Patents

Literature

101results about How to "Guaranteed location accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

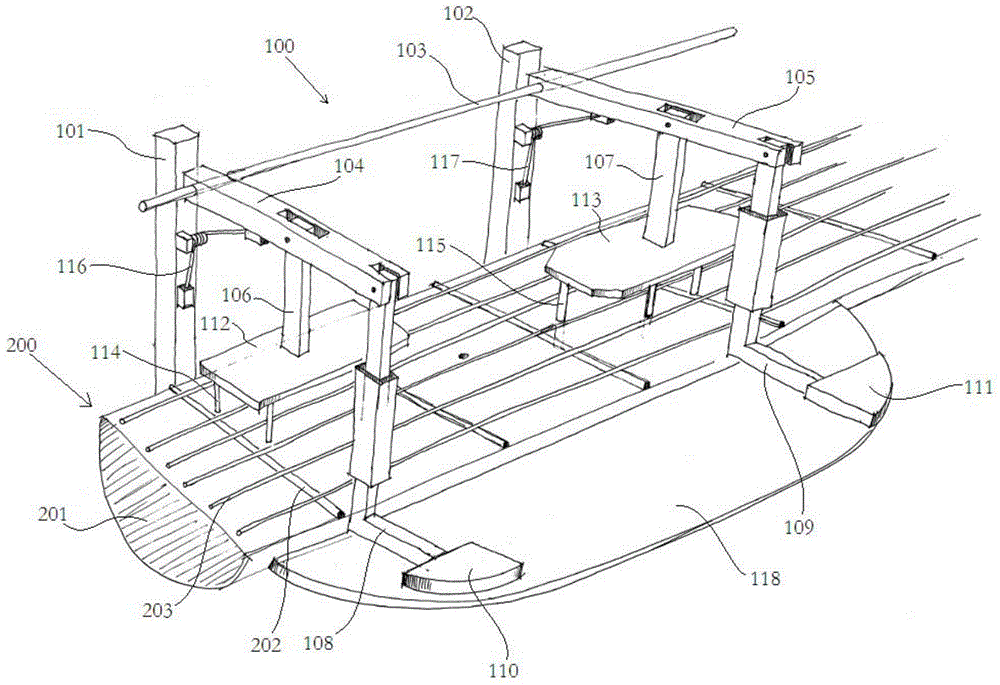

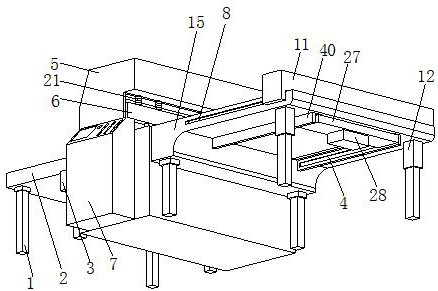

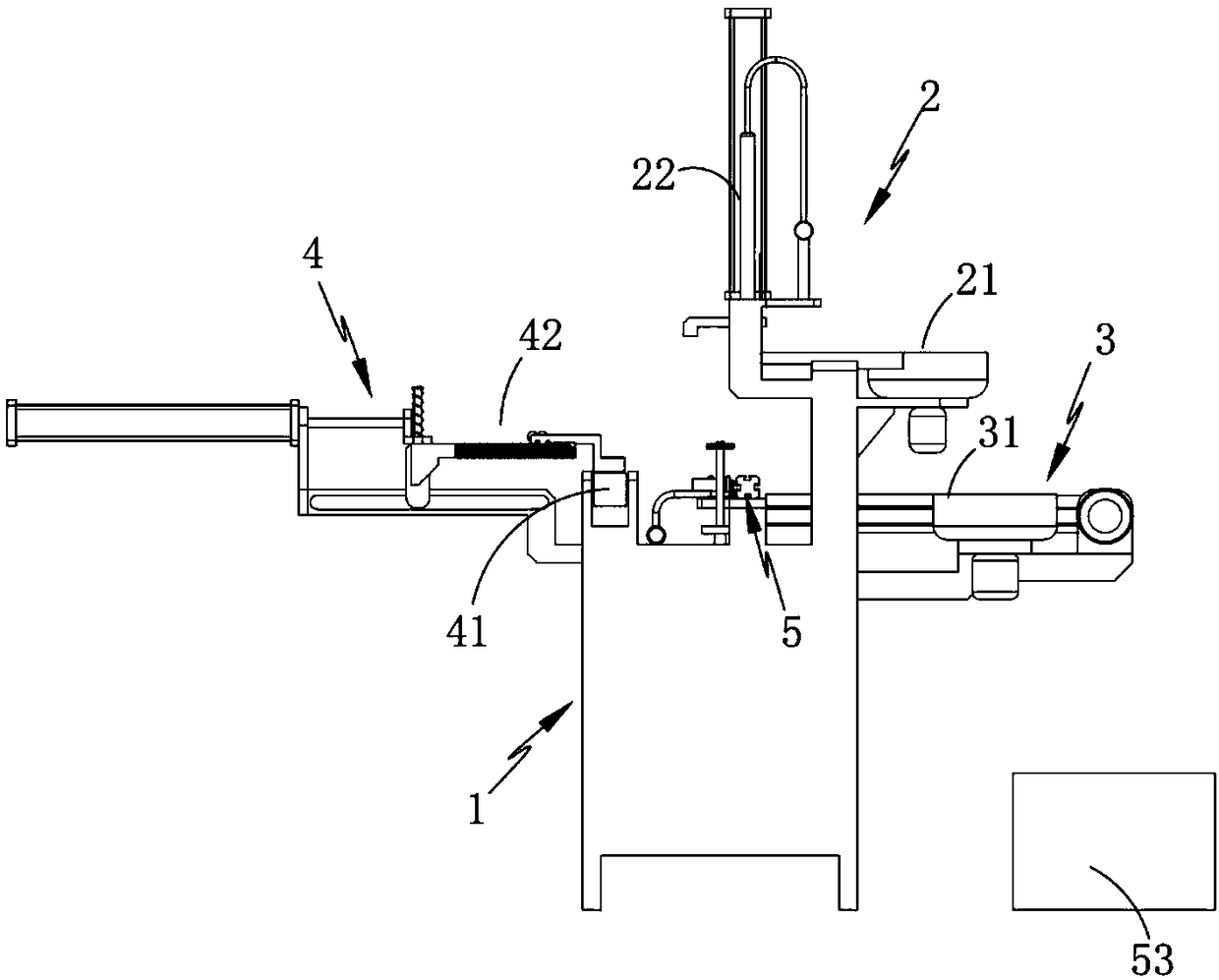

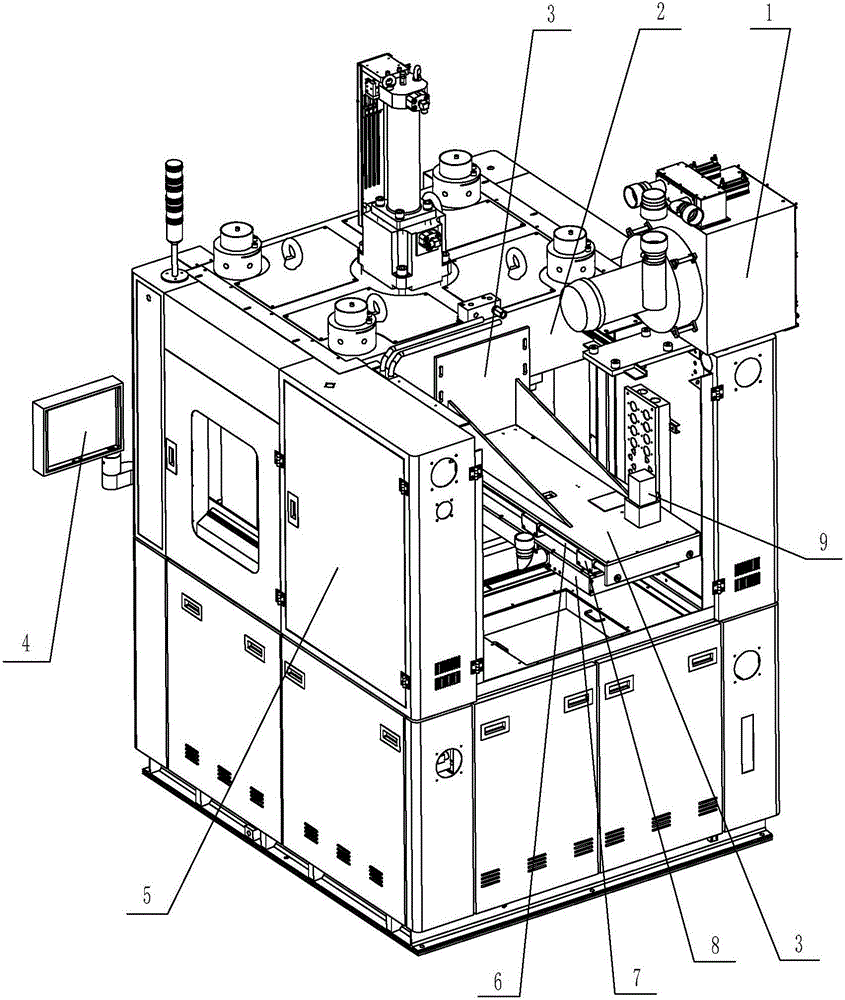

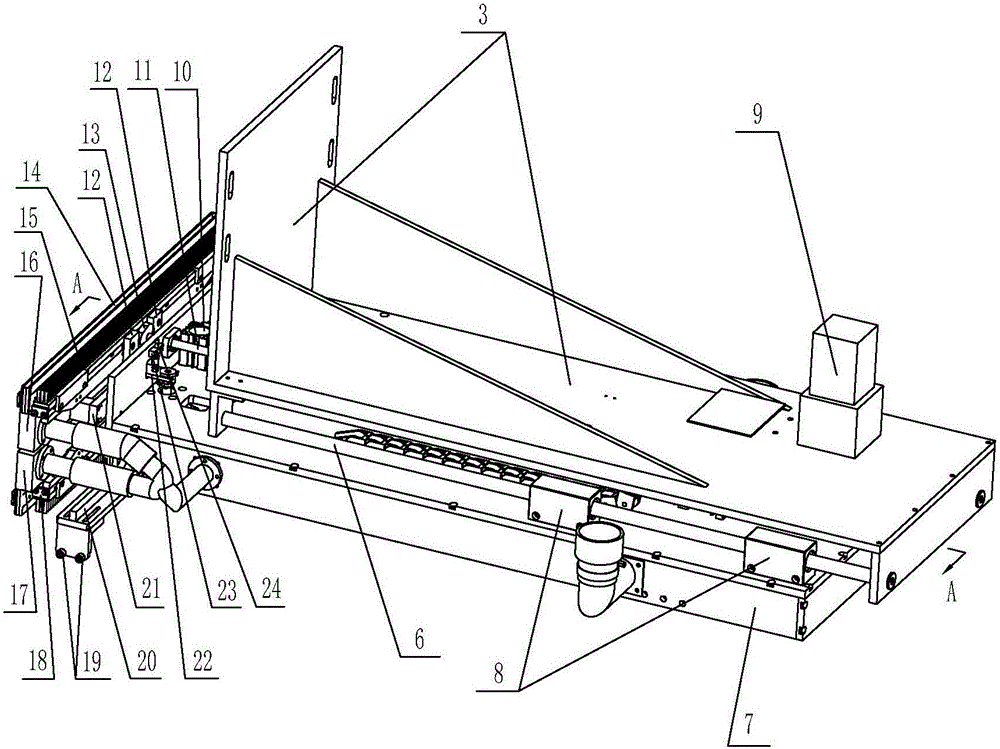

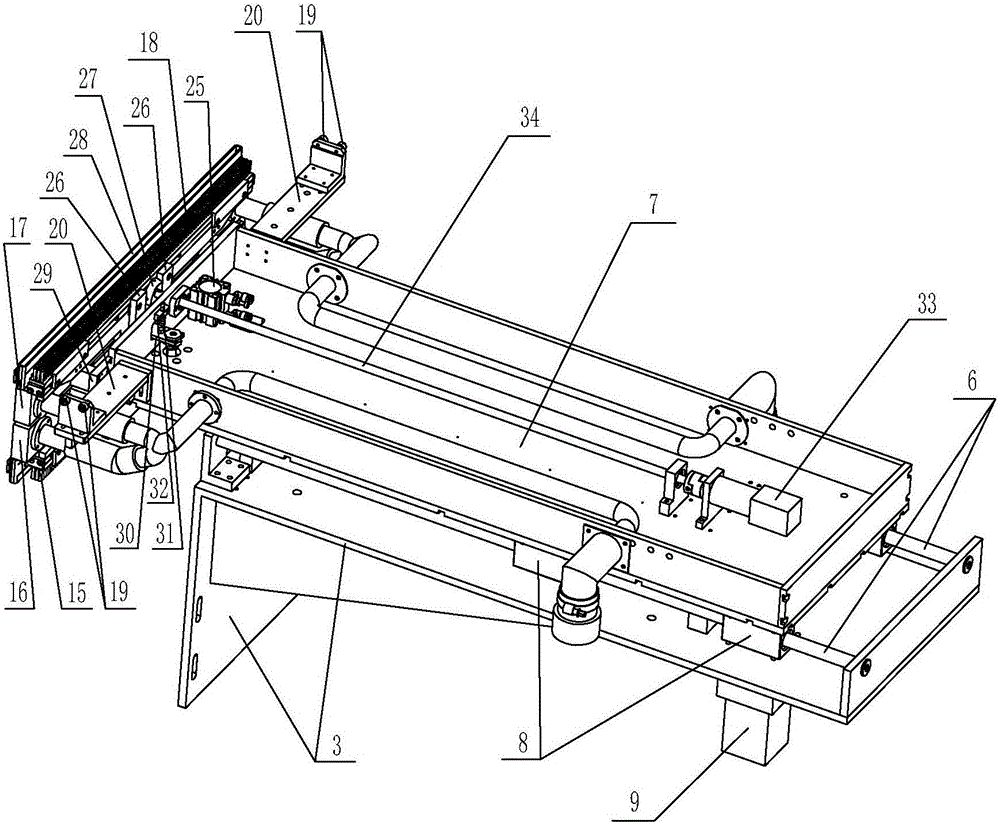

Ink-jet printer and printing method thereof

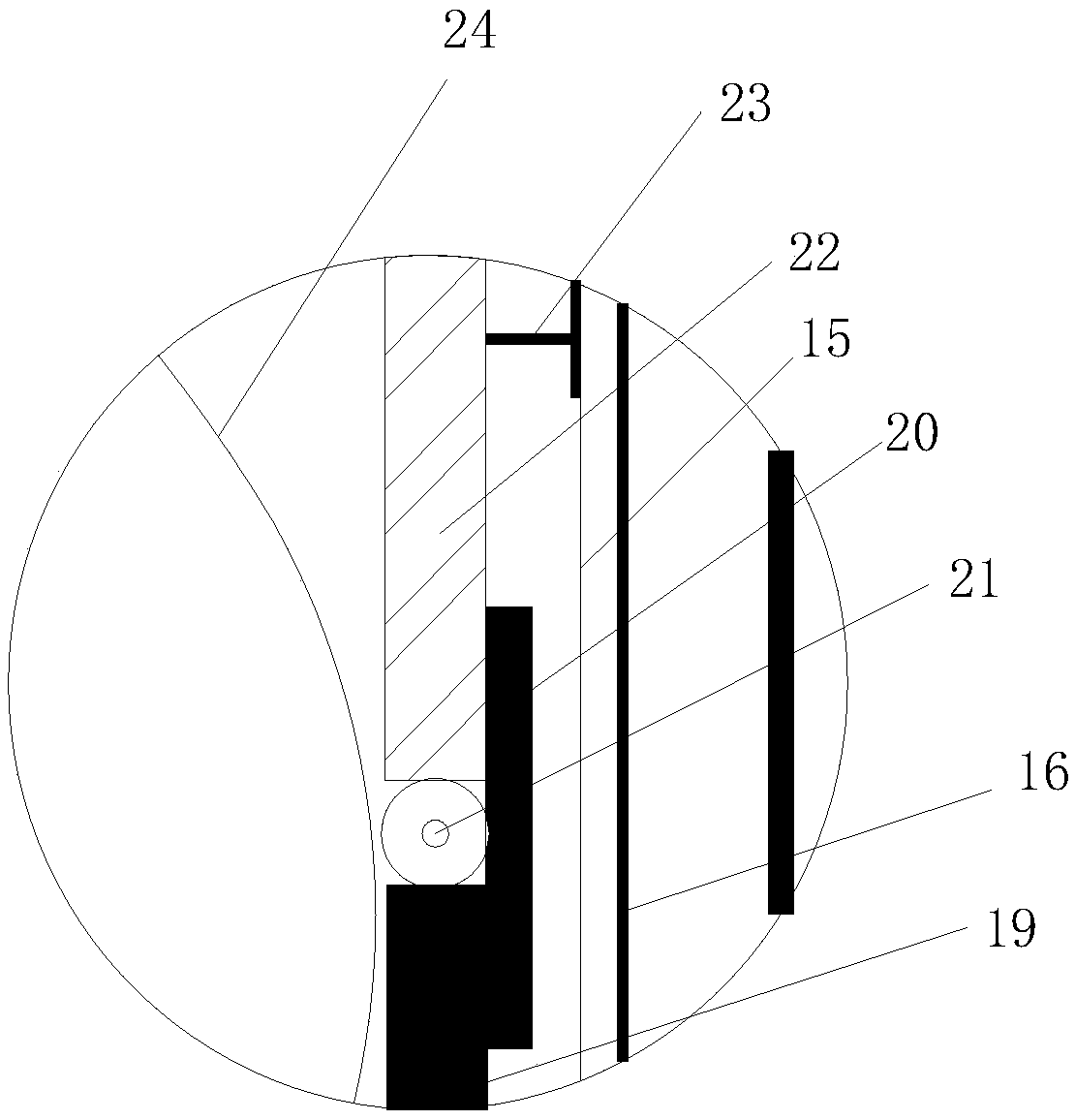

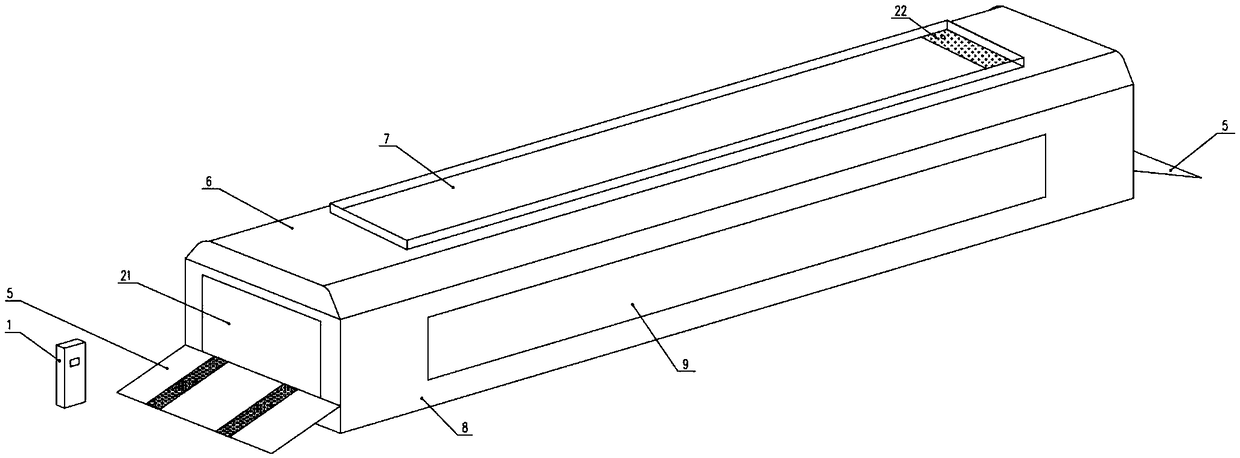

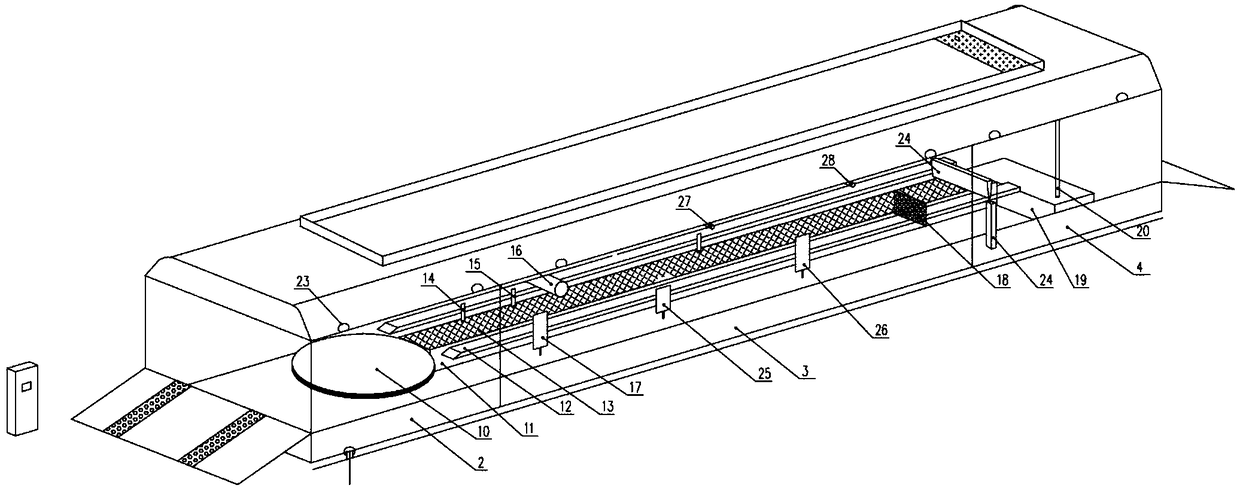

The invention discloses an ink-jet printer and a printing method thereof. The ink-jet printer comprises a printing module, supporting beams, a printing platform, an ink-scraping maintenance device and a control system. The printing module is installed above the supporting beams, a sprayer is installed at the lower end of the printing module, and the printing platform is arranged below one ends of the supporting beams. The ink-scraping maintenance device is arranged below the other ends of the supporting beams, the control system is used for controlling work of the printing module, the ink-scraping maintenance device and the sprayer. The ink-jet printer is characterized in that the ink-scraping maintenance device comprises a lifting device, and the lifting device can make lifting movement on the whole in the vertical direction, namely in the Z-axis direction; by controlling overall lifting of the ink-scraping maintenance device and horizontal movement of the printing module in the direction of the supporting beams, ink-scraping or maintenance operation of the sprayer is completed, the lifting device is skillful in structure design, and lifting smoothness and steadiness are high; and in the ink-scraping maintenance process, by approaching a sensor for automatic detection and controlling the distance between the sprayer and the ink-scraping maintenance device, accuracy can be improved, and quick and convenient ink-scraping maintenance is achieved.

Owner:BEIJING MEIKEYI

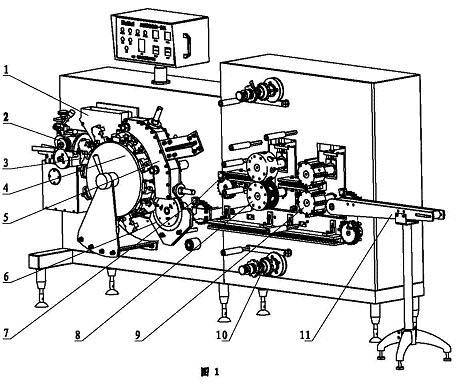

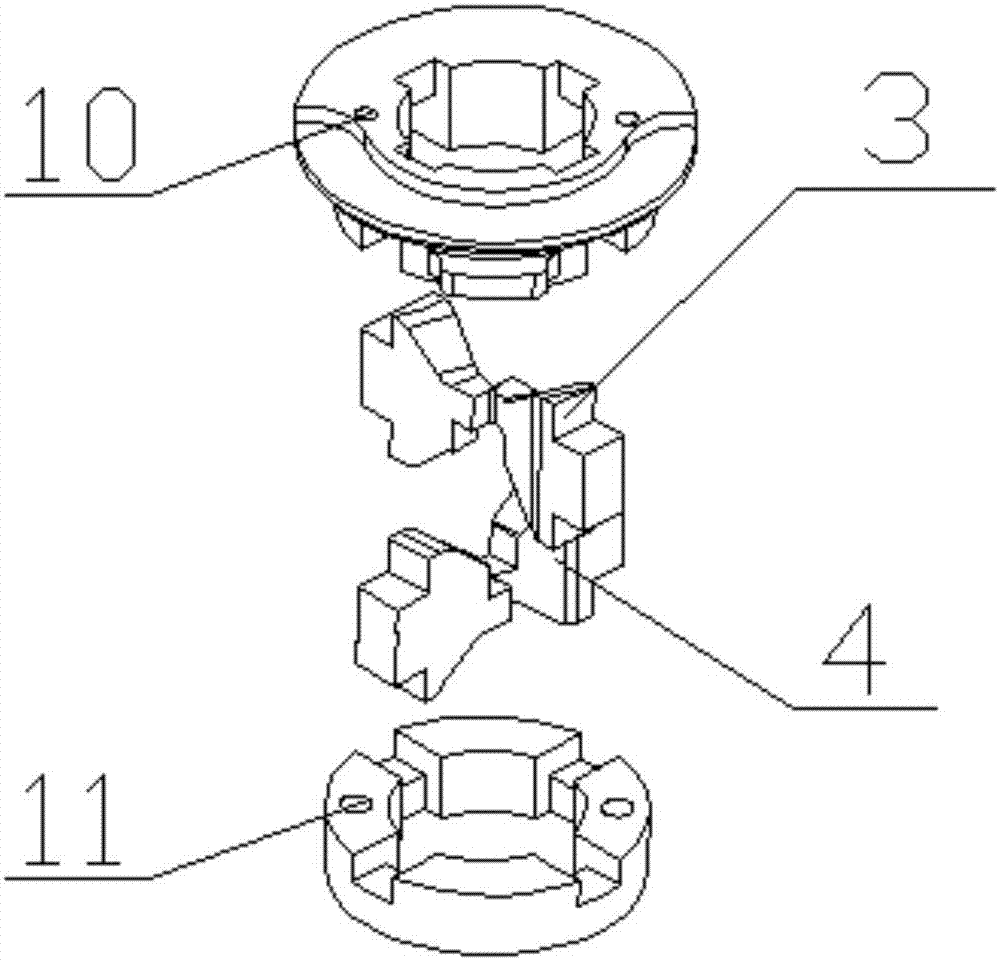

Demoulding conversion apparatus and integrated candy moulding and packaging machine thereof

InactiveCN102550771AWon't fall offLimited circumferential movementConfectionerySweetmeatsEngineeringMoulding device

The invention discloses a demoulding conversion apparatus which comprises a holding disc body, wherein, the outer circumference of the holding disc body is equantly provided with a plurality of holding grooves along an axial direction, and the holding grooves cohere with cambered surface holding seats in a manner of cambered surface gaps out of the holding disc body. The invention also discloses an integrated candy moulding and packaging machine which comprises a body, a forming device which is connected with the body and contains a forming die and a rod conveying roller, a rod bucket alternately arranged with the rod conveying roller, an elastic pressure device which is in contact connection with the forming die and contains an arc pressurization block and a paper feeding shaft arranged on the body; the demoulding conversion apparatus is adjacently installed behind the forming device, a candy conveying device is adjacently installed behind the demoulding conversion apparatus, and a pair of sealing wheels and a pair of cutting wheels are sequentially arranged in a conveying channel of the candy conveying device. According to the invention, automatic handover and conversion of candies with a handle from a moulding part to a packaging part can be realized, construction is reasonable, and high production efficiency is obtained.

