Patents

Literature

46results about How to "Small hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

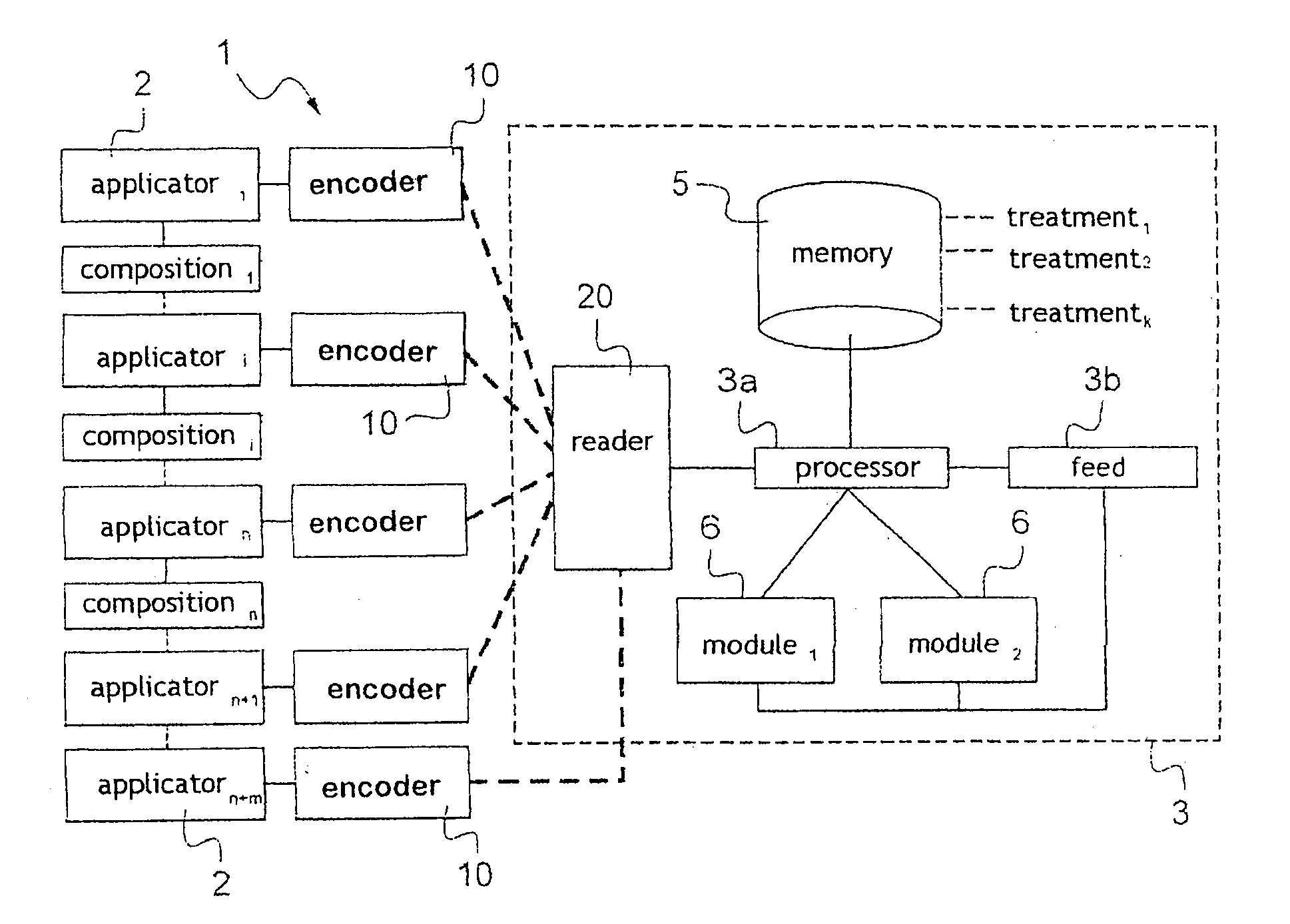

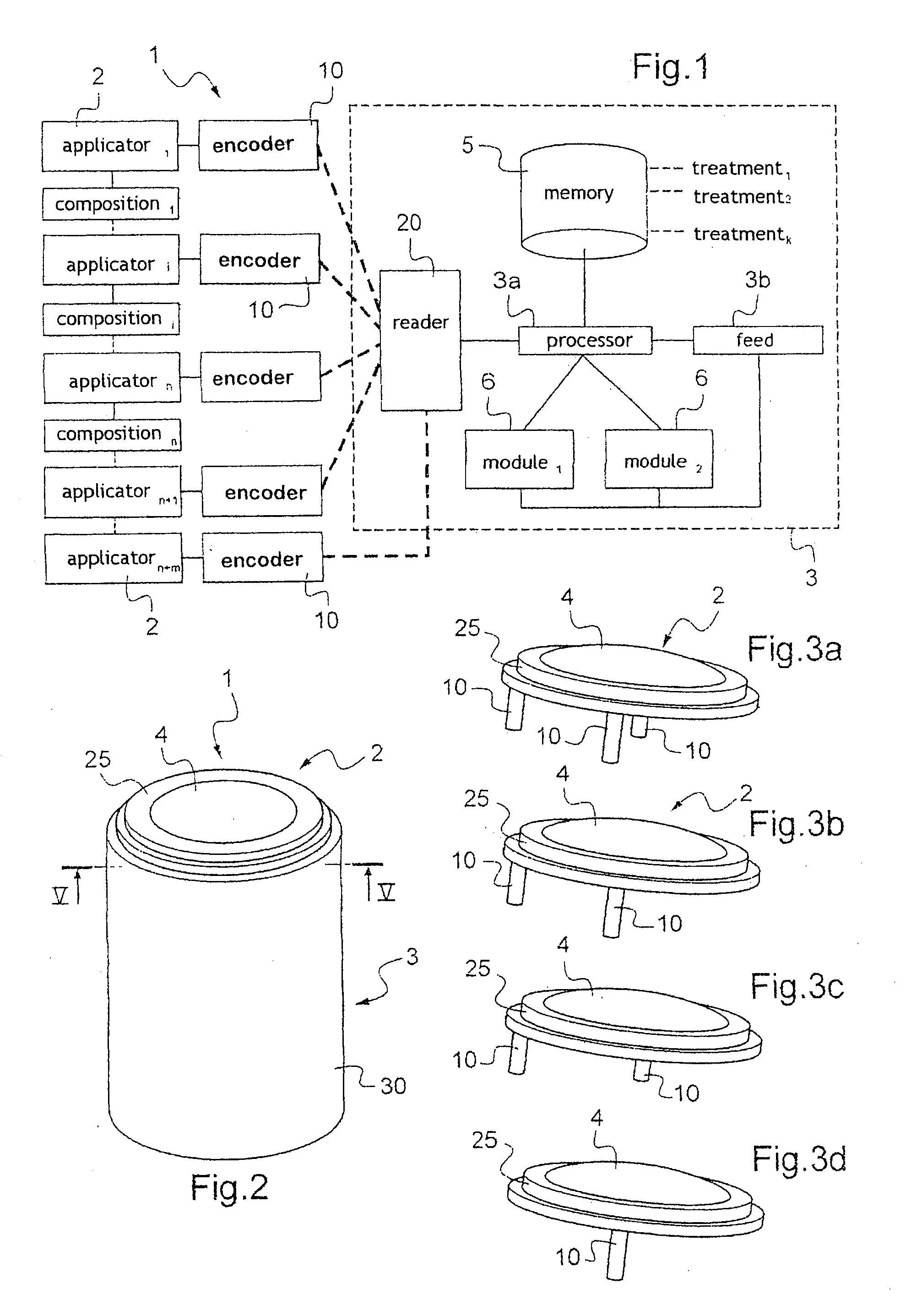

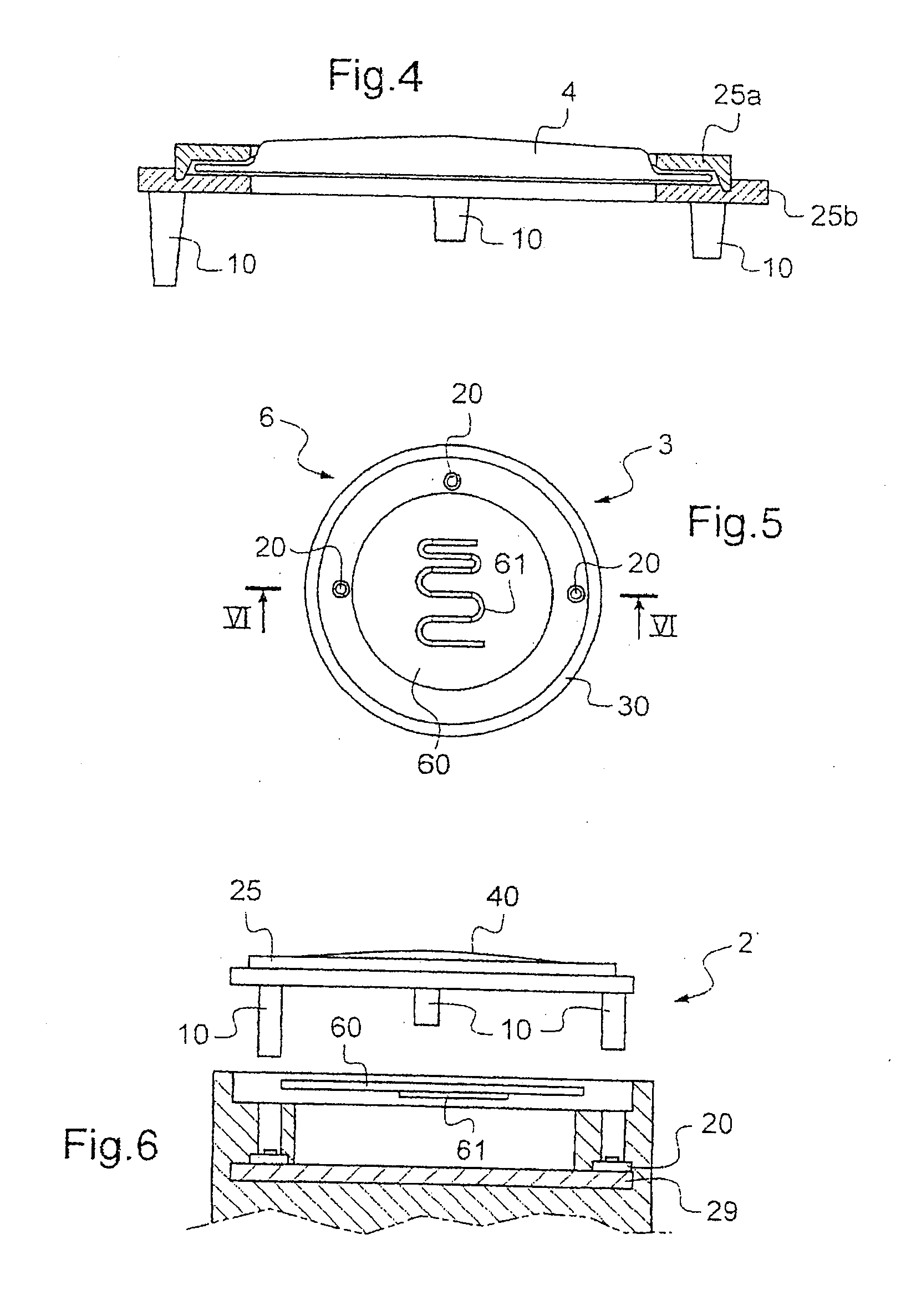

Applicator and a set including such an applicator

ActiveUS20110015463A1Small hardnessReduce cohesionElectrotherapyDiagnosticsFiberBiomedical engineering

A device for treating human keratinous materials includes an electrical appliance comprising a handpiece and a reader, and an applicator suitable for being removably fastened on the handpiece. The applicator includes a solid cosmetic or dermatological composition for applying to the keratinous materials, and / or an applicator element including fibers and / or cells suitable for enabling a cosmetic or dermatological composition to be applied on keratinous materials. The applicator also includes an encoder for encoding information arranged to be read by the reader. The operation of the handpiece depends on the information read.

Owner:LOREAL SA

Low resilience flexible polyurethane foam and process for its production

To provide a flexible polyurethane foam which is excellent in low resiliency and durability without using a plasticizer and which shows little change in hardness against a change in temperature and at the same time, has high air permeability. A process for producing a flexible polyurethane foam, which comprises reacting a polyol mixture comprising polyol (A), polyol (B) and monool (D) with a polyisocyanate compound in the presence of a blowing agent etc. at an isocyanate index of at least 90. Polyol (A) is a polyether polyol having an average of 2-3 hydroxyl groups and a hydroxyl value of from 10 to 90 mgKOH / g, obtained by ring-opening addition polymerization of an alkylene oxide to an initiator using a double metal cyanide complex catalyst; Polyol (B) is a polyether polyol having an average of 2-3 hydroxyl groups and a hydroxyl value of from 15 to 250 mgKOH / g, other than the polyol (A); and Monool (D) is a polyether monool having a hydroxyl value of from 10 to 200 mgKOH / g.

Owner:ASAHI GLASS CO LTD

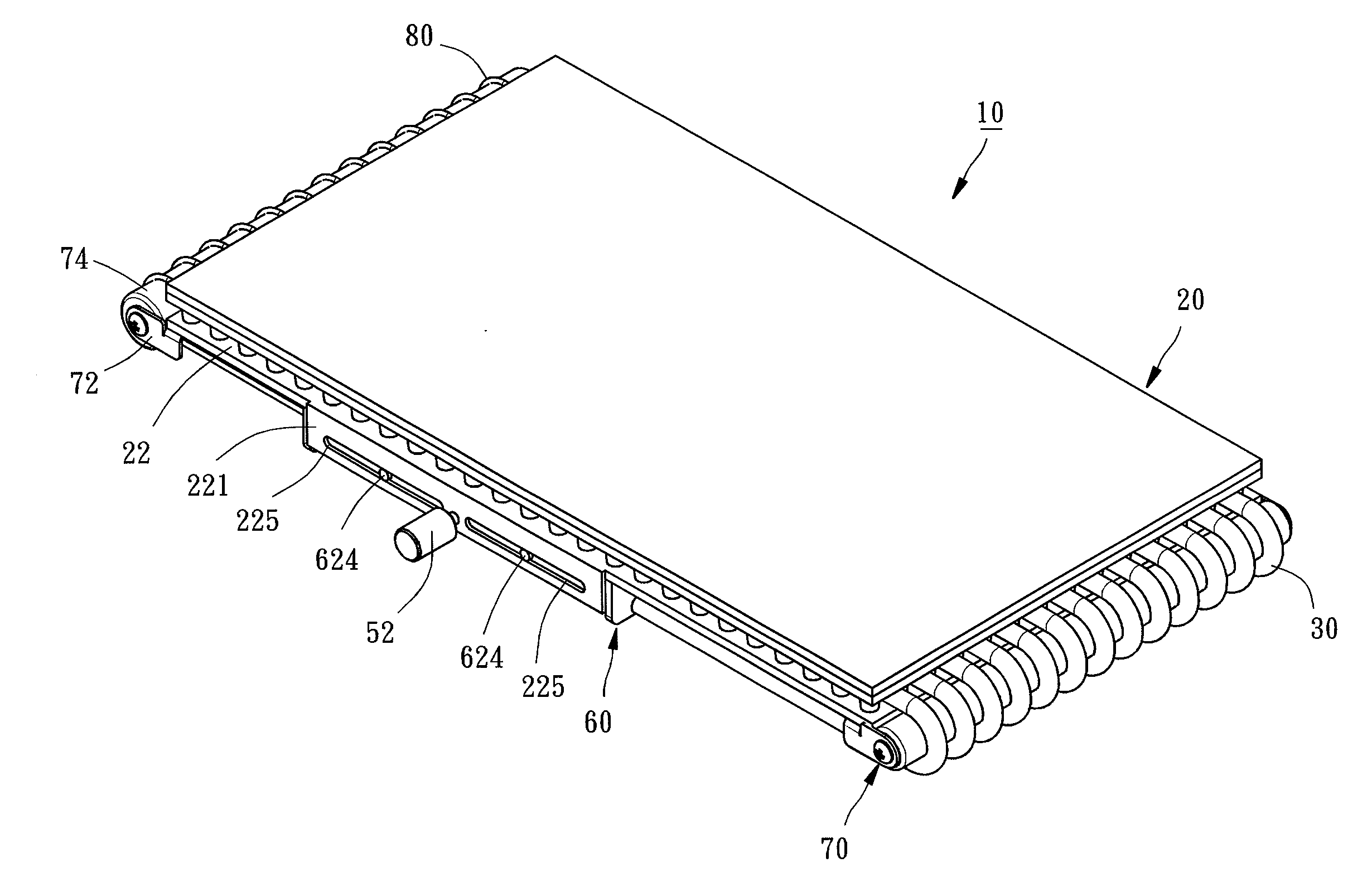

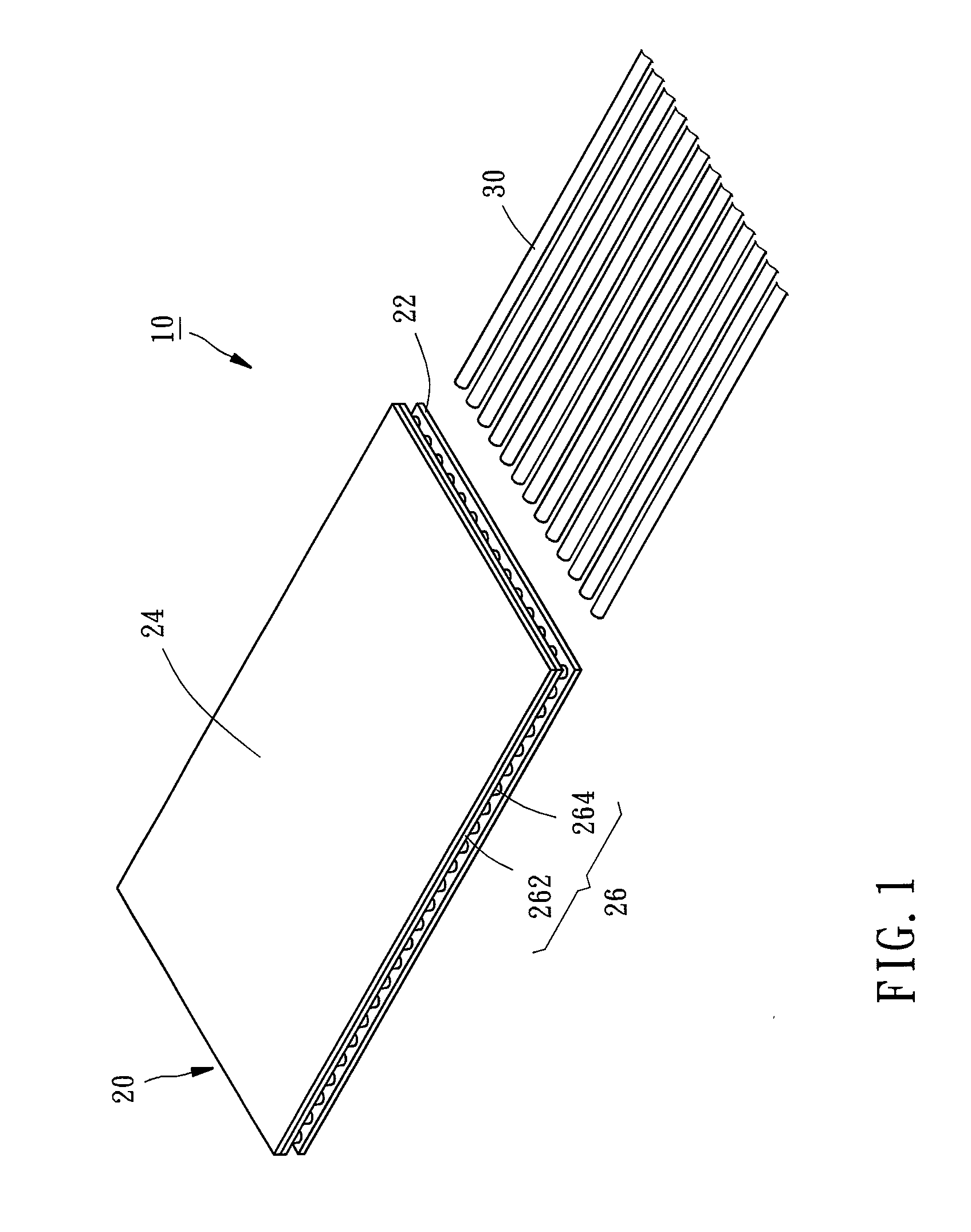

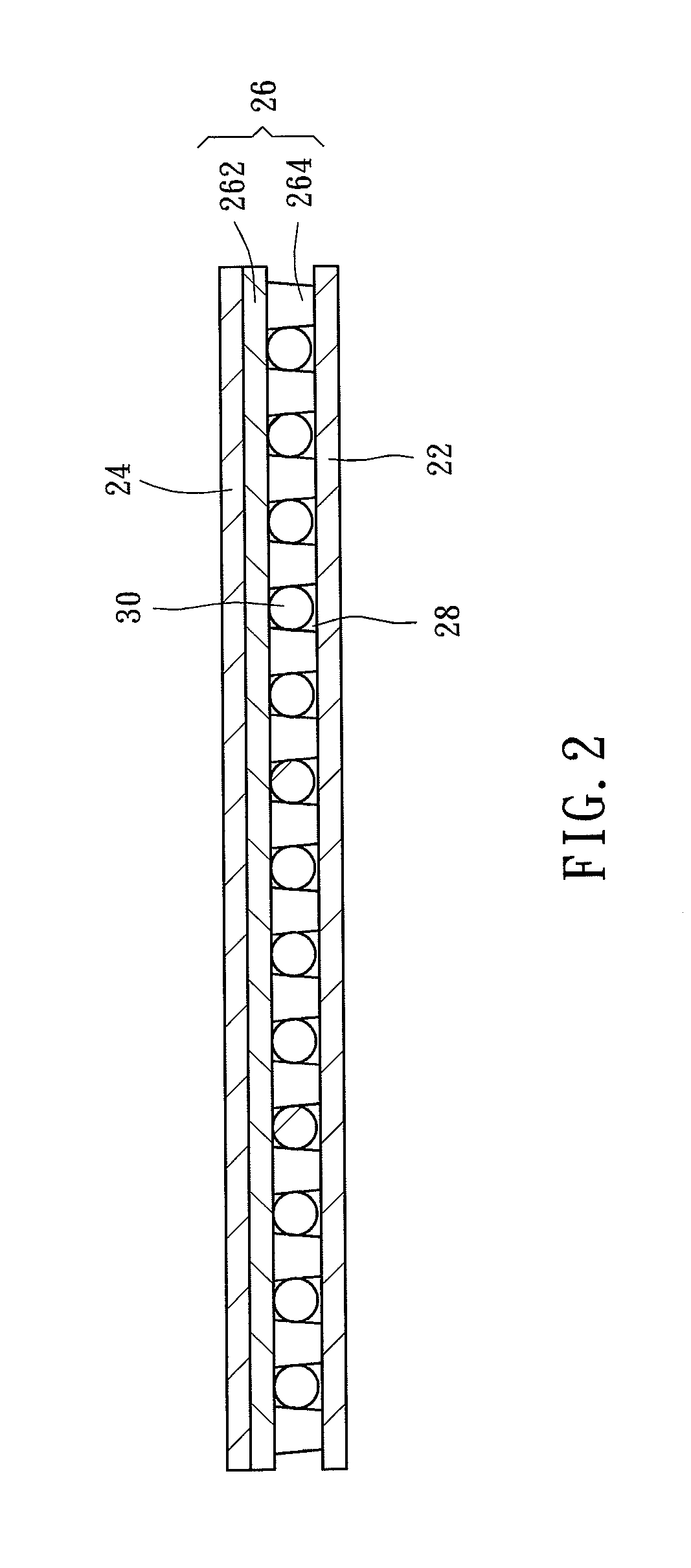

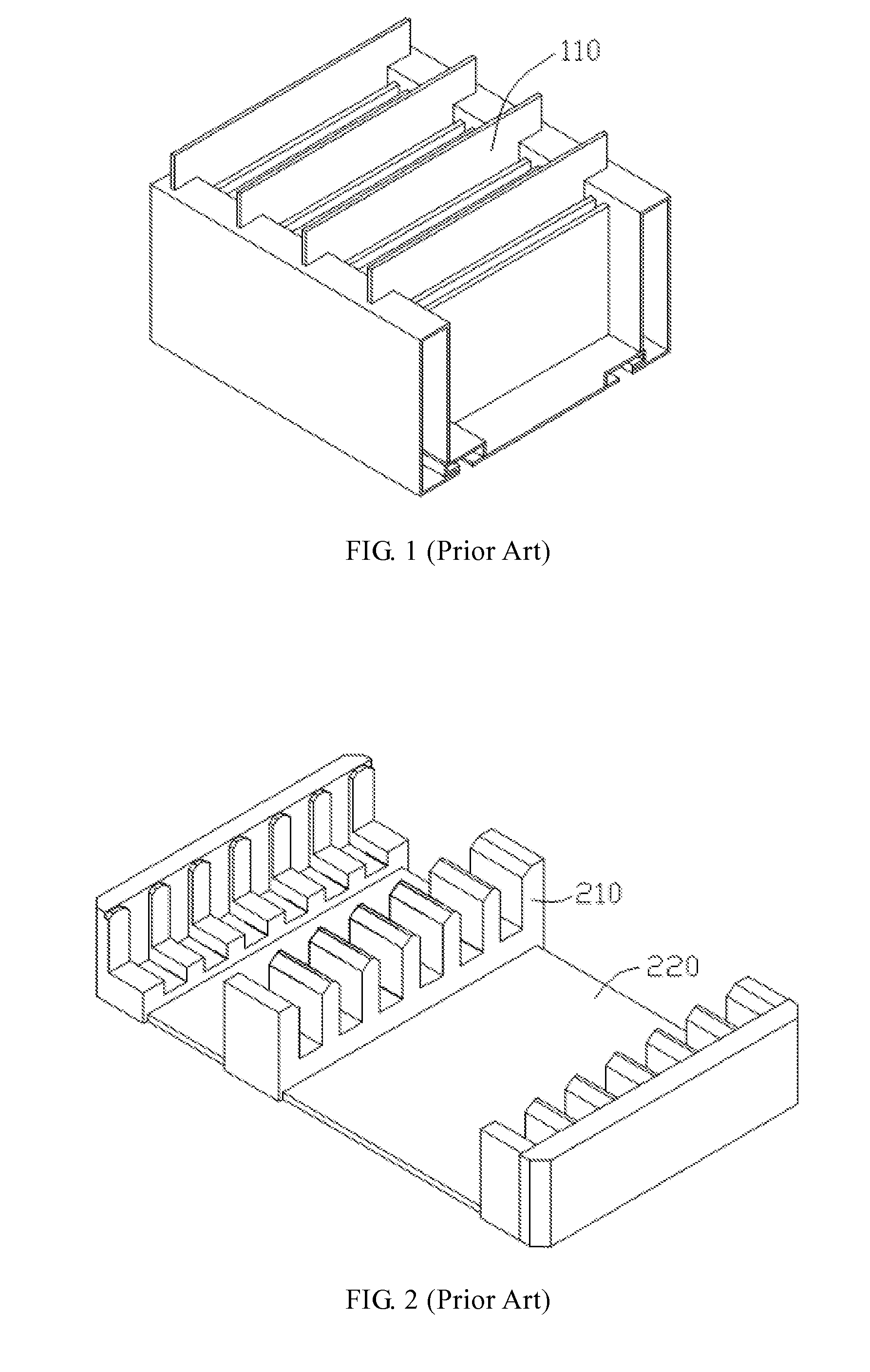

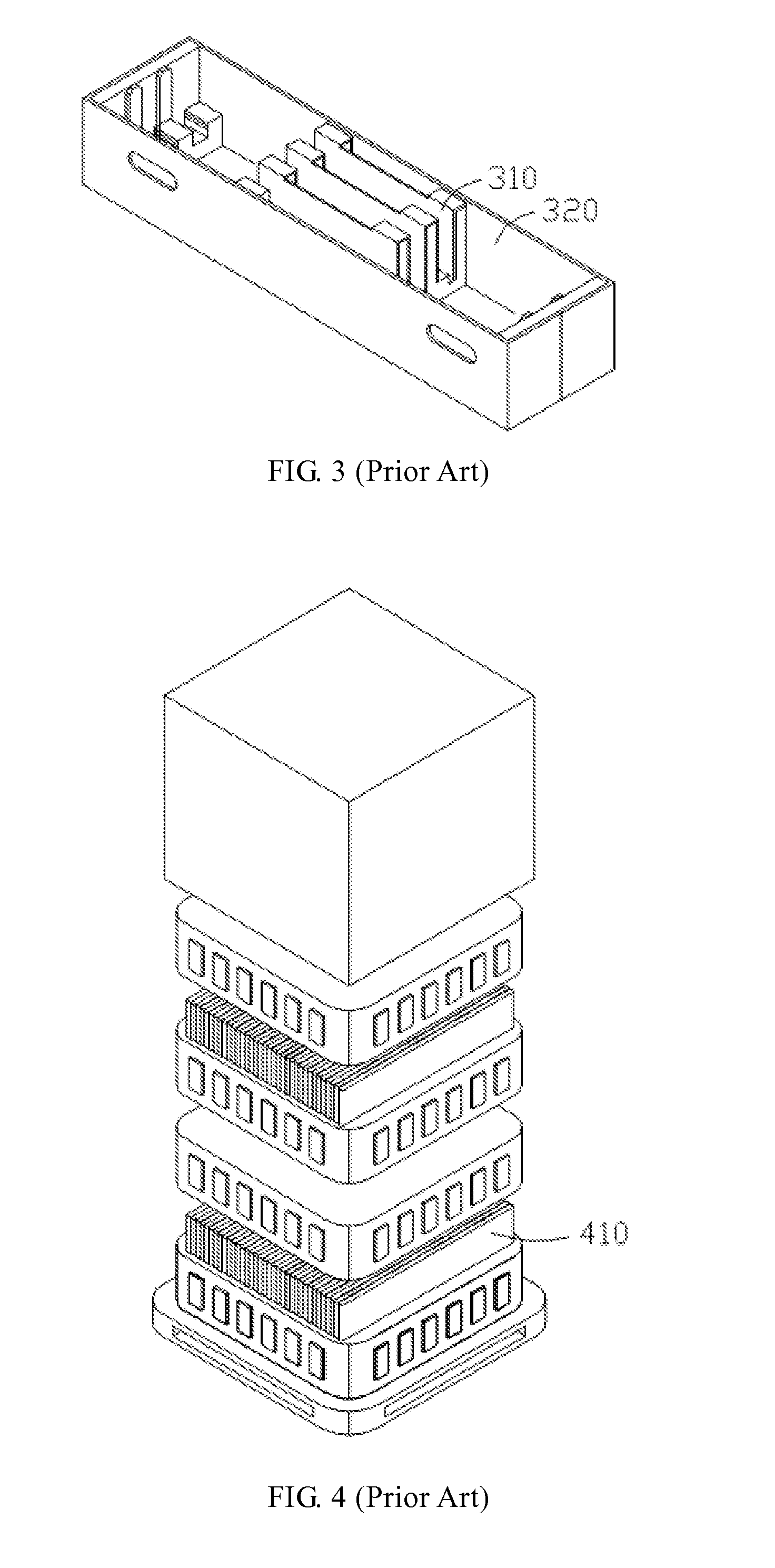

Hardness-adjustable platform for supporting conveyor belt of treadmill

InactiveUS20130130868A1Improve operational efficiencyReduce riskMovement coordination devicesCardiovascular exercising devicesInterior spaceHardness

A hardness adjustable platform for supporting a conveyor belt of a treadmill includes a platform body having internal spaces, and a plurality of elastic fillers moveably and respectively disposed in the internal spaces of the platform body for providing a cushion effect. The fillers are moveable relative to the platform body by an external force and divide the platform body into first and second regions having different hardness. As a result, the runner who uses the treadmill equipped with the aforesaid platform may adjust the positions of the fillers according to his / her physical condition and running speed to change the hardness distribution of the platform so as to enhance his / her running efficiency and reduce the risk of exercise injury.

