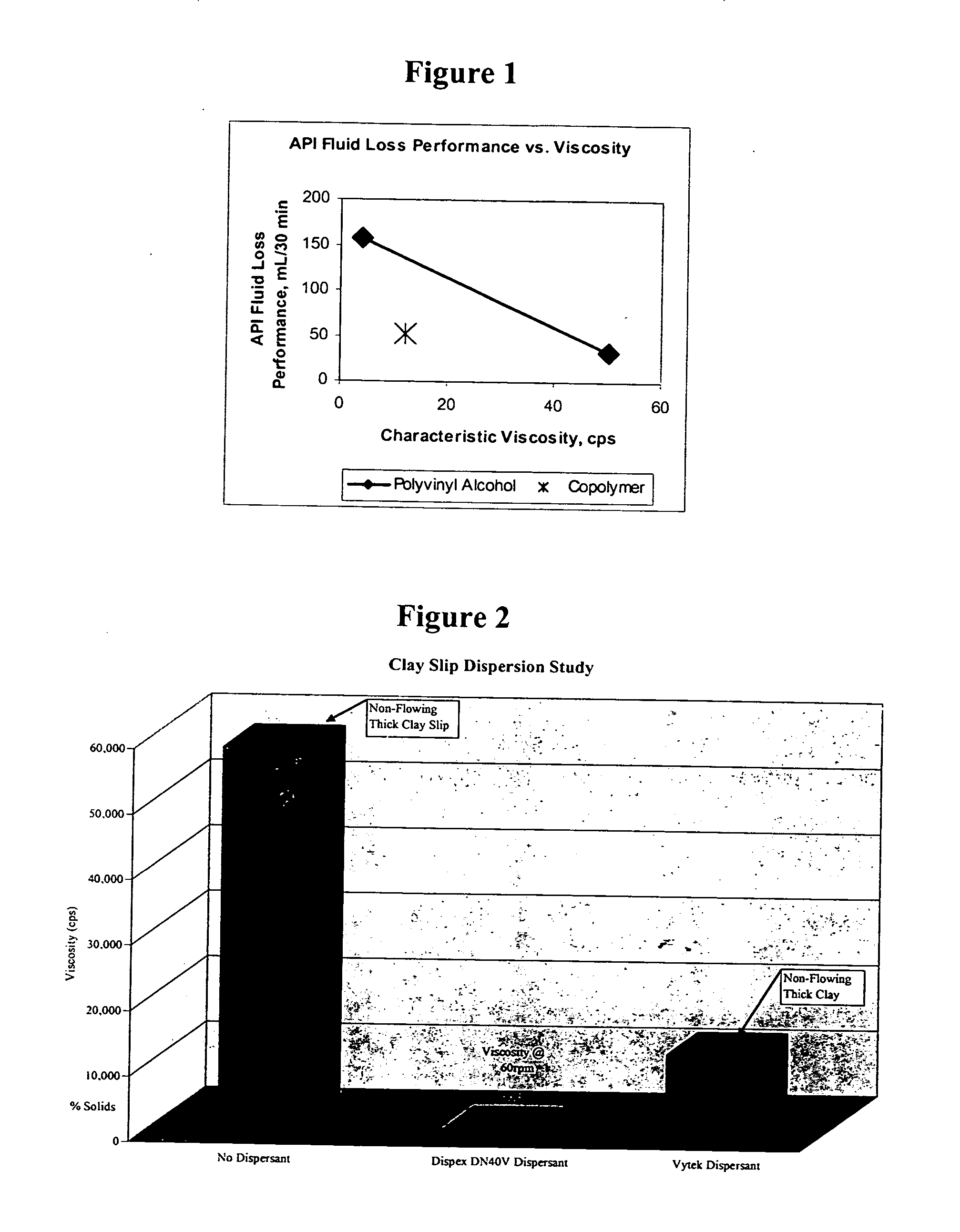

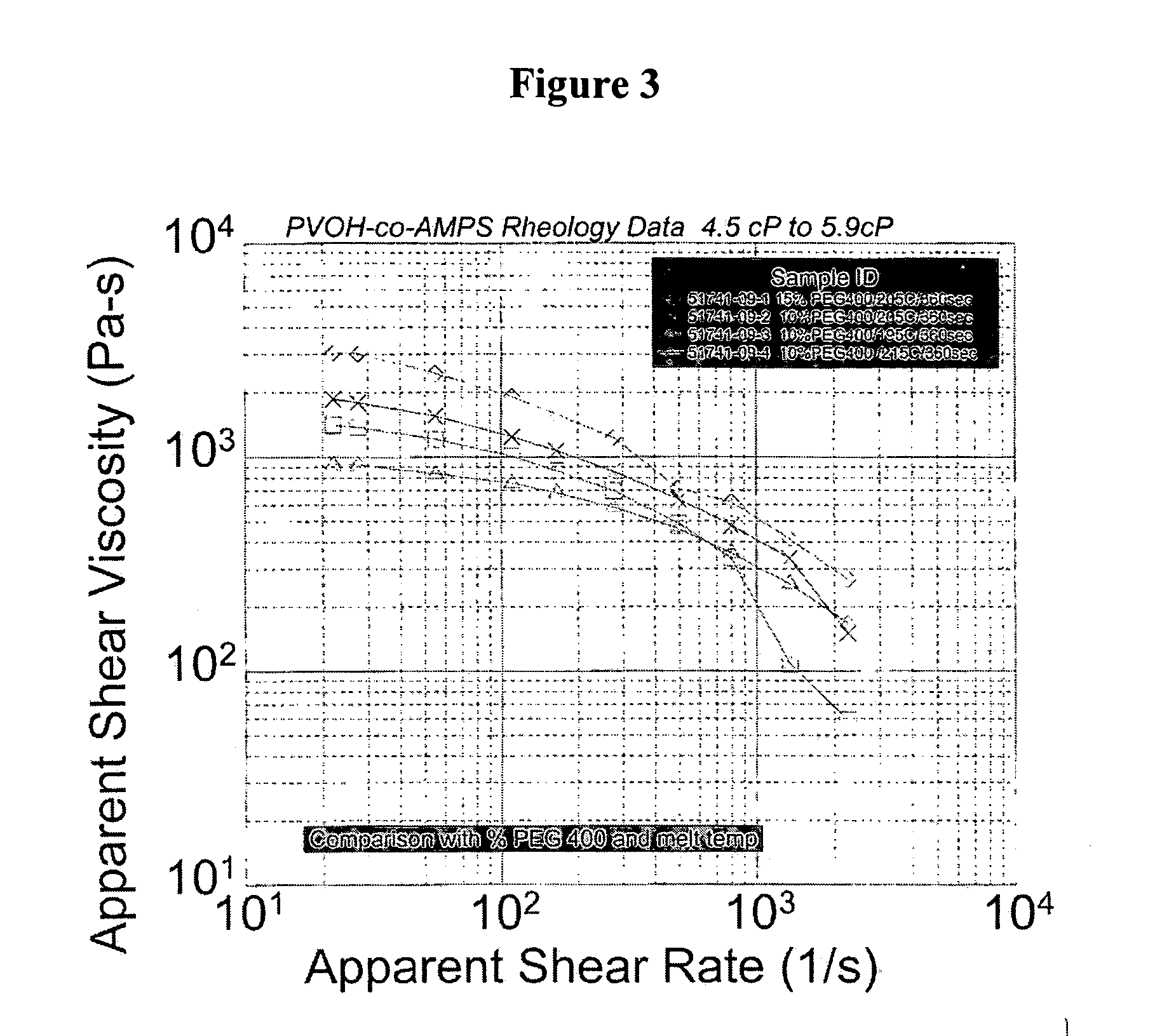

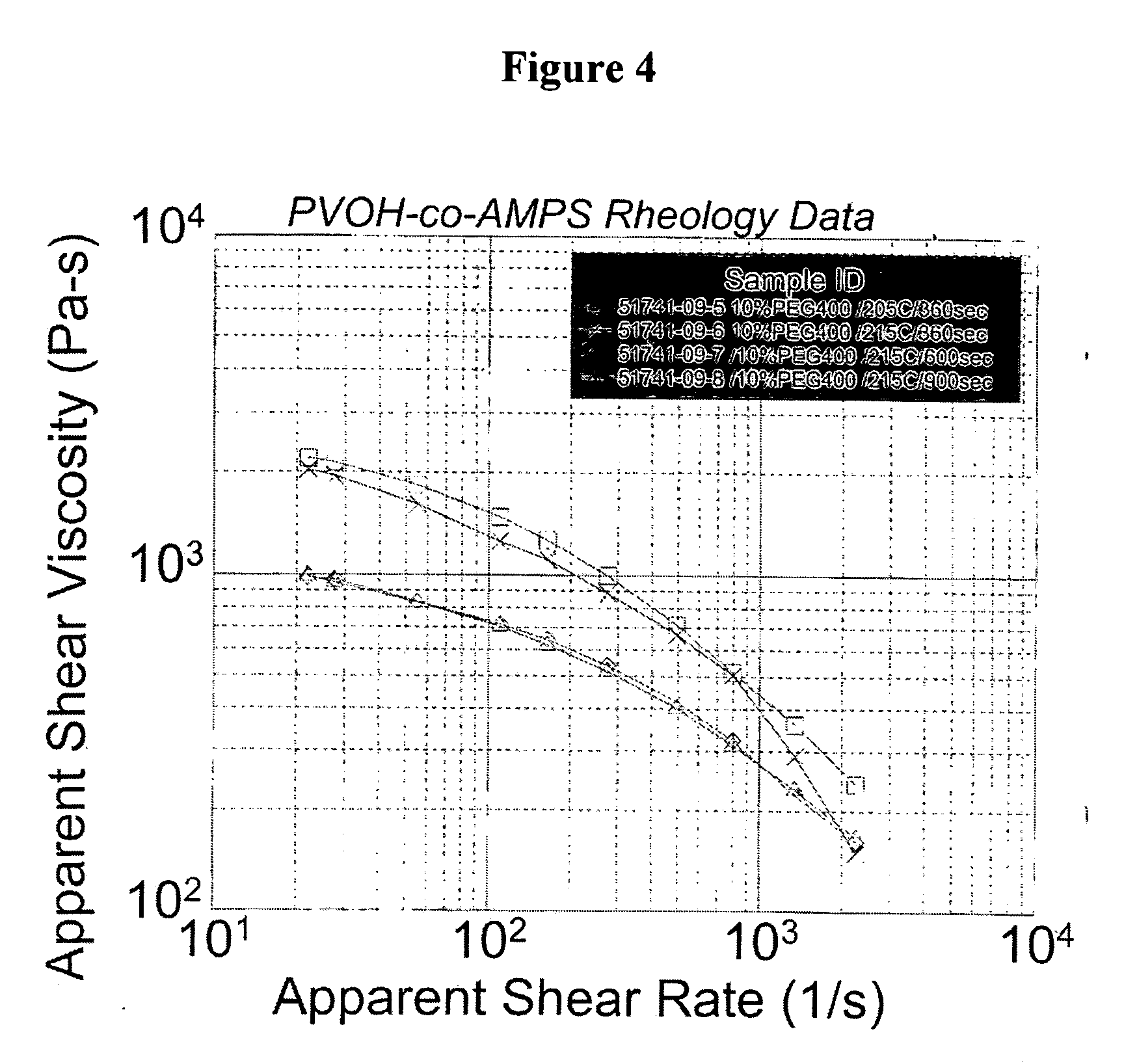

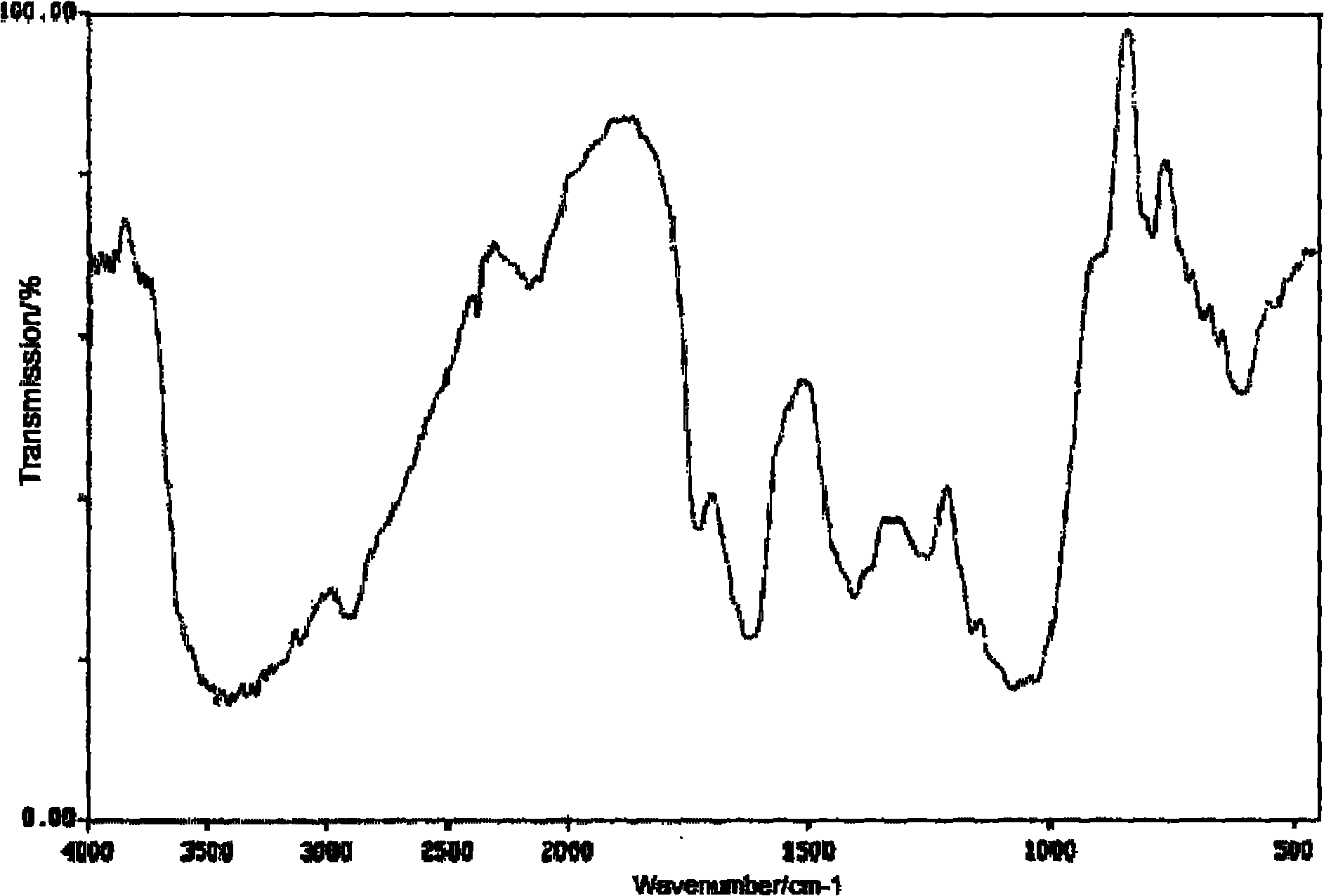

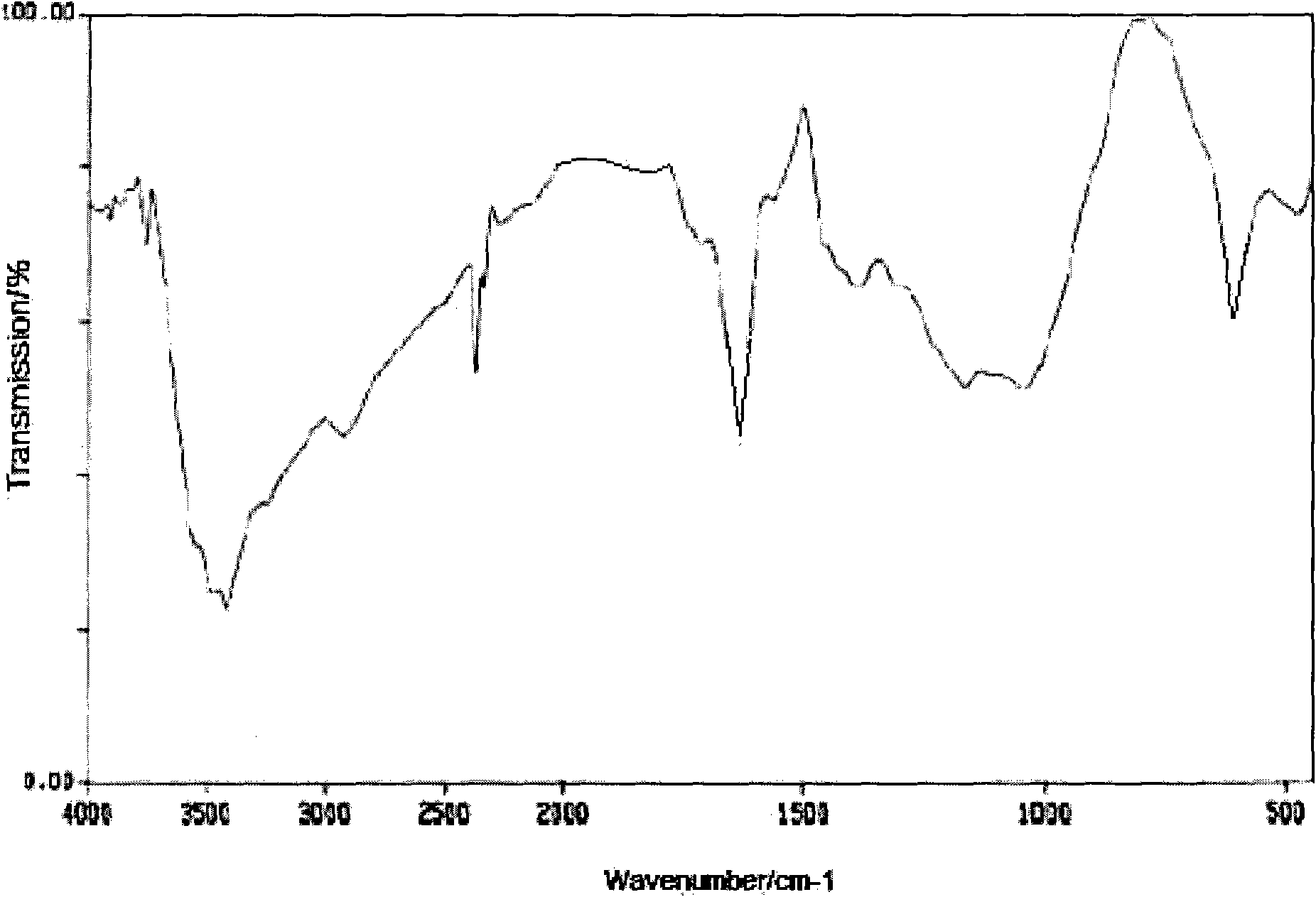

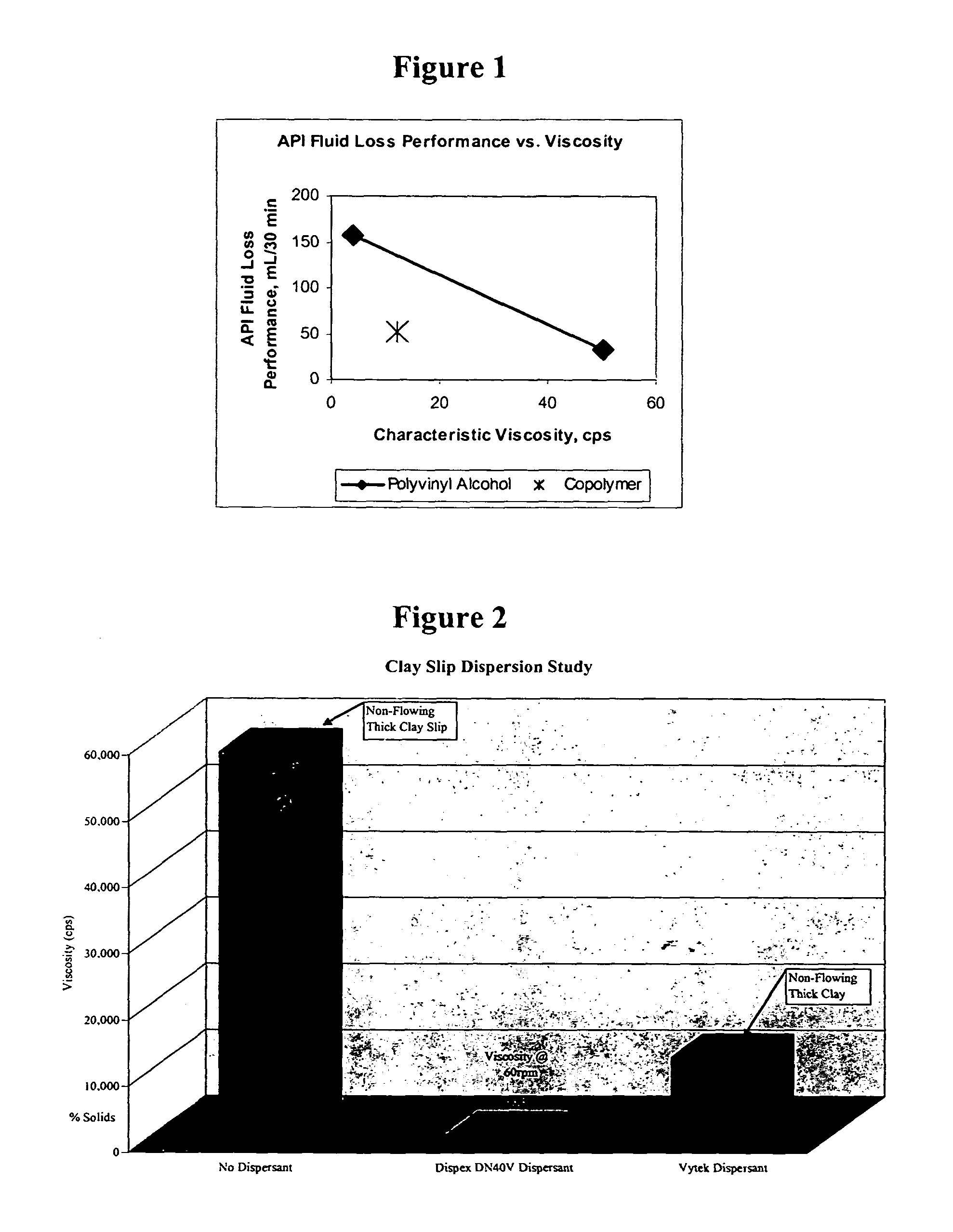

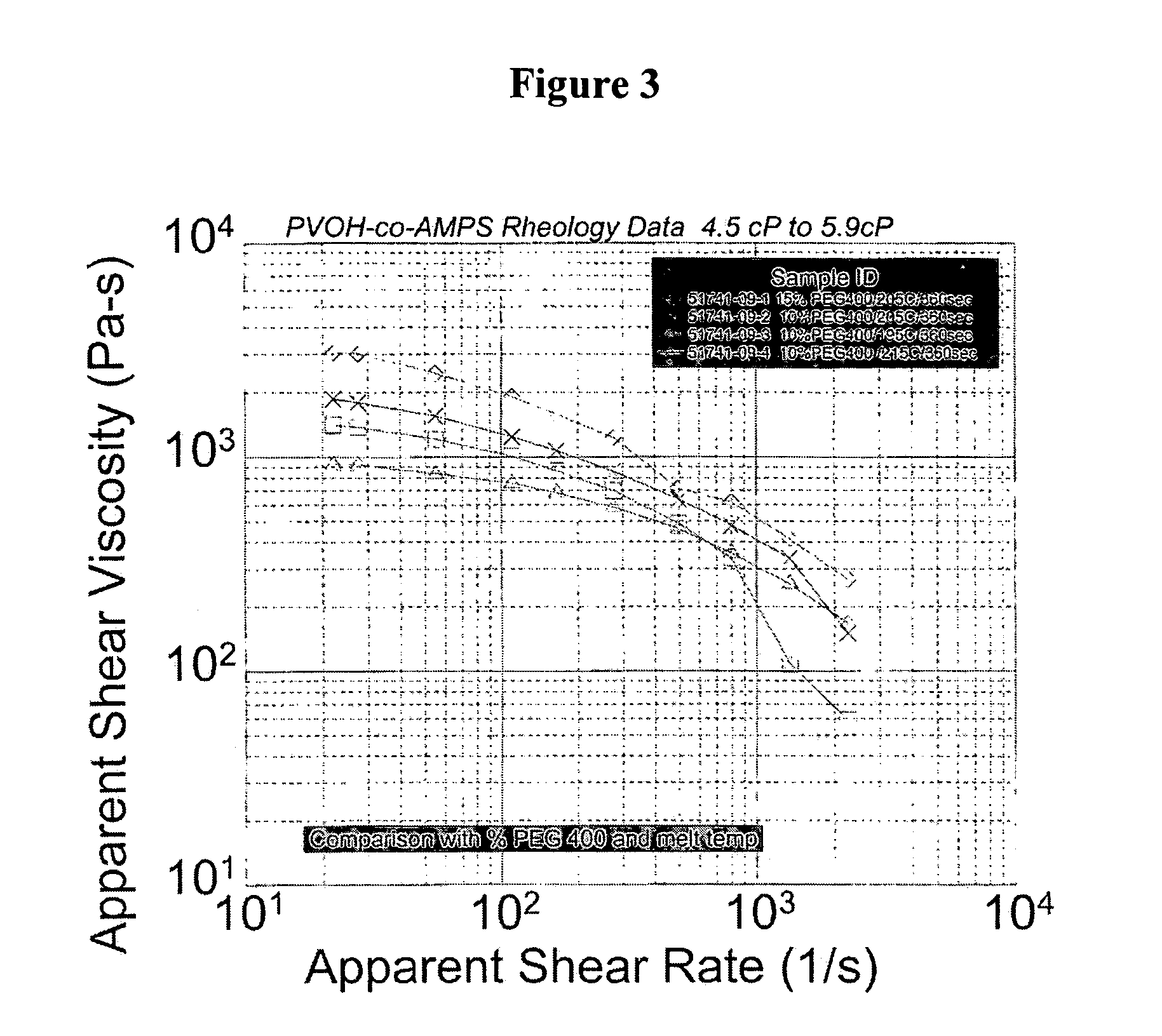

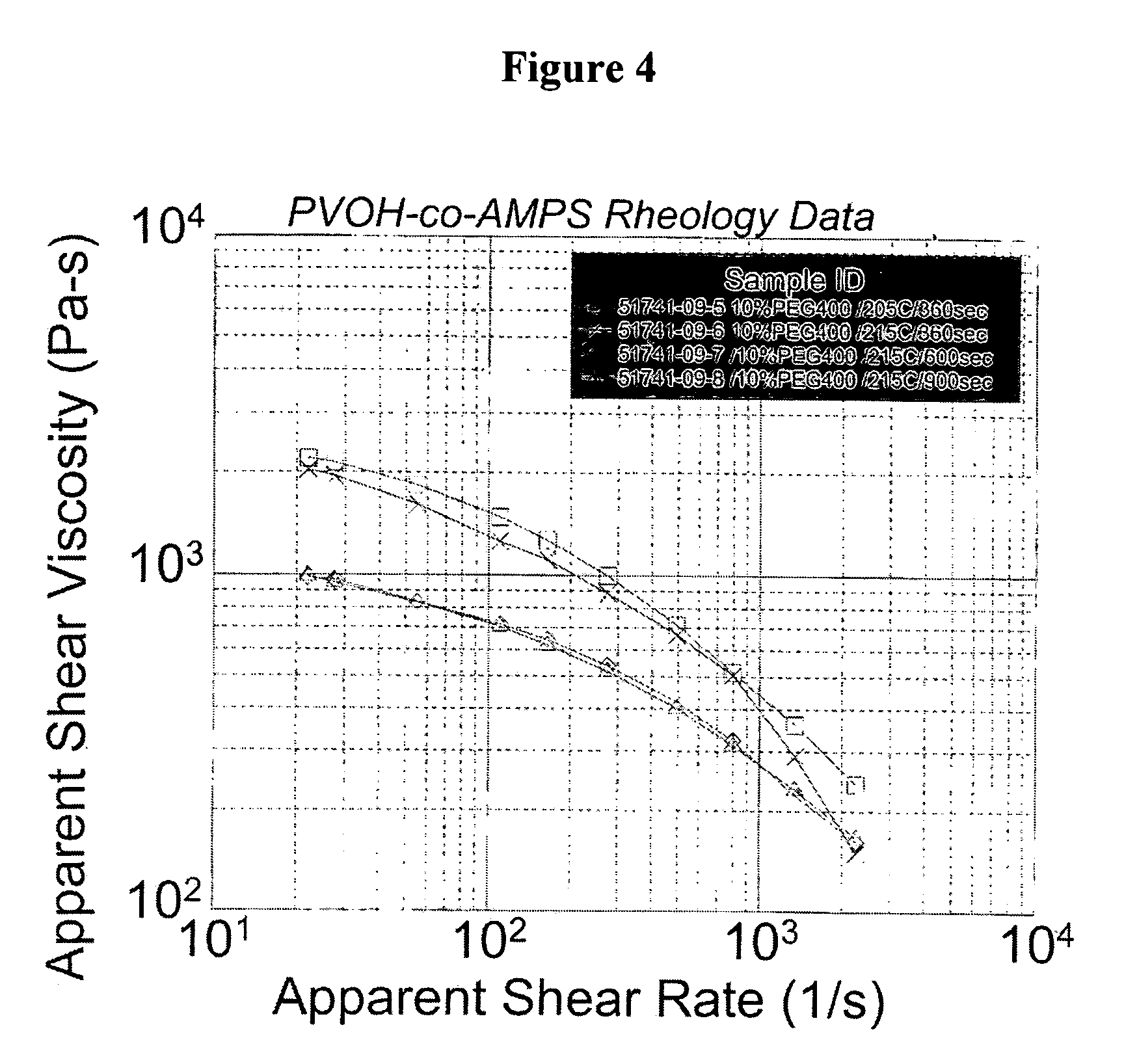

Vinyl alcohol copolymers for use in aqueous dispersions and melt extruded articles

In a method of preparing an aqueous dispersion selected from drilling fluids, hydraulic cement compositions, mineral pigment containing coatings, and papermaking furnishes or in a method of preparing a melt extrudate, the improvement comprising: a) producing a copolymer of vinyl alcohol (VOH) and 2-acrylamido-2-methyl propane sulfonic acid or a salt of such acid (AMPS) by steps including continuously feeding with agitation, vinyl acetate (VAM) and AMPS as comonomers, a free radical yielding polymerization initiator, and a solvent for said comonomers, initiator, and copolymer resulting from the copolymerization of said comonomers, maintaining the resulting reaction mass in said first reaction zone under polymerization conditions for a residence time sufficient for a major proportion of AMPS fed to said first reaction zone to polymerize, continuously feeding reaction mass from said first reaction zone with an additional supply of AMPS to a second reaction zone, maintaining the reaction mass in the second reaction zone for a residence time sufficient to polymerize a major proportion of the AMPS added to the second reaction zone, continuously withdrawing reaction mass from the second reaction zone, separating copolymer of VAM and AMPS from the latter reaction mass, and saponifying by hydrolysis and / or alcoholysis a major proportion of the acetate groups in said copolymer to form a copolymer of VOH and AMPS; and b) incorporating the saponified copolymer into the aqueous dispersion or melt extrudate.

Owner:SEKISUI SPECIALTY CHEM AMERICA