Owner:江苏海特尔机械有限公司

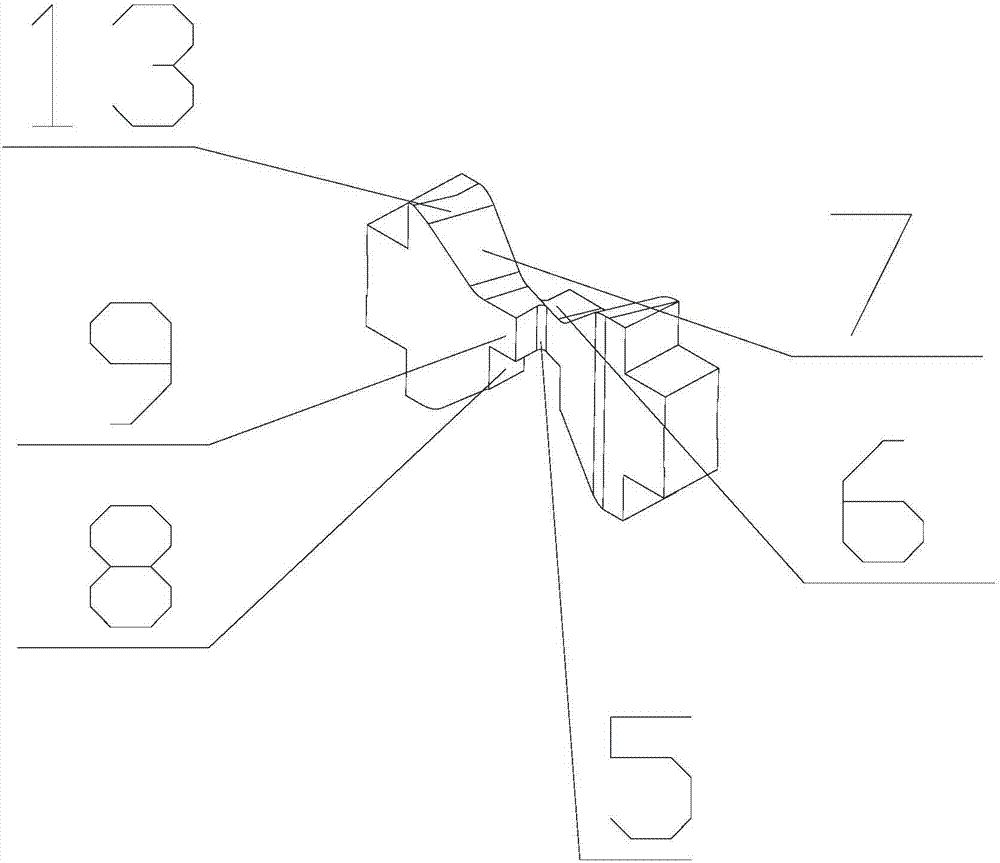

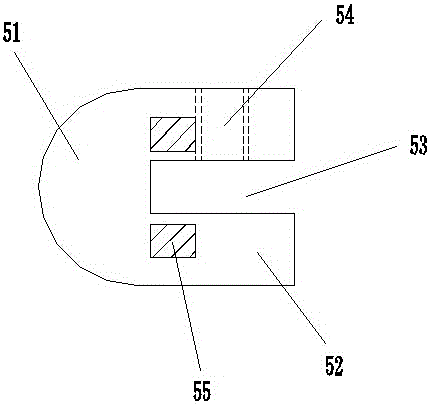

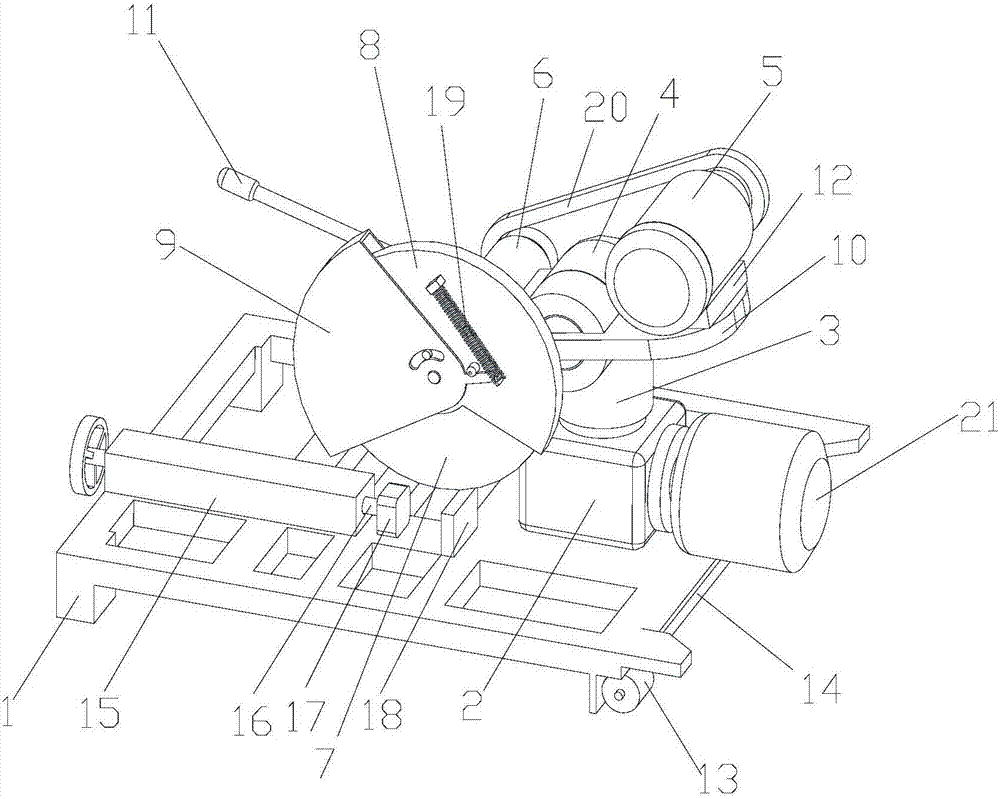

Separated type multiple cutting-edge grinding cutter unit

ActiveCN106903418AGuaranteed accuracyGrinding speed is fastElectrode featuresMechanical engineeringDouble edge

The invention provides a separated type multiple cutting-edge grinding cutter unit. The separated type multiple cutting-edge grinding cutter unit comprises an upper cutting head, a lower cutting head and cutter blades, wherein the cutter blades are a first cutter blade and a second cutter blade which are matched with each other and are clamped between the upper cutting head and the lower cutting head; and the upper cutting head and the lower cutting head are tightly connected by a bolt. The separated type multiple cutting-edge grinding cutter unit has the beneficial effects that the double edges of the two cutter blades are matched together to ensure that the cutter is in a multiple cutting-edge combination state; the cutter blades are located axially and radially through the separated type of the cutting heads which are the upper cutting head and the lower cutting head so as to ensure the accuracy of cutting edge location; the upper cutting head and the lower cutting head are connected through installing hole locations of the upper cutting head and the lower cutting head; the improvement of grinding speed of an electrode cap can be realized conveniently, simply and reliably by the cutter; and the wearing of the grinding cutter blades and the consumption of the cutting heads are reduced.

Owner:南京君哲工业自动化有限公司

Motor and controller integrated system

PendingCN109367376AImprove securityWill not flowSpeed controllerAssociation with control/drive circuitsCapacitanceElectricity

The invention discloses a motor and controller integrated system. The motor and controller integrated system comprises a shell, a first end cover, a motor body, a controller body and heat dissipationcomponents. The first end cover is arranged in the shell. An inner cavity of the shell is divided into a first cavity and a second cavity with the first end cover as the boundary. The first end coveris internally provided with first heat dissipation channels. The motor body is arranged in the first cavity. The controller body is arranged in the second cavity. The integrated system is provided with capacitance assemblies and power conversion assemblies, wherein the capacitance assemblies and the power conversion assemblies are sequentially arranged in a superposed manner from the direction away from the first end cover to the direction close to the first end cover and electrically connected. All the capacitance assemblies are located on the same layer. All the power conversion assemblies are located on the same layer. The heat dissipation components are arranged between the capacitance assemblies and the power conversion assemblies in a clamped manner and provided with second heat dissipation channels. Direct heat dissipation is conducted on the capacitance assemblies and the power conversion assemblies; indirect conduction conducted through other electronic elements is not needed;the heat dissipation effect achieved among the assemblies is particularly good; and high stability of the outputable power of the motor and controller integrated system is guaranteed.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

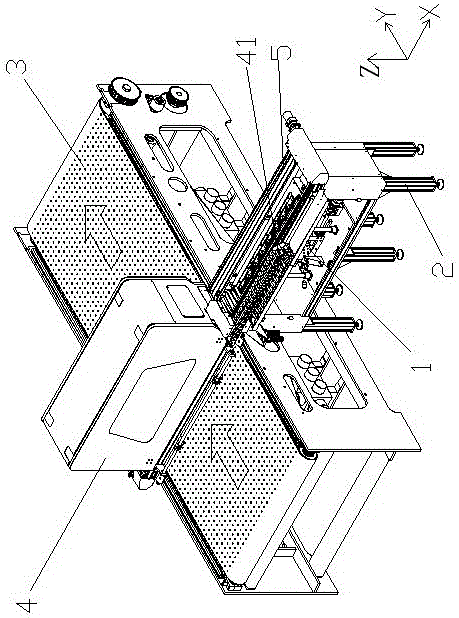

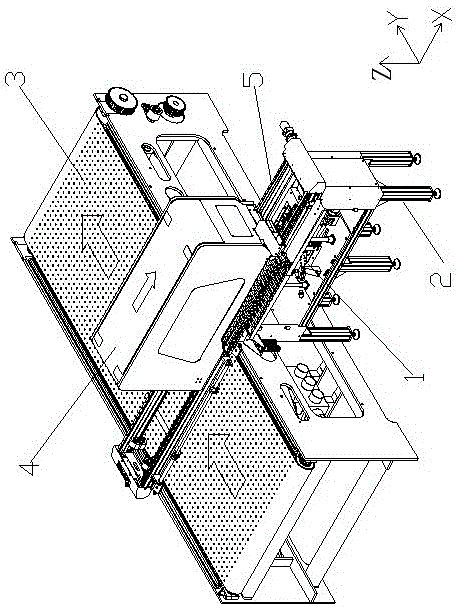

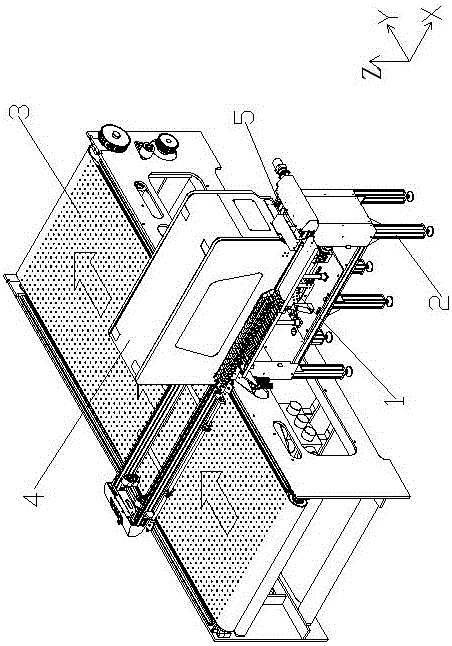

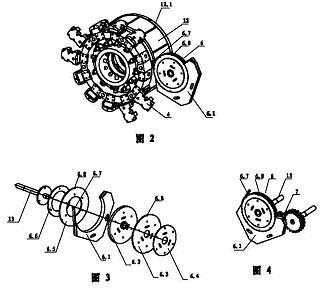

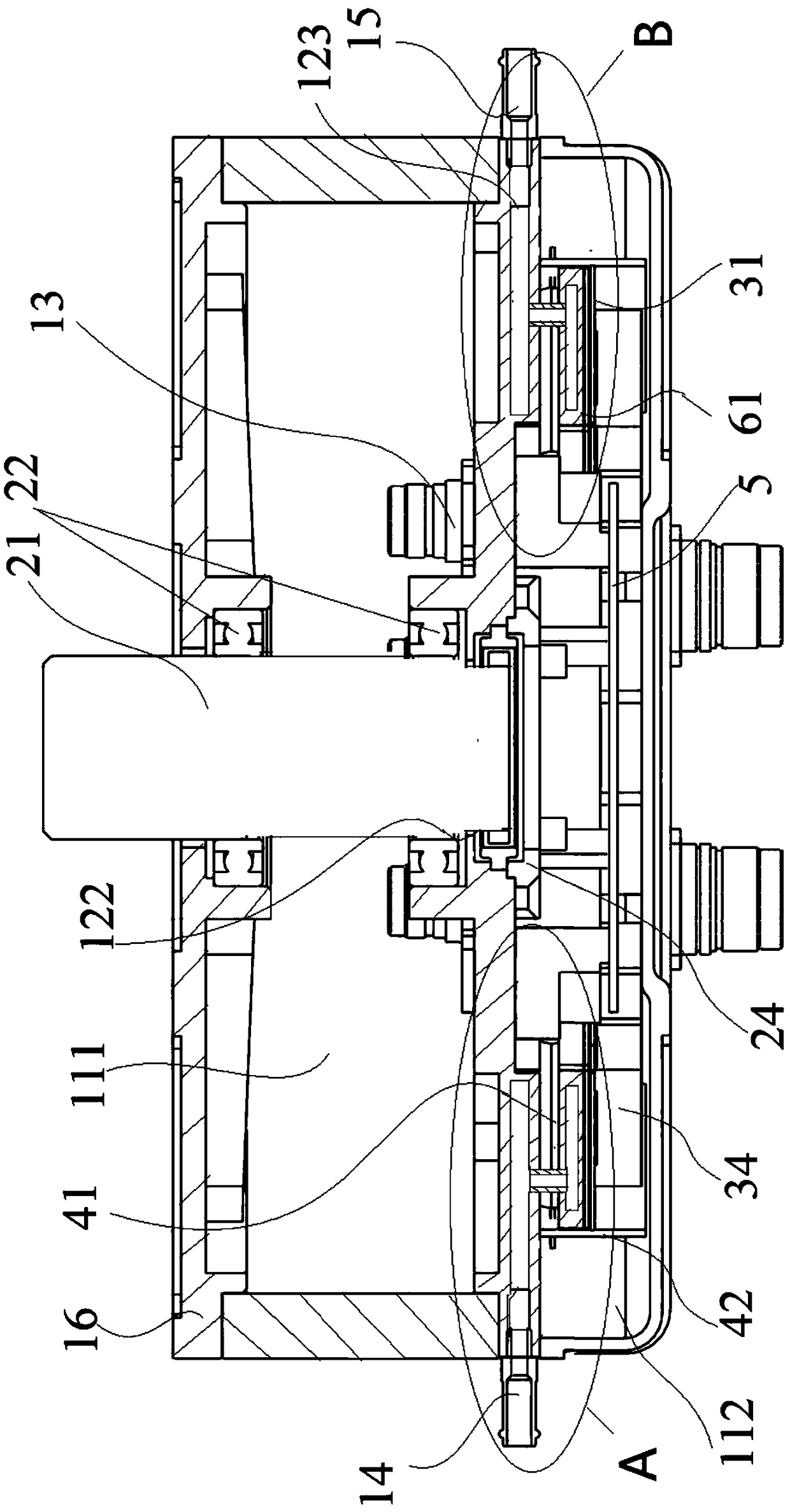

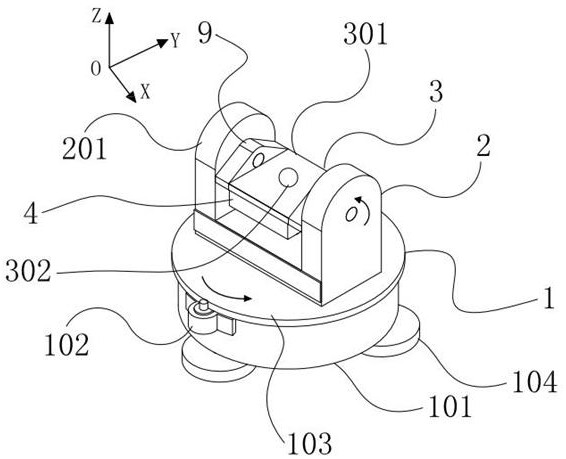

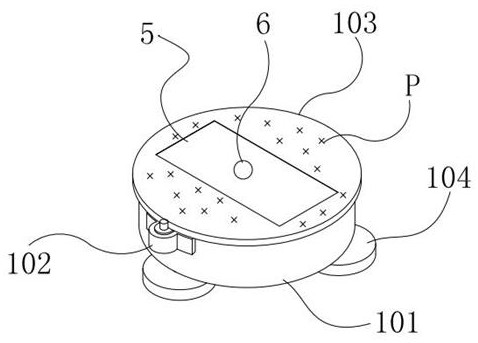

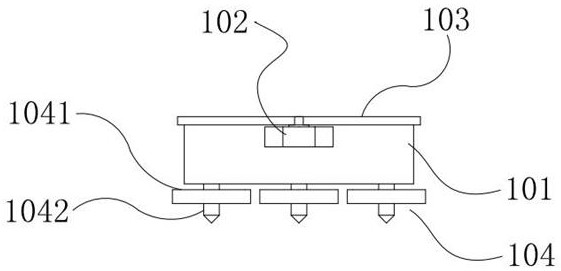

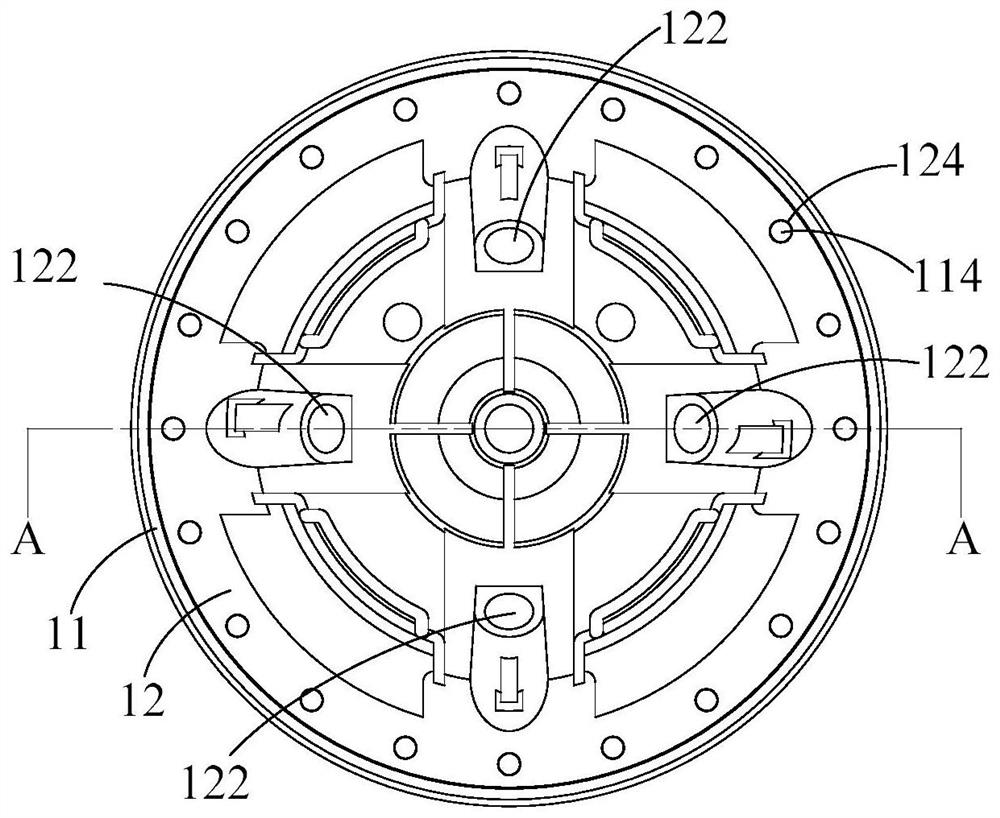

Automatic magnetic steel surface mounting device

PendingCN110829759AGuaranteed location accuracyAccurate angleManufacturing stator/rotor bodiesAxial displacementElectric machine

The invention discloses an automatic magnetic steel surface mounting device. The automatic magnetic steel surface mounting device comprises a motor rotor supporting structure, an angle rotating device, a magnetic steel surface mounting action device and an automatic dispensing device for spraying glue to magnetic steel, the angle rotating device can drive a motor rotor to rotate on the motor rotorsupporting structure, and the magnetic steel surface mounting action device comprises a storage mechanism, a discharging mechanism, a first moving mechanism and a lifting pressing mechanism. By controlling a high-precision motor, the circumferential rotation angle and the axial displacement of the device are accurate, and the position accuracy of magnetic steel surface mounting is ensured; the problems of glue overflowing, glue shortage and the like are solved; the inconvenience of manual material taking is solved; the magnetic steel is attached from bottom to top, and reliable movement and adhesion of the magnetic steel are guaranteed; the problems of inconvenience of manual operation, high labor intensity and narrow space operability are efficiently solved; and efficiency is improved, and manual labor is reduced.

Owner:KEDE NUMERICAL CONTROL CO LTD

Construction method for isolating reserved foundation slab post-cast strip

InactiveCN109024698AGuaranteed accuracyImprove stabilityArtificial islandsUnderwater structuresEngineeringCushion

The invention relates to the technical field of concrete construction, in particular to a construction method for an isolating reserved foundation slab post-cast strip. The method comprises the stepsof (1) plain concrete cushion construction; (2) lattice type stainless steel sheet installation; (3) flexible seam filling body installation; (4) tying of tie bars on the two sides; (5) fixing of vertical stainless steel clips; (6) tying of reinforcing ribs on the lower side of the post-cast strip; (7) quick and easy closing net installation; (8) inflexion type frame plate installation; (9) installation and placement of an inflatable core mold; (10) tying of reinforcement ribs on the upper side of the post-cast strip; (11) longitudinal segment limit plate installation; (12) inflation of the inflatable core mold and pouring of concrete; (13) installing of a screw closure structure and removing of the mold core; and (15) fixing of a top plate pull rod. The construction method for the isolating reserved foundation slab post-cast strip is convenient to construct, the construction efficiency of the advanced back-watering construction of the foundation backing can be improved, and the economic and technical benefits are good.

Owner:HANGZHOU JIANGRUN TECH LIMITED

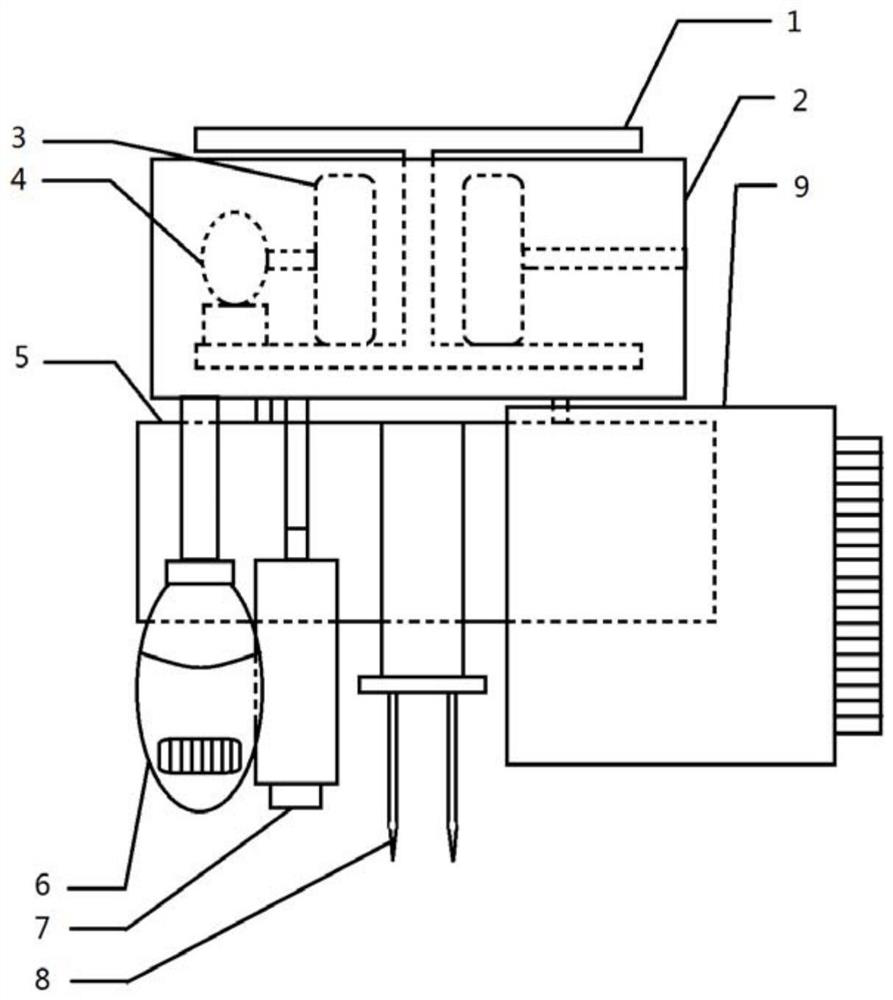

Movable intelligent car washing system

InactiveCN109334626ANo manpower requiredFully automatedGeneral water supply conservationWallsWater resourcesEngineering

The invention belongs to the technical field of intelligent car washing, and particularly relates to a movable full-automatic intelligent car washing system. The movable intelligent car washing systemtakes a modularized frame box body as a carrier for completing car washing, and space in the frame box body comprises a guiding work section, a car washing work section and an export work section inthe direction of the car washing order; all work sections complete the whole intelligent car washing process through corresponding structure arrangement, and it is ensured that a car is thoroughly cleaned in the whole car washing process. The intelligent car washing system can automatically complete car washing and fee payment, manual participation is not needed in the whole process, and the system has the advantages of being full-automatic and not needing manpower consumption; according to the movable intelligent car washing system, through the design of a sewage collecting treatment assemblyand a rainwater circulating filtering assembly, waste water of car cleaning and rainwater are effectively recycled, energy is effectively saved, and waste of water resources is avoided.

