Patents

Literature

69results about How to "High automation intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

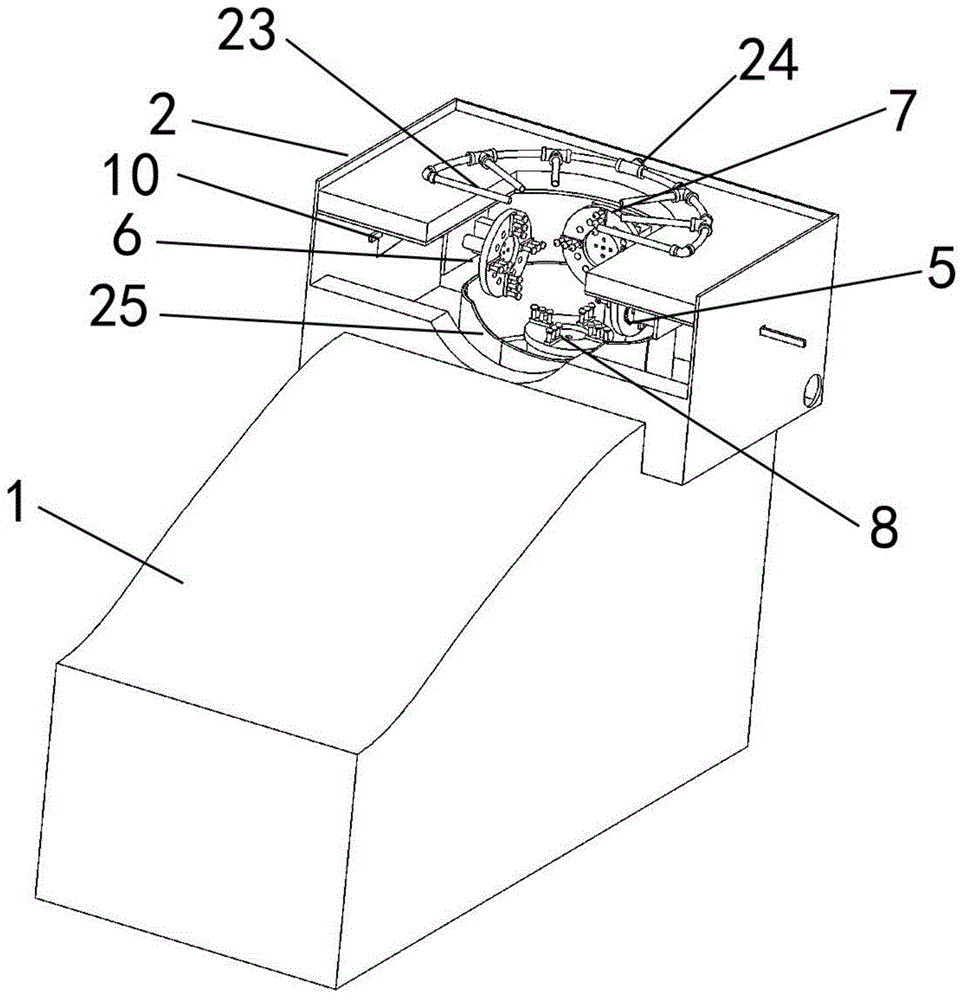

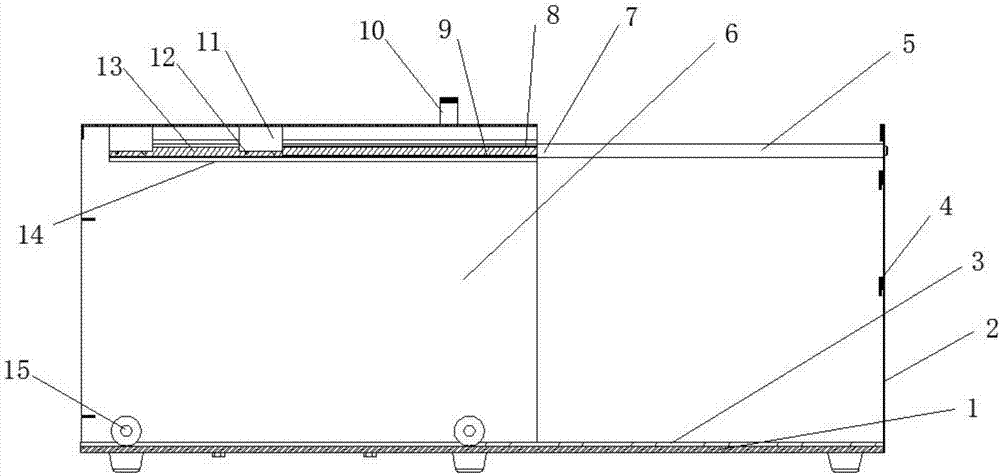

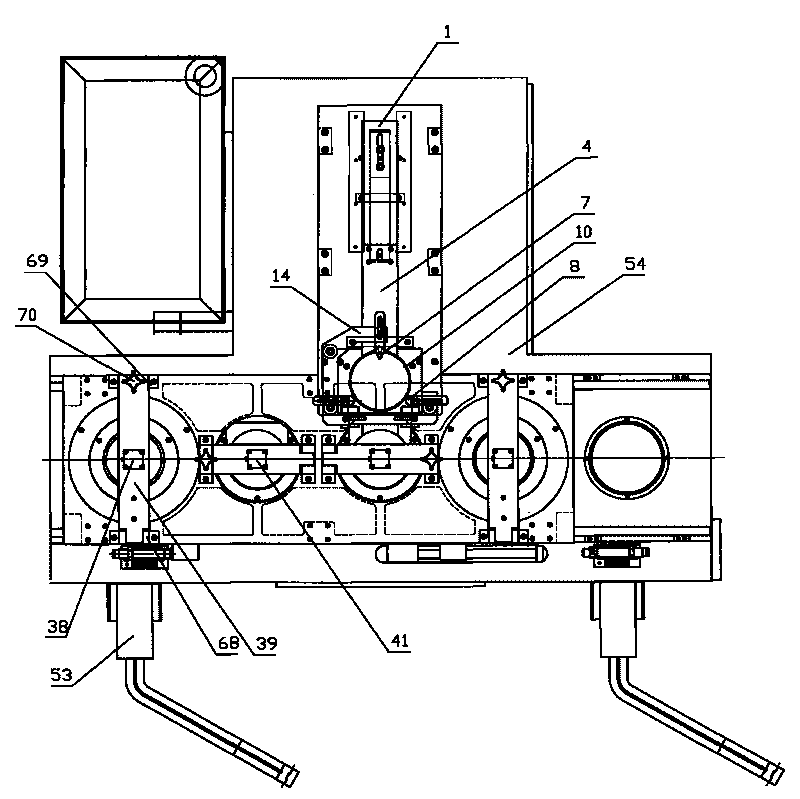

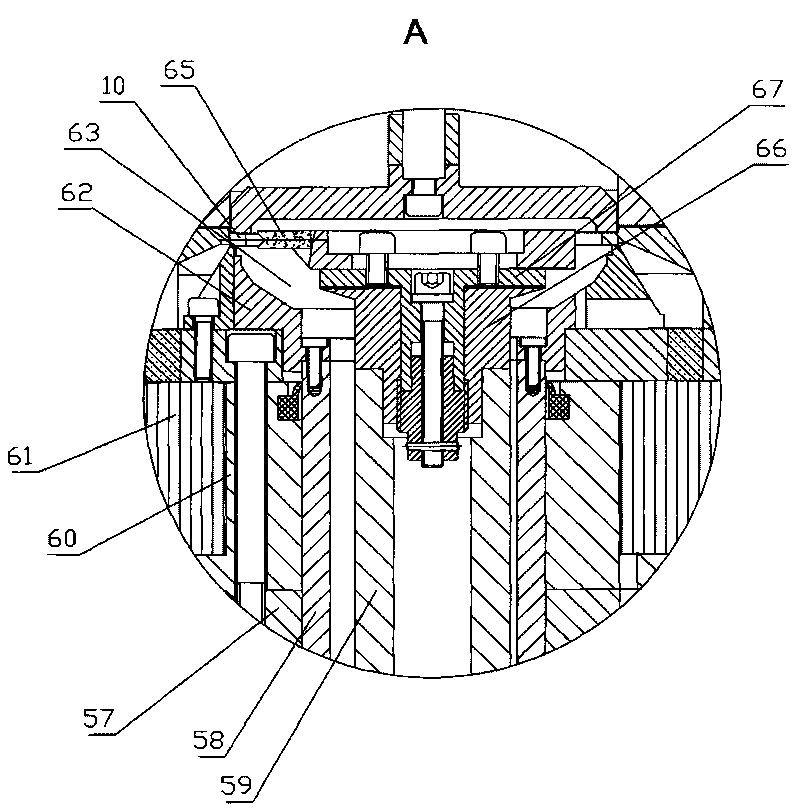

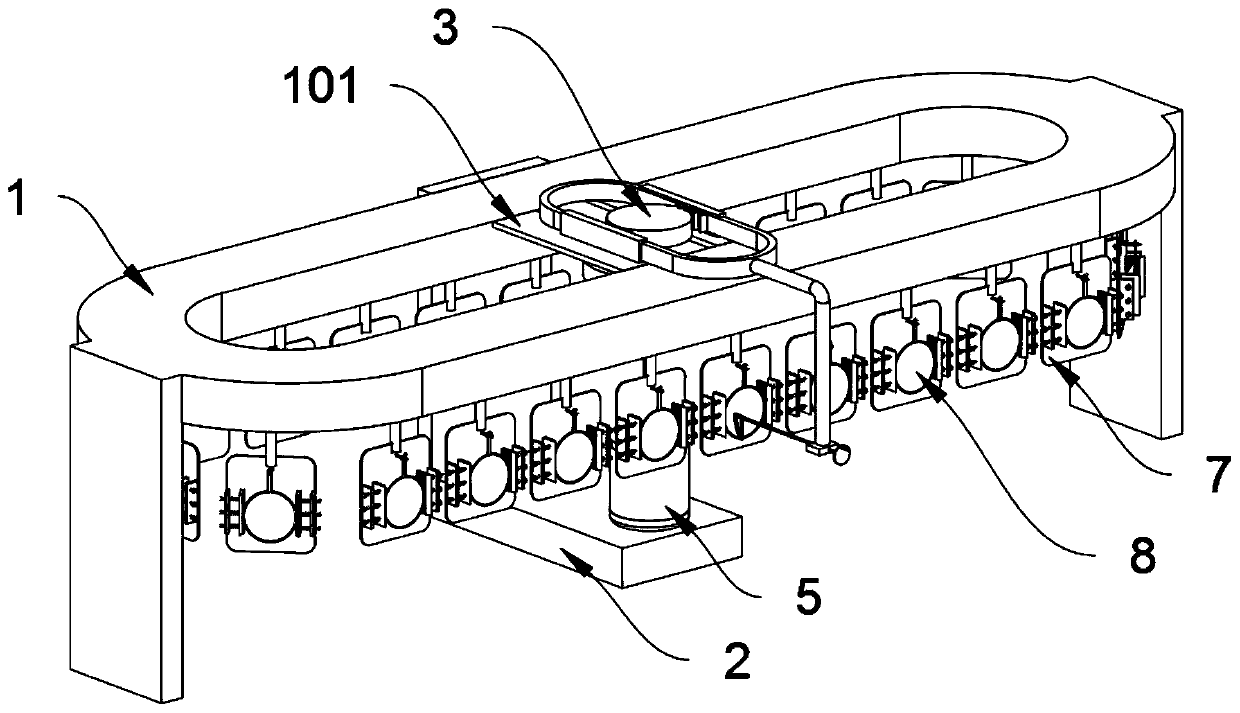

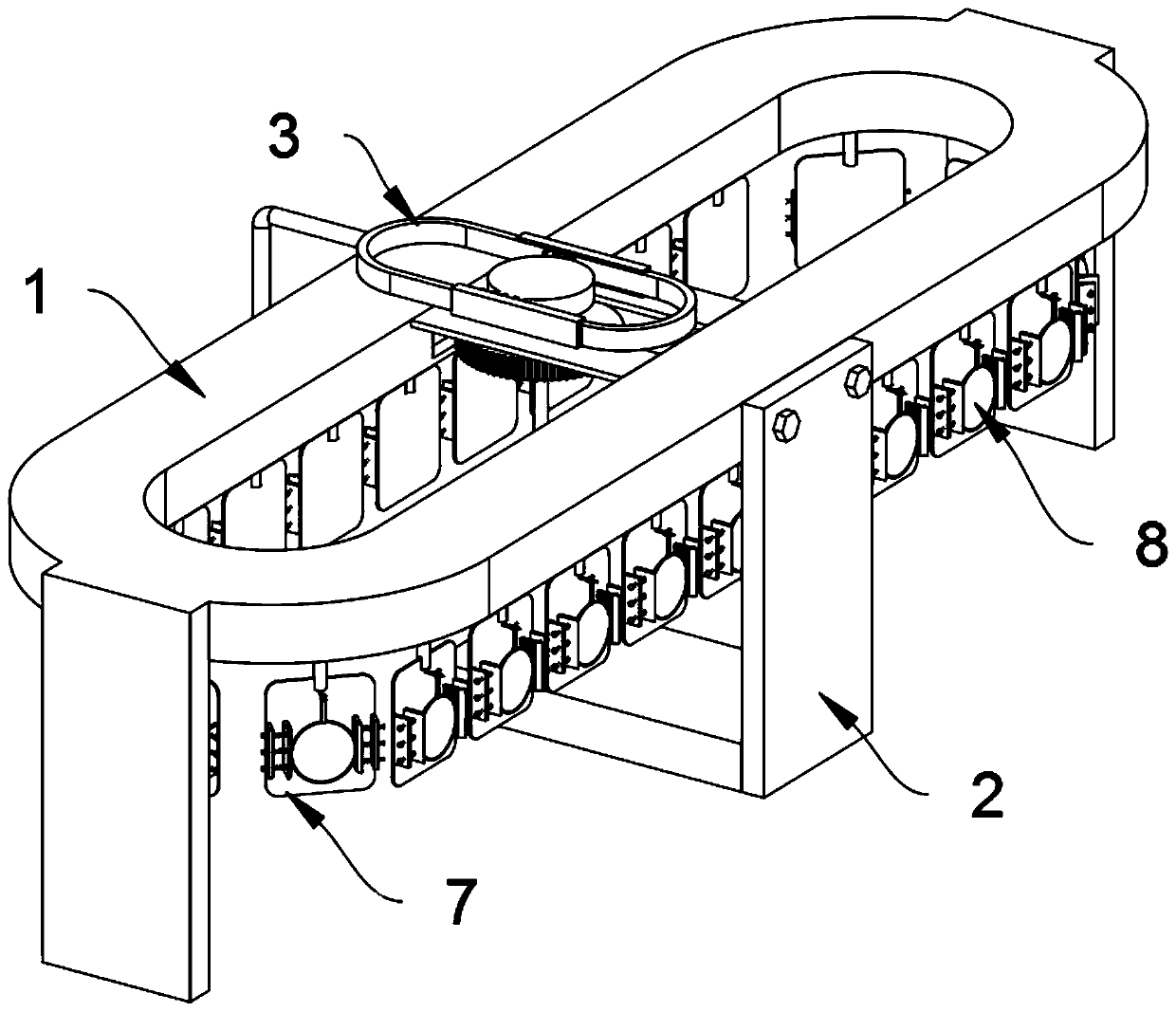

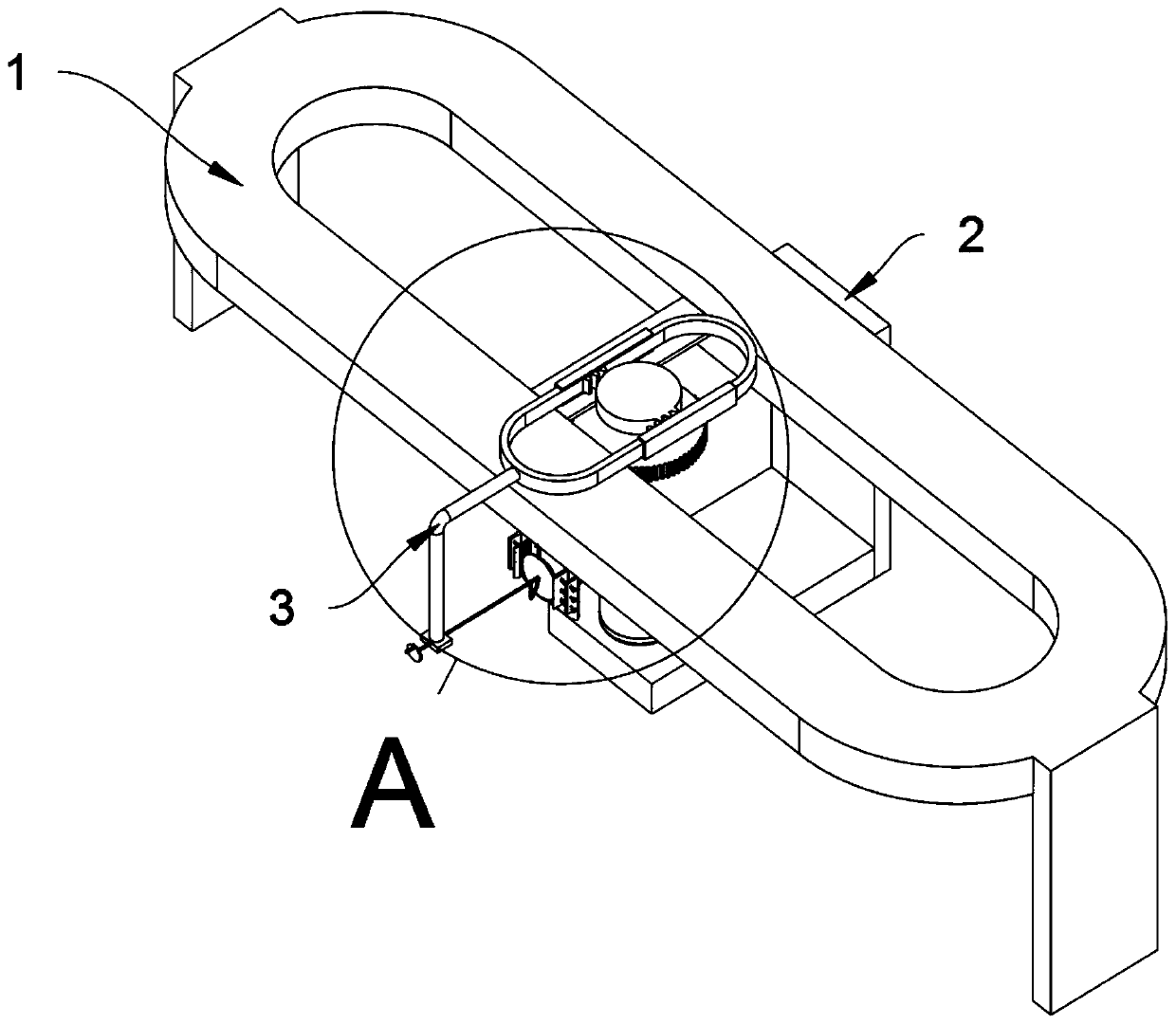

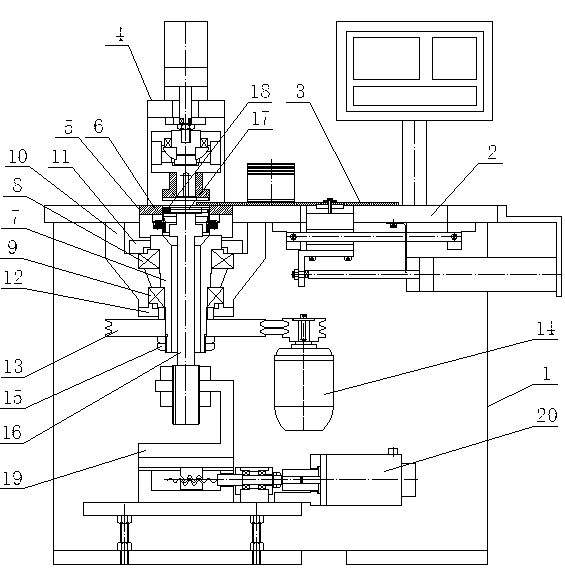

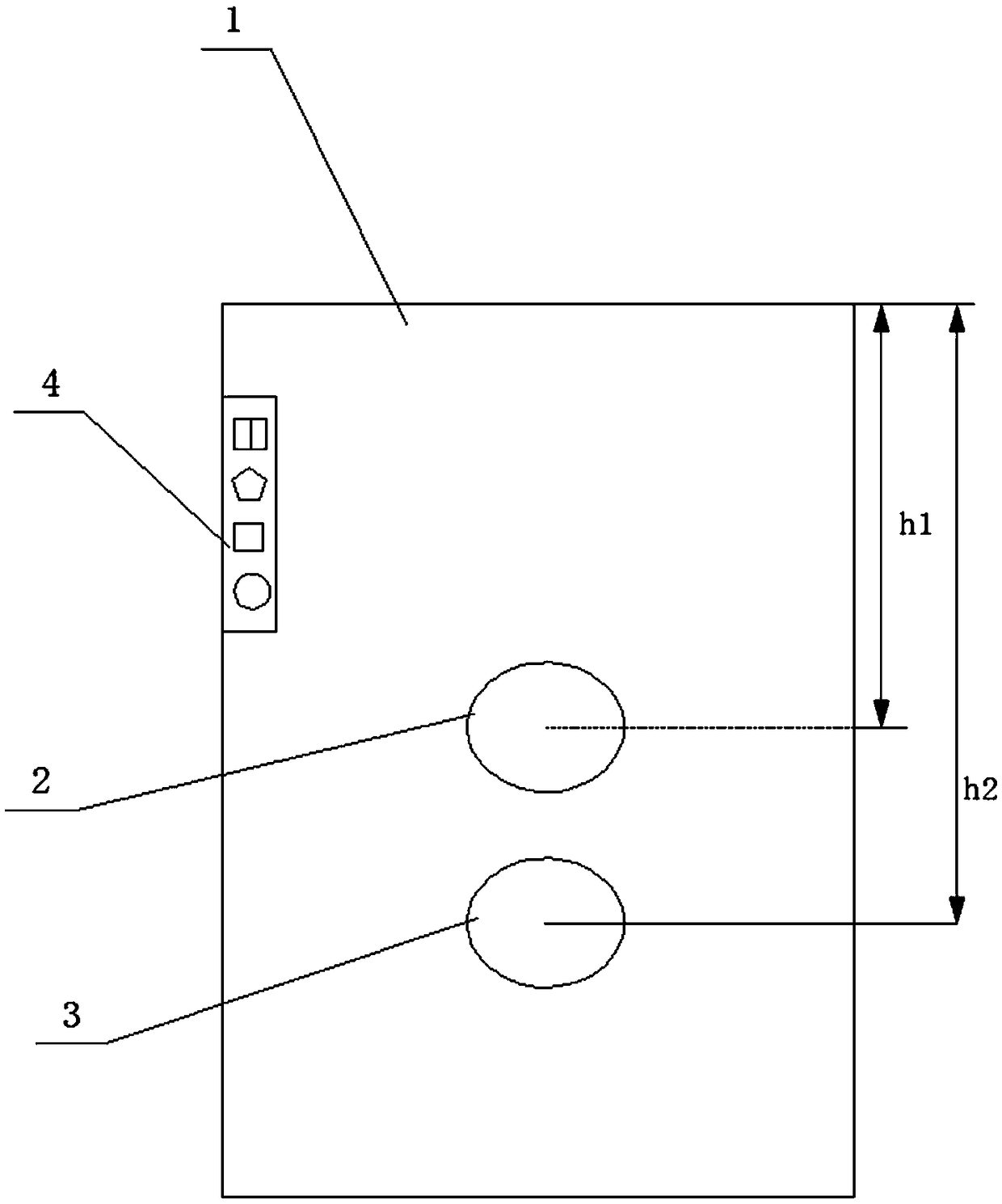

Automatic hair washing machine

InactiveCN104544883AClean upEasy to lie downTravelling articlesHair cleaningRemote controlControl system

The invention relates to an automatic hair washing machine, which comprises a bed body and a hair washing component, a remote control device and a control system; the hair washing component comprises a head left side care component, a head right side care component, a head top care component, a head back care component, a shell and an infrared distance measurement sensor; the care components respectively comprise a cross bar, a steering engine and a care face; each steering engine is fixedly arranged on the corresponding cross bar provided with a ball head structure; each care face comprises a finger plate, a cam and massage finger assemblies; the massage finger assemblies are arranged on the corresponding finger plate; each cam is located at the central position of the corresponding finger plate and is fixed to the corresponding cross bar; the head left side care component and the head right side care component also respectively comprise a stepping motor, so that the head left side care component and the head right side care component can move back and forth along the horizontal direction; the infrared distance measurement sensor is used for controlling the hair washing machine to automatically turn on, and the head form of a user is detected, and proximate head form parameters in a database are called by the control system; the remote control device can be used for controlling outflow water, outflow liquid shampoo, and the motion of the finger plates. The automatic hair washing machine disclosed by the invention is high in degree of automation, omnidirectional and is high in practicability.

