Patents

Literature

41results about How to "Improve fastening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

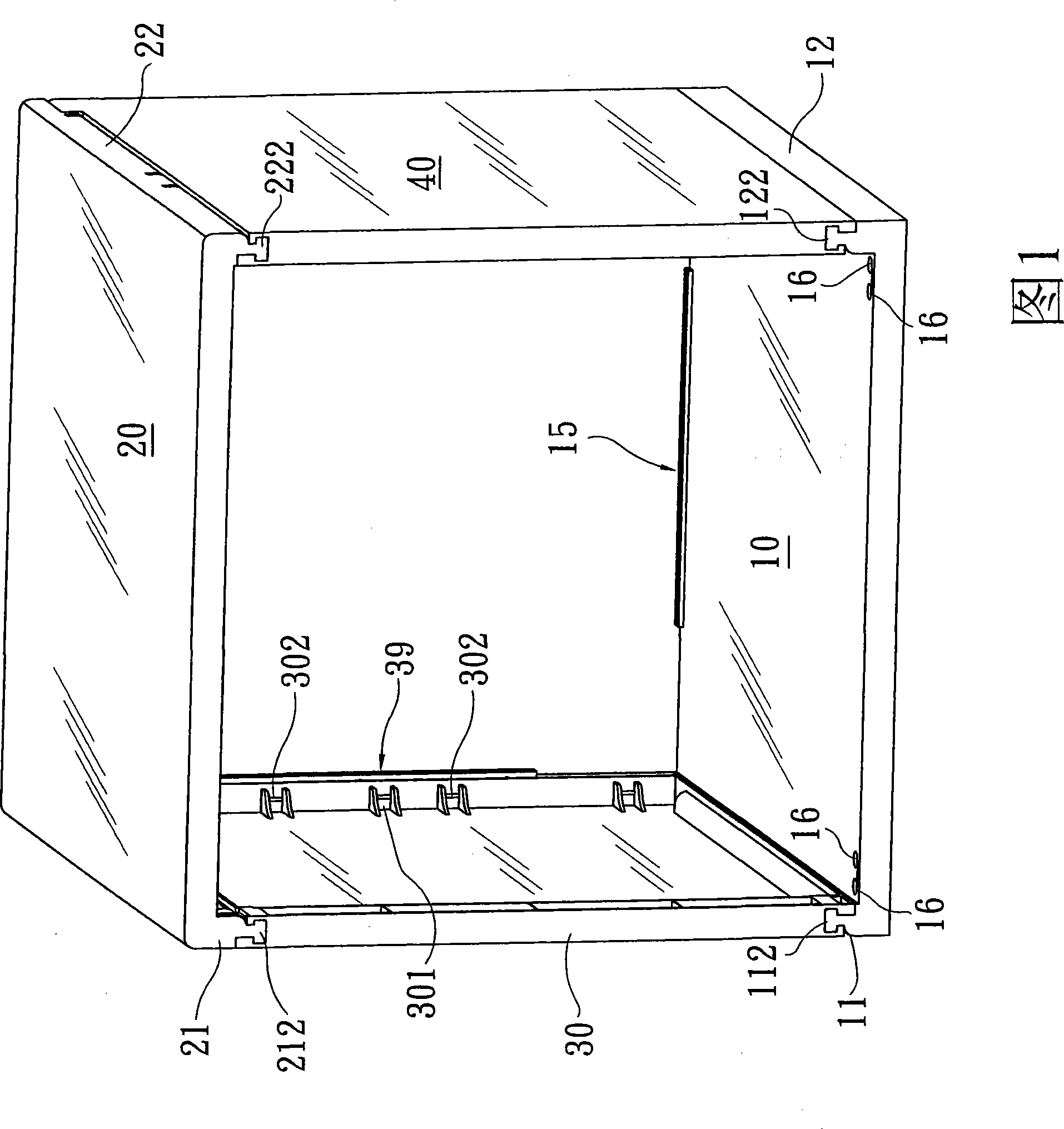

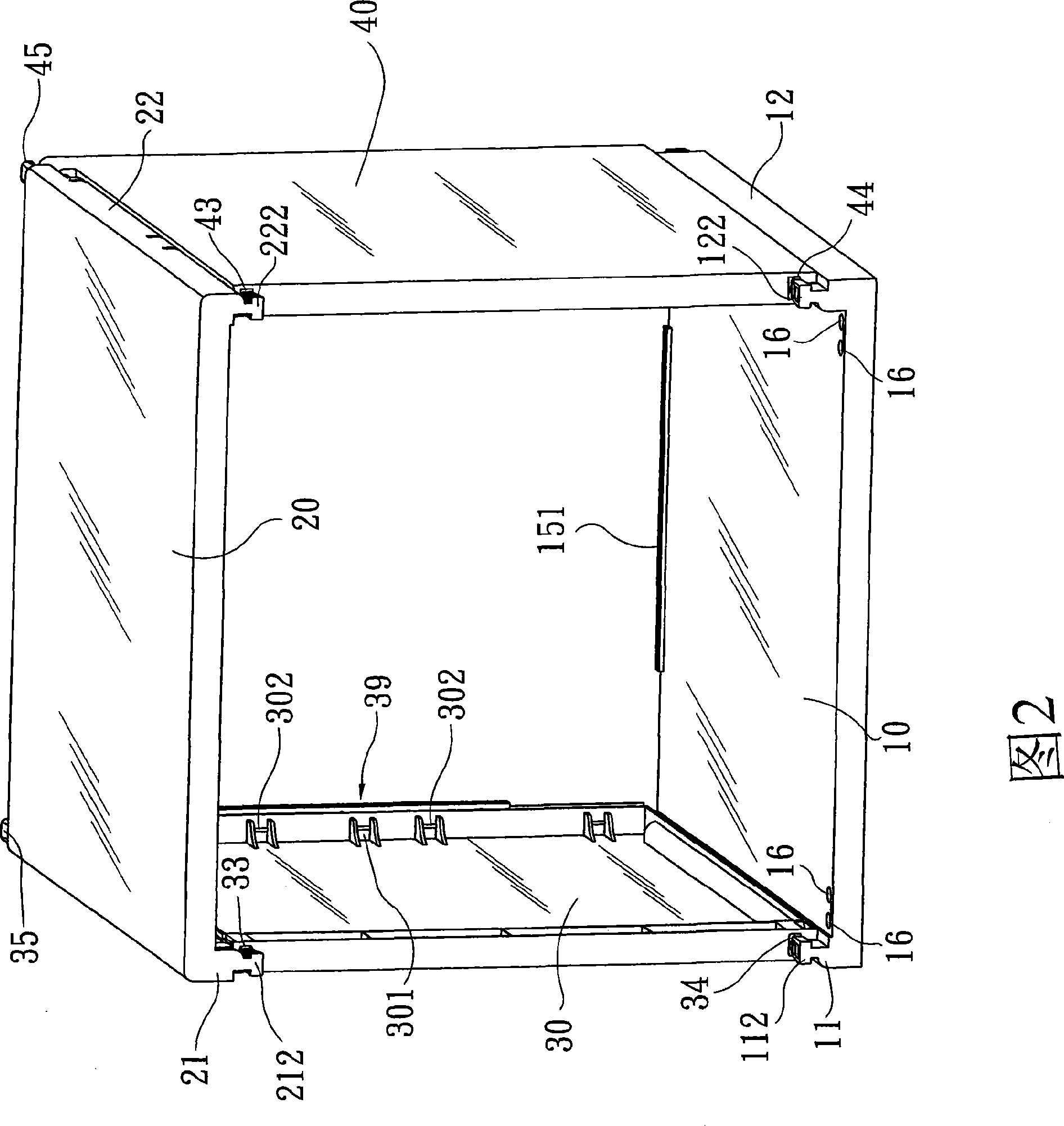

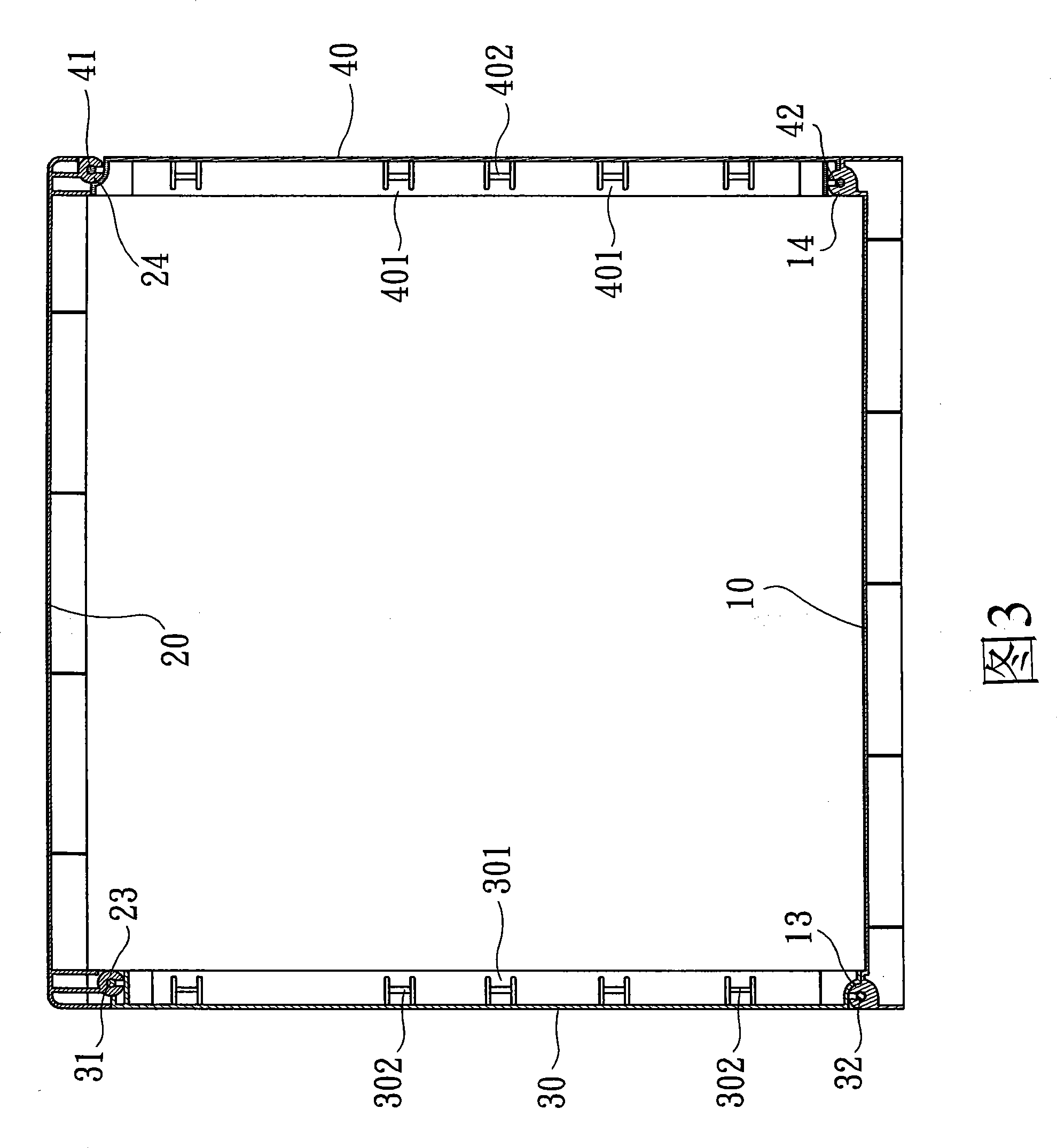

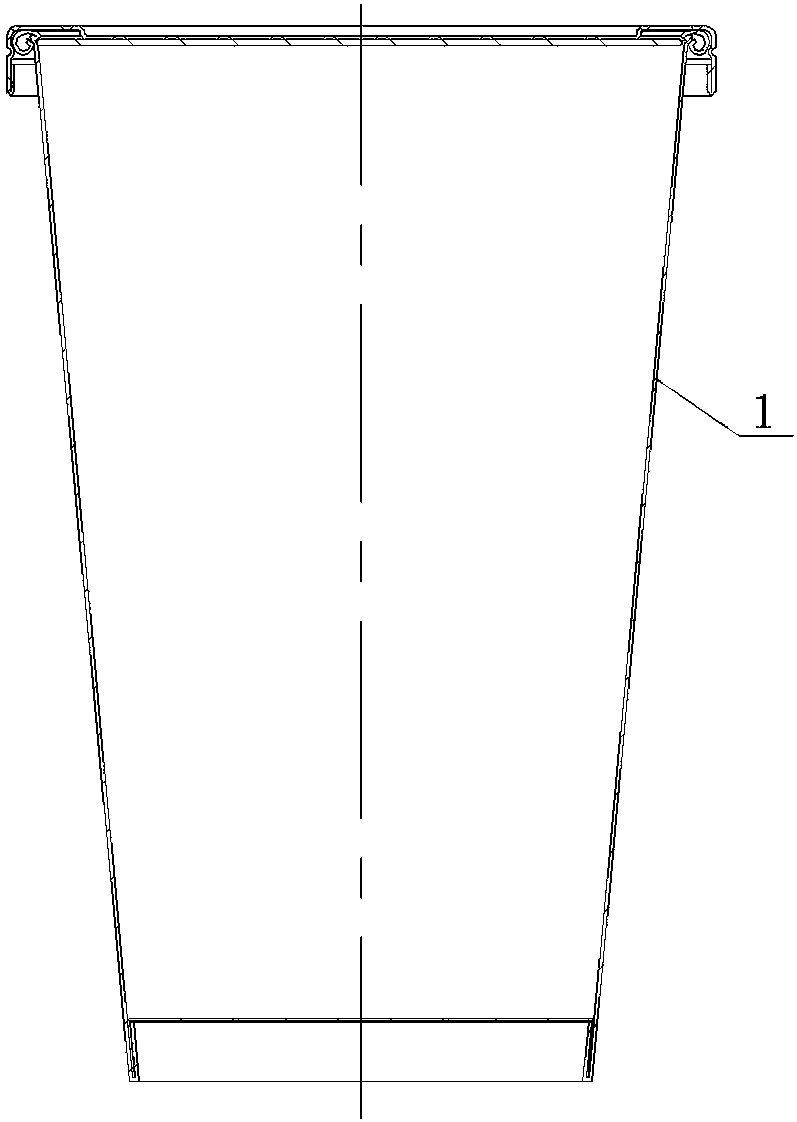

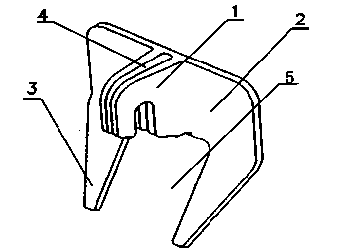

Foldable containing apparatus

InactiveCN101434307AIncrease the function of useImprove fastening effectNon-removalbe lids/coversWing arrangementsEngineeringSquare cylinder

The invention relates to a folding receiving device, which can be folded into tabular shape to reduce occupying space greatly, so as to be beneficial to storing and transporting, and also can be unfolded as a standing box so as to become a containing box which can contain things. The device comprises a bottom plate, a top plate, a left side plate and a right side plate, wherein, all the plate faces are spliced into a square cylinder body by a pivot, and each plate face can rotate by taking the corresponding pivot as an axle center to be horizontal shape or standing shape, wherein, any two connected plate faces are provided with lugs and caulking grooves, thus causing the connected plate faces to generate button and orientation effect by embedding each lug into the corresponding caulking groove in standing shape.

