Patents

Literature

237results about How to "Reduce sinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

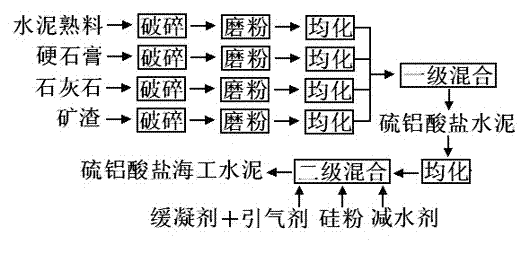

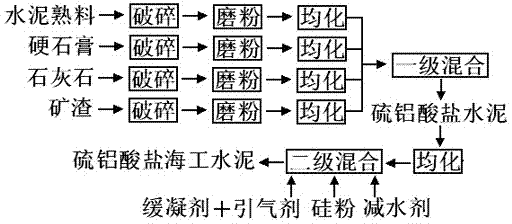

Sulphoaluminate maritime work cement and preparation method thereof

The invention discloses sulphoaluminate maritime work cement and a preparation method thereof. The sulphoaluminate maritime work cement comprises the following main raw materials in parts by weight: 50-80 parts of cement clinker, 8.0-20 parts of anhydrite, 0-30 parts of limestone, 0-30 parts of slag, 0.1-0.5 part of water reducing agent, 0.001-0.005 part of air entraining agent, 0.1-0.5 part of retarder and 2-5 parts of silicon powder. The preparation method comprises the following steps of: respectively smashing, grinding and homogenizing the sulphoaluminate cement clinker, the anhydrite, the limestone and the slag; then, burdening at a ratio, and evenly mixing; adding the water reducing agent, the air entraining agent, the retarder and the silicon powder; and mixing and homogenizing to obtain the product. The concrete mixed by the sulphoaluminate maritime work cement has the advantages of small bleeding rate and high slurry viscidity. The slurry has strong covering and supporting action on aggregate. The concrete keeps good homogeneity and has the advantages of hard and quick early strength, continuously-increased later strength, good slurry structure compactness and high volume stability and is convenient to use and operate for constructing.

Owner:广西云燕特种水泥建材有限公司

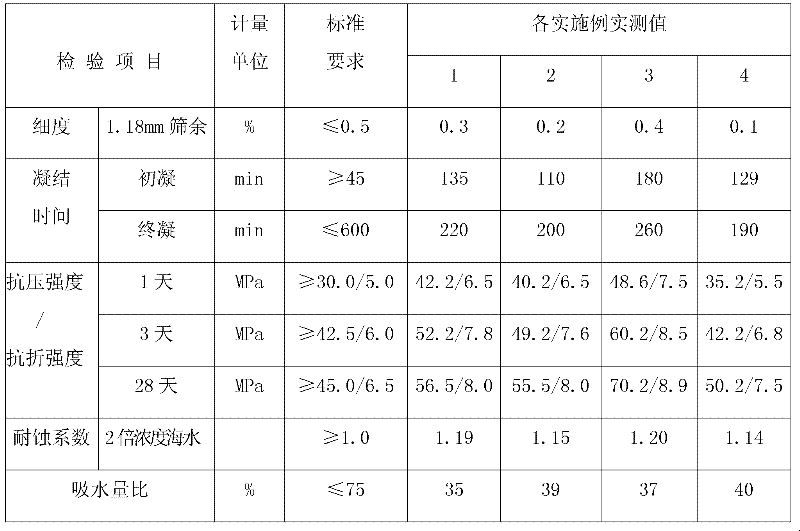

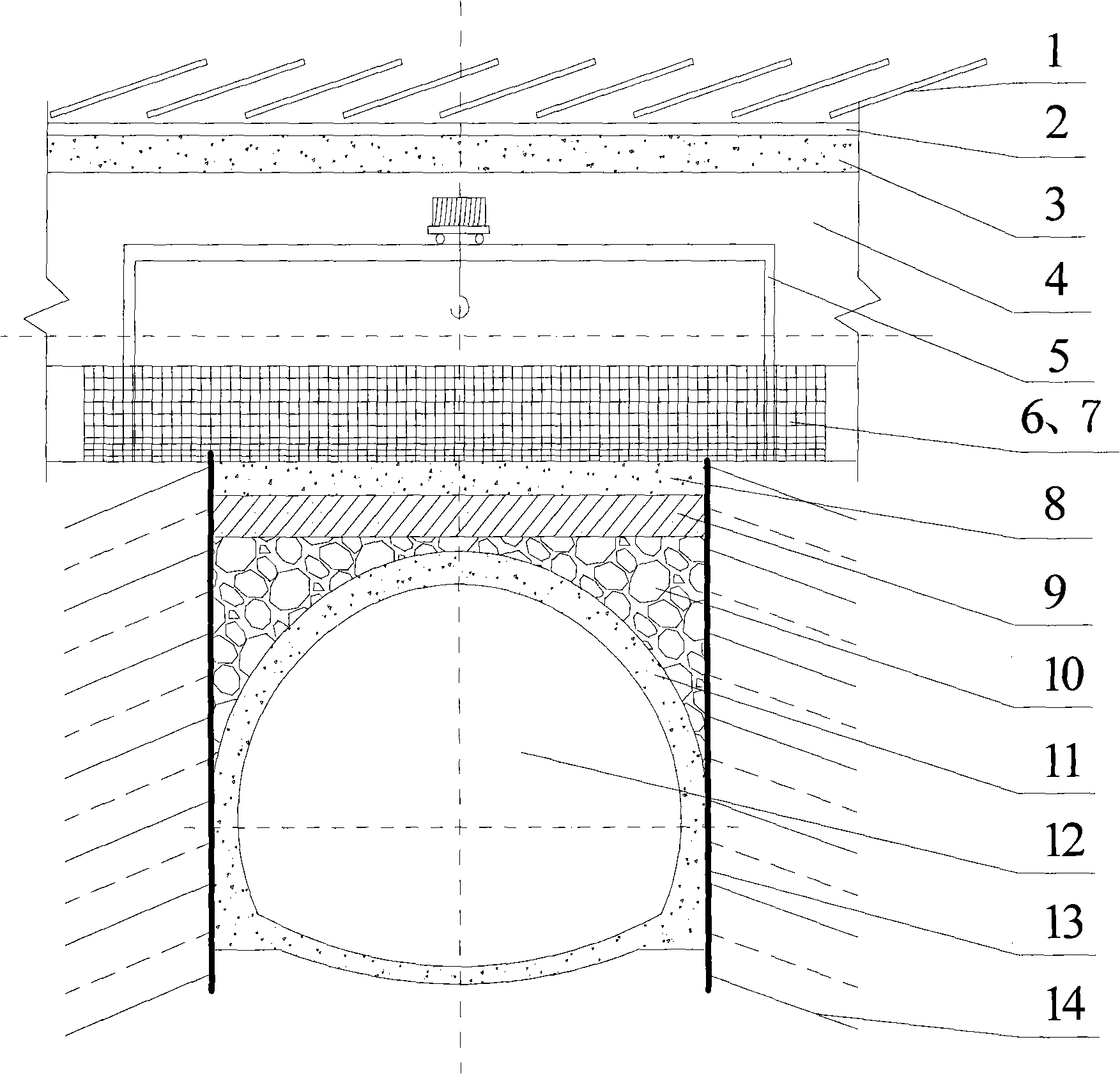

Settlement control method for shallow large-section loess tunnel

InactiveCN102345460AReduce the impactControl land subsidenceUnderground chambersTunnel liningEngineeringLoess

The invention provides a control method for a shallow large-section loess tunnel. The method solves the problem of disorder of the conventional settlement control method for the shallow large-section loess tunnel. The method comprises the following steps of: determining a settlement control standard, and formulating a settlement management value; performing construction by adopting a double side wall pilot drift method, namely digging left and right side pilot tunnels, digging an upper step and a middle step on each side, digging an upper step, a middle step and a lower step on a middle pilot tunnel, reserving core soil during digging the side pilot tunnels and the middle pilot tunnel, and finally digging an inverted arch; implementing an advanced support method of a double-layer big tube shed and small conduits; and implementing a primary support method for arch foot reinforcement, wherein the arch foot reinforcement comprises a step of setting a lock pin anchor tube and a large arch foot. Compared with the similar tunnel surface settlement control method, the method has the advantages of effectively controlling the stability of a heading side, reducing the influence of construction on the ground surface, effectively controlling the ground surface settlement, simplifying the construction process and improving the efficiency.

Owner:BEIJING JIAOTONG UNIV

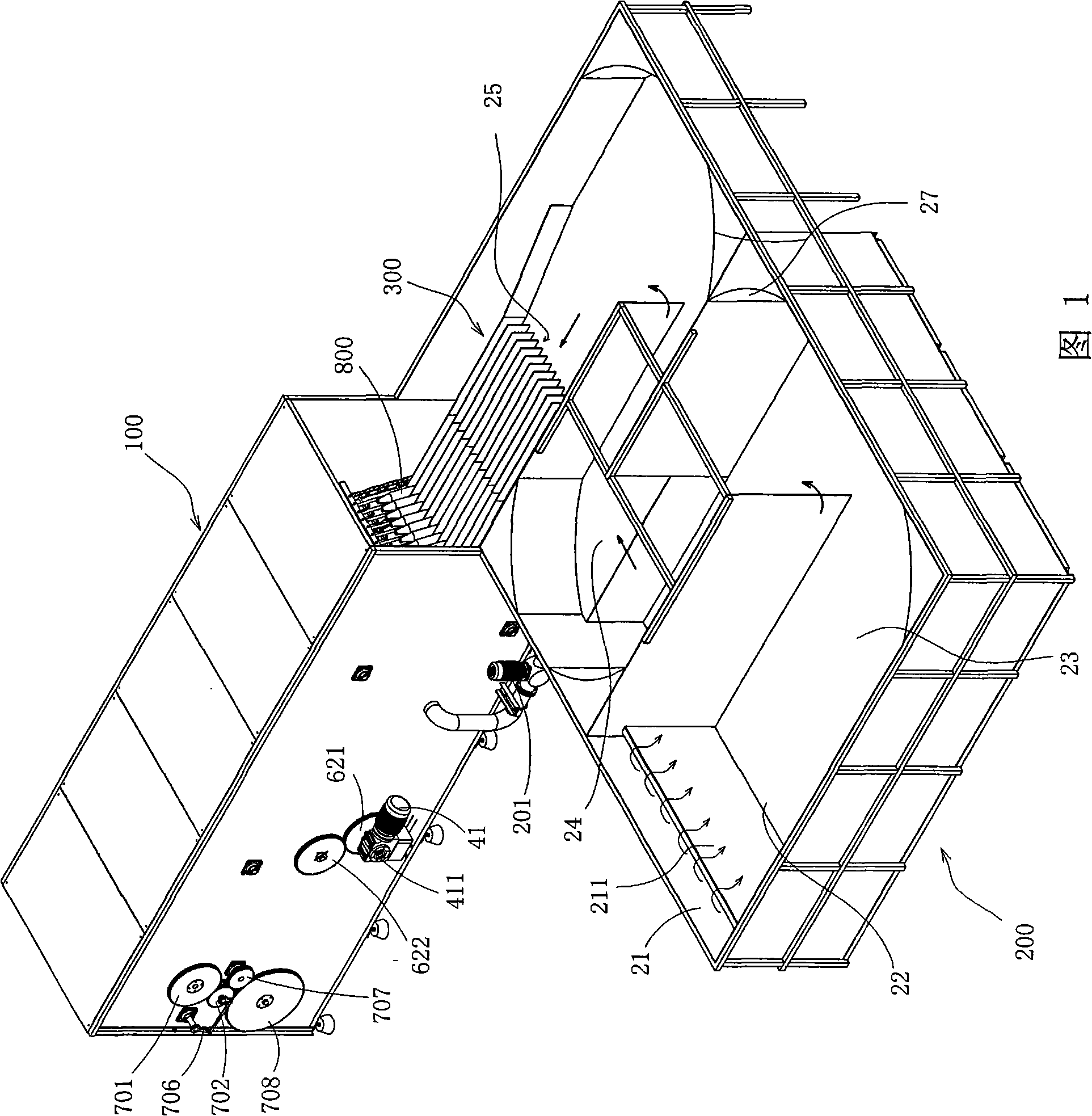

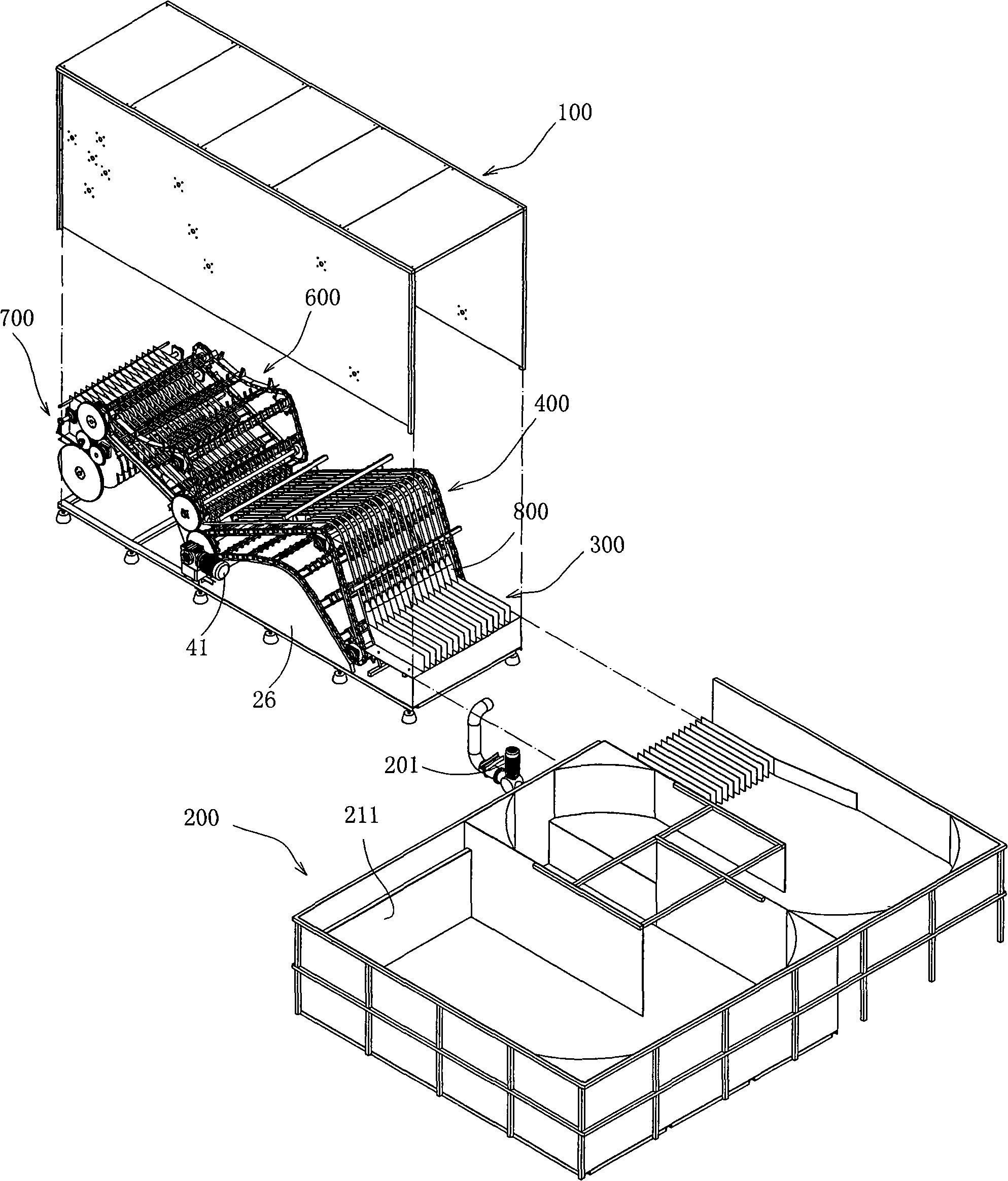

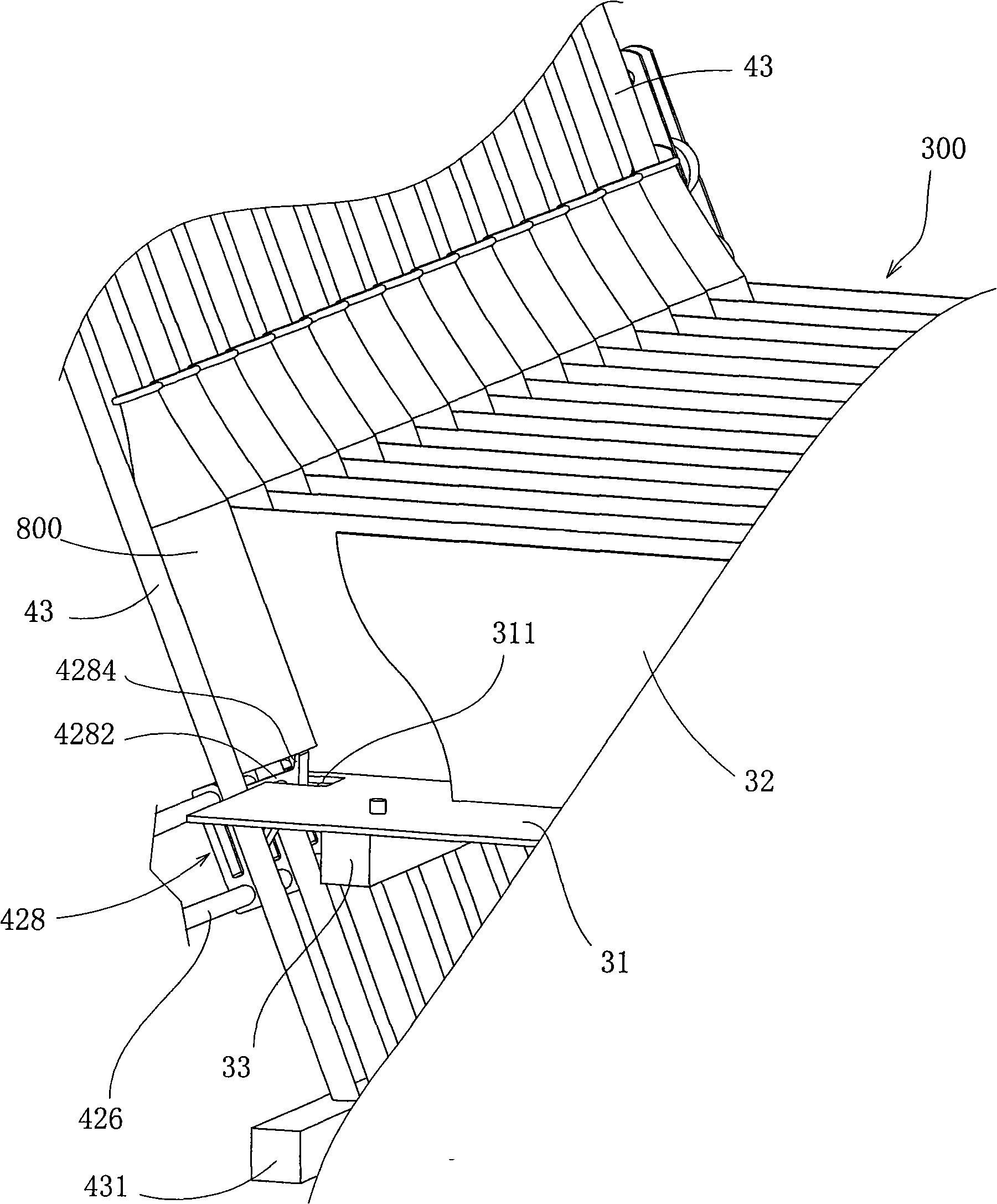

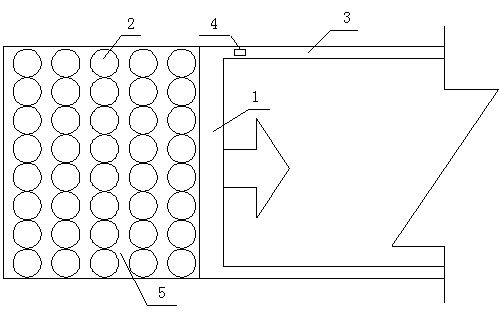

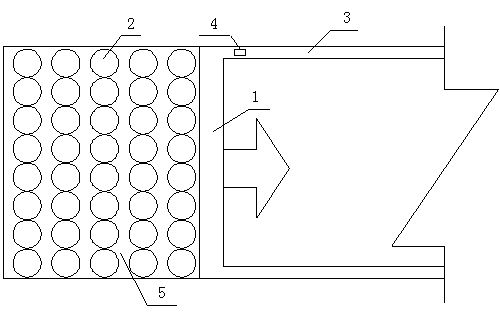

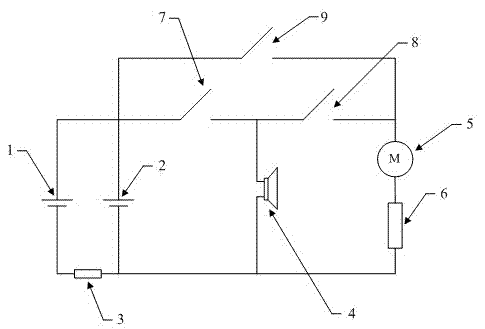

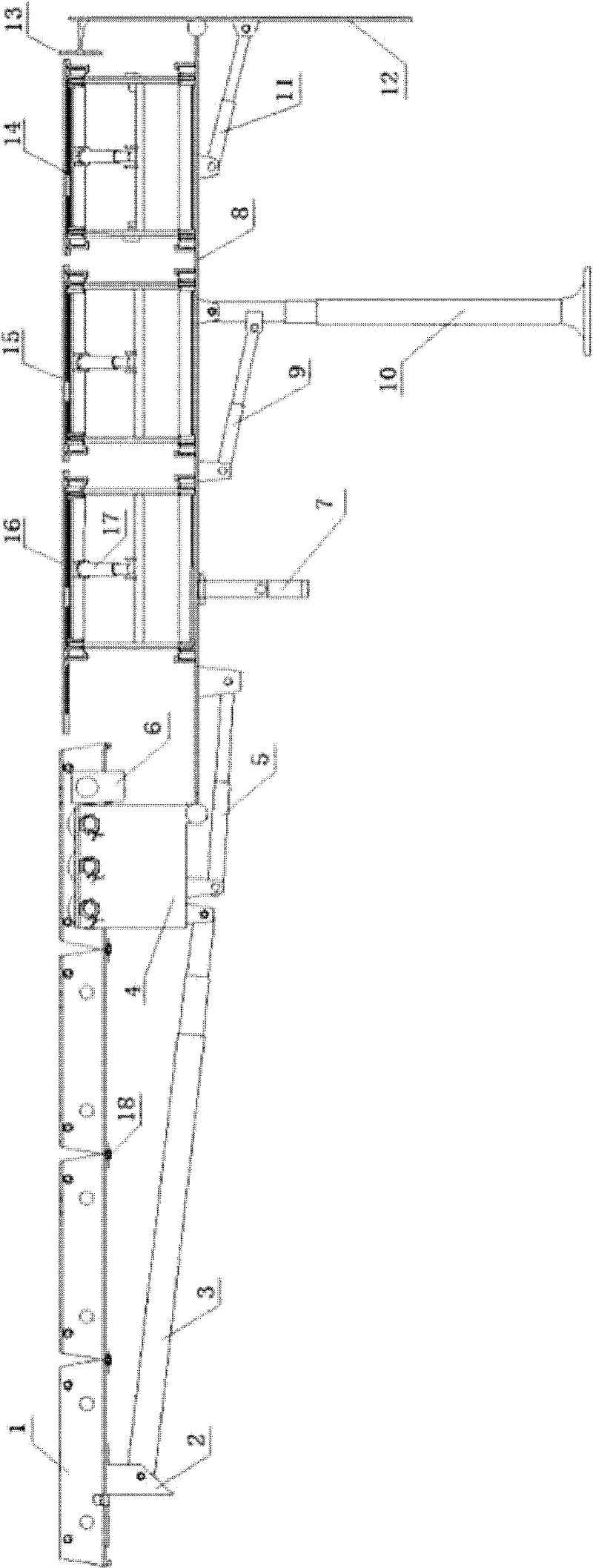

Unscrambling method and unscrambler utilizing the unscrambling method

InactiveCN101284597ASmooth floating motionReduce sinkingLiquid bottlingConveyor partsLiquid cellEngineering

The invention discloses a bottle arranging method and a bottle arranging machine thereof; a pump (201) is used for pumping liquid at the tail part of a liquid cell (200), a conveying pipe is used for conveying the liquid to the front end of the liquid cell for forming circular flowing stable liquid flow in the liquid cell; open-ended glass bottles (800) to be arranged are randomly arranged in theliquid cell; after the glass bottles are poured with certain amount of liquid, bottle openings automatically face up and lead the bottles to float on the liquid, the bottles are carried by the liquidflow to a track lane mechanism (300) and automatically array orderly into a plurality of lines; a bottle raising mechanism (400) raises the bottles from the front end of the track lane mechanism lineby line and carries the bottles to a liquid poring mechanism; the liquid in the bottle is poured out; the glass bottles are reversed to enable the bottle opening to turn vertically or obliquely upwards and vertically fall on a transitional board so as to be linked up with the next working procedure. As stable liquid flow is adopted, the glass bottles can stably float and the liquid pouring is more stable, thus better ensuring the bottle openings to vertically turn upward and float, reducing sinking, avoiding disordered collision of the glass bottles as well as reducing damage; moreover, the labor intensity and the cost are greatly reduced and the efficiency is improved.

