Patents

Literature

373results about How to "Reduce cohesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of using water-in-oil emulsion to remove oil base or synthetic oil base filter cake

ActiveUS7481273B2Improve breathabilityHighly efficient in breakingCleaning apparatusScale removal and water softeningParticulatesParaffin wax

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

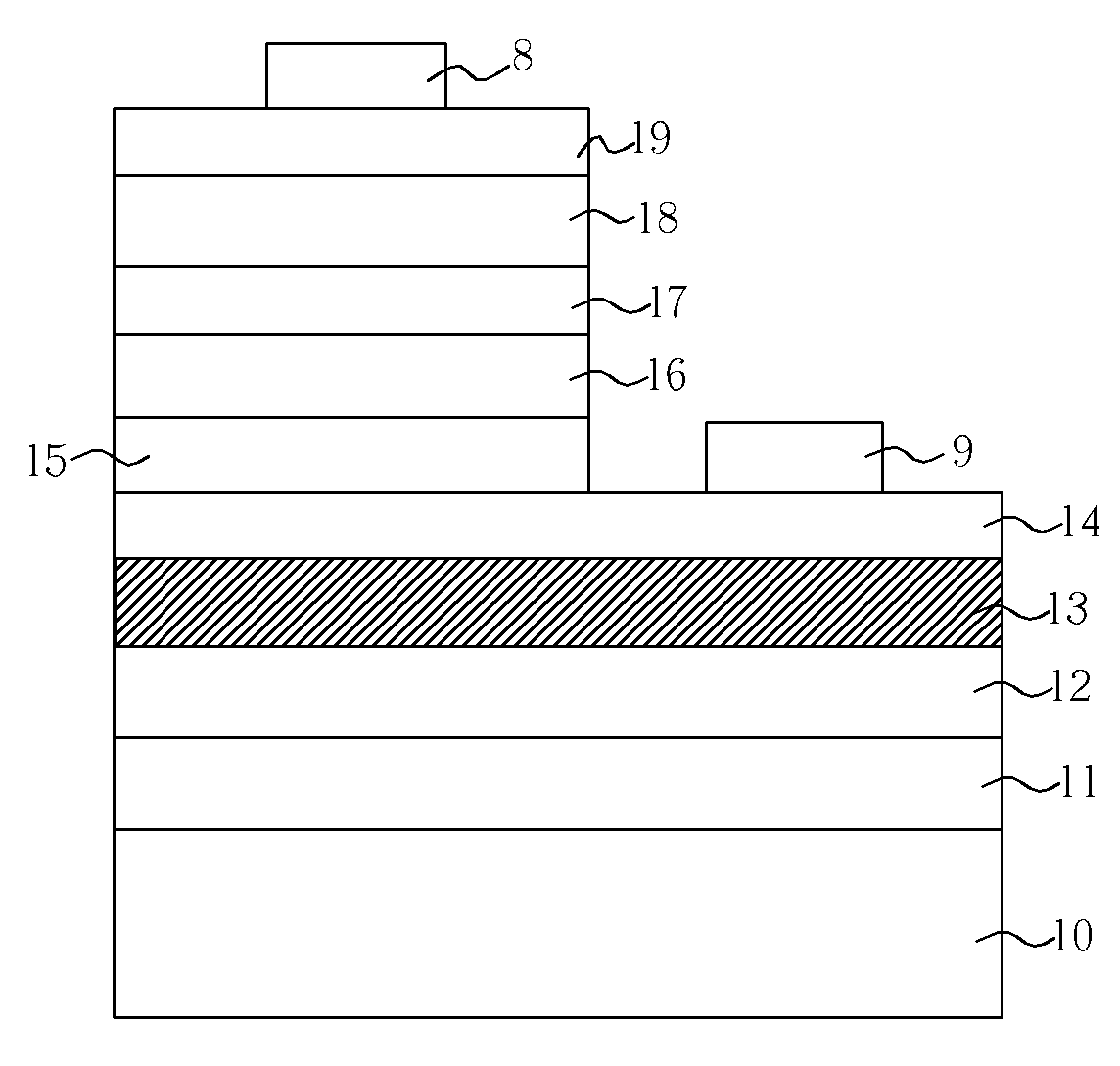

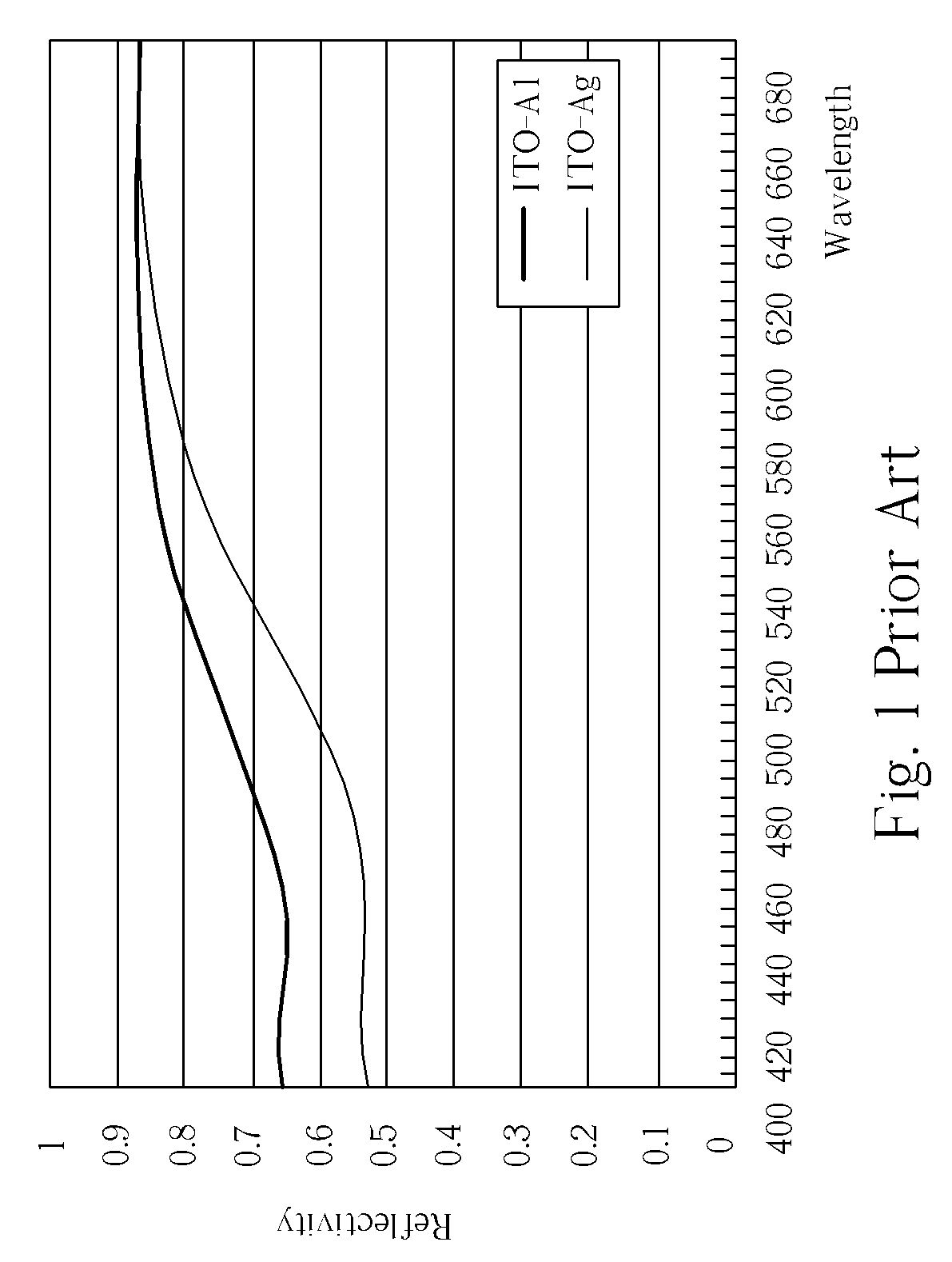

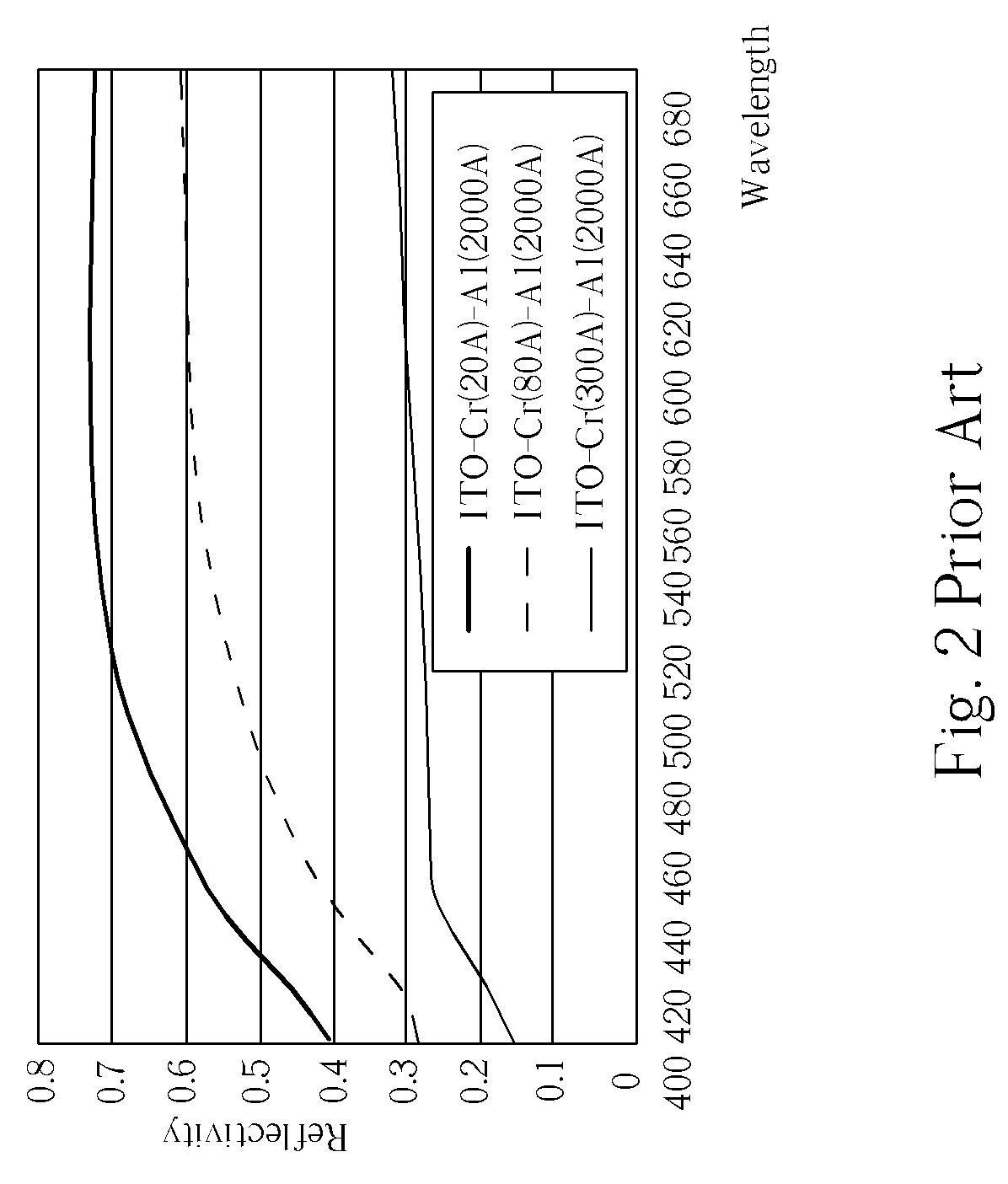

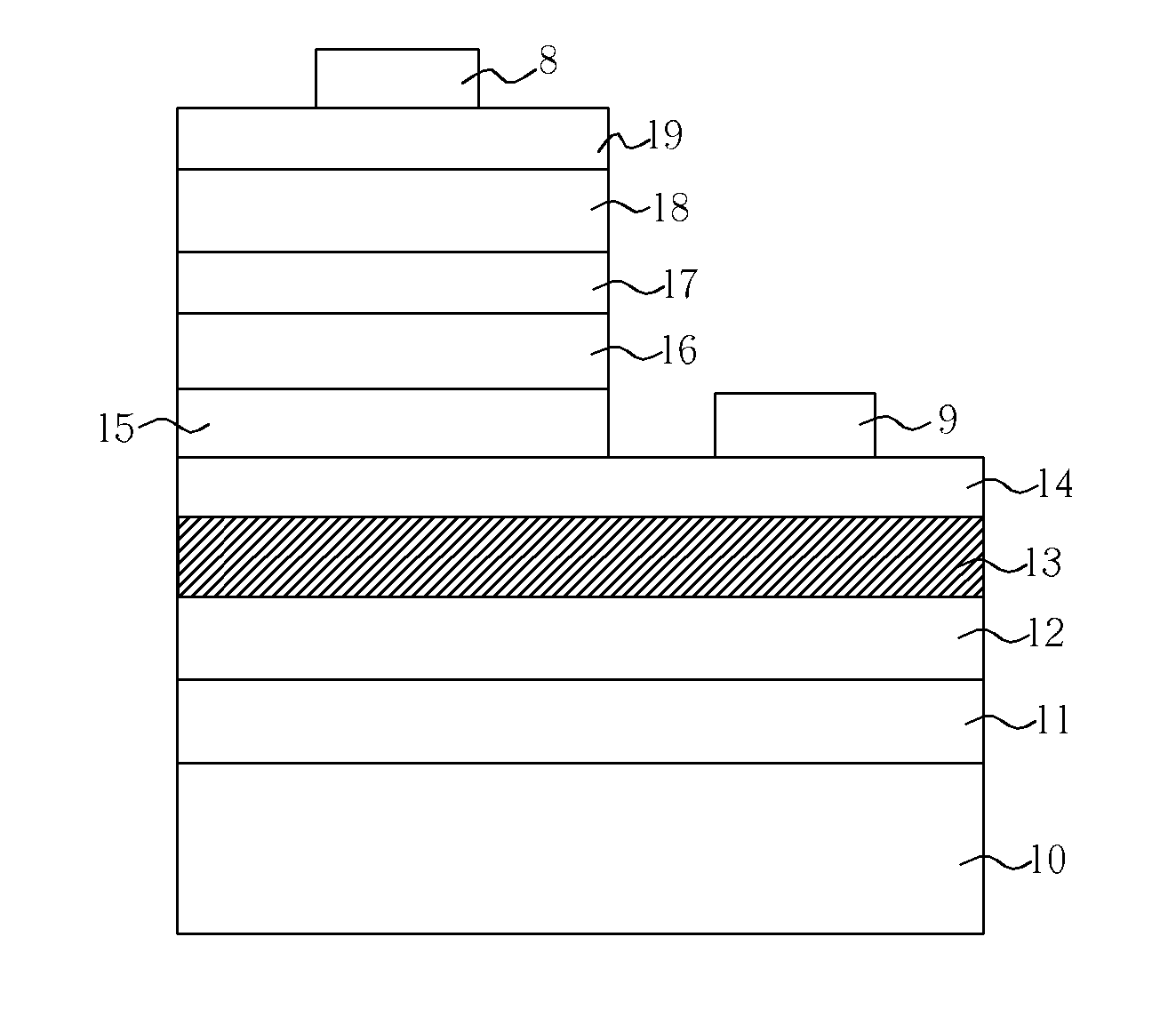

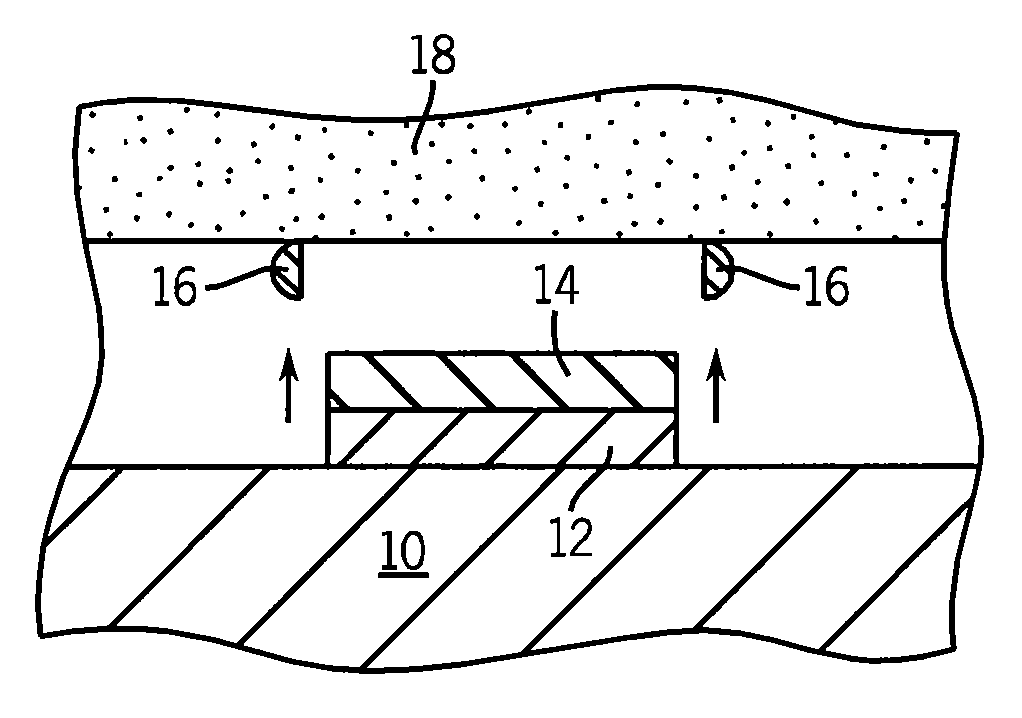

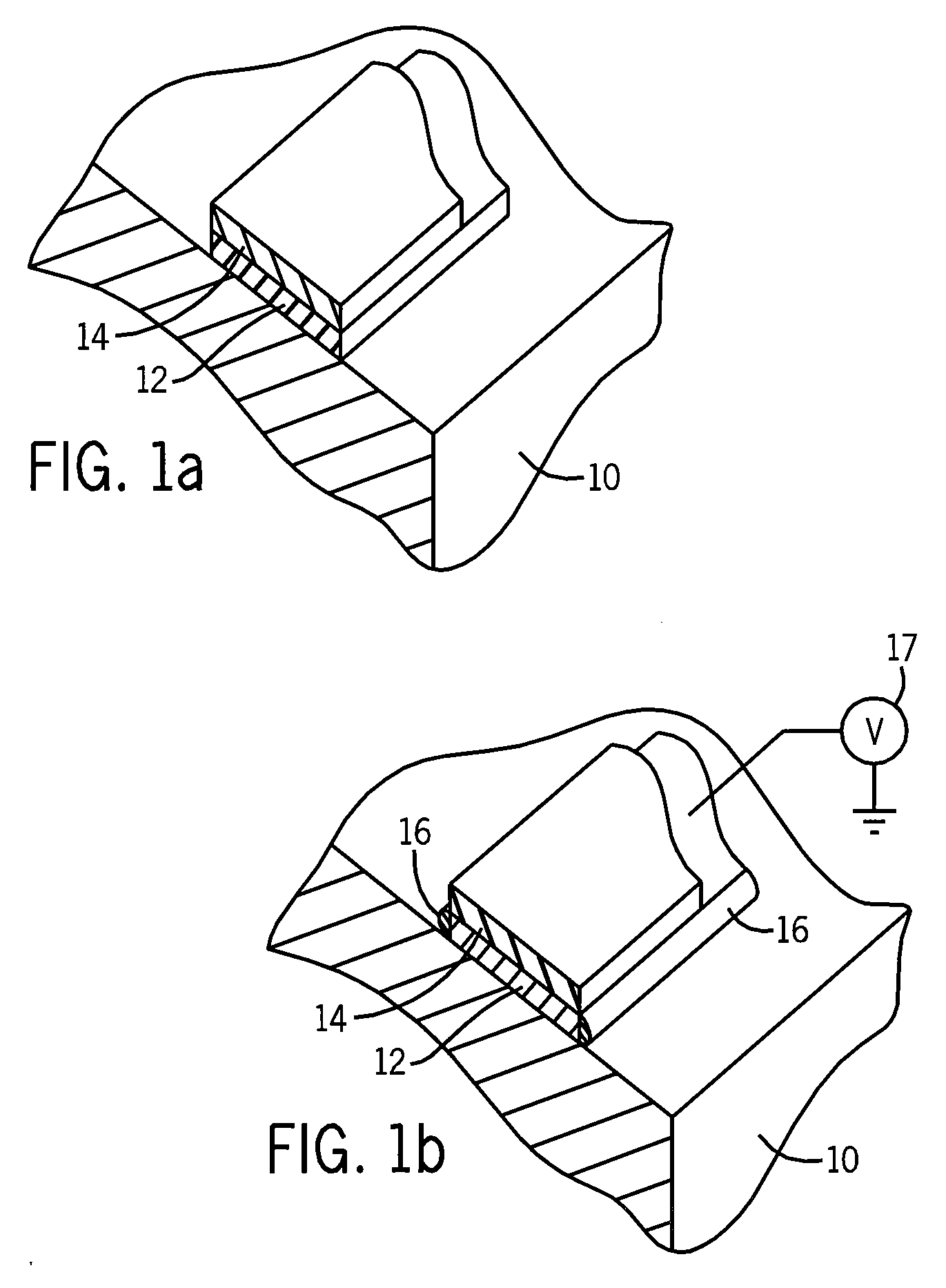

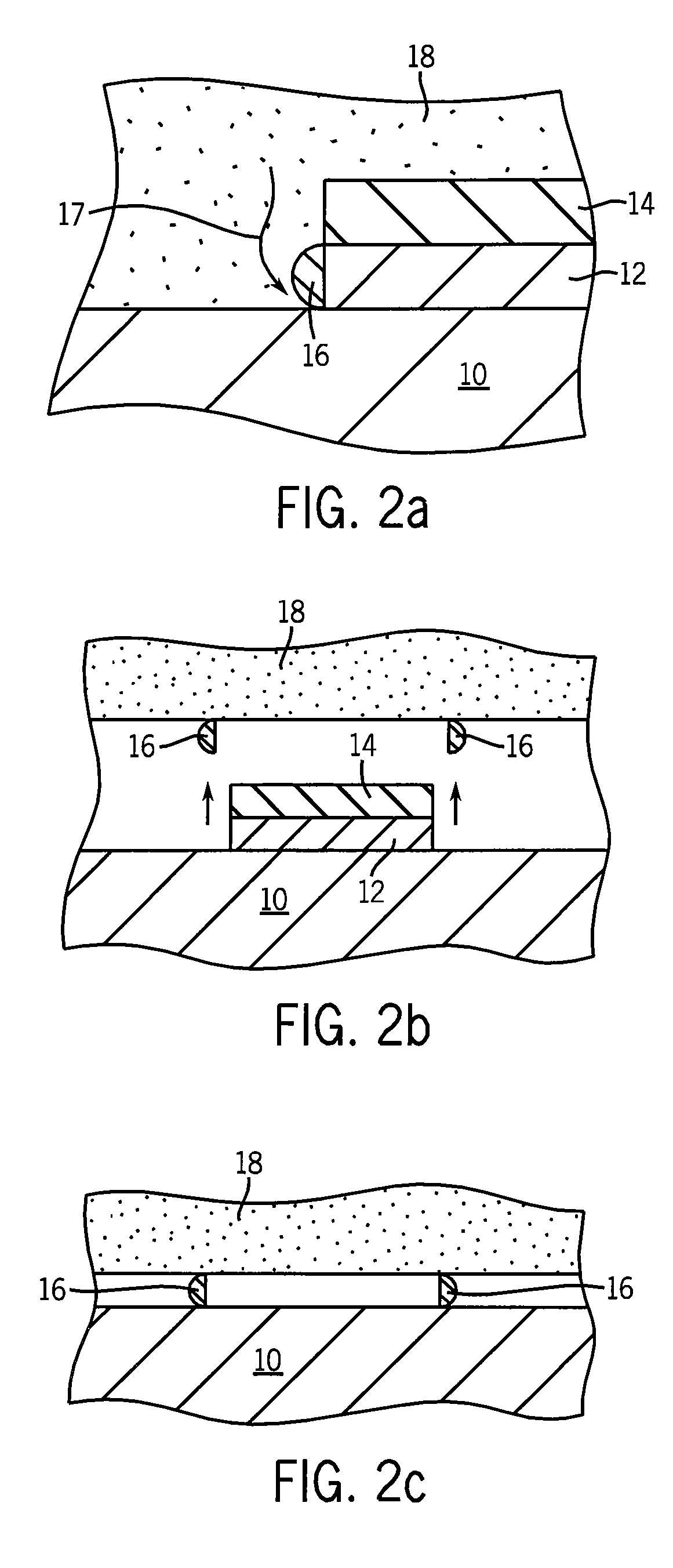

Light emitting diode having an omnidirectional reflector including a transparent conductive layer

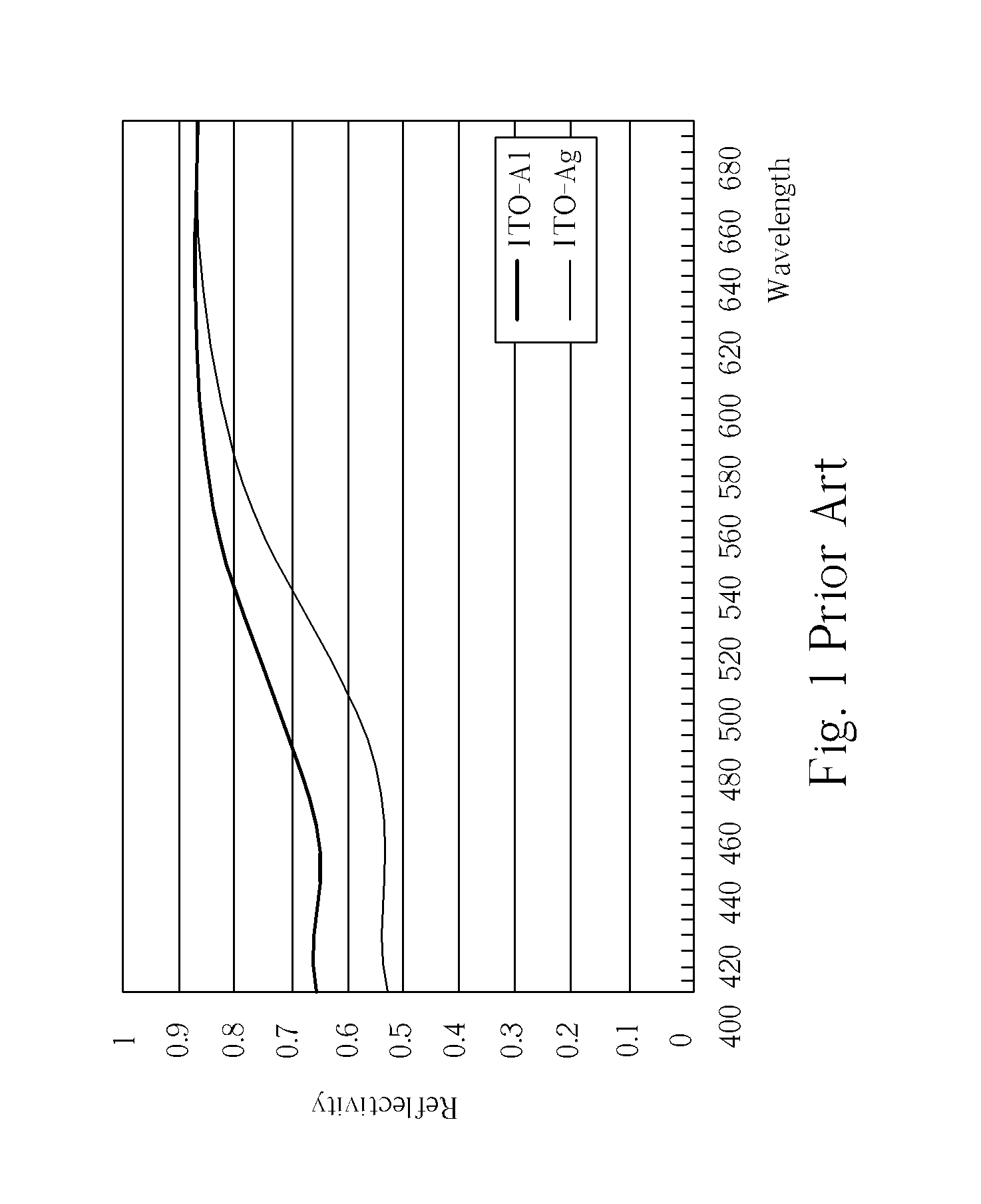

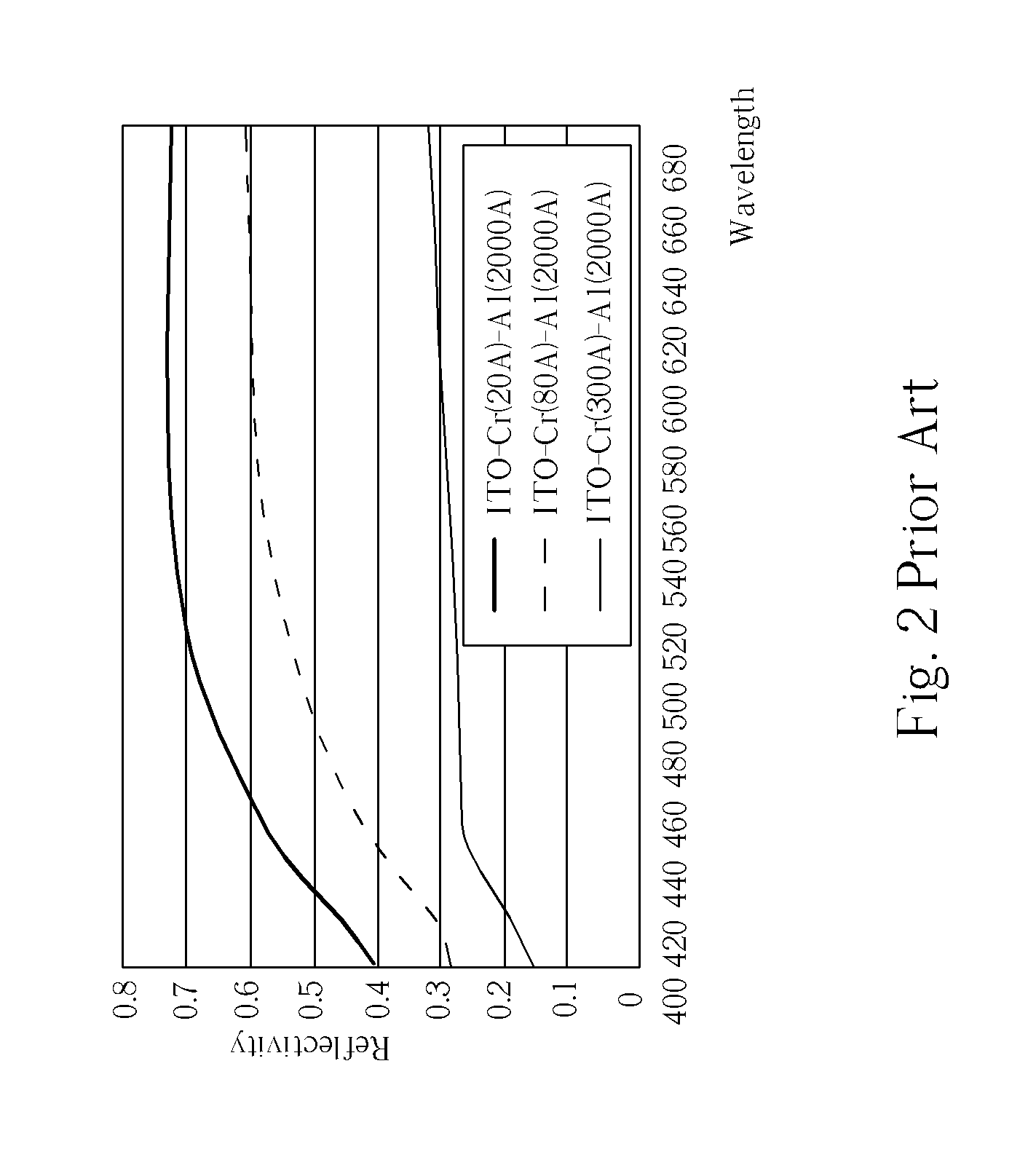

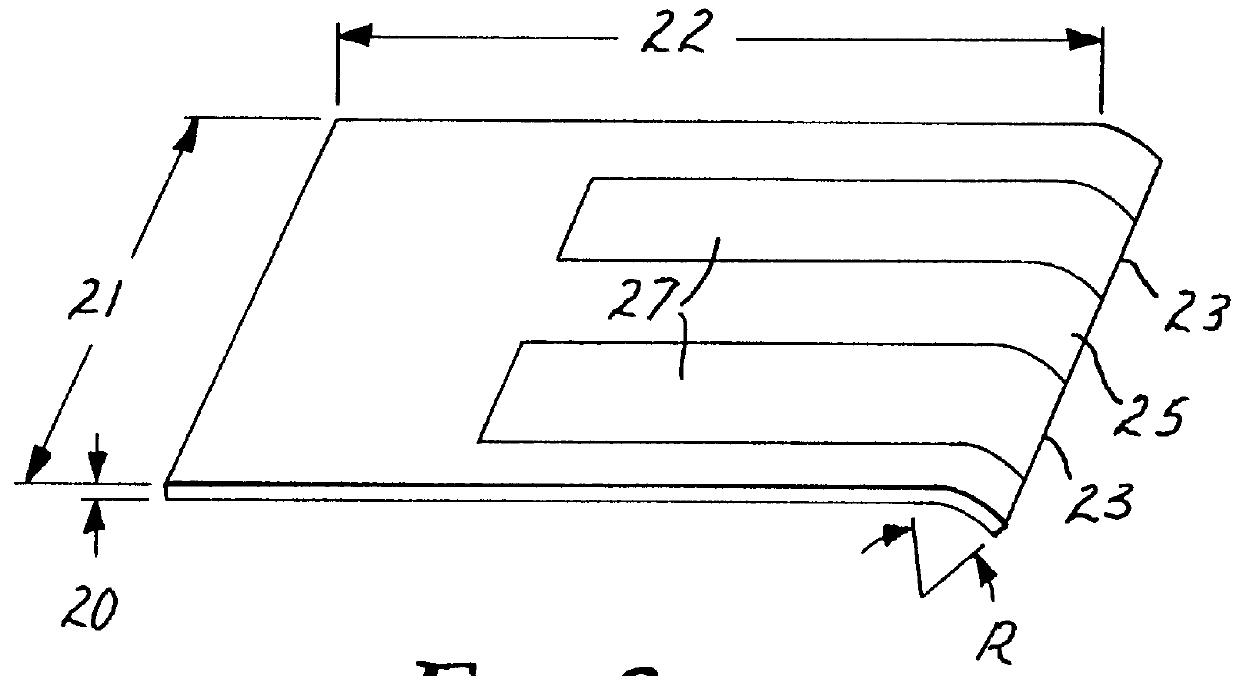

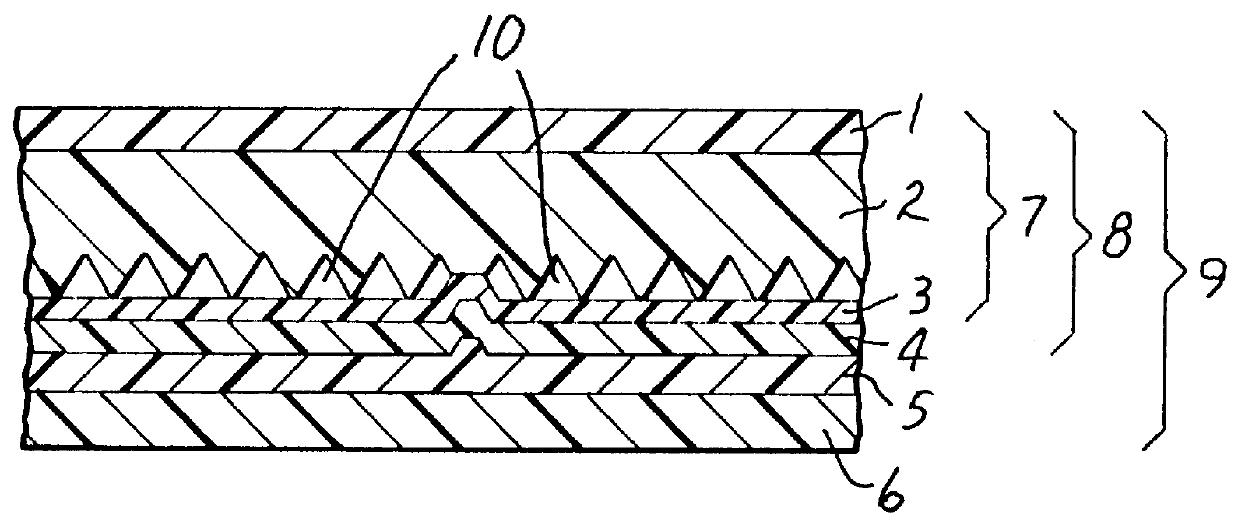

ActiveUS7326967B2Improve reflectivityIncrease brightnessSemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeReflectivity

The present invention is related to a light emitting diode of an omnidirectional reflector providing with a transparent conductive layer. In the present invention, a cohesion layer is formed between a transparent layer and a metal reflection layer to improve the cohesive force therebetween and increase the reflectivity of the light emitting diode, so as the present invention can enhance the light-emitting efficiency of the light emitting diode.

Owner:EPISTAR CORP

Light emitting diode having an omnidirectional reflector including a transparent conductive layer

