Patents

Literature

449results about How to "Achieve teleportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra high definition video image processing and transmitting system and method thereof

ActiveCN103347163AAchieve teleportationRealize the display effectTelevision system detailsStatic indicating devicesDigital videoHigh-definition video

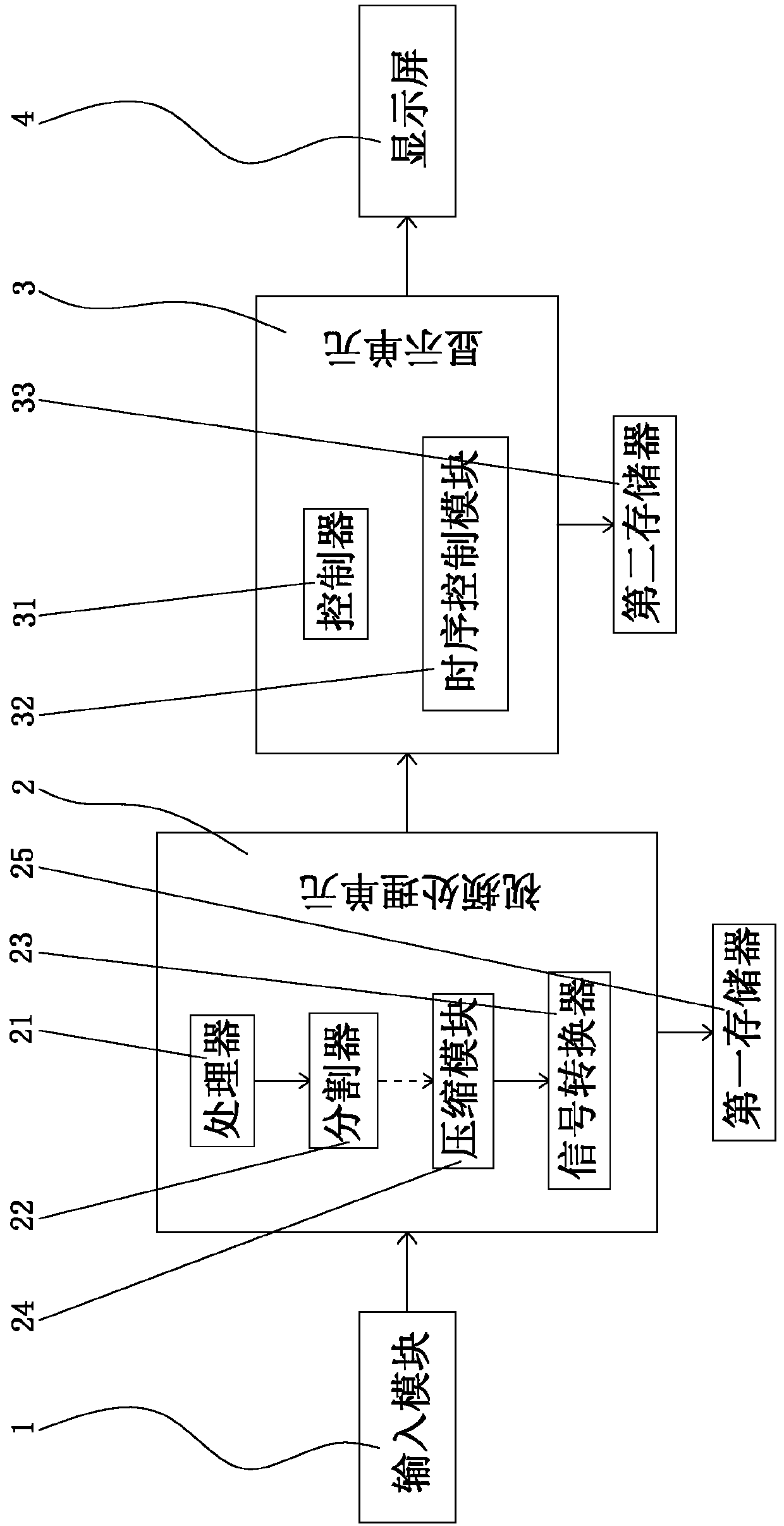

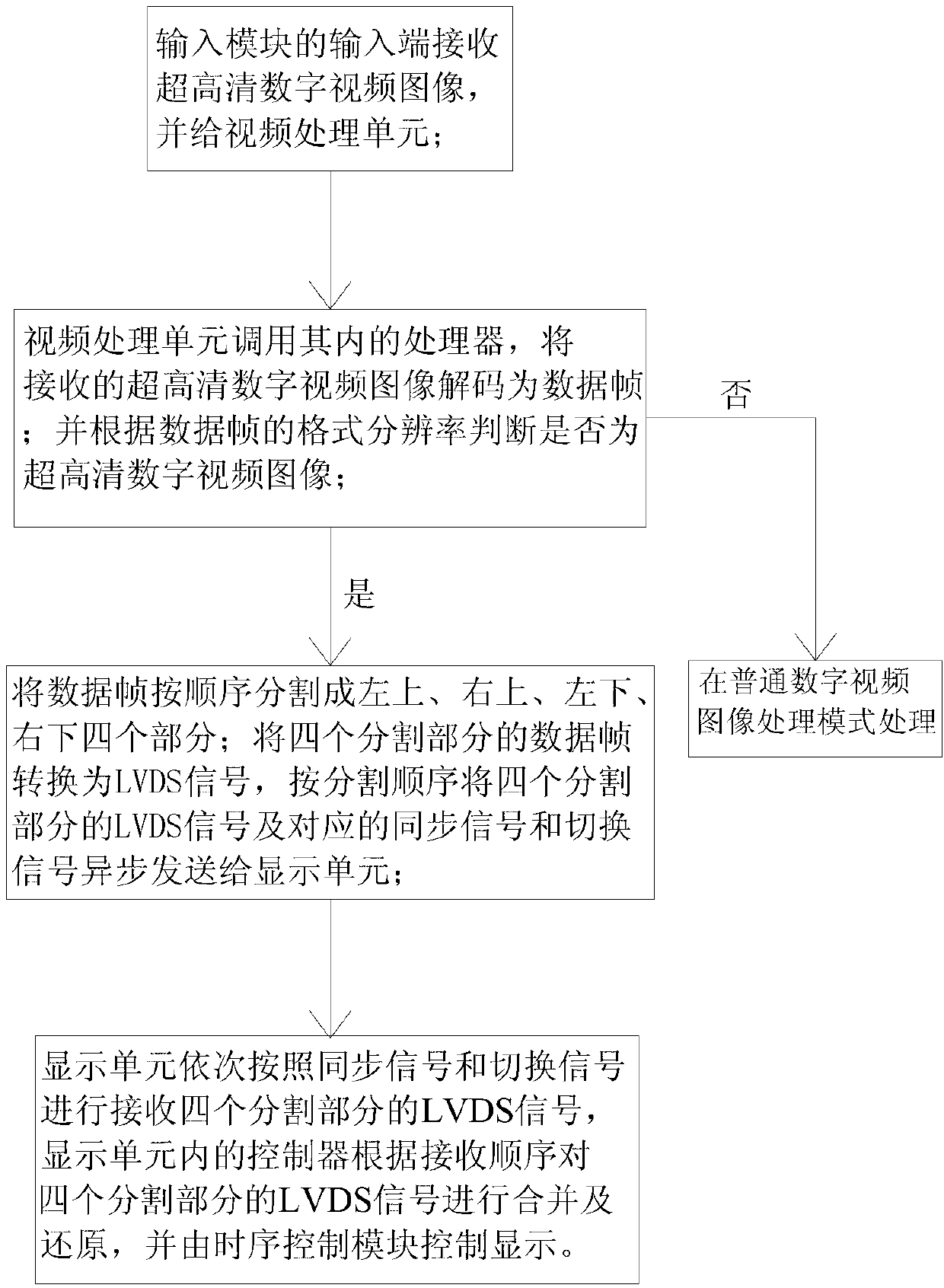

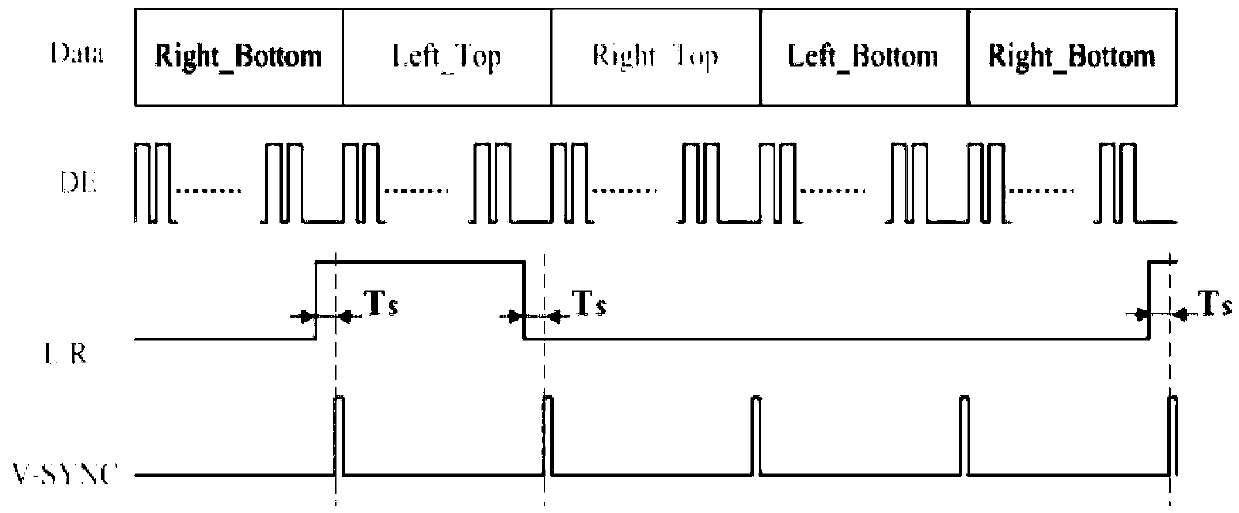

The invention discloses an ultra high definition video image processing and transmitting system which comprises an input module, a video processing unit and a display unit, wherein the input module receives ultra high definition digital video images, an output end of the input module is connected with an input end of the video processing unit, and an output end of the video processing unit is connected with an input end of the display unit; a controller and a time sequence control module which are connected to each other are arranged in the display unit. According to the ultra high definition video image processing and transmitting system, segmentation and compressing processes are carried out on image frames of the ultra high definition video images after decoding, merge application is carried out on the image frames in the display unit through asynchronous transmission, then the image frames are further amplified to be restored to original signals, and transmission and playing displaying for the ultra high definition signals are achieved. According to the processing method, the transmission data bandwidth can be compressed, the transmission bandwidth is further reduced, 4K2K ultra high definition video image transmission is achieved due to the fact that data are transmitted through an FHD interface, and the effect of transmission of a large number of ultra high definition video image data is achieved.

Owner:TPV DISPLAY TECH (XIAMEN) CO LTD

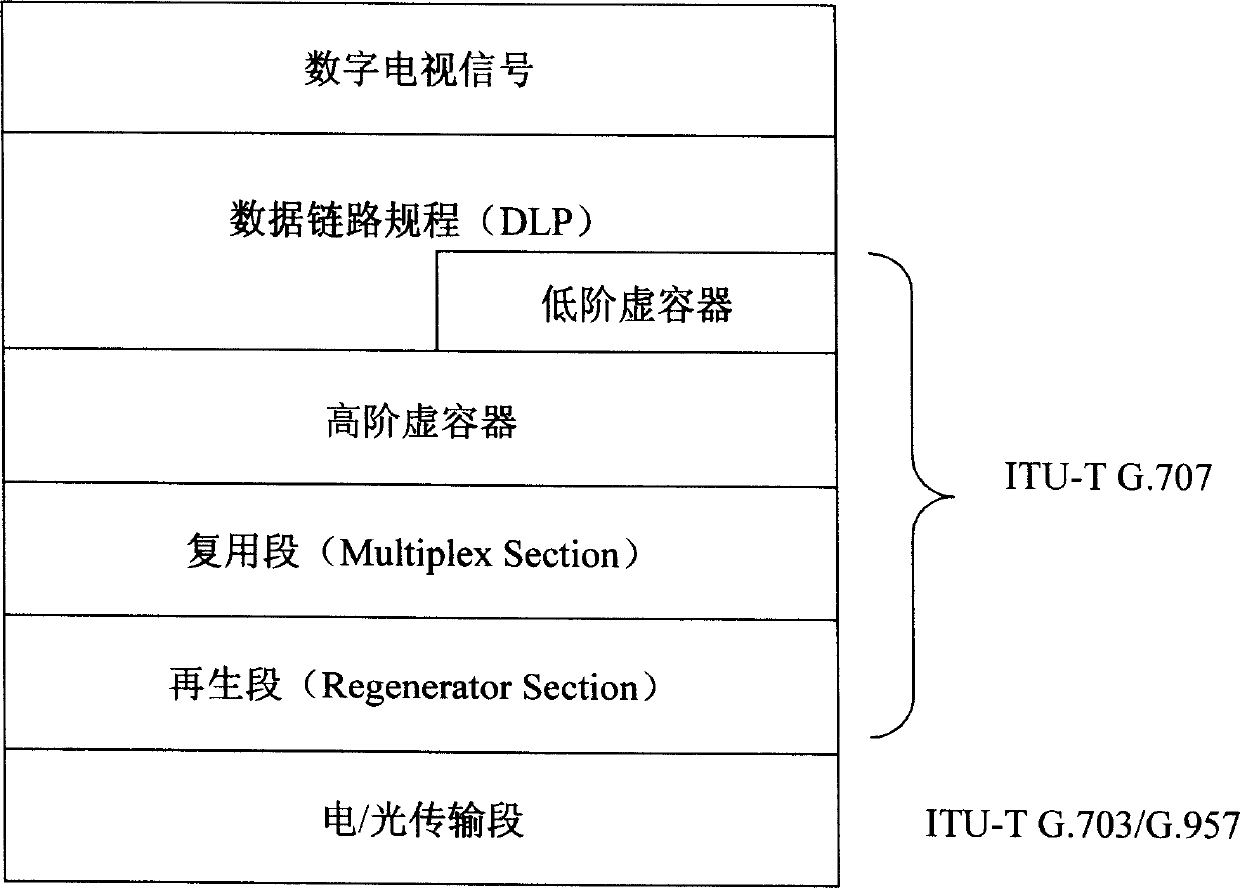

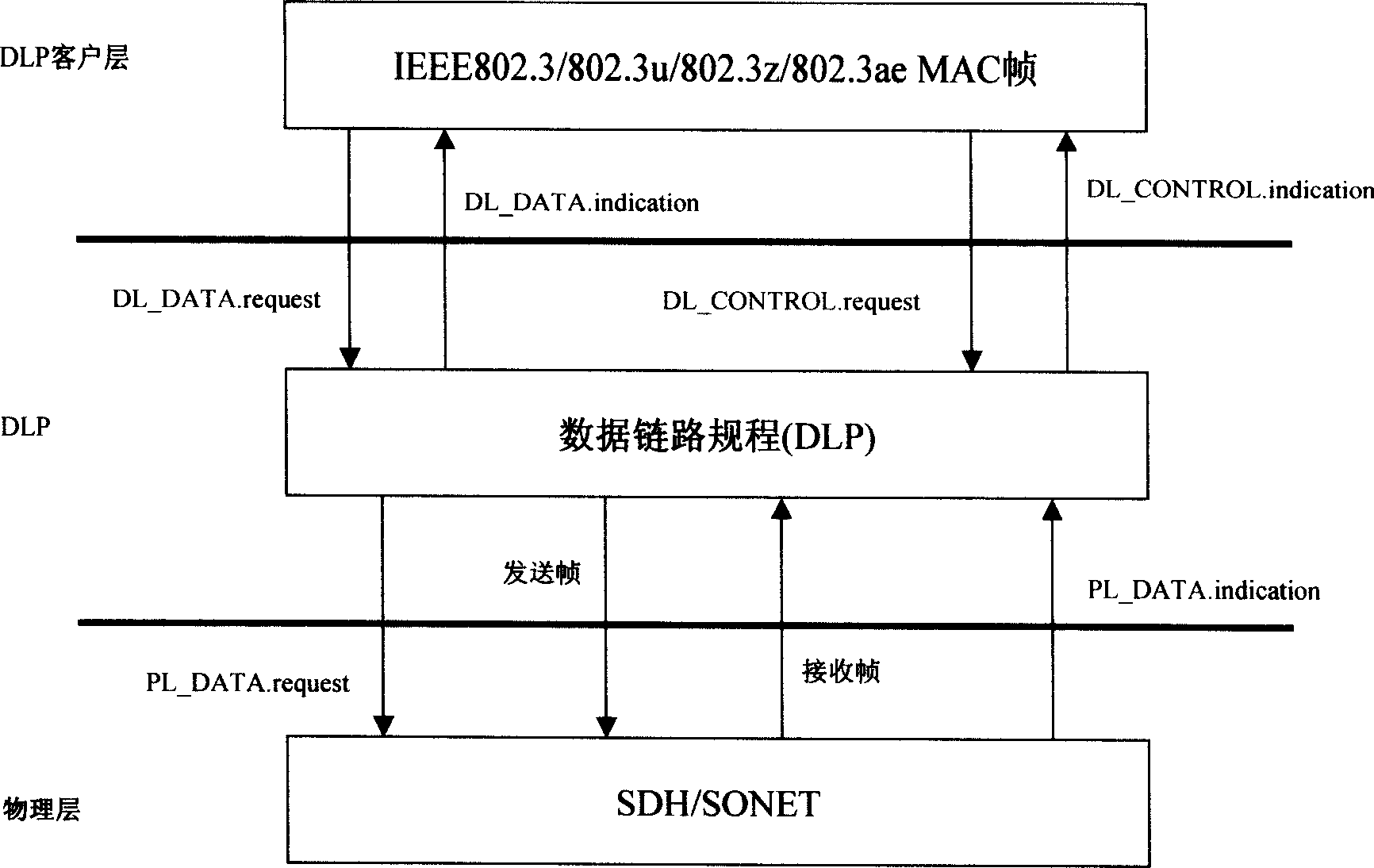

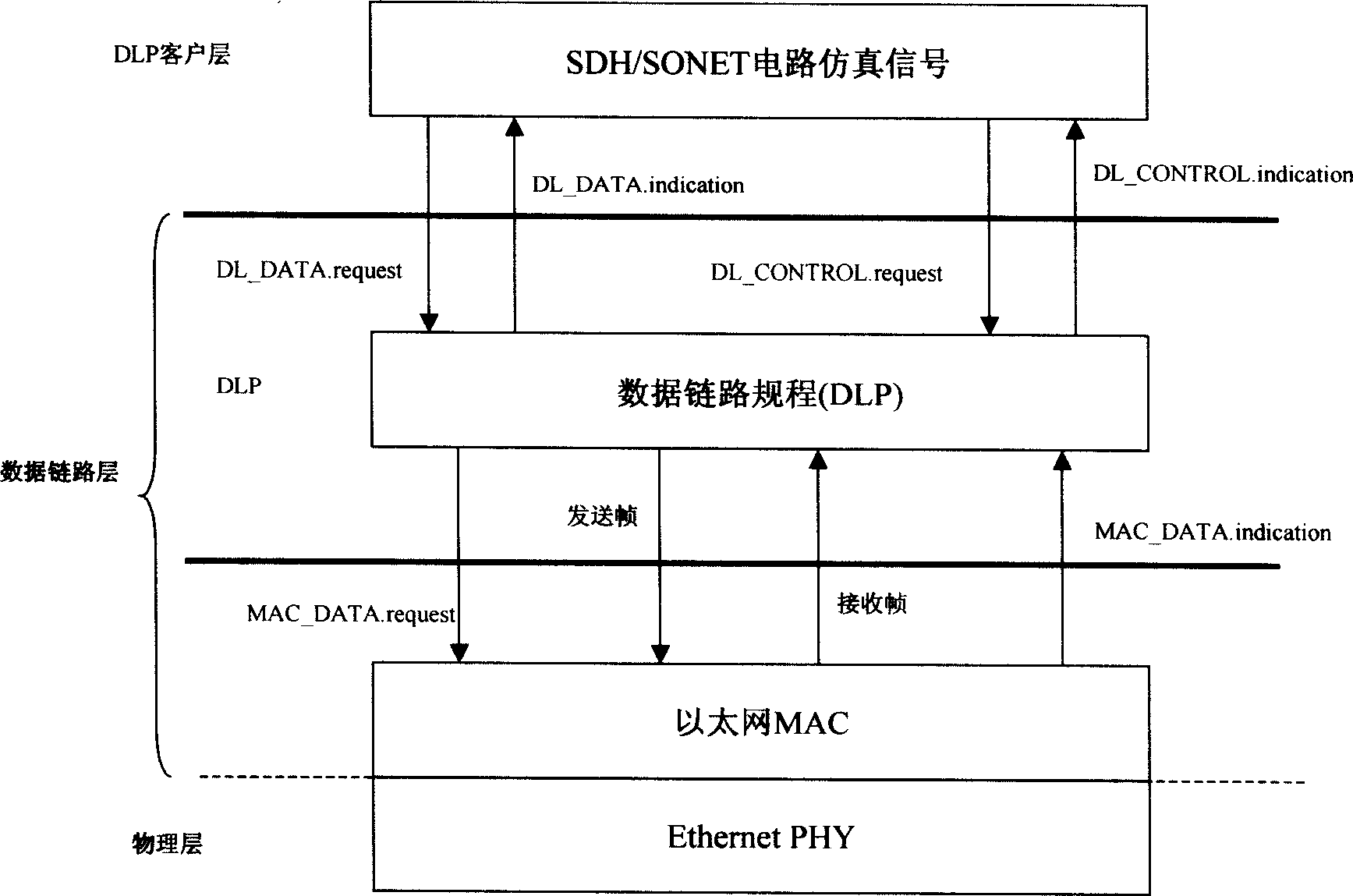

Method for transmtitig digital video

InactiveCN1728713ARealize triple playReduce networking costsTransmissionDigital videoNetwork management

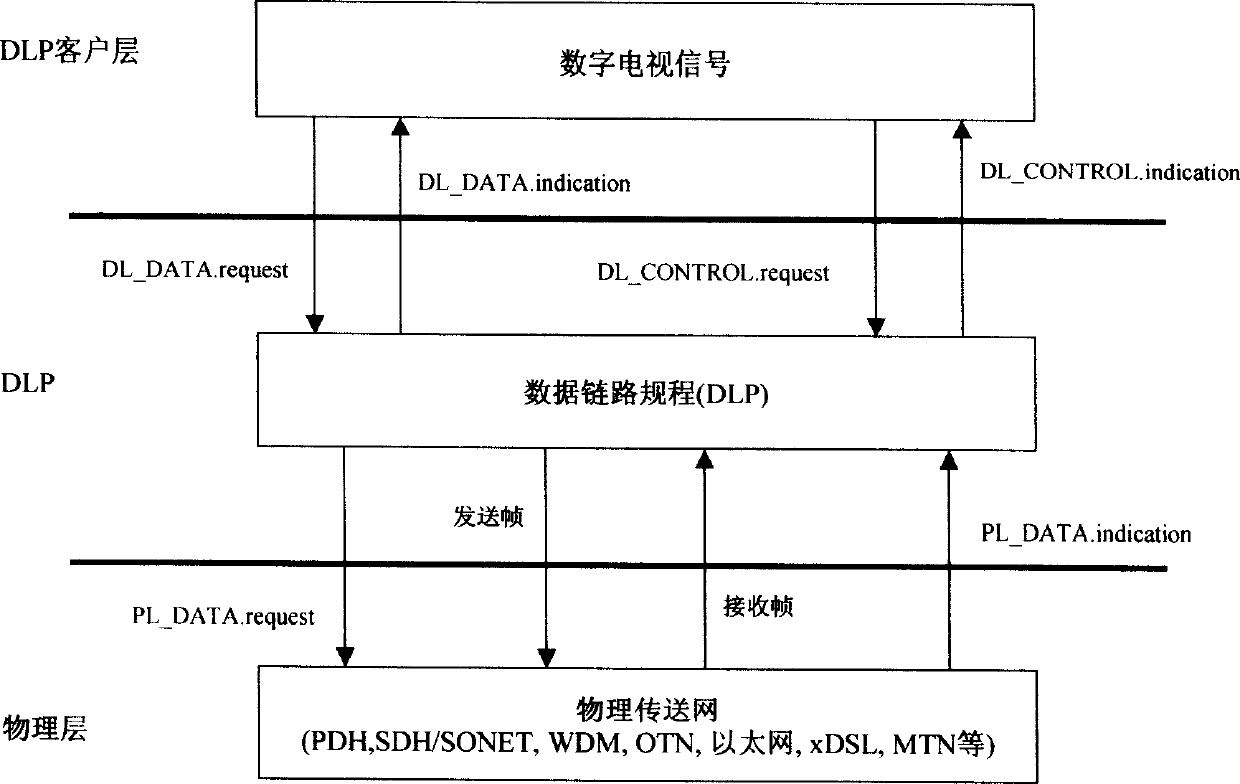

Using packet switching, the disclosed digital video transmission method can be applicable to united public network in next generation. New layer of data link layer protocol - data link procedure (DLP) is introduced between digital video service layer and each physical layer. Using DLP protocol defined destination address code and source address code compatible to current telephone number system as addresses of sending end and receiving end of digital video signal realizes forwarding and exchanging digital video signal in two layers, as well as realizes purpose compatible between packet voice network and IP network. Using safety mechanism, network control management mechanism, flow management mechanism provided by DLP realizes network management control function such as two layer protected rearrangement in two layers, performance management, fault management etc. The method makes current communication network transits to united public network in next generation smoothly.

Owner:邓里文

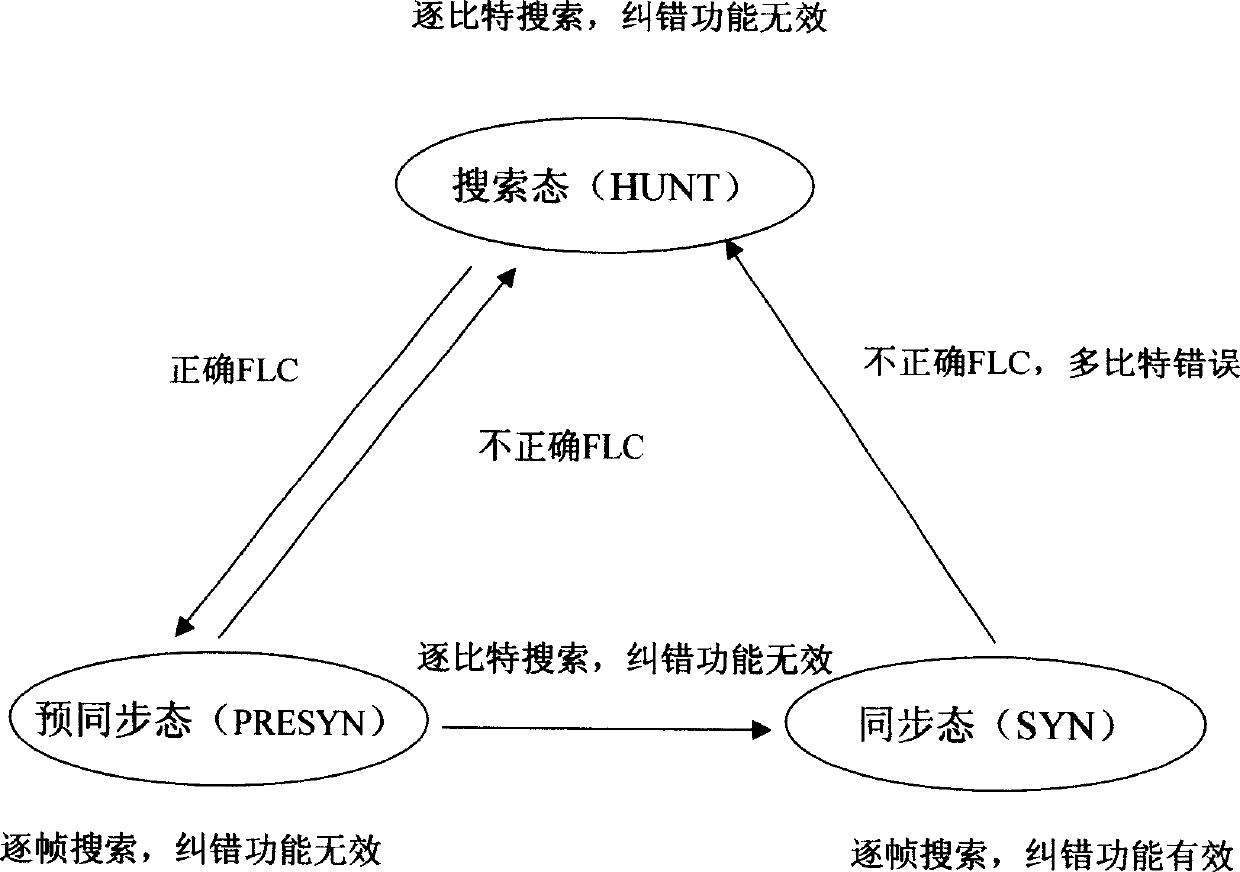

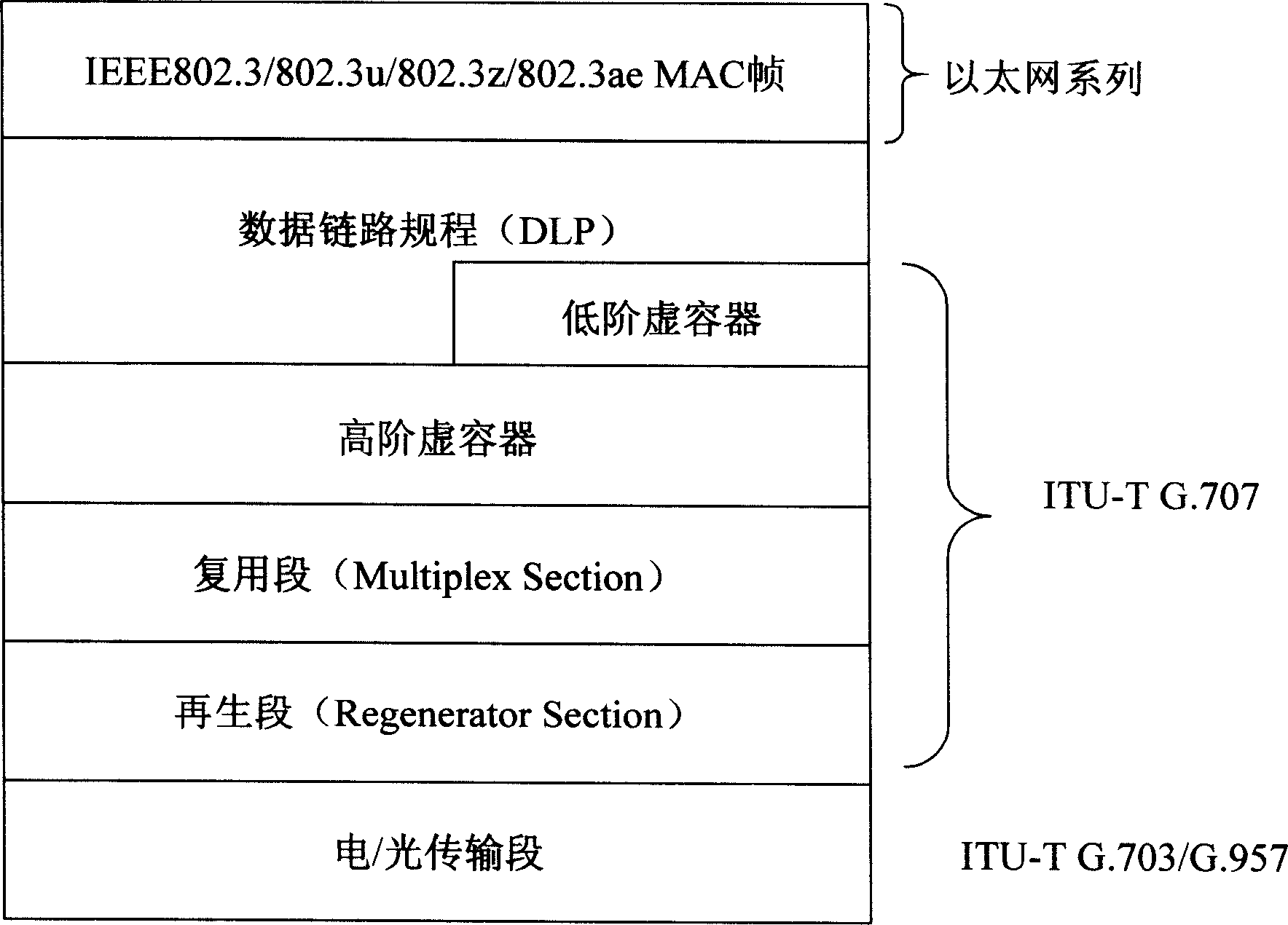

Adaptation method in use for syncretizing Ethernet and SHD or synchronous optical network

InactiveCN1728720AIncreased complexityAchieve teleportationTransmissionNetwork ConvergenceDigital video

New layer of data link layer protocol - data link procedure (DLP) is introduced in the invention to realize syncretizing adaptation between Ethernet and SDH / SONET in order to overcome shortage of current adaptation technique including not matched interface speed, not supporting dynamic bandwidth allocation based on packets, and not possible to transmit SDH / SONET on Ethernet, not compatible to IP and packet voice service etc. The method realizes direct transmission of Ethernet on SDH / SONET, and SDH / SONET on Ethernet as well as realizes compatibility to IP network and packet voice network. Using safety mechanism, network control management mechanism, flow management mechanism provided by DLP realizes network management control function such as two layer protected rearrangement, performance management, fault management etc. The method makes current communication network transits to united public network in next generation of using packet switching technology smoothly.

