Patents

Literature

59results about How to "Reduce lifting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

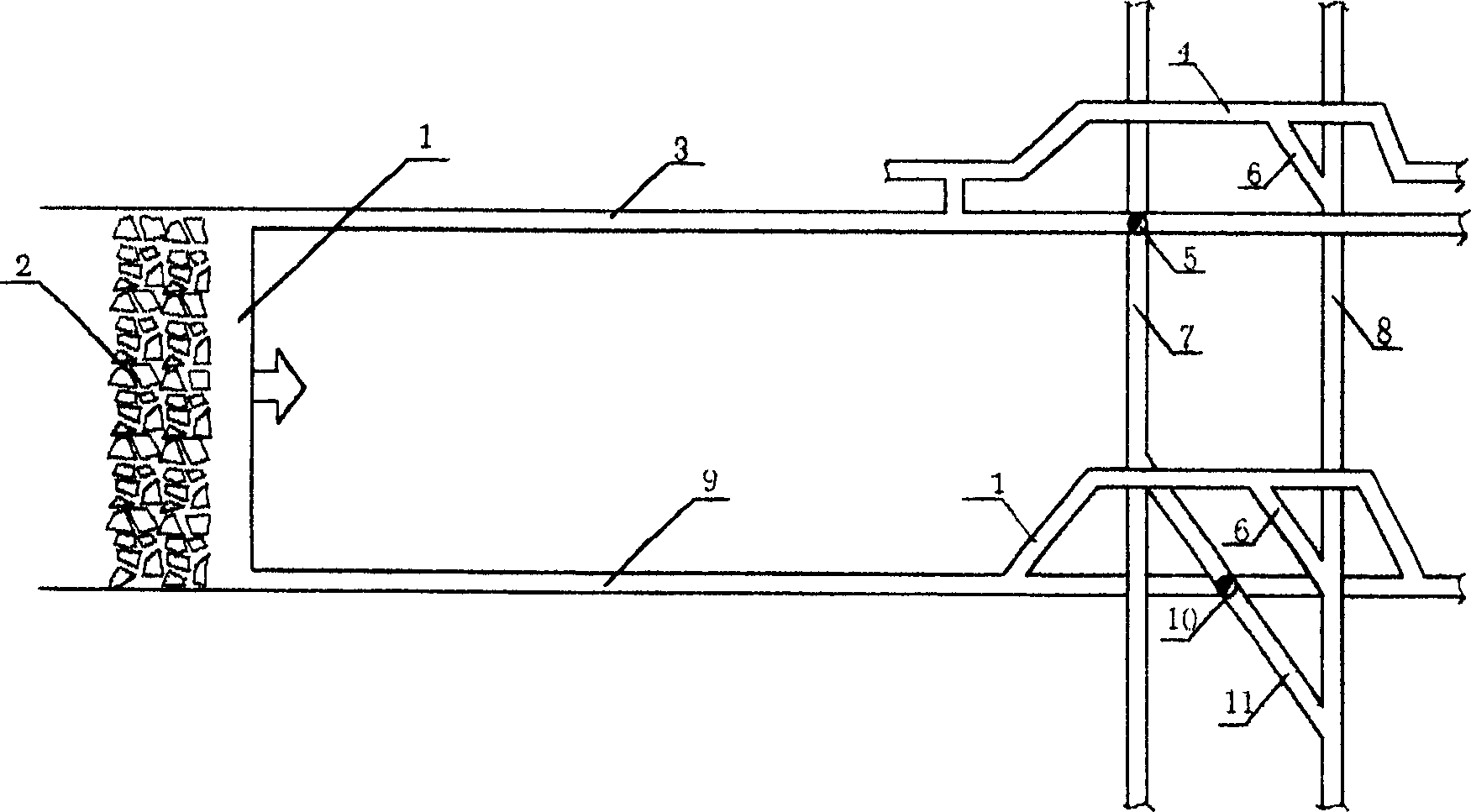

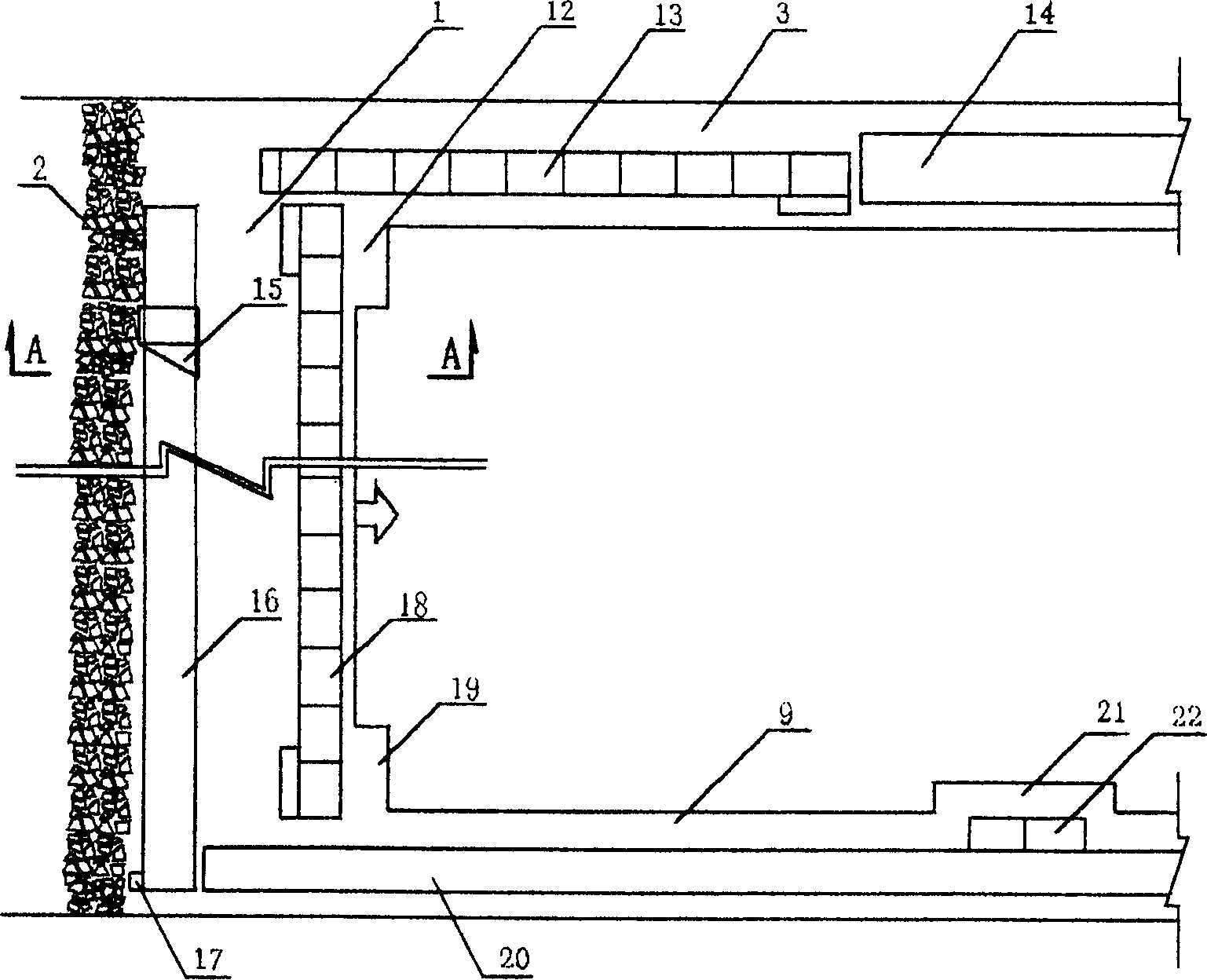

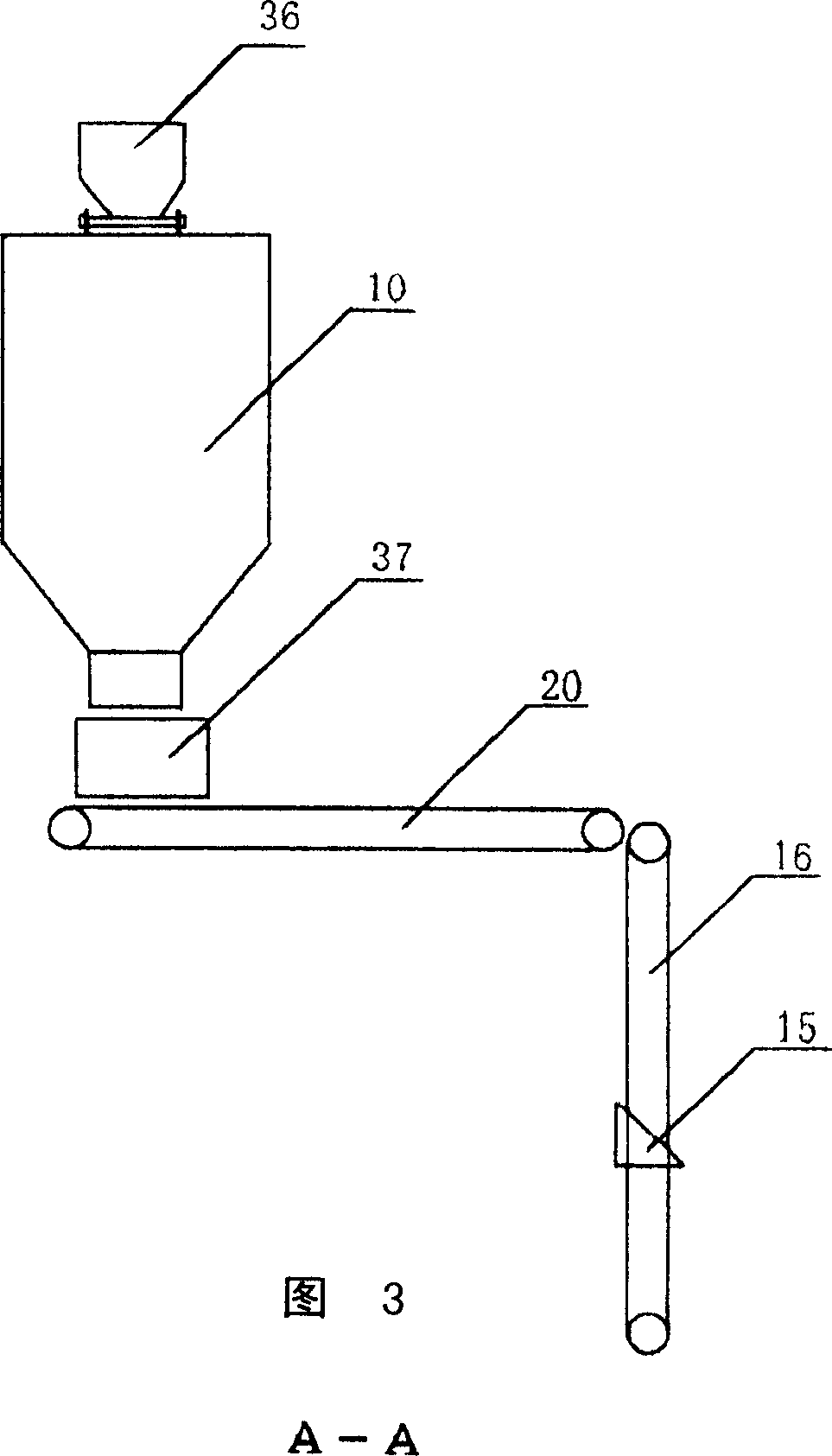

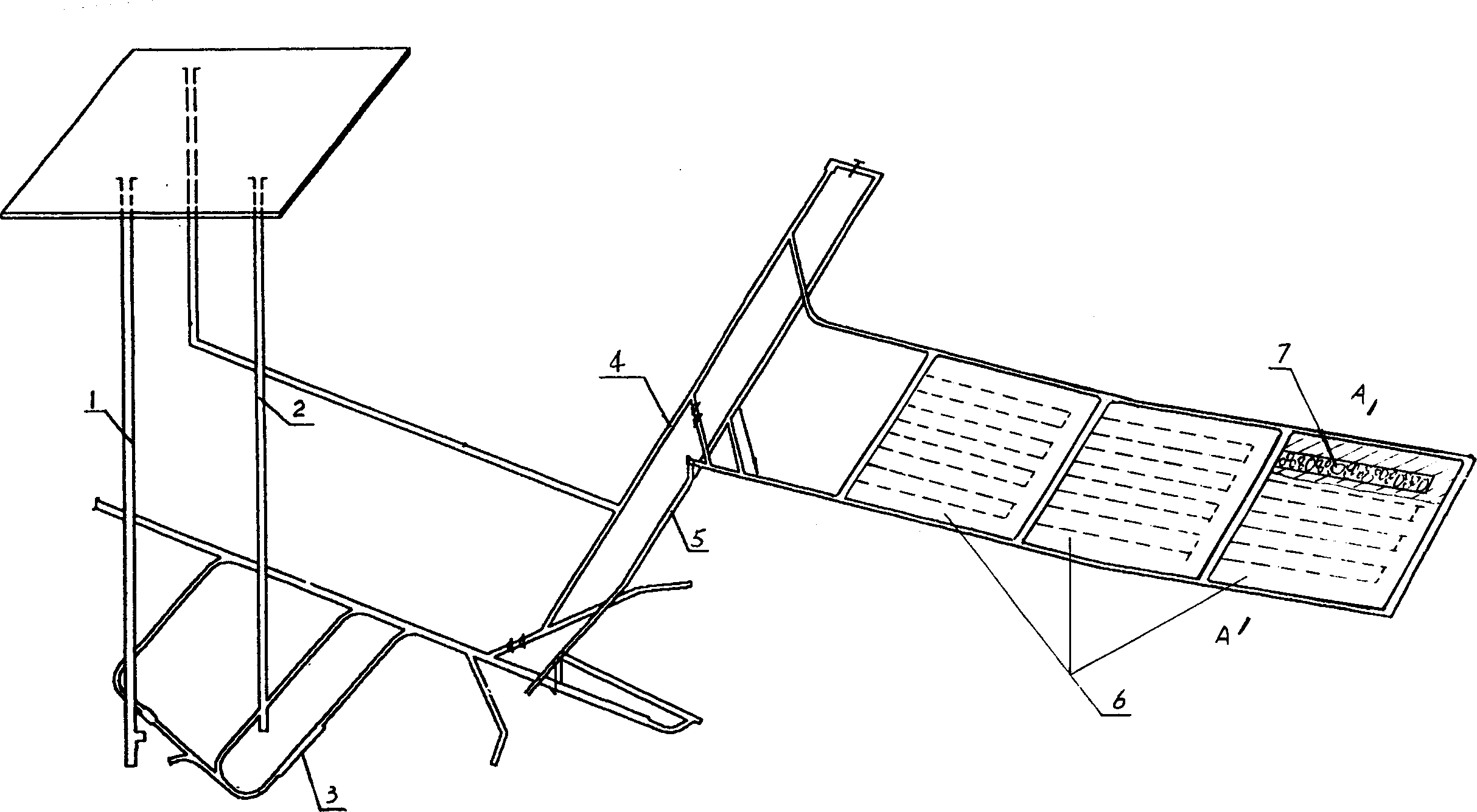

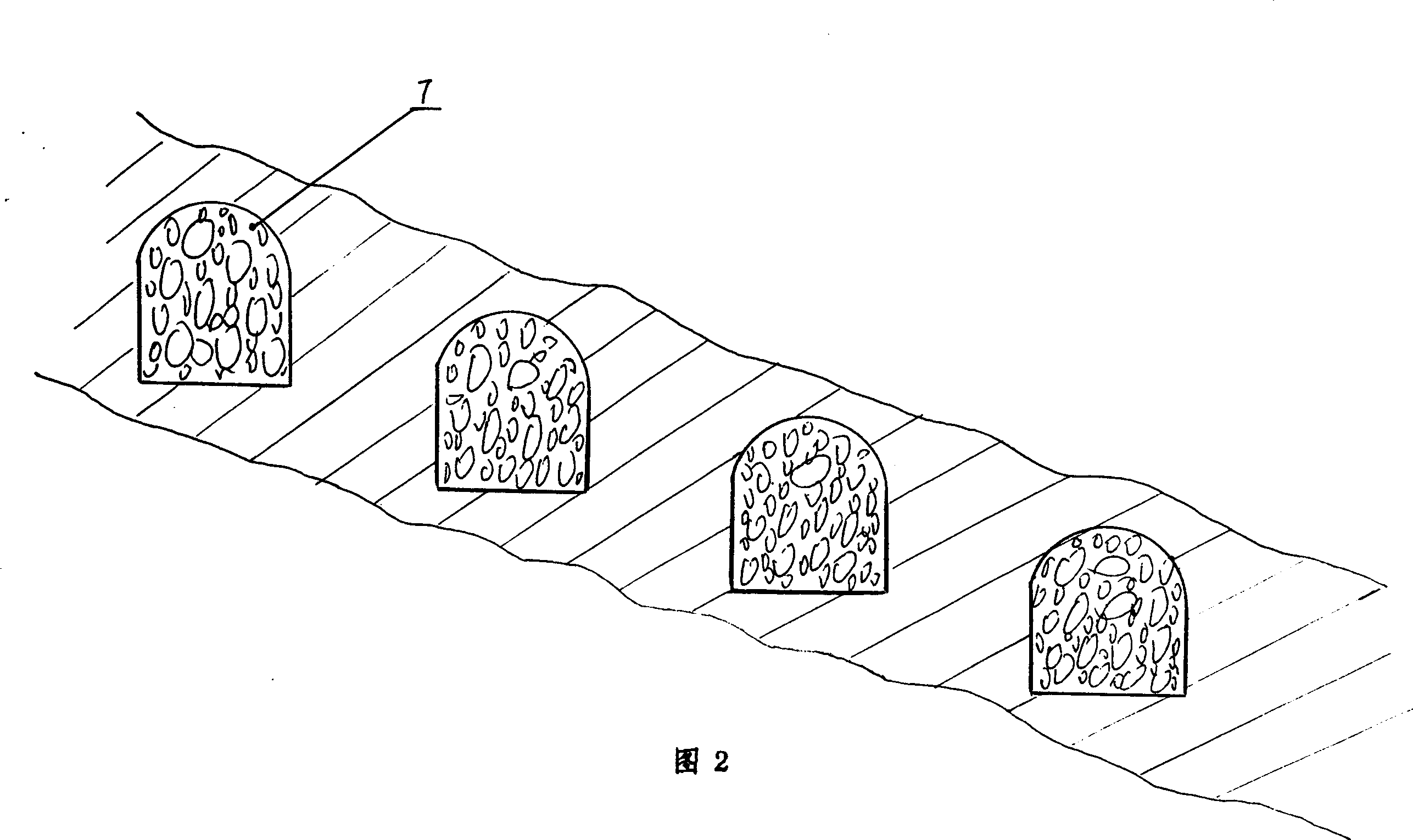

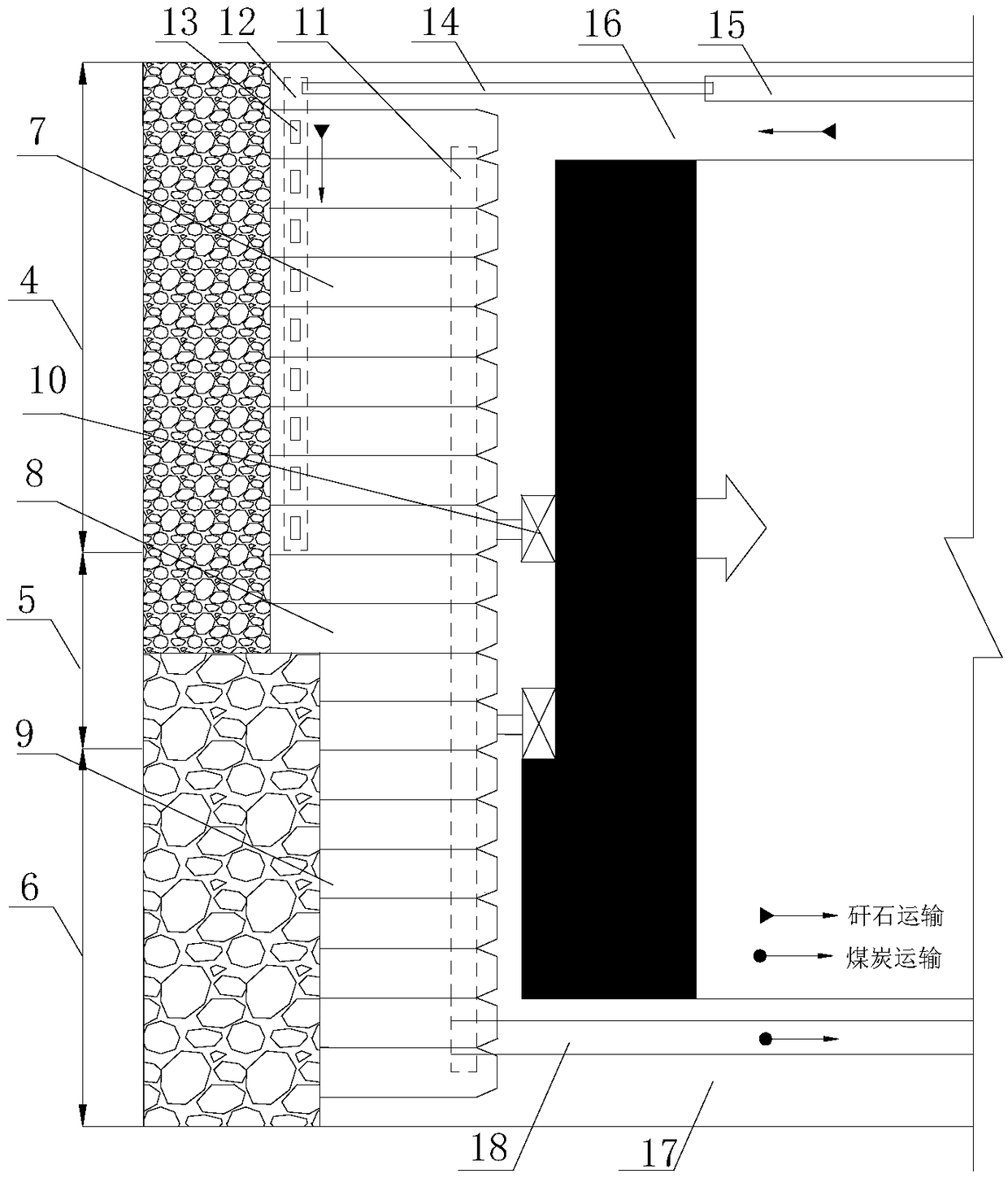

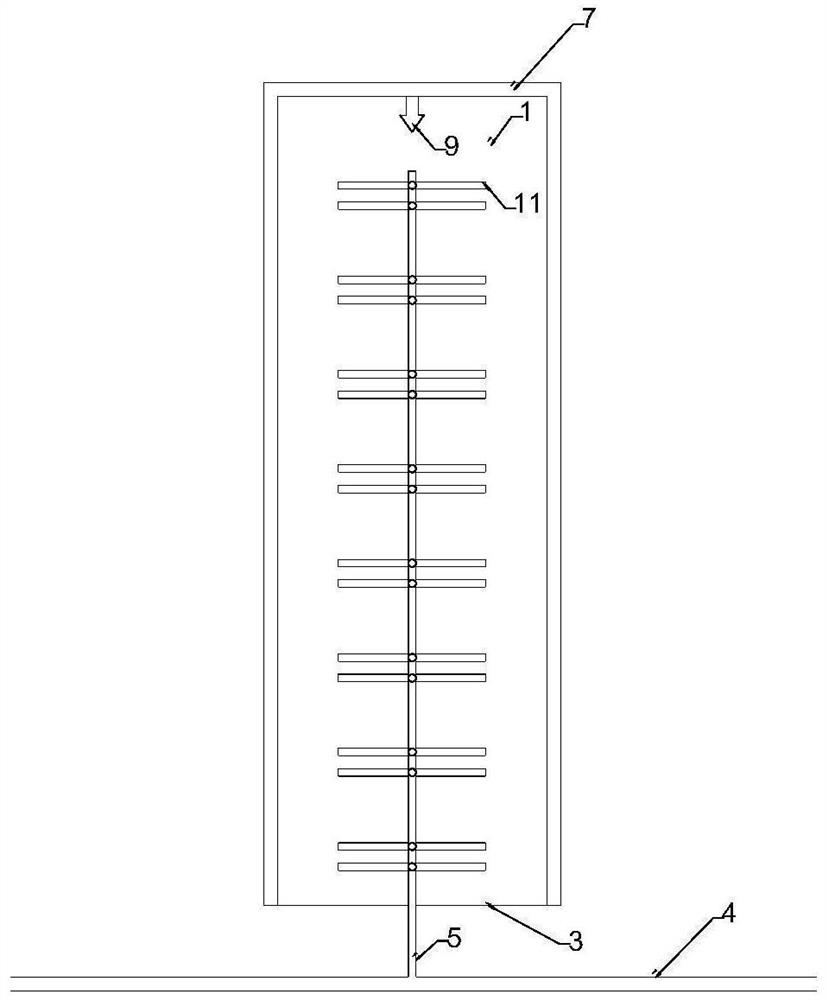

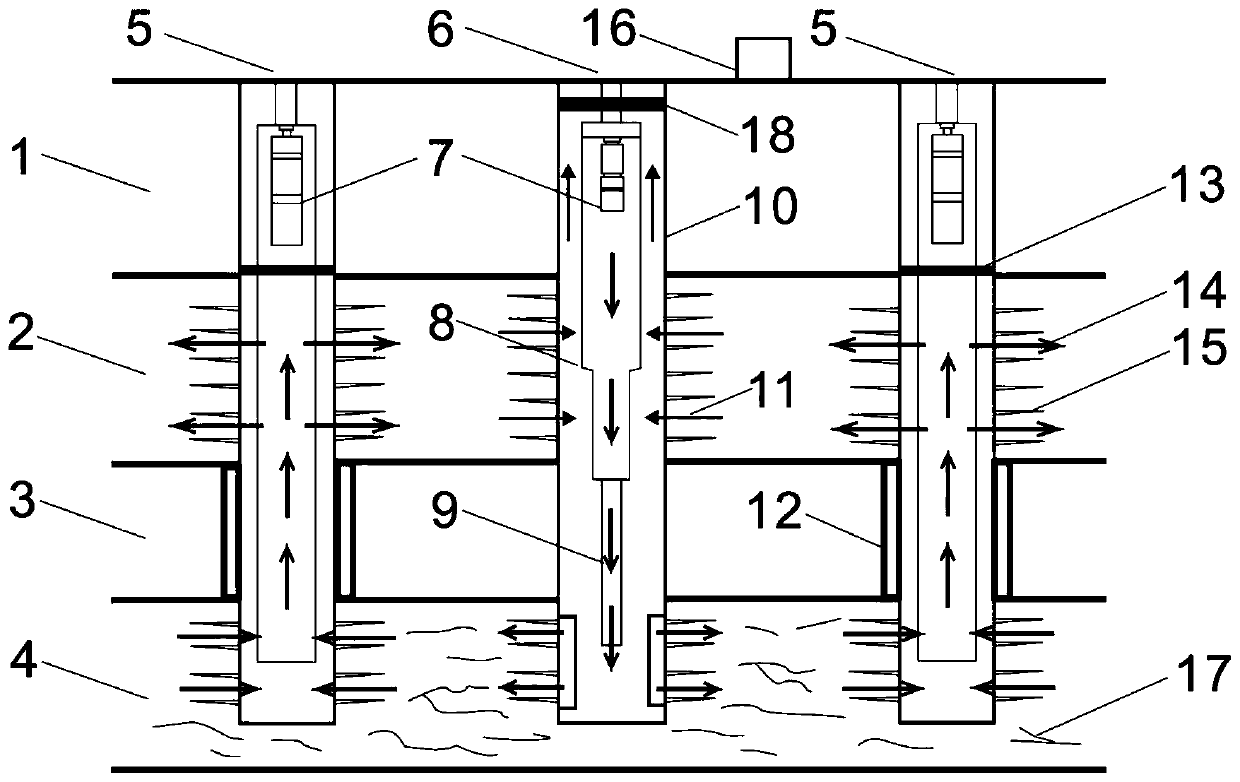

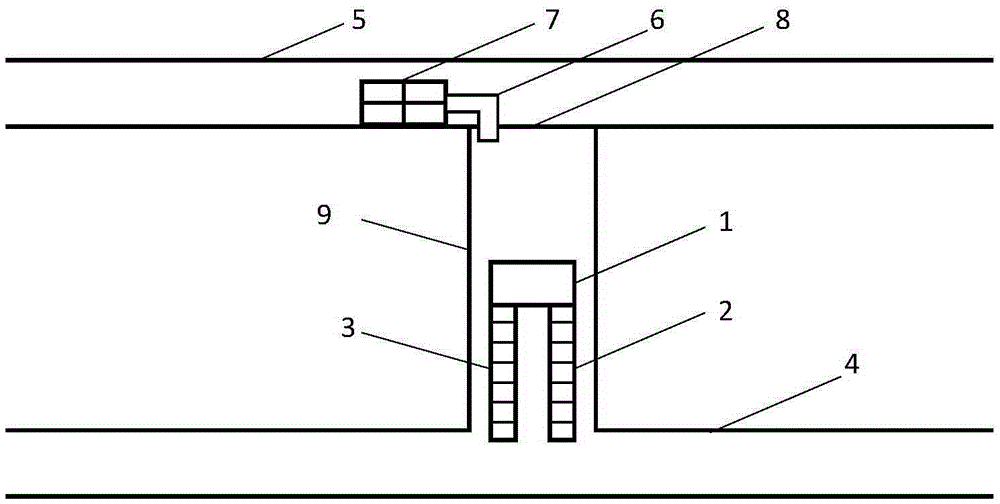

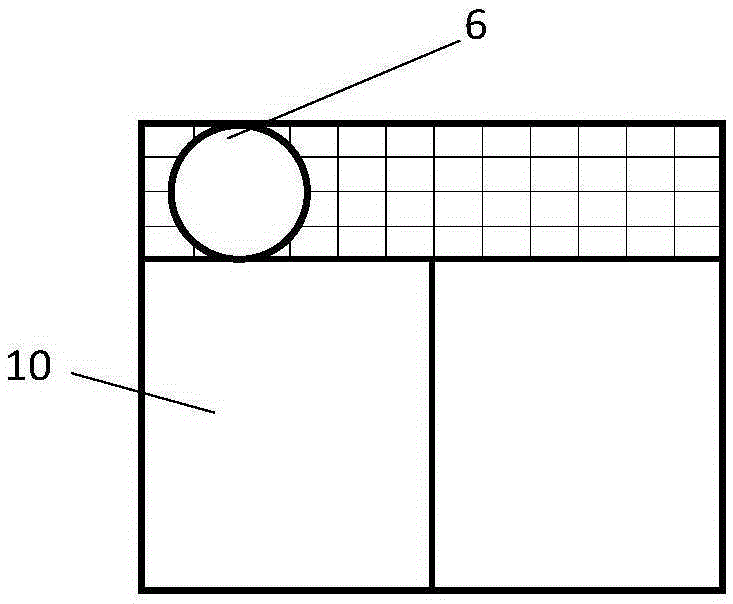

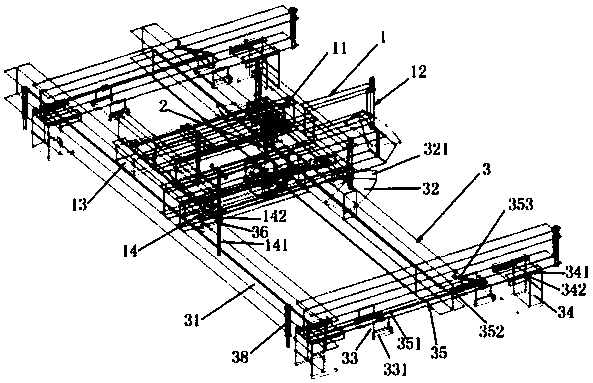

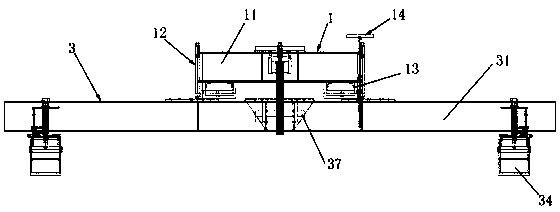

Method for filling goaf by gangue

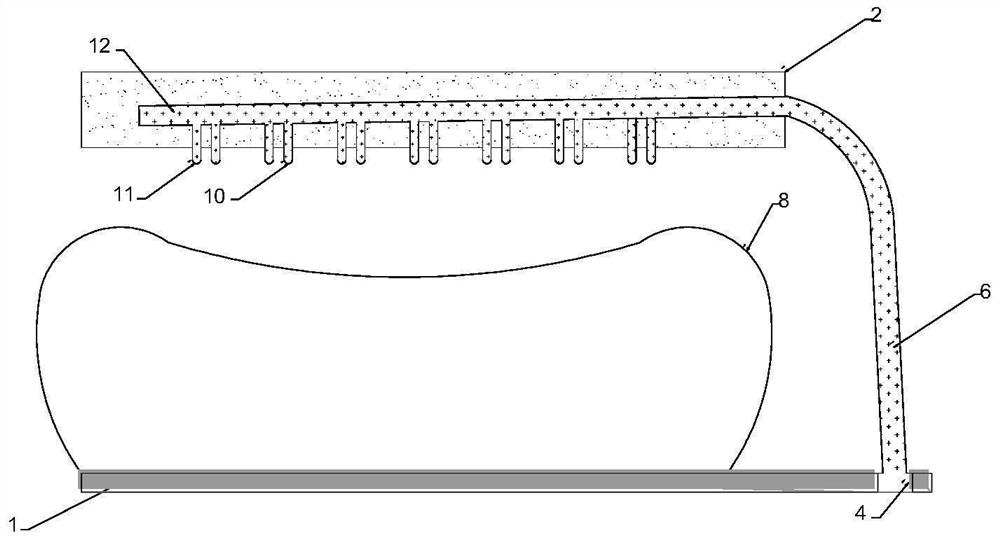

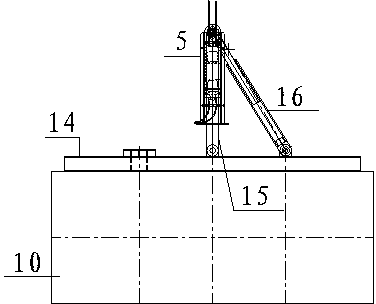

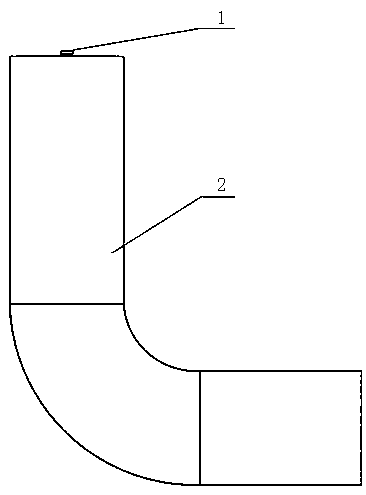

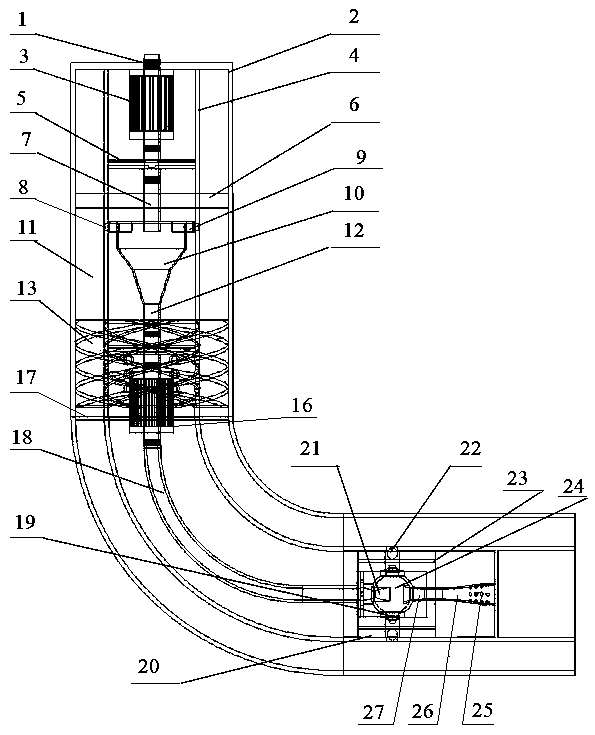

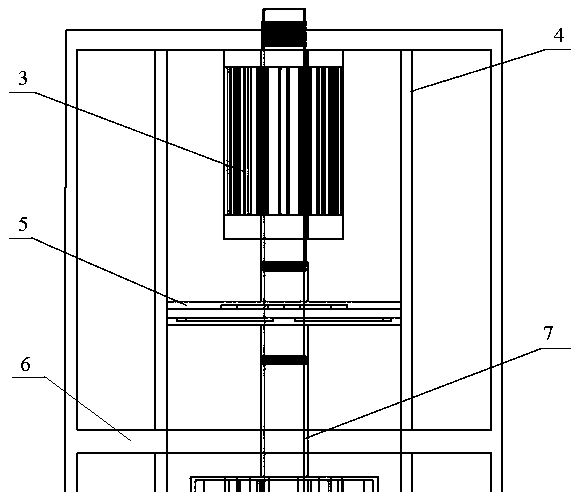

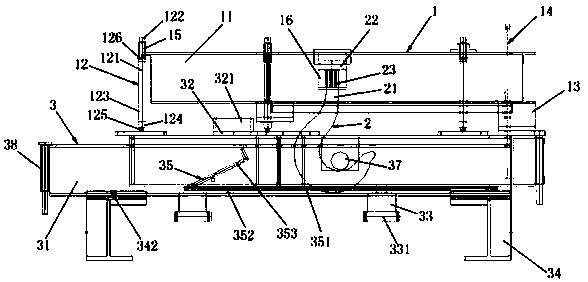

The invention relates to a method for using stone to fill the worked-out section under the coal well, which arranges a stone bin (10) outside the working surface to transfer the under-well stone or the ground stone to the stone bin (10) to be broken by the breaker; and using the stone belt machine (20) on the producing surface to transfer them to the upper end of producing surface (1); the producing surface (1) is supported by the filling brackets or the brackets whose back have extending beams; when the bracket is self-motion type, suspending a small belt device (16) on the