Owner:杨晖伟

Filling and mining method of coal gases

InactiveCN102155225ALow costWide variety of sourcesUnderground miningSurface miningMining engineeringHigh pressure

The invention relates to a filling and mining method of coal gases, comprising the following steps: arranging a gas pressurization room on the ground and then arranging an underground gas booster pump connected with a ground high-pressure gas storage tank pipeline in a mining region haulage way in front of an underground coal mining working face; distributing a row of cylindrical rubber airbags in a gob behind the coal mining working face when the coal mining working face is advanced for 5-8 m from the open-off cut; filling gas into the cylindrical rubber airbags till the top is tight; sealing the openings of the cylindrical rubber airbags to finish filling gas into one cylindrical rubber airbag; continuously distributing a row of cylindrical rubber airbags behind the row of gas-filling cylindrical rubber airbags when the coal mining working face is advanced for each step along with the continuous advance of the coal mining working face and charging gas in rows till finishing the gas filling and supporting in the whole gob. In the invention, the filling method is simple, the gas filling speed is high, the cost is low and the filling capacity is great, and the method is convenient for onsite underground operation.

Owner:CHINA UNIV OF MINING & TECH

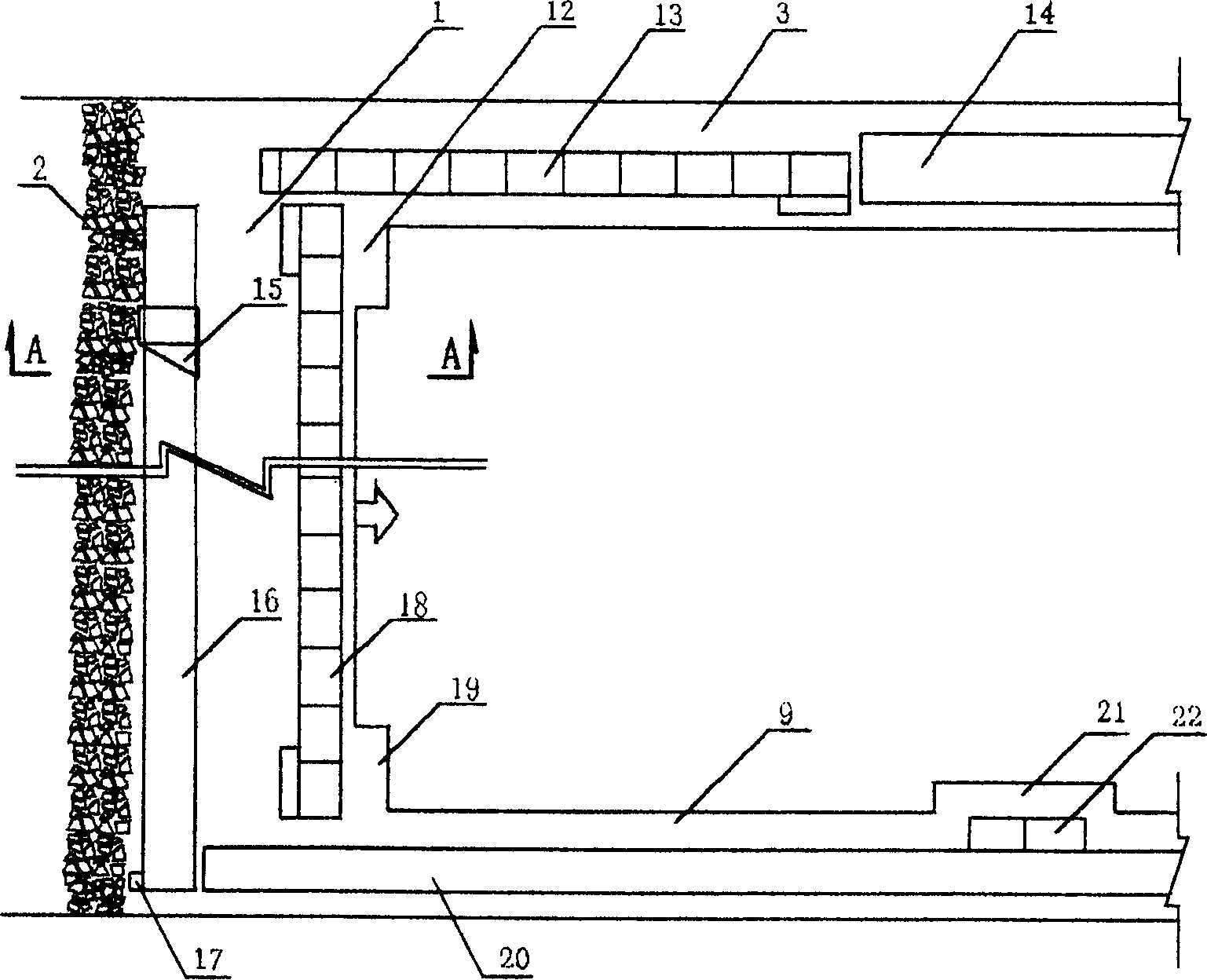

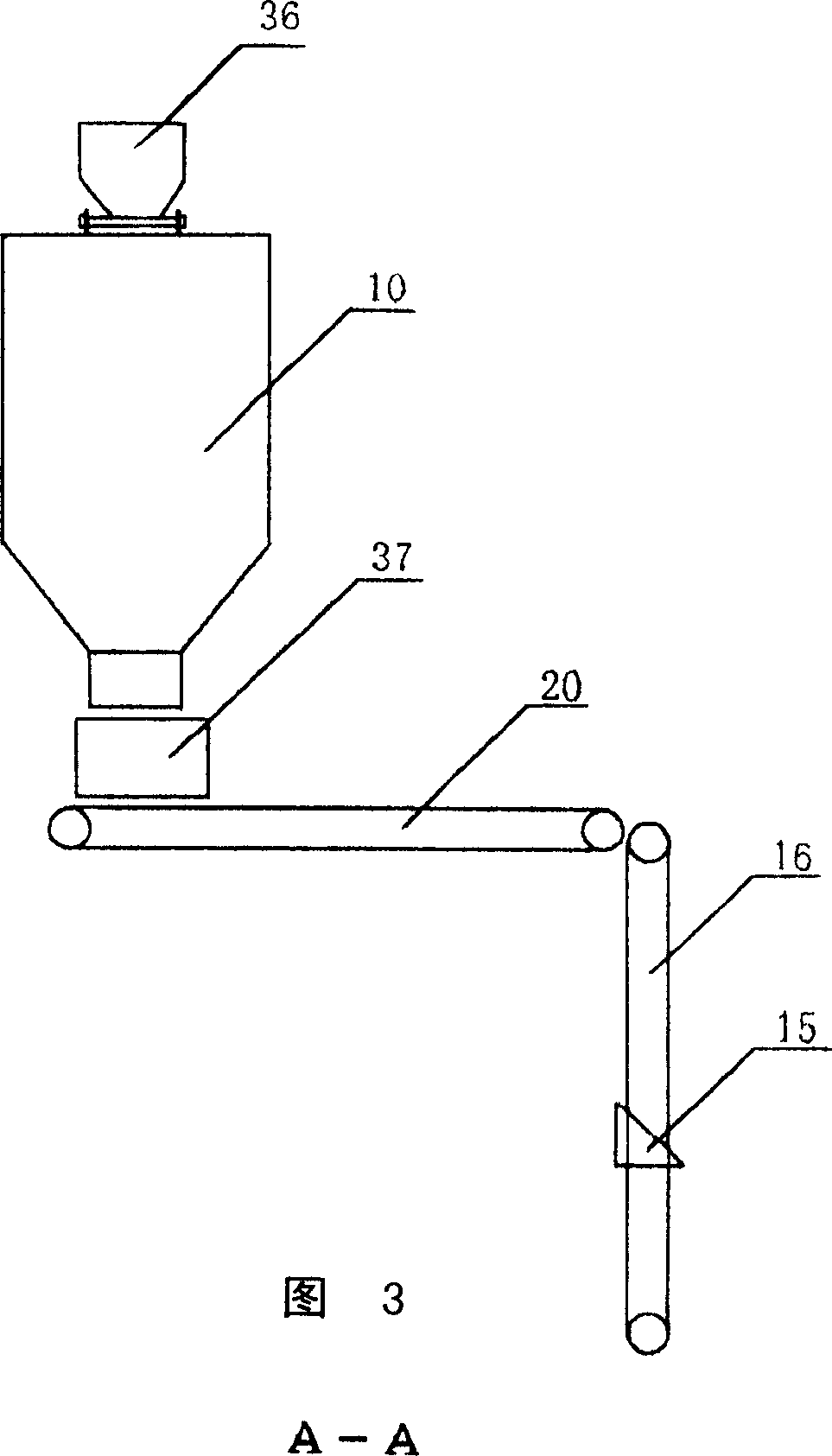

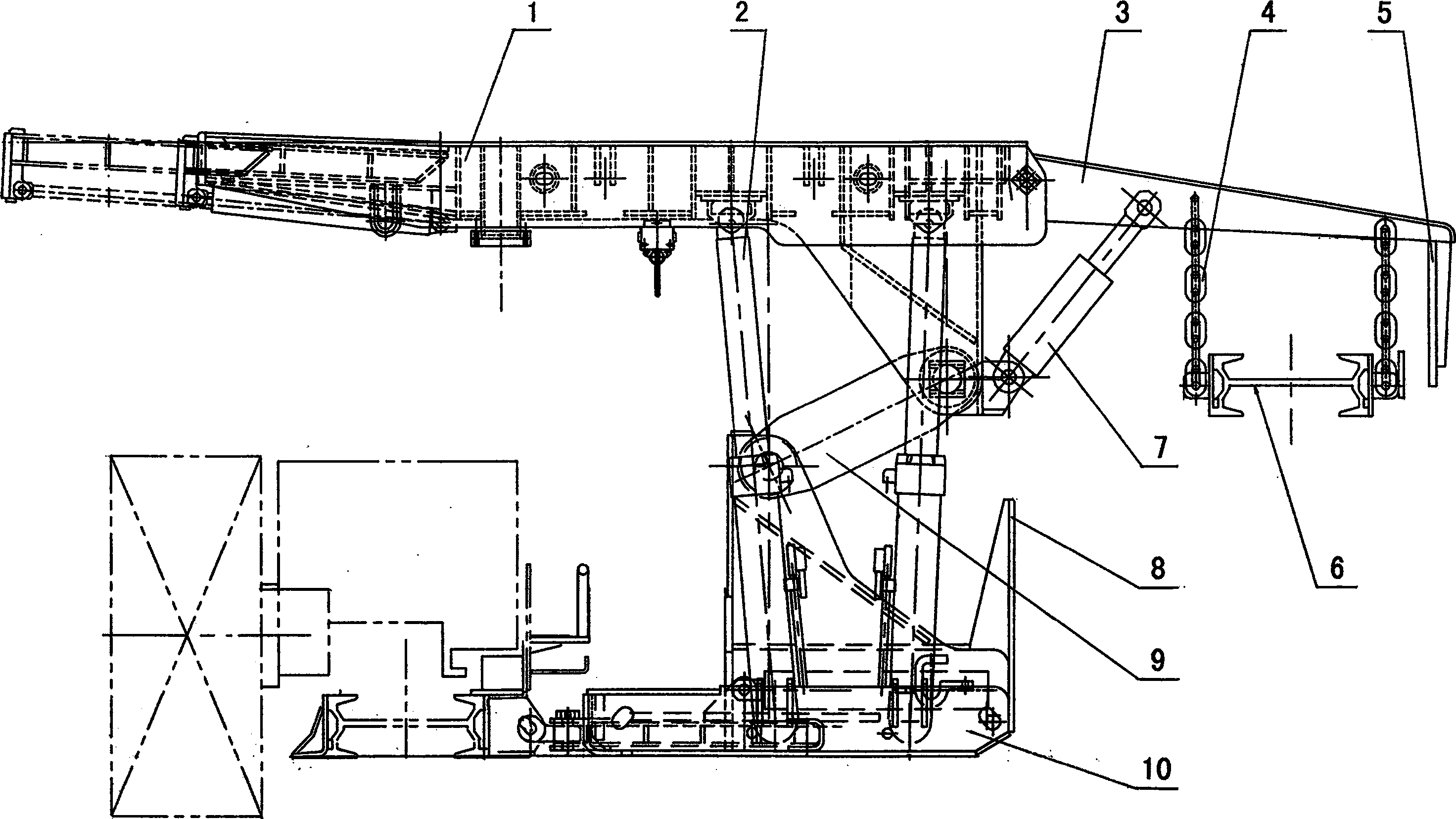

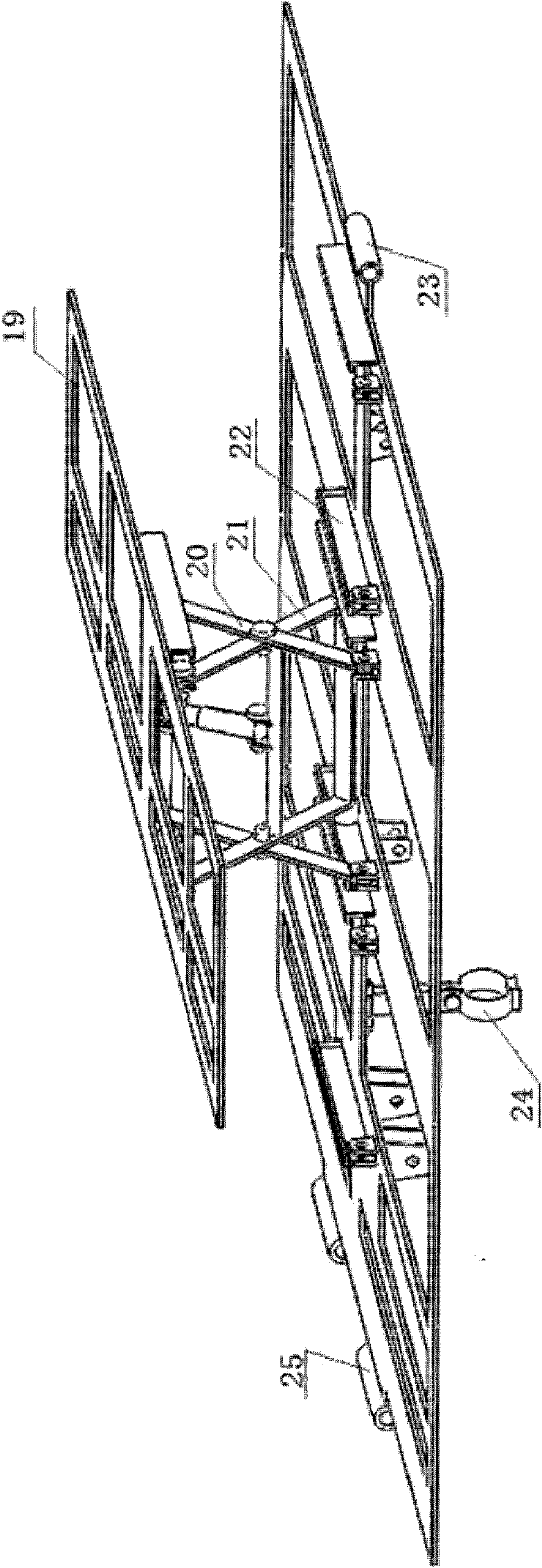

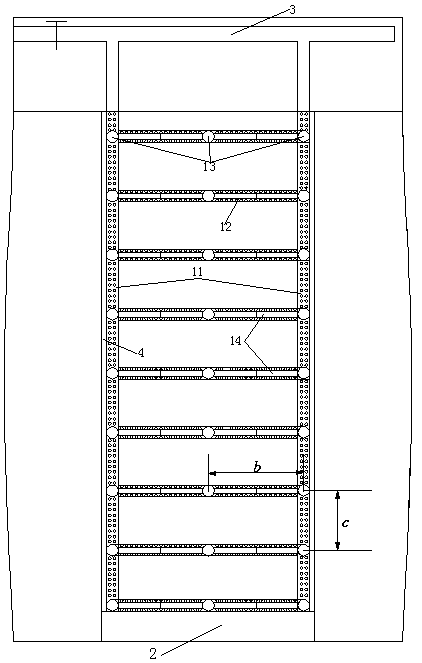

Method for filling goaf by gangue

The invention relates to a method for using stone to fill the worked-out section under the coal well, which arranges a stone bin (10) outside the working surface to transfer the under-well stone or the ground stone to the stone bin (10) to be broken by the breaker; and using the stone belt machine (20) on the producing surface to transfer them to the upper end of producing surface (1); the producing surface (1) is supported by the filling brackets or the brackets whose back have extending beams; when the bracket is self-motion type, suspending a small belt device (16) on the extending beam and moving ahead with the bracket; when the bracket is not self-motion type, the small belt device (15) is arranged at the bottom plate under the extending beam and using slide device to move ahead; the small belt device (16) is mounted with a self-motion stone unload cart (15); transferring the small belt device (16) to the upper end of producing surface to unload the stone to the worked-out section. The invention can reduce the earth sink, effectively treat the stone, and reduce the accommodation area of stone and the pollution, with simple device and lower cost.

Owner:新汶矿业集团汶南煤矿有限责任公司

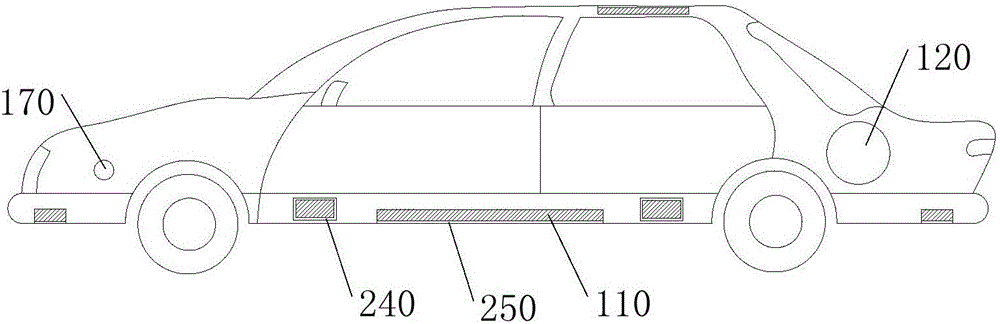

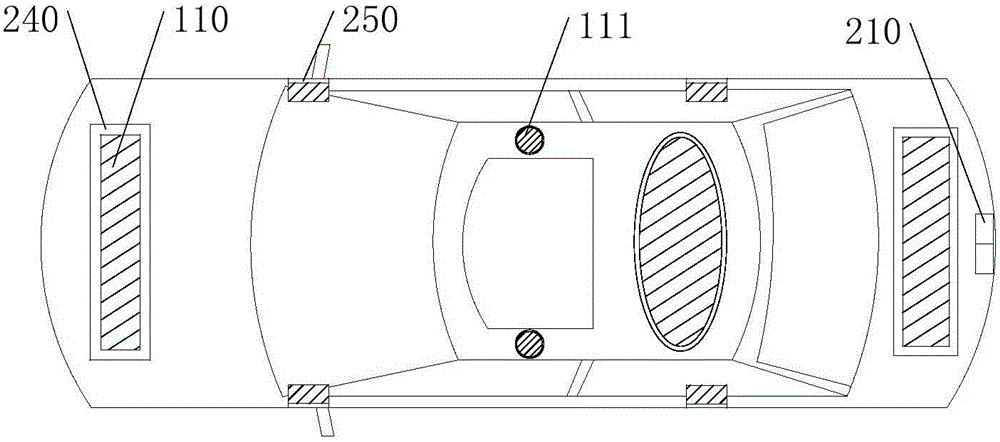

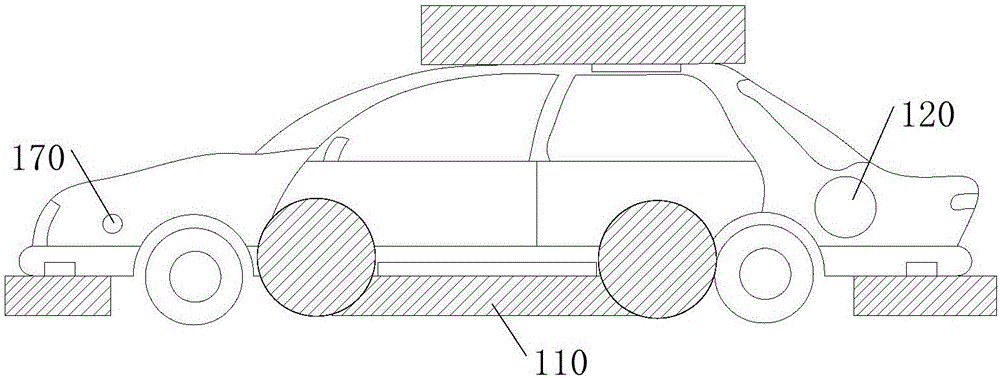

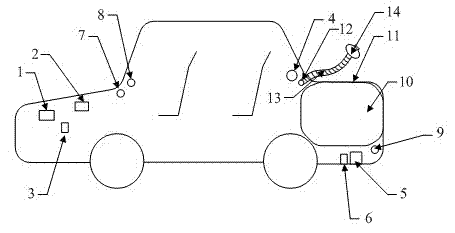

Anti-settling protection device and automobile

PendingCN106740629AAlleviate underinflationAlleviate problems caused byLife-buoysPedestrian/occupant safety arrangementElectricityEngineering

The invention provides an anti-settling protection device, and relates to the technical field of automobile security devices. The anti-settling protection device comprises an air storage tank and a plurality of air bags, wherein the air bags are arranged at the chassis, top and two sides of the automobile, and all communicate with the air storage tank via air-guide tubes; an inflation control valve is arranged on each air-guide tube, and electrically connected with an automobile controller; and a water detection element is arranged on the automobile chassis, and electrically connected with the automobile controller. The invention also discloses an automobile comprising an automobile body and an anti-settling protection device installed on the automobile body. By installing the settling protection device on the automobile body, the inflation device can be started before the automobile falls into water or after the automobile falls, so that the air storage tank can inflate each air bag, the automobile can be lifted up or reduced in settling speed under the effect of buoyancy of water, and thus life security of personnel in the automobile is ensured.

