Patents

Literature

605results about How to "Reduce human involvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

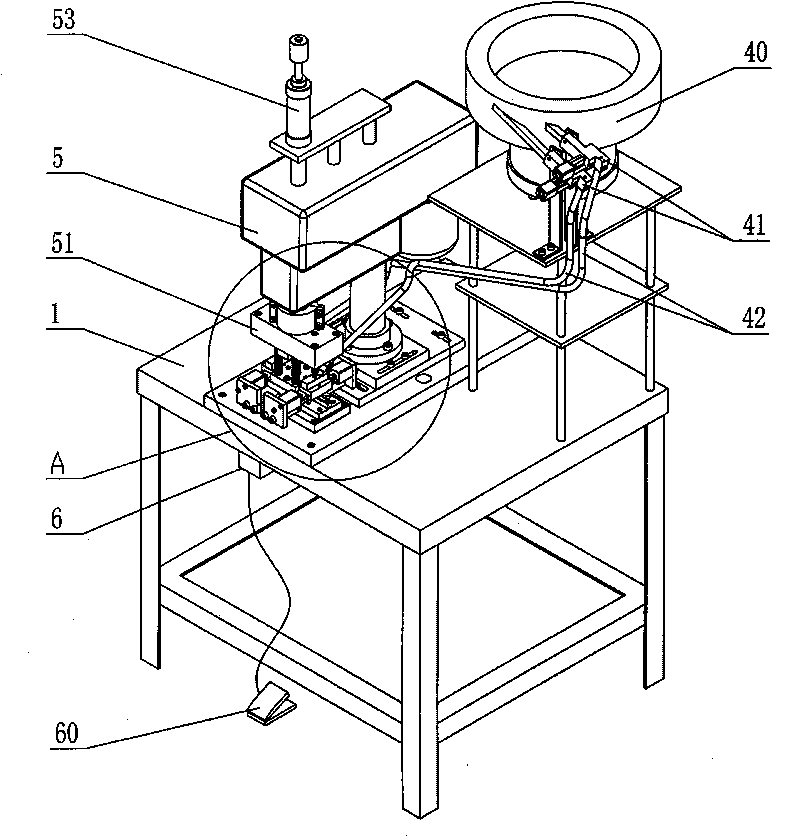

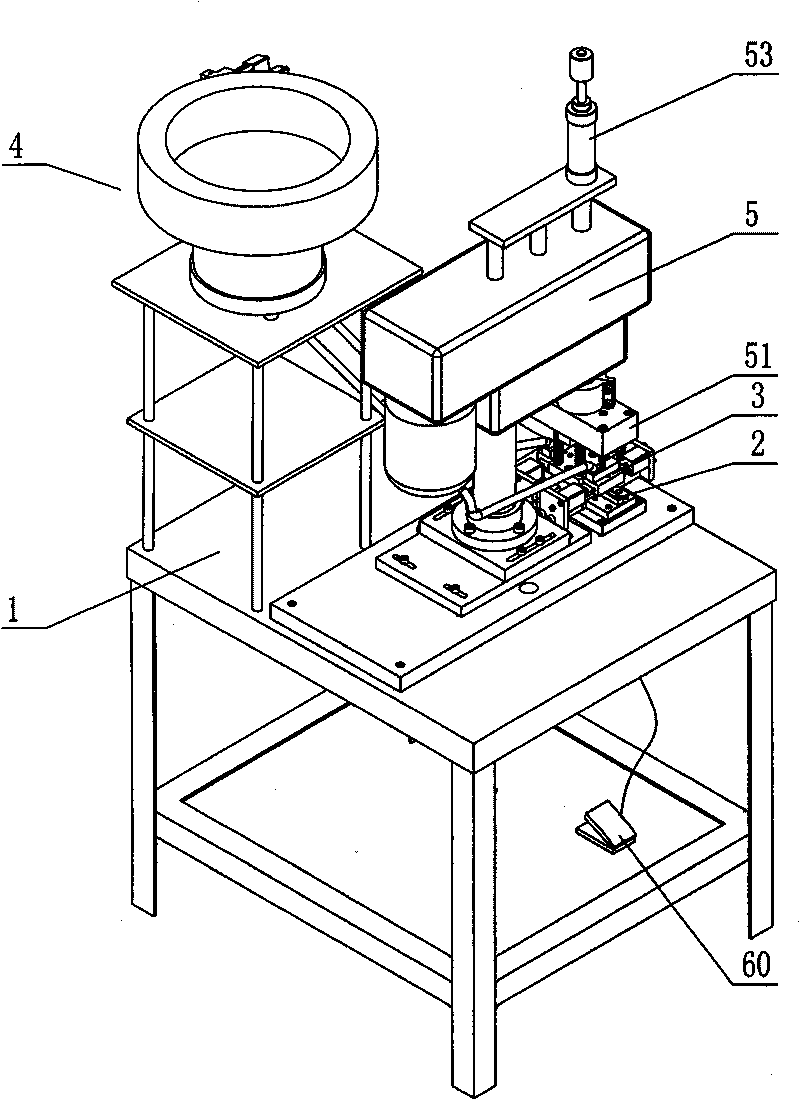

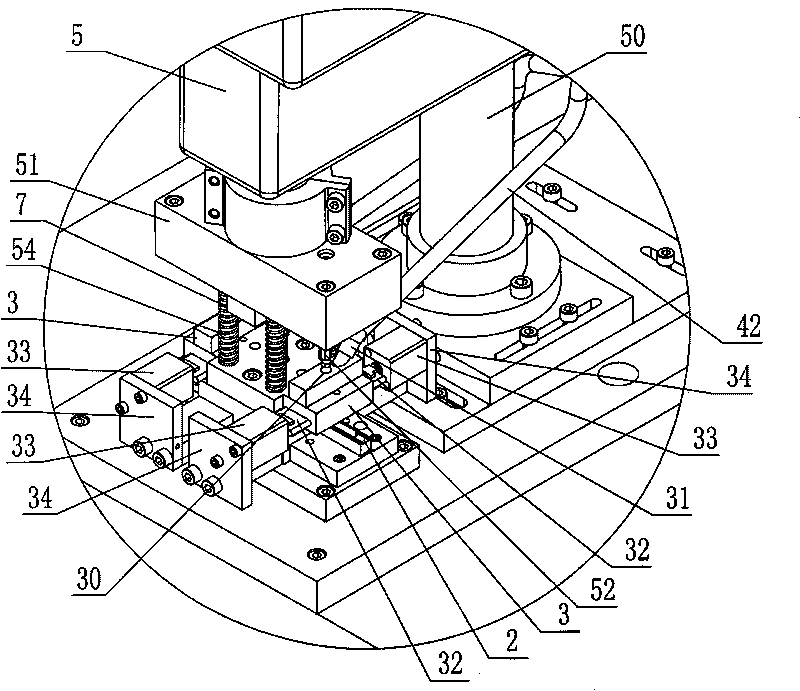

Hinge component assembling machine

ActiveCN101733634AReduce human involvementReduce manufacturing costAssembly machinesWork holdersElectrical controlControl switch

The invention relates to a hinge component assembling machine which assembles a permanent pedestal and a hinge arm component of a hinge together by a bolt. The hinge component assembling machine comprises a pedestal positioning seat arranged on a worktable, a bolt positioning seat positioned positioned above the pedestal positioning seat, a bolt feeding mechanism for transporting the bolt to the bolt positioning seat, a bench drill for assembling the bolt on the permanent pedestal and the hinge arm component, and a control switch connected with an electrical control device; the bolt positioning seat comprises a bolt assembling guide hole which is formed on the bolt positioning seat and is communicated up and down, a blanking port connector which is used for sending the bolt to the bolt assembling guide hole by the bolt feeding mechanism, guide grooves formed on two sides of the bolt positioning seat, bolt aligning splints arranged on the guide grooves, and a cylinder for controlling the bolt aligning splints to close up or separate from the bolt assembling guide hole; and the cylinder is fixed by a fixing plate which is arranged on the worktable. The hinge component assembling machine with the structure can effectively improve production efficiency and reduce production cost.

Owner:GUANGDONG ADAMS METALS FABTE

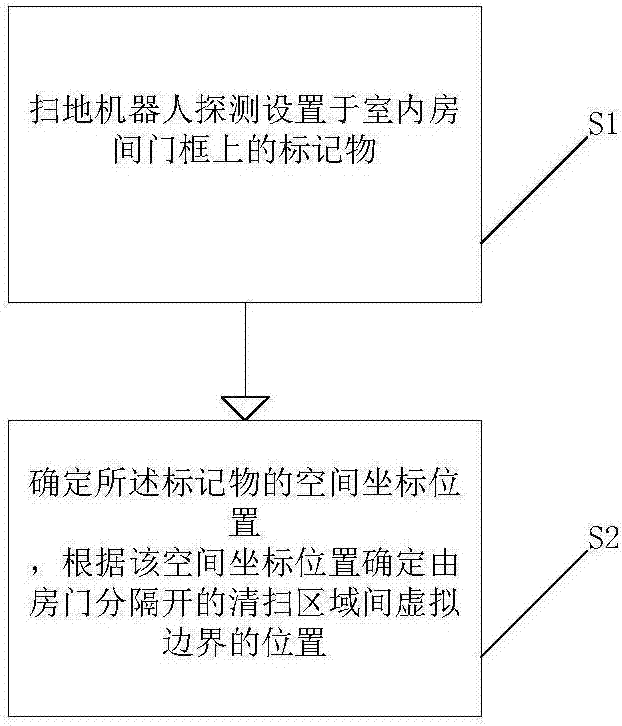

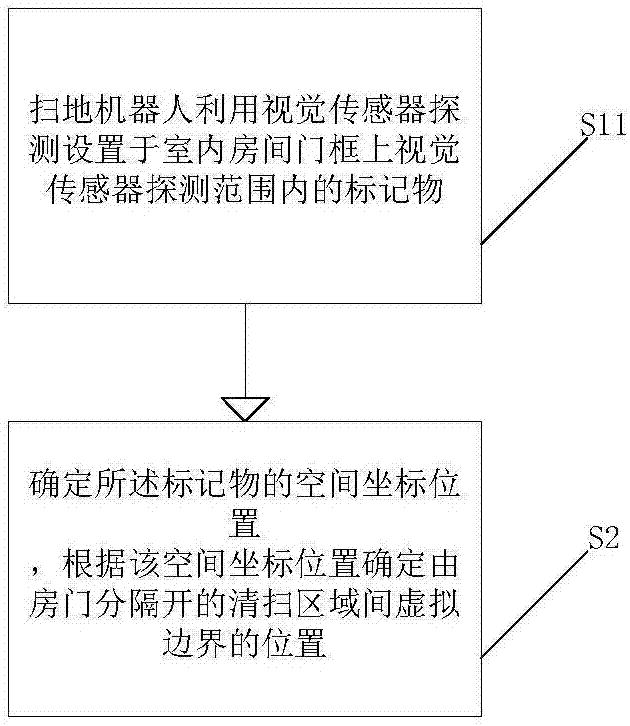

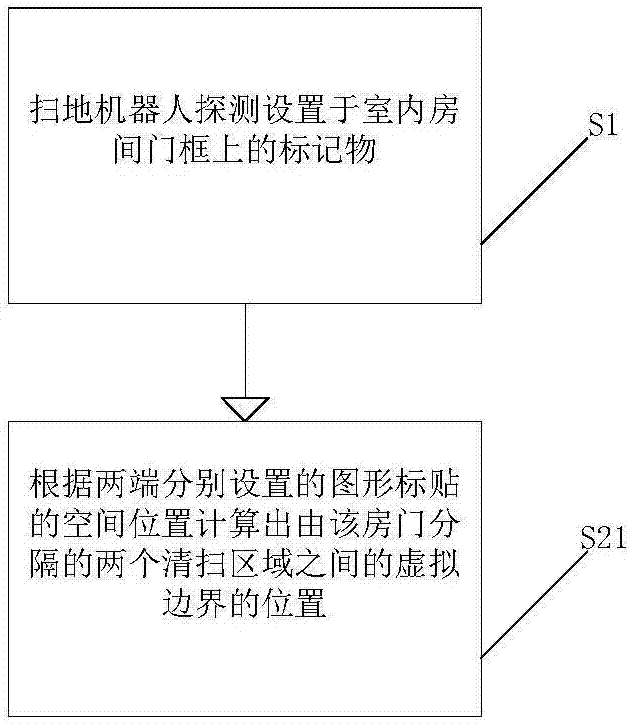

Indoor area dividing method and sweeping robot

The invention discloses an indoor area dividing method and a sweeping robot. The indoor area dividing method comprises: detecting, by the sweeping robot, markers arranged on door frames of indoor rooms; determining spatial coordinates of the marker, determining positions of virtual boundaries of cleaning areas divided by doors. Boundaries are judged via graphical labels, area dividing is reasonable, the size is smaller, long-time setting is available, operating is more convenient, and cost can be reduced.

Owner:SHENZHEN FREE DYNAMICS DEV CO LTD

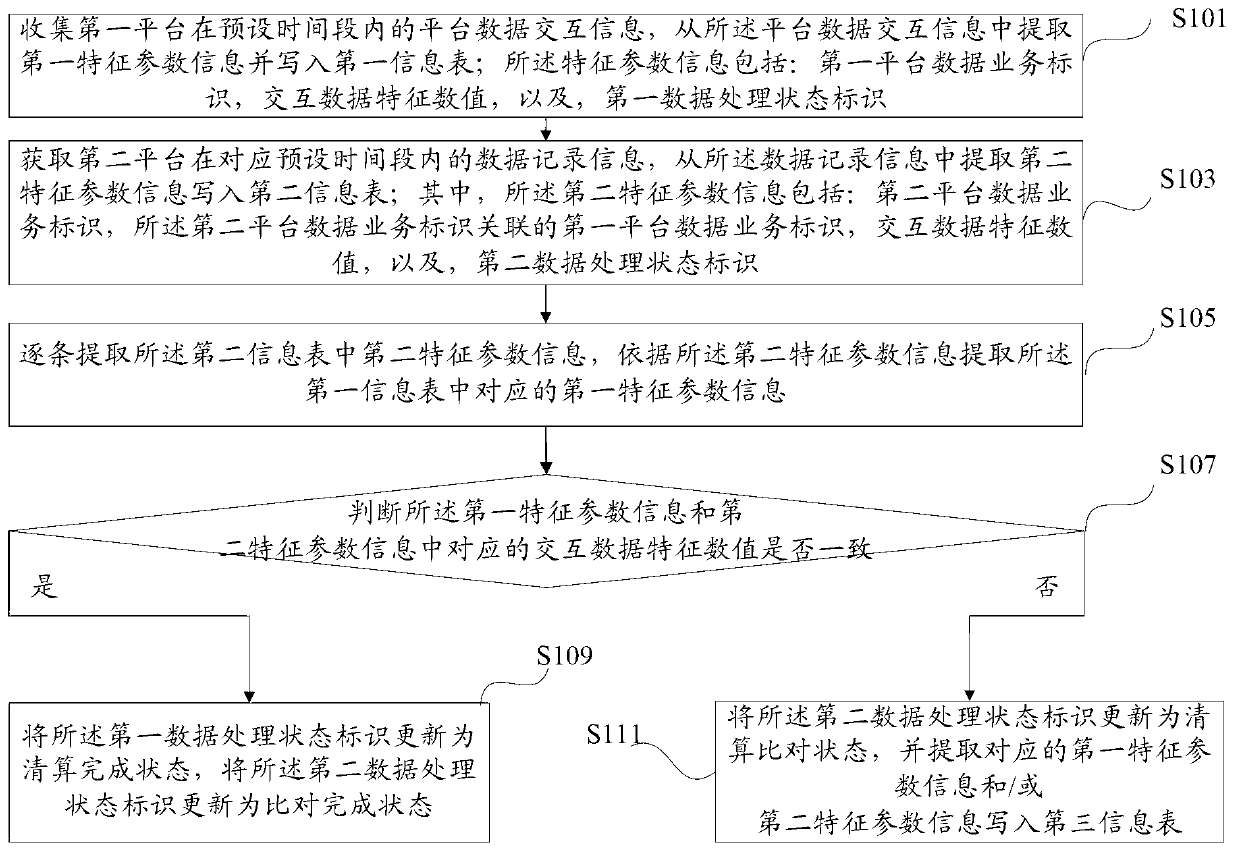

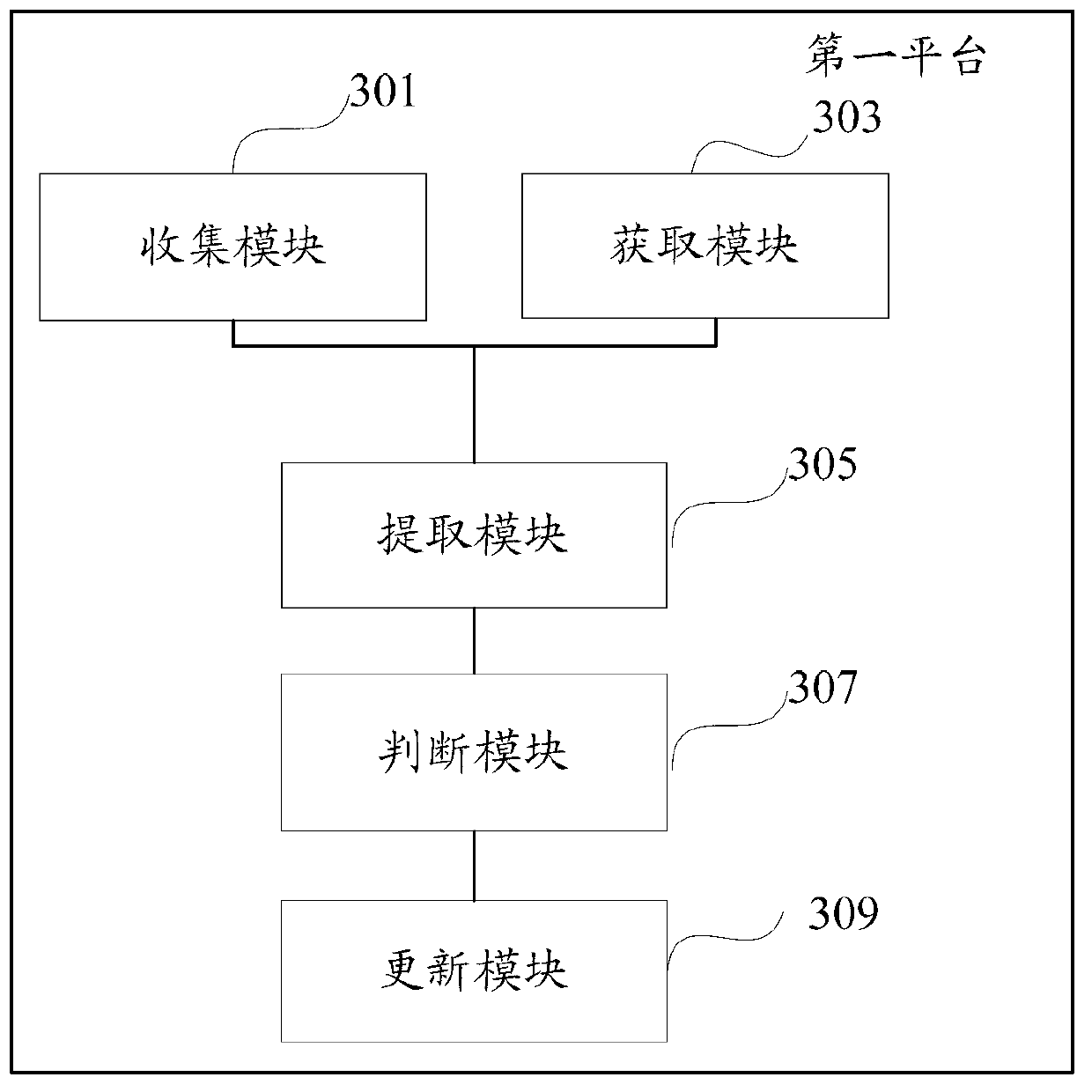

Method and system of verifying data consistency between multiple platforms

InactiveCN103345487AEnsure consistencyConsistency of protectionSpecial data processing applicationsTime rangeMultiple platform

The invention discloses a method of verifying data consistency between multiple platforms. The multiple platforms comprise a first platform and a second platform which is in communication with the first platform. The method comprises the following steps that platform data interaction information of the first platform within a preset time range is collected, and first characteristic parameter information is extracted from the platform data interaction information and written in a first information table; data recording information of the second platform is obtained within the corresponding preset time range, and second characteristic parameter information is extracted from the data recording information and written in a second information table; whether corresponding interaction data characteristic values in the first characteristic parameter information and the second characteristic parameter information are consistent or not is judged. By means of the method, data distributed between the platforms can be automatically obtained and compared, inconsistent interaction data characteristic values between the platforms can be accurately and timely found, human participation is reduced, and waste of resources of the platforms is reduced.

Owner:BEIJING QIHOO TECH CO LTD +1

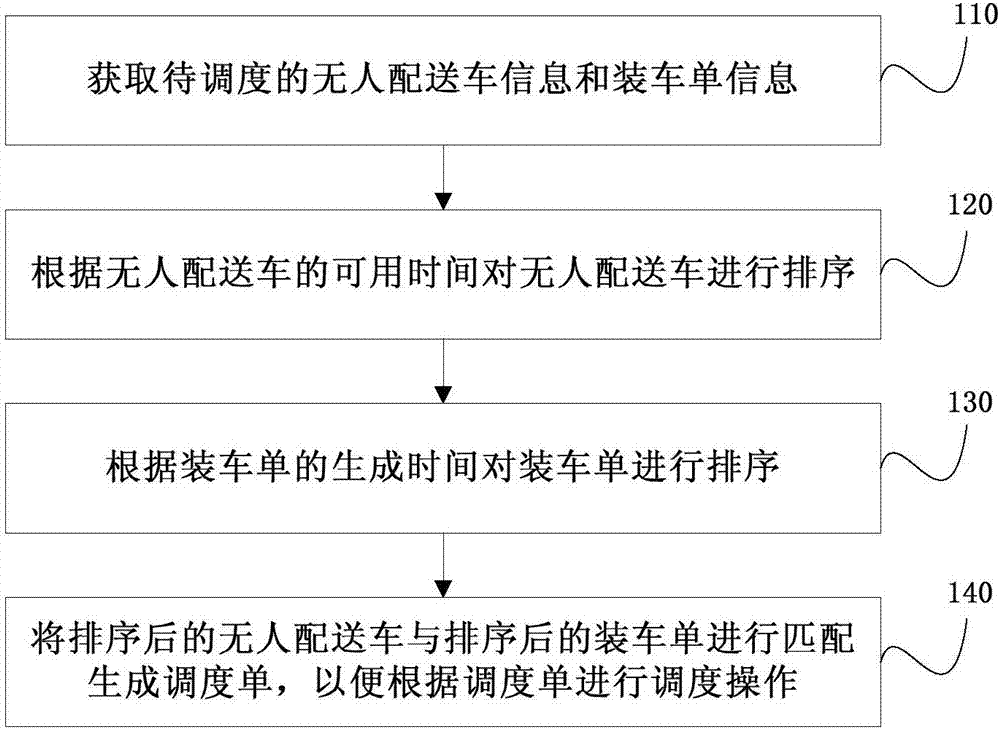

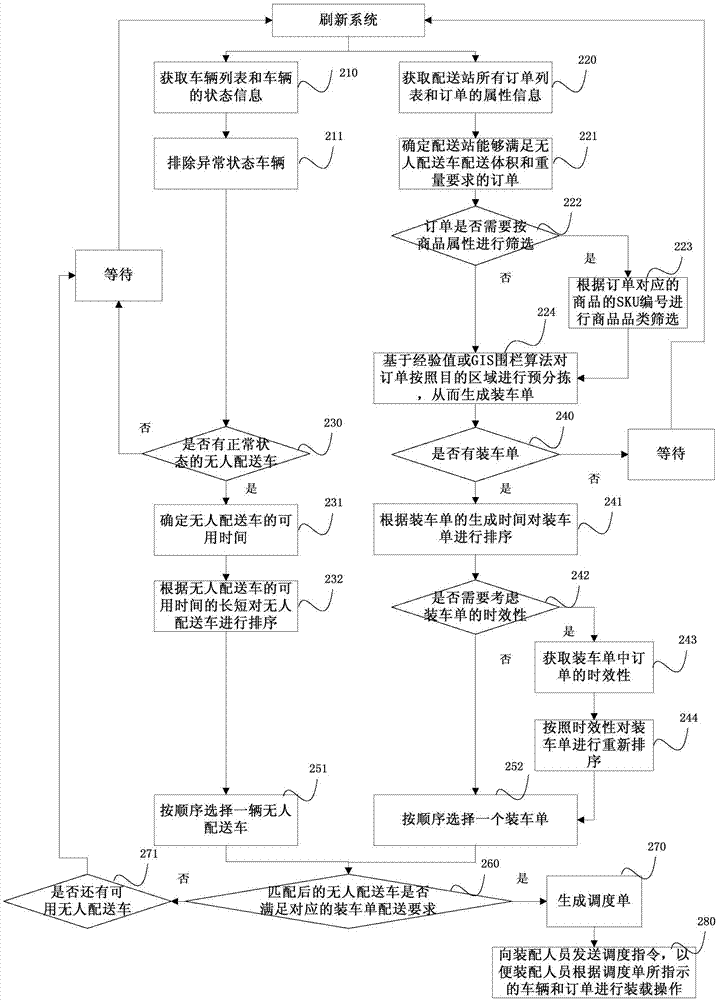

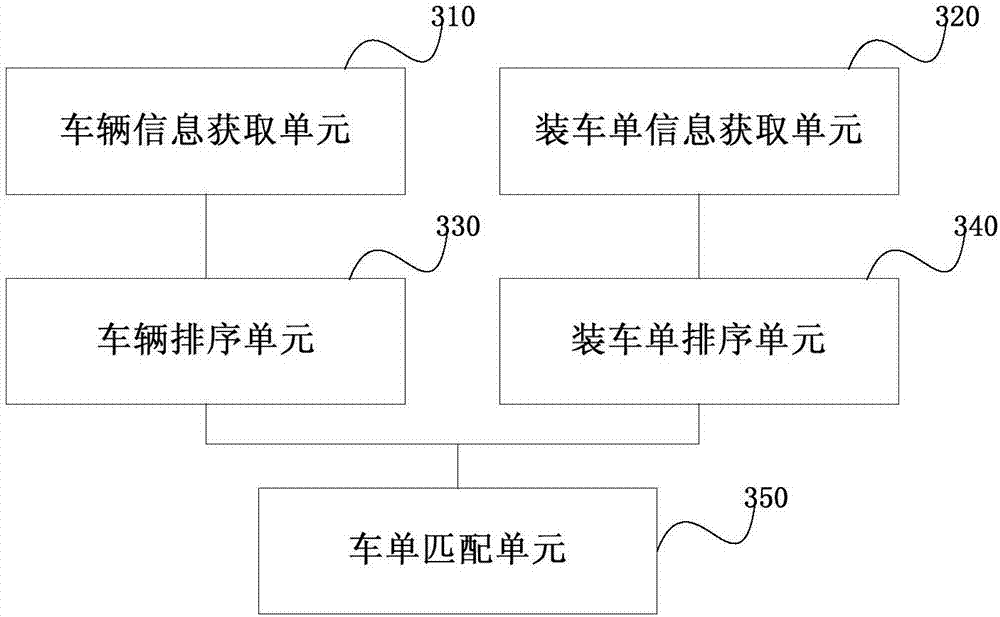

Method and system for dispatching based on unmanned delivery vehicles

InactiveCN106855966AIncrease profitImprove processing efficiencyResourcesLogisticsDelivery vehicleComputer science

The invention discloses a method and a system for dispatching based on unmanned delivery vehicles, and relates to the field of logistics automation. The method comprises the steps of acquiring information of unmanned delivery vehicles to be dispatched and information of loading lists to be dispatched, wherein orders in the same loading list have the same destination region; sorting the unmanned delivery vehicles according to the available time of the unmanned delivery vehicles; sorting the loading lists according to the generation time of the loading lists; matching the sorted unmanned delivery vehicles with the sorted loading lists to generate a dispatching list so as to perform a dispatching operation according to the dispatching list. The method considers from the two dimensions of vehicles and orders, the utilization rate of the vehicles and the processing efficiency of the orders are improved, the whole working process is enabled to be low in manual intervention degree, and thus the goods delivery efficiency of the unmanned delivery vehicles is improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

