Patents

Literature

37results about How to "Low operating precision requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of ordinary steel bar and finished deformed bar mixed reinforcement assembled pier

ActiveCN108560423AGood self-resetting performanceImprove post-earthquake functionalityBridge structural detailsBridge erection/assemblyReinforced concretePre stress

The invention discloses a construction method of an ordinary steel bar and finished deformed bar mixed reinforcement segmental assembled pier. The ordinary steel bar and finished deformed bar mixed reinforcement segmental assembled pier comprises a concrete bearing platform, a prefabricated segmental reinforced concrete pier body and two through longitudinal bars and an unbonded prestressed tendon, wherein the two through longitudinal bars and the unbonded prestressed tendon are used for connecting each prefabricated segment. Metal corrugated pipes are placed in the bearing platform and the prefabricated segmental pier body to reserve pore passages; during construction, firstly, each prefabricated segmental pier body is vertically overlapped first, the unbonded prestressed tendon is made to penetrate into the pore passages reserved on the section and is tensioned, each segmental pier body is integrally connected, and mortar does not need to be grouted into the pore passages to seal thepore passages; secondly, ordinary steel bars and finished deformed bars vertically penetrate into the pore passages and pressure grouting is carried out on the pore passages; and thirdly, the mixed reinforcement segmental assembled pier is formed.

Owner:HENGQIN GONGE TECH CO LTD

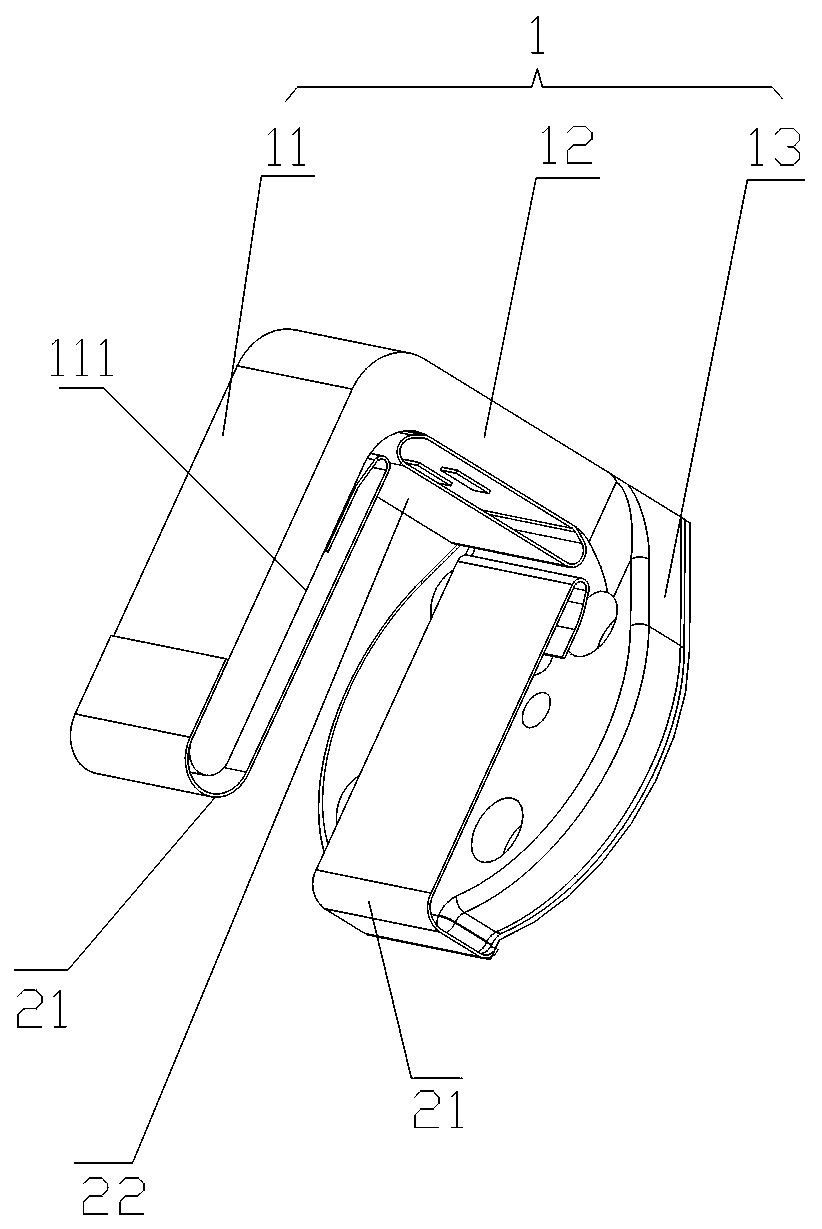

Terminal executing device capable of measuring force and used for robot

PendingCN107838950AReduce Rigid DamagePlay a shock absorbing roleProgramme-controlled manipulatorSimulationStrain gauge

The invention discloses a terminal executing device capable of measuring force and used for a robot. The terminal executing device comprises a terminal body; the terminal body comprises a plurality ofbearing pieces which are sequentially connected in a bent mode, elastic elements arranged on the inner sides of the bearing pieces and strain gauges, wherein each elastic element at least comprises an assembling part capable of being connected to the corresponding bearing piece in a fastening mode and an elastic part arranged to extend from the corresponding assembling part, and the elastic partsand the inner walls of the bearing pieces keep a certain distance; and the strain gauges are arranged on the inner wall, facing towards the inner wall direction of the bearing pieces, of the elasticparts. By implementing the terminal executing device capable of measuring force and used for the robot, real time strain can be measured in the operation process so as to reduce the control difficulty; and the structure is simplified, rigidity damage to the terminal and a manipulator due to rigid collision can be reduced, reliability is high, adaptability is wide, and the cost is easy to control.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

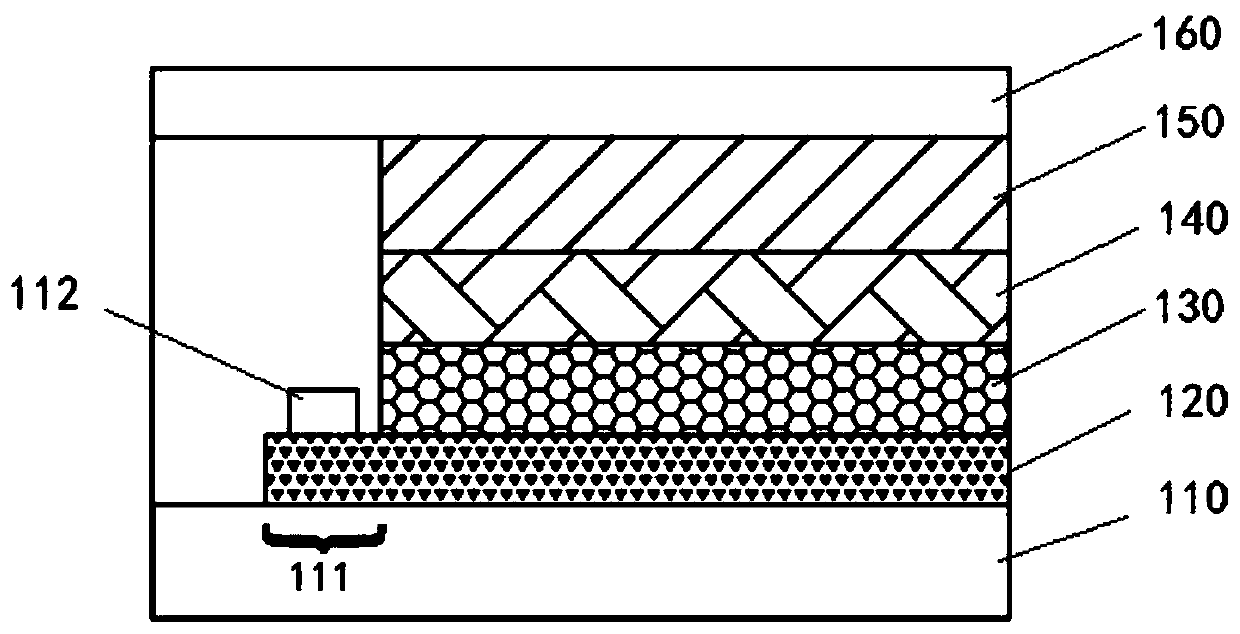

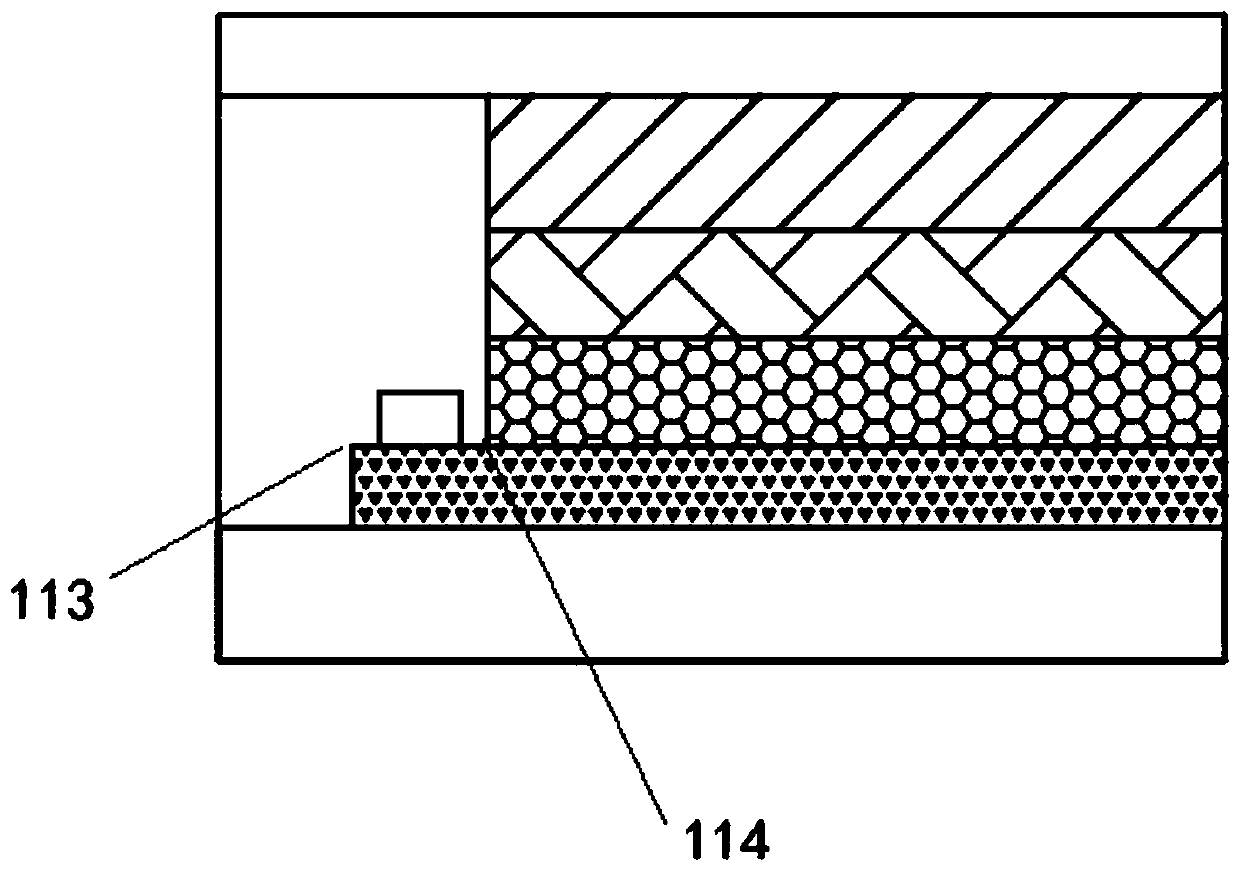

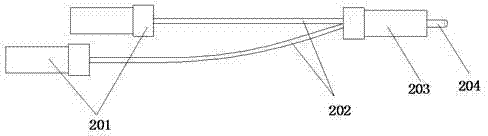

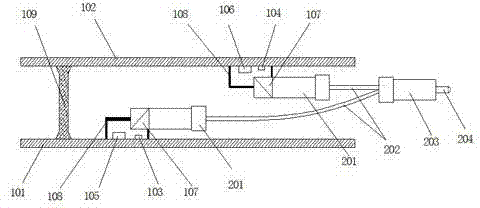

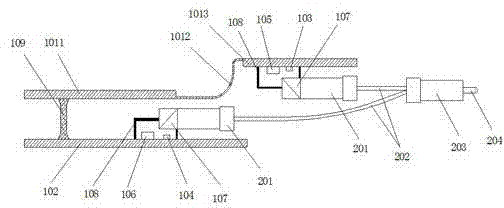

High-density type parallel transmission optical device

ActiveCN103323921AImprove cooling effectReduce signal crosstalkCoupling light guidesElectromagnetic transceiversHigh densitySurface mounting

The invention discloses a high-density type parallel transmission optical device which is applicable to a CXP encapsulating and plug type optical device and a CXP active optical cable (AOC), wherein the CXP encapsulating and plug type optical device and the CXP AOC are applied to data communication currently. The high-density type parallel transmission optical device comprises a transmitting PCB, a receiving PCB, a multi-path transmitting chip, a multi-path receiving chip, a transmission driving chip, a receiving amplifying chip, multi-path lens arrays, sealing cover plates and a connecting line, wherein the number of the multi-path lens arrays is two, and the number of the sealing cover plates is two. The high-density type parallel transmission optical device is characterized in that the parallel transmission optical device further comprises a changeover array optical fiber jumper assembly. The high-density type parallel transmission optical device is capable of effectively reducing the surface-mounting accuracy requirements of the multi-path transmitting chip and the multi-path receiving chip to further reduce encapsulating difficulty, effectively solving the signal crosstalk problem and the radiating problem, and improving the performance stability.

Owner:WUHAN TELECOMM DEVICES

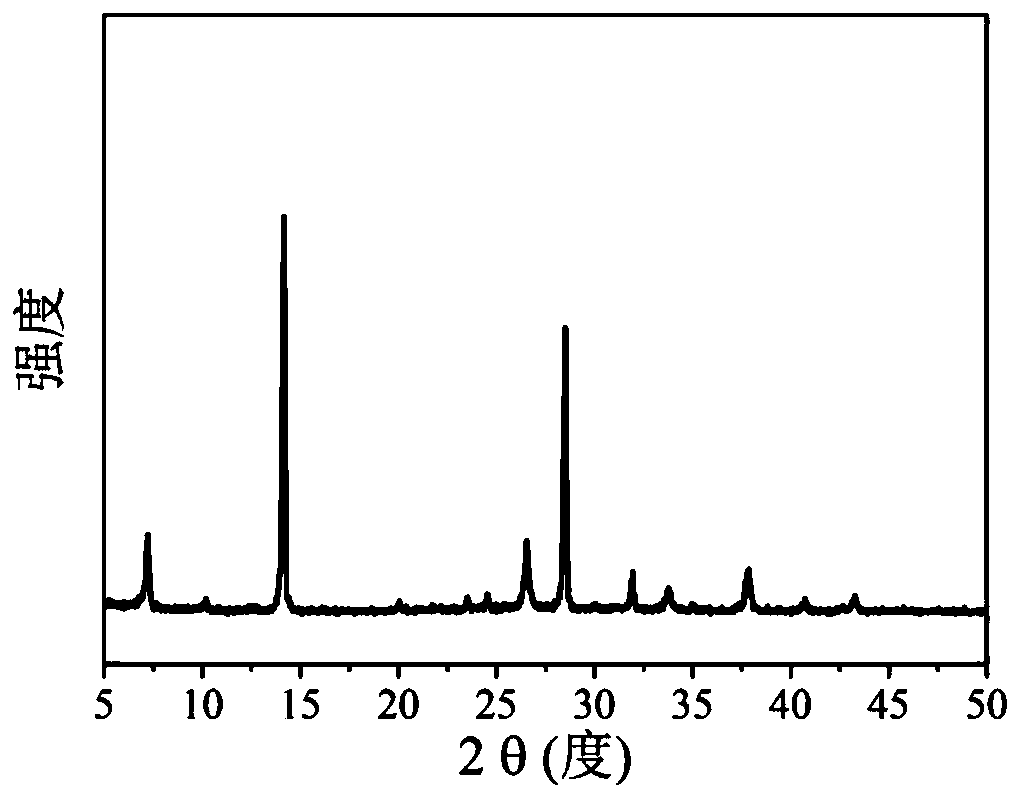

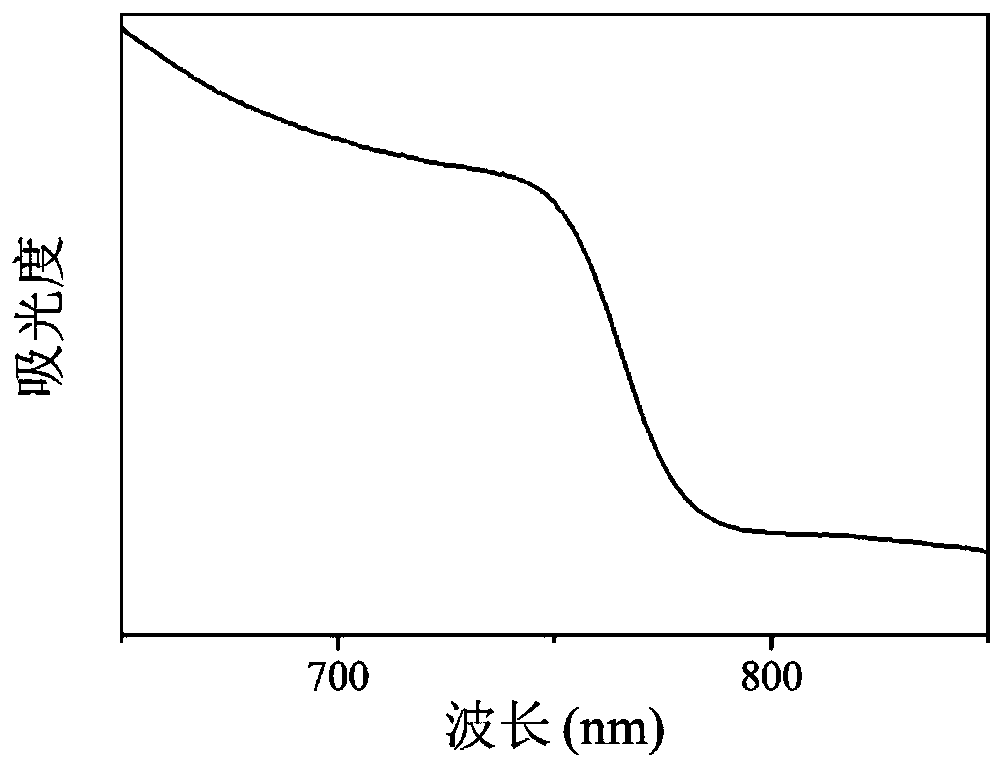

Method for improving photoelectric performance of perovskite

InactiveCN110429178AEase of large-scale industrial productionImprove insensitivityFinal product manufactureSolid-state devicesPerovskiteAmmonium

The invention provides a method for improving the photoelectric performance of perovskite. The method comprises the following steps of: S1, dissolving a certain amount of quaternary ammonium salt in asolvent to obtain a solution A; S2, immersing a perovskite film in the solution A for a certain period of time; and S3, removing the residual solvent on the surface of the soaked perovskite film by adopting air flow, and performing annealing. According to the method for improving the photoelectric performance of perovskite, the perovskite film obtained by the method of the invention is compact inthe surface and good in stability, and the device prepared based on the processed film shows the excellent photoelectric performance. The method is convenient to operate, and is suitable for large-scale production in factories.