Owner:周小平

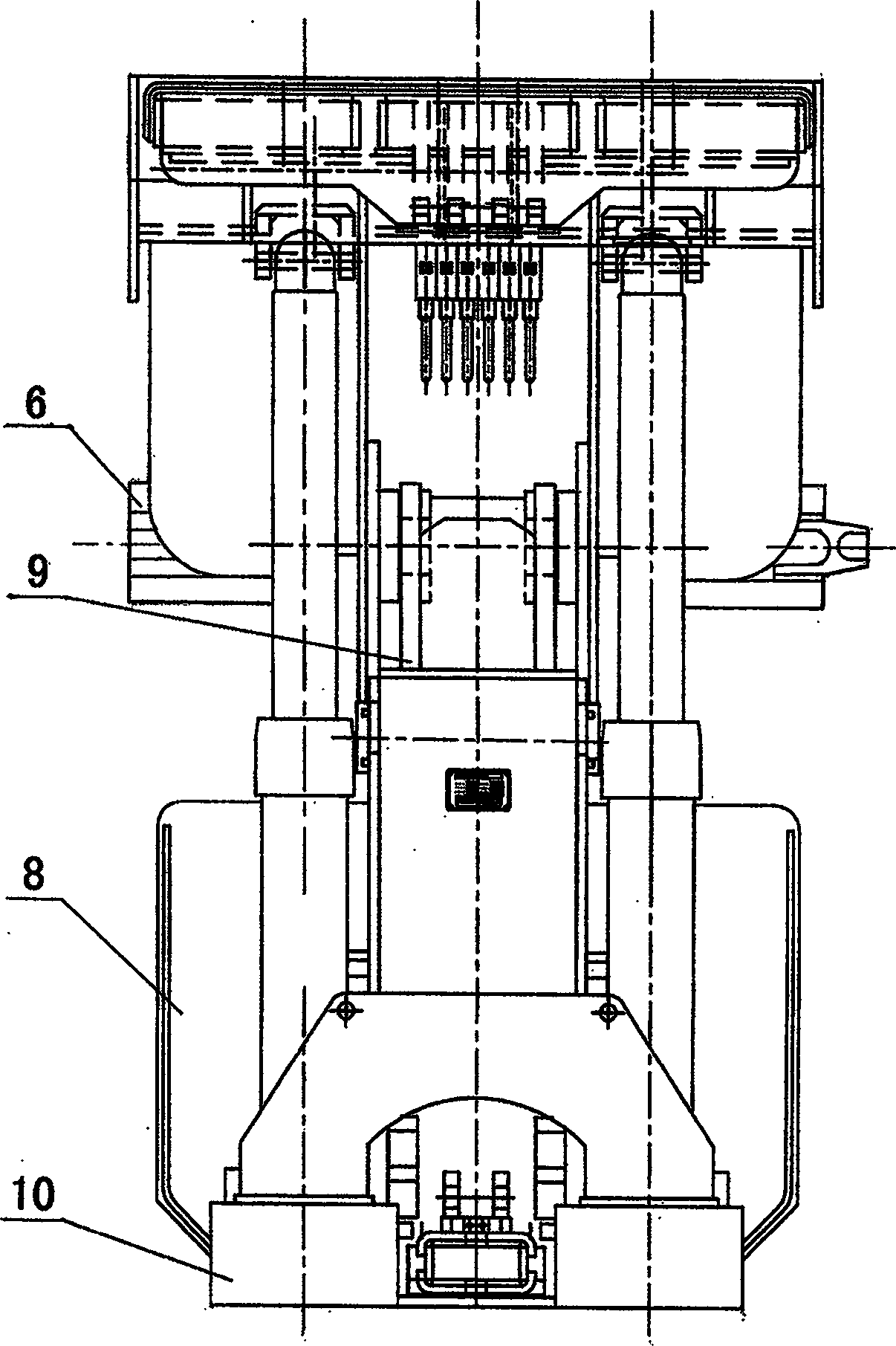

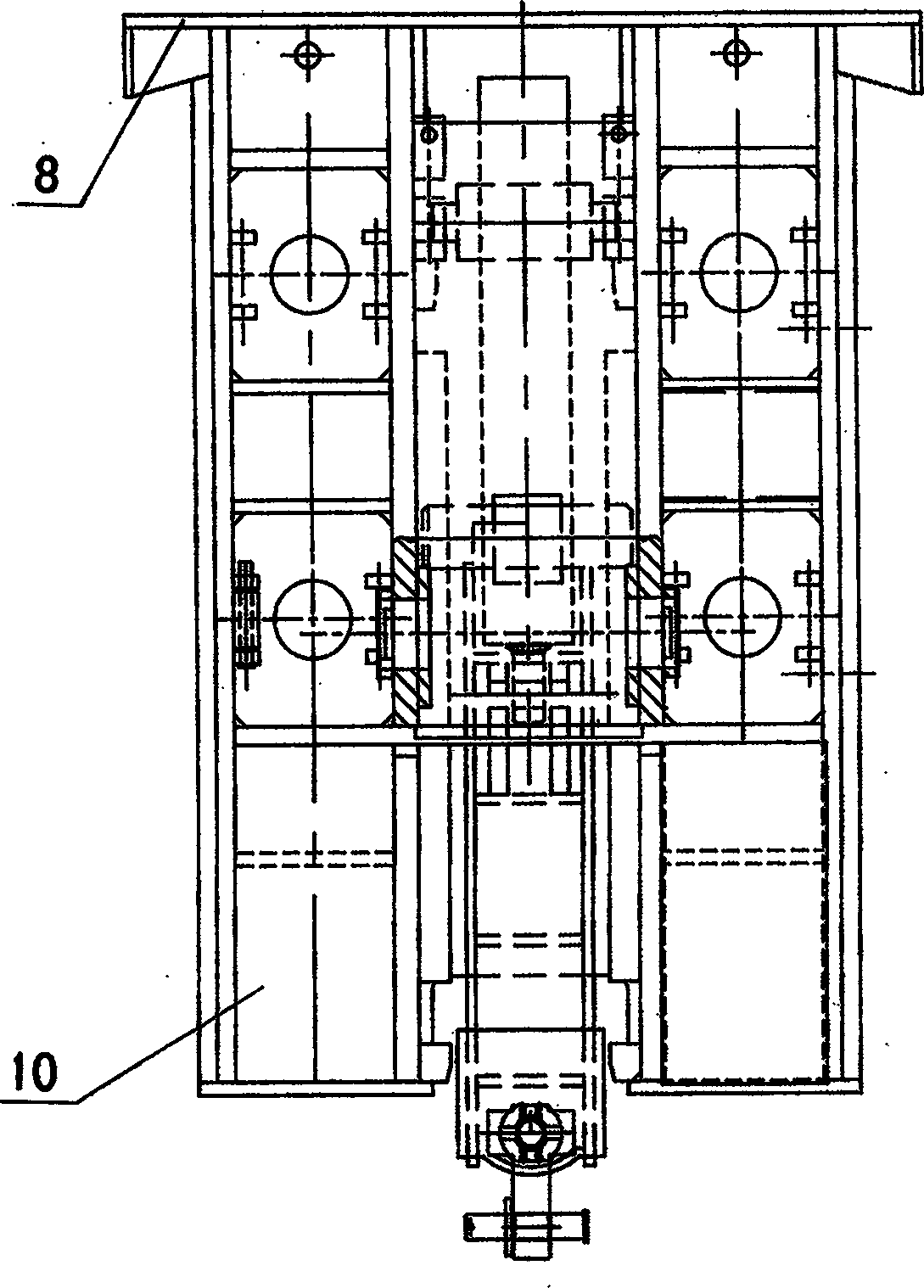

Hydraulic support for filling waste rock

A hydraulic frame for filling waste rock is composed of top beam, vertical column, base, tail beam, jack of tail beam and scraper conveyor chute suspended under tail beam. It is featured as opening waste rock leaking hole on frid of suspension chute, connecting suspension chutes to each other in sequence then connecting them with chute head and chute end at working face to form a complete set of scraper conveyor.

Owner:佟强

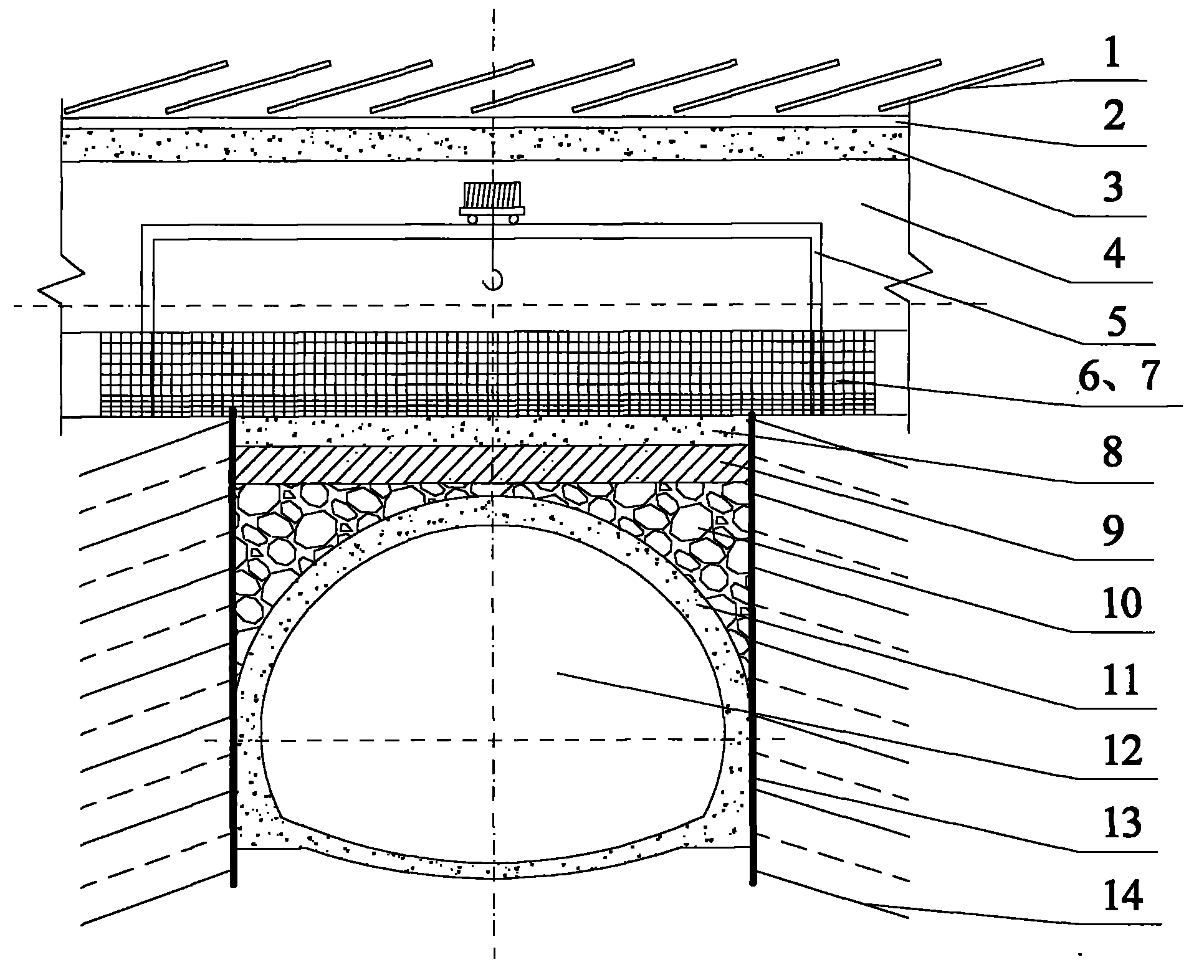

Zero spacing construction method for overlapping part of upper main tunnel and lower main tunnel of underground overpass

InactiveCN101775987AAvoid influenceAvoid secondary perturbationUnderground chambersMaterial fill-upReinforced concreteRebar

The invention discloses a zero spacing construction technical method for an intersecting and overlapping part of an upper main tunnel and a lower main tunnel of an underground overpass, which belongs to construction technologies of tunnel engineering. The method comprises four procedure steps of: (1) excavating and supporting an upper-layer tunnel CRD (cross diaphragm) and strengthening the construction of reinforced concrete edge beams; (2) excavating and supporting a base pit of a lower-layer tunnel; (3) carrying out secondary lining construction outside the lower-layer tunnel; and (4) refilling the upper part of the secondary lining outside the lower-layer tunnel. The invention realizes the technical method which does not retain soil mass at the intersecting and overlapping part of the upper-layer main tunnel and the lower-layer main tunnel of the underground overpass and finishes the construction of the excavation and the support structure of the upper main tunnel and the lower main tunnel of an intersecting section in one step and solves the problems of structure influence to early built tunnel by the late built tunnel and the secondary disturbance to the ambient soil mass which are caused by the upper penetration or lower penetration due to the early and late construction of the upper main tunnel and the lower main tunnel.

Owner:BEIJING JIAOTONG UNIV

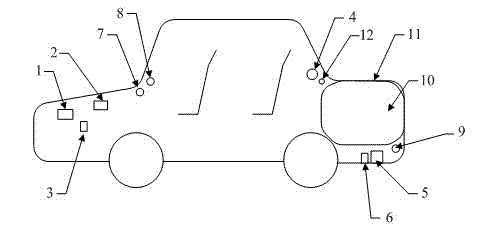

Method and device for anti-sinking of automobile falling into water

InactiveCN102259626AReduce sinkingSimple structurePedestrian/occupant safety arrangementAirbagFall into water

The invention relates to a method and device for preventing an automobile which falls into water from sinking. A supercharging device and a vacuum supplementary restraint system are arranged in a boot of the automobile, and the vacuum supplementary restraint system in the boot of the automobile is connected with a main supplementary restraint system and a secondary supplementary restraint system of a common cab at the front of the automobile into a whole. When the automobile falls into water, the vacuum supplementary restraint system in the boot is aerated and the main supplementary restraintsystem and the secondary supplementary restraint system of the cab are simultaneously rapidly aerated by virtue of the supercharging device; and the vacuum supplementary restraint system in the boot fills in the boot after being aerated so as to prevent water from entering, and the vacuum supplementary restraint system as well as the main supplementary restraint system and the secondary supplementary restraint system provide a buoyancy force to an automobile body, thus the automobile body is delayed from sinking. The head of an air inlet pipe of the supercharging device is provided with an elastic hose and a float, thus an air inlet pipe orifice of the supercharging device can be guaranteed to be always above water surface. The vacuum supplementary restraint system adopted in the invention is expanded by virtue of the supercharging device and a certain pressure is produced, and a gap of the sealed boot is effectively filled, so that water is prevented from entering, a certain buoyancyforce is produced, and the automobile is delayed from sinking, thus being beneficial to rapid and efficient fixed-point rescue.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

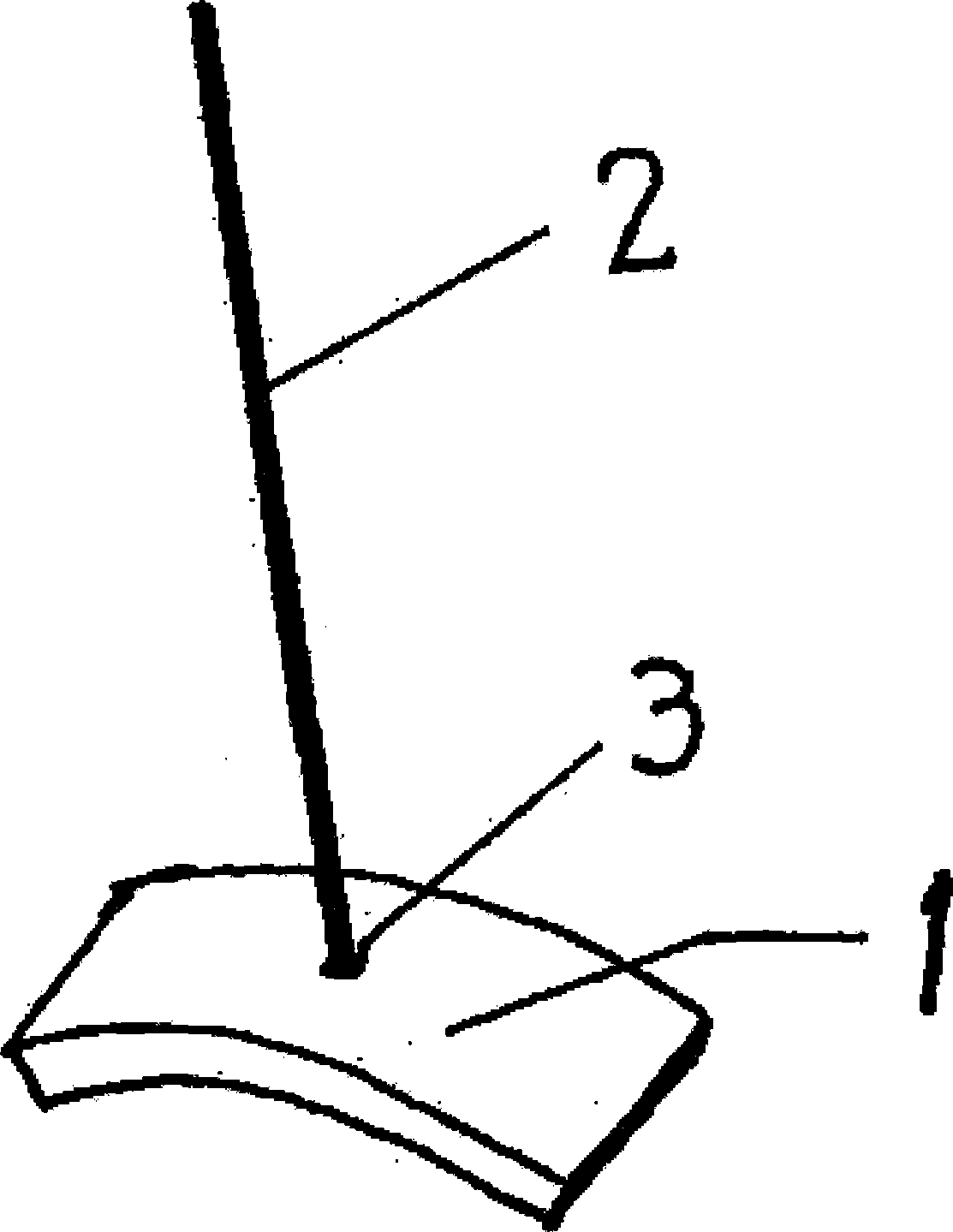

Shield tunnel segment lining-anchor rod structure system

InactiveCN101392654AEnhanced longitudinal deformation resistanceReduce sinkingUnderground chambersTunnel liningEngineeringShield tunnelling

The invention discloses a shield tunnel segment lining-anchor rod structural system. Anchor rods are driven around a shield tunnel segment lining, and the effective connection between the anchor rods and the segment lining is established through steel bolts. The shield tunnel segment lining-anchor rod structural system introduces the anchorage function of the anchor rods into a shield tunnel segment lining structure, which can reduce the settlement or the floatation of tunnels, lighten the influence of recessive characters of surrounding soil bodies, strengthen the rigidity of adverse positions such as corners of the tunnels, stratum catastrophe positions and so on, and improve the whole and local stability of tunnel structures.

Owner:SHANGHAI UNIV

Road reflective marker line coating

InactiveCN101338152AImprove compactnessImprove liquidityTraffic signalsRoad signsFluorescenceCalcite

The invention discloses a road light-reflective mark coating which comprises components in the following mass percent: 15 percent to 25 percent of C5 petroleum resin, 1 percent to 2 percent of ethylene-acetic acid polyvinyl, 1 percent to 1.5 percent of Tissuemat E, 3 percent to 5 percent of titanium white powder, 8 percent to 12 percent of quartz sand, 1.5 percent to 2 percent of di-1-octyl, 8 percent to 12 percent of 1.5RI glass beads, 8 percent to 12 percent of 1.93RI glass beads, 0.1 percent to 0.3 percent of calcium stearate, 36 percent to 46 percent of calcite powder, 0.25 percent to 0.29 percent of bentonite and 0.02 percent to 0.04 percent of optical brightener. The coating of the invention is fine; the coating interface of the glass beads is quite smooth and close to an ideal concave mirror, can focus the light and has good reflection effect. The glass beads which are added in have high refraction rate and small refraction angle of the light; the refraction angle for the reflected light to be obliquely incident from water into the air is small, and the return reflection effect in rainy nights is good.

Owner:潘东海

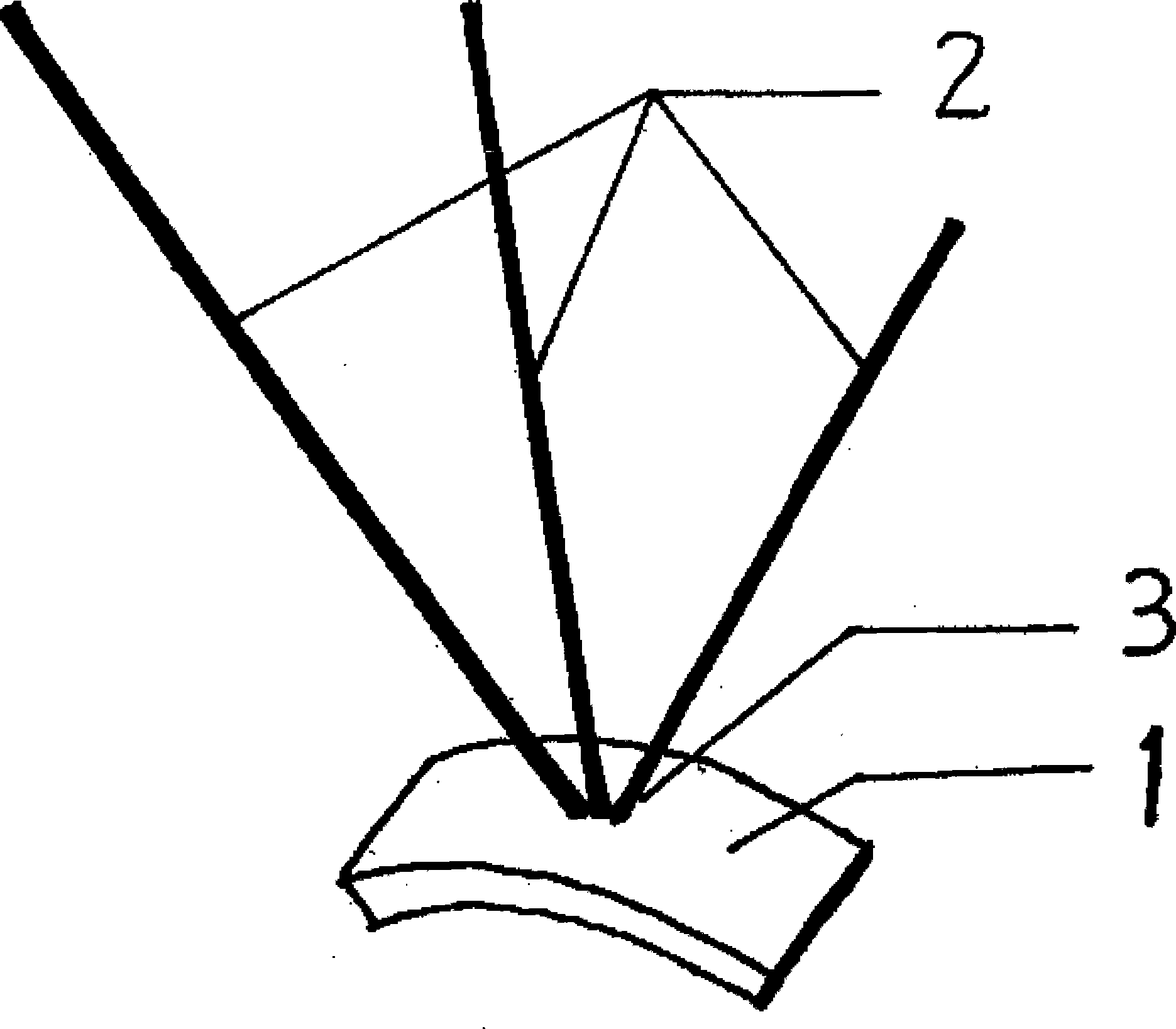

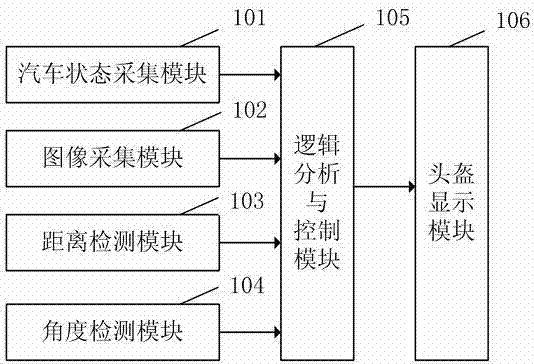

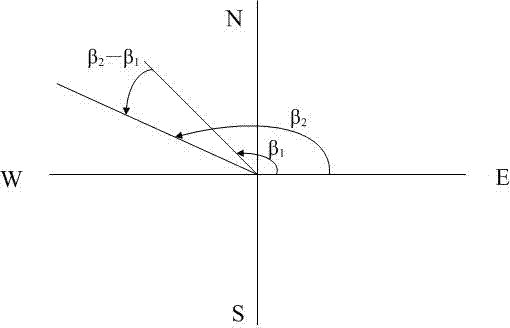

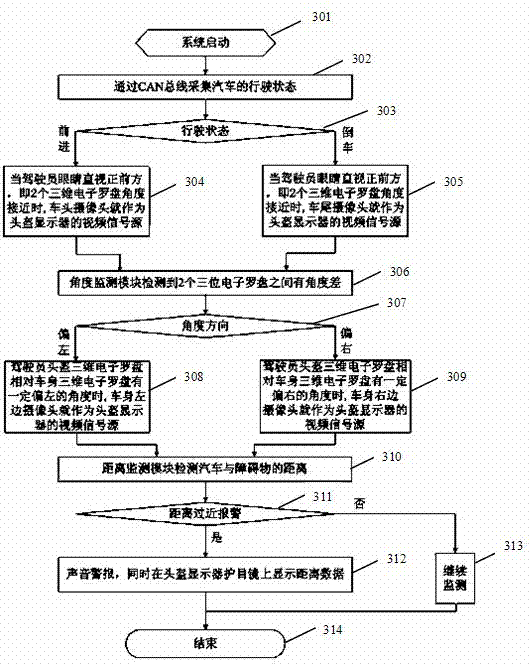

Driving assistance system and method based on head-mounted display and used for automatic scene selection for display

InactiveCN103802728AHumanized operationAvoid traffic accidentsHelmetsHelmet coversDriver/operatorDisplay device

The invention discloses a driving assistance system and method based on head-mounted display and used for automatic scene selection for display. Four wide-angle cameras and six groups of radar transmitting and receiving devices are mounted all around a car body so as to collect images around the car and detect distances between the car and surrounding obstacles in real time, a relative direction (angle) between a diver head (sight) and an automobile is calculated through relative angles collected by a three-dimensional electronic compass on a driver helmet and a three-dimensional electronic compass mounted on the car body, then a logical analysis and process function module performs operation processing, and finally, real-time synchronous display is performed on the head-mounted display (goggles). Therefore, through a panoramic parking helmet, the driver can see the position of the car and the obstacles around the car conveniently and intuitively when sitting in the car.