Owner:翁凯 +1

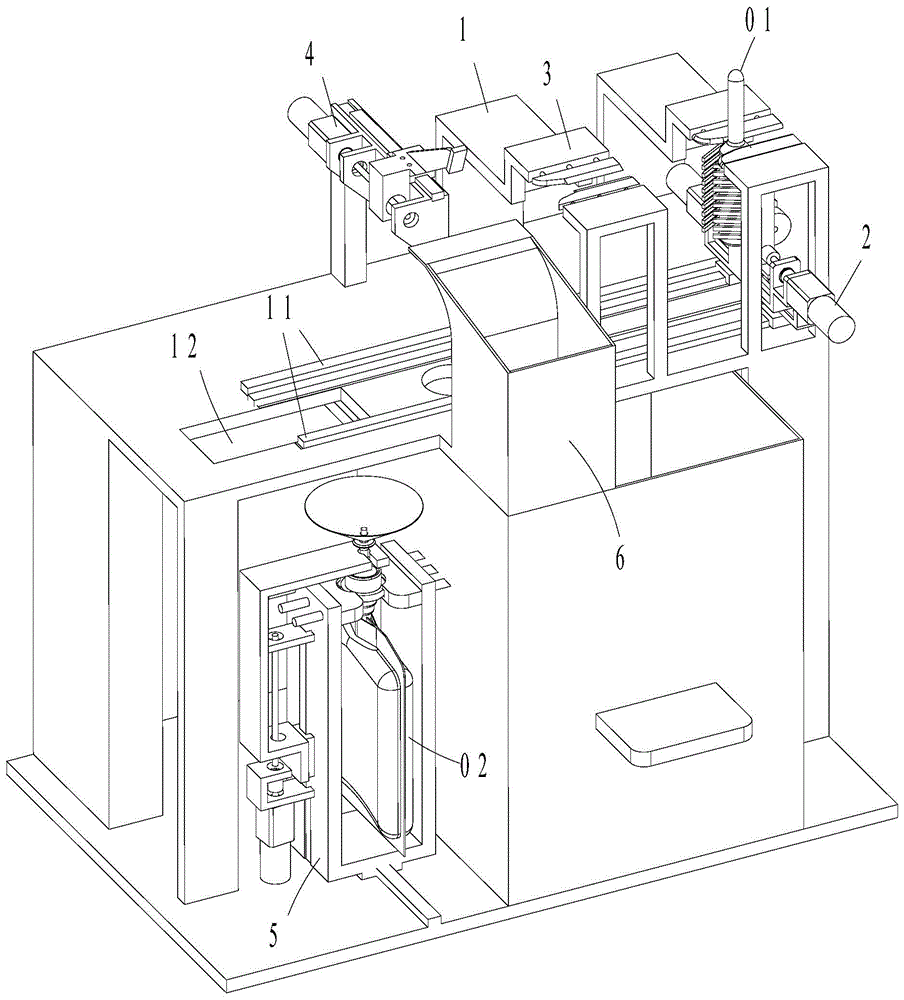

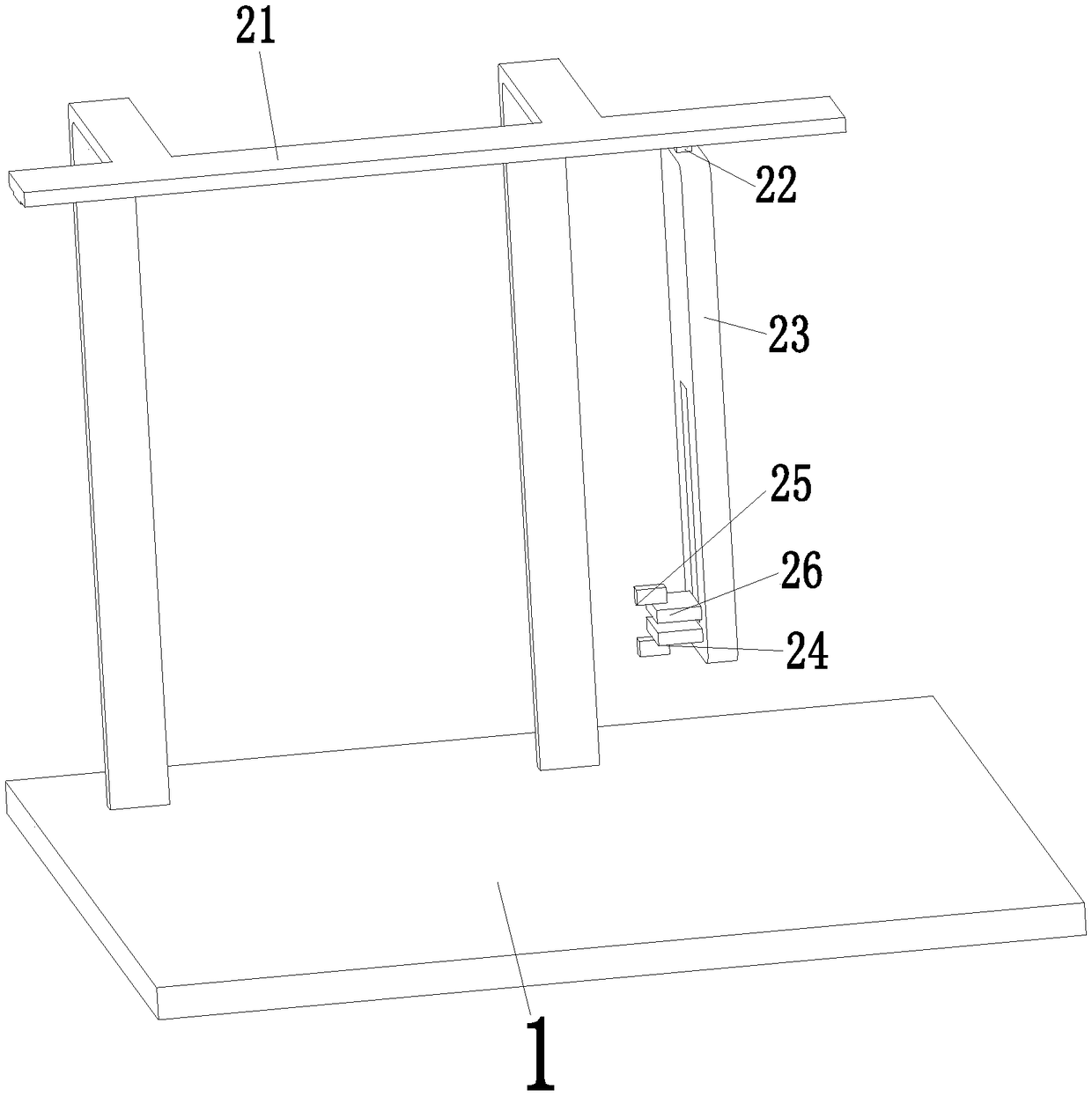

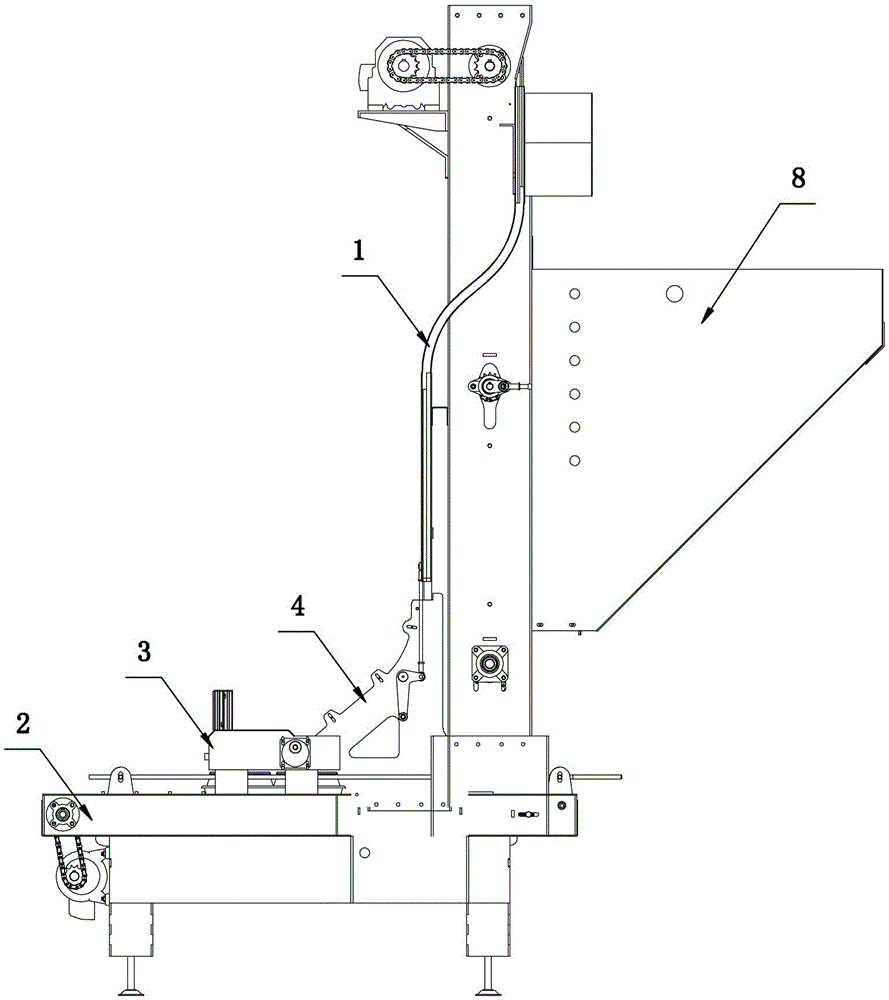

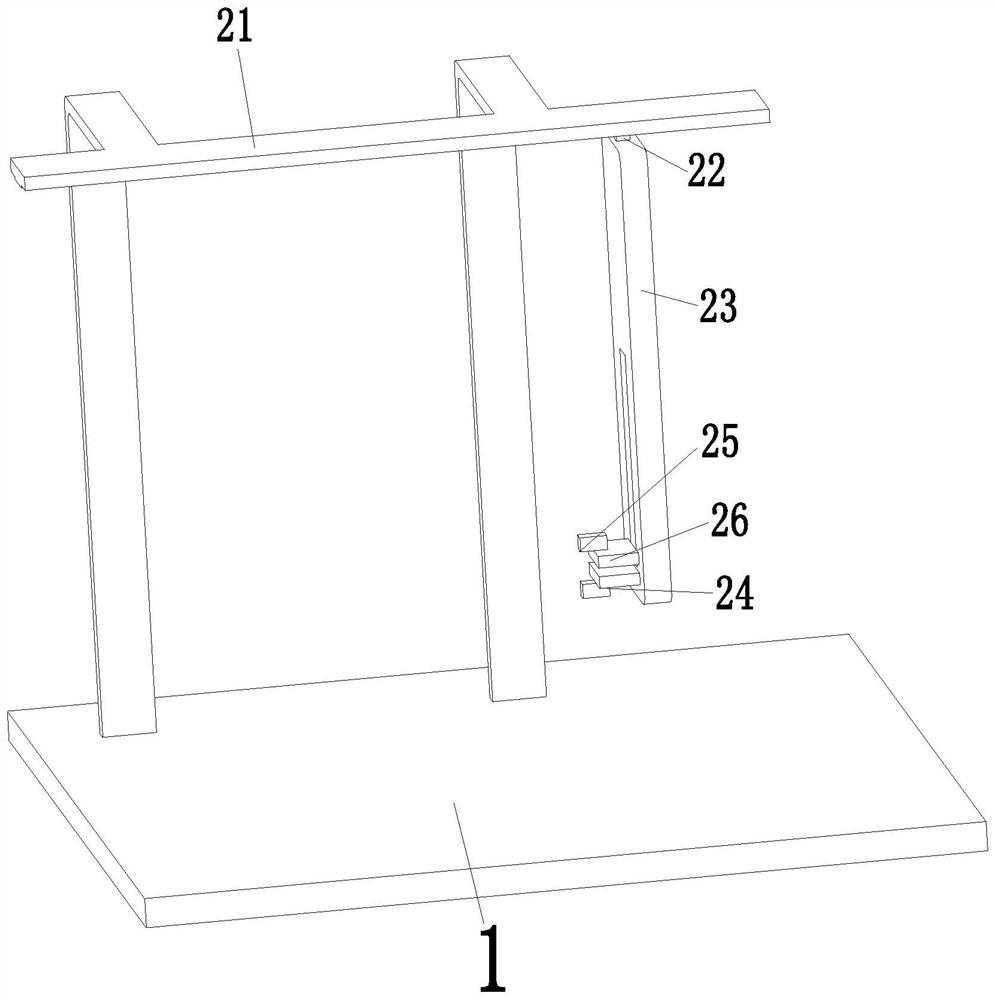

Medicine dispensing device and medicine dispensing method for ampoule bottle

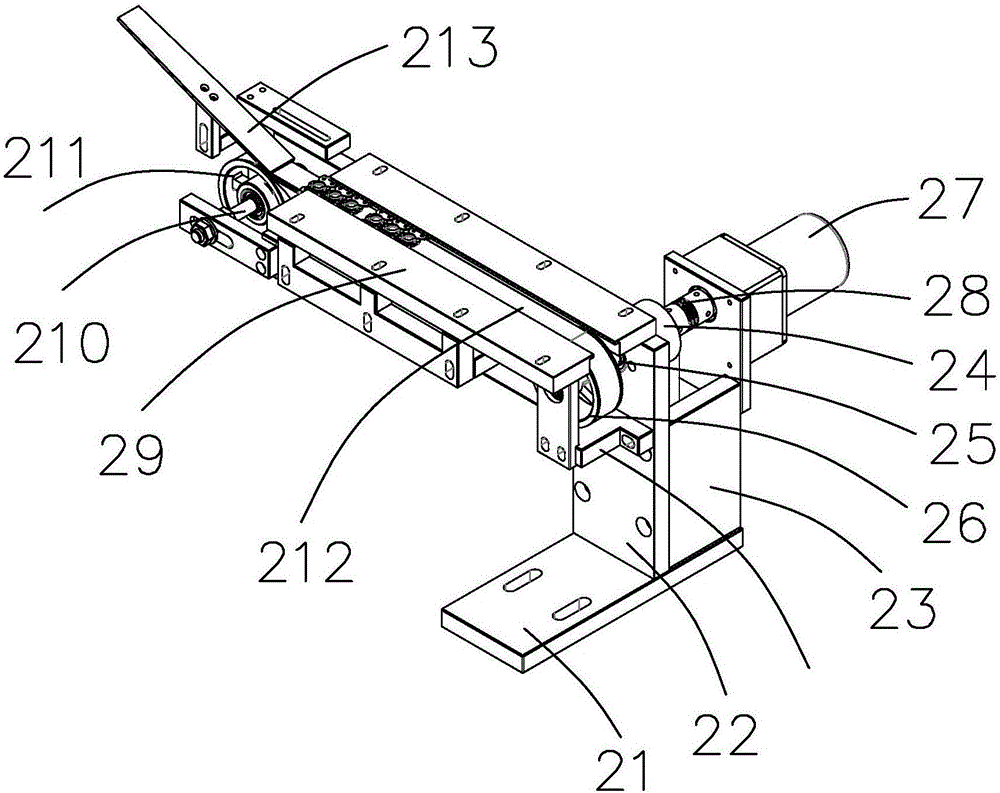

ActiveCN104800912ARealize automatic clampingSimple structurePharmaceutical containersMedical packagingManual medicineBottle

The invention discloses a medicine dispensing device and a medicine dispensing method for an ampoule bottle. The medicine dispensing device for the ampoule bottle comprises a support, wherein a clamping part for clamping the ampoule bottle, a bottle cutting part for cutting the bottleneck of the ampoule bottle, a bottle hitting part for breaking the bottle head of the ampoule bottle, and a liquid receiving part for receiving medicine liquid of the ampoule bottle are arranged on the support; the clamping part comprises a translation mechanism for translating the ampoule bottle relative to the support, and a rotary mechanism for overturning the ampoule bottle; the liquid receiving part comprises a liquid bag and a funnel. According to the medicine dispensing device for the ampoule bottle, the clamping part comprises the translation mechanism for translating the ampoule bottle, and the rotary mechanism for overturning the ampoule bottle, so that the ampoule bottle is clamped automatically, the bottleneck of the ampoule bottle is cut automatically, the bottle head of the ampoule bottle is automatically broken, and the medicine liquid of the ampoule bottle is poured into the liquid bag automatically; the device is simple and compact in structure, less in occupied space, lower in cost, high in automation degree, and convenient to operate, the manual medicine dispensing intensity is reduced, and the medicine dispensing efficiency is greatly improved.

Owner:成都彼维仕科技有限公司

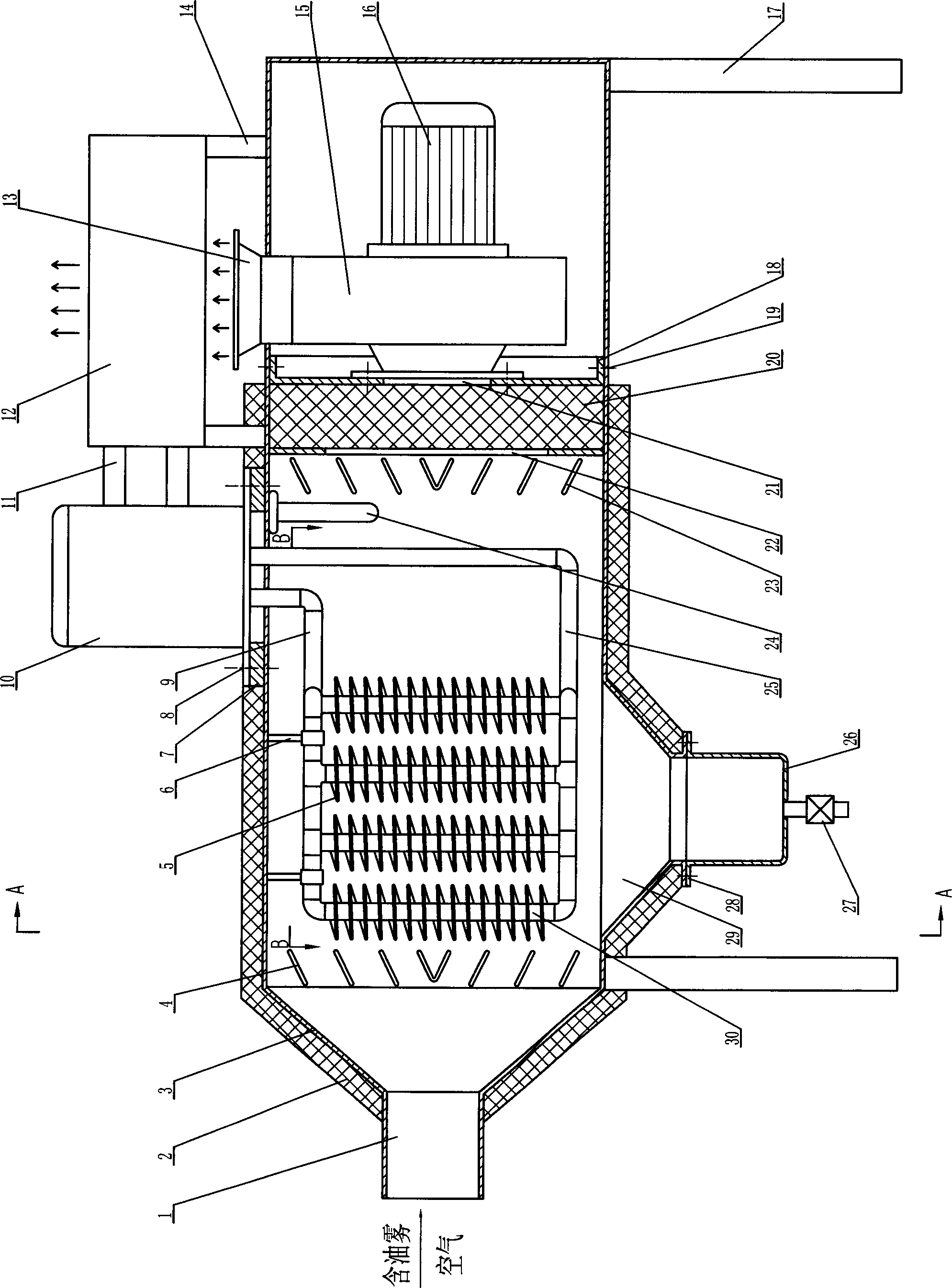

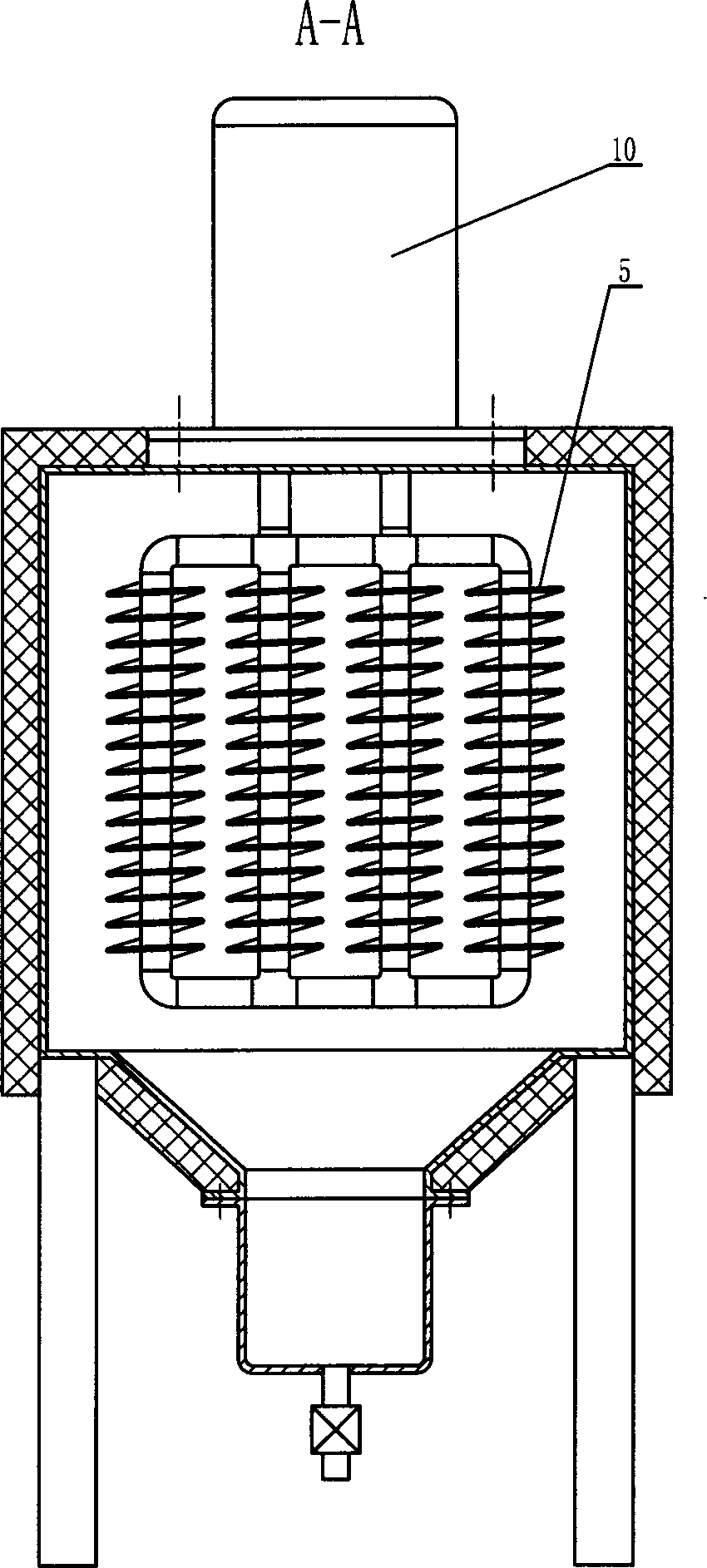

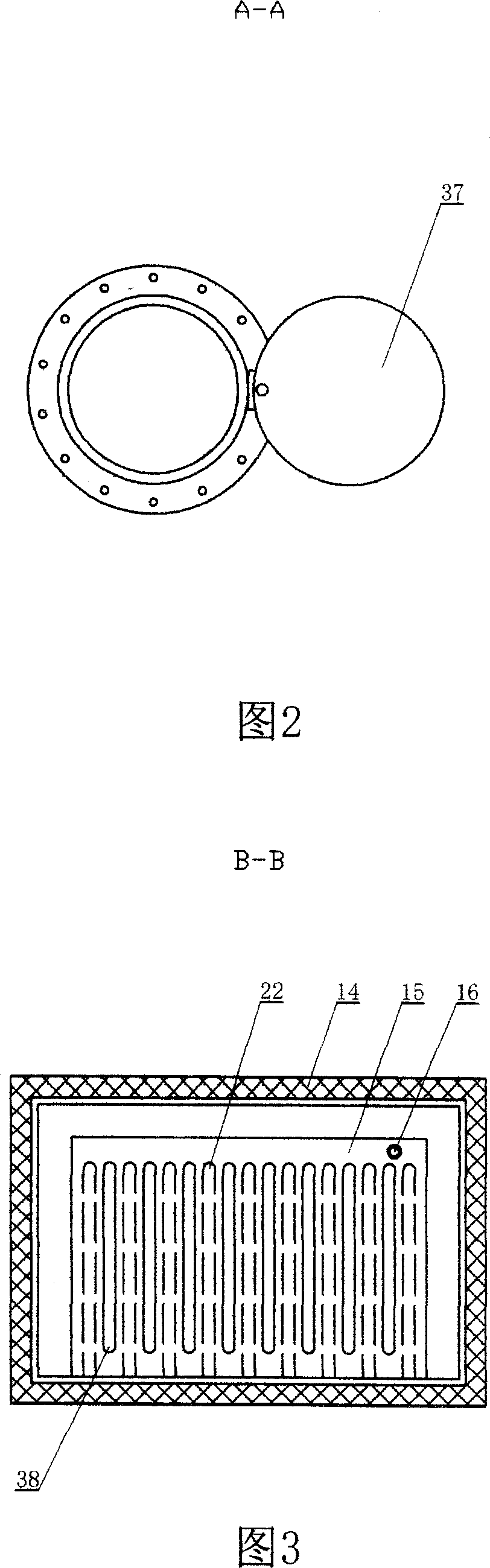

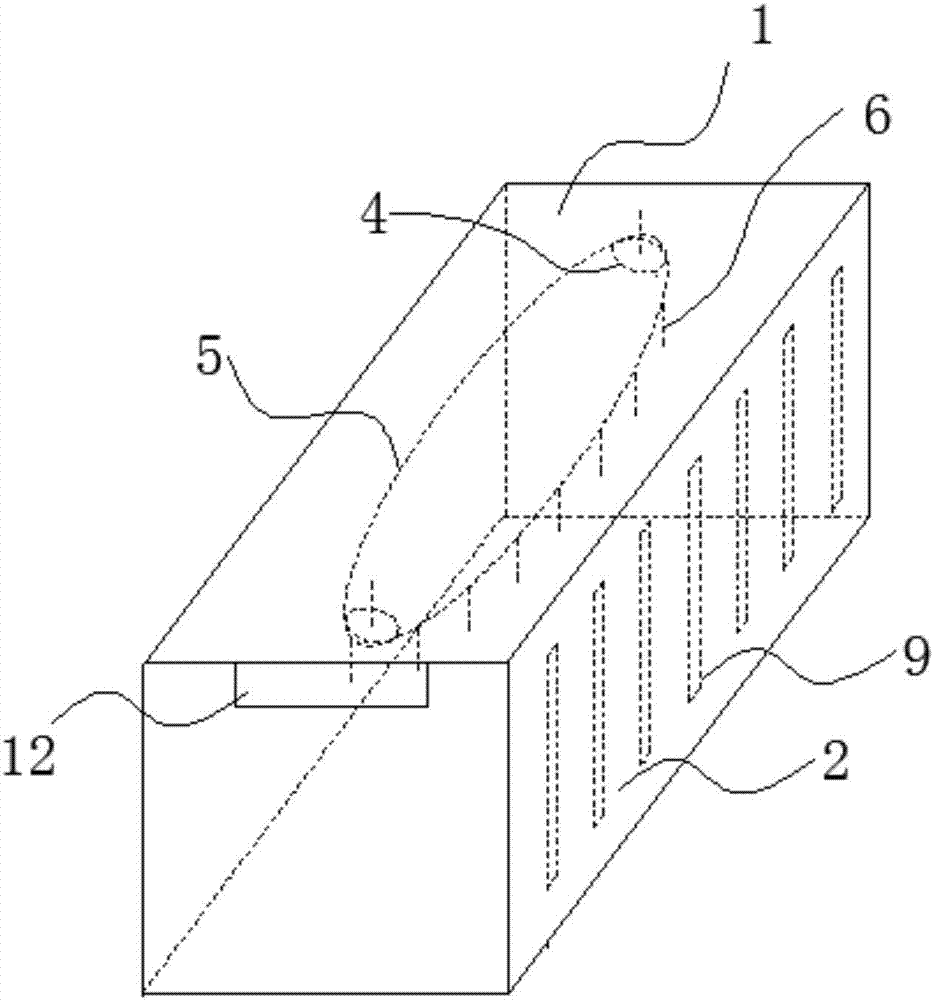

Condensing oil mist purifier

InactiveCN102430256AAchieve the technical effect of condensation and purification of oil mistAvoid lossDispersed particle filtrationVapor condensationRefrigeration compressorElectricity

The invention discloses a condensing oil mist purifier. The technical key points of the purifier are that: a condensing purification part of the device consists of a plurality of groups of staggered heat exchange fins in a sealed shell, a heat exchange tube, a cooling medium outlet pipe, a cooling medium inlet pipe, a refrigerating compressor and a radiator; and a power part of the purification device consists of a honeycomb filter layer, a fan and a motor. The front end of the sealed shell is provided with an oil mist inlet and a front air equalizing plate, and the rear part of the sealed shell is provided with a rear air equalizing plate; and the lower part of the sealed shell is provided with an oil collection cup and is wrapped by a heat insulating layer. The technical scheme can be widely applied to the field of purification of overflow oil mist of an engine bearing lubricating part sleeve.

Owner:HARBIN XUNPU TECH DEV

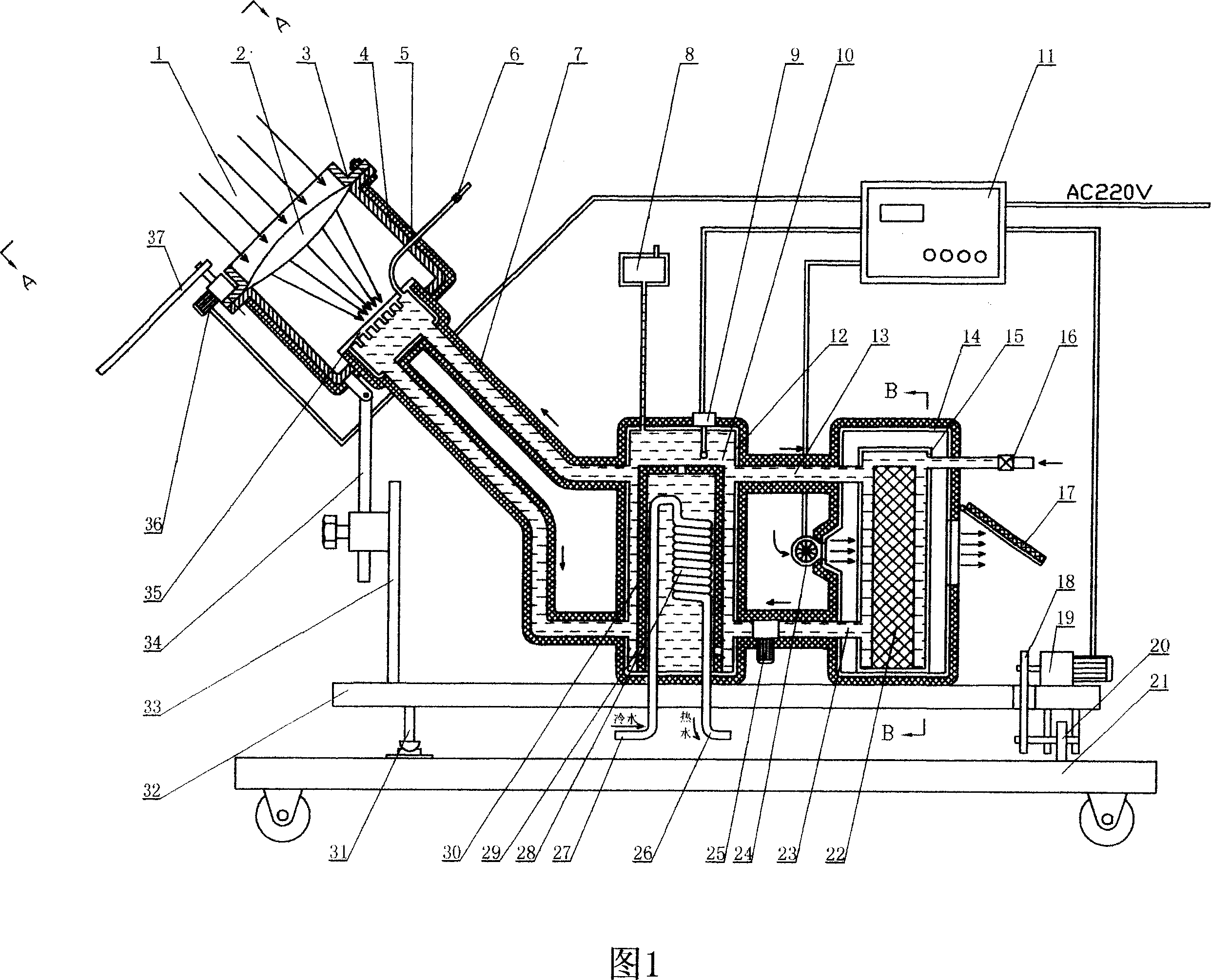

Movable solar energy storage heating device

InactiveCN101071003ARealize mobile storageNovel ideaSolar heat devicesSolar thermal energy generationStored energySolar energy storage

The invention provides a movable solar energy storage and heating device. Its characteristic including: the solar energy is projected on the spinouts heat conduction device by convex glass and make the accumulation energy mediator the ultimate temperature and storage energy through the oil and solid materials to the high limit. The expansion oil container and temperature sensor are fixed on the insulating stored-energy tube and the spiral water preheater and solid materials stored-energy tube air fixed in it. The cross flow blower and the outlet of hot air are fixed on the incubator of radiator and many solid materials stored-energy boards are fixed in it. They are connected by soft pipe and hot circuit pipe fixed with circuit jar.