Owner:PROTREND ENTERPRISE CO LTD

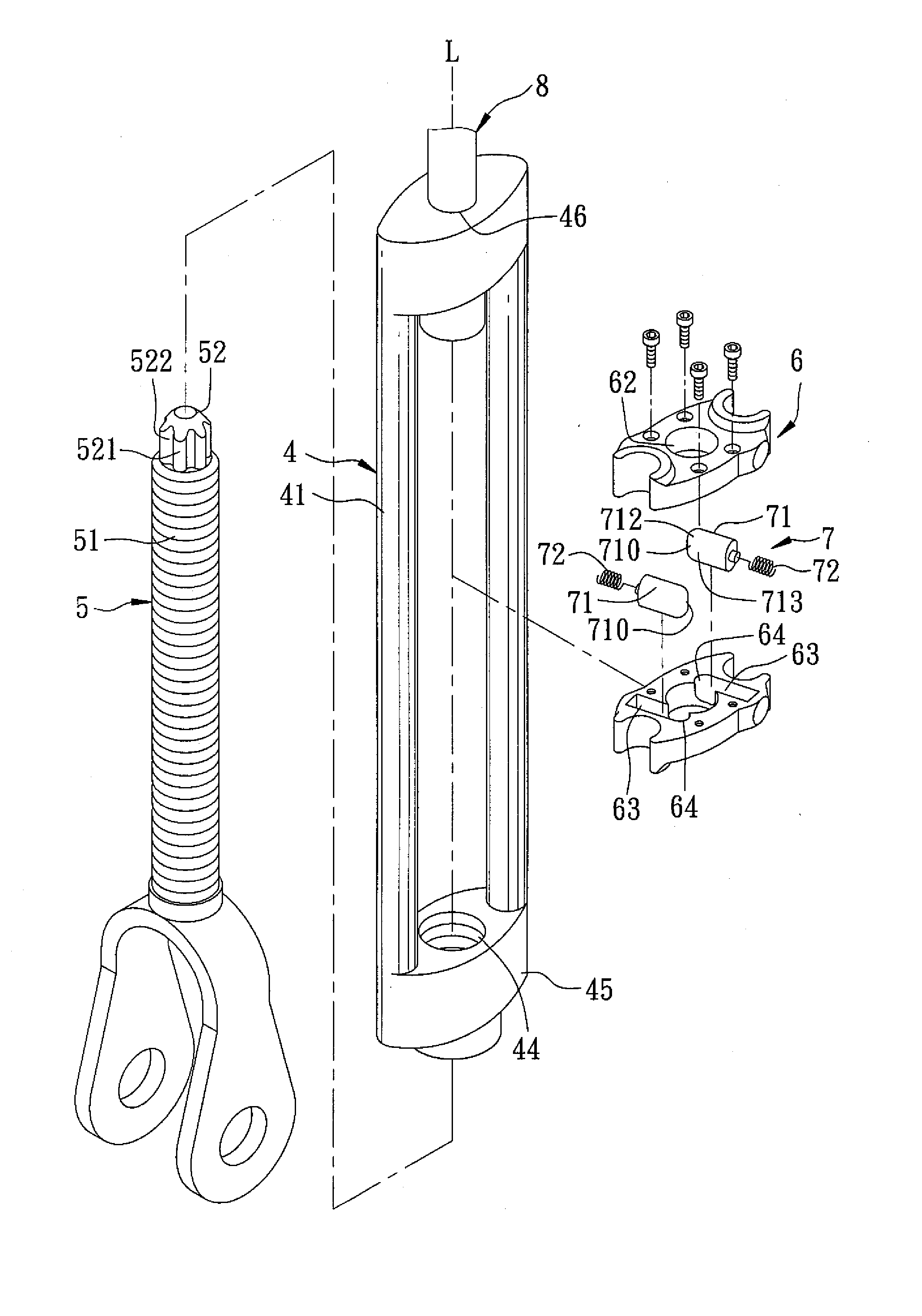

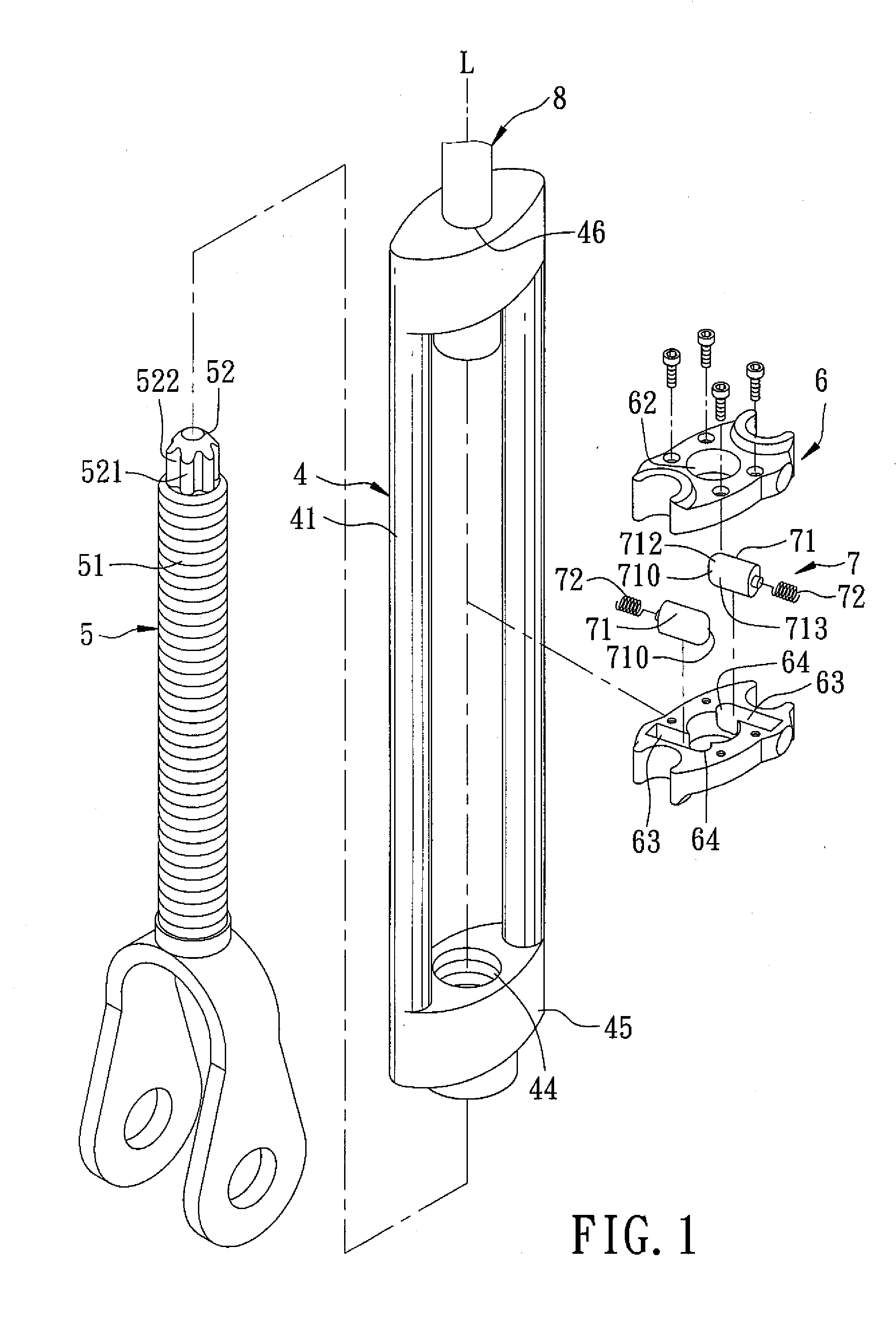

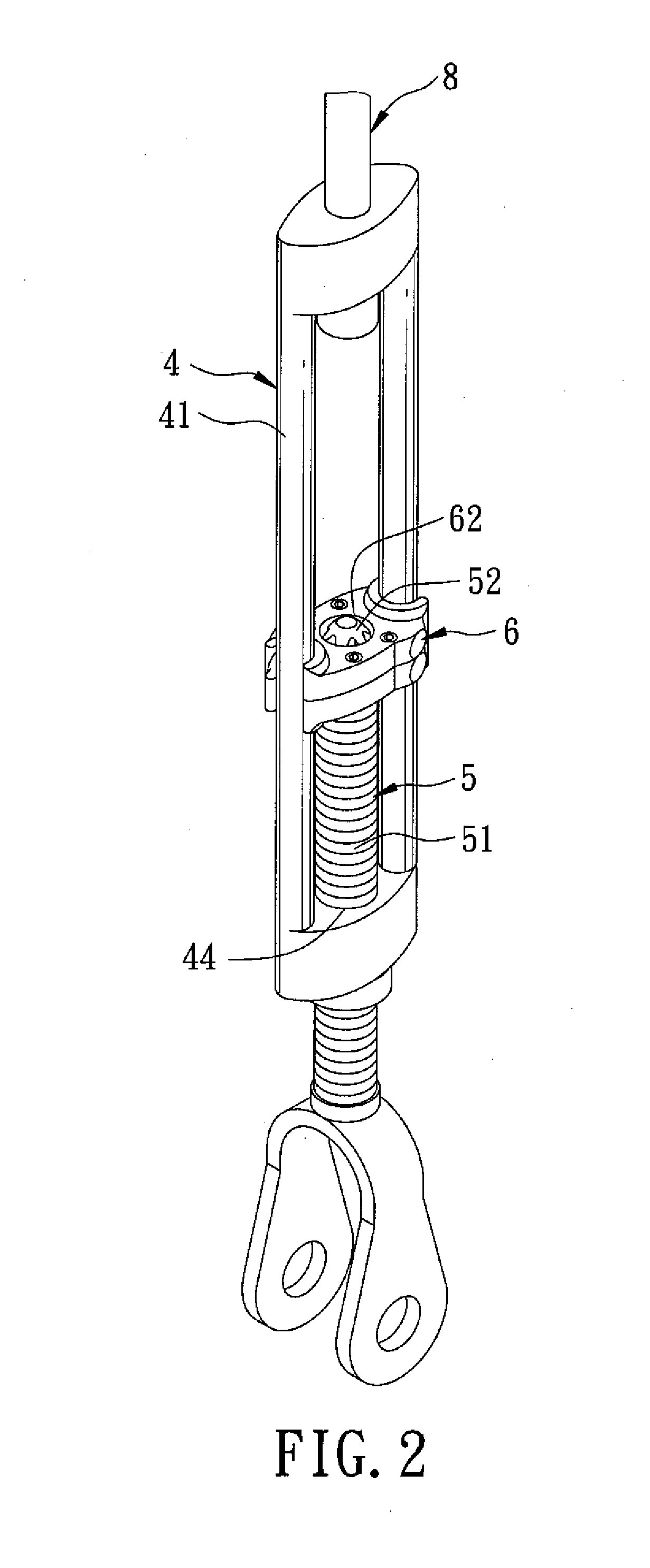

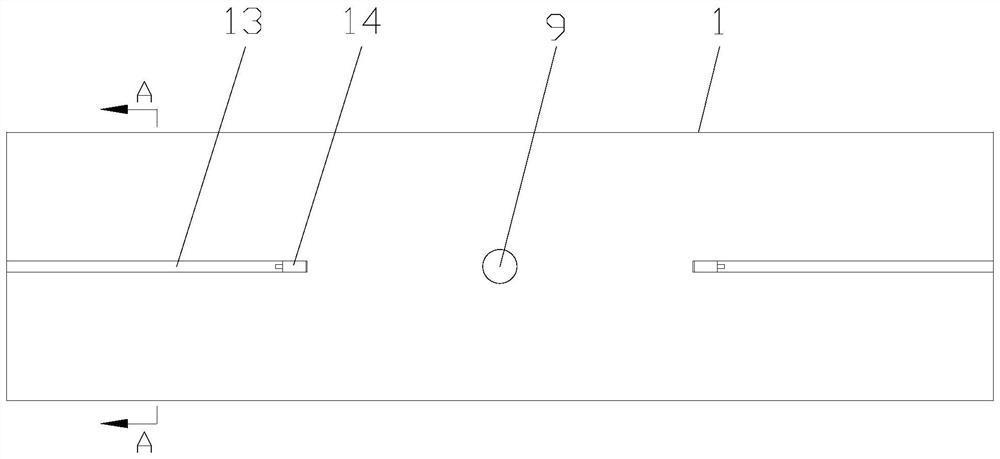

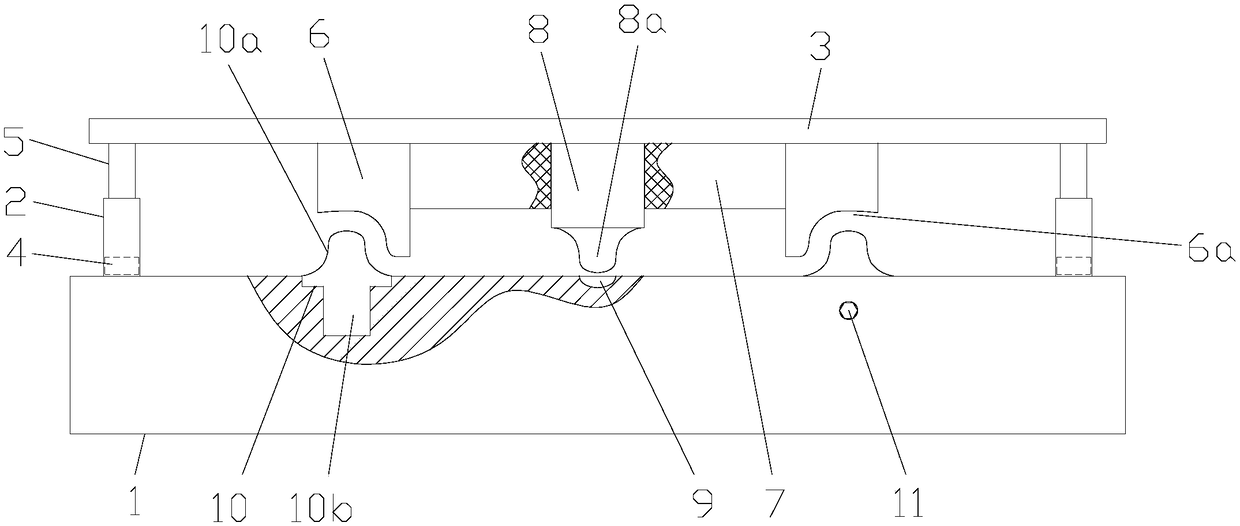

Fastener for securing a cargo container

A fastener for securing a cargo container includes: a first fastener component including a pair of rails; amounting seat mounted slidably on the rails; a second fastener component including a toothed part extending into the a central through-hole in the mounting seat and formed with teeth, each of which has a contact surface; and an engagement unit including an engaging element that is mounted in a retaining recess in the mounting seat and that has a free end portion extendable into the central through-hole in the mounting seat. The free end portion of the engaging element has a flat contact surface that extends into the central through-hole to abut against the contact surface of an adjacent one of the teeth in such a manner to arrest rotation of the mounting seat relative to the second fastener component in a direction.

Owner:HSIEH DAVID

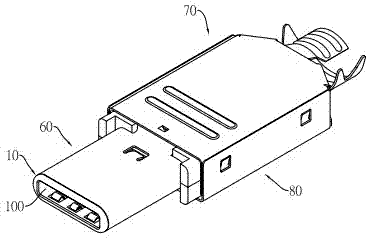

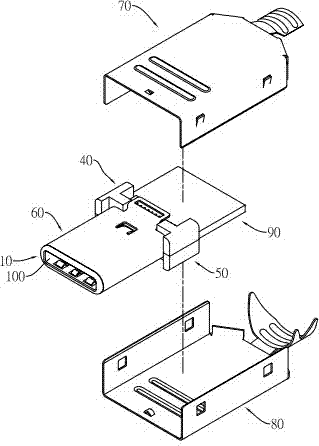

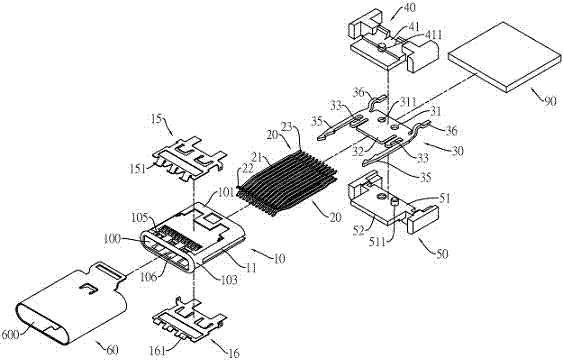

Plug electric connector

InactiveCN104505663AAvoid interferenceImprove fastening effectTwo-part coupling devicesCoupling protective earth/shielding arrangementsElectricityMechanical engineering

Owner:LIANZHAN TECH ELECTRONICS KUNSHAN CO LTD

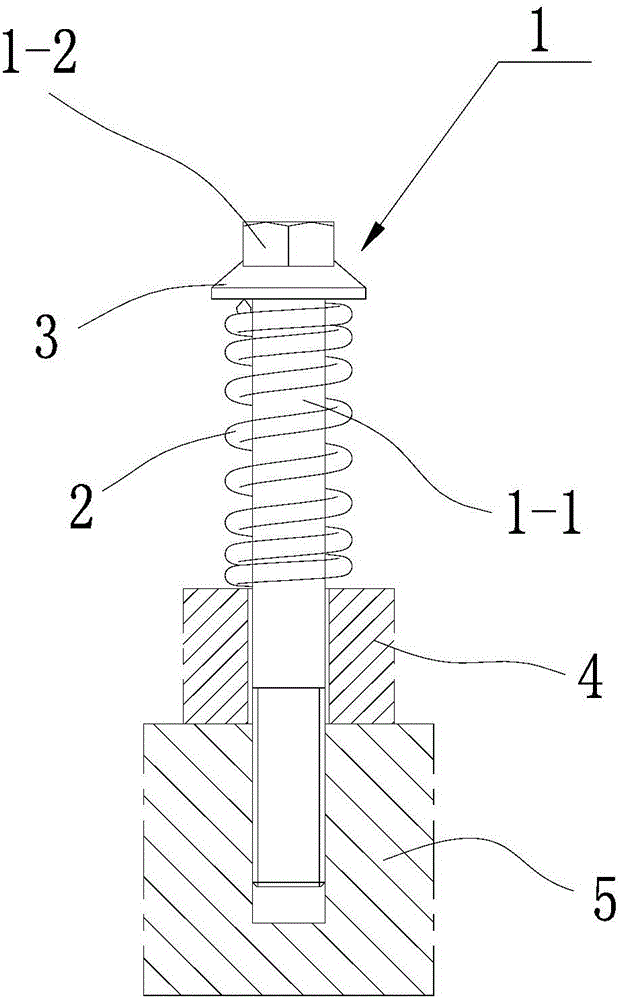

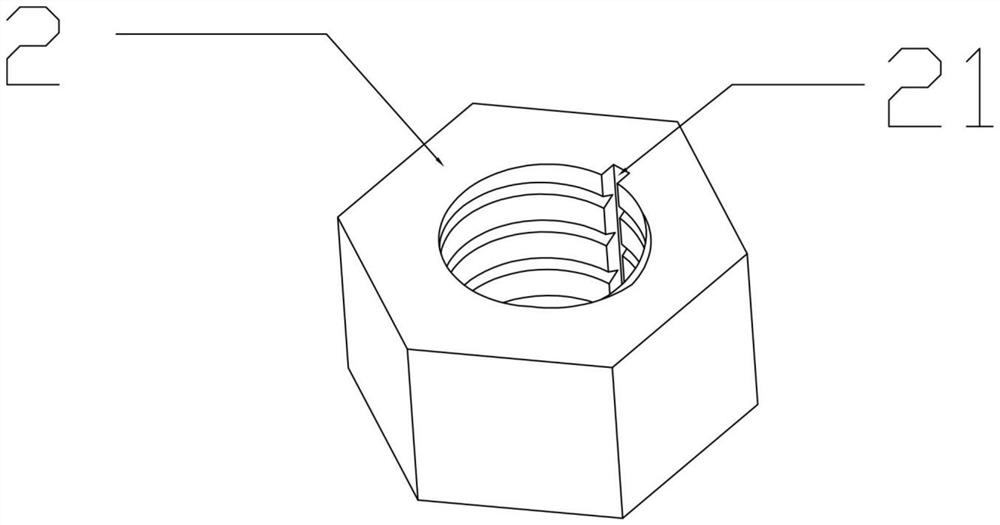

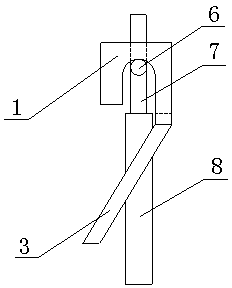

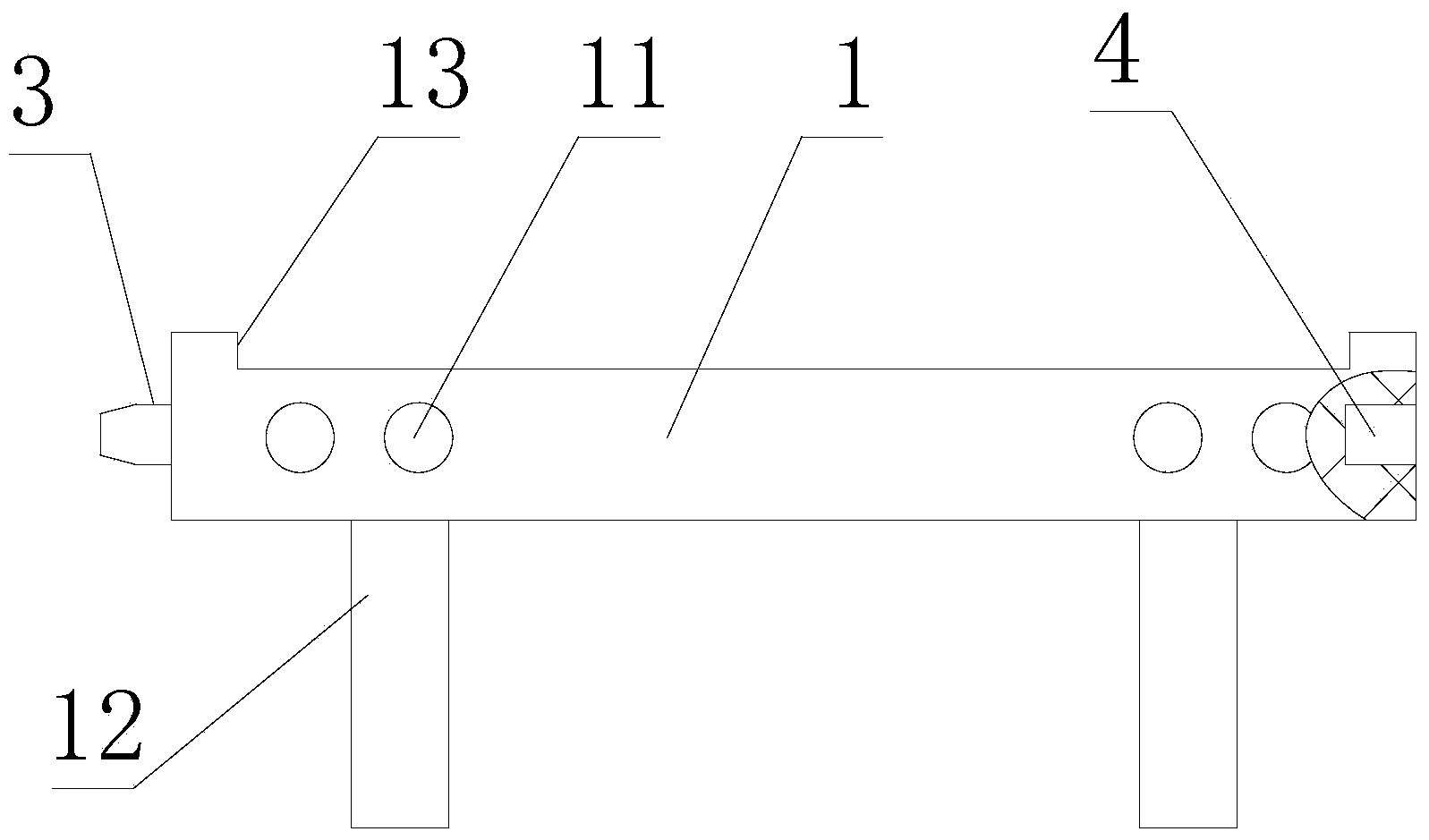

Looseness-prevention connecting structure with controllable pretightening force of engine cylinder head cover

InactiveCN106015266AIncreased friction between threadsImprove fastening effectCasingsNutsEngineeringFriction force

The invention relates to an anti-loose connection structure with controllable pretightening force of an engine cylinder head cover, comprising an engine and a cylinder head cover and a bolt assembly connecting the engine and the cylinder head cover, characterized in that: the bolt assembly includes bolts and springs, The bolt includes a screw body, the upper end of the screw body is provided with a nut, and the lower part of the nut is integrally provided with a pressure cap; the screw body is covered with a spring, and the lower end of the screw body passes through the cylinder head cover and the engine thread connected, the spring is in contact with the upper surface of the cylinder head cover. With the above technical solution, on the one hand, the elastic force of the spring is used to increase the contact pressure between the threads, and the friction between the threads is increased, which enhances the fastening effect; Tight force. It solves the problem that the bolts of the cylinder head cover are loose during the operation of the engine and the aluminum cylinder head cover is easily crushed under the excessive bolt pre-tightening force, and requires a simple structure and low cost.

Owner:TIANJIN LOVOL ENGINES

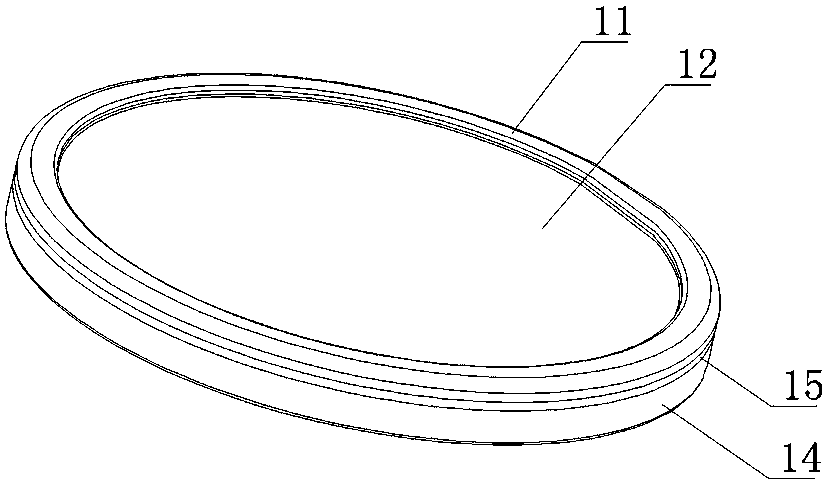

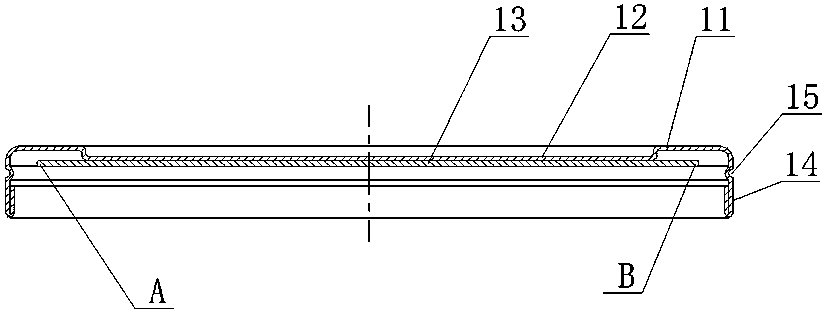

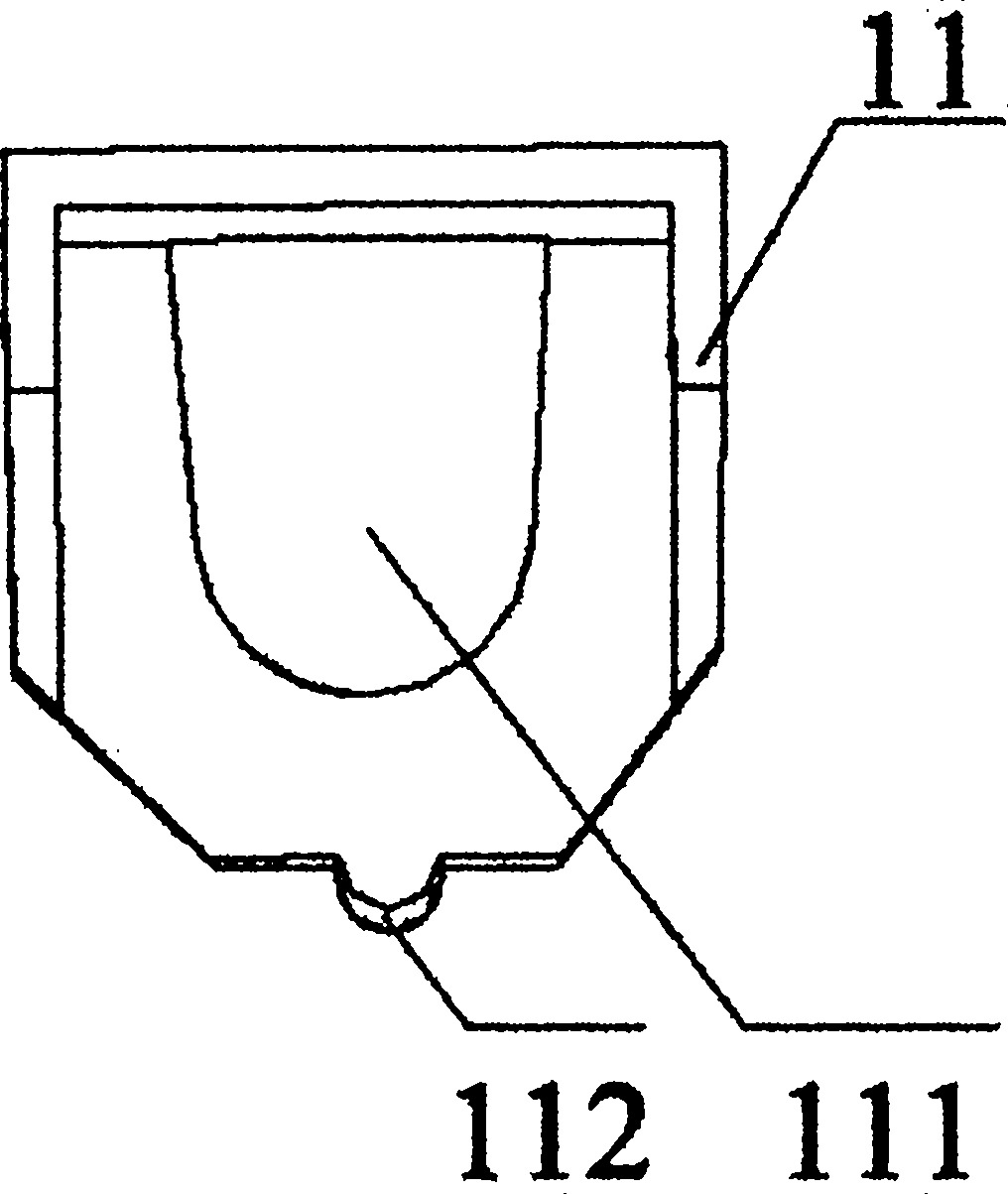

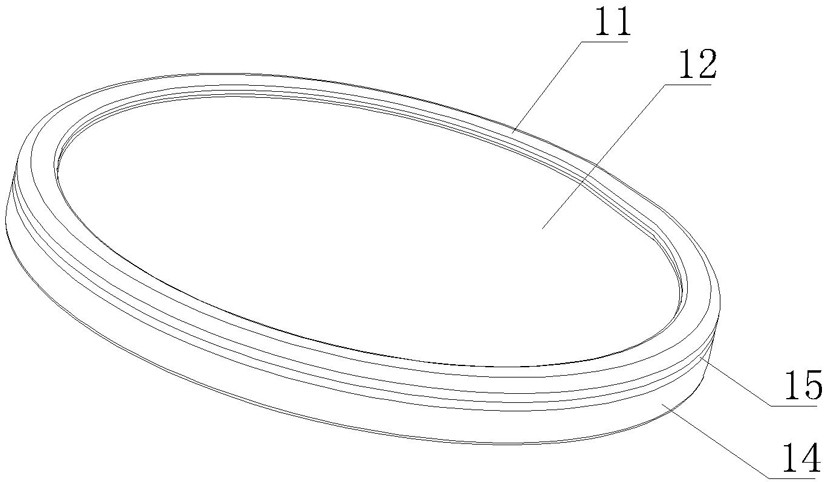

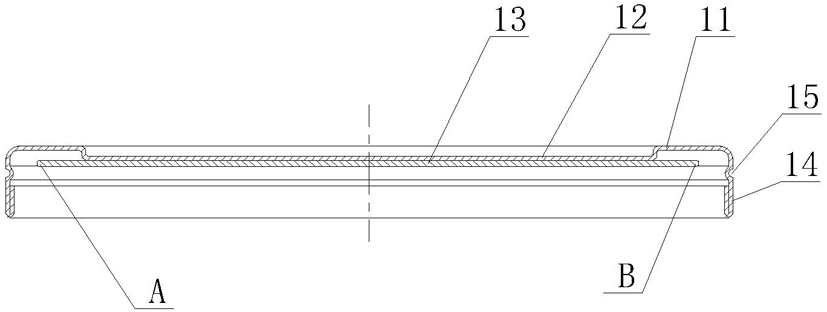

Production process of outwards-buckled type paper cup cover

ActiveCN109591379AInhibit sheddingImprove sealingPaper/cardboard articlesPulp and paper industryPaper cup

The invention discloses a production process of an outwards-buckled type paper cup cover. The production process is characterized by comprising the following steps that a, a circular sheet material for producing a paper cup cover is manufactured; b, the peripheral sides of the circular sheet material are bent downwards to form cup cover outer edges, and a middle unbent portion of the circular sheet material becomes a cup cover body; c. the bottoms of the cup cover outer edges are bent upwards to form a cup cover folding bottom; d, the middle portion of the cup cover body is downwards bent to form a sinking step; e. a round inwards-buckling paper sheet is made; and f, an inwards-buckling paper sheet is attached to the bottom of the sinking step, and the inwards-buckling paper sheet and thecup cover body have certain eccentricity. By means of the outwards-buckled type paper cup cover produced by the above process, cup cover falling can be effectively prevented during use in cooperationwith a paper cup with an inwards-buckling part, and it is ensured that the interior of a cup is sealed and reliable.