extending beam and moving ahead with the bracket; when the bracket is not self-motion type, the small belt device (15) is arranged at the bottom plate under the extending beam and using slide device to move ahead; the small belt device (16) is mounted with a self-motion stone unload cart (15); transferring the small belt device (16) to the upper end of producing surface to unload the stone to the worked-out section. The invention can reduce the earth sink, effectively treat the stone, and reduce the accommodation area of stone and the pollution, with simple device and lower cost.

Owner:新汶矿业集团汶南煤矿有限责任公司

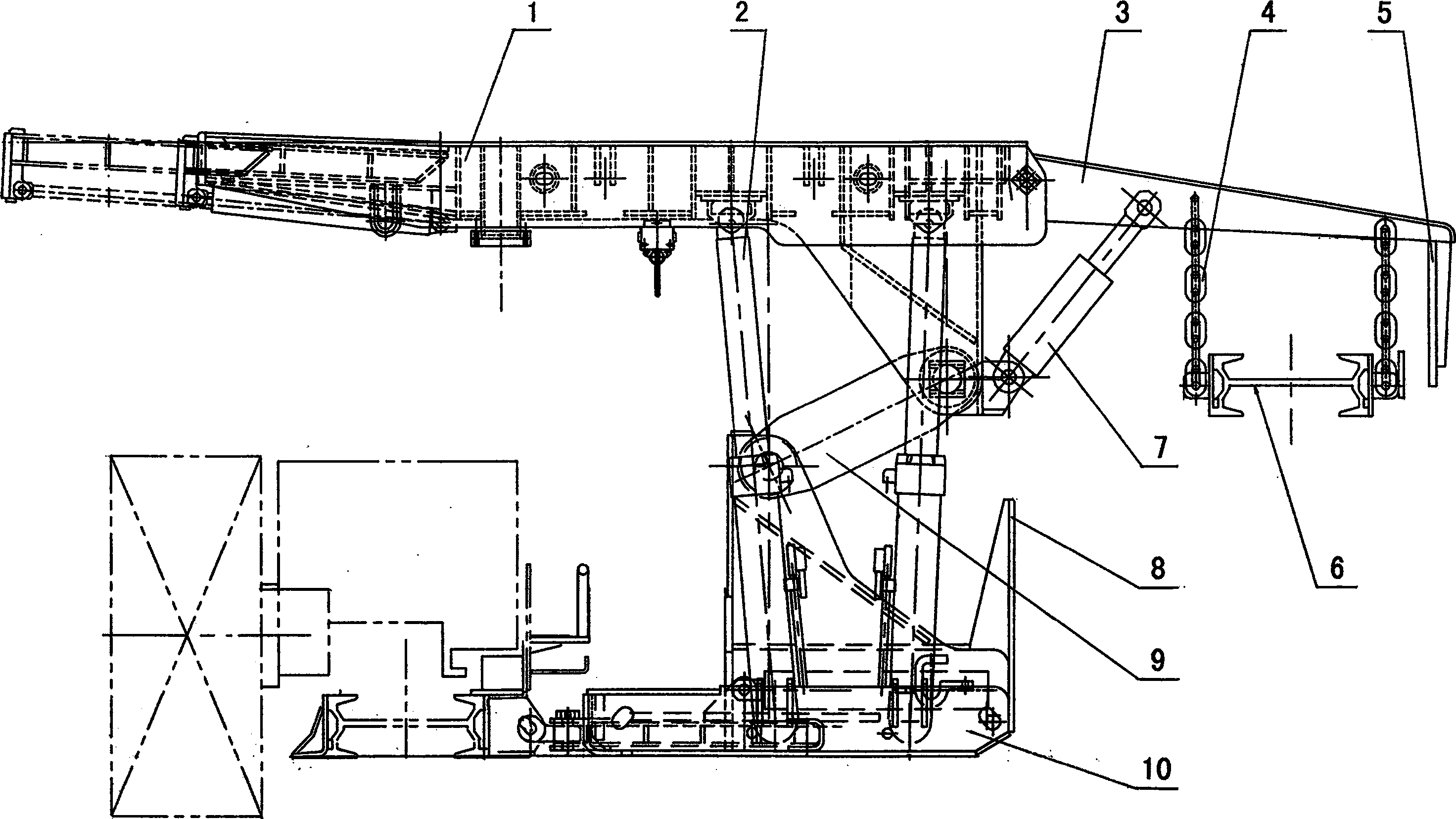

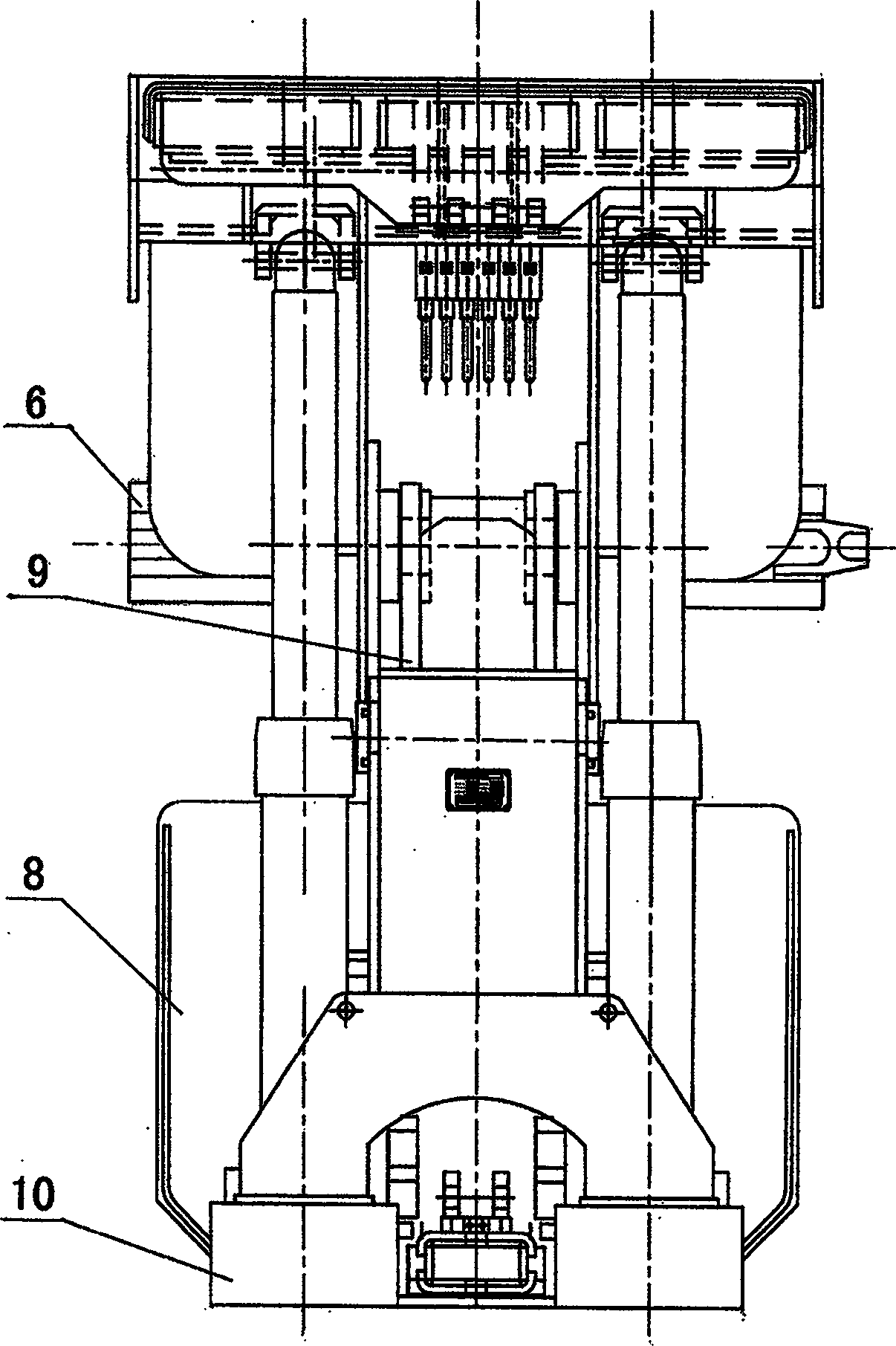

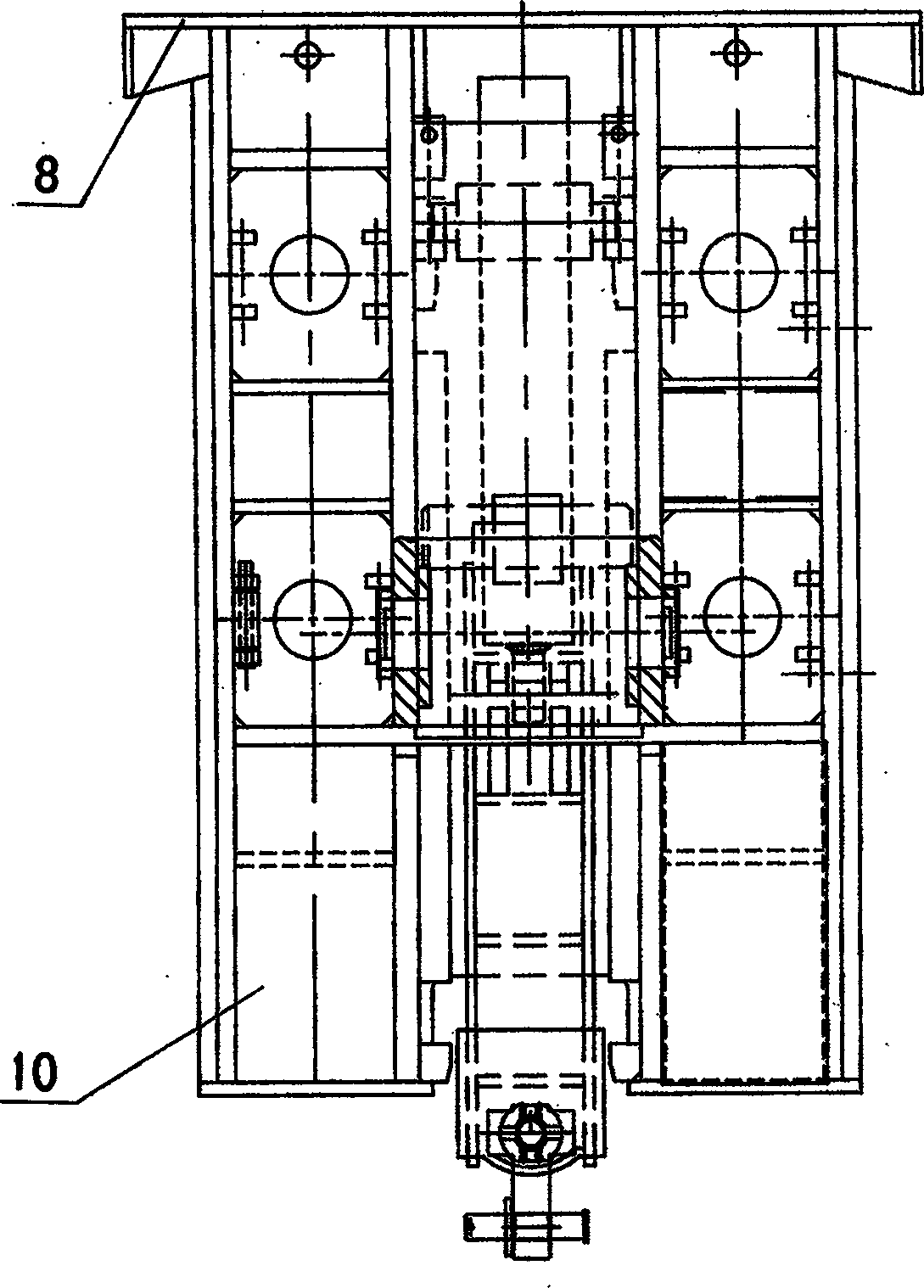

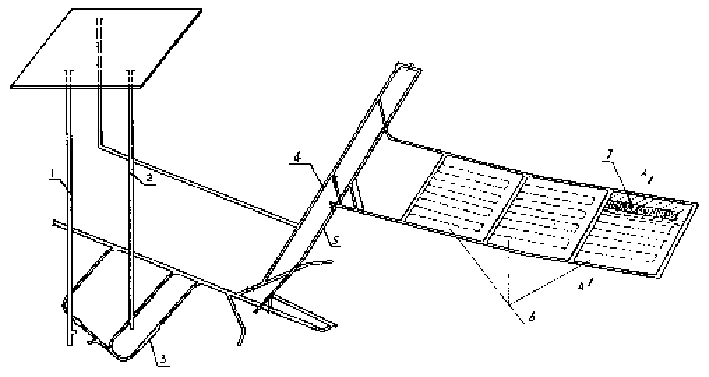

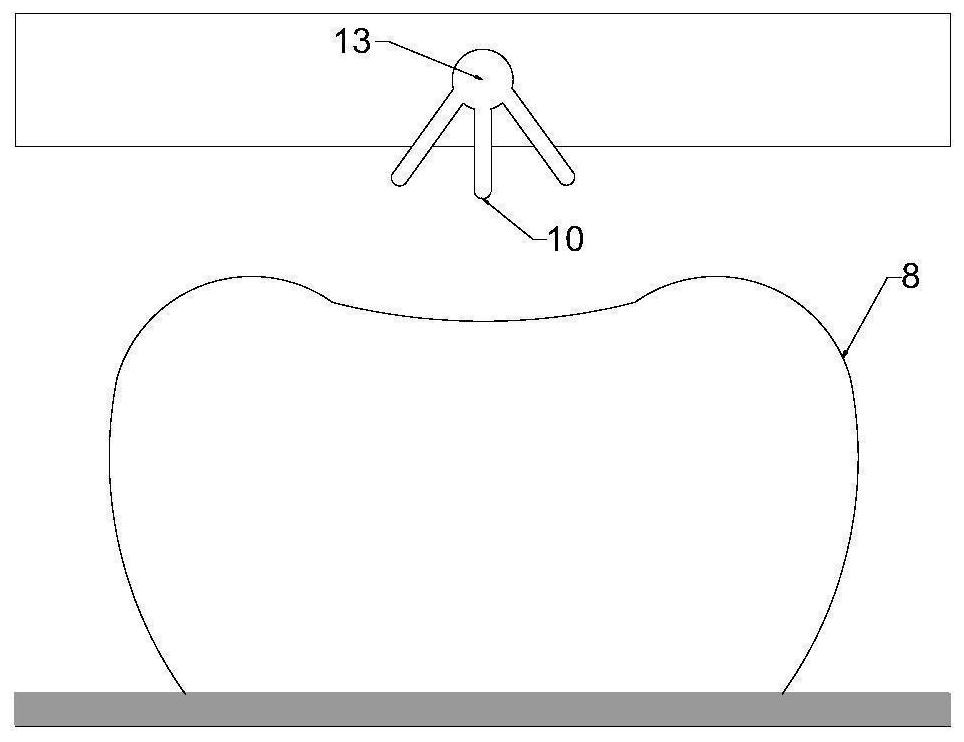

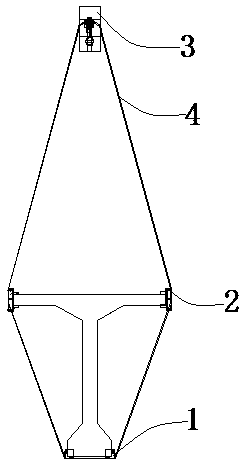

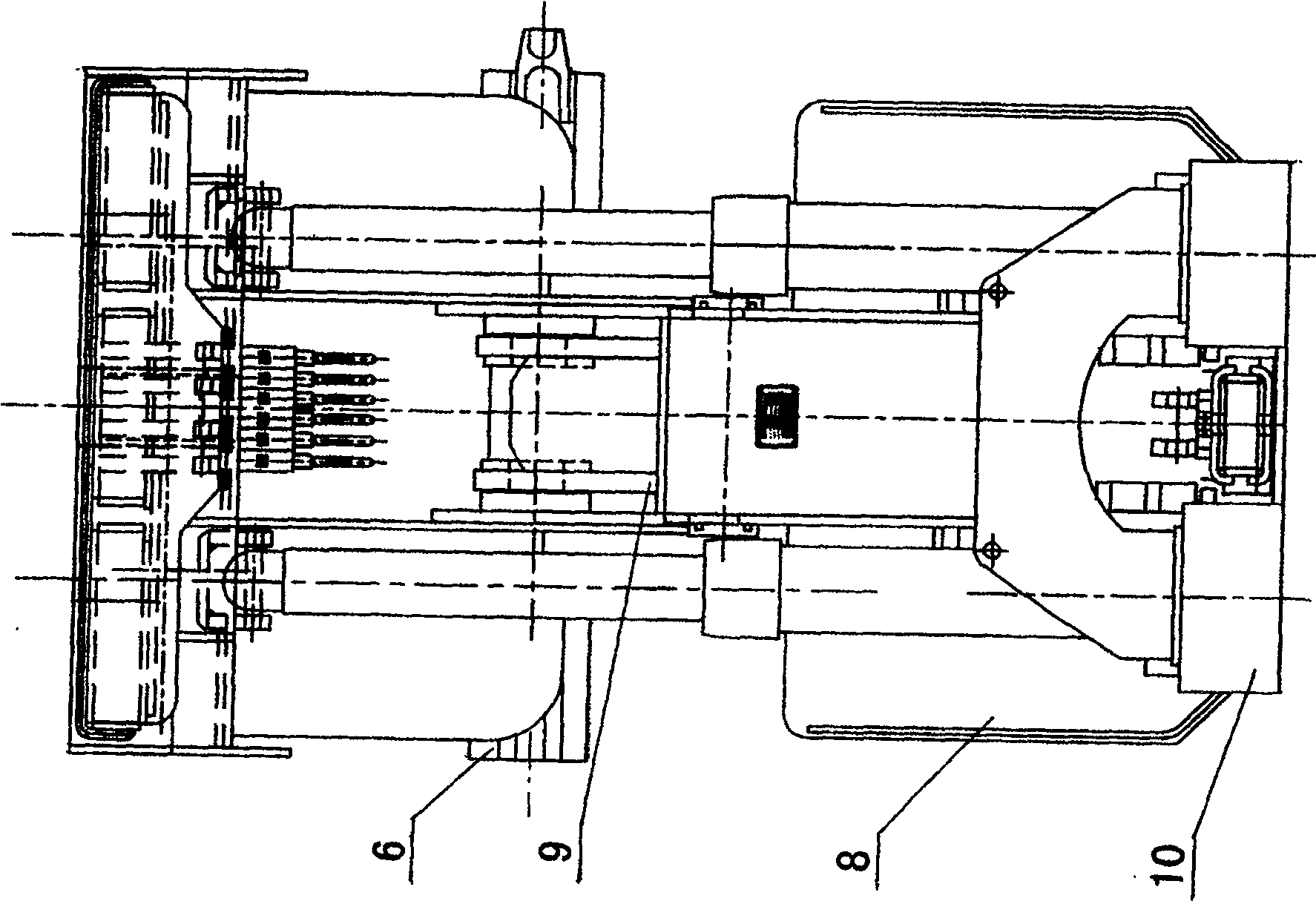

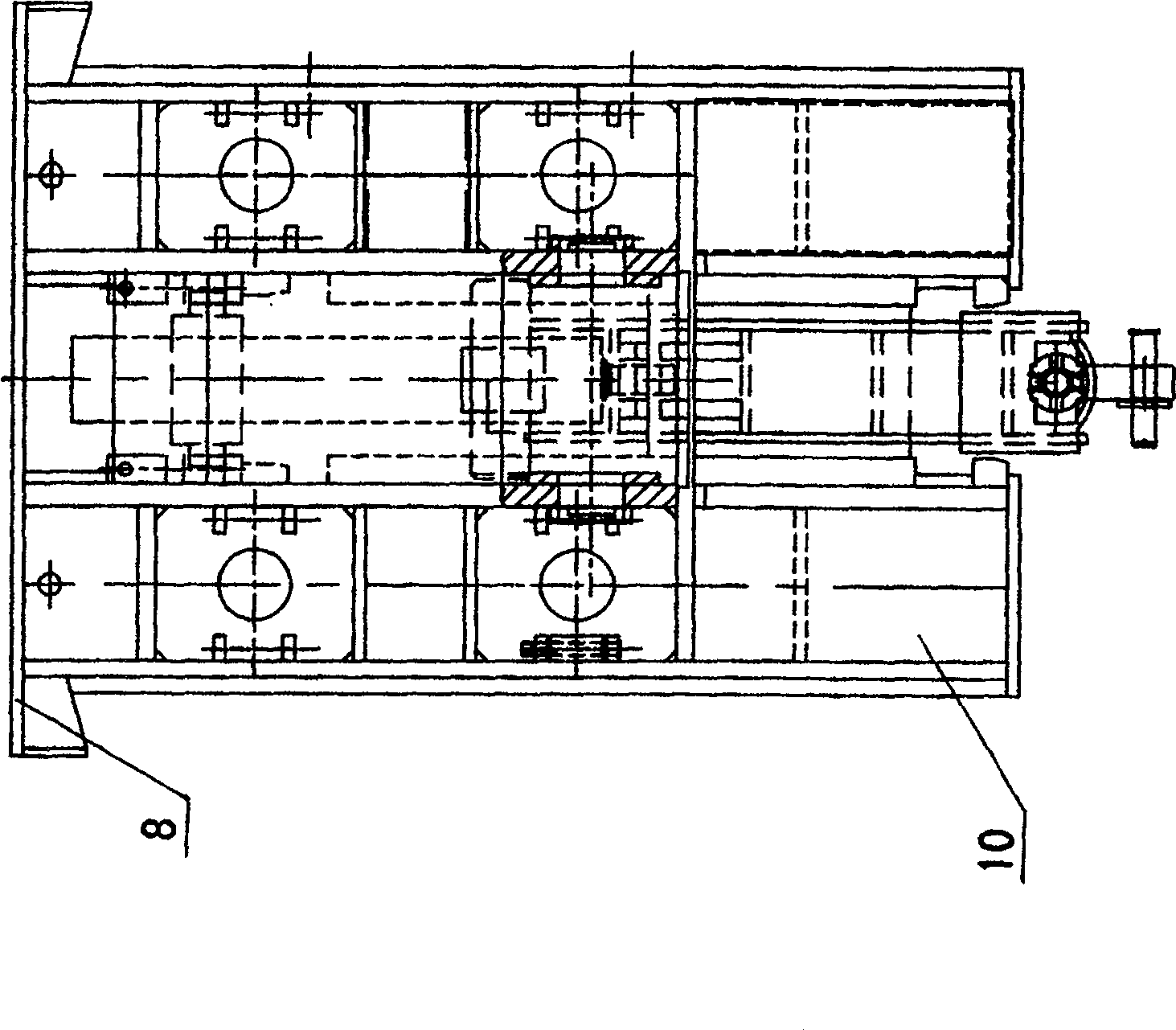

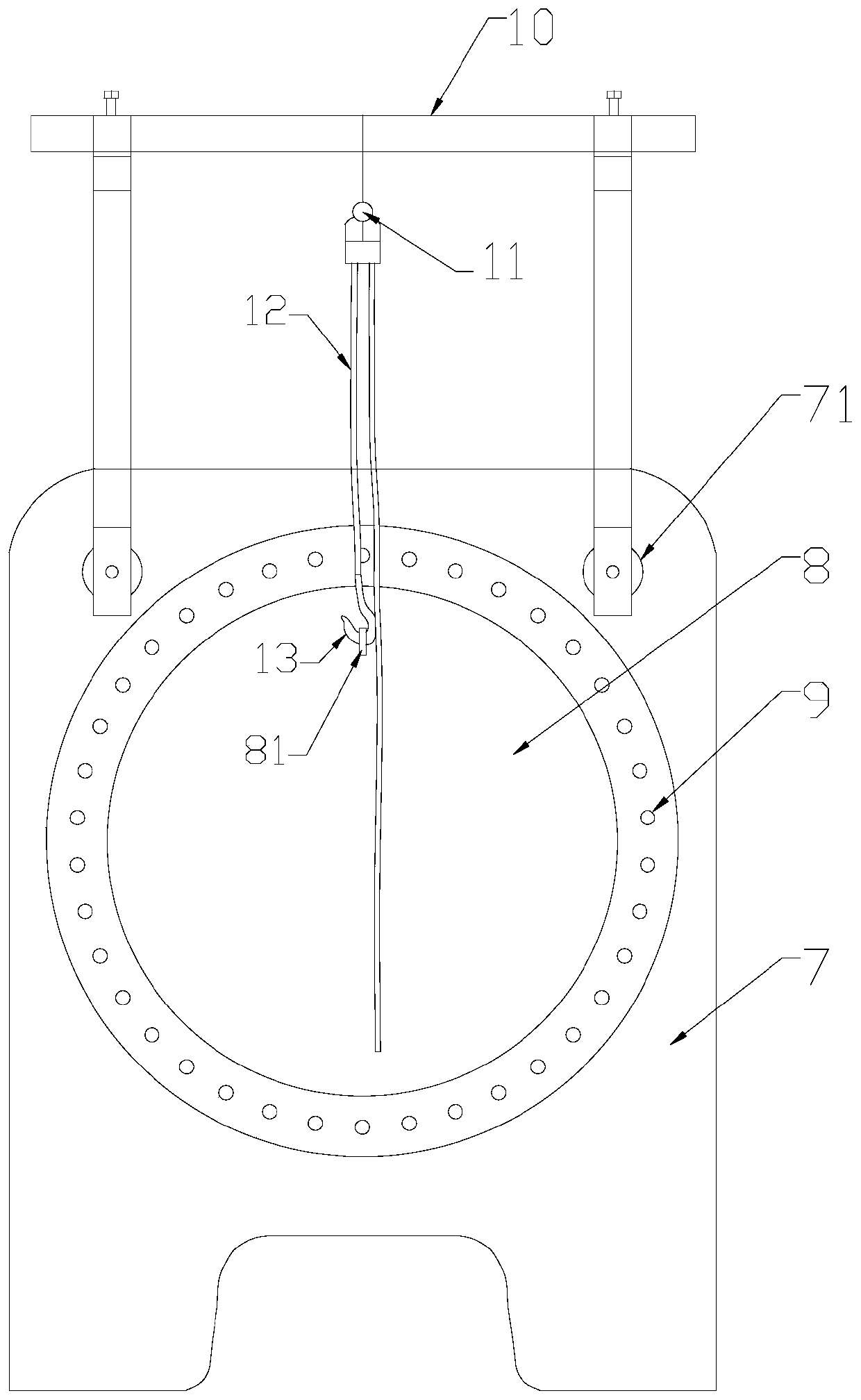

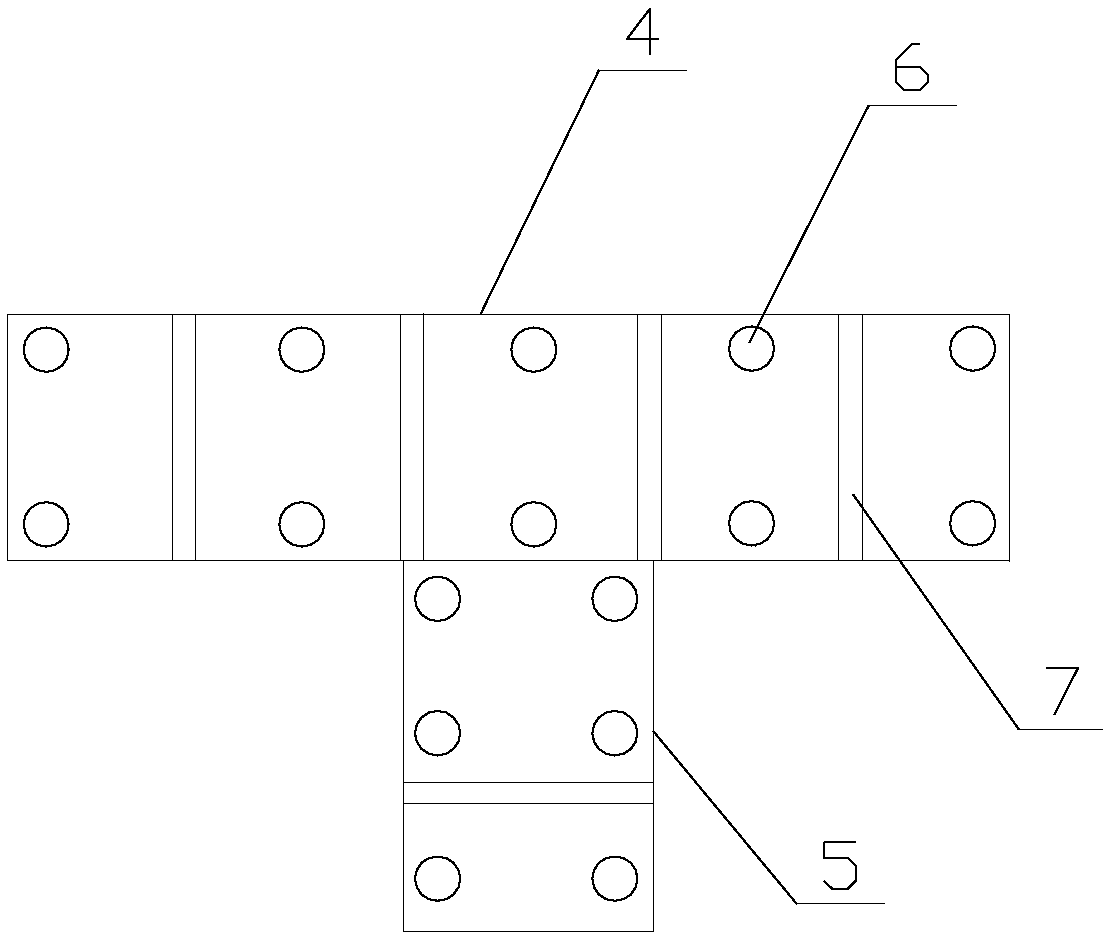

Hydraulic support for filling waste rock

A hydraulic frame for filling waste rock is composed of top beam, vertical column, base, tail beam, jack of tail beam and scraper conveyor chute suspended under tail beam. It is featured as opening waste rock leaking hole on frid of suspension chute, connecting suspension chutes to each other in sequence then connecting them with chute head and chute end at working face to form a complete set of scraper conveyor.