Owner:GUANGDONG COAGENT ELECTRONICS SCI & TECH

Production process for weaving all-cotton cutting motif fabric by air-jet loom

The present invention discloses a production process for weaving all-cotton cutting motif fabric by an air-jet loom. The production process comprises the following steps of winding process, warping process, sizing process, drawing-in process, weft preparation, and weaving process. The cutting motif fabric is usually weaved by a rapier loom and is not suitably weaved by a high-speed air-jet loom. According to production process, the cutting motif fabric is weaved by the air-jet loom, product quality and production efficiency are ensured, and enterprises gain considerable benefits. Ground warp threads are drawn in front zones of heald frames, and droppers are drawn in back zones, thereby facilitating reduction of tension force of the ground warp threads. Colored warp threads are drawn in the back zones of the heald frames, droppers are drawn in the front zones, and tension force of the colored warp threads is relatively small, thereby facilitating increase of the tension force of the colored warp threads and reduction of knees defects. When the former processes are performed for production, the winding and warping processes are performed at a low speed, air splicing is configured to the winding process so as to reduce yarn hairiness, coating is important in the sizing process, the weaving process is assisted by early opening, large tension force and late weft insertion and the like, and the problem of weft stop is solved.

Owner:NANTONG HONGJINBEI ELECTRONICS TECH CO LTD

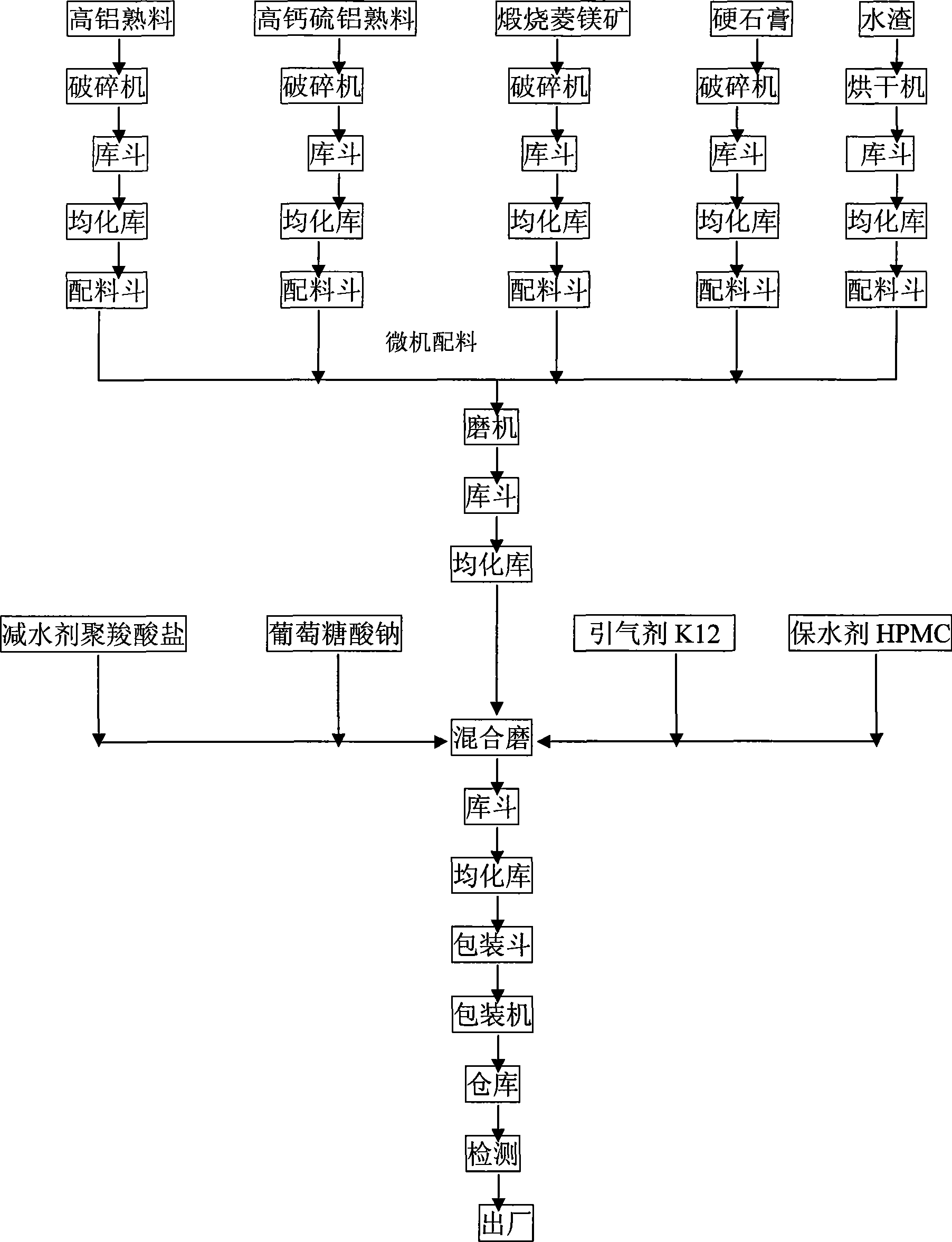

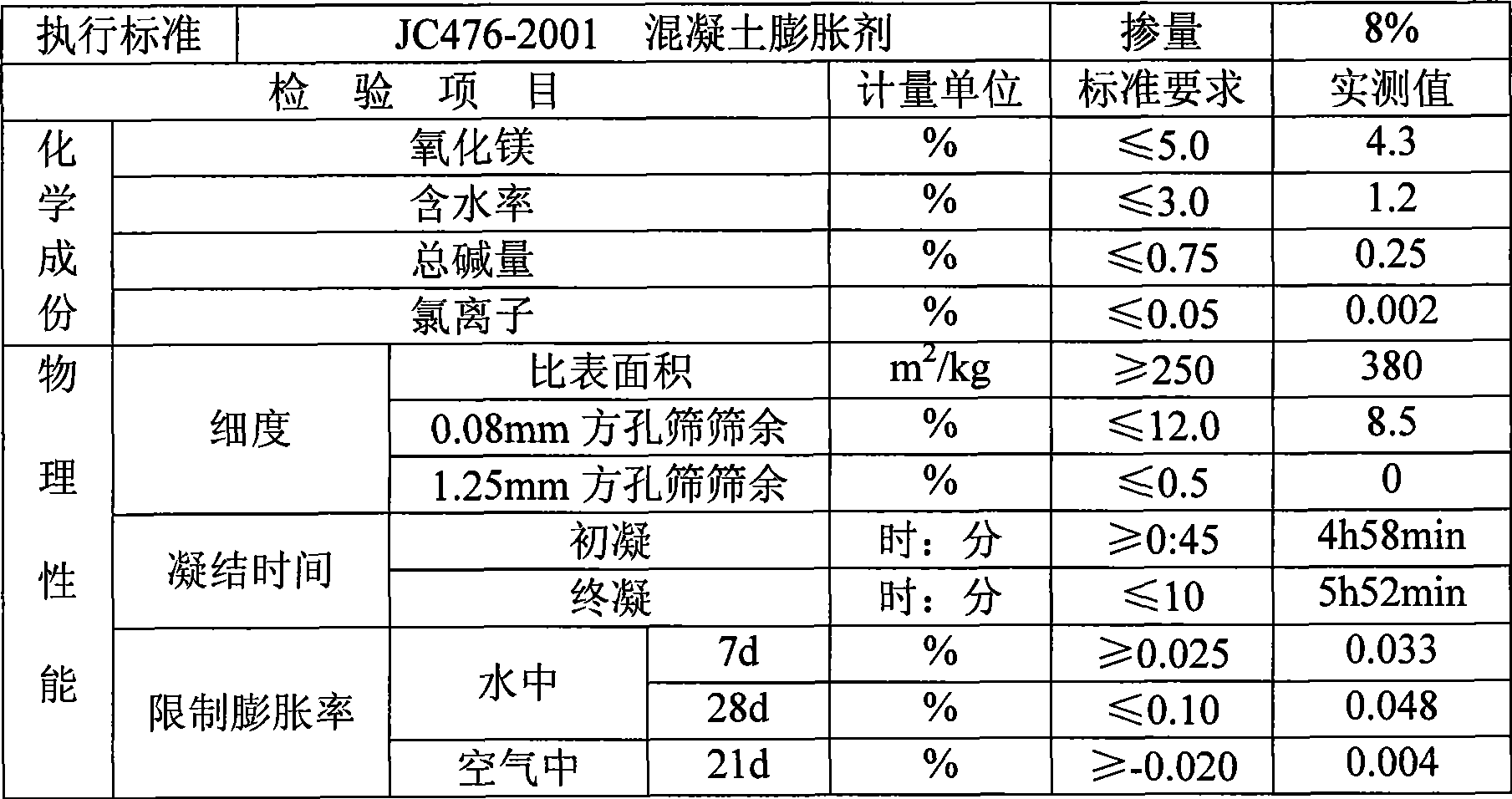

Retardation pumping type three-expansion source cement expansive material

The invention discloses a slow hardening pump deliver type three expansion source concrete expansion agent, which is characterized by comprising preparation of raw materials such as anhydrite, high alumina chamotte, high-calcium sulphoaluminate chamotte, calcined magnesite and so on by weight portion and externally doped slushing agent, water retention agent, air entraining agent and retardant. The preparation method of the expansion agent comprises steps of crushing, common mixture, mixing and grinding and external doping mixture and finish product forming. The product has low alkali content, excellent expansion performance, strong suitability with concrete, balanced mechanical property after hardening, and small gradual slump loss of concrete shrinkage compensation, contributes to improving safety and durability of reinforced concrete, obviously improves the cracking resistance, volume stability, impermeability and frost resistance, and is simple and convenient to use and easy to control quality in construction. The slow hardening pump deliver type three expansion source concrete expansion agent can meet construction use requirements of commercial concrete, long distance pump-delivering concrete and mass concrete.