Owner:邓里文

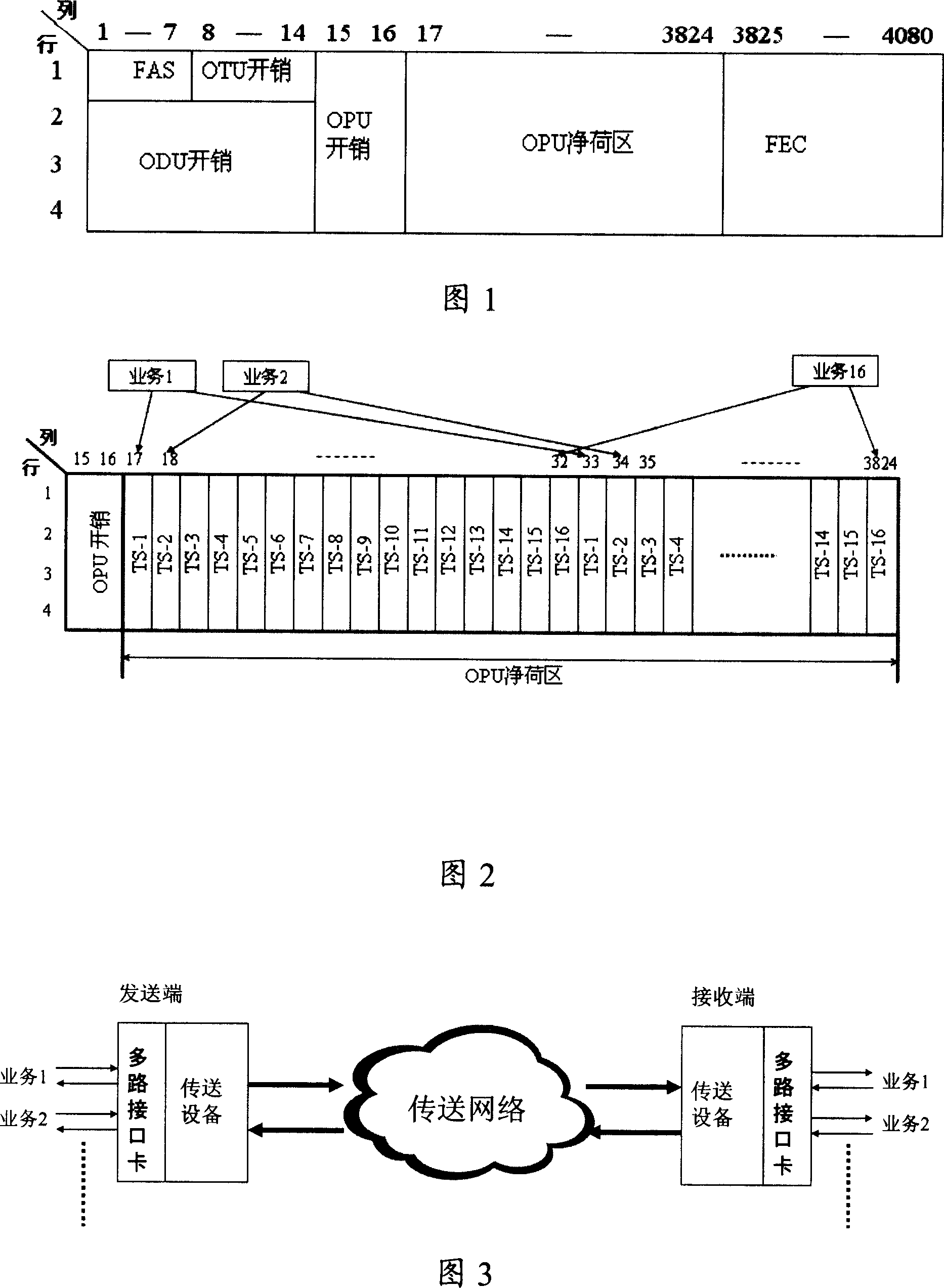

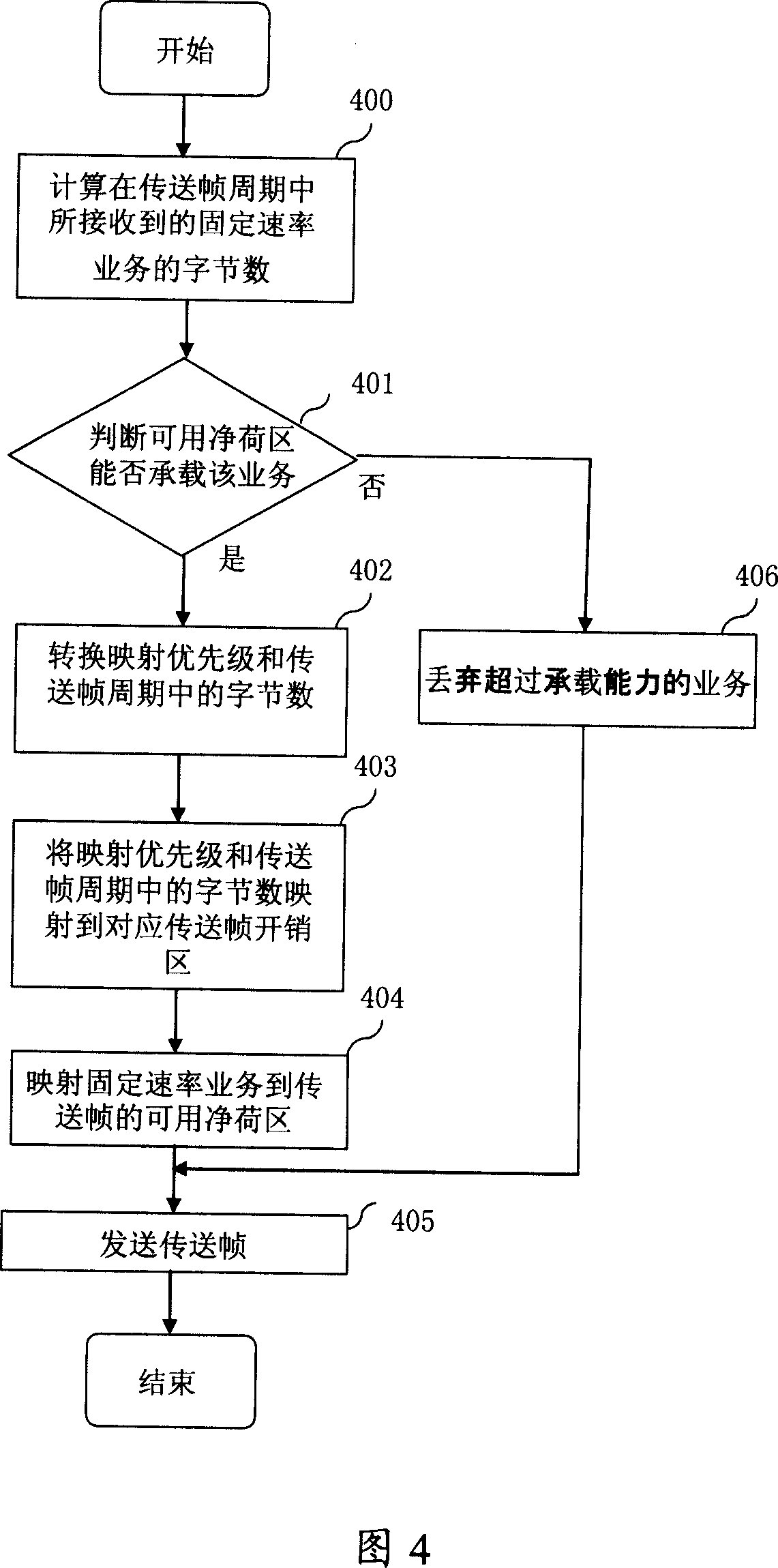

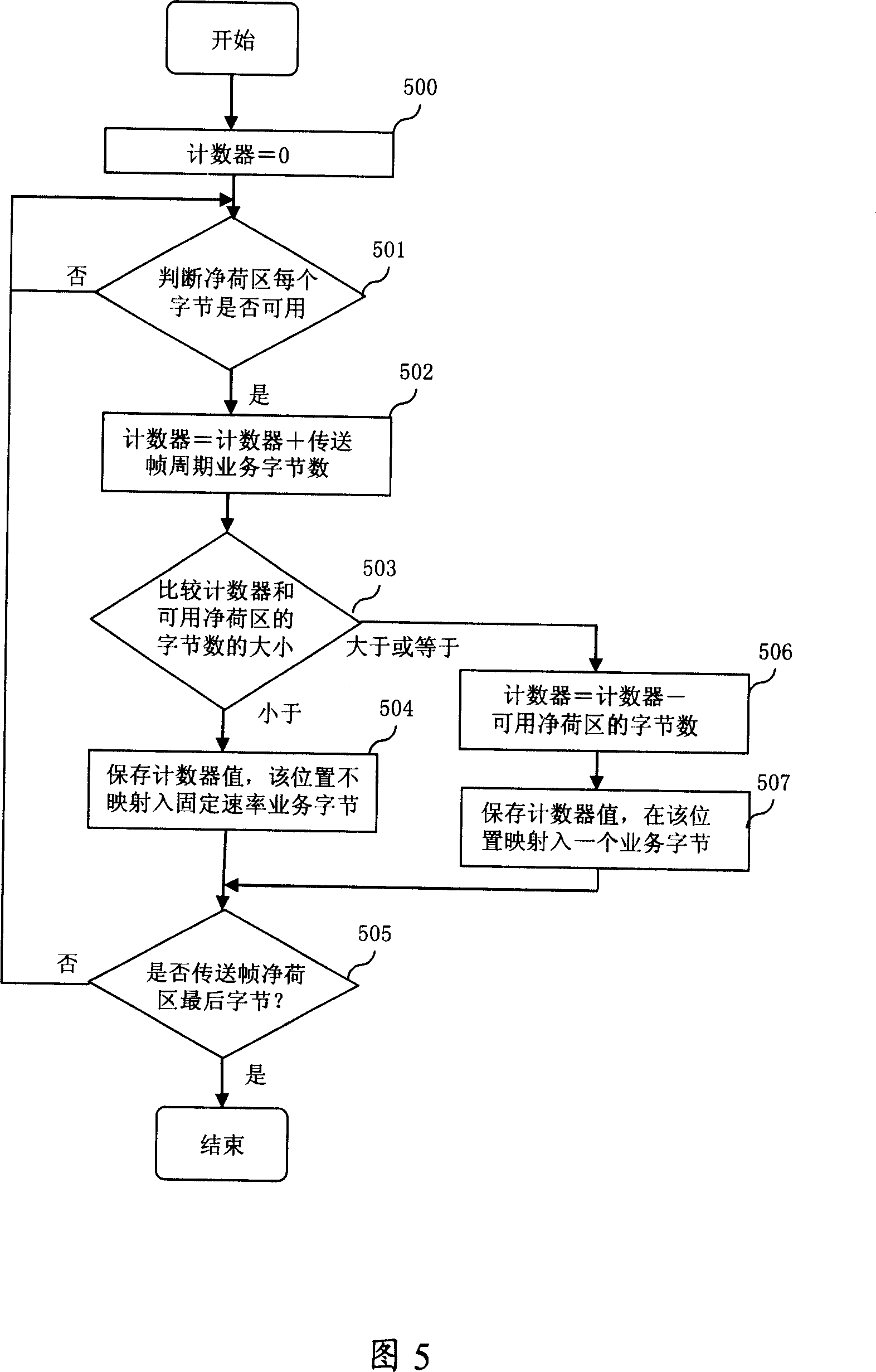

Method and apparatus for fixed velocity service transmission

InactiveCN101155006ARealize transparent transmissionAchieve teleportationTime-division multiplexTransport systemEngineering

The present invention relates to the communication transmitting field, especially relates to a method which is suitable for the fixed-speed business transmitting in the transmitting system of the OTN (optical transport network) and the device. The invention judges whether the available net loading area of the transmitting frame can support the fixed-speed business by confirming the bite number of the fixed-speed business which is received in the transmitting frame period, maps the multiplex fixed-speed business distributedly to the transmitting frame, realizes the transmitting to the unknown fixed-speed business and uses the net loading area of the transmitting frame to maximum; meanwhile the invention need not analyze and process the business agreement and can realize the transparent transmitting of the business.

Owner:HUAWEI TECH CO LTD

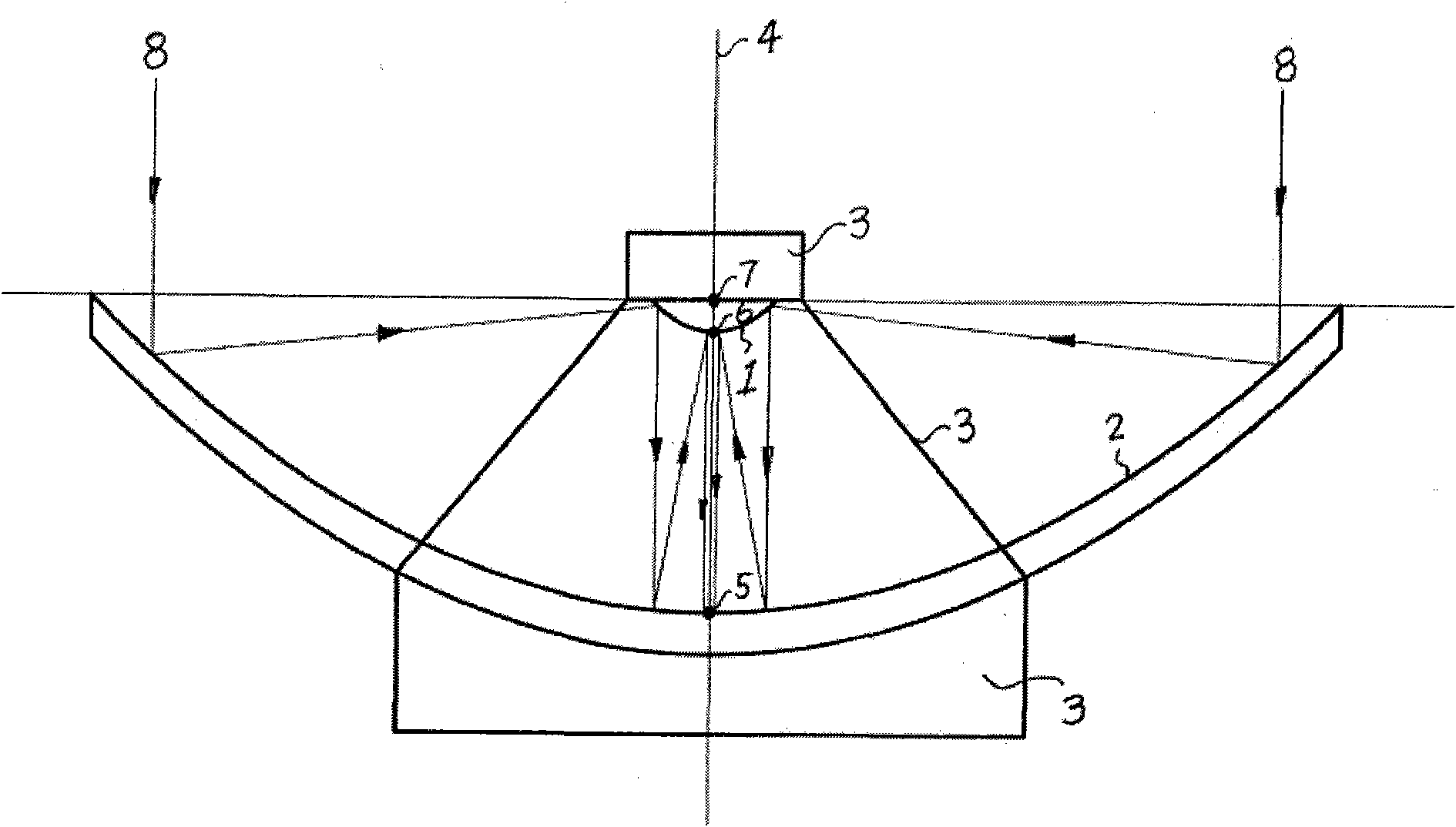

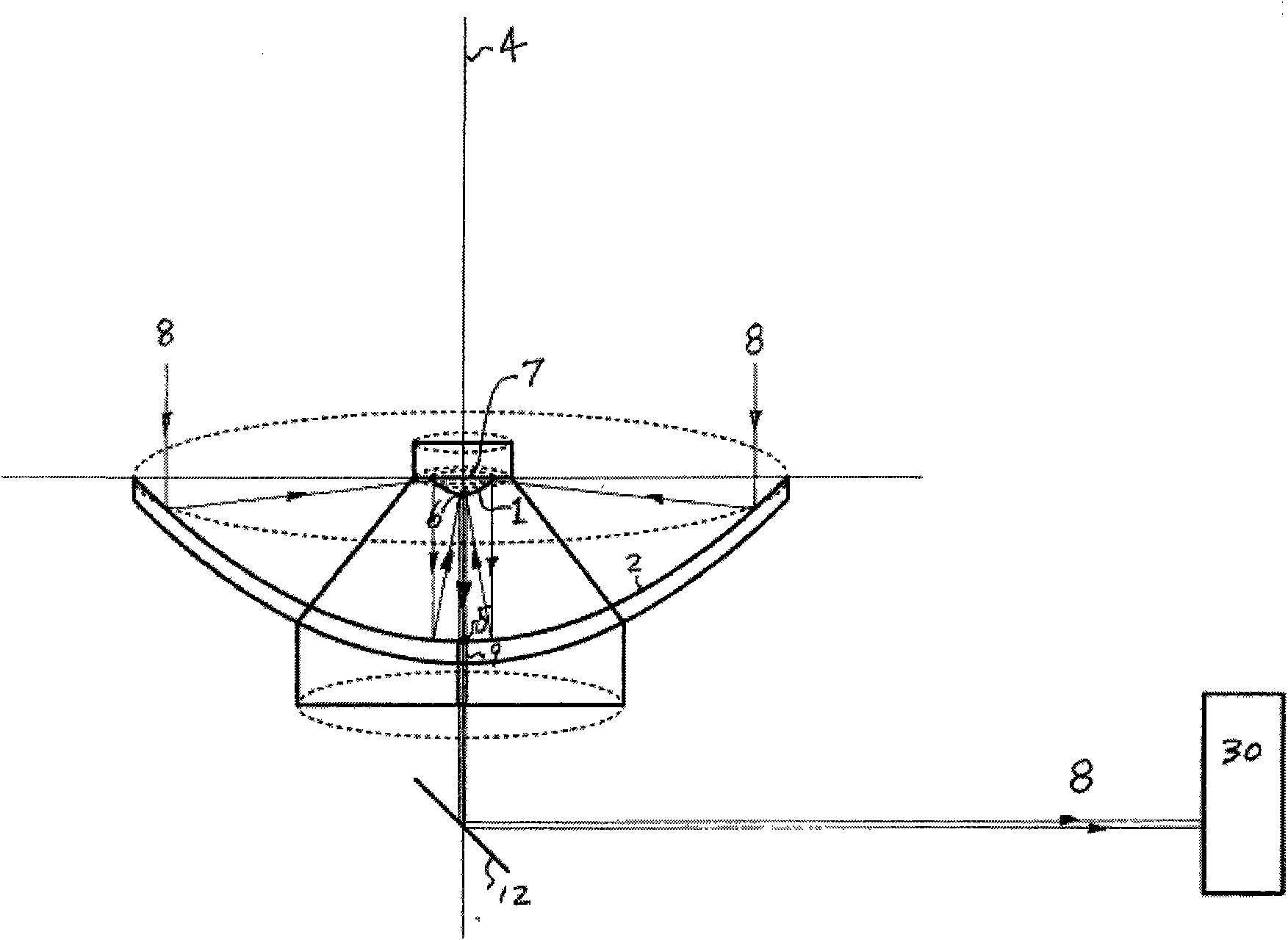

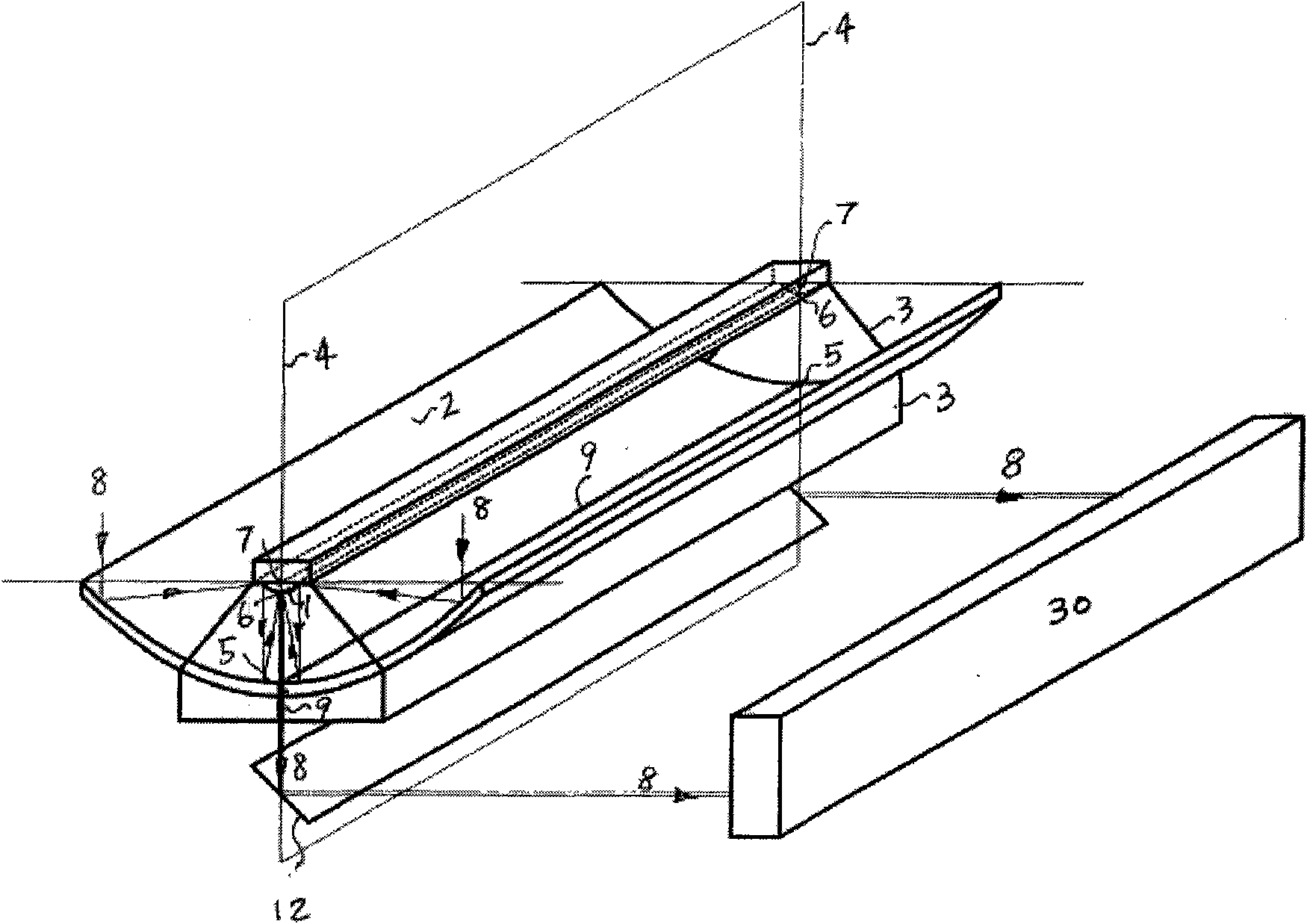

Device for transmitting luminous energy by utilizing paraboloidal mirror

InactiveCN101576649AAchieve teleportationSolar heating energyControl using feedbackConvex sideOptical energy

The invention provides a device for transmitting luminous energy by utilizing a paraboloidal mirror. The device comprises at least one parabola convex reflector and at least one parabola concave reflector. The convex surface of the parabola convex reflector is a parabolic reflecting surface, and the concave surface of the parabola concave reflector is a parabolic reflecting surface. The reflecting surfaces of the parabola convex reflector and the parabola concave reflector are oppositely arranged, and parabola shapes of the two reflecting surfaces are similar to each other. The geometric dimension of the reflecting surface of the parabola concave reflector is larger than that of the reflecting surface of the parabola convex reflector. The axes of the reflecting surfaces of the two parabola reflectors are overlapped at a common axis, and the focuses of the reflecting surfaces are overlapped at a common focus. The device takes advantage of the special ray reflecting characteristics of the paraboloidal mirror to effectively gather or disperse parallel rays entering the device, thereby realizing multiple different actual applications.