Owner:ZHEJIANG NEW DEBAO MACHINERY

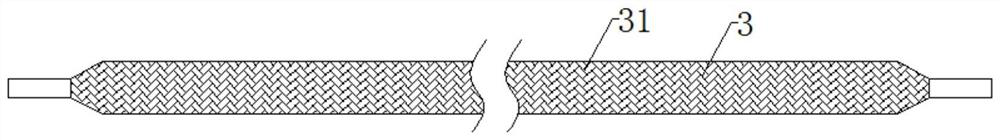

Tufted chemical fiber carpet capable of being completely recycled and preparation method thereof

PendingCN112659687AWon't happenSimple processSynthetic resin layered productsLaminationPolymer scienceAdhesive

The invention discloses a tufted chemical fiber carpet capable of being completely recycled and a preparation method thereof. The carpet is composed of a carpet surface layer and a base cloth layer. The base cloth layer is a composite base cloth layer formed by a chemical fiber knitted or woven fabric and a needle-punched chemical fiber non-woven fabric; the carpet surface layer comprises a tufting layer which is formed on one side of the chemical fiber knitted or tatted fabric after tufting processing is performed on the composite base cloth layer by using chemical fiber yarns; and the roots of the chemical fiber yarns raised on the bottom surface of the base cloth layer and the needled chemical fiber non-woven fabric at the bottom of the composite base cloth layer are fused into a whole by utilizing high-temperature fusion. The tufted chemical fiber carpet capable of being completely recycled has an excellent fluff fixing effect and has an antiskid effect; other chemical substances such as adhesives and anti-skid materials are not used in the whole production process, and no pollution is generated; and the whole product can be completely recovered and then melted and granulated again, so that secondary utilization is realized, and pollution and damage to the environment are greatly reduced.

Owner:KUNSHAN YIJIAJU TEXTILE CO LTD

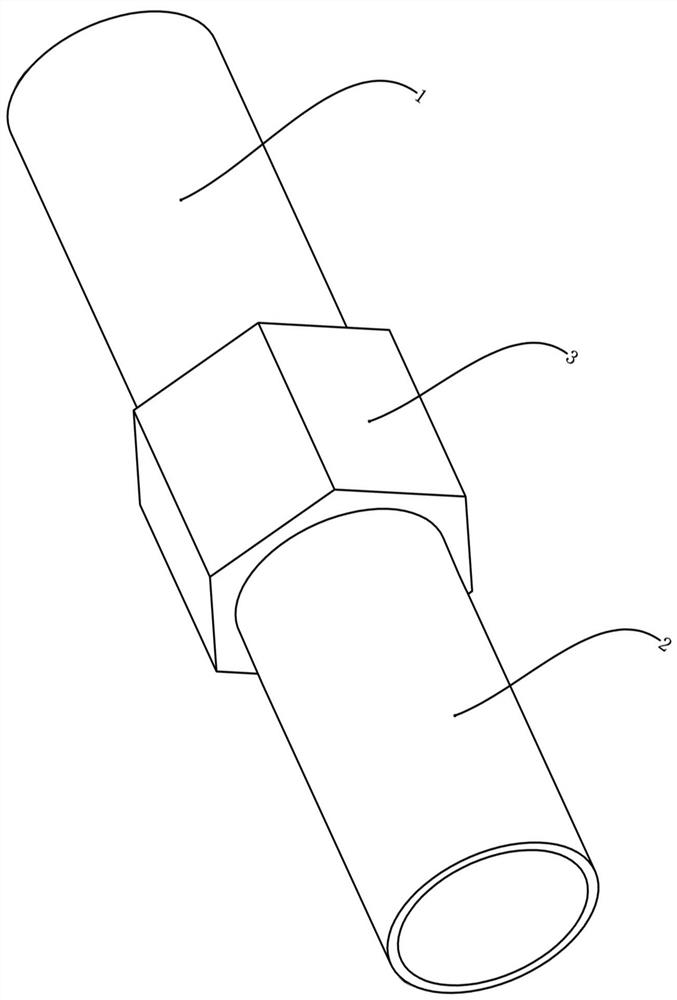

Half-type pipeline rush-repair segment

InactiveCN106813045AEasy to installEasy to disassemblePipe elementsMechanical engineeringEngineering

Owner:CHONGQING KEZHONG MACHINERY

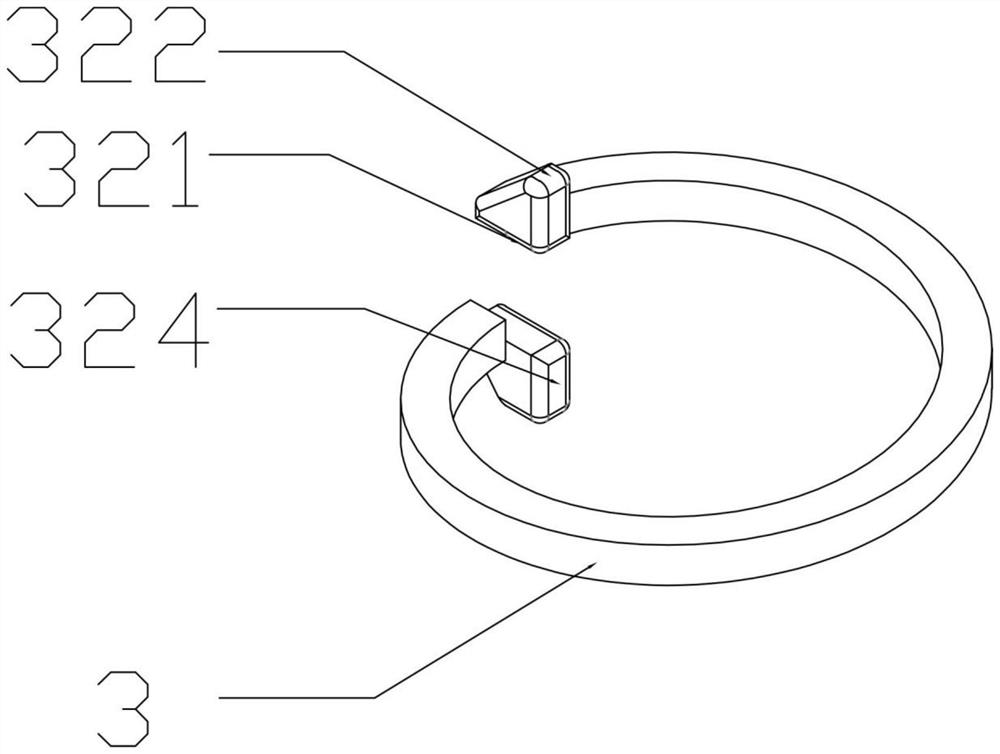

Screw, nut and gasket combination

The invention discloses a screw, nut and gasket combination, a screw and a nut are respectively provided with a first groove and a second groove which transversely penetrate through threads, and the two ends of a gasket are provided with protruding parts. After the screw rod, the nut and the gasket are tightly connected, the protruding parts are clamped in the first groove and the second groove. According to the combination, a fastened nut can be effectively prevented from loosening under the vibration condition, the fastening effect of the nut is improved, and the good market value is achieved.

