Laser marking machine

A laser marking machine and laser technology, applied in the field of marking machines, can solve problems such as unstable performance, poor marking quality, and complex structure, and achieve the effects of compact structure, convenient operation, and high marking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

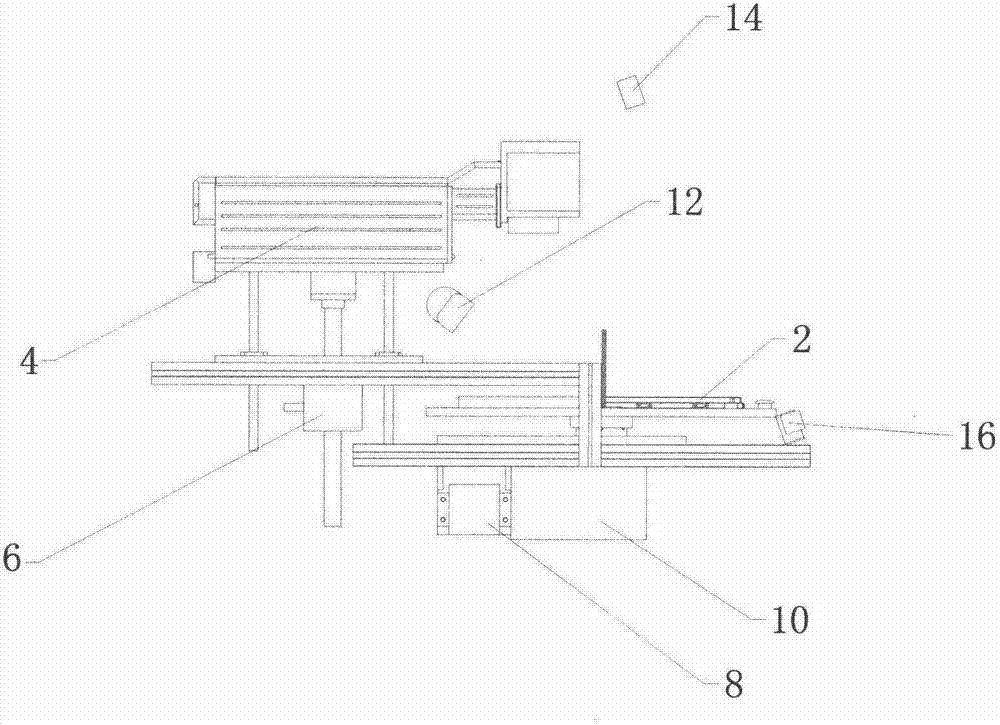

[0016] like figure 1 As shown, a laser marking machine of the present invention includes a workbench 2, a laser 4, an elevator 6 and a working motor 8, wherein the laser 4 is installed above the workbench 2, and the elevator 6 is installed below the laser 4 for driving The laser 4 moves up and down, and the working motor 8 is installed under the workbench 2 and is connected to the workbench 2 through a divider 10 . In actual use, in order to keep the working environment clean, a fume extraction device 12 is installed above the workbench 2. The fume extraction device 12 can promptly remove the fume generated during laser marking, thereby maintaining a cleaner working environment. At the same time, in order to improve the operation safety of the laser marking machine, a No. 1 safety grating 14 and a No. 2 safety grating 16 are installed on the top and side of the workbench 2 respectively. In case of misoperation, the laser marking machine can be stopped in time, so as to achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com