Patents

Literature

150 results about "Logistics automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Logistics automation is the application of computer software or automated machinery to improve the efficiency of logistics operations. Typically this refers to operations within a warehouse or distribution center, with broader tasks undertaken by supply chain management systems and enterprise resource planning systems.

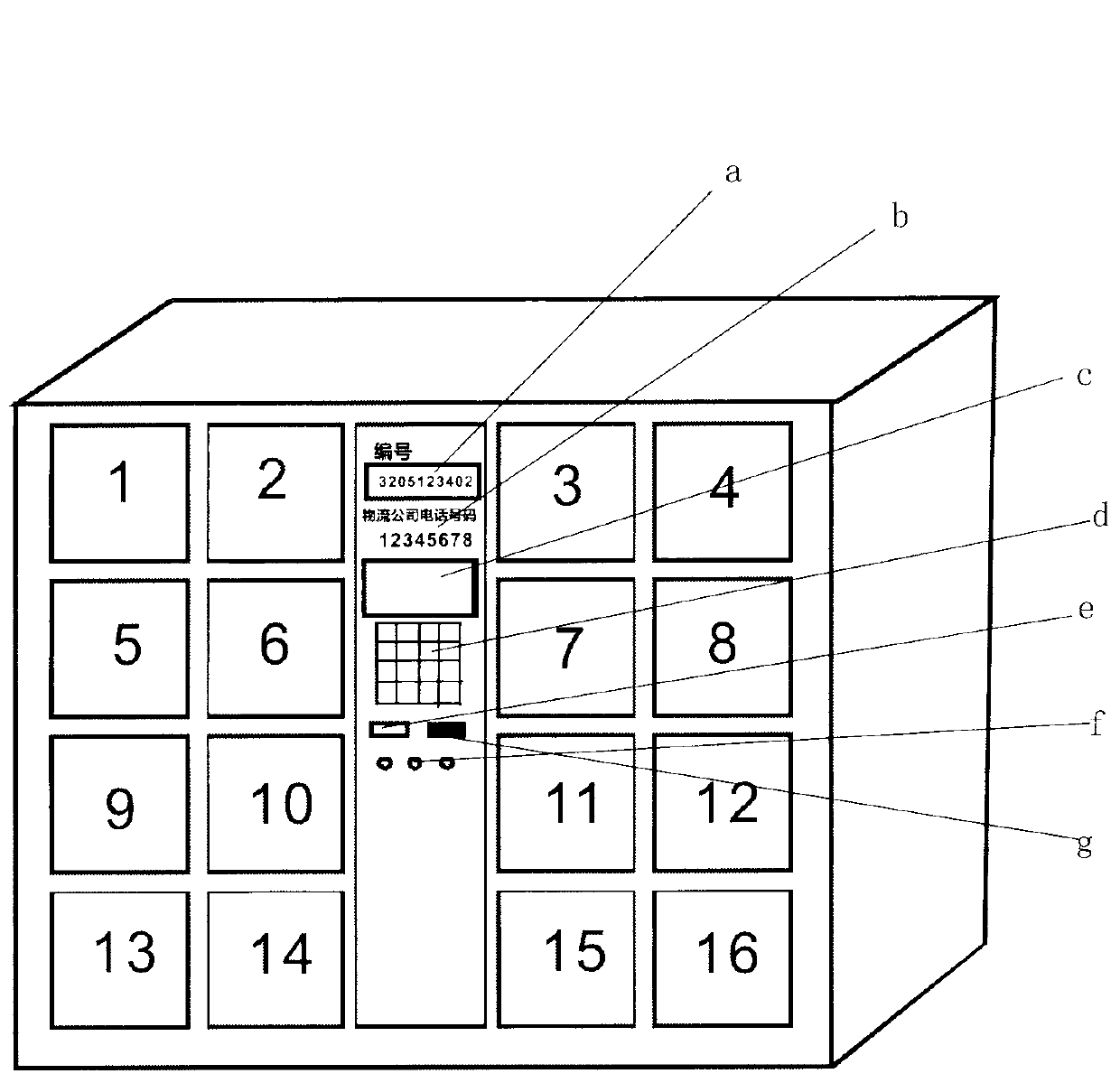

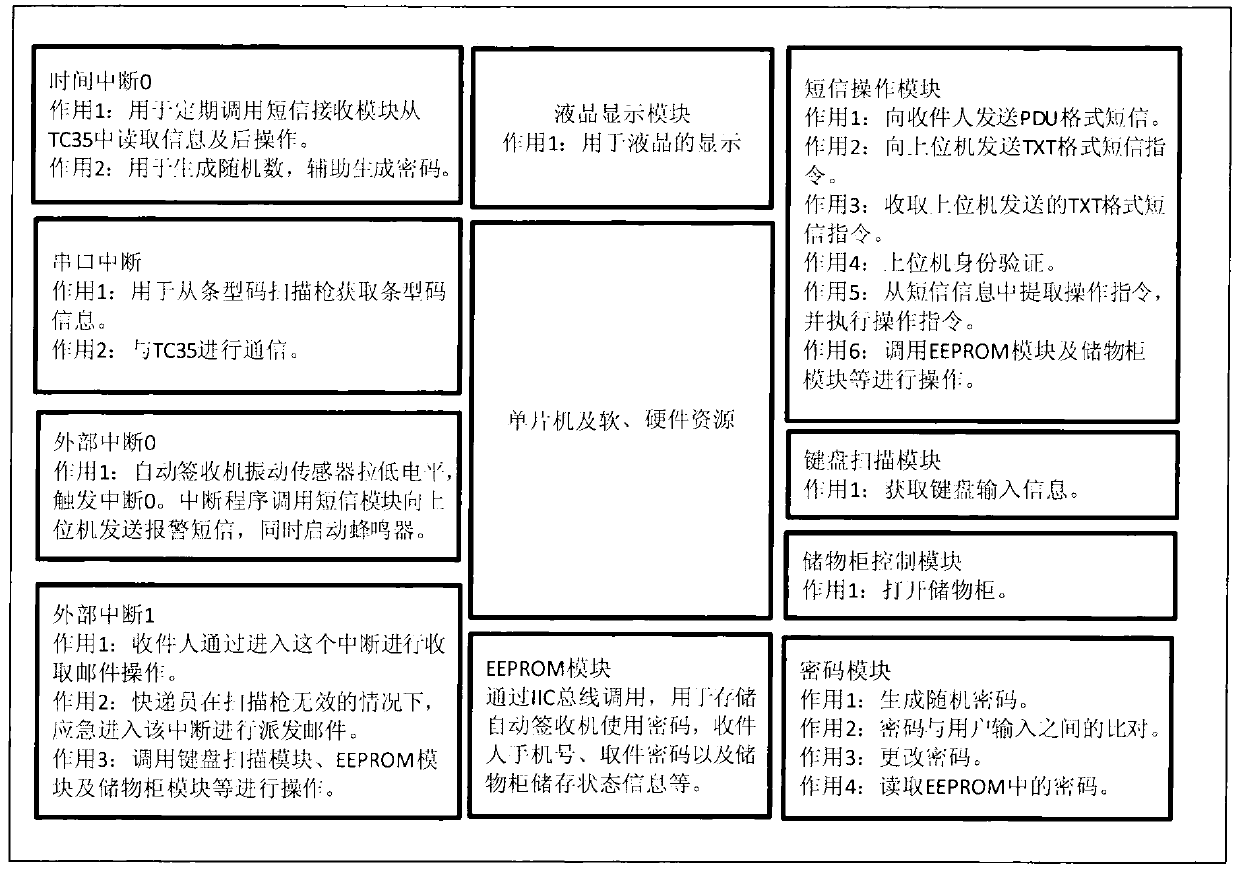

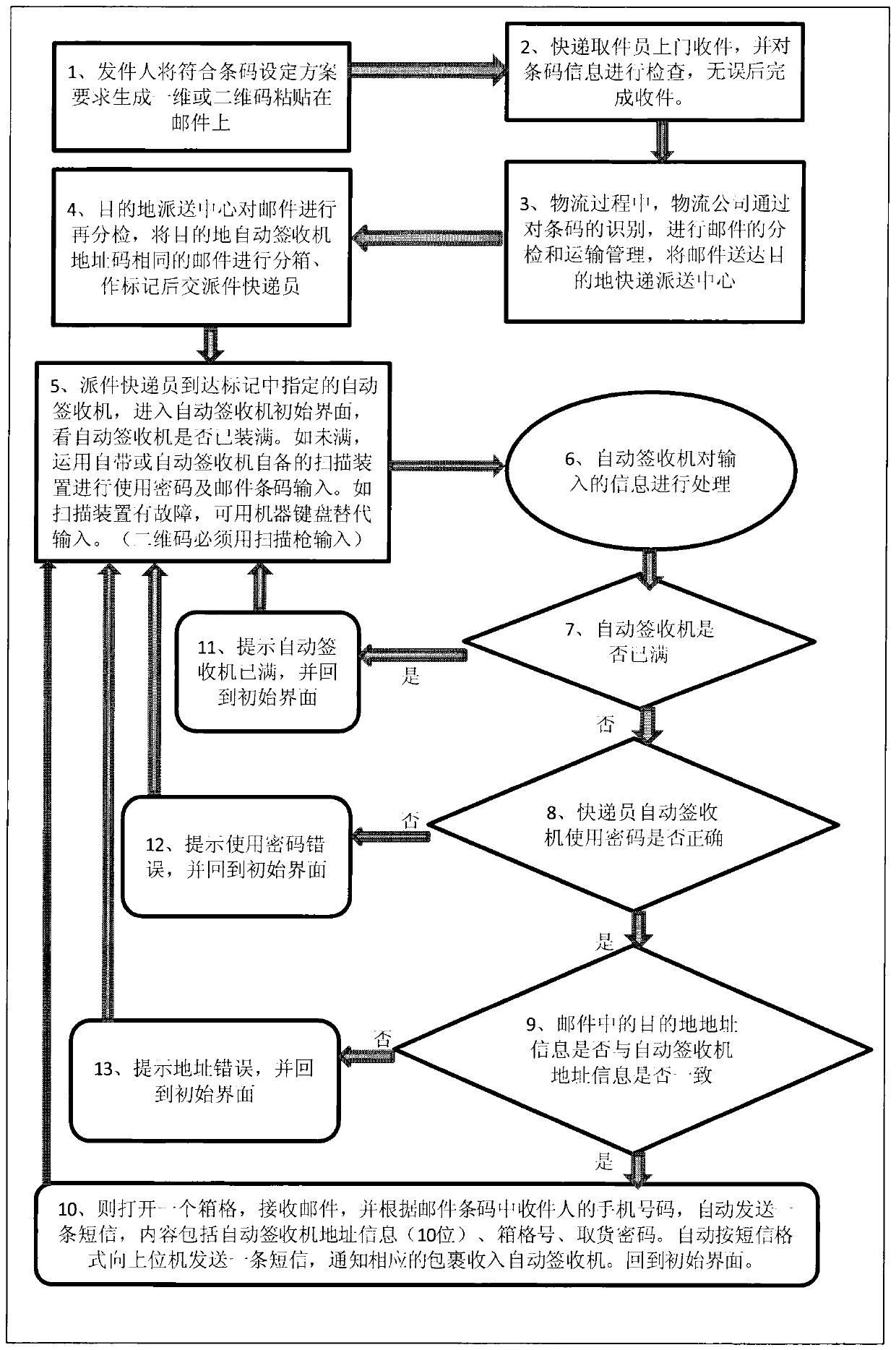

Automatic sign-in machine and automatic sign-in application technical scheme

The invention discloses an automatic sign-in machine and an automatic sign-in application technical scheme. The automatic sign-in machine comprises a singlechip smallest system, a multi-cell storage cabinet, a global system for mobile communication (GSM) module and the like. By means of an automatic sign-in machine address code setting scheme, a mail bar code setting and applying scheme, a short message order format scheme, a pick-up password generation and storage scheme, a multi-logistics company shared scheme and the like, the automatic sign-in application technical scheme can achieve functions of automatic sorting, classified collecting, automatic sign-in and delivery notice of mails in the logistics process, can expand logistics automatic process to deliver taking link of addressees, solves 'the last one mile problem' of logistics express delivery, and greatly improves the efficiency of the logistics express delivery. The automatic sign-in machine can further apply encrypted two-dimension codes to protect personal information of the addressees in the logistics process. Besides, the automatic sign-in machine and the automatic sign-in application technical scheme are low in production and use cost, convenient to maintain, low in energy consumption, stable in performance, simple in operation process and favorable for popularization and application.

Owner:赵海城

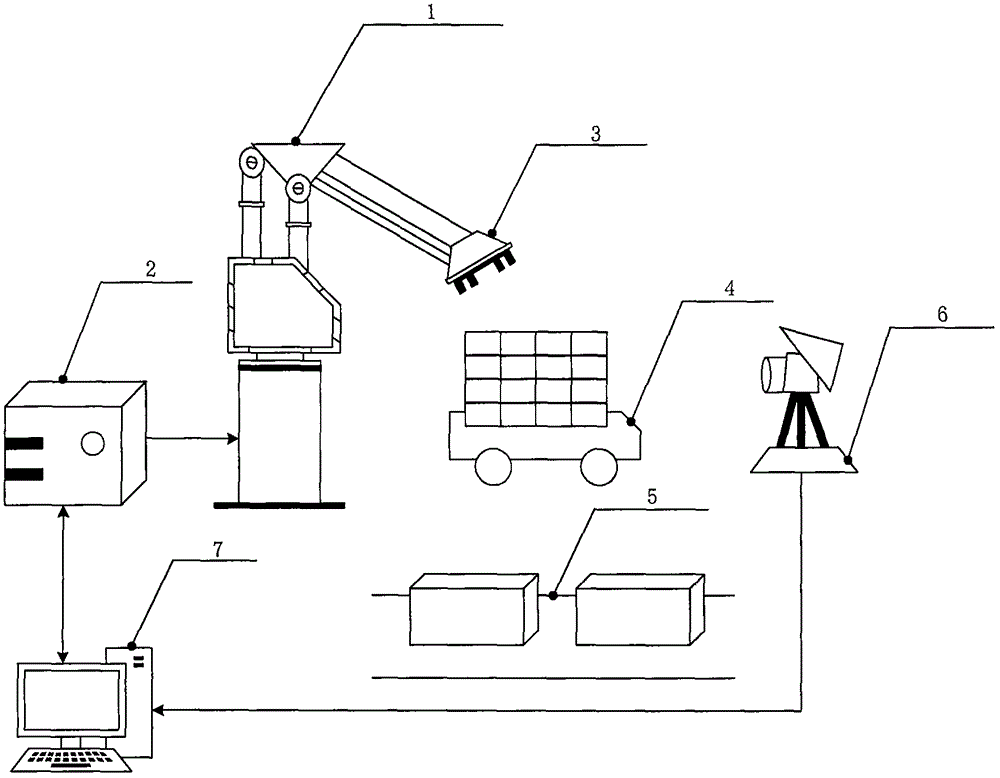

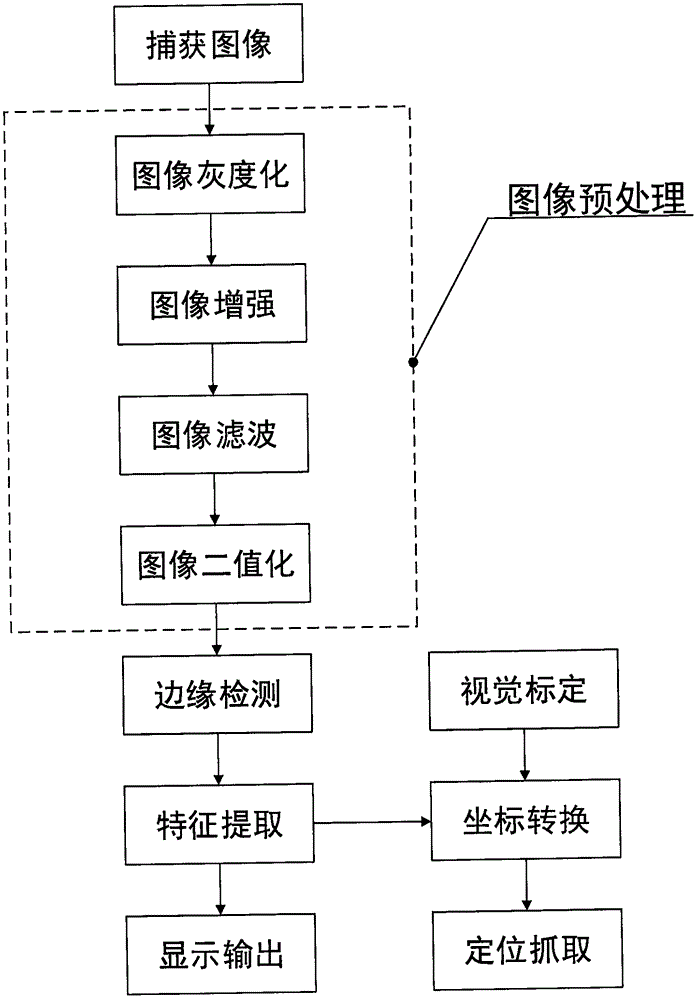

Tracking and monitoring system and method of stacking robot based on machine vision

InactiveCN106695792AInteraction logic is clearImprove flexibilityProgramme-controlled manipulatorComputer monitoringEngineering

The invention discloses a tracking and monitoring system and method of a stacking robot based on machine vision. The tracking and monitoring system comprises the stacking robot, a control cabinet of the stacking robot, a conveyor belt, an automatic guided vehicle (AGV), a vacuum sucker device, and a vision acquisition system, wherein the stacking robot is in communication connection with the control cabinet, and is used for stacking products which are sequentially transferred by the conveyor belt to a cargo loading plane of the AGV; the loaded cargos are transported into a storehouse by the AGV; the vacuum sucker is mounted at the tail end of the stacking robot; the vision acquisition device is used for uploading working video images of the stacking robot to upper computer monitoring software in a real-time manner, and performing image processing on the obtained video, so that real-time monitoring of the stacking process is realized, and abnormal circumstances of dropping of objects during stacking and the like can be analyzed and processed, so that the automated intelligent degree of logistics is increased, acceleration of the working efficiency of the whole plant is facilitated, and the manual cost and the time cost are saved.

Owner:CHINA JILIANG UNIV

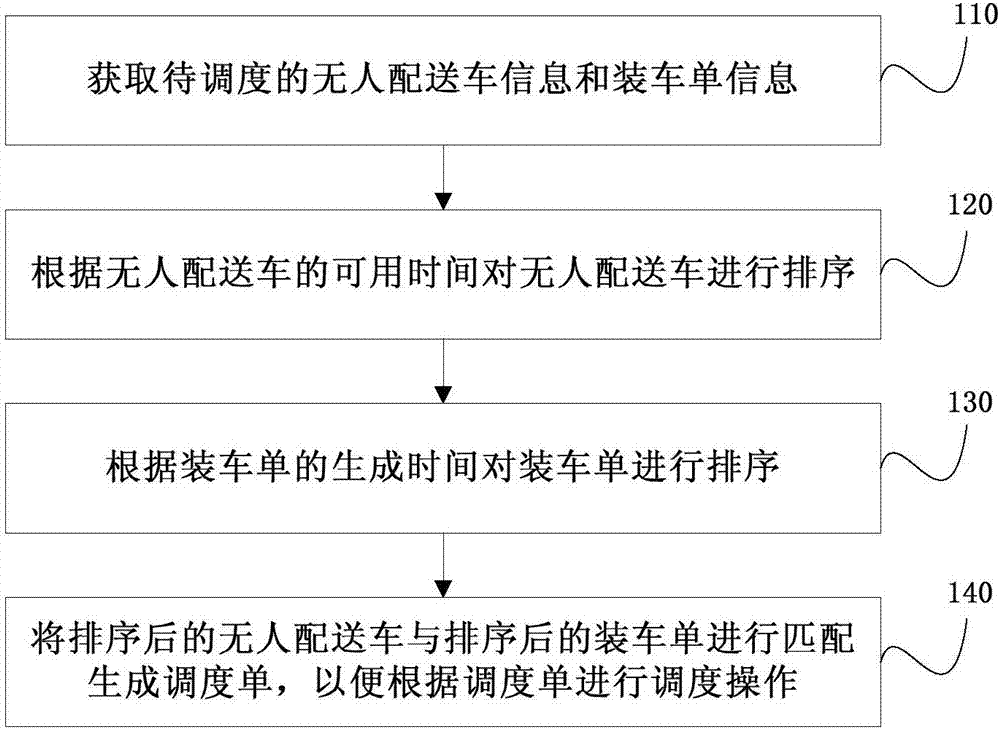

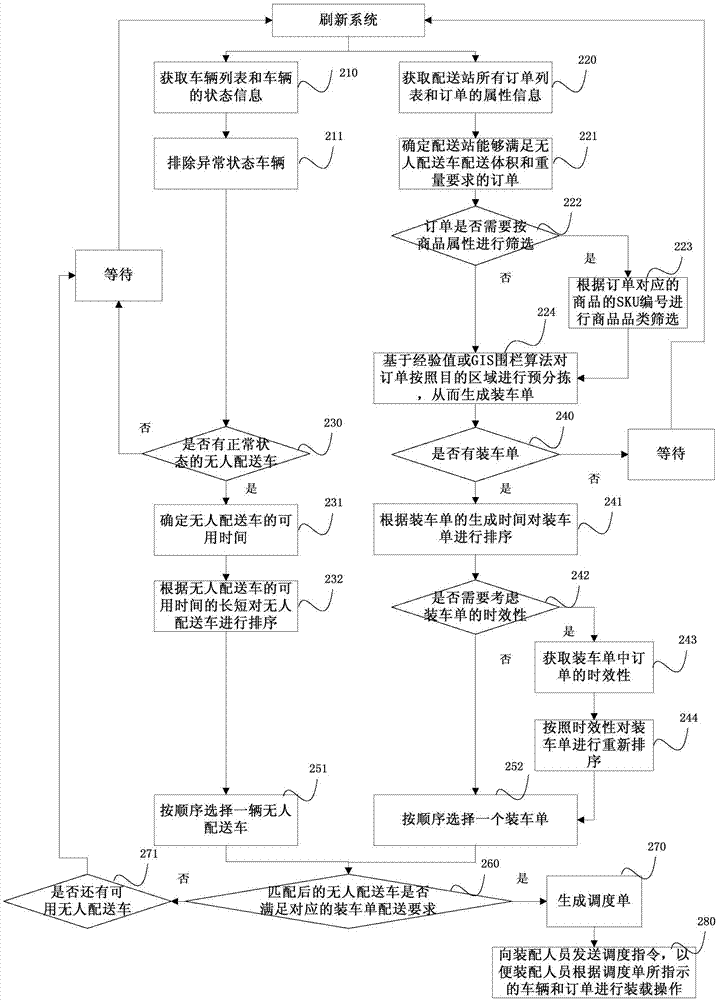

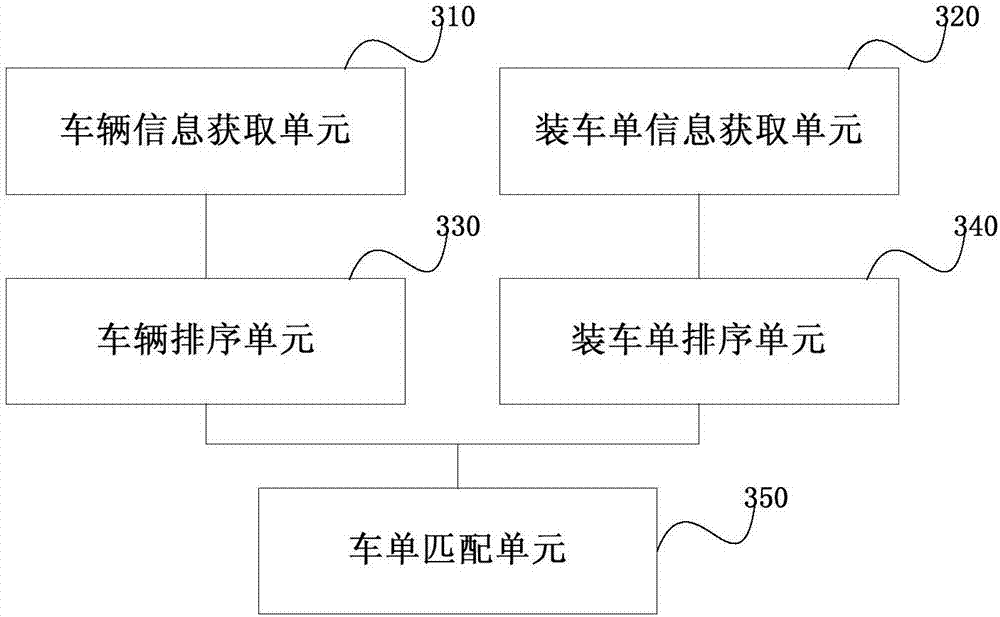

Method and system for dispatching based on unmanned delivery vehicles

InactiveCN106855966AIncrease profitImprove processing efficiencyResourcesLogisticsDelivery vehicleComputer science

The invention discloses a method and a system for dispatching based on unmanned delivery vehicles, and relates to the field of logistics automation. The method comprises the steps of acquiring information of unmanned delivery vehicles to be dispatched and information of loading lists to be dispatched, wherein orders in the same loading list have the same destination region; sorting the unmanned delivery vehicles according to the available time of the unmanned delivery vehicles; sorting the loading lists according to the generation time of the loading lists; matching the sorted unmanned delivery vehicles with the sorted loading lists to generate a dispatching list so as to perform a dispatching operation according to the dispatching list. The method considers from the two dimensions of vehicles and orders, the utilization rate of the vehicles and the processing efficiency of the orders are improved, the whole working process is enabled to be low in manual intervention degree, and thus the goods delivery efficiency of the unmanned delivery vehicles is improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Control method of storing and taking trays for magnetic stripe guide type vehicle

ActiveCN105775540ARealize automatic guidanceNo manual drivingConveyorsControl devices for conveyorsCost ControlsEngineering

The invention relates to the field of logistics automation control, in particular to a control method of storing and taking trays for a magnetic stripe guide type vehicle. The technical purpose of the control method is realized through the following technical scheme. According to the technical scheme of the control method of storing and taking the trays for the magnetic stripe guide type vehicle, the transferring vehicle and a magnetic stripe arranged on the ground and used for guiding the transferring vehicle to move are included, the transferring vehicle is provided with a magnetic conductance sensor used for sensing the magnetic stripe, and a plurality of operation steps are included. According to the control method of storing and taking the trays for the magnetic stripe guide type vehicle, the trays can be automatically guided, stored and taken, the efficiency is high, cost control is good, locating is accurate, and reverse driving of the magnetic stripe guide type transferring vehicle and tray storing and taking can be well realized.