Owner:韩宏波

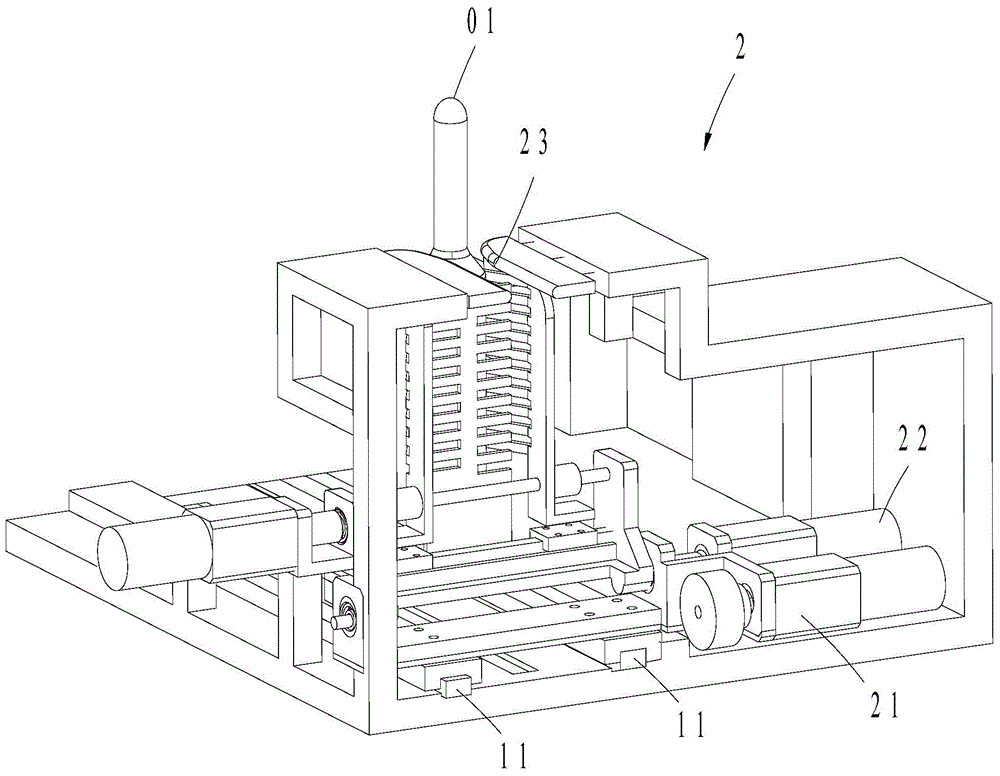

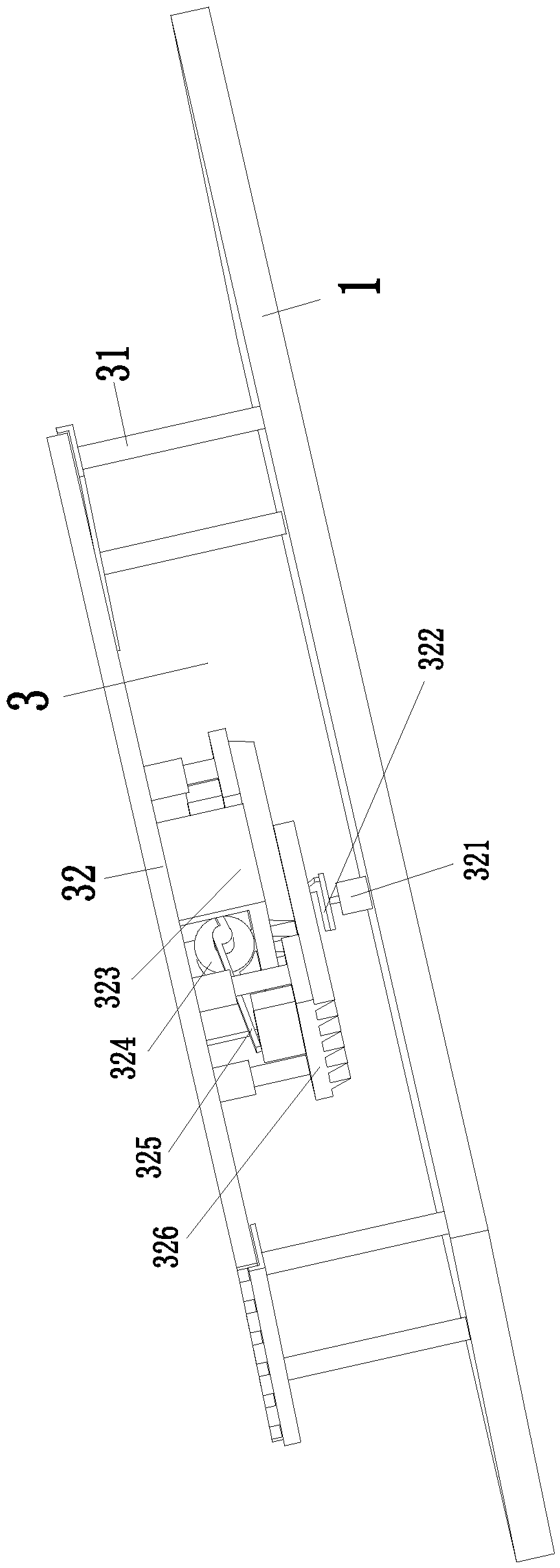

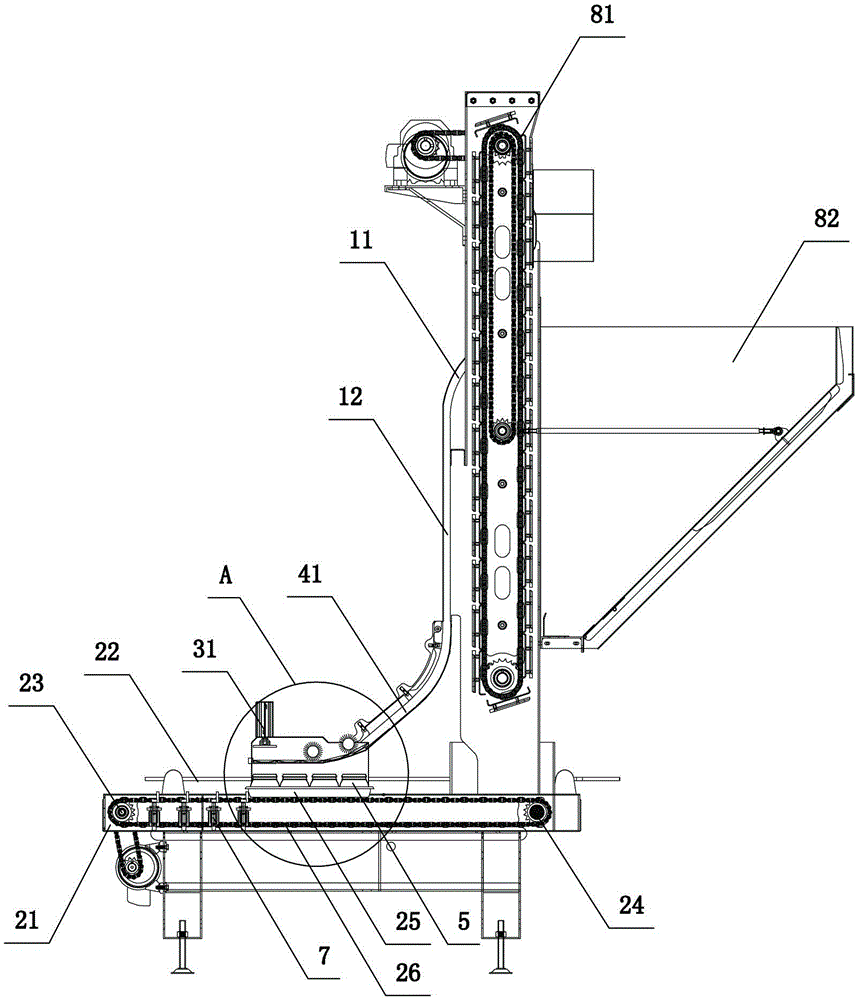

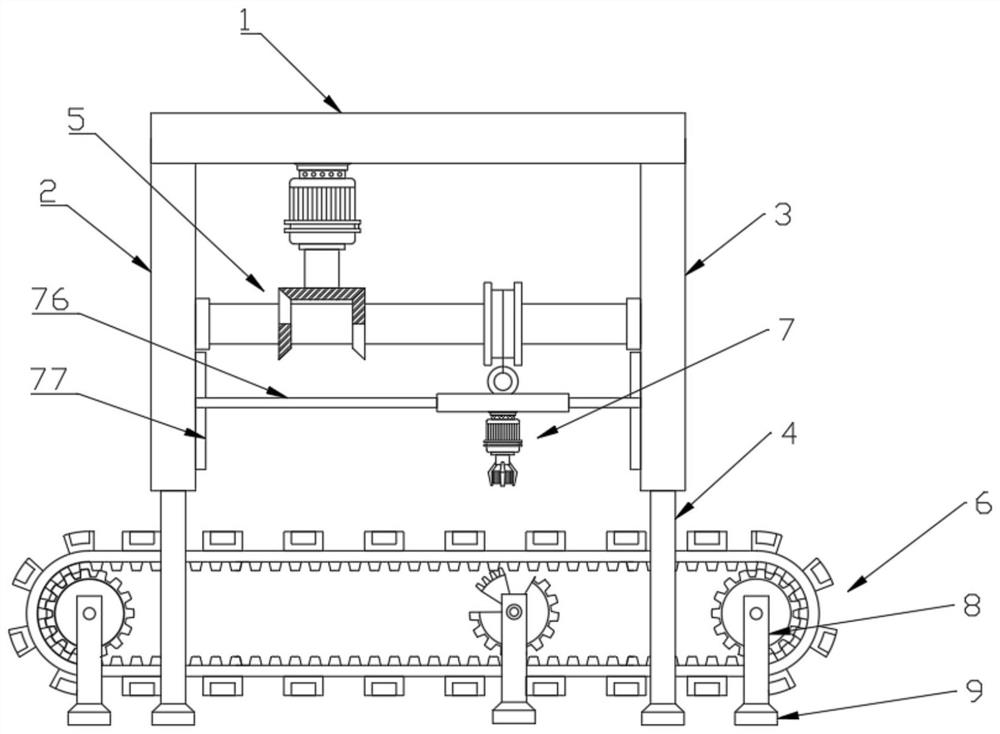

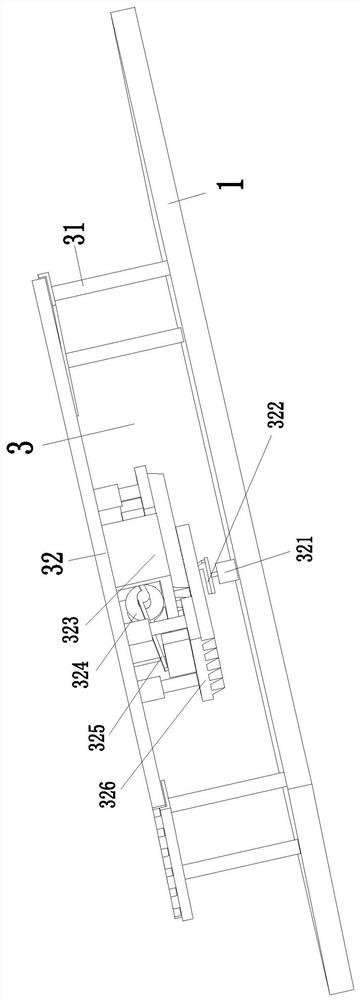

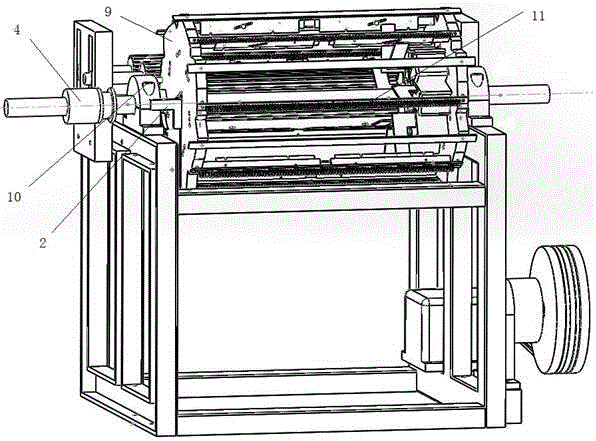

Chain sheet punching and blanking device

ActiveCN107737850AReasonable structural designHigh automation intensityMetal-working feeding devicesStripping-off devicesPunchingEngineering

The invention discloses a chain sheet punching and blanking device which comprises a punching working table; a punching die is erected above the punching working table, and one side of the punching working table is provided with a feeding mechanism; the punching working table is divided into two sections, namely, the conveying section and the sheet pressing section; guiding grooves which are formed at intervals are distributed in the positions, on the punching working table, of the conveying section and internally provided with lifting guiding rolls; open holes are formed in the positions, onthe punching working table, of the sheet pressing section and internally provided with lifting guiding plates in a matched mode; open grooves are formed in the guiding plates, and conveying rolls matched with the open grooves are arranged below the guiding plates; a waste material circulating conveyor belt is arranged on the other side of the punching working table, and a waste material receivingmechanism is arranged at the end of the waste material circulating conveyor belt; and a finished product receiving mechanism is arranged below the circulating conveyor belt. According to the chain sheet punching and blanking device, on the one hand, continuous material supplying can be achieved, and on the other hand, product materials and waste materials can be conveyed and received correspondingly; and in the whole process, the automatic strength is high, the manual labor strength is small, the time and labor are saved, and the use requirements are met.

Owner:绩溪山合机械有限公司

Telescopic electric sliding door structure

InactiveCN107246202AHigh automation intensityImprove speed controllabilityPower-operated mechanismWing arrangementsDrive motorUltimate tensile strength

The invention provides a telescopic electric sliding door structure. The telescopic electric sliding door structure comprises a sliding door and a sliding door bottom plate, wherein the sliding door is arranged on the sliding door bottom plate; a vertical baffle plate is vertically arranged at one end of the sliding door; the sliding door and the vertical baffle plate are connected through a telescopic pen-shaped electric push rod; telescopic sliding grooves are horizontally formed in the sliding door; one end of the electric push rod is fixed to the side surface of the vertical baffle plate; the other end of the electric push rod is arranged in the telescopic sliding grooves in the sliding door; two driving motors are arranged in the telescopic sliding grooves; the two driving motors are connected with the side surface of the electric push rod through a linkage gear; and a switch at the top end of the sliding door is connected with the two driving motors. According to the telescopic electric sliding door structure, automation strength of the sliding door can be improved, manpower workload is reduced, stability of pushing speed can be improved, speed controllable degree of the sliding door is improved, damage of the sliding door is reduced, and service life of the sliding door is prolonged.

Owner:合肥九晟机电科技有限公司

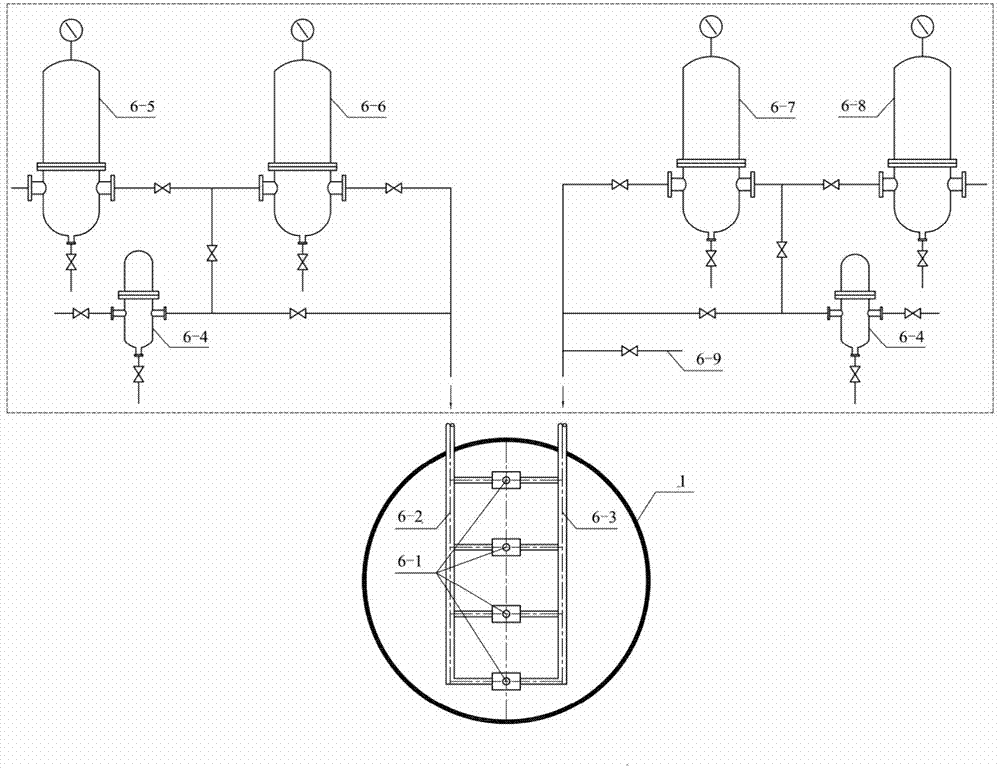

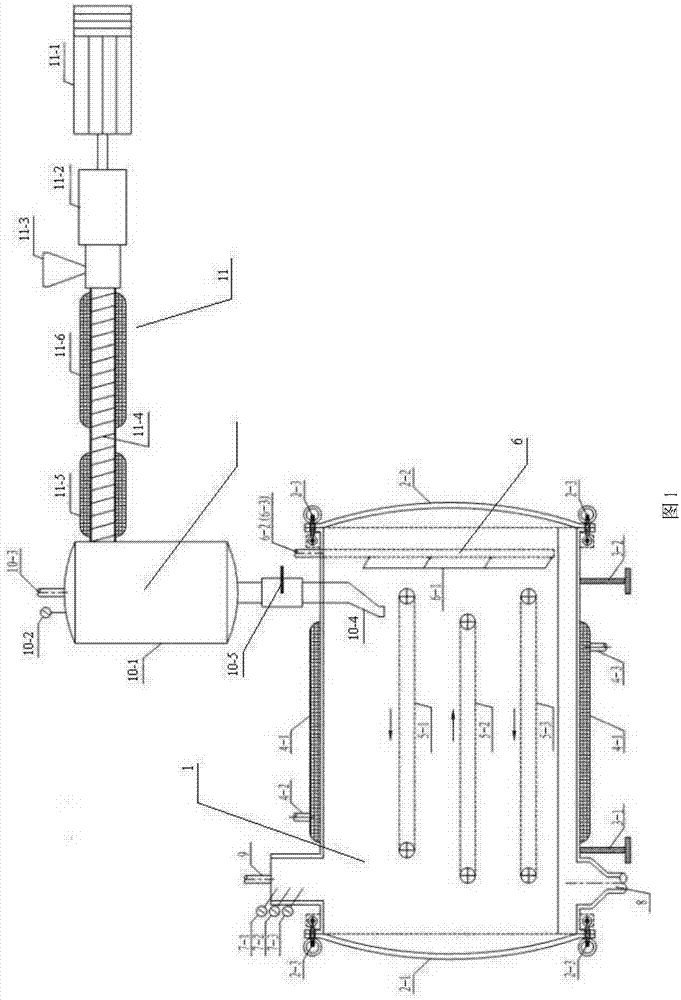

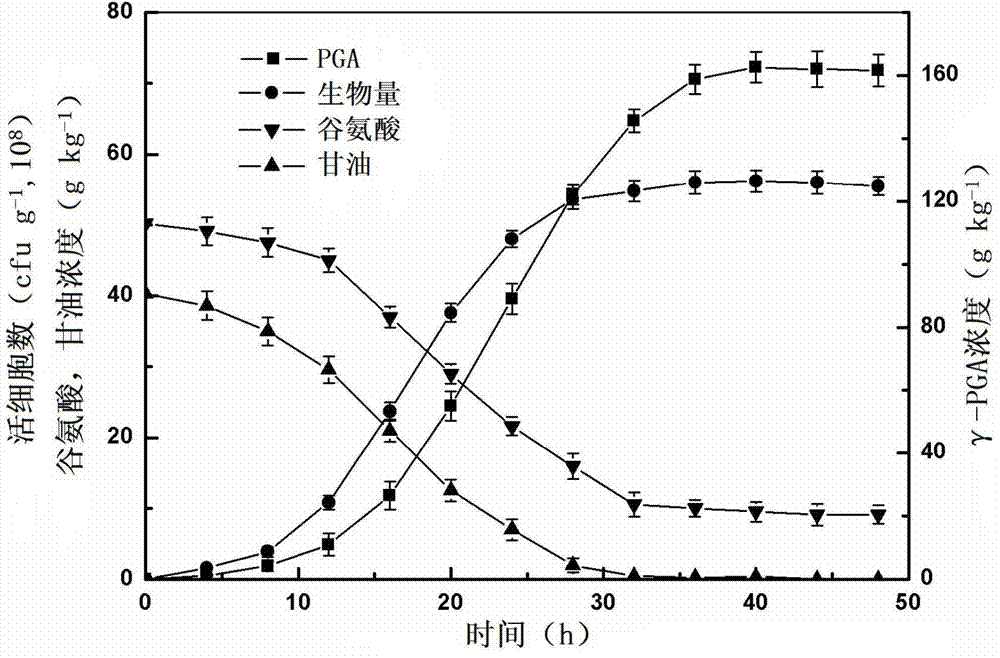

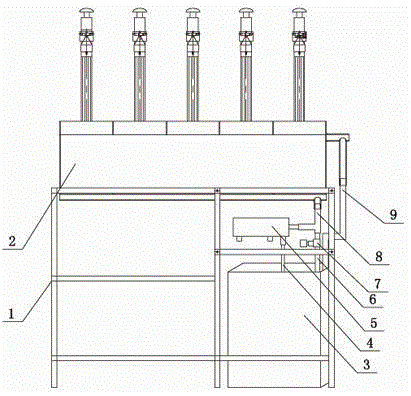

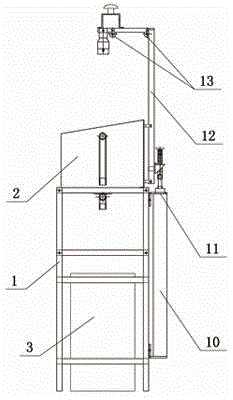

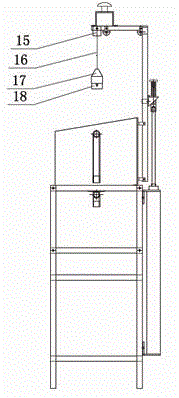

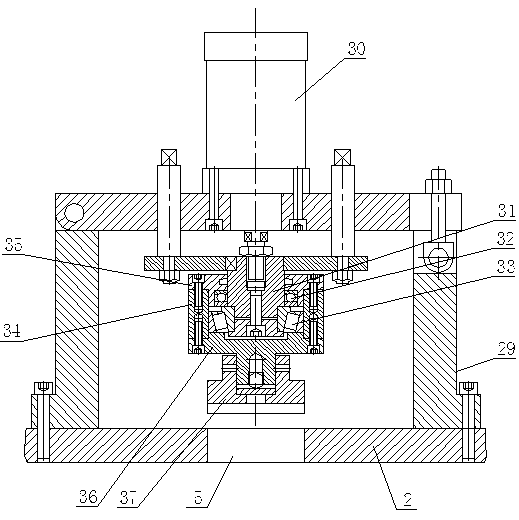

Integrated solid state fermentation reactor and application thereof

InactiveCN104845876AHigh automation intensityStable fermentationBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNozzle

The invention discloses an integrated solid state fermentation reactor. The reactor comprises, sequentially connected, a charging system, a fermentation tank and a rotary vacuum double-cone drying machine; and the charging system comprises, sequentially connected, an electric motor, a charging hopper, a conveying screw and a discharging tube, a stainless steel jacket is welded on the outer wall of the body of the fermentation tank, and the fermentation tank is also provided with a gas outlet, probes, a steam inlet, a steam outlet, a discharge opening, movable top covers and a two-fluid nozzle device. The invention also discloses an application of the reactor in solid state fermentation of aerobic, anaerobic and facultative anaerobic microbes. Compared with reactors in the prior art, the reactor has the advantages of high automation intensity, stable fermentation process, simple operation, realization of single-batch and multi-batch fermentation production, and facilitation of industrial application of solid state fermentation.