Owner:SHANGHAI JIAO TONG UNIV

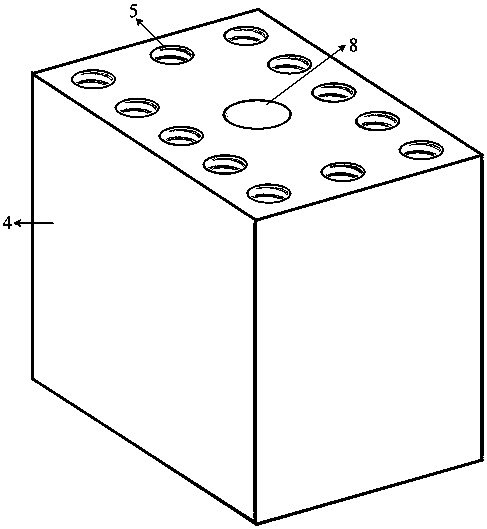

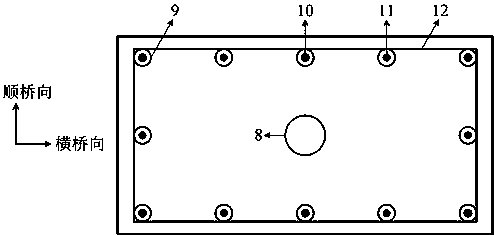

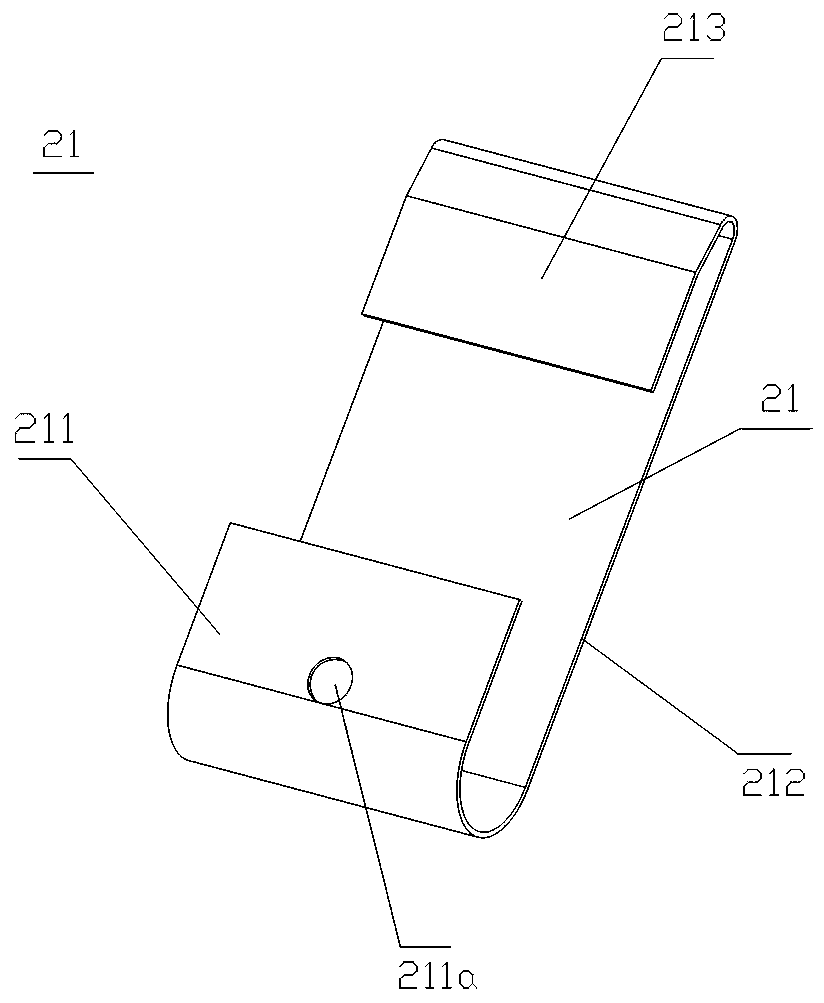

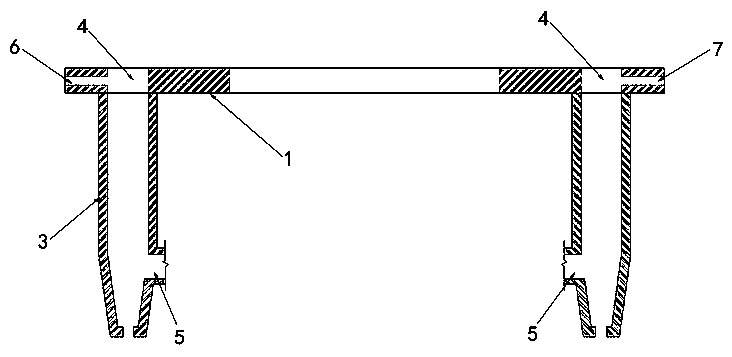

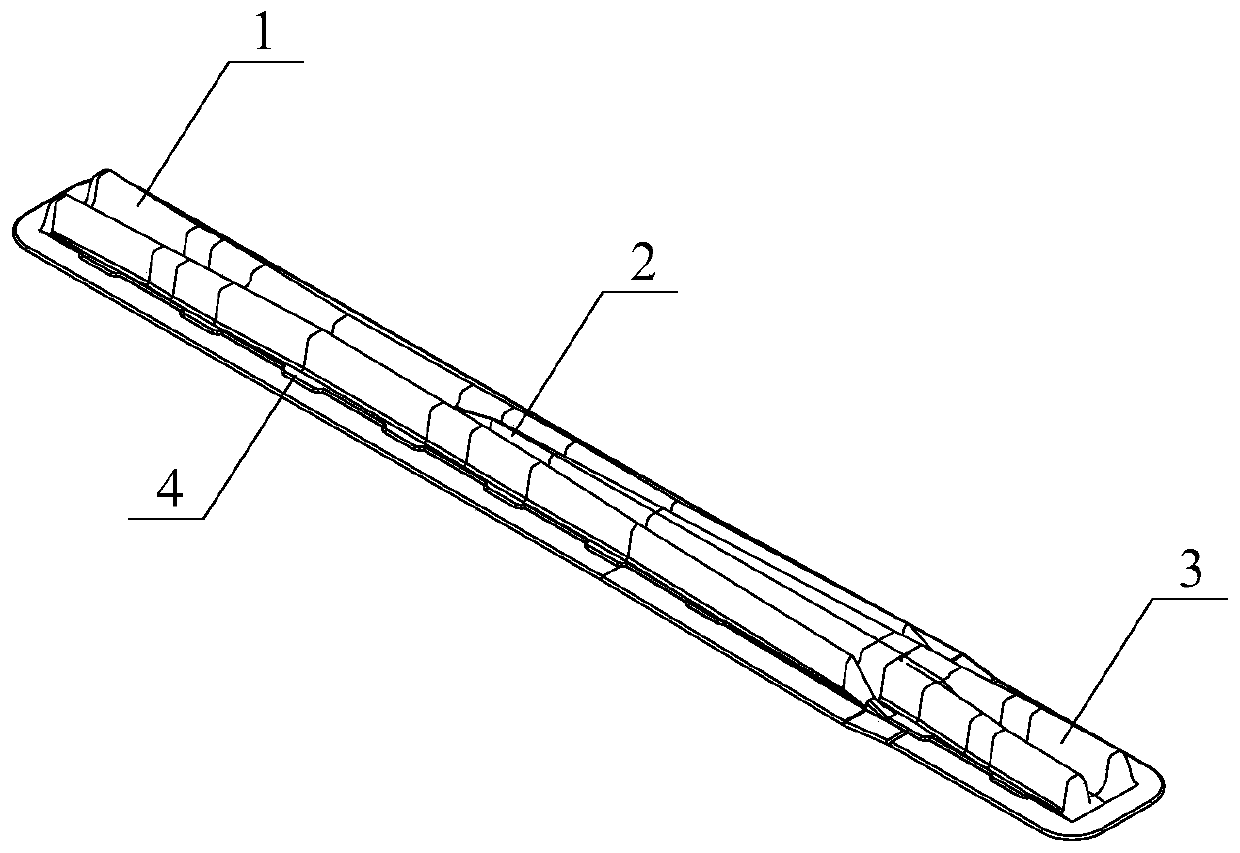

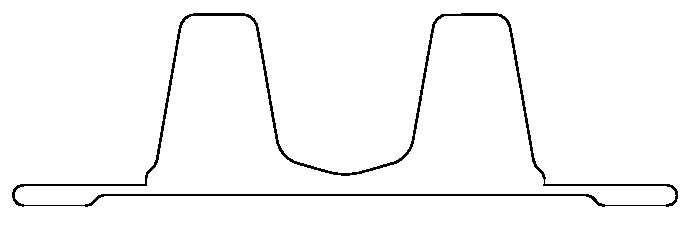

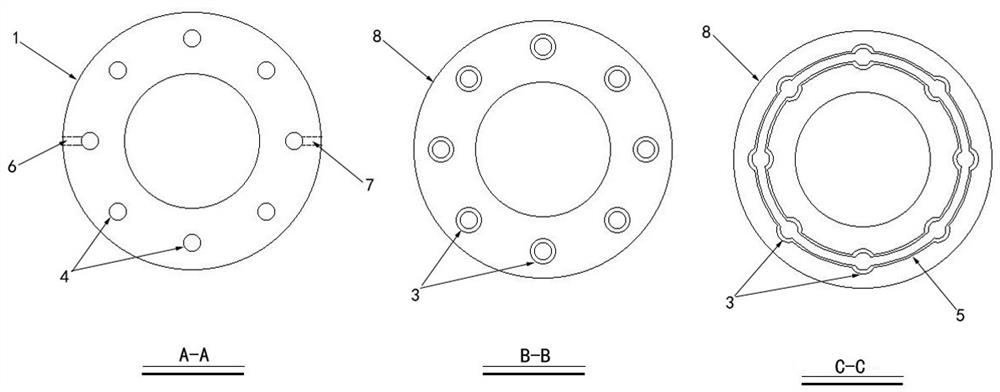

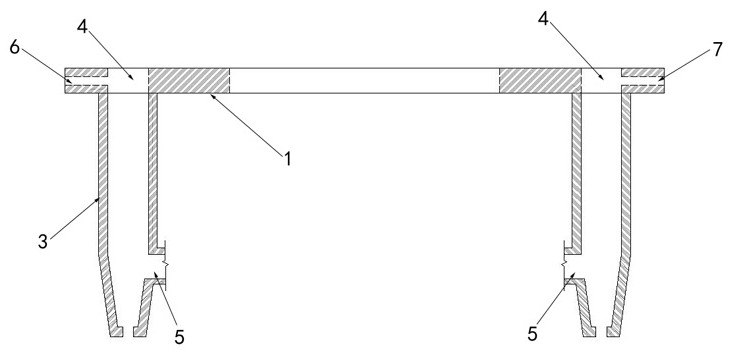

Sleeve end plate for achieving grouting connection and PHC pipe pile

ActiveCN111576403AAchieve connectionIncreased bending stiffnessBulkheads/pilesPre stressArchitectural engineering

The invention relates to the field of prestressed high-strength concrete pipe pile structures of civil engineering pile foundations, in particular to a sleeve end plate for achieving grouting connection and a PHC pipe pile. A plurality of steel sleeves are arranged on the lower end face of the end plate, a communicating pipeline is arranged between the lower portions of every two adjacent steel sleeves, an inner cavity of each communicating pipeline communicates with an inner cavity of the corresponding adjacent steel sleeve, a through hole allowing a prestressed steel bar to pass through is formed in the bottom face of each steel sleeve, and the ends, penetrating in the steel sleeves, of the prestressed steel bars are in stop fit with the bottom faces of the steel sleeves. A grouting holeand a grout outlet hole are formed in the end plate in the radial direction. The sleeve end plate can be used for anti-pulling connection of a PHC pipe pile body, can also be used for reliable connection of the PHC pipe pile and a bearing platform, and can adapt to the prefabricating and assembling construction pace of the bearing platform. The defects of end plate welding connection and mechanical connection are overcome, the requirement for the pile splicing operation precision is low, the sleeve end plate is suitable for complex engineering conditions, and the effect is guaranteed.

Owner:TAIYUAN UNIV OF TECH

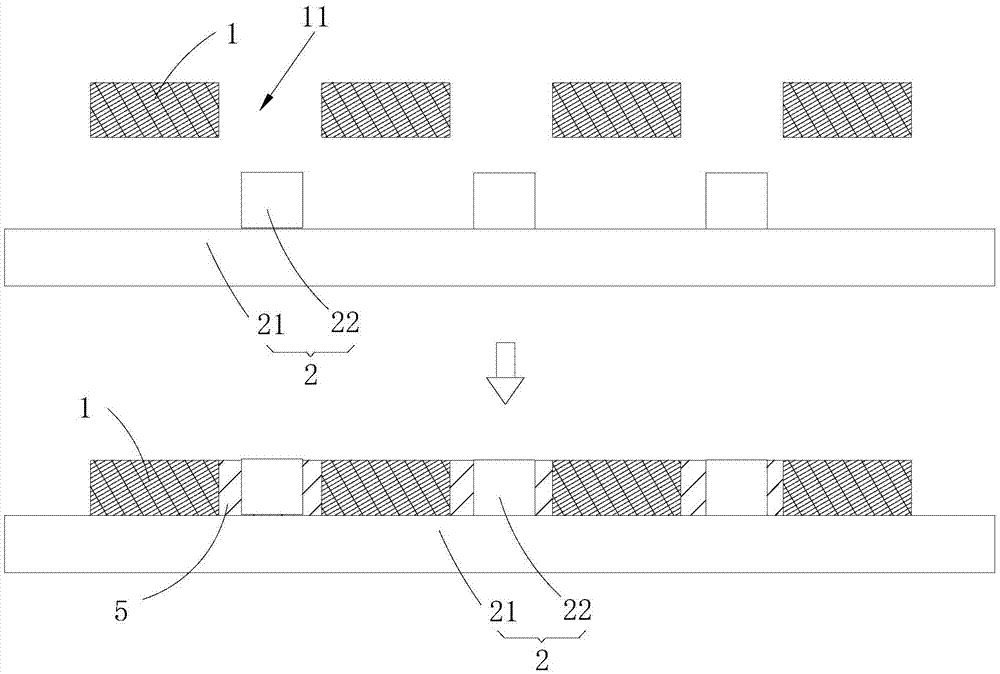

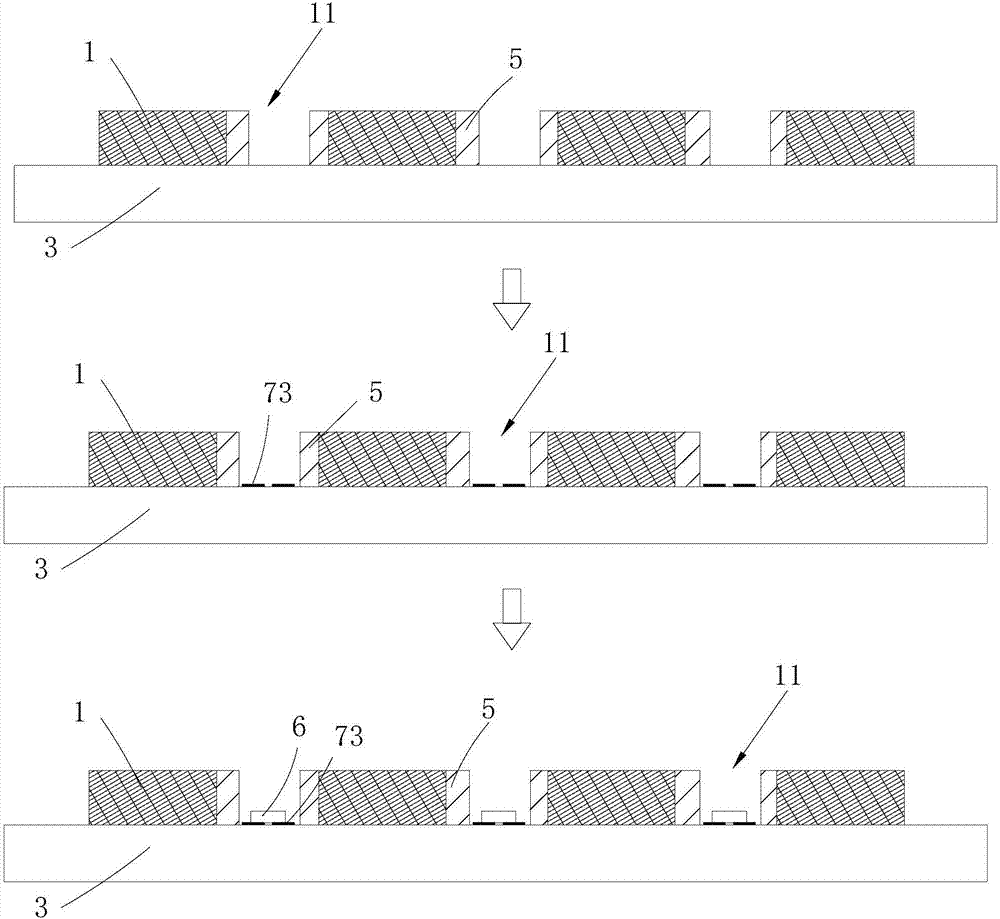

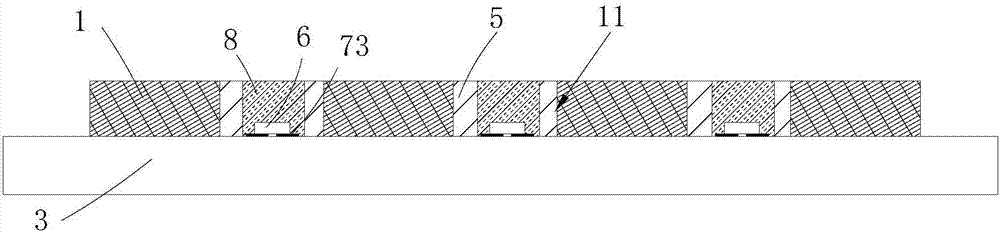

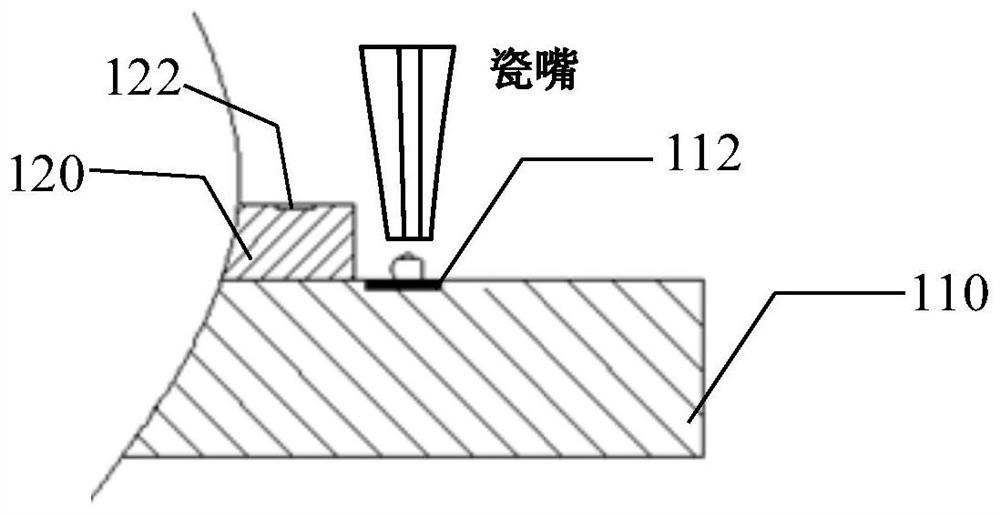

Packaging component and manufacturing method thereof

PendingCN107275459AAvoid exceedingEnsure uniformity of lightSemiconductor devicesWaferingMold removal

The invention provides a manufacturing method of a packaging component. The manufacturing method comprises the steps of dam installation, wafer fixing, packaging colloid injecting and packaging and mold removing. The invention further provides a packaging component which is manufactured by applying the packaging component manufacturing method. The packaging component is used for being mounted on a circuit board. The packaging component comprises a wafer, a bonding pad assembly arranged at one side of the wafer, packaging colloid packaging outside the wafer and the bonding pad assembly and a dam enclosing outside the packaging colloid, wherein the bonding pad assembly comprises a positive bonding pad, a negative bonding pad and metal pieces used for connecting the circuit board and the positive bonding pad and the negative bonding pad, the metal pieces are connected with the positive bonding pad and the negative bonding pad in a one-to-one correspondence manner, and the area of the metal piece is greater than or equal to the area of the positive bonding pad or the negative bonding pad. Batch production is performed by adopting cooperation of various molds, so that mass production can be carried out more conveniently. In addition, the positions of the wafer and the packaging colloid relative to the dam can be better limited, and the light emitting angle and the light color uniformity of an optical design are effectively ensured.

Owner:深圳市科艺星光电科技有限公司

Grid mesh electrode and preparation method thereof

ActiveCN107768229AImprove pass rateAvoid cutsTime-of-flight spectrometersElectron/ion optical arrangementsEngineeringConductor Coil

The invention provides a grid mesh electrode and a preparation method thereof. The grid mesh electrode comprises an electrode frame. The electrode frame comprises a first winding part and a second winding part which are arranged opposite to each other. The grid mesh electrode further comprises a grid mesh hole defined by the electrode frame, and a grid mesh. Te grid mesh is arranged in the grid mesh hole. The grid mesh is composed of a plurality of metal wires arranged in parallel relative to one another. The two ends of the plurality of metal wires are respectively fixed on the first windingpart and the second winding part. The grid mesh formed by parallel metal wires is adopted instead of a mesh metal net. In this way, the grid mesh electrode is formed through the simple winding processinstead of the metal net attaching process higher on the operation precision requirement. The grid mesh electrode has at least one of the following advantages: low cost, simple preparation, high passing rate and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