Owner:黄建文

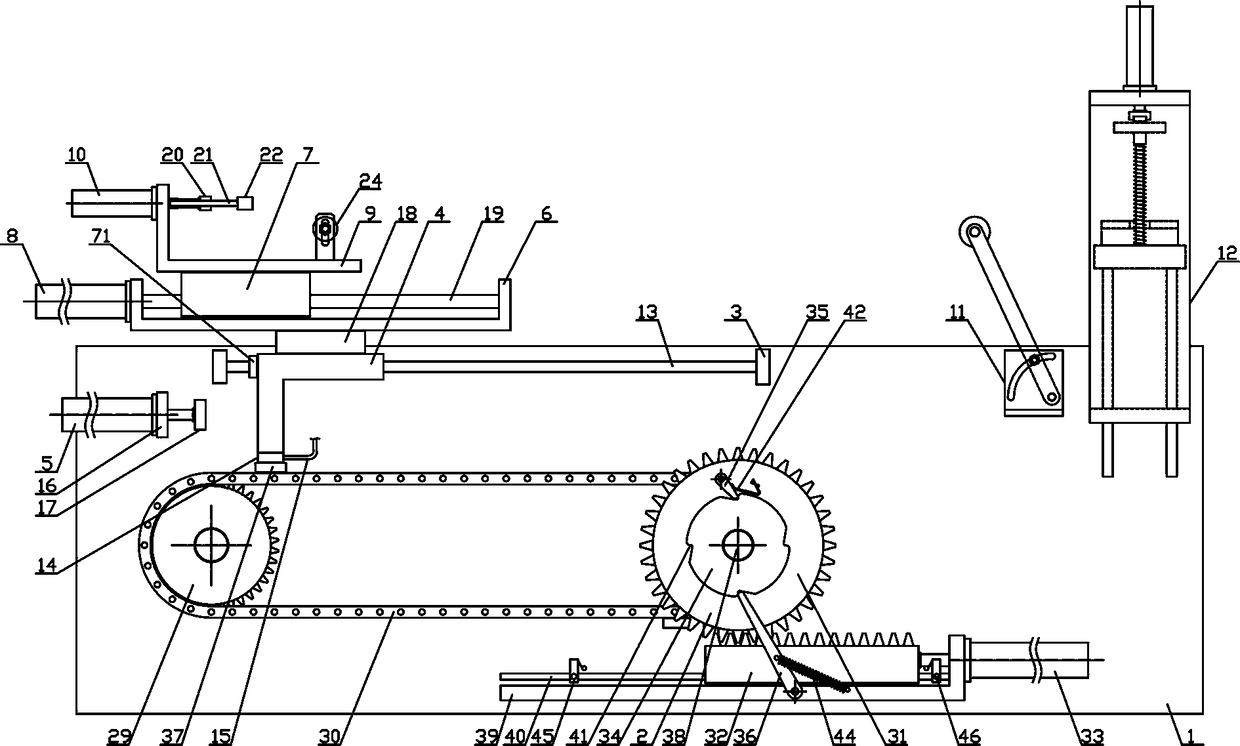

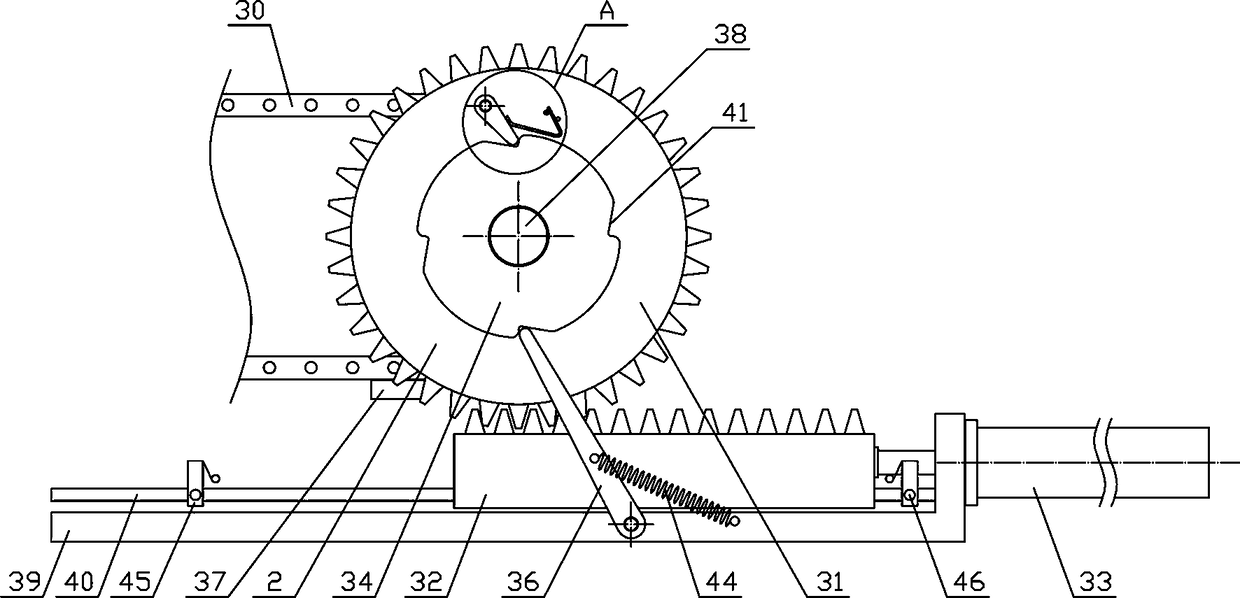

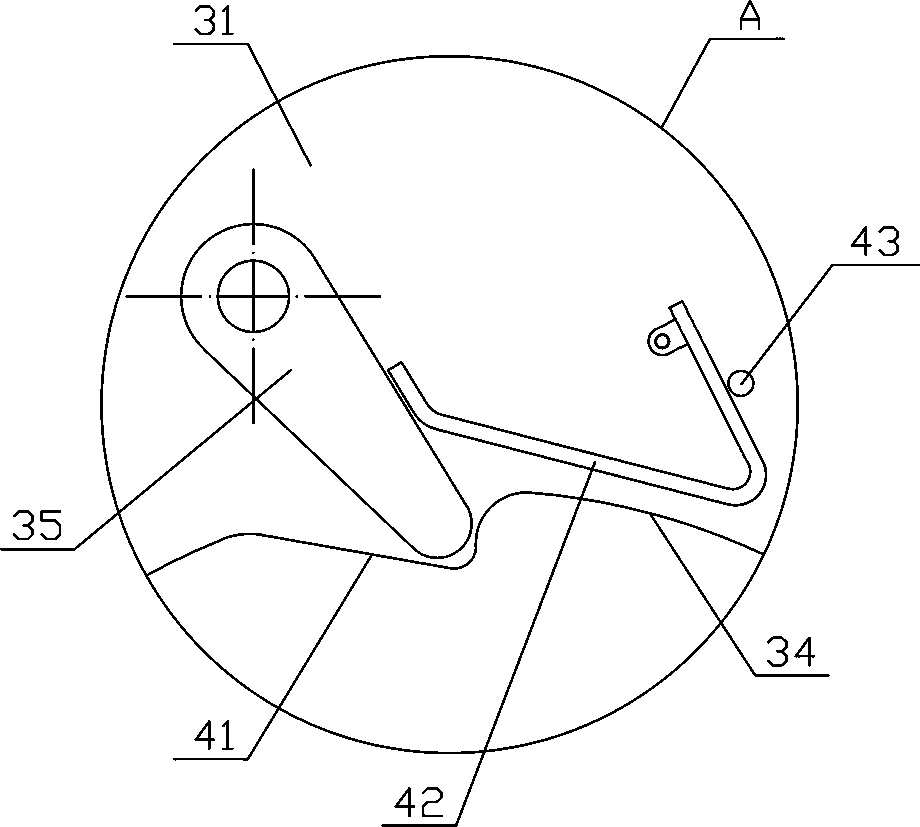

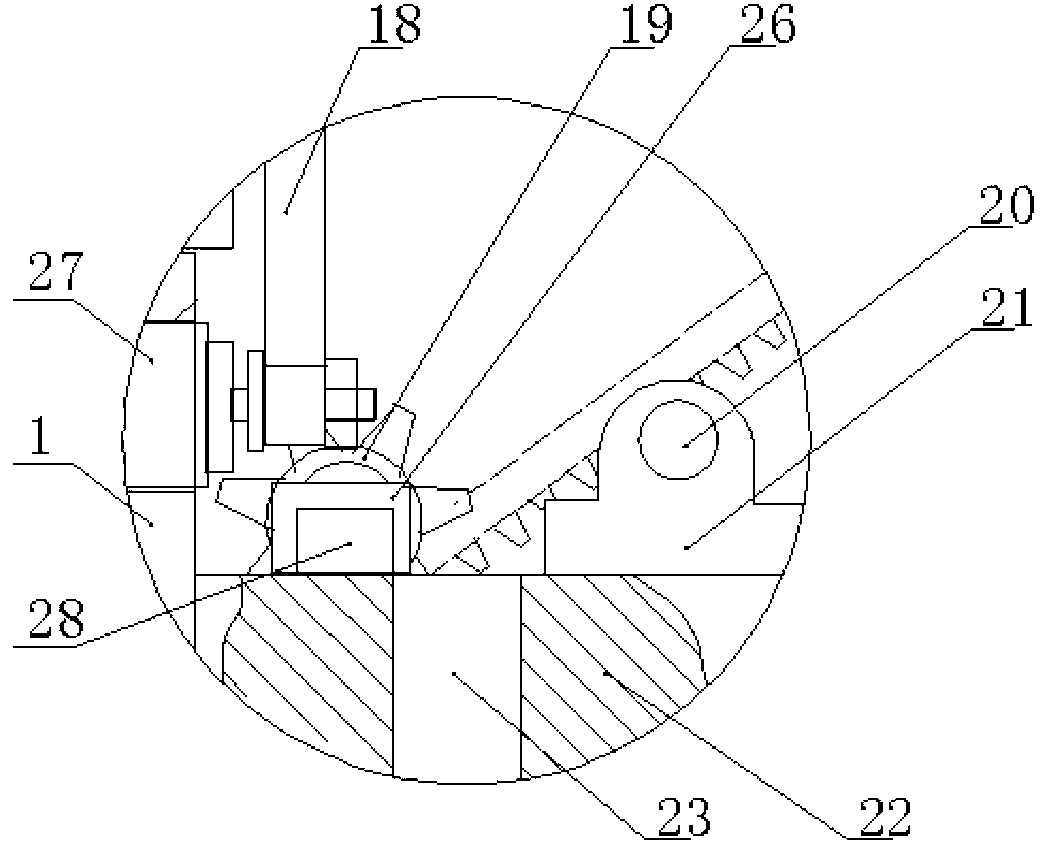

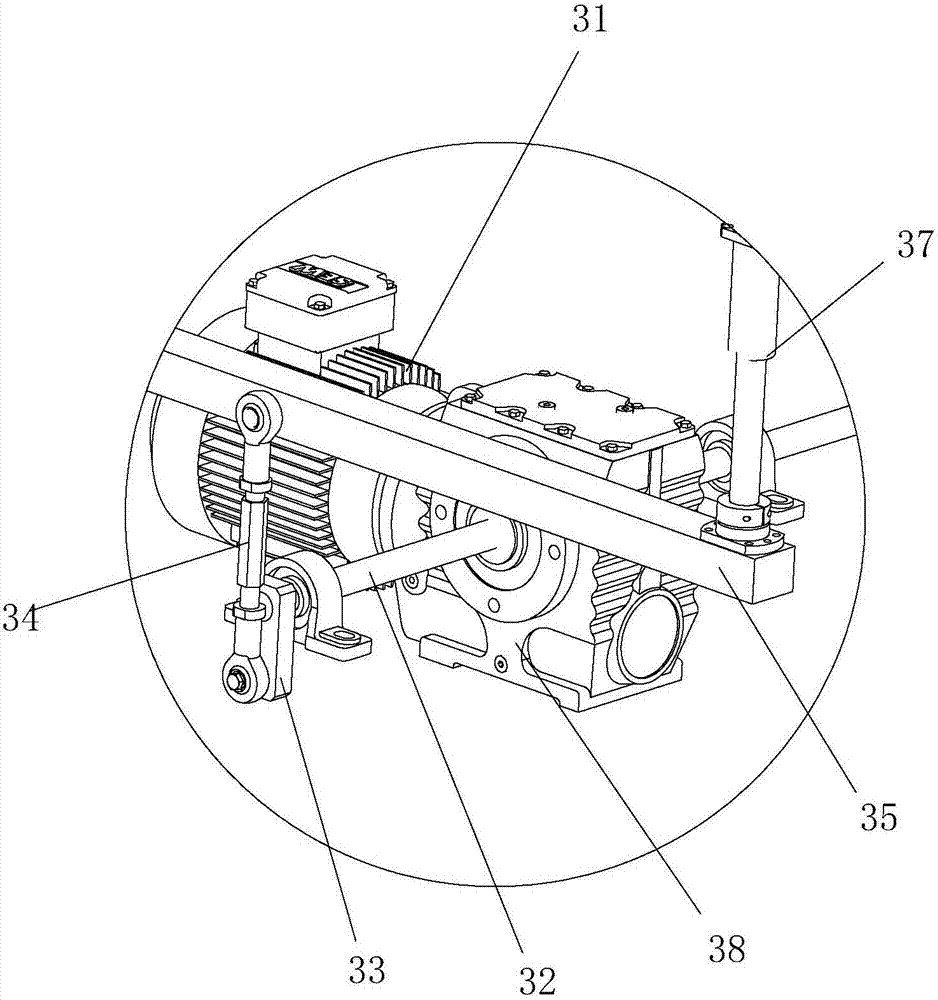

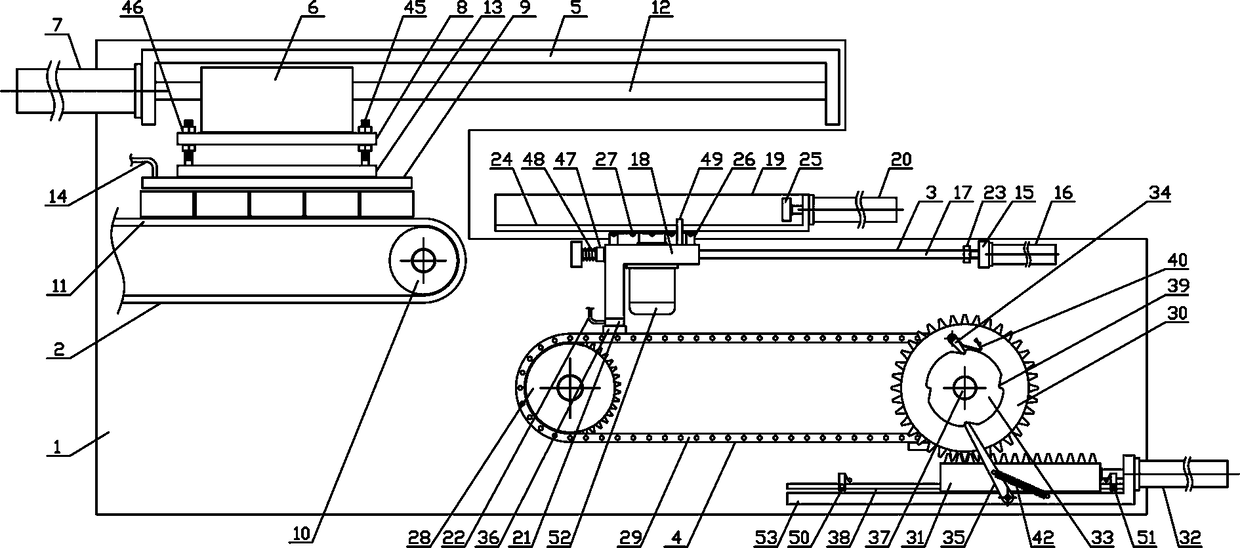

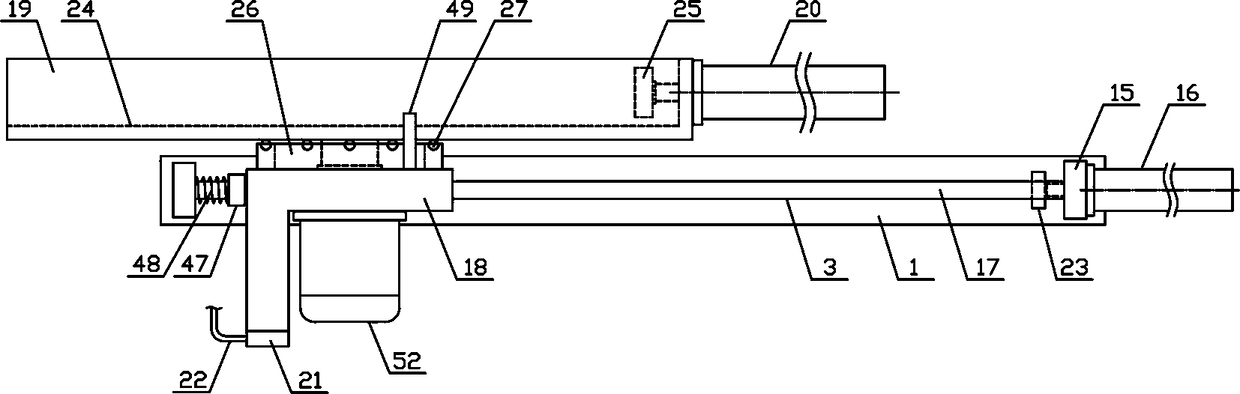

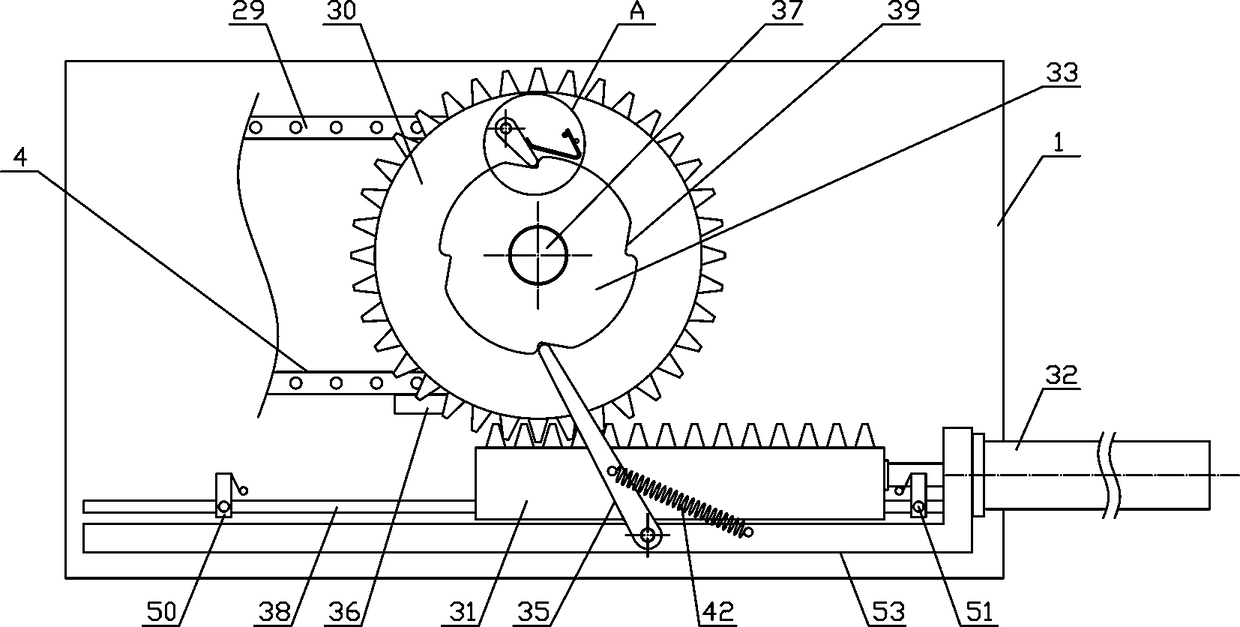

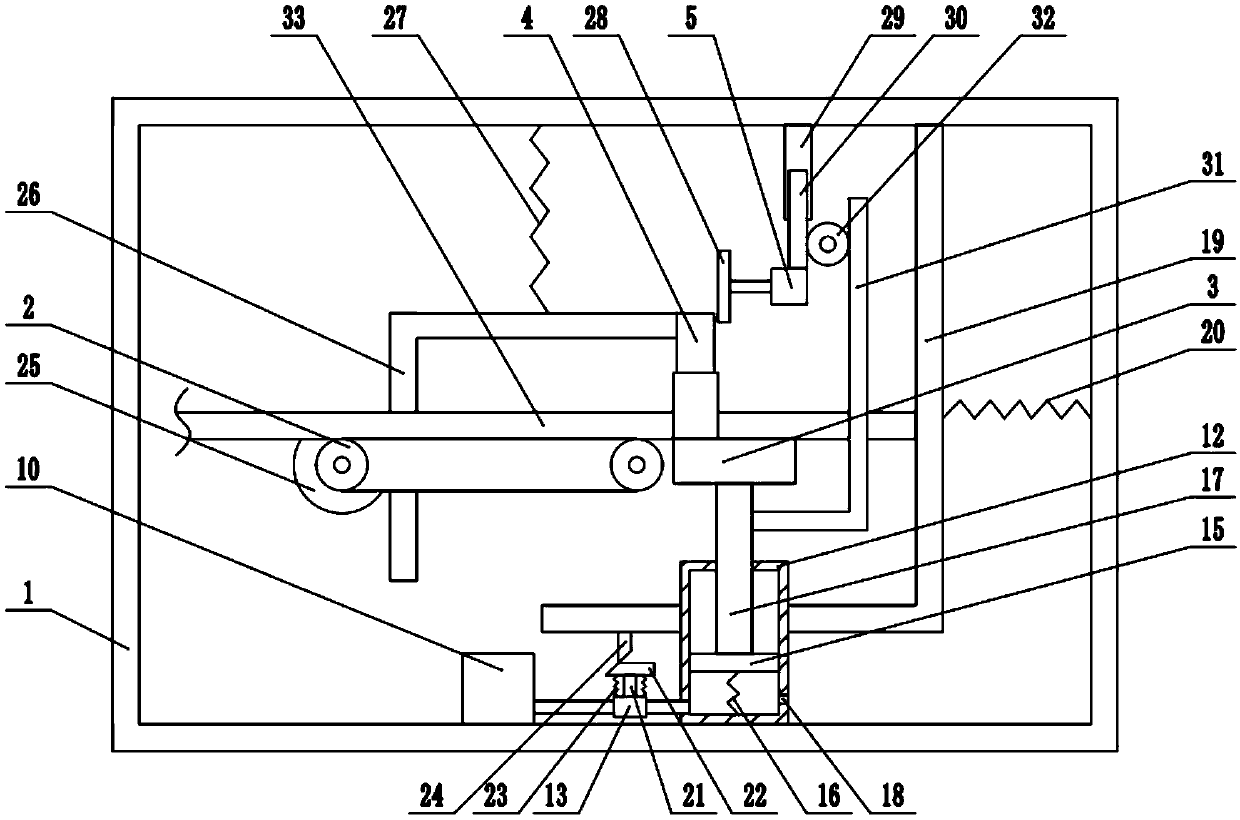

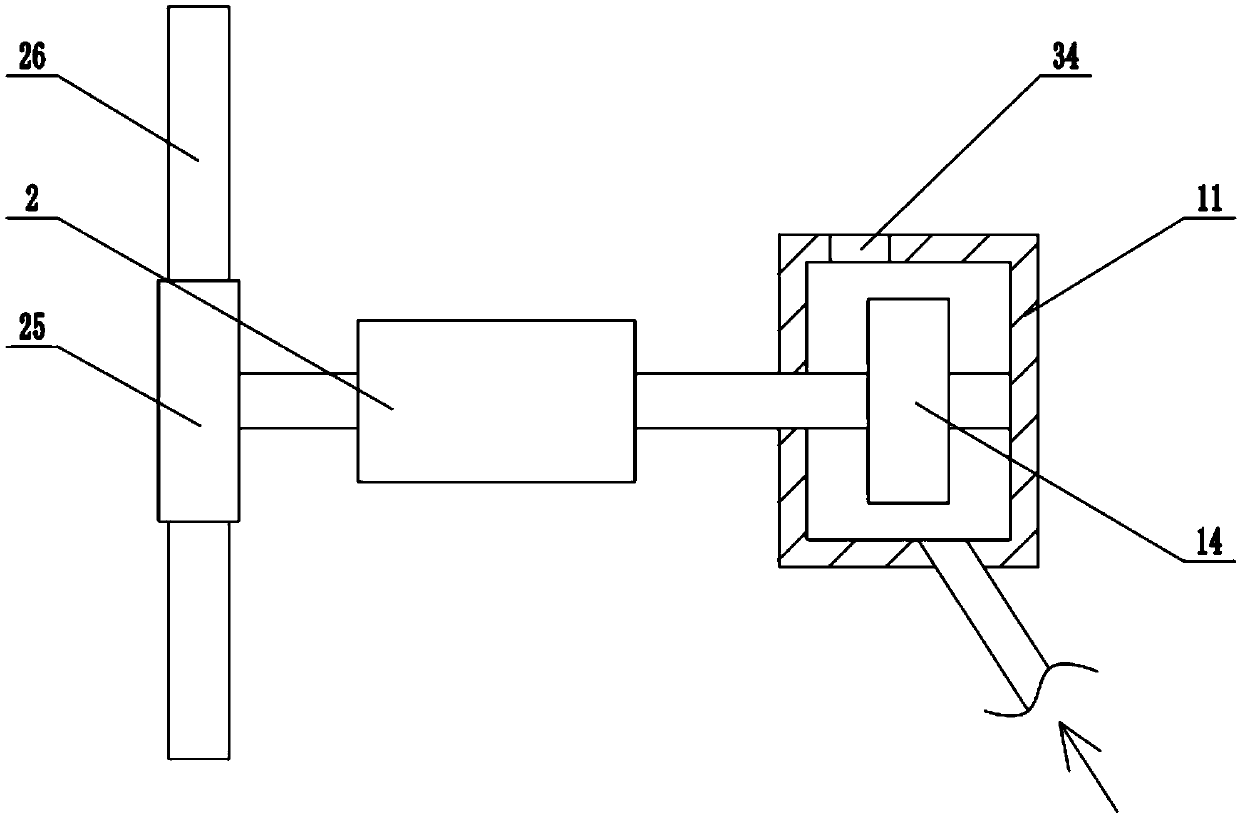

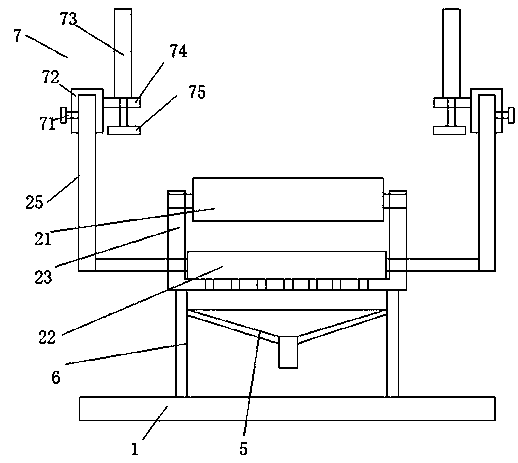

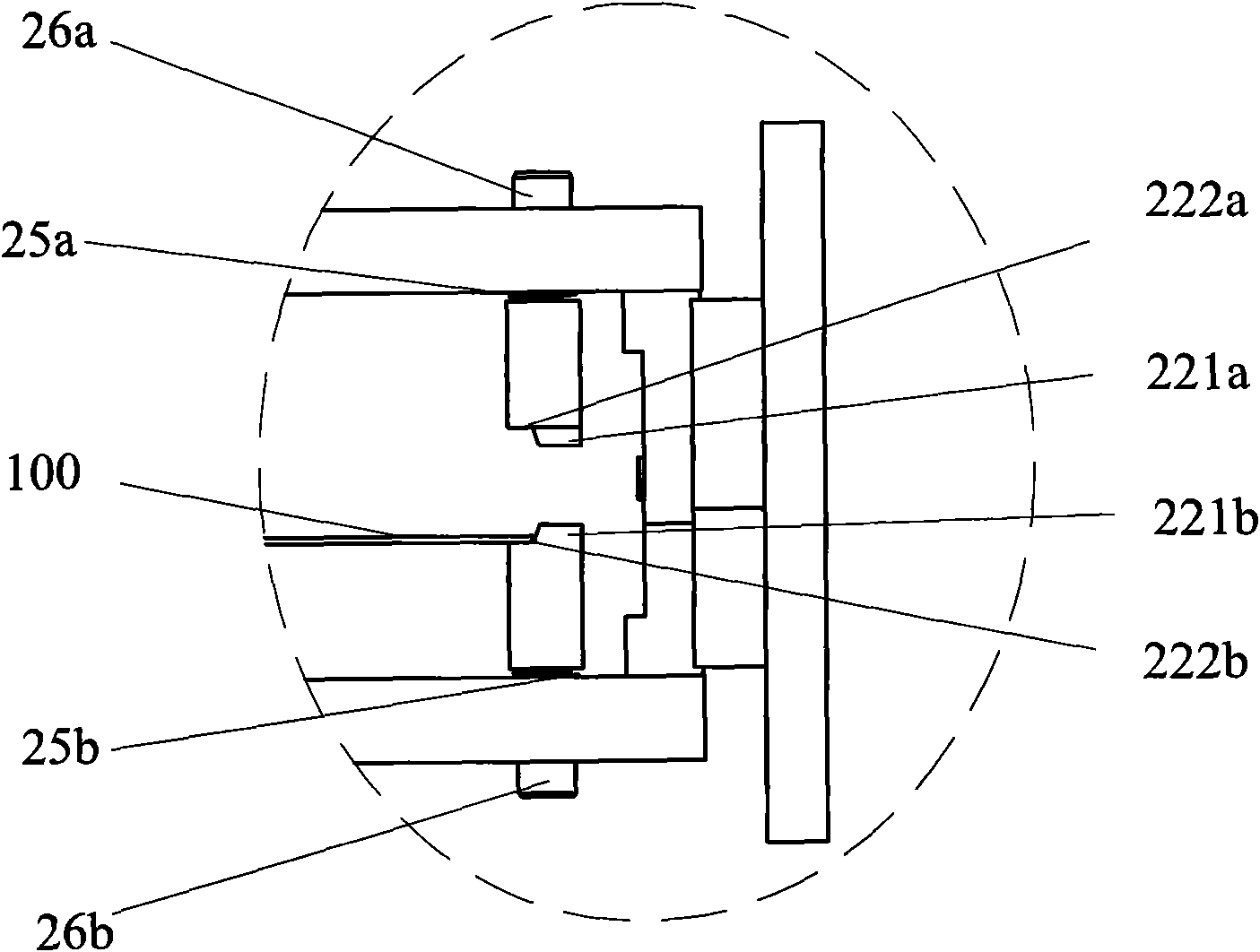

Sectional material feeding and punching mechanism

InactiveCN108526508AReasonable structural designPlay the role of speed reduction and shock absorptionMetal working apparatusBoring/drilling componentsBuilding materialMultiple dimension

The invention discloses a sectional material feeding and punching mechanism, and belongs to the field of building material processing mechanical equipment. According to the sectional material feedingand punching mechanism, a driving mechanism is horizontally arranged on one side of the lower portion of a feeding support, and a rear material bearing mechanism and a punching mechanism are fixedly arranged on one side of the upper portion of the feeding support in sequence in the horizontal direction. A feeding guide plate is arranged on a horizontal movement guide rod in a sliding mode in the horizontal direction, an adjusting guide plate is arranged on an adjusting guide rod in a sliding mode in the horizontal direction, and a material clamping support is horizontally and fixedly arrangedon the upper side of the adjusting guide plate. Two attraction armatures are uniformly and fixedly arranged on the outer side of a feeding chain, a feeding gear is vertically connected with the portion, located on one side of a feeding ratchet, of a feeding rotating shaft in a rotating mode, and a horizontal movement rack is arranged on a driving guide rod in a sliding mode in the horizontal direction. The sectional material feeding and punching mechanism is reasonable in structural design, can conduct stable accurate and intermittent feeding of sectional materials, can conduct efficient punching machining of the sectional materials as required, is suitable for feeding and machining of the sectional materials with multiple dimensions, and meets the requirements for machining and utilization.

Owner:沈洁

Intelligent meal delivery robot

InactiveCN103340514AImprove compatibilityGuaranteed smoothnessTable equipmentsServing tablesBiomedical engineeringMeal

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

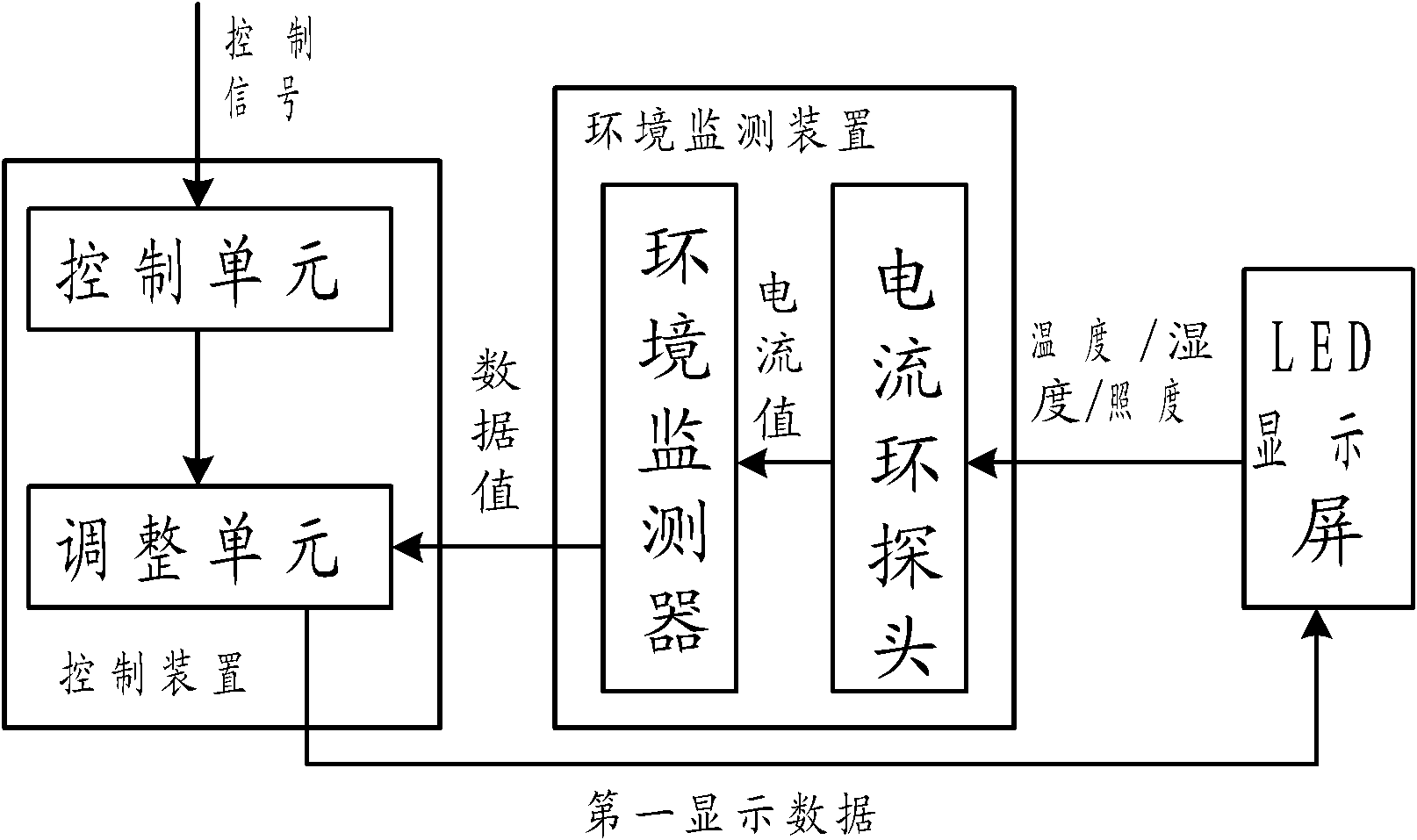

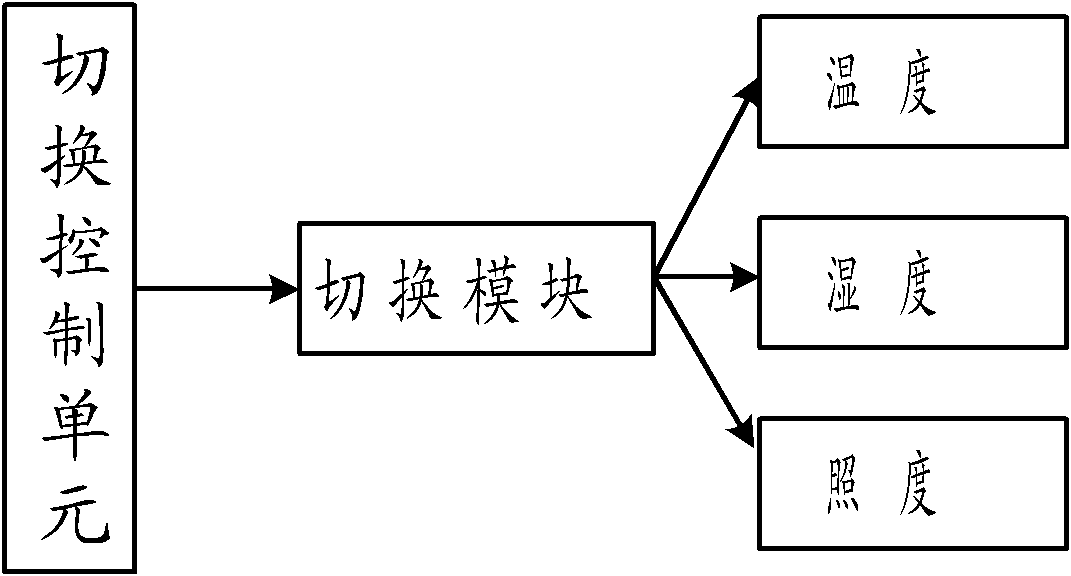

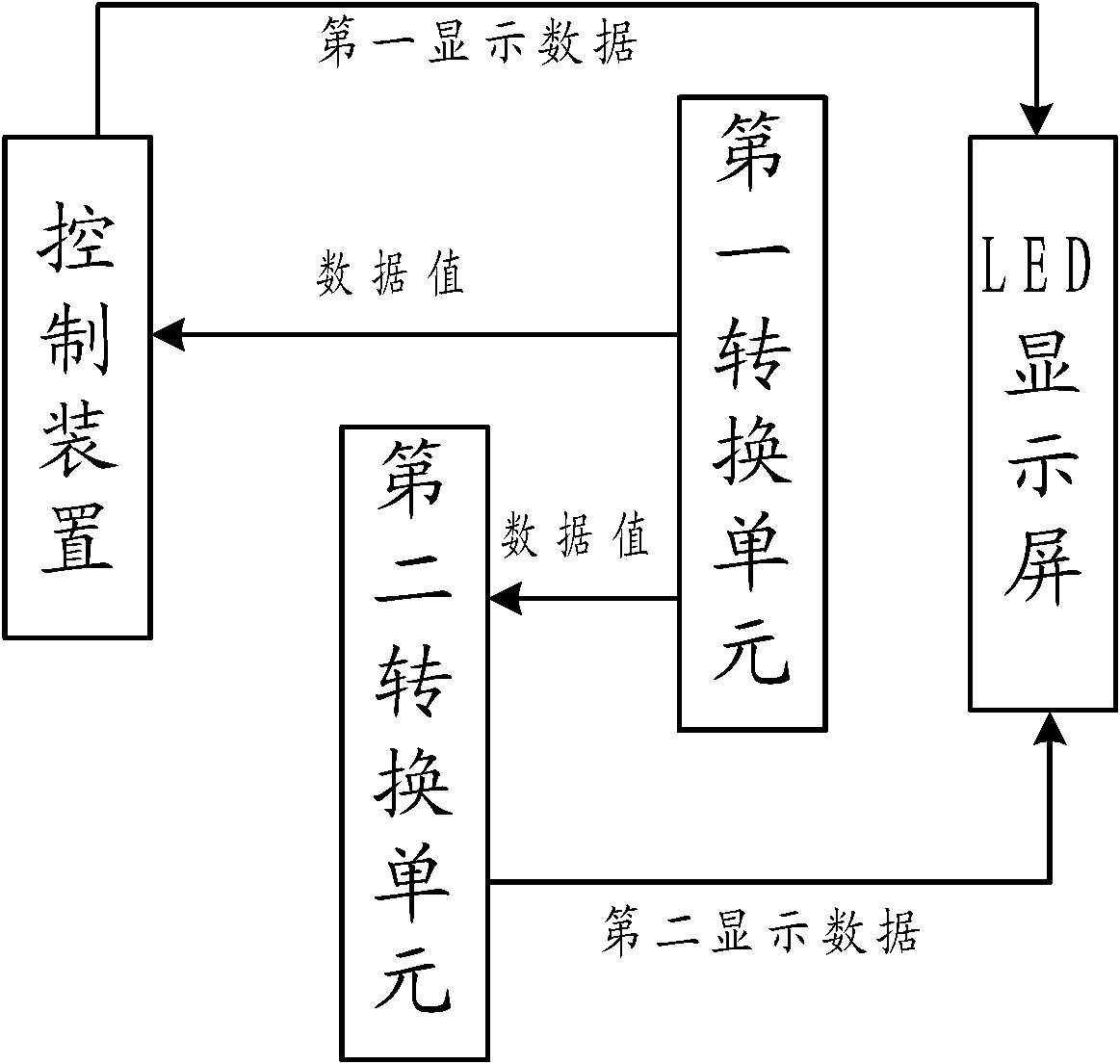

Environment monitoring system of LED (Light-Emitting Diode) display screen

ActiveCN101923817AImprove the display effectGood full screen display effectMeasurement devicesStatic indicating devicesLight-emitting diodeControl unit

The invention discloses an environment monitoring system of an LED display screen, comprising a control device and an environment monitoring device, wherein the control device is provided with a control unit and is used for generating first display data so as to make the external LED display screen display the first display data; the environment monitoring device comprises a current loop probe and an environment monitor; the current loop probe is used for detecting the influencing factors of the surrounding environment of the LED display screen and transmitting current values corresponding to the influencing factors to the environment monitor; the environment monitor is provided with a first converting unit and is used for converting the current values into data values and sending the data values to the control device; and the control device is also provided with an adjusting unit and is used for adjusting the display brightness of the first display data according to the data values. The invention can detect the influencing factors of the surrounding environment of the LED display screen, has flexible and rapid detection mode and accurate detection result and can carry out automatic and accurate adjustment according to the detection result to make the LED display screen reach the best display effect under the most energy-saving state of the LED display screen.