Owner:佟强

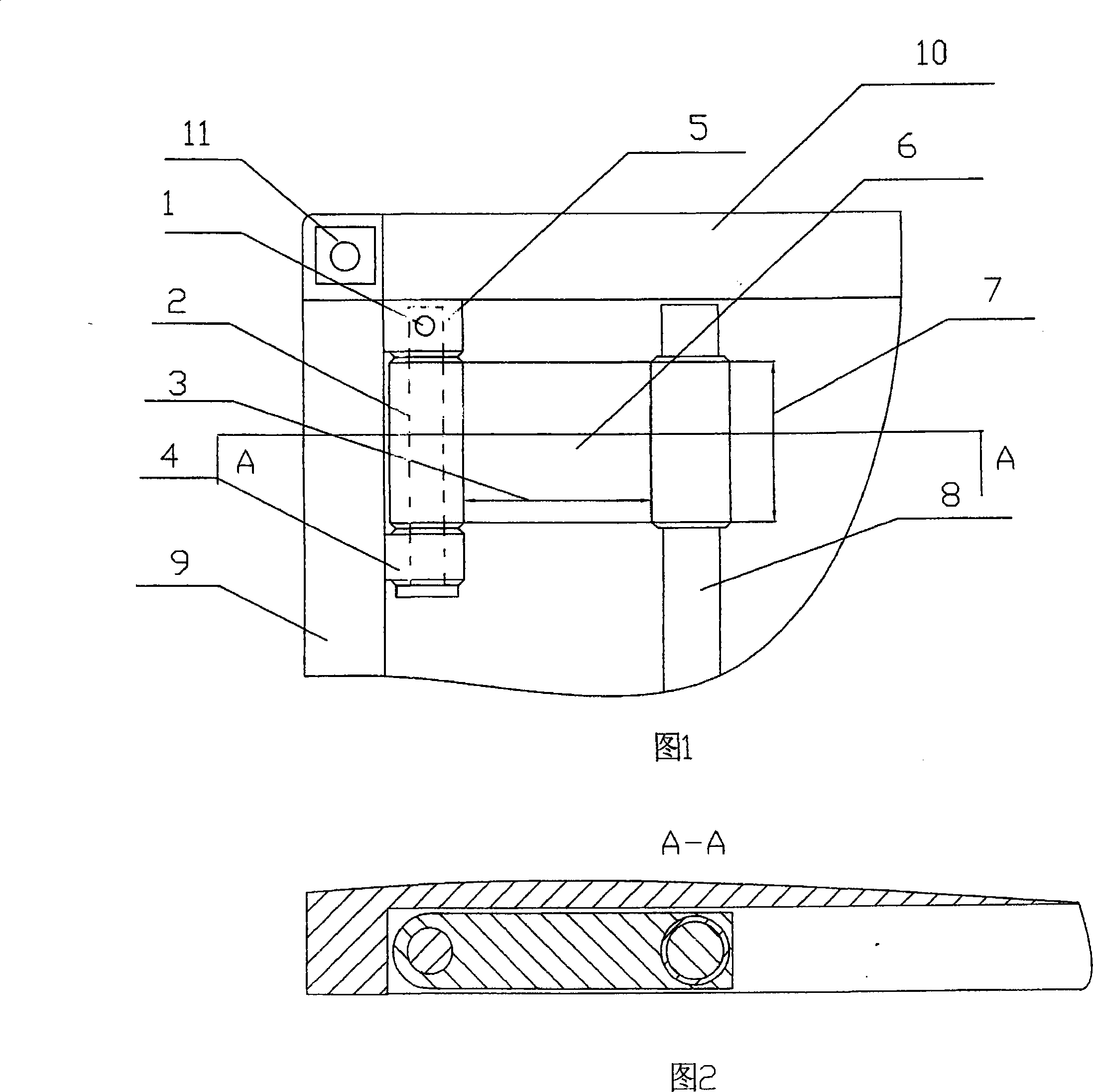

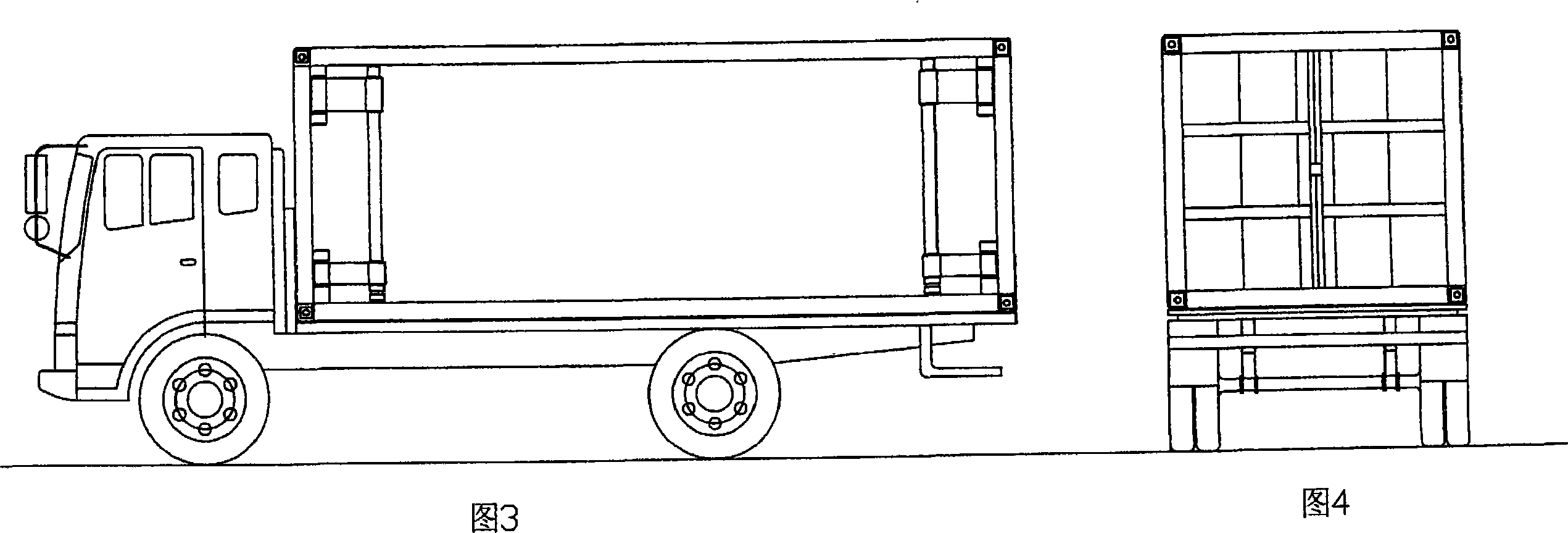

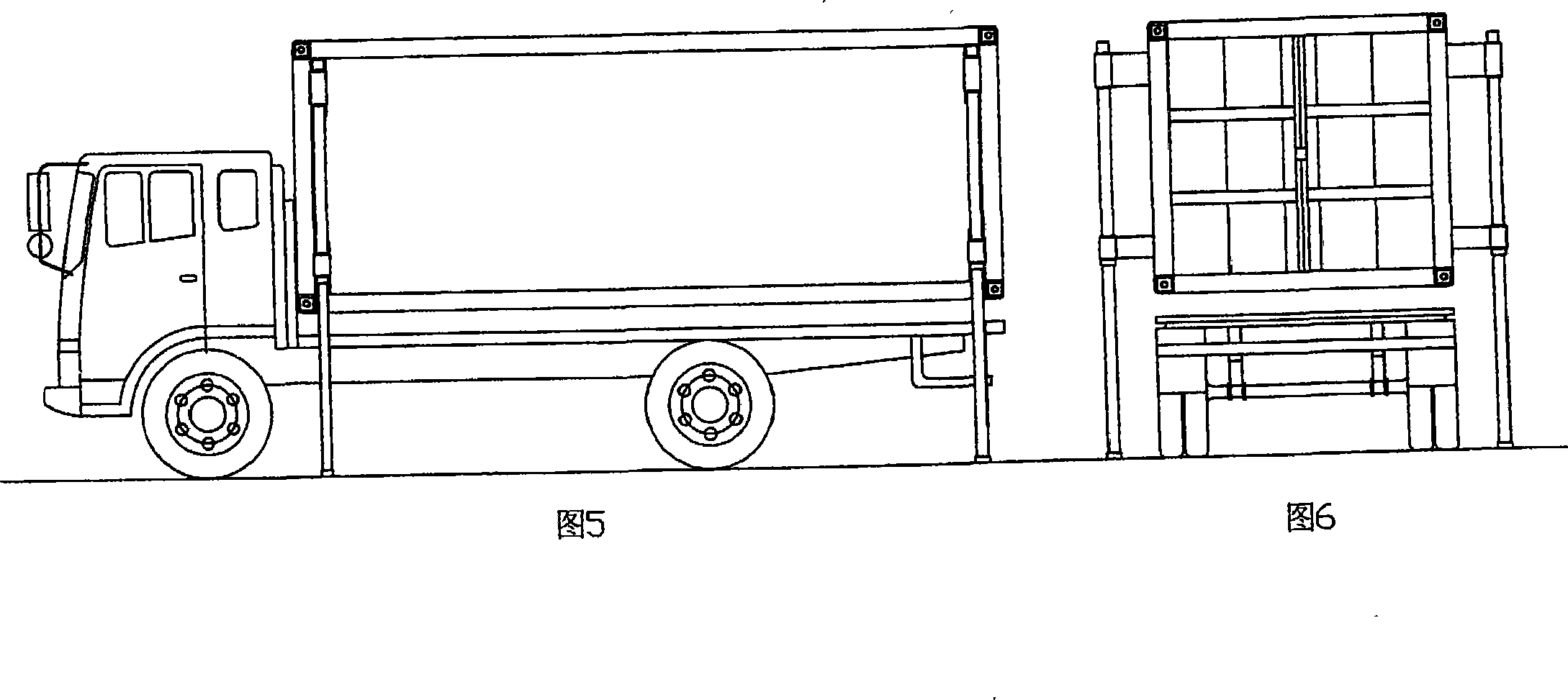

Method for producing up-down container or analogue and device, and application thereof

InactiveCN101195469AFaster turnaroundSolve transportation and loading and unloading problemsLifting devicesHoisting equipmentsEconomic benefitsEngineering

Provided is a lifting container or similar objects (the whole formed by space or large-sized equipment wrapped by a cubic and rigid frame of similar containers), which is characterized in that a lifting device capable of rotating around a bracing column is installed on the side wall of the container, or a bearing column with a lifting device is capable of rotating around the side wall. The invention occupies no space with the weight of about 180 kilograms, and none of standards and any structures of the container are changed, thereby saving costs of lifting containers for most of middle and small clients, being convenient for loading, accelerating goods turnover, extending the transport chain, namely from the containers of port-to-port transport to door-to-port, port-to-door and door-to-door transport, enlarging service range, speeding up turnover of the containers and occupying no driving time in loading and unloading goods. The lifting container has the advantages of no potential safety hazard, easy production, convenient maintenance, simplicity and simple operation. The container is added with lifting function, thereby changing logistics mode and bringing enormous economic benefits.

Owner:沈军

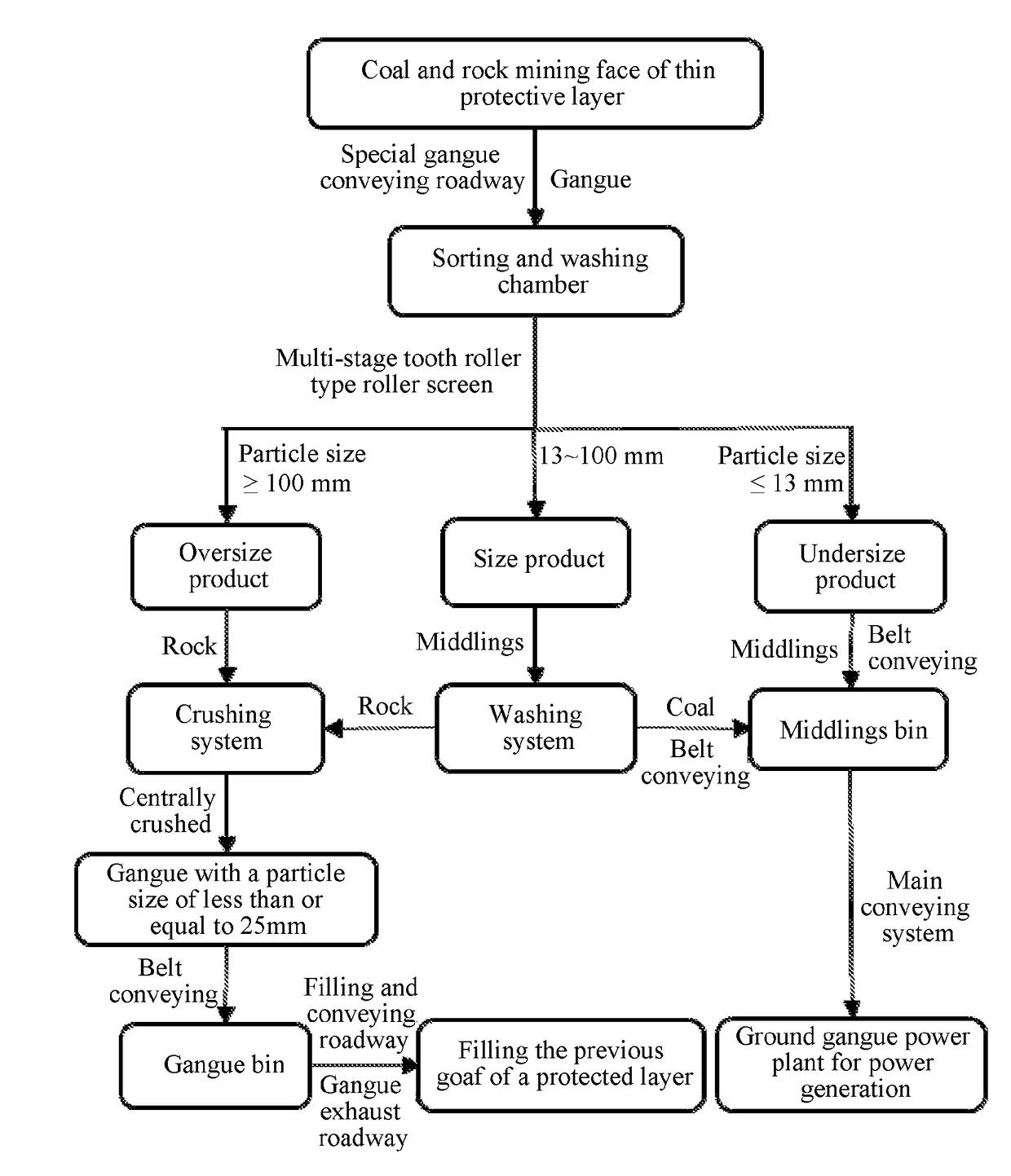

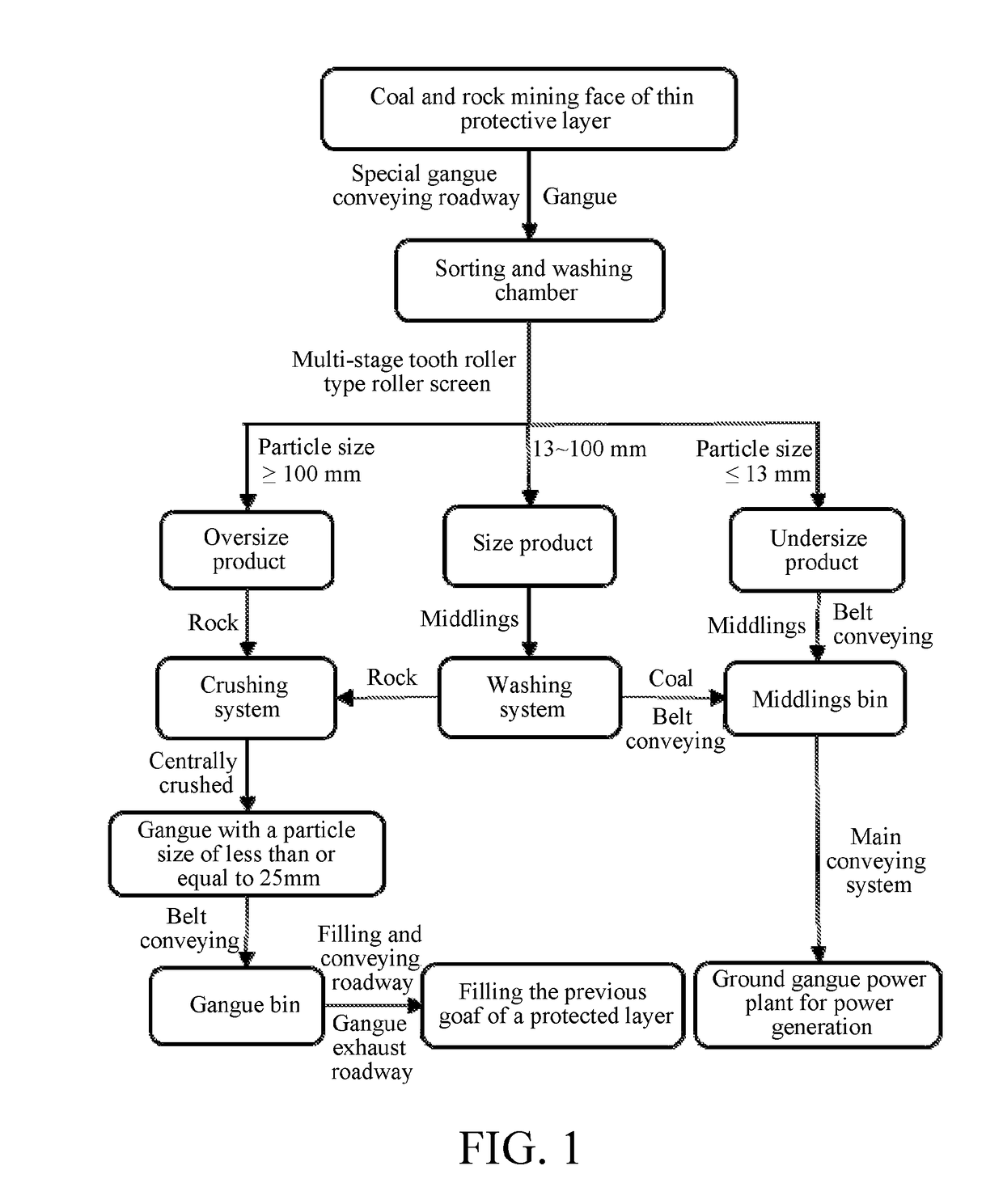

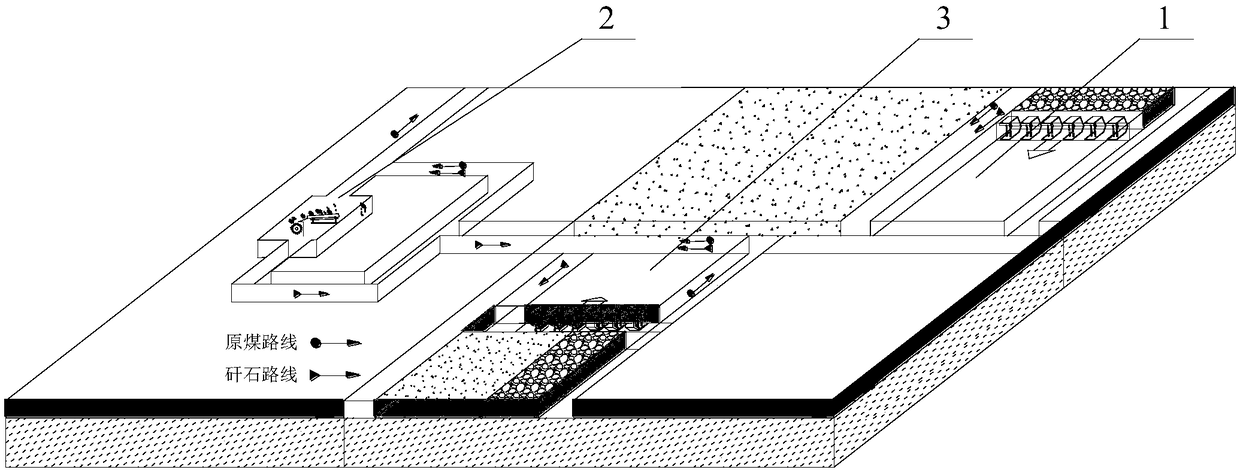

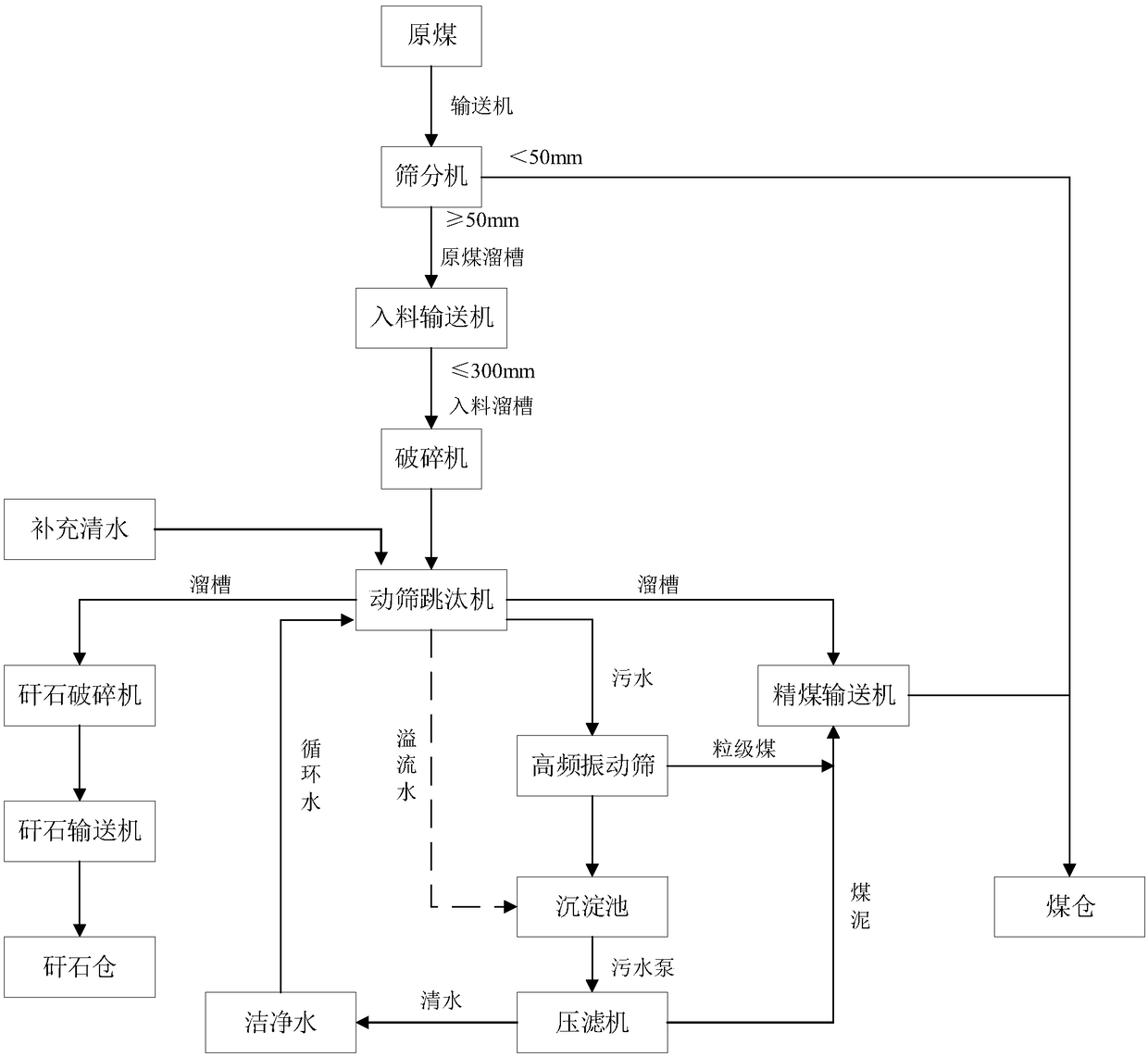

METHOD OF SORTING AND UTILIZING COAL AND ROCK FOR COAL AND ROCK Combined MINING FACE

ActiveUS20180229245A1Low costQuality improvementMining devicesUnderground miningGround subsidenceSocial benefits

The present invention relates to a method for sorting and utilizing coal and rock for a coal and rock combined mining face, and is especially applicable to the sorting and utilization of coal and rock mined from a coal and rock combined mining face when an extremely thin coal seam is used as a protective layer in combined mining of multiple coal seams. Underground gangue transport, storage and filling systems are directly established underground to convey a large amount of coal and gangue mined from the coal and rock mining face to an underground sorting and washing chamber for efficient separation of the coal and the gangue, sorted gangue is crushed and then filled in a mined-out area of a protected layer, thus realizing the environment-friendly cut and fill mining of the protective layer while the gangue is not lifted, and effectively preventing the ground subsidence caused by combined mining of multiple coal seams; sorted middlings are conveyed to a gangue power plant on the ground for power generation through a main conveying system, so that the pressure on mine coal quality is alleviated when benefits are created in the power plant, and thus the average ash content of commercial coal is reduced, and the selling price is increased. The method provided by the invention realizes the efficient utilization of coal and rock while realizing the efficient separation of coal and gangue, and has remarkable economic and social benefits and excellent promotional value.

