Patents

Literature

662results about How to "Improve weighing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

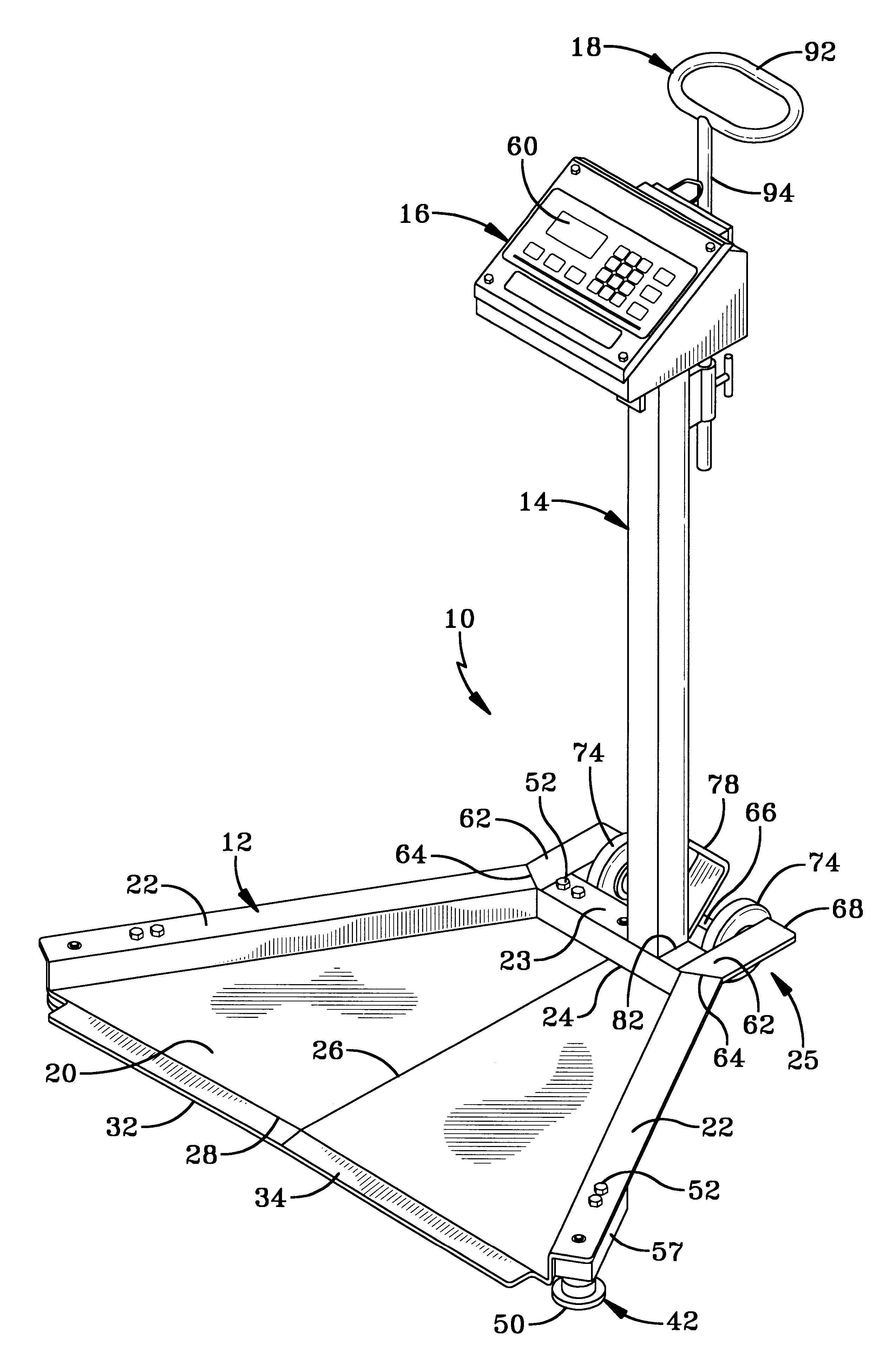

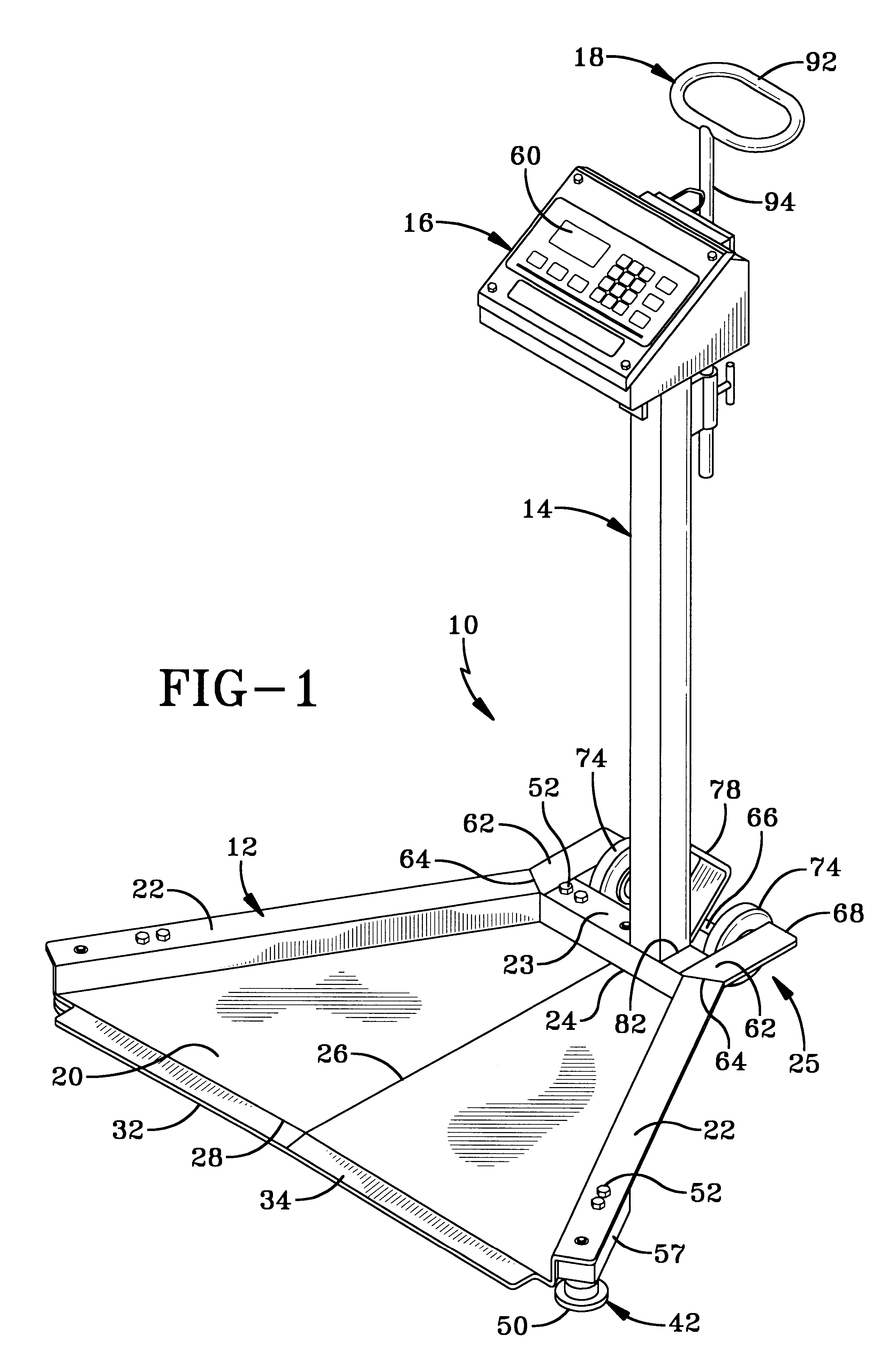

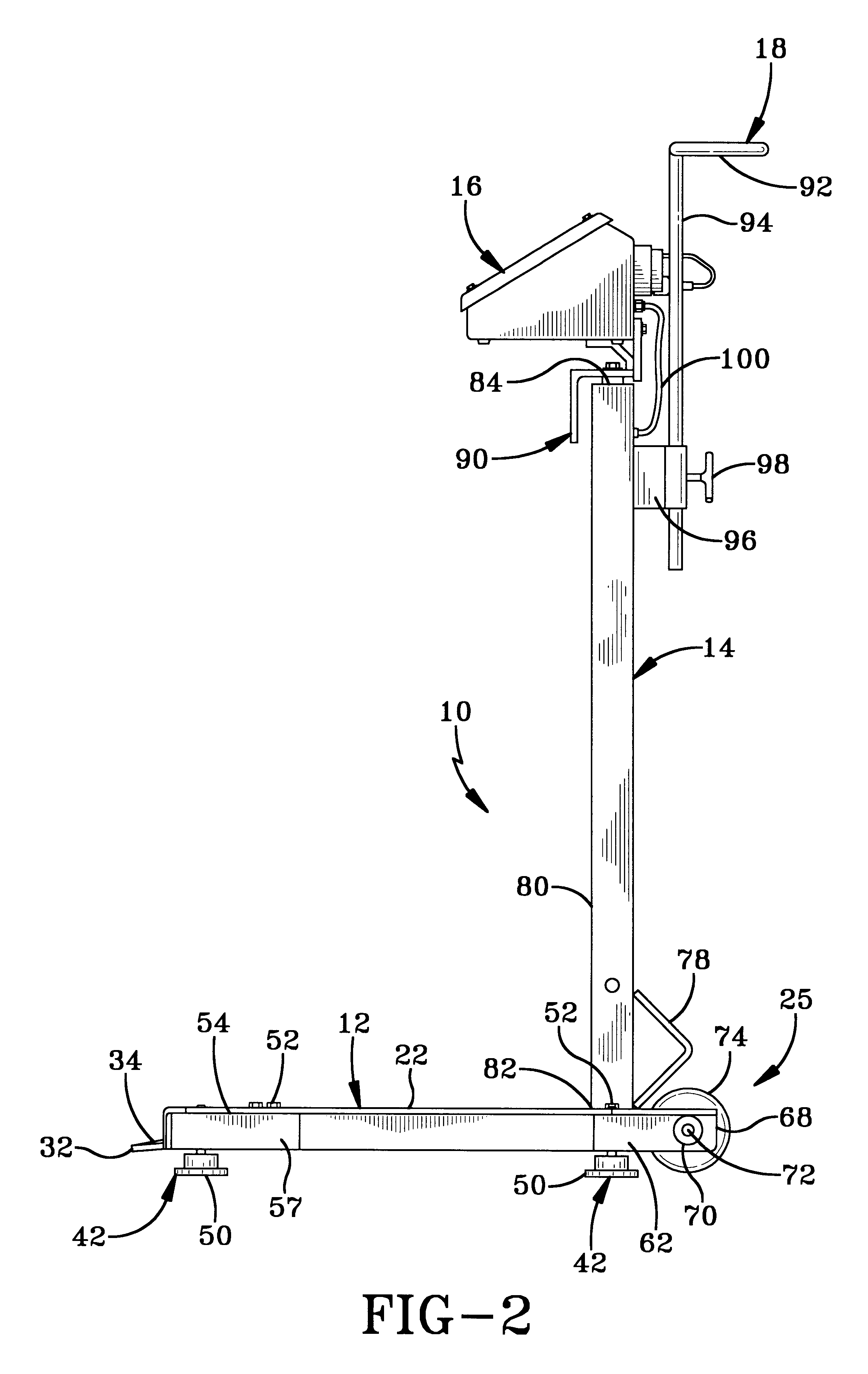

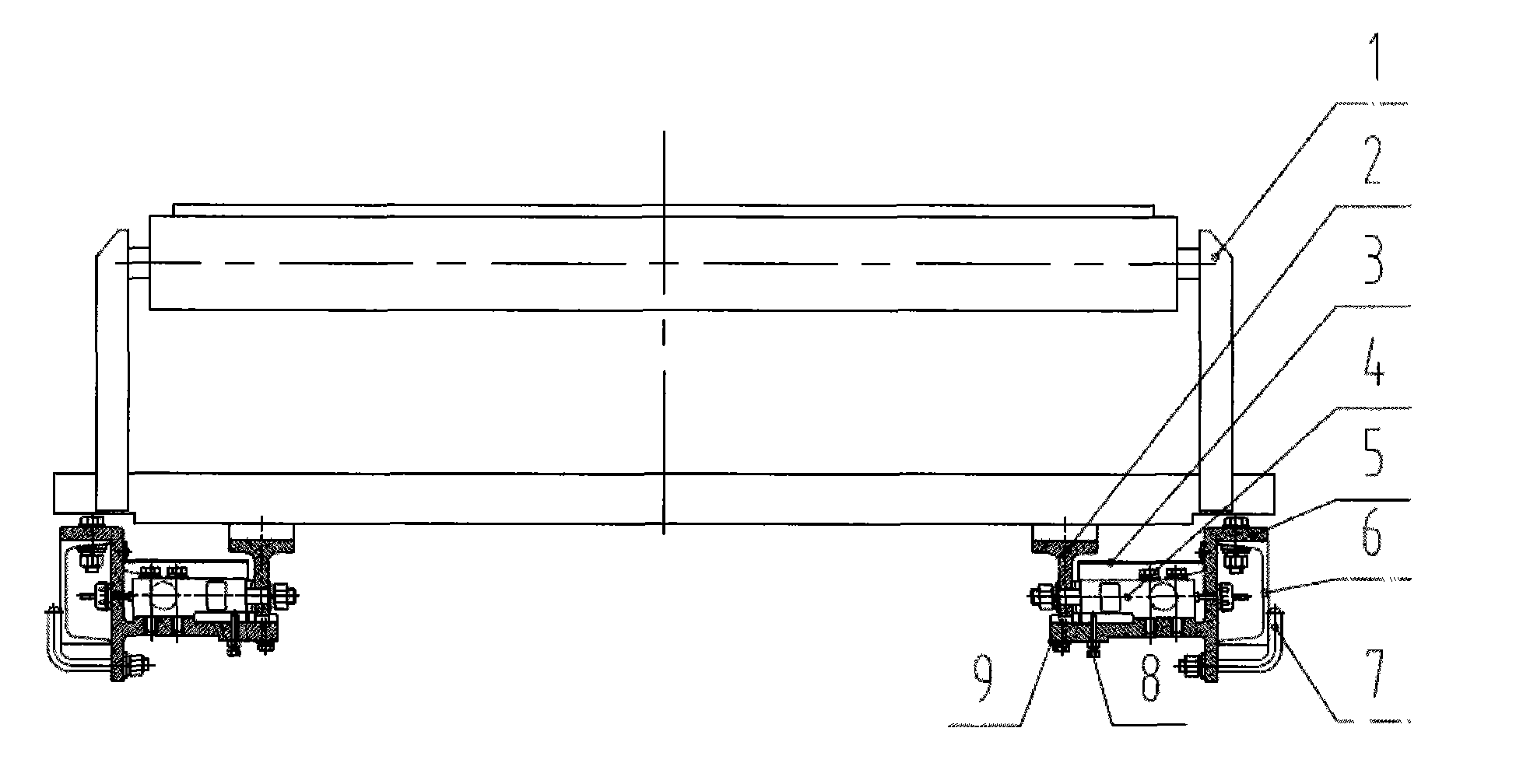

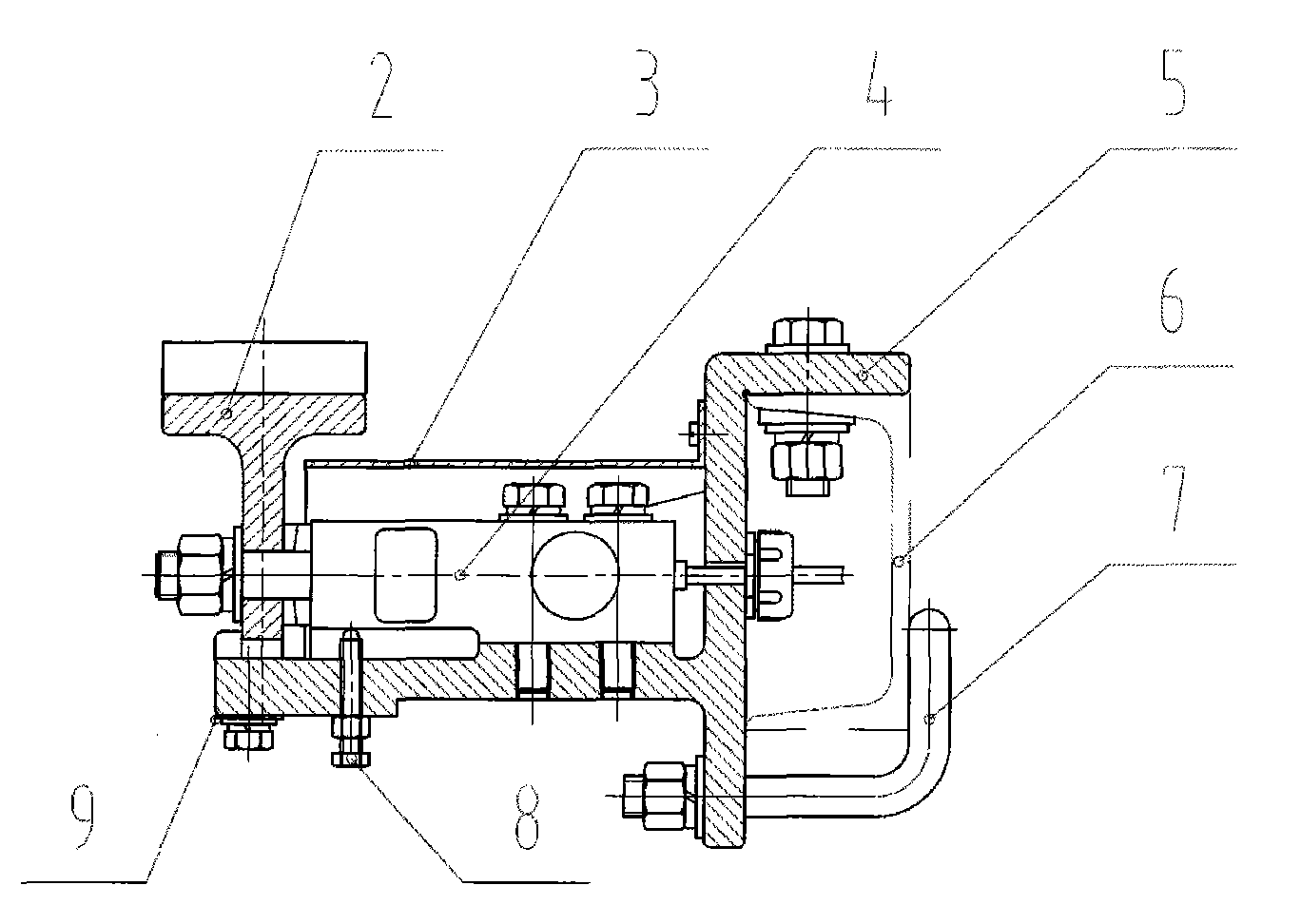

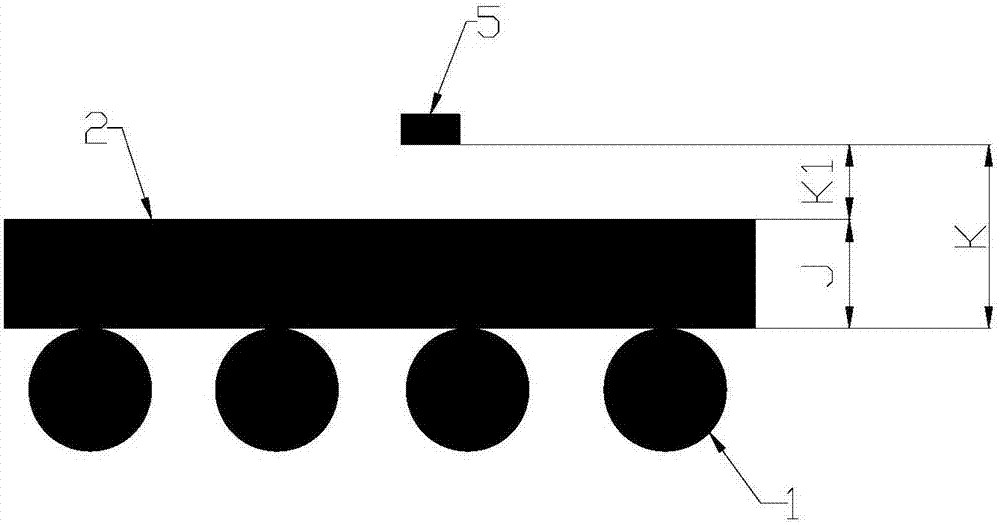

Dolly type drum scale

InactiveUS6222137B1High precisionImprove weighing accuracyWeighing apparatus detailsSpecial purpose weighing apparatusEngineeringMechanical engineering