Owner:李荣生

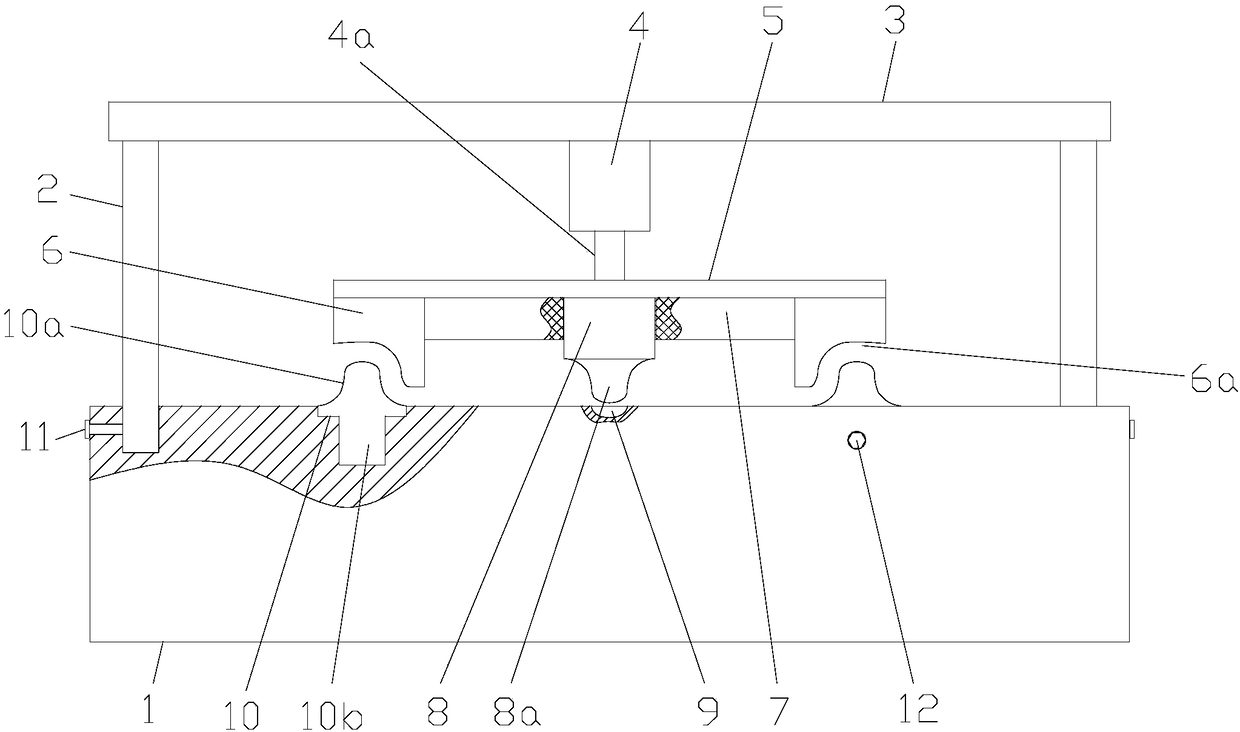

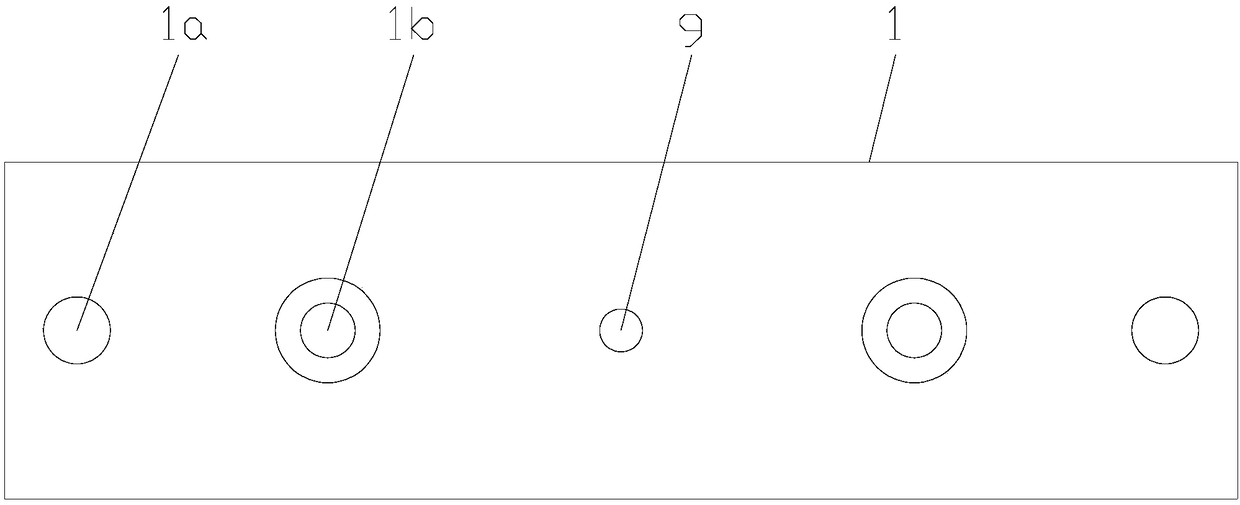

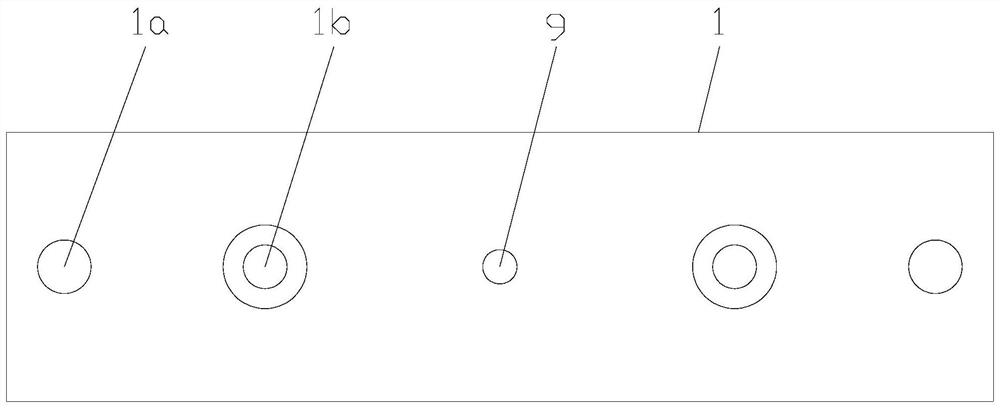

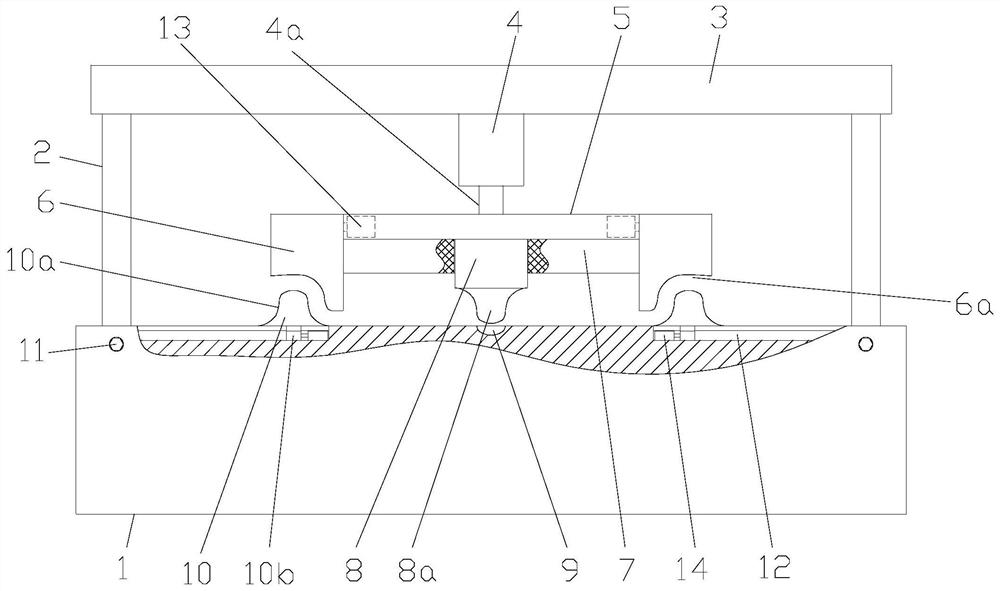

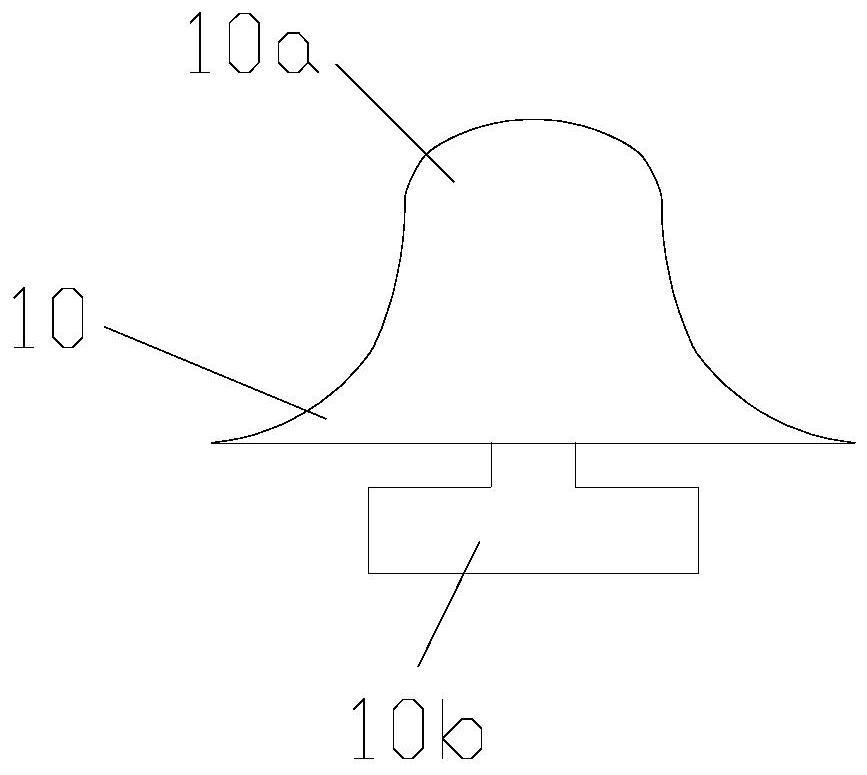

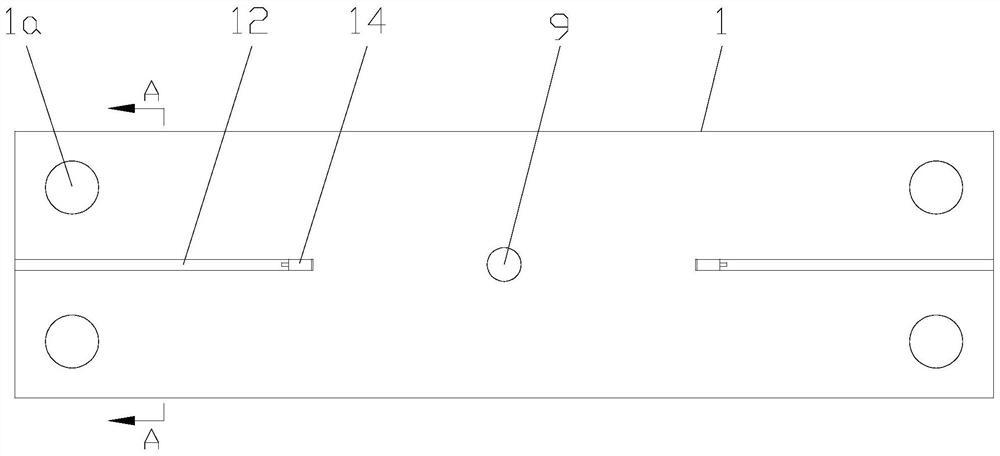

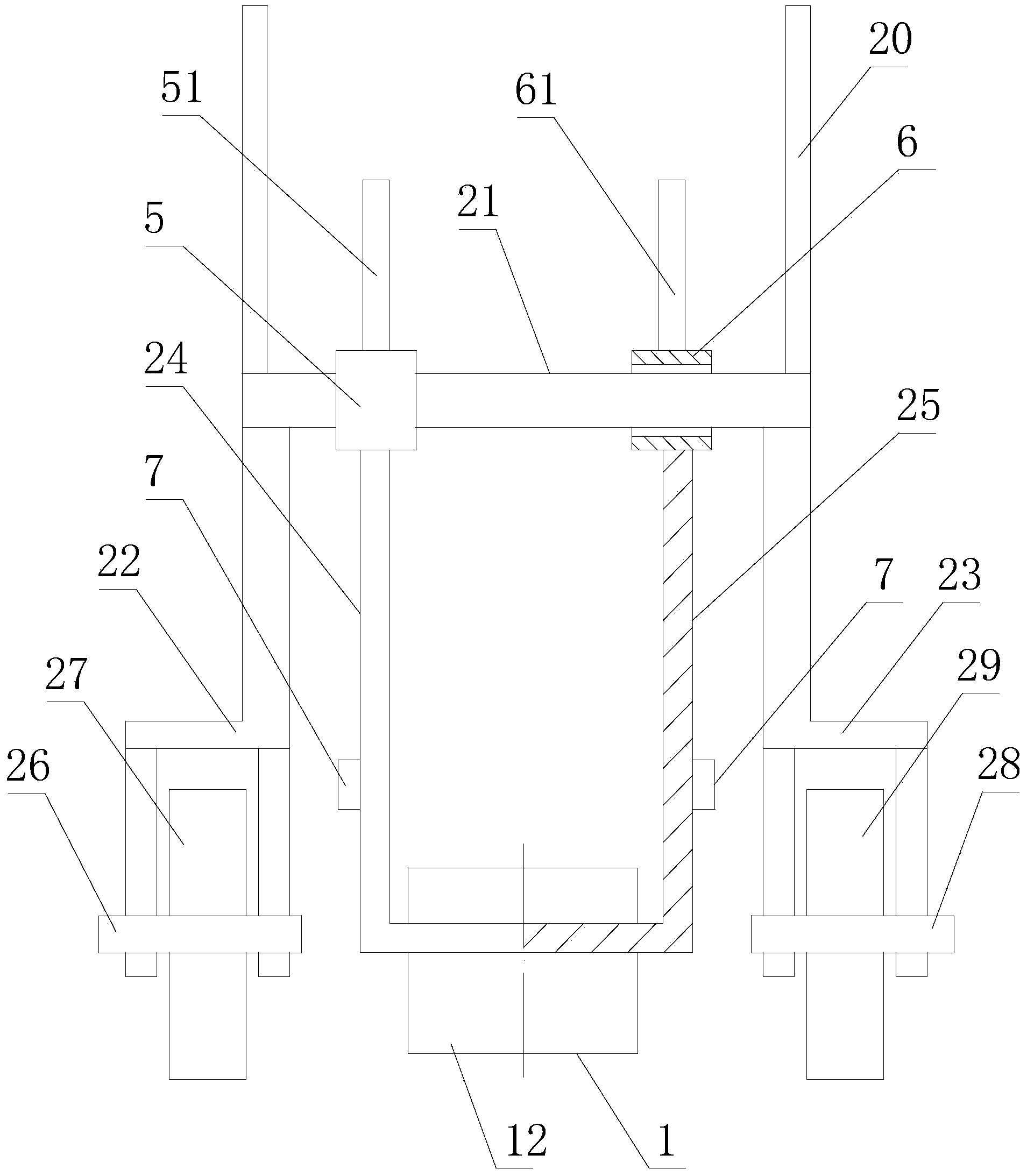

Workpiece fastening and clamping mechanism

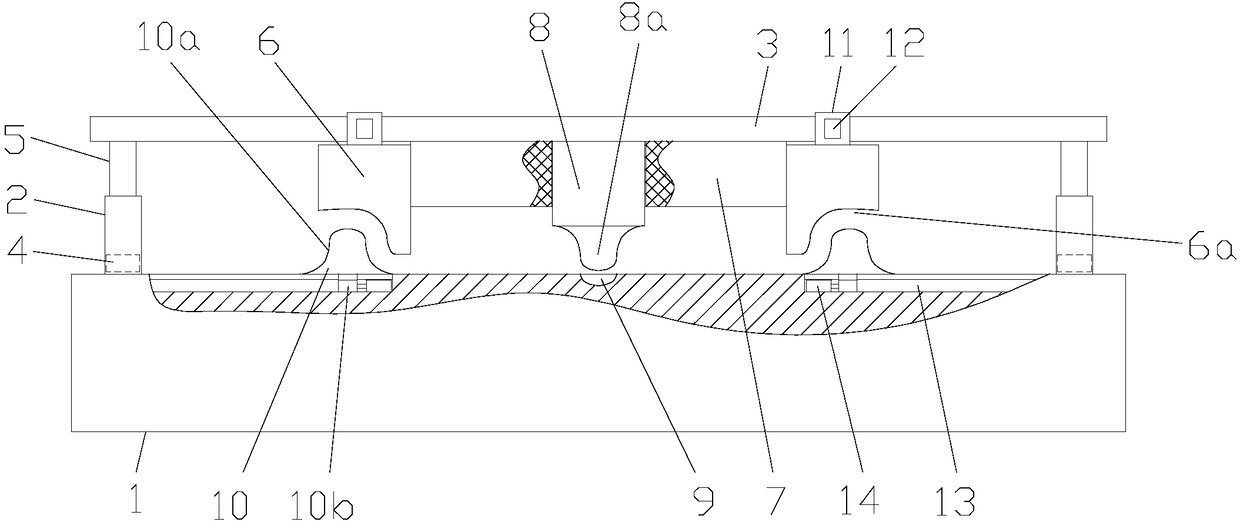

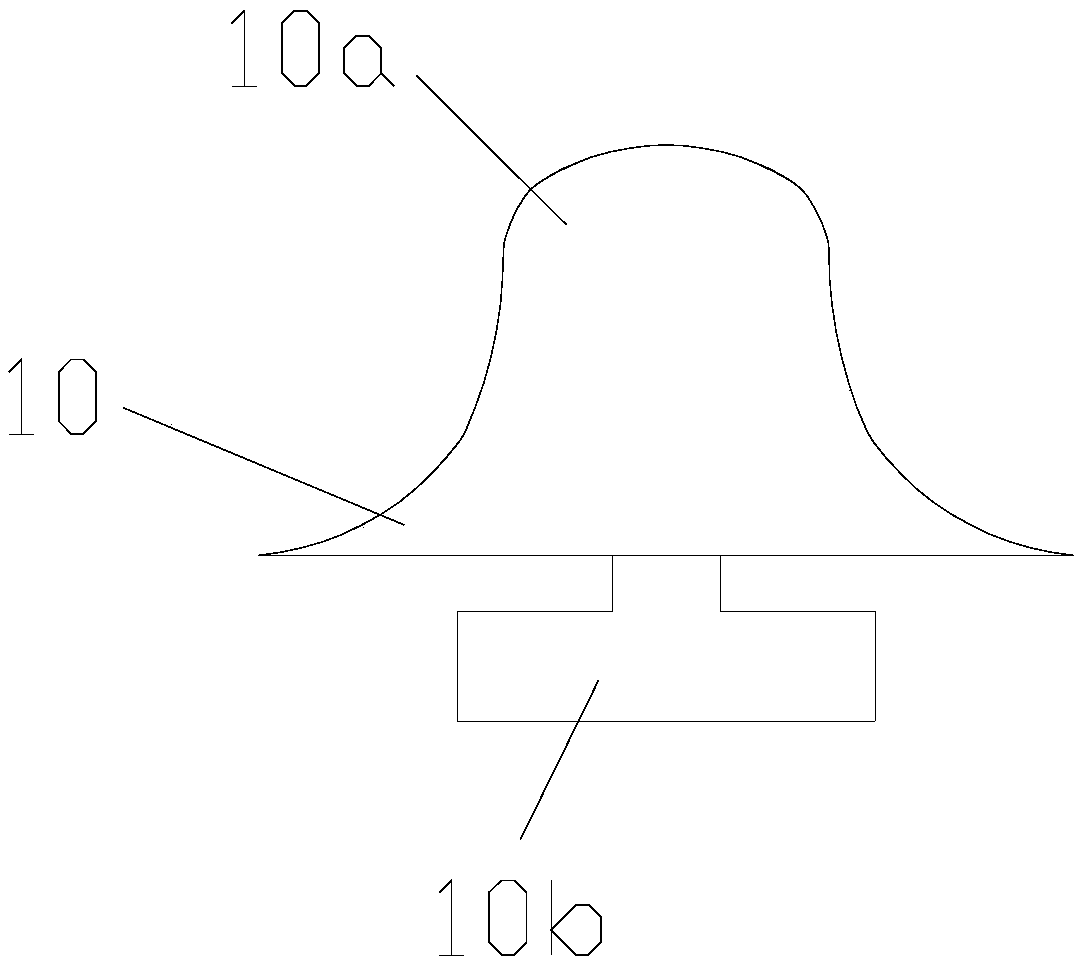

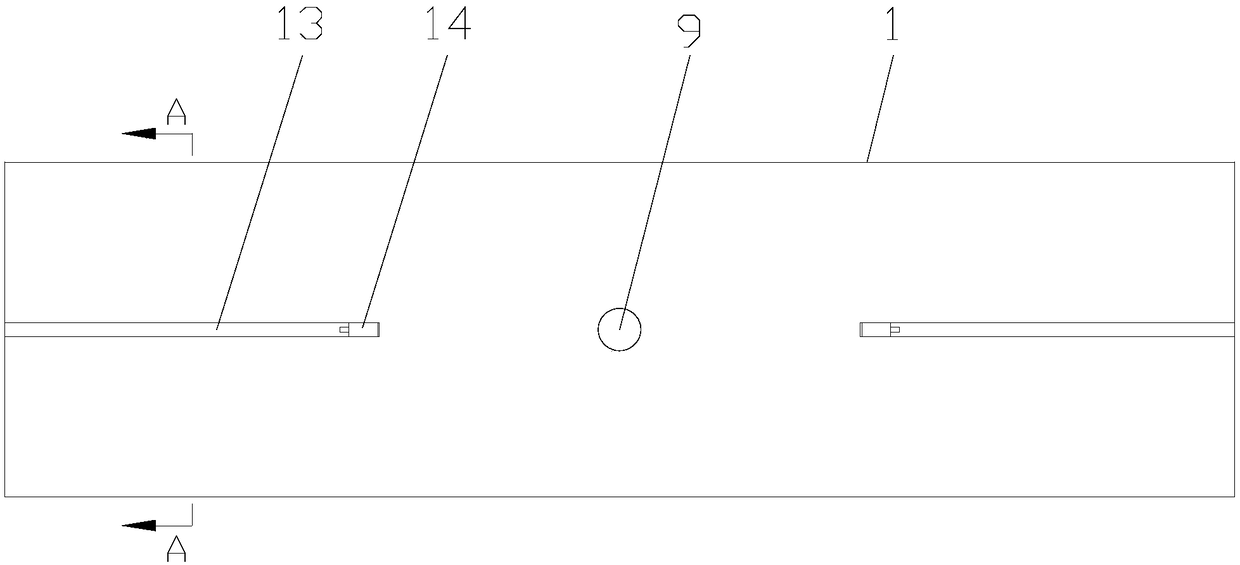

ActiveCN108406265AQuick snapEfficient fasteningWork holdersMetal working apparatusEngineeringPiston rod

The invention discloses a workpiece fastening and clamping mechanism. The workpiece fastening and clamping mechanism comprises a working platform, a support frame and a hold-down component, wherein the support frame comprises uprights and a transverse support beam; the hold-down component comprises a lift cylinder, a connecting plate, pressure blocks I, a pressure block II and a buffer piece; thelift cylinder is fixed at the bottom of the transverse support beam; the connecting plate is fixed to the end part of a piston rod of the lift cylinder; the pressure blocks I, the pressure block II and the buffer piece are fixed at the bottom of the connecting plate; the two pressure blocks are symmetrically arranged on two sides of the buffer piece; two jacking blocks are arranged on the top surface of the working platform and respectively located right below the corresponding pressure blocks; an arc-shaped notch portion is formed in the lower end of each of the two pressure blocks I; a bulbI matched with the corresponding arc-shaped notch portion is arranged at the upper end of each the two jacking blocks; a bulb II is arranged at the lower end of the pressing block II; and the workingplatform is provided with a concave cavity matched with the bulb II. The workpiece fastening and clamping mechanism is simple in structure and convenient to use, realizes efficient and quick fasteningof a workpiece, and can achieve stamping operation, the production efficiency is improved, and the cost is lowered.

Owner:重庆恩光科技有限公司

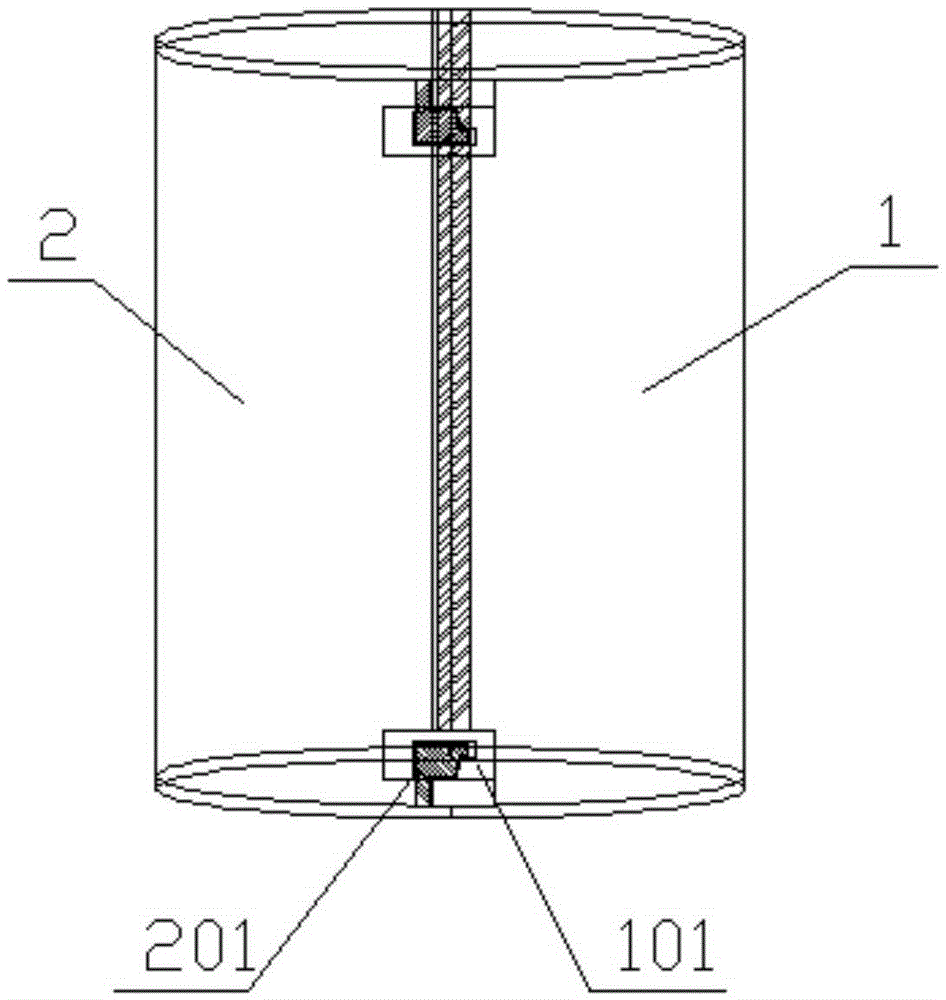

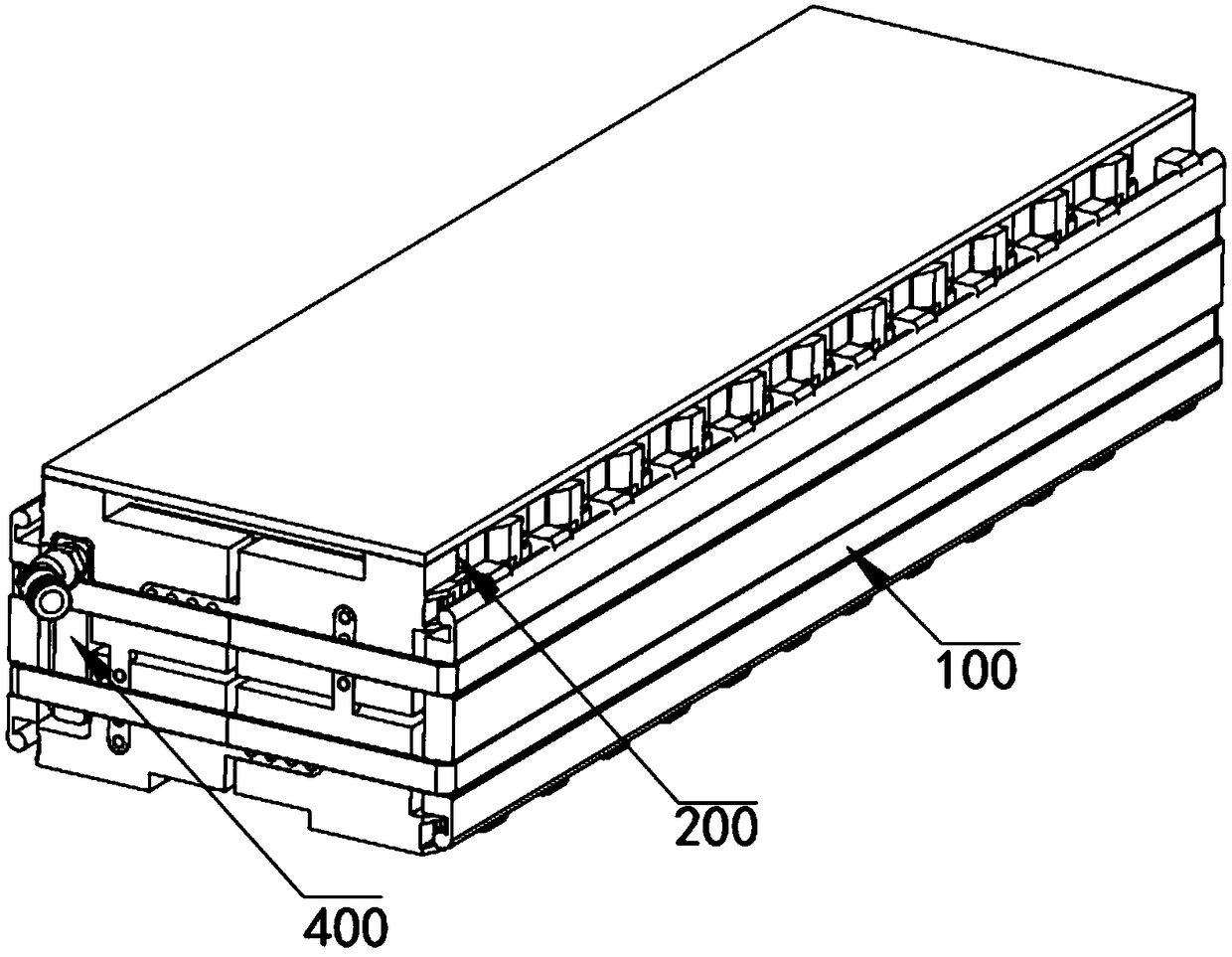

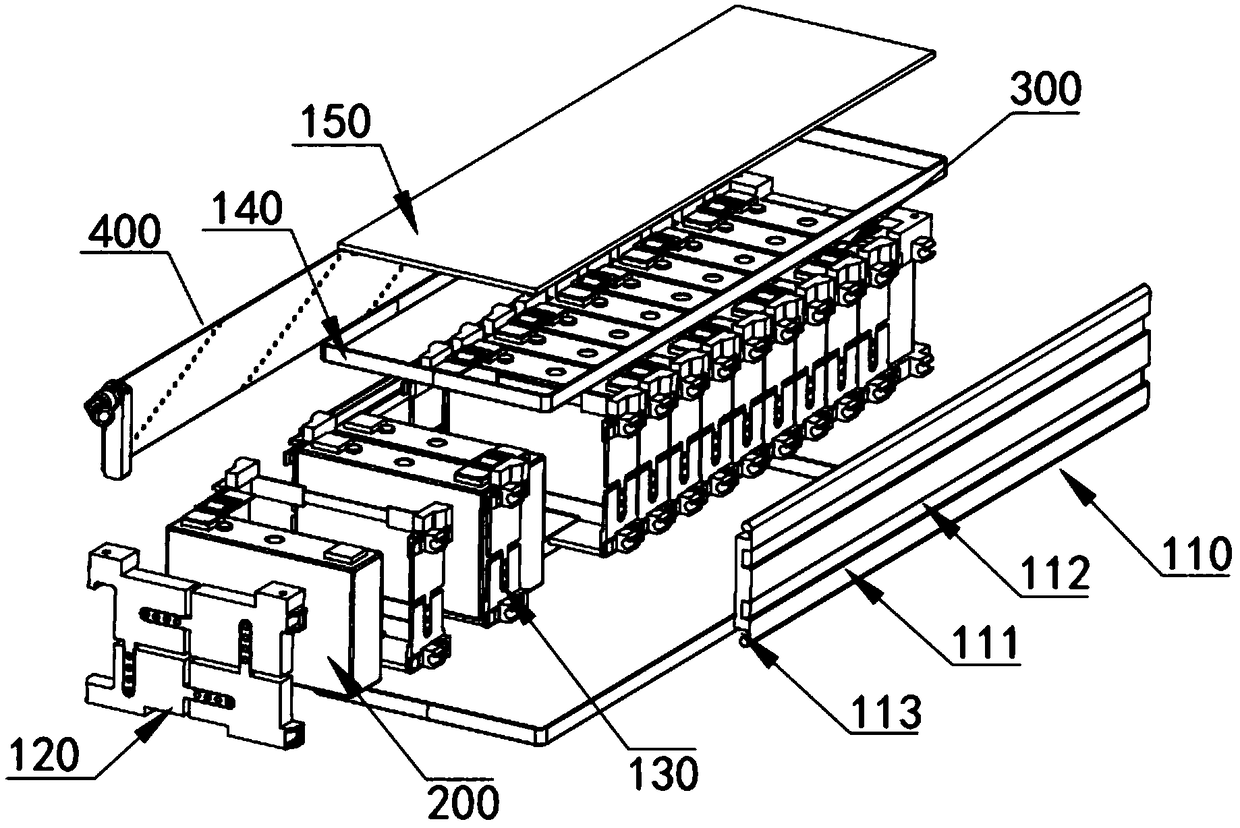

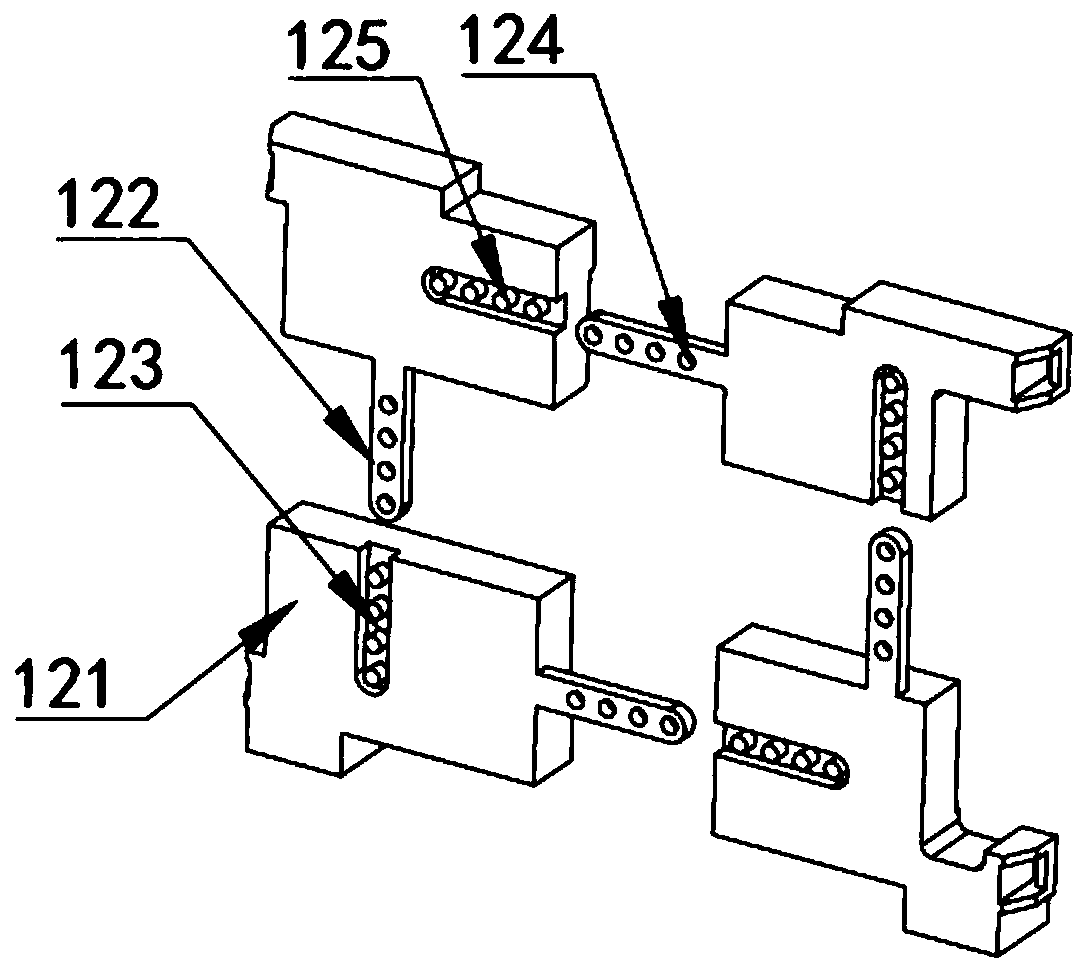

Efficient power battery module

PendingCN108923007AEasy to installGood fixed effectSecondary cellsCell component detailsEngineeringPower battery