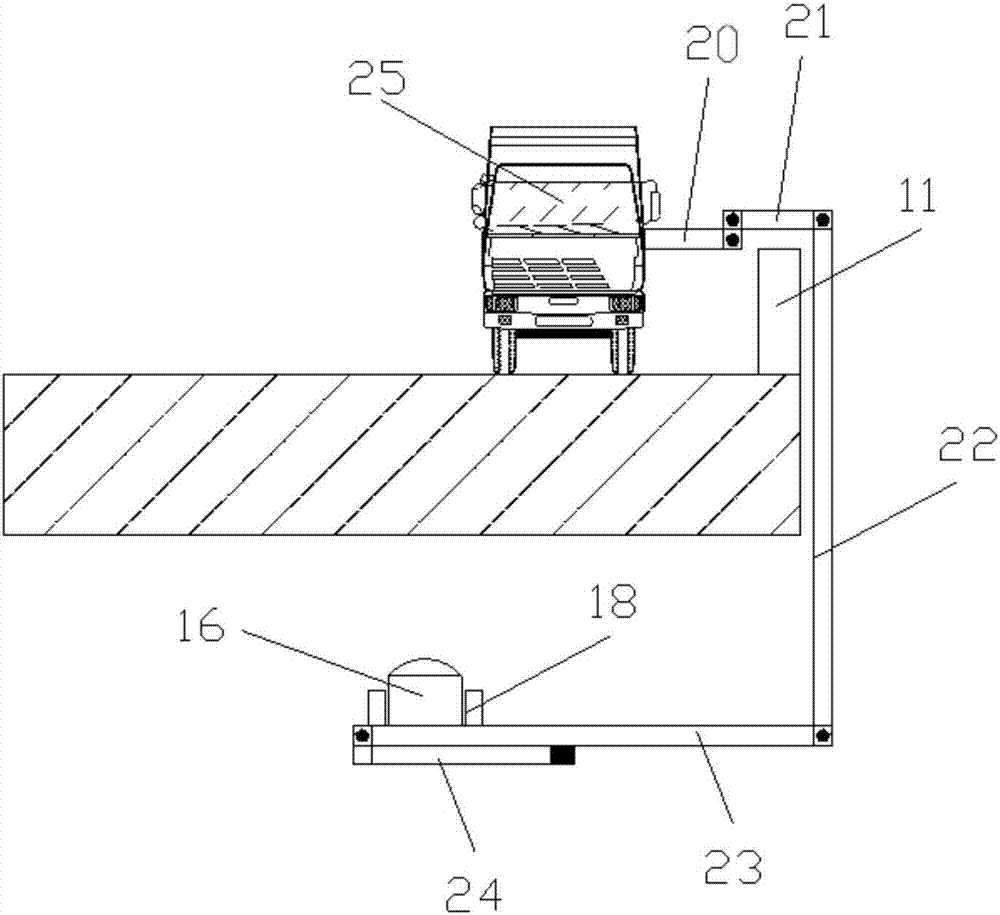

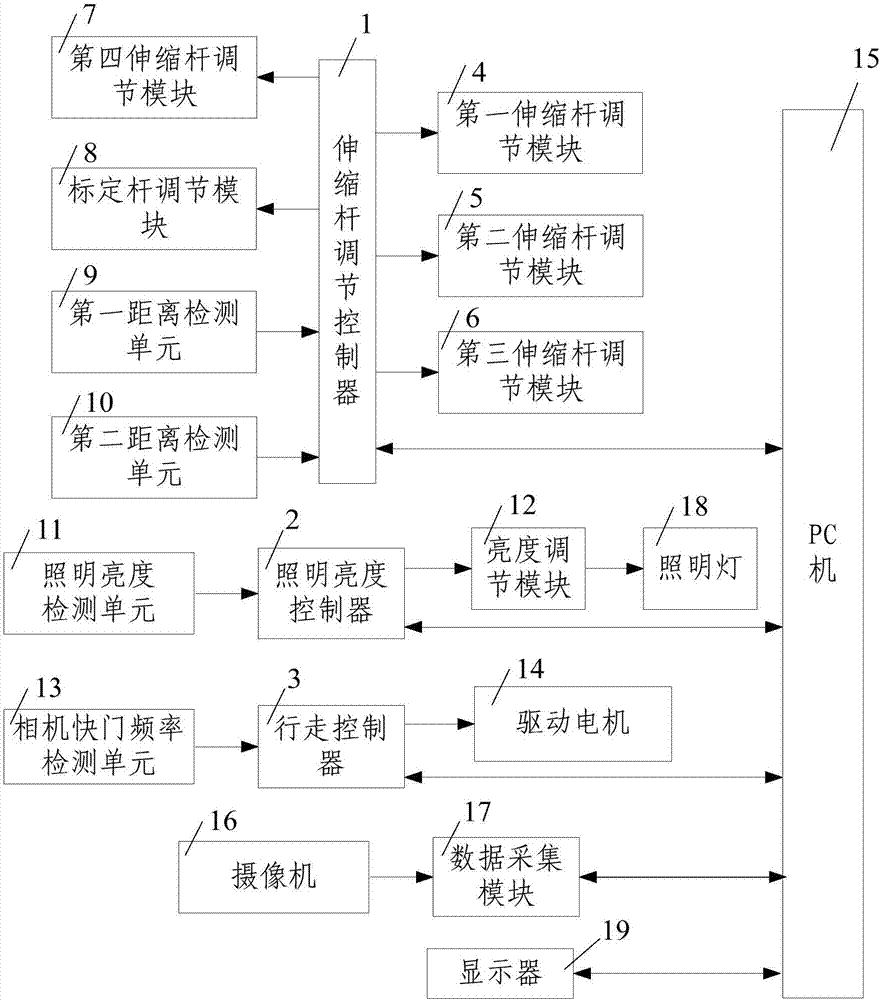

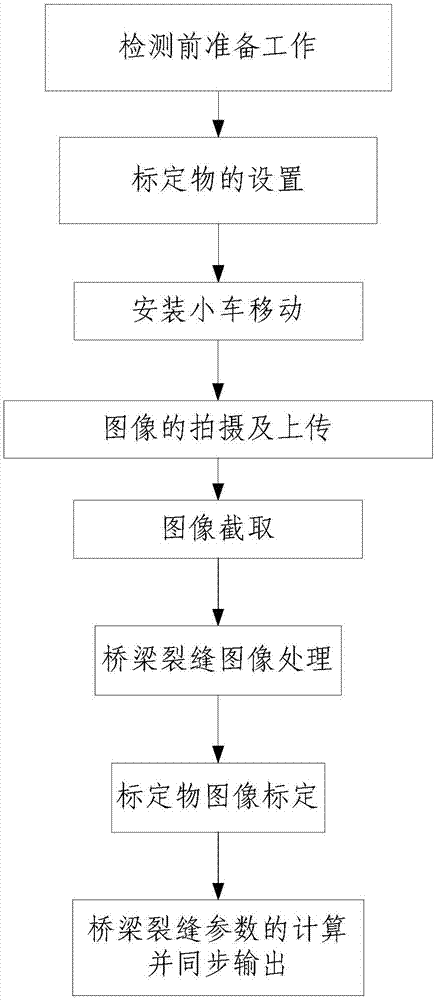

Bridge crack detection device and detection method

ActiveCN107064169ASimple structureReasonable designOptically investigating flaws/contaminationImaging processingImage calibration

The invention discloses a bridge crack detection device and detection method. The automatic bridge crack detection device comprises a control device, an installation car, a telescopic rod mechanism and a detection device, wherein the control device comprises a data processing device, a display, a walking controller, a camera shutter frequency detection unit, a telescopic rod adjusting device, a telescopic rod adjusting controller, a first distance detection unit, a second distance detection unit, an illuminating brightness detection unit, a brightness adjusting module and an illuminating brightness controller. The detection method comprises the steps of (1) preparatory work before detection; (2) shooting and uploading of an image; (3) image capturing; (4) bridge crack image processing; (5) calibration object image calibration; and (6) calculating and synchronous outputting of bridge crack parameters. The bridge crack detection device is simple in structure, reasonable in design, and convenient to use and operate, accurate and quick detection of the size of bridge cracks can be achieved, and the work efficiency of bridge crack detection and the reliability of detection data are improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

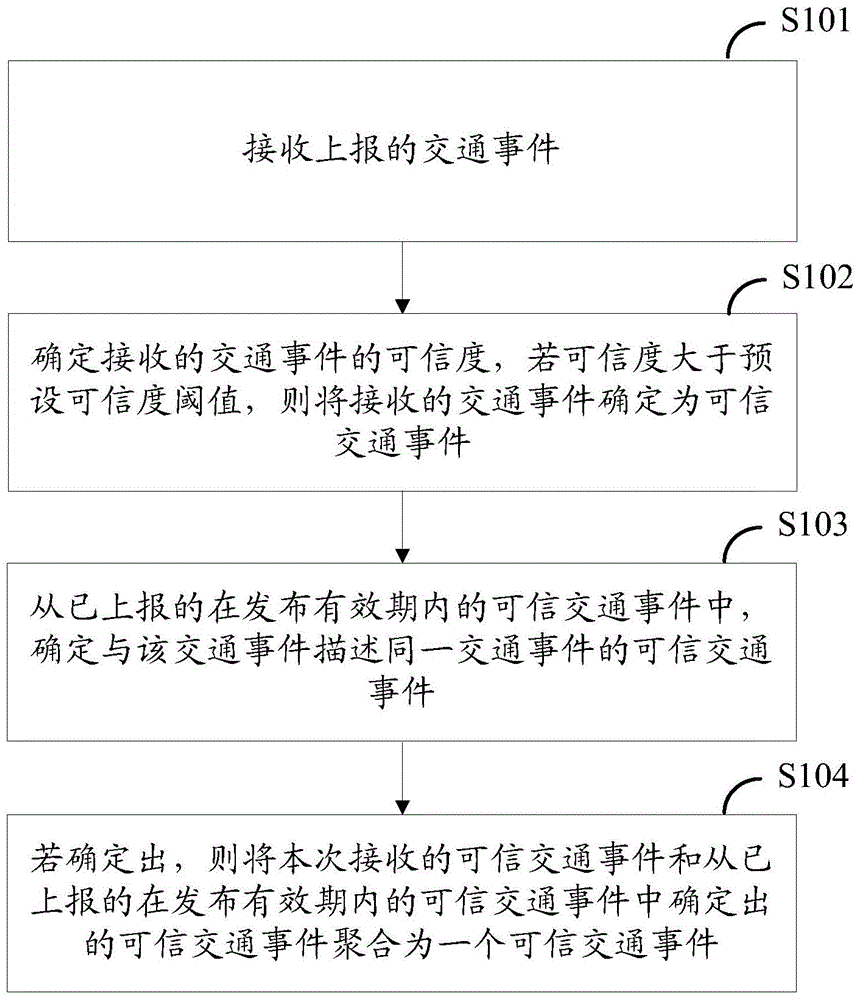

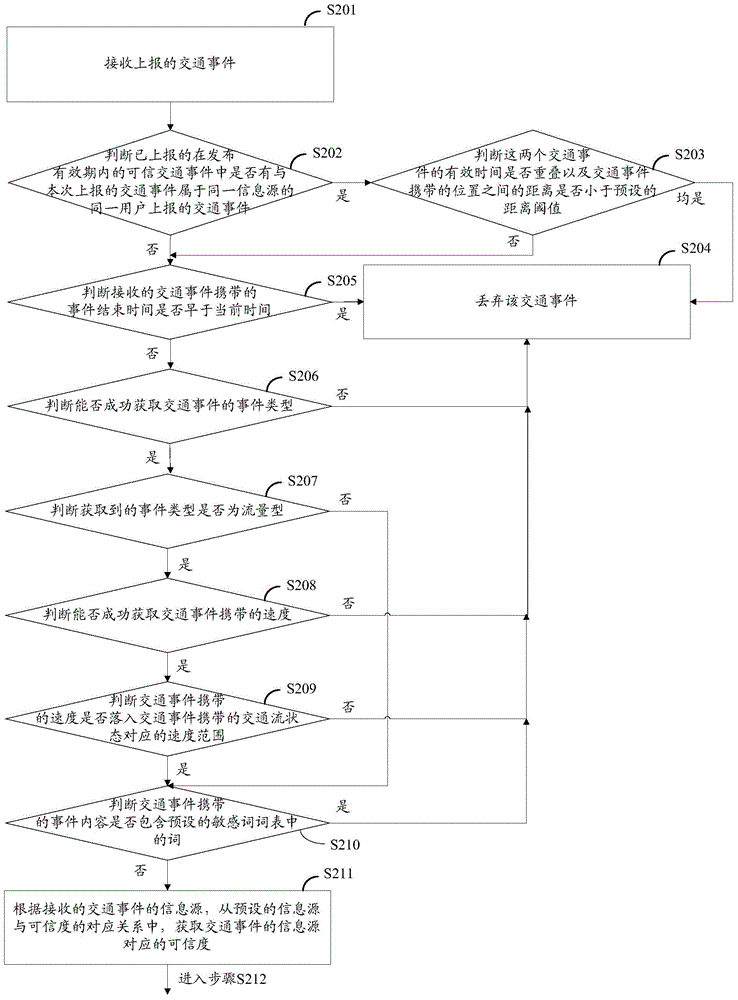

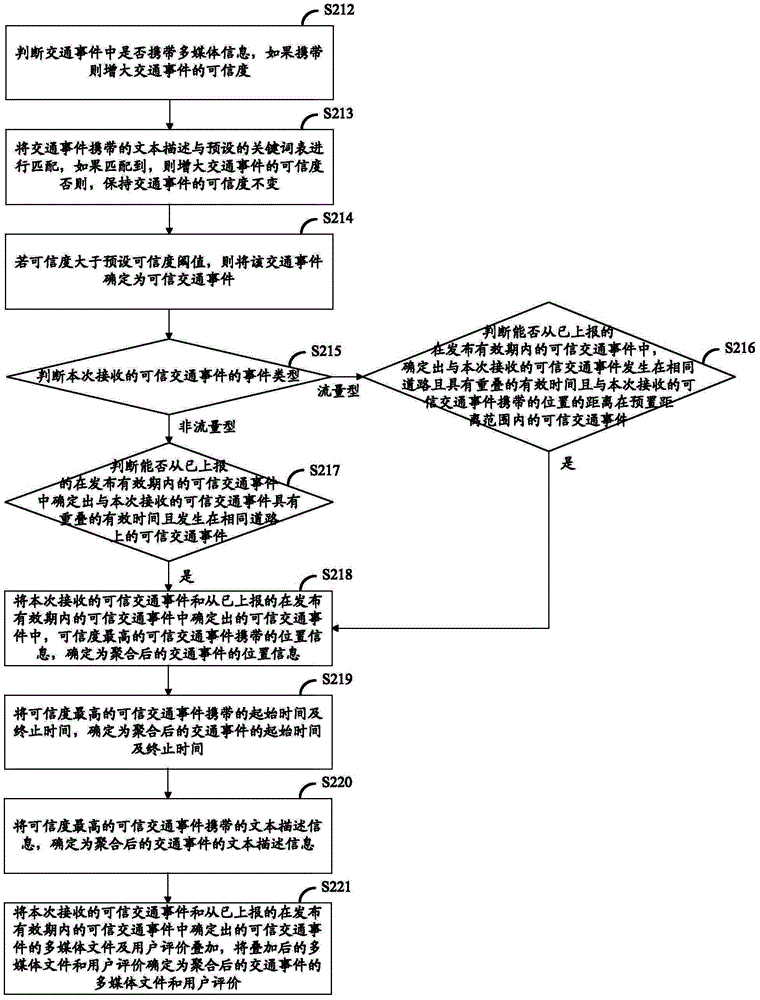

Traffic event processing method and traffic event system

ActiveCN105321338AGuaranteed accuracyGuaranteed validityRoad vehicles traffic controlSpecial data processing applicationsReal-time computing

An embodiment of the invention provides a traffic event processing method and a traffic event system. The method comprises the following steps of receiving a reported traffic event; determining a credibility of the received traffic event; if the credibility is greater than a preset credibility threshold, determining the traffic event to be a trusted traffic event; from the reported trusted traffic events in a published validity period, determining the trusted traffic event whose description is the same with that of the traffic event; after the determination is finished, the received trusted traffic event of this time and the trusted traffic event determined from the reported trusted traffic events in the published validity period are polymerized into one trusted traffic event. In the prior art, the traffic event obtained through processing has problems that accuracy is low, validity is poor and real-time performance is poor too. By using the method and the system of the invention, the above problems are solved.

Owner:ALIBABA (CHINA) CO LTD

Automatic welding device for battery top cover

PendingCN107570869ACompact layoutAdd action functionLaser beam welding apparatusAction functionEngineering

The invention relates to an automatic welding device for a battery top cover. The automatic welding device for the battery top cover comprises a conveying device, a feeding device, a laser welding device, a clearing device, a detecting device and a rubberizing device; the conveying device comprises an annularly closed conveying belt which is provided with a clamping device; and the feeding device,the laser welding device, the clearing device, the detecting device and the rubberizing device are arranged on corresponding stations on the outer side of the conveying belt correspondingly. Automatic feeding and discharging are adopted for the automatic welding device for the battery top cover, in combination with an automatic assembling production mode of a cyclic flow channel, the whole machine arrangement is compact, space is saved, and maintaining operation is facilitated; and the action functions of a whole machine device are increased, all station actions are linked compactly, the manual participation degree is low, and the machine table automation degree and the safety and stability of the whole machine device are improved.

Owner:海目星(江门)激光智能装备有限公司

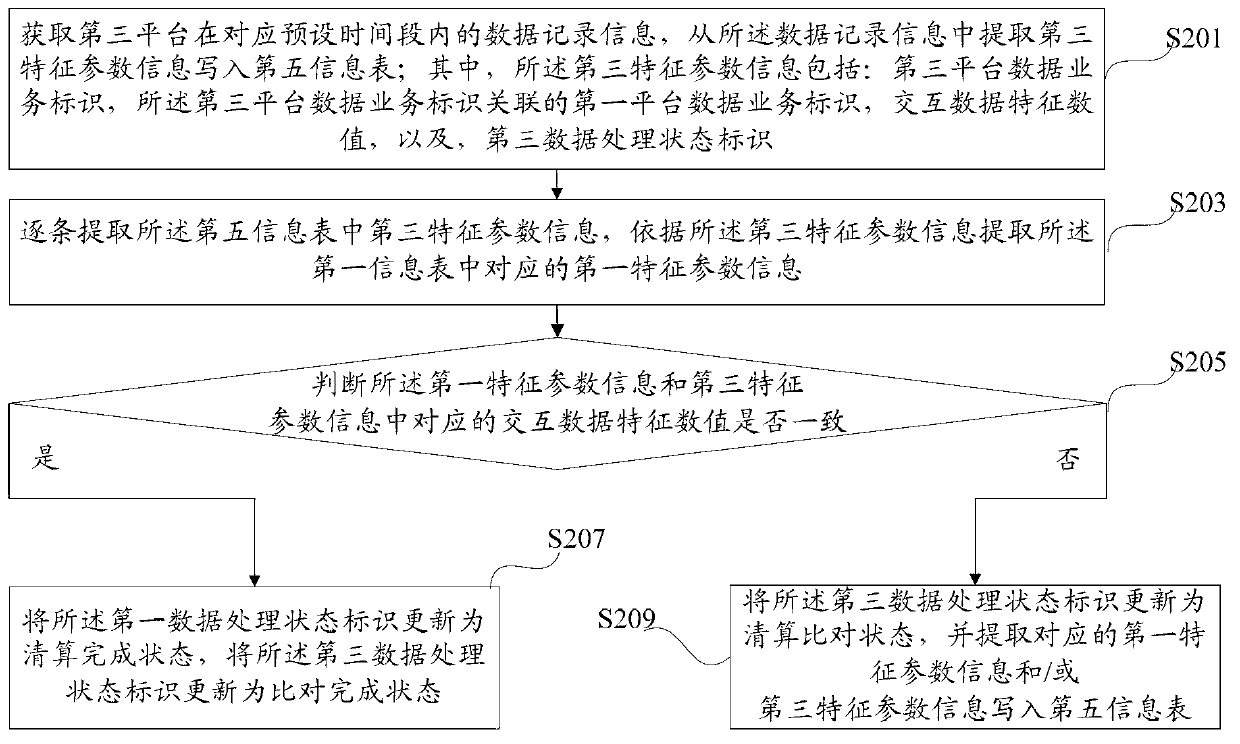

Method and system for consistency verification of data among multiple platforms

ActiveCN103391311AImprove the efficiency of data verificationEnsure consistencyTransmissionCommerceTime segmentMultiple platform

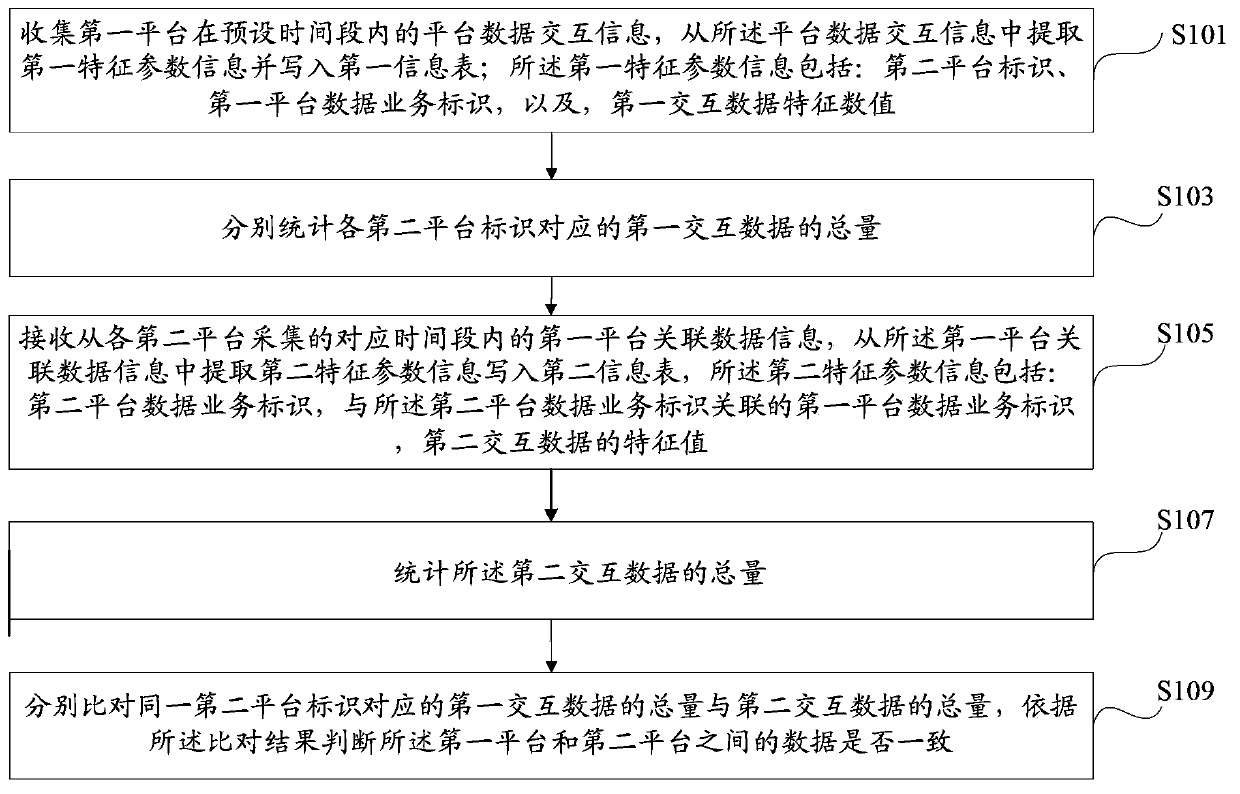

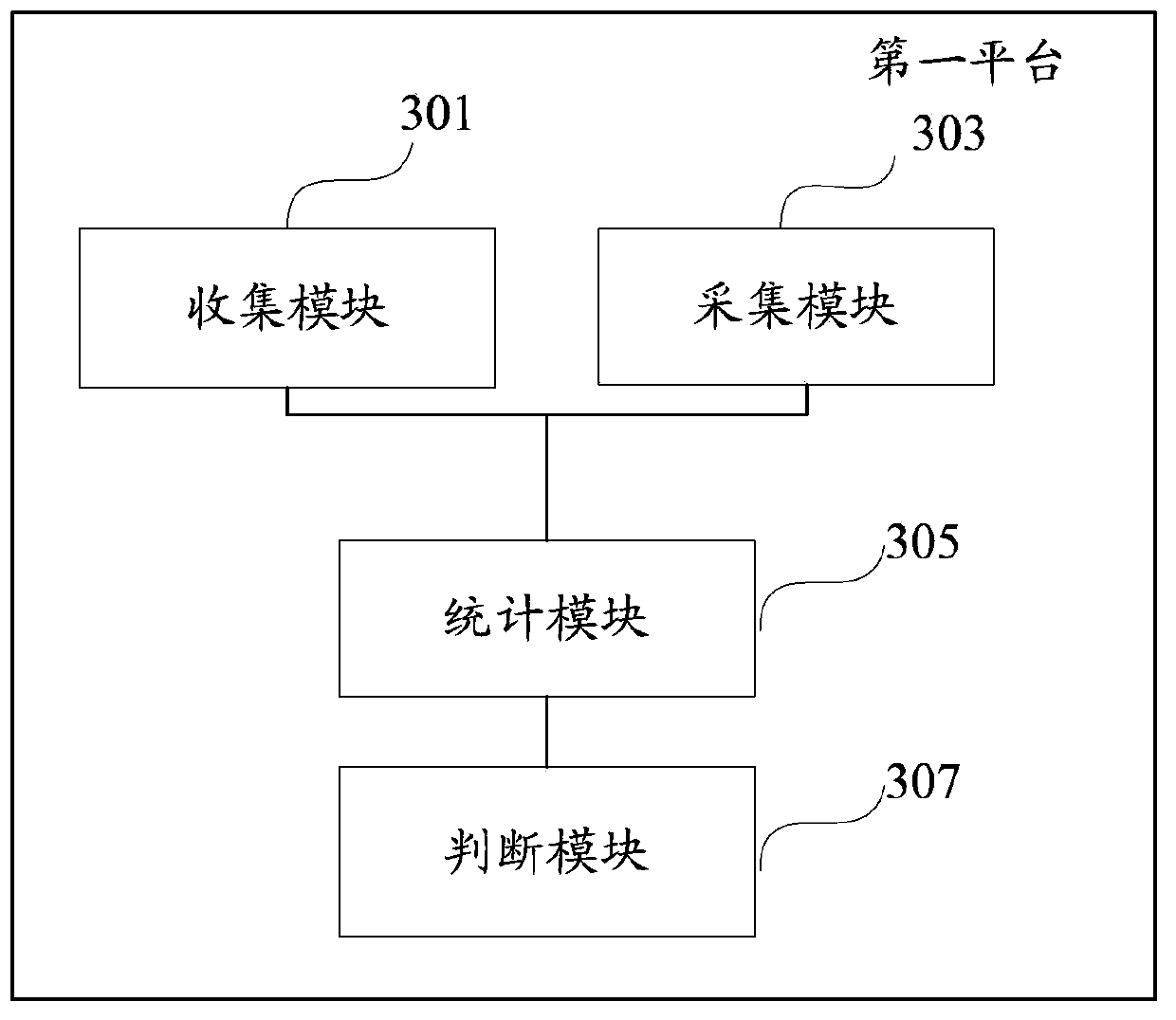

The invention discloses a method and system for consistency verification of data among multiple platforms. The method comprises the steps of collecting platform data mutual information of a first platform within a preset time period, extracting first characteristic parameter information from the platform data mutual information and writing the first characteristic parameter information into a first information sheet; respectively calculating total quantities of first interactive data corresponding to second platform marks; receiving first platform relevant data information collected from a second platform within the corresponding time periods, extracting second characteristic parameter information from the first platform relevant data information and writing the first platform relevant data information into a second information sheet; respectively comparing the total quantities of the first interactive data and total quantities of second interactive data corresponding to the same second platform mark, and judging whether data between the first platform and the second platform are consistent according to comparison results. The method and system for consistency verification of the data among the multiple platforms are used for improving verification efficiency of the data among the multiple platforms, consistency of the data among the multiple platforms is protected, and robustness of services among the multiple platforms is guaranteed.

Owner:北京鸿享技术服务有限公司

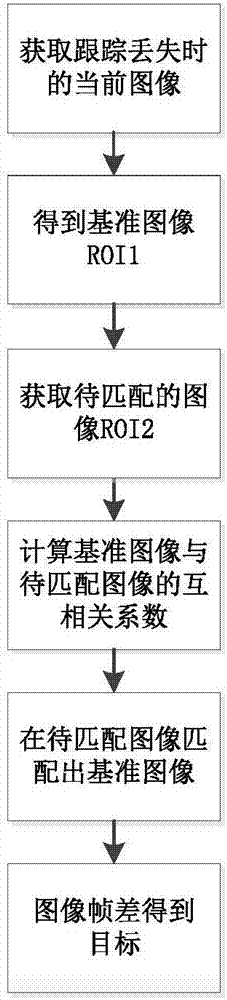

Weak moving target tracking loss reinspection method based on NCC match frame difference

ActiveCN106875419AGuaranteed real-time processingPrevent false detectionImage enhancementImage analysisFrame differenceReference image

The invention discloses a weak moving target tracking loss reinspection method based on NCC match frame difference. The method includes the following steps of acquiring the video data; performing target tracking of continuous frames of images, and for each frame in the continuous N frames of images of the tracked image, calculating the multidimensional characteristics of the target area to be the normal characteristics and calculating the offset amount of each characteristic with respect to the mean value to be the normal offset amount; when the target in the fth frame of image is lost, intercepting the reference image in the fth frame of image, intercepting the larger image to be matched in the f+kth frame of image, and calculating the cross correlation coefficient matrix; interrupting the area of the set size by taking the position with the largest cross correlation coefficient as the center, obtaining the candidate region by the frame difference method, extracting the multidimensional characteristics of the candidate region, if the deviation between the offset amount of each feature and the normal offset amount is within the set range, taking the candidate region as the target area; otherwise, k automatically increases k, repeating the above processes. The method can prevent the error detection in the traditional method.