ActiveUS20060006402A1Improve cohesionIncrease brightnessSemiconductor/solid-state device manufacturingSemiconductor devicesReflective layerLight-emitting diode

The present invention is related to a light emitting diode of an omnidirectional reflector providing with a transparent conductive layer. In the present invention, a cohesion layer is formed between a transparent layer and a metal reflection layer to improve the cohesive force therebetween and increase the reflectivity of the light emitting diode, so as the present invention can enhance the light-emitting efficiency of the light emitting diode.

Owner:EPISTAR CORP

Compositions for treating a well penetrating a subterranean formation and uses thereof

ActiveUS20070265171A1Excellent particle suspension capacityAvoid re-depositionScale removal and water softeningCleaning apparatusParaffin waxWater in oil

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

Retroreflective sheeting articles

InactiveUS6012818ASuitable flexibility and transparencyReduce cohesionLayered productsAldehyde/ketone condensation polymer adhesivesDynamic viscoelasticityAdhesive

A retroreflective sheet comprises a film having a substantially flat surface and a large number of pyramidal projections having retroreflectivity on the opposite surface, and a colored layer and an adhesive layer disposed on the surface of the film having the projections. The adhesive layer comprises a heat-sensitive adhesive containing an acrylic polymer and a phenolic resin, and exhibits an elastic modulus (by dynamic viscoelasticity measurement, compression mode) at 30 DEG C. ranging from about 1x106 to 1x108 dyn / cm2.