Owner:上海诺力智能科技有限公司

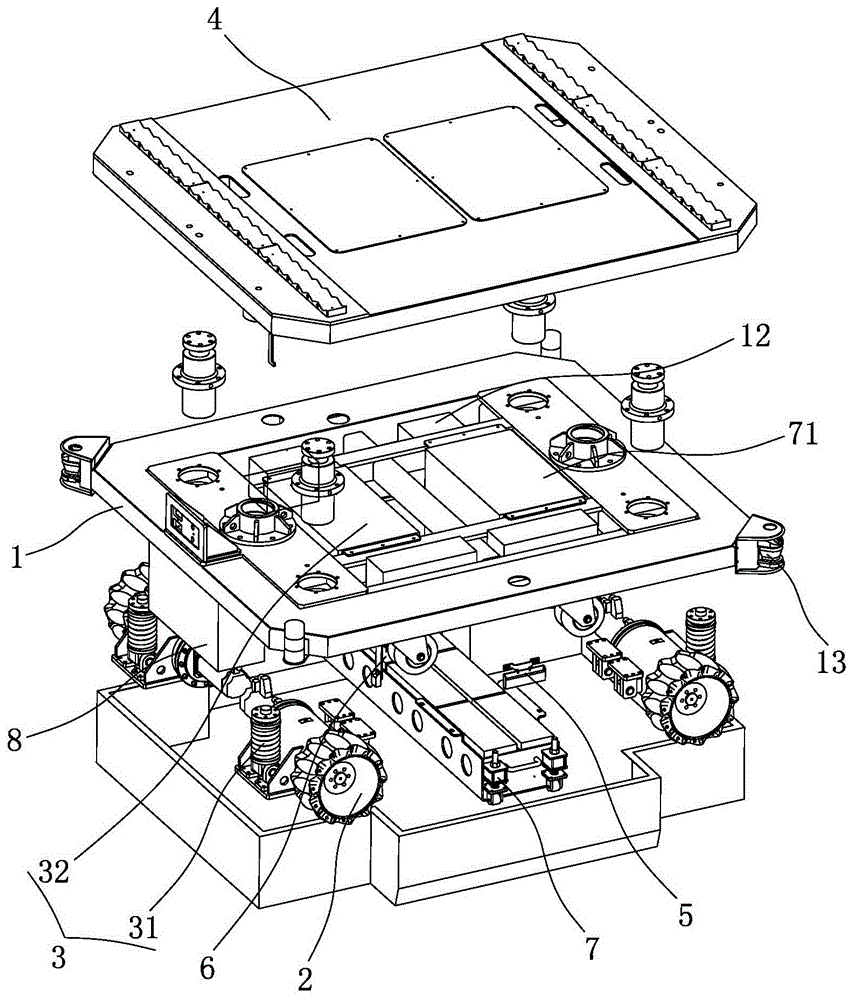

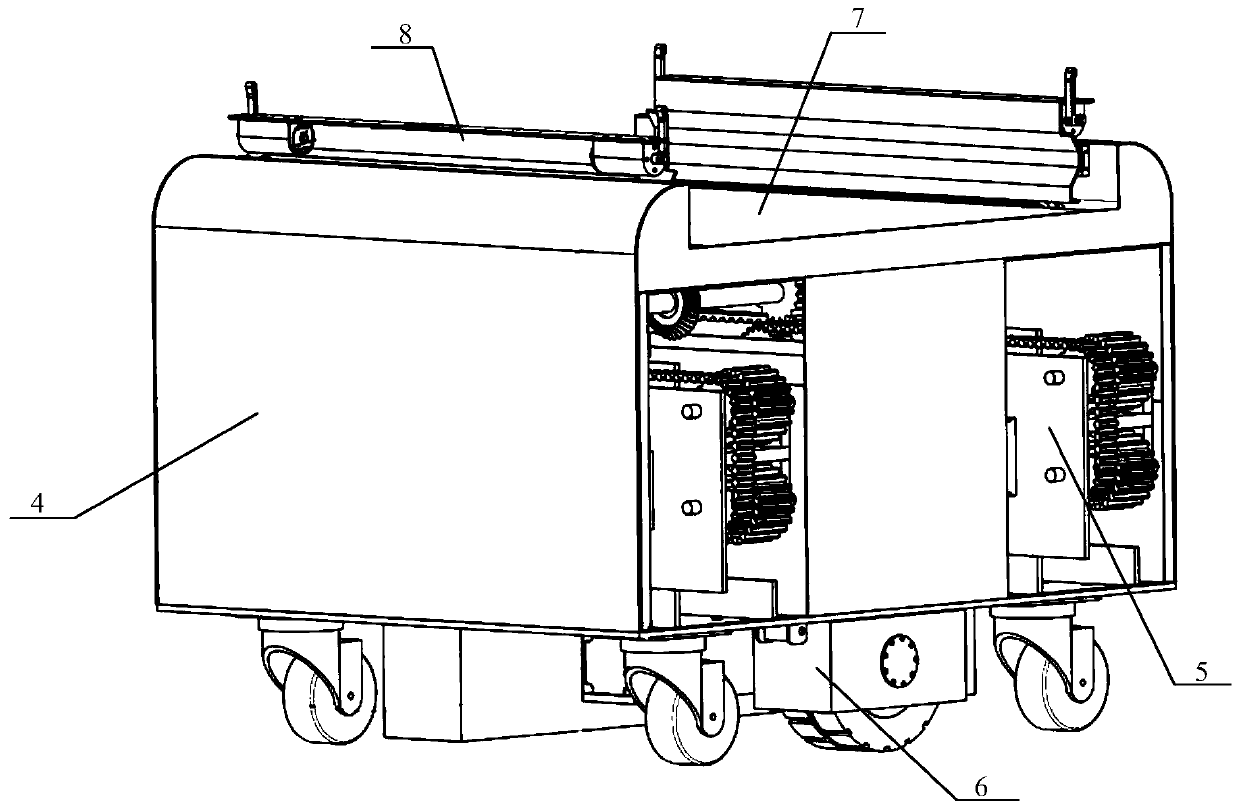

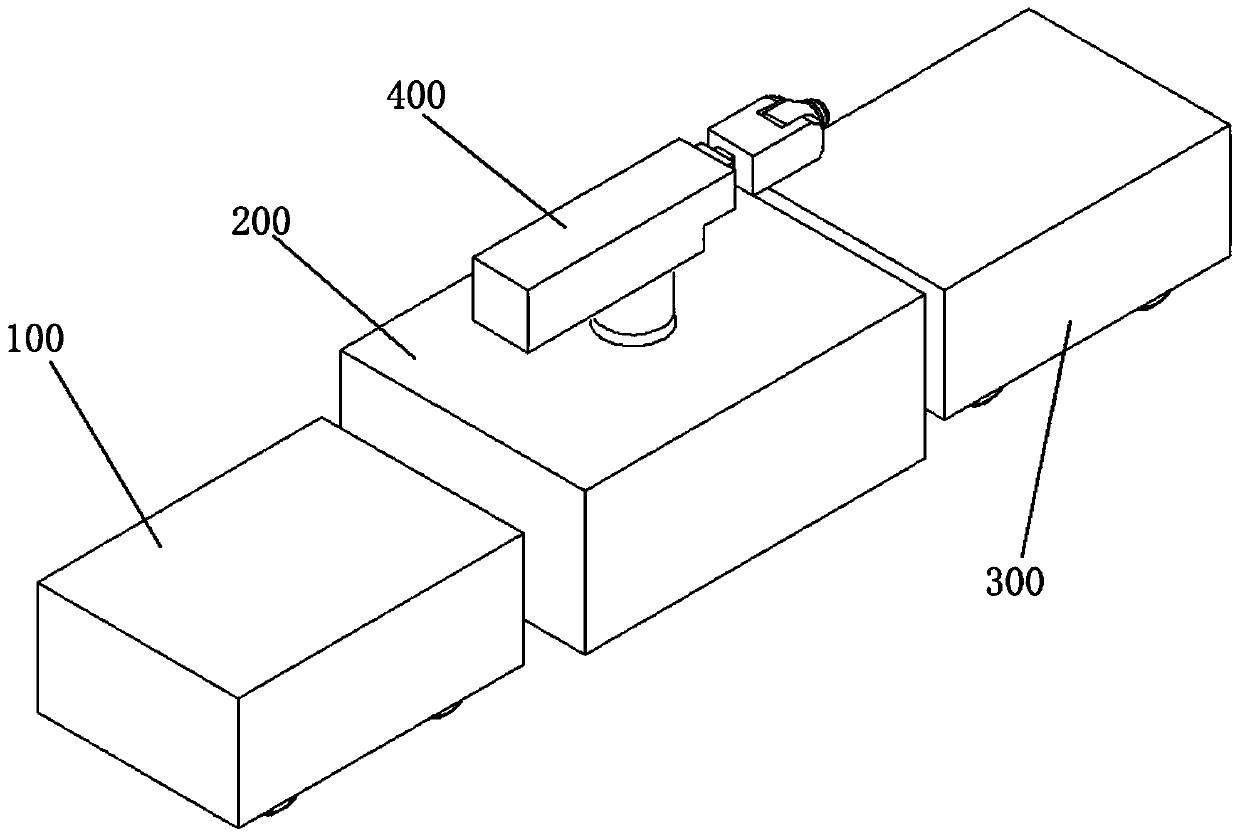

Heavy-load automated guided vehicle

The invention discloses a heavy-load automated guided vehicle. Mecanum wheel drive mechanisms are installed on the bottom of a frame and drive the frame to move in an all-dimensional mode; a lifting mechanism is installed on the frame, and a work table is installed on the lifting mechanism; a magnetic navigation sensor is installed on the bottom of the frame, detects ground magnetic stripes and drives the frame to drive along the magnetic stripe; an RFID landmark sensor is installed on the bottom of the frame, recognizes the landmark information for obtaining the position coordinates and implements the starting action, the stopping action and the turning action according to commands; a vehicle-mounted power source supplies power to the Mecanum wheel drive mechanisms, the lifting mechanism, the magnetic navigation sensor, the RFID landmark sensor and a PLC, and the PLC controls the Mecanum wheel drive mechanisms, the lifting mechanism, the magnetic navigation sensor and the RFID landmark sensor to work. The heavy-load automated guided vehicle can transfer material efficiently, accurately and flexibly, realizes logistics automation, improve the production efficiency and lower the production cost.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

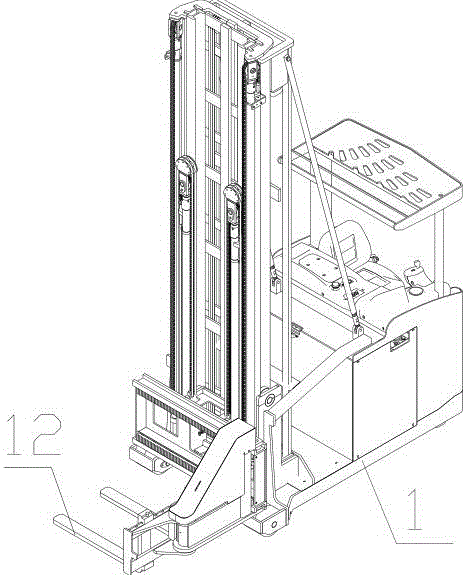

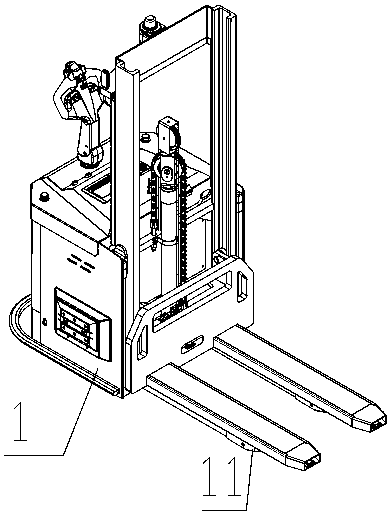

Tunnel automatic guide vehicle, guide system, and operating method for guide system

ActiveCN105974922AMinor changesImprove construction efficiencyPosition/course control in two dimensionsVehiclesAutomated guided vehicleLogistics automation

The invention relates to the field of logistics automation, and specifically relates to a tunnel automatic guide vehicle, a guide system, and an operating method for the guide system. The invention is implemented through the following technical scheme that the guide vehicle comprises a vehicle body and a pallet fork disposed on the vehicle body; the pallet fork is a bidirectional pallet fork which can stretch out in two directions along the width of the vehicle body or is a three-direction pallet fork which can stretch out in two directions along the width of the vehicle body and also can stretch out towards the front of the vehicle body. The vehicle body is provided with a path guide device which is used for guaranteeing the traveling path of the vehicle, and a positioning device which is used for the positioning of the vehicle. The objective of the invention lies in providing the vehicle, the guide system and the operating method for the guide system. Parallel guide rails in a tunnel are used for achieving the linear traveling in the tunnel, and the reconstruction cost of a cabin is low. The vehicle comprises the positioning device, so the positioning is precise.

Owner:上海诺力智能科技有限公司 +1

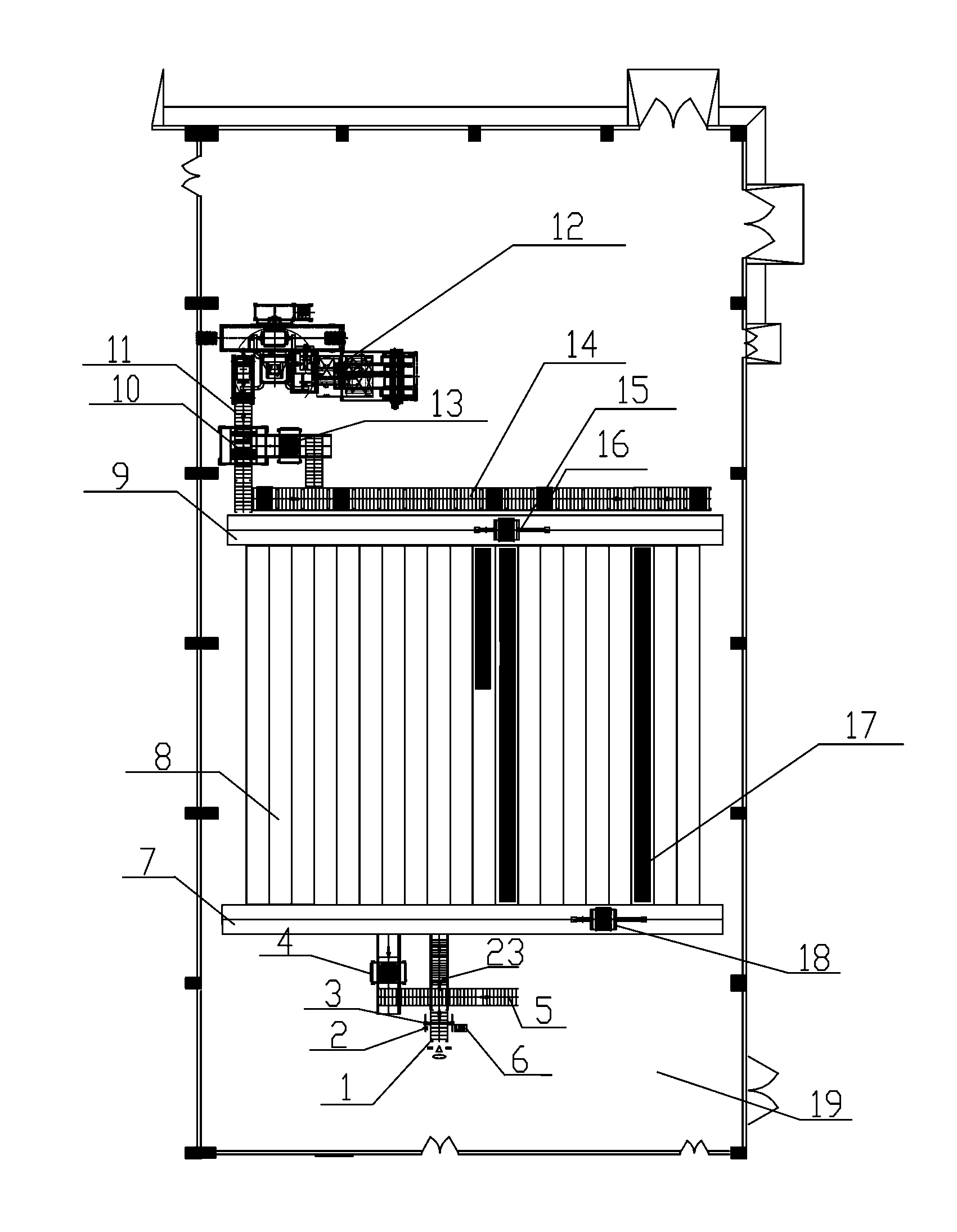

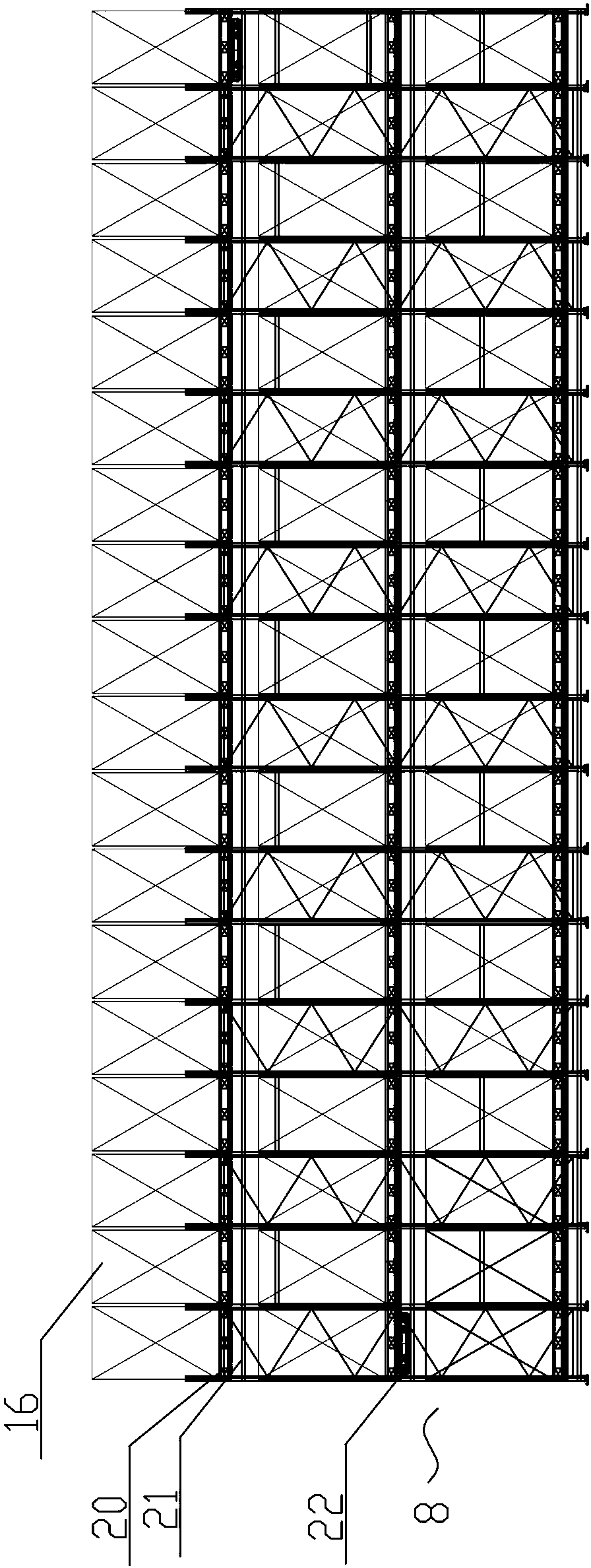

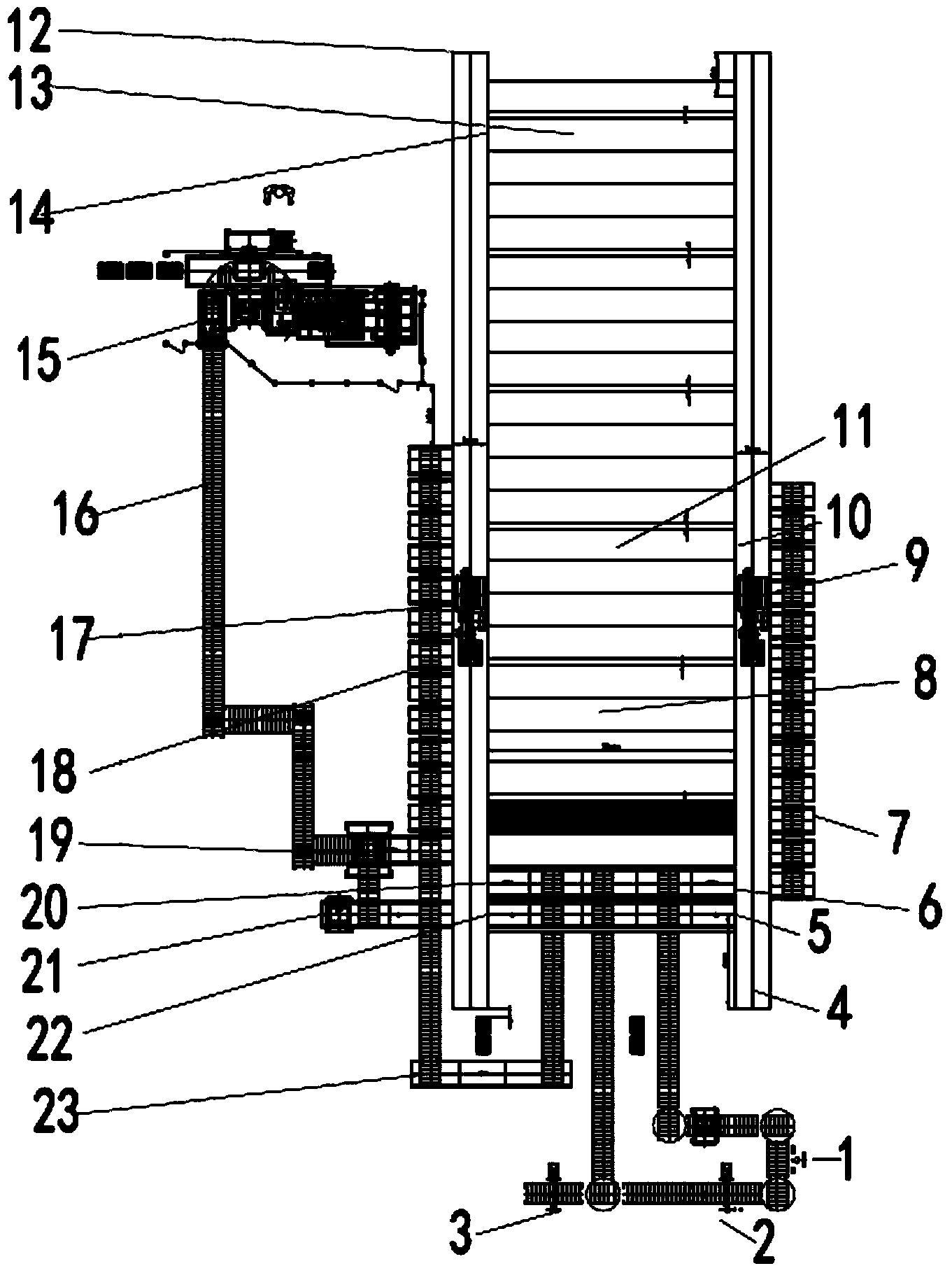

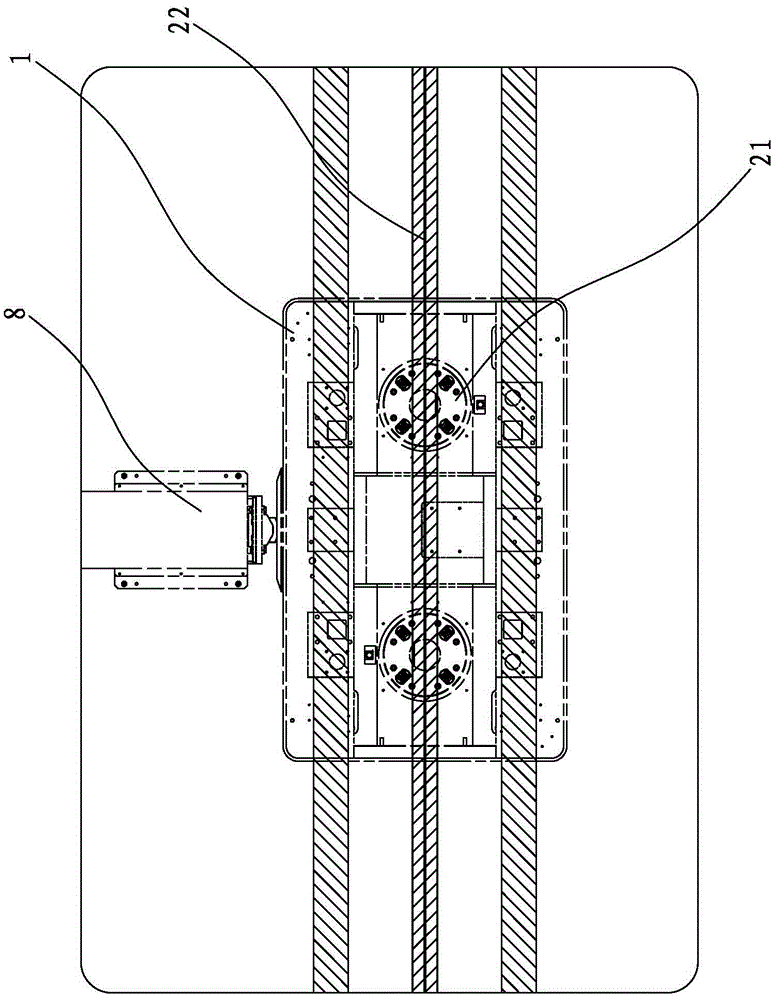

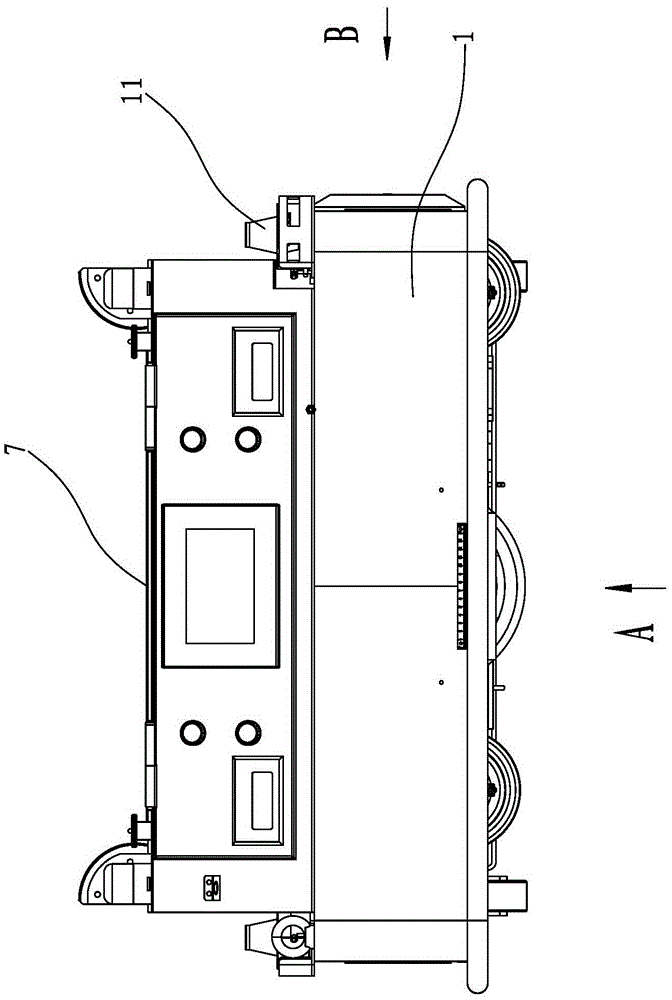

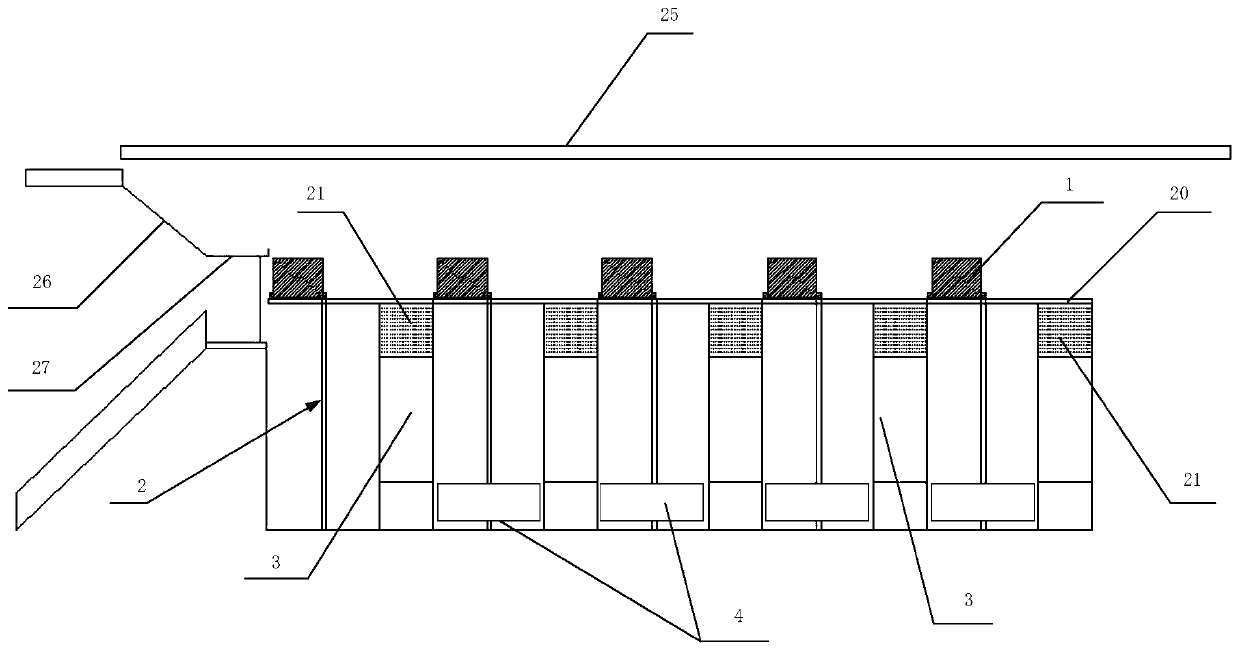

Shuttle shelf type flue-cured tobacco lamina formula warehouse logistics automation system

InactiveCN103057887AIncrease library capacityImprove inbound and outbound production capacityStorage devicesEngineeringLogistics automation

The invention discloses a shuttle shelf type flue-cured tobacco lamina formula warehouse logistics automation system. A warehousing stacker roadway for running of a warehousing stacker is arranged between a warehousing system and a shuttle shelf, an ex-warehouse stacker roadway is for running of an ex-warehouse stacker is arranged between an ex-warehouse feeding system and the shuttle shelf, the warehousing system comprises a warehousing conveying line in butt joint with the warehousing stacker, the ex-warehouse feeding system comprises a flue-cured tobacco lamina packet feeding sequence arrangement buffer in butt joint with the ex-warehouse stacker, the flue-cured tobacco lamina packet feeding sequence arrangement buffer is connected with an unpacking machine through a feeding conveying line, a flue-cured tobacco lamina packet clamping and holding machine is arranged at the position, between the flue-cured tobacco lamina packet feeding sequence arrangement buffer and the unpacking machine, on the feeding conveying line, the shuttle shelf is provided with a plurality of passages with multiple goods allocations, and the warehousing stacker and the ex-warehouse stacker are in butt joint with a goods inlet end and a goods outlet end of each passage respectively. The system achieves dense storage and automatic warehousing and ex-warehouse of flue-cured tobacco lamina packets, and is less in investment and capable of flexibly and conveniently improving warehousing and ex-warehouse capacity as required.