Owner:南通格美工业数控设备有限公司

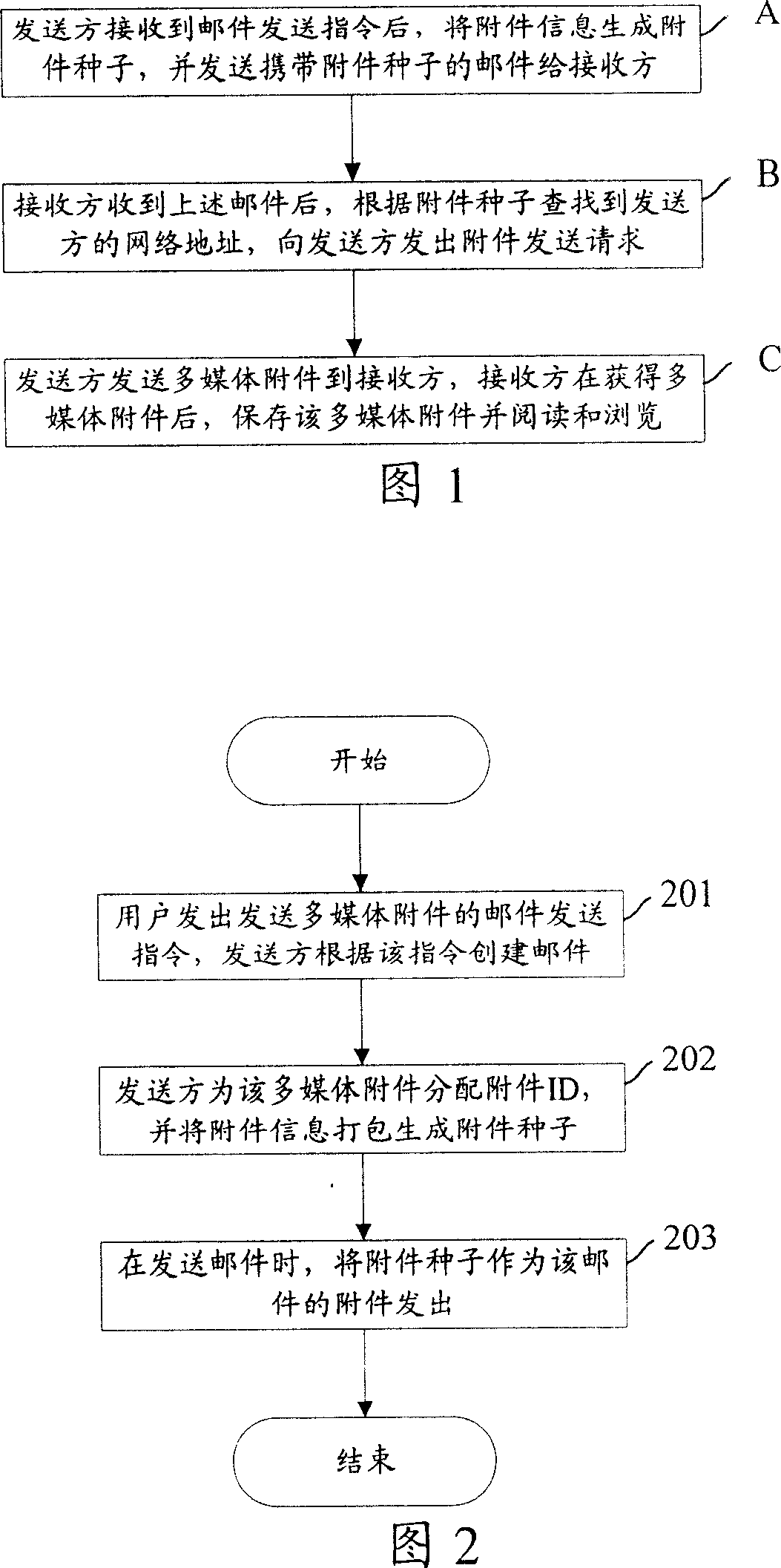

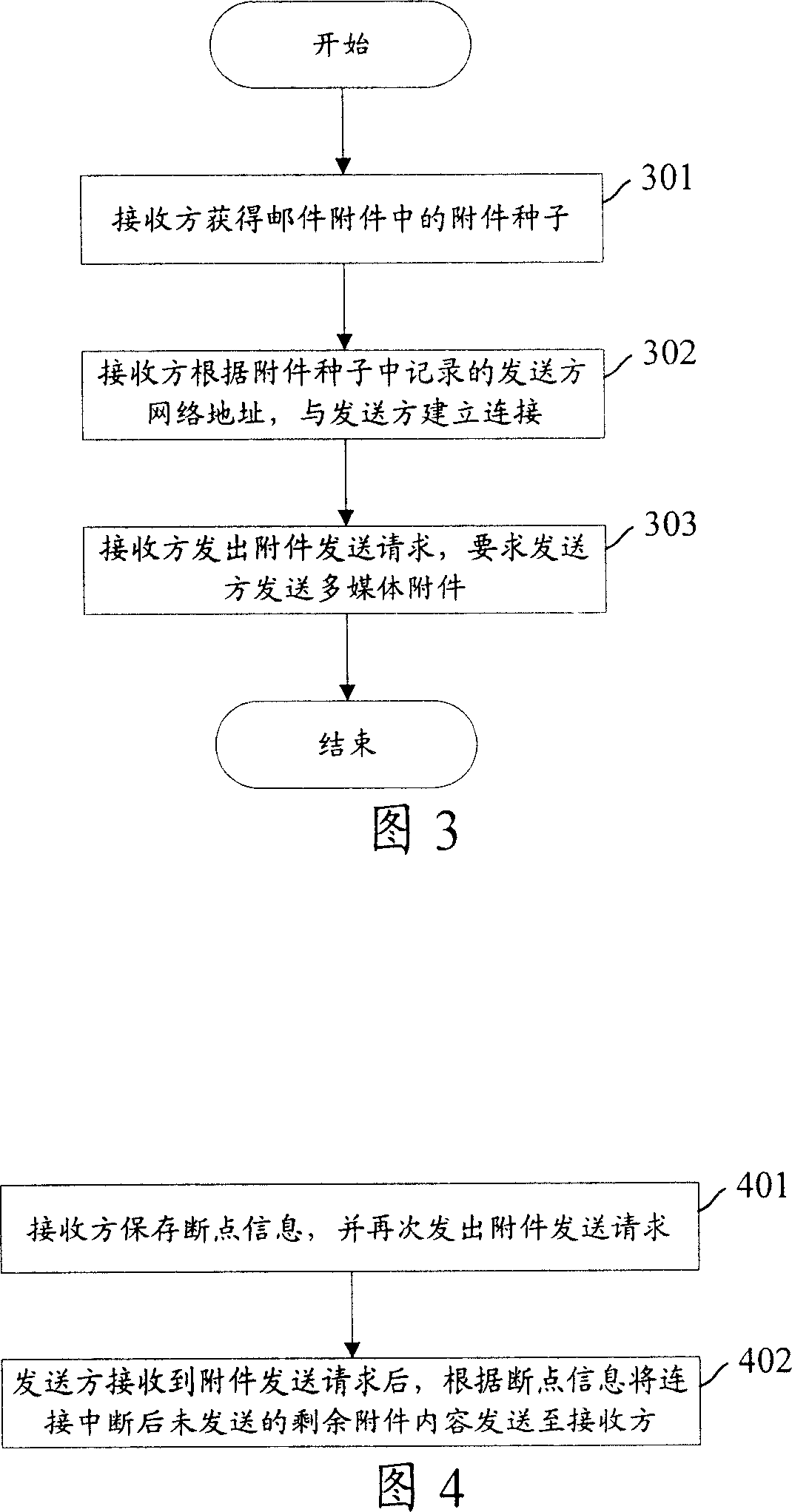

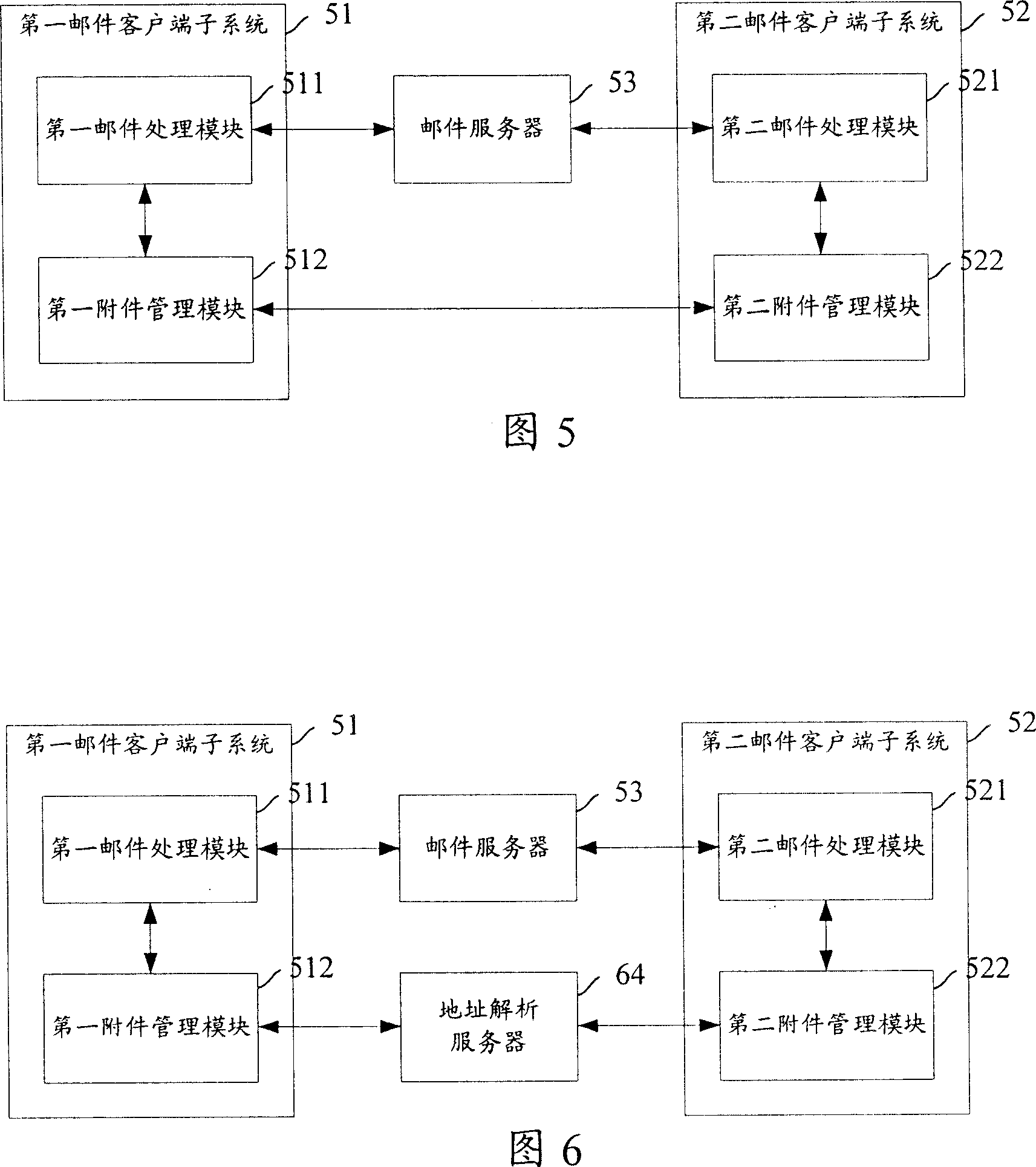

A transmission method and system for attachment of multimedia mail

ActiveCN1972250ASupport transmissionAvoid double sendingData switching networksNetwork addressingNetwork address

This invention discloses one multi-media appendix send method and system, which comprises the following steps: a, send part receives multi-media mail orders and sends appendix mail label and network address to receive part and storing on self position; b, receive part establishes connection according to mail network address and send one and sends appendix send requires with multi-media appendix; c, send part finds self stored appendix and sends it to receive part for an end.

Owner:TENCENT TECH (SHENZHEN) CO LTD

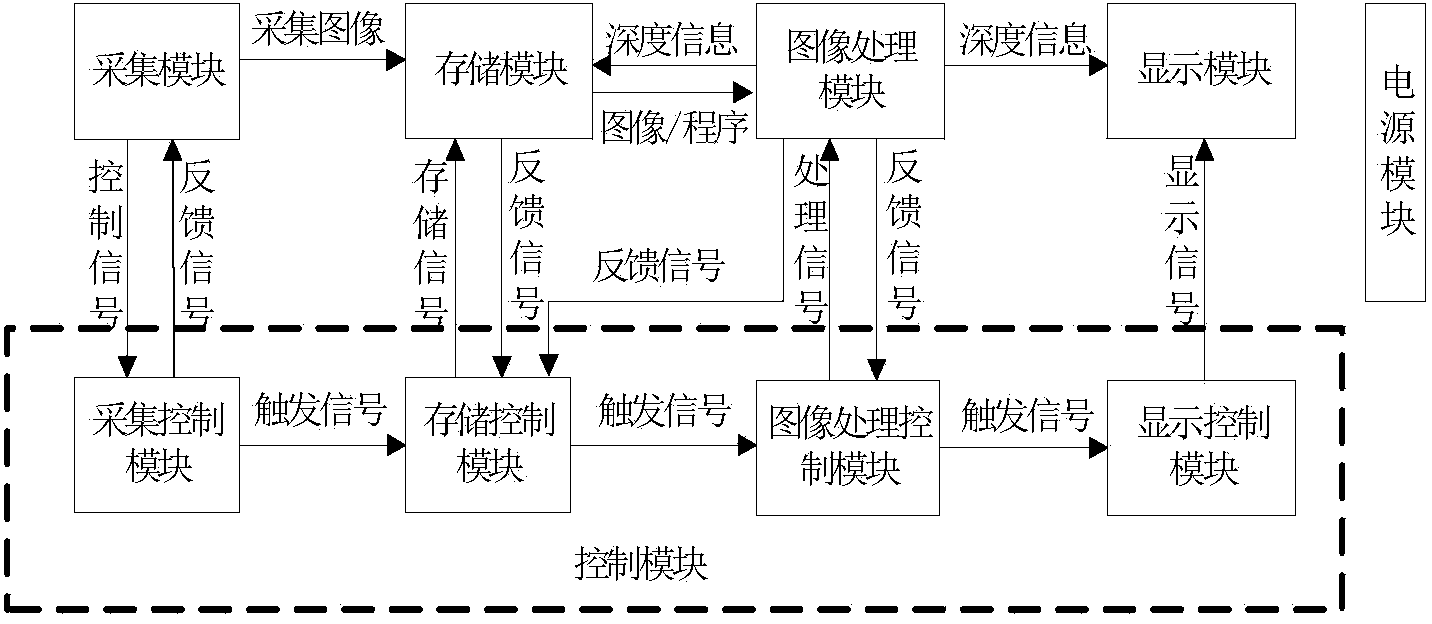

Intelligent system for acquiring underwater polarization target depth map and method thereof

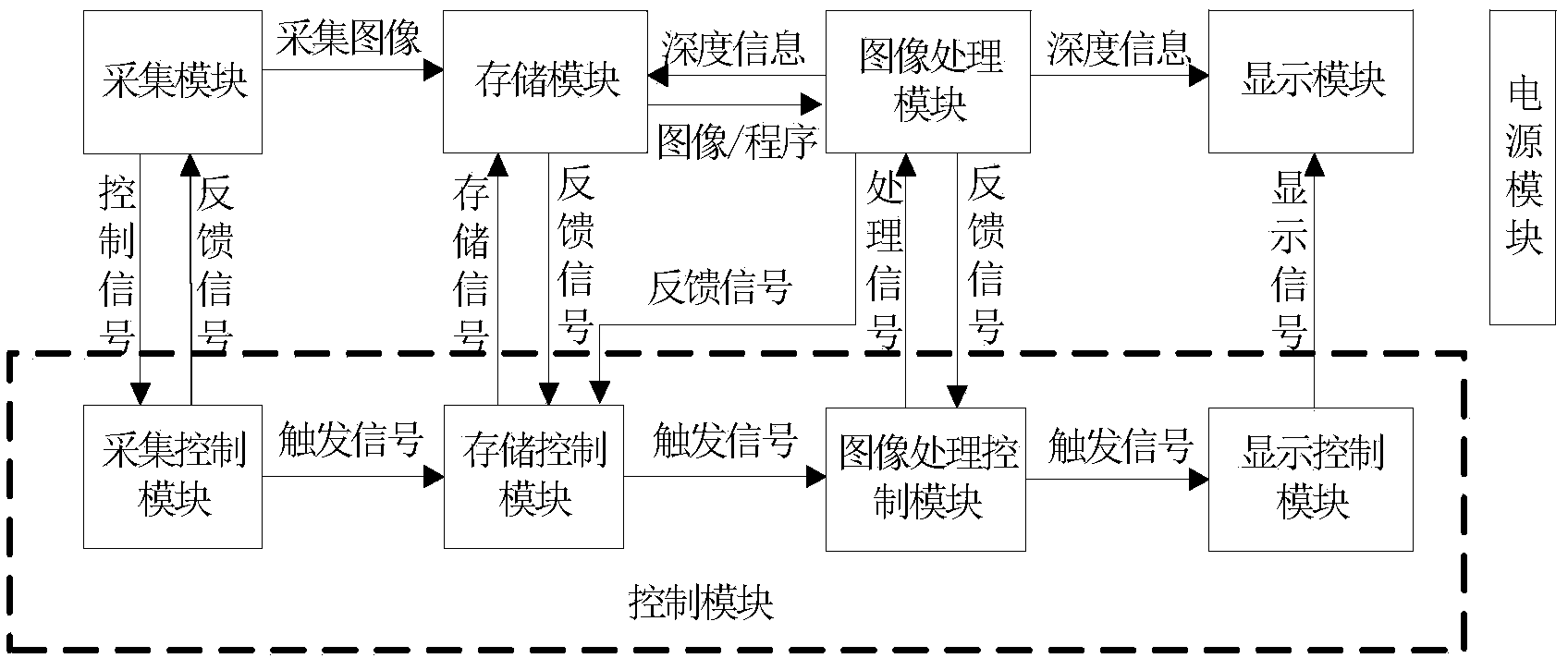

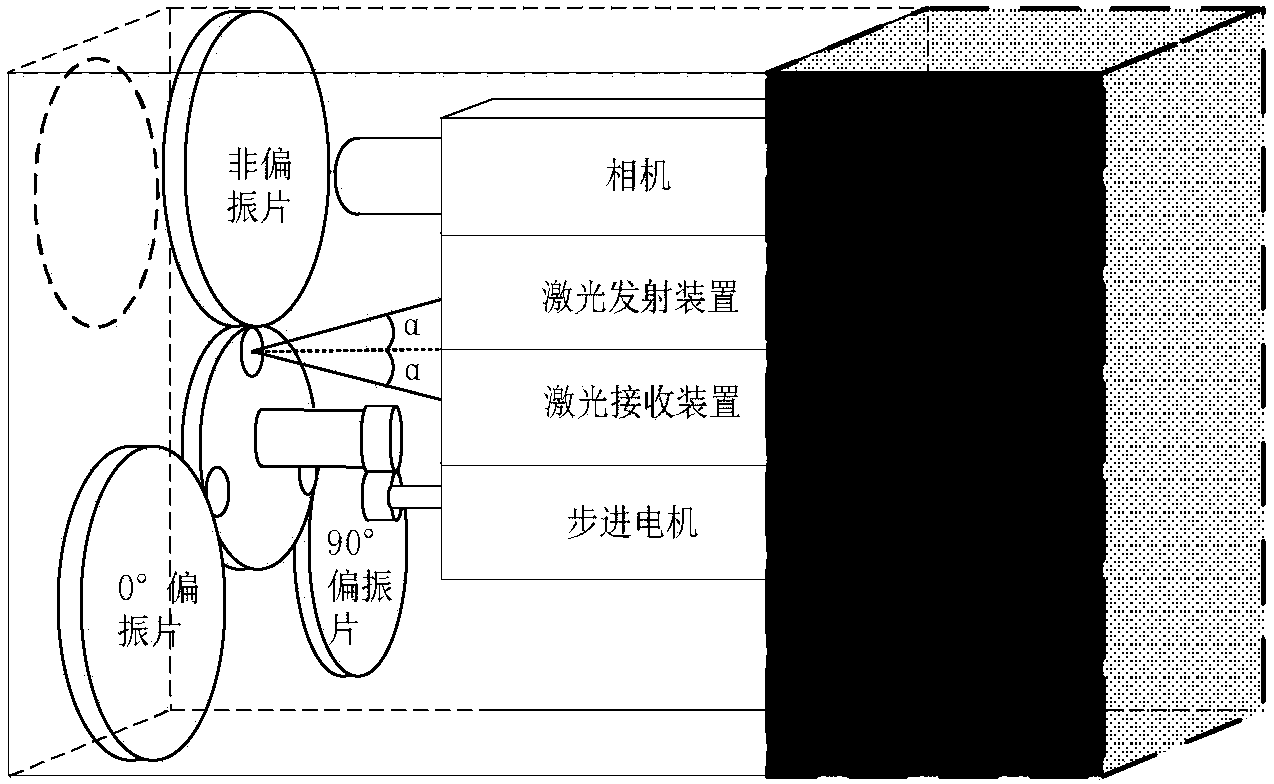

ActiveCN104052967ARealize acquisitionRealize processingClosed circuit television systemsUsing optical meansCamera lensMotor drive

The invention discloses an intelligent system for acquiring an underwater polarization target depth map and a method thereof. The intelligent system for acquiring the underwater polarization target depth map comprises an image acquisition module, a control module, an image processing module, a storage module, a display module and a power module, wherein the image acquisition module comprises a camera, a rotating camera lens arranged in the front of the camera, a linkage device composed of the rotating camera lens and a laser emitting / receiving device and a stepping motor driving the linkage device, the control module is used for controlling the stepping motor to rotate to adjust the linkage device, the image processing module is used for processing input image information, the storage module is used for storing the image information acquired by the acquisition module and depth image information obtained after processing of the image processing module, the display module is used for displaying the depth image information obtained after processing of the image processing module under the effect of a control signal of the control module, and the power module is used for supplying power. By means of the intelligent system for acquiring the underwater polarization target depth map, acquisition and display of the underwater polarization target depth map can be effectively achieved, and processing time and storage space are saved.

Owner:HOHAI UNIV

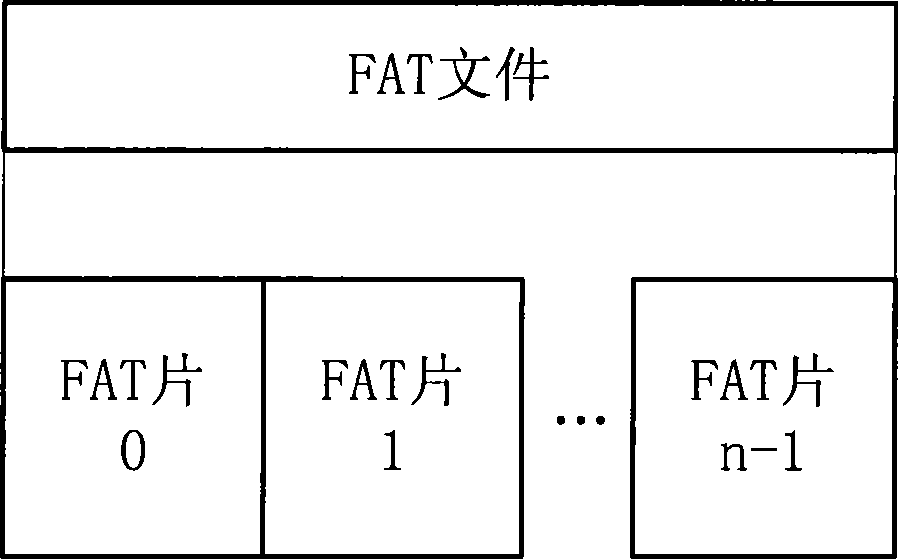

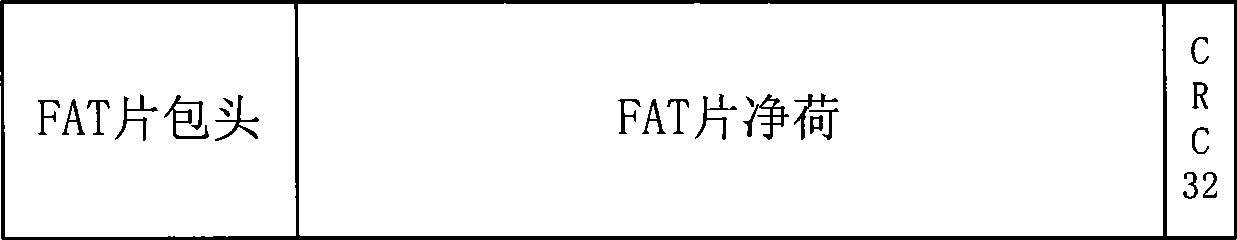

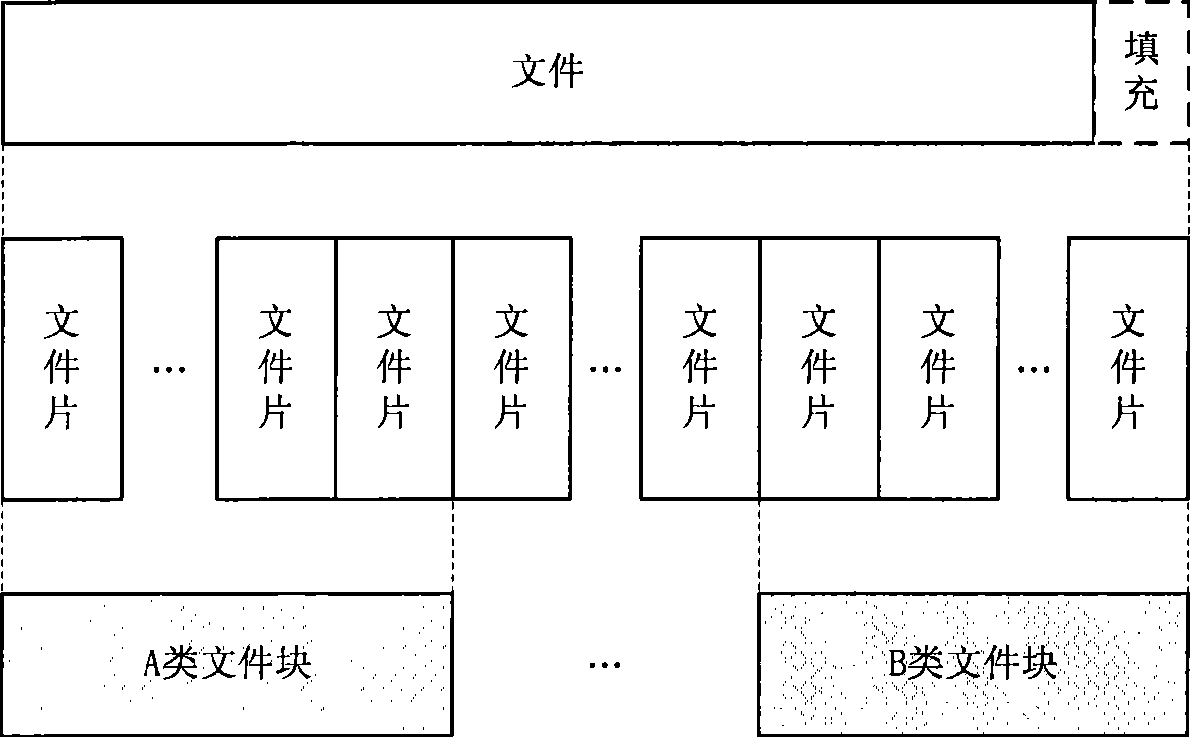

Document transmission method based on unidirection link

InactiveCN101465791AAchieve teleportationAchieve receptionBroadcast-related systemsData switching networksDirectory structureData traffic

The invention discloses a file transfer method based on unidirectional links, which is used to transfer a file to a plurality of users in a unidirectional transmission network. The method takes a file attribute table to describe the file composition, the file attribute and the transfer segmentation parameters of the data traffic and partitions the file to be transferred into data patches at equal length, and if the last data patch is not long enough, the last patch can be supplemented through 0x00; then the file patches are packed into data patch packets according to a data patch encapsulation grammar, and a data block is checked to form a parity block which closely follows the data block; and then the parity block is partitioned into pieces which are then packed into parity piece packets which are transferred closely following the corresponding data patch packets. A terminal first receives and analyzes the file attribute table and then completely restores a file and a catalogue structure consistent with the originating terminal at home according to the information indicated by the file attribute table. The method simply and effectively realizes the transmission and reception of the file in the unidirectional transmission network and the users can conveniently and quickly receive the file data traffic, thus greatly satisfying the requirements of the users.

Owner:ACAD OF BROADCASTING SCI SARFT

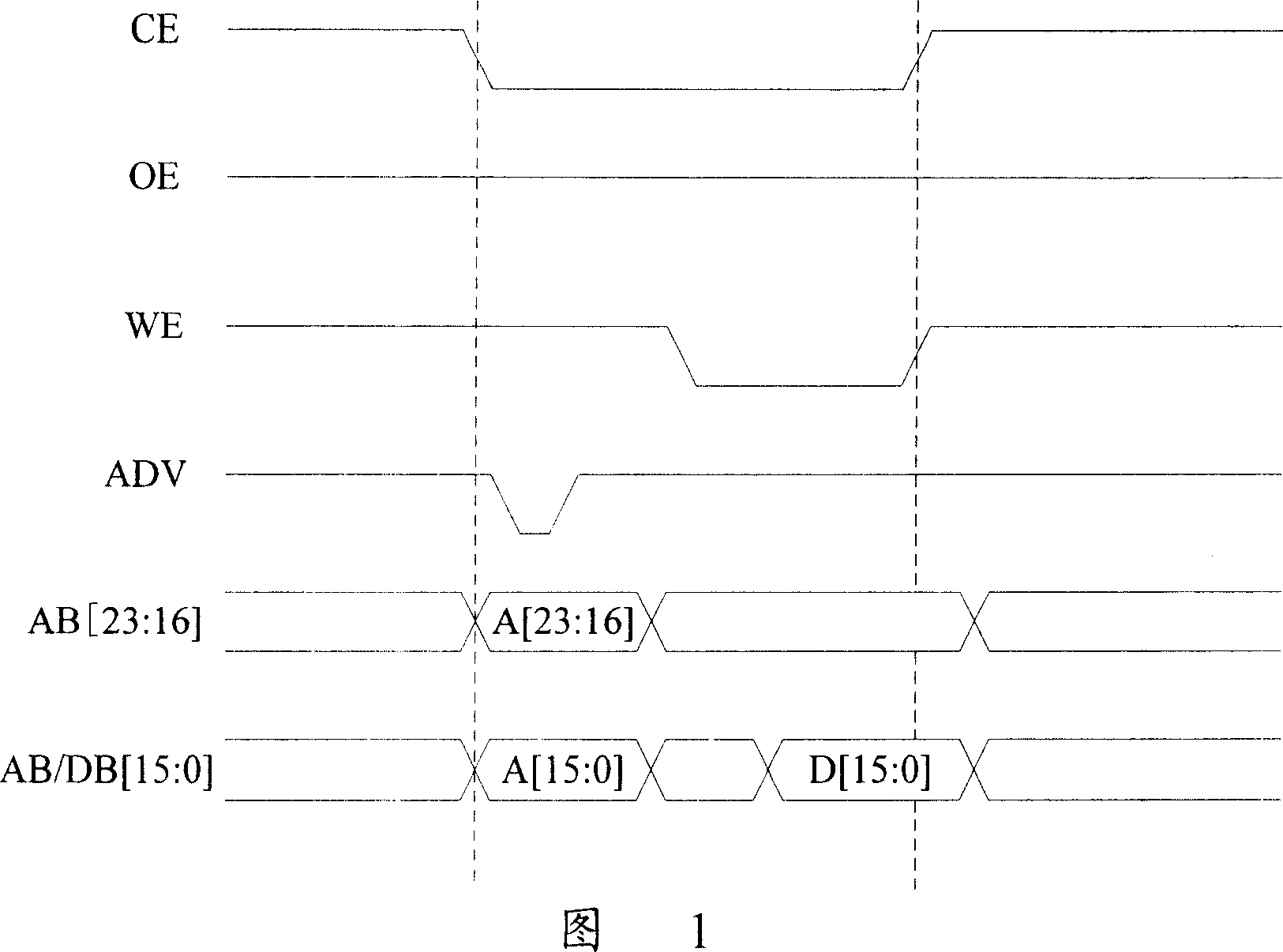

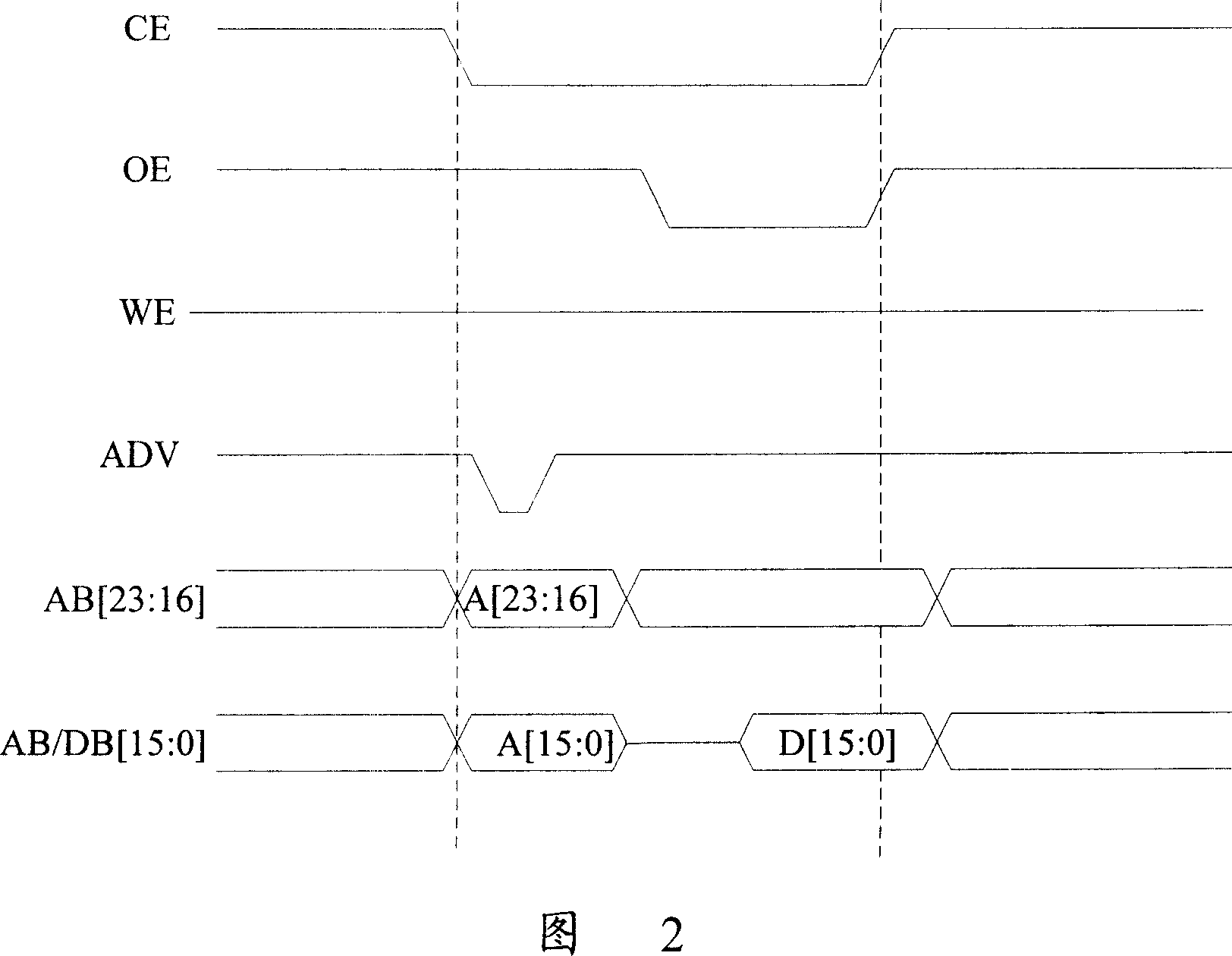

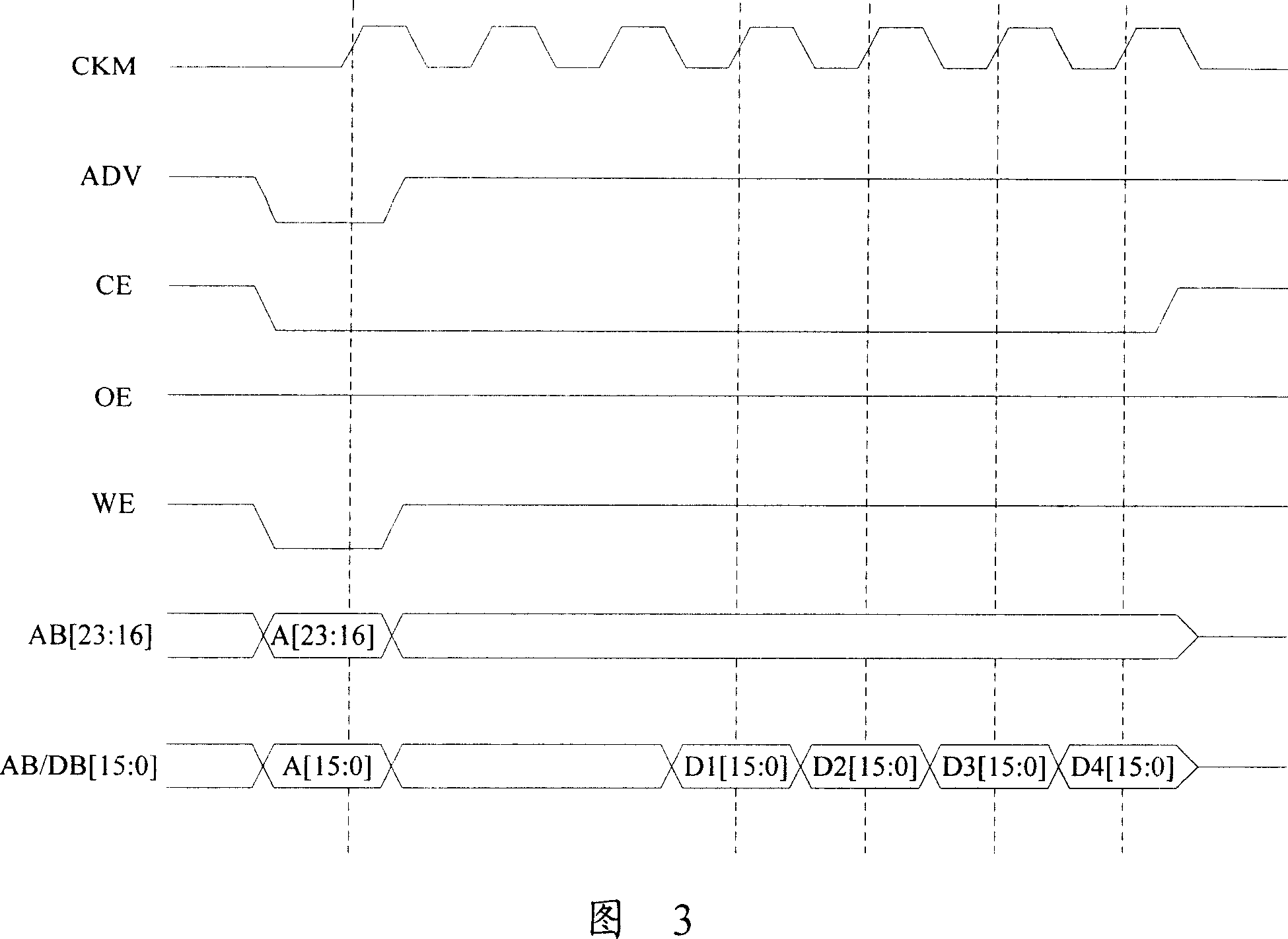

Bus interface devices and method

A method for realizing data transmission on bus interface includes confirming frequency n of sectional transmission according bus bit width ratio of the first system with low bit width bus to the second system with high bit width bus, receiving n numbers of information from the first system and piecing them together to send them to bus of the second system when information stream is from the first system to the second system or otherwise receiving information from the second system and disconnecting it to be n numbers of information being sent to bus of the first system.