Owner:HEALTHSTREAM TAIWAN INC

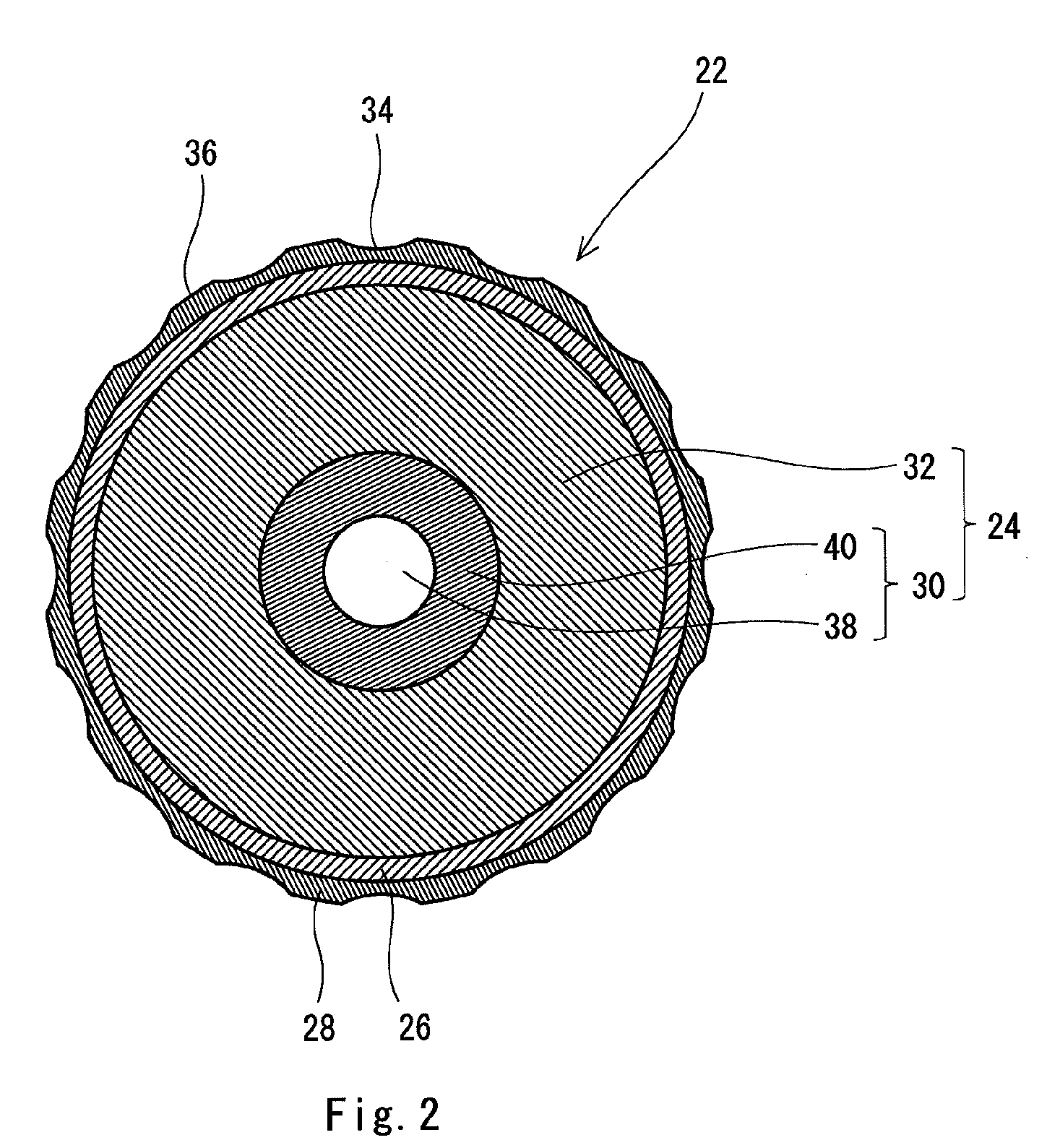

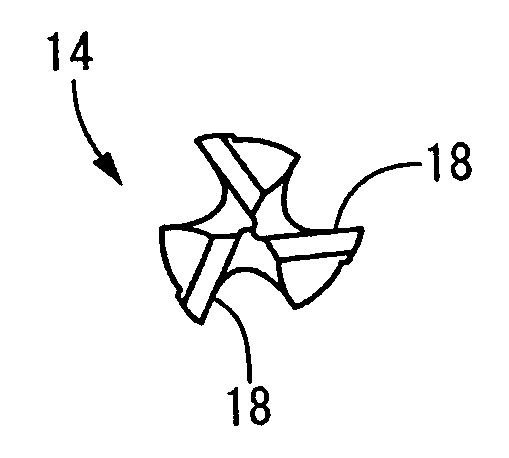

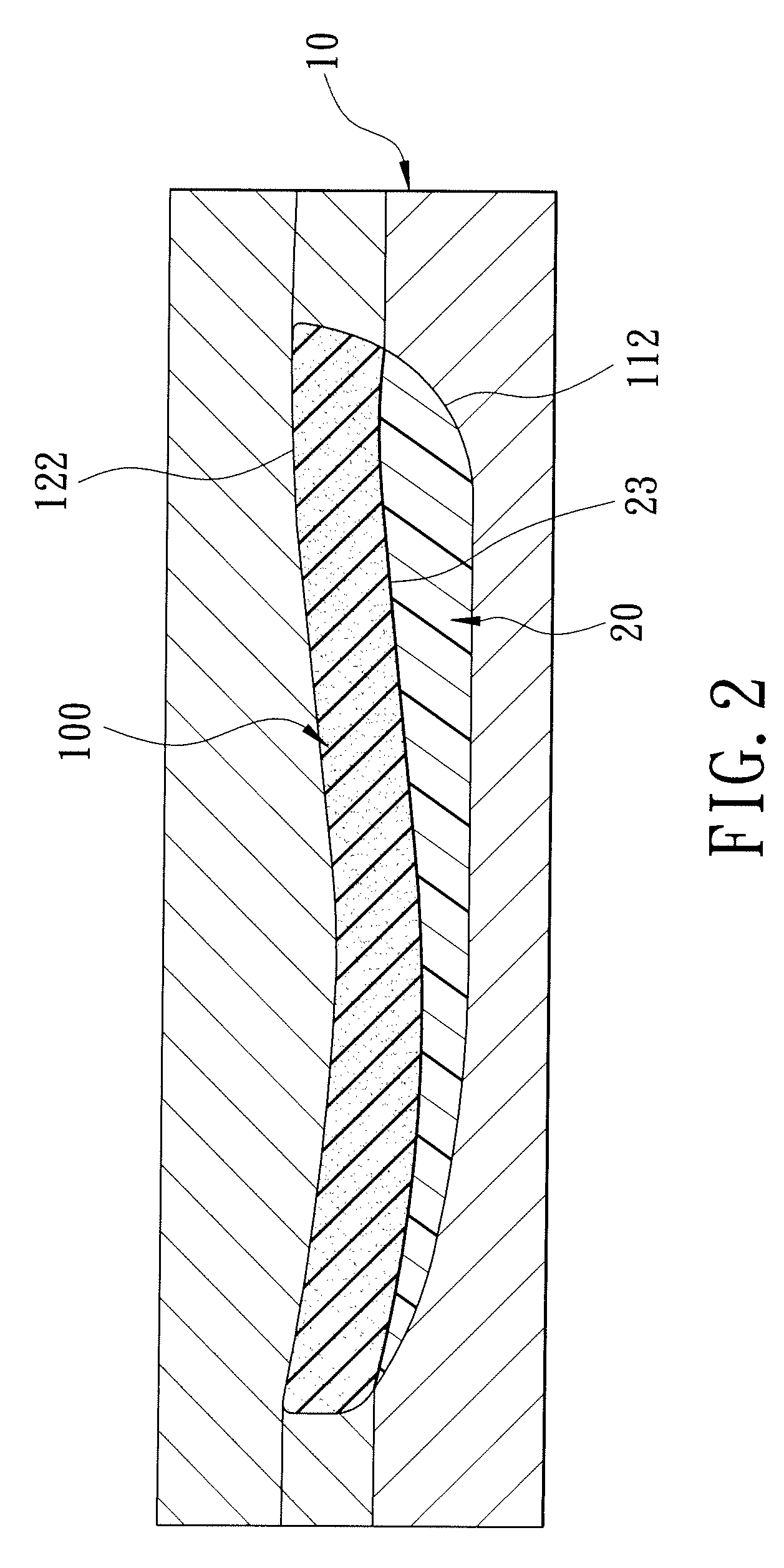

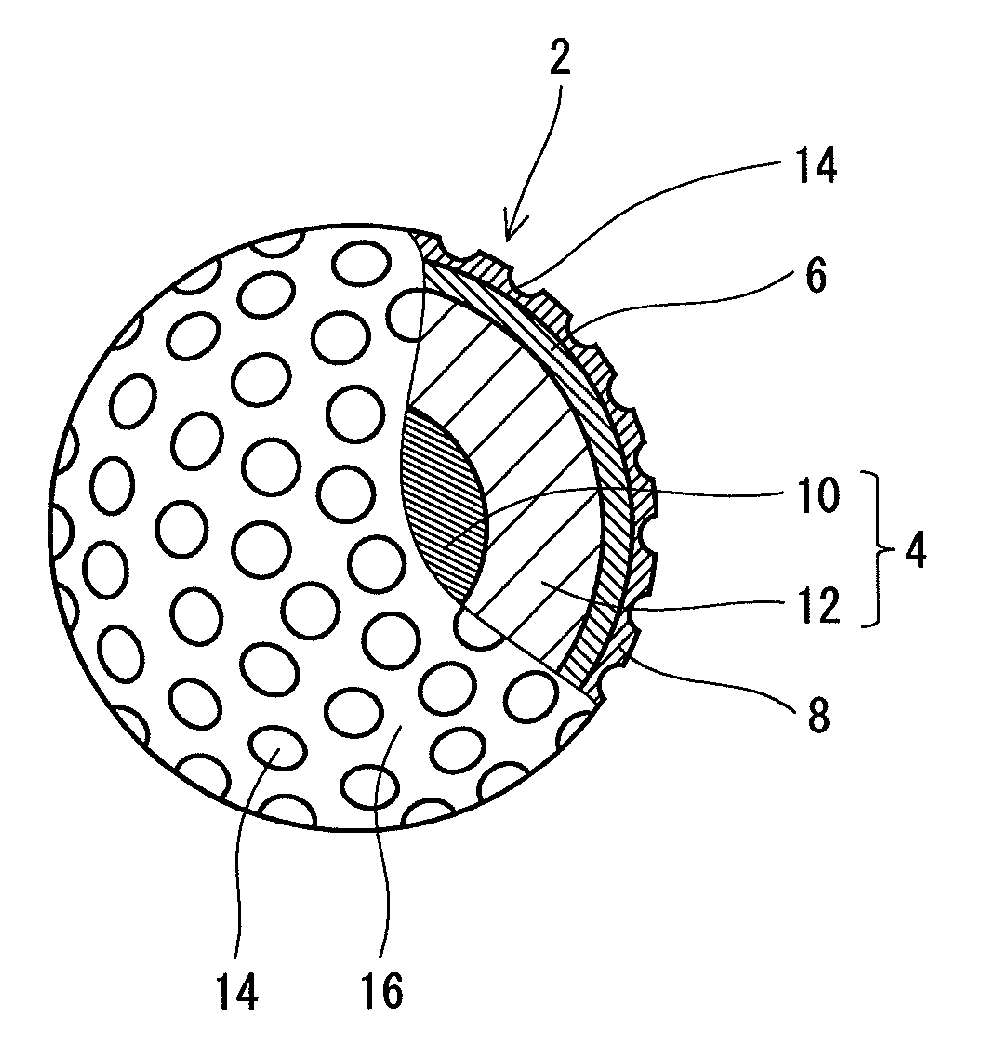

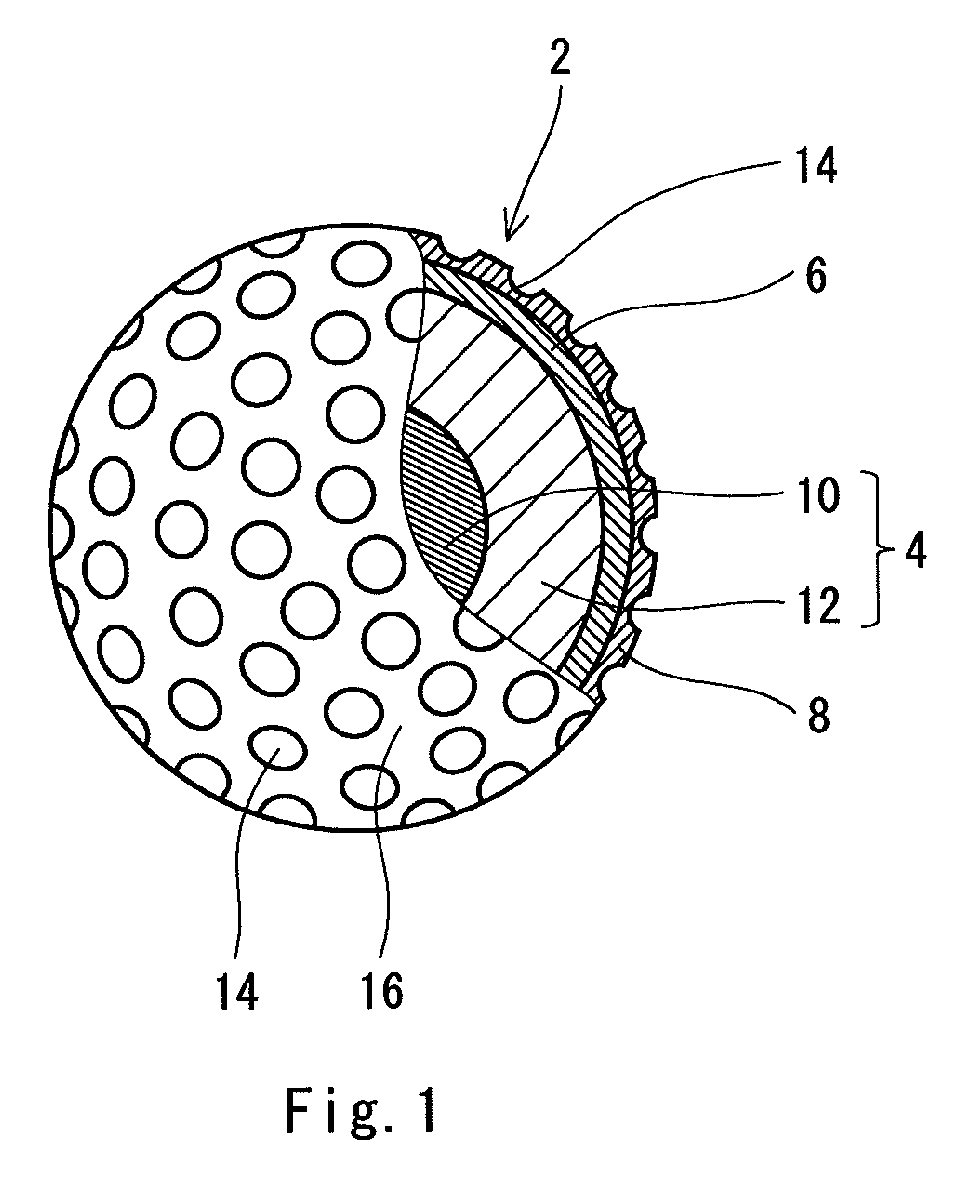

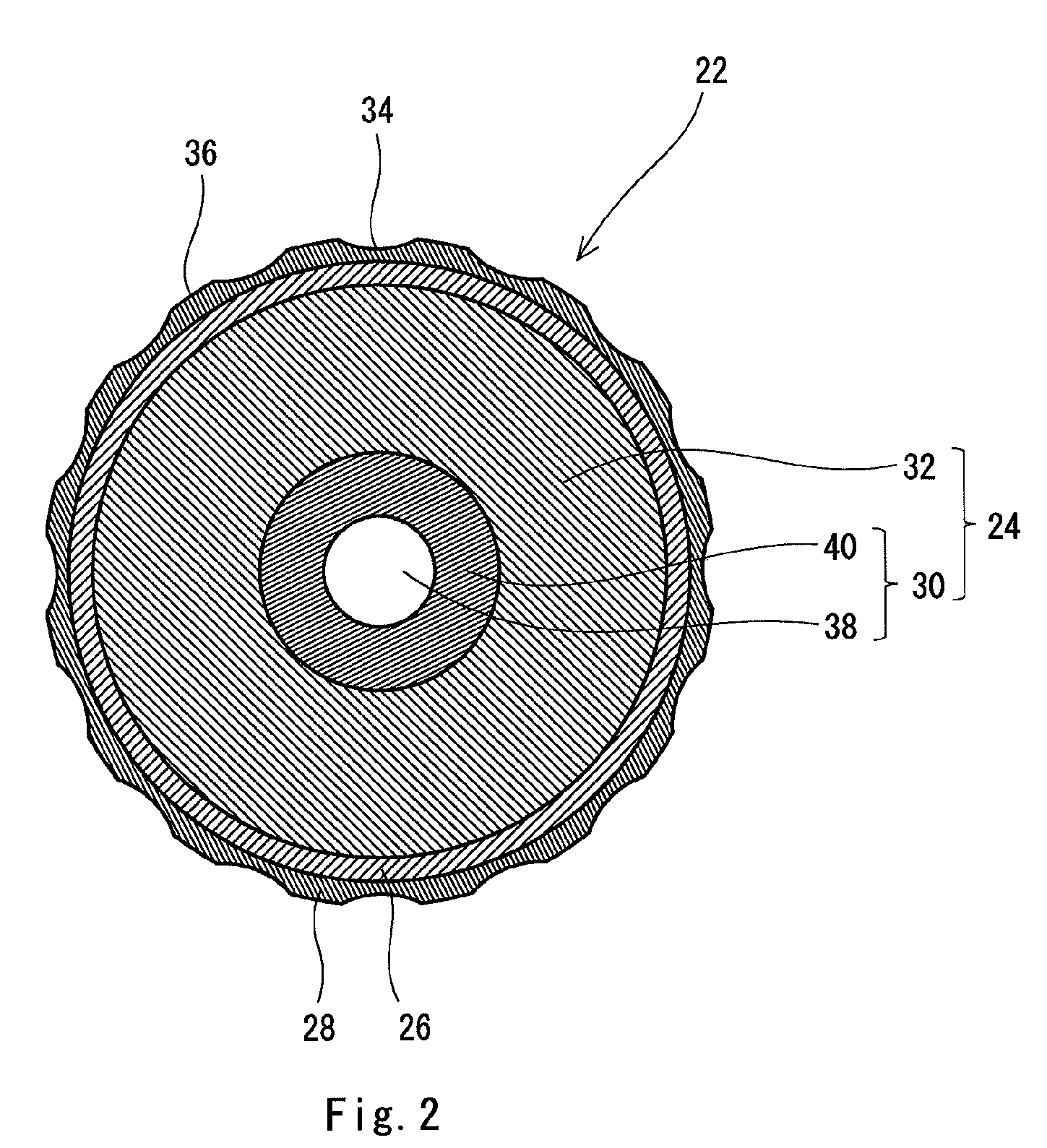

Golf ball

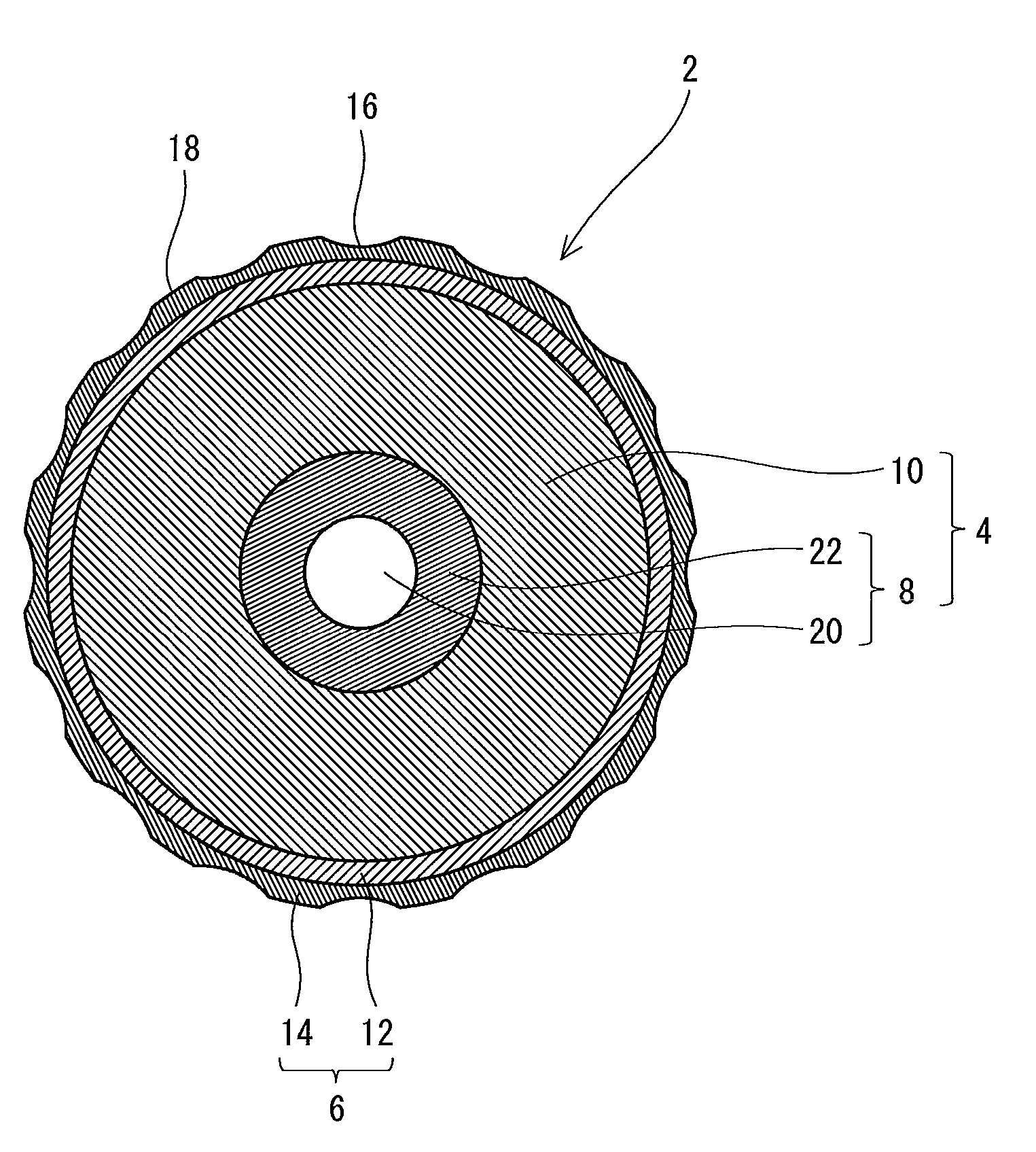

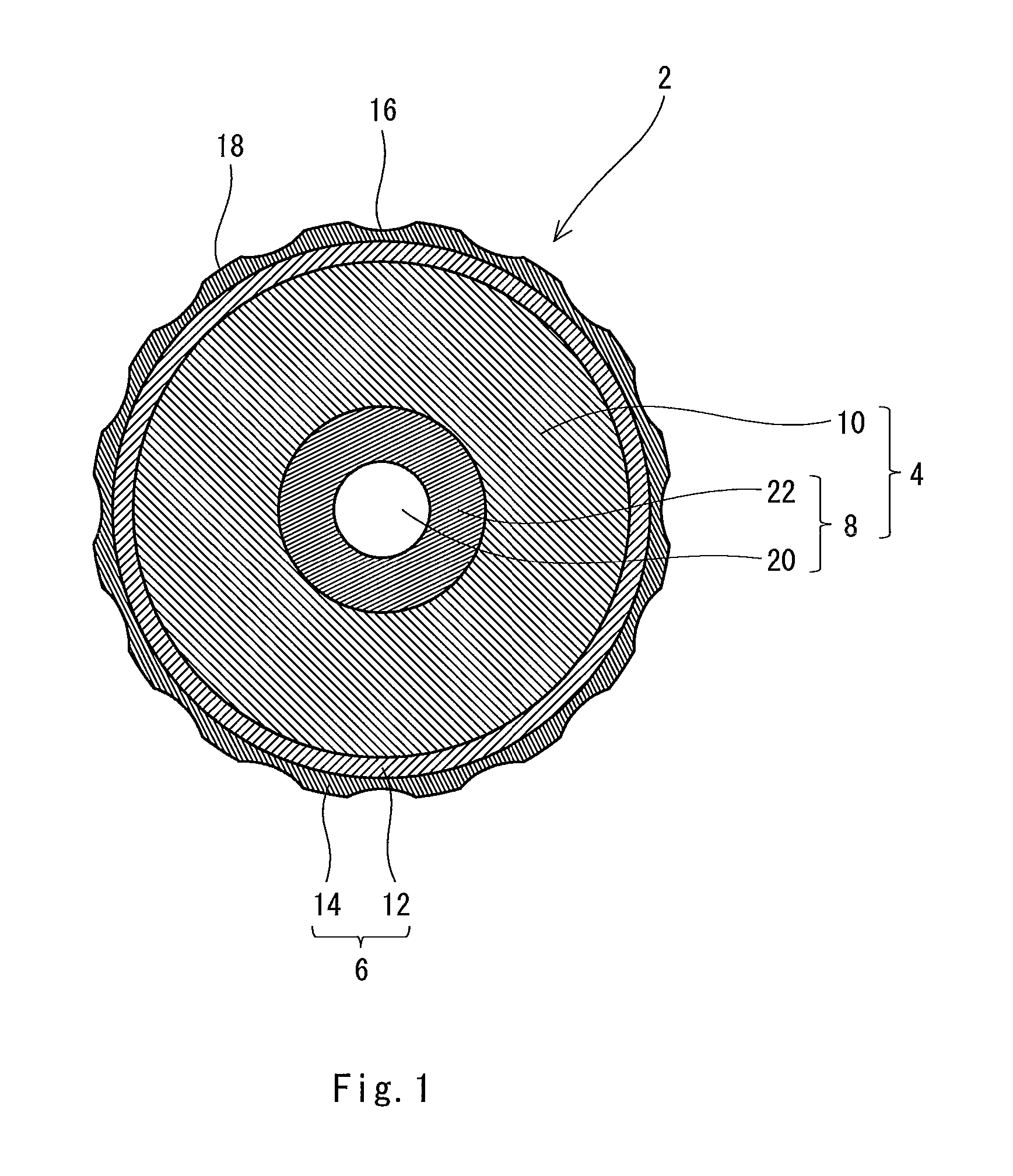

A golf ball 2 includes a spherical core 4, a mid layer 6 positioned outside the core 4, and a cover 8 positioned outside the mid layer 6. The core 4 includes a spherical center 10 and an envelope layer 12 positioned outside the center 10. The center 10 has a diameter of 1 mm or greater and 15 mm or less. The center 10 has a JIS-C hardness H1, at its central point, of 20 or greater and 50 or less. The difference (H4−H3) between the JIS-C hardness H4 of the core 4 at its surface and the JIS-C hardness H3 of the envelope layer 12 at its innermost portion is equal to or greater than 10. The cover 8 has a flexural modulus of 300 MPa or greater and 1000 MPa or less, and has a tensile modulus of 400 MPa or greater and 1500 MPa or less.

Owner:SUMITOMO RUBBER IND LTD

Process for producing flexible polyurethane foam

To provide a flexible polyurethane foam which is excellent in low resiliency and durability without using a plasticizer and which shows little change in hardness against a change in temperature and at the same time, has high air flow.A process for producing a flexible polyurethane foam, which comprises reacting a polyol mixture comprising the following polyol (A), the following polyol (B) and the following monool (D) with a polyisocyanate compound in the presence of a blowing agent and a foam stabilizer, at an isocyanate index of at least 90, wherein:Polyol (A) is a polyether polyol having an average of from 2 to 3 hydroxyl groups, a hydroxyl value of from 10 to 60 mgKOH / g and an oxyethylene group content of from 0 to 30 mass %, obtained by ring-opening polymerization of an alkylene oxide to an initiator using a phosphazene compound, a Lewis acid compound or an alkali metal compound catalyst;Polyol (B) is a polyether polyol having an average of from 2 to 3 hydroxyl groups and a hydroxyl value of from 70 to 250 mgKOH / g; andMonool (D) is a polyether monool having a hydroxyl value of from 10 to 200 mgKOH / g.

