Refractory material full-automatic production line

A refractory, fully automatic technology, applied in the field of mechanical processing, can solve problems such as harm to the health of on-site workers, diffusion, and adverse effects on the quality of refractory bricks, and achieve the effects of shortening production cycles, reducing labor costs, and improving weighing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The concrete implementation process of this embodiment is illustrated below in conjunction with accompanying drawing:

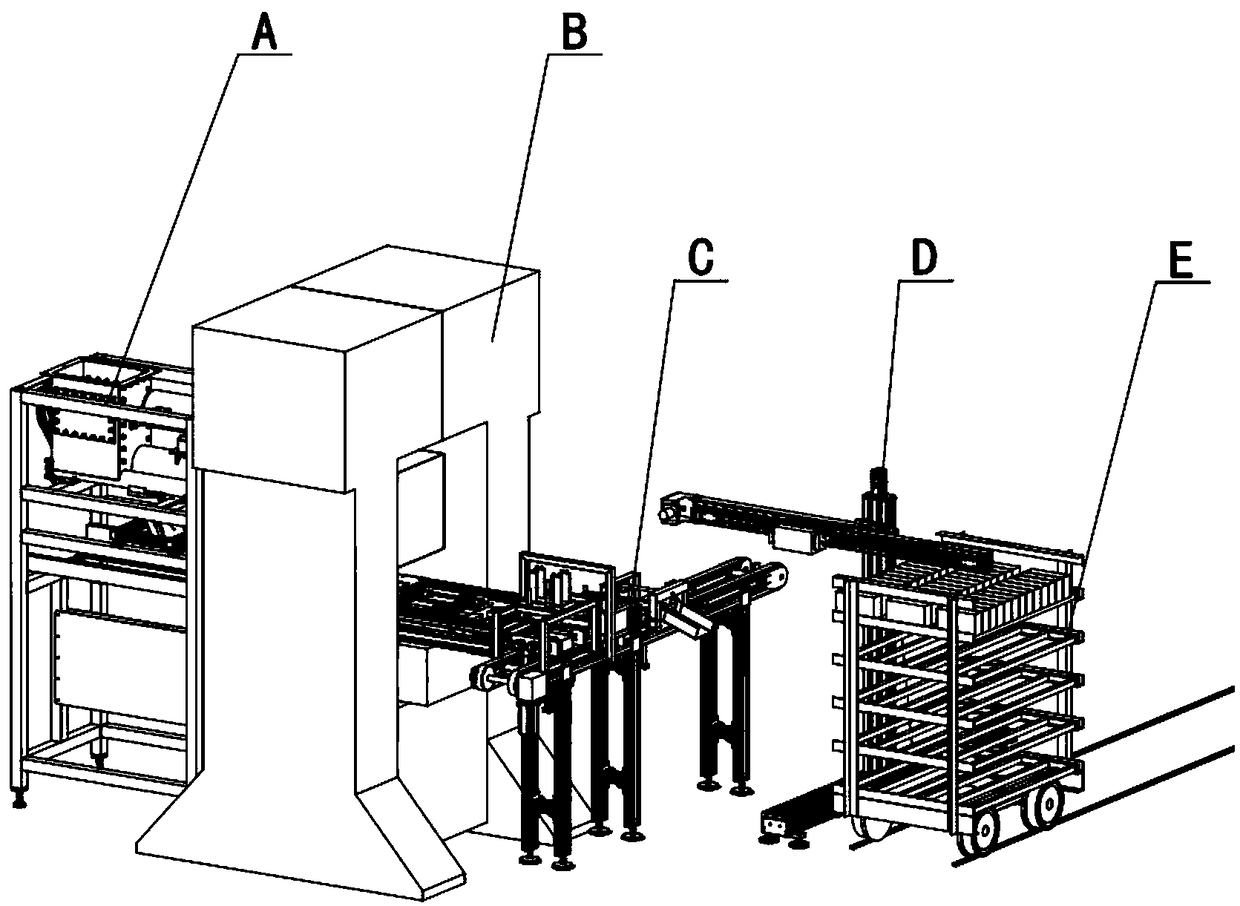

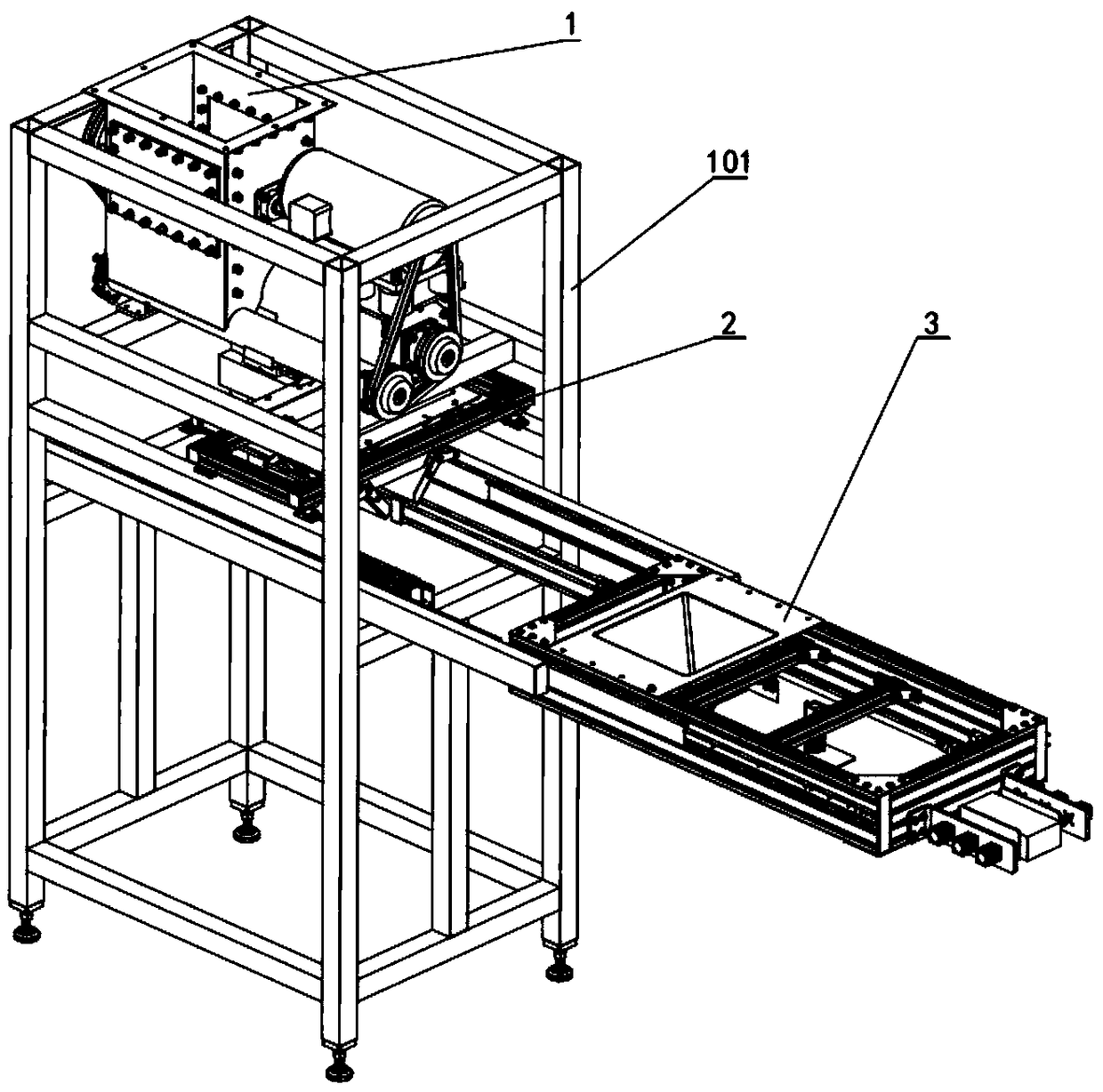

[0043] A fully automatic production line for refractory materials, characterized in that it includes a weighing and distributing device A, a press B, a detection conveyor line C, a palletizing robot D, and a transport trolley E. The weighing and distributing device A includes a fixed frame 101 and is installed on the fixed frame The unloading mechanism 1, the weighing mechanism 2, and the cloth mechanism 3 on 101;