Owner:CHINA UNIV OF MINING & TECH

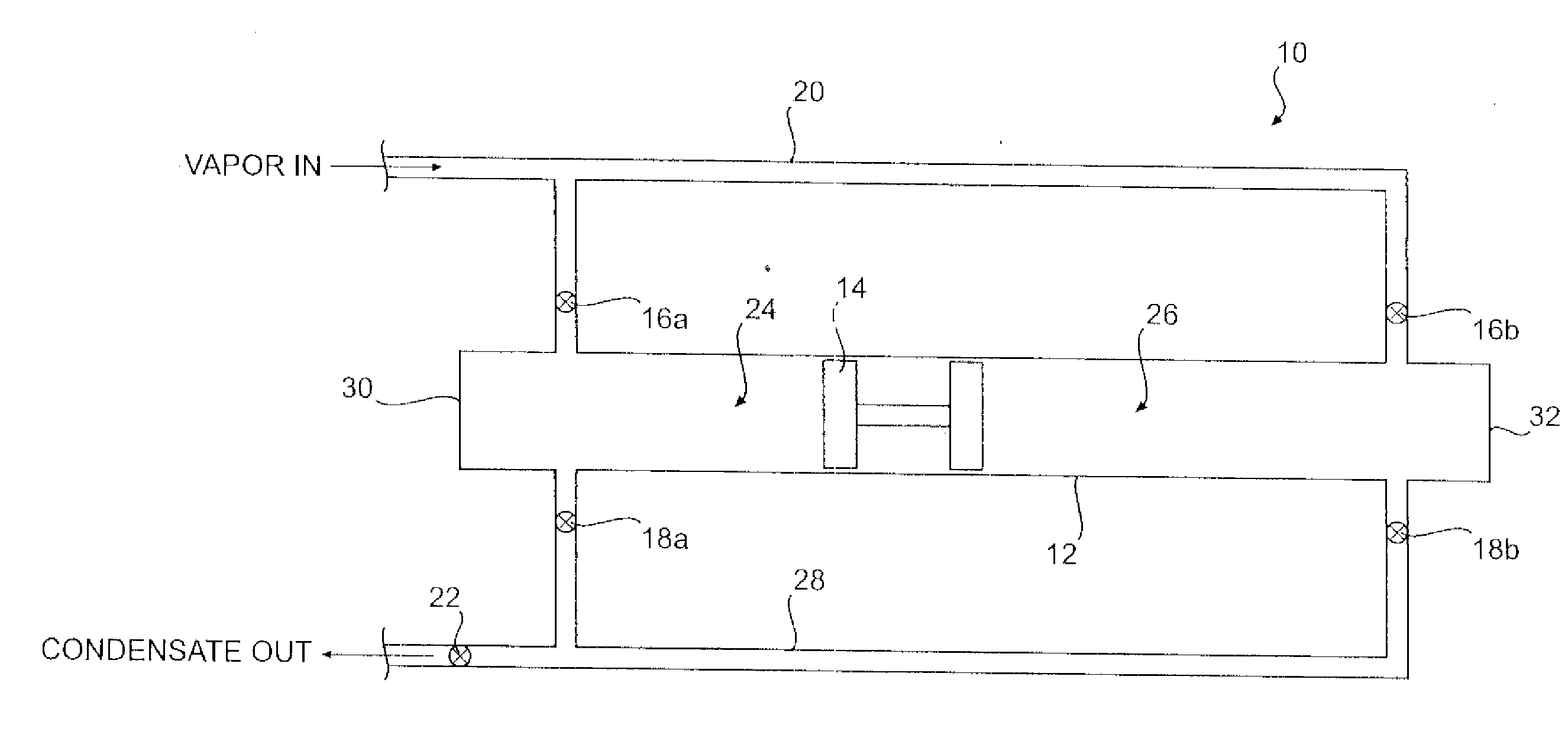

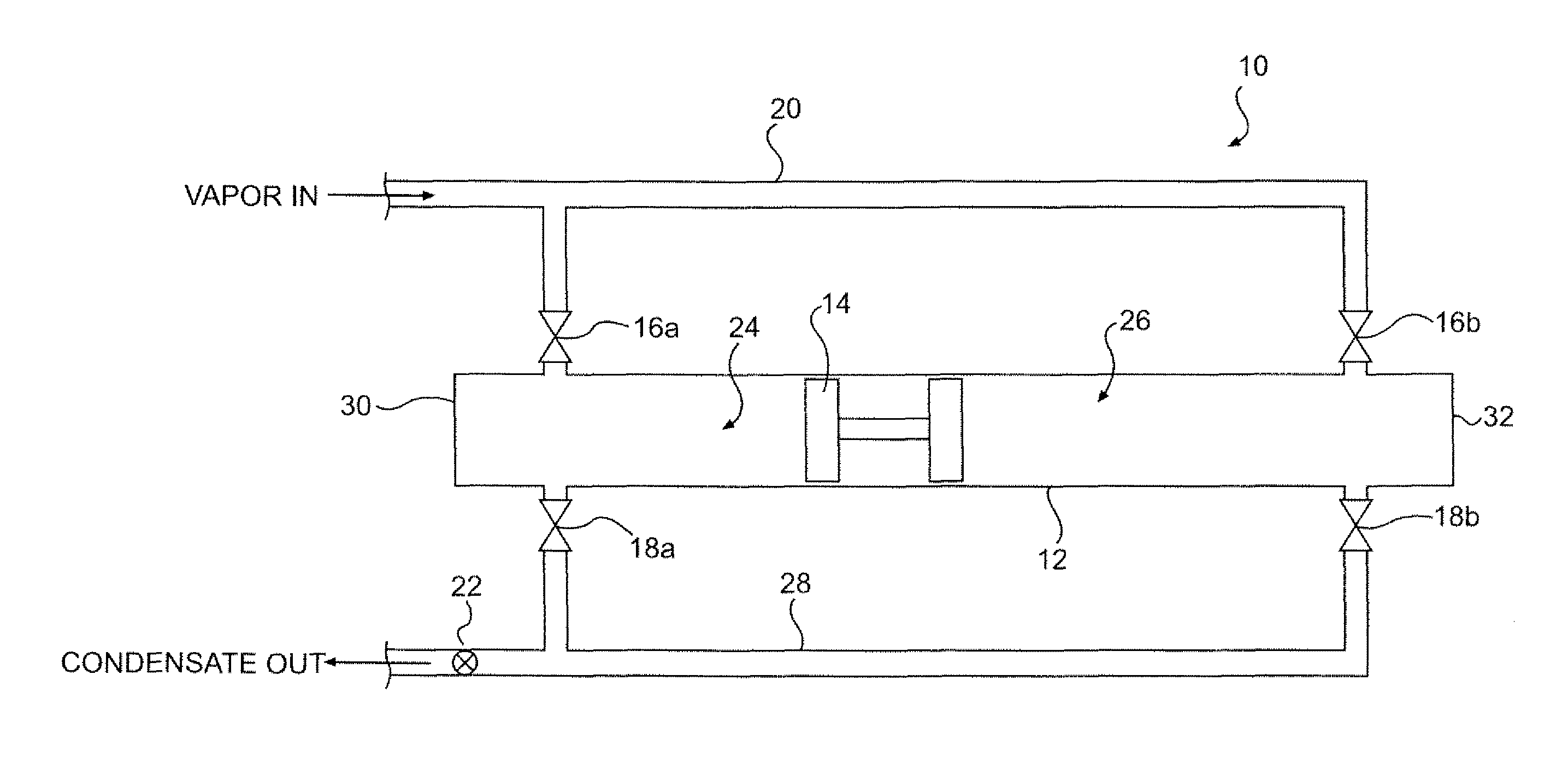

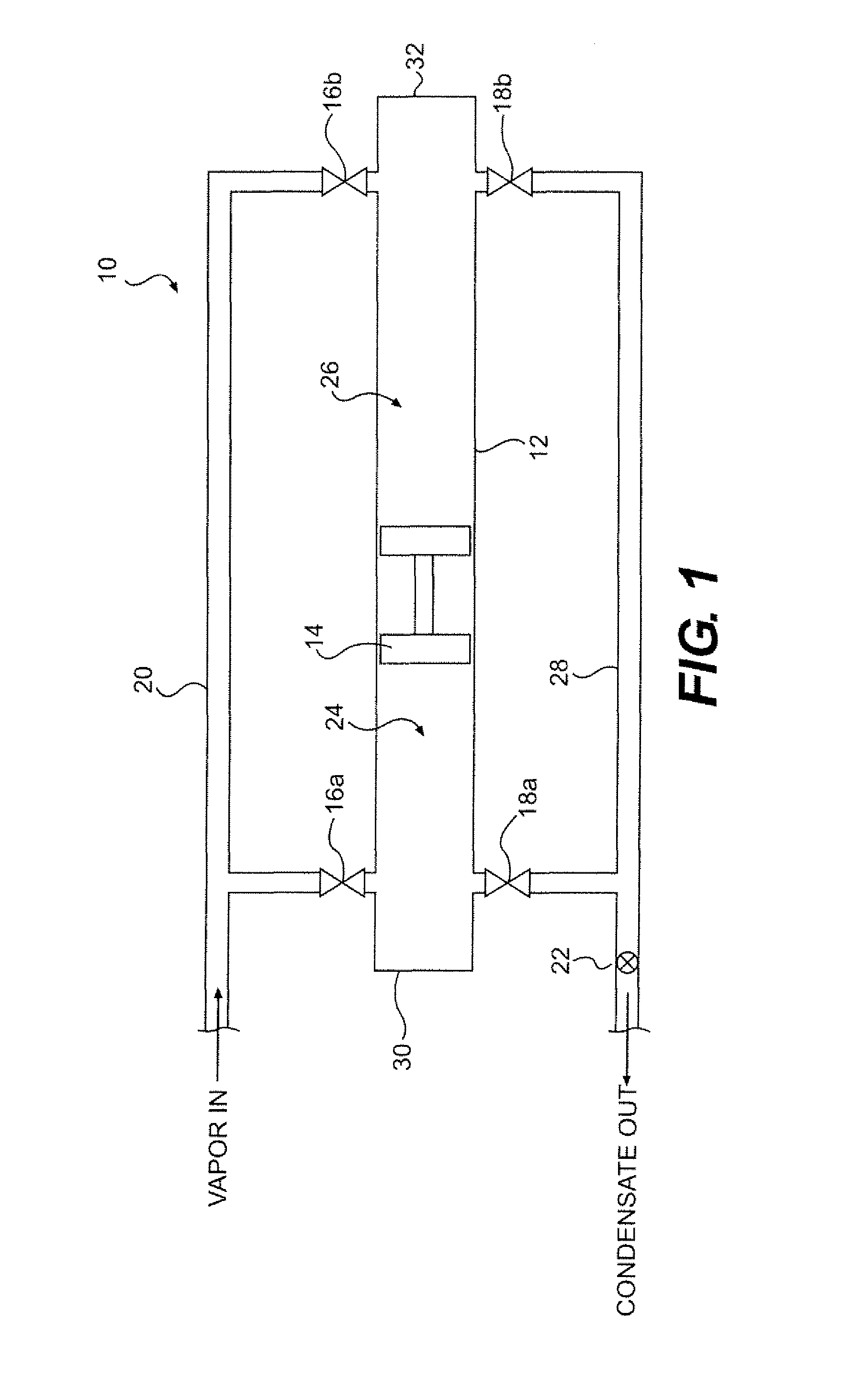

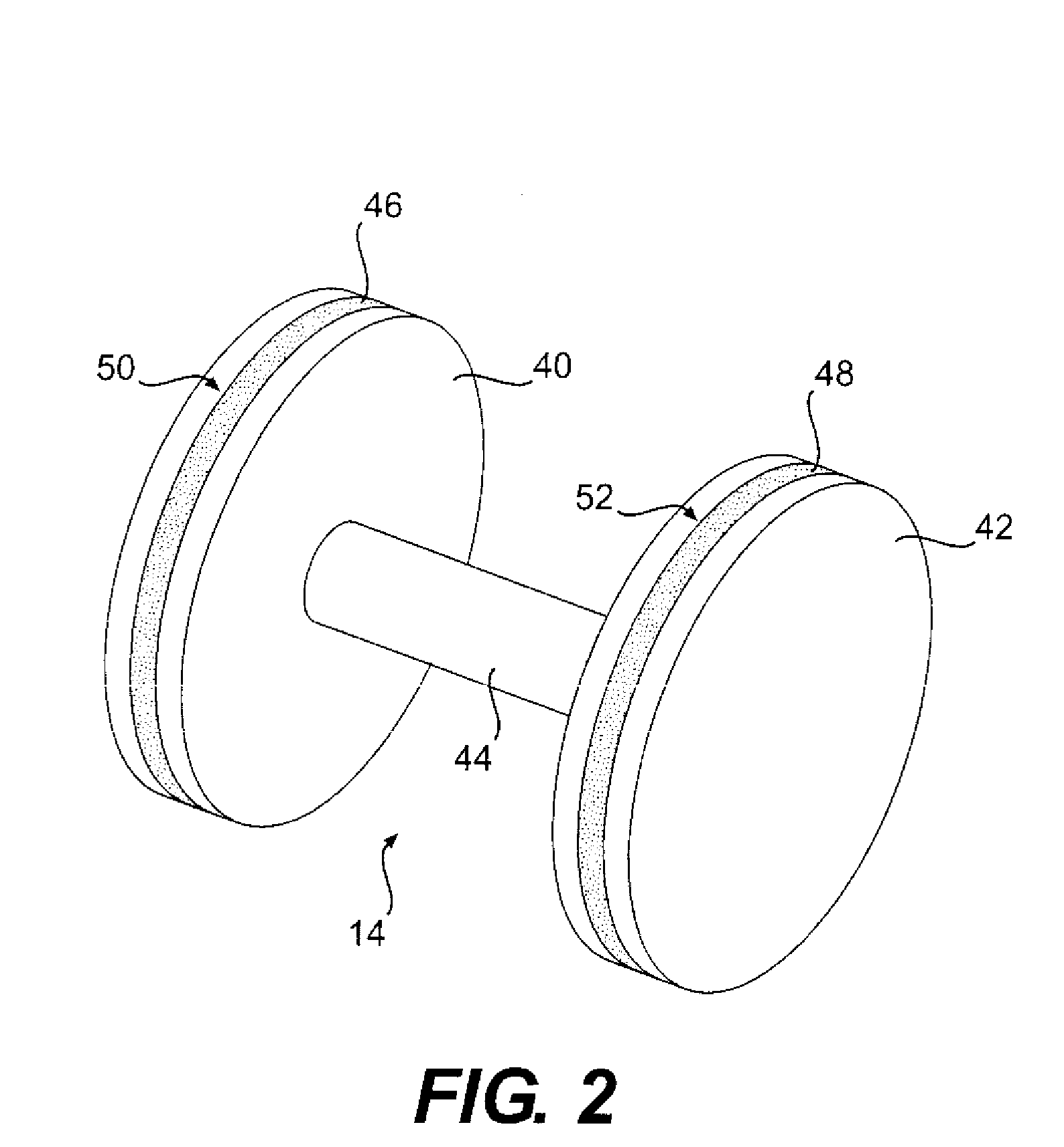

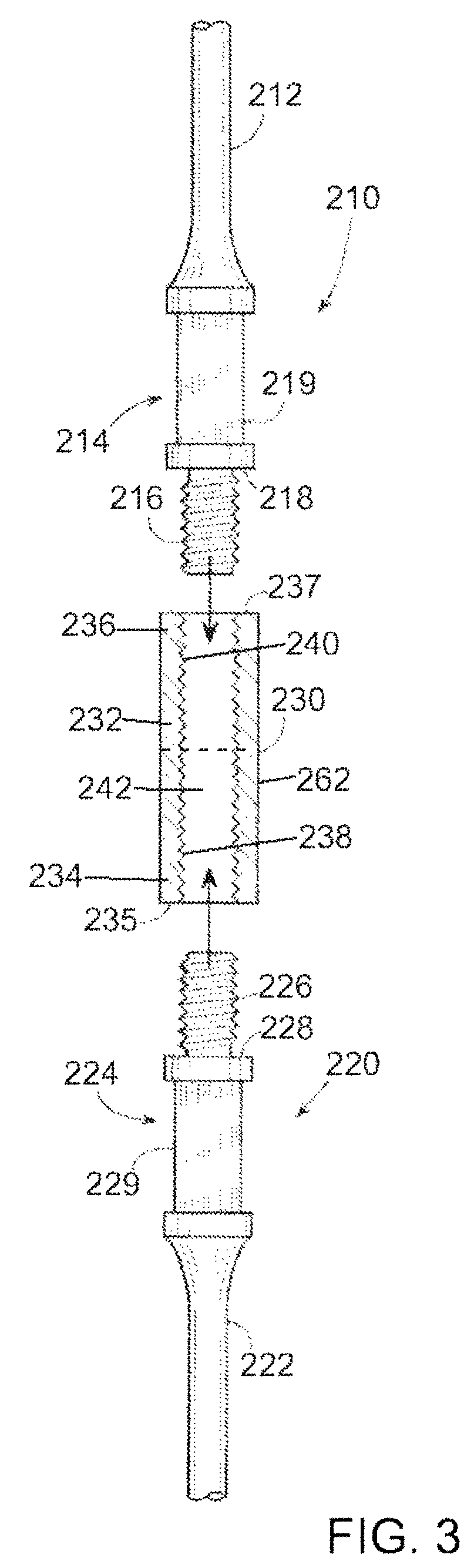

Open Loop Heat Pipe Radiator Having A Free-Piston For Wiping Condensed Working Fluid

An open loop heat pipe radiator comprises a radiator tube and a free-piston. The radiator tube has a first end, a second end, and a tube wall, and the tube wall has an inner surface and an outer surface. The free-piston is enclosed within the radiator tube and is capable of movement within the radiator tube between the first and second ends. The free-piston defines a first space between the free-piston, the first end, and the tube wall, and further defines a second space between the free-piston, the second end, and the tube wall. A gaseous-state working fluid, which was evaporated to remove waste heat, alternately enters the first and second spaces, and the free-piston wipes condensed working fluid from the inner surface of the tube wall as the free-piston alternately moves between the first and second ends. The condensed working fluid is then pumped back to the heat source.

Owner:NASA

Cavern filling type coal mining method

InactiveCN1483921AEliminate worriesSolve the problem of difficult miningUnderground miningSurface miningMining engineeringFilling rate

The present invention relates to a cancem filling type coal-mining method. Said method includes the following steps: building main shaft, auxiliary shaft, road large tunnel, haulage drift, ventilation drift and setting stope face, and when the coal is extracted, it adopts cavem filling mode, including the following steps: dividing stope face, presetting horizontal drief on the stope face, one-by-one extracting coal form horizontal drift, after every drift is extracted, filling the empty drift with coal gangue, and its filling rate is greater than or equal to 80%.

Owner:杨新兴

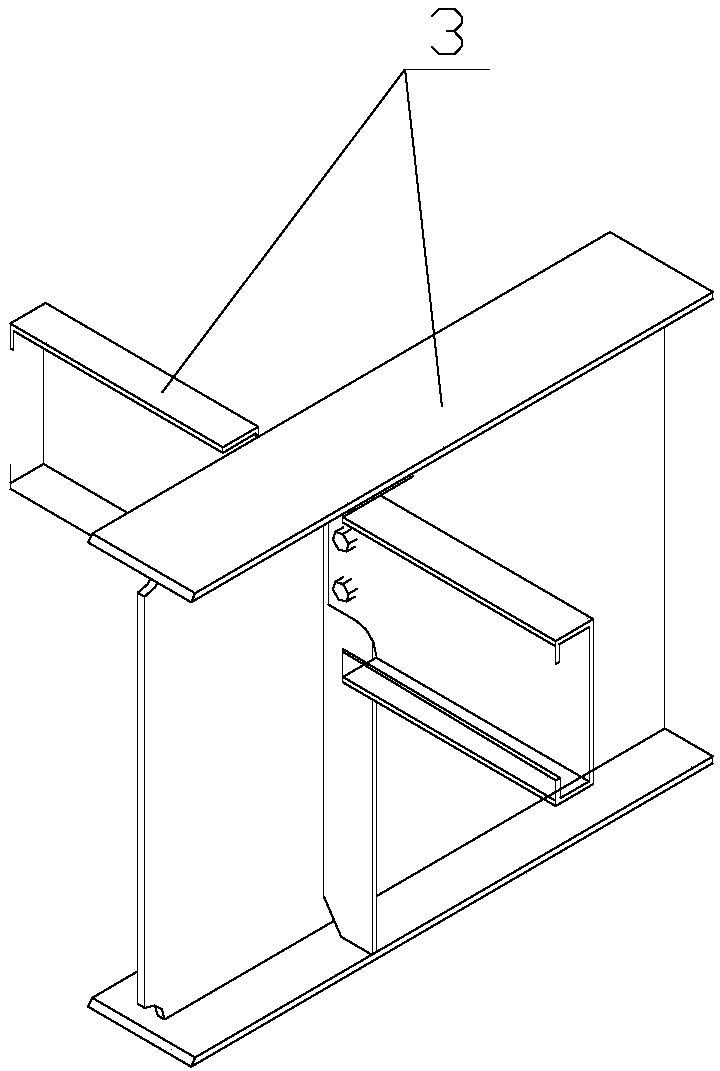

Installing method of roof mast

The invention relates to an installing method of a roof mast. The method comprises the following steps: firstly, lifting up a whole steel tube assembly by a windlass; and stopping the windlass when the bottom of the steel tube assembly reaches a base of the lowest place; secondly, connecting a pair of hand-drive block stringers to an outermost layer of steel tube and lifting up or down the steel tube assembly in an alternative working manner in order to fine adjusting the height of the steel tube assembly till the outermost layer of the steel tube is arranged at the base of the lowest place and a base of the lower place, and then keeping the position of the steel tube assembly and welding and fixing the steel tube assembly; connecting the hand-drive block stringers to an innermost layer ofsteel tube in the steel tube assembly, lifting up the innermost layer of the steel tube in an alternative working manner, and stopping the lifting when the length of the sleeved part of the lower endof the innermost layer steel tube and the upper end of an inner layer steel tube sleeved on the innermost layer steel tube is ranged from 0.3-2 m, and then welding and fixing the innermost layer of the steel tube with the inner layer of steel tube; and finally, repeatedly lifting up and welding each remained section of steel tubes sleeved in the outermost layer of the steel tube, and then finishing the installation of the roof mast.

Owner:CHANGZHOU NO 1 CONSTR GRP

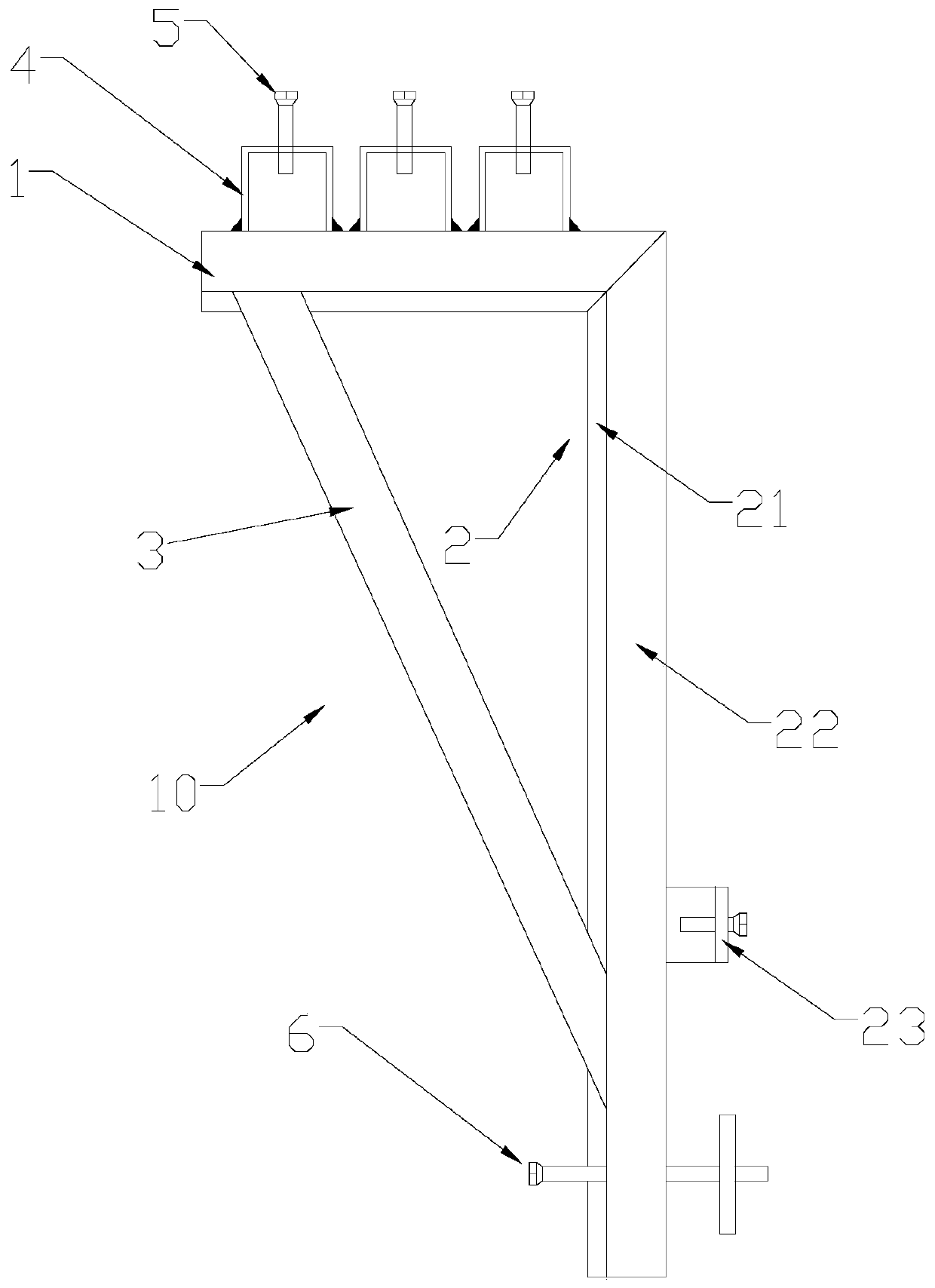

Mining method with mining-dressing and filling treatment

InactiveCN109488301AWide range of sorting particle sizeReduce water consumptionUnderground miningSurface miningControl measureCoal gangue

The invention discloses a mining method with mining-dressing and filling treatment, which includes design of main gangue sources for a little gangue working face, and gangue-reducing measures; ganguesorting system arrangement and equipment, and sorting process; filling-cooperated caving-type coal efficient stoping system arrangement and equipment, and production process; environmental influence pretreatment and pre-control measures before and after gangue filling; design principle and steps of the mining method with 'mining-dressing and filling treatment'. The method herein helps solve the long-range conveying problem of gangue, reduce underground gangue lifting cost, reduce mine auxiliary lifting and surface coal washery burden, effectively treat coal gangue to reduce surface piling areaof coal gangue, reduce mine ecological environment damage, protect the ecological environment; gangue filling and coal efficient stoping face has high unit production under high unit efficiency, therequirements of modern mines for production capacity can be met, and the method herein has a good application prospect.

Owner:CHINA UNIV OF MINING & TECH

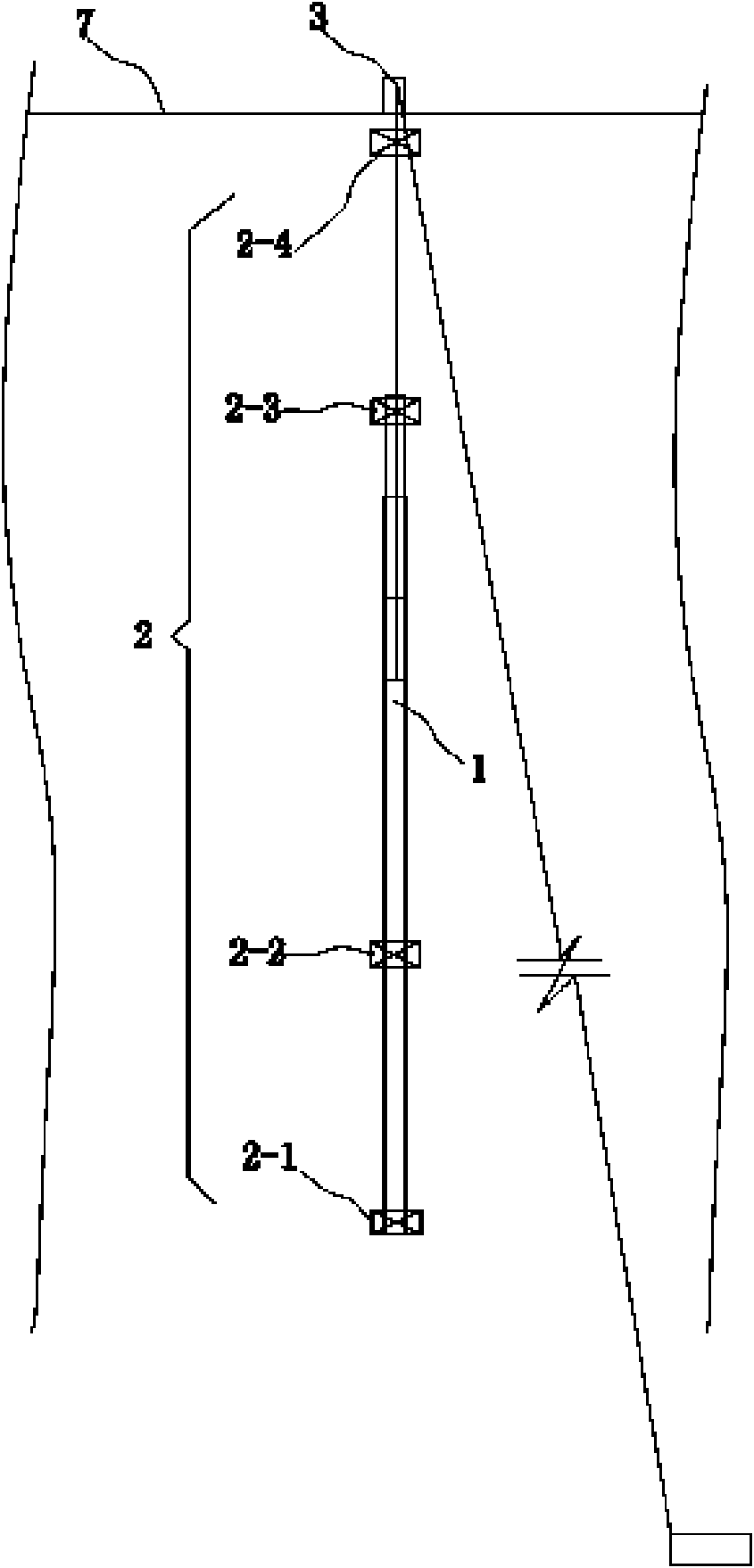

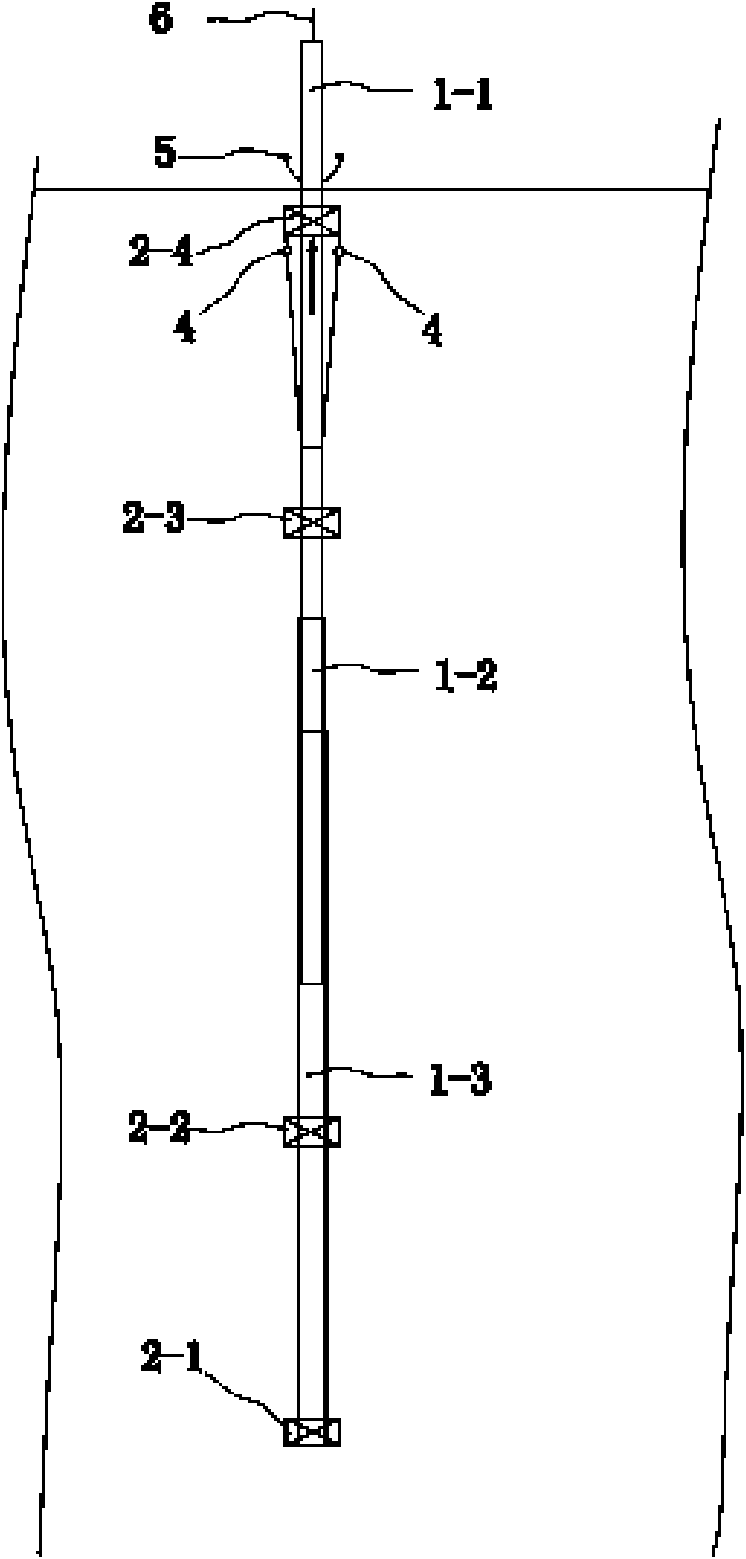

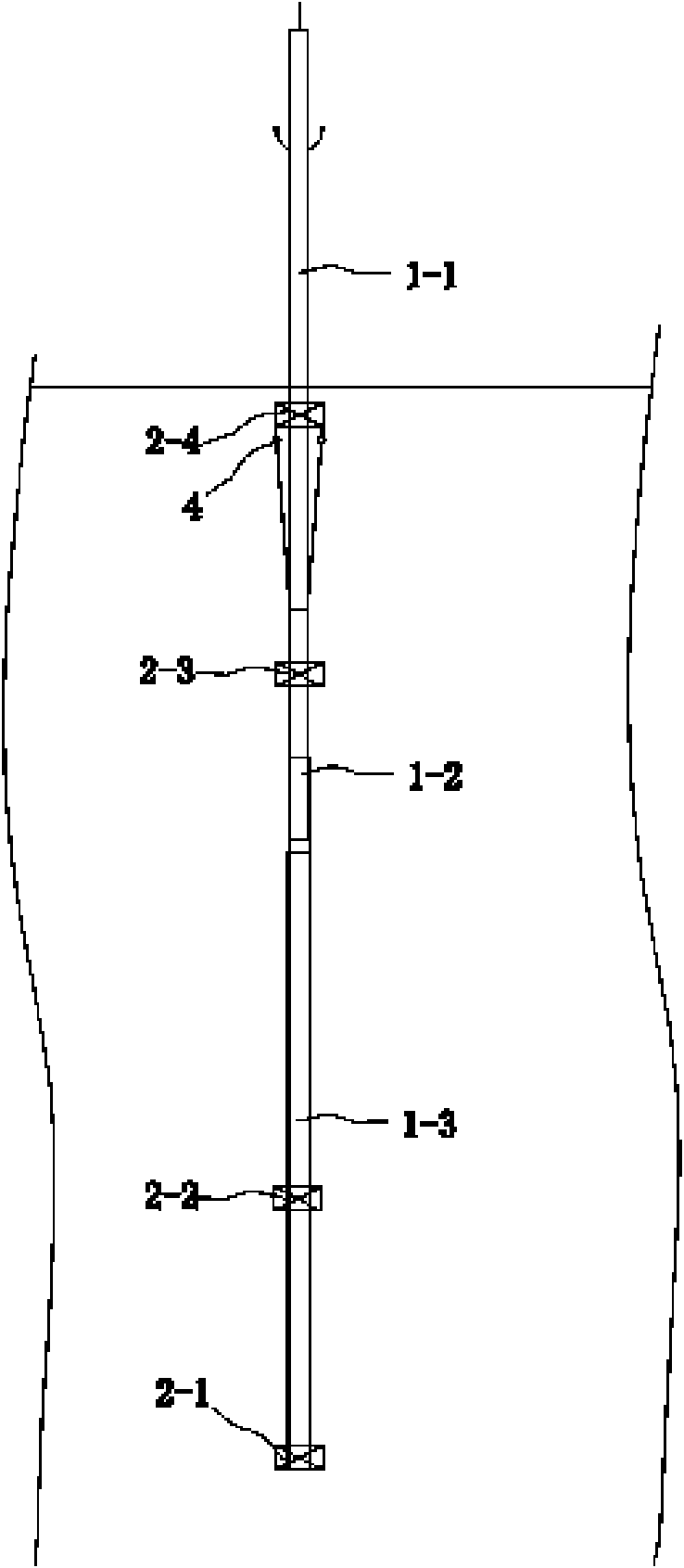

Overlying strata isolation grouting filling method for underground emission reduction of coal gangue

ActiveCN113605970ARealize no MasuiAvoid land occupationDirectional drillingMaterial fill-upMining engineeringSlurry

The invention relates to an overlying strata isolation grouting filling method for underground emission reduction of coal gangue, and belongs to the field of emission reduction of coal gangue in coal mining. The overlying strata isolation grouting filling method comprises the steps that according to information of a coal face, a grouting filling key layer is determined, and a plurality of branch holes are downwards constructed in a main hole of directional drilling from the directional drilling of an underground roadway to the interior of the grouting filling key layer; and a grouting and filling system is built underground, tunneling gangue and selected gangue of a mine are crushed and ground into filling slurry, cracks below a key layer are filled with the filling slurry through directional drilling, the key layer is effectively supported, and rock stratum movement and surface subsidence are controlled. According to the overlying strata isolation grouting filling method for underground emission reduction of the coal gangue, the coal gangue generated by the mine is directly prepared into the filling slurry underground and then is filled into the overlying strata mining-induced fractures, so that harmless treatment is realized.

