Three-point lifting equipment for large castings

A technology for hoisting equipment and large castings, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of high hoisting cost, high labor intensity, hidden safety hazards, etc., to reduce hoisting cost, labor intensity, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

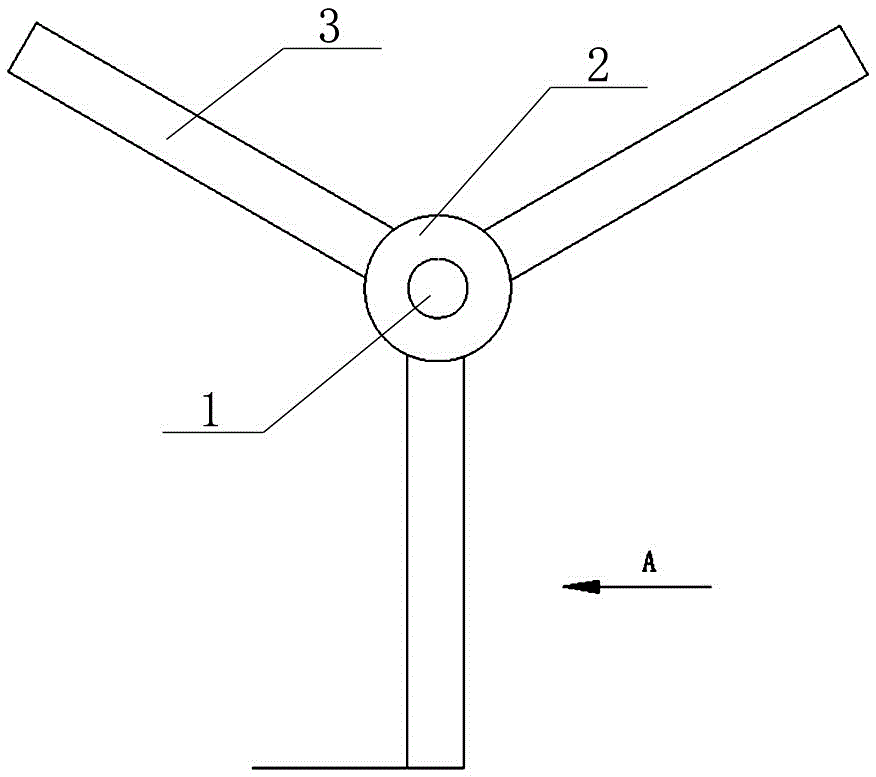

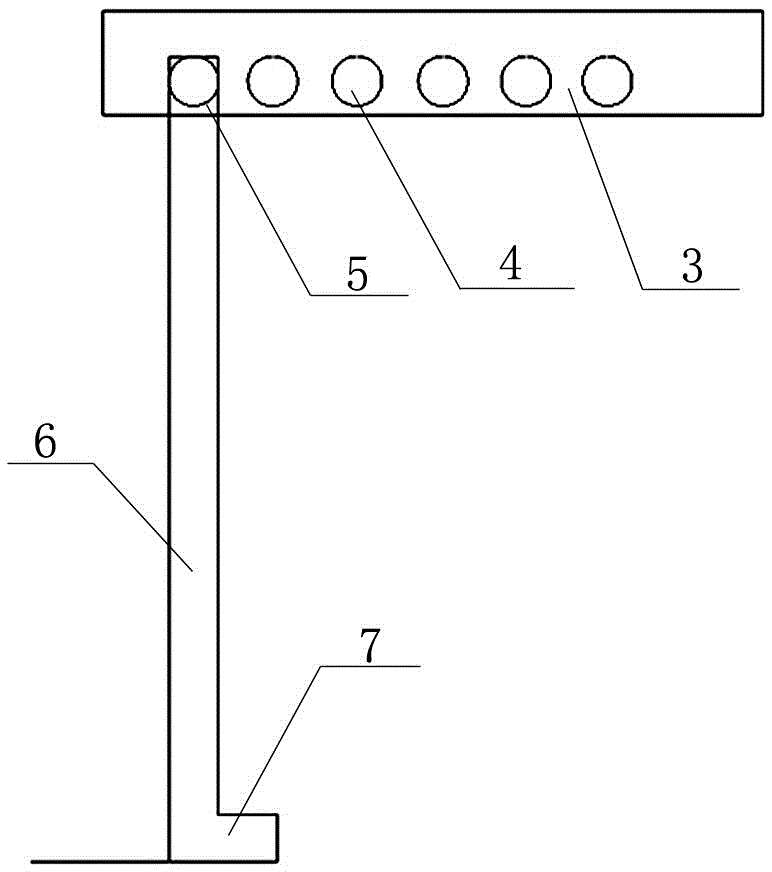

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the three-point hoisting equipment of a large casting according to the present invention includes a center frame 2 with a lifting seat 1 in the middle, and three evenly distributed, The beam frame 3 extending flat outward is provided with a row of positioning holes 4 evenly distributed on the beam frame 3, and a hanging hook rod 6 is connected with a pin shaft 5 through the positioning holes 4. The lower end of the hook rod 6 is provided with an inwardly extending hook portion 7; selecting positioning holes 4 at different positions from the center frame 2 can satisfy casting products with different diameters, and using the hook rod 6 hook portion 7 Hooking castings, especially cylindrical castings, through three points to determine a plane fixing method, can effectively fix the castings on the transportation equipment, ensuring the safety of lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com