Owner:VIMICRO CORP

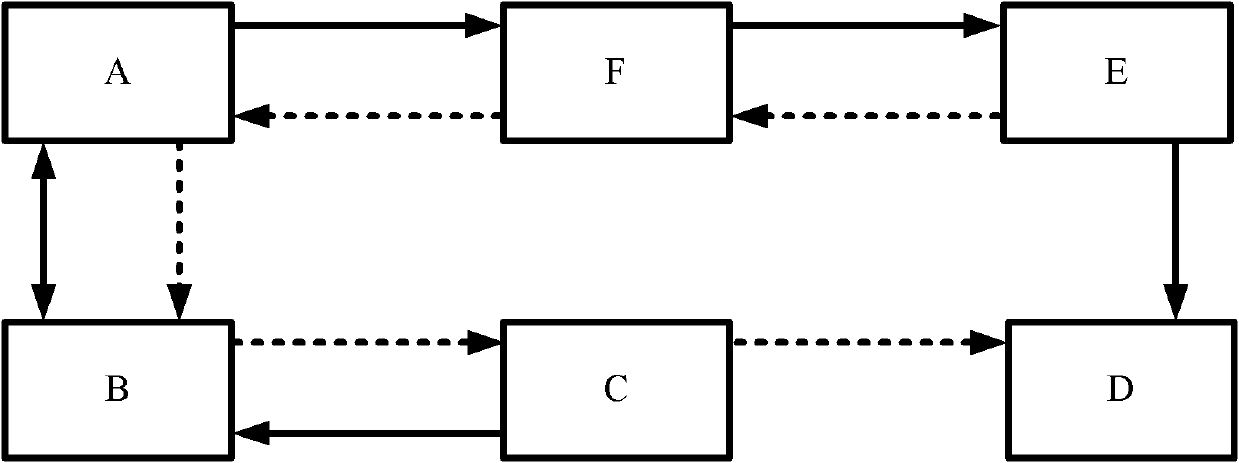

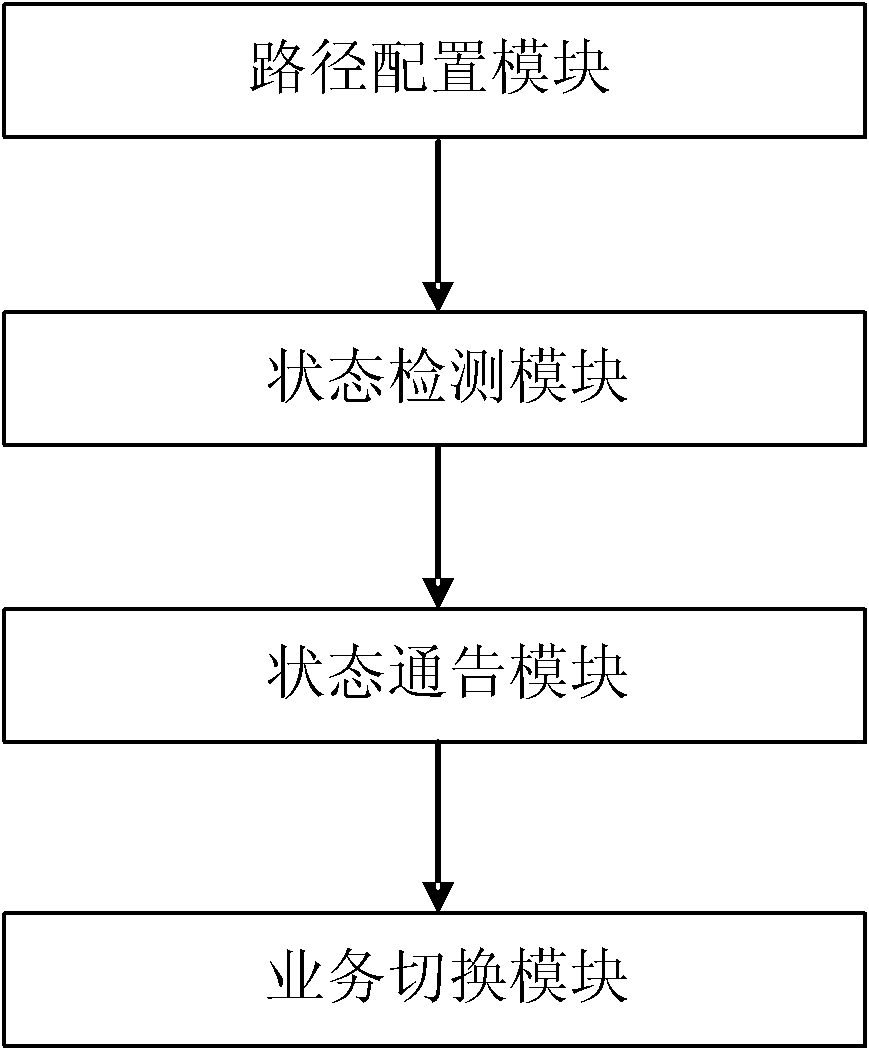

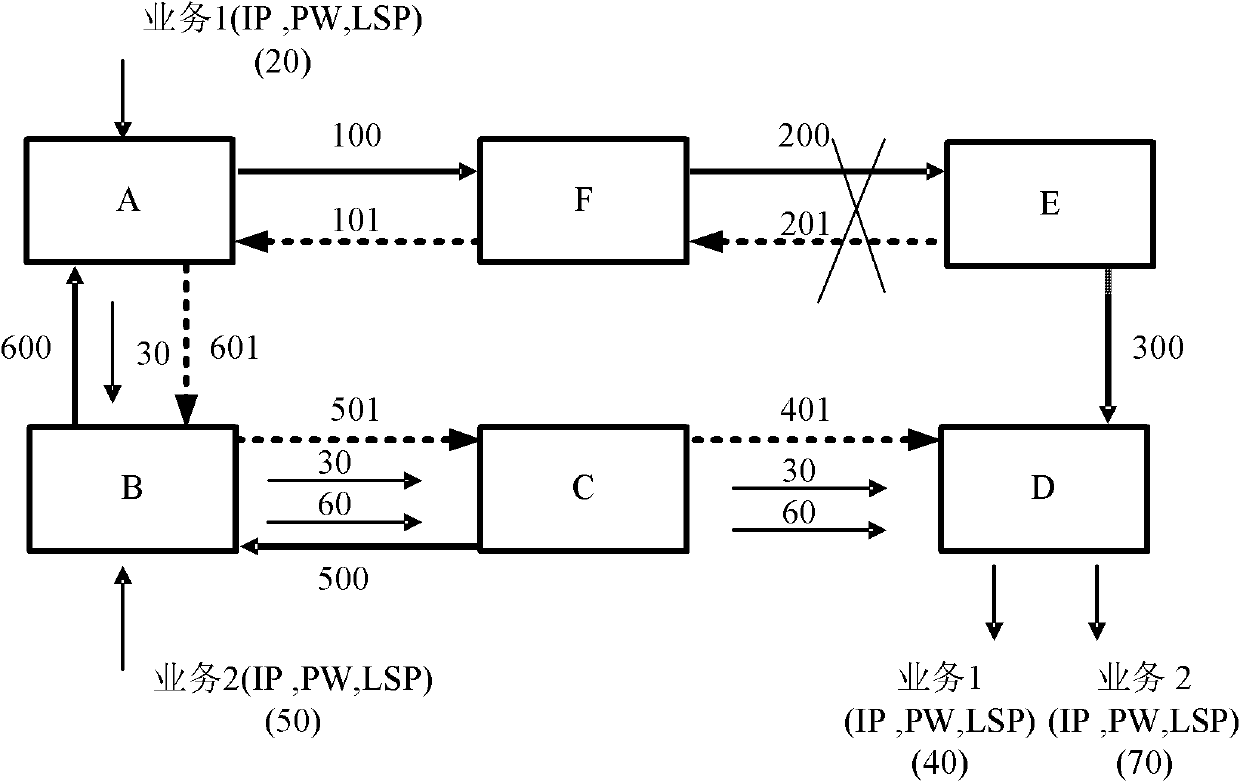

Shared path-based looped network tunnel configuration method, and method and system for switching service

ActiveCN102891787AAchieve teleportationAchieve protectionConnection managementData switching networksDistributed computingMultiple node

The invention discloses a shared path-based looped network tunnel configuration method, and a method and a system for switching service. Lower looped nodes of looped service are taken as target nodes, and operation tunnels and protection tunnels which mutually protect on the basis of the shared path are configured. The method comprises the following steps of: configuring the operation tunnels from one adjacent node of the node to the node clockwise or counterclockwise; and configuring the protection tunnels from the other adjacent node of the node to the node along the direct opposite to the operation tunnel. The service from multiple-node in-loop to the same node out-loop is loaded by means of the shared path of multipoint to point (MP2P) established on the loop. Compared with the prior art, the method has the advantages that: the configuration complexity is prevented; the configuration is optimized; and the looped service is transmitted and protected by means of the protection tunnels which reach certain nodes on the loop.

Owner:盐城捷恒仓储有限公司

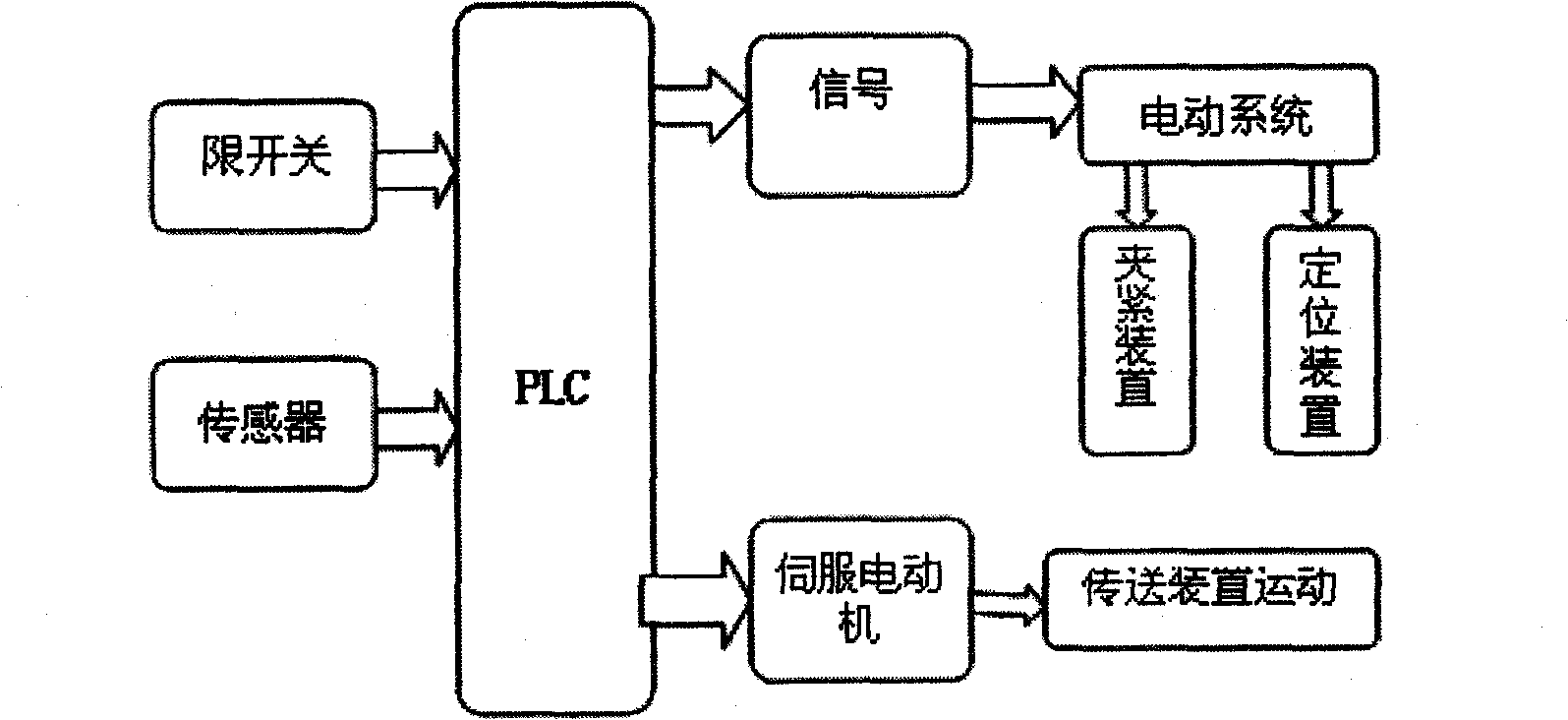

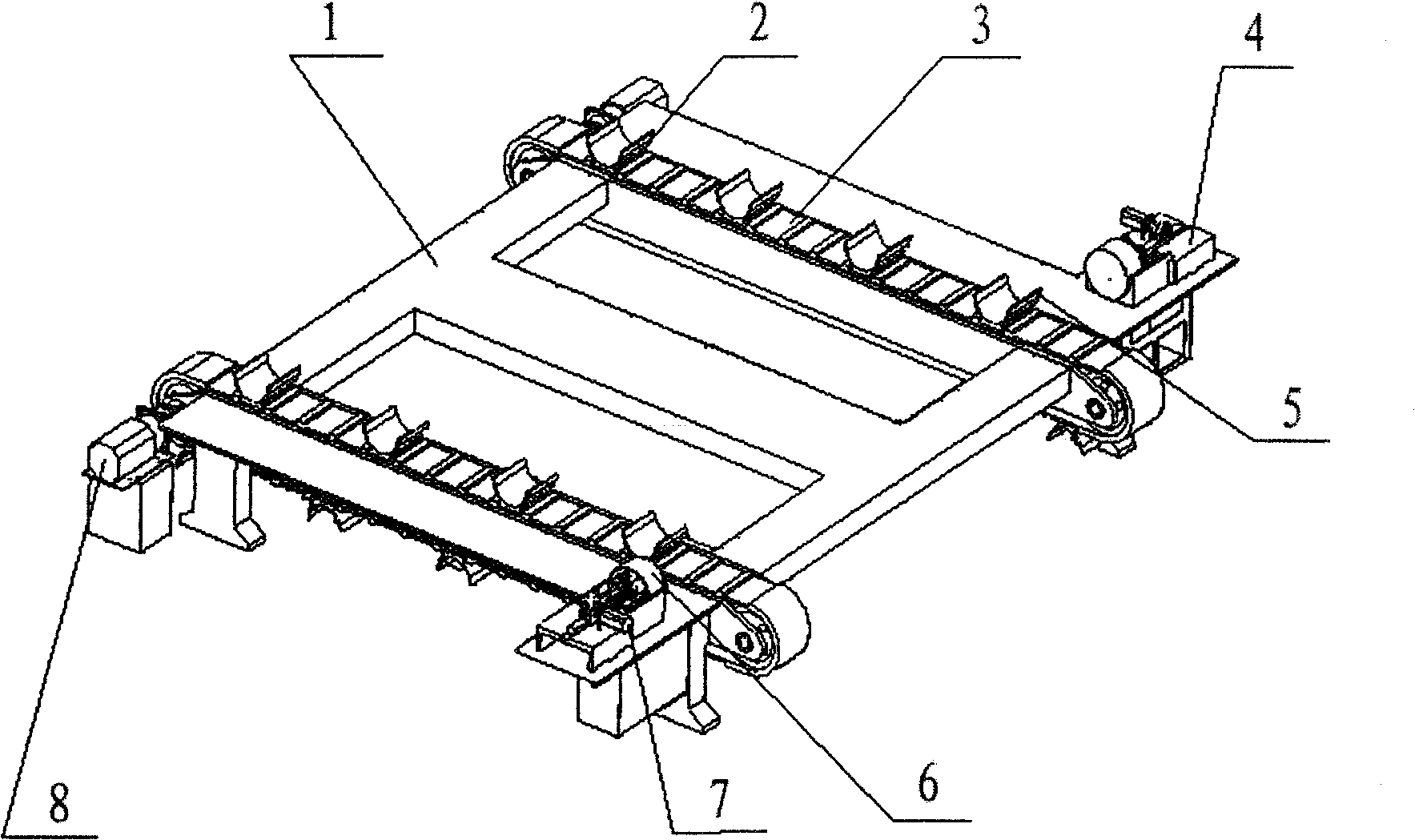

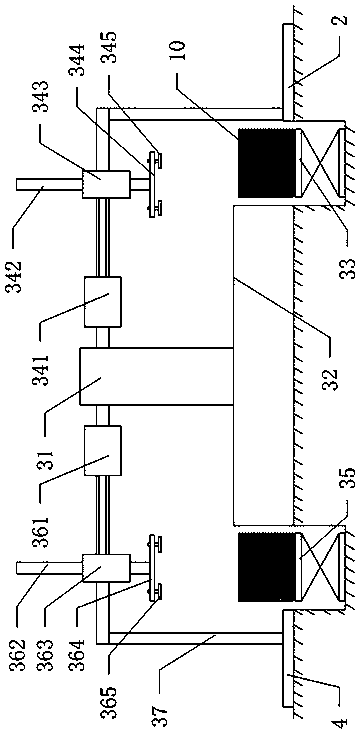

Hole positioning welded pipe conveying device

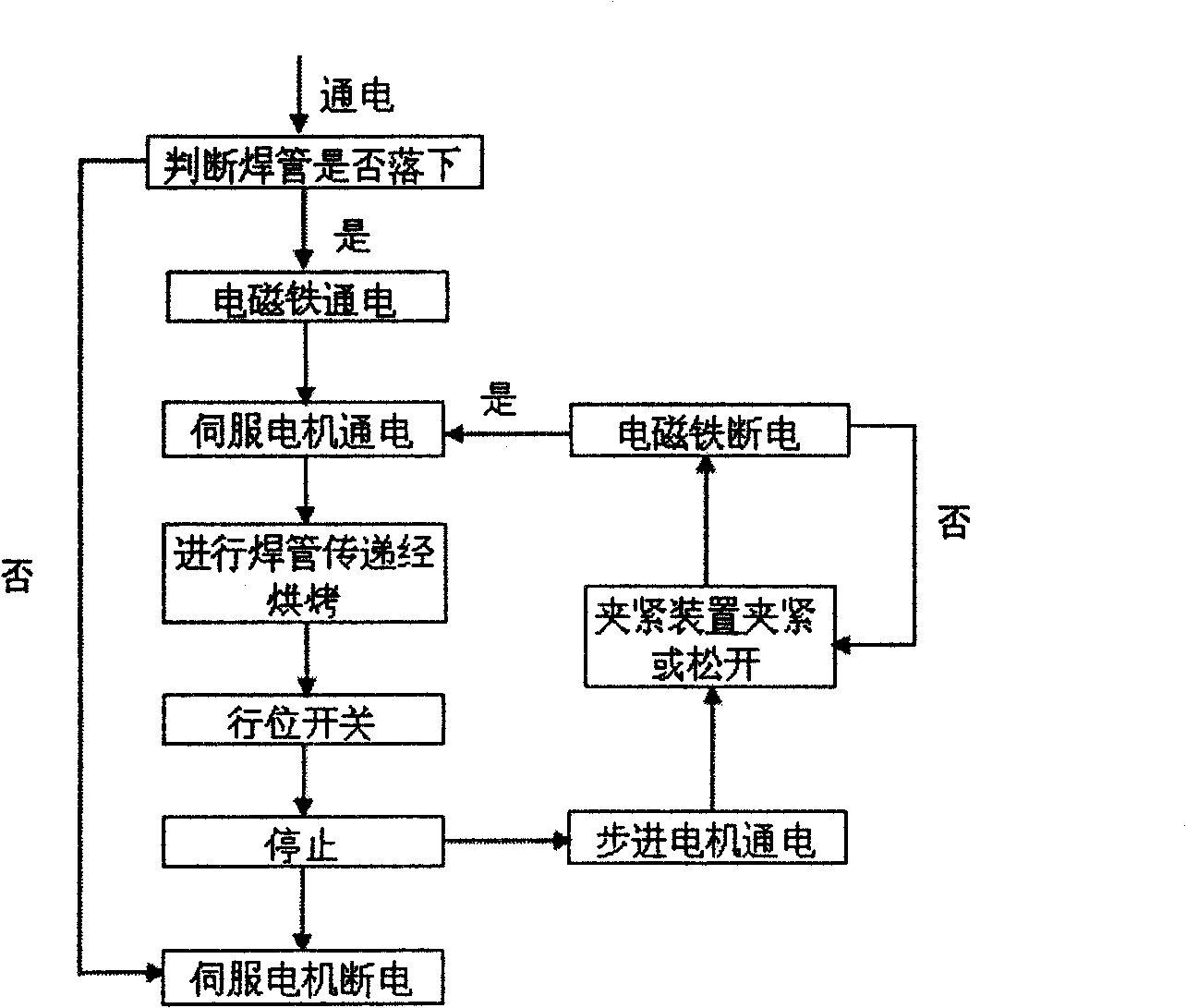

InactiveCN102069993ASimple structureEasy to useConveyorsControl devices for conveyorsMotor driveControl signal

The invention discloses a hole positioning welded pipe conveying device, which comprises a bracket, a V-shaped positioning mechanism, a caterpillar chain conveying mechanism, a clamping and repositioning mechanism, a positioning block, an ejecting cylinder, a step motor, and an alternating current servo motor. In the device, the V-shaped positioning block is adopted to position a welded pipe, an electromagnet performs attraction and pressing, the alternating current servo motor drives the caterpillar chain to convey the welded pipe to a specified position after passing through a baking chamber, and a clamping device performs hole positioning again. An electrical control system uses programmable logic controller (PLC) as a core control element, adopts a fully-automatic production flow line and controls the operation and stop of the alternating current servo motor through the input and output of a PLC control signal according to the change of the signal to realize the automatic conveying of the welded pipe.

Owner:王雪

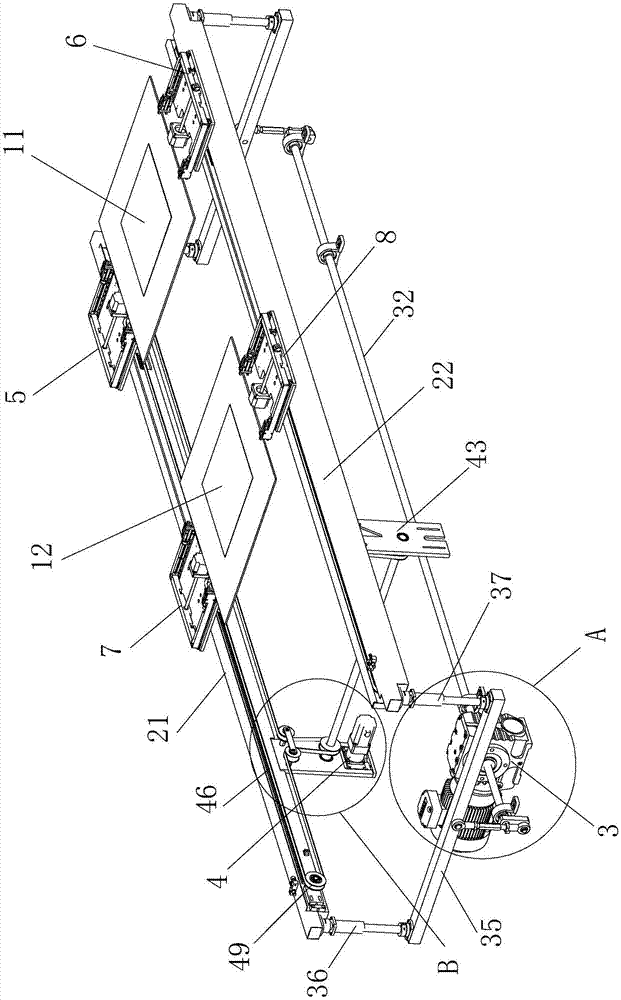

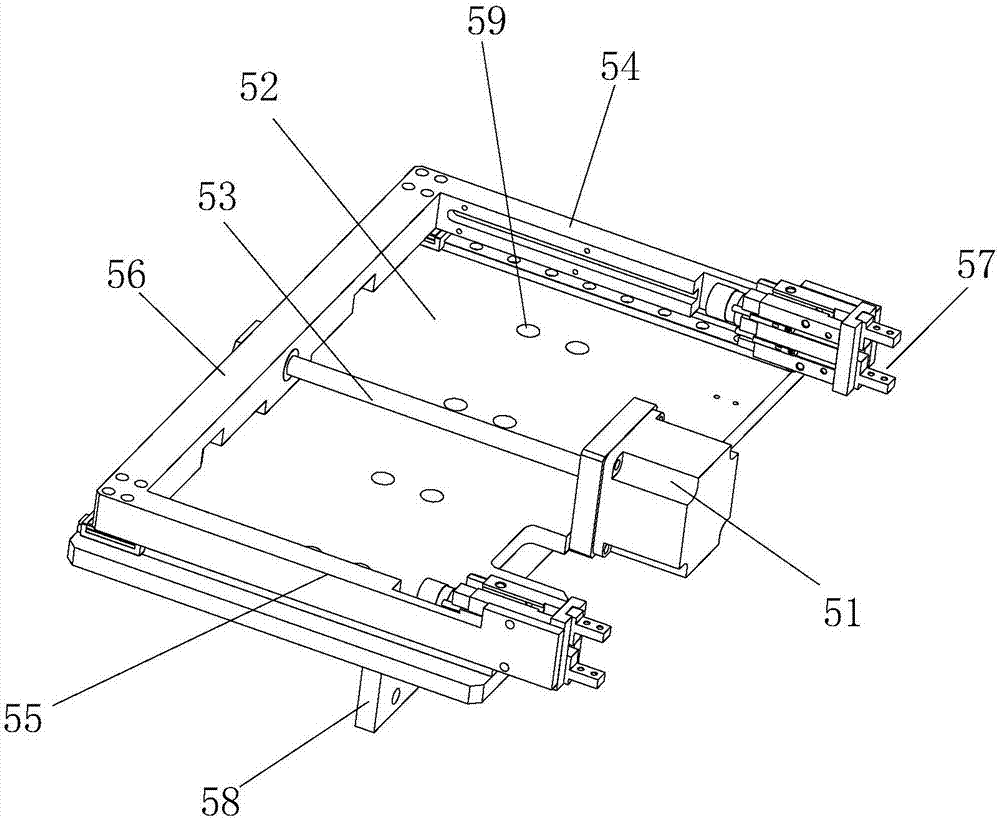

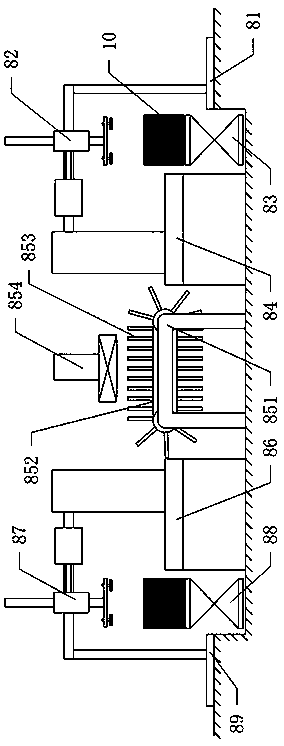

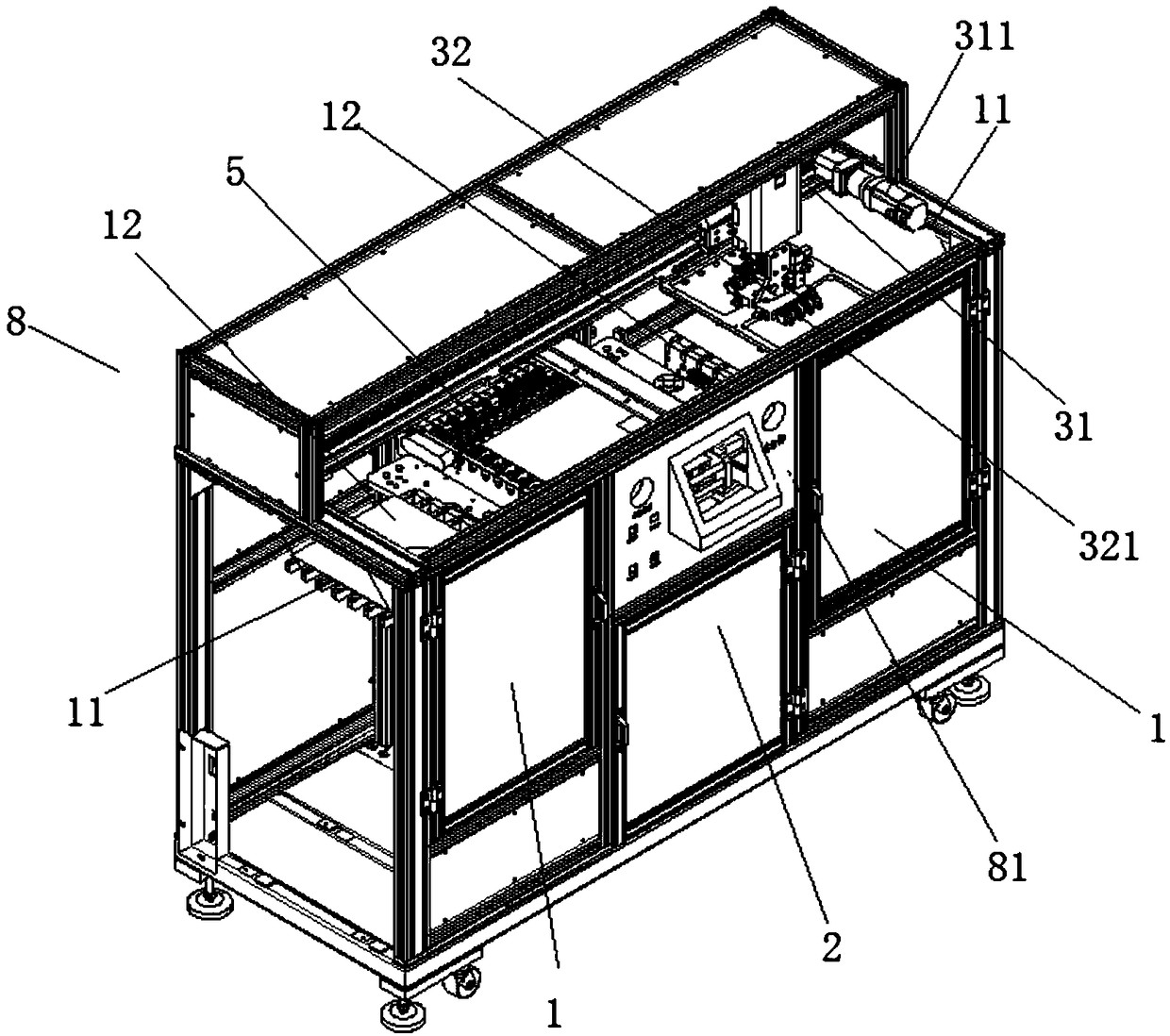

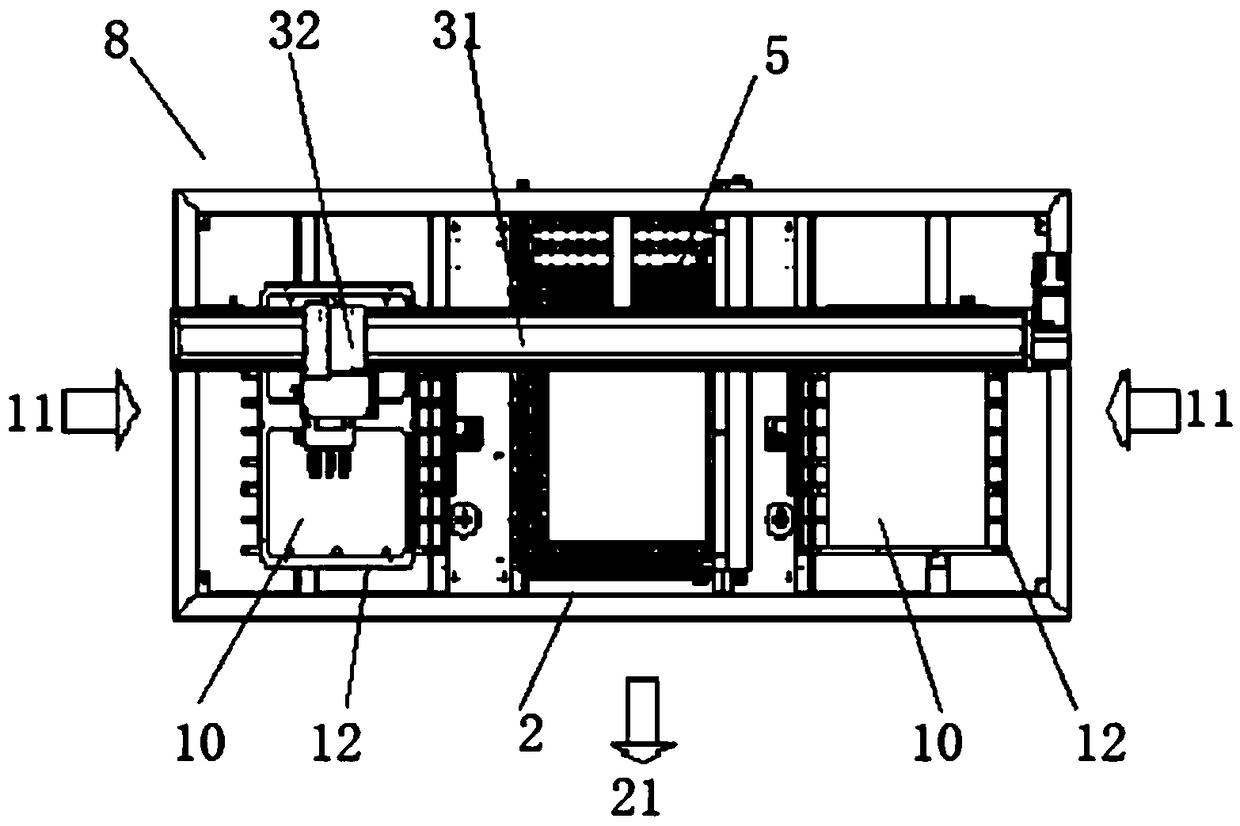

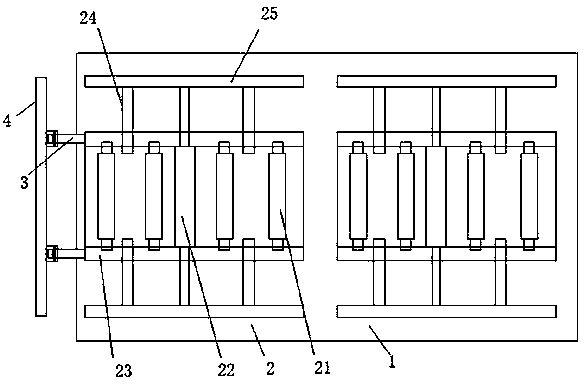

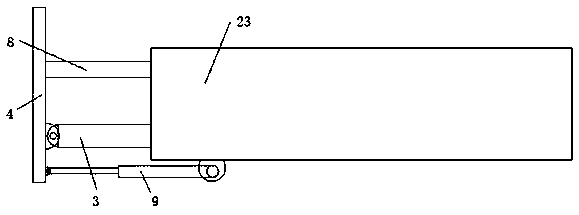

PCB clamping and conveying mechanism and working method thereof

ActiveCN107010401ASuitable for continuous automated productionAchieve clampingConveyor partsIndustrial engineering

The invention relates to a PCB clamping and conveying mechanism and a working method of the PCB clamping and conveying mechanism. The PCB clamping and conveying mechanism comprises a left clamping arm, a right clamping arm, a left clamping arm support beam and a right clamping arm support beam, wherein the left clamping arm and the right clamping arm are arranged in a paired manner and of the same structure, and the left clamping arm support beam and the right clamping arm support beam are arranged in parallel. Each of the left clamping arm and the right clamping arm comprises a bottom plate and a clamping assembly. The bottom plate of the left clamping arm is in sliding fit with the left clamping arm support beam so that the left clamping arm can slide in the extending direction of the left clamping arm support beam. The bottom plate of the right clamping arm is in sliding fit with the right clamping arm support beam so that the right clamping arm can slide in the extending direction of the right clamping arm support beam. The clamping assemblies are in sliding fit with the corresponding bottom plates. The sliding direction of the clamping assemblies is perpendicular to the sliding direction of the left clamping arm / right clamping arm so that a support assembly of the left clamping arm and a support assembly of the right clamping arm can oppositely slide towards the opposite inner sides of the left clamping arm support beam and the right clamping arm support beam on the bottom plate, and the opposite inner side ends of all the clamping assemblies are each provided with a transverse U-shaped opening.

