Temperature transmitter measurement channel resistance value automatic transmitting device and method

A technology for temperature transmitters and measurement channels, which is applied to measuring devices, thermometer testing/calibration, thermometers, etc., and can solve problems such as incorrect calculation of the resistance value of the thermometer, incorrect adjustment of the resistance value of the resistance box, and the unsuitability of instrument control personnel for a long time. Achieve the effects of high automation intensity, strong practicability, and reduced operating environment risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A device and method for automatically sending the resistance value of a temperature transmitter measurement channel provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

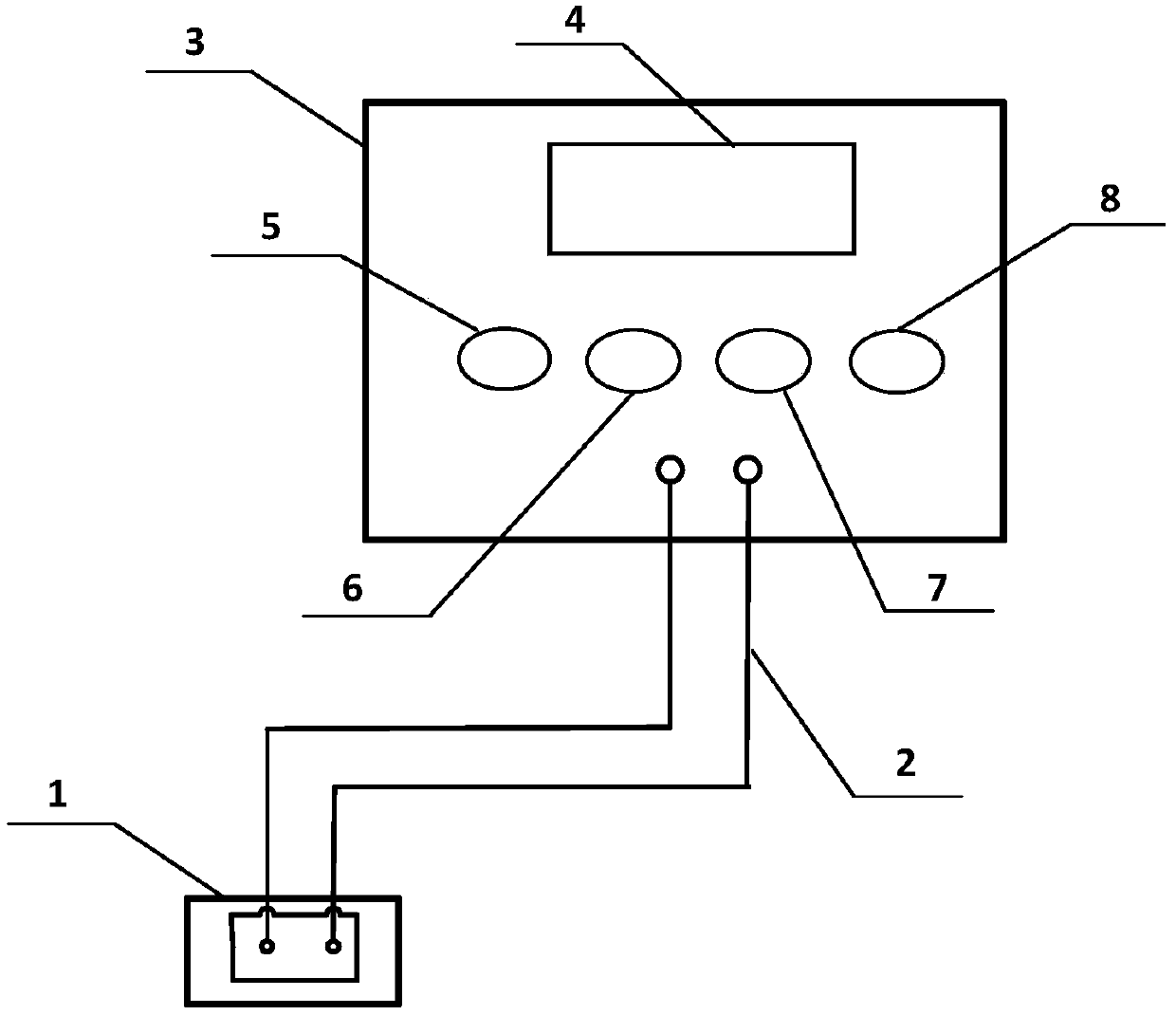

[0030] Such as figure 1 As shown, a temperature transmitter measurement channel resistance automatic transmission device provided by the present invention includes a cable connector 1, a connecting cable 2, a resistance box 3, a display screen 4, a temperature range setting key 5, an interval time setting key 6, Unit setting key 7, information query key 8, the cable connector 1 is connected to the resistance box 3 through the connection cable 2, and the length of the connection cable 2 is determined according to actual needs; the temperature range setting keys 5 and intervals arranged side by side are arranged on the panel of the resistance box 3 Time setting key 6, unit setting key 7, information query key 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com