Patents

Literature

230results about How to "Cooperate smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

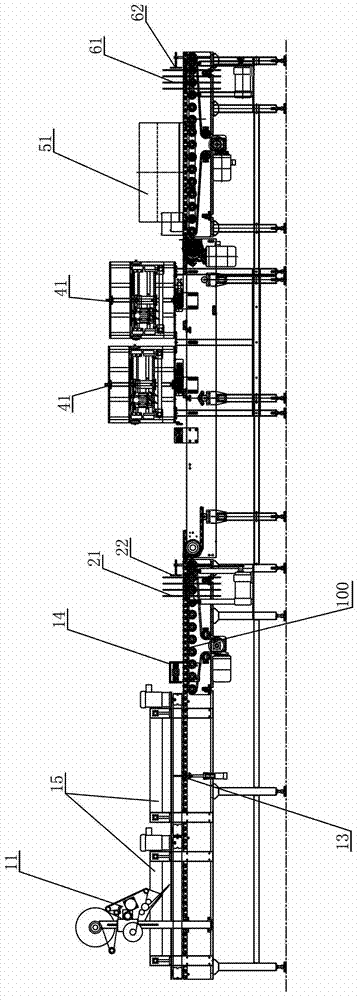

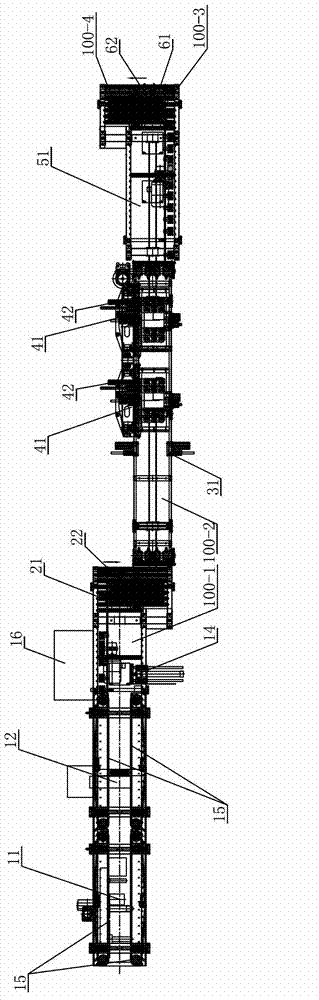

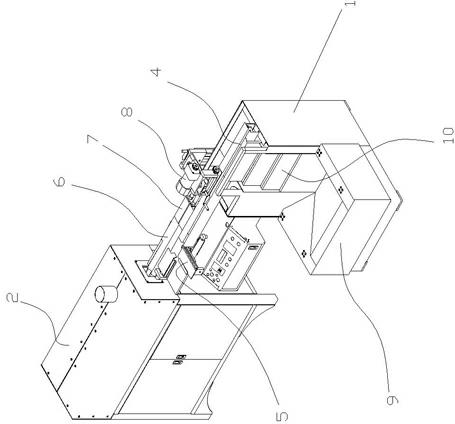

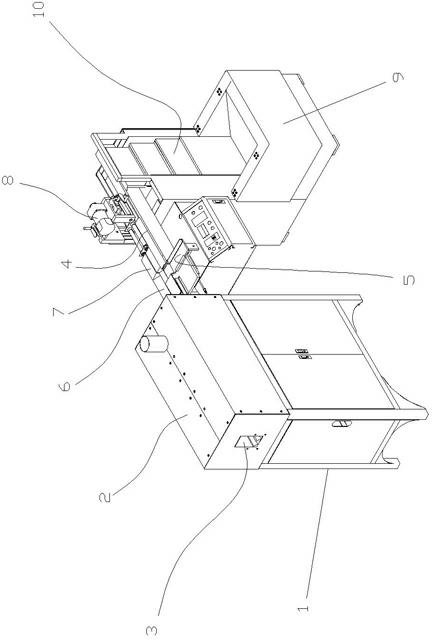

Storage battery package assembly line

The invention provides a storage battery package assembly line. The storage battery package assembly line comprises a storage battery pipeline, wherein a code station, a first turning station, a temporary storage station, a printing station and a print drying station are arranged along the storage battery pipeline. The stations are reasonably arranged, various mechanisms can be smoothly matched with continuous operation, labeling, coding, printing and drying of the storage battery are realized, and the storage battery is full mechanically conveyed in the processes, the manual labor is reduced, the working efficiency is improved, the safety is improved, and the storage battery package assembly line can serve as the basis to realize full automation of the storage battery package.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

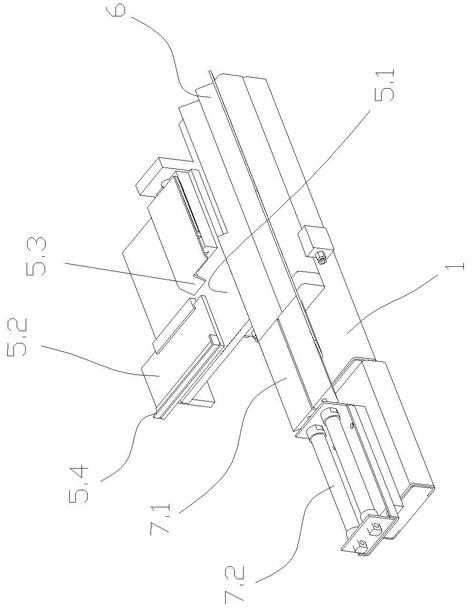

Cutting and trimming machine for plastic pipes

ActiveCN104128950AAccurate up and down movement guideOrientation is accurateMetal working apparatusHobbingEngineering

A cutting and trimming machine for plastic pipes comprises a frame and a pipe cutting and trimming mechanism. The frame comprises an upper frame and a lower frame, A front slide rail mounting rod and a rear slide rail mounting rod are mounted on the upper frame and the lower frame. A front slide rail and a rear slide rail are mounted on the front slide rail mounting rod and the rear slide rail mounting rod. A front slider and a rear slider rail are disposed on the front slide rail and the rear slide rail. The pipe cutting and trimming mechanism is disposed on the front slider and the rear slider. The pipe cutting and trimming mechanism comprises a left main plate, a middle main plate and a right main plate. A motor is mounted below a base plate. A left pipe clamp and a left pushing air cylinder are mounted outside the left main plate. A right pipe clamp is mounted outside the right main plate. A left hobbing cutter cylinder bearing, a cutter holder push plate, a cutting feeding rack, a hobbing cutter cylinder and a right hobbing cutter cylinder bearing are disposed between the left main plate and the middle main plate. An upper mounting rod, a lower mounting rod and a cutter feeding rack slide rail are disposed on the hobbing cutter cylinder. A pipe cutting device is mounted on the upper mounting rod. A pipe trimming device is mounted on the lower mounting rod. The cutter feeding rack which contacts with the cutter holder push plate is disposed outside the hobbing cutter cylinder. An upper fixing rod and a lower fixing rod are disposed on the cutter feeding rack. A hobbing cutter guide rack matched with the pipe cutting device is disposed on the upper fixing rod. A roller guide rack matched with the pipe trimming device is mounted on the lower fixing rod. A belt pulley connected with a motor shaft through a belt is disposed between the middle main plate and the right main plate.

Owner:YONGGAO CO LTD

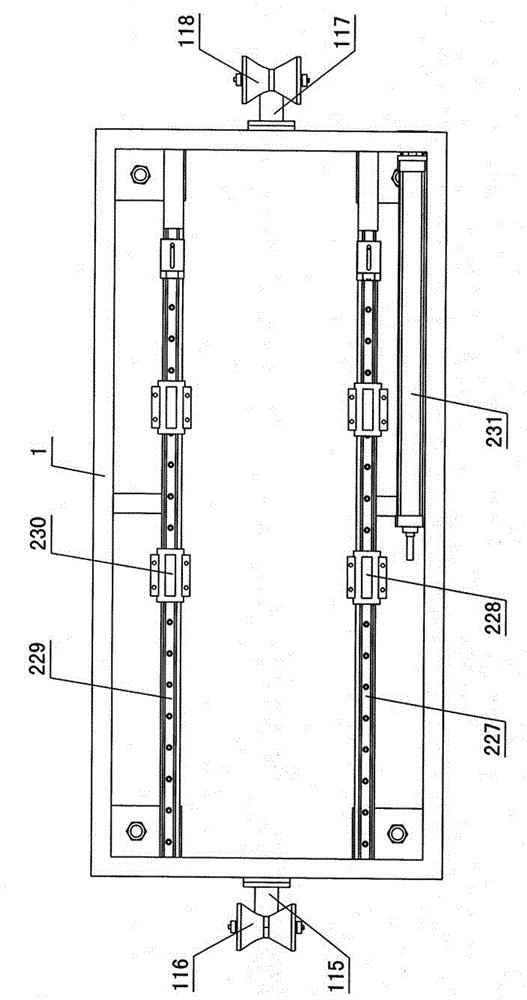

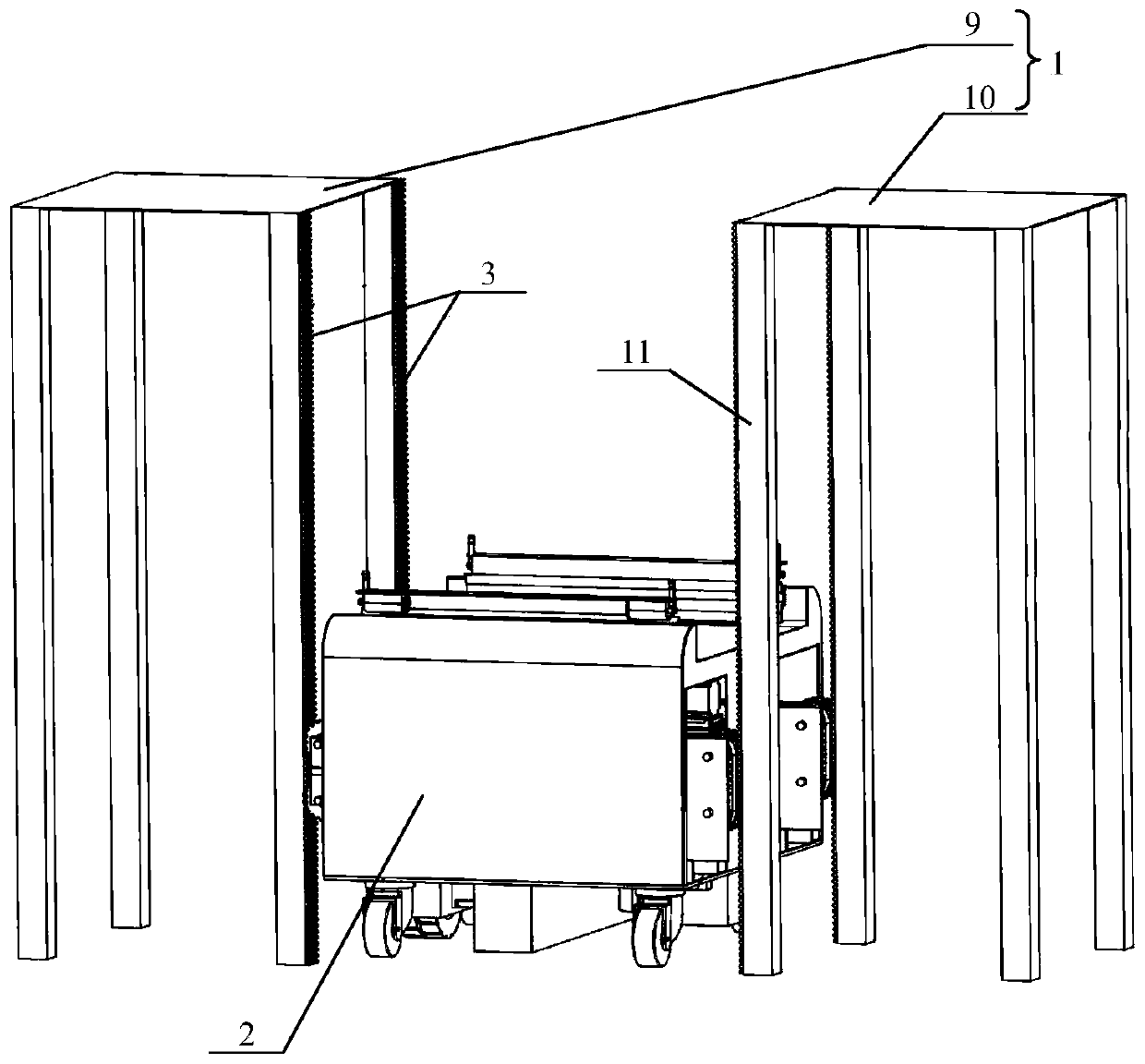

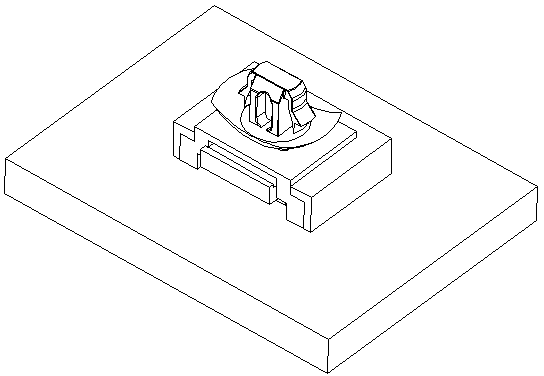

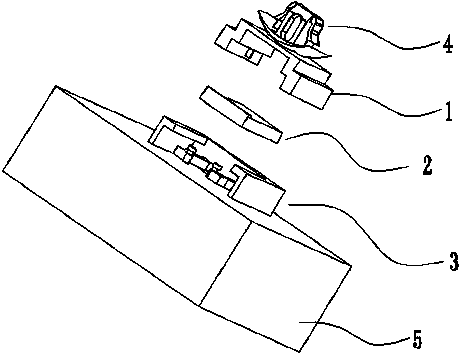

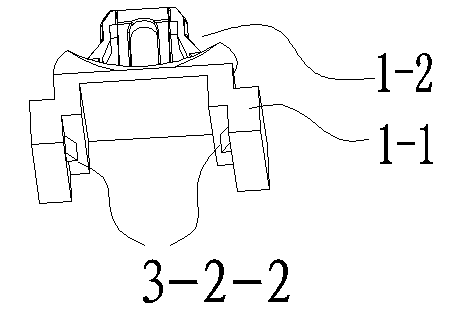

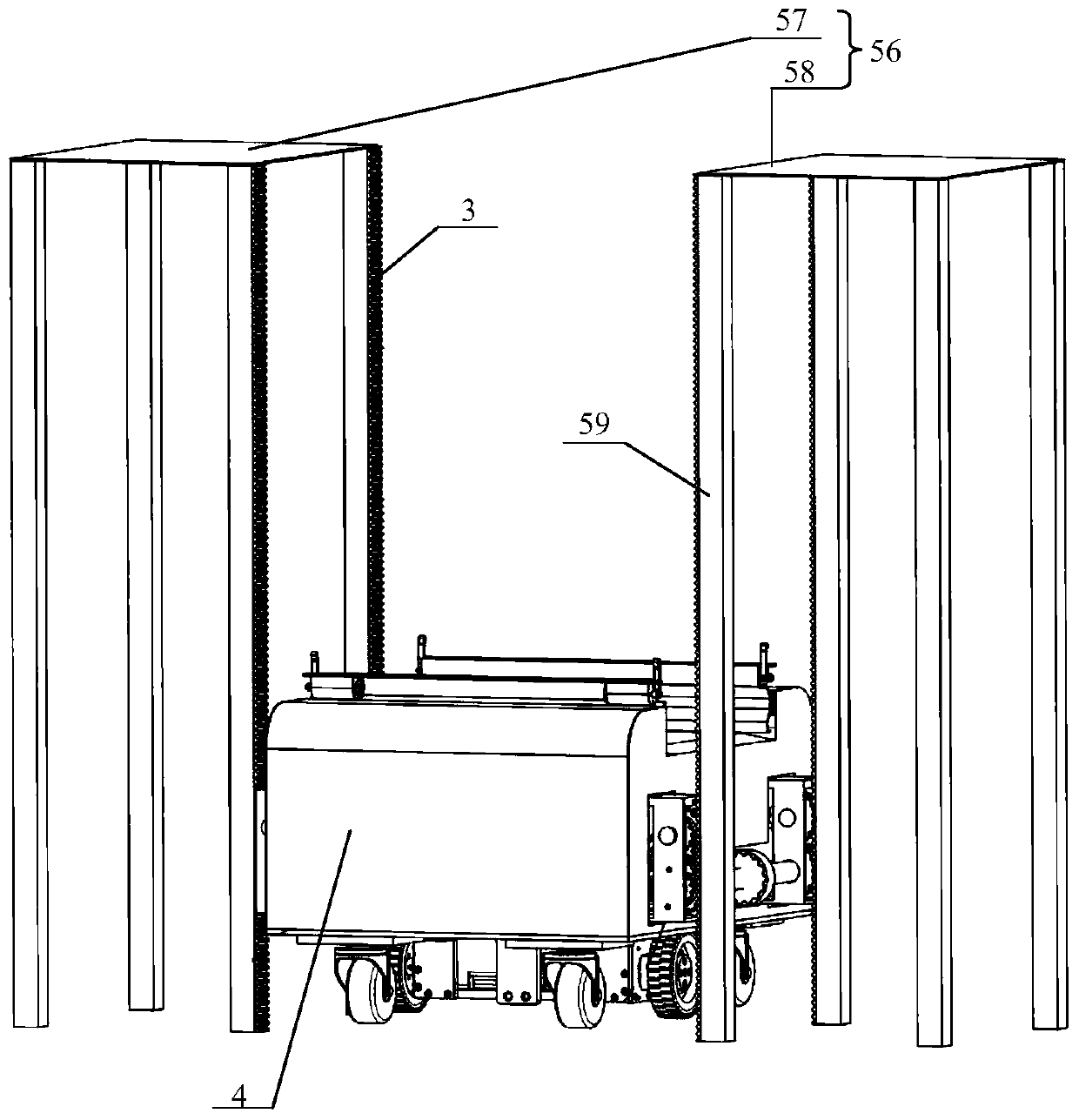

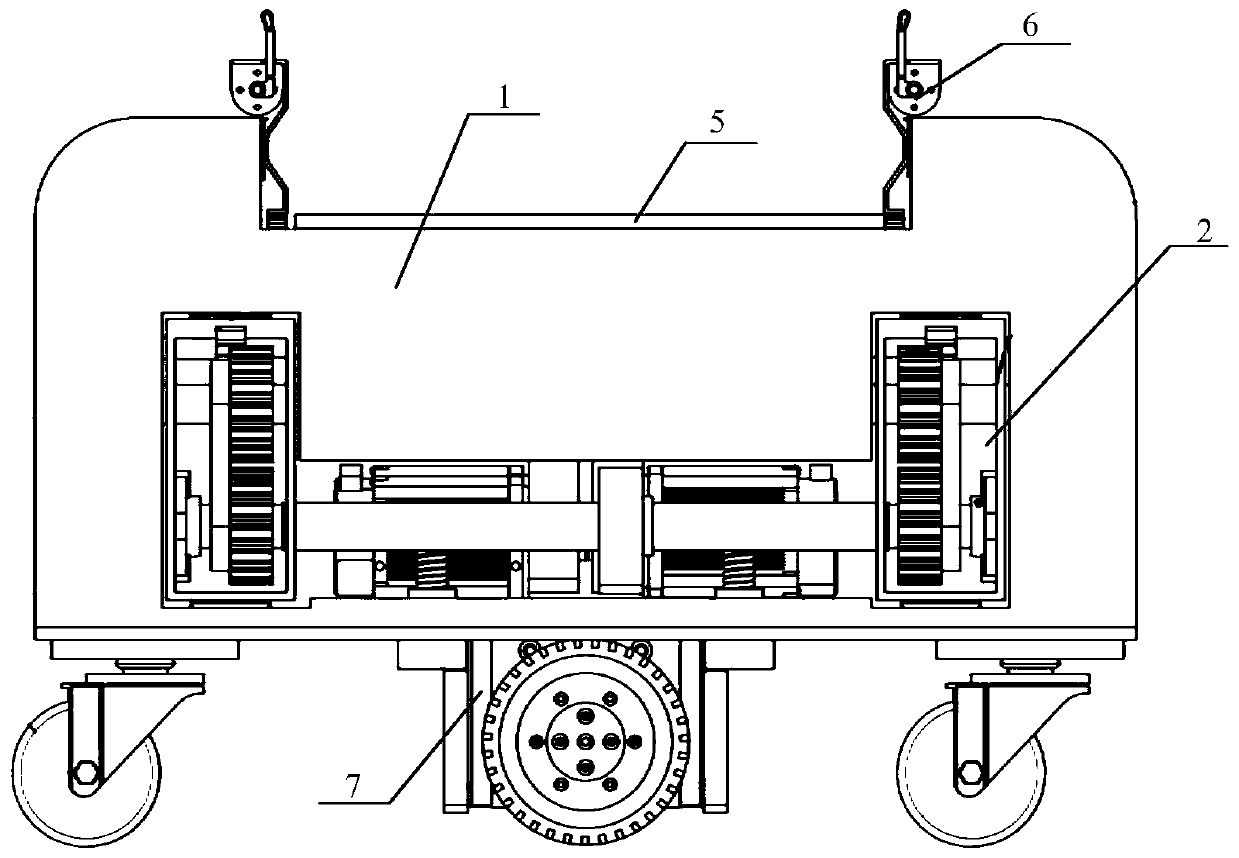

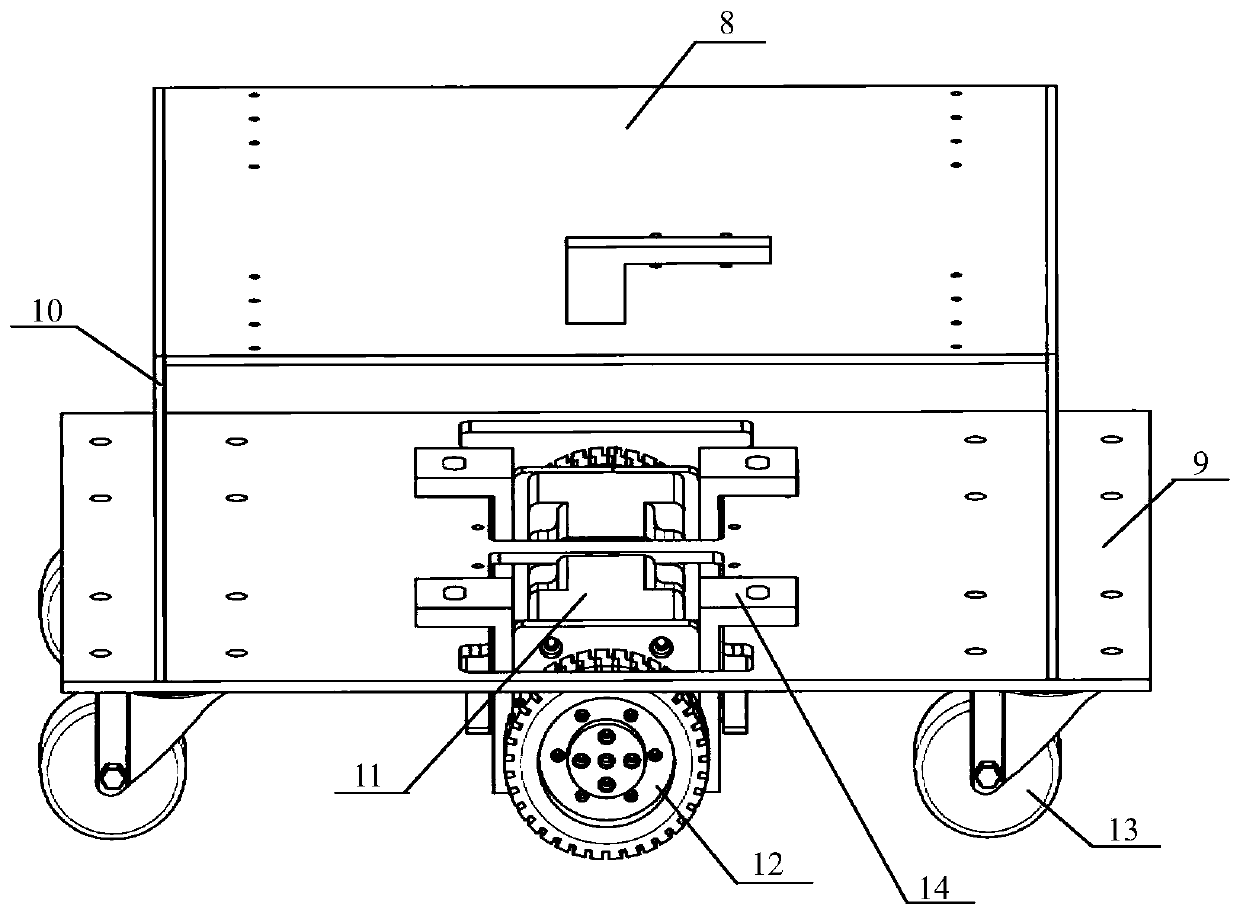

AGV type automatic storage device and application thereof

ActiveCN110775502ACooperate smoothlySave human effortStorage devicesLogistics managementControl engineering

The invention relates to an AGV type automatic storage device and application of the AGV type automatic storage device, and belongs to the technical field of logistics automation machinery. The AGV type automatic storage device comprises storage racks and an AGV located between the storage racks, a climbing track is arranged on the storage racks, the AGV comprises a vehicle body and a climbing mechanism arranged on the vehicle body, and the climbing mechanism is used for driving the vehicle body to move on the climbing track; the vehicle body comprises a traveling mechanism, a cargo carrying platform and an extension fork type transfer mechanism used for transferring cargos, the climbing mechanism comprises a telescopic mechanism and a climbing mechanism, the telescopic mechanism is used for controlling the extension and retraction of the climbing mechanism, and the climbing mechanism is used for being matched with the climbing track for realizing the up-and-down movement of the vehicle body. The AGV type automatic storage device can walk in the vertical direction to store and transport cargos, lifting equipment is not needed, investment of automatic storage equipment is reduced, and operation efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Heating furnace

InactiveCN102538449AImprove heating efficiencyHigh degree of automationFurnace typesEngineeringHeating furnace

The invention relates to a heating furnace, which comprises a framework. A heating chamber is arranged on the framework, a feeding device and a conveying device are disposed on the framework, the conveying device is used for conveying a workpiece to be processed into the heating chamber, a discharge outlet of the feeding device is communicated with the conveying device, the conveying device is communicated with the heating chamber, and a discharge outlet is disposed at the tail of the heating chamber. Special auxiliary equipment is configured for the heating chamber, the workpiece to be processed is automatically fed to the conveying device by the feeding device, the workpiece is conveyed into the heating chamber to be heated by the conveying device, and is discharged from the discharge outlet after being heated, automation degree of an integral heating process is high, labor intensity of workers is greatly reduced, heating efficiency of the workpiece is greatly improved, and the heating furnace is suitable for batch production and is favorable for lowering production cost.