Owner:NANJING UNIV OF TECH

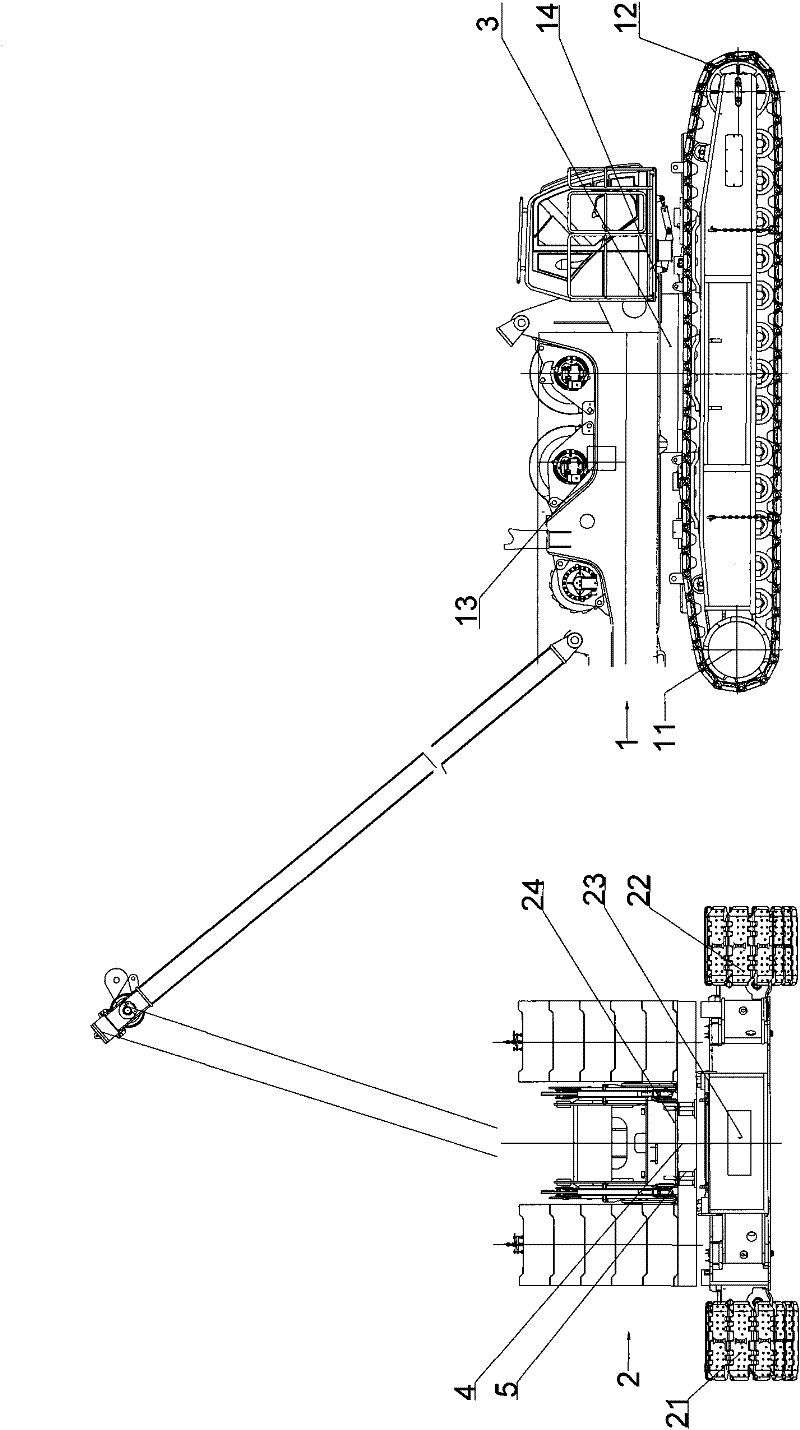

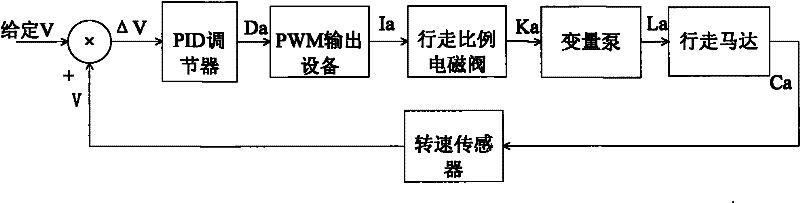

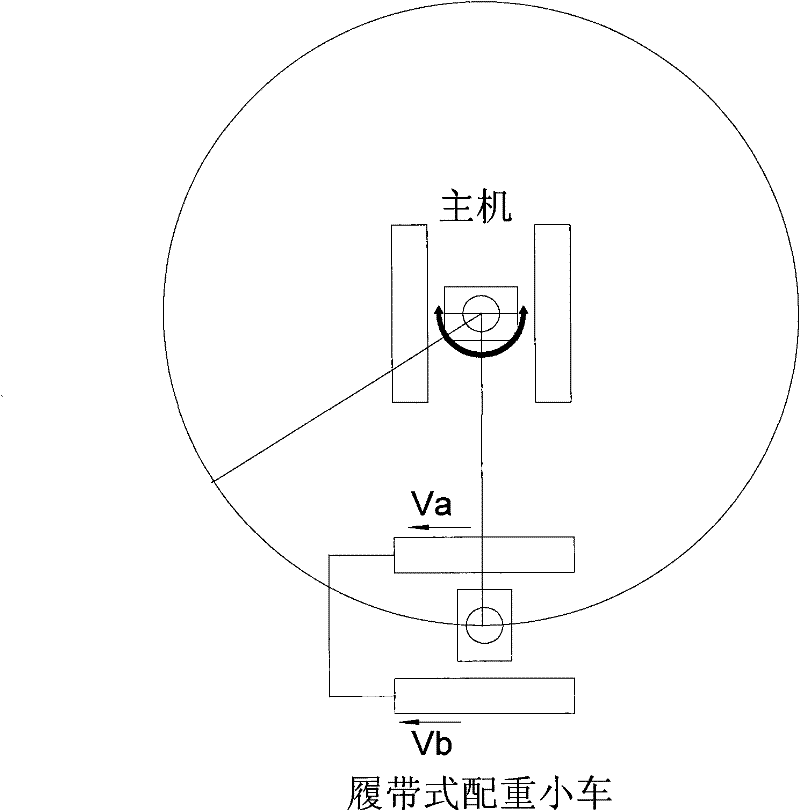

Electrical control device for crawler-type counter weight trolley and control method thereof

ActiveCN102234076AHigh automation intensityIncreased lifting capacityCranesLoad-engaging elementsElectrical controlMachine control

The invention relates to an electrical control device for a crawler-type counter weight trolley, comprising a main machine control component arranged on a main machine of a crane and a counter weight trolley control component arranged on a counter weight trolley of the crane, wherein the main machine control component comprises a right main machine crawler travelling motor rotating speed sensor, a left main machine crawler travelling motor rotating speed sensor, a main machine controller and a main machine rotation angle displacement sensor; the counter weight trolley control component comprises a right counter weight trolley crawler travelling motor rotating speed sensor, a left counter weight trolley crawler travelling motor rotating speed sensor, a counter weight trolley controller anda counter weight trolley rotation angle displacement sensor; and the main machine controller and the counter weight trolley controller are connected to communicate by virtue of a CAN bus. By adoptingthe electrical control device provided by the invention, synchronous control on the main machine and the counter weight trolley is realized, and actions of the main machine and the counter weight trolley are combined to generate diversified operating modes, thus the automation strength is improved, the lifting capacity is improved, a counter weight is convenient to move, and the problem that desynchronization is caused by adverse impact of personal factors can be avoided.

Owner:ZHEJIANG SANY EQUIP

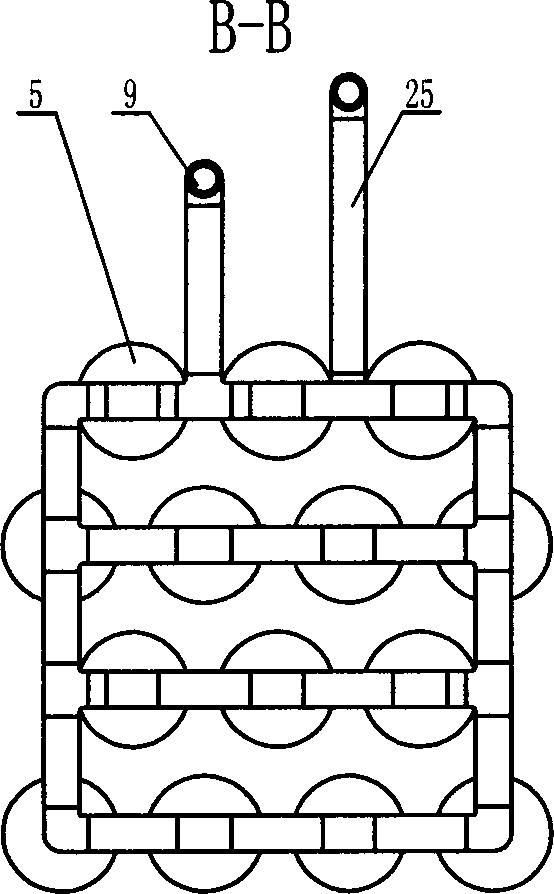

Suspension type drying room structure

InactiveCN107036418ASimple structureImprove thermal insulation performanceDrying chambers/containersDrying machines with progressive movementsEngineeringDrive motor

The invention discloses a suspension type drying room structure. The suspension type drying room structure comprises a three-dimensional frame, wherein the three-dimensional frame is composed of a top plate, a left side plate, a right side plate and a bottom plate, and openings are formed in the front end and the rear end of the three-dimensional frame correspondingly. A conveying structure is arranged on the inner surface of the top plate and comprises driving motors, a circulating conveying chain in the horizontal direction and a plurality of suspension rods, wherein the driving motors are located at the two ends of the circulating conveying chain and fixedly connected with the top plate; and the upper ends of the suspension rods are fixed to the circulating conveying chain at equal intervals, and the suspension rods are driven by the circulating conveying chain to move. A plurality of heating pipes are distributed on the side plates at interval intervals. A plurality of temperature sensors are distributed on the top plate, the side plates and the bottom plate correspondingly. The suspension type drying room structure further comprises a PLC, and the driving motors, the heating pipes and the temperature sensors are all electrically connected with the PLC. The suspension type drying room structure is suitable for suspension drying of big articles or heavyweight products, heat-preservation and heat-insulation effects are good, the constant-temperature state at the temperature of 160-170 DEG C is maintained, and the product drying effect is guaranteed.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

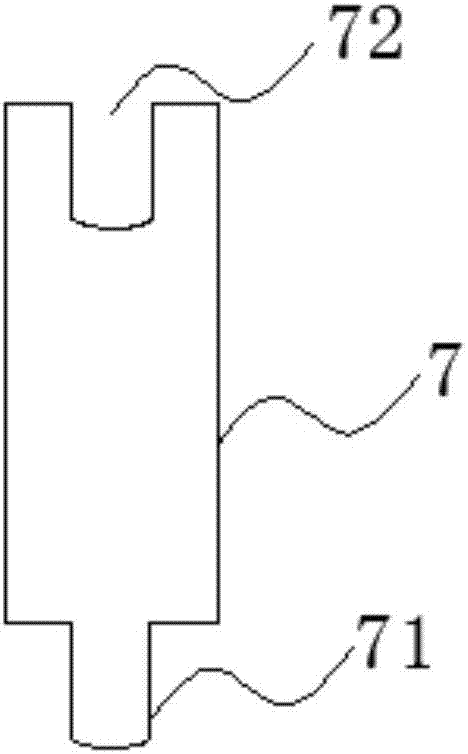

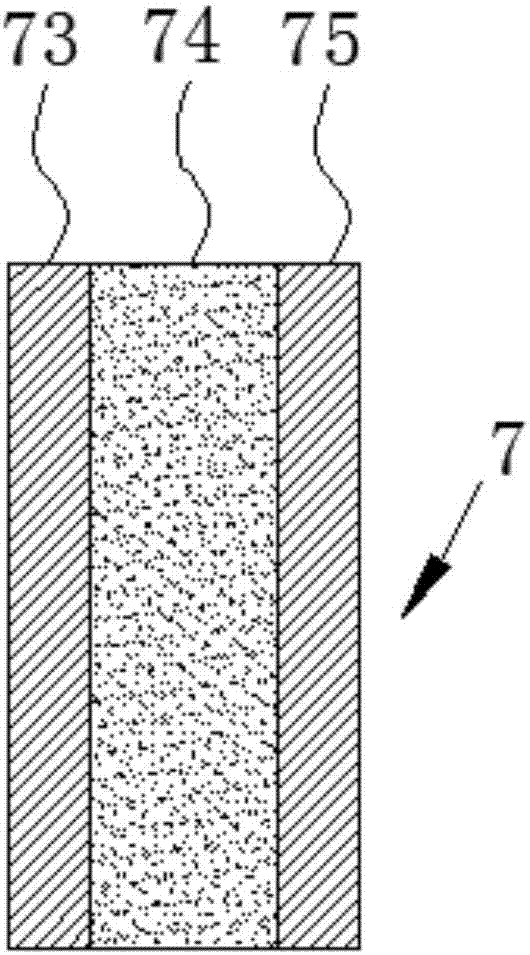

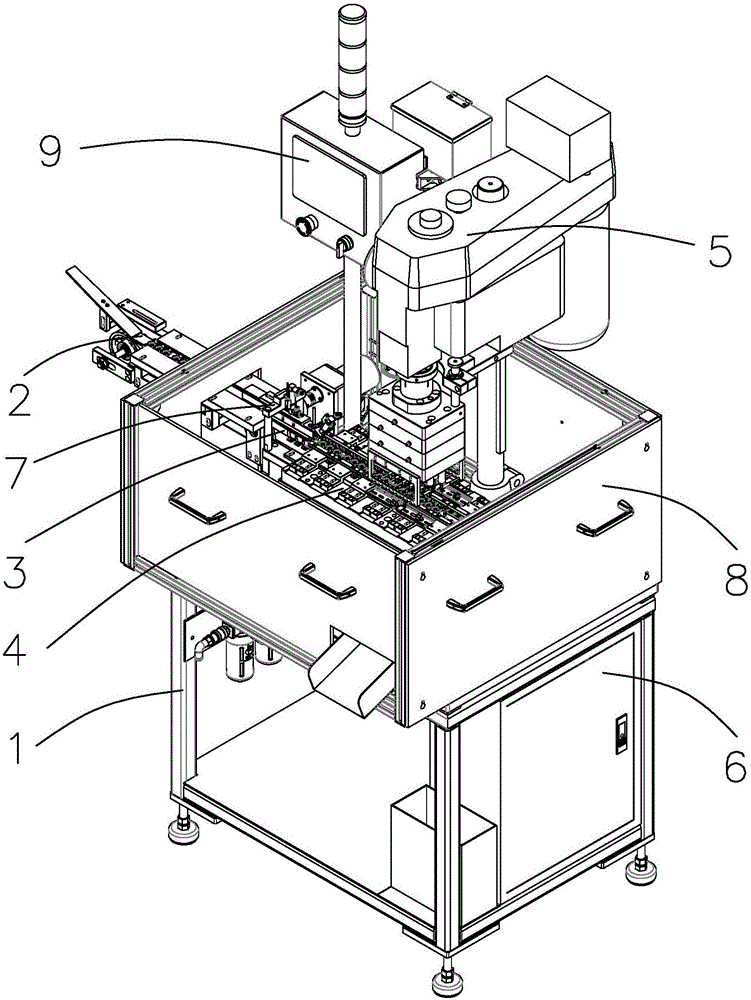

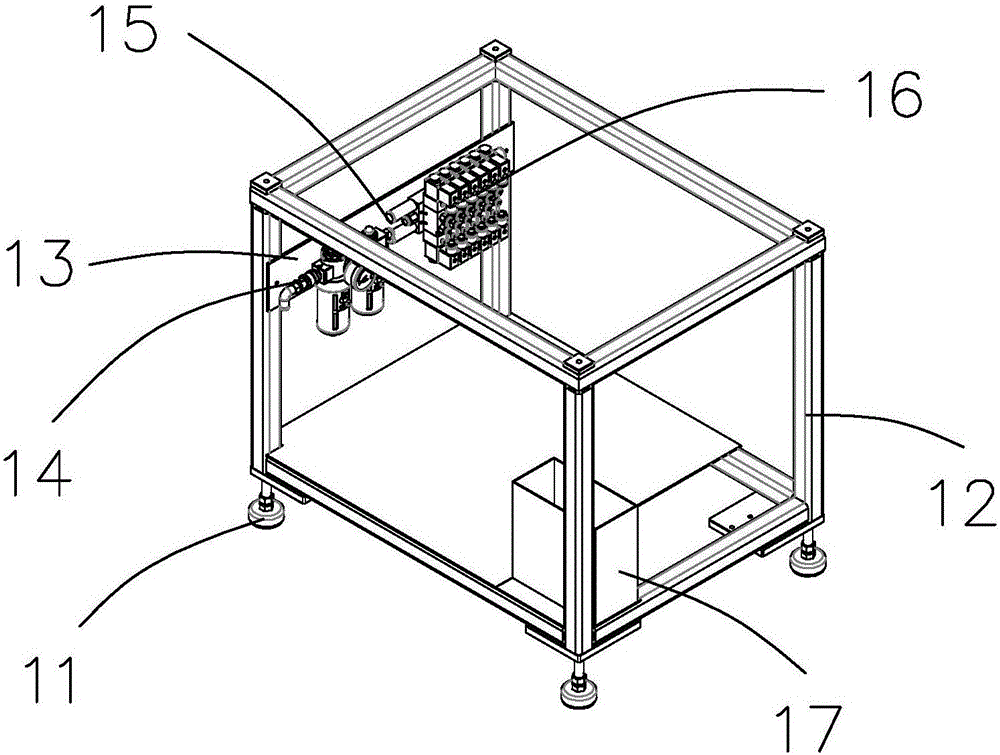

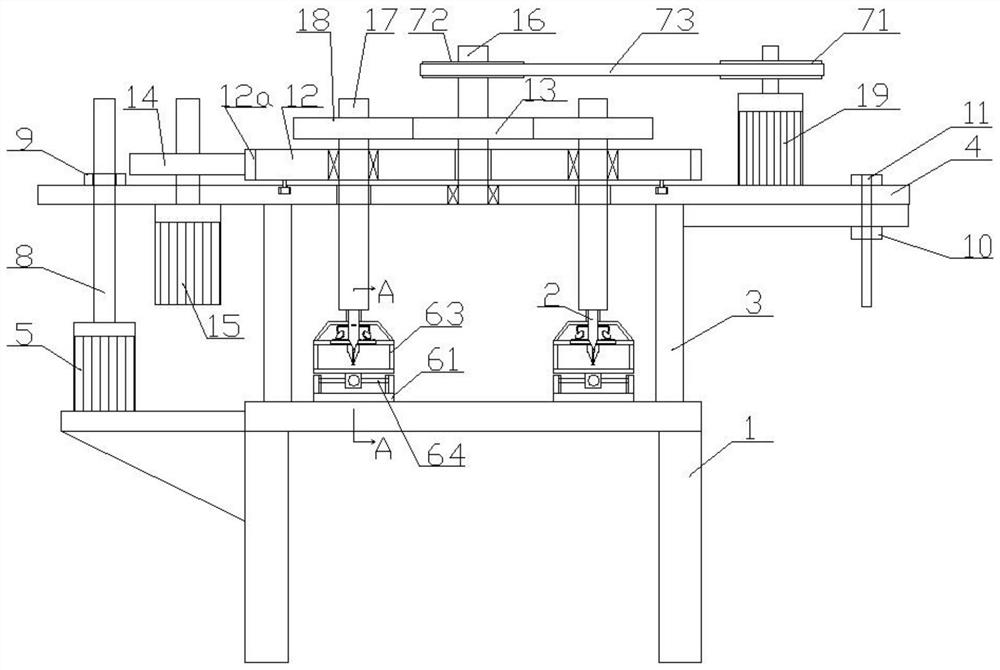

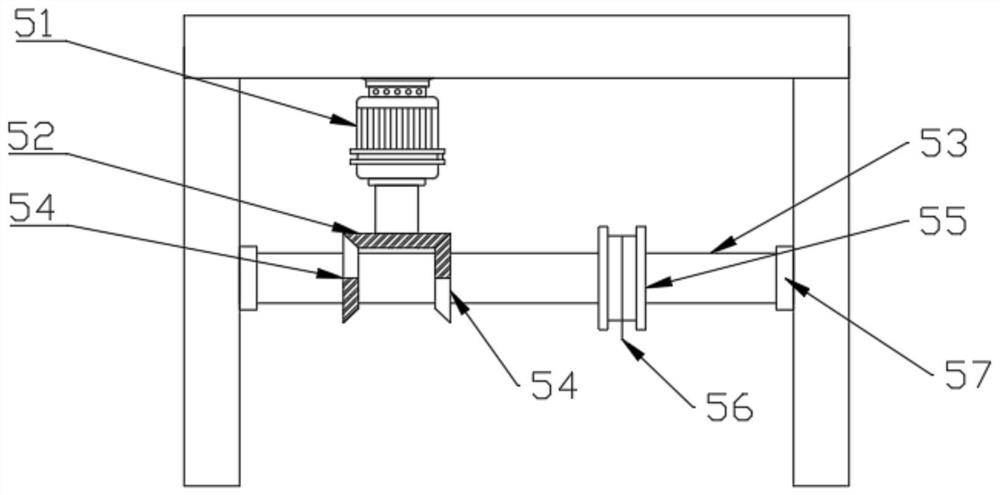

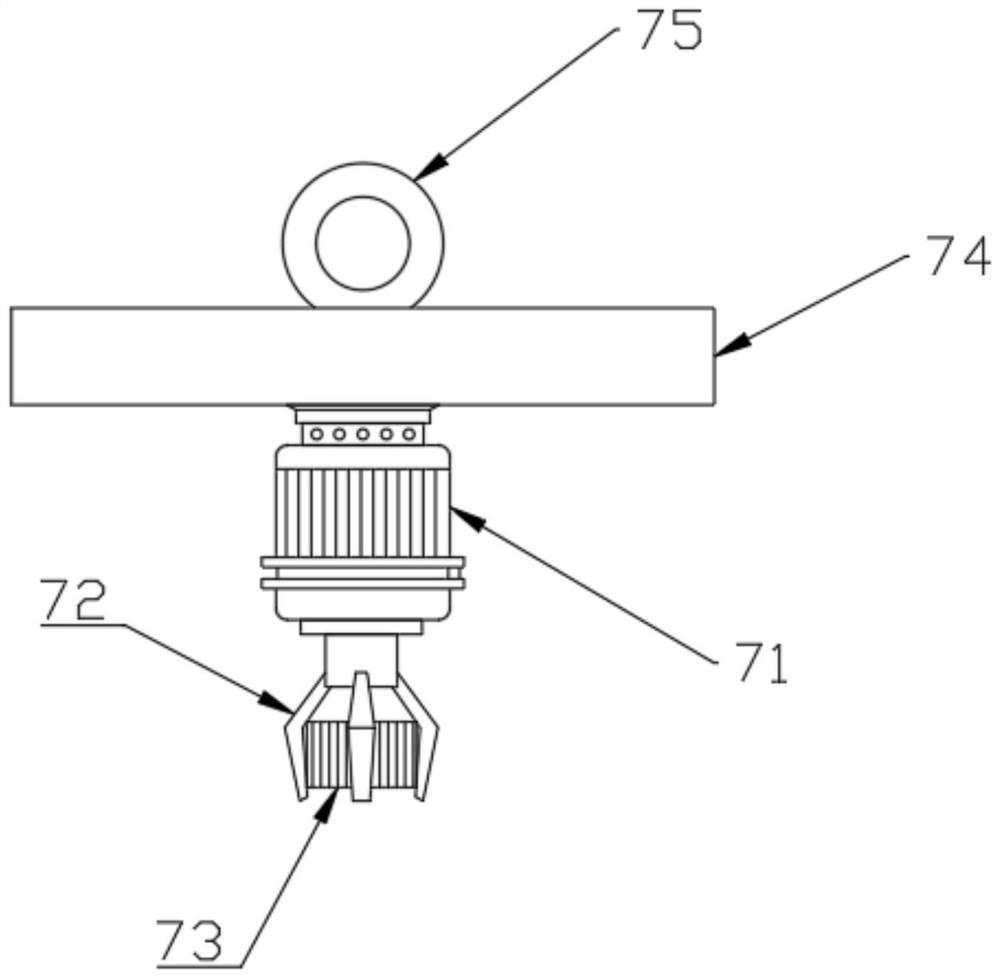

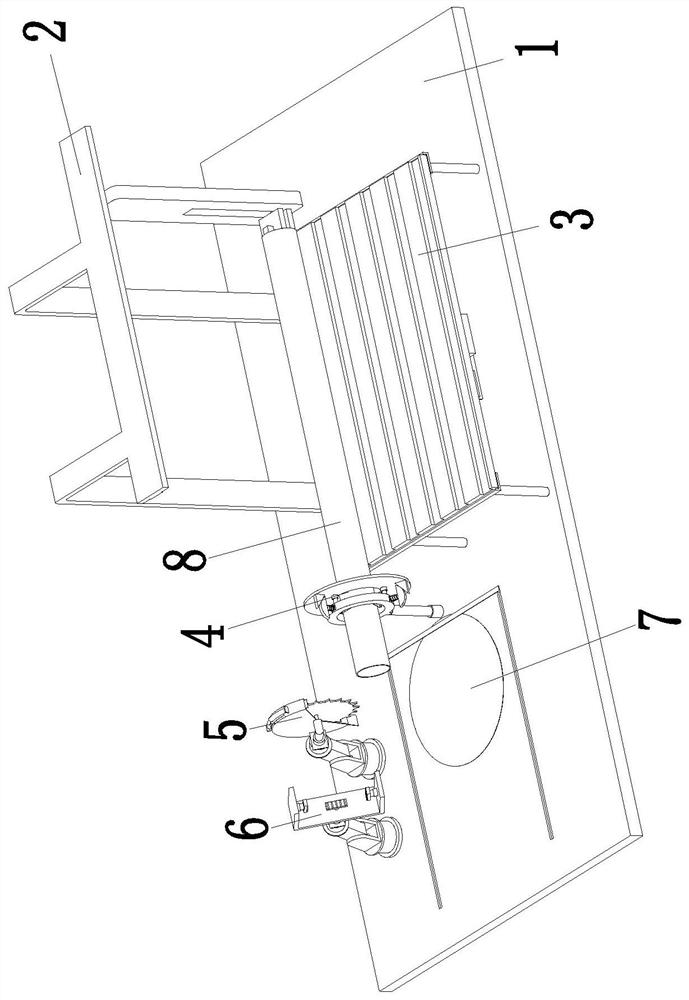

Automatic tapping machine

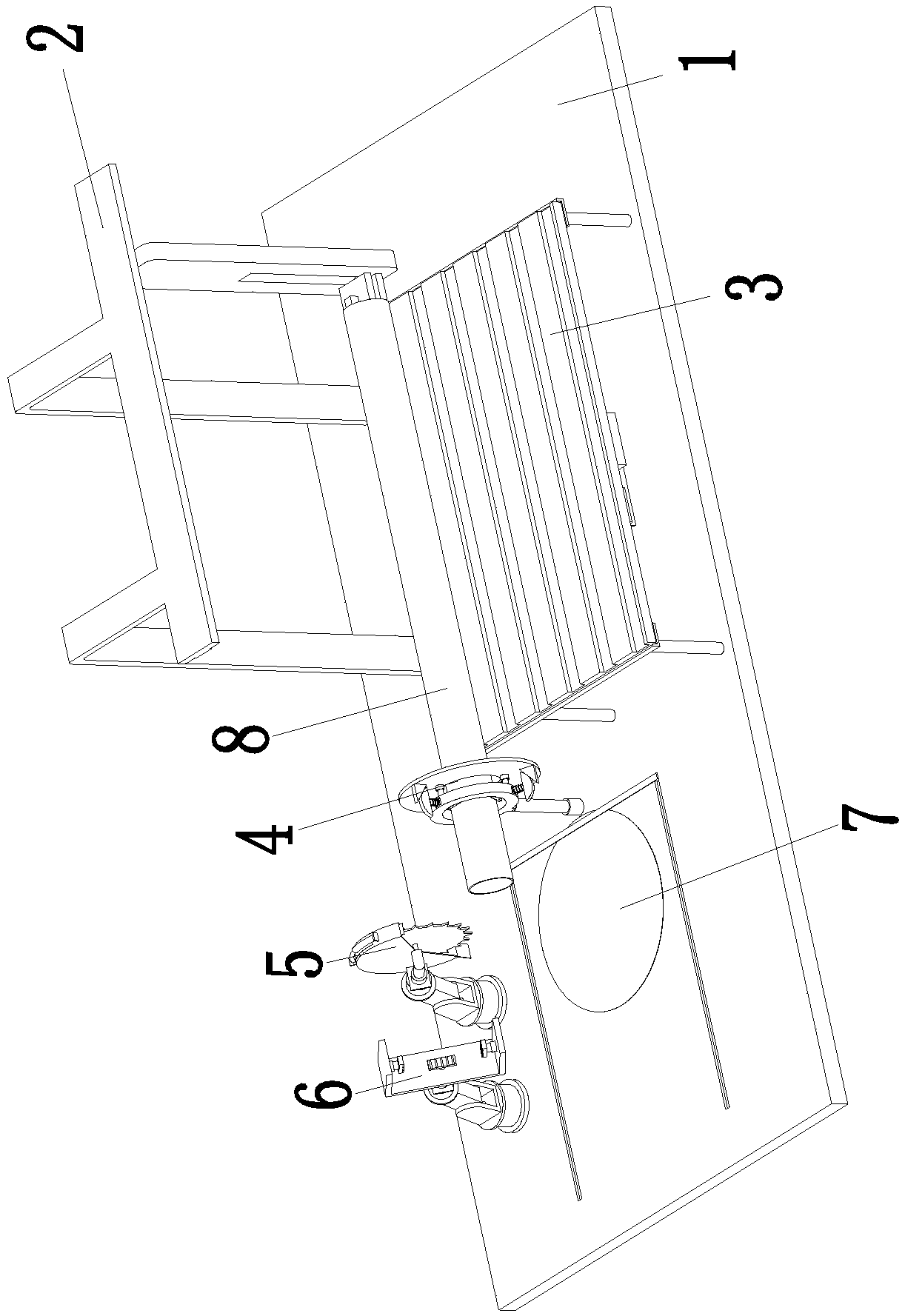

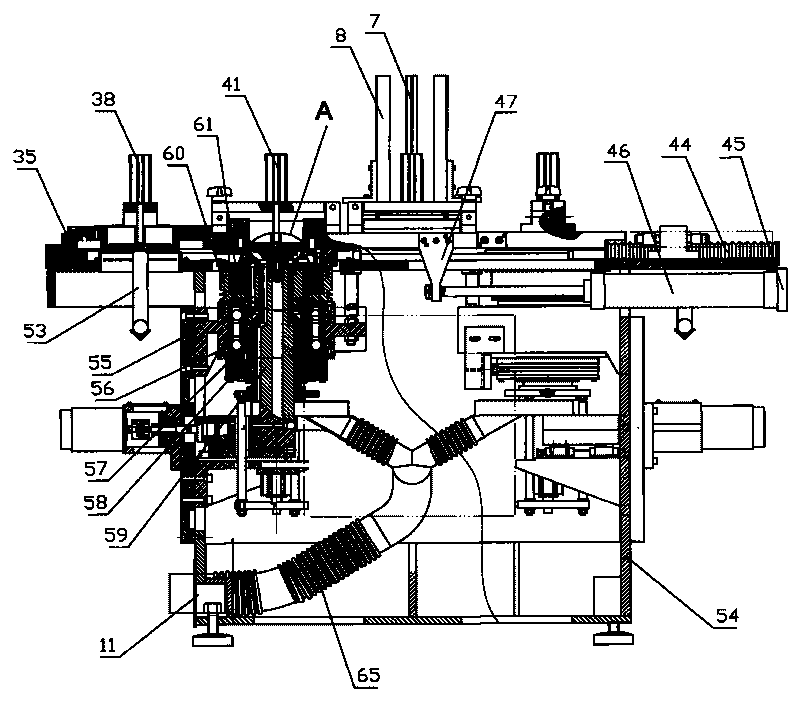

PendingCN107520512AHigh degree of automationSave human effortThread cutting feeding devicesThread cutting machinesEngineeringManipulator

The invention relates to an automatic tapping machine. The automatic tapping machine comprises a rack assembly, a conveying belt assembly, a guide rail assembly, manipulator assemblies, a tapping machine assembly and a control cabinet assembly; the conveying belt assembly is installed on the rack assembly; the guide rail assembly is installed on the rack assembly, and is communicated with the conveying belt assembly; the manipulator assemblies are installed on the two sides of the guide rail assembly; the tapping machine assembly is erected above the manipulator assemblies; and the control cabinet assembly is used for controlling tapping of the machine. According to the automatic tapping machine, materials are conveyed onto the guide rail assembly through the conveying belt assembly, the materials are clamped according to groups through the manipulator assemblies and are conveyed to a guide rail under the tapping machine body, and at the moment, the tapping machine assembly performs tapping on the group of materials; and then, the manipulator assemblies continue to clamp a next group of materials and push the materials after being subjected to tapping out of the guide rail, in this way, the tapping machine achieves automatic material conveying and continuously performs tapping on the materials according to the groups, the automation degree is high, and manpower is saved.

