Cavern filling type coal mining method

A coal mining method and filling technology, which is applied in ground mining, earth drilling, underground mining, etc., can solve problems such as spontaneous combustion and environmental pollution, and achieve the effects of saving lifting costs, easy operation, and eliminating worries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

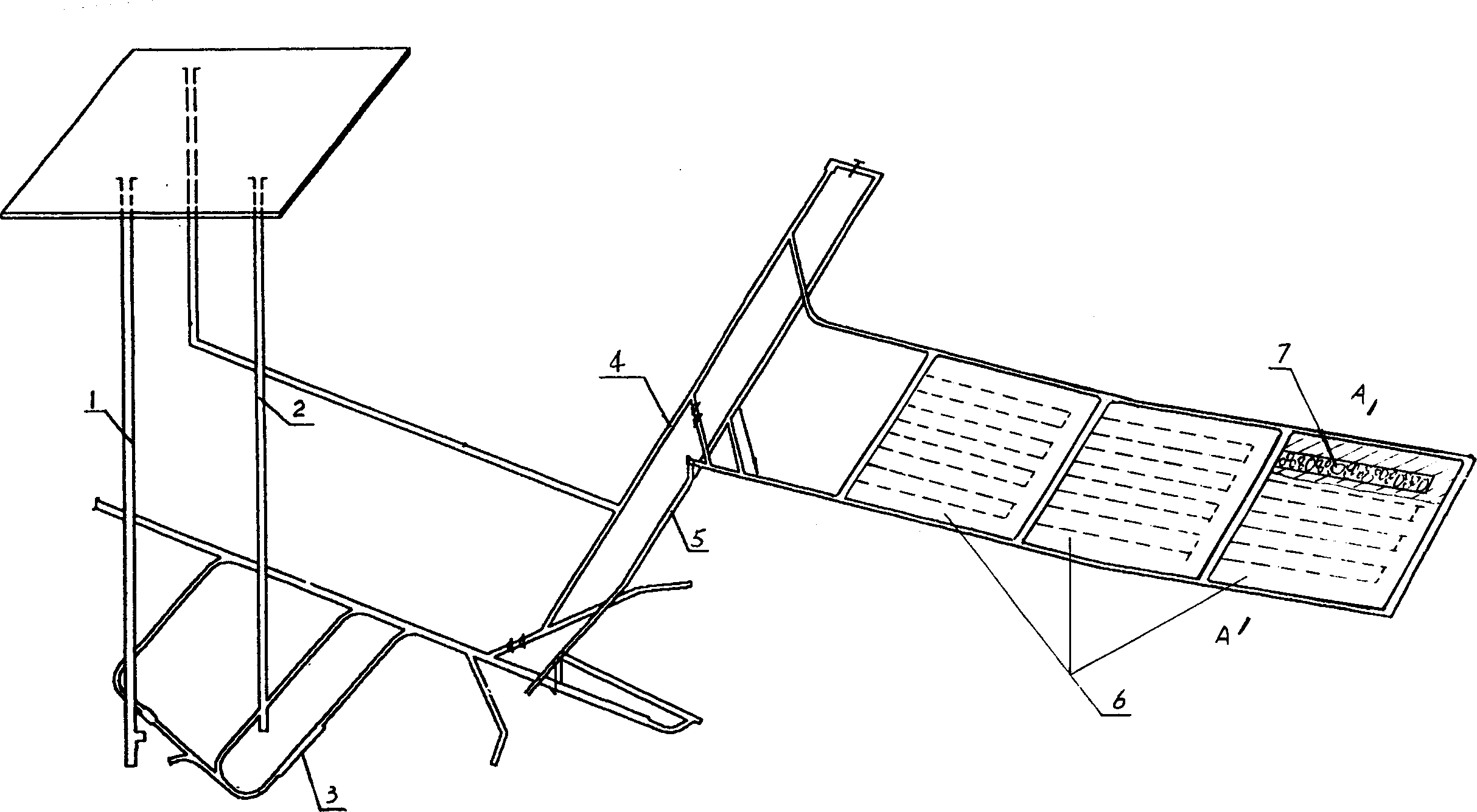

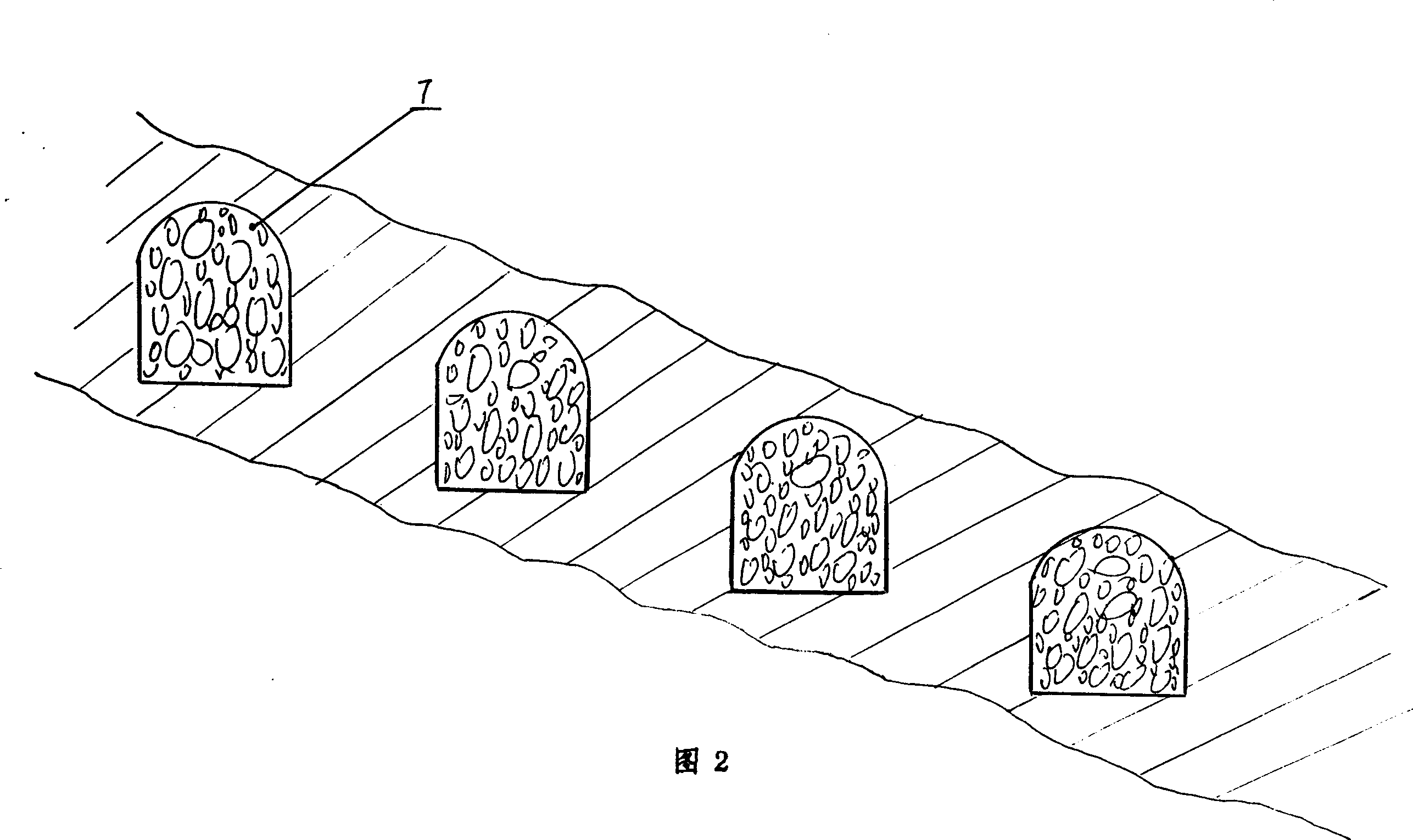

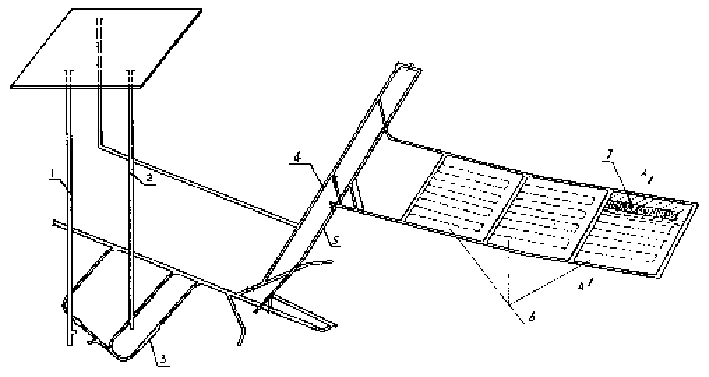

[0018] refer to figure 1 2. Assuming that the coal seam shown in the figure is a gently inclined coal seam, and the thickness of the coal seam is about 4 meters, the main steps of mining are: establish the main shaft 1, the auxiliary shaft or ventilation shaft 2, the parking lot at the bottom of the shaft 3, and excavate the uphill road leading to the mining face The track 4 and the transport track 5 pre-delineate a row of horizontal roadways 7 in the mining face 6, and a plurality of parallel horizontal roadways are arranged at intervals from top to bottom along the inclination direction of the coal seam. The section shape of the roadway is arched, and the entrance of each roadway is connected with the uphill track and the uphill transportation. The width of the roadway is 4 meters, the height is 3.5 meters, and the distance between the upper and lower roadways is also 4 meters. The coal in the topmost horizontal roadway is mined first, and after the mining is completed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com