Owner:NINGBO SHENGAN ROBOT TECH CO LTD

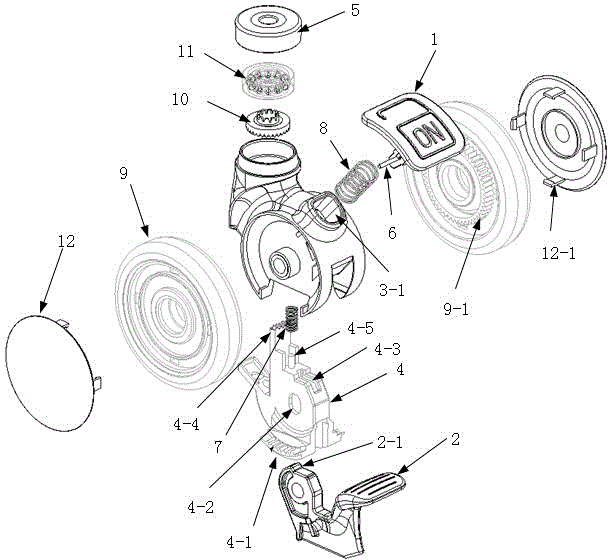

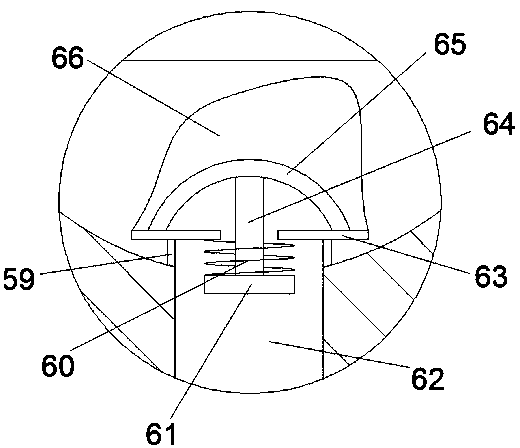

Dual-pedal-control caster wheel

InactiveCN102975575ACooperate smoothlyFlexible useBraking element arrangementsFoot actuated initiationsEngineeringCam

The invention relates to a dual-pedal-control caster wheel. The dual-pedal-control caster wheel comprises a caster wheel main frame, wherein wheel sheets and side covers are arranged at the two sides of the caster wheel main frame, the wheel sheets are provided with brake gear rings, a brake slide block is arranged in an internal cavity of the caster wheel main frame, a first offsetting spring is arranged between the upper side part of the brake slide block and the internal cavity of the caster wheel main frame, a sectorial brake rack is arranged at a side part of the brake slide block, the brake slide block is a hollow slide block, of which the middle part is provided with a long slotted hole, a brake pedal is sleeved on a transverse rod of the internal cavity of the caster wheel main frame, and a cam part is arranged on the brake pedal; and a brake-off pedal which is used for brake-off is further arranged on the caster wheel main frame in a penetrating manner, a driving end of the brake-off pedal can extend into a slotted hole of the upper side part of the brake slide block and be matched with the brake pedal, and a second offsetting spring is arranged between the brake-off pedal and an upper through hole of the caster wheel main frame. According to the dual-pedal-control caster wheel, the brake pedal and the brake-off pedal are arranged at the same side part, so that the stress directions are the same during braking and braking-off operation, and the use is flexible and convenient.

Owner:FUJIAN SECURE MEDICAL TECH

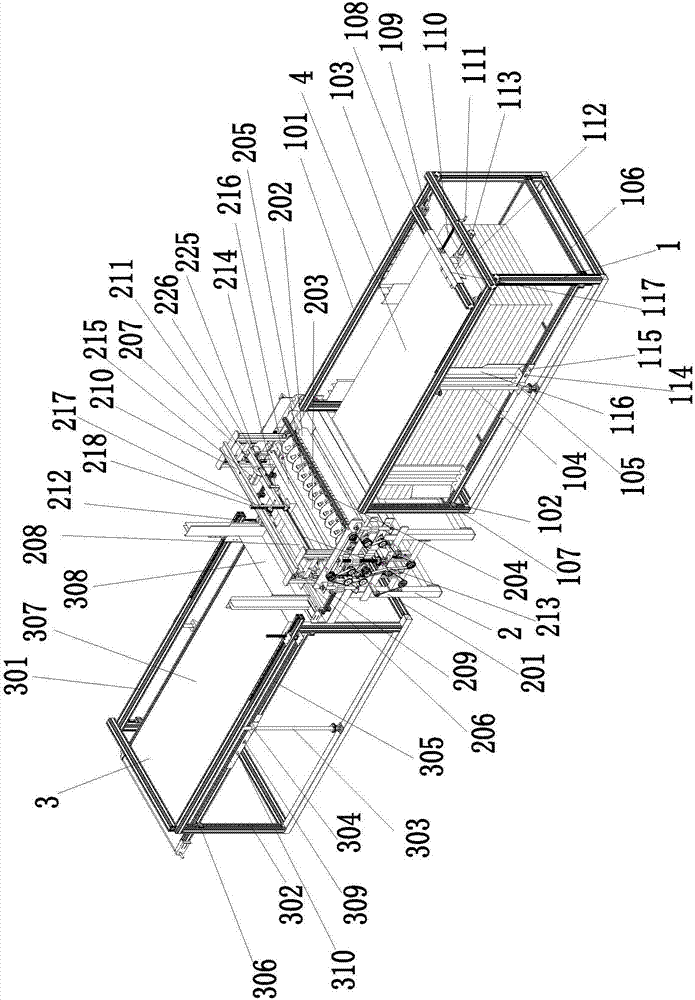

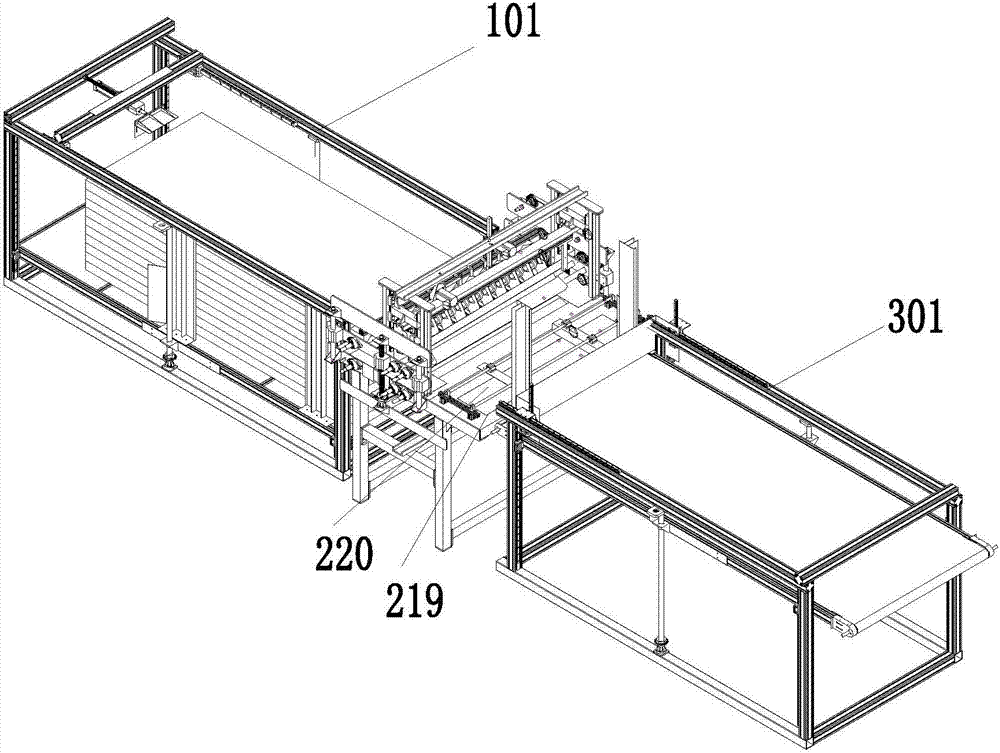

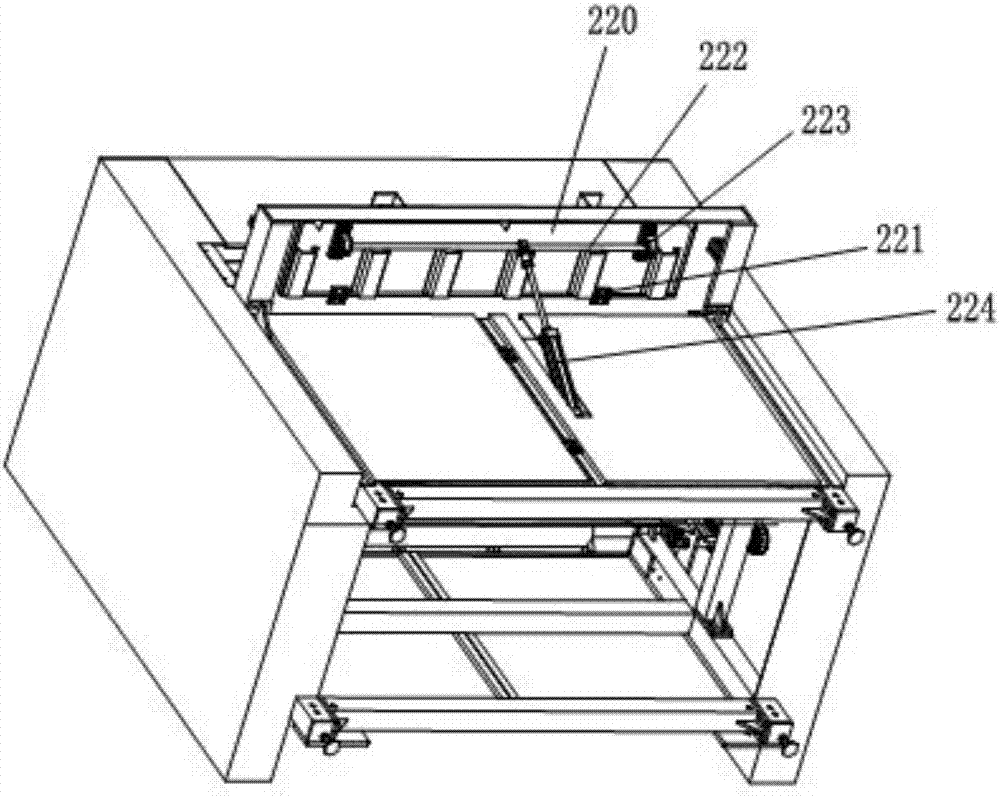

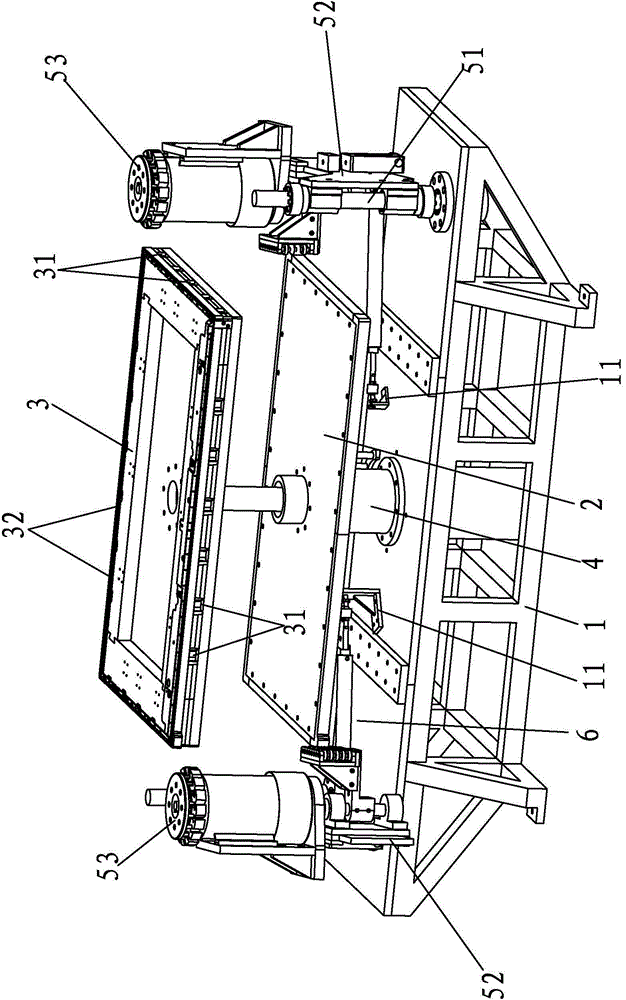

Full-automatic cutting all-in-one machine for pearl wool

ActiveCN107214750ANeatly stackedSave human effortClimate change adaptationMetal working apparatusIntegrated productionProduction quality

The invention discloses a full-automatic cutting all-in-one machine for pearl wool. The full-automatic cutting all-in-one machine for the pearl wool comprises an automatic feeding mechanism, a transverse and vertical cutting mechanism and a material stacking and discharging mechanism; the automatic feeding mechanism comprises a feeding frame, a feeding lifting mechanism and a feeding lifting machine frame, wherein the pearl wool is stacked on the feeding lifting machine frame, and a feeding push part mechanism and a push plate are arranged on the upper part of the feeding frame; the transverse and vertical cutting mechanism comprises a cutting frame, a conveying guide roller set, a vertical cutting mechanism and a transverse cutting mechanism, wherein the vertical cutting mechanism comprises a rotating shaft and a vertical cutter set, and the transverse cutting mechanism comprises a transverse cutting lifting mechanism, a transverse cutting translation mechanism and a transverse cutter; and the material stacking and discharging mechanism comprises a discharging frame, a discharging lifting mechanism, a discharging lifting machine frame and a conveying belt. The full-automatic cutting all-in-one machine for the pearl wool has the advantages that batching, automatic feeding, cutting and stacking integrated production of the pearl wool can be realized, and therefore the cutting precision can be improved, the material waste can be reduced, and in addition, the production quality and the production efficiency of the pearl wool can be improved.

Owner:杭州华飞包装材料有限公司

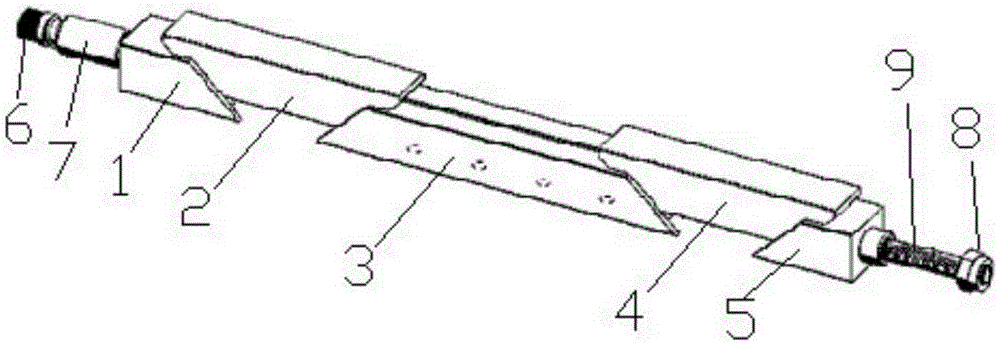

Locking mechanism

ActiveCN105263285AAvoid flippingSimple structureCasings/cabinets/drawers detailsLocking mechanismAcute angle

The present invention provides a locking mechanism, comprising a screw, and a fastening component, a top block, a first upper sliding block, a lower sliding block, a second upper sliding block, a screw block and a nut which are successively arranged on the screw in a penetrated way and cooperate with each other; wherein two ends of first upper sliding block and the second upper sliding block are both wedge-shaped surfaces with the angle of alpha, the end portion of the top block adjacent to the first upper sliding block, two ends of the lower sliding block, and the end portion of the screw block adjacent to the second upper sliding block are all wedge grooves having the angle of alpha, the wedge grooves are matched with the wedge-shaped surfaces; and the alpha is an acute angle. The locking mechanism of the present invention has the beneficial effects of simple structure, smooth cooperation of all portions, convenient use, assembling and disassembling, capacity of preventing overturn of a wedge block, having a self-aligning function, and excellent locking effect.

Owner:成都瑞雪丰泰精密电子股份有限公司

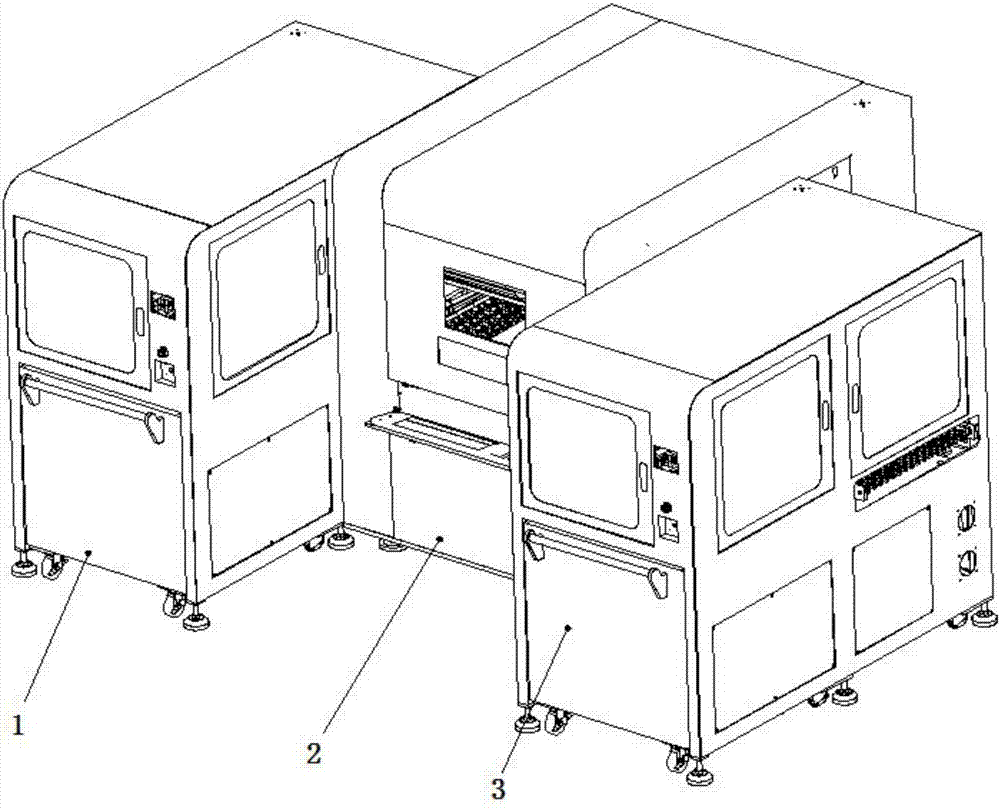

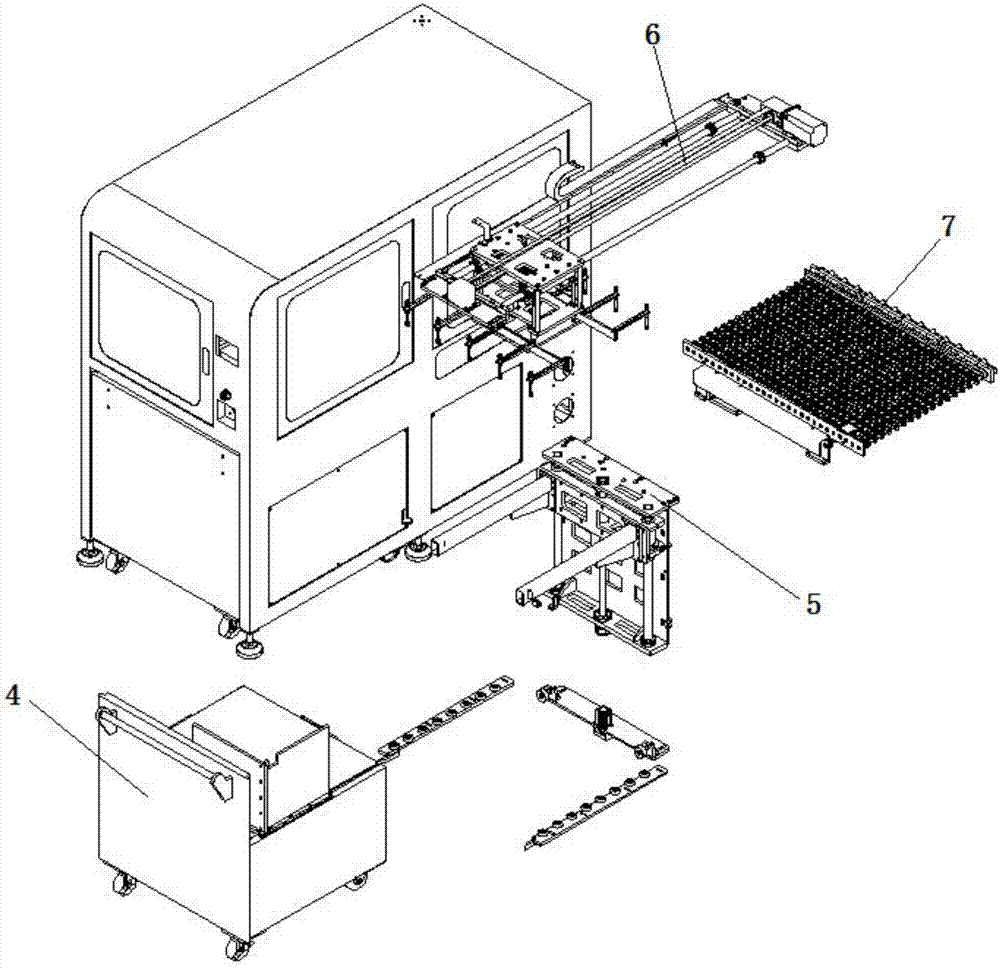

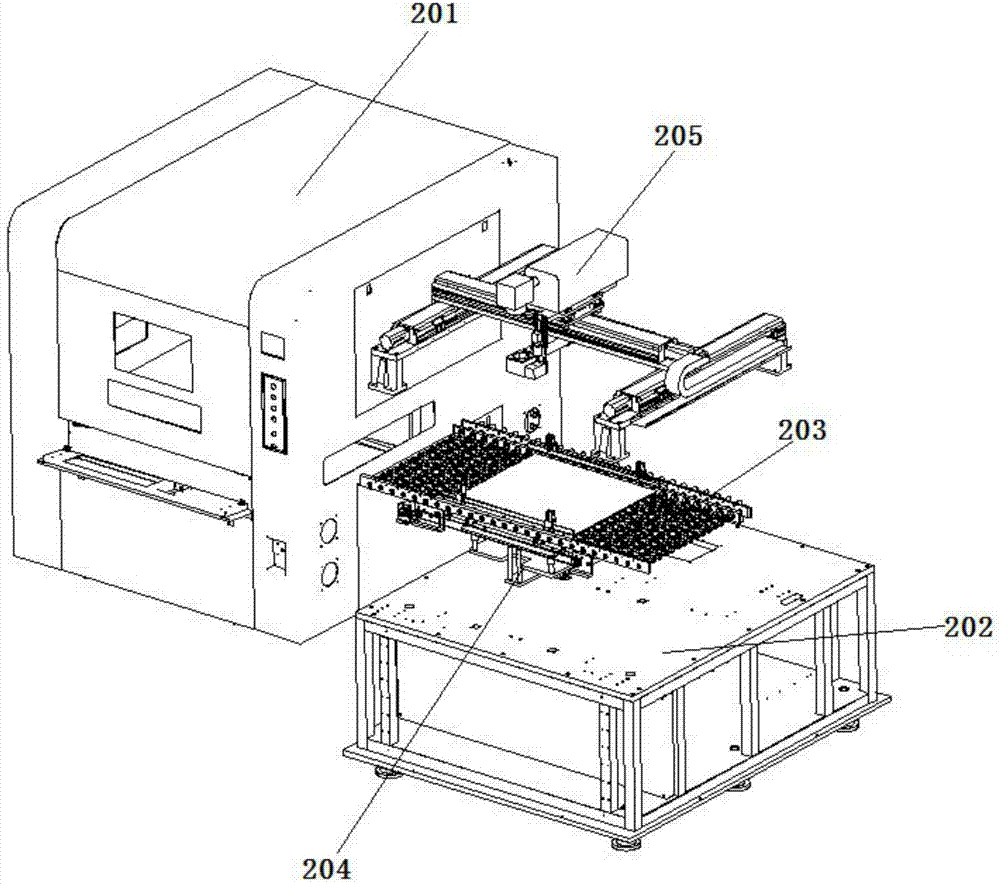

Automatic marking system

ActiveCN107009028AClosely connectedCooperate smoothlyLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses an automatic marking system which comprises a plate feeding device, a laser marking device and a plate discharging device, wherein a plate outlet of the plate feeding device corresponds to a plate inlet of the laser marking device; and a plate outlet of the laser marking device is opposite to a plate inlet of the plate discharging device. According to the system provided by the invention, the plate feeding device and the plate discharging device can realize automatic plate feeding and discharging; and all the components of the system are closely connected, and different working procedures are cooperated smoothly. A portal assembly in the laser marking device is of a dual-Y-shaft and X-shaft cooperation driving structure, and the double Y shafts can solve the problems of asynchronization of the two Y shafts, heavy shaking and the like in case of a large cross beam span. The marking speed and the precision are improved to a relatively large extent; and the height of a laser device can be finely adjusted (within a range of positive and negative 15 mm) through a screw rod, so that the automatic marking system can adapt to marking procedures of various PCBs with different thicknesses.

