Patents

Literature

67 results about "Short tail" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

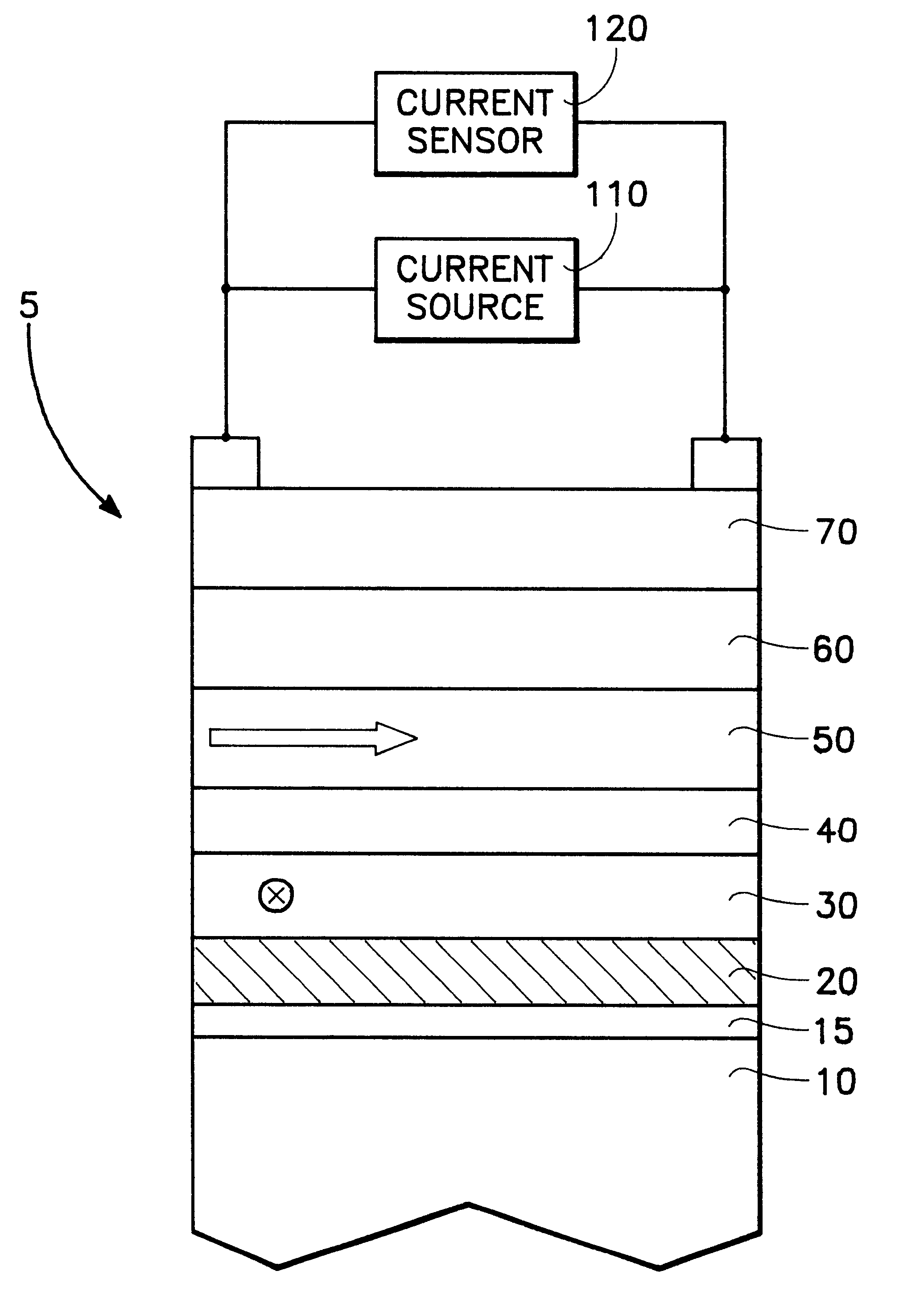

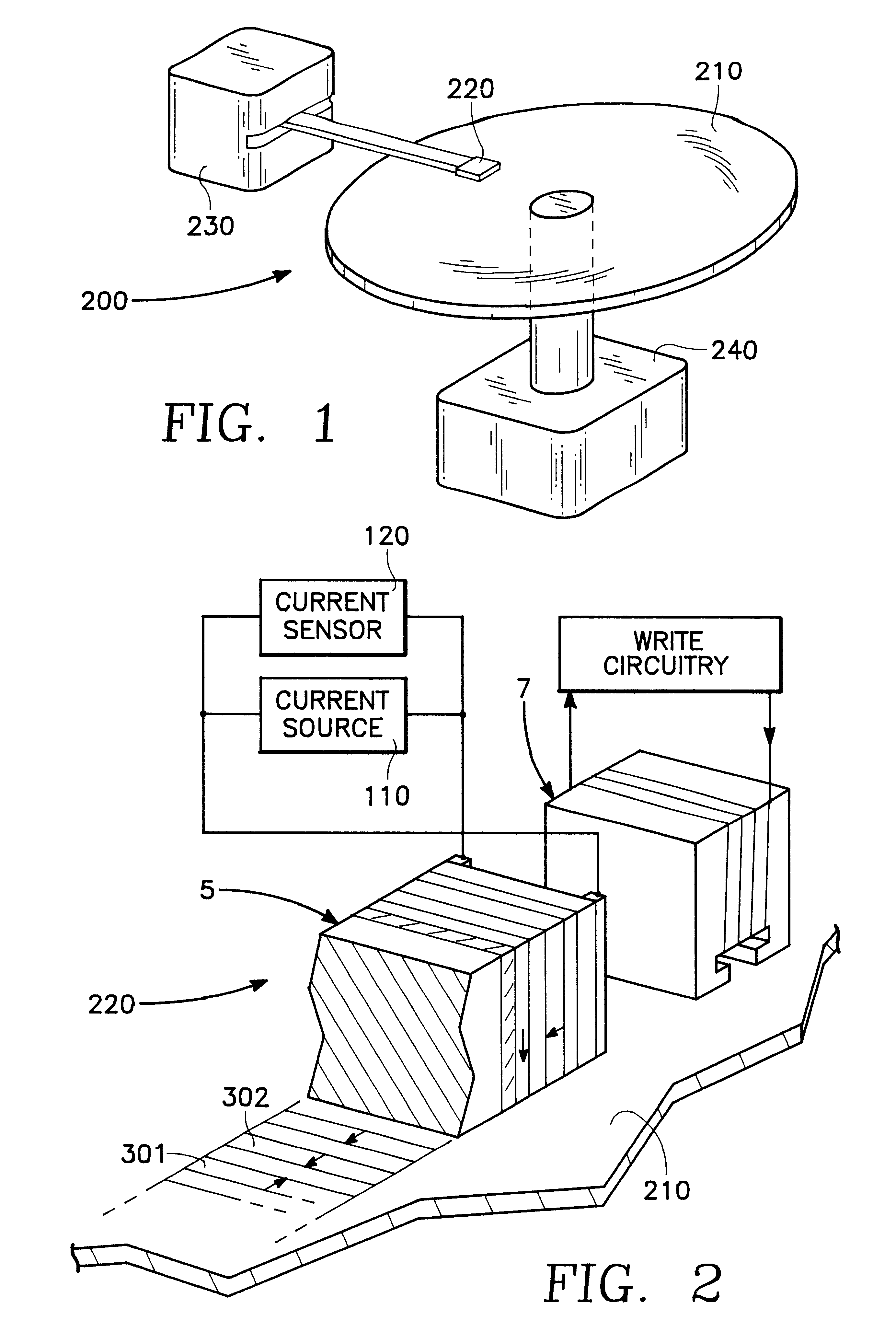

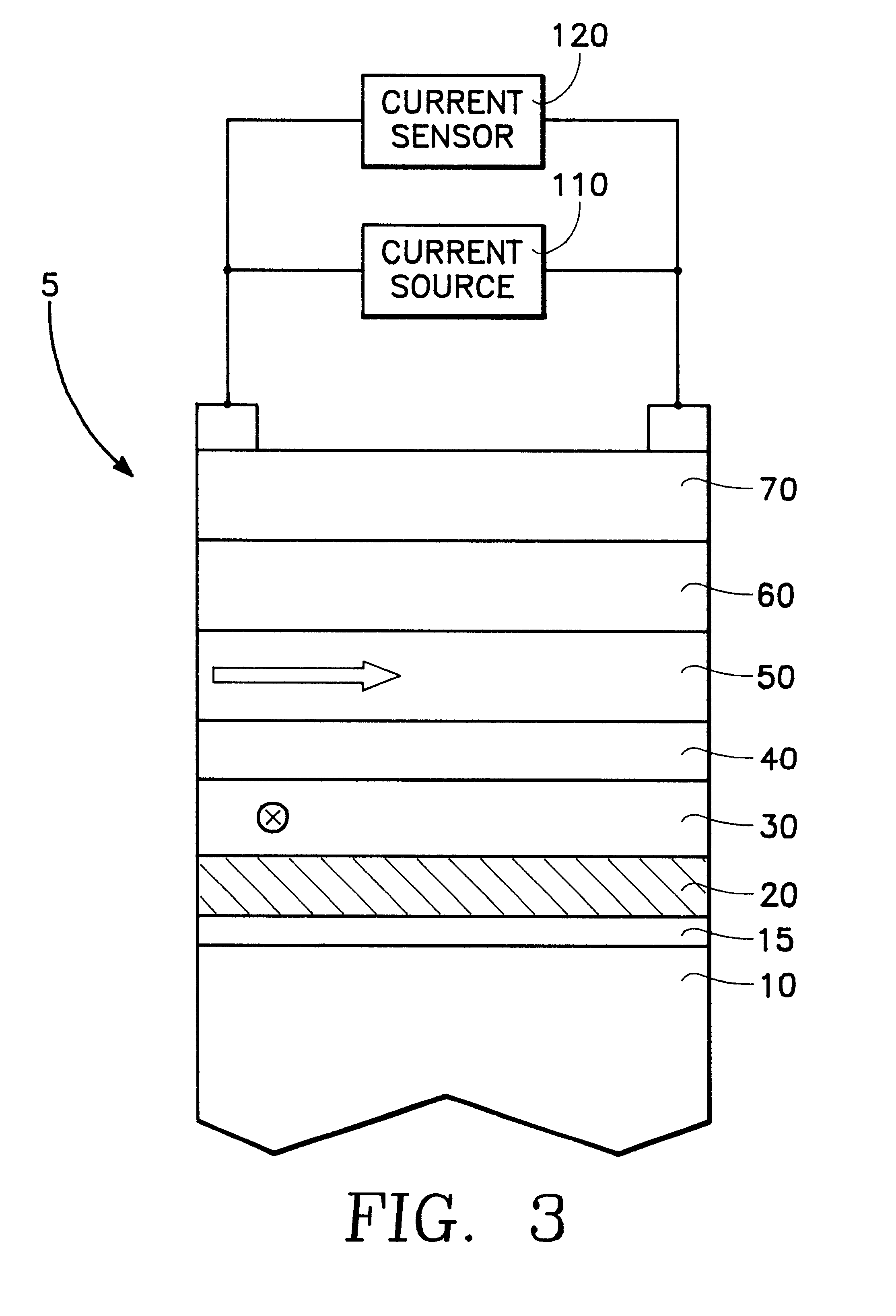

Top spin valve with improved seed layer

InactiveUS6687098B1Improved exchange bias fieldNanostructure applicationNanomagnetismEngineeringHigh resistivity

The present invention provides an improved top spin valve and method of fabrication. In the preferred embodiment of the top spin valve of the present invention, a seed layer is formed of non-magnetic material having the elements Ni and Cr. In the preferred embodiments, the seed layer material has an ion milling rate comparable to that of the free layer material. This allows free layer sidewalls to be formed with shorter tails, improving free layer-to-magnetic bias layer junction, thus improving free layer domain structure and track width. In one embodiment, the seed layer may have NiFeCr, with Cr from about 20% to 50%. In another embodiment, the seed layer may have NiCr, with about 40%. Some embodiments may have the seed layer formed on an optional Ta pre-seed layer. Such embodiments provide an improved fcc (111) texture particularly for NiFe and for NiFe / CoFe free layers grown on a seed layer improving spin valve performance, and especially in embodiments having very thin NiFe free layers, ultra thin NiFe free layers, and free layers without NiFe, such as a free layer of CoFe. Such a seed layer can improve AFM pinning layer texture to improve the exchange bias, thus providing better thermal stability. Such a seed layer also provides high resistivity and can improve the magnetostriction of adjacent NiFe free layer material or improve the soft properties of an adjacent CoFe free layer.

Owner:WESTERN DIGITAL TECH INC

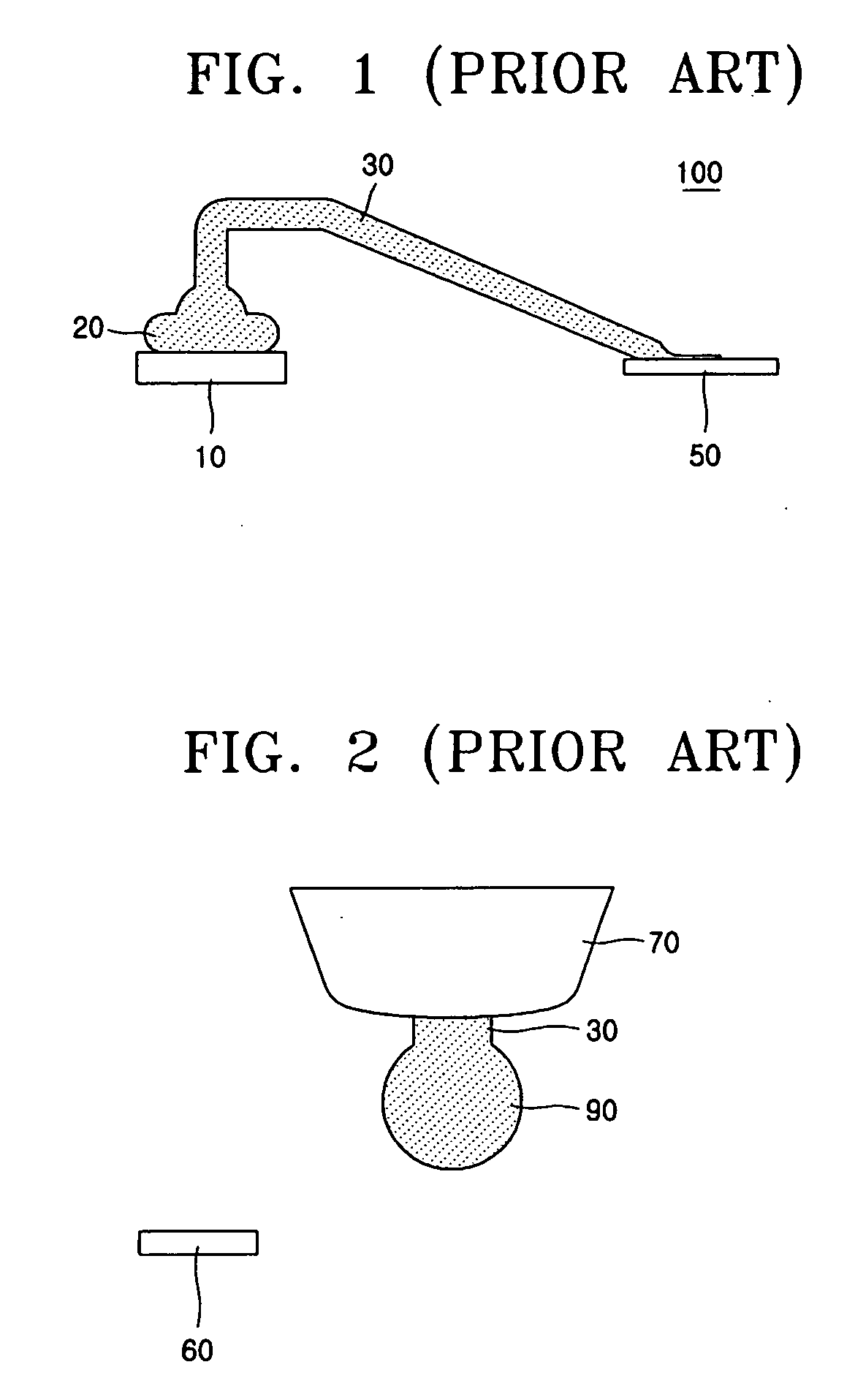

Copper bonding wire for semiconductor packaging

InactiveUS20060186544A1Improving a metal squeeze out of a chip padShort tail of the bonding wireLiving organism packagingSemiconductor/solid-state device detailsSemiconductor chipSemiconductor package

Provided is a copper bonding wire formed of a high purity copper of 99.999% or more including at least one of P and Nb within a range between 20 wt ppm and 100 wt ppm and at least one of Zr, Sn, Be, Nd, Sc, Ga, Fr, and Ra within a range between 1 wt ppm and 100 wt ppm. Here, a total content of the added elements is restricted within a range between 20 wt ppm and 200 wt ppm, and a residual amount of the copper bonding wire is a high purity copper of 99.98% or more. As a result, metal squeeze out and chip cratering can be reduced in a general semiconductor chip and a low dielectric semiconductor chip. Also, a short tail of the copper bonding wire occurring during bonding of the copper bonding wire to a lead finger can be reduced.

Owner:MK ELECTRON

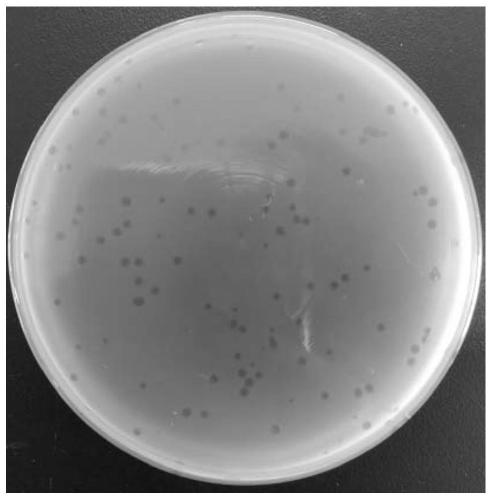

Short-tailed coliphage and application thereof

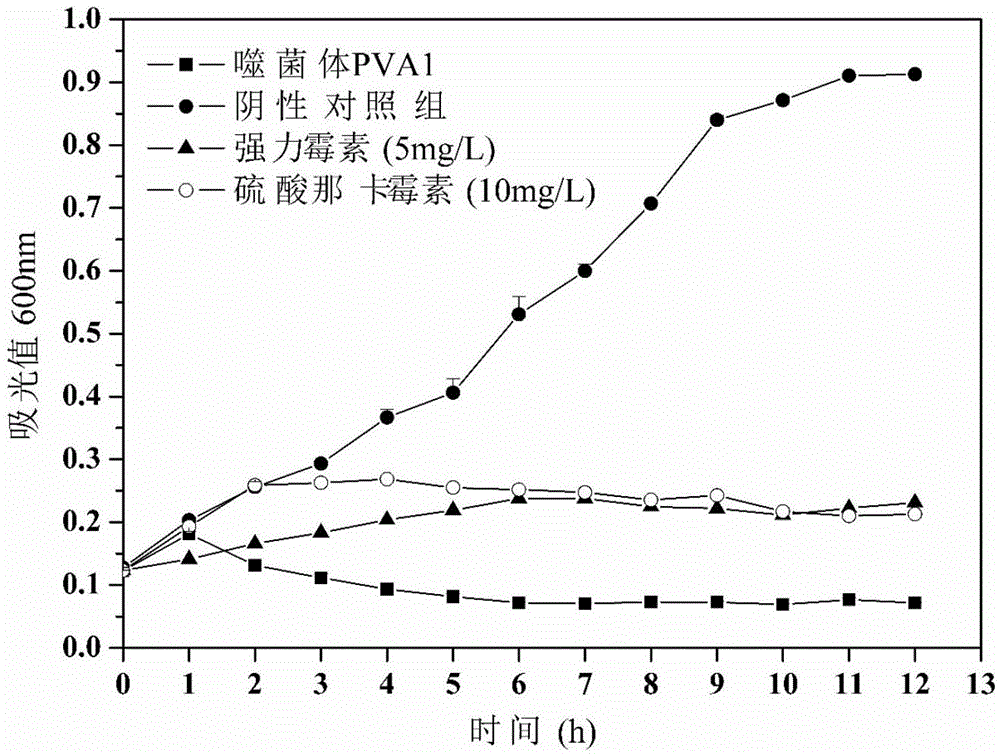

ActiveCN110129283AIncrease lytic activityNo side effectsAntibacterial agentsBiocideEscherichia coliMicroorganism

The invention relates to a coliphage and application thereof, in particular to a short-tailed highly-lytic coliphage. The coliphage named PD38 is collected in the China General Microbiological CultureCollection Center on September 26, 2018, wherein the collection number is CGMCC No. 16391. The coliphage has a good lytic effect on escherichia coli, has a good killing effect on the escherichia coliin food and culture environment, and can prevent and treat diseases caused by the escherichia coli of chicken.