Corrosion and scale inhibitor for industrial recirculated cooling water

InactiveCN101302060AGood anti-scaling effectGood synergyScale removal and water softeningEutrophicationTricarboxylic acid

The invention provides a corrosion and scale inhibitor for industrial circulated cooling water, which is applicable to a composite for mitigating metal corrosion added into a water body with ultra-low hardness, low alkalinity and strong corrosiveness. The corrosion and scale inhibitor is characterized by comprising the following compositions in percentage by weight: 5 to 20 percent of 2-hydroxyphonoacetic acid, 5 to 25 percent of 2-phosphonobutane-1, 2, 4 - tricarboxylic acid, 10 to 40 percent of acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer, 1 to 8 percent of zinc chloride, 1 to 5 percent of copper corrosion inhibitor, and the balance being water. The corrosion and scale inhibitor has lower contents of inorganic phosphorus and zinc salt, can prevent scale sedimentation of medicine on one hand, and can reduce eutrophication of the water body and heavy metal pollution on the other hand, thereby facilitating the environmental protection.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD +1

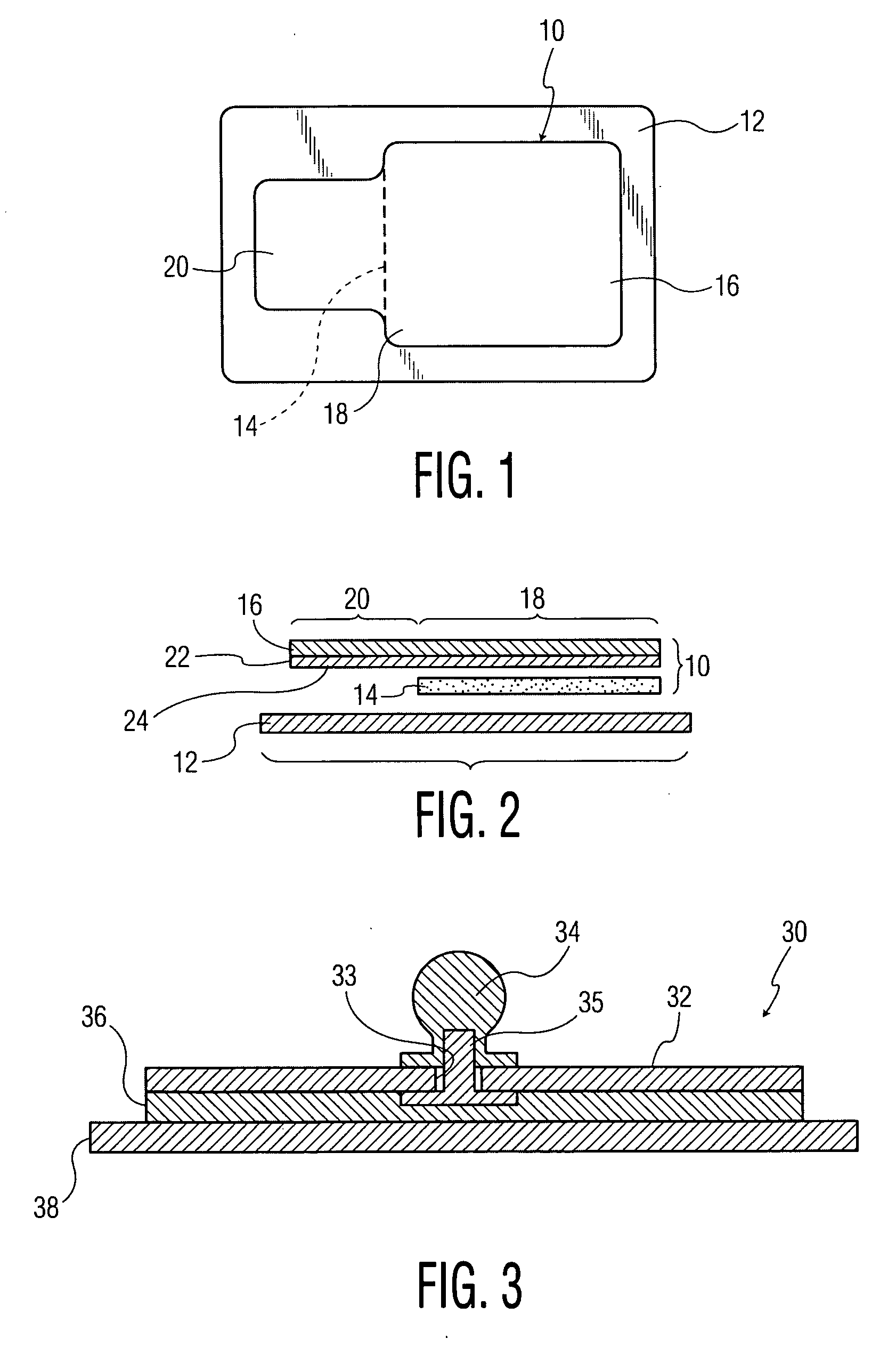

Formulations And Method For Post-CMP Cleaning

ActiveUS20110136717A1Organic detergent compounding agentsNon-surface-active detergent compositionsSulfonateAmmonium hydroxide

The present invention is a method of cleaning to removal residue in semiconductor manufacturing processing, comprising contacting a surface to be cleaned with an aqueous formulation having a polymer selected from the group consisting of acrylamido-methyl-propane sulfonate) polymers, acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer and mixtures thereof and a quaternary ammonium hydroxide having greater than 4 carbon atoms or choline hydroxide with a non-acetylinic surfactant.The present invention is also a post-CMP cleaning formulation having the components set forth in the method above.