Owner:CHINA UNIV OF MINING & TECH

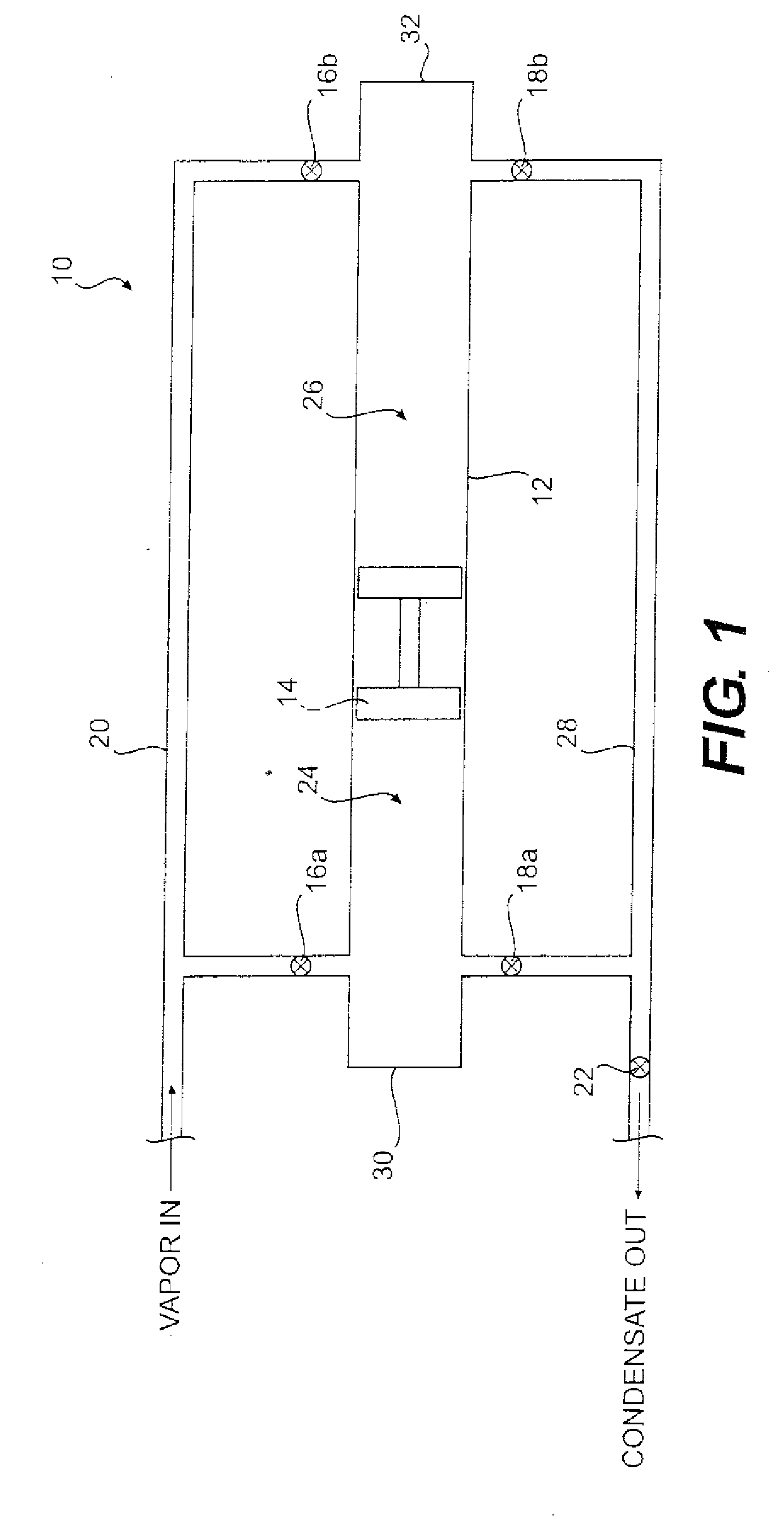

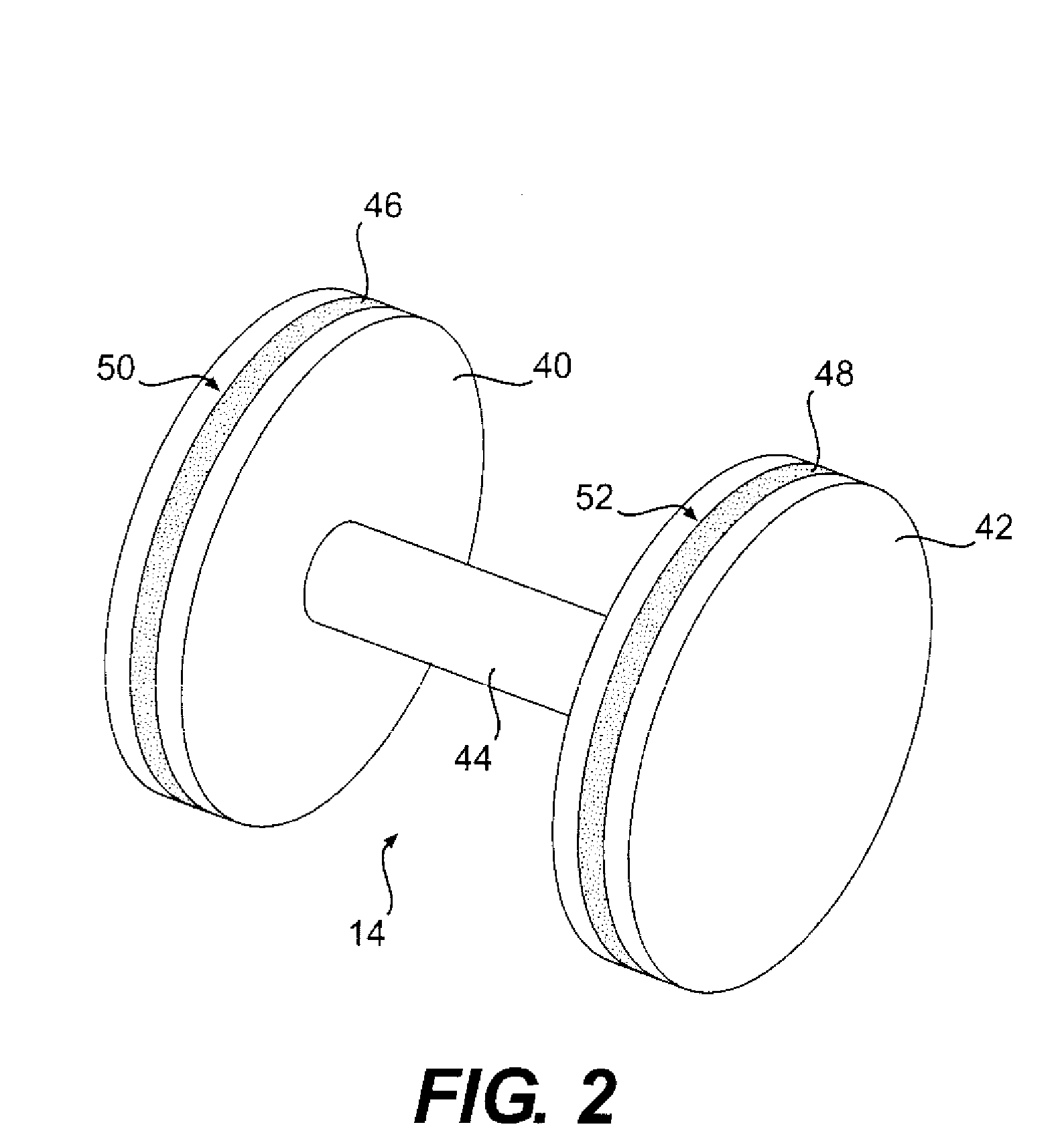

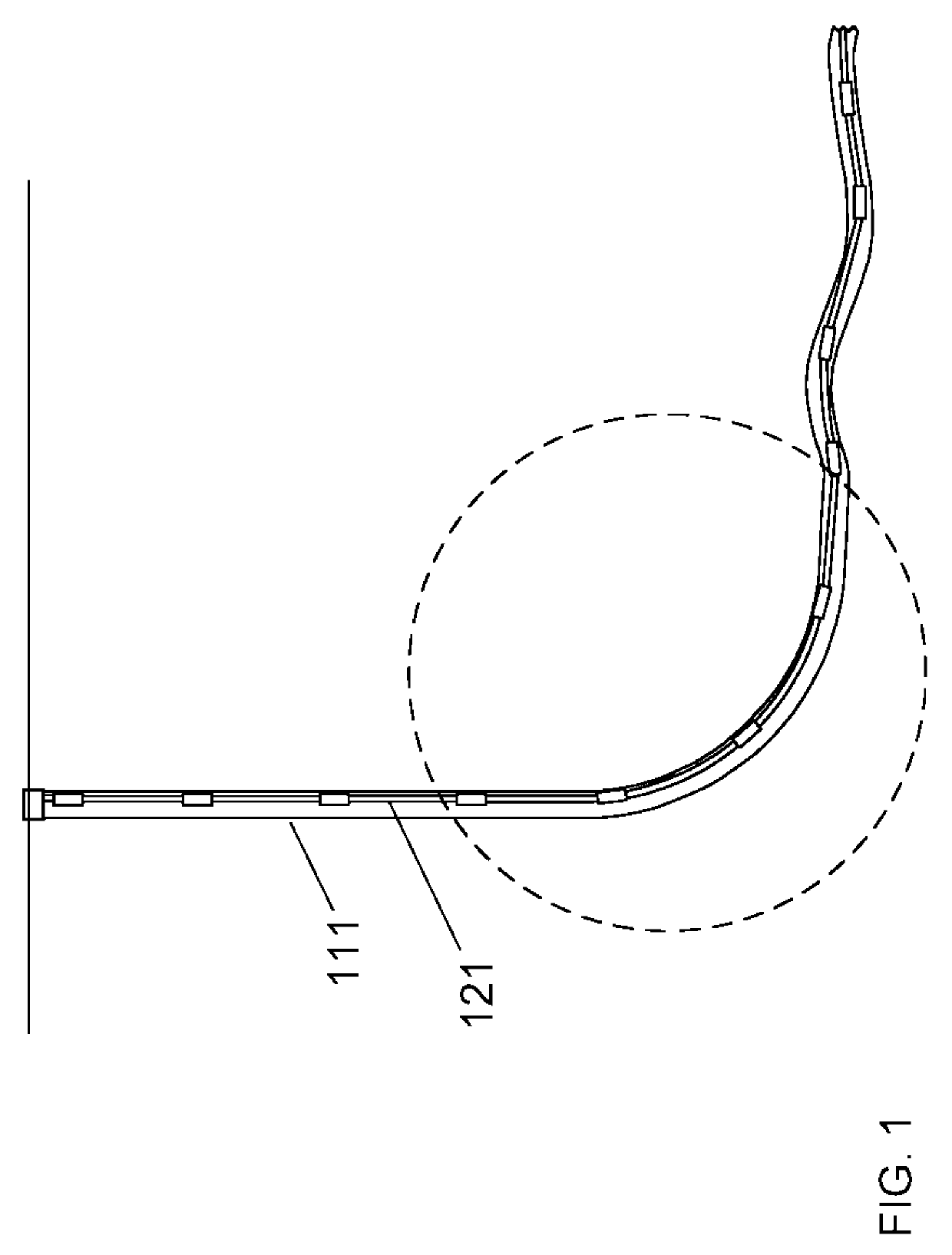

Open loop heat pipe radiator having a free-piston for wiping condensed working fluid

InactiveUS9091490B2Low mass-to-power ratioReduce lifting costsIndirect heat exchangersWorking fluidEngineering

An open loop heat pipe radiator comprises a radiator tube and a free-piston. The radiator tube has a first end, a second end, and a tube wall, and the tube wall has an inner surface and an outer surface. The free-piston is enclosed within the radiator tube and is capable of movement within the radiator tube between the first and second ends. The free-piston defines a first space between the free-piston, the first end, and the tube wall, and further defines a second space between the free-piston, the second end, and the tube wall. A gaseous-state working fluid, which was evaporated to remove waste heat, alternately enters the first and second spaces, and the free-piston wipes condensed working fluid from the inner surface of the tube wall as the free-piston alternately moves between the first and second ends. The condensed working fluid is then pumped back to the heat source.

Owner:NASA

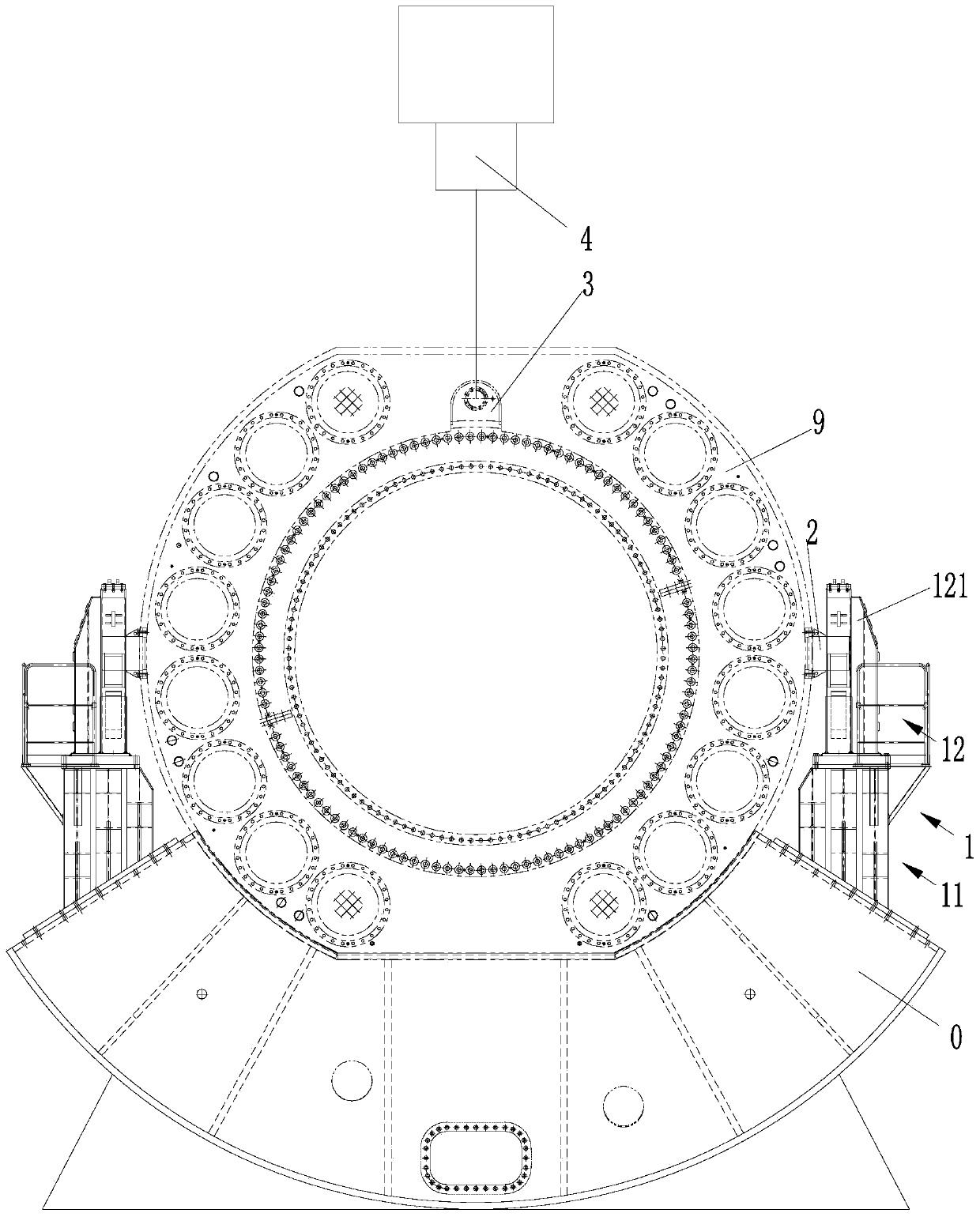

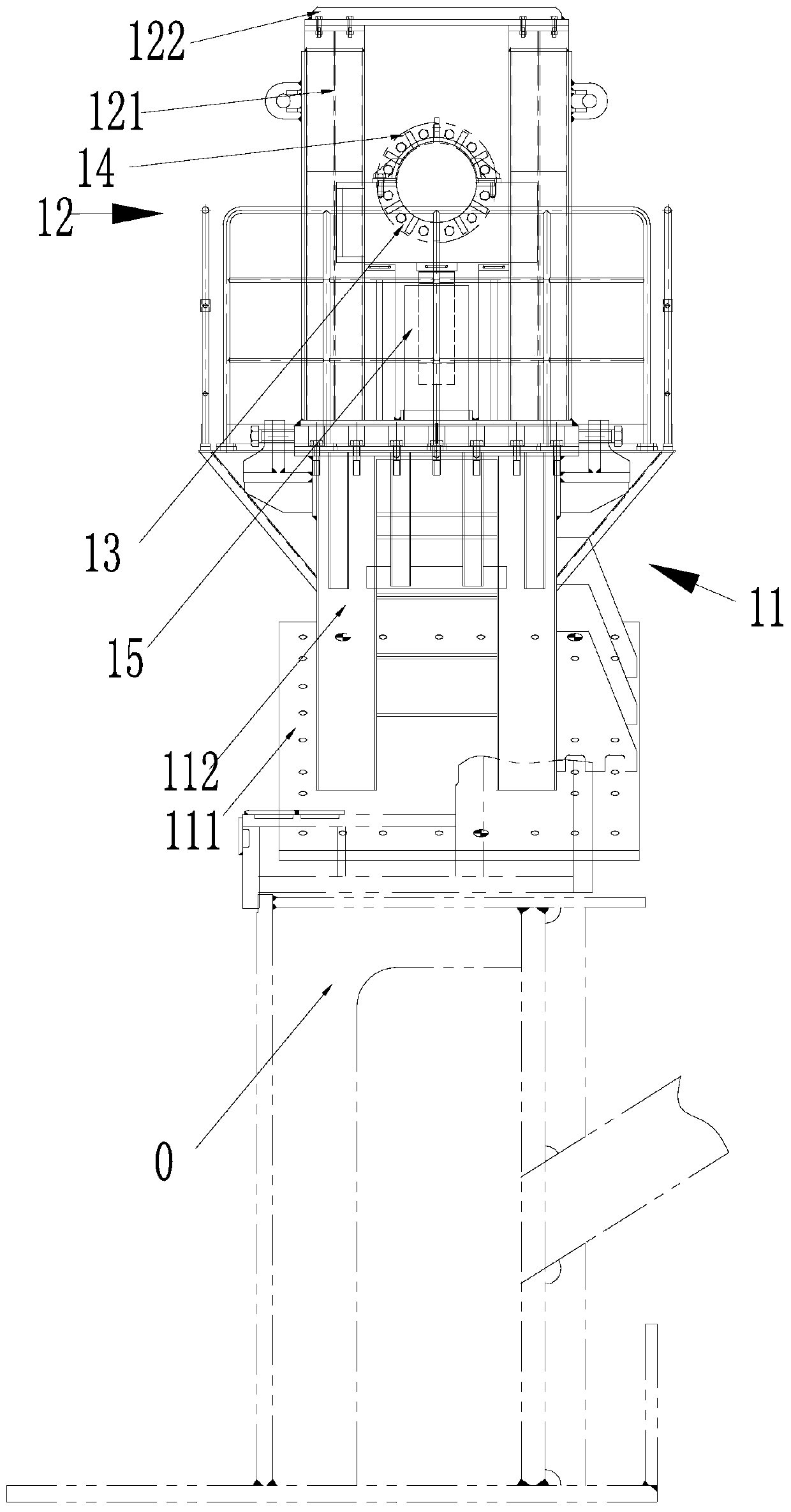

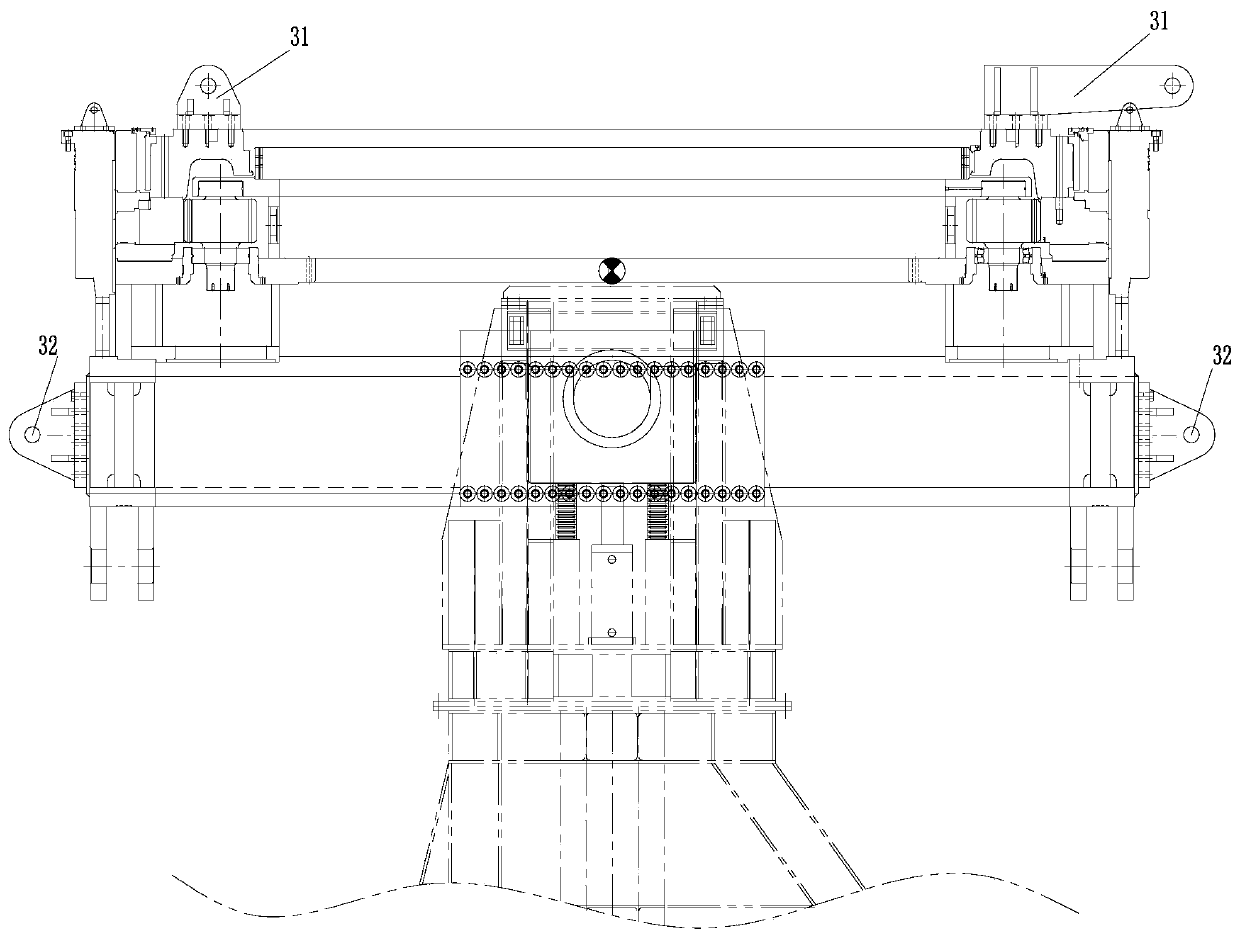

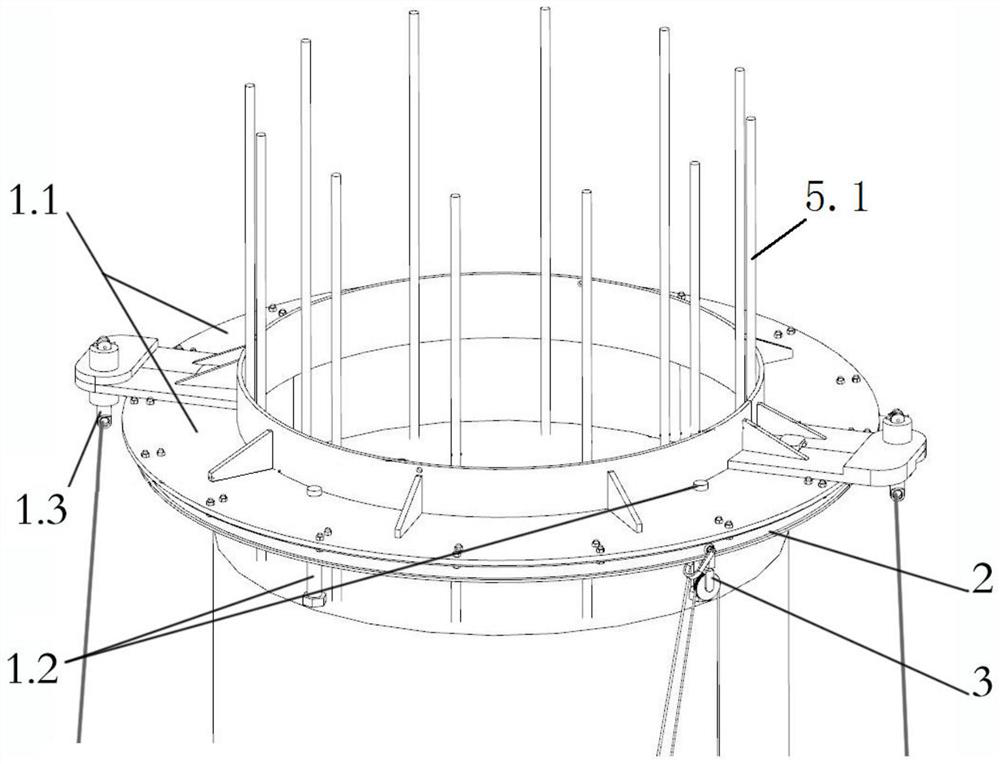

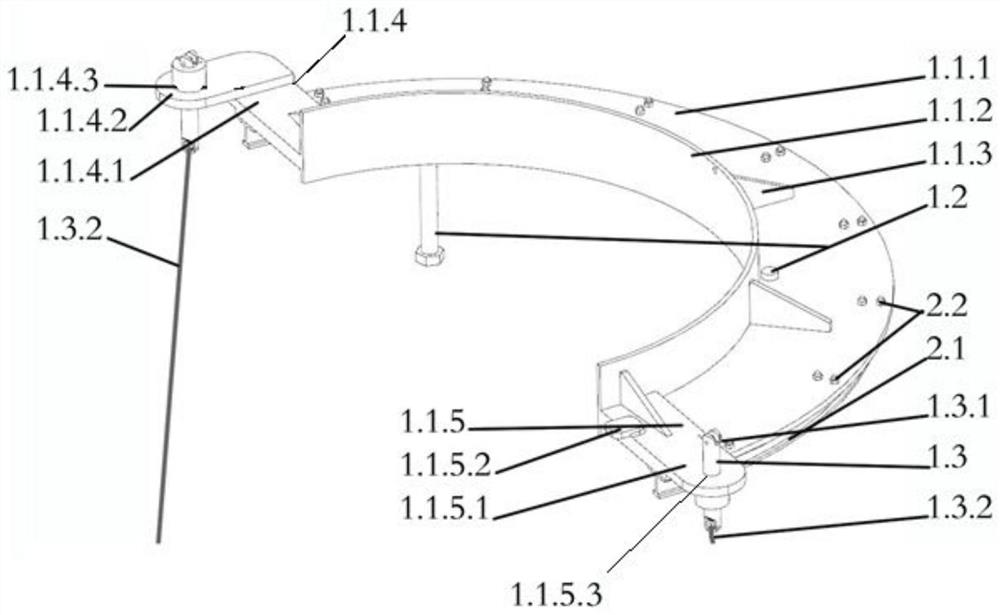

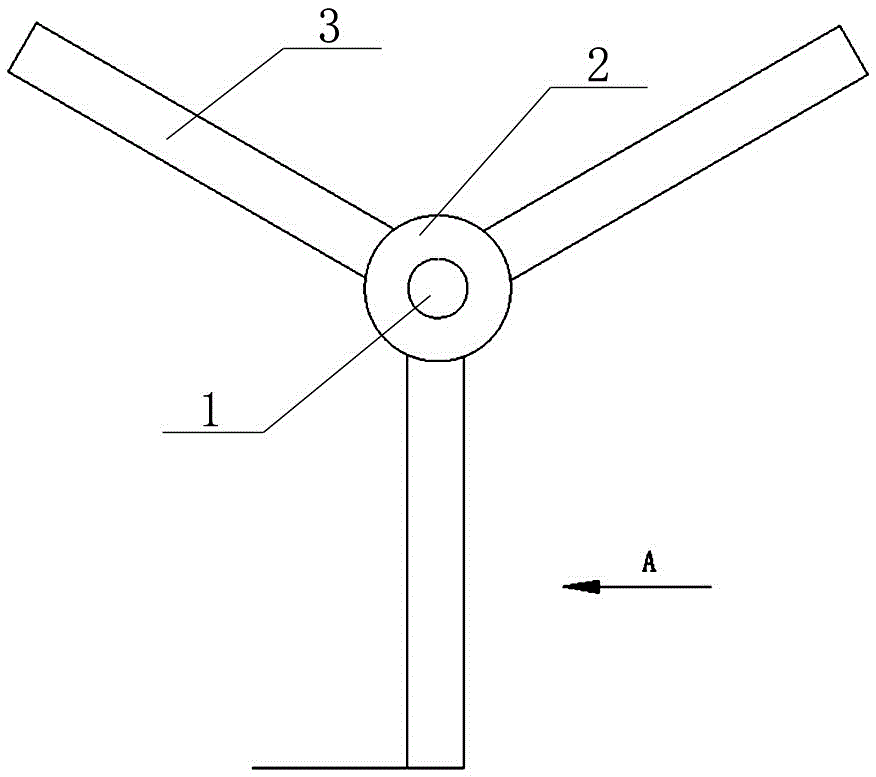

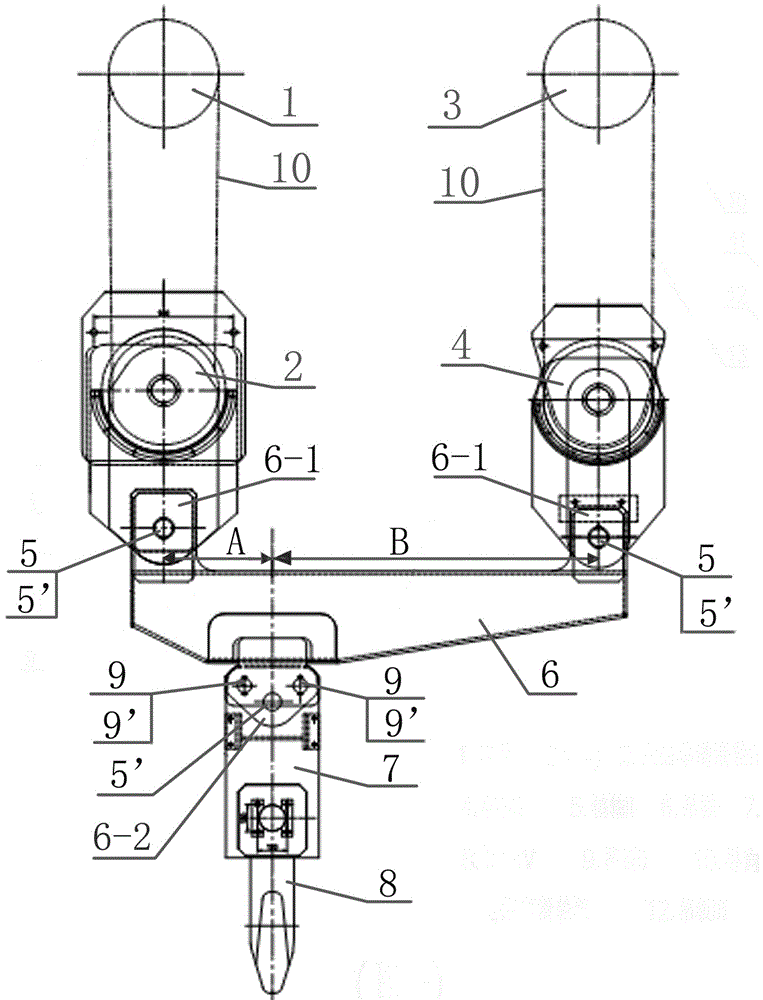

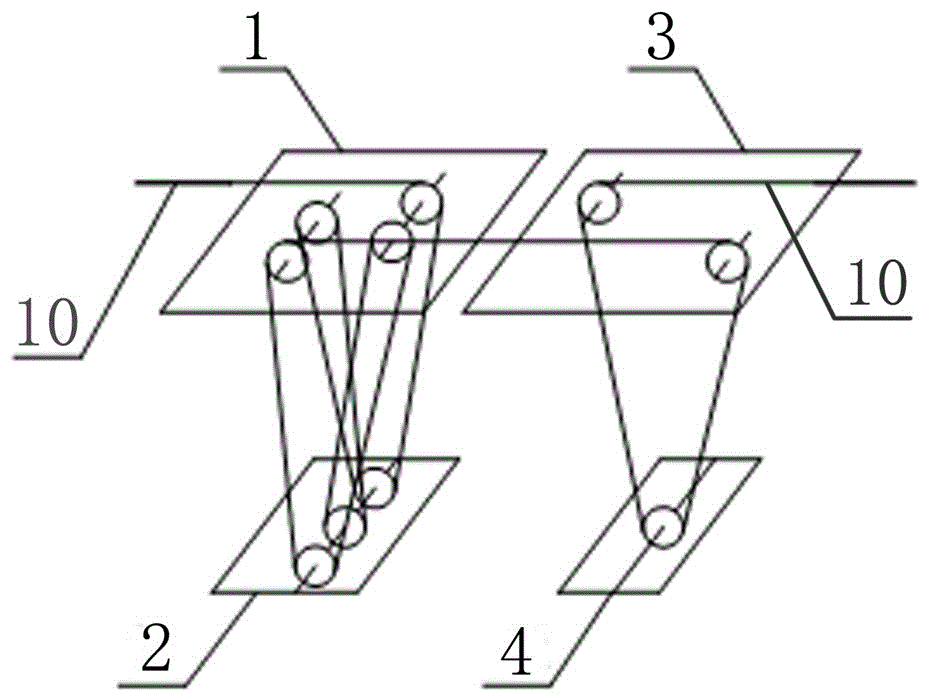

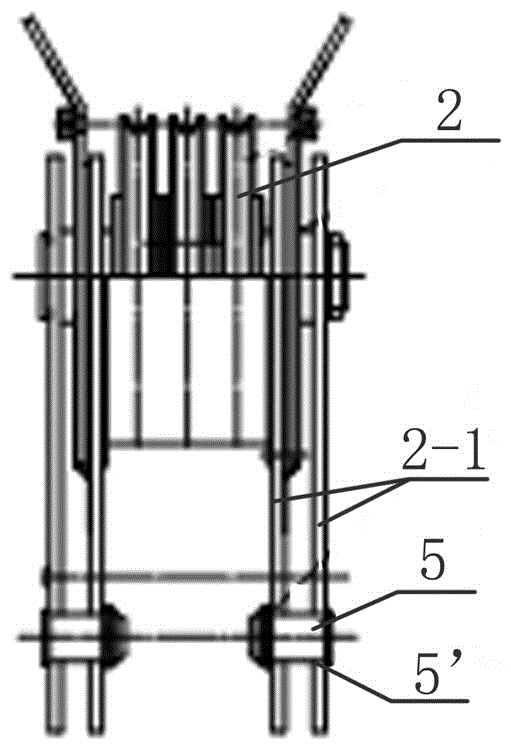

Main drive turn-over device and method for super-large-diameter shield tunneling machine

PendingCN110950242AReduce lifting forceRealize the purpose of overturning heavy objectsLoad-engaging elementsControl engineeringElectric machinery

The invention discloses a main drive turn-over device and method for a super-large-diameter shield tunneling machine. The main drive turn-over device comprises an arc-shaped turn-over base, and turn-over parts mounted at the two ends of the turn-over base. The main drive turn-over method comprises the following steps: the lower part of a shield body block serves as the turn-over base; an upward turning part is lifted; lifting lugs are connected for turning over; after a main drive rotates by 90 degrees, hook replacing operation is conducted; after hook replacing is successful, turning over continues; when the main drive rotates by 180 degrees, after a motor and a speed reducer are mounted, lifting hooks are connected, and two lifting parts reversely act till the main drive is located in the vertical position; and the main drive is lowered through hydraulic oil cylinders on the two sides. Previous overall lifting turning-over operation of the main drive is cleverly converted into rotation turning-over operation, when the main drive turns over through the mode, rotation lifting force provided by a crane only needs to overcome rolling friction resistance generated by the self-weight of the main drive, thus the lifting force of the crane can be decreased by about 10 times or above, and the purpose that large heavy objects are turned over by the small crane is achieved.