Owner:ASAHI GLASS CO LTD

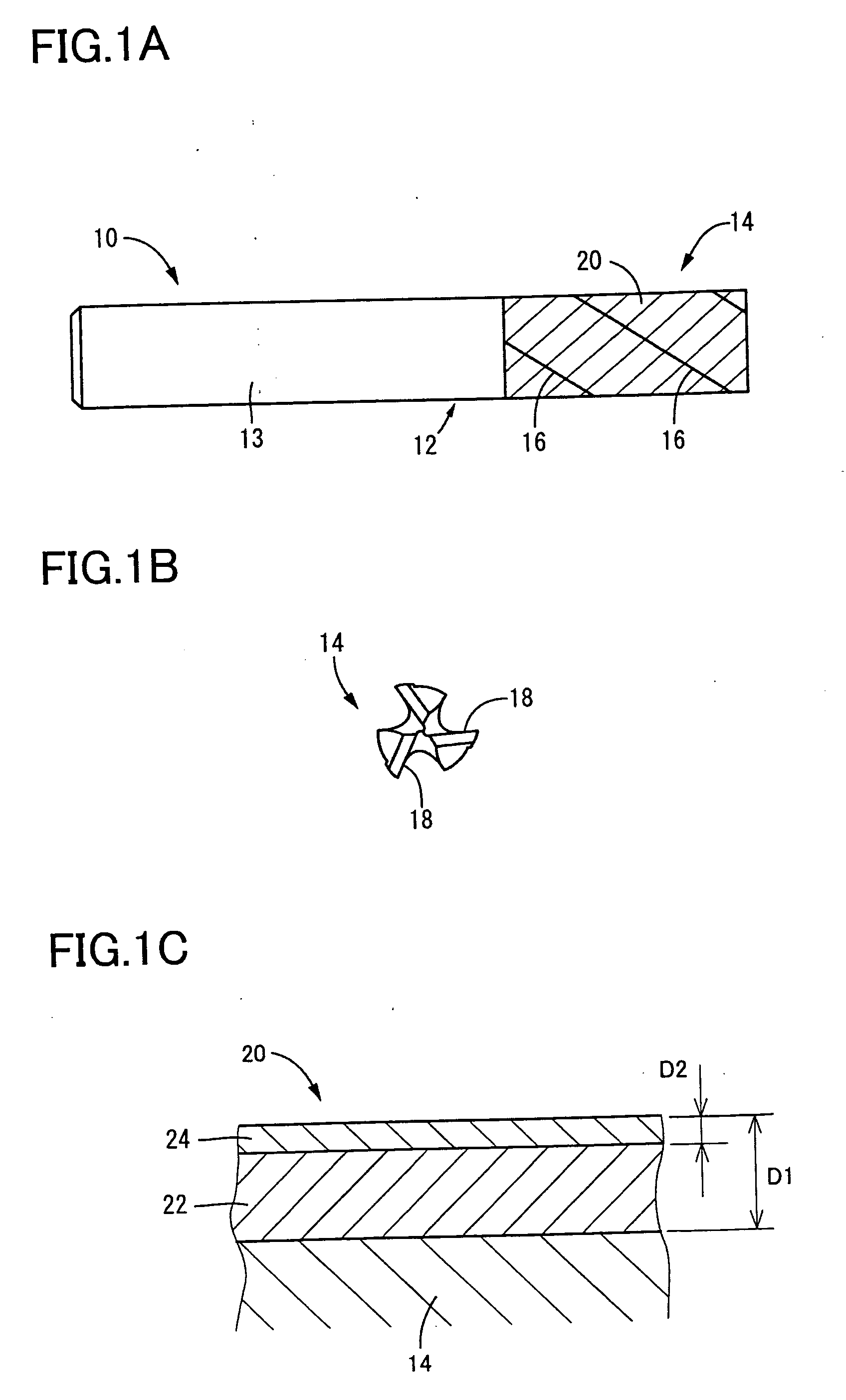

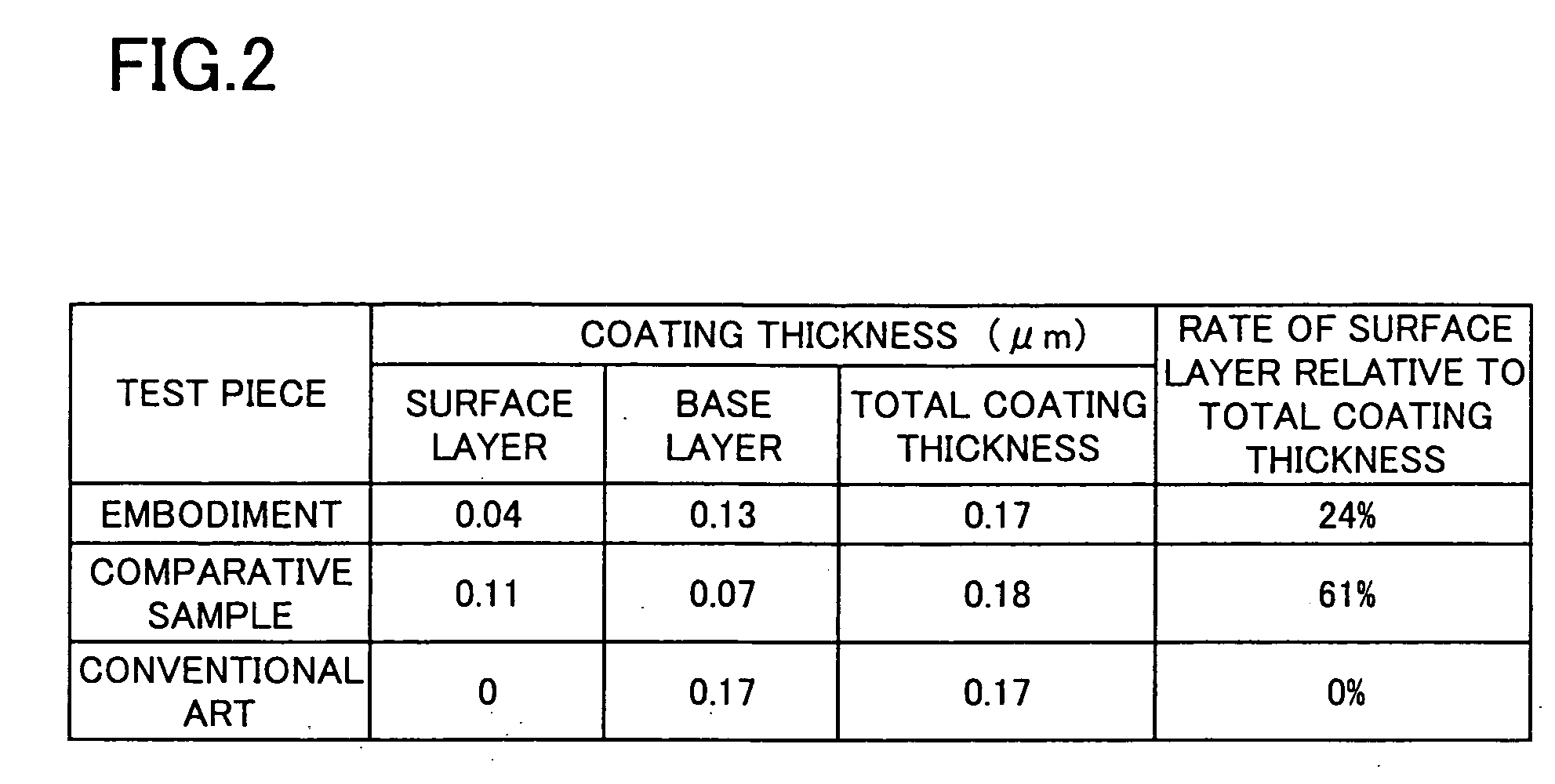

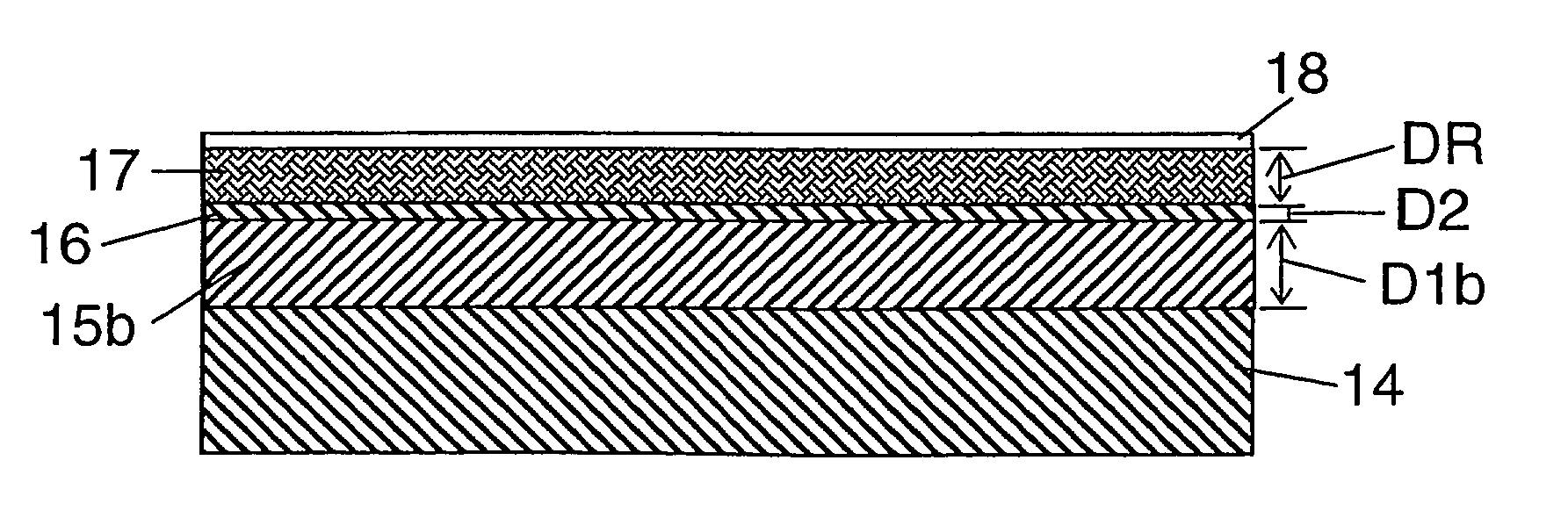

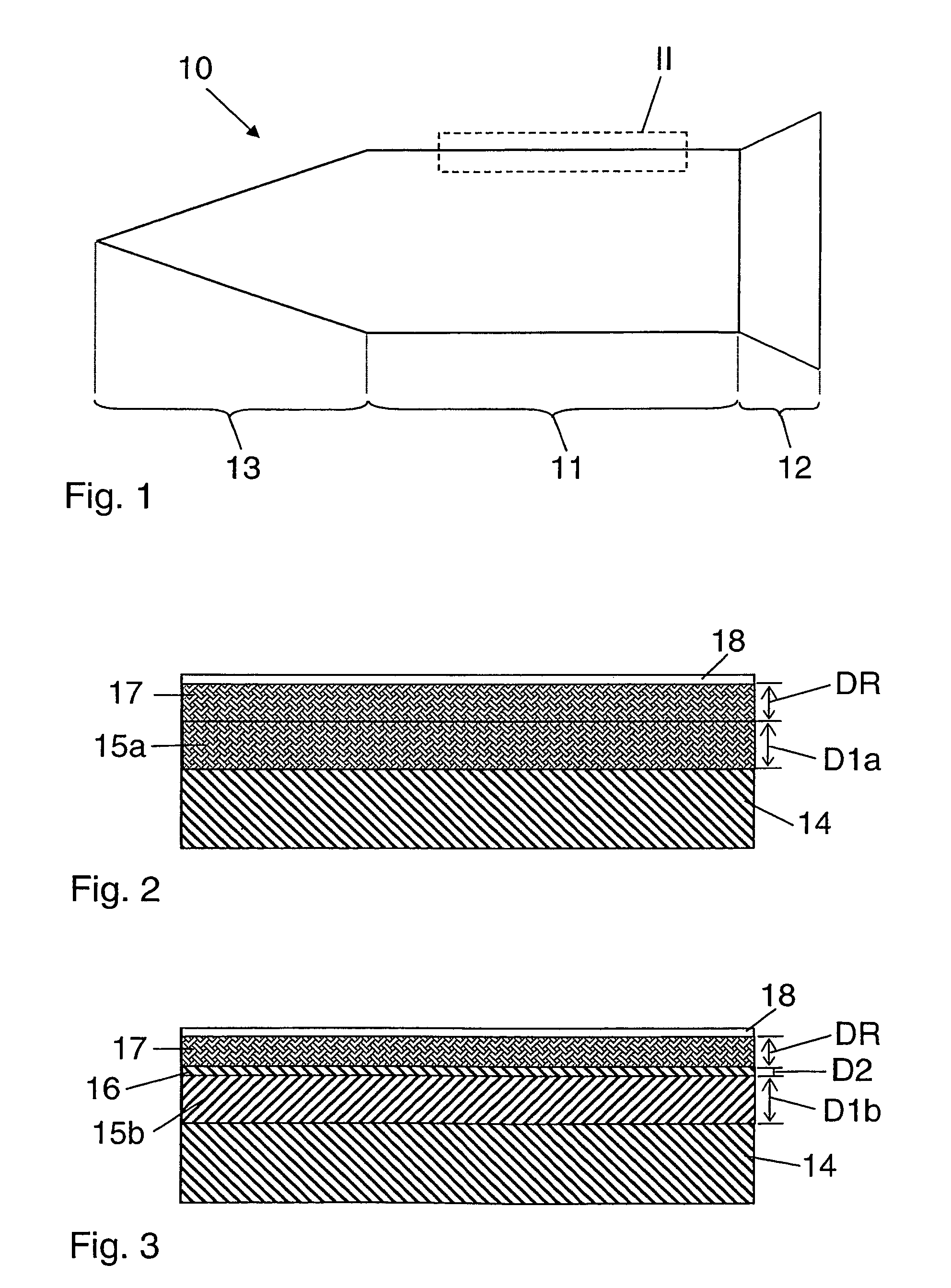

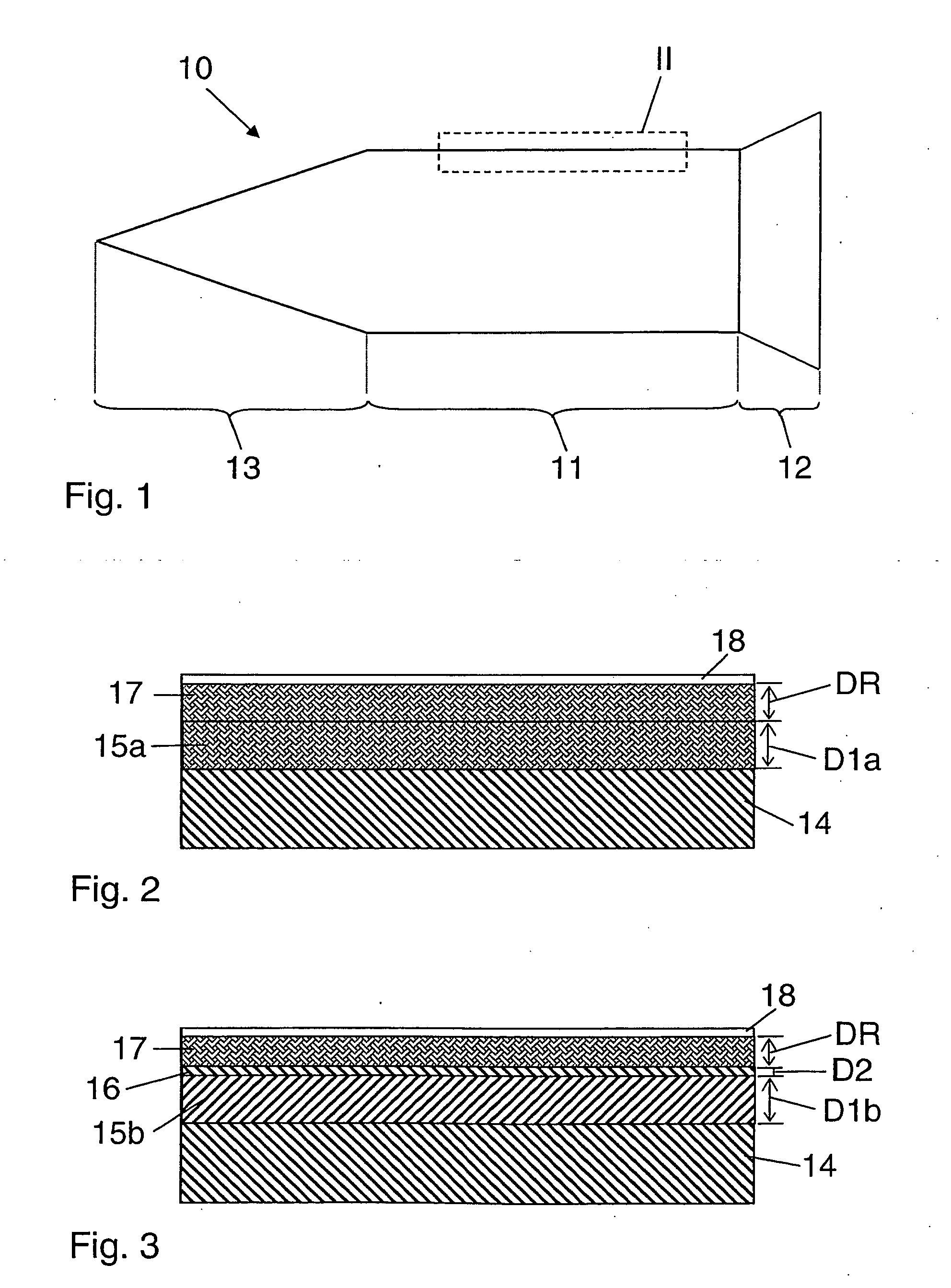

DLC coating, and DLC coating coated tool

InactiveUS20070104953A1Satisfactory lifetimeAvoid excessive hardnessLayered productsMilling cuttersDlc coatingHydrogen

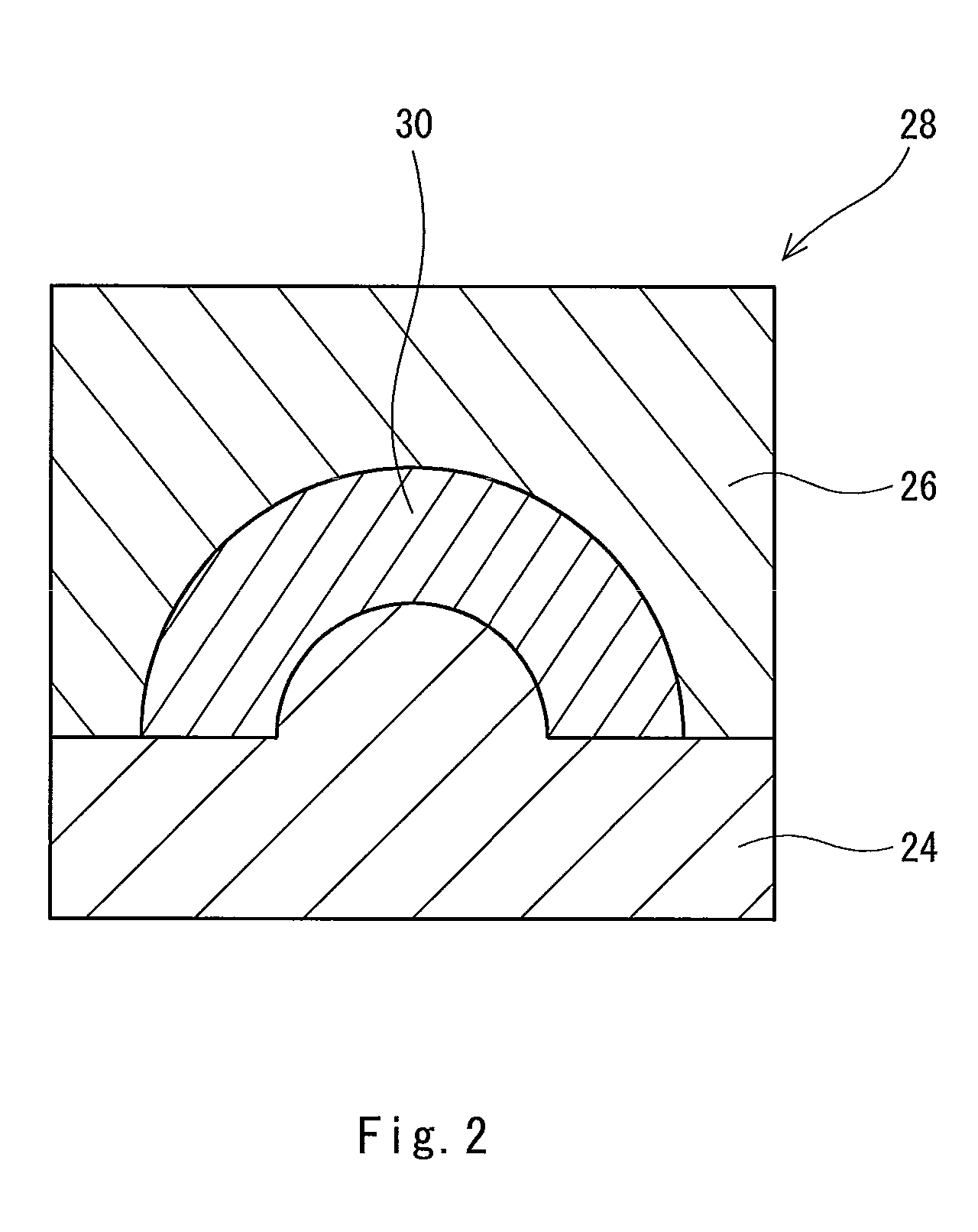

A DLC coating (20) coating a surface of a predetermined member (12) comprises a base layer (22) not containing hydrogen substantially, and a hydrogen containing layer (24) containing hydrogen ranging from 2 atom % to 20 atom %. The base layer (22) and the hydrogen containing layer (24) disposed thereon constitute a two-layer structure.

Owner:OSG

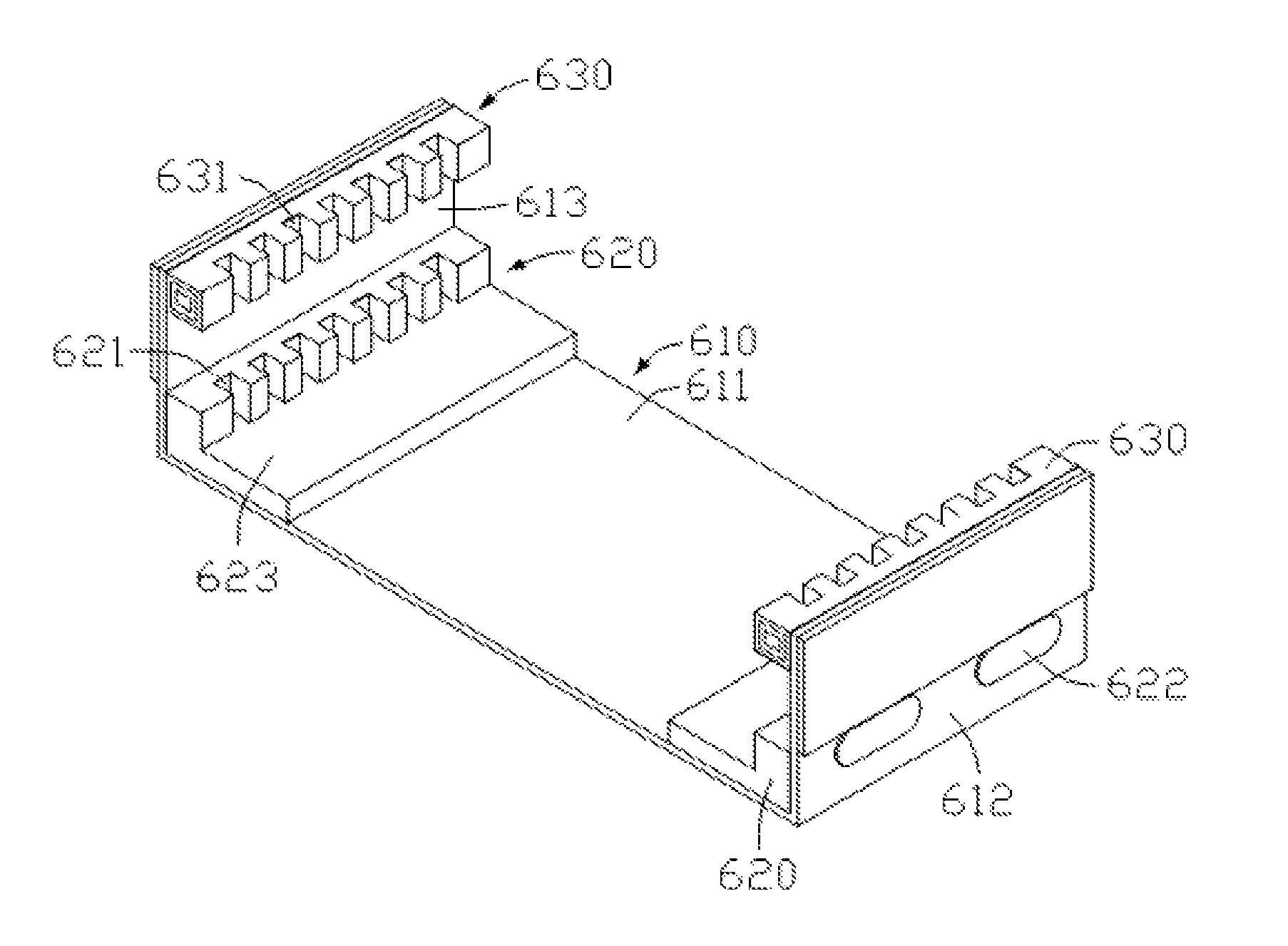

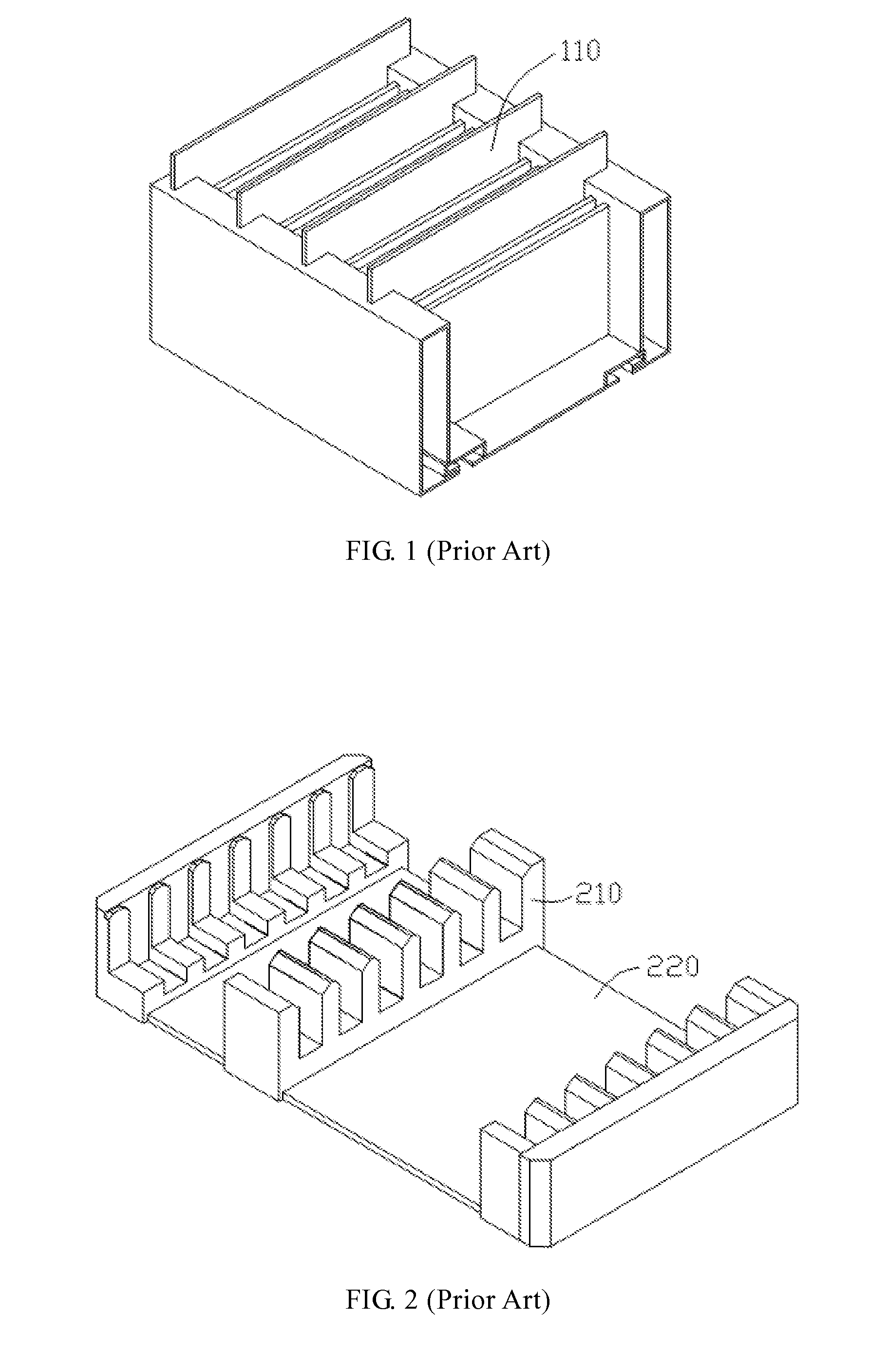

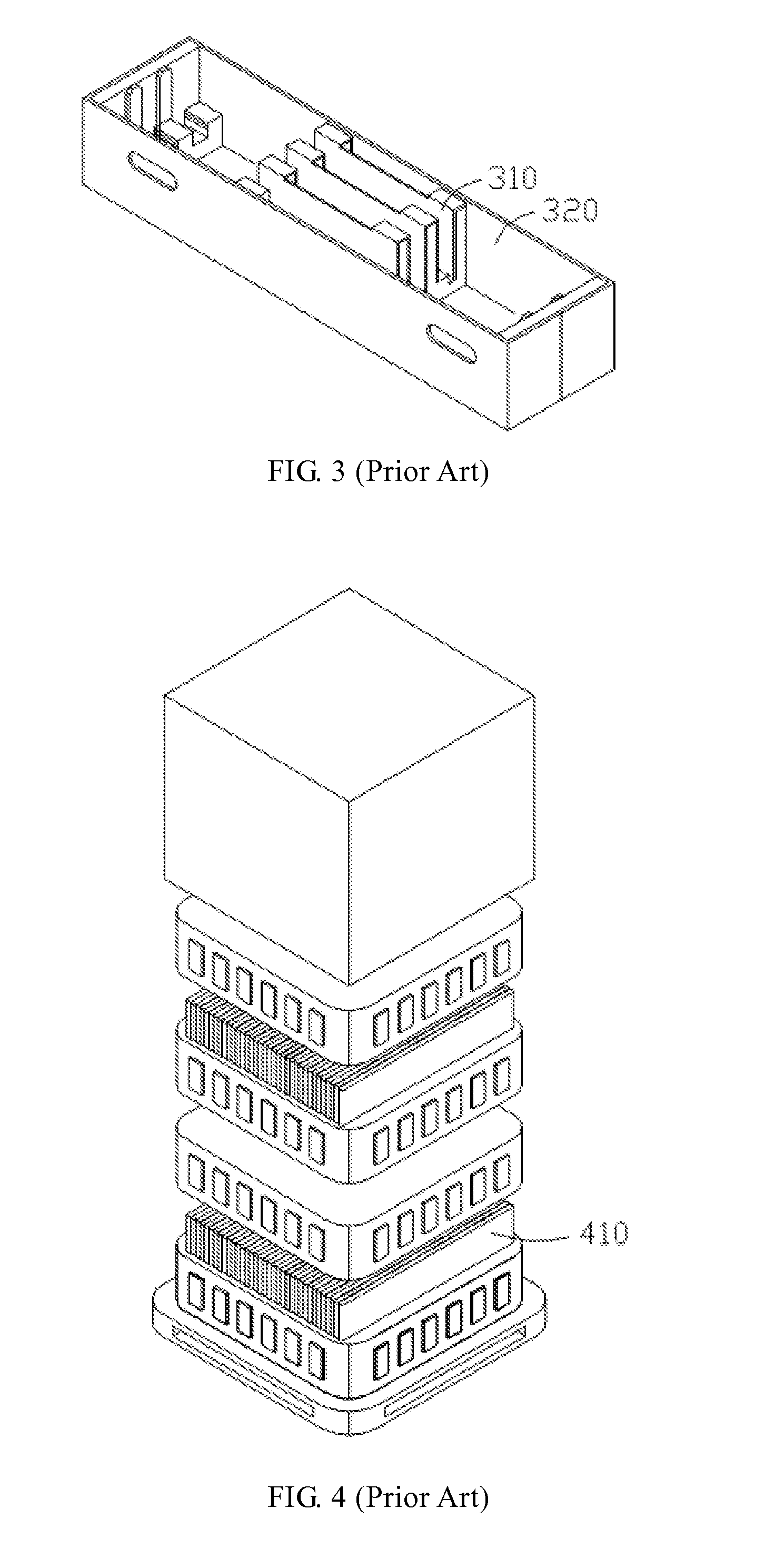

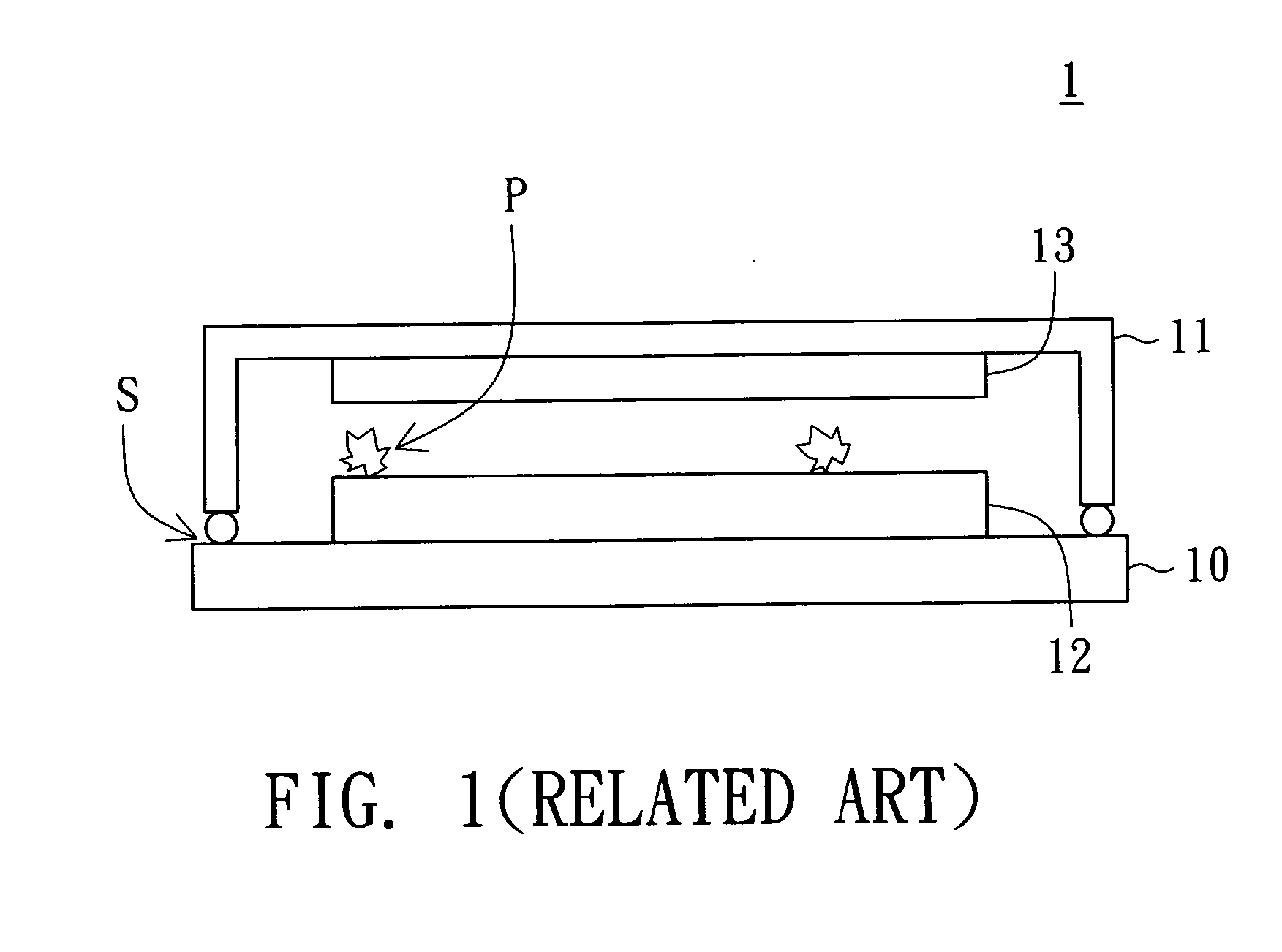

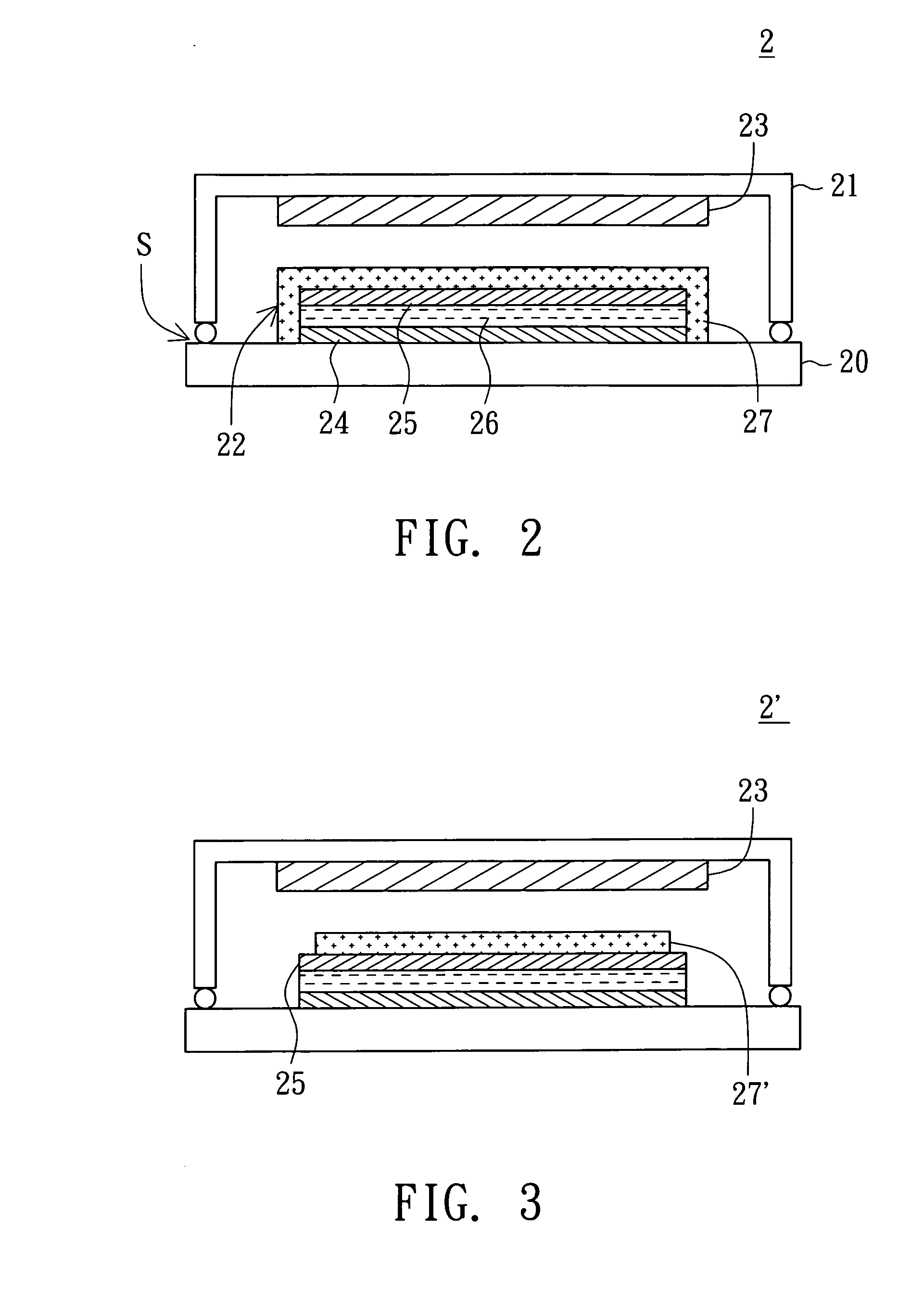

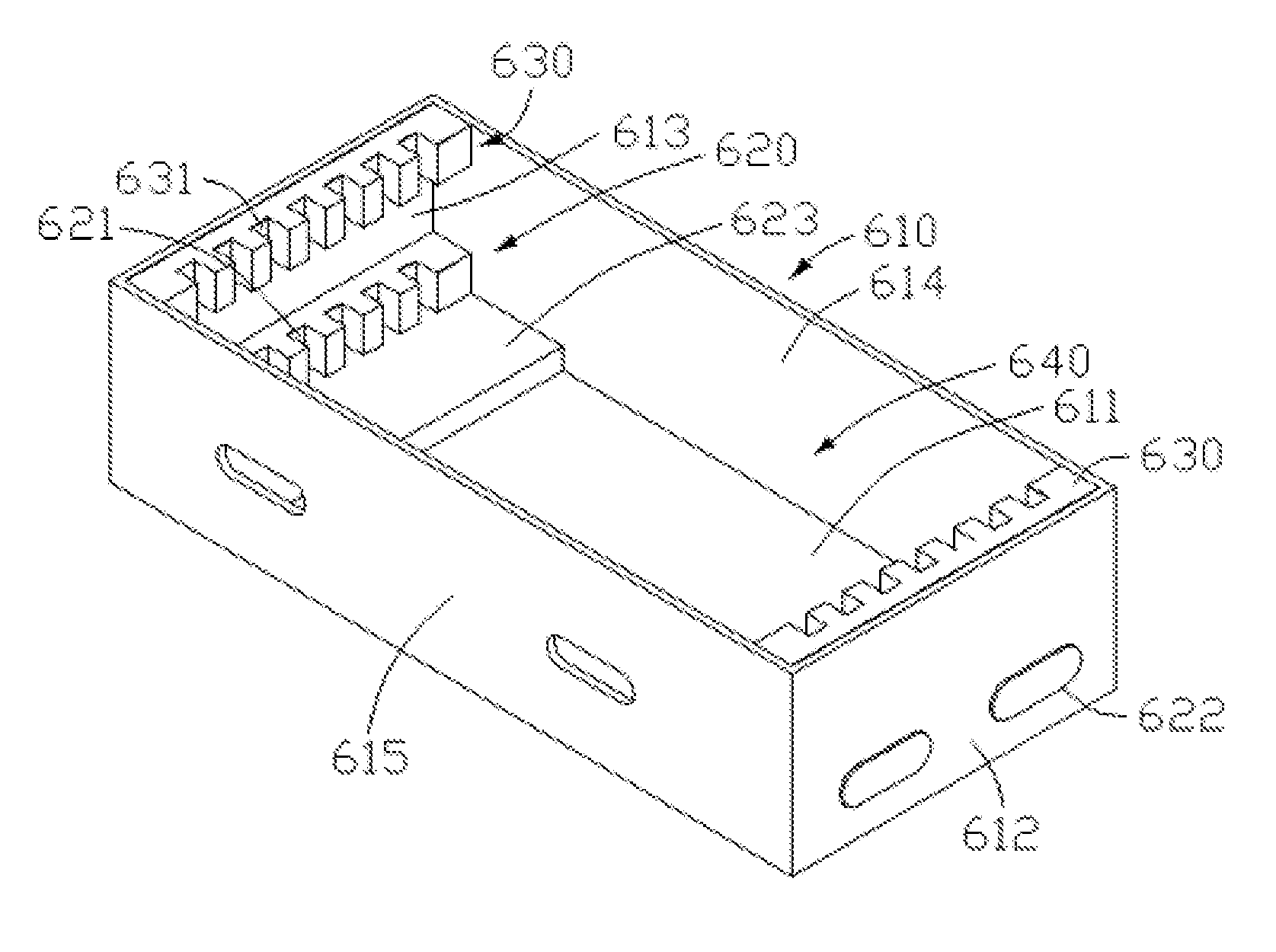

Lower cushioning structure and package cushioning structure for display panel

ActiveUS8720691B2Low structural requirementsSatisfactory cushioning for display panelOther accessoriesContainer/bottle contructionCushioningEngineering

A lower cushioning structure and a package cushioning structure for a display panel are disclosed. The lower cushioning structure comprises: a supporting frame, comprising a baseplate as well as a first side plate and a second side plate extending upwards from two opposite sides of the baseplate respectively; two first cushions, being disposed at a location where the first side plate of the supporting frame borders the baseplate and a location where the second side plate of the supporting frame borders the baseplate respectively; and two second cushions, being disposed on an inner wall of the first side plate and an inner wall of the second side plate of the supporting frame respectively, wherein the second cushions are located above the first cushions. The present invention has a low cost and can provide satisfactory cushioning for the display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