Owner:北京理工雷科电子信息技术有限公司

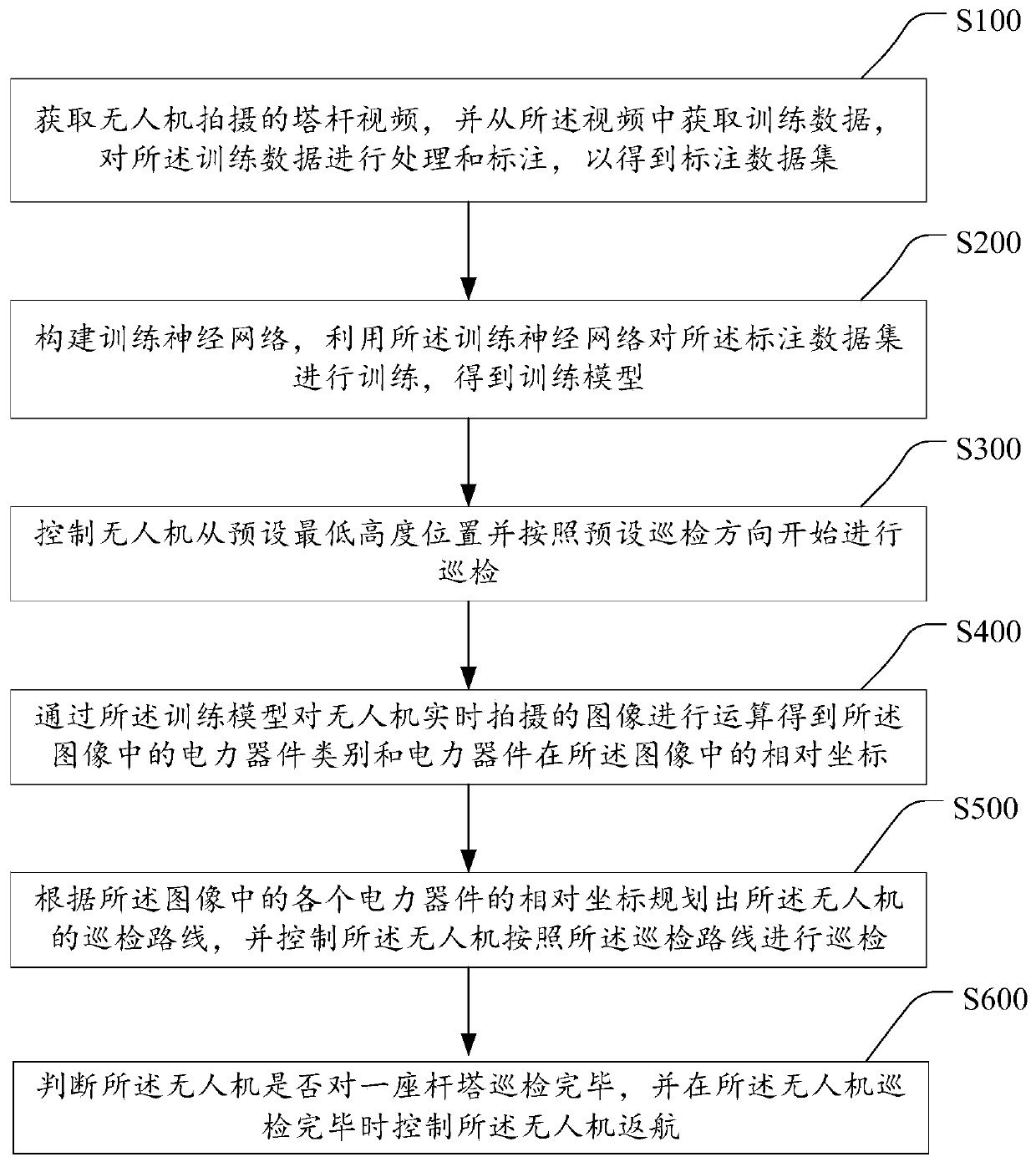

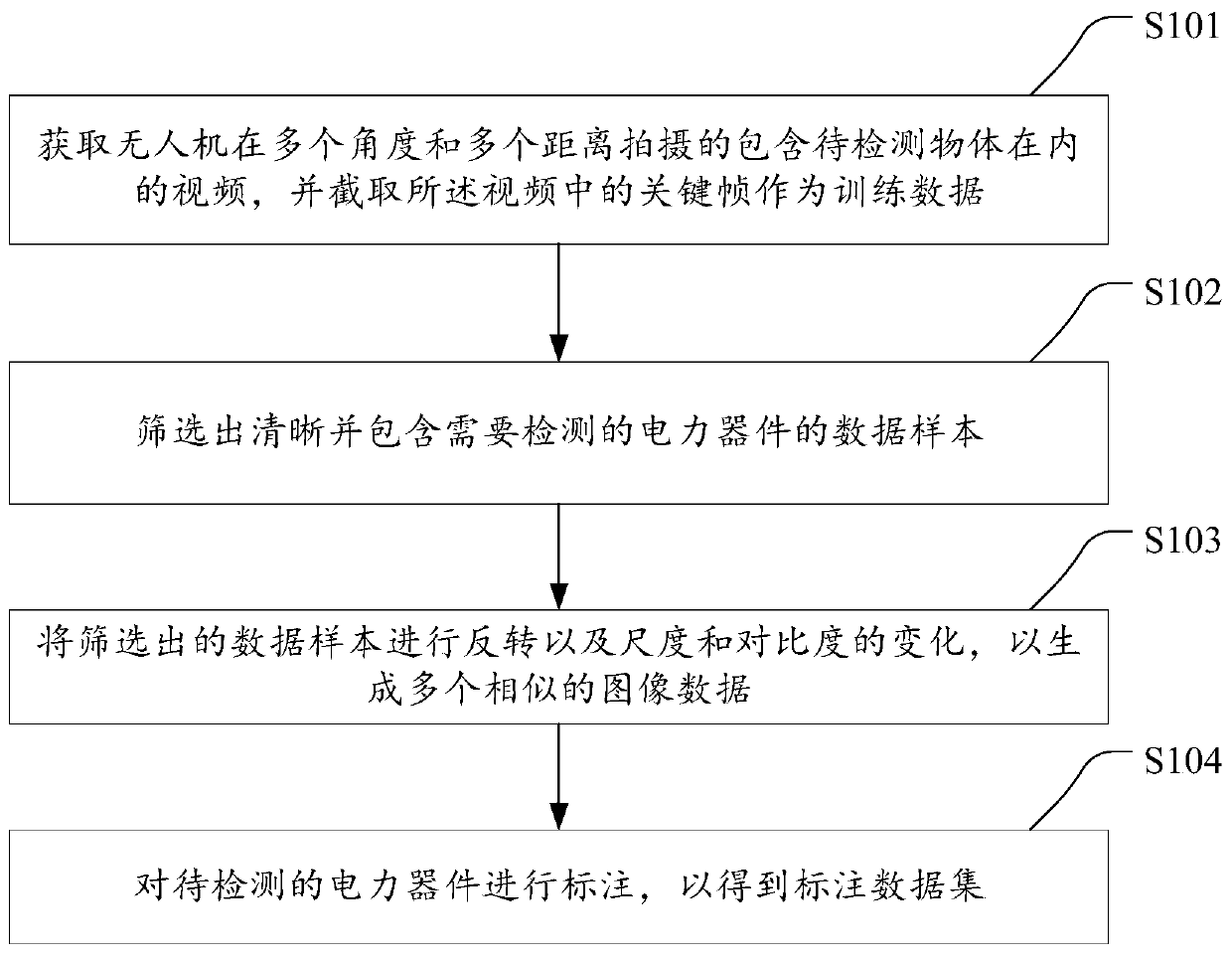

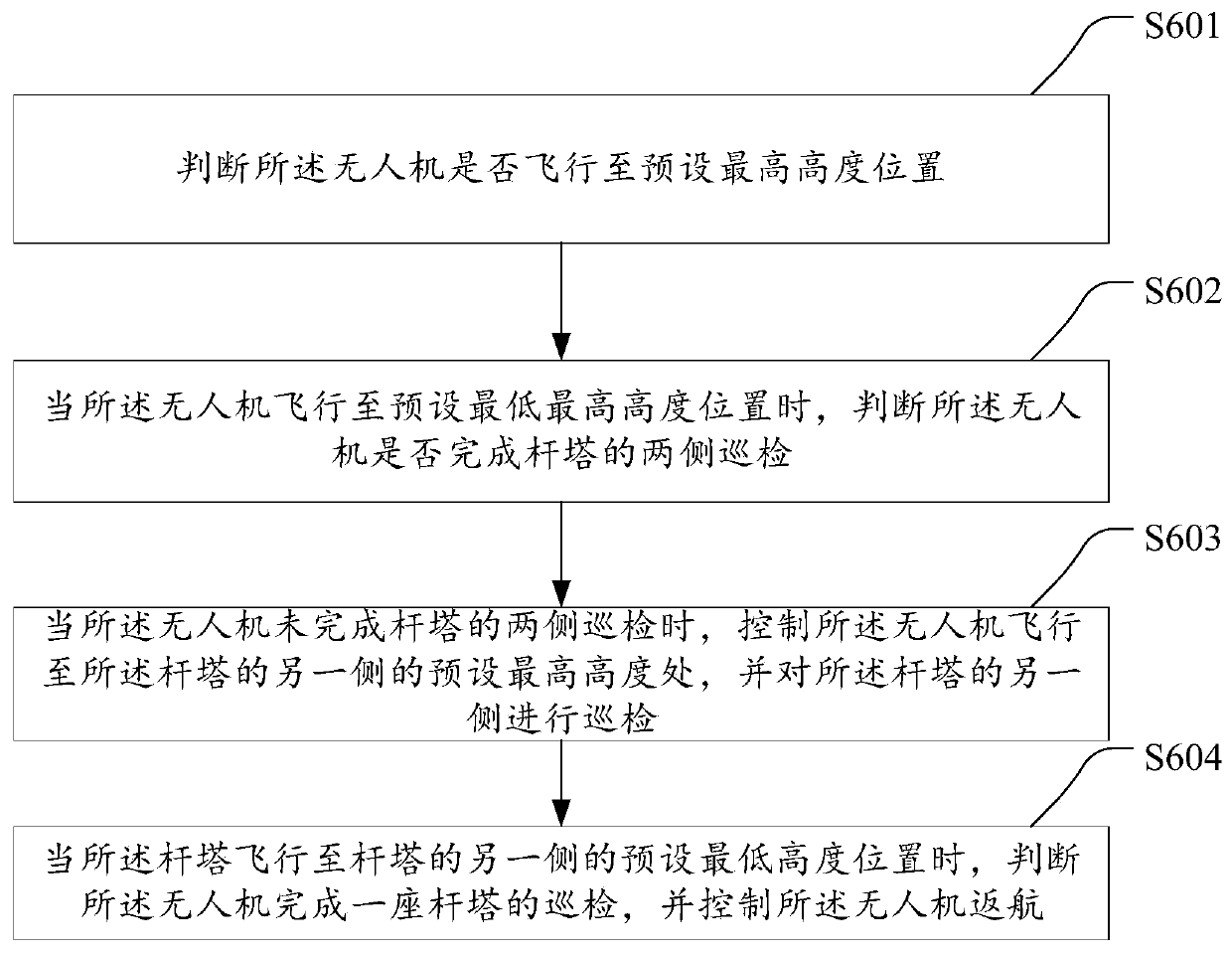

Unmanned aerial vehicle electric power inspection method and device and storage medium

InactiveCN111401146AReduce human involvementData processing applicationsScene recognitionNerve networkData set

The invention discloses an unmanned aerial vehicle electric power inspection method and device and a storage medium, and the method comprises the steps: obtaining a pole video shot by an unmanned aerial vehicle, obtaining training data from the video, and processing and annotating the training data; constructing a training neural network, and training the annotation data set by using the trainingneural network to obtain a training model; controlling the unmanned aerial vehicle to start inspection; calculating an image shot by the unmanned aerial vehicle in real time through the training modelto obtain a power device category in the image and the relative coordinate of the power device in the image; planning the inspection route of the unmanned aerial vehicle according to the relative coordinates of each power device in the image, and controlling the unmanned aerial vehicle to inspect according to the inspection route; and judging whether the unmanned aerial vehicle completes the inspection of one tower or not, and controlling the unmanned aerial vehicle to return when the unmanned aerial vehicle completes the inspection. The flight path of the unmanned aerial vehicle is automatically guided, and the manual participation degree is reduced.

Owner:YANGTZE UNIVERSITY

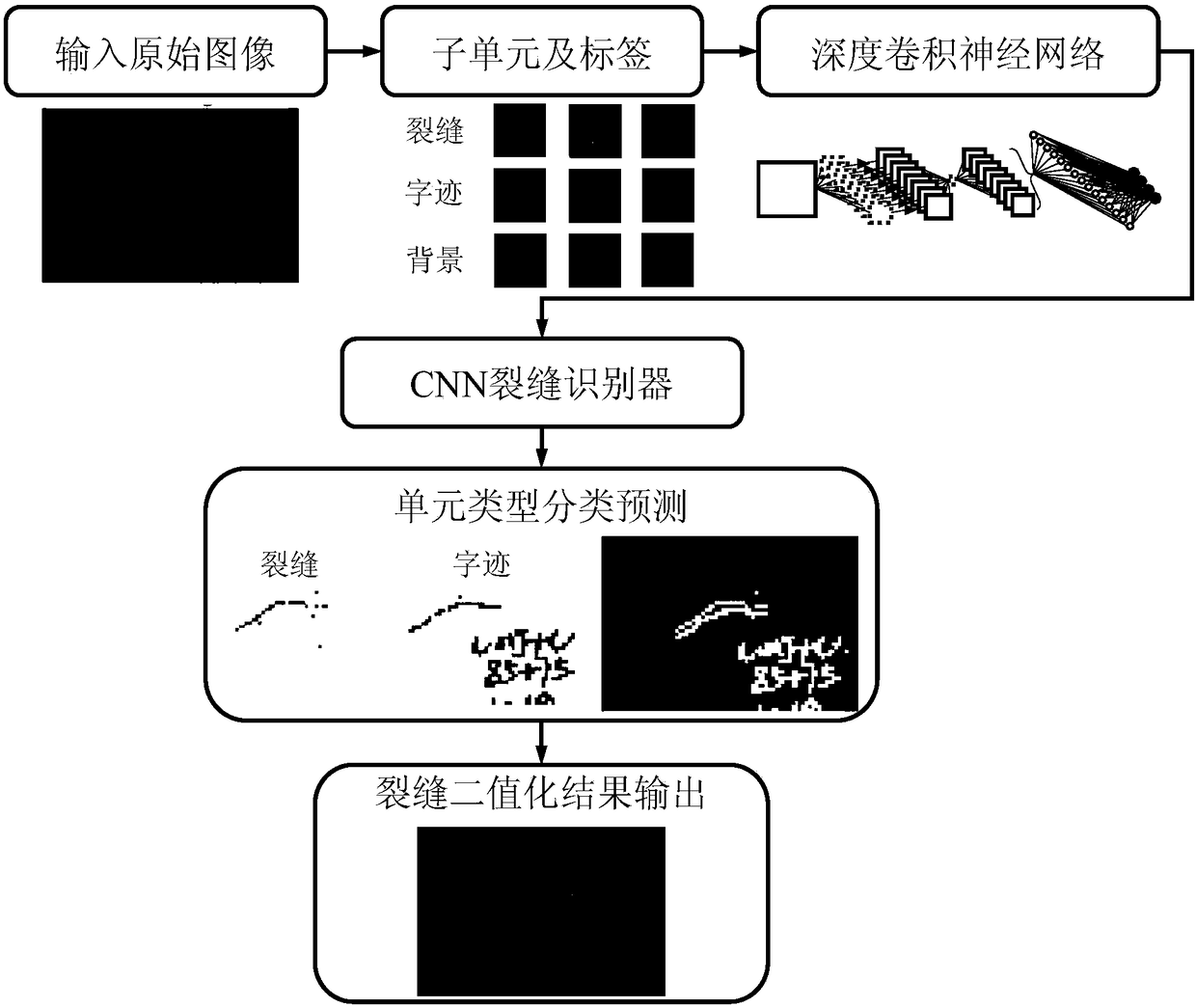

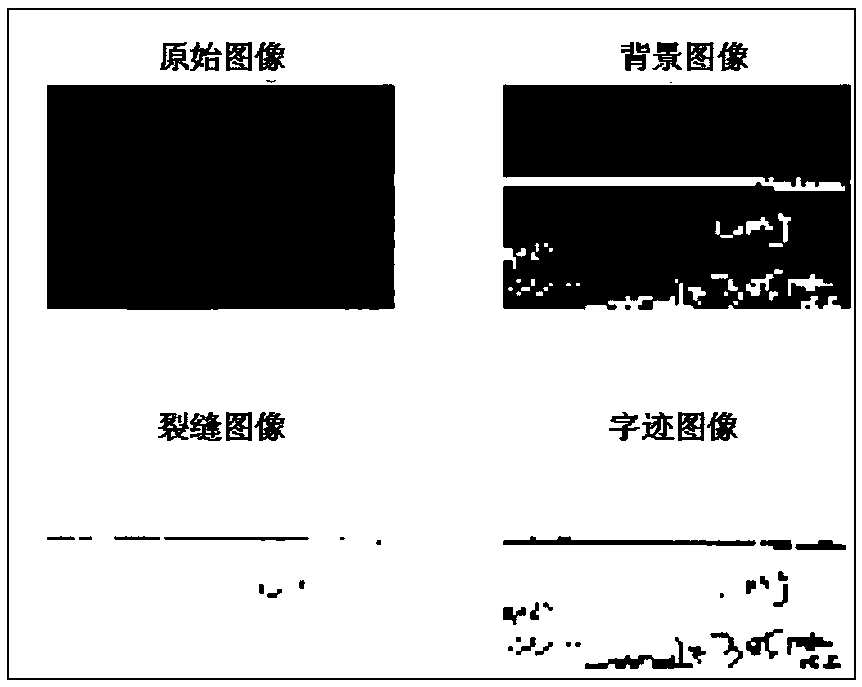

Method for automatically detecting and recognizing bridge cracks based on computer vision

ActiveCN108346144AImprove detection efficiencyReduce human involvementImage enhancementImage analysisPattern recognitionNetwork model

The invention discloses a method for automatically detecting and recognizing bridge cracks based on computer vision. By constructing a training depth network model, taking a captured image as an input, and calculating respective hidden layers, the method finally outputs the classification label of the image to realize crack identification and complete the computer's understanding of the input image content. The method, for the automatic monitoring and recognition of bridge cracks, and realizes the whole process automatic processing of model training, crack recognition and result display of crack images of real steel box beams containing complex background interference information. The method is convenient and accurate, and improves the efficiency of bridge crack detection and the accuracyand stability of the detection results.

Owner:HARBIN INST OF TECH

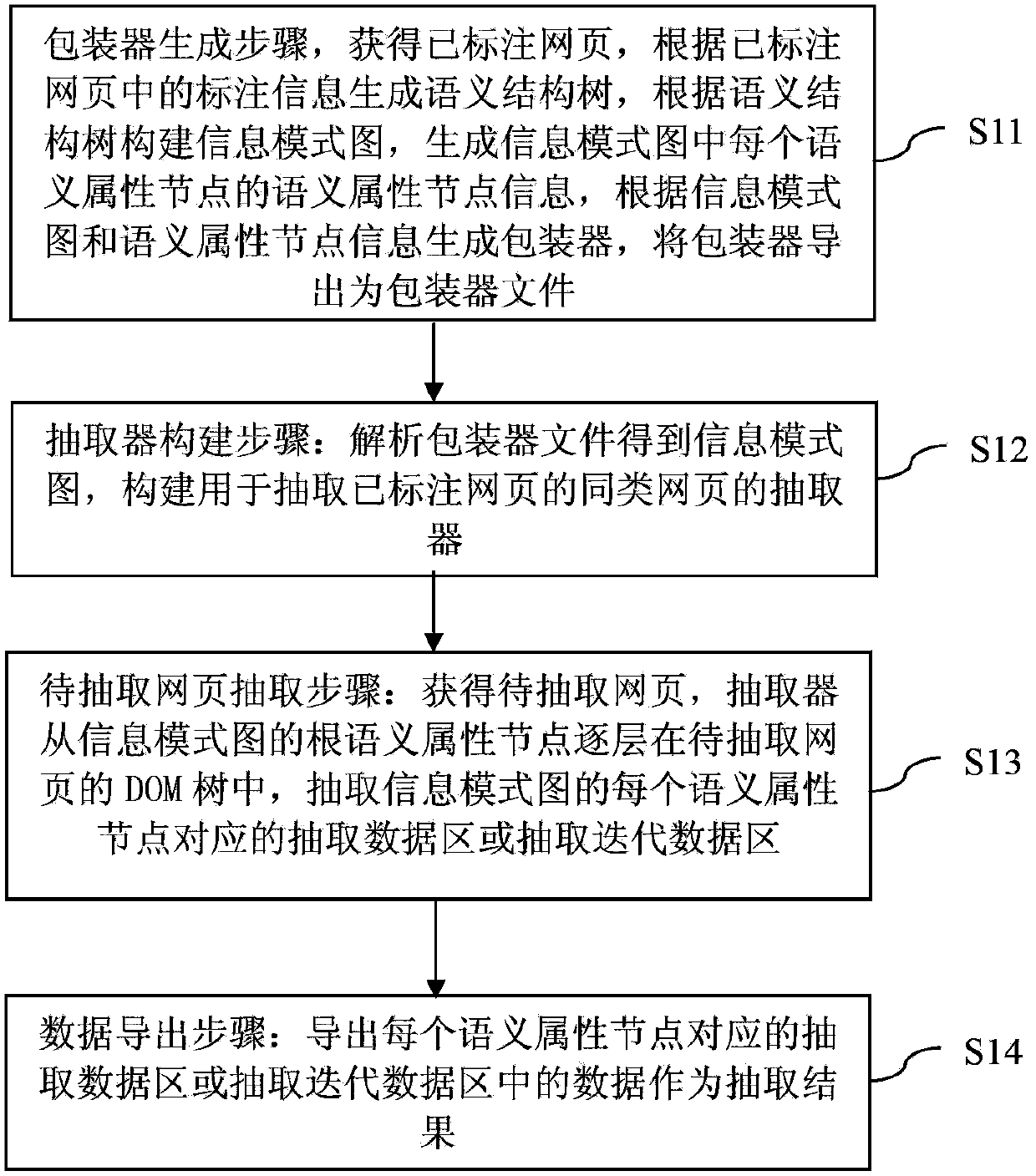

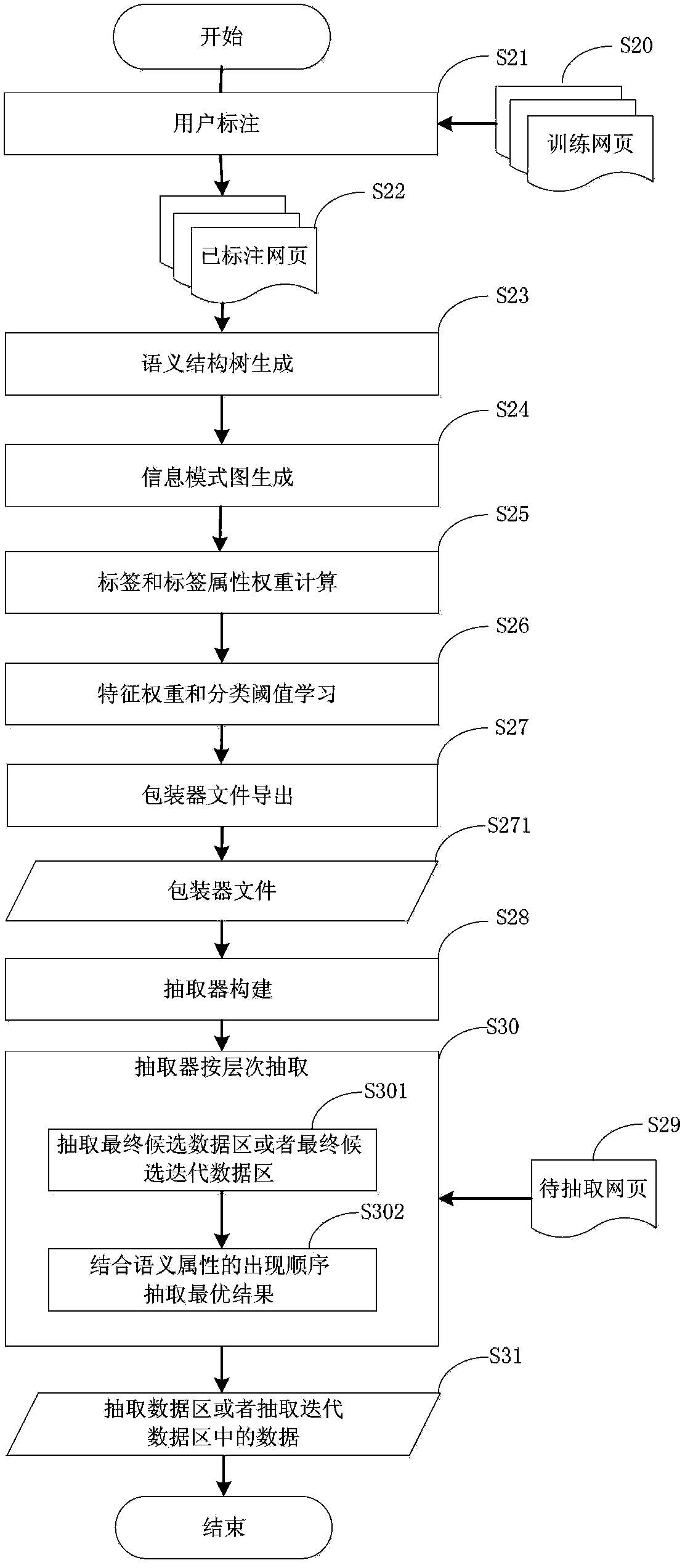

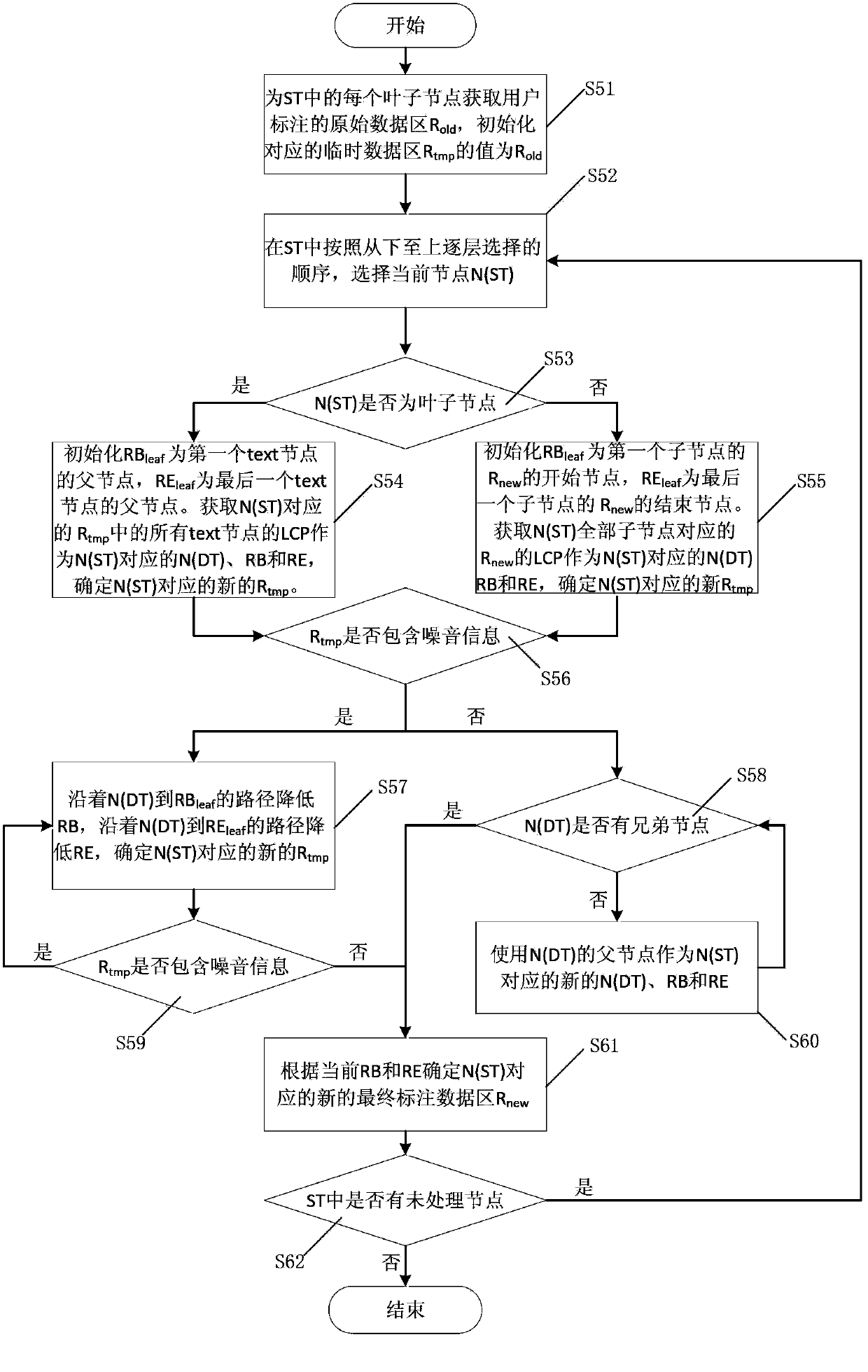

Webpage information extraction method and system

ActiveCN103870506AImprove versatilityEasy to handleWeb data indexingSpecial data processing applicationsExtensibilityFault tolerance

The invention discloses a webpage information extraction method and system. The method includes the steps: acquiring a marked webpage, generating a semantic structure tree, building an information mode pattern, generating semantic attribute node information of each semantic attribute node in the information mode pattern, generating a wrapper and deriving the wrapper into a wrapper document; building an extractor for extracting webpages similar to the marked webpage; acquiring the webpages to be extracted, and recursively extracting a data extraction area or an iterative data extraction area corresponding to each semantic attribute node in the information mode pattern layer by layer from the root semantic attribute node in the information mode pattern in a DOM (document object model) tree of the webpages to be extracted by the extractor; deriving data in the data extraction area or the iterative data extraction area corresponding to each semantic attribute node as extraction results. The method has high universality, generalization capability, fault tolerance and expandability and low manual involvement degree, and online extraction efficiency is ensured, so that practicability is high.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