Owner:WAYAC

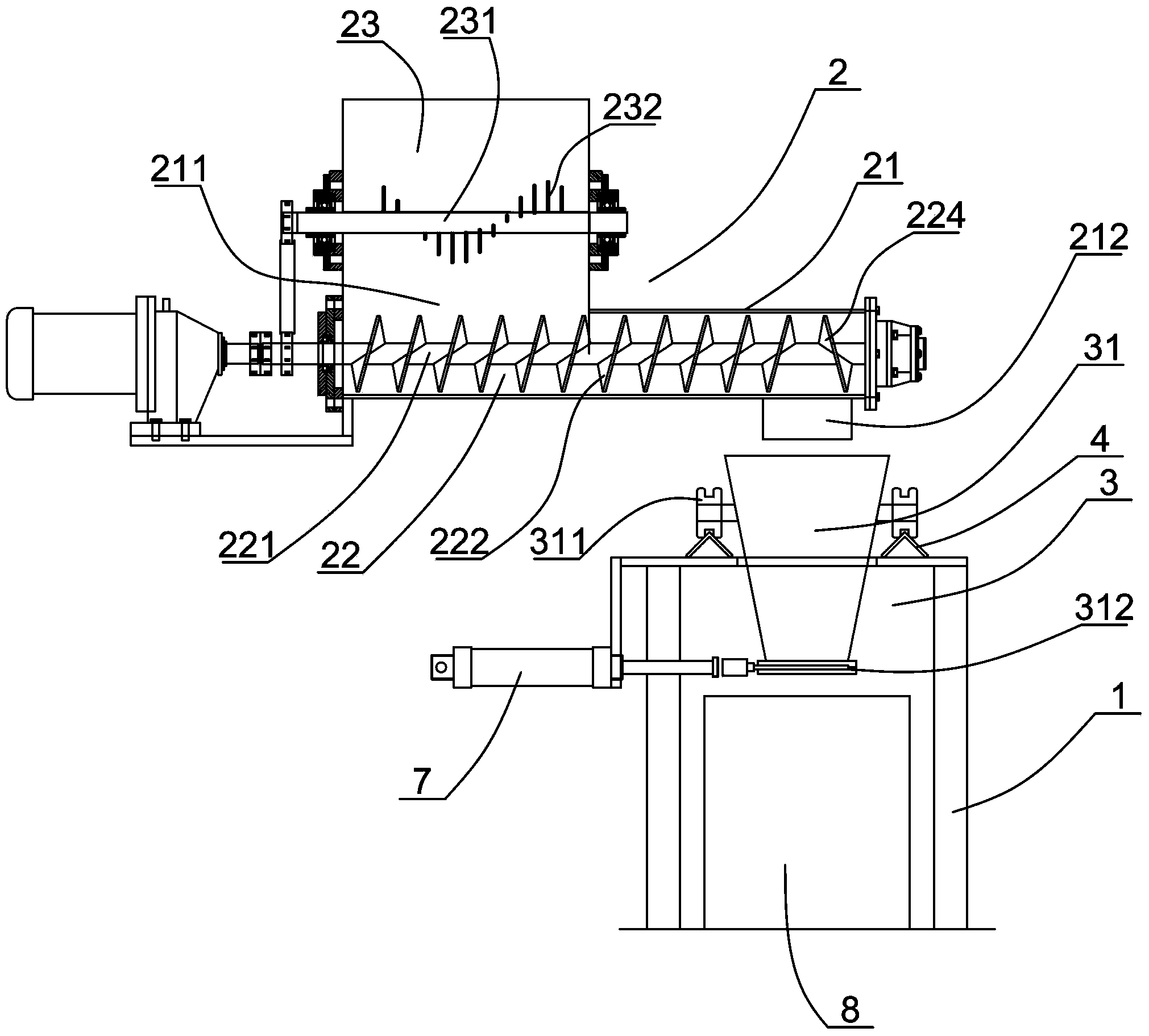

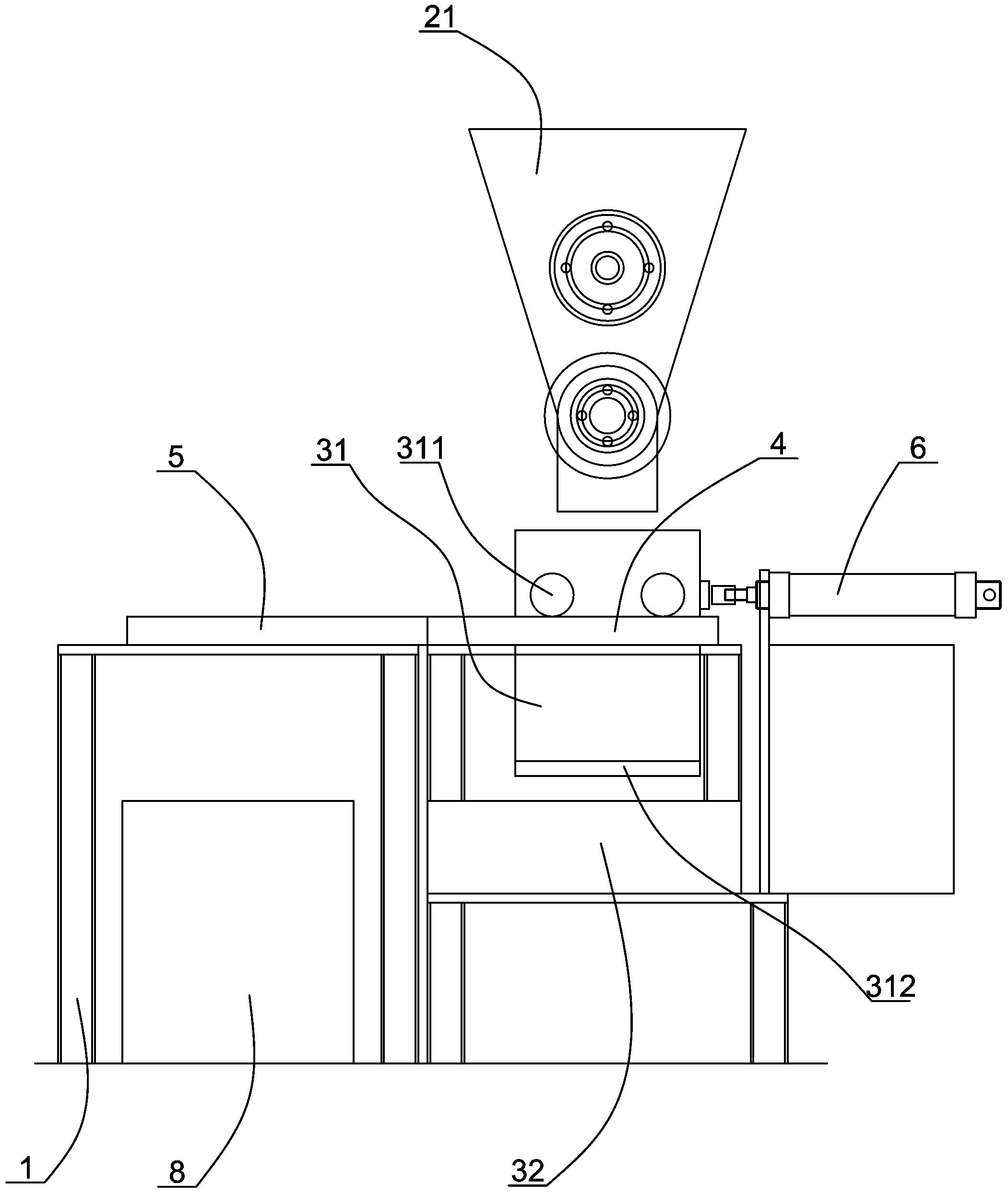

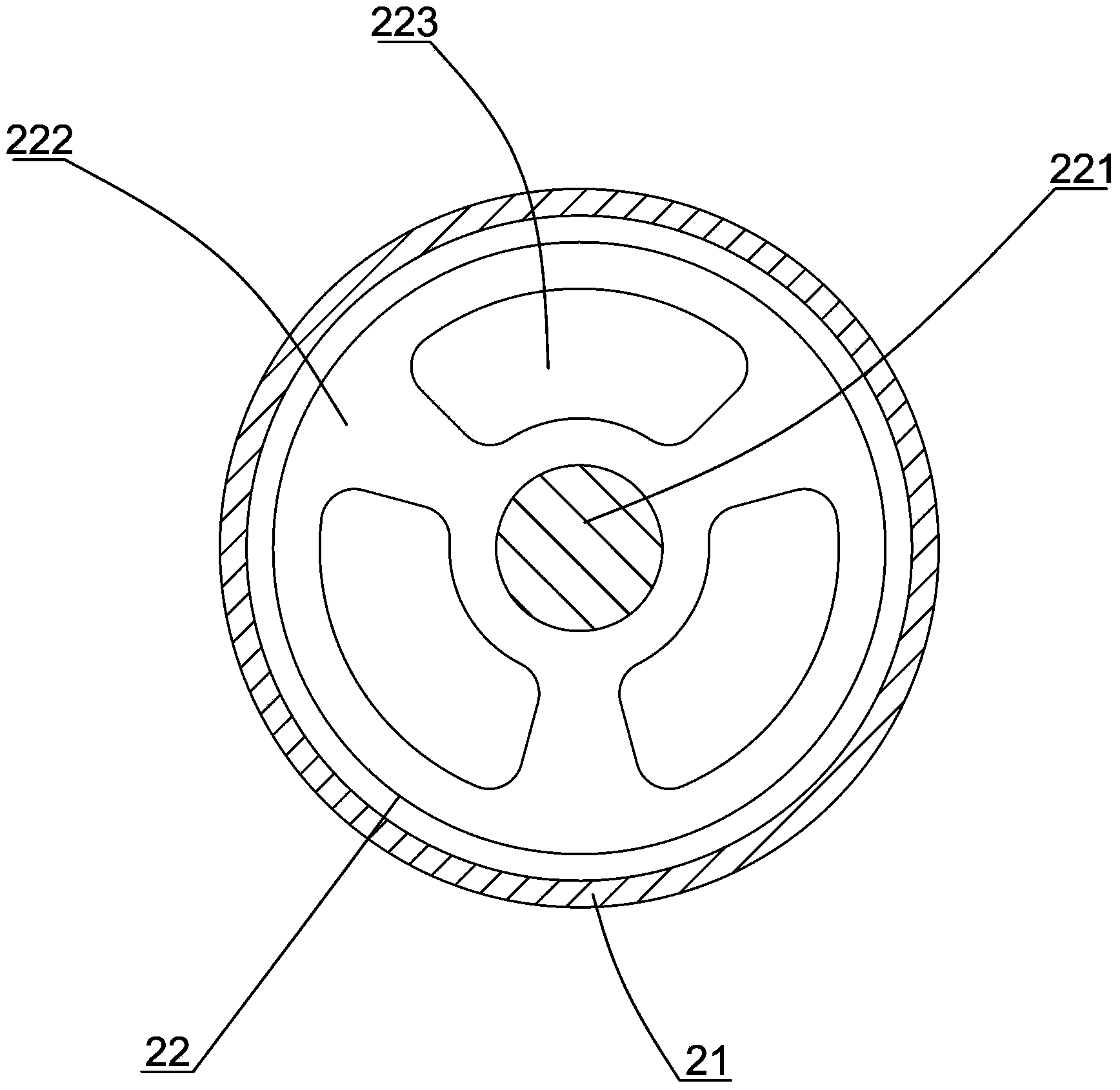

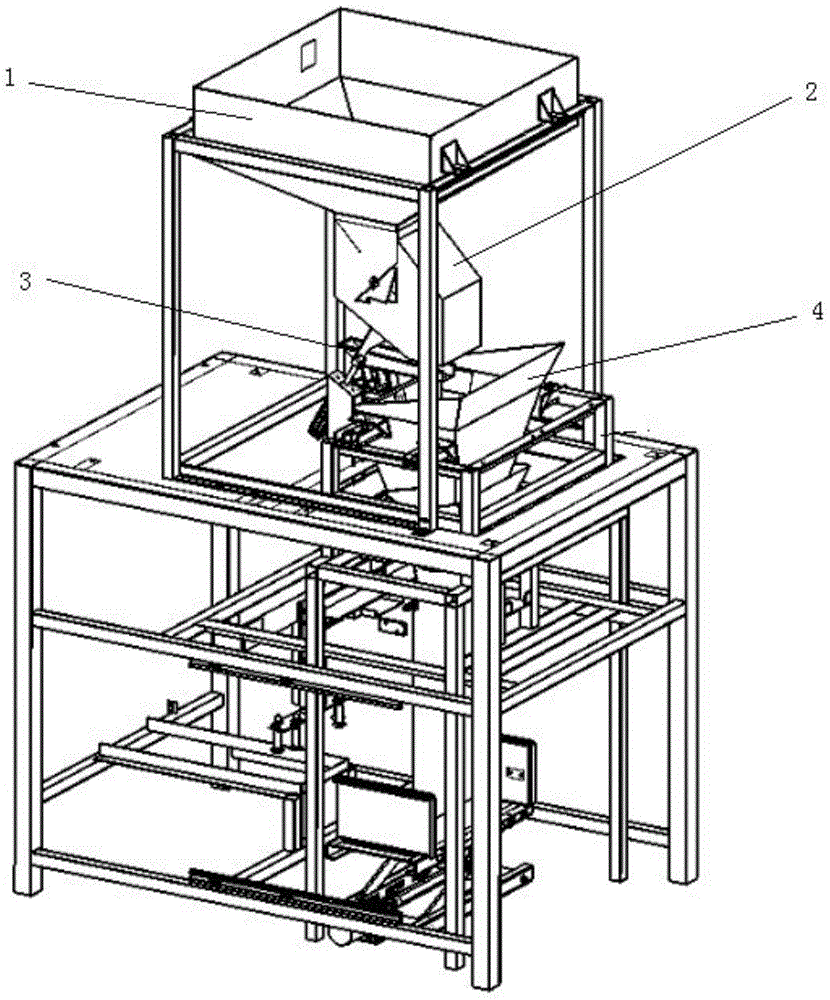

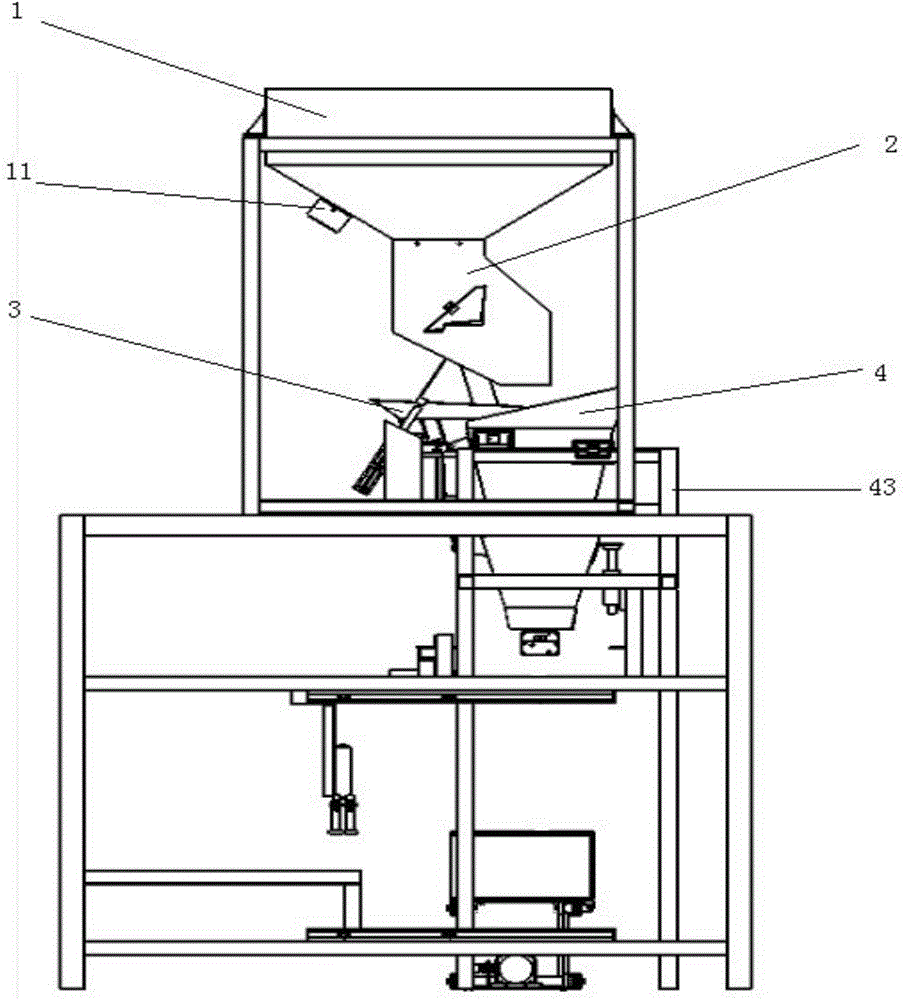

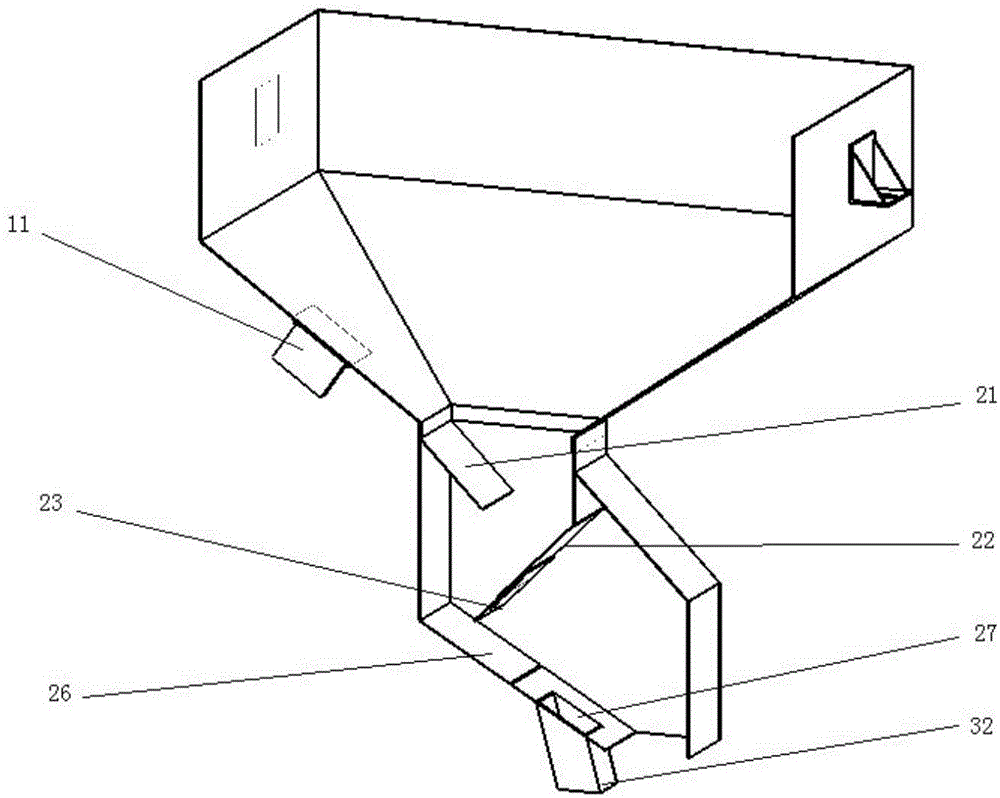

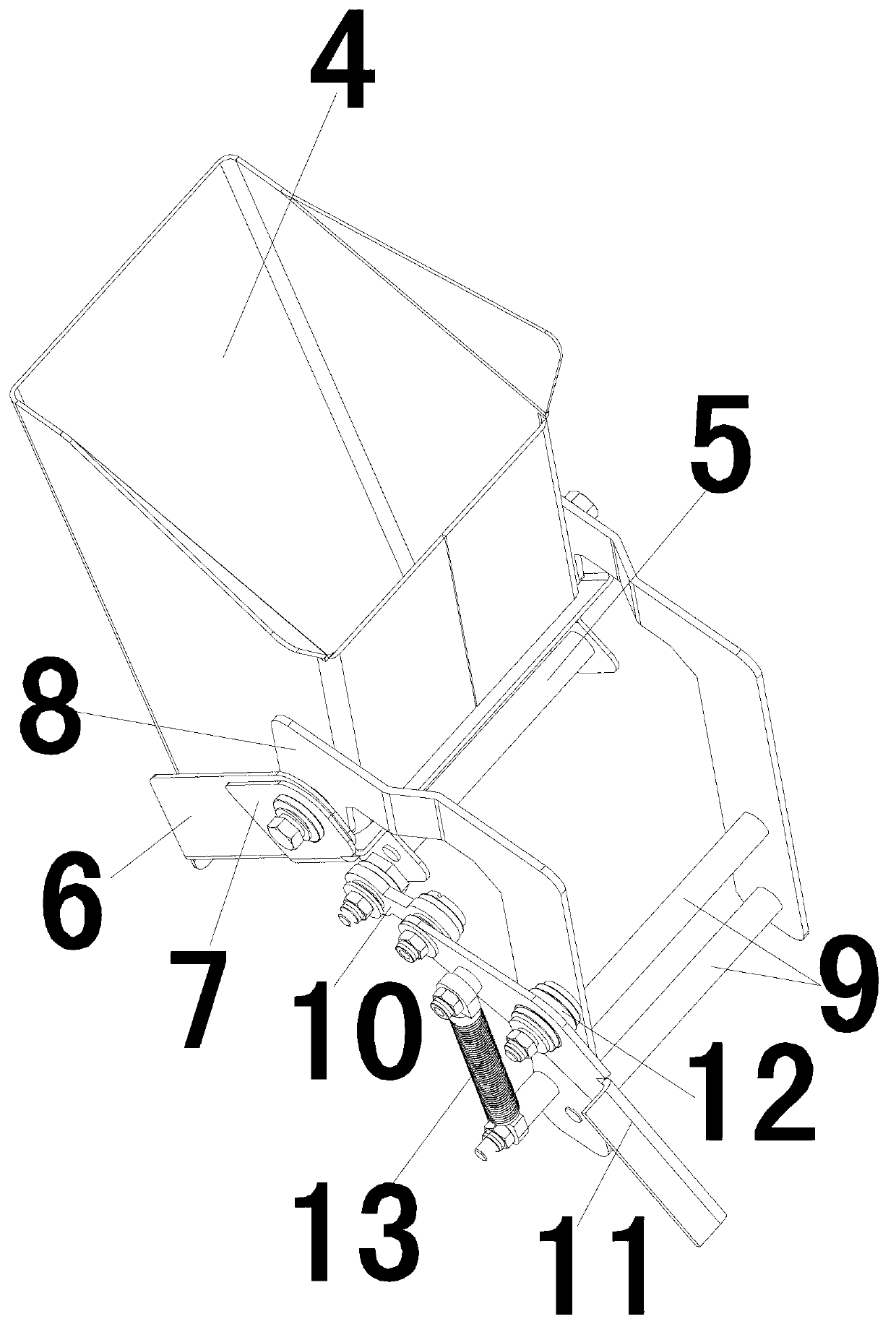

Automatic feeding device used by brake pad formation

InactiveCN103407017AAvoid easy cloggingImprove weighing accuracyWeighing apparatus with automatic feed/dischargeBrake padGate valve

The invention discloses an automatic feeding device used by brake pad formation, which comprises a rack, and a feeding unit and a weighting unit arranged on the rack, wherein the feeding unit comprises a material barrel and a spiral convey shaft arranged in the material barrel; a hopper is arranged at a feed port of the material barrel; the spiral convey shaft comprises a shaft rod and spiral feeding blades; a plurality of backspacing holes are formed in the feeding blades; the weighting unit comprises a weighting container positioned below a discharge port and an electronic scale below the weighting container; two paralleled first slide tracks are arranged on the weighting platform face of the electronic scale; the weighting container and the first slide tracks are in sliding connection; a gate valve is arranged at the bottom of the weighting container; the rack is further provided with two second slide tracks positioned above a mould; the second slide tracks and the first slide tracks are coaxially arranged; the rack is provided with a convey air cylinder driving the weighting container, and a discharging air cylinder capable of connecting the gate valve. The device has the advantages that the weighting precision is high, and materials are not easy to block; the over-all structure is simple, and the working efficiency is high.

Owner:HANGZHOU JINGCHENG AUTOMATIC CONTROL ENG

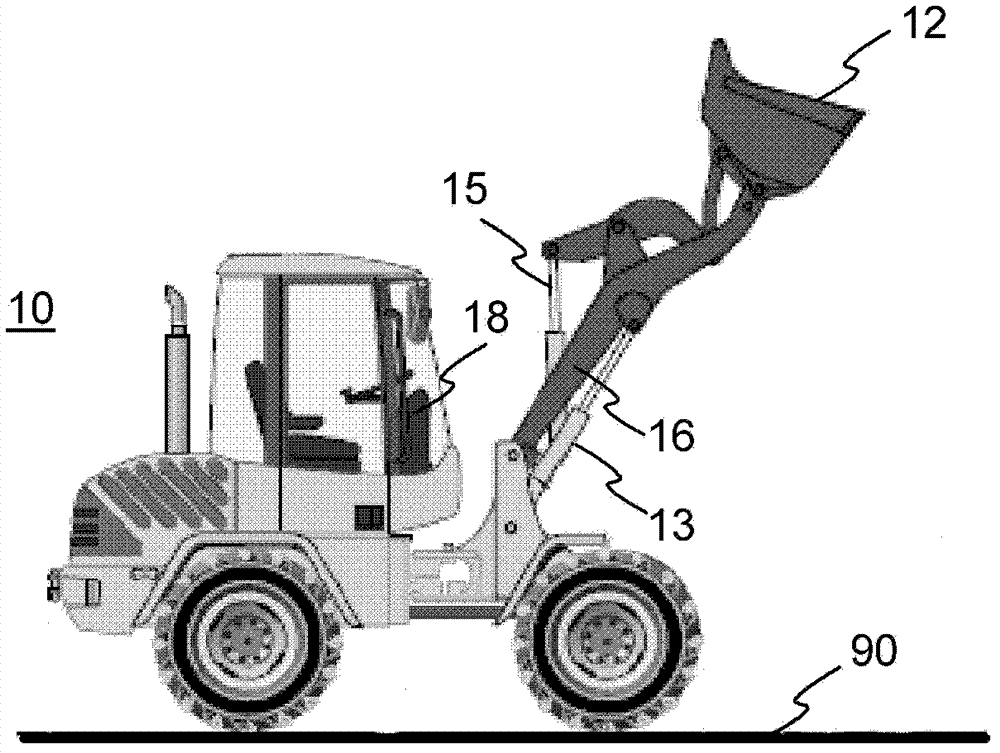

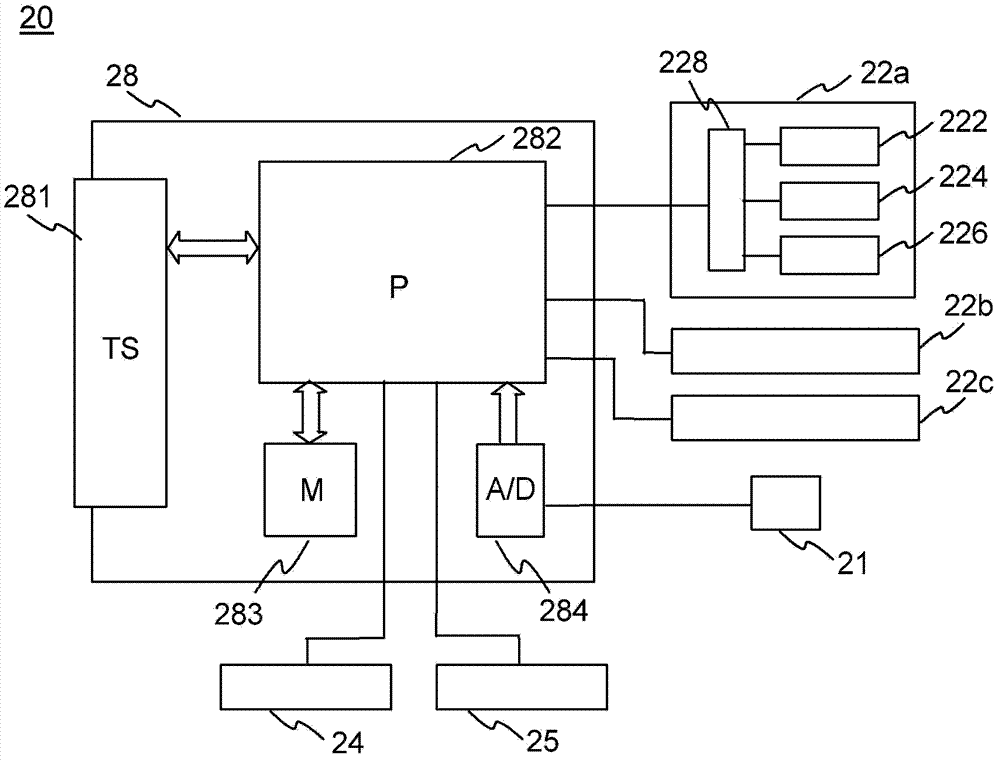

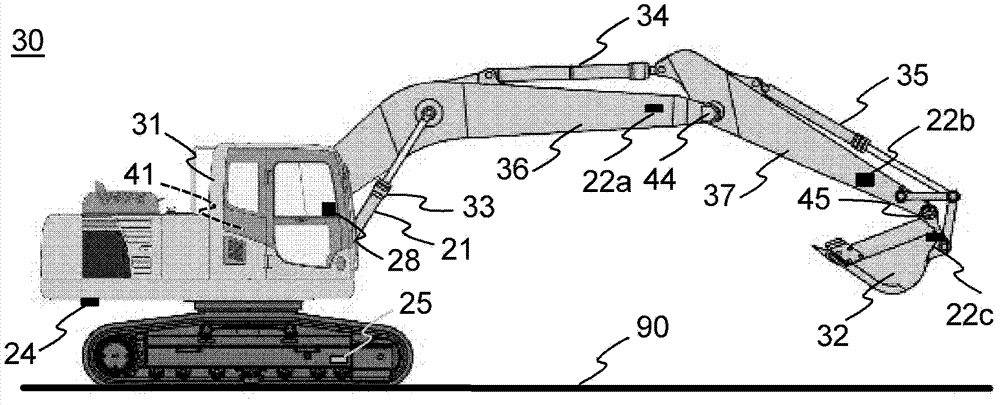

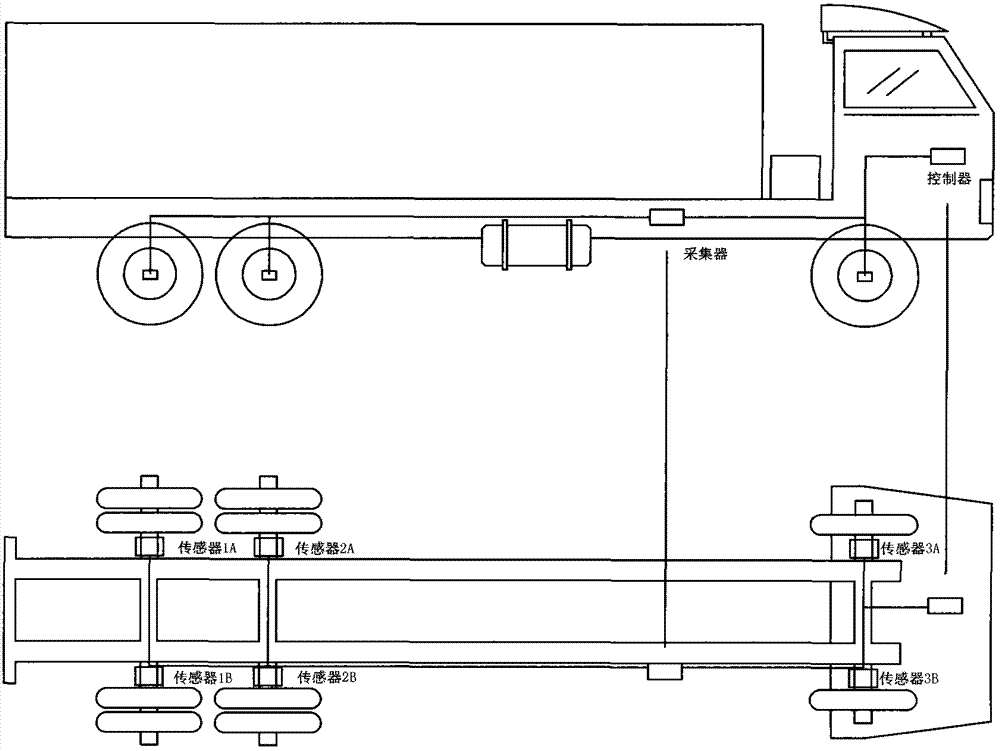

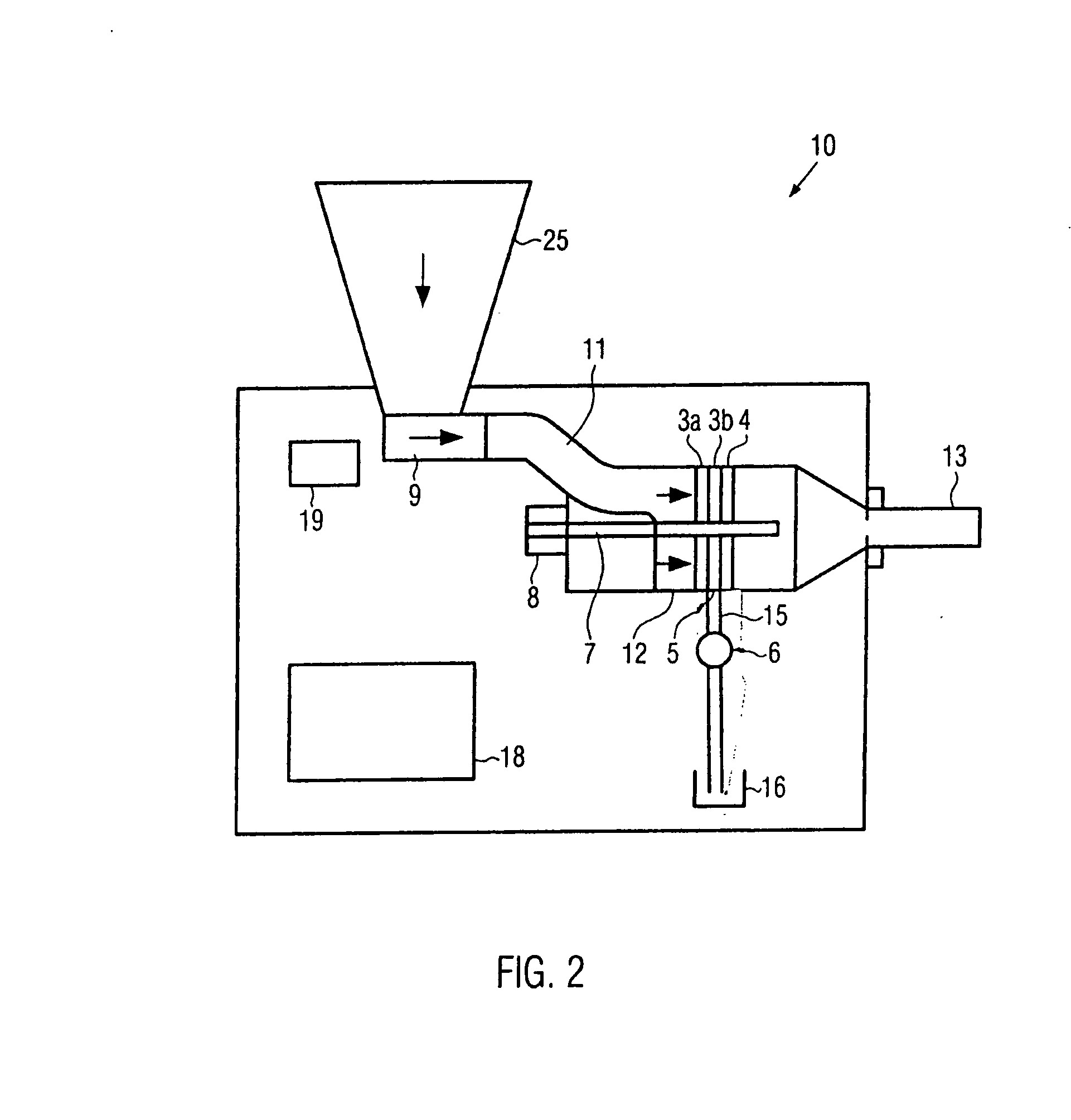

Measurement system for a material transfer vehicle

ActiveCN102735318AQuick and accurate responseImprove weighing accuracySoil-shifting machines/dredgersSpecial purpose weighing apparatusGyroscopeForwarder

This invention relates generally to a measurement system (20) of a material transfer vehicle. The present invention can be applied in weighing a load of the vehicle. The material transfer vehicle may be e.g. a wheel loader, a forklift, an excavator, a dumper, a forwarder, a harvester, a crane, a passenger hoist, a timber jack, or a truck such as a a fire truck, forklift truck, a pallet truck, a reach truck, or a garbage truck. Prior art measuring systems often have insufficient capability to compensate varying positions and movement of the material transfer vehicle structures. The object of the invention is met by a solution, wherein a material transfer vehicle has at least one first sensor unit (21) including a weighing sensor for weighing a load of a vehicle, and at least one second sensor unit (22a, 22b, 22c) for measuring an angular position / movement of a boom and / or a carrying means of the vehicle. According to the invention, the second sensor unit has a gyroscope.

Owner:TAMTRON OY

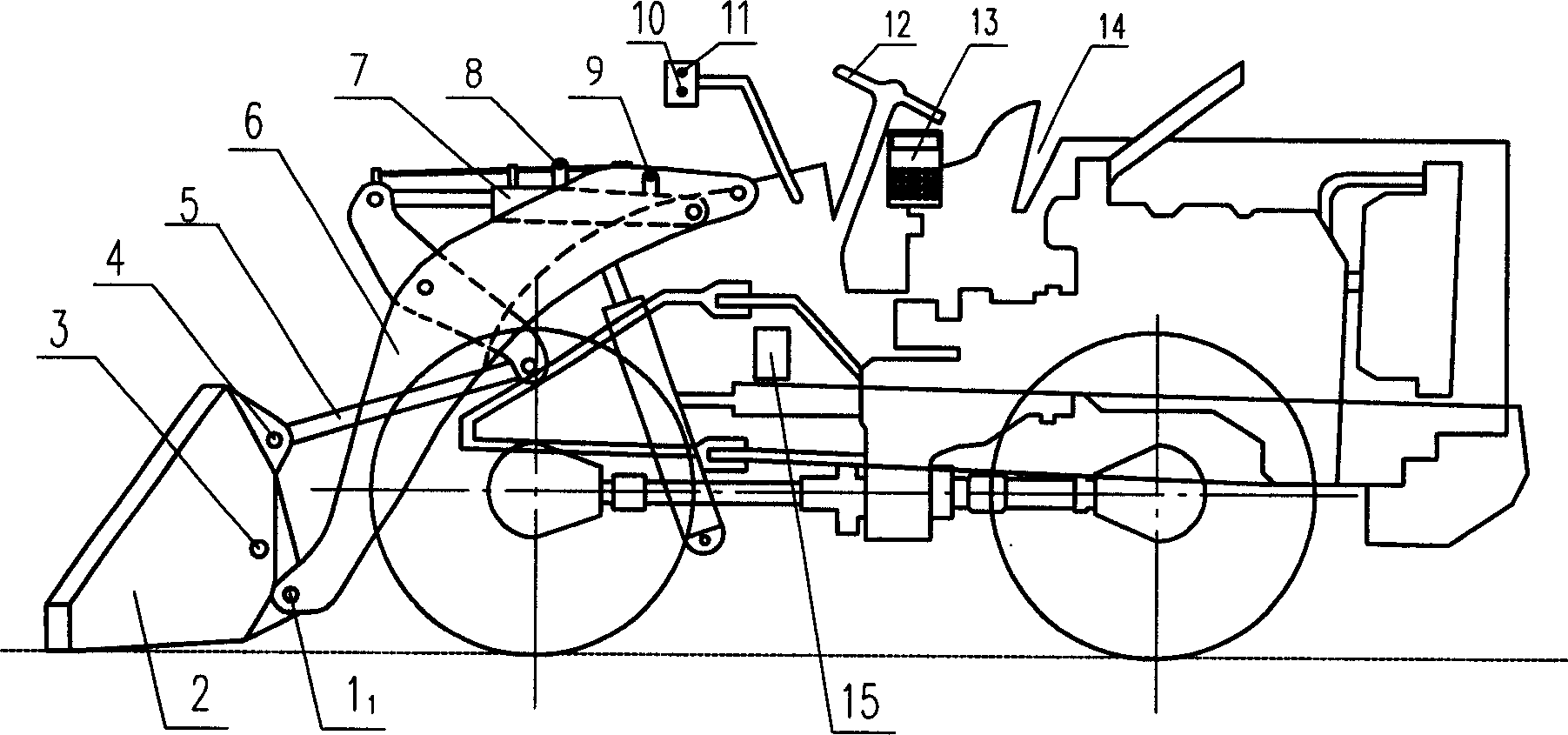

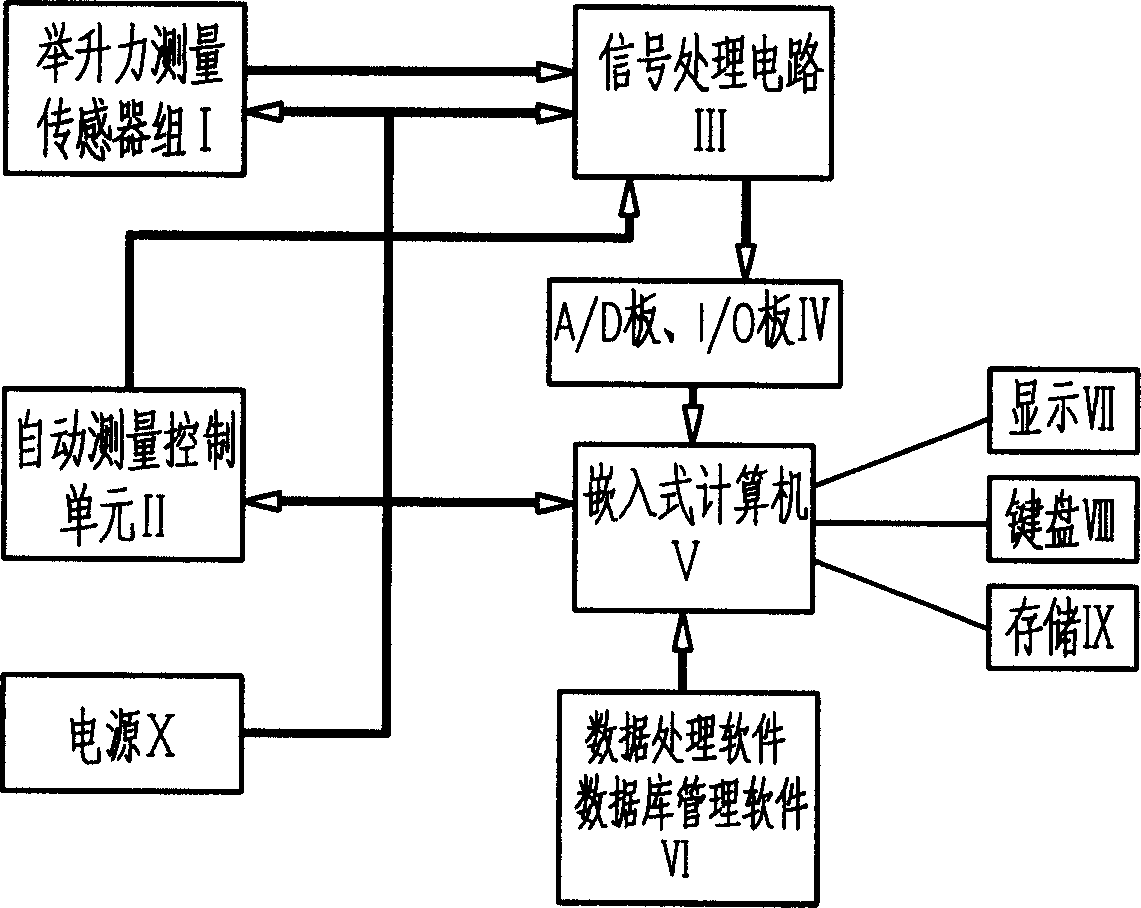

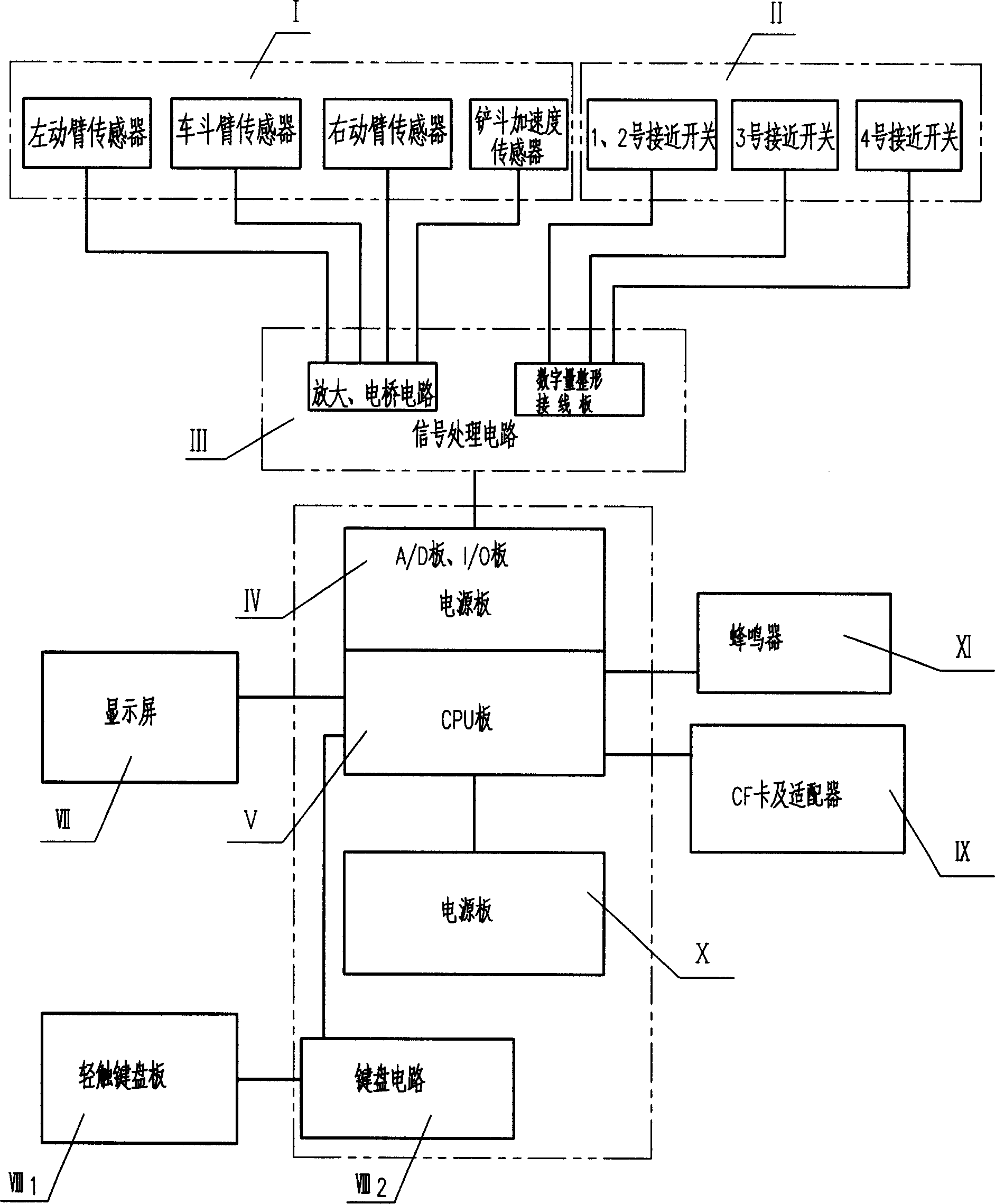

Electronic weighing system for loading machine and method for metering loading capacity

InactiveCN1749710AReasonable structureReasonable distributionLoading/unloadingSpecial purpose weighing apparatusRelevant informationSignal processing circuits

The electronic weighing system includes sensors, automatic measuring and controlling unit, signal processing circuit, computer and processing system, and power source. The lifting force measuring sensors and the bucket position measuring switches as the automatic measuring and controlling unit have outputs connected to the inputs of the signal processing circuit, and the signal processing circuit has output connected via A / D converting module and I / O port to the embedded computer with weighing software. The loaded amount measuring method is to measure the lifting force of the bucket with the said system to measure the mass of the material inside the bucket, and includes the steps of power-on system test, inputting relevant information, reset, automatic weighing, accumulating, reset, re-weighing, etc. The present invention has relatively high weighing accuracy.