Owner:QINGDAO PHAGEPHARM BIO TECH CO LTD

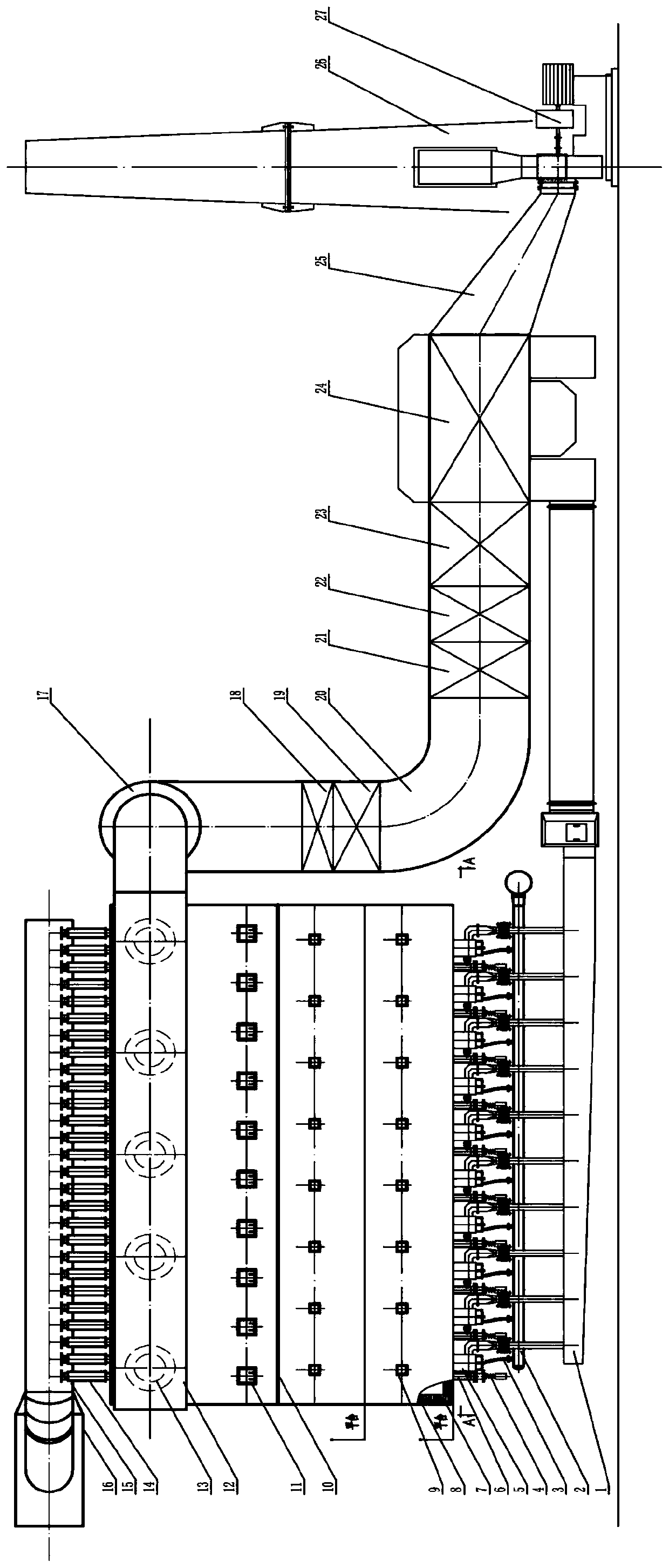

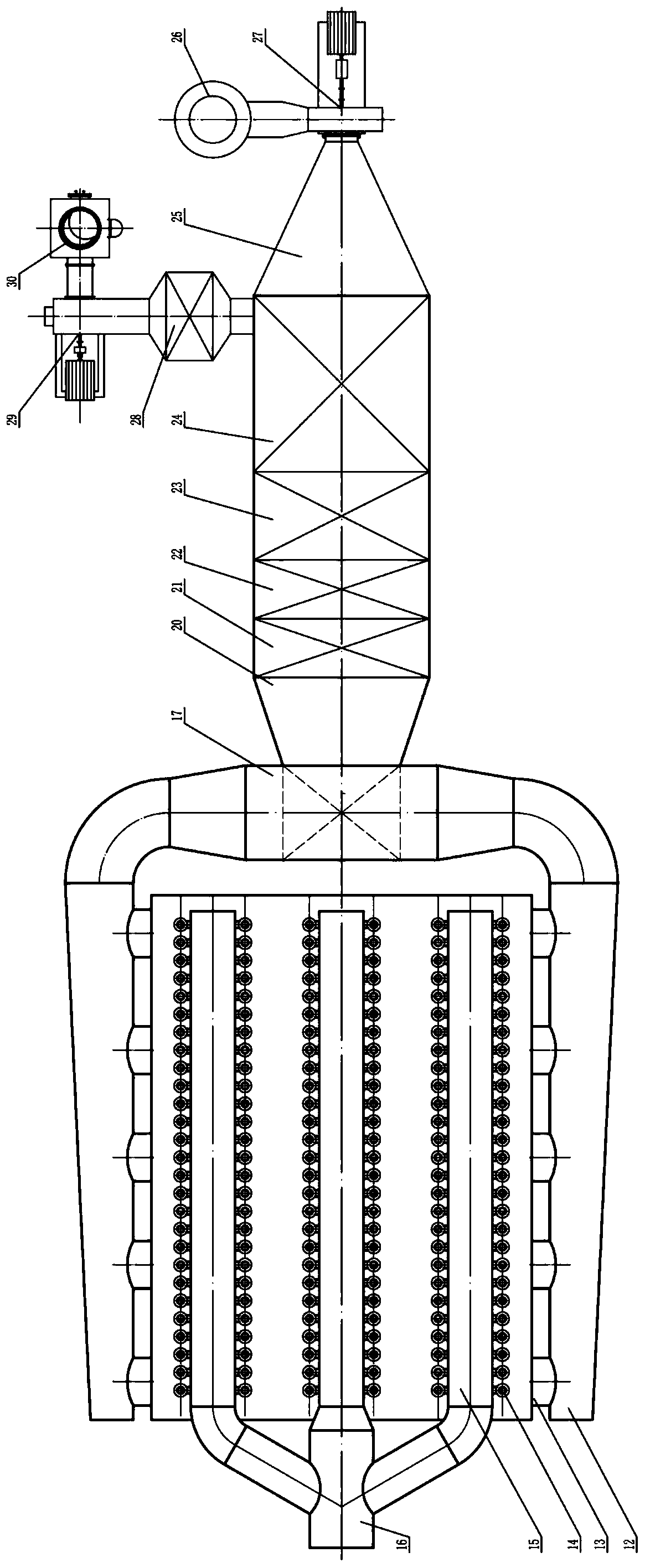

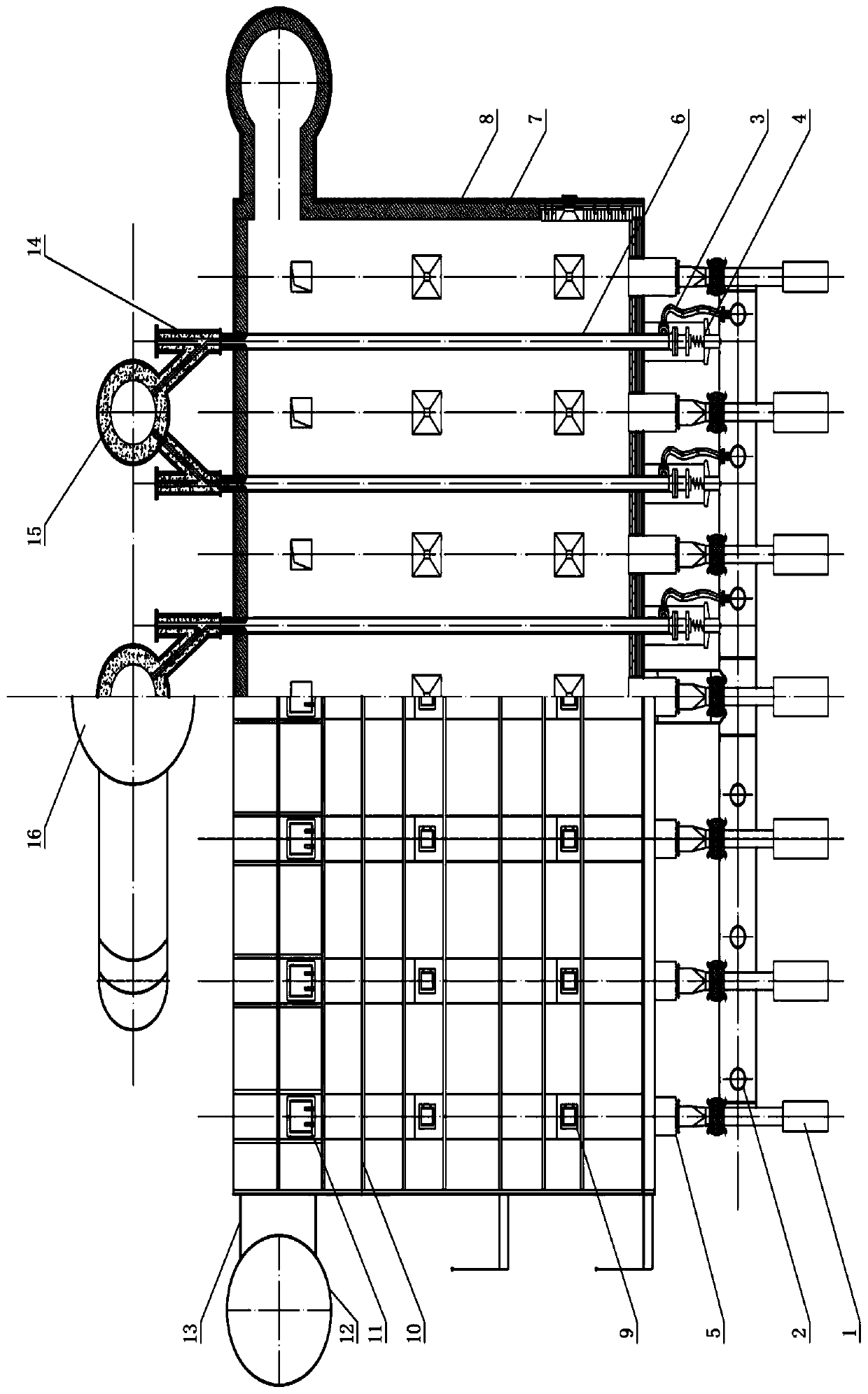

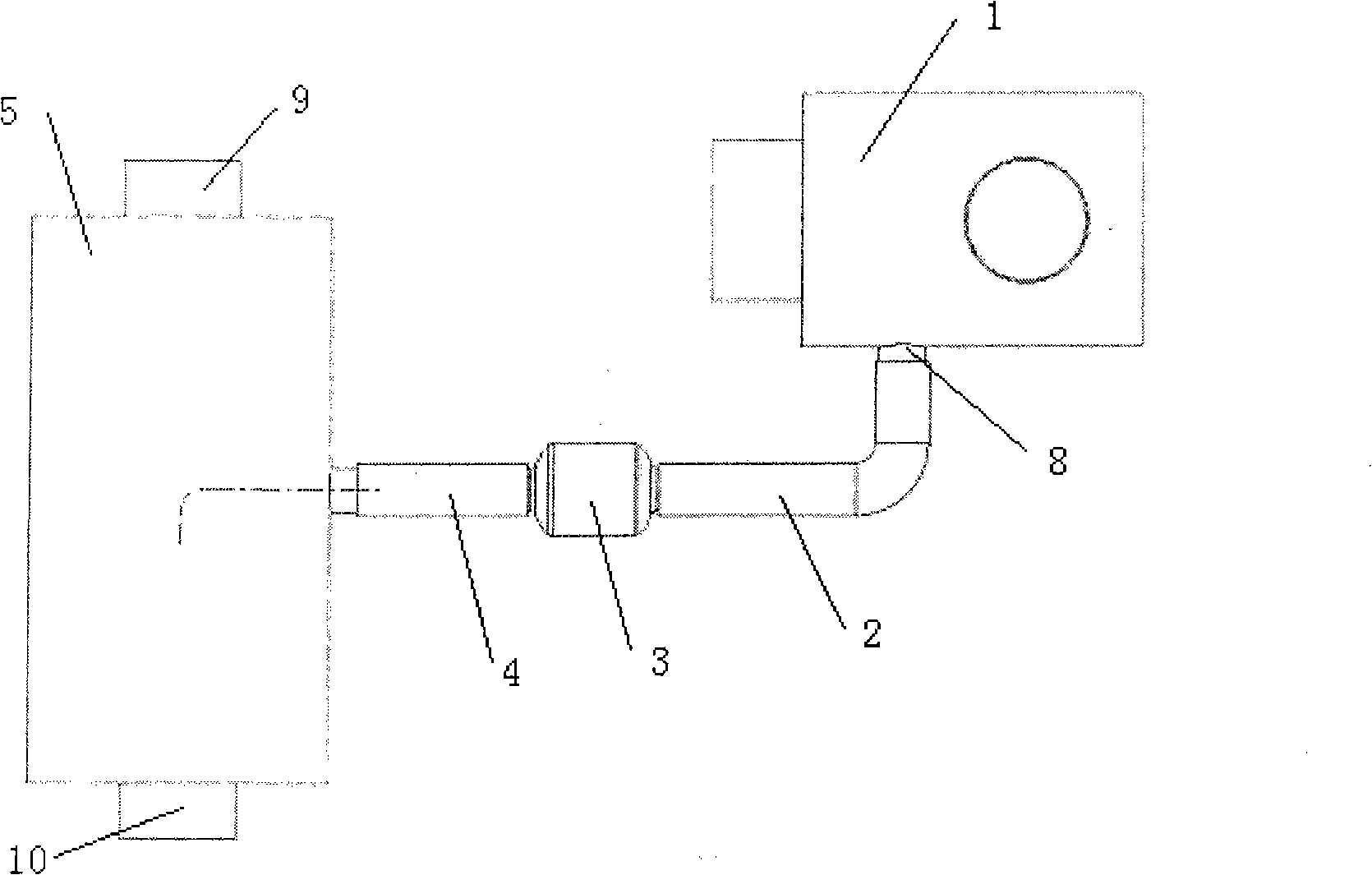

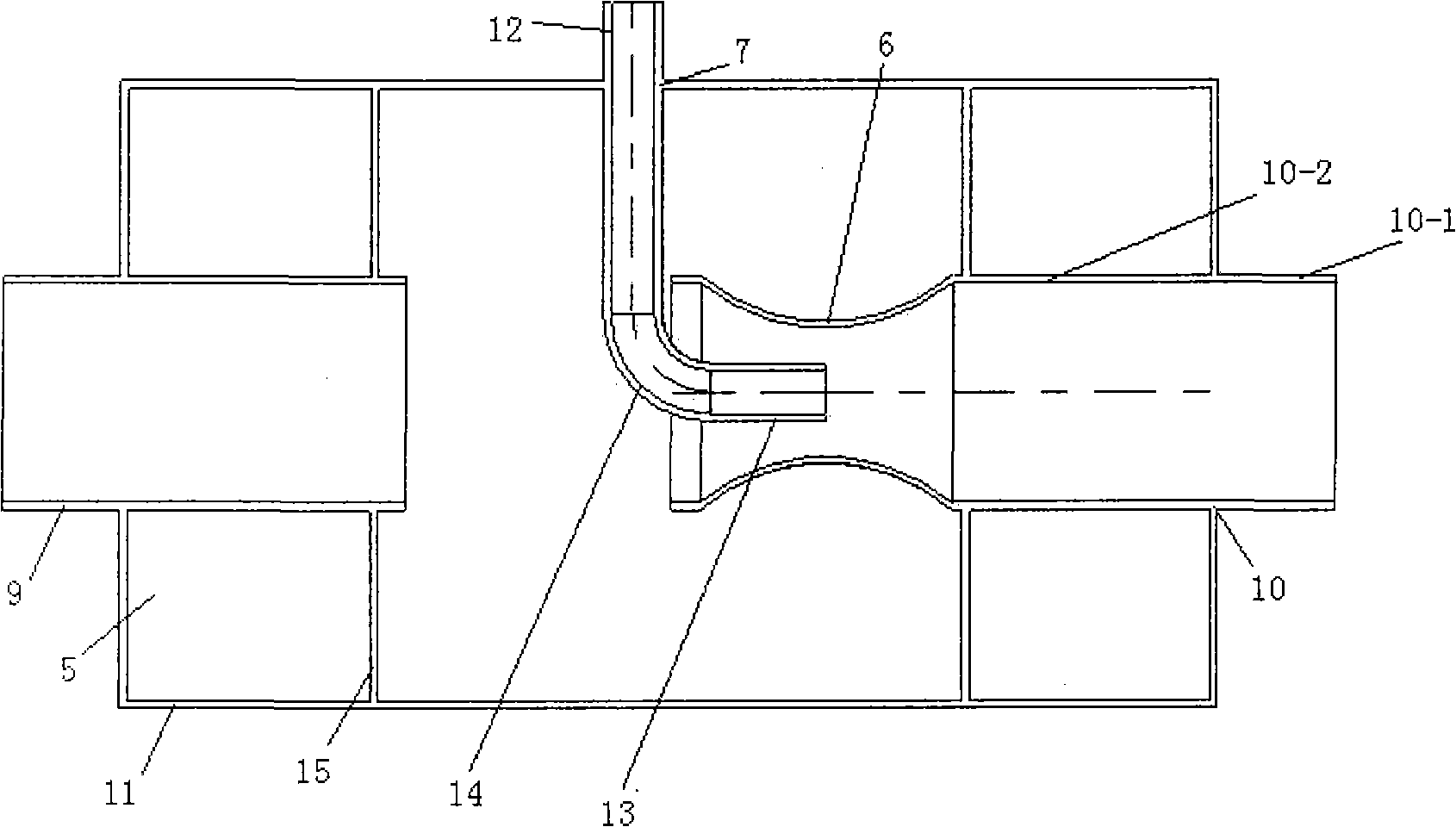

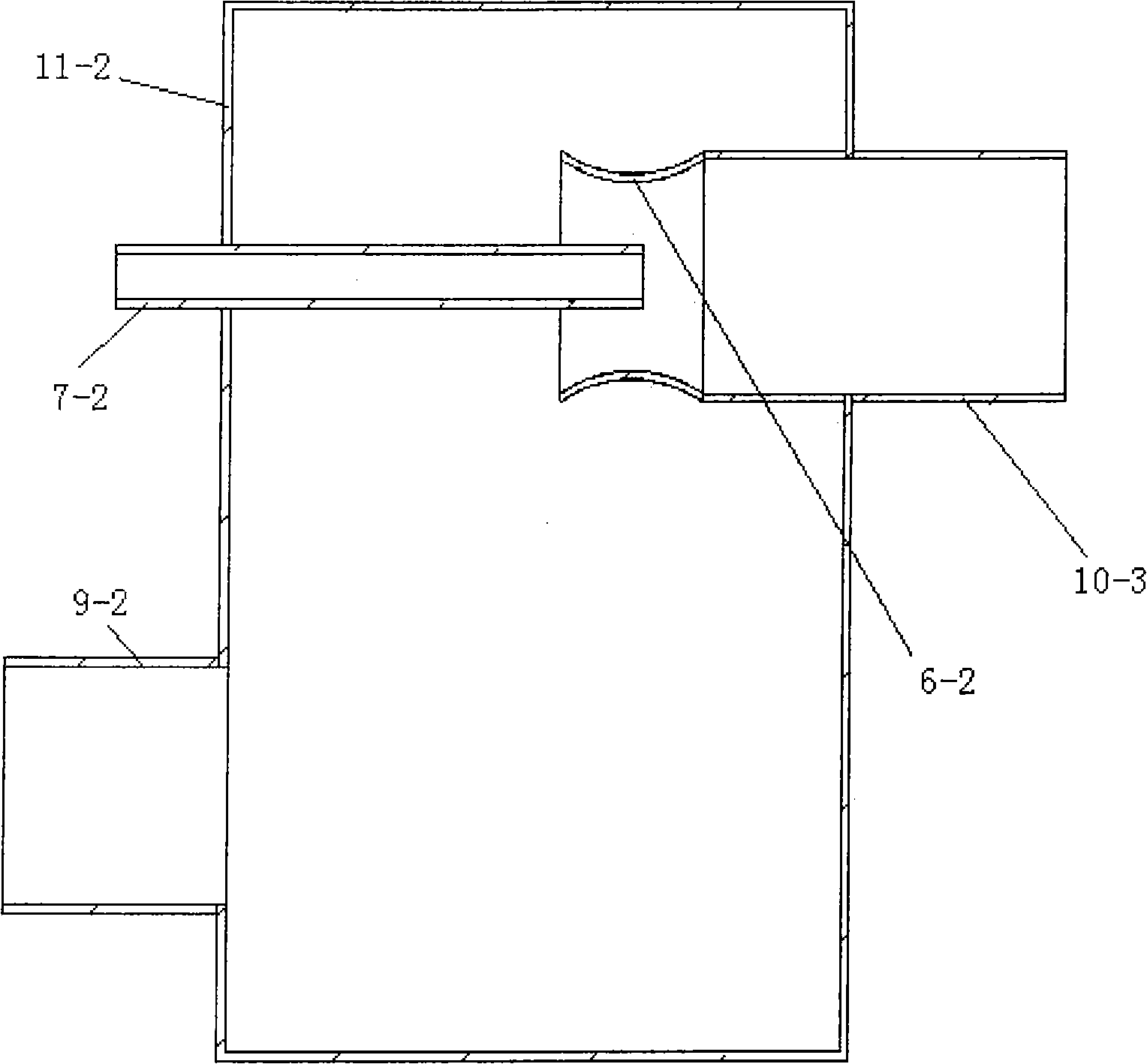

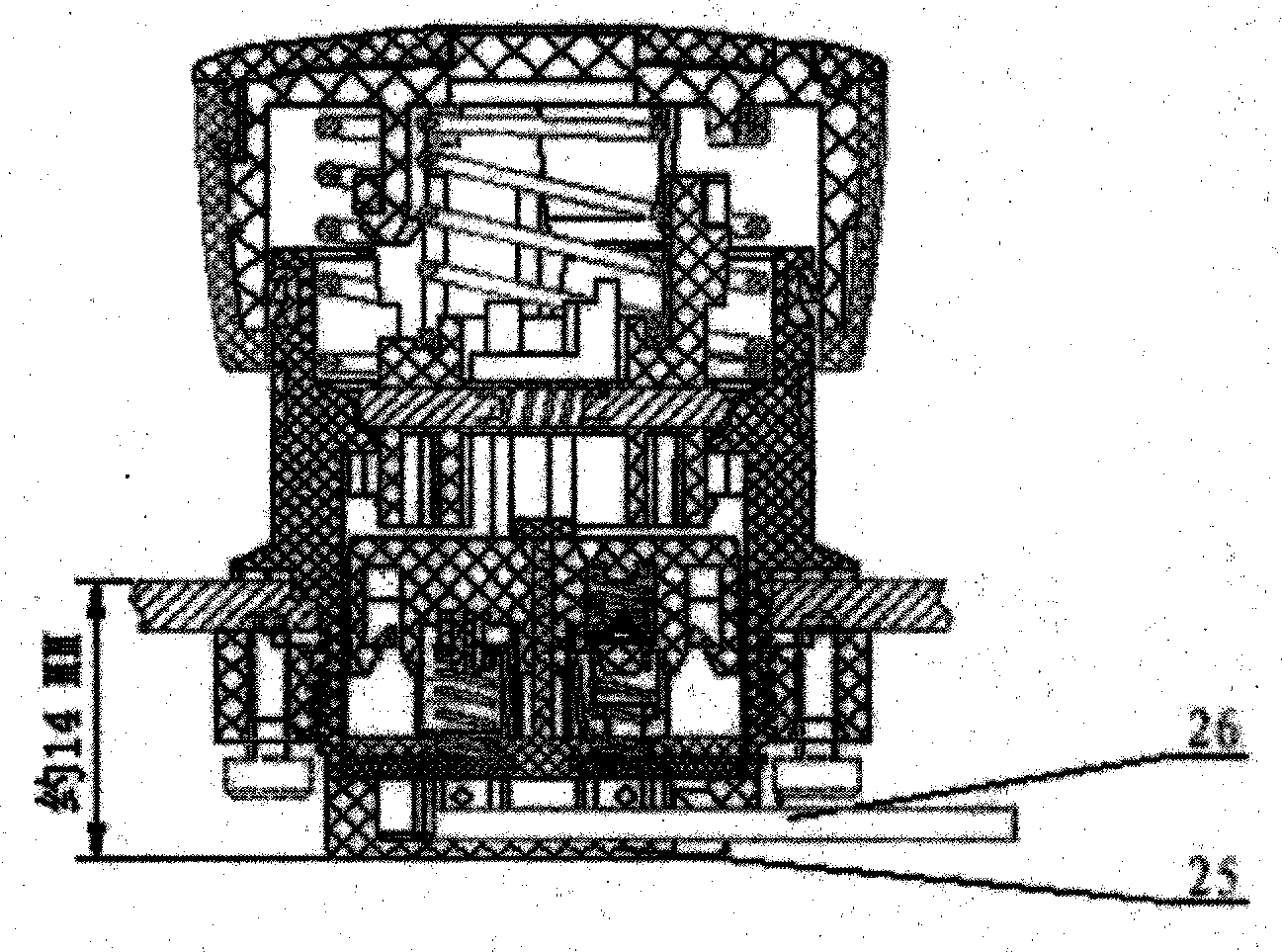

Novel reforming furnace for preparing reducing gas

PendingCN110578027ALess investmentSmall footprintCombustible gas catalytic treatmentEnergy inputEngineeringRaw material

The invention provides a novel reforming furnace for preparing reducing gas, and belongs to the technical field of metallurgy and petrifaction. The reforming furnace comprises a lining radiation chamber, a reforming furnace pipe, a reforming gas port pipe system, a transition section, a convection section and an air and flue gas system. The reforming furnace pipe adopts a large caliber to reduce the furnace pipe number, so that the investment is reduced; a reforming gas inlet pipe is connected with the reforming furnace pipe by adopting a flexible pipe, so that the axial and radial heat displacements of the furnace pipe are conveniently absorbed, and the heat stress of a furnace pipe system is reduced; an elastic bracket is arranged at the bottom of the reforming furnace pipe for bearing part weight of the furnace pipe and facilitating recovery of the furnace pipe after heat expansion under the working condition of parking; a radiation chamber furnace top inclined tee joint replaces atraditional heat pipe wall, and a short tail box is canceled, so that materials are saved, and the investment is reduced; and high-temperature smoke is guided to the transition section from multiple channels at the upper parts of the two sides of the radiation chamber, and is fed in the convection section for preheating air and reforming raw material gas and fuel gas to generate high-quality vapor, so that the smoke discharge heat loss is reduced, and the heat efficiency of the reforming furnace is improved.