Owner:钱强

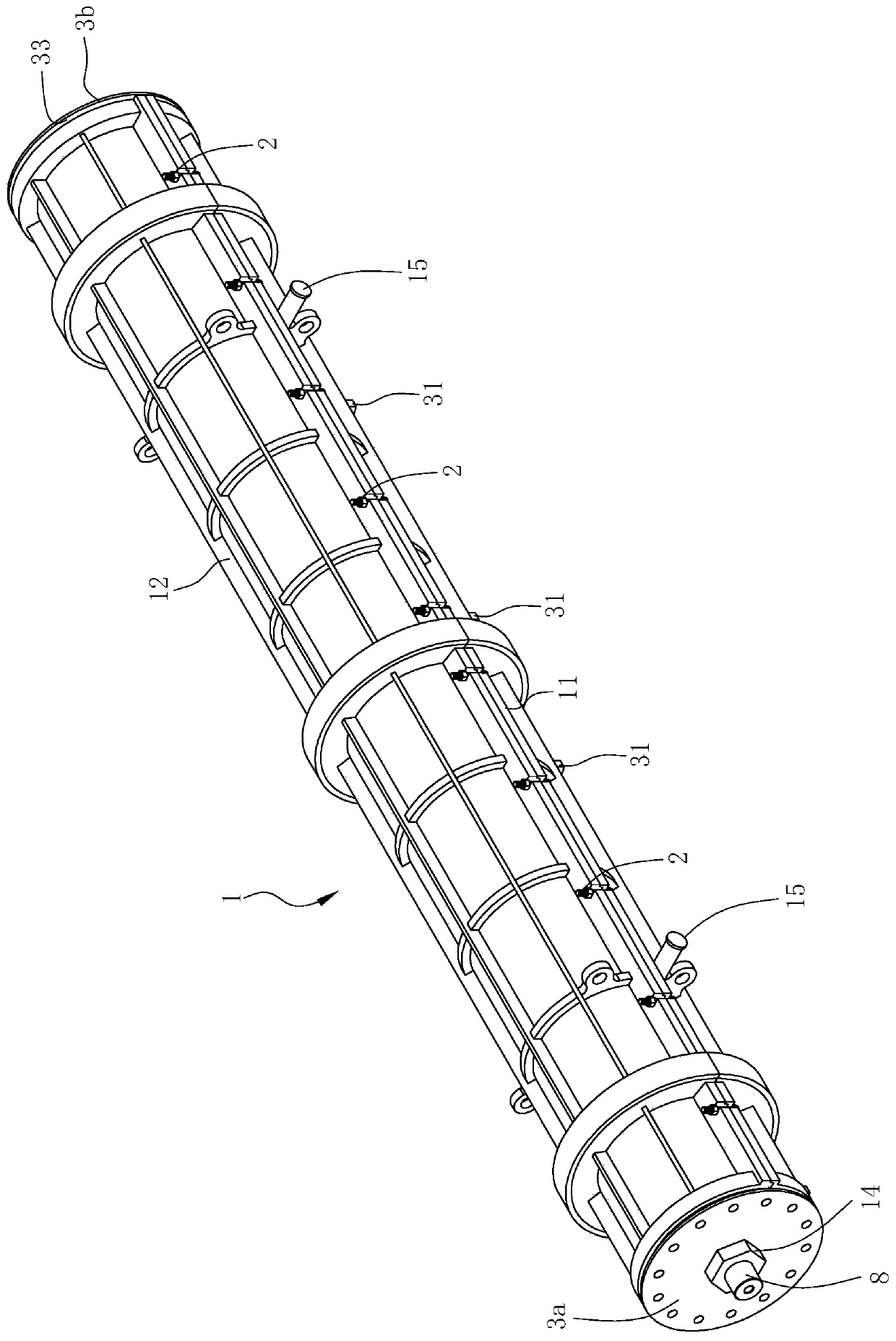

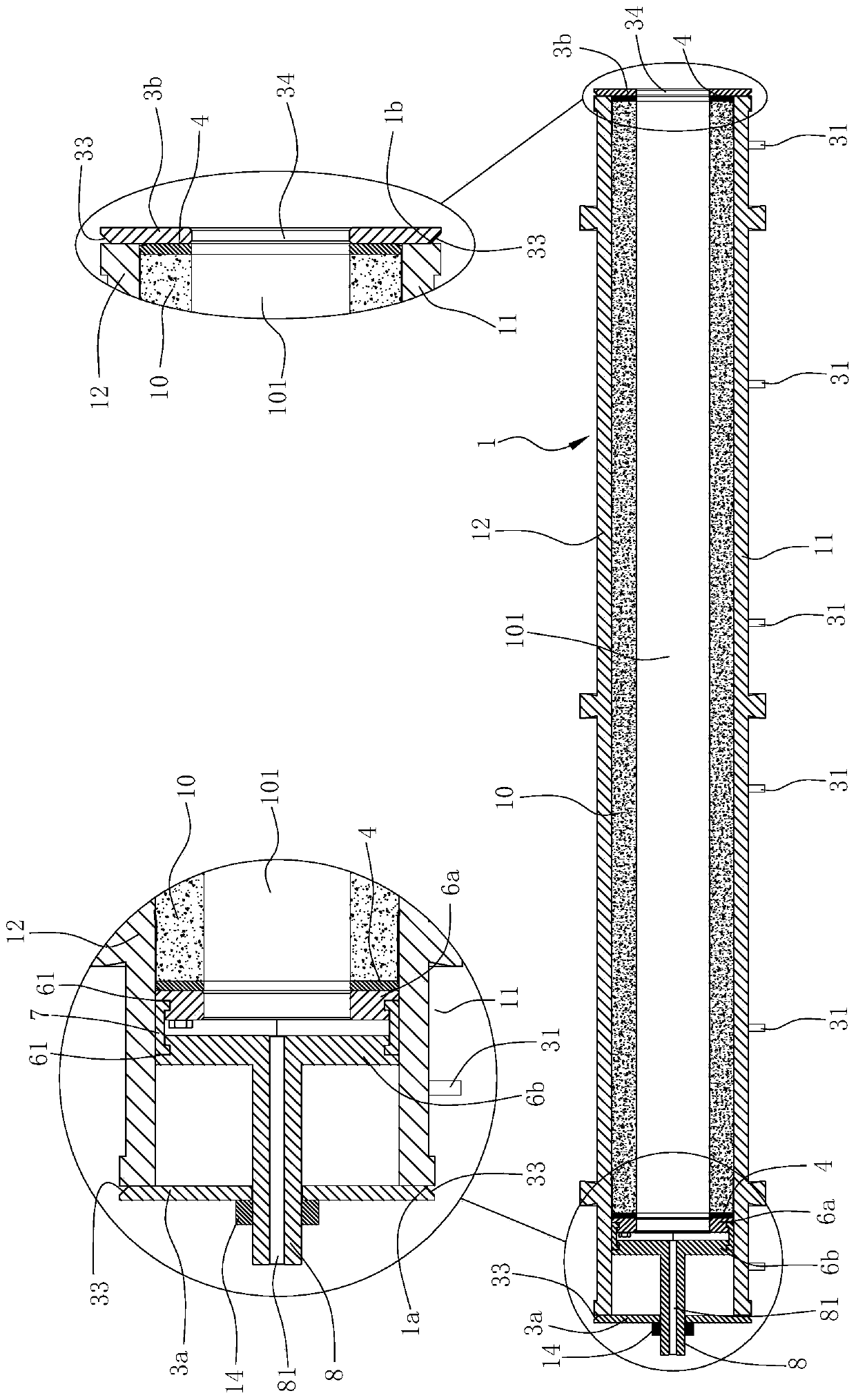

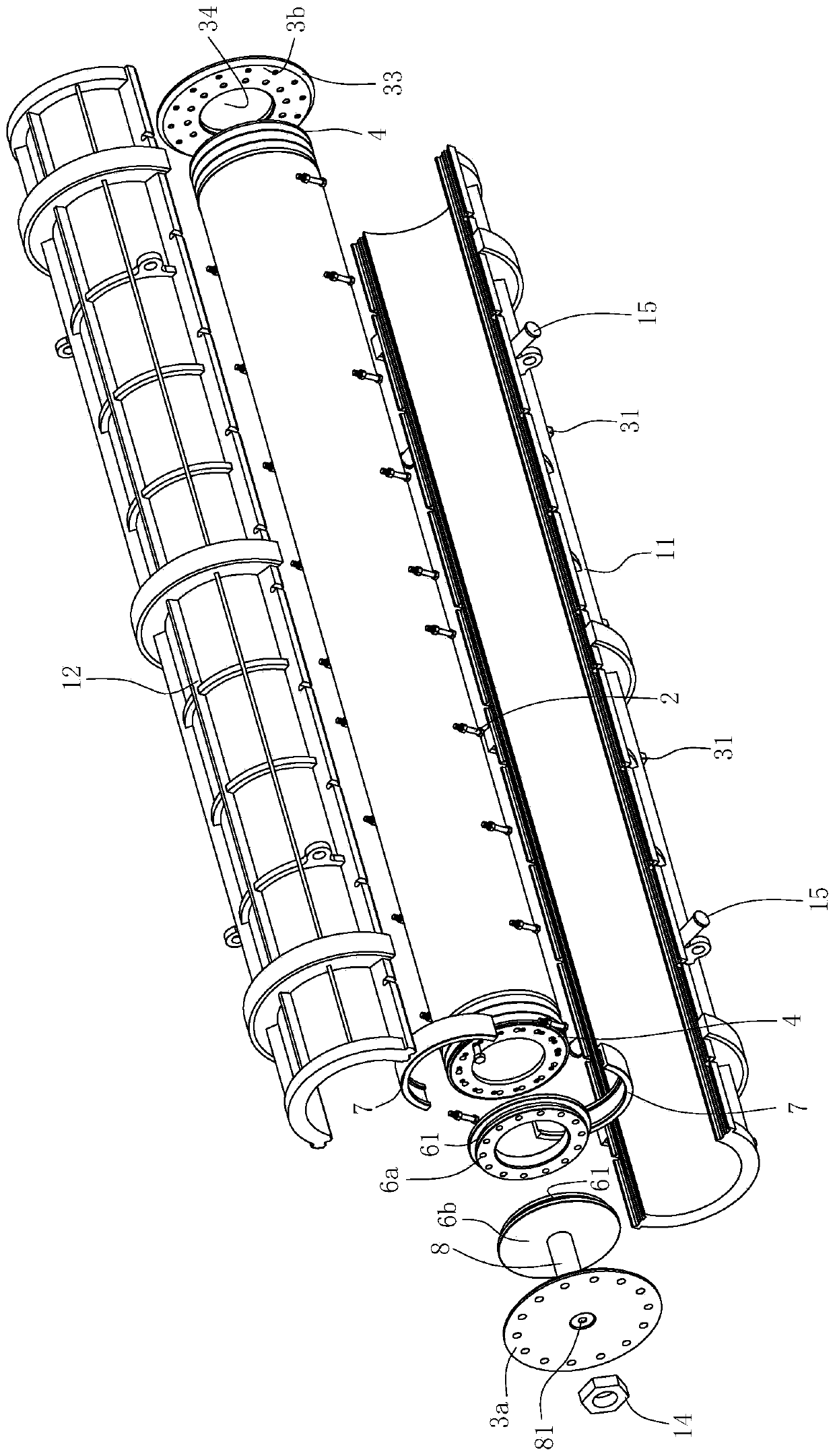

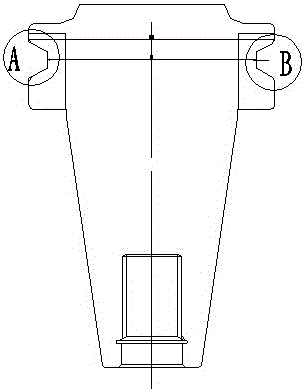

Centrifugal concrete pile mold and flat car for shelving centrifugal concrete pile mold

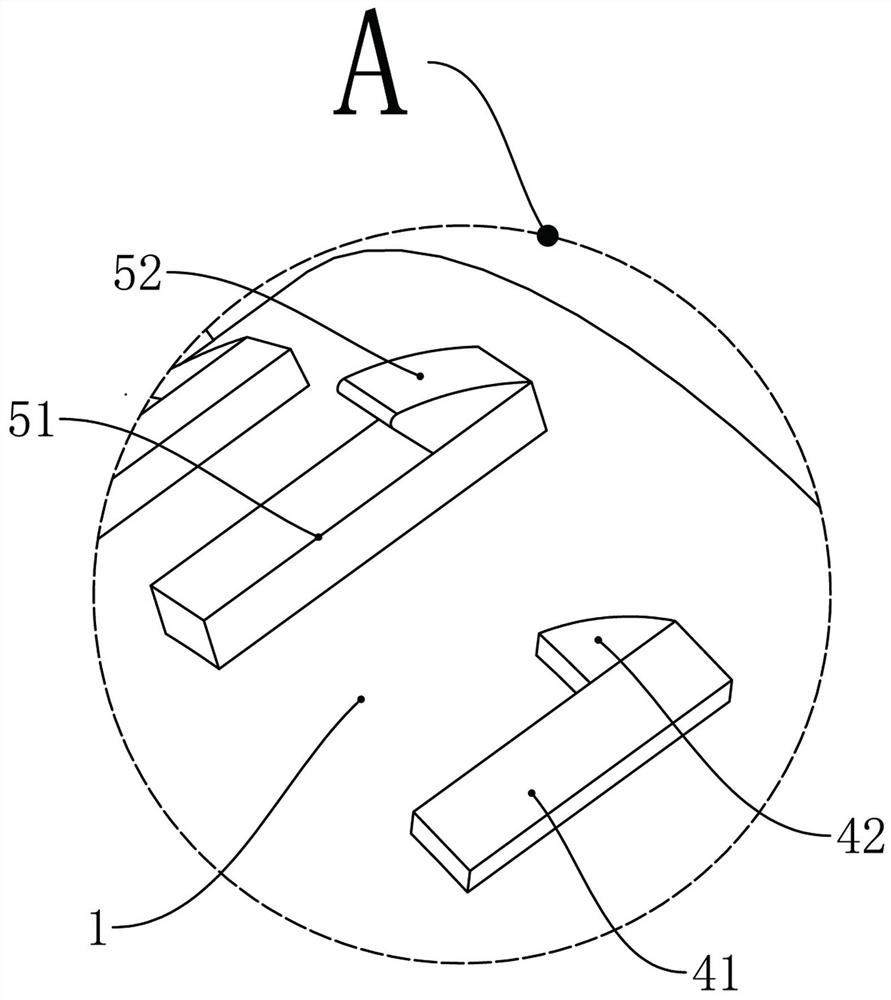

PendingCN110238958AGuaranteed location accuracyAchieve precise positioningMouldsShaping reinforcementsProduction lineBack support

The invention relates to a centrifugal concrete pile mold which is composed of a mold body (1) folded by a lower half mold (11) and an upper half mold (12) and a mold closing bolt assembly (2) for connecting the lower half mold (11) and the upper half mold (12). A front supporting plate (3a) and a back supporting plate (3b) are separately fixed to a front end surface (1a) and a back end surface (1b) of the mold body (1). The mold body is characterized in that annular wedge-shaped surfaces (33) are arranged on the peripheries of the end surfaces, attached to the mold body (1), of the front supporting plate (3a) and the back supporting plate (3b). The mold is the centrifugal concrete pile capable of positioning mold closing of the mold precisely and provides probability that a mold hosting route and a centrifugal machine are on same axis, so that a centrifugal concrete pile production line is optimized favorably. The invention also relates to a flat car matched with the mold in use.

Owner:俞晓东

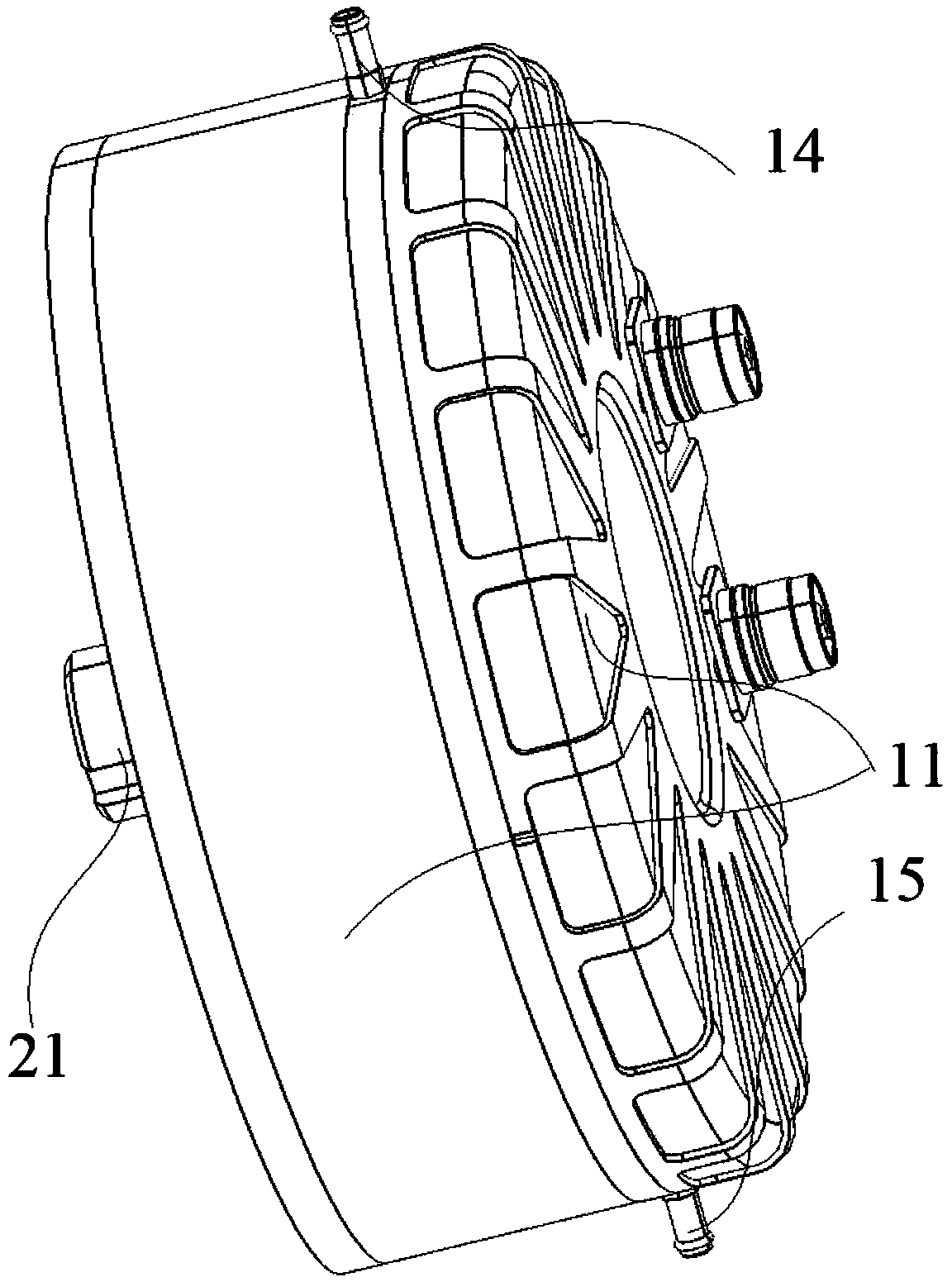

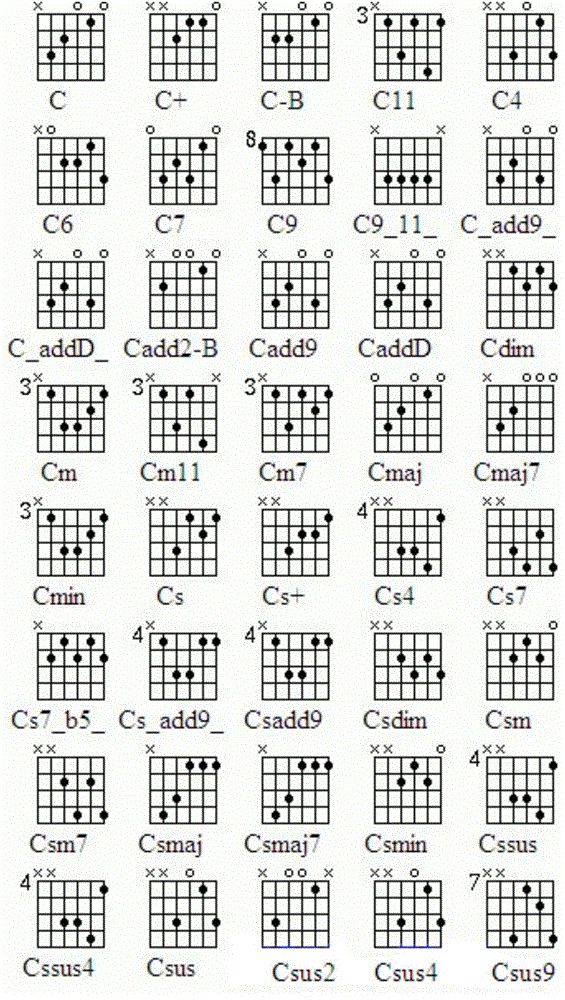

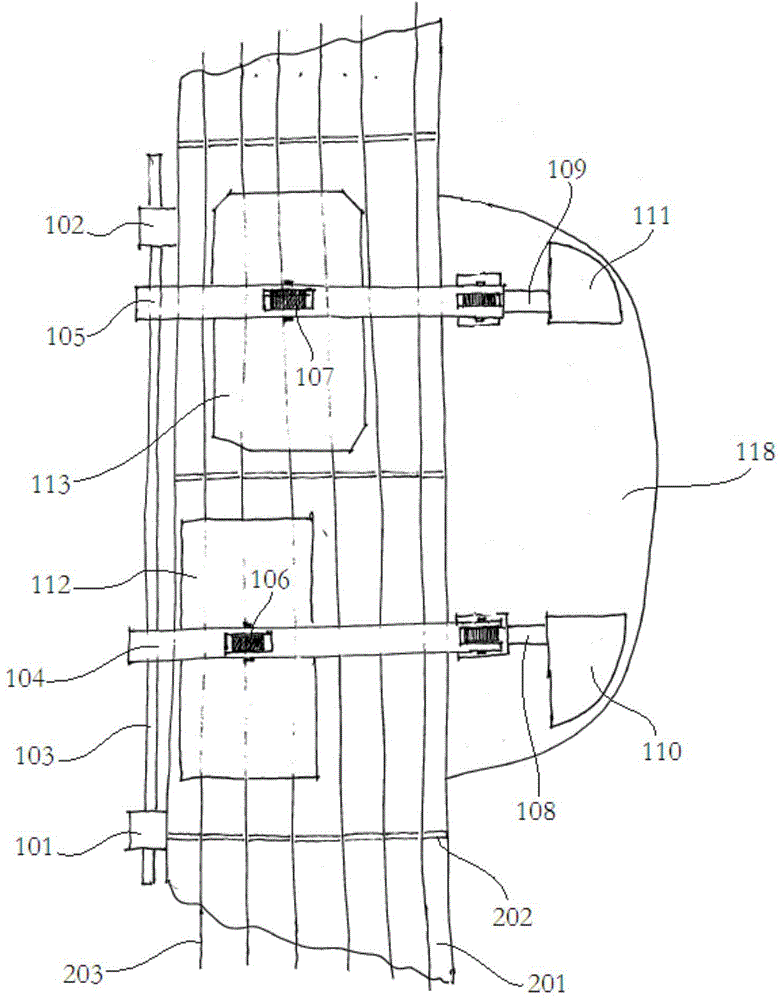

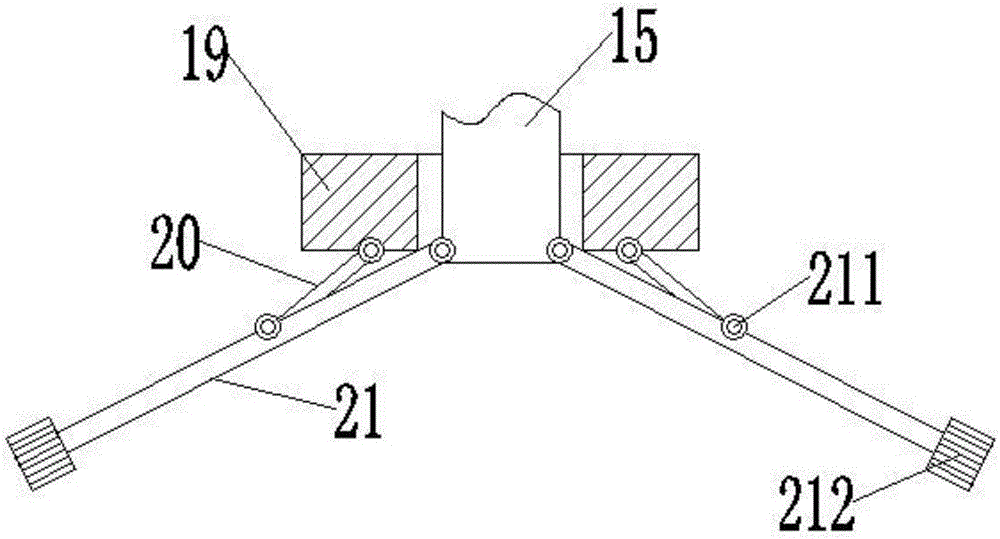

Guitar chord fingering device

InactiveCN105006225AHigh string pressureEasy to operateStringed musical instrumentsEngineeringGuitar

The invention provides a guitar chord fingering device. The device comprises: a housing; L-shaped key rods provide with keys extending from one side of the housing; pressing rods, the lower ends of which are provided with pressing boards, wherein branch pressing rods are arranged below the pressing boards according to a chord fingering score; rotating arms, one ends of which are rotationally connected to the housing, the other ends of which are rotationally connected to the L-shaped key rods, and the middle parts of which are connected to the pressing rods; and return springs, which enable the branch pressing rods to press strings when the keys are pressed and the rotating arms rotate to press the pressing rods, and enable the rotating arms return when the keys are relieved. The guitar chord fingering device makes a player comfortable and convenient when playing chord.