Owner:台山市江口电器制造有限公司

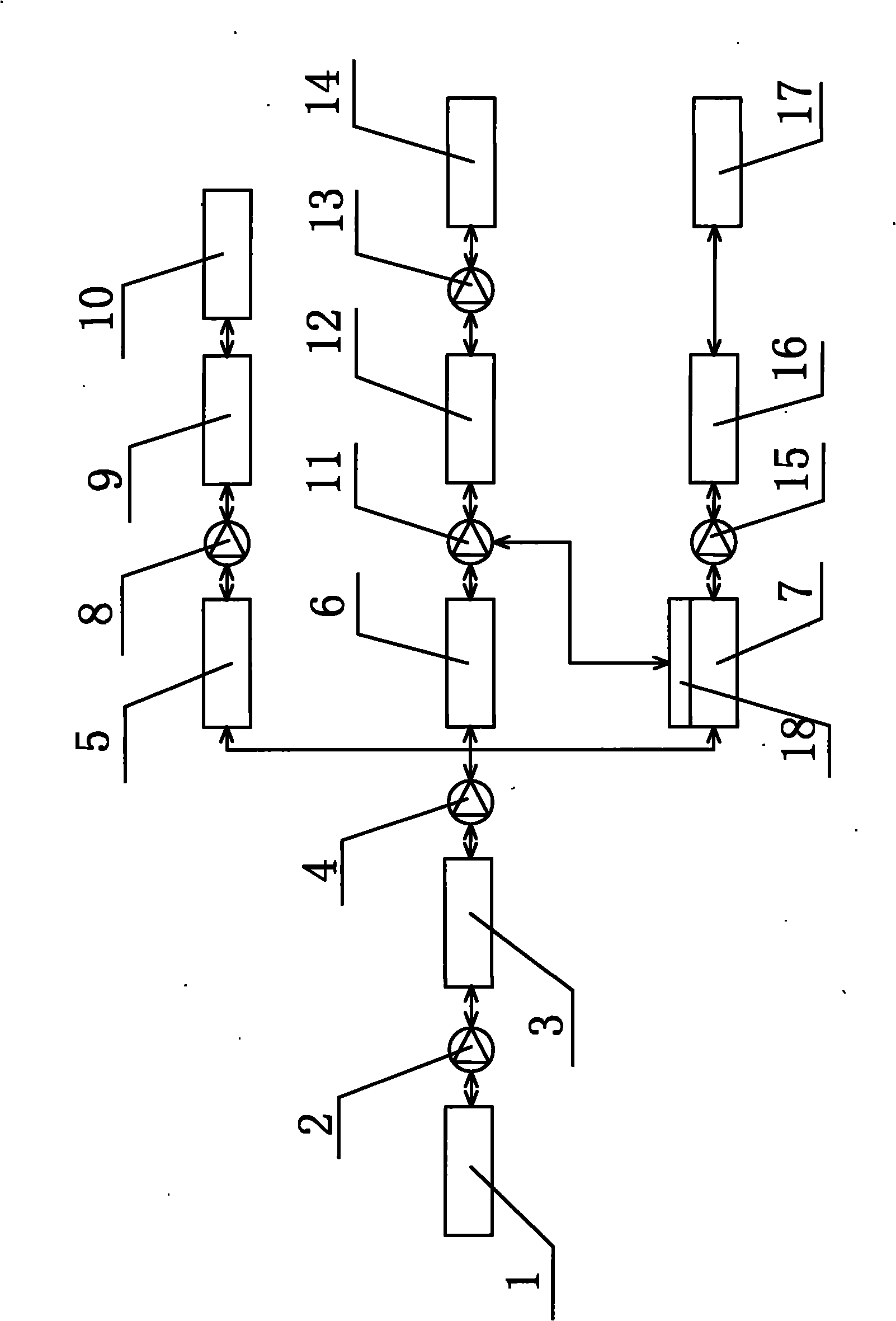

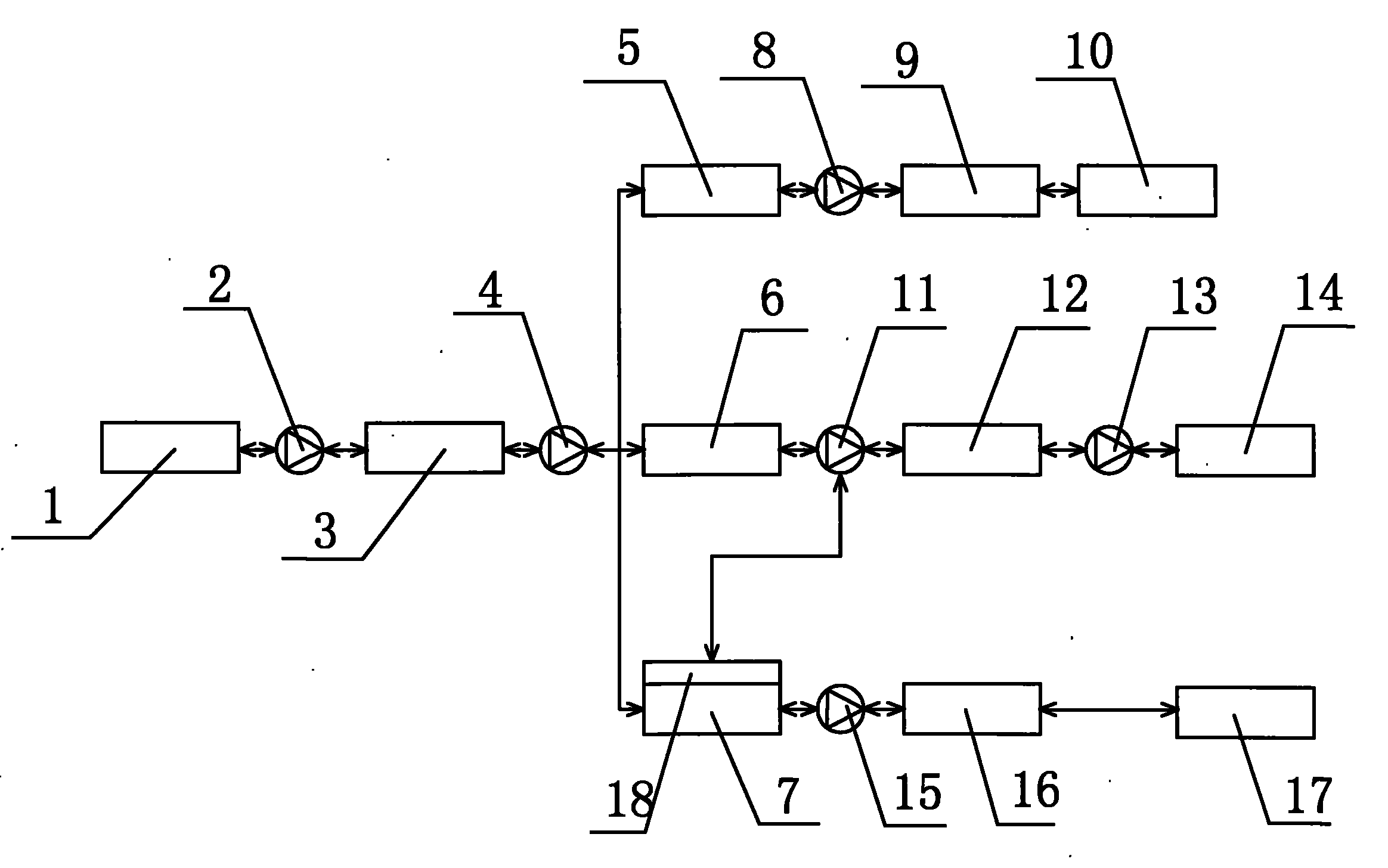

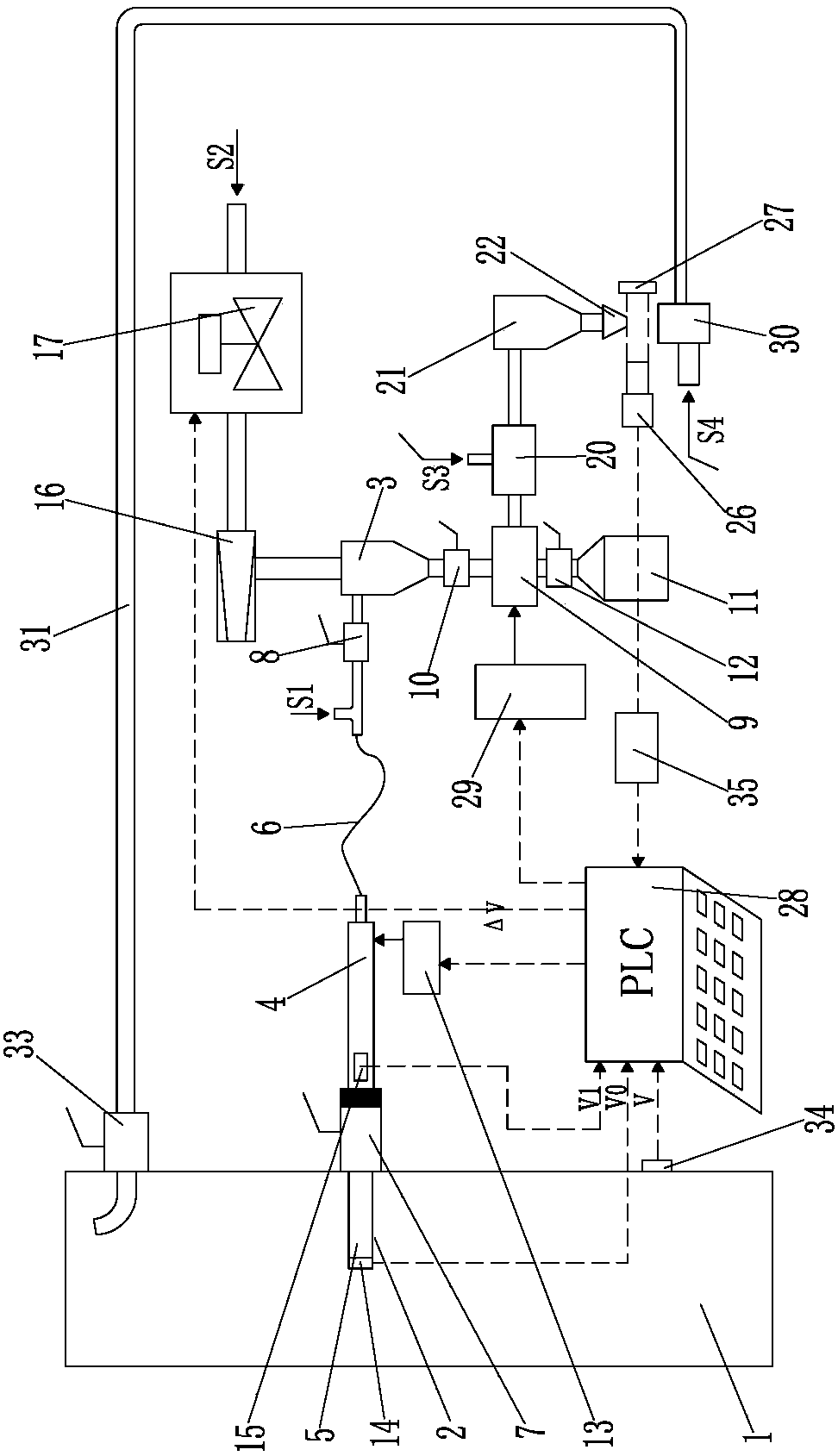

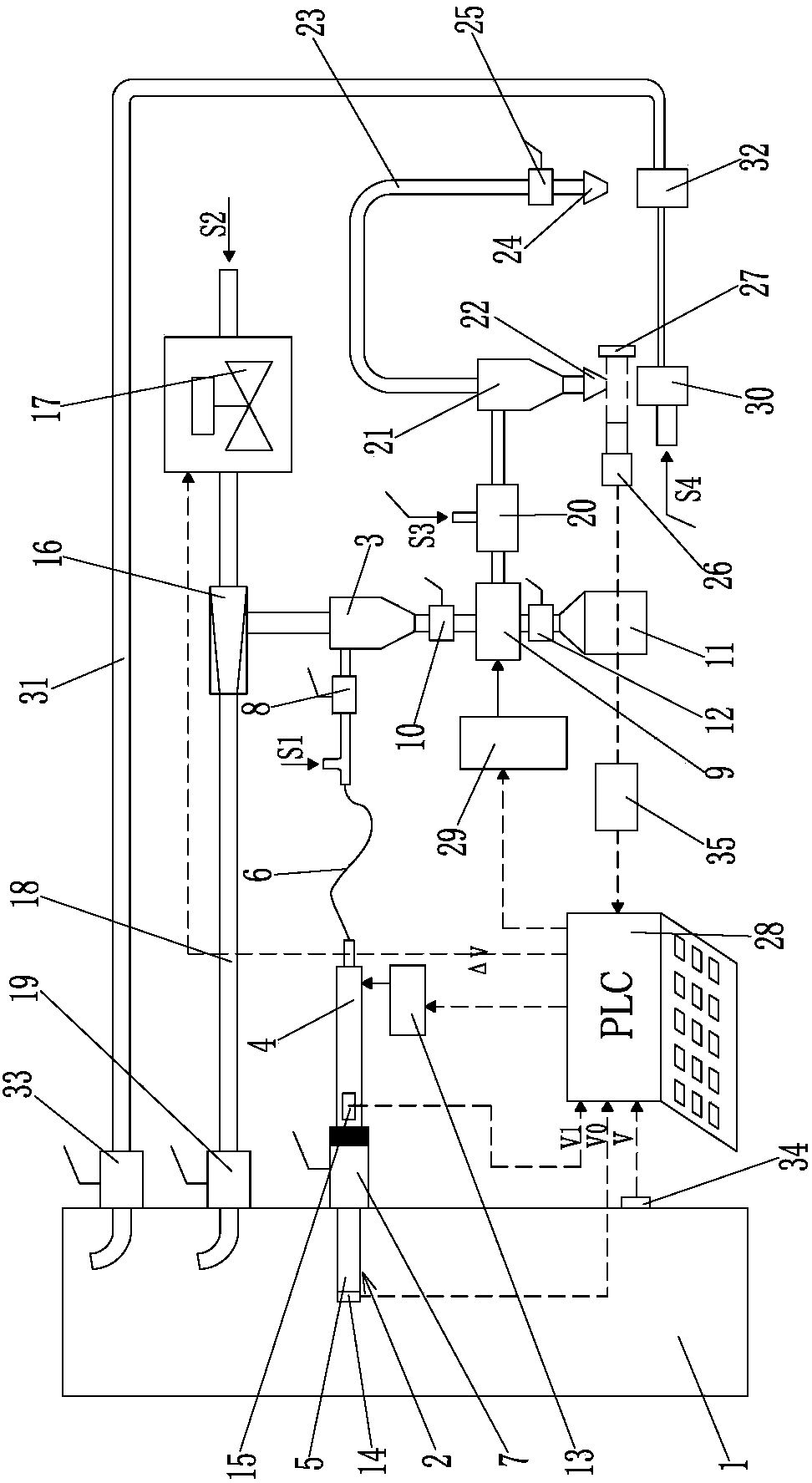

Heating and cooling system using swallet waste heat by industrial and mining enterprises

InactiveCN101893348ADoes not consume water resourcesChange energy structureHeat recovery systemsInsulationWater sourceResource utilization

The invention discloses a heating and cooling system using swallet waste heat by industrial and mining enterprises, relating to the field of residual heat waste heat resource utilization. The heating and cooling system comprises a well-head freeze protection water source heat pump unit (5), a worker bath water source heat pump unit (6), an industrial heating and cooling water source heat pump unit (7), a mine water recycle pump (2), a primary water recycle pump (4), three secondary water recycle pumps, a bath water heating recycle pump (13), two plate-type heat exchangers and a sub-water catcher (17). In the invention, a water source heat pump technology is used and reclaimed water waste heat in a mine water treatment plant is comprehensively utilized for worker bath, industrial heating in winter, well-head freeze protection and cooling of office buildings and apartment blocks in summer; a coal-fired boiler system is thoroughly replaced; a water source heat pump system only extracts the heat of the reclaimed water of the treated mine water and domestic sewage, and additional water resources are not consumed; and the heating and cooling system has the advantages of remarkable energy saving effect, obvious economic benefit, outstanding environmental benefit and the like.

Owner:SHANDONG TONGFANG ENERGY ENG TECH

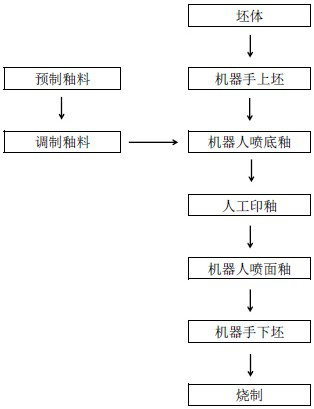

Glaze spraying process of robot glaze spraying circulation line and ceramic closestool prepared by glaze spraying process

The invention relates to the technical field of ceramic processing, in particular to a glaze spraying process of a robot glaze spraying circulation line and a ceramic closestool prepared by the glazespraying process. The robot glaze spraying circulation line comprises a robot glaze spraying line, the robot glaze spraying line is provided with a plurality of robots and further provided with a ballmill and a dispersion machine, the glaze spraying process of the robot glaze spraying circulation line comprises a glaze prefabricating step, a glaze blending step and a robot glaze spraying step, and the glaze prefabricating step comprises the following steps: S1) burdening according to set raw material components, S2) putting into the ball mill, adding a water reducing agent, and grinding to prepare glaze slurry, and S3) detecting that specific gravity, fluidity and fineness of glaze slip are all qualified, so as to obtain prefabricated glaze material. According to the glaze spraying process of the robot glaze spraying circulation line, the phenomenon that the glaze slip flows down from a green body is avoided after glaze spraying, the thickness of a glaze layer is uniform and consistent, the utilization rate of the glaze slip is high, and the prepared ceramic closestool is smooth in glaze surface, free of pores, low in defect rate and high in production efficiency.

Owner:JIANGXI DONGPENG BATHROOM CO LTD +1

Intelligent processing robot of stainless steel tube

ActiveCN109128364AEnsure safetyRealize automatic cutting productionMetal sawing devicesMetal sawing accessoriesAgricultural engineeringSteel tube

The invention relates to an intelligent processing robot of a stainless steel tube. The intelligent processing robot comprises a bottom plate, a conveying device, a cutting and feeding device, a sleeve type fixing device, a cutting device, a clamping device, an adsorption and cleaning device and a stainless steel hollow tube body, wherein the conveying device, the cutting and feeding device, the sleeve type fixing device, the cutting device and the clamping device are installed on the bottom plate in sequence from left to right, and the adsorption and cleaning device is installed on the bottomplate. According to the intelligent processing robot, the problems that a multi-caliber stainless steel hollow tube cannot be preferably clamped and fixed when the stainless steel hollow tube is cutin the prior art, sweeps which are generated when the stainless steel hollow tube is cut cannot be preferably prevented from splashing and hurting people, people need to wear protective equipment forprotection, the sweeps which are generated in a cutting process need to be manually cleaned and collected so as to be recycled and the people are easy to hurt by the sweeps which are generated when the stainless steel hollow tube is manually cut can be solved.

Owner:泰州市银杏舞台机械工程有限公司

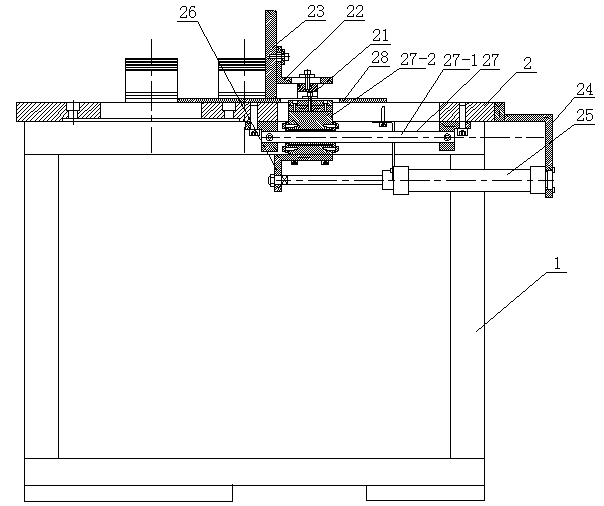

Piston ring inner circle chambering machine

InactiveCN101704123AReduce labor intensityHigh automation intensityMilling equipment detailsEngineeringFuselage

A piston ring inner circle chambering machine relates to machining equipment and comprises a machine body and two ring-arranging mechanisms, wherein an automatic feed mechanism and a sliding table are arranged above the machine body; the sliding table can slide on the machine body transversely; two blanking mounting holes and two station mounting holes are arranged on the sliding table symmetrically; ring falling molds are respectively fixed above the blanking mounting holes of the sliding table; a first compression ring mechanism is arranged above each ring falling mold; charging barrels are respectively fixed above the station mounting holes; a second compression ring mechanism is arranged above each charging barrel; the machine body is internally installed with two main shafts; each main shaft is internally and coaxially provided with shaft sleeves in a penetrating way, and each shaft sleeve is sheathed with a cutter bar; each main shaft is connected with a rotary driving mechanism; the lower end of each shaft sleeve is connected with an air cylinder; the upper end of each main shaft is fixed with an electromagnetic chuck; the upper end of each electromagnetic chuck is fixed with a locating ring; each locating ring is internally provided with a ring ejection machine; the upper end of each cutter body is fixed with a cutter head, a cutter base and a cutter tool; and the left side and the right side of the piston ring inner circle chambering machine can be conducted simultaneously, and has high production efficiency.