Owner:广西云燕特种水泥建材有限公司

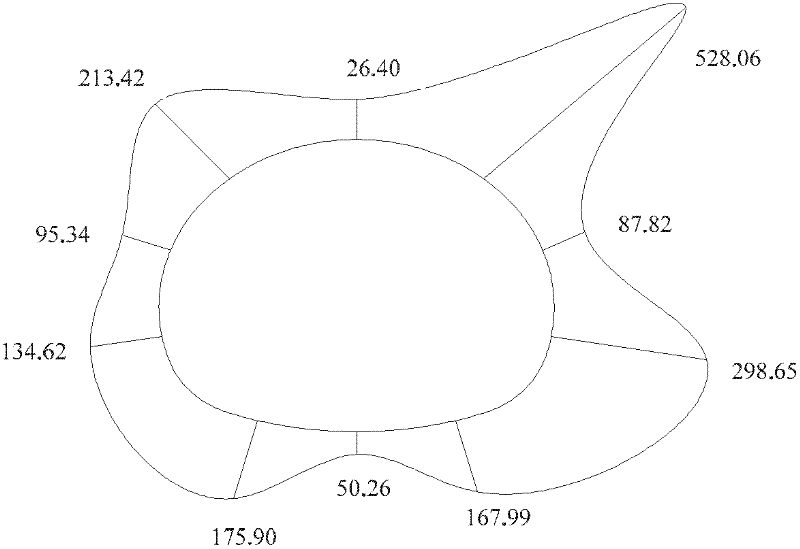

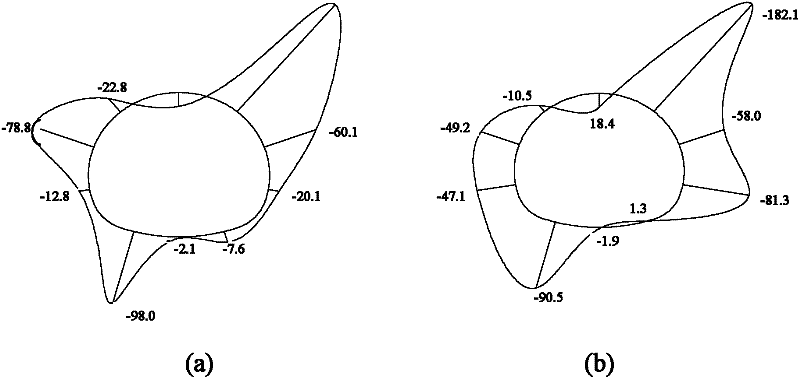

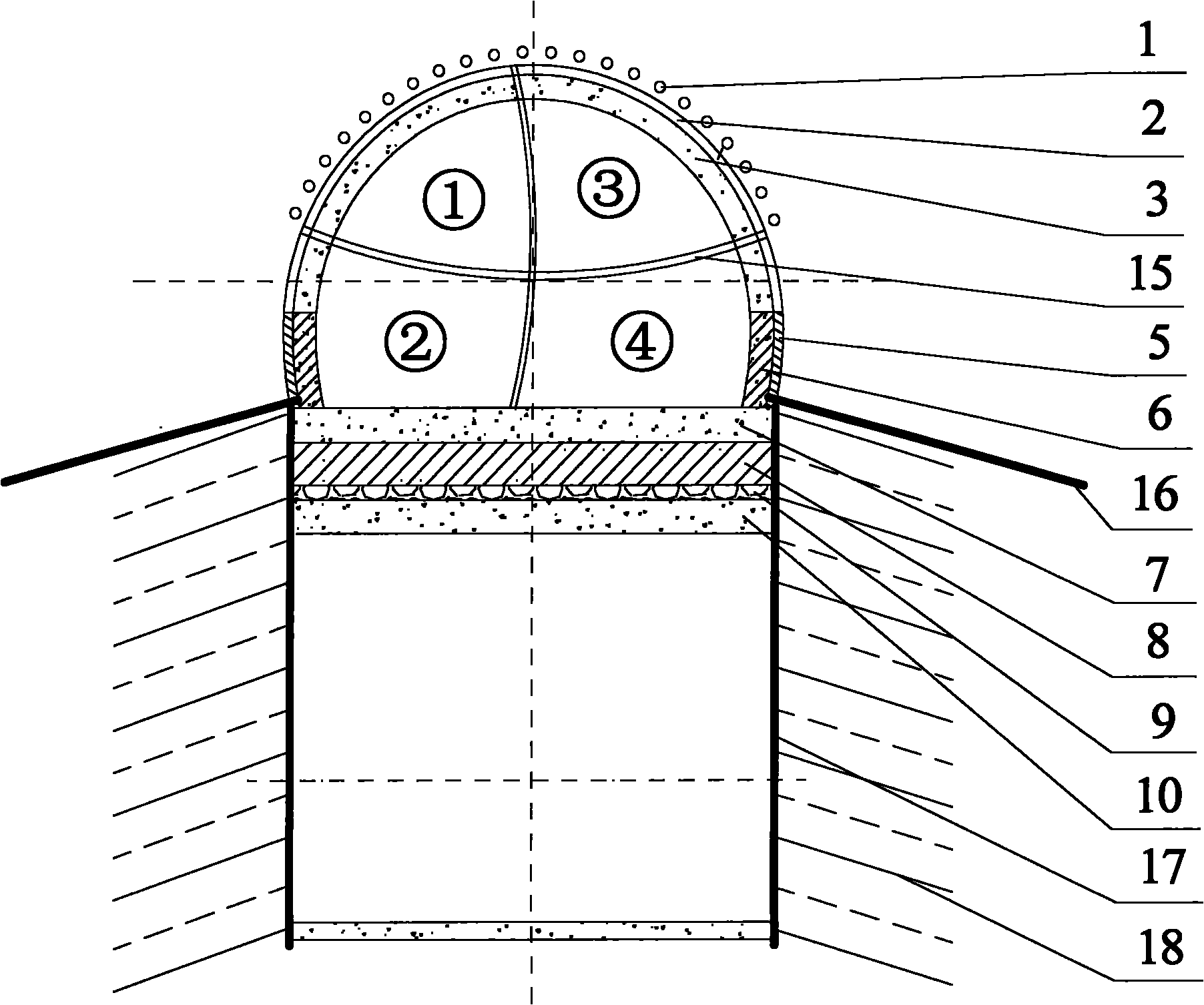

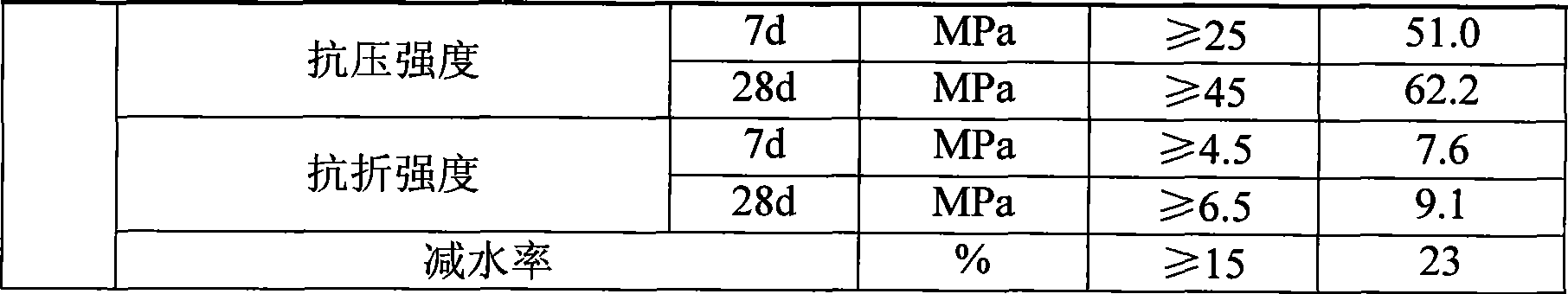

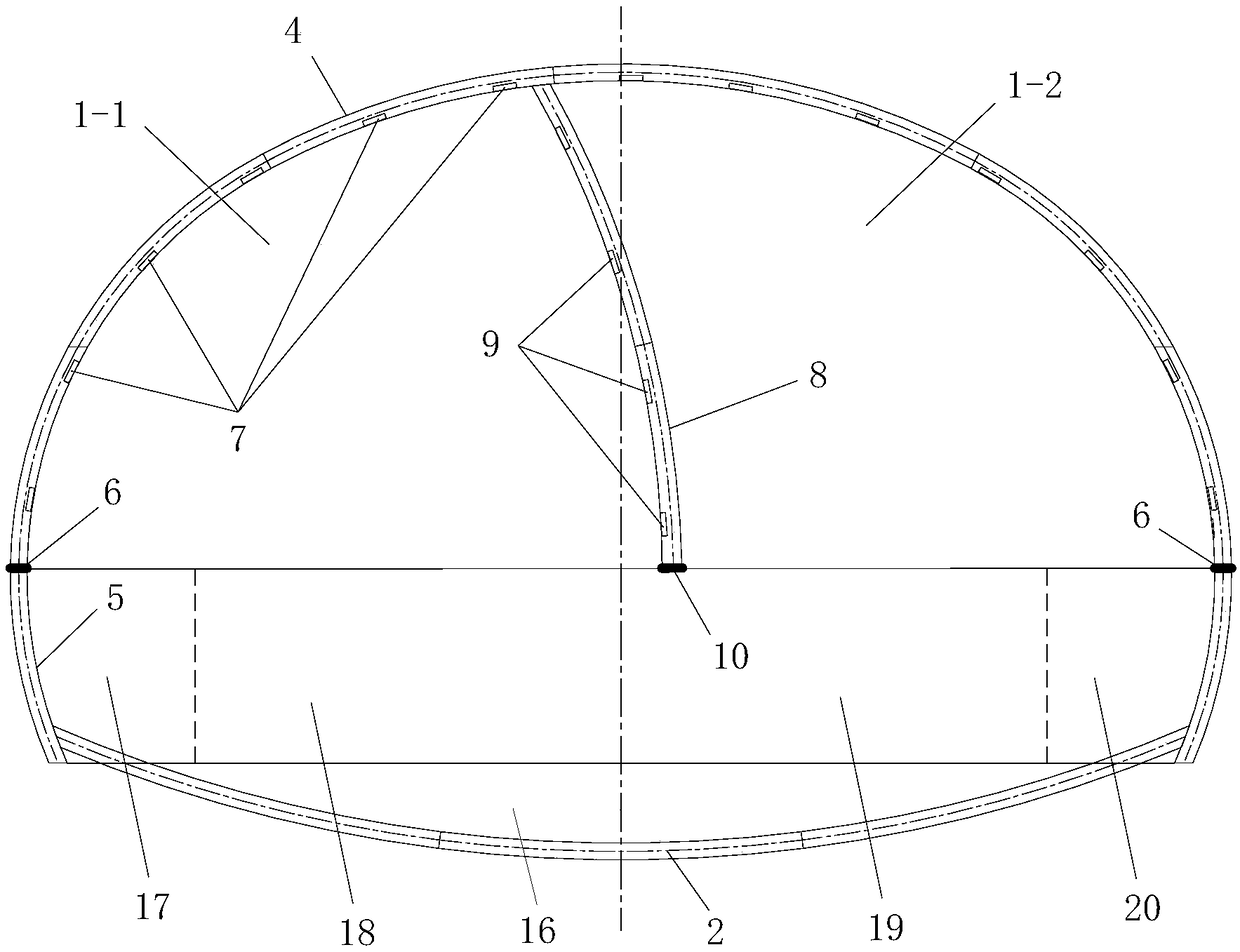

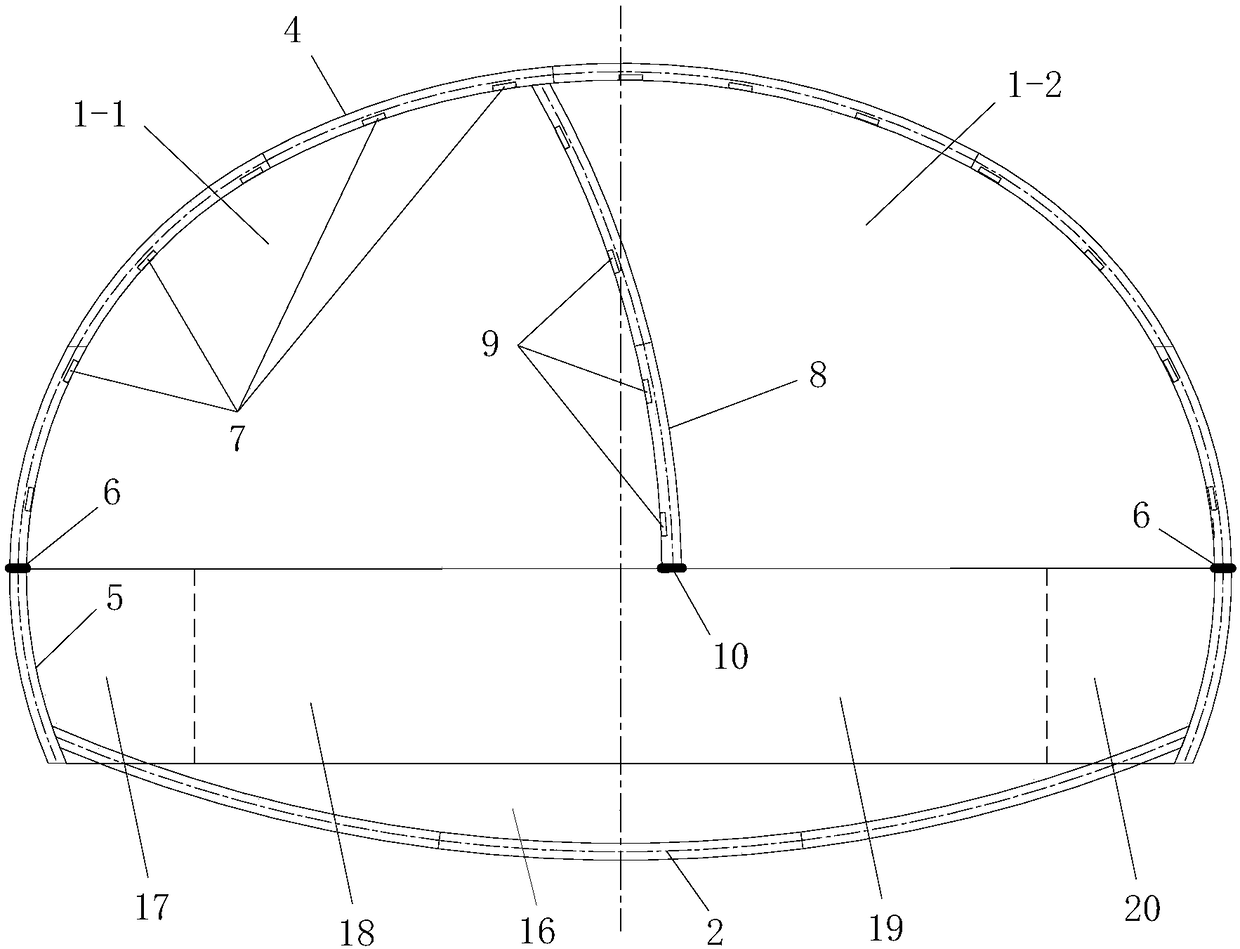

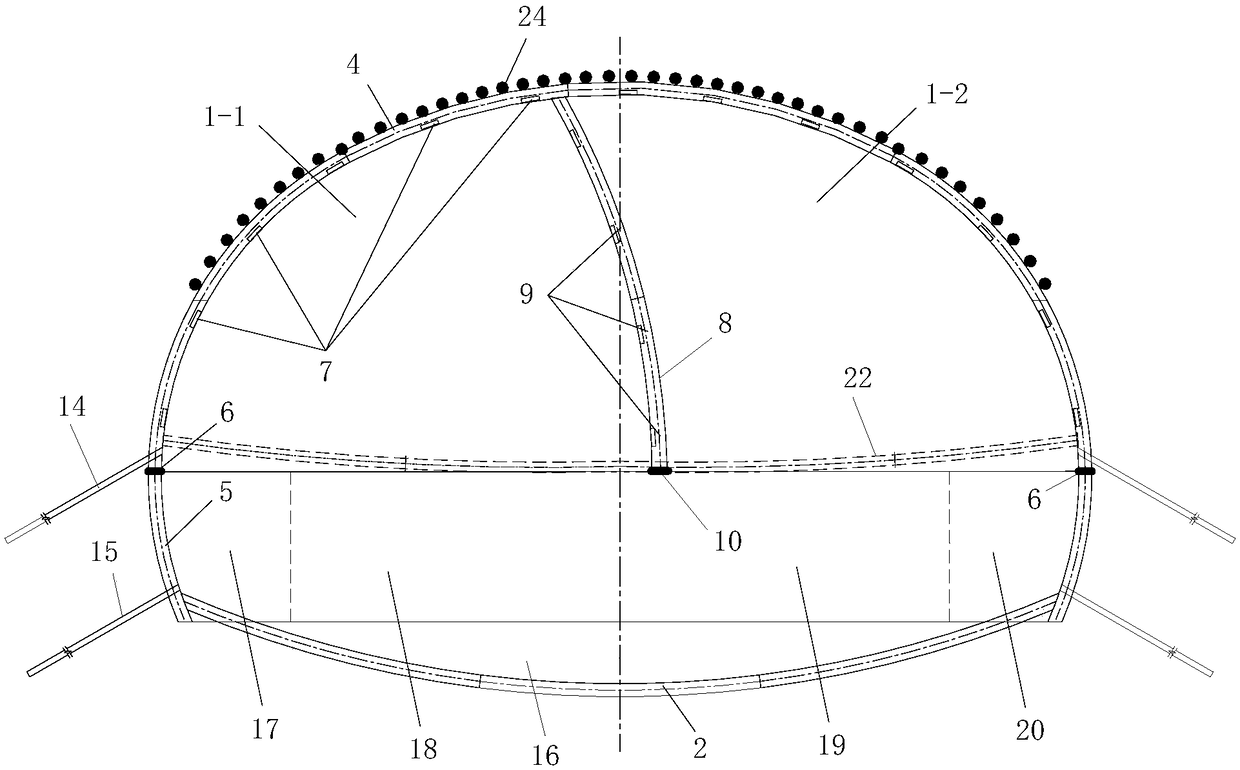

Excavation and support method of large cross-section tunnel through fault fracture zone

ActiveCN108843332AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

The invention discloses an excavation and support method of large cross-section tunnel through fault fracture zone. The initial support structure of tunnel comprises a whole cross-section support system and the lattice girder and shotcrete support structure of the tunnel. A temporary support structure of middle-partition wall is arranged between a left pilot tunnel and a right pilot tunnel. The actual construction includes the steps: 1, excavation of the upper tunnel body; 2, the judgment of the initial support deformation of the tunnel arch wall and the construction of the replacement arch; 3, excavation of the lower tunnel body. The excavation and support method of large cross-section tunnel through the fault fracture zone has reasonable design, simple construction, and good use effect.Only the upper half section of the tunnel is excavated by the center diaphragm method, and the excavation cross-section is reduced so that the stability of the arch roof is ensured. The whole cross-section support system and the temporary support structure of middle-partition wall are supported by the underpass beam and joined together to form a stable monolithic support system, which can avoid the sinking of the supporting arch and ensure the stability of the initial support effectively. Besides, the construction of replacement arch is conducted on only half cross-section of the tunnel and the cost can be saved, and the construction safety can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