Owner:XIAMEN TOBACCO IND

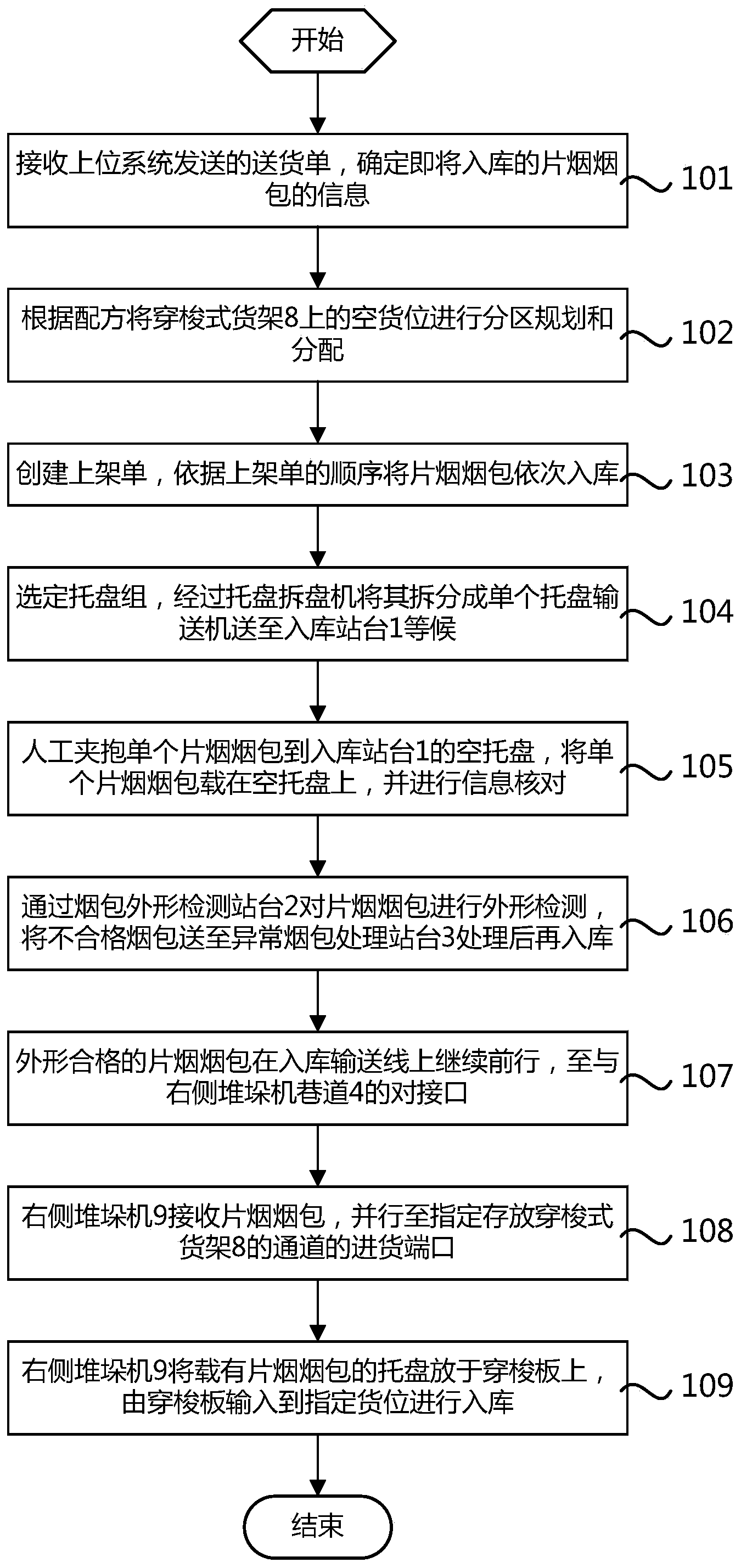

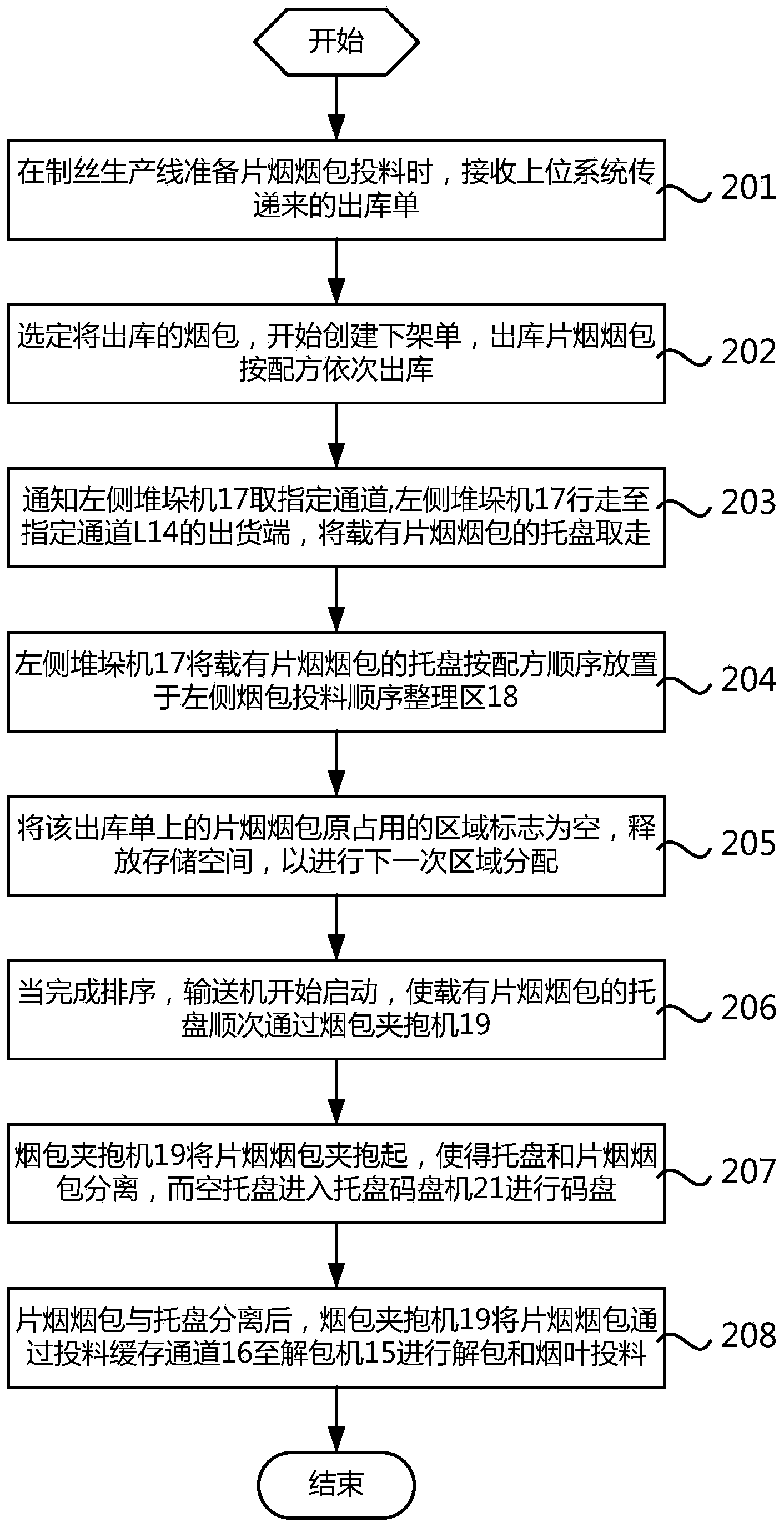

Double-path shuttle goods shelf type tobacco flake formula logistics automation system and handling method

The invention relates to a double-path shuttle goods shelf type tobacco flake formula logistics automation system and a handling method. The double-path shuttle goods shelf type tobacco flake formula logistics automation system comprises a shuttle goods shelf, a warehouse management control system, a warehousing system, an ex-warehouse feeding system and two stackers, wherein the shuttle goods shelf is used for providing goods allocation for placement of tobacco flake packets, the warehouse management control system is used for carrying out communication with an upper system, carrying out district planning and distribution on the goods allocation of the shuttle goods shelf, and creating an addition list or a removal list according to instructions of the upper system, the warehousing system comprises double paths of terminals, and is used for carrying out warehousing operation of the tobacco flake packets according to the addition list provided by the warehouse management control system, the ex-warehouse feeding system comprises double paths of front ends, and is used for carrying out ex-warehouse operation on the tobacco flake packets according to the removal list provided by the warehouse management control system, the stackers are in butt joint with the double paths of the terminals of the warehousing system respectively, are in butt joint with the double paths of front ends of the ex-warehouse feeding system respectively, and are used for carrying out stacking operation on the tobacco flake packets. The double-path shuttle goods shelf type tobacco flake formula logistics automation system and the handling method can solve the problem that the warehousing flow and the ex-warehouse flow are not balanced, and stability of the double-path shuttle goods shelf type tobacco flake formula logistics automation system is improved.

Owner:XIAMEN TOBACCO IND

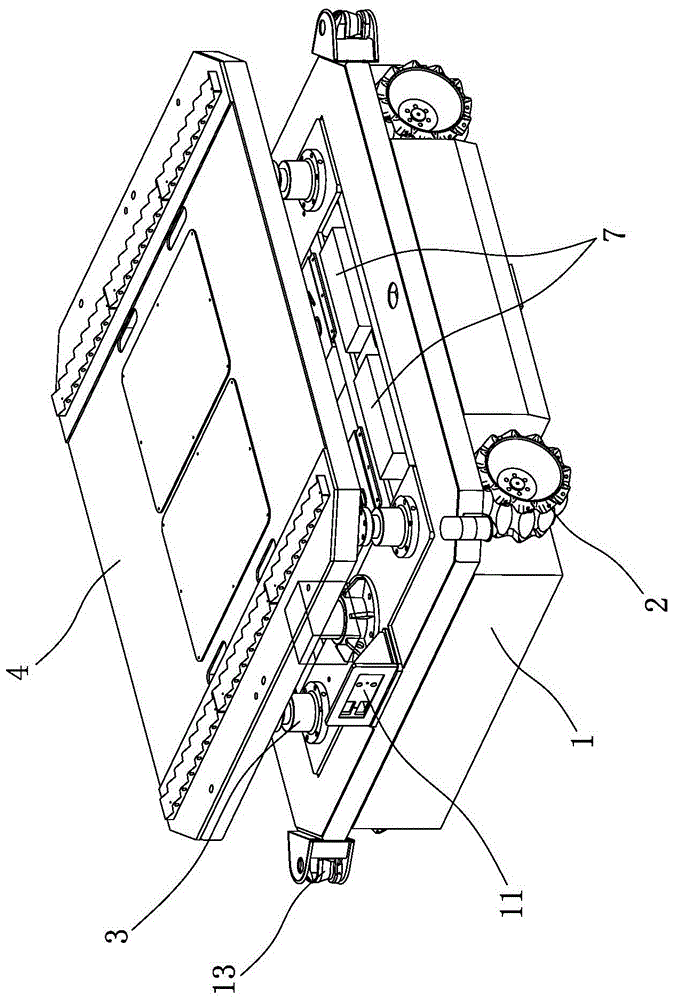

Heavy load lifting type AGV

InactiveCN105467998AEfficient handlingPrecise handlingPosition/course control in two dimensionsElectricityVehicle frame

The invention discloses a heavy load lifting type AGV (Automatic Guided Vehicle); a magnetic stripe is laid on the ground, a magnetic navigation sensor arranged on a vehicle frame transmit a sampled signal to an industrial wireless mobile communication module, the industrial wireless mobile communication module is arranged on the vehicle frame and can control a floating type steering wheel mechanism to drive along the magnetic stripe, and universal casters are arranged on the bottom of the vehicle frame to support the vehicle frame; an elevator is arranged in the vehicle frame, and a workbench is arranged on the elevator; batteries are arranged on the vehicle frame to provide electricity for the magnetic navigation sensor, the floating type steering wheel mechanism and the industrial wireless mobile communication module, the industrial wireless mobile communication module is electrically connected with the magnetic navigation sensor, the floating type steering wheel mechanism and the elevator separately, and the industrial wireless mobile communication module is controlled by a central scheduling system. According to the invention, the material conveying can be effectively, accurately and flexibly completed, the logistics automation is realized, the production efficiency is improved, and the production cost is reduced.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

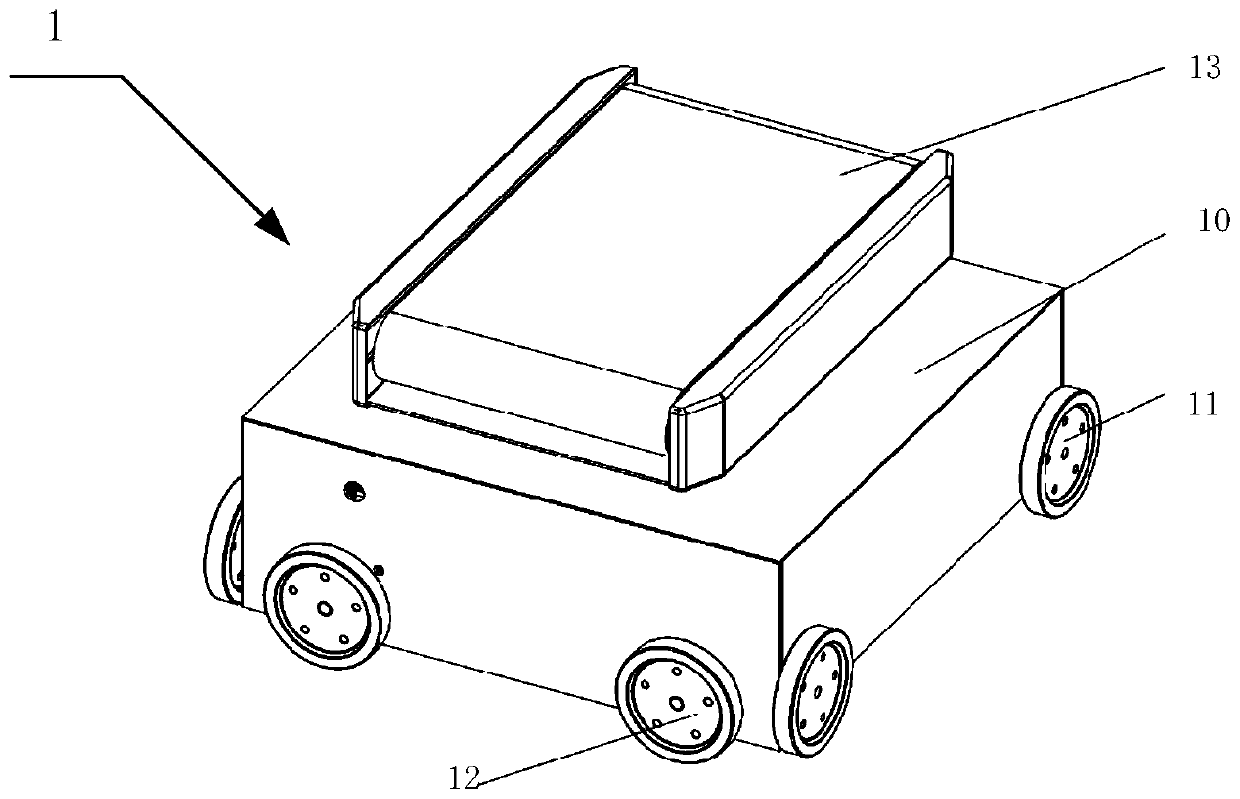

AGV type automatic storage device and application thereof

ActiveCN110775502ACooperate smoothlySave human effortStorage devicesLogistics managementControl engineering

The invention relates to an AGV type automatic storage device and application of the AGV type automatic storage device, and belongs to the technical field of logistics automation machinery. The AGV type automatic storage device comprises storage racks and an AGV located between the storage racks, a climbing track is arranged on the storage racks, the AGV comprises a vehicle body and a climbing mechanism arranged on the vehicle body, and the climbing mechanism is used for driving the vehicle body to move on the climbing track; the vehicle body comprises a traveling mechanism, a cargo carrying platform and an extension fork type transfer mechanism used for transferring cargos, the climbing mechanism comprises a telescopic mechanism and a climbing mechanism, the telescopic mechanism is used for controlling the extension and retraction of the climbing mechanism, and the climbing mechanism is used for being matched with the climbing track for realizing the up-and-down movement of the vehicle body. The AGV type automatic storage device can walk in the vertical direction to store and transport cargos, lifting equipment is not needed, investment of automatic storage equipment is reduced, and operation efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

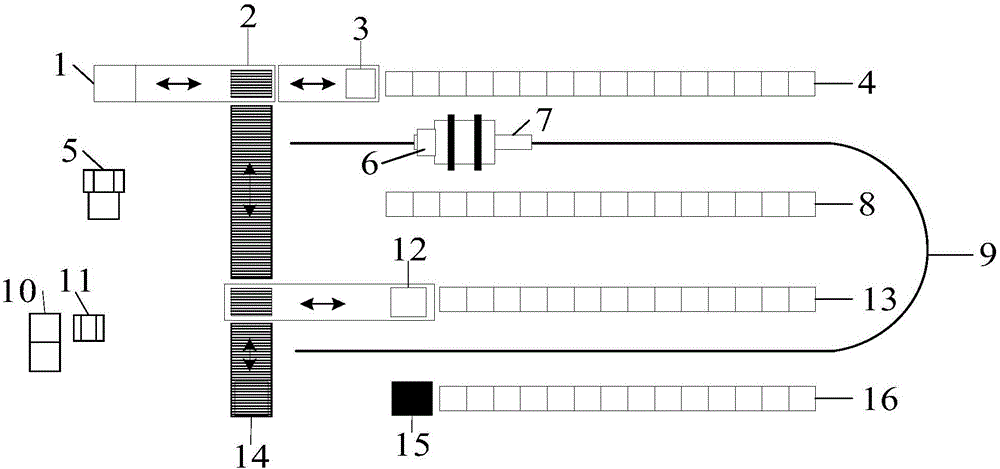

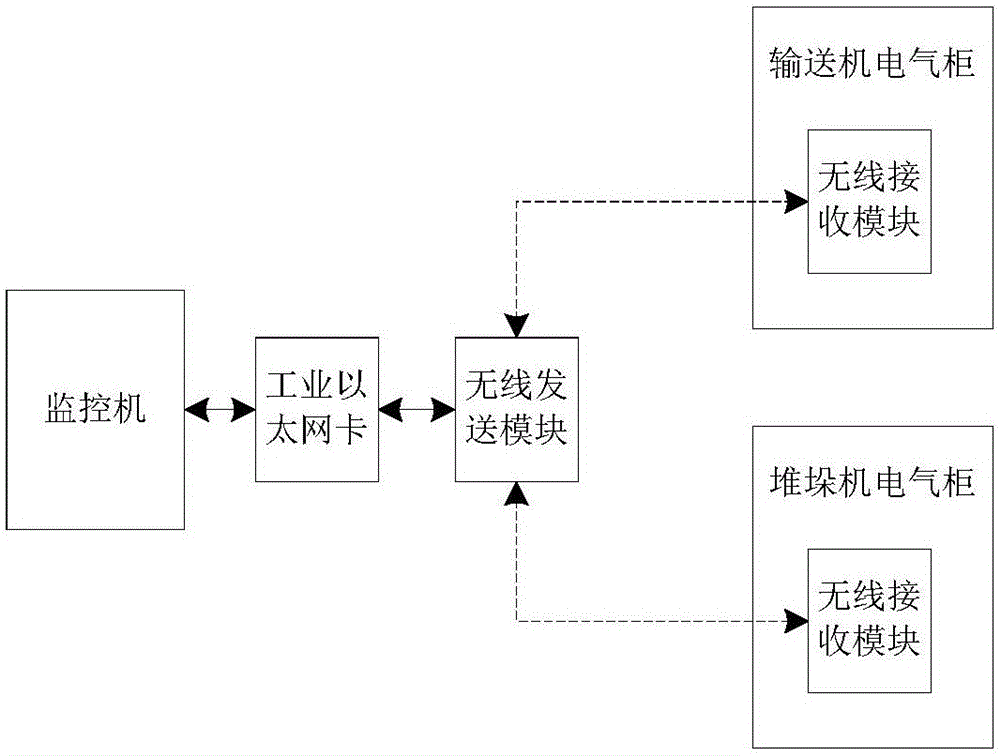

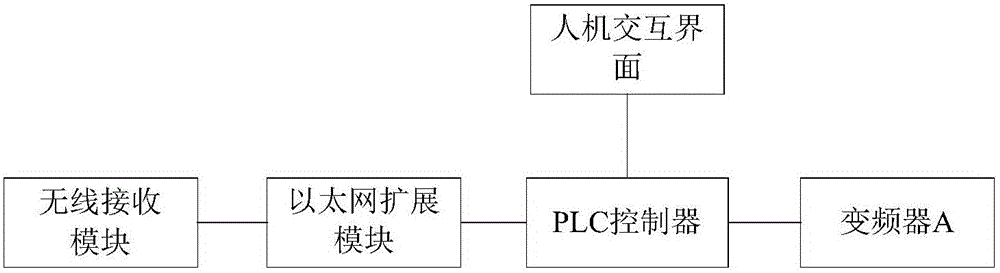

Control system for turn roadway stereoscopic warehouse

The invention discloses a control system for a turn roadway stereoscopic warehouse and belongs to the technical field of logistics automation. The control system comprises a monitoring management system, a stacking machine control system and a conveyer control system, wherein a sensor arranged in the stacking machine control system for judging the running position of a stacking machine comprises two limiting switches, two speed reducing electromagnetic switches and two roadway recognition switches, all of which are arranged on a lower cross beam of the stacking machine, and correspondingly, two roadway limiting switch plectrums, two roadway end position speed reducing magnets, two bend speed reducing magnets and two roadway recognition switch plectrums are arranged on a U-shaped rail. The control system is simple in structure and convenient to construct; the electromagnetic switches are used as speed reducing detection switches in the running direction of the stacking machine, the sensor is in a non-contact type, and reliability is high; and the stacking machine runs in a U-shaped roadway and is in communication with a conveyor system and an upper computer through the wireless Ethernet, and convenience and rapidness are achieved.