Owner:周建峰

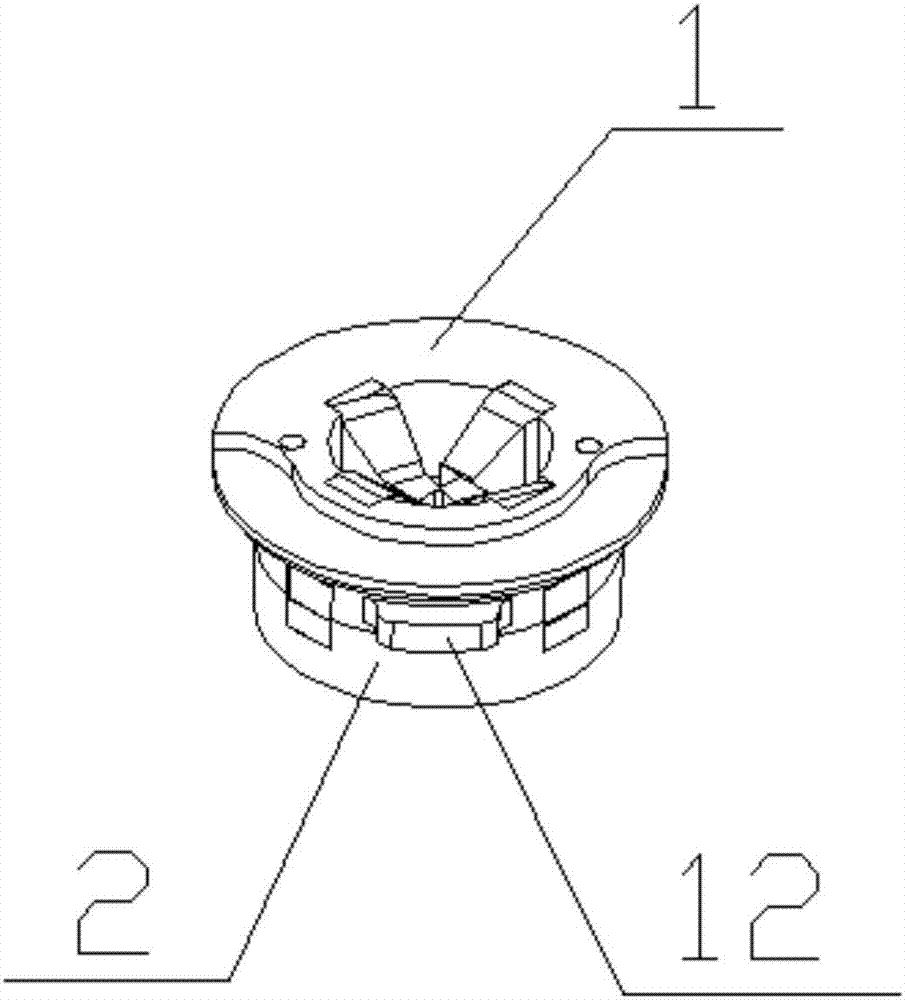

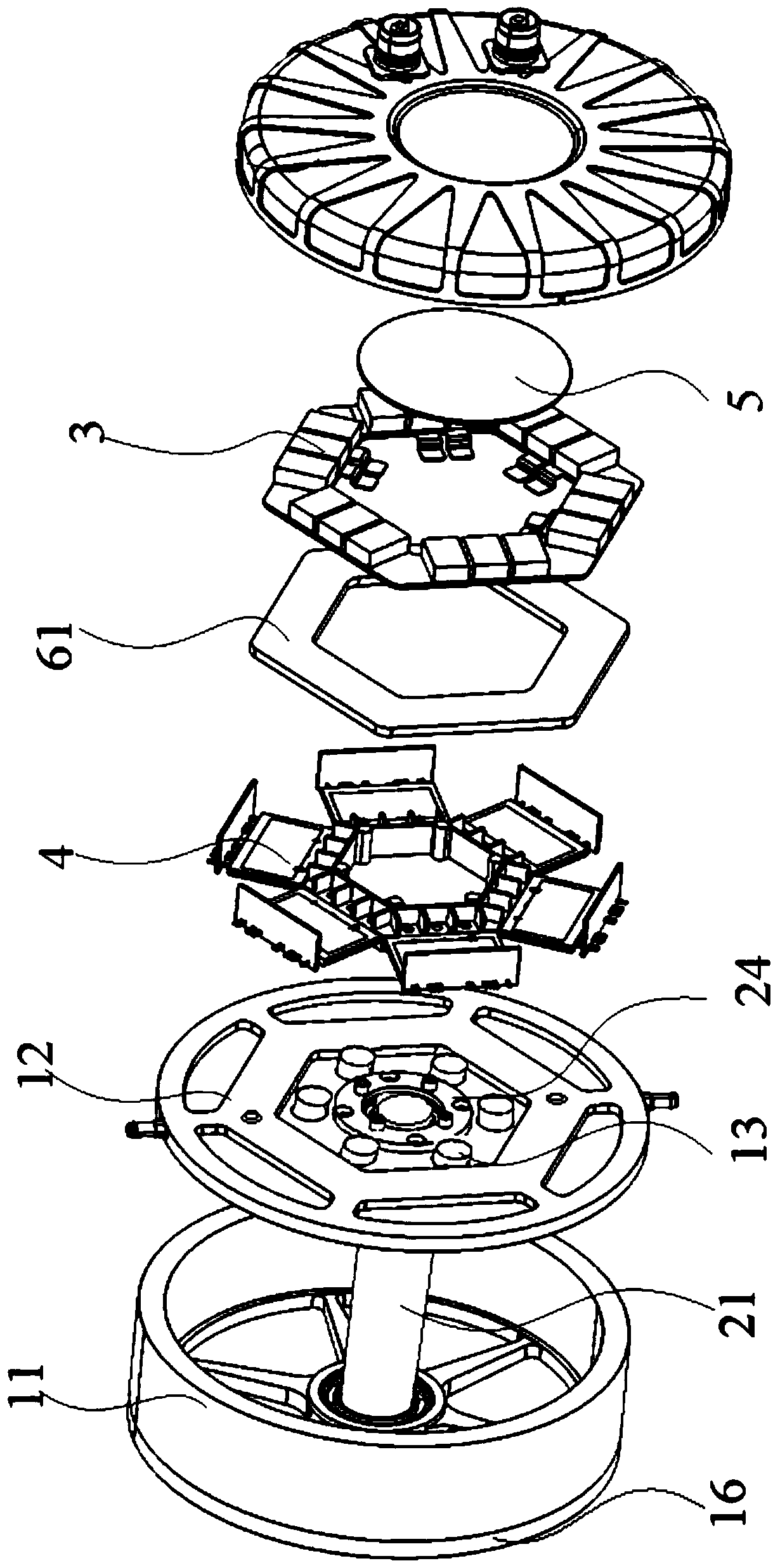

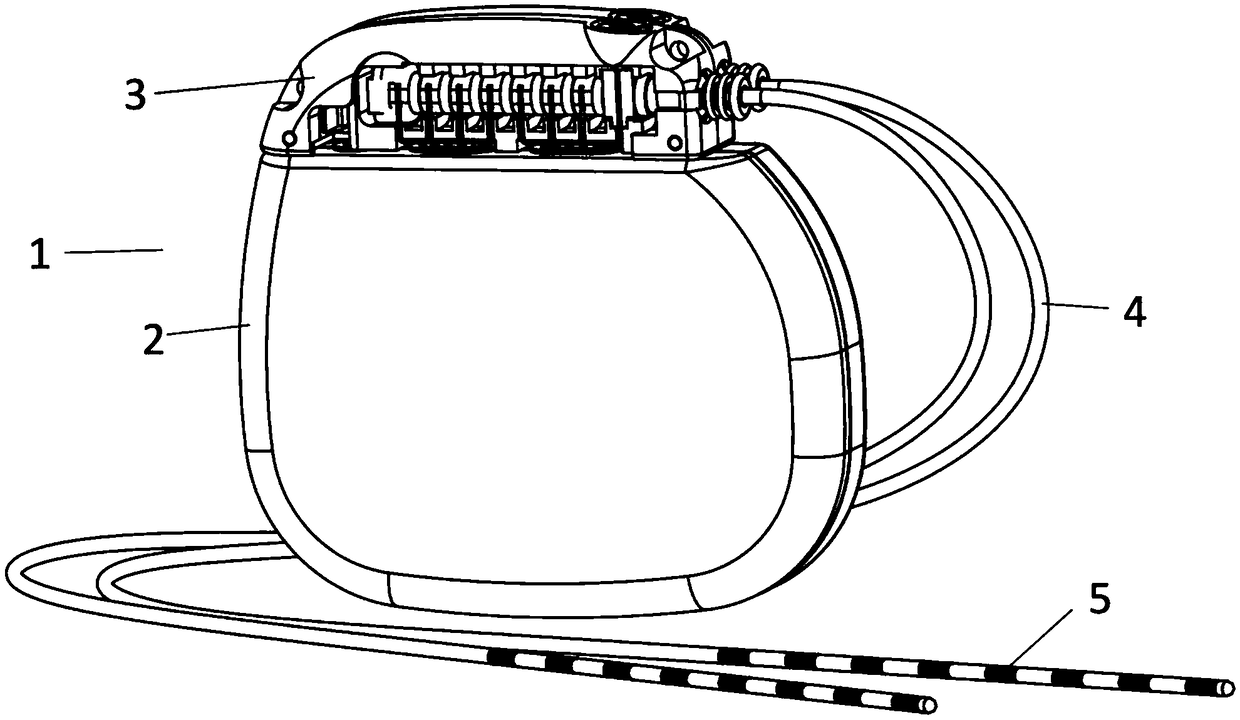

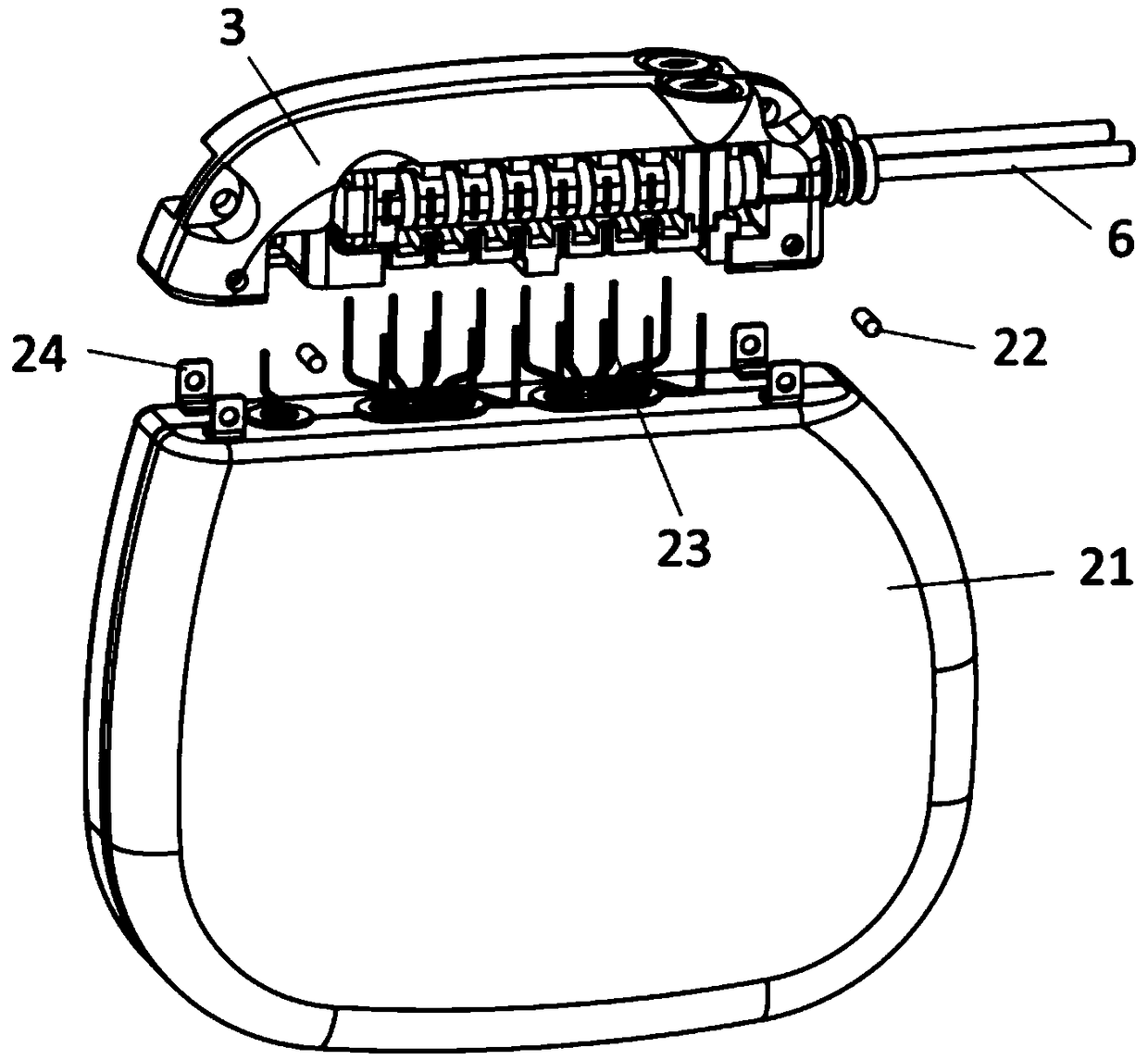

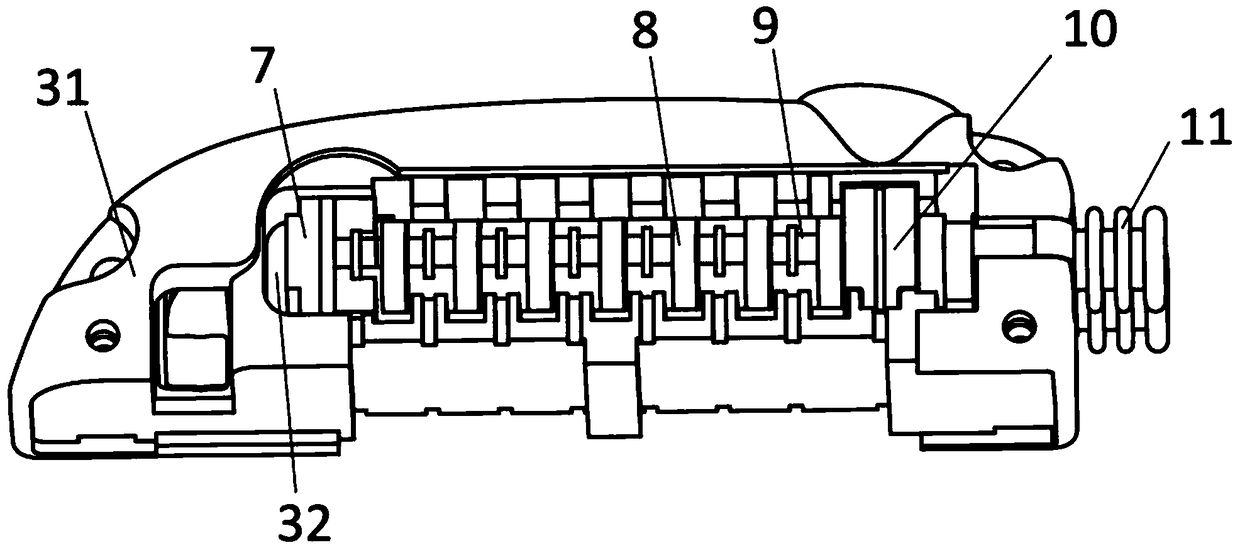

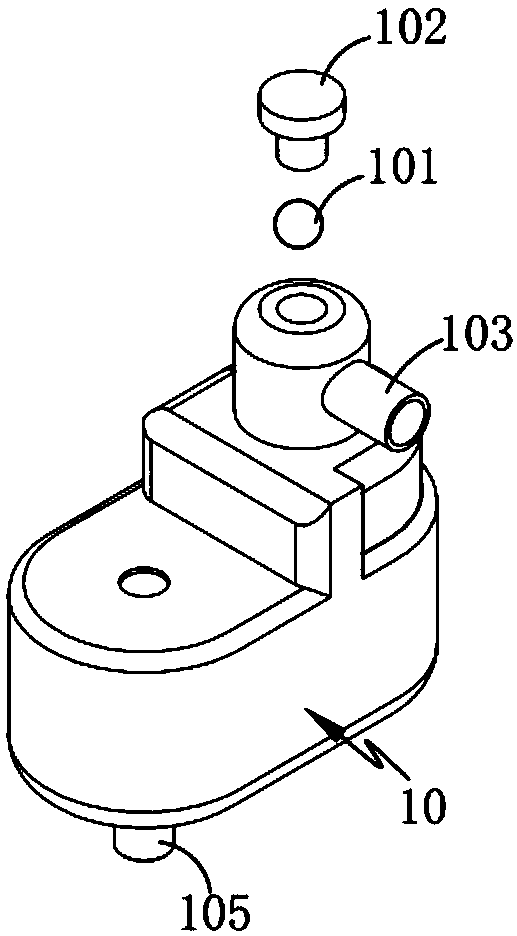

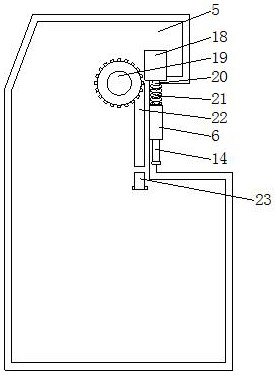

Top cover component, pulse generator and implantable electrical stimulation system

ActiveCN109364372APrevent disengagementGuaranteed location accuracyElectrotherapyArtificial respirationElectricityEngineering

The invention provides a top cover component, a pulse generator and an implantable electrical stimulation system. The top cover component comprises a connector, an intermediate sealing ring and a locking member for locking an insertion end, wherein the connector, the intermediate sealing ring and the locking member are connected in a sleeved manner, and each has electrode through holes allowing electrodes to pass through; and a plurality of the electrode through holes form a matching cavity matched with the insertion end. The top cover component further comprises a top cover body having an accommodating groove, wherein a first glue dispensing groove is formed in the accommodating groove corresponding to the periphery of the intermediate sealing ring; and the top cover body is sealed and fixed to the connector, the intermediate sealing ring and the locking member by means of liquid silicone rubber. By adopting the design, firstly, the sleeved matching can ensure the coaxiality of the parts and prevent the entry of the liquid silicone rubber; secondly, filling and solidification of the liquid silicone rubber are realized by forming the first glue dispensing groove, and the liquid silicone rubber is combined with the intermediate sealing ring to isolate the adjacent connectors completely; thirdly, the positioning and anti-releasing structure is formed with the top cover body, thereby ensuring the positional precision and preventing the parts from disengaging from the end part of the top cover body.

Owner:BEIJING PINS MEDICAL +1

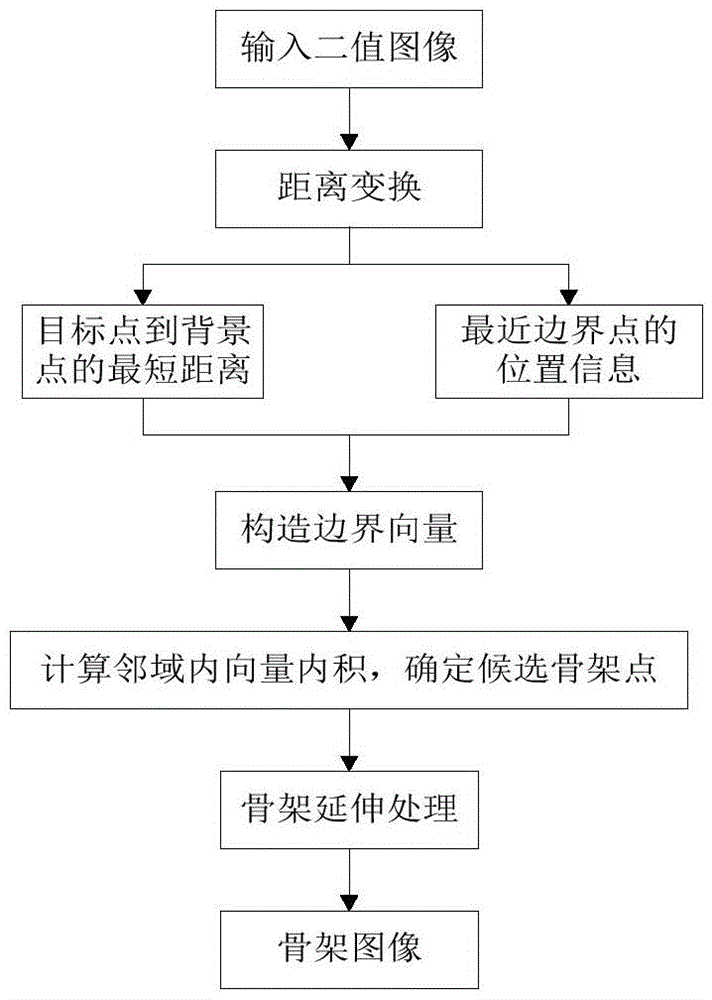

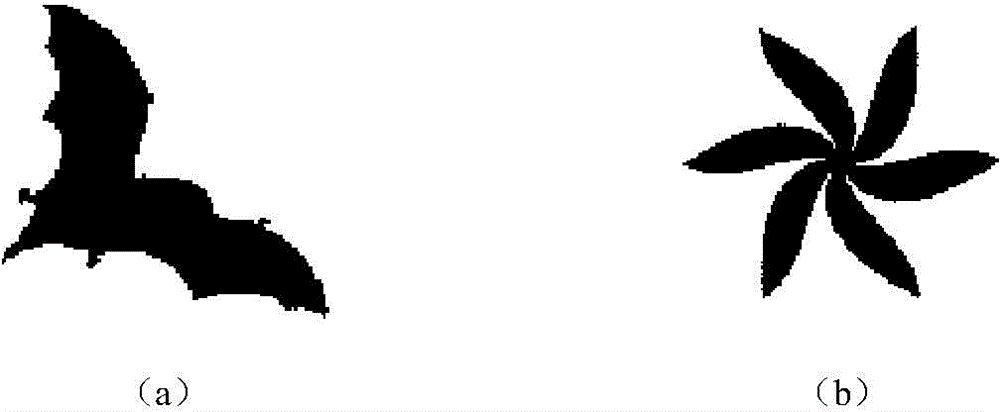

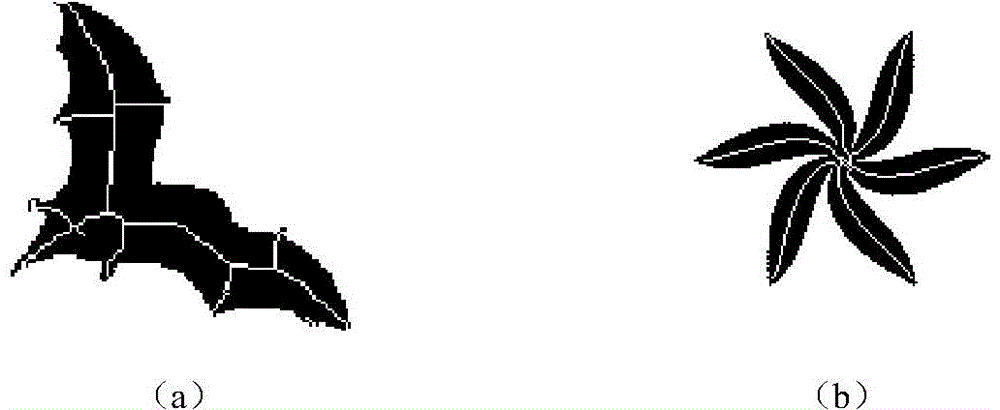

Vector inner product-based skeleton extraction method

InactiveCN105631843ASolve decision problemsGuaranteed connectivityImage analysisRegression analysisImaging analysis

The invention provides a vector inner product-based skeleton extraction method. The method comprises the following steps of obtaining an internal pixel point and a position of a nearest boundary point corresponding to the internal pixel point through the distance transformation process so as to construct a boundary vector pointing from the internal pixel point to the nearest boundary point; based on the vector inner product, judging the variation trend of the direction of each boundary vector in the neighborhood of the internal pixel point 8 so as to determine the position of a candidate skeleton point; based on the analysis of regression, completing the skeleton extension and finally obtaining a connected skeleton. The method of the invention effectively solves the problems that other skeleton extraction methods are easily influenced by the boundary noise and there isn't an equilibrium between the connectivity and the skeleton position accuracy in the prior art. Based on the method of the invention, the extracted skeleton is accurately positioned and good in connectivity. Meanwhile, the running speed meets the requirement of an image analysis system. Therefore, the method has the practical application value.