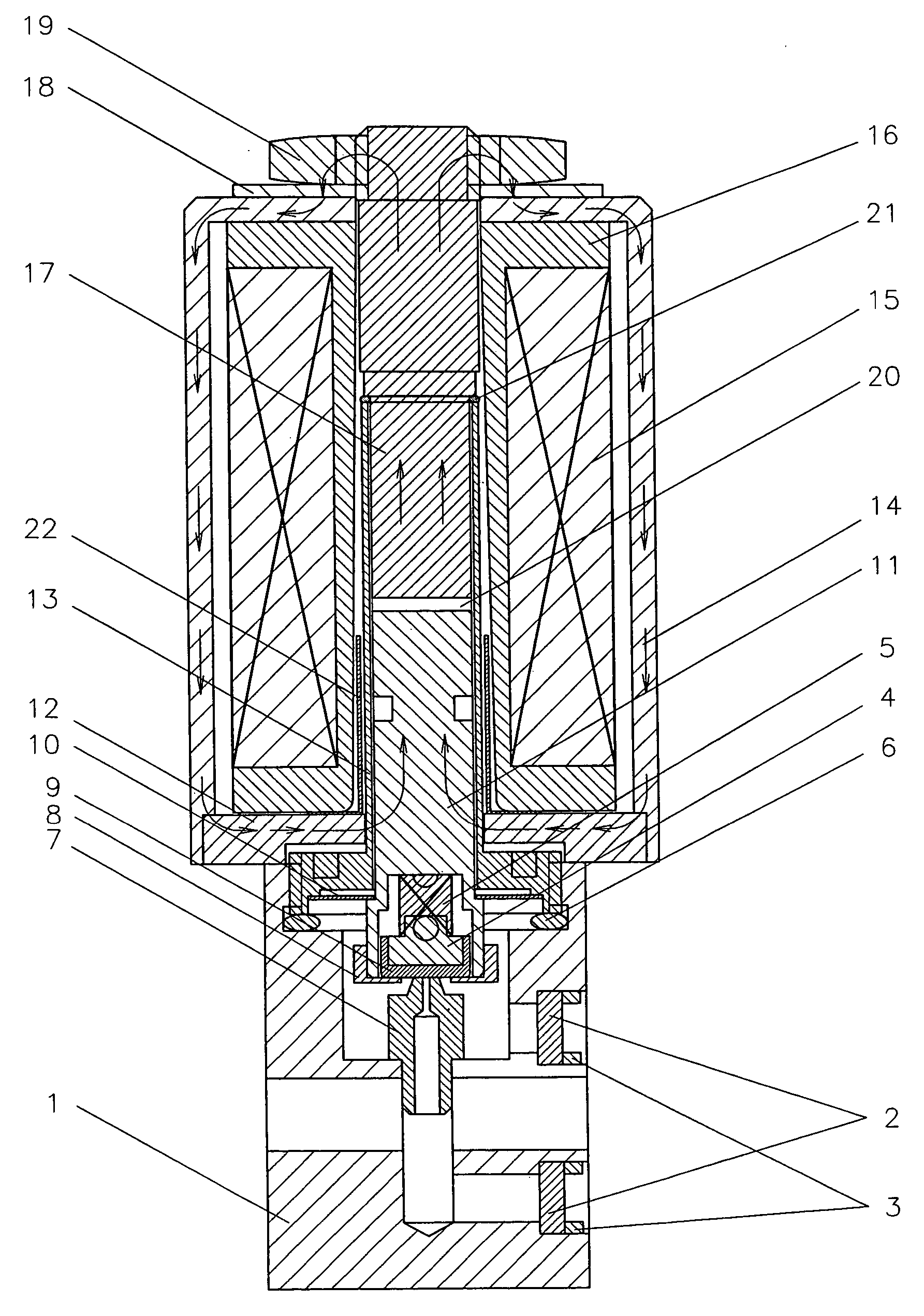

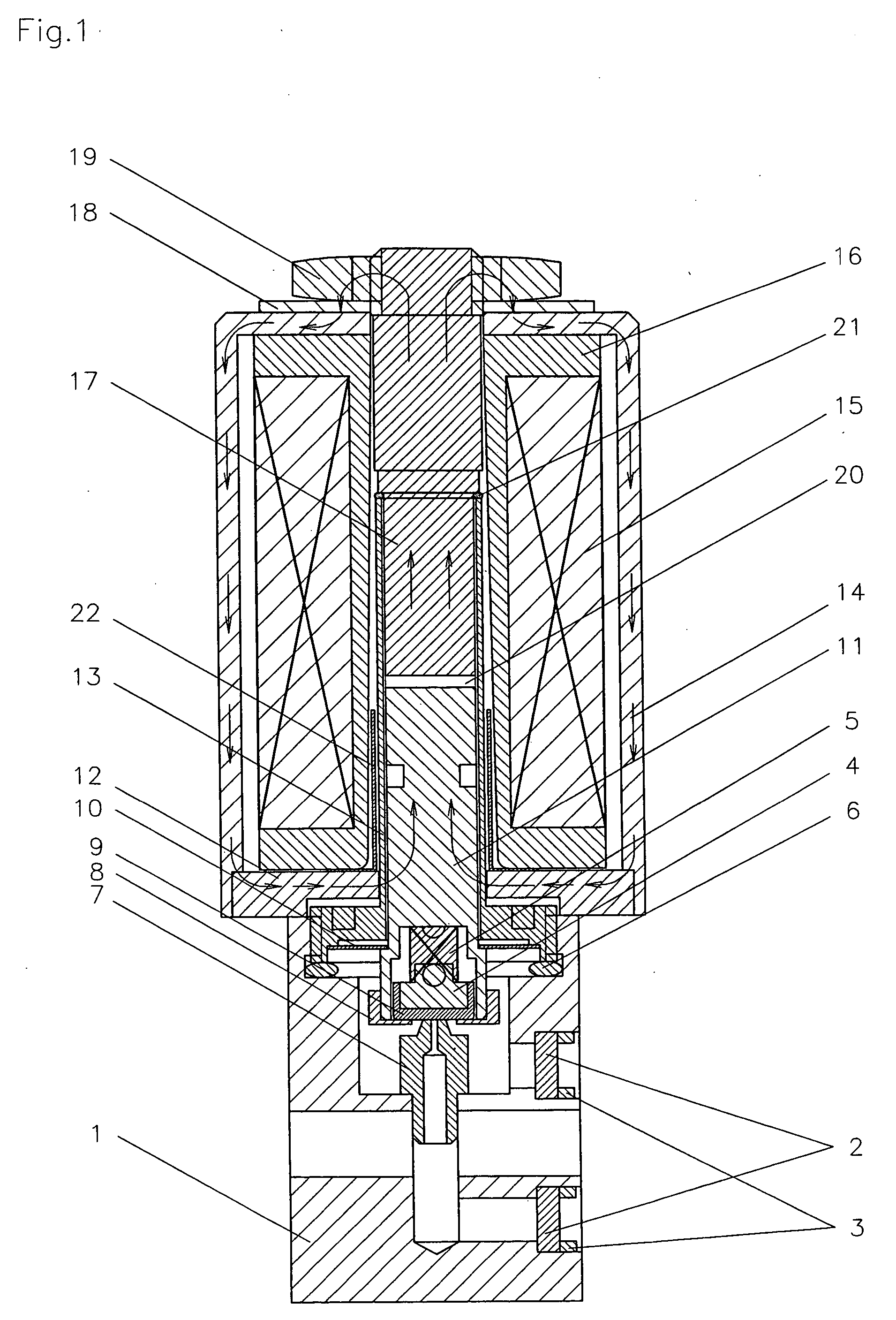

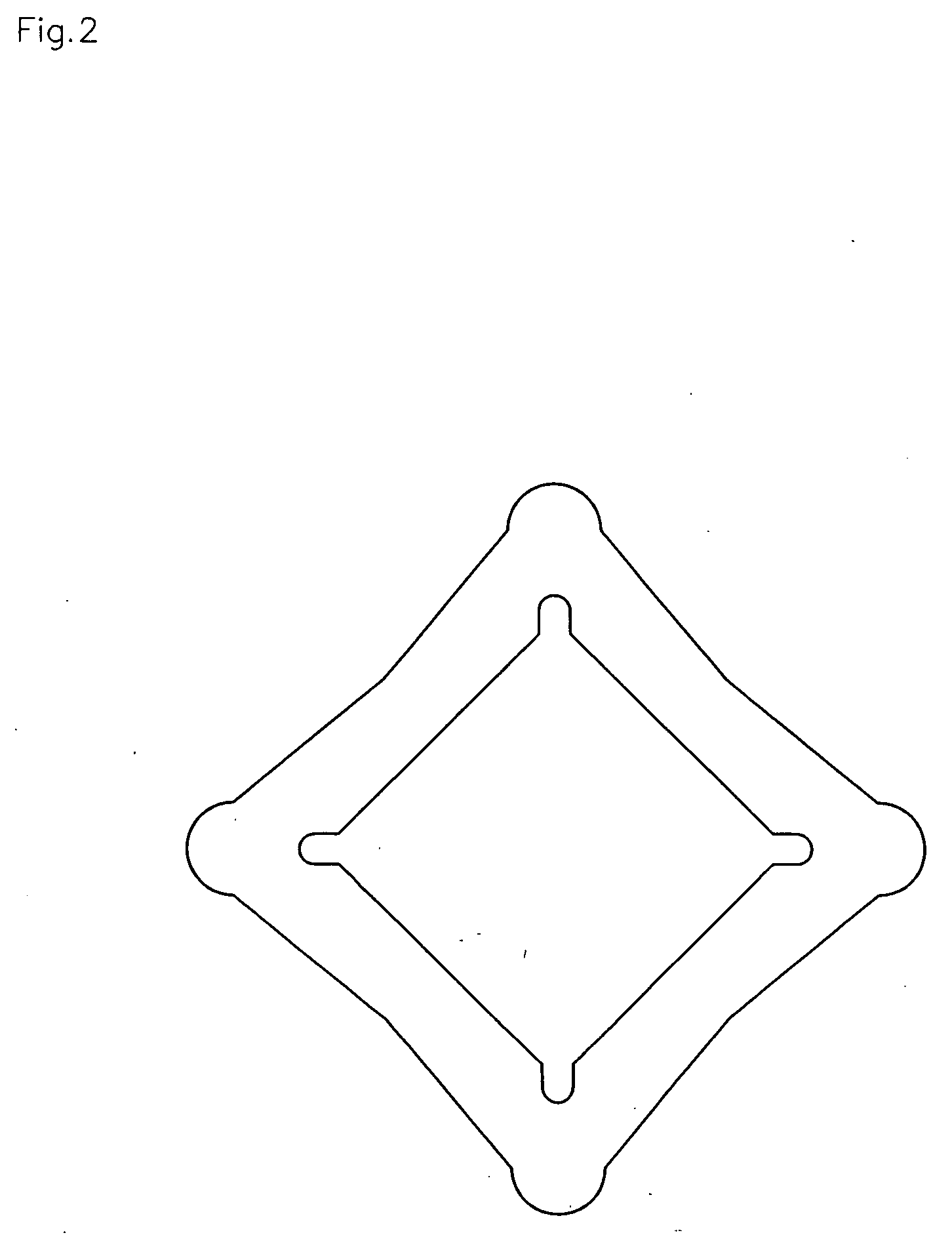

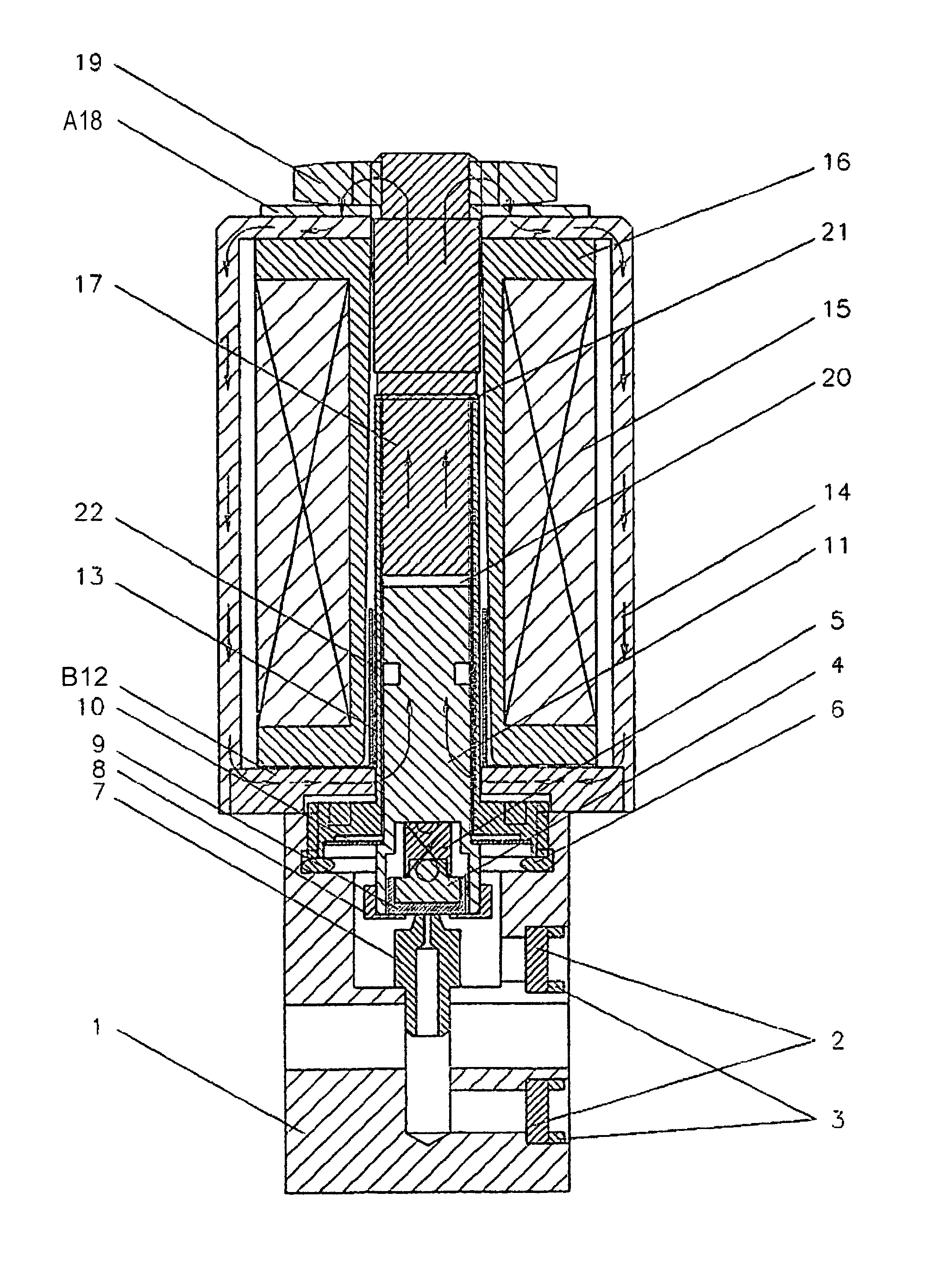

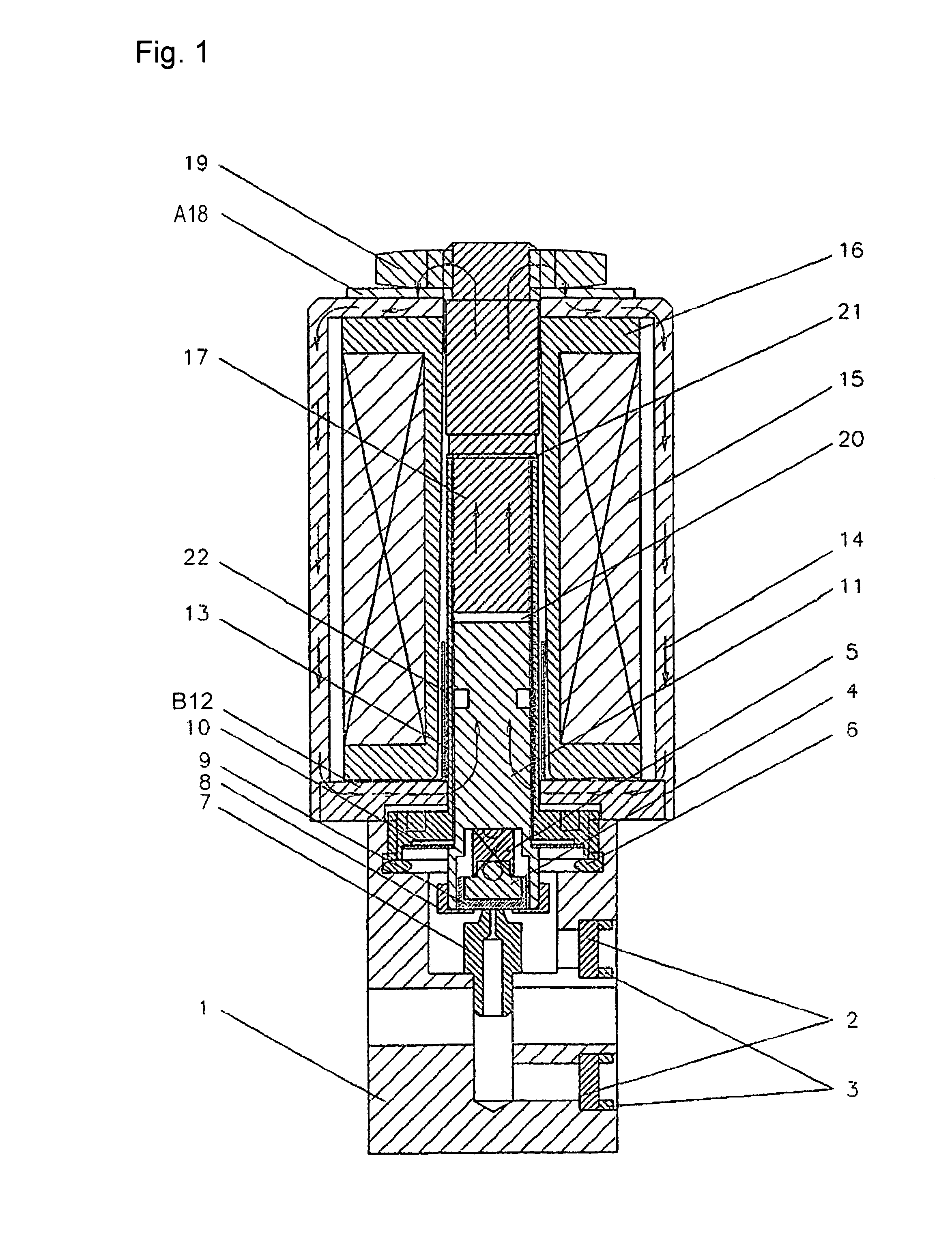

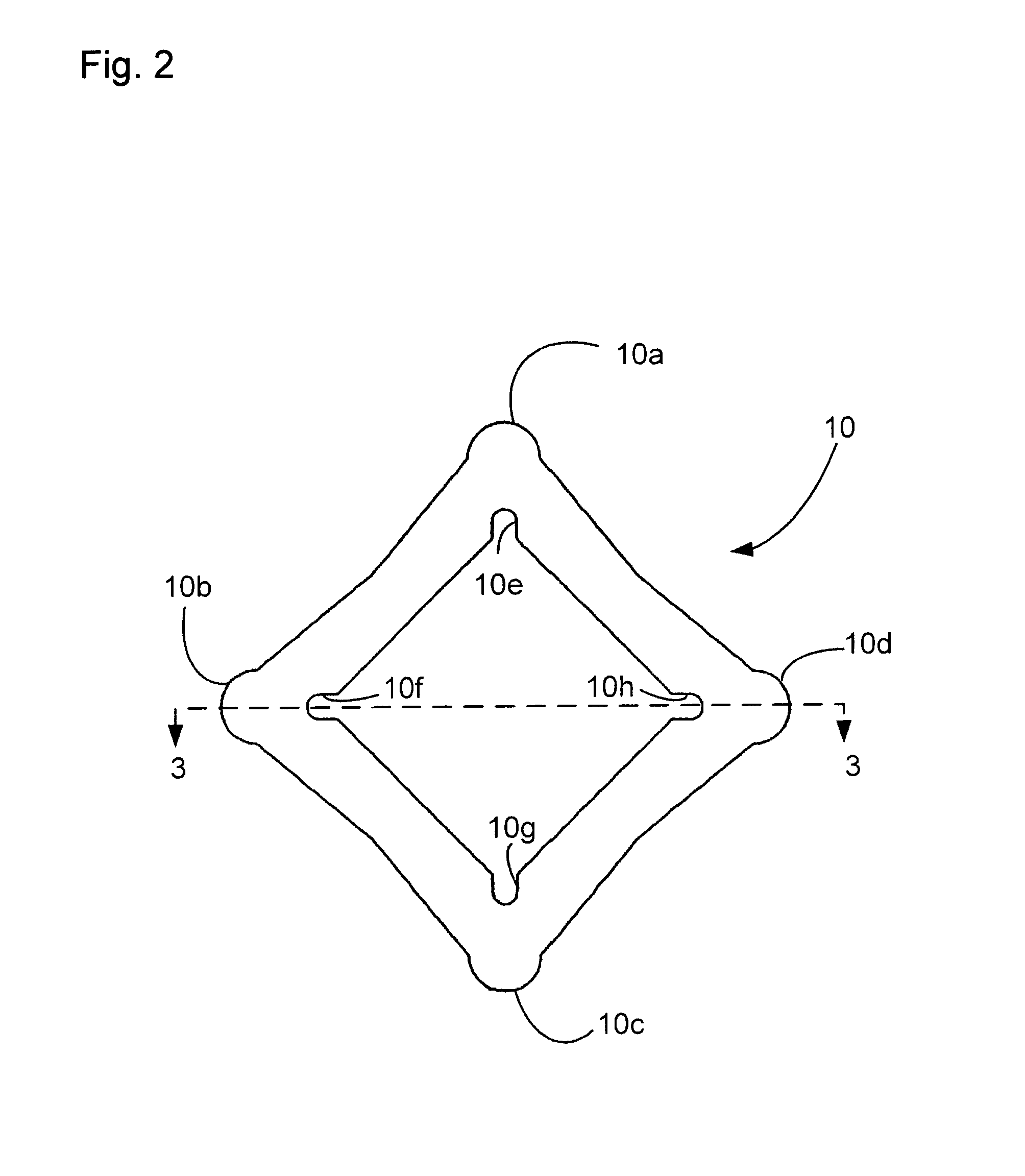

Proportional solenoid control valve

InactiveUS20050173664A1Made smallSmall hardnessOperating means/releasing devices for valvesMachines/enginesHysteresisSolenoid valve

A proportional solenoid control valve comprises a flat square spring which is wide in maintaining width with respect to displacement of a spring having a greater spring constant, so that accurate control of fluid is realized. The flat square spring has four tubs and is supported with respect to a step face with outer peripheral section thereof. The valve further comprises a sealing mechanism loaded with rubber resilience compensates instability of armature construction and resilient sealing section. The spring constant of the flat square spring is improved by strengthening the magnetic force, thus hysteresis can be made to be smaller.

Owner:KOFUROTSUKU

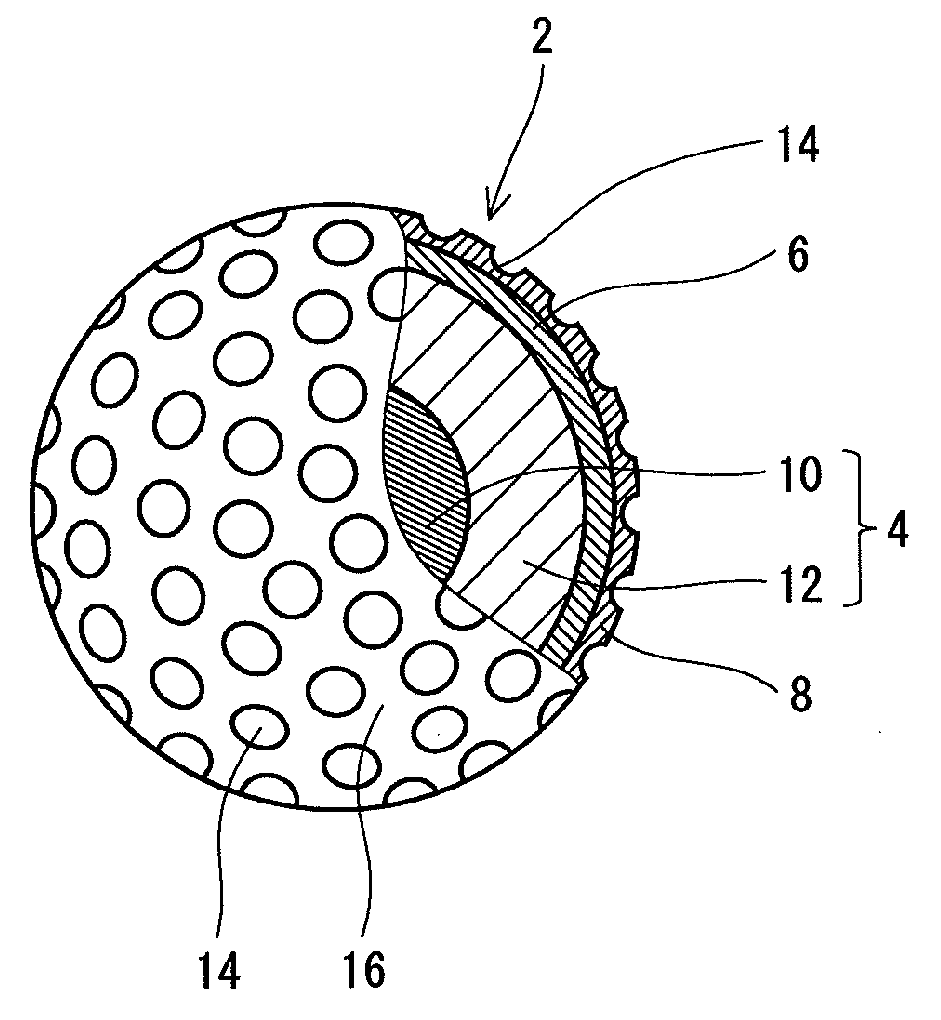

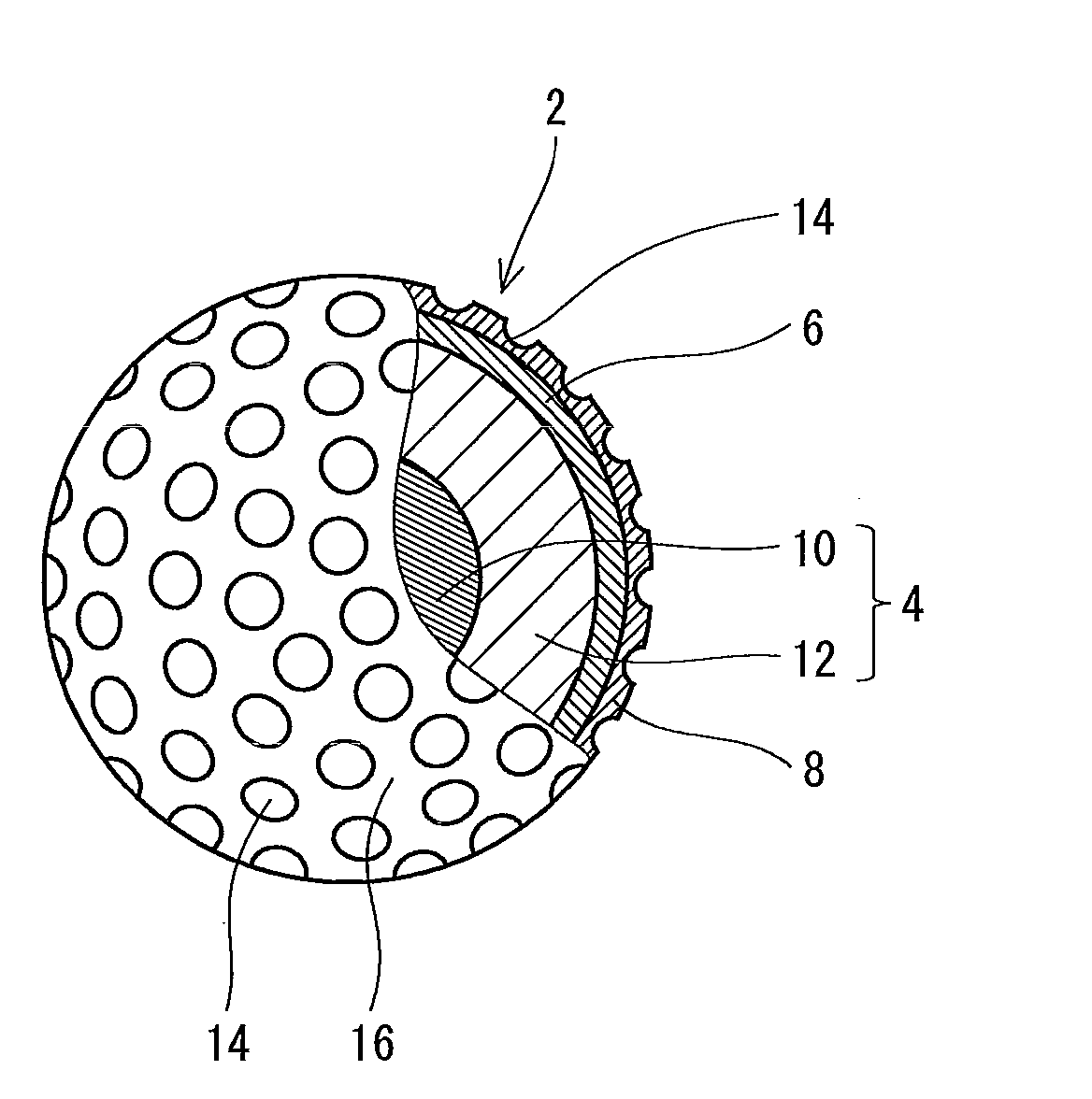

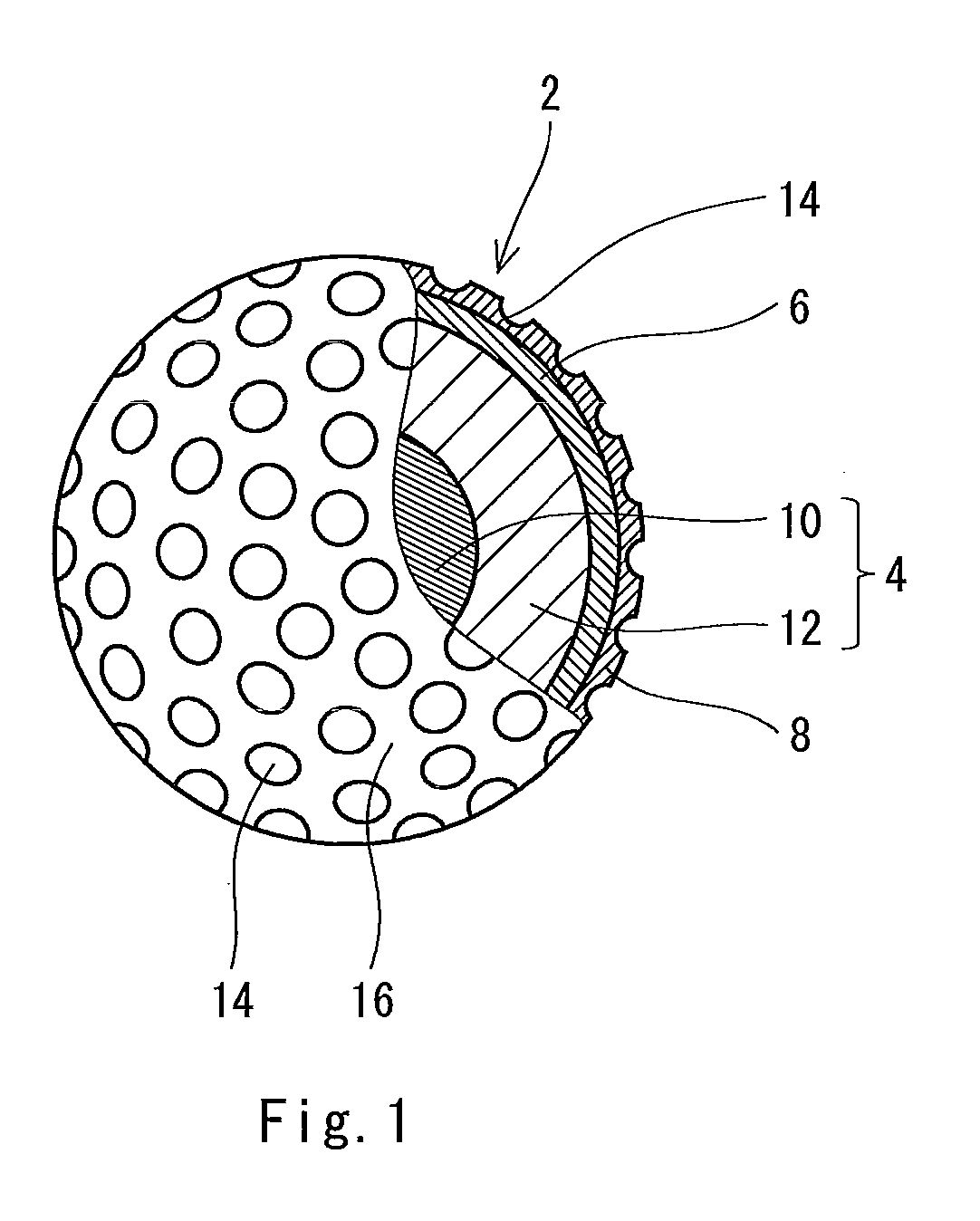

Golf ball

InactiveUS20100035704A1Improve continuityNot deteriorate resilience performanceGolf ballsSolid ballsEngineeringGolf Ball

A golf ball 2 has a core 4, an inner cover 6 positioned outside this core 4 and an outer cover 8 positioned outside the inner cover 6. The core 4 has a spherical center 10 and a mid layer 12 positioned outside this center 10. The center 10 is formed by crosslinking a rubber composition. The mid layer 12 is formed by crosslinking a rubber composition. The inner cover 6 is made of a thermoplastic resin composition. The outer cover 8 is made of a thermoplastic resin composition. The center 10 has a diameter of 1 mm or greater and 15 mm or less. The center 10 has a central point having JIS-C hardness H1 of 20 or greater and 50 or less. A difference (H4−H3) between a hardness H4 of a surface of the core and a hardness H3 of an innermost part of the mid layer is equal to or greater than 10. A hardness H5 of the inner cover is smaller than a hardness H6 of the outer cover.

Owner:SUMITOMO RUBBER IND LTD

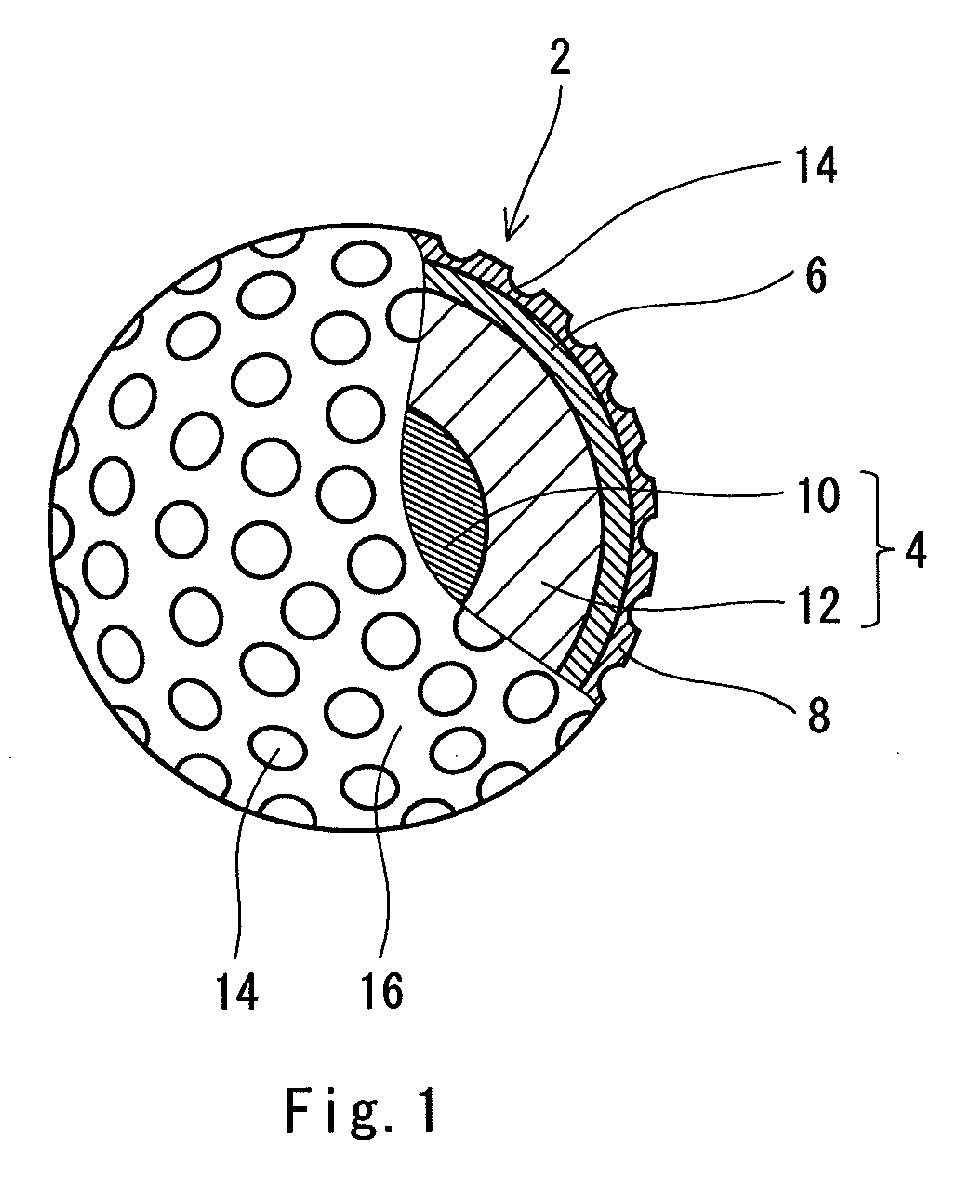

Golf ball

InactiveUS20100056301A1Small hardnessGood continuityHollow non-inflatable ballsGolf ballsNatural rubberEngineering

A golf ball 2 has a hollow center 8, a mid layer 10, an inner cover 12 and an outer cover 14. The center 8 is formed by crosslinking a rubber composition. The rubber composition contains a natural rubber as a base polymer. The rubber composition contains sulfur. The mid layer 10 is formed by crosslinking a rubber composition. This rubber composition includes butadiene as a principal component of the base polymer. The center 8 has an inside diameter of 2 mm or greater and 13 mm or less. The center 8 has an outside diameter of 5 mm or greater and 15 mm or less. The center 8 has a surface JIS-C hardness H2 of 25 or greater and 55 or less. A difference (H4−H3) between a surface JIS-C hardness H4 of the mid layer 10 and a JIS-C hardness H3 of an innermost part of the mid layer is equal to or greater than 10.

