Automated culture process and system for tremella

A technology of cultivation process and cultivation system, which is applied in the field of tremella automated cultivation technology and system, can solve the problems of tremella quality instability, labor cost input, insufficient automation, etc., and achieve the effects of labor cost saving, high production efficiency and high automation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

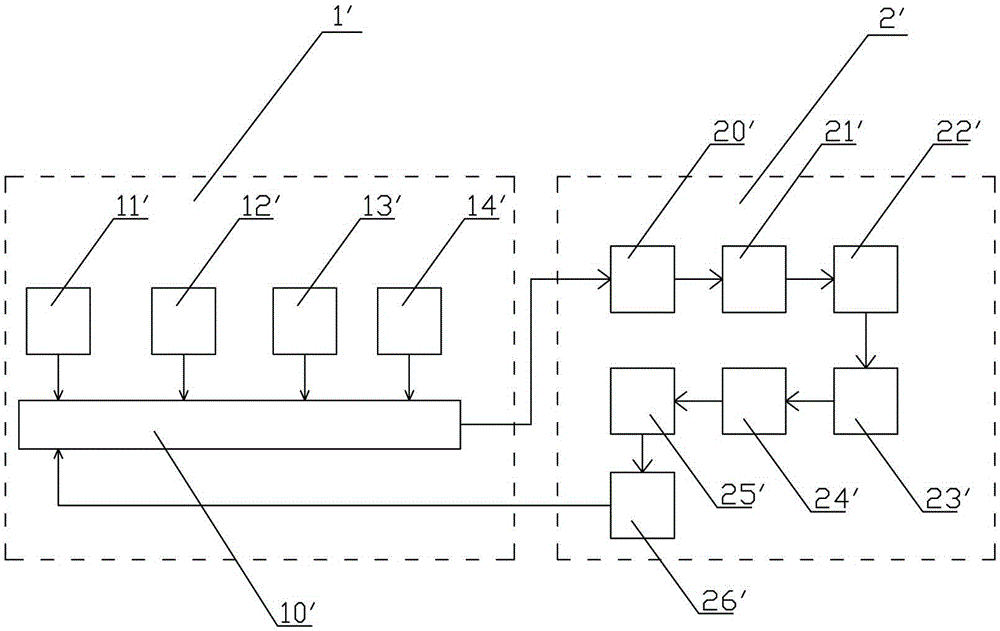

AI Technical Summary

Problems solved by technology

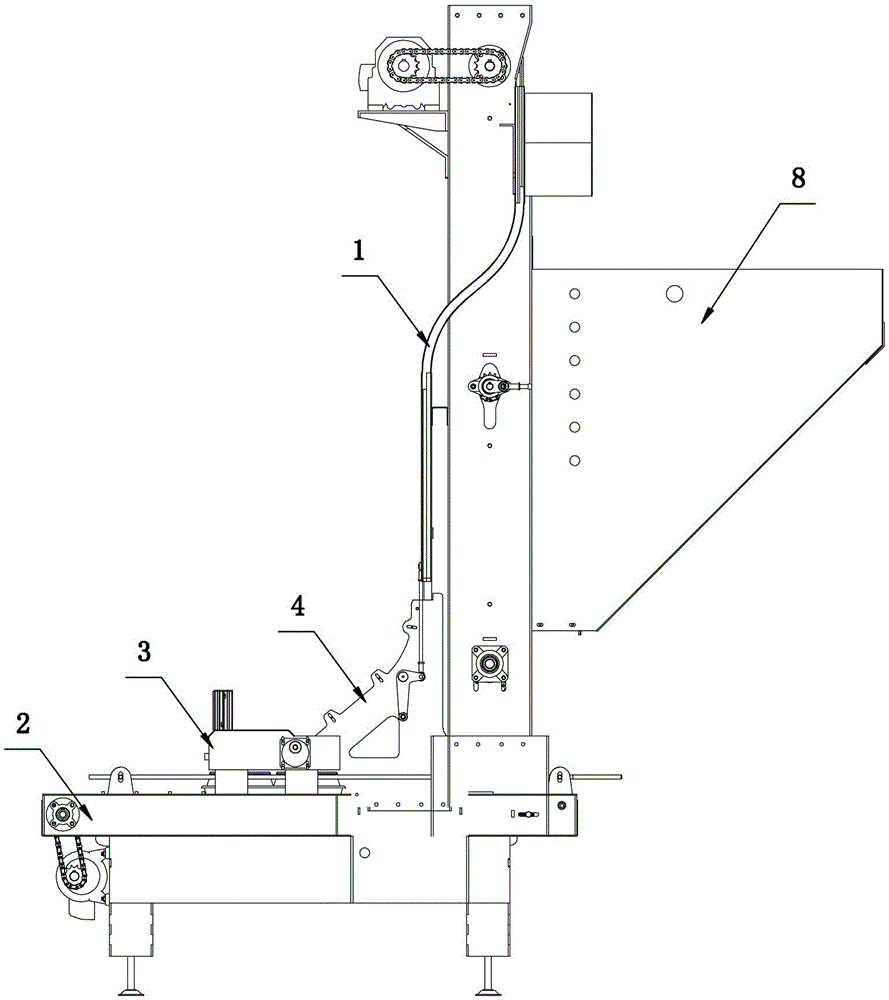

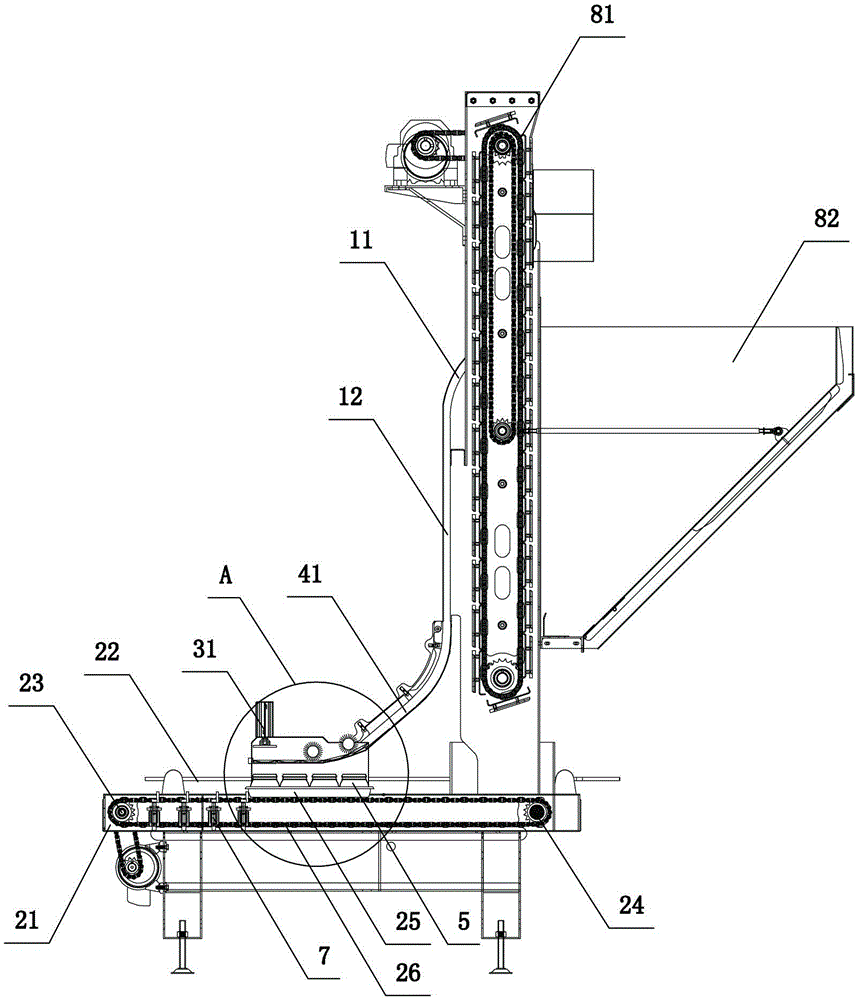

Method used

Image

Examples

specific Embodiment 1

[0031] The white fungus automatic cultivation process is characterized in that it includes the following steps: 1) Automatic canning, the white fungus matrix is put into the culture tank by a full-automatic filling machine, and automatically output.

[0032] 2) Automatic punching, punching five holes in the matrix in the culture tank at one time, and automatically outputting.

[0033] 3) The opening of the culture tank is automatically cleaned, and the culture tank is transported to the washing machine through the conveying mechanism, and the cleaning brush on the washing machine cleans the opening of the culture tank.

[0034] 4) Automatically cover the inner cover, through the inner cover machine to automatically cover the inner cover of the tank mouth of the culture tank, and automatically output.

[0035] 5) Automatically cover the outer cover, the tank mouth of the culture tank is automatically covered by the outer cover machine, and the outer cover is automatically out...

Embodiment 2