Owner:BEIJING CTROWELL INFRARED TECHN

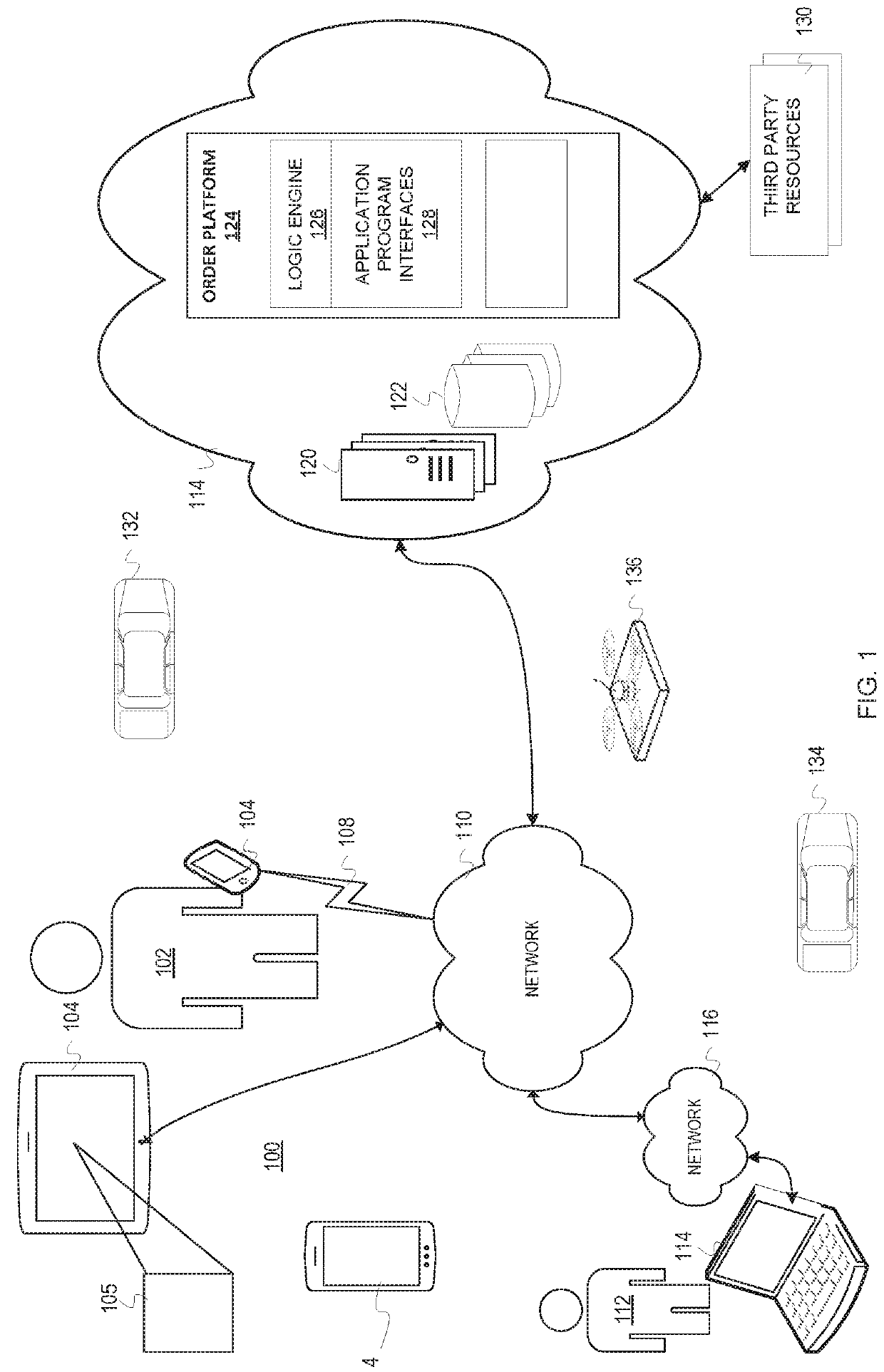

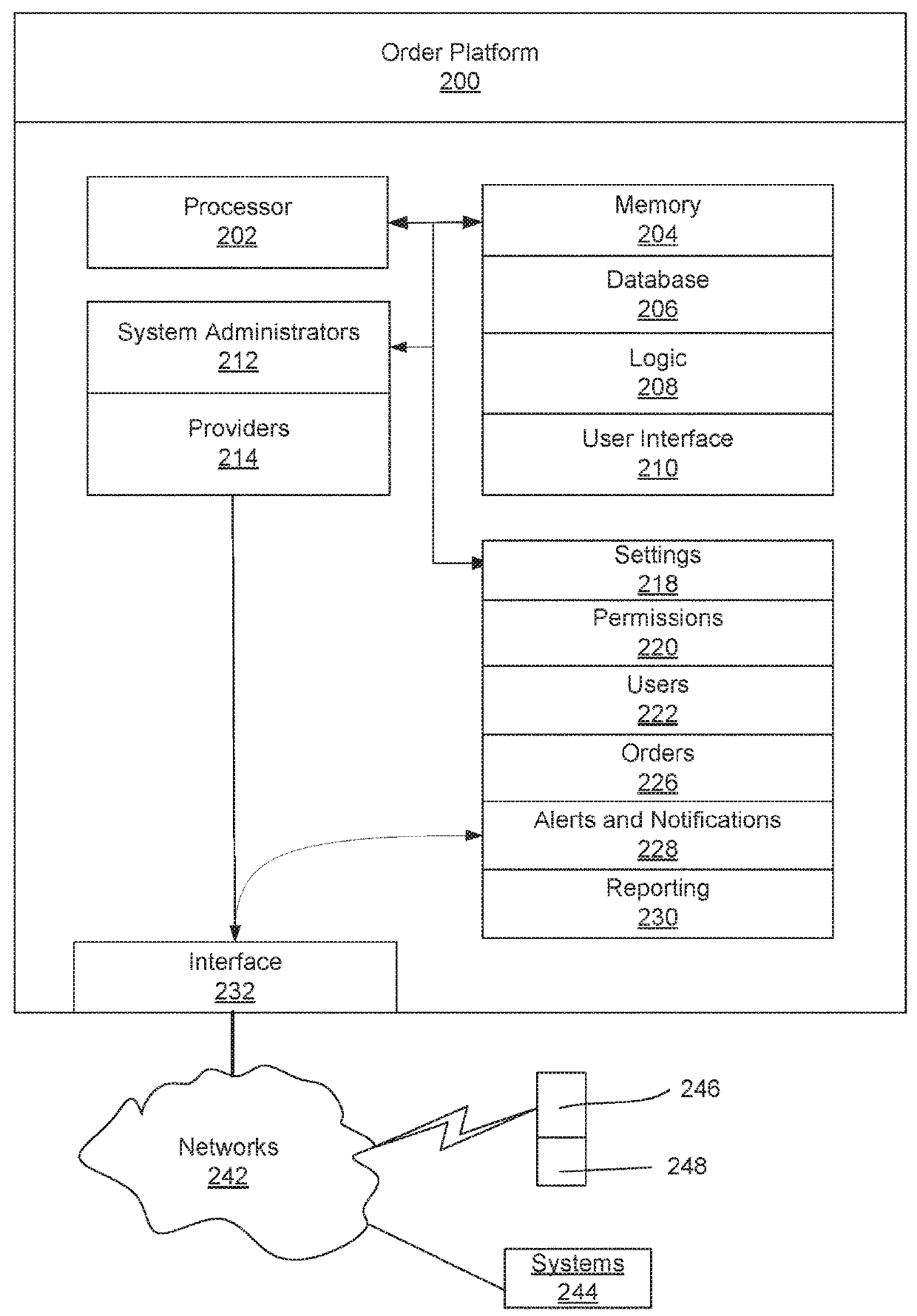

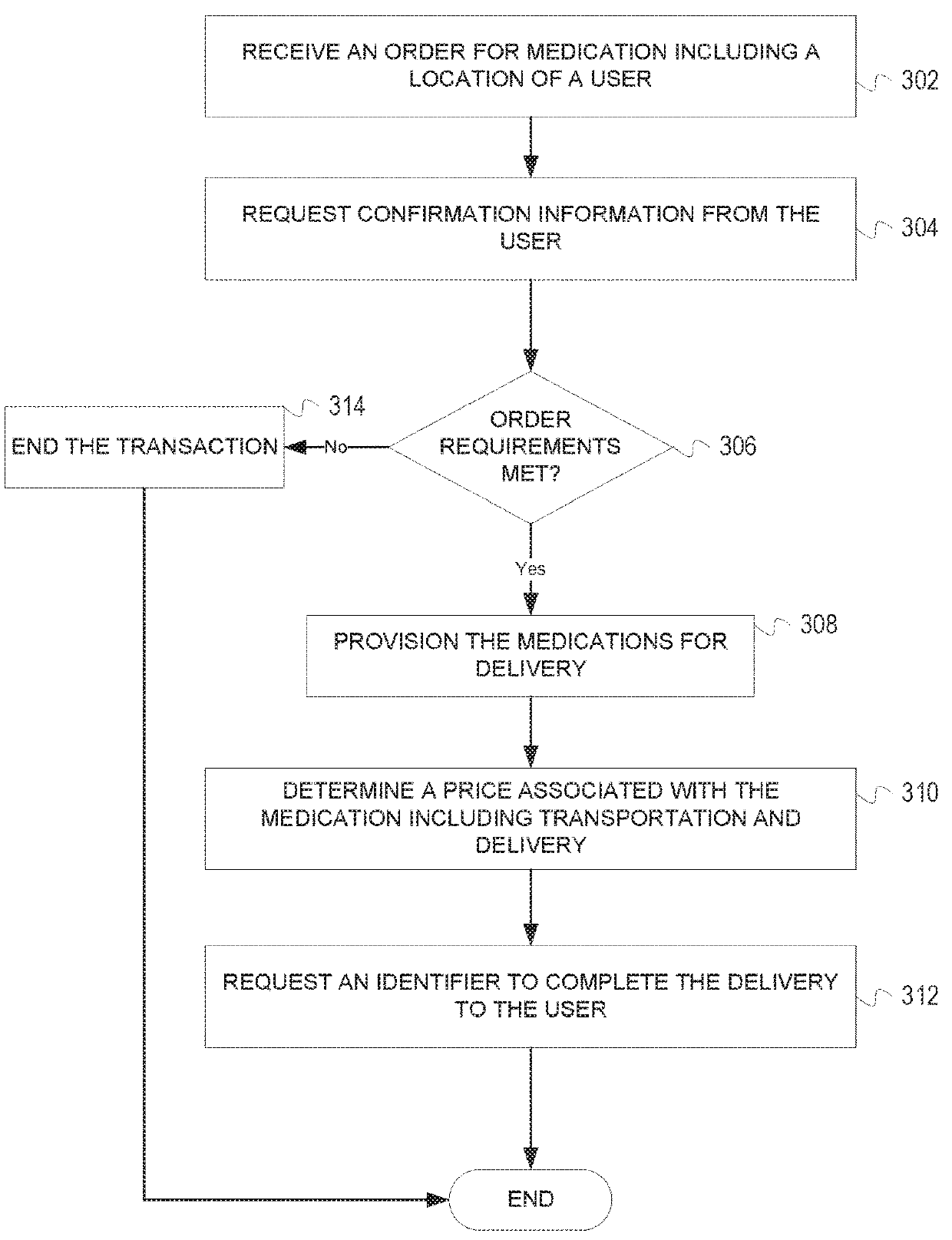

Secure Network Based Order Confirmation, Transportation, and Delivery Processes Utilizing Logistics Automation

One embodiment provides a system, method, platform, and server for processing orders for medication. An order for medication is received including a location of a user performing the order. Confirmation information is requested from the user. A determination is made the order requirements are met. The medications are provisioned for delivery. One or more identifiers are requested to complete the delivery to the user.

Owner:WEB ACCESS LLC

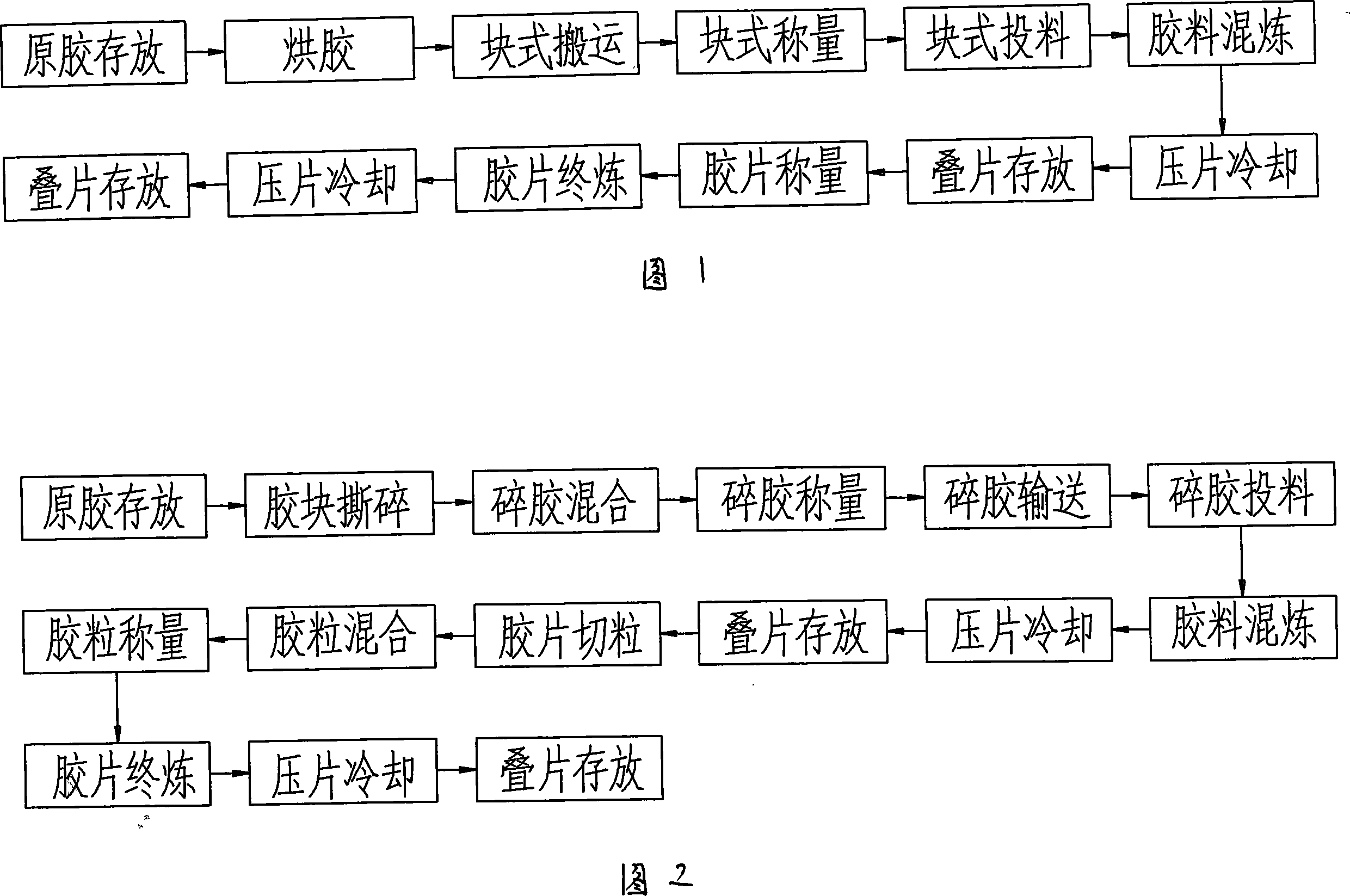

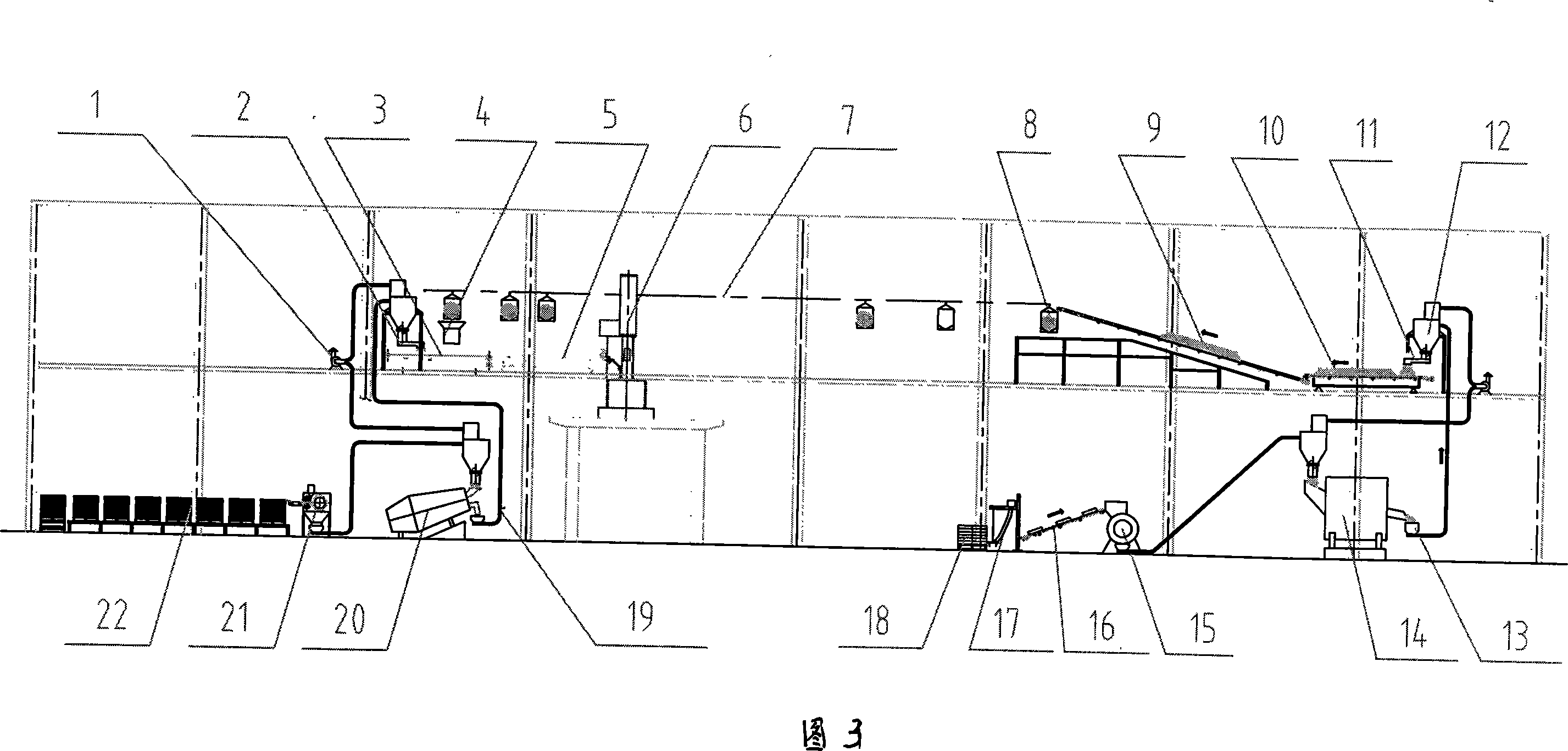

Broken glue feeding rubber mixing technique

ActiveCN101214705AStable and uniform qualityIncrease the level of automationRubber materialEngineering

The present invention relates to a cuttings-feeding rubber mixing technique, which belongs to the field of rubber-processing machines. The technique includes the following steps: (1) the storage of raw rubber, (2) the ripping of rubber blocks, (3) the weighing of cuttings, (4) the conveying of the cuttings, (5) the charging of the cuttings, (6) the mixing of the rubber material, (7) sheeting and cooling, (8) the stacking and storing of rubber sheets, (9) the granulating of the rubber sheets, (10) the mixing of rubber particles, (11) the weighing of the rubber particles, (12) the final mixing of rubber sheets, (13) sheeting and cooling, and (14) the stacking and storing of the rubber sheets. By the ripping of the rubber blocks, the granulating of the mother rubber sheets and two times of uniform mixings, the present invention realizes the uniform mixings of multiple batches of materials, so that the quality of the rubber material is more uniform and stable, and therefore the banburying effect is more ideal, and the following effects are achieved: The uniformity and stability of rubber mixing is improved, the efficiency of rubber mixing is increased, the impact damage of equipement is abated, and the automatization degree of material flowing is increased.

Owner:TRIANGLE TIRE

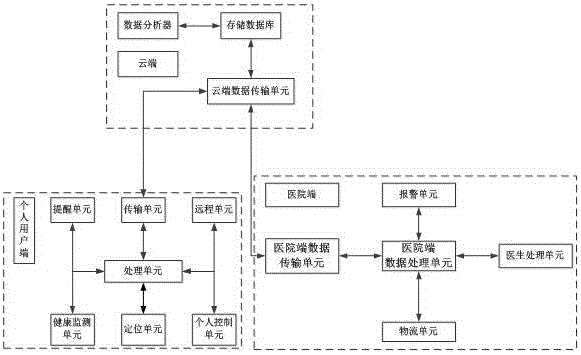

All-round personal medical management device, system and method

InactiveCN105827734AHealth data real-time monitoringRealize all-round managementTransmission systemsEvaluation of blood vesselsThe InternetEmergency medicine

The invention discloses an all-round personal medical management equipment, system and method, and relates to the medical field. The system includes: devices for real-time monitoring of the user's health status, such as blood oxygen sensors and heart rate sensors; monitoring of the user's arterial and venous blood oxygen content and heart rate, and storing and analyzing the information. It mainly consists of three parts: user end, cloud and hospital end. The user end includes: reminder unit, transmission unit, remote unit, processing unit, health monitoring unit, positioning unit, personal control unit; the hospital end includes: alarm unit, hospital end data processing unit, hospital end data transmission unit, A doctor processing unit and a logistics unit; the cloud includes: a data analyzer, a storage database and a cloud data transmission unit. The system takes the concept of Internet + as the guiding ideology and realizes the integration of personal medical management, including: real-time personal health status monitoring, personal health early warning, remote medical treatment, personal health data analysis, drug logistics automation and other advantages.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

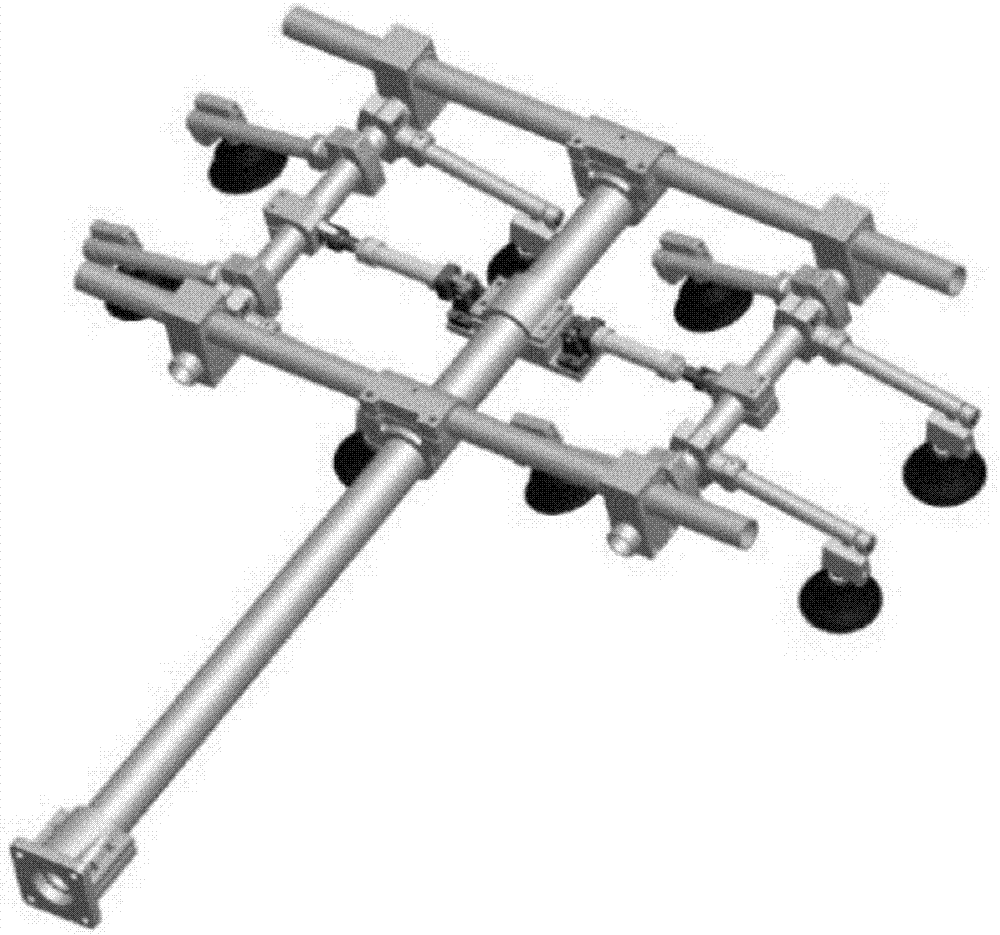

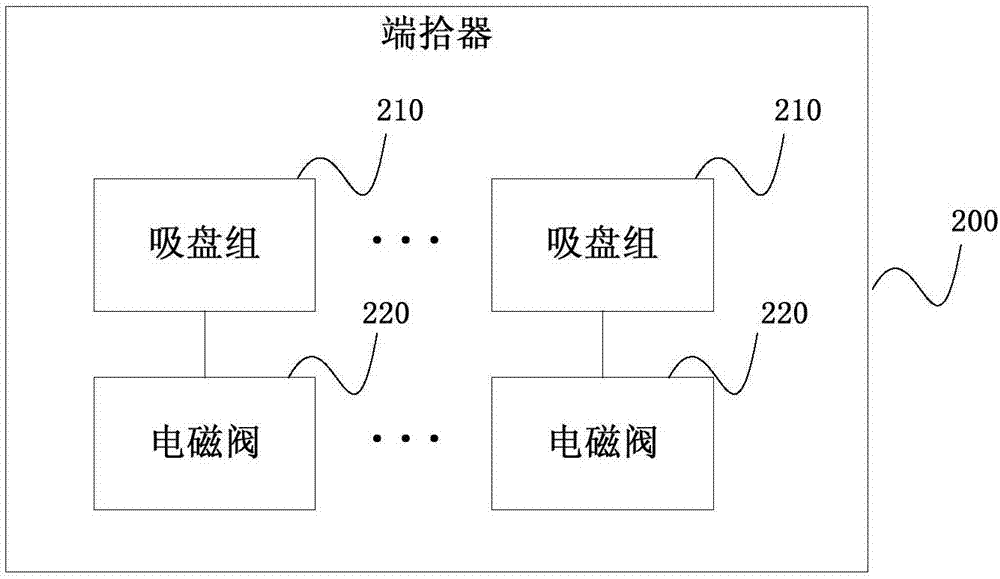

End picker goods sorting method and device and end picker

The invention discloses an end picker goods sorting method and device and an end picker, and relates to the field of logistics automation. The end picker comprises a plurality of suction cup sets and a plurality of electromagnetic valves. Each suction cup set is connected with one electromagnetic valve so that the electromagnetic valve can be used for controlling the corresponding suction cup set. According to the end picker goods sorting method and device and the end picker, zone control can be conducted on suction cups of the end picker, in other words, selective sorting work can be conducted on goods, and therefore the sorting work efficiency of the end picker can be improved.