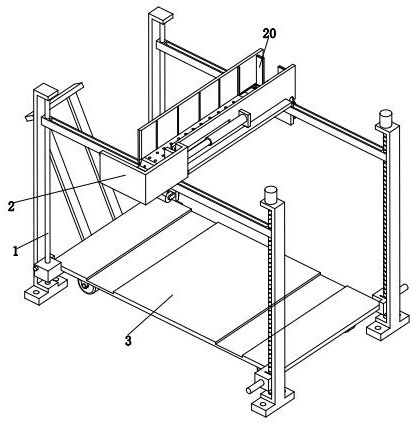

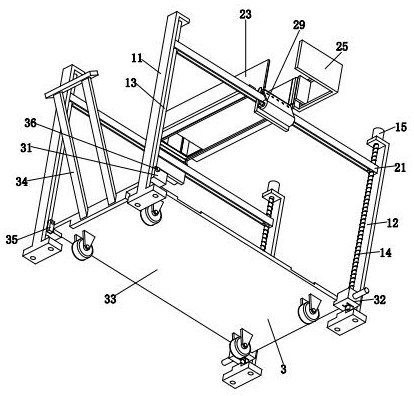

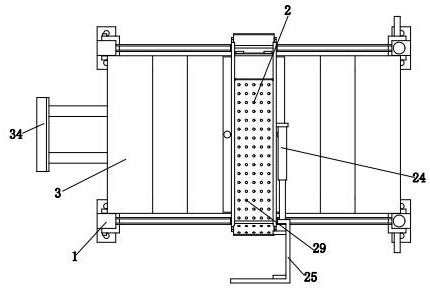

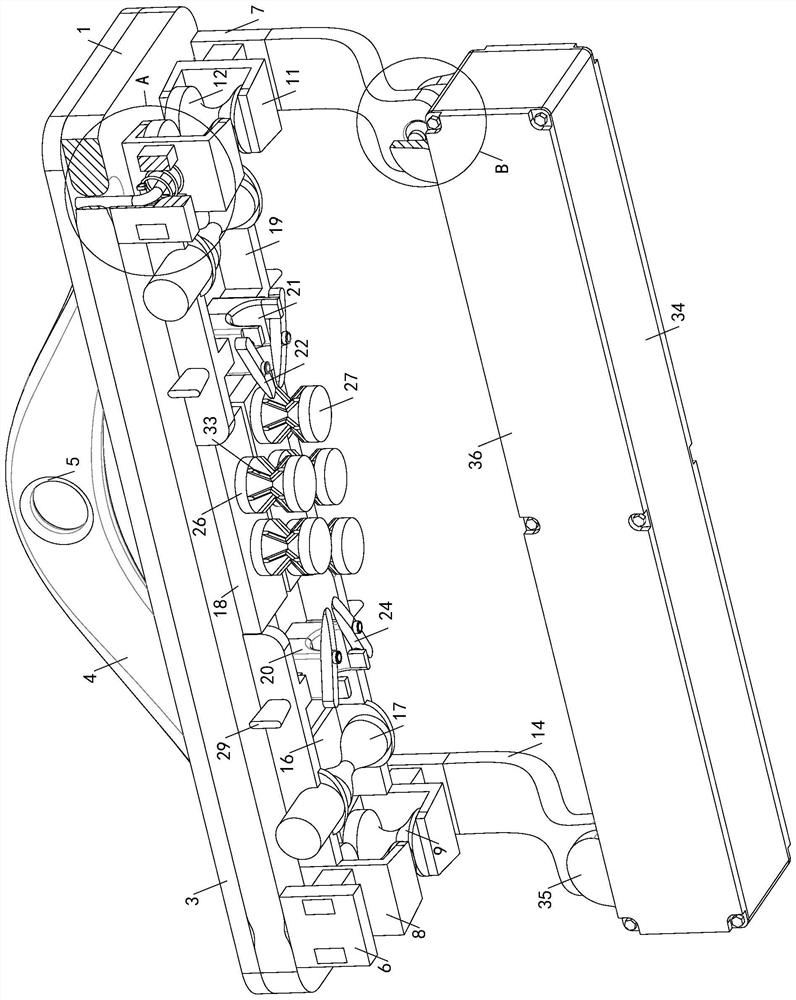

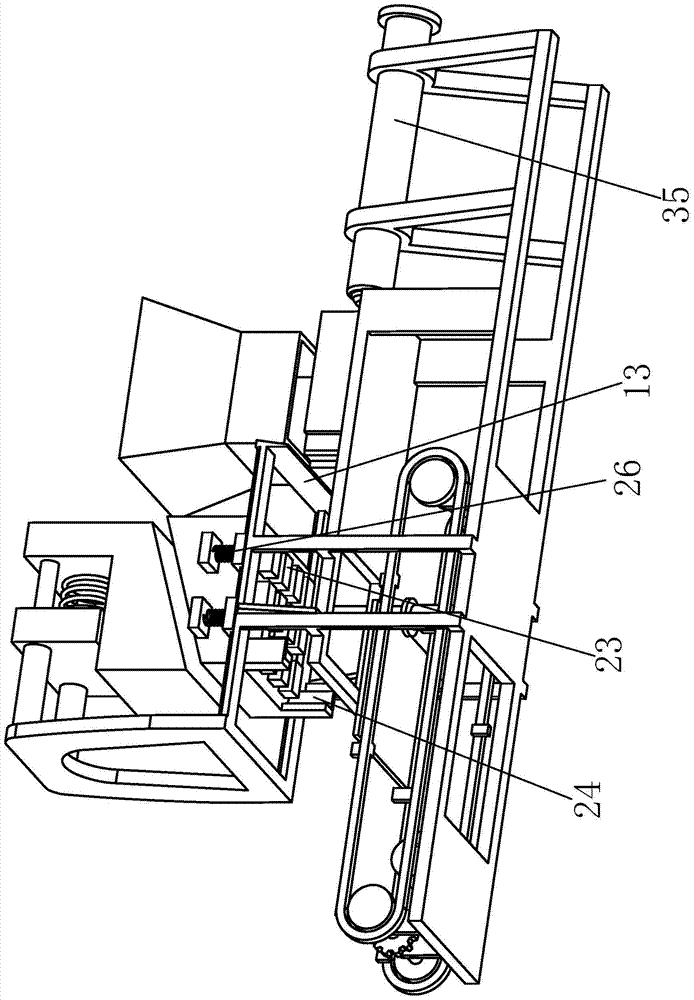

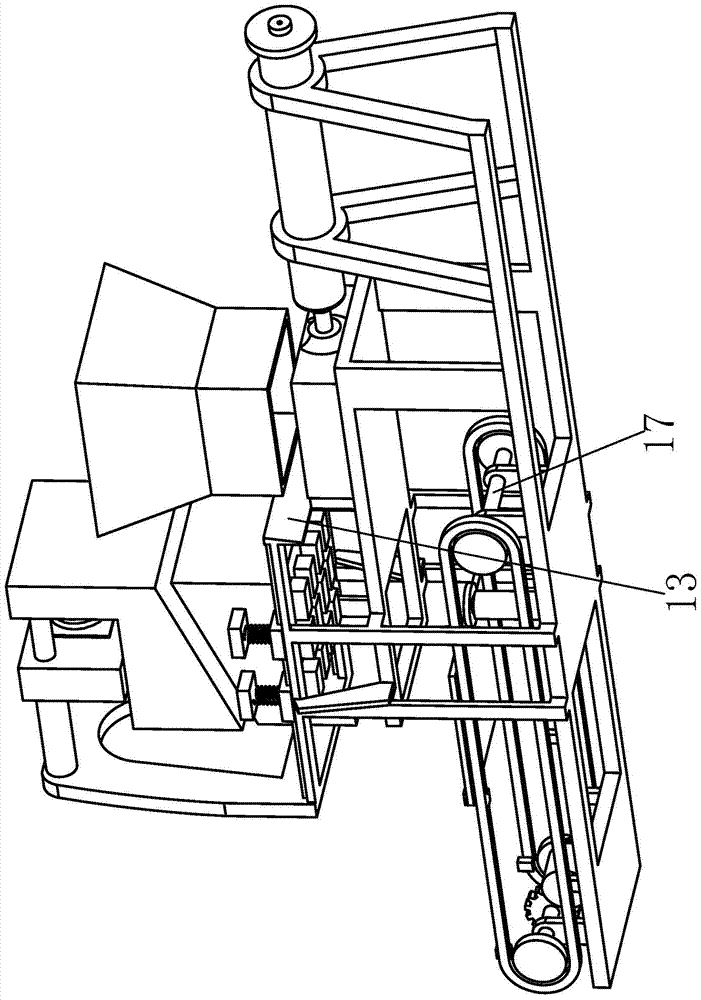

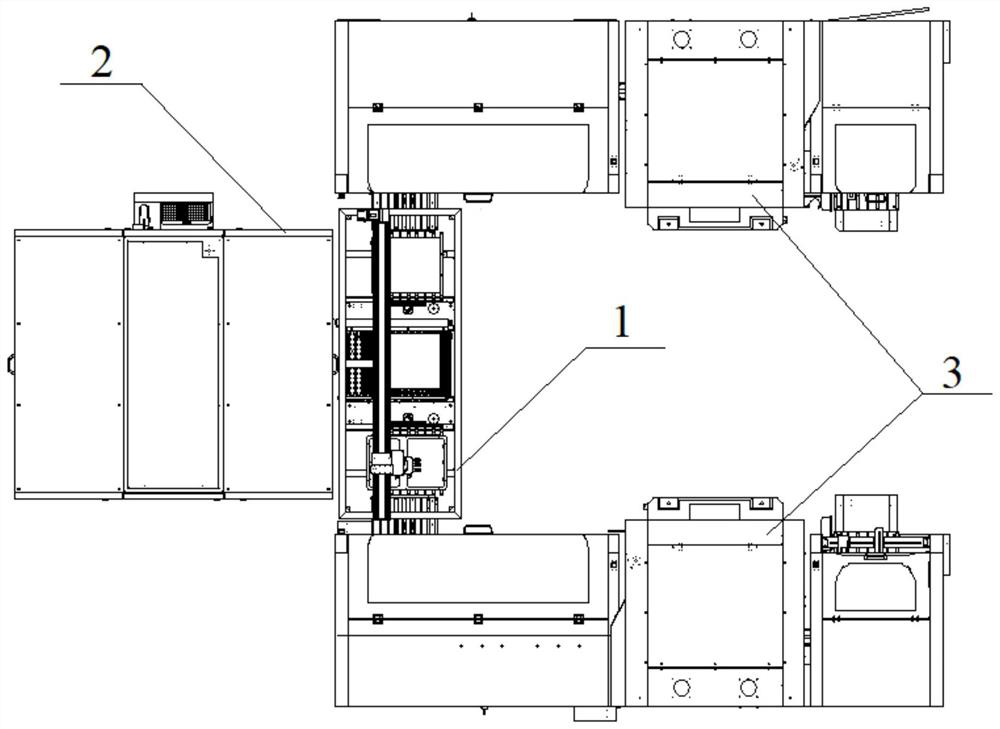

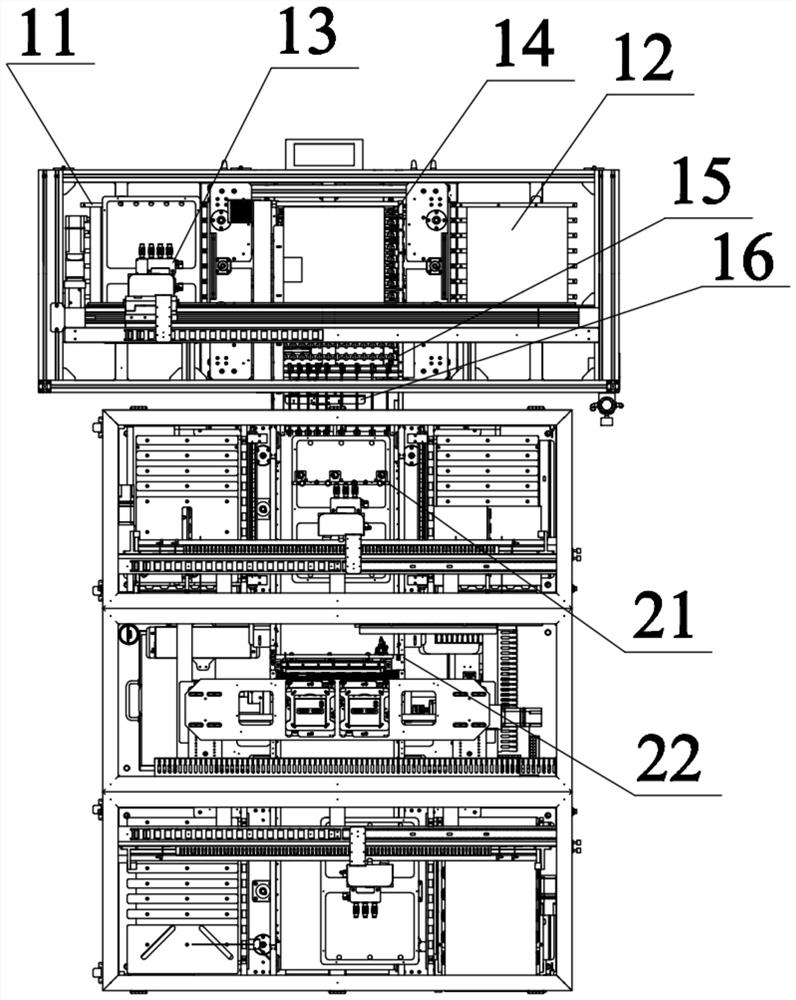

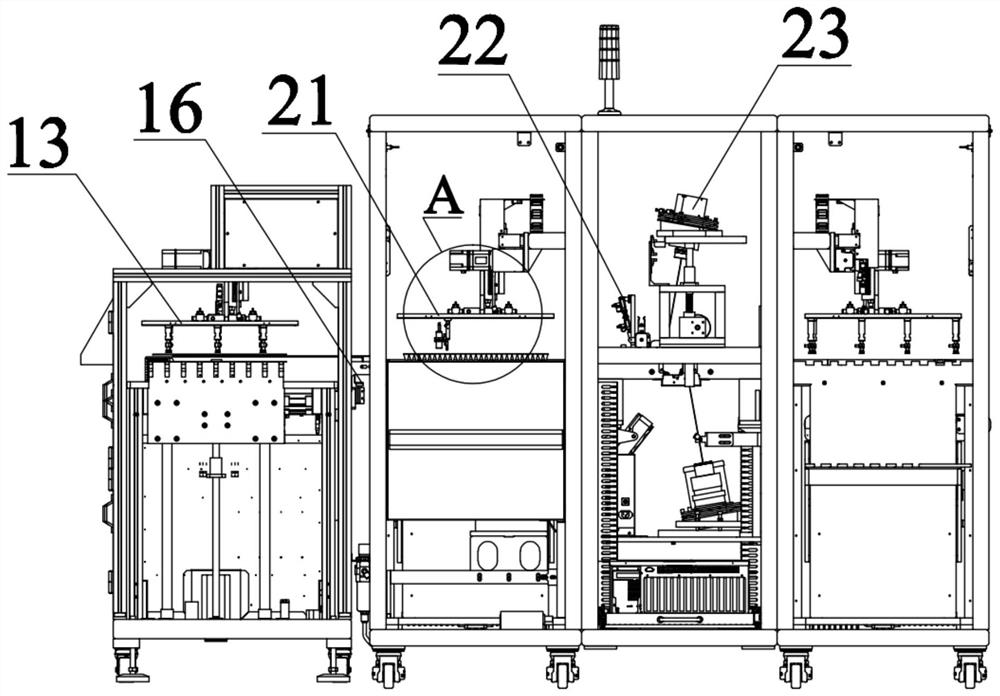

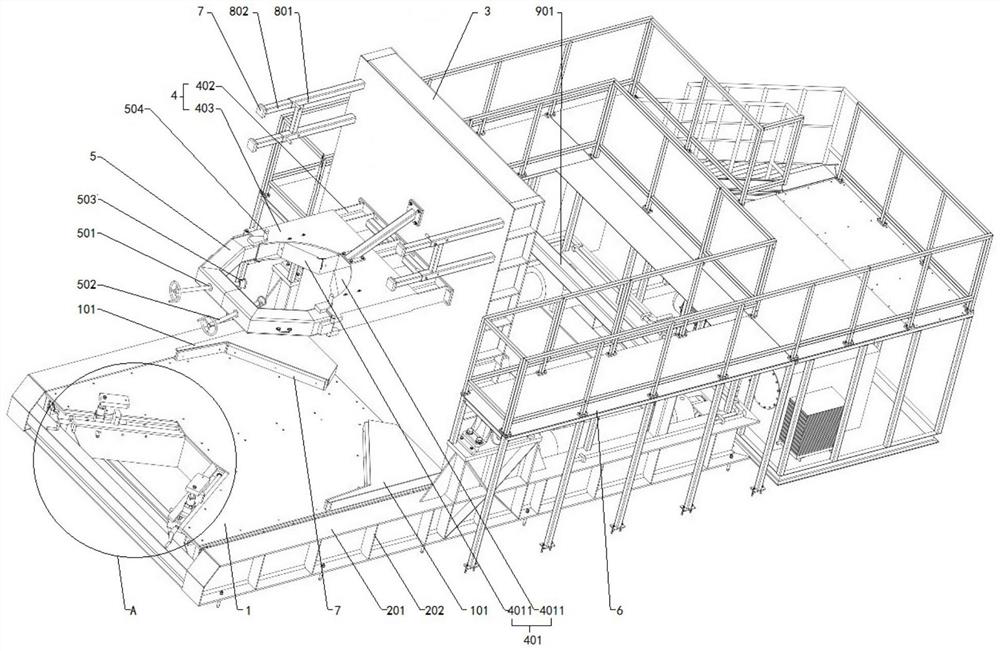

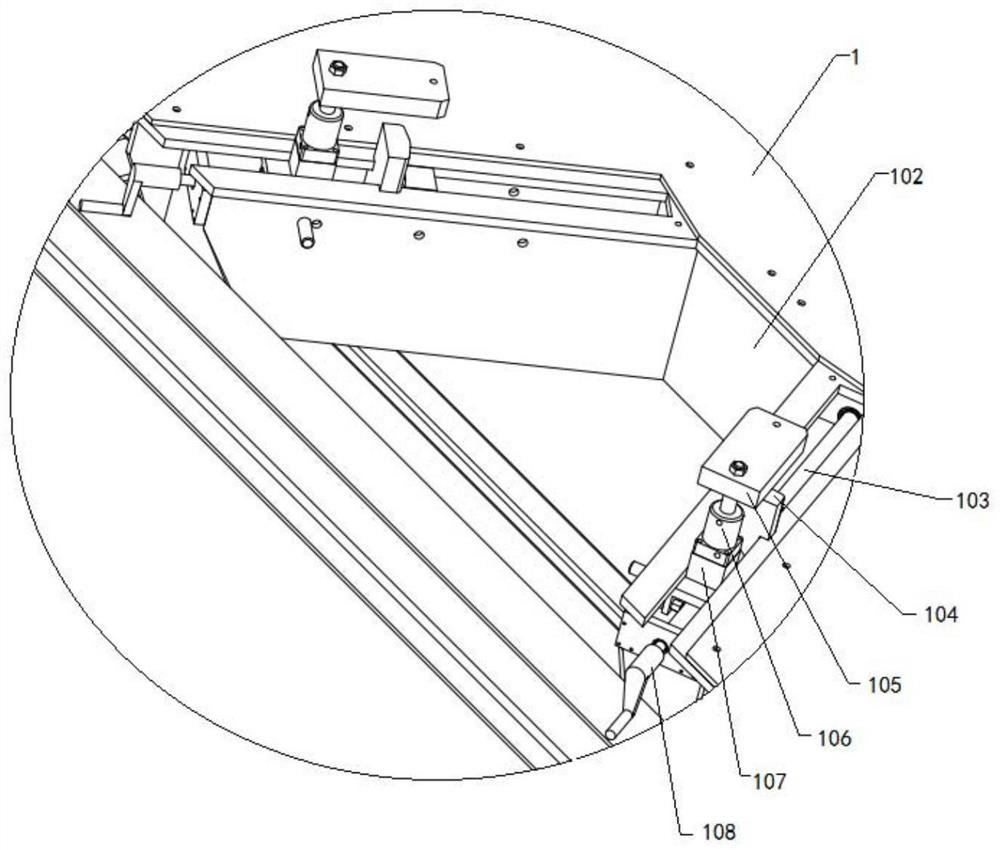

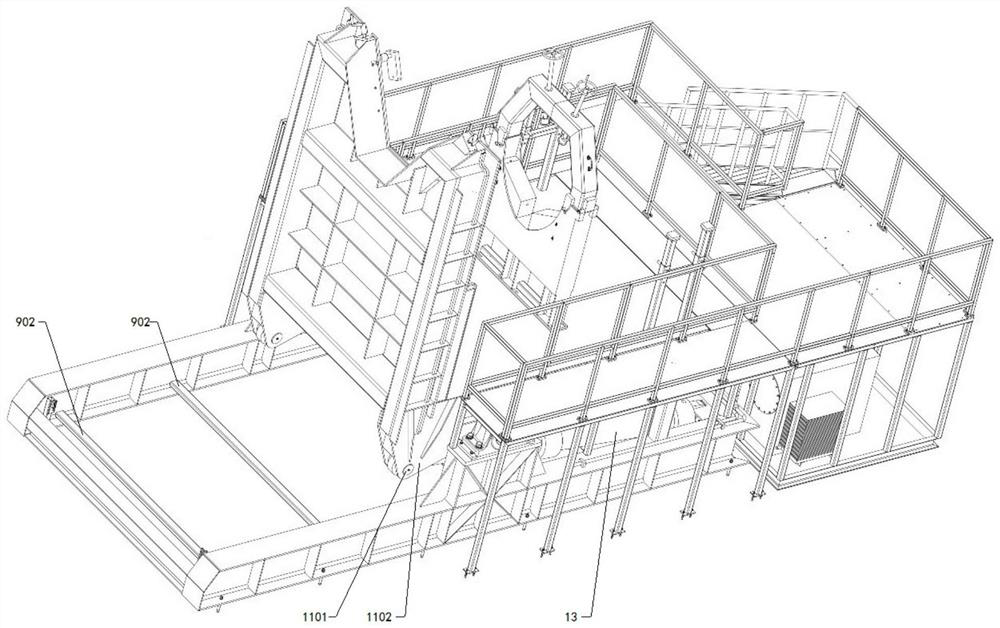

Automatic stacking machine for book making

ActiveCN114644219AReduce operating proceduresShorten the timeStacking articlesSupporting framesHydraulic cylinderRobot hand

The invention belongs to the technical field of book making, and particularly relates to an automatic stacking machine for book making. The automatic stacking machine comprises a driving unit, a stacking unit and a bearing unit, and the driving unit is sequentially provided with the stacking unit and the bearing unit from top to bottom; the stacking unit comprises a fixing frame, an electric sliding block, a vertical plate, a pushing hydraulic cylinder, a pushing frame, a mounting plate, a rotating roller, a rotating motor, a conveying belt and a baffle. Books are stacked on the tray layer by layer through joint cooperation of the driving unit, the stacking unit and the bearing unit, and in the stacking process, the pushing mechanism and the conveying belt replace a mechanical arm to achieve the book stacking function, so that the time for switching the tightness state of the mechanical arm and adjusting the position of the mechanical arm is saved, and the working efficiency is improved. The stacking operation procedure is reduced, the requirement for the operation precision is relatively low, and the equipment investment cost and the later maintenance cost are reduced accordingly.

Owner:南通恒懋智能科技发展有限公司

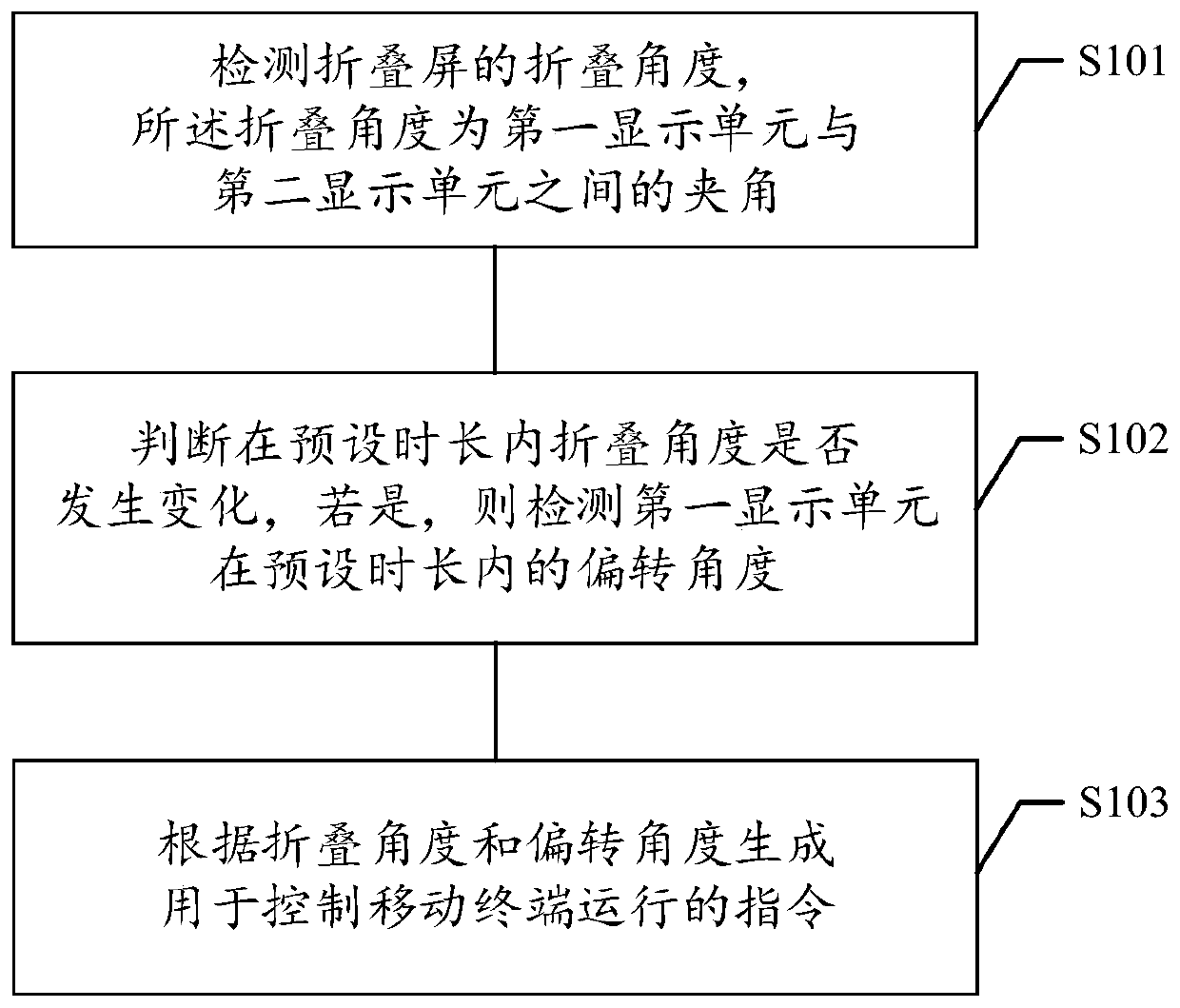

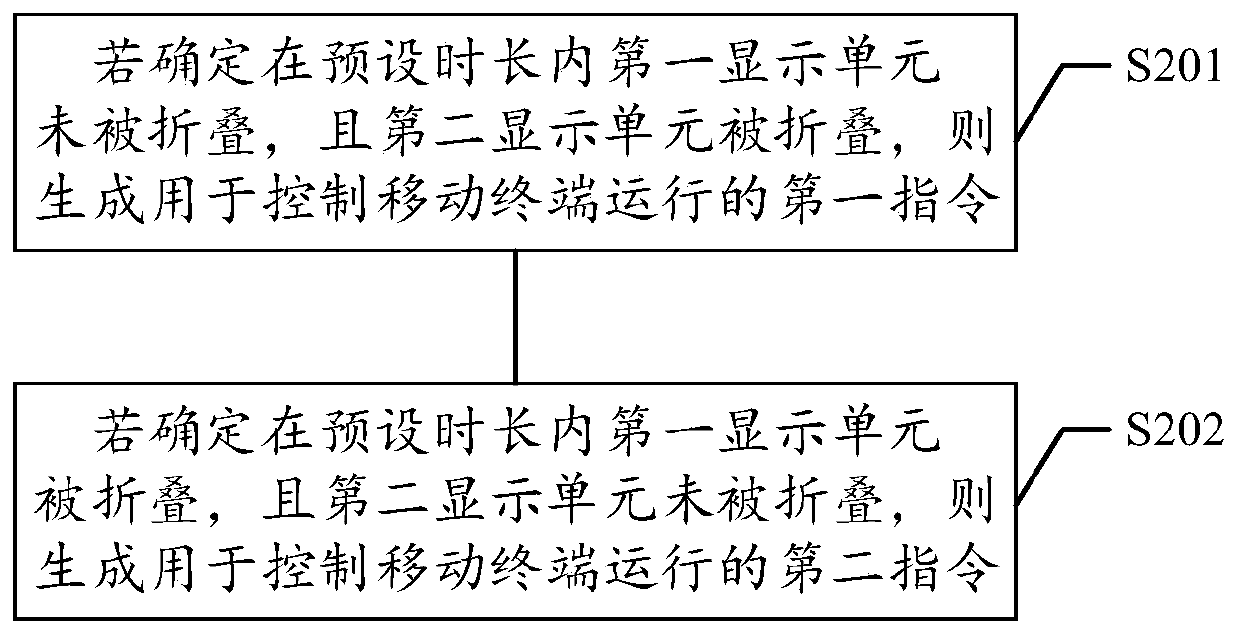

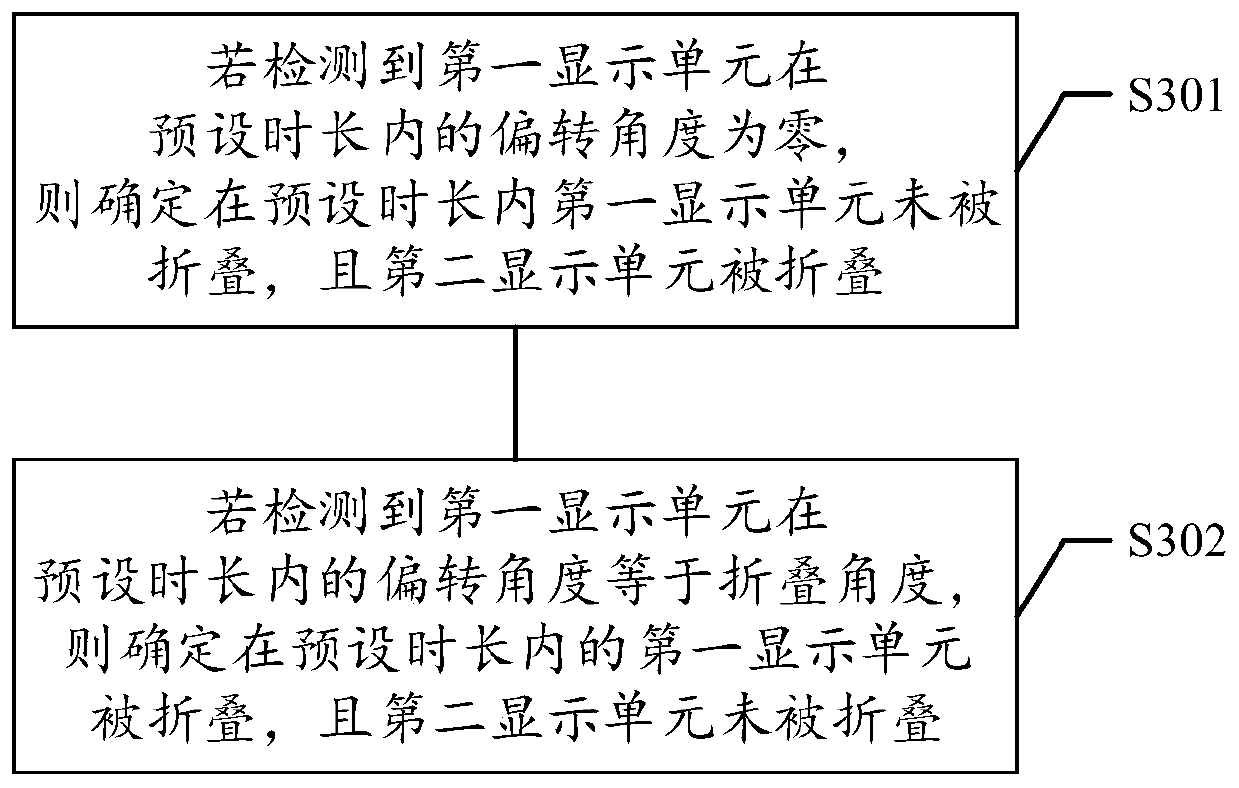

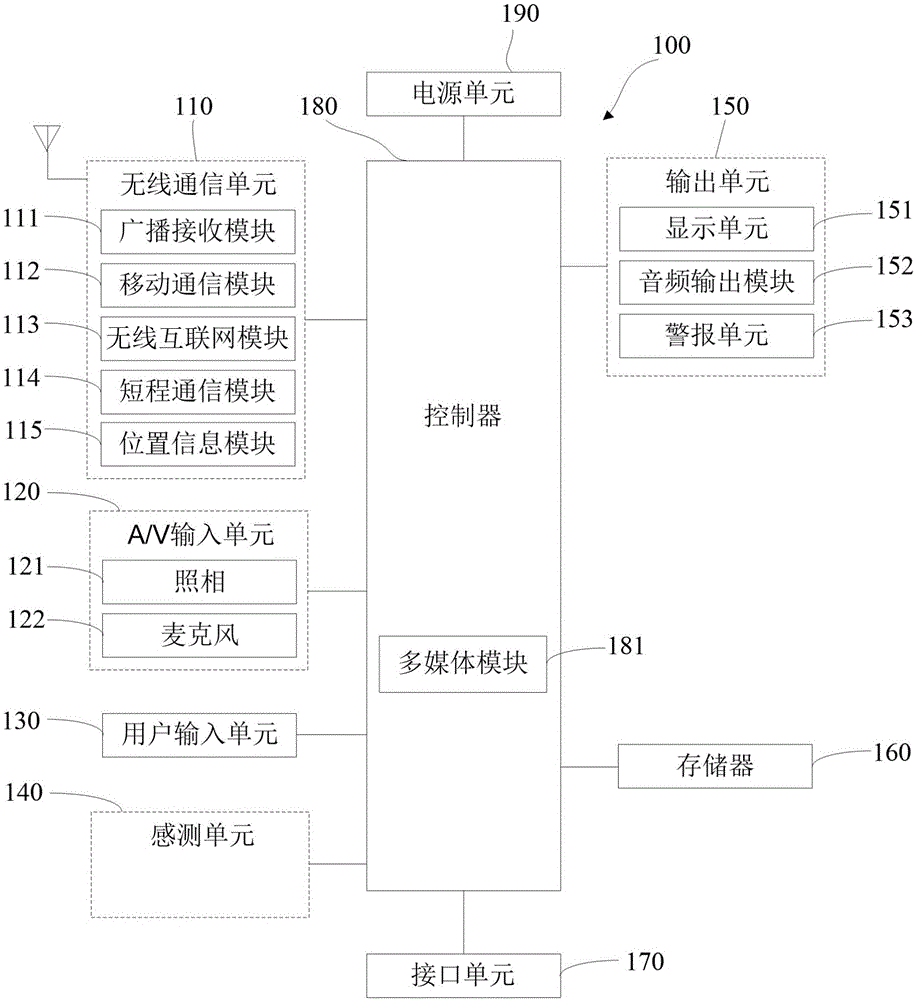

Mobile terminal control method and device, storage medium and electronic equipment

InactiveCN110209243ASave spaceLow operating precision requirementsDigital data processing detailsInput/output processes for data processingComputer terminalElectric equipment