Owner:SHENZHEN SHENGDAKANG TECH CO LTD

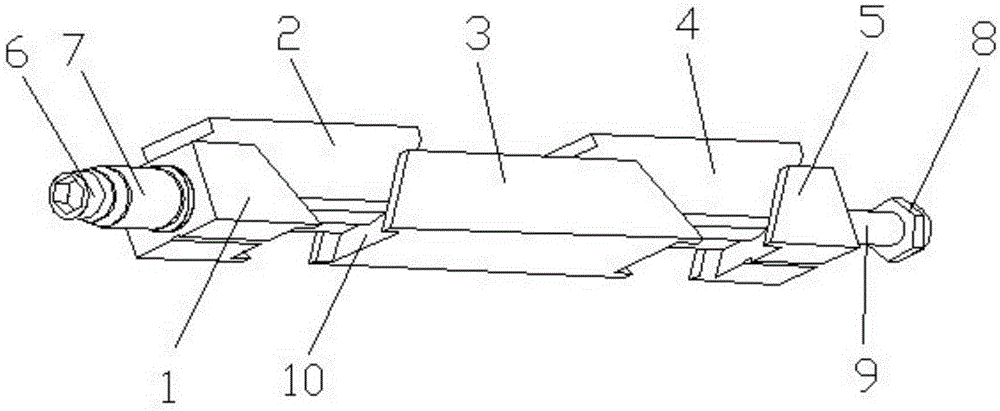

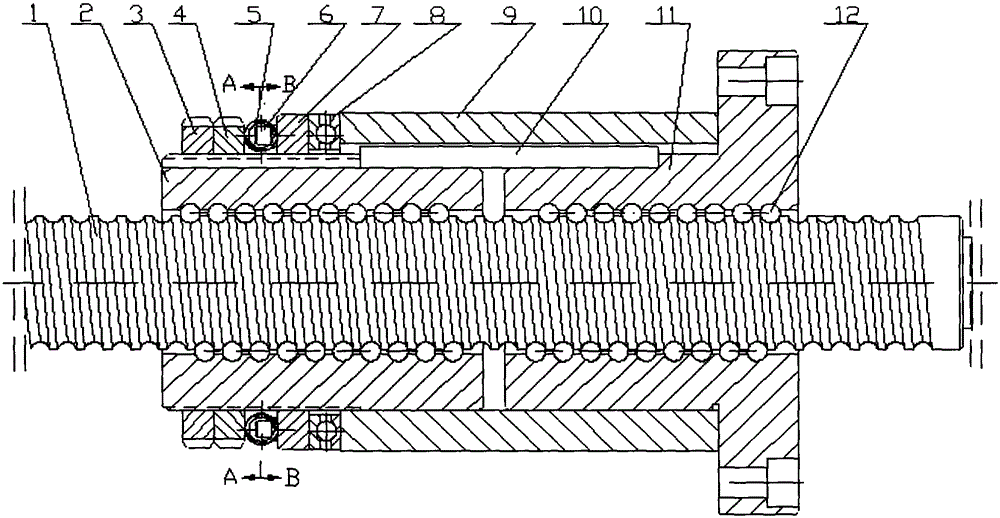

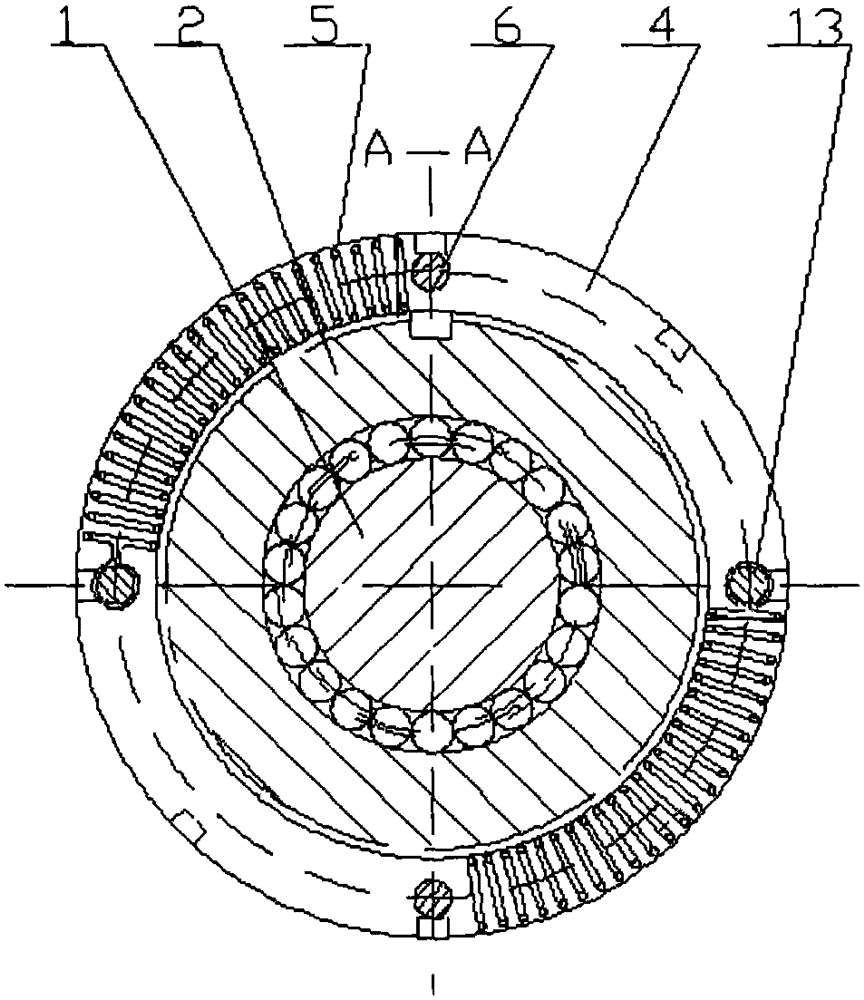

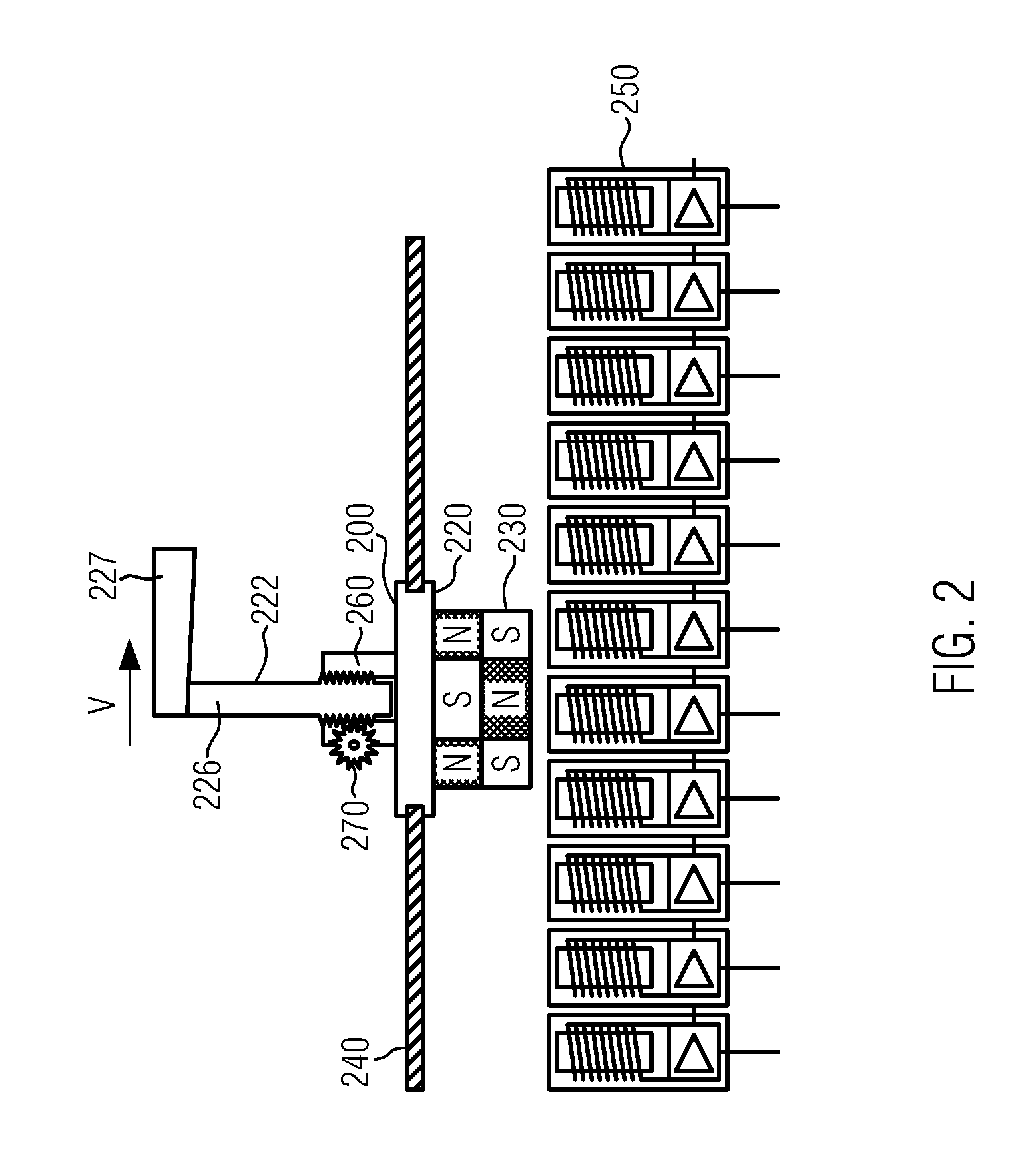

Automatic pre-tightening device for ball screws

The invention provides an automatic pre-tightening device for ball screws. The automatic pre-tightening device is composed of a ball screw, a clearance-eliminating ball nut, a lock nut, a torque applying nut, an energy storage spring, a left spring pile, a right spring pile, a pre-tightening nut, an end bearing, an outer sleeve, a flat key, a transmission ball nut and a ball, wherein the clearance-eliminating ball nut and the transmission ball nut sleeving the ball screw are closely mounted in the outer sleeve; and the end bearing, the pre-tightening nut, the energy storage spring, the torque applying nut and the lock nut are mounted on a fine pitch thread arranged on the outer surface of the clearance-eliminating ball nut. The torque applying nut applies pre-tightening torque to the energy storage spring, the energy storage spring stores energy and transfers the pre-tightening torque to the pre-tightening nut, and the pre-tightening nut applies axial thrust to the outer sleeve through the end bearing under the torque action of the energy storage spring. When a ball screw assembly gets clearance, the transmission ball nut generates relative axial displacement relatively to the clearance-eliminating ball nut, and the transmission clearance between the transmission ball nut and the ball screw is eliminated.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

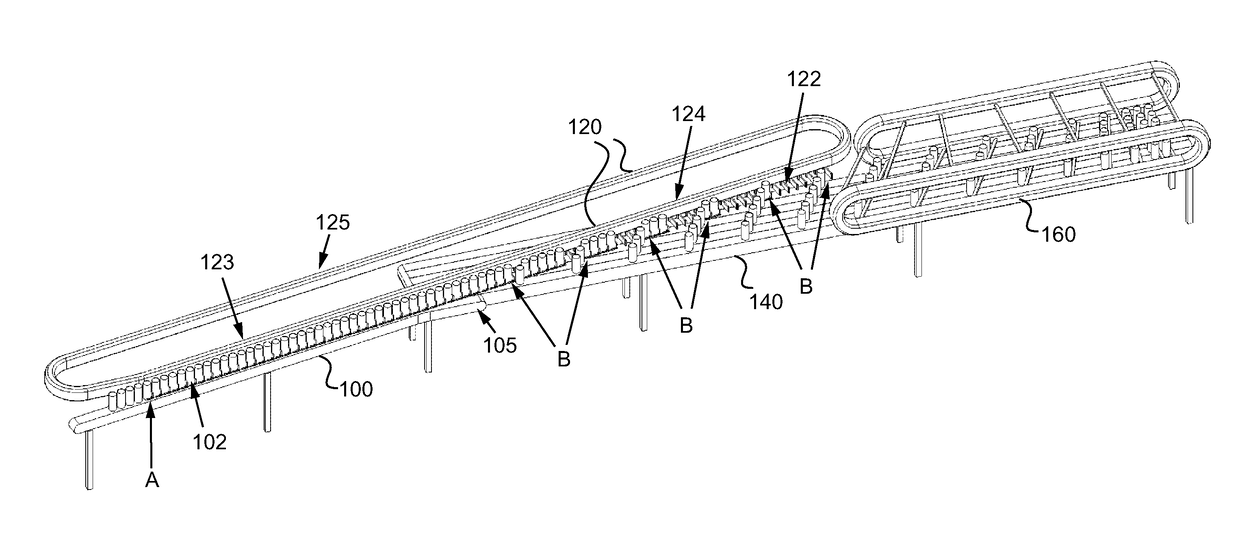

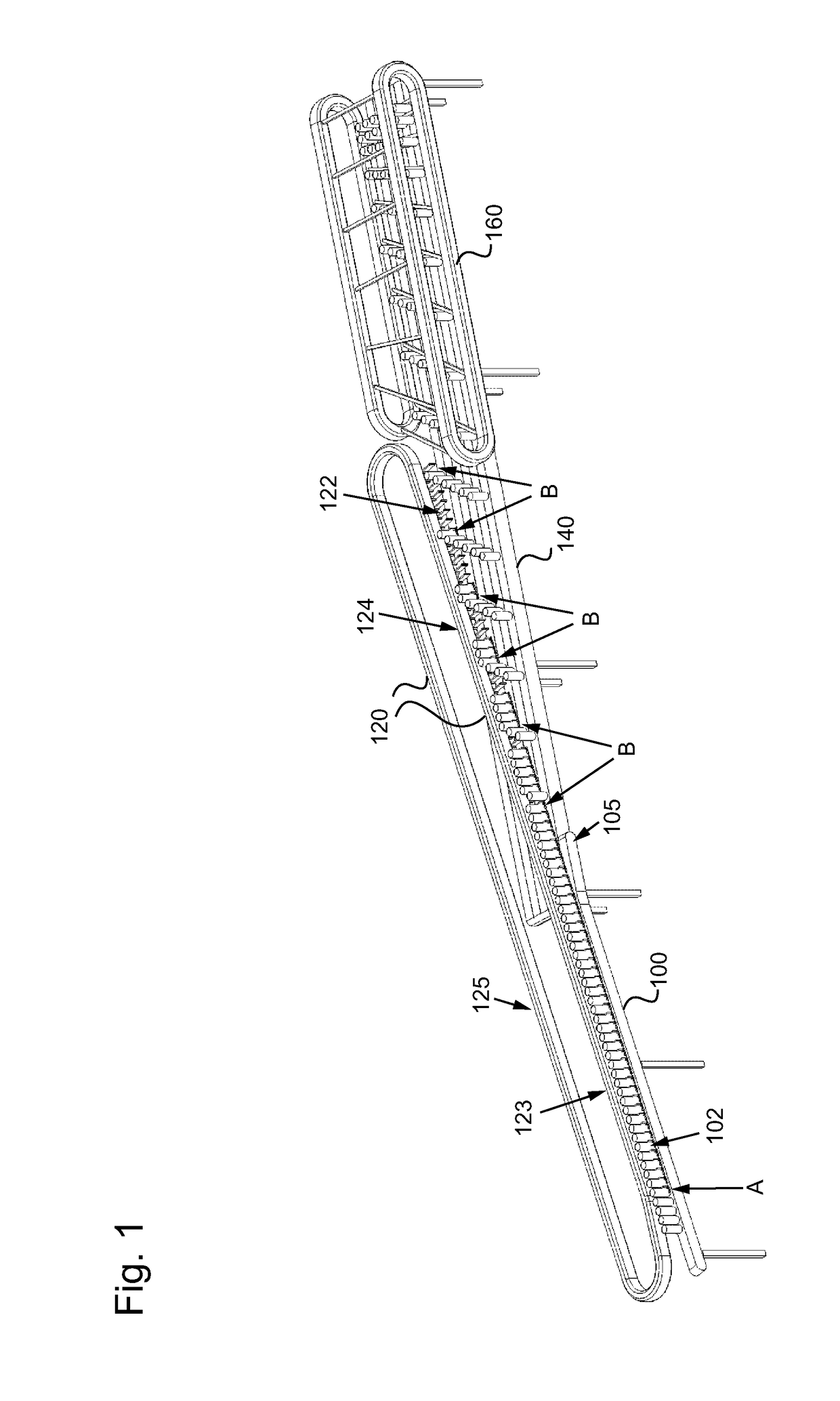

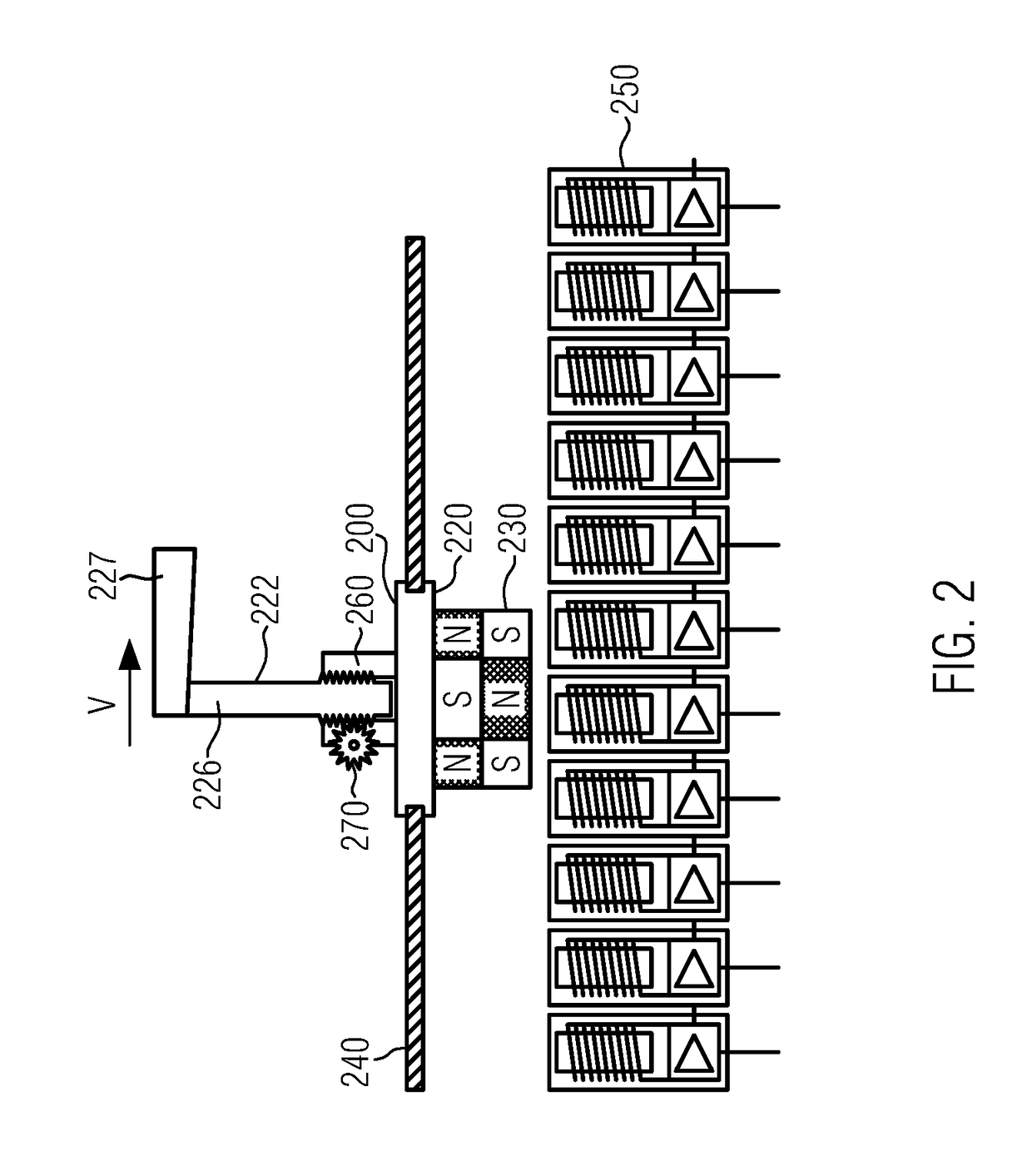

Device and Method for Distributing and Grouping Containers

ActiveUS20160244271A1Cooperate smoothlyReduce installation costsNon-mechanical conveyorsPackaging bottlesMechanical engineering

A device for distributing and grouping containers in a container treatment assembly, including an infeed conveyor which is configured to convey a plurality of containers in a single-lane infeed flow; an outfeed conveyor which is configured to convey the containers away in multiple lanes; and a transfer conveyor associated with the infeed and the outfeed conveyor and having a plurality of circulating guide elements for the containers; where the transfer conveyor is adapted to separate the containers in a standing position by way of the circulating guide elements from the single-lane infeed flow to the multi-lane outfeed flow by selective guiding, in particular, by pushing them forward and / or decelerating them.

Owner:KRONES AG

Detachable connecting device and corresponding connecting device of wire harness connector and buckle

ActiveCN104051906ACooperate smoothlyCooperate with solid connection smoothlyCoupling device detailsStructural engineeringMechanical engineering

Owner:曼德汽车零部件(泰州)有限公司

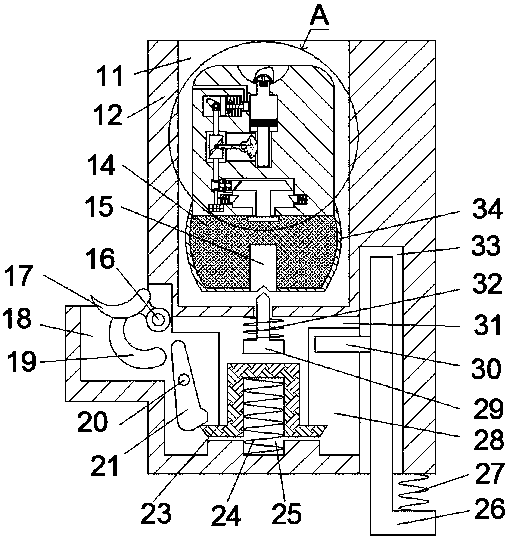

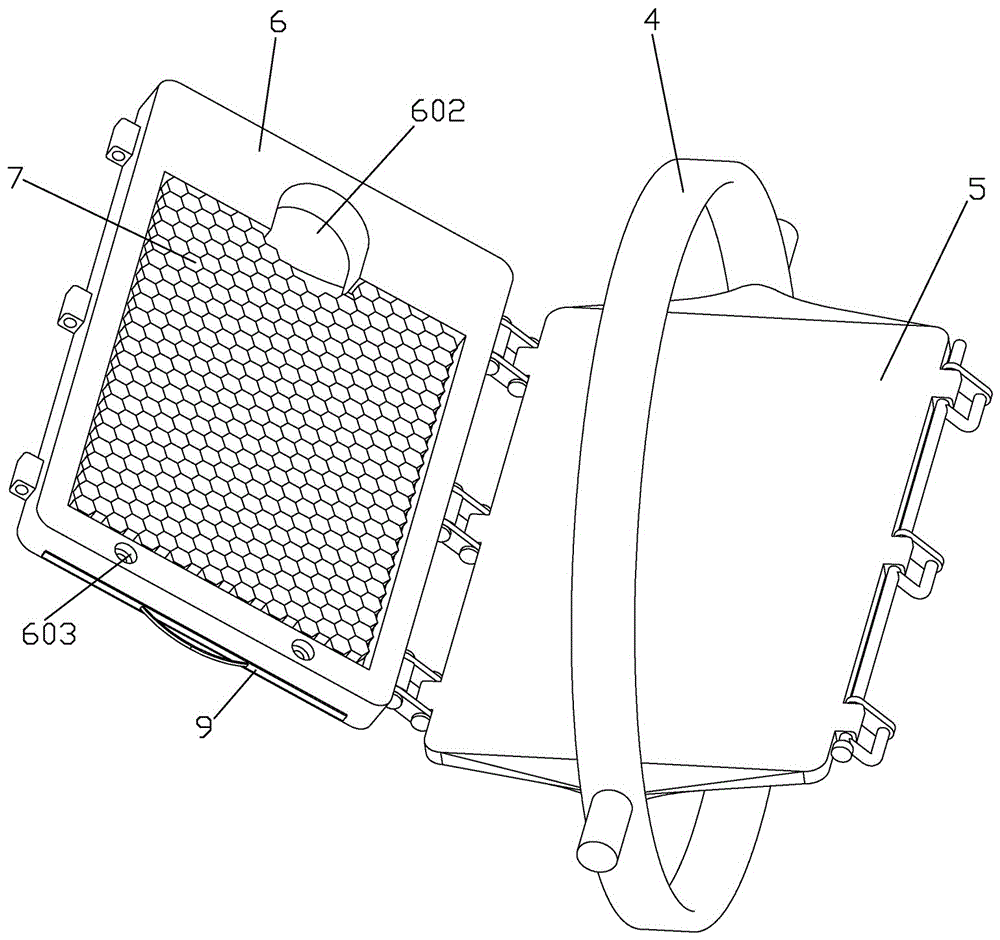

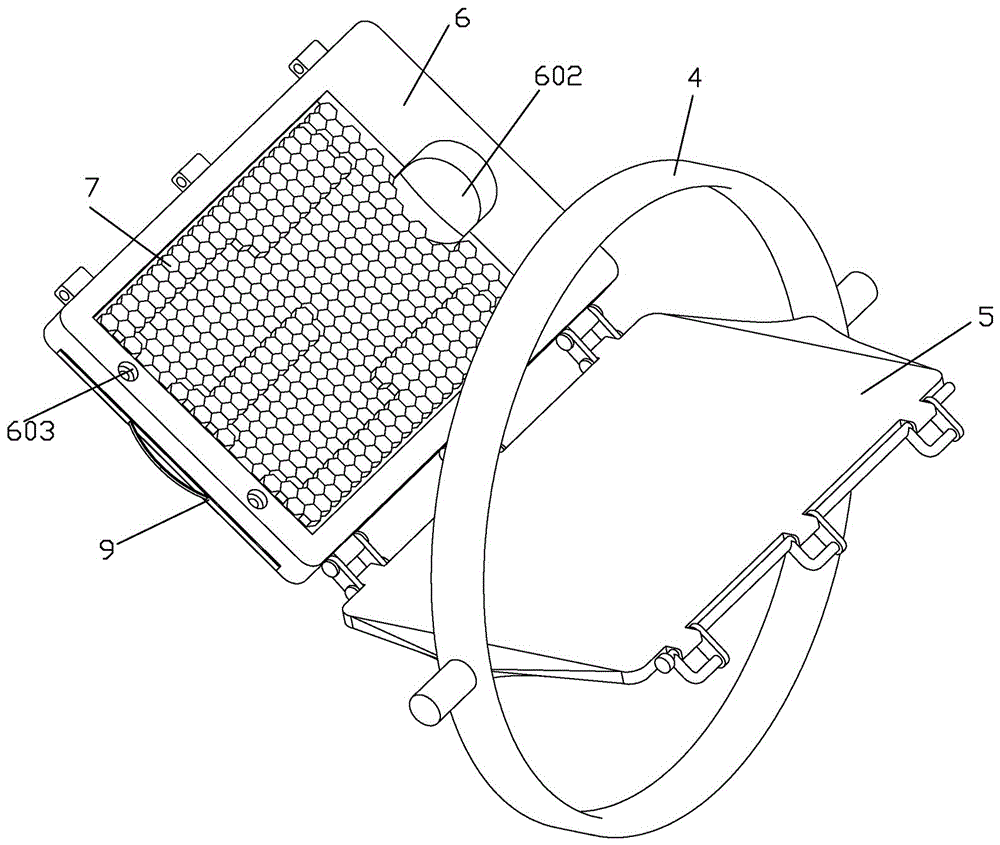

Smoke alarm

ActiveCN110363940AEasy to sendMake up for no signalSmoke/fire/colored-gas signallingDistress signalling devicesSmoke bombSmoke Emission

The invention discloses a smoke alarm, which comprises a body and a launching cavity with an upward opening, wherein the launching cavity is formed in the body, a smoke bomb combustion shell body is arranged in the launching cavity, the central position of the inner wall of the smoke bomb combustion shell body is fixedly connected with an ignition block cooperatively, the smoke bomb combustion shell body is filled with smoke ammunition, and a slidable smoke bomb device is arranged in the smoke bomb combustion shell body. According to the smoke alarm, the energy generated after the combustion of the smoke ammunition sends the smoke bomb device into the air, a trigger movable assembly is designed at first, thus the smoke bomb can be launched simply and conveniently, the smoke bomb device isdesigned at the same time, an inflatable activating assembly, a balloon inflatable assembly, a piston driving assembly and an inspiration assembly are designed in the smoke bomb device, a balloon marked with an SOS distress signal can be automatically inflated, and the smoke alarm is simple in structure and convenient to operate.

Owner:桐乡市织盟知识产权运营有限公司

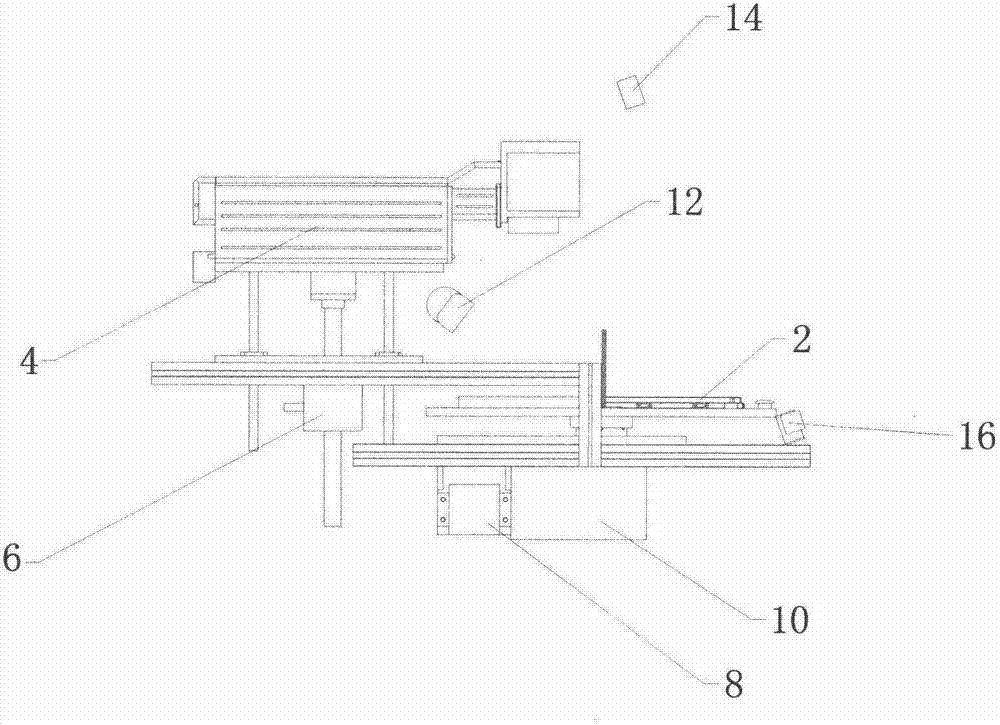

Laser marking machine

The invention discloses a laser marking machine, which comprises a workbench (2) and a laser (4) arranged above the workbench (2) and is characterized by comprising an elevator (6) and a working motor (8), wherein the elevator (6) is installed below the laser (4) and is used for driving the laser (4) to reciprocate, and the working motor (8) is installed below the workbench (2) and is in transmission connection with the workbench (2) by a splitter (10). The laser marking machine has the advantages of simple structure, stable performance and better marking quality.

