Thin-oil-doped heavy oil gas lift technology pipe column and implementation method

A technology of a process string and an implementation method, which is applied in the field of thick oil mixed with dilute gas lift process string, can solve the problems of unsuitable process, low efficiency of dilute oil, and large amount of thin oil, so as to improve the lifting effect and improve the economic efficiency. Benefits, the effect of reducing lifting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

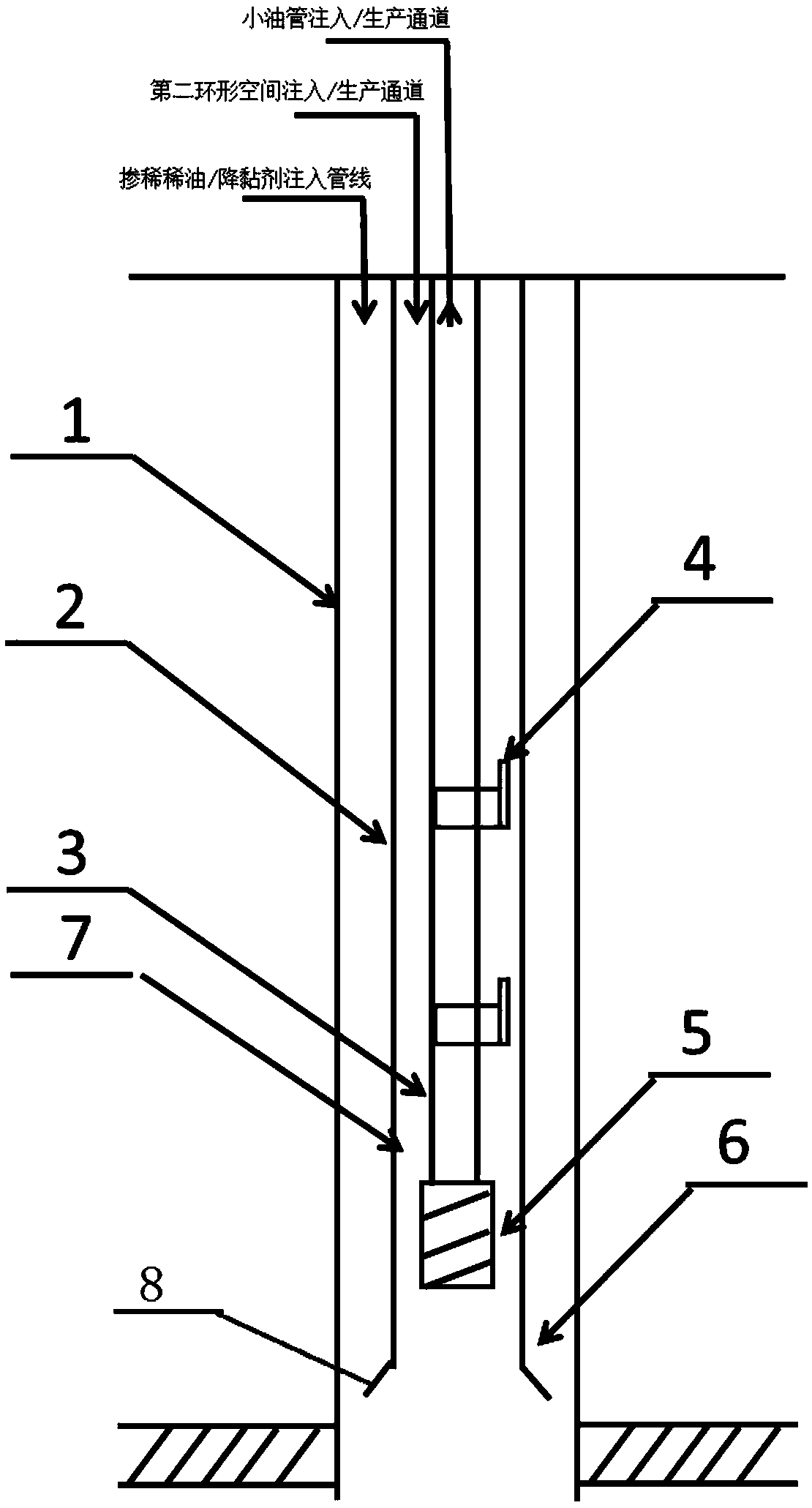