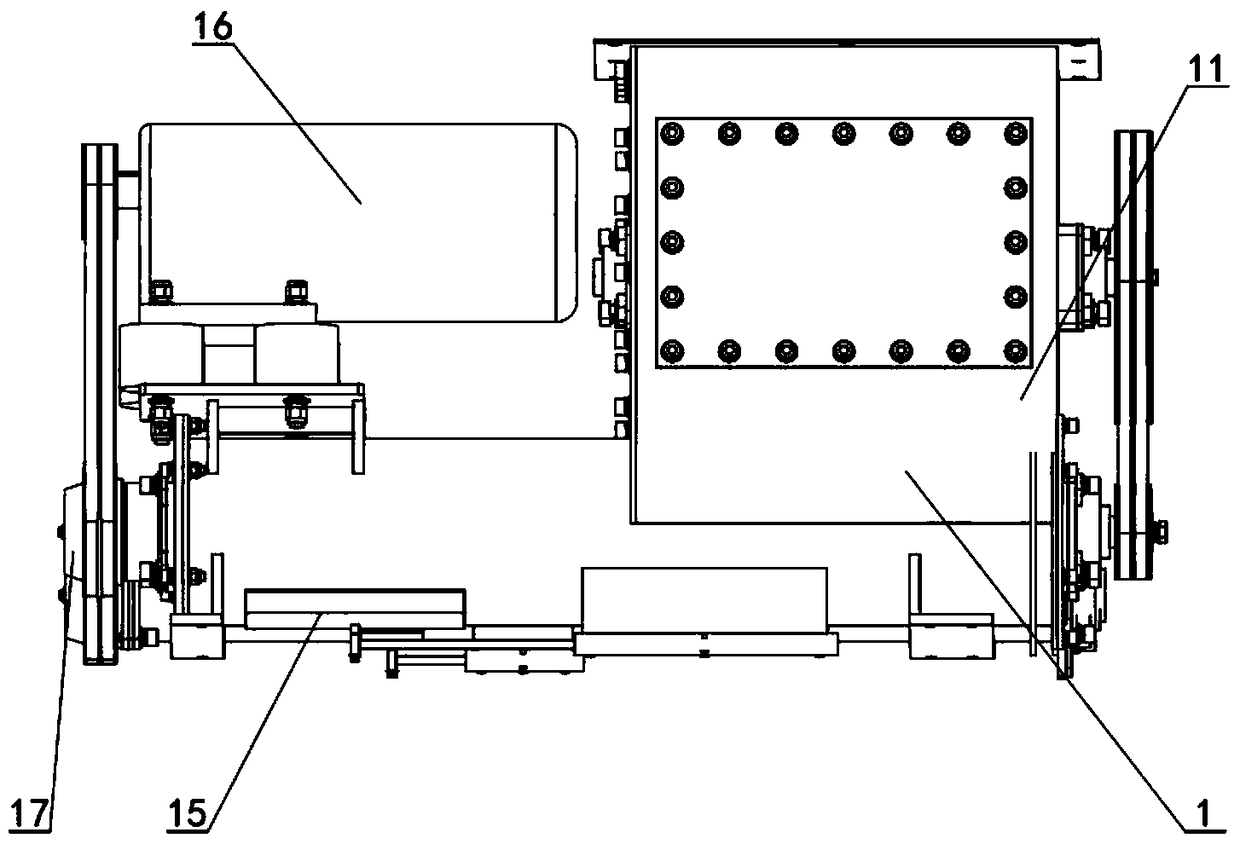

[0044] The unloading mechanism 1 is located at the top of the fixed frame 101, the unloading mechanism 1 is provided with a storage bin 11, a feed inlet is arranged on the top of the storage bin 11, and an agitator 12 and an agitator 12 are arranged in the storage bin 11 Coarse and fine screw conveyors below the agitator 12, the agitator 12 is located below the feed inlet, and a storage gate 15 is arranged at the bottom of the storage bin 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com