Owner:SUMITOMO RUBBER IND LTD

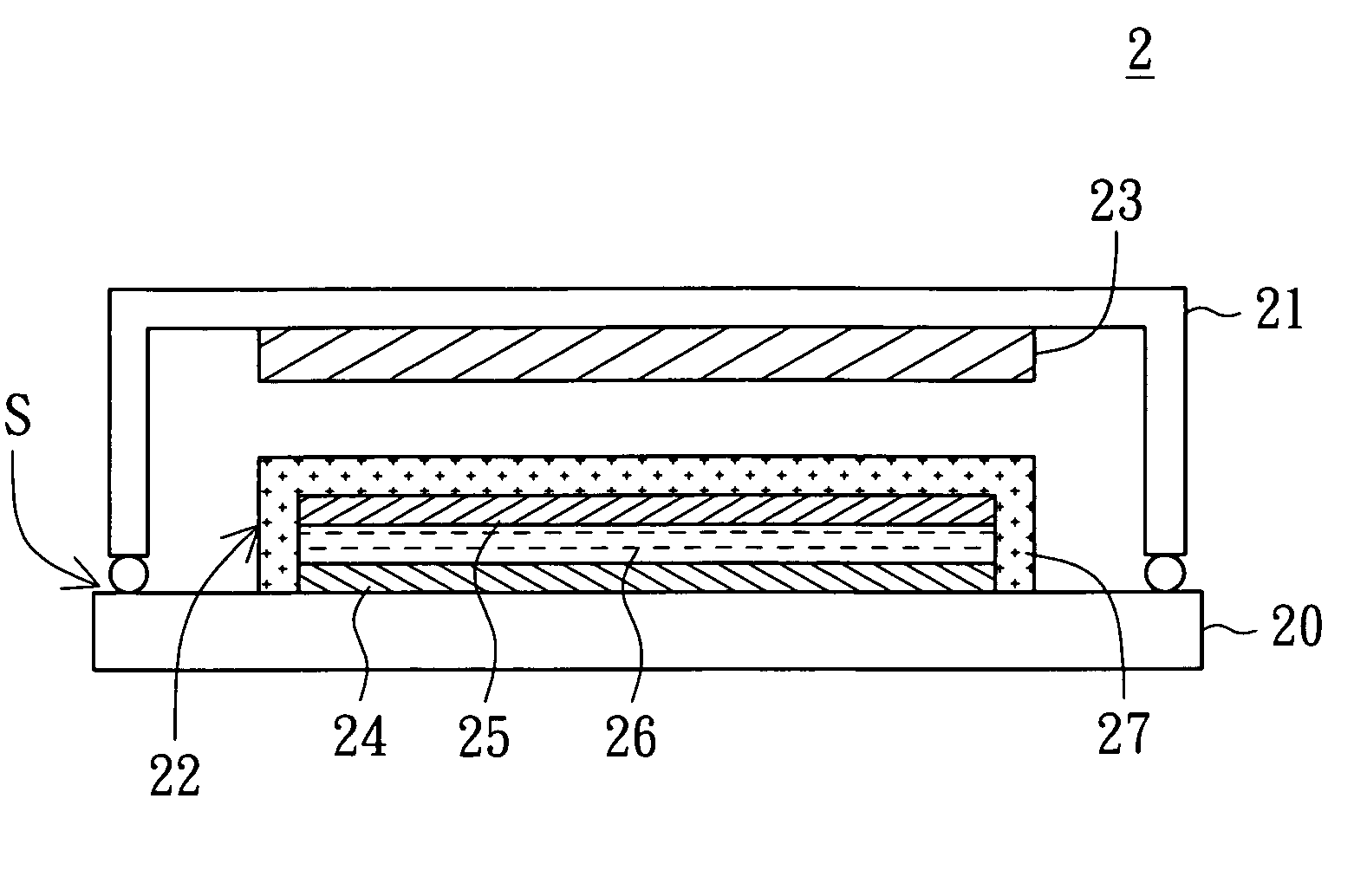

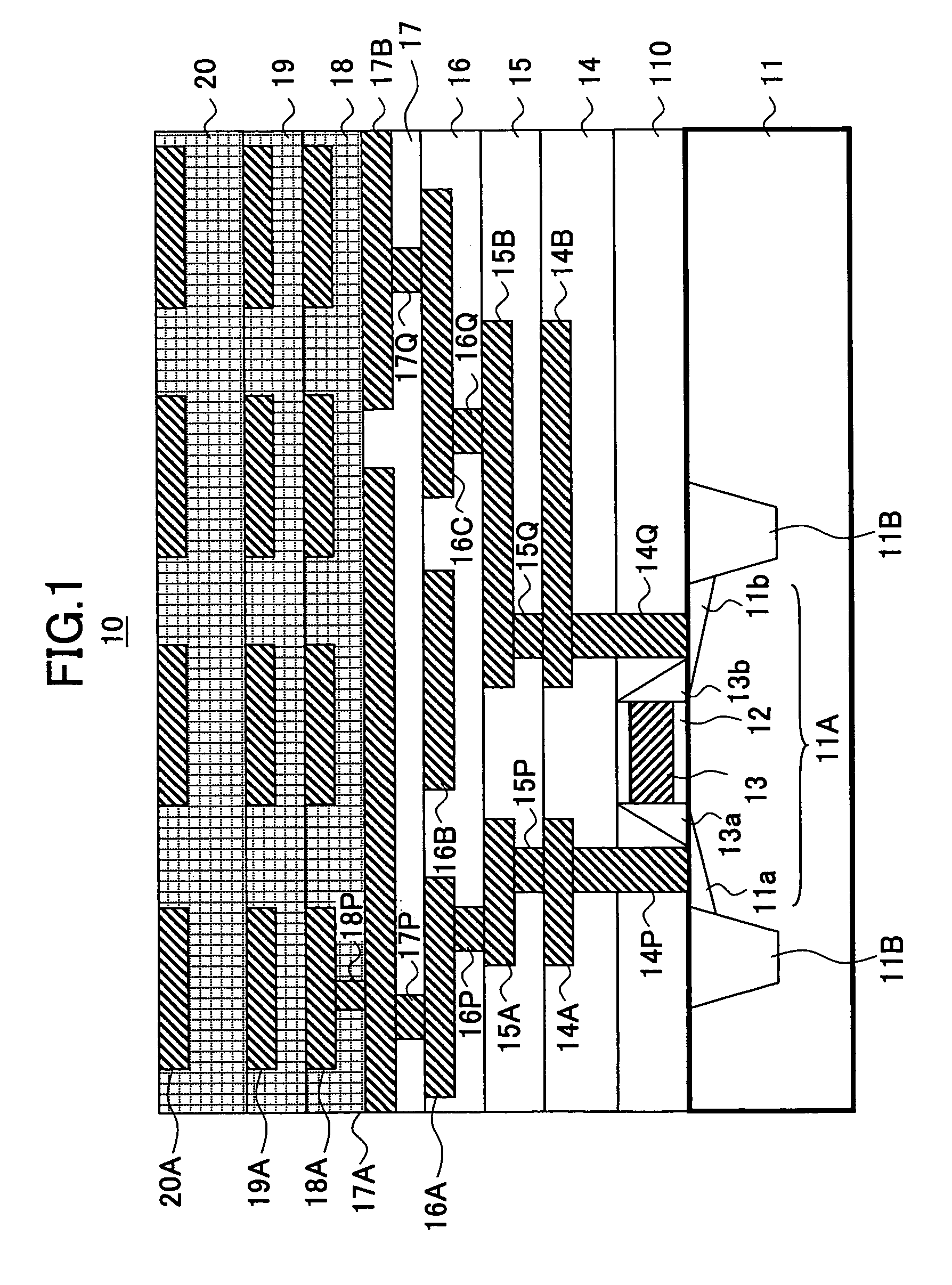

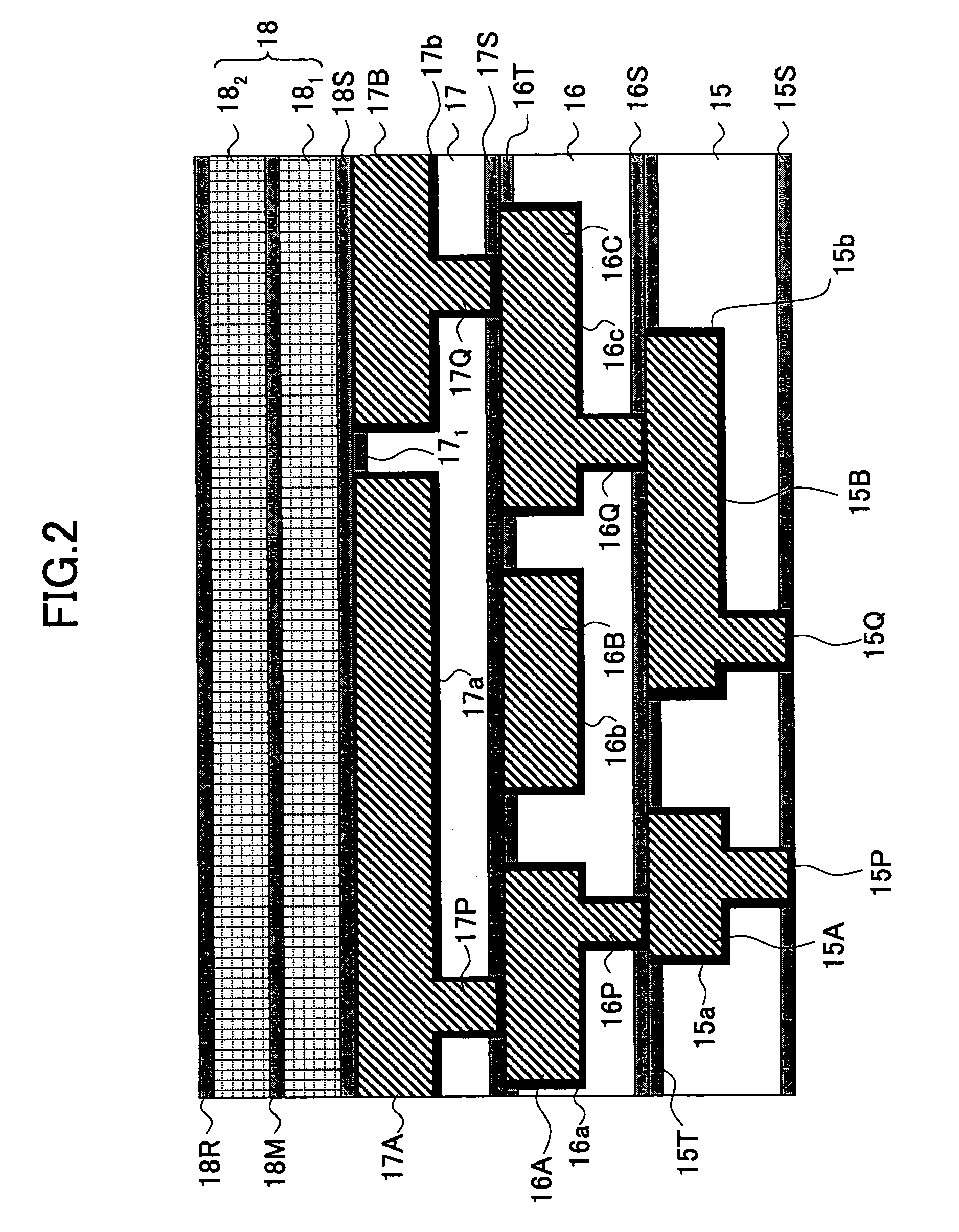

Organic electroluminescence device and organic electroluminescence panel using the same

ActiveUS20070278950A1Small hardnessDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsHardness

An organic electroluminescence device (OELD) and a display panel are provided. The OELD comprises a first electrode, a second electrode, an emissive layer and a shielding structure. The second electrode is disposed above the first electrode. The emissive layer is disposed between the first electrode and the second electrode. The shielding structure is disposed above the second electrode. The hardness of the shielding structure is smaller than that of the second electrode.

Owner:AU OPTRONICS CORP

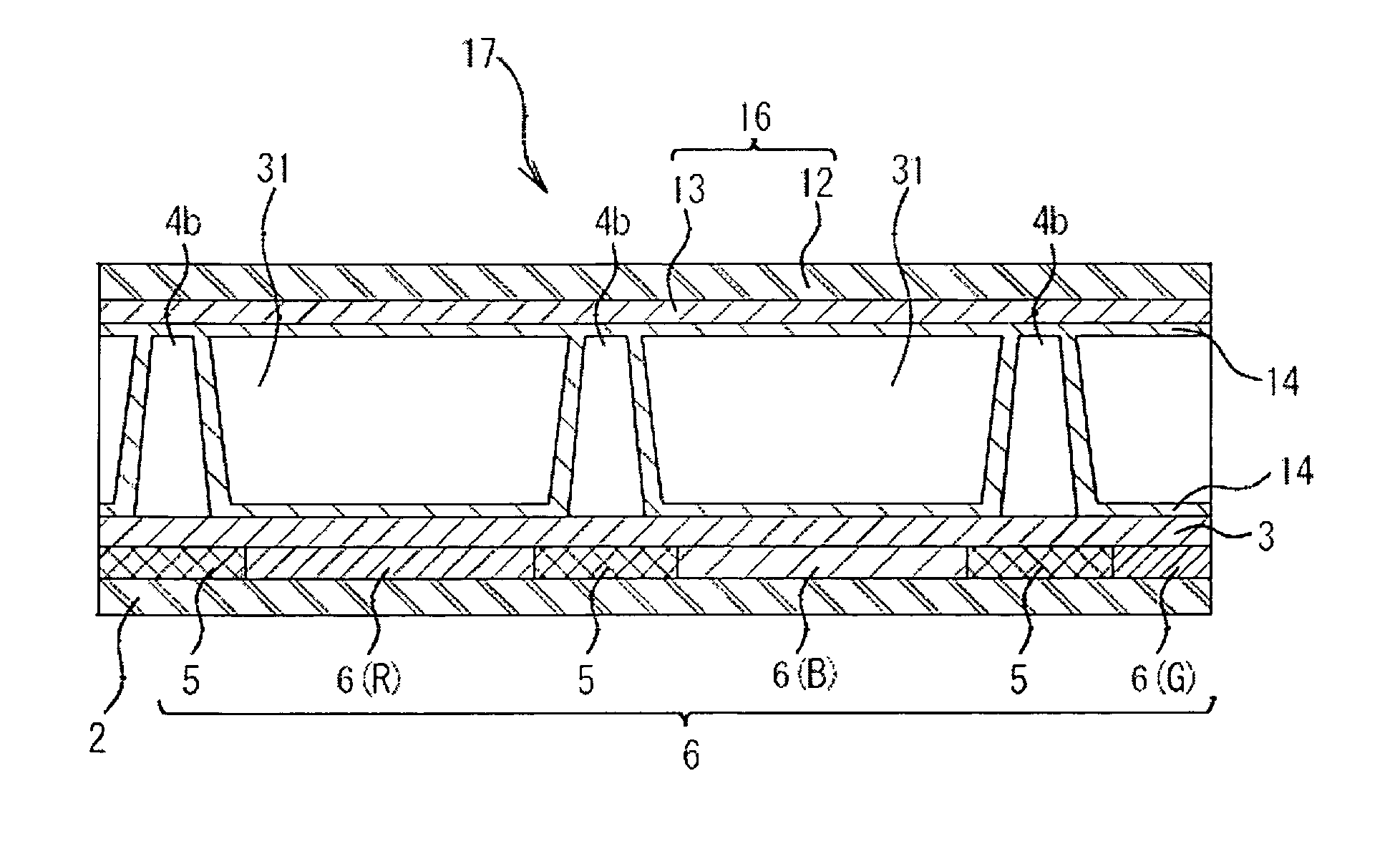

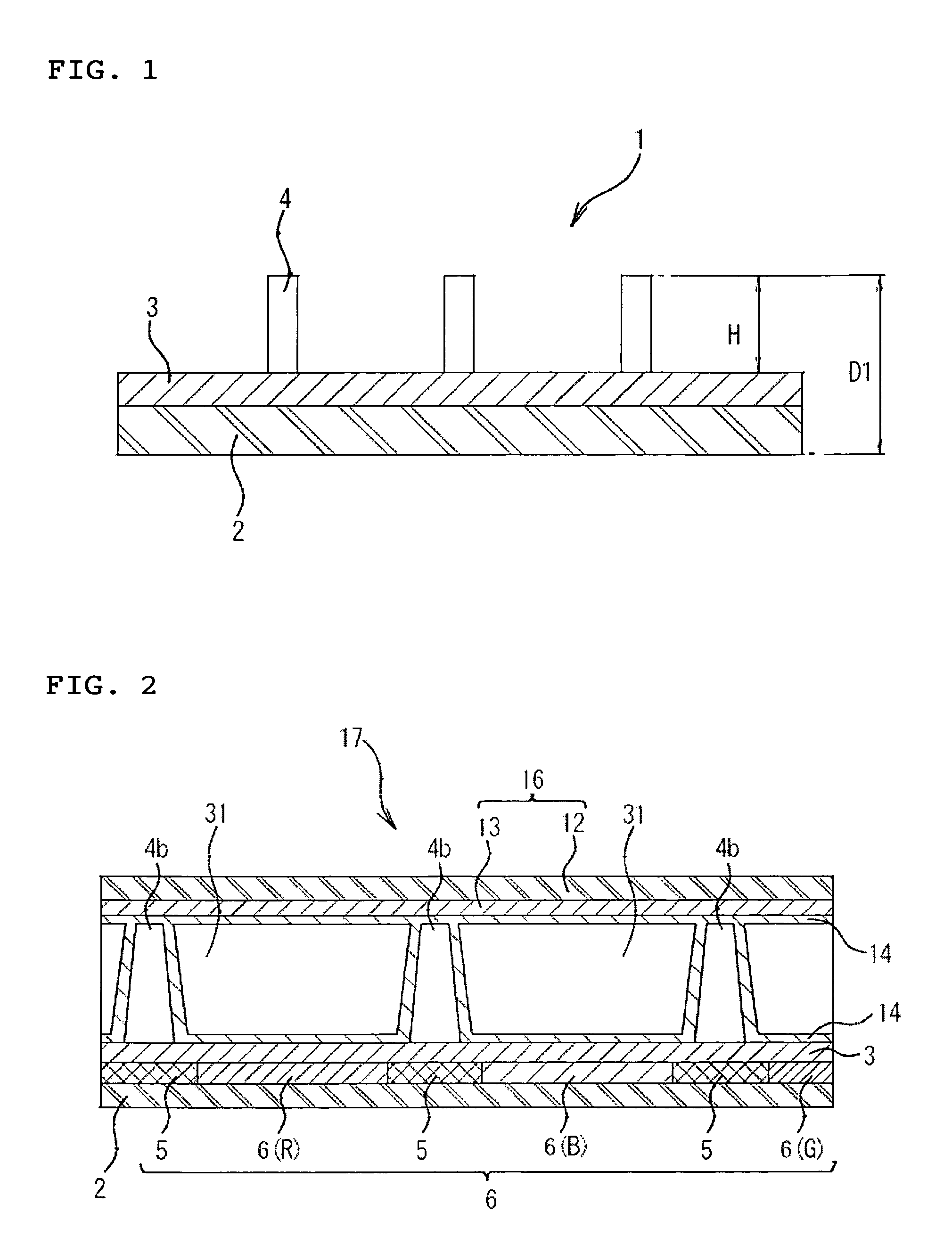

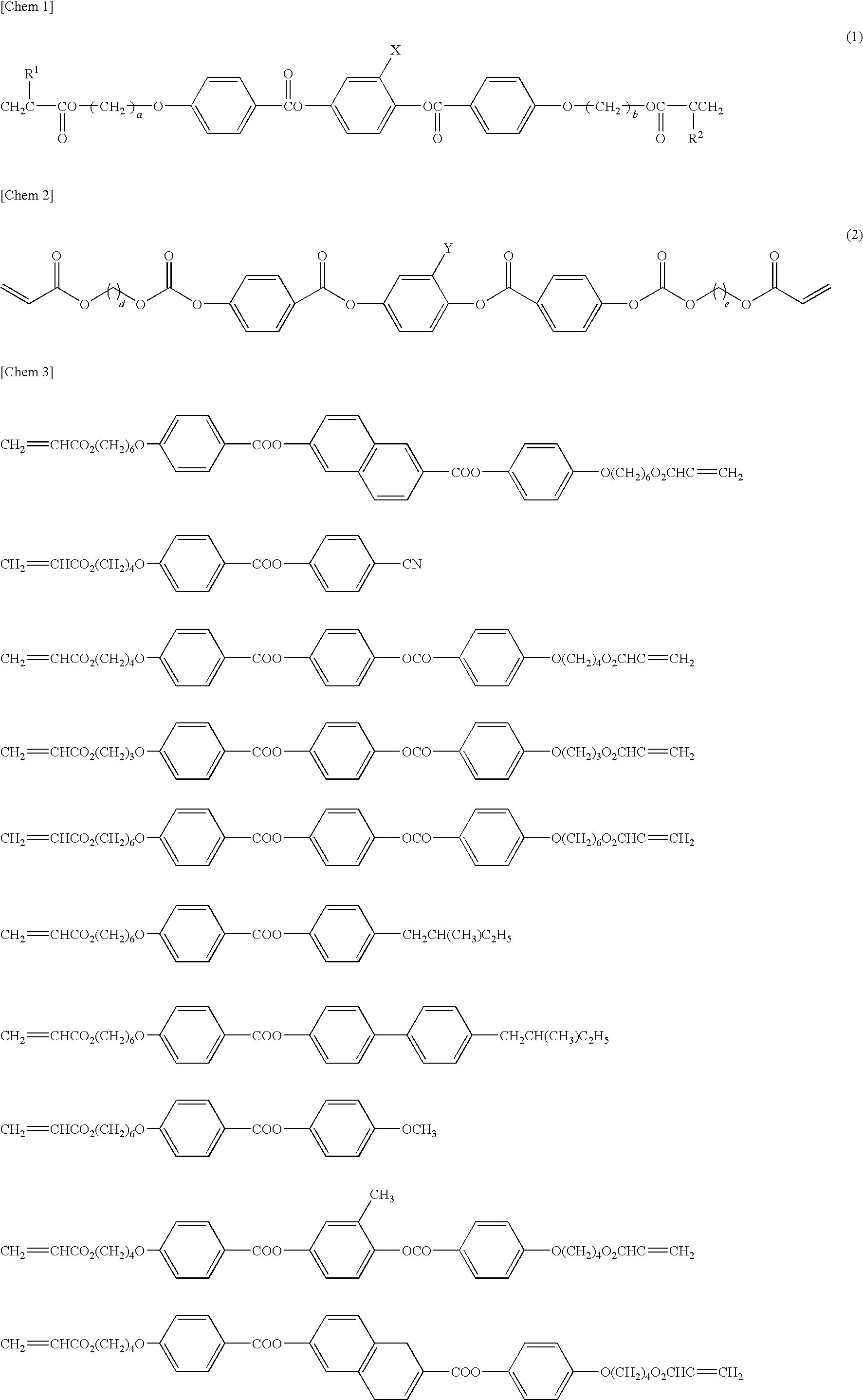

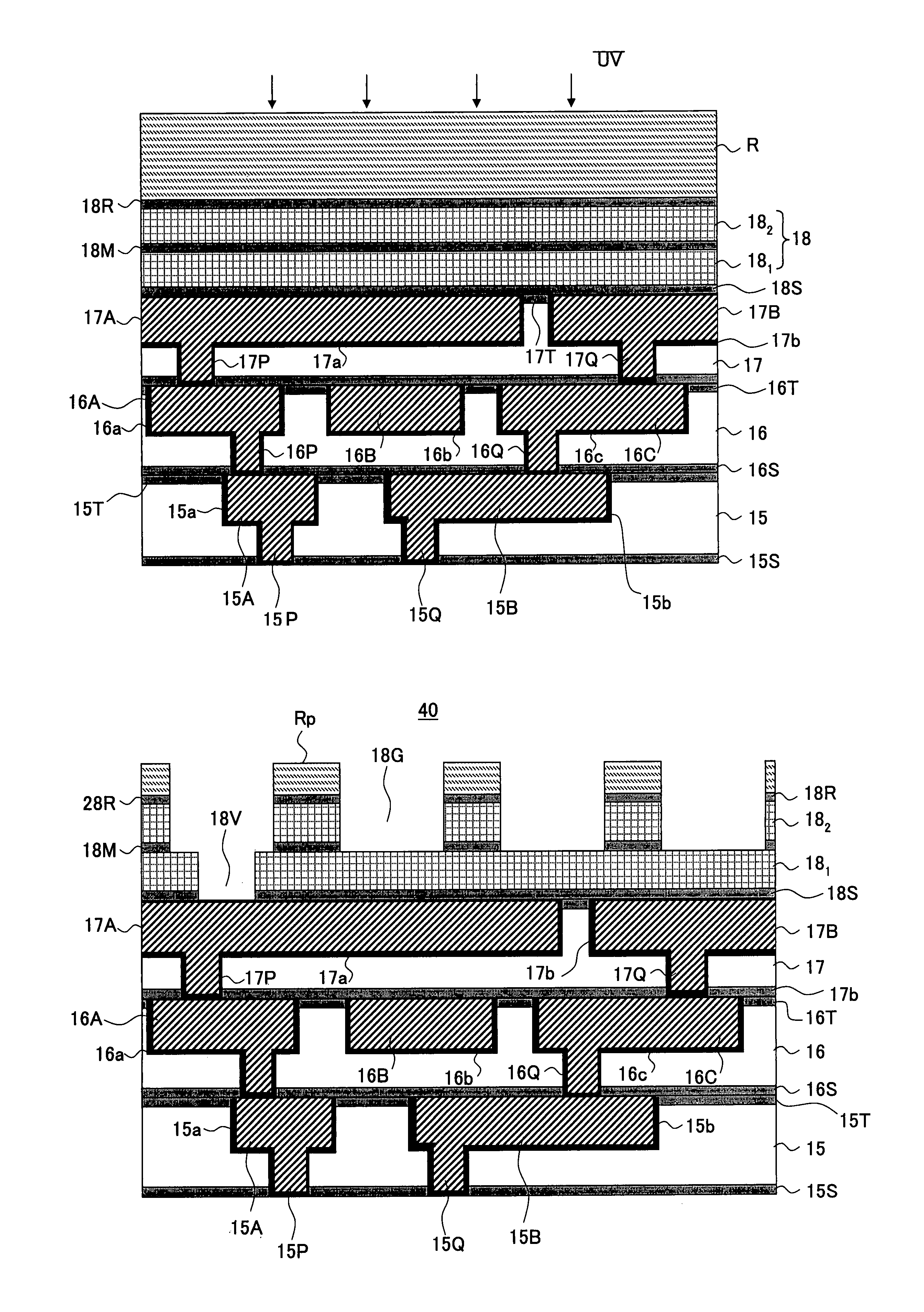

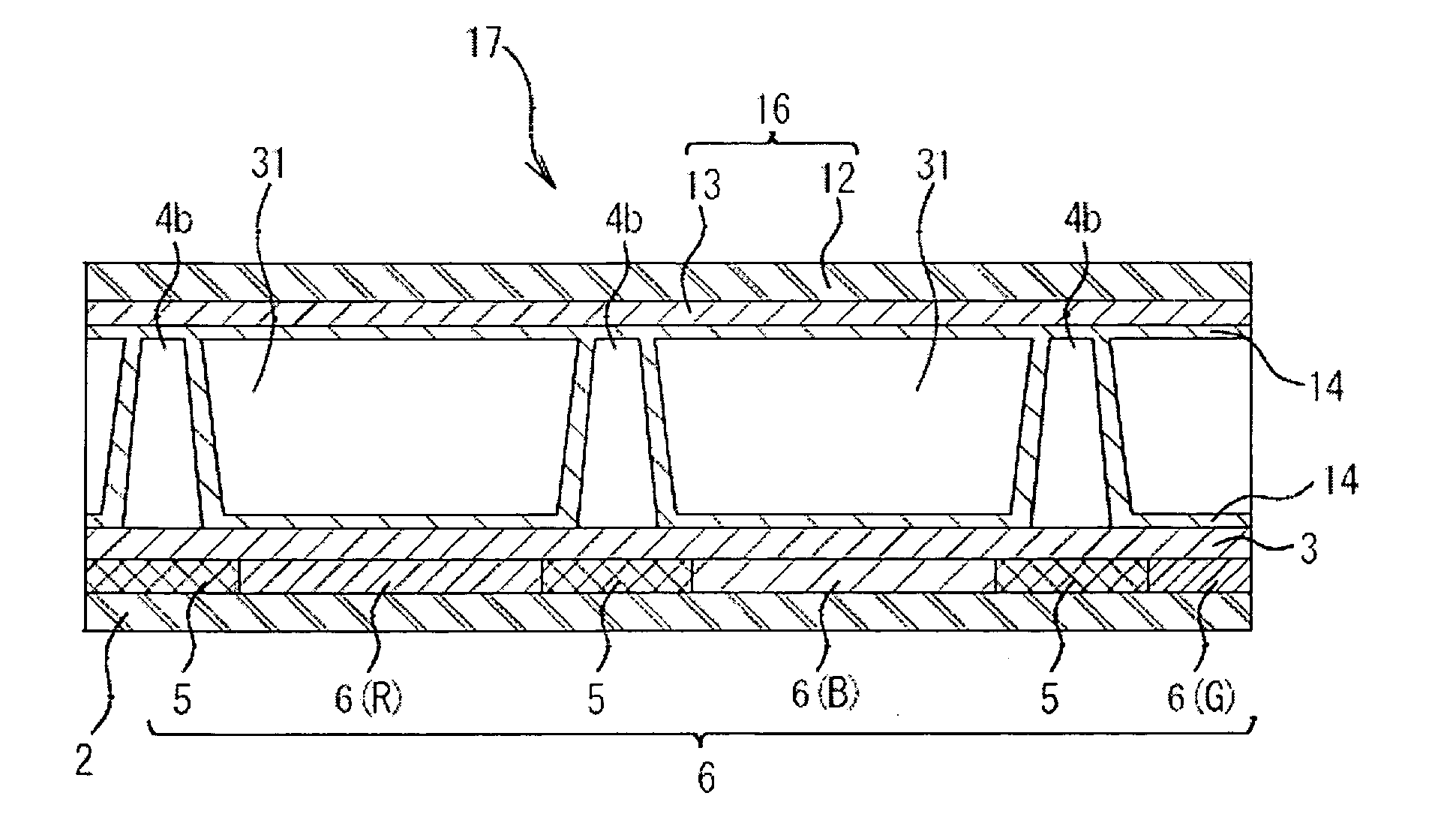

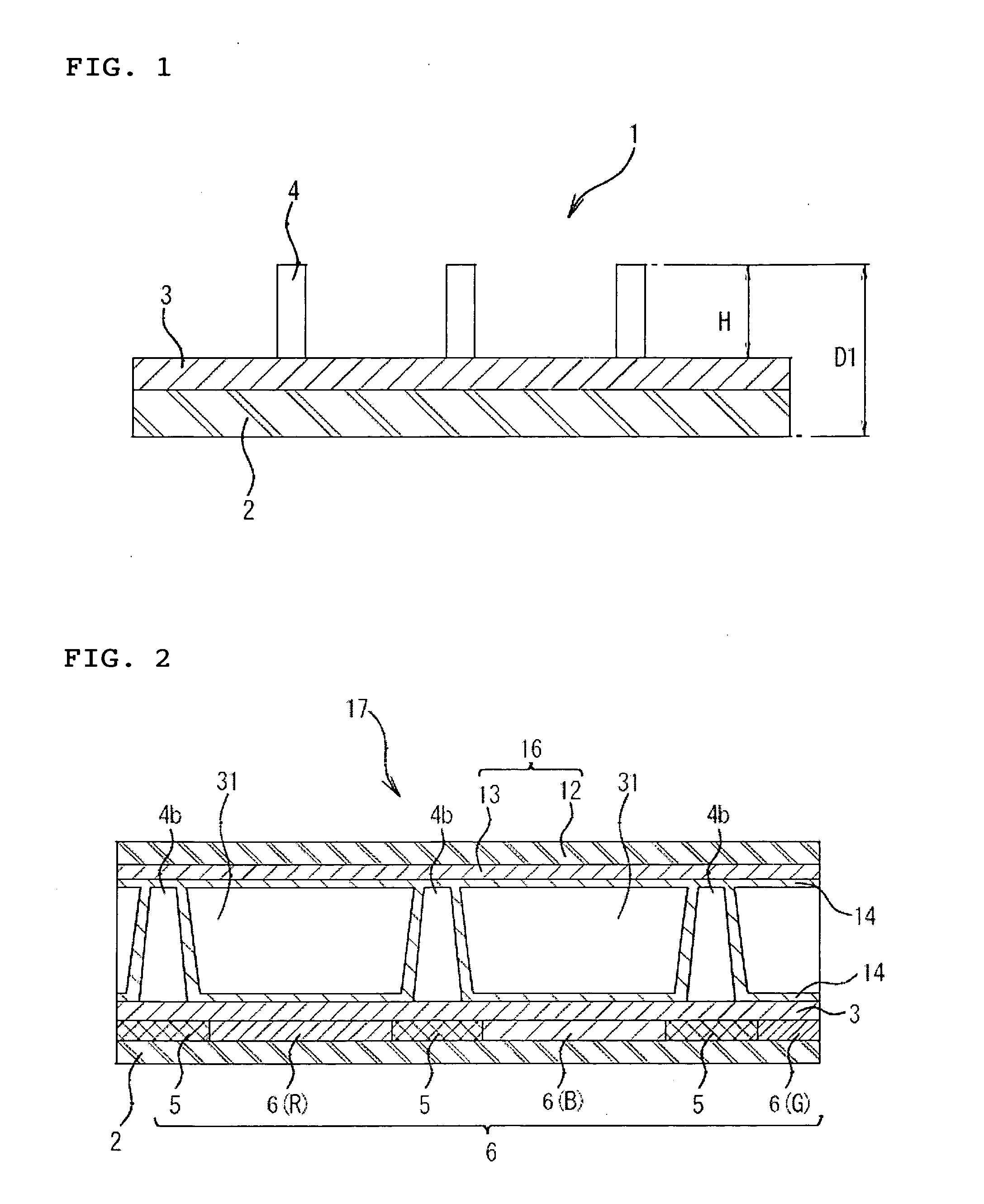

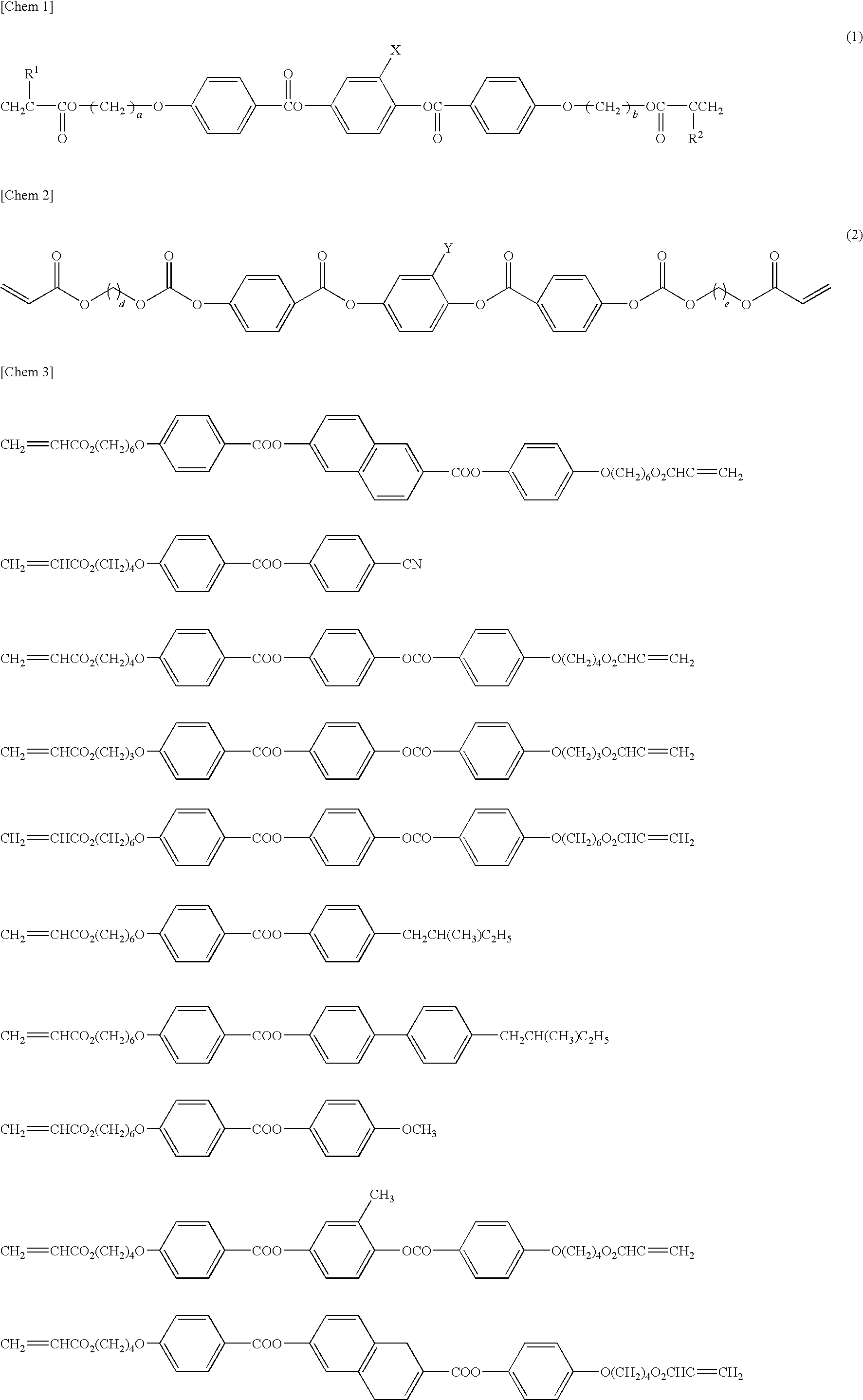

Optical member with retardation control function and liquid crystal display

InactiveUS7961273B2Effectively inhibited from subsiding in the retardation layerQuality improvementNon-linear opticsOptical elementsEngineeringLiquid crystal cell

The invention provides a retardation-controlling optical member that includes a retardation layer obtained by aligning and fixing crosslinkable liquid crystal molecules and columnar structures disposed on the retardation layer. When a liquid crystal cell is formed by use of the retardation-controlling optical member, the columnar structures are effectively inhibited from subsiding in the retardation layer to locally make the cell gap smaller even when pressure is externally applied in a thickness direction of the liquid crystal cell. A sum total of lower bottom areas of columnar structures disposed on a retardation layer is made larger sufficiently compared to a total area of, in particular, an effective display region of a retardation layer surface where the columnar structures are disposed, whereby pressure applied from a thickness direction is dispersed.