Owner:SINOPEC NANJING ENG & CONSTR +1

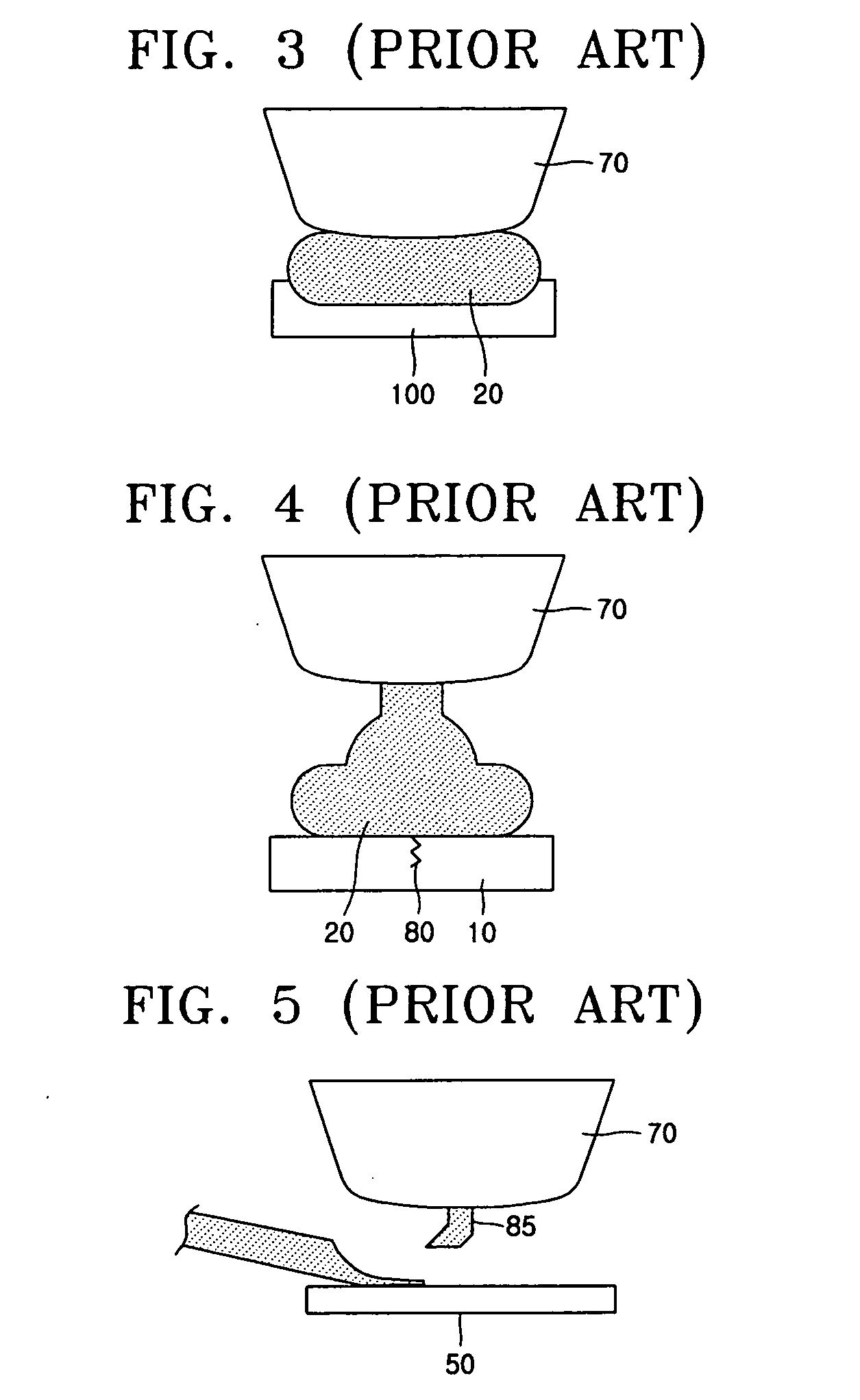

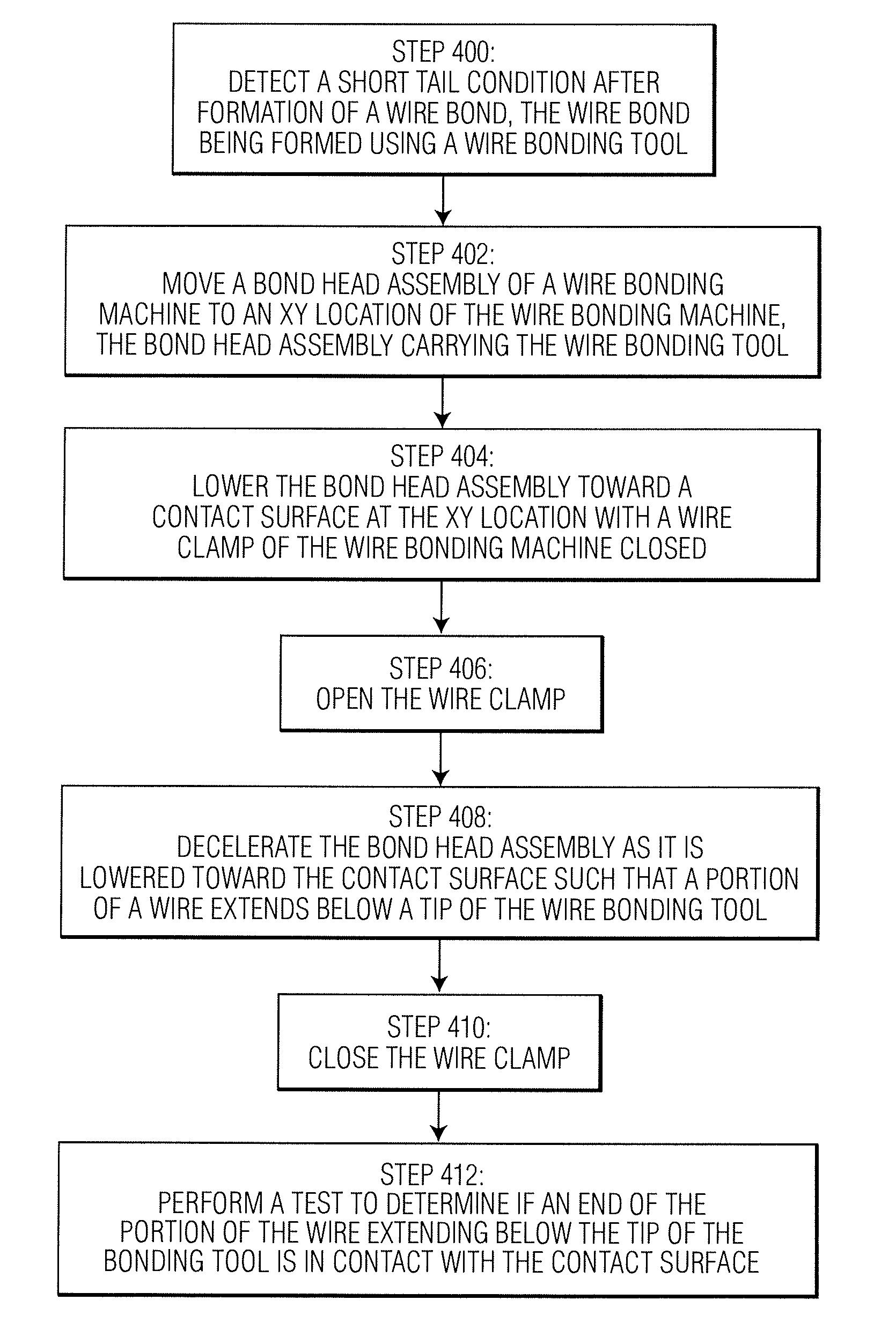

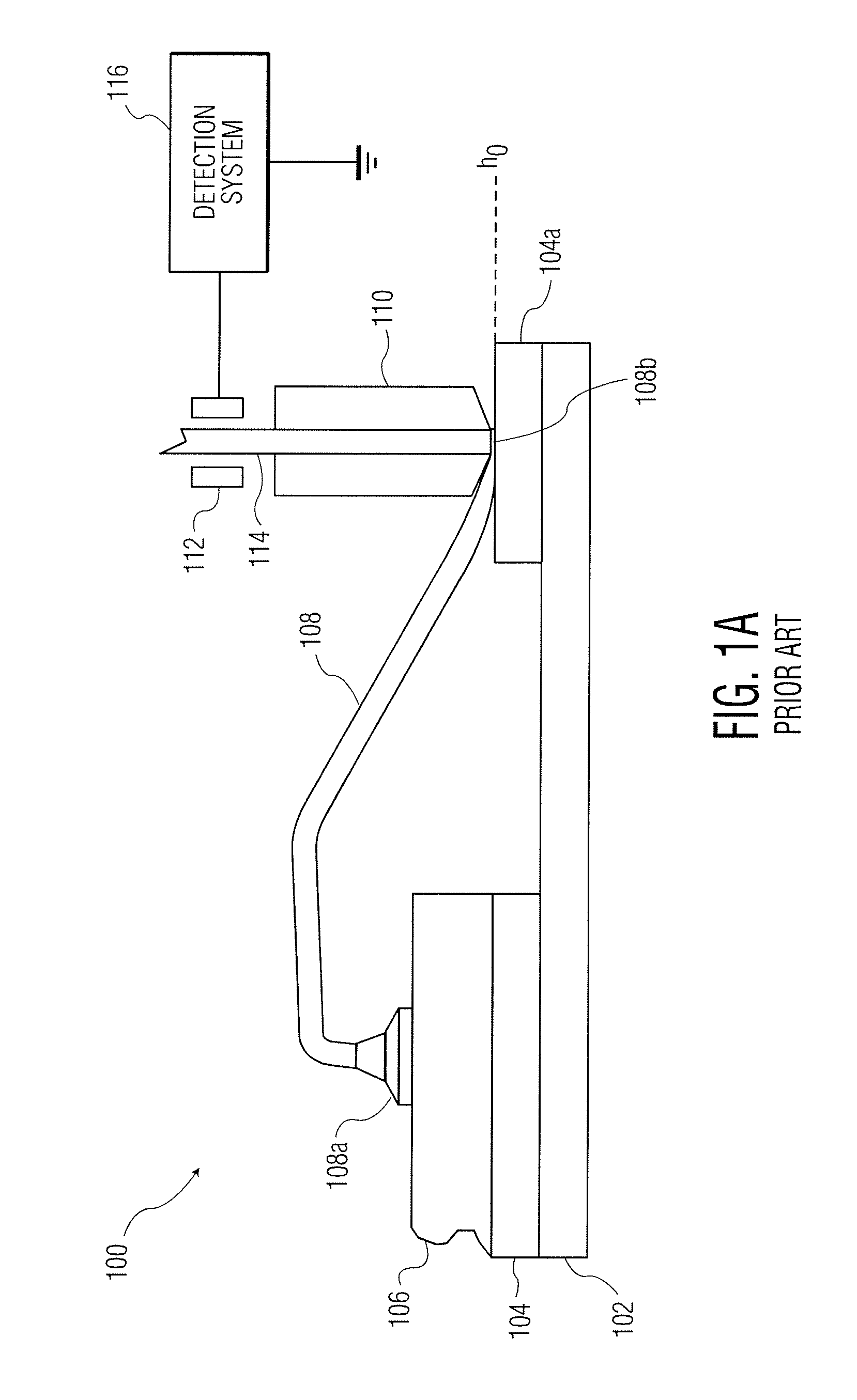

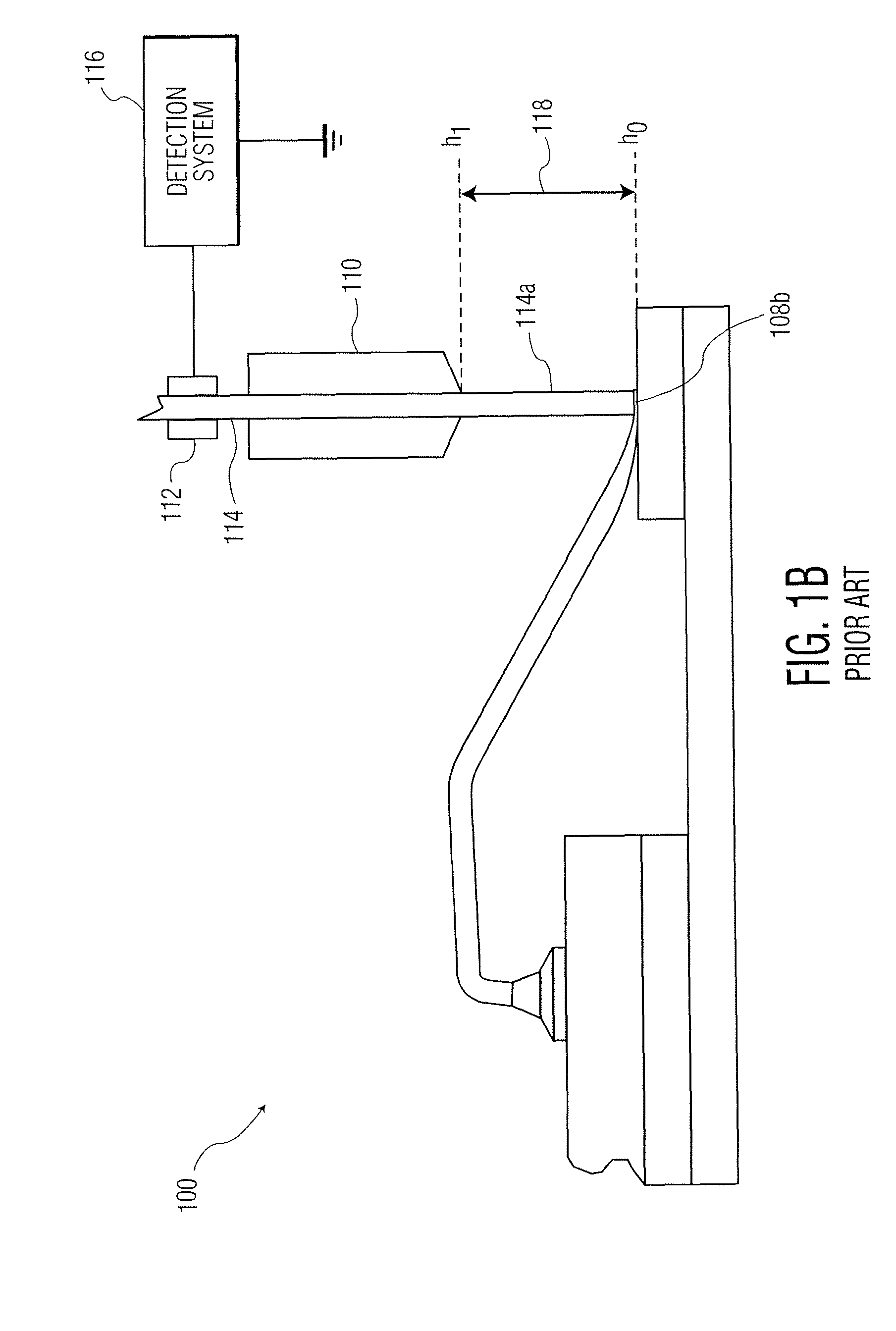

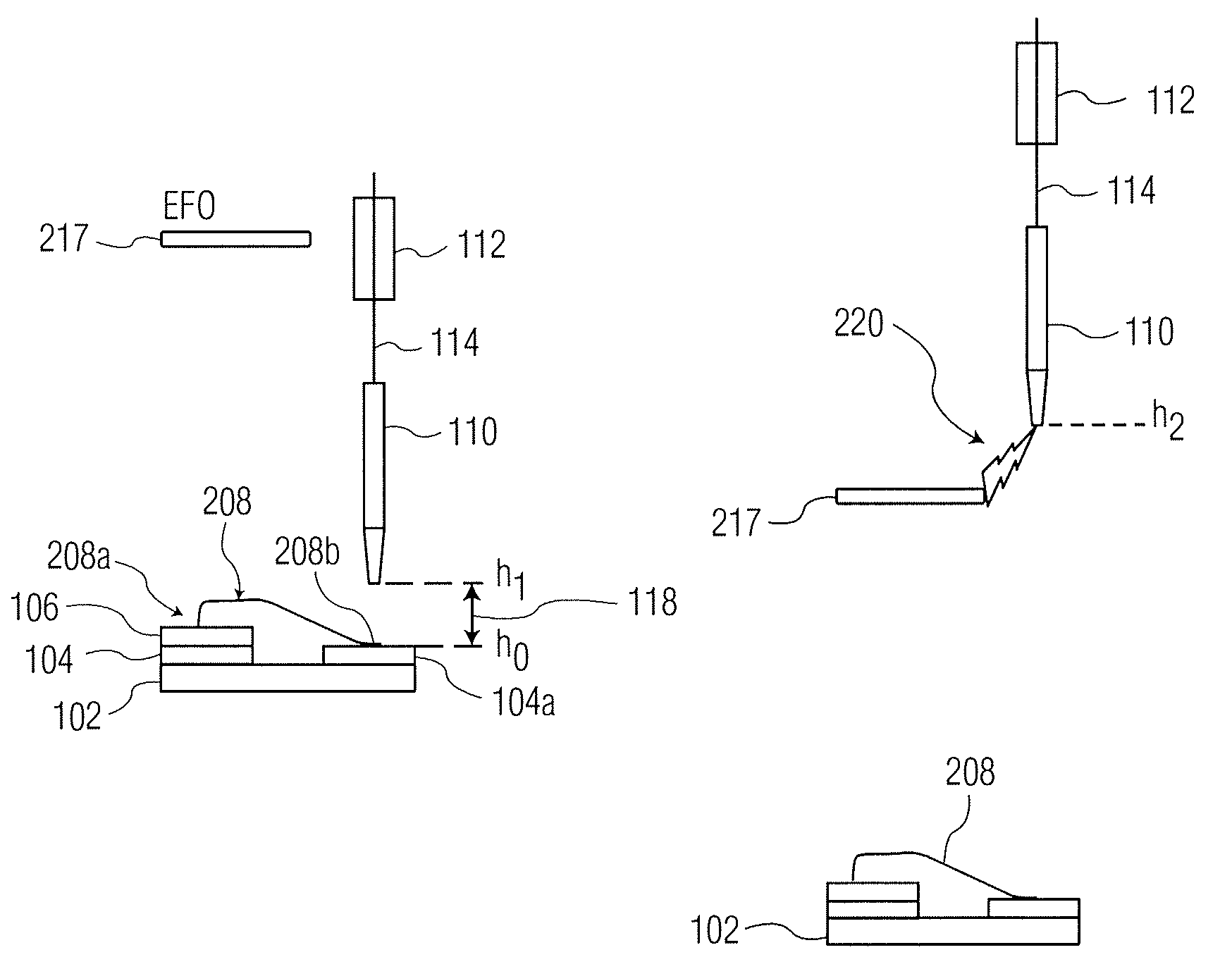

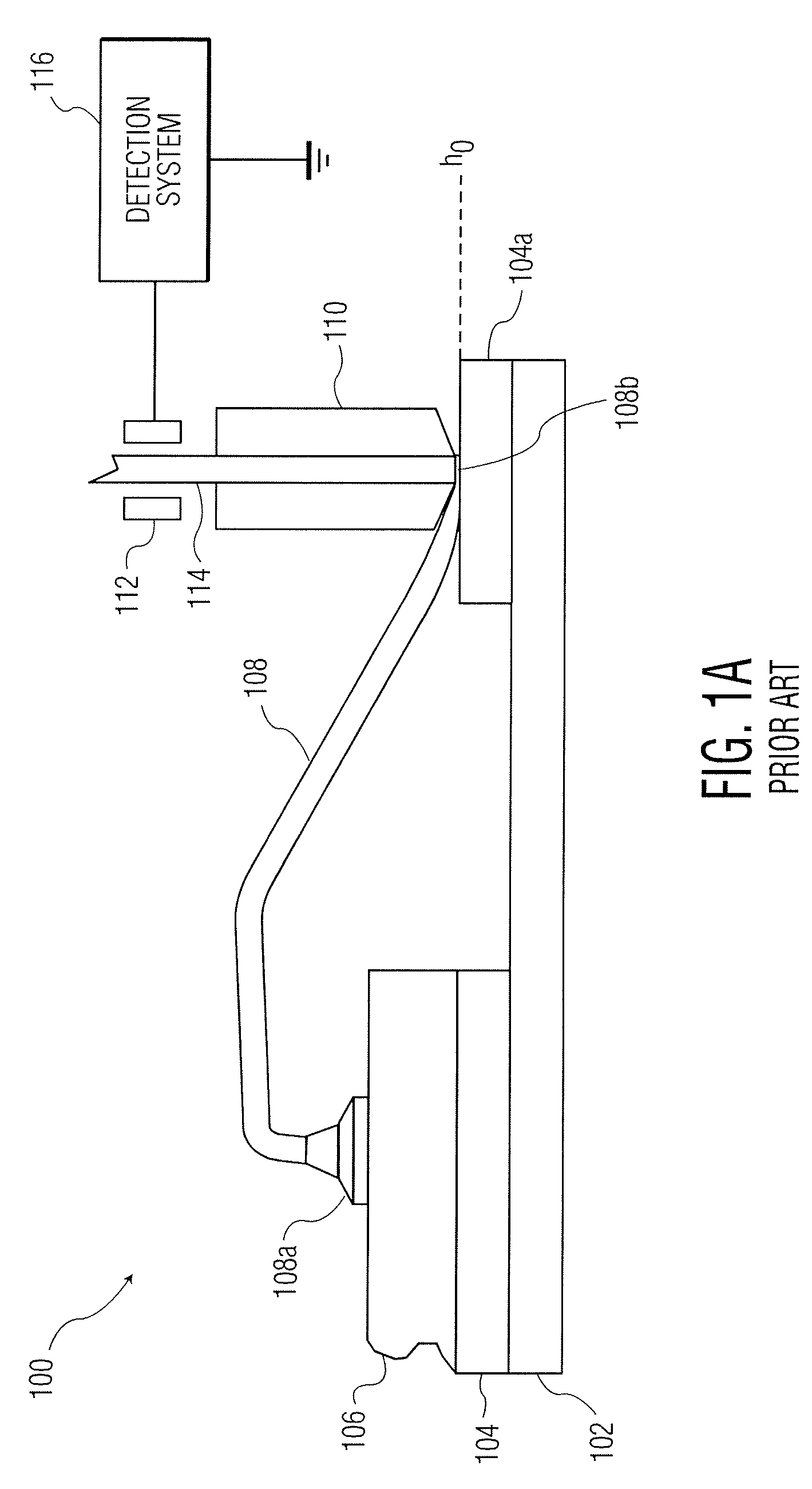

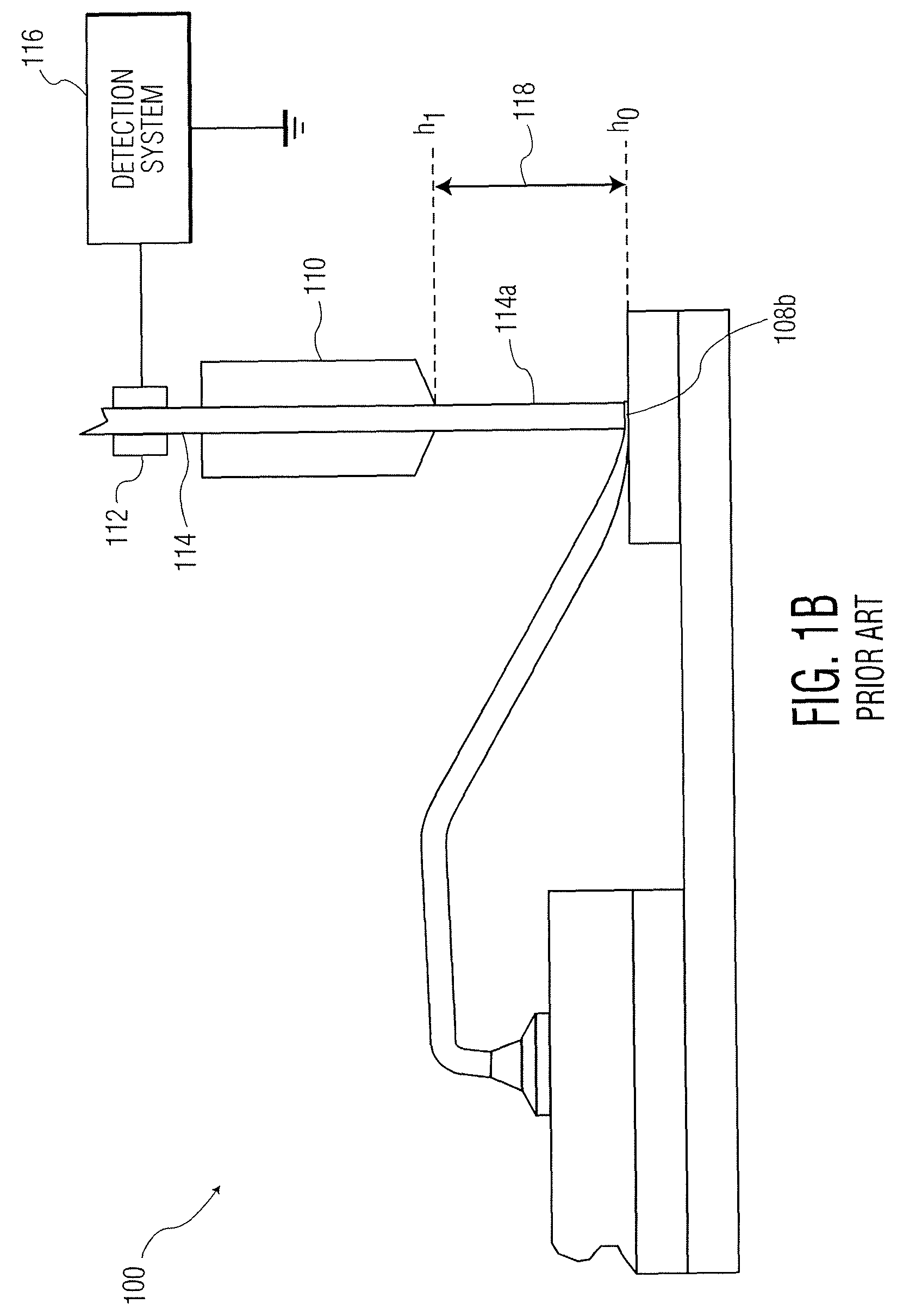

Short tail recovery techniques in wire bonding operations

ActiveUS20150200143A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsShort tailRecovery techniques

A method of operating a wire bonding machine is provided. The method includes: detecting a short tail condition after formation of a wire bond formed using a wire bonding tool; providing a bond head assembly of a wire bonding machine at an xy location of the wire bonding machine, the bond head assembly carrying the wire bonding tool; lowering the bond head assembly toward a contact surface at the xy location with a wire clamp of the wire bonding machine closed; opening the wire clamp; decelerating the bond head assembly as it is lowered toward the contact surface such that a portion of a wire extends below a tip of the wire bonding tool; closing the wire clamp; and performing a test to determine if an end of the portion of the wire extending below the tip of the bonding tool is in contact with the contact surface.

Owner:KULICKE & SOFFA IND INC

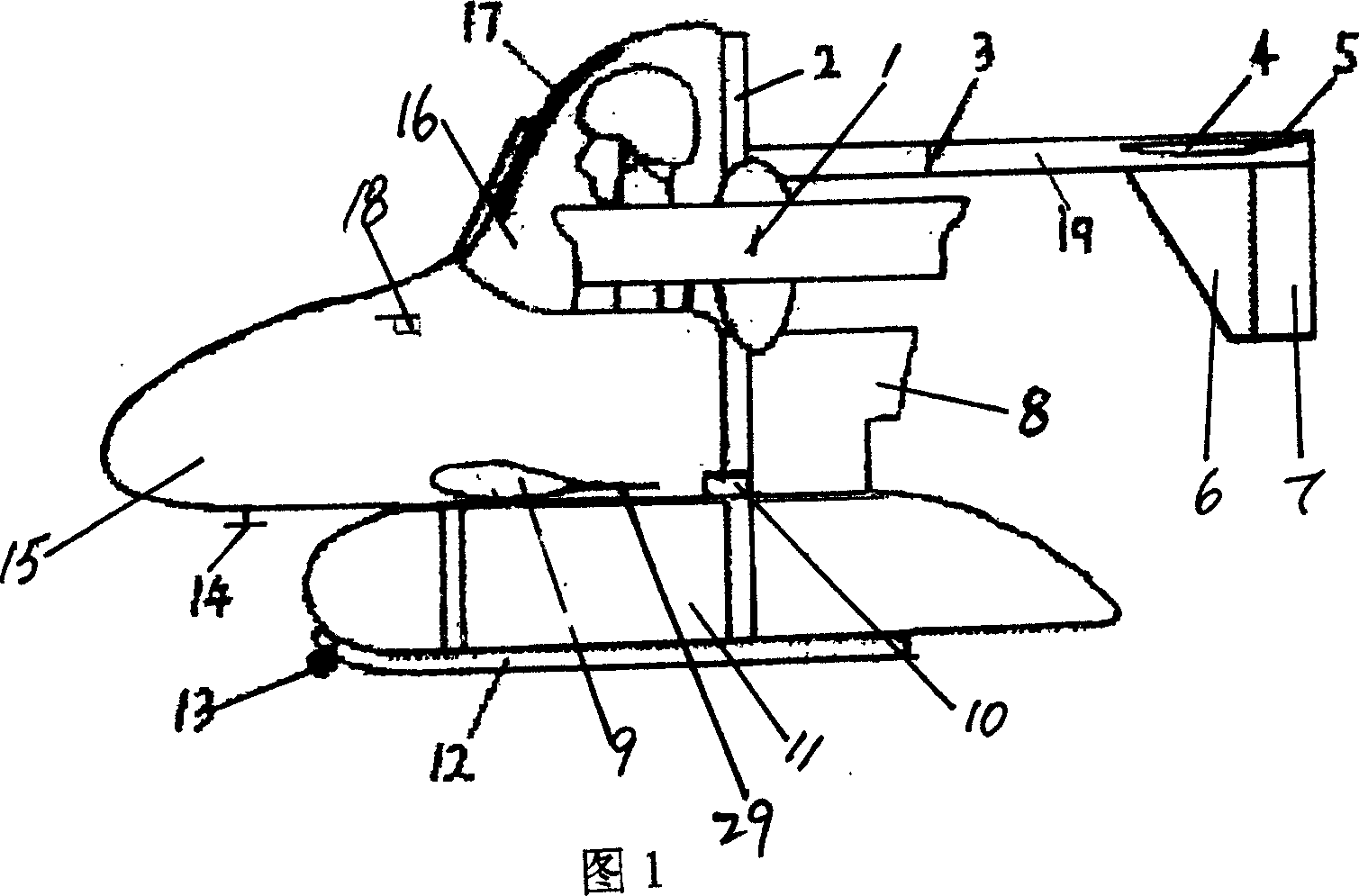

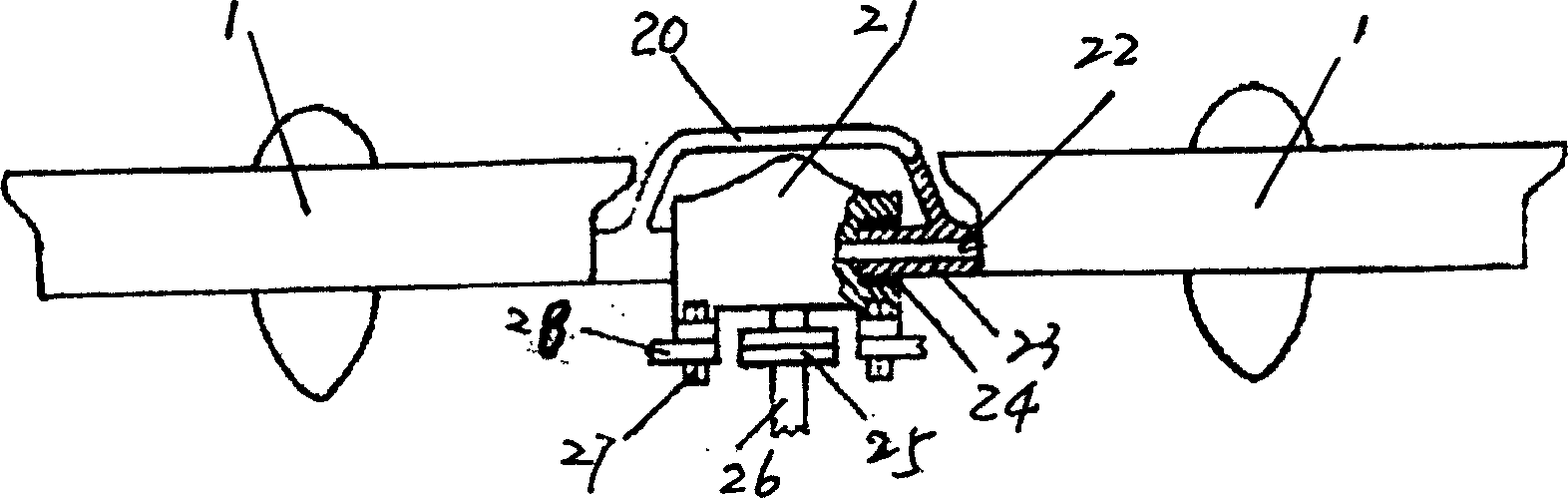

Oneman vertical takeoff and landing aerial craft with double leaning and rotating culvert fan

The invention provides a single-person vertical rising-falling aerocraft with tilt double-culvert fan, it has bearing frame, there are cabin and engine installed on the bearing frame, there is a short-tail beam installed on the bearing frame behind the cabin, the tail end of the short-tail beam is installed with vertical tail fin, horizontal tail fin, direction helm and lift helm, the bearing frames on the two sides of the lower part of the cabin are installed with short wings, respectively, the bottom of the cabin is installed with a skid landing gear, the bearing frames on the two sides of the cabin are installed with culvert fans able to synchronously tilt in the horizontal forward-tilting and up tilting directions in the range greater than 90 degrees, respectively, and the two culvert fans are connected by rocker link rod and the rocker link rod controls the synchronous action of the two fans. It can complete high-speed horizontal flying, low-speed forward flying, vertical rising and falling, hovering, backward flying, and other flying actions, and at the same time can solve the driving fatigue problem of driver, etc.

Owner:穆骞

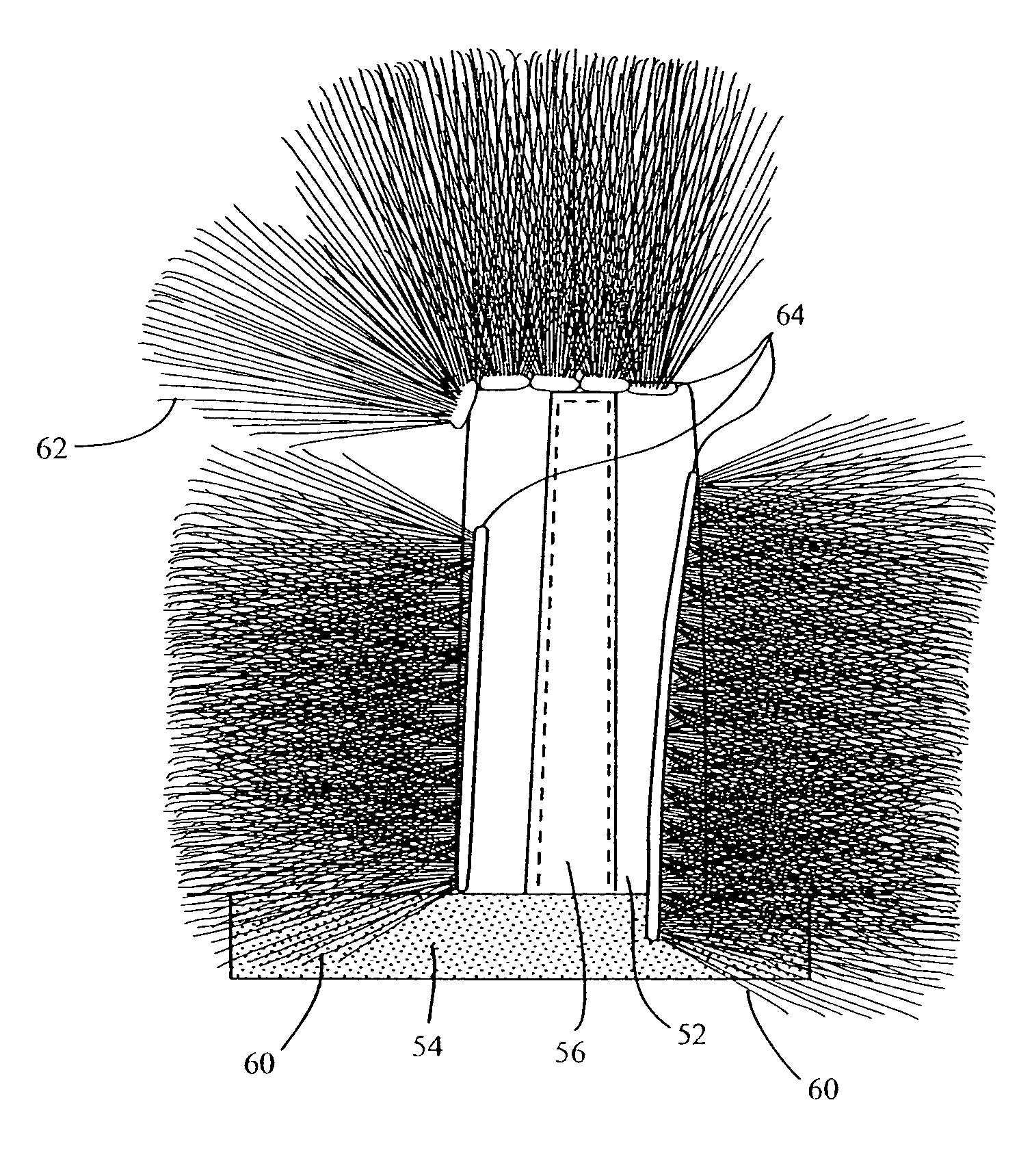

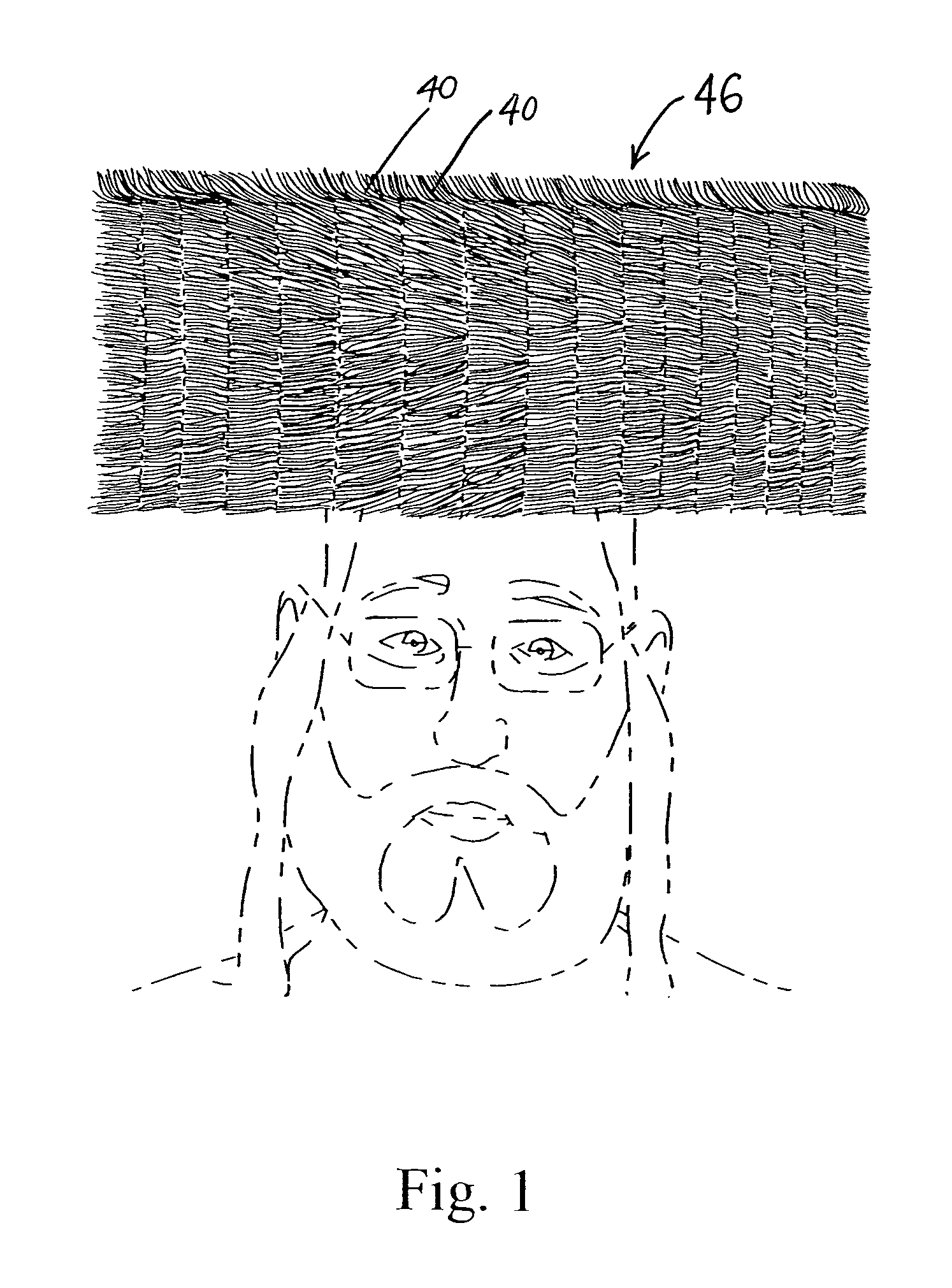

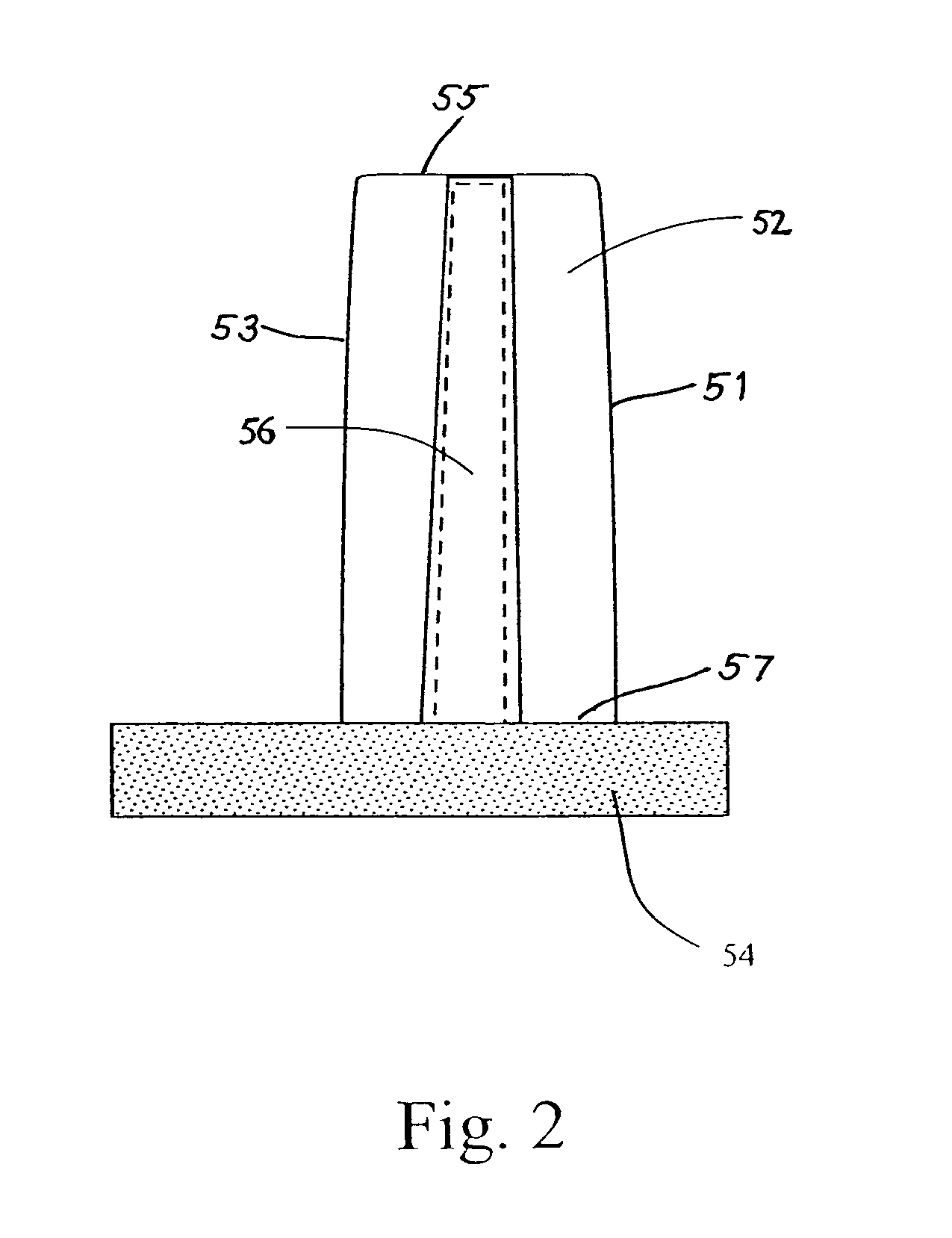

Method of manufacturing a fur hat using tail fur

A method of making a fur plate includes cutting lengthwise at least one elongate animal tail skin having fur to form a plurality of split tail pieces, and cutting at least one of the split tail pieces to form a plurality of short tail pieces. A plate backing material form is provided by a tongue of backing material having a pair of sides which form a long dimension, and a pair of ends which form a short dimension, the ends comprising a proximal end and a distal end. A split tail piece is attached to the tongue along each of the sides and layers of short tail pieces are attached to the tongue adjacent to the distal end. To make a hat, a plurality of fur plates are attached to the crown of a hat shell by attaching the proximal ends of the tongues to the crown so that the tongues overlap and form a ring bounded by the fur on the sides.