Owner:TIANJIN JINGDONG SHENTUO ROBOT TECH CO LTD

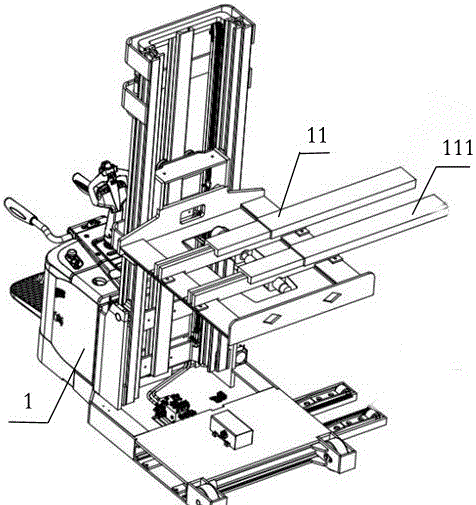

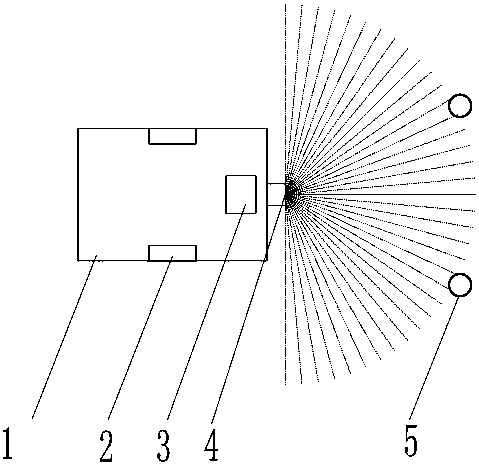

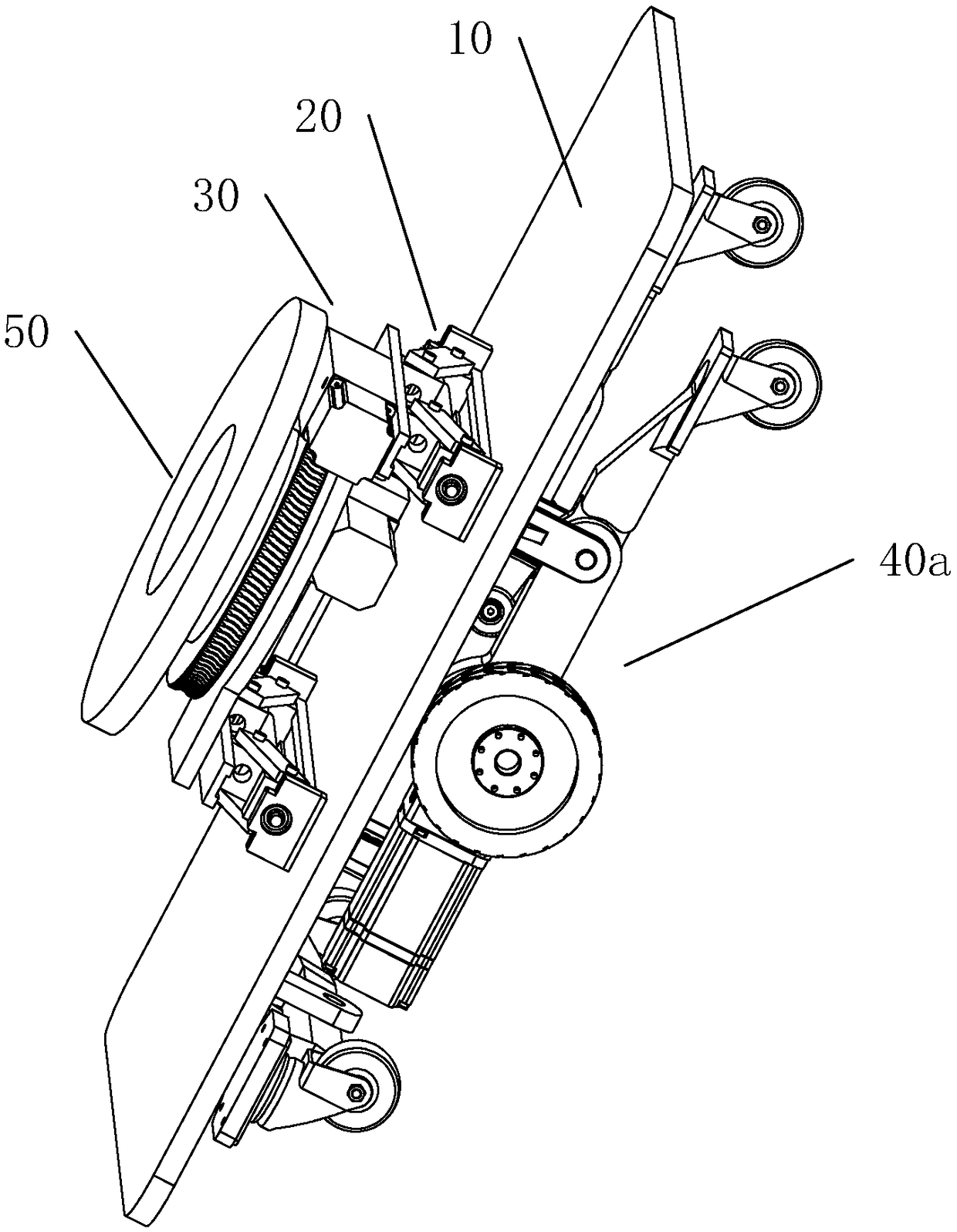

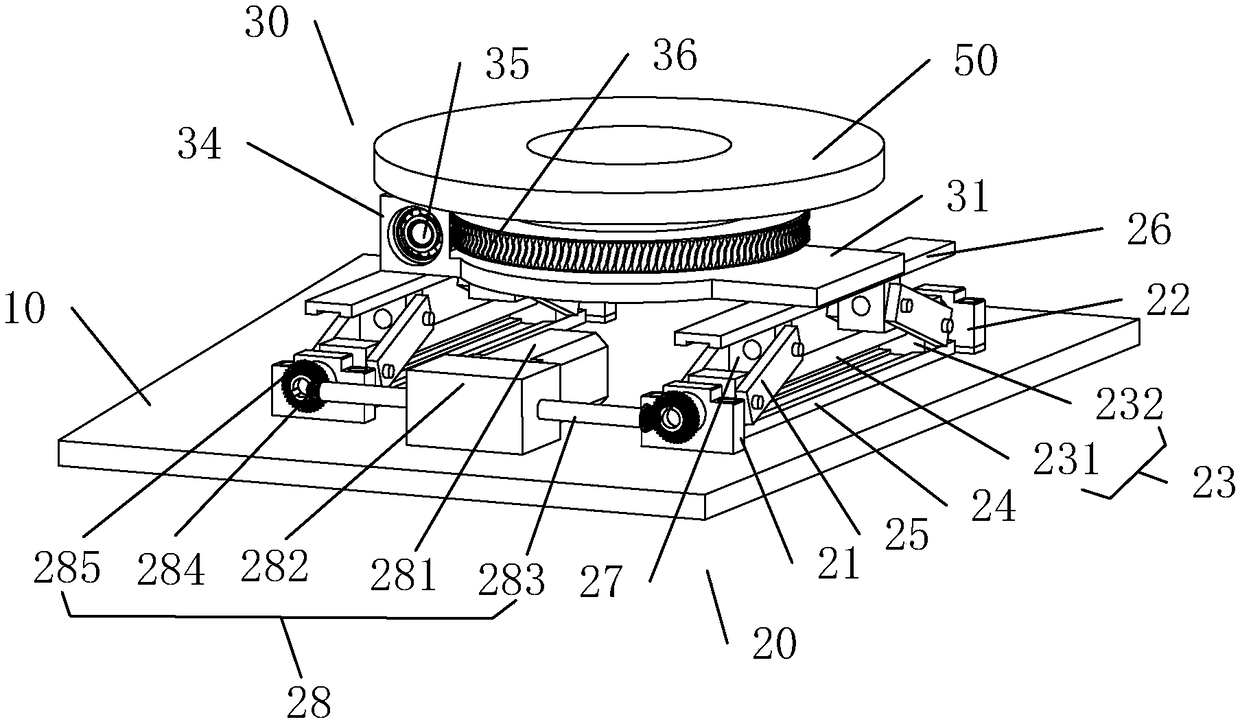

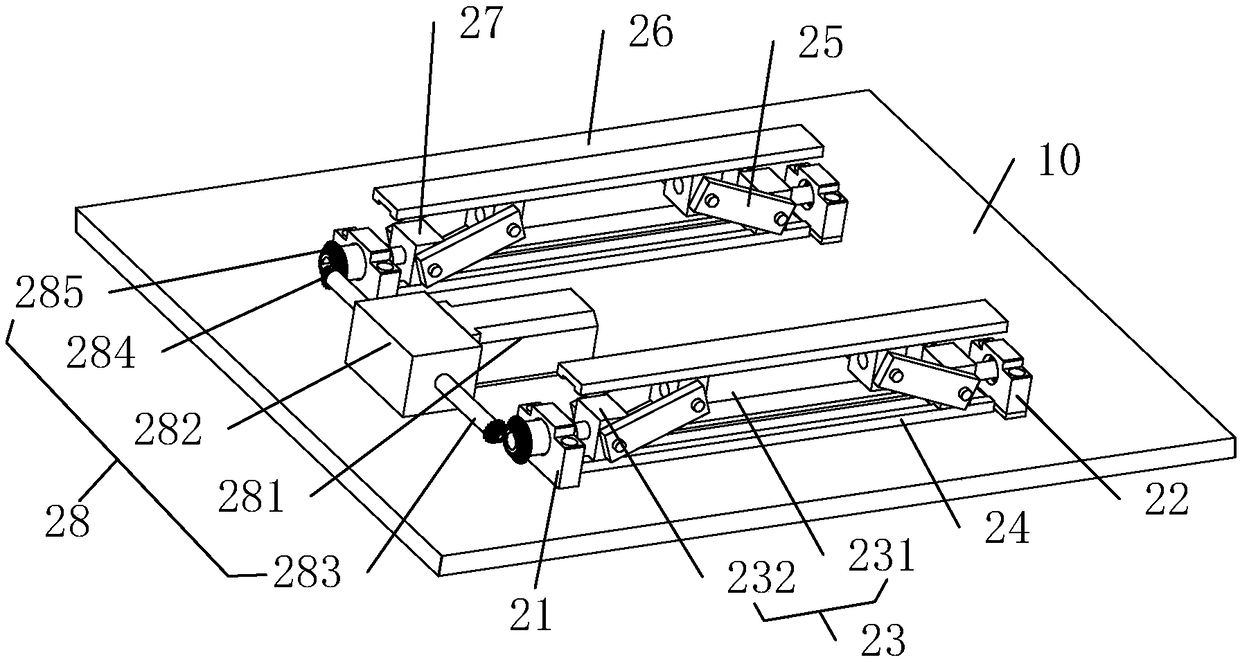

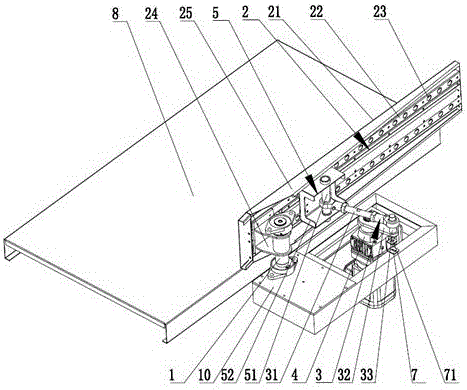

High-precision parking AGV vehicle fork-taking device and parking method thereof

PendingCN107814153AImprove accuracyLow degree of modificationMechanical conveyorsDistance sensorsPosition sensor

The invention relates to the field of logistics automation, in particular to a high-precision parking AGV vehicle fork-taking device and a parking method thereof. The following technical scheme is adopted: the high-precision parking AGV vehicle fork-taking device comprises an AGV trolley and an auxiliary positioning part, wherein the AGV trolley comprises a trolley body and an induction componentmounted on the trolley body; the trolley body comprises trolley legs; a traveling wheel component is mounted on each trolley leg; a transverse mechanism capable of moving transversely is arranged on the trolley body; forks are connected to the transverse mechanism; and the induction component comprises at least two distance sensors for distance detection and a position detection sensor mounted onthe transverse mechanism. The invention aims to provide the high-precision parking AGV vehicle fork-taking device and the parking method thereof, and by virtue of the distance sensors, the position detection sensor and the transverse mechanism, the position control accuracy of three controlled quantities of the trolley is effectively improved.

Owner:上海诺力智能科技有限公司

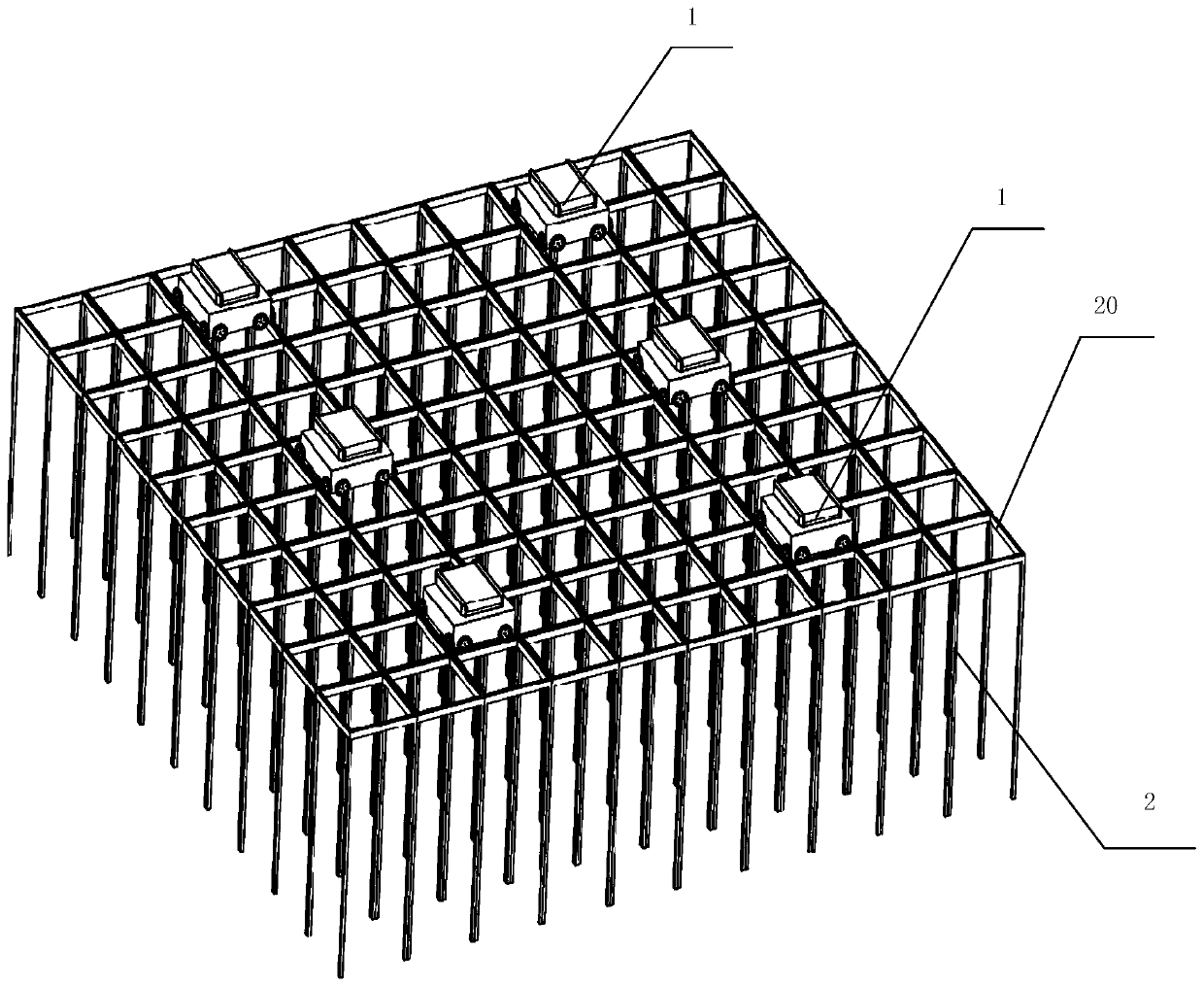

Logistics object allocating system and method

InactiveCN111038892AIncrease freedom of movementEfficient designSortingStorage devicesLogistics managementGrid cell

The invention provides a logistics object allocating system and method, and belongs to the field of logistics automation equipment manufacturing. The logistics object allocating system comprises a logistics object bearing structure and at least one carrying equipment running on the logistics object bearing structure. The logistics object bearing structure comprises multiple continuously-arranged grid units, and a grid type rail used for running of the carrying equipment is arranged above each grid unit. A grid opening used for logistics object allocating can be arranged above each grid unit. The carrying equipment comprises carrying equipment bodies and conveying devices located on the carrying equipment bodies. The corresponding conveying manners of logistics objects are confirmed according to the kinds of the conveying devices. By means of the system, the carrying equipment can freely walk on the logistics object bearing structure, grid openings used for logistics object allocating can be arranged below the grid units, and design of the grid openings on the logistics object bearing structure can be maximized.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

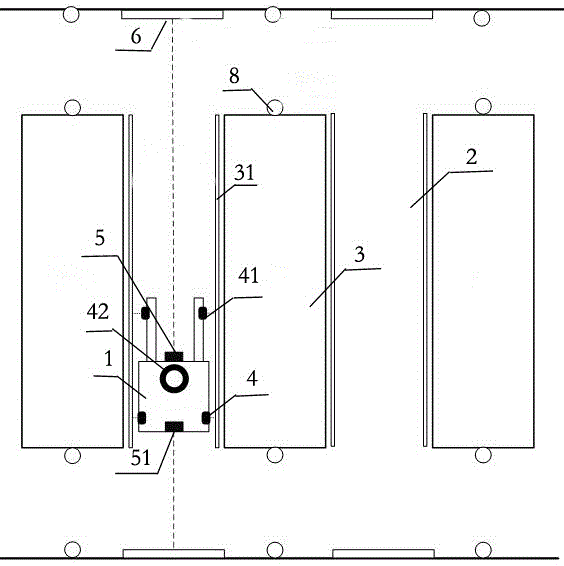

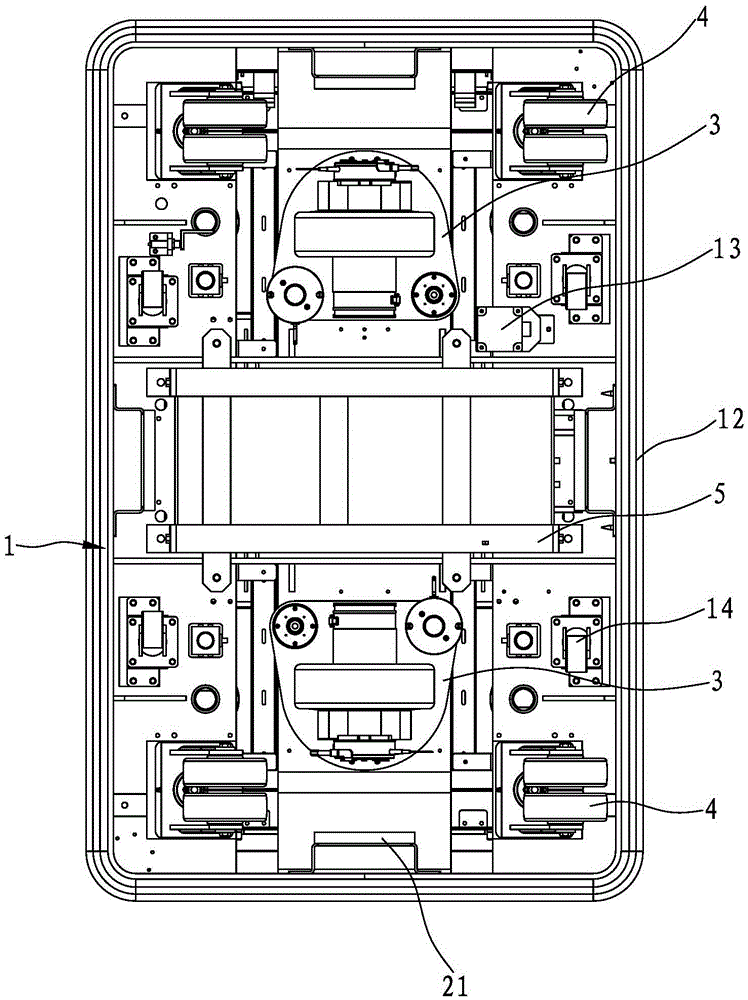

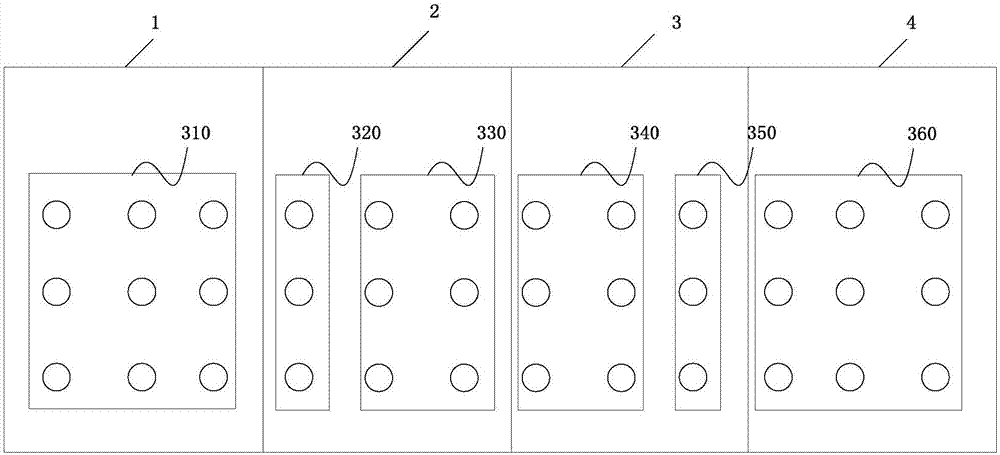

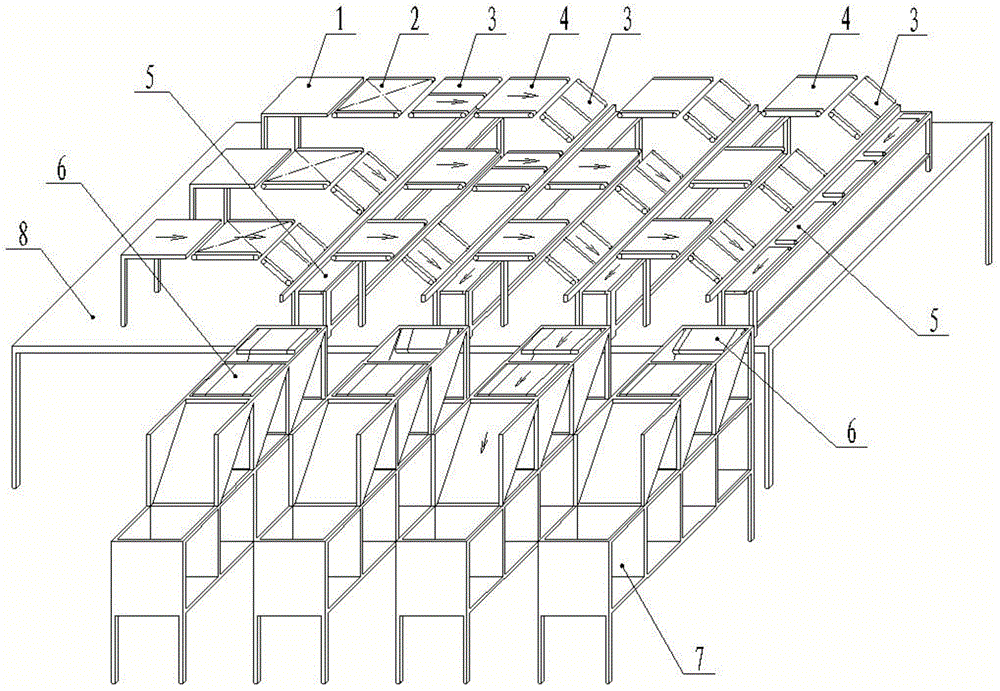

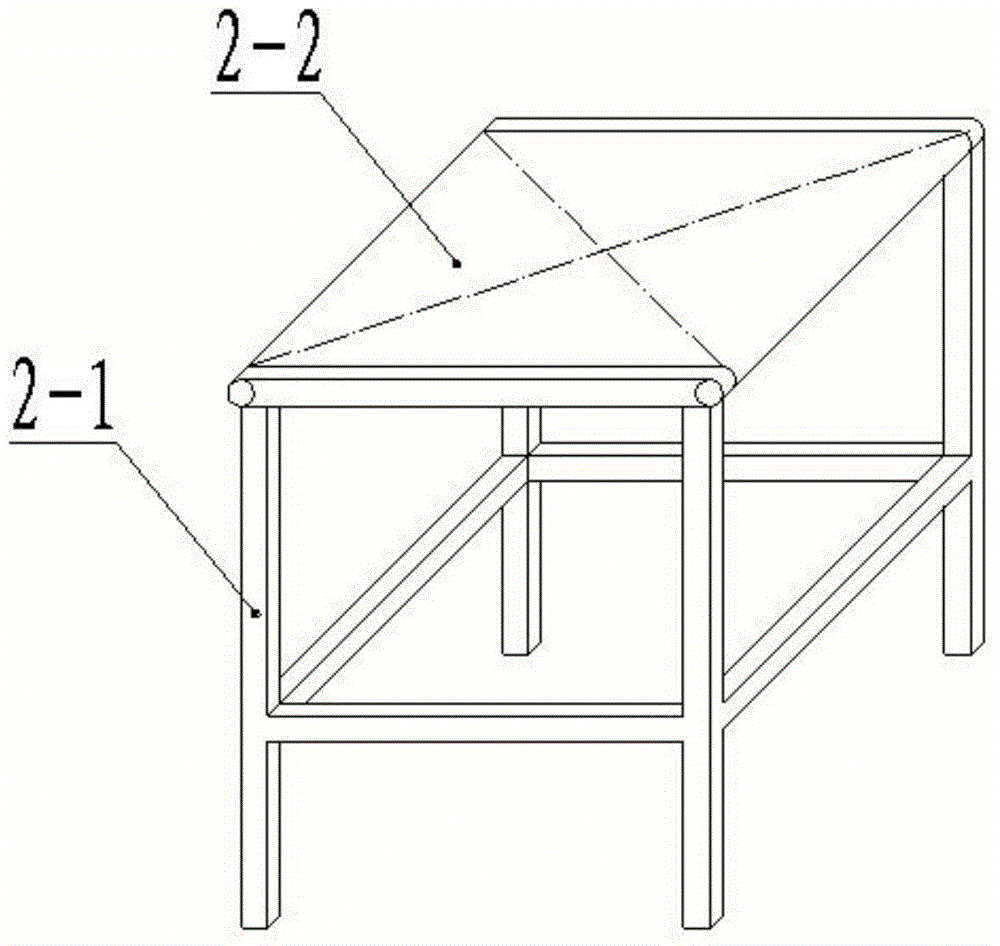

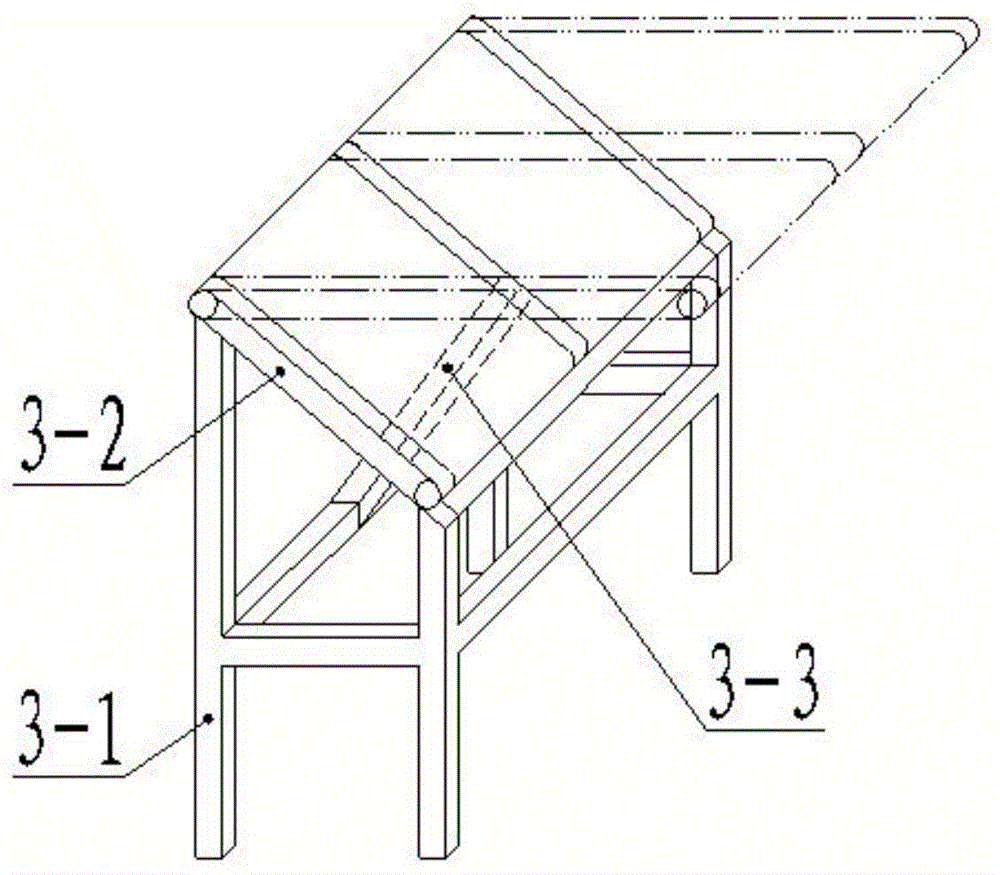

Matrix type sorting system

ActiveCN104590840AImprove flexibilityImprove availabilityMechanical conveyorsEngineeringLogistics automation

The invention discloses a matrix type sorting system, belongs to automatic logistic sorting devices, and aims to provide an automatic logistics sorting device which is good in system allocation flexibility and high in sorting efficiency and automation level. The matrix type sorting system comprises a plurality of article stacking platforms, article supplying devices, a conveying line and a sorting and collecting device, wherein the conveying line is formed by a plurality of longitudinal conveying lines (5), transverse conveying devices (4) located above the longitudinal conveying lines (5) and reversing devices (3) located between every two adjacent longitudinal conveying lines (5); each article supplying device (2) is communicated with an adjacent longitudinal conveying line (5) or an adjacent transverse conveying device (4) through another reversing device (3); the sorting and collecting device is communicated with all longitudinal conveying lines and is formed by a sorting device (6) and a collecting device (7). The matrix type sorting system provided by the invention has the advantages that the structure is simple, standard designing, manufacturing and maintaining are facilitated, and the article sorting is continuous, ordered, accurate and efficient.