Owner:VERSUM MATERIALS US LLC

Xanthan gum graft copolymer oil displacement agent as well as preparation method and application thereof

ActiveCN102051165AImprove heat stabilityImprove biostabilityFluid removalDrilling compositionSide chainHeat resistance

The invention provides a xanthan gum graft copolymer oil displacement agent as well as a preparation method and application thereof. Based on molecular design, at least two of acrylamide (AM), 2-acrylamido-2-methylpropane sulfonic acid (AMPS), N-vinylpyrrolidone (NVP) and N,N-dimethylacrylamide (DMAM) are graft-copolymerized to xanthan gum macromolecules. Since the copolymerized side chain is introduced, the viscoelasticity, heat resistance and biological stability of the xanthan gum macromolecules can be greatly enhanced; the xanthan gum graft copolymer can be used as an oil displacement agent for tertiary oil recovery simultaneously; and the solution rate of the xanthan gum graft copolymer is obviously increased, and the xanthan gum graft copolymer can not easily generate gel in brine. When the xanthan gum graft copolymer oil displacement agent is used in a high-temperature high-salinity oil reservoir, the oil displacement effect is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

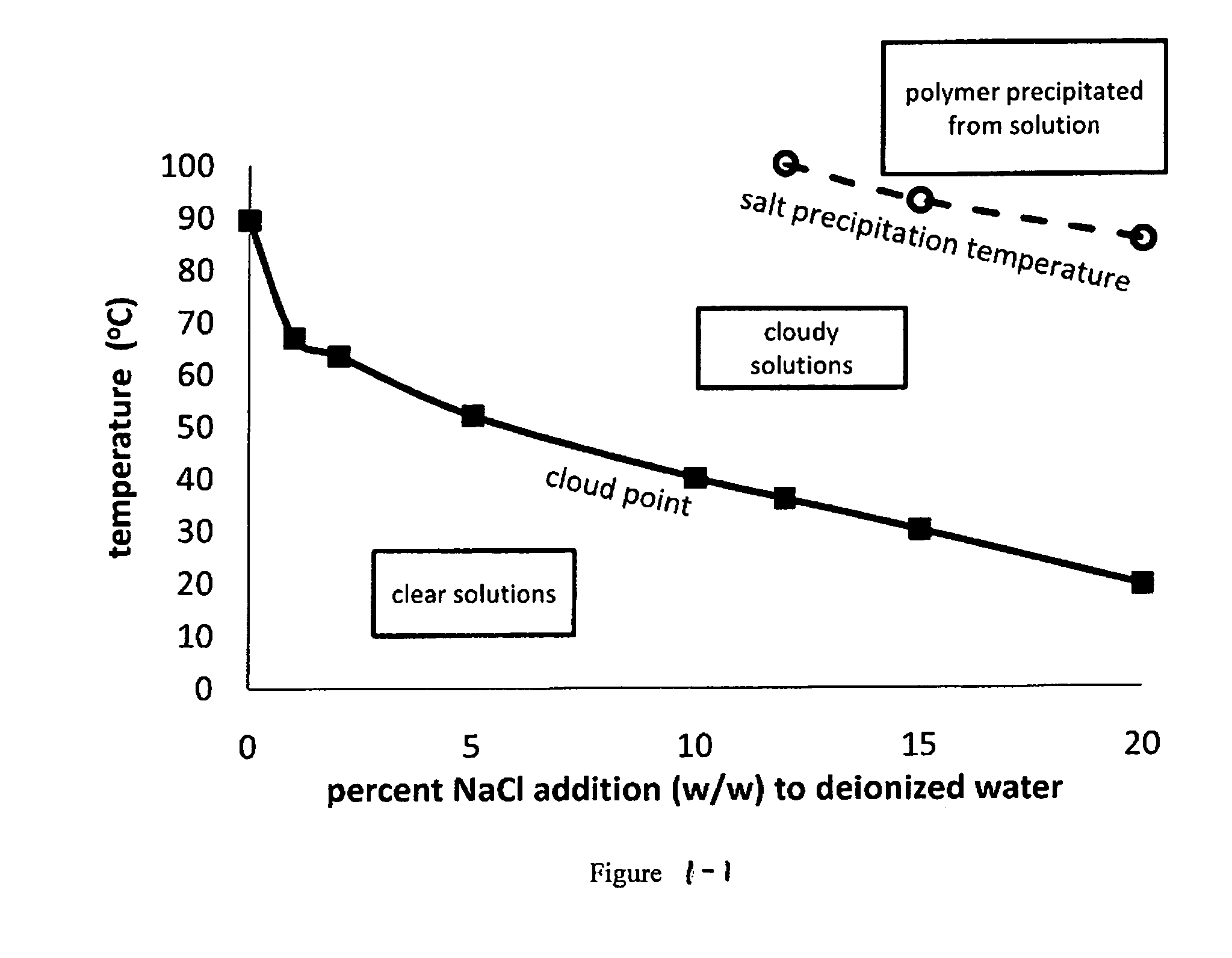

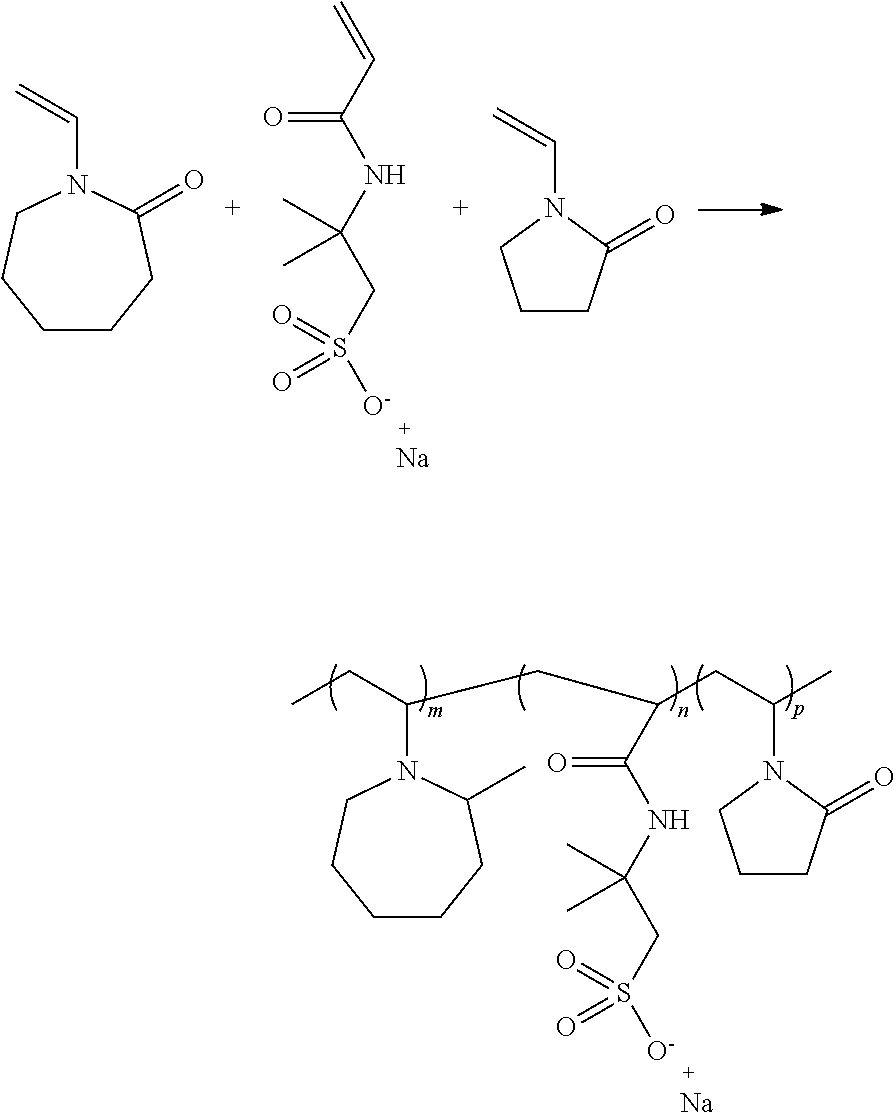

Non-homopolymers exhibiting gas hydrate inhibition, salt tolerance and high cloud point

Polymers are provided that offer gas hydrate inhibition, salt tolerance, and high cloud point. The polymers are polymerized from at least (A) 50 mole percent or more of a monomer selected from the group consisting of: N-vinyl-2-caprolactam, one of its analogues, and combinations thereof, (B) an alkenyl sulfonic acid monomer, salt thereof, or combinations thereof, and (C) an TV-vinyl amide, a (meth)acrylamide or one of its analogues, or combinations thereof. In one embodiment, the (A) monomer is N-vinyl-2-caprolactam, the (B) monomer is 2-acrylamido-2-methylpropane sulfonic acid or salt thereof, and the (C) monomer is N-vinyl-2-pyrrolidone, acrylamide, methacrylamide, or combinations thereof.

Owner:ISP INVESTMENTS INC

Vinyl alcohol copolymers for use in aqueous dispersions and melt extruded articles

In a method of preparing an aqueous dispersion selected from drilling fluids, hydraulic cement compositions, mineral pigment containing coatings, and papermaking furnishes or in a method of preparing a melt extrudate, the improvement comprising:a) producing a copolymer of vinyl alcohol (VOH) and 2-acrylamido-2-methyl propane sulfonic acid or a salt of such acid (AMPS) by steps including continuously feeding with agitation, vinyl acetate (VAM) and AMPS as comonomers, a free radical yielding polymerization initiator, and a solvent for said comonomers, initiator, and copolymer resulting from the copolymerization of said comonomers, maintaining the resulting reaction mass in said first reaction zone under polymerization conditions for a residence time sufficient for a major proportion of AMPS fed to said first reaction zone to polymerize, continuously feeding reaction mass from said first reaction zone with an additional supply of AMPS to a second reaction zone, maintaining the reaction mass in the second reaction zone for a residence time sufficient to polymerize a major proportion of the AMPS added to the second reaction zone, continuously withdrawing reaction mass from the second reaction zone, separating copolymer of VAM and AMPS from the latter reaction mass, and saponifying by hydrolysis and / or alcoholysis a major proportion of the acetate groups in said copolymer to form a copolymer of VOH and AMPS; andb) incorporating the saponified copolymer into the aqueous dispersion or melt extrudate.

Owner:SEKISUI SPECIALTY CHEM AMERICA

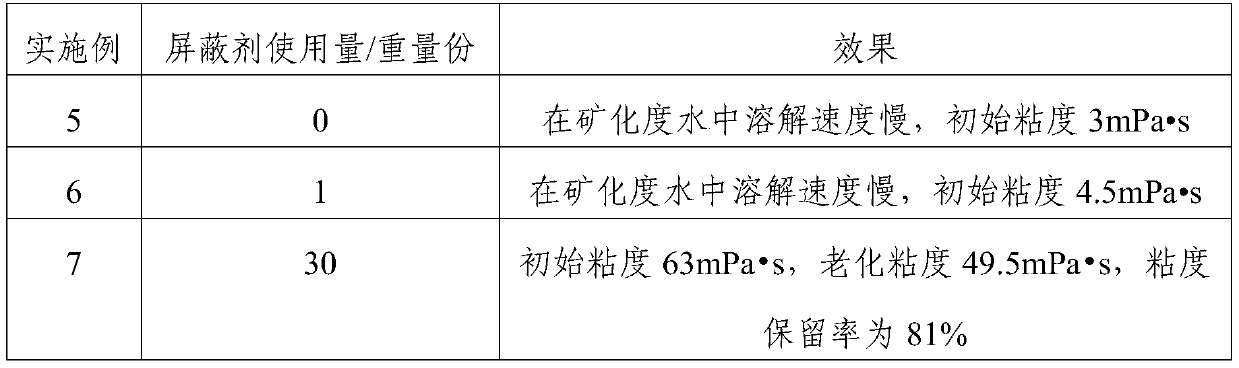

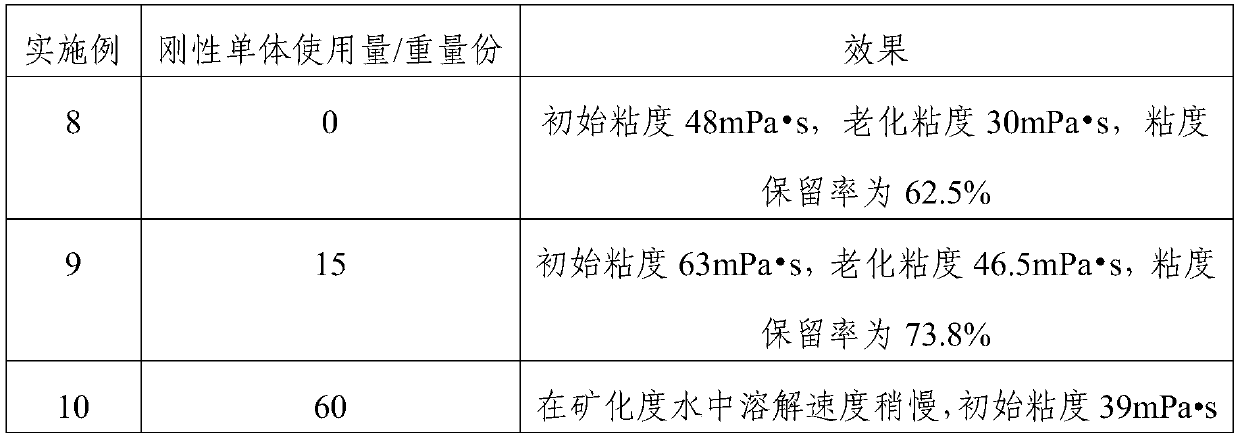

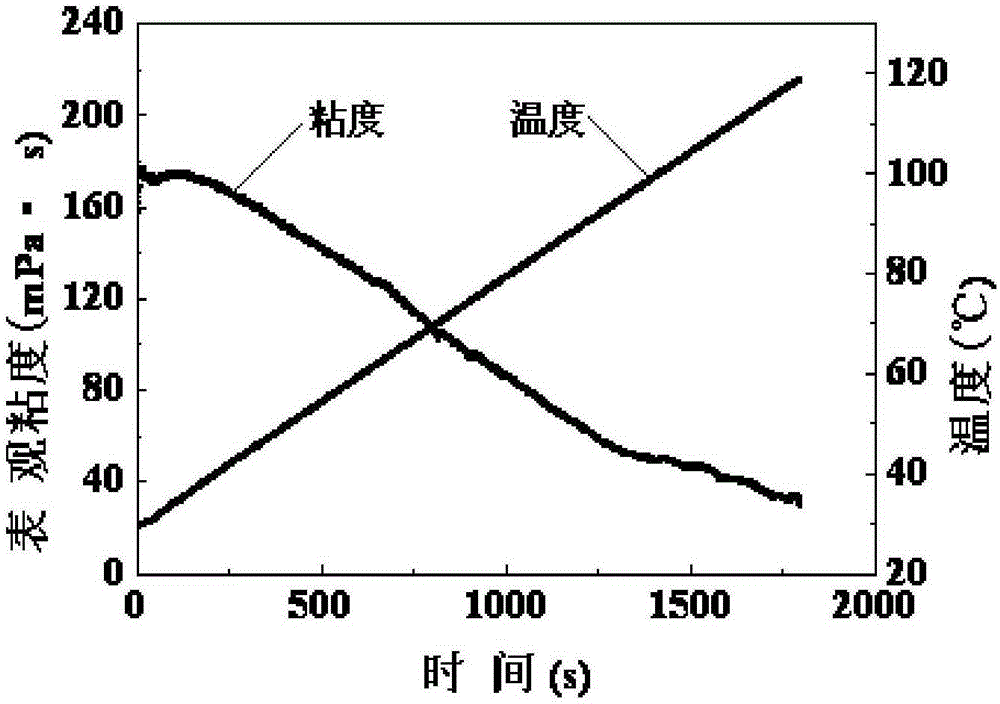

Composition, temperature-resistant salt-resistant fracturing fluid thickening agent prepared from composition, and preparation method thereof