Owner:中国铁路南宁局集团有限公司科学技术研究所 +1

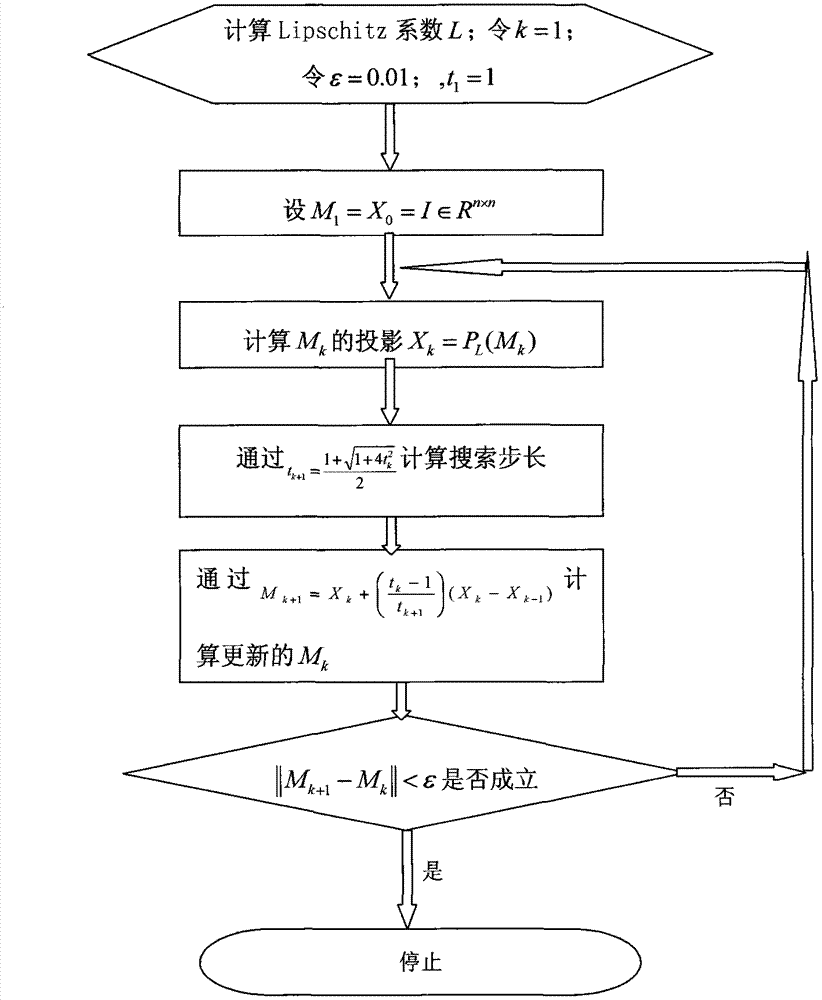

Transducer calibration method for vehicle weighing system

ActiveCN103592014ASimple structural designEasy to manufactureWeighing apparatus testing/calibrationEngineeringCalibration coefficient

The invention discloses a transducer calibration method for a vehicle weighing system. The method mainly comprises the following steps that a strain resistance type analog transducer is arranged on an automobile axle, the transducer is calibrated, a calibration coefficient of the transducer is calculated by adopting nonlinear least squares based on L2 regularization, and cargo weight of a heavy-duty lorry is calculated according to an AD value output by the transducer and the calibration coefficient of the transducer. In the driving process of an automobile, stable cargo weight data with high precision also can be obtained through the transducer calibration method for the vehicle weighing system.

Owner:建平东鑫智能装备有限公司

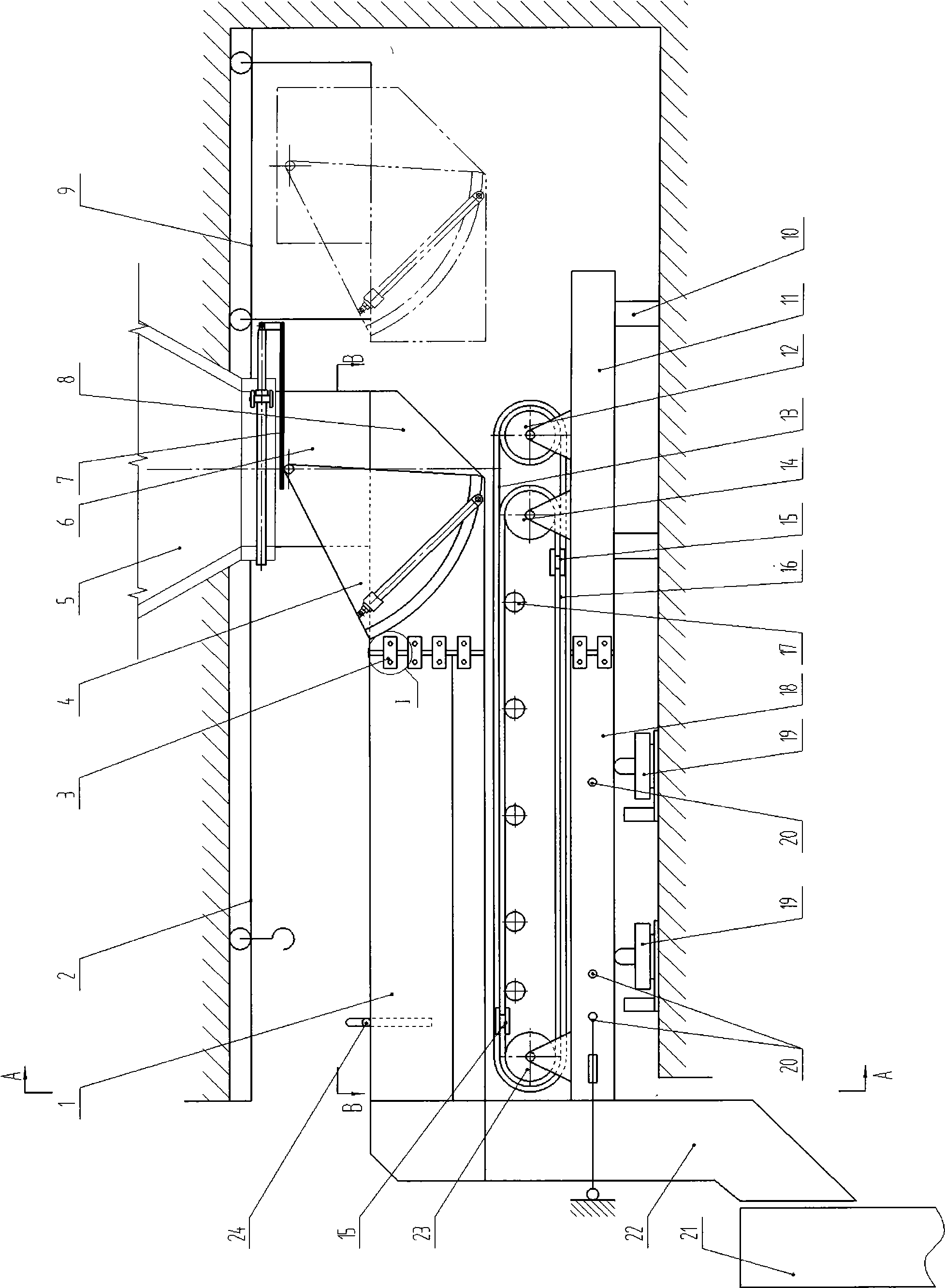

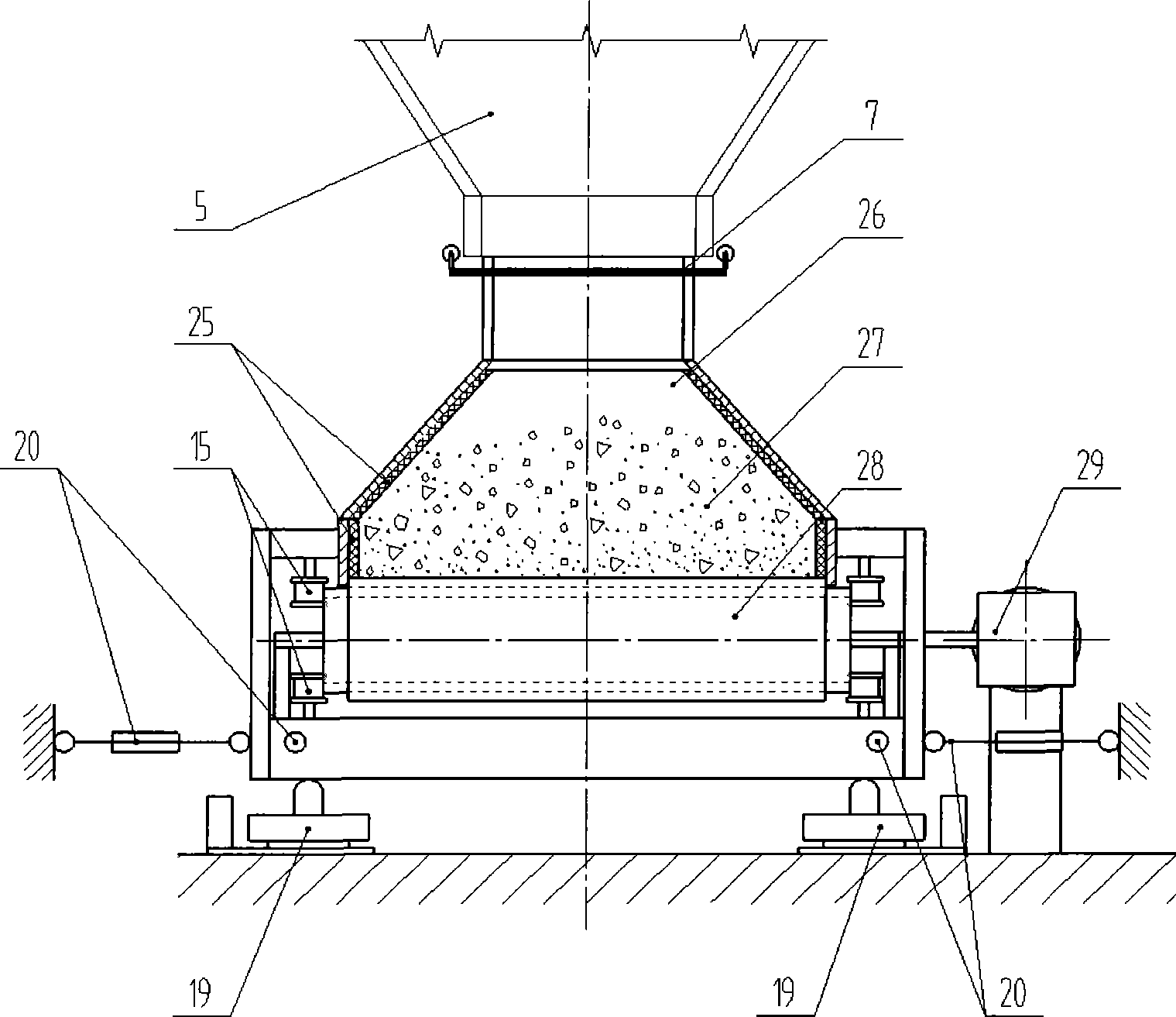

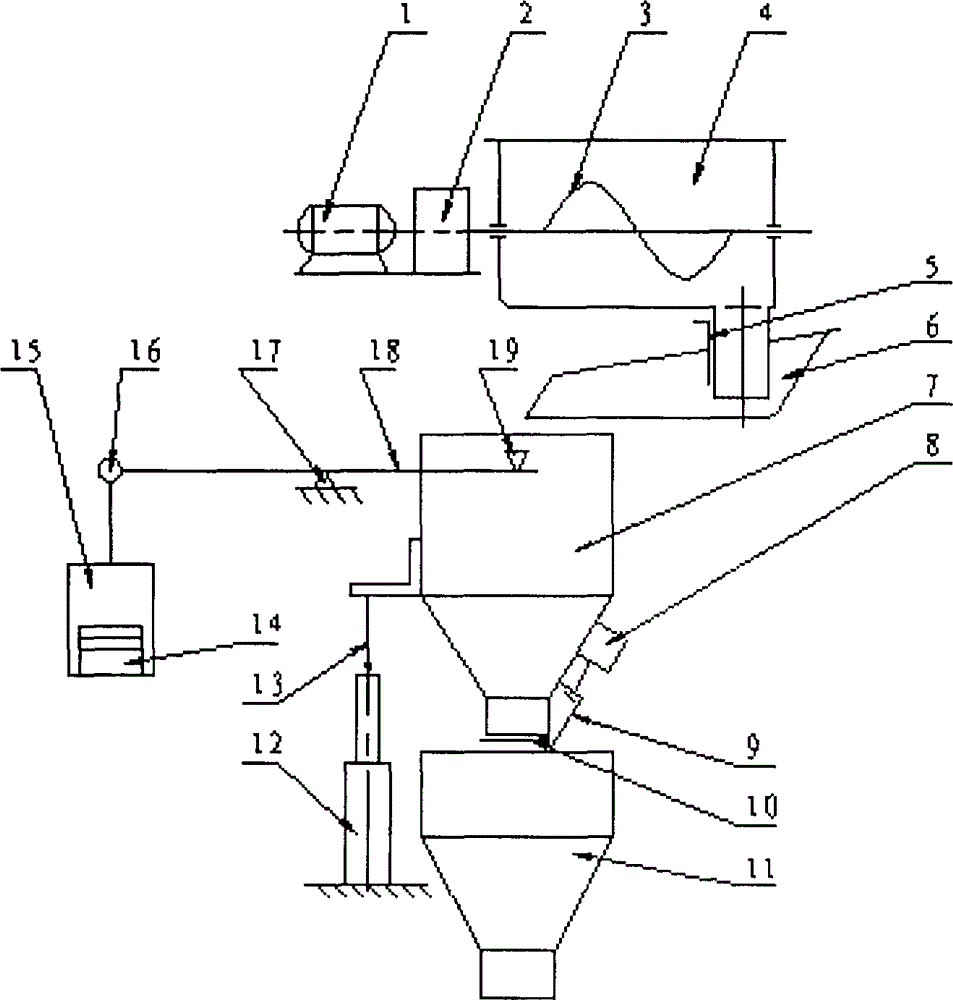

Quantitative particle material feeding system

ActiveCN104608947AReduce volumeImprove work efficiencySolid materialMotor driveElectromagnetic vibration

The invention discloses a quantitative particle material feeding system. The quantitative particle material feeding system comprises a stock bin, a feeding mechanism, a supplementing mechanism, a metering device and a control device. The discharging port of the stock bin is fixedly connected with the feeding port of the feeding mechanism. The feeding mechanism comprises an upper material blocking plate, a lower material blocking plate, an adjustable material blocking plate, an inclined discharging slide way and a flow adjusting mechanism on the discharging slide way, wherein the upper material blocking plate, the lower material blocking plate and the adjustable material blocking plate are arranged in the feeding channel. The flow adjusting mechanism comprises a material baffle and a motor drive mechanism of the material baffle, and the material baffle can be moved in a stepless mode. A mini-type electromagnetic vibration feeder is adopted in the supplementing mechanism and used for accurate feeding, and the feeding port of the mini-type electromagnetic vibration feeder is formed in the discharging slide way of the feeding mechanism. The metering device is a hopper-shaped metering scale, and a scale body of the hopper-shaped metering scale is provided with an independent landing support. A PLC is adopted in the control device. The quantitative particle material feeding system is suitable for moderate and small quantitative feeding of particle materials and particle materials not suitable for being extruded, and the working efficiency and the weighing precision are high. High adaptability is achieved for the size and the ration of the material particles.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH

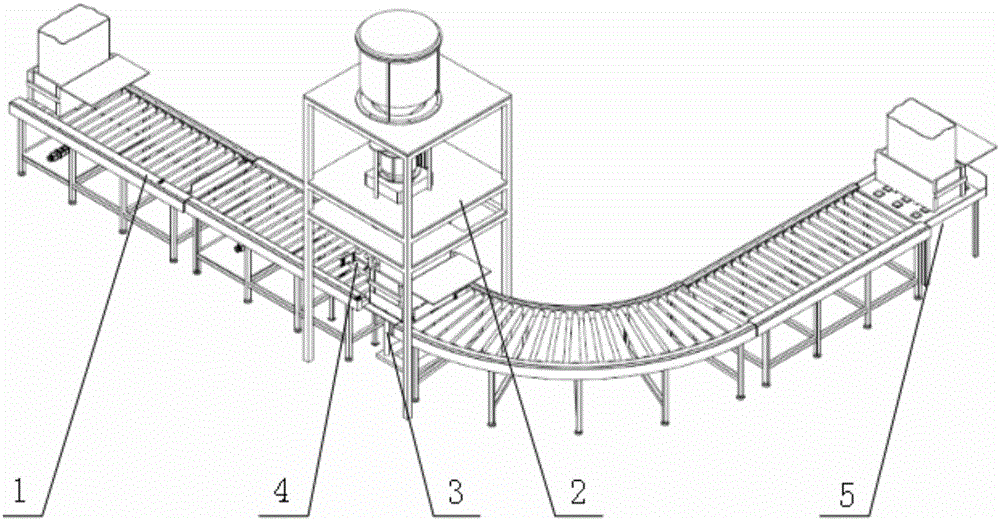

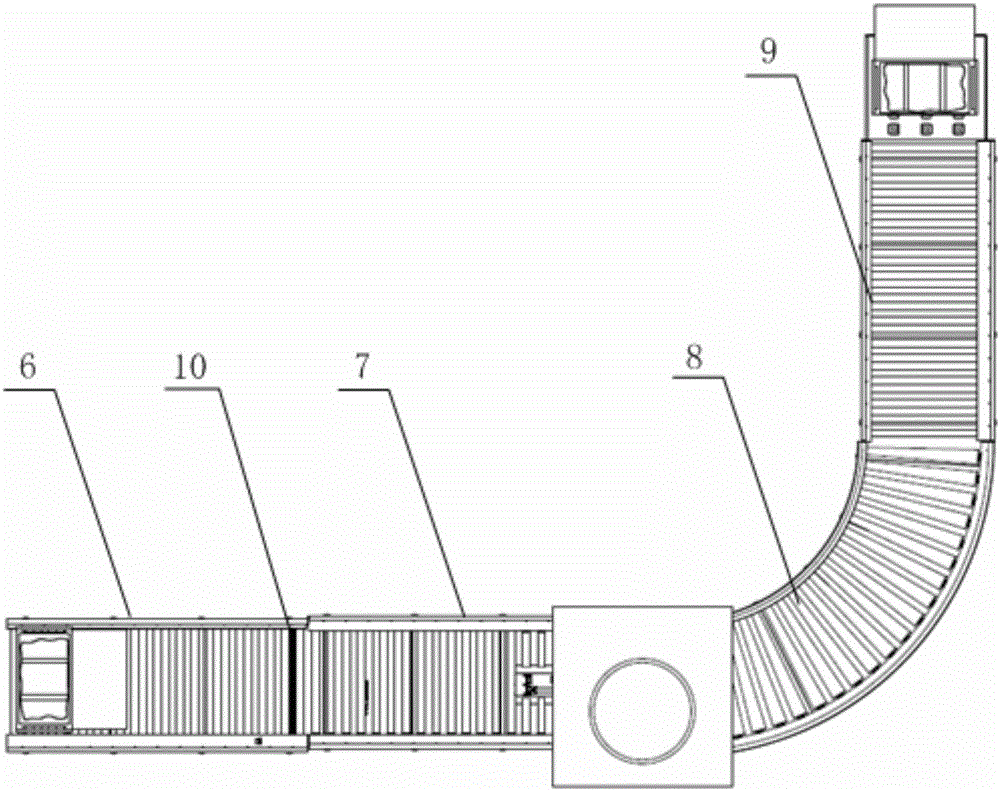

Fixed-weight loading equipment

InactiveCN101497402AGuaranteed uptimeReduce frictionConveyorsControl devices for conveyorsLoad cellMechanical engineering

The invention relates to a fixed weight loading device for bulk materials, and belongs to the field of mine transportation equipment. The fixed weight loading device for the bulk materials comprises a drive unit, a material guide groove, a conveying device and a support, wherein the material guide groove is arranged on the conveying device which is connected with the support. The fixed weight loading device for the bulk materials is characterized in that the support and the material guide groove are divided into a material receiving part and a weighing part; a weighing sensor is arranged under the weighing part, namely the support; a conveyer belt of the conveying device can be an adhesive tape, a shell belt or a composite adhesive tape and shell belt; the material receiving part and the weighing part, namely the support and the material guide groove are in flexible connection of which the displacement in the vertical direction is not limited; the weighing part, namely the support, is provided with a tensioning device for limiting the displacement in the horizontal direction; and side-slipping resistant wheels are arranged on both sides of the adhesive tape or the shell belt close to a directive point of a roller. The fixed weight loading device for the bulk materials combines a shell belt feeder and force sensor technology, and has the advantages of high weight measuring precision, small mounting space, strong universality, small operating power, reliable use, convenient maintenance, low operating cost and strong environmental adaptation ability.

Owner:孟凡英

Washing machine and control method thereof

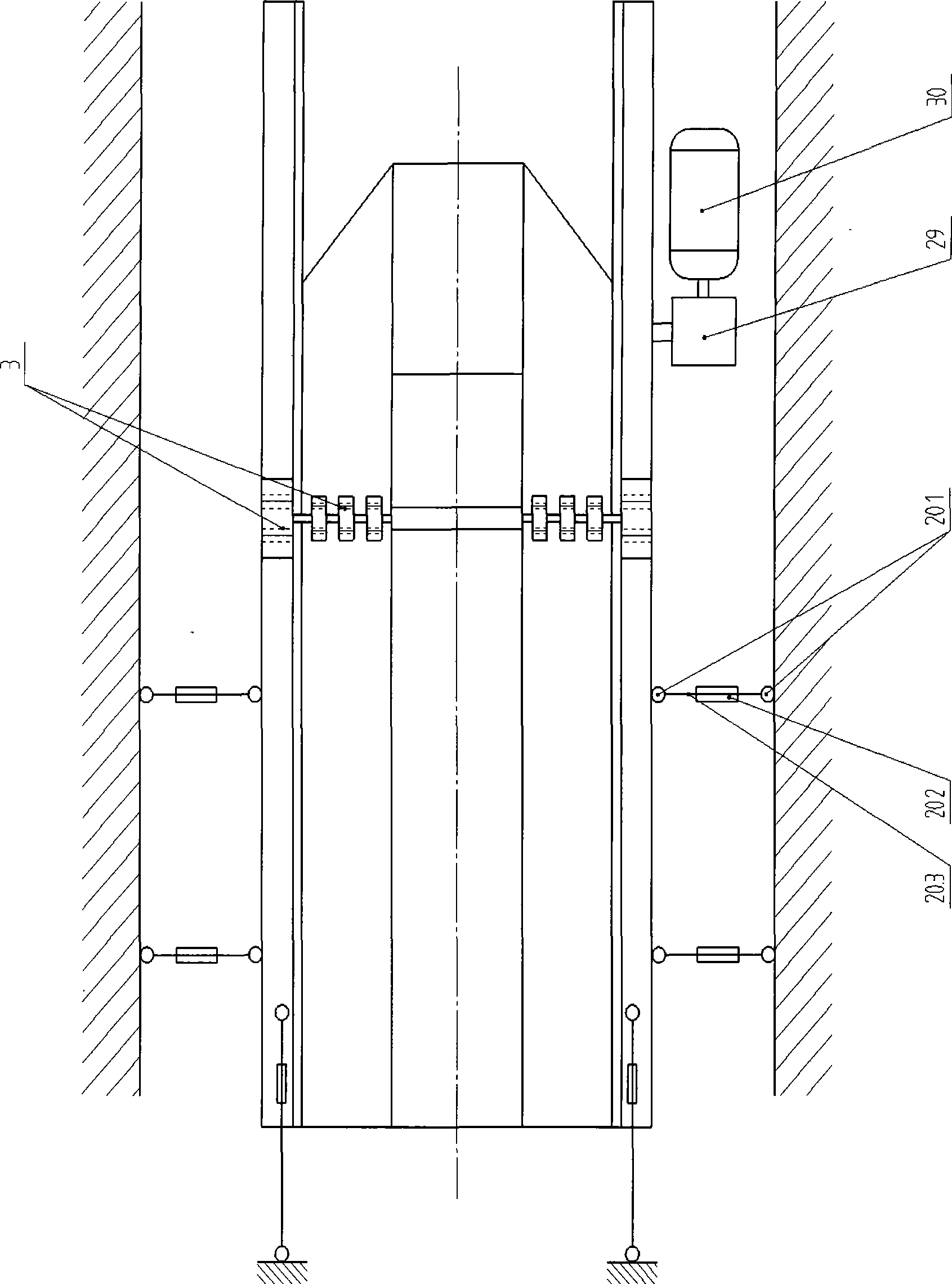

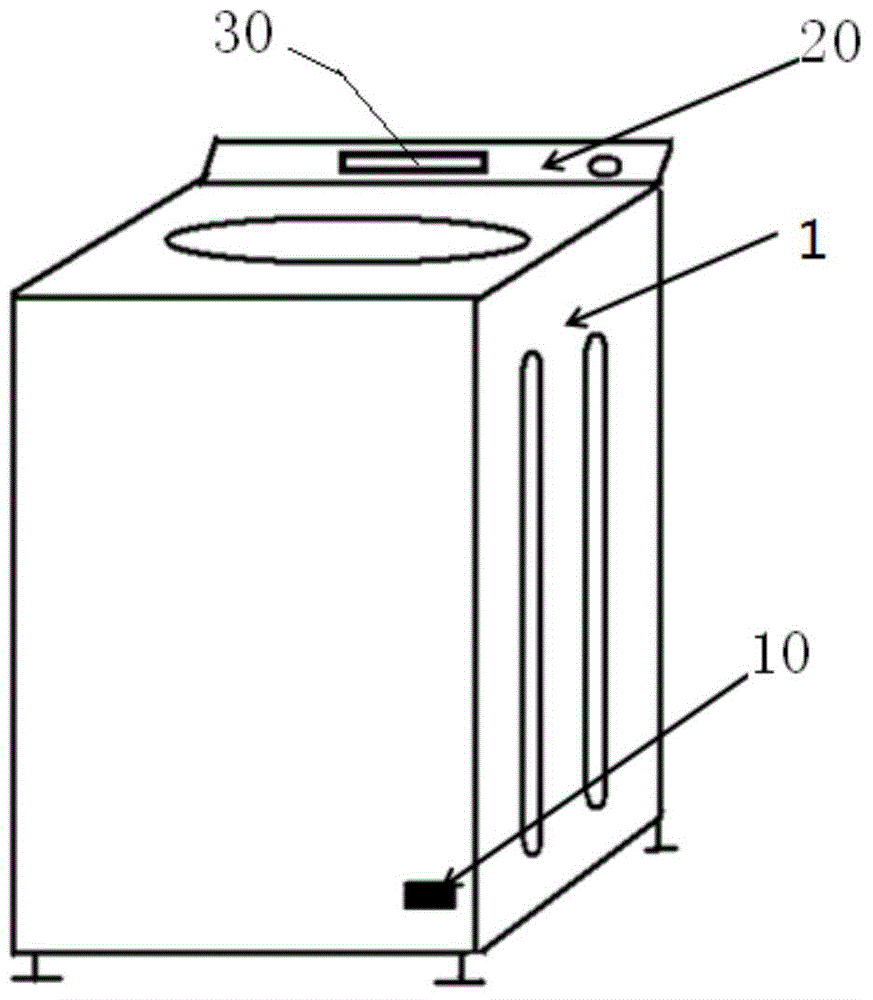

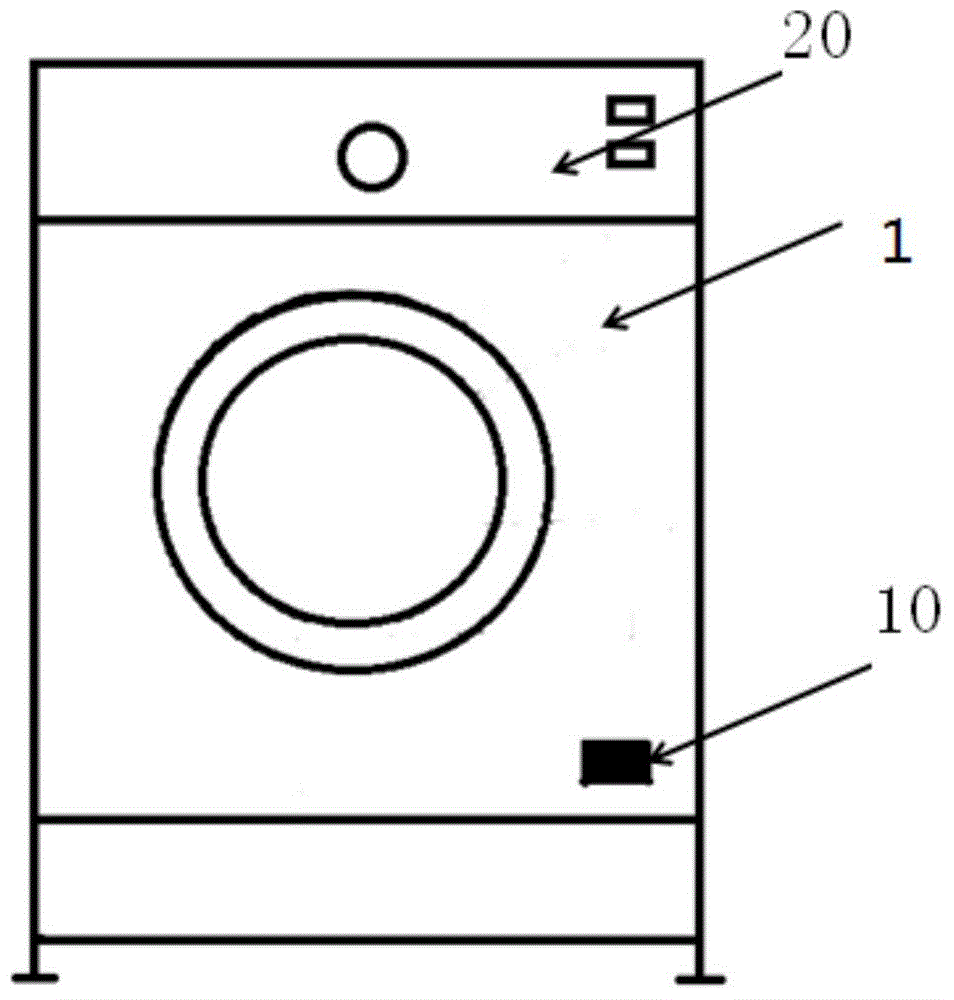

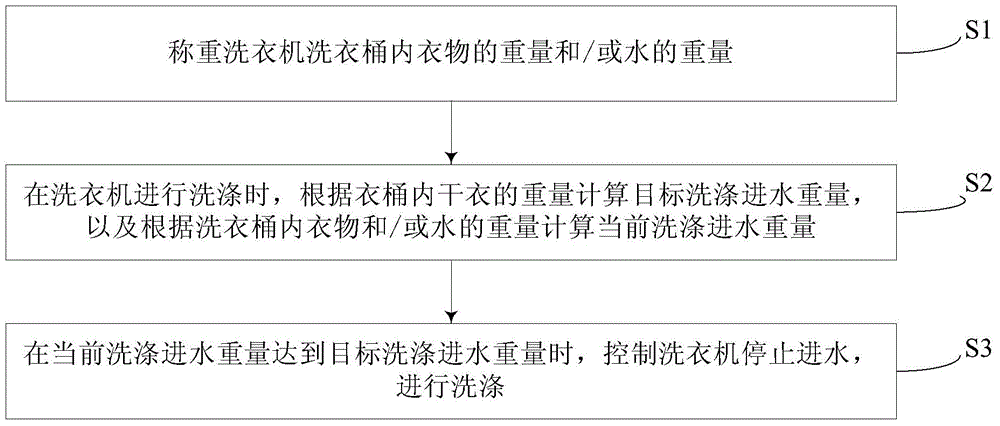

ActiveCN104975469AImprove weighing accuracyFulfil requirementsOther washing machinesControl devices for washing apparatusProcess engineeringWater level

The invention provides a washing machine and a control method thereof. The washing machine comprises at least one weighing sensor and a controller. The weighing sensors are used for obtaining the weight of clothes and / or water in a washing drum of the washing machine through weighing. When the washing machine performs washing, the controller calculates the weight of target washing inflow water according to the weight of dry clothes in the washing drum and calculates the weight of current washing inflow water according to the weight, obtained by the weighing sensors, of the clothes and / or water in the washing drum; when the weight of the current washing inflow water reaches the weight of the target washing inflow water, the controller controls the washing machine to stop water inflow. The washing machine can achieve accurate weighing, the water inflow can be controlled in washing or rinsing without water level detection, fuzzy prediction on dewatering time can be achieved, increasing user requirements can be met, and a foundation is laid for development of new functions of washing machines.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Integrated anti-cheating dynamic weighing method and system

ActiveCN104501930AImprove weighing accuracyEffectively judge cheating behaviorWeighing apparatus testing/calibrationSpecial purpose weighing apparatusEngineeringMechanical engineering

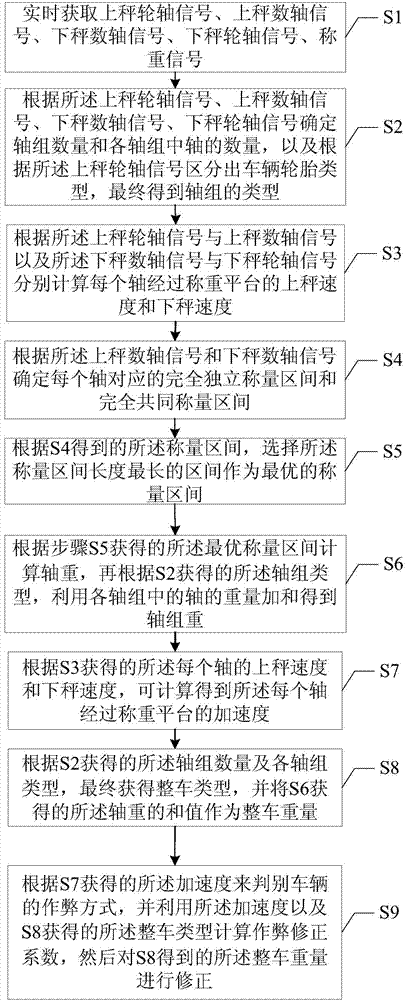

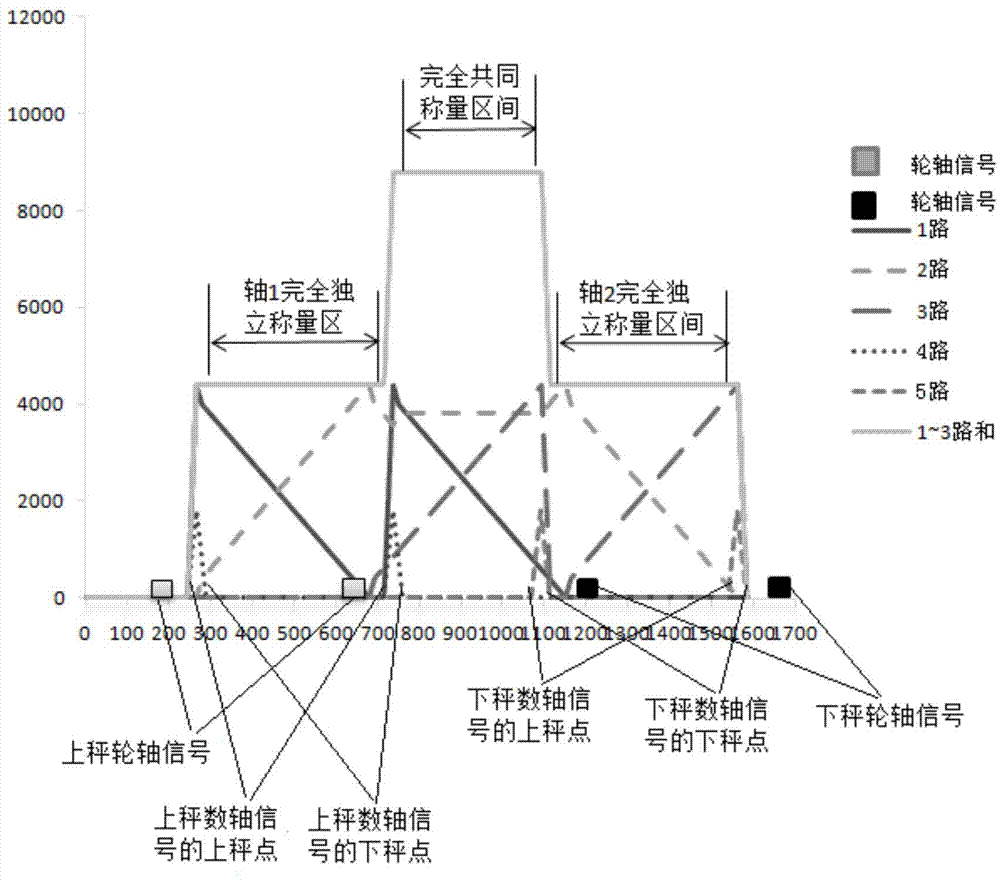

The invention discloses an integrated anti-cheating dynamic weighing method and an integrated anti-cheating dynamic weighing system, and relates to the field of dynamic weighing of vehicles. According to the method, a scale loading wheel axle signal, a scale loading number axis signal, a scale unloading number axis signal and a scale unloading wheel axle signal are received, and meanwhile, a scale loading wheel axle sensor, a scale loading number axis sensor, a scale unloading number axis sensor and a scale unloading wheel axle sensor are arranged, so that the scale loading speed, the scale unloading speed and the weighing platform passing acceleration of each axle of a vehicle can be accurately calculated, and the cheating behavior of the vehicle can be distinguished according to the acceleration; the scale loading wheel axle sensor, the scale loading number axis sensor, the scale unloading number axis sensor and the scale unloading wheel axle sensor are arranged, so that the type of an axle group can be accurately distinguished, and a basis can be provided for identifying the type of the whole vehicle; the cheating weight of the vehicle can be corrected by virtue of the acceleration and the type of the whole vehicle, so that the phenomenon of weight loss is avoided, and the irregular weighing behaviors of bouncing scale, scale dragging and the like are inhibited.