Owner:TIANHE MECHANICAL EQUIP MFG

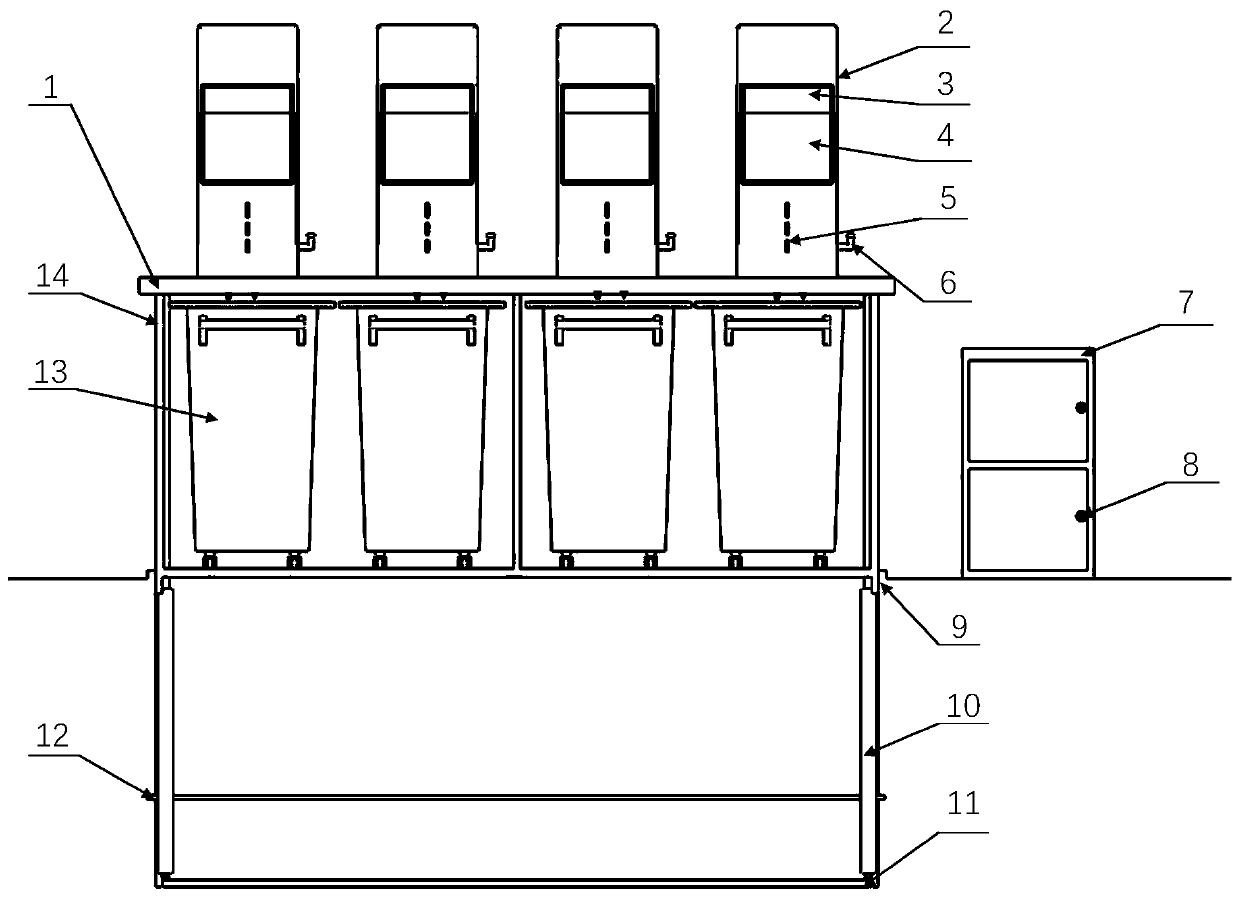

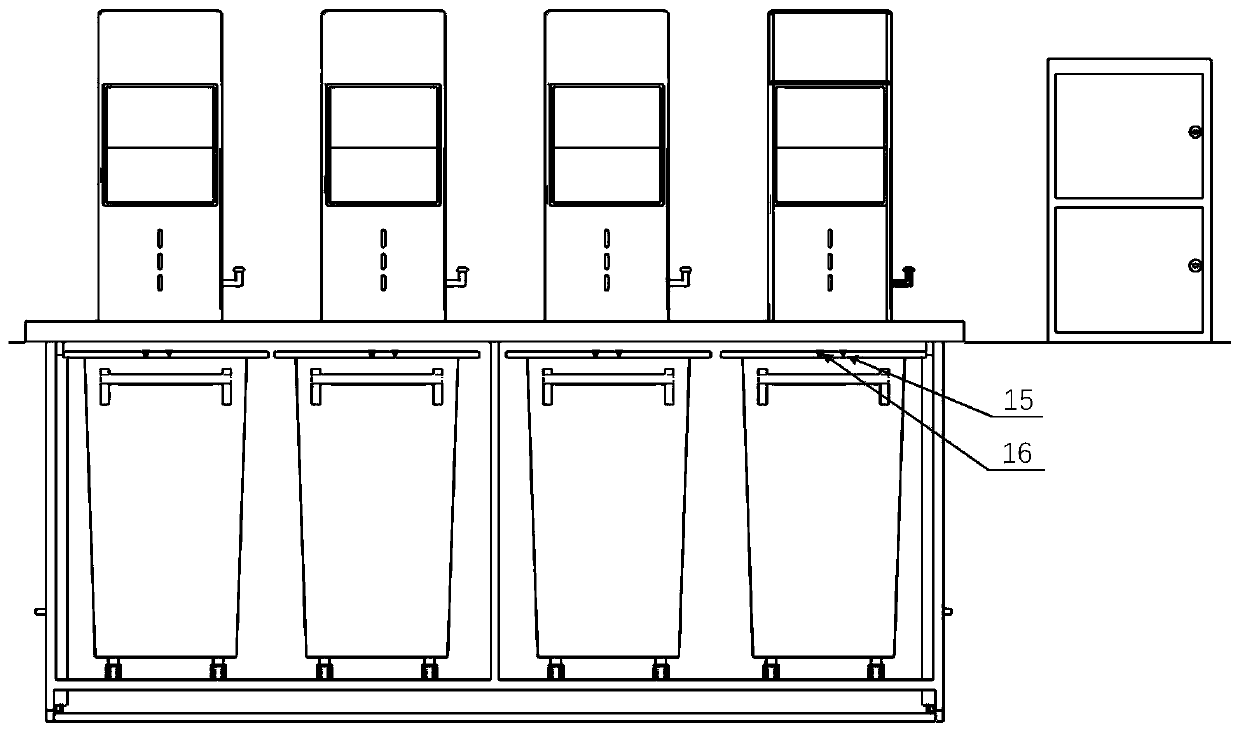

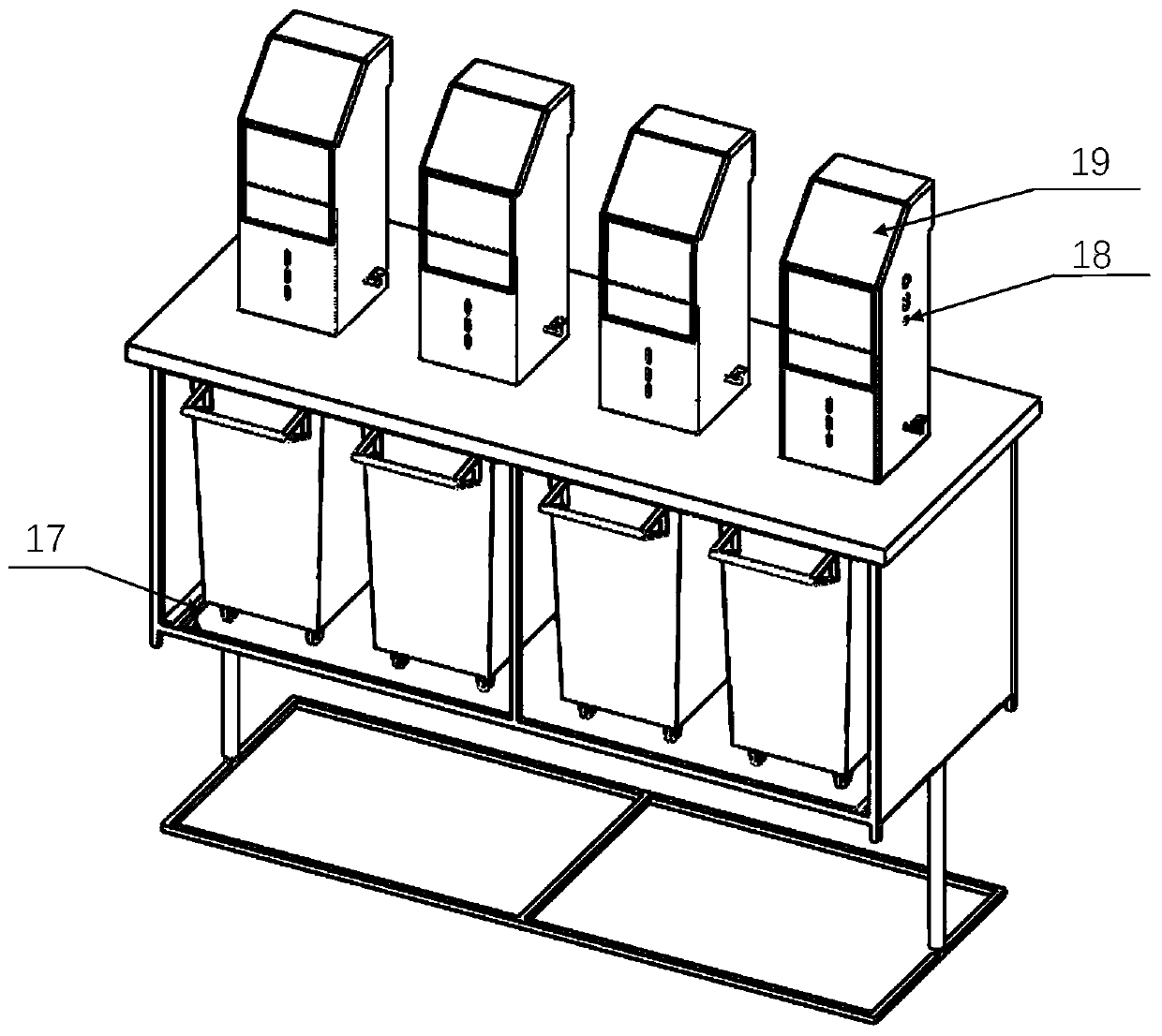

Four-classification buried multifunctional garbage can

PendingCN111591628AEasy to replaceSolve cleaning difficultiesWaste collection and transferRefuse receptaclesHydraulic cylinderAgricultural engineering

The invention discloses a four-classification buried multifunctional garbage can which comprises a foundation pit formed in the ground, throwing boxes, a lifting platform, a frame, a bottom frame, hydraulic cylinders and garbage can bodies. The lifting platform and the frame are connected together in a welded mode, and the lifting platform and the bottoms of the throwing boxes are welded together;and the garbage can bodies are evenly placed under a square hole of the lifting platform, and the garbage can bodies are placed on the frame. A square hole is formed in the bottom of each throwing box; and the left sides and the right sides of the frame and the bottom frame are connected through the two hydraulic cylinders. The garbage can is automatically lifted to the ground by controlling thehydraulic cylinders, sanitation workers do not need to manually take out the garbage can, the garbage can is convenient to replace, the problem that the garbage can is difficult to clean is solved, arrangement of special transportation equipment of the garbage can is not needed, and meanwhile the automation degree is improved; and the four classification garbage can bodies are arranged in the four-classification buried multifunctional garbage can, classification variety diversification is improved, the technical problem that the garbage utilization rate is low is solved, and recyclable garbageis generated.

Owner:永昊环境科技(集团)有限公司

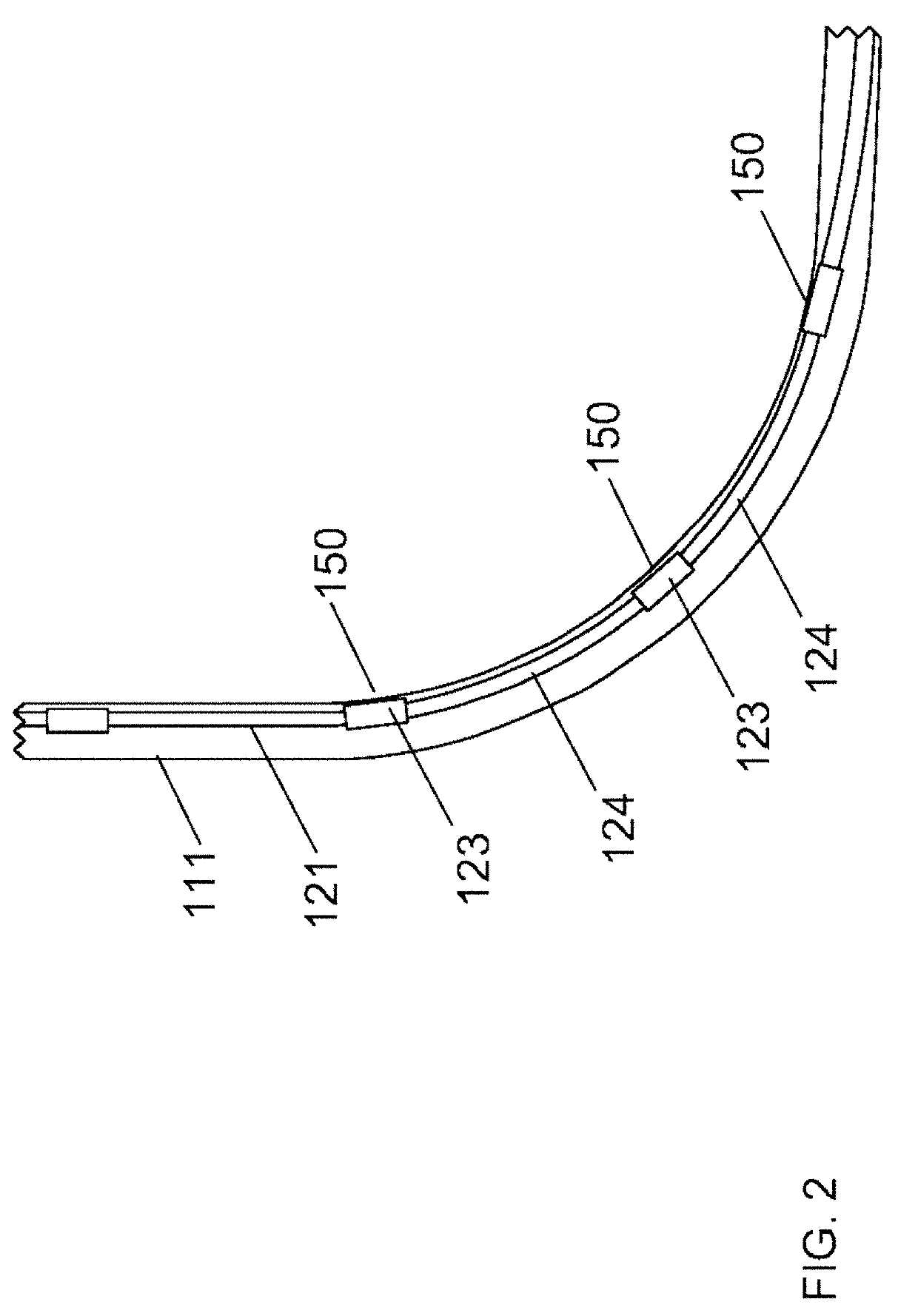

Low friction and high wear resistant sucker rod string

ActiveUS20190242197A1High strengthHigh wear resistanceDrilling rodsConstructionsCouplingWear resistant

A sucker rod string is formed from sucker rods and sucker rod couplings. The sucker rod couplings are formed from a spinodally-hardened copper alloy comprising from about 8 to about 20 wt % nickel, and from about 5 to about 11 wt % tin, the remaining balance being copper, and having a sliding coefficient of friction of 0.4 or less when measured against carbon steel. The sucker rod string has low friction and improved pumping stroke, enhanced pumping capacity, and less load in the overall system.

Owner:MATERION

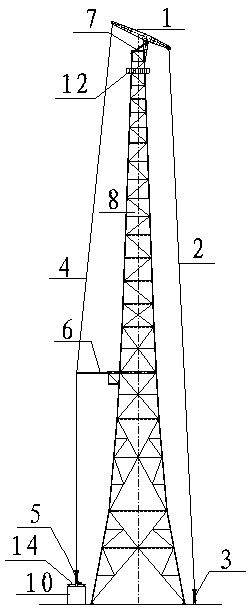

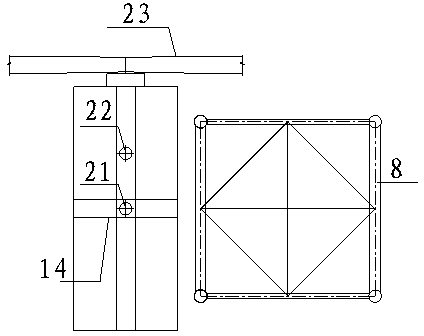

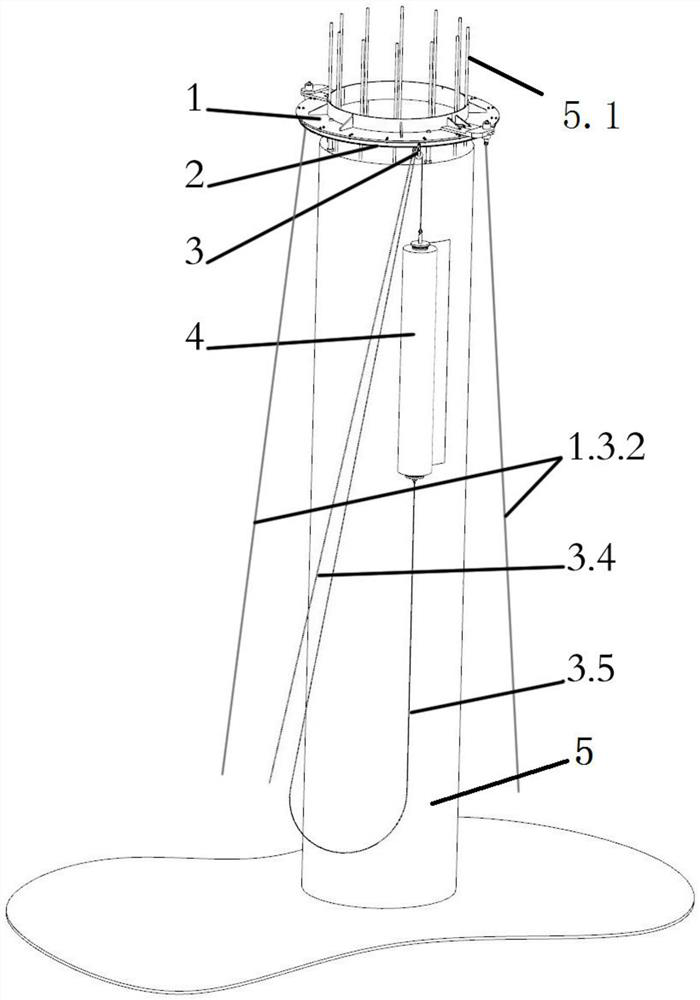

Wind power generation tower attached pick crane

The invention discloses a wind power generation tower attached pick crane, which comprises a crane boom, a post-tensioning steel strand, a ground anchor oil cylinder, a hoisting steel strand, a hydraulic lifting system, a telescopic oil cylinder and a stretching steel strand. The crane boom is hinged to the top of a wind power generation tower, the hoisting part of the crane boom stretches over the top of the wind power generation tower, and one end of the hoisting part of the crane boom is connected to the post-tensioning steel strand, the other end of which is in connection with the ground anchor oil cylinder fixedly disposed on the ground. The other end of the hoisting part of the crane boom is connected to the hoisting steel strand, the other end of which is connected to the hydraulic lifting system. The hydraulic lifting system is in connection with a fan engine room. The telescopic oil cylinder is fixedly disposed at a position between the middle part and the lower part of the wind power generation tower. The telescopic rod of the telescopic oil cylinder is in connection with the hoisting steel strand. The top of the wind power generation tower is hinged with the stretching steel strand, the other end of which is hinged to the support part of the crane boom. The equipment provided by the invention can be mounted and used repeatedly, and has the advantages of large one-time hoisting weight, great hoisting height, one hoisting time, cost saving, and the like.

Owner:QINGDAO SINOSTRO TECH CO LTD

Jet pump-double-screw pump same-well injection-production composite lifting system and method

ActiveCN111350487AShort processReduce development costsFluid removalPump installationsOil fieldOil water

The invention relates to a jet pump-double-screw pump same-well injection-production composite lifting system and method. The jet pump-double-screw pump same-well injection-production composite lifting system comprises a production system, an underground oil-water separation system and an injection system, wherein an upper connector of the production system is connected with an outlet of an upperscrew pump, and the upper screw pump is connected with a swirler overflow pipe through an upper coupler; an annular space between an oil pipe and a sleeve is separated into a liquid storage cavity through an upper packer and a lower packer; a liquid inlet hole formed in the oil pipe communicates with the liquid storage cavity; a guide blade arranged in the liquid storage cavity is fixed to the oilpipe; one end of a wedge-shaped guide hole in the oil pipe communicates with an inlet of a swirler, and the other end of the wedge-shaped guide hole in the oil pipe is communicated with the liquid storage cavity; the hydrocyclone is arranged in the oil pipe corresponding to the liquid storage cavity, and a swirler underflow pipe is connected with an inlet of a lower screw pump through a lower coupler; and the injection system comprises the lower screw pump, a jet pump and a bridge packer. According to the system and the method, composite lifting is achieved under the condition that a ground power device does not need to be additionally arranged, and the oilfield development cost is greatly reduced.

Owner:NORTHEAST GASOLINEEUM UNIV

Hierarchical synchronous hydraulic jacking process for large-tonnage ocean engineering structure

ActiveCN102101629ALow surrounding space requirementShorten the construction periodLifting devicesEngineeringEngineering structures

The invention discloses a hierarchical synchronous hydraulic jacking process for a large-tonnage ocean engineering structure. The process comprises the following steps of: 1, arranging a plurality of hydraulic jacks and a plurality of temporary protective supports below the structure and connecting a synchronous oil pump with the hydraulic jacks by using oil pipes; 2, controlling the plurality ofhydraulic jacks to simultaneously jack an oil cylinder through the synchronous oil pump; 3, arranging cushion blocks below the plurality of temporary supports; 4, arranging cushion blocks below the hydraulic jacks; 5, retracting the hydraulic jacks into the oil cylinder; 6, arranging the cushion blocks below the hydraulic jacks again; 7, repeating the steps 2 to 6 until the structure is jacked toa proper height; and 8, jacking the structure to remove the cushion blocks below the temporary supports after a transport vehicle enters the structure, and connecting the temporary supports of the same height below the structure. The process has lower requirement on space around the large-tonnage ocean engineering structure; the site utilization ratio is improved; meanwhile, the lifting cost of the large-tonnage ocean engineering structure is reduced; and the construction period of the large-tonnage ocean engineering structure is shortened.

Owner:CHINA NAT OFFSHORE OIL CORP +2

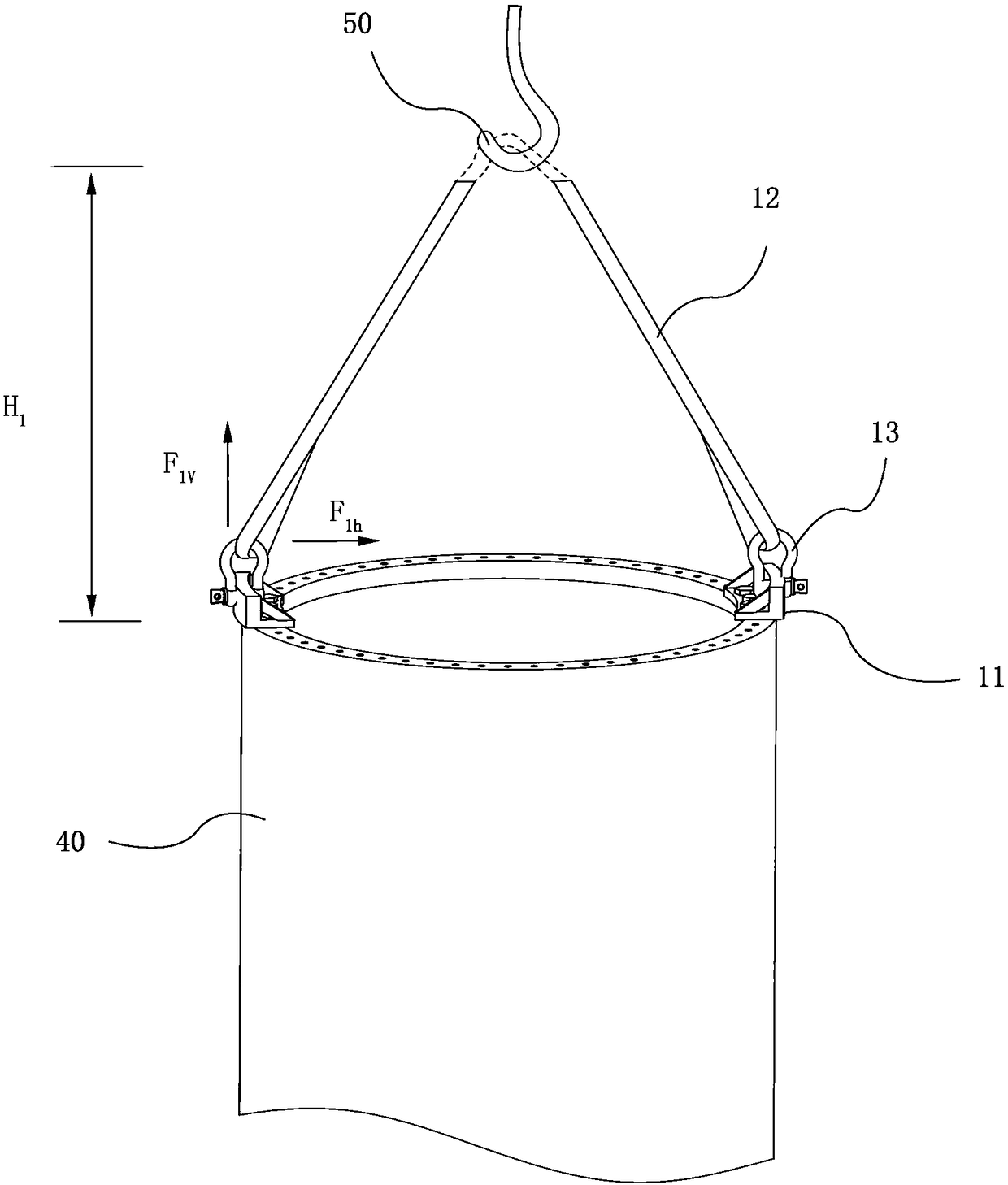

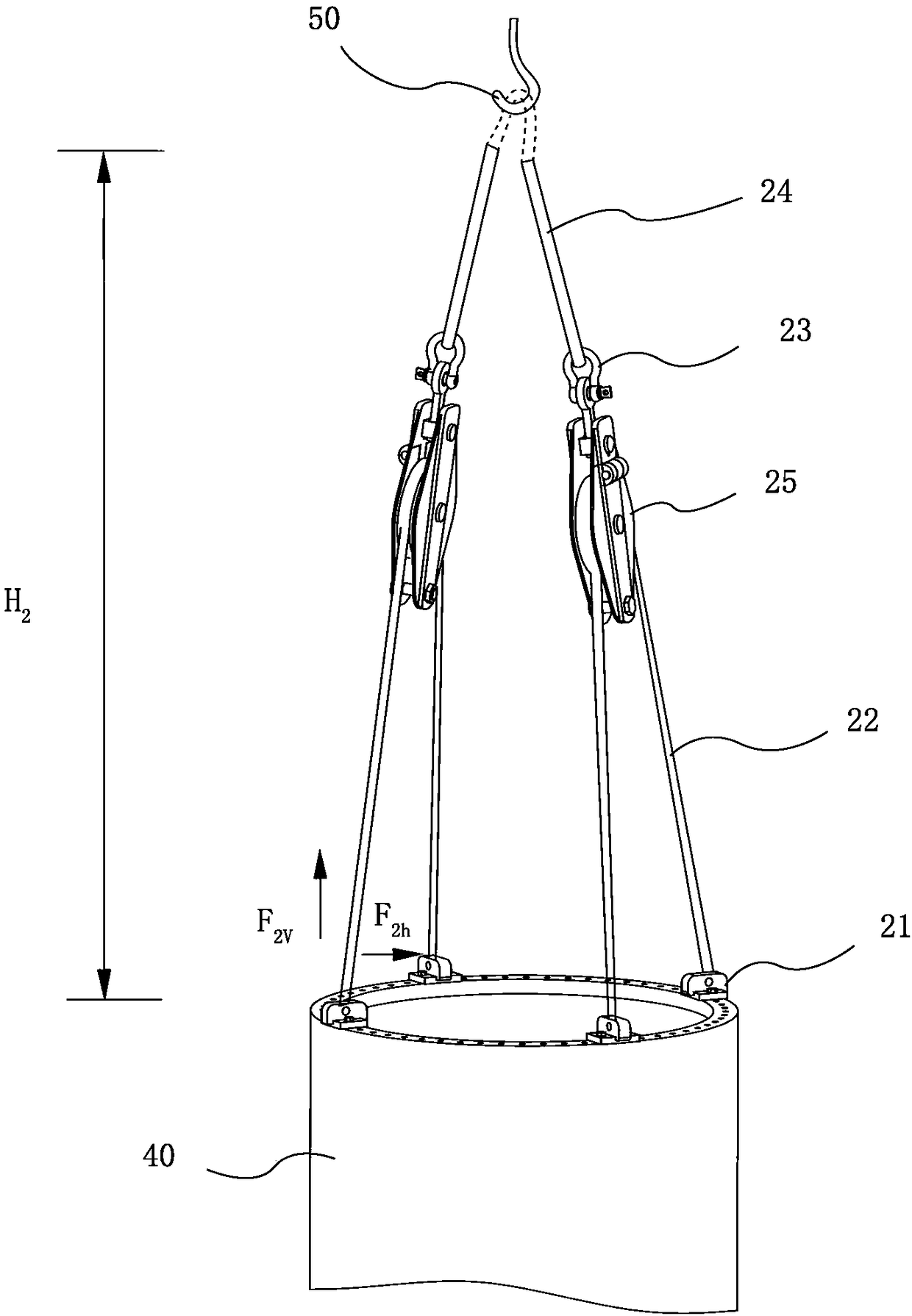

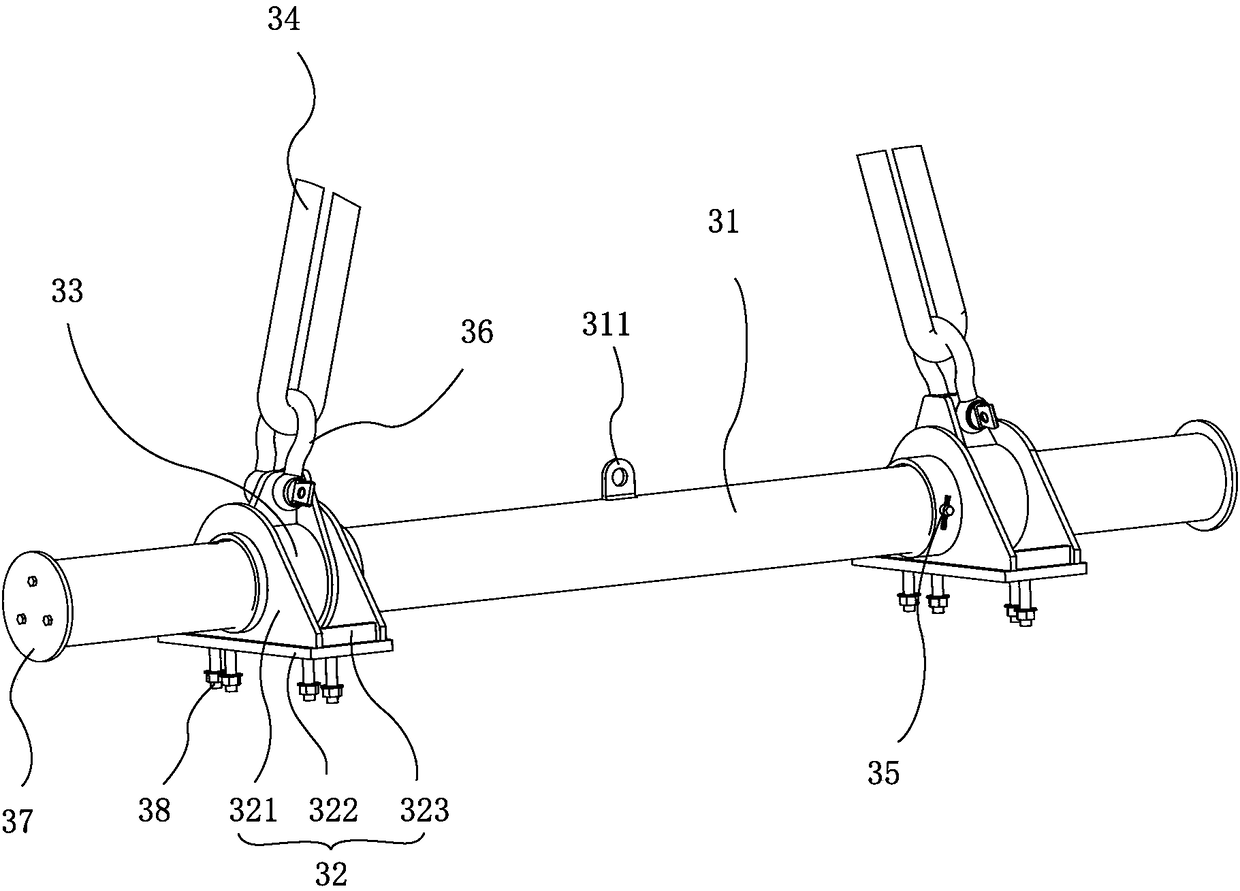

Lifting appliance

ActiveCN108358037AAffect assemblyReduce lifting heightLoad-engaging elementsTowerIndustrial engineering

The invention provides a lifting appliance. The lifting appliance comprises a lifting beam, lifting lugs, lifting rings and lifting belts, wherein the at least two lifting lugs are detachably installed on the lifting beam to connect a piece to be lifted; the lifting rings rotationally sleeve the lifting beam and are arranged in the accommodating spaces of the lifting lugs, and the lifting lugs canbe abutted against the lifting rings and prevent the lifting rings from moving in the length direction of the lifting beam; and the lifting belts are connected to the lifting rings. According to thelifting appliance provided by the invention, through the arrangement for the lifting beam, the flange of a tower barrel can be prevented from being deformed due to the effect of a radial component force in a lifting process to influence assembly for the tower barrel.