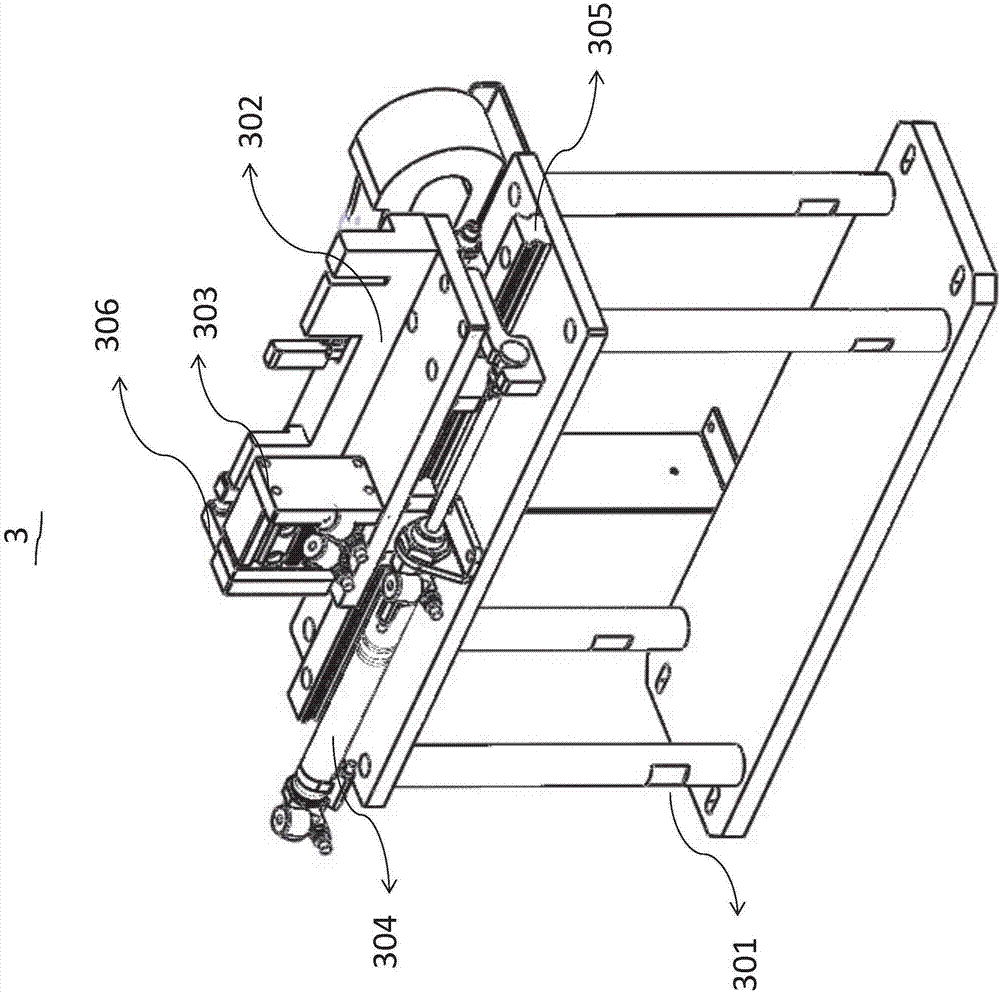

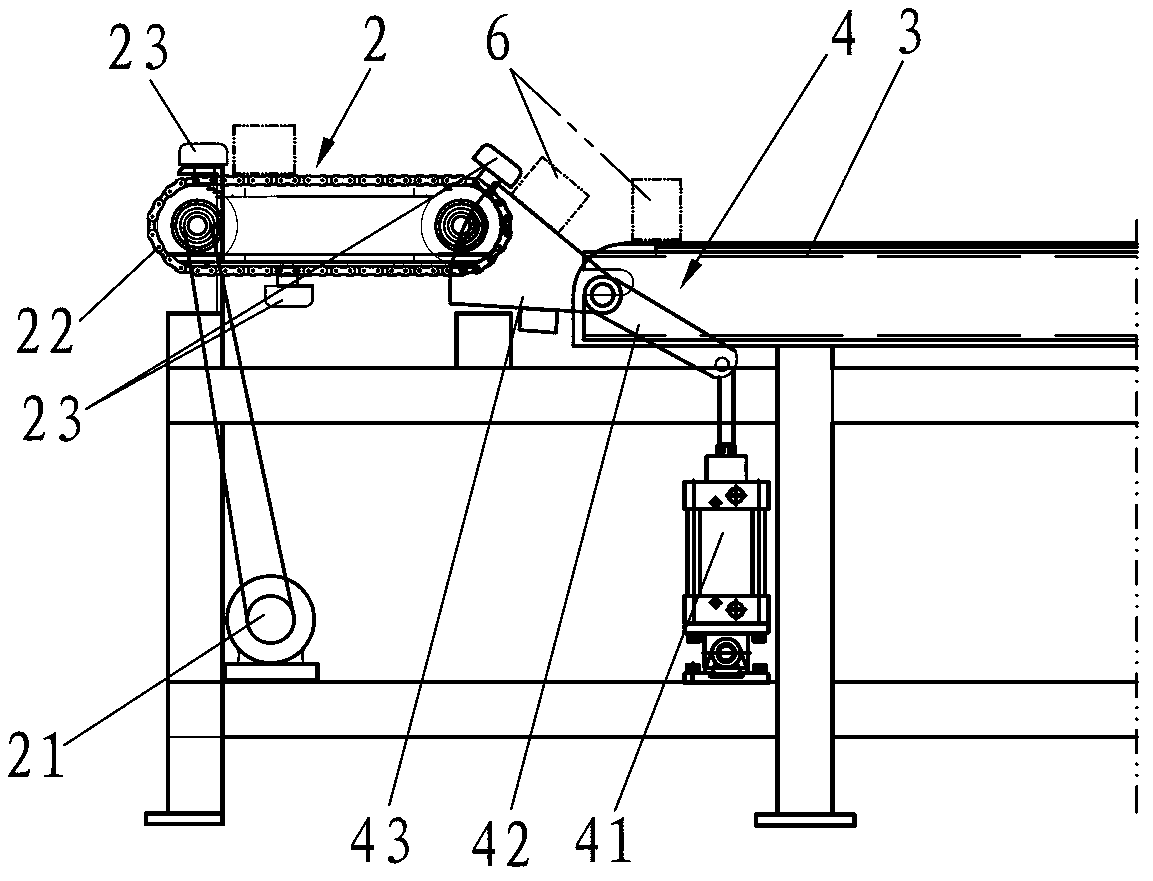

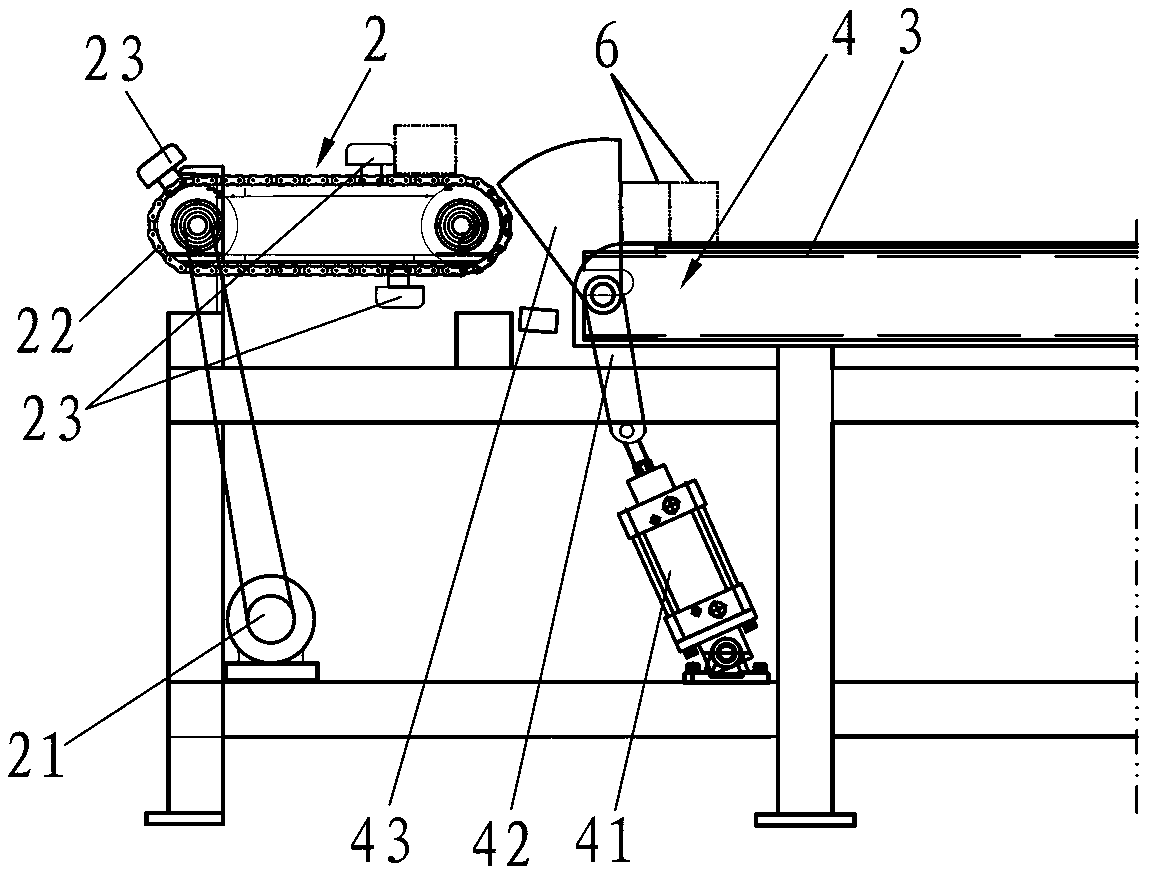

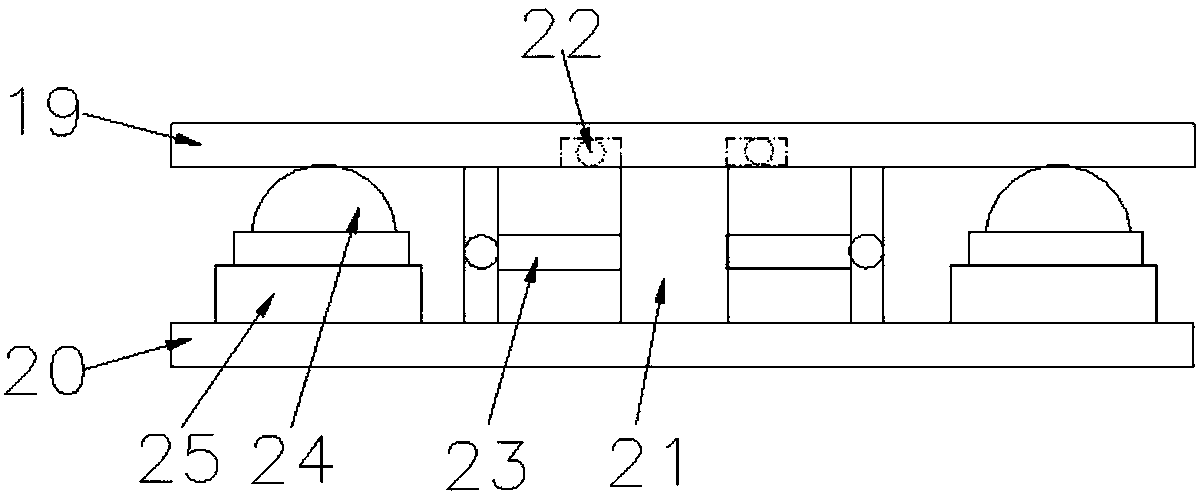

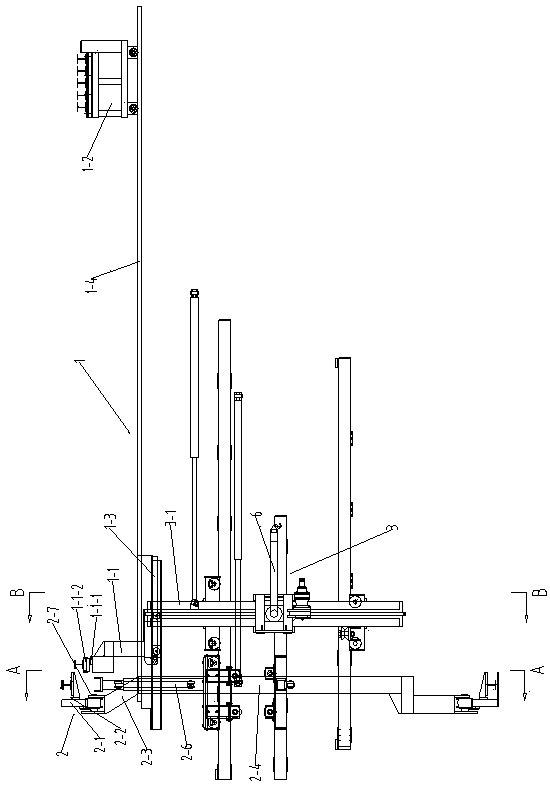

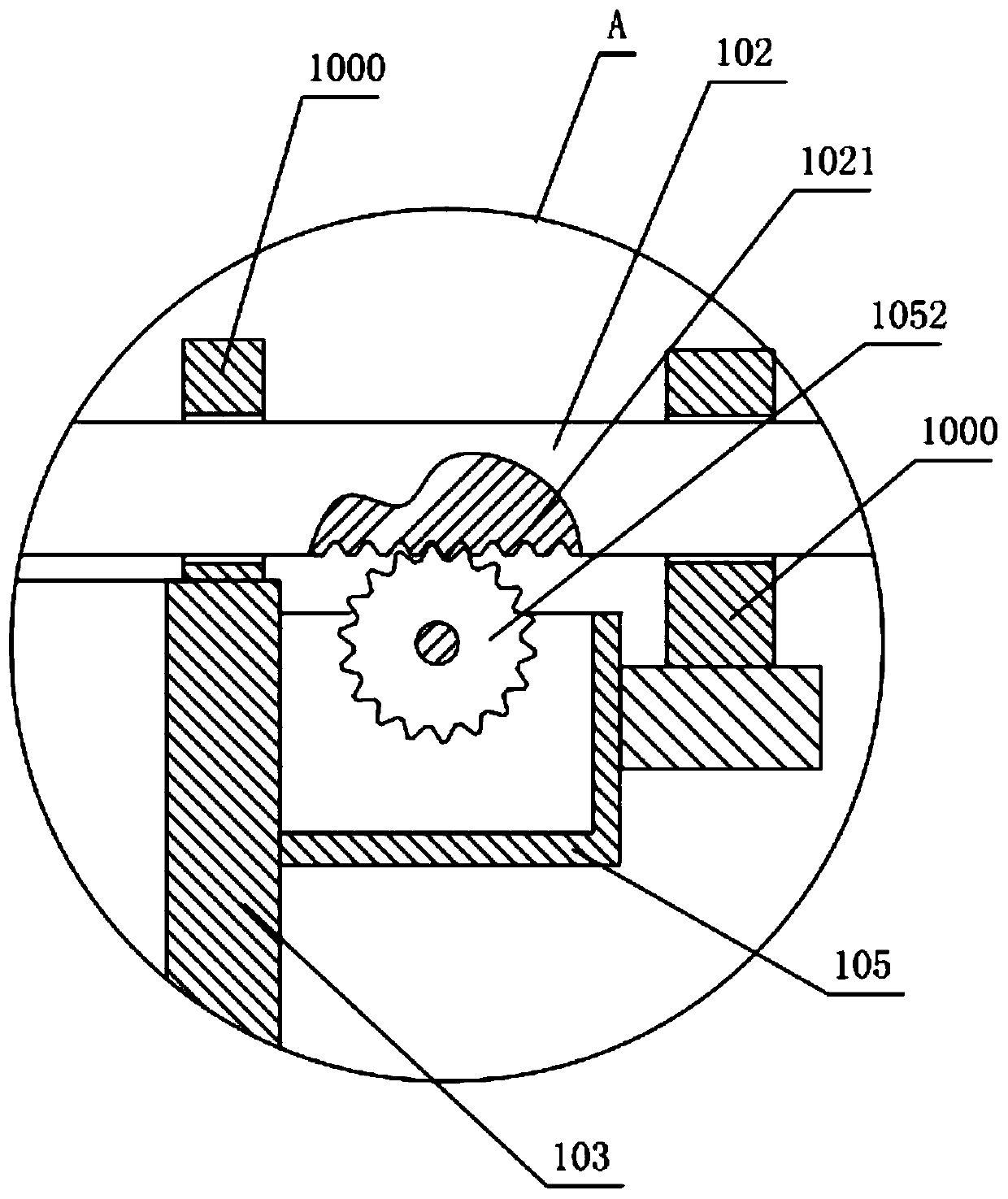

Adhesive-coated batten overturning and primary splicing mechanism of plank splicing machine

The invention relates to the technical field of wood processing, in particular to an adhesive-coated batten overturning and primary splicing mechanism of a plank splicing machine. The primary splicing mechanism comprises an incoming material delivery wheel set. A transverse material shifting device is arranged on the lower sides of incoming material delivery wheels. The transverse side faces of the incoming material delivery wheels are connected with a primary material splicing table, and a wood overturning device is arranged between the incoming material delivery wheels and the primary material splicing table. After wood with an upward adhesive-sprayed surface is fed through the incoming material delivery wheels, the transverse material shifting device shifts the wood transversely. When the wood is conveyed to the lateral sides of the incoming material delivery wheels, the wood overturning device turns over the upward adhesive-sprayed surface to the lateral side and pushes the upward adhesive-sprayed surface to the primary material splicing table, so that the adhesive-sprayed surface of the wood which is pushed in the primary material splicing table is primarily glued together with a non-adhesive opposite surface of an adhesive-sprayed surface of former wood to realize primary splicing. When the quantity of the wood reaches a certain number, a one-piece primarily spliced material is formed, and then the one-piece primarily spliced material enters a splicing and compressing device to be compressed and solidified into a whole. In the primary splicing process, a person is not needed for wood overturning and the primary splicing, so that participation of manpower is reduced, efficiency is improved, and cost is lowered.

Owner:东莞市新崚晟机械有限公司

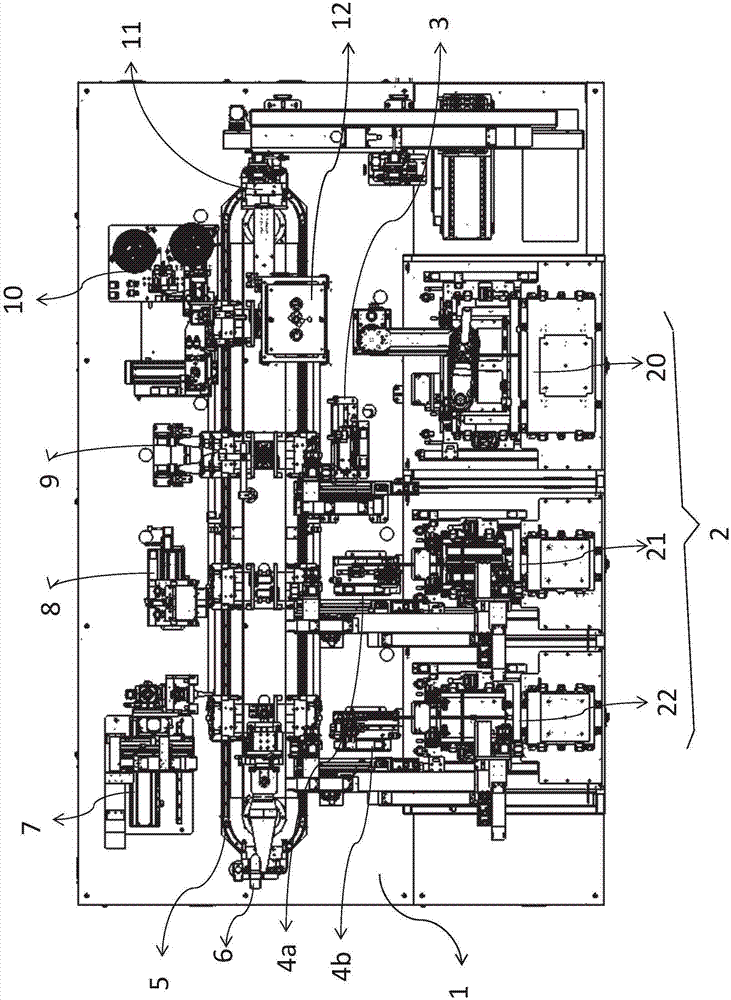

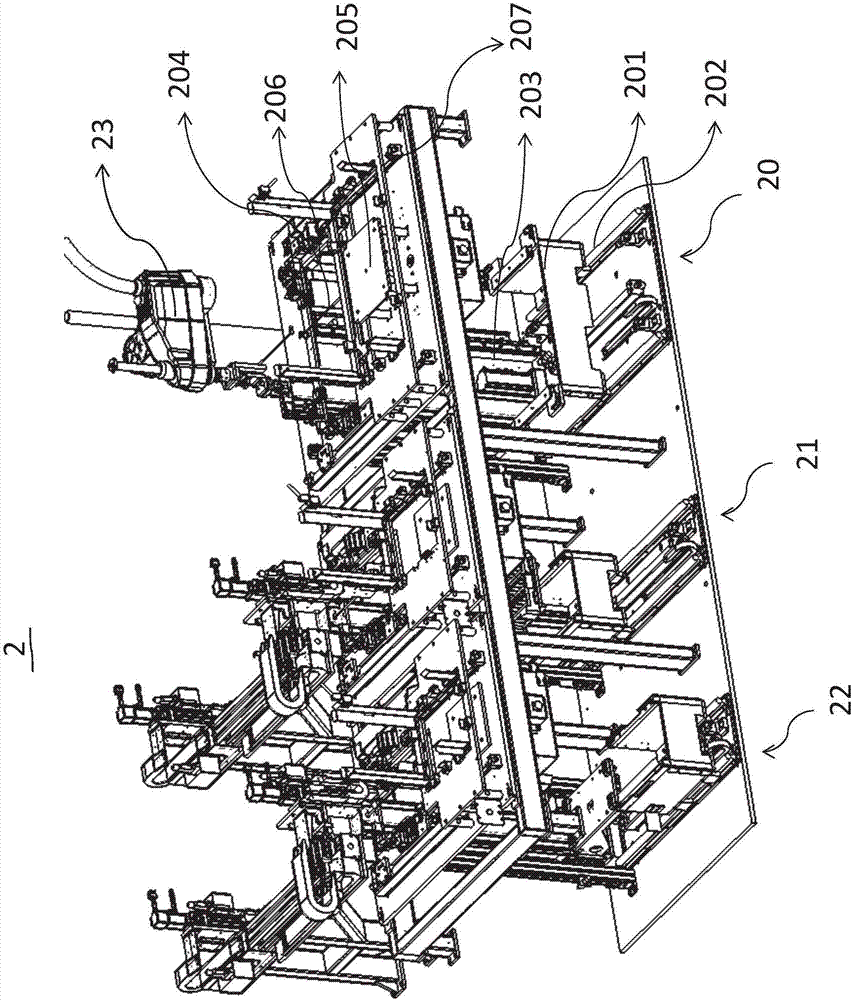

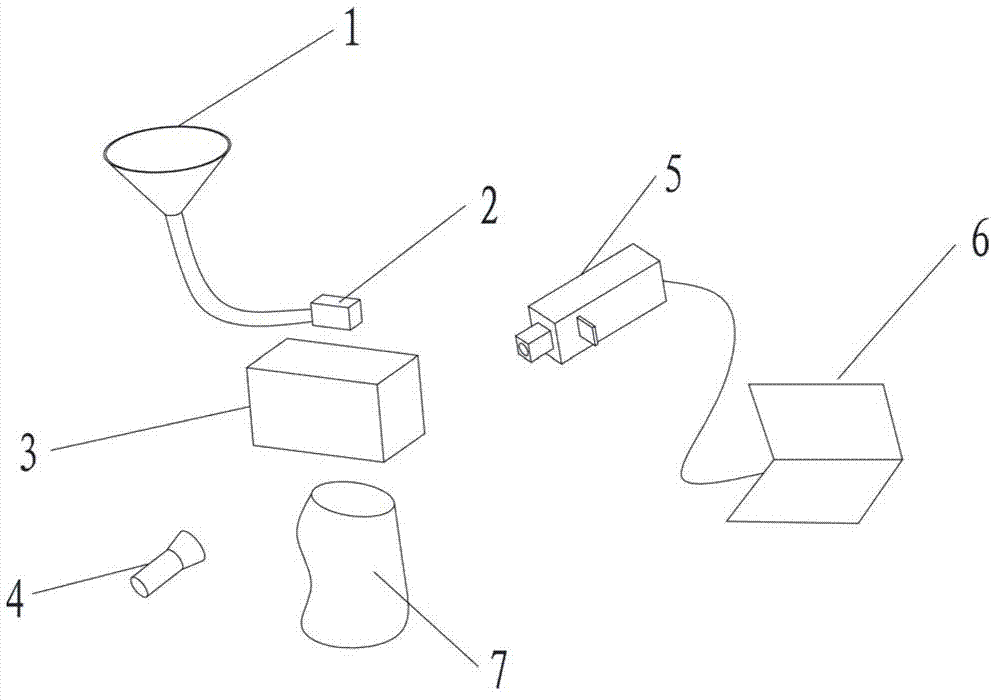

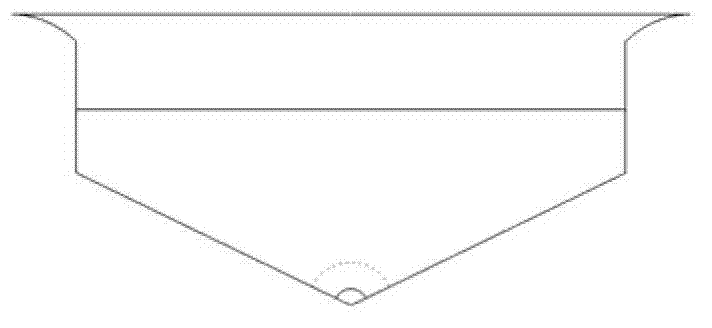

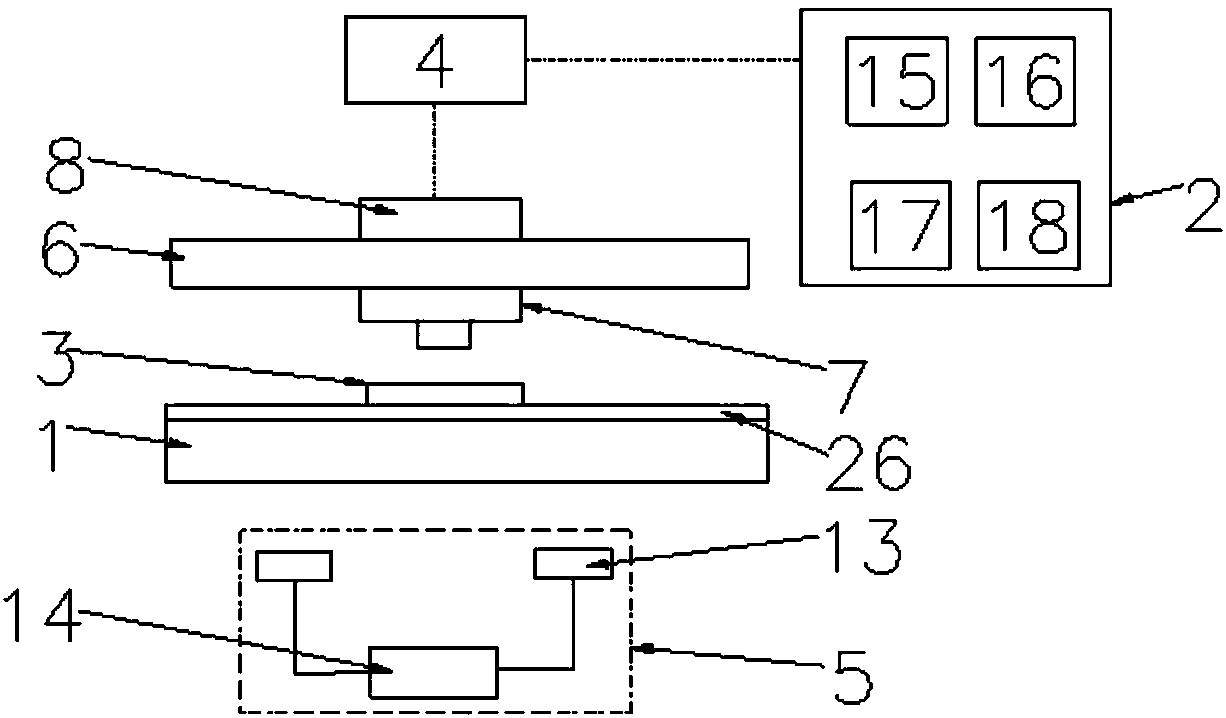

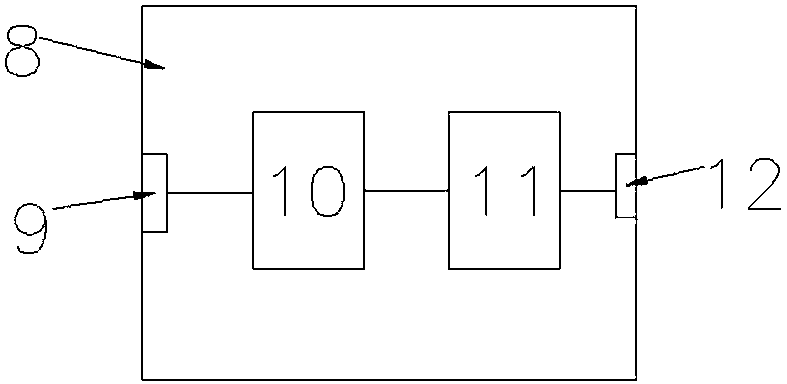

Analytical equipment for detecting particle size and/or particle form

InactiveCN102768172AEasy to operateReduce human involvementParticle size analysisImaging processingTest sample

The invention provides analytical equipment for detecting the particle size and / or the particle form. The analytical equipment comprises a sample inlet device (1), a counting device (2), a dispersing system (3), a light source (4), an imaging system (5) and an image processing system (6), wherein the sample inlet system (1) is used for loading test samples and conveying the test samples to the dispersing system (3), the counting device is used for recording the number of the test samples, the dispersing system (3) is used for allowing the test samples to pass through in the falling process to enter a test region, the light source (4) is used for providing an irradiation light source, the imaging system (5) is used for collecting dynamic image information of the test samples and transmitting the dynamic image information to the image processing system (6), and the image processing system (6) is used for displaying dynamic images of the test samples and treating and outputting the particle size and / or particle form data of the test samples. The analytical equipment has the advantages that the defects in the aspects of detection speed, data reliability, operation convenience and the like of the exiting equipment are overcome, the automatic operation is easily realized, and in addition, the work efficiency can be obviously improved.