The invention relates to the field of lithium batteries, in particular to an efficient power battery module, which comprises an outer frame, a plurality of batteries disposed in the outer frame, and aconnector for connecting the plurality of batteries in series. The outer frame comprises two parallel side plates, two end plates connected to the two ends of the two parallel side plates and a plurality of partition plates which are arranged between the two side plates and parallel to the end plates; the plurality of groups of batteries are partitioned through the partition plates; and the outerframe further comprises a heat conducting plate which is arranged on the inner side of the partition plate and attached to the batteries. The efficient power battery module in the invention is convenient for installation, good in stability and strong in reliability and facilitates reduction of potential safety hazards.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

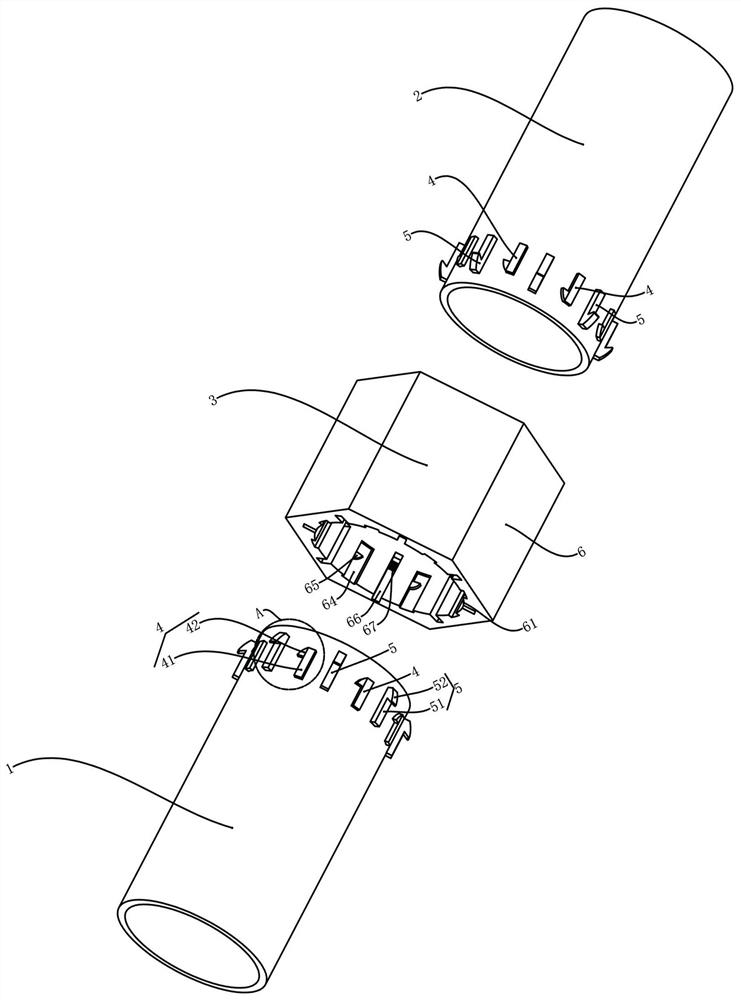

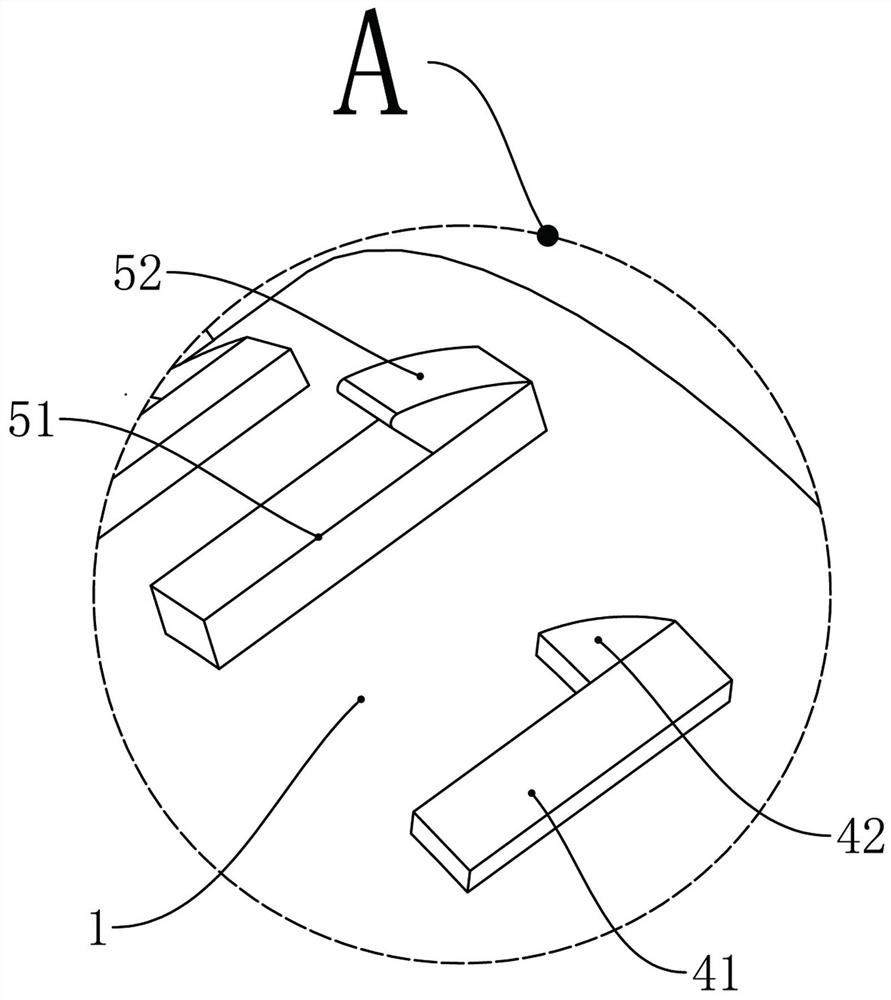

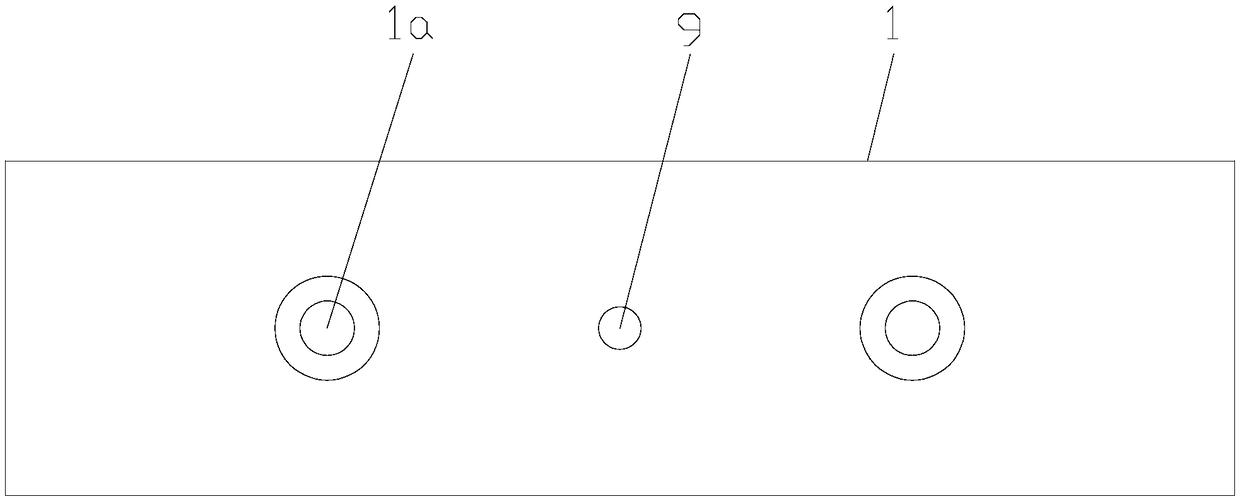

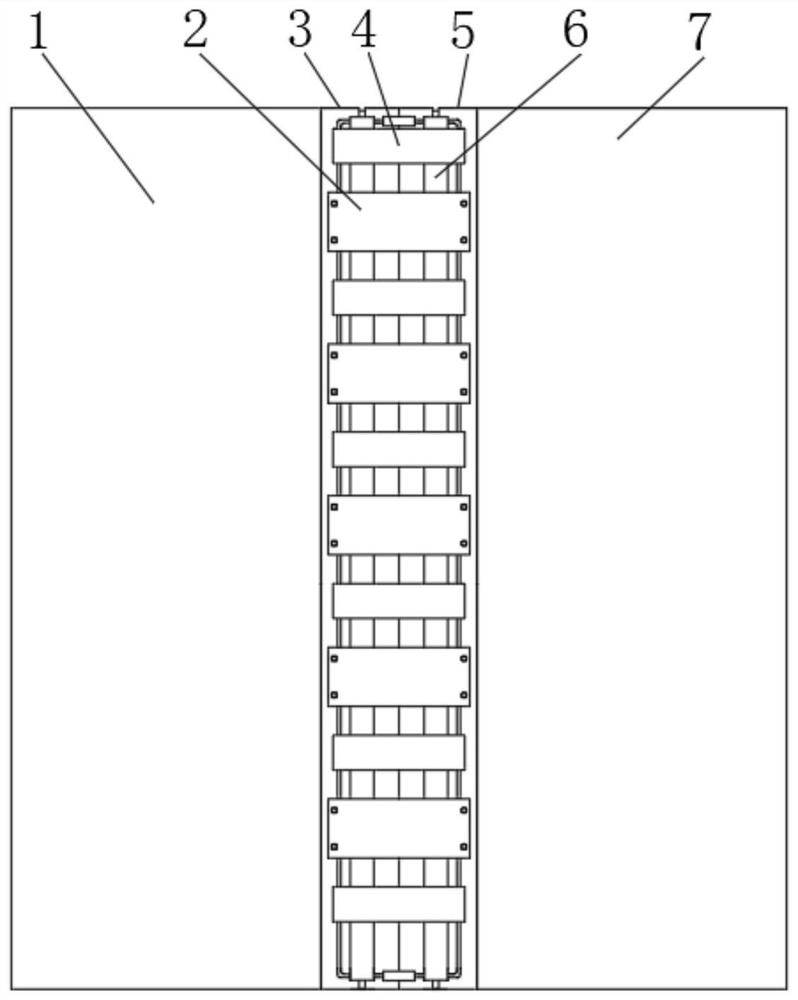

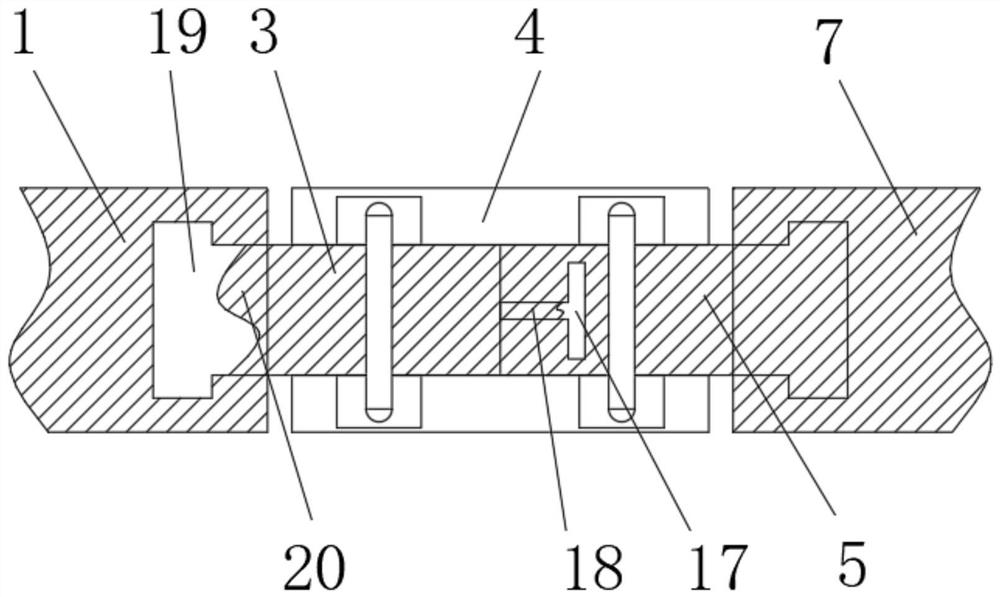

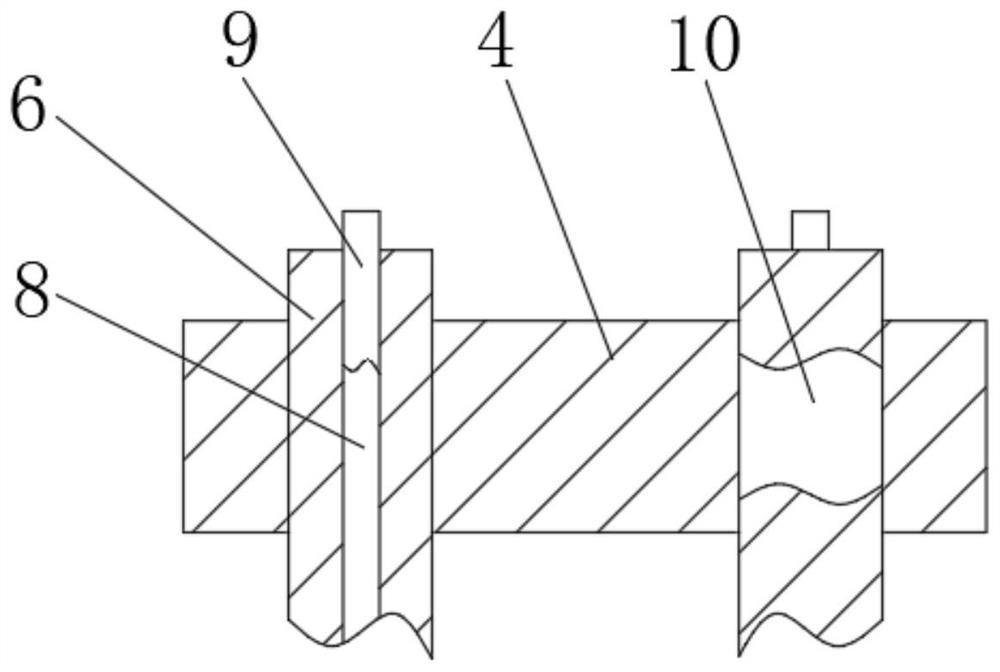

Efficient pipeline connecting buckle

ActiveCN114838229AImprove fastening effectGuaranteed location accuracyCouplingsPipe connection arrangementsStructural engineeringMechanical engineering

Owner:焦作淄华塑胶管业有限公司

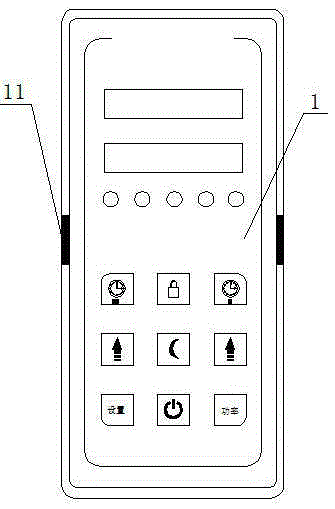

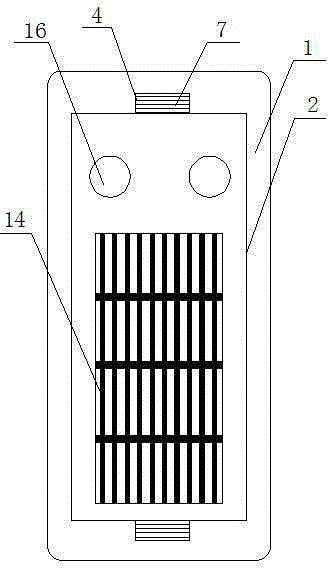

Specialized detachable temperature controller for electric heater

ActiveCN105240929ARealize detachable connectionQuick releaseLighting and heating apparatusSpace heating and ventilation detailsEngineeringInjection moulding

The invention discloses a specialized detachable temperature controller for an electric heater. The specialized detachable temperature controller comprises an operation panel and a protective shell, wherein a baseplate is arranged in the protective shell; the top and bottom of the joint surface of the operation panel and the protective shell are connected by a clamping device in a clamping manner; the left and right sides of the joint surface of the operation panel and the protective shell are connected by a fastening device in a fastening manner; both the top and bottom of the protective shell are also provided with embedded connectors which are integrally injected and molded on the top and the bottom; the embedded connectors and the electric heater are arranged in an embedded manner; and the left and right sides of the front of the operation panel are also provided with dismantling rings. The specialized detachable temperature controller has the advantages of convenience to install, dismantle and overhaul, simple structure, good clamping connection and fastening effects, accurate and rapid location, shortening of installation and dismantling time, good installation stability, time saving and labor saving.