The invention belongs to the technical field of computers, and relates to a mobile terminal control method and device, a computer readable storage medium and electronic equipment. A mobile terminal isprovided with a folding screen. The folding screen comprises a first display unit and a second display unit. The method comprises the steps of detecting the folding angle of the folding screen, wherein the folding angle is an included angle between the first display unit and the second display unit; judging whether the folding angle is changed within a preset time length or not, and if yes, detecting a deflection angle of the first display unit within the preset time length; and generating an instruction for controlling the operation of the mobile terminal according to the folding angle and the deflection angle. On one hand, an effective control instruction is generated through folding operation. The operation precision requirement is low. Operation is easy. Detection is easy, and the invention is suitable for various scenes. On the other hand, a new discretized input mode does not need to set an entity control on the interface, so that screen space is saved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

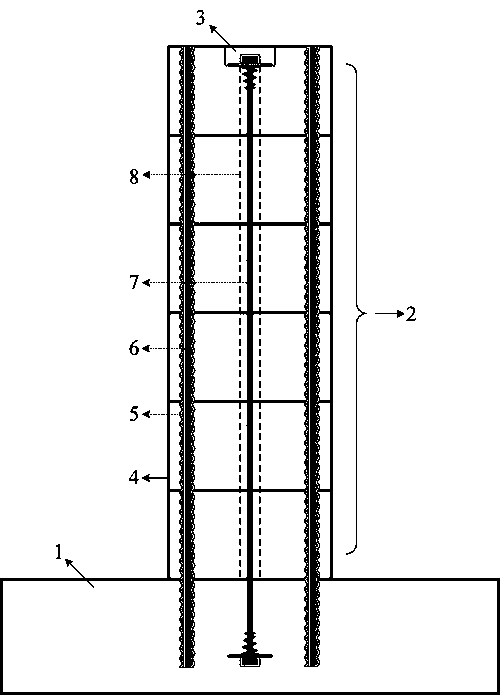

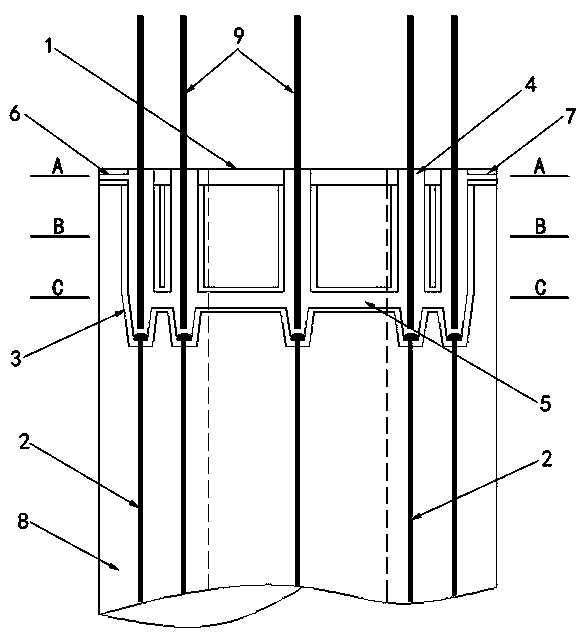

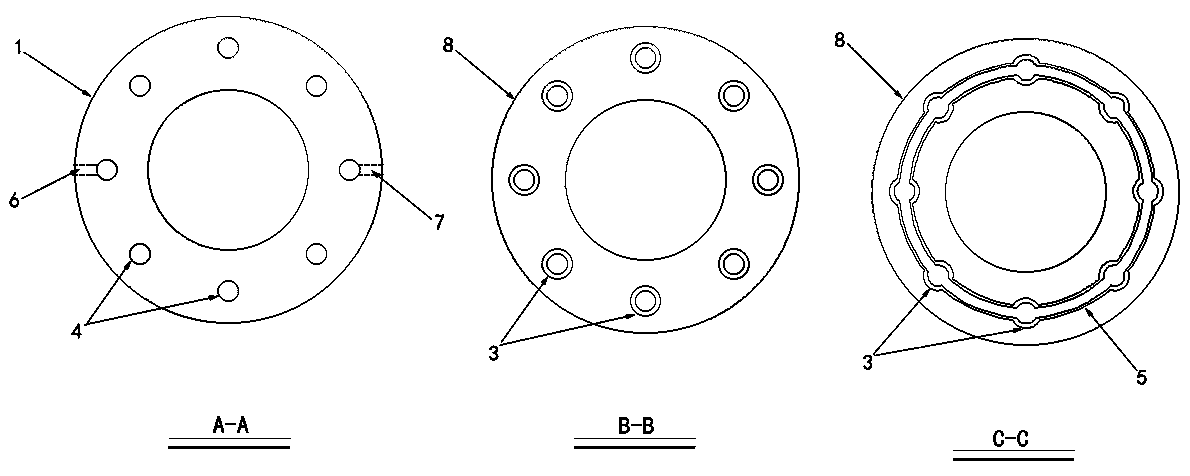

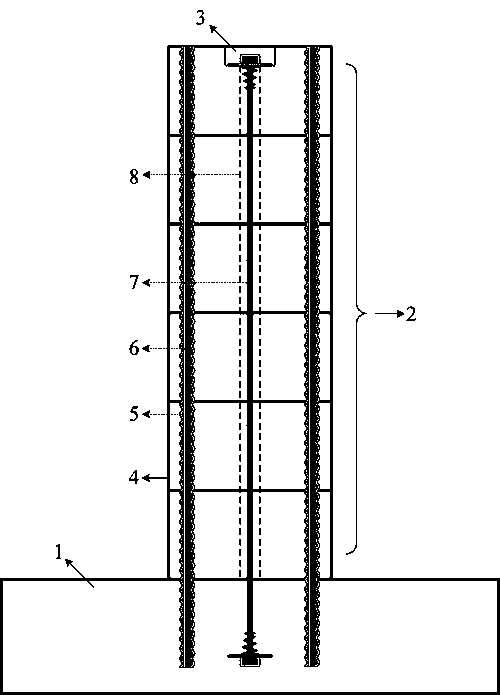

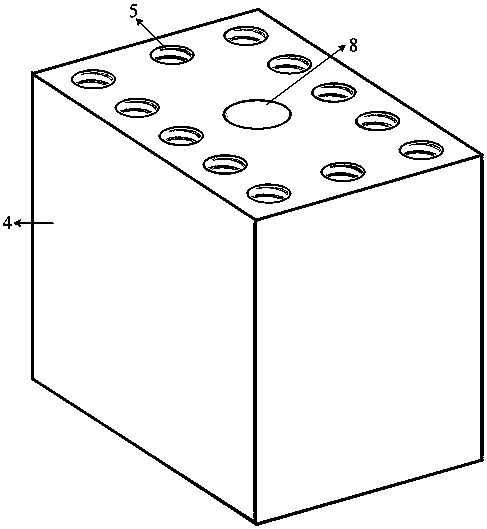

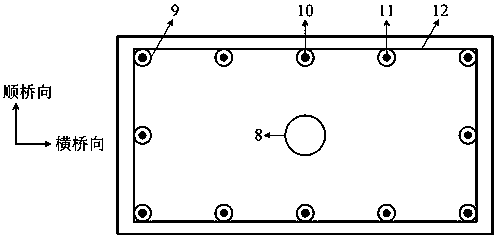

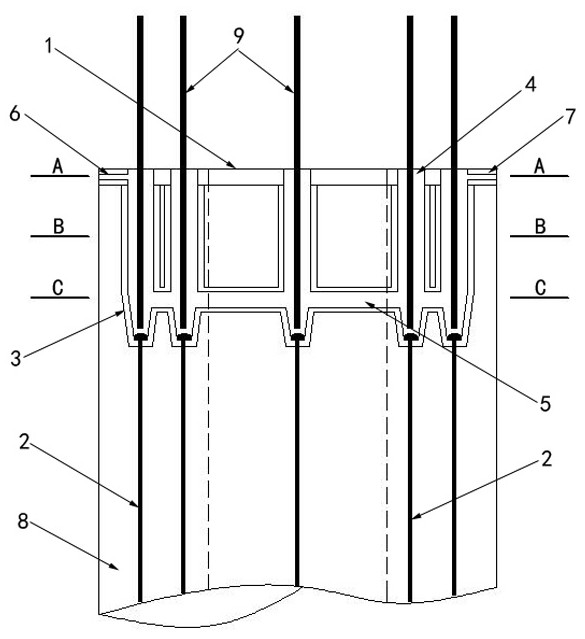

Assembled pier using mixed reinforcements of ordinary steel bars and screw-thread steel bars

InactiveCN108316130AGood self-resetting performanceImprove post-earthquake functionalityBridge structural detailsBridge erection/assemblyPile capPre stress

The invention provides an assembled pier using mixed reinforcements of ordinary steel bars and screw-thread steel bars. The assembled pier using the mixed reinforcement of the ordinary steel bar and the screw-thread steel bar comprises a concrete pile cap (1), assembled pier bodies (2), a through longitudinal bars (6) and an unbonded prestressing tendon (7) and is characterized in that the throughlongitudinal bars (6) are obtained by mixing the ordinary steel bars and the screw-thread steel bars; and the through longitudinal bars (6) and the unbonded prestressing tendon (7) connect the concrete pile cap (1) with each assembled pier body (2) to form a complete pier system.

Owner:HENGQIN GONGE TECH CO LTD

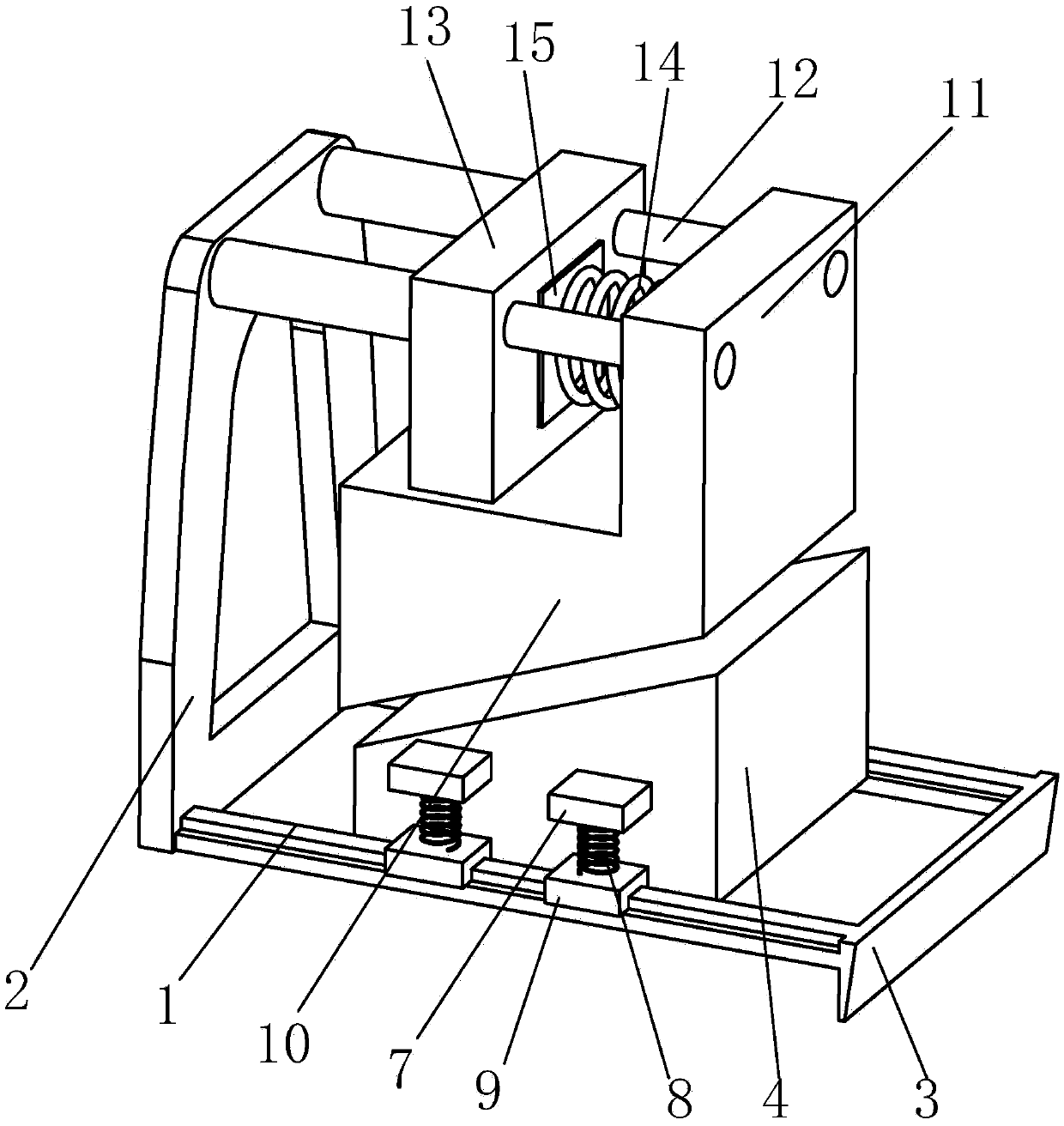

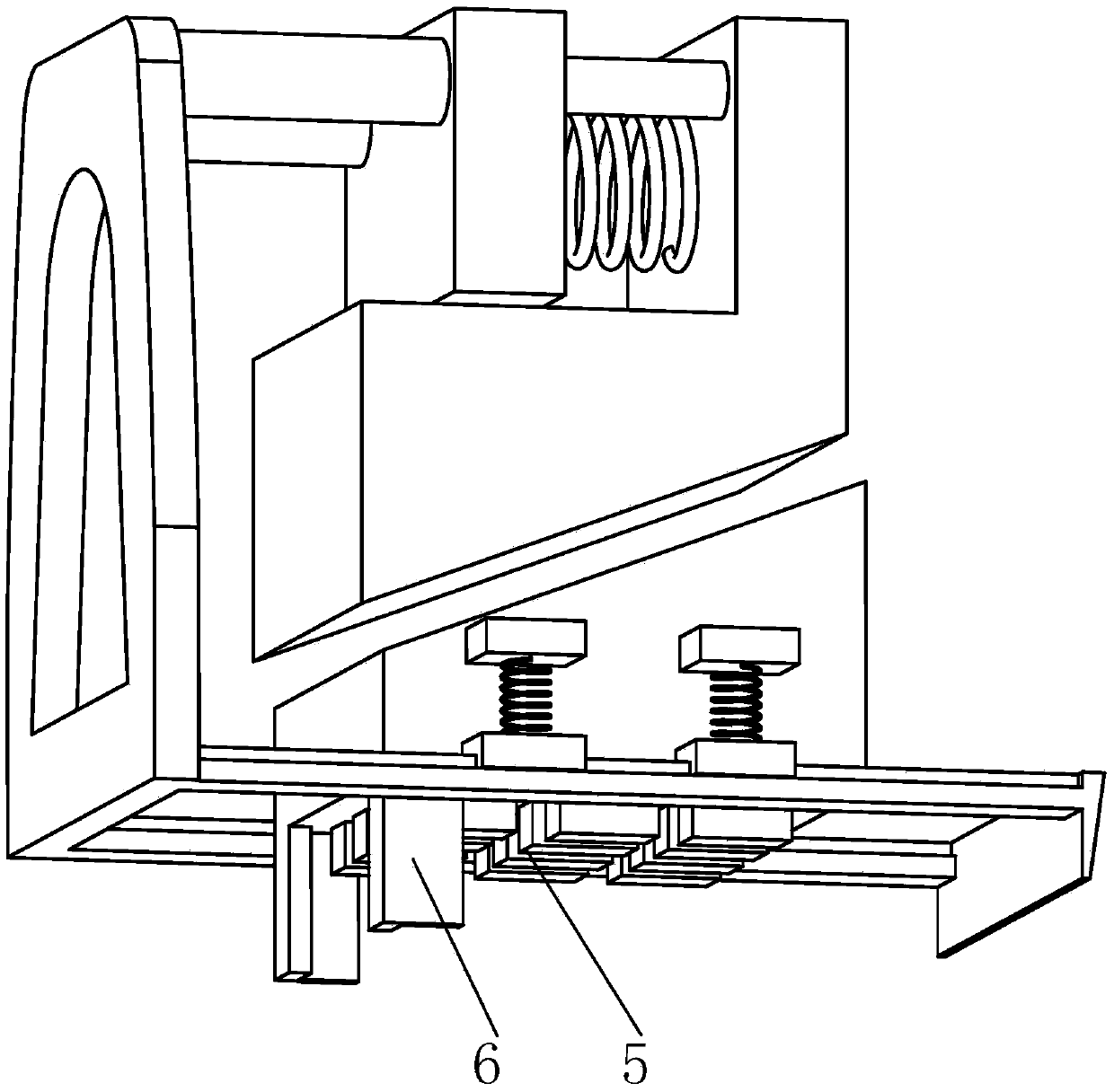

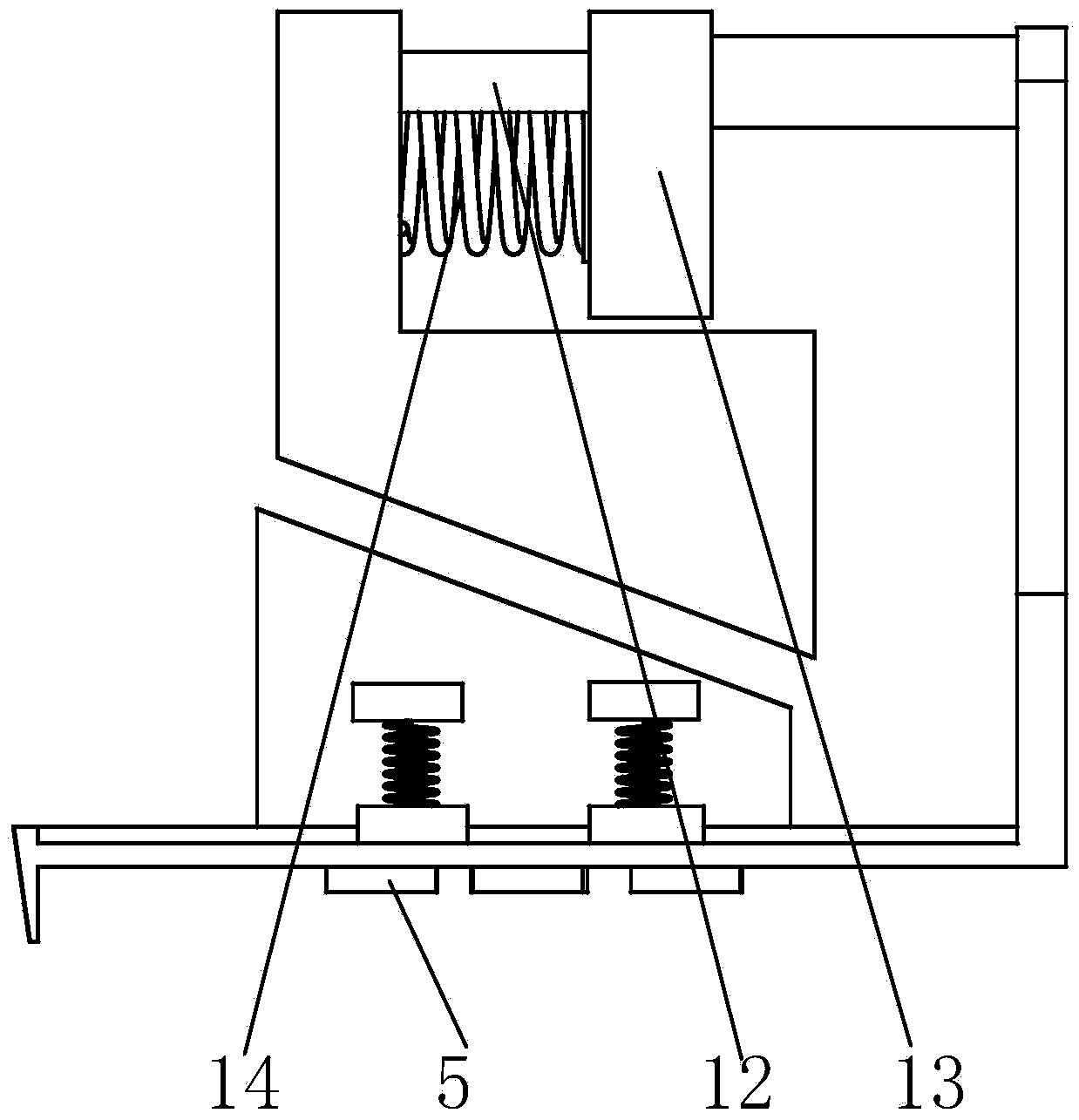

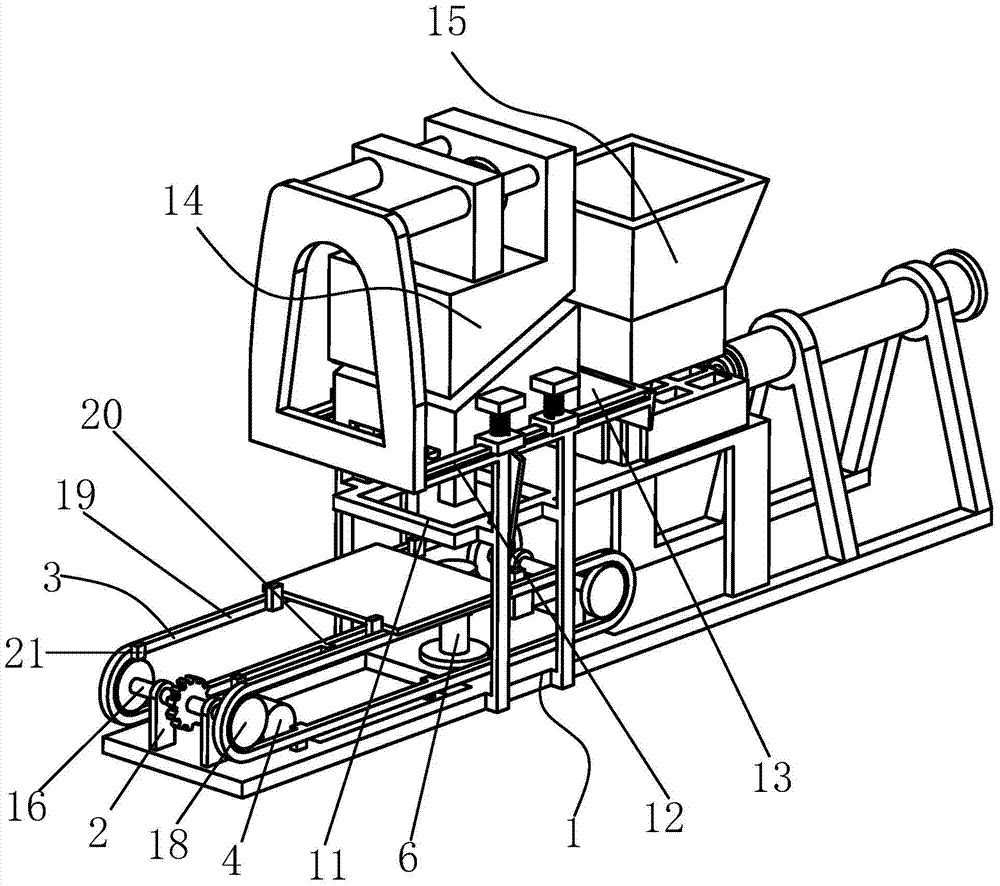

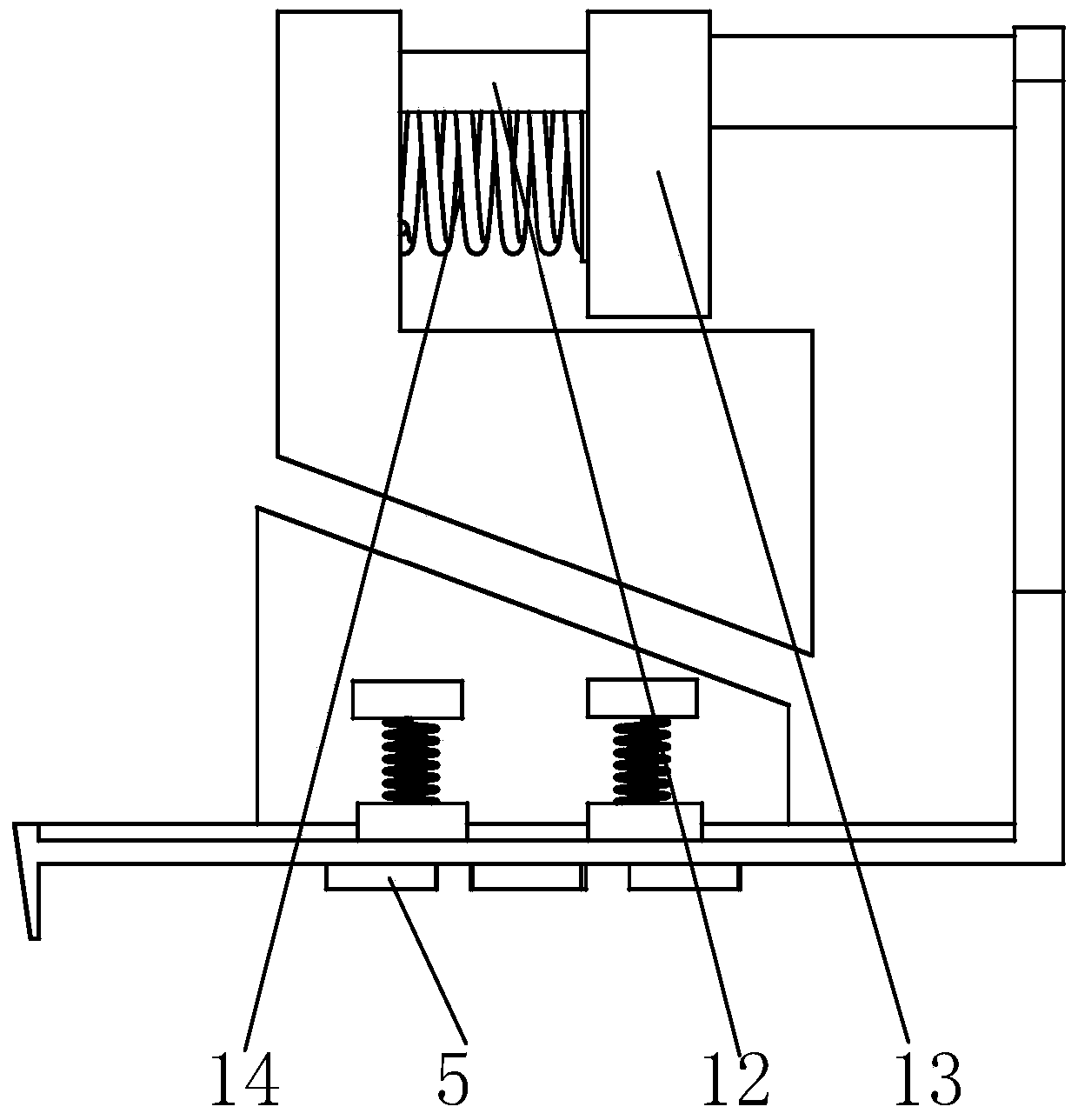

Transverse pushing and longitudinal pressing mechanism for hollow brick pressing forming machine

ActiveCN105365032ALow operating precision requirementsLower performance requirementsAuxillary shaping apparatusShaping press ramHydraulic cylinderBrick

The invention relates to a transverse pushing and longitudinal pressing mechanism for a hollow brick pressing forming machine. The transverse pushing and longitudinal pressing mechanism comprises two parallel sliding rails. A lower pressing mold is arranged between the sliding rails. Rectangular brick pressing convex blocks are evenly distributed on the lower end face of the lower pressing mold. Baffle plates are arranged at the left end of the lower pressing mold. The upper end face of the lower pressing mold is an inclined face, and the included angle between the upper end face of the lower pressing mold and a horizontal plane is an acute angle. Wing arms are fixed to the front end face and the rear end face of the lower pressing mold, and springs are arranged on the lower end faces of the wing arms. An upper pressing mold is arranged above the lower pressing mold, and the lower end face of the upper pressing mold is an inclined face parallel to the upper end face of the lower pressing die. A sliding sleeve is arranged above the right side of the upper pressing mold, sliding columns pass the sliding sleeve, and a check block is fixed to the left ends of the sliding columns. The check block is mounted on a side supporting plate, and a damping spring is arranged between the right end face of the check block and the left end face of the sliding sleeve, and connected with a pressure sensor. The method that the vertically compressing brick manufacturing raw materials through a hydraulic cylinder is adopted to form bricks in the prior art is improved, and the instability of the forming quality and forming size of the bricks is reduced.