Owner:BEIJING WANJI TECH

Cross section integrated laser vision fixed weight cutting method for continuously cast bloom and weight fixing device

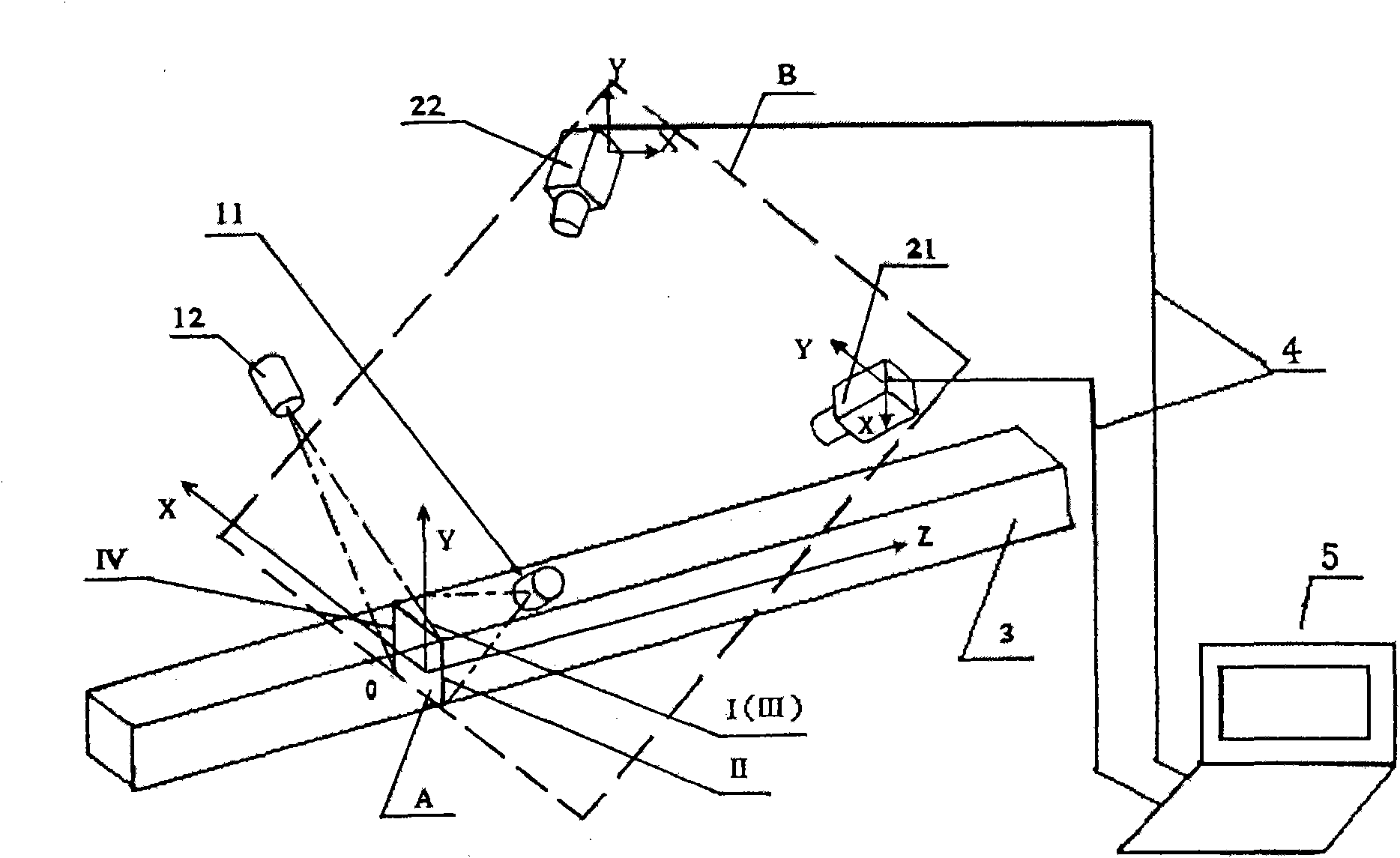

The invention discloses a cross section integrated laser vision fixed weight cutting method for a continuously cast bloom and a weight fixing device. Real-time integration of the cross section outline area of the continuously cast bloom in the continuously cast bloom conveying speed direction is realized by using a laser device, a camera and a computer installed with image processing and weight fixing software through a synchronous technology of a visual imaging system and a cutting system so as to realize real-time high-precision calculation of the cross section outline area of the continuously cast bloom; the conventional fixed scale cutting system technology is upgraded into a fixed weight cutting system technology so as to greatly improve the fixed weight precision of the continuouslycast bloom, reduce the reject rate of subsequent steel products and improve the production efficiency and the economic benefit; and the weight fixing device has simple composition and accurate calculation. The method is applied in a steel or iron smelting process, and realizes fixed weight cutting of the continuously cast bloom.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

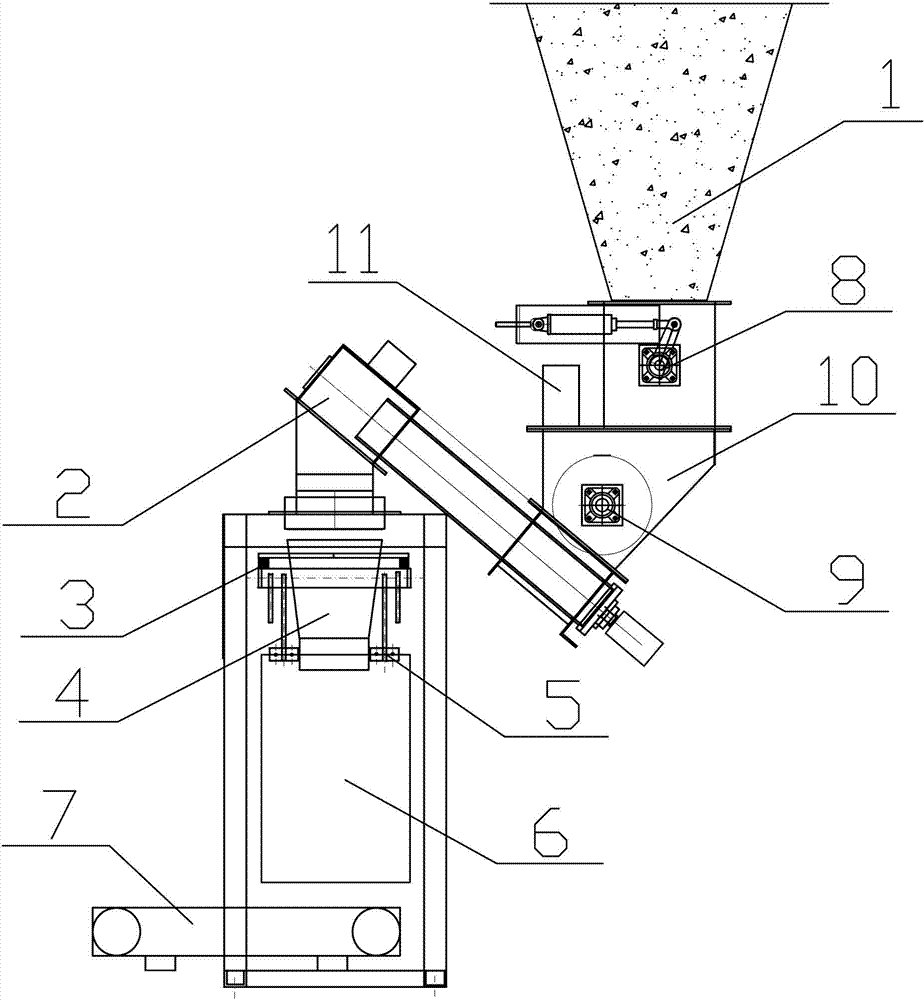

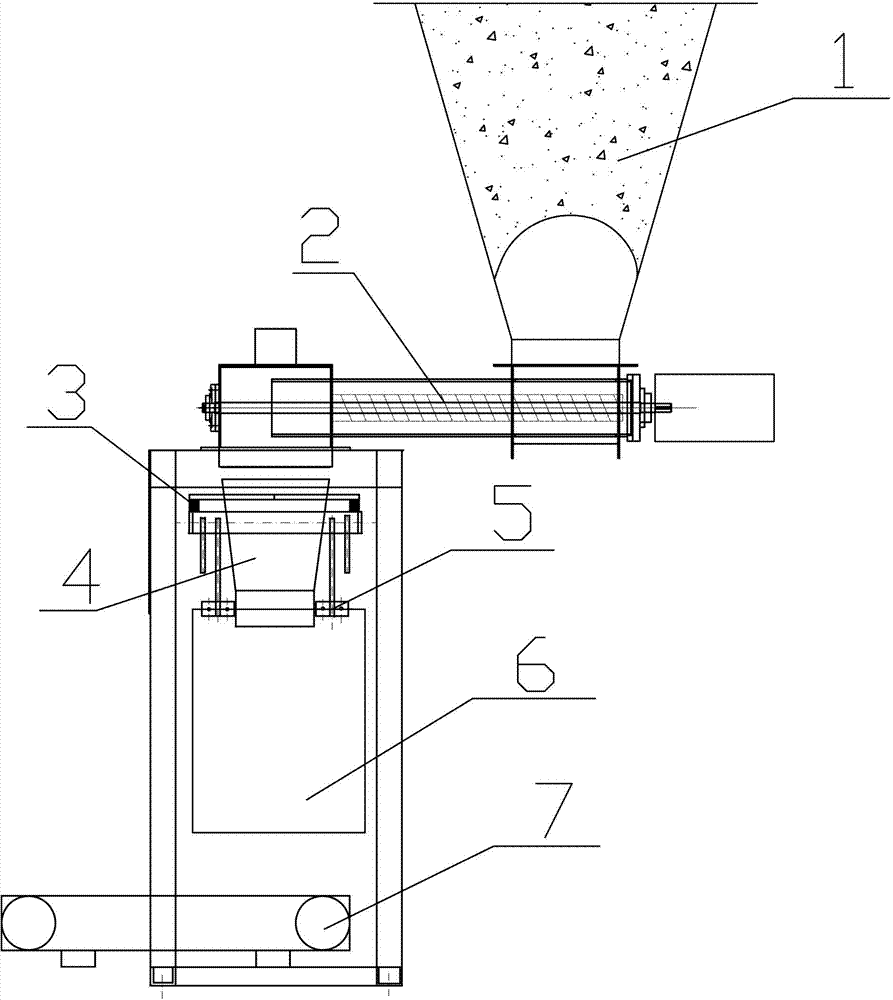

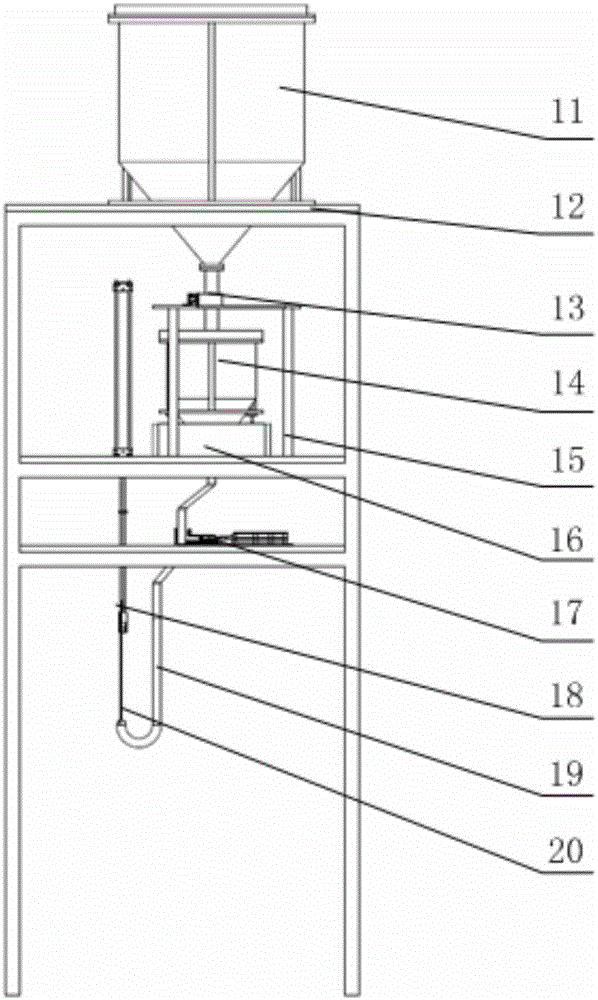

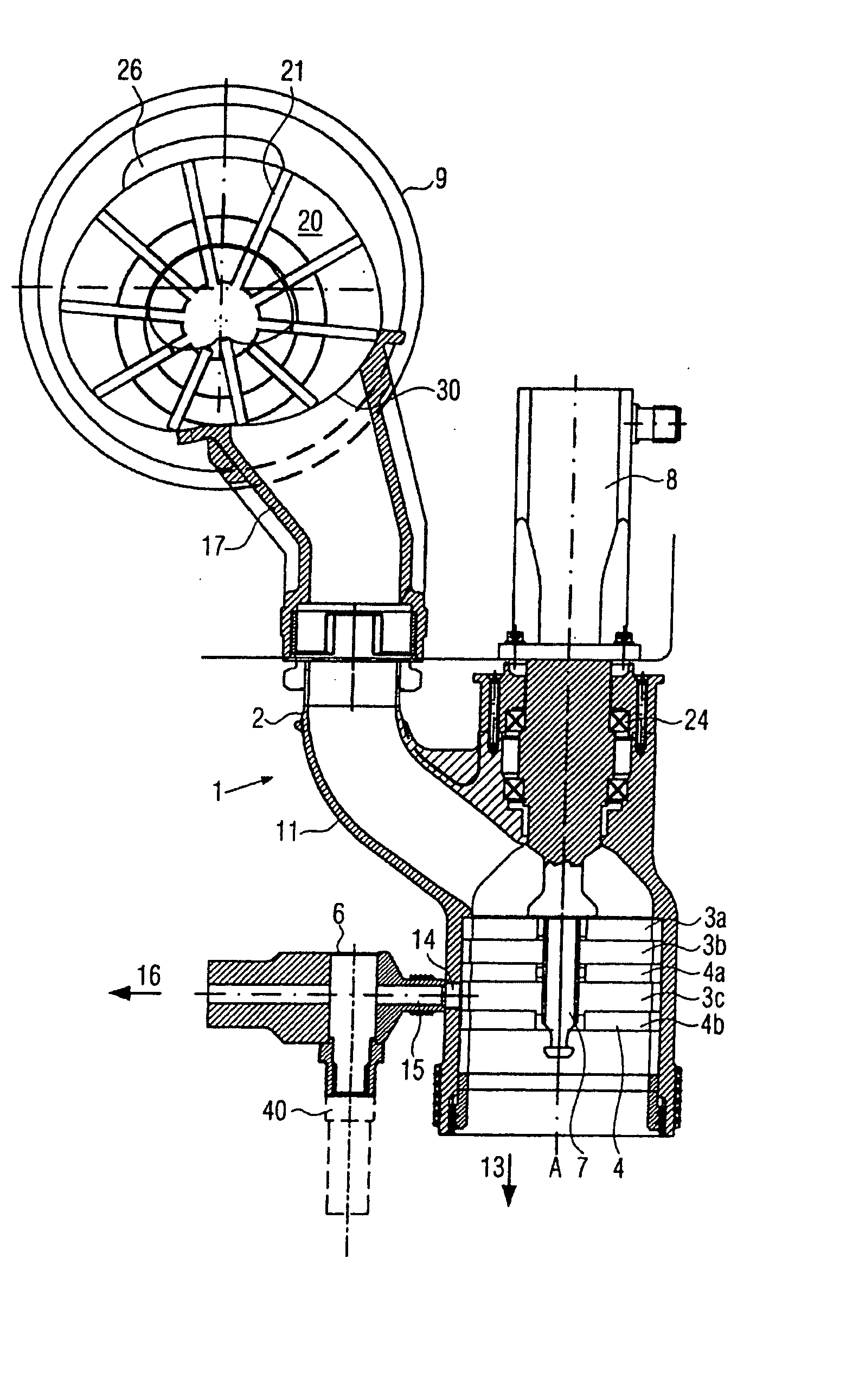

Precise packing scale for powdered materials

The invention discloses a precise packing scale for powdered materials. The precise packing scale comprises a finished product bin and a spiral feed device. An opening of the finished product bin is connected to the spiral feed device. The tail end of the spiral feed device is mounted on a support. A weighing sensor, a weigh bucket and a bag clamp are mounted on the support. The bag clamp clamps a packing bag. A belt conveyor is disposed below the packing bag. A lower opening of the finished product bin is connected with the upper portion of a stirring bin. The lower portion of the stirring pin is connected with the head of the spiral feed device. The tail of the spiral feed device is connected to the support. An outlet of the spiral feed device corresponds to the position of the weight bucket. The spiral feed device is mounted obliquely at a certain angle. The tail of the spiral feed device is higher than the head of the spiral feed device. A pneumatic baffle and a stirring device are disposed between the finished product bin the spiral feed device, powdered materials are more stable and smooth during delivering, no empty area exists, and accordingly weighing precision of the precise packing scale for powdered materials is improved greatly.

Owner:三维汉界机器(山东)股份有限公司

Double-loop-line intersected belt sorting machine, intersected belt sorting system and sorting method thereof

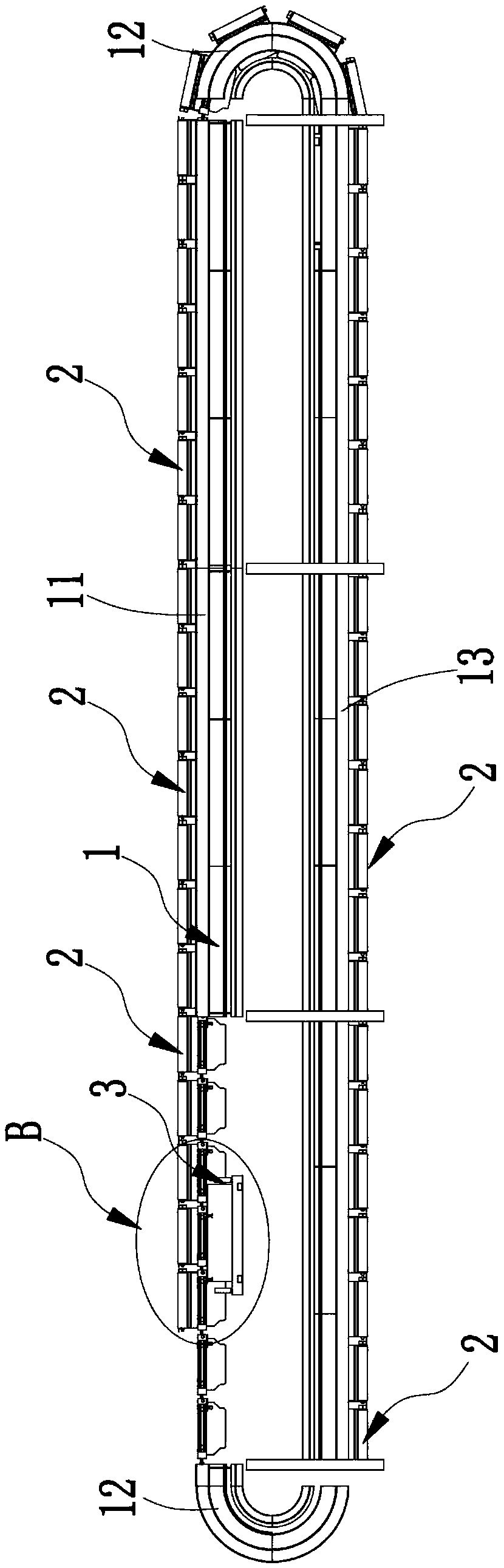

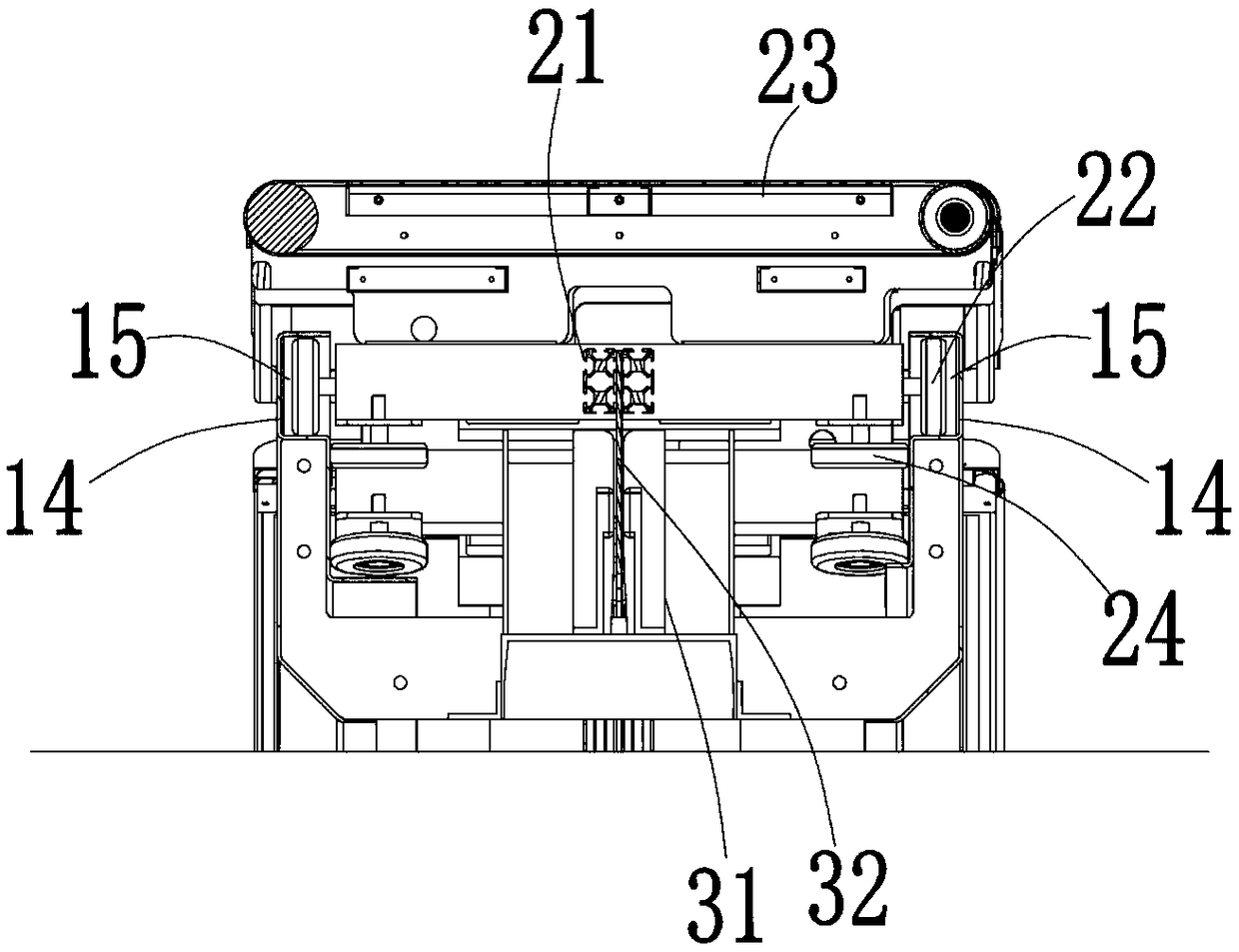

PendingCN109335538AReduce vacancy rateIncrease the number ofPackagingConveyor partsEngineeringMechanical engineering

The invention discloses a double-loop-line intersected belt sorting machine, an intersected belt sorting system and a sorting method thereof. The double-loop-line intersected belt sorting machine comprises at least one annular rail, two sets of intersected belt cars for forming two conveying loop lines circularly rotated on the annular rails side by side, and a power device for driving the two sets of intersected belt cars to move along the annular rails. The double-loop-line intersected belt sorting machine is delicate in design and simple in structure; as two sets of cars are used in one annular rail, the number of the intersected belt cars is increased by using internal space of the loop lines under the precondition of not increasing the floor area to multiply the sorting capacity, theuse efficiency of the sorting machine is improved, and the equipment cost is reduced; and meanwhile, parcels can be transferred between two conveying annular intersected belt cars, so that the idlingrate of the cars can be reduced, meanwhile, the parcel loading flexibility is improved, and the arrangement requirements and the occupied space of a particle loading line are reduced.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

Automatic weighing and boxing device for powder blasting supplies

InactiveCN105857756ARealization of automatic weighingRealize automatic unloadingSolid materialMechanical engineeringAutomatic testing

The invention discloses an automatic weighing and boxing device for powder blasting supplies. The automatic weighing and boxing device is composed of a roller conveying line, a feeding and weighing device, a vibration platform, an auxiliary device and a finished product packaging table. Part of the roller conveying line and the finished product packaging table are installed outside a semi-closed workshop. The roller conveying line is formed by sequentially connecting a plurality of roller conveyors in the conveying sequence. An explosion-proof motor and power chain wheel type rollers are adopted by the roller conveyors, and the roller conveyors are subjected to dust-proof treatment, so that automatic conveying of products is achieved. Weighing of materials and automatic filling of the materials are completed by the feeding and weighing device. The vibration platform is used for jolt-ramming of the materials, the number of gaps between the materials is reduced, and the materials are prevented from being piled up. The auxiliary device is used for pushing material boxes onto the vibration platform and pushing the material boxes off the vibration platform after the material boxes are filled with the materials. The finished product packaging table is used for product packaging. The automatic weighing and boxing device is provided with pneumatic elements, the explosion-proof structure design is adopted, and unmanned operation is achieved; and the automatic weighing and boxing device has the characteristics of being simple in structure, high in weighing precision and convenient and fast to operate.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

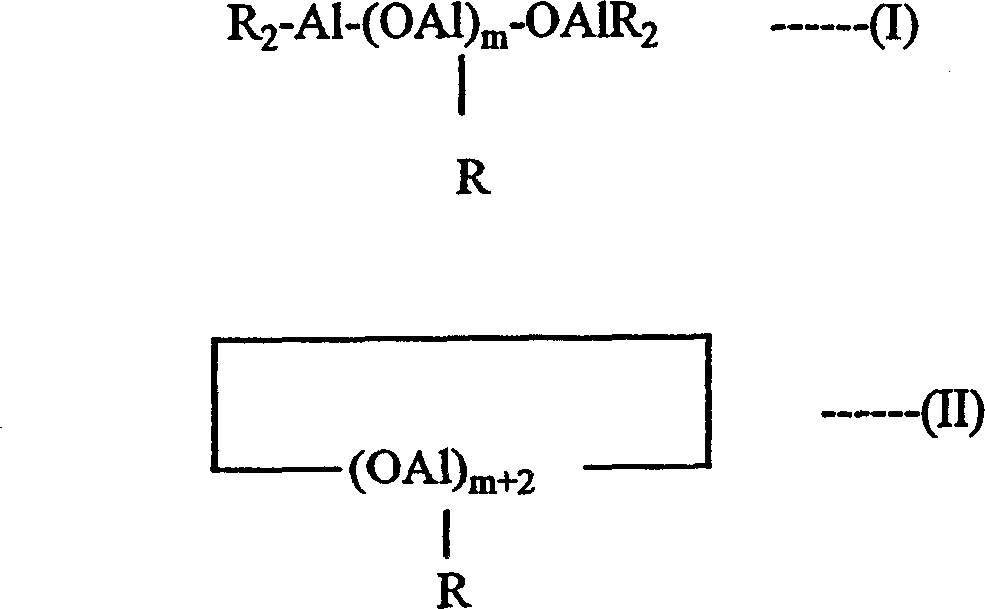

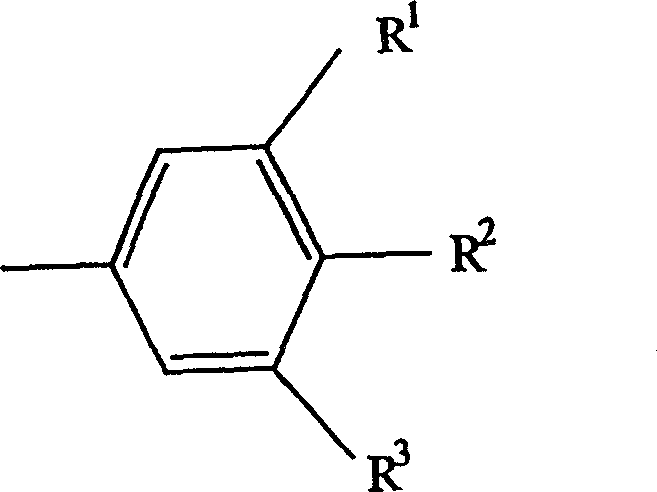

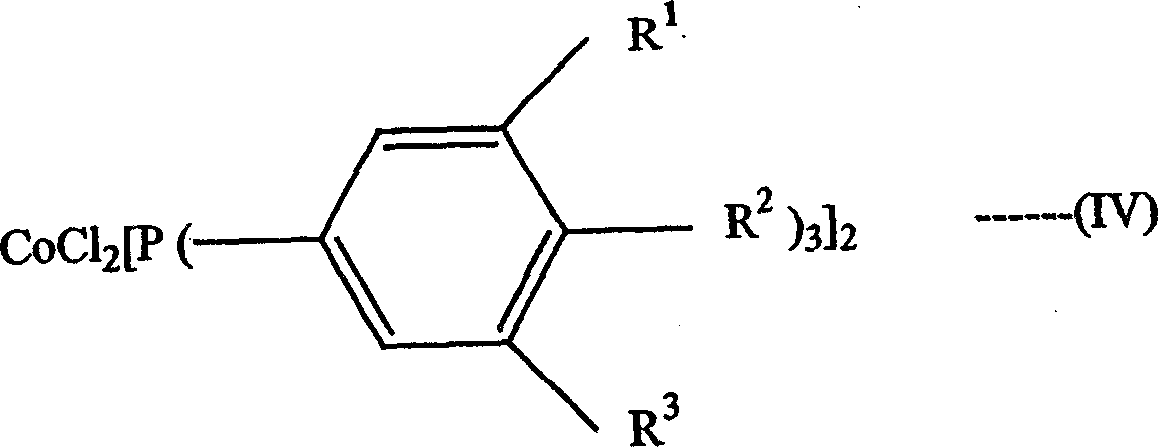

Oil extended 1,2-polybutadiene and method of manufacturing polybutadiene, and composition and formed product thereof

InactiveCN1511176AExcellent formabilityHigh mechanical strengthSynthetic resin layered productsHeelsFoaming agentWear resistance

Disclosed are oil-extended 1,2-polybutadiene containing an extender oil in a specific amount based on 1, 2-polybutadiene and a production method thereof, and a composition further containing another (co)polymer, a foaming agent, a crosslinking agent, a softening agent and other additives. The resulting oil-extended 1,2-polybutadiene and the composition thereof has excellent functions characterizing conventional 1,2-polybutadiene and is further excellent in wear resistance, fluidity (processability), coloring properties (high distinctness of images), flexibility, attachability and the like, so that they can be applied to various formed articles, shoe sole materials and laminate having high performances.