Owner:DAI NIPPON PRINTING CO LTD

Proportional solenoid control valve

InactiveUS7055798B2Small hardnessHigh hardnessOperating means/releasing devices for valvesMachines/enginesHysteresisSolenoid valve

A proportional solenoid control valve comprises a flat square spring which is wide in maintaining width with respect to displacement of a spring having a greater spring constant, so that accurate control of fluid is realized. The flat square spring has four tubs and is supported with respect to a step face with outer peripheral section thereof. The valve further comprises a sealing mechanism loaded with rubber resilience compensates instability of armature construction and resilient sealing section. The spring constant of the flat square spring is improved by strengthening the magnetic force, thus hysteresis can be made to be smaller.

Owner:KOFUROTSUKU

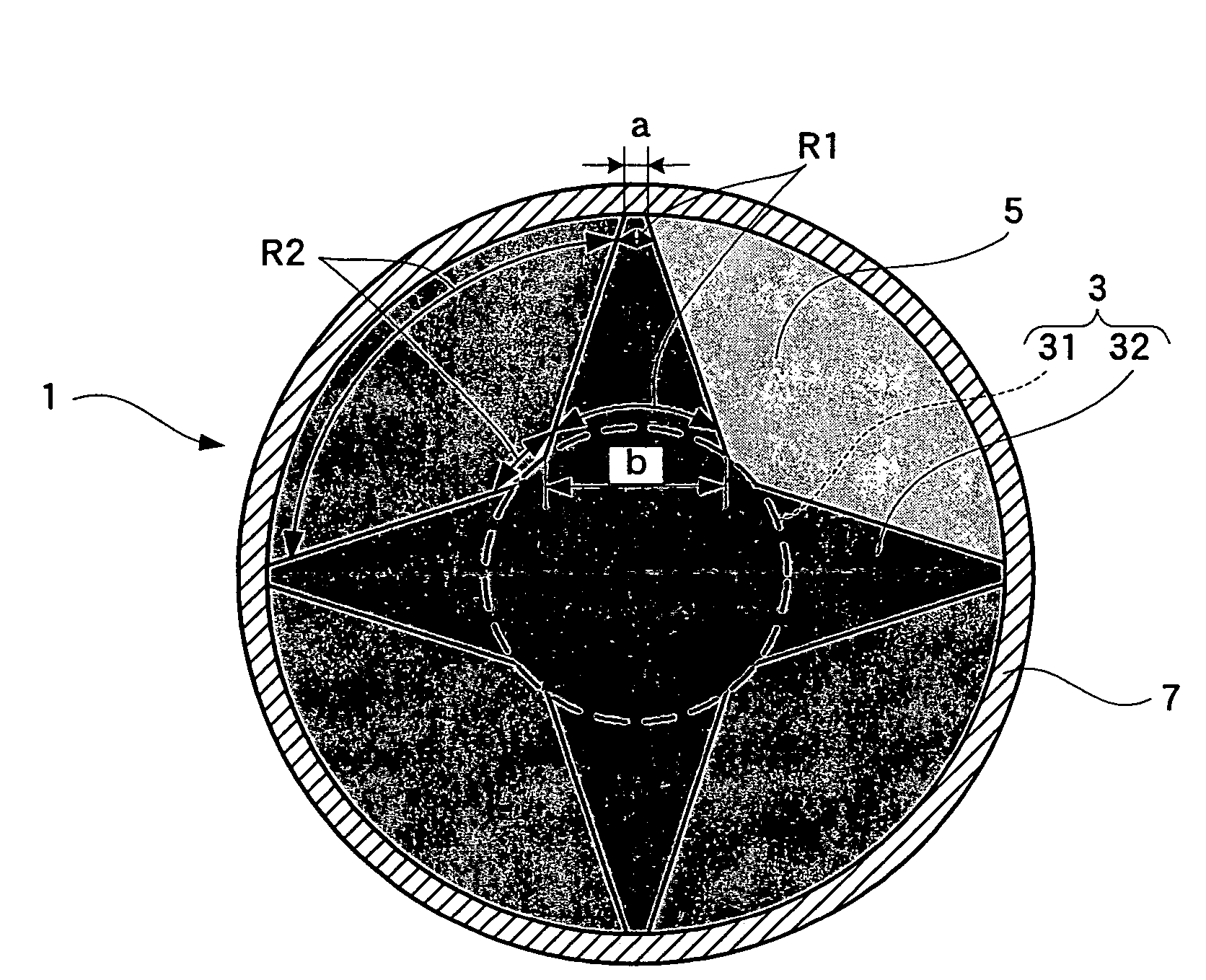

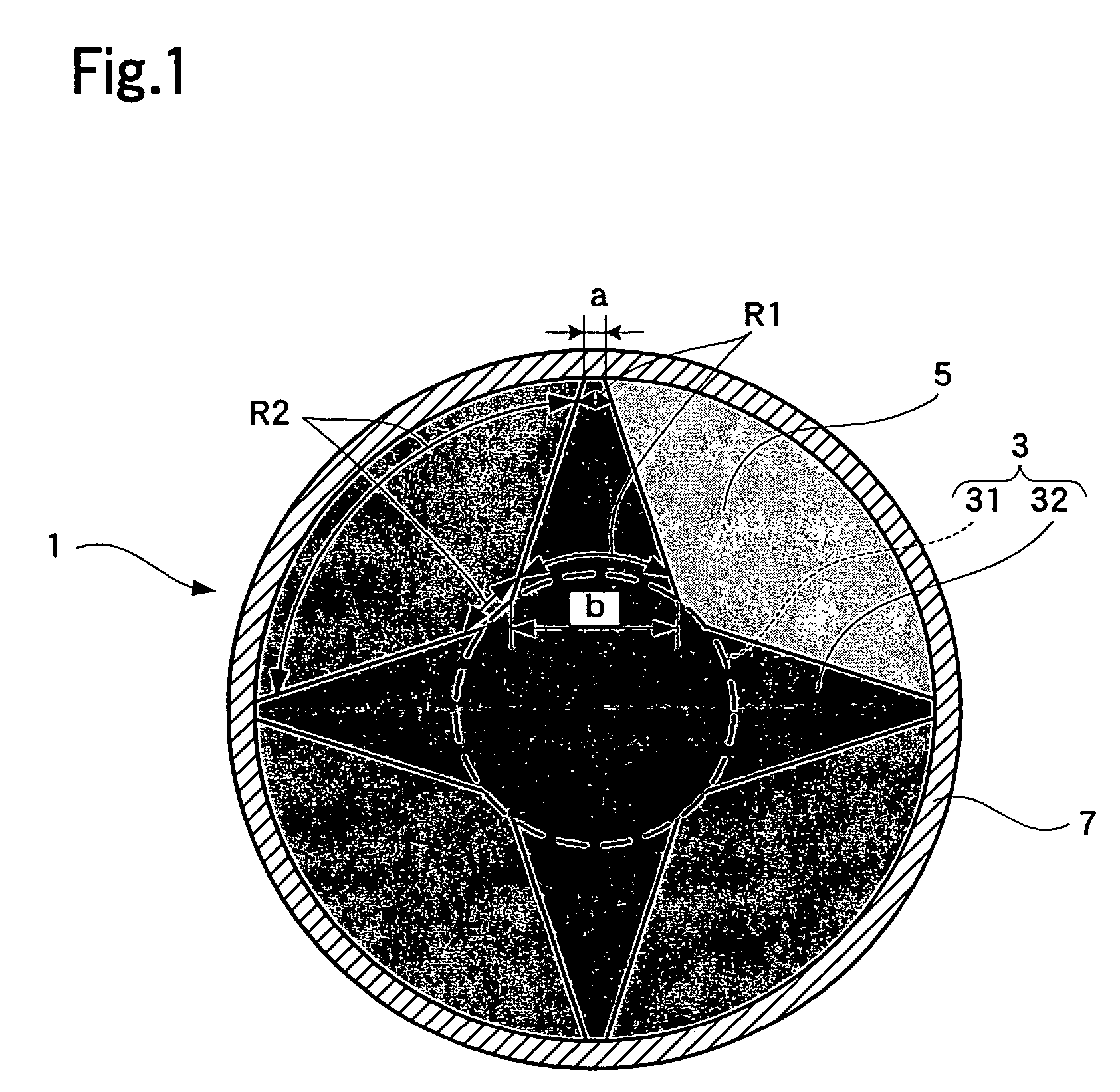

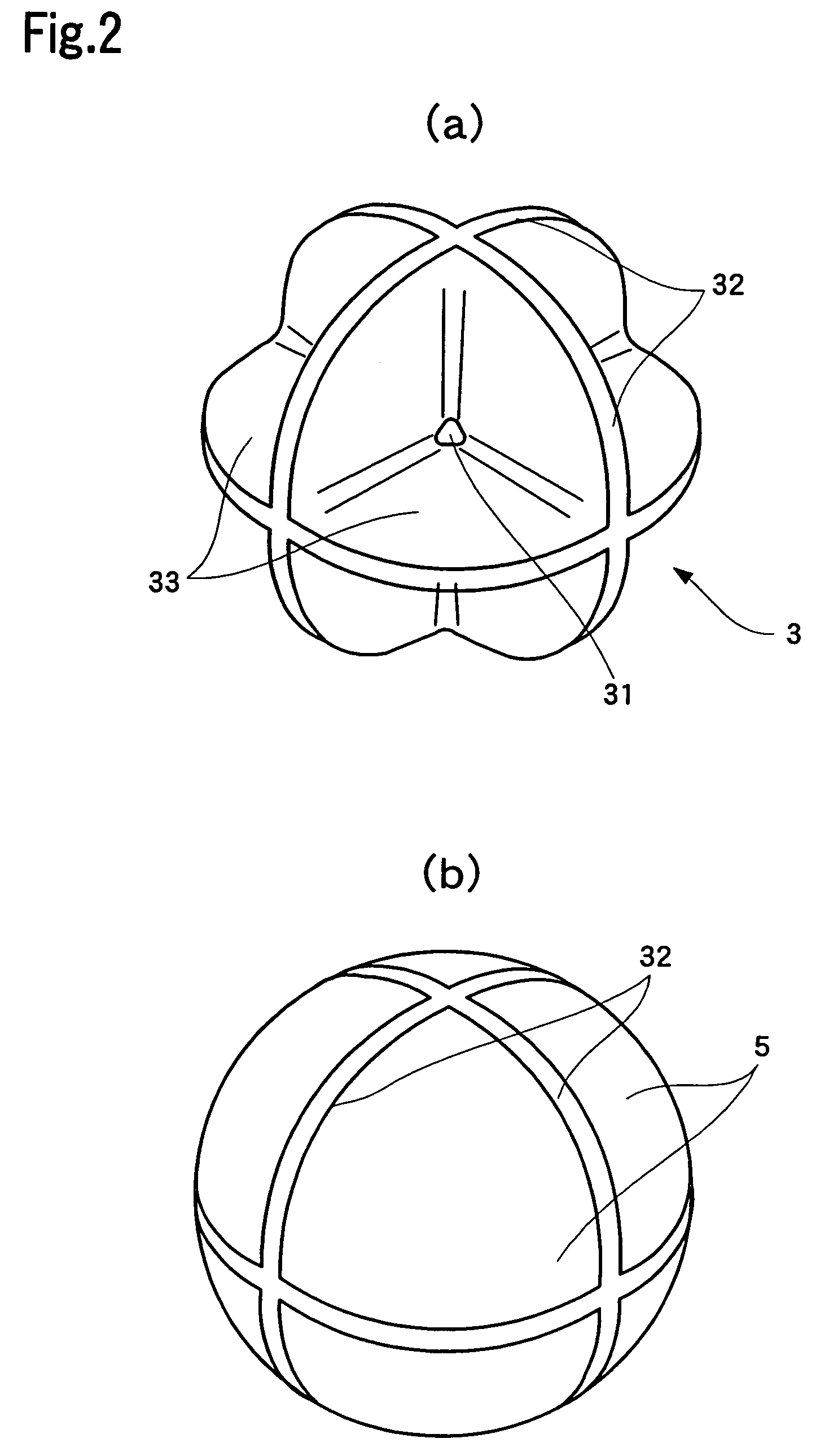

Multi-piece golf ball and manufacturing method thereof

A multi-piece golf ball has a core (3), an interlayer (5), and a cover (7), the core (3) being provided with a spherical main part (31) and a plurality of ribs (32) formed on the main part (31), the interlayer (5) being accommodated in depressions (33) surrounded by the ribs (32) and having a thickness substantially the same as the height of the ribs (32), each of the ribs (32) extending in such a manner that the width thereof becomes greater from the cover towards the core, each of the depressions (33) being formed into a cone-like shape by side faces of the ribs (32), and the hardness of the interlayer (5) being less than that of the core (3). This structure achieves satisfactory soft feeling and high bounce resilience.

Owner:MIZUNO CORPORATION

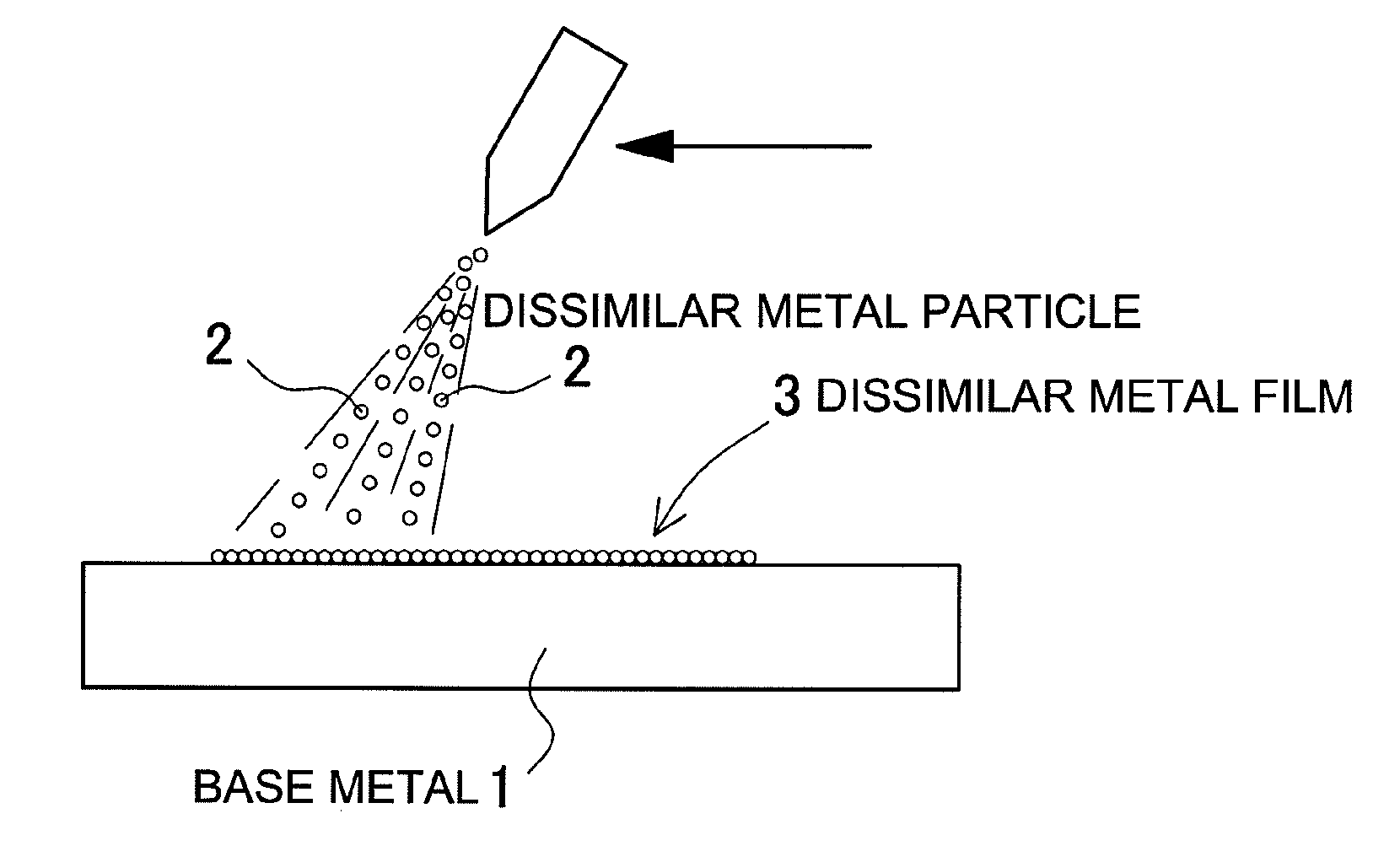

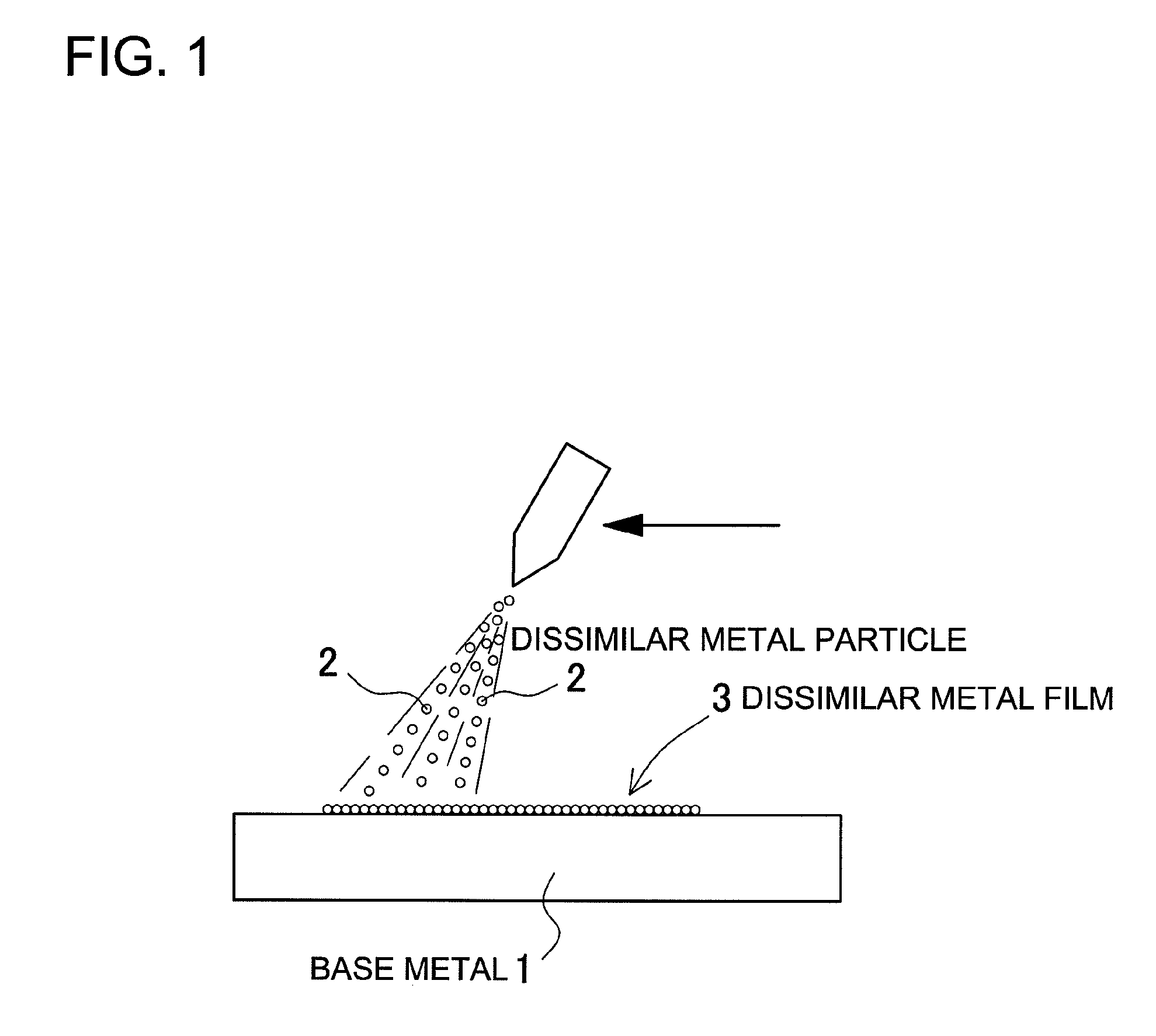

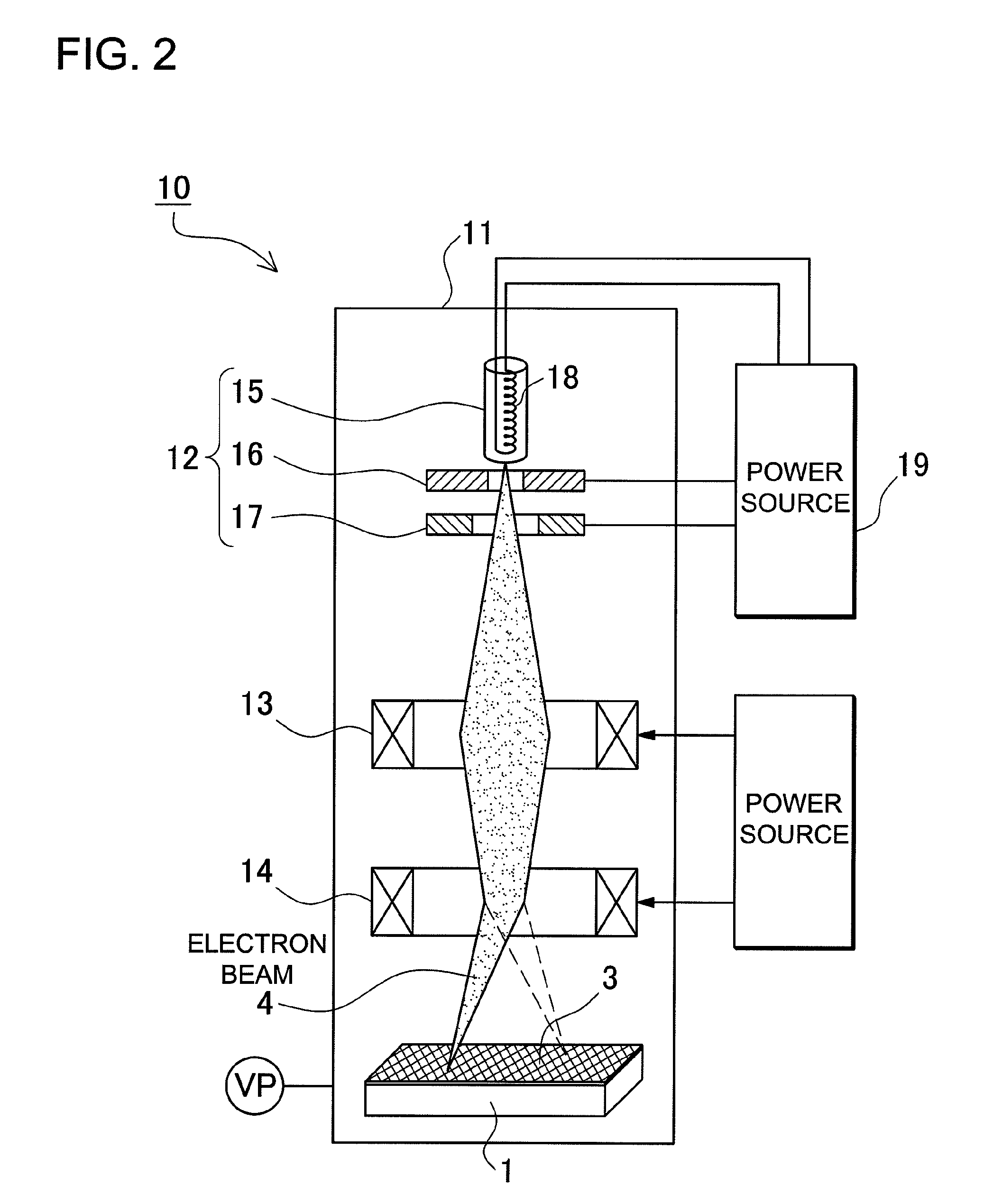

Metal surface treatment method

InactiveUS20090314824A1Simple and easy and efficient mannerBonded firmlySoldering apparatusWelding apparatusMetal particleElectron

A metal surface treatment method includes: a shot-peening step of shot-peening a dissimilar metal particle (2) on a surface of a base metal (1), the dissimilar metal particle (2) being a metal particle different from the base metal (1), to provide a dissimilar metal film (3) on the surface of the base metal (1); and an electron beam irradiation step of irradiating the surface of the base metal (1) with an electron beam (4), the surface of the base metal (1) having been provided with the dissimilar metal film (3) in the shot-peening step, to bond the dissimilar metal film (3) and the base metal (1) together.

Owner:KAZUO SAWAGUCHI +1

Method for making a foamed sole

A method for making a foamed sole includes the steps of: a) preparing a mold having a lower mold part and an upper mold part removably covering the lower mold part, the lower mold part having a top surface and a lower mold cavity recessed from the top surface, the upper mold part having a bottom surface to contact the top surface of the lower mold part, and an upper mold cavity recessed from the bottom surface; b) filling and molding a first molding material in the upper mold part to form a first sole portion; and c) filling and molding a second molding material in the lower mold part to form a second sole portion having a hardness smaller than that of the first sole portion and bonding directly with the first sole portion.

Owner:SKYJOY INT

Low resilience flexible polyurethane foam and process for its production

To provide a flexible polyurethane foam which is excellent in low resiliency and durability without using a plasticizer and which shows little change in hardness against a change in temperature and at the same time, has high air permeability. A process for producing a flexible polyurethane foam, which comprises reacting a polyol mixture comprising polyol (A), polyol (B) and monool (D) with a polyisocyanate compound in the presence of a blowing agent etc. at an isocyanate index of at least 90. Polyol (A) is a polyether polyol having an average of 2-3 hydroxyl groups and a hydroxyl value of from 10 to 90 mgKOH / g, obtained by ring-opening addition polymerization of an alkylene oxide to an initiator using a double metal cyanide complex catalyst; Polyol (B) is a polyether polyol having an average of 2-3 hydroxyl groups and a hydroxyl value of from 15 to 250 mgKOH / g, other than the polyol (A); and Monool (D) is a polyether monool having a hydroxyl value of from 10 to 200 mgKOH / g.

Owner:AGC INC

Lower Cushioning Structure and Package Cushioning Structure for Display Panel

ActiveUS20120211398A1Low costPoor cushioning effectOther accessoriesContainer/bottle contructionCushioningEngineering

A lower cushioning structure and a package cushioning structure for a display panel are disclosed. The lower cushioning structure comprises: a supporting frame, comprising a baseplate as well as a first side plate and a second side plate extending upwards from two opposite sides of the baseplate respectively; two first cushions, being disposed at a location where the first side plate of the supporting frame borders the baseplate and a location where the second side plate of the supporting frame borders the baseplate respectively; and two second cushions, being disposed on an inner wall of the first side plate and an inner wall of the second side plate of the supporting frame respectively, wherein the second cushions are located above the first cushions. The present invention has a low cost and can provide satisfactory cushioning for the display panel.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Flexible polyurethane foam and process for its production

A process for producing a flexible polyurethane foam, which comprises reacting a polyol mixture with a polyisocyanate compound in the presence of a urethane-forming catalyst and a blowing agent, characterized in that the polyol mixture comprises the following polyol (A) and the polyol (B), and the proportion of the polyisocyanate compound to the polyol mixture is at least 90 by isocyanate index, and the total amount of Zn and Co contained in the polyol mixture is from 0.1 to 200 ppm.