Owner:TSINGHUA UNIV

Machine vision-based 3D printing forming quality detection system and method

PendingCN107941808AQuick checkImprove compatibilityOptically investigating flaws/contaminationThe InternetEngineering

The invention discloses a machine vision-based 3D printing forming quality detection system and method. A rotary platform is mounted on a workpiece placement platform, a 3D printed product is placed on the rotary platform, an image acquisition device is connected to an upper computer through a communication device, a backlight is arranged below the workpiece placement platform, the rotary platformcomprises an upper plate and a lower plate parallel to the upper plate, the bottom end of a center shaft is fixedly connected to the center of the lower plate, the center shaft is sleeved by a surface bearing, the surface bearing is sandwiched between the upper and lower plates, and multiple rolling parts are uniformly installed between the edges of the upper and lower plates in intervals. The method comprises acquiring surface images of a 3D printed finished product through an area-array camera, inputting an image capture card into the upper computer, carrying out image pre-processing, and analyzing the images to detect contour defects or surface defects. The system and method can realize fast detection of the quality of the 3D printed finished product, have a high detection precision and improve the qualified rate of the workpiece.

Owner:CHINA JILIANG UNIV

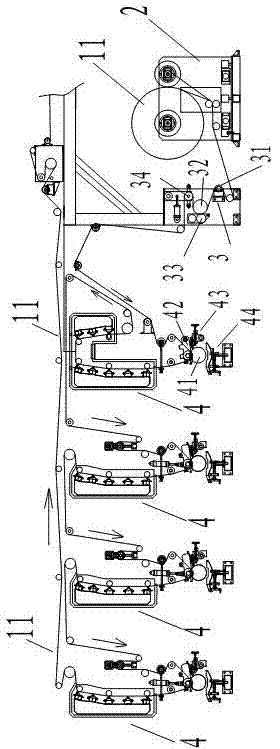

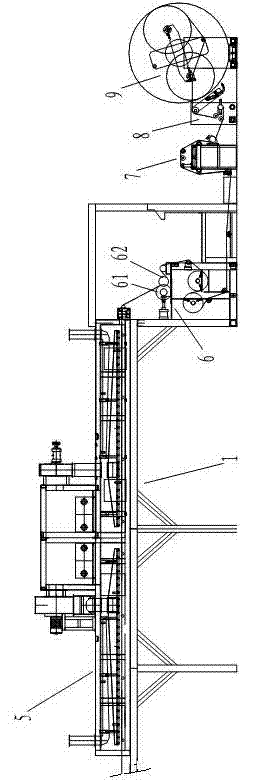

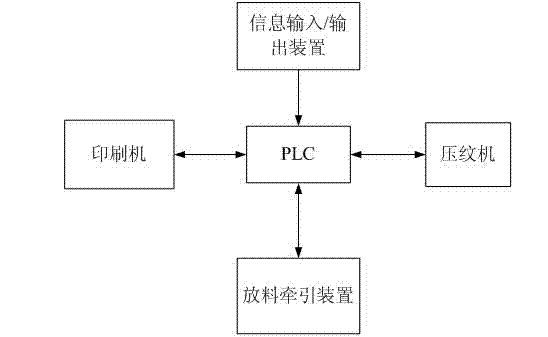

Printing synchronous embossing production device for leatherette paper

InactiveCN102815087AIncrease productivityImprove product qualityRotary pressesPrinting press partsPulp and paper industryPrinting press

The invention discloses a printing synchronous embossing production device for leatherette paper, which comprises a frame, an unreeling machine, an emptying dragging device, a printer, a foaming oven, an embosser, an edge-cutting halving device, a receiving dragging device, a reeling machine and a PLC (Programmable Logical Controller), wherein the printer is arranged on the left bottom side of the frame; the reeling machine is arranged at a feeding end of the printer; the emptying dragging device is arranged between the printer and the unreeling machine; the foaming oven is arranged at the top of the frame; the embosser is arranged on the right bottom side of the frame; the edge-cutting halving device is arranged at a discharging end of the embosser; the receiving dragging device is arranged at a discharging end of the embosser; the reeling machine is arranged at the discharging end of the receiving dragging device; and the PLC is respectively in electric connection with the printer, the emptying dragging device and the embosser. The printing synchronous embossing production device for the leatherette paper is used for effectively solving the technical problem of ultrahigh degree of manual participation of the present printing embossing production device for the leatherette paper in the prior art. The production efficiency and the product quality of the leatherette paper are increased.

Owner:广东壹晨科技有限公司

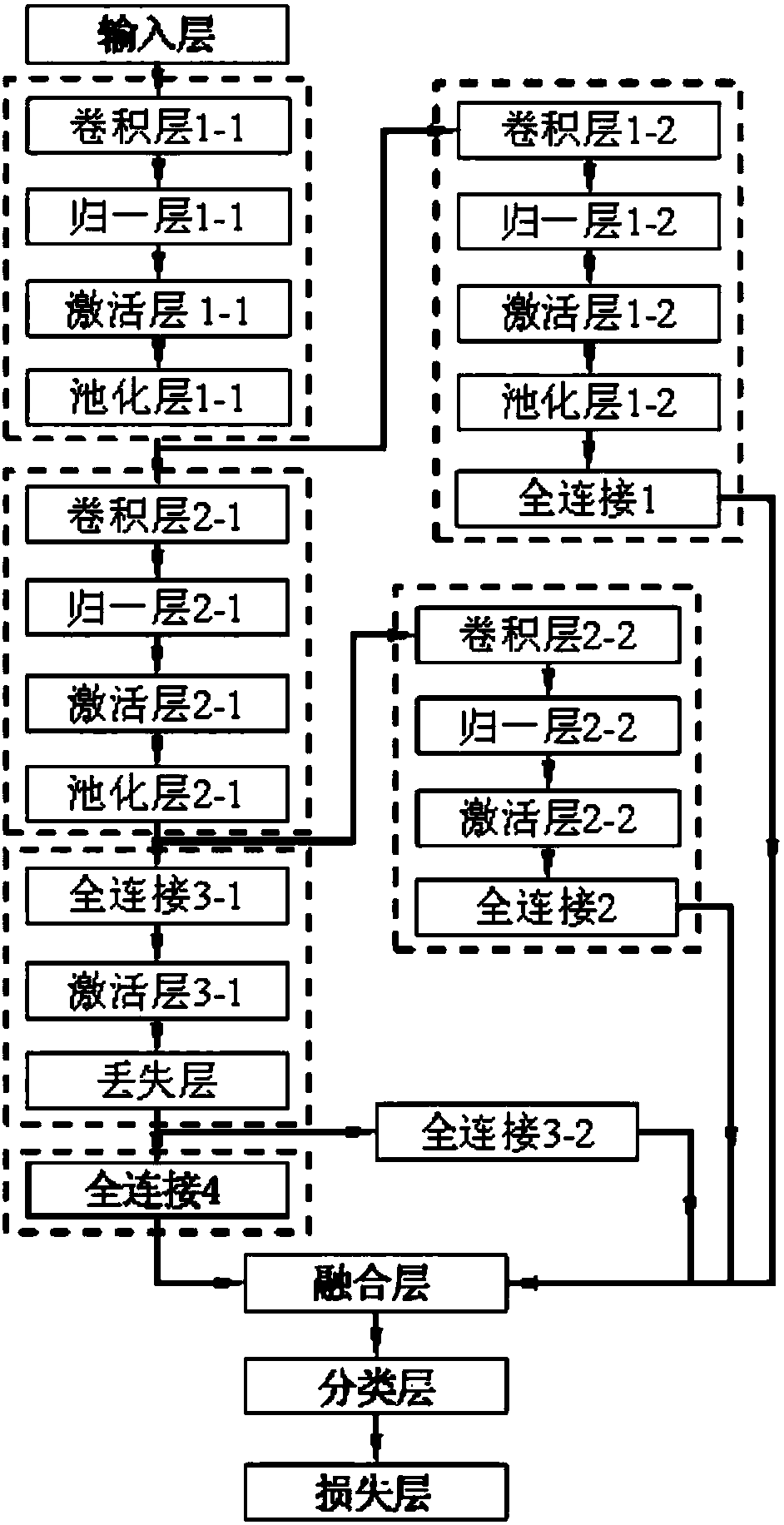

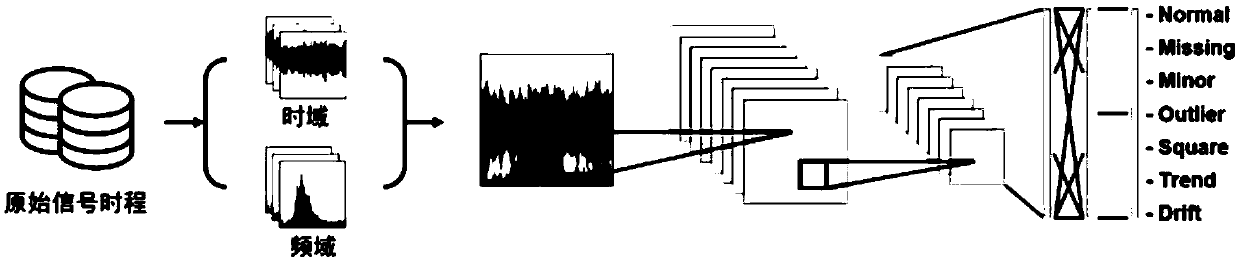

Structural health monitoring abnormal data diagnosis method based on computer vision and deep learning technology

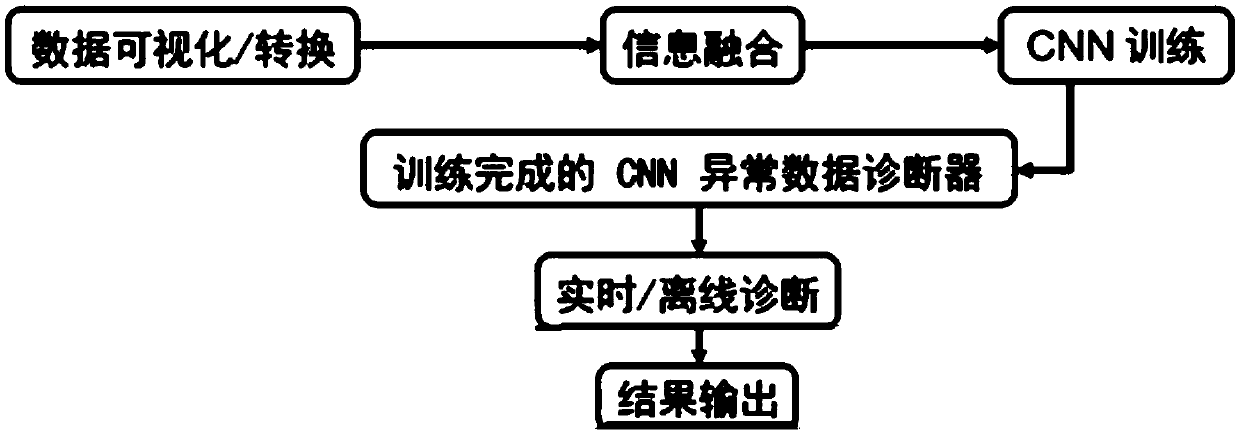

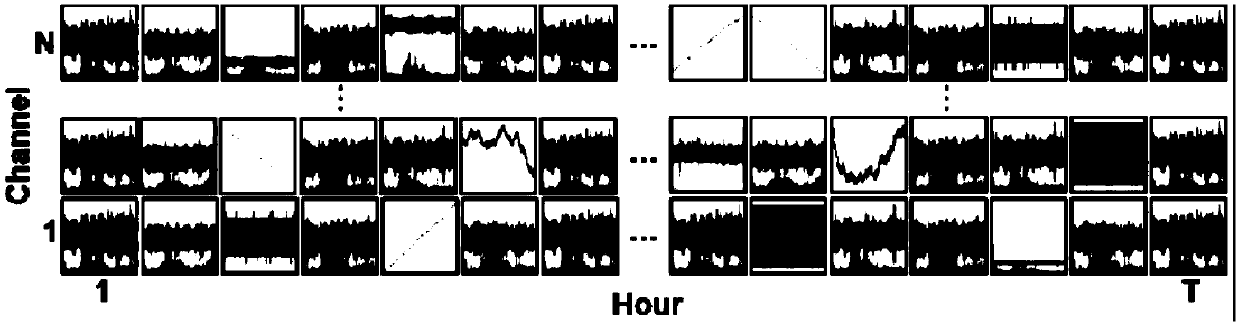

ActiveCN108764601AImprove analysis efficiencyImprove reliabilityResourcesNeural architecturesData segmentPresent method

The invention provides a structural health monitoring abnormal data diagnosis method based on computer vision and deep learning technology, and aims at solving the problems of overtreatment and under-treatment due to the fact that the present method has difficulty to handle the situations with multiple abnormal patterns and the disadvantages of low degree of automation and high cost of manual expert intervention. The method comprises the steps that the monitoring data to be diagnosed are converted into the time domain response image data and the frequency domain response image data from the time sequent data through data visualization processing; a two-channel time-frequency response diagram is formed according to the time domain response image data and the frequency domain response imagedata corresponding to the same data segment; the samples are selected from the two-channel time-frequency response diagram and the abnormal type of the samples is marked so as to form a training set;the training set is inputted to a convolutional neural network model, and the trained model acts as the abnormal data diagnosis instrument; and the monitoring data to be diagnosed are inputted to theabnormal data diagnosis instrument so as to obtain the diagnosis result. The method is suitable for structural health data monitoring.

Owner:HARBIN INST OF TECH

Indoor AGV automatic navigation system and navigation method based on laser SLAM

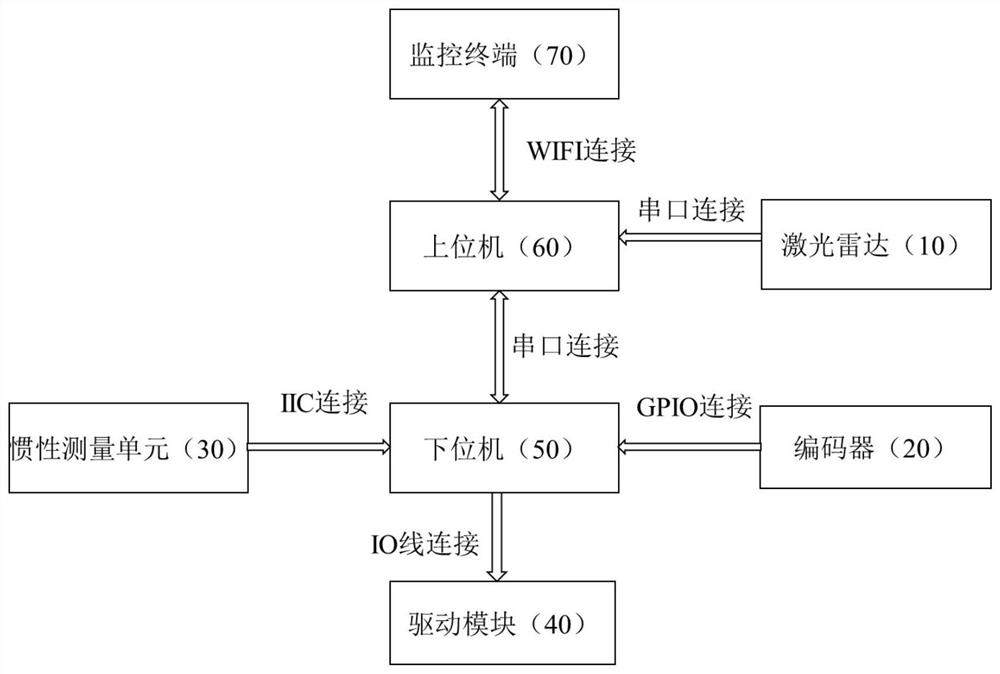

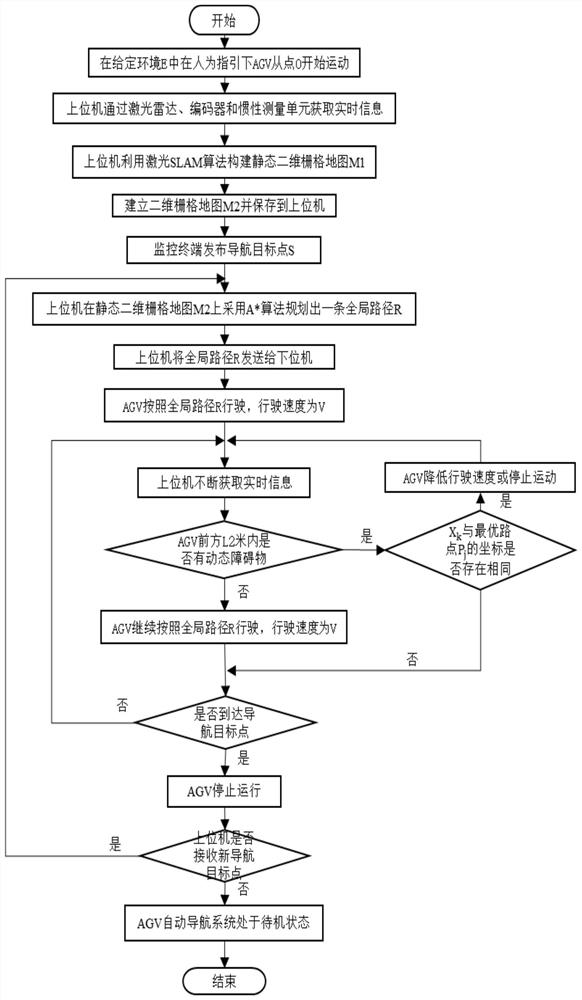

ActiveCN112066989AStrong ability to navigate independentlyReduce human involvementNavigational calculation instrumentsNavigation by speed/acceleration measurementsRadarEngineering

The invention relates to an indoor AGV automatic navigation system and navigation method based on laser SLAM, and relates to the technical field of mobile robot automatic navigation. The indoor AGV automatic navigation system comprises an upper computer, a lower computer, a ground monitoring computer, a driving module, a laser radar, an inertia measurement unit and an encoder. An upper computer constructs a two-dimensional grid map according to a laser SLAM mapping program through obstacle position information collected by a laser radar and AGV acceleration information, AGV angular speed information, AGV speed information, AGV circulating angle information and AGV driving mileage information transmitted by a lower computer; and the upper computer receives tasks allocated by the ground monitoring computer through wireless WIFI, and carries out global path planning on the established map. According to the invention, the distributed framework and the open source code of the ROS are utilized, so that AGV indoor autonomous navigation can be realized.

Owner:HEFEI UNIV OF TECH

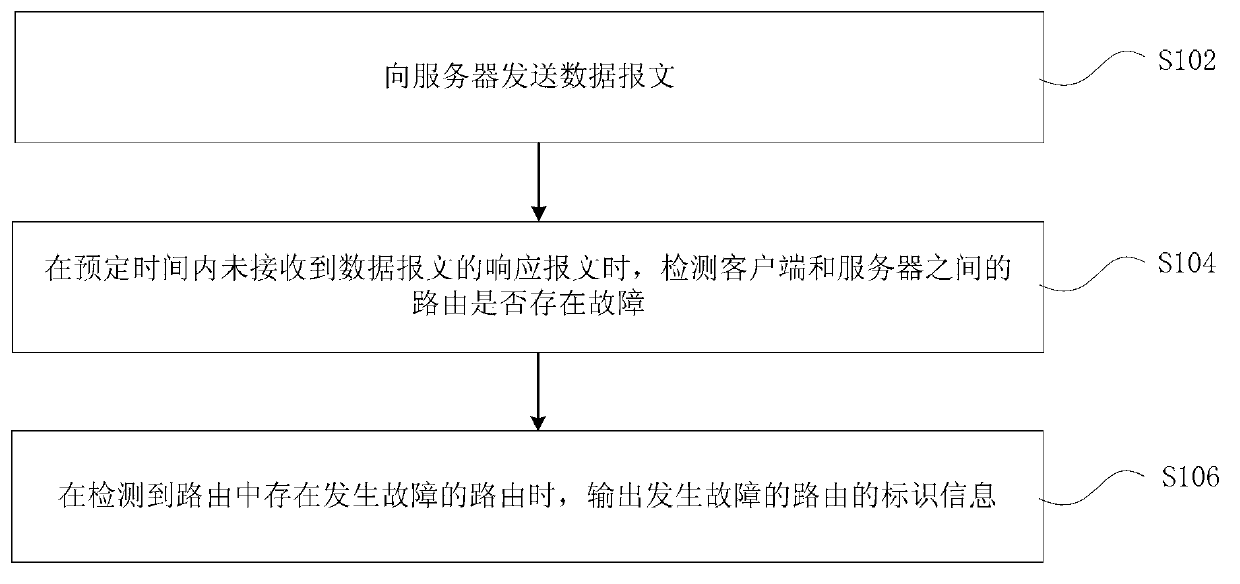

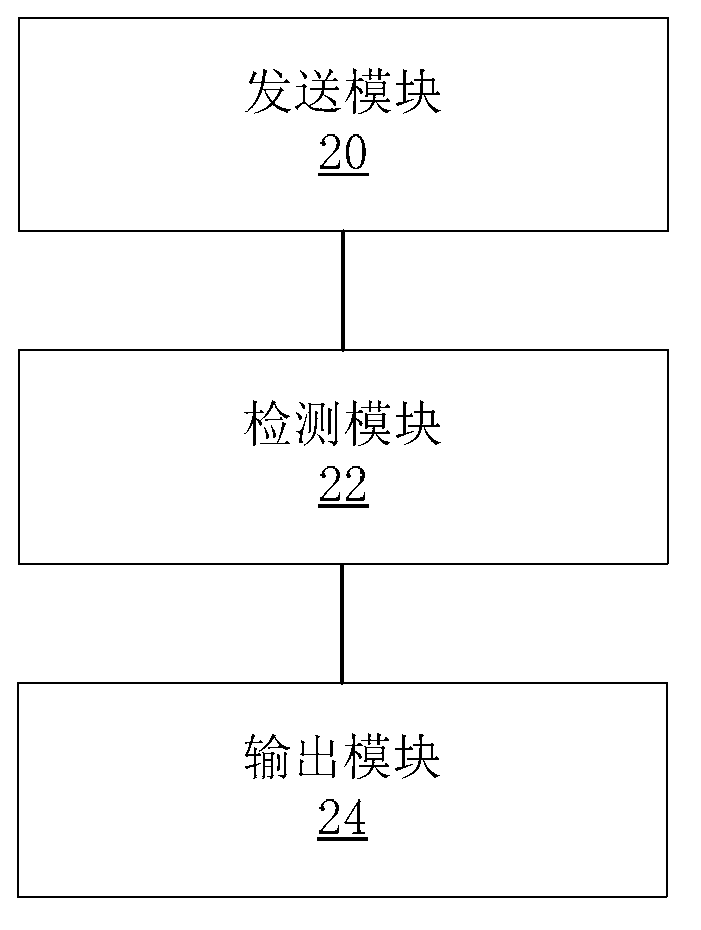

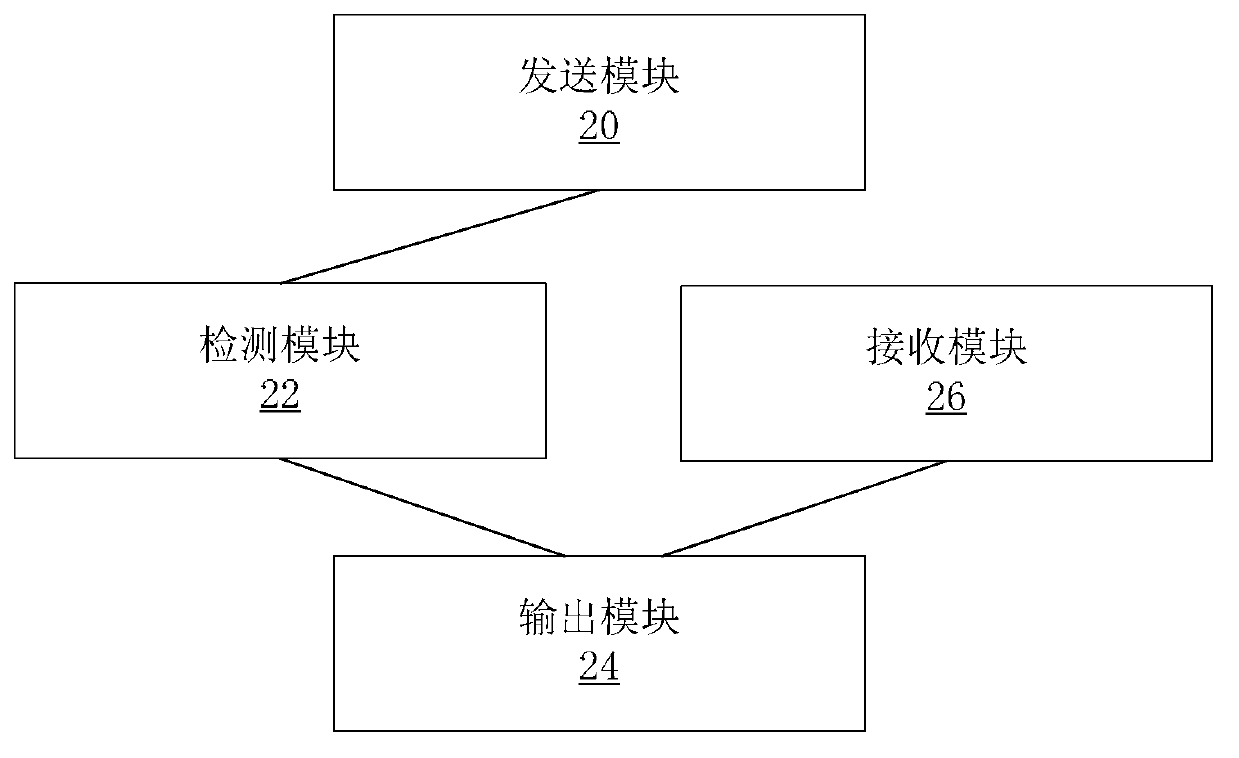

Positioning treatment method and positioning treatment device of network faults

ActiveCN103138988AReduce human involvementReduce processing timeData switching networksClient-sideReal-time computing

The invention provides a positioning treatment method and a positioning treatment device of network faults. The positioning treatment method of network faults comprises the steps of sending a data message to a server; detecting whether the route between a client terminal and the server has a fault when not receiving a response message of the data message within scheduled time; and outputting marking information of the route having a fault when detecting that the route having a fault. By means of the technical scheme, manual participation of network fault detection is lowered to some extent, the treatment time of fault transmission is shortened, and management cost at various aspects relevant to network transmission is lowered.

Owner:北京德瑞塔时代网络技术有限公司

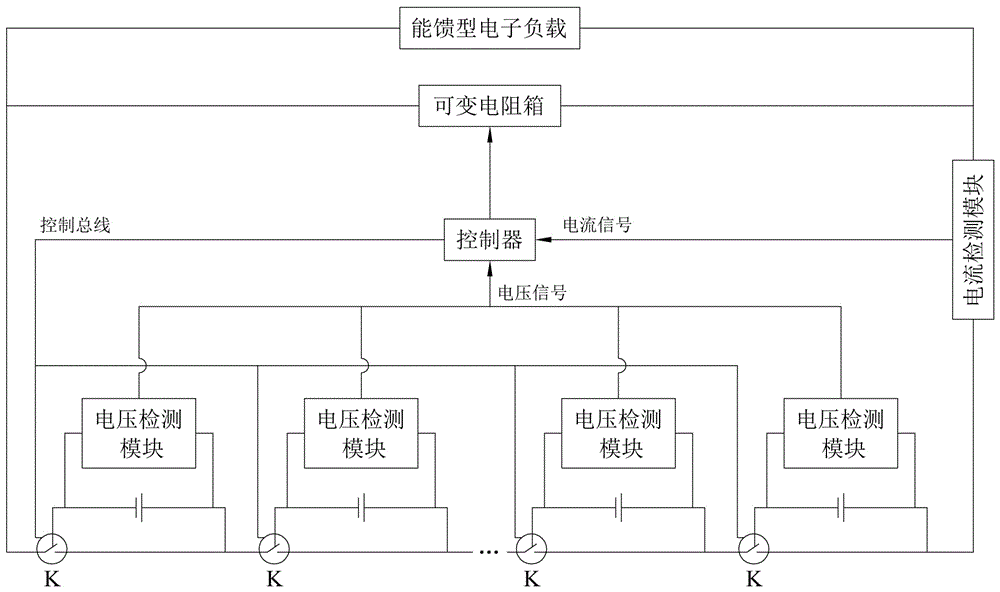

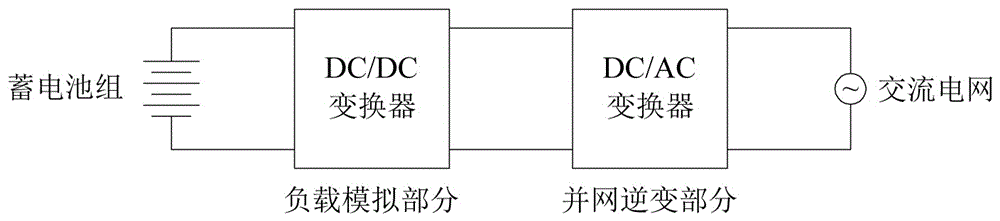

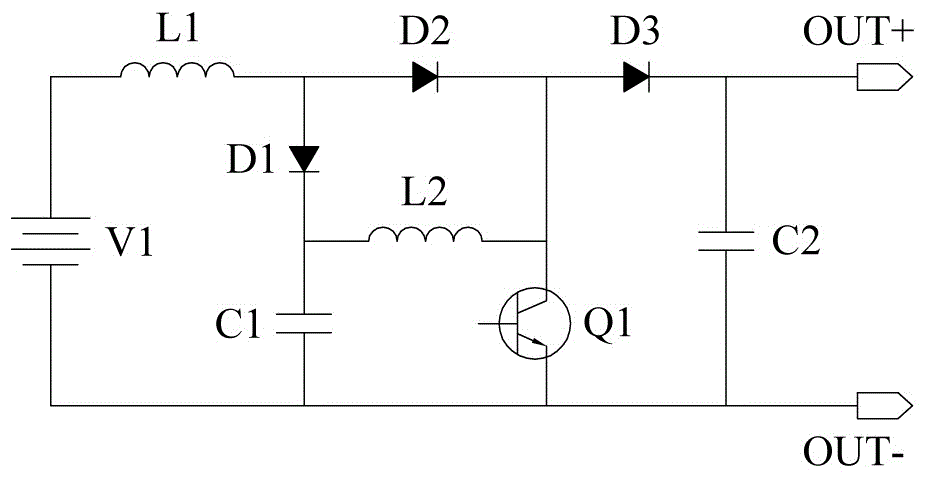

Storage battery pack with automatic capacity verifying function and used for power substation

PendingCN106443491AReduce human involvementPrecise resistance adjustmentElectrical testingSecondary cellsElectronic loadTerminal voltage

The invention relates to a storage battery pack with an automatic capacity verifying function and used for a power substation. The storage battery pack comprises a plurality of storage batteries, an energy-feedback electronic load and a capacity verifying unit. The capacity verifying unit comprises a variable resistance box, a control switch, a plurality of voltage detecting modules, a current detecting module, a controller and a power module, wherein the variable resistance box is serially connected with the storage batteries to form a capacity verifying loop, the control switch is used for controlling the storage batteries to connect or disconnect with the capacity verifying loop, the voltage detecting modules are used for detecting terminal voltage of the storage batteries respectively, the current detecting module is used for detecting a current value of the capacity verifying loop, and the controller is used for controlling and regulating a value of interposing resistance of the variable resistance box, controlling the storage batteries to connect or disconnect with the capacity verifying loop, recoding various parameters in a capacity verifying process and calculating the capacity of the storage battery pack. The storage battery pack has the advantages that the value of the interposing resistance in the capacity verifying loop can be regulated automatically, the capacity of the storage battery pack can be verified, low degree of worker participation during verification is realized, the resistance is regulated precisely, and a verification result is more precise and more stable.

