Thick oil viscosity reducer and preparation method and application thereof

A heavy oil viscosity reducer and oil displacement technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as poor viscosity reduction effect and viscosity rebound, and achieve convenient construction, reduce cohesion, and improve heavy oil. The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

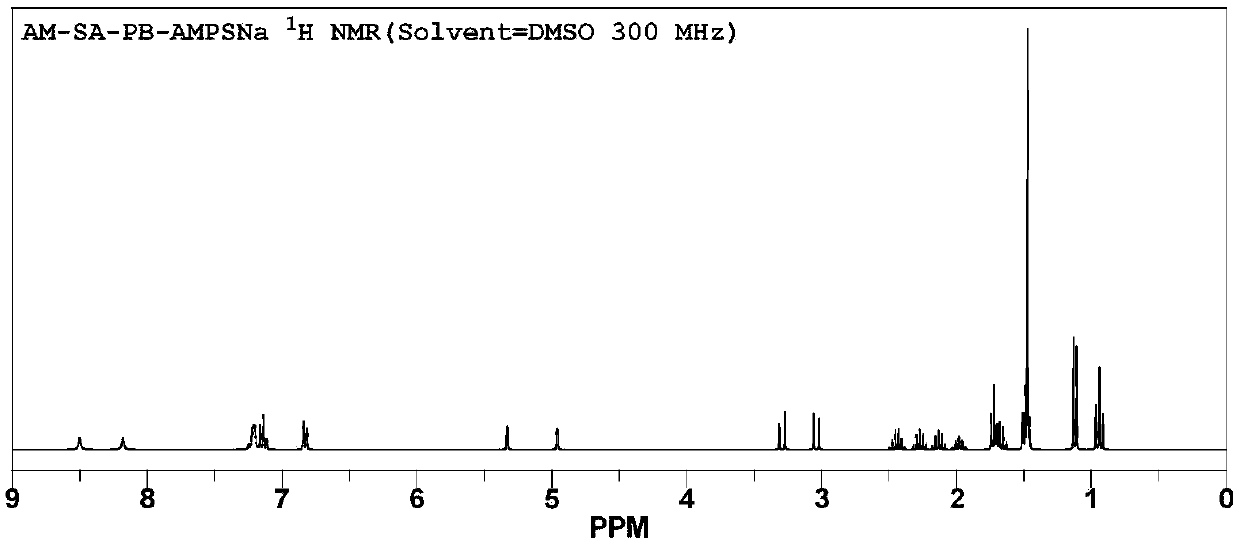

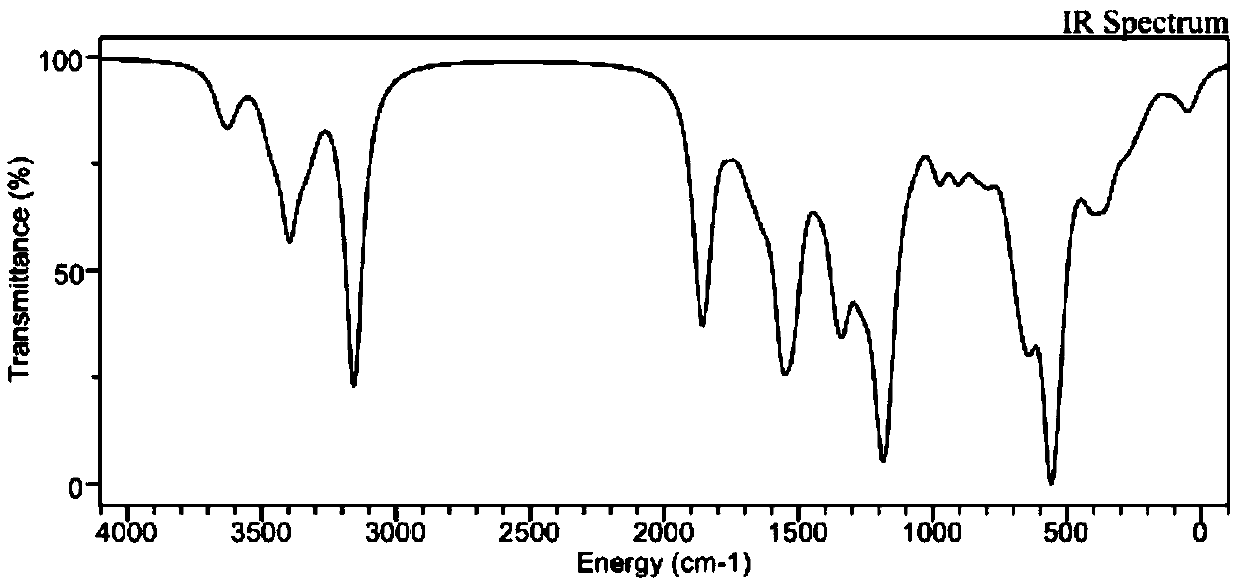

Method used

Image

Examples

Embodiment 1

[0042] Add 300g of deionized water and 100g of kerosene into a 1500mL three-neck round bottom flask, stir with a magnet, then add 60g of acrylamide (AM), 10g of sodium acrylate (AA), 20g of 1-butenylphenyl (PB) and propylene Amide-2-methylpropanesulfonic acid (AMPS) 5g, stirred until completely dissolved and formed a white emulsion. Add catalyst tetramethylethylenediamine (TEMED) 0.15g subsequently, add Na after stirring evenly 2 CO 3 Adjust the pH to 8. The temperature was raised to 70°C, and nitrogen gas was passed through to remove oxygen for 30 minutes. Then add 5g of isopropanol, 0.15g of ammonium persulfate and 0.15g of azoisobutyronitrile (AIBN), react until the solution becomes viscous and when the magnet stops rotating, turn off the stirring and stop the nitrogen, and react for 8h. The gel block in the flask was taken out, cut into pieces, and then placed in an oven at 80° C. for heating and dehydration for 6 hours, ground and granulated, and the yield was 75.2%. ...

