Weighing device with memory function and for combination scale and achieving method thereof

A technology for weighing devices and combined scales, applied in the direction of weighing indicating devices, special scales, measuring devices, etc., can solve the problems of cumbersome manufacturing process, high manufacturing process and cost requirements, hopper opening and closing doors, etc., and achieve a simple overall structure , fast feeding and unloading speed, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

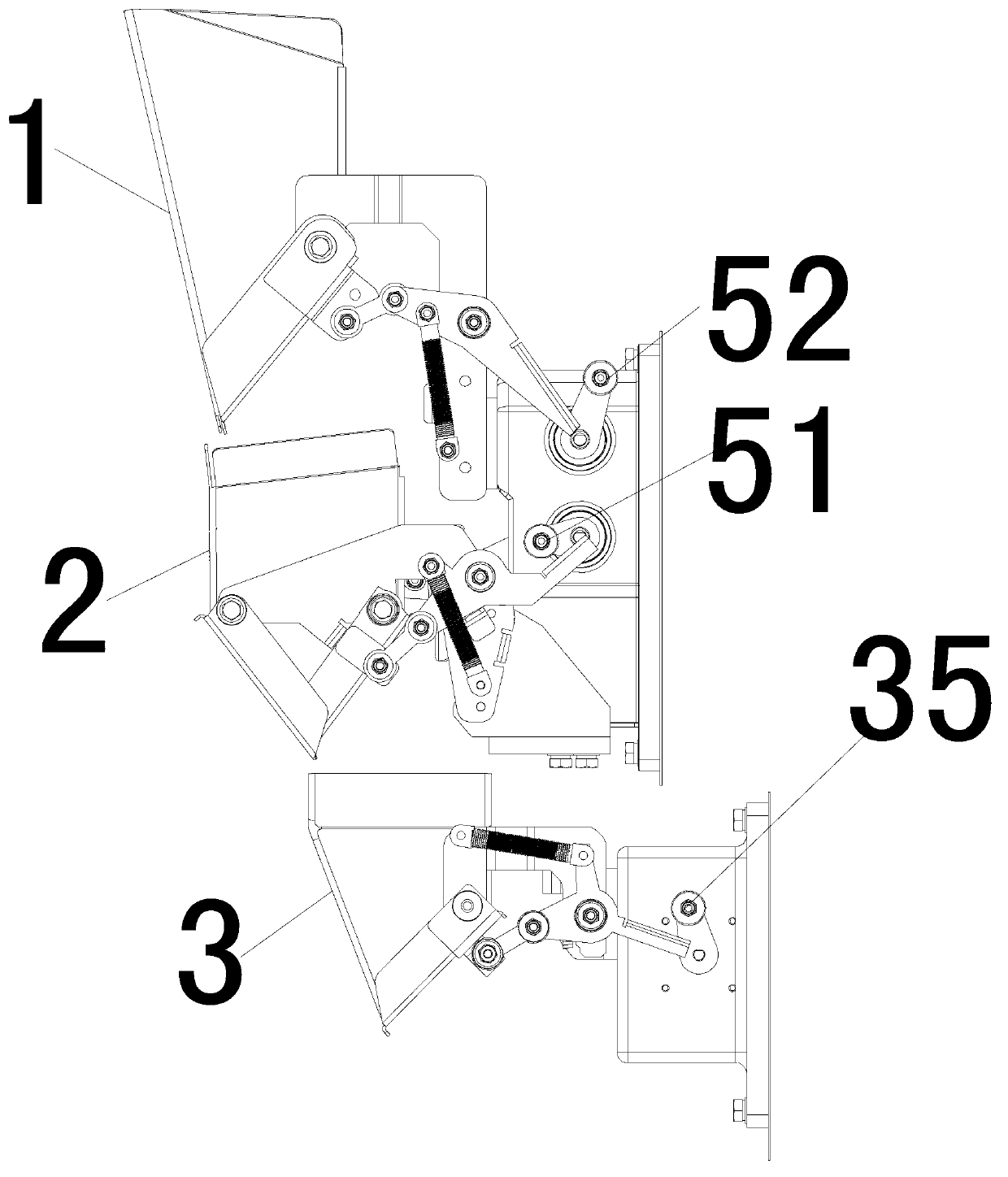

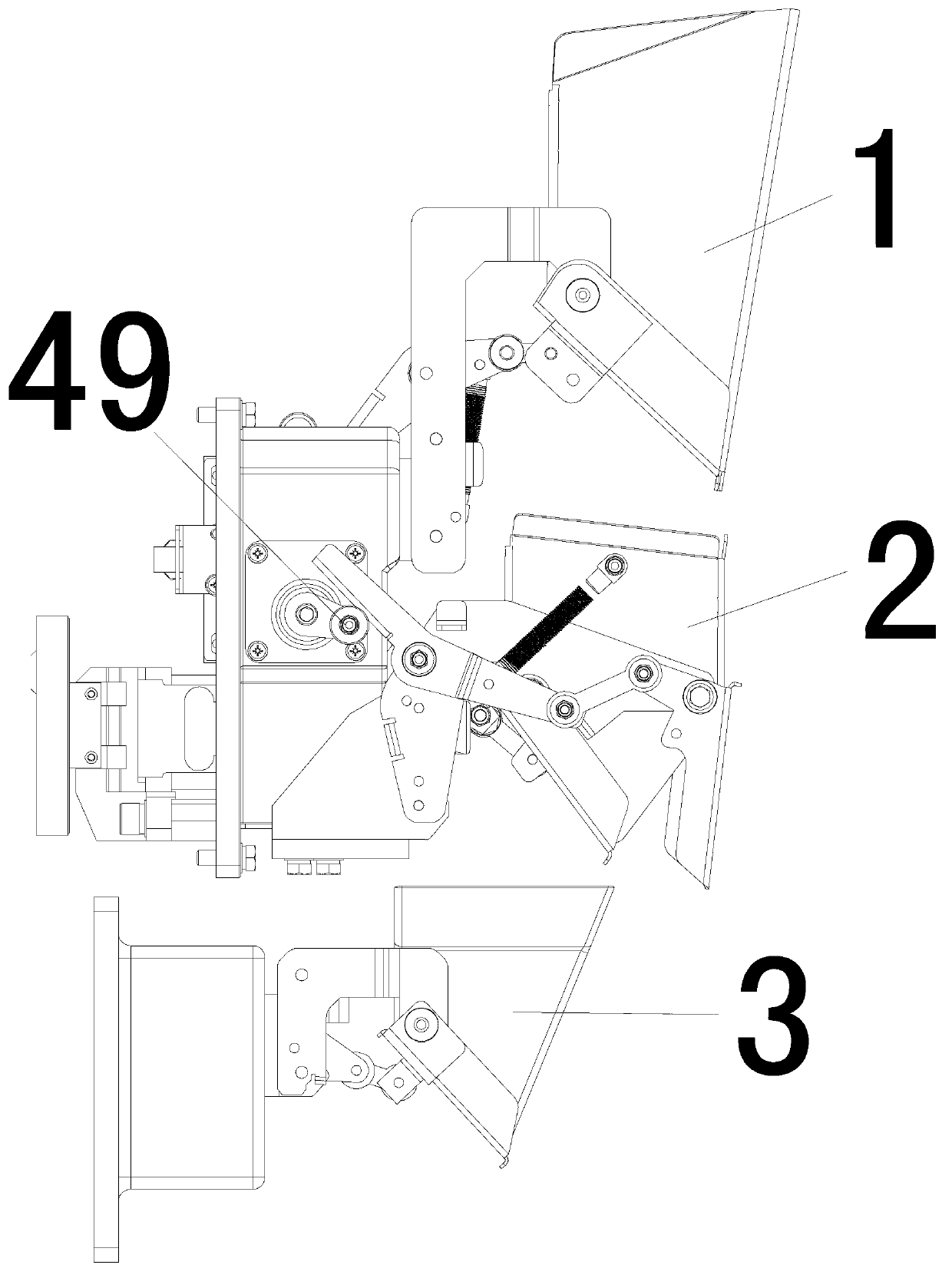

[0044] This embodiment adopts 16 sets of 3-layer combination scale structure, that is, 16 buffer buckets 1, 16 weighing buckets 2 and 16 memory buckets 3. packaging machine.