Owner:SUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +1

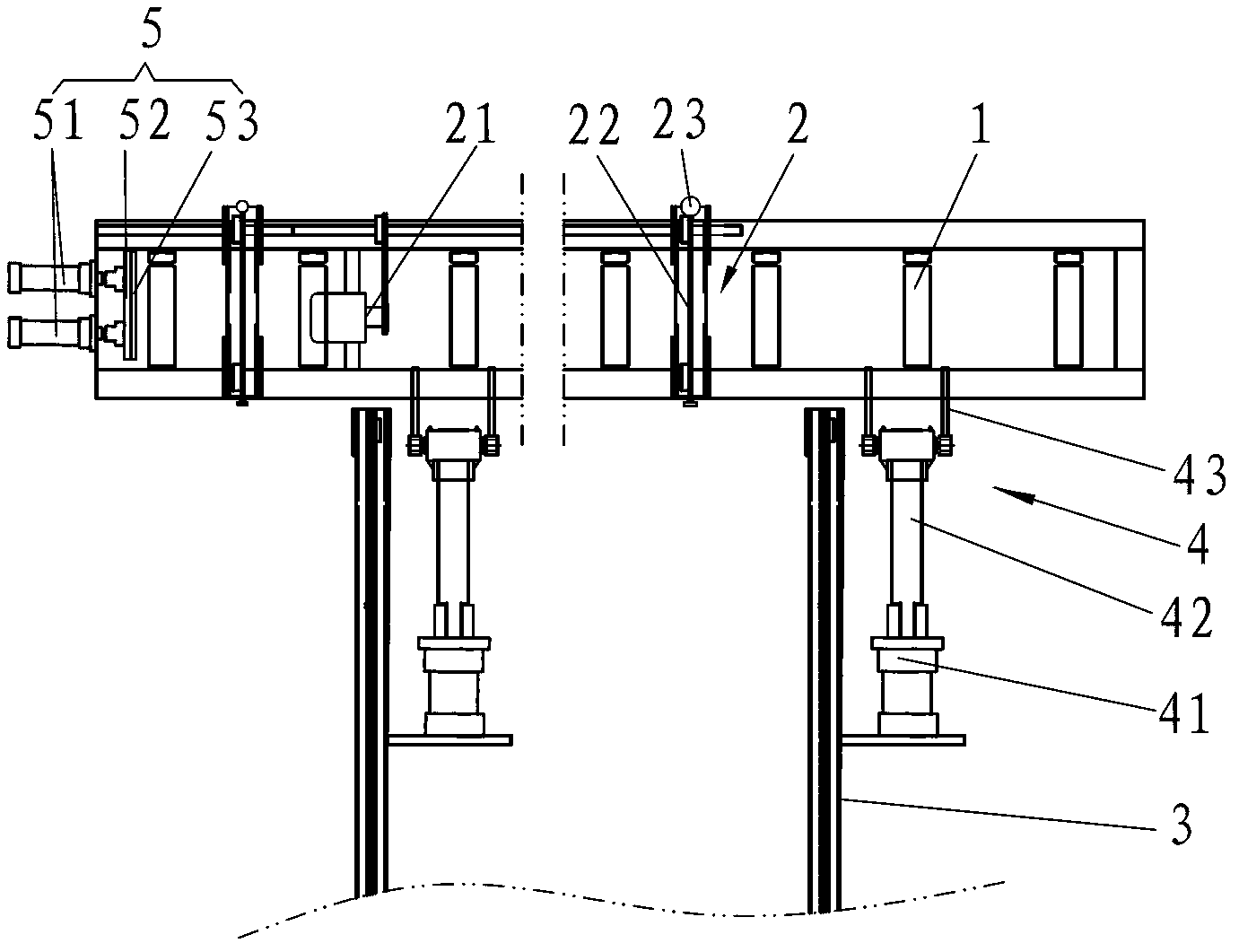

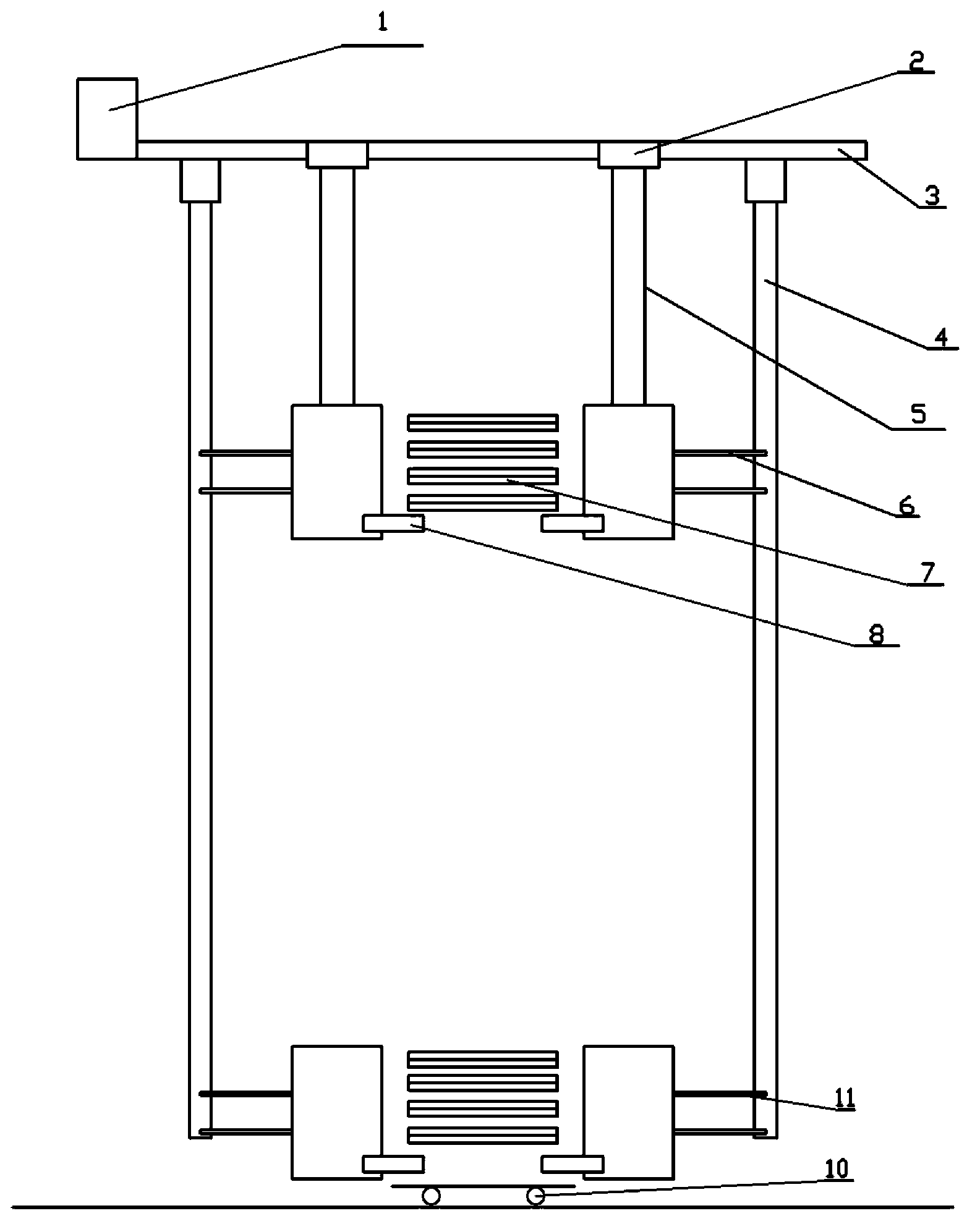

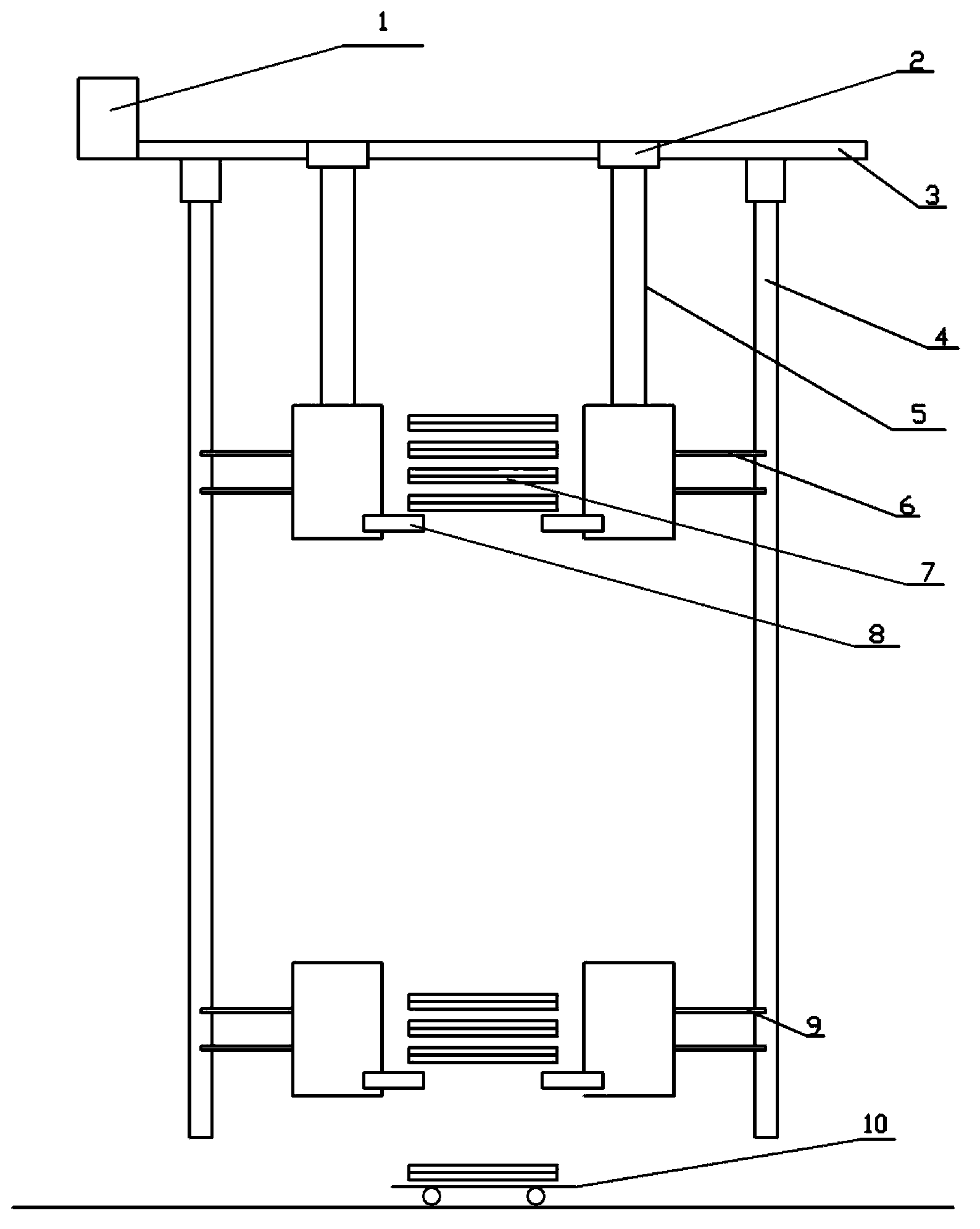

Layering device

ActiveCN103231921AThe process of solving the automatic individual layeringReduce manufacturing costDe-stacking articlesRobot handReciprocating motion

The invention relates to a layering device, comprising a clamping mechanism, a sliding and lifting mechanism and a conveying mechanism, wherein the clamping mechanism is at least used for supporting superposed supporting discs at a first station and is separated from the supposed supporting discs at a second station; the sliding and lifting mechanism is at least used for supporting the clamping mechanism to do reciprocating motion between the first station and the second station; the conveying mechanism is at least used for conveying more than one supporting disc which is separated from the supposed supporting discs at the second station; the sliding and lifting mechanism comprises more than one group of vertical lifting mechanism for driving the clamping mechanism to do lifting motion between the first station and the second station; the clamping mechanism comprises more than two symmetrical mechanical arms which at least can do opposite or face-to-face motion along the direction vertical to the motion direction of the clamping mechanism; and the sliding and lifting mechanism also comprises more than one group of horizontal sliding mechanism for drawing the mechanical arms to move along the direction vertical to the motion direction of the clamping mechanism. The layering device has a simple structure, the production efficiency is improved, and the production cost is reduced.

Owner:YIHONG ENVIRONMENTAL PROTECTION MACHINERY SUZHOU

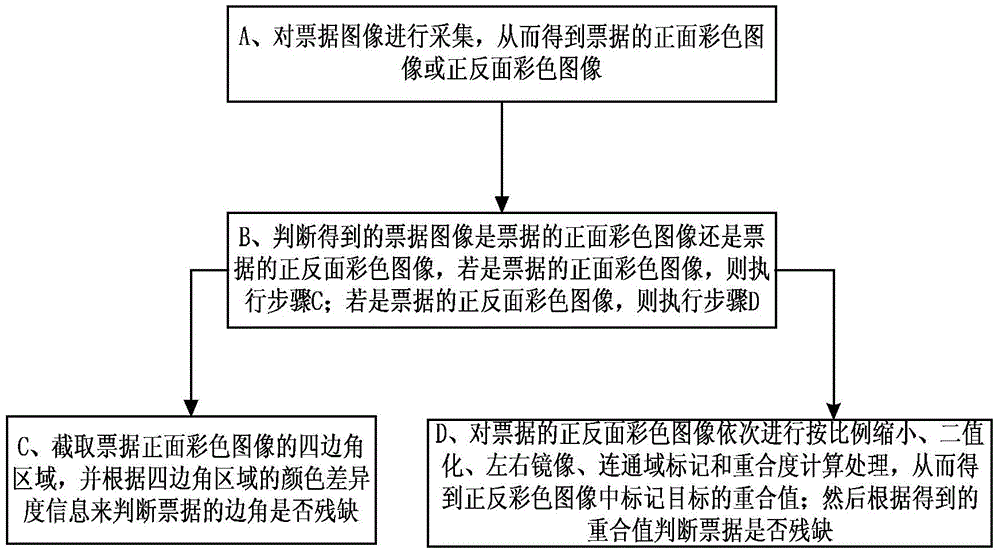

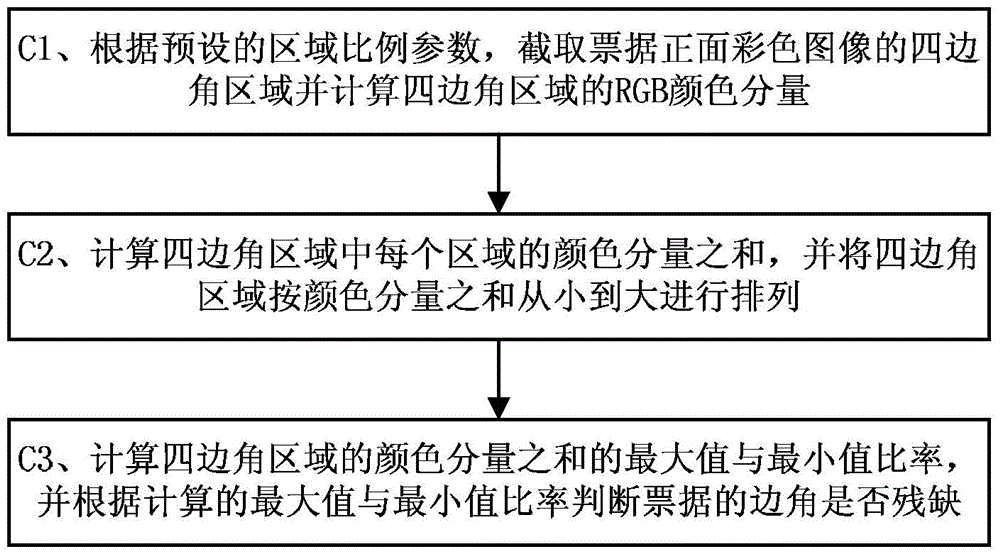

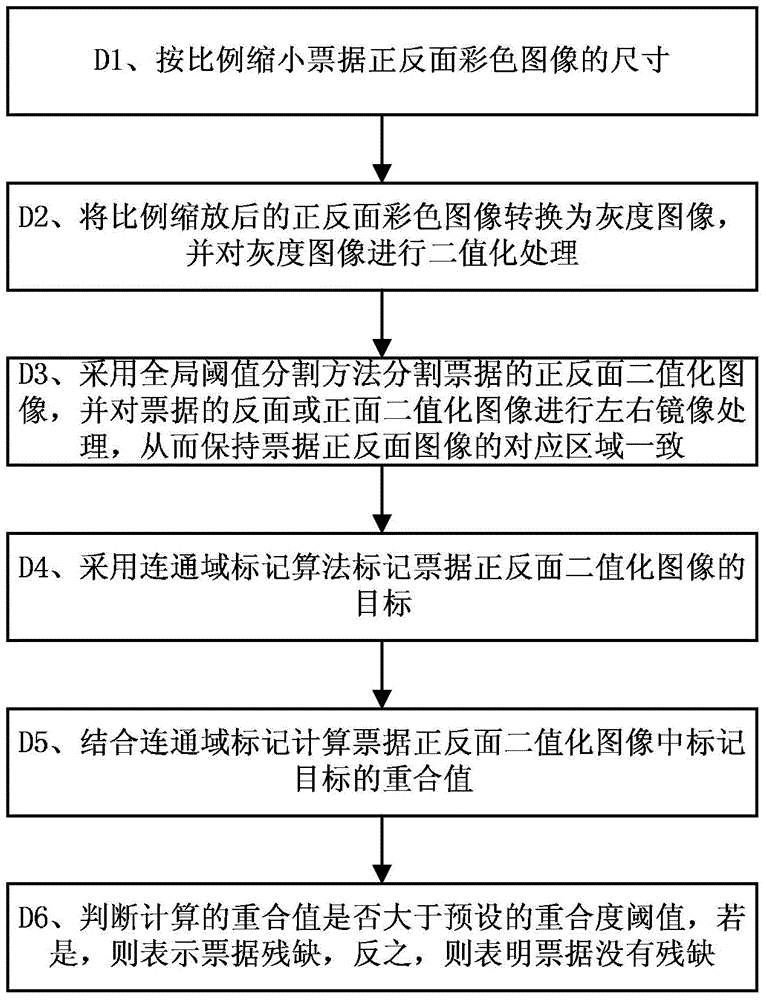

Method and system for automatically detecting whether bill is incomplete or not

InactiveCN103914833AReduce human involvementImprove detection efficiencyImage analysisCoincidenceColor difference

The invention discloses a method for automatically detecting the incomplete degree of a bill or paper money. The method includes the steps of A, collecting an image of the bill, thereby obtaining a front face color image or a front face and back face color image of the bill; B, judging whether the obtained image of the bill is the front face color image or the front face and back face color image of the bill or not, carrying out the step C if the obtained image of the bill is the front face color image of the bill, and carrying out the step D if the obtained image of the bill is the front face and back face color image of the bill; C, cutting out the four corner areas of the front face color image of the bill, and judging whether the corners of the bill are incomplete or not according to the color difference degree information of the four corner areas; D, carrying out scaling down, binaryzation, left and right mirroring, connected domain marking and coincidence degree calculation on the front face and back face color image of the bill in sequence, thereby obtaining the coincidence value of marked targets in the front face and back face color image, and then judging whether the bill is incomplete or not according to the obtained coincidence value. The method and system for automatically detecting whether the bill is incomplete or not are high in detection efficiency, high in recognition rate, stable and reliable, and can be widely applied to the intelligent identification field.

Owner:AUTOMATED TOUCHSTONE MACHINES

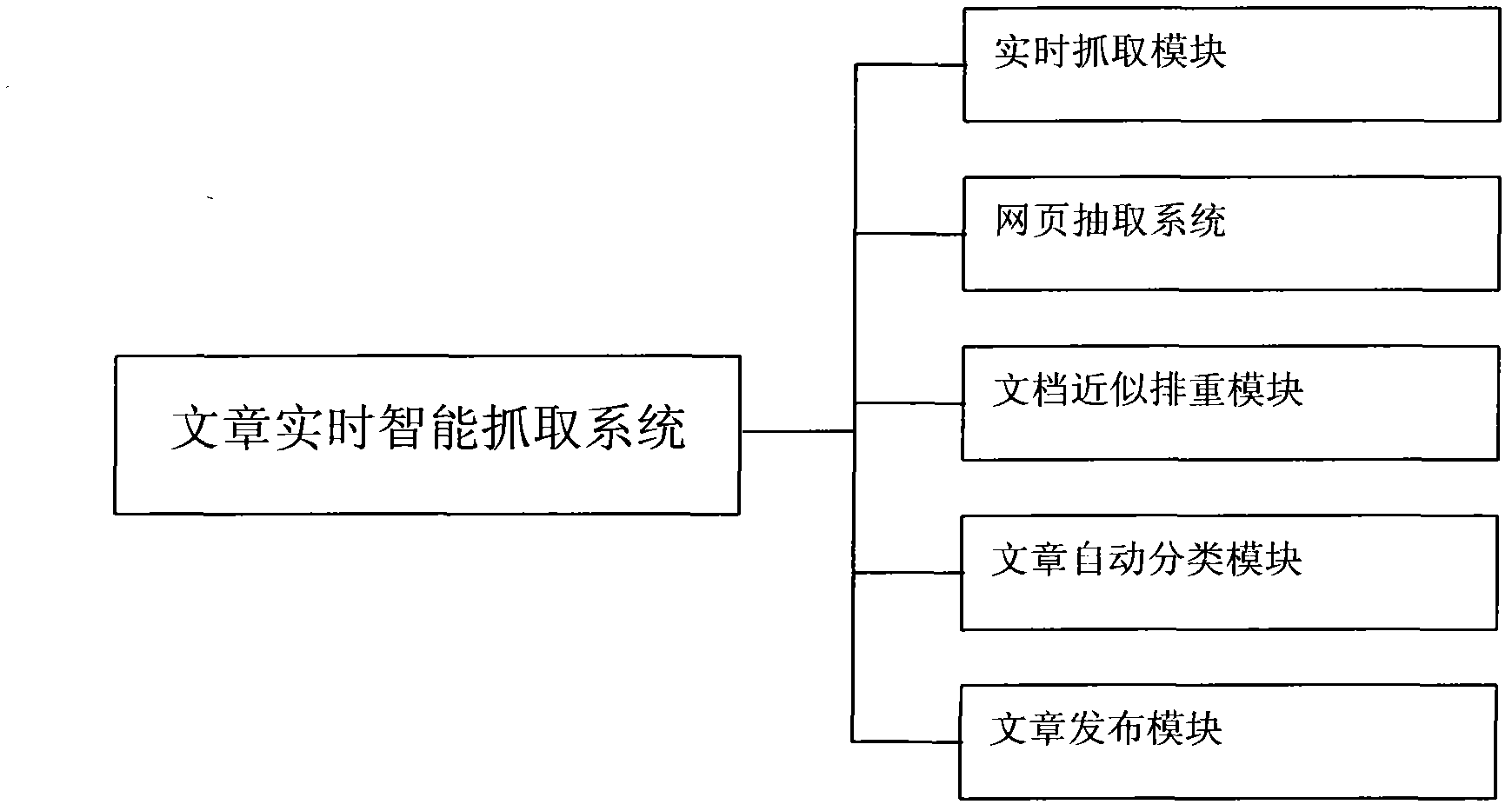

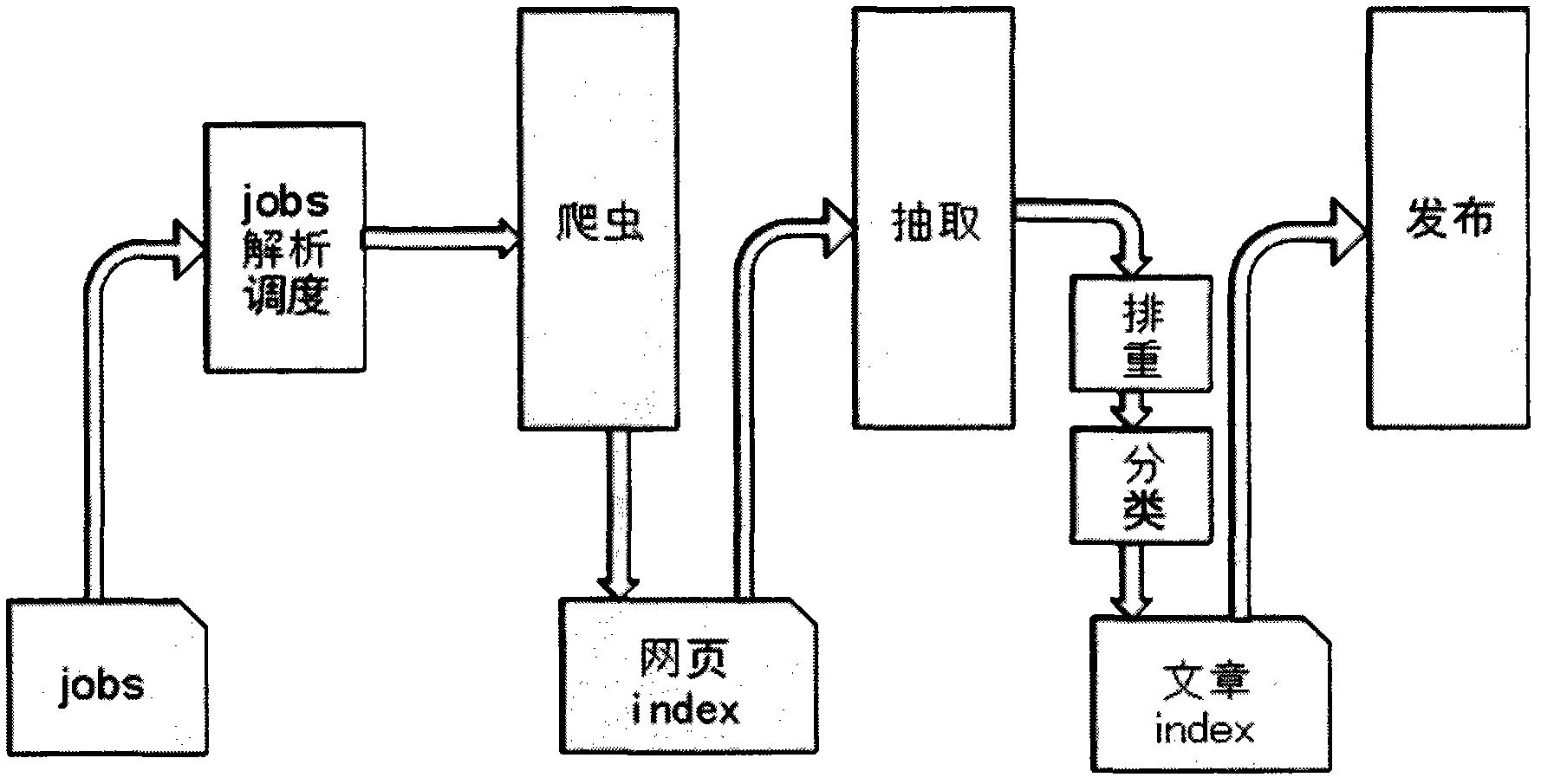

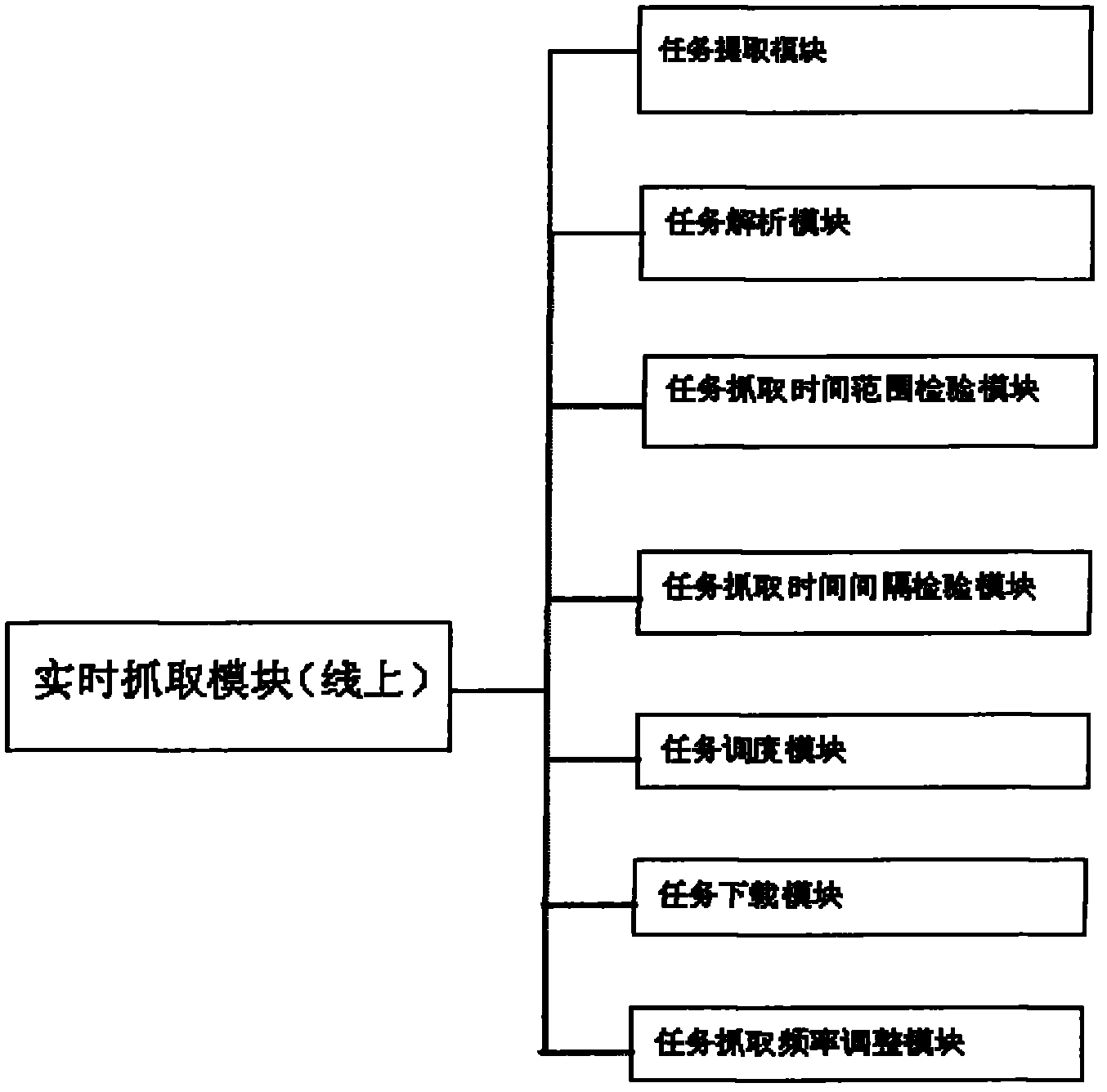

System and method for real-time intelligent capturing of article

ActiveCN102402627AAuto filterFlexible configurationSpecial data processing applicationsTime rangeTask analysis

The invention discloses a system for real-time intelligent capturing of an article. The system comprises a real-time capturing module, a webpage extraction system, a similar document duplicate-removing module, a document automatic classification module and an article publishing module. The real-time capturing module further comprises seven modules running online: a task extraction module, a task analysis module, a task capturing time range test module, a task capturing time interval test module, a task scheduling module, a task downloading module and a task capturing frequency regulation module; and the real-time capturing module still comprises three modules running offline: a task capturing time range discovery module, a task capturing time internal discovery module and a nonprofit agent collection and authentication module.