Owner:仪征双环设备制造有限公司

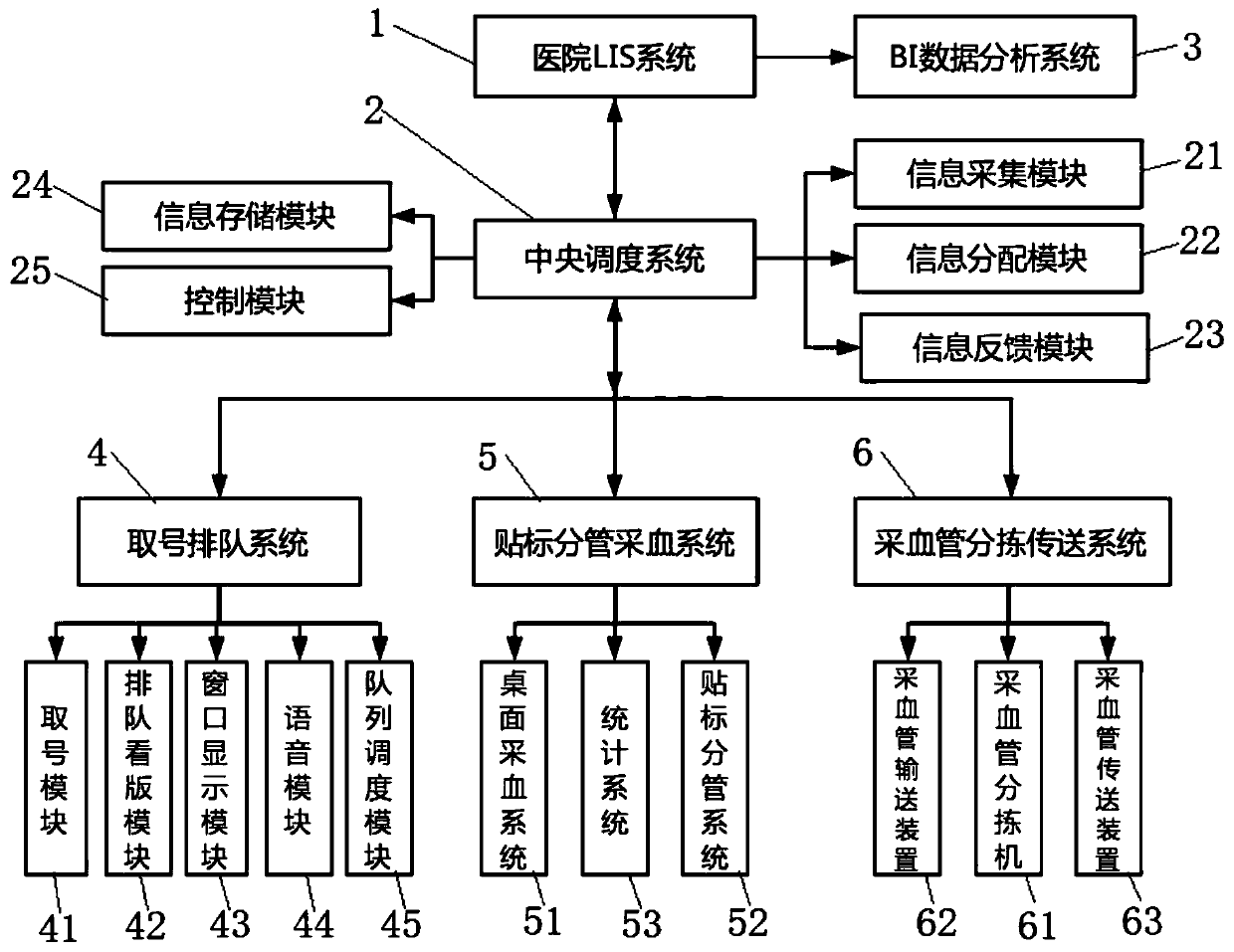

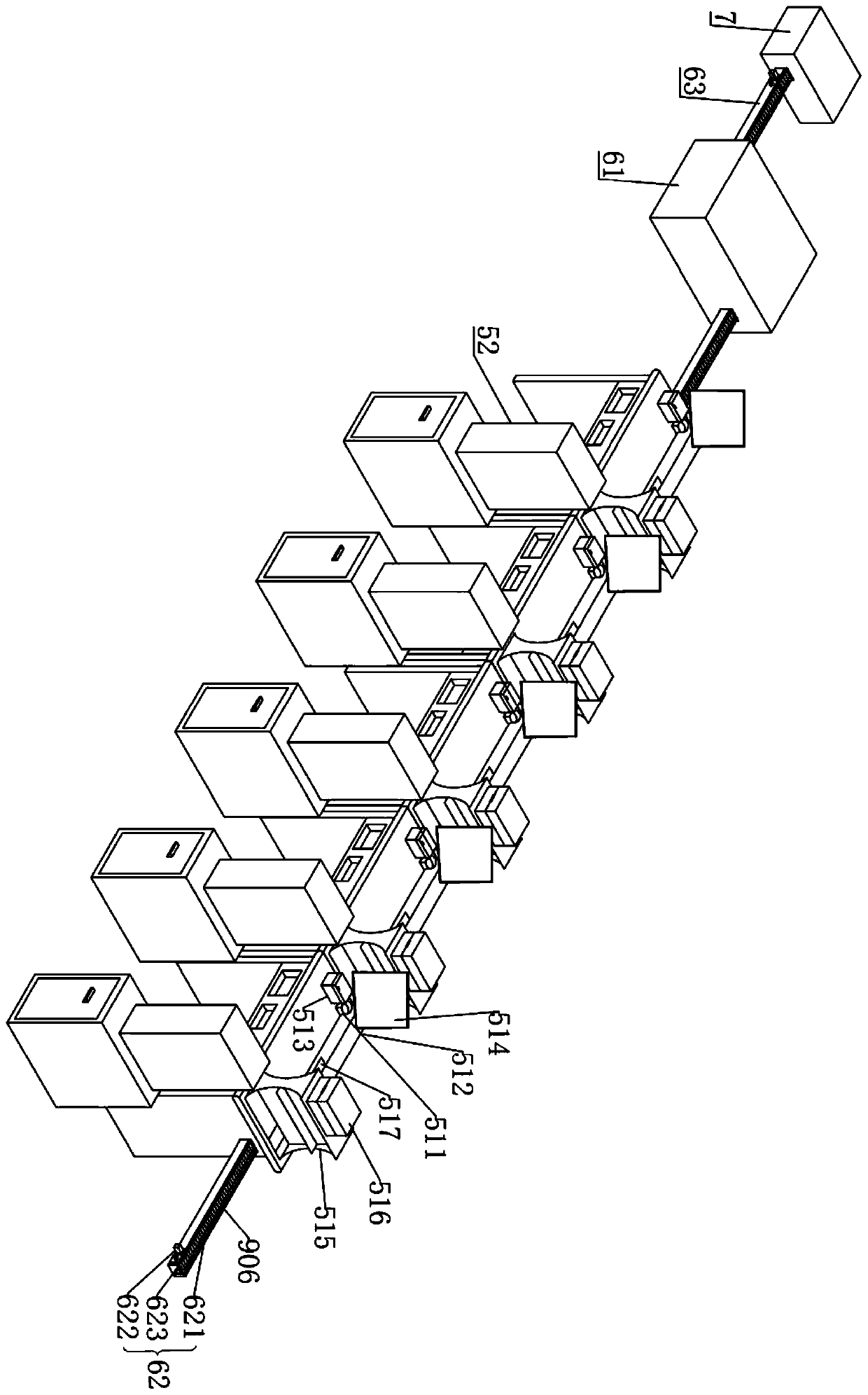

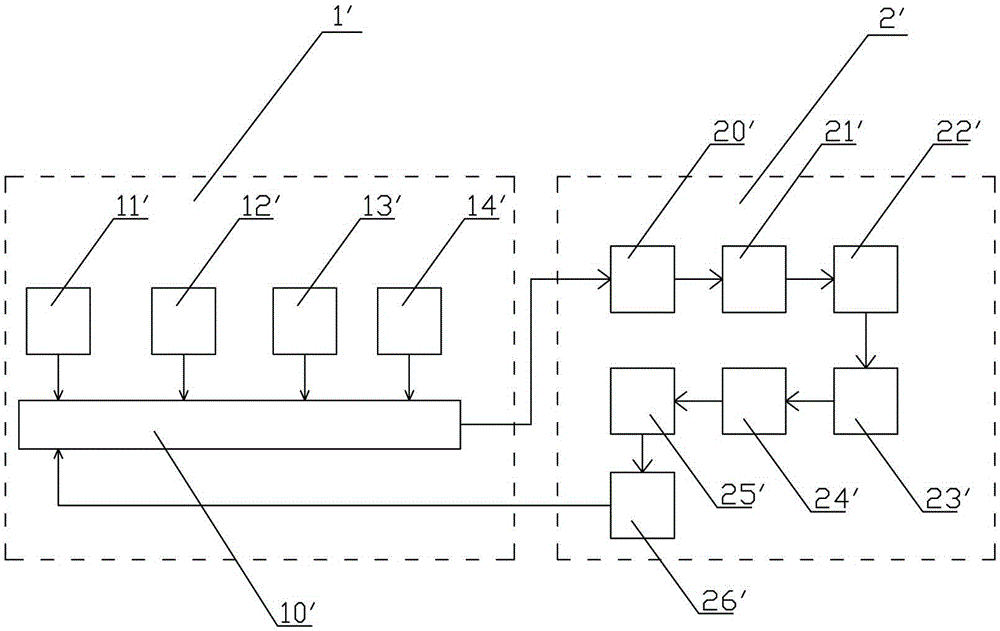

Intelligent blood sampling management system and management method thereof

ActiveCN110993082ARealize intelligent managementDiversified ways of taking numbersHealthcare resources and facilitiesBlood Collection TubeInformation resource

The invention discloses an intelligent blood sampling management system and a management method thereof. On the one hand, the intelligent blood sampling management system comprises a hospital LIS system; a central dispatching system which is connected with the hospital LIS system and can carry out information interaction with the hospital LIS system; a BI data analysis system which is connected with the hospital LIS system and can collect, process and manage information resources of the hospital LIS system. The system also comprises a number taking queuing system, a labeling branch pipe bloodsampling system and a blood sampling pipe sorting and conveying system, which are connected with the central dispatching system and can carry out information interaction with the central dispatching system. On the other hand, the invention further provides a management method adopting the intelligent blood sampling management system. The system has diversified number taking modes, is ordered in queuing management, can achieve the test tube selection, labeling, checking, sorting and transmission automatically, and can finely manage blood sampling service data.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

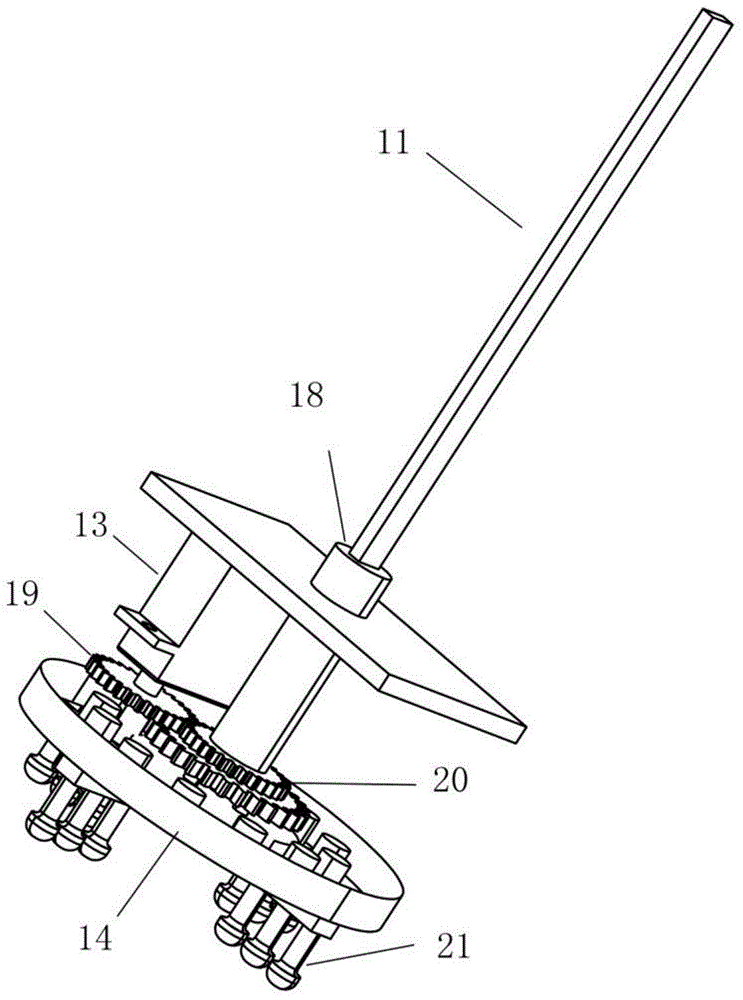

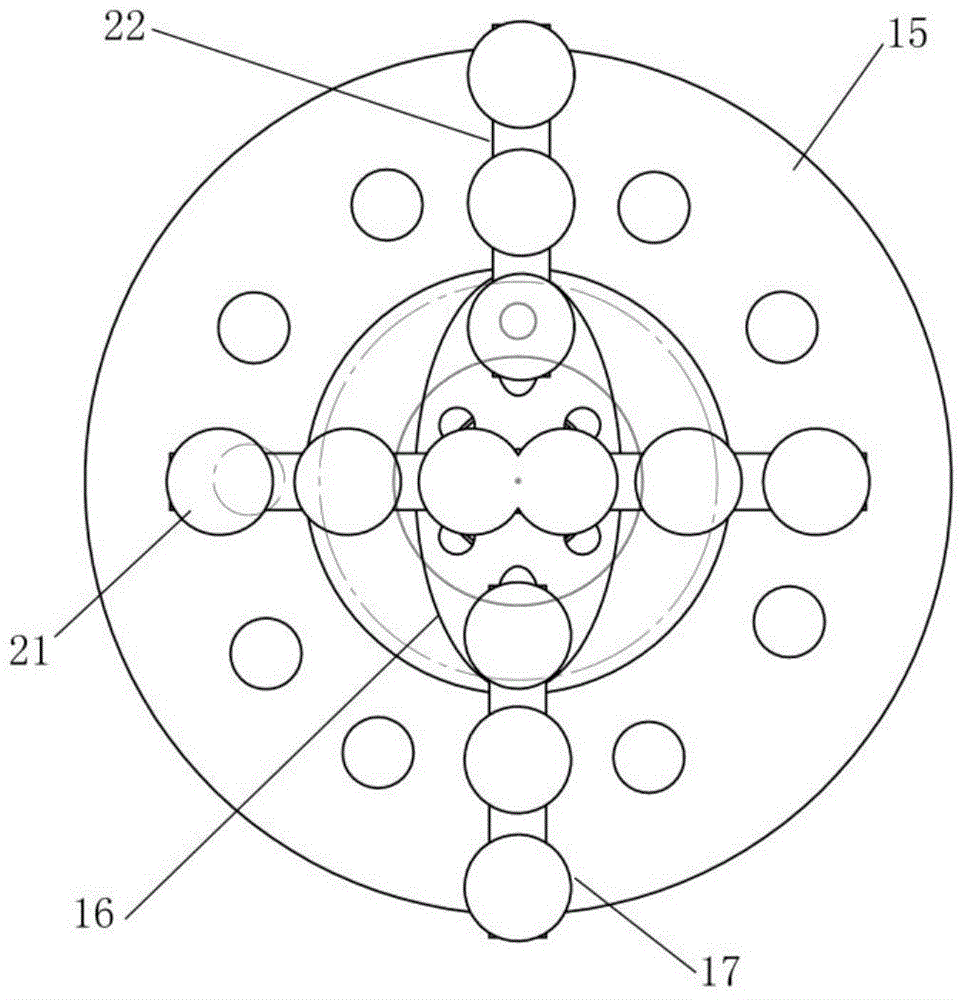

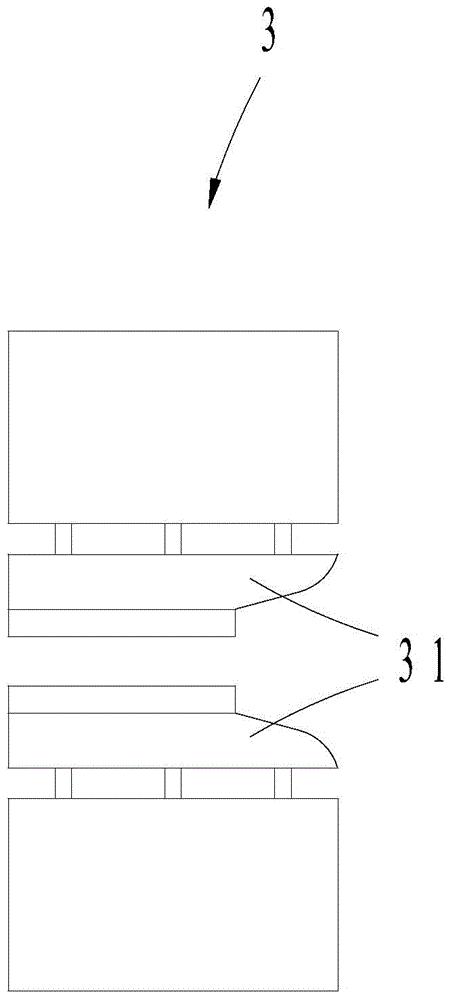

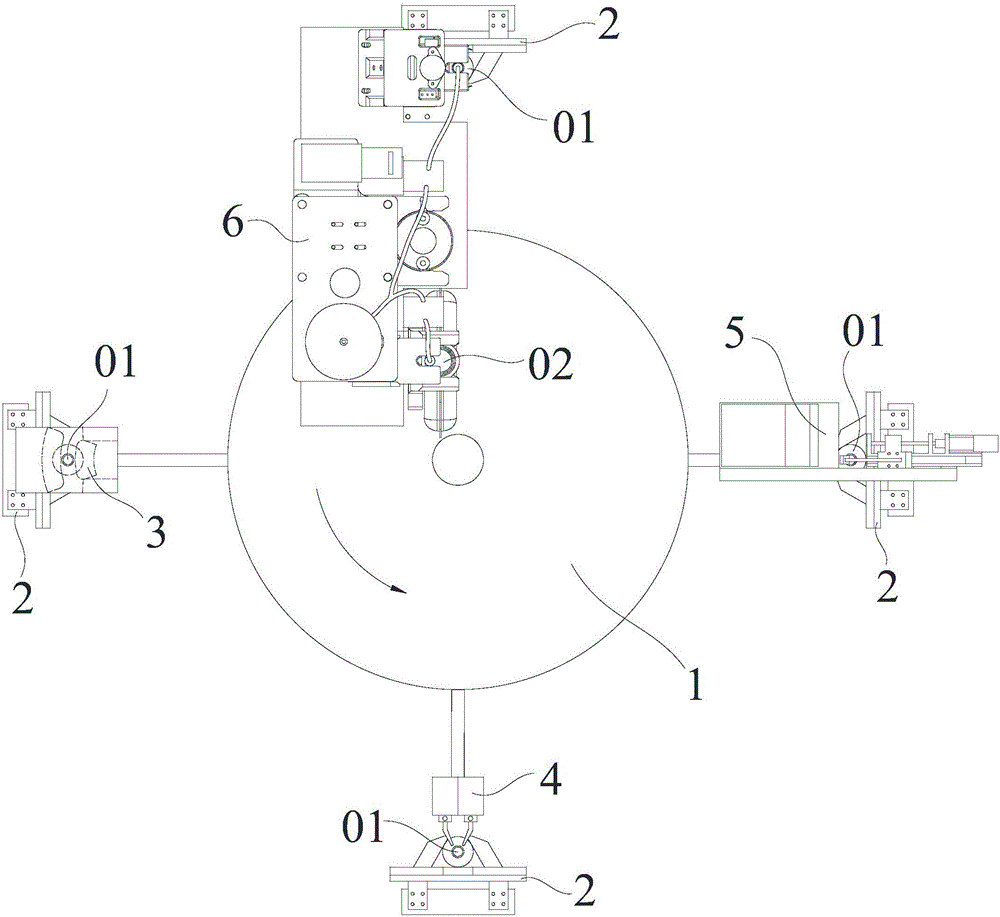

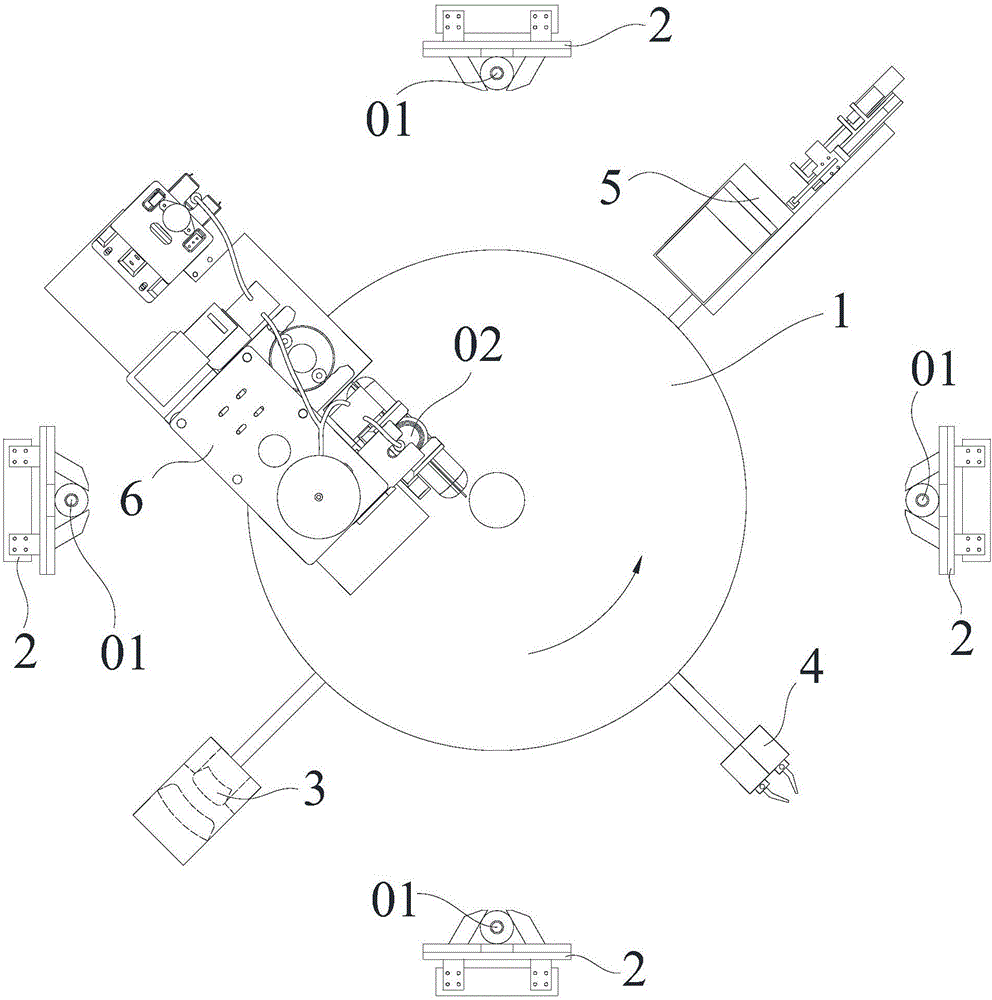

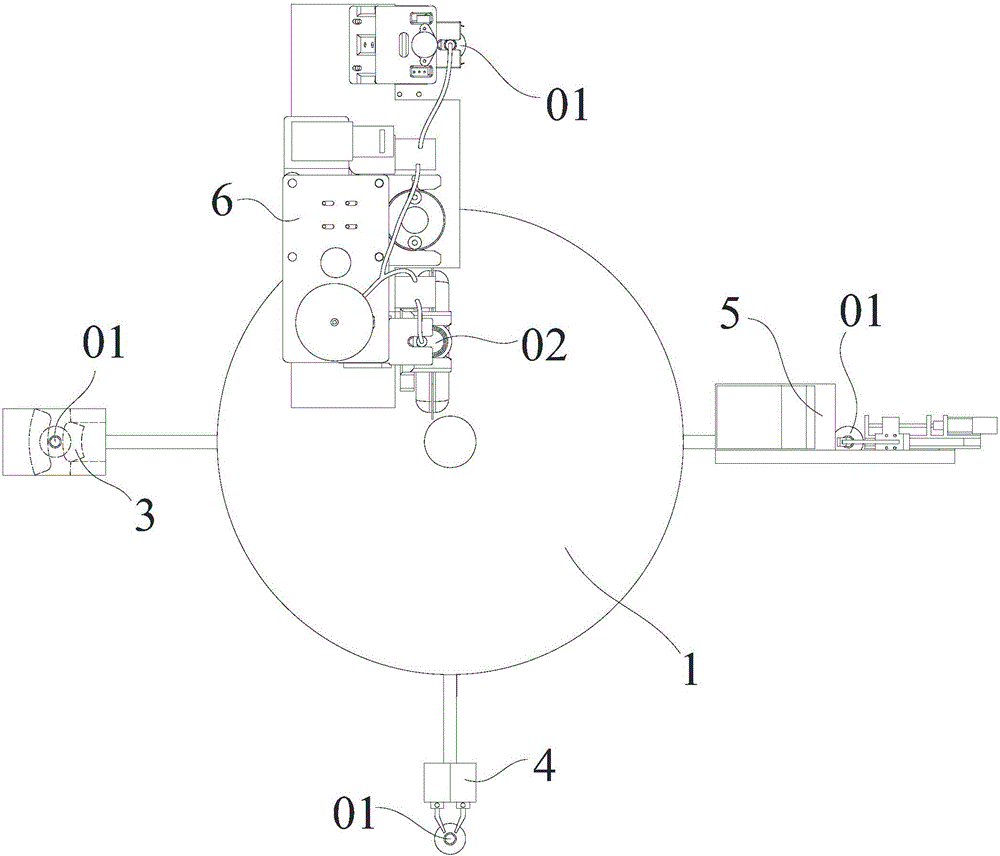

Dispensing device and dispensing method of ampoule bottle

InactiveCN105853226ASimple structureCompact structureBottle/container closurePower operated devicesControl systemBottle neck

The invention discloses a dispensing device and dispensing method of an ampoule bottle. The device comprises a rotating part and a control system; the rotating part is provided with bottle cutting modules, disinfecting modules, bottle breaking modules and sucking modules, clamping modules for clamping the ampoule bottle are fixed at the periphery of the rotating part, and the control system controls the rotating part to rotate to the position over the clamping modules to complete bottle cutting or disinfecting or bottle breaking or sucking work of the ampoule bottle. By applying the device, manual operation is replaced by arranging the rotating part which can drive the bottle cutting modules for automatically cutting the bottle neck of the ampoule bottle, the disinfecting modules for automatically disinfecting the bottle neck of the ampoule bottle, the bottle breaking modules for automatically breaking the bottle neck of the ampoule bottle and the sucking modules for automatically sucking medicine liquid of the ampoule bottle into an infusion bag to rotate to be matched with the clamping modules for clamping the ampoule bottle; the device is simple and compact in structure, small in occupied space, low in cost, high in automation intensity, convenient to operate and capable of reducing manual dispensing intensity and greatly improving the dispensing efficiency.

Owner:CHENGDU JIESHIDE SCIENCE AND TECHNOLOGY CO LTD

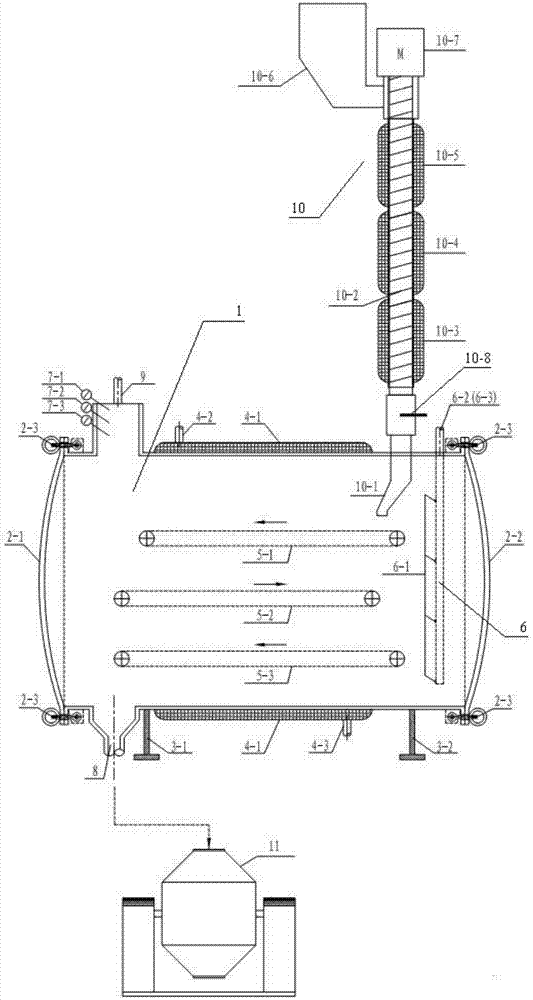

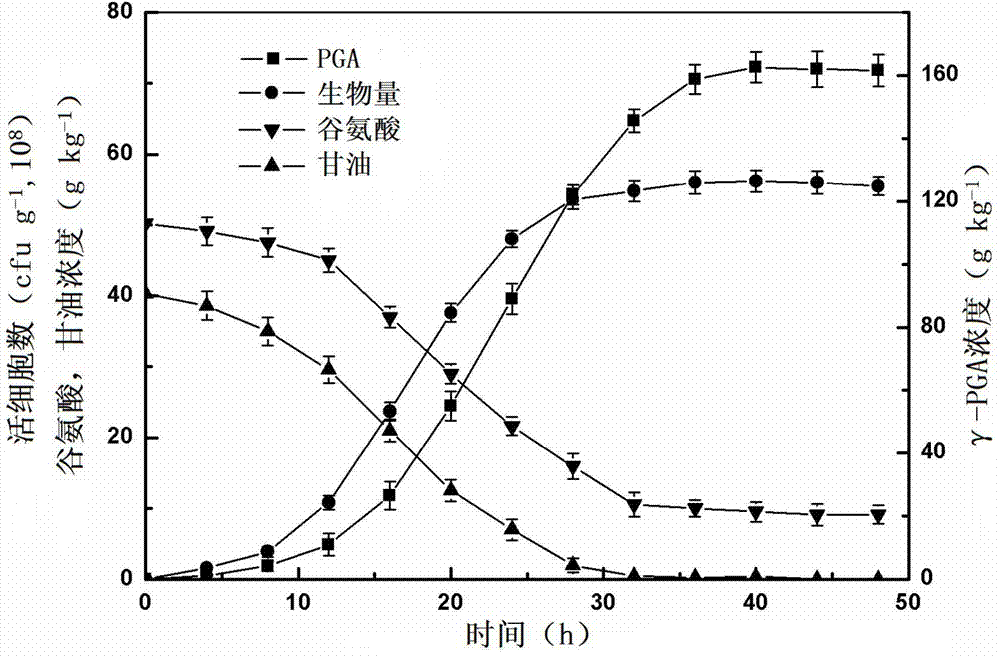

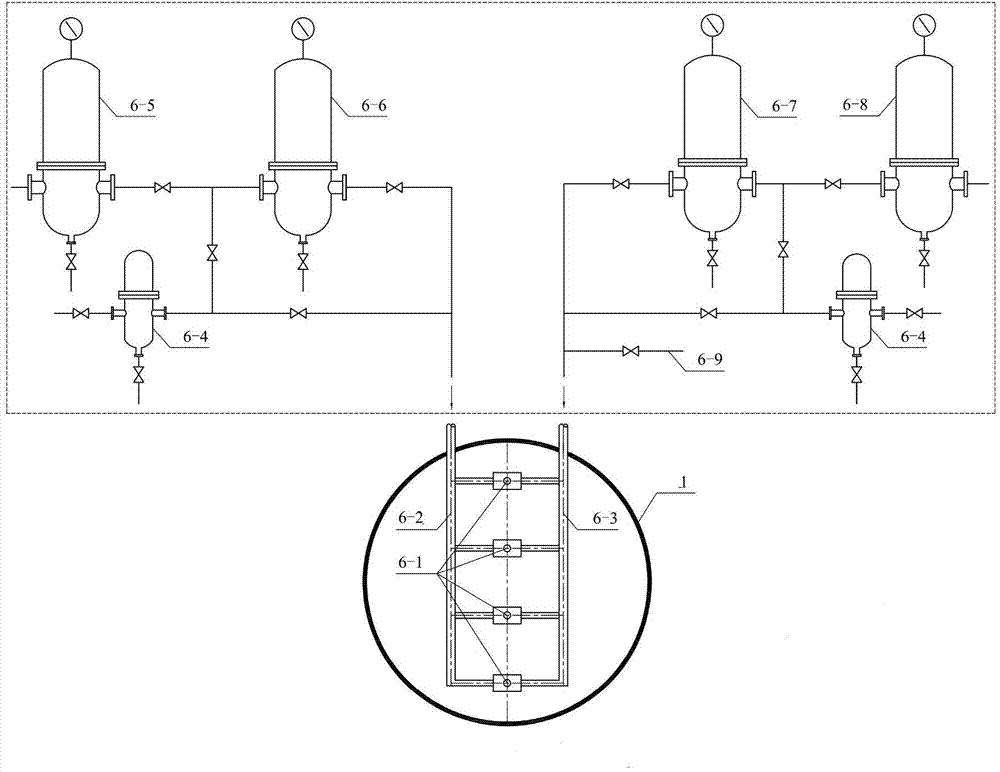

Solid state fermentation belt reactor and application thereof

ActiveCN104845885AHigh automation intensityThe fermentation process is stableBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSewage

The invention discloses a solid state fermentation belt reactor. The solid state fermentation belt reactor comprises a fermentation tank, a medium preparation tank and a conveyor belt system, the periphery of the fermentation tank is provided with a jacket, and the fermentation is also provided with a gas outlet, probes, a steam inlet, a steam outlet, a sewage outlet, movable top covers and a two-fluid nozzle device. The invention also discloses an application of the solid state fermentation belt reactor in cultivation of aerobic, anaerobic and facultative anaerobic microbes. The reactor has the advantages of high automation intensity, stable fermentation process, simple operation, realization of single-batch and multi-batch fermentation production, and facilitation of industrial application of solid state fermentation.