Owner:无为县华标新型墙体材料有限公司

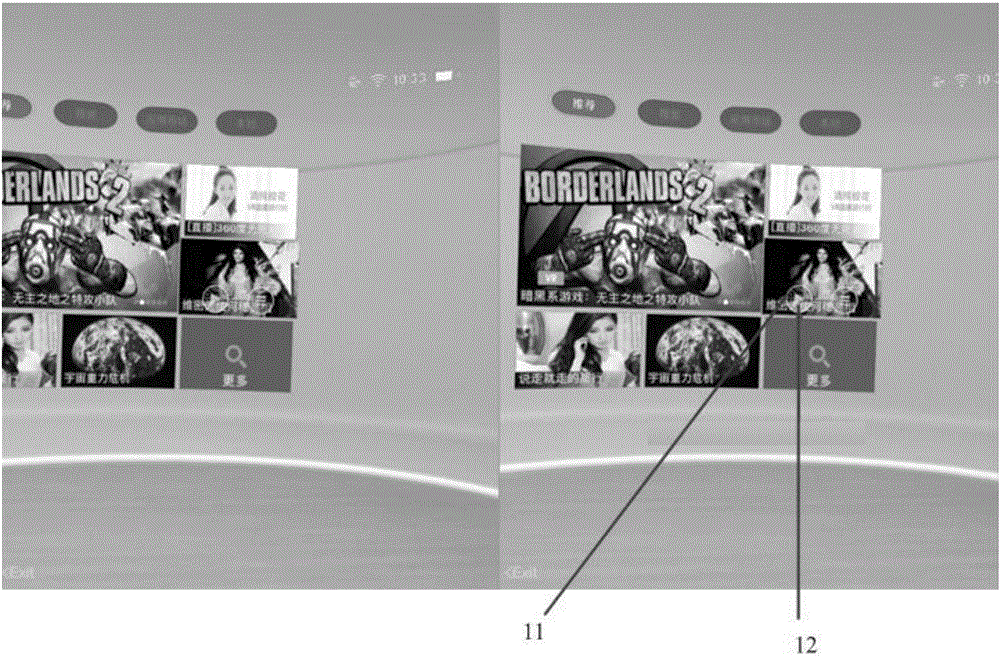

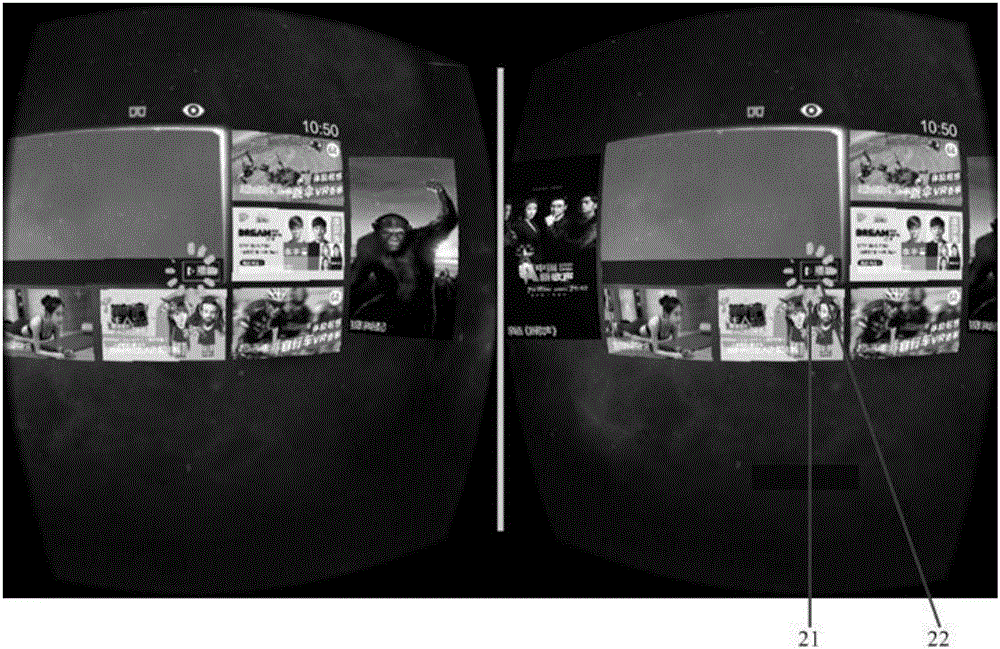

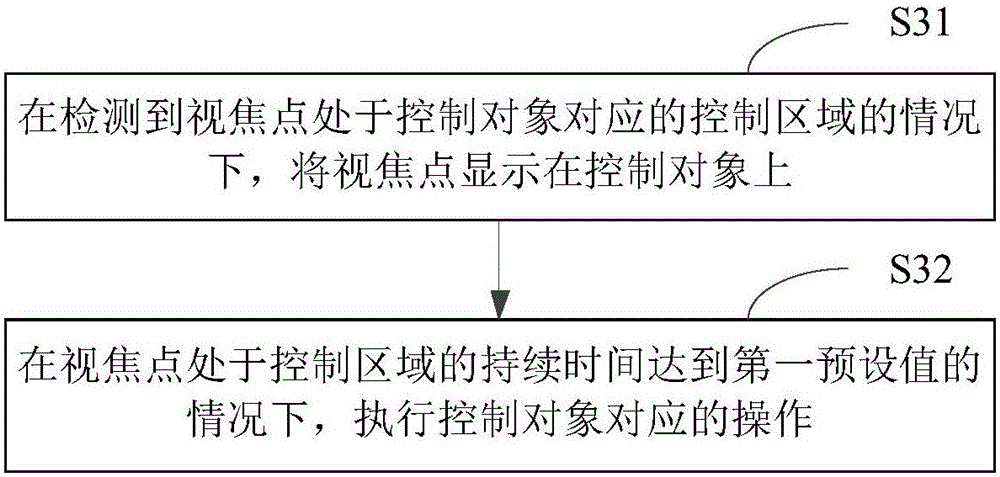

Interaction control method and device based on virtual reality

ActiveCN106445085AReduced operating precision requirementsImprove user experienceInput/output processes for data processingExecution controlControl area

The invention relates to an interaction control method and device based on virtual reality. The method comprises the steps that when it is detected that a visual focus is located in a control area corresponding to a control object, the visual focus is displayed on the control object; when duration of the visual focus located in the control area reaches a first preset value, an operation corresponding to the control object is executed. Due to the fact that when it is detected that the visual focus is located in the control area corresponding to the control object, the visual focus is displayed on the control object, and when duration of the visual focus located in the control area reaches the first preset value, the operation corresponding to the control object is executed, according to the interaction control method and device based on the virtual reality, the requirement of the operation precision of a user can be lowered, and therefore the user experience can be improved.

Owner:ALIBABA (CHINA) CO LTD

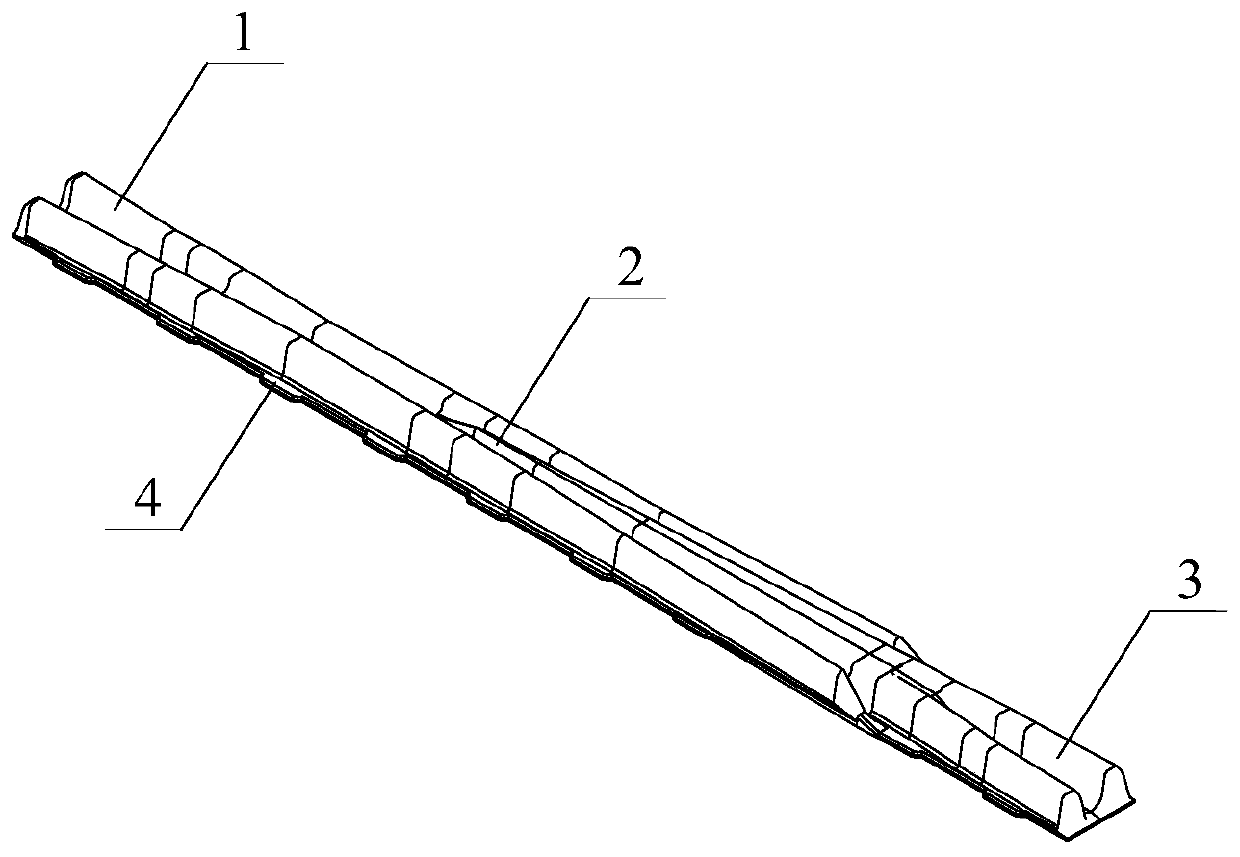

Bus bar, solar cell module and manufacturing method of solar cell module

PendingCN109817746AEasy transferLow costFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The embodiment of the invention relates to the field of solar power generation, and discloses a solar cell bus bar, a solar cell module and a method for manufacturing the solar cell module. The technical solution of the invention is as follows: a pure aluminum bus bar is adopted, the bus bar and the electrode layer of the solar cell are welded by using an ultrasonic welding method; the contact surfaces of the two are firmly combined; formation of good ohmic contact is realized, and the bus bar can better transmit electric power generated by the solar cell. Compared with the prior art that expensive conductive adhesives or conductive silver paste is required to be coated and then imported hot melt tin welding equipment with a complex structure is used for welding, the bus bar has the advantages that the material and equipment cost is lower, the requirement on the operation precision is lower, and the production cost of the thin film solar cell is reduced.

Owner:上海祖强能源有限公司

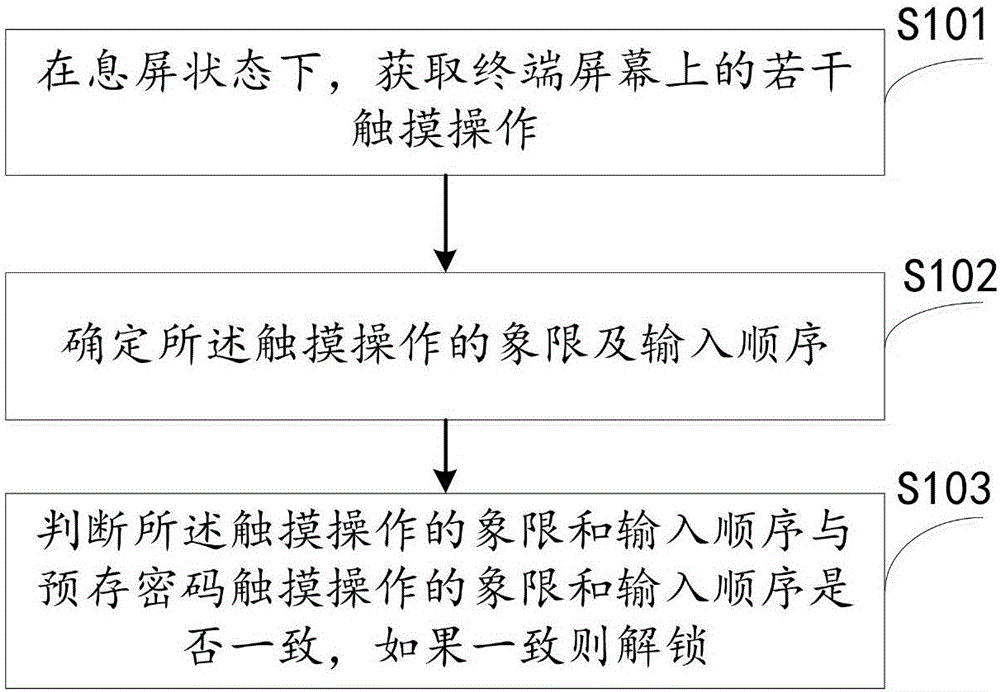

Method and device for unlocking terminal

InactiveCN106650357ALow operating precision requirementsReduce learning costsDigital data authenticationInput/output processes for data processingComputer terminal