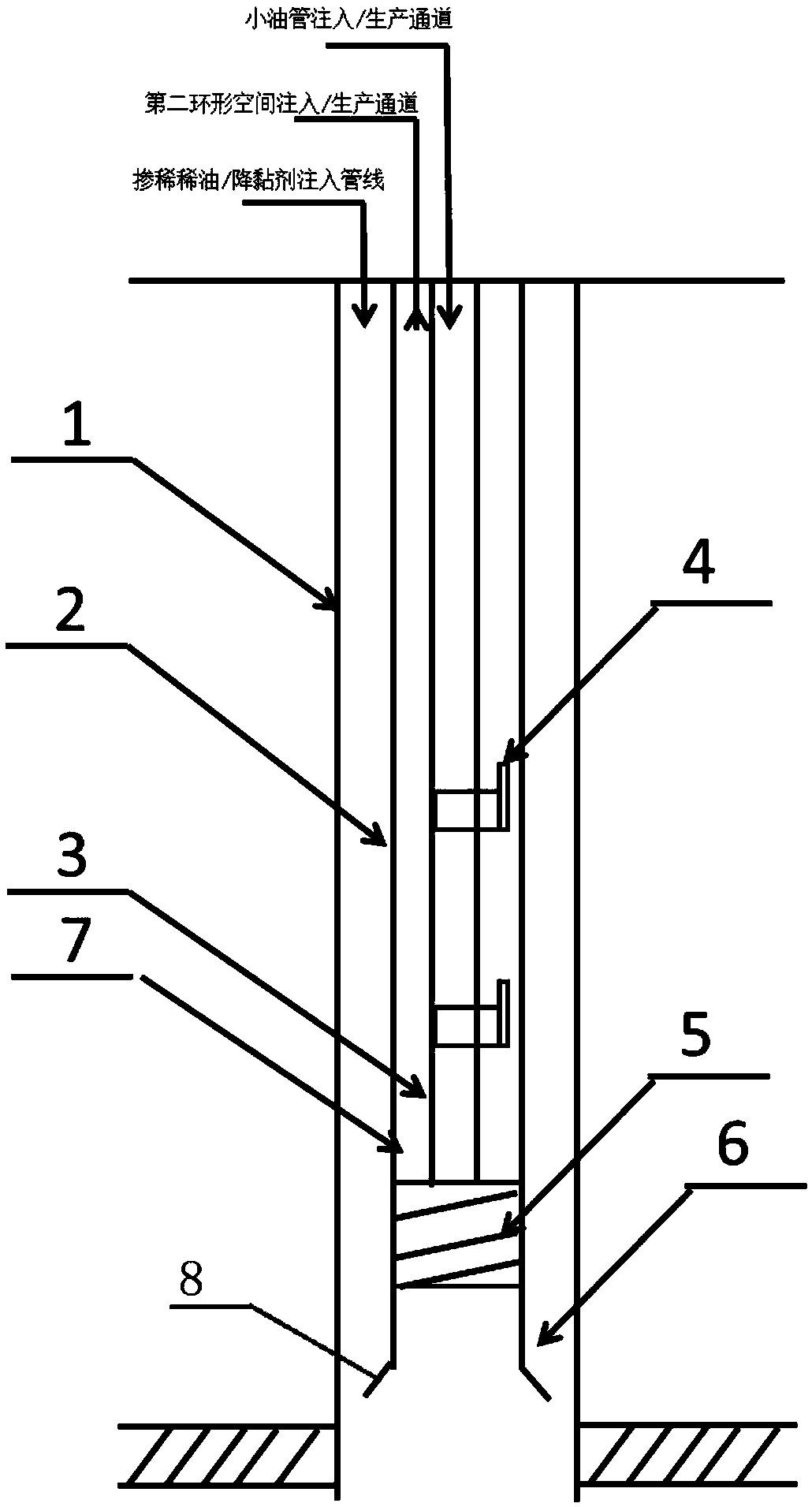

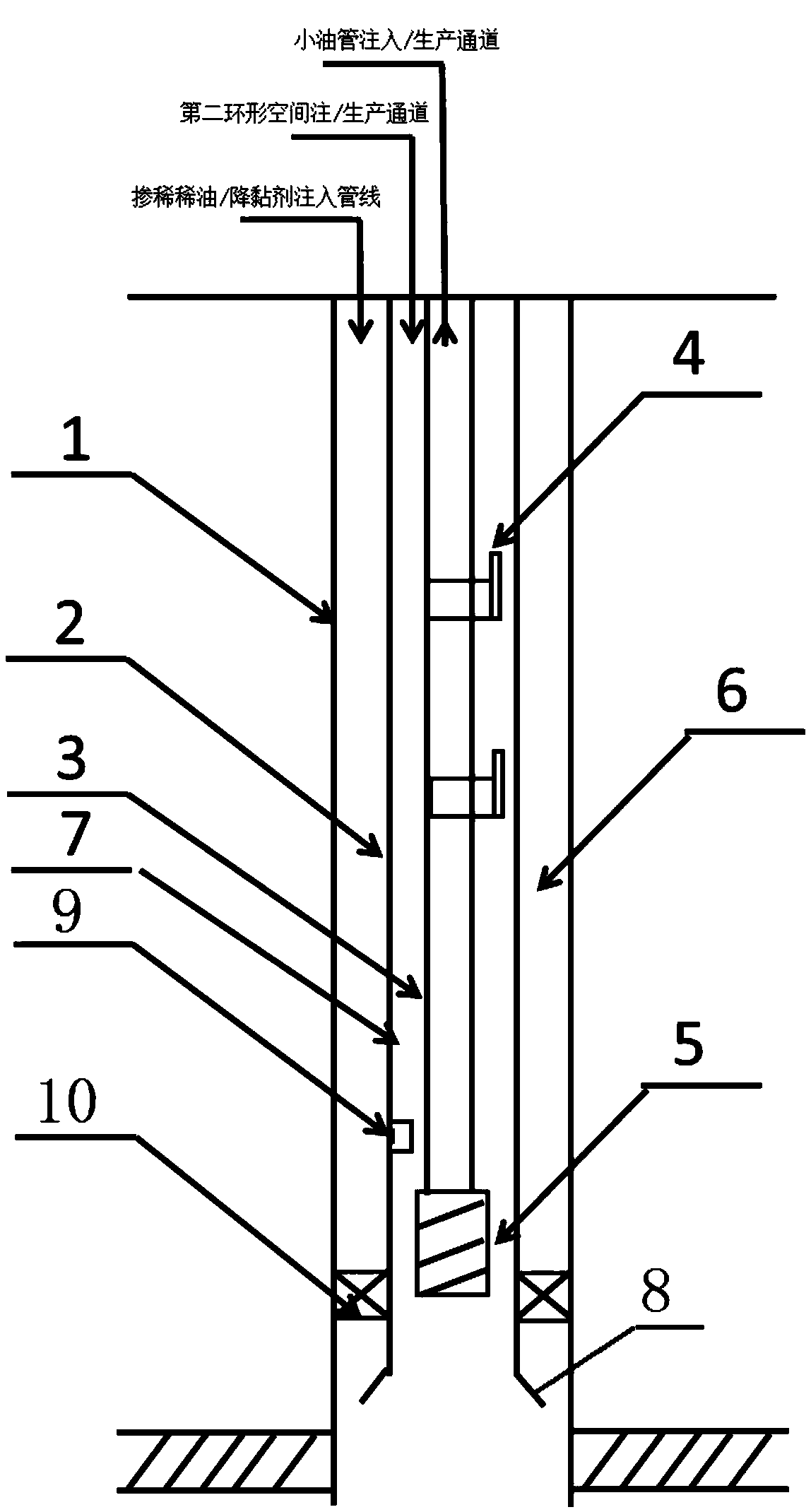

[0069] The implementation method of the thick oil mixed with dilute gas lift process string of the heavy oil mixed with dilute gas lift process of the present invention comprises the following steps:

[0070] Step 1: Use a bridge plug to seal off the oil and gas well 2-5m above the starting position of the tubing shoe;

[0071] Step 2: Run a small tubing with a diameter smaller than the diameter of the tubing into the well, and connect the gas lift mandrel and gas lift valve according to the design parameters of the gas lift process before running the small tubing;

[0072] Step 3: After running the small tubing string, pressurize from the wellhead to the wellbore, and the central axis of the bridge plug will drop to connect the reservoir and the wellbore.

[0073] Step 4: Inject dilute oil / viscosity reducer into the first annular space formed between the casing and the oil pipe, inject gas lift gas into the second annular space formed between the oil pipe and the small oil pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com