Half-type pipeline rush-repair segment

A repair section, Huff-style technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as pipeline gas or liquid leakage, poor sealing performance, and affect the work efficiency of emergency repairs, so as to avoid Leakage, easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

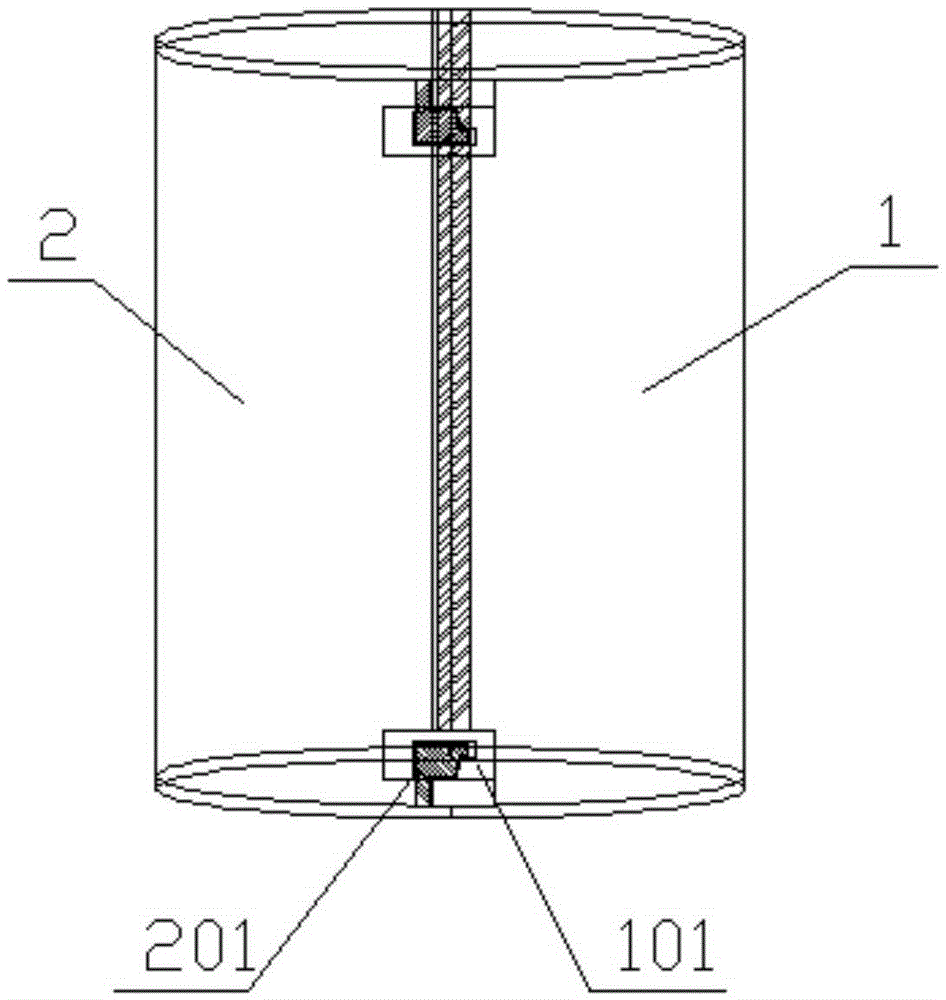

[0017] Such as figure 1 As shown, a Hough type pipeline emergency repair joint includes two first shells 1 and second shells 1 that are matched with each other, the first shell 1 and the second shell 2 are semicircular shells, On both sides of the first housing 1 and at the joint with the second housing 2, a lock 101 is provided, and the second housing 2 is provided with a groove 201 that is fastened with the lock 101, The edge of the groove 201 is provided with a sealing film, the axial sides of the first housing 1 are provided with ribs, and the second housing 2 is provided with corrugations corresponding to the ribs of the first housing 1. There are grooves that fit and fasten with the ribs.

[0018] The inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com