Owner:NUBIA TECHNOLOGY CO LTD

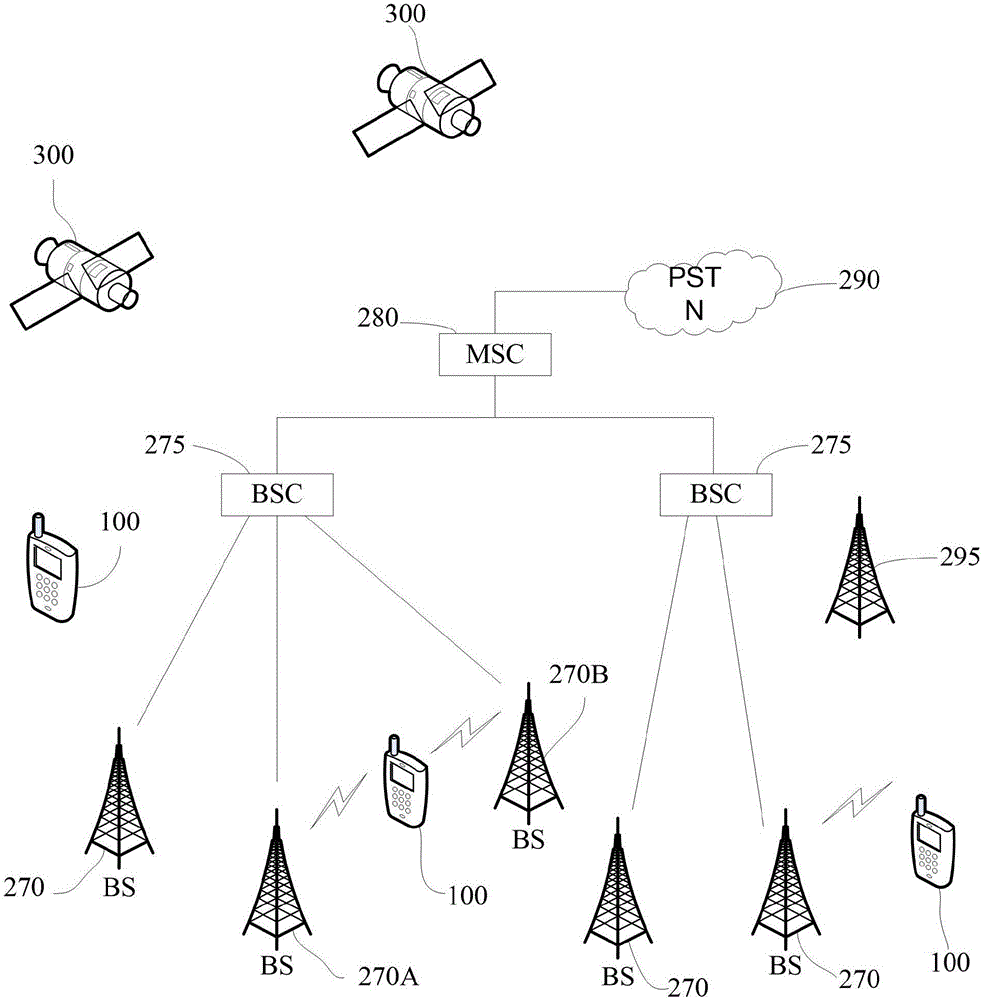

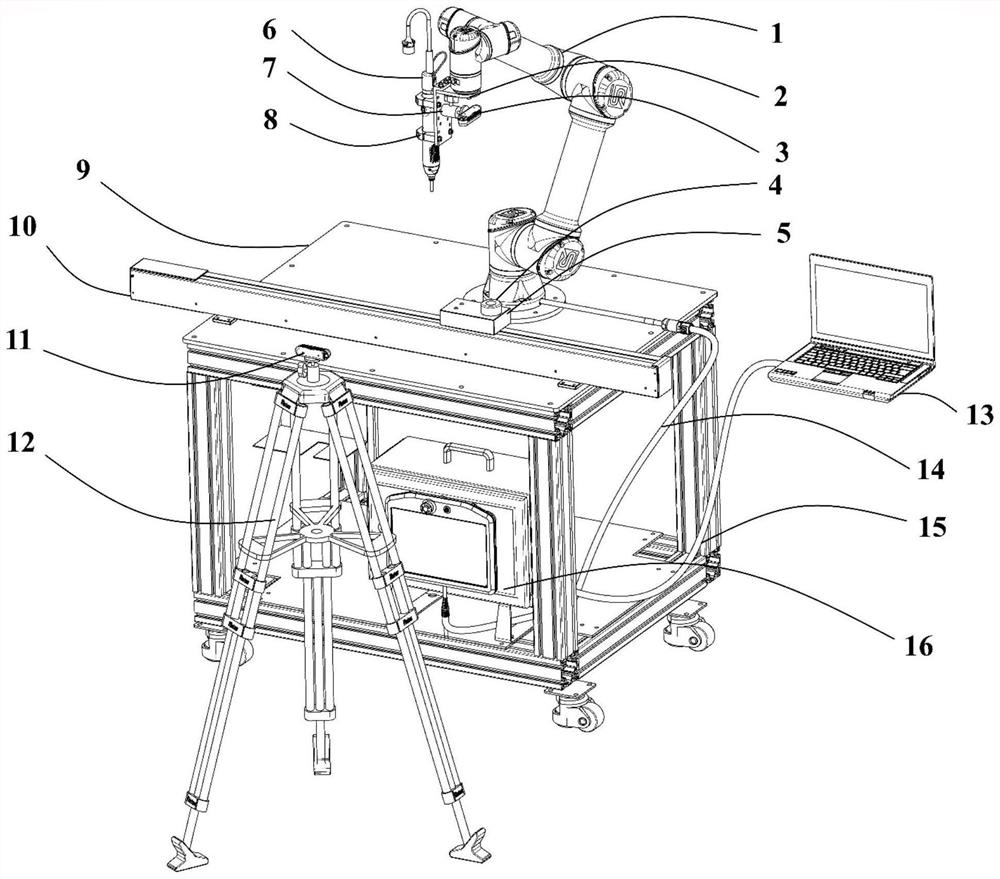

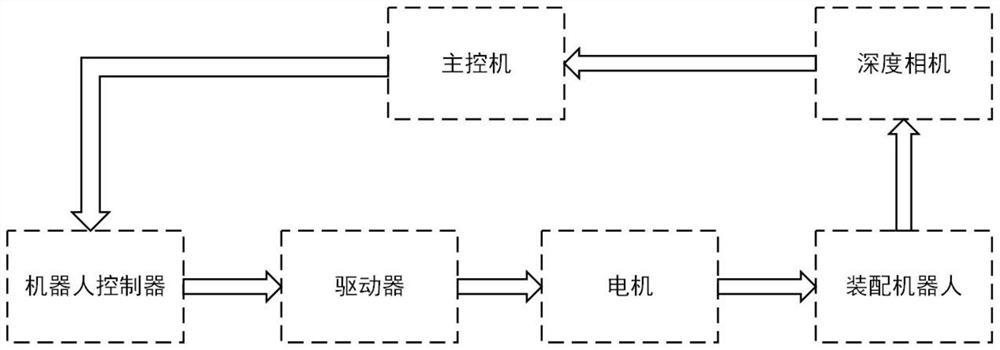

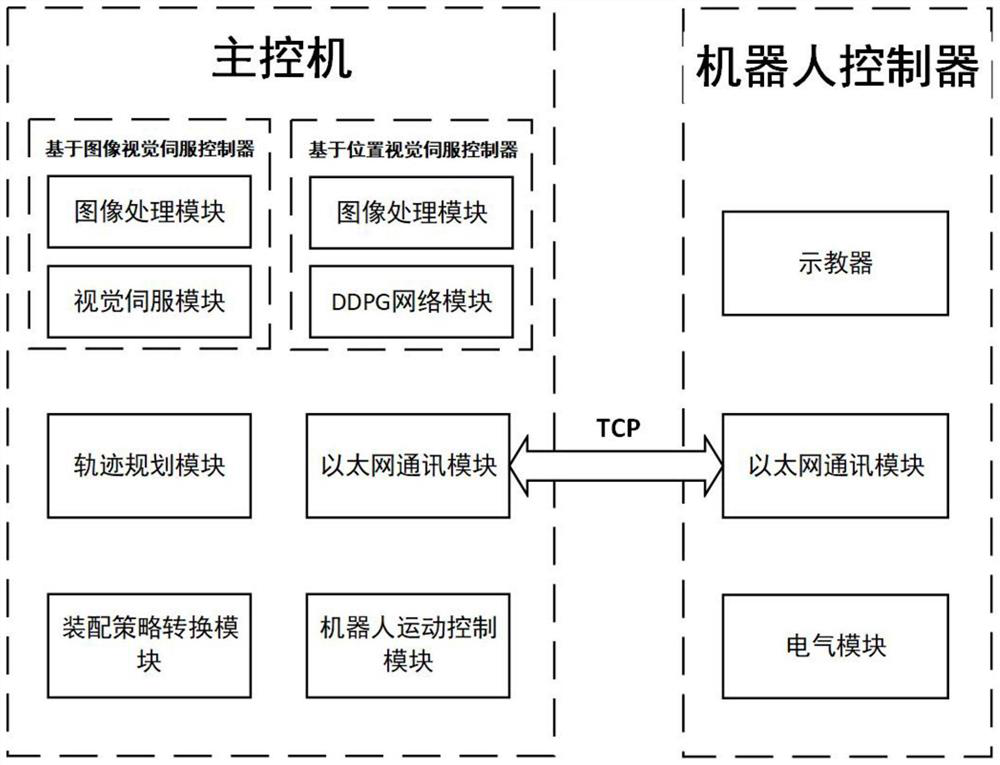

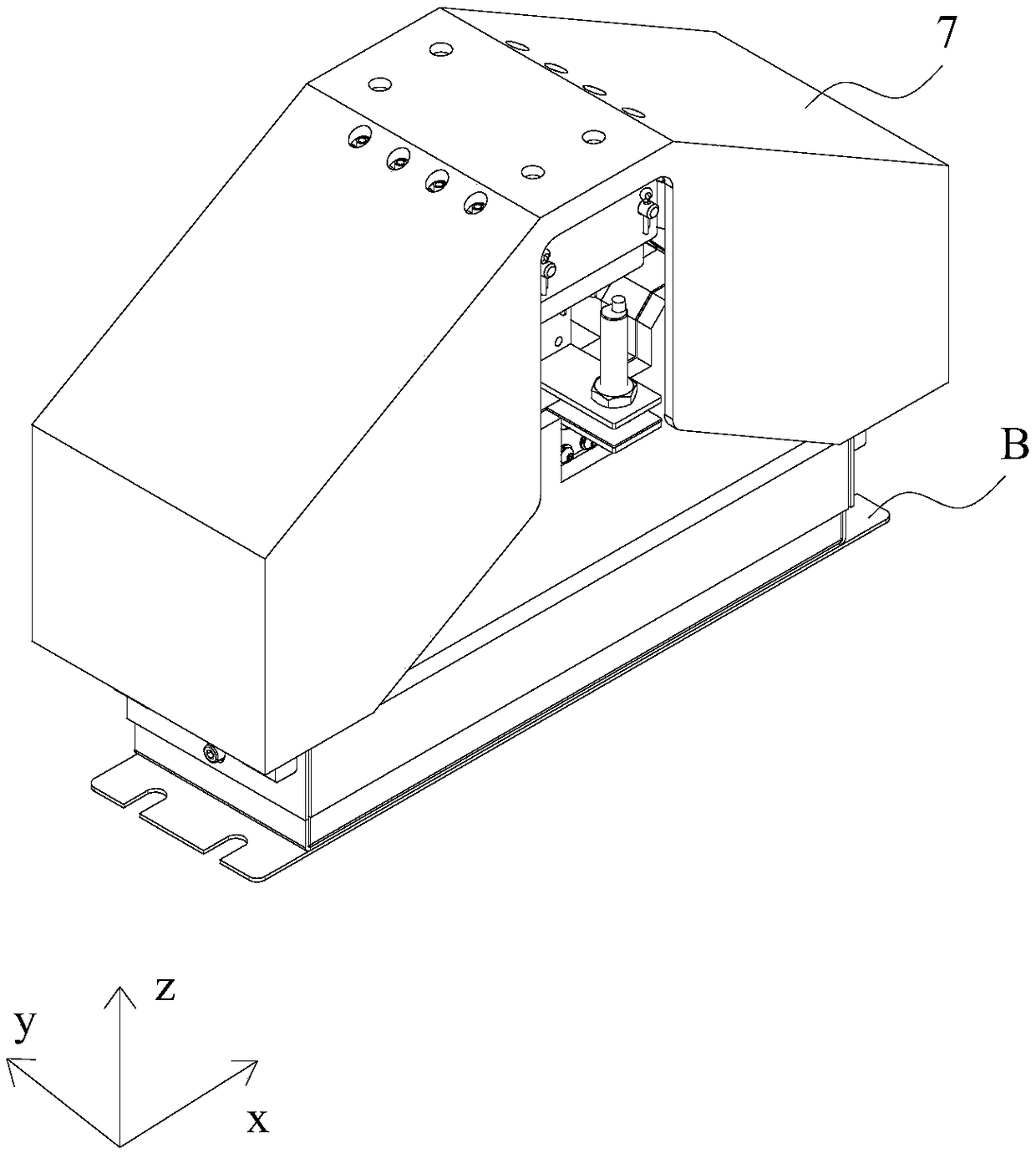

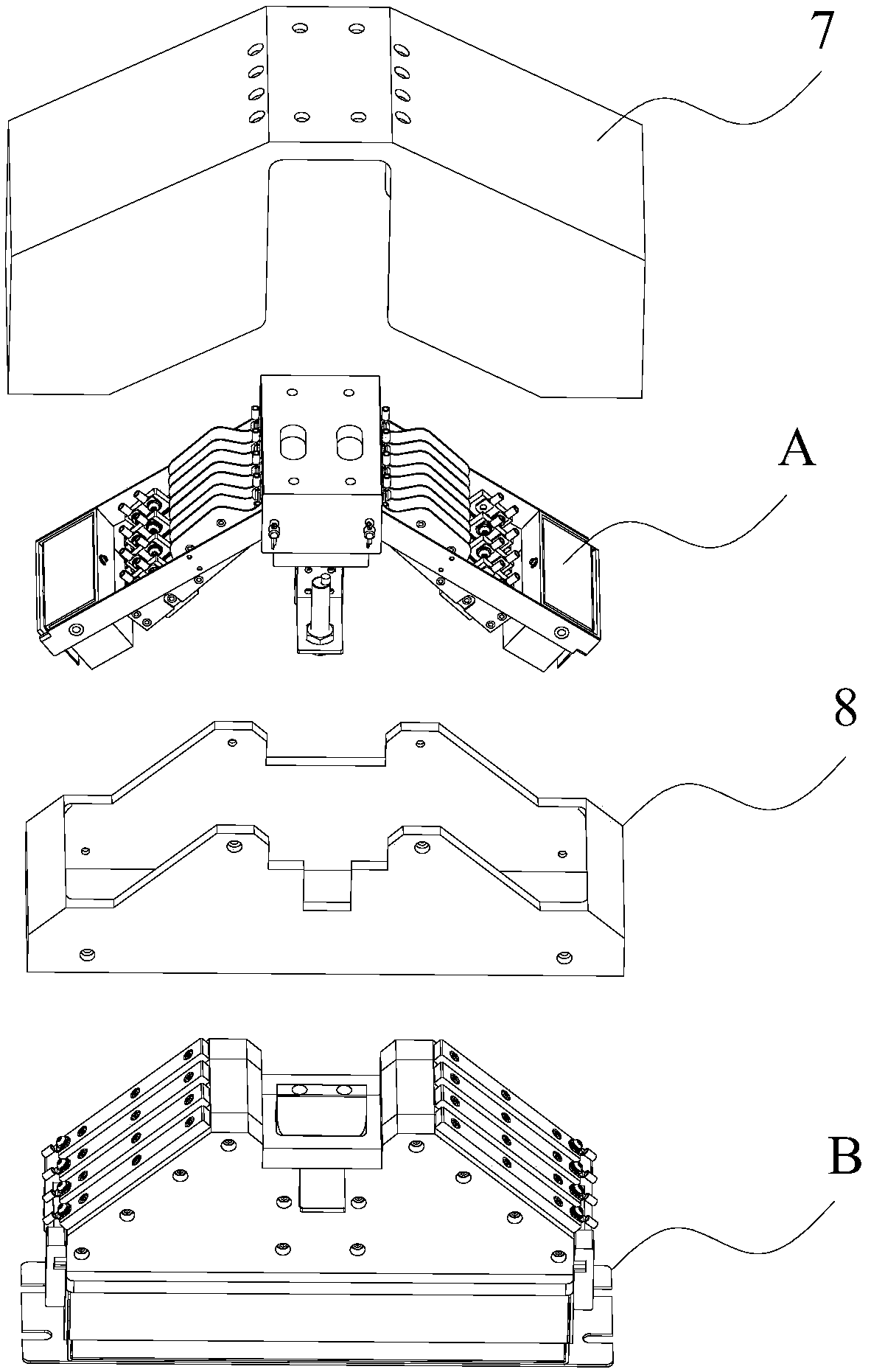

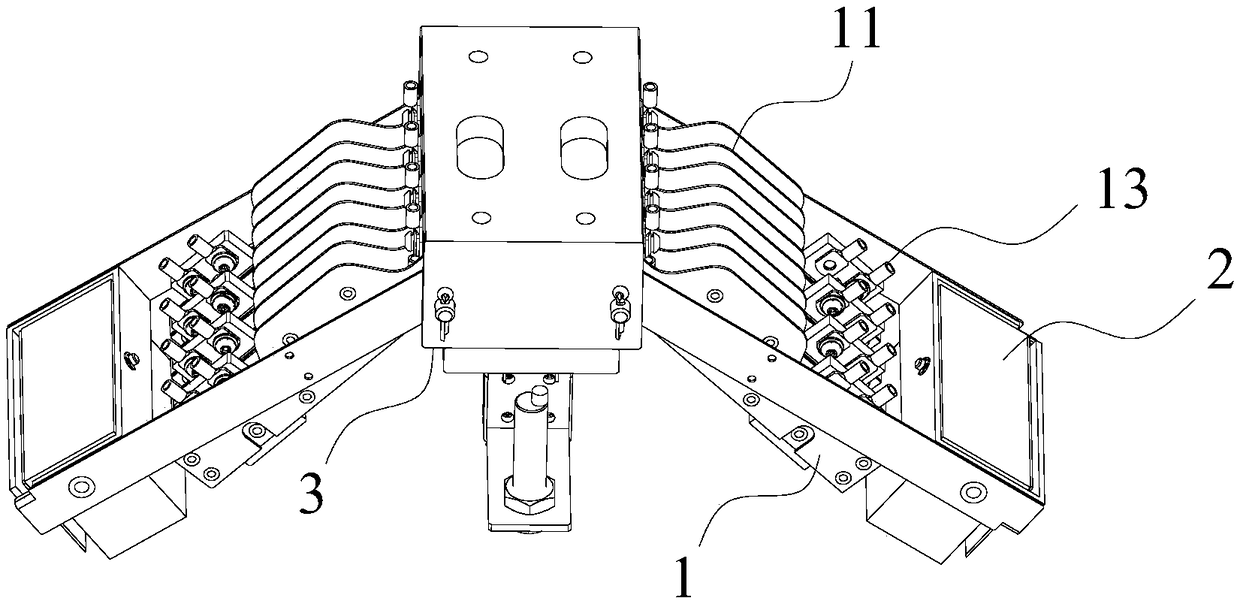

Dynamic shaft hole assembling device and method based on multi-camera visual servo

PendingCN112548527AOvercoming the problem of dynamic position uncertaintyAvoid occlusionProgramme-controlled manipulatorMetal working apparatusLinear motionVisual servoing

The invention discloses a dynamic shaft hole assembling device and method based on multi-camera visual servo, and belongs to the field of mechatronics. The dynamic shaft hole assembling device comprises a mechanical part and a control part, wherein the mechanical part comprises an operation platform, an assembly robot, a tool flange, a driving shaft support, a driving shaft, a camera holder, a linear guide rail, an assembling hole, an assembling platform and a tripod; the assembly robot and the linear guide rail are fixed to the operation platform; the linear guide rail can drive the assembling platform to do linear motion, and the assembling platform can drive a to-be-assembled hole to do linear motion; and the control part comprises a main control computer, a robot controller and depth cameras. According to the dynamic shaft hole assembling device, the position deviation of the moving assembling hole and the driving shaft can be automatically recognized, and the position deviation isautomatically adjusted by means of a visual servo controller, so that dynamic shaft hole assembling of the moving assembling hole is achieved, and more efficient automatic assembling can be achieved.

Owner:扬州舞指芯创智能科技有限公司

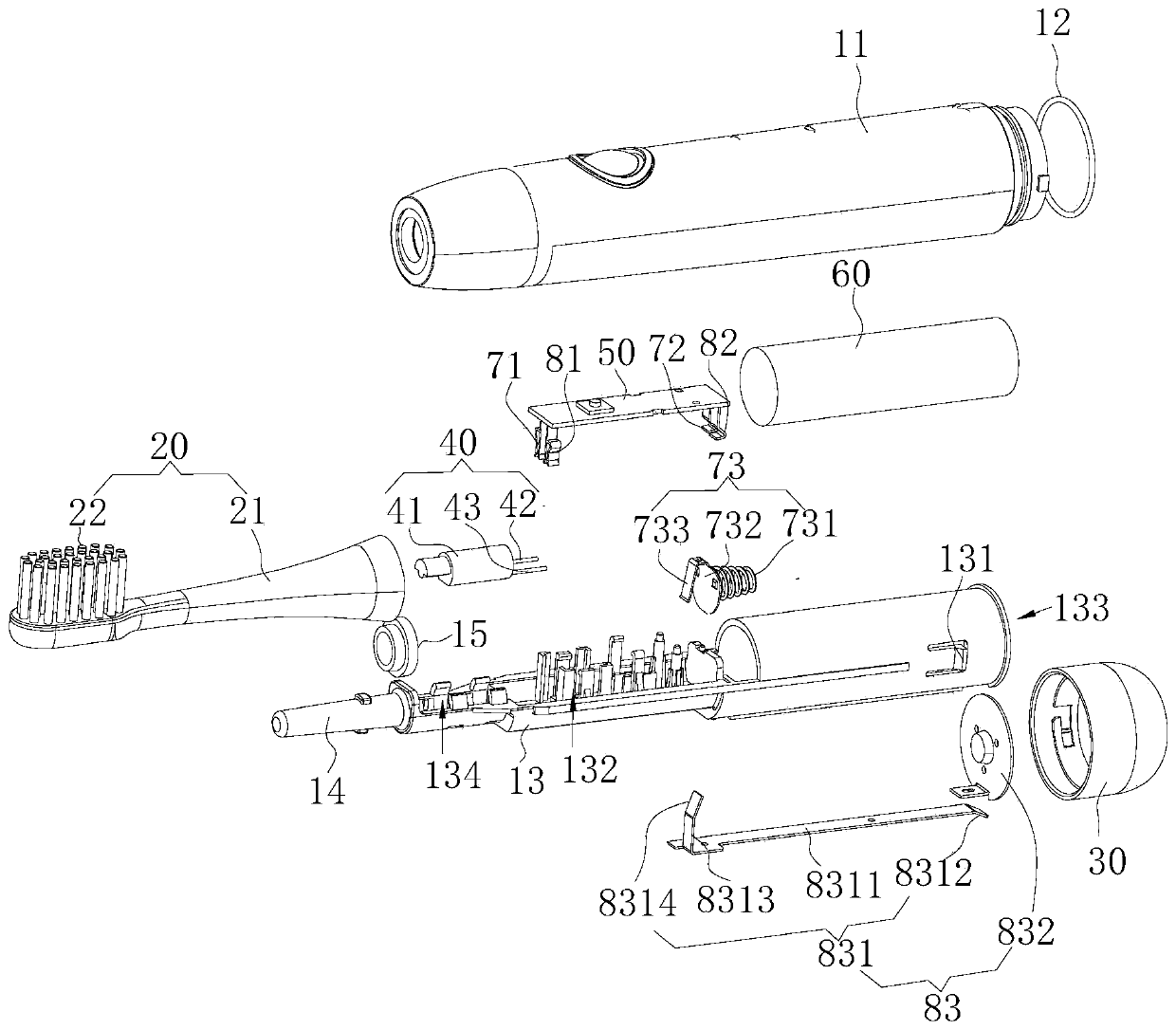

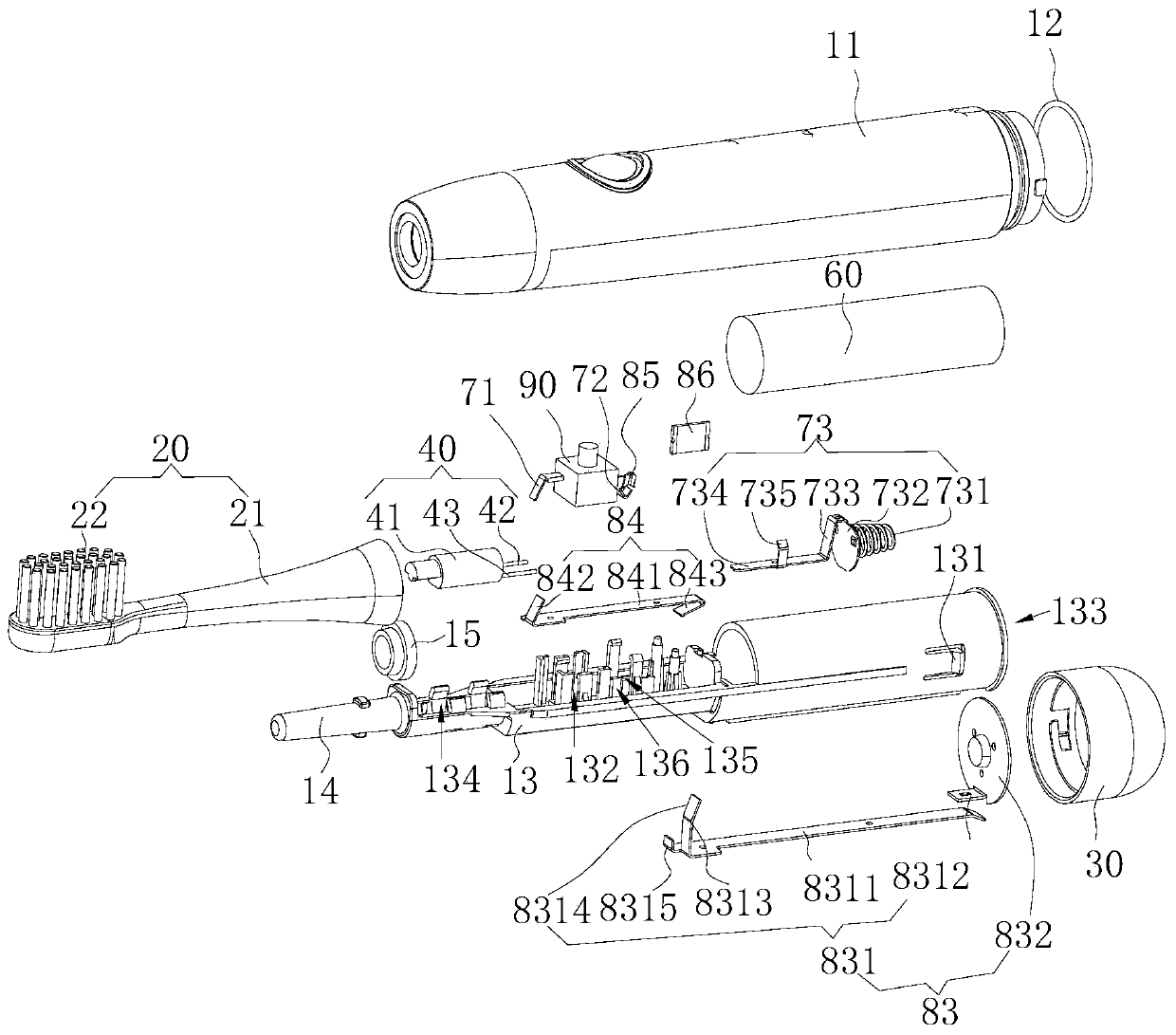

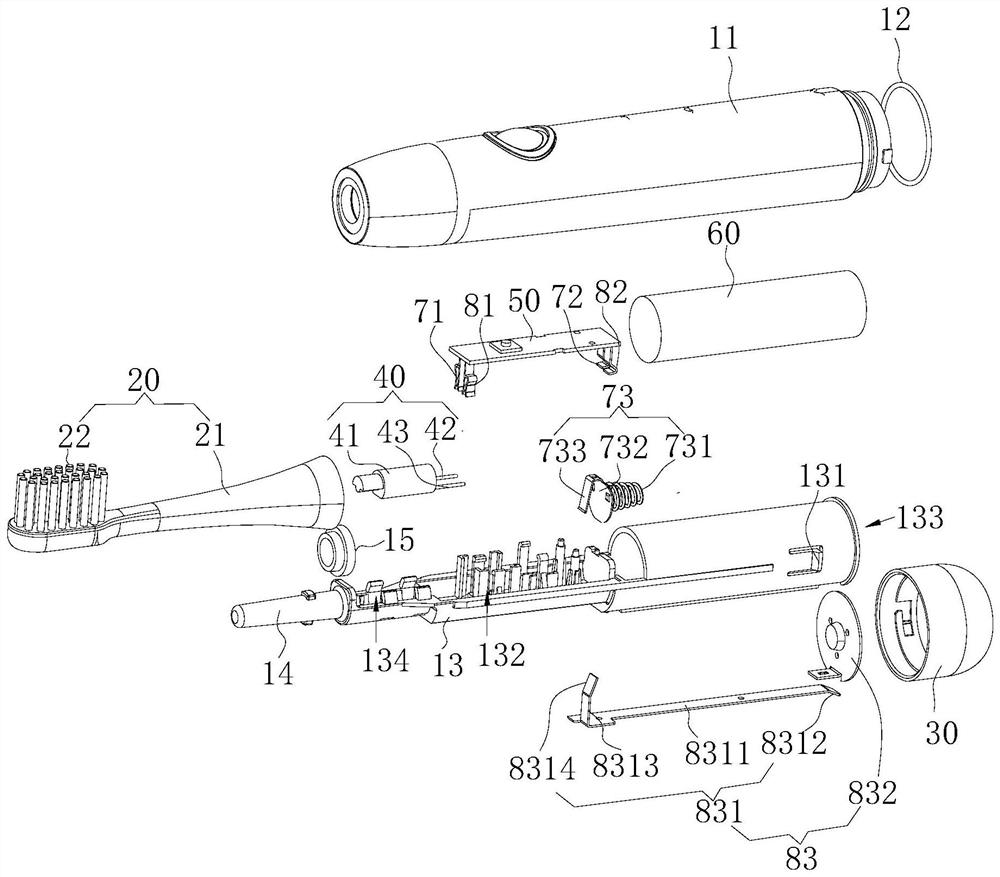

Contact type electrified electric toothbrush

PendingCN110559098AEasy to controlElectrical connectivity achievedTooth cleaningElectricityEngineering

The invention provides a contact type electrified electric toothbrush. The contact type electrified electric toothbrush comprises a driving mechanism, a power supply mechanism and a control mechanism,wherein the driving mechanism comprises a motor, a first contact rod and a second contact rod, and the first contact rod and the second contact rod are arranged in a separated manner and are conductive; the power supply mechanism has a first electrode and a second electrode; the control mechanism comprises a controller, a first electric connection assembly and a second electric connection assembly, two ends of the first electric connection assembly respectively abut against the first contact rod and the first electrode so as to enable the first contact rod to electrically communicate with thefirst electrode, the second electric connection assembly respectively abuts against the second contact rod and the second electrode so as to enable the second contact rod to electrically communicatewith the second electrode, and at least one of the first electric connection assembly and the second electric connection assembly is electrically connected with the controller. The contact type electrified electric toothbrush realizes the control of the driving mechanism by the controller through the interference connection without welding through electric leads, is simple in installation steps and convenient and quick in assembly, and reduces the requirement on operation precision.

Owner:SHENZHEN LEBOND TECH CO LTD

Power transmission line deicing system

PendingCN114465185AReduce dependenceLittle need for powerOverhead installationUncrewed vehicleElectric machinery

The invention relates to the technical field of deicing systems, and provides a power transmission line deicing system which can realize autonomous walking, is less dependent on an unmanned aerial vehicle in the deicing process, is more energy-saving, is better in use sustainability, is easier to get close to and get away from an electric wire needing to be deiced, is better in practicability, and is higher in practicability. Comprising a plurality of first motors and a basic mounting frame, a plurality of rope penetrating holes are formed in the basic mounting frame, traction ropes are arranged in the rope penetrating holes, the traction ropes are provided with a lifting frame, a gradually-changed lifting plate is mounted in the lifting frame, the basic mounting frame is connected with two left frames and two right frames, the two left frames are connected with left wheel frames, and the two right frames are connected with right wheel frames. The two left wheel carriers are connected with left change gears, left springs are arranged between the two left wheel carriers and the two left frames, the two right frames are connected with right wheel carriers, right change gears are connected in the two right wheel carriers, right springs are arranged between the two right wheel carriers and the two right frames, and the traction ropes are connected with the left wheel carriers and the right wheel carriers respectively.