Owner:JSR CORPORATIOON

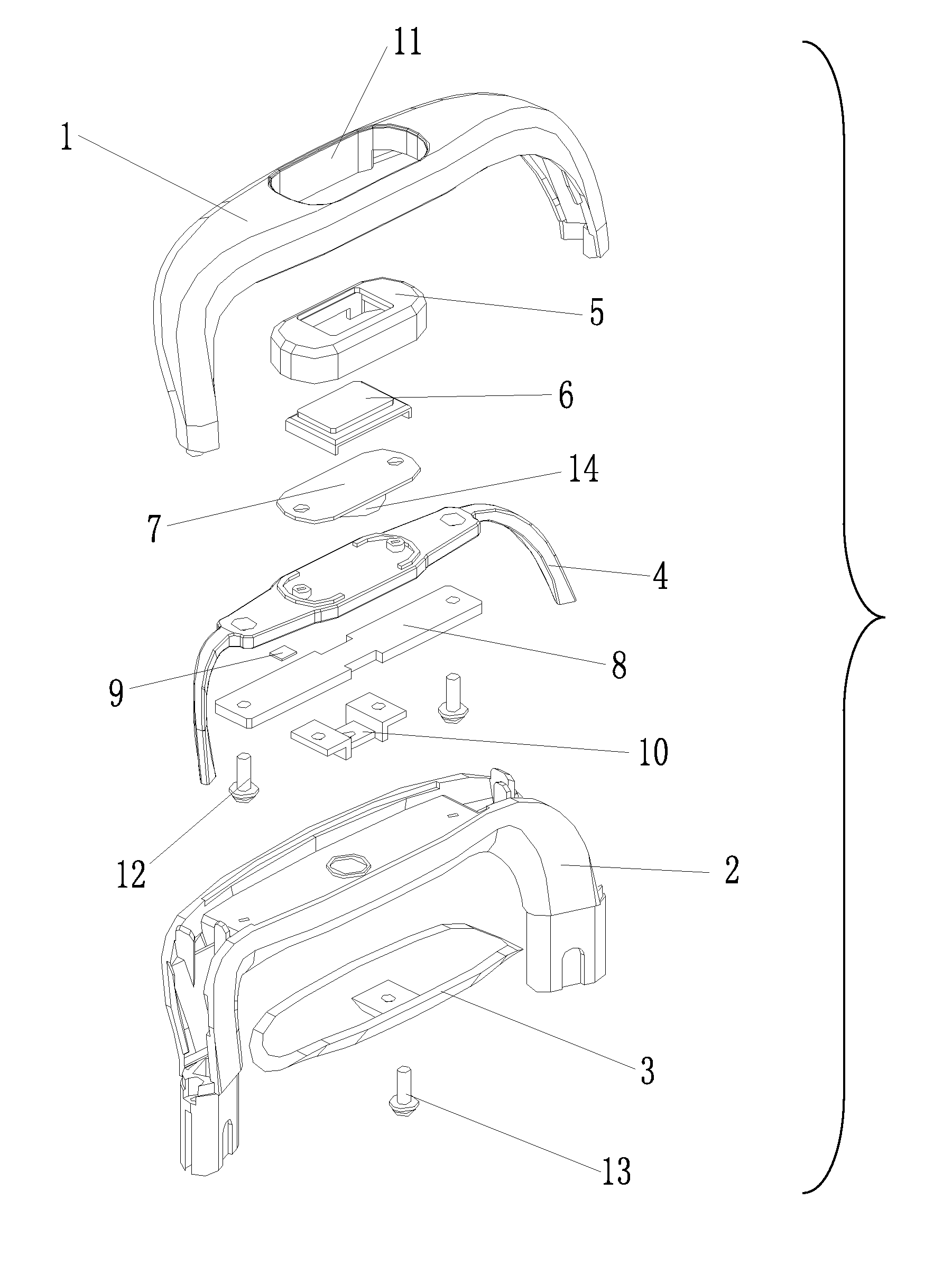

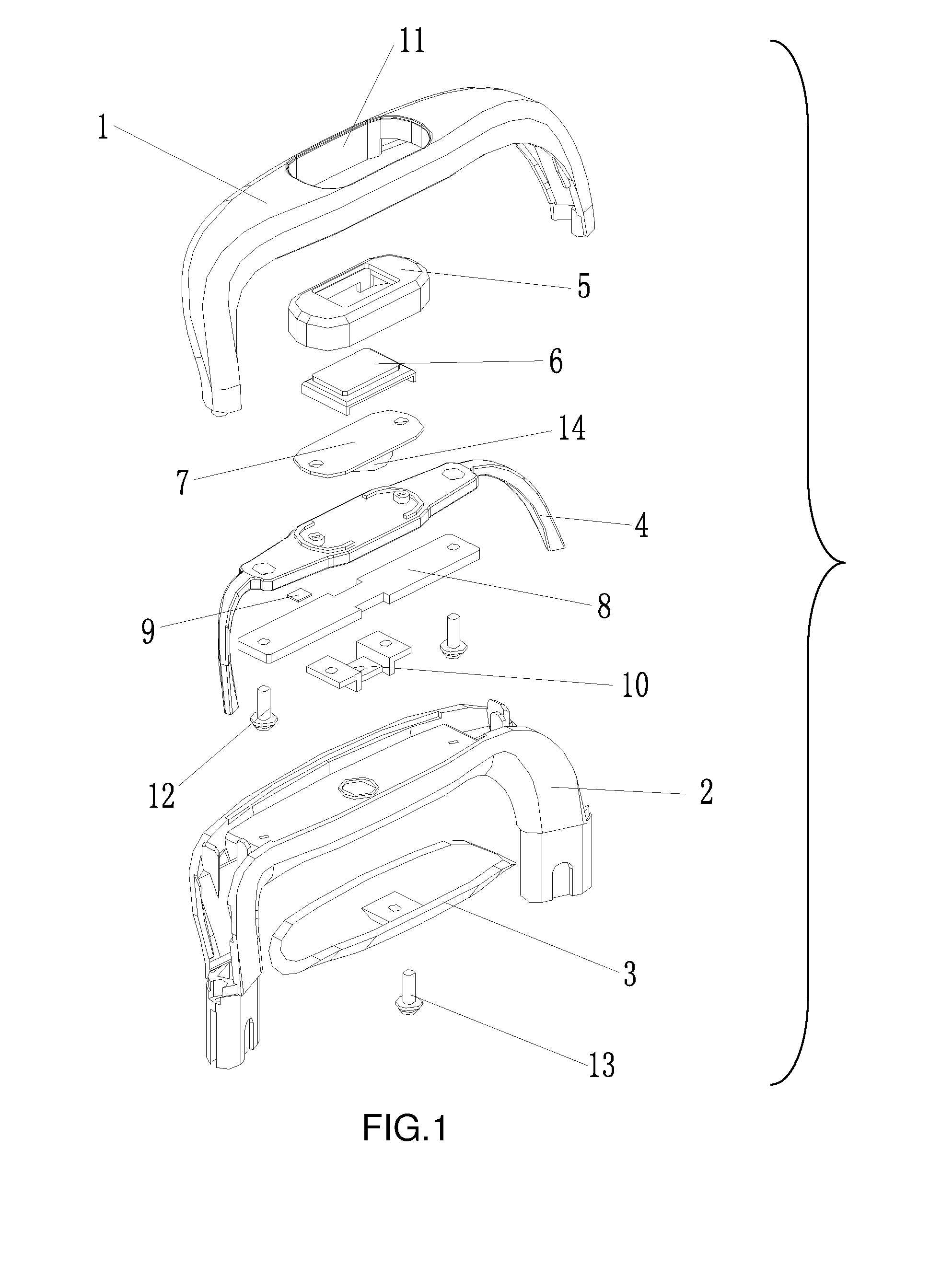

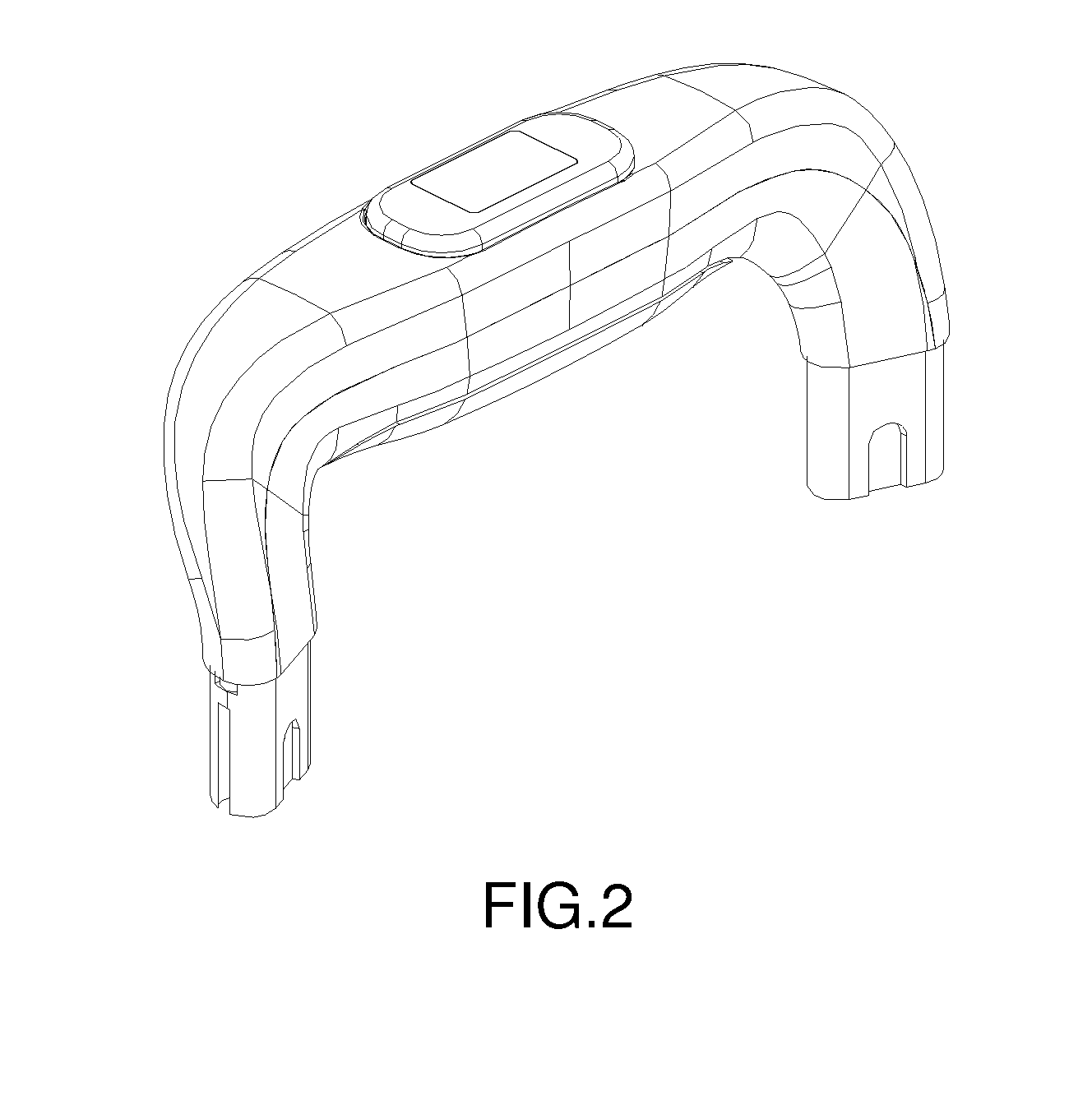

Case handle with weighing display

InactiveUS20120222904A1Accurate measurementSolution to short lifeOther accessoriesSpecial purpose weighing apparatusManganeseDisplay device

The present invention relates to a case candle, particularly relates to a case candle with weighing display, which includes a handle seat and a connection that is connected between the handle seat and case body, which is characterized in that, the handle seat has a manganese steel sheet inside, a bend sensor is fixed at the top of the manganese steel sheet, the bend sensor is connected to a PCB board, the PCB board is connected to battery and display respectively. The present invention with the above-mentioned structure, when the case is pulled, the manganese steel sheet makes blending deformation under force, the blend sensor permanently connected with the manganese steel sheet induces the deformation, and accurately measures the weight of the case body through pre-set parameters and calculate method, has advantages such as accurate weighing, long life and so on.

Owner:LANGKE PLASTIC SHENZHEN

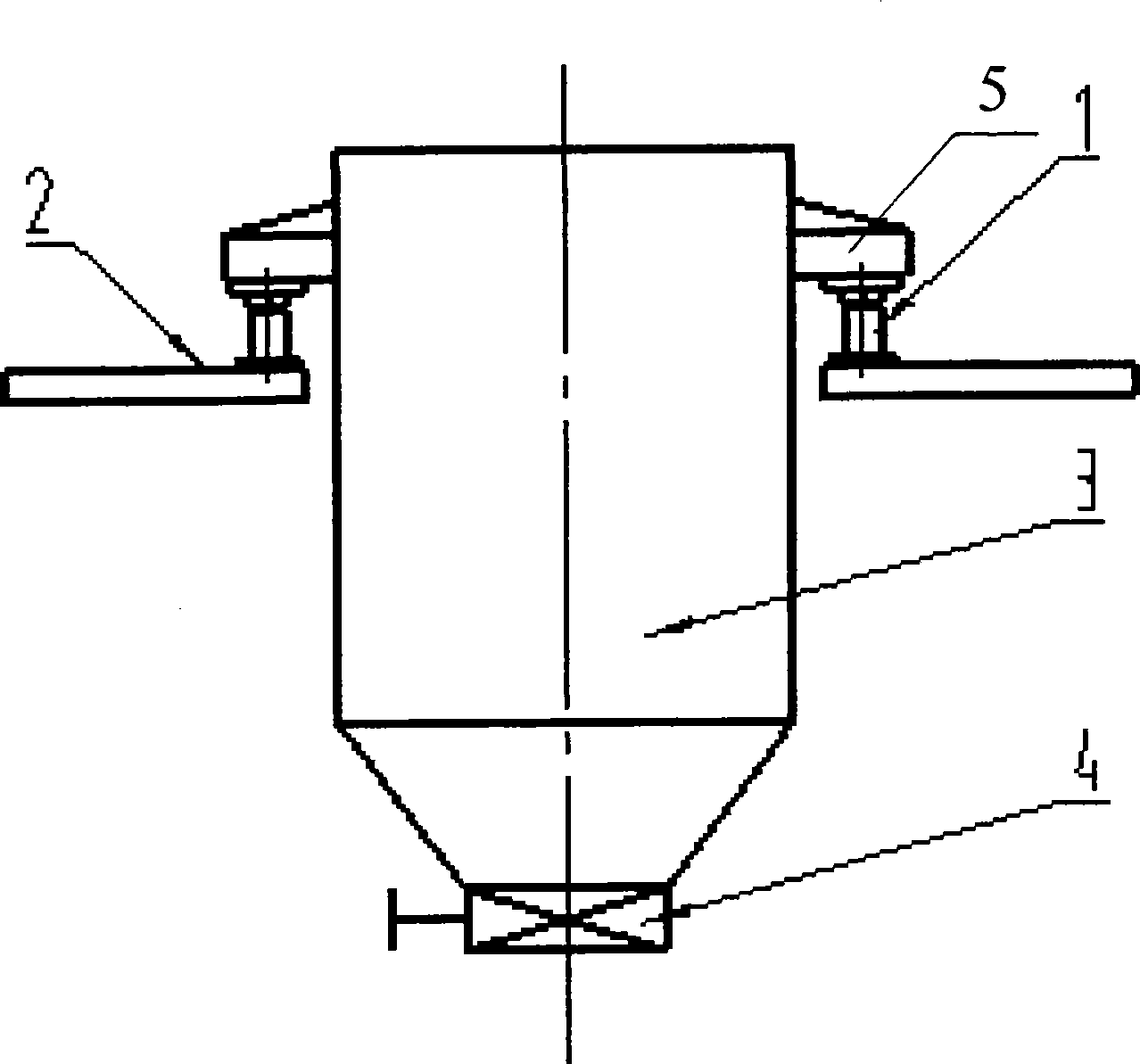

Large tonnage material level electronic scale and correcting method of weigh without counter poise

ActiveCN101363750ASimple structureEasy to installWeighing apparatus testing/calibrationWeighing apparatus for materials with special property/formCorrection methodCost performance

The invention relates to a large-tonnage level electronic scale and a non-weight weighing correction method. The electronic scale body is provided with a charging barrel bin, and four or more uniformly distributed support bearing lug seats. A weighing sensor with a cylindrical structure is installed below each support bearing lug seat; the weighing sensor is installed on a base; a spherical surface is formed on the upper end of the weighing sensor and connected with a pressure with an end surface being an concave spherical surfaced; an upper press plate and a lower press plate are connected with the scale body and the base; an adjusting shim is placed on the upper loaded press plate so as to adjust the installation height of each sensor. The non-weight weighing connection method is suitable for the weighing correction of a plurality of resistance strain sheet type weighing sensors in parallel connection, and comprises the steps of calculating an output signal value of a weighing sensor, figuring out a consistent correction coefficient of a weighing instrument and working out the correction efficient of the weighing instrument. The invention has the advantages of simple structure, convenient installation, high weighing precision, great cost performance and convenient weighing correction.

Owner:YUYAO PACIFIC WEIGHING ENG

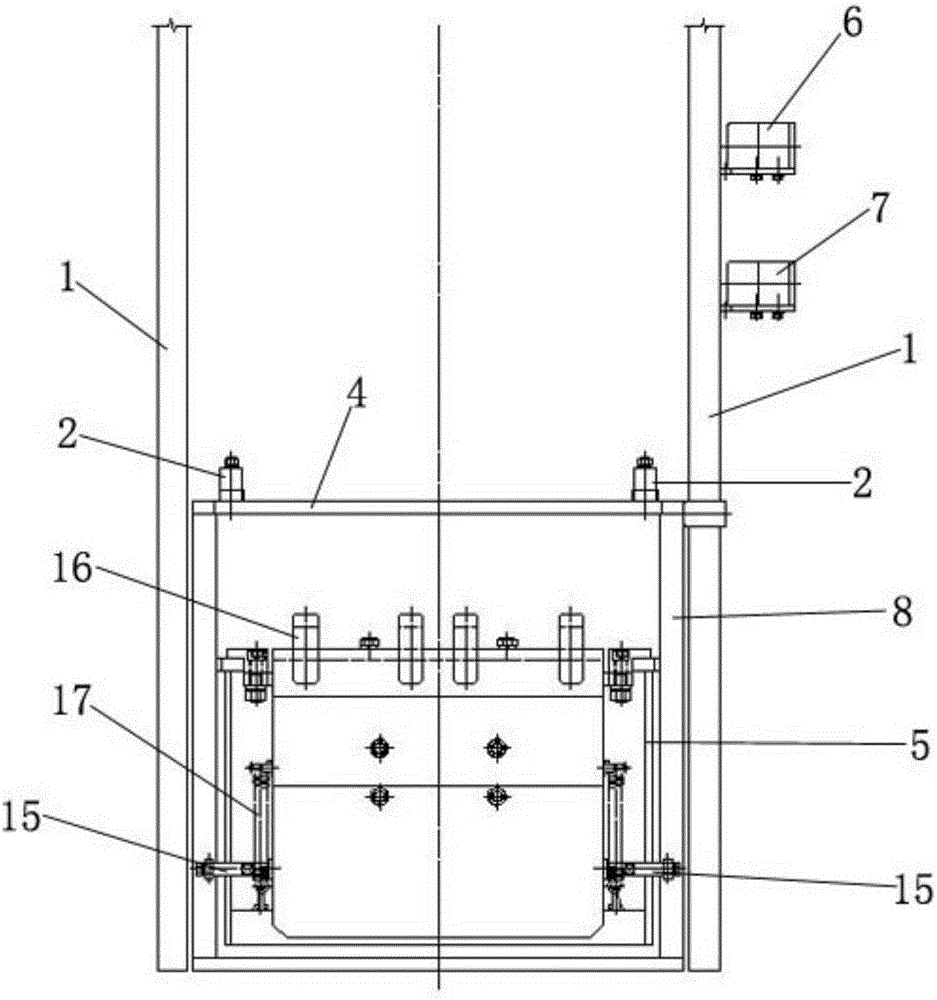

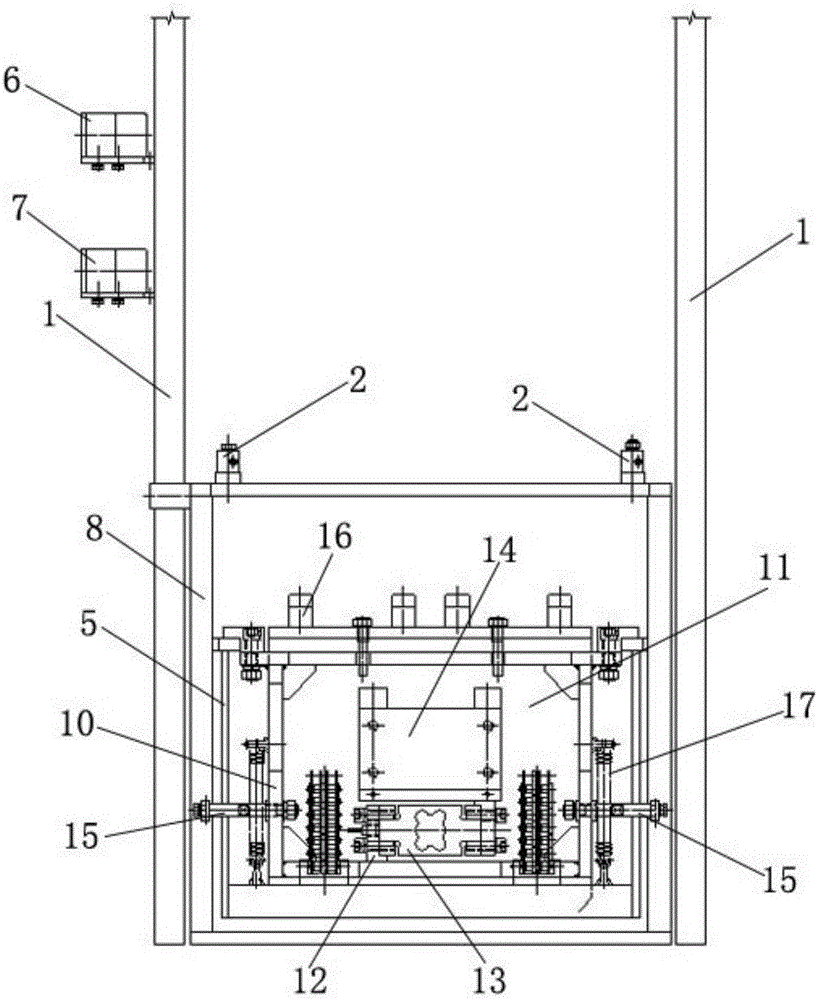

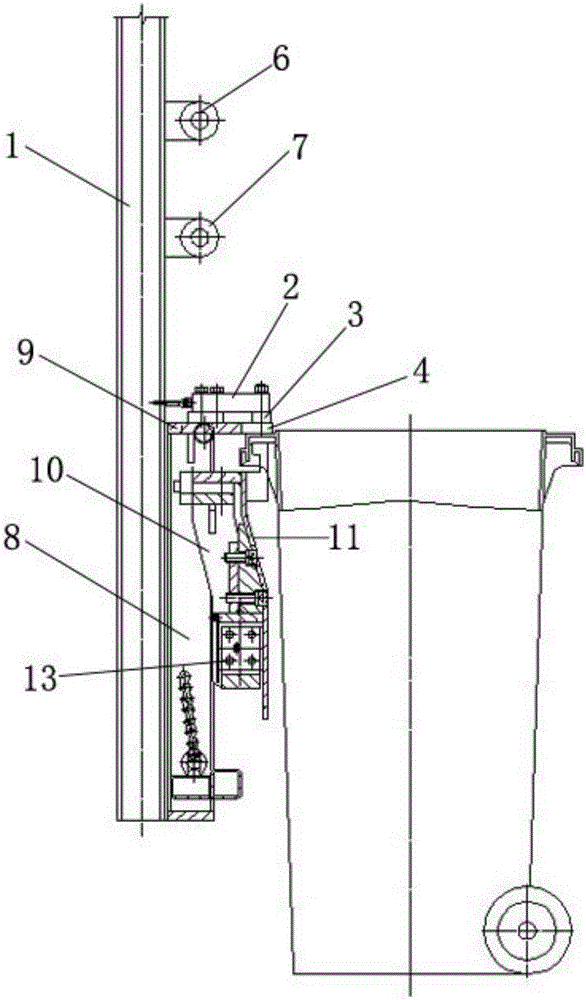

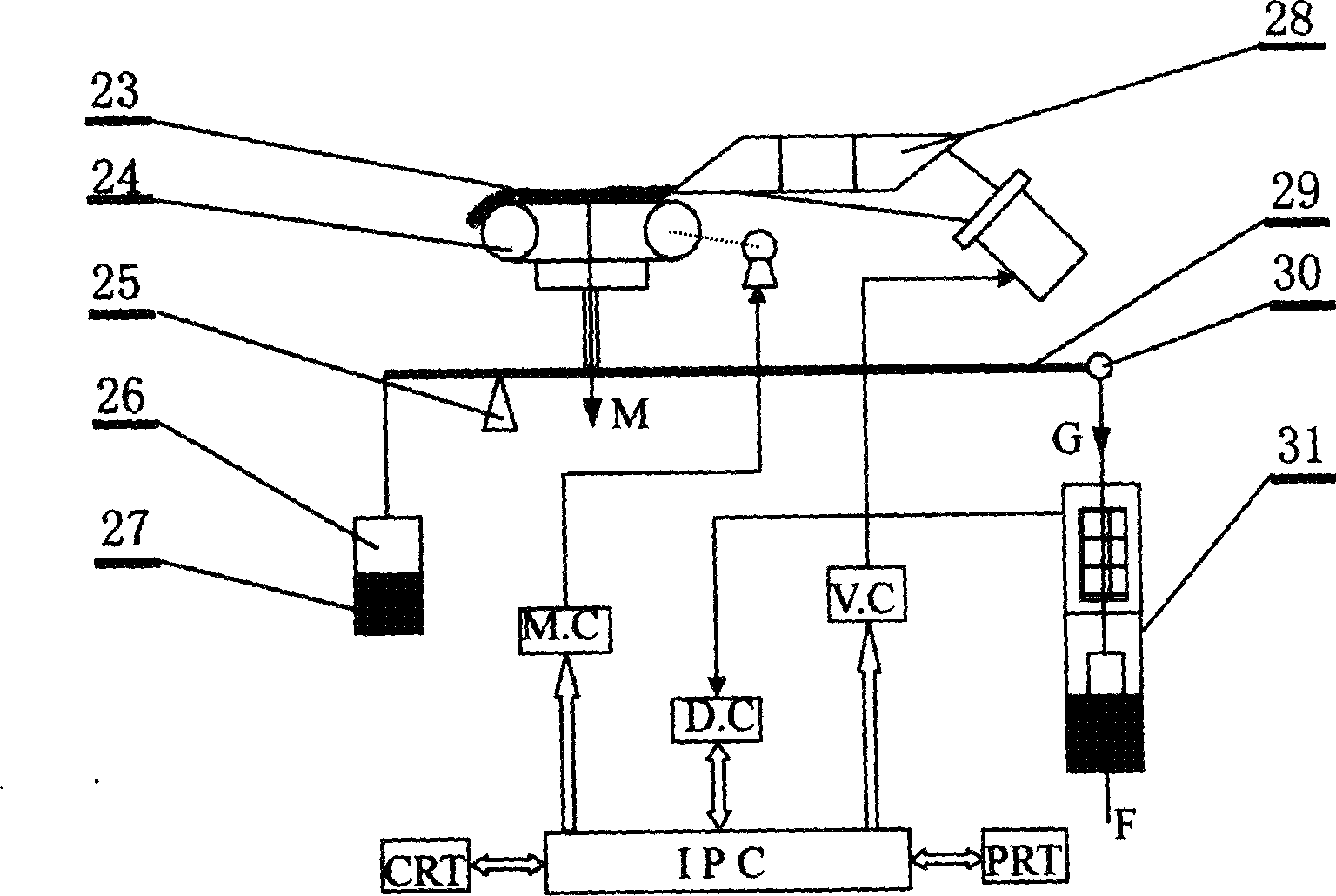

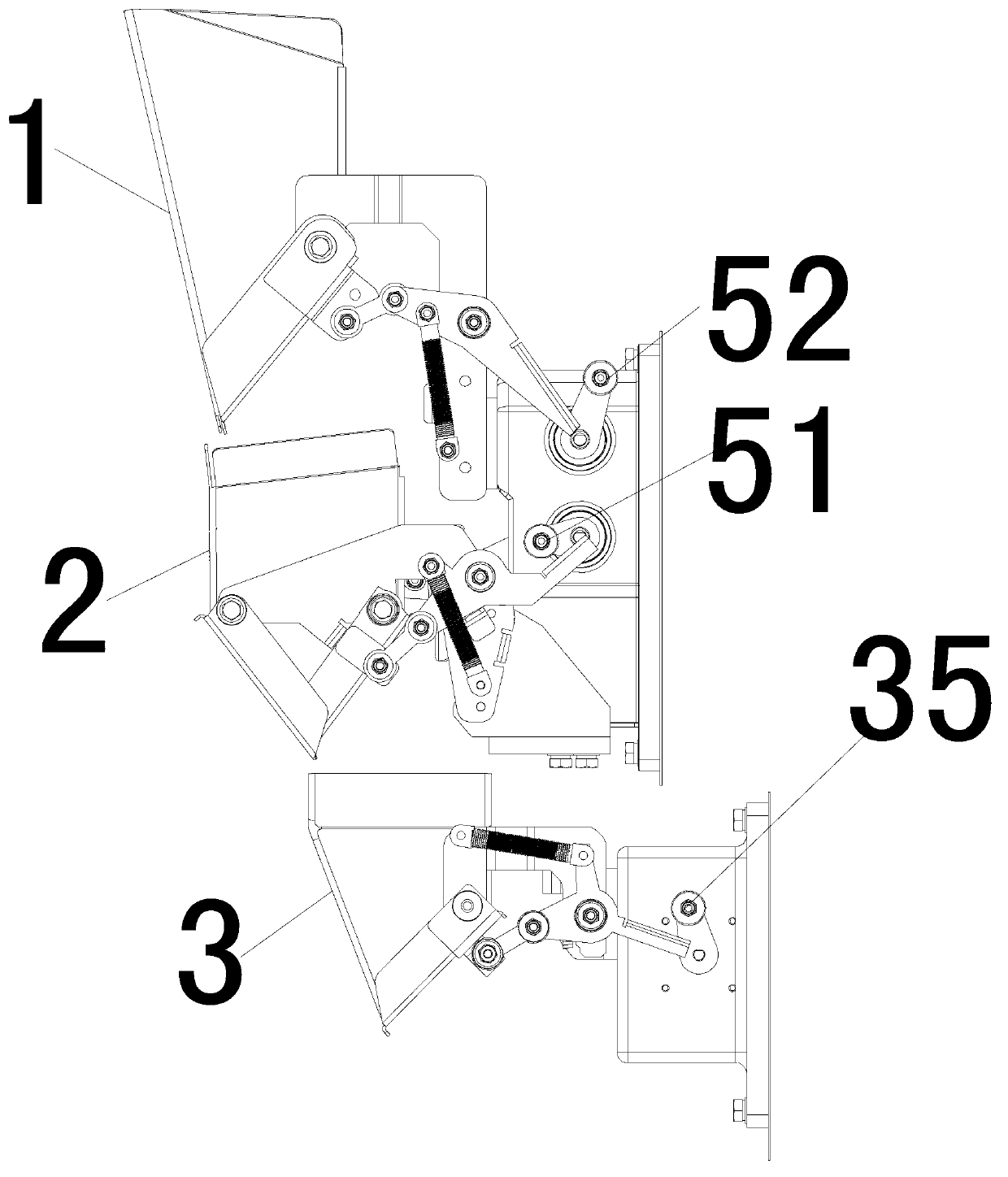

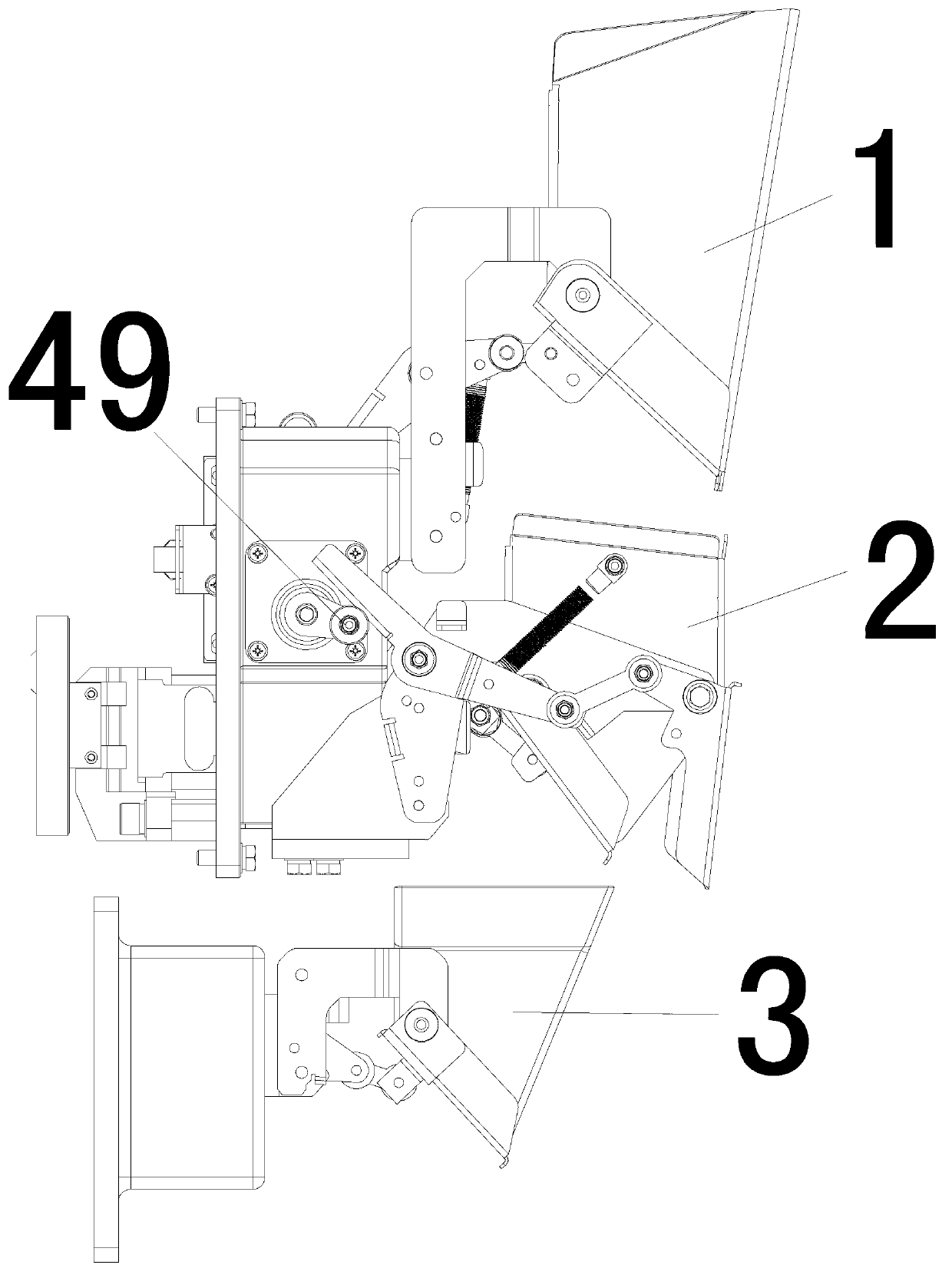

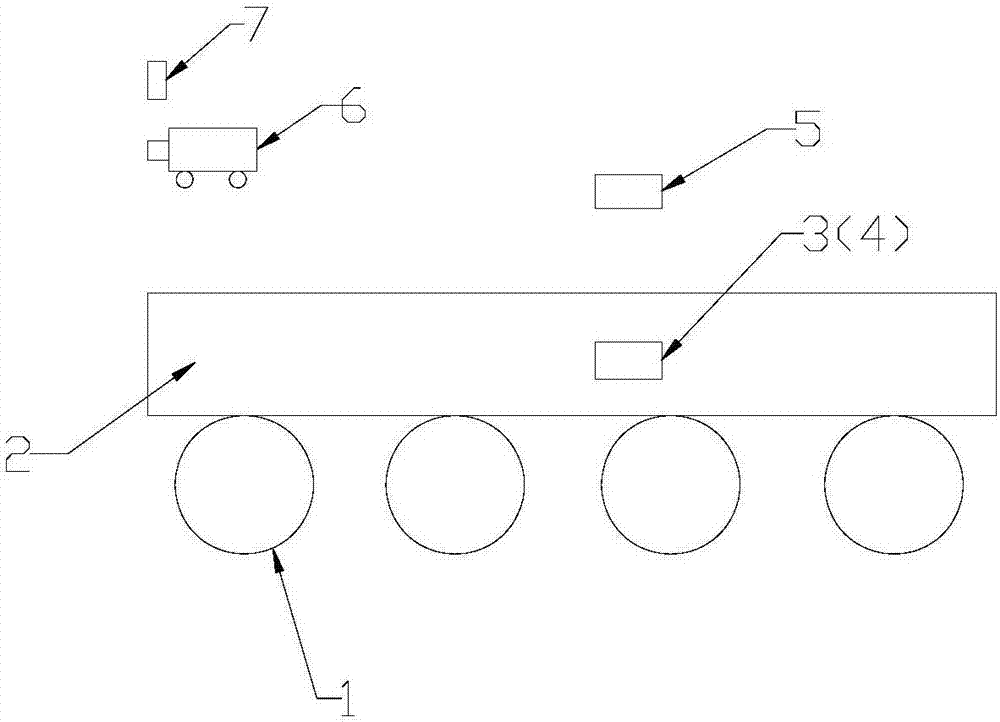

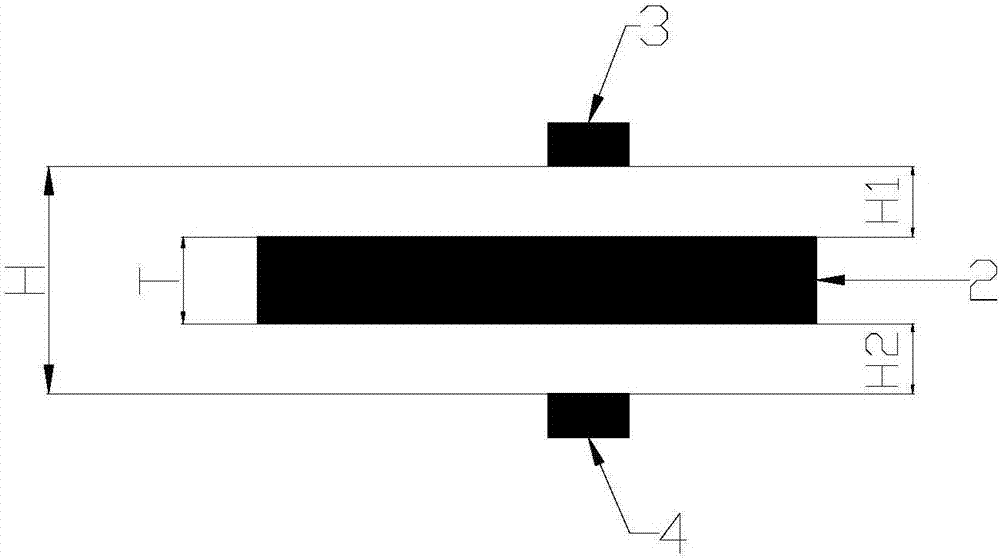

Dynamic automatic weighing system of kitchen garbage vehicle

ActiveCN105021267AIncrease weighing pressure dynamic performance compensation designImprove weighing accuracySpecial purpose weighing apparatusMechanical engineeringOn the fly