Owner:NORTHEAST FORESTRY UNIVERSITY

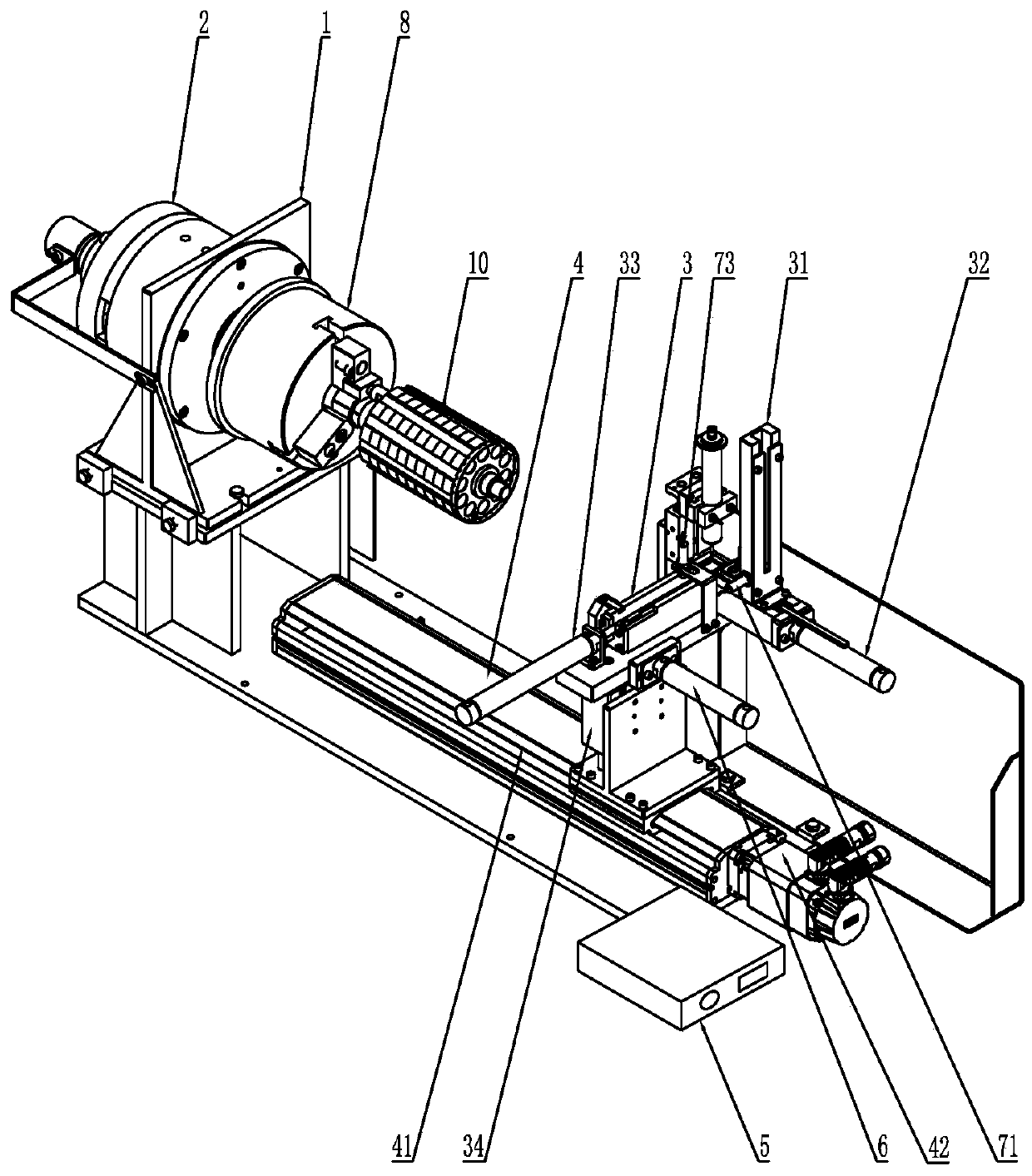

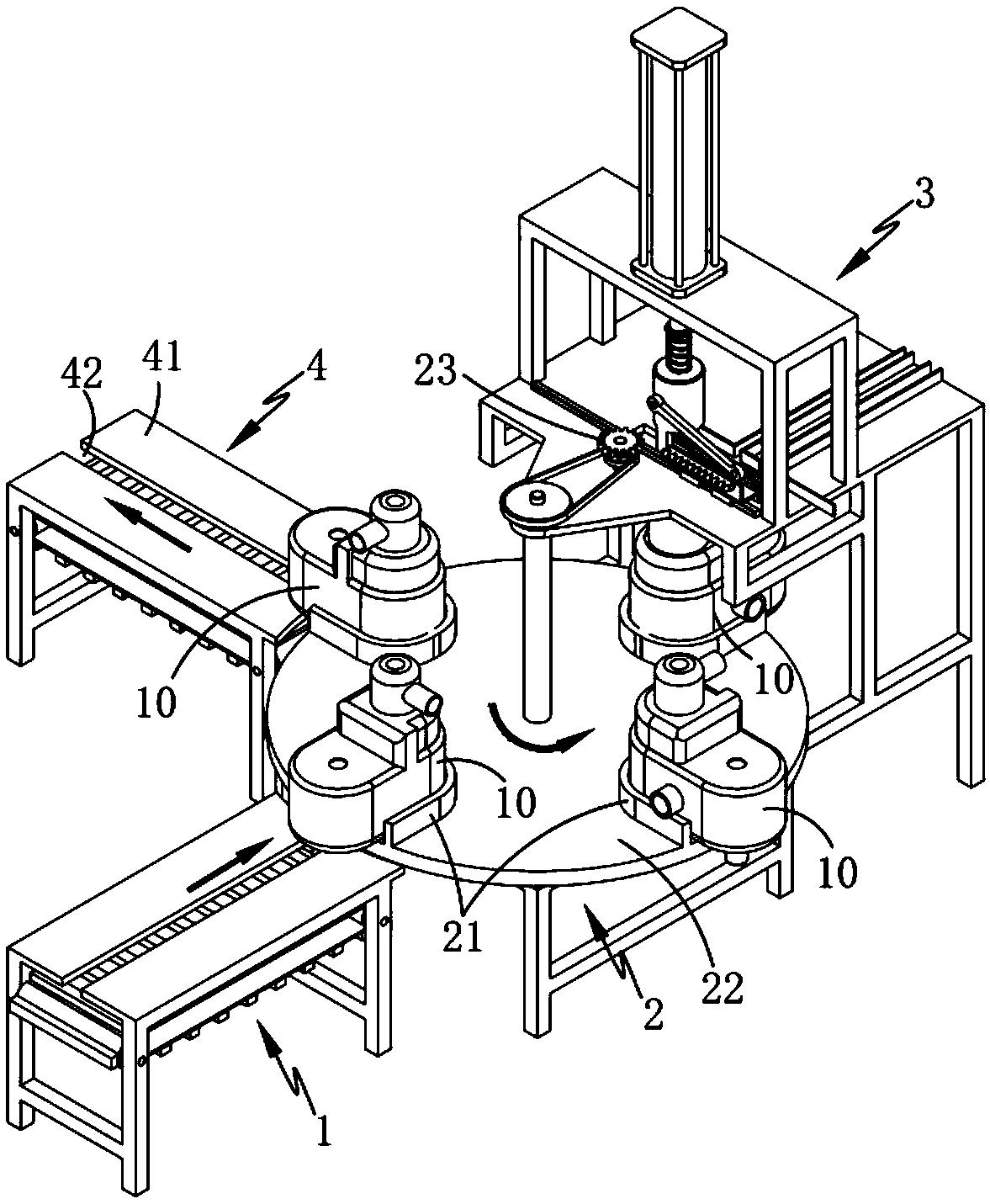

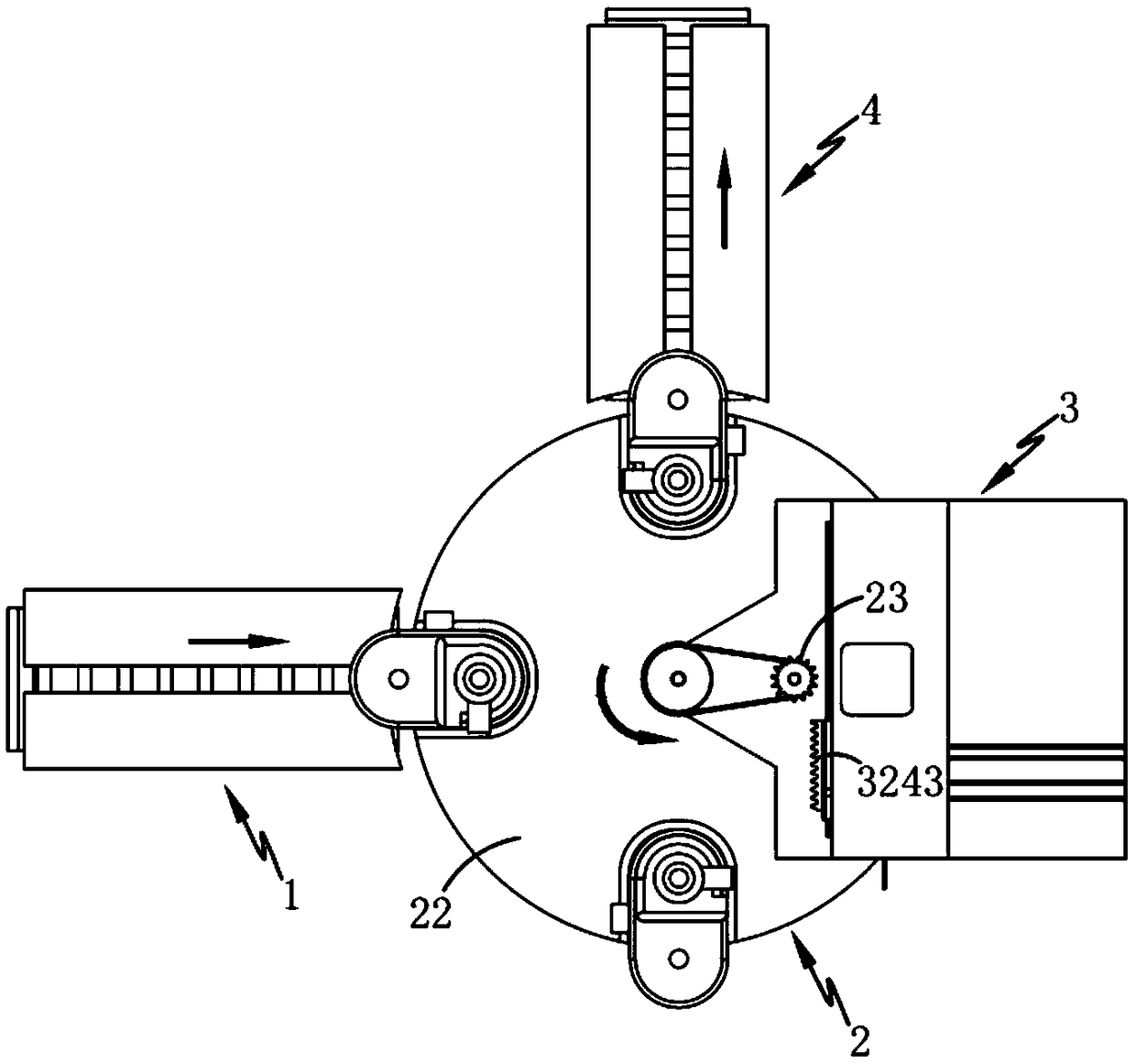

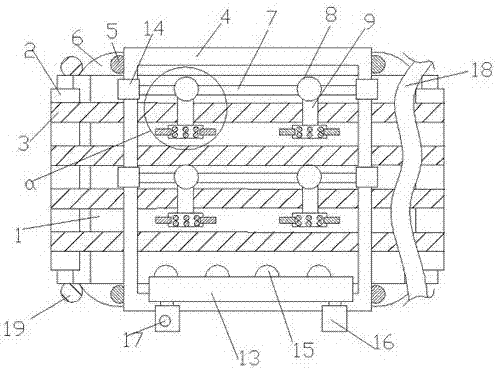

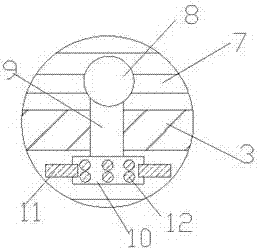

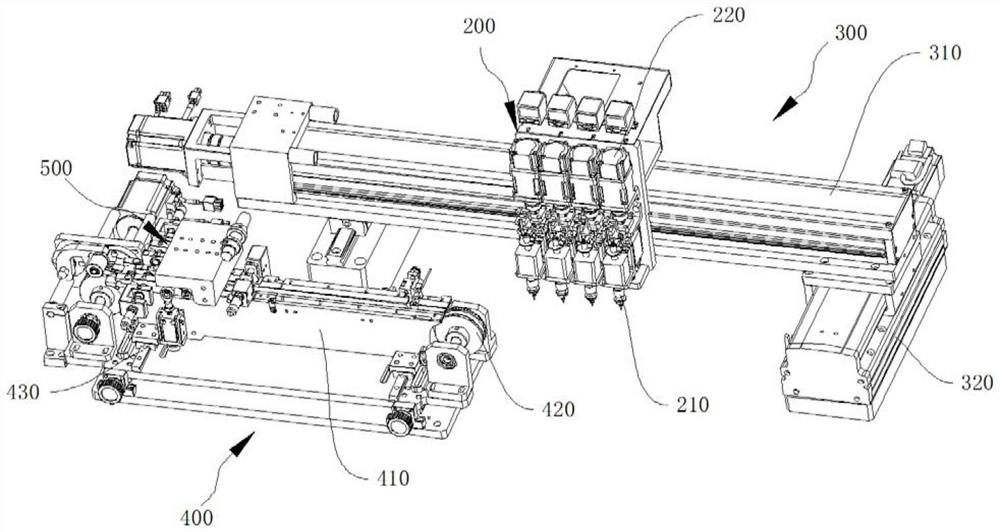

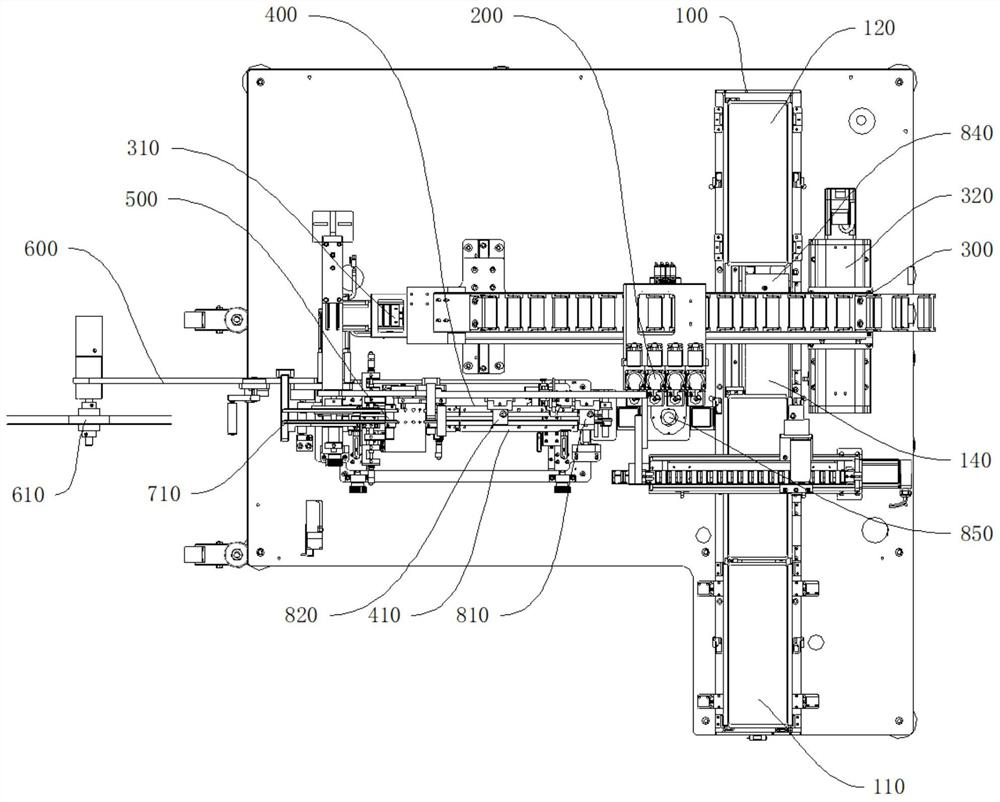

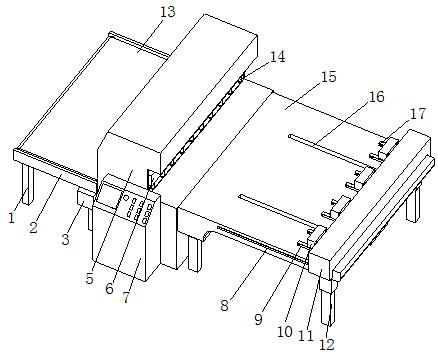

Multi-station automatic assembling production line for oil pump

ActiveCN109227118ARealize fully automatic productionSolve technical problems with low automationAssembly machinesMetal working apparatusProduction lineSteel ball

The invention relates to the technical field of oil pump assembling production, in particular to a multi-station automatic assembling production line for an oil pump. The production line comprises a feeding mechanism, a station switching mechanism, a press-fitting mechanism and an outputting mechanism; the press-fitting mechanism comprises a rack, a positioning assembly, a material transferring assembly and a press-fitting assembly, after the material transferring assembly transfers a steel ball and a plug into the positioning assembly, the positioning assembly fastens and positions an oil pump body, and the press-fitting assembly press-fits the steel ball and the plug into the oil pump body; the station switching mechanism is driven by the material transferring assembly to operate. When the press-fitting assembly moves upwards, the station switching mechanism is driven to perform station transferring of the oil pump body, meanwhile, the material transferring assembly is driven to perform automatic feeding of the steel ball and the plug, the press-fitting assembly moves downwards to perform press-fitting of the steel ball and the plug, and meanwhile, the positioning assembly is driven to position and fasten the oil pump body. Thus, full-automatic press-fitting production of the oil pump body is realized, and the technical problem that in the prior art, the automation degree ofoil pump press-fitting is low is solved.

Owner:CHANGXING BEST MASCH CO LTD

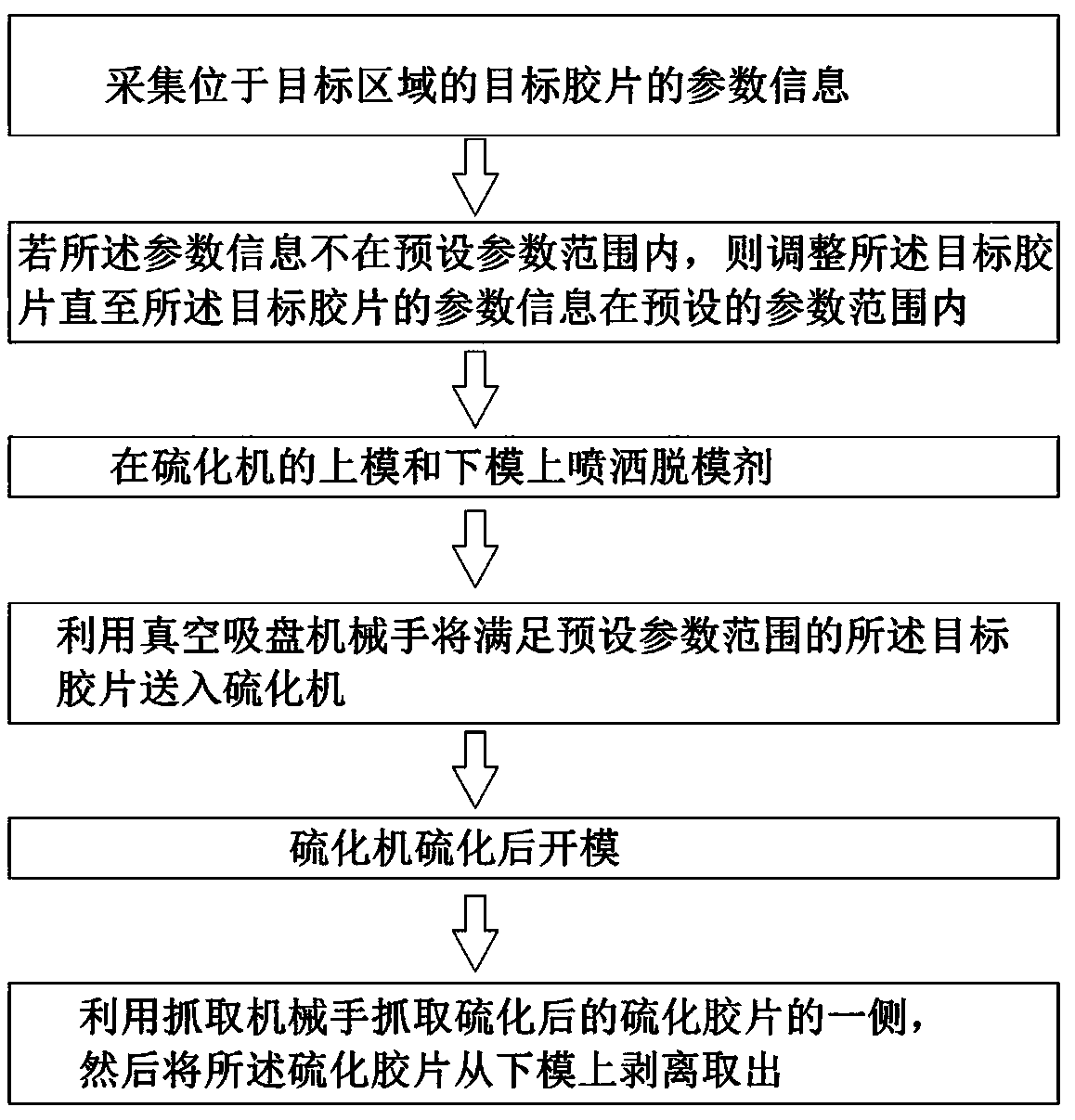

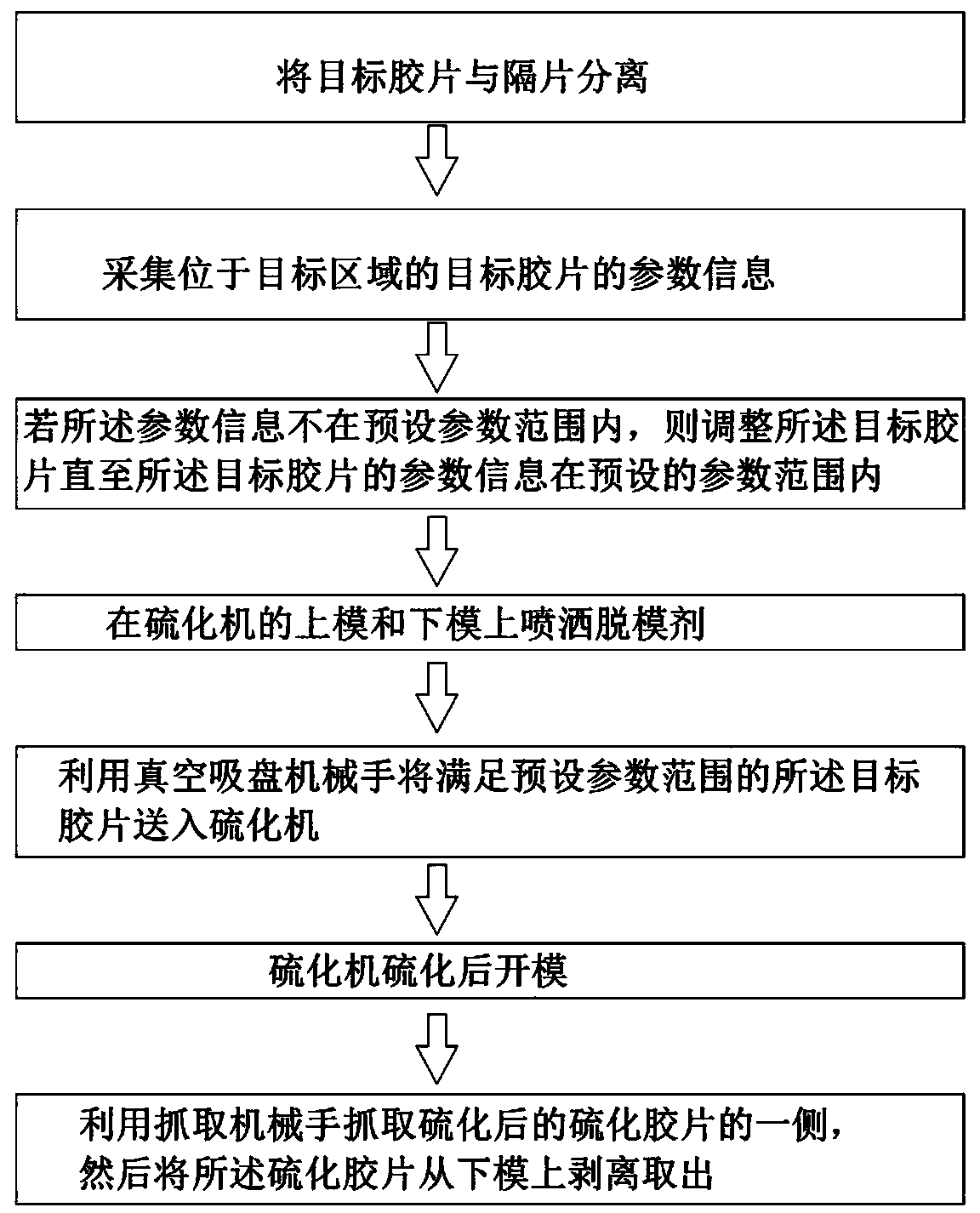

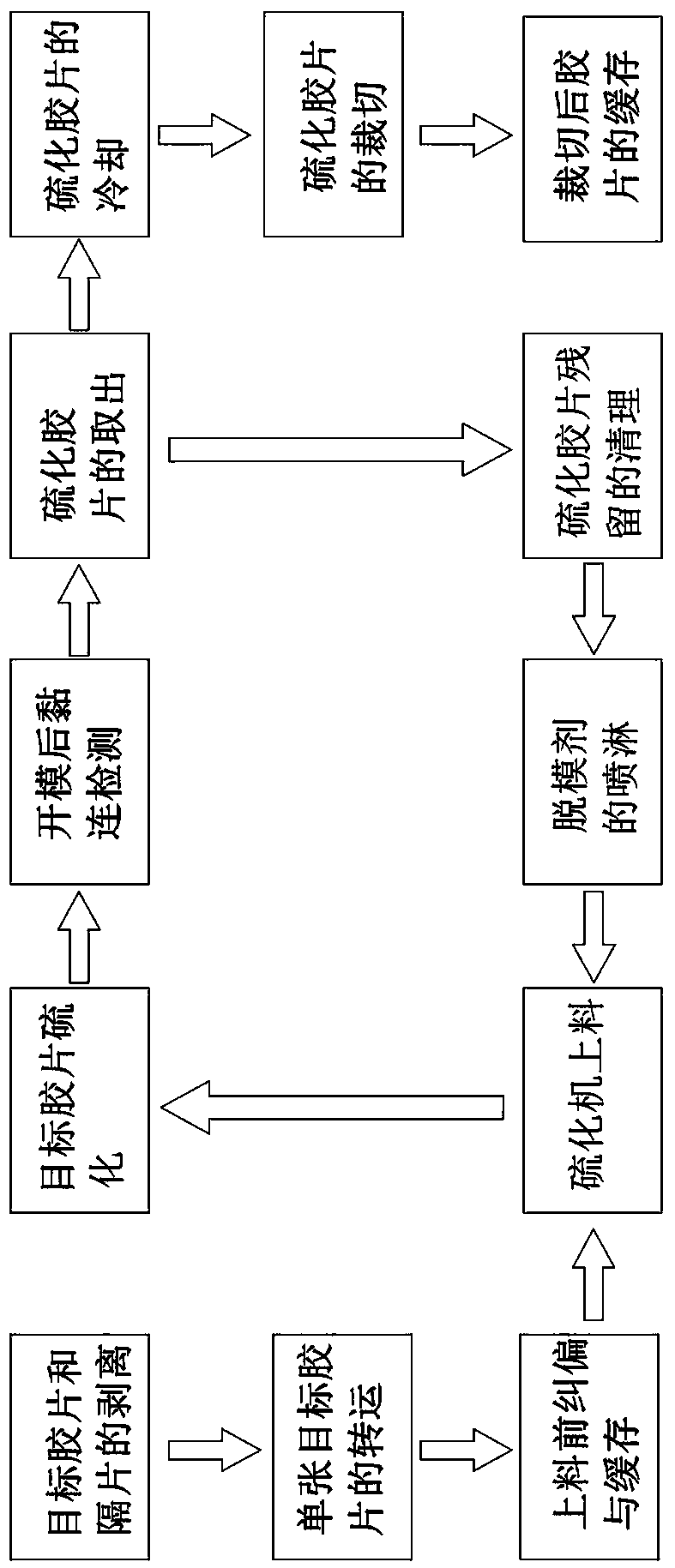

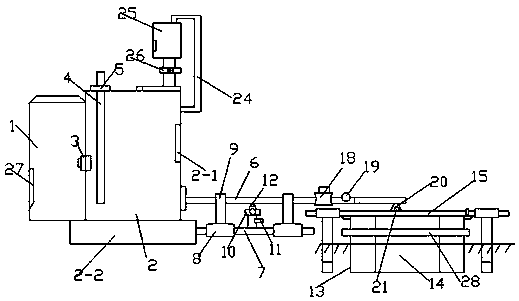

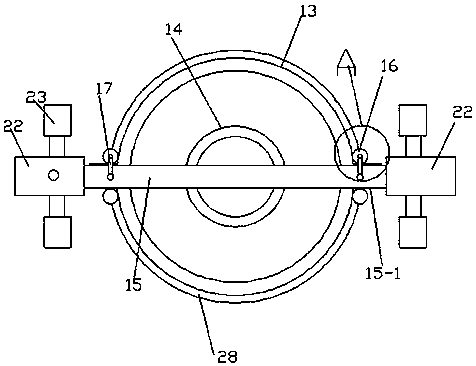

Producing technological method for vulcanized film

The invention provides a producing technological method for a vulcanized film, and belongs to the technical field of rubber plug production. The method includes the steps that an unvulcanized target film is stripped from a separating plate to be placed to a target area; parameter information of the target film located in the target area is collected, wherein the parameter information includes position parameters and angle parameters; if the parameter information is not within the preset parameter range, the target film is adjusted until the parameter information of the target film is within the preset parameter range; an upper mold and a lower mold of a vulcanizing machine are sprayed with a release agent; a vacuum chuck manipulator is used for sending the target film meeting the preset parameter range to the vulcanizing machine; mold opening is carried out after vulcanizing is carried out through the vulcanizing machine; and a grab manipulator is used for grasping one side of the vulcanized film, and then the vulcanized film is stripped from the lower mold and taken out. The producing technological method for the vulcanized film is beneficial to realizing automatic operation, reduces labor intensity of workers and improves the production efficiency.