Owner:陈景

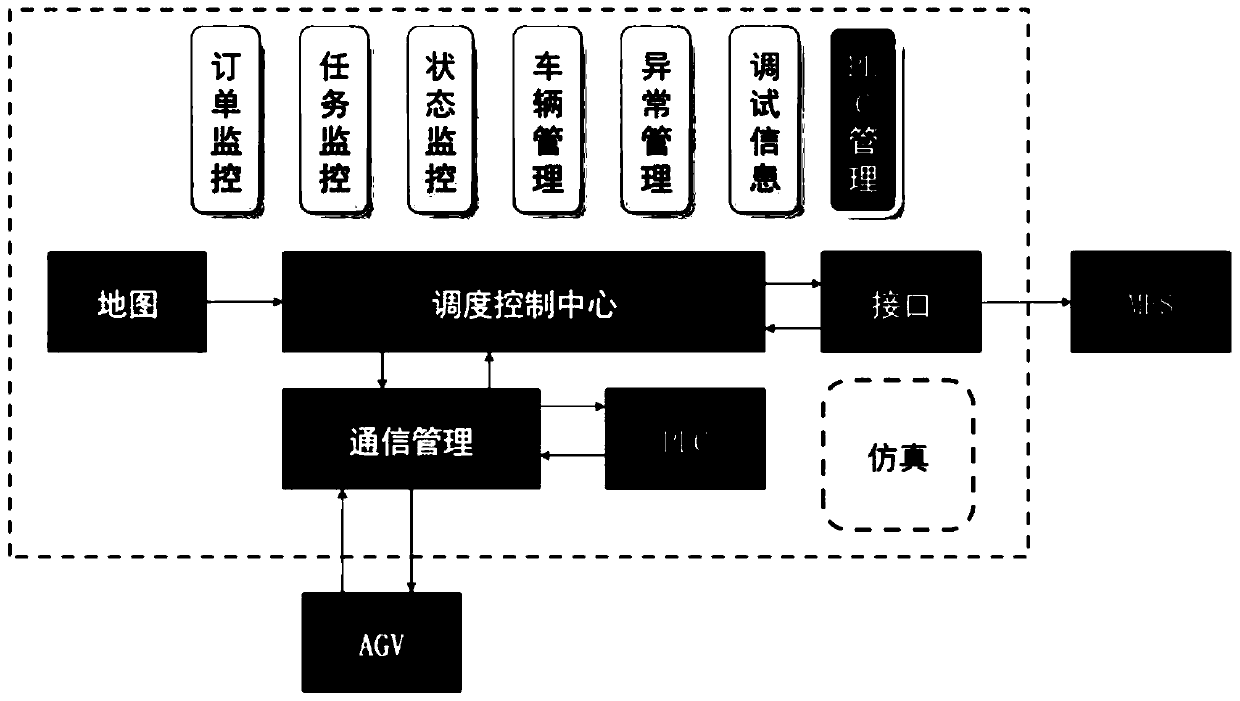

Intelligent AGV logistics automation system

InactiveCN110282319AIncrease the simulation functionLearn about planning statusStorage devicesVehiclesLogistics managementMarine navigation

The invention discloses an intelligent AGV logistics automation system. The system involves a first AGV trolley, a second AGV trolley, a third AGV trolley, and a six-axis robot; and the first AGV trolley is used for conveying materials from a feeding position to an operation position along a designated guide path, the second AGV trolley with the six-axis robot grabs the materials on the first AGV trolley and conveys the materials to the operation station through actions of lifting, stretching, retracting and rotating, and after operation is completed, the second AGV trolley moves the materials from the operation position and places the materials to the third AGV trolley for discharging. According to the system, lasers guide the AGV trolleys to walk freely in the guide area and to carry out accurate positioning, the walking paths of the trolleys can be changed at any time according to actual requirements in the navigation range, so that the flexibility of an AGV can be brought into full play, and the production efficiency is improved; and in unmanned workshop management, the system can be used for feeding and carrying, operation, discharging and carrying and the like of the materials so that manual work can be replaced, the cost is reduced and the working efficiency is improved.

Owner:潍坊海丰自动化科技有限公司

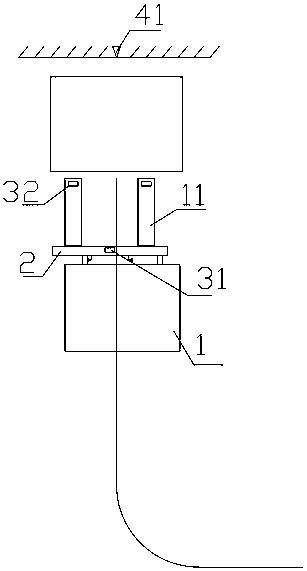

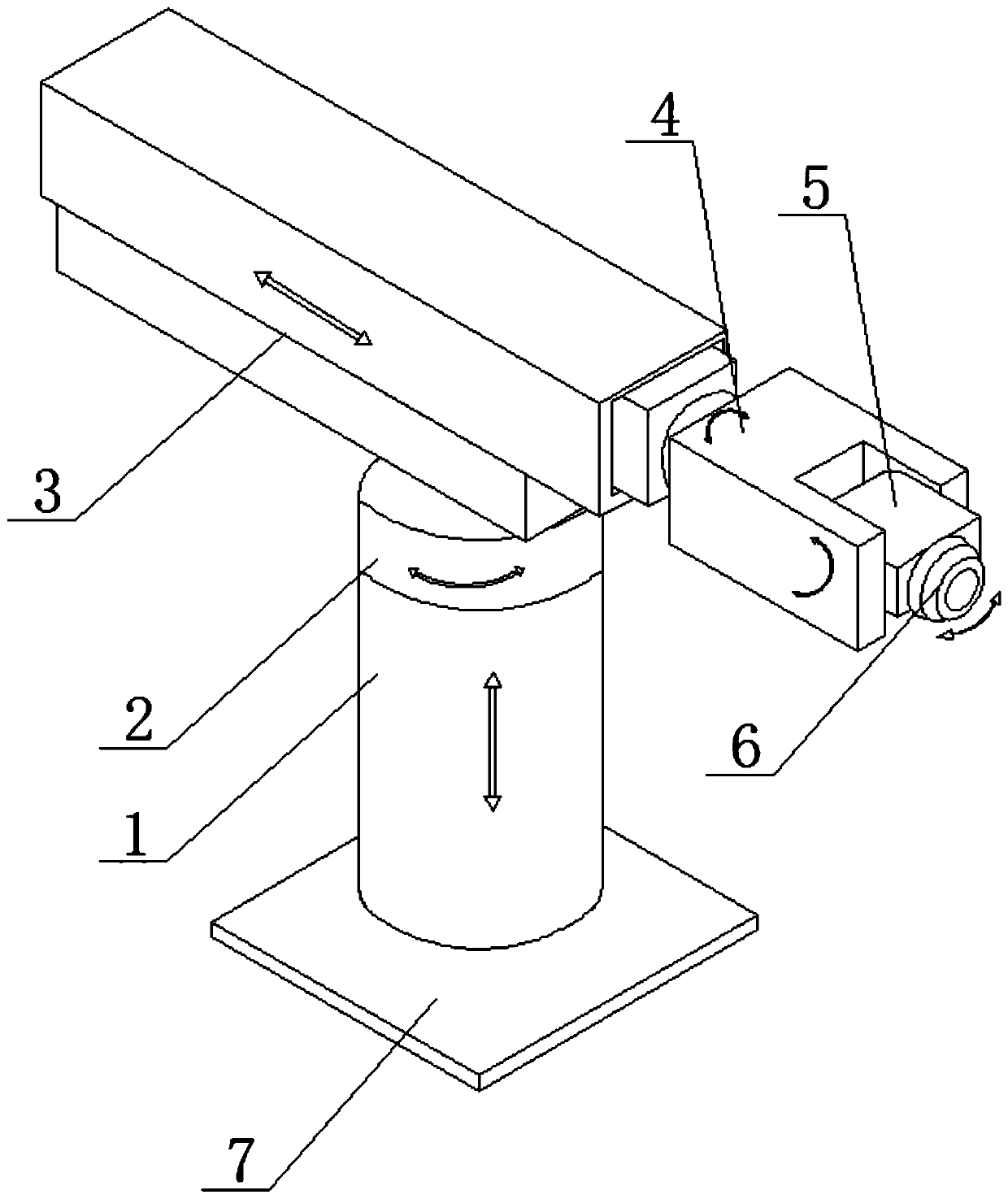

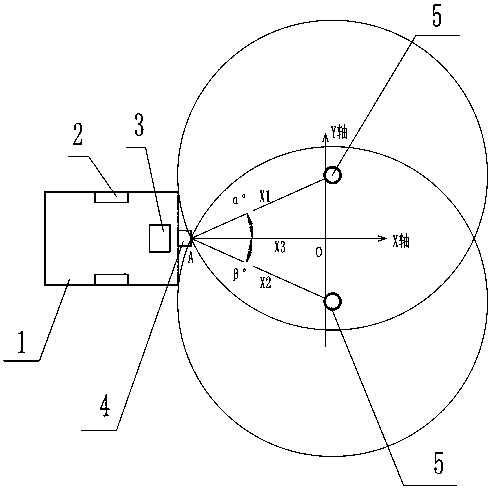

Control system and method for secondary precise positioning of AGV

PendingCN107817803AAutomatic switchingGuaranteed efficiencyPosition/course control in two dimensionsVehiclesControl systemLogistics automation

The invention relates to the field of logistics automation, and specifically relates to a control system and method for the secondary precise positioning of an AGV. The system is implemented through the following technical scheme that the system comprises an AGV and an auxiliary positioning device; the AGV comprises a vehicle body, a drive unit, a controller and a scanning device disposed on the vehicle body; the controller comprises a switching device for switching a positioning algorithm. The objective of the invention lies in providing the control system and method for the secondary precisepositioning of the AGV, and the system can trigger the secondary precise positioning in a large work occasion, and switches the positioning algorithm, and continues to work at high precision.

Owner:上海诺力智能科技有限公司

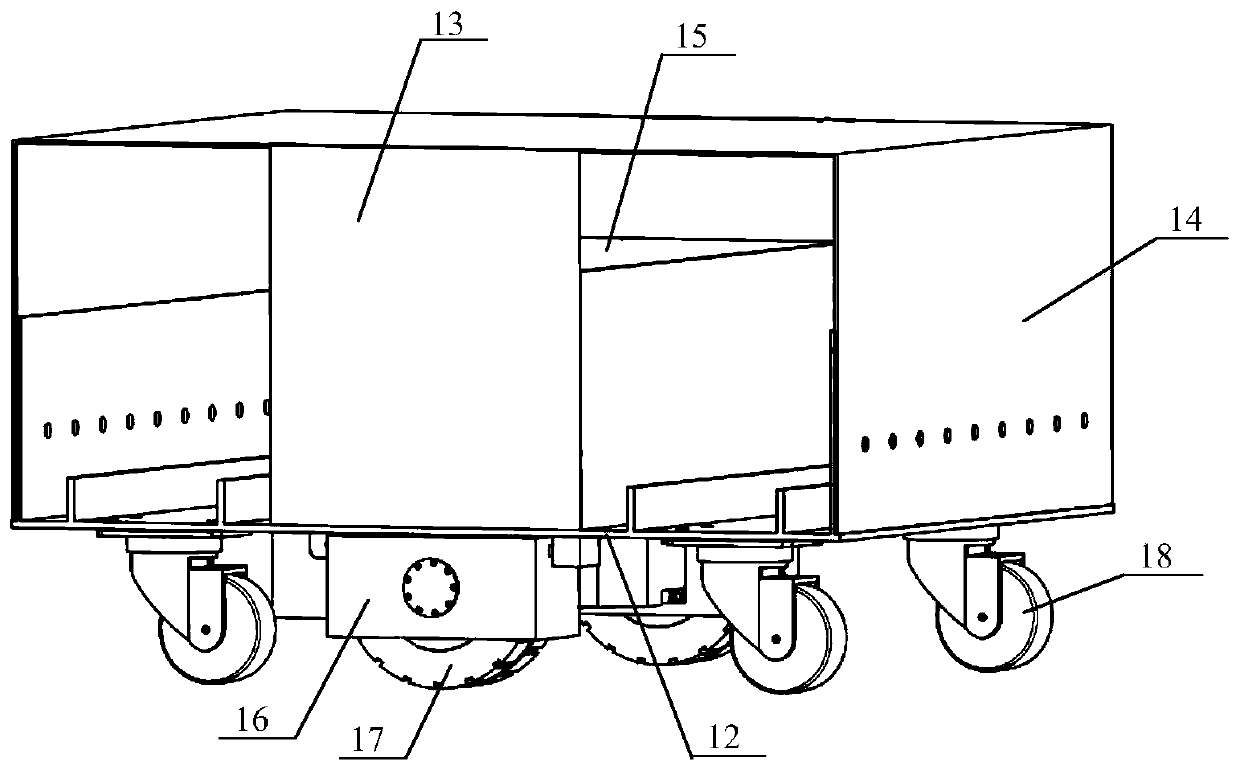

Unmanned carrying trolley

The invention relates to an unmanned carrying trolley, and belongs to the technical field of logistics automation equipment. The unmanned carrying trolley comprises a vehicle body, jacking mechanismsarranged at the upper end of the vehicle body and a driving mechanism arranged at the bottom of the vehicle body. The jacking mechanisms comprise fixed seats fixedly arranged at the upper end of the vehicle body, supporting seats fixedly arranged at the upper end of the vehicle body and arranged opposite to the fixed seats, double-head screw rod structures, power structures driving screw rods to rotate and slide rails fixedly arranged at the upper end of the vehicle body and positioned on the lower sides of the screw rods, wherein the two ends of the double-head screw rod structures are separately and rotatably arranged on the fixed seats and the supporting seats. Two threaded seats of the double-head screw rod mechanisms are slidably arranged on the slide rails, and threaded seats are hinged to connecting pieces. The unmanned carrying trolley further comprises a bearing plate. The other ends of the two connecting pieces are separately hinged to the two ends of the bearing plate. The unmanned carrying trolley has a simple structure, and especially when articles are jacked, the driving torque is small and stable.

Owner:SHENZHEN JINGZHI HI TECH ROBOT CO LTD

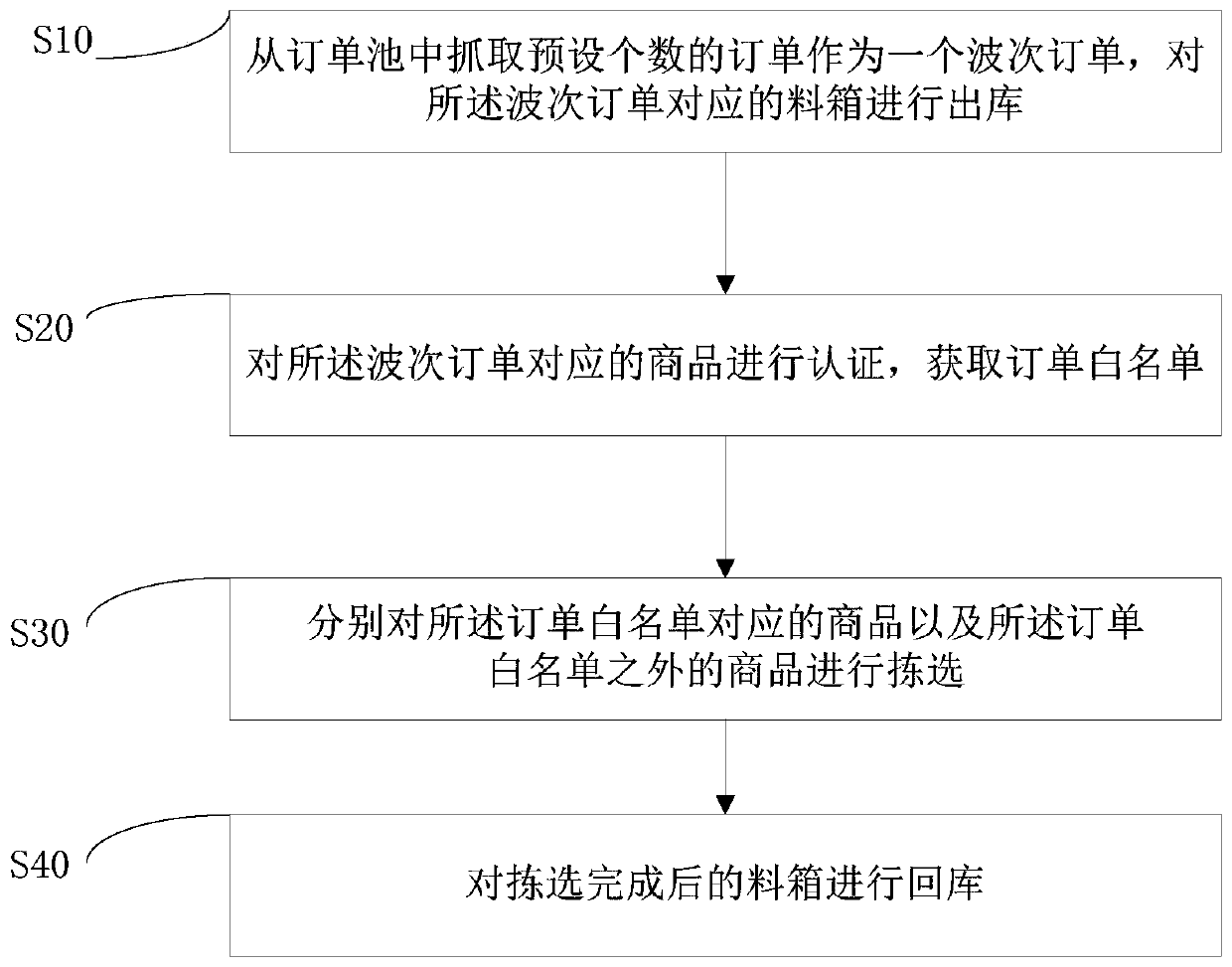

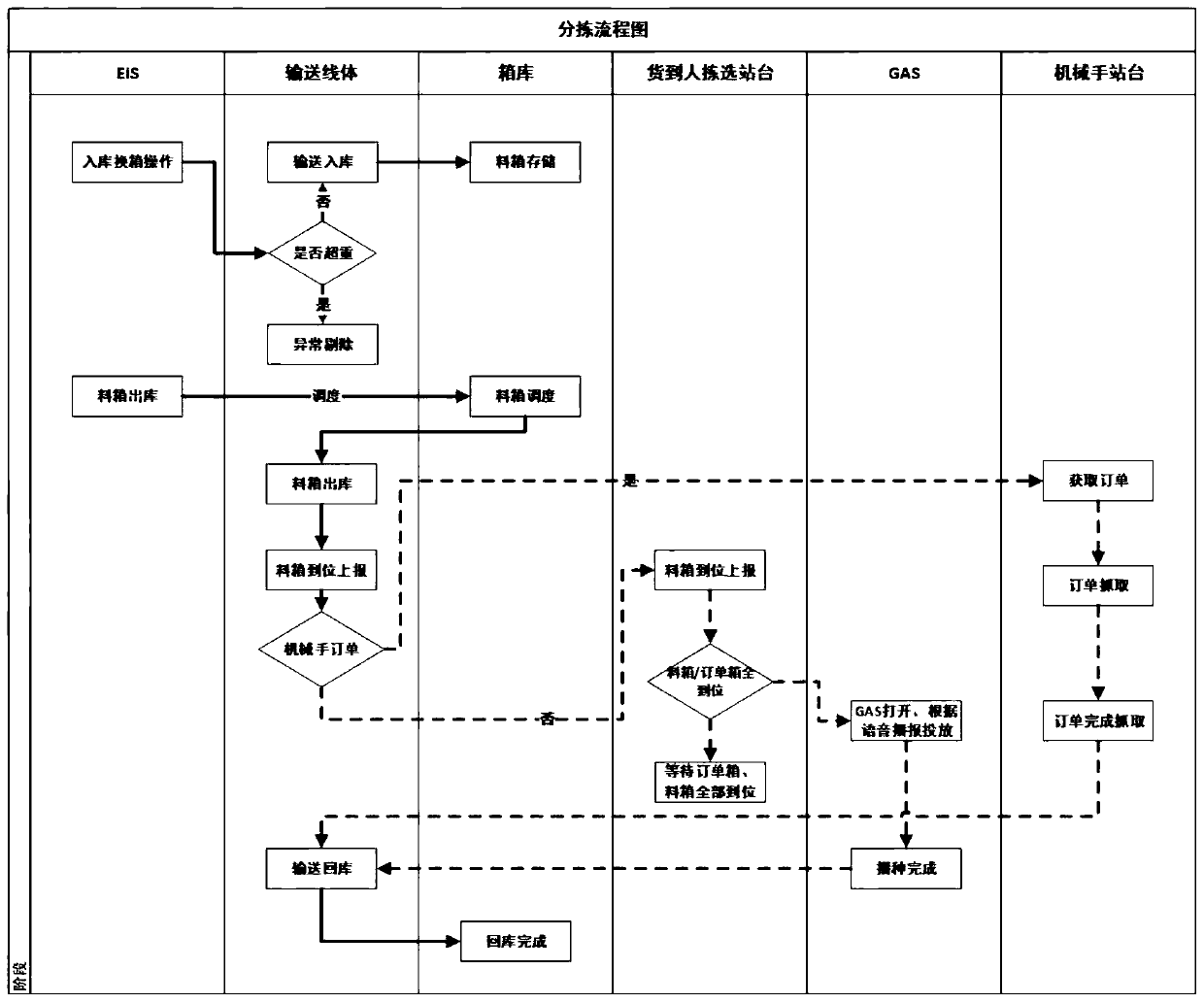

Intelligent sorting method and system

ActiveCN110264323AImprove order picking timeImprove order picking efficiencyBuying/selling/leasing transactionsResourcesSorting timeComputer science

The invention discloses an intelligent sorting method and system, belongs to the field of logistics automation, and the intelligent sorting method and system solve the problems of low sorting time efficiency, low labor efficiency, low efficiency per square meter and high sorting cost in the prior art. The method comprises the steps that orders with the preset number are grabbed from an order pool to serve as a wave picking order, and material boxes corresponding to the wave picking order are delivered out of a warehouse; a commodity corresponding to the wave picking order is authenticated to obtain an order white list; commodities corresponding to the order white list and commodities outside the order white list are picked respectively; and the sorted material boxes are returned to the warehouse. The time efficiency of order picking, the labor efficiency of order picking and the storage efficiency are improved, and meanwhile the picking cost is reduced.

Owner:智芯科技(湖北)有限公司

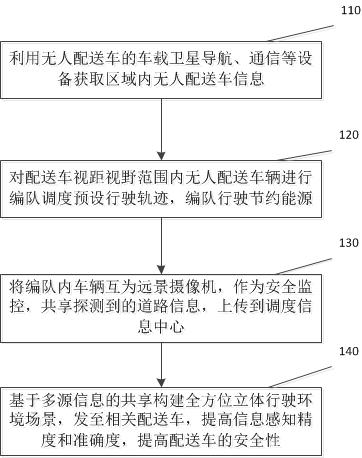

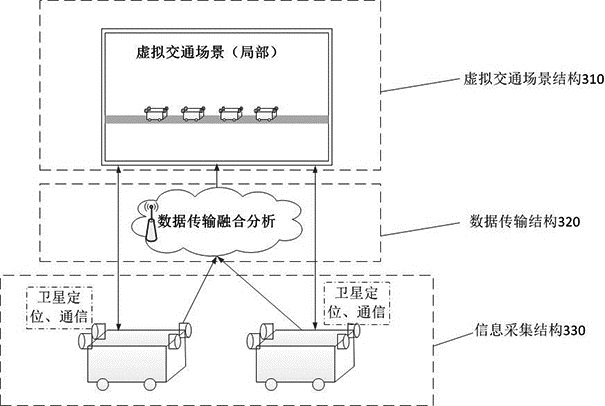

Unmanned distribution vehicle formation information sharing information scene construction method based on coincidence travel

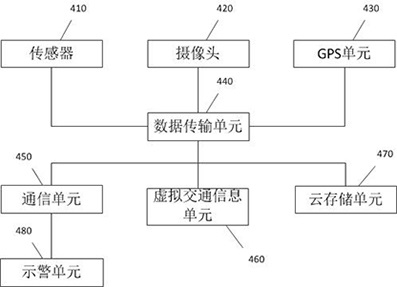

PendingCN113066280ARegistering/indicating working of vehiclesParticular environment based servicesView cameraDelivery vehicle

The invention discloses an unmanned distribution vehicle formation information sharing information scene construction method based on coincidence travel, and relates to the field of logistics automation. The method comprises the following steps: acquiring unmanned delivery vehicle information in a region by using vehicle-mounted satellite navigation equipment, communication equipment and other equipment of the unmanned delivery vehicle, including the position and speed of satellite positioning and information returned by a camera, and synthesizing with static traffic information to obtain a virtual traffic scene; performing formation scheduling on unmanned distribution vehicles in the distribution vehicle sight distance visual field range, and presetting a driving track, wherein formation driving saves energy; using the vehicles in the formation as mutual distant view cameras for safety monitoring and sharing detected road information, uploading the information to a dispatching information center, and forming an information sharing body; based on sharing of multi-source information, constructing an omnibearing three-dimensional driving environment scene and sending to a related distribution vehicle so that the information sensing precision and accuracy are improved, and the safety of the distribution vehicle is improved. According to the invention, through sharing respective information perception, the unmanned delivery vehicles are enabled to be visual monitoring information for each other, and the information is complementary and expands an information acquisition mode; through sharing of multi-source information, an omnibearing virtual driving scene is constructed, information perception precision and accuracy are improved, scheduling management is optimized, and distribution safety is improved.