ActiveCN109705834AGood suspension effectImprove shear resistanceDrilling compositionSaline waterSalt resistance

The invention relates to a composition used for preparing a temperature-resistant salt-resistant fracturing fluid thickening agent, the temperature-resistant salt-resistant fracturing fluid thickeningagent prepared from the composition, and a preparation method thereof. The composition comprises following components: acrylamide, acrylic acid, a hydrophobic monomer, 2-acrylamido-2-methylpropane sulfonic acid, a rigid monomer, a surfactant, and a shielding reagent. According to the temperature-resistant salt-resistant fracturing fluid thickening agent, excellent sand suspension effect can be achieved without crosslinking with a crosslinking agent, the temperature resistance and salt resistance are better; after 2h of aging in a simulated brine with total mineralization degree of 50000mg / L at 160 DEG C, the viscosity retention rate of the temperature-resistant salt-resistant fracturing fluid thickening agent is equal to or larger than 80%. Solution gel breaking of the temperature-resistant salt-resistant fracturing fluid thickening agent is complete, no water insoluble substance is left, flowback is complete, the ground is not destroyed, and no oil layer pollution is caused.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Thickener and preparation method and application thereof

ActiveCN106279523AGood drag reduction effectGood thickening effectDrilling compositionFracturing fluidPropenyl

The invention provides a thickener and a preparation method and application thereof. The preparation method of the thickener includes the following steps that 1, 25-35 parts by weight of hydrophilic propenyl monomers are dissolved in 65-75 parts by weight of water, then the pH value is regulated, and a solution with the pH of 6.5-7.5 is obtained; 2, 1-5 parts by weight of hydrophobic monomers and 0.5-2 parts by weight of emulsifier are added into the solution, stirring is carried out, and 0.05-0.3 part by total weight of initiator is added in batches under a protective atmosphere for a polymerization reaction, wherein the hydrophilic propenyl monomers include acrylamide, acrylic acid and 2-acrylamido-2-methylpropane sulfonic acid in the weight ratio of (15-20):(4-5):(5-15). By adding the thickener in the process of preparing fracturing fluid from highly mineralized water, the fracturing fluid with a high thickening capacity can be formed, and fracturing construction requirements can be effectively met.

Owner:PETROCHINA CO LTD

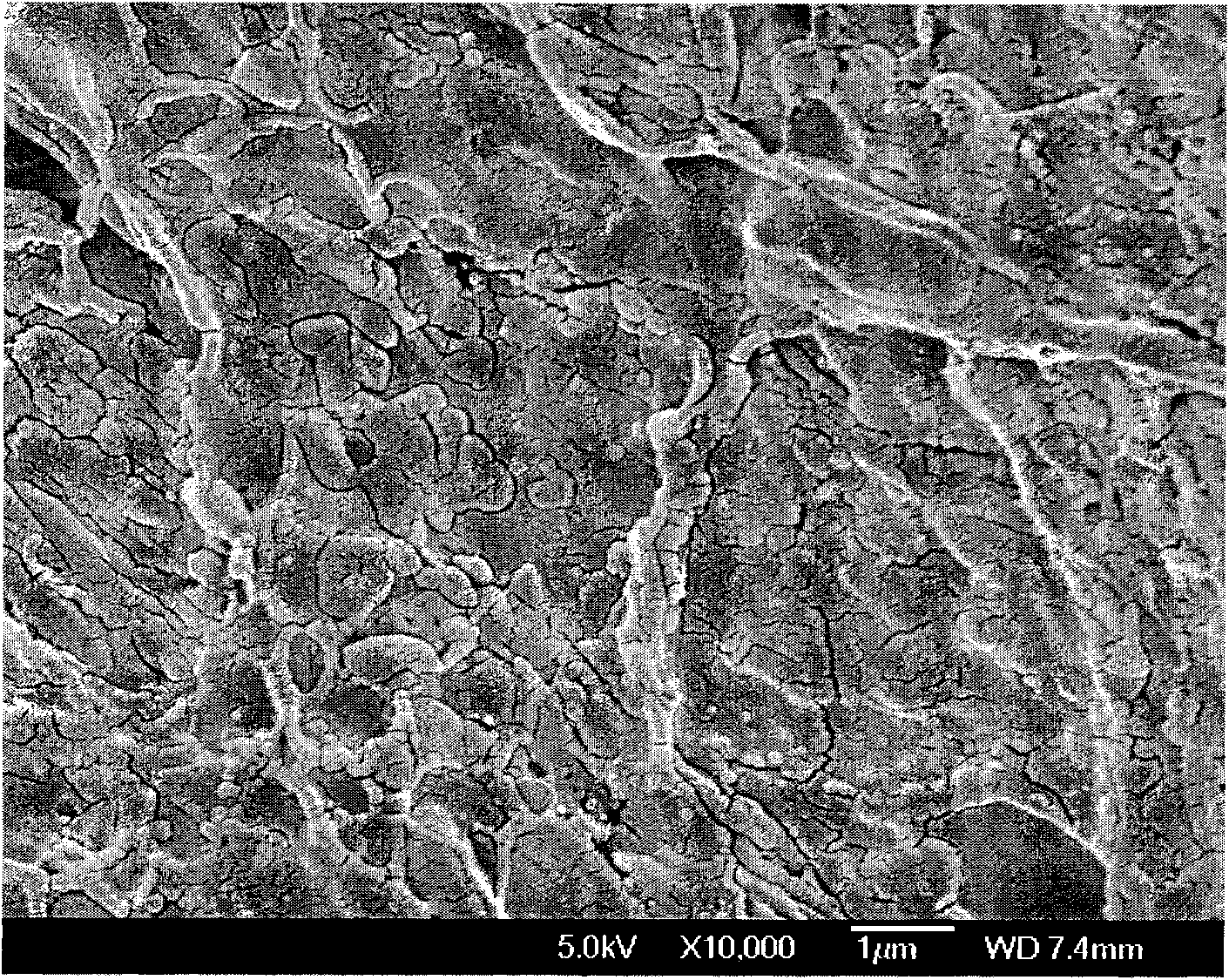

Anti-pollution separation membrane and preparation method

ActiveCN102728241AStrong bindingImprove anti-pollution performanceSemi-permeable membranesMethacrylateMethyl carbonate

The invention discloses an anti-pollution separation membrane and a preparation method, wherein aiming at the shortages of a preparation technology for the present anti-pollution PVDF (polyvinylidene fluoride) separation membrane, the invention provides a novel method for preparing an anti-microbial pollution PVDF separation membrane. The novel method provided by the invention comprises the following steps of: synthesising the random copolymer with a zwitterionic structure, of MMA (methl methacrylate), DMC (dimethyl carbonate) and AMPS (2-acrylamido-2-methylpropane sulfonic acid) via free radical polymerization at first, adding the copolymer and a porogenic agent, i.e., polyethylene glycol (PEG) in PVDF, and preparing the anti-pollution separation membrane by using N,N-dimethyl formamide (DMF) as a solvent and using water as a coagulating agent through a phase inversion method. Electropositive quaternary amine group and electronegative sulfonic group exist in the structure of the copolymer simultaneously, and have a binding capacity for water molecules which is much stronger than the binding capacity of traditional polyethylene glycol and the derivatives of the traditional polyethylene glycol, and the formed hydration layer is more stable; therefore, the prepared novel PVDF membrane is lasting in anti-pollution performance.

Owner:TIANJIN POLYTECHNIC UNIV

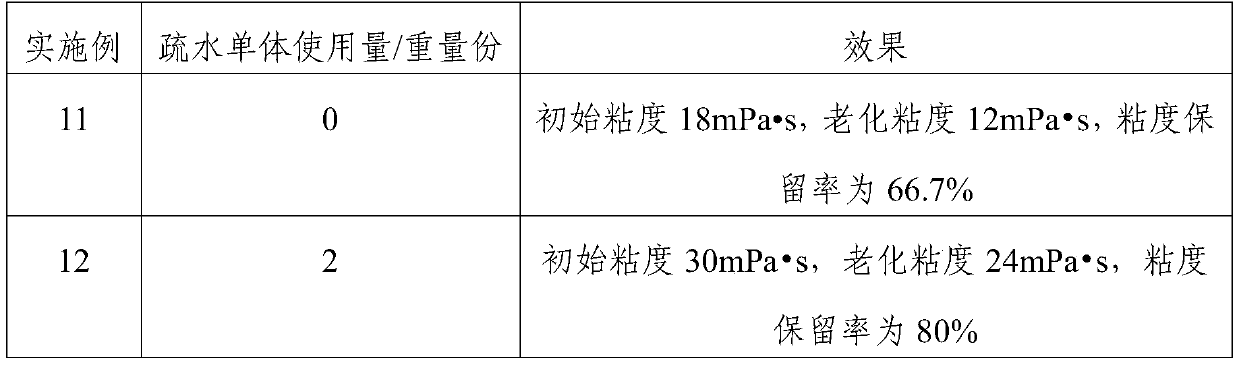

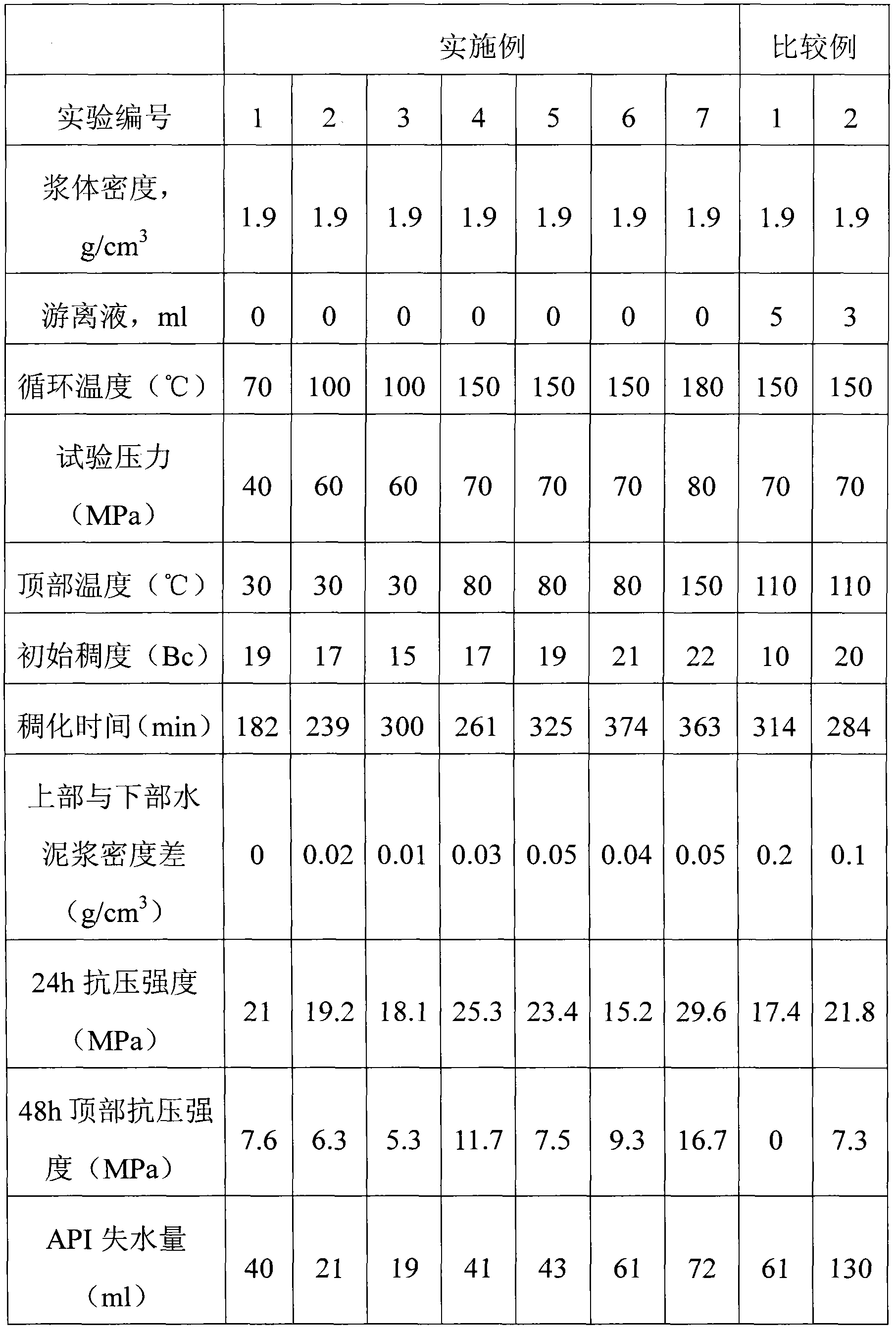

Cementing slurry system suitable for large range of temperature

ActiveCN102127404AImprove performanceRapid development of strengthDrilling compositionPhosphateDiethylenetriamine

The invention relates to a cementing slurry system suitable for large range of temperature. The cementing slurry system comprises the following components in parts by weight: 100 parts of cement, 0-40 parts of high temperature stabilizer, 2-6 parts of filtrate reducer, 0.3-3 parts of retarder and 40-55 parts of water, wherein the cement is G-grade high sulfate-resistant oil well cement; the filtrate reducer is 2-acrylamido-2-methylpropane sulfonic acid (AMPS)-acrylamide polymer, the molar ratio of AMPS to acrylamide polymer monomer is 7:3 and the number average molecular weight is 0.7-1.5 millions; the retarder is a diethylenetriamine derivative with carboxyl groups, phosphate groups and sulfonate groups, the molar ratio of the carboxyl groups to the phosphate groups and sulfo groups is 3:2:1; and the high temperature stabilizer is amorphous silica of which purity is more than 95% and average diameter is 0.1-0.15 micron. The circulating temperature range of the cementing slurry is 70-180 DEG C; under high temperature, the cementing slurry has good slurry stability, low fluid loss water amount and no free liquid; and the cementing slurry system can meet the deep well cementing construction requirement and can be used to increase the cementing quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Medical electrode containing a hydrophilic polymer

Conductive compositions whose electrical properties do not change significantly due when stored open to the atmosphere, methods for preparing the compositions, and medical electrodes that comprise the compositions are disclosed. The compositions are hydrogels that comprise about 33 wt % to about 68 wt % of a humectant or a mixture of humectants; about 1 wt % to about 8 wt % of an electrolyte or mixture of electrolytes; about 6 wt % to about 20 wt % of water; about 18 wt % to about 45 wt% of a copolymer. The copolymer comprises, in polymerized form, about 80 mol % to about 95 mol % of a first monomer, which is a mixture of acrylic acid and a salt thereof, about 5 mol % to 20 mol % of a second monomer. preferably a salt of 2-acrylamido-2-methylpropane sulfonic acid, and, optionally a crosslinking agent. The conductive composition has a pH of about 7.0 or less.