Owner:3M INNOVATIVE PROPERTIES CO

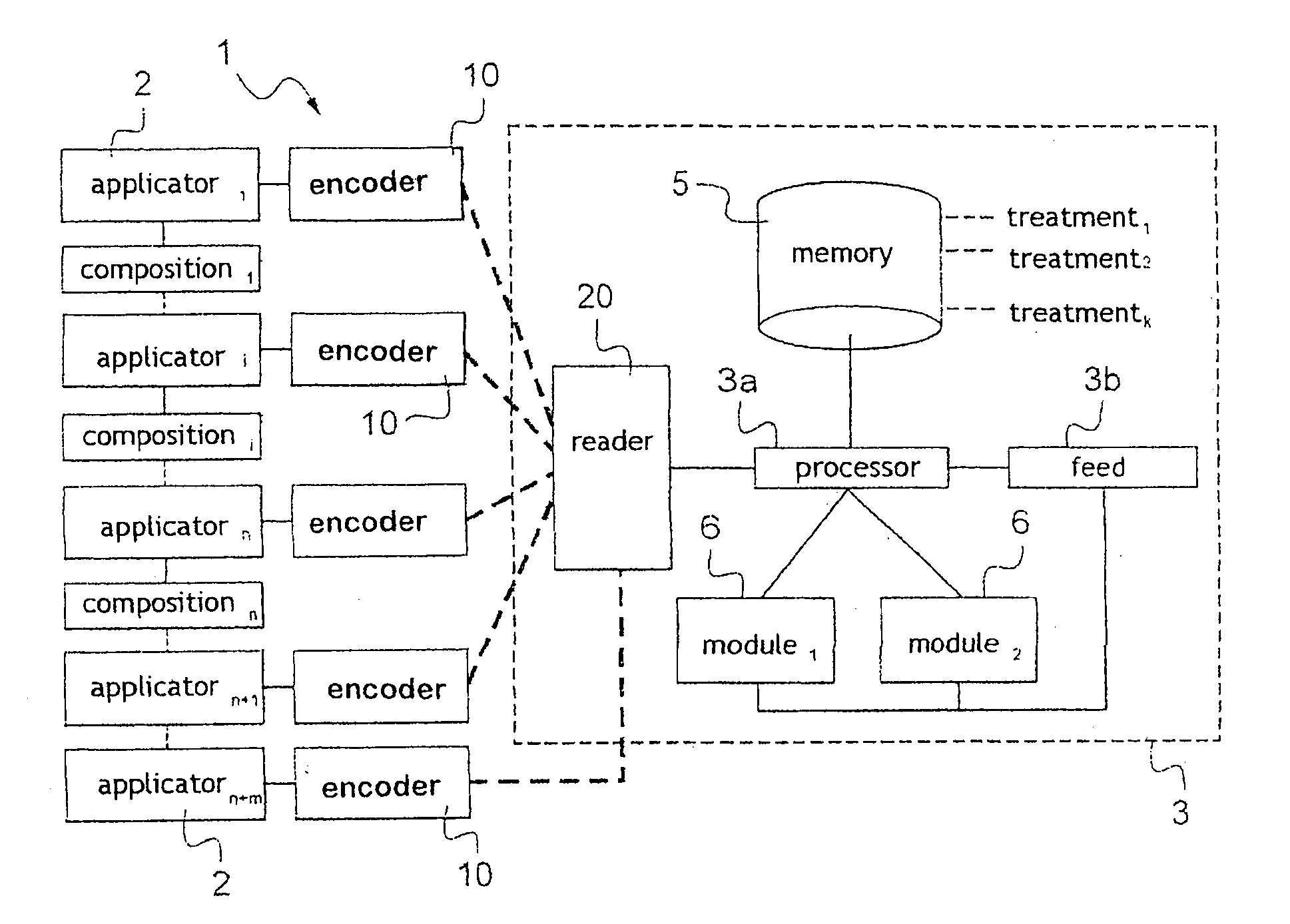

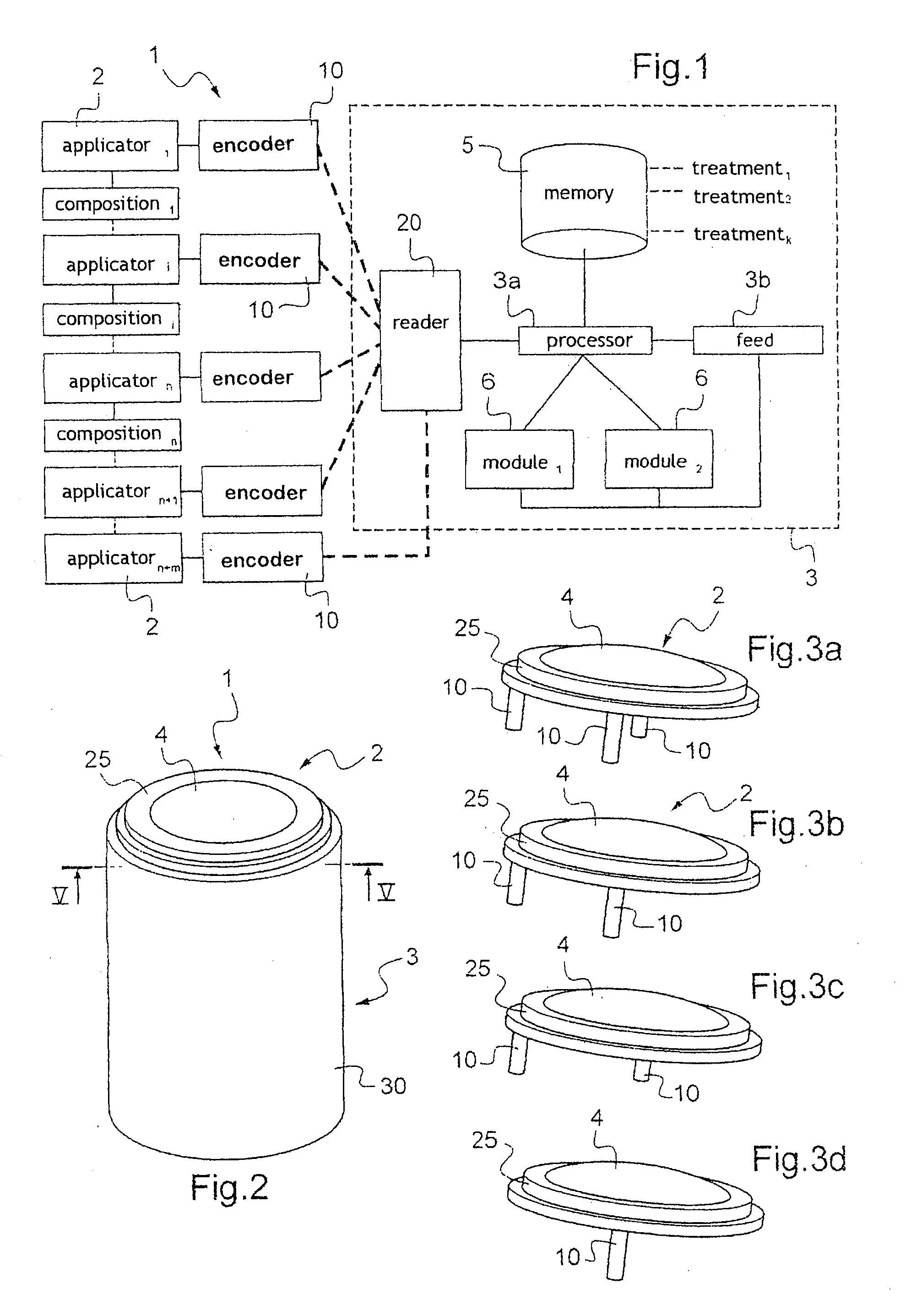

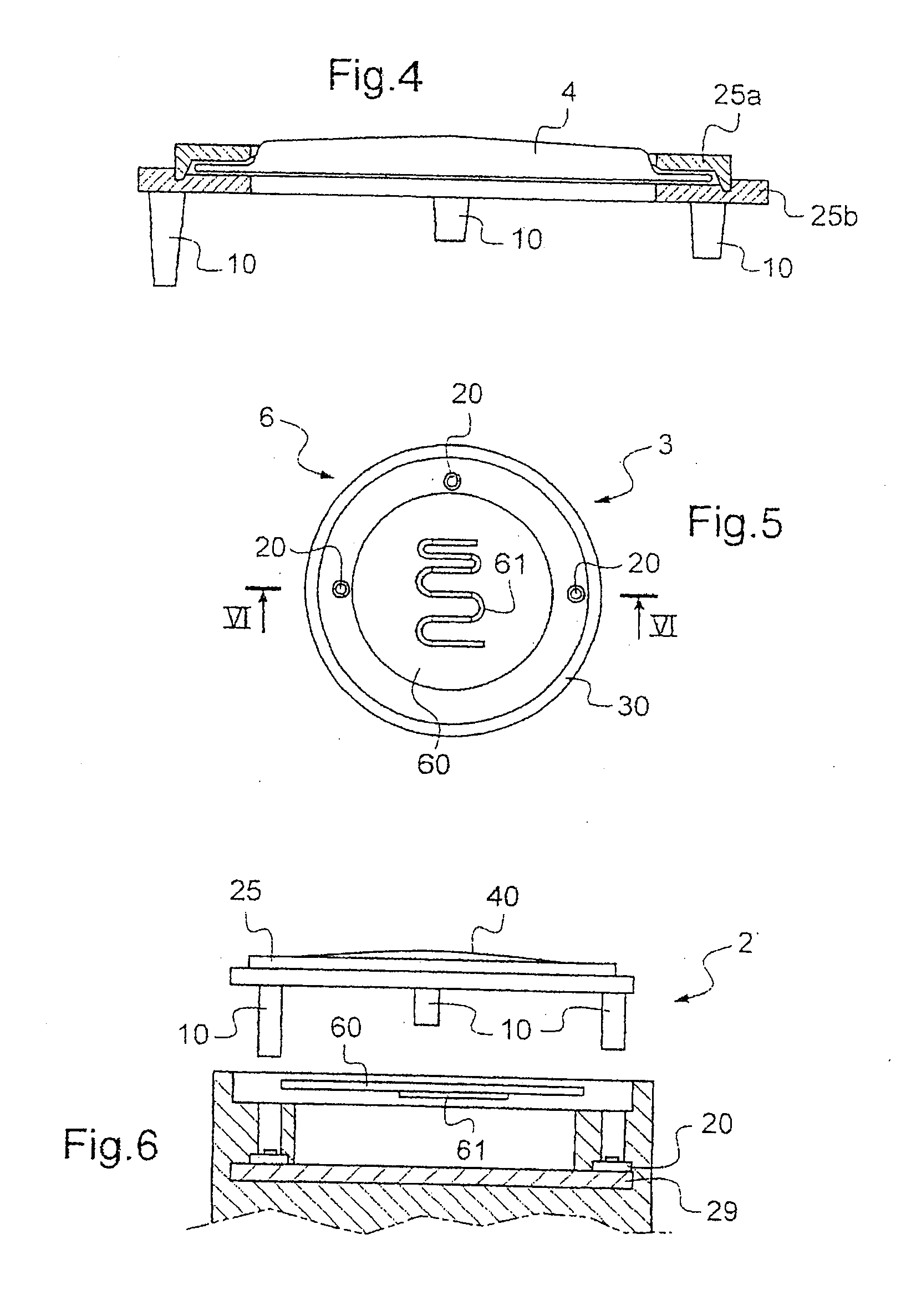

Applicator and a set including such an applicator

ActiveUS20110015463A1Small hardnessReduce cohesionElectrotherapyDiagnosticsFiberBiomedical engineering

A device for treating human keratinous materials includes an electrical appliance comprising a handpiece and a reader, and an applicator suitable for being removably fastened on the handpiece. The applicator includes a solid cosmetic or dermatological composition for applying to the keratinous materials, and / or an applicator element including fibers and / or cells suitable for enabling a cosmetic or dermatological composition to be applied on keratinous materials. The applicator also includes an encoder for encoding information arranged to be read by the reader. The operation of the handpiece depends on the information read.