Owner:MILLER ARMIN

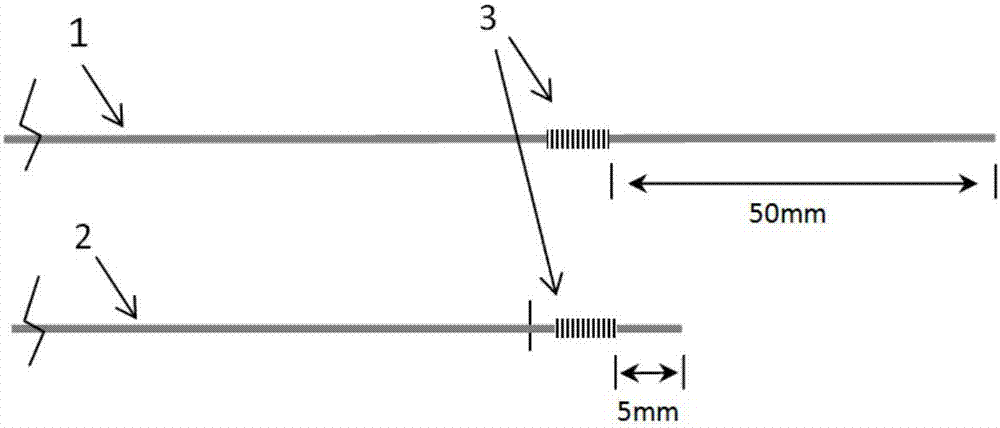

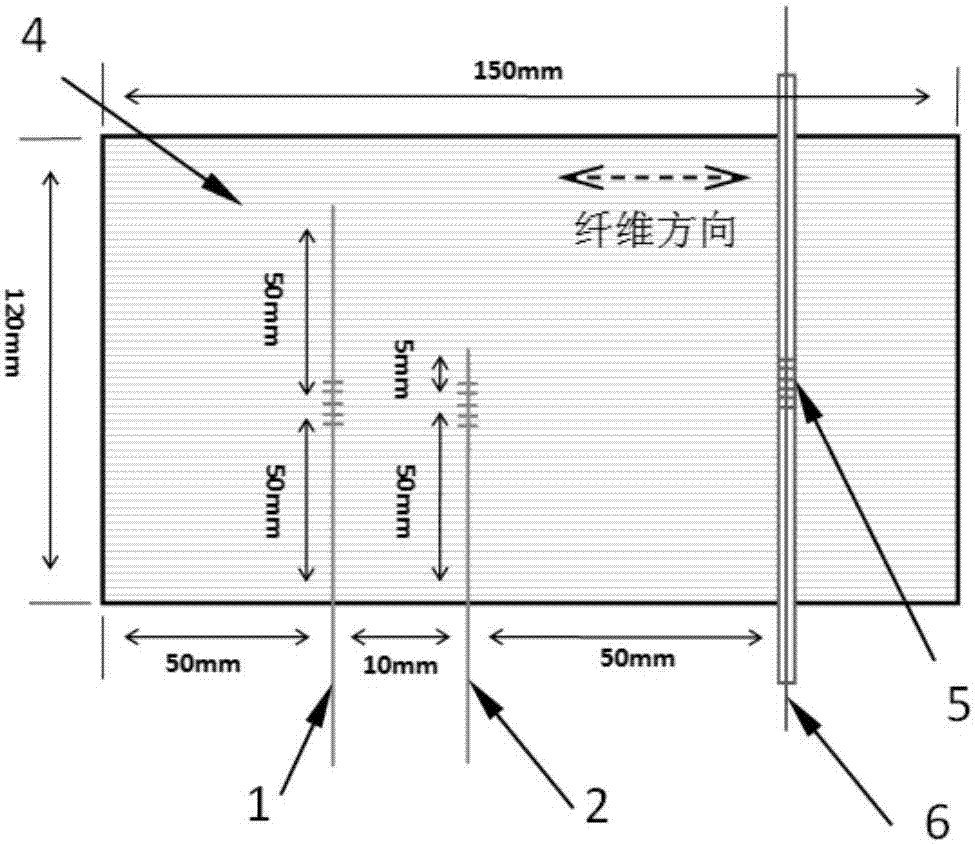

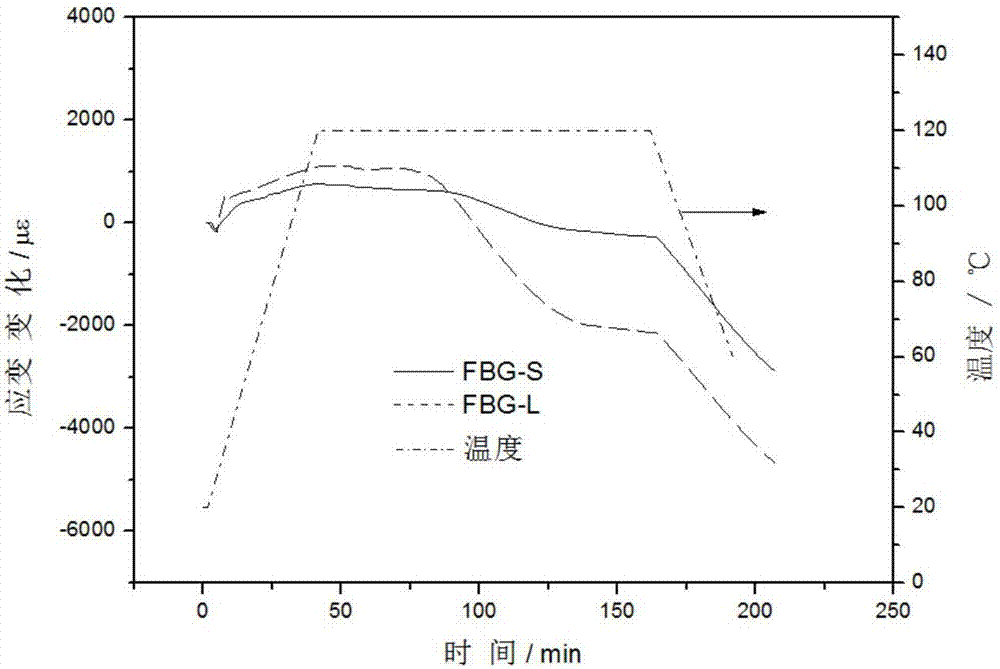

Method of monitoring effective chemical shrinkage rate of thermoset composite in real time

InactiveCN107367523ARealize real-time monitoringOptimizing the curing processMaterial thermal coefficient of expansionUsing optical meansGratingFiber Bragg grating

The invention provides a method of monitoring an effective chemical shrinkage rate of a thermoset composite in real time. The method comprises the following steps of: 1) selecting a truncated FBG (fiber bragg grating) group and a temperature reference grating, burying the truncated FBG group and the temperature reference grating in a unidirectional laminate of the thermoset composite, 3) performing curing molding, recording central wavelength variations of the truncated FBG group and the temperature reference grating in a curing process at the same time, 4) subtracting a central wavelength variation value of the temperature reference grating from central wavelength variation values of a long-tail FBG sensor and a short-tail FBG sensor, then dividing by a strain sensitivity coefficient to form strain variations of the long-tail FBG sensor and the short-tail FBG sensor, and 5) selecting a gel point and a glass transition point, and taking a strain variation value monitored by the long-tail FBG sensor between the gel point and the glass transition point at constant temperature stage in the curing process as the transverse effective chemical shrinkage rate of the composite, wherein the truncated FBG group comprises the long-tail FBG sensor and the short-tail FBG sensor. The method is simple, practicable and high in testing accuracy.

Owner:WUHAN UNIV OF TECH

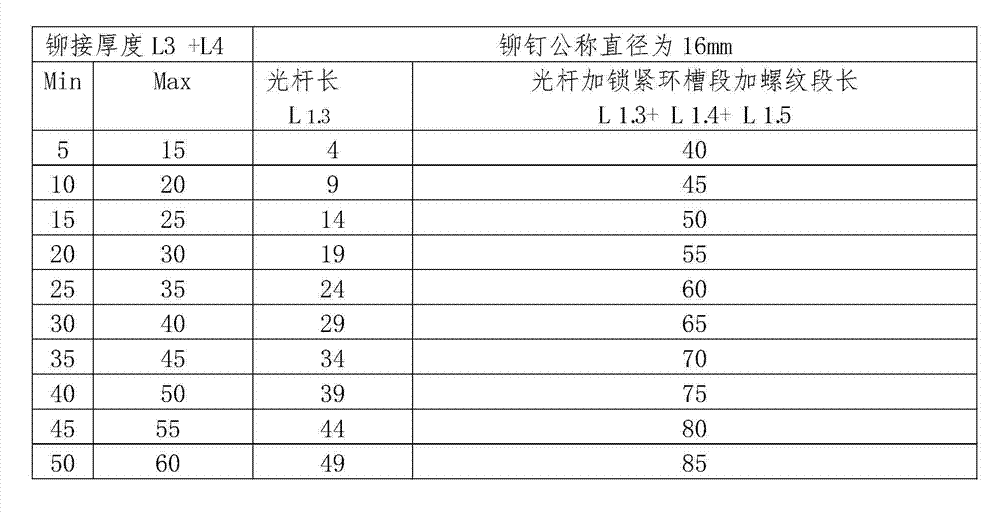

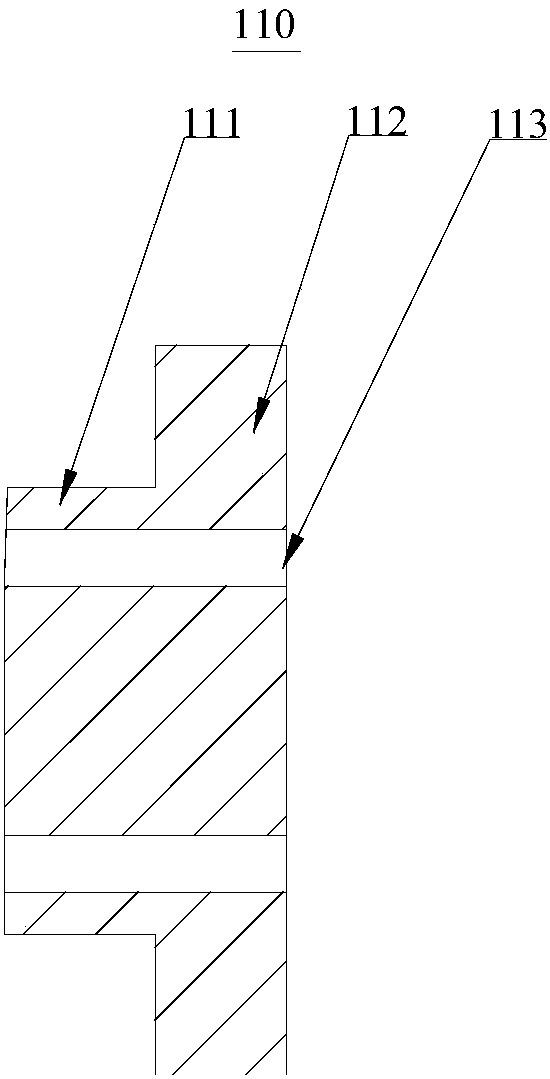

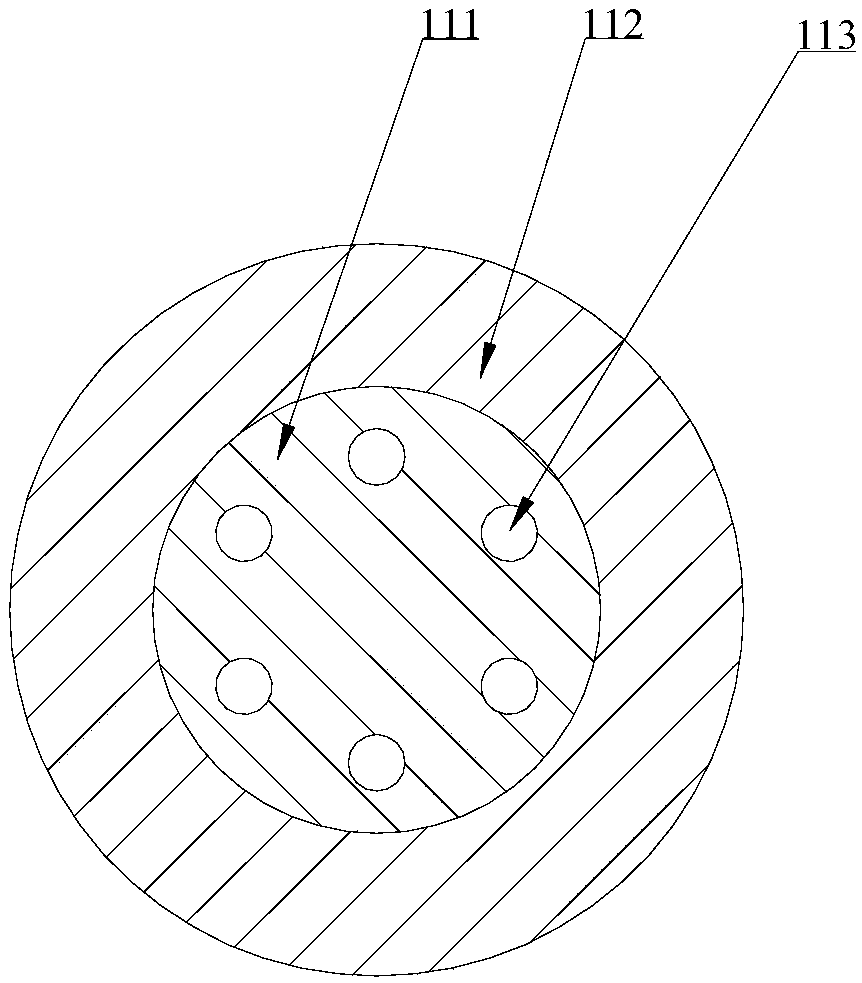

Bobtail tension rivet and riveting method

The invention discloses a short-tail tension rivet and a riveting method thereof. The tension rivet consists of a rivet head, a rivet rod and a sleeve ring. The rivet rod is provided with a feed rod section, a ring groove section which is extruded and matched with the sleeve ring, and a short and thin ring groove section clamped by a riveting device collet from the front to the back. Compared to the prior tension rivet, a separating groove on the rear end of the tension rivet and a groove section tension rod are removed, so that the rivet rod is shortened and the material is saved by one third; when the rivet is riveted, the separating groove can not be broken; the riveting steps are reduced from the prior four steps to three steps, and the riveting is accelerated; and riveting can not cause impact, and the assembling place has no noise. If the prior same riveting device and the riveting stroke are adopted, the length of the ring groove section or a thread section can be lengthened correspondingly, so that rivets with the same specification can be applied to multiple riveting thicknesses, and the range of application is widen. The rear end of an inner hole of the sleeve ring for thread riveting is provided with a small section of screw thread; before the start of the riveting device, the sleeve ring is rotated manually and moved advance on the screw thread section, and positioned and sleeved on the screw thread section, so that when the riveting device is operated by operating staff for next step, the sleeve ring is not required to be held manually, and further the rivet is riveted relaxedly, conveniently and quickly. The screw thread and the groove riveting can be selected according to occasions.

Owner:CRRC MEISHAN

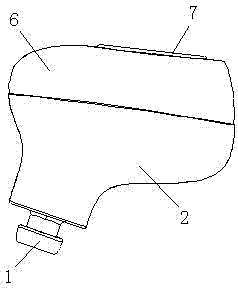

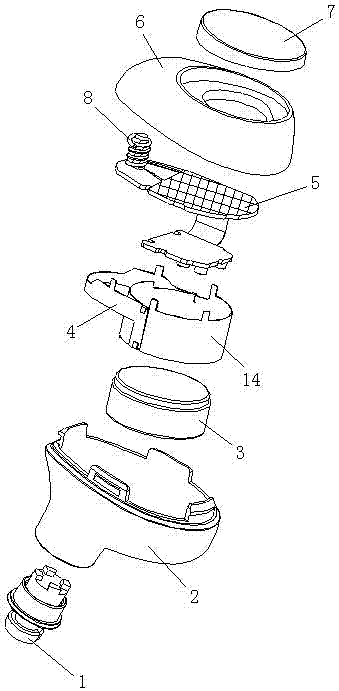

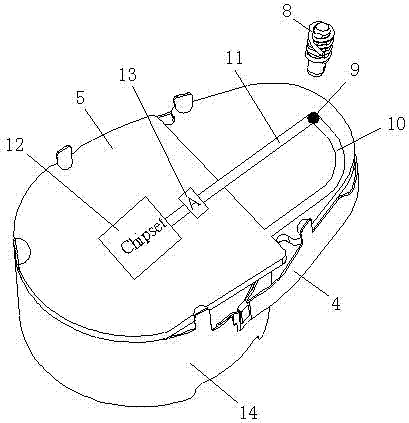

Wireless earphone using short-tail helical antenna and short-circuited L-shaped radiator

InactiveCN107331953AZero reductionIncrease ground areaAntenna supports/mountingsRadiating elements structural formsCapacitanceCapacitive effect

The invention discloses a wireless earphone using a short-tail helical antenna and a short-circuited L-shaped radiator. The wireless earphone comprises a circuit board, a battery, a loudspeaker, a housing, a switch button and an antenna system. The antenna system comprises the short-tail helical antenna and the short-circuited L-shaped radiator. The short-circuited L-shaped radiator is an L-shaped structure. An input point is arranged on a circuit board. The short-tail helical antenna is connected with the input point in a spiral structure and the short-circuited L-shaped radiator is also connected with the input point. The input point is connected with a wireless module through a transmission line. The wireless earphone is provided with the short-tail helical antenna and the short-circuited L-shaped radiator in an orthogonal structure so that a diversity effect can be formed and can reduce the number of zero points of the antenna to greatly enhance the antenna receiving capability of the wireless earphone. In addition, the inductive effect of the short-circuited L-shaped radiator and the capacitive effect of the short-tail helical antenna form a resonant structure to increase the bandwidth of the antenna system, thereby improving the signal receiving performance and the acoustic effect of the earphone.

Owner:FUJIKON INDAL

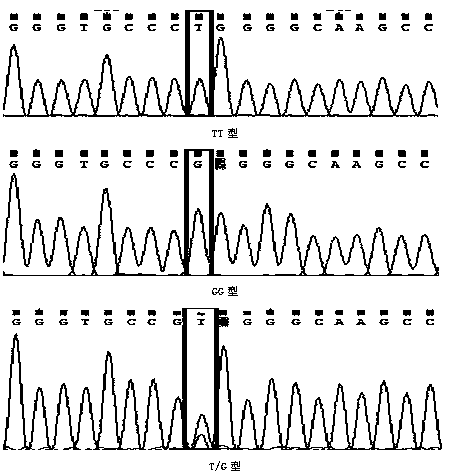

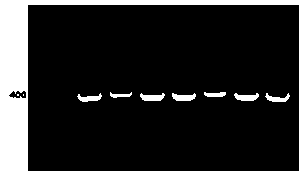

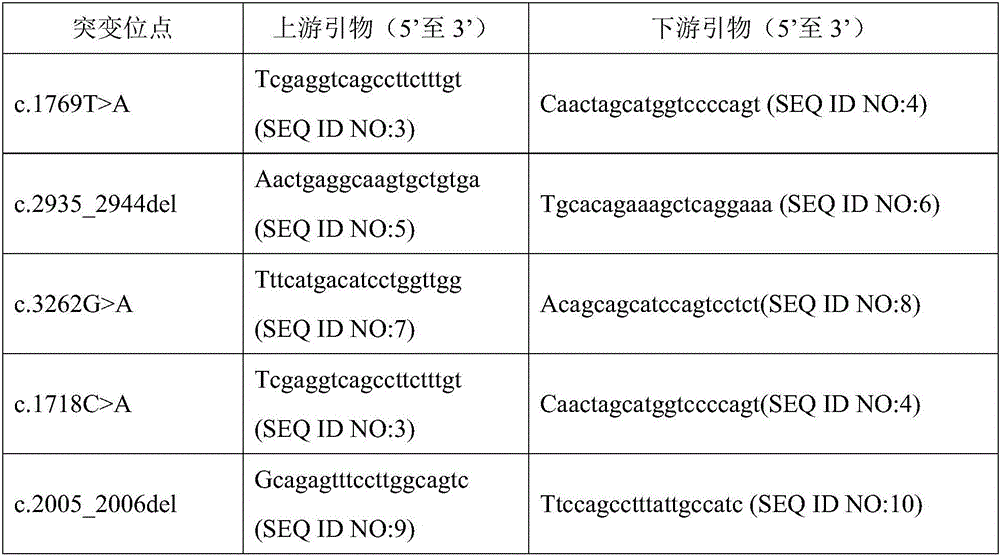

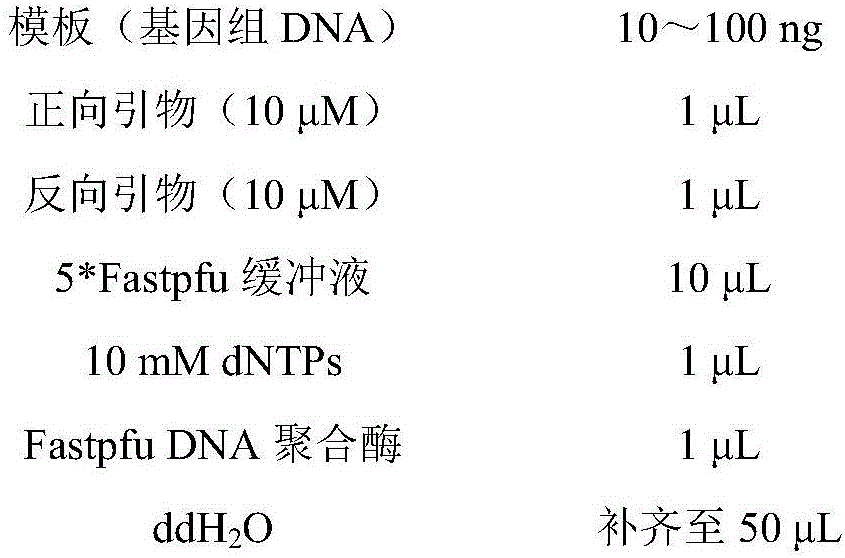

SNP marker related to tail type trait of fat tail type sheep, and applications thereof

ActiveCN108384859ASpeed up the breeding processAn Accurate and Reliable Method for Detecting Single Nucleotide Polymorphism of T Gene in Fatty-tailed SheepMicrobiological testing/measurementDNA/RNA fragmentationTailRestriction fragment length polymorphism

The invention relates to a SNP marker related to the tail type trait of fat tail type sheep, and applications thereof, and belongs to the biological field, wherein the SNP marker is located at the 87804589-th base pair of sheep chromosome 8, the sheep with the base of T at the locus has the short tail trait, and the sheep with the base of G has the normal tail length. The invention further provides primers for detecting the SNP marker, a kit containing the primers, and applications of the SNP marker in identification of the tail type trait of lipid tail type sheep and in breeding of Chinese sheep, wherein the SNP marker related to the tail type trait of fat tail type sheep is screened by using a polymerase chain reaction (PCR) and a sequencing technology, and the genotype of to-be-detectedsheep is detected through a restriction fragment length polymorphism (RFLP) method. According to the present invention, with the SNP marker, the breeding of the dominant species with the tail type trait of fat tail type sheep is performed according to the genotype so as to accelerate the breeding process of the fat tail type sheep.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