Owner:王旭明

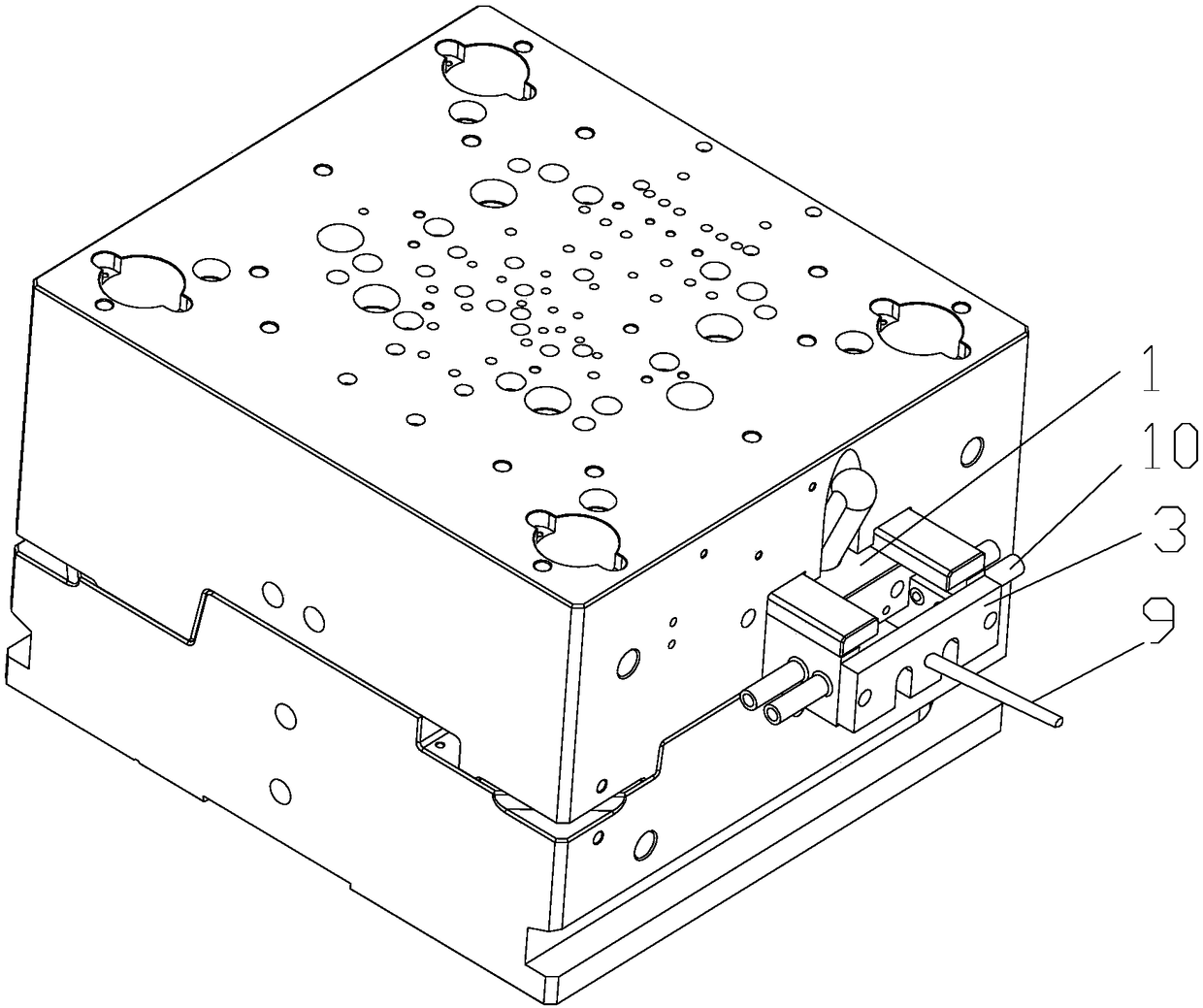

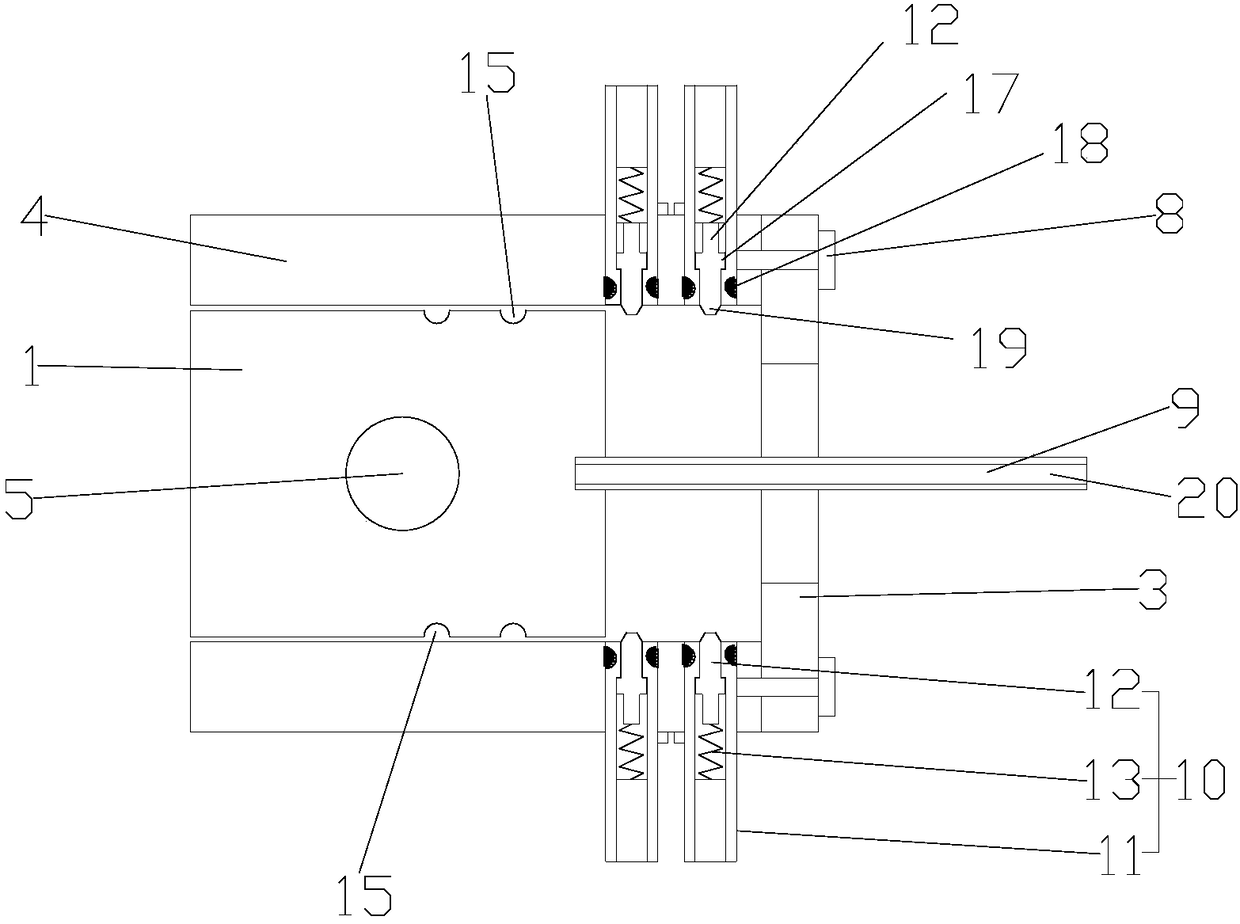

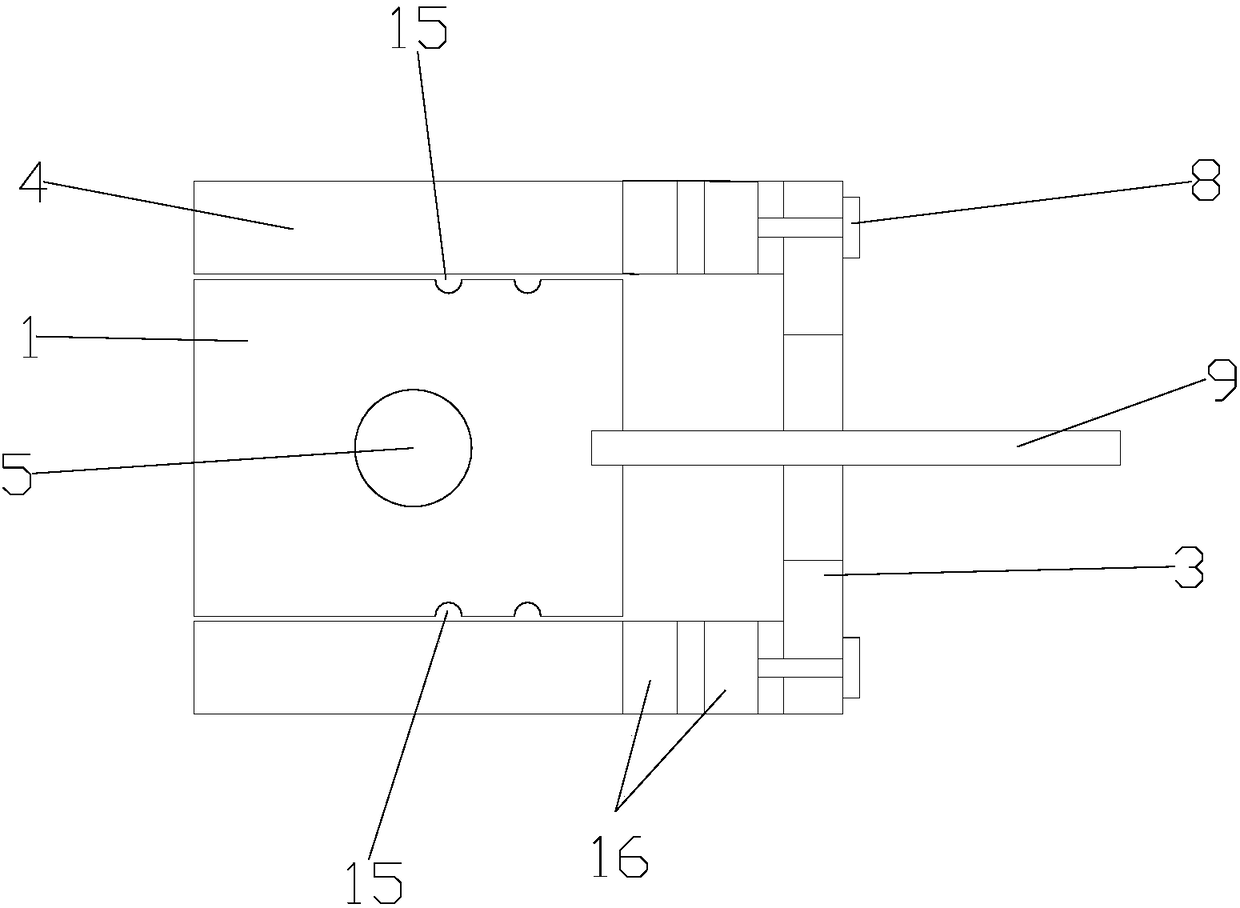

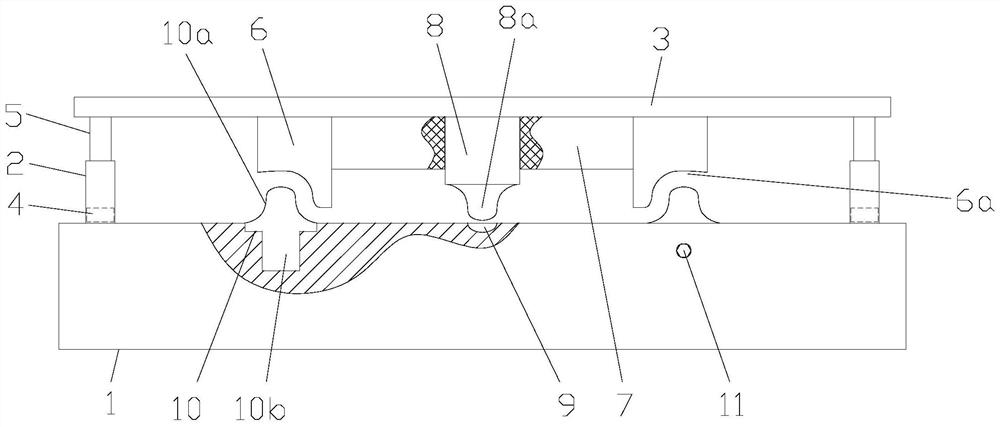

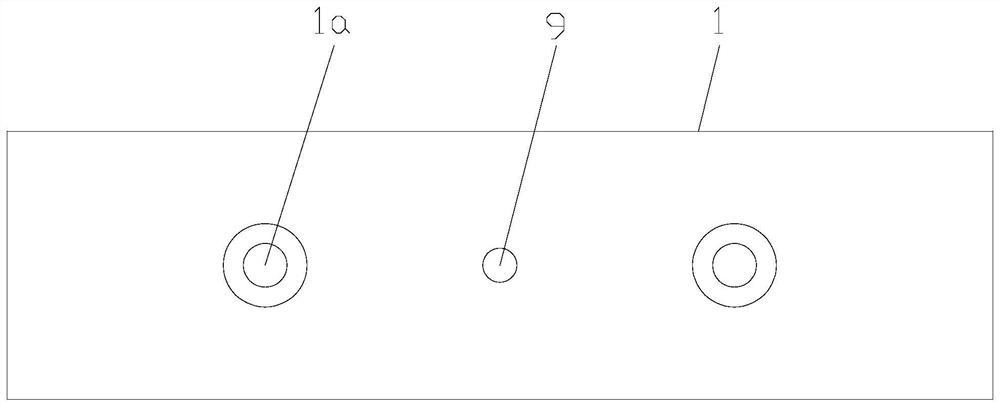

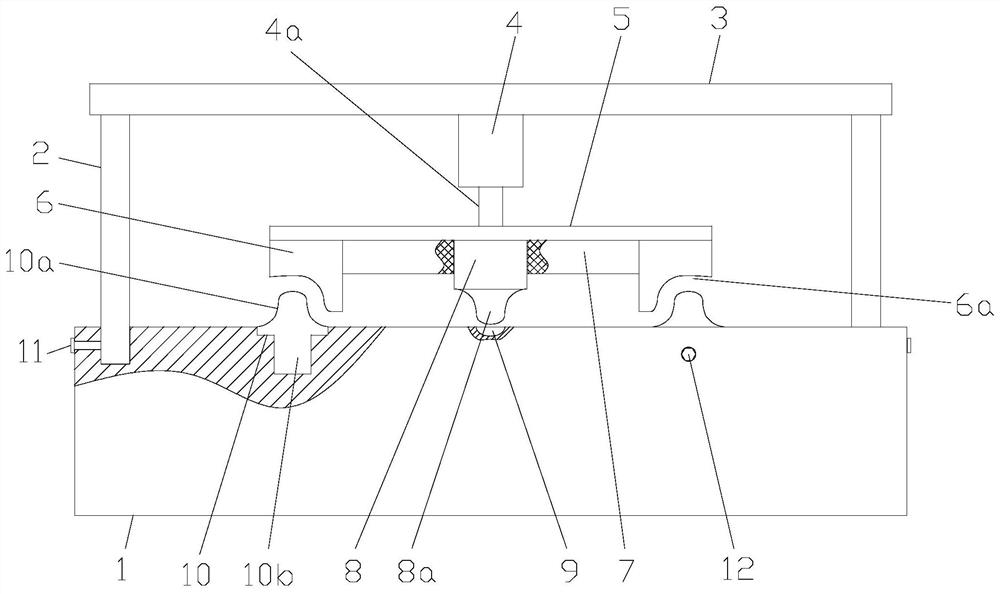

Sliding block mechanism of die-casting die

The invention discloses a sliding block mechanism of a die-casting die. According to the technical scheme, the sliding block mechanism comprises a sliding block, an inclined guide column, limiting blocks and pressing strips; an inclined hole is formed in the sliding block, the inclined guide column penetrates through the inclined hole, and the sliding block is connected between the pressing stripsin a sliding mode; the limiting blocks are arranged between the pressing strips, a spring is arranged between the limiting blocks and the sliding block, and bead shifting mechanisms are arranged on the pressing strips; the bead shifting mechanisms comprise bead sleeves, shifting beads and pressure springs, and the shifting beads and the pressure springs are arranged in the bead sleeves correspondingly; the shifting beads are connected with one ends of the pressure springs, the bead sleeves are arranged on the pressing strips, and bead holes are formed in the two sides of the sliding block; and the bead holes correspond to the shifting beads. When the die is opened, the sliding block is pulled by the spring, so that the sliding block is fixed so as to prevent the condition that due to thefact that the spring loses effect when the die is closed, the sliding block moves to cause the die to be damaged, and in the process that the sliding block moves outwards, the bead shifting mechanismis used for carrying out the limitation, so that the safety coefficient of the sliding block during die closing is improved.

Owner:宁波埃利特模具制造有限公司

Clamping device for fastening workpieces

ActiveCN108393672BQuick snapFastening efficiencyMetal-working feeding devicesMetal working apparatusCollapsed cavityEngineering

The invention discloses a clamping device for workpiece fastening, which includes a working platform and a pressing mechanism. The pressing mechanism includes a support frame, a pressing block I, a pressing block II, and a buffer member. The supporting frame includes a lifting rod assembly and a horizontal The support beam, the pressing block I, the pressing block II, and the buffer are fixed at the bottom of the middle of the horizontal support beam. There are two pressing blocks I and are symmetrically arranged on both sides of the buffer. The top blocks are respectively located directly below the corresponding briquetting blocks I, and the opposite sides of the lower ends of the two briquetting blocks I are respectively provided with arc-shaped notches. At the bottom of the cross support beam, the lower end is provided with a ball head II, and the top surface of the working platform is provided with a concave cavity. The invention can not only realize high-efficiency and fast buckling of workpieces, improve production efficiency and reduce cost, but also realize stamping operation, and meanwhile, the overall structure is simple, and it is convenient for installation and replacement.

Owner:重庆恩光科技有限公司

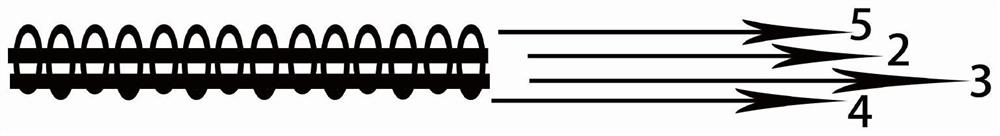

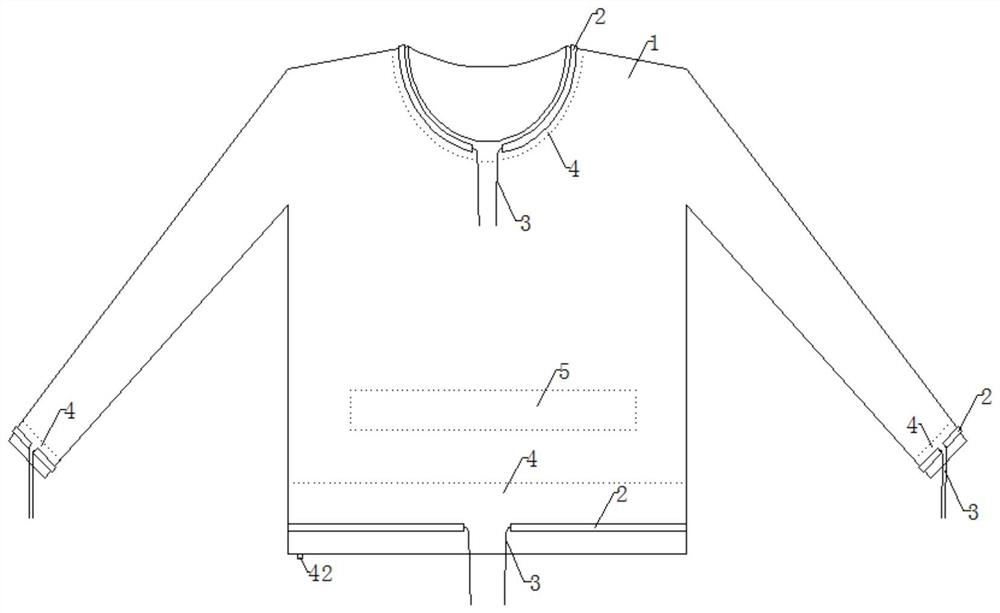

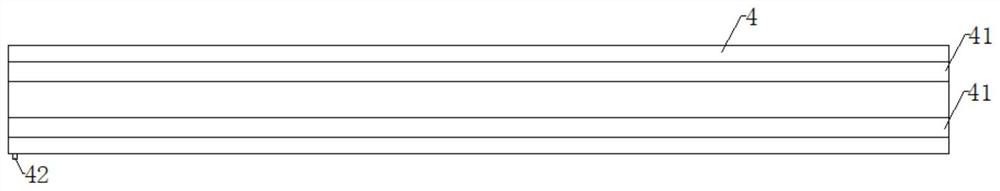

Functional garment

The invention relates to a functional garment, which belongs to the field of garment, and comprises a garment body, a heating wire is arranged in the fabric of the garment body, a bridle sleeve is arranged on the periphery of a collar and / or cuffs and / or a lower hem of the garment body, a water hose is arranged in the bridle sleeve, a bridle is arranged in the bridle sleeve, and the bridle comprises a bridle body. The bridle body is formed by weaving water stimulation shape memory fibers, the water stimulation shape memory fibers comprise long-strip-shaped fiber bodies and scaly structures arranged on the peripheries of the fiber bodies, a power source is arranged on the inner surface of fabric of the garment body, and the power source is electrically connected with the electric heating wires through a switch. Wherein the plurality of water hoses are provided with water holes. The warm-keeping garment can solve the problem that an existing warm-keeping garment is poor in warm-keeping performance.

Owner:安徽天孚服装智能制造有限责任公司

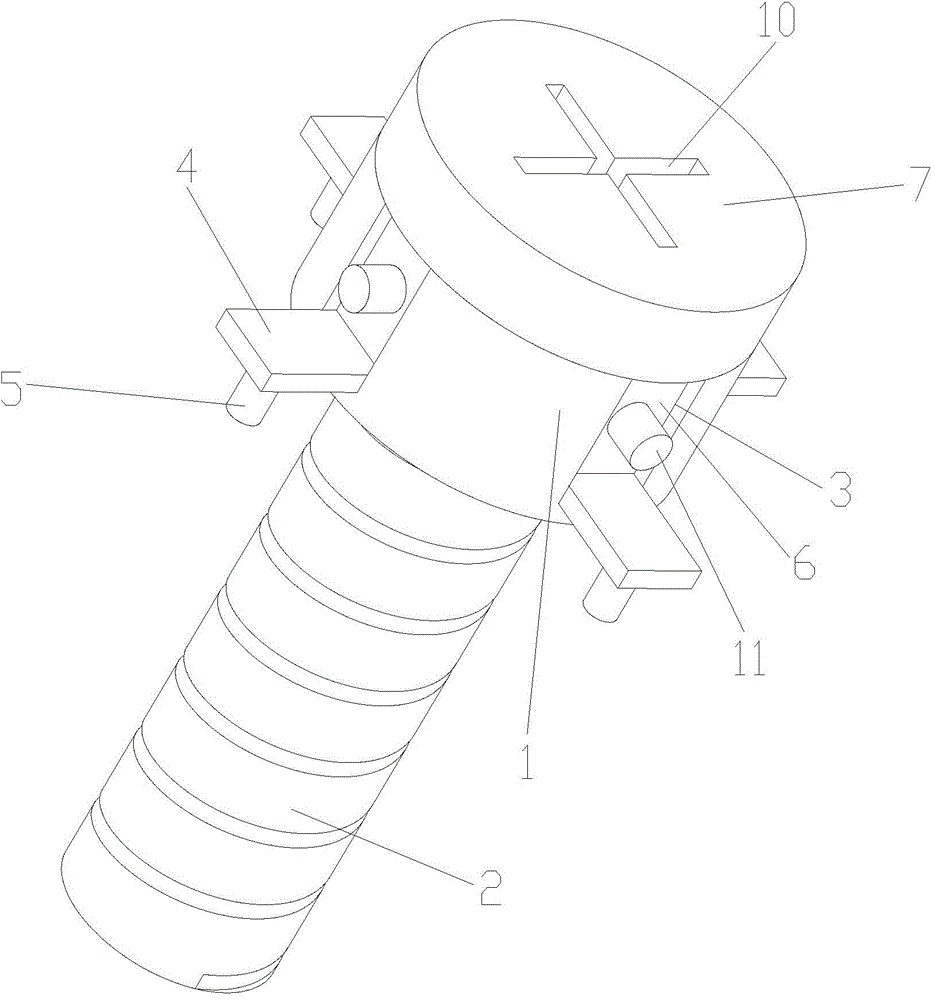

Bolt for mixer

The invention discloses a bolt for a mixing machine. The bolt comprises a bolt head and a screw. The bolt head and the screw are integrated. At least two fixing grooves are in annular array on the upper surface of the bolt head and are communicated with the outside. Fixing blocks are arranged in the fixing grooves. One ends of the fixing blocks extend out of the bolt head. Fixing columns are arranged on the lower surfaces of the portion, extending out of the bolt head, of the fixing blocks. Fastening blocks are arranged in the fixing grooves and above the fixing blocks. The upper surfaces of the fastening blocks are flush with the upper surface of the bolt head. A retaining block is arranged on the upper surface of the bolt head. The area of the lower surface of the retaining block is larger than or equal to the area of the upper surface of the bolt head. The bolt does not shake due to large mechanical vibration caused during working of the mixing machine, thread abrasion and weakening of bolt fastening effect are avoided, and accordingly, working performance and stability of the mixing machine are improved.