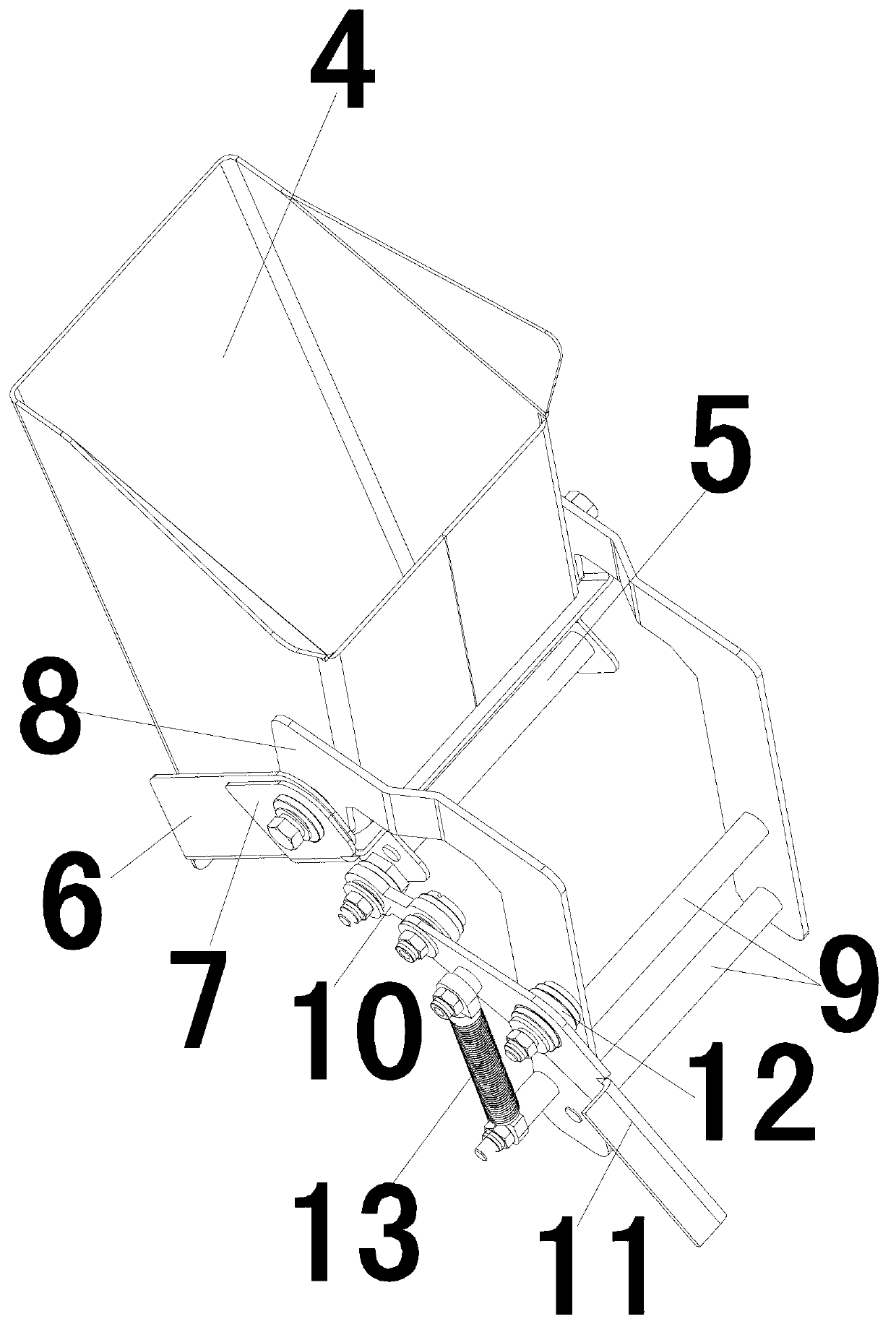

[0045] Such as Figure 1~9 As shown, a weighing device with a memory function for a combination scale includes a buffer bucket 1 for buffering materials falling from a wire vibrating plate and feeding the weighing bucket, for weighing materials and feeding materials The weighing bucket 2 is used to store the materials conveyed by the weighing bucket, the buffer bucket 1 and the weighing bucket 2 are connected with each other from top to bottom. The first drive aluminum box is connected, the memory bucket 3 is connected with the second drive aluminum box 37, the first drive aluminum box and the second drive aluminum box 37 are arranged on the frame 39, the first drive aluminum box and the second drive aluminum box 37 respectively connected to the controller.

[0046] Such as Figure 8 As shown, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com