[0056] The implementation manner of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0057] 1) Sterilization treatment, send the culture tank into the sterilization room, first, control the temperature of the sterilization room at 105 degrees, and control the time for 20 minutes; thirdly, adjust the temperature of the sterilization room to 110 degrees, and control the time In 30 minutes; again, adjust the temperature of the sterilization room to 125 degrees, and control the time at 150 minutes; finally, turn off the heating device in the sterilization room, and let the culture tank stay in the sterilization room for 2 hours.

[0058] 2) Refrigeration treatment, send the culture tank into the refrigeration room, firstly, enter the filtered outside air into the refrigeration room, so that the temperature in the room drops to about 35 degrees, and then start refrigeration, so that the temperature is controlled at 20 degrees , the time is control...

Embodiment 3

[0061] The implementation manner of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0062] 1) Sterilization treatment, send the culture tank into the sterilization room, first, control the temperature of the sterilization room at 105 degrees, and control the time for 20 minutes; thirdly, adjust the temperature of the sterilization room to 115 degrees, and control the time In 30 minutes; again, adjust the temperature of the sterilization room to 125 degrees, and control the time at 180 minutes; finally, turn off the heating device in the sterilization room, and let the culture tank stay in the sterilization room for 2 hours.

[0063] 2) Refrigeration treatment, send the culture tank into the refrigeration room, firstly, enter the filtered outside air into the refrigeration room, so that the temperature in the room drops to about 35 degrees, and then start refrigeration, so that the temperature is controlled at 22 degrees , the time is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com