Owner:LOREAL SA

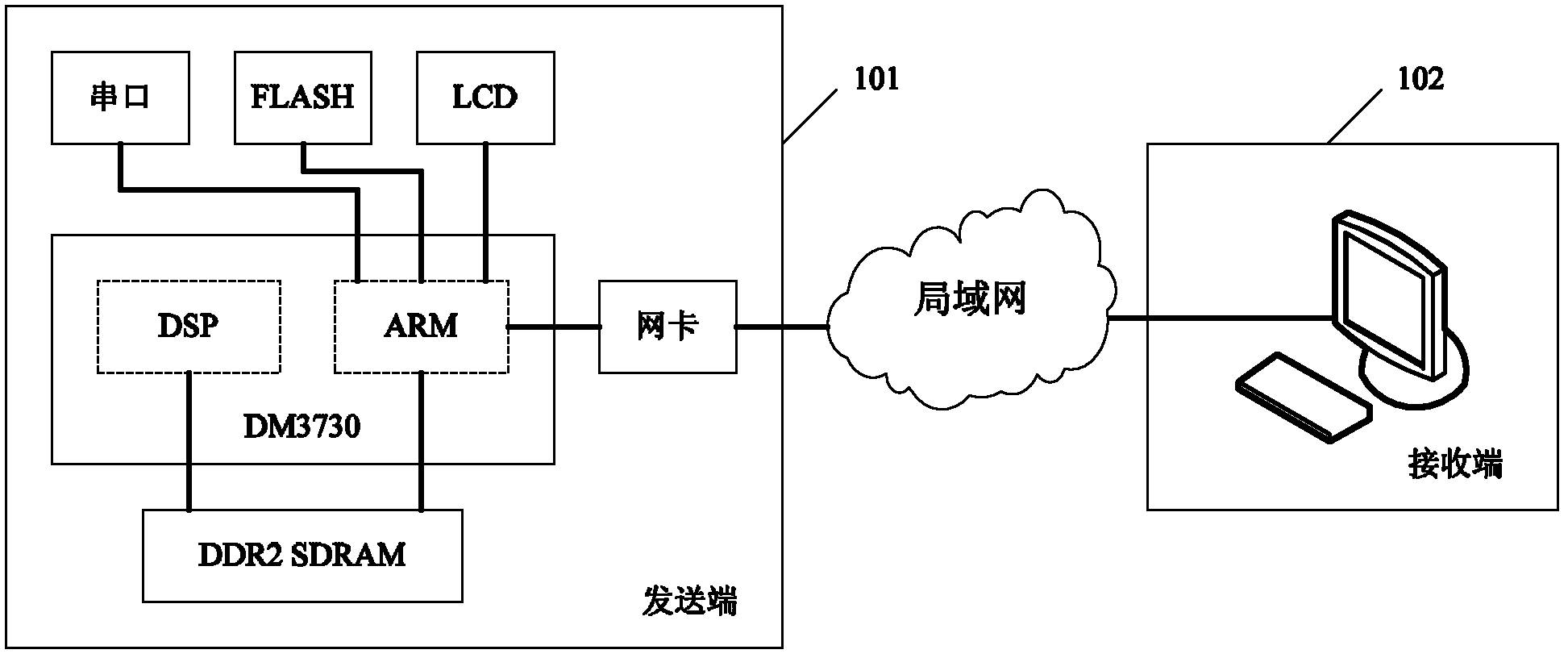

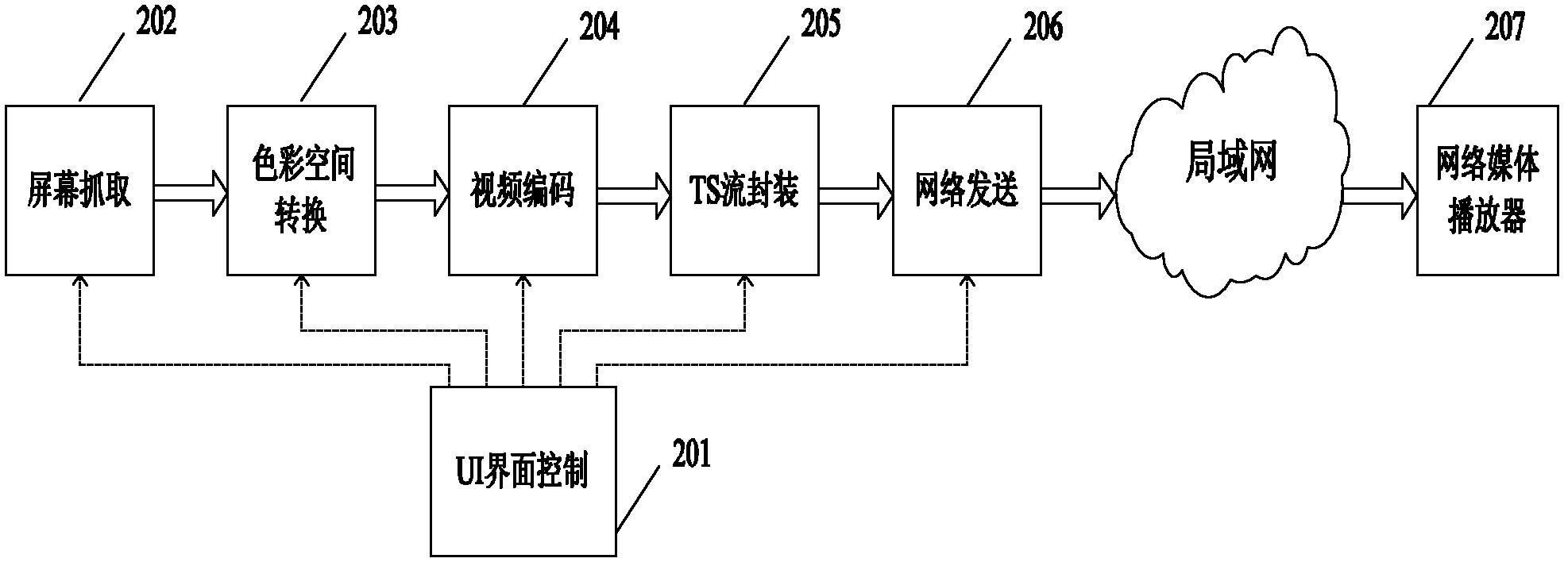

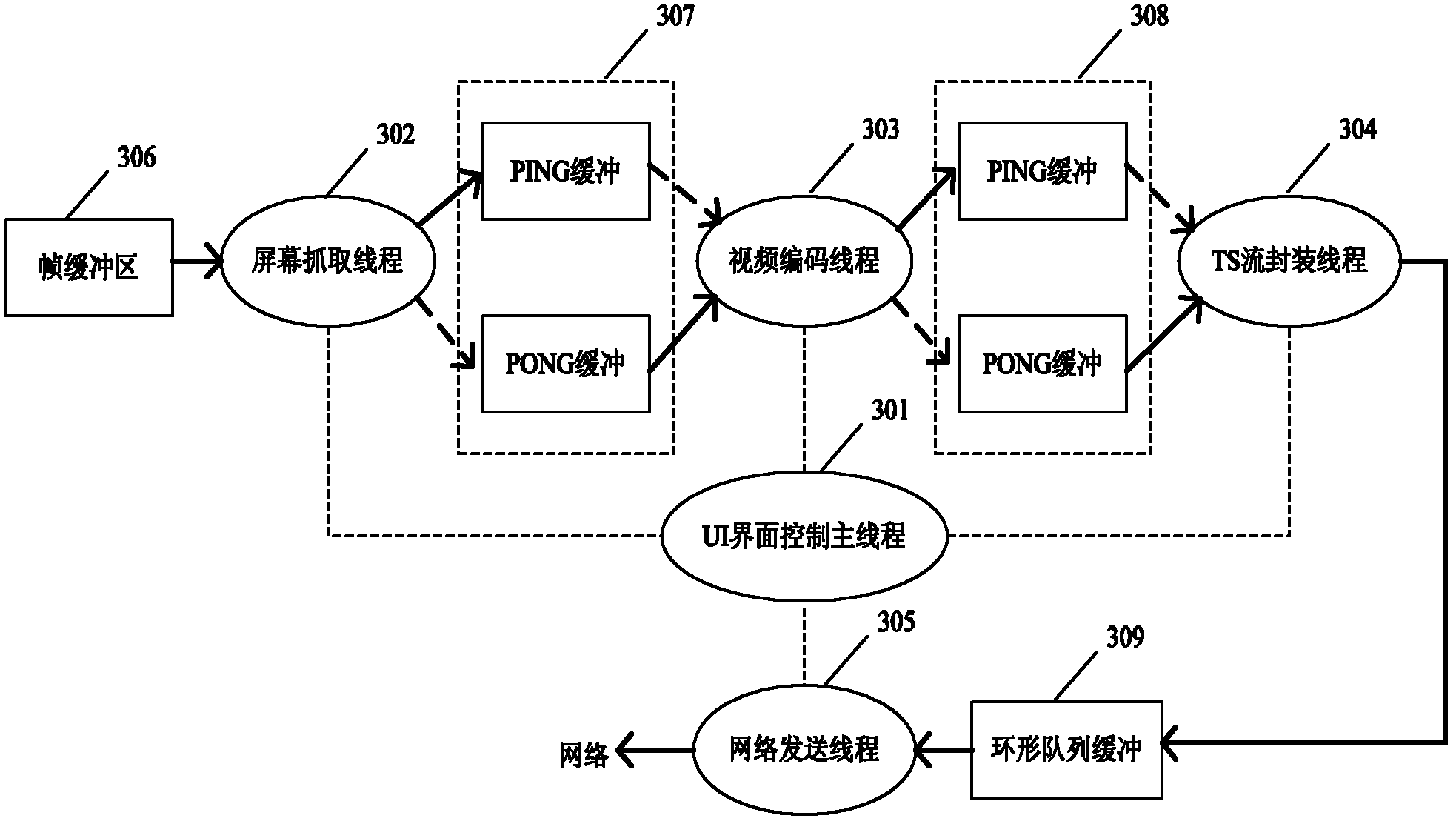

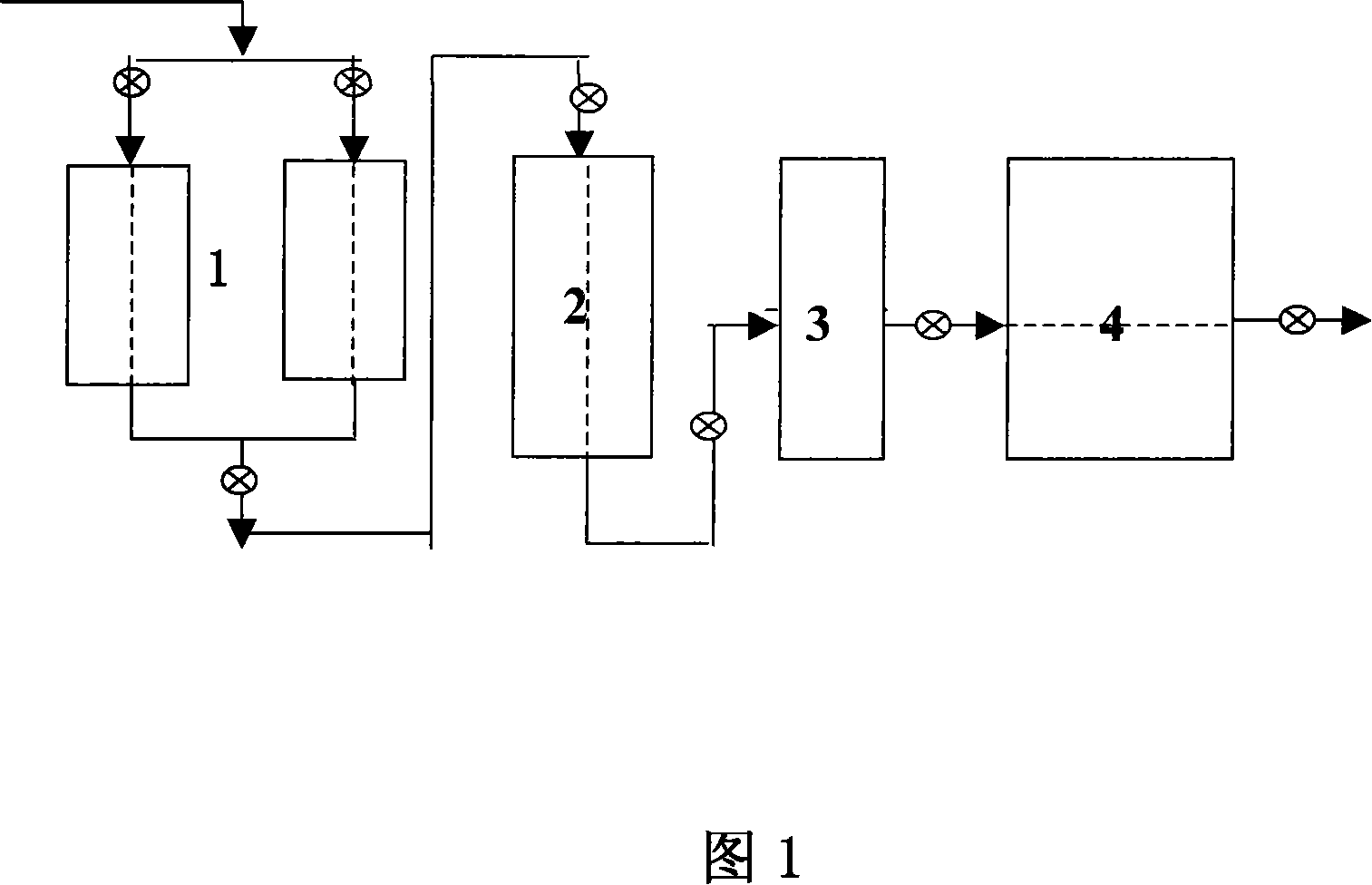

Embedded screen transmission system and operating method thereof

InactiveCN102665135AClear division of laborImprove cohesionSelective content distributionDigital signal processingDual core

The invention discloses an embedded screen transmission system and an operating method thereof. The system comprises a screen sending terminal and a screen receiving terminal which are connected in a local area network, wherein the screen sending terminal takes a T1 Davinci platform DM3730 as a core and adopts a dual-core framework formed by an ARM microprocessor and a digital signal processor (DSP); the ARM microprocessor is used for running a Linux system and a main screen sending program; the DSP is responsible for large-data-amount operations such as color space format conversion, video coding; the screen receiving terminal runs on a personal computer (PC) and displays a screen of the sending terminal in real time; the ARM microprocessor comprises a user interface (UI) control module, a screen capture module, a color space conversion module, a video coding module, a transport stream (TS) packaging module and a network sending module. The embedded screen transmission system adopting a modular design has the advantages that the development cycle is effectively shortened, the development cost is reduced, and the display content of the screen of the screen sending terminal can be transmitted to the screen receiving terminal to be displayed through a network.

Owner:SHANDONG UNIV

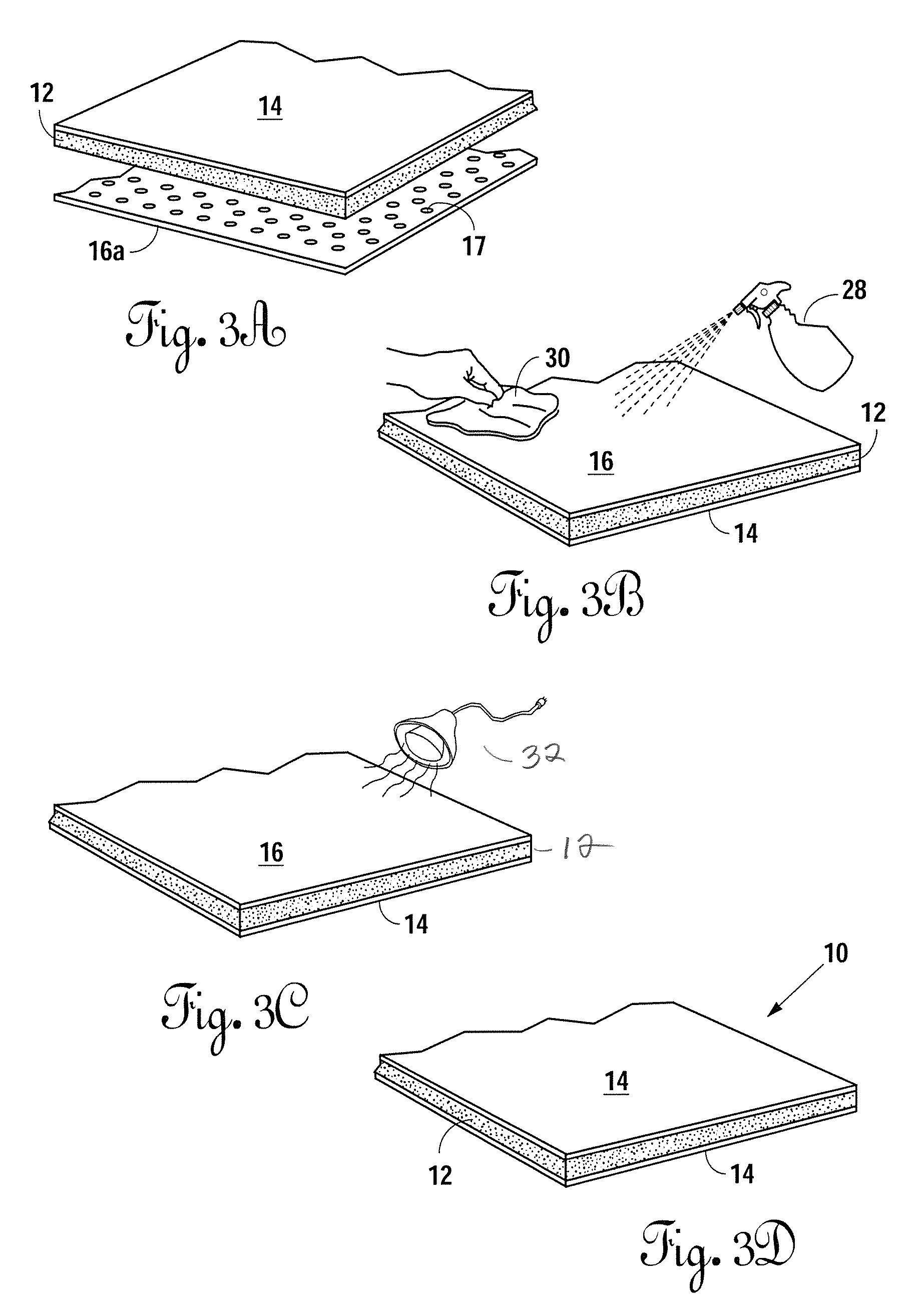

Polishing pad

ActiveUS20100048102A1Improve the level ofHigh polishing rateAbrasion apparatusSemiconductor/solid-state device manufacturingEndcappingPolyol

A polishing pad capable of maintaining a high level of dimensional stability upon moisture absorption or water absorption and providing high polishing rate includes a polishing layer of a polyurethane foam having fine cells, wherein the polyurethane foam includes a cured product of a reaction of (1) an isocyanate-terminated prepolymer (A) that includes an isocyanate monomer, a high molecular weight polyol (a), and a low molecular weight polyol, (2) an isocyanate-terminated prepolymer (B) that includes a polymerized diisocyanate and a polyethylene glycol with a number average molecular weight of 200 to 1,000, and (3) a chain extender.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Uncured polyurethane waterproofing coating and preparation method thereof

ActiveCN103923565AGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses an uncured polyurethane waterproofing coating and a preparation method thereof, belonging to the technical field of polyurethane waterproofing coatings. The uncured polyurethane waterproofing coating is prepared from the following raw materials in percentage by weight: 13-20% of prepolymer, 30-65% of asphalt, 1.0-1.5% of latent curing agent, 3-15% of compatilizer, 2-9% of thermoplastic elastomer and 0-3% of powder stuffing, wherein prepolymer is a substance synthesized by reaction between polyether and isocyanate. The uncured polyurethane waterproofing coating mainly aims to improve the material proportion and polymerization process of polyurethane, and the problem that a hot-melted asphalt material is needed to be heated by using a machine is solved; the uncured polyurethane waterproofing coating is convenient in construction and good in flowability; the viscosity of the constructed material can be automatically enhanced, so that the constructed material can become an elastic plastic body and a favorable waterproofing layer without internal stresses; in addition, the uncured polyurethane waterproofing coating can be well bonded with a coiled material and can be compounded to be waterproof so as to form a waterproofing layer capable of overcoming tension fracture caused by basement layer cracking and preventing puncturing; the uncured polyurethane waterproofing coating is simple and convenient in process, rapid in construction, free of maintenance, high in working efficiency and capable of becoming the development direction of building waterproofing in the further.

Owner:浙江鲁班建材科技股份有限公司

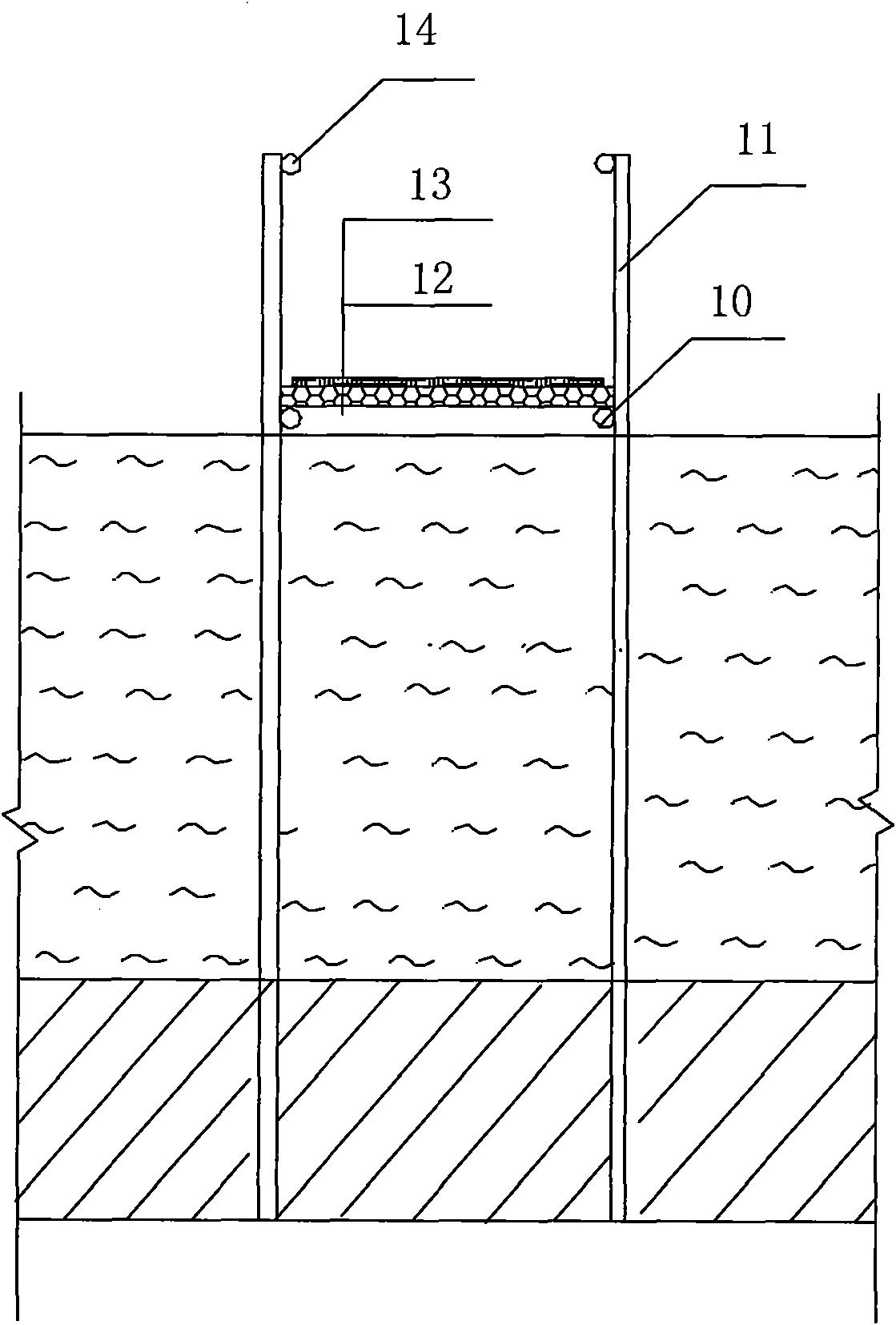

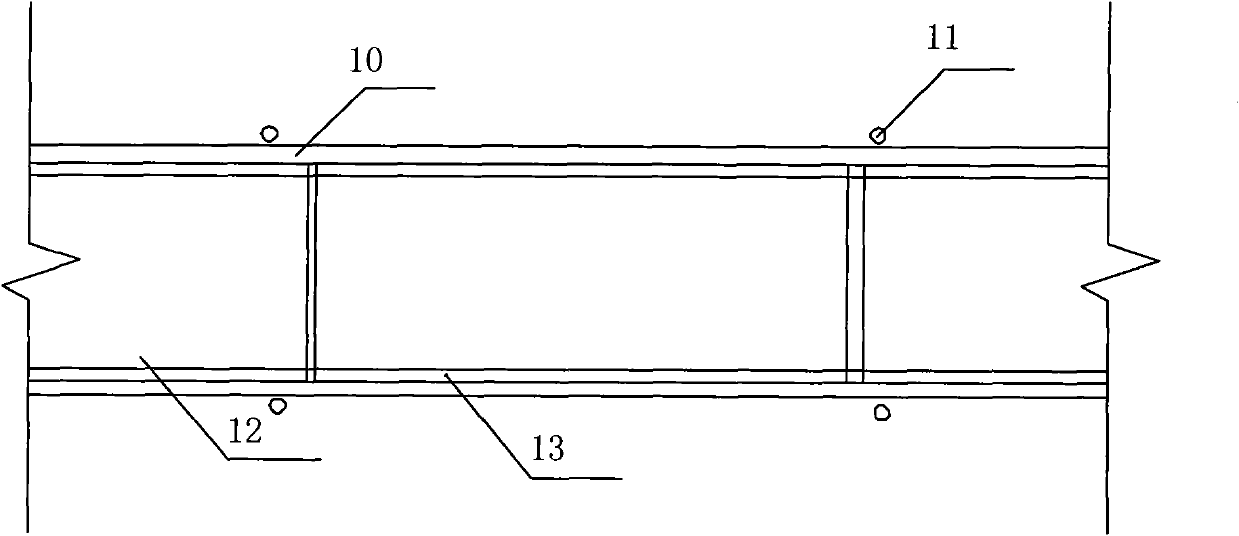

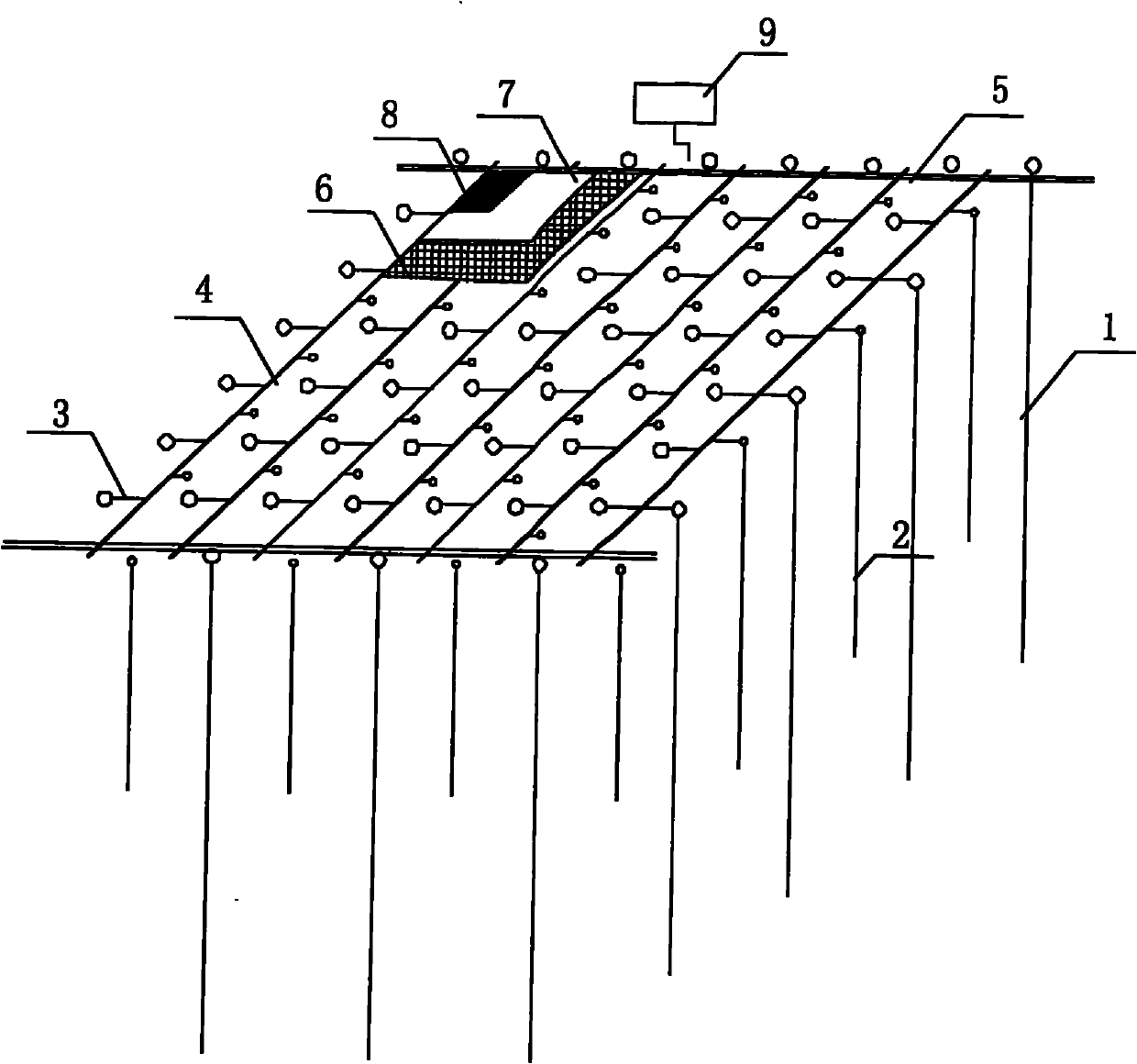

Fast consolidation method of blow-filled soft soil for land reclamation

The invention relates to a fast consolidation method of blow-filled soft soil for land reclamation, comprising the following process steps of: erecting a floating bridge; paving a plastic woven cloth; paving a main pipe and a branch pipe; inserting a plastic drainage plate; embedding a joint and a vacuum degree meter of a vacuum pump and a pore pressure meter monitoring device; paving a geotextile; paving a vacuum film; distributing the vacuum pump and trying to vacuumize; vacuumizing; monitoring construction; and carrying out vacuum water covering united pre-loading and unloading detection, wherein the step of erecting the floating bridge comprises: erecting the floating bridge on the blow-filled soft soil requiring the treatment and building a construction platform and a channel on mud. The invention has the advantages that construction members carry out operations of paving the plastic woven cloth, inserting the plastic drainage plate, laying pipes, paving the geotextile and the like on the floating bridge, thereby the technical problem that the follow-up treatment on the new blow-filled soft soil cannot be instantly carried out by using the traditional soft soil foundation treatment technology is solved, and 2-5 years for consolidating the new blow-filled soft soil naturally before retreatment are saved.