Owner:KPR U S LLC

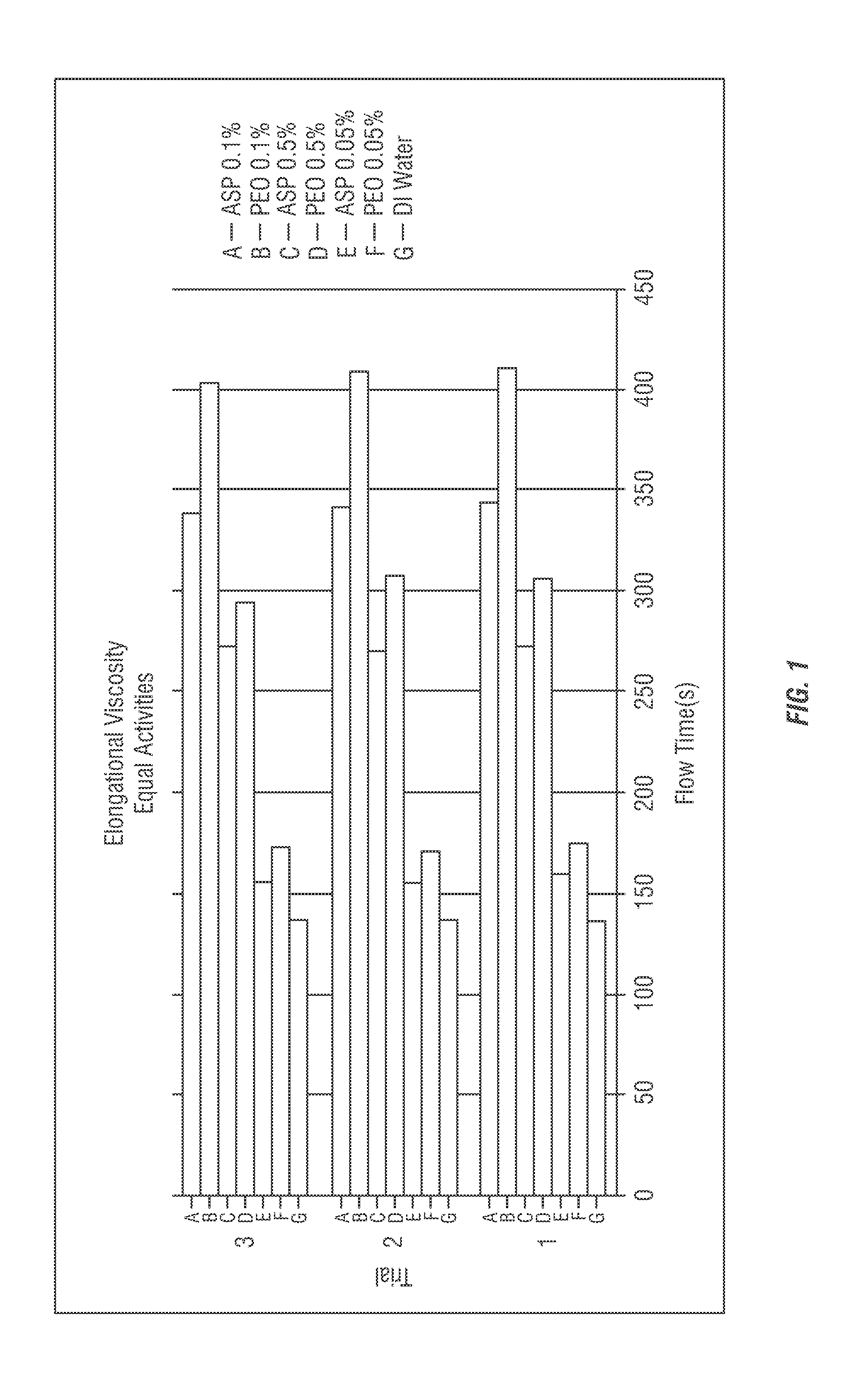

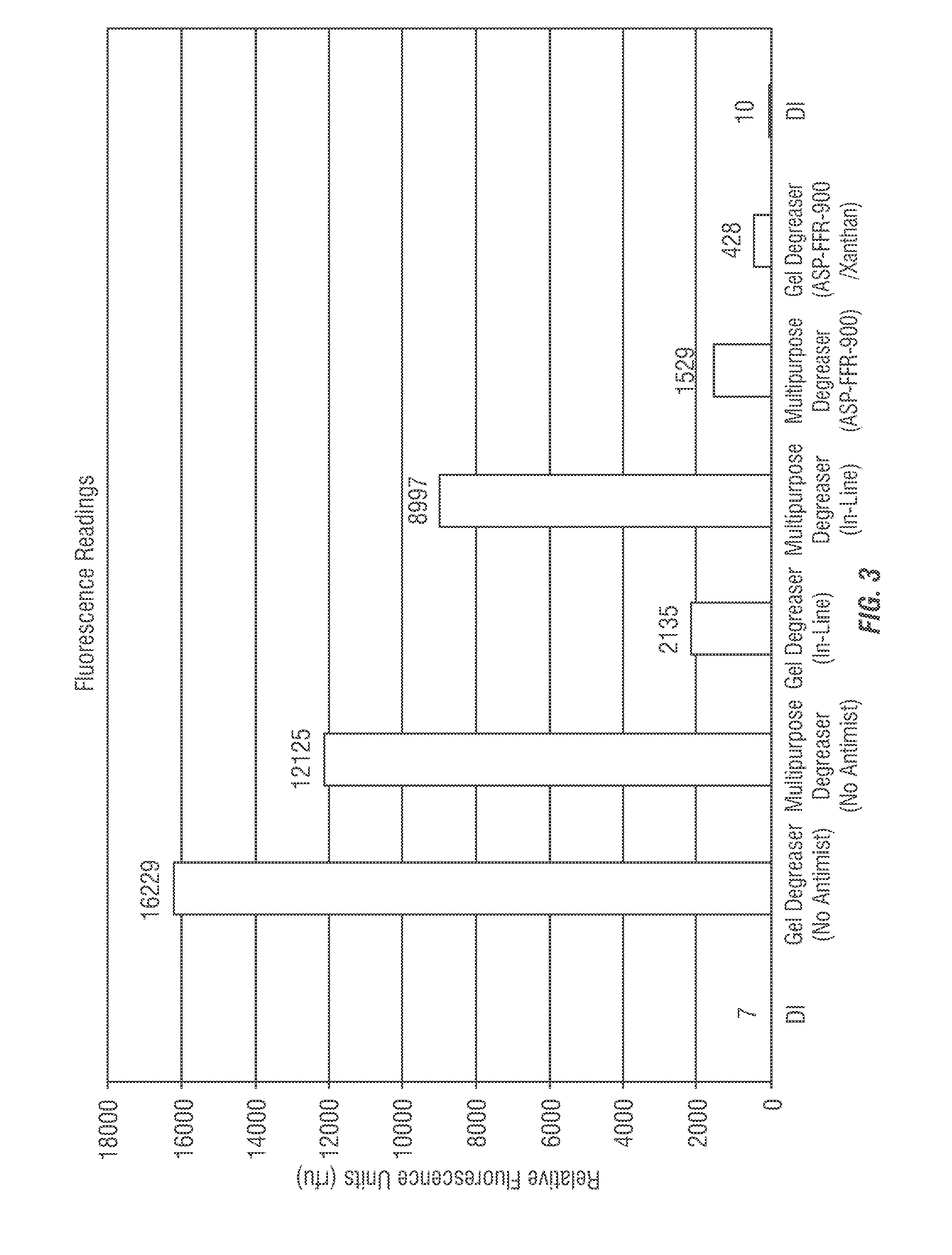

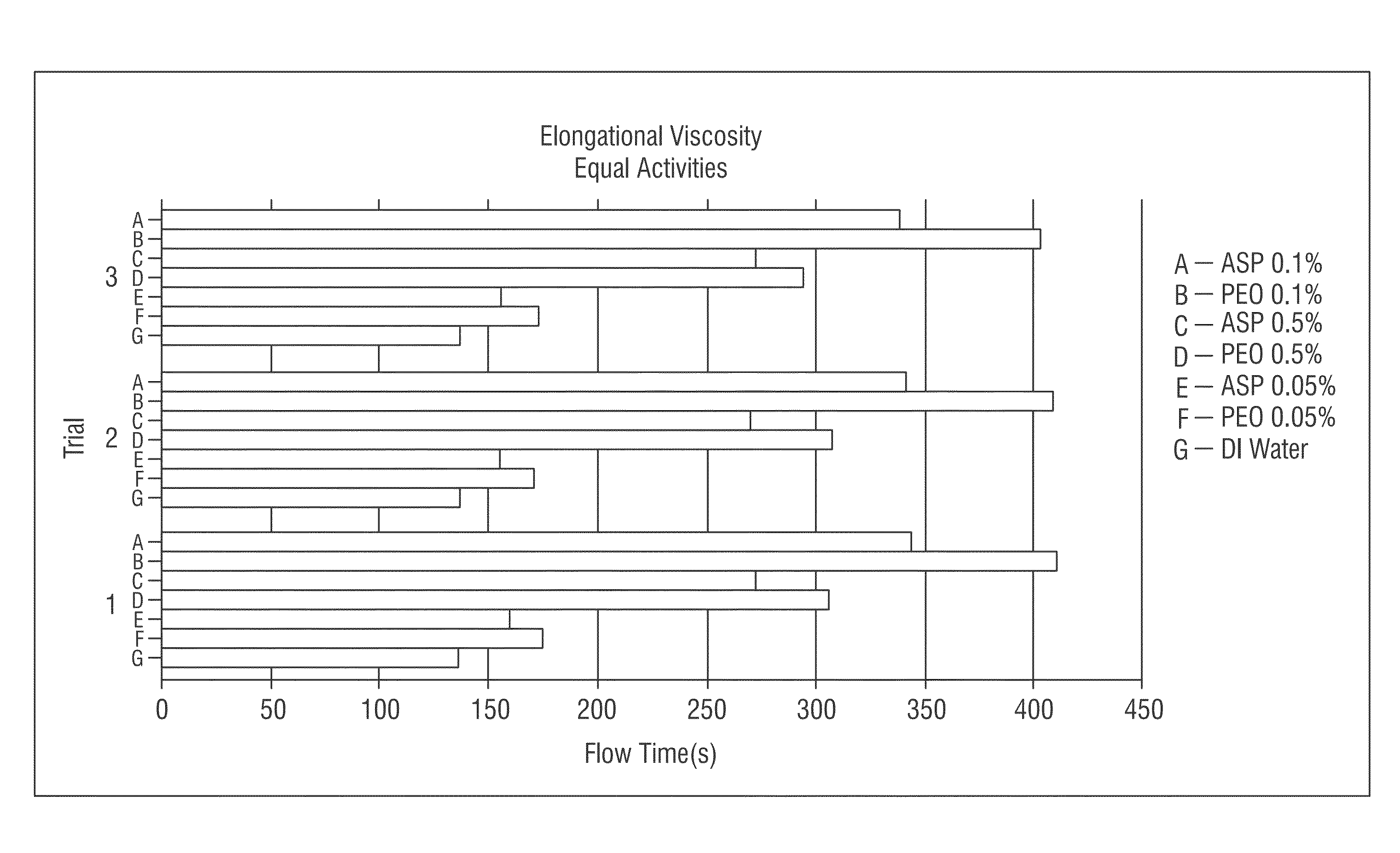

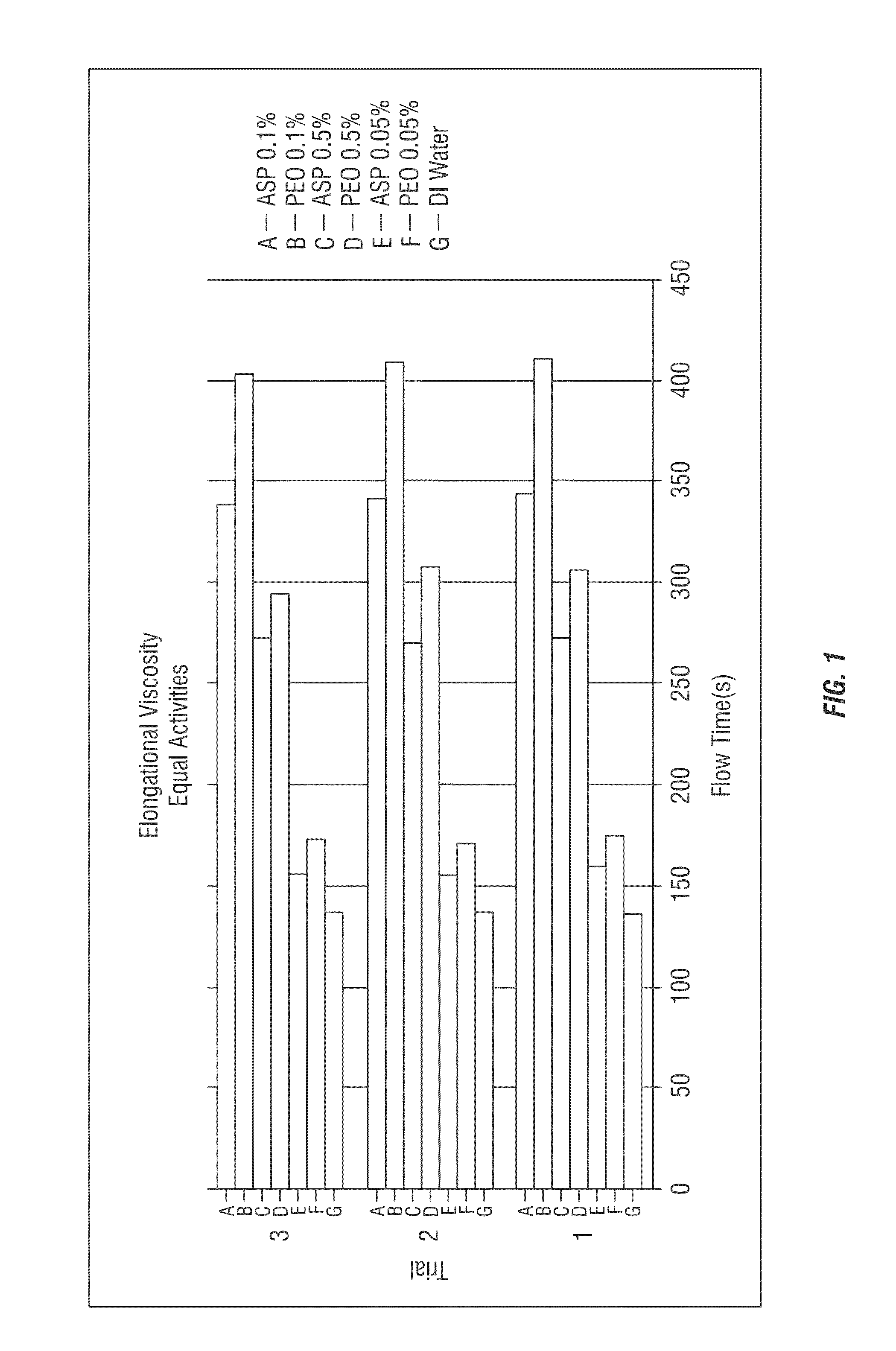

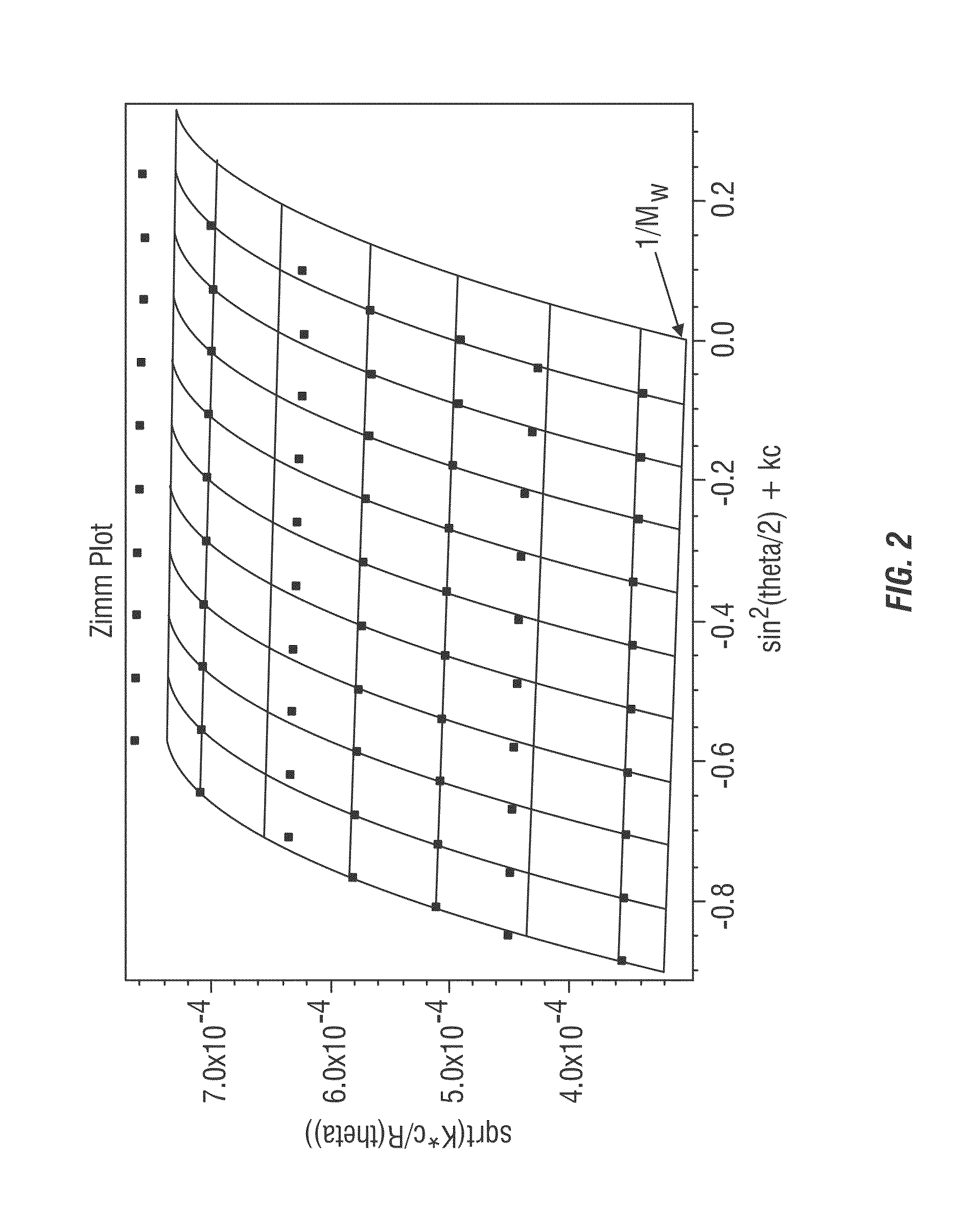

Reduced misting alkaline cleaners using elongational viscosity modifiers

ActiveUS20130284205A1Easy to removeOrganic detergent compounding agentsAnionic surface-active compoundsAlkalinitySulfonate

Alkaline spray-on cleaners that can be delivered by pump or pressurized gas aerosol spray have been made with reduced choking mists are disclosed. The cleaning composition comprises the use of anti-mist components consisting of large anionic copolymer comprised of acrylamide and AMPS (acrylamide-sodium 2-acrylamido-2-methylpropane sulfonate), and polyethylene oxide polymers that create non-Newtonian solutions. The composition also includes a surfactant, and a source of alkalinity.