Owner:青岛时间河智能科技有限公司

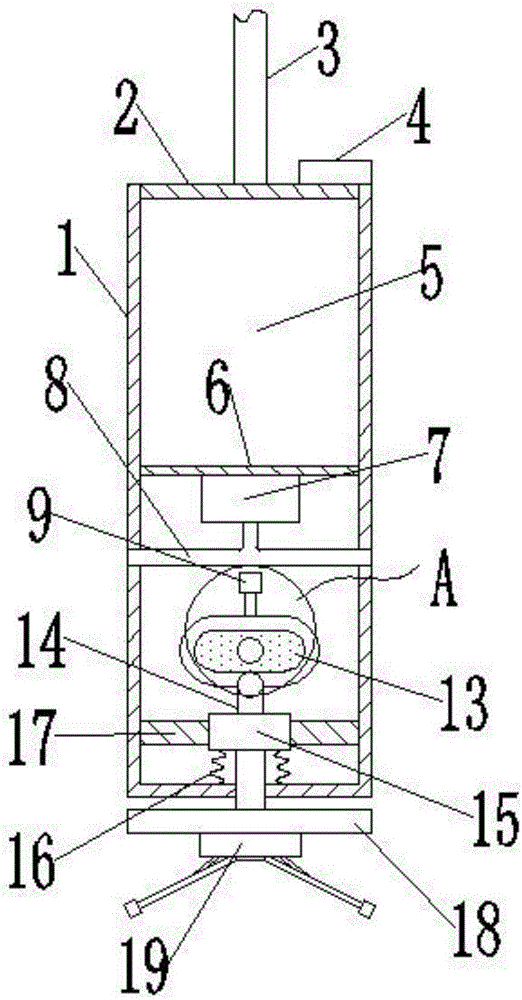

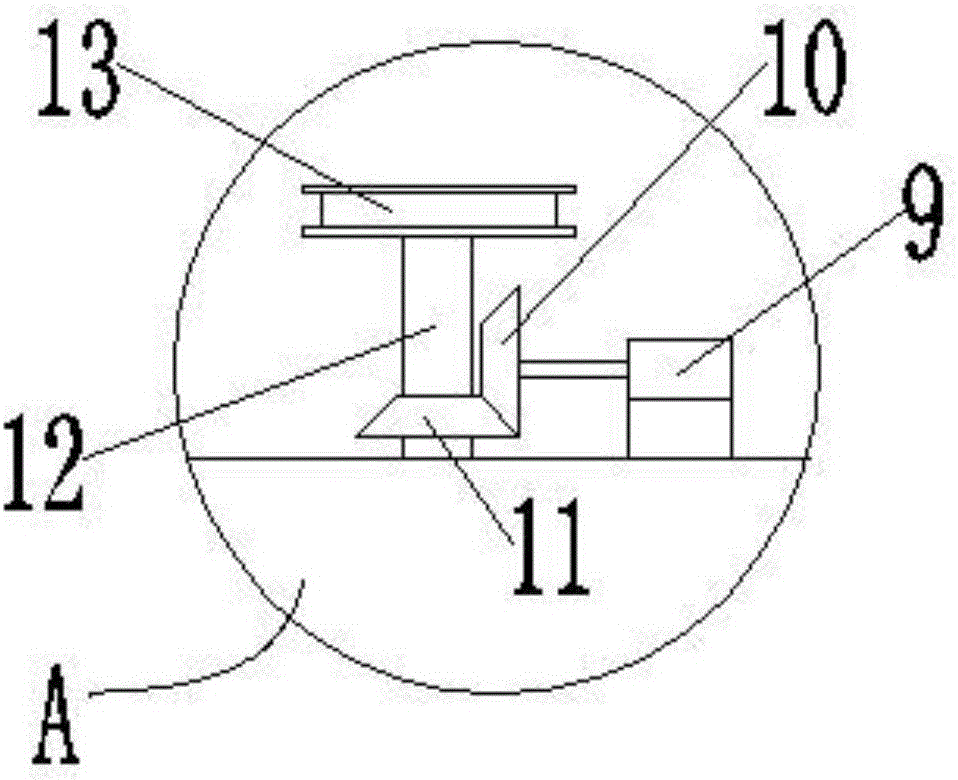

Automatic water replenishing and measuring device for soil infiltration

ActiveCN110849789APrevent affecting sensitivityNo shakingPermeability/surface area analysisEnvironmental engineeringSoil infiltration

The invention provides an automatic water replenishing and measuring device for soil infiltration. The device comprises a first water replenishing bin, an automatic water replenishing bin and an infiltration ring combination device which are orderly arranged; the first water replenishing bin is connected with the automatic water replenishing bin through a first transfer pump; a vent pipe is vertically inserted into the automatic water replenishing bin; a first liquid level sensor is arranged inside the automatic water replenishing bin; the automatic water replenishing bin is fixed on an automatic lifting support base; the lower end of the automatic water replenishing bin is provided with a water replenishing pipe on the same horizontal plane as the bottom of the vent pipe; one end of the automatic lifting support base is slidably provided with an extension rod; a calibration component is fixedly arranged on the extension rod; the calibration component comprises a digital display dial gauge and a control induction alarm; the infiltration ring combination device comprises an outer infiltration ring and an inner infiltration ring located in the inner cavity of the outer infiltration ring; and concentric positioning rods are fixed on top parts of the outer infiltration ring and the inner infiltration ring. The automatic water replenishing and measuring device for the soil infiltration provided by the invention can improve the accuracy of soil infiltration speed measurement.

Owner:TARIM UNIV

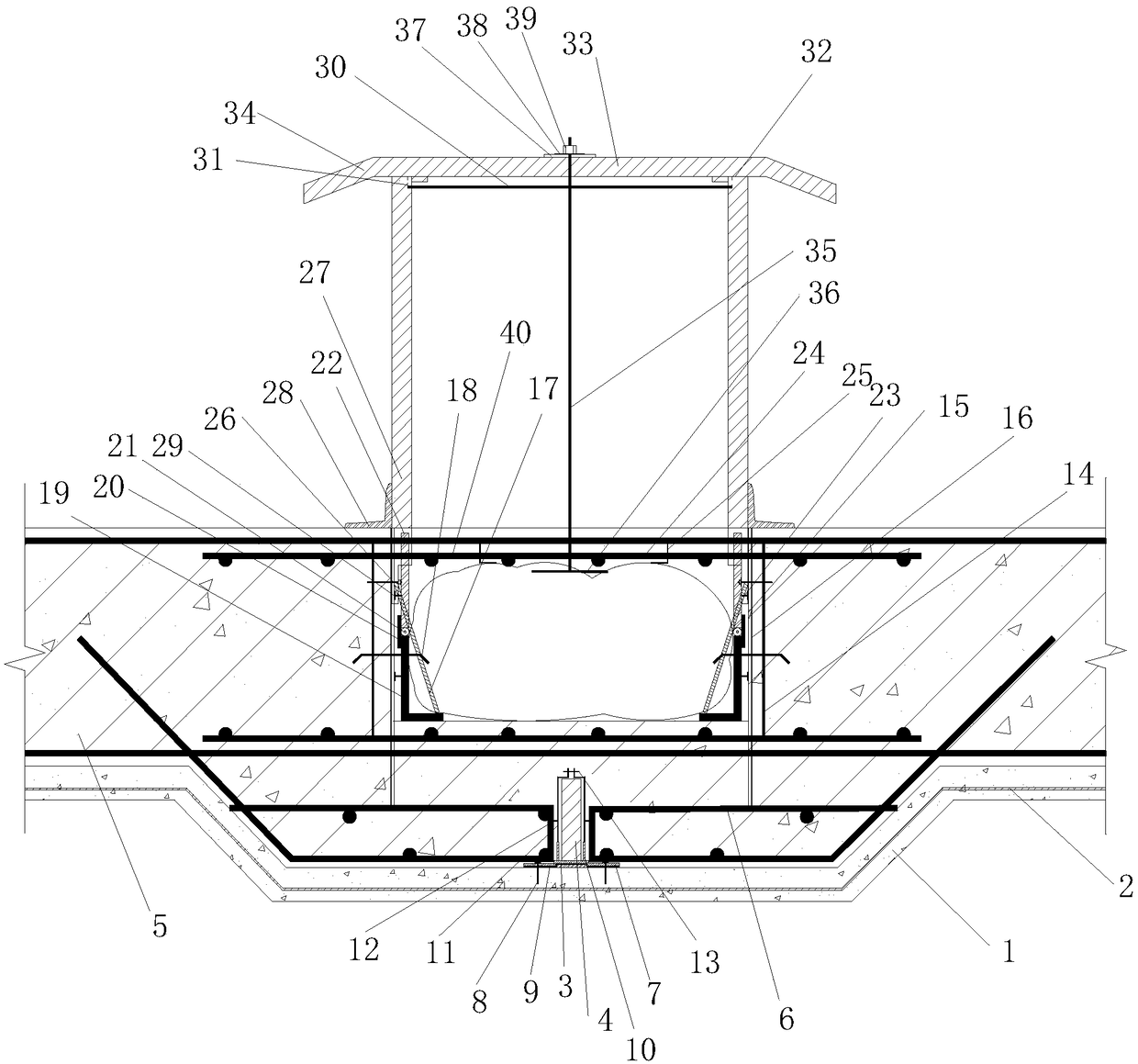

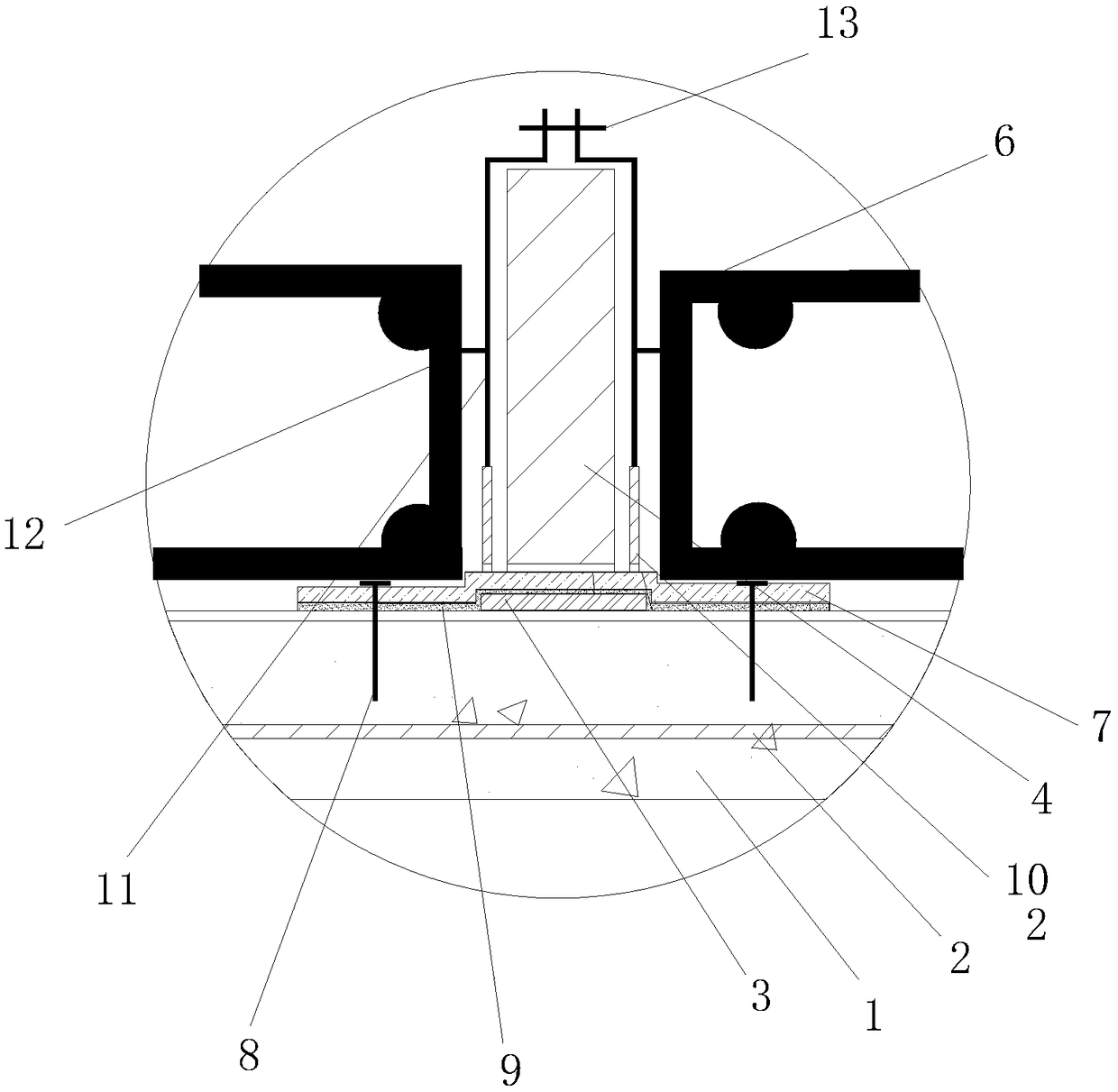

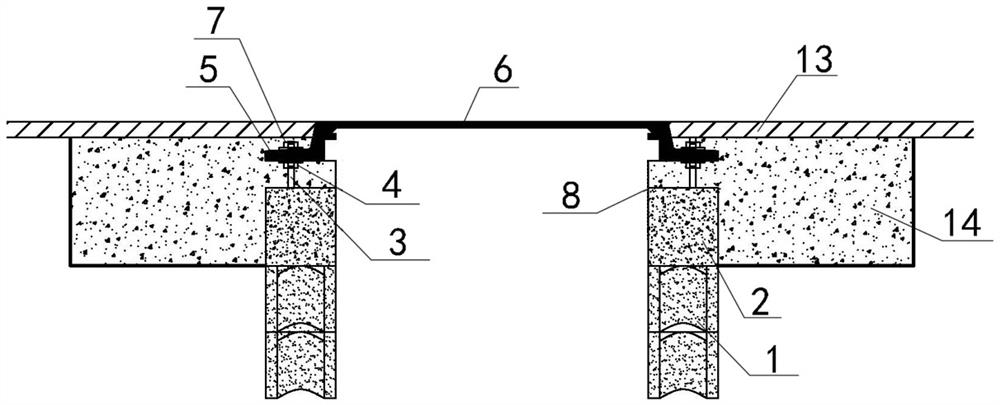

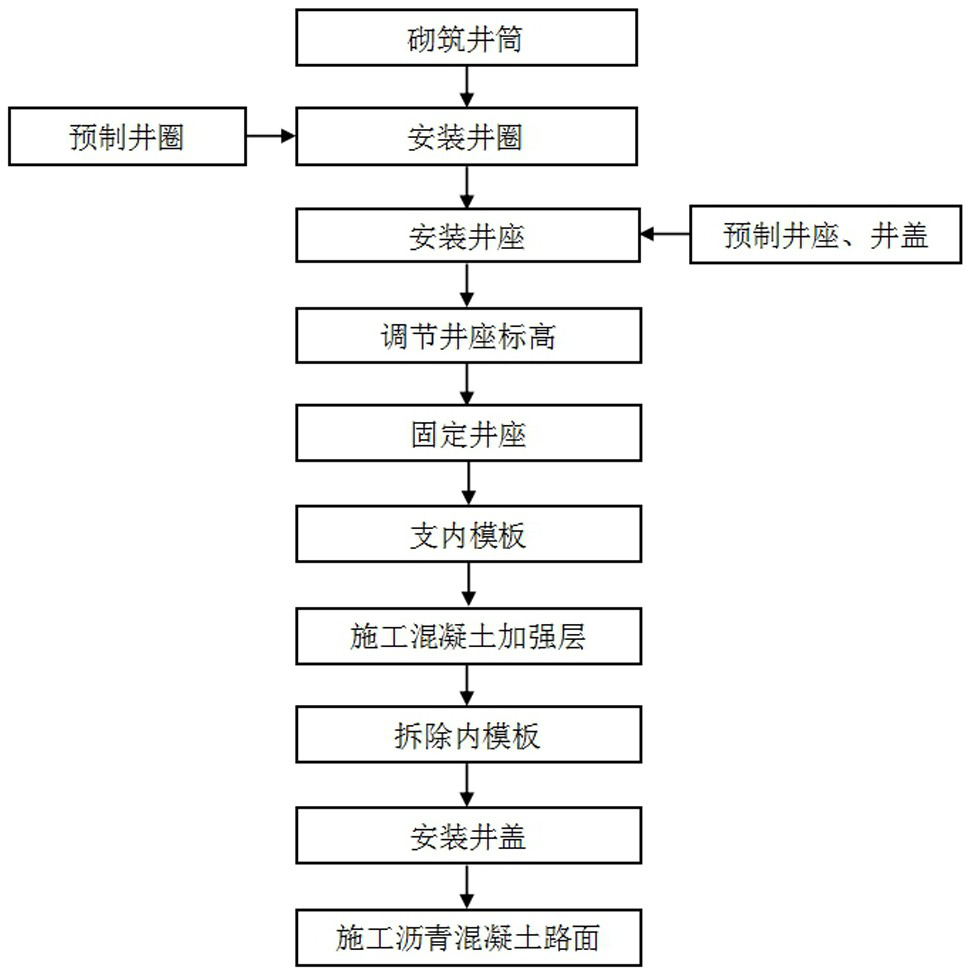

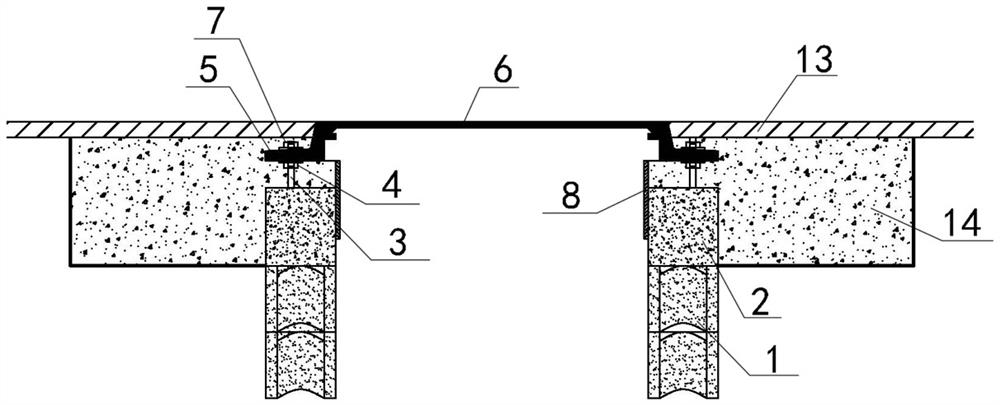

Prefabricated well ring and well lid integrated structure of asphalt concrete pavement and construction method thereof

ActiveCN112376619AGuaranteed location accuracyGuarantee the construction qualityArtificial islandsUnderwater structuresRoad engineeringArchitectural engineering

The invention discloses a prefabricated well ring and well lid integrated structure of asphalt concrete pavement and a construction method thereof and belong to the field of municipal road engineering. A lengthened screw is pre-embedded into a prefabricated well ring, and elevation of a well lid base can be adjusted by adjusting a nut on the lengthened screw, so that on one hand, an adjusting amplitude of the well lid elevation can be increased, and accuracy and control precision of the well lid elevation are improved, on the other hand, a distance between the prefabricated well ring and the well lid base as well as a concrete pouring thickness are further increased to improve concrete pouring compactness and guarantee finished product strength of concrete on the lower part of the well lid. The method is simple in construction, good in effect, improves construction progress, improves the lower strength of the well lid, guarantees the construction quality, reduces later-stage maintenance times, and reduces road maintenance cost. After road traffic opening, the structure can effectively resist vehicle load, prevents well lid settlement and well periphery pavement damage due to insufficient well-mouth strength, and has better guarantee for travelling comfort and travelling safety.