Owner:温州泰昌港湾工程有限公司

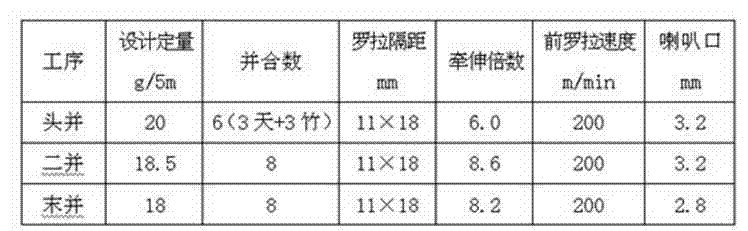

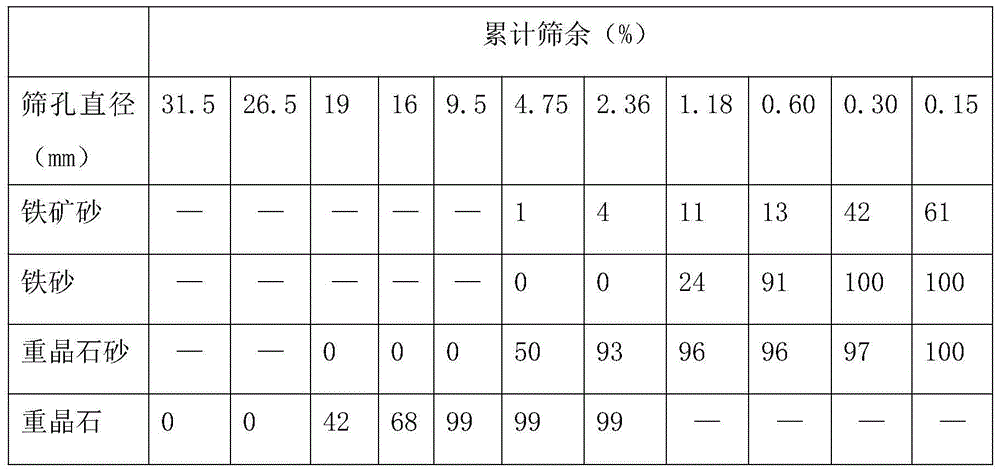

Natural bamboo fiber shirt fabric and manufacture method thereof

The invention provides natural bamboo fiber shirt fabric which has silky gloss, good feel and drapability, and is rich in graceful feeling, antibiosis, moisture-adsorption and ventilating. Warps and wefts of the fabric are both natural fiber / bamboo viscose blended yarns, the blending ratio of the warps and the wefts is 1:1, the warp density is 512 / 10cm, and the weft density is 338.5 / 10cm. A manufacture method of the natural bamboo fiber shirt fabric comprises the following steps: a, blending: opening picking, carding cotton, drawing out, roving and spun yarn; b, drum yarn dying: tube loosening, pretreatment, dying, dehydration and drying, wherein the pretreatment comprises bleaching and enzyme treatment; during bleaching: soda ash is 1-3g / L, hydrogen peroxide is 1-2g / L, the temperature is 95 DEG C, the time is 35-45min; and during the enzyme treatment, HontonezymePA is 1-1.5g / L, pH value is 4.5-5.5, the bath ratio is 1:15, and the time is 25-35min; and during dying, the drum yarn density is 0.33-0.35g / cm<3>, and MegafixB type reactive dying is adopted; c, weaving: winding, warp pulp connection, drawing in or warp tying and weaving; and d, after treatment: singeing, desizing, sizing and preshrinking.

Owner:JIANGSU YDTEX GRP LTD

Sheet for whitening cosmetics and method for using the same

InactiveUS6458379B1Easy to storeEfficient use ofCosmetic preparationsBiocideVitamin CMagnesium phosphate

A sheet for whitening cosmetics comprises a sheet-like substrate and an adhesive layer which comprises a wet pressure-sensitive adhesive composition formed on the substrate. The whitening component includes vitamin C or its derivatives such as magnesium L-ascorbyl-2-phosphate, vitamin E nicotinate, kojic acid, hydroquinone, ellagic acid, albumin, galenical extracts, and rice bran extracts. Kojic acid and magnesium L-ascorbyl-2-phosphate are preferred. By contacting the adhesive layer with water and / or a hydrophilic medium such as alcohols, e.g., methanol, ethanol, etc., the wet pressure-sensitive adhesive composition exhibits excellent stickiness and excellent applicability to skin as well as excellent whitening effect with alleviating or eliminating stains, freckles, non-transparency, etc. on the skin.

Owner:NITTO DENKO CORP

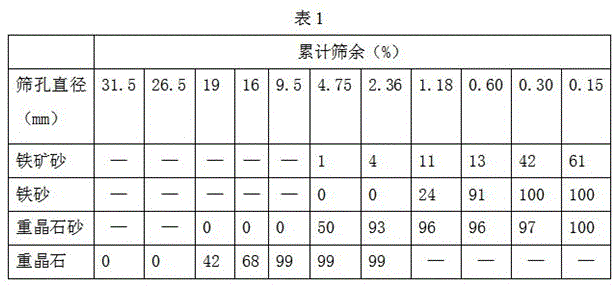

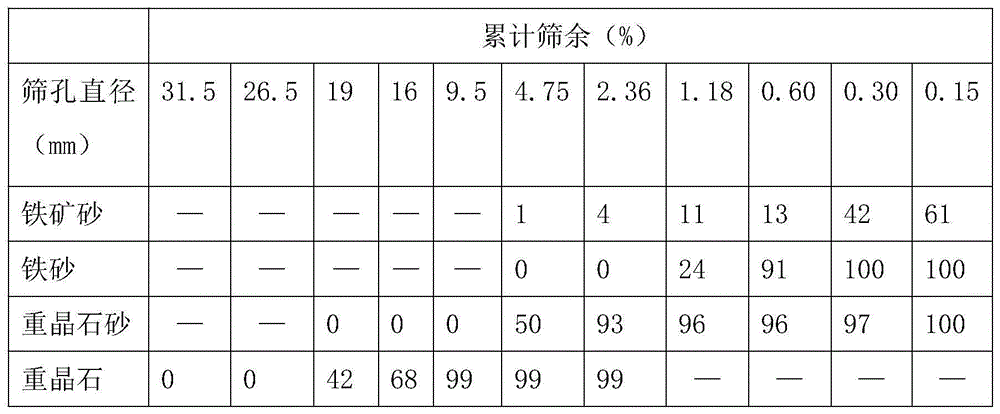

Neutron irradiation preventing low-hydration-heat barite concrete

ActiveCN104529297AImprove Radiation PerformanceReduce liquiditySolid waste managementNeutron irradiationSlag

The invention relates to the technical field of concrete, and particularly relates to neutron irradiation preventing low-hydration-heat barite concrete. The neutron irradiation preventing low-hydration-heat barite concrete comprises the following components in content: 163.8-168kg / m<3> of water, 200-280kg / m<3> of cement, 90-140kg / m<3> of slag powder, 9.5-10.5kg / m<3> of boron glass powder, 850-900kg / m<3>of iron ore sand, 340-360kg / m<3> of iron sand, 1558-1600kg / m<3> of barite, 300-330kg / m<3> of barite sand, 0.85-0.95kg / m<3> of polypropylene fiber and 4% to 7% of a polycarboxylate-type water reducing agent. The neutron irradiation preventing low-hydration-heat barite concrete disclosed by the invention is larger than 3600kg / m<3> in apparent density, larger than 110kg / m<3> in retained crystal water and good in neutron irradiation prevention effect; when being applied to a large-size concrete structure of which the minimum geometric dimension is larger than 1.2m, the neutron irradiation preventing low-hydration-heat barite concrete is low in hydration heat, the internal and external temperature difference is smaller than or equal to 20 DEG C, the adiabatic temperature rise is smaller than or equal to 55 DEG C, and the neutron irradiation preventing low-hydration-heat barite concrete is applicable to a large-size radiation-proof structure. The concrete can reach relatively high requirements in aspects such as retained crystal water, fluidity, cohesiveness and water retention property and has the advantages of guaranteeing the strength and the compactness and controlling the hydration heat.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR +1

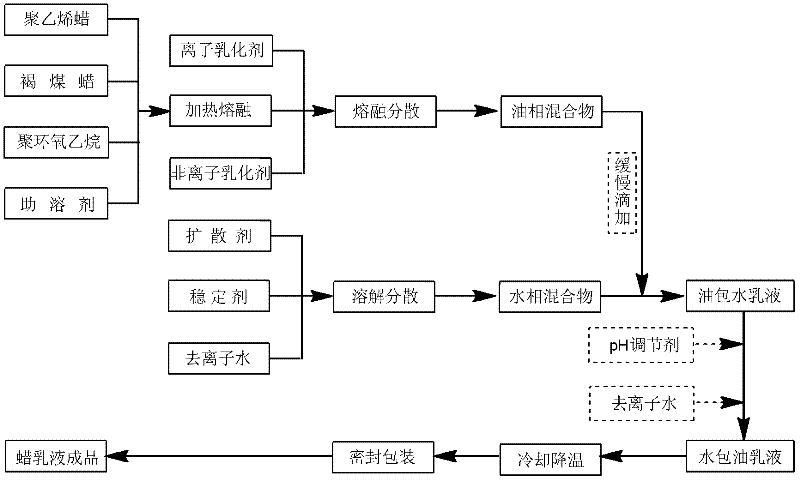

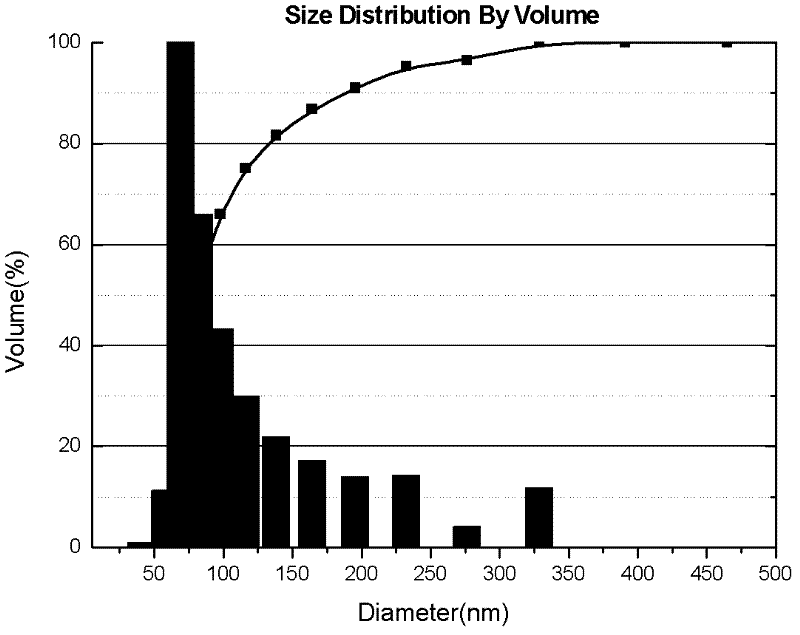

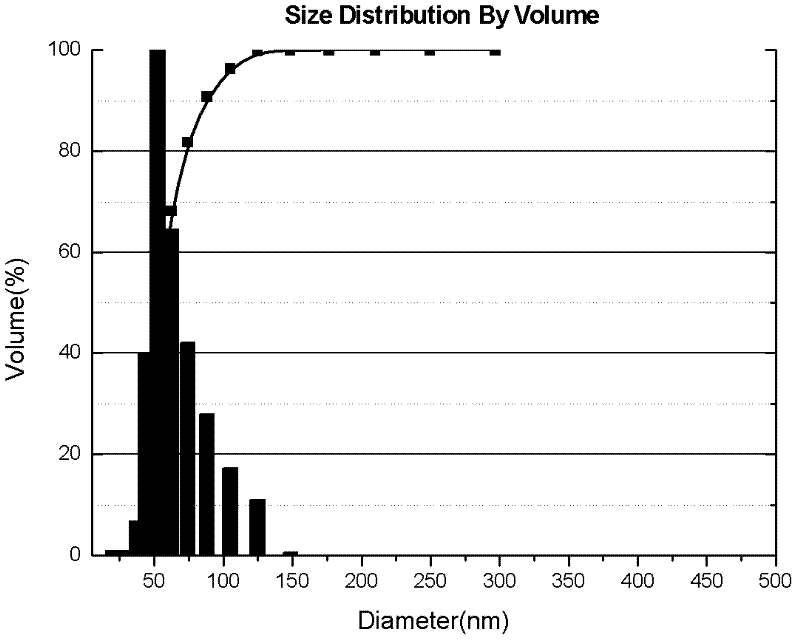

Nano wax emulsion and preparation method for nano wax emulsion

The invention provides nano wax emulsion which comprises the following components: polyethylene wax, montan wax, polyethylene oxide, cosolvent, ionic emulsifying agent, non-ionic emulsifying agent, dispersing agent, stabilizing agent, pH (potential of hydrogen) modifier and deionized water. The invention further provides a preparation method for the nano wax emulsion, the preparation method comprises the steps of (1) preparing oil-phase dispersing mixture, (2) preparing water-phase dispersing mixture, (3) preparing nano wax emulsion, and then finally obtaining high melting point and high solid content nano wax emulsion of which the wax content is 30-48%. The wax emulsion prepared in the invention solves the problem that high melting point wax is hard to emulsify; the wax content can reach 30-48%; and additive amount of the emulsifying wax in the using process and production cost are reduced, meanwhile, the prepared wax emulsion has good stability and narrow particle diameter distribution and is little influenced by multivalent metal ions; and the average particle diameter is 50-120 nm, and the nano wax emulsion is convenient for storage and transportation and can be used in continuous industrial production.

Owner:GUANGDONG LEPUTAI NEW MATERIAL TECH

Nanowire and microwire fabrication technique and product

ActiveUS20090242016A1Reduce cohesionSmall sizeMaterial nanotechnologyTurning machine accessoriesNanowireElectrode

A method of fabricating nanowires or microwires employs a robust conductive surface whose edges define electrodes for promoting electrochemical deposition of nanowire material at those edges. Controlled deposition times and thin conductive layers allow extremely small diameter wires to be created and then removed without destruction of the pattern and the wires to be applied to a second substrate or used for composite materials.

Owner:WISYS TECH FOUND

Artificial leather and preparation method thereof

ActiveCN103469607ALess flexibilityReduce usageSynthetic resin layered productsTextiles and paperSurface layerPlasticizer

The invention discloses artificial leather and a preparation method thereof. The artificial leather comprises the following components in parts by weight: a base material, a shell fabric, 100 parts of a bonder and a piece of base cloth, wherein the shell fabric comprises the following components in parts by weight: 100 parts of polyvinyl chloride resin and 50-60 parts of a plasticizer; the base material comprises the following components in parts by weight: 100 parts of the polyvinyl chloride resin, 70-80 parts of the plasticizer and 100 parts of a filling agent. The preparation method comprises the following steps: preparing shell fabric slurry; preparing base material slurry; applying the obtained shell fabric slurry to release paper, and drying; applying the base material slurry to a surface layer, and foaming at the temperature of 180-190 DEG C; uniformly applying the bonder to a foaming layer, and bonding the base cloth with the foaming layer; drying an obtained product at the temperature of 140-170 DEG C to prepare the leather. According to the preparation method, the surface properties of the leather are improved and the leather is good in wear resistance, odor-free and good in smooth feel.

Owner:FUJIAN POLYTECH TECH CO LTD

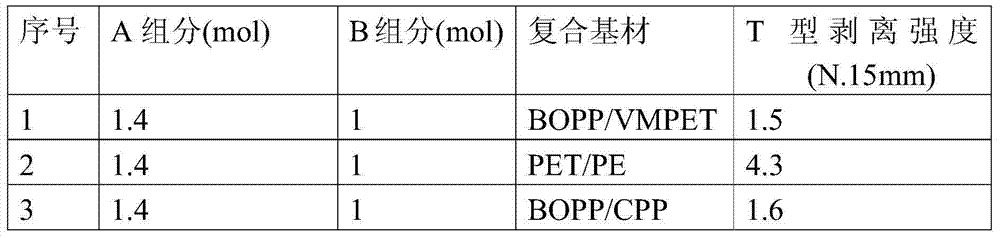

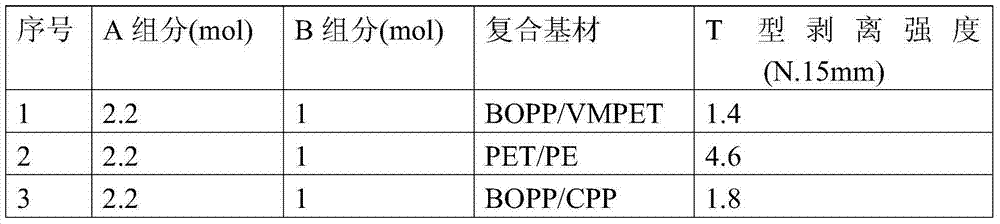

Flexible packaging composite resin and preparation method thereof

ActiveCN103614108ALow viscosityMeet the process requirementsPolyureas/polyurethane adhesivesPolyesterResin-Based Composite

The invention discloses flexible packaging composite resin and a preparation method thereof. The flexible packaging composite resin consists of a component A and a component B, wherein the component A is a polyurethane prepolymer containing isocyanate groups (-NCO); the component B is a mixture of polyester and polyether polyol containing hydroxyl groups (-OH), and the application proportion requirement of the component A and the component B is as follows: the mol ratio of the functional group -NCO to the functional group -OH is (1.4-2.2): 1.0. At the application state, the viscosity of a binder obtained by mixing the component A and the component B according to the stipulated ratio is relatively low, and the binder has an excellent coating performance under the normal-temperature condition, also has extremely high in adhesion strength after being bonded, can meet the technological requirement an existing normal-temperature coating process in China and is relatively high the inertial adhesion, and the quality flaws such as tunnel and crinkling after the binder is coated can be avoided.

Owner:JIANGSU LIHE ADHESIVE

Method of treating oil or gas well with biodegradable emulsion

ActiveUS7392845B2Efficient crackingImprove efficiencyCleaning apparatusFluid removalParaffin waxDemulsifier

A biodegradable water-in-synthetic oil base emulsion, effective in the removal of filter cakes, consists of an external phase of a surfactant emulsified in a paraffinic base oil. The emulsion is particularly effective in breaking-down the interfacial rheological properties of oil base mud and synthetic oil base mud filter cakes and acts as a demulsifier to break the water-in-oil emulsions present in such oil base and synthetic oil base muds.