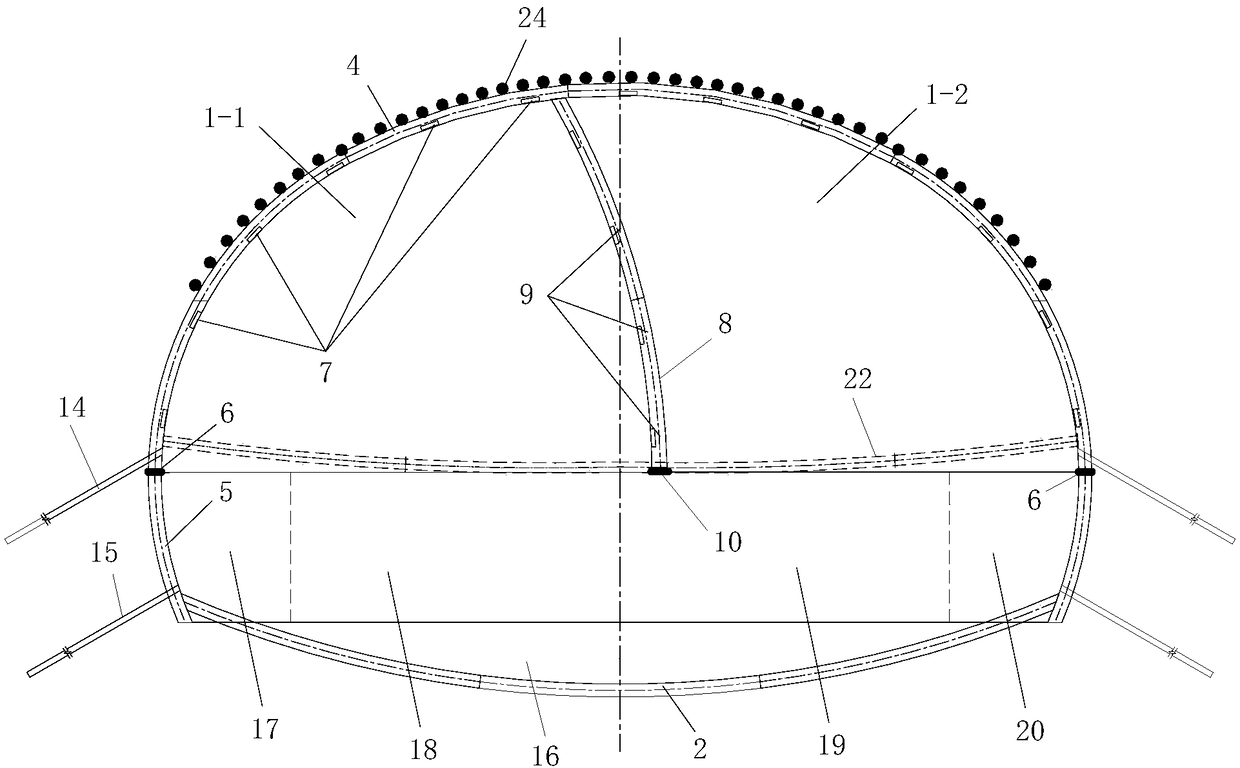

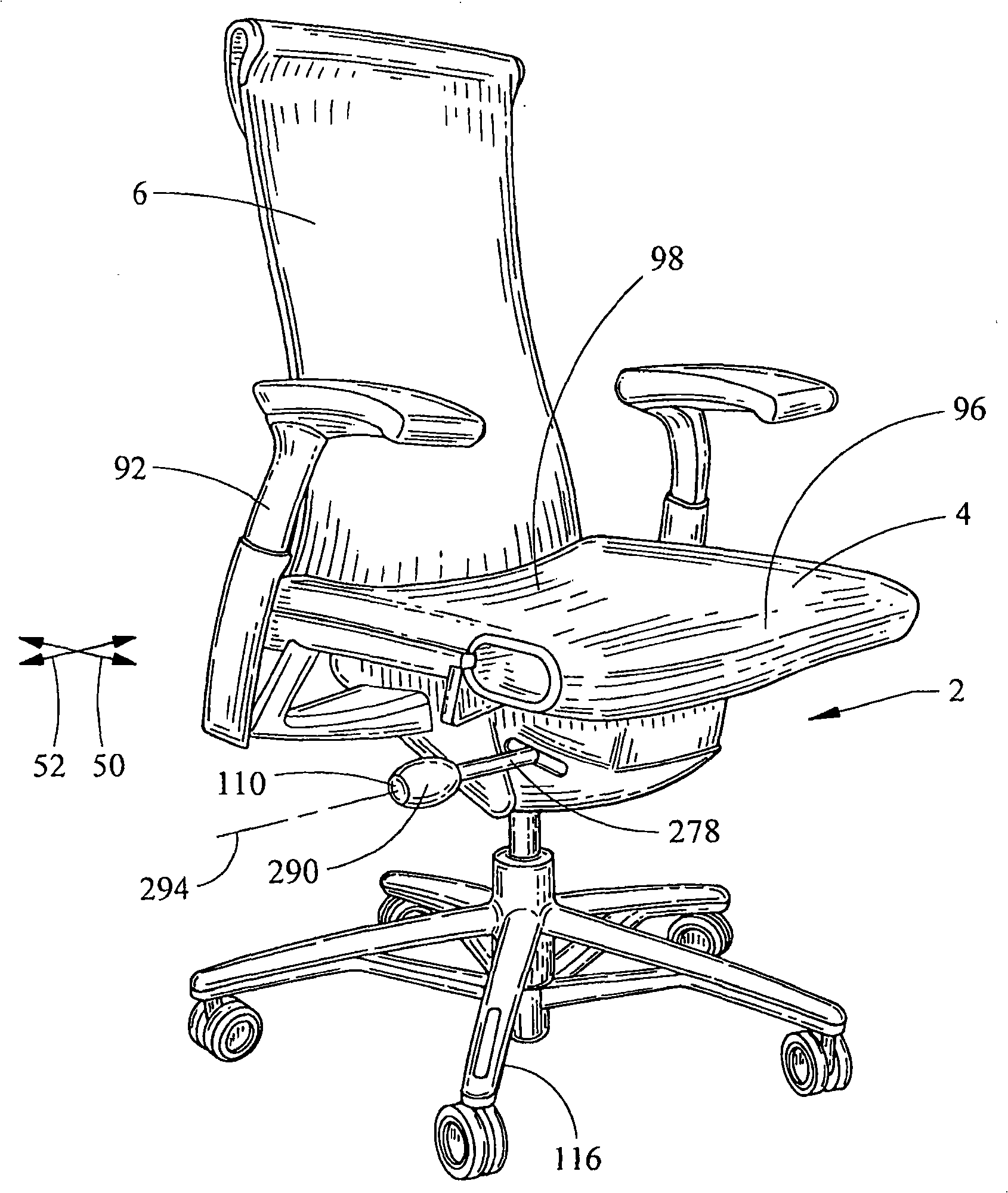

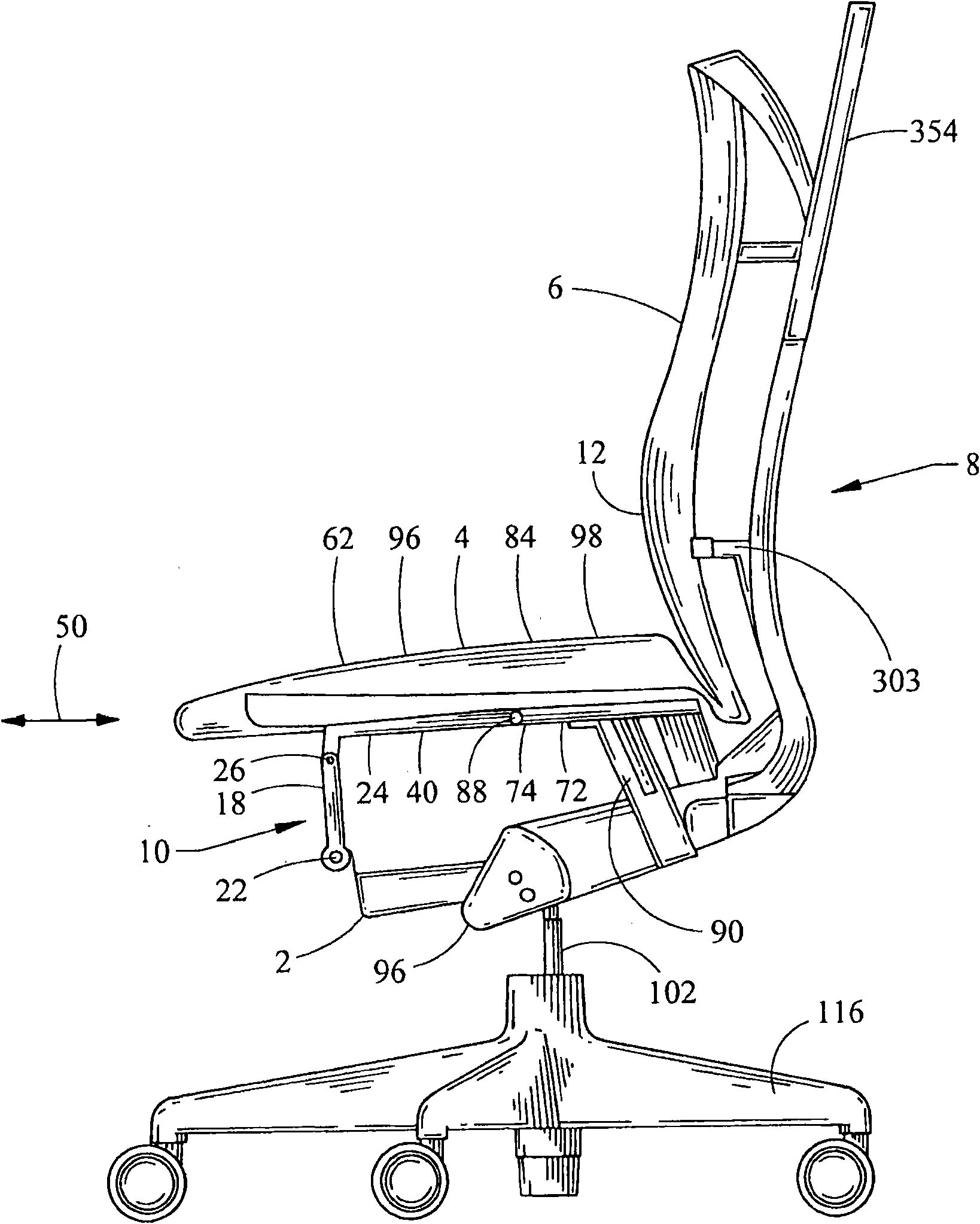

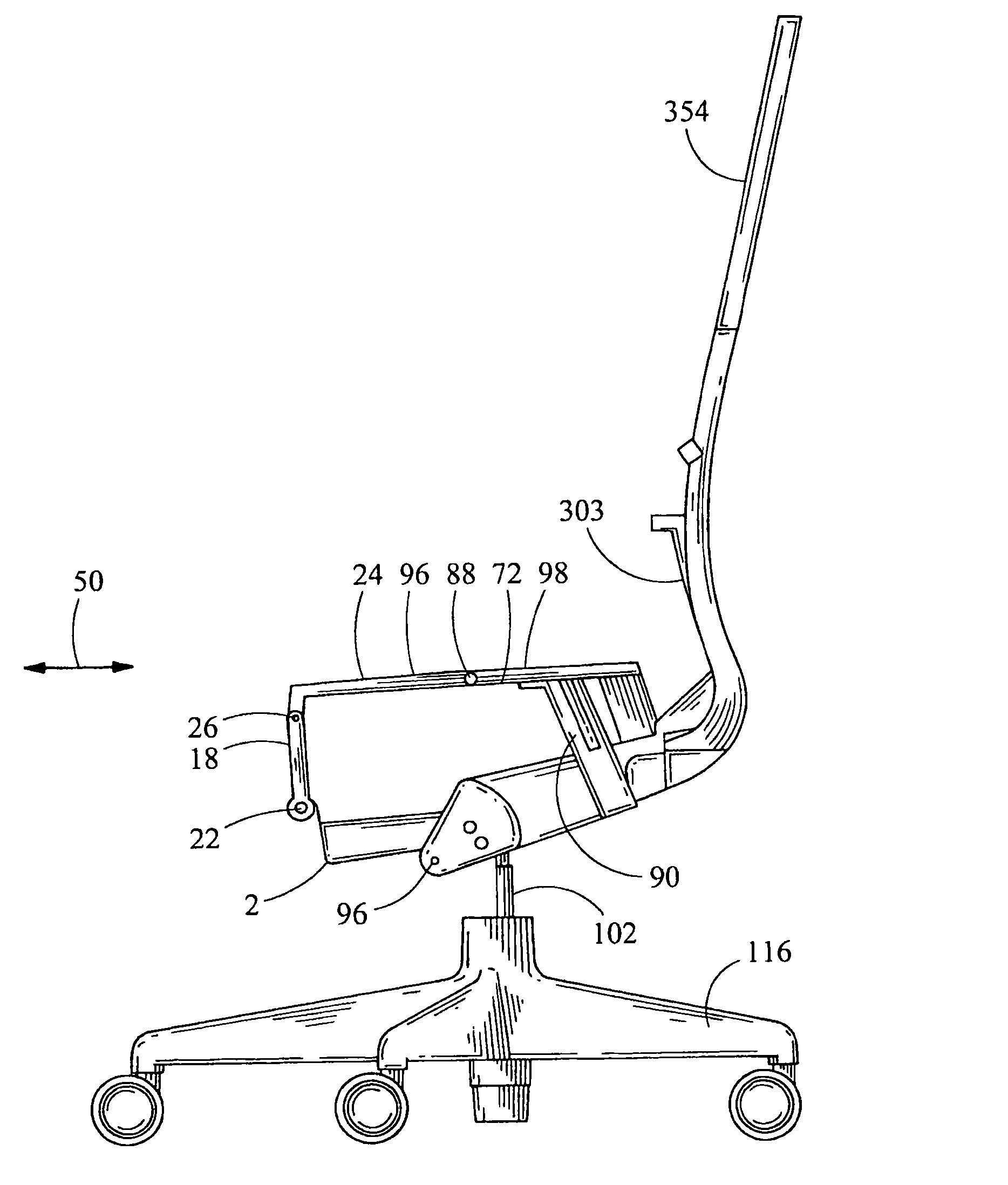

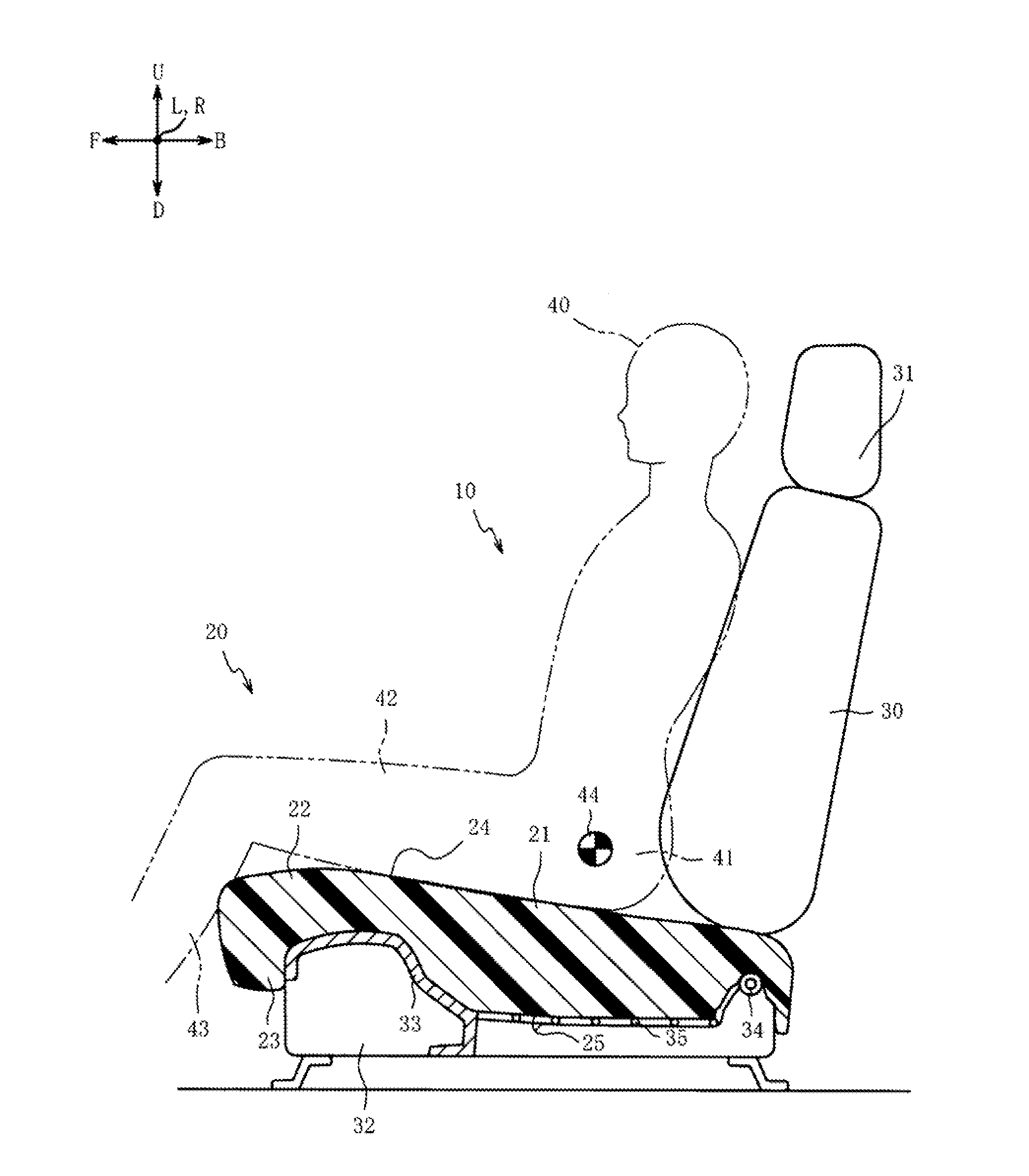

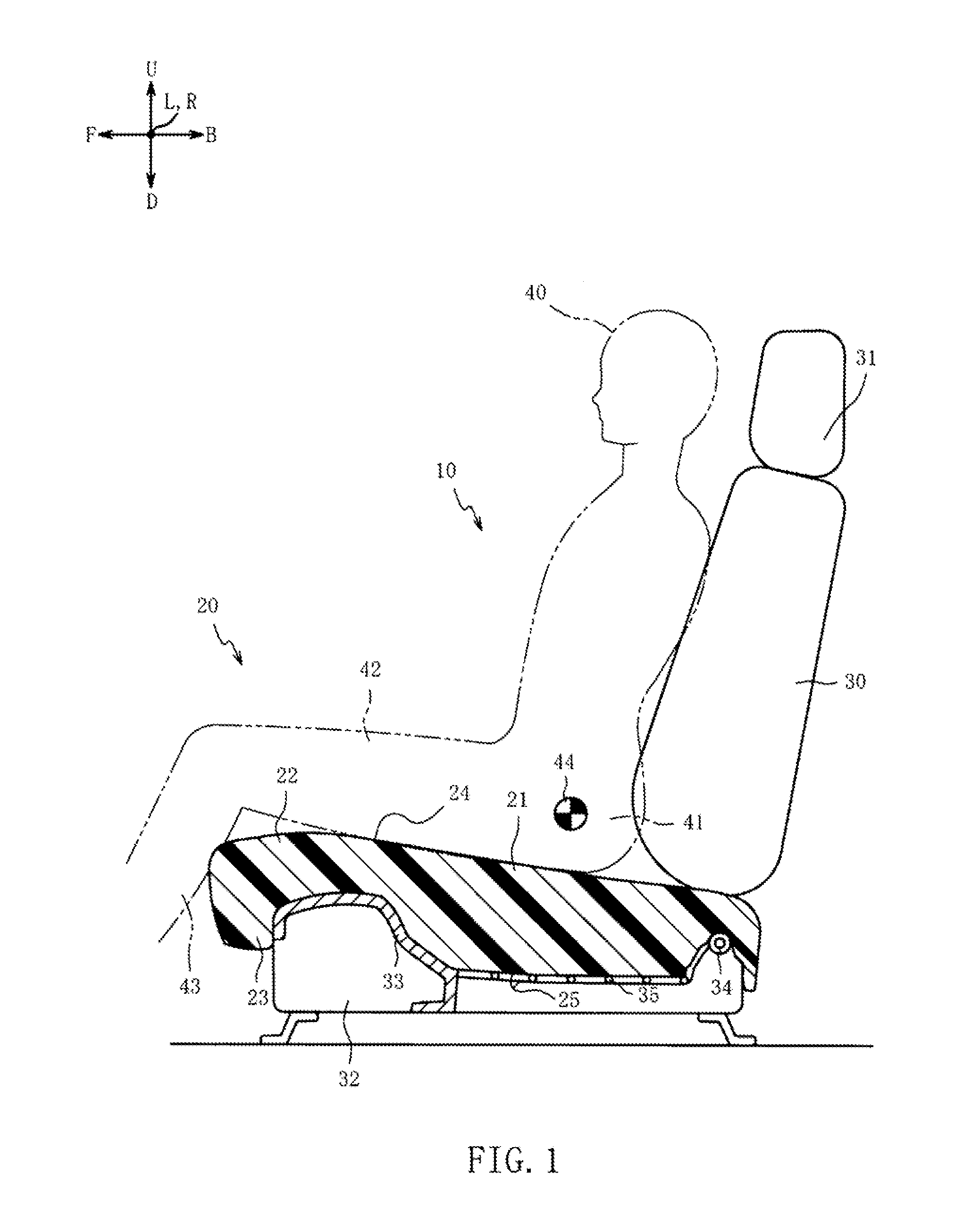

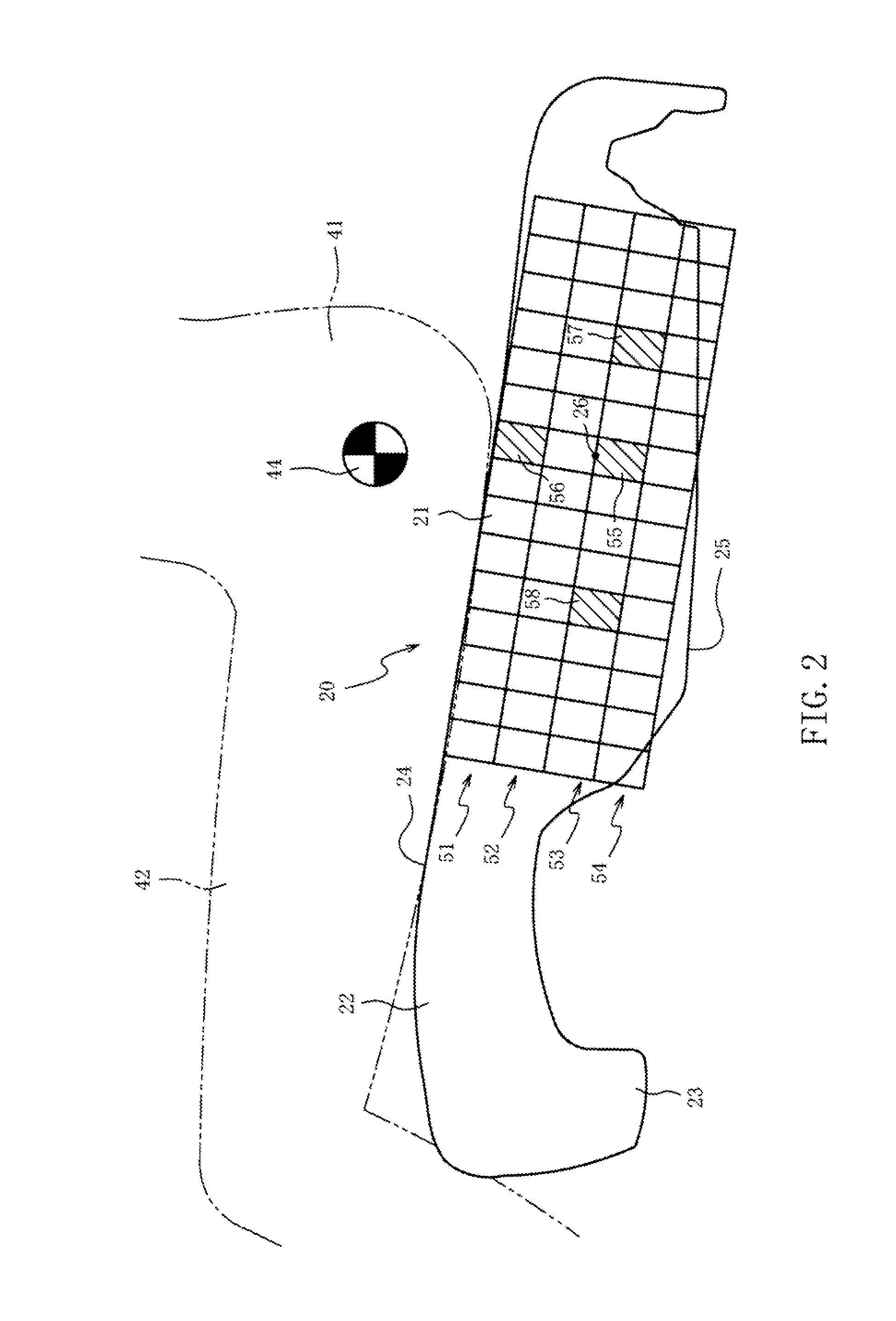

Seating structure and methods for the use thereof

ActiveCN101641035APrevent slidingReduce sinkingStoolsAdjustable chairsClassical mechanicsEngineering

A seating structure has an articulated seat and back. A rear portion of the seat is automatically pivotable relative to a forward portion of the seat as the seat is tilted between upright and reclinedtilt positions. An upper portion of the back is pivotable relative to the lower portion between a neutral position and an extended position, with the upper portion being pivotable relative to the lower portion independent of the tilt position of the back. In one aspect, an adjustment mechanism is coupled between lower and upper back support members and pivots the upper support member between at least first and second support positions. A seat with an adjustable seat depth is also provided, along with various methods for operating the different aspects and embodiments of the seating structure.

Owner:HERMAN MILLER INC

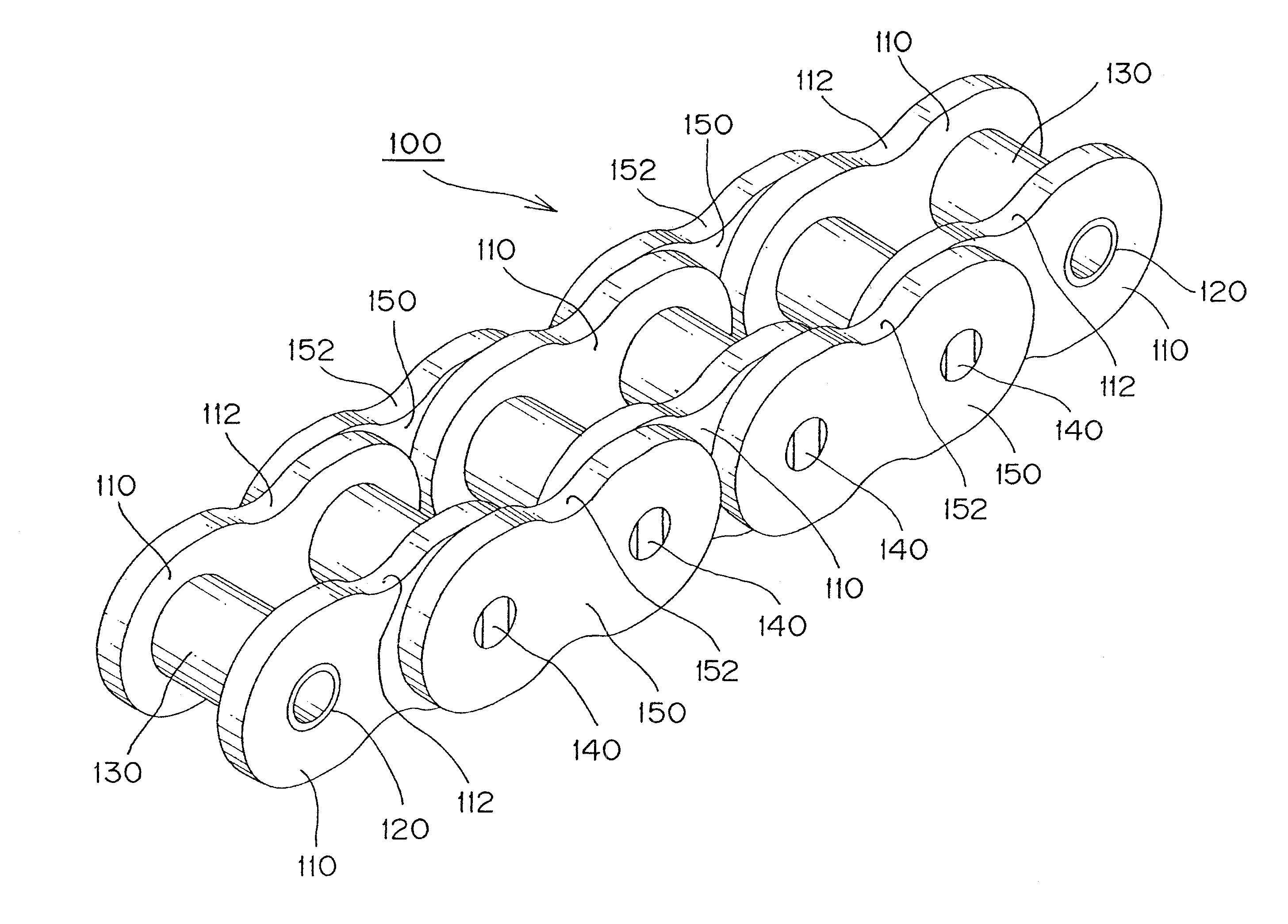

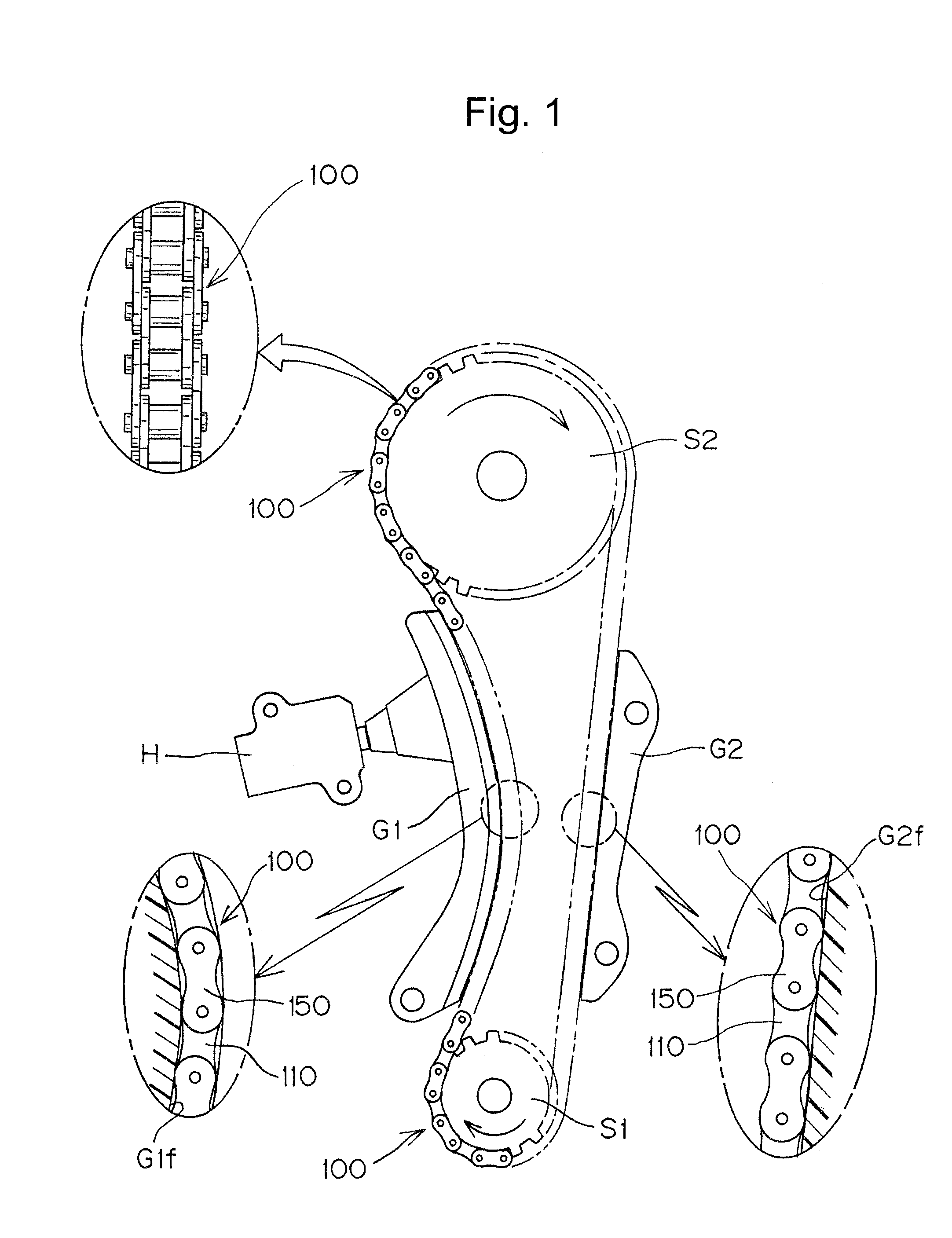

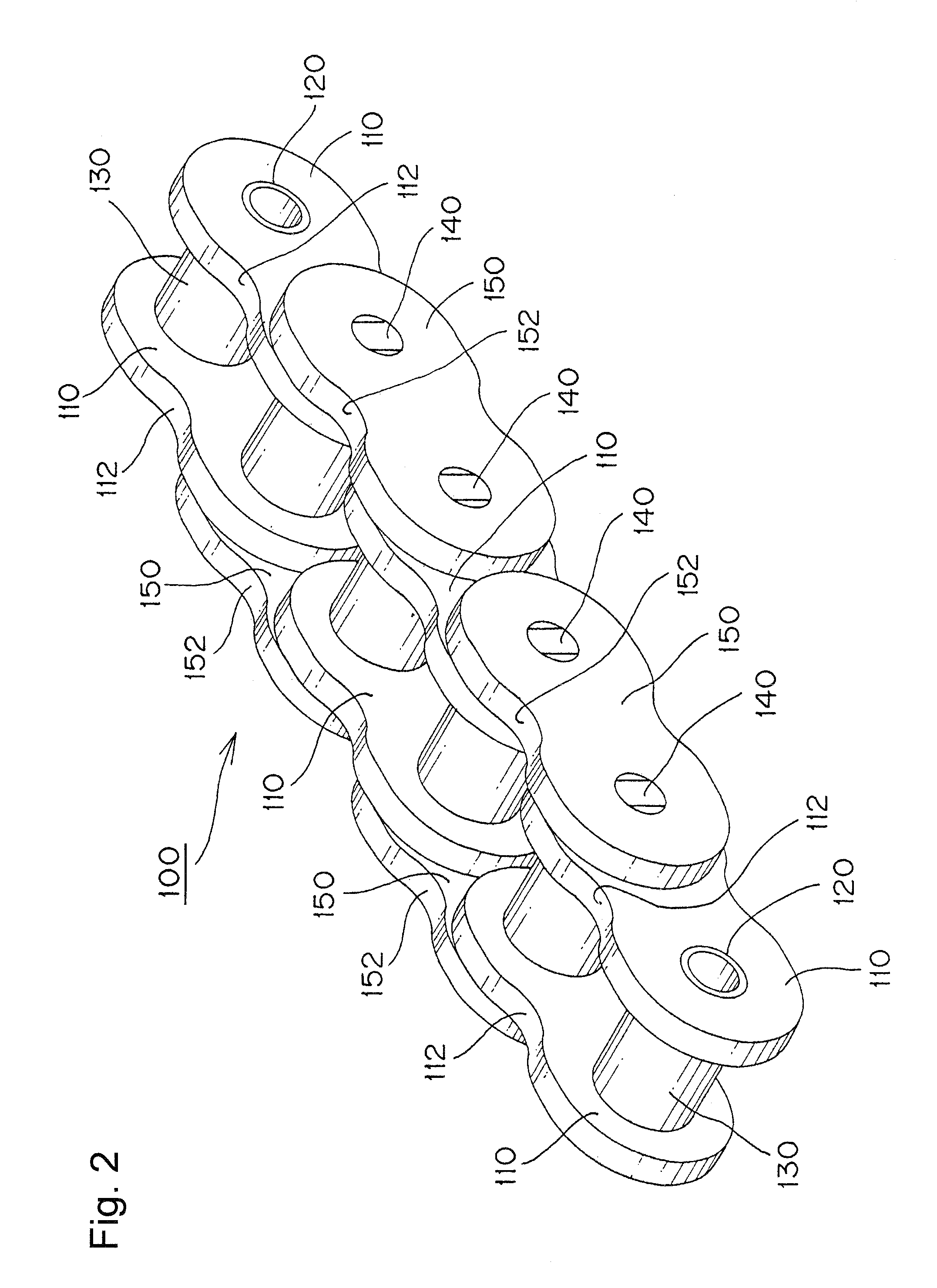

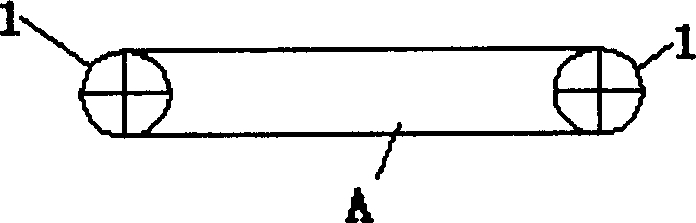

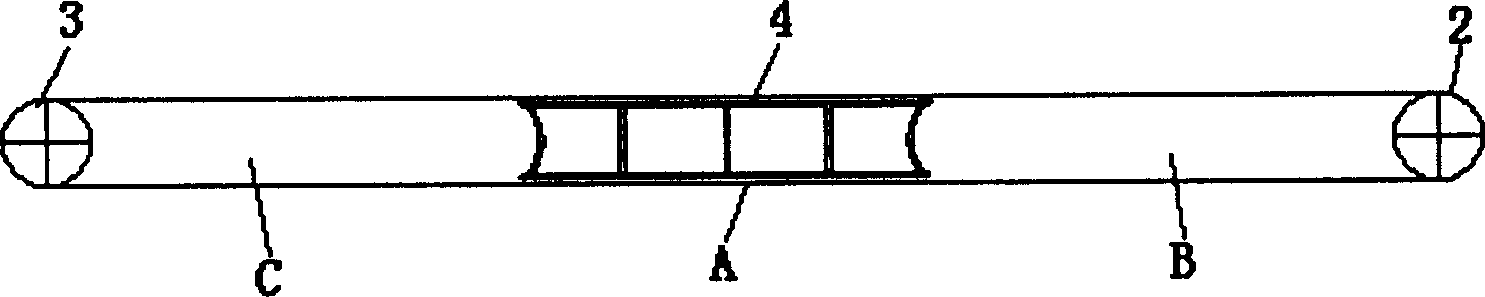

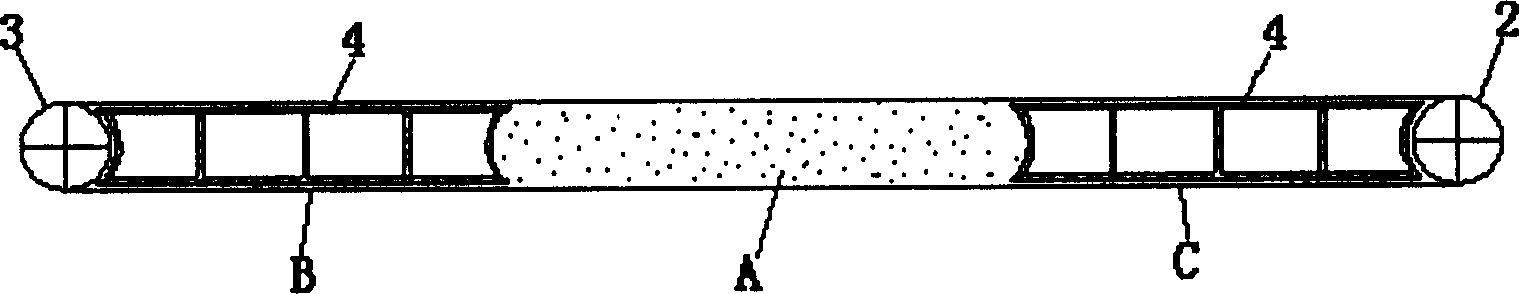

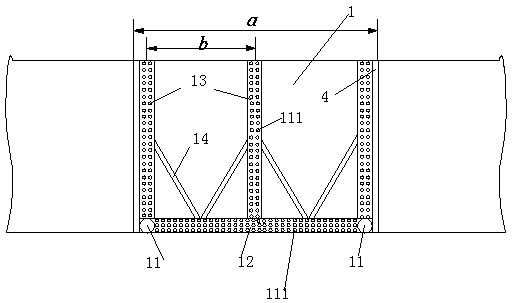

Transmission chain for use in engine

The plates of transmission chain for an engine are formed with a guide-contacting configuration composed of spaced flat surfaces that come into sliding contact with a flat chain guide, and convex surfaces, continuous with and between the flat surfaces, for sliding contact with a convex chain guide. The convex surfaces are connected by a concave surface that, with the guide surface, forms an oil-retaining clearance. The radius of curvature of the convex curved surfaces of the plate preferably increases gradually from the location where they meet the flat surfaces toward the location where they meet the concave surface. The plates can have the same configuration on the side facing the inside of chain loop as on the side facing the outside of the chain loop.

Owner:TSUBAKIMOTO CHAIN CO

Construction method of large-section tunnel crossing fault fracture zone

ActiveCN108915720AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

The invention discloses a construction method of a large-section tunnel crossing fault fracture zone. The construction tunnel cavern is divided into a tunnel upper cavern body, a tunnel lower cavern body and a tunnel bottom cavern body from top to bottom; the tunnel upper cavern body comprises a left pilot tunnel and a right pilot tunnel; the tunnel lower cavern body is divided into a left cavernbody, a left-middle cavern body, a right-middle cavern body and a right cavern body from left to right; practical construction comprises the following steps: (I) excavating the tunnel upper cavern body; (II) excavating the tunnel lower cavern body; (III) excavating the tunnel bottom. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in construction and good using effect; only the upper half section of the tunnel is excavated by median septum excavation, thus the excavation section is reduced, and the vault stability is guaranteed; moreover, the left and right pilot tunnels have enough space and thus the construction is facilitated; meanwhile, a full-section support system and a mid-partition temporary support structure are both supported through lower bearing beams and are connected to form an overall support system with a stable structure, thus sinking of the primary support arching can be avoided while the stability of primary support is effectively guaranteed.