Owner:ASAHI GLASS CO LTD

Method for fabricating a semiconductor device

ActiveUS7183200B2High hardnessLarge elastic modulusSemiconductor/solid-state device detailsSolid-state devicesResistInterconnection

Owner:FUJITSU SEMICON LTD

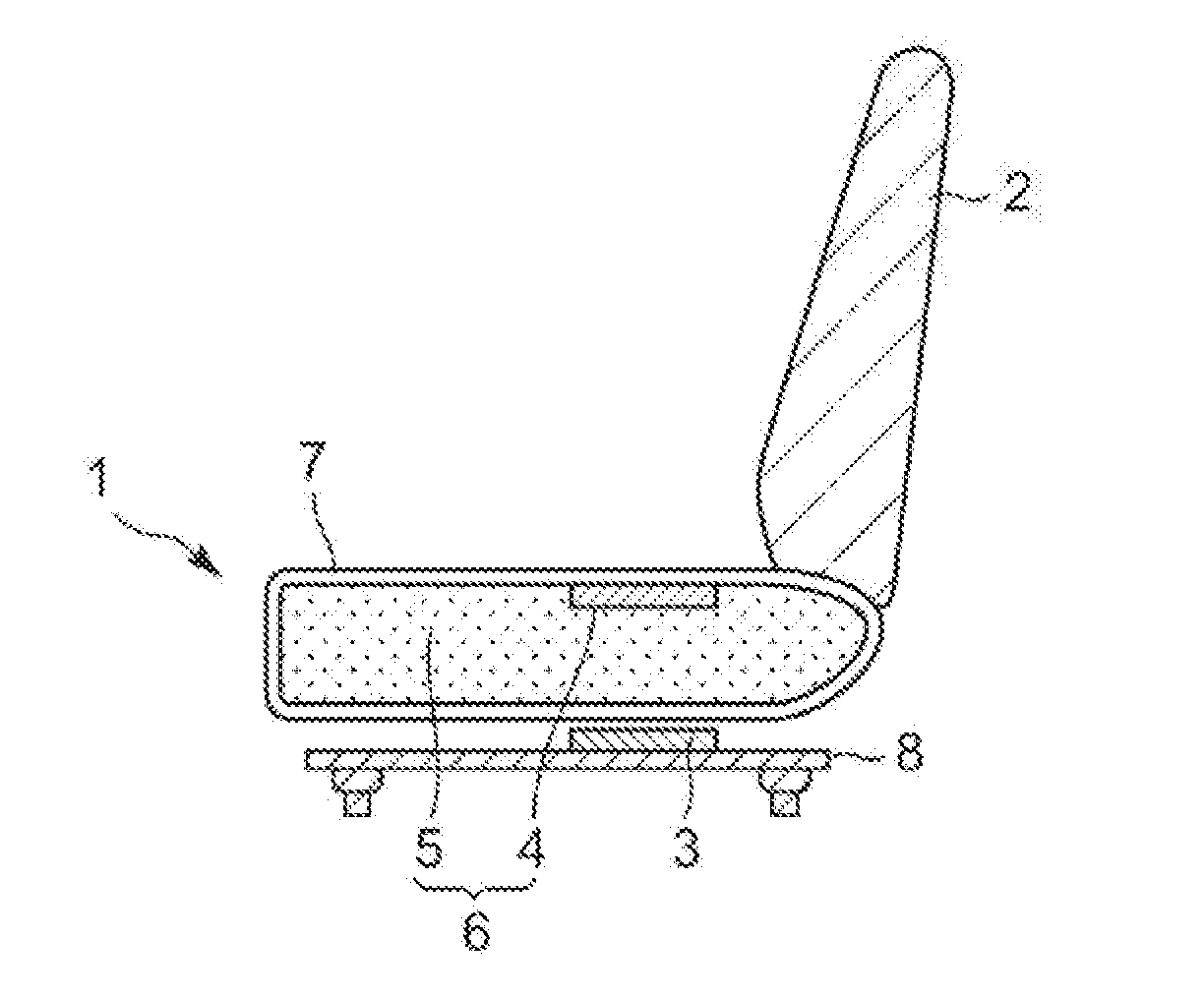

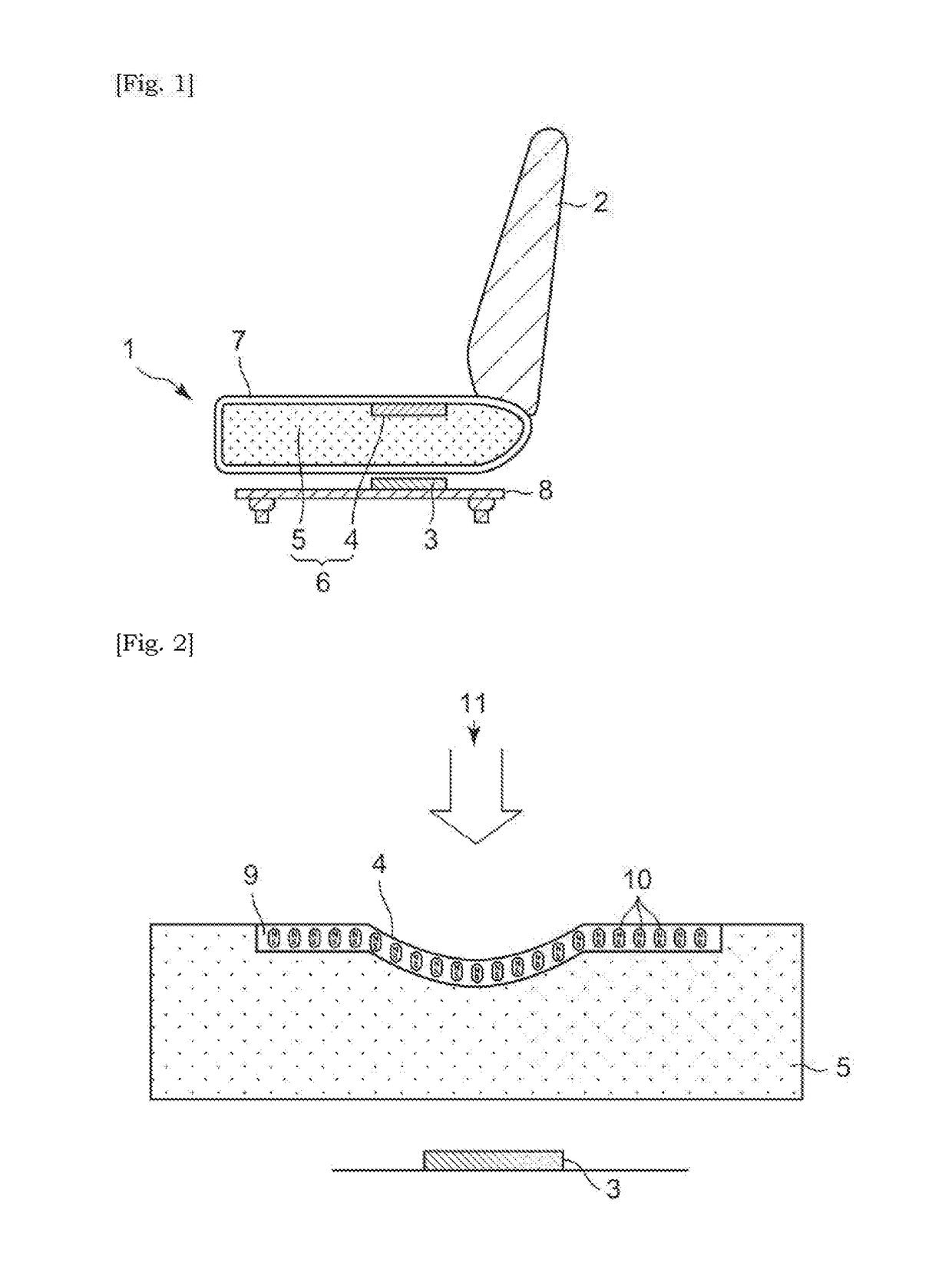

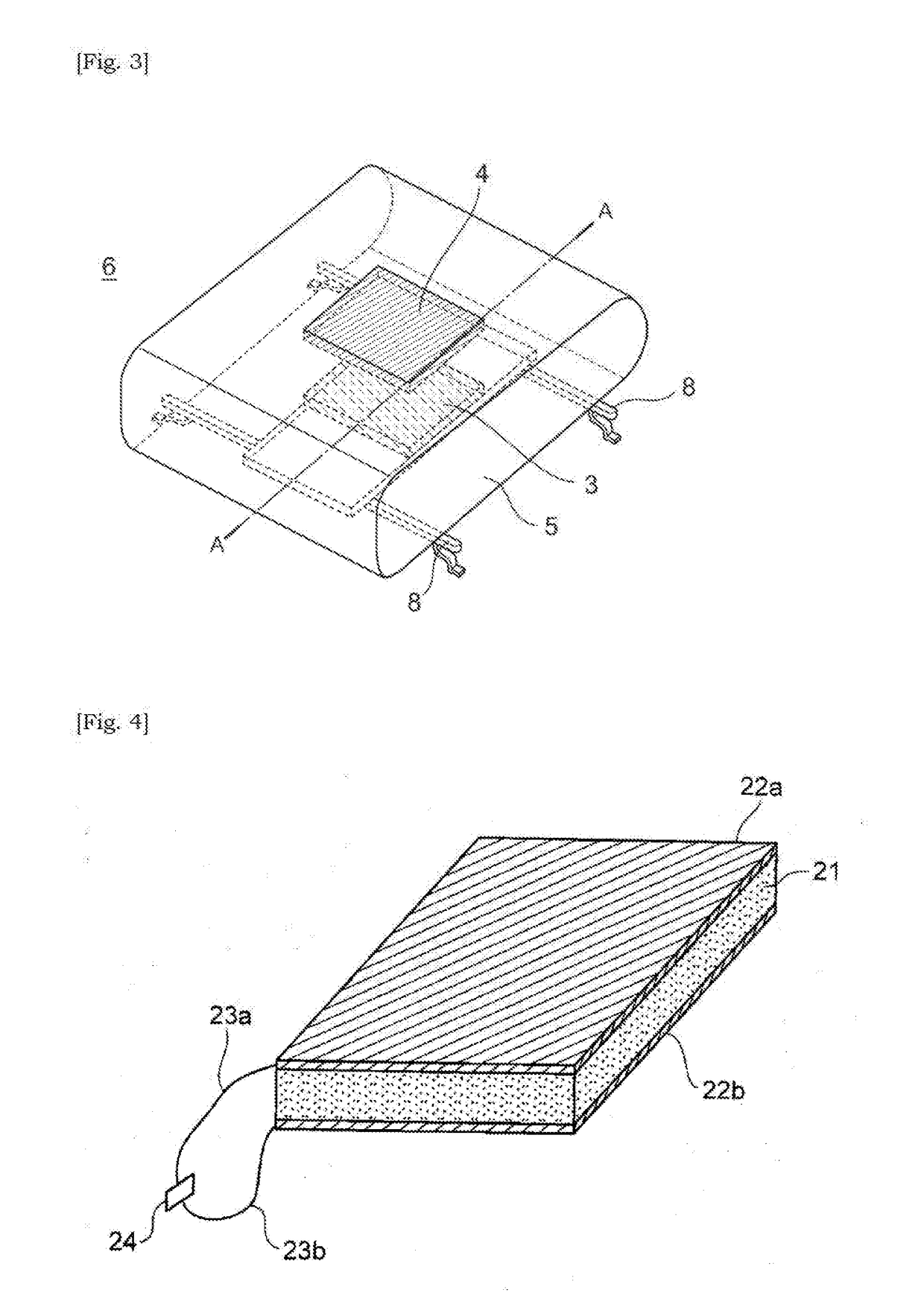

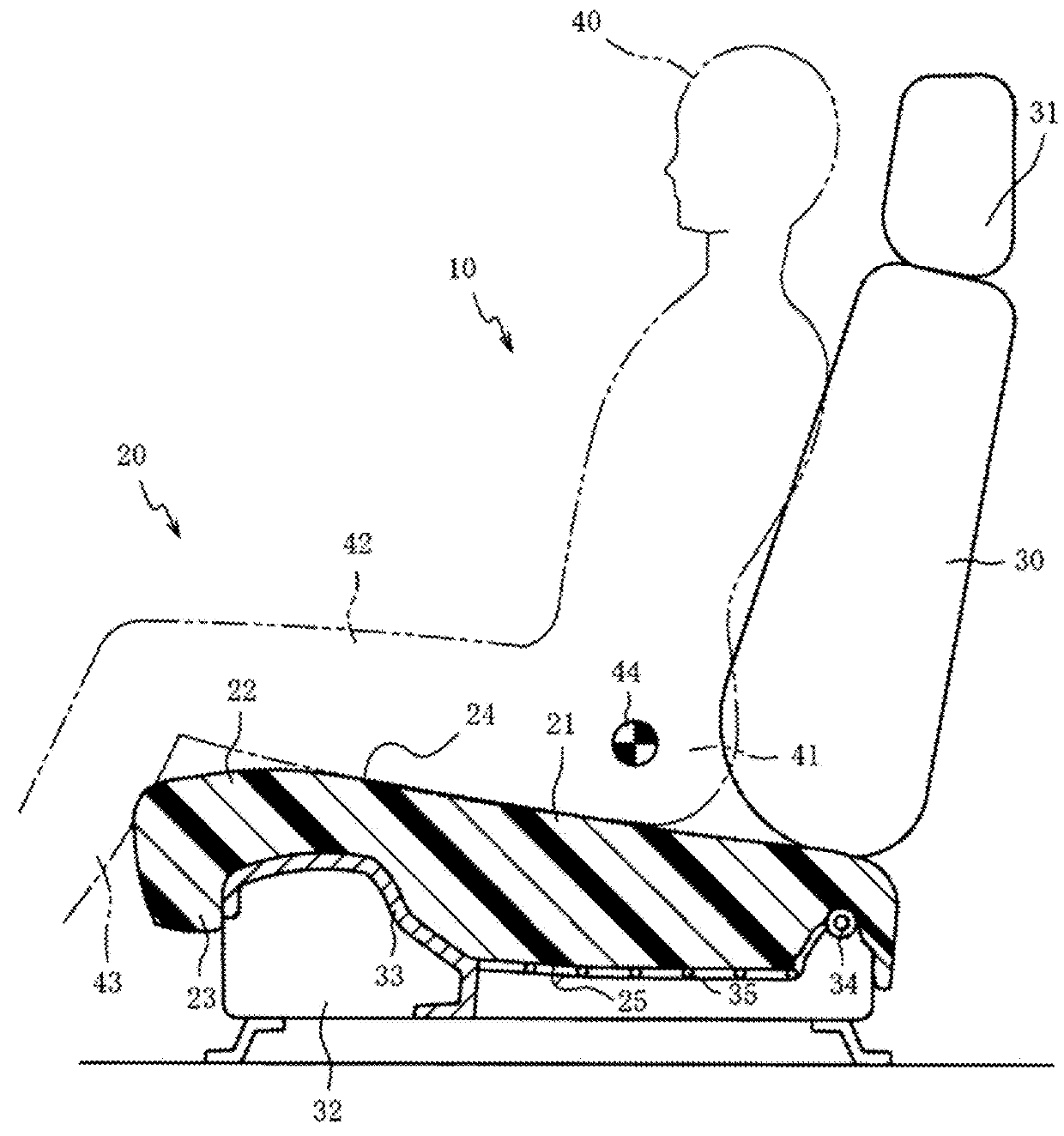

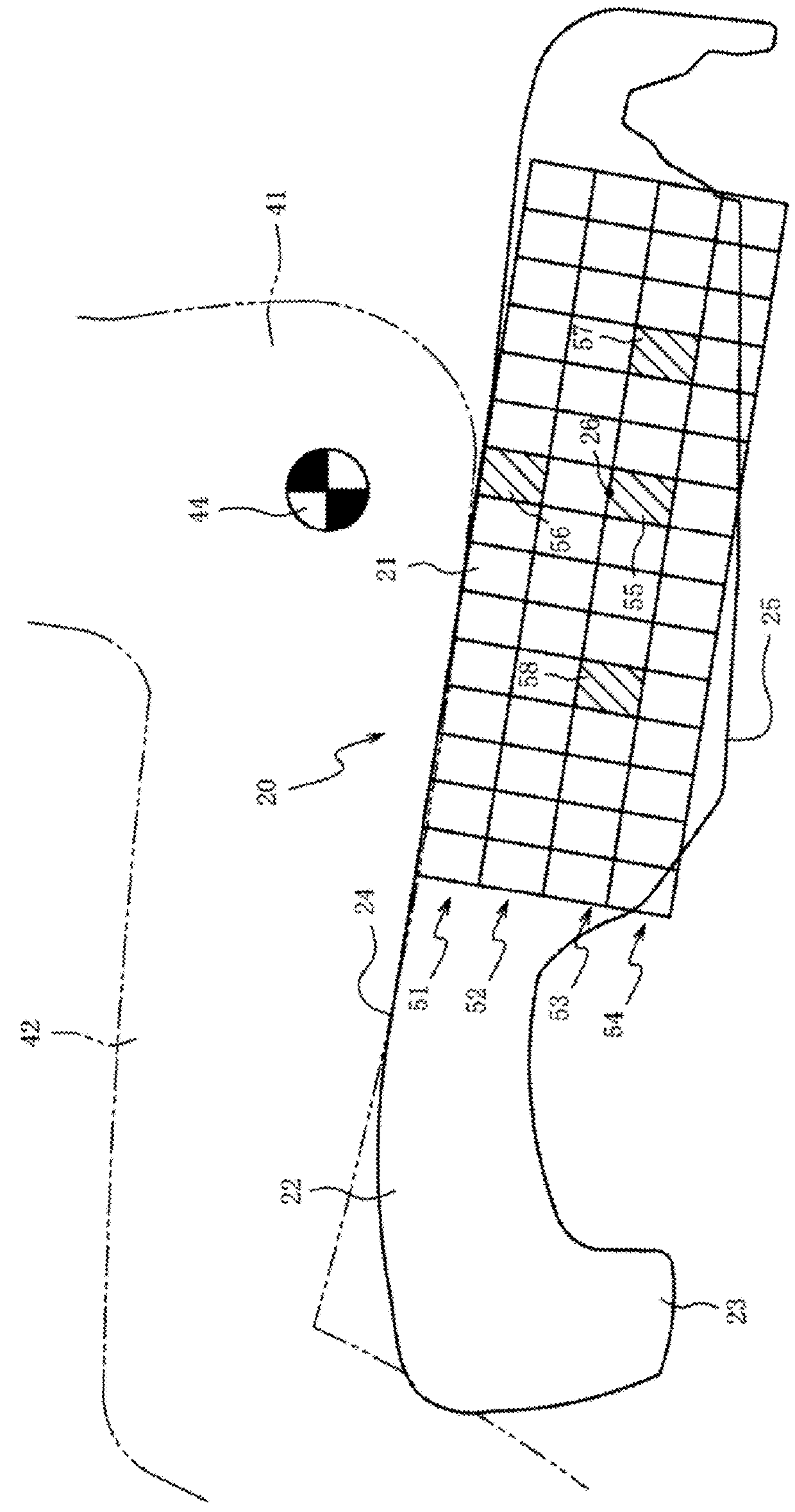

System for detecting deformation of cushion pad and production thereof

InactiveUS20170184390A1Good sittingPoor durabilityVehicle seatsUsing electrical meansElectricityHardness

The present invention provides a cushion pad with improved durability without feeling of a foreign object.The present invention thus provides a system for detecting a deformation of a cushion pad, comprising;the cushion pad comprising a matrix layer, in which electroconductive or magnetic filler is dispersed, and a soft polyurethane foam including the matrix layer incorporated therein, anda detecting portion that detects an electric or magnetic change caused by a deformation of the cushion pad,wherein the matrix layer has a hardness lower than the soft polyurethane, and it production method.

Owner:TOYO TIRE & RUBBER CO LTD

Golf ball

ActiveUS8366568B2Improve continuityNot impair resilience performanceGolf ballsSolid ballsGolf BallPhysics

Owner:SUMITOMO RUBBER IND LTD

Optical Member With Retardation Control Function And Liquid Crystal Display

InactiveUS20100165256A1Quality improvementHigh-quality image displayNon-linear opticsOptical elementsEngineeringLiquid crystal cell

The invention provides a retardation-controlling optical member that includes a retardation layer obtained by aligning and fixing crosslinkable liquid crystal molecules and columnar structures disposed on the retardation layer. When a liquid crystal cell is formed by use of the retardation-controlling optical member, the columnar structures are effectively inhibited from subsiding in the retardation layer to locally make the cell gap smaller even when pressure is externally applied in a thickness direction of the liquid crystal cell.A sum total of lower bottom areas of columnar structures disposed on a retardation layer is made larger sufficiently compared to a total area of, in particular, an effective display region of a retardation layer surface where the columnar structures are disposed, whereby pressure applied from a thickness direction is dispersed.