The invention discloses a dynamic automatic weighing system of a kitchen garbage vehicle. The dynamic automatic weighing system comprises a lifting track, a turnover mechanism, a lifting rack, a weighing mechanism, a pressure compensation mechanism and a data control device; and the lifting track is assembled on a garbage vehicle body, the turnover mechanism can longitudinally be turned over and movably installed on the lifting track in the vertical direction, the lifting track is fixedly installed on the turnover mechanism, the weighing mechanism is movably installed on the lifting rack in the vertical direction, the upper end of the turnover mechanism is provided with the pressure compensation mechanism, the barrel pressing force compensation mechanism comprises a barrel pressing force compensation sensor, a force transmission connector and a barrel pressing plate, the barrel pressing plate is connected below the barrel pressing force compensation sensor through the force transmission connector, signals of the weighing mechanism and the barrel pressing force compensation mechanism are output to the data control device, and then garbage weight operation is performed. The system needs no manual operation in the whole process, is provided with the dynamic weighing barrel pressing force compensation structure, satisfies a good dynamic weighing performance requirement, and has the advantage of high weighing precision.

Owner:HANGZHOU SIFANG ELECTRONICS WEIGHING APP FACTORY

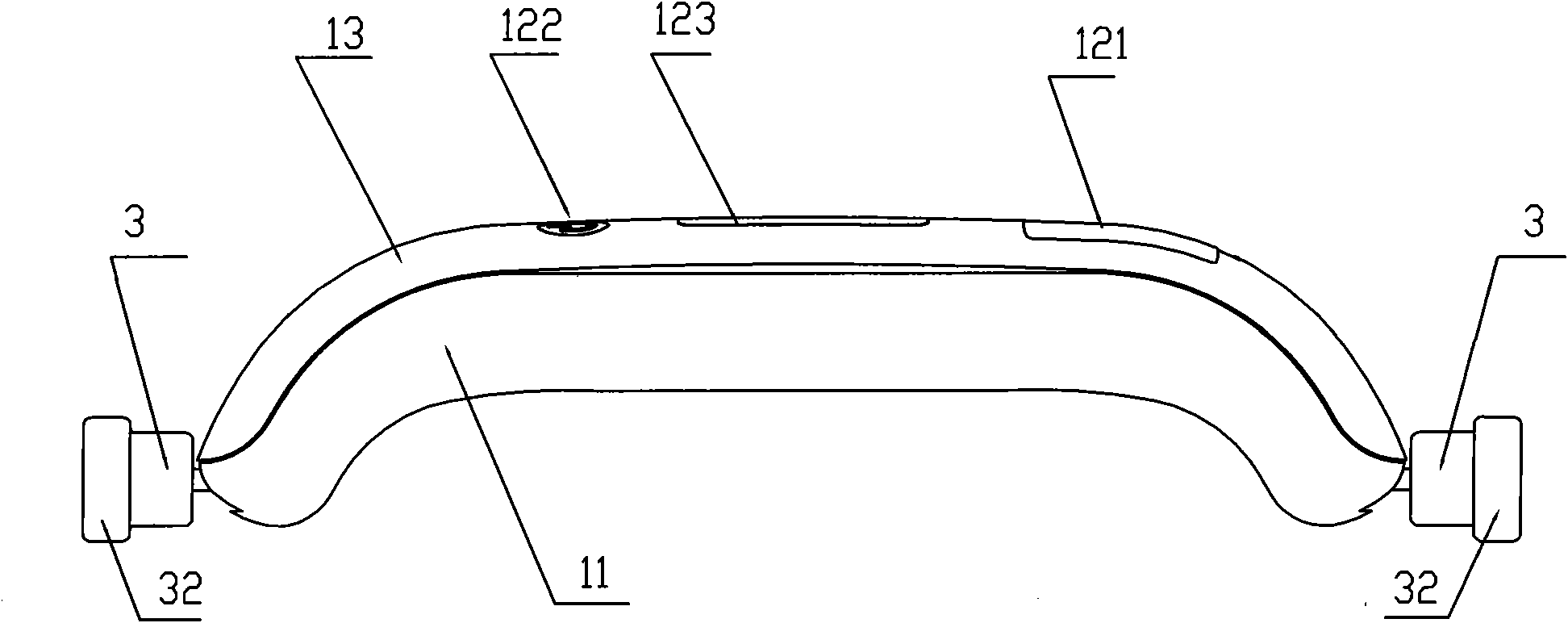

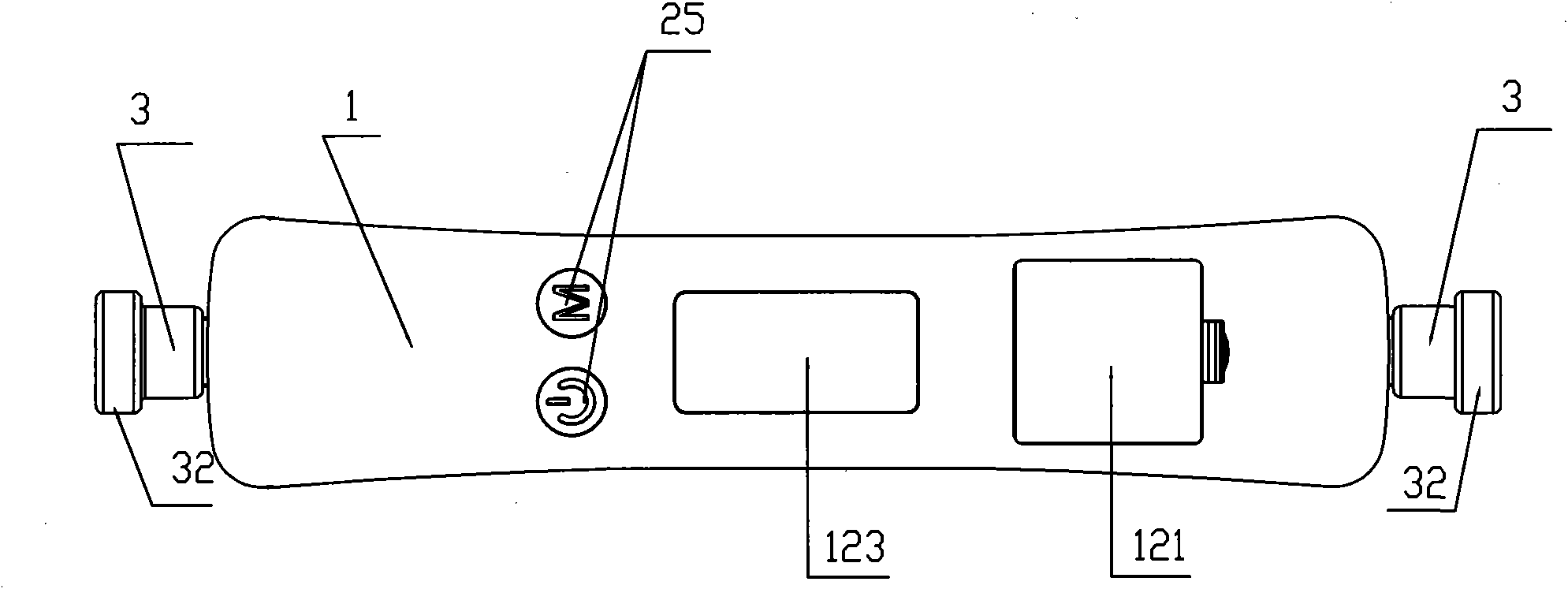

Lifting handle with weighing function

InactiveCN101773330AReasonable structureSimple structureOther accessoriesSpecial purpose weighing apparatusEngineeringManufacturing cost reduction

The invention discloses a case and bag lifting handle with the weighing function, which comprises a lifting handle body, a function switch and a display screen, wherein the lifting handle body consists of a handle bottom cover and a handle upper cover and is provided with a handle cavity, a battery compartment is arranged in the lifting handle body, the function switch and the display screen are arranged on the lifting handle body. The invention is characterized in that a weighing sensor connected with the display screen and the function switch which are arranged on the lifting handle body is arranged in the handle cavity, the weighing sensor is provided with two symmetrical loading ends, and the two symmetrical loading ends are both connected with case and bag connecting elements and respectively extend out from cavity openings at both ends of the lifting handle body. The invention adopts one sensor, the structure is reasonably simplified and becomes compact, the operation is more convenient, in addition, the invention has the characteristic of high weighing accuracy, and at the same time, the manufacture cost is reduced. The connecting elements of both ends of the lifting handle can be designed to present a hinging connection mode according to the characteristics of cases and bags, so the lifting handle arranged on the cases and the bags can vertically stand and can also be folded, and the lifting function of the invention is completely equal to that of the existing case and bag lifting handle.

Owner:SHENZHEN LANTER ELECTRONICS CO LTD

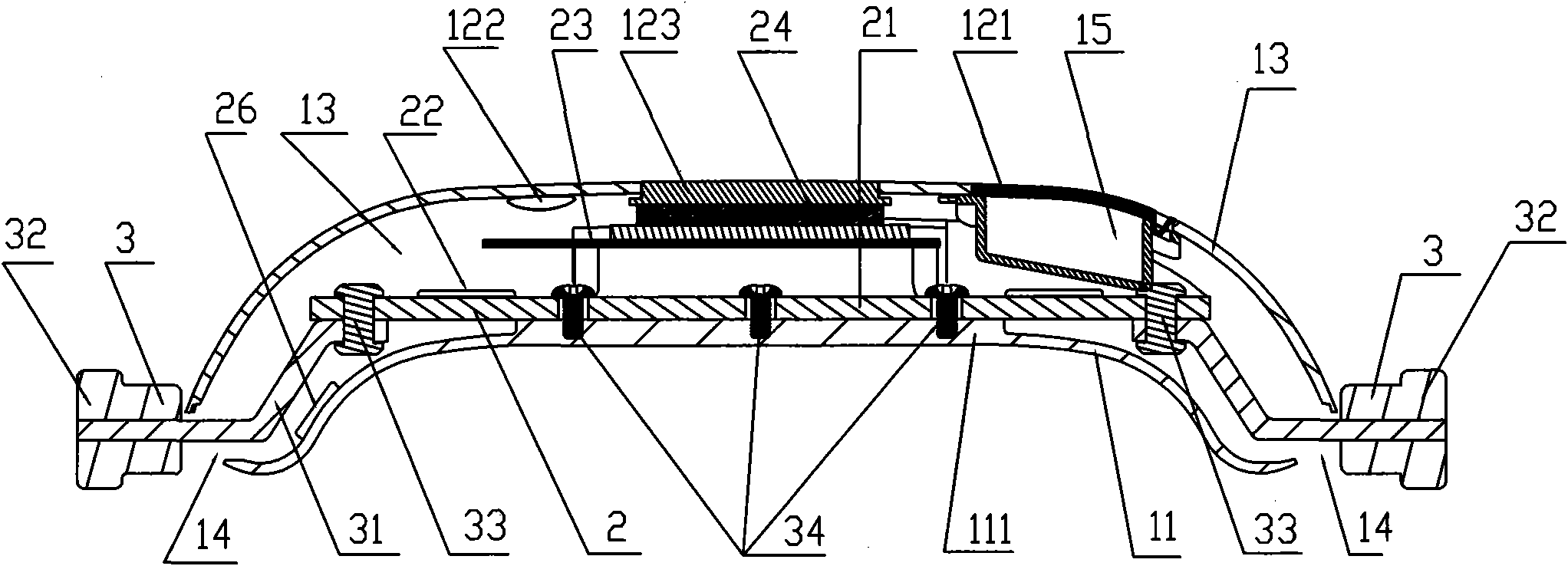

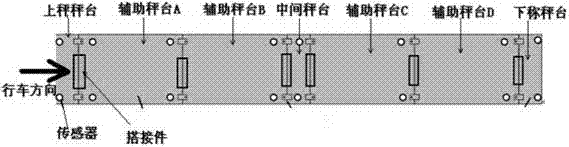

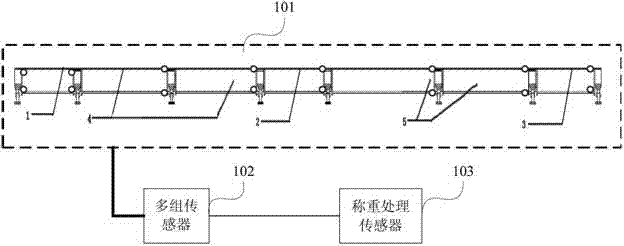

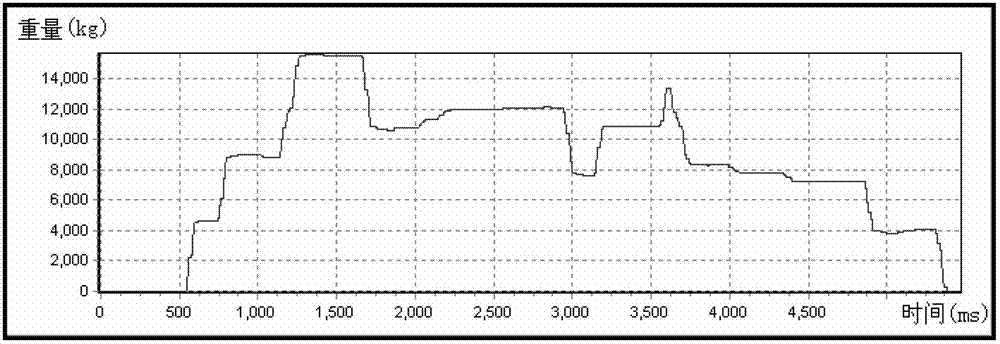

Dynamic complete-vehicle-type automatic weighing system and method

ActiveCN102759393AImprove weighing accuracyWeighing apparatus detailsSpecial purpose weighing apparatusEngineeringLoad cell

The invention discloses a dynamic complete-vehicle-type automatic weighing system which comprises an upper weigh platform, a middle weigh platform, a lower weigh platform, a plurality of auxiliary weigh platforms, multiple sets of weighing sensors and a weighing data processor, wherein the plurality of auxiliary weigh platforms are arranged among the upper weigh platform, the middle weigh platform and the lower weigh platform, and the weigh platforms are used for bearing driving weighed vehicles; the upper weigh platform, some of the plurality of auxiliary weigh platforms, the middle weigh platform, the rest of the plurality of auxiliary weigh platforms, and the lower weigh platform are sequentially arranged along the travelling direction, the upper weigh platform is used for computing the number of axles of the weighted vehicle in the process of being put on the weight, the lower weigh platform is used for computing the number of axles of the weighted vehicle in the process of leaving the weight, and the middle weigh platform is used for separating the vehicles on the weigh platform; the multiple sets of weighing sensors are respectively arranged on the upper weigh platform, the middle weigh platform and the lower weigh platform and the plurality of auxiliary weigh platforms, and used for acquiring axle load signals of each axle of the weighted vehicle; and the weighing data processor is used for receiving the axle load signals, and generating axle load data and axle driving state data of the weighted vehicles according to the axle load signals.

Owner:BEIJING WANJI TECH

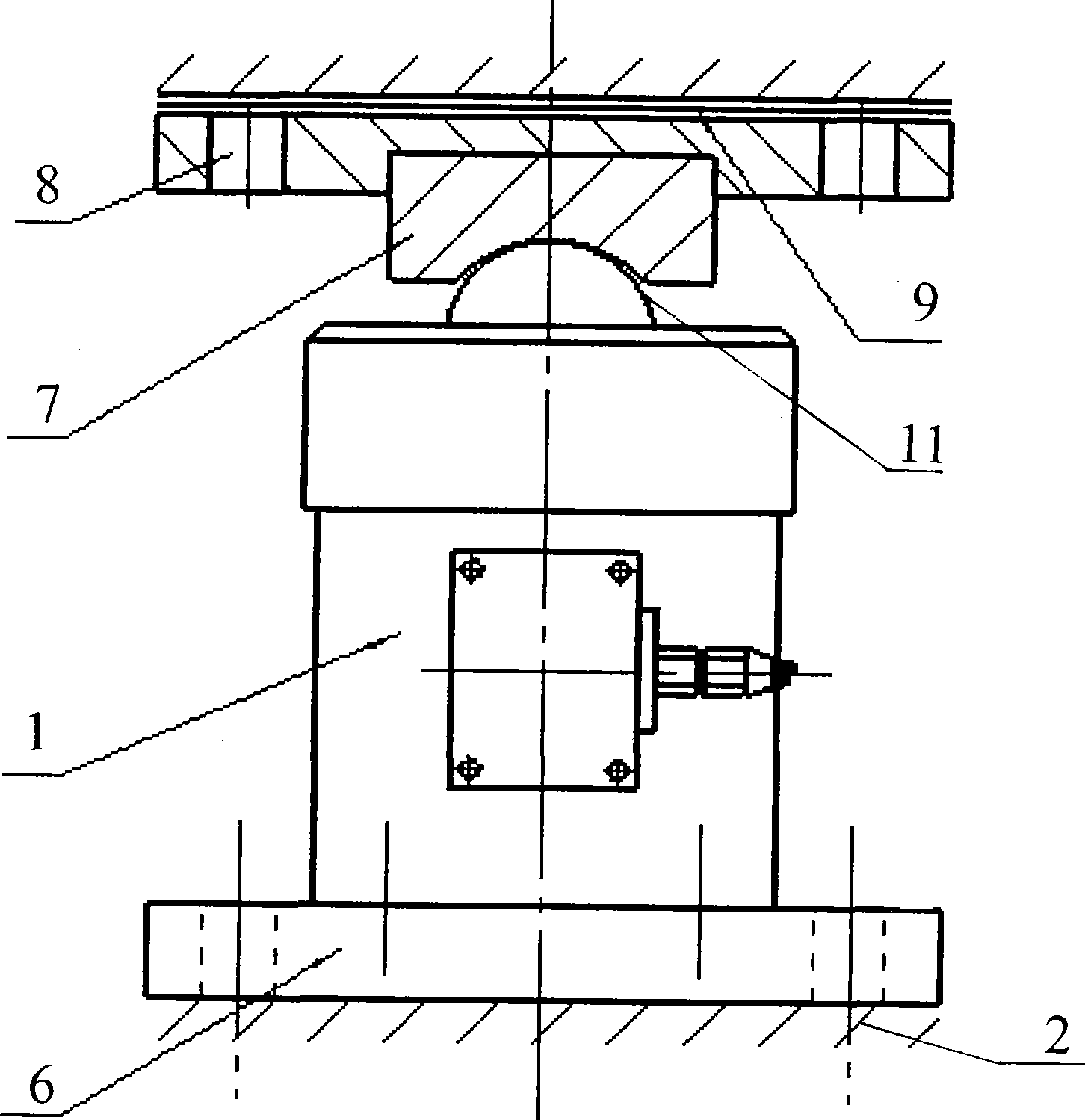

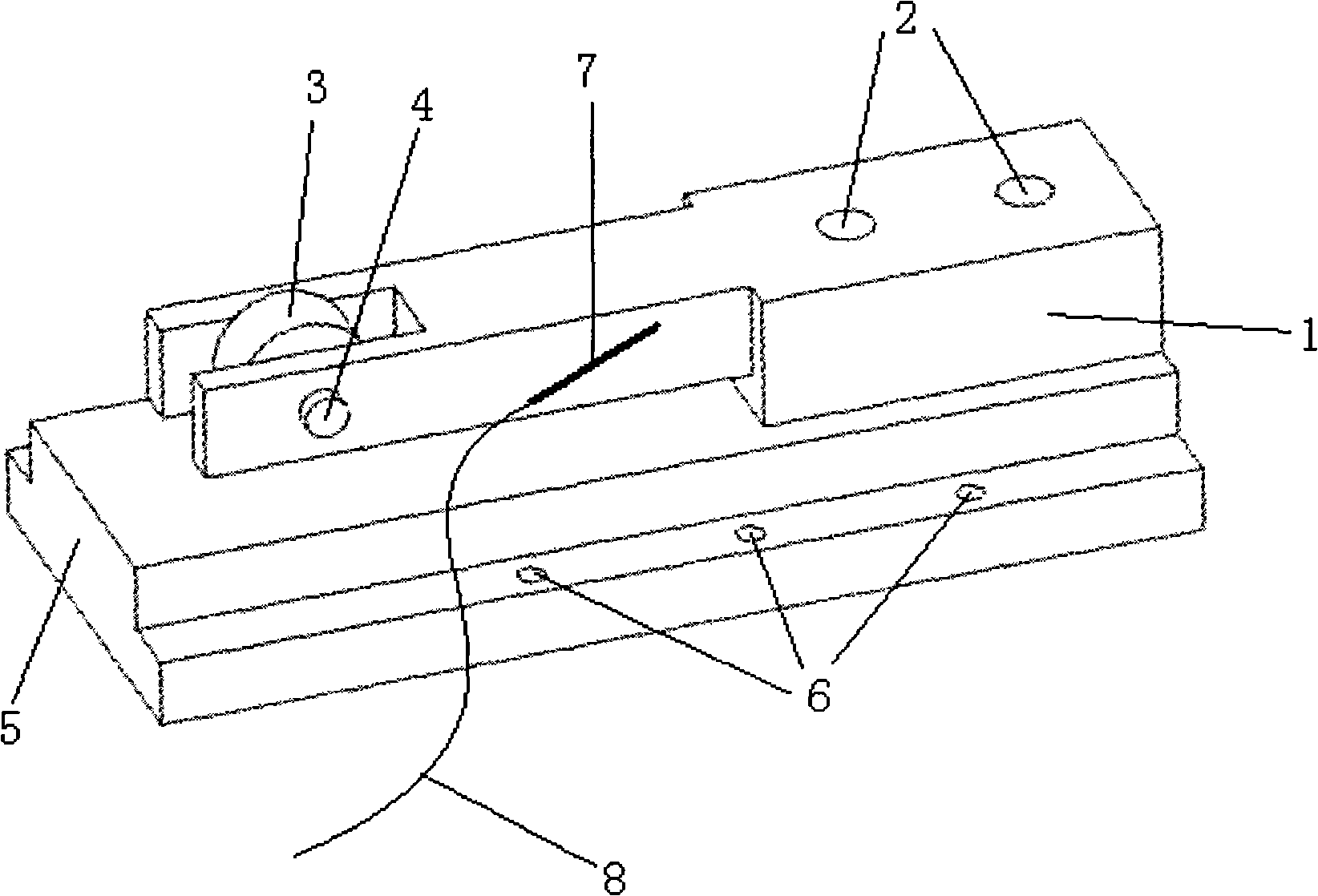

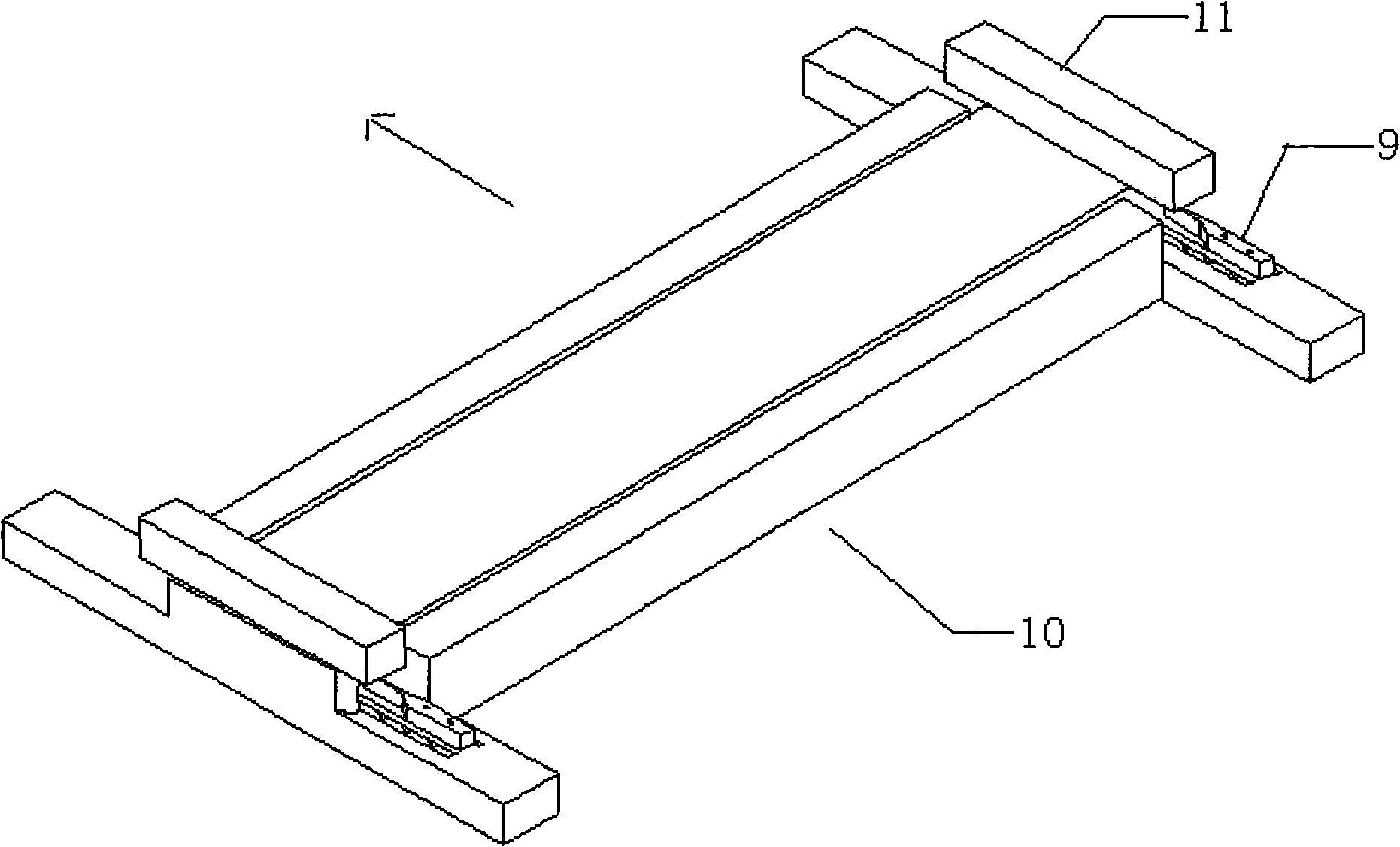

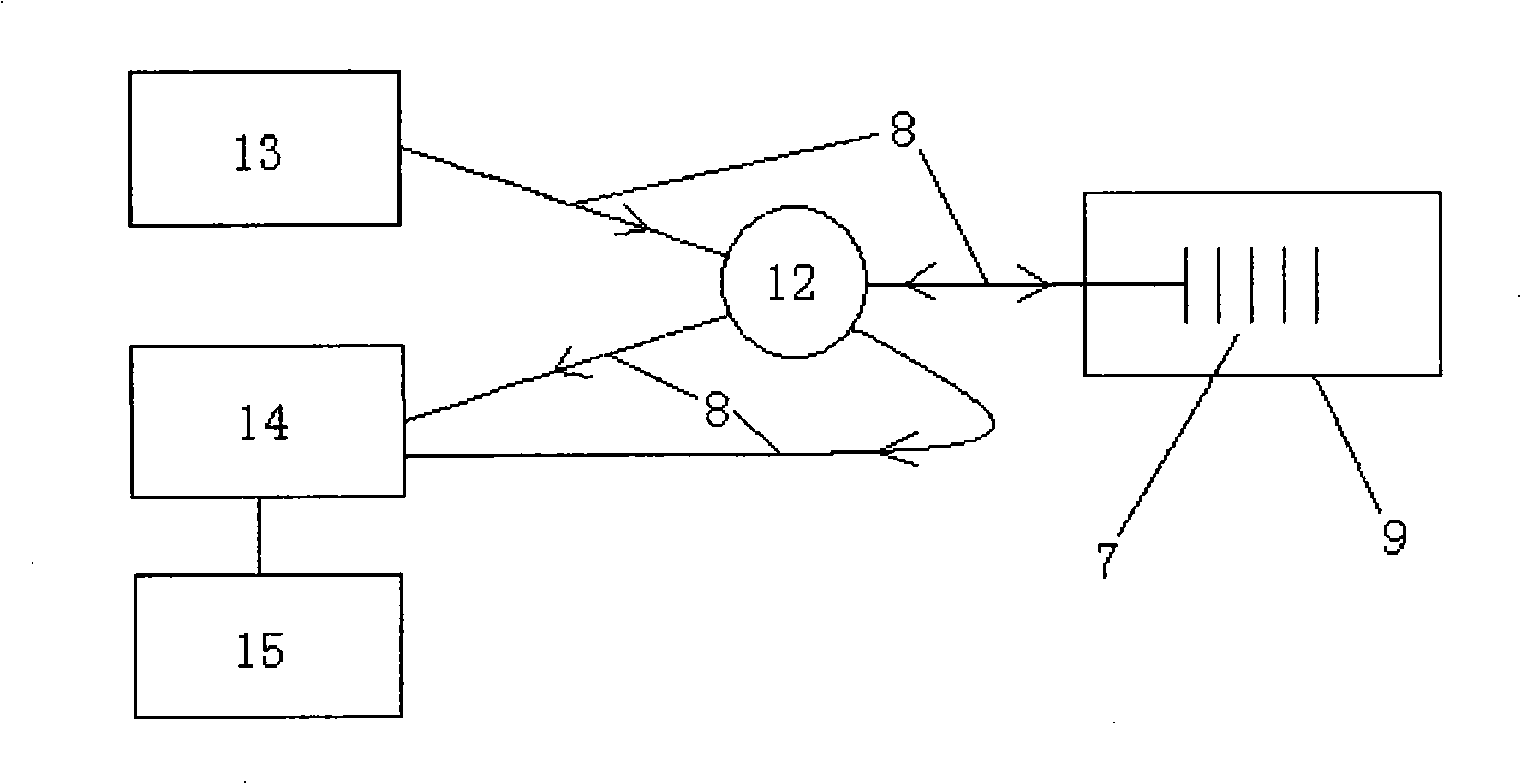

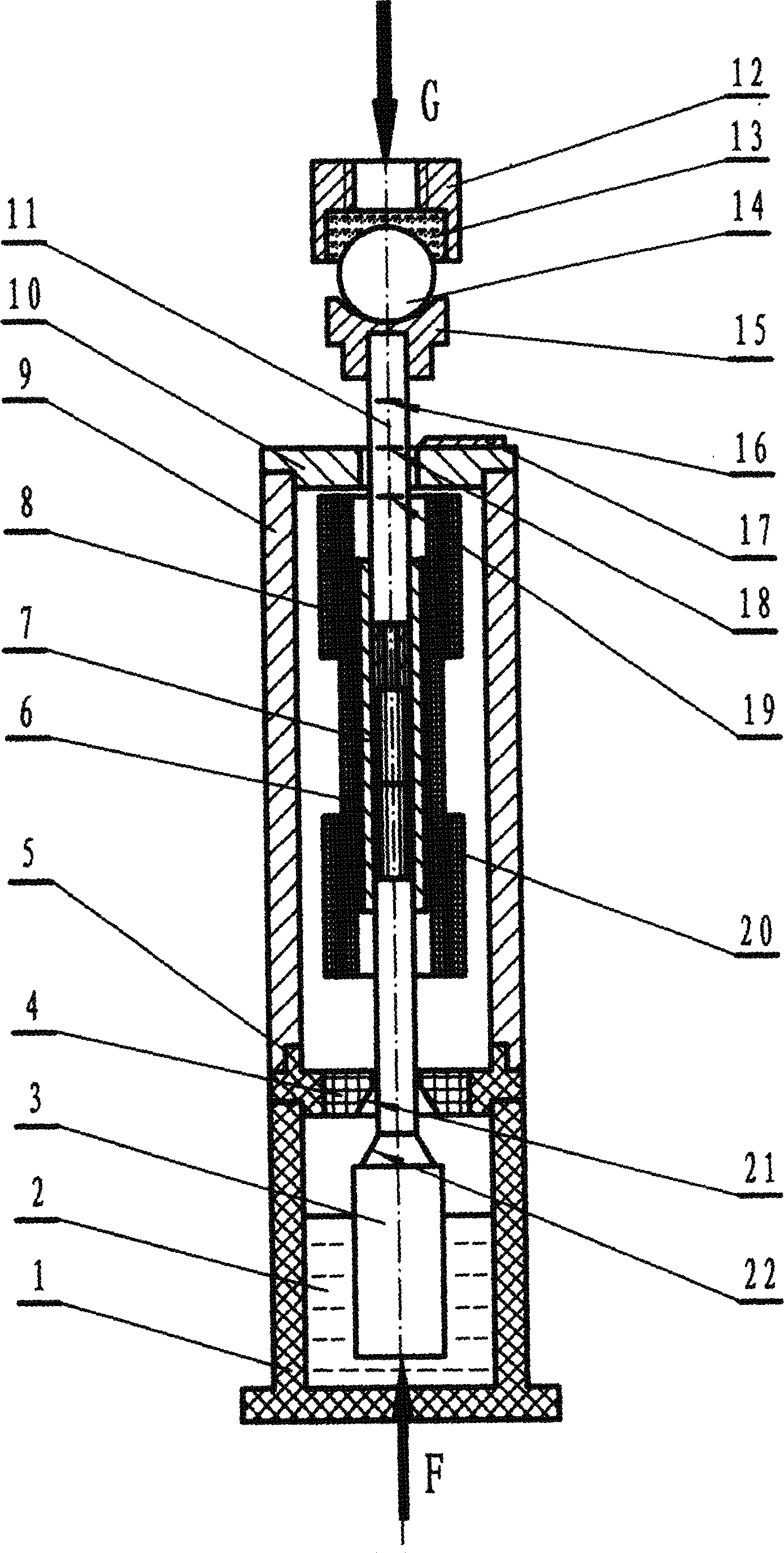

Weighting sensor with intensity demodulation chirped fiber grating

InactiveCN101526389AInsensitive to external temperature changesFast measurementConverting sensor output opticallySpecial purpose weighing apparatusFiberGrating

The invention provides a weighting sensor with intensity demodulation chirped fiber grating. The sensor is insensitive to temperature variation and is mainly used in the weighing field of dynamic vehicles, which adopts a cantilever beam structure. The chirped fiber grating (7) obliquely attaches to the side surface of the cantilever beam (1); the cantilever beam (1) is fixed on a weighting base (5) by a screw through a screw hole (2); a bearing (3) is mounted at the free end of the cantilever beam (1) by a bolt (4). Through the influence of load on reflection spectrum bandwidth of the chirped fiber grating, load weight signals can be converted into changes of reflected light power of the chirped fiber grating. Signals provided by the sensor can be widely used for various dynamic weighing and charging systems such as roads, bridges and the like through remote transmission by the fiber. The sensor can reliably work for a long time in formidable outdoor environments such as dampness, waterlogging, big environmental temperature variation, strong electromagnetic interference and the like, and has high measuring accuracy and low manufacturing and maintenance costs.