Owner:URUMQI GOLDWIND TIANYI WIND POWER CO LTD

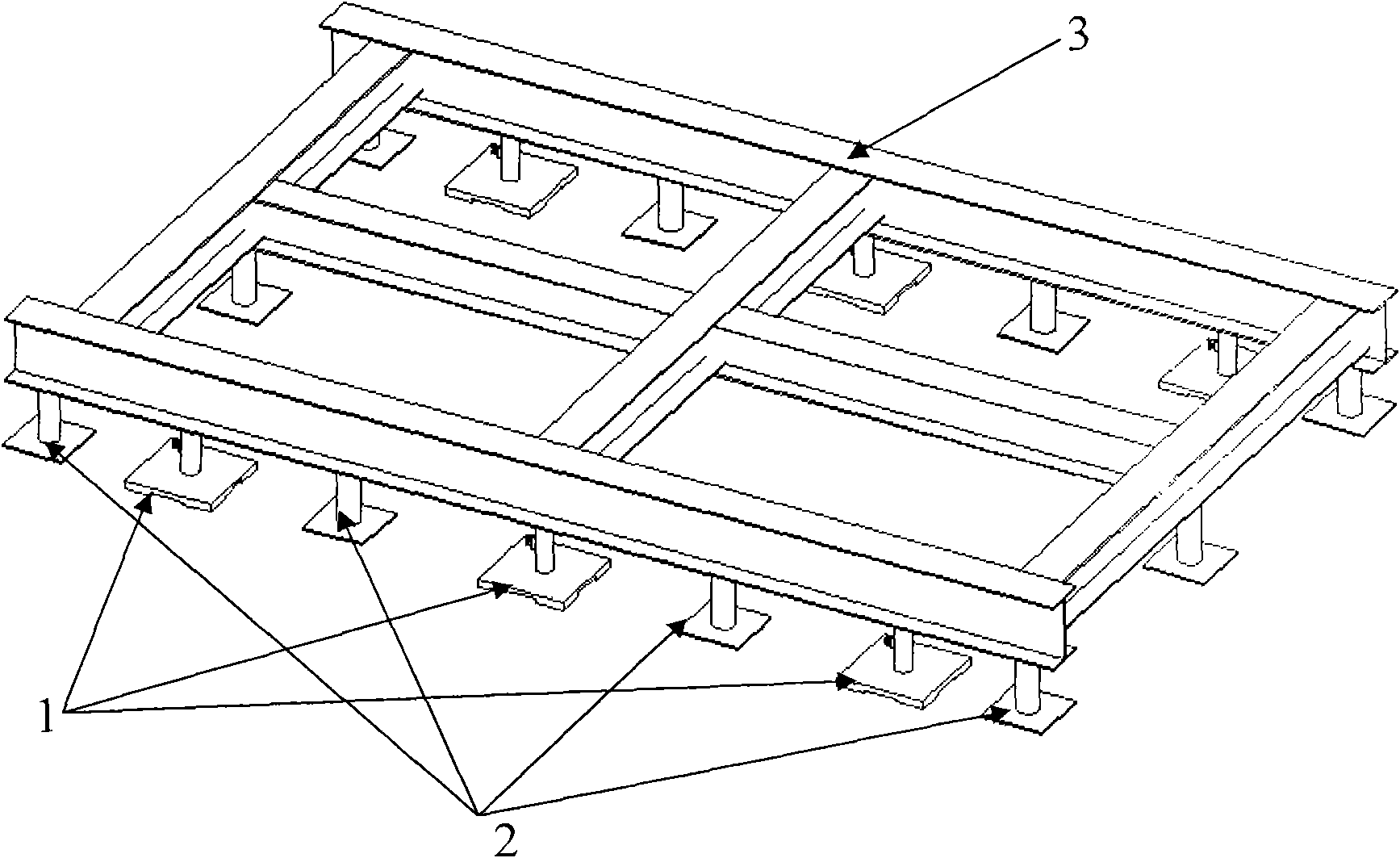

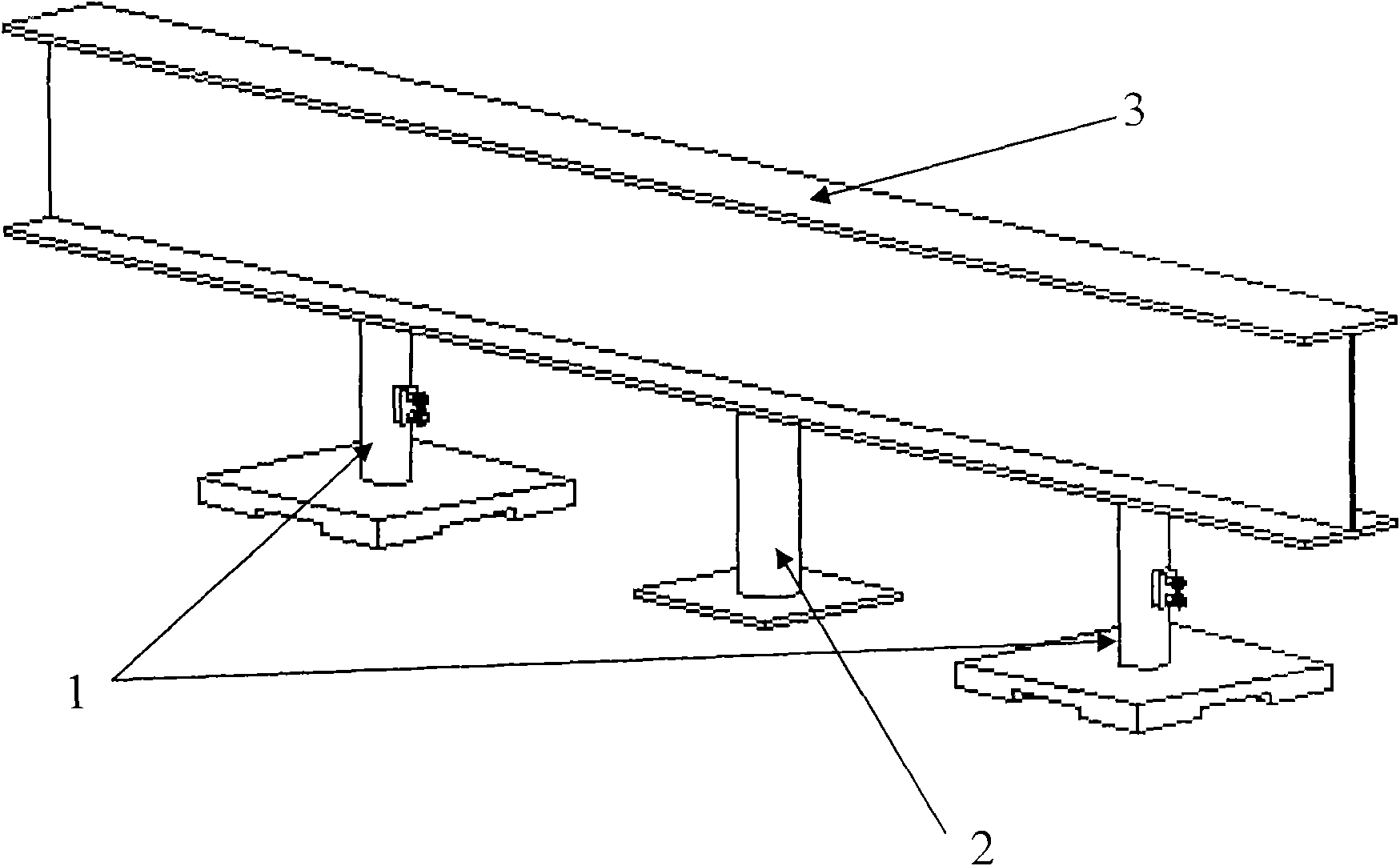

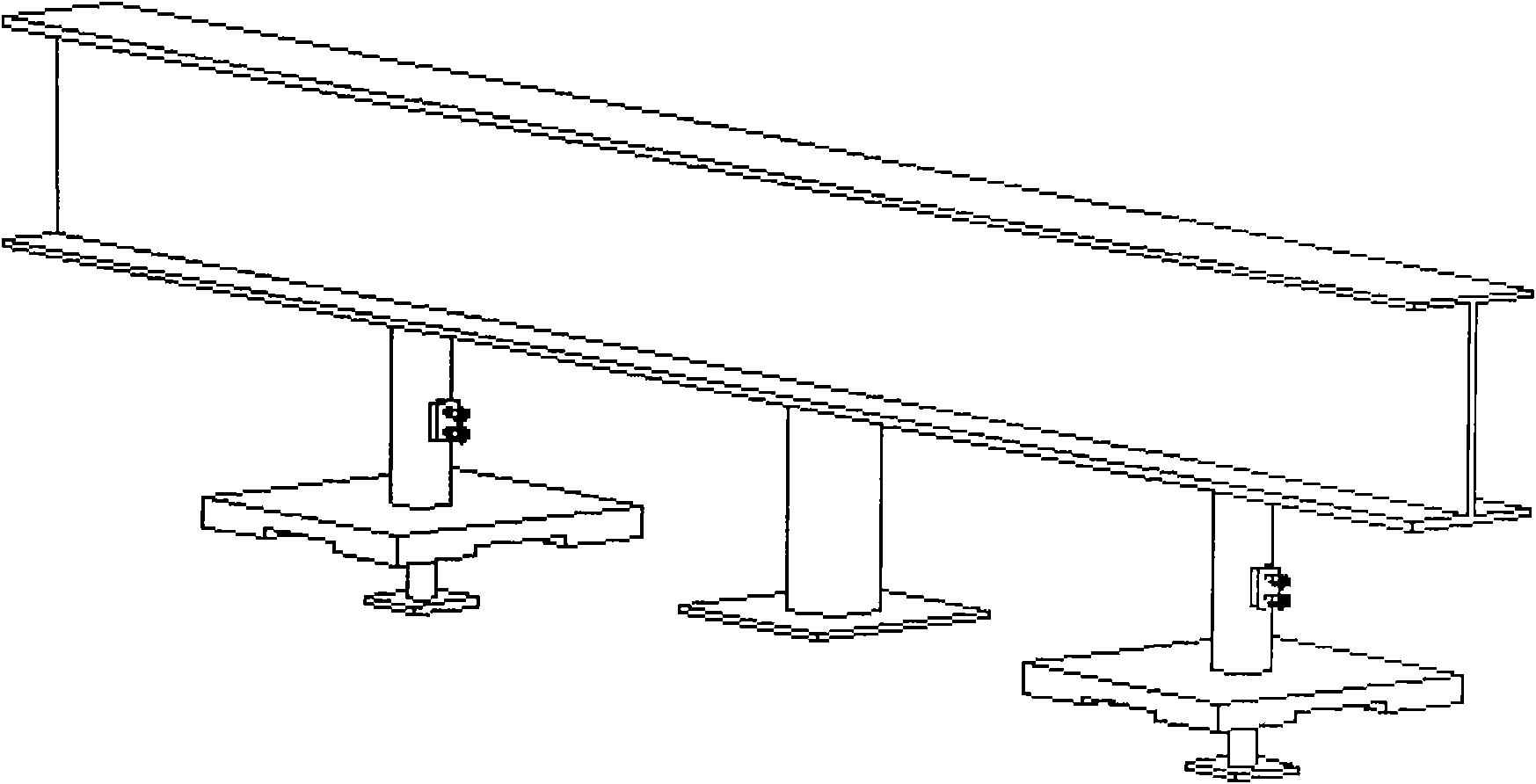

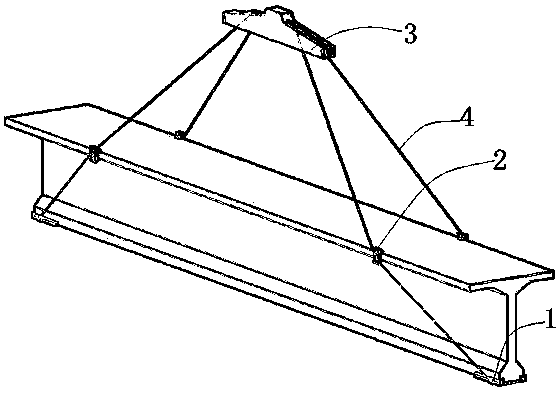

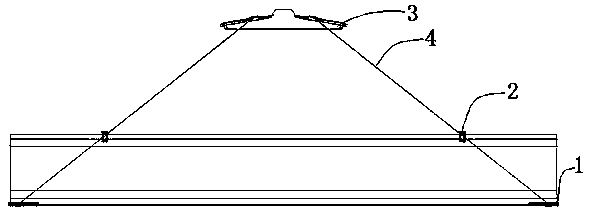

Precast beam precise lifting device and method thereof

PendingCN111170138ASolve the phenomenon of "top-heavy"Improve lifting efficiencyLoad-engaging elementsControl theoryWire rope

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR

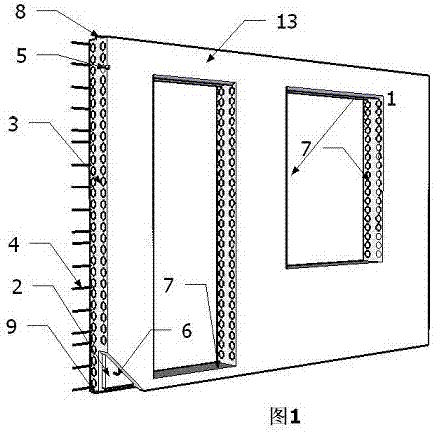

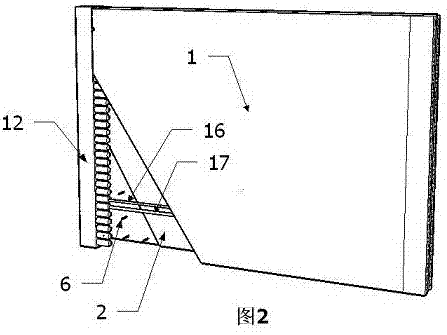

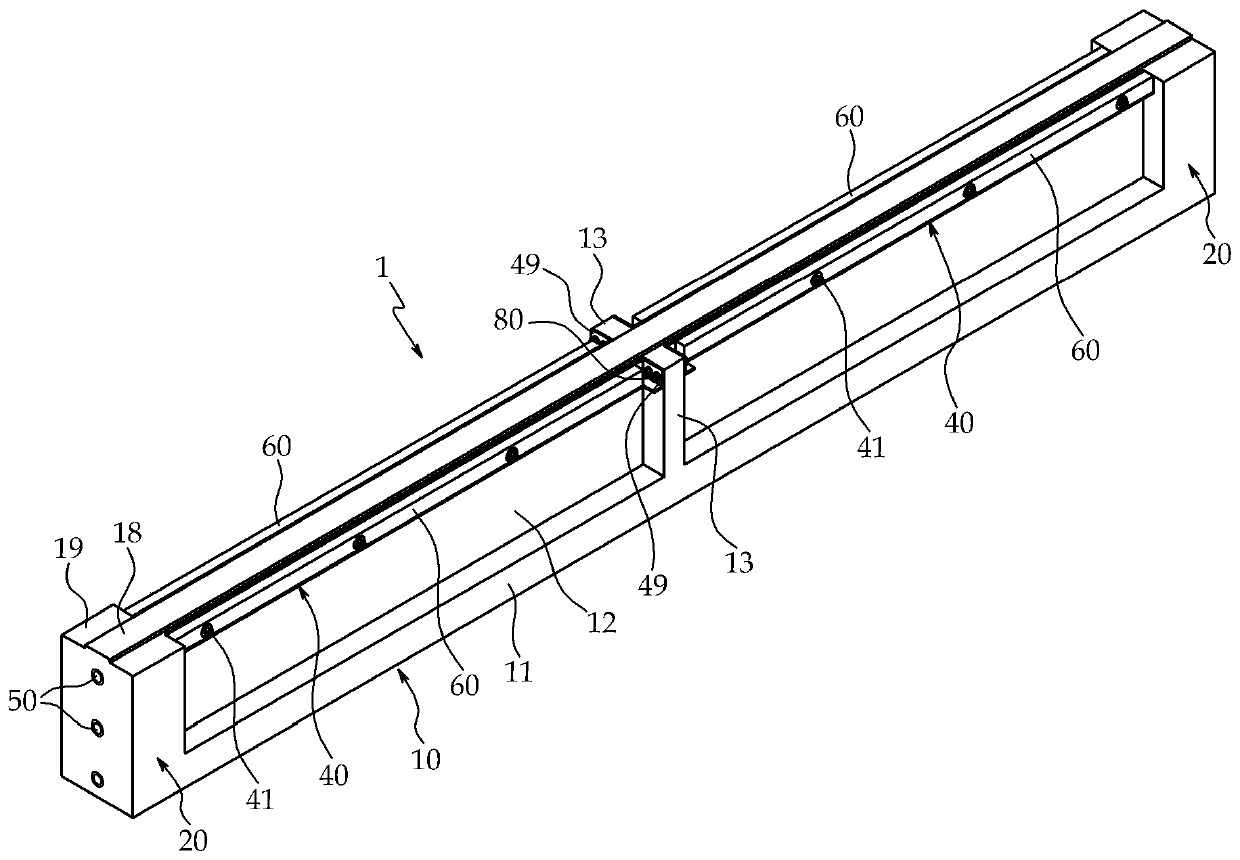

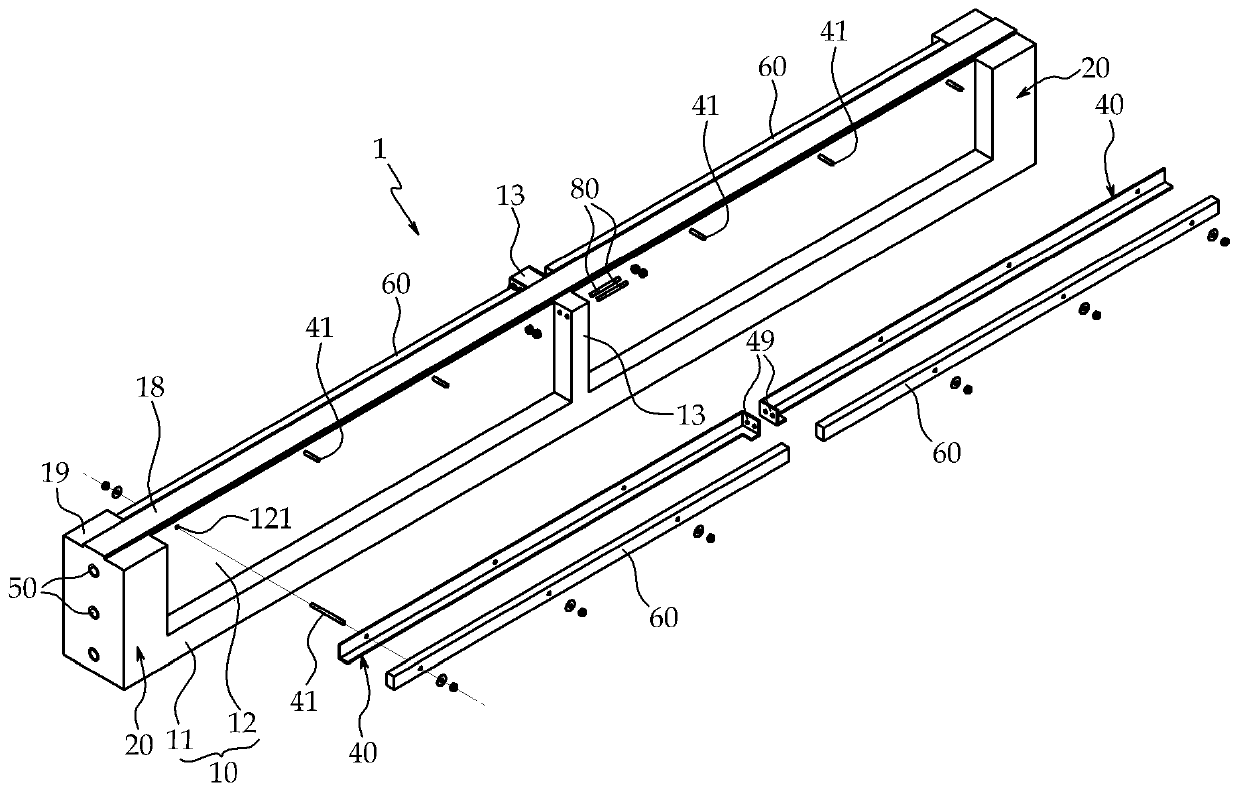

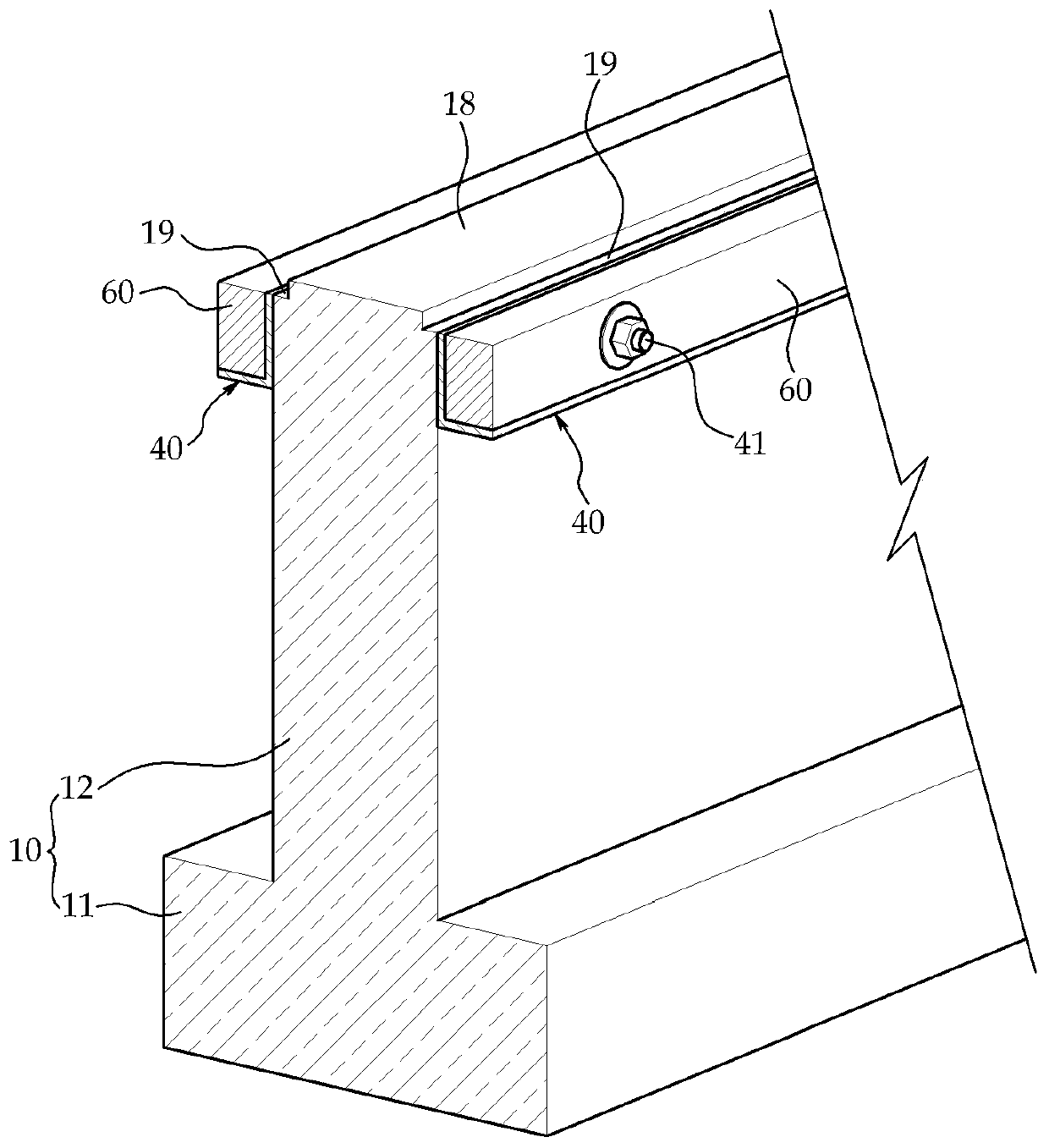

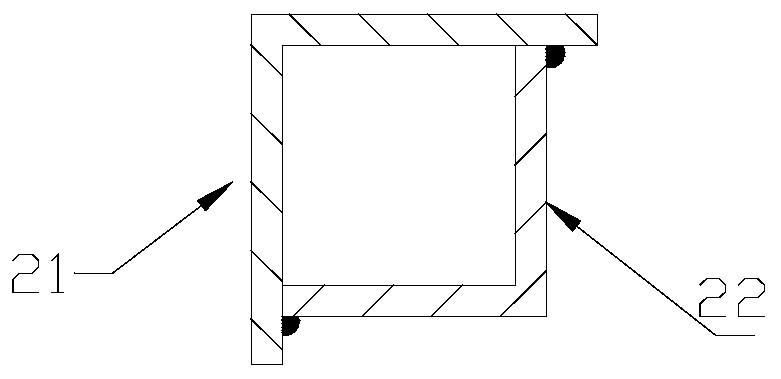

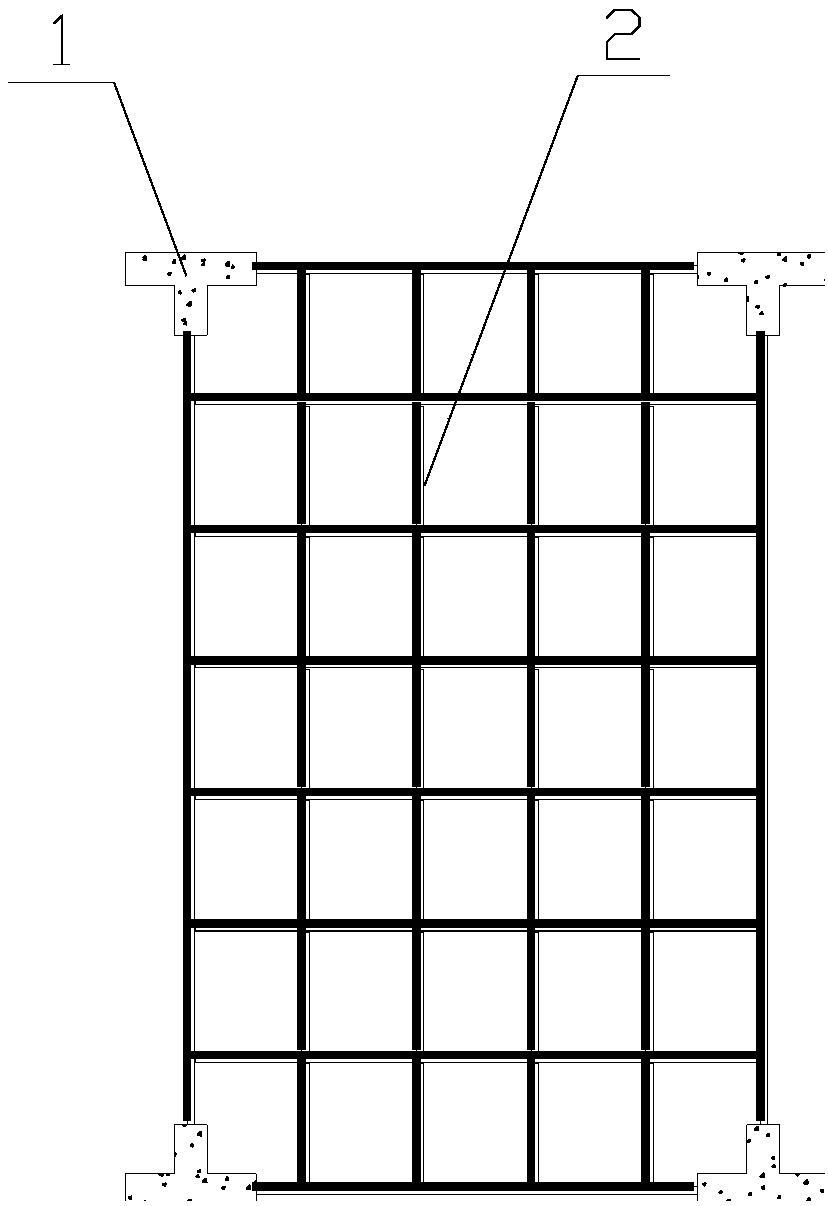

Large horizontal hole overall prefabricated wall plate

InactiveCN106930433AFirmly connectedImprove bindingWallsHeat proofingHeat transfer coefficientWall plate

The invention discloses a large horizontal hole overall prefabricated wall plate. In terms of a house assembled from wall plates, a wall body of each standard room is formed by building the large horizontal hole overall prefabricated wall plate (1) in the mode that internal horizontal holes are kept horizontal. After the wall body is built, a plurality of long hollow horizontal holes (3) which are horizontal are formed between every two top end stand columns (12). According to the large hollow overall prefabricated wall plate developed by the invention, the problems that the self weight is large, the thermal insulating performance is poor, the cost is high, hoisting is impossible, pulling is difficult and the like are solved, and the hollow structure reduces the heat transfer coefficient of the concrete wall body, a building foundation load and the foundation treatment cost.