Owner:CHINA RAILWAY 20 BUREAU GRP

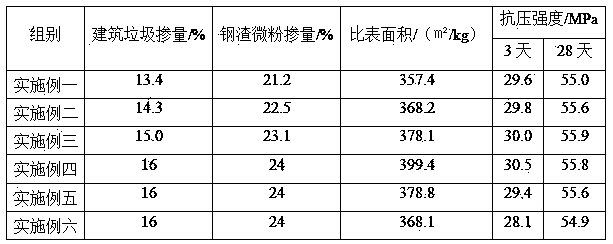

Method for producing green ecological cement resistant to seawater corrosion by using construction wastes

The invention discloses a method for producing green ecological cement resistant to seawater corrosion by using construction wastes. The cement comprises the following raw materials in parts by weight: 40-50 parts of sulphoaluminate cement clinkers, 5-20 parts of construction wastes, 20-25 parts of steel slag powder, 0.06-0.08 part of compound activating agent, 2-5 parts of early strength agent, 0.3-0.5 part of water reducing agent, 0.005-0.007 part of air entraining agent and 0.3-0.5 part of retarder. The production method is characterized by breaking, grinding and homogenizing the construction wastes, the sulphoaluminate cement clinkers, the compound activating agent and the early strength agent respectively, preparing the materials in proportion, mixing the materials, homogenizing the mixture, then adding the water reducing agent, the air entraining agent and the retarder, mixing the materials and homogenizing the mixture, thus preparing the product. The green ecological cement resistant to seawater corrosion has the excellent characteristics of high strength, resistance to seawater corrosion and seawater scouring, and the like besides the properties of ordinary cement, and is especially suitable for underground engineering, ports, wharfs and other engineering suffering corrosion of erosion media.

Owner:广西云燕特种水泥建材有限公司

Method for producing seawater corrosion-resistant green ecological cement from stone waste

ActiveCN104291717AReduce stone dust pollutionWide variety of sourcesCement productionScrapCorrosion resistant

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from stone waste. The seawater corrosion-resistant green ecological cement comprises the following raw materials in parts by weight: 30-40 parts of stone waste, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of a complex activator, 2-4 parts of an early-strength agent, 0.3-0.5 part of a water-reducing agent, 0.005-0.007 part of an air entraining agent, and 0.3-0.5 part of a retarder; and the production method comprises the following steps: respectively crushing the stone waste, sulphate aluminum cement clinker, complex activator and early-strength agent, grinding, homogenizing, then mixing and homogenizing according to a proportion, then adding the water-reducing agent, air entraining agent and the retarder, mixing and homogenizing to obtain the seawater corrosion-resistant green ecological cement. The seawater corrosion-resistant green ecological cement has the excellent properties of being high-strength, seawater corrosion-resistant, seawater scouring-resistant and the like besides the performances of common cement, and is especially applicable to underground engineering, ports, wharfs and other engineering corroded by erosion media.

Owner:广西云燕特种水泥建材有限公司

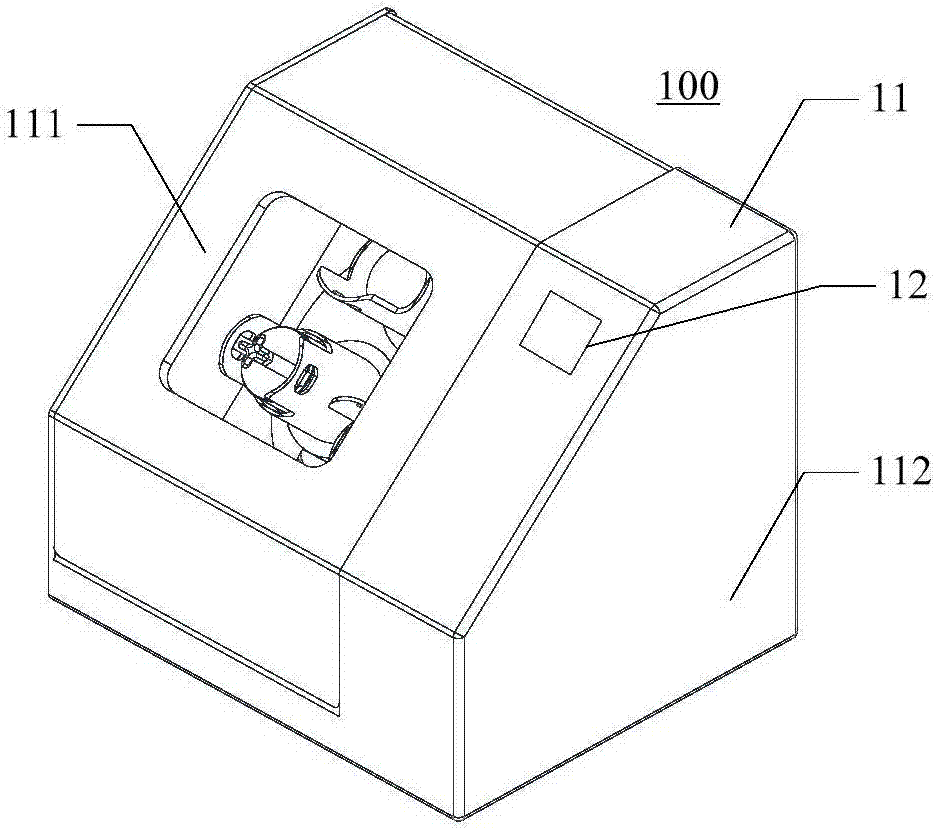

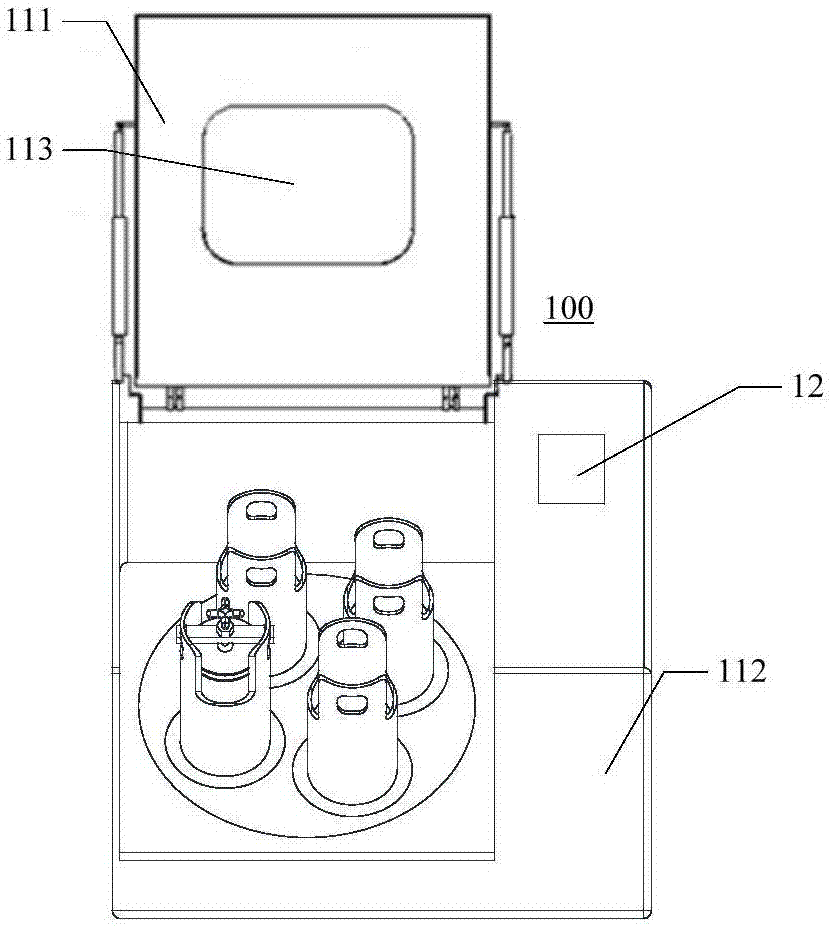

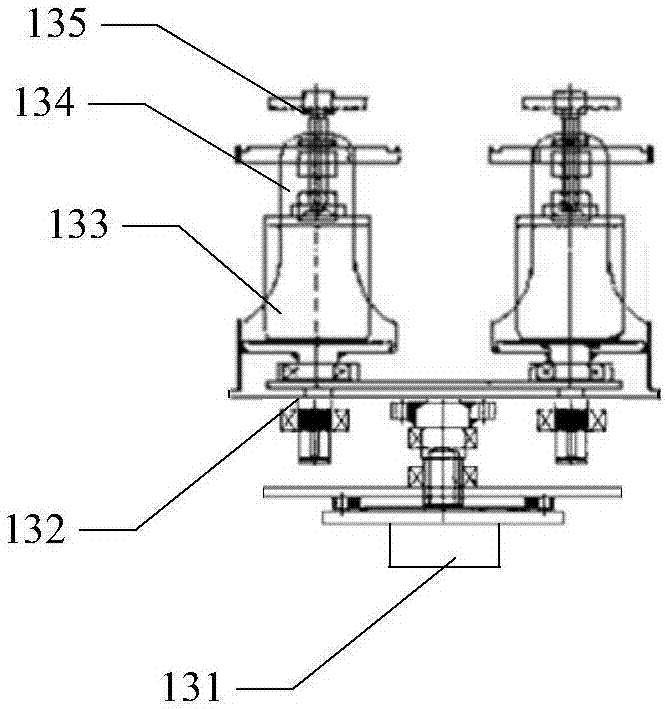

Obliquely vertical planetary ball mill and system

PendingCN106944199AAvoid blind spotsReduces deposits to the bottom of the grinding jarGrain treatmentsControl systemElectric machinery

The invention provides an obliquely vertical planetary ball mill and a system and relates to the technical field of powder grinding equipment. The obliquely vertical planetary ball mill comprises a shell, a rotary table part, grinding jar compressing parts and a control system, wherein the rotary table part comprises a speed reduction motor, a rotary table, grinding jar sleeves and grinding jars, the speed reduction motor is located below the rotary table, the grinding jar sleeves are mounted on the rotary table, the speed reduction motor drives the rotary table to revolve through a planetary bearing and simultaneously drives the grinding jars to rotate, and the grinding jars are fixed in the grinding jar sleeves through the grinding jar compressing parts; the bottom of each grinding jar is level, and the connecting part between the bottom and the jar wall of each grinding jar is arc; the rotary table is installed in the shell through a rotary table frame, and the rotary table frame enables the grinding jar sleeves to be oblique relative to the horizontal surface. The obliquely vertical planetary ball mill reduces the situation that grinded objects deposit to the bottoms of the grinding jars, reduces the occurrence probability of the jar adhesion phenomenon and improves the work efficiency of the equipment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Suspension type driftage temporary supporting device and use method thereof

The invention discloses a suspension type driftage temporary supporting device and a use method thereof. The device comprises an I-shaped steel suspending beam, a supporting platform, a lifting platform, a moving frame and a plurality of hydraulic cylinders. The components are used for realizing the quick and continuous driftage, reducing the sinking and layering of a top tray, reducing the accidents of head-on roof caving and deviation, and reducing the labor intensity.

Owner:ANHUI UNIV OF SCI & TECH

Method for construction of underground continuous steel jacket box

ActiveCN1793527AReduce sinkingReduce the possibility of collapseArtificial islandsExcavationsSlurry wallSteel jacket

The invention discloses an underground diaphragm wall steel lagging box construction method. It includes the following steps: forming groove segment to groove; cleaning hole; pouring concrete; cutting into steel lagging box; doing as the same for the adjacent; drawing out; cutting it into the second finished groove segment; filling back the first cavity by earthwork. The method adopts í‹one male and one femaleíŒ groove segment jumping type to use steel lagging box to construct. It can reduce the possibility of sinking and collapsing of approach wall, and the influence on groove wall earth from outer loading. It has the advantages of fast construction speed, good foundation ditch lump protection effect, and obvious economic benefit.

Owner:SHANGHAI CONSTR NO 1 GRP

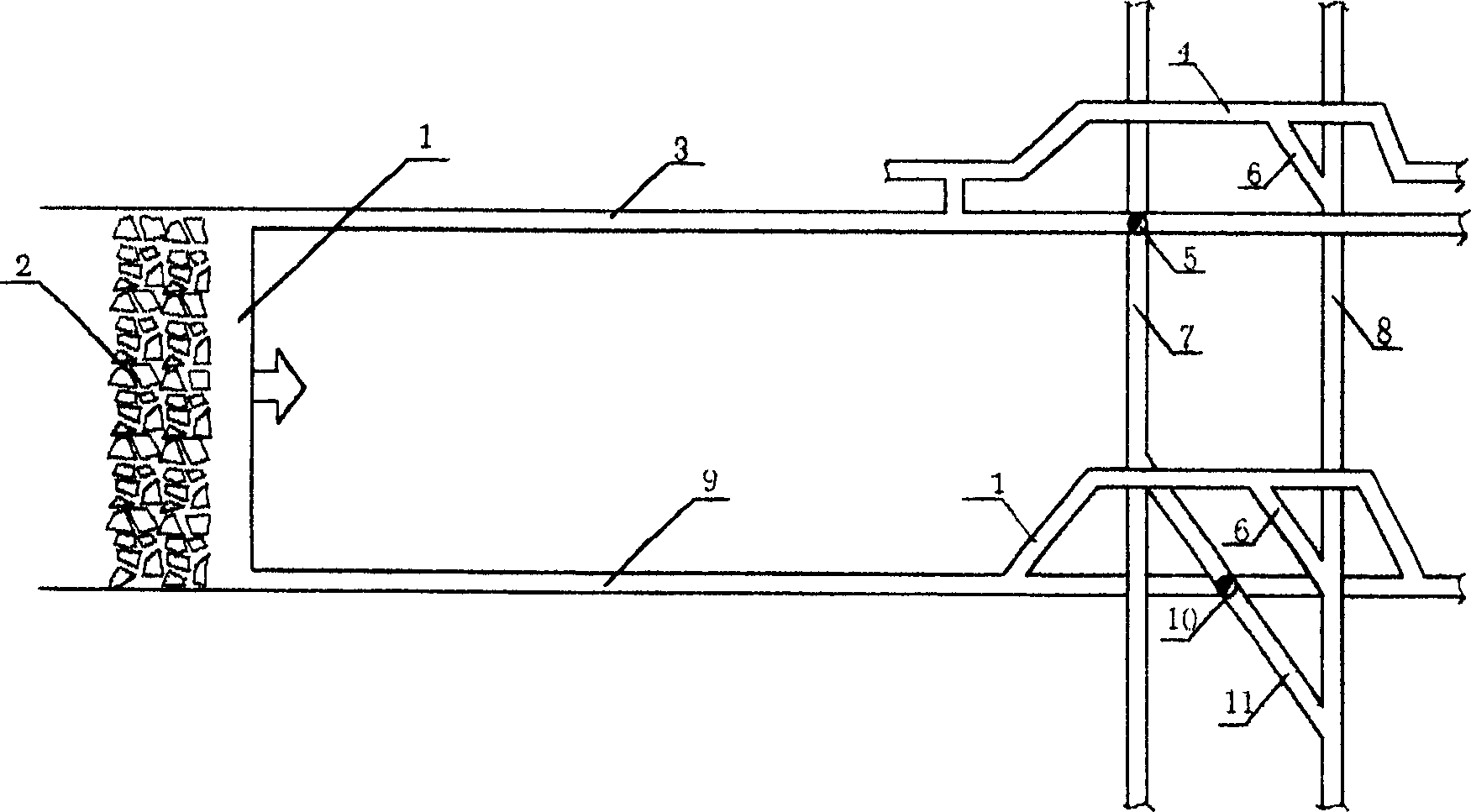

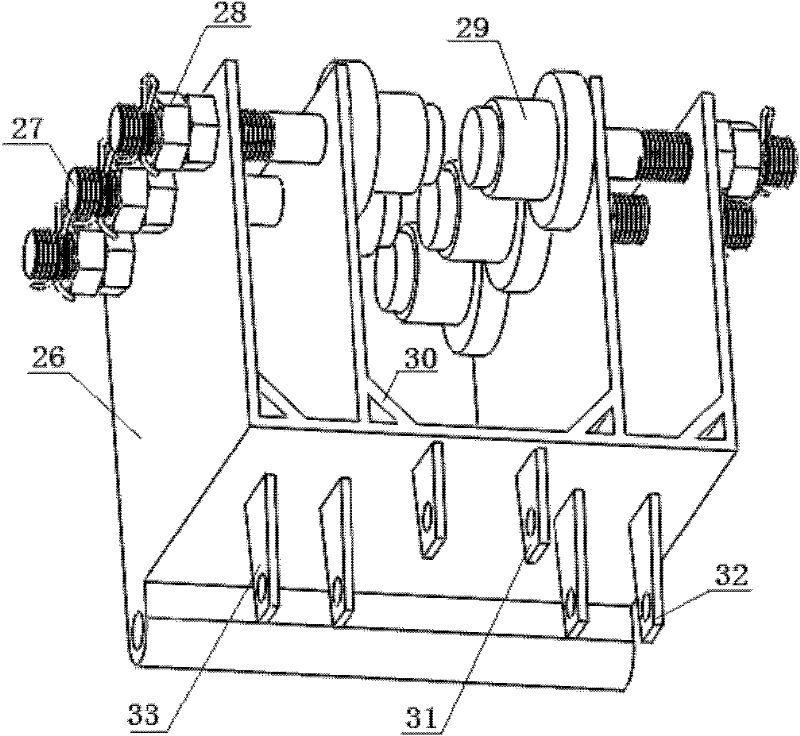

Gangue filling three-dimensional grouting construction method of short-wall roadway mining horizontal working face

ActiveCN108625894AGood dust reduction effectAchieve weight lossUnderground chambersMaterial fill-upEngineeringSlurry

The invention discloses a gangue filling three-dimensional grouting construction method of a short-wall roadway mining horizontal working face and relates to a gangue filling grouting construction method. Two-side grouting pipes on the two sides of the bottom of a roadway, a plurality of horizontal grouting pipes connected between the grouting pipes on the two sides, and vertical grouting pipes vertically fixedly connected with the horizontal grouting pipes are designed, a stable frame-type structure is formed, after gangue stacking, grouting is conducted, and the better grouting effect is guaranteed through the three-dimensional grouting process; fixing diagonal bracings are designed between the horizontal grouting pipes and the vertical grouting pipes to enable the frame-type structure to be more stable; and after grout in the vertical grouting pipes is solidified, supporting pipes containing the solidified grout are formed, under the effect of the grout, the supporting pipes and gangue stacking bodies form joint bearing bodies to support overlying strata jointly, thus sinking of the overlying strata is small, and the ground surface dust reduction effect is good.