Owner:CHINA JILIANG UNIV

High-precision electronic belt scale and weighing algorithm of same

InactiveCN102322925AHigh sensitivityImprove calculation efficiencyWeighing apparatus for continuous material flowEngineeringLoad cell

The invention relates to a high-precision electronic belt scale and a weighing algorithm of the same. A tensioning structure of the traditional electronic belt scale cannot well maintain constant tension of a belt, and is easy to result in insensitive weighing. The high-precision electronic belt scale comprises a carrier roller, the belt and a motor which are arranged on a machine frame, and is characterized in that: the carrier roller comprises a weighing carrier roller, a primary carrier roller and a secondary carrier roller, the primary carrier roller and the secondary carrier roller are arranged at two ends of the belt, the primary carrier roller is connected with the motor, a speed sensor is connected at the outer part of the secondary carrier roller, a fixed rod is arranged at the lower part of the secondary carrier roller, a steel rope surrounds the secondary carrier roller and the fixed rod in sequence, and is connected with a counterweight block, one end of the steel rope is fixed, a weighing sensor is arranged at the lower part of the weighing carrier roller, and the weighing sensor, the motor and the speed sensor are connected with a controller. In the invention, the load of the weighing sensor can be adjusted to be zero through adjusting the counterweight block, so that the sensitivity of the electronic belt scale is increased; and the weighing sensor only receives a vertical force, and does not receive a tangential force produced during the operation of the belt.

Owner:杭州四五〇九机电设备有限公司

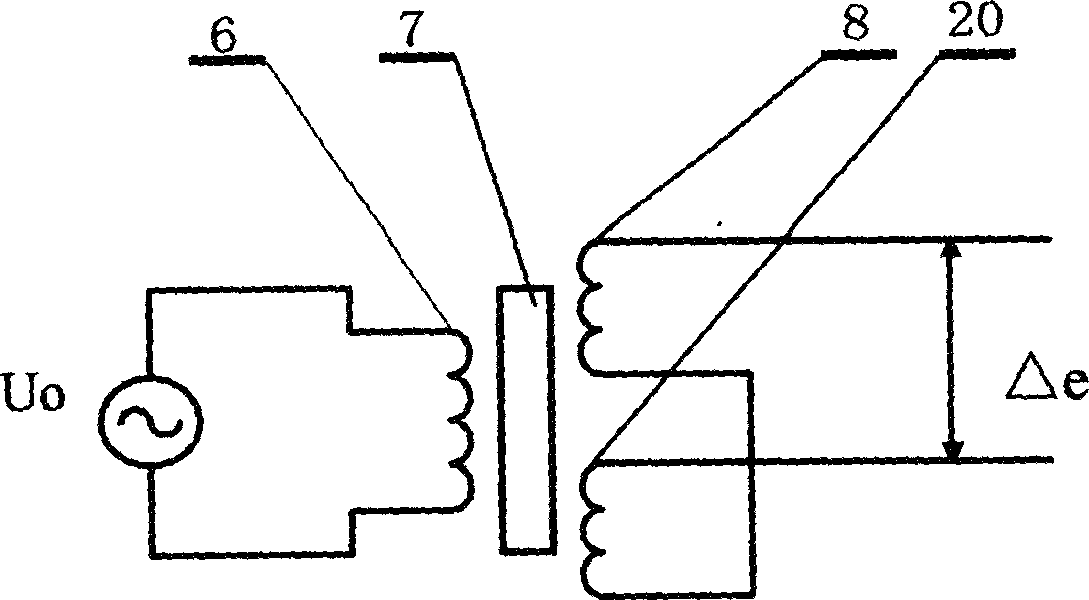

Float weighing sensor and PID deviation control method for dynamic coeighing

InactiveCN1598498AHigh sensitivityImprove weighing accuracyWeighing apparatus using fluid action balancingMechanical pressure/force controlNegative errorEngineering

The invention belongs to weight sensing technology field. The flotage weight sensor is made up of flotage balancer, weighing liquid leakage preventing mechanism, shit signal transmitting device and magnetic centering suspending mechanism. It converts the linear relation of gravity value based on the flotage theory into prominent shift value, and outputs with electric signal. It has no technology deficiencies such as slow change and zero point, and sensitivity excursion. The invention also provides a method for flotage weight sensor in PID error control when in dynamic weight metering. What is detected and controlled by the method is error of the weighted material to the set weight in dynamic weighing process. The positive and negative error value measured by the method, they counteracted in the dynamic weighing process, thus the accuracy of weighing can be upgraded greatly.

Owner:孔令宇

Weighing device with memory function and for combination scale and achieving method thereof

ActiveCN102997982ASimple structureIncrease the feeding speedWeighing indication devicesSpecial purpose weighing apparatusQuality controlEngineering

The invention discloses a weighing device with a memory function and for a combination scale. The weighing device comprises a buffer hopper, a weighing hopper and a memory hopper used for storing materials delivered by the weighing hopper. The buffer hopper and the weighing hopper are connected with a first driving aluminum box from top to bottom, the memory hopper is connected with a second driving aluminum box, the first driving aluminum box and the second driving aluminum box are arranged on a frame, and the first driving aluminum box and the second driving aluminum box are connected with a controller respectively. An achieving method of the weighing device with the memory function and for the combination scale is further disclosed. The weighing device and the method effectively resolve the problems of large consumption power, high manufacture process requirement and cost, easily-damaged structure, large shock, inaccurate weighing, difficulty in quality control and the like, and have the advantages of being simple in structure, high in feeding and discharging speed, small in consumption power, small in vibration, small in noise, high in weighing accuracy, convenient to process and the like.

Owner:GUANGODNG HIGH DREAM INTELLECTUALIZED MACHINERY

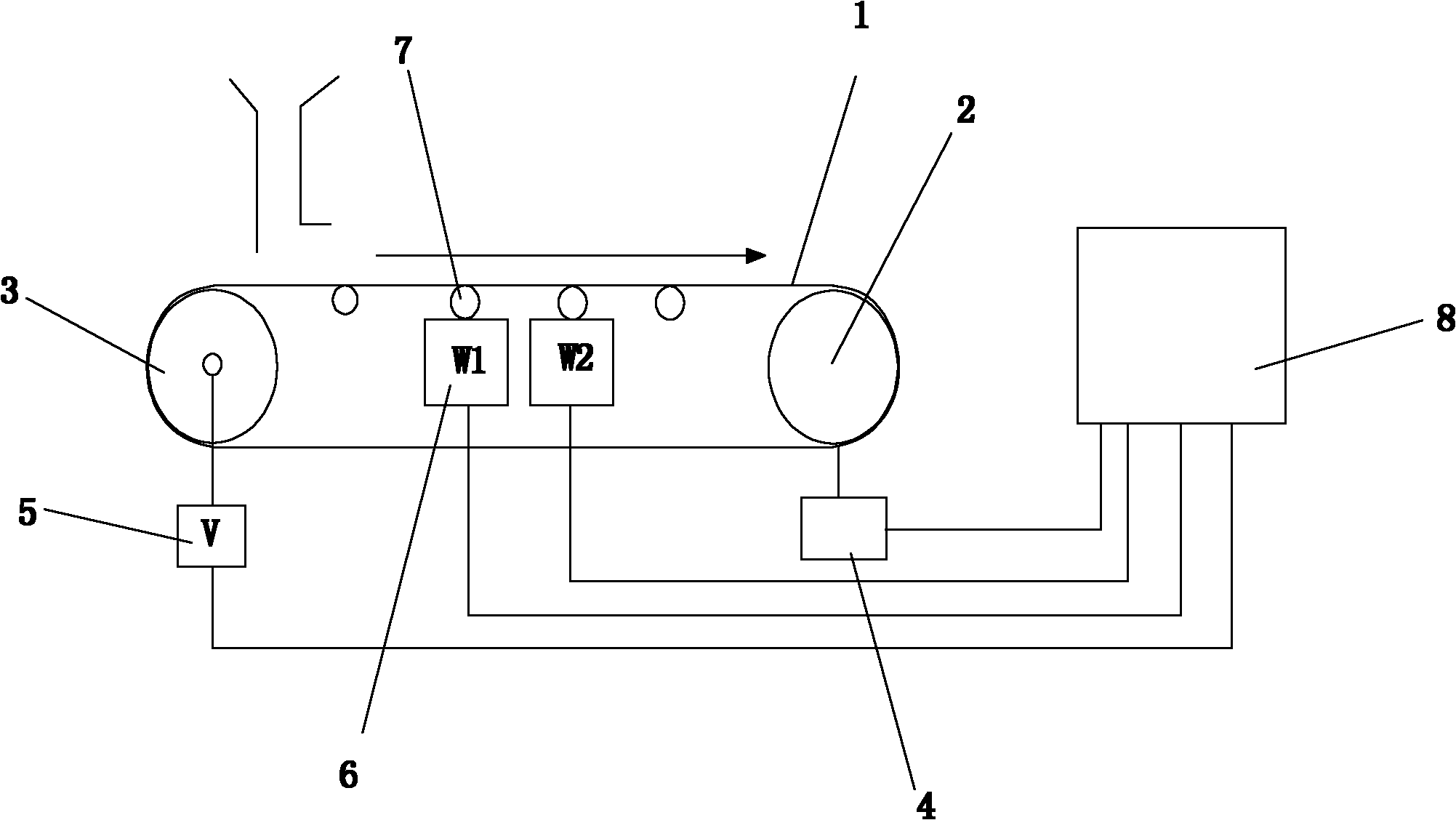

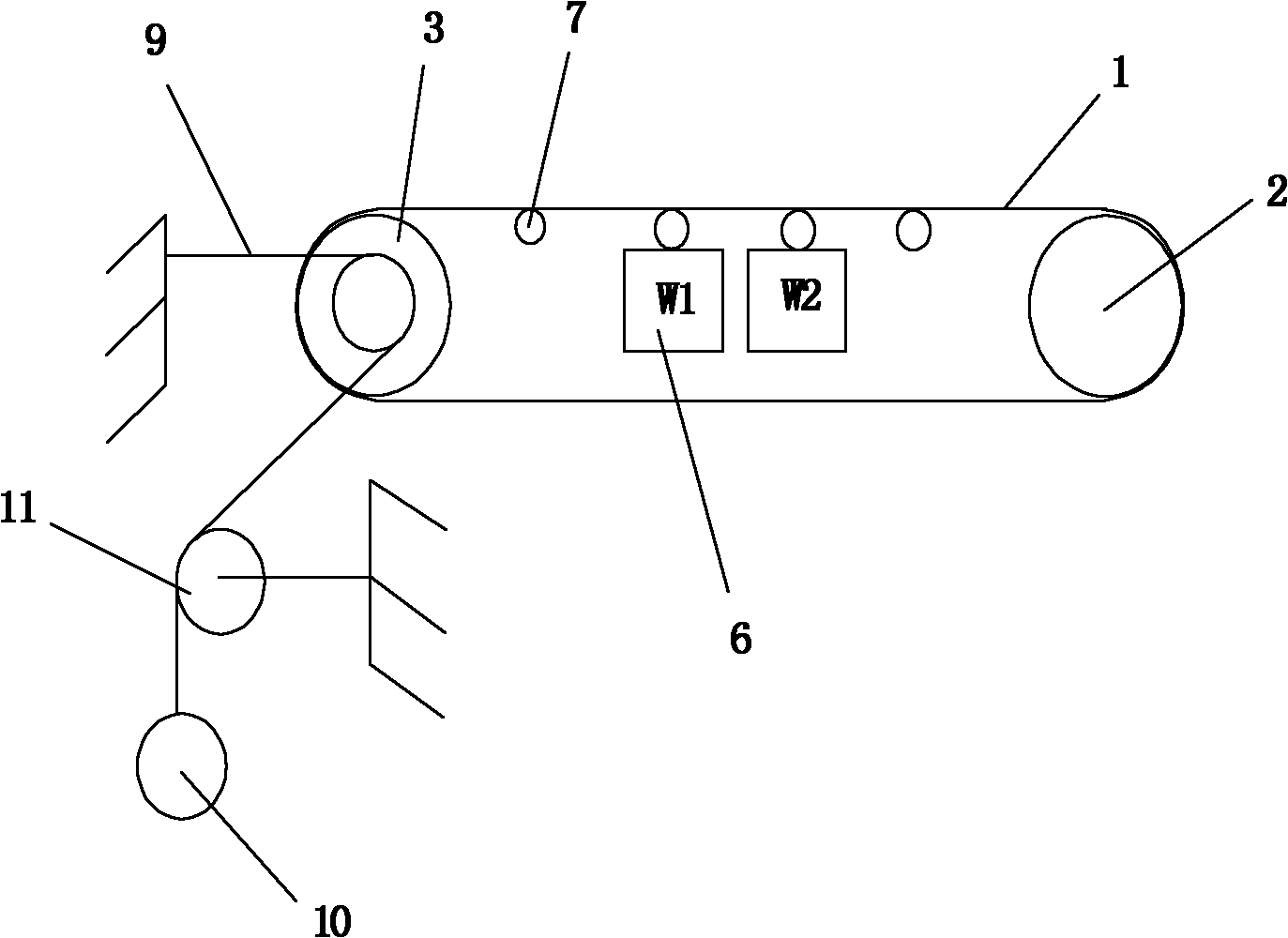

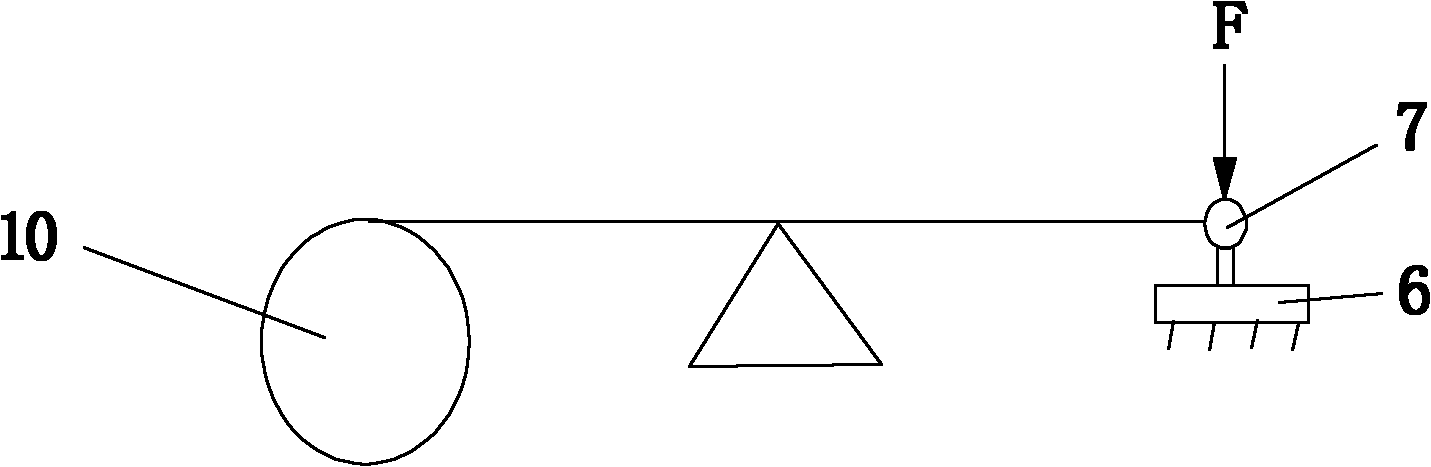

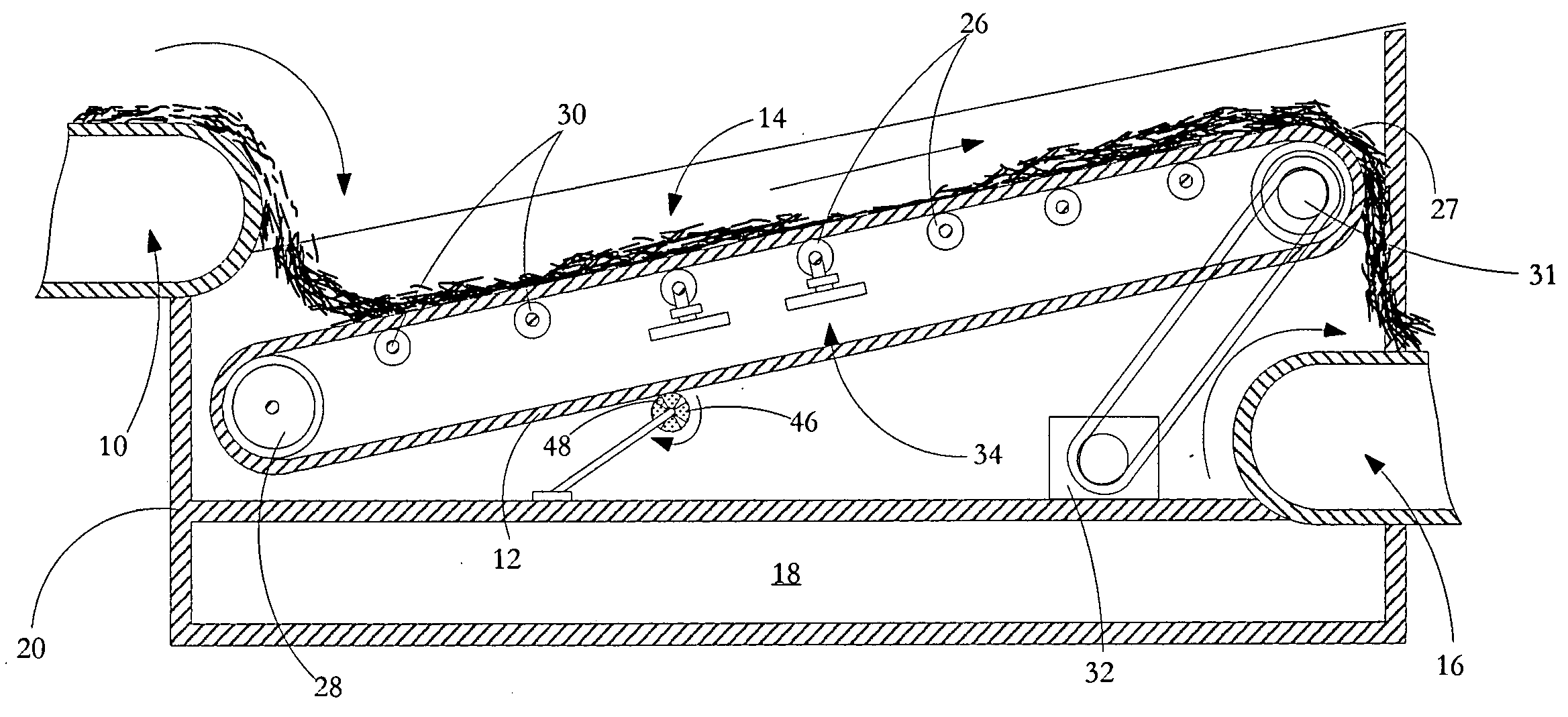

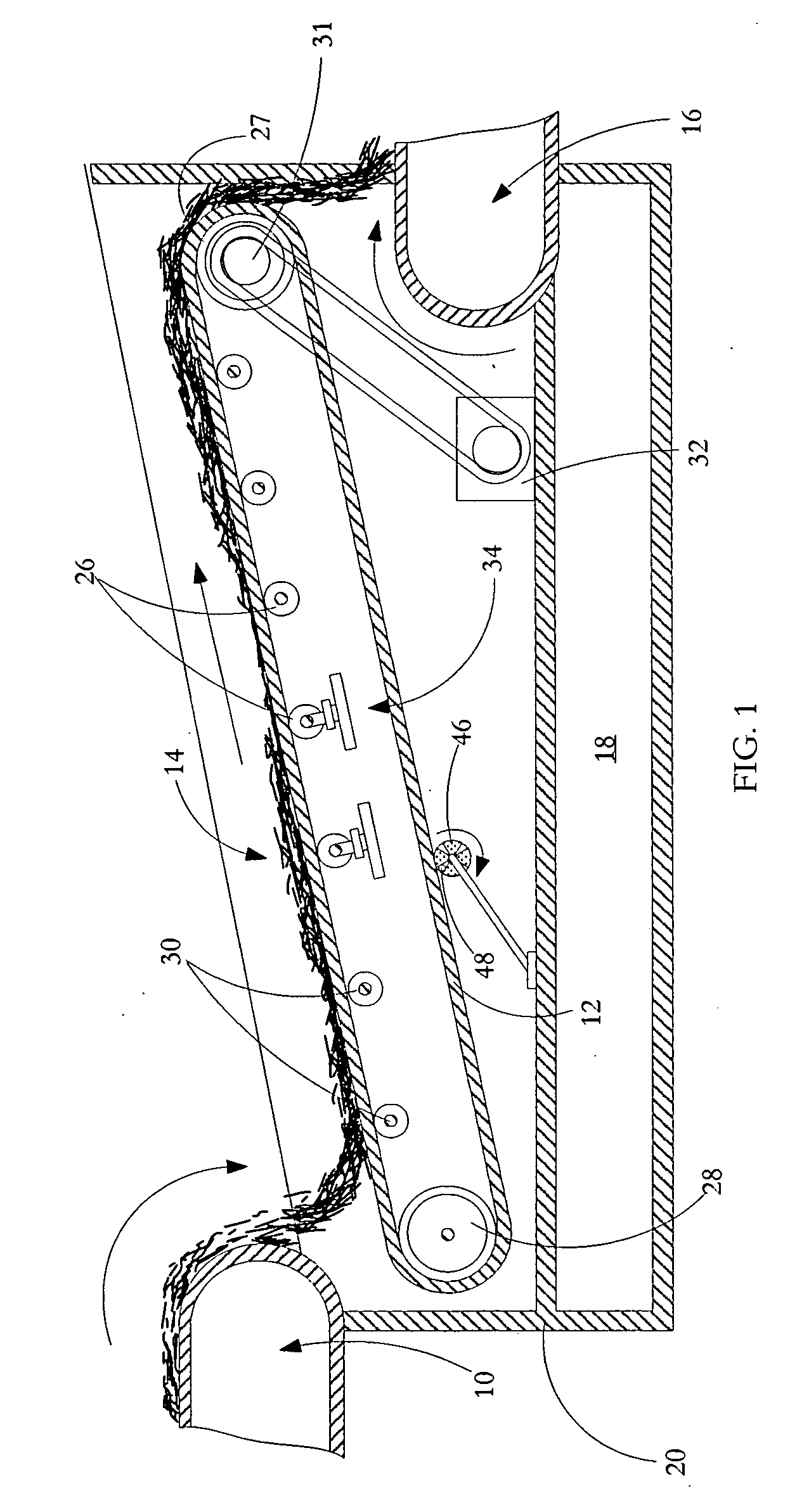

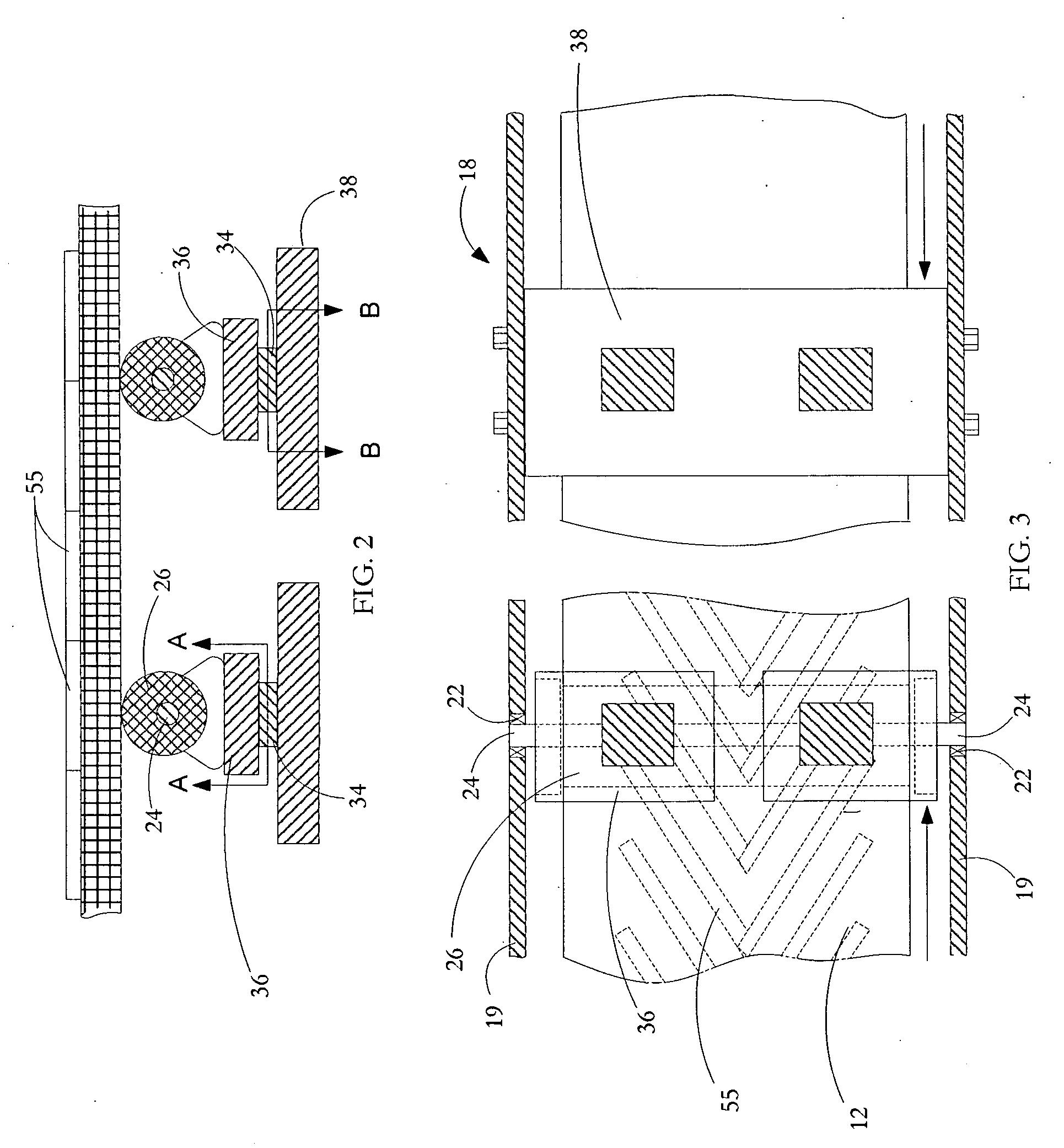

System and method for weighing particulate material moving on a conveyor

ActiveUS20100059291A1Improve weighing accuracyHigh resolutionWeighing apparatus for continuous material flowWeighing apparatus with automatic feed/dischargeProcess engineeringParticulate material

A system and method for weighing varying throughput of conveyed particulate material. The system has a weighing unit for measuring weight of material conveyed on a span of the conveyor and a speed monitoring unit to monitor the speed of the conveyor. A control module is programmed to calculate the instant value of material conveyed per unit length of the conveyor. An output from the control module reduces conveyor speed in response to a reduction in measured weight of material conveyed and increases conveyor speed in response to an increase in measured weight of material conveyed. High accuracy of measurement of the weight of particulate material being conveyed even when the conveyor is lightly loaded.

Owner:EQUIPFIX

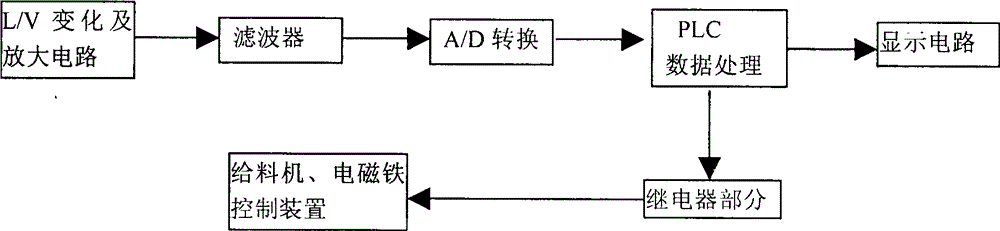

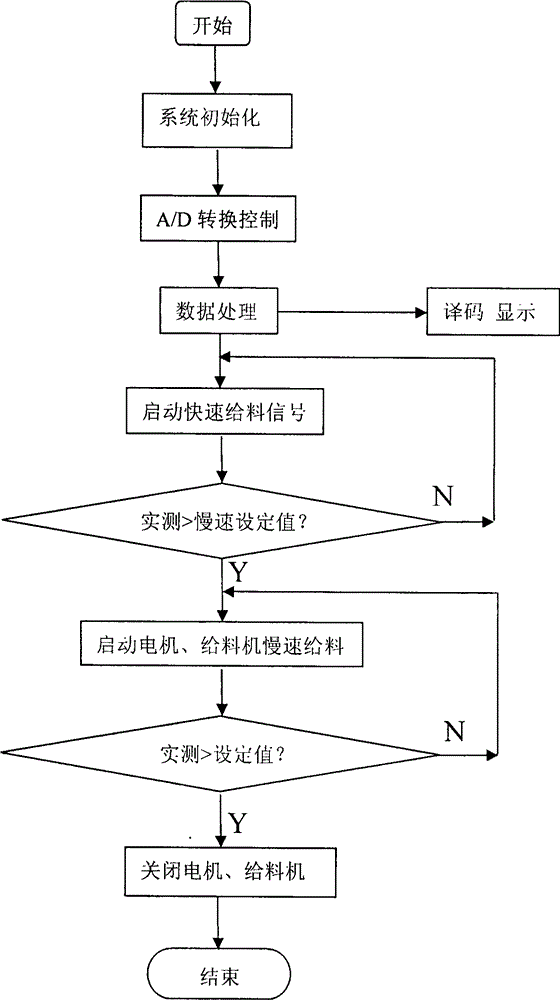

Variable speed feeding quantitative weighing system based on buoyant weighing and sensing principle

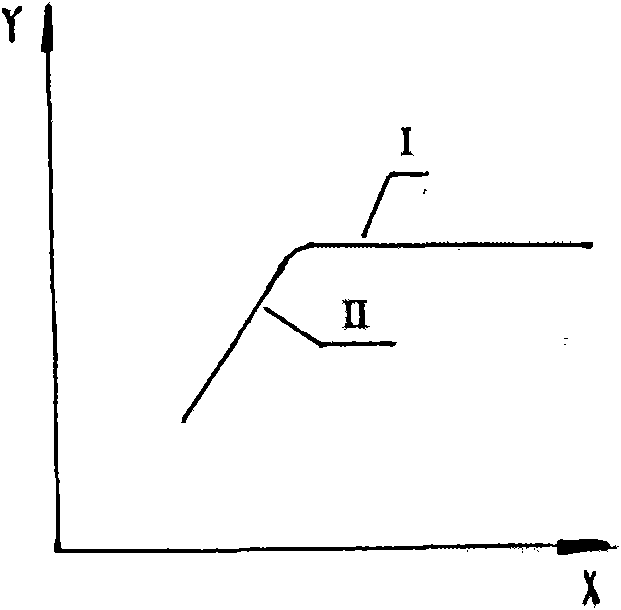

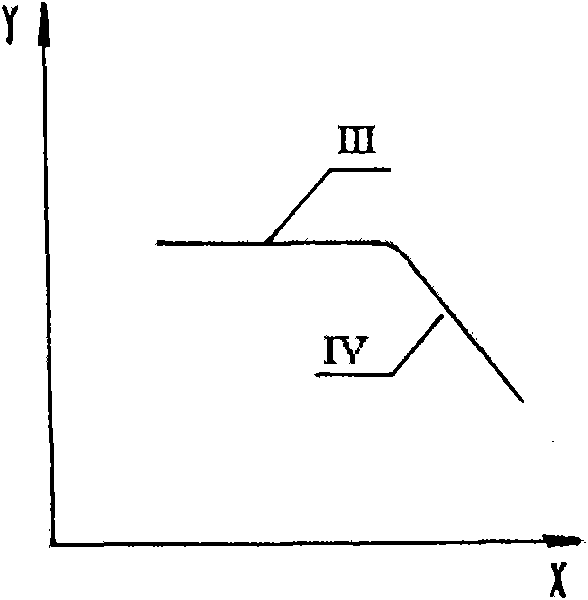

InactiveCN102879064AEasy programmingImprove metering accuracyWeighing apparatus using fluid action balancingGraduated cylinderAutomatic control

The invention belongs to the technical field of online quantitative weighing and an automatic control system thereof, and in particular relates to a variable speed feeding quantitative weighing system based on a buoyant weighing and sensing principle. A mechanical system of the variable speed feeding quantitative weighing system consists of a feeding mechanism, a feeding machine, a weighing cylinder mechanism, a leverage which transfers a quantitative weighing force value during the weighing, a discharging mechanism, a discharging cylinder, a dowel bar, a buoyant weighing sensor and weights which can adjust the quantitative weighing value; and a programmable logical control (PLC) measurement and control system of the variable speed feeding quantitative weighing system consists of a chord length (L) / instantaneous velocity (V) variation and voltage amplification module, a filter module, an analog (A) / digital (D) conversion module, a PLC central processing module, a display module, a relay part, a feeding mechanism and an electromagnet control device. The basic principle of the system is that after the buoyant weighing sensor compares the measured weighing value with a preset weighing value range, when the output electrical signal value reaches the preset signal value, the PLC measurement and control system can be used for accelerating and slowing down the feeding machine, and thus, the dual purposes of increasing the production efficiency and improving the weighing accuracy are realized.