Owner:凤凰在线(北京)信息技术有限公司

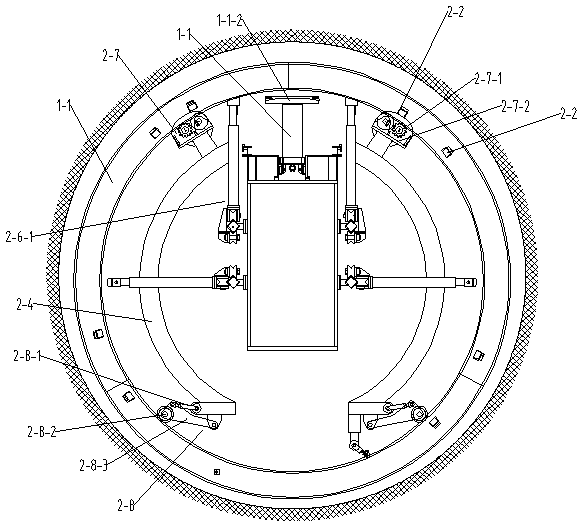

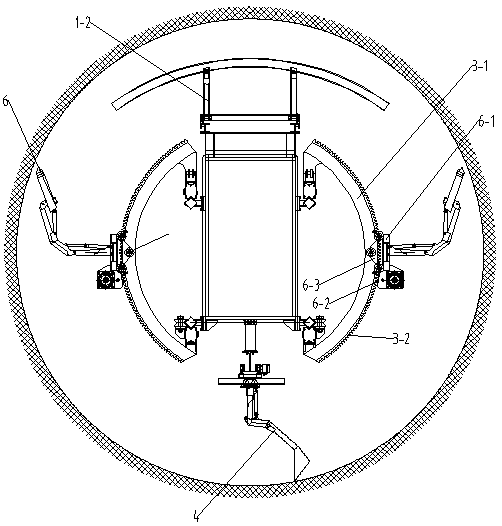

Intelligent steel arch frame assembling robot

ActiveCN108278121AHigh technology maturityRealize assembly robot operationUnderground chambersTunnel liningSlagEngineering

The invention discloses an intelligent steel arch frame assembling robot. The intelligent steel arch frame assembling robot comprises a transporting system, an assembling system, an installing systemand a slag clearing system. The slag clearing system is installed on the lower end surface of a main beam of a hard-rock tunnel boring machine (TBM, for short). The transporting system comprises a transporting trolley and a transporting track. The transporting track is fixed to the upper end face of the TBM main beam. The transporting trolley reciprocates on the transporting track to transport assembling annular pieces into an assembling annular channel of the assembling system. The assembling annular channel is installed on a supporting seat of a supporting ring and rotates on the supportingseat. The supporting ring is installed at the side end of the TBM main beam. A mechanical arm of the installing system is matched with the assembling annular pieces on the assembling annular channel,and the assembling annular pieces are assembled together. The mechanical arm is installed on an installing track through a base in a rolling mode. The installing track is fixed to the side end of theTBM main beam and is parallel to the assembling annular channel. According to the intelligent steel arch frame assembling robot, intelligent installing is achieved, manpower is liberated, the installing quality and stability are improved, the technical maturity is high, and cooperating and efficient operation of a single mechanical arm or multiple mechanical arms is achieved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

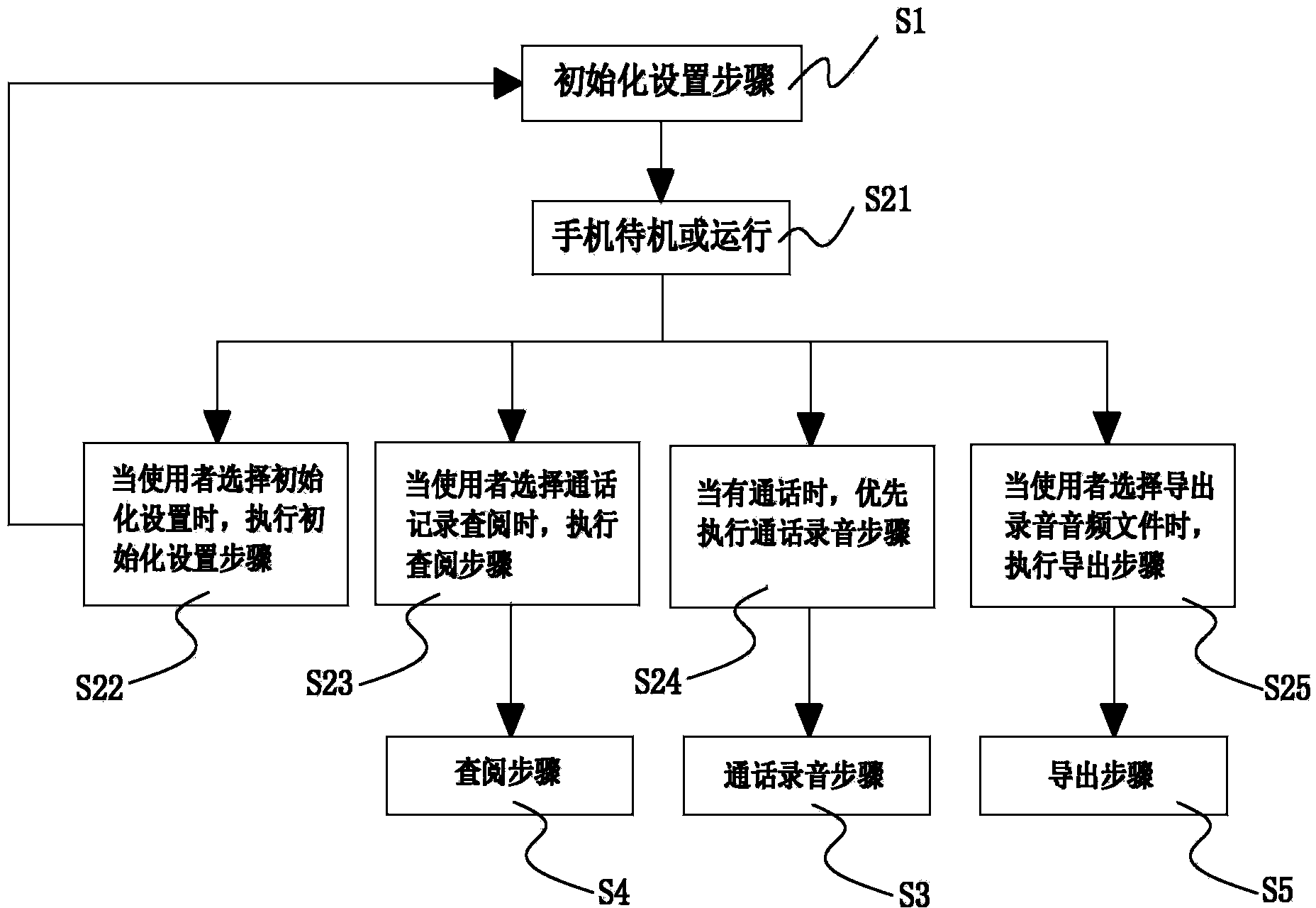

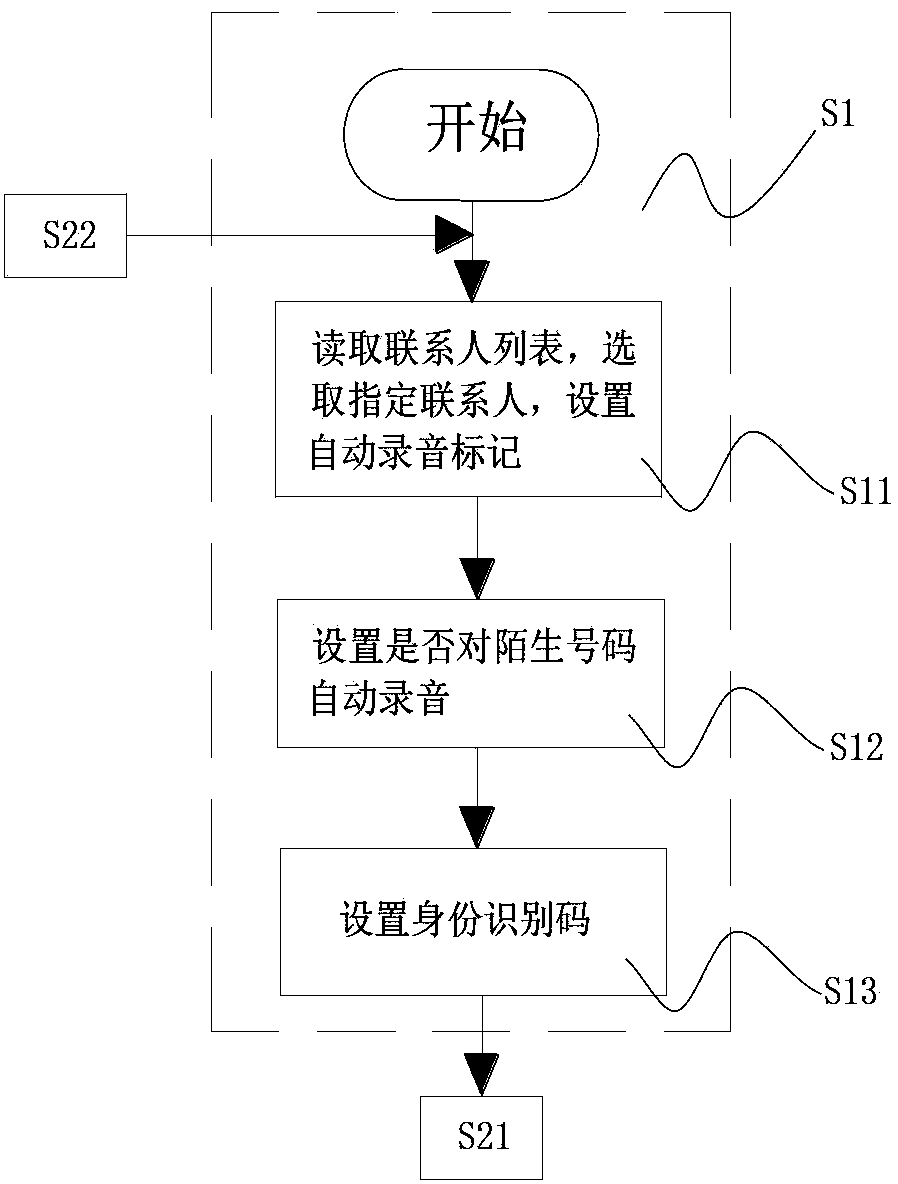

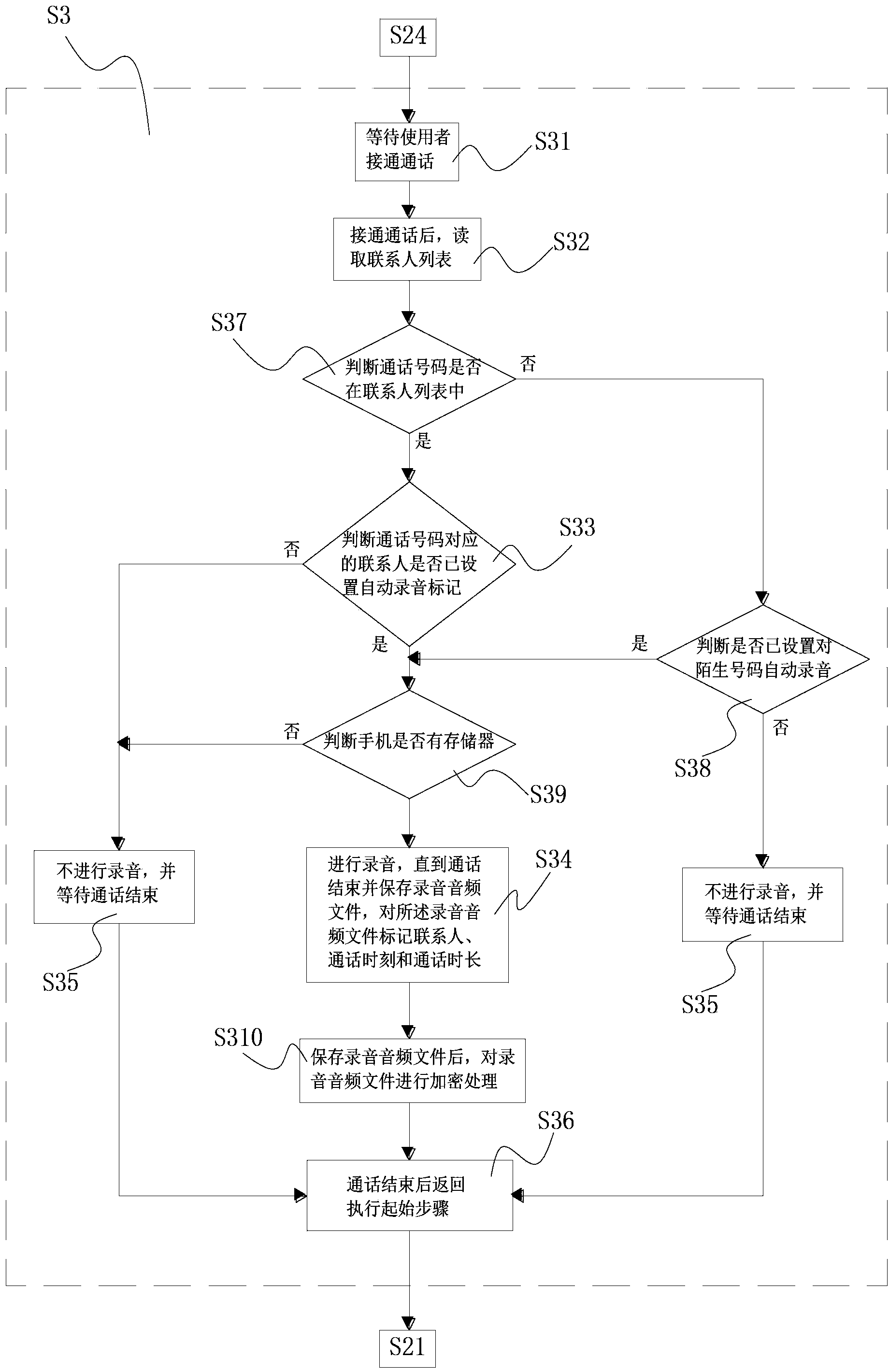

Mobile phone intelligent recording and communication management method and device

InactiveCN103414816AReduce human involvementAccurate operationAutomatic call-answering/message-recording/conversation-recordingRecord information storageManagement functionsComputer hardware

The invention provides a mobile phone intelligent recording and communication management method. The method includes the step of initialization setting, the step of starting, the step of communication recording and the step of looking up. Accordingly, the invention further provides a mobile phone intelligent recording and communication management device which comprises an initialization setting device, a starting device, a communication recording device and a looking up device. According to the mobile phone intelligent recording and communication management method and device, management of communication recording and management of communication records are combined together, the manual participation degree of a user is greatly lowered, faulty operations and missed operations are effectively avoided, and the management function is actually and effectively put into effect.

Owner:SHENZHEN CAREDEAR COMM TECH

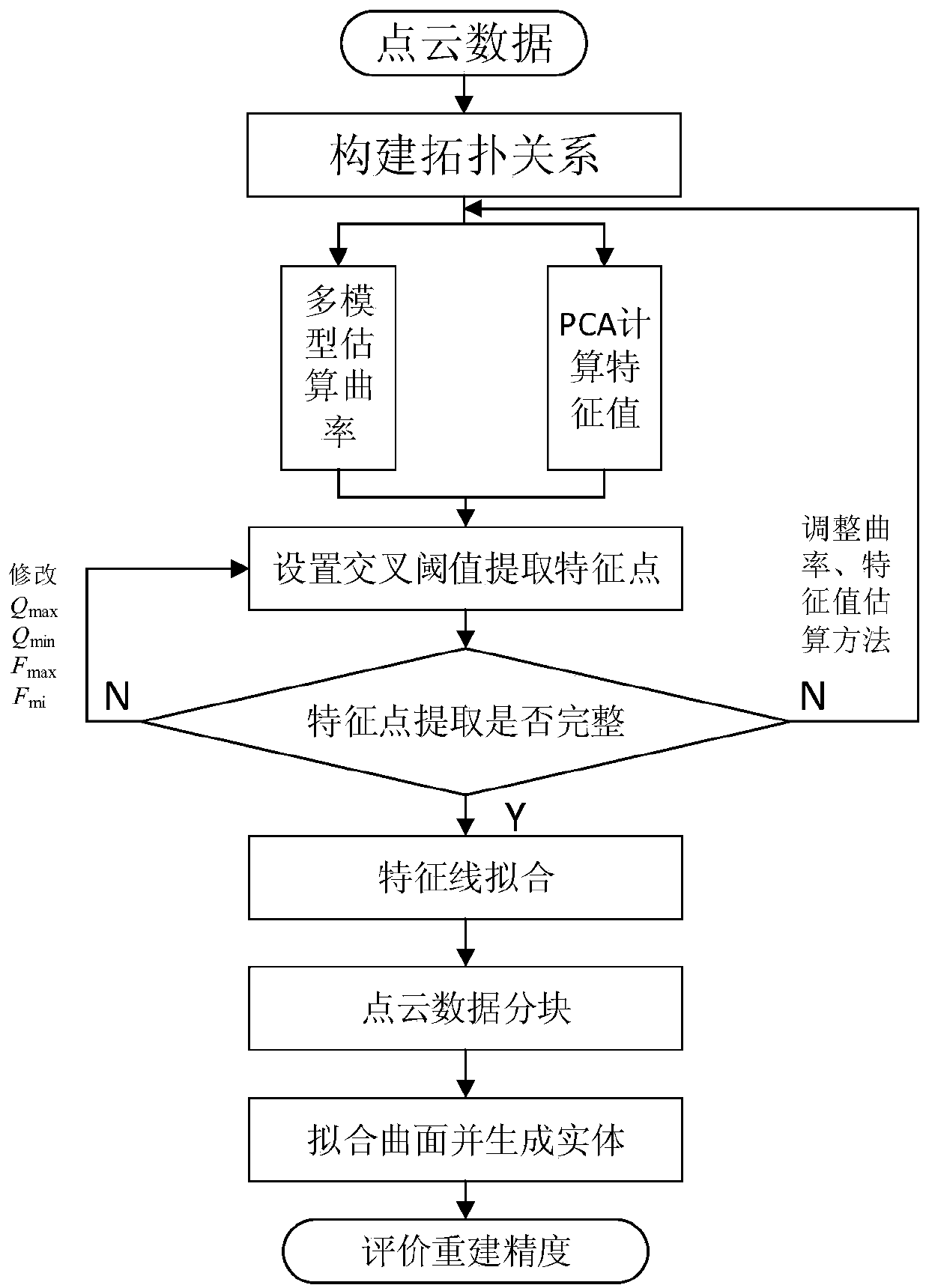

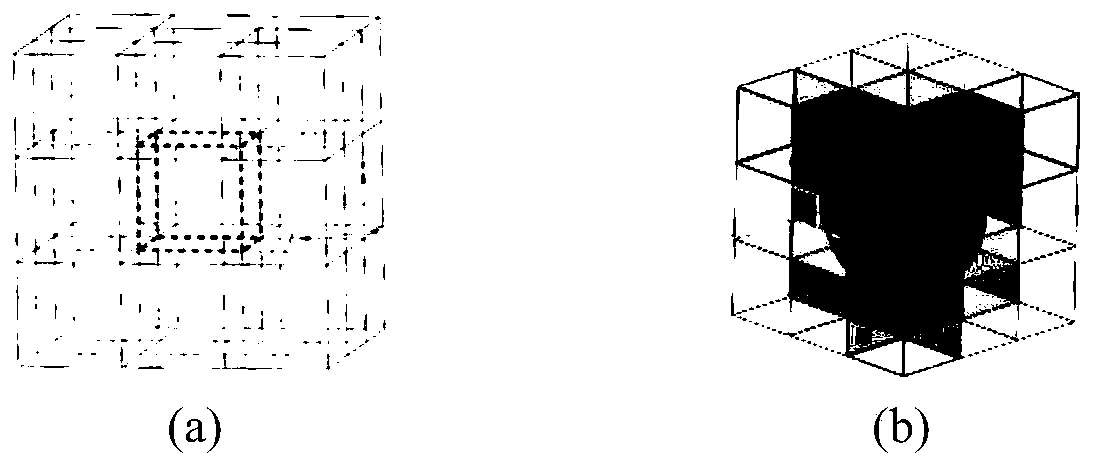

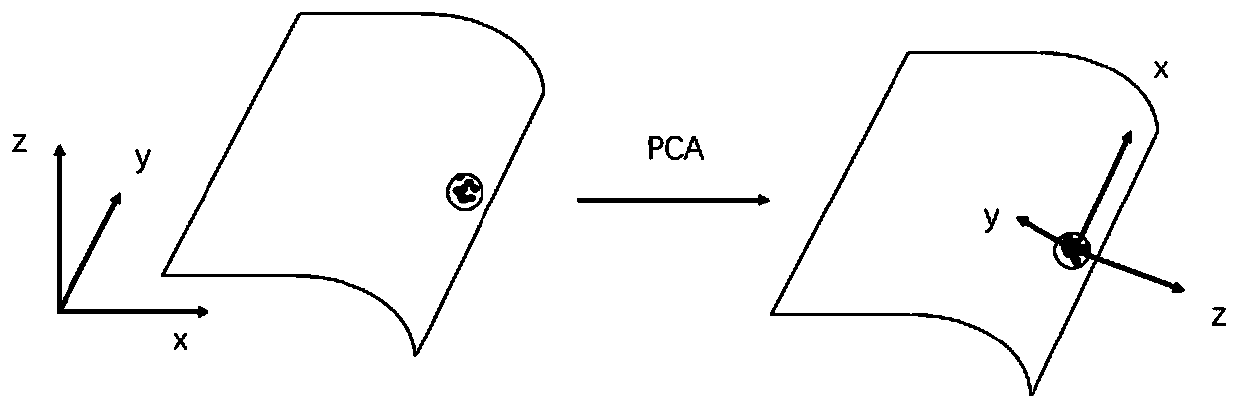

A micro complex part modeling method based on feature recognition

PendingCN109740227AReduce human involvementImprove accuracy and efficiencySpecial data processing applicationsManufacturing computing systemsNear neighborData partitioning

The invention discloses a miniature complex part modeling method based on feature recognition, namely a method for reconstructing a CAD (Computer Aided Design) model by using a physical sample piece,which comprises the following steps of: establishing a point cloud topological relation, extracting feature points, partitioning point cloud data, reconstructing a model and the like. Wherein the stepof establishing the point cloud topological relation is responsible for finding k nearest neighbor points of each sampling point; the feature point extraction step is responsible for extracting feature points of the point cloud model; the point cloud data partitioning step is responsible for constructing feature lines and segmenting point clouds belonging to the same curved surface; and the modelreconstruction step is responsible for generating a curved surface by using the point cloud and the feature line, and obtaining an entity through curved surface projection. According to the modelingmethod, reconstruction of the complex curved surface part model can be completed with less manual participation. The modeling method provided by the invention has simple steps and higher efficiency, and can be suitable for reverse modeling of parts with similar geometrical characteristics.