Owner:江苏智子自动化科技有限公司

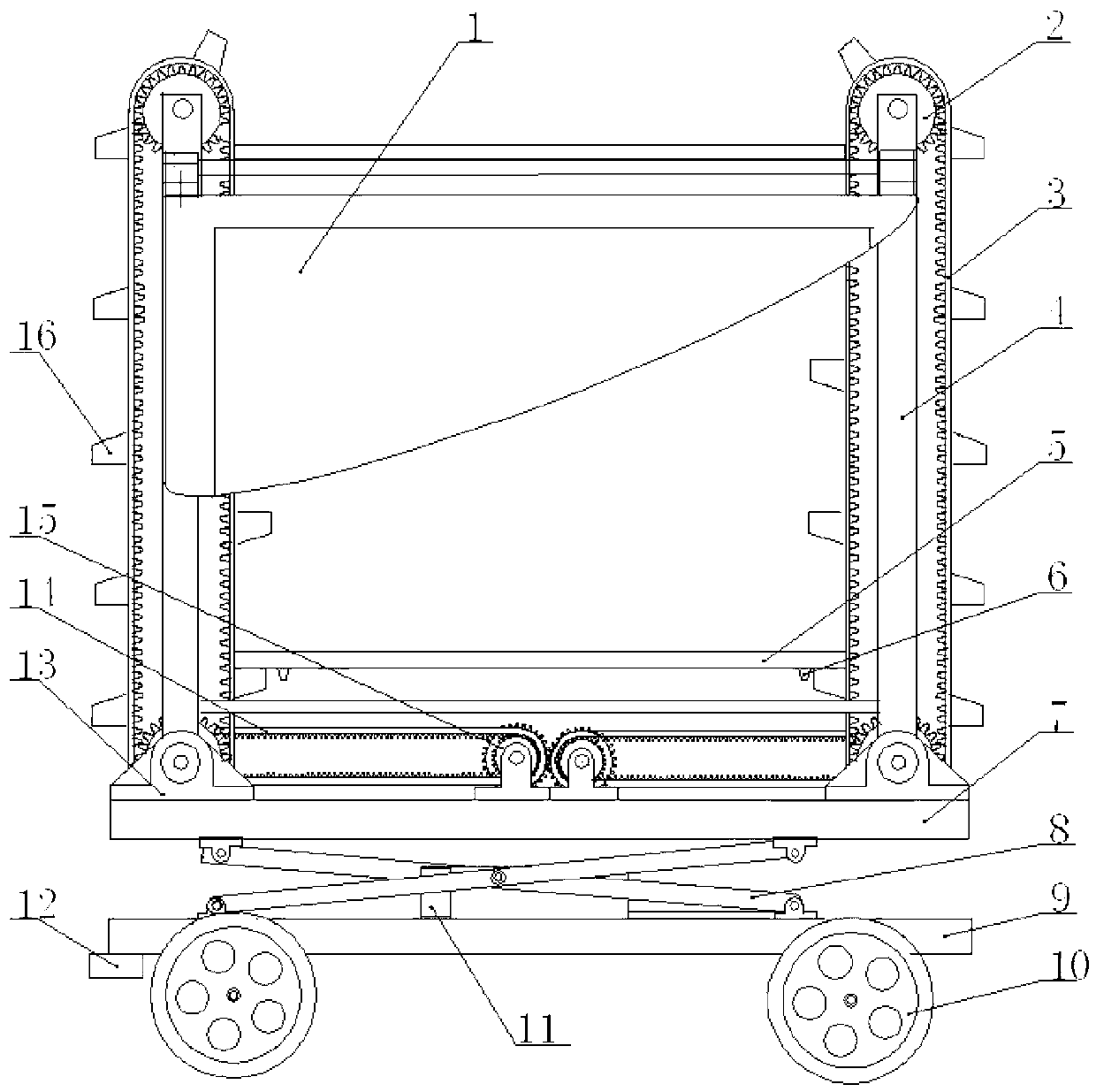

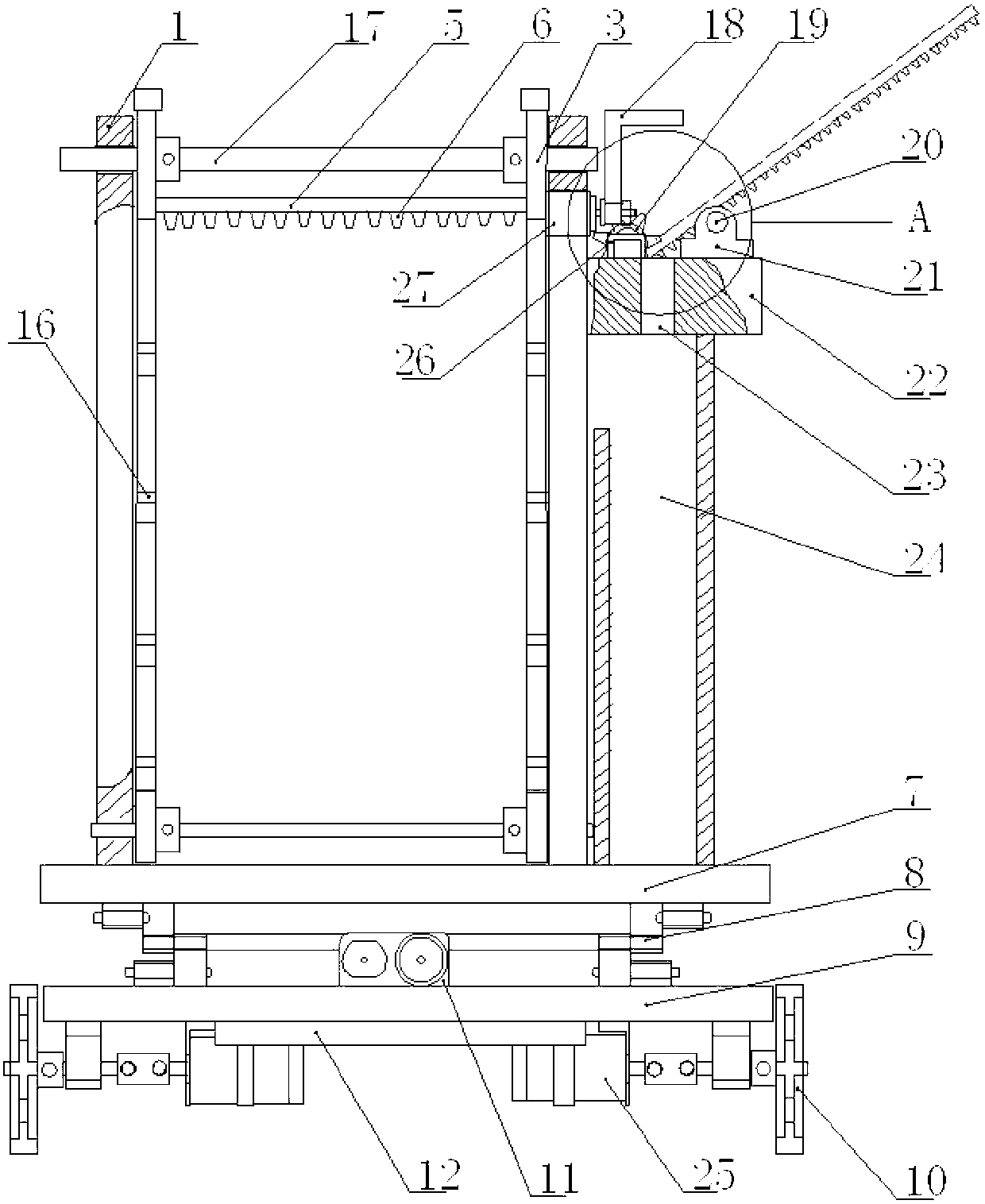

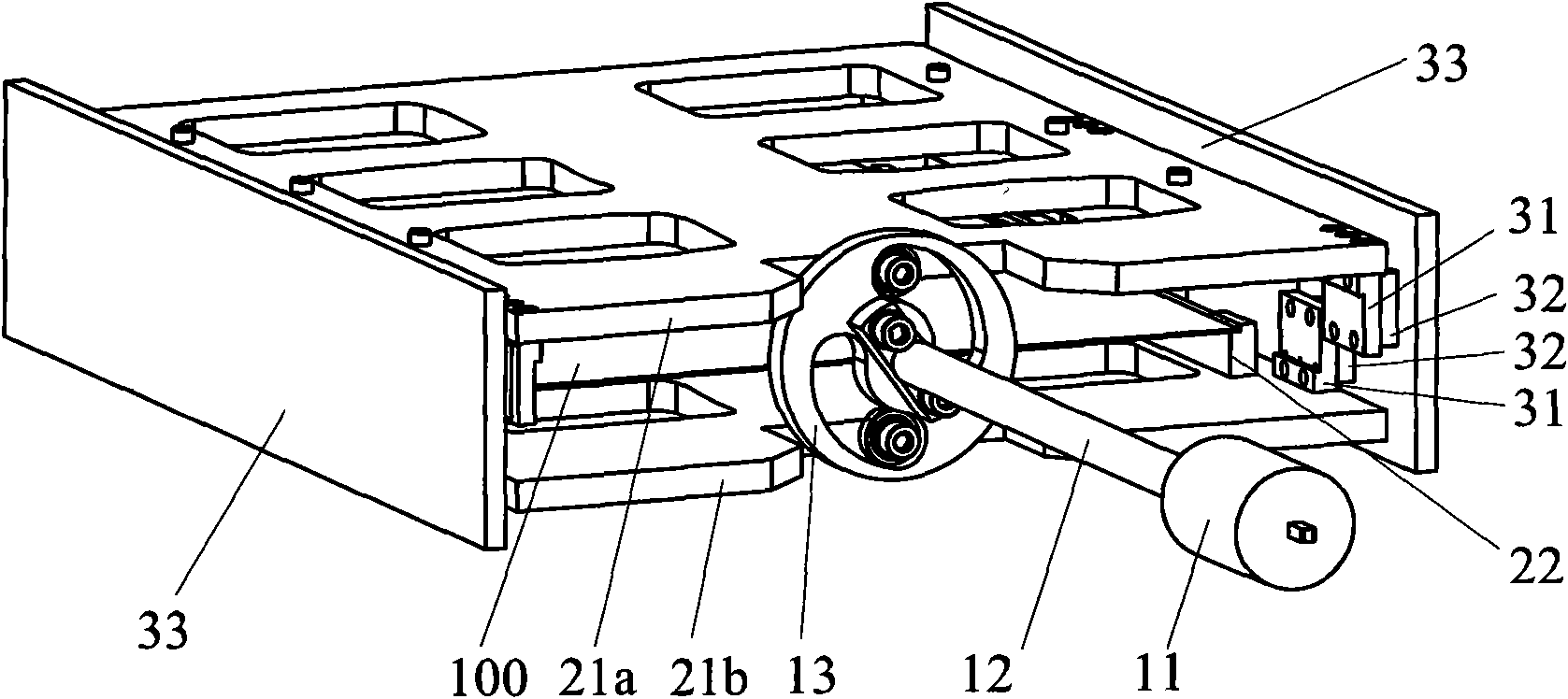

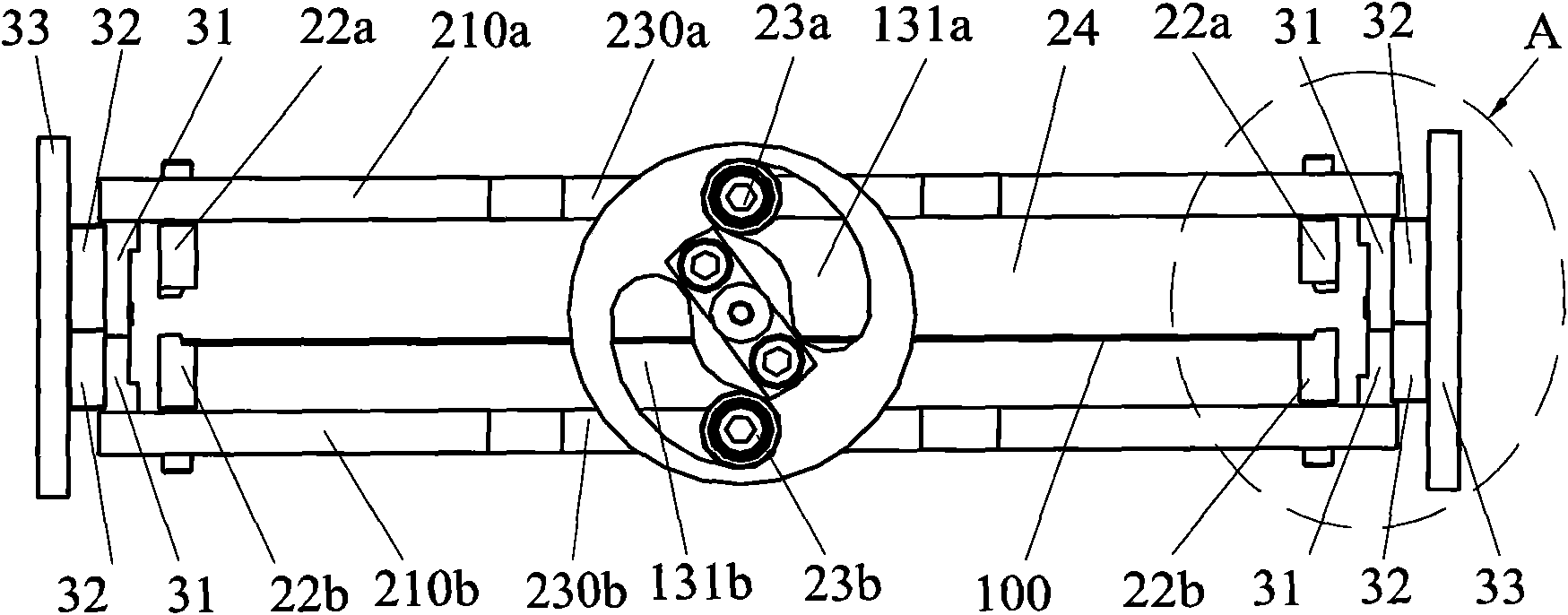

Continuous shunting feeding mechanism

InactiveCN108689088AReasonable structural designQuick and easy translation resetConveyorsEngineeringMechanical equipment

The invention discloses a continuous shunting feeding mechanism, and belongs to the field of workpiece conveying mechanical equipment. A material pushing mechanism is horizontally and fixedly arrangedon the feeding bracket at one side of the feeding mechanism, an intermittent driving mechanism is horizontally arranged on the feeding bracket at the lower side of the material pushing mechanism, a material suction electromagnet is horizontally and fixedly arranged on the lower side of a connecting guide plate, a rotating base is rotatably connected to middle of the lower side of a material bearing bracket, a material pushing cylinder is horizontally and fixedly arranged on one side of the material bearing bracket, two adsorption armatures are uniformly and fixedly arranged on the outer sideof a feeding chain, a feeding rotating shaft on one side of a feeding ratchet wheel is vertically and rotatably connected with a feeding gear, the feeding gear is connected with the upper side of a translation rack in a meshing mode, and a plurality of the conveying guide belts on the upper side of the feeding bracket are perpendicular to feeding guide rods. The continuous shunting feeding mechanism has reasonable structural design, can carry out translational feeding on a plurality of workpieces as a whole, and can carry out shunting feeding and conveying on the fed workpieces one by one in an orderly manner to meet the requirements of machining and use.

Owner:沈洁

Method and system for holding terminal nomadism in mobile broadcast television service

InactiveCN1829389AEfficient use ofOvercoming the drawbacks of limited bandwidthTelephonic communicationAnalogue secracy/subscription systemsSupporting systemRoaming

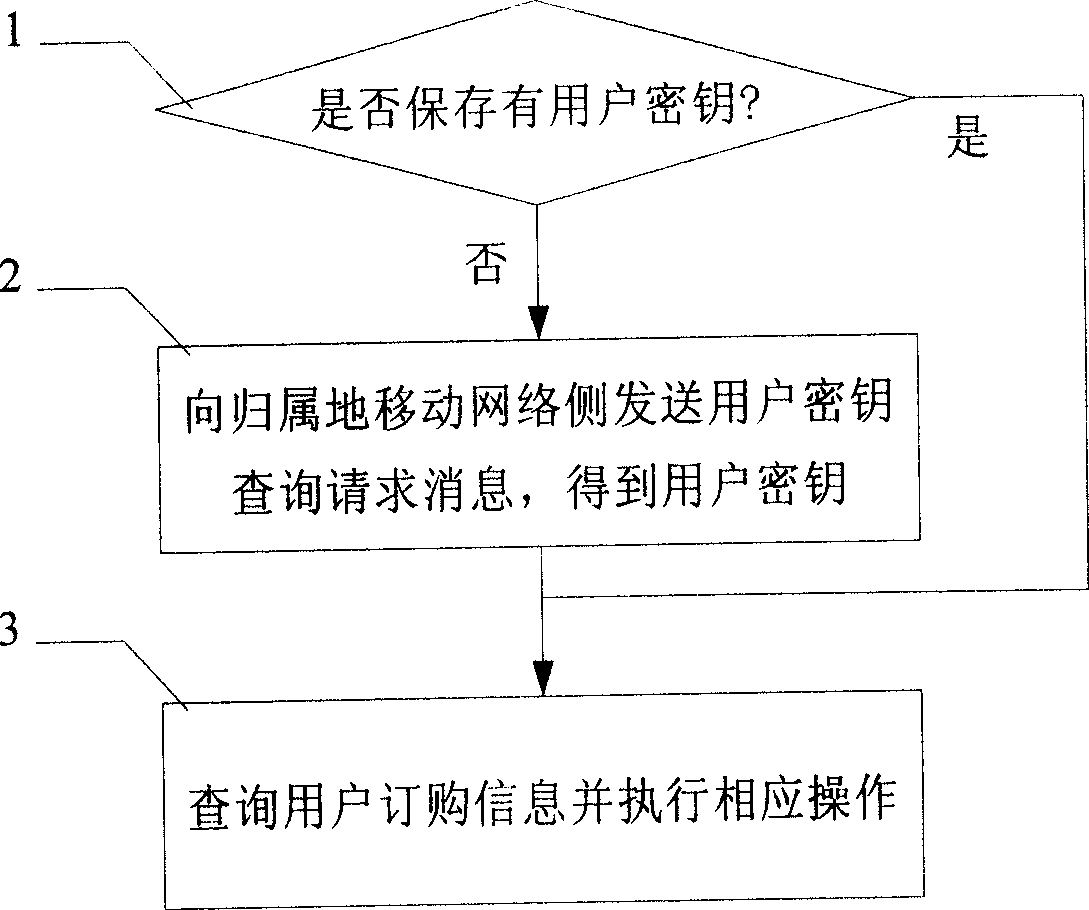

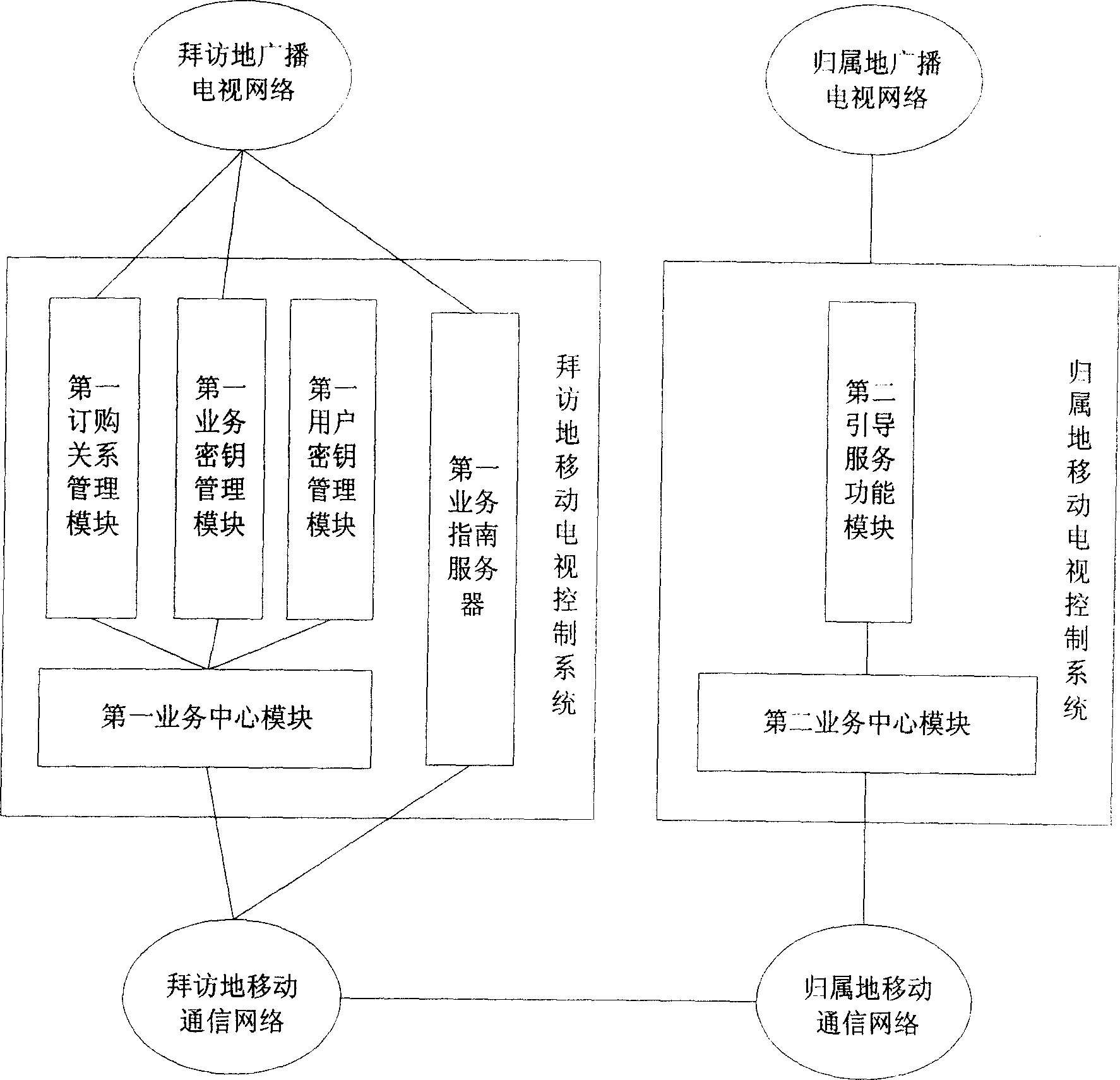

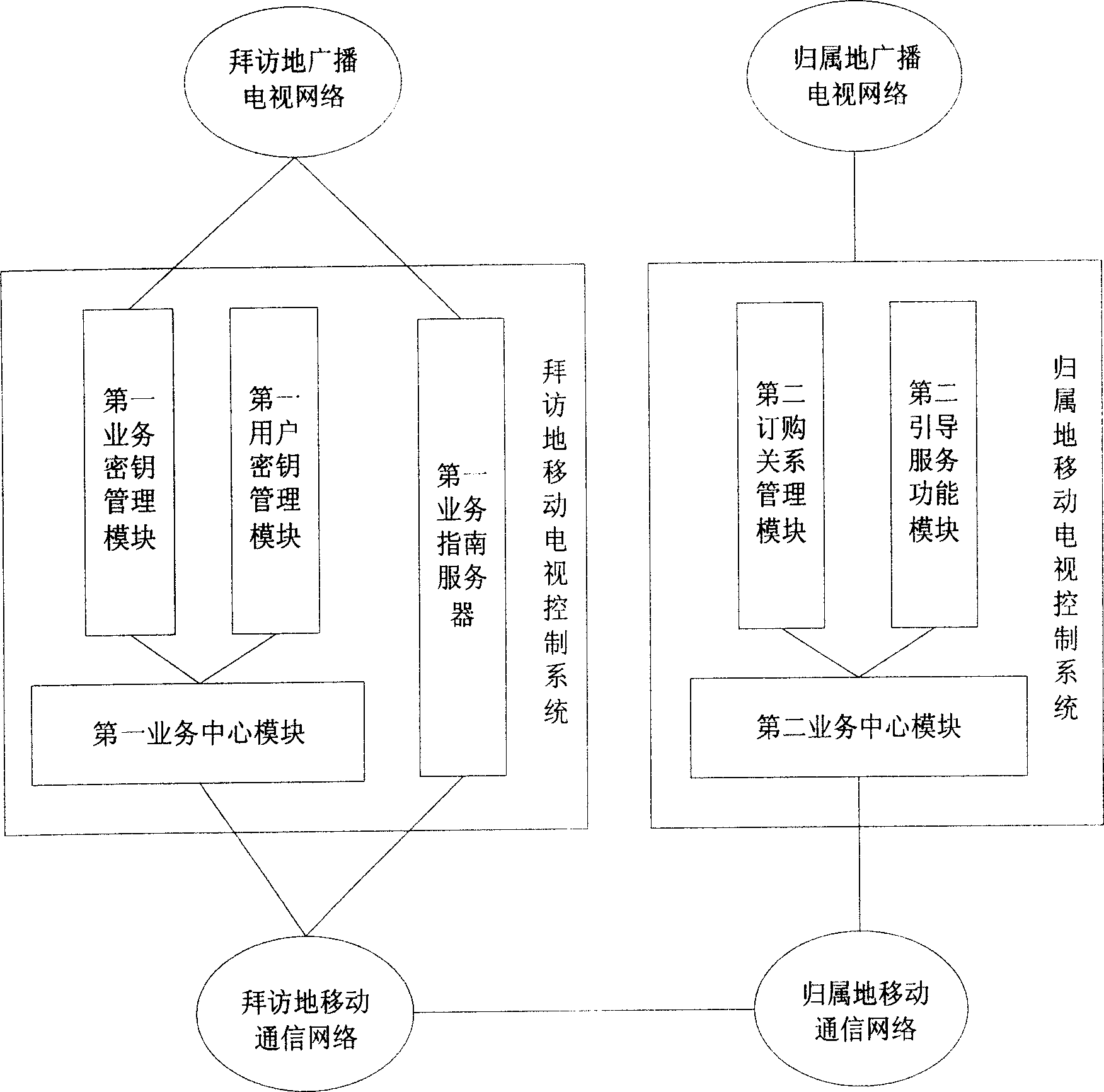

The present invention provides terminal roaming supported method in mobile radiated television service. It contains 1, visiting area mobile communication network side receiving terminal sent service authorizing request message, querying whether pre - saving said terminal user encryption key, if it is then executing steps 3 otherwise executing steps 2, 2, visiting area mobile communication network side transmitting user encryption key obtaining request message to attributed area mobile network side, obtaining attributed area mobile network side returned said terminal user encryption key, 3, visiting area mobile communication network side querying said terminal user corresponded order information, according to said user order information, judging whether said terminal user ordering said radiated television program and executing relevant operation. Said invention also provides terminal roaming supported system in mobile radiated television service and supports terminal roaming, service authentication and charging in mobile radiated television service.