Owner:ECOLAB USA INC

Alkali swellable acrylic emulsions without surfactants, use thereof in aqueous formulations, and formulations containing them

ActiveUS20110319500A1Time stableThickening effectivenessCosmetic preparationsMaterial nanotechnologyWater basedEmulsion

The present invention pertains to new alkali swellable thickening emulsions, free of surfactants and solvents other than water: as a result, all drawbacks related to the use of solvents, or to the formation of foam in the case of surfactants, are avoided. These new emulsions contain a certain quantity of 2-acrylamido-2-methylpropane sulfonic acid (or AMPS, CAS #: 40623-75-4). They have proven effective at thickening aqueous mediums, particularly water-based paints, paper coatings, aqueous suspensions of mineral materials, detergents, cosmetic formulations, or formulations containing a hydraulic binder.

Owner:COATEX SA

Well cement additives, compositions and methods

Improved well cement additives, compositions and methods of using the compositions are provided. The well cement additives are basically comprised of a first monomer selected from the group of 2-acrylamido-2-methylpropane sulfonic acid, 2-allyloxy-2-hydroxy-1-propane sulfonic acid and vinylsulfonic acid, a second monomer selected from the group of N,N-dimethylacrylamide, acrylamide, N-vinylpyrrolidone, N-vinylacetamide and acrylonitrile and a third monomer selected from the group of C6 to C22 dimethylaminopropylmethacrylamide bromide, chloride and iodide and C6 to C22 dimethylaminoethylmethacrylate bromide, chloride and iodide.

Owner:HALLIBURTON ENERGY SERVICES INC

Reduced misting alkaline cleaners using elongational viscosity modifiers

ActiveUS9206381B2Easy to removeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsExtensional viscosityAlkalinity

Alkaline spray-on cleaners that can be delivered by pump or pressurized gas aerosol spray have been made with reduced choking mists are disclosed. The cleaning composition comprises the use of anti-mist components consisting of large anionic copolymer comprised of acrylamide and AMPS (acrylamide-sodium 2-acrylamido-2-methylpropane sulfonate), and polyethylene oxide polymers that create non-Newtonian solutions. The composition also includes a surfactant, and a source of alkalinity.

Owner:ECOLAB USA INC

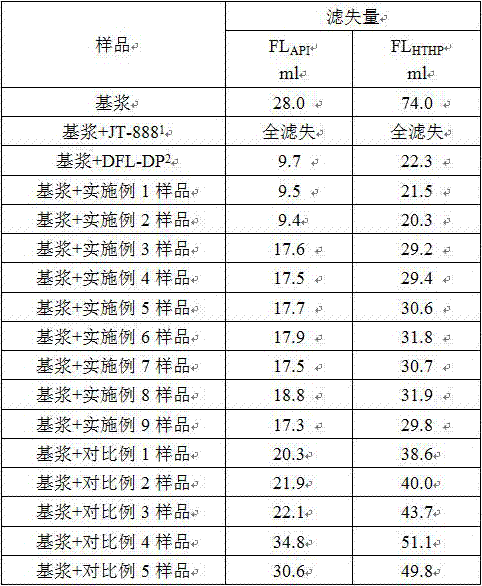

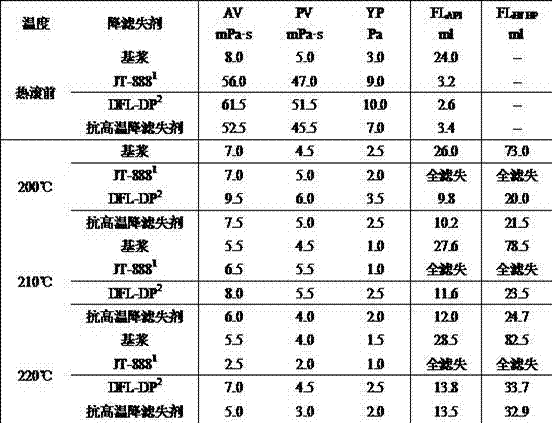

Preparation method of high-temperature-resisting filtration-loss reducer for drilling fluid

The invention discloses a preparation method of a high-temperature-resisting filtration-loss reducer for drilling fluid. The high-temperature-resisting filtration-loss reducer is prepared from the following raw materials, including acrylamide, acrylic acid, 2-acrylamido-2-methylpropane sulfonic acid and N-vinylpyrrolidone; the optimum condition for synthesis is that the four monomers are used in parts by weight: 35-45 parts of acrylamide, 25-30 parts of acrylic acid, 25-35 parts of 2-acrylamido-2-methylpropane sulfonic acid and 5-8 parts of N-vinylpyrrolidone, which are subjected to aqueous solution polymerization to obtain the high-temperature-resisting filtration-loss reducer; the reducer also comprises 1-3 parts of an initiator assistant, namely chitosan Mn-bentonite; the reaction temperature is 30-40 DEG C, the reaction time is 8h, the ratio of oxidation / reduction initiator, namely n sodium persulfate to n sodium sulfite being 1.2 to 1, 0.3 part by weight of the initiator, is adopted, and the optimum pH value of a monomer solution is 7-8. The product can resist high temperature of 210 DEG C, and the filtration loss reducing effect is good.

Owner:新沂市中诺新材料科技有限公司

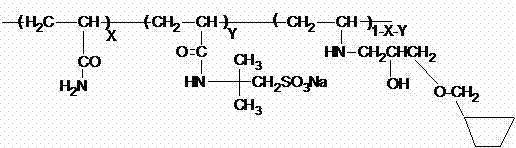

Acrylamide/2-acrylamido-2-methylpropane sulfonic acid sodium/cyclodextrin modified acrylamide (AM/AMPS-Na/MAM) copolymer and preparation method thereof

InactiveCN102199251AControl vectorThe preparation method is simple and feasibleDrilling compositionEthylenediamineAcetic acid

The invention discloses acrylamide / 2-acrylamido-2-methylpropane sulfonic acid sodium / cyclodextrin modified acrylamide (AM / AMPS-Na / MAM) copolymer serving as a fluid loss reducer for drilling fluid in oilfield, and a preparation method thereof, which can solve the problems of short cement paste thickening time, failure of an additive and high filter loss due to strata pressure and temperature rise. The technical scheme is that: the copolymer is prepared by polymerizing 83 to 85 percent of acrylamide AM, 15 to 16 percent of 2-acrylamido-2-methylpropane sulfonic acid sodium AMPS-Na and 1 to 2 percent of cyclodextrin modified acrylamide MAM. The preparation method comprises the following steps of: adding aqueous solution of the AM, solution of the MAM and solution of the AMPS-Na into a reaction container; adding ethylene diamine tetraacetic acid, potassium peroxydisulfate and sodium hydrogensulfite; and stirring uniformly, and reacting at the temperature of between 40 and 50DEG C for 5 to 6 hours under the protection of nitrogen to obtain the AM / AMPS-Na / MAM copolymer. The AM / AMPS-Na / MAM copolymer serving as a drilling fluid treating agent has high thermal stability, high temperature resistance, and better fluid loss reducing effect; the preparation method is simple and practicable, and the reaction conditions are mild; and the AM / AMPS-Na / MAM copolymer is used as the drilling fluid treating agent in the oilfield.

Owner:SOUTHWEST PETROLEUM UNIV

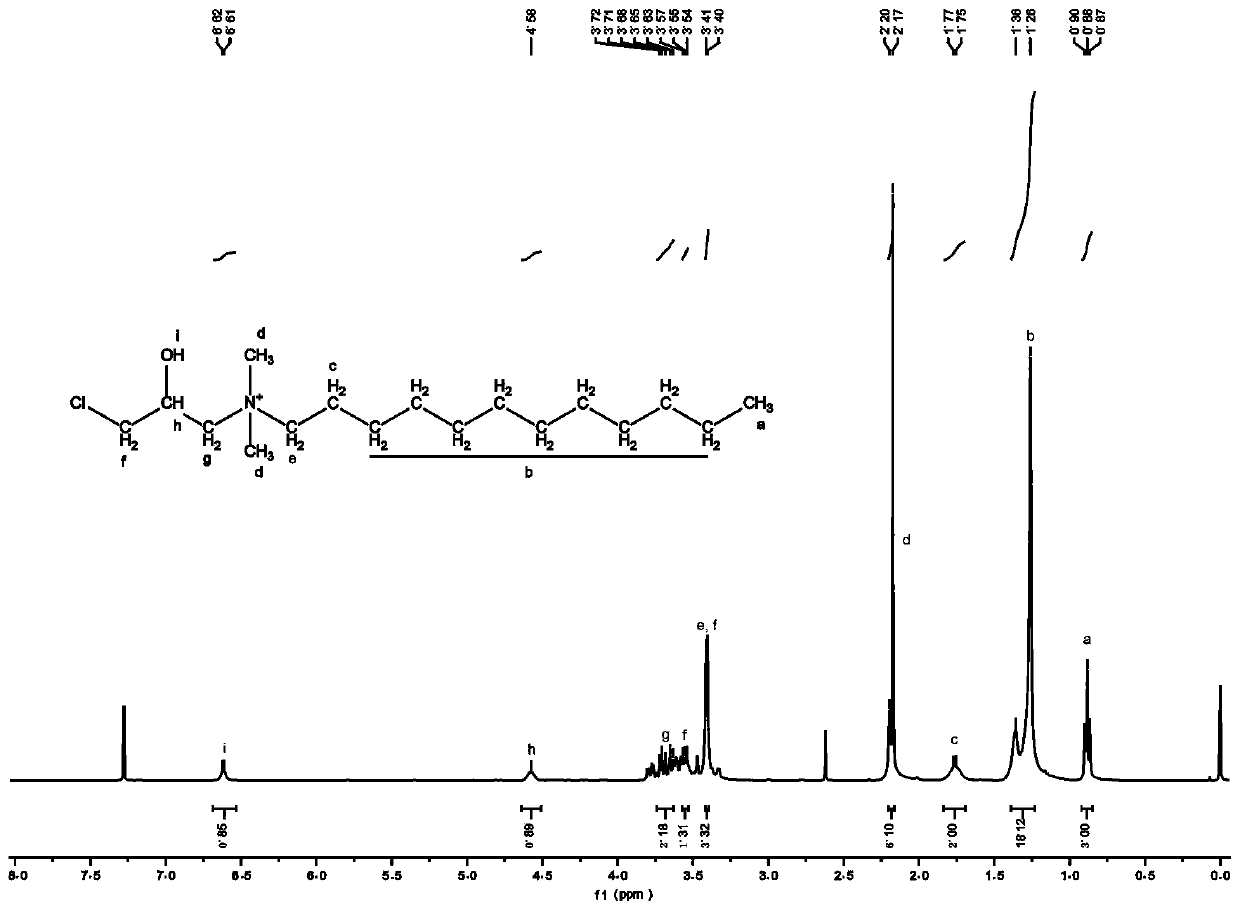

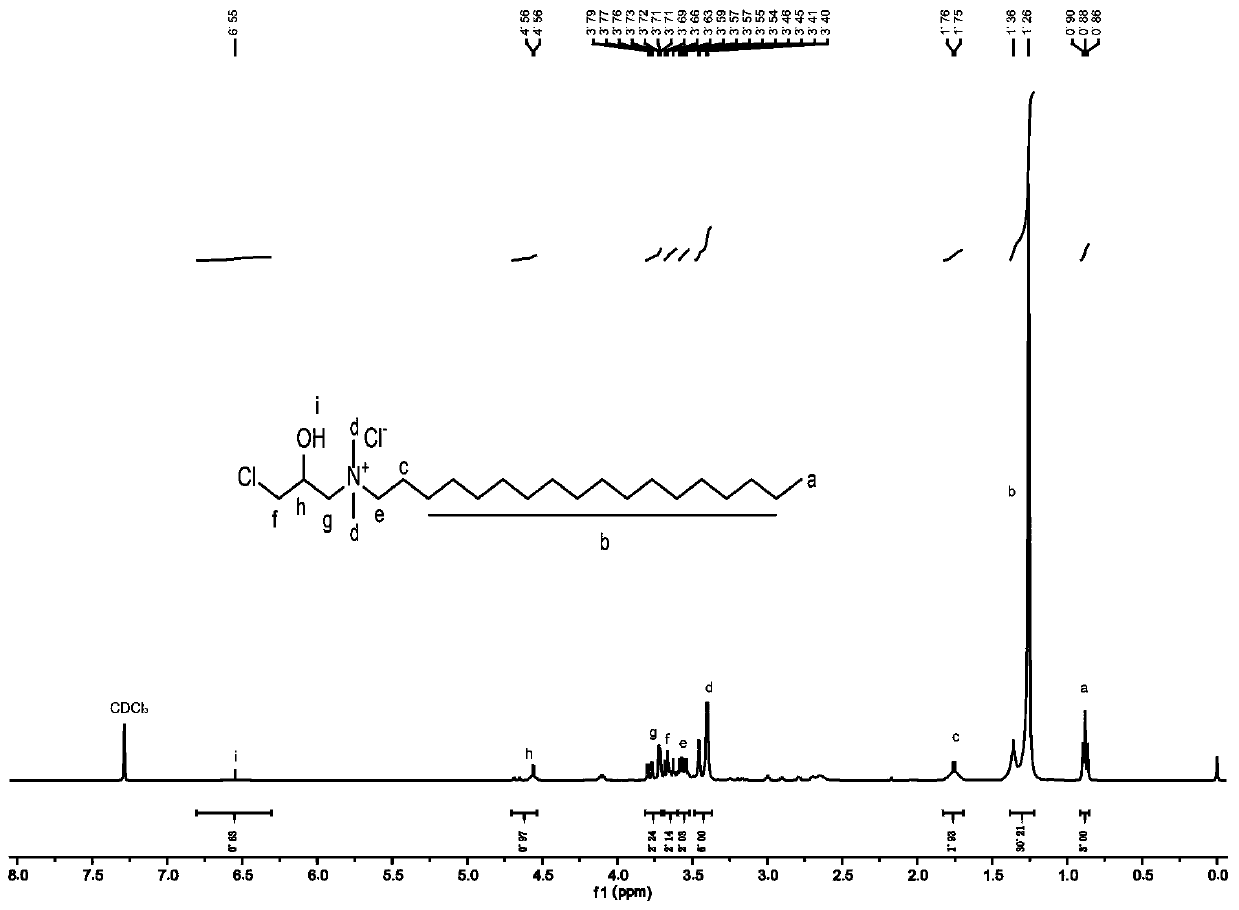

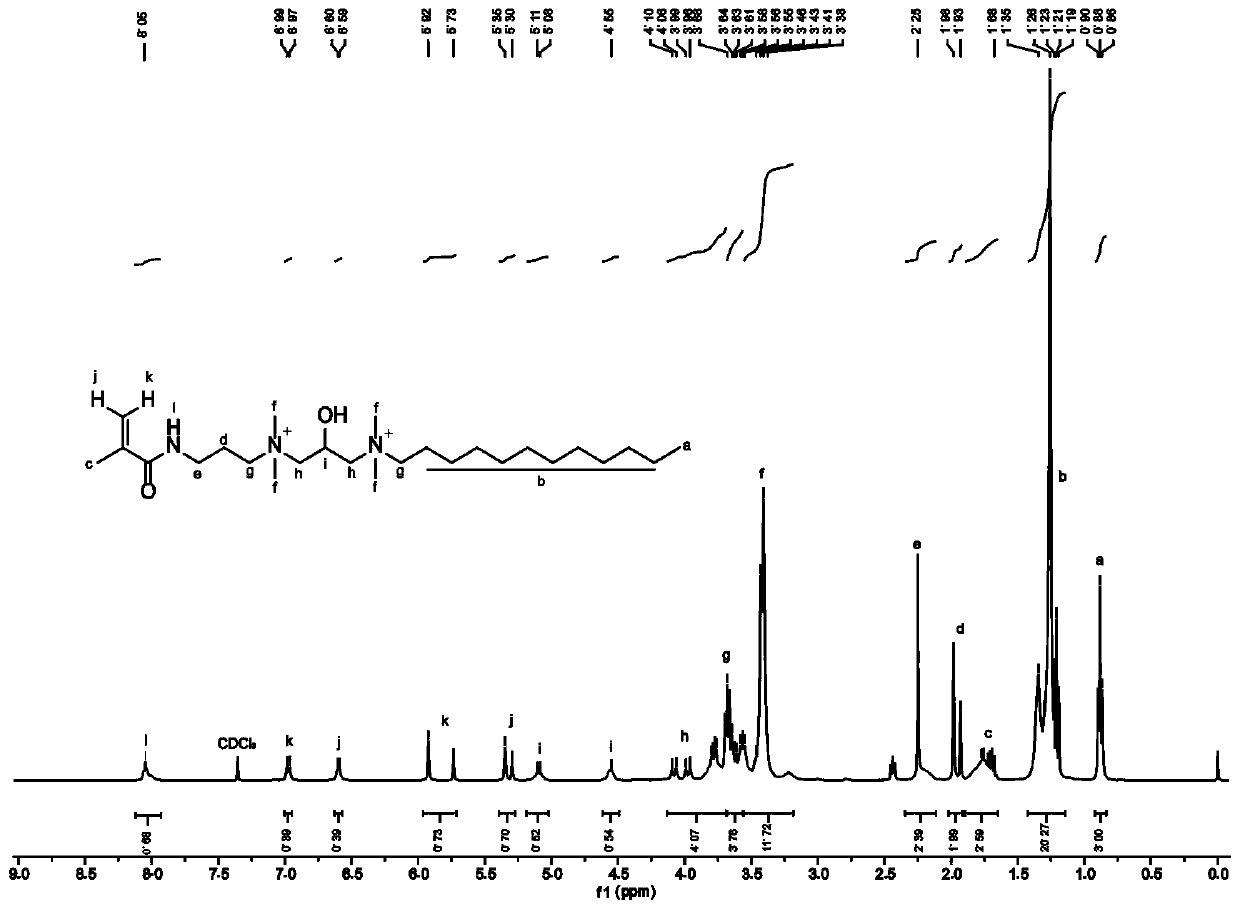

Double electron type polymerizable surfactant monomer, and preparation method and applications thereof

InactiveCN109896974ALow costHigh yieldOrganic compound preparationCarboxylic acid amides preparationEpoxyPolymer science

The invention discloses a double electron type polymerizable surfactant monomer. A preparation method comprises following steps: 1, epoxy chloropropane and a long chain tertiary amine are subjected toring-opening reaction in a hydrochloric acid solution so as to obtain an intermediate EPT; 2, EPT and N-dimethyl aminopropyl methacrylamide are subjected to quaterisation so as to obtain a finial product. The double electron type polymerizable surfactant monomer, acrylamide, acrylic acid, and 2-acrylamido-2-methylpropane sulfonic acid are subjected to polymerization, drying, crushing, and sievingat room temperature so as to obtain a polymer thickening agent powder; the polymer thickening agent powder is prepared into a 0.3wt% solution which is taken as a fracturing fluid. The preparation method is friendly to the environment; cost is low; yield and purity are relatively high; the hydrophobic associated polymer solution based on the monomer possesses excellent viscoelasticity and temperature resistance and salt resistance, so that the fracturing liquid prepared from the monomer is capable of solving technical problems in the prior art that conventional hydrophobic associated polymer fracturing liquid cost is high, and sand suspension capacity is poor.