Owner:SUZHOU INDAL PARK TAIGE ELECTRONICS SCI &TECH

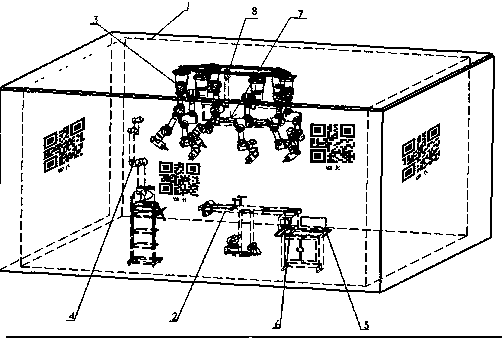

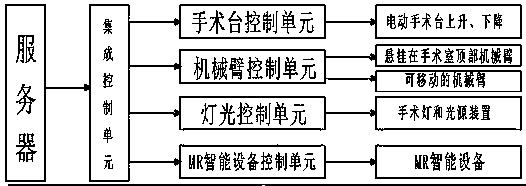

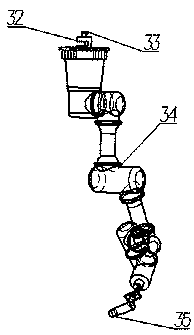

Operating room where mixed reality technology can be applied efficiently

The invention relates to configuration and control of an operating room, in particular to an operating room where a mixed reality technology can be applied efficiently. The operating room includes thecomponents of an operating room body, basic operating facilities and operating instruments, the operating room body is of a cubic structure, a plurality of evenly distributed locating devices are arranged on the wall, an operating table capable of being automatically risen and lowered is installed at the true center of the operating room body, a mechanical arm is installed over the operating table, a camera shooting device or a laser sensor or combination of the camera shooting device or the laser sensor is installed on the mechanical arm, an operating lamp and a light source device are installed above the operating table correspondingly, and the operating room body is further provided with a mobile mechanical arm, a displayer, a server and MR smart equipment. According to the operating room, a three-dimensional model can be matched with patient lesions quickly and accurately, patient location information can be obtained in real time, and the convenience of application of the mixed reality technology to clinical operation is improved.

Owner:无锡蓝软智能医疗科技有限公司

Device and method for distributing and grouping containers

ActiveUS9950875B2Cooperate smoothlyReduce installation costsNon-mechanical conveyorsPackaging bottlesEngineeringSingle vehicle

A device for distributing and grouping containers in a container treatment assembly, including an infeed conveyor which is configured to convey a plurality of containers in a single-lane infeed flow; an outfeed conveyor which is configured to convey the containers away in multiple lanes; and a transfer conveyor associated with the infeed and the outfeed conveyor and having a plurality of circulating guide elements for the containers; where the transfer conveyor is adapted to separate the containers in a standing position by way of the circulating guide elements from the single-lane infeed flow to the multi-lane outfeed flow by selective guiding, in particular, by pushing them forward and / or decelerating them.

Owner:KRONES AG

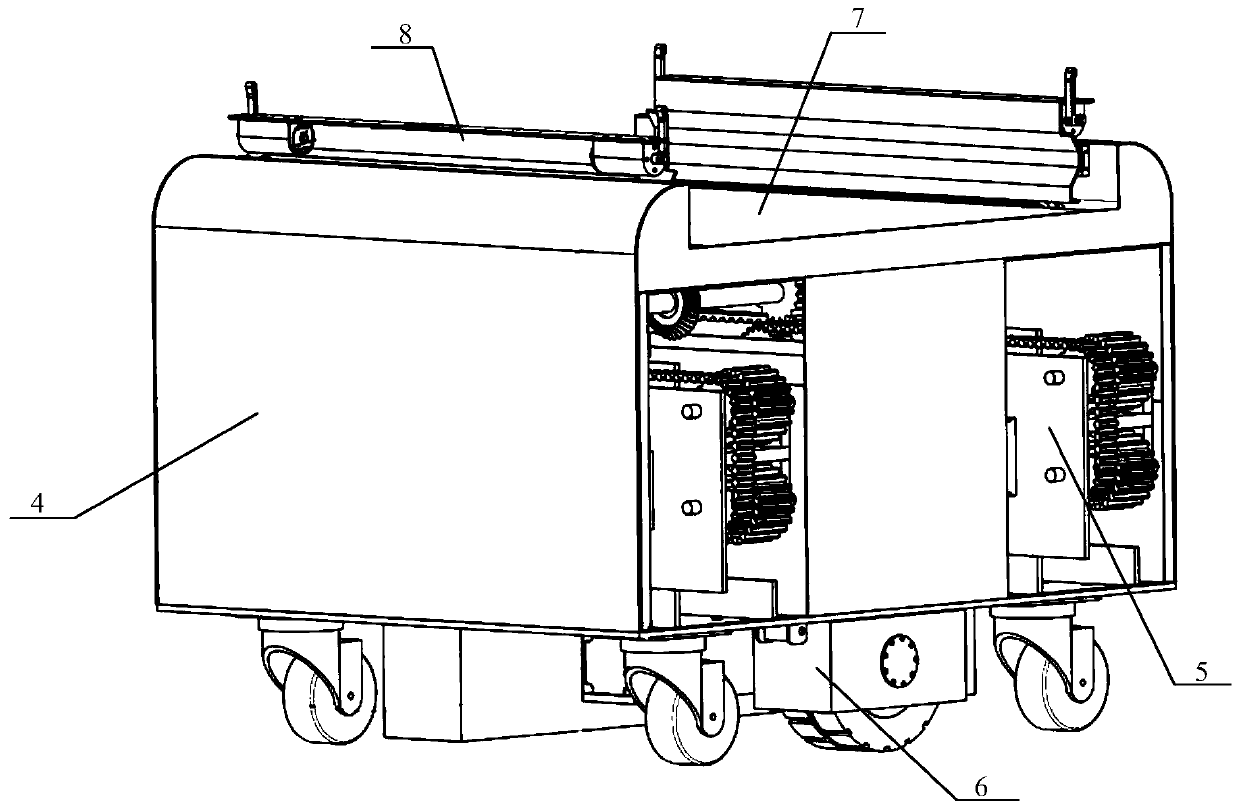

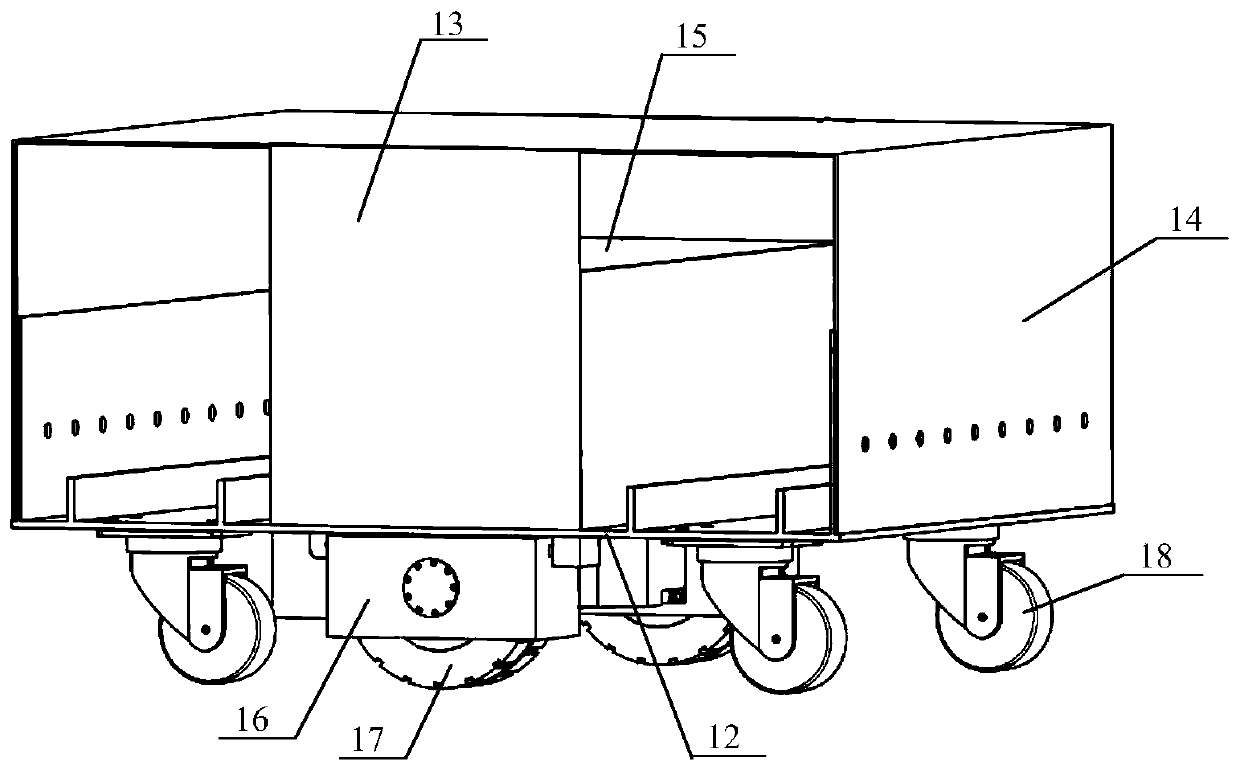

AGV, automatic storage device and working method

ActiveCN110775501AEasy outward movementCooperate smoothlyStorage devicesLogistics managementControl engineering

The invention relates to an AGV, an automatic storage device and a working method, and belongs to the technical field of automated logistics. The AGV includes a vehicle body and climbing mechanisms arranged on the vehicle body, each climbing mechanism includes a telescopic mechanism and a climbing mechanism body, and the two sets of climbing mechanisms are symmetrically distributed on the left andright sides of the vehicle body, work synchronously and independently complete expansion and contraction; the climbing mechanisms are used for cooperating with a climbing track to drive the AGV to move up and down; and a cargo carrying platform and an extending fork type transfer mechanism are arranged above the vehicle body, and a walking mechanism is arranged below the vehicle body. The AGV canwalk in the vertical direction to store and transport cargoes, is matched with the storage device without the need of using lifting equipment, reduces the investment for the automatic storage deviceand improves the operation efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

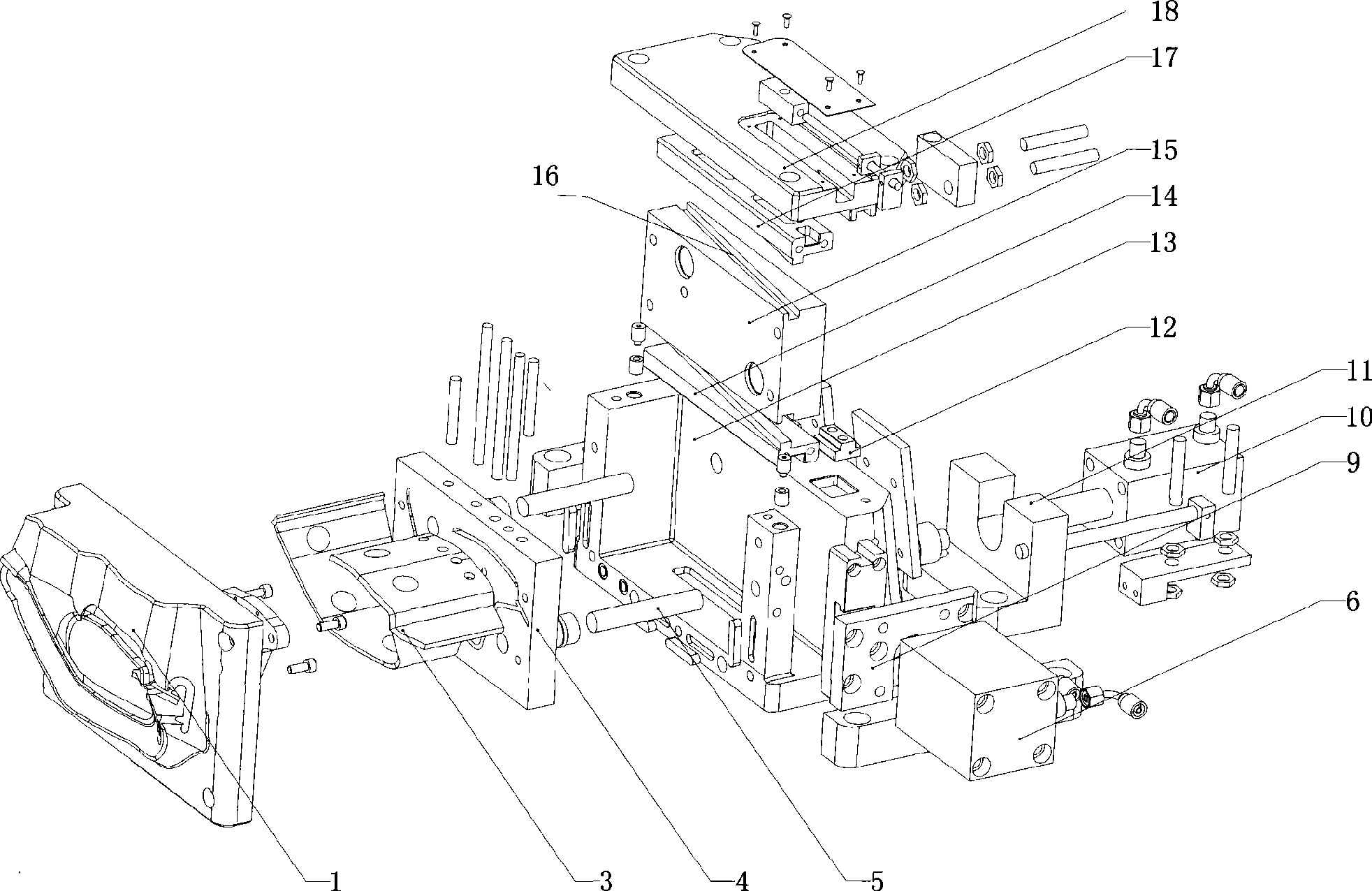

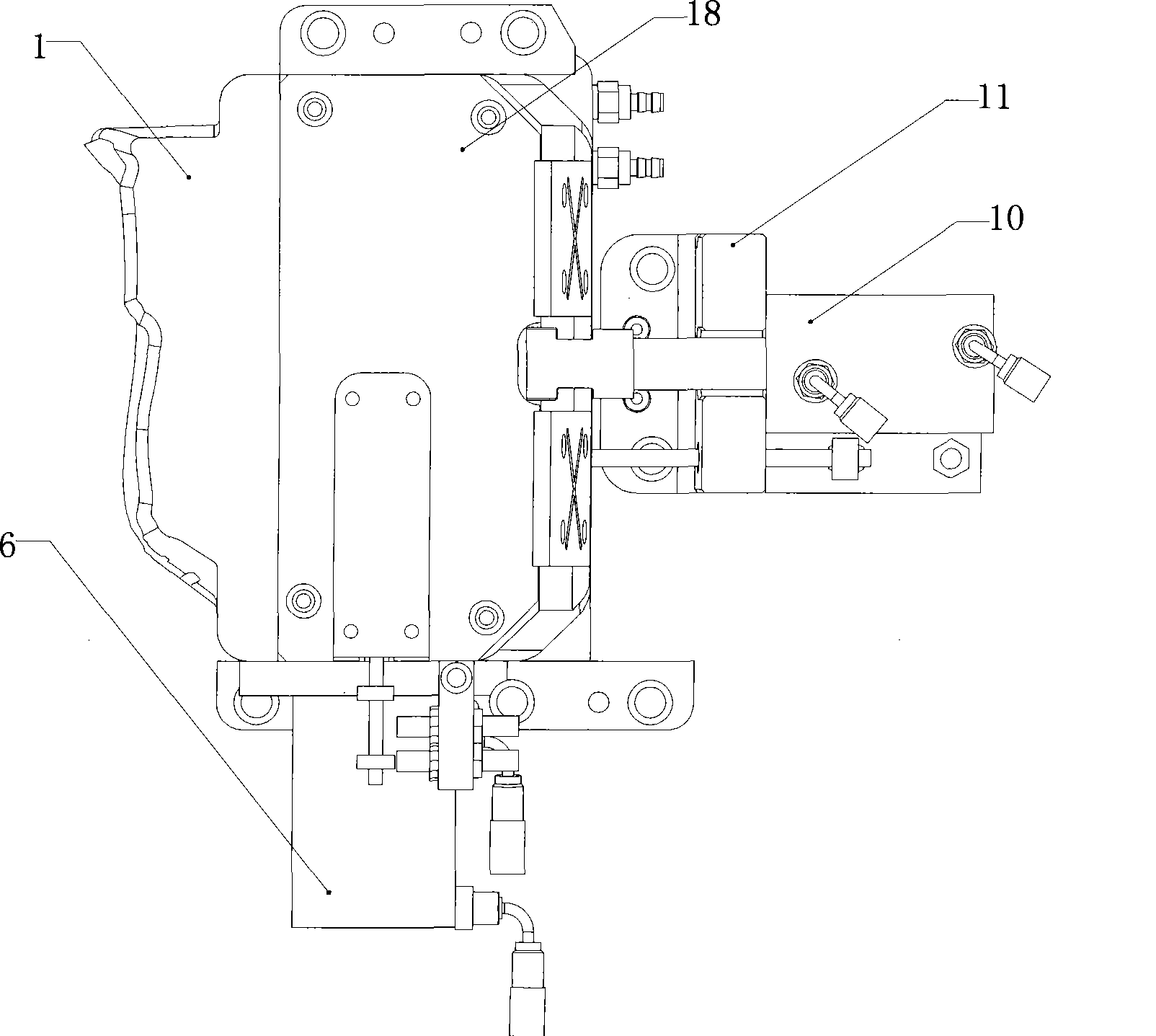

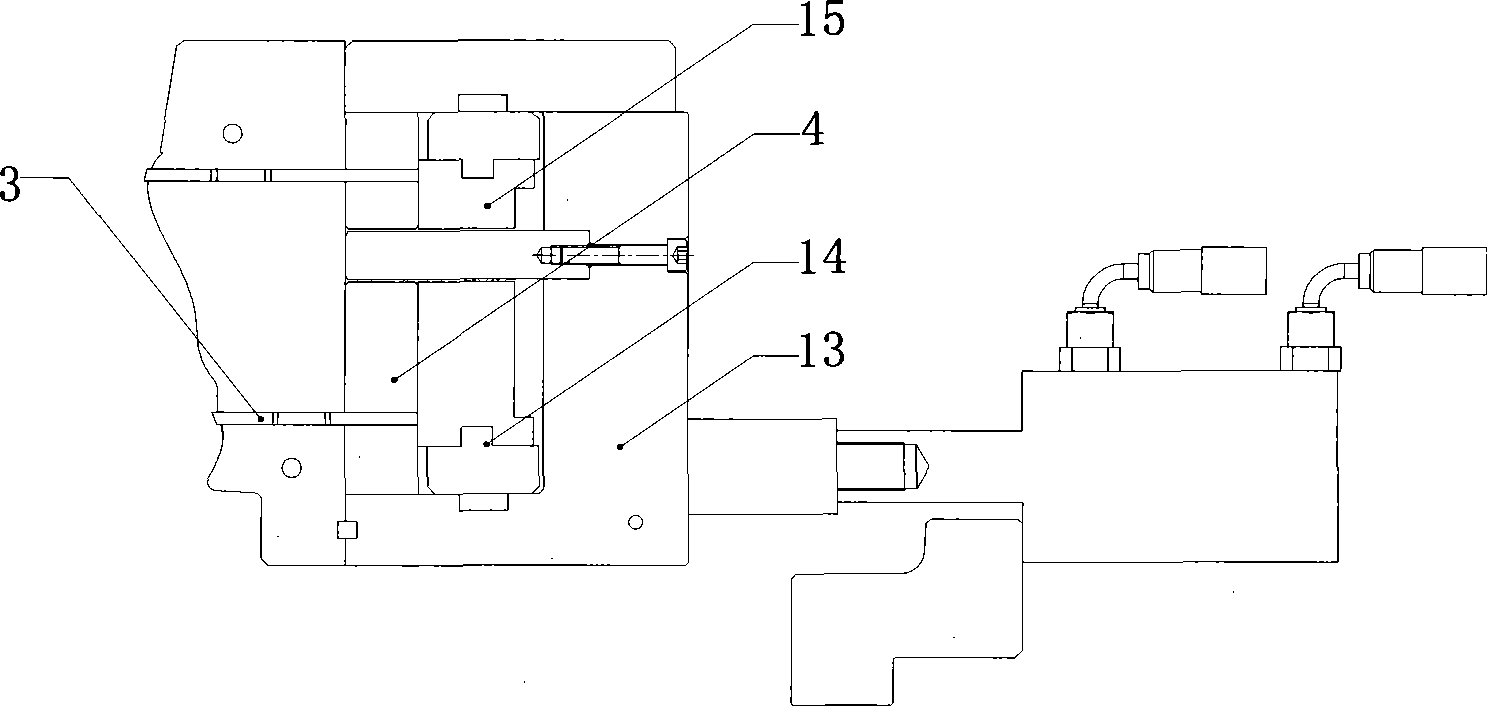

Composite core-pulling device for realizing single mould cavity and dual injection mould

The invention discloses a composite core-pulling device used for realizing single-die cavity and double injection molds; the die is provided with a die cavity; the core pulling device is arranged in the die cavity; the composite core pulling device consists of a primary core pulling device and a secondary core pulling device which have different functions; the primary core pulling device is used for separating and perforating of the die cavity spaces of two materials; the secondary core pulling device is used for leading the product to be completely formed and leading the product to be in a state of demoulding, ejecting and taking-out; the two core pulling devices can be assembled together to realize the forming of double injection product in the single die cavity.

Owner:HUANGYAN XINGTAI PLASTIC MOLD

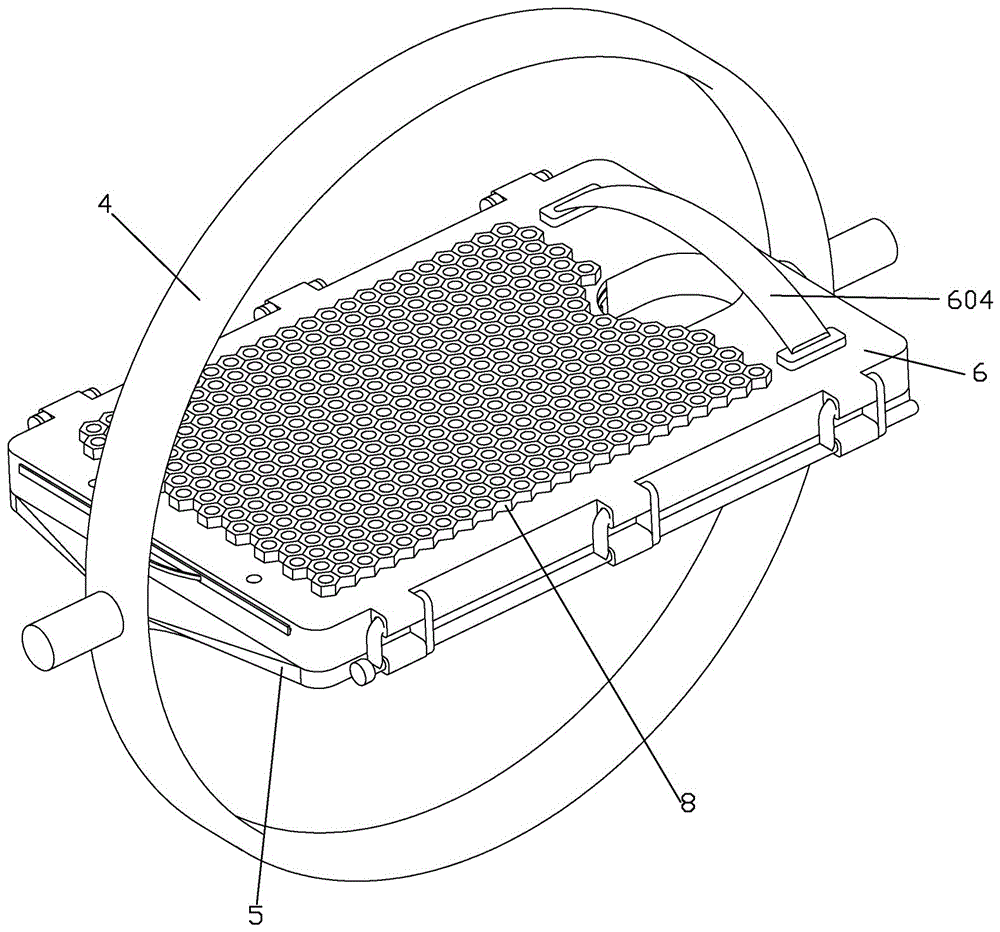

Turnover nursing bed adaptive to human body surface shapes

The invention discloses a turnover nursing bed adaptive to human body surface shapes. The turnover nursing bed comprises a turnover frame and a bed body. The turnover frame is of an annular structure, the bed body comprises a bed plate and a human body fixing device, the bed plate is fixed into the turnover frame, the human body fixing device is used for fixing human bodies and comprises a human body fixing plate, and the human body fixing plate is connected with the bed plate. The turnover nursing bed is characterized in that the human body fixing plate comprises a human body fixing plate body and a plurality of slide bars, concave fixing grooves are formed in the surface, which clings to the bed plate, of the human body fixing plate body, a human head hole which is communicated with the fixing grooves is formed in an end of the human body fixing plate body, head fixing bandage is arranged outside the human head hole, and a plurality of slide bar holes are uniformly formed in the bottoms of the fixing grooves. The turnover nursing bed has the advantages that patients can be fixed by the aid of shapes formed in the fixing grooves according to different body types of the patients, the slide bars can be fixedly positioned by limiting plates, and the shapes formed in the fixing grooves for fixing the patients can be kept.