Owner:CHINA MOBILE COMM GRP CO LTD

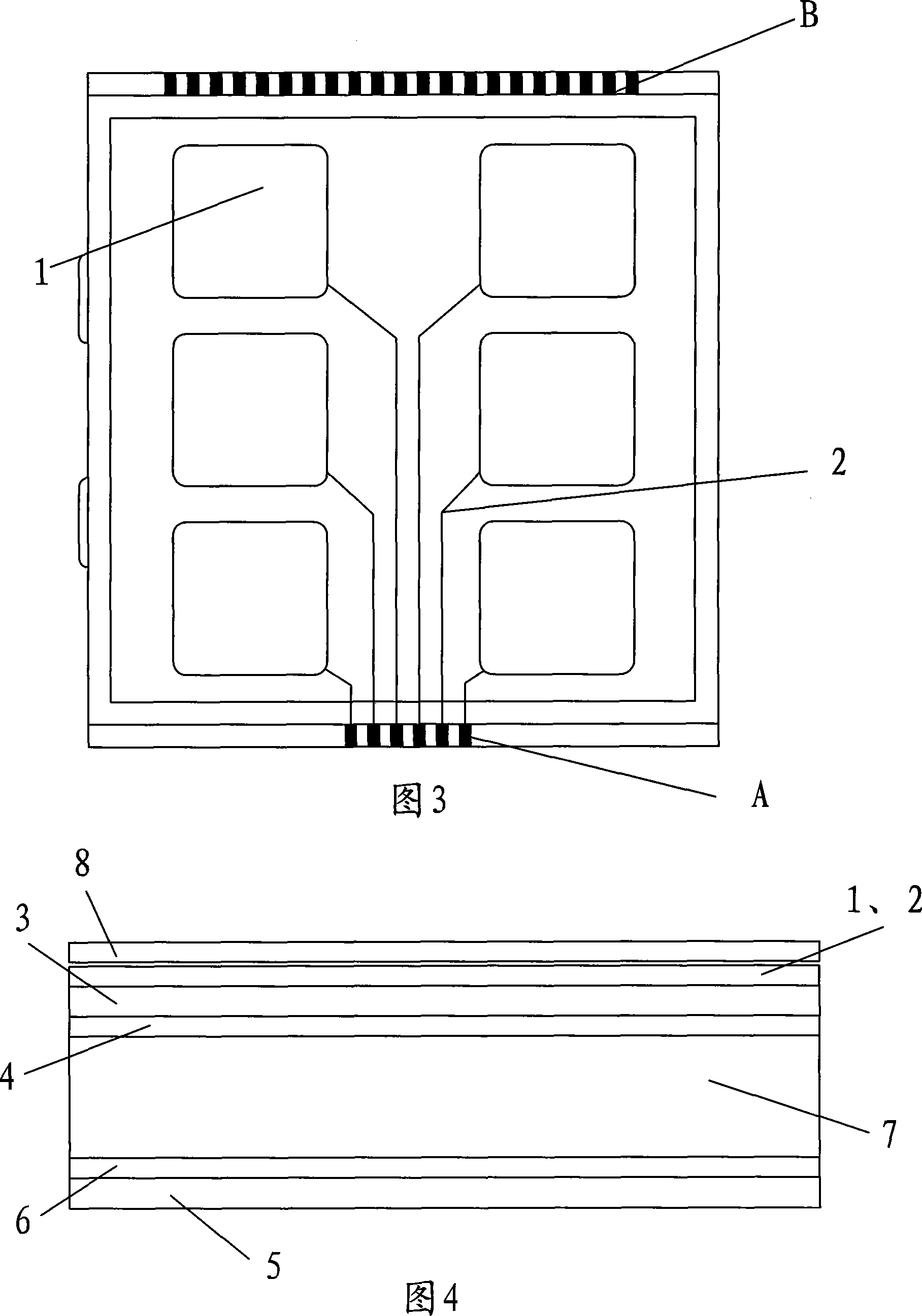

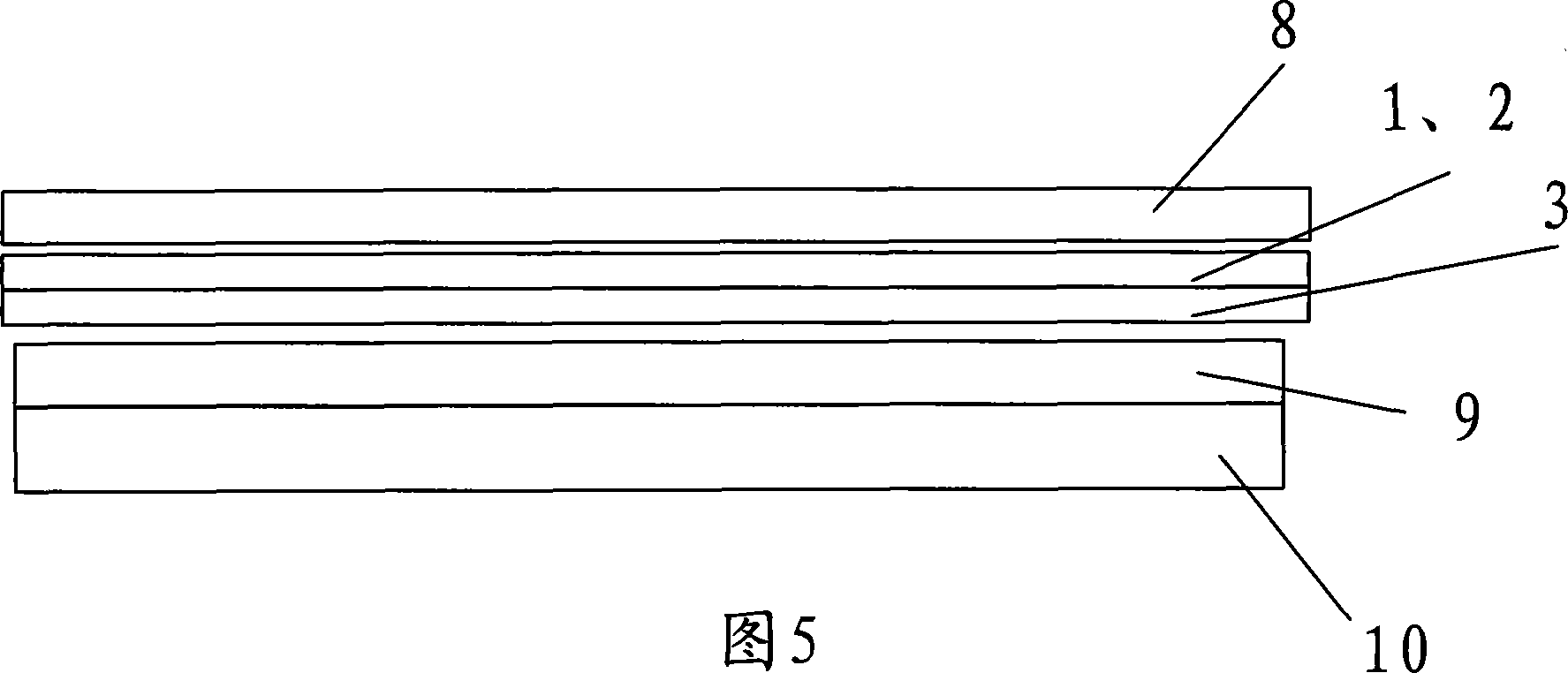

Condenser type contact screen and its manufacture method

InactiveCN101126849AAchieve teleportationLow costStatic indicating devicesPhotomechanical apparatusCapacitanceKey pressing

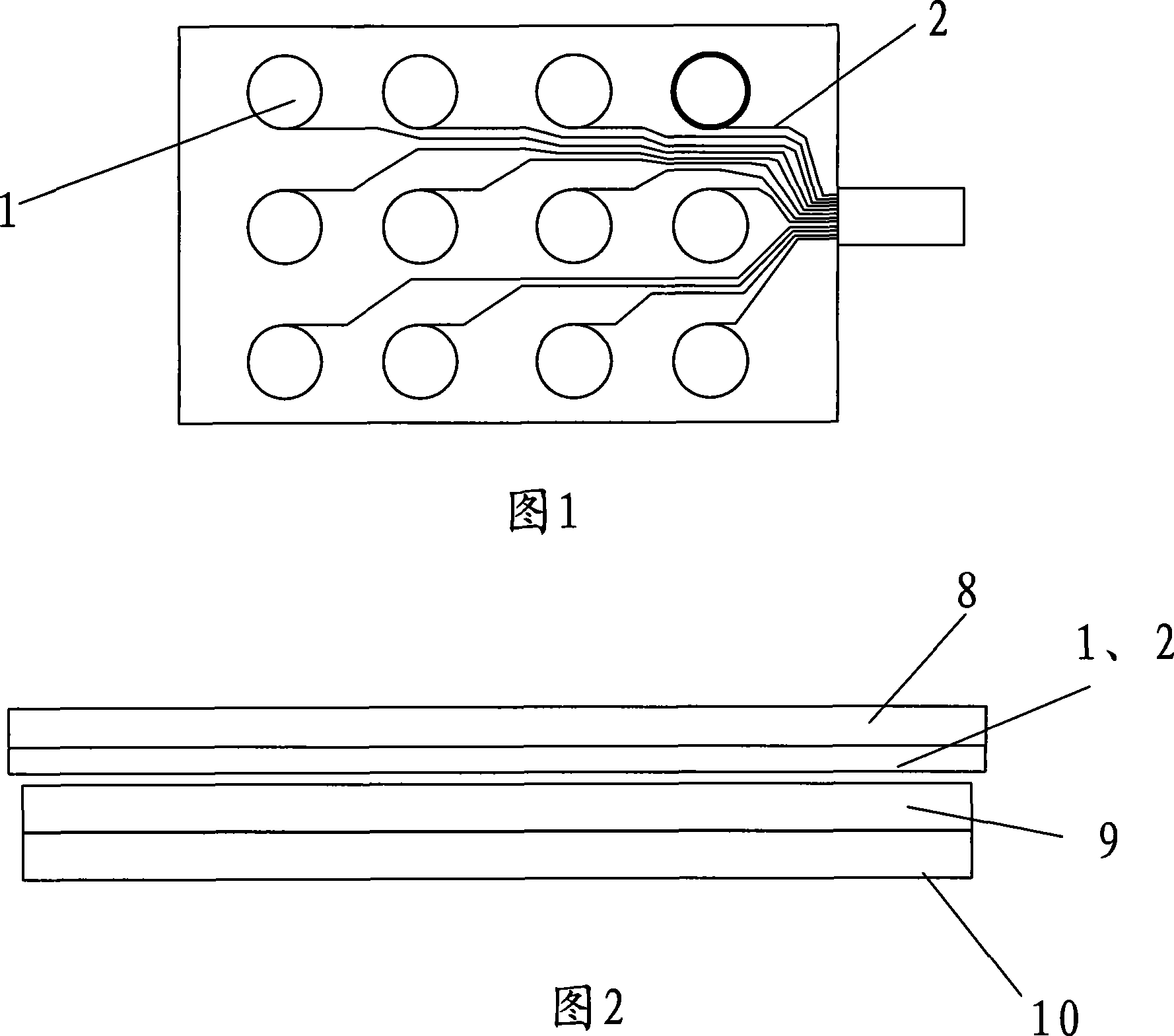

The utility model relates to a capacitance touch screen, comprising a tin / indium oxides layer and a transparent protection layer on the tin / indium oxides layer. Key shapes are etched on the tin / indium oxides layer, and each press-key with one or more outgoing etched lines, is connected with a capacitance touch chip by the line. A manufacturing method of the capacitance touch screen comprises the following steps: A1) set the first tin / indium oxides layer; A2) etch the keys and lines on the first tin / indium oxides layer through photo-etching technology. Because keys and lines of the capacitance touch screen are directly etched on the tin / indium oxides layer in the utility model, signal transmission along the lines can be realized in the simplest way, and the key pressed can be estimated in the shortest time, hence lower cost and higher efficiency. The integration of the LCD and touch screen makes the display and the touch screens in the same plane without adding any thickness or holes to be drilled on the structure. The touch screen has advantages of convenient installation and attractive appearance.

Owner:SHENZHEN H&T INTELLIGENT CONTROL

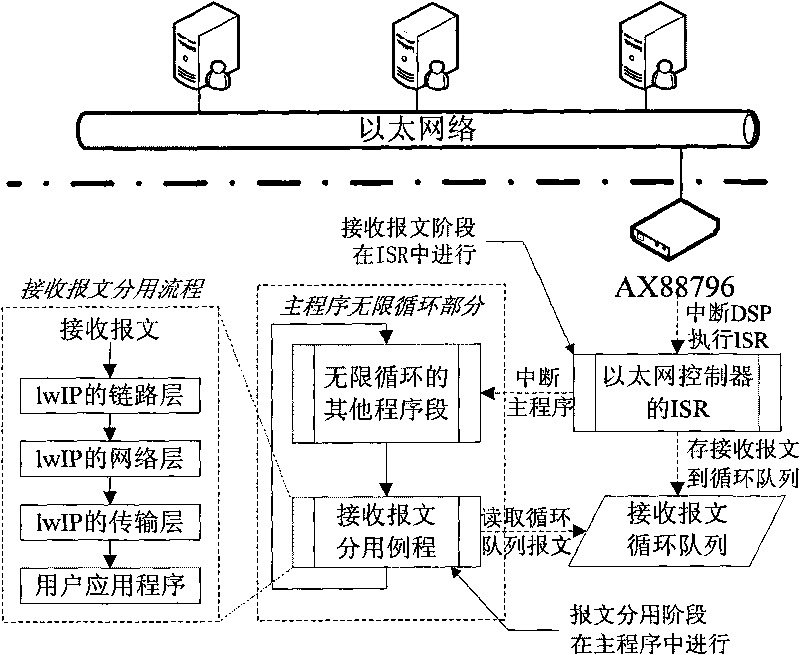

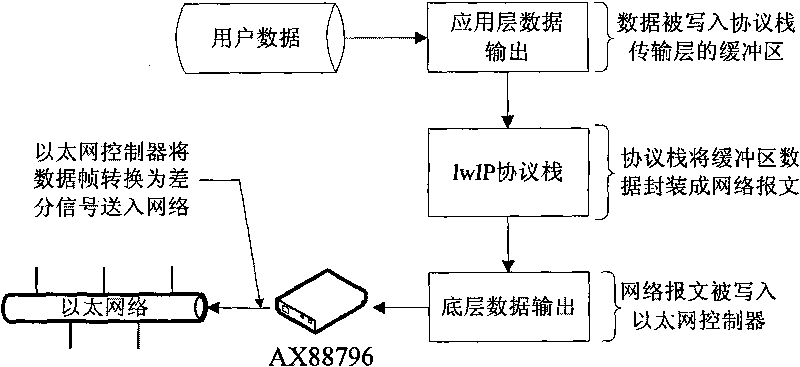

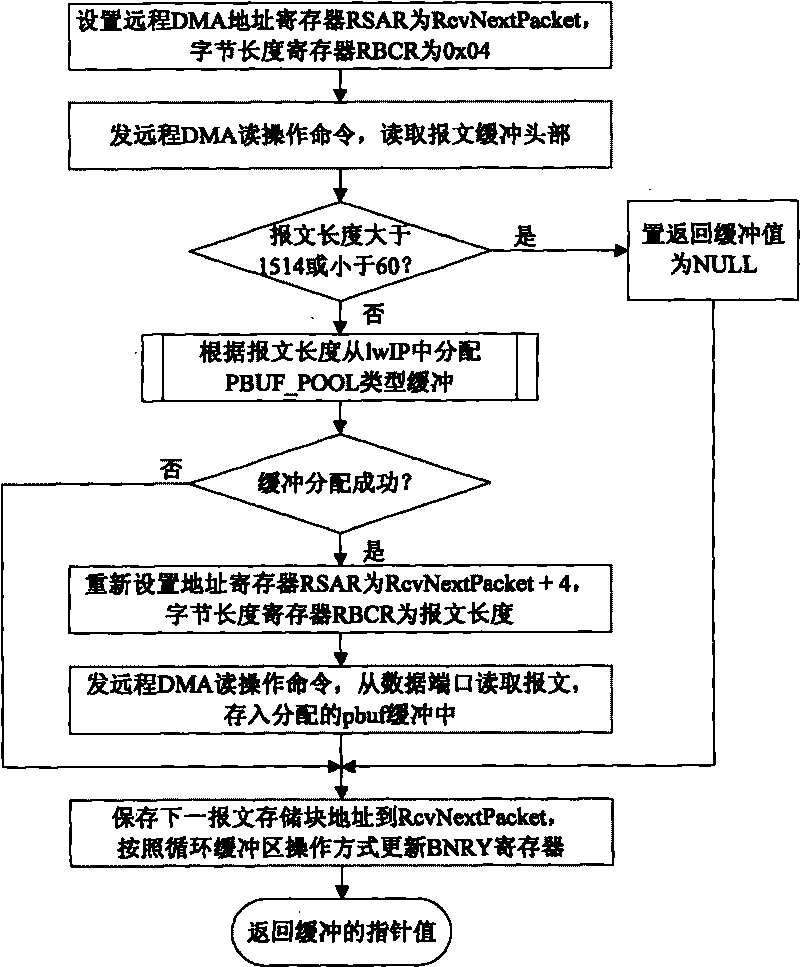

DSP based Ethernet communication method in fault recording system

ActiveCN101707599AReduce memory capacityAchieve teleportationData switching by path configurationFault locationEthernet communicationData information

The invention discloses a DSP based Ethernet communication method in a fault recording system, comprising the following steps of: (1) after a message interrupt service routine is received, storing received messages into Pbufs chain buffers, also sequentially storing pointers of the chain buffers storing the messages into a self-defined received message circulating array without directly transmitting to a protocol stack, when the messages are completely received, interrupting the service routine, i.e. quitting; (2) transmitting the messages inside the circulating array to a 1wIP protocol stack for demultiplex; (3) inputting application layer data; (4) outputting the application layer data; (5) encapsulating the messages written into a buffering area of a transmission layer of the protocol stack into network messages; (6) writing the network messages into an Ethernet controller, and transforming data frames into differential signals to be transmitted to a network by the Ethernet controller. The DSP based Ethernet communication method in the fault recording system can realize that the data information of the fault recording system is fast communicated through the Ethernet.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

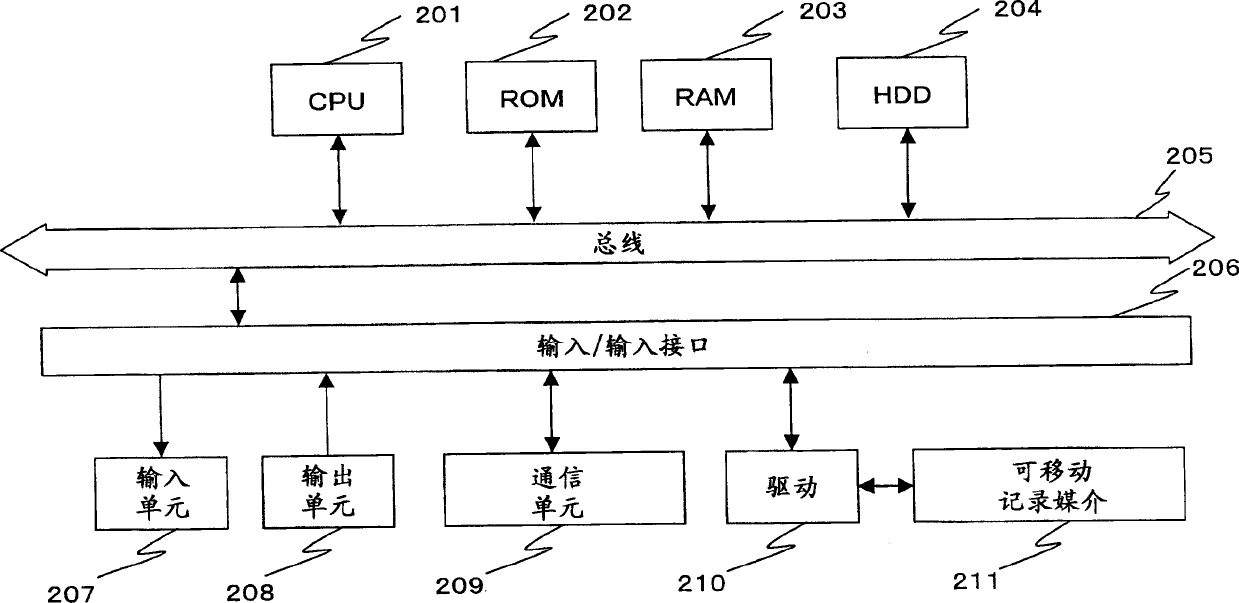

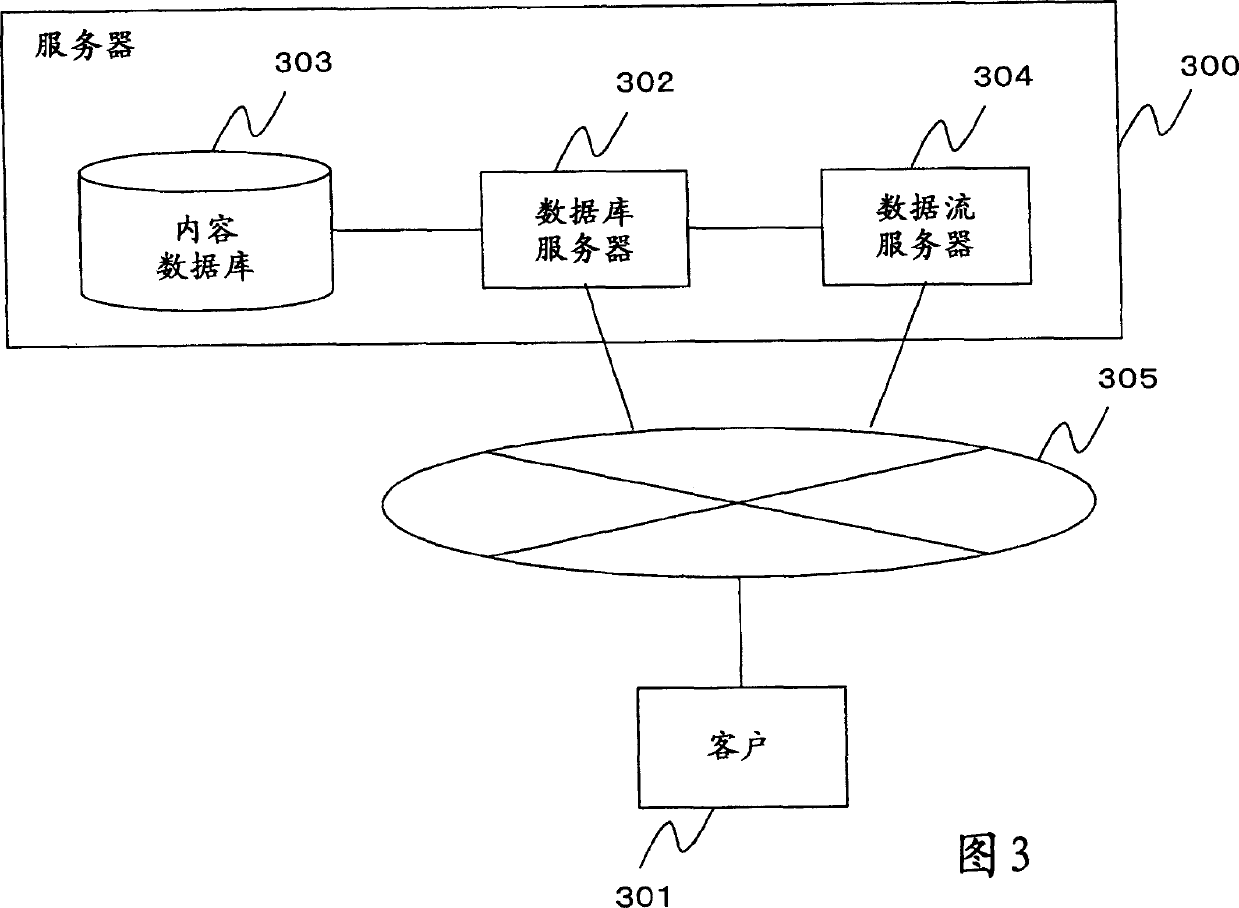

Information processing device and method, content distribution device and method and computer program

InactiveCN1533535AAchieve teleportationLow chance of deteriorationData processing applicationsTwo-way working systemsContent distributionInformation processing

Content that is appropriate according to a specification of client equipment is distributed without having to prepare content of a plurality of formats. When a data list request is received from a client, a server sets a content URL and conversion identification information indicating that the content is original content for content that does not require data conversion. In the case of content for which data conversion is necessary, a virtual URL embedded with data conversion specifying information and conversion identification information indicating the necessity of conversion are set the URL and returned to the client. The server then receives the URL from the client for analysis. If there is no data conversion specifying information, the content is transmitted as it. If data conversion specifying information is embedded, the content is sent to the client after data conversion in accordance with the data conversion specifying information.

Owner:SONY CORP

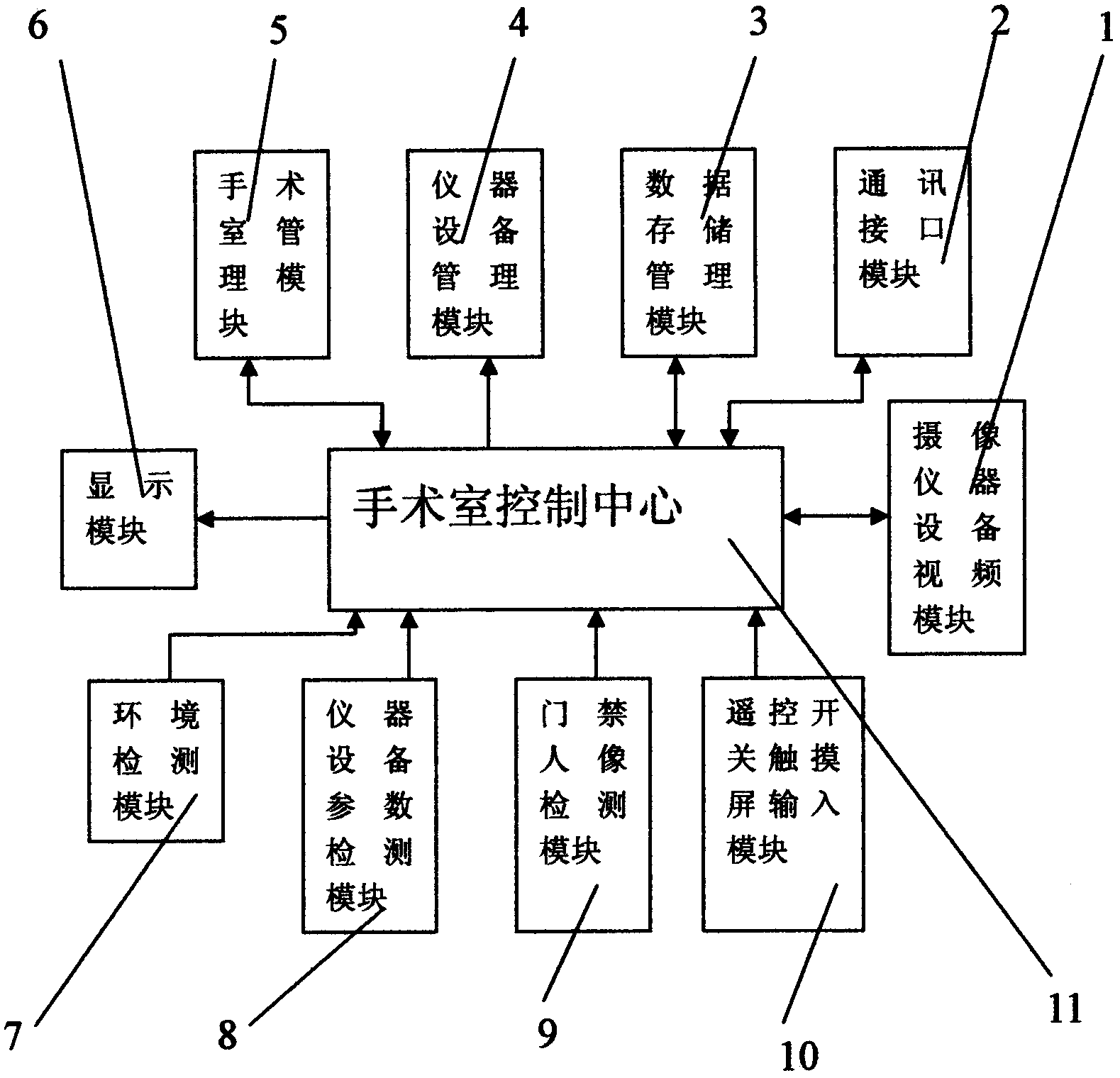

Operating room information acquisition and control system

InactiveCN103676862ARealize acquisitionAchieve teleportationProgramme total factory controlCommunication interfaceOperating room management

The invention relates to an information acquisition and control system, in particular to an operating room information acquisition and control system. The operating room information acquisition and control system comprises a shooting instrument video module, a communication interface module, a data storage and management module, an instrument management module, an operating room management module, a display module, an environment detecting module, an instrument parameter detecting module, an entrance guard image detecting module, a remote switch touch screen input module and an operating room control center. The operating room information acquisition and control system has the advantages that various medical instruments in an operating room can be monitored in a centralized mode, high-definition video acquisition and transmission are achieved, using and operation are convenient, and the control method is flexible.

Owner:WUXI HANJIA SEMICON TECH

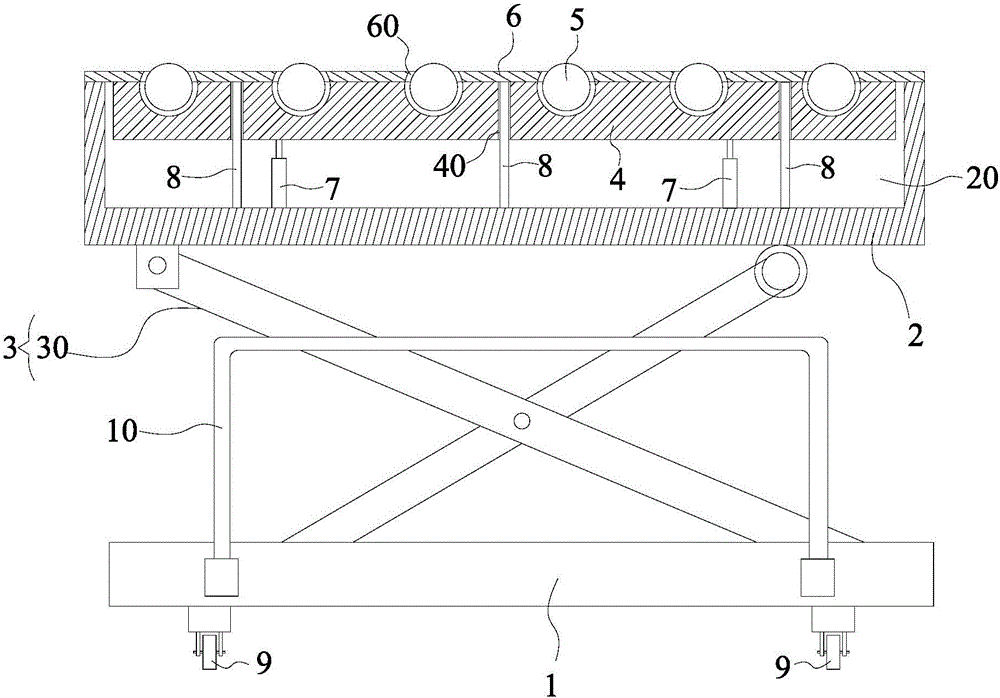

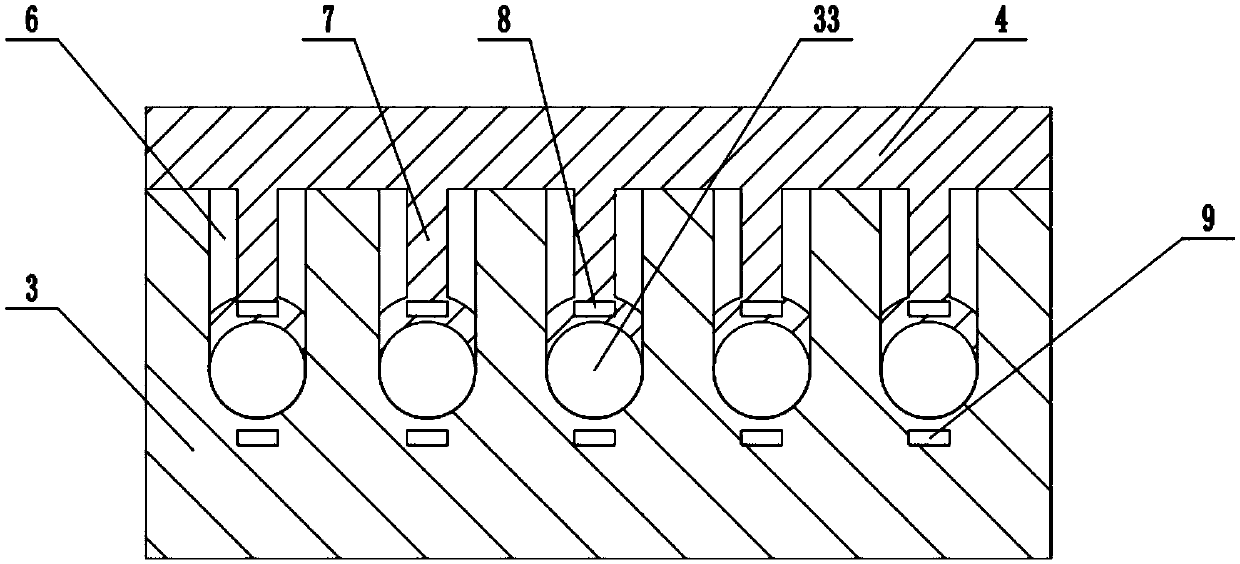

Ball hydraulic elevator

The invention relates to a ball hydraulic elevator. The ball hydraulic elevator comprises a base, a bearing platform and a lifting mechanism, wherein a groove of which an opening is arranged upwards is formed in the bearing platform; the elevator also comprises a mounting base, a plurality of balls and a cover plate; the mounting base is positioned in the groove and can vertically lift along the height direction of the groove; the balls are arranged on the mounting base and can freely roll; the cover plate is proved with avoiding holes for upper surface of the balls to penetrate through and is used for closing the opening of the groove; the upper surfaces of the balls are arranged to be flush; when the balls need to be used for conveying materials, the mounting base ascends, the balls penetrate through the avoiding holes and protrude out of the upper surface of the cover plate; and when the balls need to be stopped conveying the materials, the mounting base descends, the balls retract into the avoiding holes, and the materials are stood on the cover plate. According to the ball hydraulic elevator disclosed by the invention, by contacting and separating the balls and the materials, the conveying of the materials is realized; and meanwhile, an effect of strict enforcement can be realize. The ball hydraulic elevator has the advantages of high practicality, simplicity in operation and convenience in implementation.