Owner:NANJING UNIV OF TECH

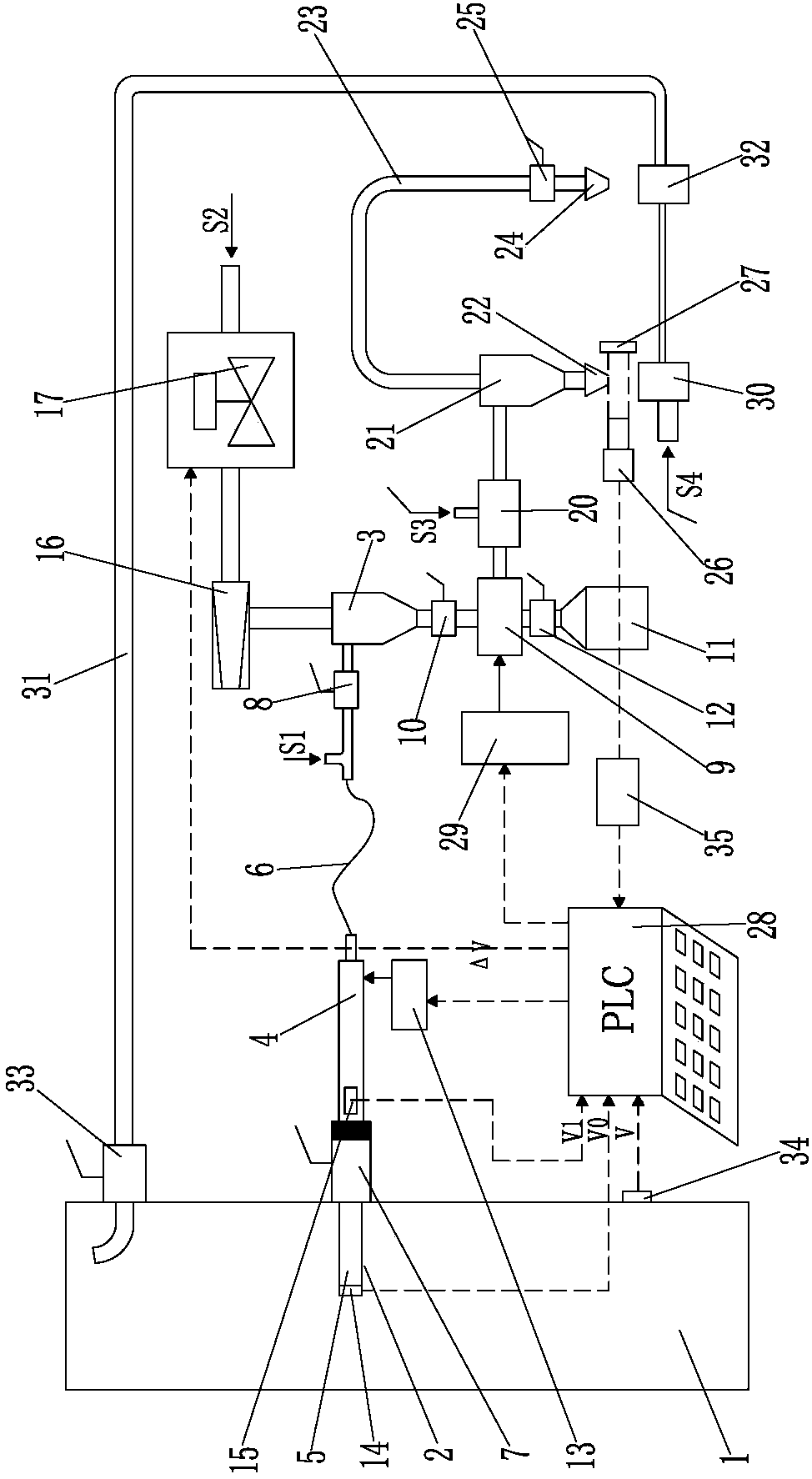

Online measuring method and measuring device of fineness of automatic sampling pulverized coal

PendingCN107589053AGood real-time performanceHigh automation intensityParticle size analysisMeasurement deviceFineness

The invention discloses an online measuring method of the fineness of automatic sampling pulverized coal. The method comprises the following steps of driving a sampling gun to stretch into a pulverized coal pipeline by using a control mechanism, controlling the negative pressure and suction of an air extracting mechanism to realize sample pulverized coal particles, and enabling the pulverized coalparticles to be collected under the action of a cyclone separator; controlling the collected pulverized coal particles by using the control mechanism so as to be processed into dropping pulverized coal fluid with thin surfaces via using a pulverized coal particle processing mechanism, collecting pictures by using an image collecting mechanism, and analyzing the size and distribution of the pulverized coal particles from pictures by using an image processing unit; the control mechanism is used for controlling a pulverized coal recycling mechanism to recycle the pulverized coal particles collected by the image collecting mechanism to a raw pulverized coal pipeline; the measuring device comprises a sampling mechanism for collecting the pulverized coal particles, the suction mechanism, the pulverized coal particle processing mechanism, the image collecting mechanism for collecting the pictures of the pulverized coal particles and the pulverized coal recycling mechanism for recycling the pulverized coal particles. The measuring device can be used for online measurement of the fineness of the pulverized coal in real time, does not need people to participate in measurement, saves both time and labor, is high in measurement accuracy and resistant to pollution, and can be used for a long time.

Owner:BEIJING ENLANDAR TECH

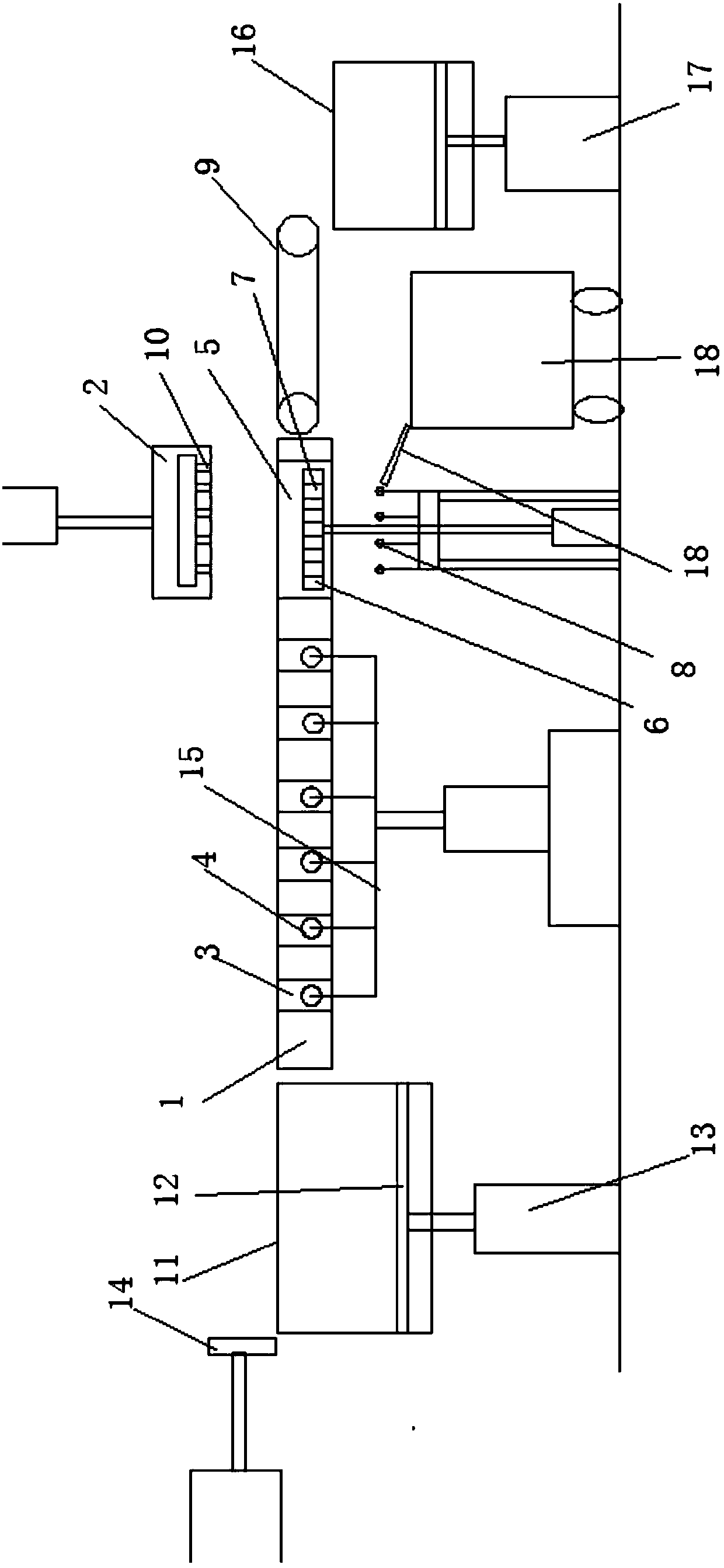

Automated culture process and system for tremella

ActiveCN105230343AImprove qualityHigh automation intensityCultivating equipmentsMushroom cultivationPunchingTremella

Provided is an automated culture process for tremella. The automated culture process comprises following steps: automatic canning operation, automatic punching and automatic cap-in-cap operation, bactericidal treatment, refrigeration treatment, inoculation treatment, outer-cap-opening treatment, management of producing mushrooms, harvest of mushrooms, taking out inner caps of cultivating pots, digging matrixes in the cultivating pots and canning cultivating pots after conveying the above to a full-automatic can filler in the first step. The automated culture process and system for tremella have following beneficial effects: due to automated culture of the process, high automation degree of scale production is achieved so that manual cost is greatly saved; high production efficiency and yield are obtained; and cultured tremella has stable quality.

Owner:FUJIAN XIANGYUN BIOTECH DEV CO LTD

High-temperature bluing device for iron pan

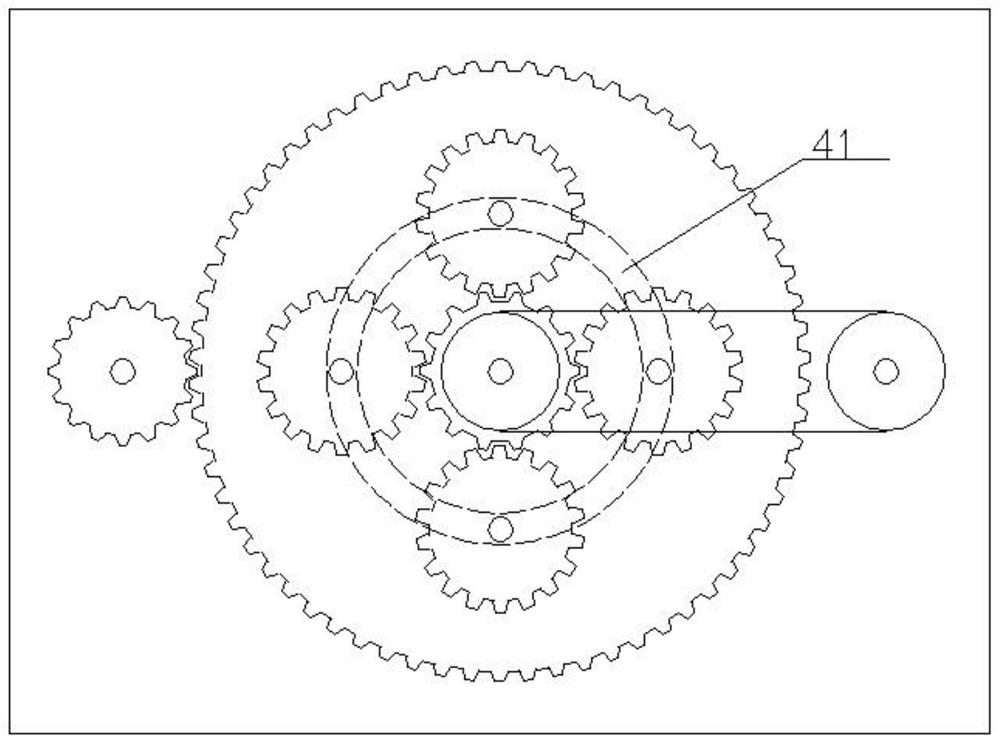

ActiveCN110863168ARealize automatic switchingHigh automation intensitySolid state diffusion coatingGear wheelElectric machinery

The invention provides a high-temperature bluing device for an iron pan, and relates to the field of iron pan bluing. The problems that the fatigue strength of workers is large, the efficiency is low,when the iron pan is fixed, the method is clumsy, and the iron pan is prone to shaking in the bluing process are solved. The high-temperature bluing device for the iron pan comprises circulation chain, wherein a motor mounting base is fixedly connected to the circulation chain through bolts, and a servo motor is fixedly connected to the motor mounting base. According to the high-temperature bluing device, through cooperation of a spray head seat adjusting structure and an incomplete gear B, linkage cooperation of the circulation chain and the spray head seat structure can be realized, and automatic switching of the working state and the non-working state of the spray head seat structure and automatic switching of the iron pan mounting seat structure are achieved. Compared with an existingdevice, the automatic strength of the device is high; through the arrangement of the iron pan mounting seat structure, when the iron pan is used, on one hand, the stability of the iron pan during fixation can be improved through hooks, and on the other hand, the hooks of the conical structure can improve the convenience of the iron pan during installation.

Owner:王美欢

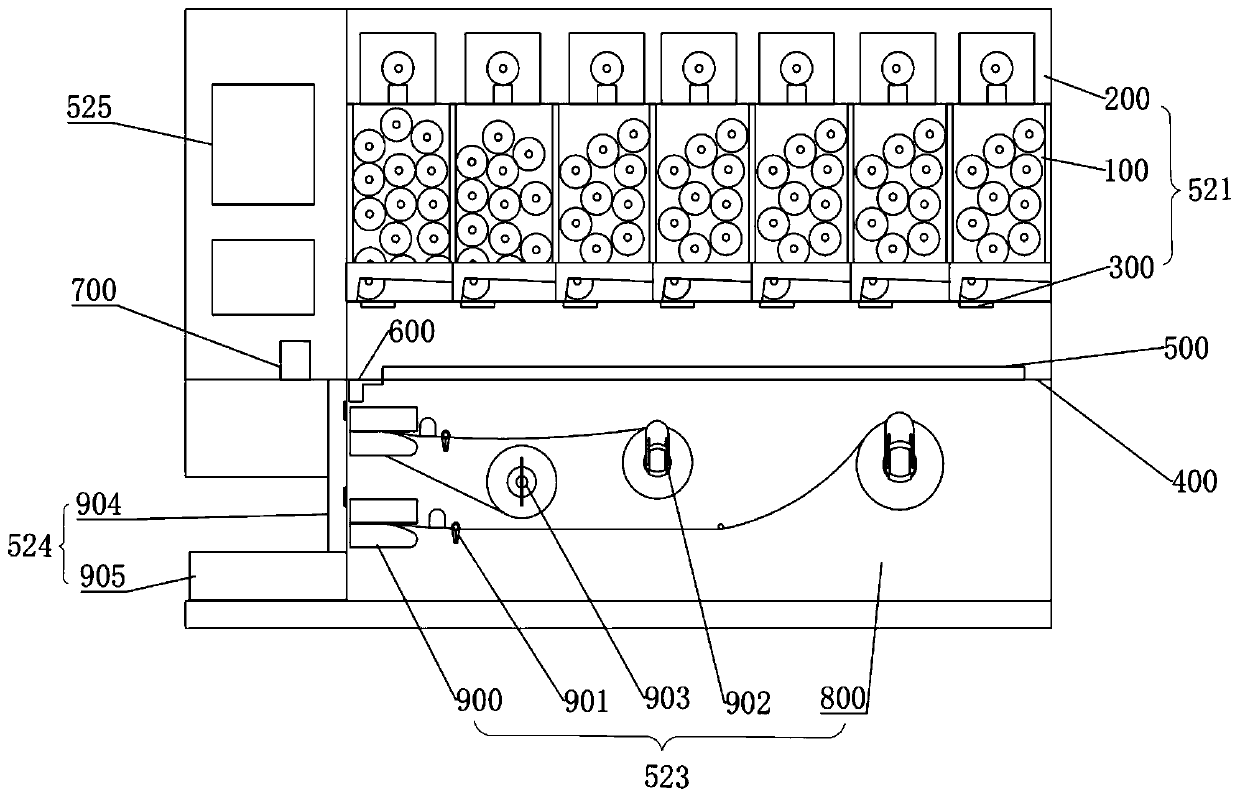

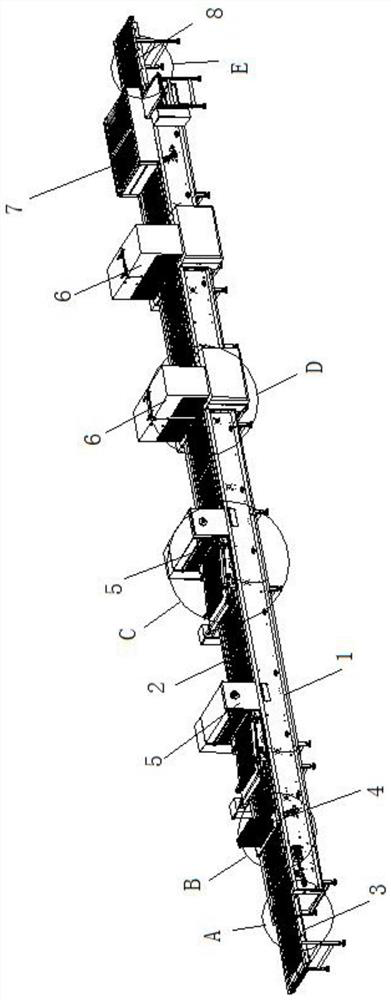

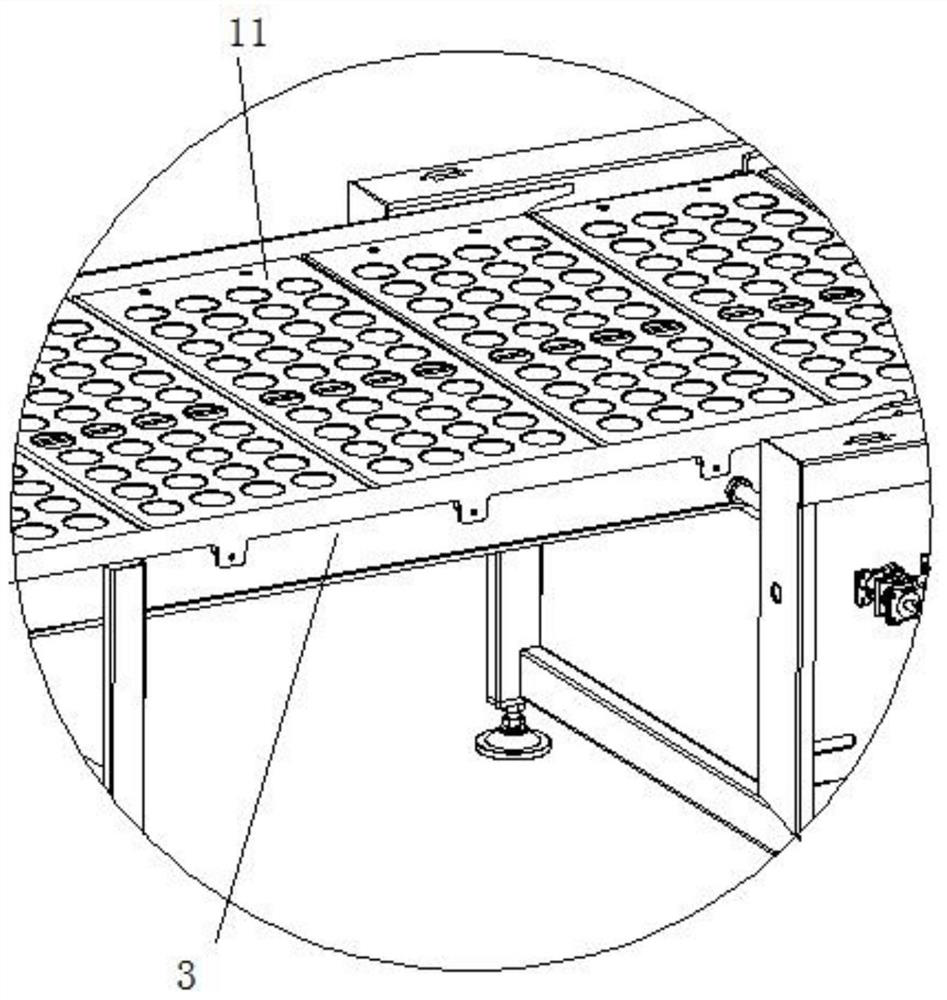

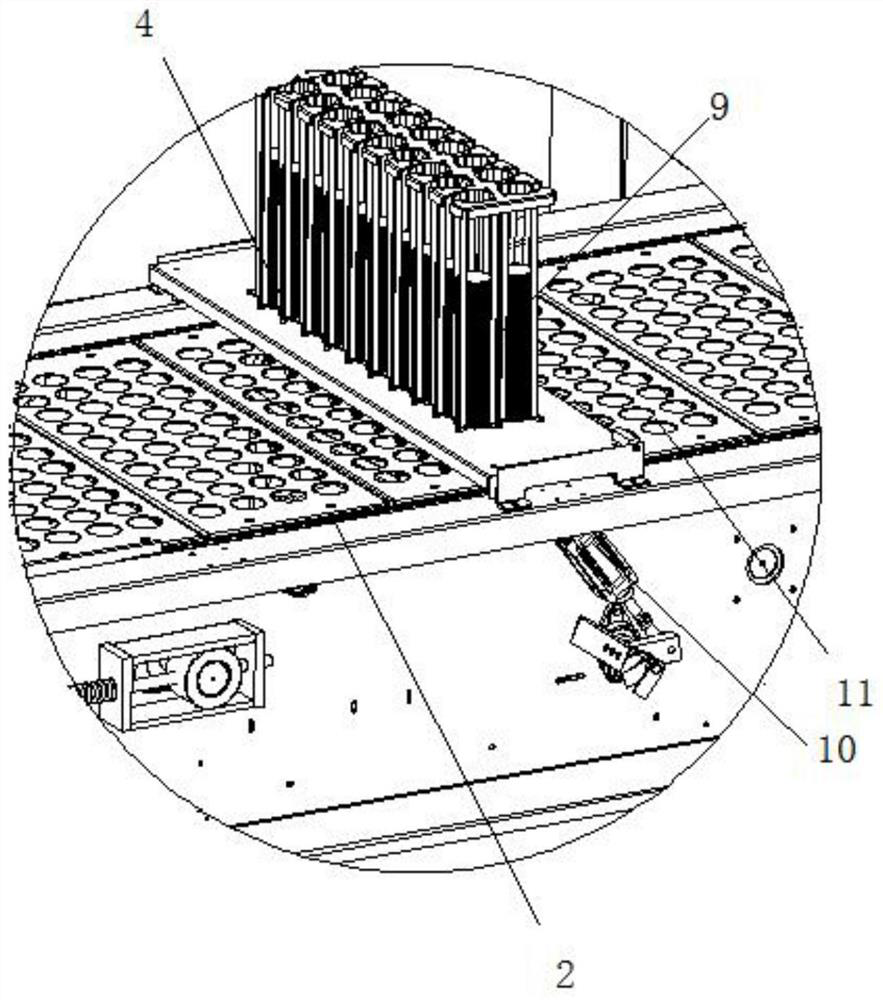

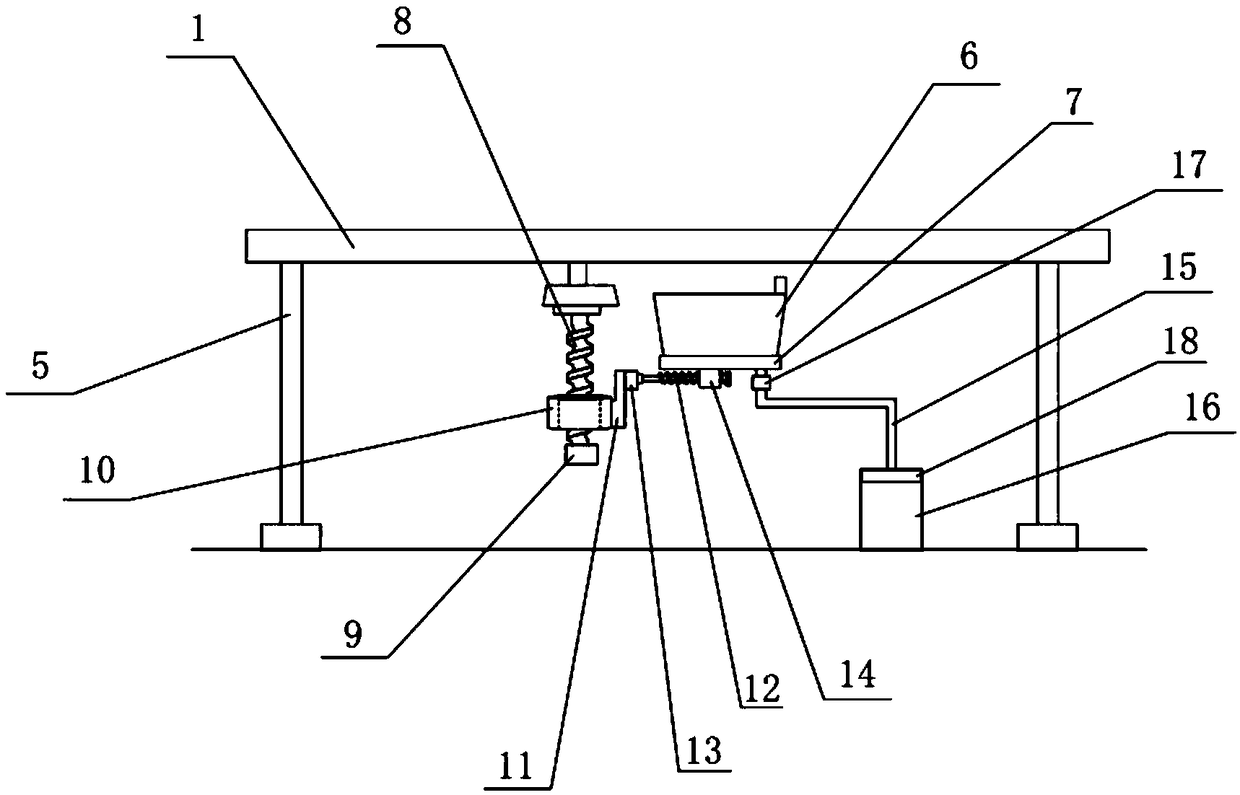

Full-automatic egg tart forming production line

PendingCN112568254ARealize automatic reclaimingEasy to operateDough shaping and cutting apparatusProduction lineMechanical engineering

The invention discloses a full-automatic egg tart forming production line which comprises a rack, a circulating conveying chain is erected on the rack, an aluminum support discharging station, a doughblank discharging station, a mold forming station and a tray removing station are sequentially arranged on the circulating conveying chain from the feeding end to the discharging end, the feeding endof the circulating conveying chain is a tray supplying station, and the discharging end of the circulating conveying chain is a tray discharging station. A flat plate placing frame in butt joint withthe circulating conveying chain is erected on the tray supplying station, the aluminum support discharging device is erected on the aluminum support discharging station, the dough blank discharging station comprises two quantitative slicing machines arranged in a spaced mode, two egg tart punch forming devices arranged in a spaced mode are erected on the mold forming station, and a tray removingdevice used after egg tart forming is erected on the tray removing station. A discharging frame is erected on the tray discharging station. The aluminum support discharging device, the quantitative slicing machines, the egg tart punch forming device and the tray removing device are integrated into a whole to form a production line, manual participation is not needed from aluminum support feeding,dough blank discharging and egg tart forming and stripping, and the automation strength is high.