Owner:BEIJING URBAN CONSTR FIFTH CONSTR GRP

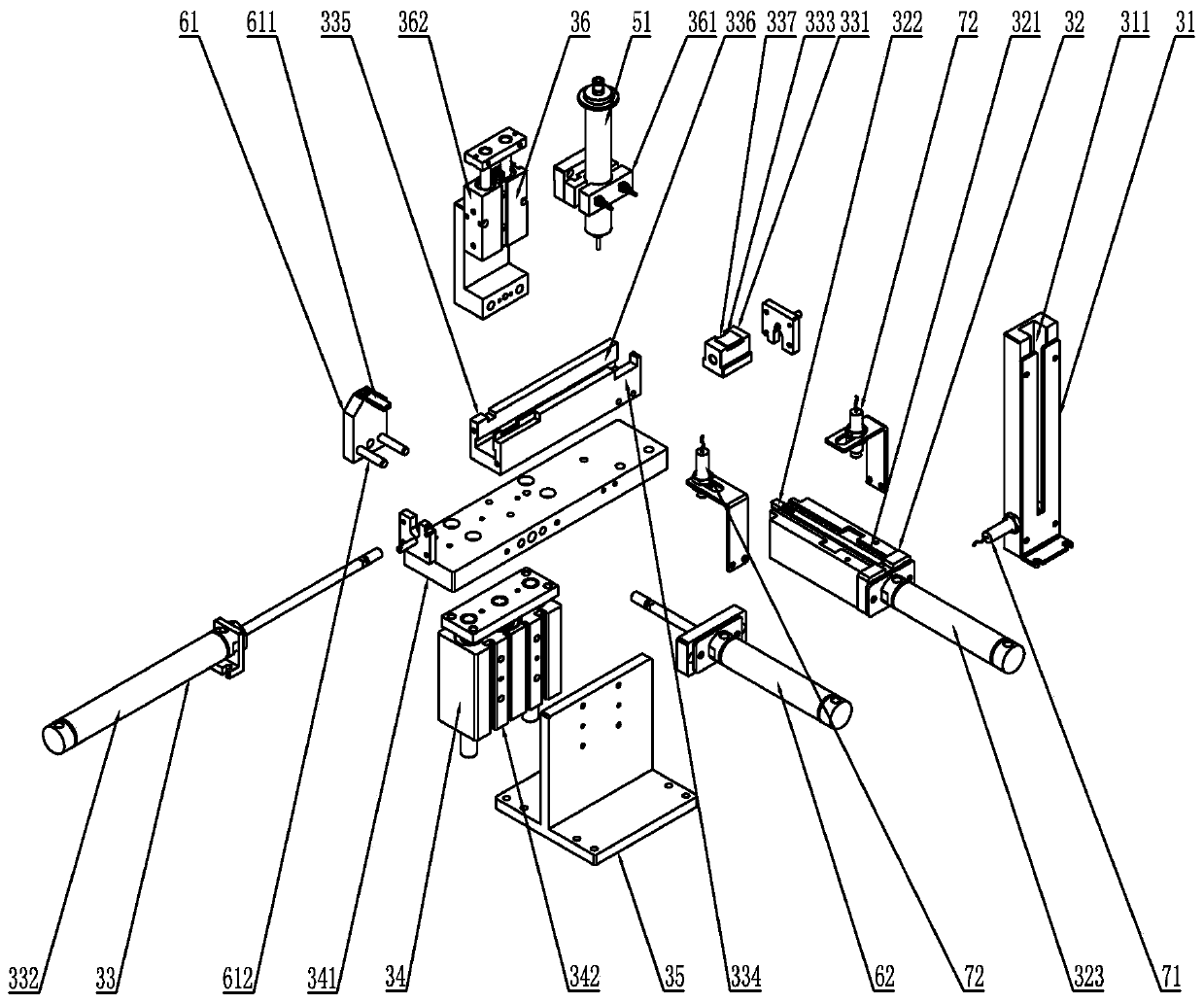

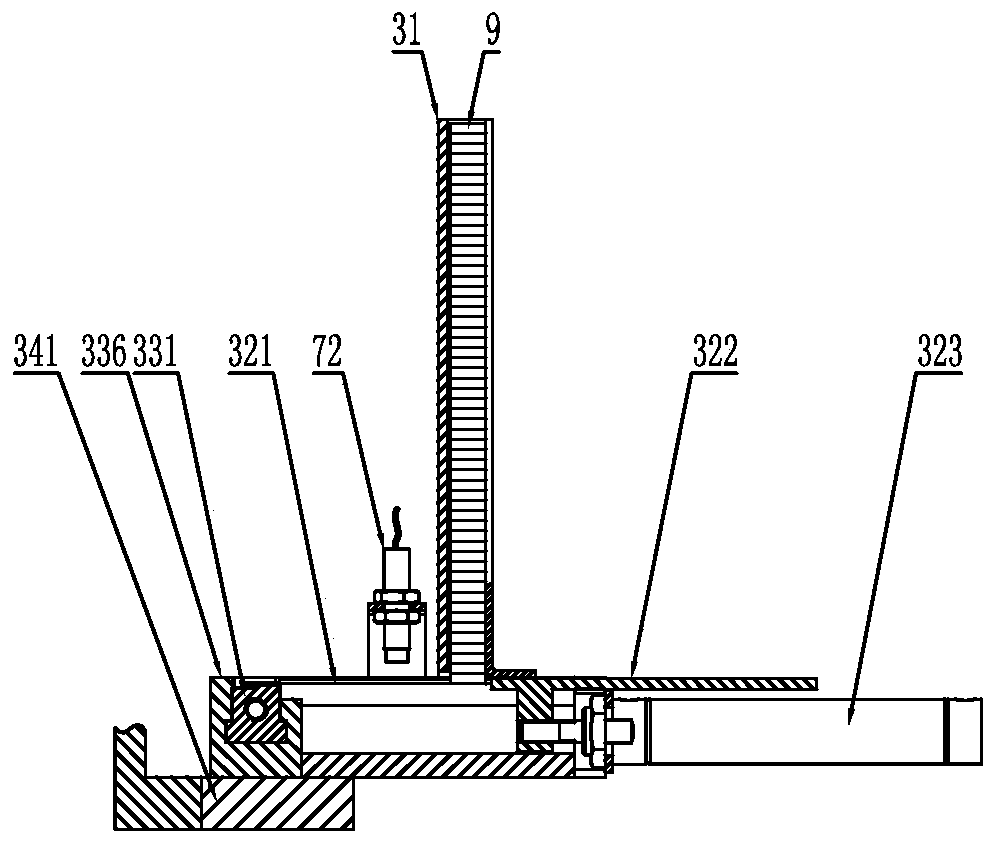

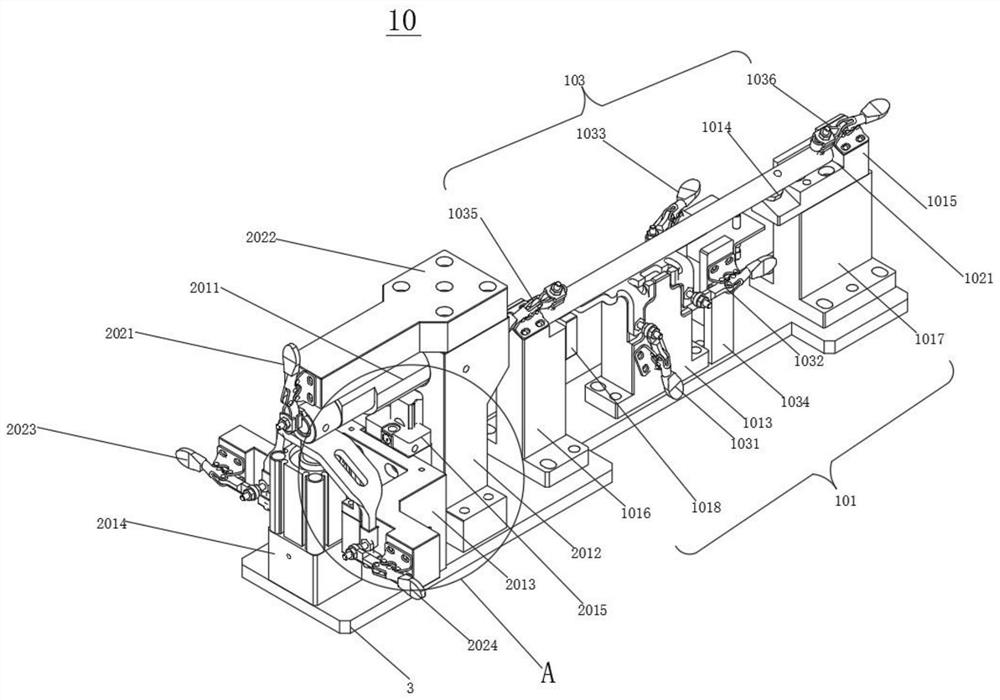

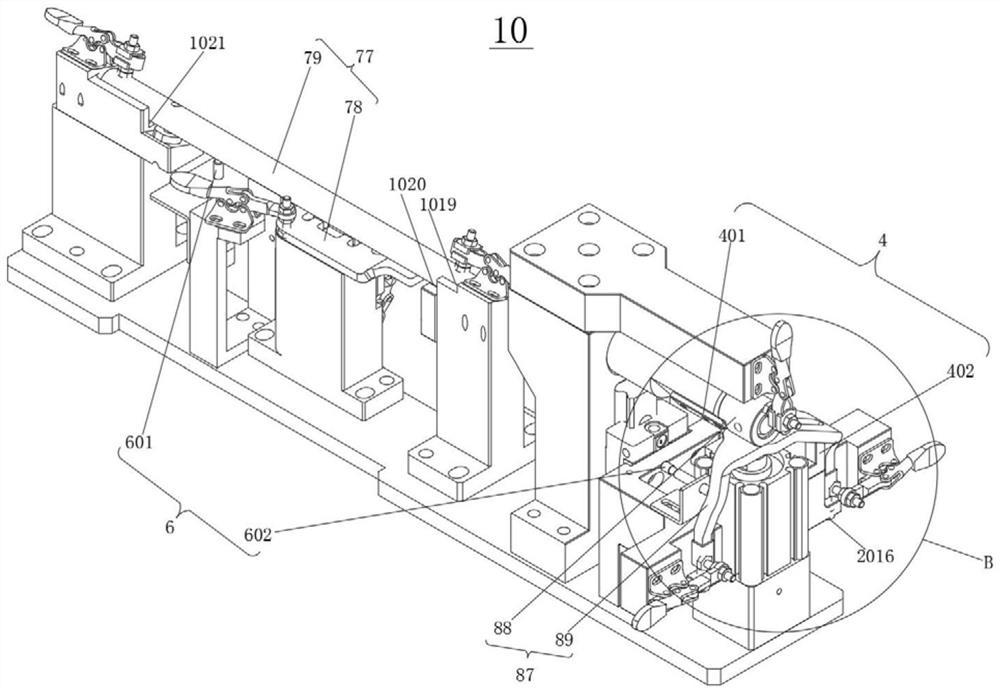

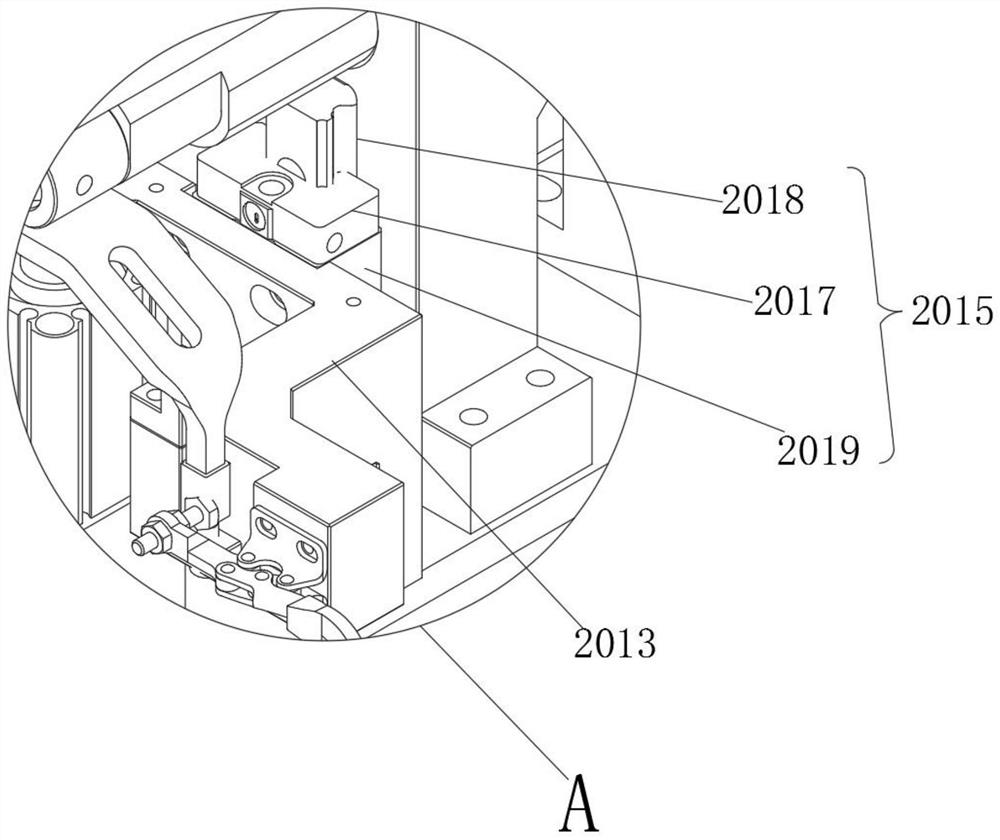

Shifting fork assembly combined welding clamp and shifting fork assembly combined welding system

ActiveCN112388153AGuaranteed location accuracyGuaranteed accuracyLaser beam welding apparatusControl engineeringControl theory

The invention discloses a shifting fork assembly combined welding clamp which comprises a forward gear shifting fork assembly clamp, a fifth-sixth gear shifting fork assembly clamp and a base, and theforward gear shifting fork assembly clamp and the fifth-sixth gear shifting fork assembly clamp are fixedly installed on the base. The forward gear shifting fork assembly clamp is used for fixing anautomobile forward gear shifting fork assembly and comprises a forward gear positioning mechanism and a forward gear locking mechanism. The forward gear positioning mechanism is arranged on the base,and the forward gear locking mechanism is arranged on the forward gear positioning mechanism. The fifth-sixth gear shifting fork assembly clamp is used for fixing an automobile fifth-sixth gear shifting fork assembly and comprises a fifth-sixth gear positioning mechanism and a fifth-sixth gear locking mechanism. The fifth-sixth gear positioning mechanism is arranged on the base and adjacent to theforward gear positioning mechanism, and the fifth-sixth gear locking mechanism is arranged on the fifth-sixth gear positioning mechanism. According to the shifting fork assembly combined welding clamp and the shifting fork assembly combined welding system, the welding efficiency, the welding precision and the automation degree of an automobile forward gear and fifth-sixth gear shifting fork assembly welding process are improved, and the labor cost is reduced.

Owner:HANS LASER TECH IND GRP CO LTD +1

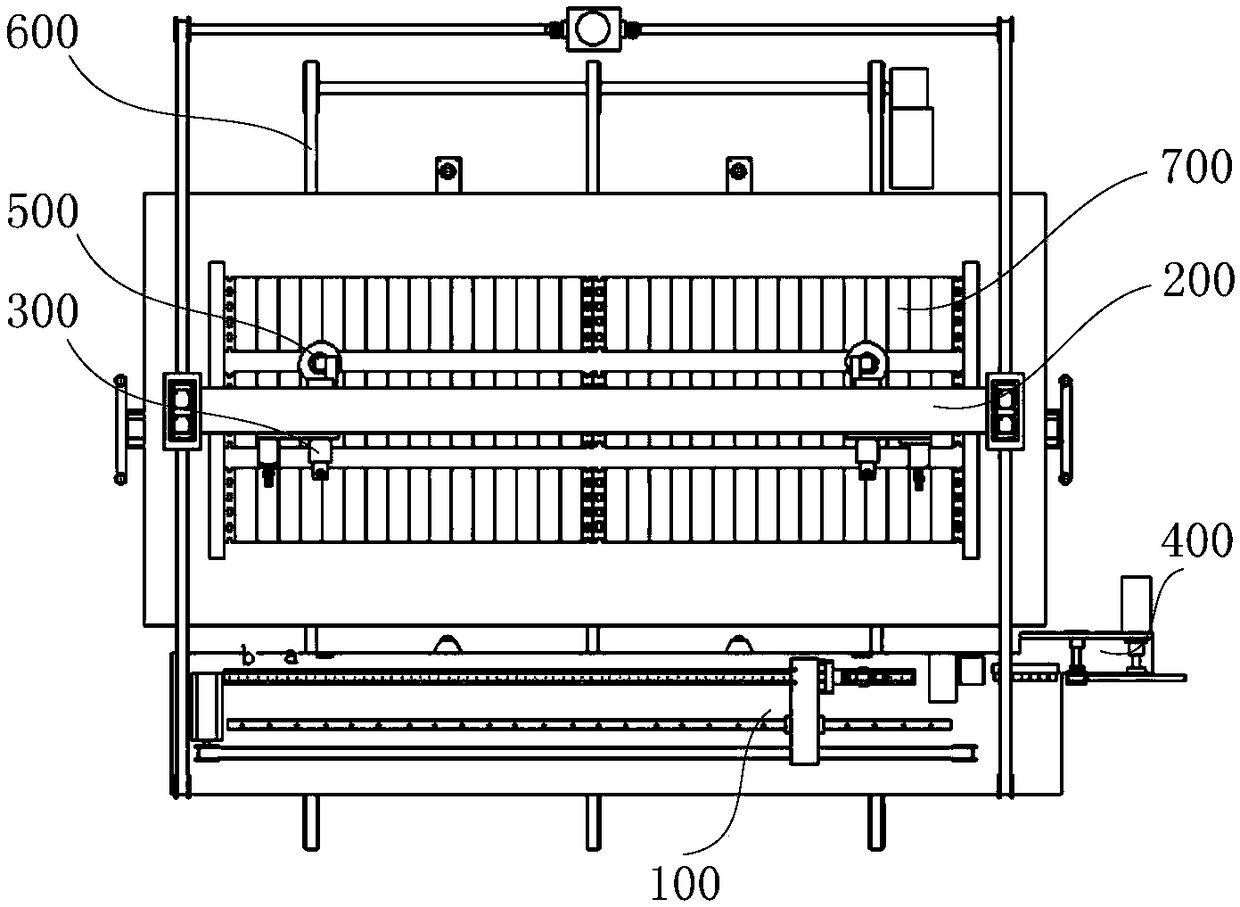

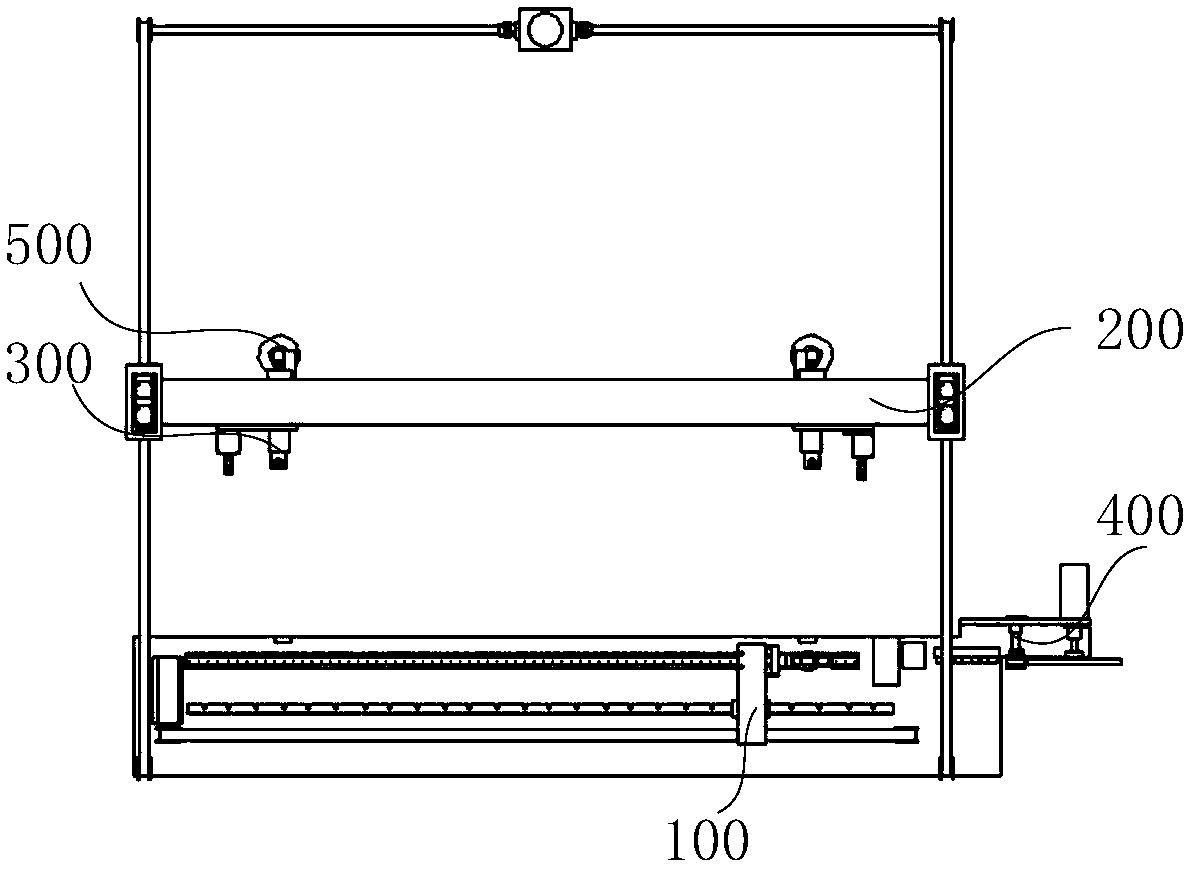

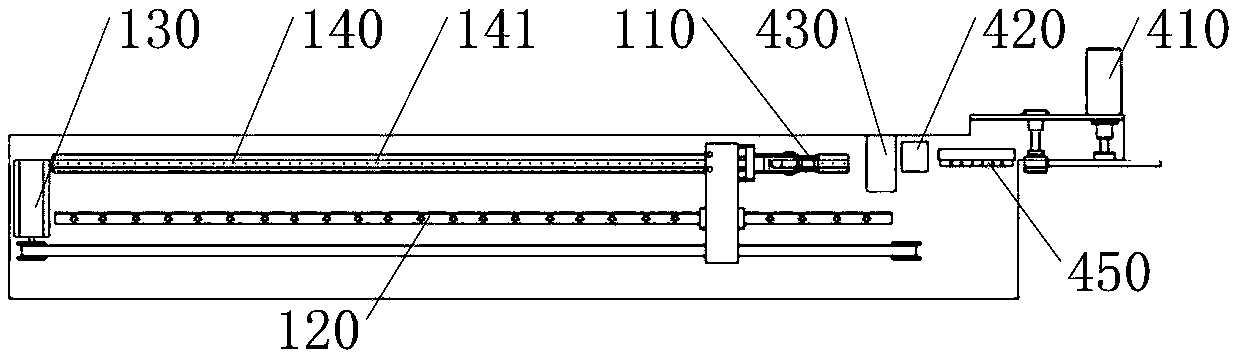

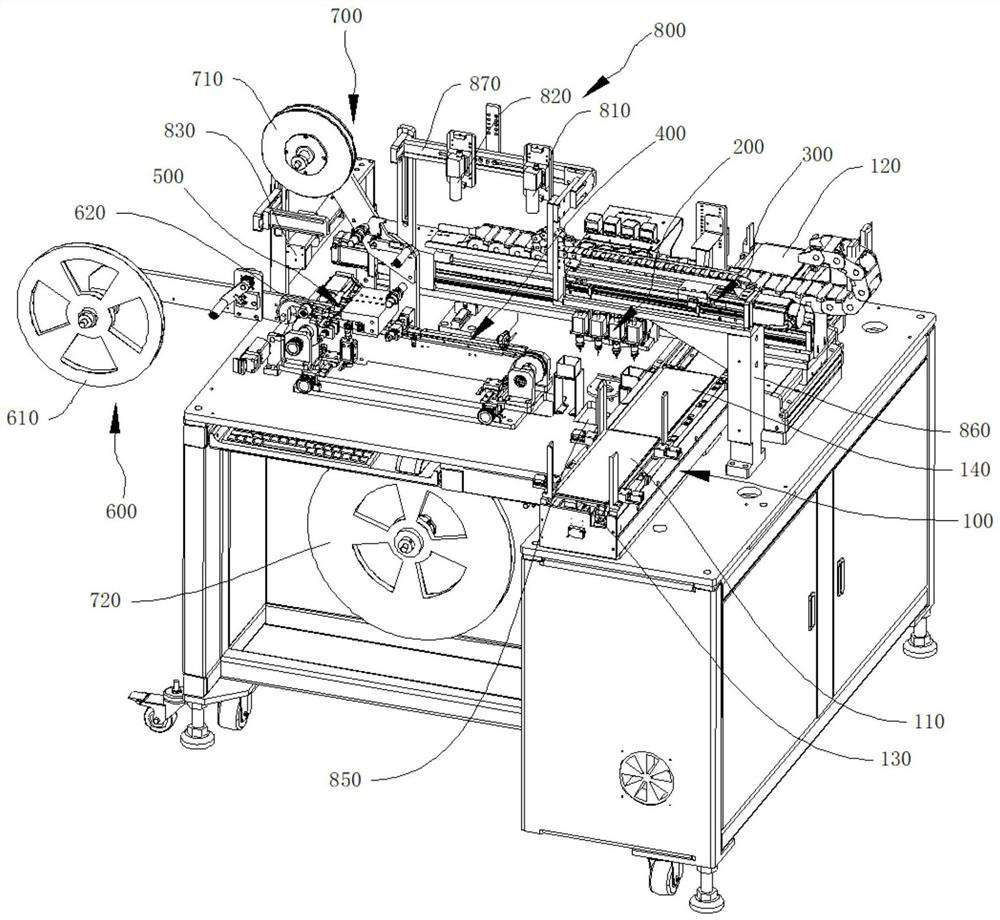

Carpet processing, pre-evaporating and flatting operation platform device

InactiveCN106906587ATimely and smooth deliveryClean up in timeMechanical cleaningPressure cleaningEngineeringConveyor belt

The present invention provides a carpet processing pre-steaming and flattening operation table device, which includes an operation table, two sides of the operation table are provided with transmission rollers, and the two transmission rollers are connected and fixed by several conveyor belts; A fixed frame is provided directly above the operating table, wherein the fixed frame is connected and fixed with the adjustment plate on the operating table through a spring; several fastening rods are arranged on the fixed frame in sequence, each of the fastening rods Sliding and fixing several fixing pieces, each of the fixing pieces is provided with an extension rod, and the end of the extension rod is connected to the pressure roller; wherein the two sides of the pressure roller are respectively connected to the cleaning wheel; wherein the surface of the pressure roller is set There are several pressing balls; a limiting frame is arranged on one side of the operating table. The beneficial effects of the invention are: reasonable design, perfect function, timely and omnidirectional conveying of the carpet and timely cleaning, while ensuring the accuracy of the position, and improving the efficiency and effect of processing.

Owner:盐城思科钛机械有限公司

Welding equipment

PendingCN109158804AAccurate locationHigh positioning accuracyFinal product manufactureWelding/cutting auxillary devicesEngineeringMechanical engineering

The invention provides welding equipment, and relates to the technical field of battery manufacturing equipment. The welding equipment comprises a welding strip pulling device, a welding strip conveying device and a welding device, wherein the welding strip pulling device is used for pulling out a welding strip from an unwinding device, the welding strip conveying device is used for transferring the pulled welding strip to a to-be-welded piece, and the welding device is used for welding the welding strip on the to-be-welded piece. The welding equipment solves the problems that the welding precision is low, and the efficiency is low in the prior art are solved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Packaging machine

InactiveCN112455764AGuaranteed location accuracyIncrease flexibilityPackaging automatic controlPhysicsElectrical and Electronics engineering

The invention relates to the technical field of mechanical equipment, and discloses a packaging machine which comprises a conveying device and a feeding device. The conveying device comprises a positioning and adjusting device and a film pressing device, the positioning and adjusting device can position and adjust the position of a carrier tape, and conveying of the carrier tape is prevented fromdeviating from the winding position. The film pressing device is used for closely pasting a film on the carrier tape. It is ensured that the film wraps a chip placed on the carrier tape, after installing of the positioning and adjusting device is completed, then positions of a positioning mechanism and a conveying mechanism in the positioning and adjusting device are adjusted, high flexibility isachieved, rapid debugging before production is benefited, and the production efficiency is improved. The feeding device is used for feeding the chip to the carrier tape, the position of the chip can be adjusted in the direction perpendicular to a limiting groove, thus it is further ensured that the chip is placed at a designated position on the carrier tape, and position accuracy of the chip is effectively ensured.

Owner:深圳市奥特姆自动化设备有限公司

Cleaning pipe for cleaning material filtering corrugated tubes

ActiveCN106311687AImprove sealingGuaranteed reciprocating motionHollow article cleaningGear wheelEngineering

The invention discloses a cleaning pipe for cleaning material filtering corrugated tubes, and belongs to the technical field of cleaning pipes. The cleaning pipe comprises a pipe body, wherein a sealing cover is arranged on the top of the inner chamber of the pipe body, a handle is arranged on the top of the sealing cover, a control device is arranged on the right side of the handle, and the control device is arranged on the top of the sealing cover. According to the cleaning pipe for cleaning material filtering corrugated tubes, the airtightness of a dust chamber is improved because the sealing cover is arranged, and it is guaranteed that the dust in the dust chamber will not drop off again; because the handle is arranged, the pipe body is provided with a traction device, and the pipe body can be taken out smoothly; because the dust chamber is arranged, the dust sucked in by the dust chamber can be dealt with in a centralized manner; because a dust sucking pipe is arranged, the dust can be sucked away by a dust collector in a centralized manner; and the control device is used for controlling a motor to rotate so as to drive a bevel gear to rotate, the bevel gear rotates to drive a transmission gear to rotate, the transmission gear rotates to drive a rotating shaft to rotate, and the rotating shaft rotates to provide rotation power for a crank block.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

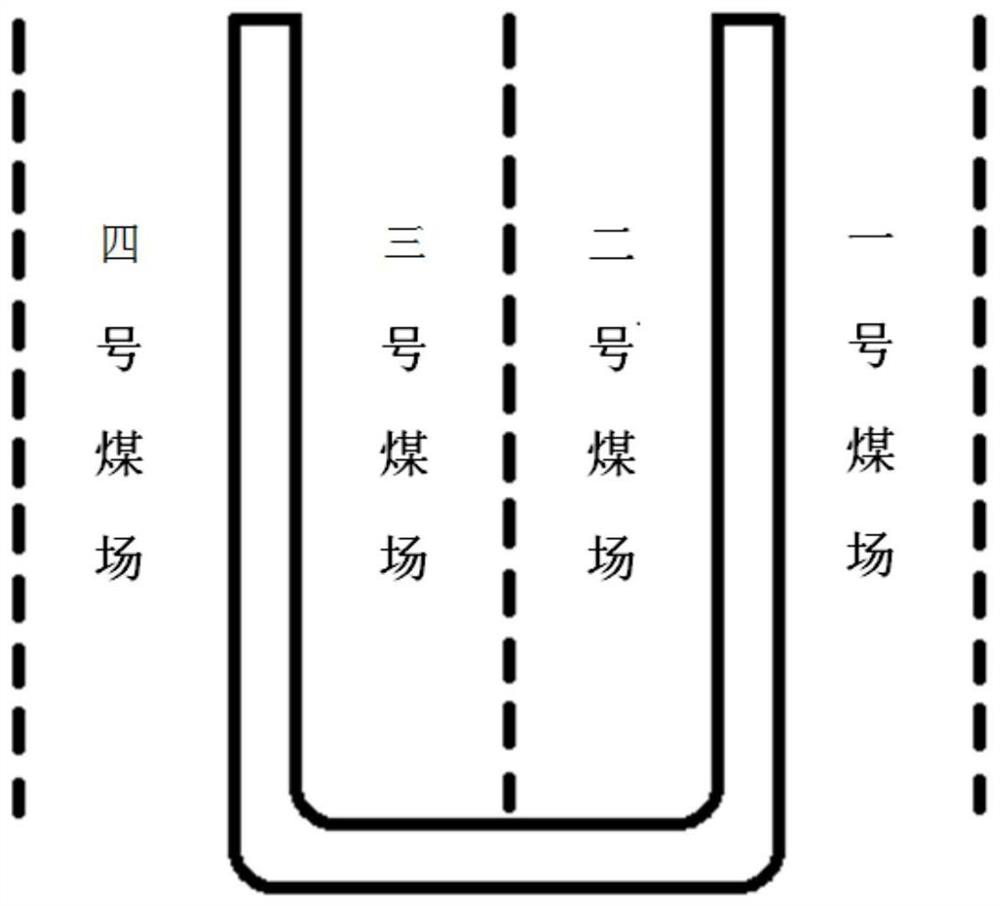

Closed coal yard U-shaped monorail mobile laser coal inventory device

PendingCN112284458ALow costAdjustable lengthMonorailsMeasurement devicesInstrument trolleyLaser scanning

The invention relates to a closed coal yard U-shaped monorail mobile laser coal inventory device. The device comprises a U-shaped monorail 1 erected on a steel structure ceiling of a coal yard, and acoal inventory instrument trolley which is used for moving along a rail route to inventory coal in the whole coal yard is arranged on the U-shaped monorail in an inverted mode. And the coal inventoryinstrument trolley is provided with a coal inventory instrument device for carrying out actual specific full-coverage scanning coal inventory on the whole coal yard. A U-shaped monorail laser scannerwith an omnidirectional holder is adopted, during coal inventory scanning, two different modes of inner-ring scanning and outer-ring scanning are selected, internal and external sites covered by the U-shaped monorail can be completely scanned in the process that the trolley walks back and forth, the laser coal inventory instrument is not limited by coal yard conditions any more; and meanwhile, theU-shaped monorail can be laid in a segmented mode according to the actual size and the scanning range of the closed coal yard, track cost is saved, installation difficulty is reduced, and universality of the coal inventory device is enhanced.

Owner:HUANENG POWER INTERNATIONAL +1

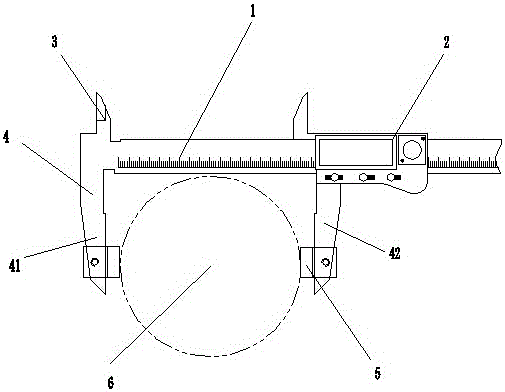

Vernier caliper with auxiliary members

The invention discloses a vernier caliper with auxiliary parts, which comprises a main ruler, a vernier, an inner measuring claw for measuring the inner diameter and an outer measuring claw for measuring the outer diameter, the outer measuring claw includes a fixed claw fixed on the main ruler and slides with the vernier The free claws, the corresponding ends of the fixed claws and the free claws are respectively provided with an auxiliary part, and the auxiliary parts have a U-shaped fixed part and an arc-shaped measuring part integrally formed, and the U-shaped fixed part passes through the opening slot It is connected with the fixed claw or the free claw, and one side of the slot also has a fixed hole. The caliper of the invention is easy to use, has high measurement accuracy, and can fulfill the requirement of measuring a specific measurement point of a specific workpiece.