Owner:ZHENGZHOU UNIV

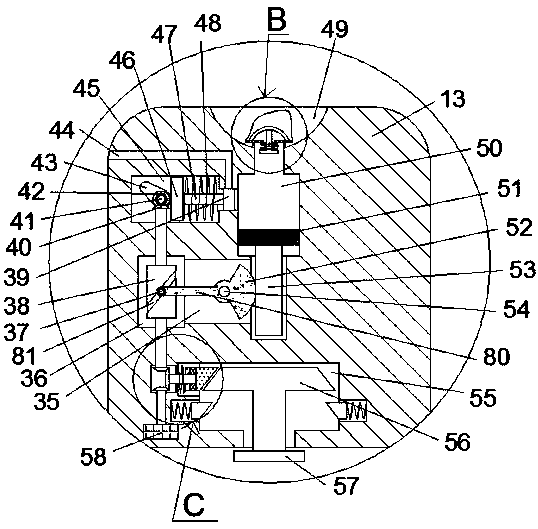

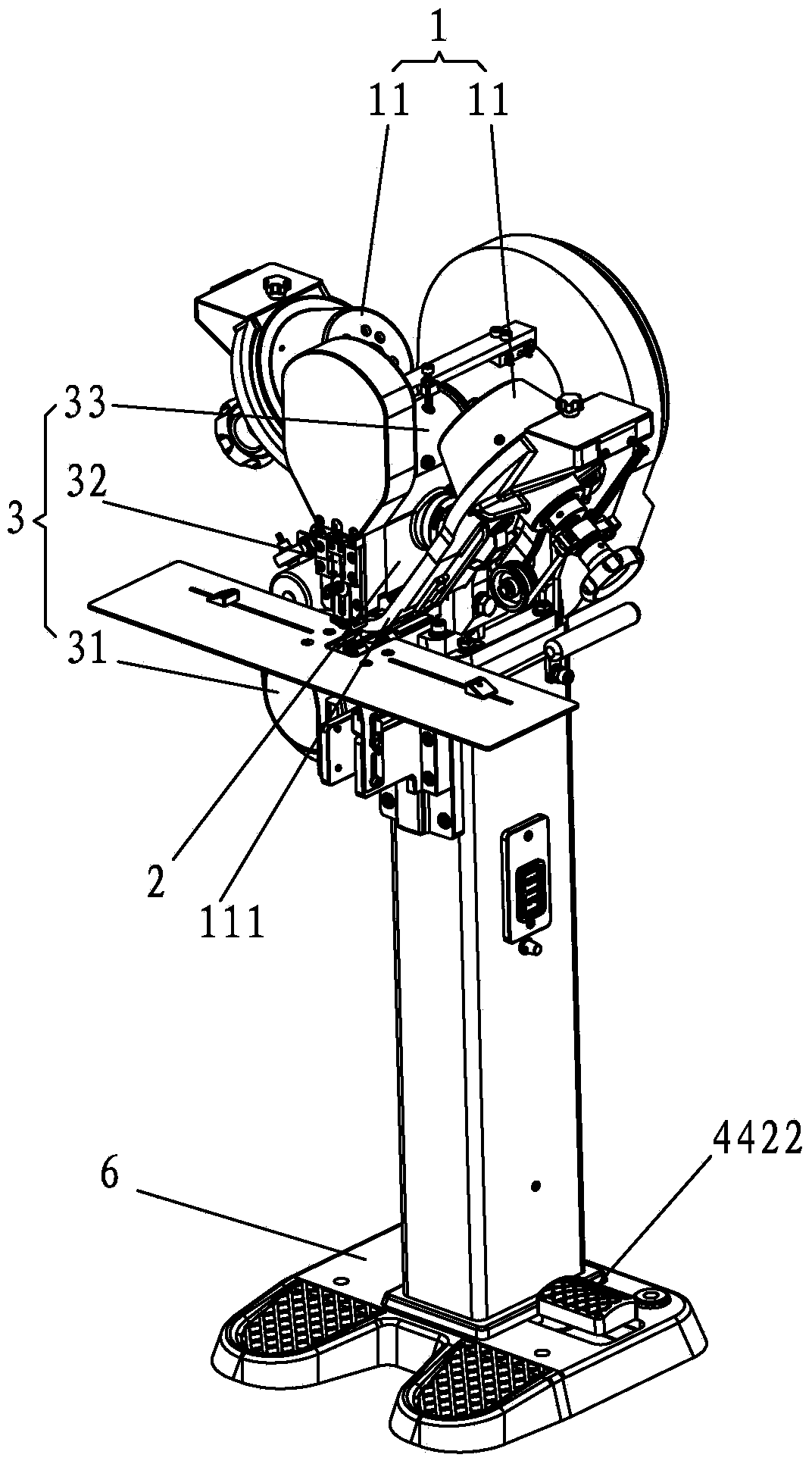

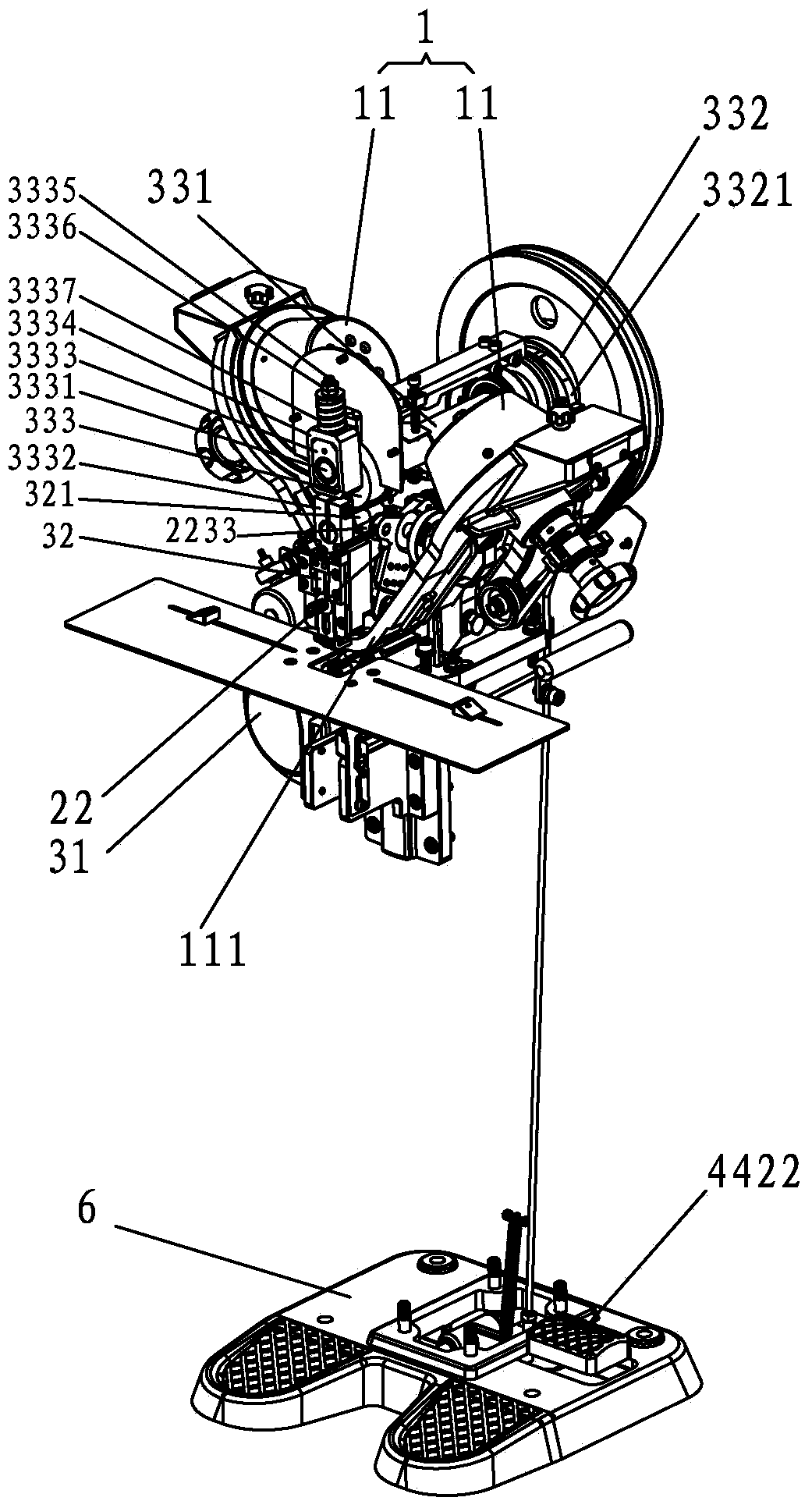

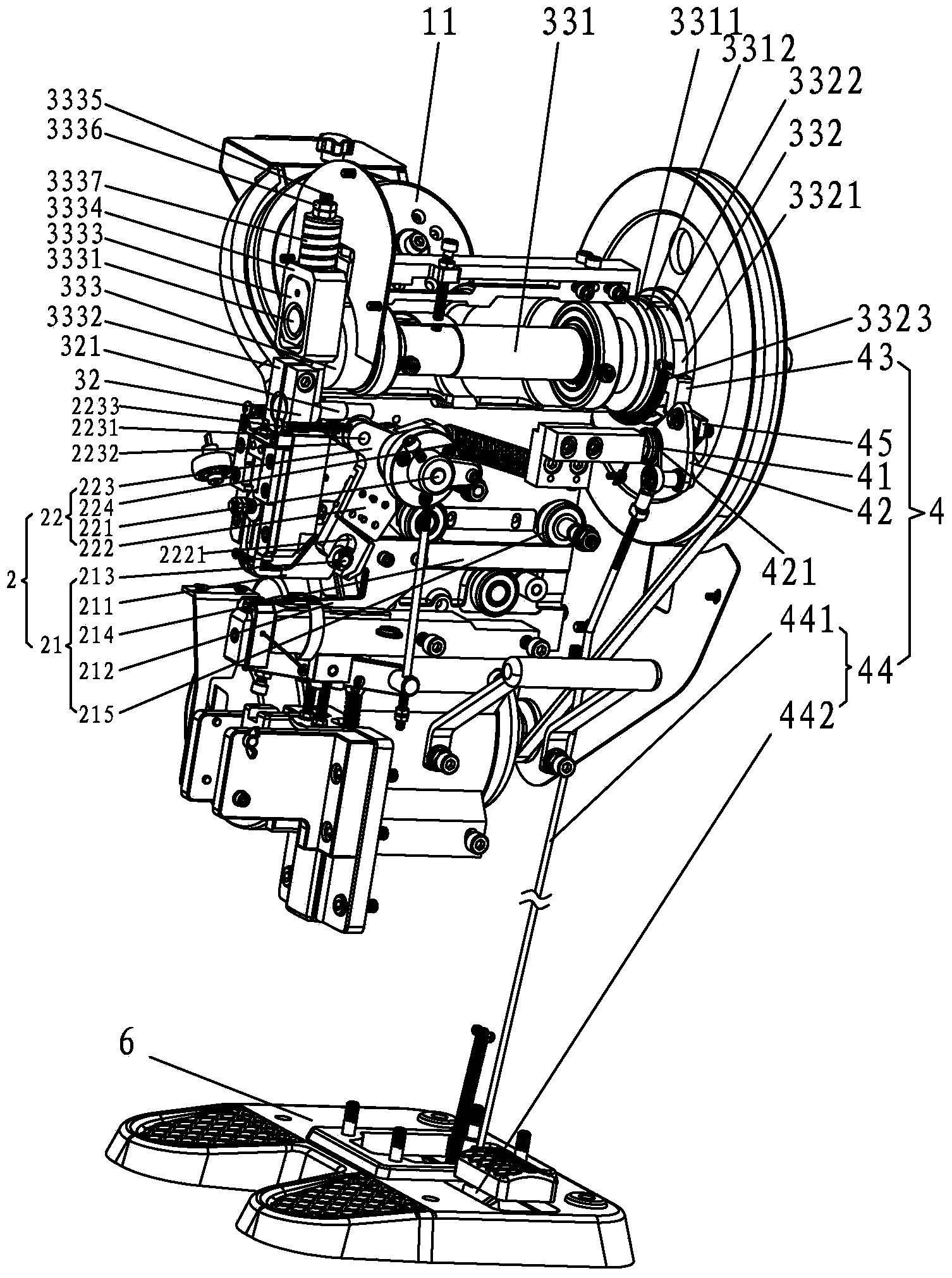

Novel fastener-holing machine with improved material pushing mechanism

ActiveCN103504680ANovel and reasonable structureTight and smoothClothes making applicancesFastenerEngineering

The invention provides a novel fastener-holing machine with an improved material pushing mechanism. The fastener-holing machine comprises a fastener-holing machine body provided with a feeding mechanism, a fastener-holing mechanism and the material pushing mechanism. The material pushing transmission mechanism comprises a first rotating pendulum pivoted onto the fastener-holing machine body through a rotary shaft and used for pushing, pulling and shifting the material pushing mechanism, wherein a shifted handle for enabling a punching device to shift and swing is formed on the first rotating pendulum, the punching device is provided with a shifting handle corresponding to the shifted handle, and the first rotating pendulum is provided with a first return spring. After adopting the technical scheme and compared with the prior art, a structure pattern of a traditional fastener-holing machine is broken through, the material pushing mechanism is novel and reasonable in structure, parts are tight and smooth in matching, and material pushing is smooth. The overall structure matching is smooth, the fastener-holing quality is high, and the practicability is good.

Owner:HUA LIAN GARMENT COMPONENT ENTERPRISE

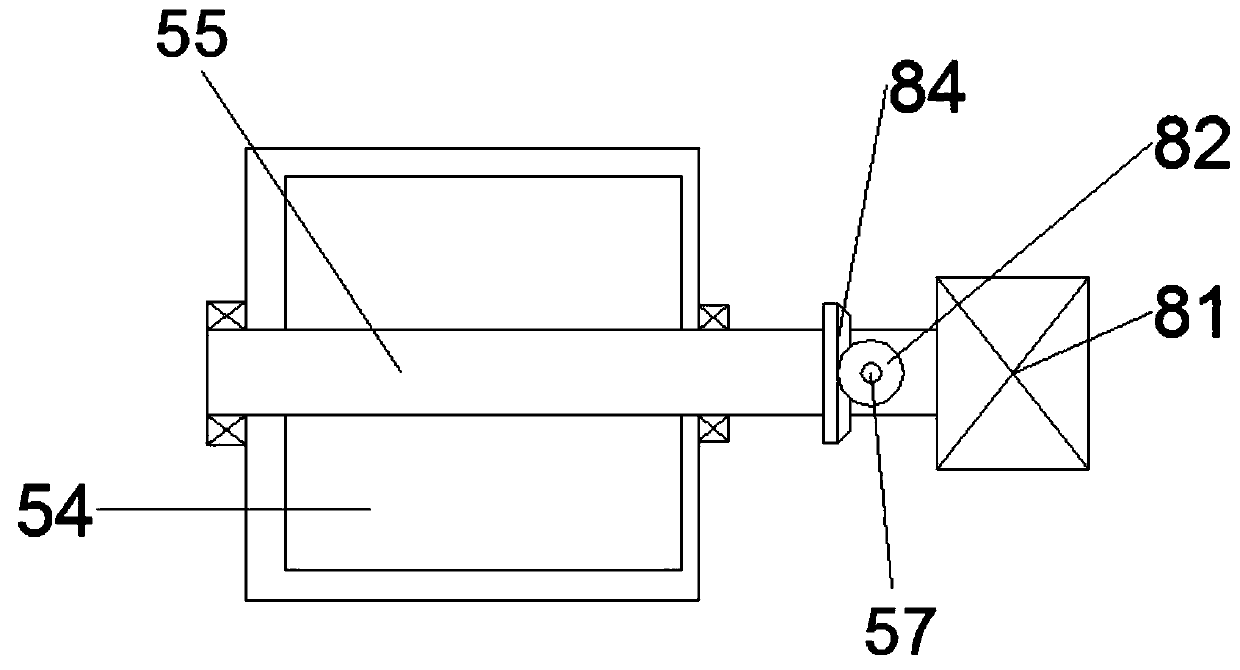

Television border polisher

ActiveCN104440498AHealth problemsAvoid Problems That Affect Polishing QualityPolishing machinesGrinding drivesLiquid-crystal displayEngineering

The invention discloses a television border polisher capable of mechanically and automatically polishing a liquid crystal display television border and having the advantages of high polishing efficiency, time and labor saving, better polishing quality and the like. The television border polisher comprises a base, a lower guide frame and an upper mounting frame, wherein the lower guide frame and an upper mounting frame are sequentially arranged above the base, a rotating motor is mounted on the upper surface of the base, the lower guide frame and the upper mounting frame are connected with an output shaft of the rotating motor, and the base is provided with a polishing device comprising a mounting column, a swing arm and a polishing disc. The mounting column is vertically fixed on the base, the swing arm is movably mounted on the mounting column, a swing driving device is arranged on the base, a mounting plate is fixedly mounted on the swing arm, a guide pulley matched with the side of the lower guide frame is fixedly mounted on the mounting plate, a polishing disc driving motor is vertically arranged on the swing arm, a polishing disc is sleeved with an output shaft of the polishing disc driving motor, the partial part of the circumference of the polishing disc is fitted to the liquid crystal display television border outside the upper mounting frame, and the circumference of the polishing disc is completely or partially a polishing side.