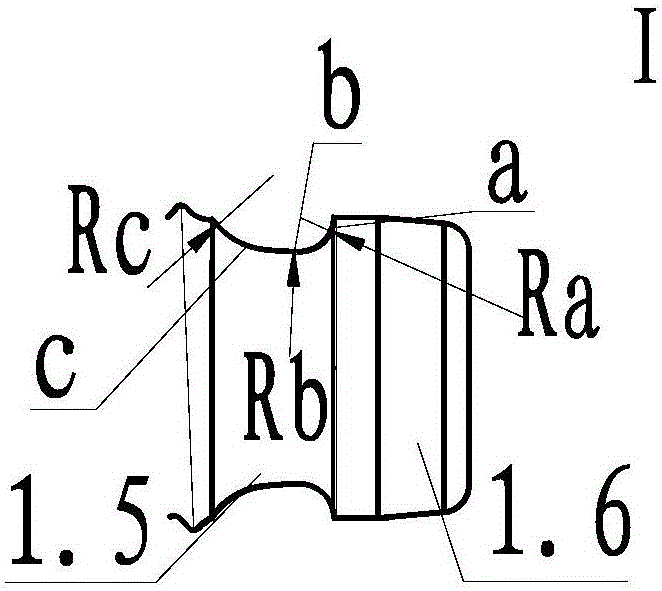

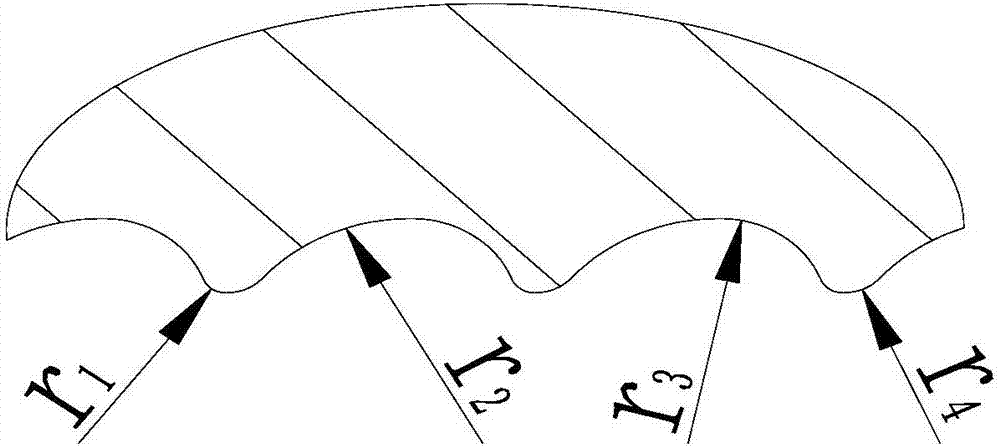

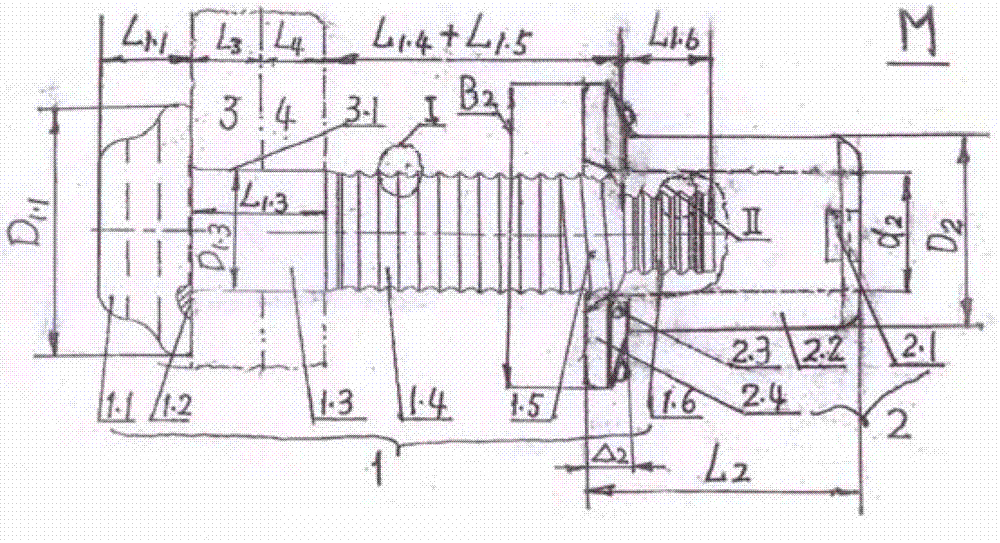

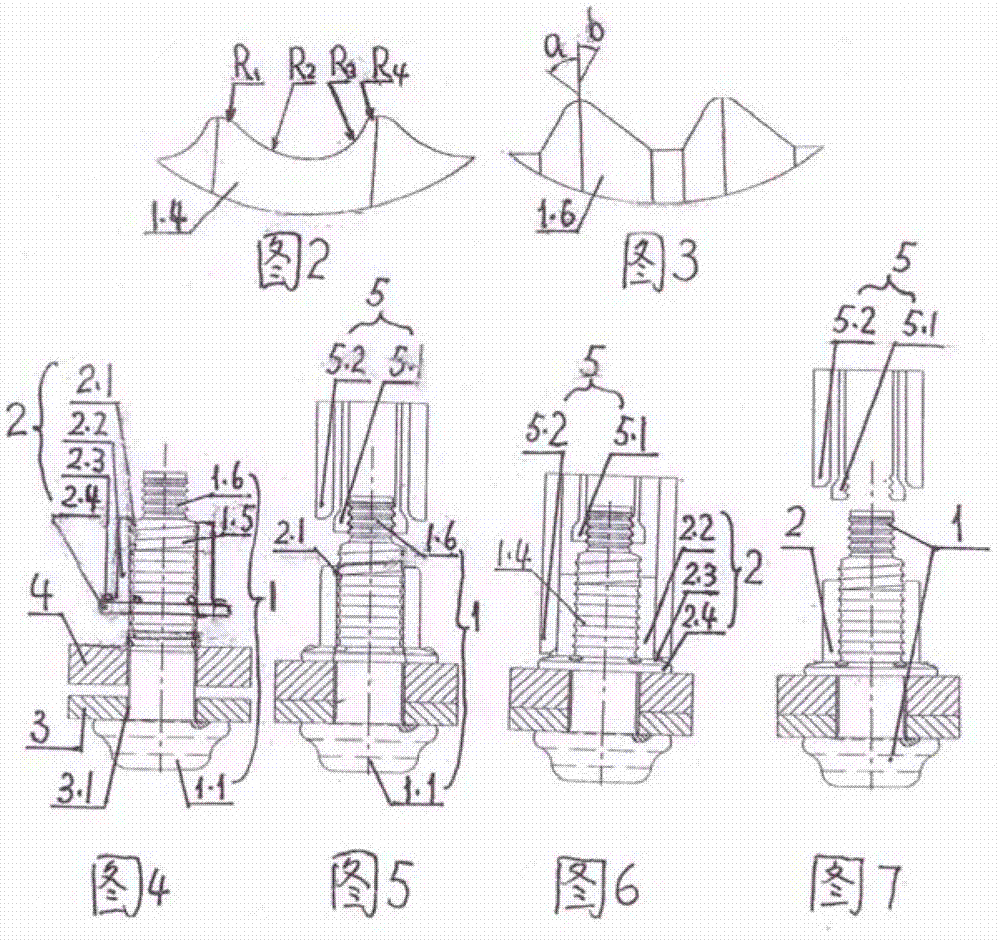

Dismountable high-intensity pull riveting pin and connecting and dismounting method

ActiveCN106351929AEasy to manufactureReduce manufacturing costRivetsScrewsStress concentrationHigh intensity

The invention relates to a dismountable high-intensity pull riveting pin and a connecting and dismounting method. The pull riveting pin consists of a cap, a pin post, a short polished rod, a locking groove section, a tail pin shaft, a sleeve ring and a gasket. The single-groove short tail with a continuous smooth arc surface pull groove is designed; the manufacturing is easy; the cost is low; the installation is convenient; three sections of circular arc surfaces with different radii are used. The problems of riveting stress concentration and clamping of the tail are solved. During the riveting, the end surface is positioned; the clamp claw is automatically engaged to the optimum position; the locking groove section thread type is a curve combining a circular arc with a straight line; the fastening force is greatly enhanced. A dismounting groove is formed in the root part of the cap, so that the cap fracturing and falling due to root part stress concentration are effectively prevented. The depth of a hardening layer on the surface of the pin post is 2 to 6mm; the surface hardness and the wear resistance are effectively improved; the service life is prolonged. The pin shaft short tail which cannot be broken through pulling and the high-intensity pin post are used for realizing the sleeve ring cutting of a cutting device; the dismounting is convenient; the repeated use of the pin shaft is convenient; the utilization rate is improved; the use and maintenance cost is reduced; the dismountable high-intensity pull riveting pin is used for the connection and the dismounting in positions of antitheft locks of hinging structures, horseshoe-shaped hinging pulleys on a train and the like.

Owner:MEISHAN CRRC FASTENING SYST CO LTD

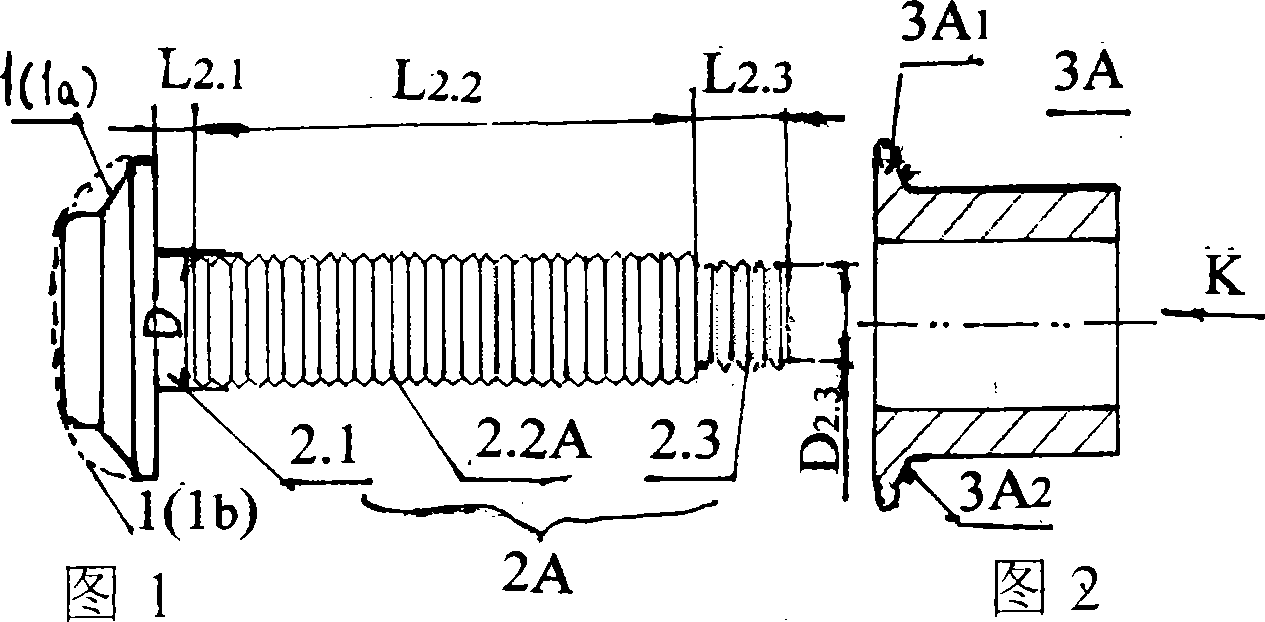

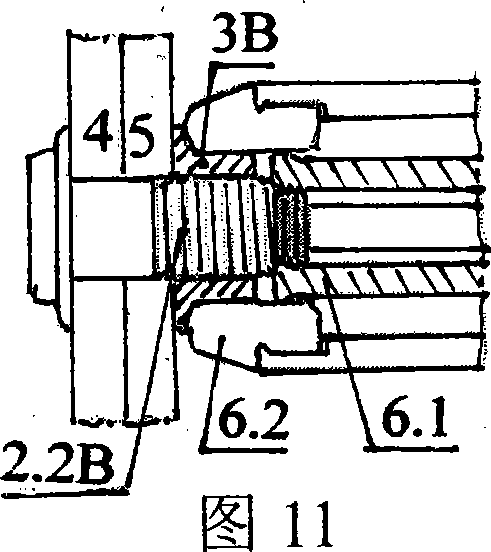

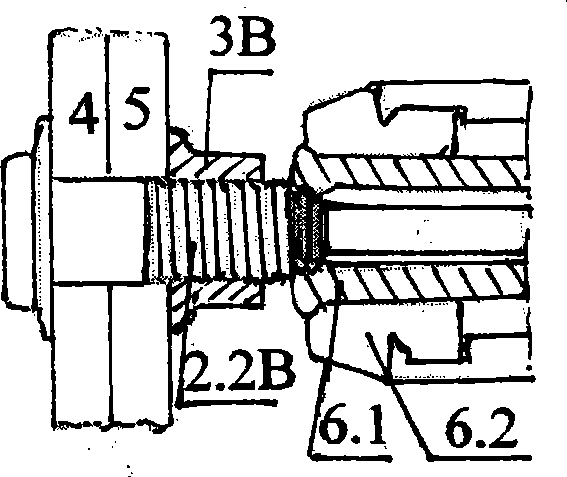

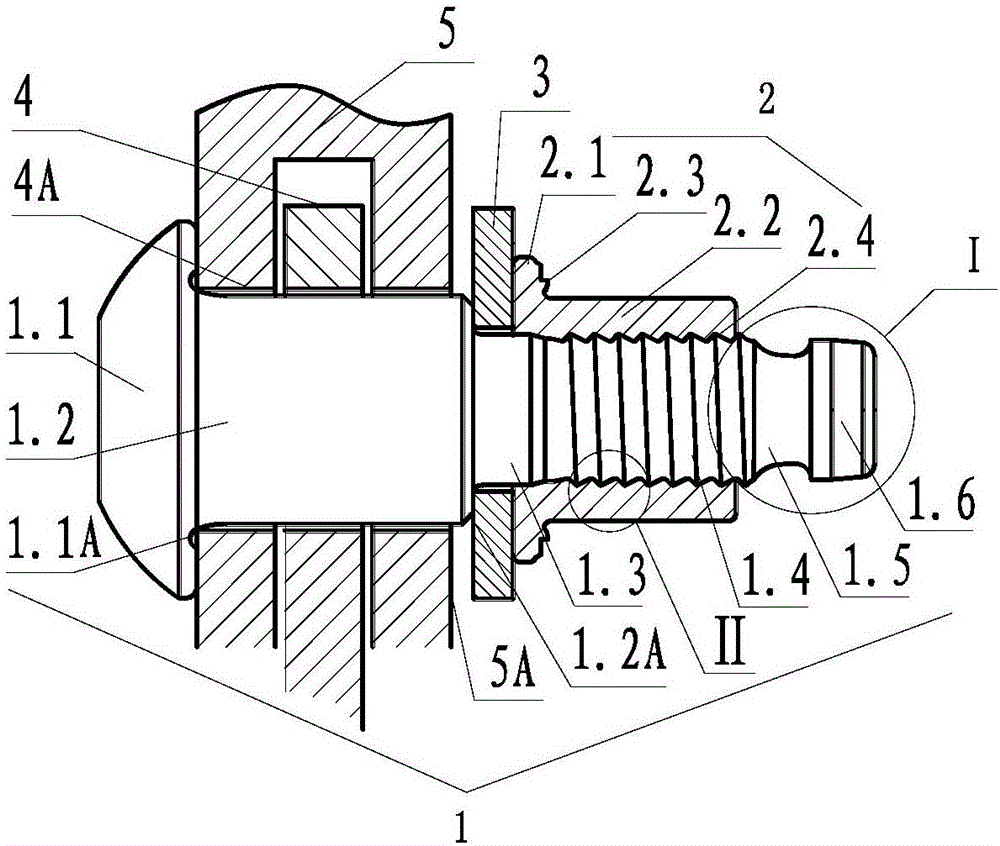

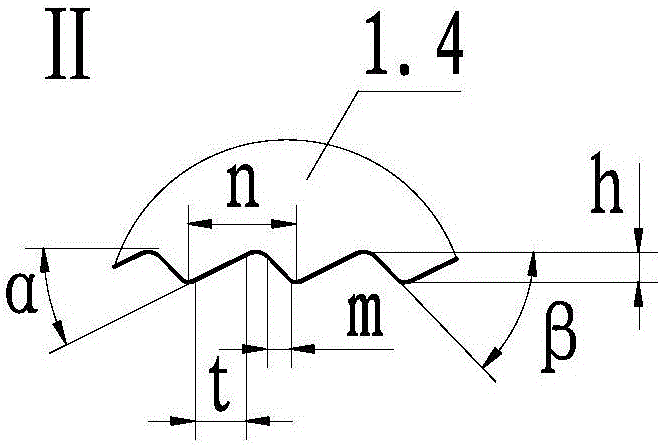

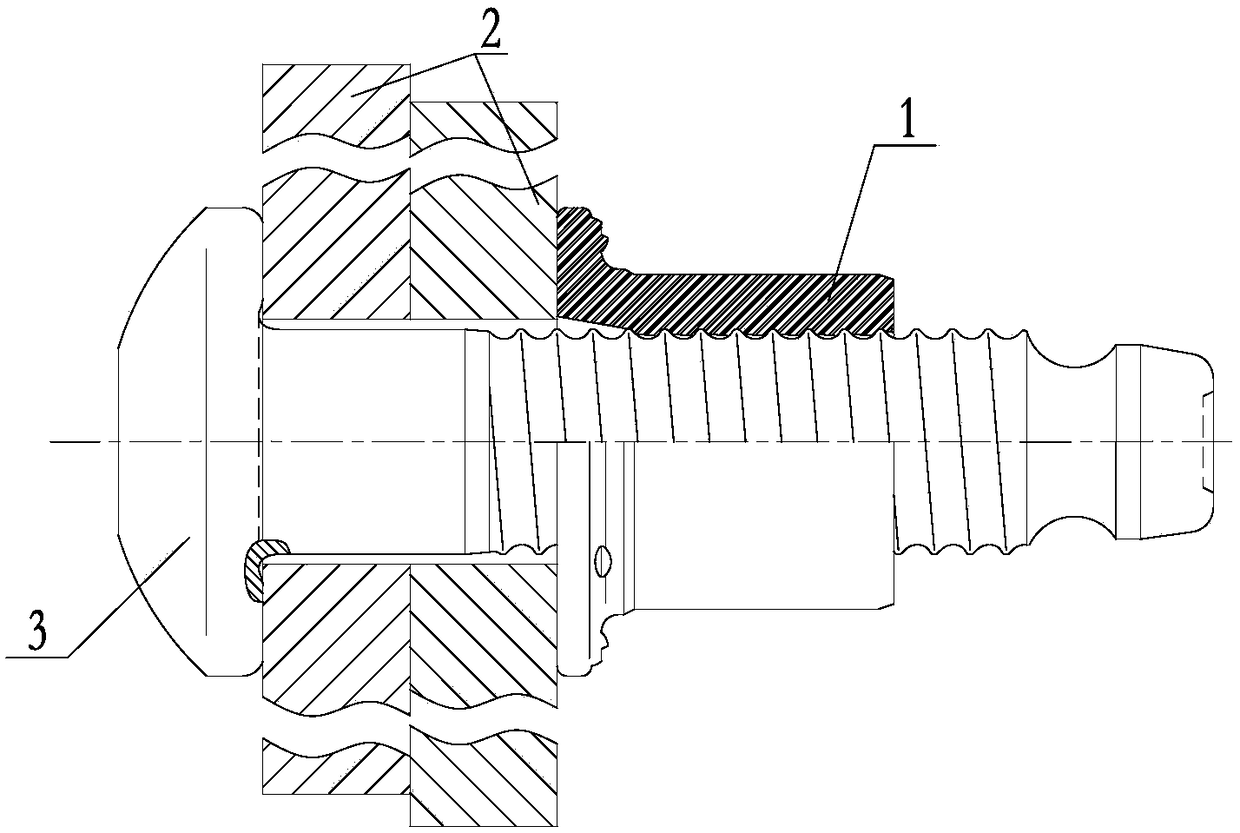

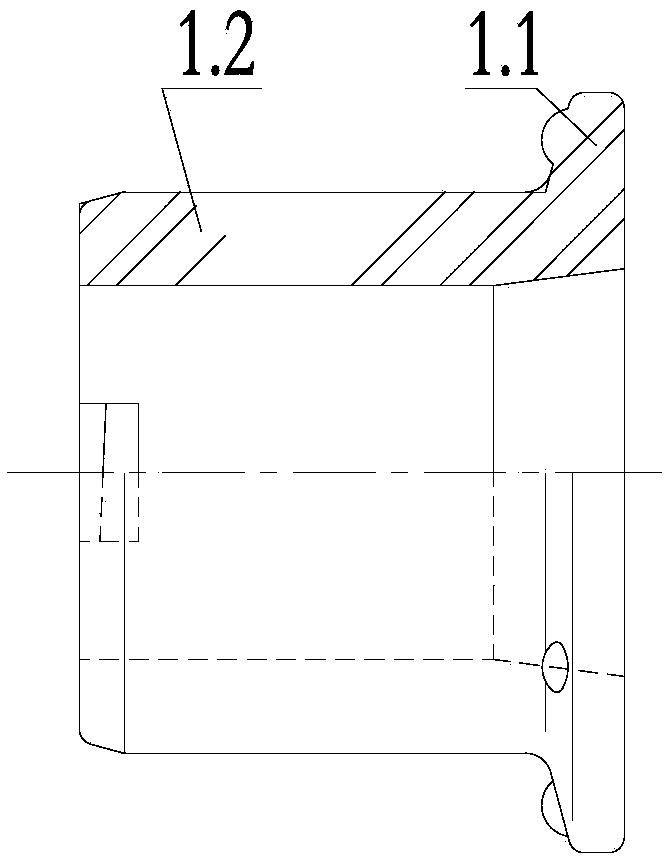

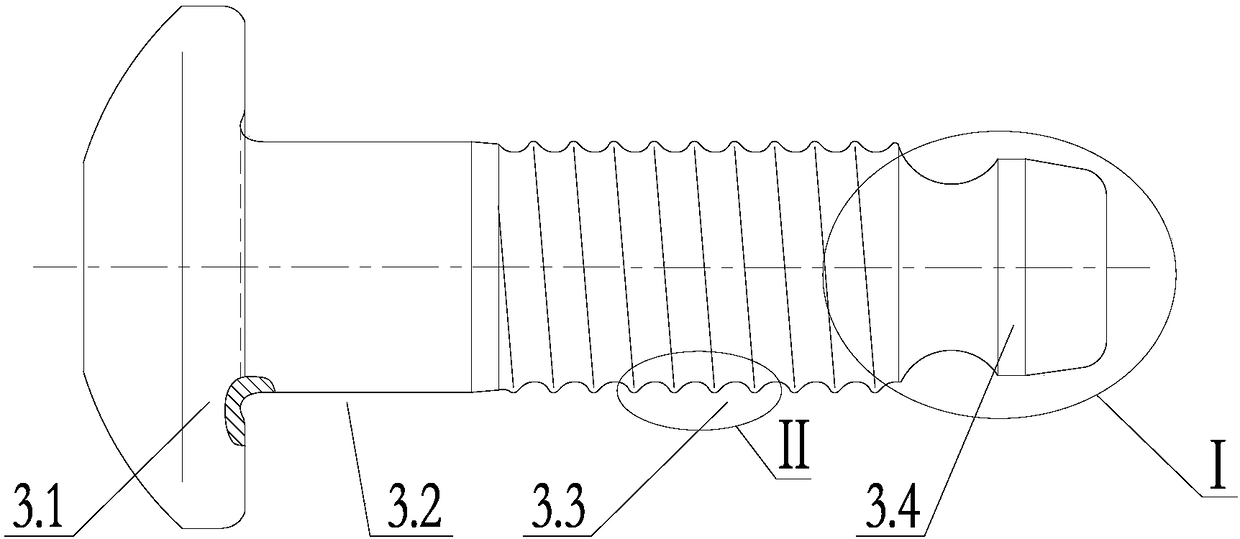

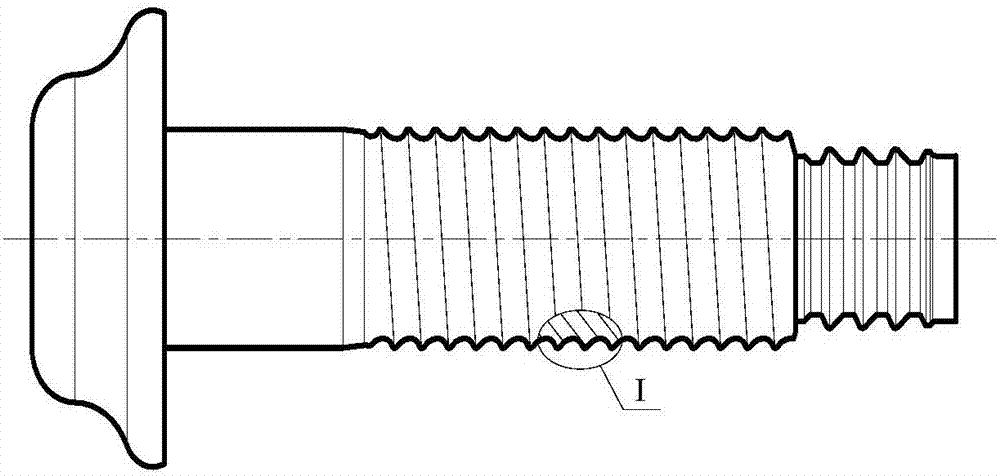

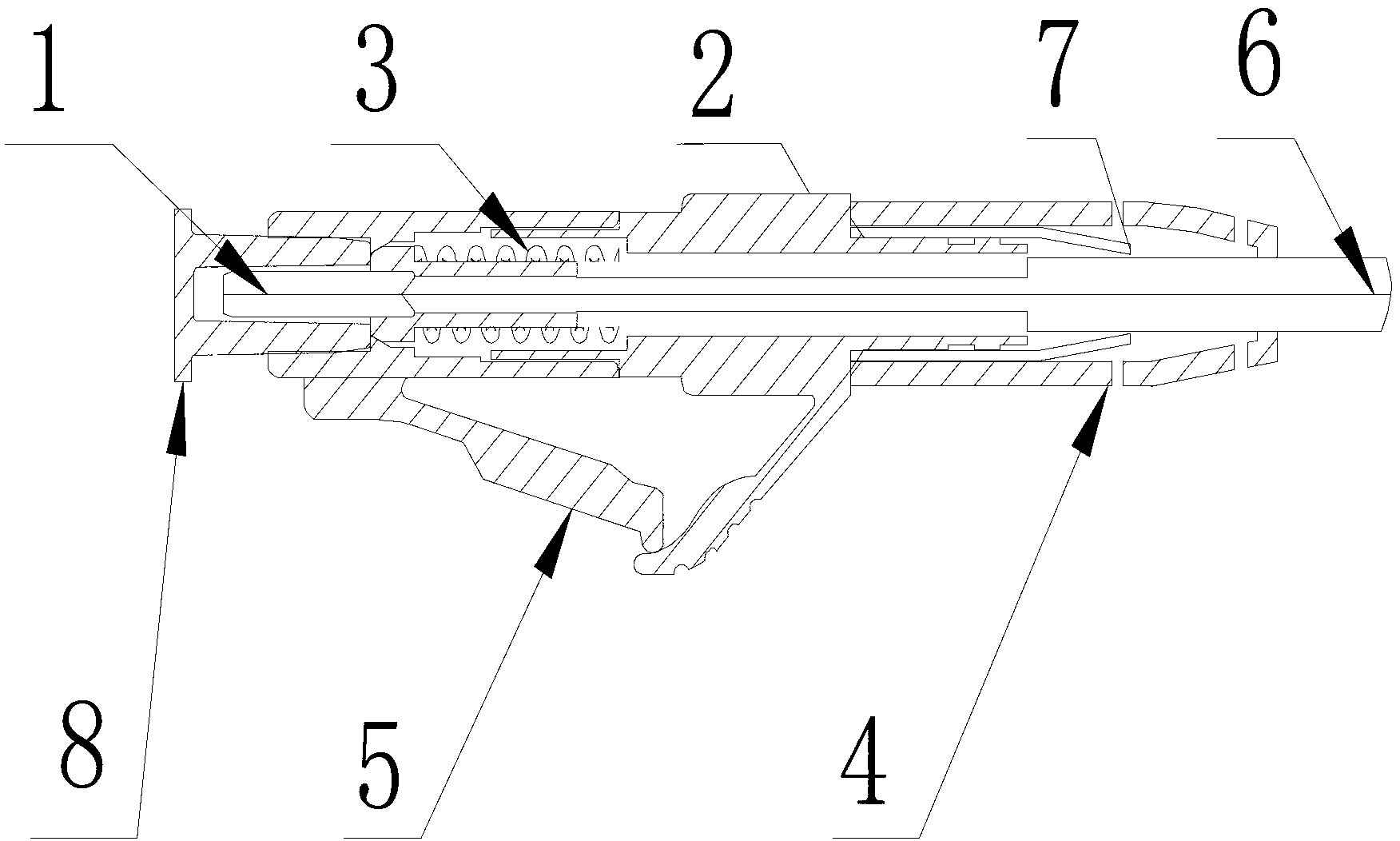

Short tail rivet pulling fastening suite, disassembly and assembly tool and using method of disassembly and assembly tool

PendingCN108131373AImprove the installation effectImprove wear resistanceRivetsNutsStress concentrationEngineering

The invention relates to the technical field of machining and discloses a short tail rivet pulling fastening suite, a disassembly and assembly tool and a using method of the disassembly and assembly tool. The short tail 3.4 rivet pulling fastening suite comprises a short tail 3.4 bolt and a sleeve ring 1. The disassembly and assembly tool comprises a mounting tool 4 and a disassembly tool 5. Whenconcretely in use, fixation and removal of the sleeve ring 1 on the short tail 3.4 bolt are realized through the disassembly and assembly tool to realize mounting and taking off of a component 2. By adopting the short tail 3.4 rivet pulling fastening suite, the basic requirements for rapid mounting and precision positioning of the short tail 3.4 rivet pulling bolt are met, the reliability and thestability of a short tail 3.4 structure and an elastic block button 4.2 in the application process; and the problems of difficulty in processing during production and difficulty in positioning in themounting process of the existing short tail 3.4 rivet pulling fastener are solved, the clamping force of a short tail 3.4 is improved, the stress concentration effect is lowered, and the service lifeof the elastic block button 4.2 is prolonged, and therefore, the short tail rivet pulling fastening suite is worthy of popularization and use.