Owner:JIANGNAN UNIV

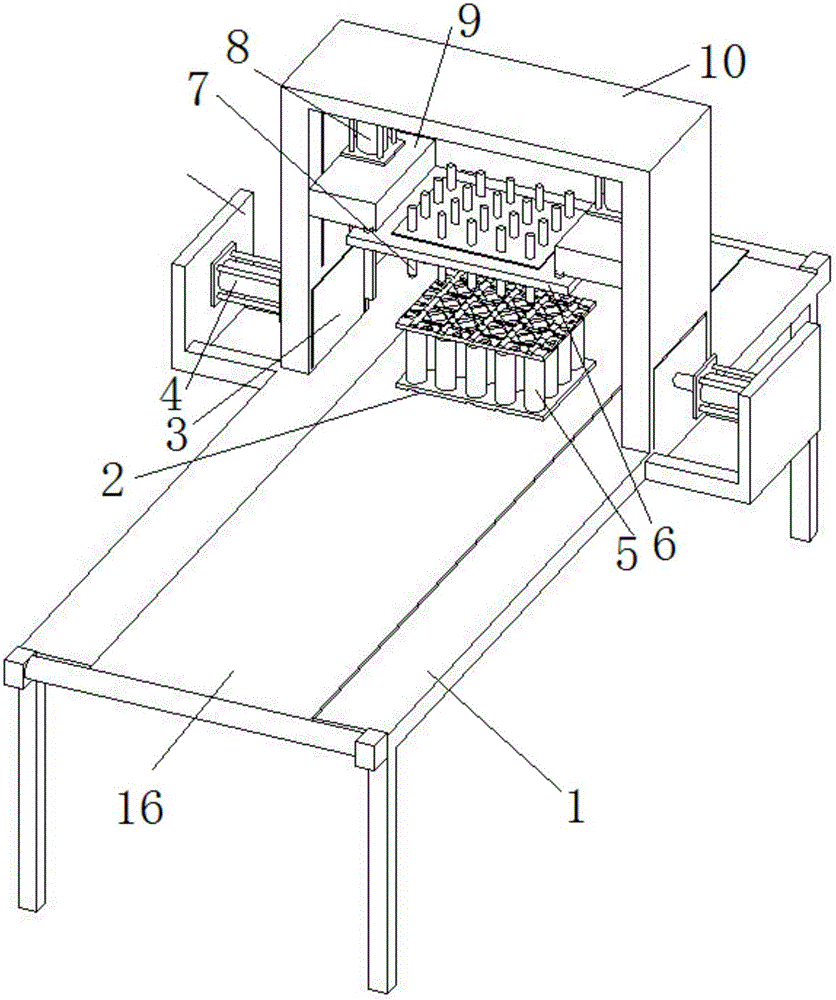

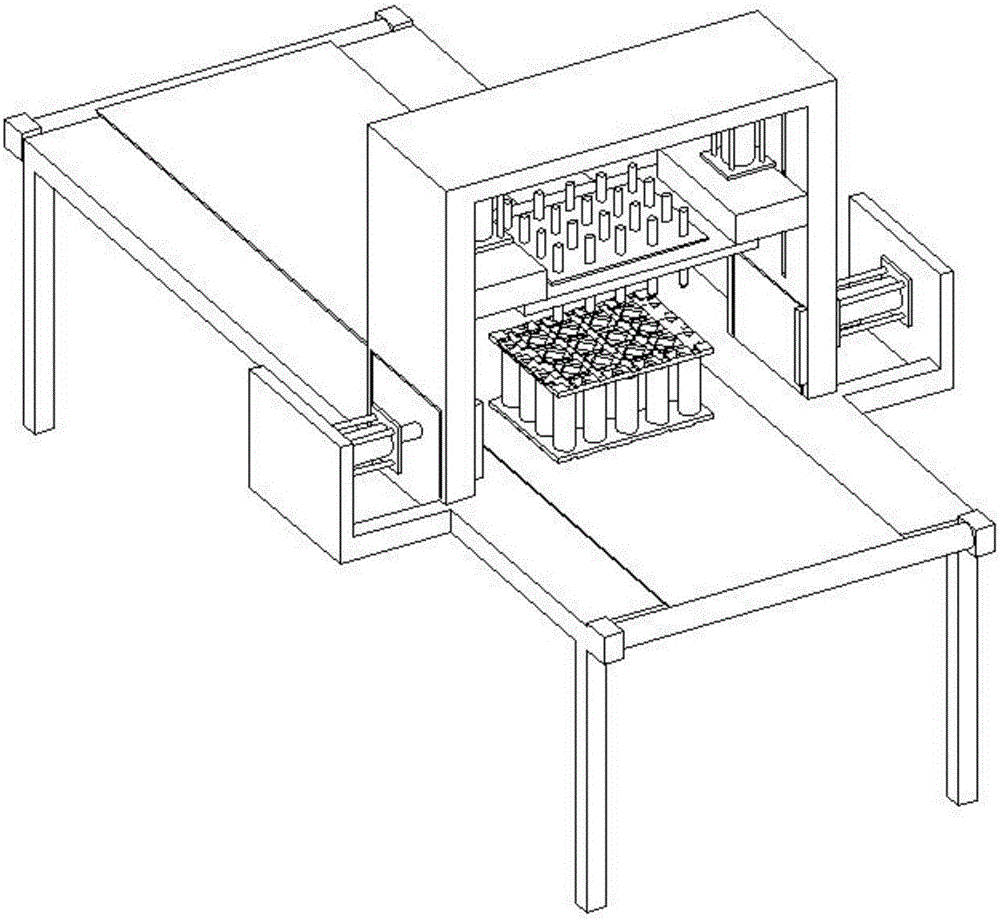

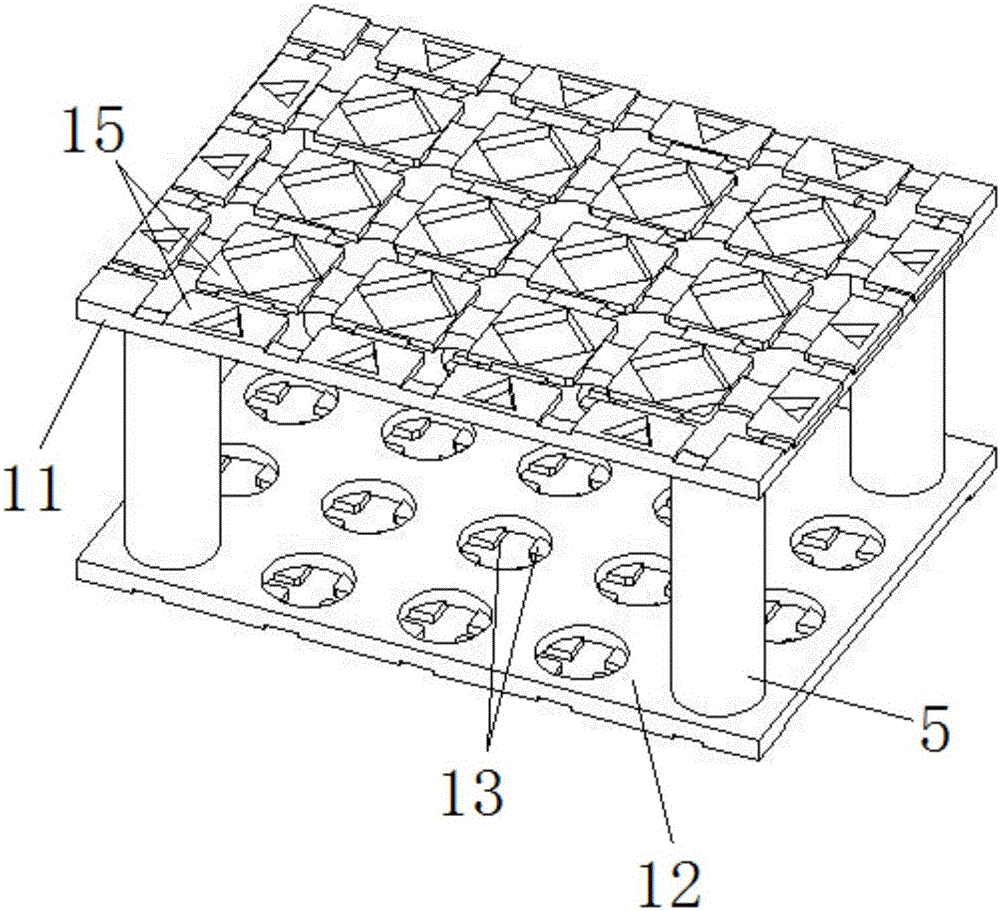

Automatic spot welding method for battery electrodes

InactiveCN105921868AReduce human involvementHuman Engagement Made EasyWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryBattery electrode

The invention discloses an automatic spot welding method for battery electrodes. The automatic spot welding method of the battery electrodes comprises the steps that (a) a plurality of batteries are vertically fixed to battery fixing mechanisms, the to-be-welded electrode of the batteries are arranged upwards and exposed out from clamping holes of upper clamping blocks, and the multiple battery fixing mechanisms are sequentially placed on a conveying belt; (b) a system controls the conveying belt to drive the first battery fixing mechanism to a station below a pressing plate, and the two clamping blocks are driven by clamping air cylinders on the two sides to be ejected and clamp the two ends of the first battery fixing mechanism correspondingly; and (c) piston rods of two pressing air cylinders are ejected to drive the pressing plate to press, a plurality of sets of welding needles make contact with the to-be-welded electrodes of the batteries in a one-to-one corresponding mode, and the system conducts discharging welding on the to-be-welded electrodes of the battery below all the sets of welding needles in sequence. The automatic spot welding method for the battery electrodes has the following advantages that spot welding is conducted on the to-be-welded electrodes of the multiple batteries at the same time, welding is accurate, mistaken welding or welding damage is avoided, and the welding efficiency is greatly improved.

Owner:安徽安耐捷新能源科技有限公司

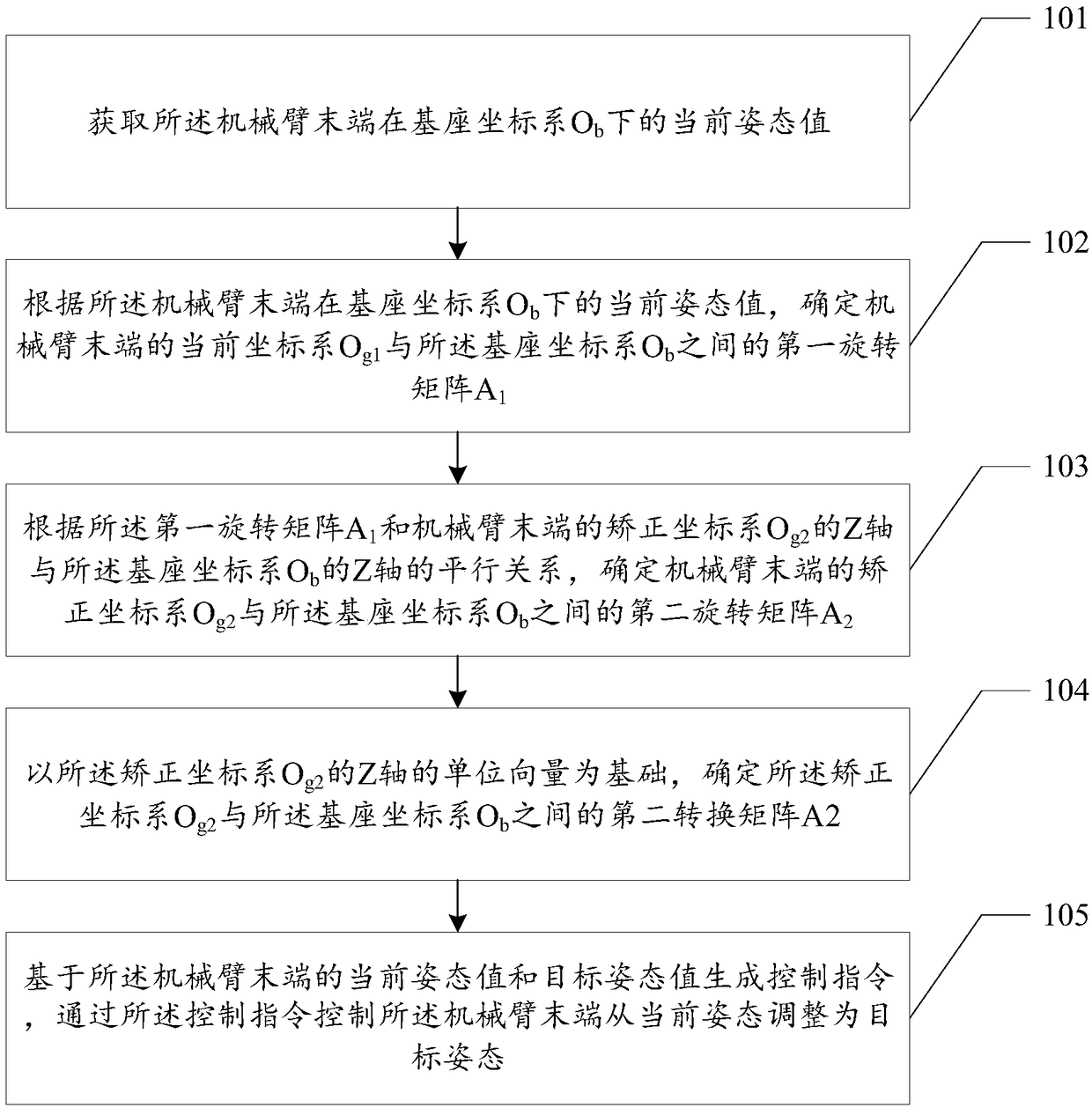

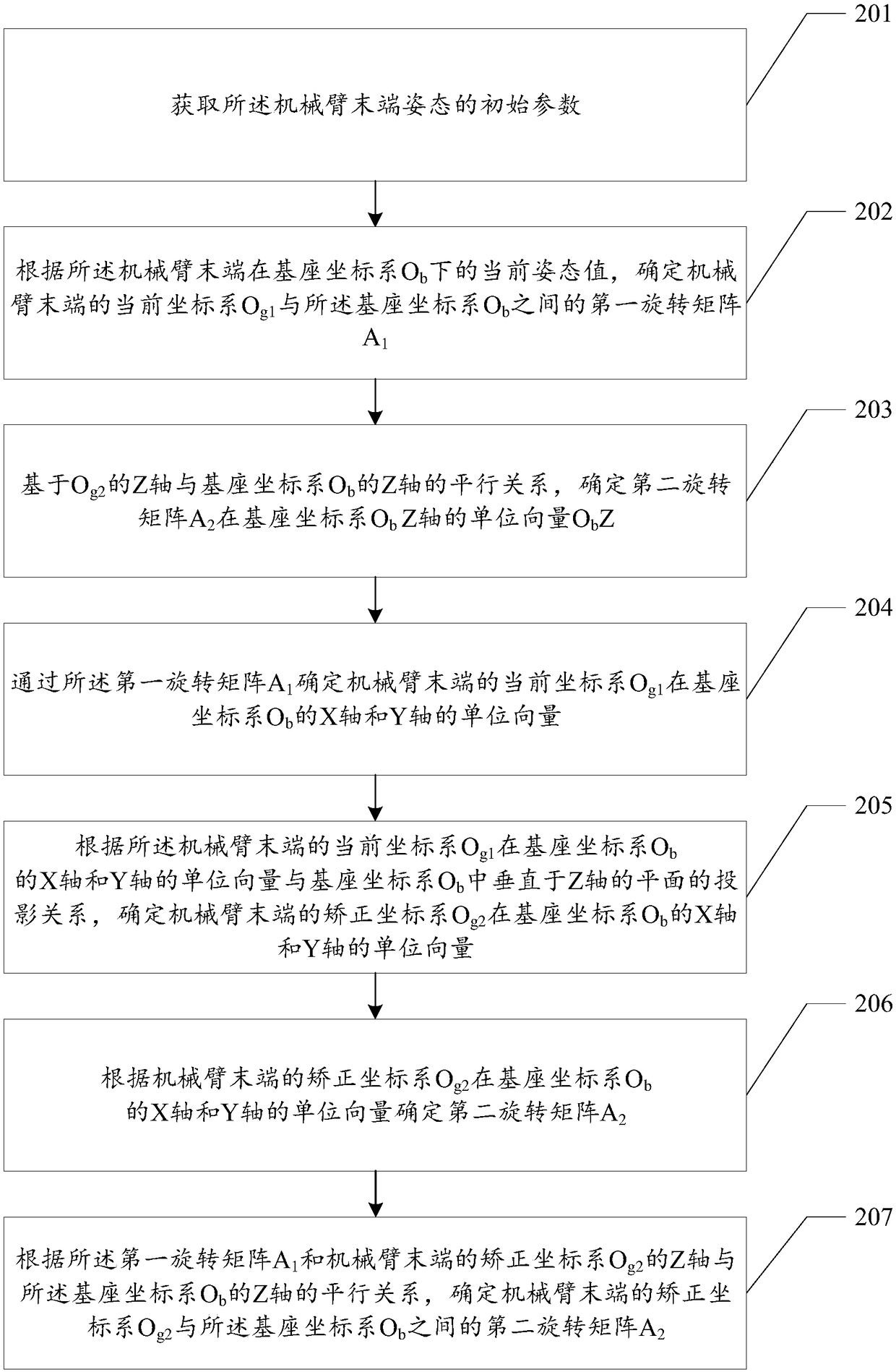

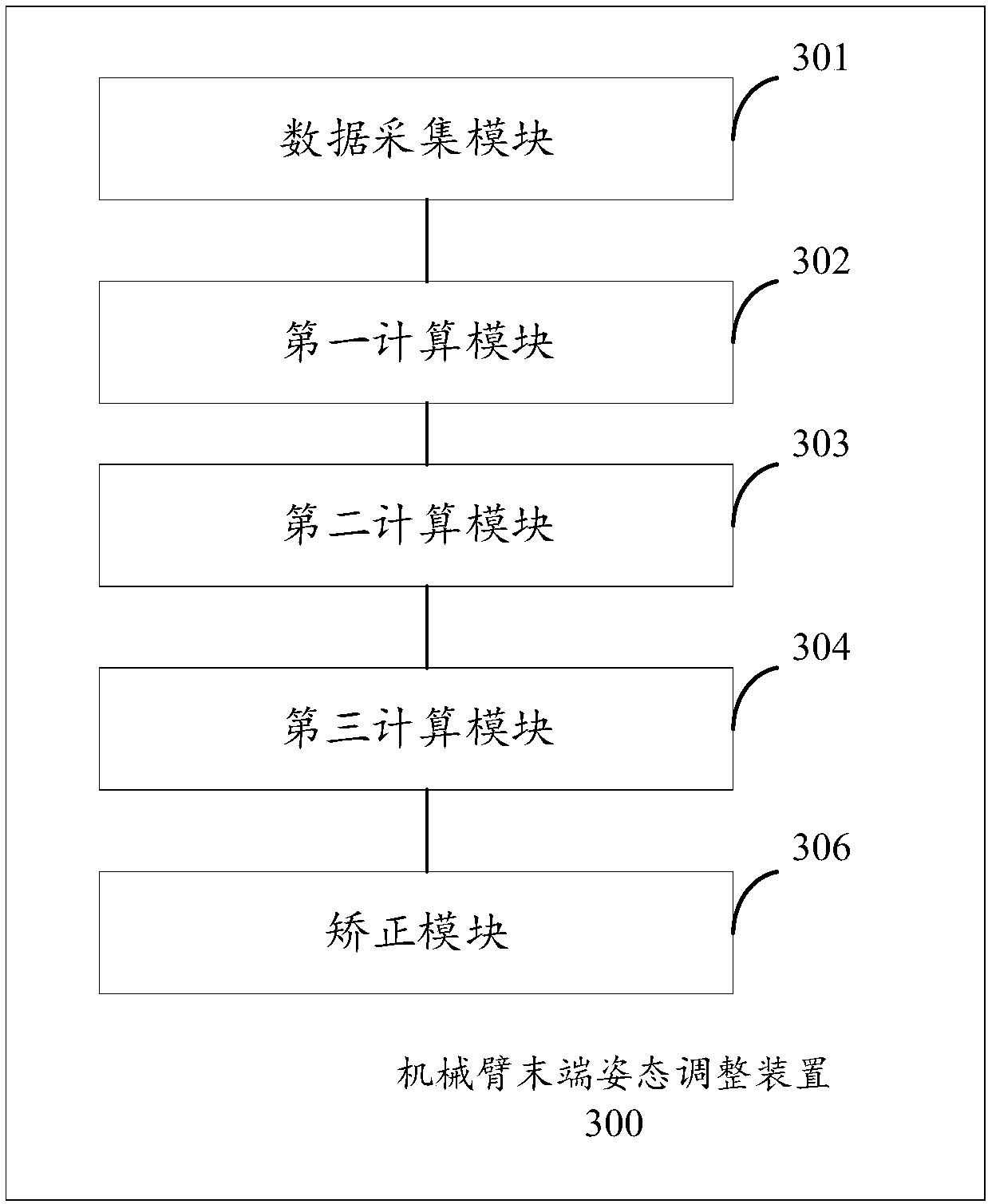

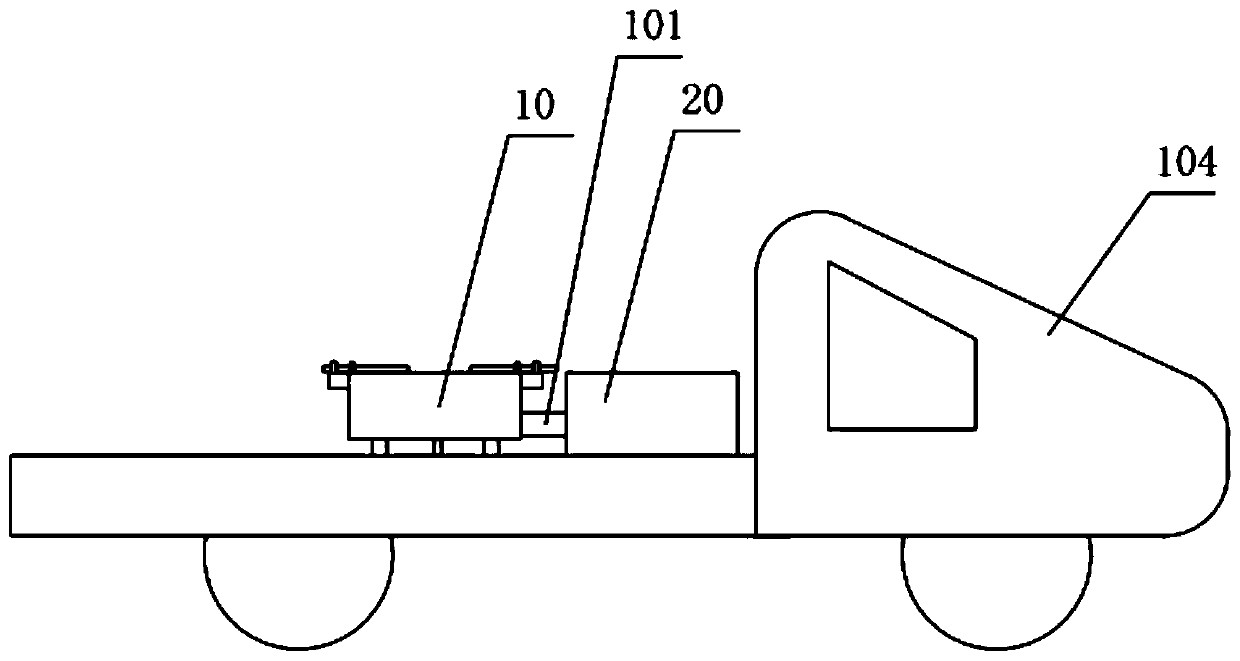

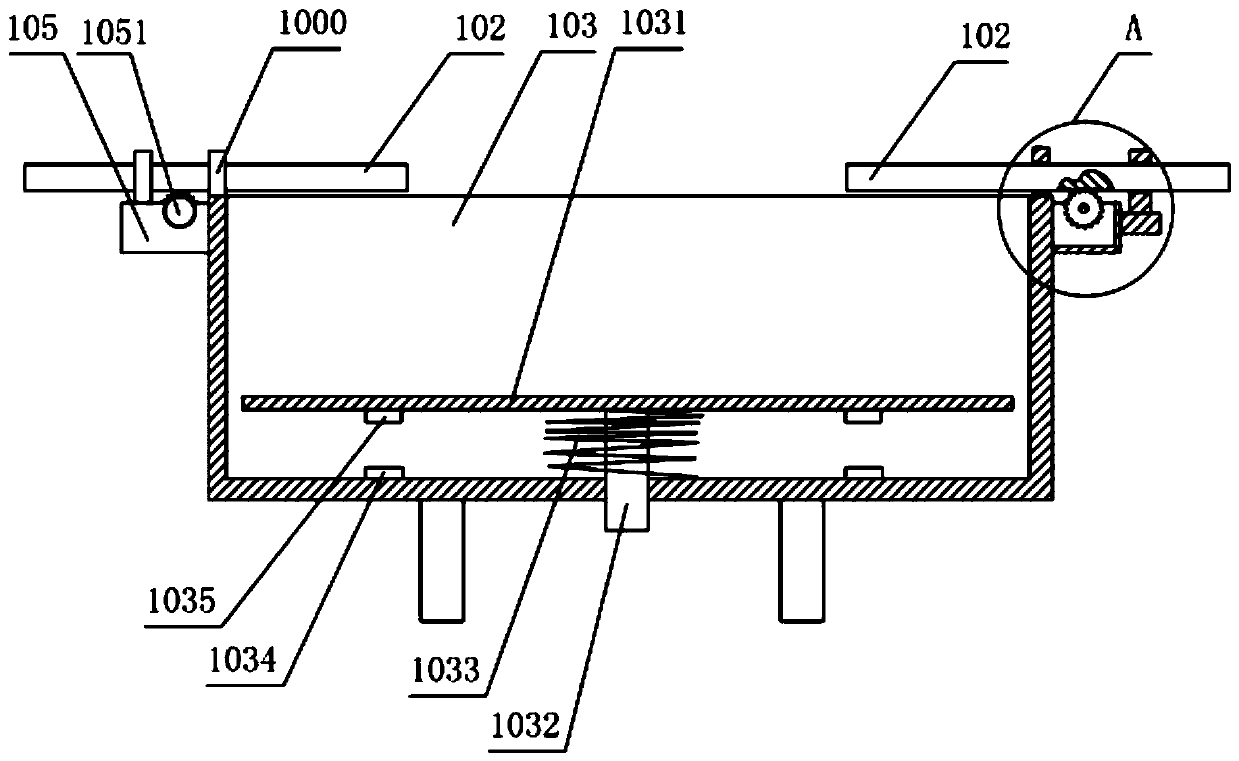

Method and device for adjusting tail end attitude of mechanical arm

ActiveCN108927801AHigh control precisionReduce human involvementProgramme-controlled manipulatorRotation matrixControl theory

The invention discloses a method and device for adjusting tail end attitude of a mechanical arm. The method and device for adjusting the tail end attitude of the mechanical arm is applied to an intelligent robot. The intelligent robot includes a base and the mechanical arm. The method includes the steps that under a preset condition, a current attitude value of the tail end of the mechanical arm under the base coordinate system O is acquired; according to the current attitude value of the tail end of the mechanical arm under the base coordinate system O, a first rotation matrix A<1> between the current coordinate system O<g1> of the tail end of the mechanical arm and the base coordinate system O is determined; according to the first rotation matrix A<1> and the parallel relationship between a Z-axis of the corrected coordinate system O<g2> of the tail end of the mechanical arm and a Z-axis of the base coordinate system O, a second rotation matrix A<2> between the correctedcoordinate system O<g2> of the tail end of the mechanical arm and the base coordinate system O is determined; a target attitude value of the tail end of the mechanical arm is determined according to the second rotation matrix A<2>; and a control command is generated based on the current attitude value and the target attitude value of the tail end of the mechanical arm, and the control command controls the tail end of the mechanical arm to be adjusted from the current attitude to the target attitude.

Owner:BEIJING ORION STAR TECH CO LTD

Vehicle-mounted unmanned aerial vehicle electric power inspection flight control method and system

ActiveCN111510686AImprove automationReduce damage rateChecking time patrolsClosed circuit television systemsIn vehicleControl system

The invention belongs to the technical field of data processing, are particularly relates to a vehicle-mounted unmanned aerial vehicle electric power inspection flight control method and vehicle-mounted unmanned aerial vehicle electric power inspection flight control system. By establishing a three-dimensional model and formulating an original inspection route through a route specifying module, anunmanned aerial vehicle management and control platform performs problem point identification on video or image information transmitted in real time in inspection, and formulates a temporary inspection route for a problem point; an unmanned aerial vehicle performs emphasized inspection on the problem point, so that errors caused by manual control are reduced, and the accuracy rate is improved; and when detecting that the humidity is too high, the wind power is too large or the electric quantity of the unmanned aerial vehicle is insufficient, the unmanned aerial vehicle management and controlplatform formulates a temporary route to recall the unmanned aerial vehicle for battery replacement or drying treatment, the failure rate is reduced, and the service life of the unmanned aerial vehicle is prolonged. The unmanned aerial vehicle is matched with the unmanned aerial vehicle management and control platform on an inspection vehicle, so that scientific management and control of electricpower inspection are realized, the service life of the unmanned aerial vehicle is prolonged, the fault probability is reduced, inspection is more automatic, the accuracy degree is improved, and the workload of people is reduced.

Owner:TIANSHENGQIAO BUREAU CSG EHV POWER TRANSMISSION CO

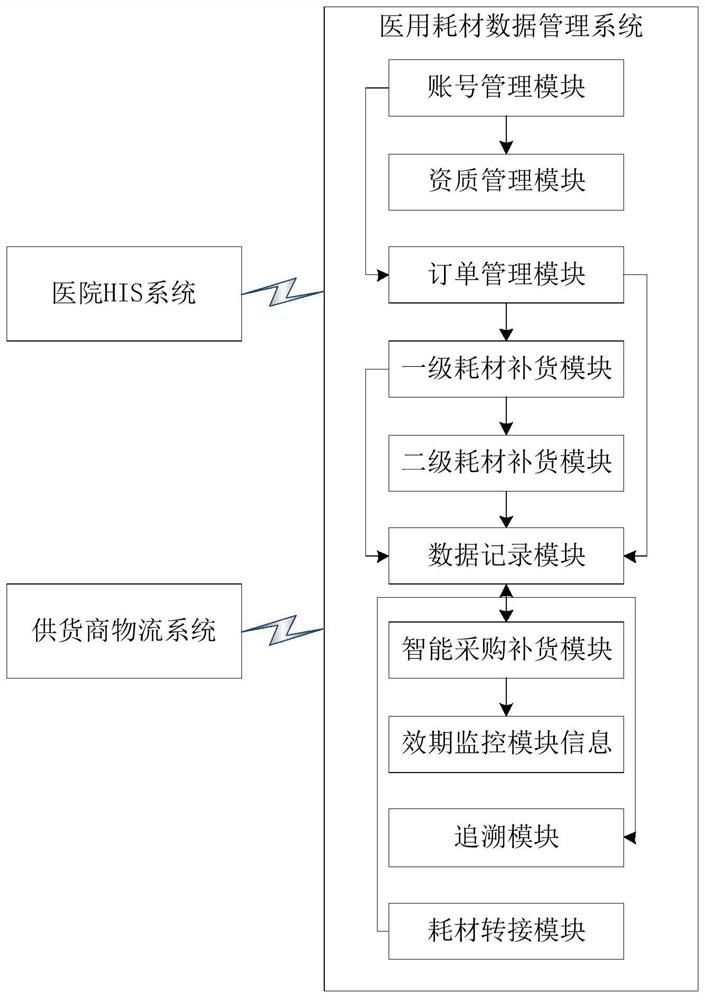

Medical consumable data management platform

PendingCN113409929AEasy accessSave intermediate timeCo-operative working arrangementsHealthcare resources and facilitiesLogistics managementComputer science

The invention relates to the technical field of data calculation processing, in particular to a medical consumable data management platform, which comprises a medical consumable data management system and a supplier logistics system, and the medical consumable data management system is applied to a hospital and is in butt joint with a hospital HIS system and the supplier logistics system; the medical consumable data management system comprises an SPD center library and a plurality of secondary intelligent warehouses arranged in a hospital; the supplier logistics system is used for obtaining delivery information provided by a supplier end for delivering to the SPD center library according to a purchase order when the purchase order of the medical consumable data management system is received; the medical consumable data management system is also used for binding the received medical consumables with the identity information of the receiver; and when the received medical consumables use the patient, binding the identity information of the patient with the received medical consumables. The problems of poor medical consumable information tracing effect and low working efficiency in the prior art are solved.

Owner:重庆博尔德医疗科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com