A material transmission method, transmission device, transmission system and readable storage medium

A material transmission system and material transmission technology, applied in the field of automated production of electronic products, can solve the problems of increasing the running distance of the PCB board and decreasing the detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

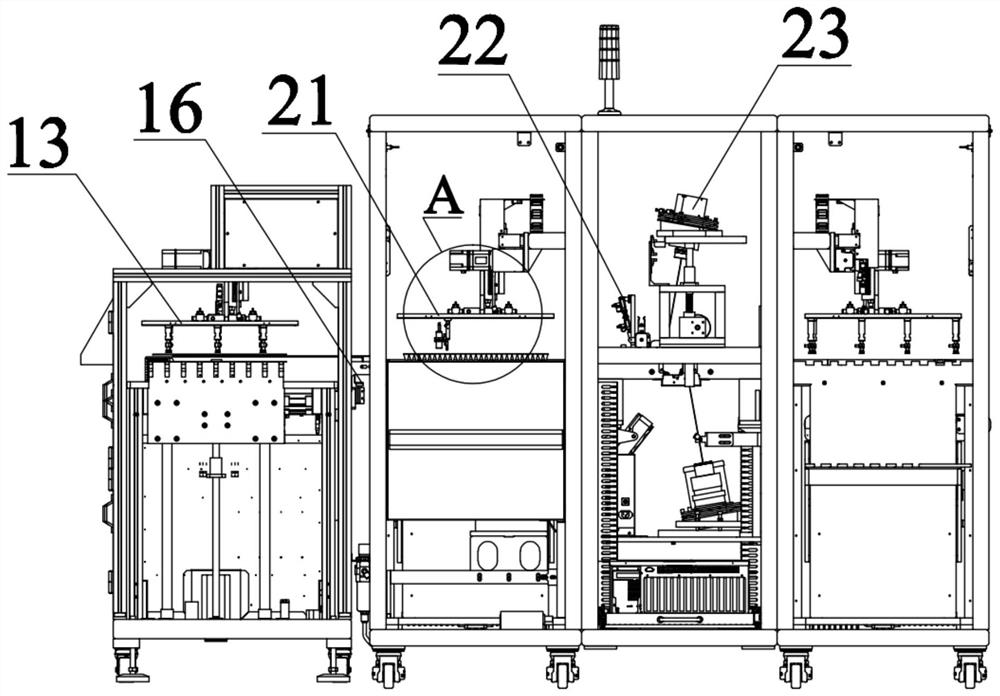

[0052] figure 2 Shows a flow chart of a material transfer method according to an embodiment of the present invention, which can be used but not limited to Figure 1A-Figure 1H Shown is the conversion platform and detection equipment interfaced with the output of the conversion platform. Such as figure 2 As shown, the material transfer method includes the following steps:

[0053] S201: Control the material to be transported to be transported to the transport surface of the first transport mechanism.

[0054] Here, when applied to Figure 1A-Figure 1H For the equipment shown, the transmission of the material to be transmitted to the first transmission mechanism can be controlled by controlling the feeding mechanism to absorb the material to be conveyed, and controlling the feeding mechanism to move above the first output mechanism and then release the material to be conveyed face. Of course, this method is not limited to Figure 1A-Figure 1H The device shown, for exampl...

Embodiment 3

[0110] Figure 5 A schematic block diagram of a material conveying device according to an embodiment of the present invention is shown, and the device can be used to implement the material conveying method described in Embodiment 1 or any optional implementation thereof. Such as Figure 5 As shown, the device includes: a feeding control module 10 , a first lifting control module 20 , a waiting judging module 30 , a second lifting control module 40 and a material transmission module 50 .

[0111] The feeding control module 10 is used to control the material to be transported to be transported to the conveying surface of the first conveying mechanism.

[0112] The first lifting control module 20 is used for controlling the lifting mechanism to drive the material to be conveyed to move along the first direction, so that the material to be conveyed is separated from the conveying surface.

[0113] The waiting judging module 30 is used to judge whether there is material at the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com