Embodiment 2-11

[0047] Adopt the technical process identical with embodiment 1, the selection of concrete parameter is referring to table 1, and wherein t is the reaction time:

[0048] Table 1 embodiment 2-10 specific experimental parameters

[0049]

[0050]

[0051] Known by embodiment 2-4, catalyst consumption increases and can improve reaction yield, and when TEMED mass fraction exceeds 0.45%, reaction yield no longer increases; Embodiment 5 and 6 know, initiator consumption improves and also can increase reaction yield, When the mass fraction exceeds 0.3%, the reaction yield no longer increases; as can be seen from Example 5, improving the consumption of chain transfer isopropanol has no effect on the reaction yield; as can be seen from Examples 8-10, the increase of monomer consumption can obviously improve Reaction yield, but when the weight fraction of AM, AA, PB and AMPS exceeds 70, 20, 30 and 10, the reaction detonates and the product cannot be obtained. In summary, the reac...

Embodiment 12

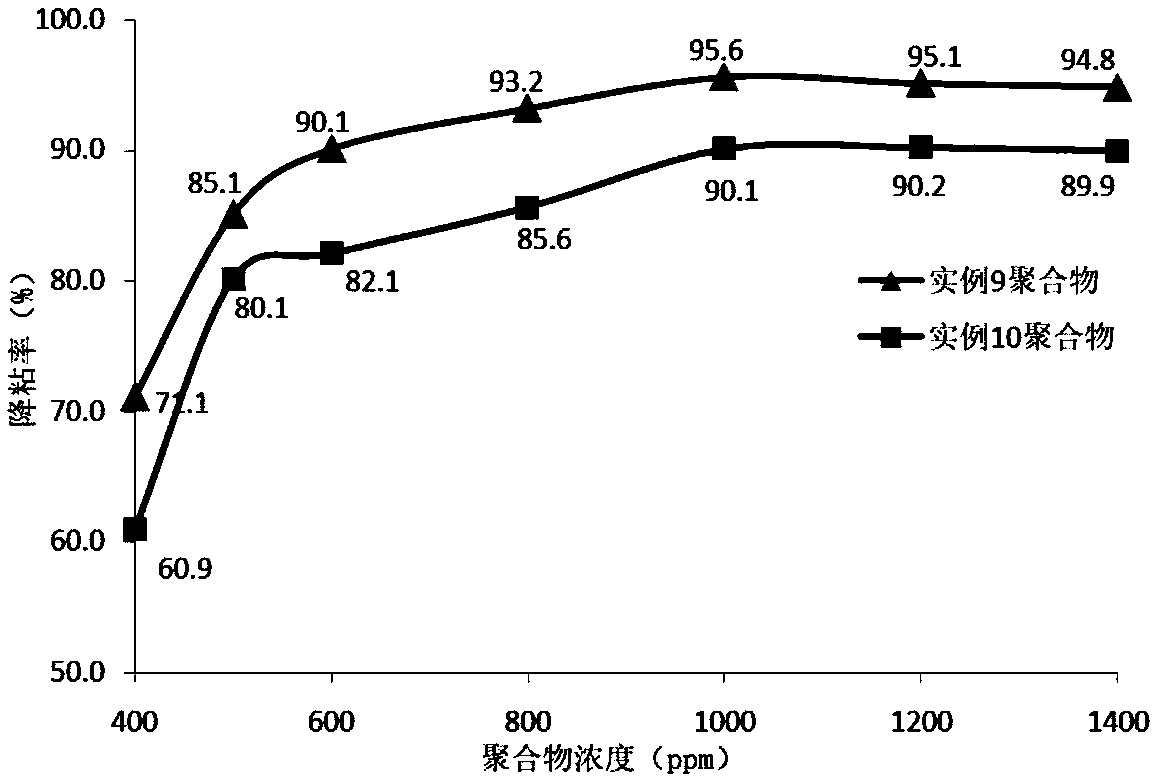

[0053] The polymers 9 and 10 prepared in the above Examples 9 and 10, according to the enterprise standard "Q / SH1020 1519-2013 General Technical Conditions for Heavy Oil Viscosity Reducing Agents" of Sinopec Shengli Administration, have a degassed viscosity of 1600mPa at 50°C Viscous reduction test was carried out on the heavy oil sample a of s, and the viscosity reduction results are shown in image 3 :

[0054] Depend on image 3 According to the data in , the viscosity reduction rate of the polymer concentration of 400ppm is only 60.9% and 71.1%, and when it rises to 500ppm, the viscosity reduction rate increases significantly, so the minimum effective concentration is 500ppm. The viscosity reduction rate increases with the increase of polymer concentration, but when the concentration is higher than 1000ppm, the viscosity reduction effect does not continue to increase, but shows a downward trend. This is because the carbon chain of the polymer is curled up at high concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com