Owner:张丽

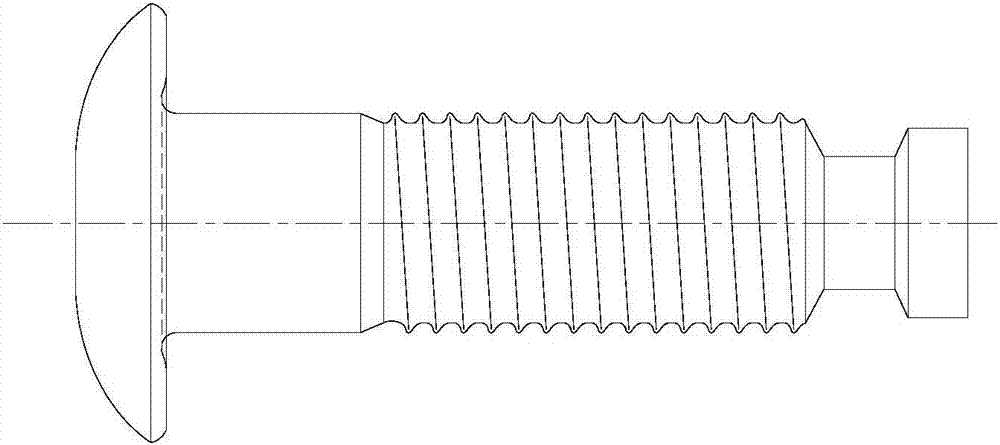

Short tail pulling rivet and detaching method thereof

PendingCN107218280AQuick installationNo stress concentrationRivetsScrewsStress concentrationEngineering

The invention discloses a short tail pulling rivet. The short tail pulling rivet comprises a rivet and a sleeve ring, wherein the rivet is matched with the sleeve ring. The rivet comprises nail heads, a polished rod, a ring-shaped locking part and a short tail, wherein the nail heads, the plished rod, the ring-shaped locking part and the short tail are connected sequentially. The short tail comprises a locking part and an expansion clamping part, wherein the locking part is connected with the ring-shaped locking part, the locking part is connected with the expansion clamping part and the ring-shaped locking part through an arc-shaped transition structure. During working, the locking part of the short tail and a axial positioning locking end face of a clamping claw in a installing tool are locked together, and the expansion clamping part of the short tail is matched with an inner concaved type spherical profiling part of the clamping claw; under axial limiting effects of the locking part of the short tail and the locking end face of the clamping claw, the clamping claw is engaged with the short tail completely, the installing tool and the sleeve ring are automatically positioned and aligned, and meanwhile stress concentrating effect of the rivet during the installing process is reduced, so that the short tail pulling rivet is effectively protected against damaging, and installing efficiency is improved at the same time. The invention further discloses a detaching method for the short tail pulling rivet.

Owner:SHANGHAI AUTOCRAFT

Discharge gas ejection dust emission device and its silencer

ActiveCN101285413ASave spaceTo achieve a parallel setupExhaust apparatusSilencing apparatusInterior spaceExhaust fumes

The invention discloses an exhaust gas ejection dust exhaust device and a muffler, comprising a muffler shell on which an inlet pipe, an ejection pipe and an outlet pipe are arranged, an inlet part of the ejection pipe is arranged out of the main shell of the muffler, the ejection pipe stretches into the muffler shell, and an outlet part of the ejection pipe stretches into a throat pipe. The muffler and the ejection pipe are formed as a whole structure creatively, which makes full use of the internal space of the muffler, realizes ejection dust exhaust with a shorter exhaust tail pipe and forms a novel muffler. The invention has a simple structure, a short tail pipe and has no need for additional fixation; is easy to arrange, low in cost, less in occupation of the whole unit and high in reliability; and can realize parallel arrangement of the ejection pipe, the throat pipe, the inlet pipe and the outlet pipe of the muffler. Moreover, shorter tail pipe (exhaust outlet) helps to produce greater negative pressure and is good in automatic dust exhaust.

Owner:DONGFENG MOTOR CORP HUBEI

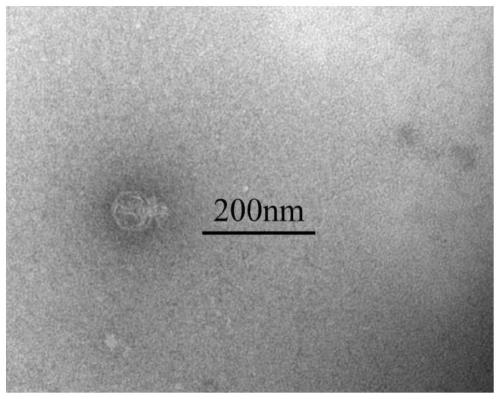

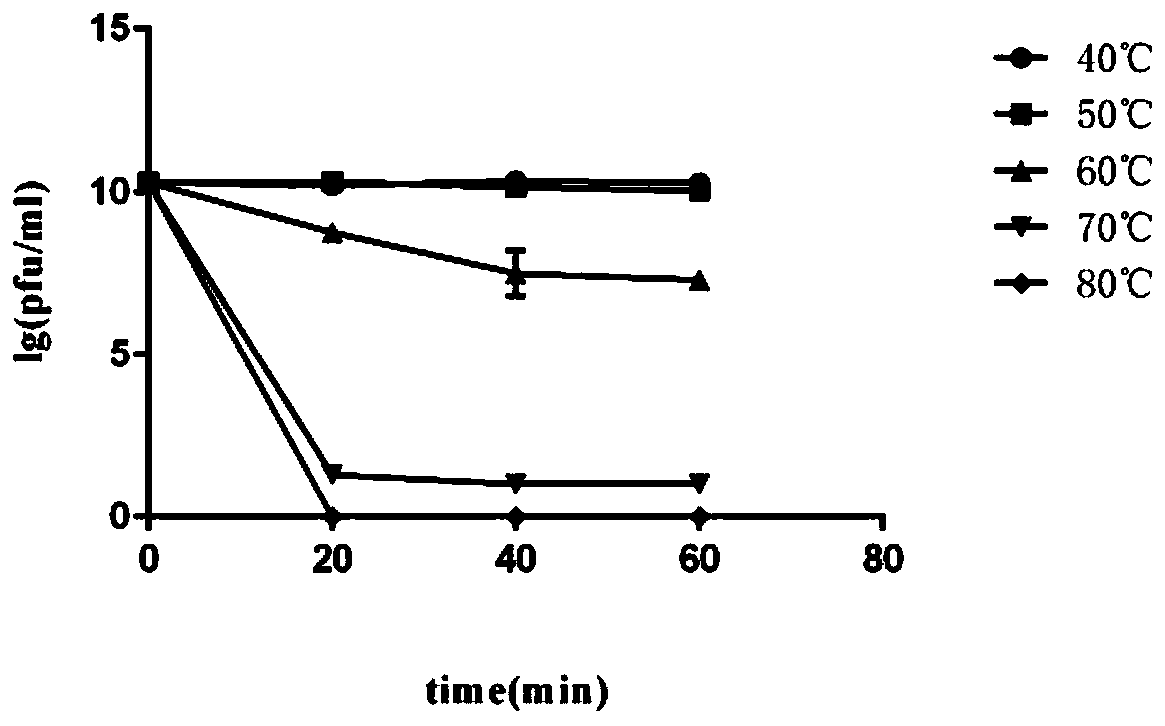

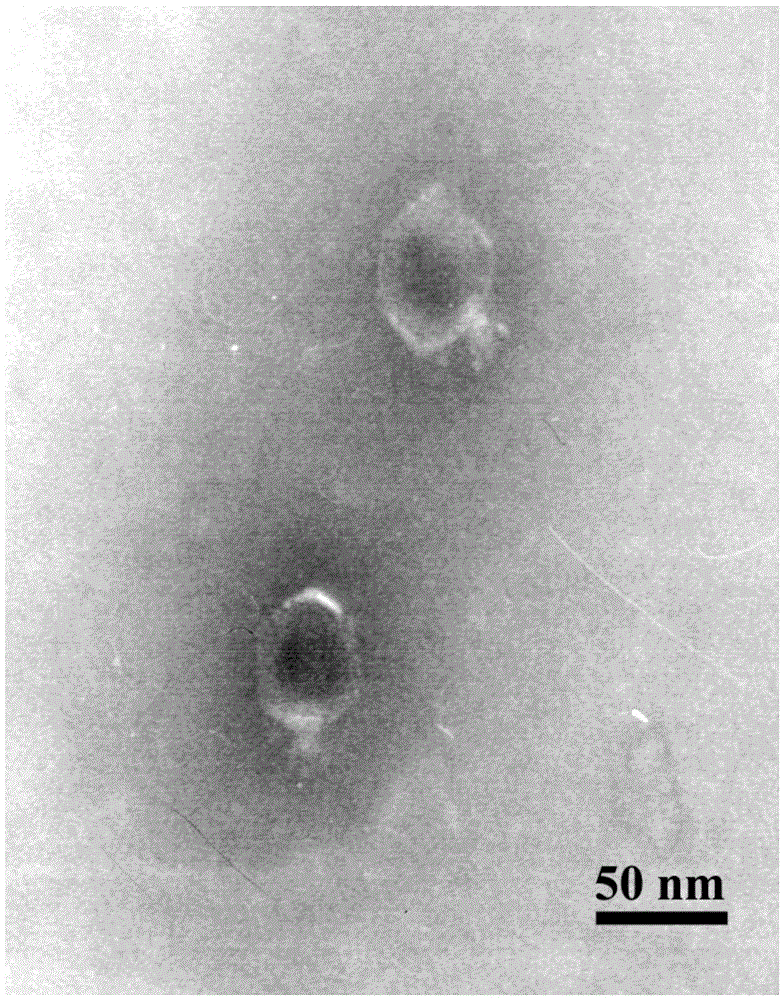

A phage of Vibrio alginolyticus and its application in disease prevention of sea cucumbers

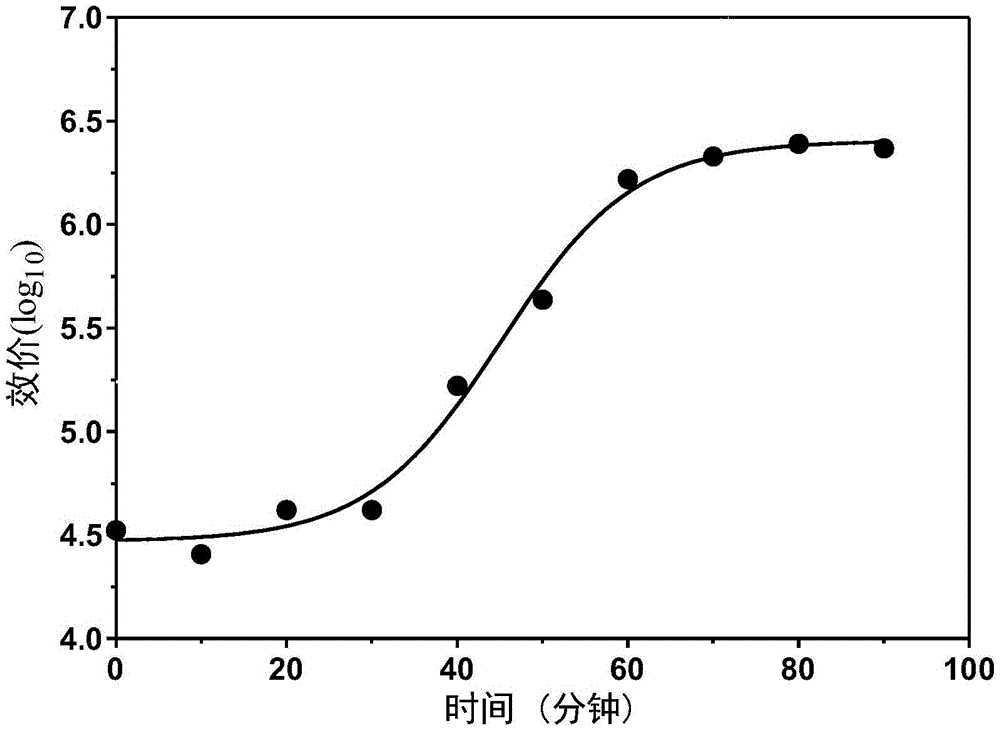

ActiveCN103898015BImprove disinfection effectGood environmental toleranceAntibacterial agentsBacteriaFiberDisease

The invention discloses a vibrio alginolyticus bacteriophage and application thereof to prevention of sea cucumber disease, belonging to the technical field of biology. The bacteriophage is collected in the China General Microbiological Culture Collection Center on March 11, 2014 and has a collection number of CGMCC No.8792 and a classification name of Vibrio alginolyticus bacteriophage; the vibrio alginolyticus bacteriophage is a short-tailed phage, has a head diameter being 50 nanometers and tail length being 15 nanometers, and has no shrinkage tail sheath and six short tail fibers. The bacteriophage is used for preventing infection and pollution caused by corresponding vibrio alginolyticus in the culturing process of sea cucumbers, and the potency is more than or equal to 10<5>PFU / mL. The bacteriophage has an inhibiting function on vibrio alginolyticus, and no vibrio alginolyticus-resistant strain is produced within 12 hours; the incubation period lasts for 28 minutes, the burse size is 79, and two orders of magnitude are lowered within 14 days in a seawater culturing environment.

Owner:DALIAN UNIV OF TECH

Bridge fabrication machine capable of building and assembling two bridge segments

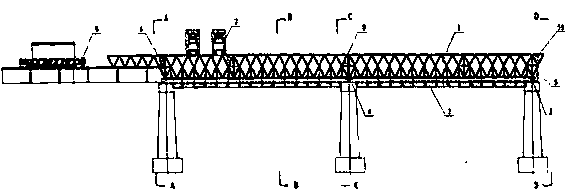

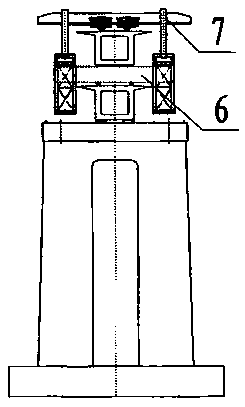

InactiveCN104179123AShorten the construction periodReduce construction costsBridge erection/assemblyPre stressingSpandrel

The invention belongs to the technical field of bridge construction and discloses a bridge fabrication machine capable of building and assembling two bridge segments. The bridge fabrication machine is characterized in that a main beam of the bridge fabrication machine adopts two horizontal truss structure sets, each truss structure set comprises two integrally crossed main truss and a short tail truss segment, a lower joist system is arranged on the lower portion of each the main truss, supporting wheel trains are arranged below the truss structures to support on bridge span piers to be built, and girder cranes are arranged upon the truss structures and longitudinally move along the trusses. The bridge fabrication machine is characterized in that box girder segments preset in a girder fabrication yard beside a bridge site are adopted and conveyed to the tail portion of the bridge fabrication machine by a girder conveying vehicle, then the girder cranes hoist the girder segments in places, concrete wet joints are cast, pre-stressed tendons are tensed to form the bridge, and the bridge fabrication machine punches. The bridge fabrication machine has the advantages such that bearing load is high, two bridge segments are achieved by one punching, construction period is shortened, and construction cost is low and is suitable to construction of simple-supported box girder bridges on high speed railways, passenger special lines or expressways having span of 40m or above.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

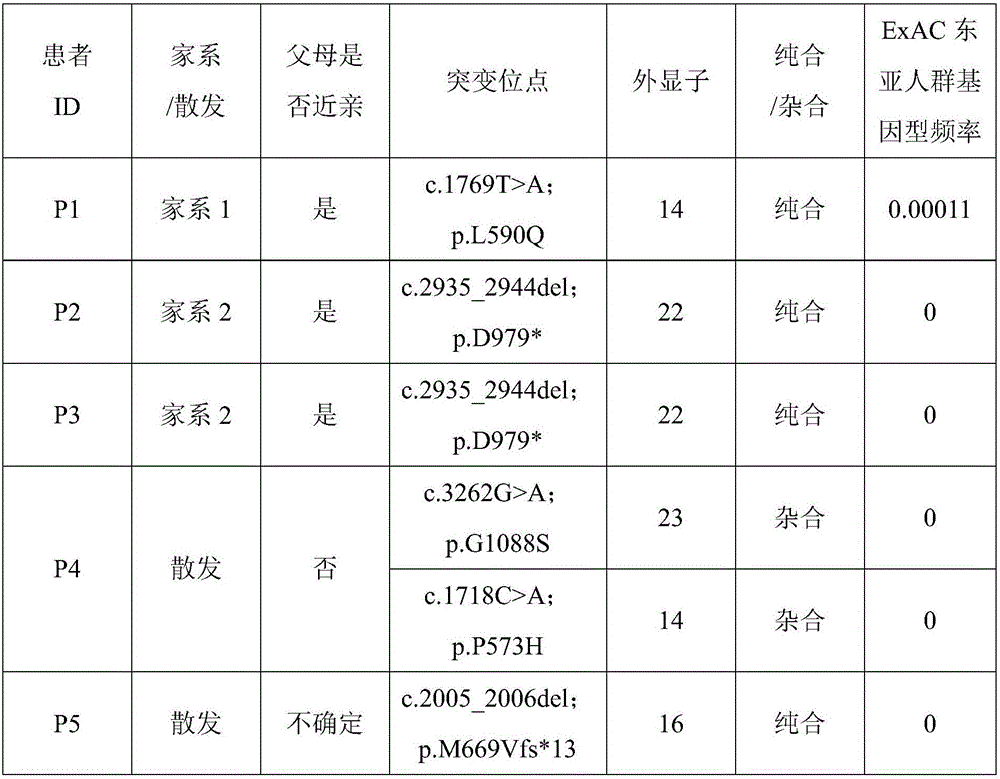

MMAF novel virulence gene and application thereof

The invention discloses an MMAF novel virulence gene and application thereof, and relates to the virulence genes, and the MMAF novel virulence gene CFAP44 is firstly found. A plurality of affected families and affected individuals of the MMAF are taken as study objects for sequencing and comparing exomes of the affected individuals in the families to find that CFAP44 genes of different patients have different gene mutations which are used for detecting short-tail sperms (MMAF).

Owner:厦门市妇幼保健院 +1

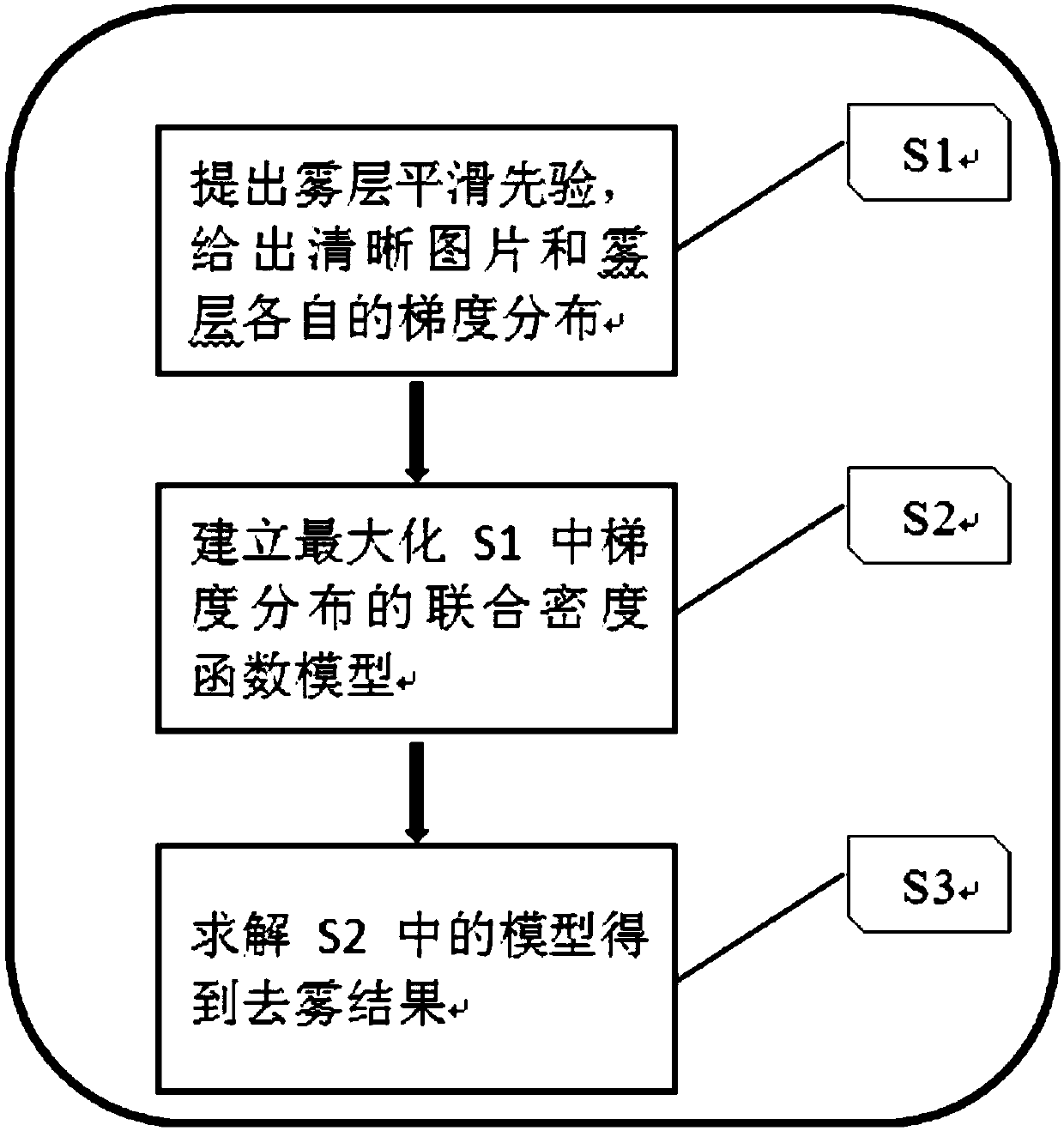

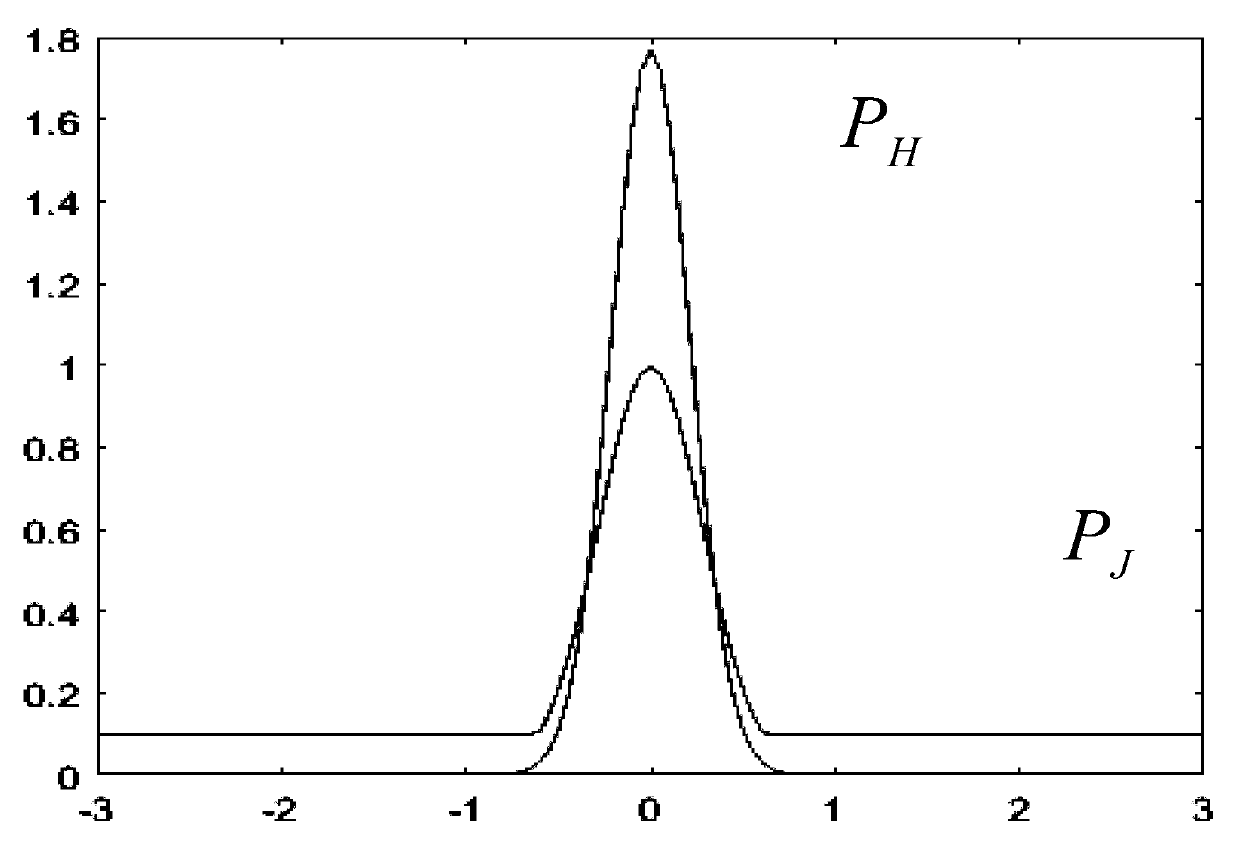

A single picture defogging method based on fog layer smoothing priori

ActiveCN109685735AImprove peak signal-to-noise ratioCharacterize smoothnessImage enhancementImage analysisSingle imagePeak value

The invention discloses a single image defogging method based on fog layer smoothing priori. According to the method, a new fog image composition model is provided according to the daily observation phenomenon, it is considered that formation of a fog image is a degraded image formed by covering a clear image with a fog layer, and therefore the purpose of the invention is to peel the clear image from the fog image. In order to recover a clear picture, fog layer smoothing priori is introduced for constraint. The priori believes that the fog layer covering the clear image is smooth, i.e., the gradient histogram of the fog layer is distributed in a short tail manner. Through analysis, the joint probability density function of the clear image gradient and the fog layer gradient is maximized, the smoothness of the fog layer can be well described, a corresponding model is provided for solving, and finally a defogged result is obtained. According to the method, a new fog graph composition structure is provided, the smooth prior of a fog layer is effectively utilized, the fog layer is separated, a clear image is obtained, and a defogging result with the peak signal-to-noise ratio and the structural self-similarity both higher than those of a current popular method is obtained.

Owner:WENZHOU UNIVERSITY

Short tail recovery techniques in wire bonding operations

ActiveUS9165842B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringMechanical engineering

Owner:KULICKE & SOFFA IND INC

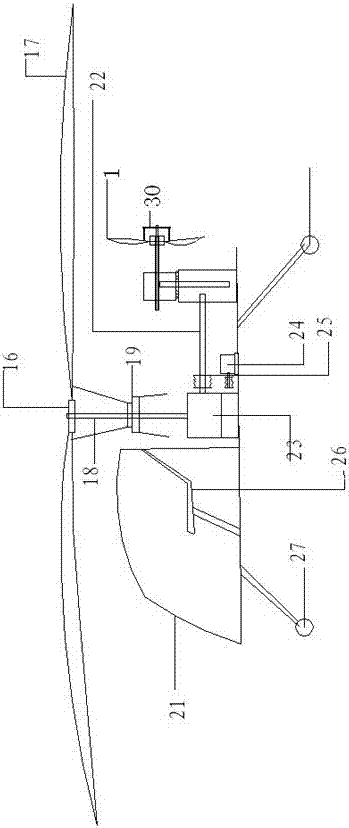

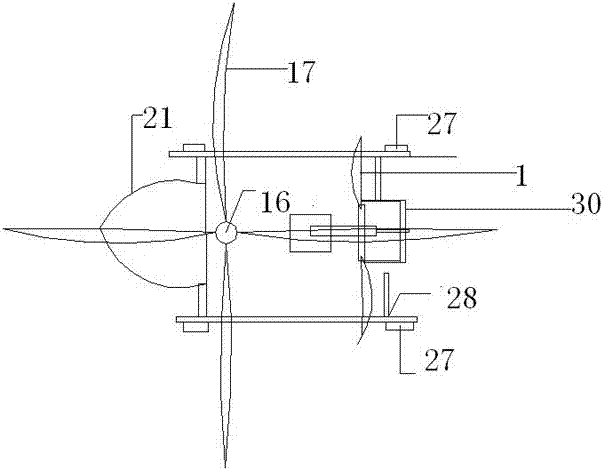

Short-tail vertical-lifting gyroplane

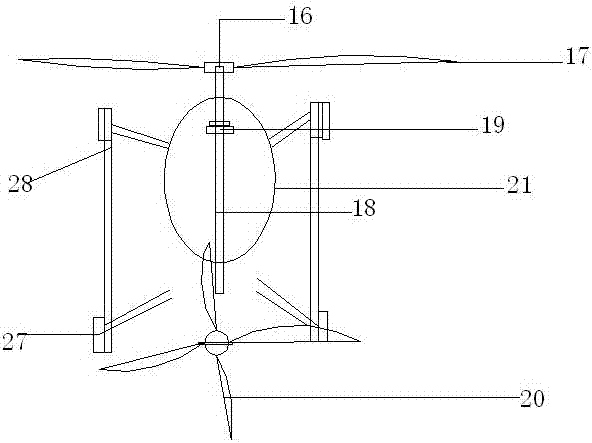

InactiveCN107303948AIncrease cruising speedDanger of rapid escape from the vortexRotocraftGear wheelTail rotor

The invention relates to a short-tail vertical-lifting gyroplane. The short-tail vertical-lifting gyroplane comprises a cabin, a single-layer main rotor wing, a range-variable propeller hub, a first vertical shaft, an automatic tilting disc, a main speed reduction box, an engine, a tail propeller assembly, undercarriage rollout wheels and a stander, wherein a rotating shaft of the engine is connected with the first vertical shaft and the tail propeller assembly through the main speed reduction box. According to the short-tail vertical-lifting gyroplane, a tail propeller structural assembly is mounted at the rear part of the helicopter, and the vertical lifting of the airplane can be realized by virtue of the tail propeller structural assembly; in a suspension process, tail propellers blow air to one side of a gyroplane body so as to defense the auto-rotation of the gyroplane body; when the helicopter flies forwards during cruising, the tail propellers gradually blow air backwards so as to provide power to an auto-rotation gyroplane; and by utilizing the tail propellers, the advantages on appearances and functions of the auto-rotation gyroplane and the vertical-lifting gyroplane can be integrated into one gyroplane model, so that the gyroplane has the advantages of namely short tail and safety of the auto-rotation gyroplane as well as the advantages of the vertical-lifting gyroplane that the vertical lifting, translation and suspension can be realized, and the gyroplane can fly to any direction and does not need to rollout.