Owner:BAKER HUGHES INC

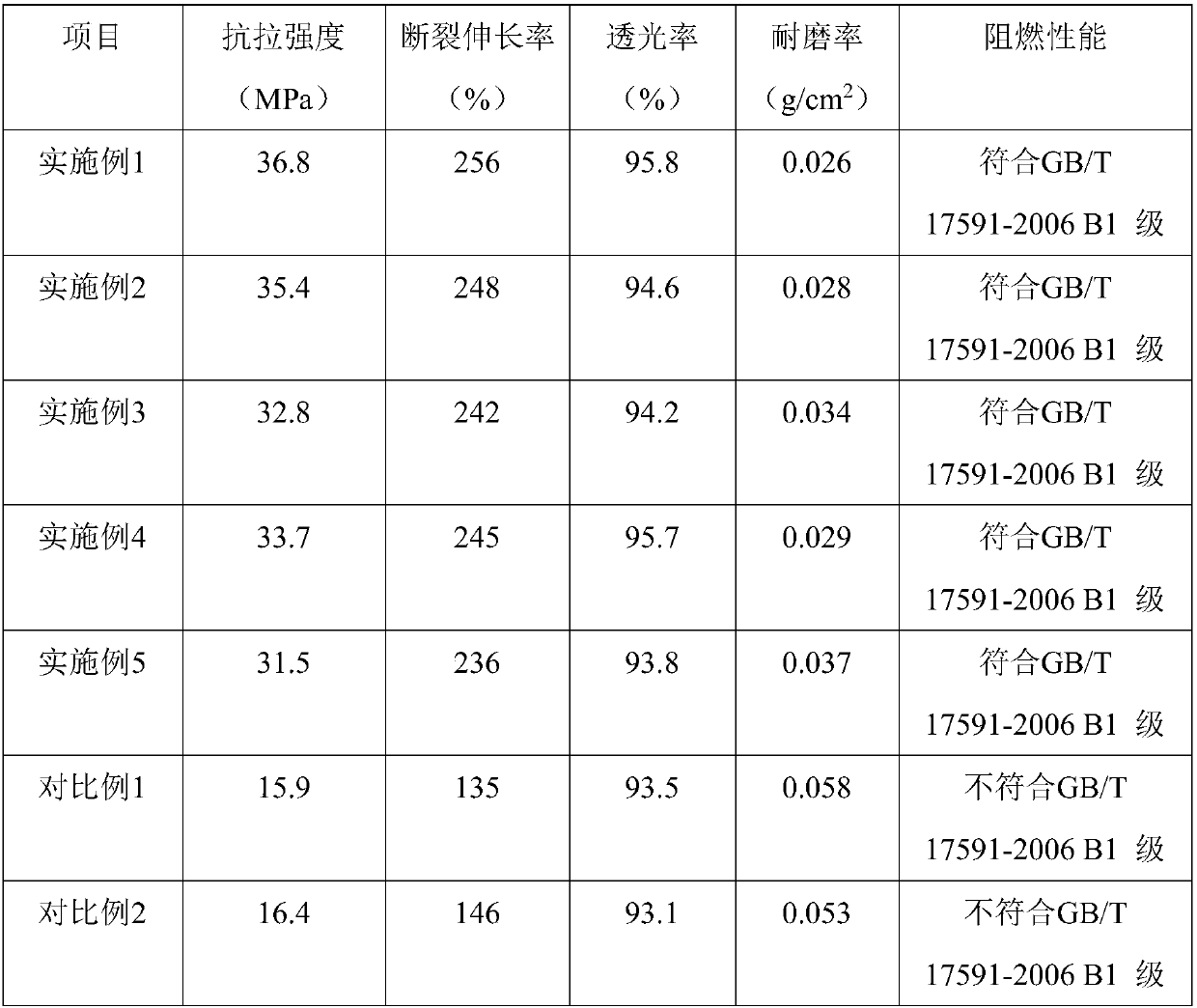

Technology for processing floor films

The invention discloses a technology for processing floor films, and relates to the field of floor film processing. The technology for processing the floor films includes steps of (1),mixing ingredients, to be more specific, weighing, by weight, PVC (polyvinyl chloride) resin powder, impact-resistant MBS (methyl methacrylate) resin, ACR (acrylamide) processing agents, di-iso-decylphthalate, internal lubricants, 3-10 parts of external lubricants and phosphate ester flame retardants, stirring the ingredients at the high speeds, and then carrying out cold stirring on the ingredients to obtain mixed materials; (2), carrying out extrusion, plasticization and calendaring molding on the mixed materials; (3), carrying out cooling and ageing treatment; (4), carrying out traction, winding and packaging. The technology has the advantages that the floor films are reasonable in composition proportion, high in light transmittance and suitable for large-scale industrial production, the technology isreasonable in design, and the toughness, the abrasion resistance, the flame retardance and the temperature resistance of the floor films can be enhanced.

Owner:安徽嘉阳新材料科技有限公司

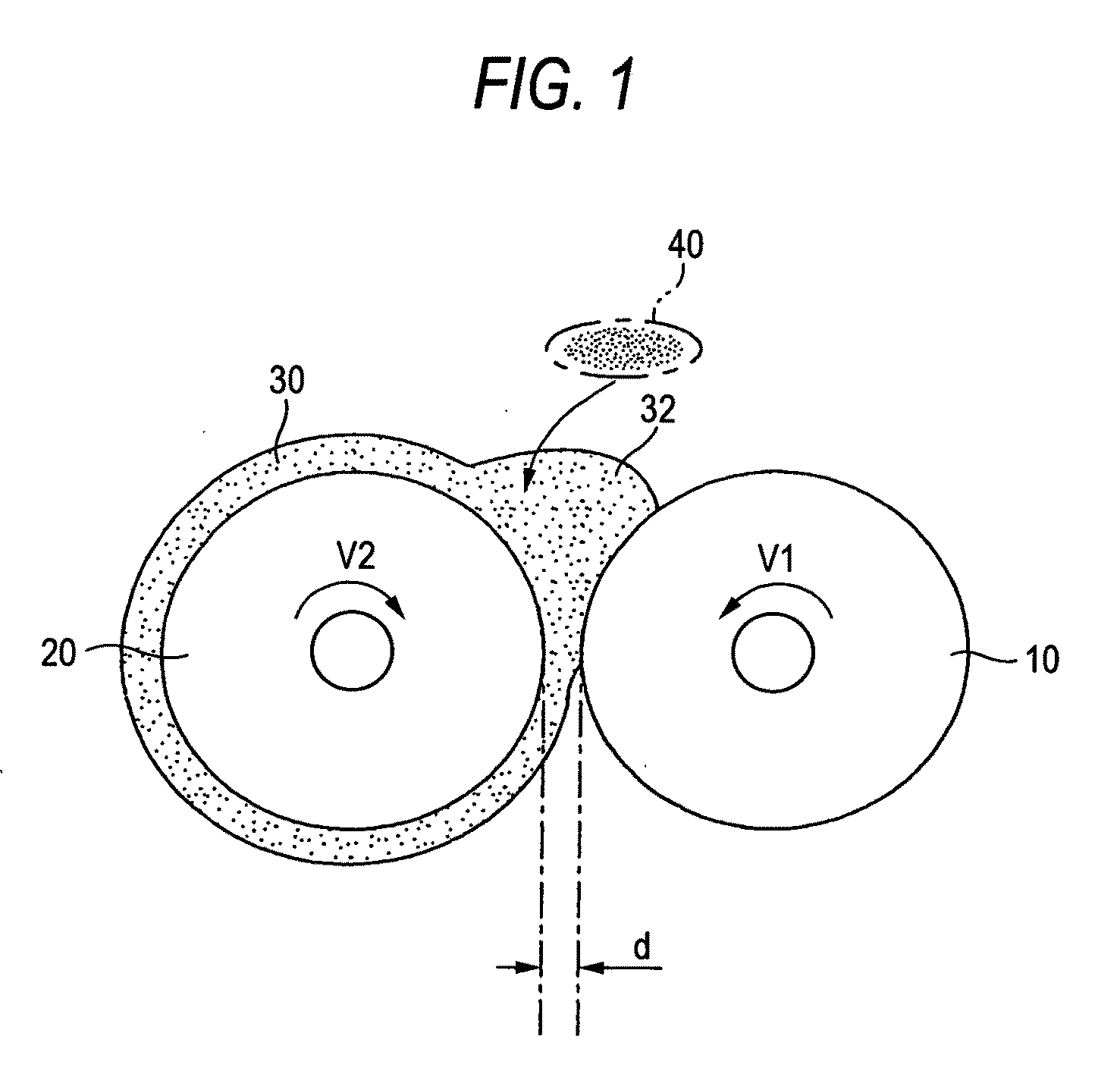

Synthetic fibers and cementitious systems including same

InactiveUS20060188719A1Superior basic hydrolysis resistanceReduce cohesionConstruction materialYarnCement compositesCementitious composite

Owner:SELIVANSKY DROR

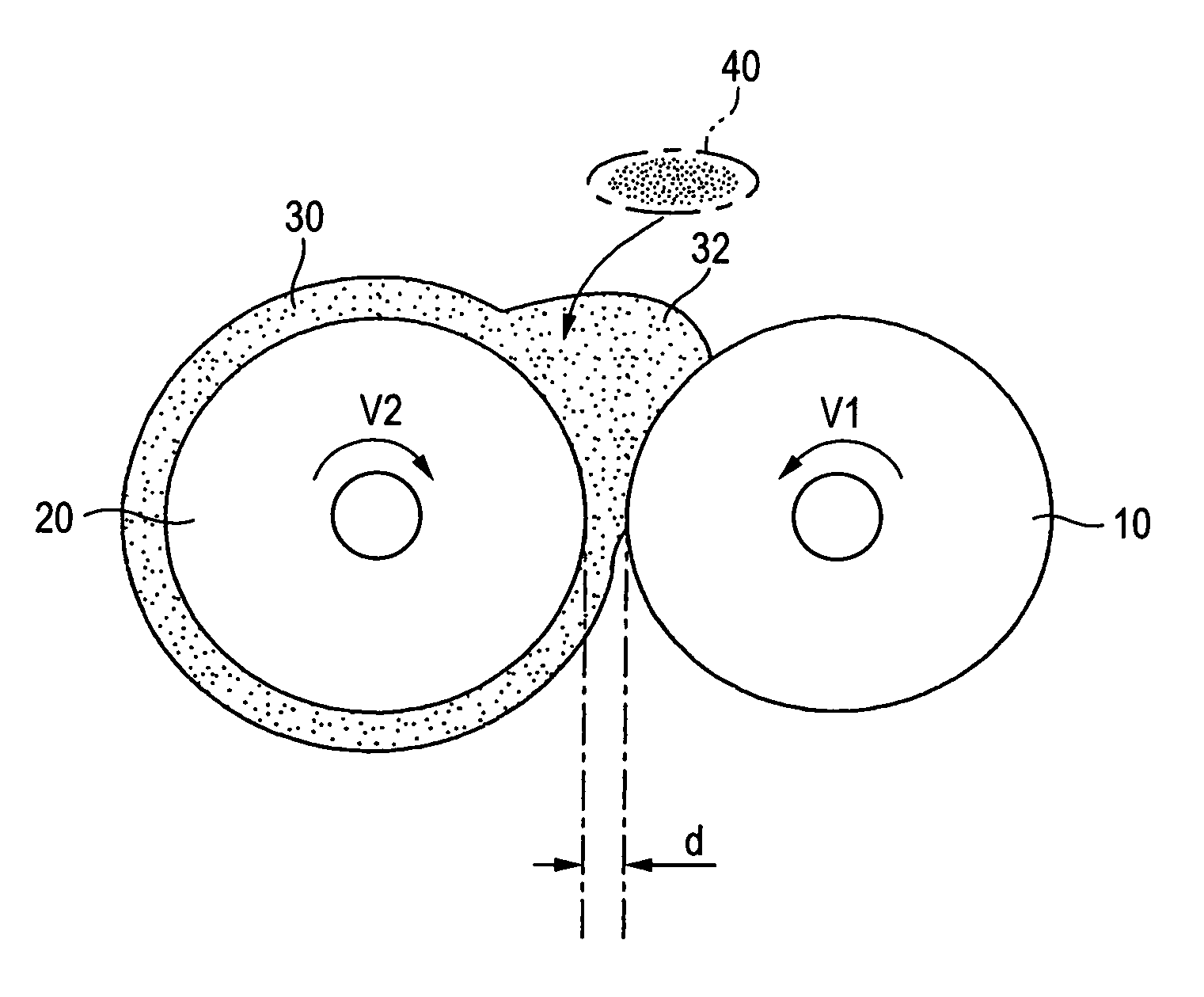

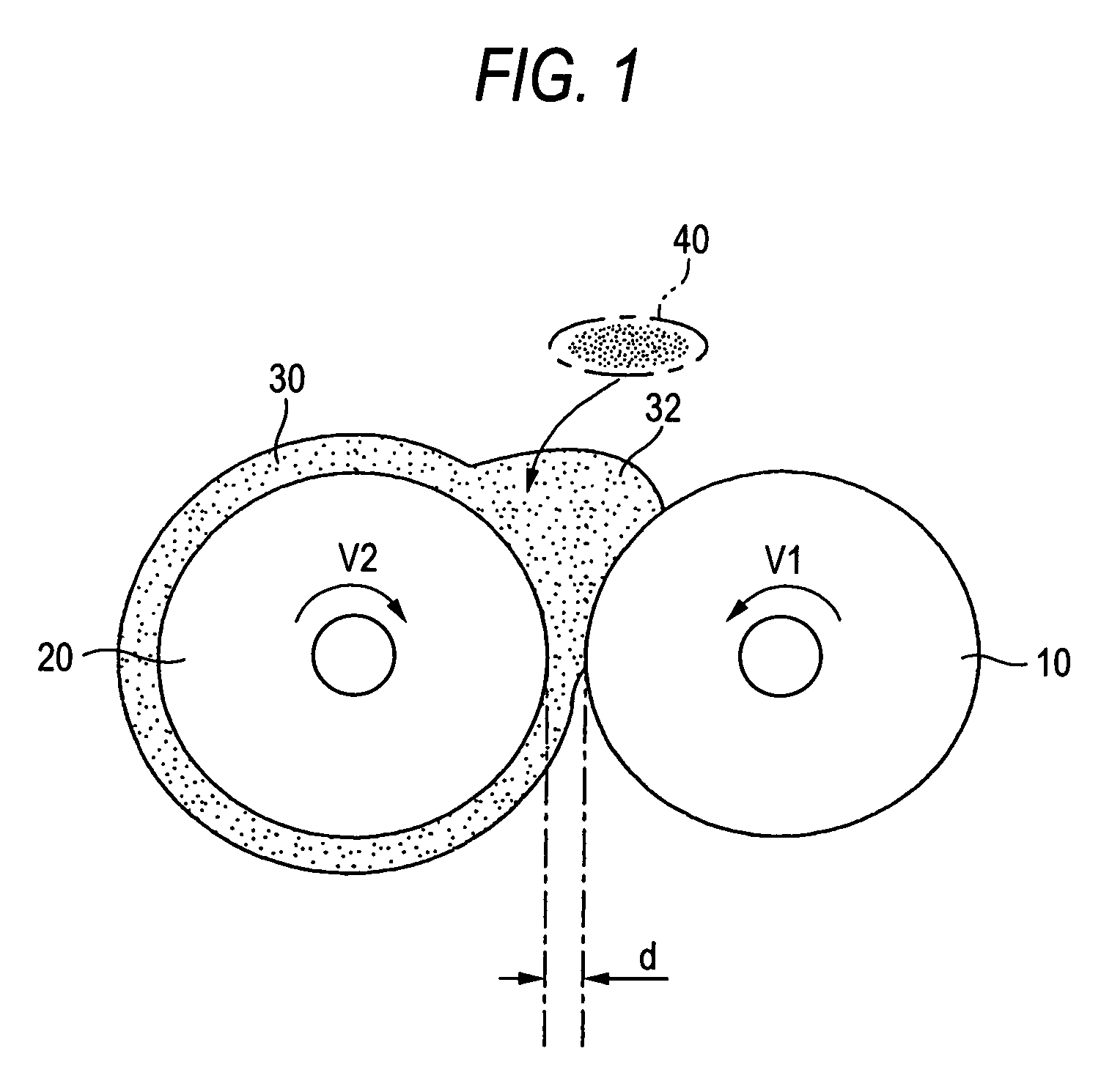

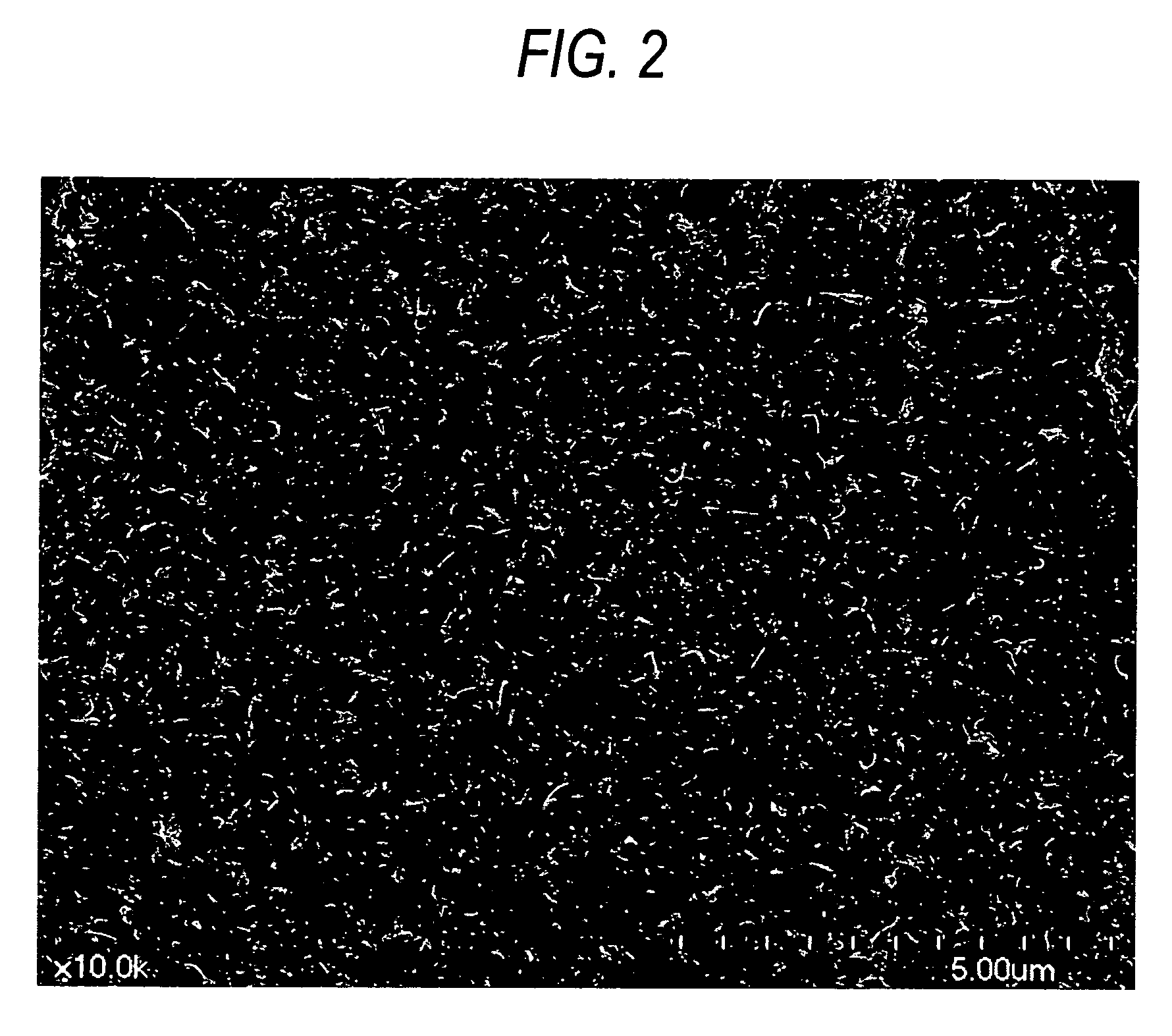

Carbon fiber composite material and process for producing the same

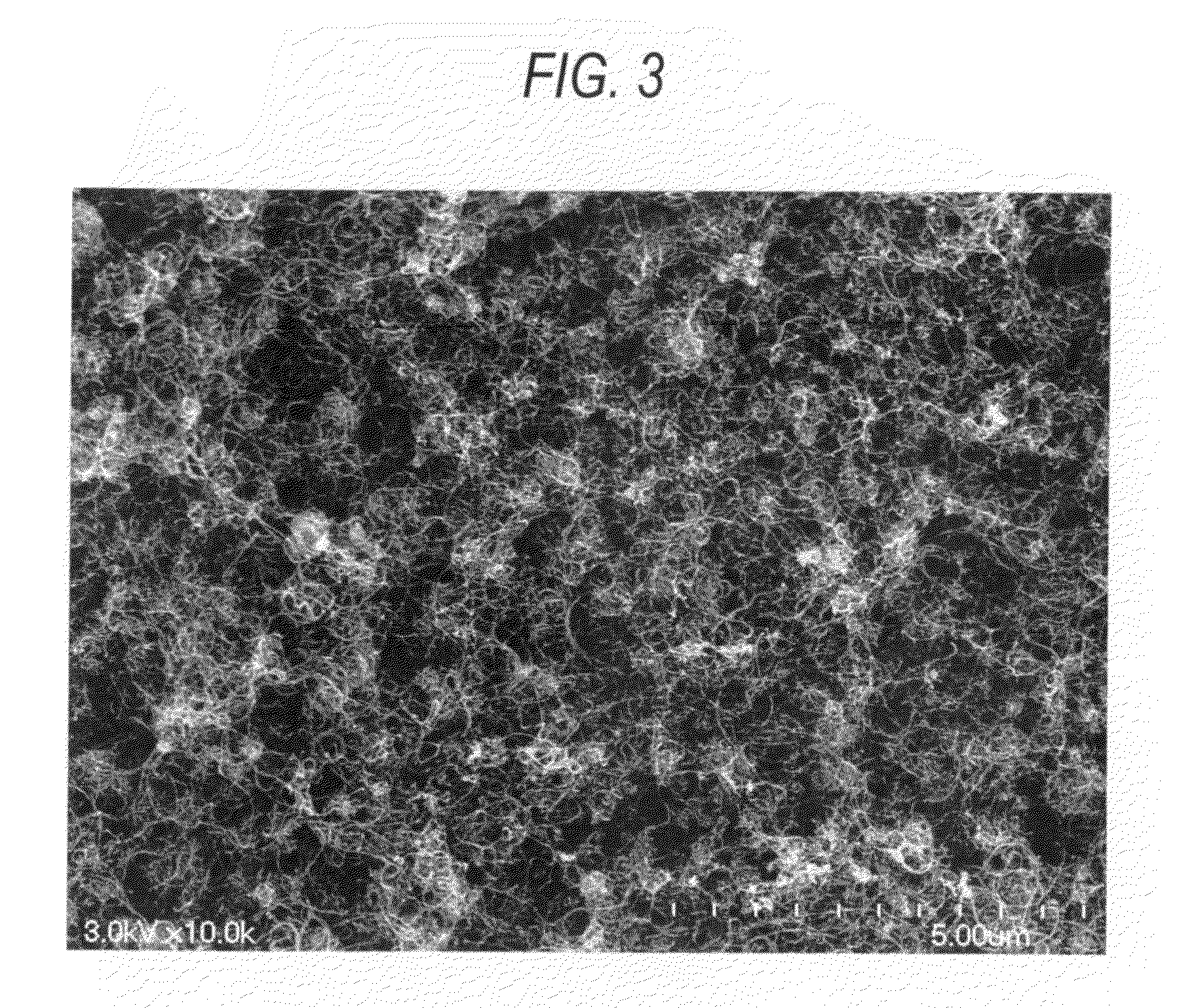

ActiveUS7785701B2Reduce cohesionGood dispersionMaterial nanotechnologyIndividual molecule manipulationElastomerFiber

The present invention provides a carbon fiber composite material comprising an elastomer and a carbon nanofiber dispersed in the elastomer, wherein the elastomer has an unsaturated bond or a group, having affinity to the carbon nanofiber. Also disclosed is a process for producing the carbon fiber composite material.