Owner:SUZHOU COMPORT HYDRAULIC ELEVATORING MACHINERY CO LTD

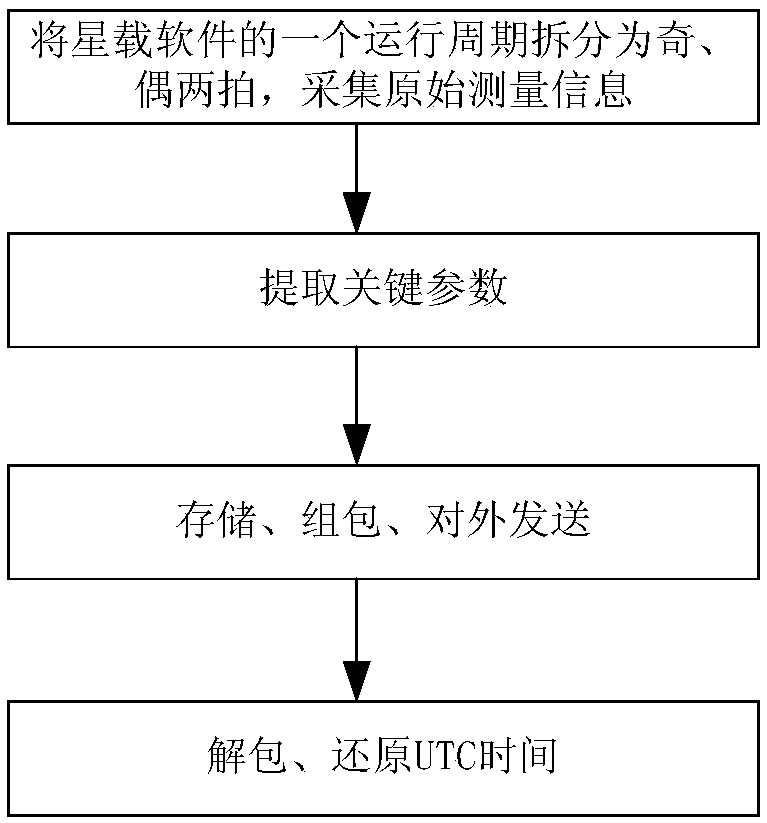

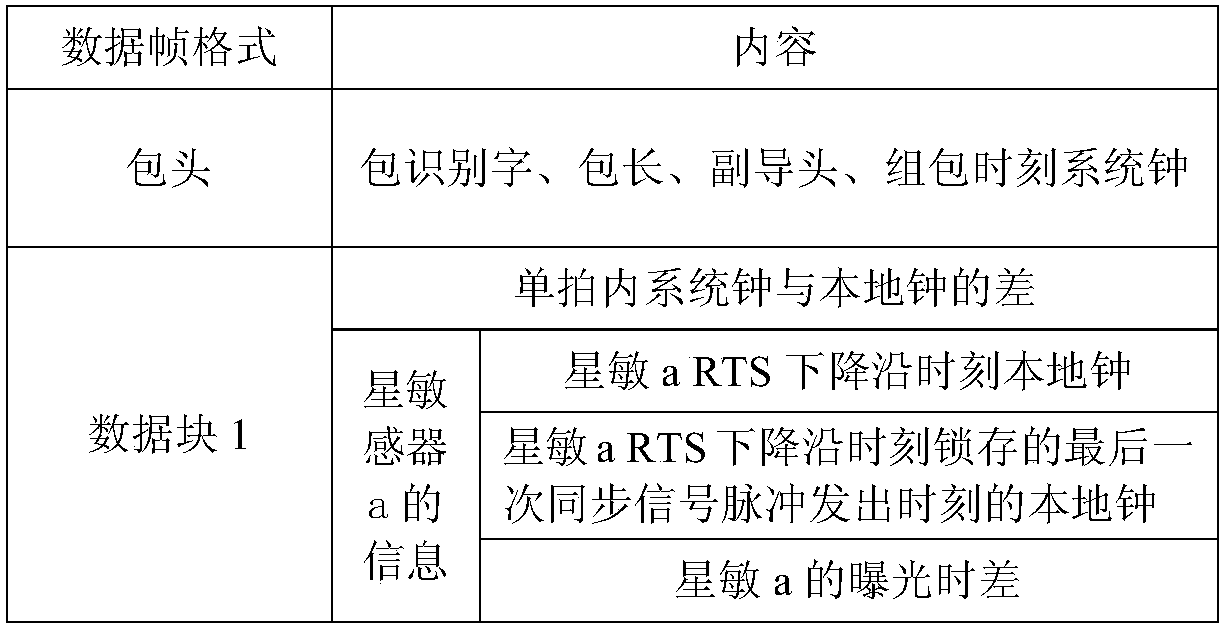

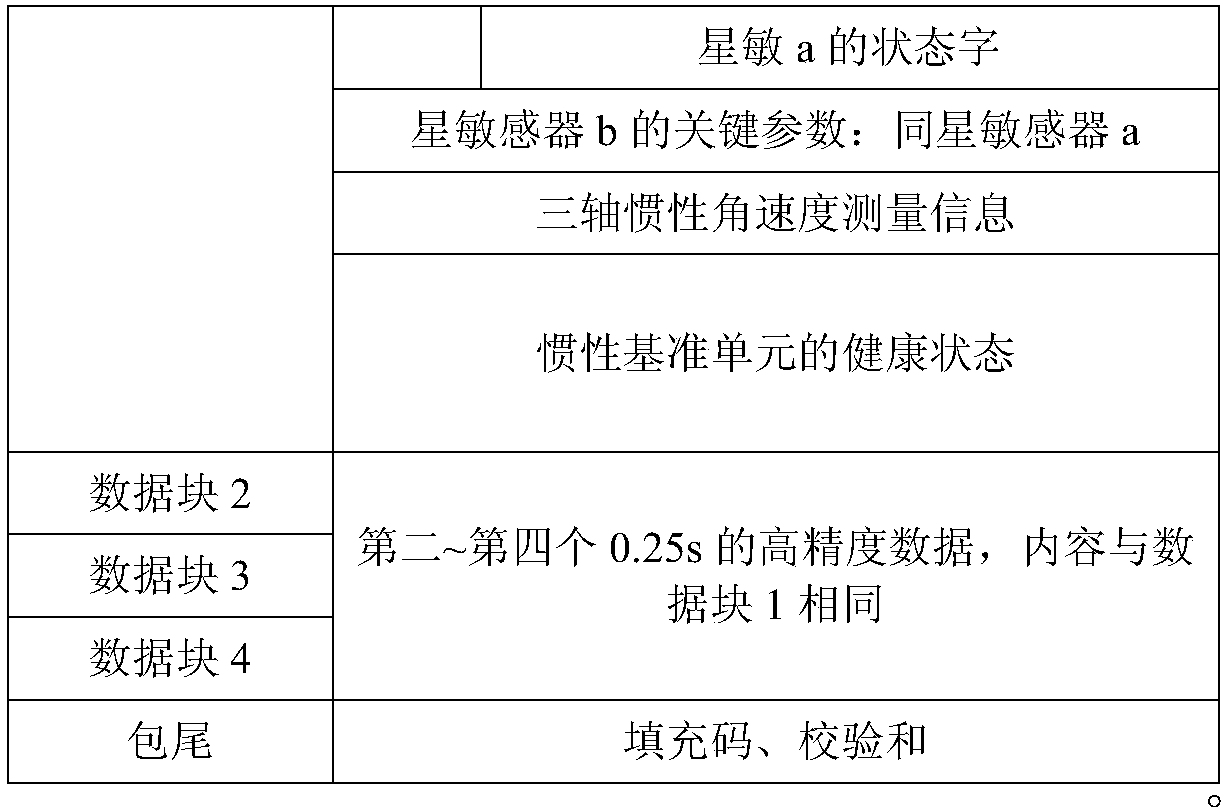

High-precision on-orbit attitude information downloading and restoring method

ActiveCN109506656ANo need to increase resourcesNo need to change the control cycleNavigational calculation instrumentsInstruments for comonautical navigationOn boardOrbit

The invention provides a high-precision on-orbit attitude information downloading and restoring method. Under the premise of not expanding on-board hardware resources, the original information and effective state words of a star sensor and an inertial reference unit, time stamp and the like are collected, downloaded and subjected to ground restoration at a frequency higher than a control cycle ofon-board software. The method is suitable for the case where a load has a higher update frequency requirement on satellite attitude, but is limited by the software operation cycle or lack of a fast download channel.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

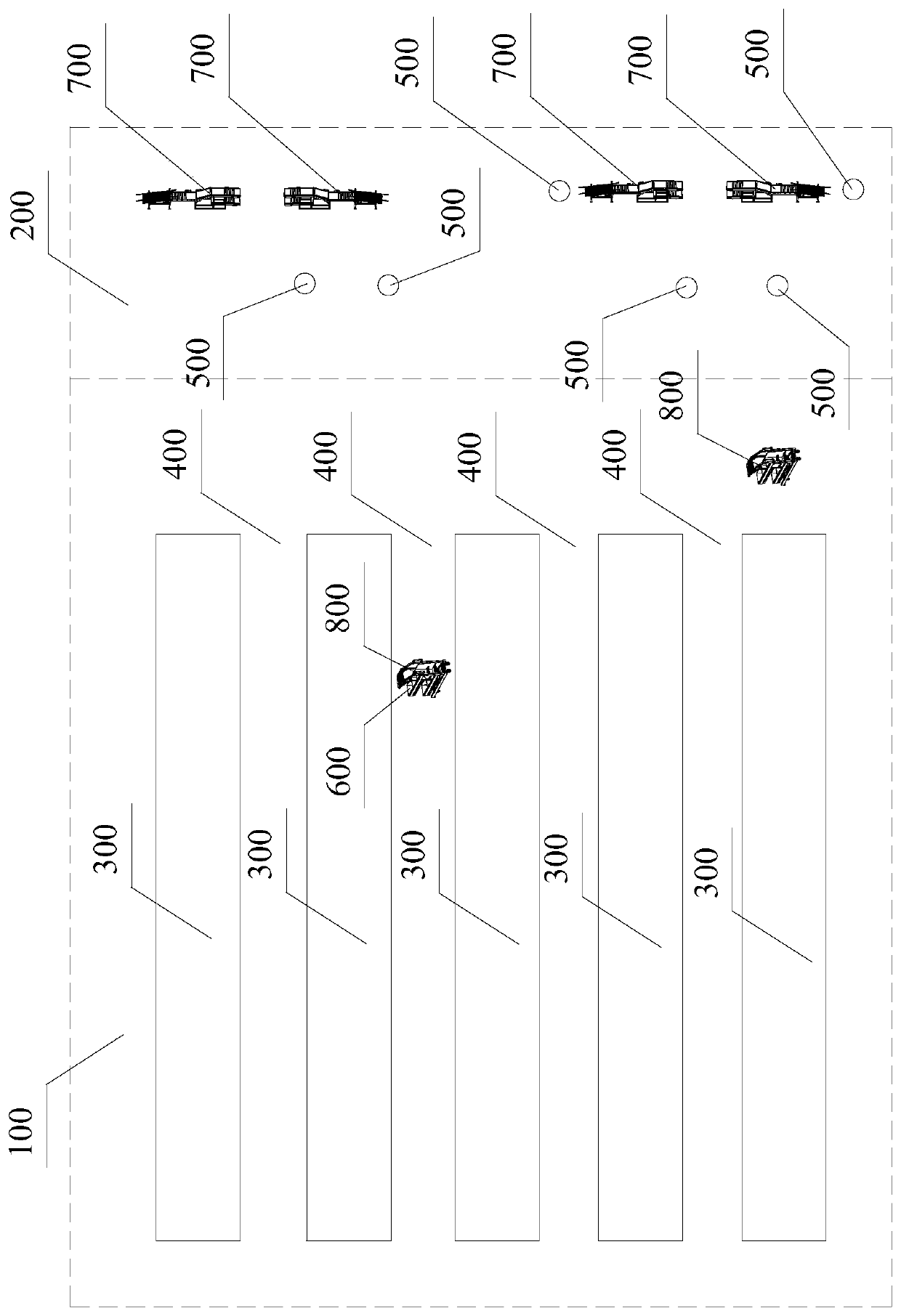

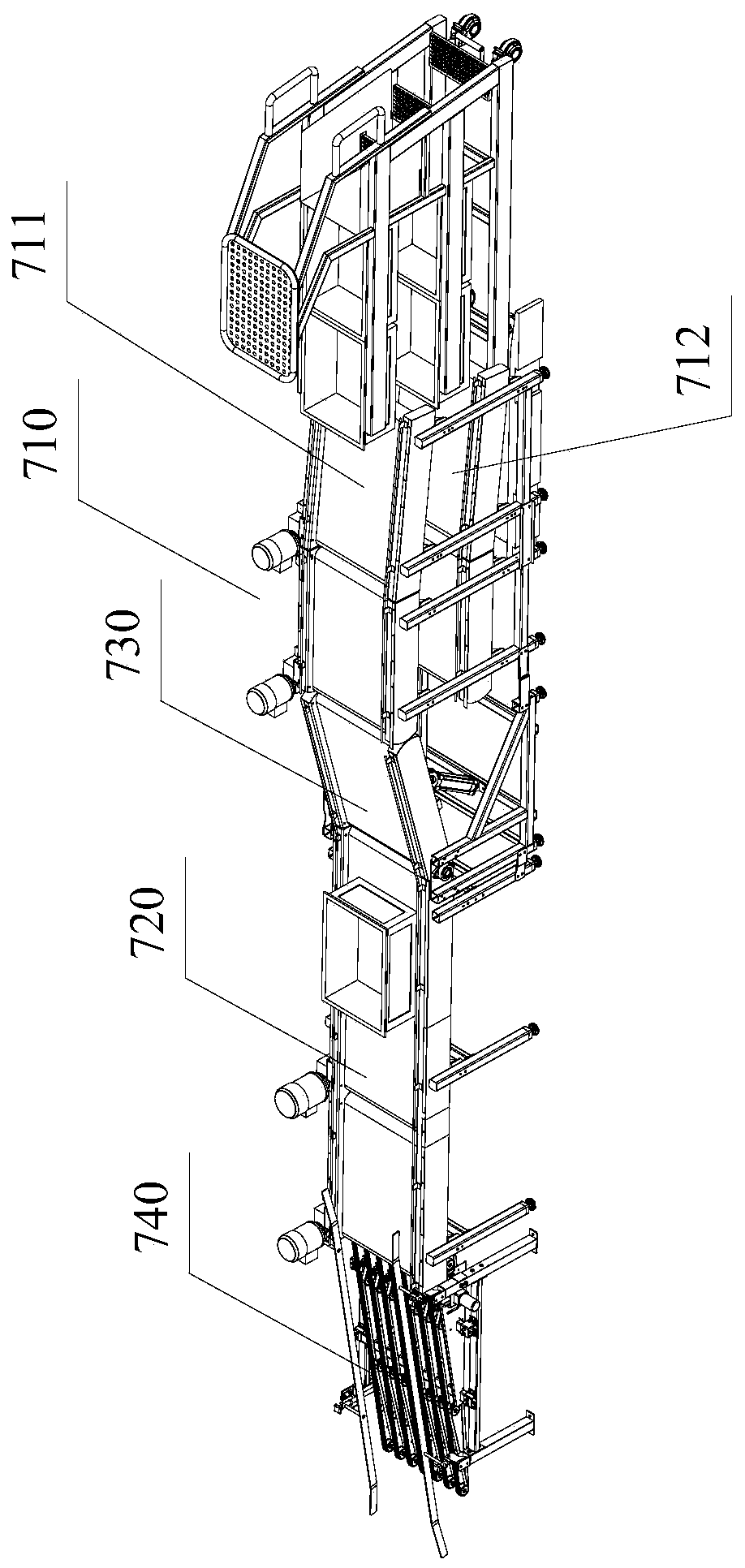

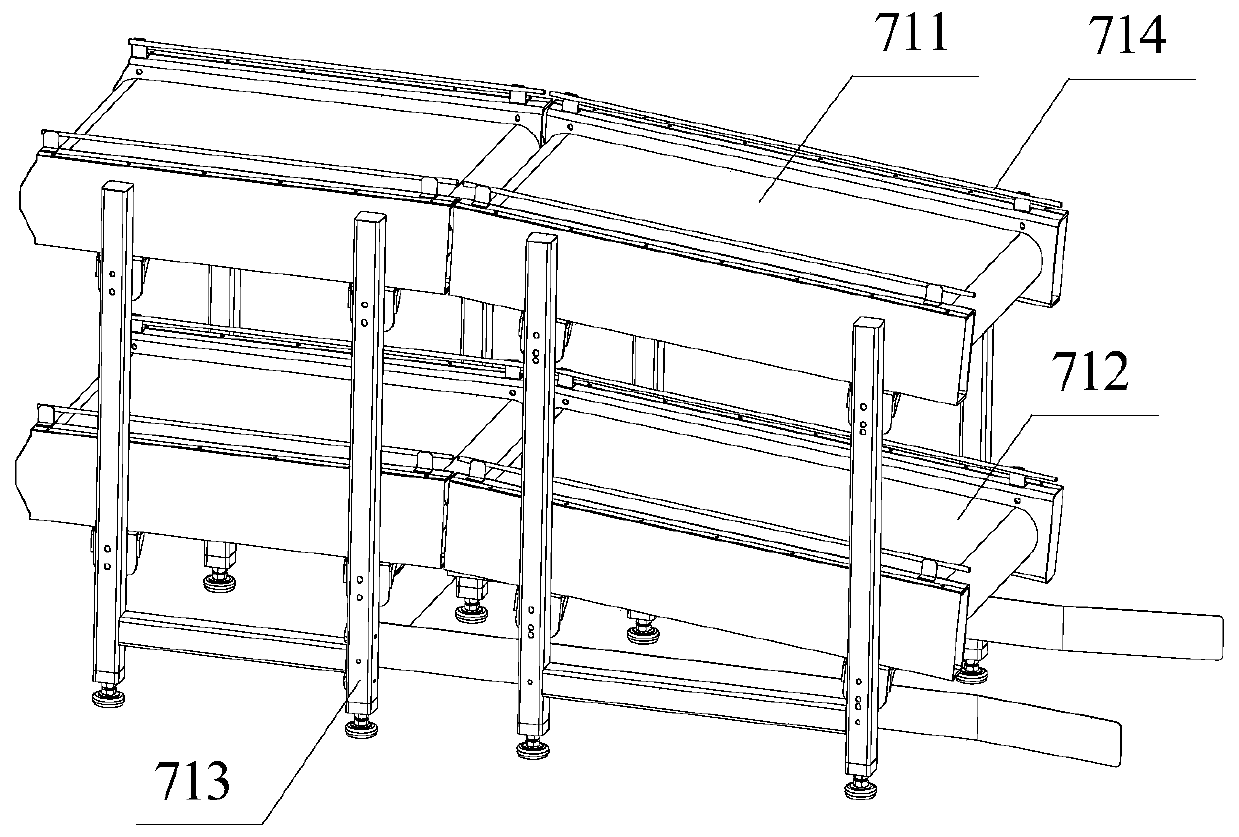

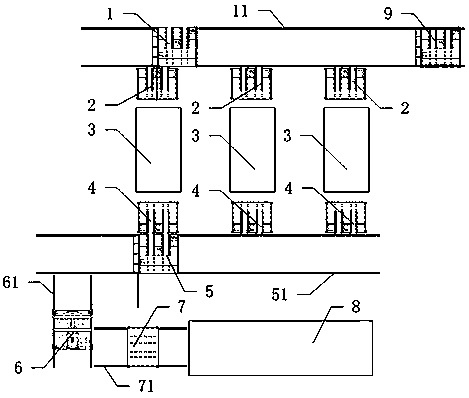

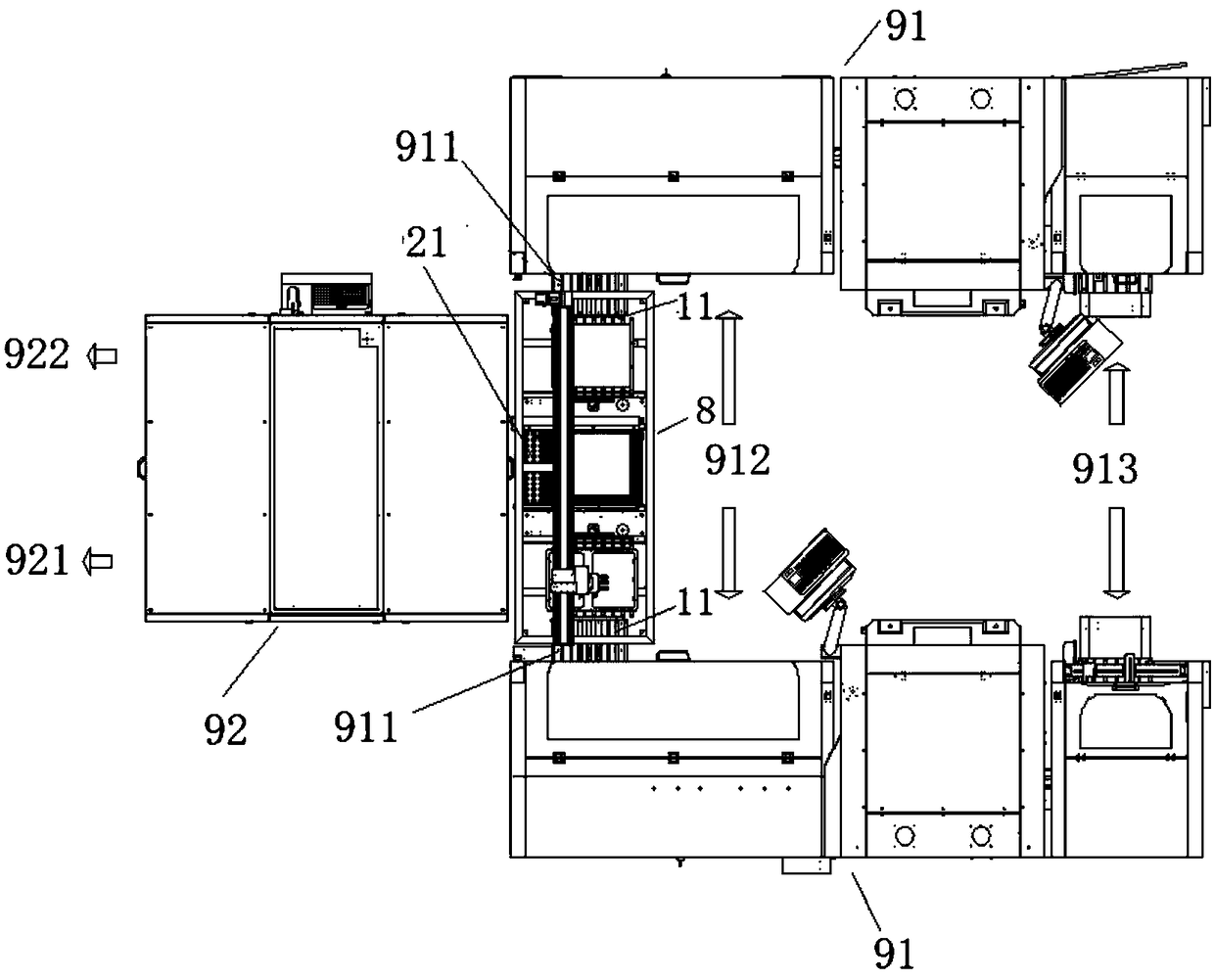

Logistics storage center and intelligent transfer station thereof

PendingCN110789902AAchieve teleportationFlexible layoutStorage devicesMechanical conveyorsLogistics managementConveyor belt

The invention discloses a logistics storage center and an intelligent transfer station thereof. The logistics storage center comprises a commodity storage area and a commodity transportation area, wherein the commodity storage area is provided with a plurality of rows of goods shelves arranged at intervals, the adjacent two rows of shelves are walking channels of a picker, the commodity transportation area is provided with the multiple intelligent transfer stations arranged at intervals, each intelligent transfer station is composed of an upper goods transfer station and a goods outlet transfer station, the intelligent transfer stations transport circulation boxes through mobile robots, and the mobile robots guide the travel along landmarks arranged on the ground of the commodity transportation area. According to the logistics storage center, each picking trolley is provided with an upper-layer support and a lower-layer support, and can be inserted onto an upper-layer conveyor belt anda lower-layer conveyor belt on each intelligent transfer station, and is selected to be in lap joint with the upper-layer conveyor belts or the lower-layer conveyor belts through bridging devices, sothat the transfer of the circulation boxes is realized. The investment cost can be reduced according to the flexible arrangement of orders.

Owner:懿力创新(厦门)科技有限公司

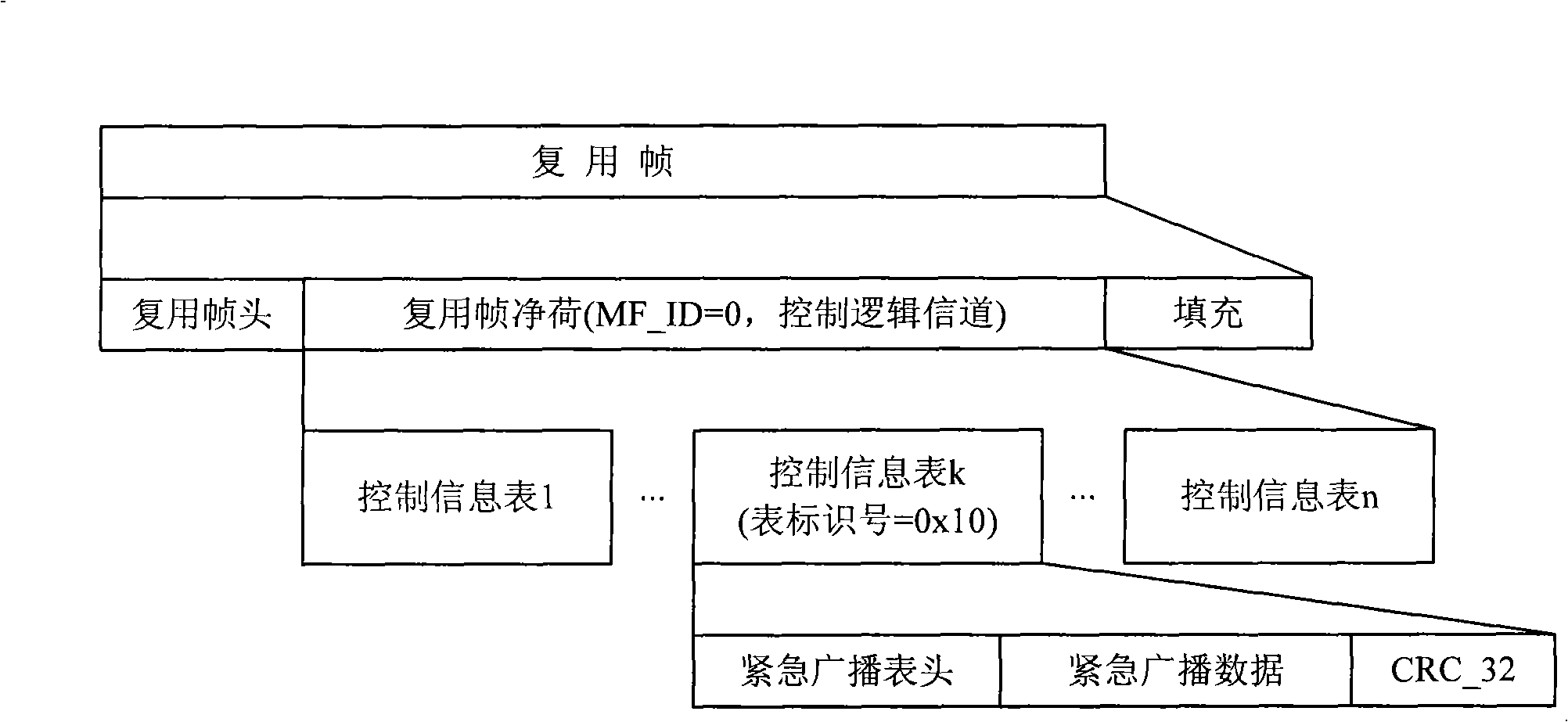

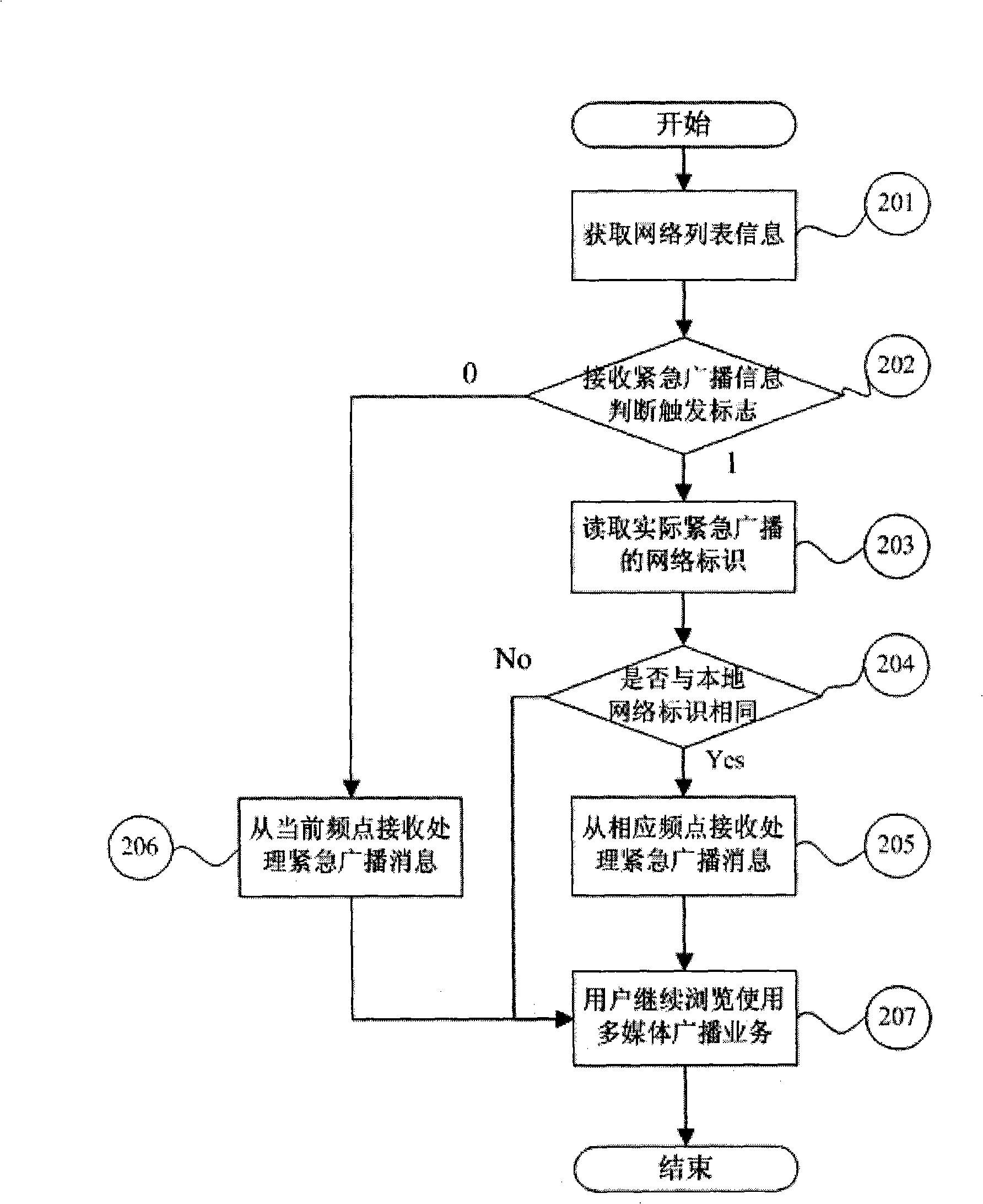

Method for conveying locality emergency broadcast message

InactiveCN101282185AReduce the amount of informationReduce occupancyBroadcast specific applicationsBroadcast-related systemsWireless broadcastControl logic

The present invention discloses a method for transmitting local emergency broadcast information, wherein a mobile multimedia broadcast system is used for transmission. The method comprises the following steps: dividing the emergency broadcast system of mobile multimedia broadcast to a national emergency subsystem and a local emergency broadcast subsystem, wherein each emergency broadcast subsystem is corresponding with a mobile multimedia broadcast network; independently setting a control logic channel by each mobile multimedia broadcast network, wherein the emergency broadcast information is transmitted in the control logic channel; and only transmitting the local emergency information the control logic channel of the local mobile multimedia broadcast network. The invention simply and effectively realizes the transmission and receiving of local emergency broadcast information in the CMMB system and increases the reasonable use to the wireless broadcast resource.

Owner:ACAD OF BROADCASTING SCI SARFT

Cutting device for electric wire machining

The invention relates to the technical field of electric wire machining, and discloses a cutting device for electric wire machining. The cutting device comprises a rack. A conveying mechanism is arranged on the rack and comprises a driving wheel. A workbench, a limiting plate and a cutting mechanism are in sliding connection to the rack. Multiple limiting grooves used for containing electric wiresare formed in the workbench. A first drive mechanism used for driving the limiting plate to slide is arranged on the rack. An air supply box, an air guide box and a cylinder body are fixedly connected to the rack. A first guide pipe communicates between the air supply box and the air guide box, and a three-way valve is arranged on the guide pipe. A second guide pipe is connected between the cylinder body and the three-way valve. A turbine coaxially connected with the driving wheel is rotationally connected in the air guide box. A piston is in sliding connection in the cylinder body. A first spring is connected between the piston and the cylinder body. A piston rod fixedly connected with the workbench is fixedly connected to the piston. An air outlet hole is formed in the cylinder body. The cutting device solves the problem that in the prior art, due to improper cutting, the percent of pass of finished products of an electric wire cutting device after machining is low.

Owner:陕西润瀚电气科技有限公司

Decorative panel production line applying intelligent RGVs (Rail Guided Vehicle)

PendingCN109501428AReduce energy consumptionReduce operating costsLamination plant layoutLaminationRenewable energyLaser ranging

The invention discloses a decorative panel production line applying intelligent RGVs (Rail Guided Vehicle). A feeding RGV and a discharging RGV are correspondingly arranged at a feeding end and a discharging end of each of a plurality of sets of panel pressing equipment respectively; a transferring RGV and a transition conveying RGV are matched to work; a decorative panel product on the discharging RGV is conveyed to a panel airing production line to finish cooling work of the decorative panel product, and the decorative panel product is conveniently conveyed into a cabin for storage subsequently. The decorative panel production line is provided with a first photoelectric approach switch, a laser range finder, a control device and the like to automatically and coordinately control the conveying work of the feeding RGV, the discharging RGV, the transferring RGV and the transition conveying RGV. The RGVs are used for replacing a previous forklift working manner, and a plurality of sets of flexible production line products can be gathered on one conveyor line, so that a transportation route is optimized and the space of a factory is saved; the energy consumption is reduced, the utilization of non-renewable energy resources is reduced, no waste gas is emitted, and the effects of energy saving and emission reduction, and pollution reduction are realized.

Owner:FOSHAN SANSHUI YUSN DECORATION IND

Transmission aligning device and butt joint equipment

The invention provides a transmission aligning device. The transmission aligning device comprises a transmission mechanism, the transmission mechanism is provided with a conveying surface for supporting and conveying materials, the transmission aligning device further comprises a lifting aligning mechanism, the lifting aligning mechanism starts aligning operations when ascending to contact the materials and stops the aligning operations when descending to be separated from the materials, and the materials are delivered to the conveying surface to make the materials be conveyed along the presetposition on the conveying surface. According to the transmission aligning device and butt joint equipment, automatic aligning is performed on the conveyed materials through the lifting aligning mechanism, regular conveying of the materials is facilitated, material damage generated in the conveying and material fetching-placing process is avoided, the production efficiency is improved and the qualified rate is increased, and the cost is lowered.

Owner:JOINT STARS TECH

Panel machining and positioning device for furniture manufacturing

InactiveCN109623966AEasy to processImprove processing stabilityProfiling/shaping machinesEngineeringWood cutting

The invention belongs to the field of furniture manufacturing, and particularly relates to a panel machining and positioning device for furniture manufacturing. For the problems that manual positioning is needed during existing wood cutting, the machining efficiency is low, and the machining stability is poor, the following scheme is provided at present, the panel machining and positioning devicecomprises a bottom plate and at least one conveying clamping mechanism located on the bottom plate; supporting frames are arranged on the two sides of the bottom end of each conveying clamping mechanism, the bottom ends of the supporting frames are fixed to the bottom plate, and a plurality of auxiliary fixing mechanisms are arranged on the two side walls of each conveying clamping mechanism; twofixing columns are welded to the side wall of one conveying clamping mechanism, wherein a limiting plate is rotationally connected to one ends of the fixing columns, a second telescopic rod is hingedto the bottom end of the conveying clamping mechanism, and an output shaft of the second telescopic rod is hinged to the side wall of the limiting plate. By means of the panel machining and positioning device, panel conveying, positioning and fixing can be achieved, subsequent machining is convenient, the machining stability is high, automatic positioning can be achieved, and the panel machining efficiency is improved.

Owner:安徽喜聚美家居有限公司

Clamping device for base plate

InactiveCN101656224AEasy to operateAchieve teleportationSolid-state devicesSemiconductor/solid-state device manufacturingCamTreadle

The invention discloses a clamping device for a base plate, comprising a driving device, a clamping device and a fixing guiding mechanism. The driving device comprises a power supply, a cam provided with two arc guide grooves, and a transmission shaft with one end connected to the power supply and the other end connected to the cam. The clamping device comprises an upper pressure pad, a lower pressure pad, an upper treadle bar, and a lower treadle bar, wherein a circular roller driven member in the two arc guide grooves is respectively disposed on the side walls corresponding to the upper andthe lower pressure pads. A clamping region is formed between the upper and the lower pressure pads. The upper treadle bar is arranged on the upper pressure pad and the lower treadle bar is arranged onthe lower pressure pad. The sliding directions of a guide way and a sliding block are vertical to the upper and the lower pressure pads. The clamping device for base plate has the advantages of stable operation for transmitting and turning over the base plate, simple structure, convenient operation, etc.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com