Owner:盐城电力设计院有限公司

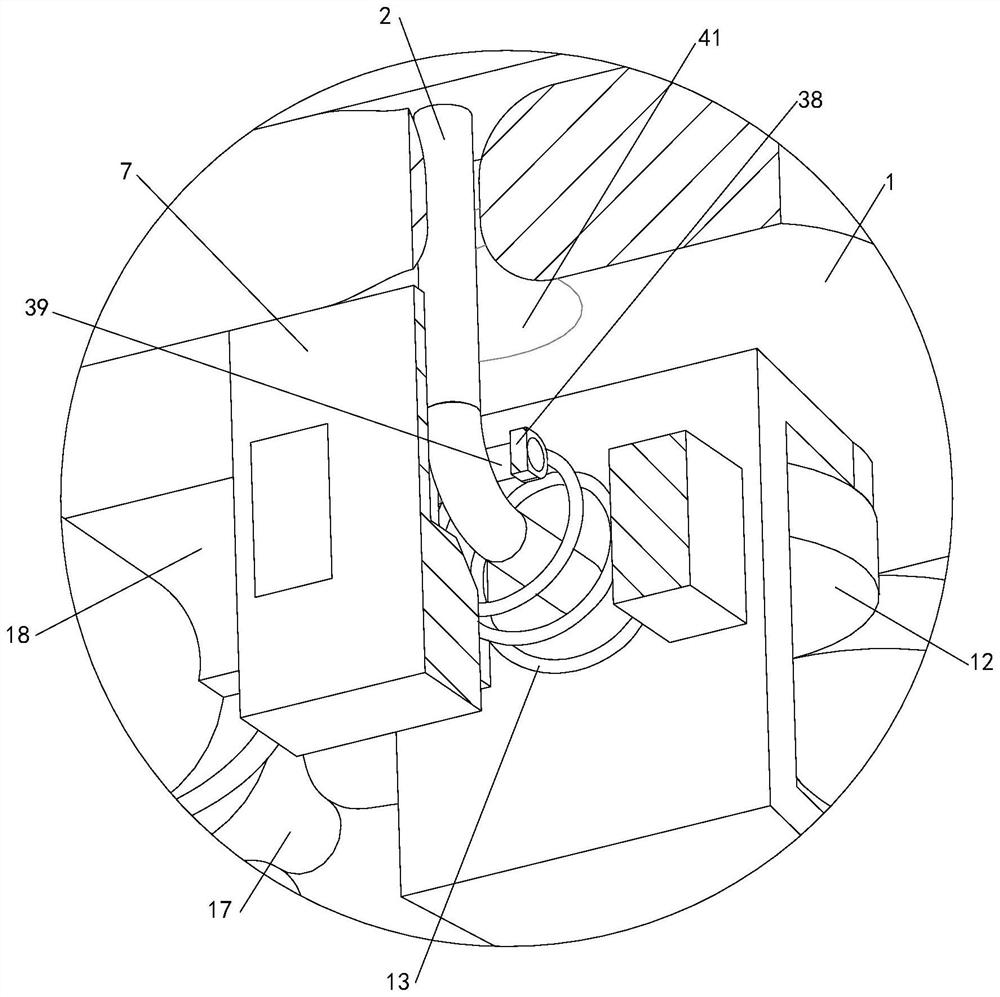

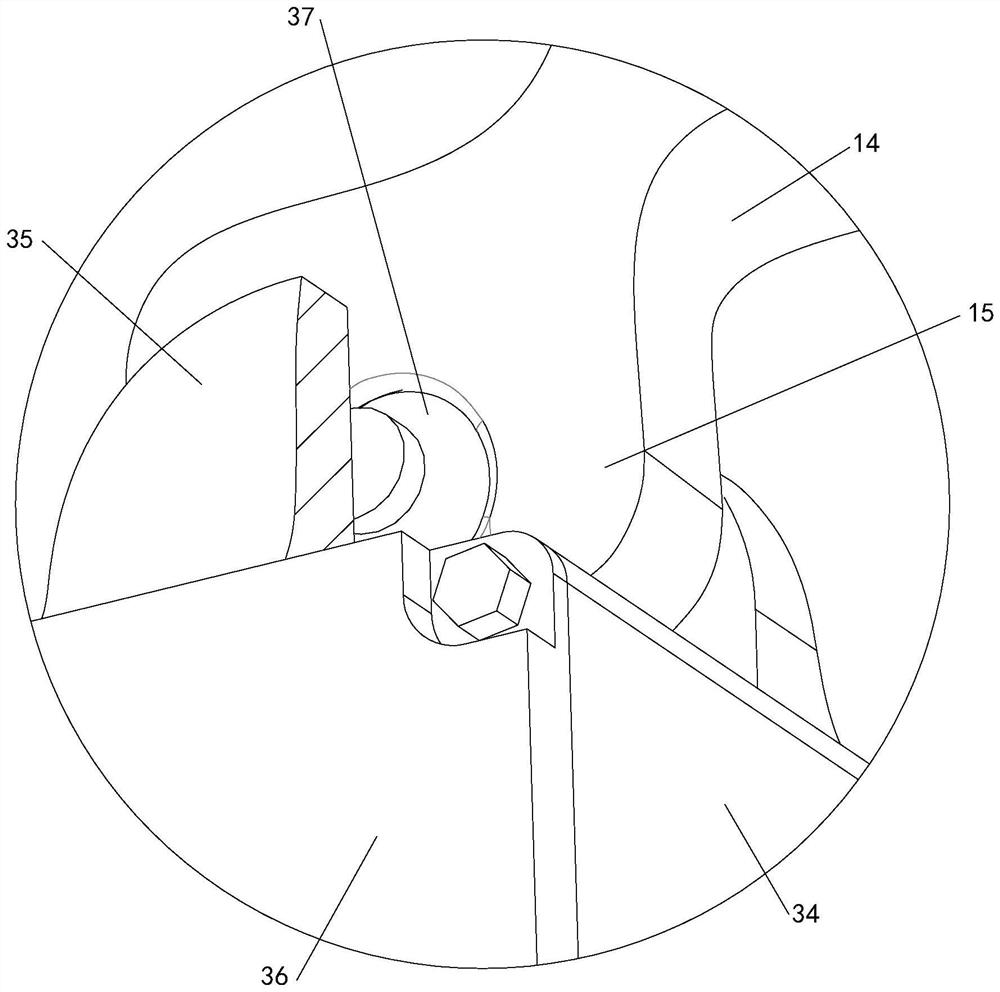

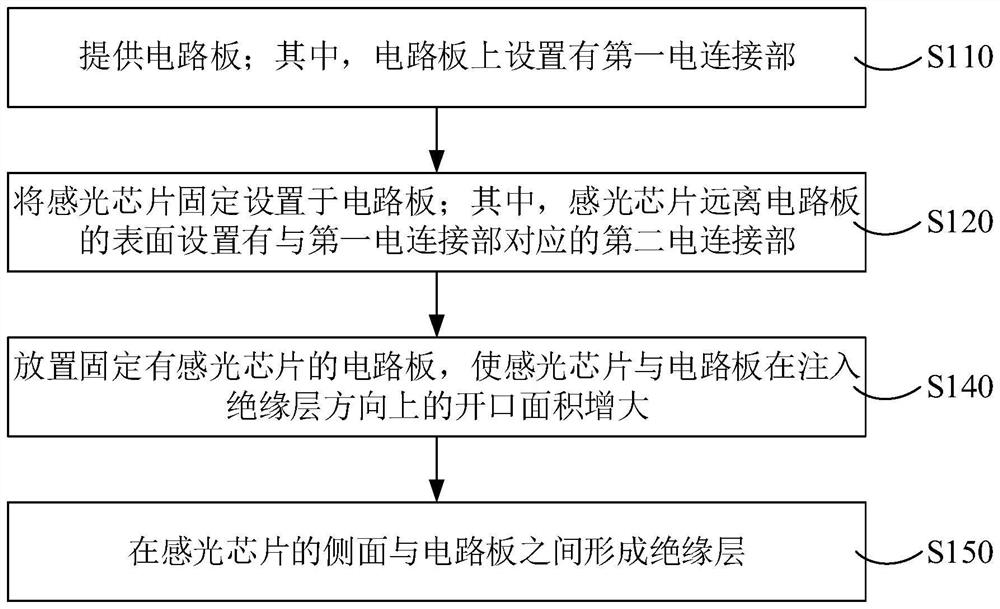

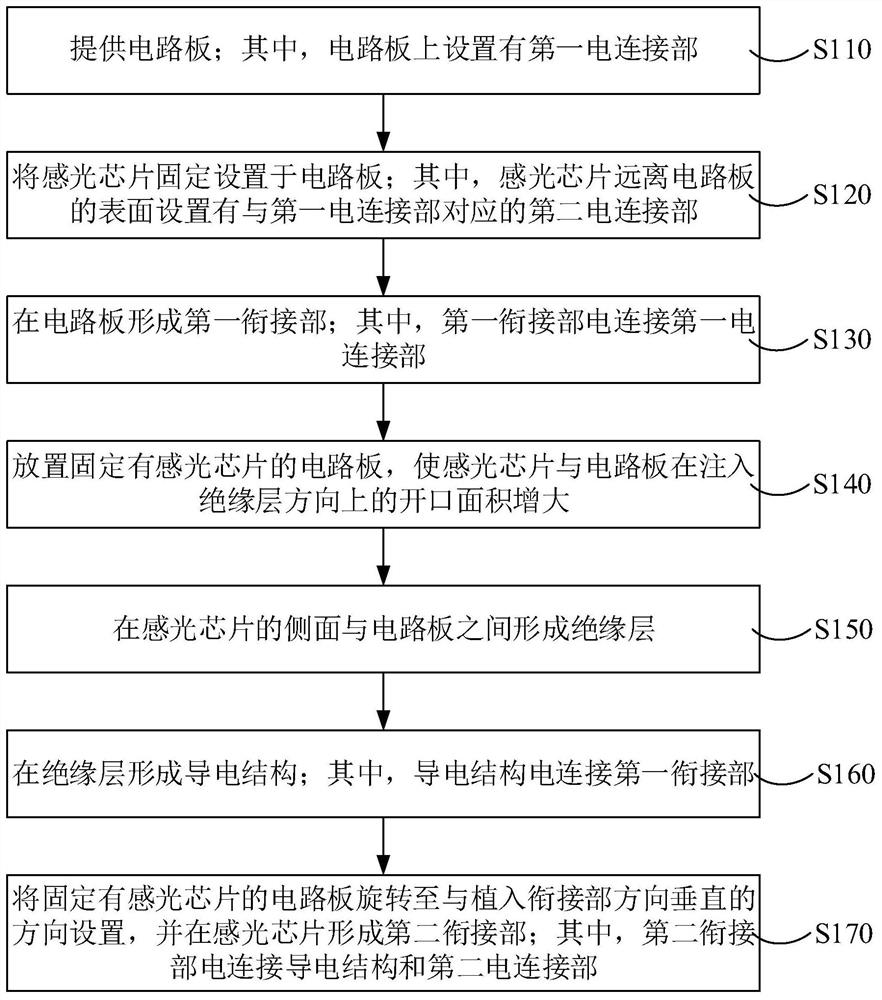

Photosensitive component manufacturing method, photosensitive component, camera module and mobile terminal

PendingCN113037952AIncrease the opening areaEasy injectionTelevision system detailsColor television detailsEngineeringCamera module

The invention relates to a photosensitive component manufacturing method, a photosensitive component, a camera module and a mobile terminal. The method comprises the following steps: providing a circuit board; arranging a first electric connection part on the circuit board, wherein the photosensitive chip is fixedly arranged on the circuit board, and second electric connection part corresponding to the first electric connection part is arranged on the surface, far away from the circuit board, of the photosensitive chip; placing a circuit board on which a photosensitive chip is fixed, so that the opening area of the photosensitive chip and the circuit board in the direction of injecting the insulating layer is increased; and forming an insulating layer between the side surface of the photosensitive chip and the circuit board, wherein the insulating layer is used for forming a conductive structure electrically connected with the first electric connection part and the second electric connection part. After the photosensitive chip is fixedly arranged on the circuit board, the circuit board on which the photosensitive chip is fixed is placed, so that the opening area of the photosensitive chip and the circuit board in the direction of injecting the insulating layer is increased, the glue is conveniently injected into the glue dispensing needle nozzle to form the insulating layer, the risk of poor electrical connection can be effectively reduced in the subsequent process, and the yield of the camera module is improved.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD

Electric coupler

PendingCN108879230AEnsure connection stabilityExtended service lifeCoupling contact membersEngineeringLead plate

The invention provides an electrical coupler comprising a first terminal portion and a second terminal portion. The first terminal portion comprises: a first terminal portion bracket; two sets of brush swing arms, wherein one ends of the two sets of brush swing arms are respectively rotatably connected to the two ends of the first terminal portion bracket, and the other ends of each brush swing arm are respectively provided with at least one brush; and a first connecting terminal. The second terminal portion comprises: a second terminal portion bracket, wherein the middle part of one side surface of the second terminal portion bracket protrudes outwards to form two inclined planes which are inclined from the middle part to the two ends; two conductive plates, which are laid on the two inclined surfaces respectively; and a second connecting terminal. When the two terminal portions are coupled, the brushes of the two sets of brush swing arms are respectively in contact with the two conductive plates, and can slide to the two ends along the two conductive plates. According to the electric coupler, the electric brush, the brush swing arm and the lead plate are matched, so that a deviation error correction mechanism during coupling alignment is provided, and the requirement on the operation precision of a drive device of the coupler is reduced.

Owner:环球车享汽车租赁有限公司

A hollow brick pressing machine

ActiveCN105382916BLow operating precision requirementsLower performance requirementsDischarging arrangementMould auxillary partsHydraulic cylinderBrick

The invention relates to a pressing molding machine for hollow bricks. The pressing molding machine comprises a combined supporting frame. A left supporting support is arranged on the left side of the upper end face of the combined supporting frame. A brick conveyor is arranged on the left supporting support. A motor is further arranged on the left portion of the upper end face of the combined supporting frame. A shaft of the motor is sleeved with a drive gear. A brick supporting hydraulic cylinder is arranged on the upper end face of the combined supporting frame. A brick supporting plate is arranged on the brick supporting hydraulic cylinder. A right supporting support is arranged on the right side of the brick supporting hydraulic cylinder. A vertical rod is arranged in the middle of the combined supporting frame. A bearing plate is arranged in the middle of the vertical rod. A brick outlet is formed in the left portion of the bearing plate. Two sliding rails which are parallel in a front-and-back manner are arranged on the top of the vertical rod. A material removing plate is arranged at the right ends of the sliding rails. A brick pressing device is arranged on the sliding rails. A die pushing device is arranged on the upper right side of the combined supporting frame. According to the pressing molding machine for the hollow bricks, the manner that a hydraulic cylinder is used for directly pressing brick molding raw materials in the prior art is changed, instability of the forming quality and the forming size of the bricks is lowered, and the requirement for operation accuracy of the hydraulic cylinder of the pressing molding machine is lowered.

Owner:无为县华标新型墙体材料有限公司

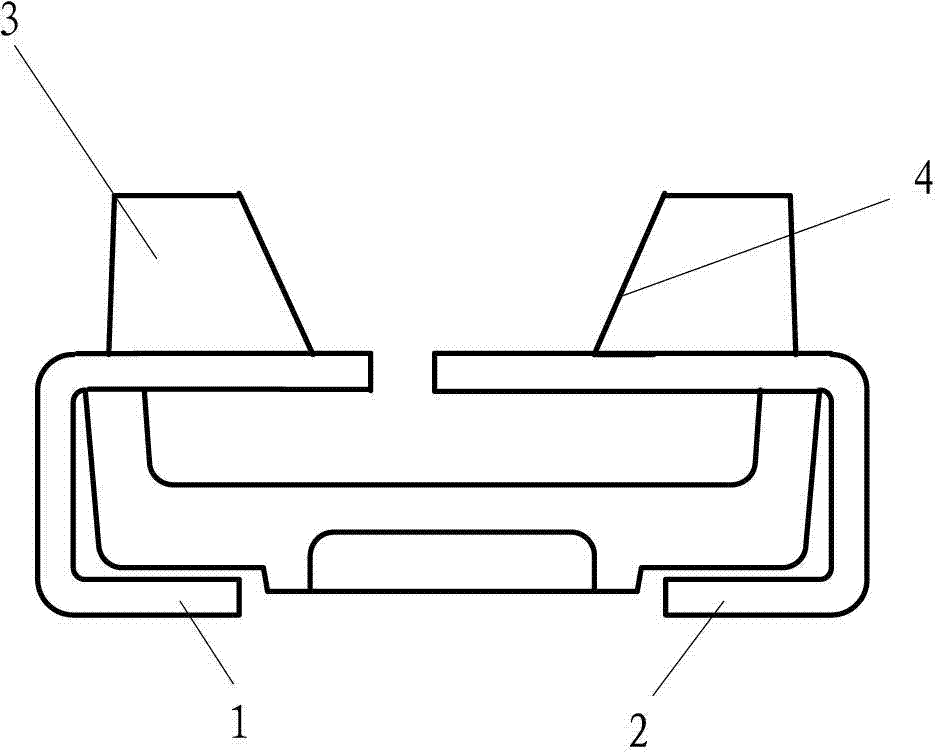

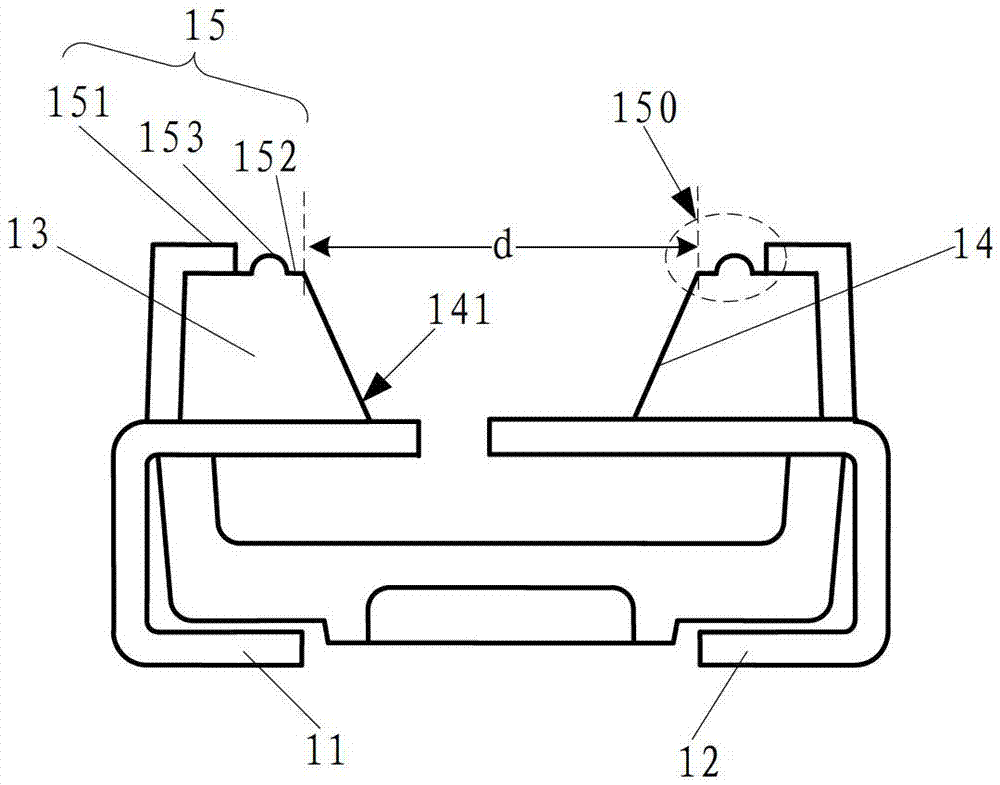

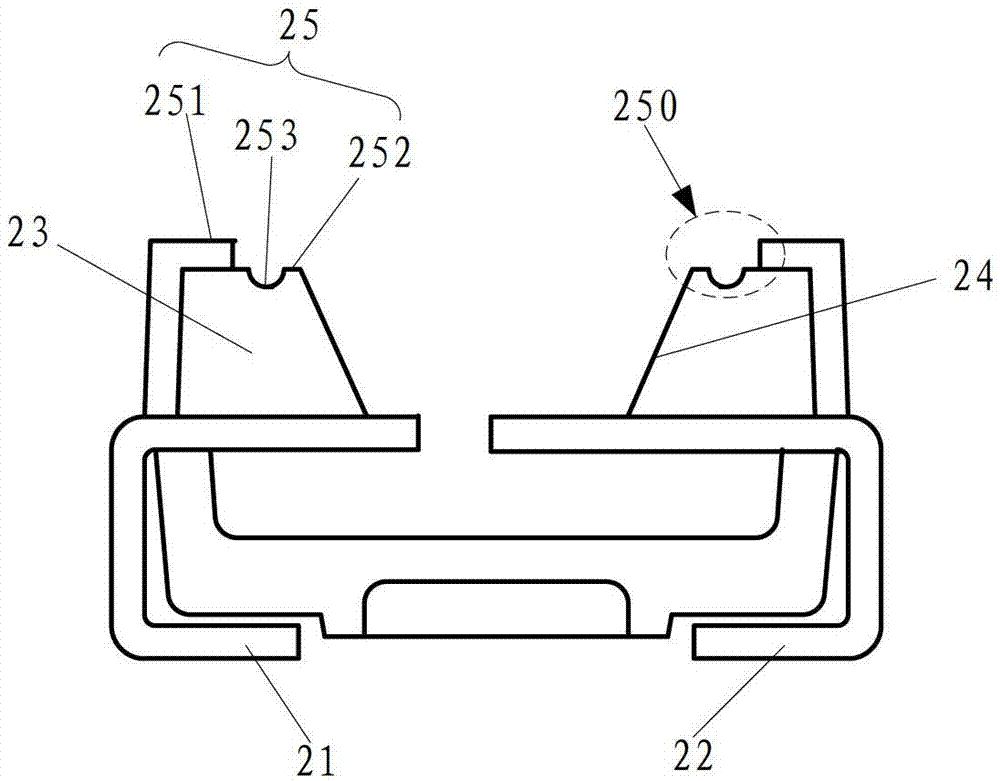

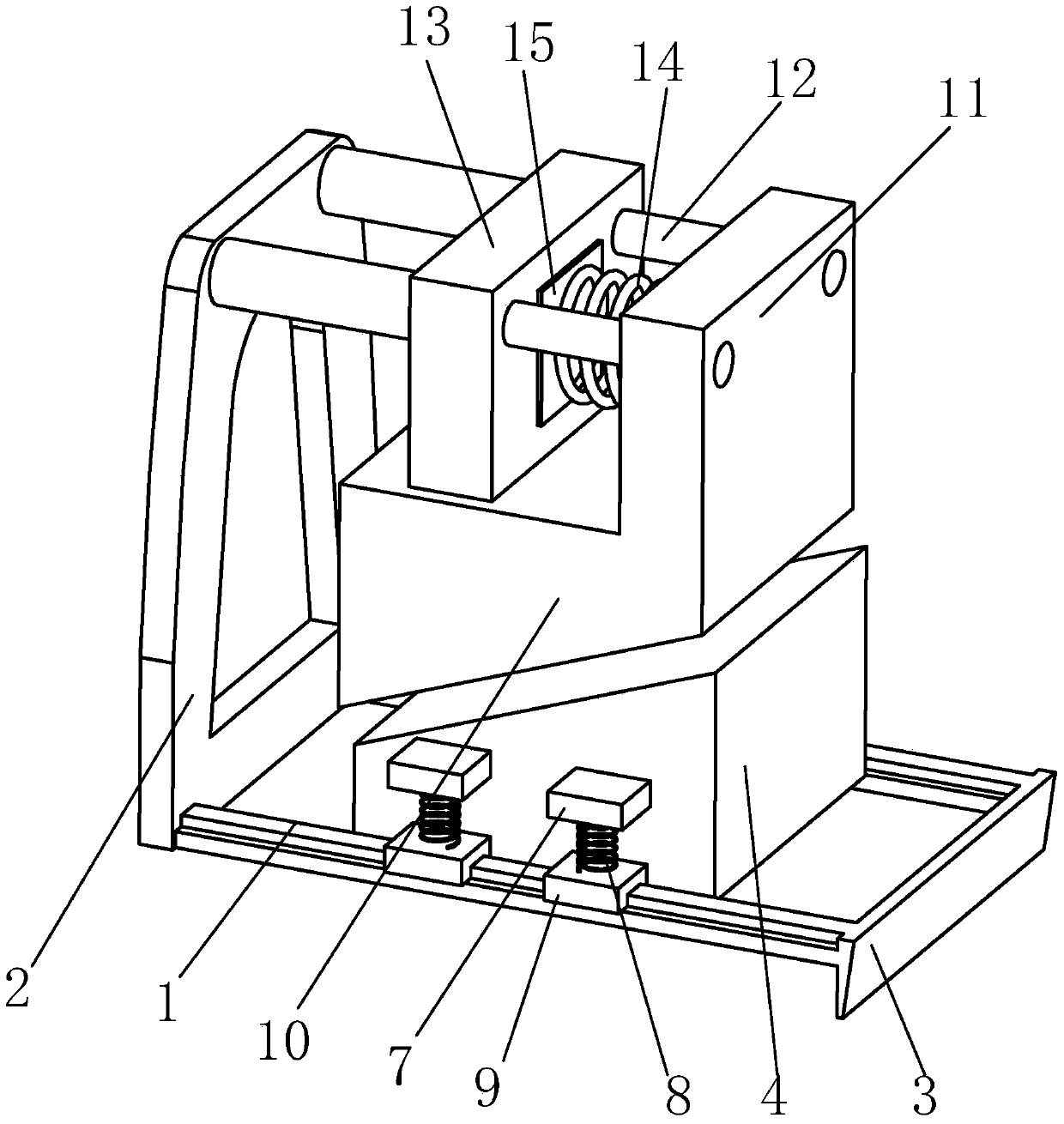

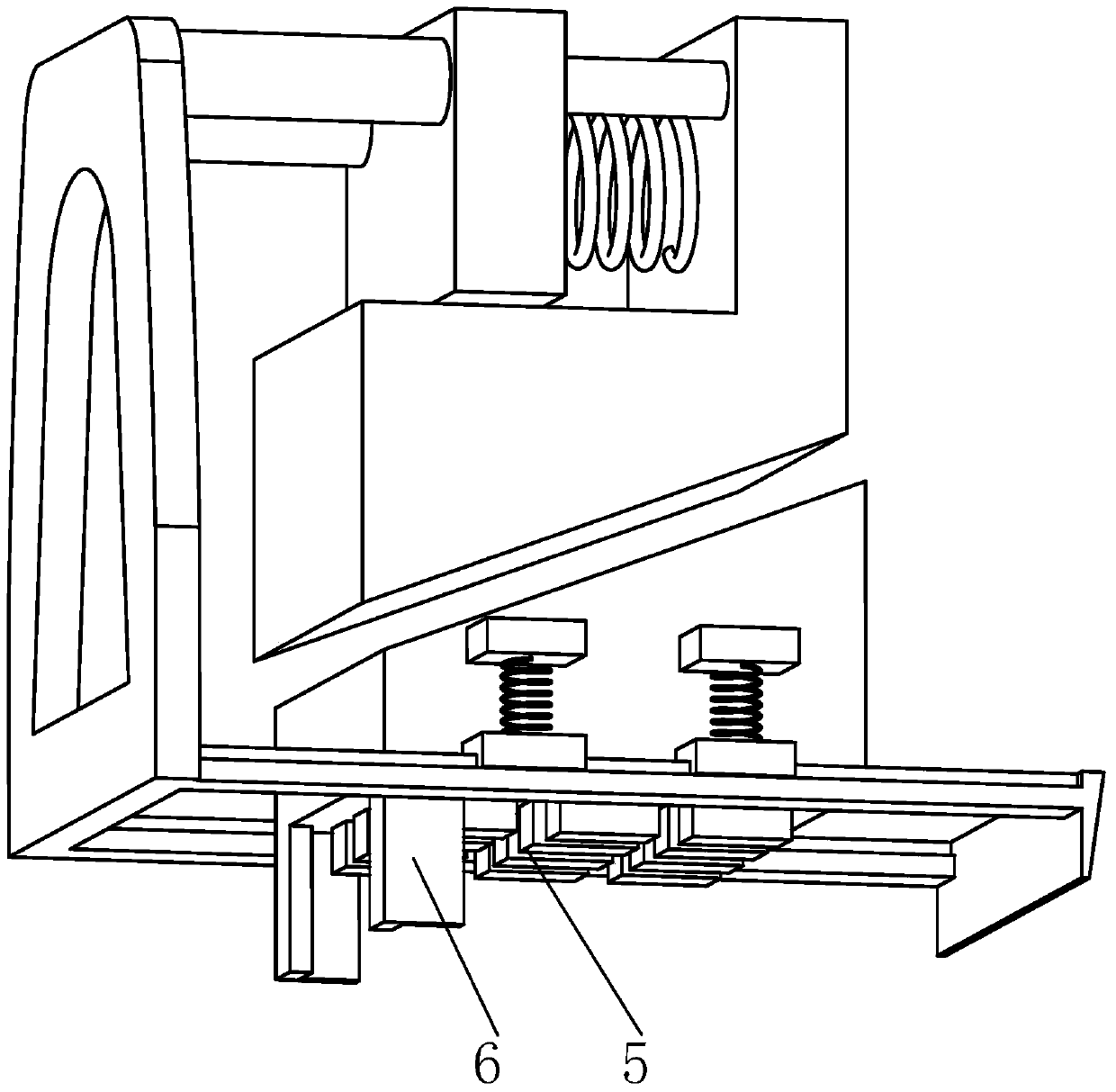

Surface-mounted type LED (light-emitting diode) bracket, surface-mounted type LED and manufacture methods thereof

ActiveCN102891241BGuaranteed flatnessLow operating precision requirementsSemiconductor devicesSurface mountingEngineering

The invention discloses a surface-mounted type LED (light-emitting diode) bracket, a surface-mounted type LED and manufacture methods of the surface-mounted type LED (light-emitting diode) bracket and the surface-mounted type LED. The surface-mounted type LED bracket comprises an anode metal substrate, a cathode metal substrate, and a plastic body which partially covers the anode metal substrate and the cathode metal substrate; the plastic body is arranged on the upper lateral surfaces of the anode metal substrate and the cathode metal substrate to form a bowl cup; an anti-overflow step is arranged at the position at the top part of the bowl cup and adjacent to the lateral wall of the bowl cup; the anti-overflow step at least comprises a first height part and a second height part, which are not equal in height; the first height part is higher than the top part of the bowl cup; the second height part is higher than or as high as the top part of the bowl cup, and the first height part and the second height part form a step surface of the anti-overflow step in the direction adjacent to the lateral wall of the bowl cup. By this mode, the surface-mounted type LED bracket can effectively prevent the plastic body from overflowing during dispensing, and the production cost is lowered by reducing the demand on the dispensing accuracy.