Owner:刘凤华

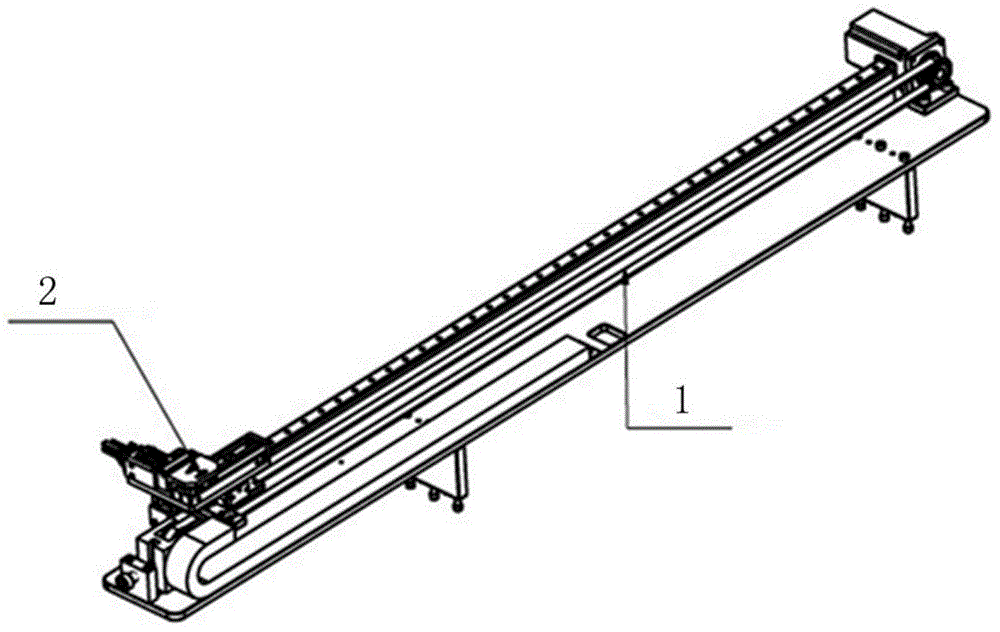

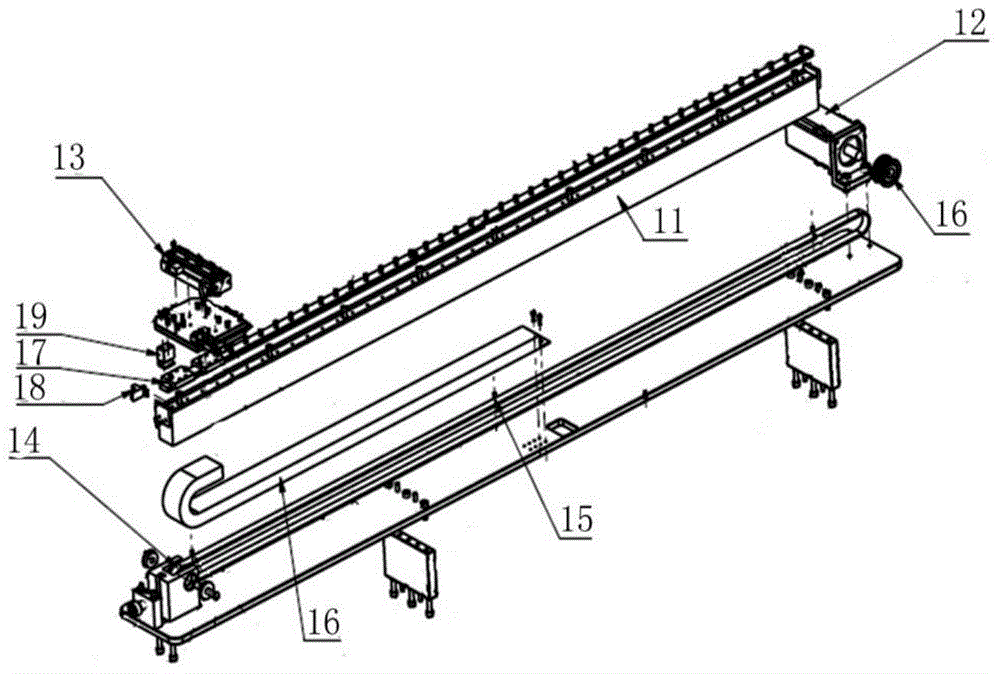

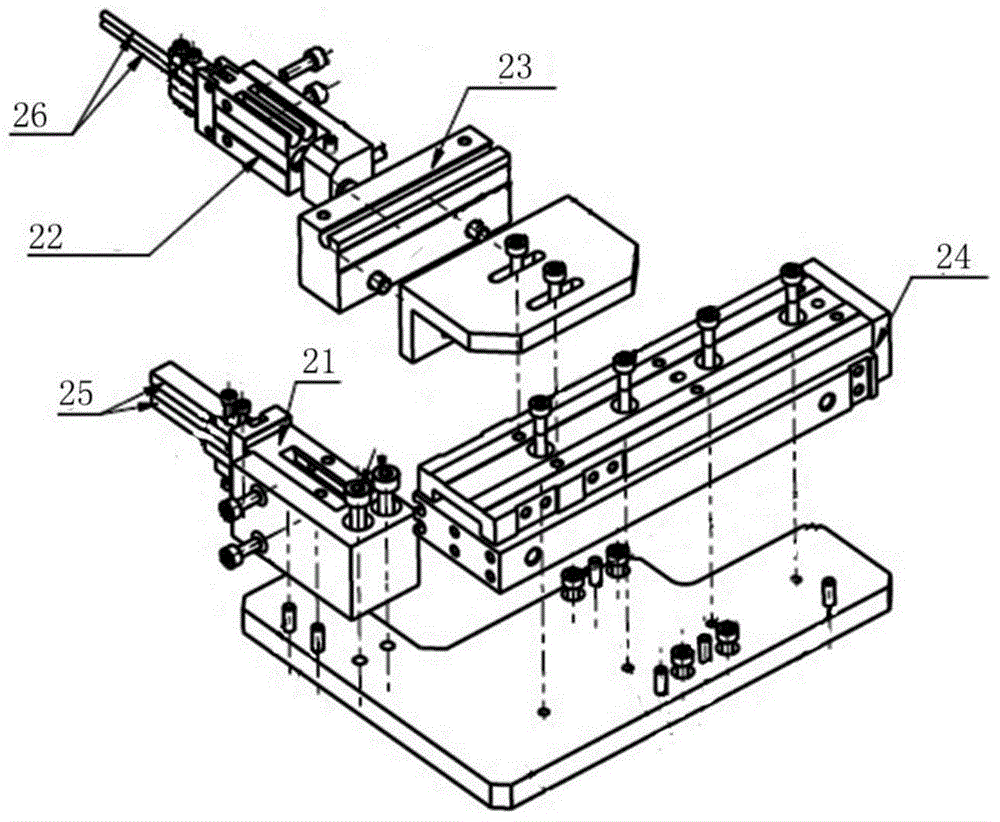

Wire separation mechanism for T2 ring wire winding machine

ActiveCN104795235AAutomation for convenienceFilament handlingCoils manufactureWinding machineEngineering

The invention provides a wire separation mechanism for a T2 ring wire winding machine. The wire separation mechanism comprises a guide rail, a T1 ring supply assembly installed on the guide rail and a wire separation assembly installed on the T1 ring supply assembly. The wire separation assembly is used for separating two longest tail wires from long tail wires and short tail wires which are all wound around a T1 ring. The T1 ring supply assembly is used for conveying the T1 ring around which the wires are wound and from which the two longest tail wires are separated to a next station. By the adoption of the wire separation mechanism for the T2 ring wire winding machine, the two longest tail wires can be found from eight head wires and tail wires which are wound around a T2 ring, and great convenience is provided for automatic conduction of following processes such as the wire twisting process and the T2 ring winding process.

Owner:ZHUHAI HENGNUO SCI & TECH CO LTD

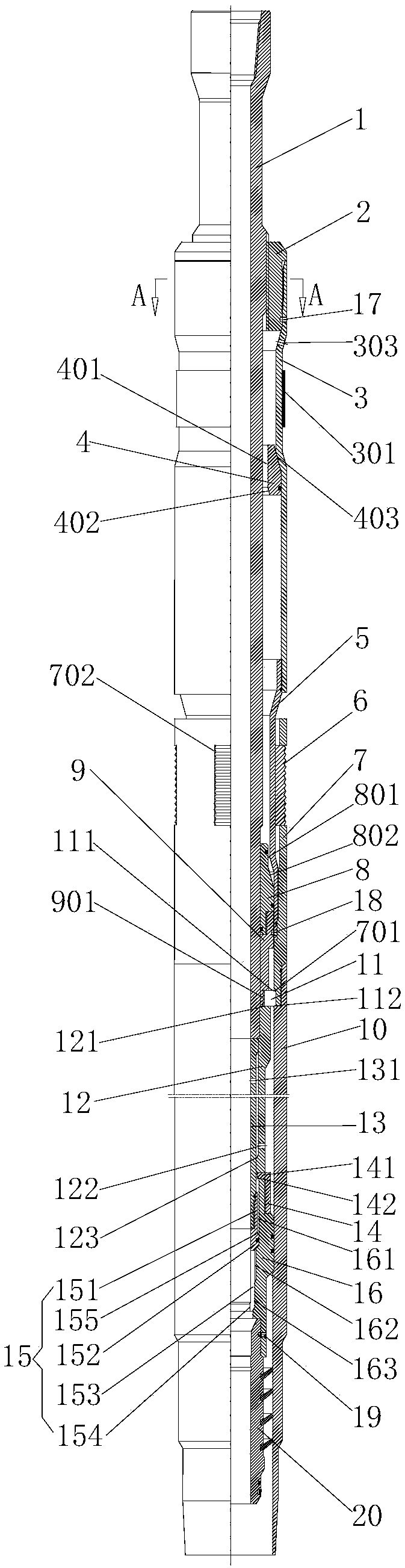

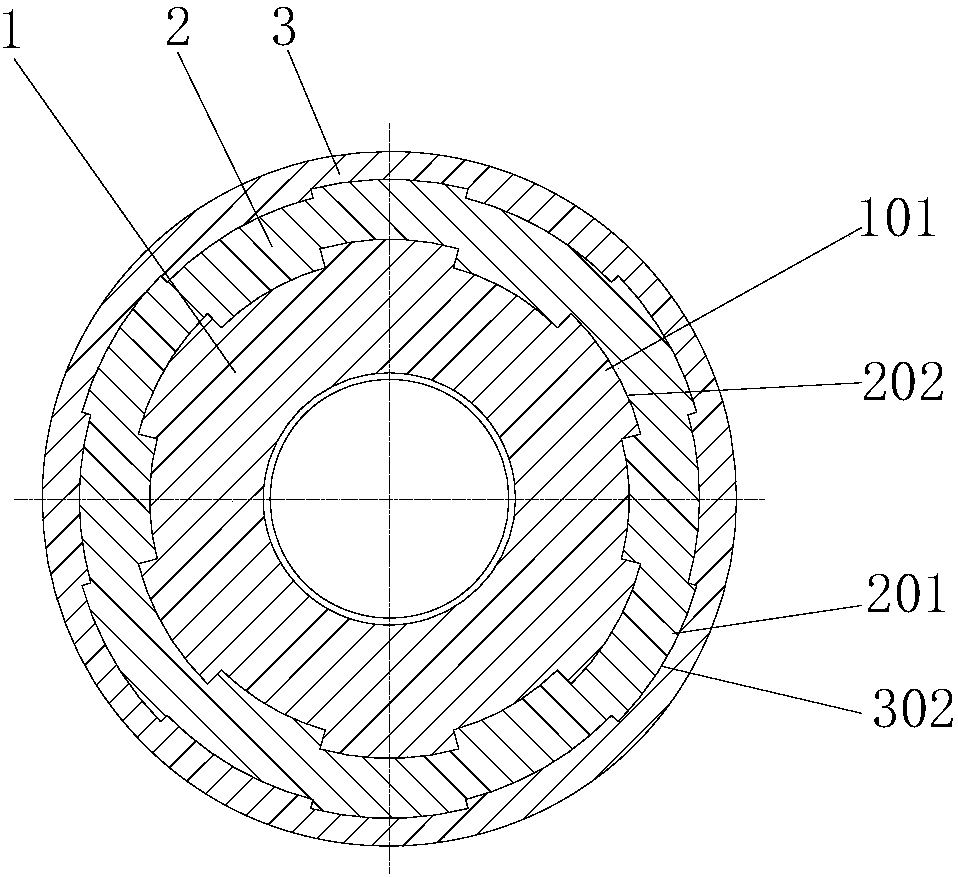

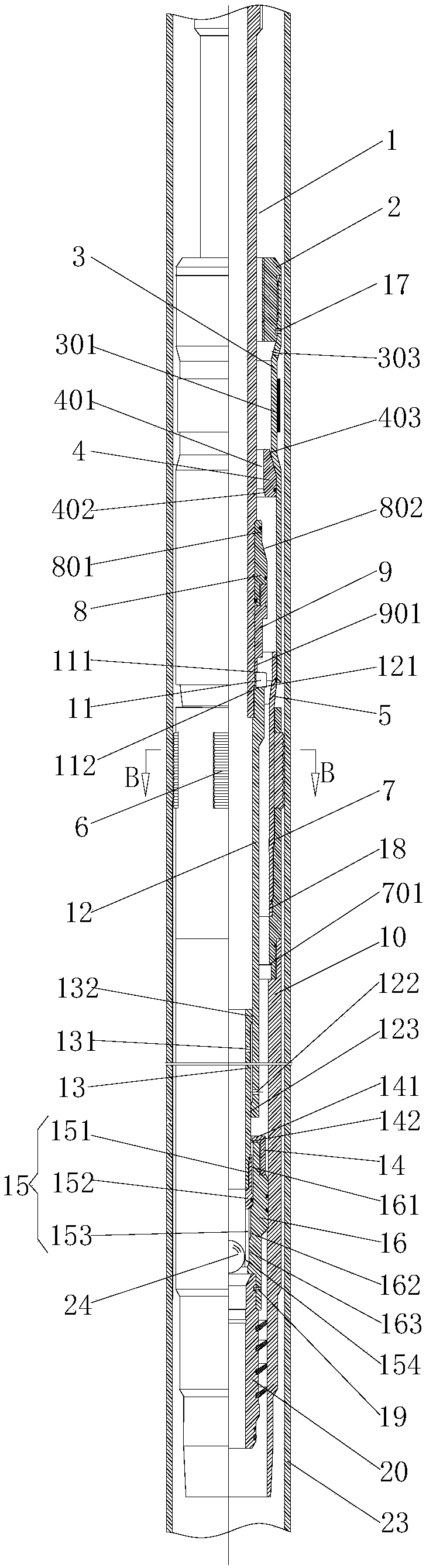

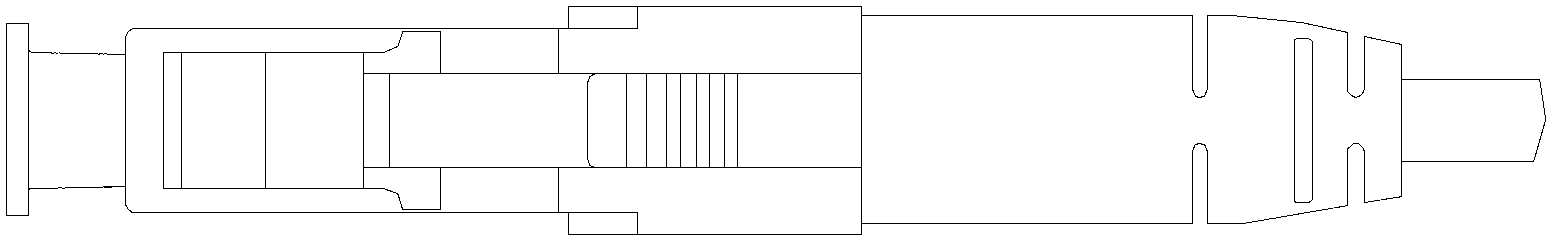

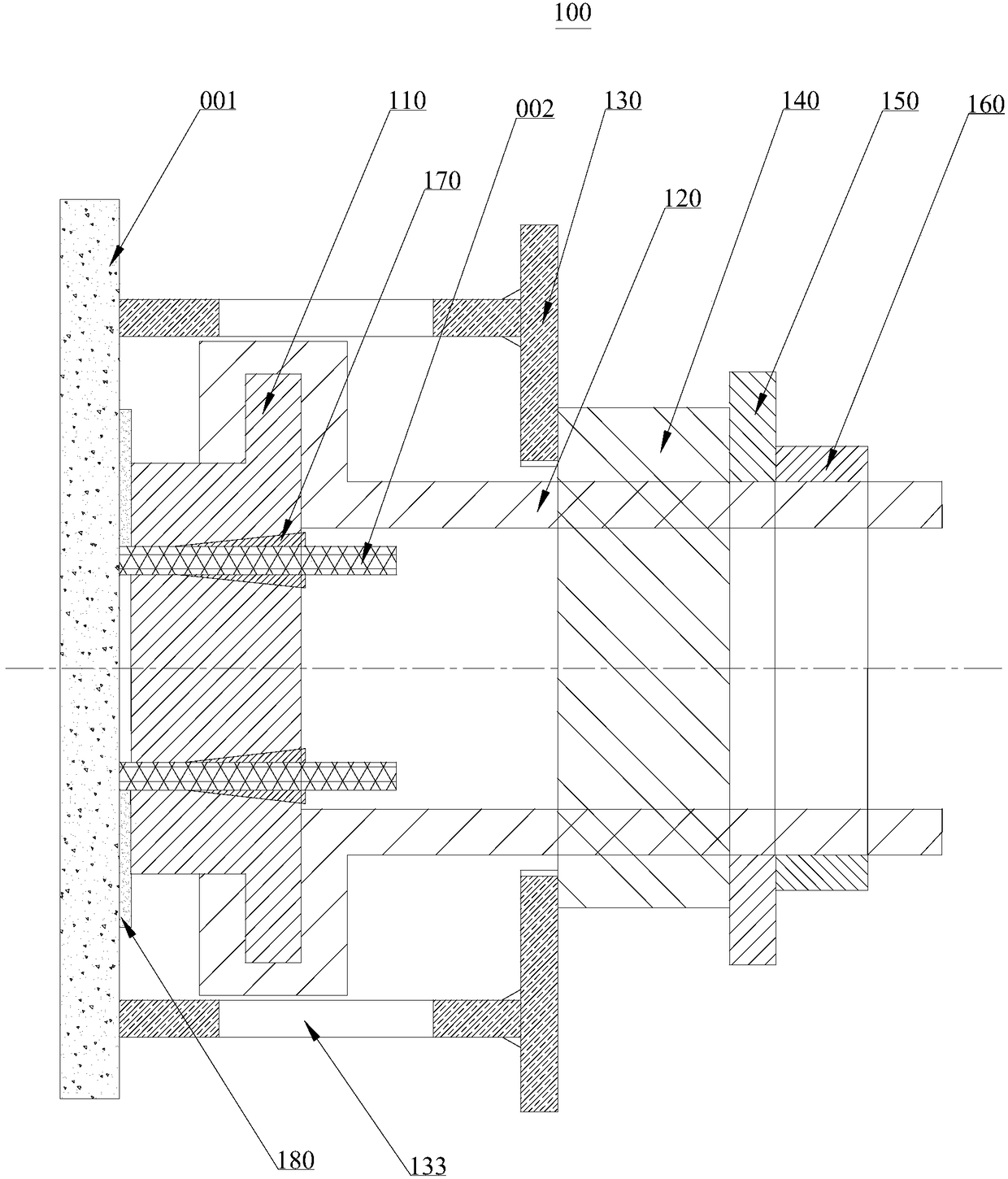

Expansion type liner hanger with slips

PendingCN107724991AAvoid the disadvantages of cementing firstEasy to operateSealing/packingEngineeringShort tail

The invention discloses an expansion type liner hanger with slips. The expansion type liner hanger comprises an outer cylinder, a core pipe and a first expansion cone, the outer cylinder comprises a first expansion pipe and a liner nipple, the first expansion pipe is connected with the liner nipple through a connecting sleeve, a plurality of slips are arranged on the connecting sleeve, the core pipe is arranged in the outer cylinder and comprises an upper center pipe and a lower center pipe, a movable core can be clamped on the inner wall of the lower center pipe and is positioned below the upper center pipe, a ball seat is arranged on the inner wall of the movable core, the outer wall is hermetically fitted with the liner nipple, the movable core is provided with a first pressure guide hole, the lower center pipe is provided with a second pressure guide hole, a liner rubber plug is arranged at the lower end of the movable core, the first expansion cone can be slidably arranged betweenthe first expansion pipe and the upper center pipe from bottom to top, and a first pressure cavity is formed among the first expansion cone, the outer cylinder, the core pipe and the movable core inan enclosed manner and communicated with the core pipe through the first pressure guide hole and the second pressure guide hole. According to the liner hanger, well cementation is performed after expansion setting, and the liner hanger is reliable in setting well cementation and low in expansion pressure.

Owner:华鼎鸿基石油工程技术(北京)有限公司

LC-type short-tail heat-shrink-tube-free optical fiber moving connector

Owner:上海永鼎光电子技术有限公司 +2

Method for fastening member with high strength and low riveting force and 10.9-level short-tail pulling rivet

The invention discloses a method for fastening a member with high strength and low riveting force and a 10.9-level short-tail pulling rivet. The method comprises the following steps that: 1) the rivet consists of a rivet head, an unloading groove, a polished rod, a locking ring groove section, a threaded section and a tail thin short ring groove section; the radius of the inner curved surface of a locking groove is reduced from front to back; the angle of the inner inclined plane of the tail is reduced from front to back; a lantern ring is provided with a convex point, and a latch is arranged in an inner hole; 2) the rivet penetrates, the latch is screwed into the threaded section, and the lantern ring is hooked with the rivet; 3) the rivet extends into a riveting device, and a clamping jaw clamps the tail; 4) the riveting device is started, the lantern ring is extruded to deform to lock a ring groove, and the lantern ring moves forwards to break the convex point; and 5) the riveting device retreats, and fastening is finished. The unloading groove can eliminate stress concentration in riveting and use. The locking groove promotes metal flowing of the lantern ring during riveting and blocks metal flowing of the lantern ring in vibration or separation after riveting, so that fastening property and loosening resistance are improved. Due to the tail groove shape, the clamping jaw is engaged with the tail without releasing, and riveting with low riveting force is promoted. Due to the latch, the lantern ring is convenient to hook, install and operate. The rivet is applied to railway vehicles and heavy trucks with high requirements for fastening property and reliability.

Owner:MEISHAN CRRC FASTENING SYST CO LTD

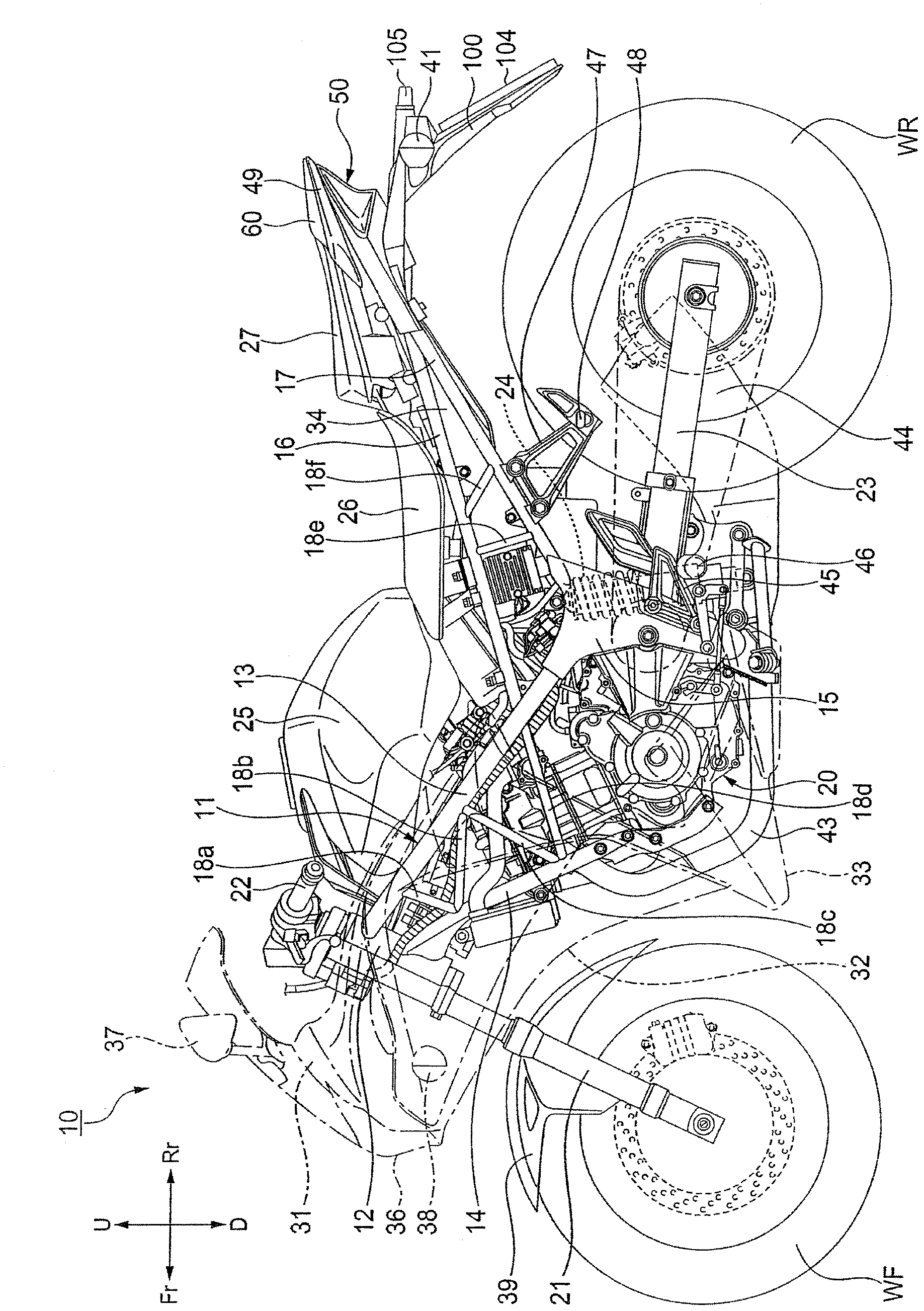

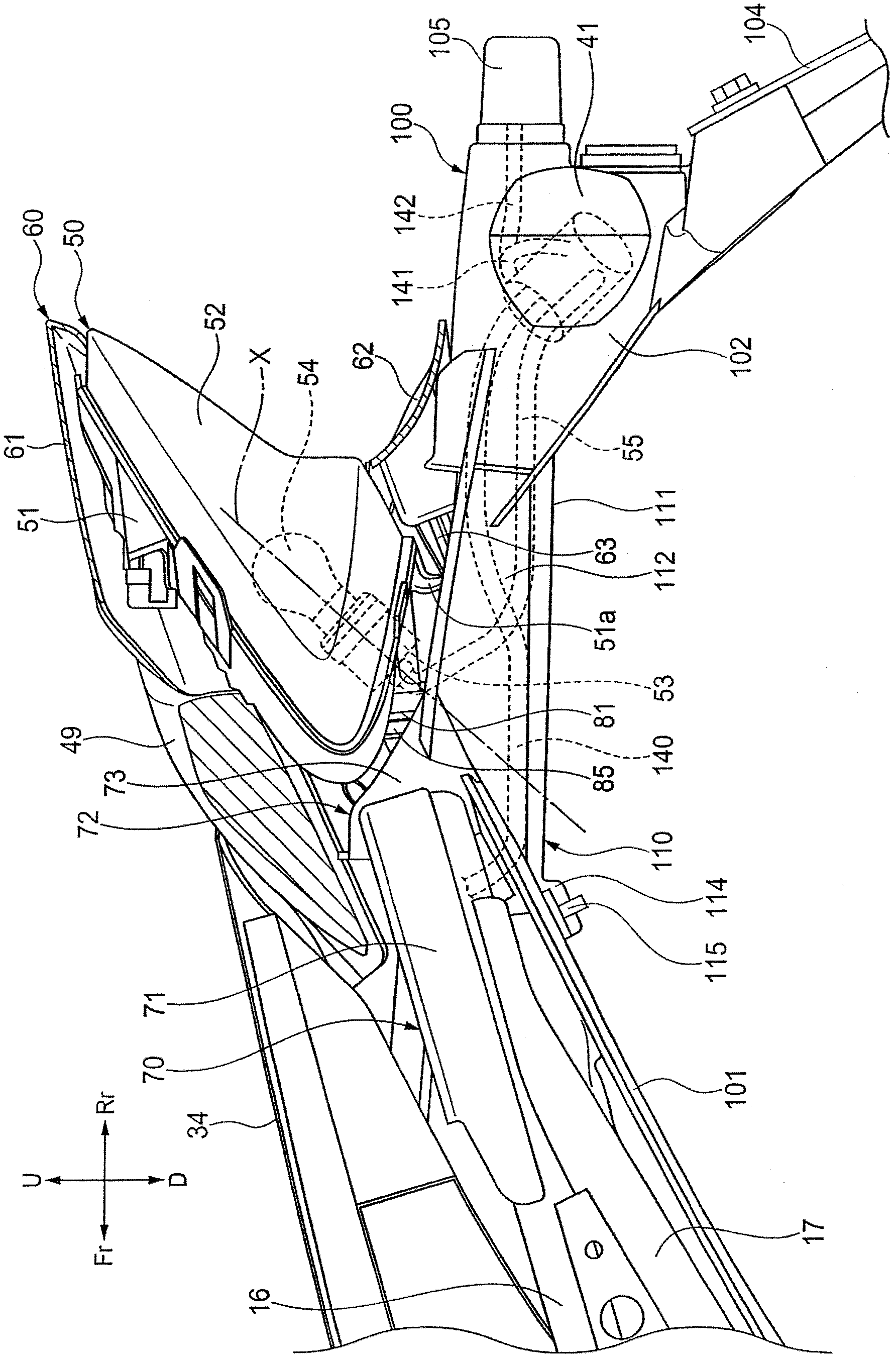

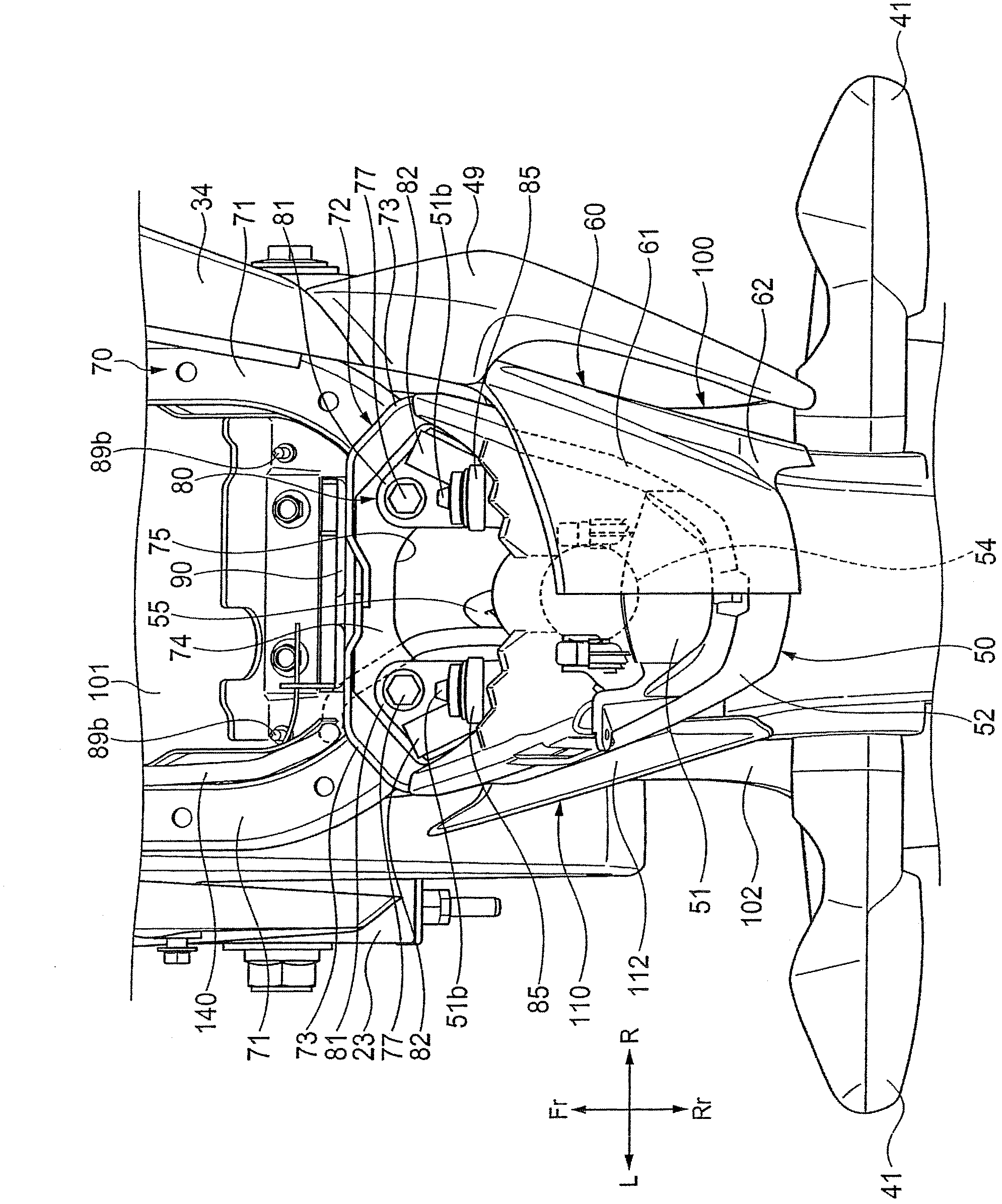

Motorcycle

ActiveCN102574556AEasy to plug and unplugIncrease the installation anglePassenger cyclesOptical signalVehicle frameEngineering

Disclosed is a motorcycle wherein the distance between a seat and a taillight device is reduced by increasing the installation angle of a taillight bulb so as to improve the degree of freedom of short tail design around the taillight of a motorcycle, thereby enabling the appearance to be enhanced, and the insertion and removal of the taillight bulb to be made easy. Specifically disclosed is a motorcycle which is provided with a rear cowl (60) installed in the rear of a vehicle frame (11), a seat catch (90) which is mounted in the rear end of the vehicle frame (11) and locks / unlocks a retractable seat (27), a taillight device (50) which is mounted in the rear of the seat catch (90) and is installed in the rear cowl (60), a taillight bulb (54) which is installed in the taillight device (50) with bent forward, and a rear fender (100) which covers the top of a rear wheel (WR), wherein an opening (103) accessible to the taillight bulb (54) is formed in a section facing the taillight bulb (54) of the rear fender (100).