Owner:CHUNG CHUN STEEL MOLD MACHINERY IND SUZHOU

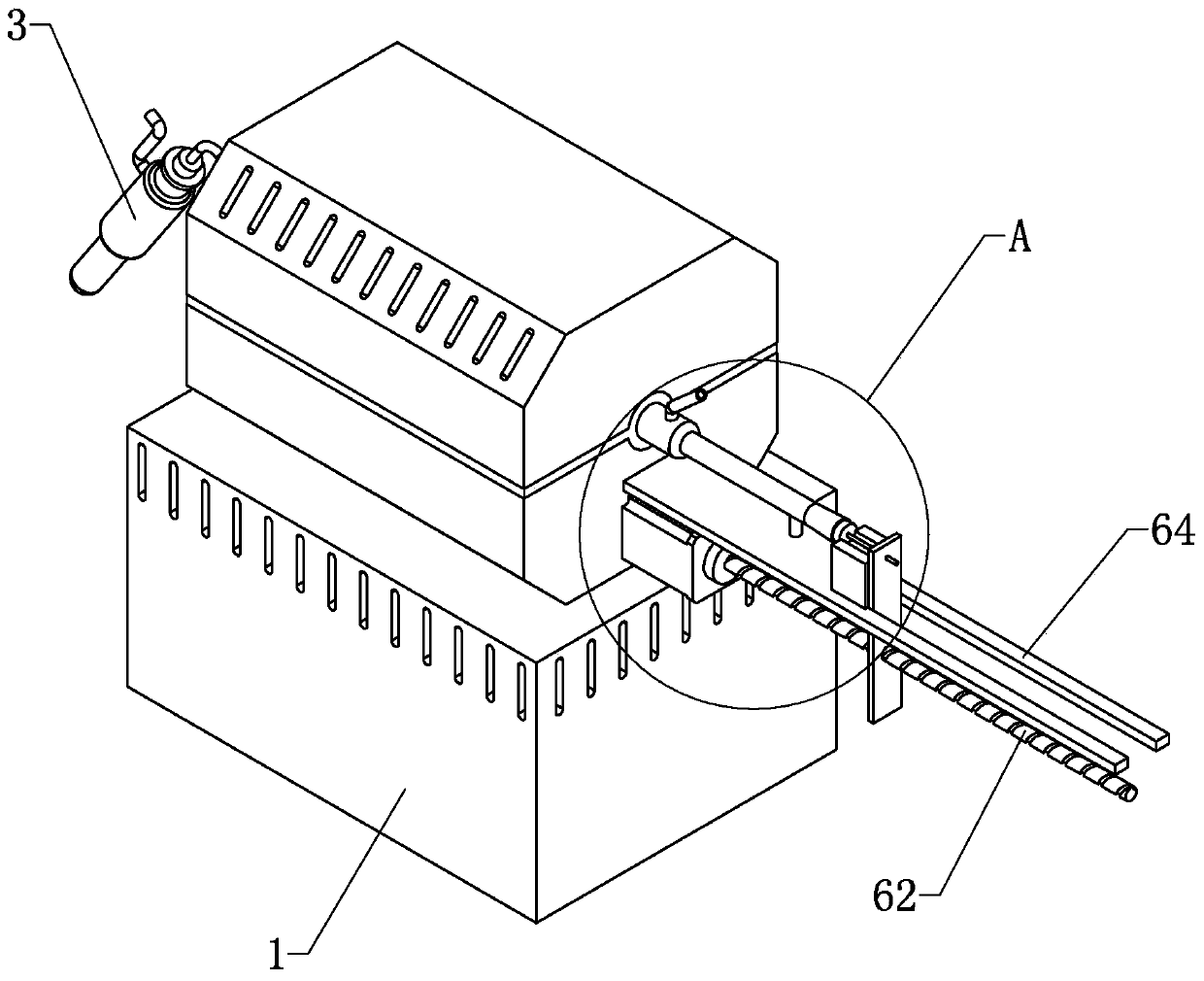

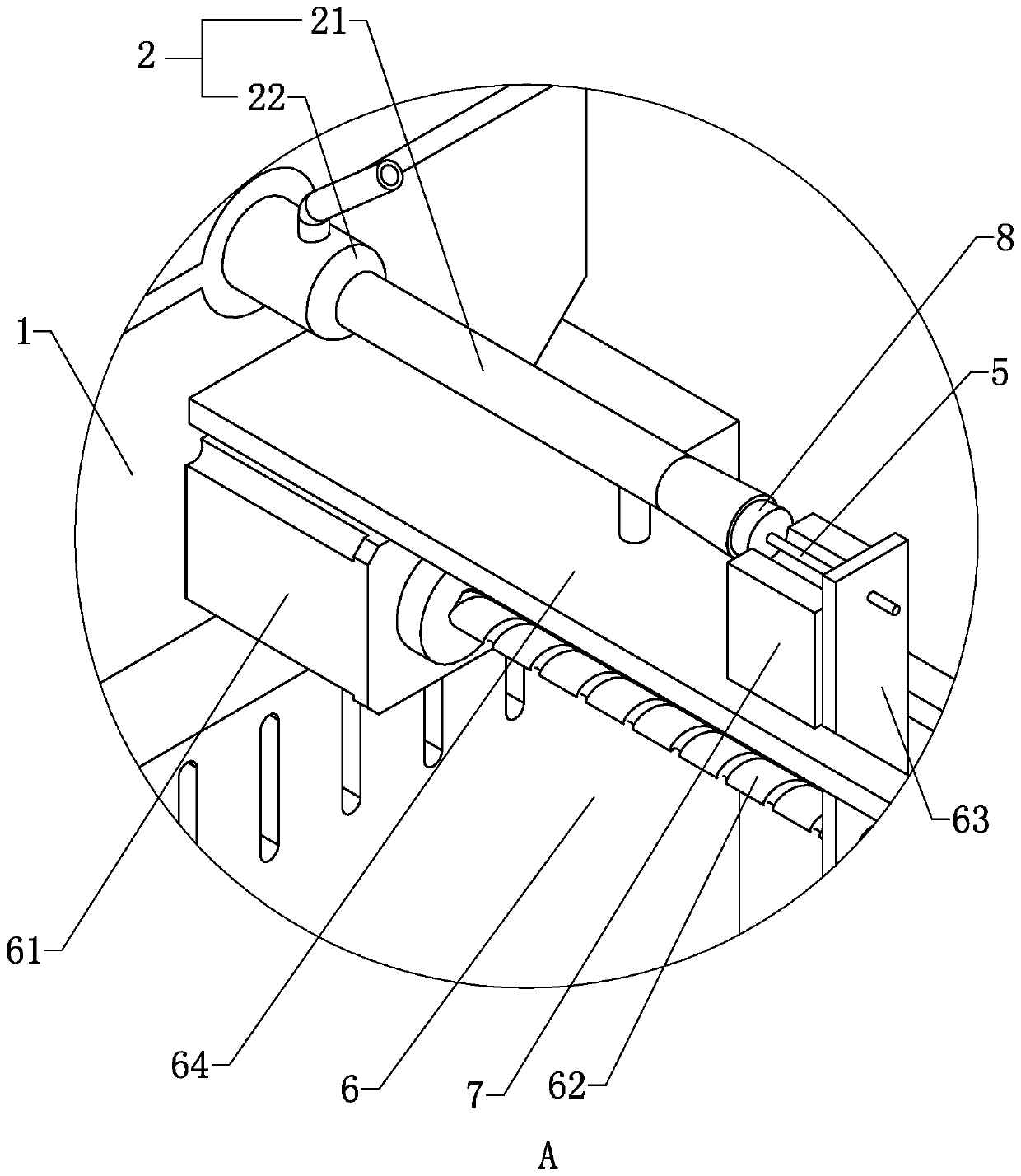

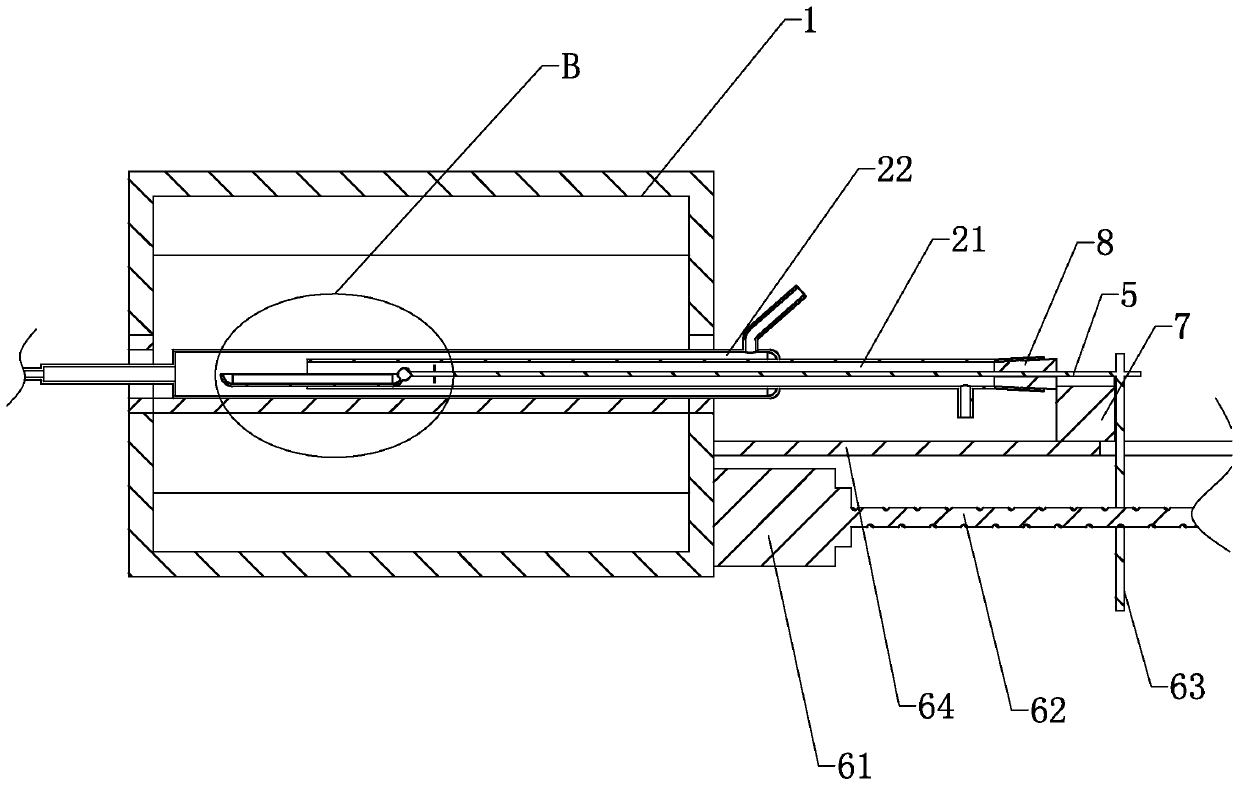

Combustion device for water quality detection

InactiveCN110231433AGuaranteed location accuracyGuaranteed accuracyChemical analysis using combustionActivated carbonCombustion

The invention relates to the field of the water quality detection, more specifically, a combustion device for water detection. The device aims at solving the problem that the measurement error occurssince the activated carbon is likely to adhere a combustion tube wall when being placed in a sample plate. The technical scheme key point is that one combustion device for the water quality detectioncomprises a combustion furnace, a combustion tube penetrating through the combustion furnace, an absorption tube connected to a piercing end of the combustion tube, and a sample plate for placing a sample; the sample plate is stored in the combustion tube, and connected with a push rod; the push rod pierces the combustion tube along a length direction of the combustion tube, and the piercing end of the push rod is connected with a driving mechanism for driving the push rod to move along the length direction of the combustion tube; and a support plate for supporting the sample plate is arrangedat a port of the combustion tube. Through the design of the driving mechanism, the sample plate can automatically extend out from the combustion tube, thereby conveniently, accurately and directly filling the activated carbon in the sample plate.

Owner:杭州广测环境技术有限公司

Non-contact photographing hole-measuring calibration device and method

The invention relates to the technical field of image measurement calibration, and discloses a non-contact photographing hole-measuring calibration device and method, the device comprises a base, a mounting platform, a calibration assembly and an illumination compensator, the mounting platform is arranged on the base, and the calibration assembly is arranged on the mounting platform; in the calibration process, the base drives the mounting platform to rotate around the Z axis so as to drive the calibration assembly to rotate around the Z axis, the mounting platform drives the calibration assembly to rotate around the X axis at the same time, the illumination compensator is used for supplementing light for the camera in the camera photographing process, and the camera system analyzes and calculates the obtained images of the calibration spherical circle contour projection. Therefore, the calibration of the connecting hole is finally realized. According to the invention, the traditional photographing hole measurement calibration is innovatively converted into the photographing hole measurement calibration ball for calibration, so that the problem that the hole is possibly distorted into an ellipse at different angles during the traditional photographing hole measurement calibration is well solved, and the calibration precision is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Angle cutting machine

InactiveCN107139059ARealize multi-angle position transformationGuaranteed location accuracyGrinding wheel securing apparatusGrinding carriagesEngineeringGrinding wheel

The invention discloses an angle cutting machine. The angle cutting machine comprises a base, a fixing block, a support pillar, an intermediate pillar, a motor, a rotating shaft, an abrasive cutting wheel, a stop ring and an elastic sleeve. The stop ring is movably connected to a fixing shaft. The elastic sleeve is connected with the fixing shaft. A clamping mechanism is further arranged on the base. The clamping mechanism comprises a rectangular block, a rectangular strip, a clamping block and a stop block, wherein the rectangular block is fixedly connected to the base; the rectangular strip penetrates the rectangular block; the clamping block is fixedly connected to the rectangular strip; and the stop block is arranged on the base. A clamping gap is formed between the clamping block and the stop block so that a to-be-cut part can be placed in the clamping gap. The rectangular strip penetrates the rectangular block so that the rectangular strip can drive the stop block to move in the length direction of the rectangular strip, and therefore the size of the clamping gap can be changed. The abrasive cutting wheel is arranged over the clamping gap. By means of the angle cutting machine, quality of a cut product can be guaranteed; the to-be-cut part does not need to be moved manually; and furthermore, manpower resource consumption is low.

Owner:WUHU TIANHANG TECH GRP

Automatic plate shearing machine for machining electric device shell

InactiveCN112296418AGuaranteed location accuracyPrevent slidingShearing machinesShearing machine accessoriesStructural engineeringIndustrial engineering

The invention discloses an automatic plate shearing machine for machining an electric device shell. The automatic plate shearing machine comprises a plate shearing machine body, a mounting box and a movable block, wherein four second telescopic springs are fixedly mounted on one side of the movable block, a clamping plate is fixedly mounted at the ends, away from the movable block, of the four second telescopic springs, and two lower clamping plates are fixedly mounted at the bottom of the clamping plate; upper clamping plates are movably mounted inside the two lower clamping plates, clampinghydraulic boxes are fixedly mounted on the sides, away from the second telescopic springs, of the clamping plates, two second telescopic rods are fixedly mounted at the bottom of a clamping hydraulicbox, and the second telescopic rods apply acting force to the upper clamping plates by mounting the clamping hydraulic box, so that the lower clamping plates and the upper clamping plates clamp and fix the electric device shell placed on the lower clamping plates, and thus, on one hand, the position accuracy of the electric device shell is guaranteed, on the other hand, the electric device shell is prevented from sliding, clamping is facilitated, automation degree is improved, and work efficiency can be effectively and further improved.

Owner:芜湖君乐电器有限公司

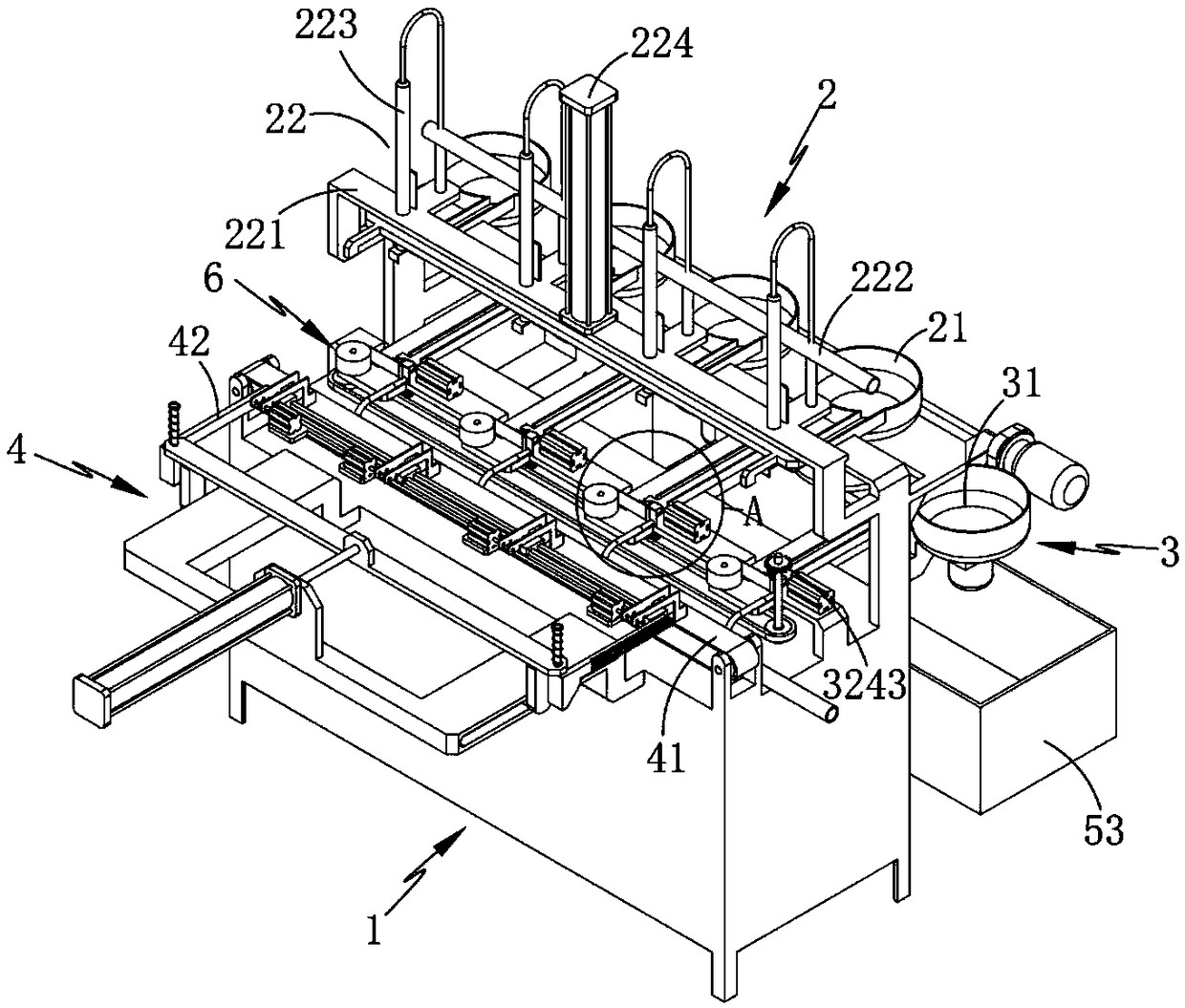

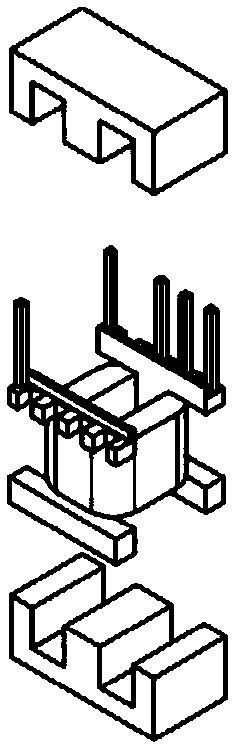

E-type inductor automatic assembly machine and assembly method thereof

InactiveCN108766751ARealize automatic outputAssembly precisionEncapsulation/impregnationCoils manufactureState of artInductor

The invention relates to the field of inductor production technology, in particular to an E-type inductor automatic assembly machine and an assembly method thereof. The E-type inductor automatic assembly machine comprises a magnetic core A transfer mechanism, a magnetic core B transfer mechanism, a coil body transfer mechanism and an output mechanism, wherein the magnetic core A transfer mechanismcomprises a sorting assembly I and a feeding assembly; the magnetic core B transfer mechanism comprises a sorting assembly II and a positioning assembly; the coil body transfer mechanism comprises aninput assembly and a loading assembly; and the output mechanism comprises a push assembly, a transfer assembly and a collection bin at the tail end of the transfer assembly. Through special structural setting of the feeding assembly and the loading assembly, rapid assembly of a magnetic core A, a coil body and a magnetic core B is realized synchronously in a transfer process of the magnetic coreA; rapid assembly film winding and outputting of an E-type inductor are realized; and the technical problem of low production efficiency in the prior art is solved.

Owner:CHANGXING SOFITEL ELECTRONICS

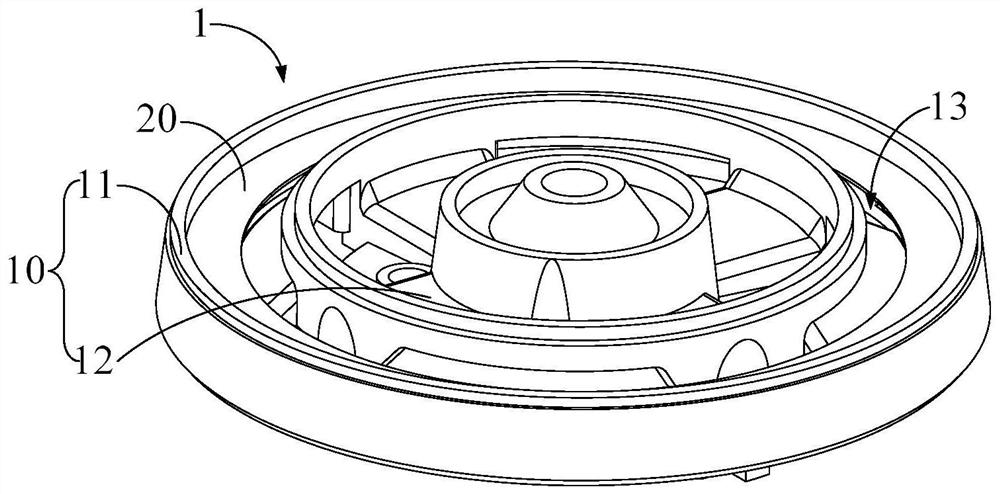

Gas distribution disc, combustor and gas stove

PendingCN111780111ASimple structureSimple molding processDomestic stoves or rangesGaseous fuel burnerThermodynamicsGas cooking stove

The invention provides a gas distribution disc, a combustor and a gas stove. The gas distribution disc comprises a gas distribution body and a gas distribution ring, wherein the gas distribution bodycomprises a gas distribution base and a gas distribution cover connected with the gas distribution base; the gas distribution body is provided with a first gas flow channel; and the gas distribution ring is installed at the position of the first gas flow channel, matched with the gas distribution base and / or the gas distribution cover and used for guiding gas in the first gas flow channel to flow. According to the scheme, the gas distribution ring is detached from the gas distribution body and independently machined and formed, the structure of the gas distribution body is simplified, and therefore the structure of the gas distribution cover and the structure of the gas distribution base can be simplified; and the structure of the gas distribution ring is simple, and therefore the formingprocess of the gas distribution disc can be simplified, the production cost is reduced, the manufacturability of the gas distribution disc is high, and large-batch production is facilitated.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

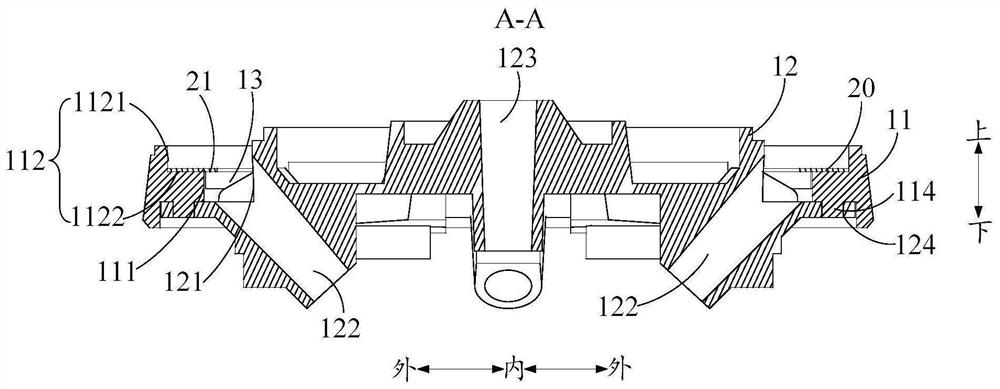

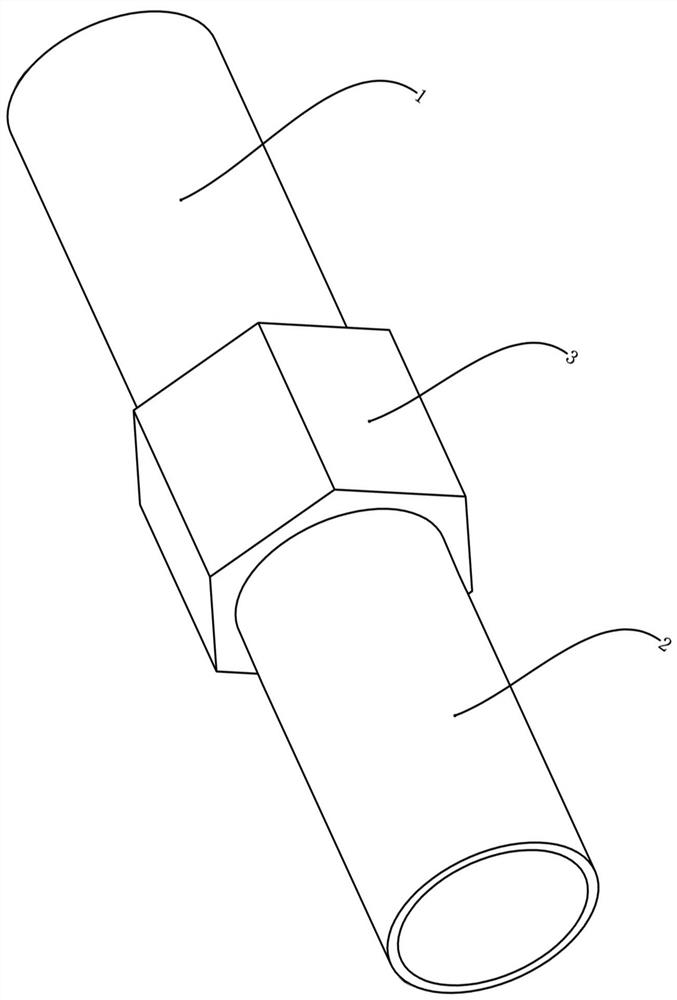

Efficient pipeline connecting buckle

ActiveCN114838229AImprove fastening effectGuaranteed location accuracyCouplingsPipe connection arrangementsStructural engineeringMechanical engineering

Owner:焦作淄华塑胶管业有限公司

Automatic sweeping and dust sucking device for encapsulation mold

An automatic sweeping and dust sucking device for an encapsulation mold comprises a fixing support, a movable plate, an upper sweeping brush, a lower sweeping brush, an upper dust suction box, a lower dust suction box and a suction machine. The fixing support and the suction machine are both installed on a mold pressing machine. The upper dust suction box is located above the lower dust suction box. The upper dust suction box and the lower dust suction box are both connected to the front portion of the movable plate in an up-down sliding manner. An inner cavity of the upper dust suction box and an inner cavity of the lower dust suction box both communicate with the suction machine. The upper dust suction box is provided with an upper dust suction port, and the lower dust suction box is provided with a lower dust suction port. The movable plate is provided with a first vertical drive device and a second vertical drive device. The upper sweeping brush slides left and right along the upper dust suction box. The lower sweeping brush slides left and right along the lower dust suction box. The movable plate is provided with an upper left-right drive mechanism and a lower left-right drive mechanism. The movable plate is in front-back sliding connection with the fixing support. A front-back drive device is arranged on the fixing support. According to the automatic sweeping and dust sucking device, sweeping and dust sucking can be conducted on the parting surface of the mold at the same time, and therefore the manual workload is reduced, the production efficiency is improved, and the personal injury is avoided.

Owner:ANHUI DAHUA SEMICON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com