Owner:SHANDONG UNIV OF SCI & TECH

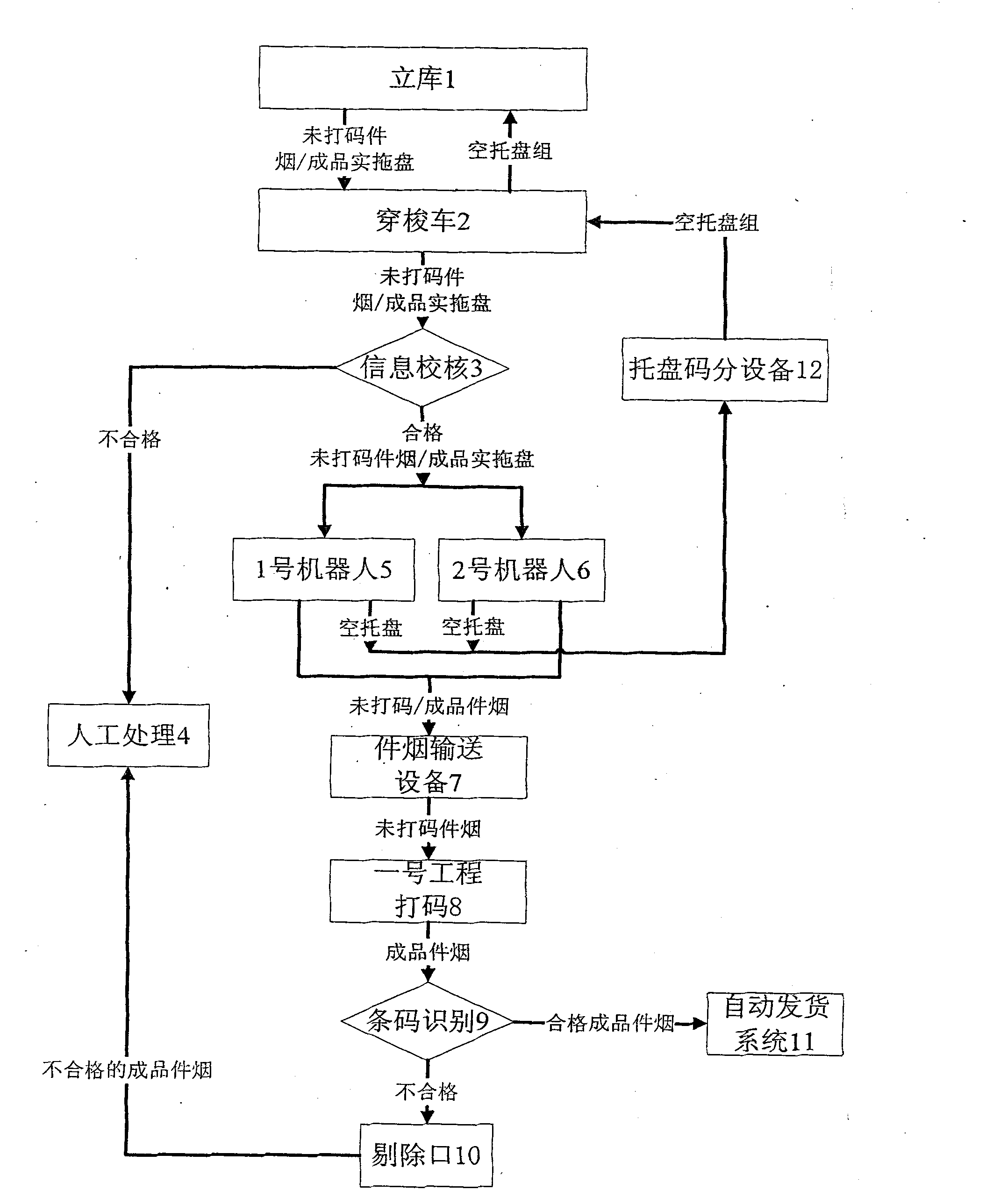

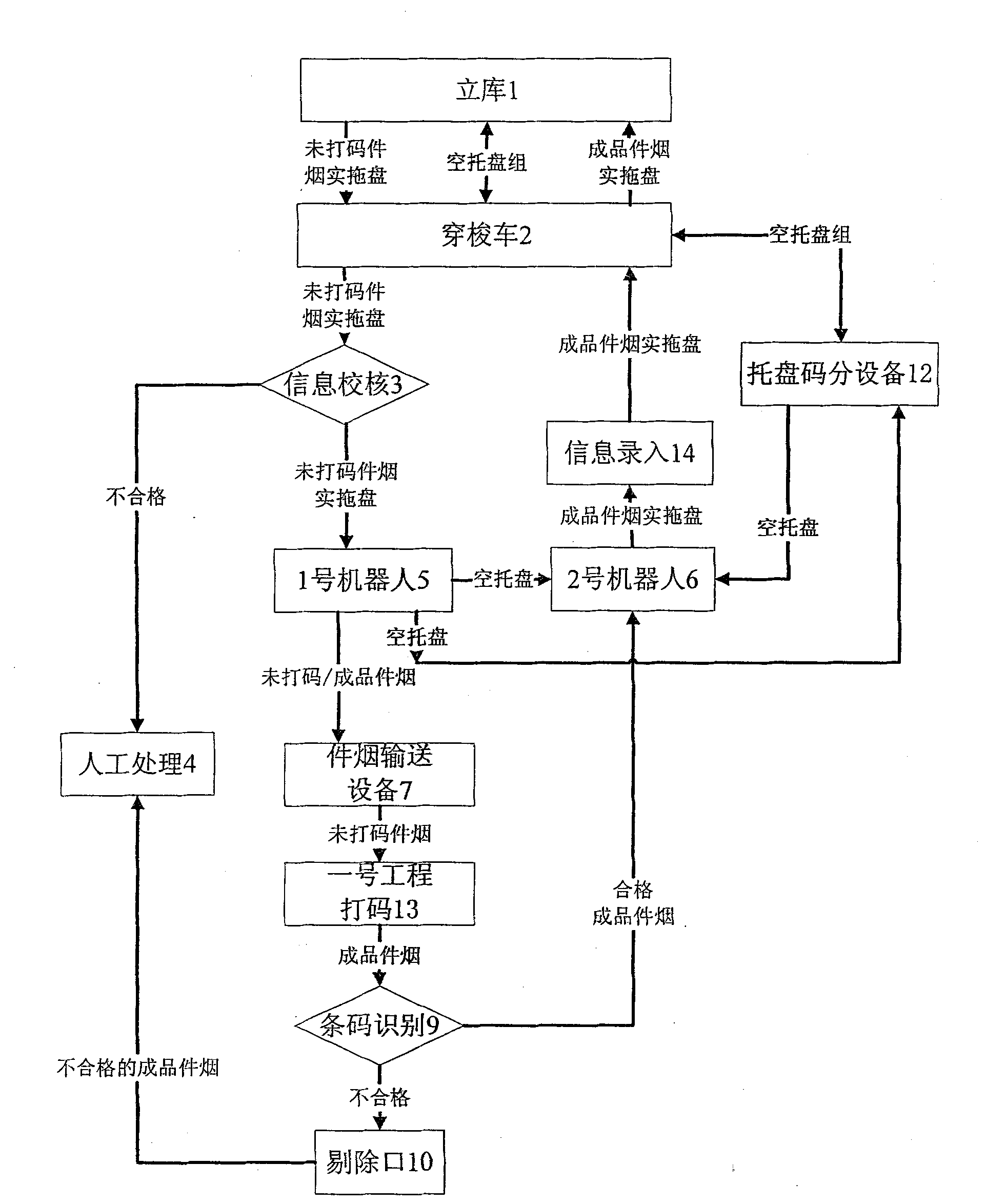

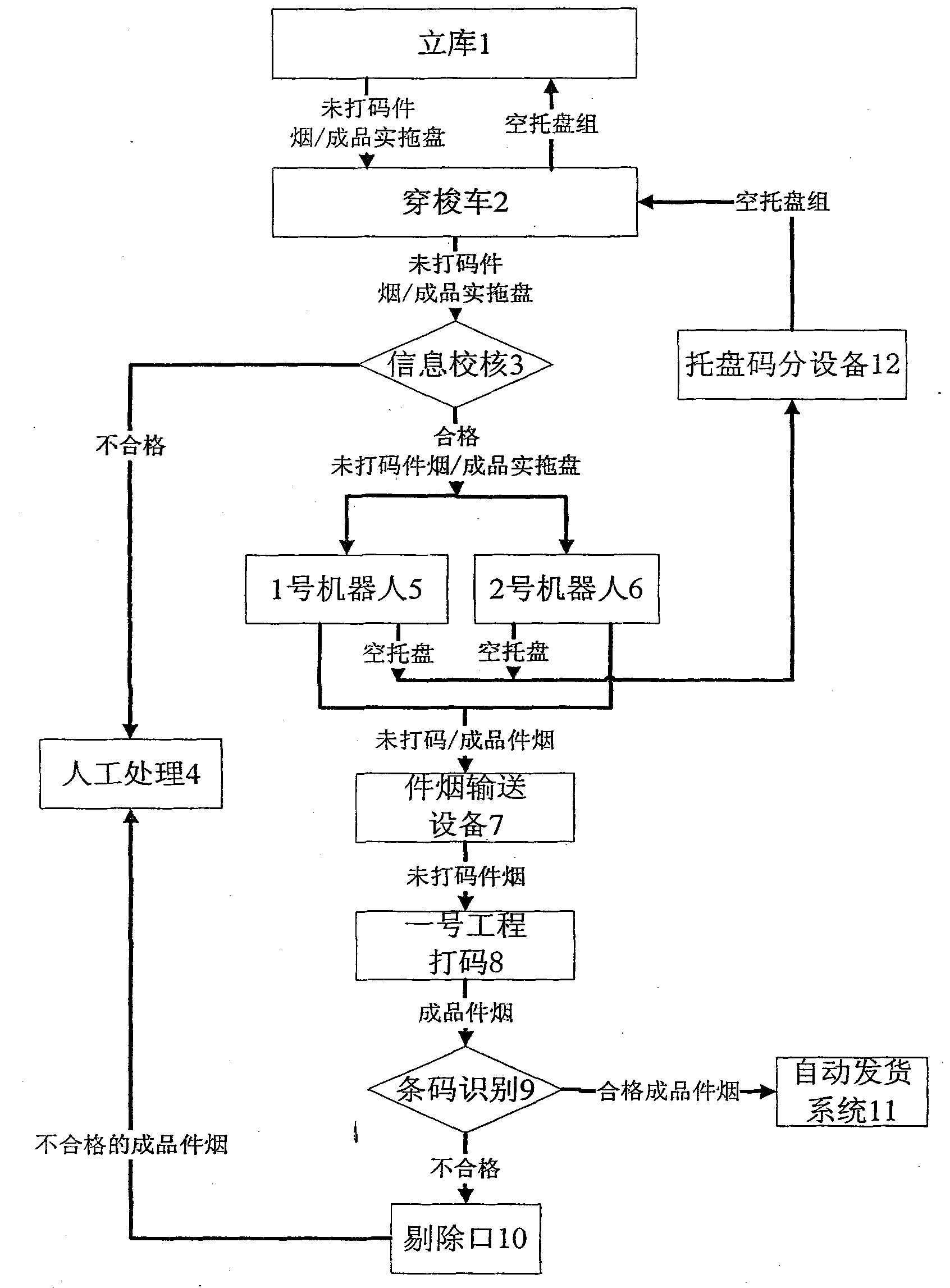

Automated code complementing process for uncoded package tobacco

ActiveCN101857092ARealize automatic cycle codingIncrease the level of automationPackagingLogistics managementInstability

The invention discloses an automated code complementing process for uncoded package tobacco. The process comprises the following steps of: controlling an unstacking and stacking robot in an uncoded package tobacco treatment region to perform corresponding treatment on an uncoded package tobacco solid tray by using a warehouse management system (WMS); performing project one coding during transportation of the package tobacco so as to form a tobacco product; if the tobacco product needs to be delivered directly, unstacking and delivering the package tobacco to an out-warehouse region and incorporating the package tobacco into an automatic delivery system by using the robot; if the tobacco product does not to be delivered directly, transporting the tobacco product to a back-station robot for stacking after performing unstacking on the uncoded package tobacco solid tray by using a front-station robot; and returning the stacked package tobacco to a vertical warehouse for storing. The process improves the utilization ratio of conventional equipment, realizes rapid code segment identification, improves logistics automation level, ensures the continuity of a logistics field process, solves the problem of inconvenient production plan regulation and control caused by the instability of code complement capacity and eliminates an error and unnecessary loss in an operational process of manual code complement at the same time.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

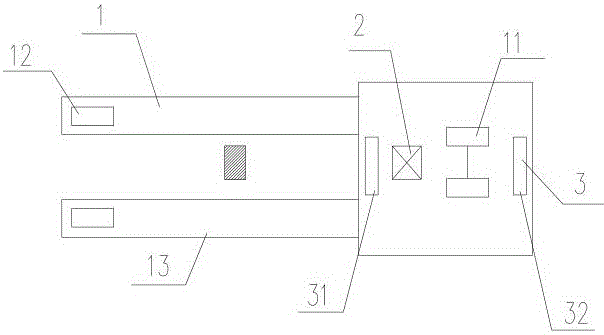

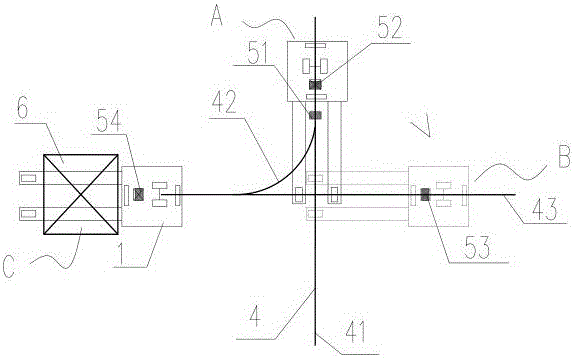

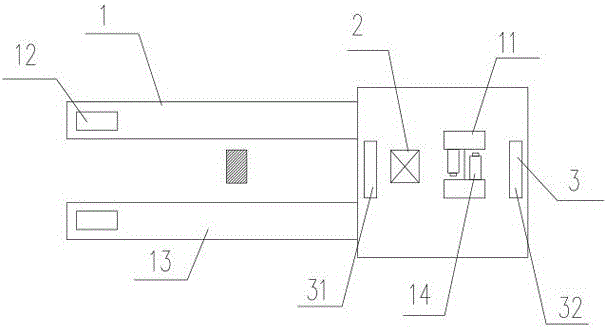

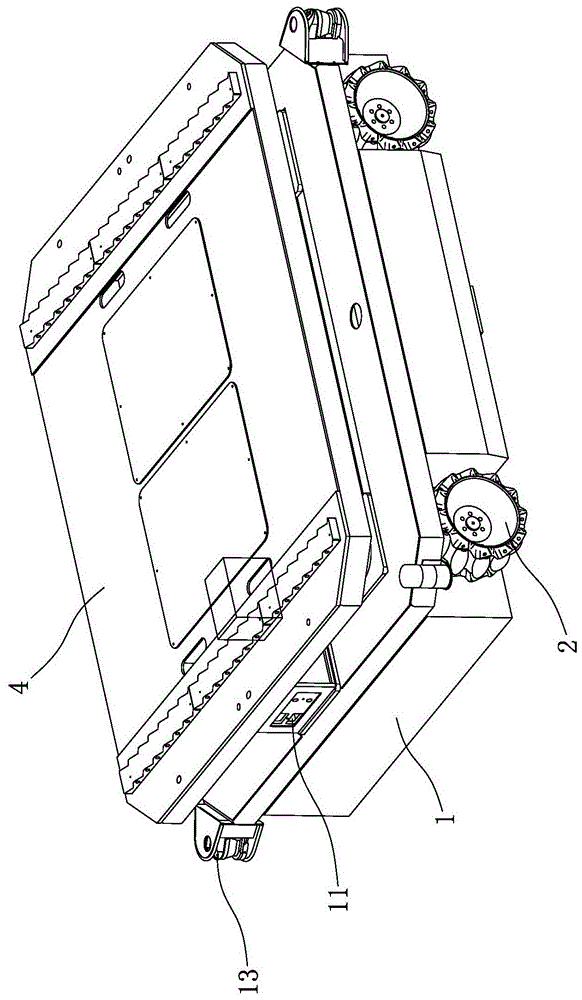

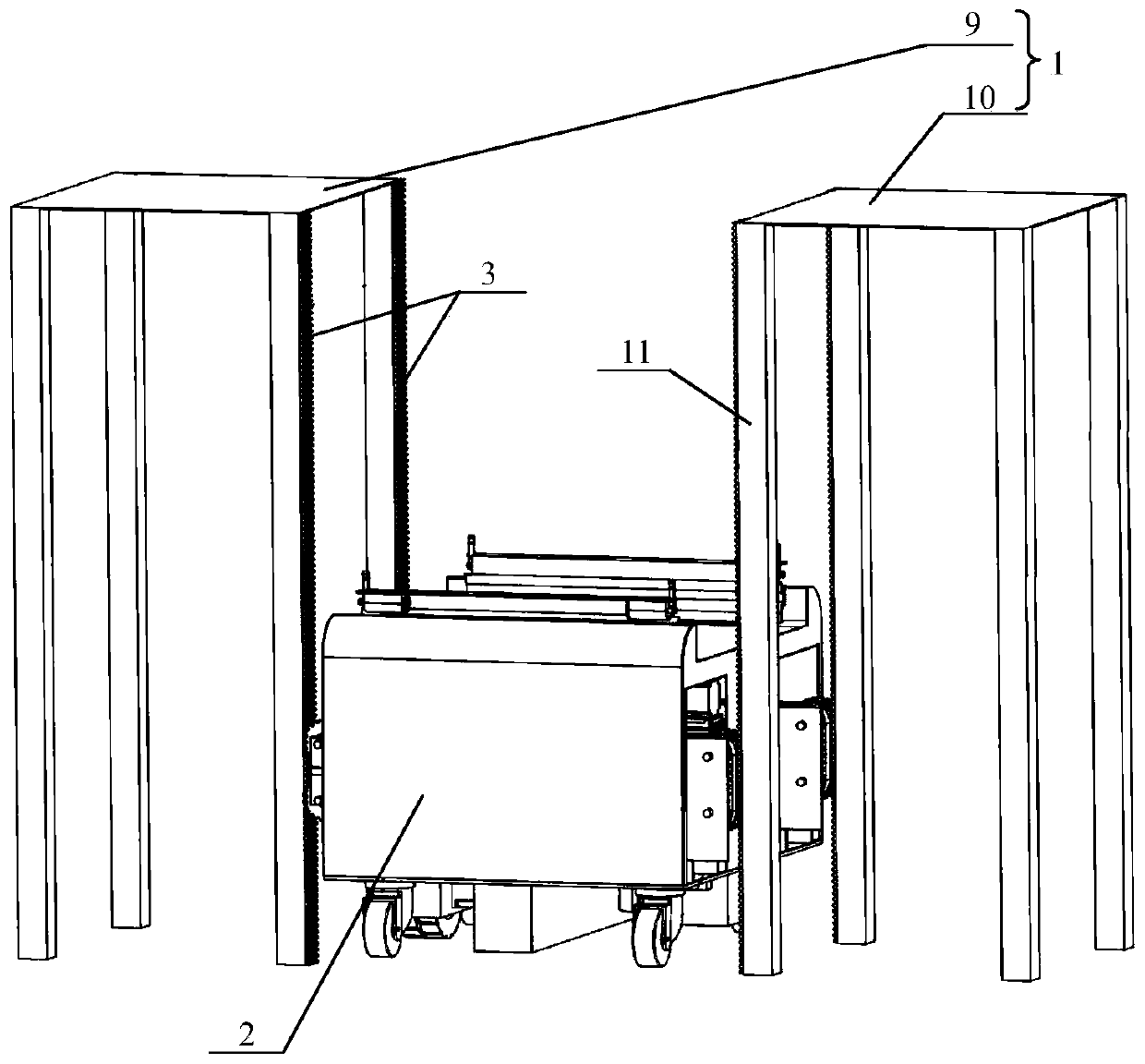

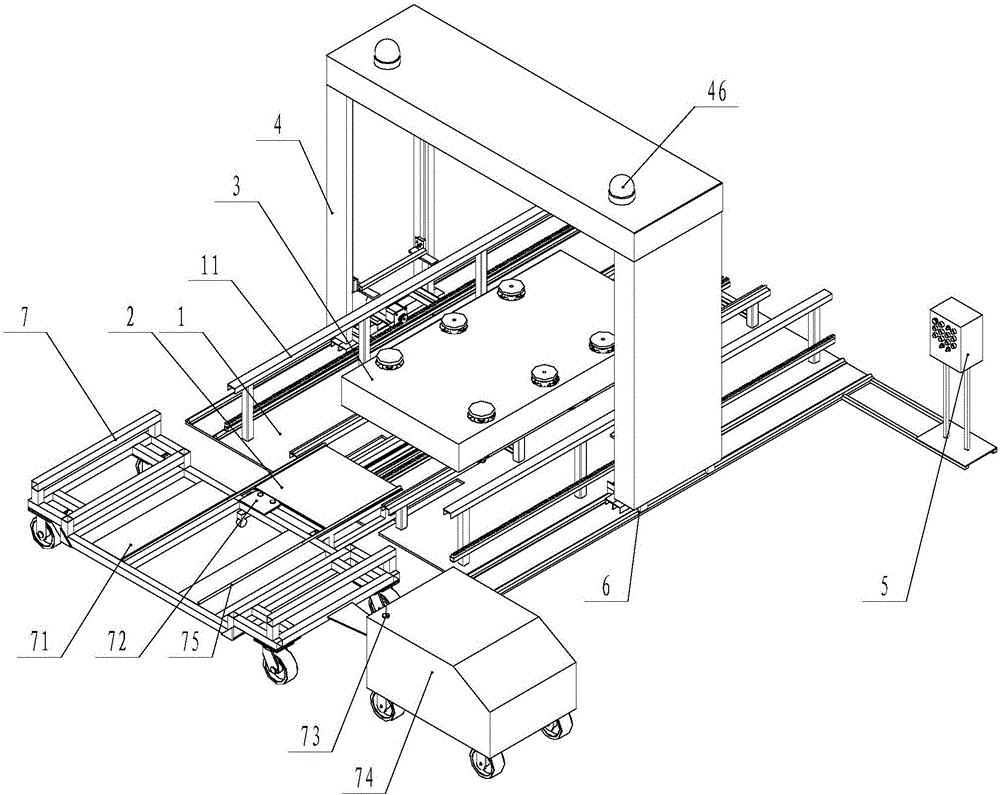

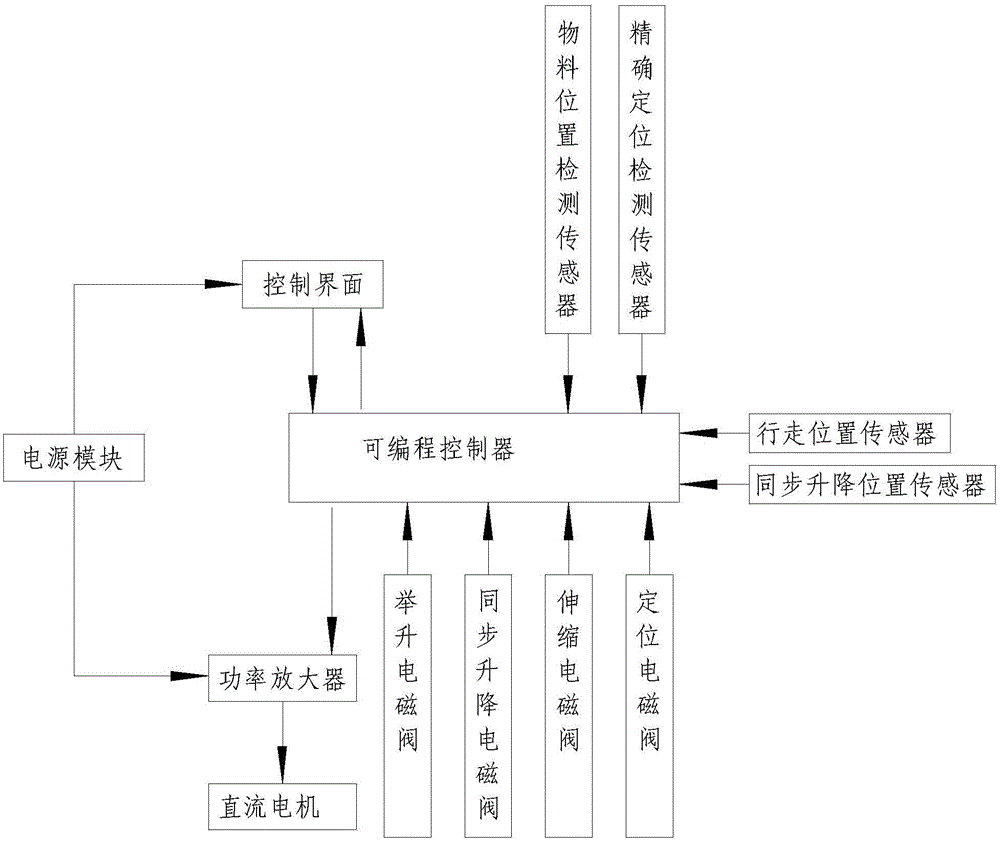

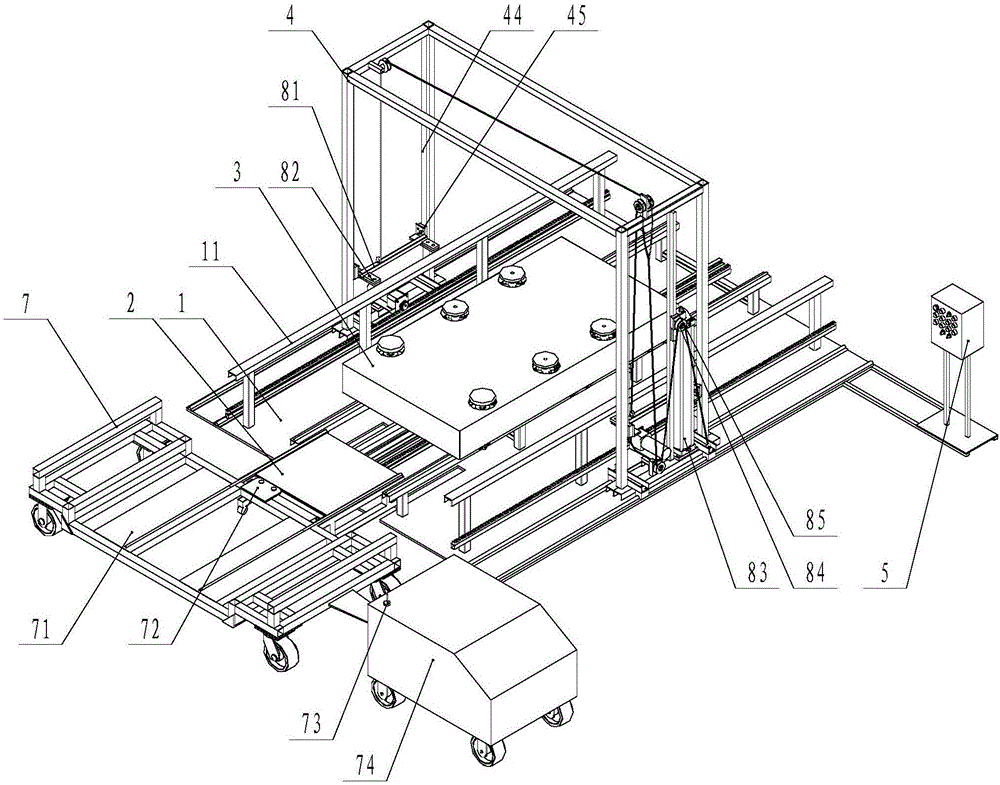

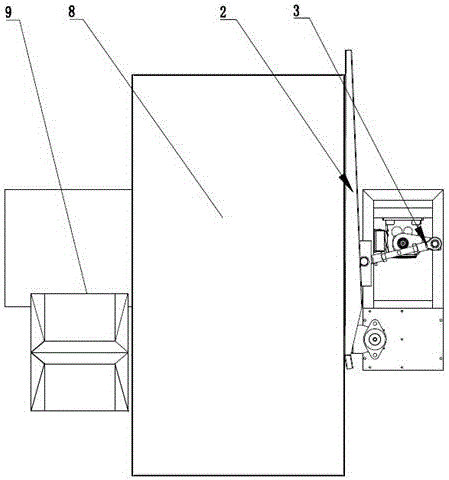

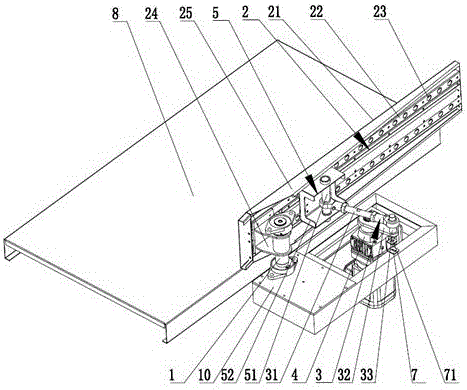

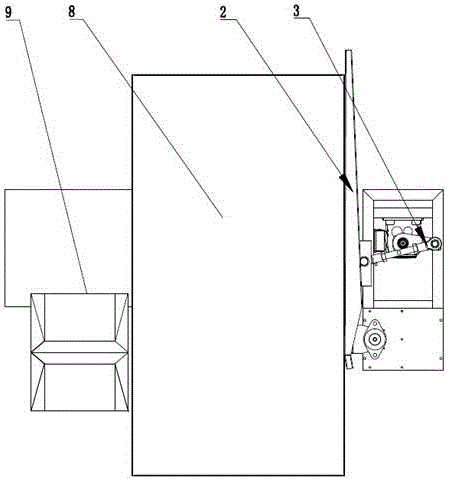

Two-box method automatic butt joint loading and unloading device

ActiveCN106144433AImprove the level of production automation equipmentRealize automatic deliveryControl devices for conveyorsMechanical conveyorsButt jointLogistics automation

The invention discloses a two-box method automatic butt joint loading and unloading device, and belongs to the field of engineering machinery. The device mainly comprises a base; support frames are respectively arranged on two sides of the base; a double-wheel support stable transition device is arranged between the two support frames; a floating butt joint device capable of moving is arranged below the double-wheel support stable transition device; and walking devices are arranged on two sides of the base, and are provided with synchronous lifting walking devices and lifting devices matched with each other. The device further comprises an automatic conveying device and a concentrated control device; the floating butt joint device is matched with the automatic conveying device; and the concentrated control device is respectively connected with the synchronous lifting walking devices, the floating butt joint device and the double-wheel support stable transition device. The device is low in cost and high in working efficiency, adopts the wireless module communication to match with the automatic conveying device to realize automation of the whole process as large material conveying, unloading and empty material frame recovery, successfully liberates labors, and promotes the logistics automation. The device is mainly applied to automatic conveying and unloading of large materials.