Owner:HONDA MOTOR CO LTD

Detachable anchor cable tensioning equipment and anchor cable secondary tensioning system

InactiveCN108167005ARealization of secondary tensionDoes not damage the structureAnchoring boltsStructural engineeringShort tail

The invention discloses detachable anchor cable tensioning equipment and an anchor cable secondary tensioning system, and relates to the technical field of anchor cable fastening. The detachable anchor cable tensioning equipment is used for secondary tensioning of existing anchor cables protruding from an existing pore wall, and the detachable anchor cable tensioning equipment includes a T-type anchor plate fixedly arranged on the existing anchor cables in a sleeving mode and a force bearing steel sleeve connected to a T-type anchor plate in a sleeving mode; and a jack capable of driving the existing anchor cables to move in the direction away from the existing pore wall is arranged around the force bearing steel sleeve, and a gasket can be arranged between the existing pore wall and the T-type anchor plate in a cushioned mode. According to the detachable anchor cable tensioning equipment, the secondary tensioning of the existing anchor cables with shorter tail portions can be realized, and the existing structures of the existing anchor cables are not destroyed by tensioning construction; and the operation is convenient and efficient, and the application is simple. According to theanchor cable secondary tensioning system, the secondary tensioning of the existing anchor cables with the shorter tail portions can be realized.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

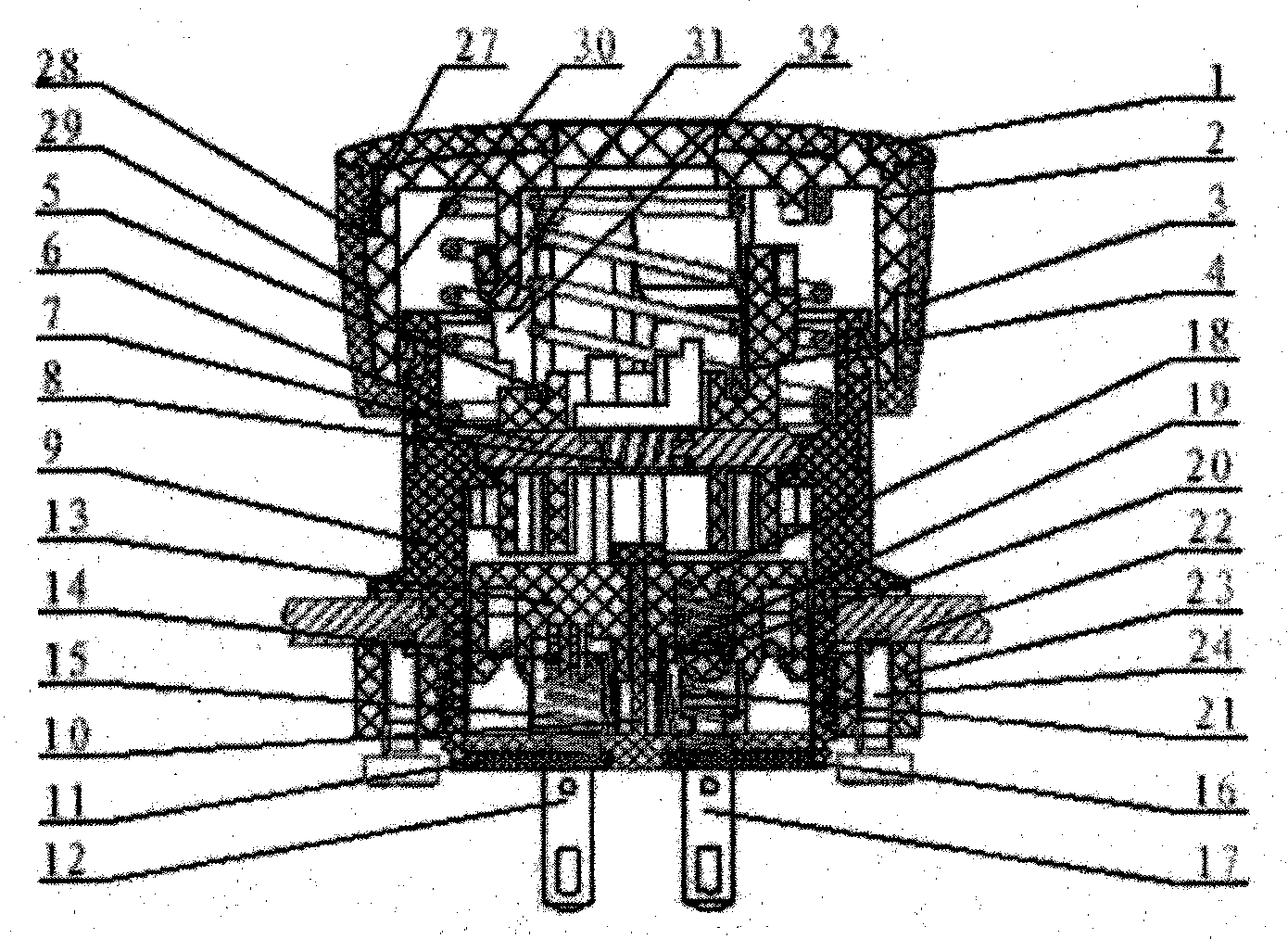

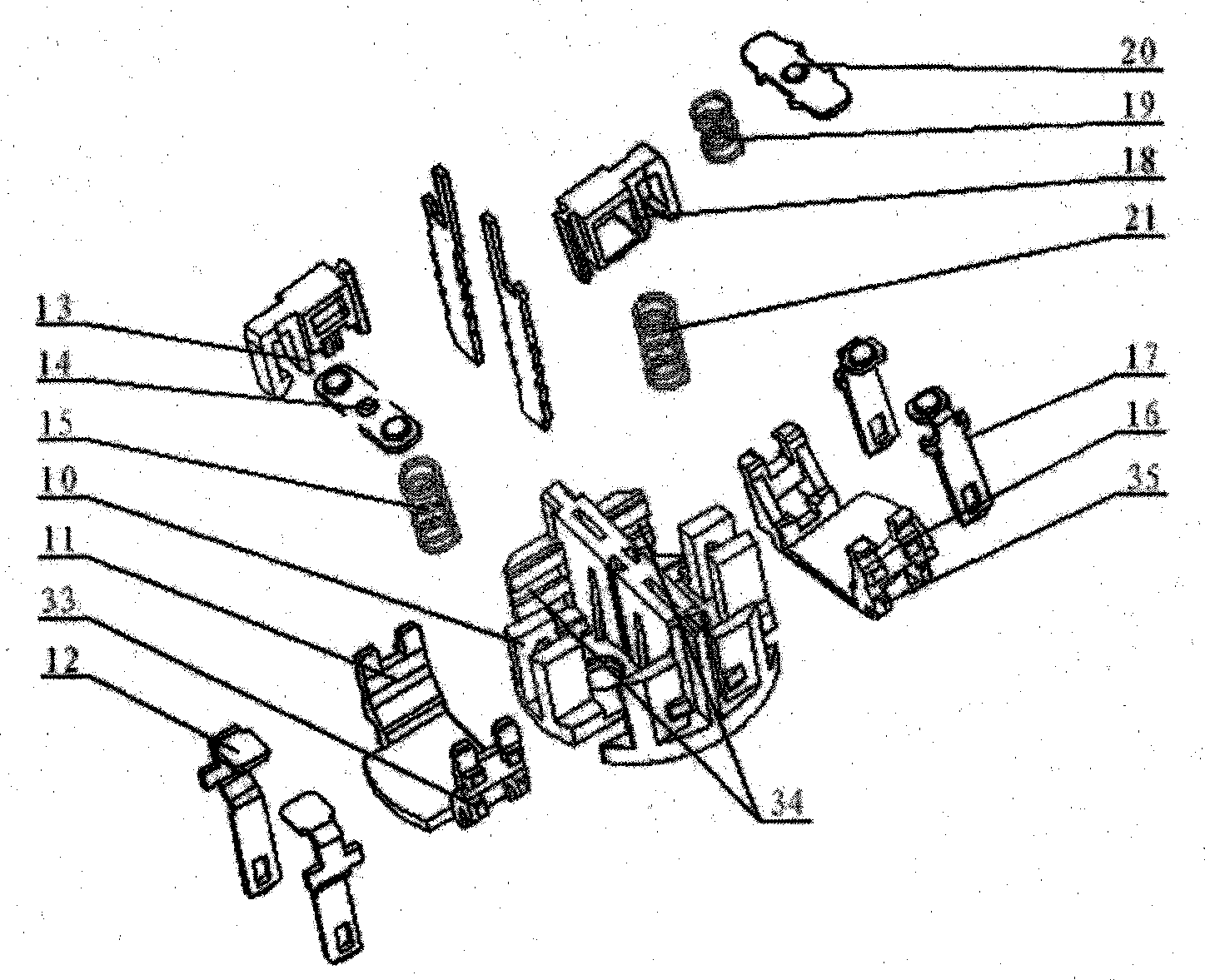

Novel structure of scram button

ActiveCN104252985AIn line with the design conceptInconvenient to installElectric switchesControl systemEngineering

The invention discloses a novel structure of a scram button. The novel structure comprises an operating system, a change-over contact system and a control system. The novel structure of the scram button is formed through natural match among the operating system, the change-over contact system and the control system, and replaces a traditional split-type structure; a mushroom head operating part of the operating system is connected with an operator by a hook; the change-over contact system is assembled in a splicing manner, and is connected in a plastic housing by a hook to enable surfaces to be perfectly combined and meet the design concept of human engineering; a base is led out from the tail of a button with a leading wire to form a fully-closed ultra-short tail, so that the inconvenience for mounting equipment at the back of a control panel is avoided.

Owner:红波按钮制造有限公司

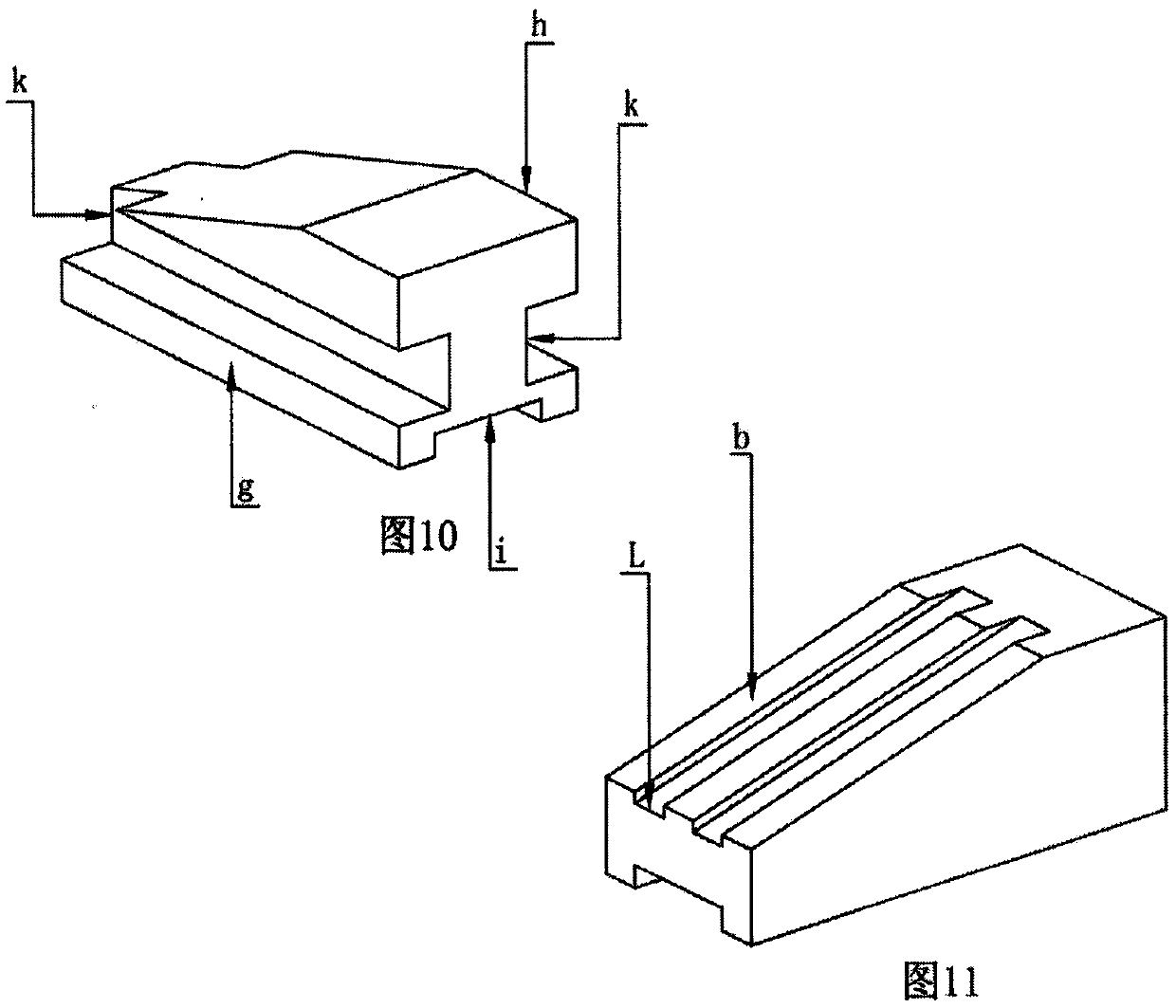

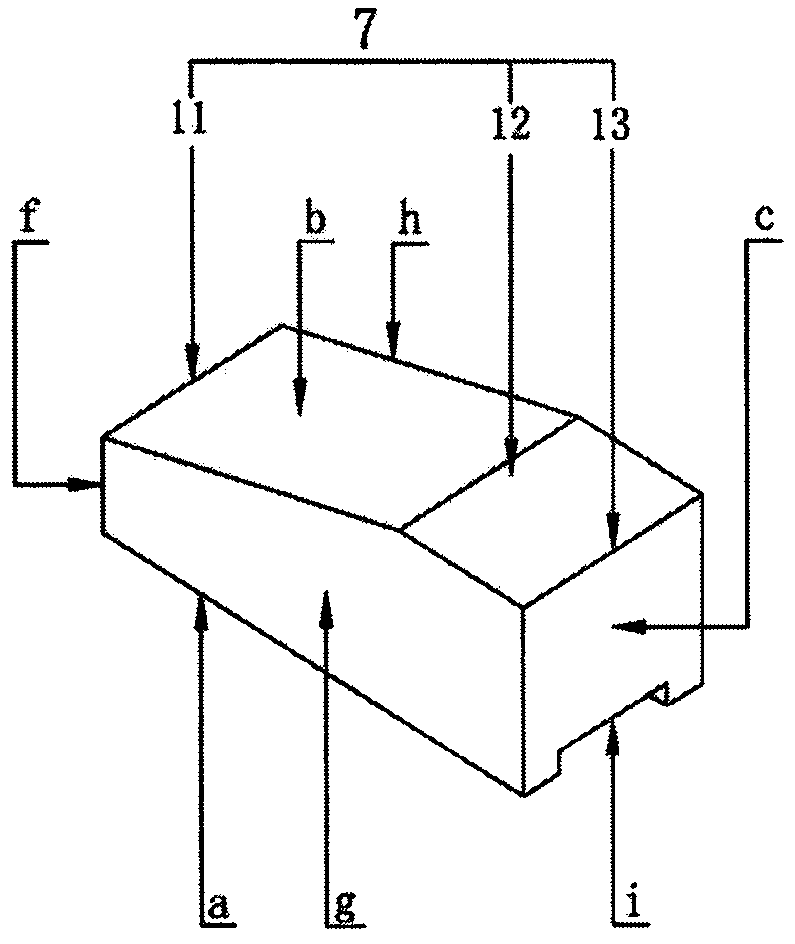

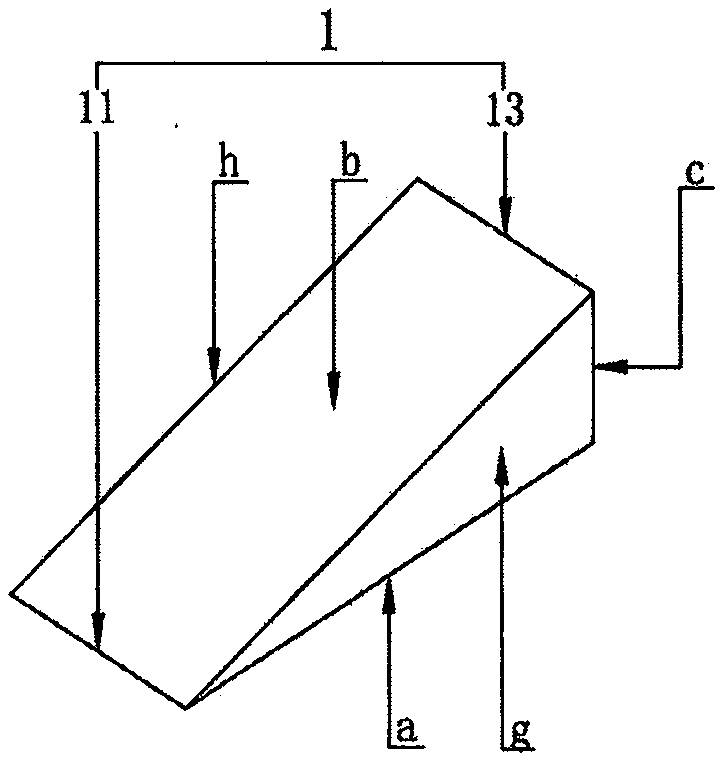

Wedge special for building, and using method and mounting protection part of wedge

The invention discloses a wedge special for a building, and a using method and mounting protection part of the wedge. The special wedge is formed by integrally pouring cementing materials for the building, and an overall base structure of the wedge can be made into a short tail wedge 1 composed of a wedge tip 11 and a wedge tail 13, or made into a long tail wedge 2 composed of the wedge tip 11, awedge body 12 and the wedge tail 13. The wedge tip 11 is composed of an acute angle formed by a wedge bottom face a and a wedge upper bevel b, and the wedge tail 13 comprises a hitting face c. Plant fiber cementing materials can be selected as the cementing materials for the building. The special wedge can be made to be in various shapes by taking the base structure of the short tail wedge 1 or the long tail wedge 2 as an example. The mounting protection part 8 is made of a metal material, is a U-shaped frame body, and comprises a left protection plate 81, a right protection plate 82 and a tail protection plate 83. An operation handle 84 is arranged on the end face of the tail protection plate 83.

Owner:姚井祥

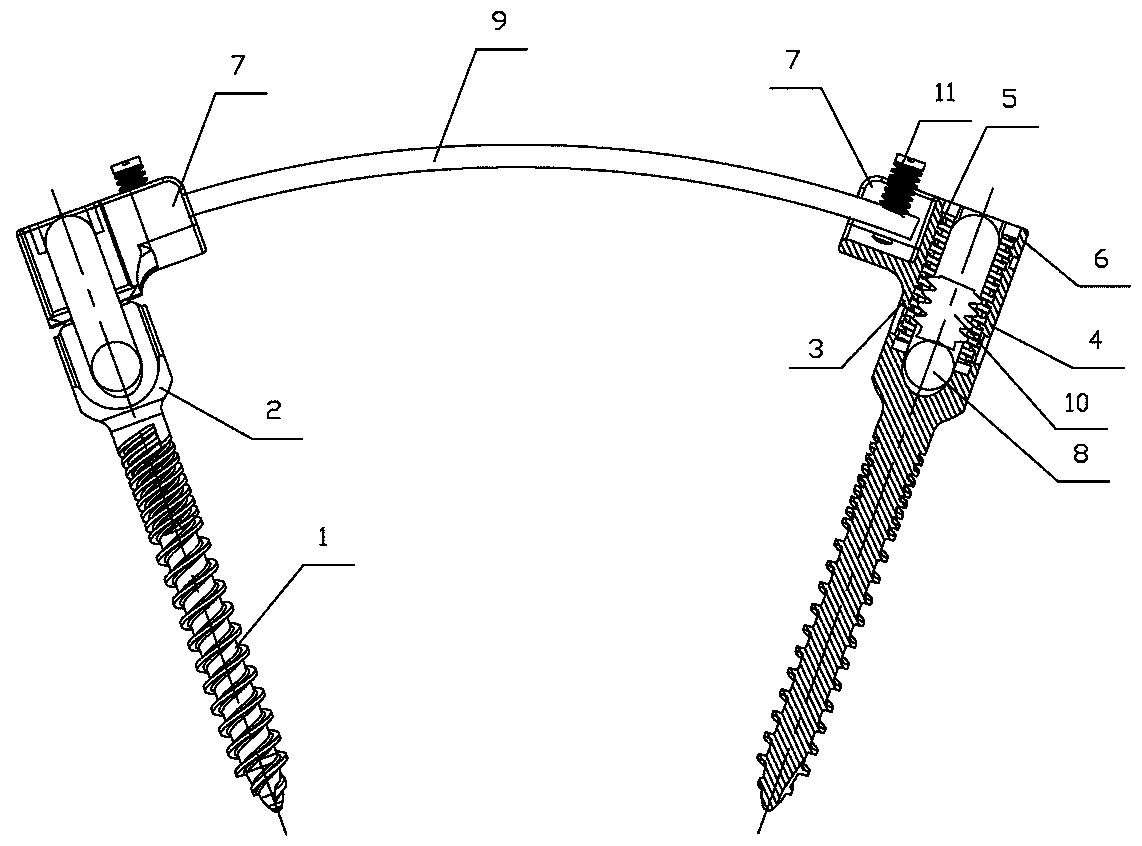

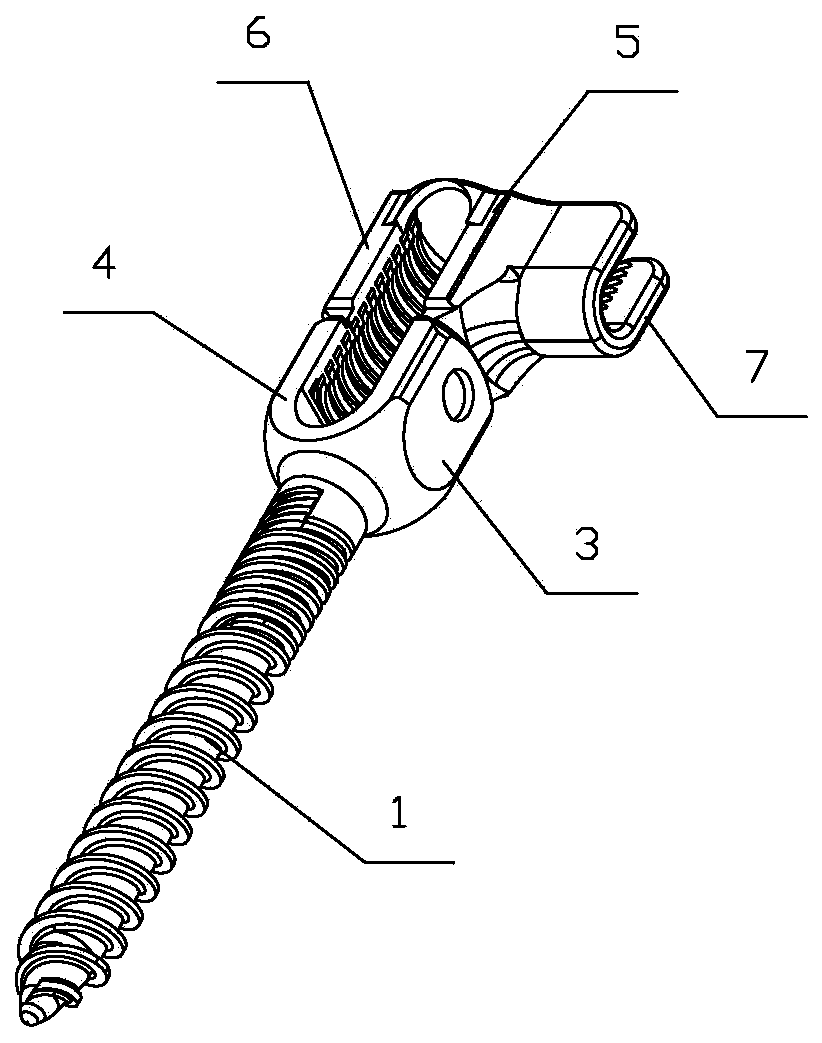

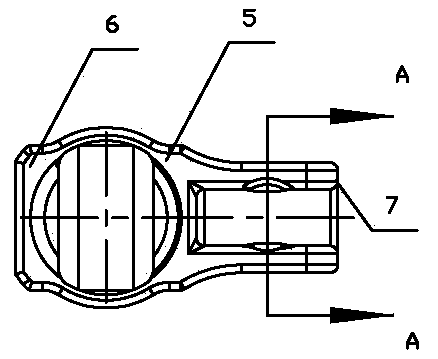

Posterior lumbar internal fixation appliance

The invention relates to the technical field of medical devices, in particular to a posterior lumbar internal fixation appliance, comprising a uniaxial pedicle screw with threads, a long tail nail holder arranged at the upper end of the uniaxial pedicle screw for mounting a longitudinal connecting rod, and a short tail nail holder arranged on the long tail nail holder for mounting a transverse connecting rod. The posterior lumbar internal fixation appliance has the advantages of simple structure, convenient use, high holding force of screw, and not easy to be prolapsed, and is particularly suitable for the surgical treatment of osteoporosis combined with lumbar vertebral diseases. The misaligned vertebral body can be restored by using the high holding force of screw during the operation, so as to achieve the purpose of correcting the deformity.

Owner:厉锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com