Owner:HITACHI ASTEMO LTD

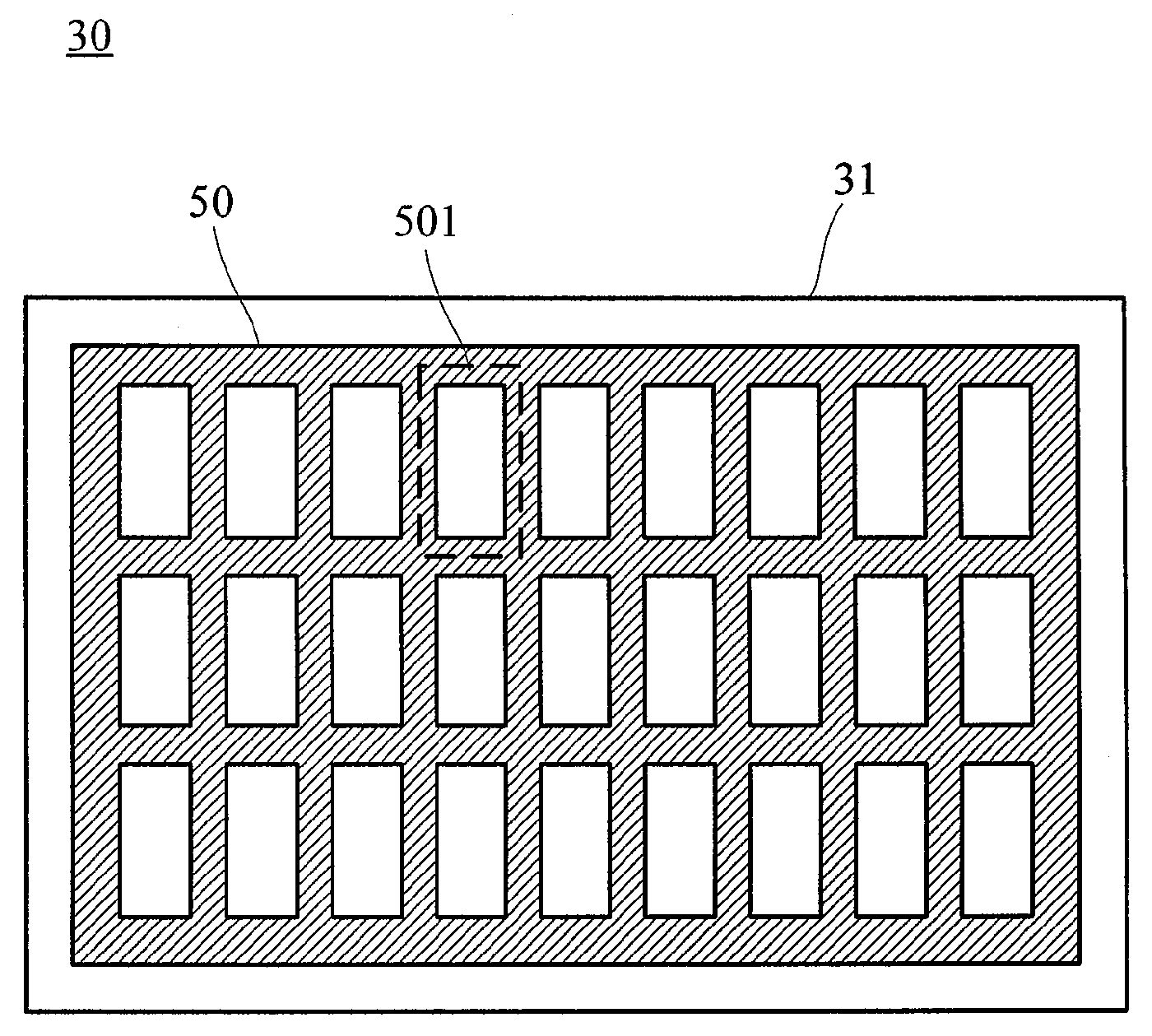

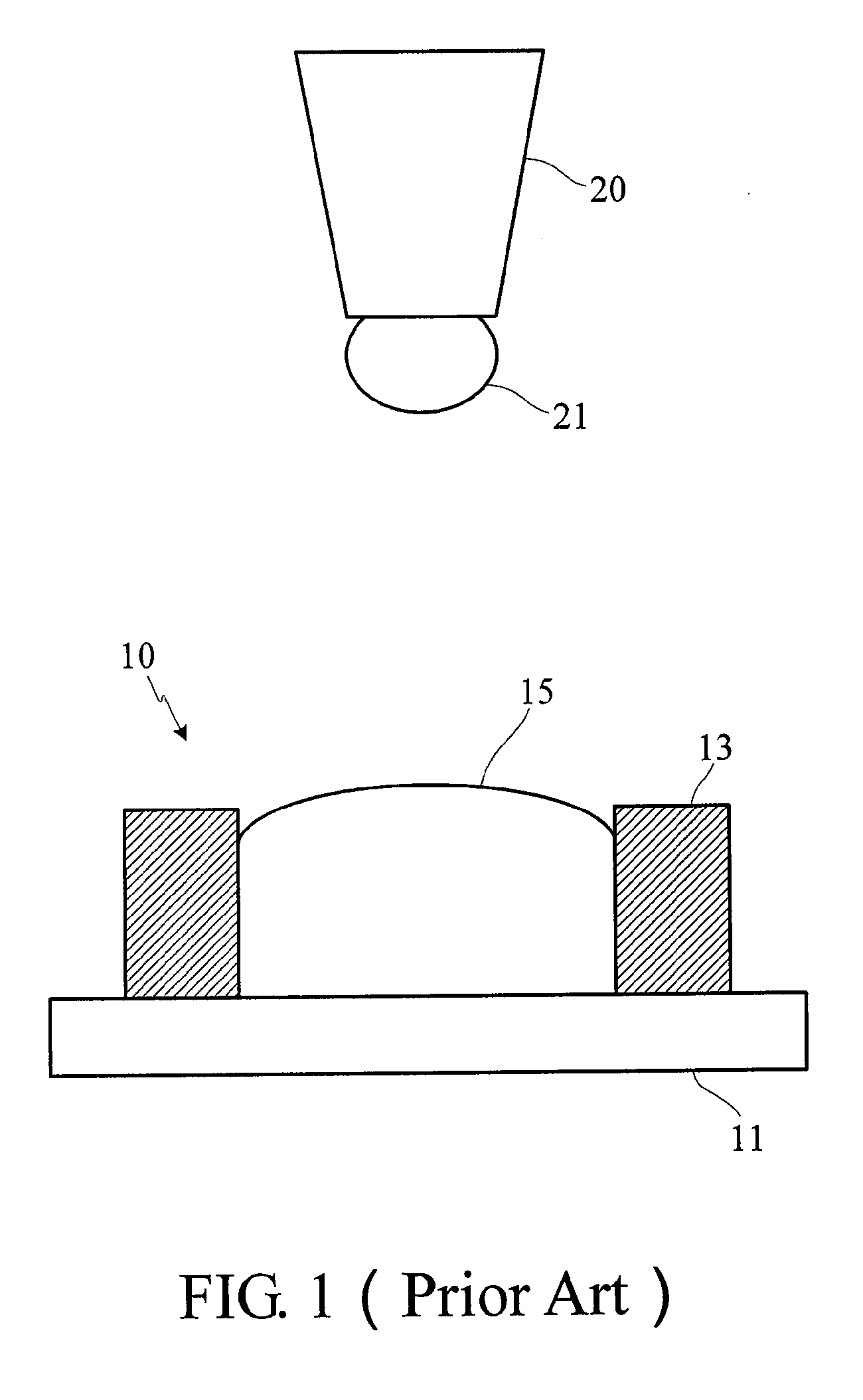

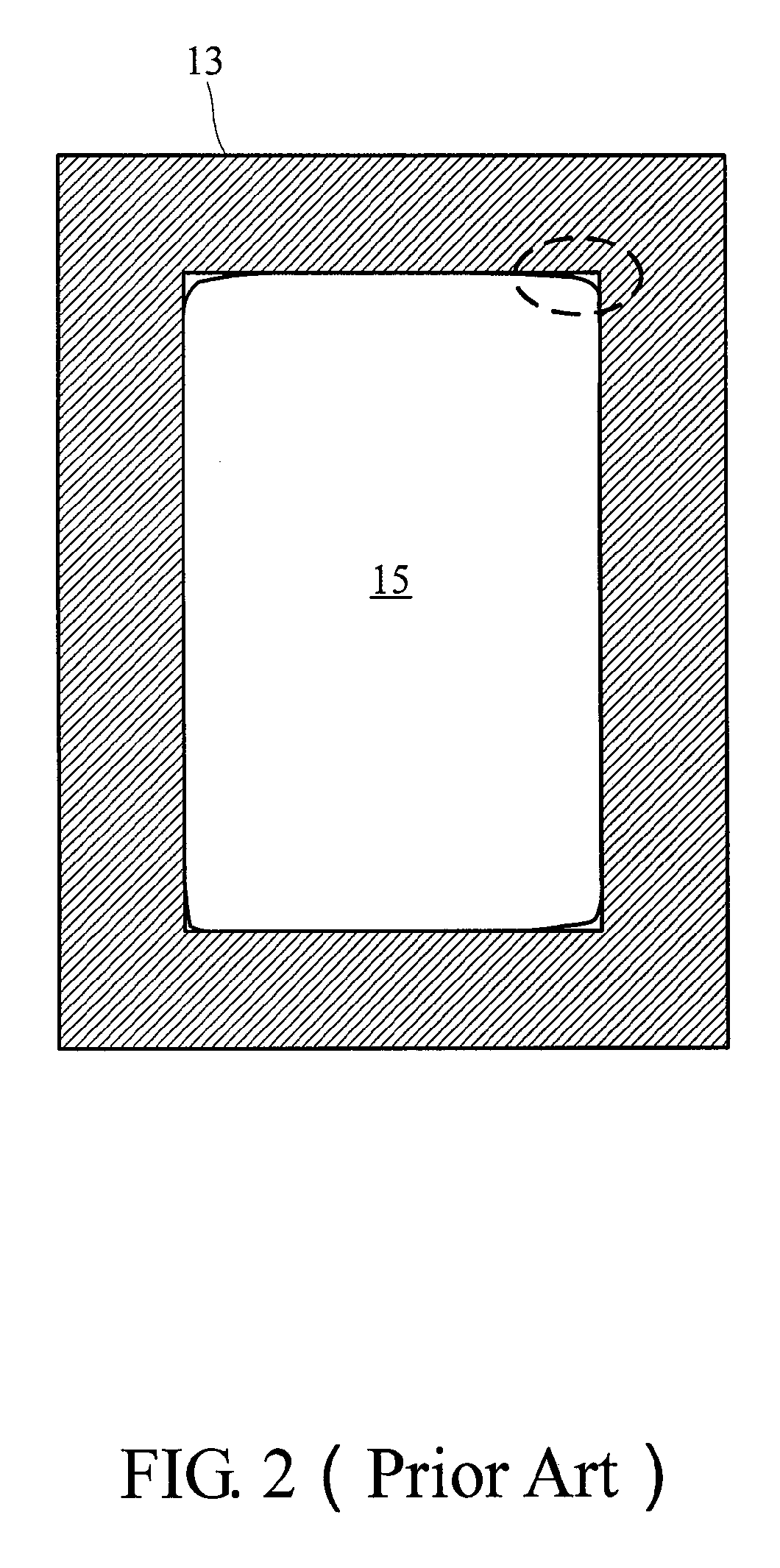

Color Filter and Black Matrix Thereof

A color filter and a black matrix thereof are provided. The black matrix disposed on the substrate comprises a frame that defines a pixel area for accommodating color filter inks when performing the ink-jet process, and a spacer disposed in each of the pixels for preventing inks from overflowing to adjacent pixel areas and improving the flatness of the formed color filter layer.

Owner:AU OPTRONICS CORP

Method for producing alumina homogenization material

ActiveCN101121604AImprove high temperature corrosion resistanceImprove fire resistanceGrain growthMaterials science

The present invention discloses a preparation method for bauxite material; which uses the aluminium bauxite mineral with loose structure and incapable of baking directly, and is formed through the following steps including matching, grilling, de-iron, filtering, molding and drying and baking. The main crystal phase of the bauxite material is Alpha- Al2O3, whose section is caesious with compact texture and inerratic crystal grain growth; most of the material is more than 15um; each physical index reaches or even exceeds the bauxite material produced in domestic; compared with the existing technology, the material has the advantages of lower baking temperature and shorter baking time and so on.

Owner:PUYANG REFRACTORIES GRP CO LTD

Adhesive preparations

InactiveUS20070083139A1Less stimulationExcellent in long time store stabilityAntipyreticAnalgesicsMedicinePlasticizer

This invention provides a patch with less skin stimulation, excellent in long time store stability and heat stability and having favorable tack during use. The patch comprising a styrene-isoprene-styrene block copolymer, polyisobutylene, tackifier, plasticizer and pharmaceutically effective ingredient, in which two or more kinds of polyisobutylene of different average molecular weight are used in combination and the viscosity of the adhesive of the patch is between 1500 and 30,000 poise (at 60° C.) and the tack of the patch is from 5 to 200 g / 10 mm.

Owner:HISAMITSU PHARM CO INC

Physical generating apparatus for fuel-oil additive

InactiveCN101070487ALow viscosityReduce surface tensionHydrocarbon oils refiningSupersonic wavesPhysical chemistry

The invention relates to a multiple physical technical disposal device which coul provide activated material and energy to fuel. It adopts four physical techniques which includes magnetization, fluctuation, supersonic wave and far infrared ray to deal with fuel, and makes physical oil adjunct. After dealed, put it with oil together, resonate with oil molecule, decrease the condensation, and the oil molecule crystalline constitution metamorphosis, then the oil viscidity and surface tension decline. The mixed mass of fuel and air increases, the air factor decreases, the burning velocity of oil, the temperature of burning area, and the viscidity of complete burning increase, ehile on the other hand, disposed fume decreases, the coking of spray nozzle is eliminated. Thus, the flow ability, flammability, cleaning ability are improved.

Owner:姜国常

Machine-spraying quick-demulsifying solidification film formation creep waterproof coating and preparation method thereof

ActiveCN103525307AGood adhesionIncrease viscosityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses a machine-spraying quick-demulsifying solidification film formation creep waterproof coating and a preparation method thereof, belonging to the technical field of waterproof coating. The waterproof coating is formed from the components A and B by atomization mixing in air and dehydration curing, wherein the component A comprises the following components in percentage by weight: 5-20% of thermoplastic elastomer polymer, 20-50% of asphalt, 30-50% of water, 1-5% of emulsifier, 5-20% of rubber latex and 0-20% of filler; the component B consists of the following components in percentage by weight: 30-40% of demulsifier and 60-70% of water. The waterproof coating overcomes the shortcomings of a common elastomer, such as quick aging in a high-stress state for a long time, stretching fatigue and the like, and always keeps good viscosity and re-bonding ability; the problem of internal stress of a waterproof layer is thoroughly solved, so that the waterproof layer has the characteristics of strong sustained bonding ability, high elongation and low-temperature flexibility; the material has good adhesive property, good heat resistance and good low-temperature flexibility, and the creep property in a shear state can exceed 0.1N / mm.

