Steel bar binding space distance identification device

A marking device and steel bar binding technology, which is applied in the field of reinforced concrete, can solve the problems of inconvenient operation and low construction efficiency, and achieve the effects of clear marking, improved work efficiency, and accurate steel bar binding spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

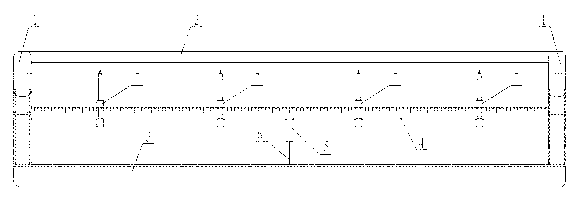

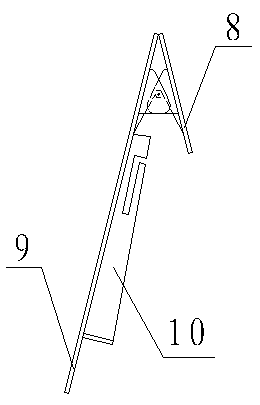

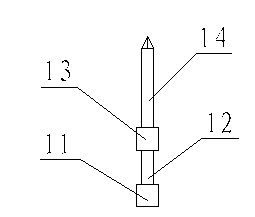

[0016] Such as figure 1 As shown, in the reinforced concrete construction of the present invention, the steel bar binding spacing marking device is composed of two positioning clamps 1, an upper connector 2, a lower connector 3, a scale 4, and a vernier pen 7, and the scale is between the upper connector and the lower connector. The two positioning clips are arranged at the two ends of the scale, the upper connecting piece and the lower connecting piece. The short tail clips 8 of the two positioning clips are connected to the lower connecting piece through superglue, and the long tail clips 9 of the two positioning clips are passed through. The superglue is connected with the upper connector, and the ruler is equipped with a plurality of vernier pens 7 .

[0017] The long-tail clips, short-tail clips, and upper and lower connectors of the positioning clip have a thickness of 4 mm, and are made of transparent PVC plastic.

[0018] The middle part of the upper edge of the scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com