Quantitative particle material feeding system

A technology of quantitative feeding and granular materials, which is applied in the field of quantitative feeding systems for granular materials, can solve the problems of large measurement accuracy uncertainty, large suitable amount, and high labor intensity, and achieve high work efficiency and weighing accuracy. Easy operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the embodiment.

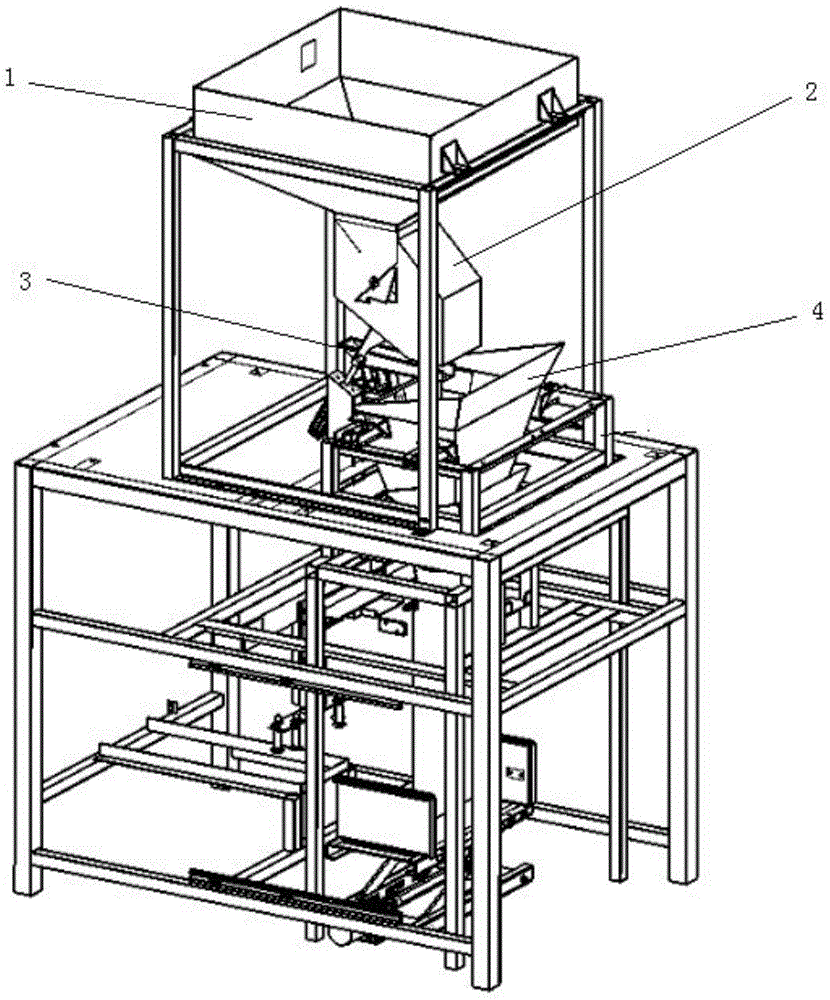

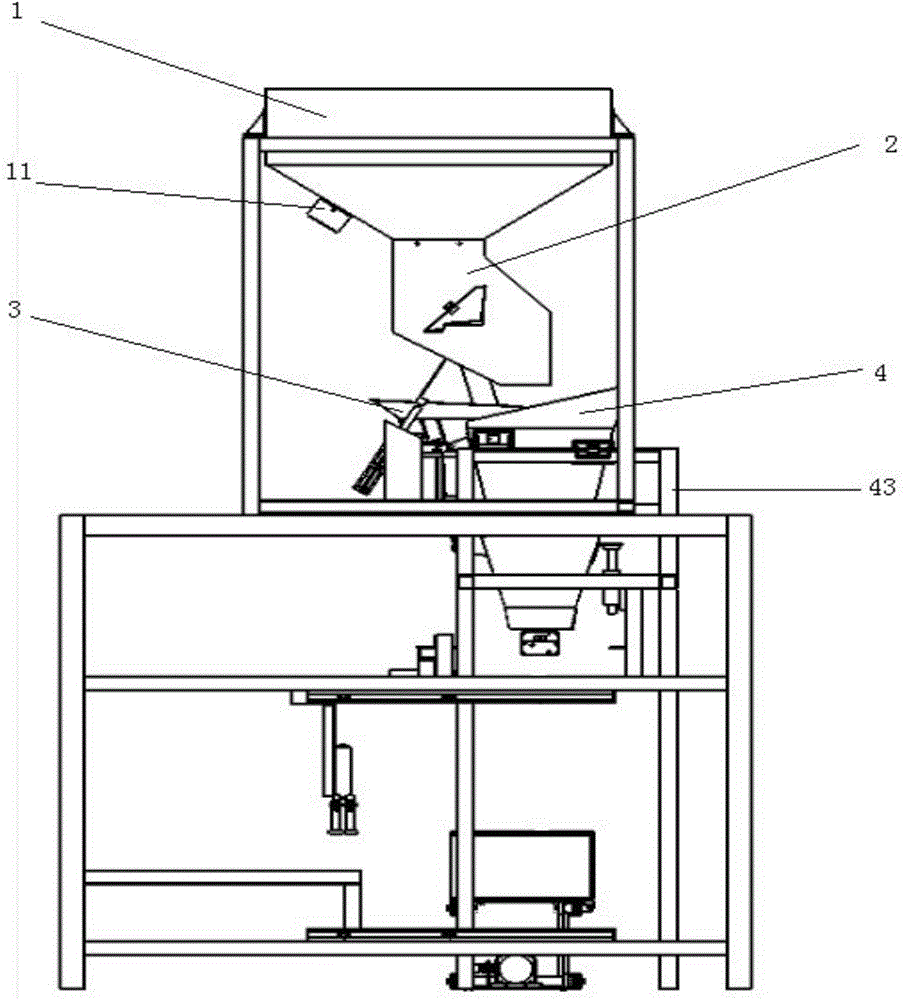

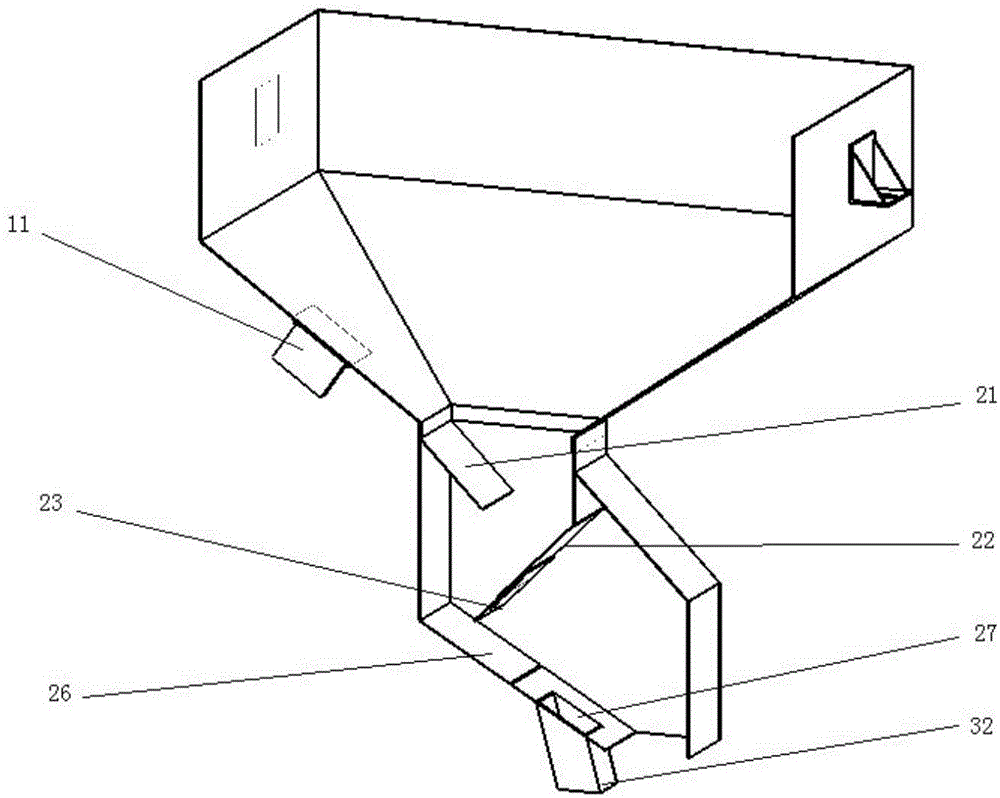

[0023] refer to figure 1 , figure 2 and image 3 , the present invention is a quantitative feeding system for granular materials, comprising: a silo 1, a feeding mechanism 2, a feeding mechanism 3, and a metering device 4.

[0024] The discharge opening of the silo 1 is rectangular, and the side wall of the silo 1 is equipped with a silo wall vibrator 11, which generally only works when removing tailings. The feeding port of the feeding mechanism 2 is fixedly connected with the blanking port of the silo 1, and the inner wall of the feeding channel of the feeding mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com