Owner:孔令宇

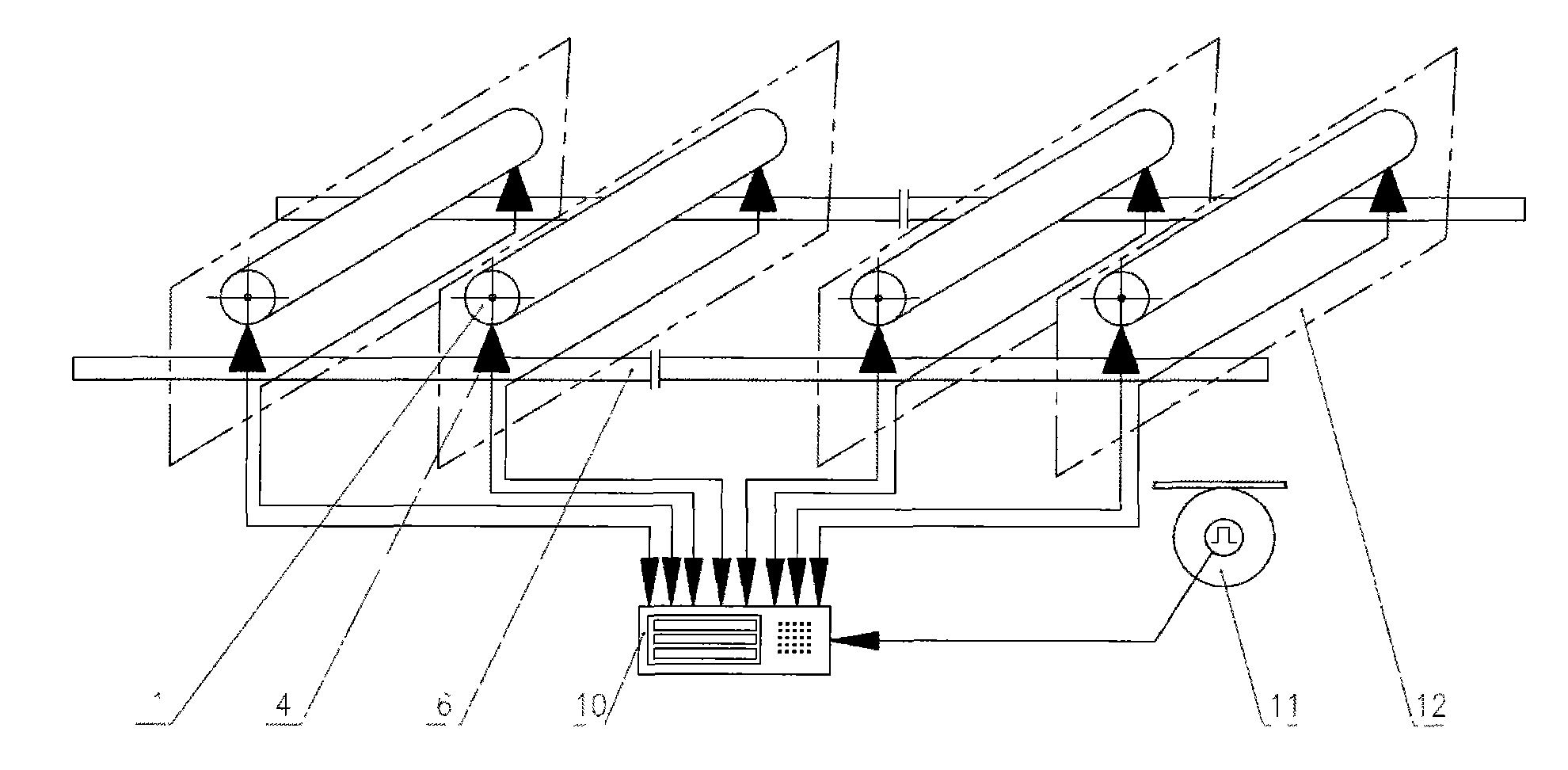

Multi-accumulation electronic belt scale

ActiveCN101614578ASimple structureStable structureWeighing apparatus for continuous material flowEngineeringWorkload

The invention relates to a multi-accumulation electronic belt scale, which is suitable for on-line precise and reliable weighting measurement of materials continuously conveyed by a belt conveyor. The multi-accumulation electronic belt scale comprises a plurality of groups of weighting units, an accumulator and a velocity sensor, wherein the accumulator accumulates and combines multiple paths of weighting signals and velocity signals of the velocity sensor into a plurality of groups of accumulation so as to perform the weight measurement and display control of a group of main accumulation and more than two groups of auxiliary accumulation on the electronic belt scale. Each weighting unit of the belt scale is a full suspended weighting unit, and the belt scale can simultaneously display the plurality of groups of accumulation, and has redundancy backup function, high reliability and accurate measuring precision; the weighting unit has simple structure and wide applicable bandwidth range; the sensor has no over-positioning; a sensor bracket has firm structure; and the multi-accumulation electronic belt scale has simple and easy installation and debugging, small maintenance workload, long service life and comprehensive practicability.

Owner:SAIMO ELECTRIC

Continuous casting billet weight-fixed and size-fixed cutting method

InactiveCN107442757AReduce labor intensityReduce security risksFlame cuttingUltimate tensile strength

The invention discloses a continuous casting billet weight-fixed and size-fixed cutting method, which comprises the following steps of calculating the sectional area of a continuous casting billet by measuring height and width of the continuous casting billet; then querying densities of the continuous casting billet at different temperatures through a density table, and calculating length of the continuous casting billet needing to be cut according to the weight of the continuous casting billet needing to be cut; and finally, detecting online length of the continuous casting billet in real time, and cutting the steel billet by a flame cutting machine when the steel billet is conveyed by a conveying roller bed to cut length. By adopting the continuous casting billet weight-fixed and size-fixed cutting method provided by the invention, online weight-fixed and length-fixed cutting of the continuous casting billet can be realized, the labor intensity of a worker is lightened, and the safety risk generated in the measuring and size fixing process of the worker at work is reduced; and meanwhile, by carrying out size-fixed cutting after weight fixing, the weight accuracy of a blank is improved, the yield of the steel billet is increased, and waste is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

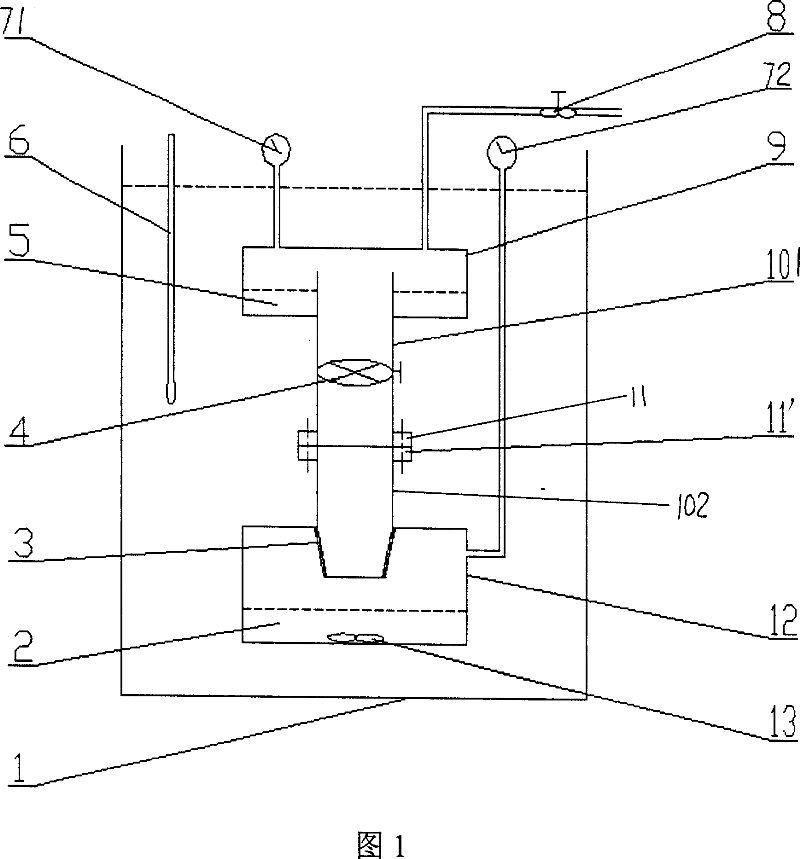

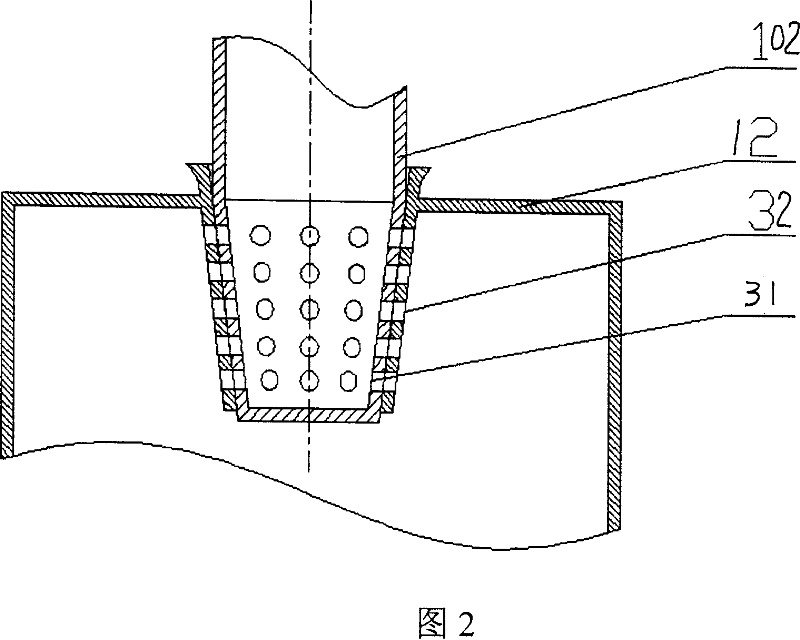

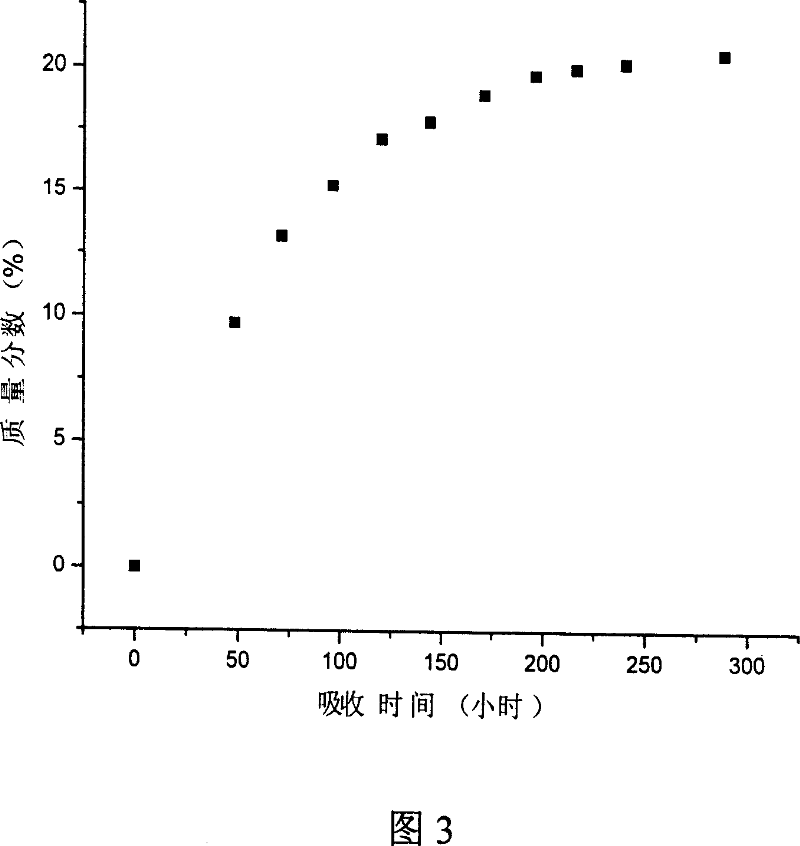

Method and device for measuring absorbing capacity of organic solvent volatile gas in ion liquid

InactiveCN101038249AFacilitate desorptionEasy to desorbWeighing by absorbing componentIonSaturable absorption

The present invention relates to a method and apparatus used for measuring the absorbing amount of an organic solvent volatile gas in an ionic liquid. Said apparatus comprises an evaporator used for a natural evaporation of an organic solvent and an absorber used for adsorbing natural volatile gases of a variety of organic solvents utilizing an ionic liquid as an absorbing agent to achieve the intention that an ionic liquid is used as an absorbing agent to remove organic solvents in industrial waste gas. A weighing method is utilized to perform detections, then the transient absorbing capacity and saturated absorbing capacity of an organic volatile gas in an ionic liquid are got through the mass difference after and before the absorption by the absorbing agent. The channel valve adopts a rotary switch type valve, which is capable of both increasing the flux and decreasing the valve weight at the same time to ensure the weighing precision. The absorber is equipped with a magnetic stirring therein and the adsorbing process is a deep absorption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

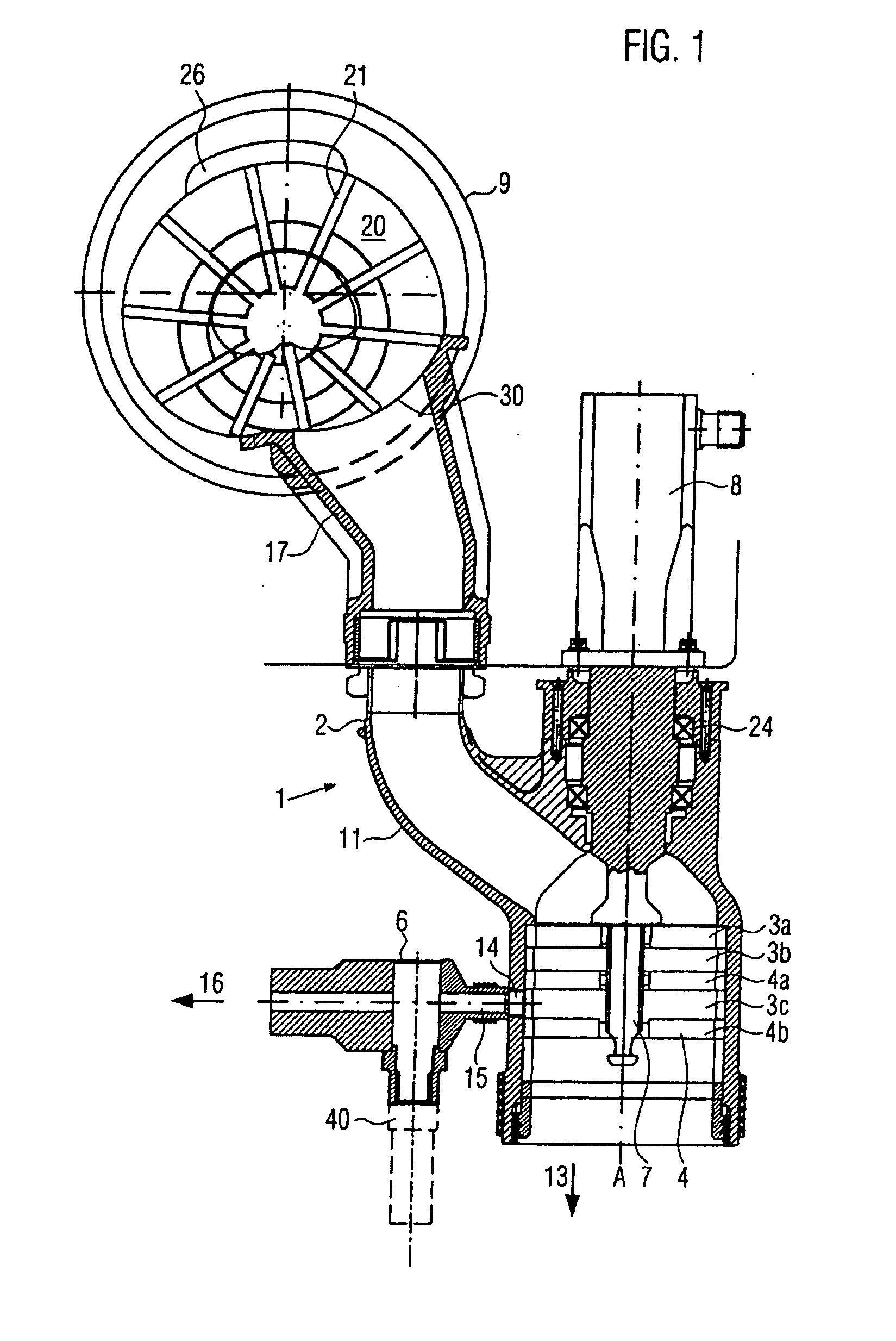

Meat mincing machine

ActiveUS20080035767A1Facilitates continuous determinationEasy to separateAnimal feeding stuffCocoaProcess engineeringFood item

A meat mincing machine and a method of producing minced foodstuffs, in particular minced meat, with an inlet, at least one blade on a following perforated disc, as well as with a separating device for separating and drawing off hard constituents wherein, to improve the weight accuracy, it has a device for the determination of the drawn-off amount of separated product.

Owner:ALBERT HANDTMANN MASCHFABRICK

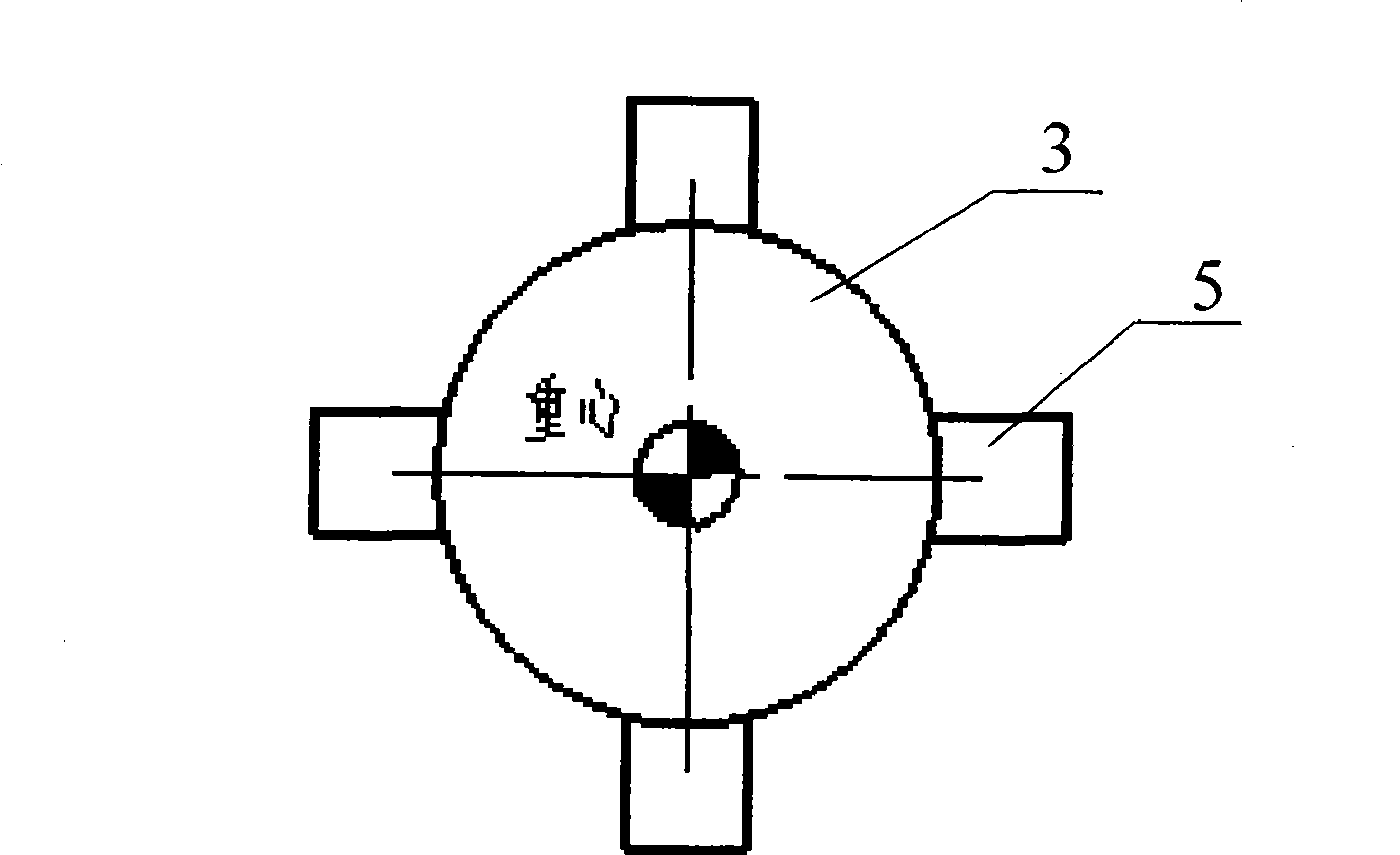

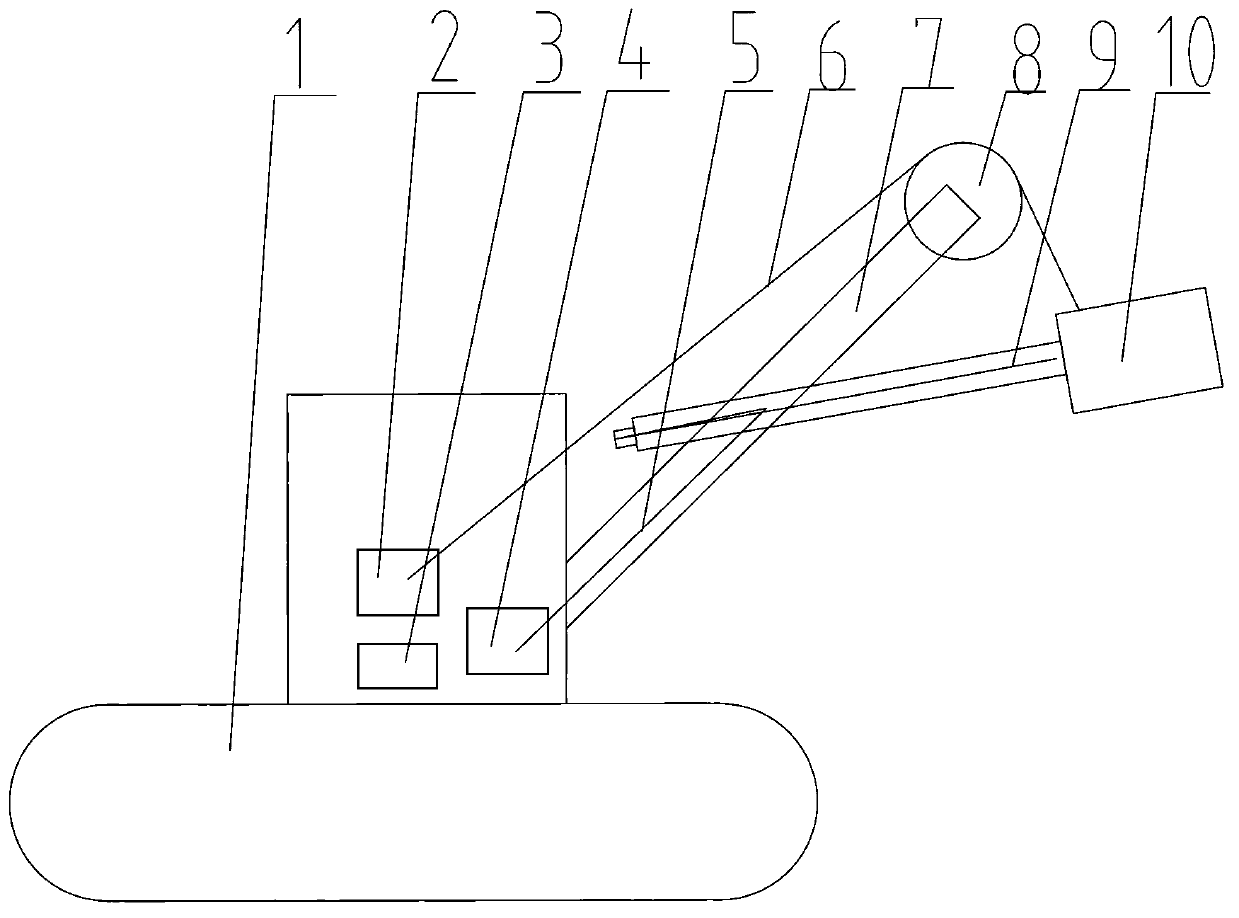

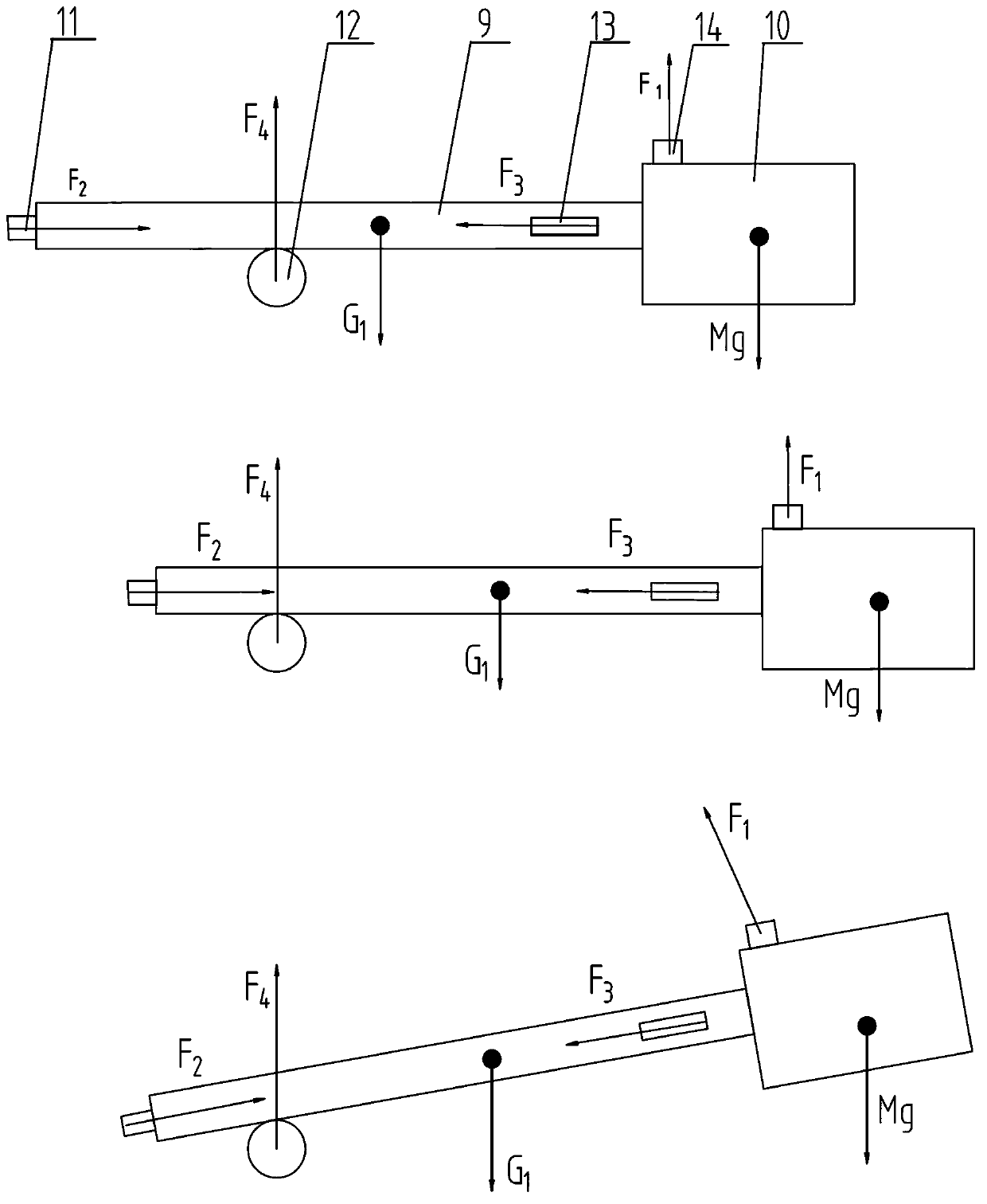

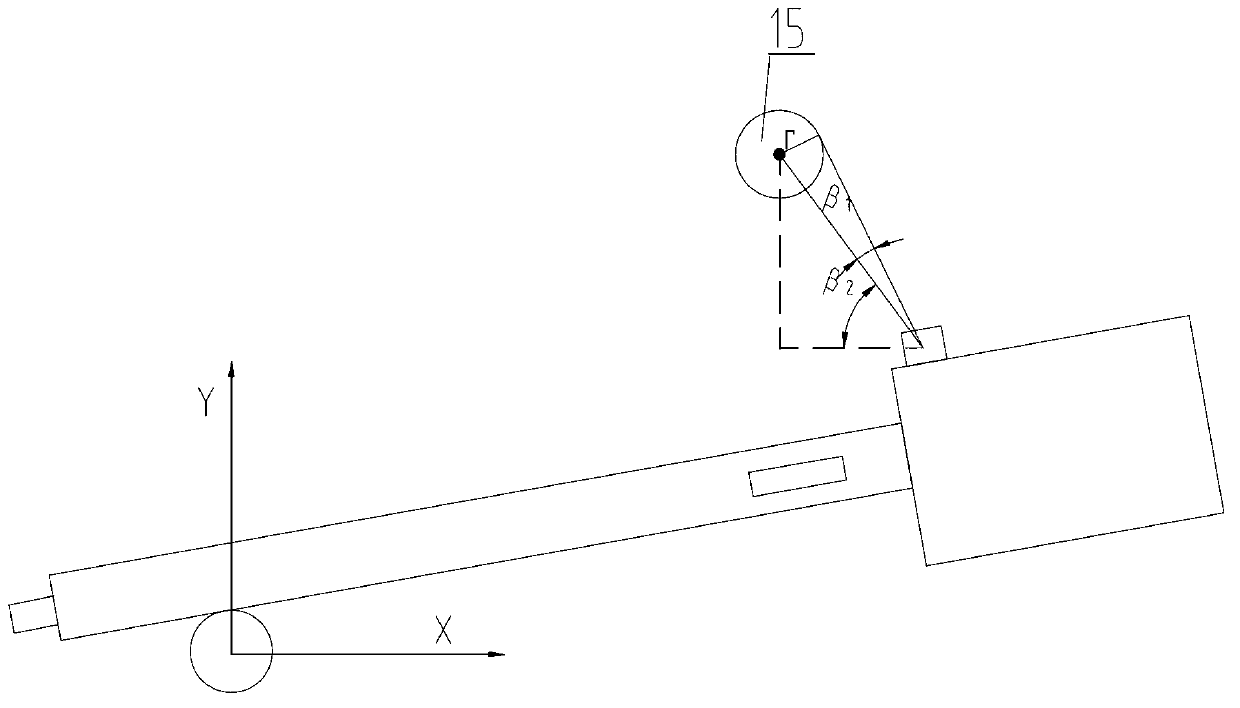

Electric excavator weighing method

ActiveCN102889917AEliminate supportImprove weighing accuracyWeighing apparatusRectangular coordinatesGravity center

The invention discloses an electric excavator weighing method for solving the technical problem of overlarge weighing error of the existing method. According to the technical scheme of the invention, the electric excavator weighing method comprises the following steps of: establishing a rectangular coordinate system by taking the center of a saddle as a moment balance point and taking the moment balance point as an original point; determining coordinates of the centers of gravities of a shovel lever, a part attached to the shovel lever and a bucket full of materials as well as action points of a lifting force and a pushing force in the coordinate system when the shovel lever is in a horizontal position, and then, solving the coordinates of the points during weighing according to a shovel lever movement locus equation, wherein the moment arm of the pushing force is equal to the vertical coordinate of the action point of the pushing force, and the moment arm of the gravity is equal to the horizontal coordinate of the center of gravity in weighing; solving the coordinate of a tangency point according to the position relationship between the action point of the lifting force as well as a hoisting rope at the right of the head sheave and the tangency point of the head sheave during weighing, listing an equation of a straight line where the hoisting rope is, and solving the moment arm of the lifting force by utilizing the distance from the center of the saddle to the straight line; measuring the pushing force and the lifting force by using a sensor; and finally, listing a torque equilibrium equation and solving the weight of the materials.

Owner:中钢集团衡阳机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com