Chain sheet punching and blanking device

A punching and chain piece technology, which is applied in the field of chain piece punching and blanking devices, can solve the problems of not meeting the requirements of automation, high manual labor intensity, and low work efficiency, and achieve high automation intensity, low manual labor intensity, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

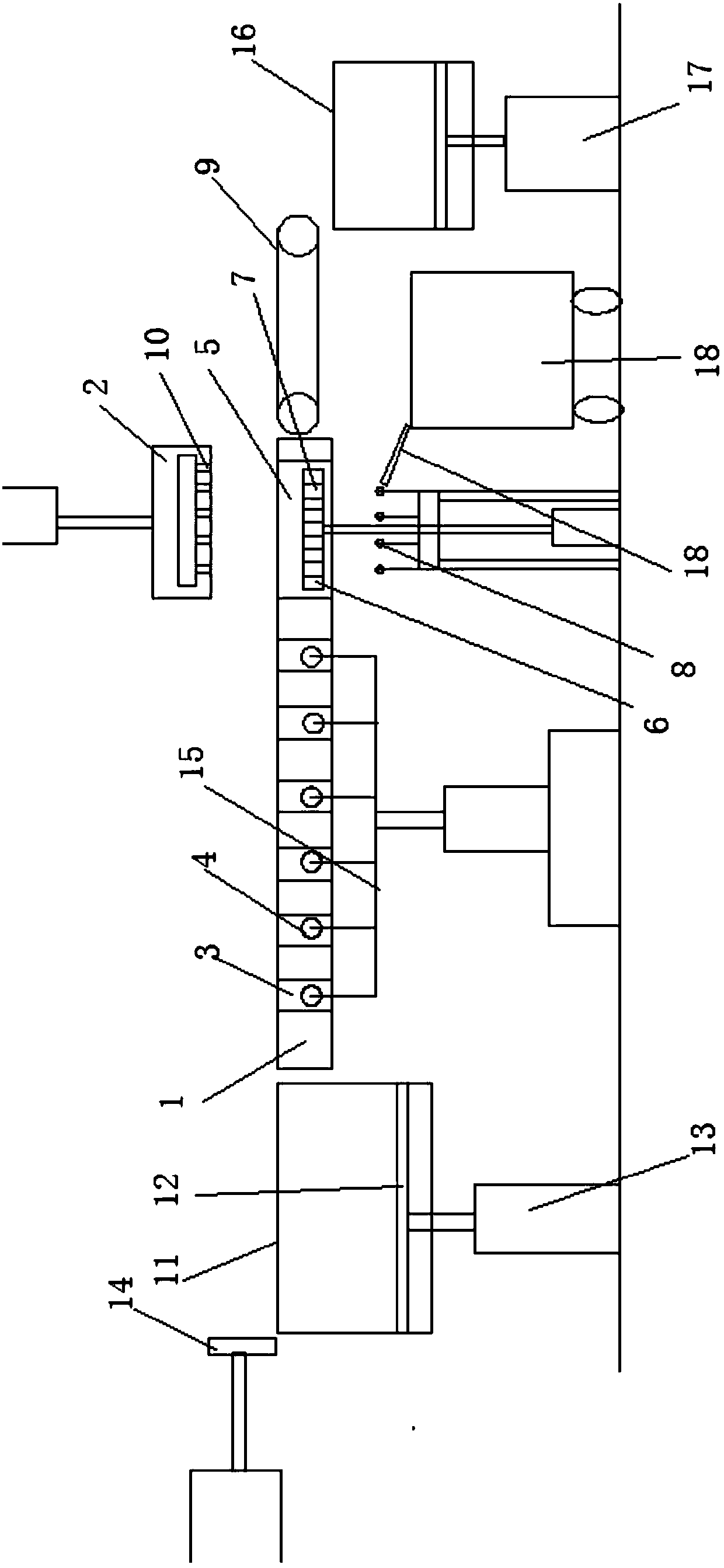

[0016] See attached picture.

[0017] A chain sheet punching and blanking device, including a stamping workbench 1, a stamping die 2 is erected above the stamping workbench 1, and a feeding mechanism is provided on one side of the stamping workbench 1, and it is characterized in that: The stamping workbench 1 is divided into two sections, one section is a conveying section, and the other section is a pressing section. The stamping workbench on the conveying section is distributed with guide grooves 3 arranged at intervals, and the guide grooves 3 are respectively provided with Liftable guide roller 4, the stamping table on the pressing section is provided with an opening 5, and a liftable guide plate 6 is installed in the opening 5, and the guide plate 6 is provided with a slot 7, so Below the guide plate 6, there is a conveying roller 8 matched with the groove, and the other side of the stamping table 1 is provided with a waste recycling conveyor belt 9, and the end of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com