Owner:FUJIAN RICHES ELECTRONICS SCI & TECH

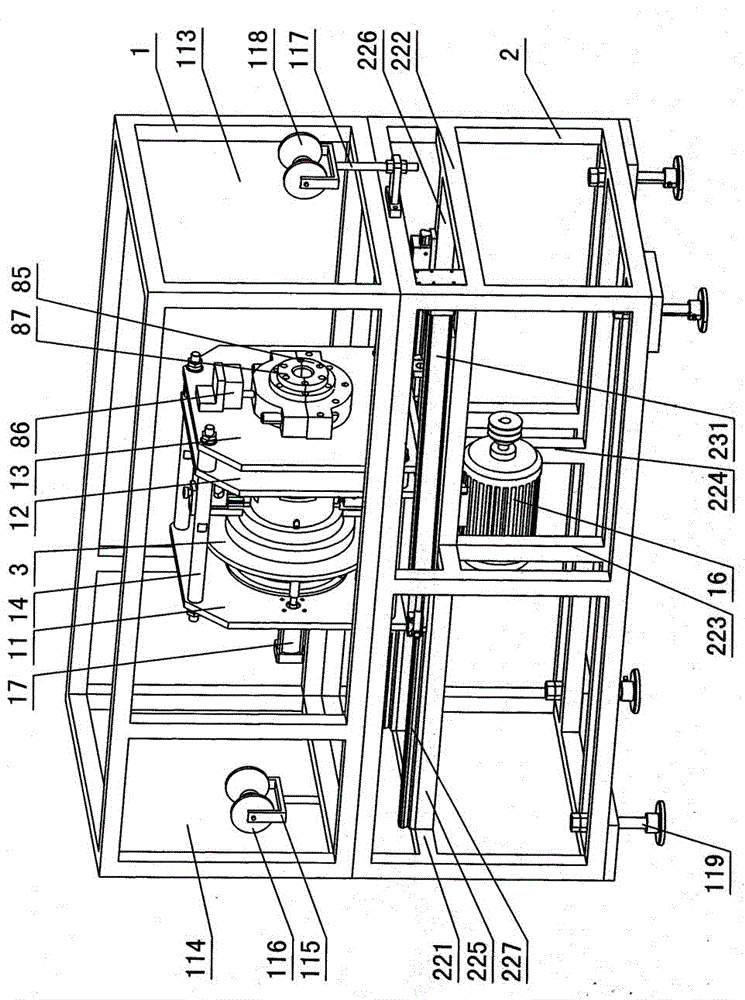

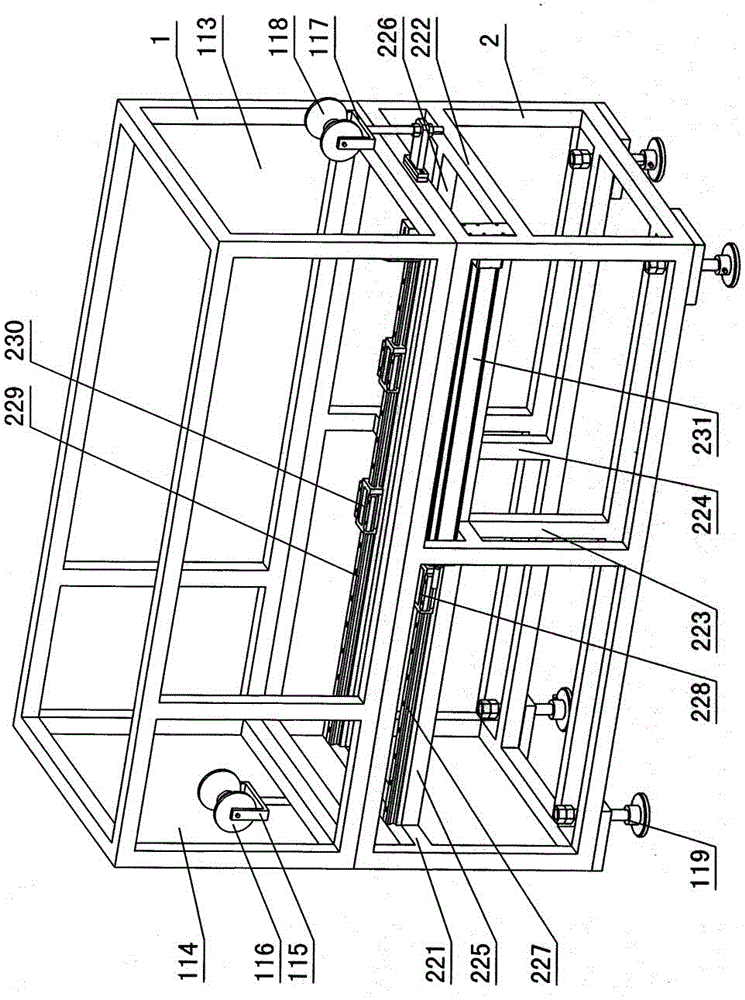

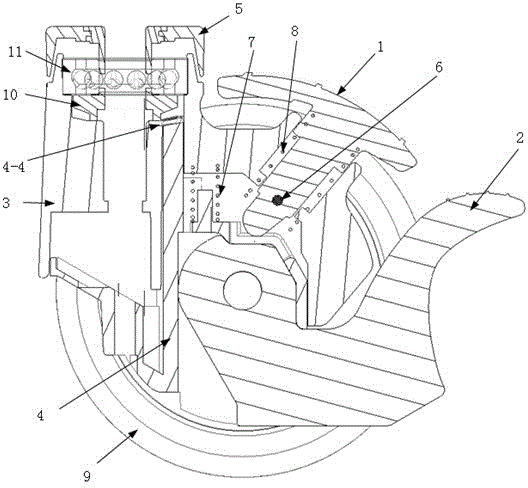

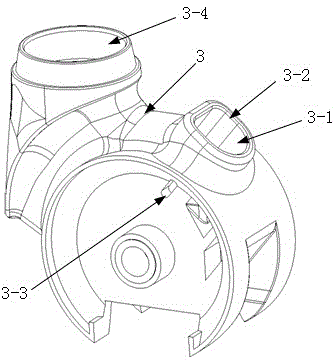

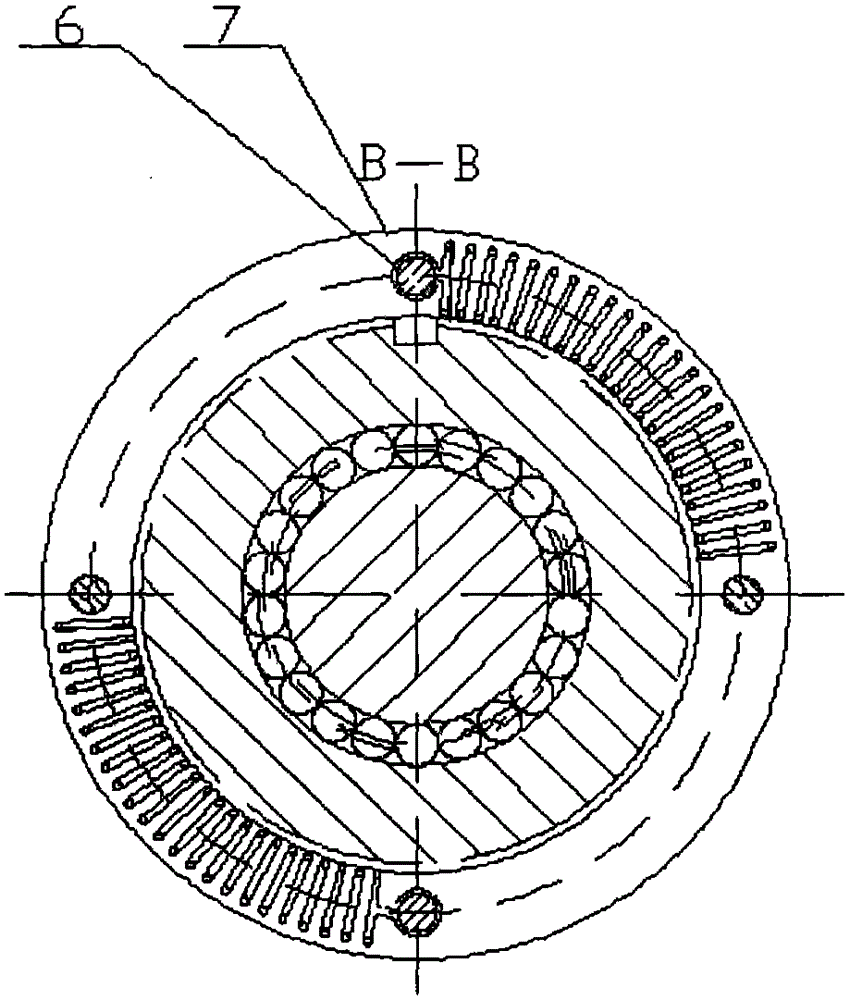

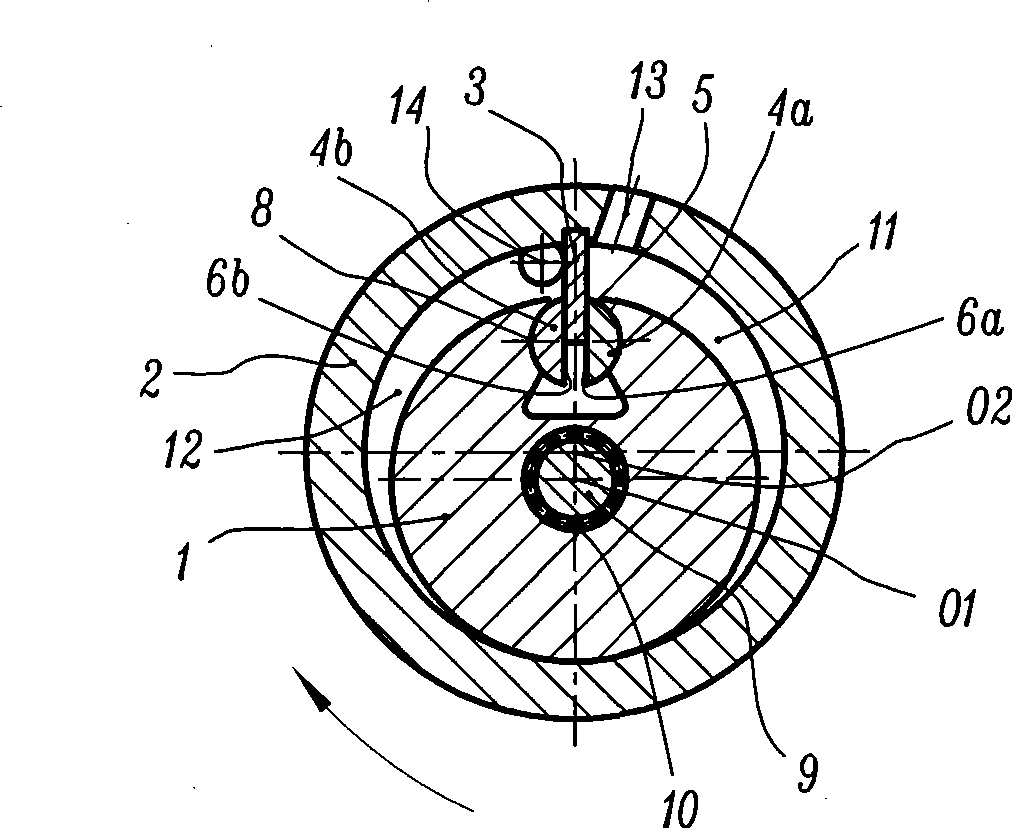

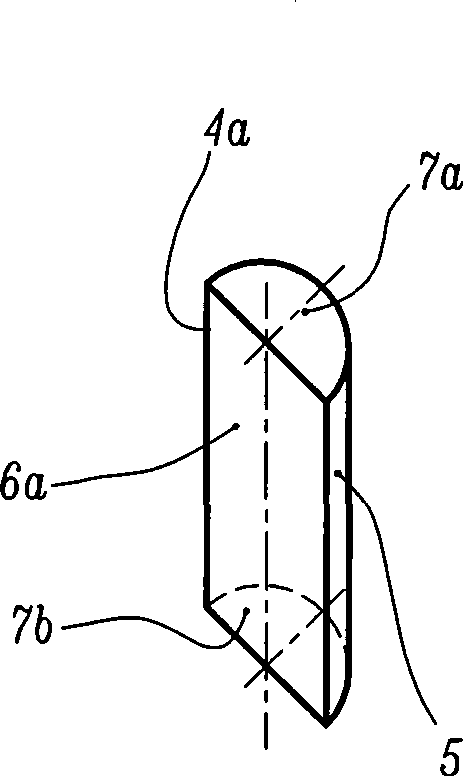

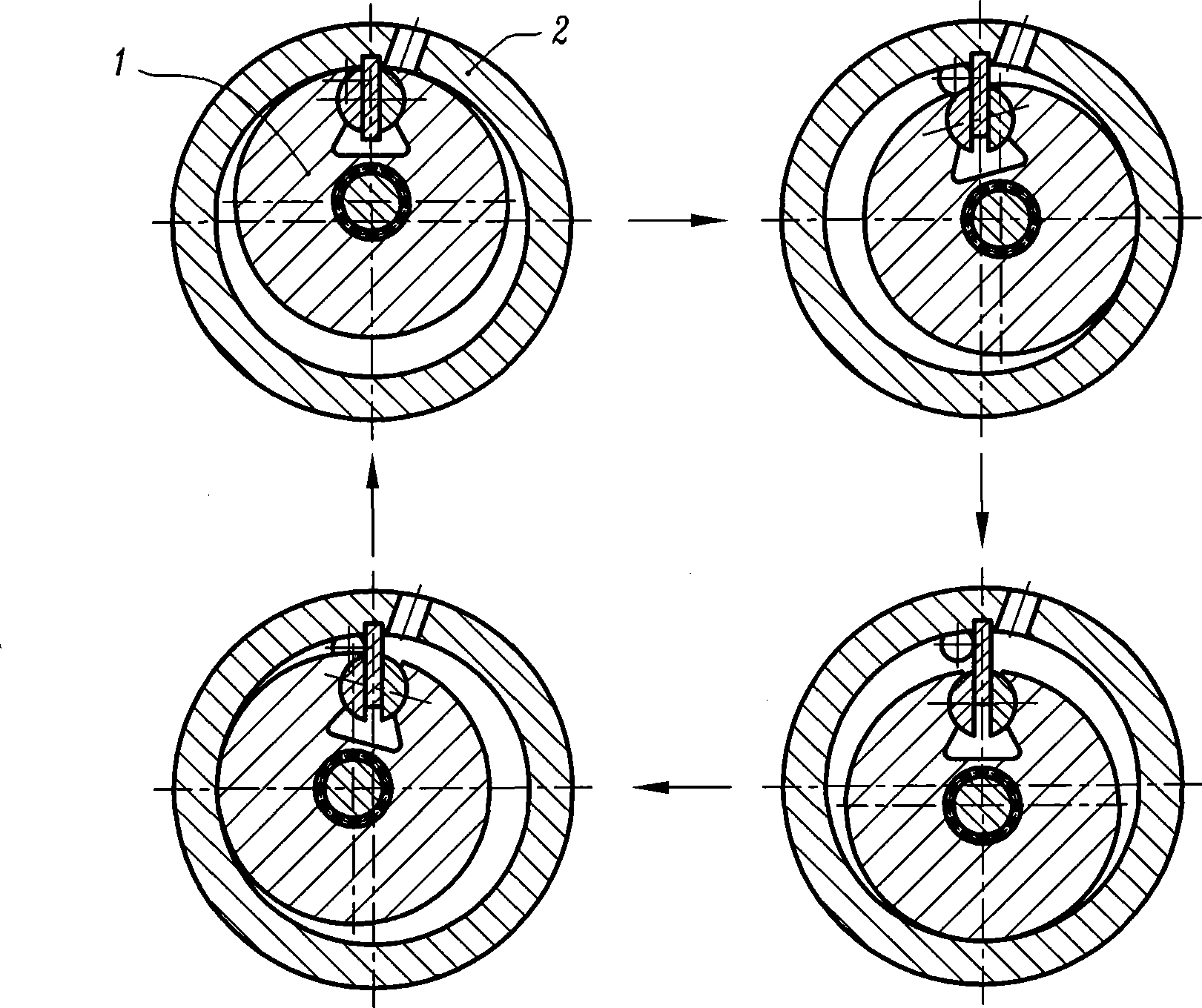

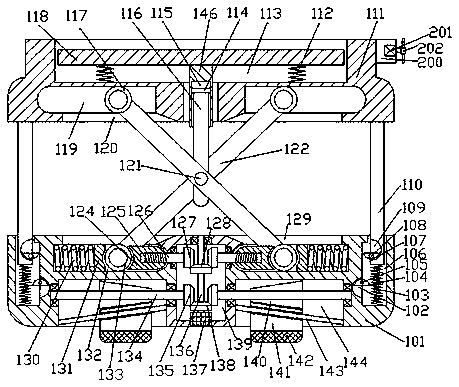

Vane type revolving compressor

InactiveCN101440806ACooperate smoothlyEasy to processRotary piston pumpsRotary piston liquid enginesFriction lossSurface roughness

The invention relates to a rotary vane compressor, which comprises a rotor 1, a cylinder 2, a vane 3 and an end cover, wherein the rotor 1 offsets in the cylinder 2; the outside surface of the rotor 1 is in tangency and contact fit with the inner hole surface of the cylinder 2; the rotor 1 is provided with an arc groove 8; and the vane 3 is in fastened and sealed connection with the cylinder 2 and two lateral ends. The rotary vane compressor is characterized in that the compressor is provided with a first slide block 4a and a second slide block 4b which are arranged in the arc groove 8 and are in rotary fit with the arc groove 8; because two independent slide blocks are adopted to replace an integral rotary column, the matching surface among the first slide block 4a, and the second slide block 4b and the vane 3 can be processed and treated conveniently, including grinding and various surface treatments, so as to obtain high precision dimension, shape, position, surface coarseness, planeness, surface rigidity and the like. Therefore, the fit among the first slide block 4a, the second slide block 4b and the vane 3 is smoother, and friction loss and leakage loss are reduced, so as to be favorable for the reduction of shaft work consumption of the compressor.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG +1

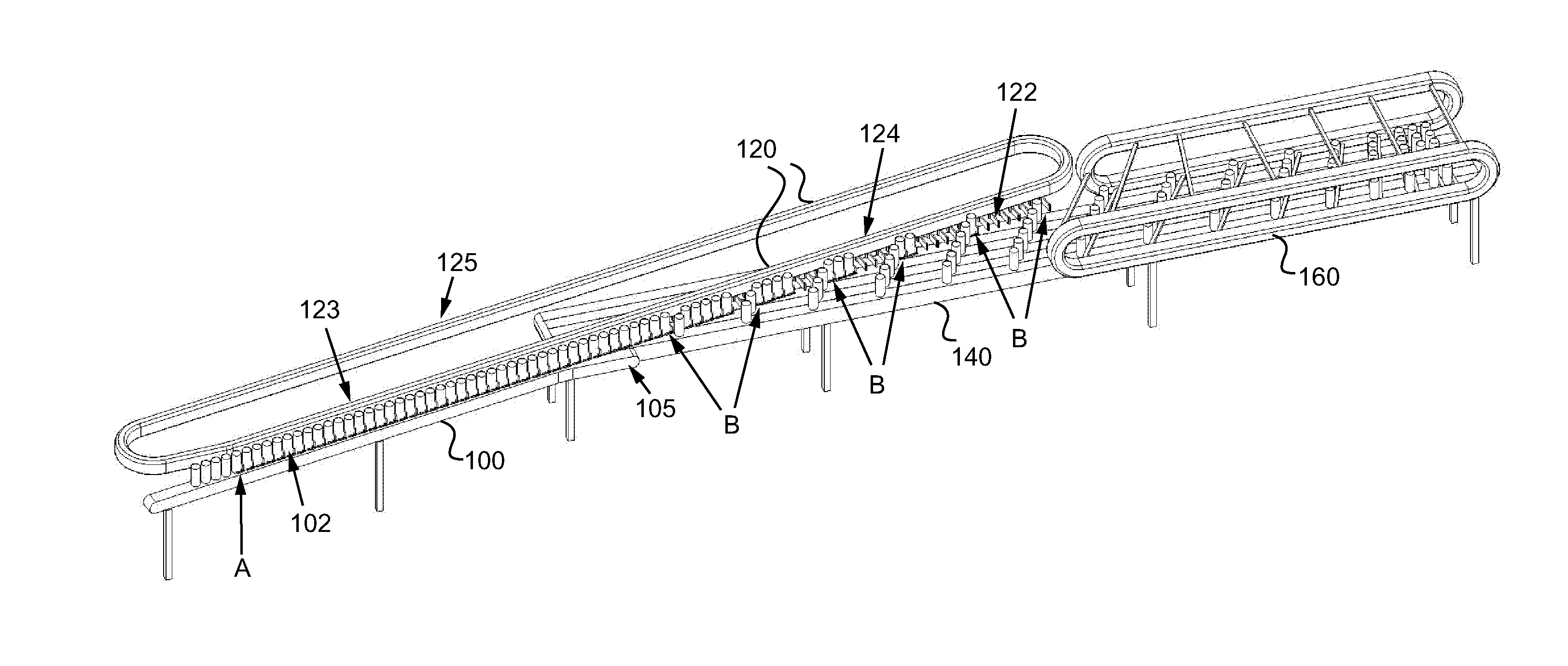

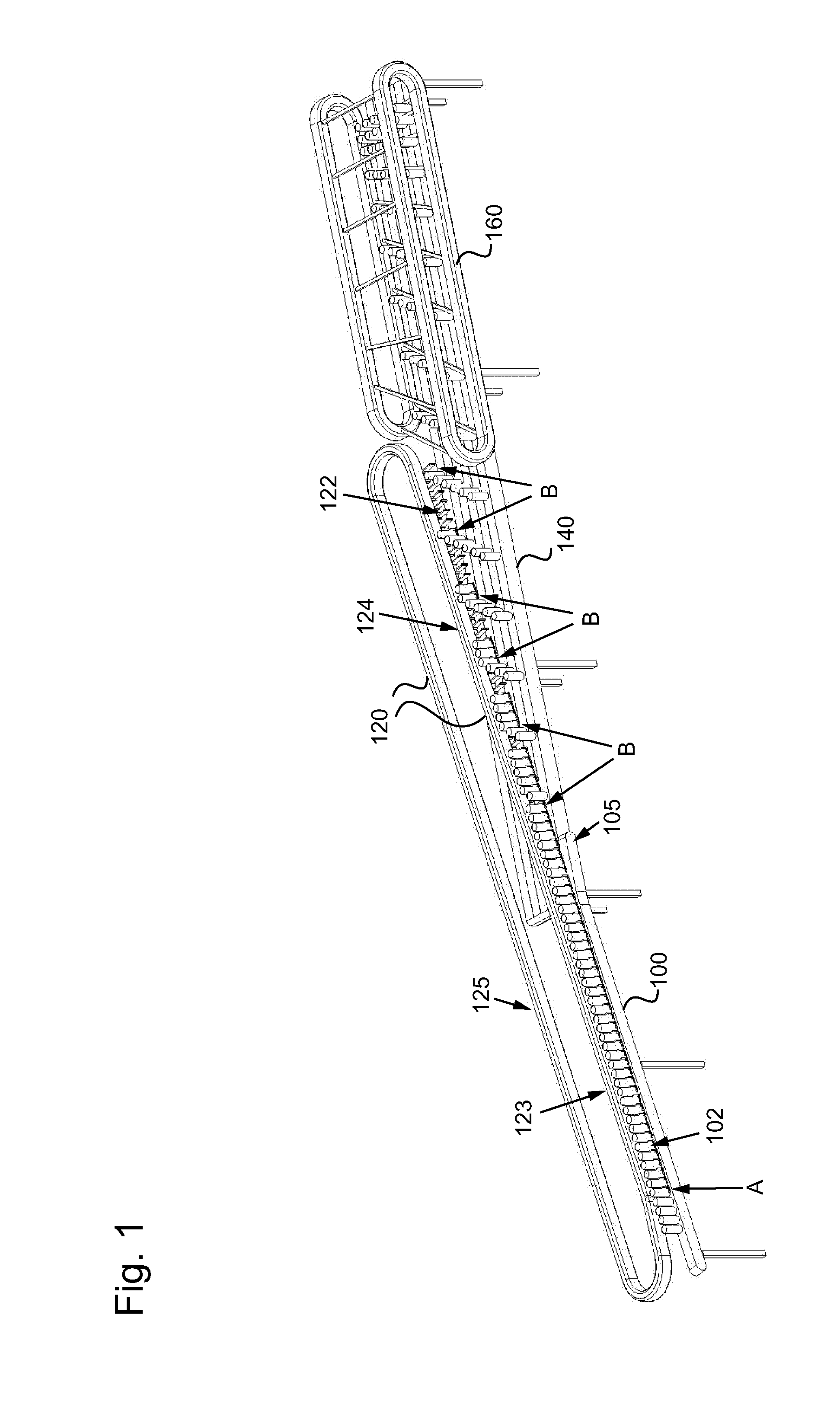

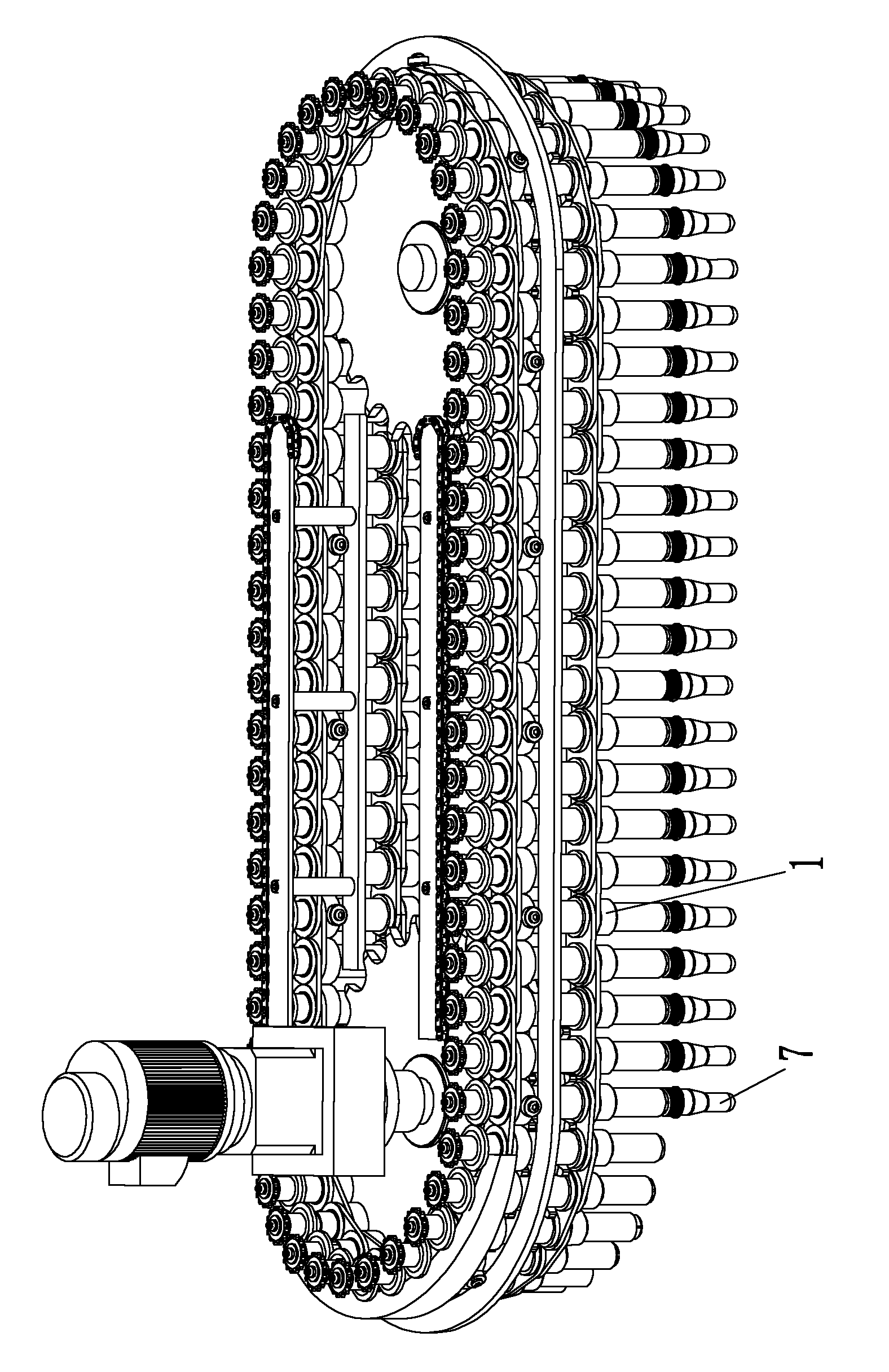

Bottle blank conveying chain of bottle blowing machine

The invention discloses a bottle blank conveying chain of a bottle blowing machine, relates to the bottle blowing machine, and solves the technical problem of large space of bottle blanks conveyed by the conveying chain of the conventional bottle blowing machine. The bottle blank conveying chain comprises bottle blank seats. The bottle blank conveying chain is characterized in that: the bottle blank seats are tubular pieces, each bottle blank seat is connected with the left and right adjacent bottle blank seats through an inner chain sheet and an outer chain sheet in up-and-down symmetry to form an annular chain respectively, the inner chain sheet and the outer chain sheet are placed horizontally and penetrated by the vertical bottle blanks, and the inner chain sheet and the outer chain sheet are superposed at the superposition part. The bottle blank seats are arranged at the positions of chain link connecting pins of the traditional chain so as to fix the bottle blanks, connect the chain sheets, optimize the structure of the conveying chain and reduce the mass of the conveying chain along with low running energy consumption; and the space of the bottle blanks can be reduced as much as possible by adopting the inner and outer chain sheets with adjacent center distance so that the radiation heat can be fully utilized.

Owner:北京华融塑胶有限公司

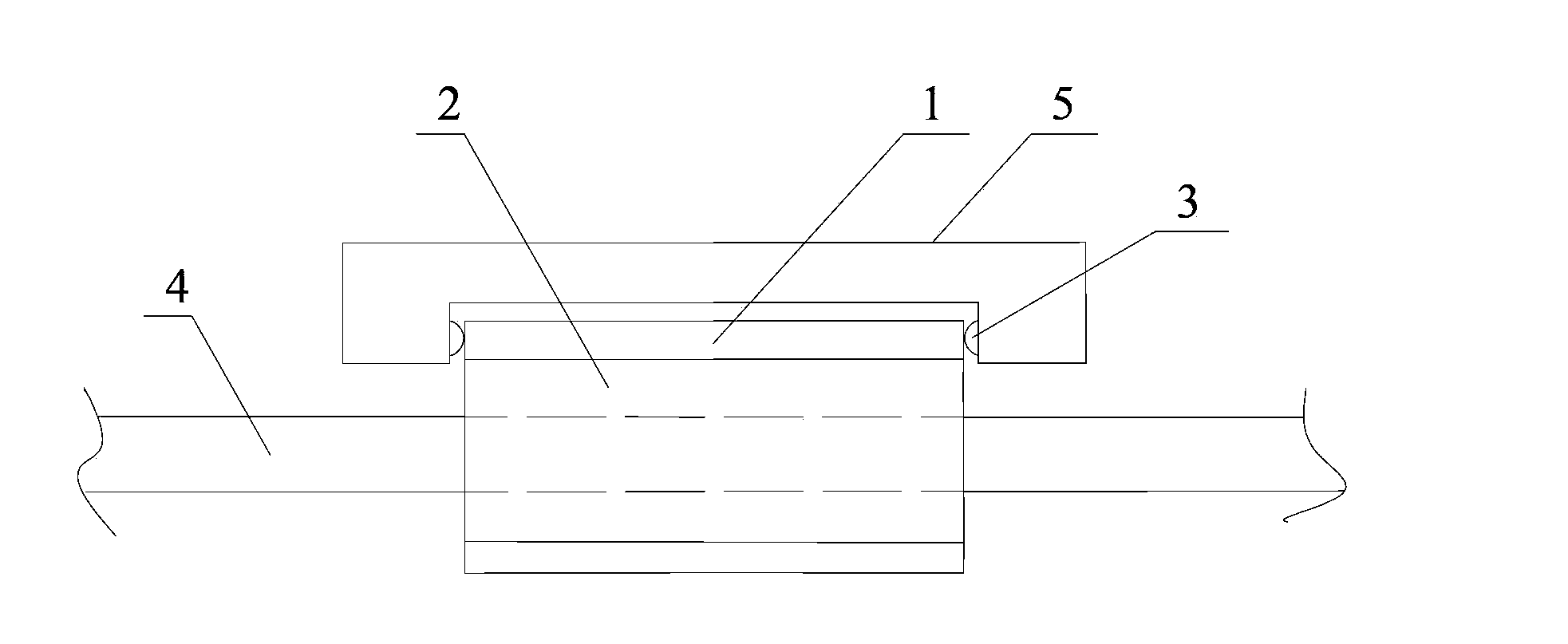

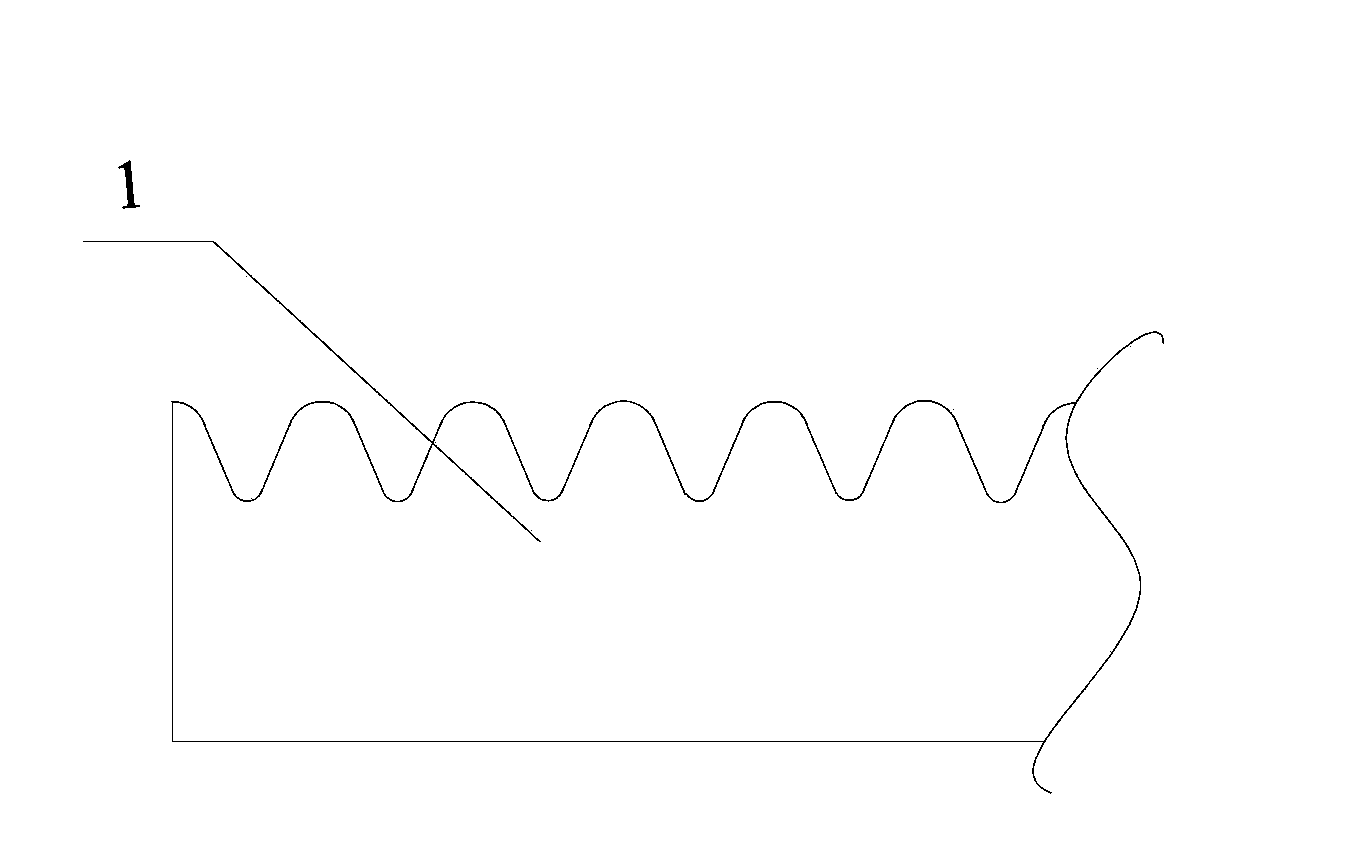

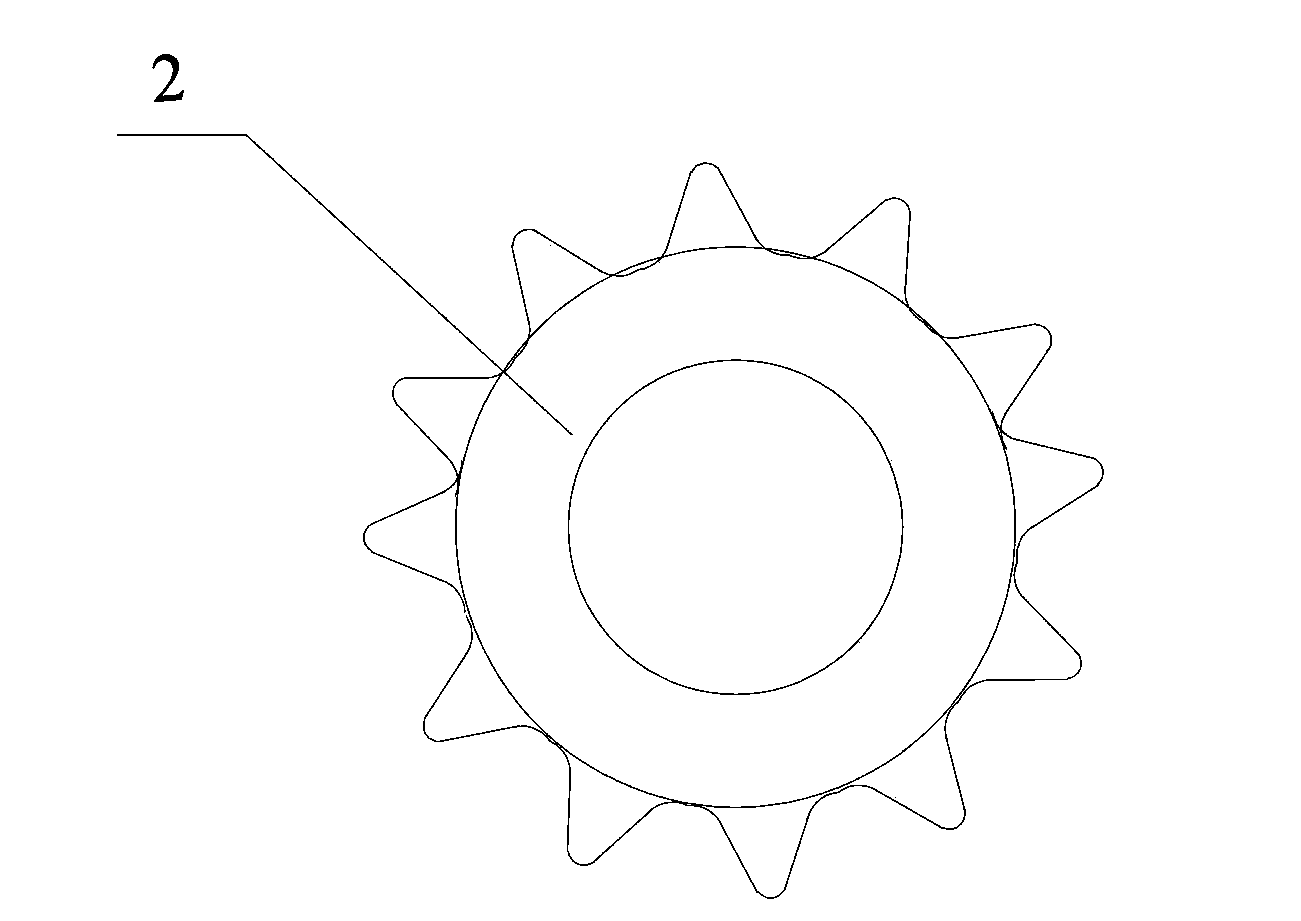

Reciprocating linear rack motion system for three-dimensional quick box-pasting machine

InactiveCN103775584ACooperate smoothlyImprove working environmentPaper-makingBox making operationsLinear motionWorking environment

The invention provides a reciprocating linear rack motion system for a three-dimensional quick box-pasting machine. The reciprocating linear rack motion system comprises a rail-dashing rack and a gear which are used in cooperation with each other. A sliding block is arranged on the rail-dashing rack. The surface of the rail-dashing rack is an inverted fillet. A ball is arranged between the sliding block and the rail-dashing rack. The reciprocating linear rack motion system for the three-dimensional quick box-pasting machine has the advantages that the rail-dashing rack is used for replacing a bearing guide rail used in the prior art, the ball is arranged between the sliding block and the rail-dashing rack, and therefore the wear resistance is greatly improved; since the surface of the rail-dashing rack is the inverted fillet and the surface of the gear is also an inverted fillet, the rail-dashing rack and the gear can be matched more smoothly, noise generated in the motion process is lowered, and the working environment of operation workers is greatly improved. The reciprocating linear rack motion system also has the advantages of being simple in structure, high in wear resistance, low in machining cost, high in production efficiency, low in noise and the like.