Owner:张宗楼

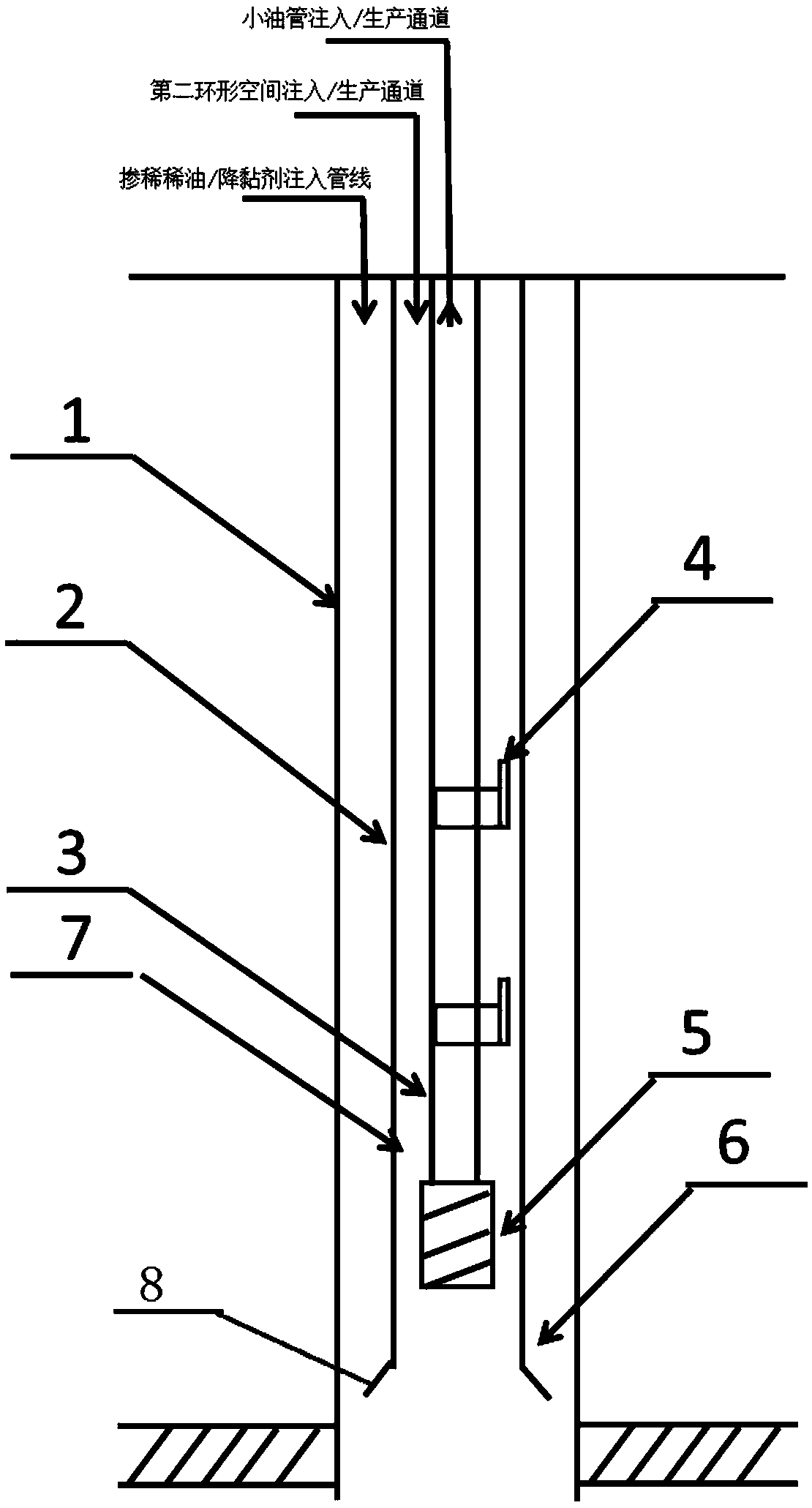

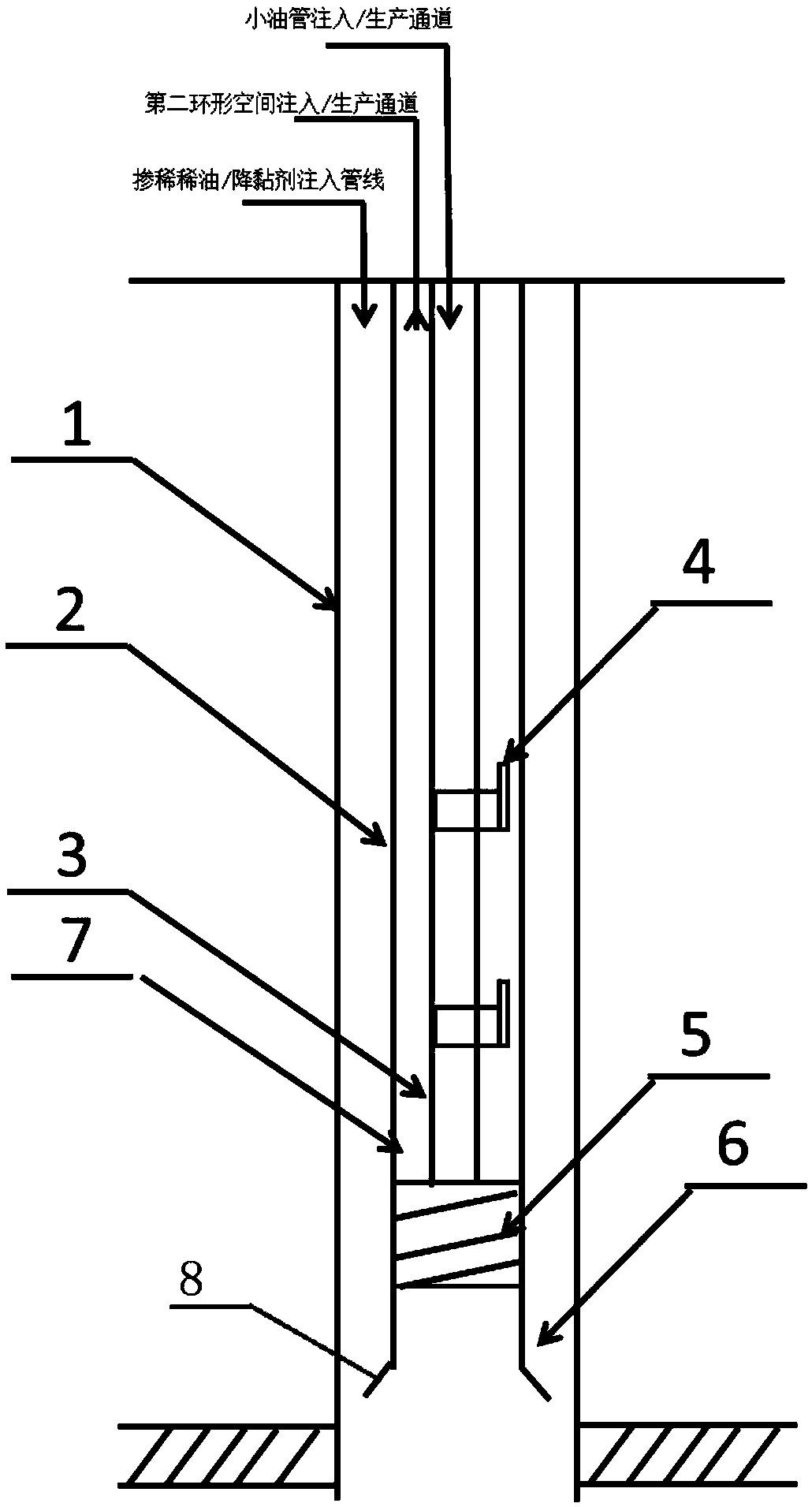

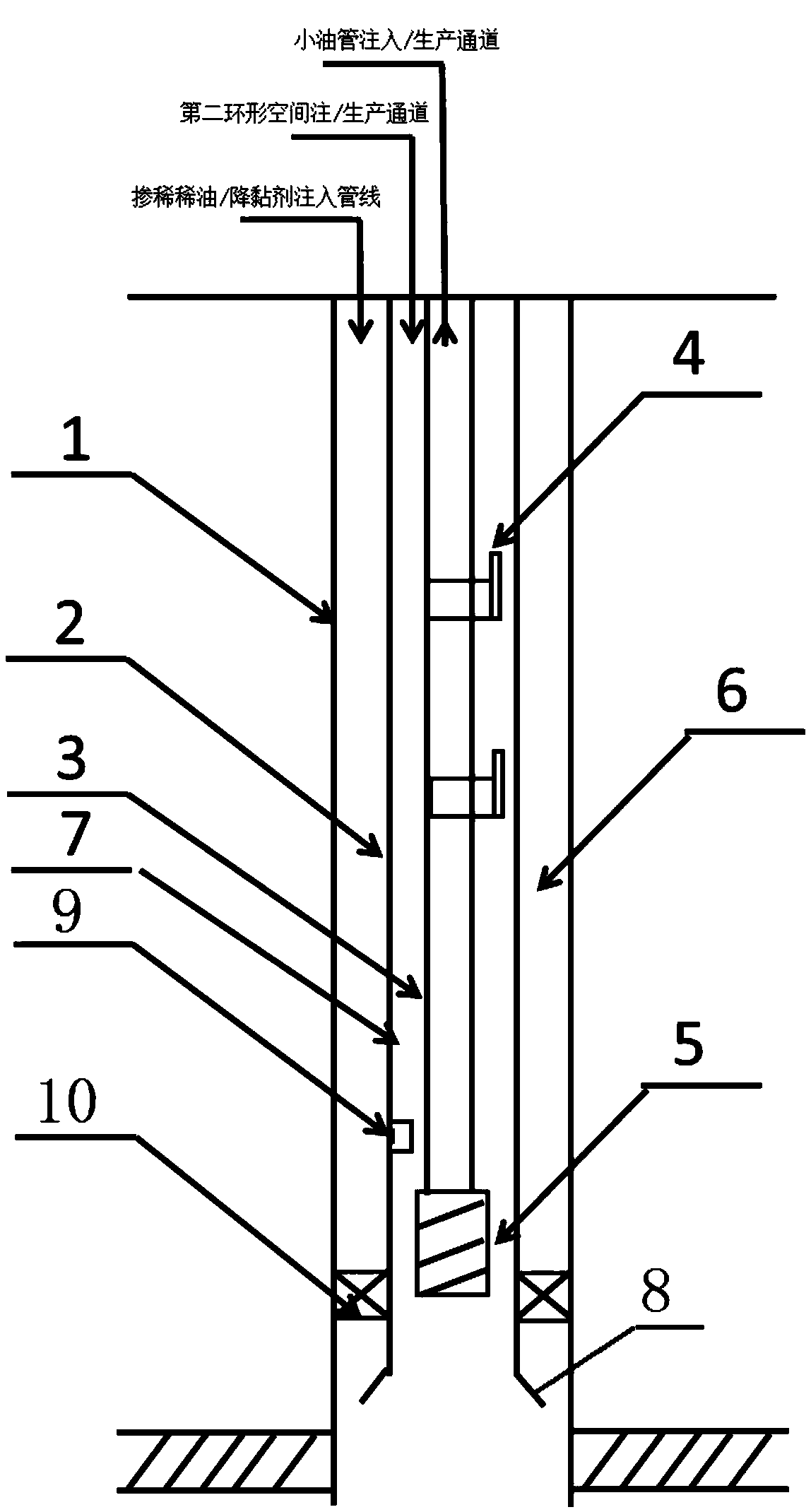

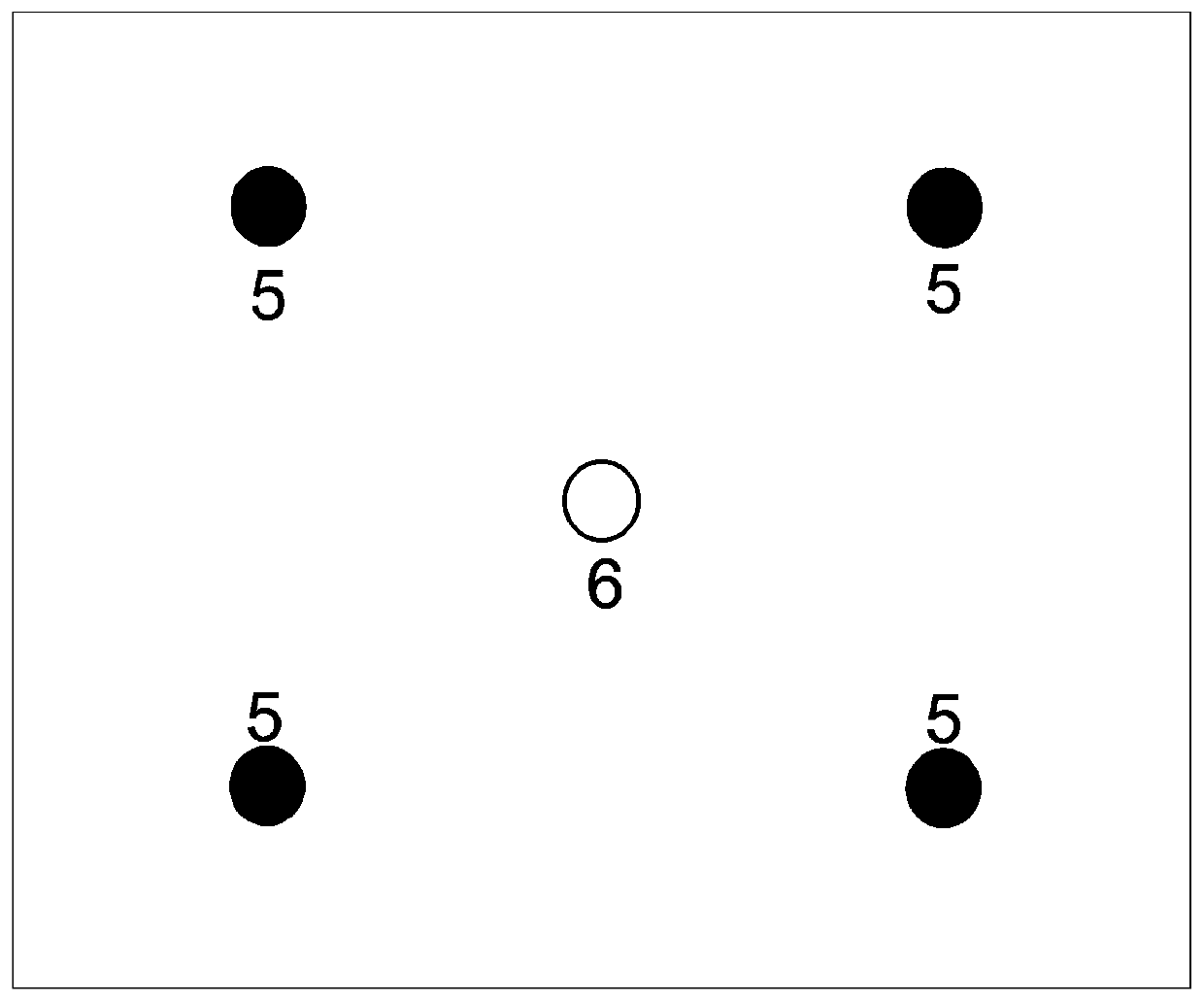

Thin-oil-doped heavy oil gas lift technology pipe column and implementation method

InactiveCN110761743AIncreased lifting capacityLow densityFluid removalDesign optimisation/simulationGas liftProduction string

The invention provides a thin-oil-doped heavy oil gas lift technology pipe column. The thin-oil-doped heavy oil gas lift technology pipe column includes a double-layer concentric oil pipe column arranged in a casing pipe, one or more gas lift valves and working barrels are arranged on a pipe column of a small oil column of the concentric oil pipe column, the bottom end of the small pipe column isconnected with a mixing device, a first annular space is formed between the casing pipe and the oil pipe of the concentric oil pipe column, and a second annular space is formed between the oil pipe and the small oil pipe. At the same time, the invention provides an implementation method of the thin-oil-doped heavy oil gas lift technology pipe column. According to the thin-oil-doped heavy oil gas lift technology pipe column, the remaining energy of the formation is effectively utilized to change the production pipe column under the premise of no well killing and no pressure, the thin-oil dopingand mixing effects are improved, injected gas is dissolved in crude oil, density and viscosity of the crude oil are further decreased, the lifting effect of a heavy oil well is improved, the cost oflifting is lowered, and the economic benefit is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined mining method for dry heat rock stratum and hydrate reservoir stratum

InactiveCN110805412AOvercome costsOvercome lossLighting and heating apparatusGeothermal energy generationVapor–liquid separatorDry heat

The invention discloses a combined mining method for a dry heat rock stratum and a hydrate reservoir stratum. The method comprises the following steps that (1), a comprehensive well is arranged in a regional center, and flowback wells are arranged around; (2), perforating is carried out on the portions, located at the hydrate reservoir stratum and the dry heat rock stratum, in the well; (3), seawater is injected into the dry heat rock stratum through an oil pipe in the comprehensive well; (4) the seawater heated by the dry heat rock stratum flows back to the hydrate reservoir stratum through the four flowback wells, so that the hydrate reservoir stratum is heated and hydrates are decomposed; (5) decomposed products of the hydrates flow into annuli of a casing pipe and the oil pipe of the comprehensive well, and downhole gas-liquid separation is carried out by a gas-liquid separator; and (6) gas separated by the gas-liquid separator is extracted through the casing pipe of the comprehensive well, and separated liquid enters the oil pipe of the comprehensive well and is injected into the dry heat rock stratum along with the seawater. According to the method, heat energy in the dry heat rock stratum is transferred to the hydrate reservoir stratum through the seawater medium, so that the comprehensive utilization of the energy of the dry heat rock stratum and the hydrate reservoir stratum is realized.

Owner:NORTHEAST GASOLINEEUM UNIV

Dust removal method for waste rock smashing in underground coal mine chamber

ActiveCN105317453AReduce lifting costsProtect healthDust removalFire preventionAtmospheric pressureDust fall

The invention discloses a dust removal method for waste rock smashing in an underground coal mine chamber. The dust removal method is suitable for dust removal and dust fall of the underground coal mine operation chamber generating a lot of dust. A smashing chamber is constructed between an air inlet way and an air return way and used for communicating the air inlet way with the air return way; an exhaust fan is arranged inside the air return way, and an adjusting door is installed on the side, connected with the air return way, of the smashing chamber; a smashing machine is then arranged inside the smashing chamber, a waste rock inlet belt and a waste rock outlet belt connected with the smashing machine are arranged on the side, connected with the air inlet way, of the smashing chamber, underground coal mine waste rock is conveyed to the smashing machine through the waste rock inlet belt, the waste rock which is smashed through the smashing machine is conveyed out of the chamber through the waste rock outlet belt, and when the waste rock is smashed in the smashing machine, air exhausting is performed through the exhaust fan, air pressure inside the air inlet way is controlled to be higher than that inside the air return way, air flows into the air return way through the smashing chamber from the air inlet way, and then dust removal is performed. In this way, air cleanness of the operation space of workers is guaranteed. According to the method, dust removal equipment does not need to be additionally arranged, design is simple, and using is safe and reliable.

Owner:CHINA UNIV OF MINING & TECH

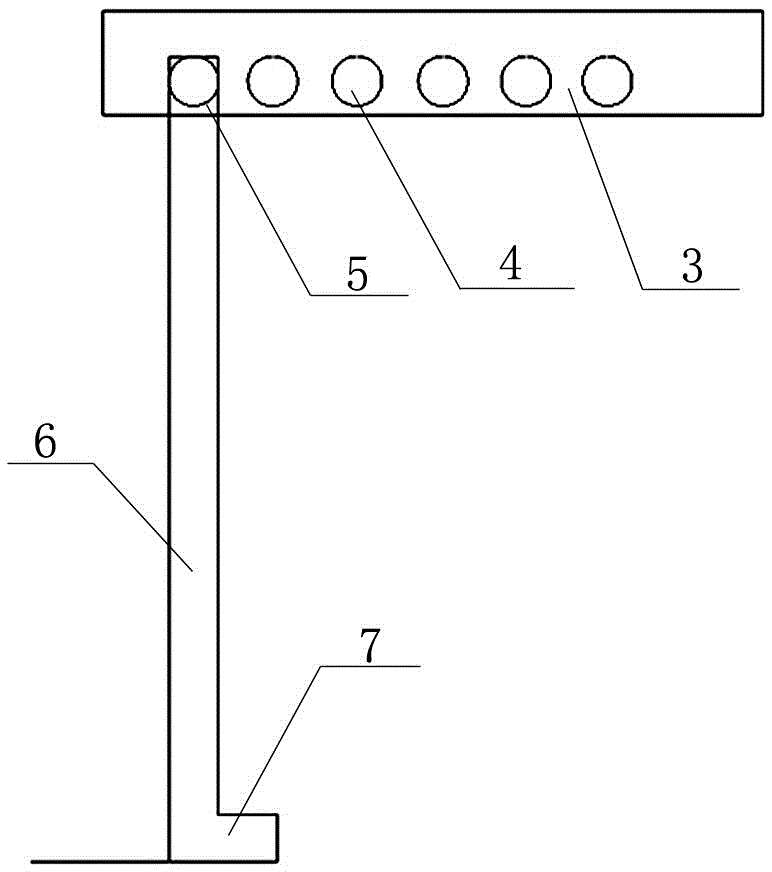

Pier column maintenance device and film covering construction method

PendingCN113756182AImprove lamination efficiencyImprove lamination qualityBridge structural detailsBridge erection/assemblyArchitectural engineeringPier

The invention relates to the field of buildings, and provides a pier column maintenance device and a film covering construction method. The pier column maintenance device comprises a rack fixed to a top of apier column, a lifting assembly slidably arranged on the rack in the circumferential direction of the pier column, and a maintenance film assembly which comprises a shaft rod and a maintenance film roll rotatably arranged on the shaft rod, wherein the shaft rod is connected with the lifting assembly; and the lifting assembly can lift or lower the maintenance film roll while sliding in the circumferential direction of the pier column so that the maintenance film roll can be wound around the pier column according to the spiral track. After the rack is hoisted at the top end of the pier column, a constructor can make the maintenance film spirally wind on the pier column on the ground through the lifting assembly, and therefore in the pier column maintenance film covering construction process, a crane does not need to be matched for construction, a support does not need to be erected, the construction period can be shortened, the construction cost can be reduced, high-altitude film covering operation of workers is avoided, and potential safety hazards of construction are eliminated.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

Three-point lifting equipment for large castings

InactiveCN105565151ASimple structureEasy to useLoad-engaging elementsUltimate tensile strengthLifting equipment

The invention discloses three-point lifting equipment for large castings. The three-point lifting equipment comprises a center base frame provided with a lifting base in middle; the side edge of the center base frame is connected with three cross beam frames uniformly distributed and flatly extending outwards; a row of positioning holes is uniformly distributed in the cross beam frames; lifting hook rods downwards dropping are connected by pin shafts through the positioning holes; hook parts flatly extending inwards are arranged at the lower end parts of the lifting hook rods; the center base frame is a short cylinder; a lifting base with a lifting ring is arranged in the center position of the upper surface of the center base frame; the cross beam frames flatly extending outwards are integrally produced on the peripheral wall surface of the center base frame; U-shaped grooves capable of being embedded in bodies of the cross beam frames from the lower parts are formed in the upper end parts of the lifting hook rods; transverse shaft holes are formed in the U-shaped grooves; and the pin shafts penetrate through the transverse shaft holes and the corresponding positioning holes in the cross beam frames to vertically fix the lifting hook rods on the bodies of the cross beam frames. The three-point lifting equipment has such characteristics as simple structure, convenience for use, safety, reliability, capability of reducing labor intensity and reduction of lifting cost.

Owner:浙江德润重工机械有限公司

Hybrid psc girder having reverse t-shaped cross section and method for constructing slab using same

ActiveCN110392758AReduce the amount of materialImprove stabilityFloorsBridge erection/assemblyEngineeringOut of plane

One aspect of the present invention presents a hybrid PSC girder having a reverse T-shaped cross section, the girder comprising: a lower flange; a web which is vertically formed upward from the widthwise central part of the lower flange and includes, at an upper part, a plurality of coupling holes formed therethrough or formed in a predetermined depth at an uniform interval in the longitudinal direction; a central body part having a reverse T-shaped cross section, which comprises reinforcing partition walls protruding from both sides of the web in a predetermined thickness to resist out-of-plane deformation; end partition walls formed at both lengthwise ends of the central body part in a predetermined length and having a box-type cross section; and reinforcing beams made of steel, having apredetermined length, and coupled in the lengthwise direction to opposite side surfaces of the upper part of the web between the reinforcing partition walls and the end partition walls by using coupling fasteners inserted into the coupling holes.

Owner:(株)知胜建设咨询公司 +1

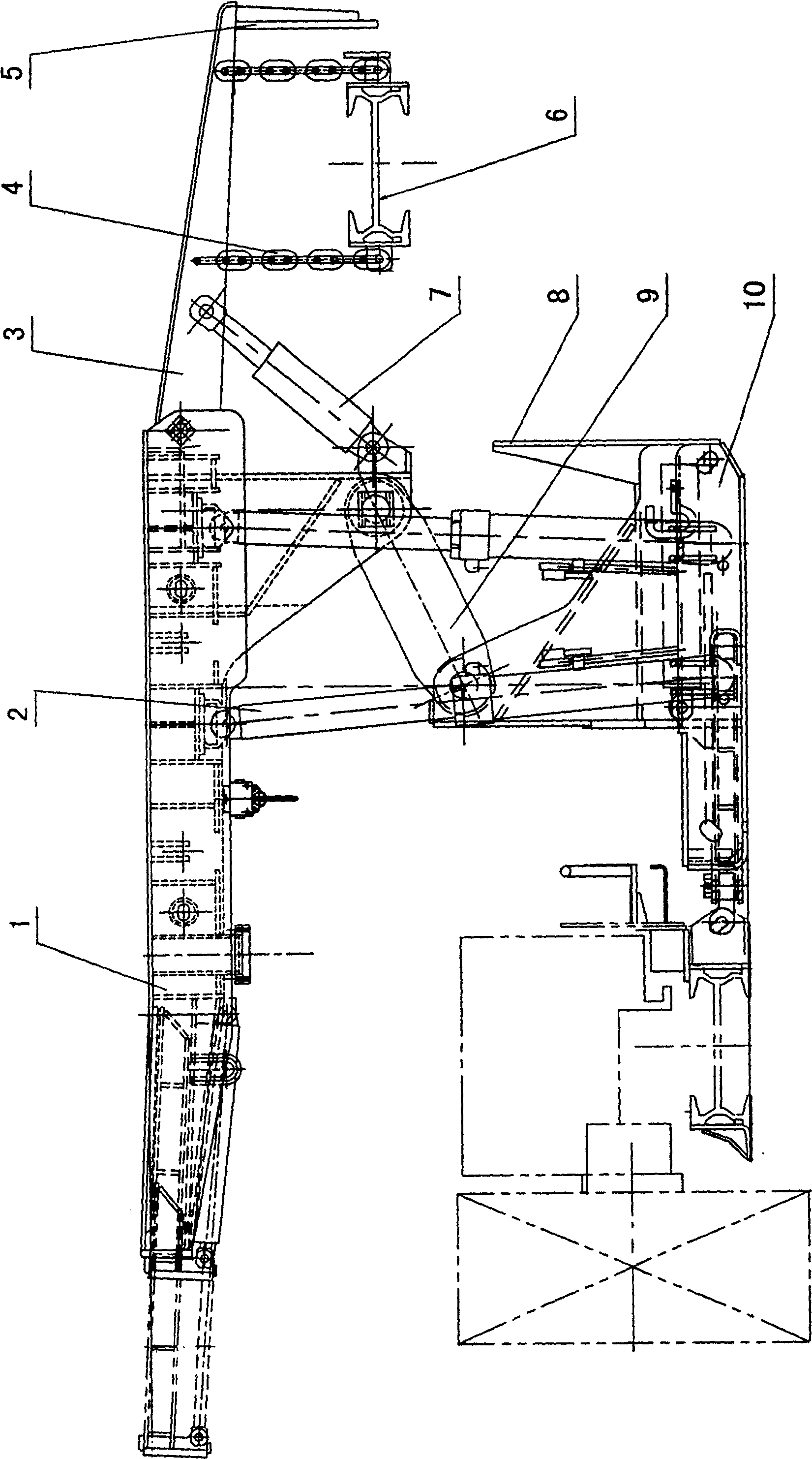

Hydraulic support for filling waste rock

A gangue filling hydraulic support for fully mechanized mining face in coal mines, comprising a top beam (1), a column (2), a base (10), a tail beam (3), a tail beam jack (7) and a tail beam (3) The bottom hanging scraper conveyor chute (6) etc. constitutes. The groove plate of hanging chute (6) has gangue leakage hole (12). The filling bracket is arranged on the fully mechanized mining face, and the suspension chute (6) is sequentially connected, and is connected with the fully mechanized mining face, the tail and the head of the lower end to form a whole scraper conveyor (26). In addition to being used as support equipment for fully mechanized mining, the filling support is also the main component of the gangue filling system. In addition to the common filling methods, the filling system has the advantages of disposing of gangue underground, reducing transportation and lifting, reducing ground subsidence, reducing land occupation and pollution of gangue hills, and has the advantages of simple system, less equipment, uncomplicated technology, and low investment. less, unaffected by frame shifting, and can be bent and transported uninterruptedly to fill gangue.

Owner:佟强

Lifting appliance for trapezoidal sleeper

PendingCN107938441AEasy to transportEasy loading and unloadingRailway track constructionControl theoryBilateral symmetry

The invention discloses a lifting appliance for a trapezoidal sleeper. The lifting appliance comprises a bearing device, a suspension device and a movable lifting device. The bearing device takes a bearing frame body as a formwork, and four balanced supporting devices are arranged on the frame body. Two fork grooves are formed in the lower portion of the frame body in a bilateral symmetry mode, and a positioning device is disposed at one corner of the frame body. The movable lifting device takes a force transmission frame body as a framework, and the frame body is provided with four angle adjustment tracks matched with the balanced supporting devices. Two positioning blocks and two movable lifting hooks are arranged below a left short-edge support and a right short-edge support respectively, and the side edges of the two short-edge supports are provided with lifting hook locking devices. The bearing frame body of the bearing device acts on the force transmission frame body of the movable lifting device through the suspension device. The lifting appliance is matched with a forklift for use, the transportation and loading and unloading operations of the trapezoidal sleeper can be completed conveniently, swiftly, safely and effectively, and the lifting appliance not only greatly reduces the production cost and improves working efficiency, but also effectively improves the finishedproduct intact rate of the trapezoidal sleeper and the safety factor of the lifting process.

Owner:广西华宏威建设工程有限公司

Multi-multiplying power balance type variable multiplying power device

InactiveCN106006423ARich lifting functionsFlexible disassemblyWinding mechanismsLow speedBlock and tackle

The invention discloses a multi-multiplying power balance type variable multiplying power device which comprises a fixed pulley, a guide pulley, a six-multiplying power movable pulley block, a two-multiplying power movable pulley block, a hook assembly and a balance beam, wherein the fixed pulley is mounted on a front trolley of a crane boom; the guide pulley is mounted on a rear trolley of the crane boom; the six-multiplying power movable pulley block is hung right under the fixed pulley through a steel wire rope; the two-multiplying power movable pulley block is hung right under the guide pulley through another steel wire rope; the hook assembly consists of a hook and a hook plate. Flexible alternation of multiple multiplying powers is achieved with different combinations of the hook assembly, the two multiplying power movable pulley blocks having different multiplying powers, and the balance beam, different requirements of multiple crane loads such as heavy-load low speed and light-load high speed in practical operation can be met, the lifting functions of a crane can be greatly enriched, and the lifting cost can be lowered; in addition, since the movable pulley blocks of different multiplying powers, the balance beam and the hook assembly are connected through hinge pins, the multi-multiplying power balance type variable multiplying power device is flexible to assemble and disassemble and convenient to use.

Owner:KERUN ELECTRO MECHANICAL ENG

Portable hoisting device

PendingCN111217273ASimple structureSmall form factorBase supporting structuresBraking devices for hoisting equipmentsEngineeringHoist device

The invention relates to a hoisting device. A central air conditioner shell-and-tube heat exchanger comprises a shell, an end cover and a heat exchanger main body arranged in the shell. A flange plateis arranged on the shell, and a pair of hoisting holes are formed in the flange plate. The device is characterized by further comprising a hoisting device, wherein the hoisting device comprises a cross beam, a support, a lifting hoist and a lifting hook, a cross rod of the support is provided with a cross beam stretcher positioning frame, the two ends of the cross beam penetrate through the crossbeam stretcher positioning frame and are placed on the support, a vertical rod of the support is detachably mounted on the hoisting holes, the lifting hoist is lifted on the cross beam, and a liftingnostril capable of being lifted by the lifting hook is arranged on the end cover. The device has the advantages of simple structure, flexible arrangement, large bearing capacity, convenience carryingand universality.

Owner:SHUNDE POLYTECHNIC

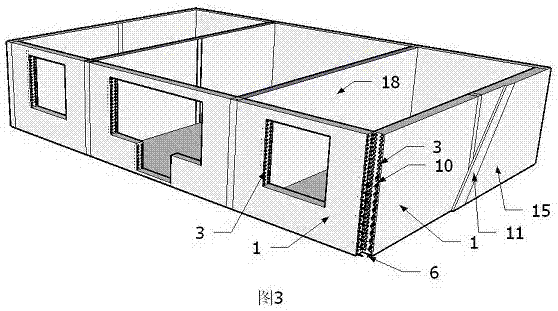

Integrated house

InactiveCN107938832AEffective pollution controlReduce pollutionBuilding constructionsBrickArchitectural engineering

The invention discloses an integrated house. The integrated house comprises light steel frameworks, a roof, floor systems, outer wall systems and inner wall systems, wherein the roof is arranged on the top of the topmost light steel framework, the light steel frameworks are assembled into a multi-layer structure which is vertically aligned, and supporting columns are arranged at four corners of each light steel framework. Each layer of the light steel framework is provided with one floor system and load bearing walls, and the periphery of each light steel framework is provided with the corresponding outer wall systems; the bottom of the light steel framework at the bottom is provided with a building base frame, and building framework guide rails are arranged on the outer edge of the building base frame; the building base frame is further provided with edge connecting pieces, and the floor systems comprise combined columns and brick plate placing frames. The integrated house is novel indesign, reasonable in structure, economical, environmentally friendly, good in bearing capacity, high in seismic resistance and easy and convenient to construct, the construction efficiency is improved, the construction cost is reduced, and the service life of a building is prolonged.

Owner:寿光市远大建筑有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com