Owner:LEDMAN OPTOELECTRONIC HZ CO LTD

Horizontal pushing and vertical pressing mechanism for hollow brick pressing machine

ActiveCN105365032BLow operating precision requirementsLower performance requirementsAuxillary shaping apparatusShaping press ramHydraulic cylinderBrick

The invention relates to a transverse pushing and longitudinal pressing mechanism for a hollow brick pressing forming machine. The transverse pushing and longitudinal pressing mechanism comprises two parallel sliding rails. A lower pressing mold is arranged between the sliding rails. Rectangular brick pressing convex blocks are evenly distributed on the lower end face of the lower pressing mold. Baffle plates are arranged at the left end of the lower pressing mold. The upper end face of the lower pressing mold is an inclined face, and the included angle between the upper end face of the lower pressing mold and a horizontal plane is an acute angle. Wing arms are fixed to the front end face and the rear end face of the lower pressing mold, and springs are arranged on the lower end faces of the wing arms. An upper pressing mold is arranged above the lower pressing mold, and the lower end face of the upper pressing mold is an inclined face parallel to the upper end face of the lower pressing die. A sliding sleeve is arranged above the right side of the upper pressing mold, sliding columns pass the sliding sleeve, and a check block is fixed to the left ends of the sliding columns. The check block is mounted on a side supporting plate, and a damping spring is arranged between the right end face of the check block and the left end face of the sliding sleeve, and connected with a pressure sensor. The method that the vertically compressing brick manufacturing raw materials through a hydraulic cylinder is adopted to form bricks in the prior art is improved, and the instability of the forming quality and forming size of the bricks is reduced.

Owner:无为县华标新型墙体材料有限公司

A high-density parallel transmission optical device

ActiveCN103323921BImprove cooling effectImprove isolationCoupling light guidesElectromagnetic transceiversHigh densitySurface mounting

The invention discloses a high-density type parallel transmission optical device which is applicable to a CXP encapsulating and plug type optical device and a CXP active optical cable (AOC), wherein the CXP encapsulating and plug type optical device and the CXP AOC are applied to data communication currently. The high-density type parallel transmission optical device comprises a transmitting PCB, a receiving PCB, a multi-path transmitting chip, a multi-path receiving chip, a transmission driving chip, a receiving amplifying chip, multi-path lens arrays, sealing cover plates and a connecting line, wherein the number of the multi-path lens arrays is two, and the number of the sealing cover plates is two. The high-density type parallel transmission optical device is characterized in that the parallel transmission optical device further comprises a changeover array optical fiber jumper assembly. The high-density type parallel transmission optical device is capable of effectively reducing the surface-mounting accuracy requirements of the multi-path transmitting chip and the multi-path receiving chip to further reduce encapsulating difficulty, effectively solving the signal crosstalk problem and the radiating problem, and improving the performance stability.

Owner:WUHAN TELECOMM DEVICES

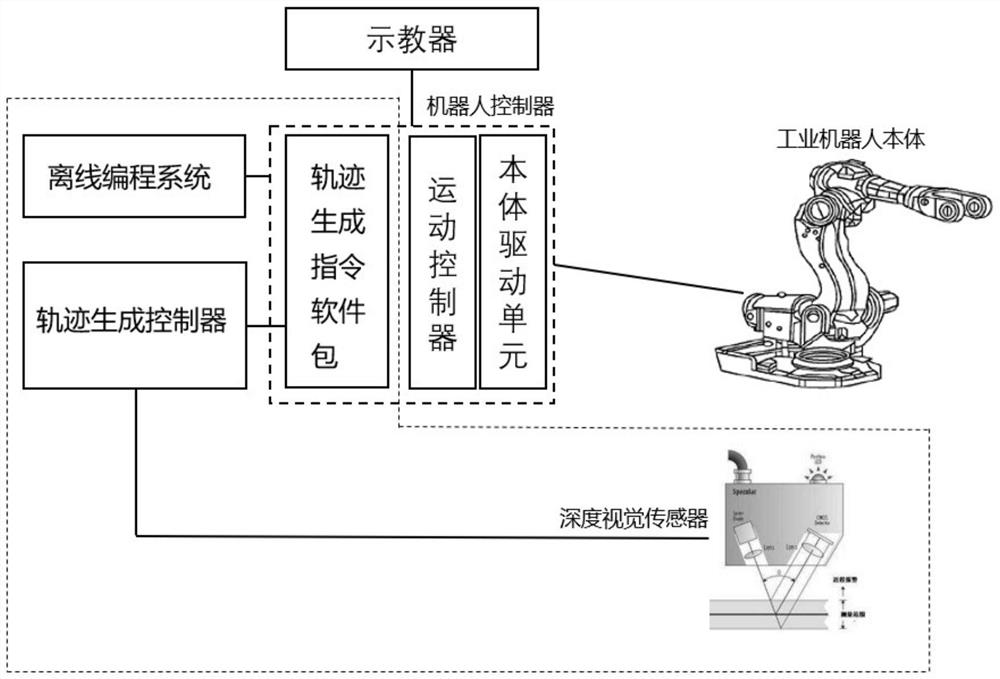

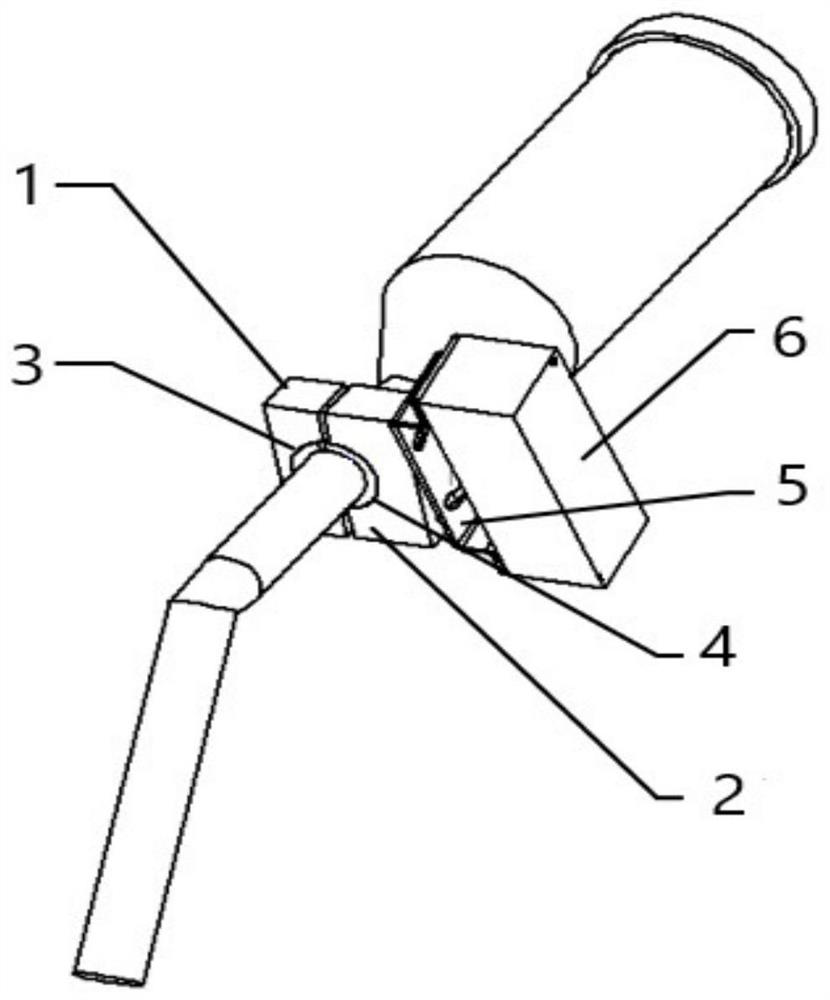

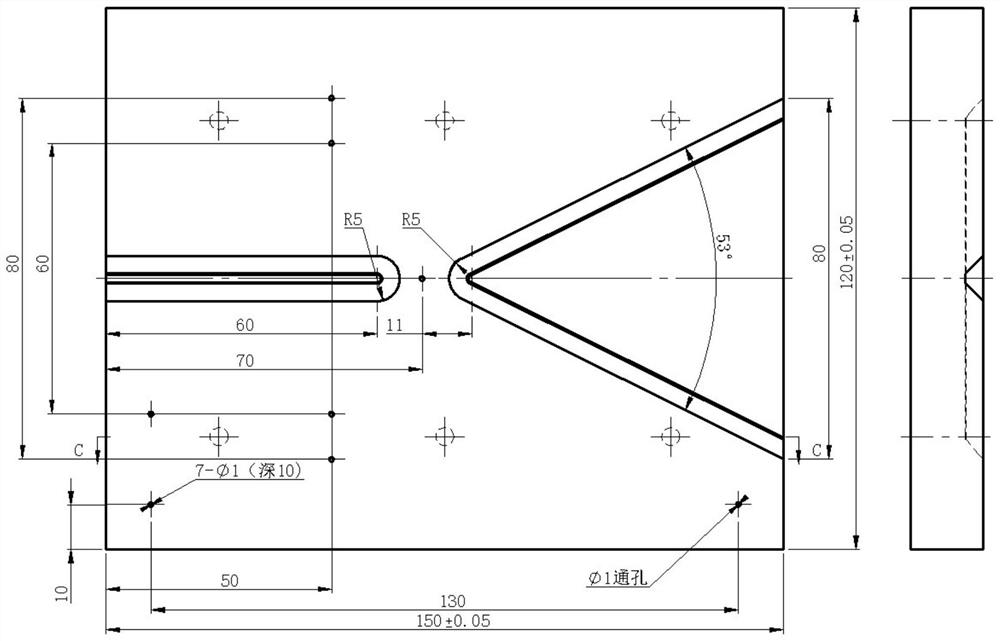

An industrial robot depth vision sensor calibration board and calibration method

ActiveCN111307033BLow operating precision requirementsImprove calibration accuracyUsing optical meansEngineeringIndustrial robotics

The invention provides an industrial robot depth vision sensor calibration board and a calibration method, which relate to the field of intelligent industrial robots. The initial position outer hole 1, the initial position outer hole 2, the origin of the calibration plate coordinate system, the initial position inner hole 1, the initial position inner hole 2, trapezoidal grooves and triangular grooves, the initial position outer hole 1, The outer hole 2 at the starting position, the inner hole 1 at the starting position and the inner hole 2 at the starting position are on the same straight line. Point 1 and datum point 2. The present invention quickly calibrates the depth vision sensor by using a calibration plate with a processing precision controlled at ±0.01mm, a simple structure and low production cost, and the method has high versatility, and can be applied to the calibration of the depth vision sensor of most industrial robots.

Owner:成都蒸汽巨人机器人科技有限公司

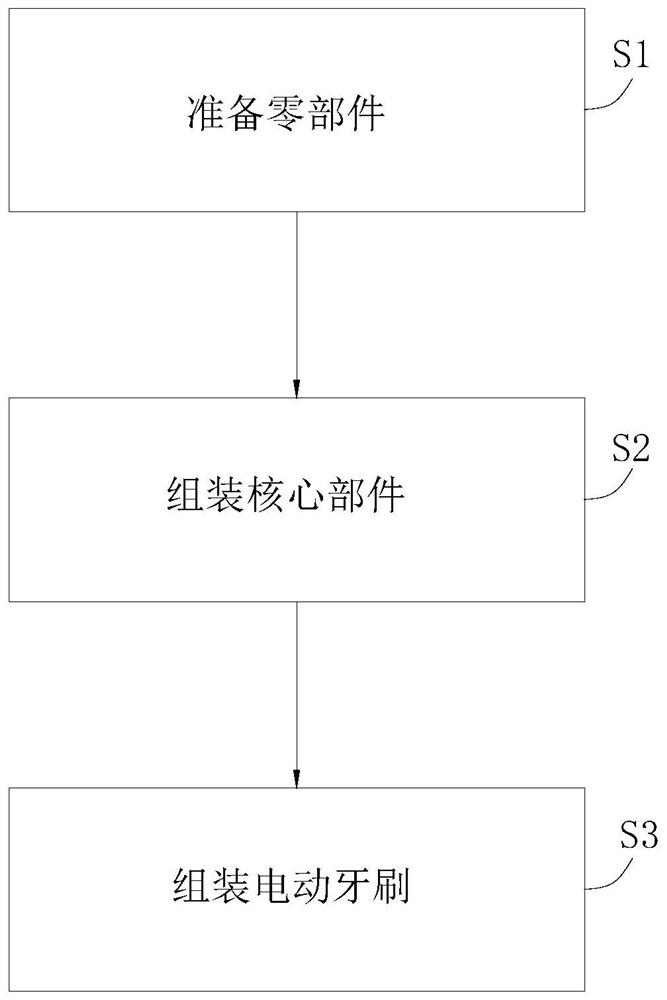

Automatic production method of electric toothbrush

ActiveCN110680533BAchieve electrical connectivityAchieve electrical connectionAssembly machinesTooth cleaningElectric machineElectrical connection

Owner:SHENZHEN LEBOND TECH CO LTD

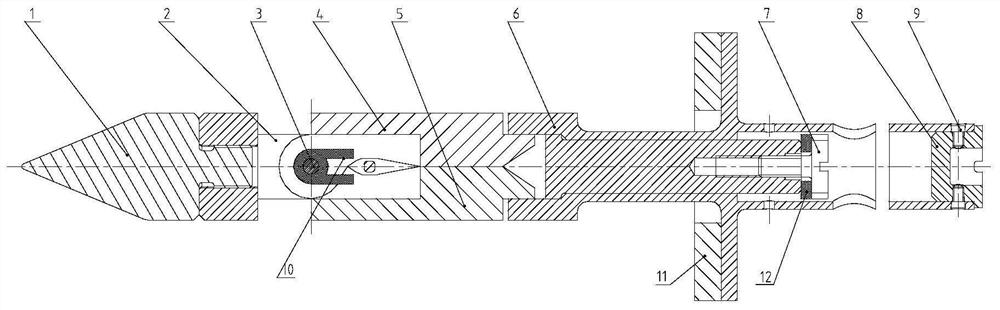

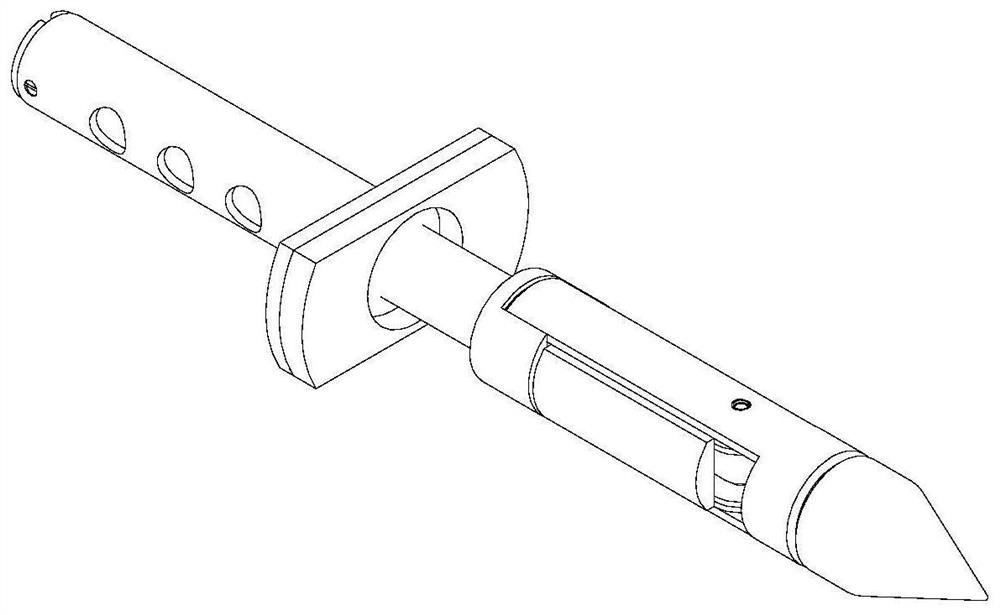

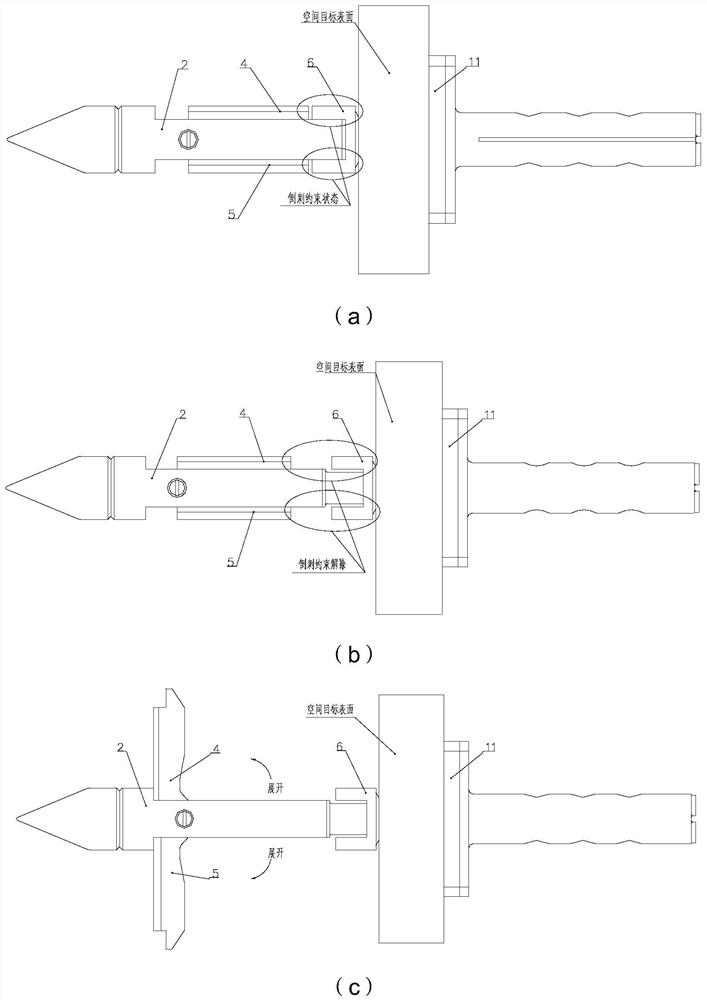

A Self-Adaptive Penetration Deployment Attachment Device for Space Target Surface Attachment

The invention relates to an self-adaptive penetrating and deploying attachment device for attaching to the surface of a space target, comprising: a nose cone, a spear body skeleton, a barb shaft, a first barb, a second barb, a baffle sleeve, a stopper Ejector rod, rear end cover, torsion spring; the tail of the nose cone is installed in the lance body skeleton; the barb shaft is introduced from the pin hole on one side of the lance body skeleton, and passes through the end mounting hole of the second barb and the torsion spring and the end mounting hole of the first barb, and enter the pin hole on the other side of the lance frame; the end with the smaller diameter of the lance frame is inserted into the baffle sleeve and can slide in the baffle sleeve, and the baffle sleeve The lugs at the end of the barrel block the ends of the first barb and the second barb; the limit push rod penetrates through the other end of the baffle sleeve and is installed at the end of the spear body with a smaller diameter, and the rear end cover is installed into the port on the other end of the baffle sleeve. The invention solves the problem of micro-damage capture of large space debris, on-orbit maintenance and off-orbit operation of faulty satellites.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

A material transmission method, transmission device, transmission system and readable storage medium

ActiveCN110510405BLow operating precision requirementsReduce labor costsControl devices for conveyorsCharge manipulationEngineeringStructural engineering

The invention discloses a material transmission method, a transmission device, a transmission system and a readable storage medium. The method includes: controlling the transmission of the material to be transmitted to the transmission surface of the first transmission mechanism; controlling the lifting mechanism to drive the material to be transmitted along the first Direction movement, so that the material to be conveyed is separated from the conveying surface; judge whether there is material at the first baffle; wherein, the first baffle is set at the discharge position of the first transmission mechanism; when there is no material at the first baffle, Controlling the lifting mechanism to move along the second direction, so that the materials to be conveyed fall onto the conveying surface; wherein, the first direction is opposite to the second direction; controlling the first conveying mechanism to convey the materials to the first baffle. By implementing the invention, when the detection equipment docked with the output end of the conversion platform is waiting for the material to be transported to be transported to the detection position, the running distance of the material to be detected is shortened from the first baffle to the detection position. The distance can improve the detection efficiency of the detection equipment.

Owner:JOINT STARS TECH

A Whole Forging Method of Frog

ActiveCN108356192BImprove mobilityReduce final forging tonnageRailway componentsMetal-working apparatusInstabilityMachining

The invention discloses an integral die-forging method for frogs. The integral die-forging method comprises the steps of cogging, pre-forging and finish-forging, wherein during the cogging, original blanks heated to reach an initial forging temperature are pre-allocated in the axial direction through cross wedge rolling to obtain blanks; during the pre-forging, the blanks heated to reach the initial forging temperature are prefabricated through die-forging to obtain prefabricated blanks; and during the finish-forging, the prefabricated blanks heated to reach the initial forging temperature areforged through the die-forging to obtain the frogs. According to the method disclosed by the invention, formation is realized in the manner of cross wedge rolling cogging, die-forging pre-forging anddie-forging finish-forging, and after the cross wedge rolling cogging and the die-forging pre-forging, the form of the mass distribution of the prefabricated blanks is gradually converted to the formsimilar to the finish-forged pieces, of a plurality of the prefabricated blanks at the two ends and a few of the prefabricated blanks at the middle in the axial direction, and a plurality of the prefabricated blanks at the two sides and a few of the prefabricated blanks at the middle in the section direction, from the uniform-section form of the original round-rod-shaped blanks; the tendency of slip of the blanks due to instability during the pre-forging is reduced through the matching of the columnar characteristic of the blanks and the guide characteristic of the pre-forged die cavities; and the integral die-forging method is high in axial machining accuracy and material utilization rate, stable in process, and capable of realizing integral die-forging for the frogs under a low tonnage.

Owner:TSINGHUA UNIV

Turnover device

PendingCN114834870AReduce human involvementReduce the difficulty of operationWind energy generationMetal working apparatusClassical mechanicsCantilever

According to the technical scheme, the overturning table comprises a bottom plate, a first V-shaped limiting structure and a sliding block are arranged on the bottom plate, and the first V-shaped limiting structure and the locked sliding block fix a workpiece in the radial direction; a buckle plate is further arranged on the bottom plate, and the buckle plate is used for axially fixing the workpiece; the overturning table further comprises a cantilever, and a second V-shaped limiting structure is arranged at the free end of the cantilever. And the two ends of the saddle clamp are connected with the free ends of the cantilevers, and an ejector rod arranged on the saddle clamp, the second V-shaped limiting structure and the ejector rod conduct radial positioning on the other position of the workpiece. After a workpiece is fixed on the overturning table through the structure, the overturning table is driven by the power device to rotate, so that the horizontal state and the vertical state of the workpiece are switched back and forth. Compared with a crown block and manual assistance to complete workpiece overturning, the overturning equipment provided by the invention has the advantages of extremely little manpower participation, small operation difficulty and high efficiency.

Owner:北京英诺腾达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com