Owner:SUZHOU JINGWEI AGRI PROD

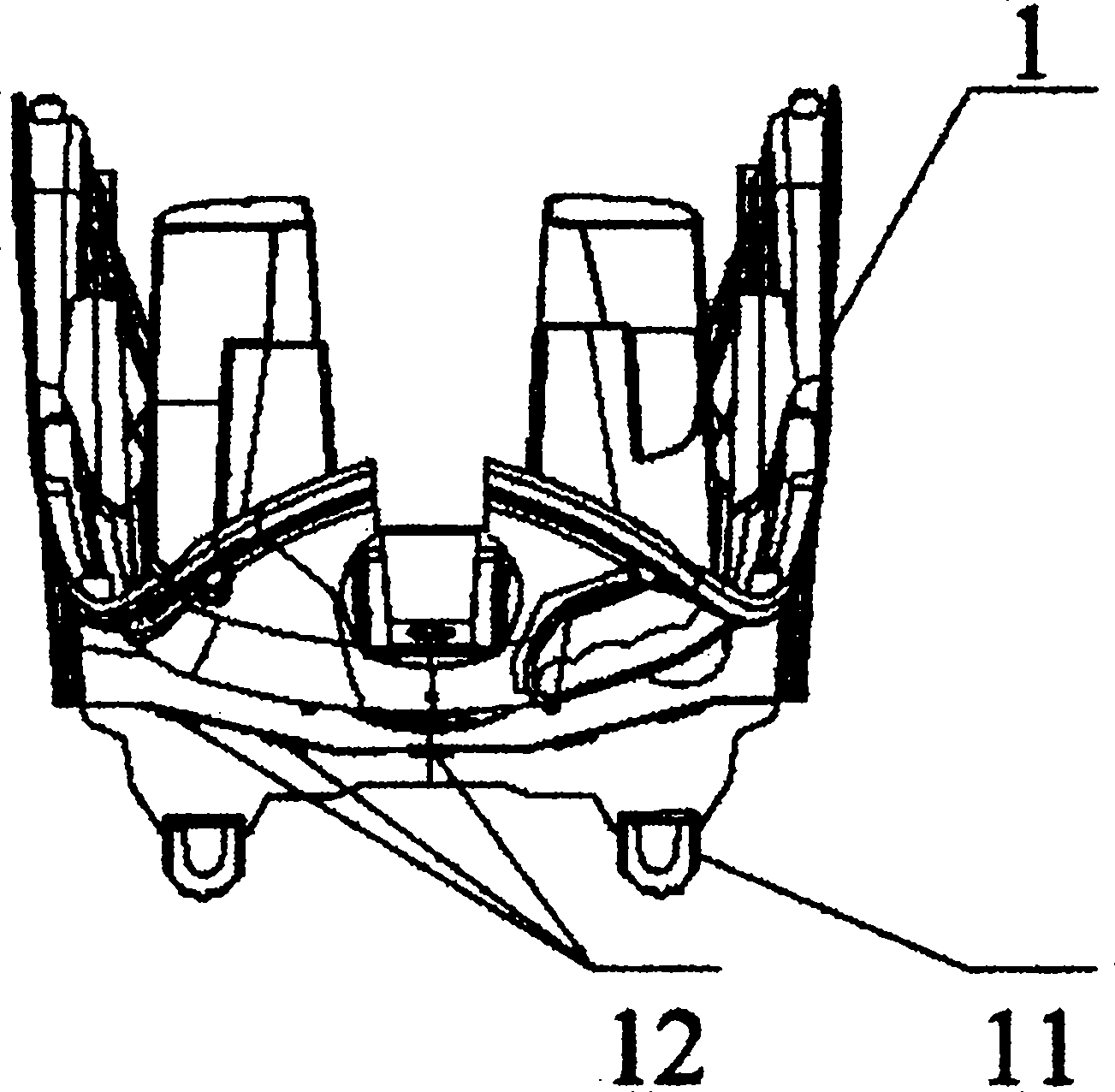

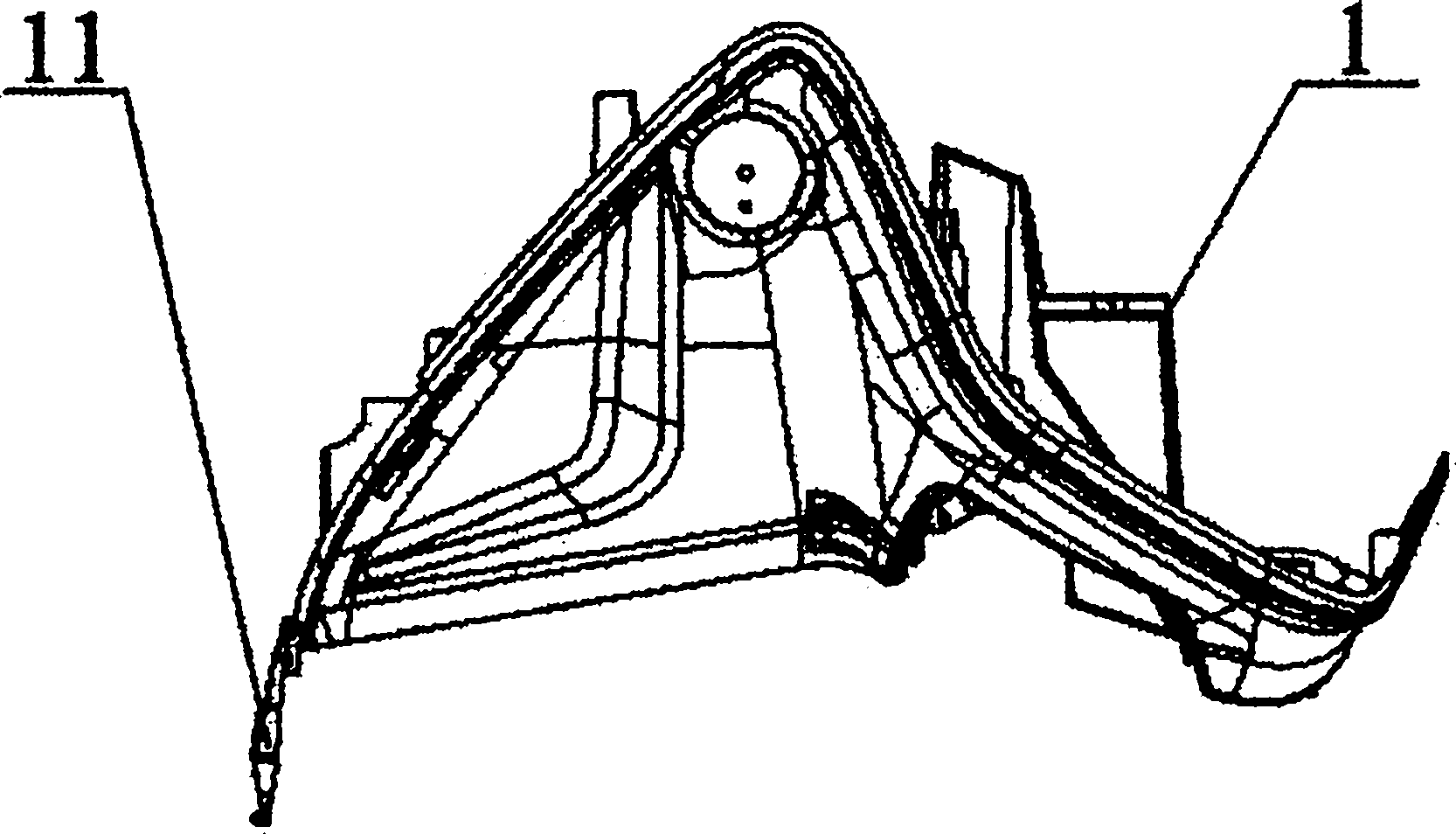

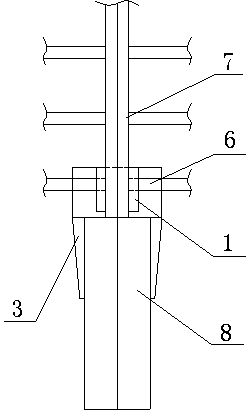

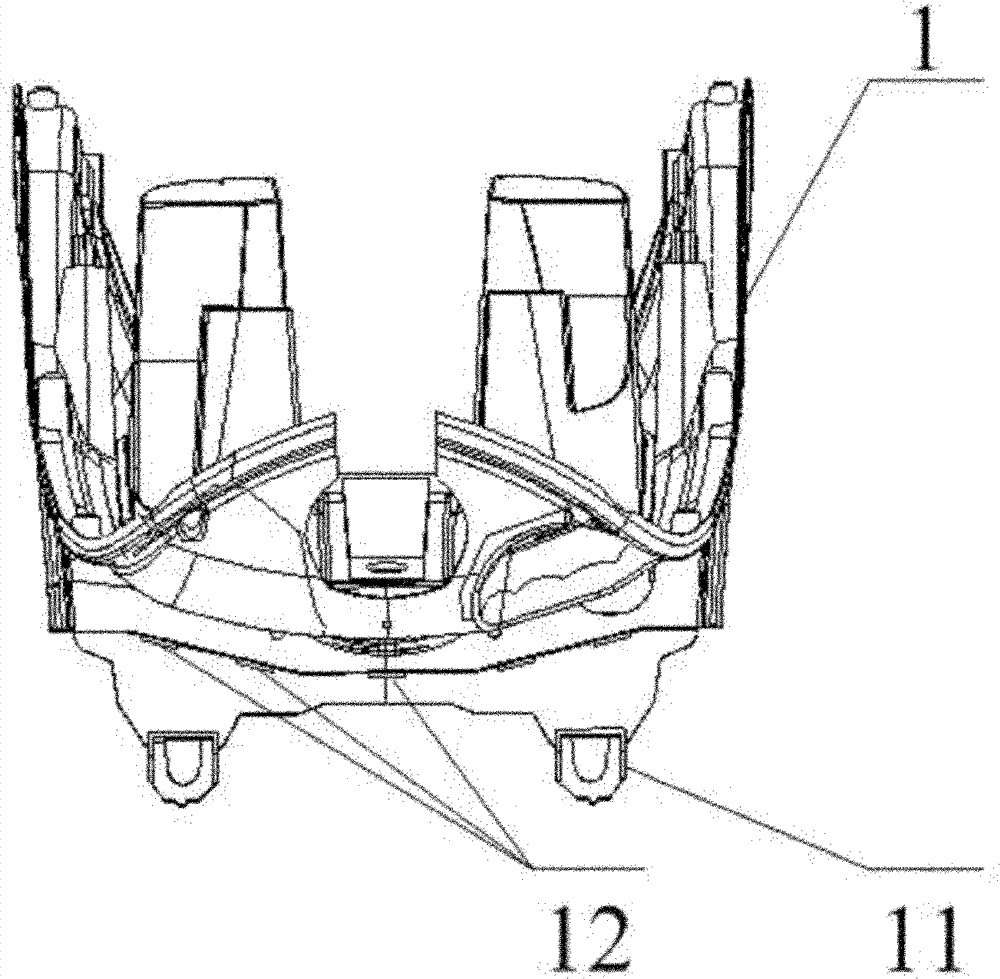

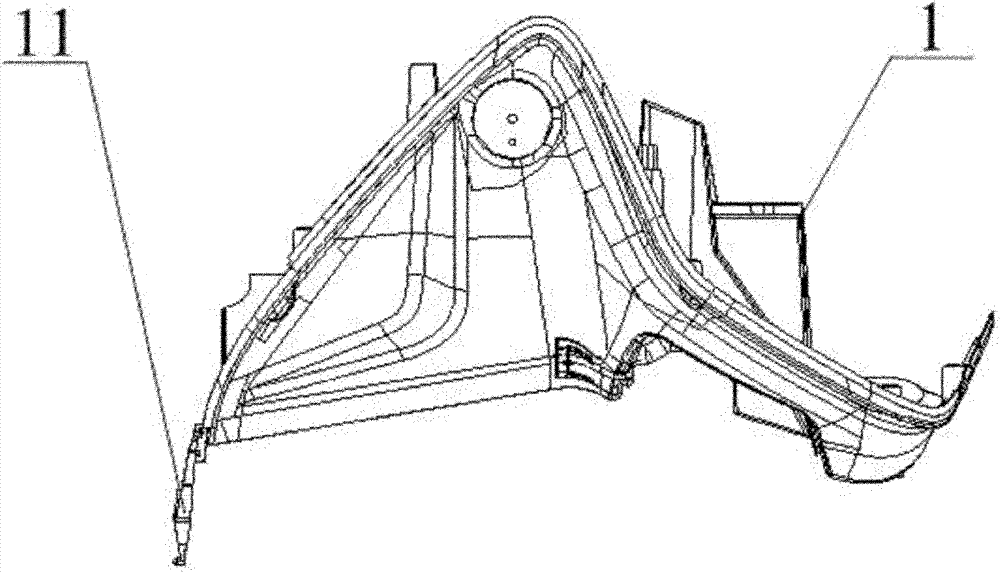

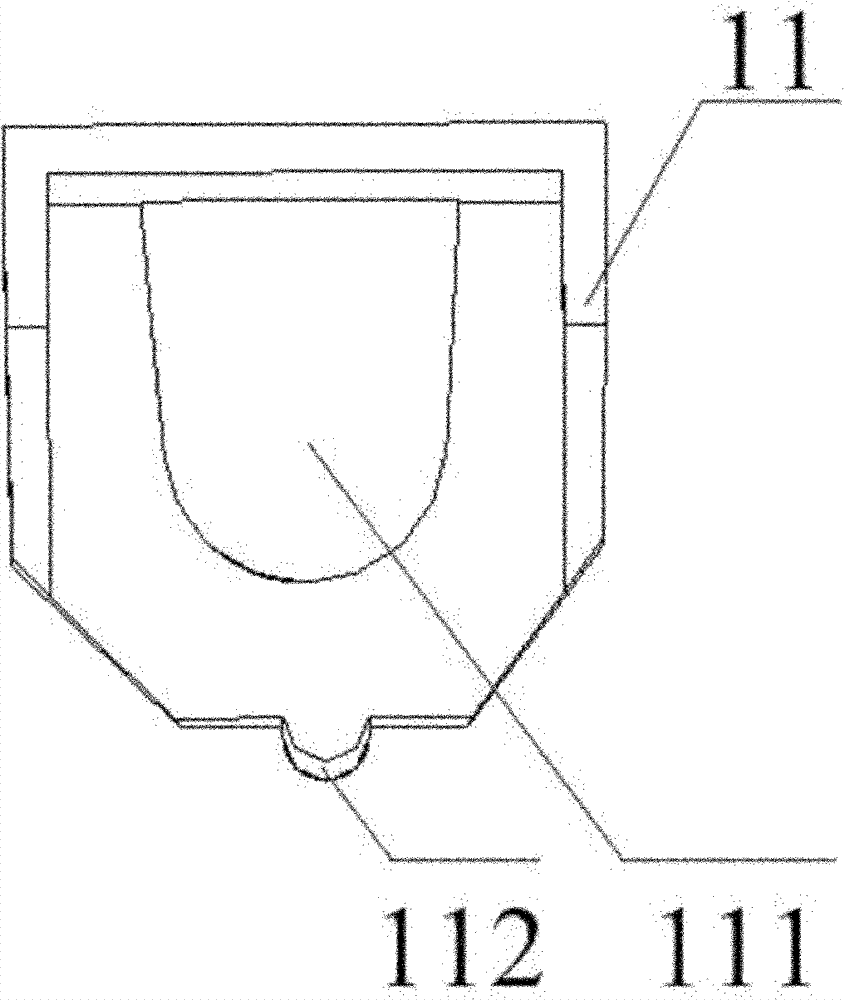

Cooperation structure for medium container and footrest of motorcycle and motorcycle

InactiveCN101973335AImprove fastening effectAvoid installation difficultiesFoot-restsMotorcyclesVehicle frameEngineering