Owner:SOUTHWEST PETROLEUM UNIV

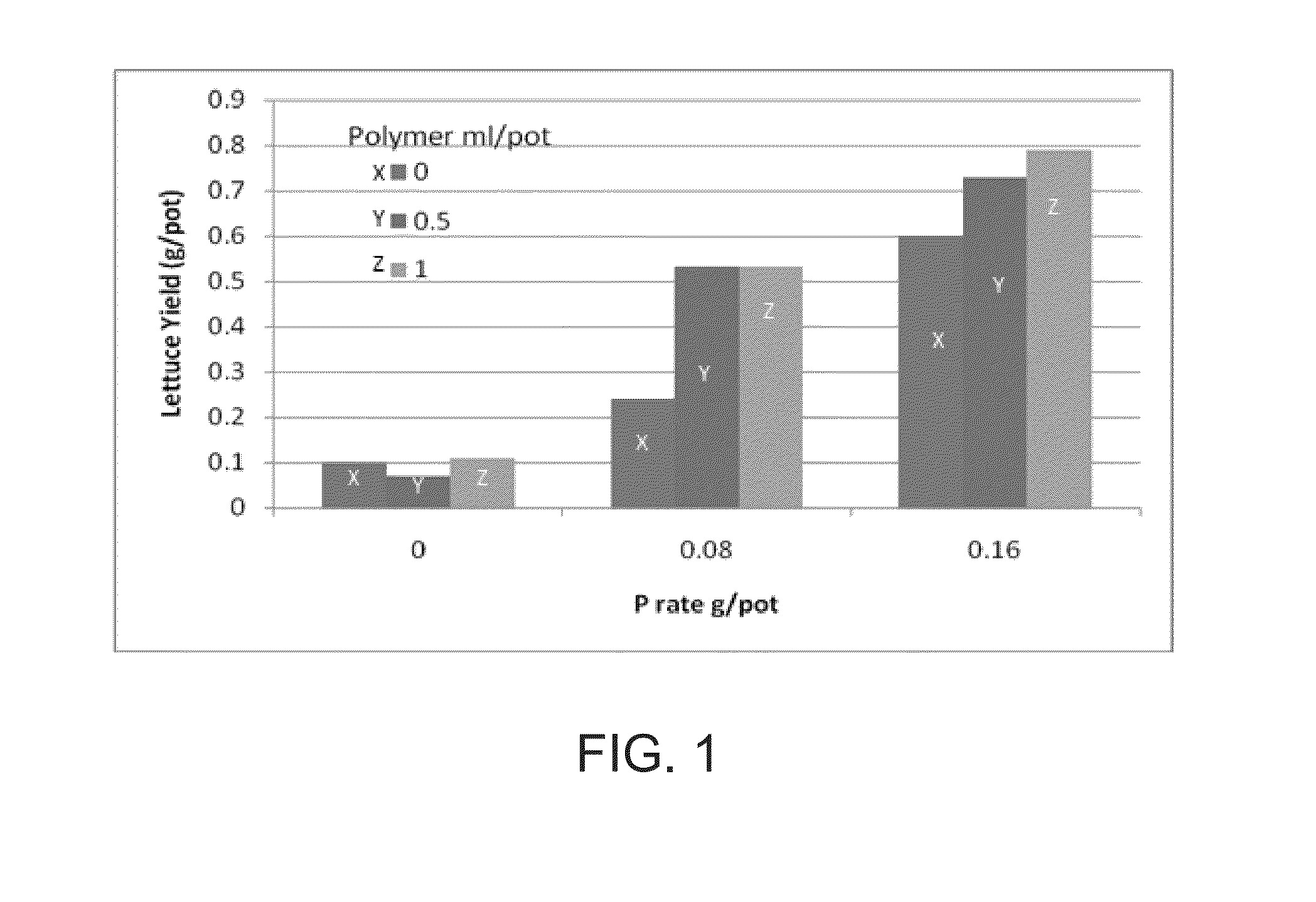

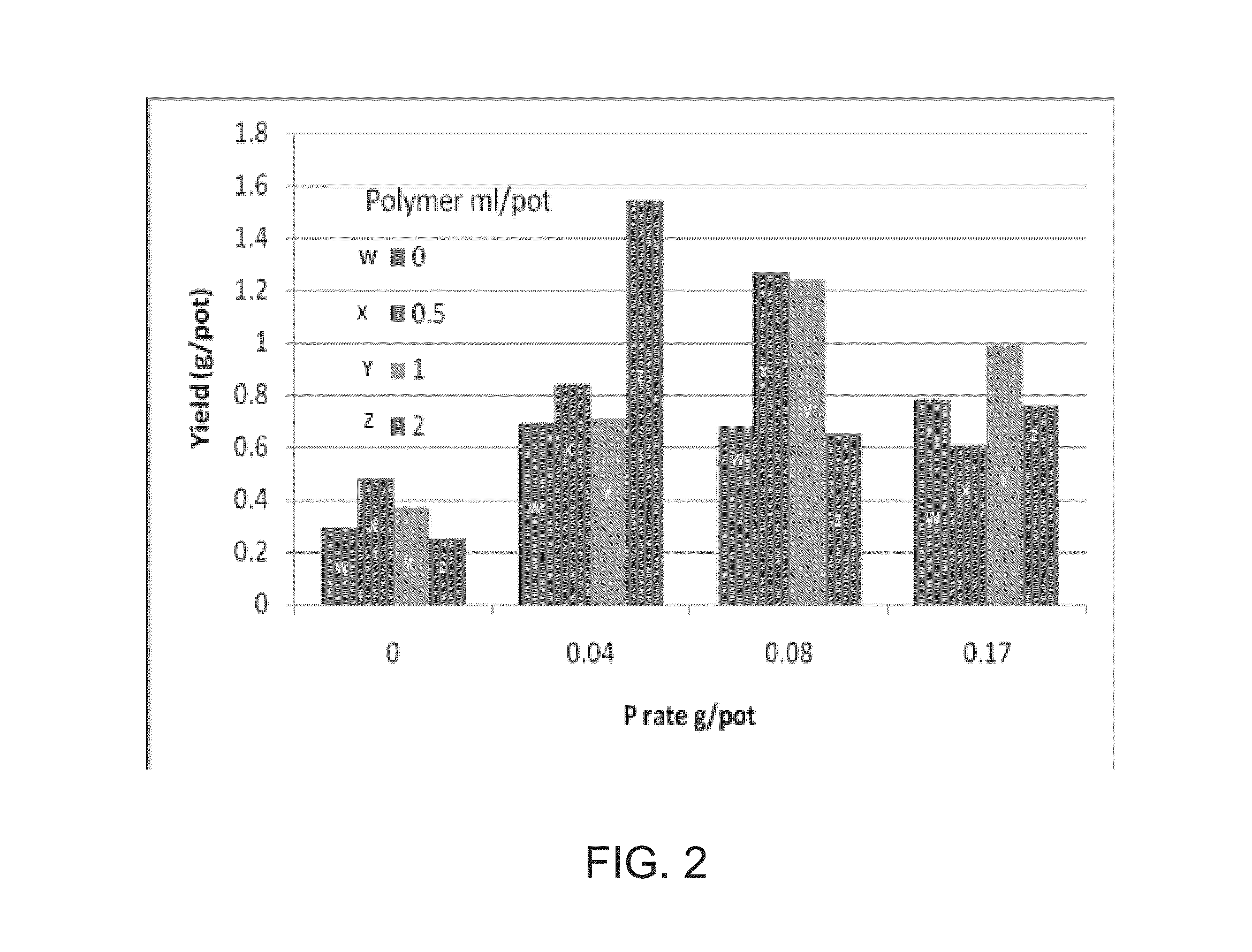

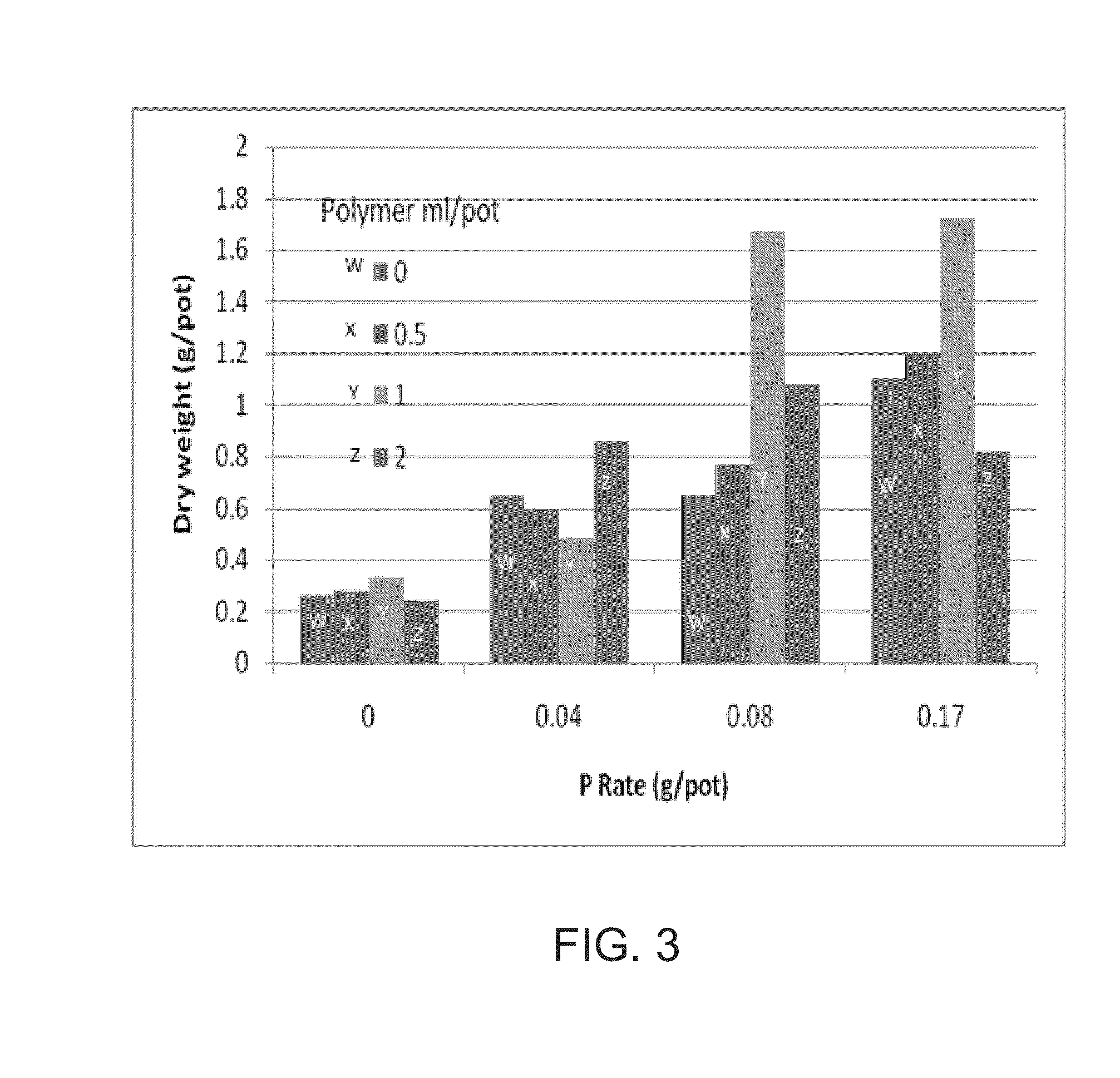

Polymers useful in agricultural applications

ActiveUS20140298872A1Programme controlLiquid fertiliser distributionSulfonateAgricultural irrigation

Methods of coating seeds with polymers and seeds coated with such polymers are disclosed herein. The polymers can be phosphonates, sulfonates, polymers of ethylenically unsaturated carboxylic acids, polyaminopolyethermethylene phosphonate, polysuccinic oligomers, acrylic acid / 2-acrylamido-2-methylpropane sulfonic acid, blends of acrylic acid / 2-acrylamido-2-methylpropane sulfonic acid with polyaminopolyethermethylene phosphonate, sulfomethylated acrylic acid / acrylamide, blends of sulfomethylated acrylic acid / acrylamide with polyaminopolyethermethylene phosphonate, polymaleic acid, acrylic acid / acrylamide copolymers, polyacrylic acid, trimethylglycine hydrochloride, blends of polyaminopolyethermethylene phosphonate with trimethylglycine hydrochloride, and any combination or salt of such polymers. Methods of monitoring, determining, and controlling the concentration of scale inhibitors in an agricultural irrigation system are also disclosed herein.

Owner:ECOLAB USA INC

Composition containing a mixed silicate, a polysaccharide and crosslinked poly(2-acrylamido-2-methyl-propane-sulphonic acid) polymer

The invention relates to a composition containing at least one mixed silicate, at least one polysaccharide and at least one crosslinked poly(2-acrylamido-2-methylpropanesulphonic acid) polymer which is at least 90% neutralized, having use in the cosmetic field as a tightening agent, in particular for tightening the skin and smoothing it so as to immediately attenuate the wrinkles and / or fine lines on the skin.

Owner:LOREAL SA

Low-density water bonding well control fluid

The invention relates to low-density water bonding well control fluid with a density between 1.00g / cm<3> and 1.01g / cm<3>. The well control fluid consists of 150-200 parts by weight of component A and 1 part by weight of component B. The component A consists of the following components in percentages by weight: 0.02-0.05% of fluorinated surfactant, 1.0-1.5% of organic cation surfactant, 0.003-0.005% of copolymer of phosphono-maleic acid and acrylic acid copolymer and the balance of water. The component B is a water absorptive resin polymer. The organic cation surfactant is formed by the reaction of equal molars of benzyl chloride and trimethylamine. The water absorptive resin polymer is a polymer of acrylic acid, acrylamide and 2-acrylamido-2 methylpropane sulfonic acid. The content of thefree water of the low-density water bonding well control fluid is not more than that of 5% of the well control fluid. The viscosity is reduced by not more than 5% after the well control fluid is sheared at the speed of 170S<-1> for 4 hours. The well control fluid can resist 135 DEG C and is suitable for wells with the stratum pressure coefficient which is not more than 0.97MPa / 100m.

Owner:PETROCHINA CO LTD

Soil stabilizer and preparation method thereof

ActiveCN105505400AAbundant raw materialsLow costBuilding constructionsOrganic fertilisersCalcium biphosphateBrick

The invention belongs to the technical field of stabilizers and particularly relates to a soil stabilizer and a preparation method thereof. The soil stabilizer mainly comprises 2-acrylamido-2-methylpropane sulfonic acid, polyacrylamide, sodium sulfate, calcium phosphate, a polysaccharide, sodium lignosulfonate, sodium silicate, sodium hydroxide and water. The formulation of the soil stabilizer provided by the invention is reasonable and scientific in matching and may effectively shorten stabilizing time of soil and enhance soil stabilizing and hardening effects, and experiments show that a solid brick obtained by stabilizing may be as hard as and even harder than a red brick, has waterproof performance also meeting the waterproof standards of red bricks and is an ideal soil stabilizer.