Owner:天津市金盛纸制品包装有限公司

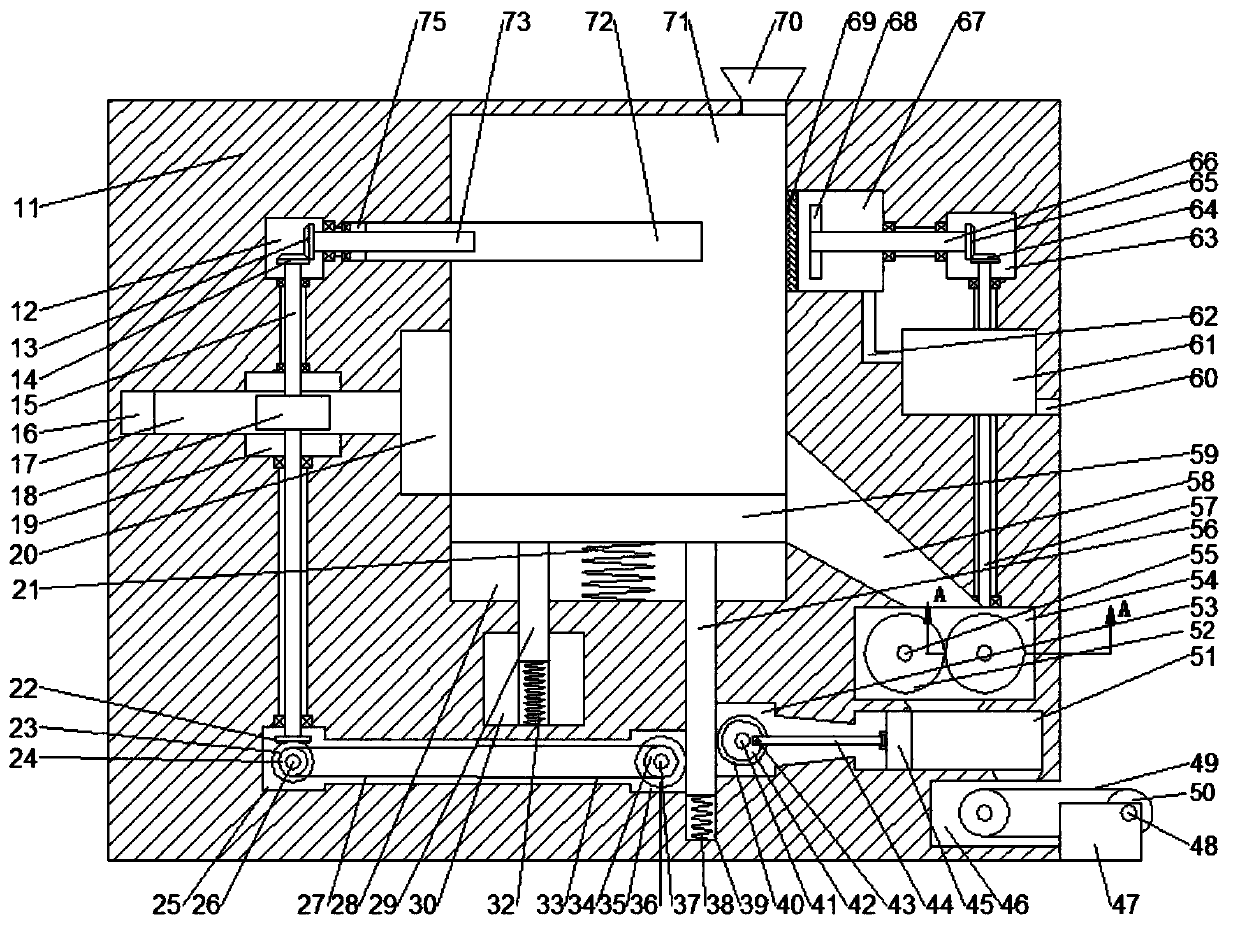

Garbage incineration pretreatment device

InactiveCN110608442AAvoid occupyingSimple structureIncinerator apparatusGrain treatmentsPre treatmentMechanical engineering

The invention discloses a garbage incineration pretreatment device. The garbage incineration pretreatment device comprises a device body extending left and right and a transfer cavity arranged in thedevice body and extending up and down. The transfer cavity communicates with a feed vessel fixedly arranged on the end face of the top end of the device body. The inner wall of the left end of the transfer cavity communicates with a sliding groove extending left and right. An upper engagement cavity is formed on the left side of the sliding groove. A thread pushing mechanism is arranged between the upper engagement cavity and the sliding groove. A rack groove extending left and right and communicating with the transfer cavity is formed below the upper engagement cavity. The garbage incineration pretreatment device is simple in structure, compact in cooperation and capable of reducing energy consumption in the transfer process. Accordingly, the garbage incineration pretreatment device has certain energy-saving performance and can prevent garbage from occupying too much space during subsequent processing or storing by mashing the garbage.