Owner:DAI NIPPON PRINTING CO LTD

Fastening element

Owner:HILTI AG

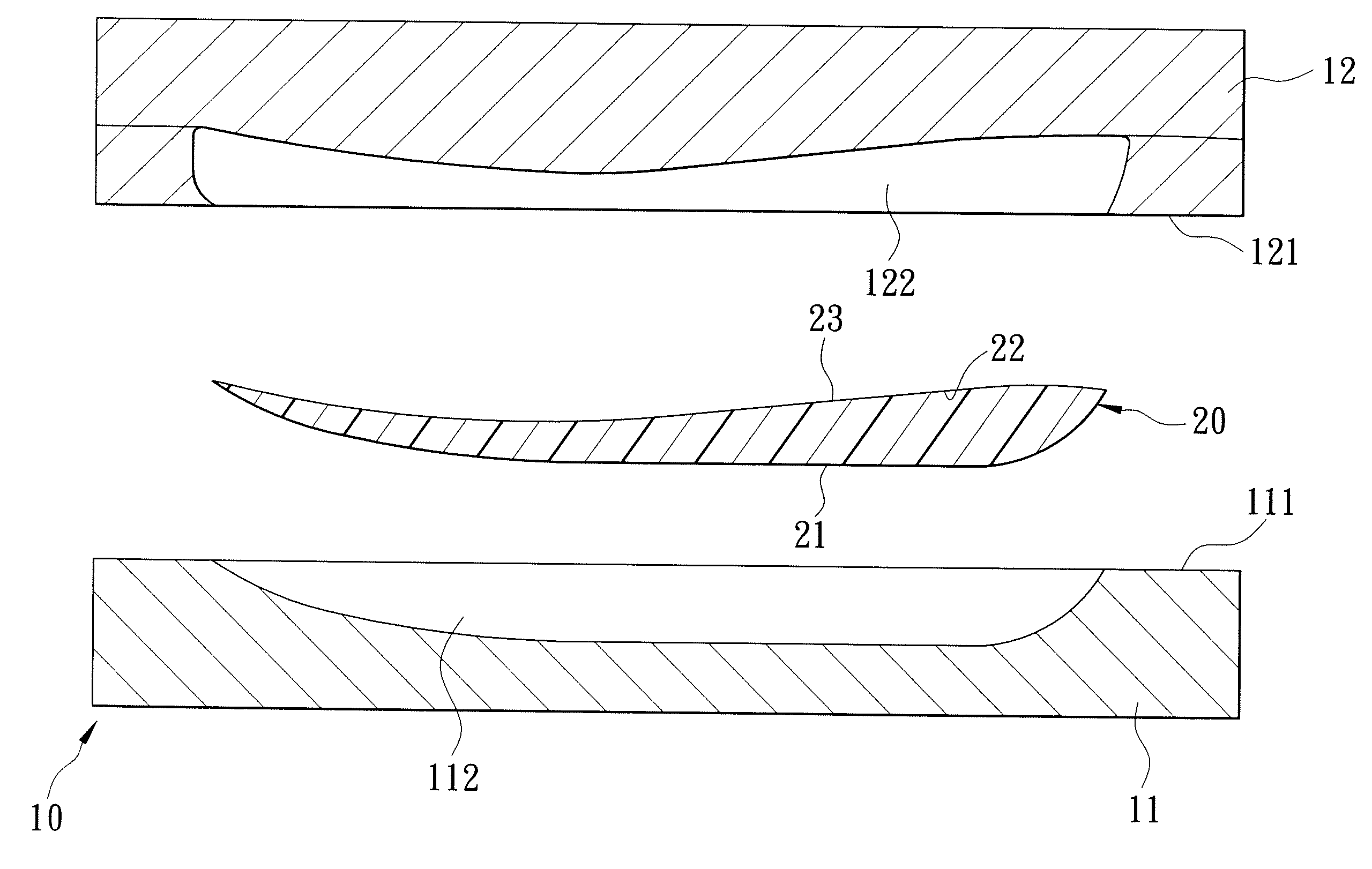

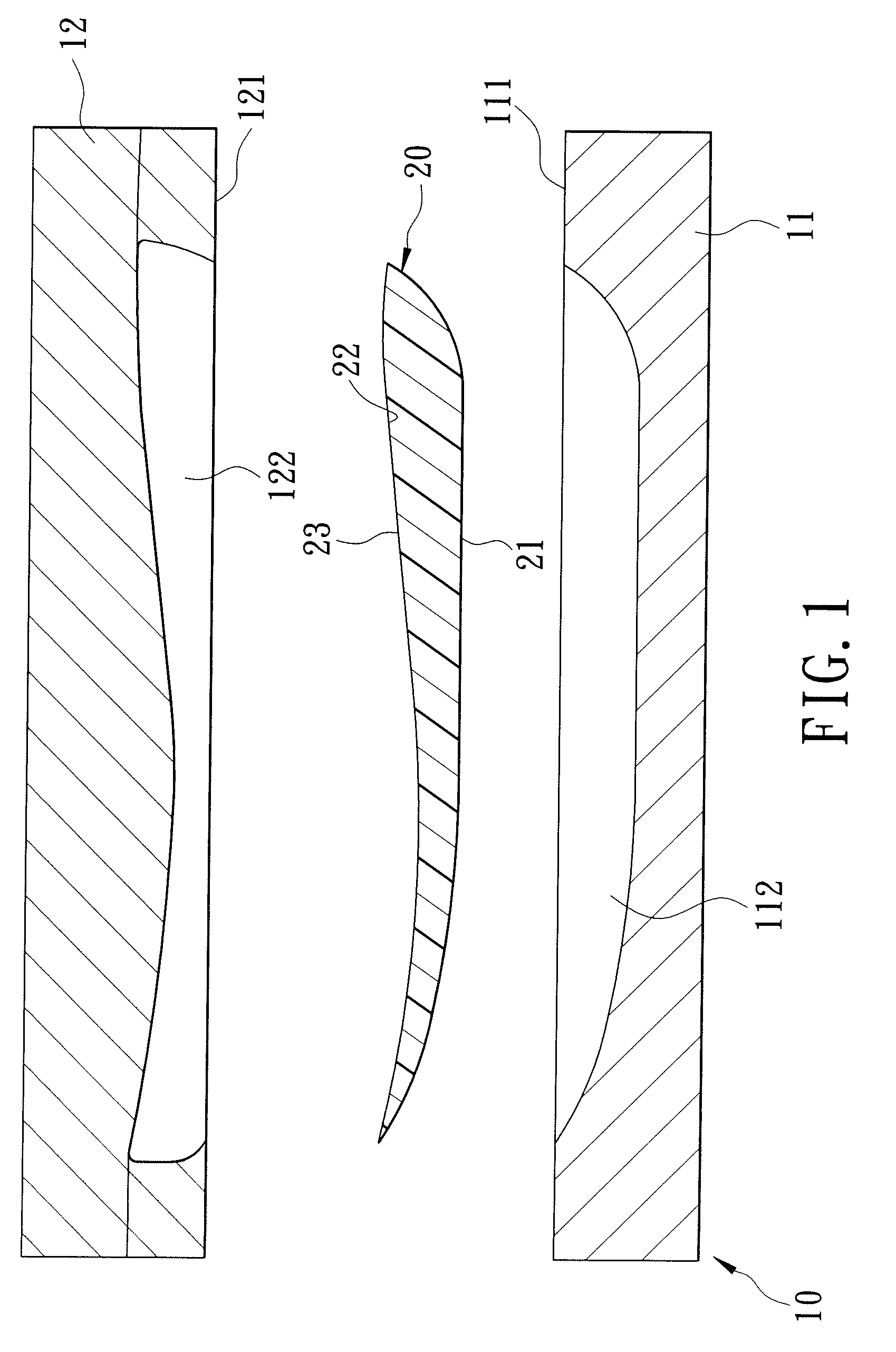

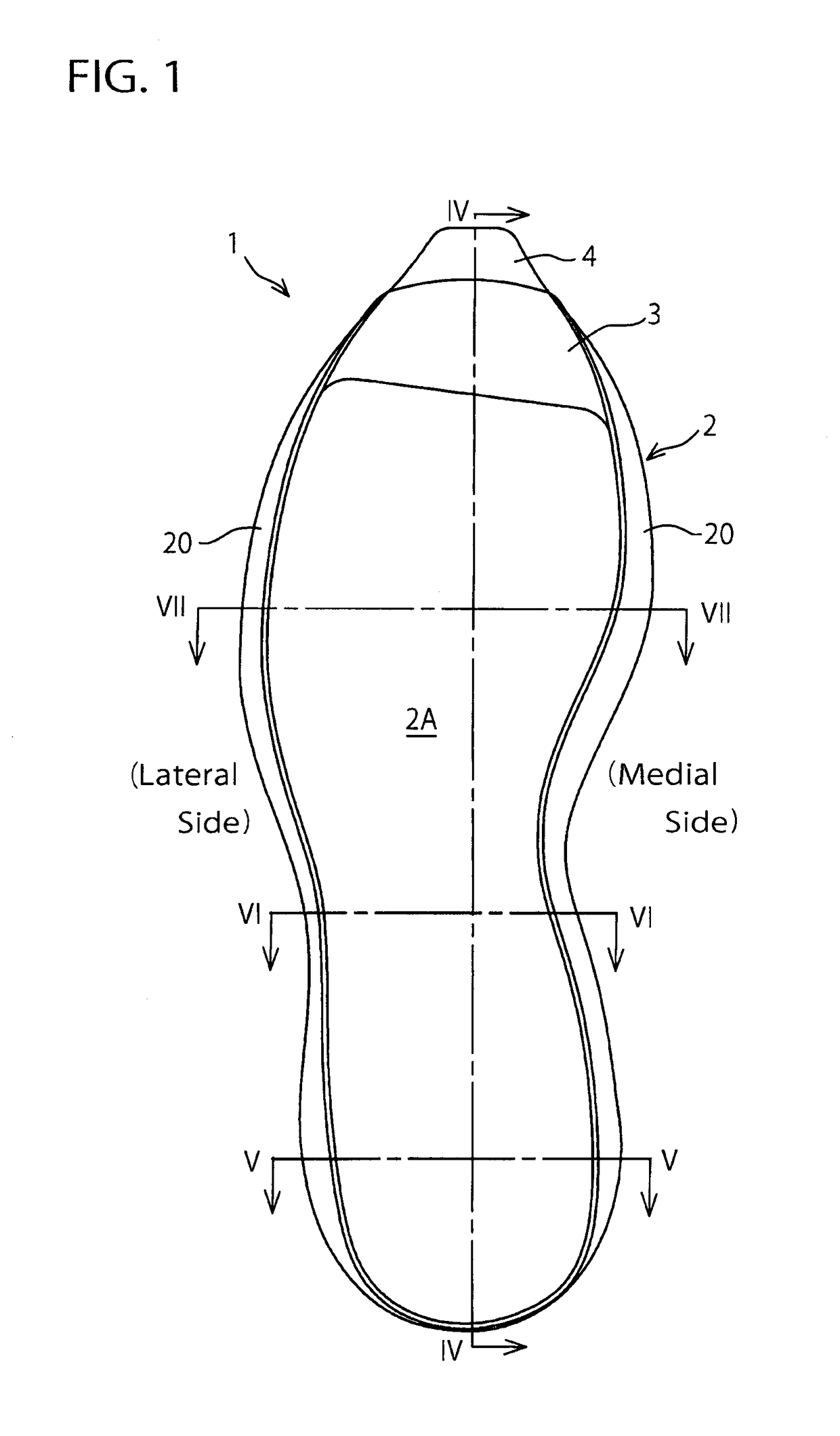

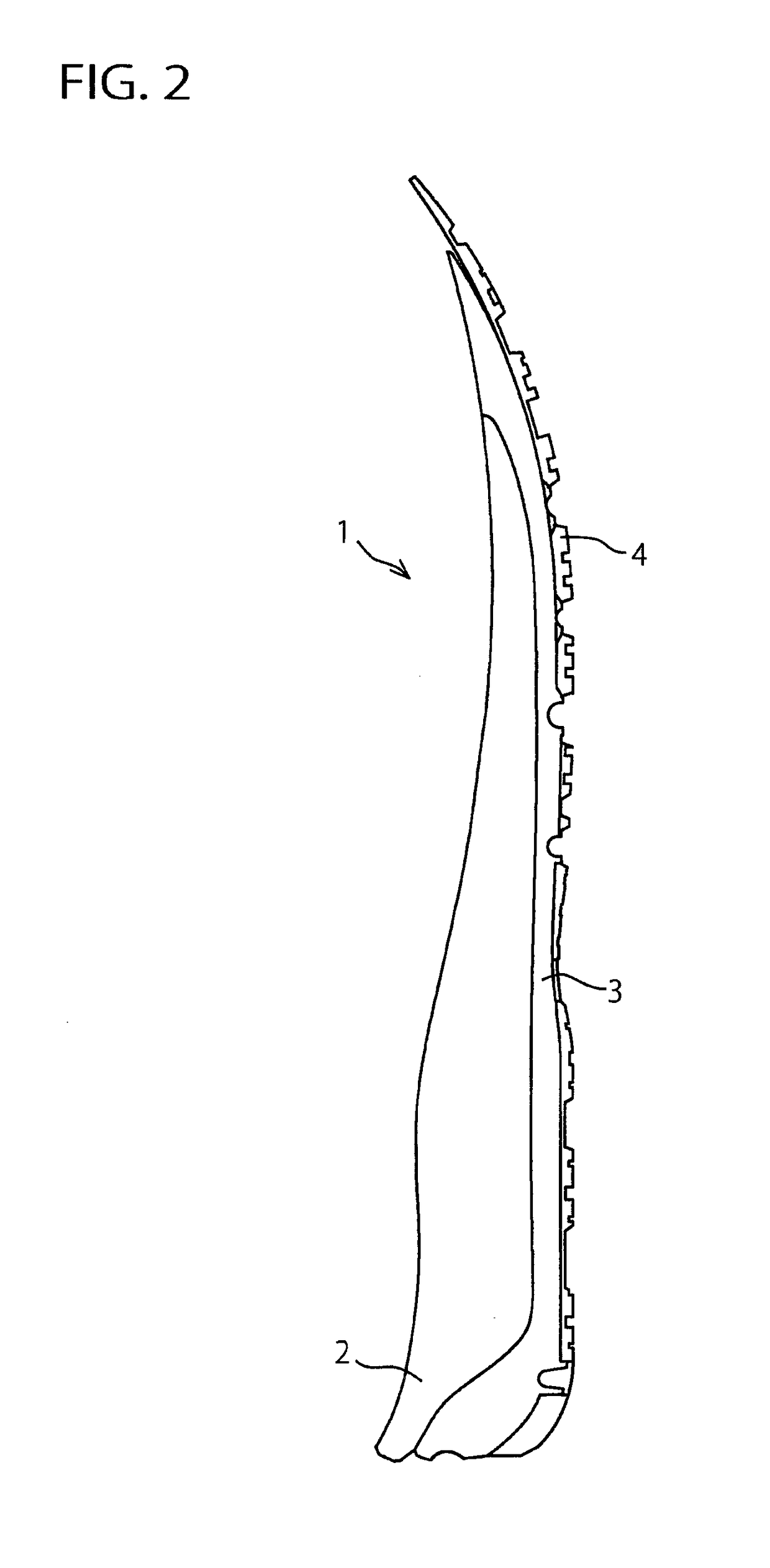

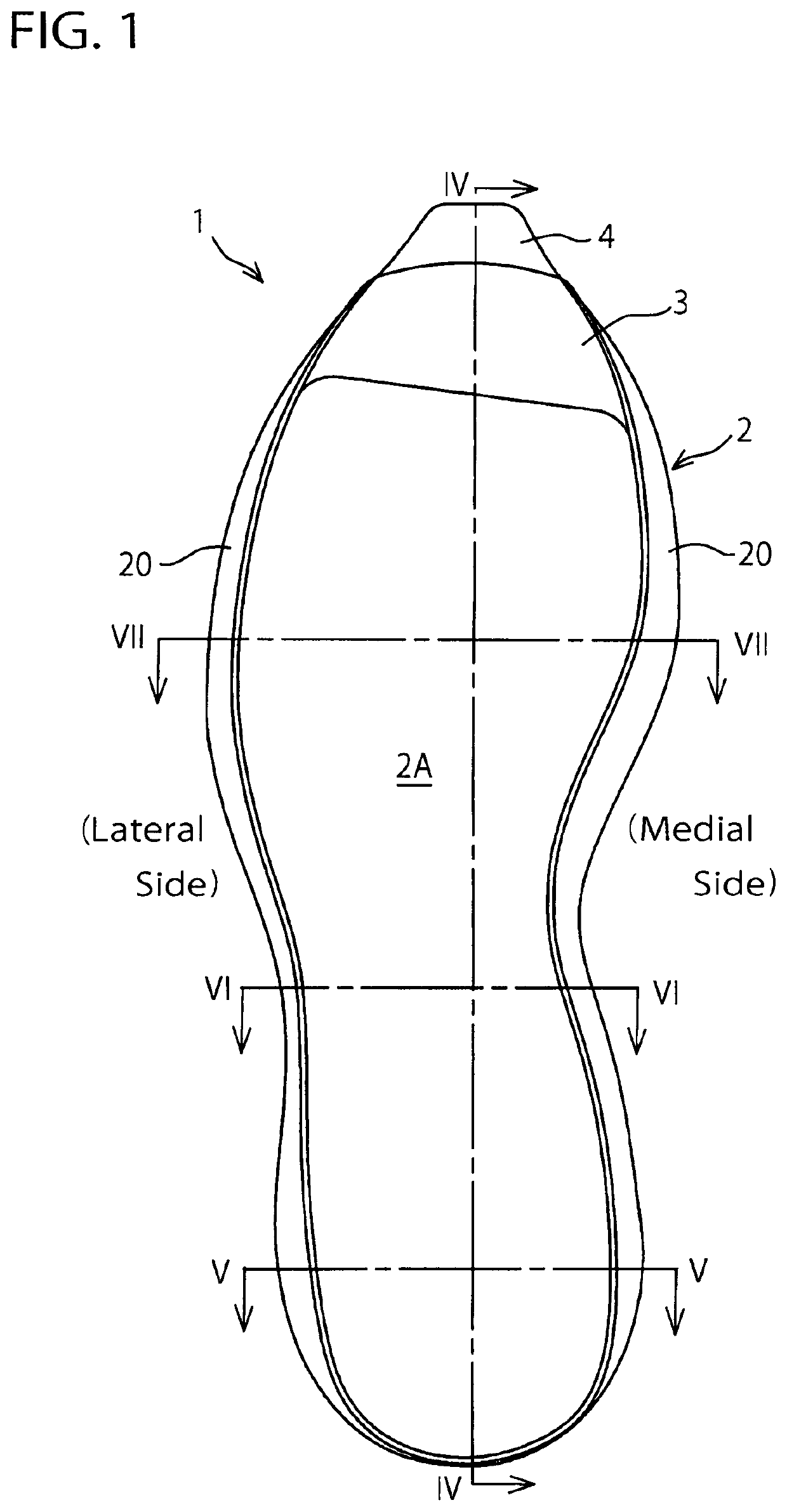

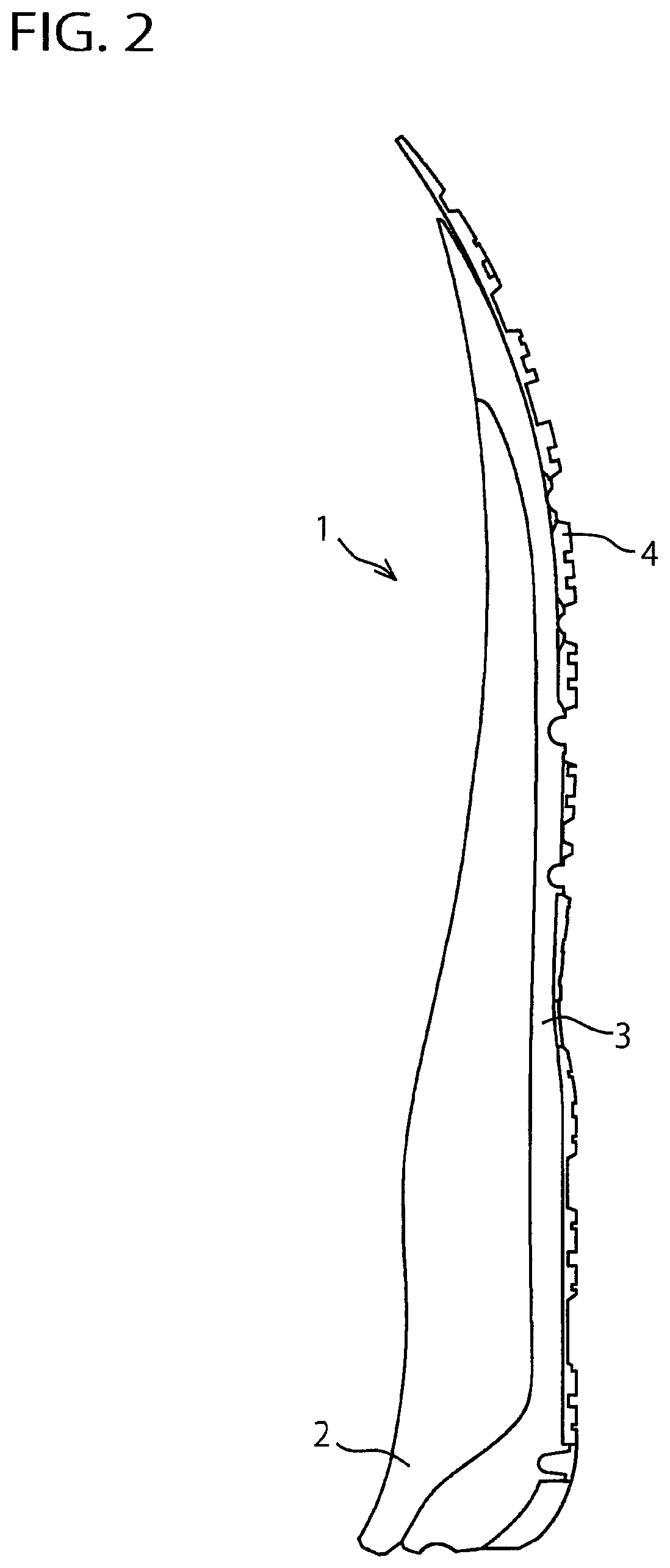

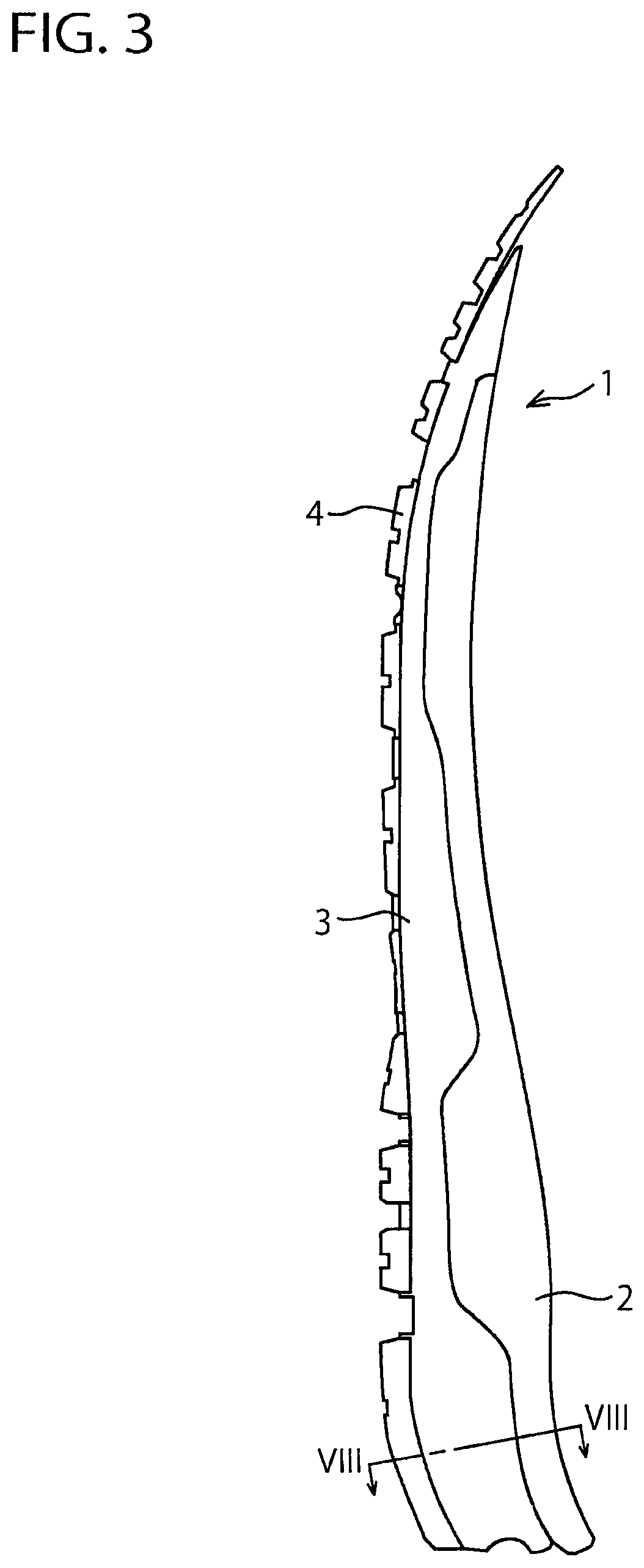

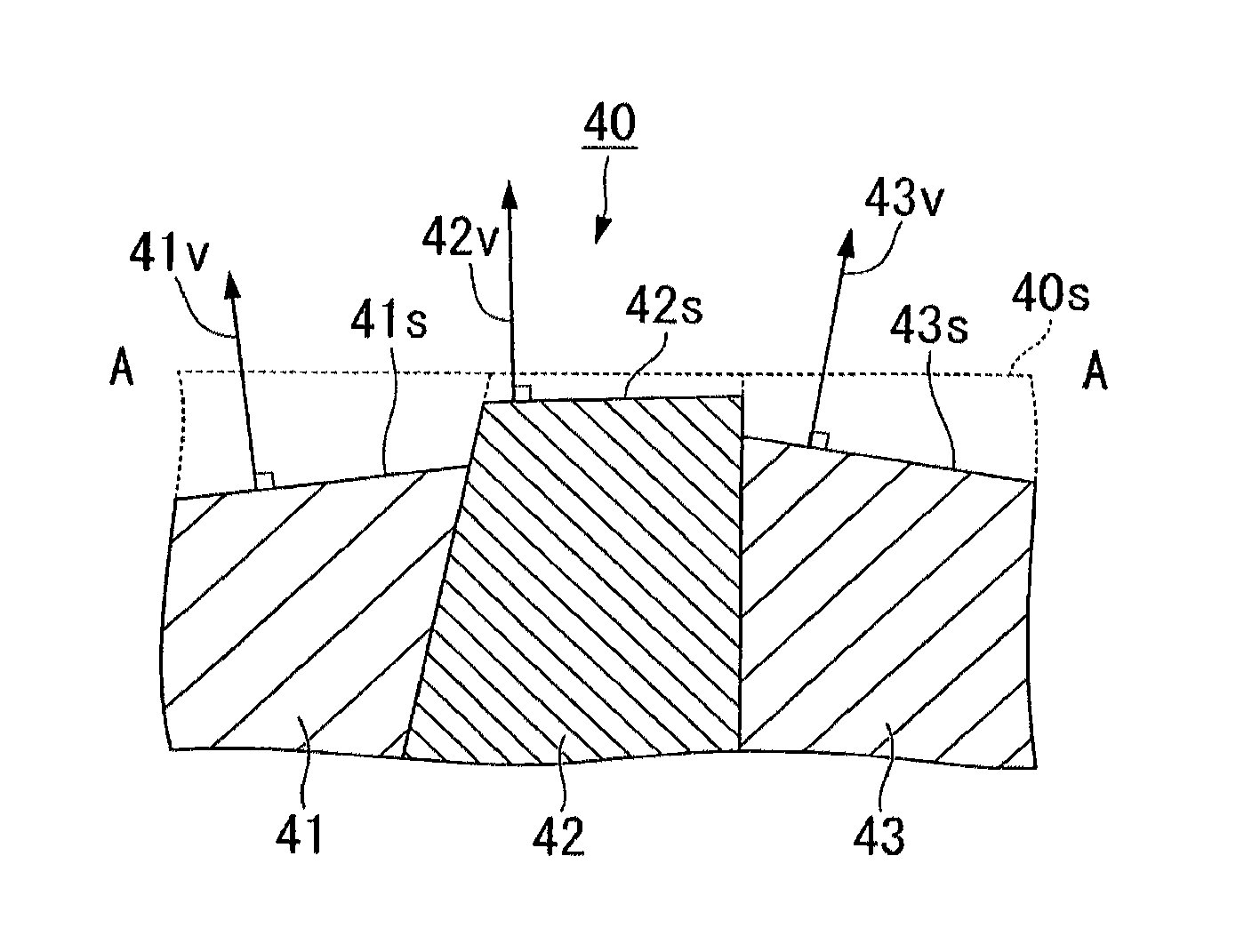

Midsole Structure for a Shoe

A midsole structure for a shoe not only maintains stability at the time of impacting the ground and improves cushioning property but also eliminates discomfort to a foot sole and improves ride feeling during running. The midsole structure (1) comprises at least two midsoles provided at a heel region of the shoe and having a hardness difference. On opposite sides of the heel region, an upper midsole (2) of a greater hardness has a thickness greater than a thickness of a lower midsole (3) of a smaller hardness. In a central part of the heel region, the lower midsole (3) of a smaller hardness has a thickness greater than a thickness of the upper midsole (2) of a greater hardness. Boundary surfaces (2B, 3A) between the upper midsole (2) and the lower midsole (3) do not appear on a top surface of the midsole structure (1) (that is, a foot sole contact surface (2A) of the upper midsole (2)).

Owner:MIZUNO CORPORATION

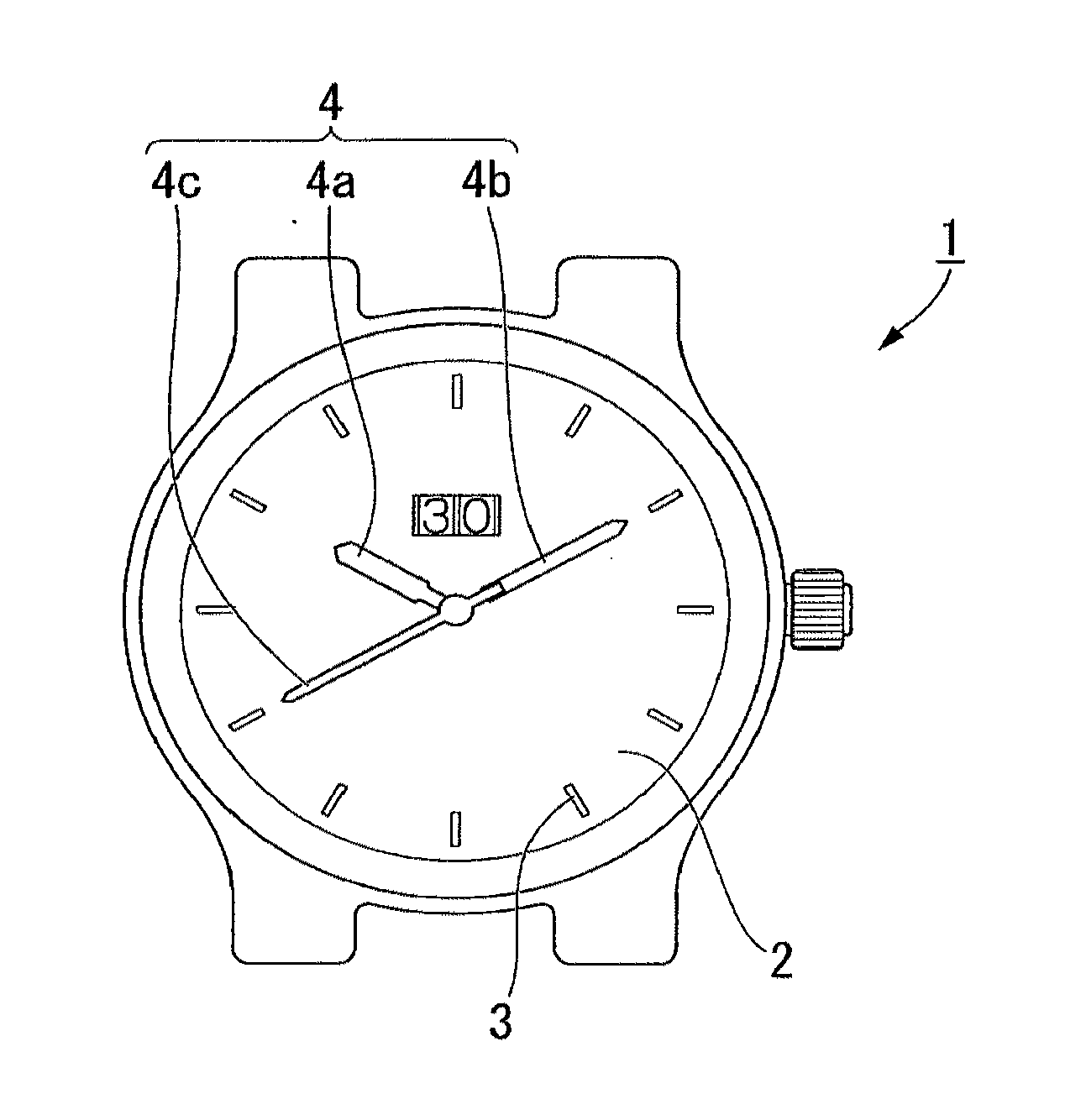

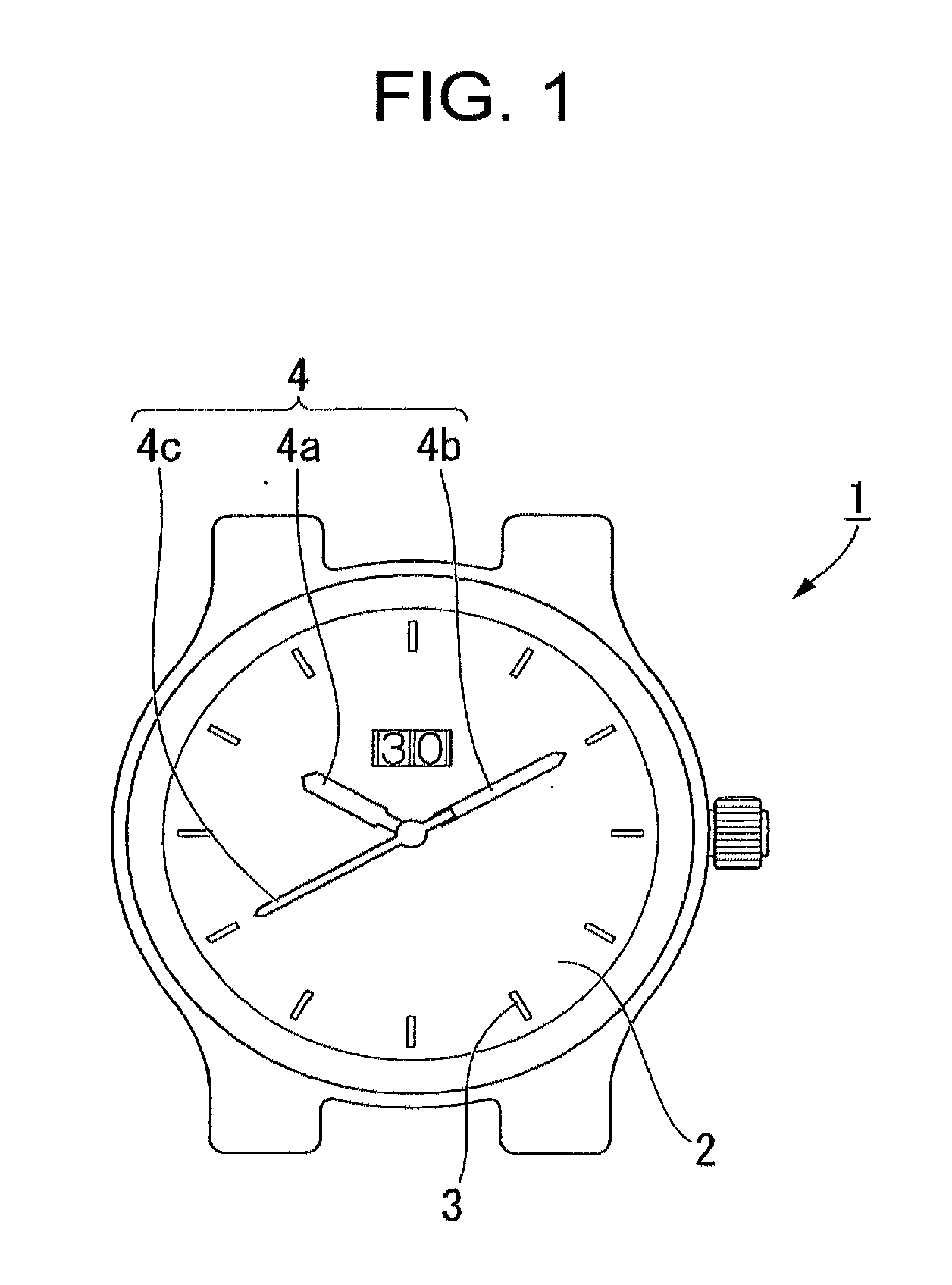

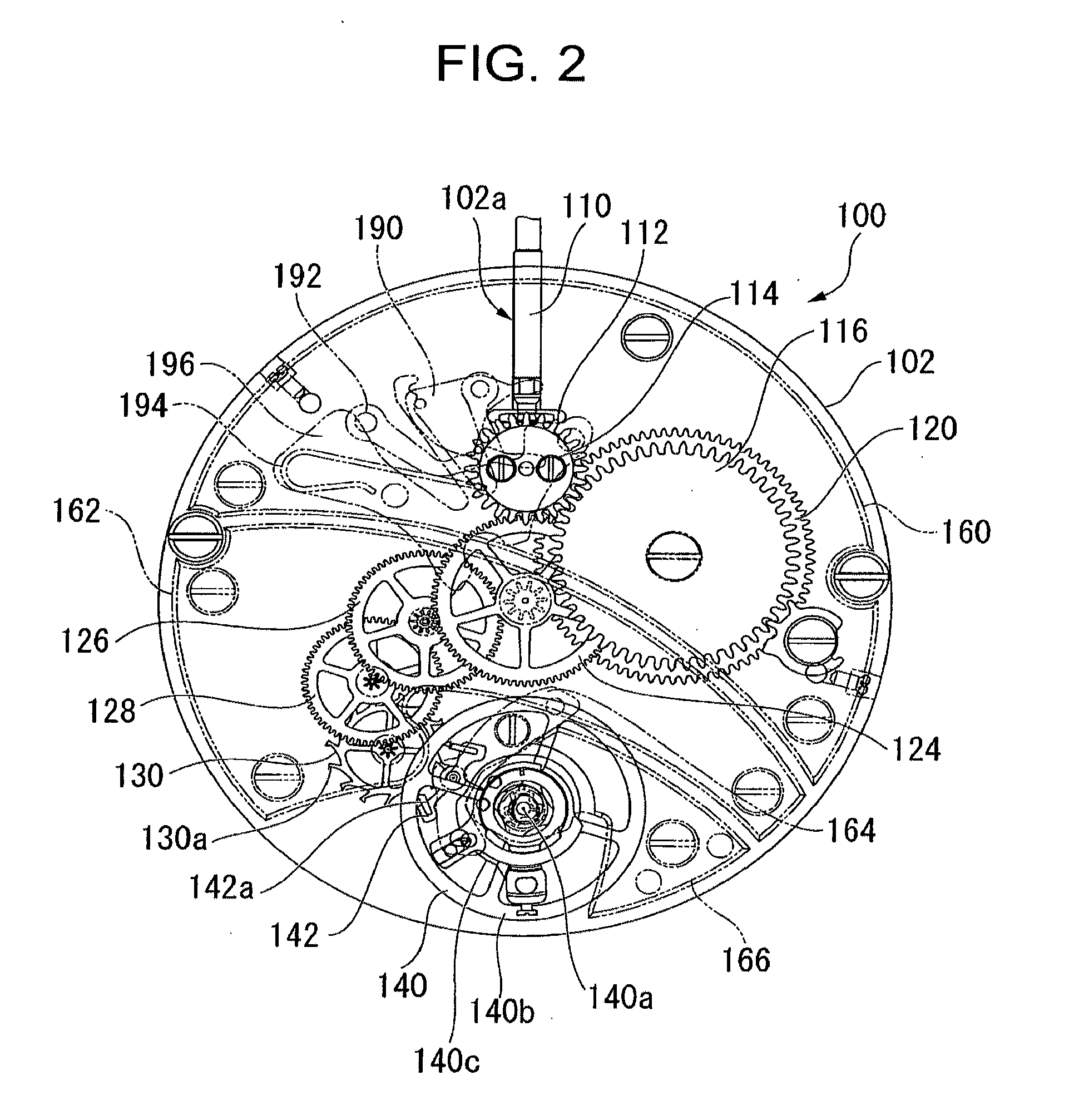

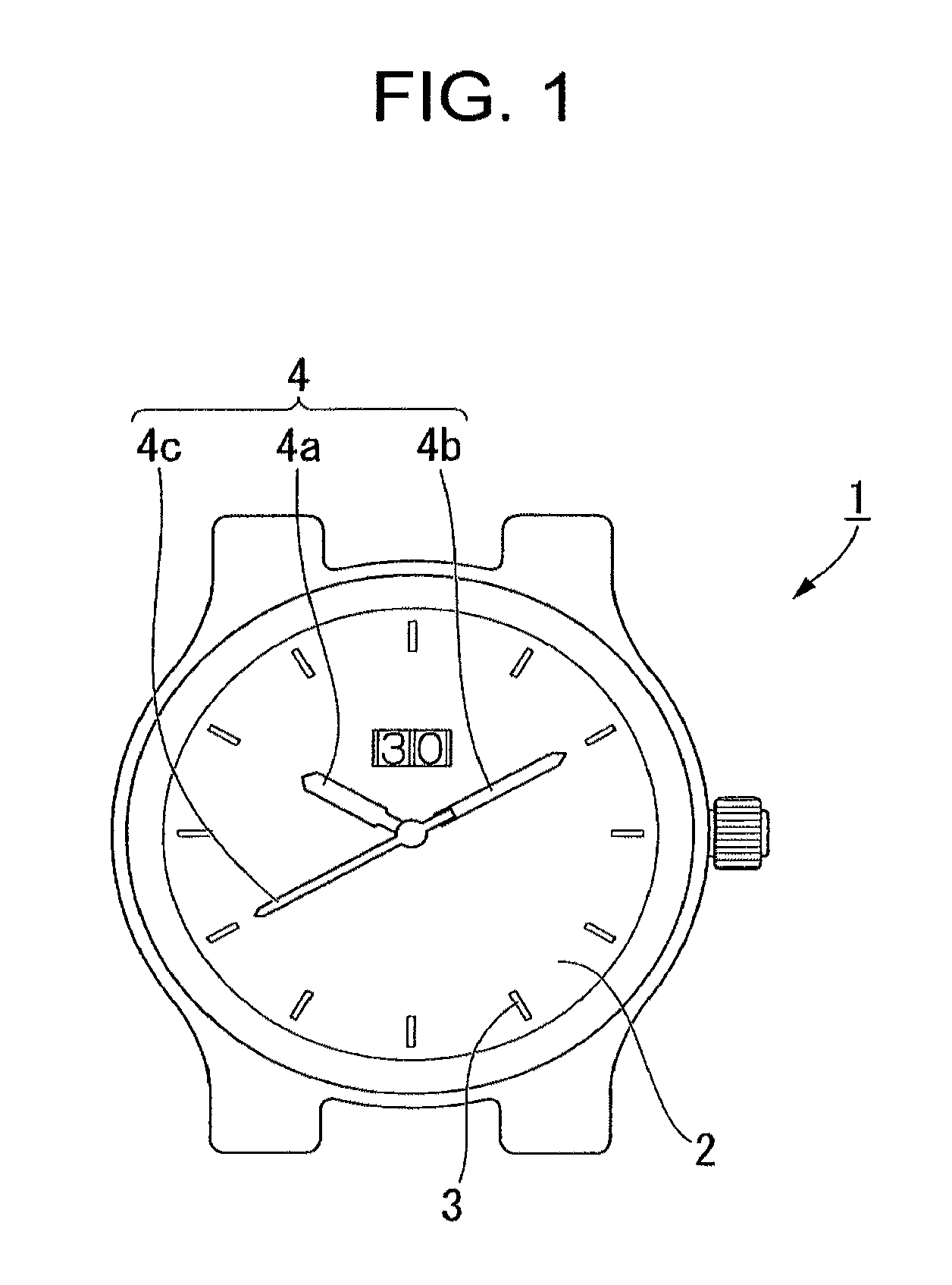

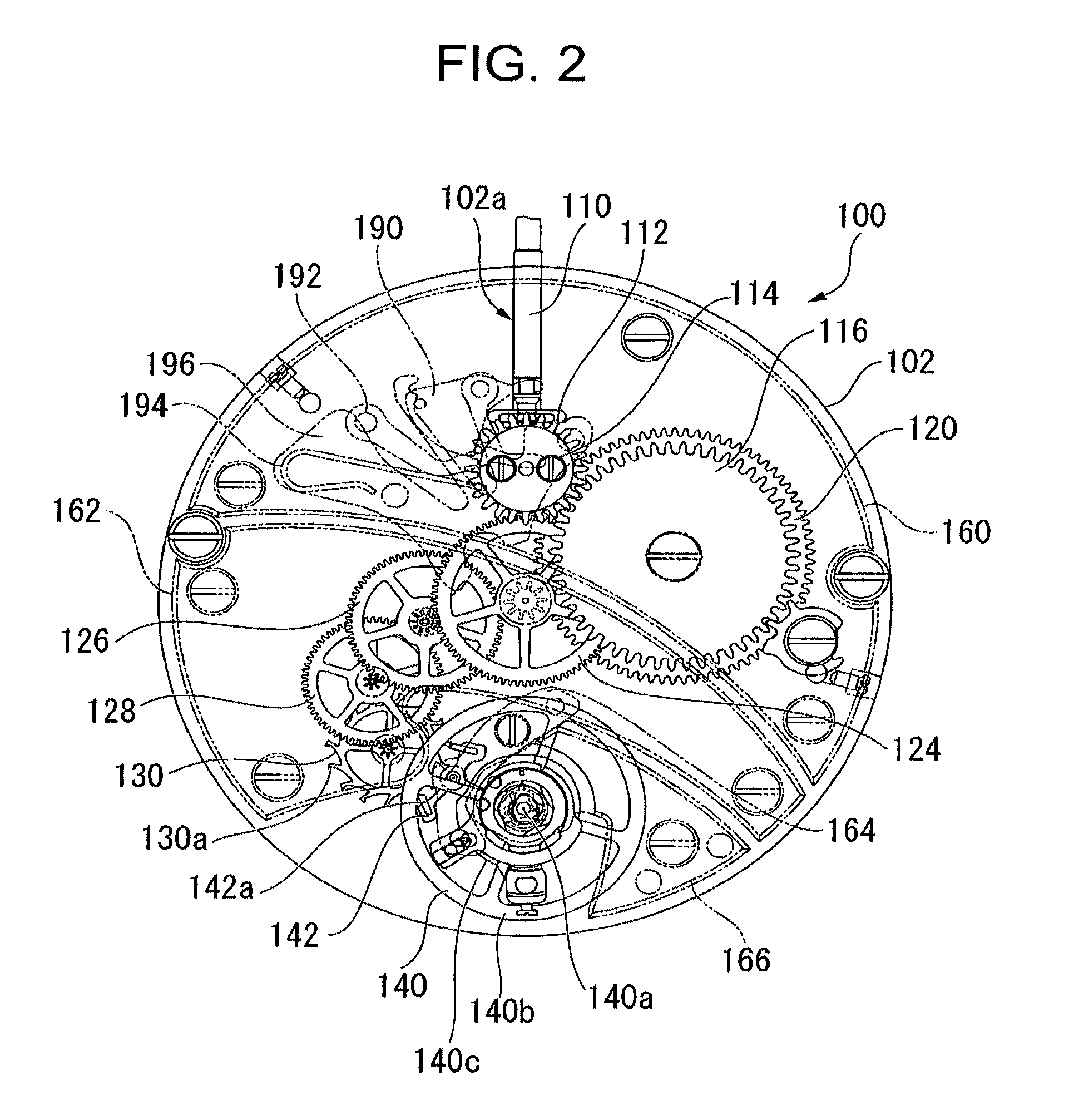

Manufacturing method of timepiece part and timepiece part

ActiveUS20120155228A1Small hardnessReduced dimensional accuracy requirementsVisual indicationGearworksAnodizingTitanium

A manufacturing method of a timepiece part which has small variation in hardness and a metallic luster is provided. Configuration includes a heat treatment process that heat-treats a timepiece part and coarsens a plurality of crystals of titanium or the like, a shape processing process that processes the shape of the timepiece part, an etching process that etches titanium or the like, mirror-finishes the surfaces of each crystal, and makes the normal directions of the surfaces of each crystal to be different from one another, and an anodizing process that performs anodizing on the surface of the timepiece part.

Owner:SEIKO INSTR INC

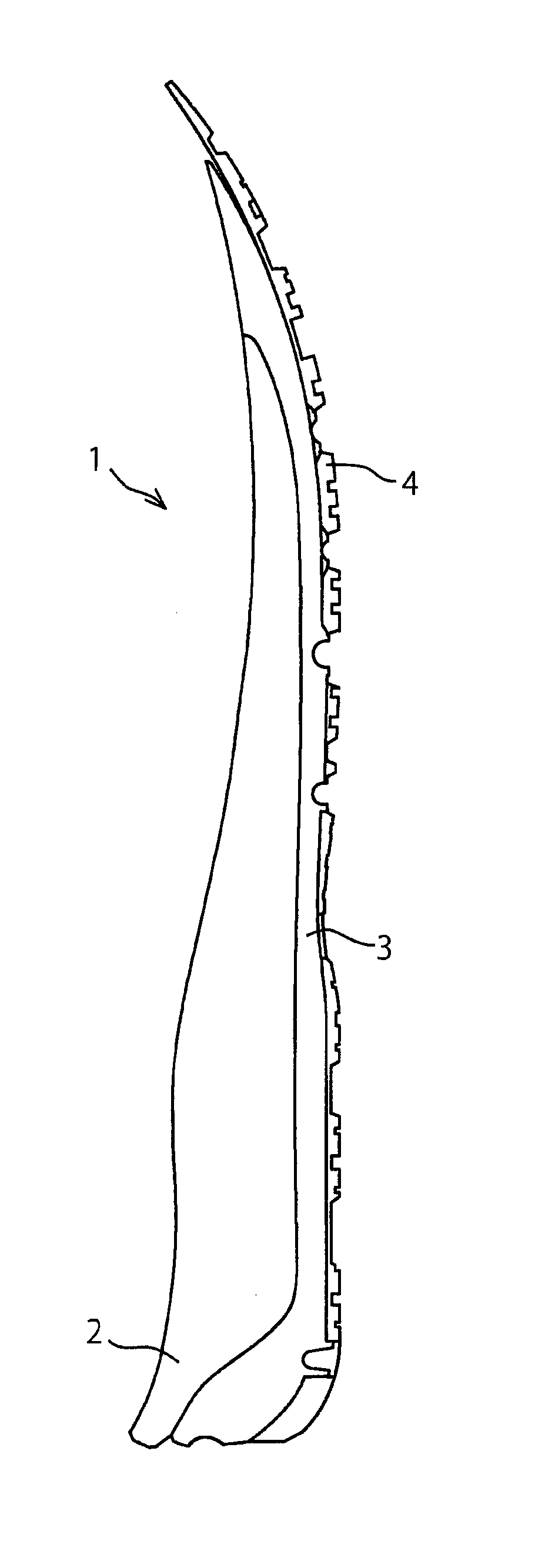

Midsole structure for a shoe

A midsole structure for a shoe not only maintains stability at the time of impacting the ground and improves cushioning property but also eliminates discomfort to a foot sole and improves ride feeling during running. The midsole structure (1) comprises at least two midsoles provided at a heel region of the shoe and having a hardness difference. On opposite sides of the heel region, an upper midsole (2) of a greater hardness has a thickness greater than a thickness of a lower midsole (3) of a smaller hardness. In a central part of the heel region, the lower midsole (3) of a smaller hardness has a thickness greater than a thickness of the upper midsole (2) of a greater hardness. Boundary surfaces (2B, 3A) between the upper midsole (2) and the lower midsole (3) do not appear on a top surface of the midsole structure (1) (that is, a foot sole contact surface (2A) of the upper midsole (2)).

Owner:MIZUNO CORPORATION

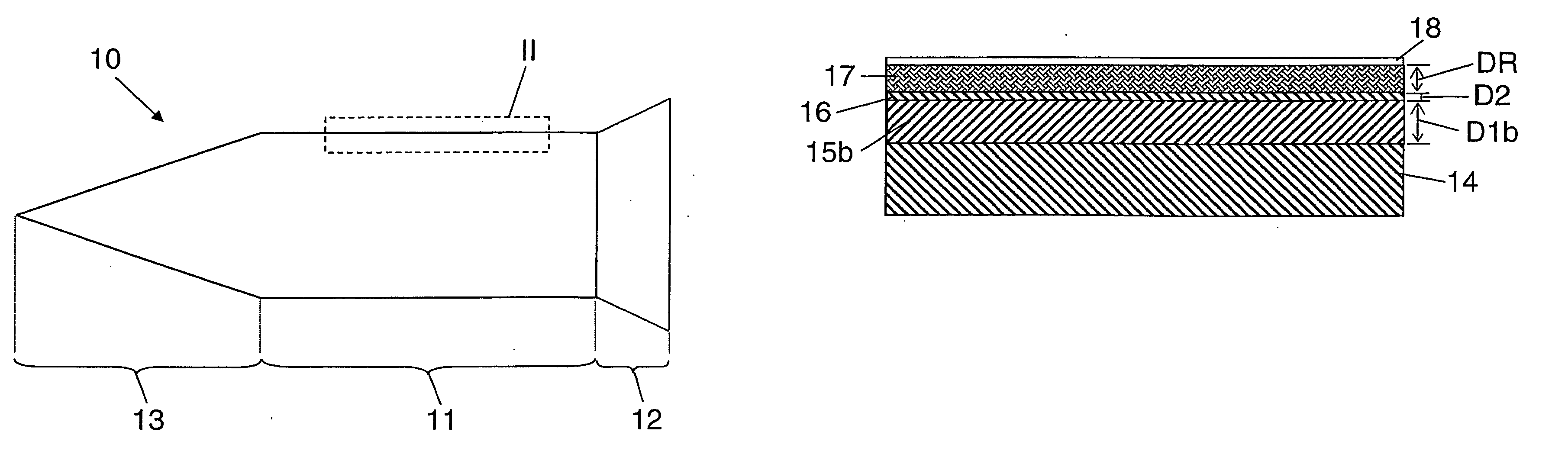

Fastening element

A fastening element has a core zone (14) formed of a relatively hard carbon steel, a skin zone (17) located outwardly of the core zone (14) and formed of a first low-carbon austenitic steel alloyed with a first alloy metal, and an intermediate zone (15a, 15b) provided between the core zone (14) and the skin zone (17) and formed of a second low-carbon steel having a smaller hardness than the steel the core zone (14) is formed of.

Owner:HILTI AG

Manufacturing method of timepiece part and timepiece part

ActiveUS9045832B2Small hardnessSuppressing a variation in the hardness of the timepiece partGearworksVisual indicationPolycrystalline materialMaterials science

Owner:SEIKO INSTR INC

Cushion pad

[Problem]To provide a cushion pad that allows reducing the oppressive feeling in a thigh and the sinking of buttocks and improving the texture and the fit feeling.[Solution]In a portion positioned underneath a hip point of a seated person, an under-buttock portion is set to have a smaller force S25 during compression to 25% in a second portion including a seating surface than S25 of the first portion positioned on a bottom surface side. The thigh supporting portion is set to have smaller S25 of a portion including the seating surface than S25 of the first portion. This allows reducing the oppressive feeling in the thigh and the sinking of the buttocks and improving the texture and the fit feeling.

Owner:TOKYO QUALITY ONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com