Variable speed feeding quantitative weighing system based on buoyant weighing and sensing principle

A weighing sensor and weighing sensor technology, applied in the direction of weighing, weighing equipment using fluid balance, measuring devices, etc., can solve the problems of difficult to improve measurement accuracy, zero drift, creep, etc., and achieve programming Convenience and quickness, improved reliability, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

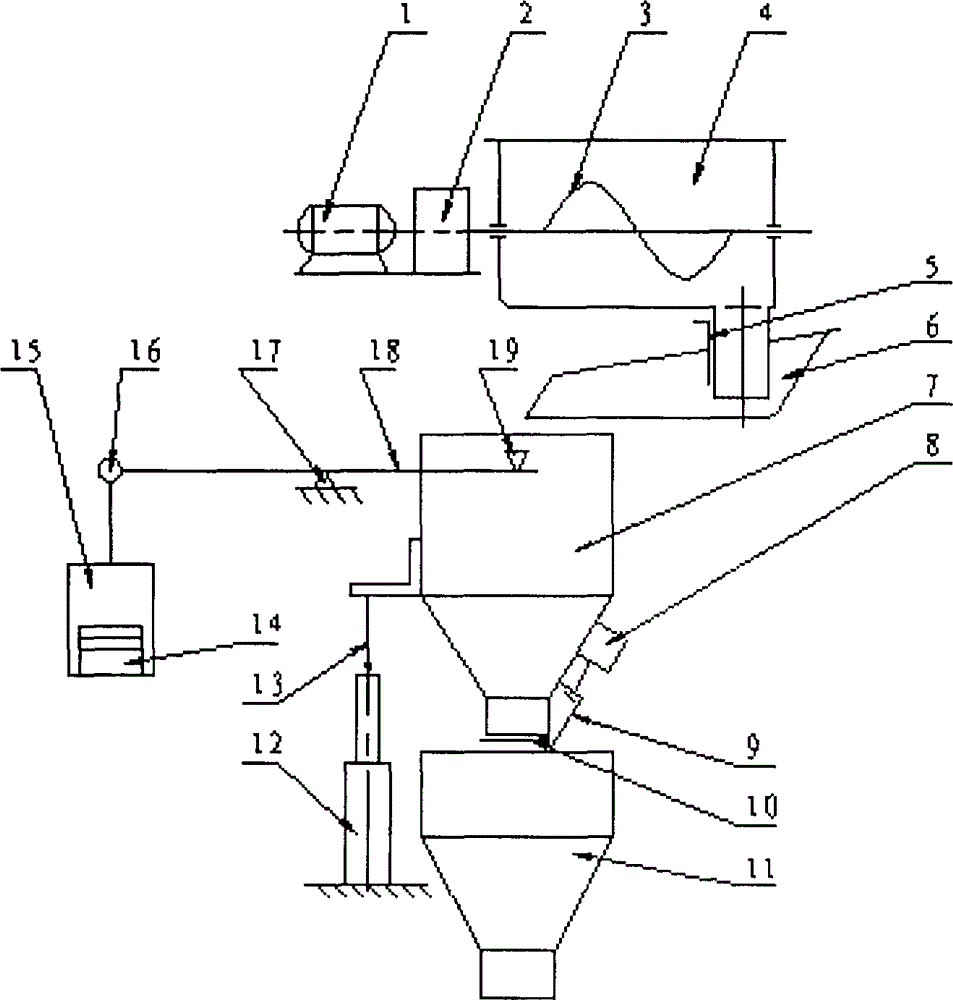

[0036] figure 1 middle:

[0037] The adjustable door 5 of the feeding mechanism is used to regulate the size of the discharge flow, and the best solution of its helical twisted blade 3 is the combination of some single-piece twisted blades, so as to be easy to disassemble. The optimal solution for the feeder 6 is to use a seat-type electric vibration feeder. The electromagnet 8 for opening the discharge valve 10 is fixed on the weighing cylinder 7 , and the movable iron core of the electromagnet 8 is connected with the discharge valve 10 through the discharge valve lever system 9 . The position of the buoyancy load cell 12 is fixed, and the optimum position of its axis is in the vertical direction, and is parallel to the axis of the weighing cylinder 7, and its parallel distance is a set value. The dowel rod 13 is fixed on the weighing cylinder 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com