Owner:安徽凯大热能科技有限公司

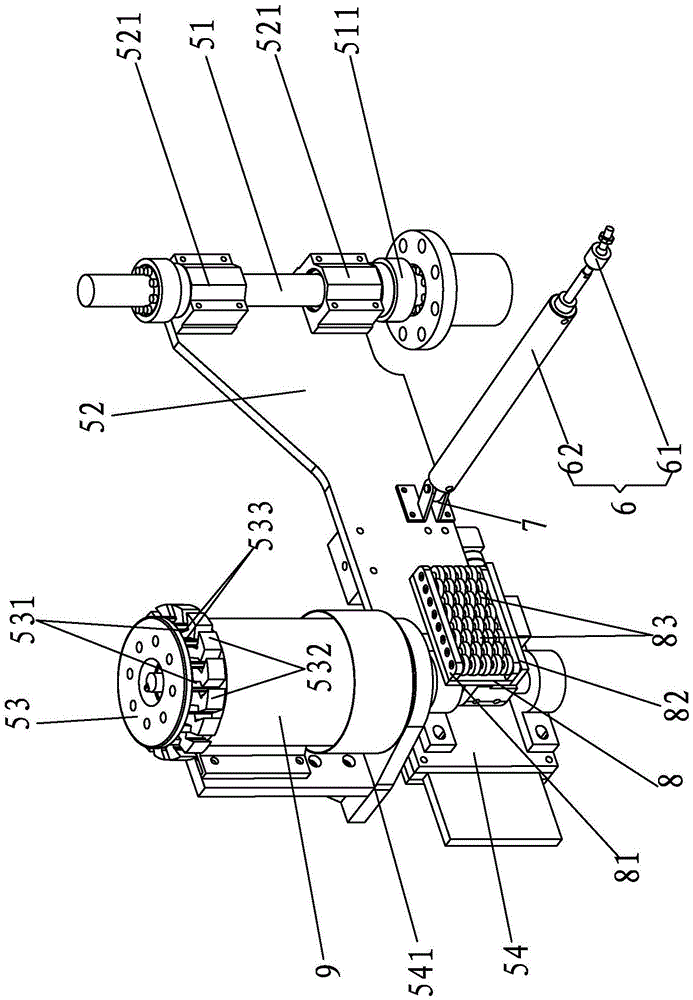

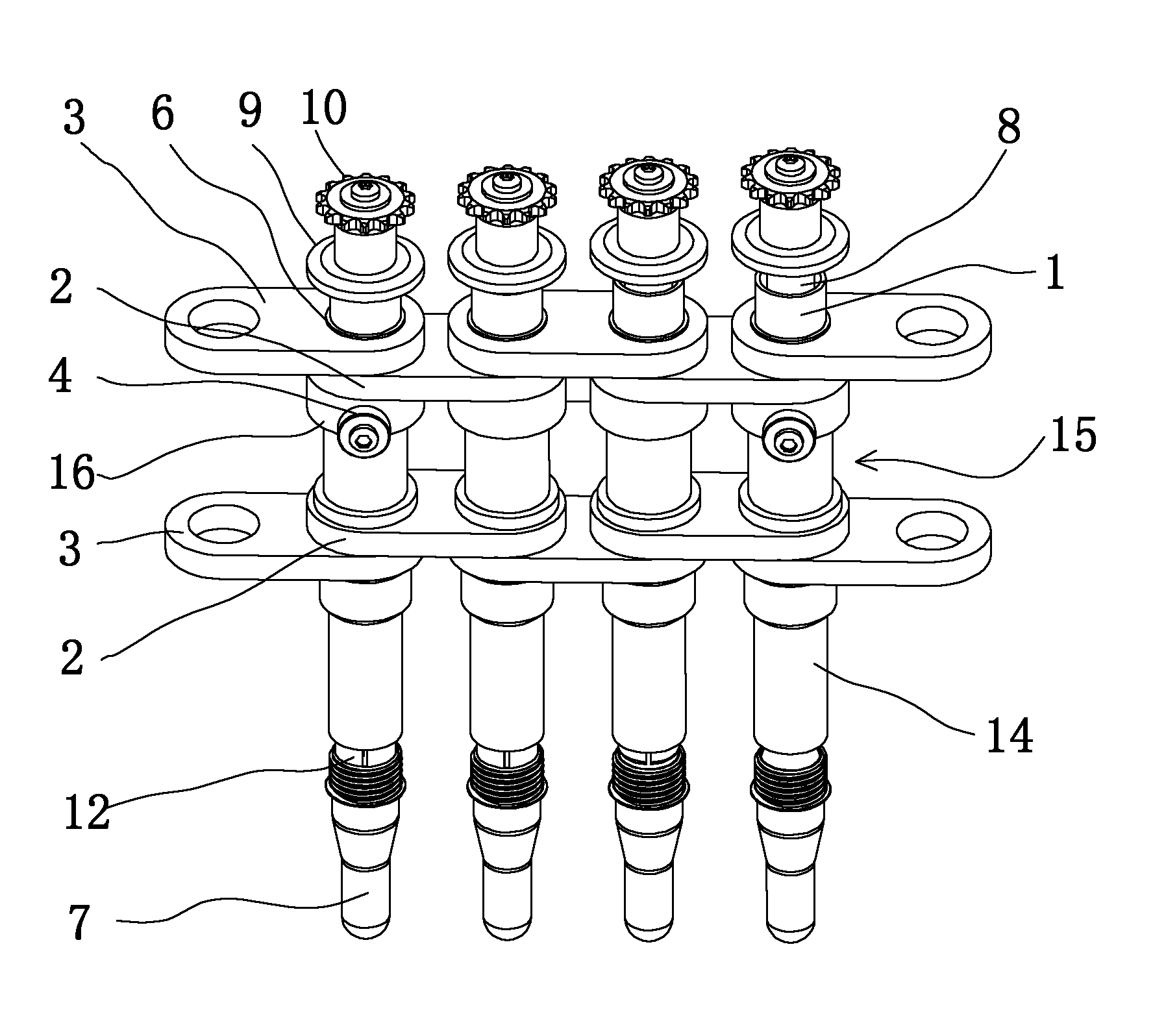

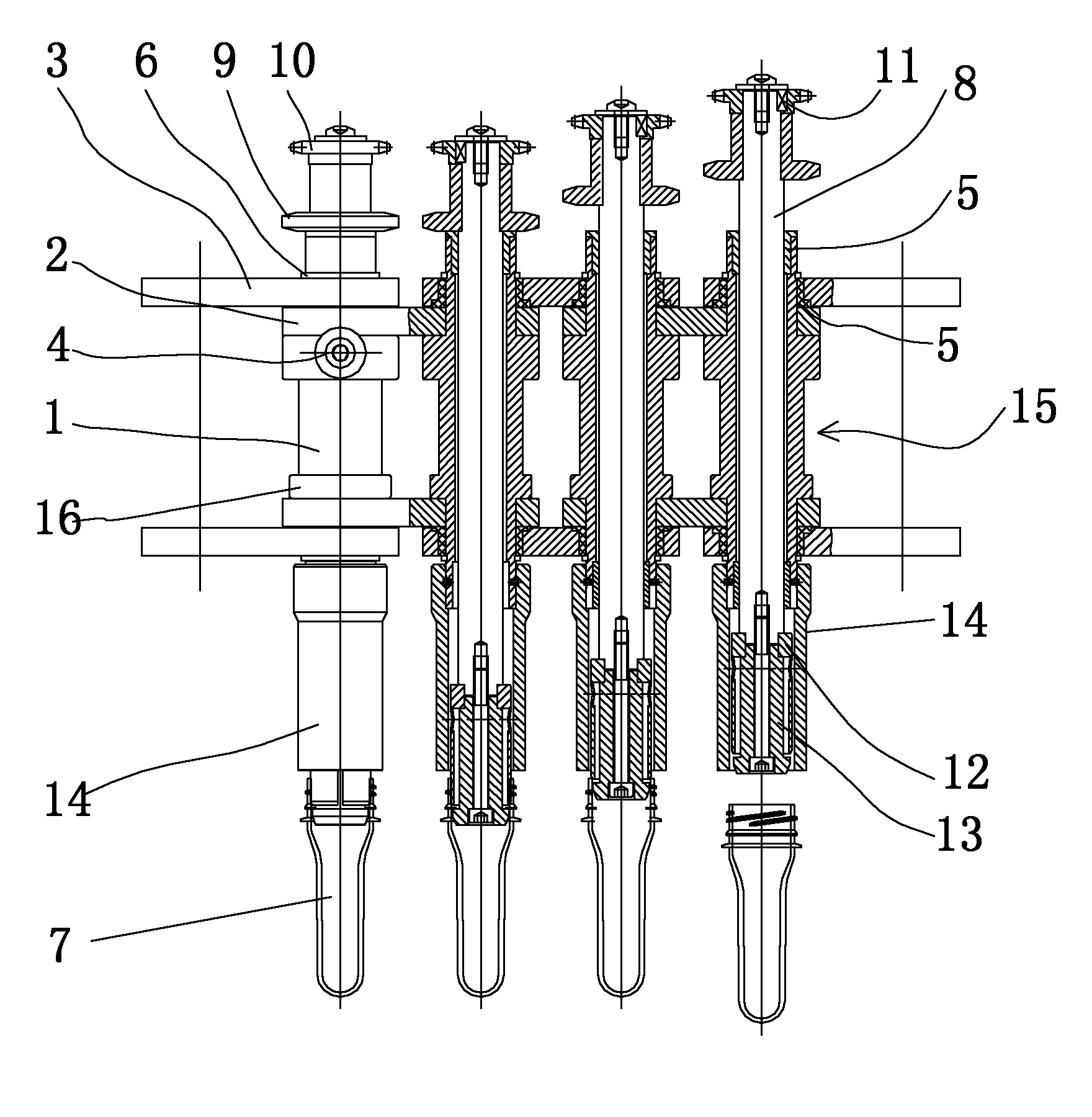

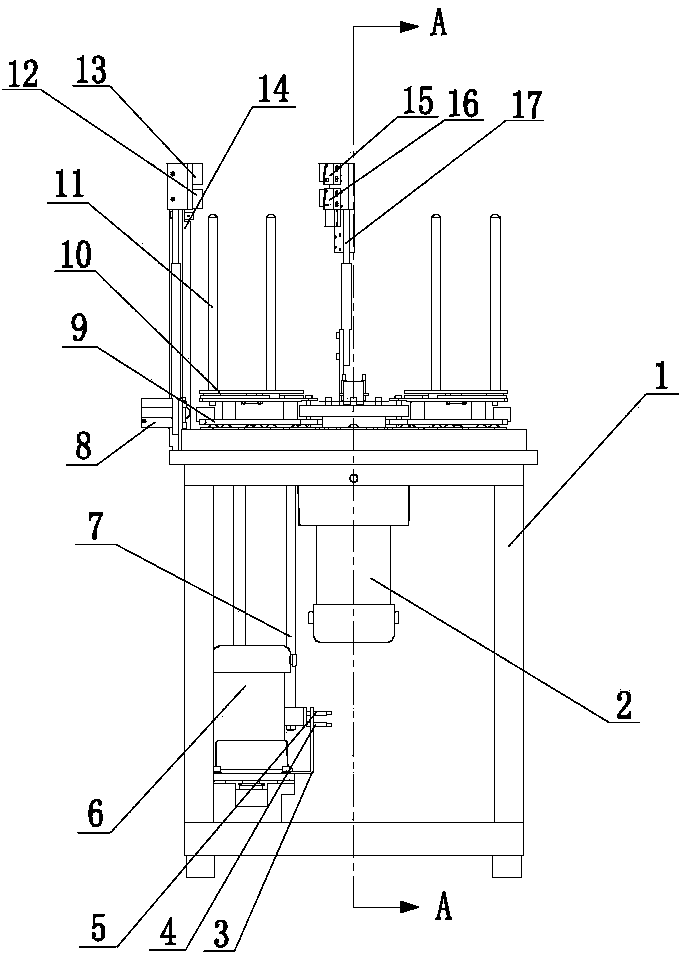

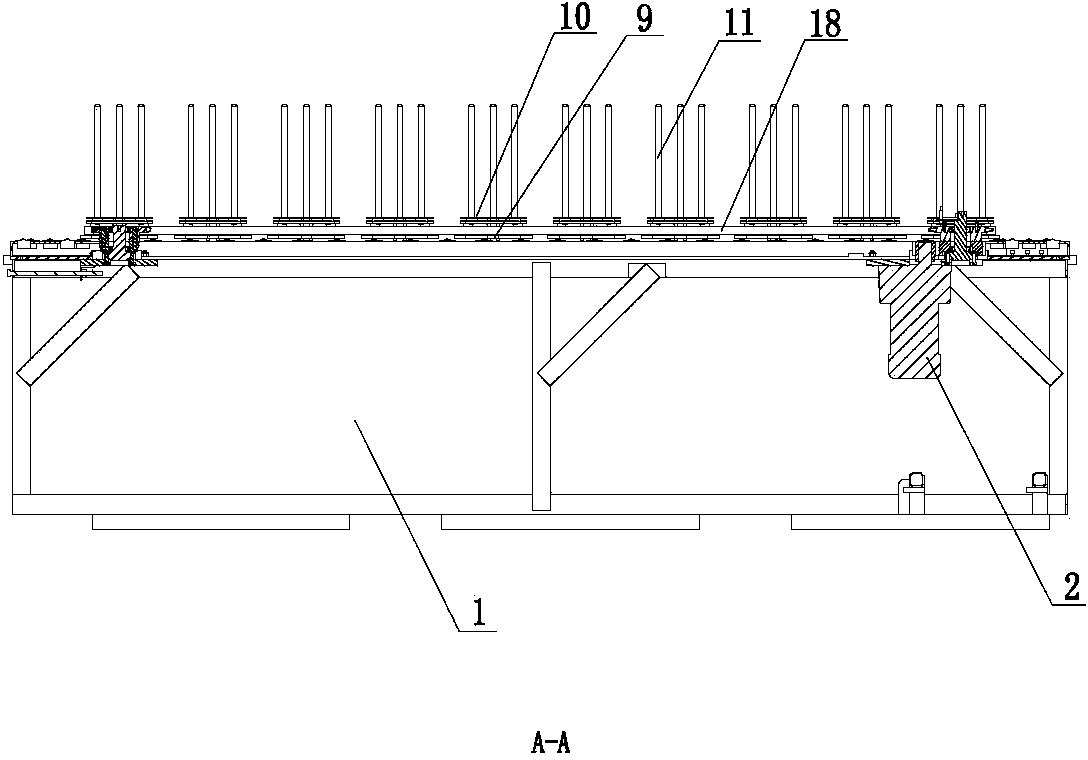

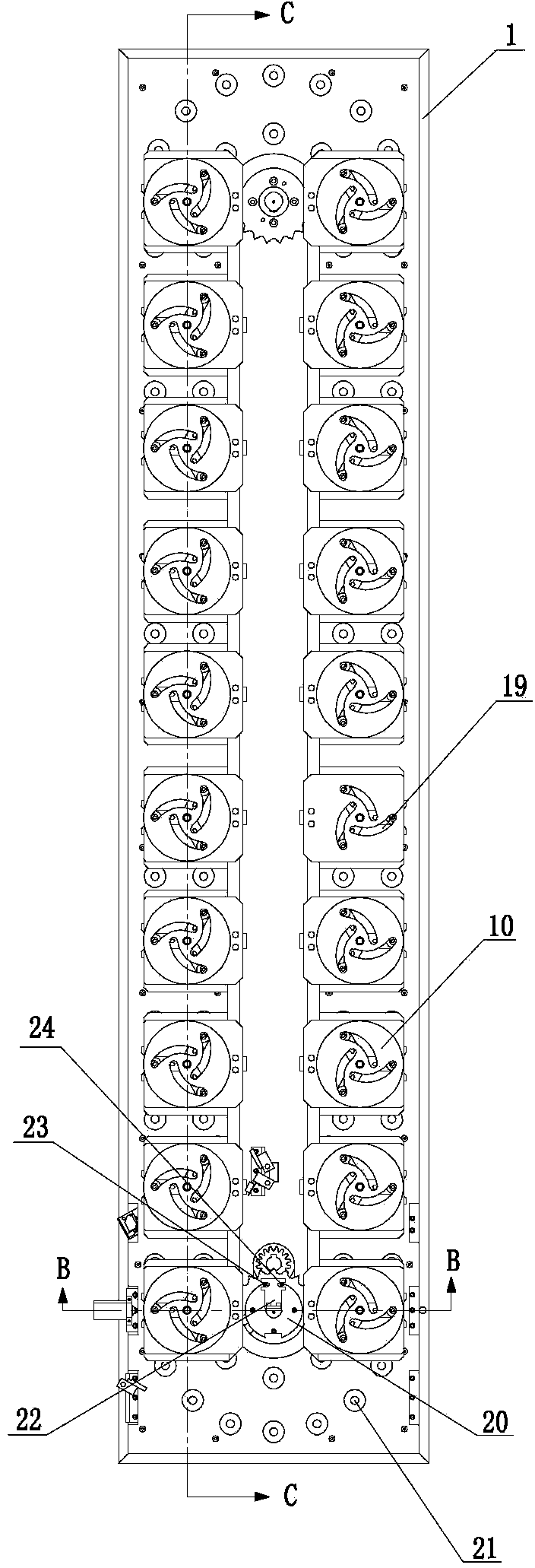

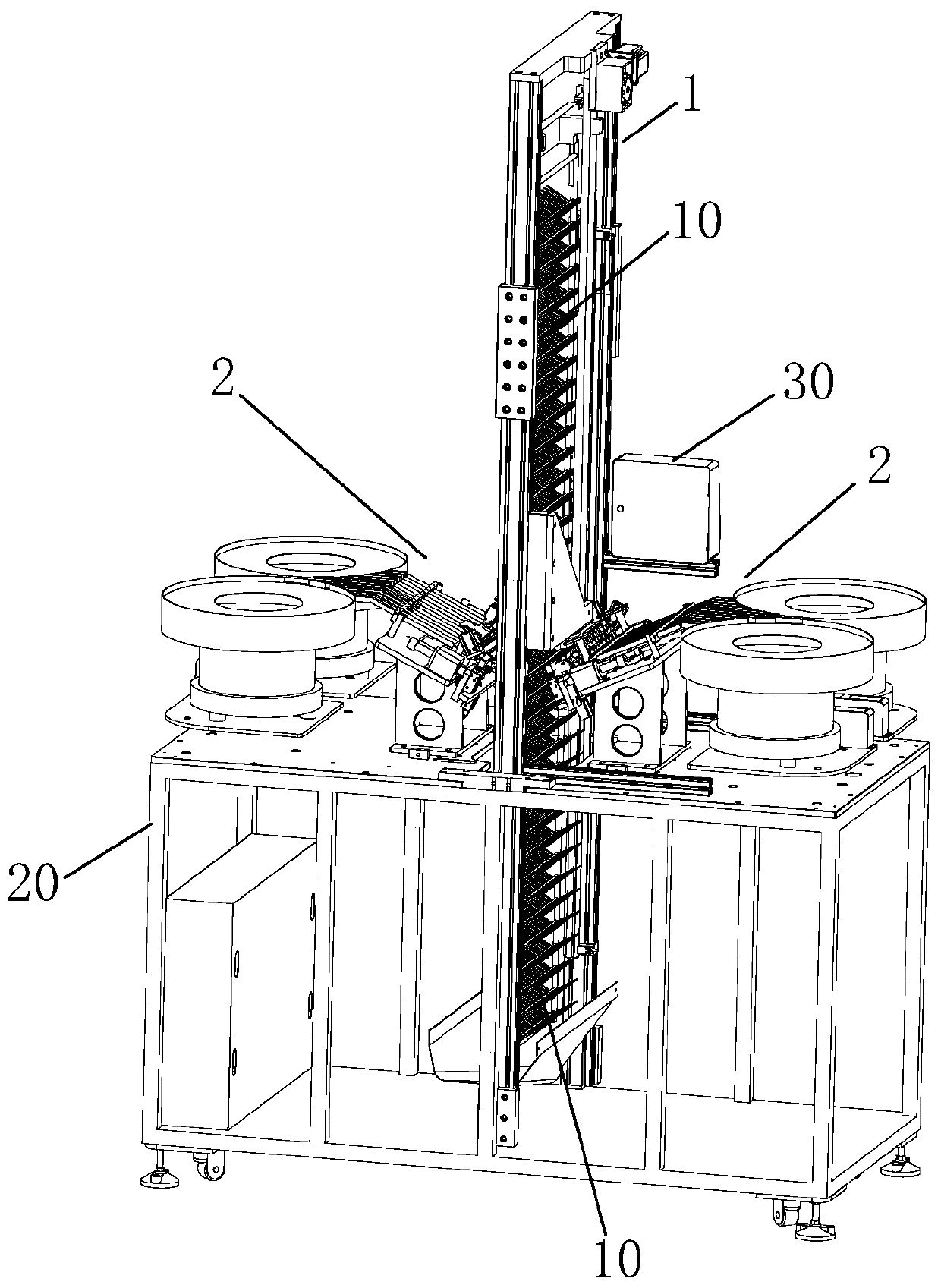

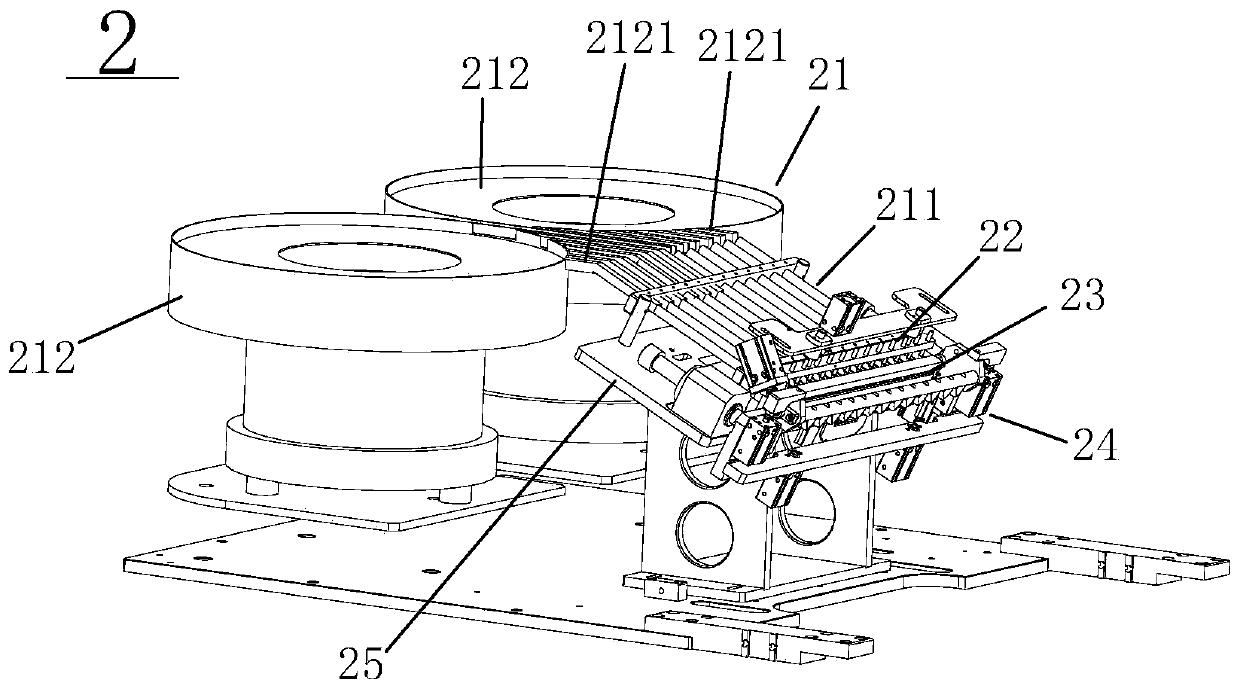

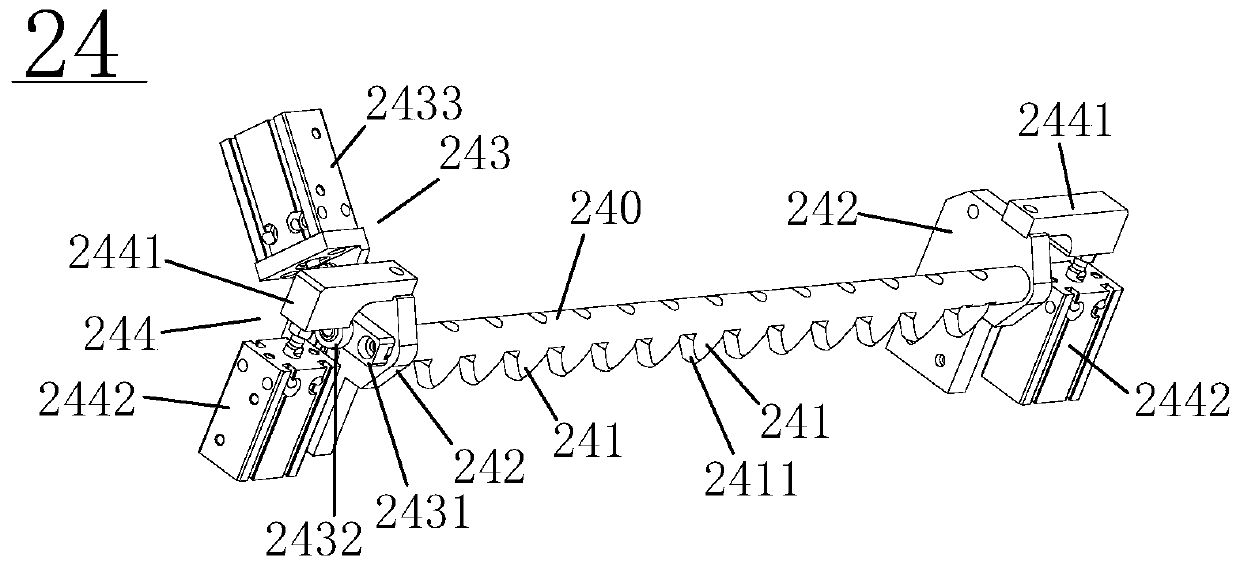

Disk feeder device of numerical control machine tool automation line

ActiveCN103449160ACooperate smoothlyIncrease productivityConveyor partsNumerical controlElectric machine

The invention relates to a disk feeder device of a numerical control machine tool automation line, and belongs to an auxiliary line-connecting device of a machine tool automation line. The disk feeder device comprises a feed support, a lifting mechanism, a sensing mechanism, an indexing mechanism, a positioning mechanism and a plurality of pallet mechanisms. A workbench is arranged on the top surface of the feeder support, the indexing mechanism comprises a sprocket drive motor, a chain and two sprockets, and the two sprockets are mounted at two ends of the workbench. A plurality of ball transfer units forming a roller path loop are arranged on the workbench, each pallet mechanism comprises a retainer plate and at least three limiting rods, each retainer plate is positioned on the ball transfer units to be connected with the chain, and each limiting rod is fixed on the corresponding retainer plate. The lifting mechanism comprises a lifting rod and a lifting driving mechanism, and the lifting rod is positioned below the workbench, aligns to a lifting through hole of the workbench, and connected with the lifting driving mechanism. The positioning mechanism comprises positioning plugs, a positioning plug drive mechanism and positioning blocks mounted on the retainer plates, the positioning plugs are connected with the positioning plug drive mechanism, and the positioning plugs and the positioning blocks are arranged in matched structures. The disk feeder device is smooth in transferring and accurate in positioning.

Owner:浙江日发精密机床有限公司

Automatic hanging device for electroplating

InactiveCN109722700AAccurateRealize fully automatic hanging operationElectrolysis componentsEngineeringElectroplating

The invention discloses an automatic hanging device for electroplating. The automatic hanging device comprises a hanging tool lifting device and at least one hanging device arranged on the side of thehanging tool lifting device; the hanging device comprises a feeding mechanism, a stopping mechanism at the end of a discharge opening of the feeding mechanism, a forward pushing hanging mechanism arranged at the end of the discharge opening of the feeding mechanism and a hanging tool opening and closing control mechanism arranged between the forward pushing hanging mechanism and the hanging toollifting device. According to the automatic hanging device for electroplating, full-automatic hanging operation is adopted for replacing manual operation, the product hanging speed and accuracy are greatly improved, the working efficiency is greatly improved, and the automation degree of the electroplating process is better improved.

Owner:东莞市倍思特自动化科技有限公司

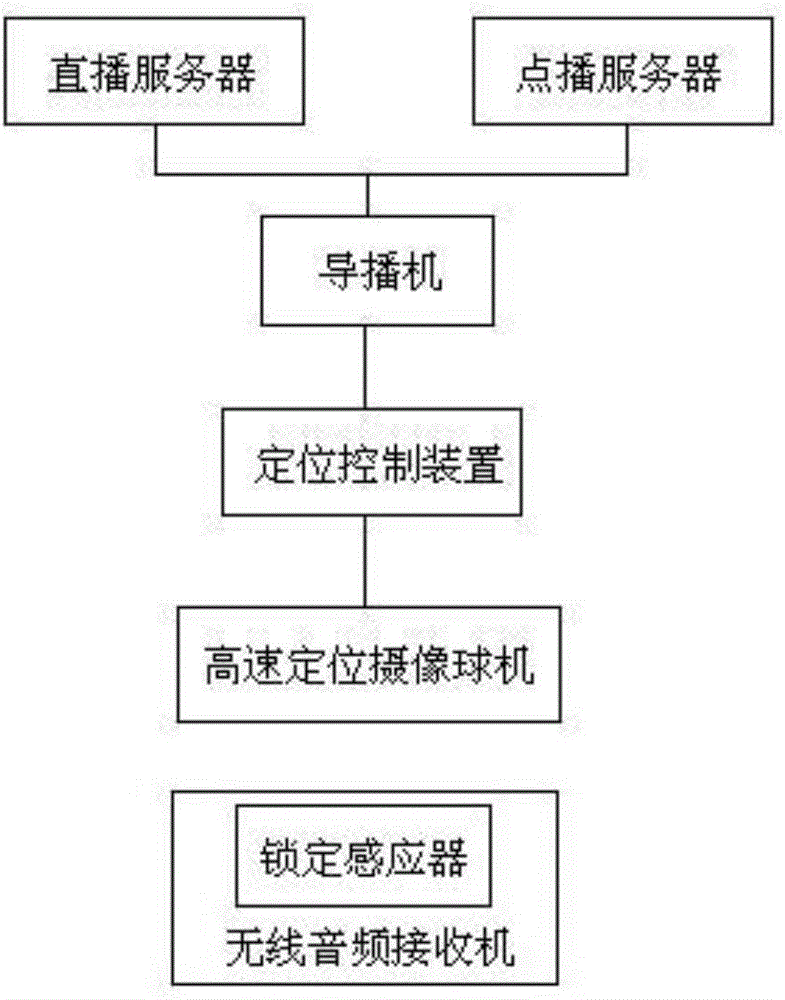

A fully intelligent broadcasting instructing system

InactiveCN104933909AFlexible scene switchingScreen with smoothElectrical appliancesInductorAudio frequency

A fully intelligent broadcasting instructing system comprises a high speed positioning shooting dome camera, a broadcasting instructing machine, a positioning control apparatus, a direct broadcasting server, a requested-item broadcasting server, a lock inductor and a wireless audio frequency reception machine. The lock inductor is integrated in a wireless audio frequency receiver worn by a teacher. The positioning control apparatus is separately connected to the high speed positioning shooting dome camera and the broadcasting instructing machine. The positioning control apparatus can sense the position of the lock inductor. The broadcasting instructing machine is separately connected to the direct broadcasting server and the requested-item broadcasting server. According to the invention, shooting can be flexibly switched from students and the teacher so as to liberate professional picture recording personnel and enable automation and intellectualization of a picture recording process. When the teacher walks to one side of a platform or writes on the blackboard. The broadcasting instructing system will intelligently and automatically switch pictures to a classroom panorama or a blackboard close-up. Phenomena that only close-up pictures of the teacher and the students are shoot during the whole class will not occur.

Owner:ANHUI ZHUANGYUANLANG ELECTRONICS TECH

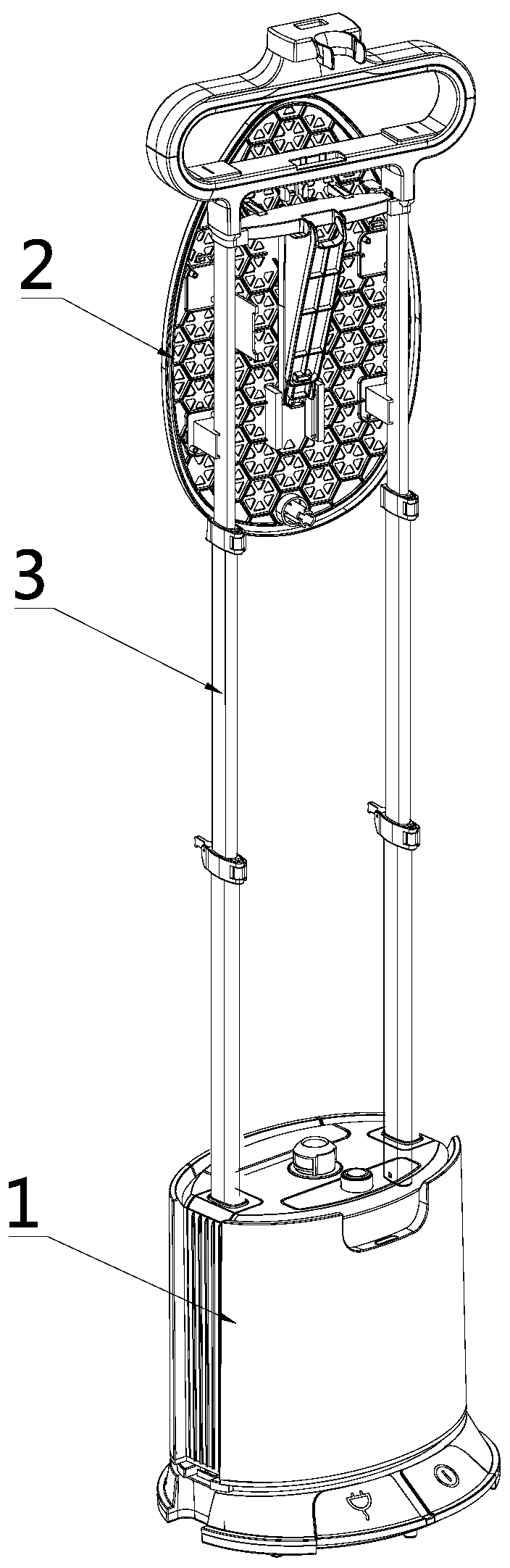

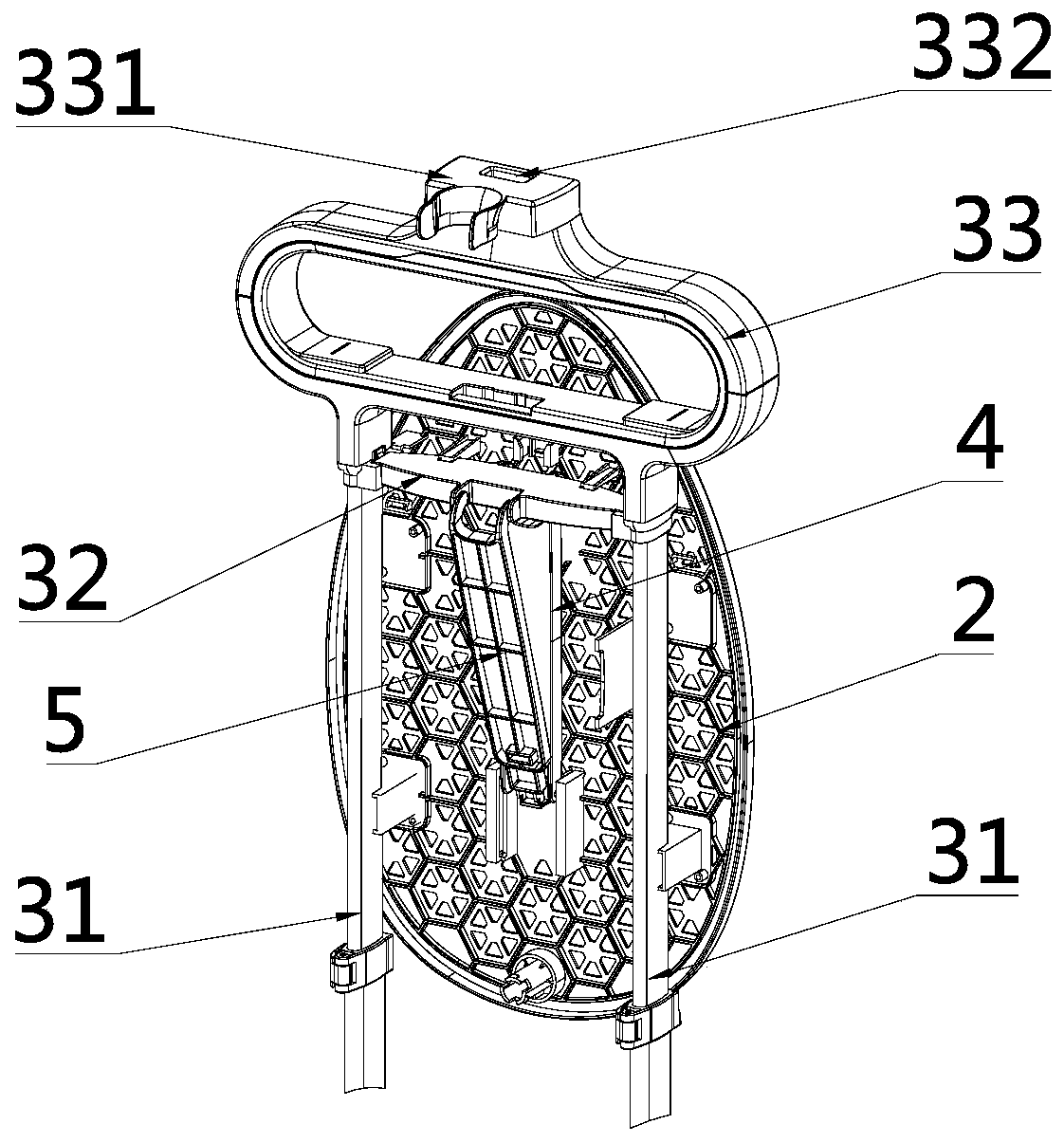

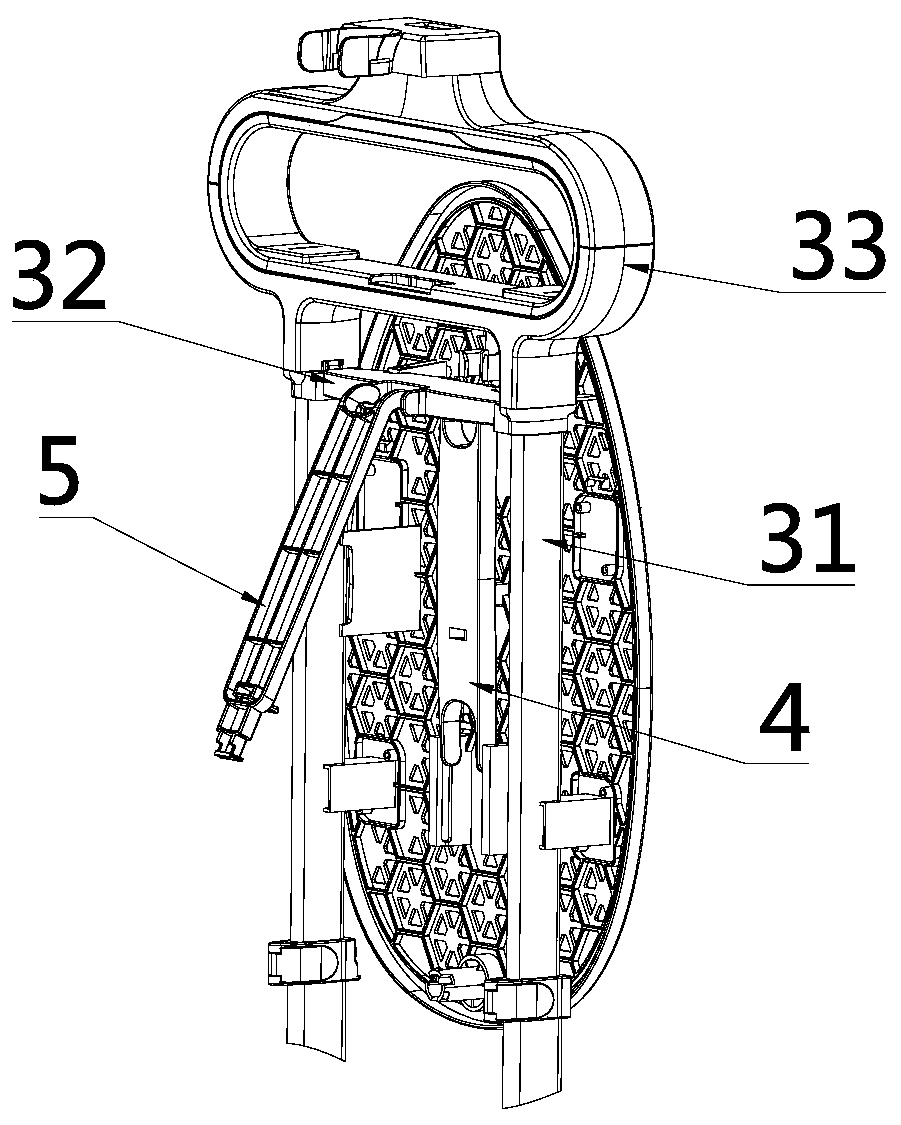

A steam ironing machine with a reversible ironing board

The invention discloses a steam ironing machine with a reversible ironing plate. The machine solves the problem of low stability of the ironing plate. The technological scheme which solves the problem mainly comprises a main body, the ironing plate, and a supporting frame disposed on the main body, wherein the front face of the ironing plate is an ironing face; the supporting frame is in rotatable connection with a first connecting part and a second connecting part; joints between the first connecting part and the second connecting part and the supporting frame are located on two sides of the supporting frame; the first connecting part is in rotatable connection with the back face of the ironing plate; when the ironing plate stays at a first installation state, the first connecting part is stored between the ironing plate and the supporting frame; the second connecting part is connected to the first connecting part and limits rotation of the first connecting part relative to the supporting frame; and the first connecting part and the second connecting part support the ironing plate when the ironing plate stays at a second installation state. According to the invention, through mutual coordination and mutual limiting of the first connecting part and the second connecting part, stability of the ironing plate at the first installation state and the second installation state can be ensured.

Owner:ZHEJIANG HUAGUANG ELECTRIC APPLIANCE GRP

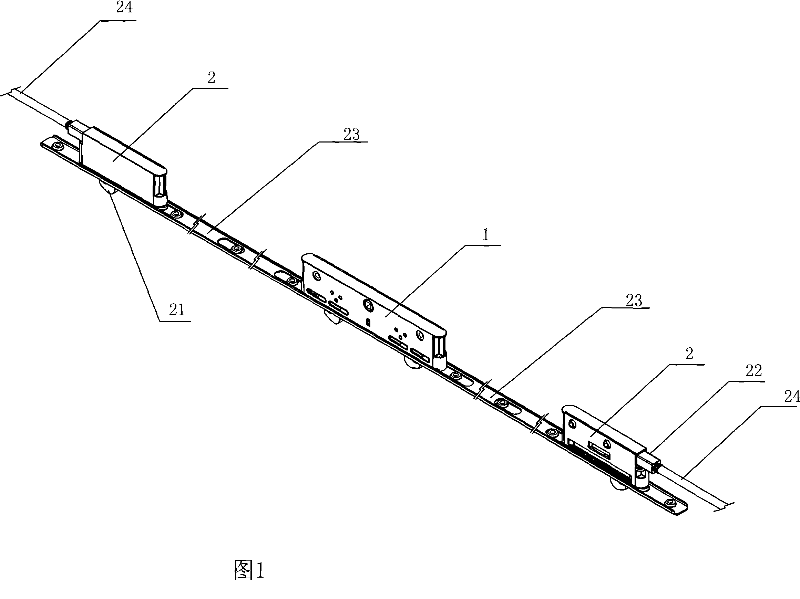

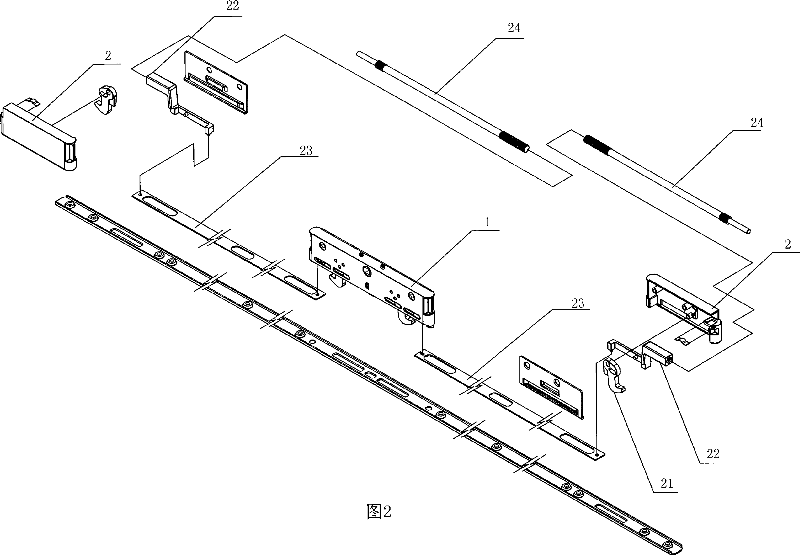

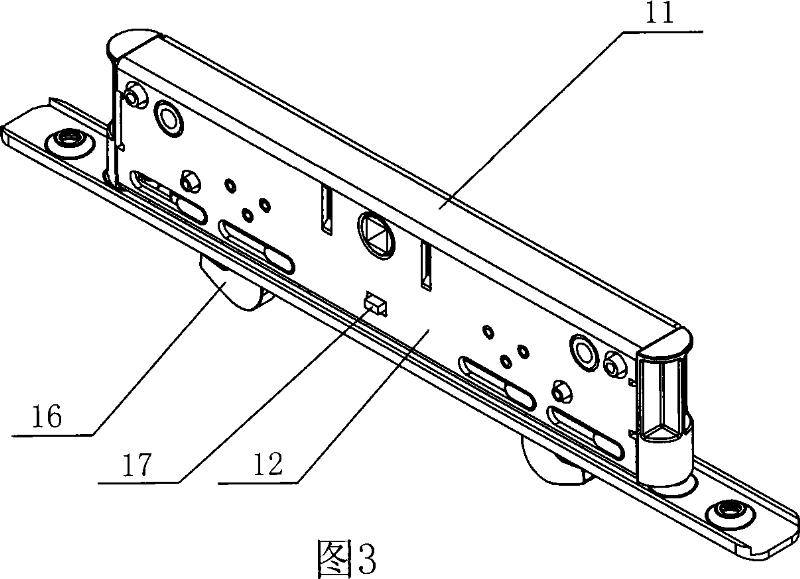

Multi-point door and window lock

InactiveCN101037904ASo as not to damageEasy to moveBuilding locksElectrical and Electronics engineeringMulti point

The invention discloses a multi-point type door and window lock, comprising a master lock and at least one auxiliary lock connected with the master lock by a connecting rod. The master lock includes a casing and side boards, and the casing is provided with driving gears, driving assembly and one or two lock hook assembly matched with driving strip assembly. Characterized in that the casing is provided with lock hook protection feature, advantages are that the lock hook can not be ejected by the driving gear when the door and window are open, thereby, the lock hook will not be damaged. Only when the door and window are closed, feeler lever contacts with sash, the feeler lever is pushed to move inwardly into the side boards to a certain distance, the securing rod releases from the locking block, and the lock hook is ejected out of the side board by the driving gear to lock the door and window.

Owner:联程机械(宁波)有限公司

Optimized bracket device with locking mechanism

InactiveCN108692150AImprove the protective effectEasy to placeStands/trestlesLocking mechanismEngineering

The invention discloses an optimized bracket device with a locking mechanism. The optimized bracket device comprises a base and a protective frame arranged above the base; a horizontal-extending guarding groove facing upwards is formed in the protective frame, and horizontal-symmetrical first sliding grooves are formed in the lower portion of the protective groove; first through openings which communicates with each other are formed in the bottom of each first sliding groove, horizontal-symmetrically rotating wheel grooves facing upwards are formed in the bottom end of the base, and horizontal-extending second sliding grooves are formed in the upper portion of the rotating wheel grooves; and horizontal-extending second through openings which communicates with each other are formed in the upper portion of the second sliding grooves, and a gear cavity extending vertically is formed between the second sliding grooves. The optimized bracket device is simple in structure and convenient to operate and has high guarding performance.

Owner:方流生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com