Owner:临沂临工智能信息科技有限公司

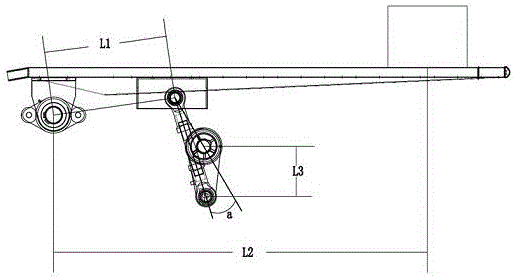

Sorting device of logistics automatic conveyor line

The invention discloses a sorting device of a logistics automatic conveyor line. The sorting device comprises a light swing arm rotating with a rotating shaft as the axis. The light swing arm is connected with a crank and connection rod mechanism driving the light swing arm to swing. The crank and connection rod mechanism is connected with a drive device. By setting the connection point position of the crank and connection rod mechanism and the light swing arm, when the light swing arm is in the contraction state, the connection point of a driven rod and a crank of the crank and connection rod mechanism is not located at the dead center position of the crank and connection rod mechanism. By means of the sorting device, the sorting accuracy and efficiency can be improved, the structure is more simplified, and lightness is achieved on the premise that the swing arm strength is ensured; and by further controlling the position of the connection point of the driven rod and the crank when the swing arm is in the contraction state, the swing arm can slow down in the retraction process with the help of the resistance of the dead center position of the crank and connection rod mechanism, stop of the crank and connection rod mechanism is facilitated, meanwhile, the influences of internal force of the dead center position to the crank and connection rod mechanism during start can be avoided, and start of the crank and connection rod mechanism is conveniently driven.

Owner:SUZHOU GP LOGISTICS SYST

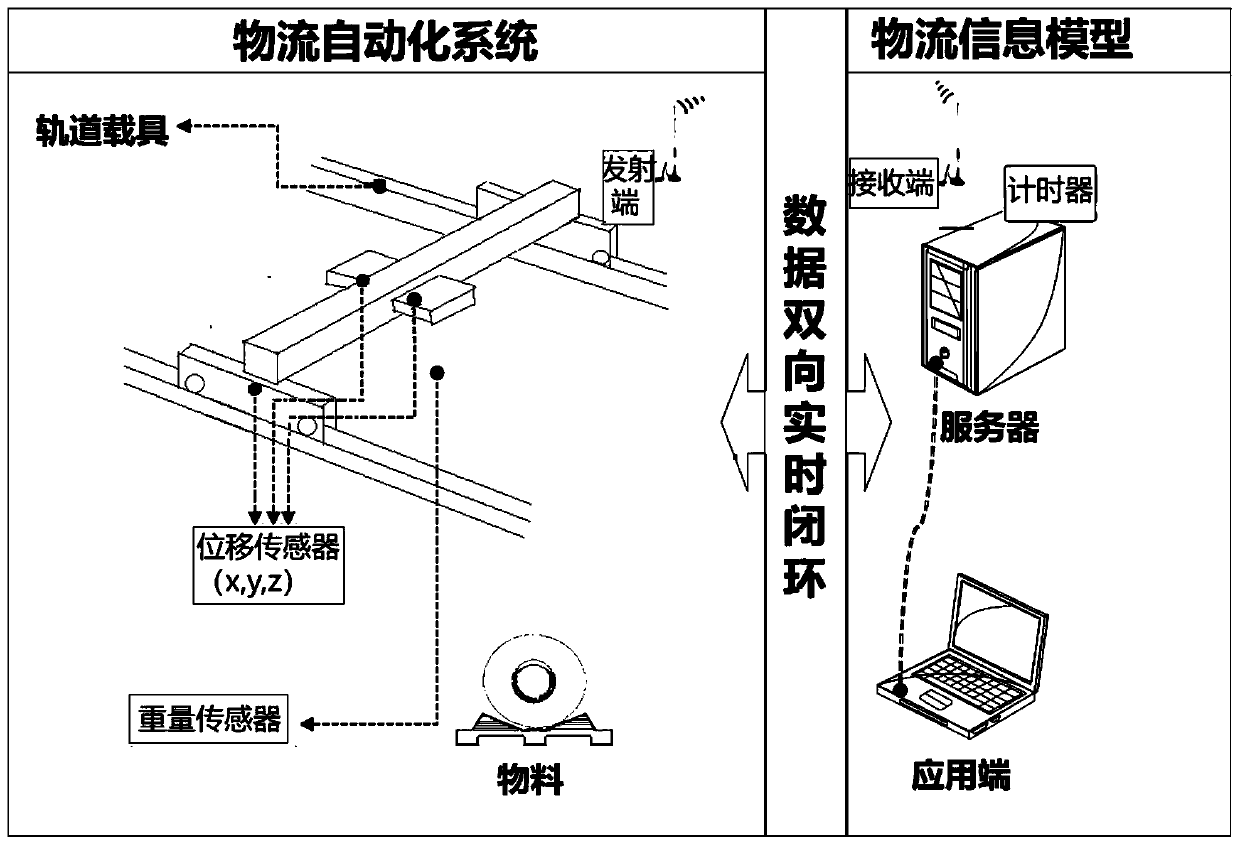

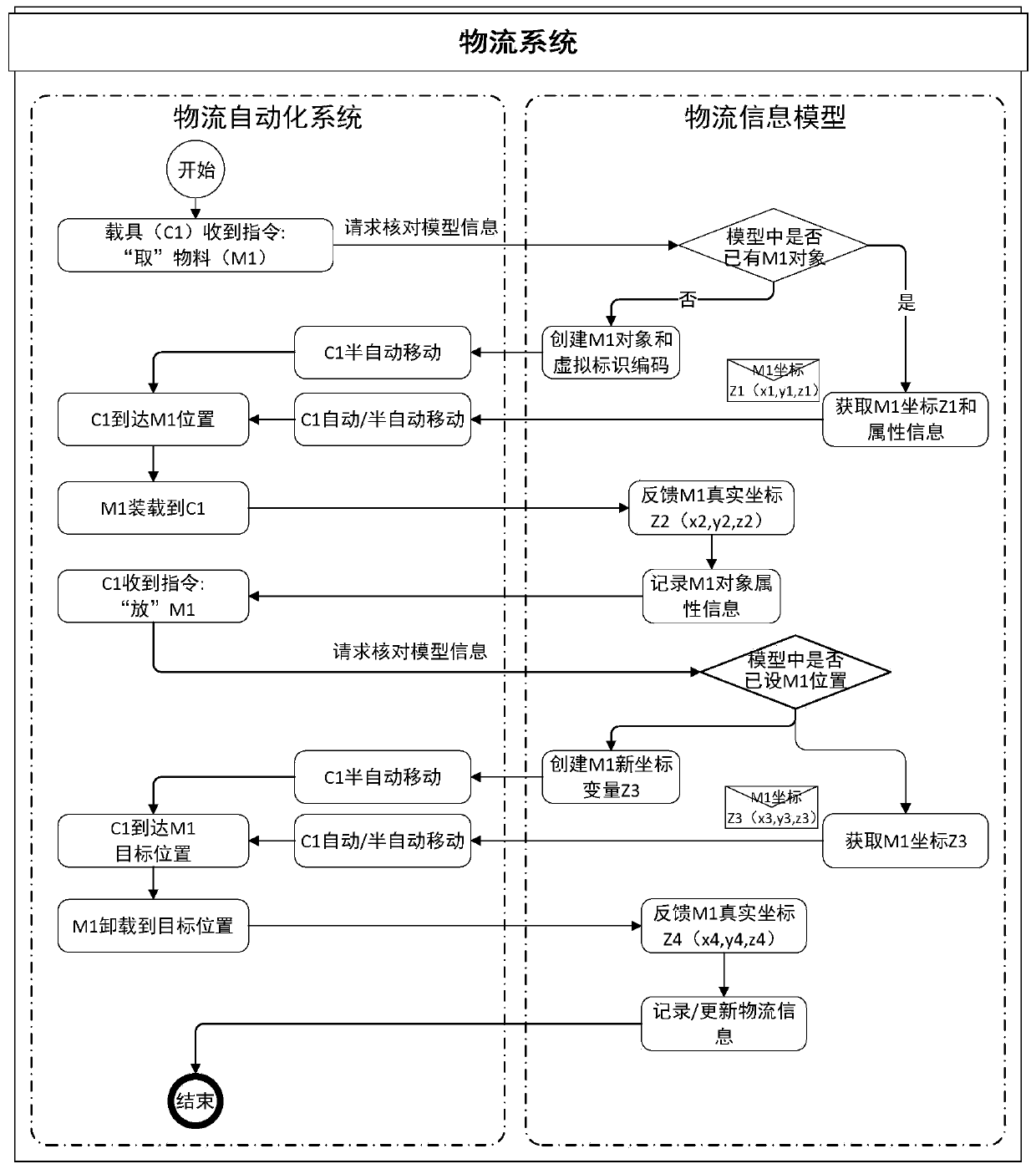

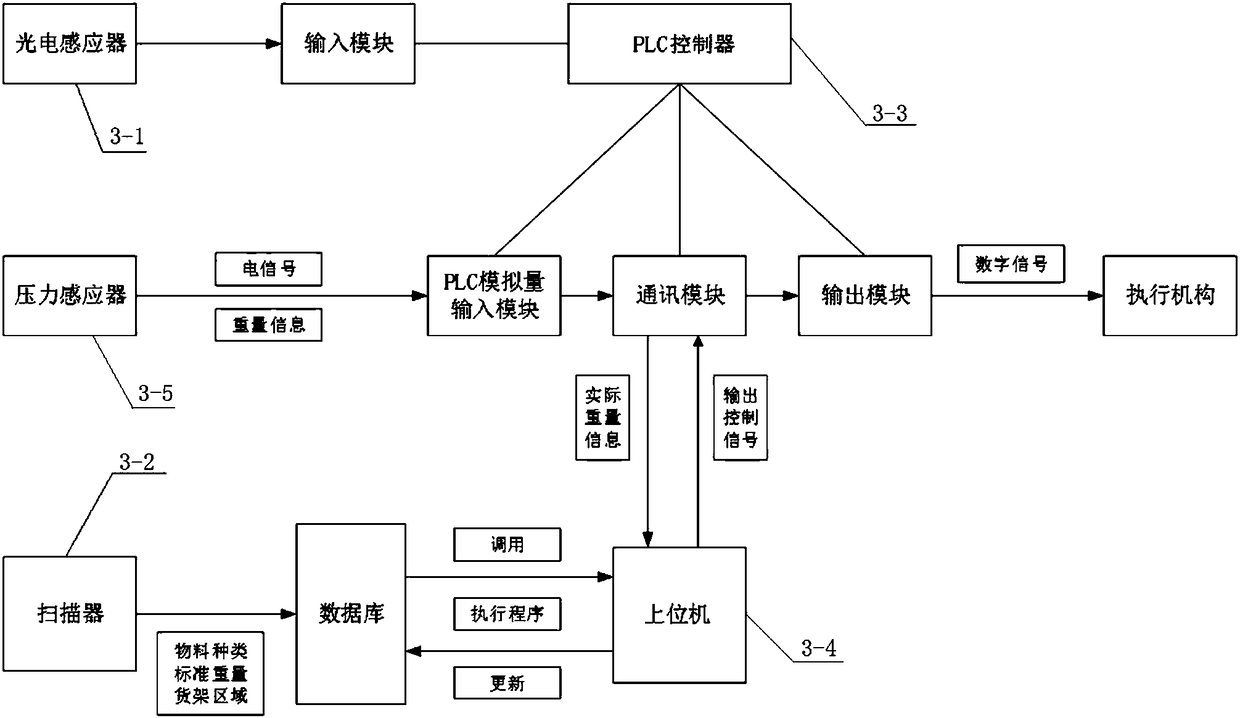

Material tracking method and system based on rail carrier

PendingCN110751431ASolve the lossReduce labor intensityOffice automationLogisticsNetwork communicationBusiness process

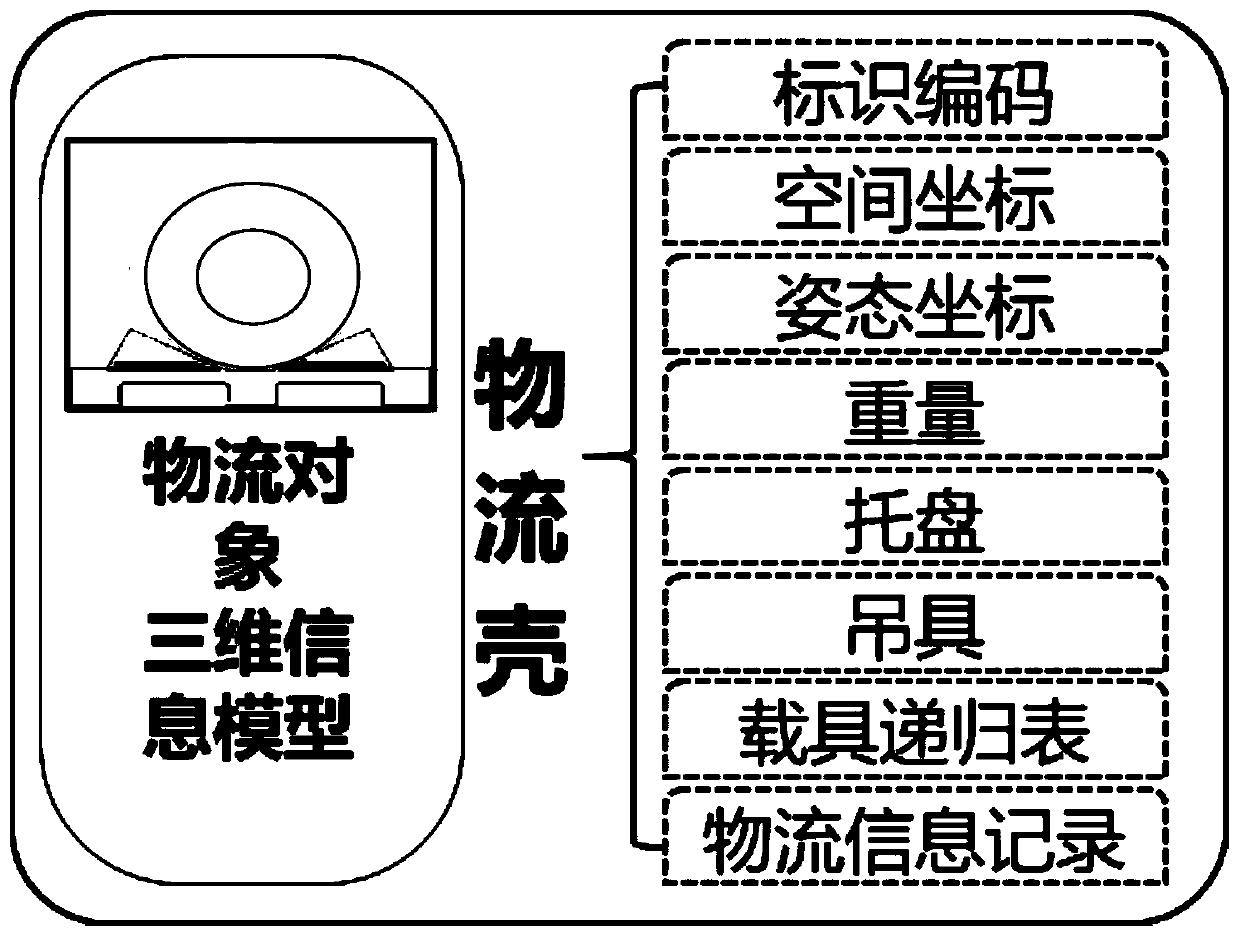

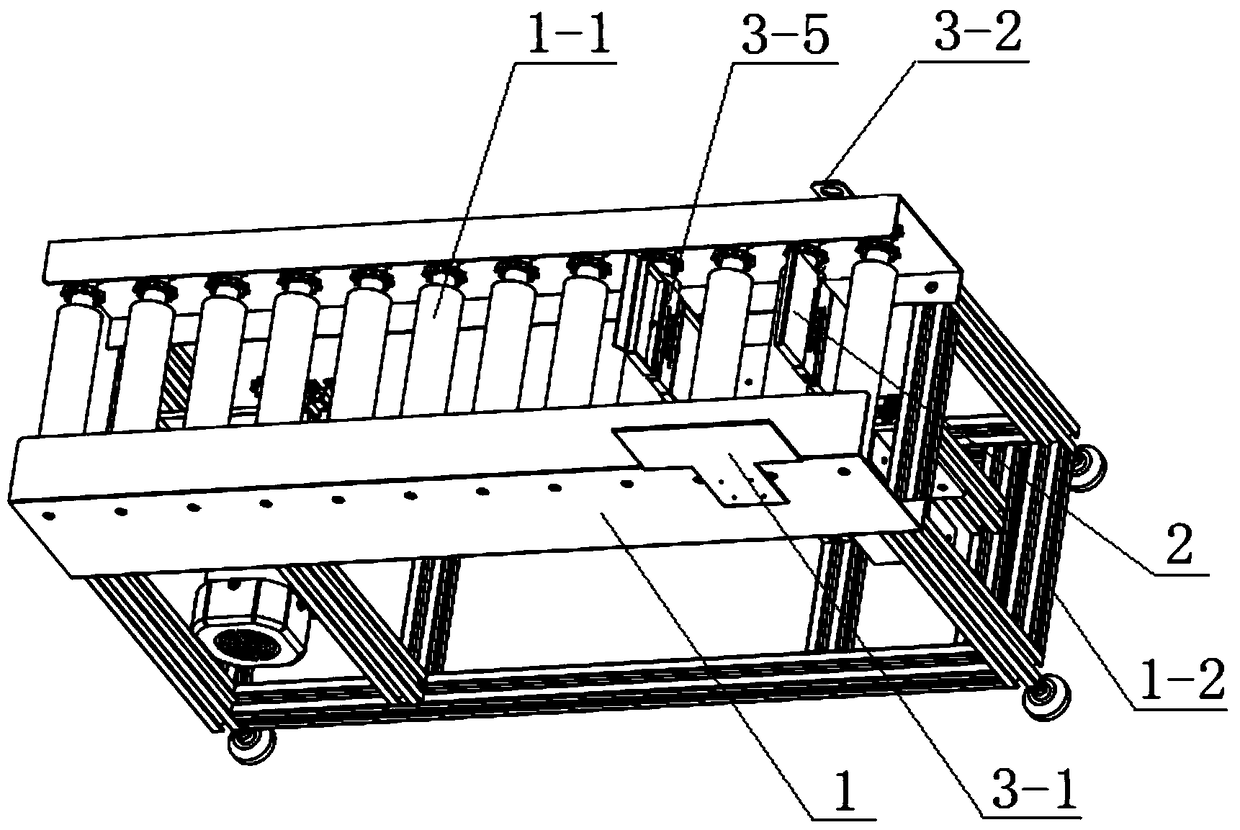

The invention discloses a material tracking method and system based on a rail carrier, relates to the technical field of material tracking, and the system comprises a logistics automation system and aphysical entity tool for realizing material handling, the logistics automation system comprises a rail carrier, a lifting appliance, an automation control system, a displacement sensor, a weight sensor and network communication equipment; and the a logistics information model is a virtual logistics information system constructed by adopting an information technology, and the logistics informationmodel comprises a software tool, an information model and a hardware support. According to the method, the virtual identification code and logistics shell technology is adopted, the problem that logistics information is lost due to damage of a physical label is solved, and the method is suitable for severe environments such as whole-process material information tracking of a hot processing production scene; logistics information tracking and a production business process are combined and applied to lean production and accurate management and control, deep application of logistics data is achieved, and higher value is brought into play.

Owner:国机工业互联网研究院(河南)有限公司

Full automatic positioning conveying stacking machine controlled by computer

InactiveCN1907822AImprove the speed of conveying and stackingReduce labor intensityStacking articlesTotal factory controlAutomatic controlStack machine

The invention relates to a stack machine with automatic control, which can reduce the broken rate, improve the flow property, and improve the producing efficiency. The invention can combine the computer, the PLC, frequency-variable device, the sensor, and the bridge stack machine, wherein it uses the central control room to automatic position, transmit, and stack the bags, to improve the stack speed, reduce the labor density and improve the automatic degree, while the producing efficiency can reach 1000-1200bag / hour.

Owner:徐水龙

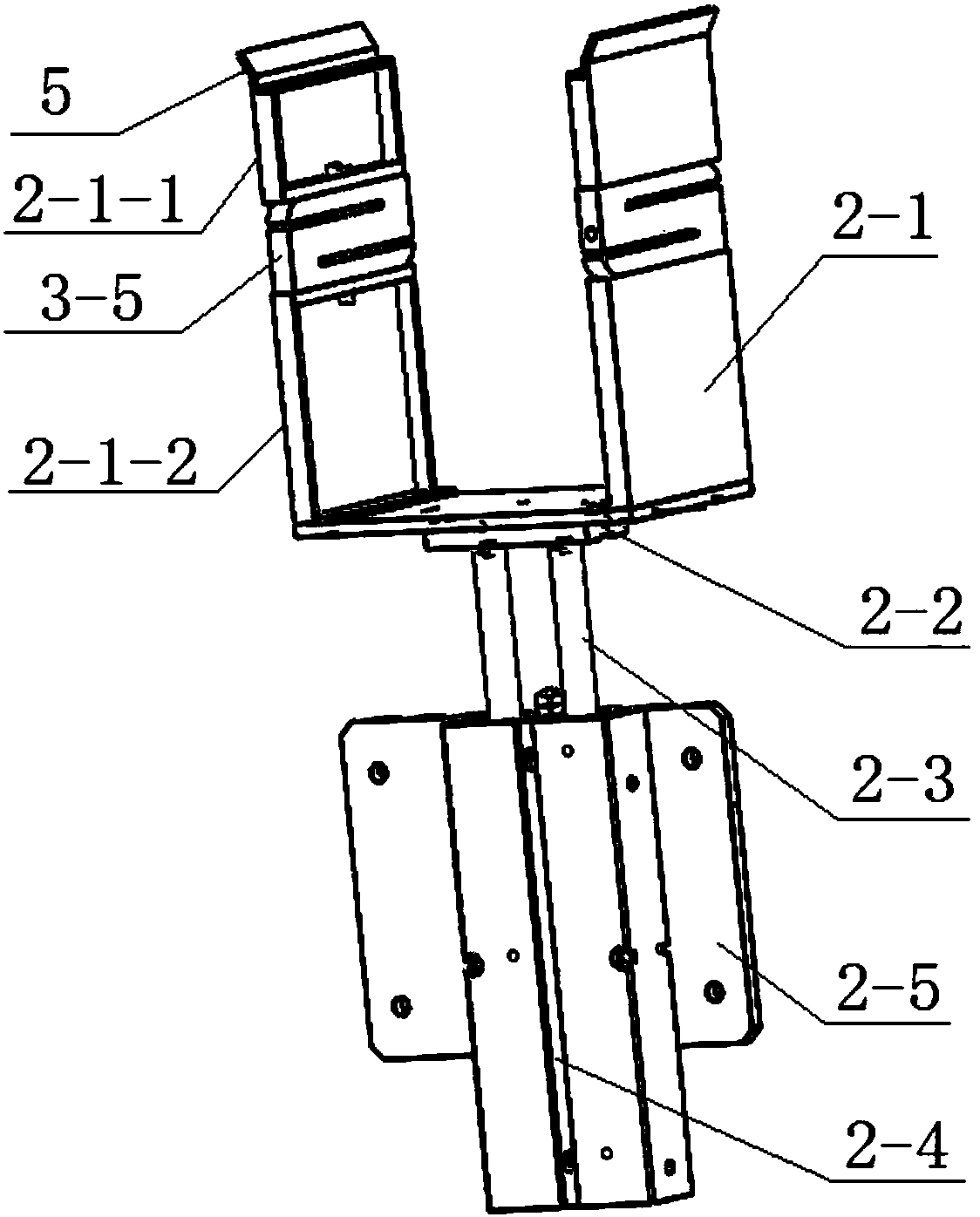

Lifting-up weighing sorting system used for logistics automatic production line and sorting method thereof

PendingCN108325862ASimple structural designThe weighing and sorting process is fast and accurateSortingProduction lineElectricity

The invention relates to a lifting-up weighing sorting system used for a logistics automatic production line and a sorting method thereof. a small and medium-sized enterprise generally uses manual work for collection, arrangement, classification and backing to a warehouse, certain large-scale manufacture enterprises increase different extra transport lines for different types of cargos and palletsfor backing to the warehouse, the efficiency is low, and the logistics cost is high. A pressure sensor is arranged at each support rod, a photoelectric sensor and a scanner are respectively arrangedat two sides of a roller conveyer, an induction end and a scanning end of the photoelectric sensor orient a gap of two support rods, the photoelectric sensor is electrically connected with a PLC controller, the scanner is electrically connected with a host computer, and a motor is electrically connected with the PLC controller. The method comprises a lifting-up heavy step, a static state weighingstep under a stable stopping state, a scanning analysis step, a decrease step, a classification step, and a dynamic weighing step. The system and the method are used for sorting the cargo.

Owner:BEIJING WUZI UNIVERSITY

Sorting device of automatic logistics conveying line

InactiveCN105819213AGuaranteed StrengthConvenient stopConveyor partsLogistics managementElectric machinery

The invention discloses a sorting device of an automatic logistics conveying line. The sorting device comprises a light-weight swing arm rotating with a rotating shaft as the axis. The light-weight swing arm is connected with a crank-link mechanism driving the light-weight swing arm to swing. The crank-link mechanism is connected with a motor. When the light-weight swing arm is in a shrinkage state, the connecting point of a driven rod and a crank of the crank-link mechanism is not located at the dead point position of the crank-link mechanism. According to the sorting device, due to the fact that the motor serves as a power source and control is conducted through a PLC system, the sorting precision and efficiency can be improved, no special air source is needed, the structure is simpler, and the light weight is achieved on the premise that the strength of the swing arm is guaranteed. Furthermore, the position of the connecting point of the driven rod and the crank is controlled when the swing arm is in the shrinkage state, the resistance at the dead point position of the crank-link mechanism can be utilized for making the swing arm decelerate in the retraction process, and stopping of the crank-link mechanism is facilitated. Meanwhile, the influence of internal force of the dead point position on starting of the crank-link mechanism can be avoided, and the crank-link mechanism can be conveniently driven to be started.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com