Owner:王晓雅

Perforating device for constructional engineering

PendingCN112916914AHigh automation intensityReduce the number of clampingFeeding apparatusPositioning apparatusElectric machineryRotational axis

The invention discloses a perforating device for constructional engineering. The perforating device comprises a rack and drill bits, wherein fixed plates are arranged at the two sides of the rack correspondingly; a lifting plate is arranged above the position between the two fixed plates; the rack is provided with a first gear motor; the first gear motor is provided with a lead screw; the lead screw is in threaded connection with a feed screw nut; the lifting plate is slidably connected to the fixed plates through a guide rod and a guide sleeve; the lifting plate is slidably connected to a disc; the disc is provided with an annular rack plate; a first driving gear is rotationally arranged at the left side of the lifting plate; the first driving gear sleeves an output shaft of a second gear motor; the lifting plate is rotationally connected to a rotary shaft; the rotary shaft is connected to a second driving gear; the lifting plate is provided with a third gear motor; the third gear motor is connected to the rotary shaft through a transmission device; the disc is rotationally connected to a plurality of rotating shafts; the rotating shafts are provided with driven gears; the driven gears are in meshed connection with the second driving gear; the tails of the rotating shafts are fixedly connected to the drill bits; and the perforating device further comprises a clamping and moving device.

Owner:南力建设集团有限公司

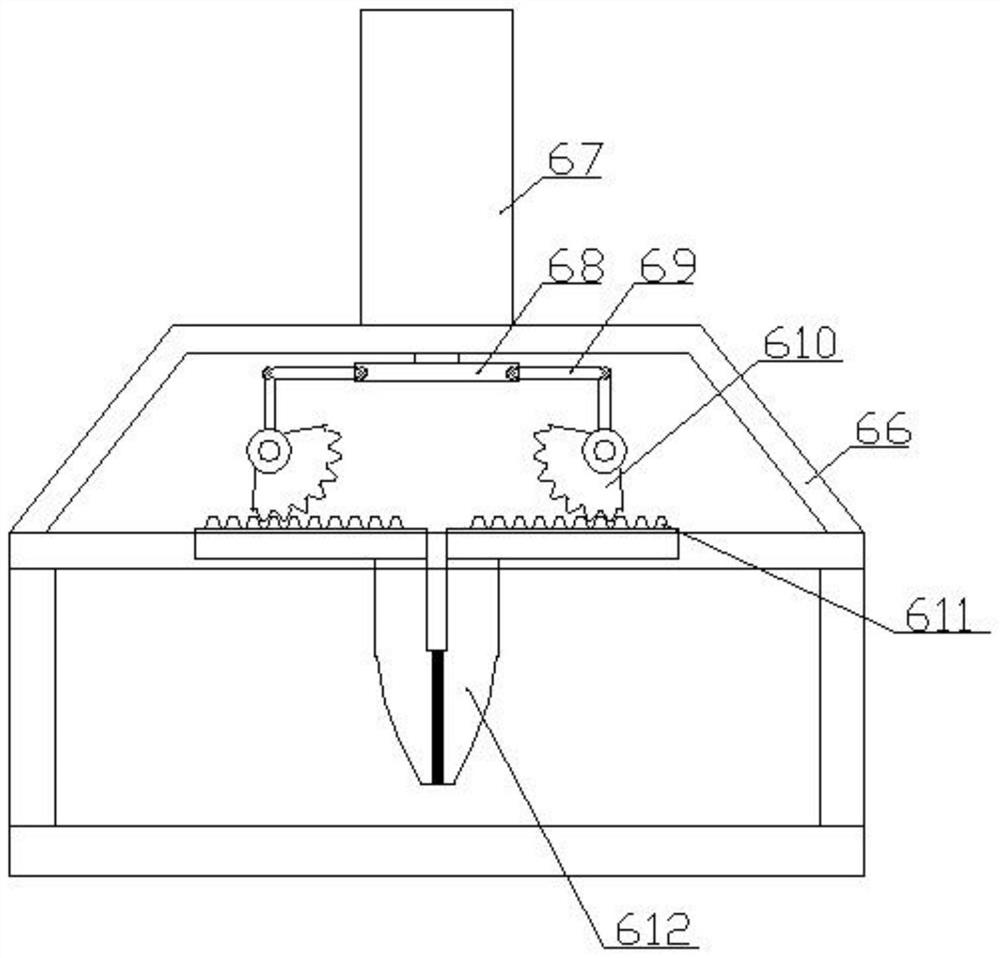

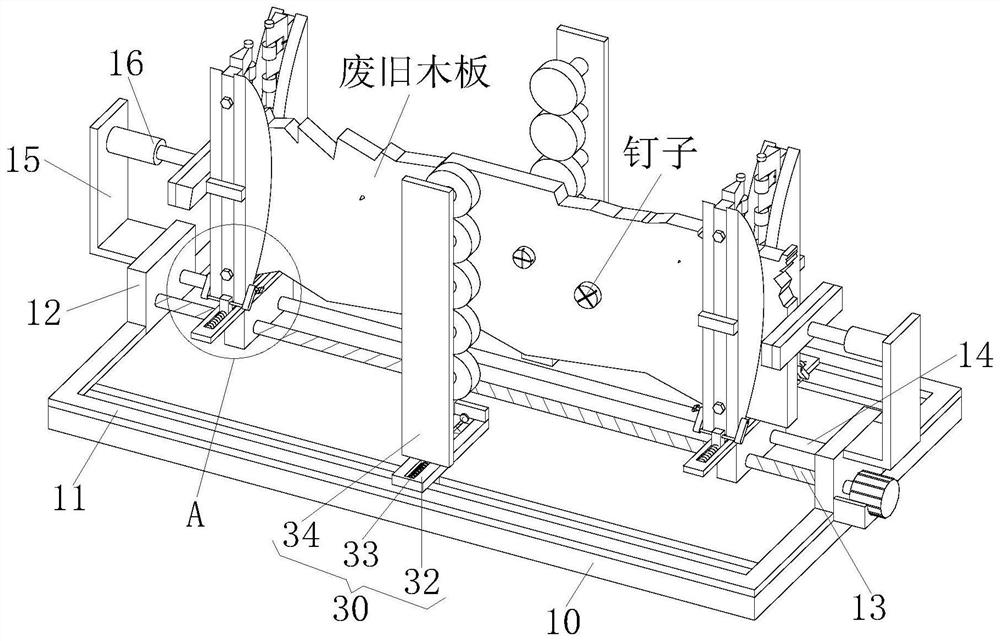

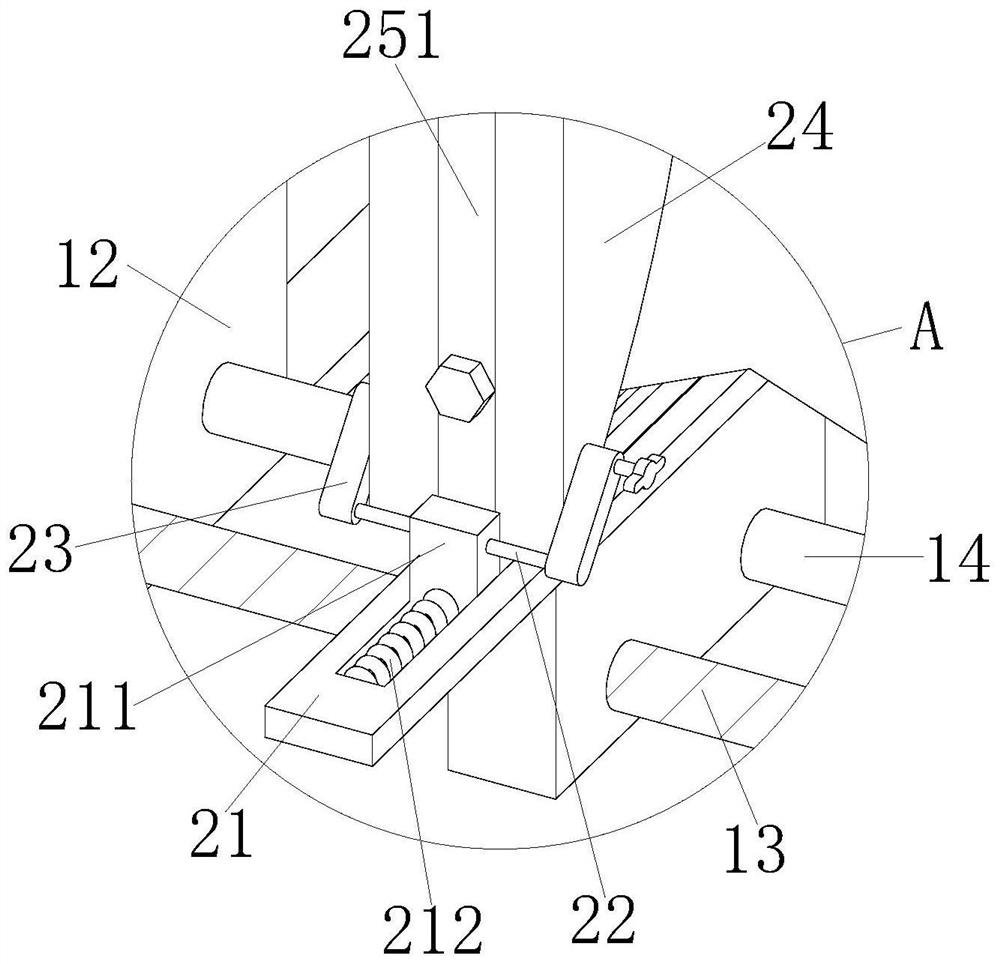

Construction waste recycling treatment system and method

ActiveCN113134505AAvoid displacementImprove stabilityConstruction waste recoverySolid waste disposalProcess engineeringWood plank

The invention relates to a construction waste recycling treatment system and method. The system comprises a workbench and a positioning device arranged between two groups of fixed plates, and the top of the workbench is provided with a flapping device. According to the construction waste recycling treatment system provided by the invention, a flapping plate is driven by a No.2 electric sliding block to beat and knock a waste wood board to be processed, so that nails on the surface of the waste wood board to be processed can be knocked out, the nails and the waste wood board to be processed are loosened, and the waste wood board to be processed is knocked to vibrate, so that scraps on the waste wood board to be processed can automatically fall in the vibration process, through cooperation of an electrode plate and a current-conducting plate, the flapping plate has magnetism when making contact with the waste wood board to be processed and can attract knocked nails, when the flapping plate is gradually separated from the waste wood board to be processed, the magnetism disappears, the nails automatically fall off to be separated from the flapping plate, the automation intensity is high, and manual operation is reduced.

Owner:中城桥路环保科技发展(广东)有限公司

Equipment for preventing metal piece from adhering welding spatters

ActiveCN103143864AAvoid phenomena that affect installationHigh automation intensityWelding/cutting auxillary devicesAuxillary welding devicesMetalAutomation

The invention discloses equipment for preventing a metal piece from adhering welding spatters. The equipment comprises a rack, a storage box, a soaking device, and a withdrawing device, wherein the storage box is fixedly connected with the upper part of the rack, the soaking device is fixedly connected onto the rack, communicated with the storage box and used for soaking the surface of the metal piece with a spatter-prevention agent, and the withdrawing device is fixedly connected onto the rack and used for withdrawing the soaked metal piece from the storage box. The soaking device can soak the surface of the metal piece with the spatter-prevention agent, the withdrawing device can be used to withdraw the soaked metal piece from the storage box in order to prevent the metal piece from adhering the welding spatters and being influenced in installation, and the equipment disclosed by the invention has the characteristics of novel structure, strong automation degree, high practicability and low cost, and is suitable for carrying out spatter-adhesion prevention treatment on the surface of the metal piece.

Owner:长城汽车股份有限公司平湖分公司

Automatic capping device for beverage production

InactiveCN112027993AAchieve teleportationAchieve intermittent exerciseCapsThreaded caps applicationTransmission beltStructural engineering

The invention discloses an automatic capping device for beverage production. The automatic capping device comprises a cross beam plate, a left side plate, a right side plate, supporting columns, a driving mechanism, a conveying mechanism and a capping mechanism, and is characterized in that the front and rear ends of the bottom surfaces of the left side plate and the right side plate are fixedly connected with the supporting columns correspondingly; and the top surfaces of the left side plate and the right side plate are fixedly connected to the left side and the right side of the bottom surface of the cross beam plate. According to the automatic capping device disclosed by the invention, beverage bottles are conveyed through transmission of a transmission belt; due to movable connection of a first fan-shaped roller and a second fan-shaped roller, when the first fan-shaped roller is meshed with the transmission belt, the transmission belt generates transmission movement; when the second fan-shaped roller is meshed with the transmission belt, the second fan-shaped roller can move along a blank fan-shaped area of the first fan-shaped roller, and at the moment, the transmission belt stops moving; when the transmission belt stops, capping action on the beverage bottles is completed; when the first fan-shaped roller is meshed with the transmission belt again, the transmission belt achieves transmission movement again, so that intermittent movement of the transmission belt is achieved.

Owner:吕瑞雪

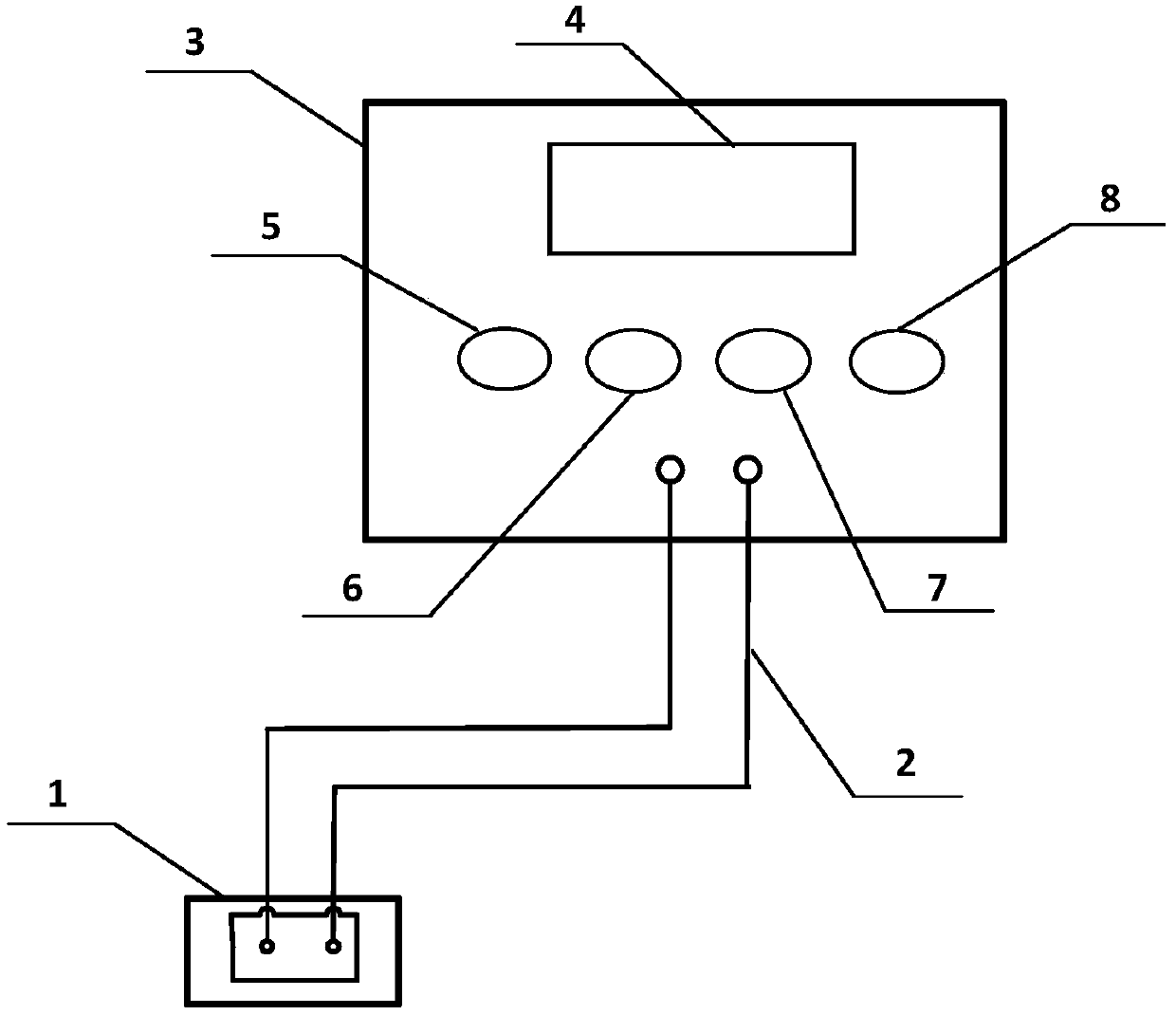

Temperature transmitter measurement channel resistance value automatic transmitting device and method

PendingCN111060222ASave time at workReduce riskNuclear energy generationNuclear monitoringControl theoryElectric cables

The invention belongs to the technical field of temperature measurement, and particularly relates to a temperature transmitter measurement channel resistance value automatic transmitting device and atemperature transmitter measurement channel resistance value automatic transmitting method. The temperature transmitter measurement channel resistance value automatic transmitting device comprises a cable joint, connecting cables, a resistance box, a display screen, a temperature range setting key, an interval time setting key, a unit setting key and an information query key, wherein the cable joint is connected with the resistance box by means of the connecting cables; the temperature range setting key, the interval time setting key, the unit setting key and the information query key are arranged on a panel of the resistance box side by side; and the display screen is further arranged on the panel of the resistance box. According to the temperature transmitter measurement channel resistance value automatic transmitting device and the temperature transmitter measurement channel resistance value automatic transmitting method, the precision verification of the measurement channel of thetemperature transmitter can be completed safely, rapidly, effectively and correctly.

Owner:JIANGSU NUCLEAR POWER CORP

A stainless steel pipe intelligent processing robot

ActiveCN109128364BEnsure safetyRealize automatic cutting productionMetal sawing devicesMetal sawing accessoriesEngineeringSS - Stainless steel

The invention relates to an intelligent processing robot of a stainless steel tube. The intelligent processing robot comprises a bottom plate, a conveying device, a cutting and feeding device, a sleeve type fixing device, a cutting device, a clamping device, an adsorption and cleaning device and a stainless steel hollow tube body, wherein the conveying device, the cutting and feeding device, the sleeve type fixing device, the cutting device and the clamping device are installed on the bottom plate in sequence from left to right, and the adsorption and cleaning device is installed on the bottomplate. According to the intelligent processing robot, the problems that a multi-caliber stainless steel hollow tube cannot be preferably clamped and fixed when the stainless steel hollow tube is cutin the prior art, sweeps which are generated when the stainless steel hollow tube is cut cannot be preferably prevented from splashing and hurting people, people need to wear protective equipment forprotection, the sweeps which are generated in a cutting process need to be manually cleaned and collected so as to be recycled and the people are easy to hurt by the sweeps which are generated when the stainless steel hollow tube is manually cut can be solved.

Owner:泰州市银杏舞台机械工程有限公司

Automatic interior-angle chamfering machine

InactiveCN102699447AReduce labor intensityRealize automatic feeding processFeeding apparatusDriving apparatusPiston ringCircular cone

The invention provides an automatic interior-angle chamfering machine, relates to mechanical processing equipment, and in particular relates to a device for carrying out interior-angle chamfering on piston rings. The automatic interior-angle chamfering machine comprises a machine frame, a panel is arranged above the machine frame, a feeding device and a swaging device are arranged on the panel, a mould mounting opening is arranged on the panel, and a mould is arranged in the mould mounting opening. A hollow spindle is connected below the mold, the hollow spindle is connected with a spindle mounting seat through an upper cone roller bearing and a lower cone roller bearing, and the spindle mounting seat is connected with the panel. An upper bearing pressing cover is arranged above the upper cone roller bearing, and a lower bearing pressing cover is arranged under the lower cone roller bearing. The hollow spindle under the spindle mounting seat is connected with a spindle belt pulley, the spindle belt pulley is connected with a power device, and the hollow spindle under the spindle belt pulley is in threaded connection with a round nut. Cutter frame shafts penetrate through the hollow spindle at intervals, the upper ends of the cutter frame shafts are connected with a cutter frame, the cutter frame is connected with a cutter, and the cutter is arranged in the mould. The lower end of the cutter frame shaft is connected with a stepping motor through a connecting piece. The automatic interior-angle chamfering machine is high in efficiency and low in cost.

Owner:YIZHENG RUNYANG MACHINERY

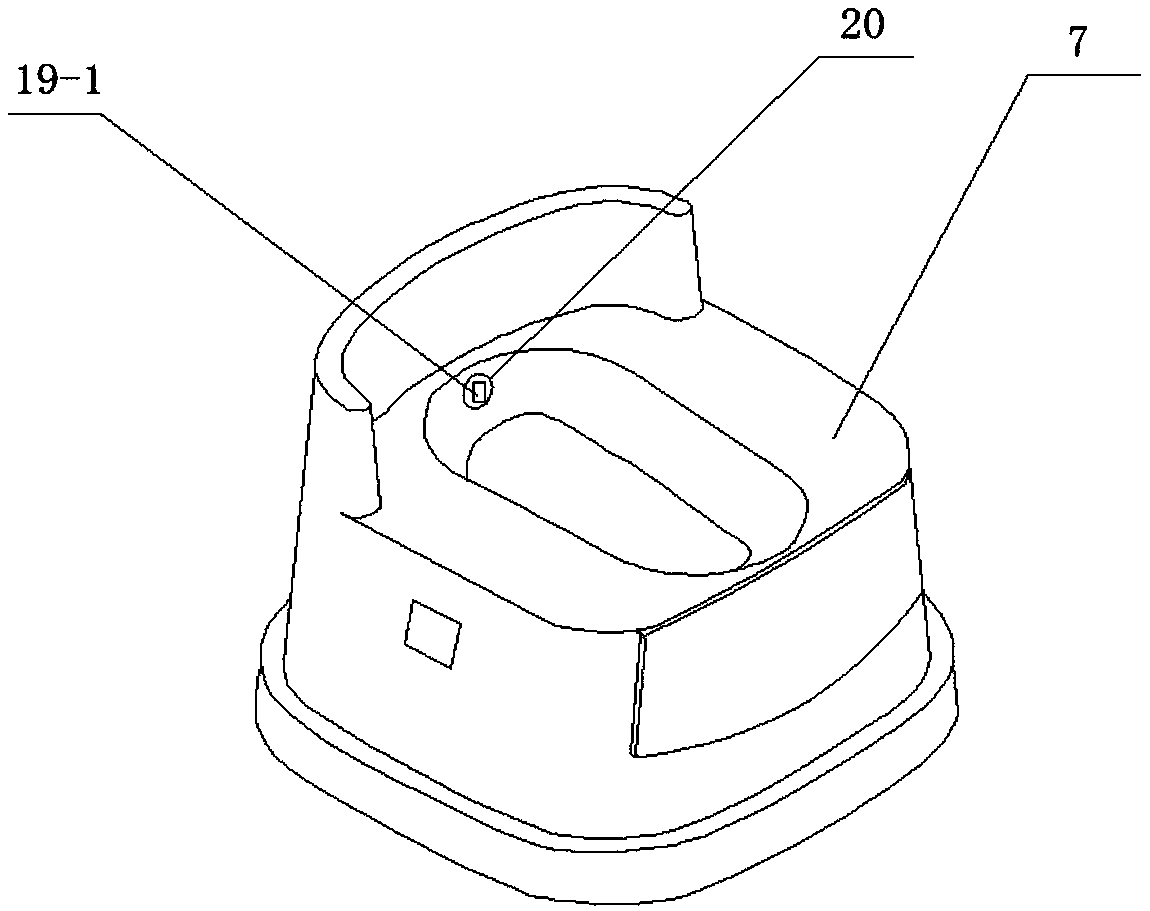

Medical bedpan integrated with sickbed

The invention discloses a medical bedpan integrated with a sickbed. The medical bedpan comprises the sickbed, a bedpan body arranged below the sickbed and a first transmission mechanism. The movementof the bedpan body in the horizontal direction is controlled through a second transmission mechanism, and the bedpan body is moved to the position right below a corresponding through hole as required;the bedpan body is controlled by the first transmission mechanism to accurately move into the through hole in the vertical direction, so that the top surface of the bedpan body and a bed plate are positioned on the same horizontal plane in order to solve the technical problem that in the prior art, people need to lift their buttocks during defecation. After defecation and urination are finished,nursing staff can operate a flushing button to clean the buttocks, urine and excrement are discharged into an excreta collecting box through a dirt discharge pipe for temporary storage, and a specialdeodorization and deodorization structure is designed. Therefore, each transmission mechanism for controlling the medical bedpan has the advantages of ingenious arrangement, a simple structure and intelligent control.

Owner:广西医科大学附属肿瘤医院

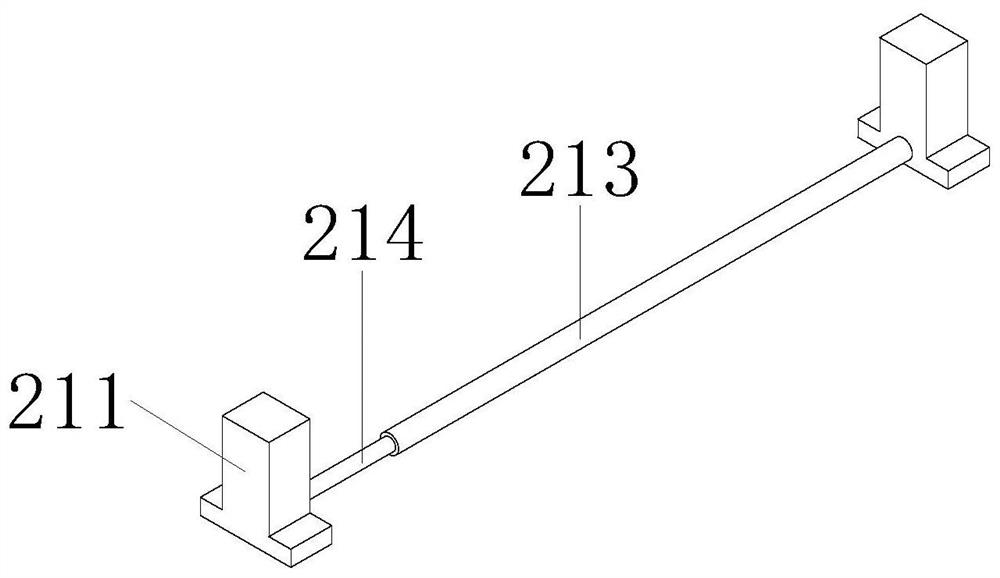

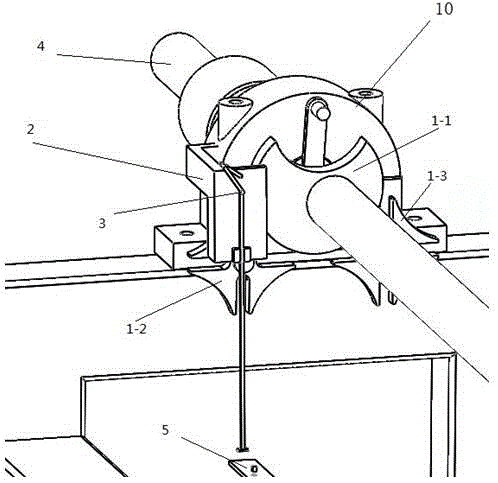

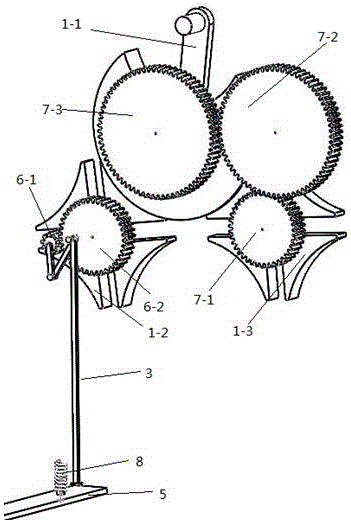

Cotton pushing device for full-automatic cotton chopping machine

ActiveCN106222807AImprove stabilityHigh precisionFibre cleaning/opening machinesEngineeringMechanical engineering

The invention provides a cotton pushing device for a full-automatic cotton chopping machine. A central shaft of the cotton chopping machine is arranged on one side of a cotton chopping roller rotary shaft bracket; one cotton chopping roller rotary shaft bracket is arranged on each of the left and right sides of a cotton chopping roller of the cotton chopping machine; crank connecting rod mechanism mounting brackets are arranged on the front sides of the two cotton chopping roller rotary shaft brackets; a rotary shaft of an upper crank of a crank connecting rod mechanism is connected with the outer sides of the crank connecting rod mechanism mounting brackets and a rotary shaft of a driving gear of a gear mechanism; the lower end of two lower connecting rods of the crank connecting rod mechanism are in contact with the upper side of a cotton pushing plate; the cotton pushing plate is connected with a cotton chopping roller through a pair of compression springs; and a composite groove wheel and the gear mechanism are arranged on one side, close to the center, of a roller blade of the cotton chopping roller. By improving an existing cotton pushing device of the cotton chopping machine, accurate positioning and movement of a cotton pushing mechanism and the roller can be smoothly realized, so that the cotton chopping quality of the cotton chopping machine is indirectly improved.

Owner:JINLING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com