Owner:CHONGQING LONCIN MOTOR

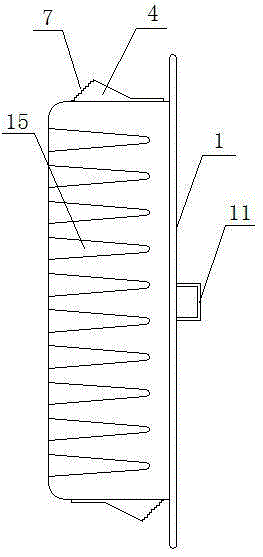

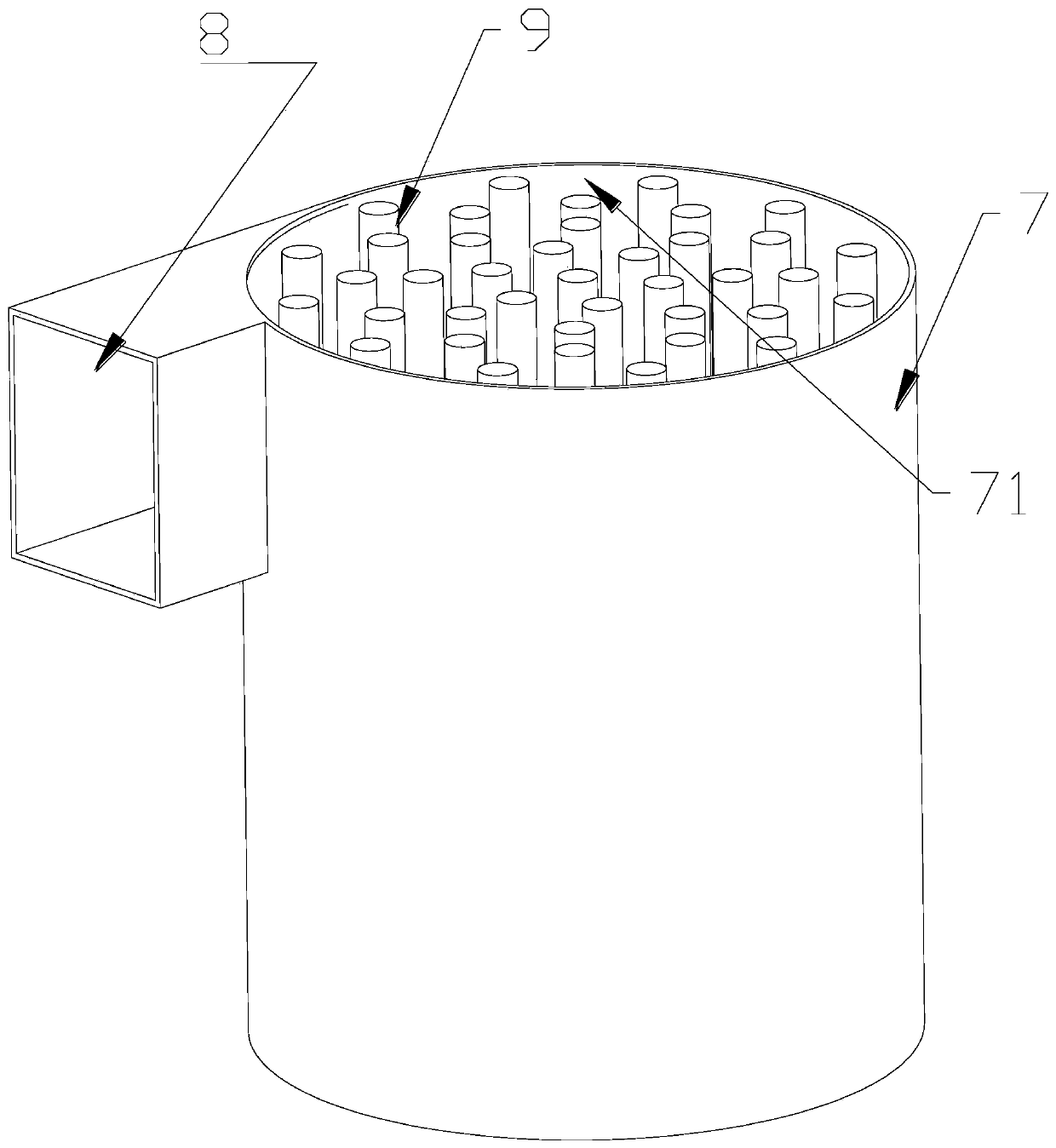

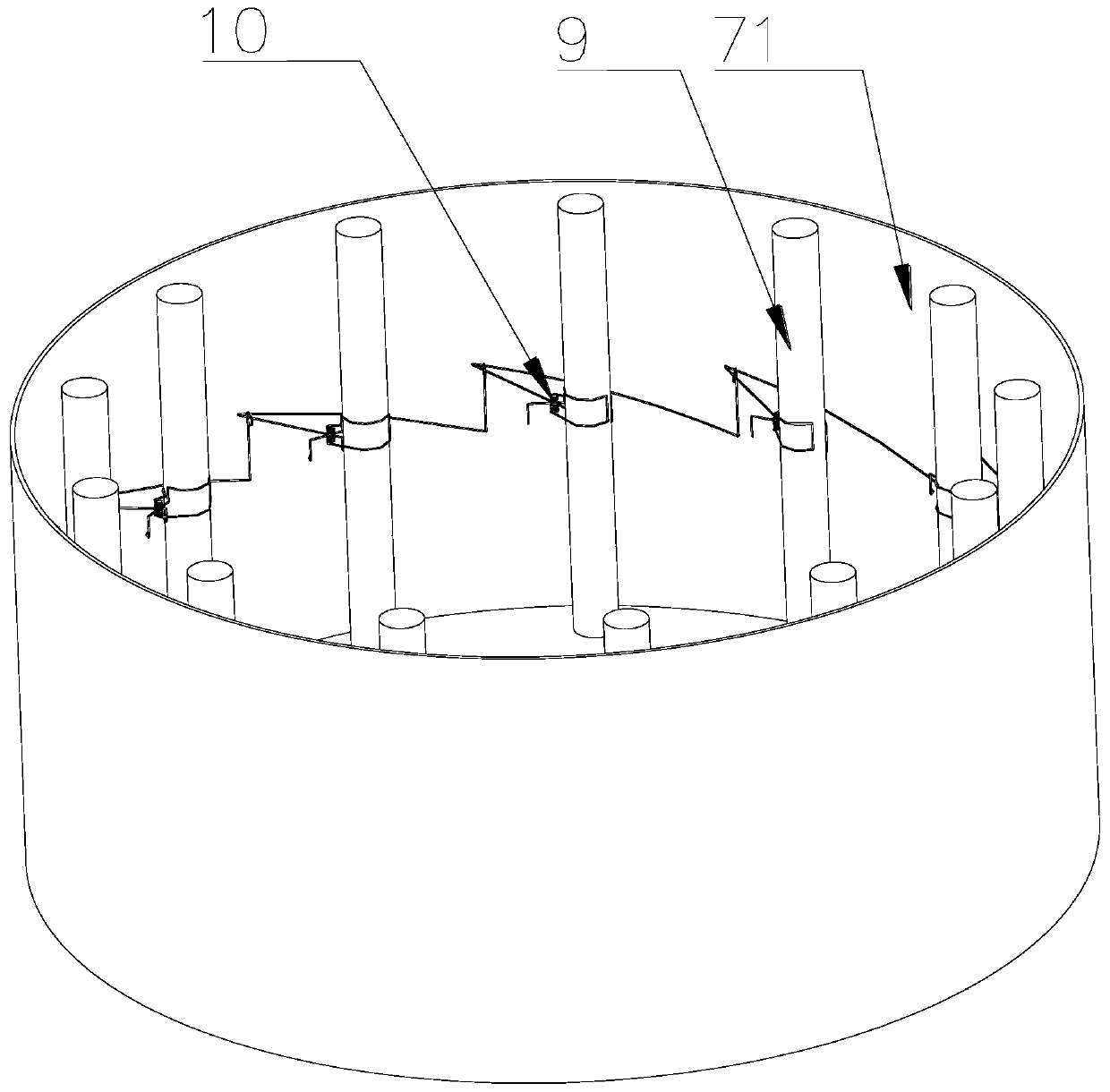

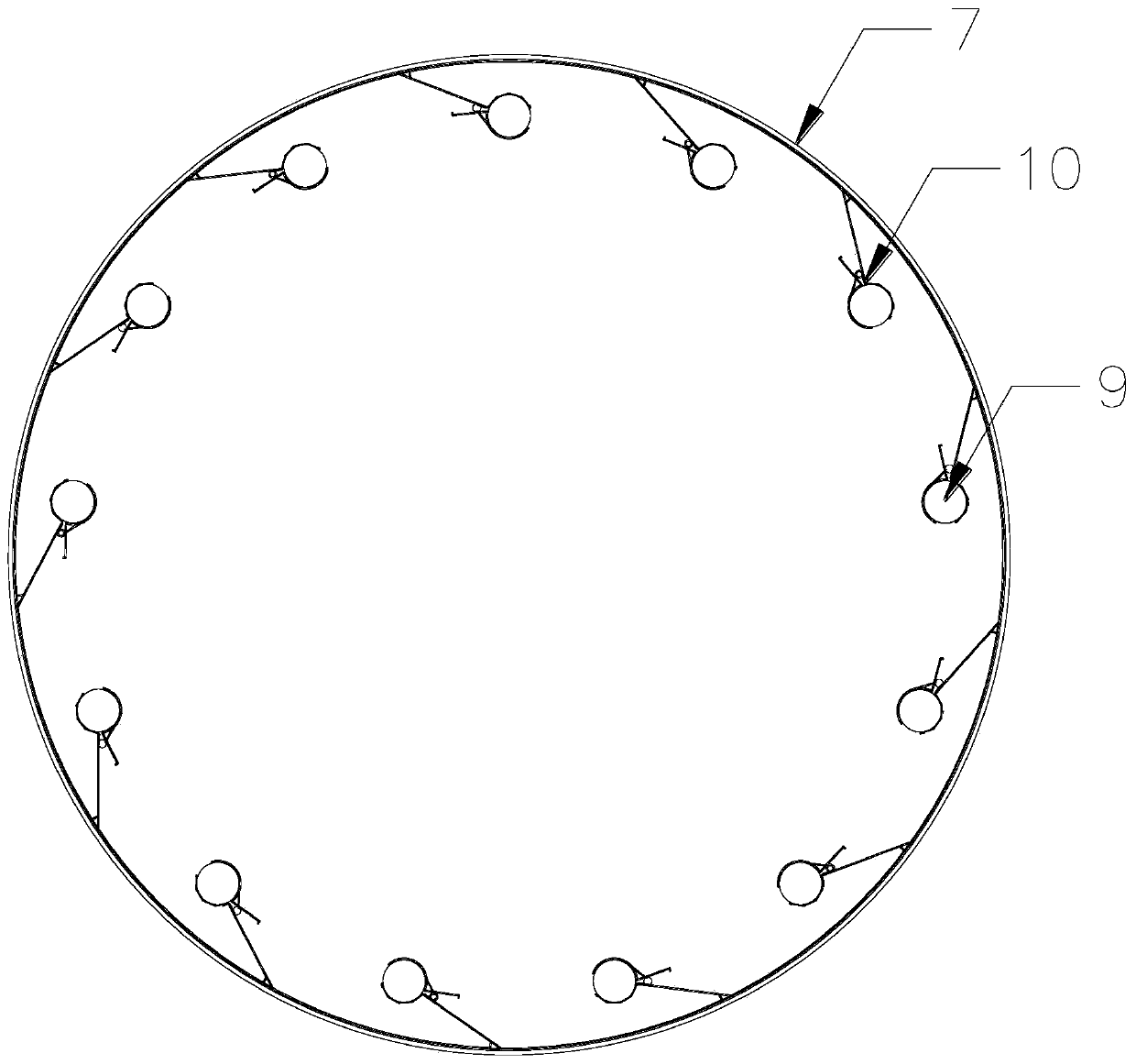

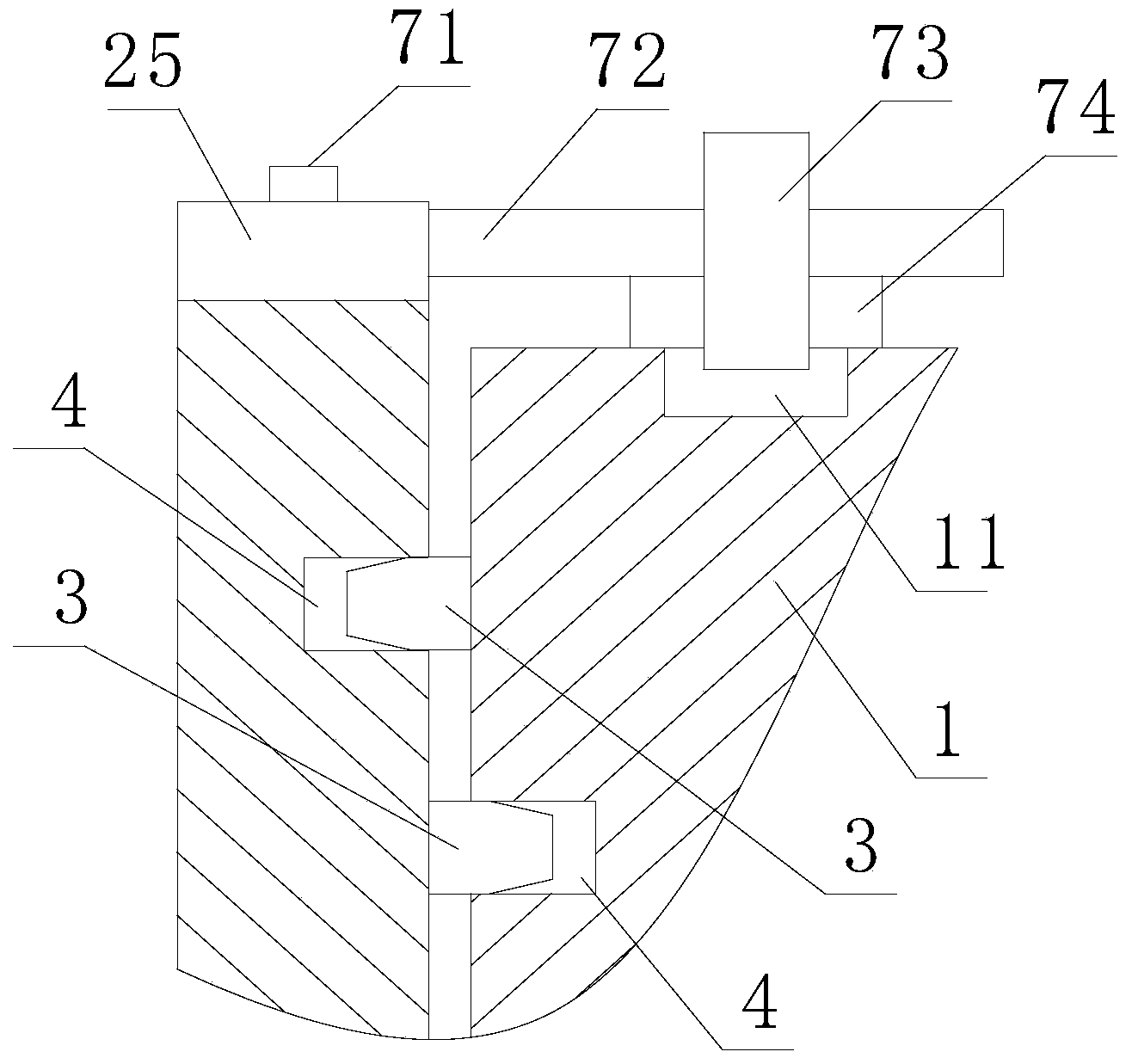

Dust removal cylinder fastening device and bag-type dust remover

ActiveCN111298535AImprove fastening effectSimple structureDispersed particle filtrationEngineeringStructural engineering

Owner:FAMSUN CO LTD

Adjustable clamping device for workpiece fastening

InactiveCN108405736AQuick snapEfficient fasteningMetal-working feeding devicesPositioning devicesEngineeringSupport plane

The invention discloses an adjustable clamping device for workpiece fastening. The adjustable clamping device for workpiece fastening comprise a working platform and a pressing mechanism, wherein a support frame of the pressing mechanism comprises a lifting rod assembly and a cross support beam; a pressing block II and a buffer piece are fixed to the bottom part of the middle of the cross supportbeam; two pressing blocks I are slidably arranged on the cross support beam along a horizontal direction; two sliding mechanisms are arranged on the cross support beam; two ejecting blocks are arranged on the top surface of the working platform, are located right under the corresponding pressing blocks I, and are slidably arranged on the working platform along a horizontal direction; arc-shaped notch parts are arranged at the lower ends of the two pressing blocks I; ball heads I are arranged at the upper ends of the two ejecting blocks; a ball head II is arranged at the lower end of the pressing block II; and a concave cavity is arranged on the top surface of the working platform. The adjustable clamping device for workpiece fastening provided by the invention can be used for high-efficiently and quickly fastening workpieces, is beneficial to improving the production efficiency and reducing the cost, can realize stamping operation, and is simple in overall structure, convenient to assemble and disassemble, capable of being freely adjusted according to the sizes of the workpieces, wide in application range and convenient to use.

Owner:重庆恩光科技有限公司

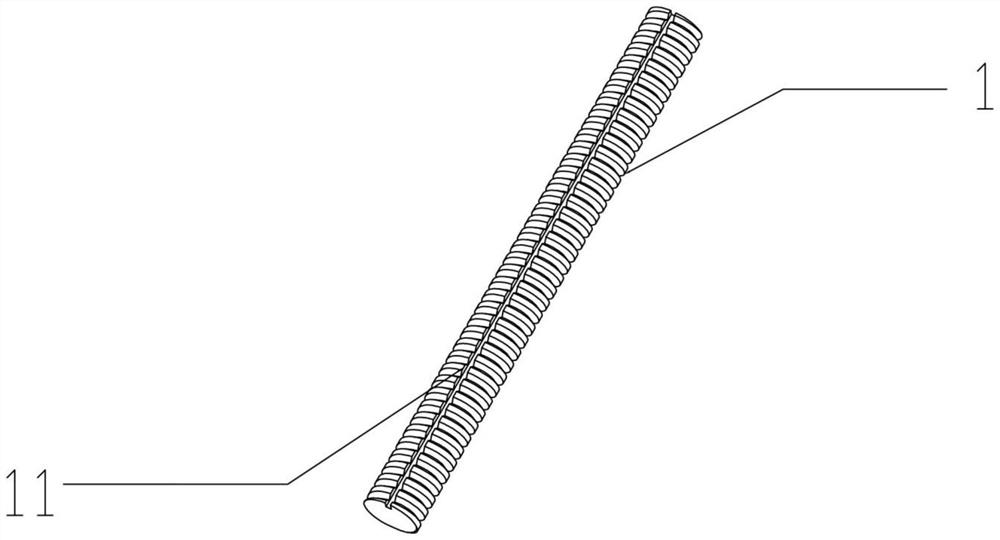

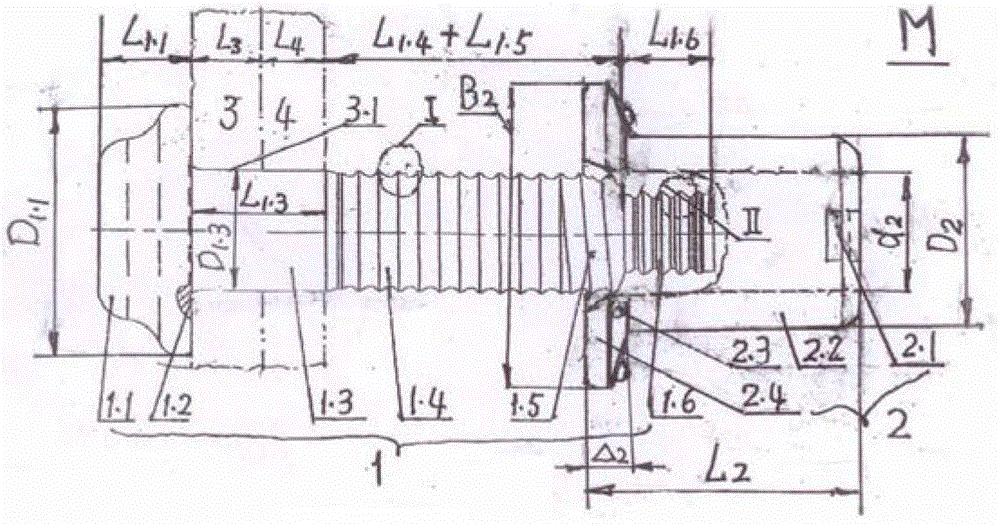

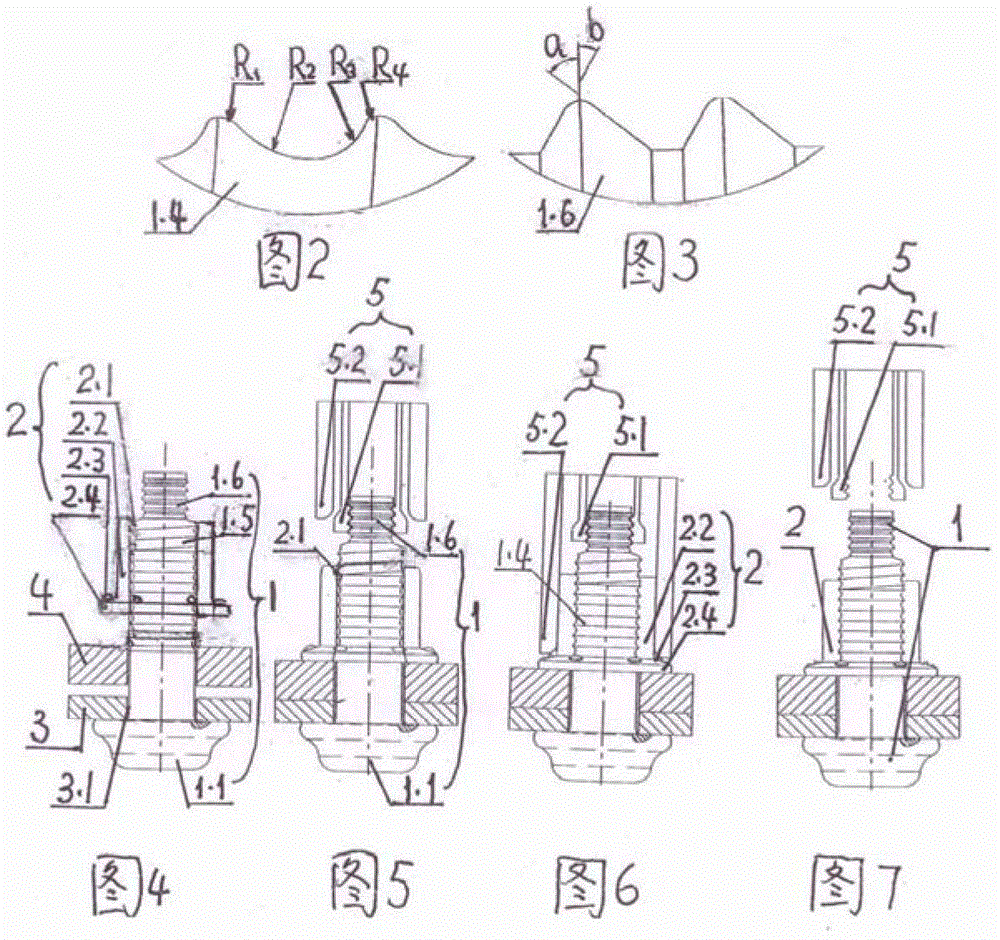

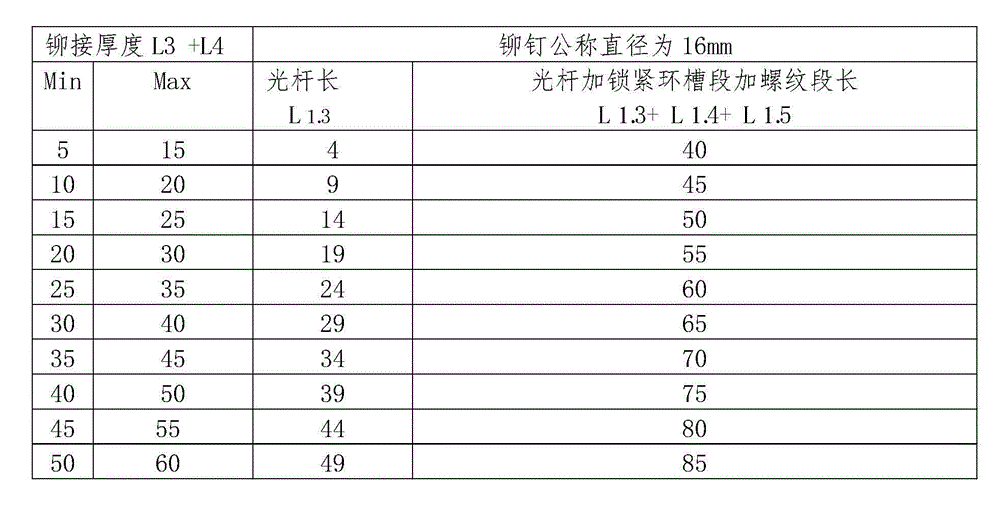

Method for fastening member with high strength and low riveting force and 10.9-level short-tail pulling rivet

The invention discloses a method for fastening a member with high strength and low riveting force and a 10.9-level short-tail pulling rivet. The method comprises the following steps that: 1) the rivet consists of a rivet head, an unloading groove, a polished rod, a locking ring groove section, a threaded section and a tail thin short ring groove section; the radius of the inner curved surface of a locking groove is reduced from front to back; the angle of the inner inclined plane of the tail is reduced from front to back; a lantern ring is provided with a convex point, and a latch is arranged in an inner hole; 2) the rivet penetrates, the latch is screwed into the threaded section, and the lantern ring is hooked with the rivet; 3) the rivet extends into a riveting device, and a clamping jaw clamps the tail; 4) the riveting device is started, the lantern ring is extruded to deform to lock a ring groove, and the lantern ring moves forwards to break the convex point; and 5) the riveting device retreats, and fastening is finished. The unloading groove can eliminate stress concentration in riveting and use. The locking groove promotes metal flowing of the lantern ring during riveting and blocks metal flowing of the lantern ring in vibration or separation after riveting, so that fastening property and loosening resistance are improved. Due to the tail groove shape, the clamping jaw is engaged with the tail without releasing, and riveting with low riveting force is promoted. Due to the latch, the lantern ring is convenient to hook, install and operate. The rivet is applied to railway vehicles and heavy trucks with high requirements for fastening property and reliability.

Owner:MEISHAN CRRC FASTENING SYST CO LTD

Production process of outer button paper cup lid

ActiveCN109591379BInhibit sheddingImprove sealingPaper/cardboard articlesPaper cupIndustrial engineering

The invention discloses a production process of an outer buckle type paper cup lid, which is characterized in that it comprises the following steps: a. preparing a circular sheet material for producing a paper cup lid; b. bending the periphery of the circular sheet material downward to form The outer edge of the cup lid, the unbent part in the middle of the circular piece becomes the lid body; c. The bottom of the outer edge of the cup lid is bent upwards to form the folded bottom of the lid; d. The middle of the lid body is bent downwards forming a sunken step; e. making a circular inner buckle paper piece; f. pasting the inner buckle paper piece on the bottom of the sunken step, the inner buckle paper piece and the cup lid body have a certain eccentricity. The outer buckle paper cup lid produced by the above process can effectively prevent the cup lid from falling off and ensure reliable sealing inside the cup when used in combination with the paper cup with inner sill.

Owner:ZHEJIANG NEW DEBAO MACHINERY

Welding method of 7-series aluminum alloy coated thin plate for aviation

A welding method of a 7-series aluminum alloy coated thin plate for aviation comprises the following steps that 1, after a coating material and a cast ingot are attached, the distance between the periphery of the coating material and the edge of the cast ingot is 20-30 mm, fixing and welding are conducted in a bolt fastening manner every 1000-1500 mm in the length direction, and a material for welding adopts 7075-F-state aluminum alloy; 2, the composite cast ingot obtained in the step 1 is heated and hot-rolled; and 3, the plate with the thickness ranging from 7.0 mm to 8.0 mm through hot rolling is subjected to three times of cold rolling till the thickness ranges from 1.6 mm to 3.25 mm. According to the method, a spot welding mode is adopted, the plate must be packaged through steel strip in the transferring process so as to avoid the falling risk, however, in the ingot soaking process, due to the fact that the temperature is high, the steel strip is prone to leaving traces on the surface, and due to the fact that the temperature of the composite ingot is reduced in the steel strip shearing process, the two factors can cause aluminum sticking of a roller in the subsequent rolling process, the problem of rolling black lines is formed, the surface quality is unqualified, and the yield of products is reduced.

Owner:SHANDONG NANSHAN ALUMINUM

Adjustable clamping device for workpiece fastening

InactiveCN108405736BQuick snapEfficient fasteningMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses an adjustable clamping device for fastening workpieces, which includes a working platform and a pressing mechanism. The support frame of the pressing mechanism includes a lifting rod assembly and a horizontal support beam, and a pressure block II and a buffer member are fixed in the middle of the horizontal support beam. There are two briquetting blocks 1, which are respectively slidably arranged on the cross support beam along the transverse direction. The cross support beam is provided with two sliding mechanisms, and the top surface of the working platform is provided with two top blocks. It is located directly below the corresponding pressing block I, and the two top blocks are respectively slidably arranged on the working platform along the transverse direction. The lower end of the block II is provided with a ball head II, and the top surface of the working platform is provided with a concave cavity. The invention can not only realize high-efficiency and fast fastening of workpieces, improve production efficiency, reduce costs, but also realize stamping operation, and the overall structure is simple, easy to assemble and disassemble, and can be freely adjusted according to the size of workpieces. It has a wide range of applications and is easy to use .

Owner:重庆恩光科技有限公司

Cage door locking structure

ActiveCN103470116AProtectiveExtended service lifeWing fastenersEngineeringElectrical and Electronics engineering

Owner:CHANGZHOU SHEPHERD CULTURE EQUIP ENG CO LTD

Cooperation structure for medium container and footrest of motorcycle and motorcycle

InactiveCN101973335BImprove fastening effectAvoid installation difficultiesFoot-restsMotorcyclesVehicle frameEngineering

Owner:CHONGQING LONCIN MOTOR

Workpiece Buckle Clamping Mechanism

ActiveCN108406265BQuick snapEfficient fasteningWork holdersMetal working apparatusPiston rodIndustrial engineering

Owner:重庆恩光科技有限公司

Adjustable clamping device for workpiece fastening

Owner:重庆恩光科技有限公司

Transportation device for prefabricated bricks

InactiveCN104129409AGuaranteed locking effectReduce vibrationHand carts with one axisBrickEngineering

The invention relates to a transportation device for prefabricated bricks. The device comprises a bottom plate and a cart main body, wherein the cart main body comprises a horizontal transverse rod, a first fixing rod and a second fixing rod; the cross section of the first fixing rod and the cross section of the second fixing rod are both in L-shaped, the connecting position of the first fixing rod and the bottom plate and the connecting position of the second fixing rod and the bottom plate are respectively provided with connecting shafts and connecting holes. The transportation device also comprises locking components for locking the cart main body on the bottom plate. The transportation device disclosed by the invention has the advantages that a first operating rod and a second operating rod are used for controlling the first fixing rod and the second fixing rod to rotate on the horizontal transverse rod, so that the connecting shafts and the connecting holes are matched to ensure that the first fixing rod and the second fixing rod are fastened on the bottom plate, and ensure that the connecting shafts can be well buckled in the connecting holes. The locking components are arranged to form connecting rods which rotate through pin shafts, and a bolt is matched with a threaded hole in the bottom plate, so that the locking effect of the bottom plate and the cart main body is ensured, and vibration generated in a transportation process of the prefabricated bricks is reduced.

Owner:长兴华久耐火材料厂

Clamping device for buckling workpiece

ActiveCN108393672AQuick snapFastening efficiencyMetal-working feeding devicesMetal working apparatusMechanical engineeringEngineering

The invention discloses a clamping device for buckling a workpiece. The clamping device comprises a working platform and a pressing mechanism. The pressing mechanism comprises a supporting frame, pressing blocks I, a pressing block II and a buffering part. The supporting frame comprises lifting rod components and a transverse supporting beam. The pressing blocks I, the pressing block II and the buffering part are fixed at the bottom of the middle of the transverse supporting beam. The number of the pressing block I is two, and the two pressing blocks I are symmetrically arranged on two sides of the buffering part. Two ejector blocks are arranged on the top surface of the working platform, and are separately positioned under the corresponding pressing blocks I. Arc-shaped notch parts are separately arranged on the back sides of the lower ends of the two pressing blocks I. Balls I are separately arranged at the upper ends of the two ejector blocks. The upper ends of the pressing blocks II pass through the buffering part to be fixed at the bottom of the transverse supporting beam. Balls II are arranged at the lower ends of the pressing block II. A cavity is formed in the top surface of the working platform. The clamping device can not only realize efficient and rapid buckling of the workpiece and be improved in production efficiency and reduced in cost, but also realize punching operation, and in addition, the integrated structure is simple, and mounting and replacing are convenient.

Owner:重庆恩光科技有限公司

Preset building wall connecting device and using method thereof

InactiveCN112343202AImprove the stabilization effectImprove fastening effectWallsStructural engineeringMechanical engineering

Owner:朱天水

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com