Owner:SHANDONG UNIV OF SCI & TECH

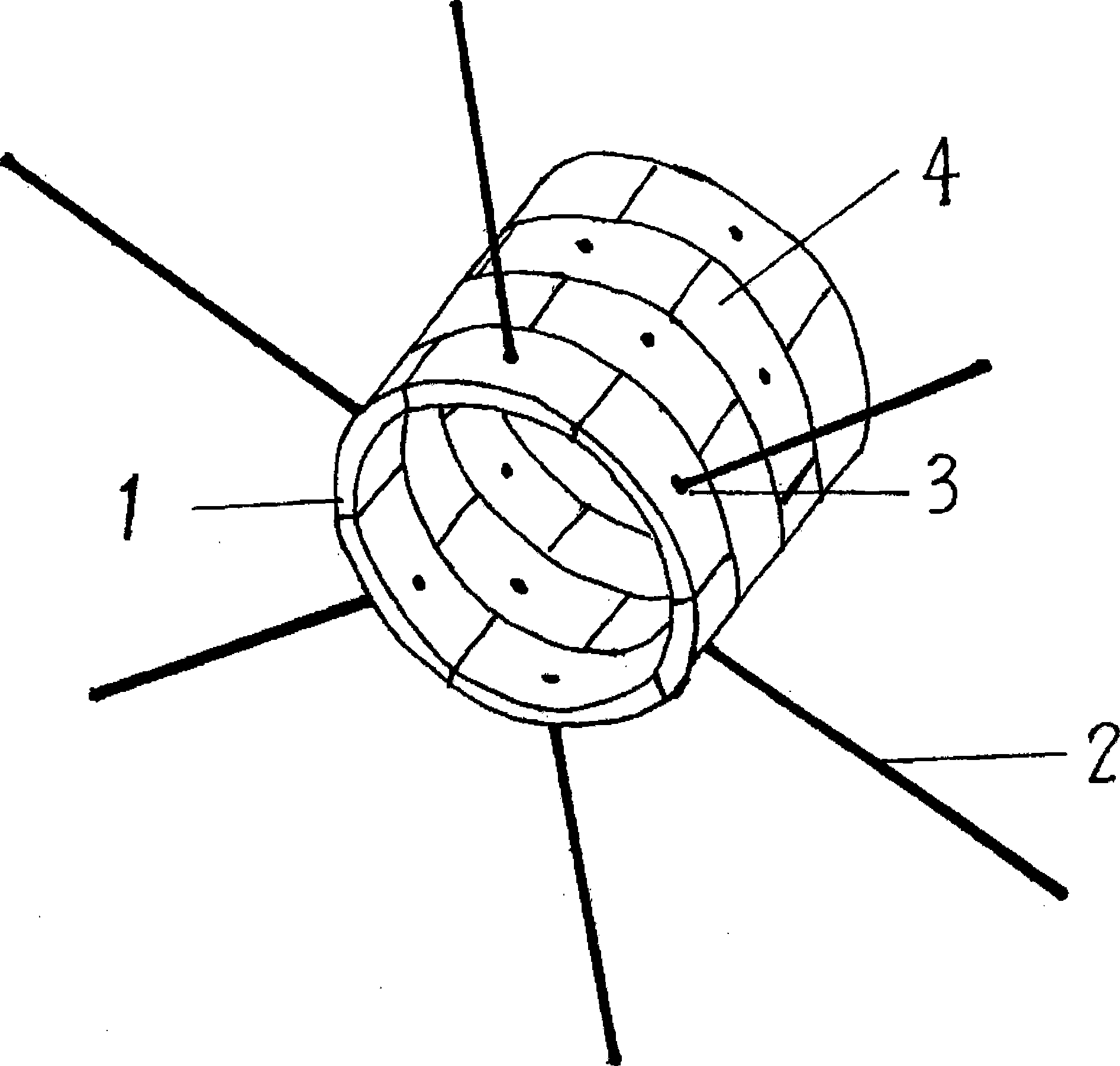

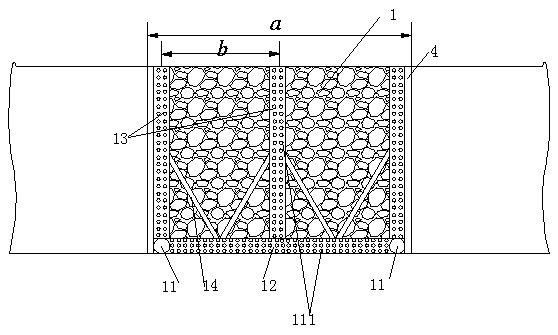

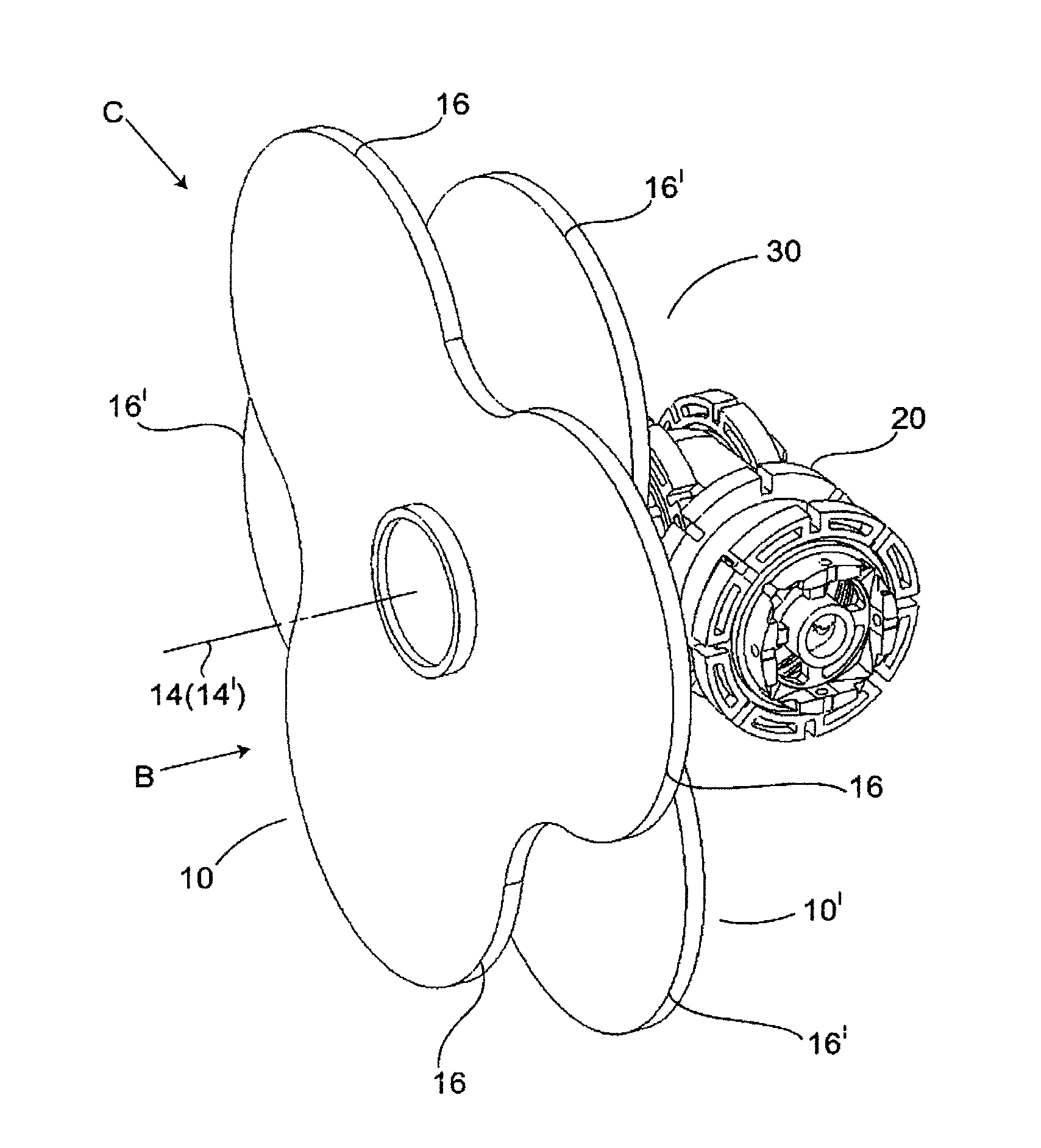

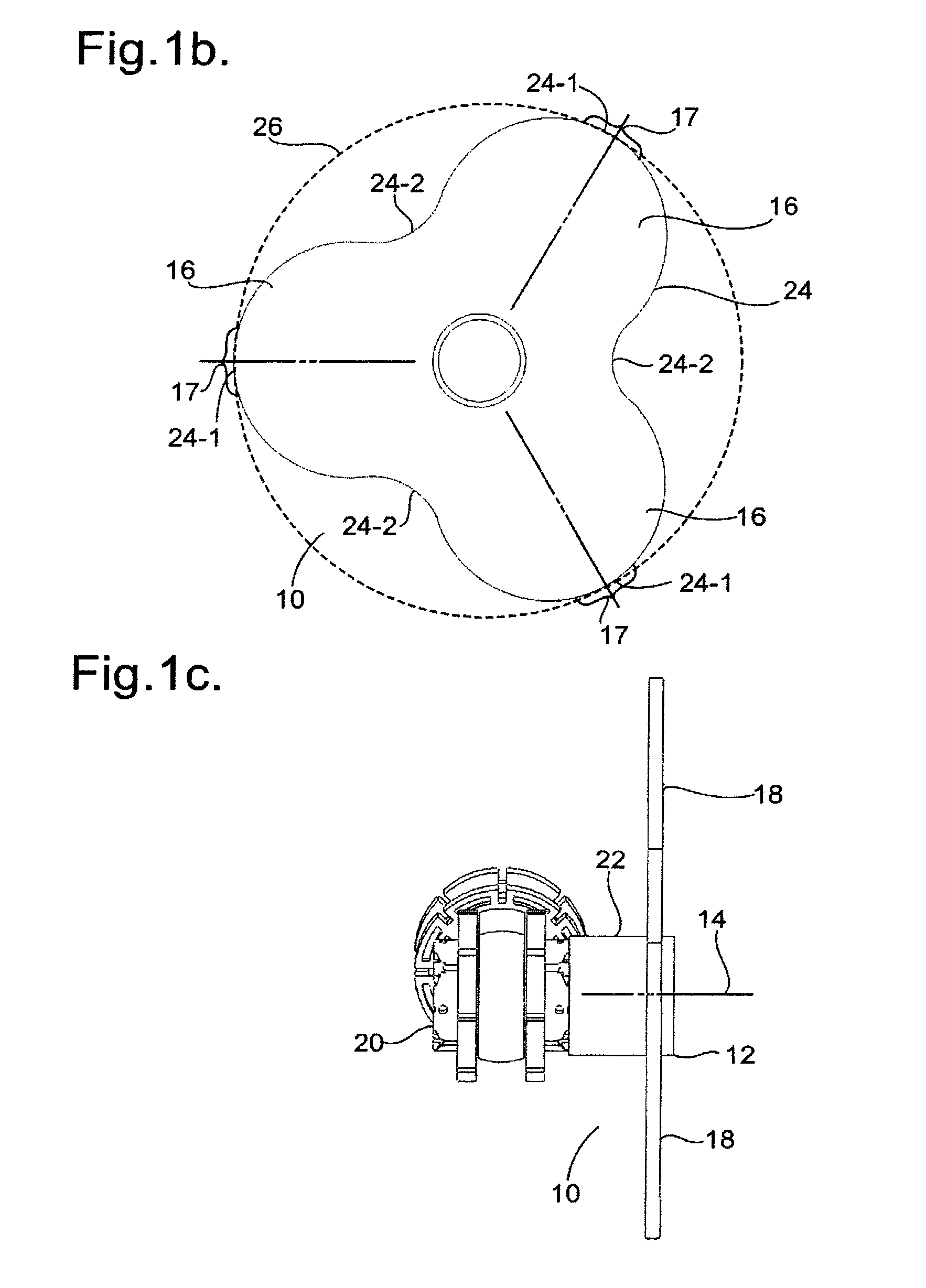

Wheel and wheel assembly

ActiveUS8905490B2Increased energy expenditureIncrease the footprintCarriage/perambulator accessoriesClimbing vehiclesEngineeringMechanical engineering

A wheel assembly and a wheel are suitable for use with a mobile platform. The wheel assembly comprising a first wheel and a second wheel, each wheel comprising a hub having a central axis of rotation, and at least two wheel lobes coupled to the hub, the wheel lobes extending radially from the hub and spaced around the central axis of the hub, where the first wheel is rotatably mounted to the second wheel on a common axis, and a control mechanism rotates the first wheel with respect to the second wheel.

Owner:ROSS ROBOTICS

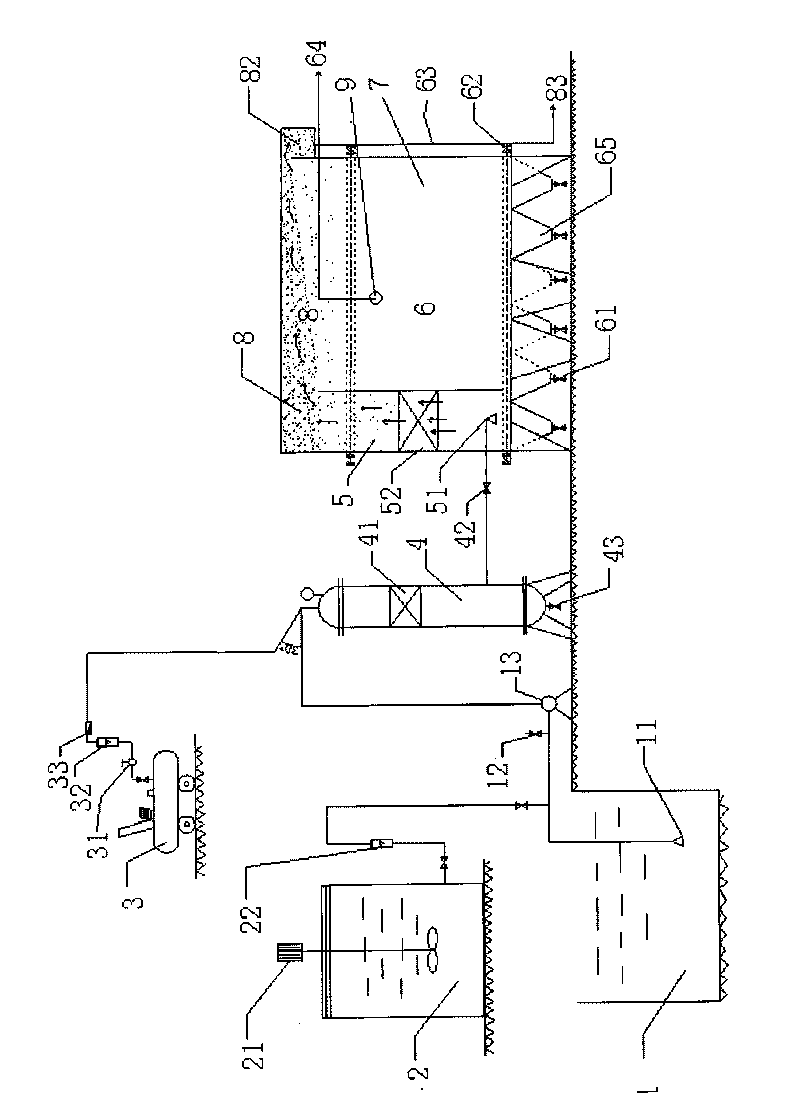

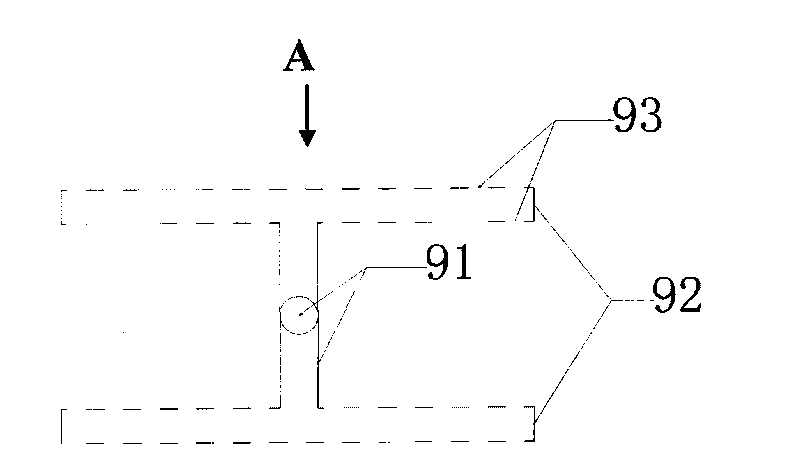

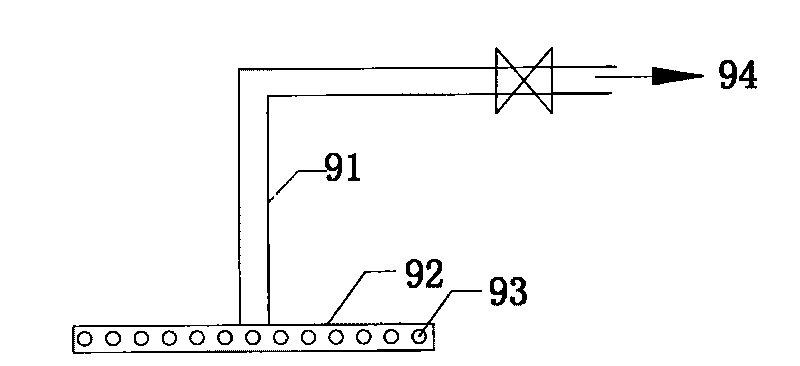

Totally-dissolved deep-layer air floatation combined device and sewage treatment method thereof

InactiveCN101759242AEasy to separateWell mixedWater/sewage treatment by flotationWater dischargeDraining tube

The invention discloses a totally-dissolved deep-layer air flotation combined device and a sewage treatment method thereof, relating to the technical field of environmental protection and aiming at solving the technical problem of unstable air floatation effect of various air floatation processes so as to further effectively improve the air floatation effect. The combined device comprises a sewage tank, a drug feeding groove, a lifting pump, a totally-dissolved air floatation pot and an air floatation tank, wherein the air floatation tank with the depth of 6 to 9m, is divided into a releasing zone and a separating zone. The upper layer of the releasing zone is connected with a mud layer of the separating zone, the middle layer is a padding layer, and a releaser arranged at the lower layer is connected (communicated) with the lower part of the totally-dissolved air floatation pot by a pipeline; the upper part of the separating zone is the mud layer for discharging floating residues, a water discharging pipe arranged at the middle part is used for discharging treated water out of the air floatation tank, and a mud bucket zone arranged at the lower part is used for discharging sinking mud residues. The invention has the characteristics of stable air floatation, good effect, high COD, color and SS removing rate, good transparency of outgoing water and less drug feeding quantity.

Owner:上海百峰环保工程有限公司

Manufacturing process of polyester cotton yarn-dyed fabric

InactiveCN107869077ALow staticReduce the probability of static electricitySingeingHeating/cooling textile fabricsYarnPolyester

The invention discloses a manufacturing process of a polyester cotton yarn-dyed fabric. The manufacturing process comprises the following technological steps: selecting a polyester cotton blended yarn; sequentially performing scouring, blanching, dyeing, soap-boiling, water washing and drying, wherein beam dyeing is adopted, and in the dyeing process, the winding density of a warp of a warping machine is 0.46-0.48 g / cm<3>; before dyeing, adding 0.2-0.4 g / L sodium sulfate into water required by dyeing, performing stirring for 8-10 min; adding sodium carbonate first at the water temperature of 35-40 DEG C; after 12-15 min, adding sodium sulfate for 12-15 min; and maintaining for 42-46 min when the temperature rises to 62 DEG C. According to the manufacturing process, the dyeing effect is improved, more uniform dyeing is achieved, the dyeing freshness is guaranteed, the static property of a spun polyester thread is reduced by an anti-static agent, the static ratio of the polyester cottonyarn-dyed fabric which is woven is favorably reduced on the whole, in addition, triple-jump, yarn breakage and yarn sinking are reduced, and the sizing percentage is increased.

Owner:JIANGSU MINGYUAN TEXTILE

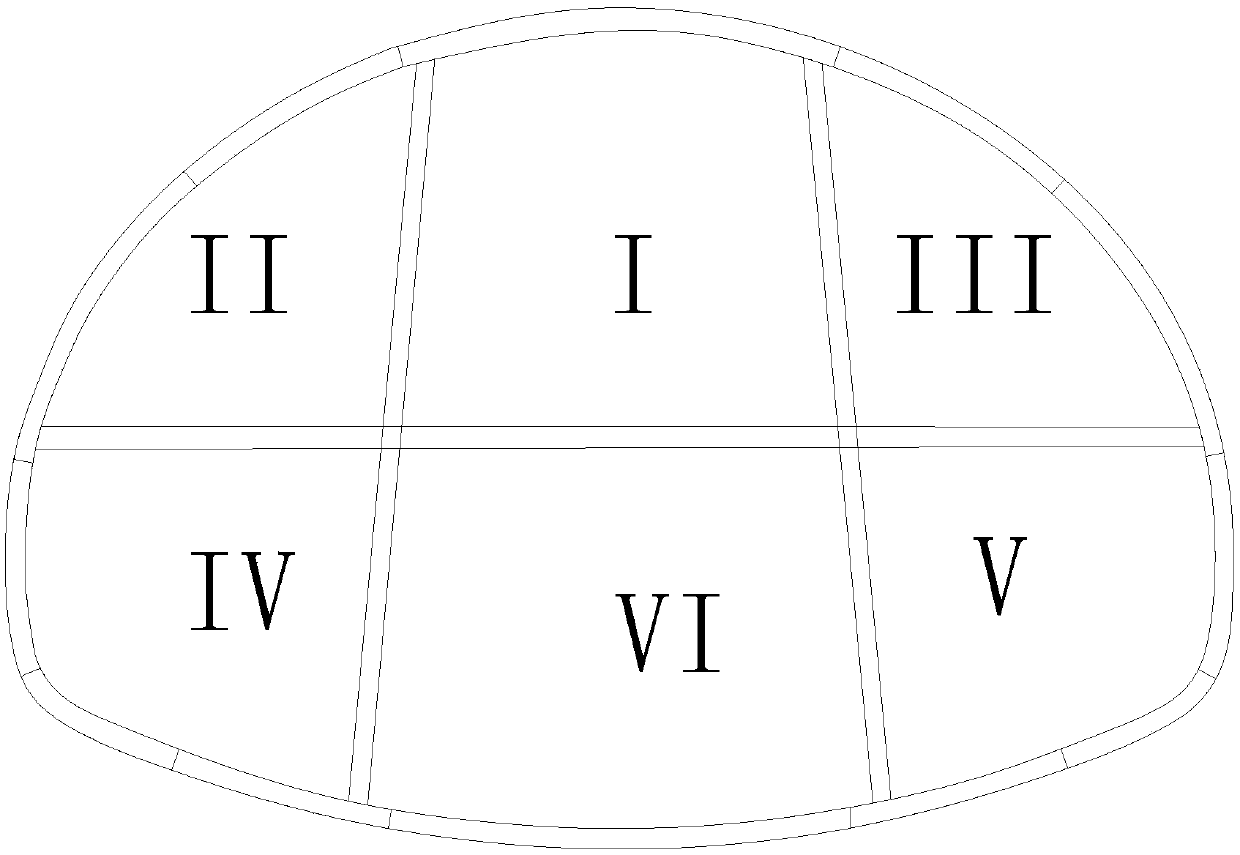

Tunnel two-expansion four-expansion excavation method

ActiveCN109595004AWide adaptability to terrainReduce sinkingUnderground chambersTunnel liningArchitectural engineeringRock tunnel

The invention relates to the field of tunnel excavation. The invention relates to a tunnel expanding excavation method. The method comprises IV-level and V-level surrounding rock tunnel construction methods and further includes an III-level surrounding rock tunnel construction method. The IV-level surrounding rock tunnel and the V-level surrounding rock tunnel construction methods comprise the following construction steps that an excavated tunnel is partitioned, and the excavation tunnel comprises a first part in the middle of an arch crown, a second part on the left side of the first part, athird part on the right side of the first part, a fourth part on the lower side of the second part, a V part on the lower portion of the third part and a VI part on the first part. According to the construction methods, double-side-wall partial excavation is adopted, and the excavation mode of first arching and then wall excavation has the advantages that the arch crown sinking is minimum, the horizontal displacement is small, the temporary supporting axial force is minimum, supporting is reliable, and the project progress is fast. And the scheme is very suitable for expanding excavation construction of tunnels with ultra-large spans, ultra-large sections and small intervals, the construction safety is high, and the phenomena of collapse and the like are avoided.

Owner:浙江省隧道工程集团有限公司

Cushion pad

[Problem]To provide a cushion pad that allows reducing the oppressive feeling in a thigh and the sinking of buttocks and improving the texture and the fit feeling.[Solution]In a portion positioned underneath a hip point of a seated person, an under-buttock portion is set to have a smaller force S25 during compression to 25% in a second portion including a seating surface than S25 of the first portion positioned on a bottom surface side. The thigh supporting portion is set to have smaller S25 of a portion including the seating surface than S25 of the first portion. This allows reducing the oppressive feeling in the thigh and the sinking of the buttocks and improving the texture and the fit feeling.

Owner:TOKYO QUALITY ONE CORP

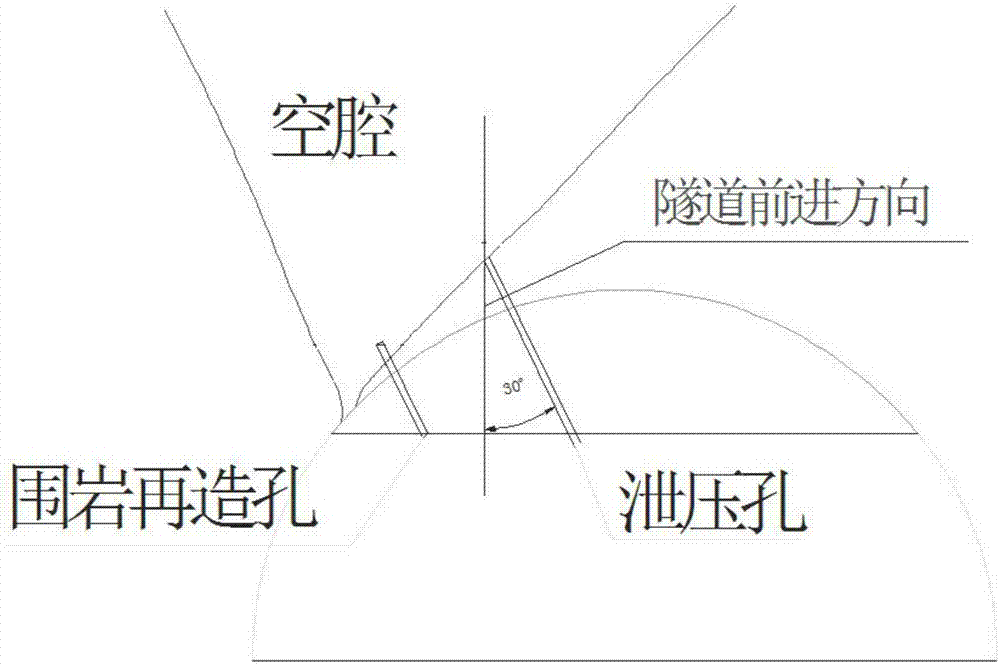

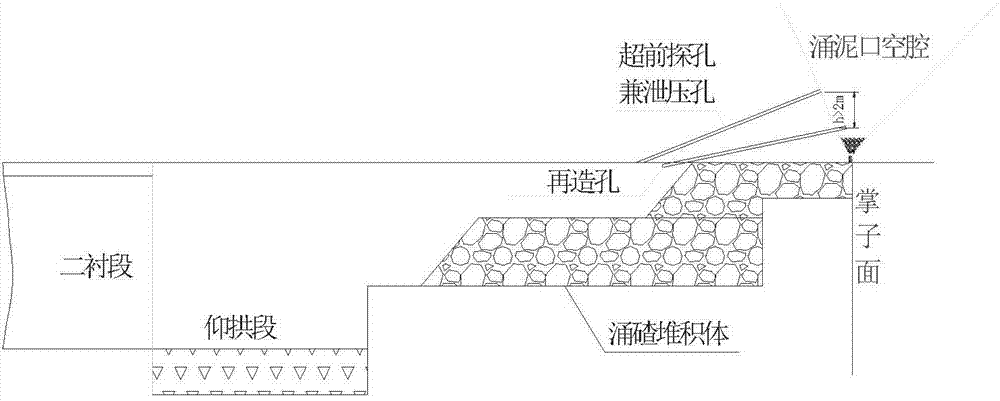

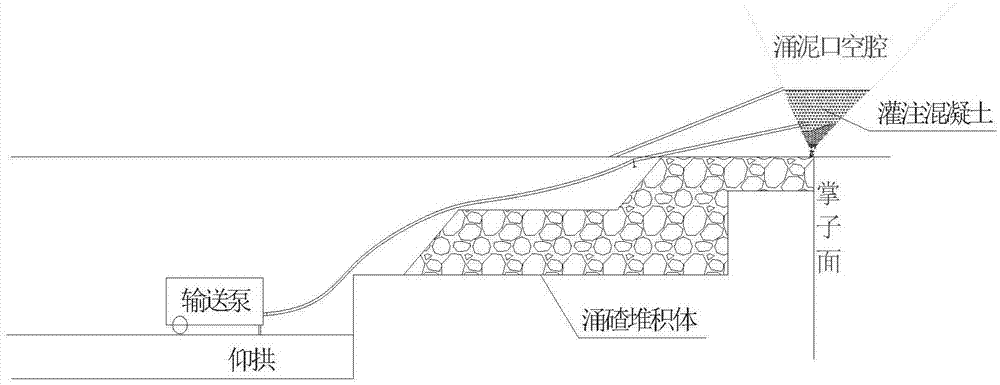

Vault cavity surrounding rock reconstruction method used after water and mud burst of large-section tunnel

ActiveCN107013228ASpeed up treatmentImprove treatment efficiencyUnderground chambersTunnel liningSoil scienceStructural engineering

The invention discloses a vault cavity surrounding rock reconstruction method used after water and mud burst of a large-section tunnel. The method mainly aims at a large-section tunnel project, tunnel vault collapse, surrounding rock breaking and large surrounding rock gap unstability which are caused by water and mud burst are transformed and controlled through surrounding rock reconstruction, integration of a tunnel vault and surrounding rock is formed, handling of the water and mud burst of the tunnel is accelerated, investment and losses are reduced, and part of safety hidden hazards are eliminated. The urrounding rock reconstruction method improves the handling efficiency of the water and mud burst of the tunnel, stability of the tunnel surrounding rock is ensured, the probability of secondary water and mud burst is reduced, and the technology is safe and reliable. After positioning, detection and analysis of a tunnel vault cavity, surrounding rock reconstruction is reasonably selected, broken and hollow tunnel vault surrounding rock becomes integrated, the situation that underwater water continues to damage and erode the water and mud burst portion is reduced, the supporting function of a large pipe shed is improved, subsidence and convergence deformation of the surrounding rock are reduced, and the construction process is accelerated.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com