Owner:浙江鲁班建筑防水有限公司

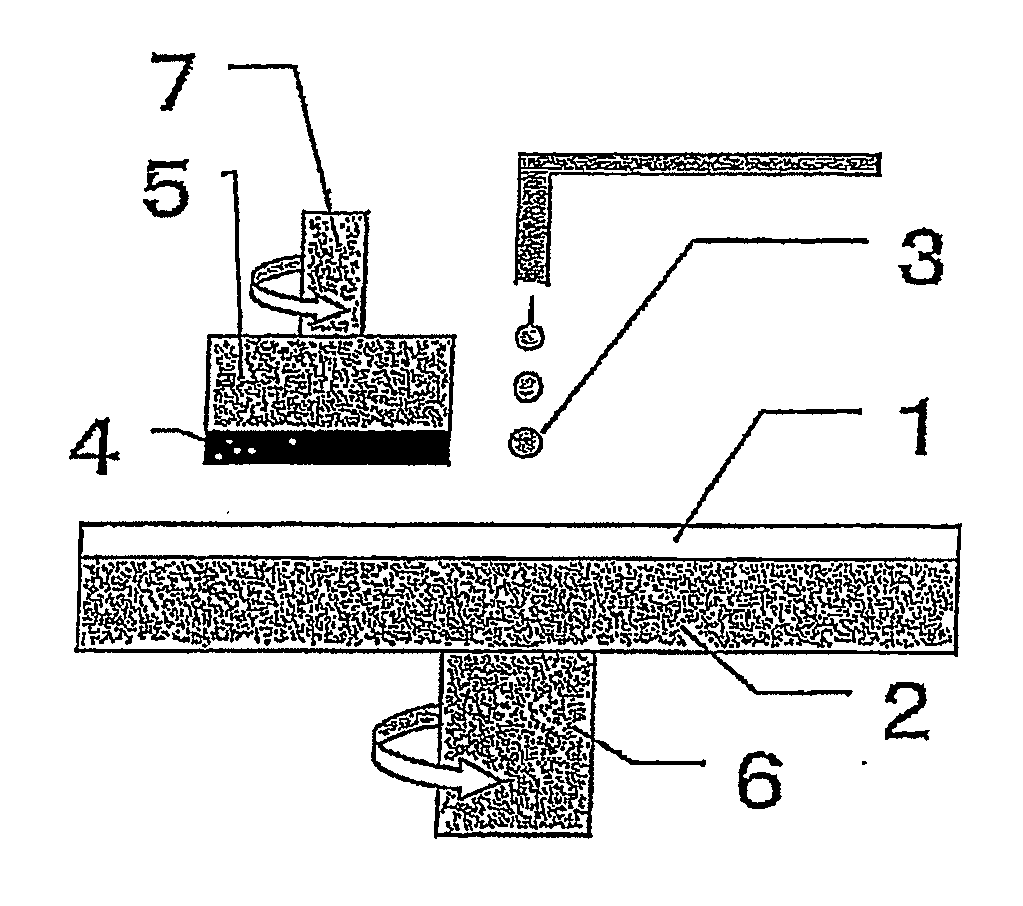

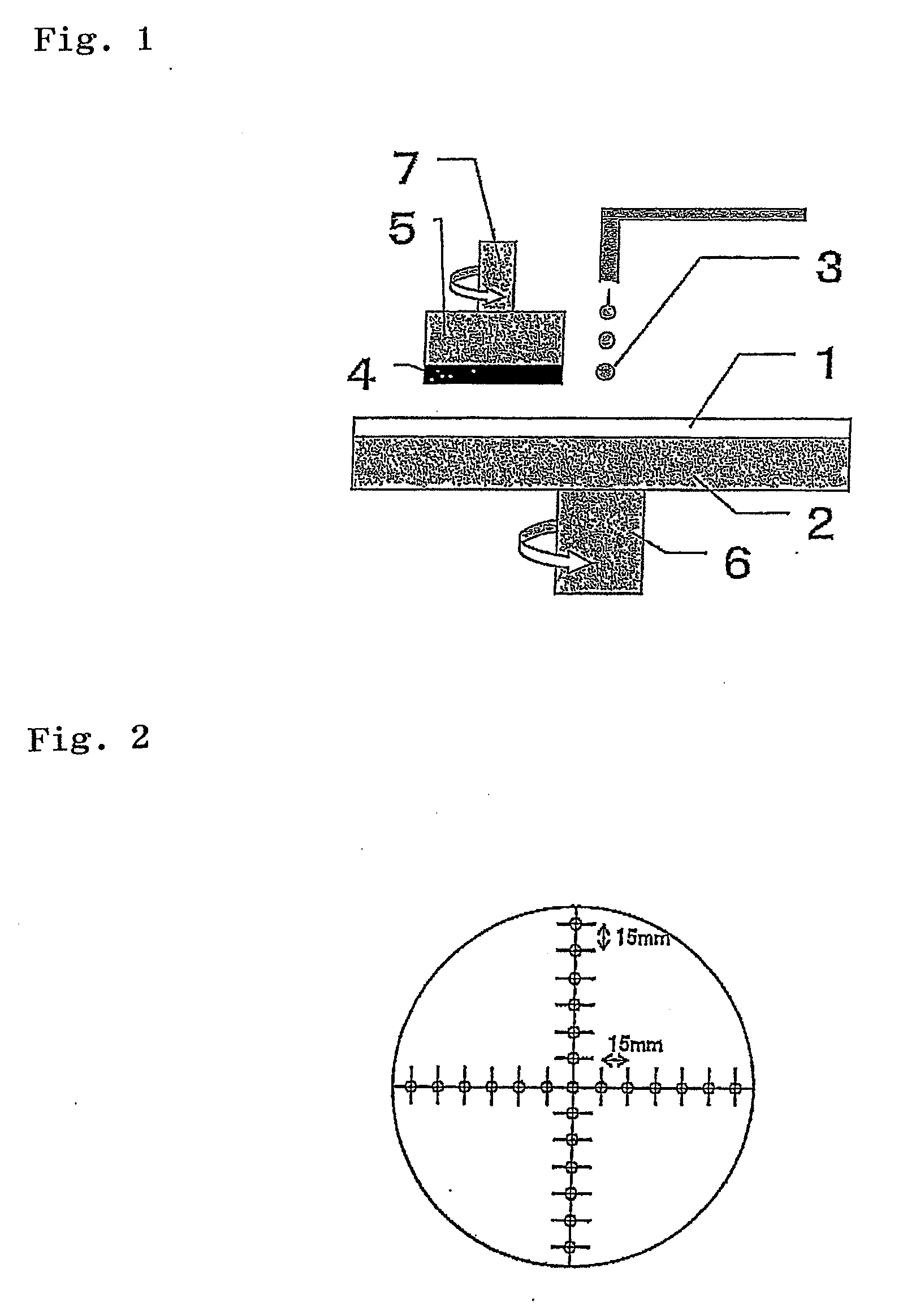

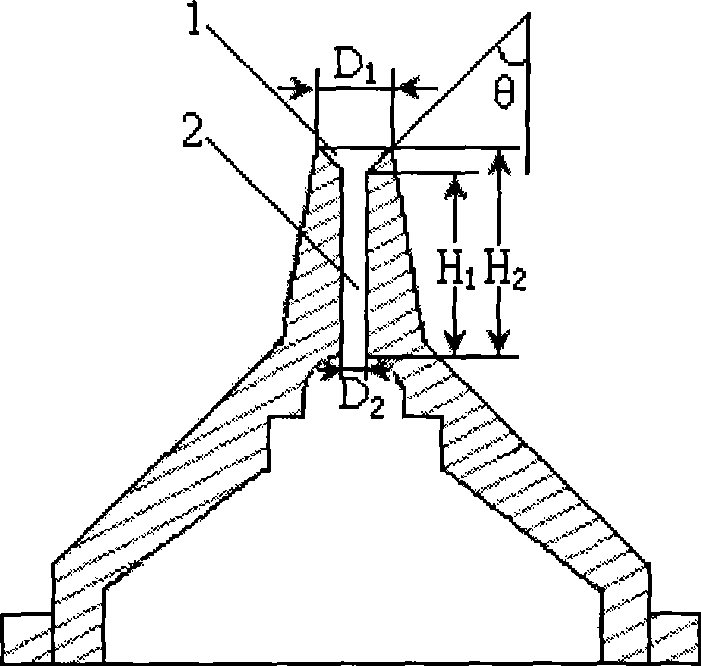

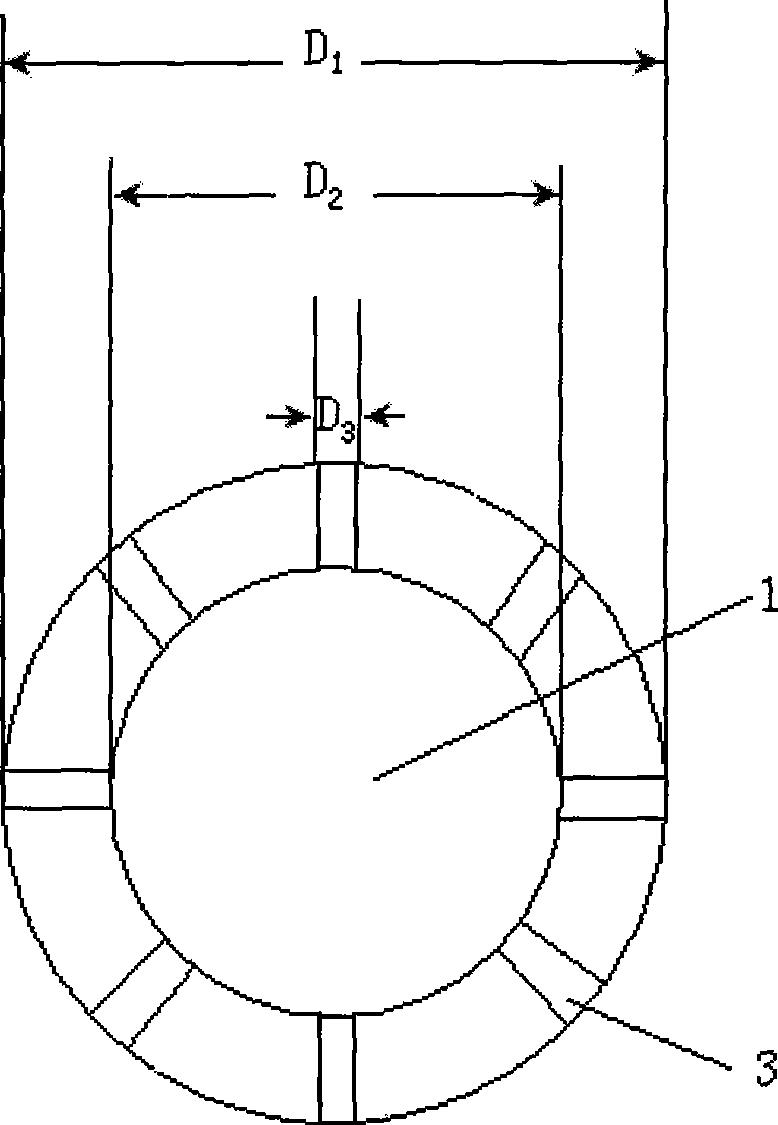

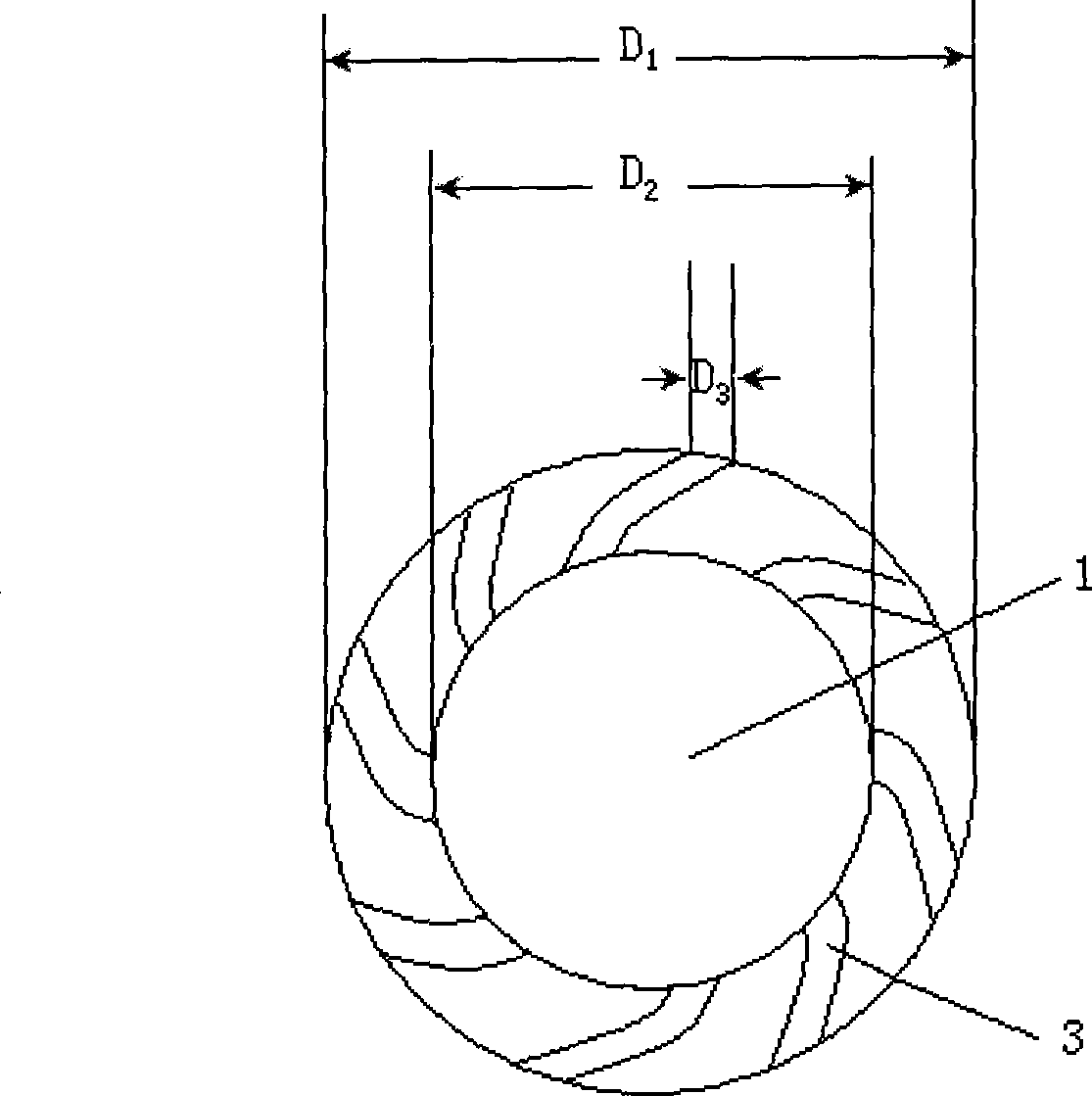

Self-twisting hollow ingot special for jet air vortex spinning

InactiveCN101476180AEasy accessReduce lossesContinuous wound-up machinesOpen-end spinning machinesFiberYarn

The invention relates to a self-twist hollow ingot special for jet blast vortex spinning which includes a fibre inlet (1) and a hollow ingot channel (2), a surface groove (3) is opened on the fibre inlet (1) and the hollow ingot channel (2), the fibre inlet (1) diameter D1 is larger than the hollow ingot channel (2) diameter D2, the fibre inlet (1) chamfer angle theta is 30-60 degree, an inner surface of the surface groove (3) is streamline. The self-twist hollow ingot provided by the invention can reduce loss amount of fibre, increase utilization rate of raw material, accordingly reduce cost for producing yarn; at the same time, enhance cohesive force among fibre in yarn greatly, accordingly, strong force of final yarn is increased.

Owner:DONGHUA UNIV

Adhesive preparations

This invention provides a patch with less skin stimulation, excellent in long time store stability and heat stability and having favorable tack during use. The patch comprising a styrene-isoprene-styrene block copolymer, polyisobutylene, tackifier, plasticizer and pharmaceutically effective ingredient, in which two or more kinds of polyisobutylene of different average molecular weight are used in combination and the viscosity of the adhesive of the patch is between 1500 and 30,000 poise (at 60° C.) and the tack of the patch is from 5 to 200 g / 10 mm.

Owner:HISAMITSU PHARM CO INC

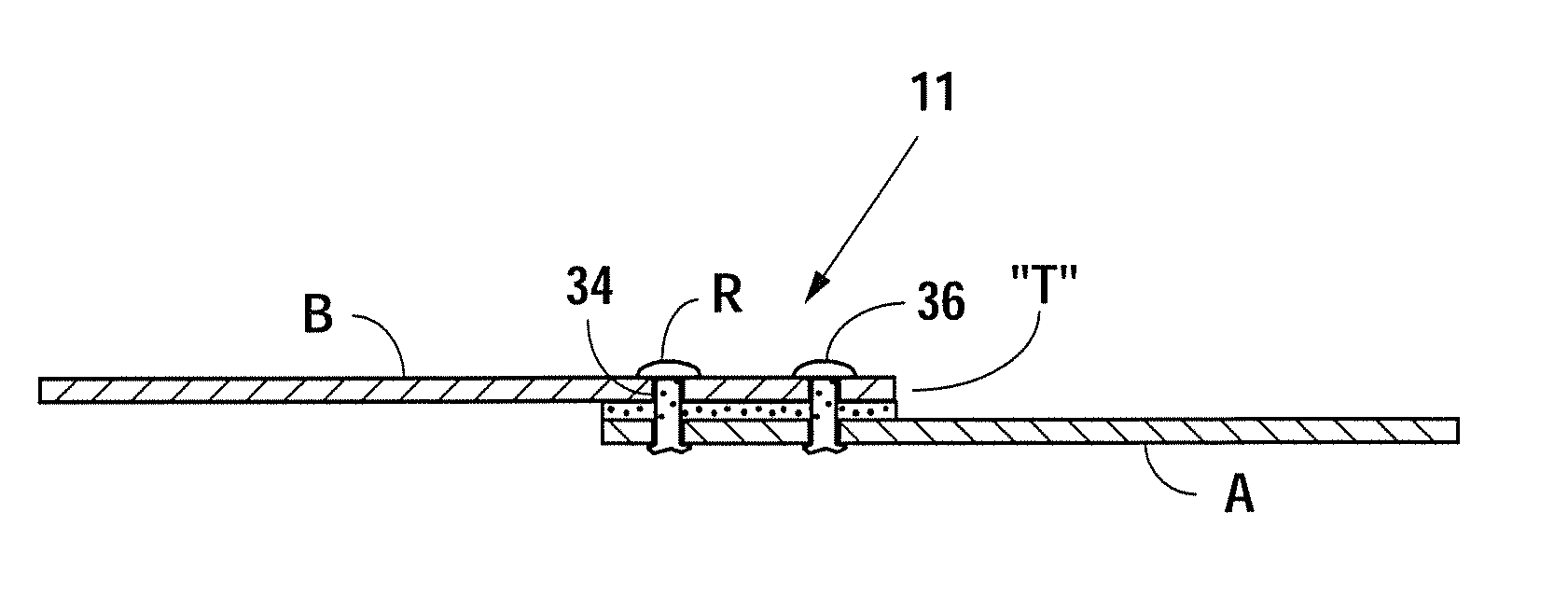

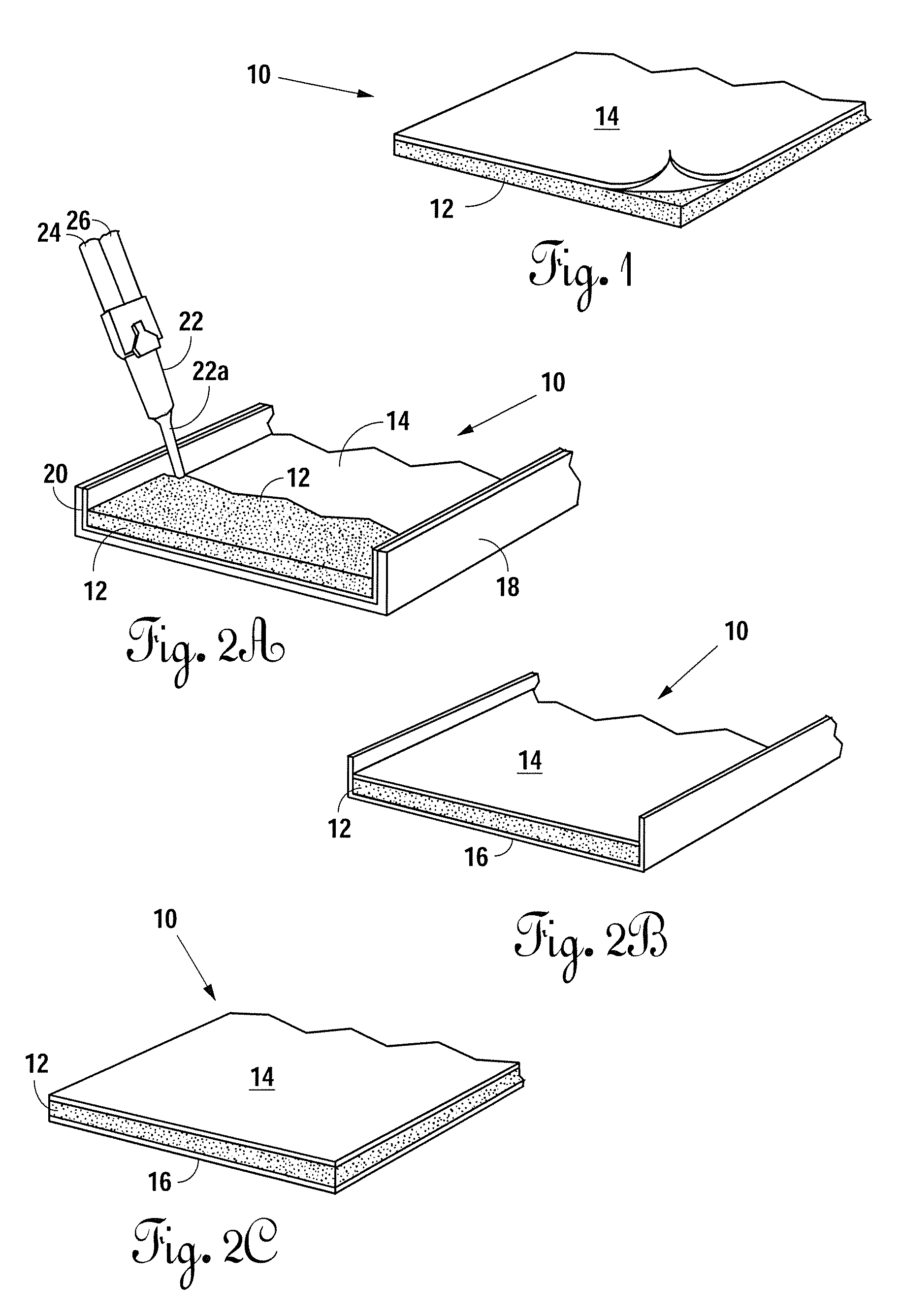

Thin gel gasket and a method of making and using the same

A thin, cured gel gasket is disclosed, including methods of making the thin gel gasket and the use of the thin gel gasket in an aircraft joint. In one embodiment, the thin gel gasket has no skeleton or other structure and is comprised of only a cured polyurethane gel and has a thickness of less than about 12 mill. It is manufactured using a release film that is adapted in a number of ways to make release from the gel prior to use easier. In one method of making and using the thin gel gasket. it is applied to a joint which is subject to compression, in one embodiment, a lap joint of an aircraft fuselage.

Owner:THE PATENT WELL LLC

Carbon fiber composite material and process for producing the same

ActiveUS20090166918A1Reduce cohesionGood dispersionMaterial nanotechnologyIndividual molecule manipulationCarbon fiber compositeCarbon nanofiber

The present invention provides a carbon fiber composite material comprising an elastomer and a carbon nanofiber dispersed in the elastomer, wherein the elastomer has an unsaturated bond or a group, having affinity to the carbon nanofiber. Also disclosed is a process for producing the carbon fiber composite material.

Owner:HITACHI ASTEMO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com