Owner:刘静沂

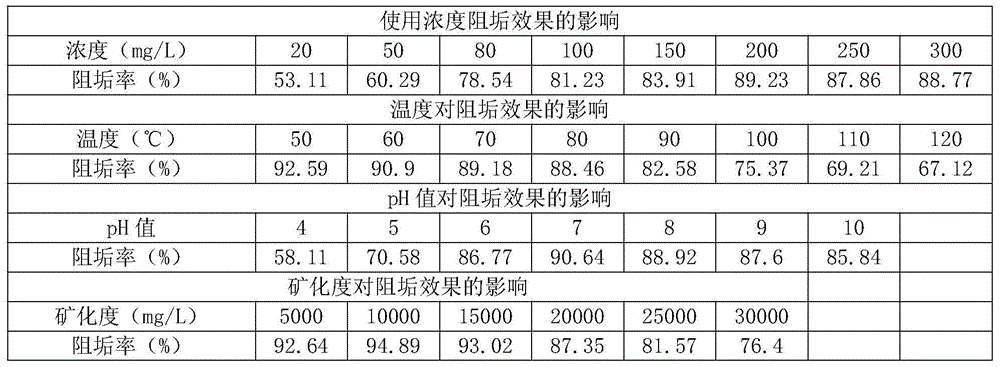

Salt-tolerant and high-temperature-resistant antisludging agent and preparation method thereof

InactiveCN104925968AGood dispersionIncrease the use concentrationTreatment using complexing/solubilising chemicalsAcetic acidDistilled water

The invention discloses a salt-tolerant and high-temperature-resistant antisludging agent. The agent is composed of, by weight, 49.5% of maleic anhydride, 18.0% of crylic acid, 10.5% of vinyl acetate, 1.0% pf 2-acrylamido-2-methylpropane sulfonic acid, 10.5% of ammonium persulfate and 10.5% of distilled water. The prepared antisludging agent is resistant to salt and high temperature, high in dispersion effect, high in use concentration and high in adaptability to the pH value.

Owner:SOUTHWEST PETROLEUM UNIV

High-temperature-resistant slow-release scale inhibitor

InactiveCN106745836ALow costWide variety of sourcesTreatment using complexing/solubilising chemicalsNitrogenous heterocyclic compoundWater treatment

The invention relates to the field of water treatment chemicals, in particular to a high-temperature-resistant slow-release scale inhibitor. The high-temperature-resistant slow-release scale inhibitor comprises the following substances in parts by weight: 6-12 parts of a starch substrate, 12-15 parts of acrylic acid, 6-10 parts of 2-acrylamido-2-methylpropane sulfonic acid, 20-25 parts of polyaspartic acid, 5-10 parts of a nitrogen-containing heterocyclic compound composition, 10-15 parts of water-soluble oxidative inorganic metal salt, 5-10 parts of water-soluble inorganic zinc salt, 5-10 parts of homopolycarboxylic acid, 5-10 parts of lignosulfonate, 10-15 parts of sodium polyhydroxy carboxylate, 5-10 parts of a cellulose derivative, 5-8 parts of a composite initiator, 3-6 parts of a dispersed activator and 5-10 parts of an auxiliary corrosion inhibitor. The high-temperature-resistant slow-release scale inhibitor provided by the invention is low in cost, wide in source, friendly to environment, nontoxic and free from secondary pollution; the scale inhibitor is resistant to high temperature, can effectively inhibit the formation of calcium carbonate scales, calcium sulfate scales, barium sulfate scales and calcium phosphate scales in an oilfield pipeline and a boiler, has a good slow release effect on the pipeline and the boiler, and can prolong the service life.

Owner:QINGDAO HUANAN SHENGYUAN FRUIT IND CO LTD

Well cement additives, compositions and methods

Improved well cement additives, compositions and methods of using the compositions are provided. The well cement additives are basically comprised of a first monomer selected from the group of 2-acrylamido-2-methylpropane sulfonic acid, 2-allyloxy-2-hydroxy-1-propane sulfonic acid and vinylsulfonic acid, a second monomer selected from the group of N,N-dimethylacrylamide, acrylamide, N-vinylpyrrolidone, N-vinylacetamide and acrylonitrile and a third monomer selected from the group of C6 to C22 dimethylaminopropylmethacrylamide bromide, chloride and iodide and C6 to C22 dimethylaminoethylmethacrylate bromide, chloride and iodide.

Owner:HALLIBURTON ENERGY SERVICES INC

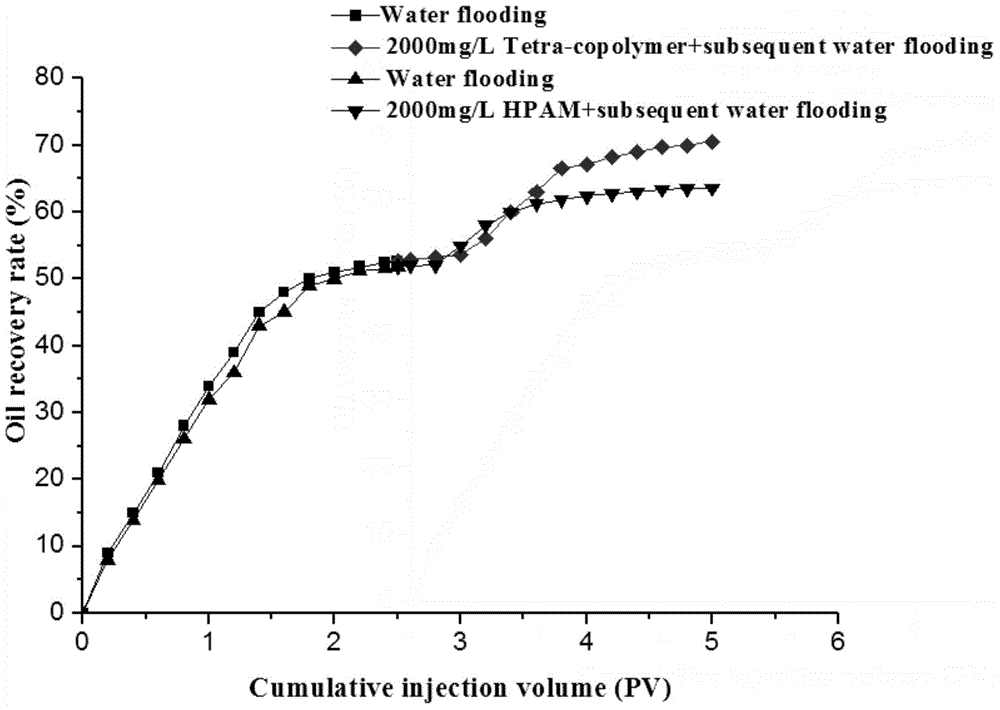

Preparation method of AA (acrylic acid)/AM (acrylamide)/AMPS (2-acrylamido-2-methylpropane sulfonic acid)/MAH (maleic anhydride)-beta-CD (cyclodextrin) quaternary oil displacement agent

InactiveCN104804149AThe synthesis method is simpleOil displacement effect is goodDrilling compositionSalt resistanceCyclodextrin

The invention discloses a preparation method of an AA (acrylic acid) / AM (acrylamide) / AMPS (2-acrylamido-2-methylpropane sulfonic acid) / MAH (maleic anhydride)-beta-CD (cyclodextrin) quaternary oil displacement agent. The preparation method has the advantages as follows: the synthetic method is simple, the oil displacement effect is remarkable, the yield is high and the cost is low. Cyclodextrin is grafted to a chain of a copolymer with a simple method, the research on temperature resistance, salt resistance and increase of oil recovery ratio is performed, salt used in an experiments comprises sodium chloride and calcium chloride, and experiment results show that the temperature resisting and salt resisting performance of the quaternary copolymer can be improved and the oil recovery ratio of the quaternary copolymer can be increased by means of introduction of cyclodextrin.

Owner:SOUTHWEST PETROLEUM UNIV

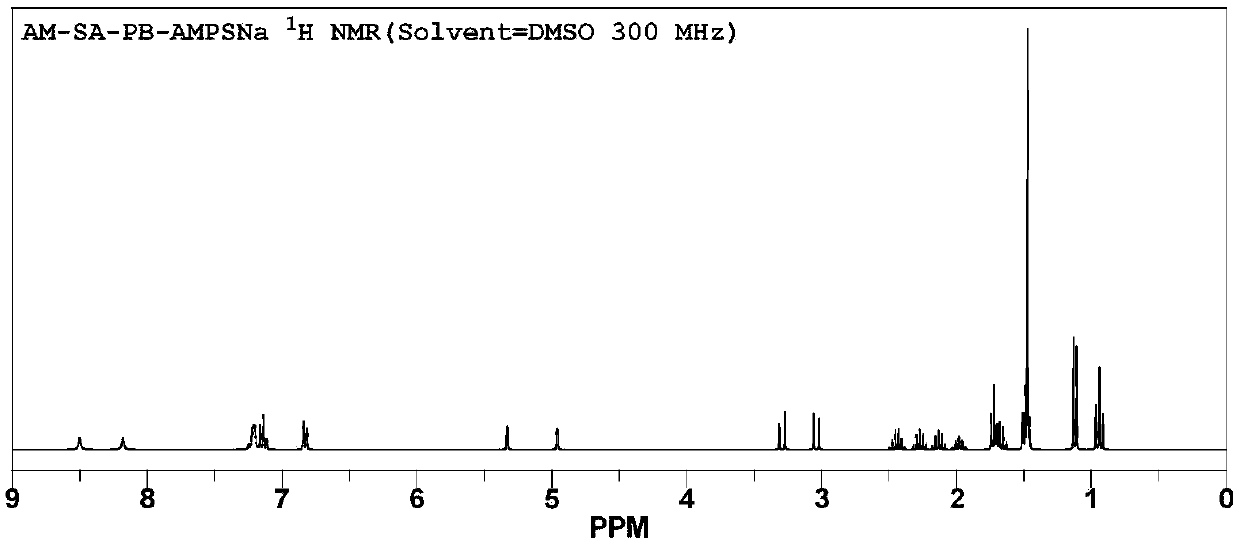

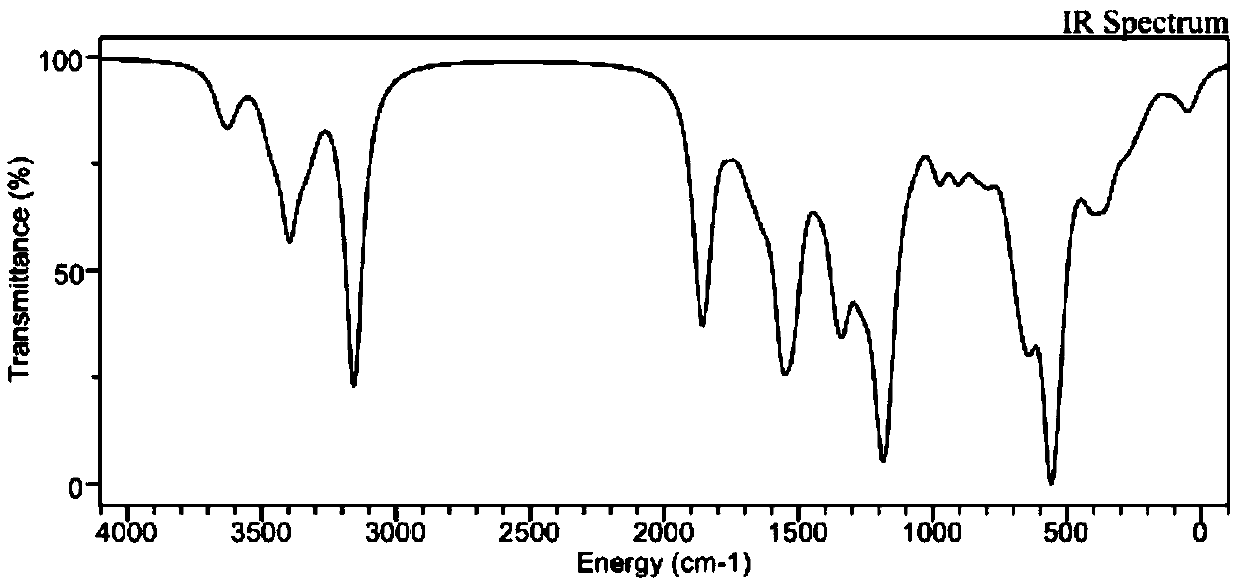

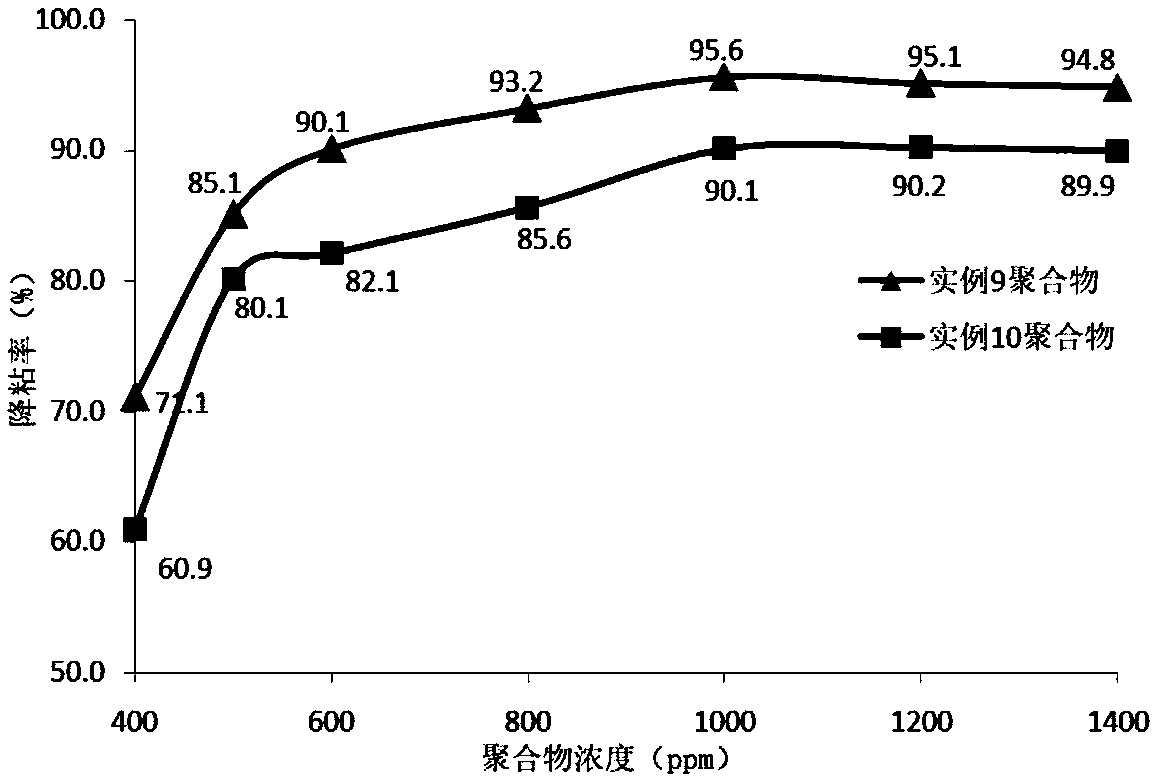

Thick oil viscosity reducer and preparation method and application thereof

The invention discloses a thick oil viscosity reducer and a preparation method and application thereof. The thick oil viscosity reducer is a quaternary oligomer, namely acrylamide (AM)-SA-phenyl-1-butene(PB)-2-acrylamido-2-methylpropane sulfonic acid (AMPS) Na and is formed by four monomers of the AM, acrylic acid (AA), the PB and the AMPS which are polymerized. The thick oil viscosity reducer hasthe advantages that the viscosity reducing effect is good, the cost is low, and the viscosity does not rebound after still standing, a preparation process is simple, the cost is low, and the thick oil viscosity reducer is suitable for practical application to oil fields.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Formulations and method for post-CMP cleaning

ActiveUS8765653B2Organic detergent compounding agentsDetergent mixture composition preparationSulfonateAmmonium hydroxide

The present invention is a method of cleaning to removal residue in semiconductor manufacturing processing, comprising contacting a surface to be cleaned with an aqueous formulation having a polymer selected from the group consisting of acrylamido-methyl-propane sulfonate) polymers, acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer and mixtures thereof and a quaternary ammonium hydroxide having greater than 4 carbon atoms or choline hydroxide with a non-acetylinic surfactant.The present invention is also a post-CMP cleaning formulation having the components set forth in the method above.

Owner:VERSUM MATERIALS US LLC

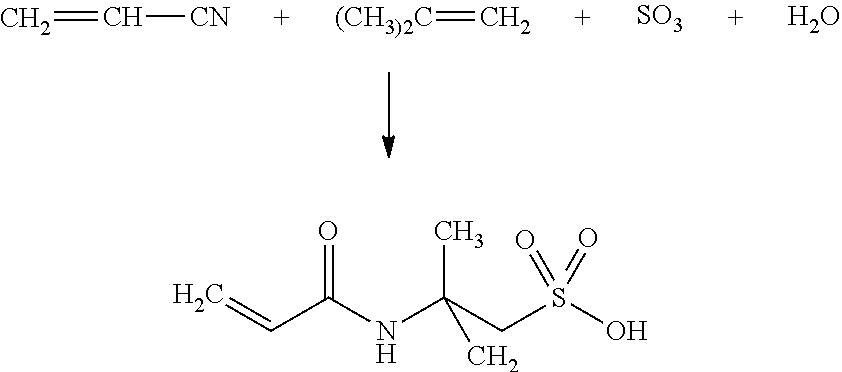

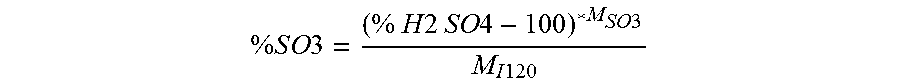

Method for producing the 2-acrylamido-2-methylpropane sulfonic acid monomer and polymer comprising said monomer

The invention relates to a method for producing 2-acrylamido-2-methylpropane sulfonic acid. Said method consists in reacting together acrylonitrile, fuming sulfuric acid and isobutylene. It is characterized in that the isobutylene contains less than 1000 ppm of butadiene and less than 1000 ppm of butene.

Owner:S P C M SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com