Multi-station automatic assembling production line for oil pump

An automatic assembly, multi-station technology, used in assembly machines, metal processing, manufacturing tools, etc., can solve problems such as low automation of oil pump press-fitting, and achieve the effect of ensuring position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

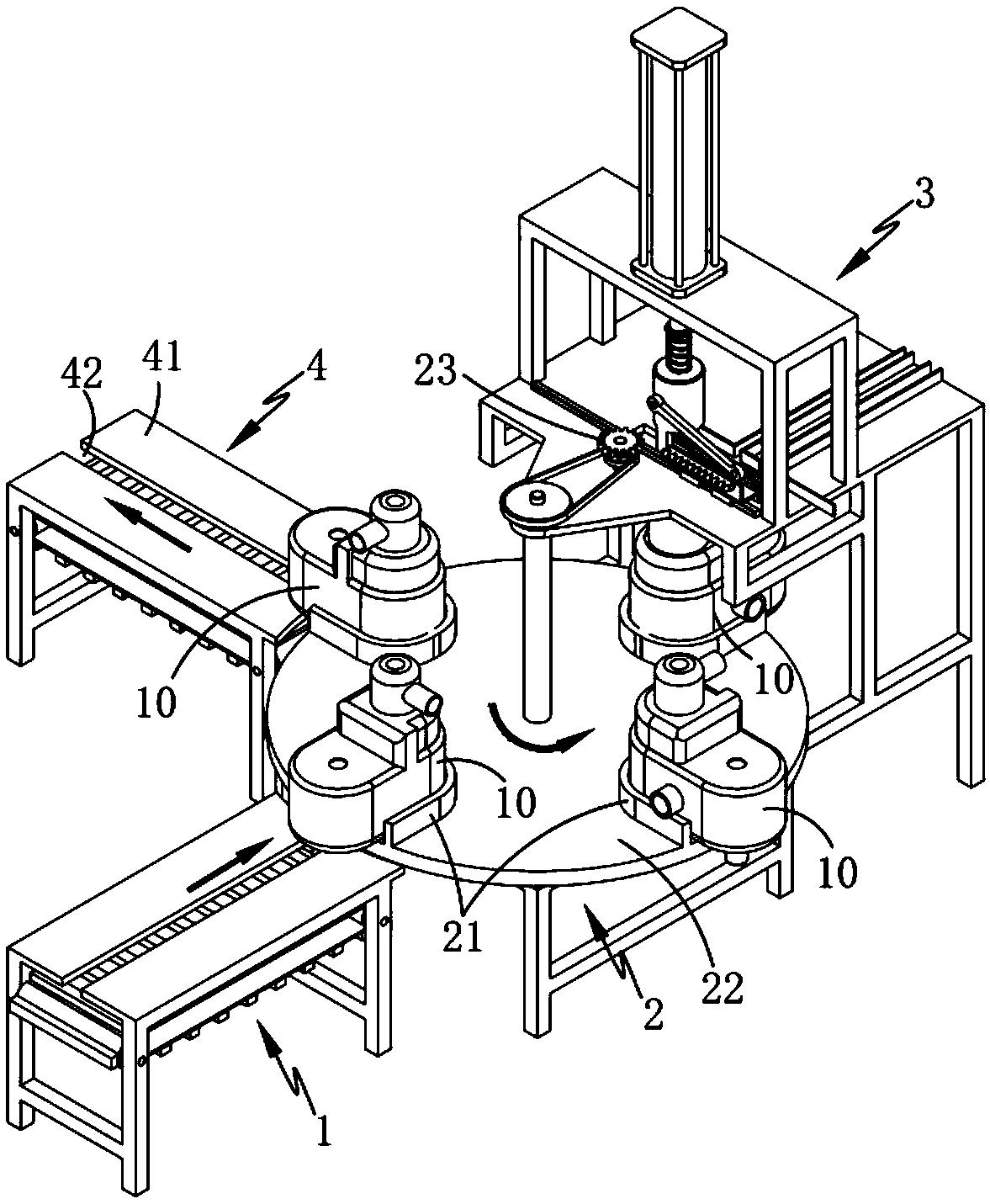

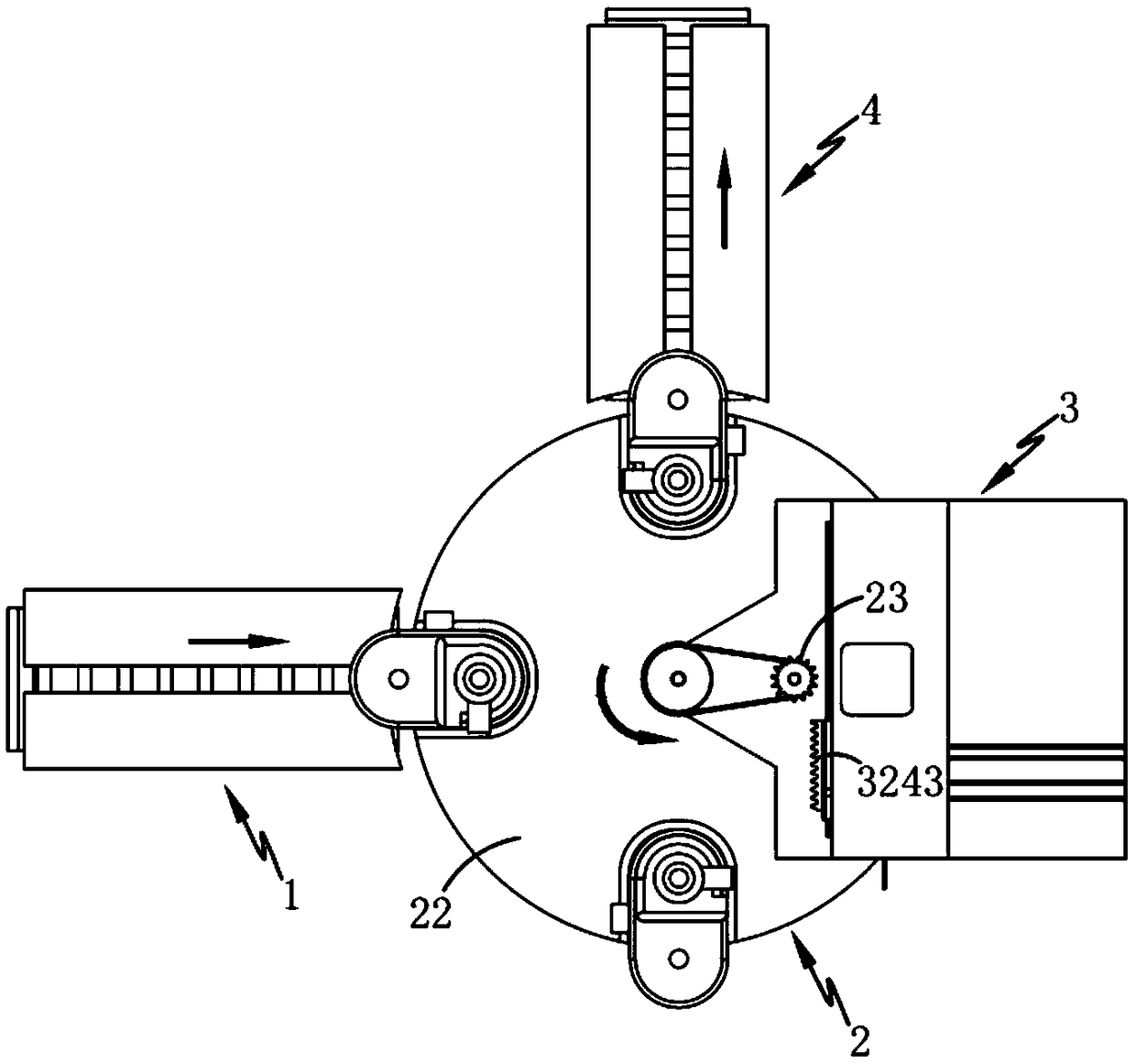

[0040] Such as Figures 1 to 5 As shown, a multi-station automatic assembly line for oil pumps includes:

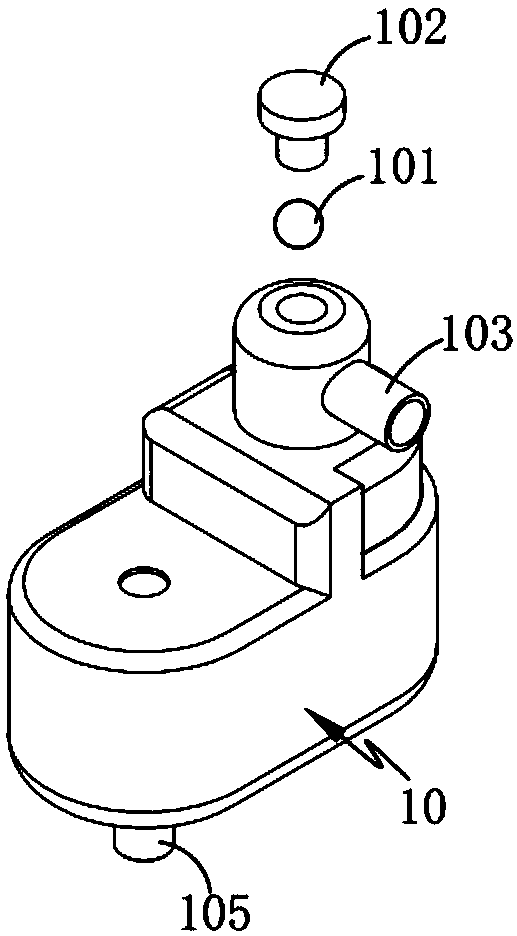

[0041]A feeding mechanism 1, which is used to transfer the oil pump body 10 to the station conversion mechanism 2;

[0042] Station switching mechanism 2, the station switching mechanism 2 is used to transfer the oil pump body 10 between various stations, and a plurality of positioning grooves 21 are arranged on it, and the positioning grooves 21 are adapted to the shape of the oil pump body 10 ; After the oil pump body 10...

Embodiment 2

[0047] Such as Figures 4 to 7 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that the transmission part 332 includes a preloading sleeve 3321, a pressure block 3322 and a pressure spring 3323, the preloading sleeve 3321 is an annular sleeve structure, and it and the compression spring 3323 are sleeved on the driving part 331 On the piston rod 3311 and the compression spring 3323 is located above the pre-tightening sleeve 3321, the pre-tightening sleeve 3321 is elastically pressed by the compression spring 3323 to the positioning assembly 31 through the compression spring 3323; The tight sleeve 3321 is arranged in sliding fit with the piston rod 3311 , and the upper end of the compression spring 3323 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com